Plasma and calcium oxide cooperation-gasified rubbish biomass gasification method and equipment

A plasma and calcium oxide technology, applied in biomass gasification and garbage fields, can solve the problems of secondary pollution, easily polluted land and groundwater, and poor economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

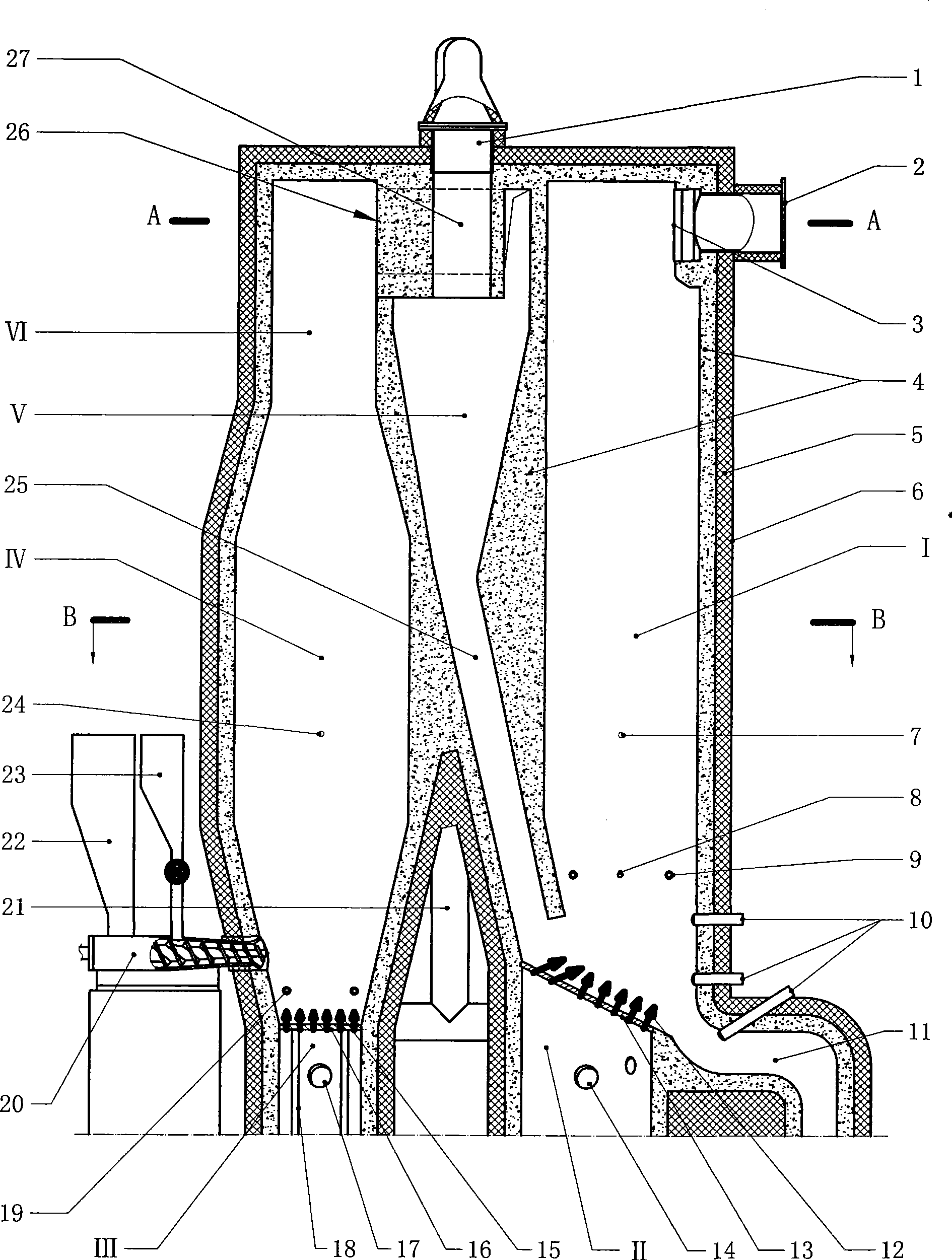

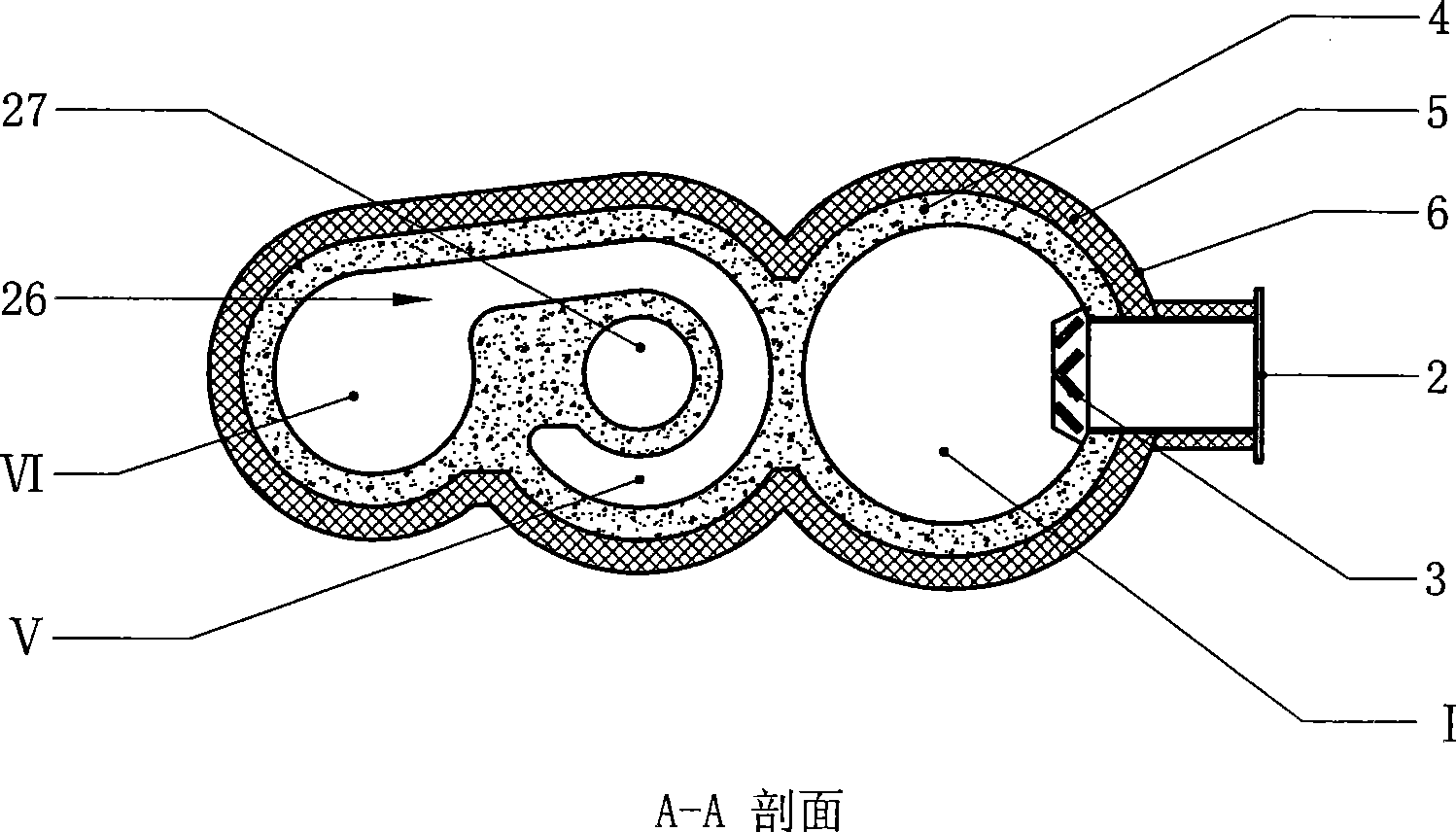

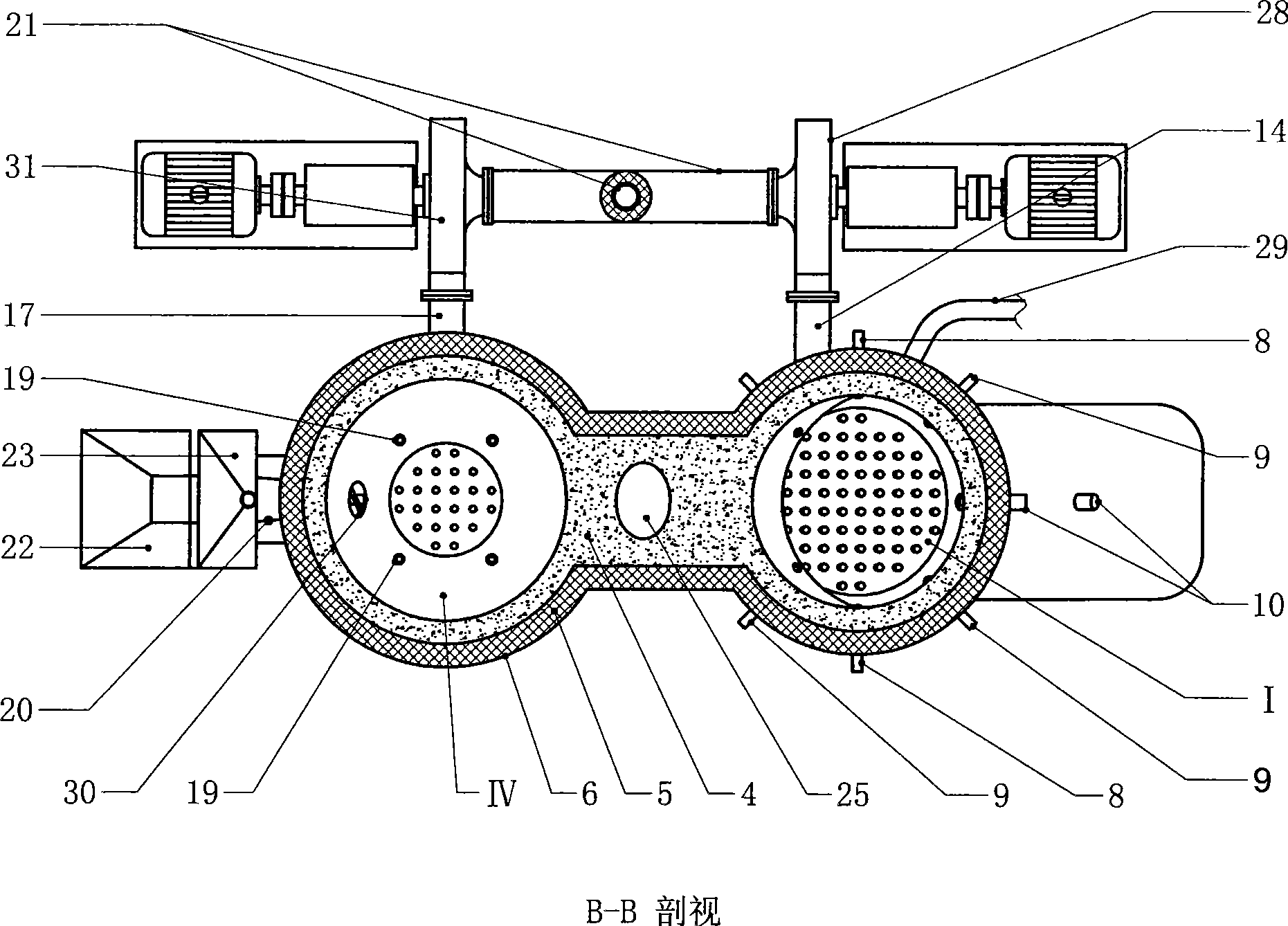

[0034] figure 1 , figure 2 , image 3In the shown embodiment, the gasification equipment mainly consists of a compression screw feeder (20), a suspension fluidized bed pyrolysis furnace (IV), a separation chamber (V), a turbulent fluidized bed gasification furnace (I), Calcium oxide spray gun (9), plasma spray gun (10), pyrolysis gas circulation pipe (21), high temperature circulation fan (31) and high temperature fan (28), wherein: suspended fluidized bed pyrolysis furnace (IV), The separation chamber (V) and the turbulent fluidized bed gasifier (I) are integrally constituted by a refractory regenerative furnace wall (4). The refractory regenerative furnace wall is poured with refractory concrete or built with refractory bricks. The refractory regenerative furnace wall The outer side is an insulating layer (5), and the insulating material is aluminum silicate plate or perlite particles, and the outer side of the insulating layer is a casing (6), and the outer casing is mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com