Patents

Literature

326 results about "Fluidized bed gasifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for converting biomass into synthesis gas using a pressurized multi-stage progressively expanding fluidized bed gasifier followed by an oxyblown autothermal reformer to reduce methane and tars

InactiveUS20100040510A1Lower Level RequirementsGasifier mechanical detailsCombustible gas catalytic treatmentSyngasFluidized bed gasifier

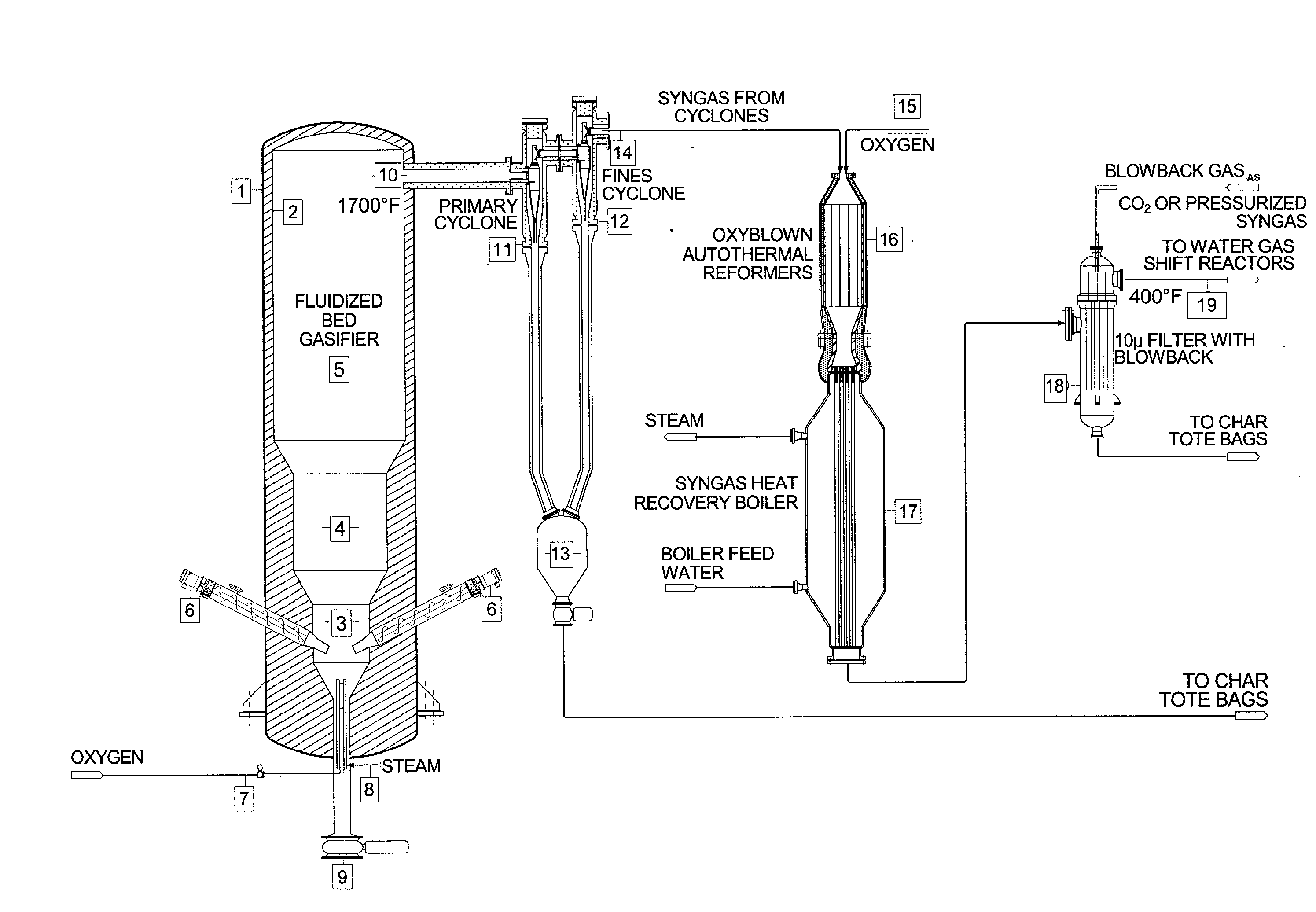

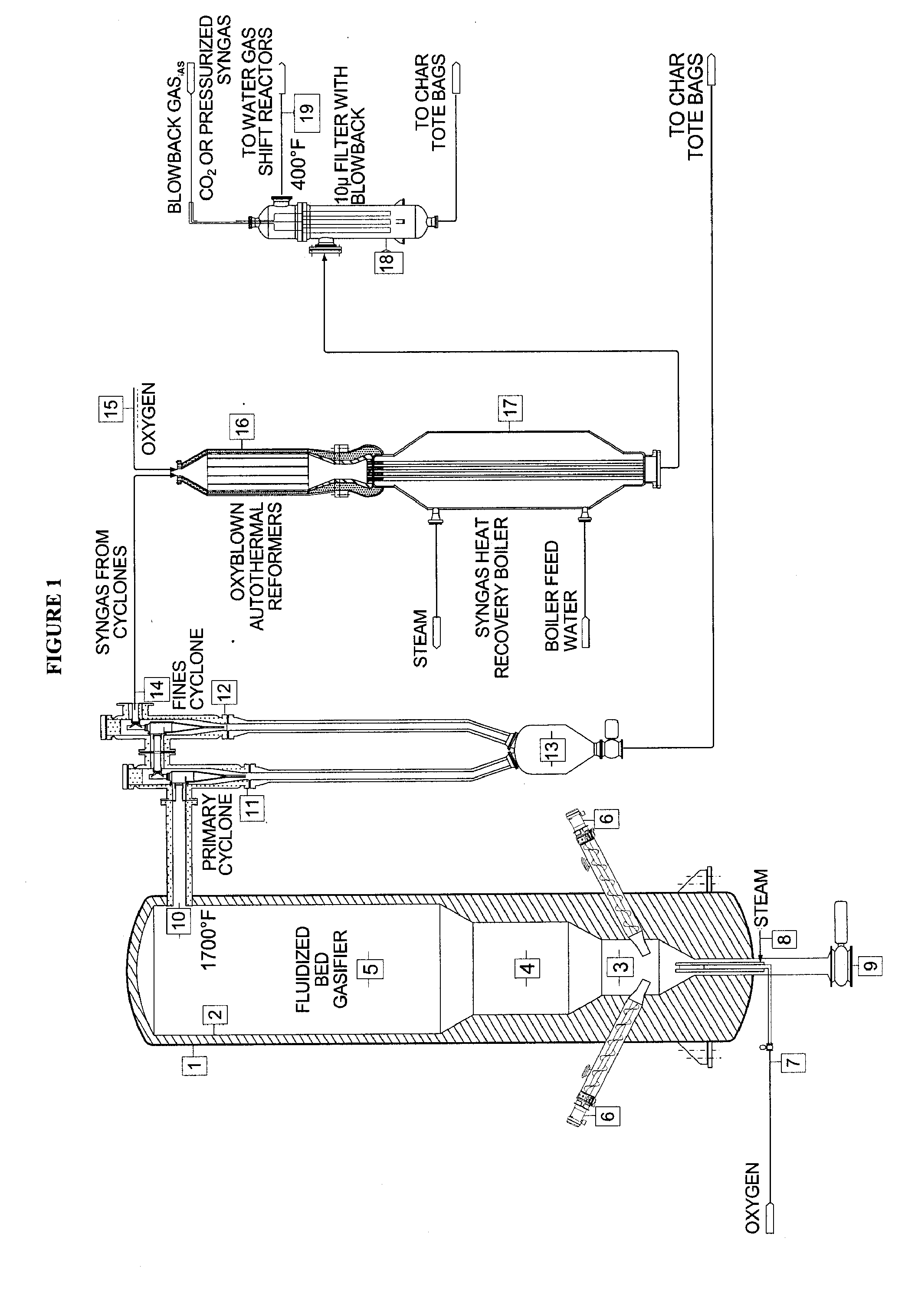

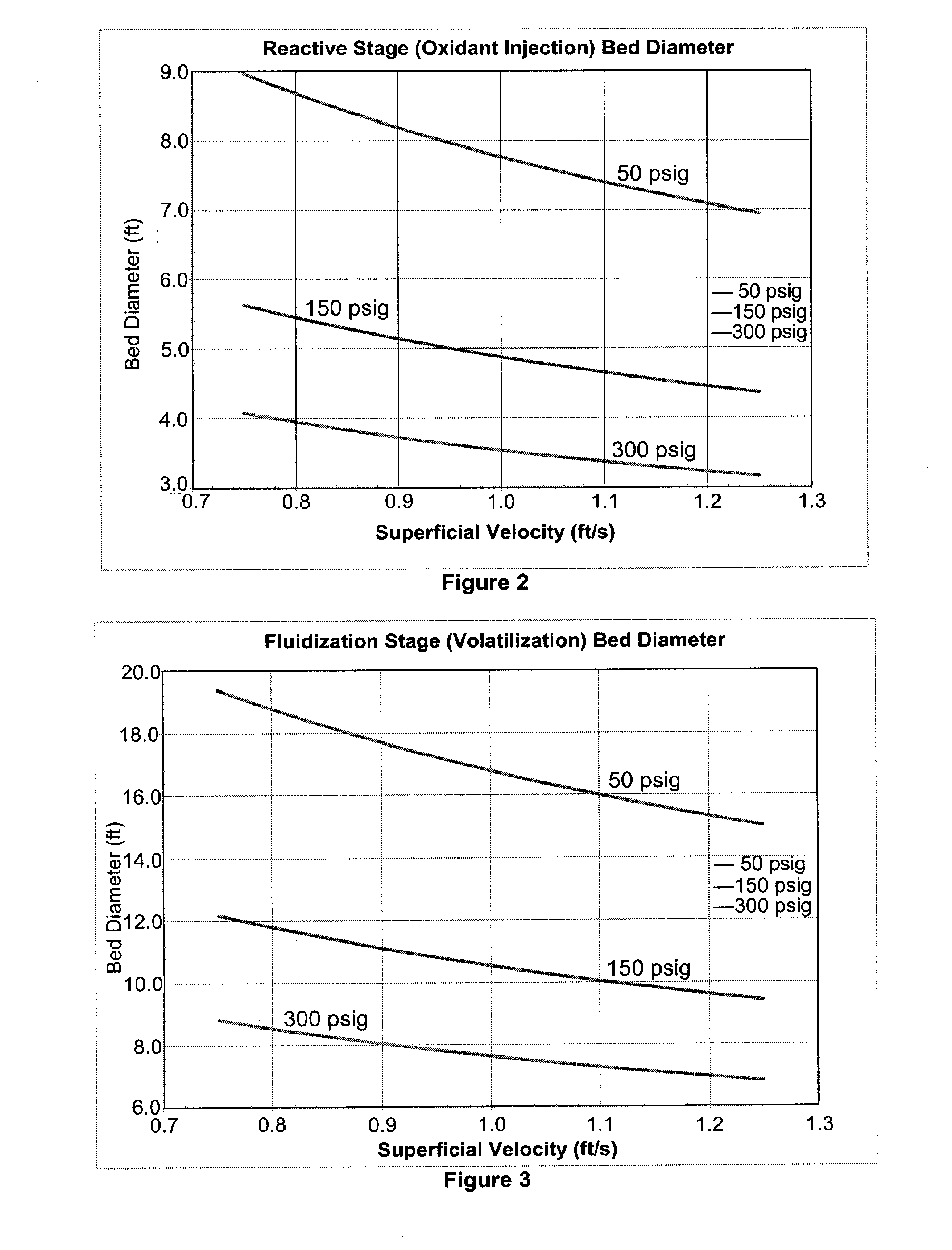

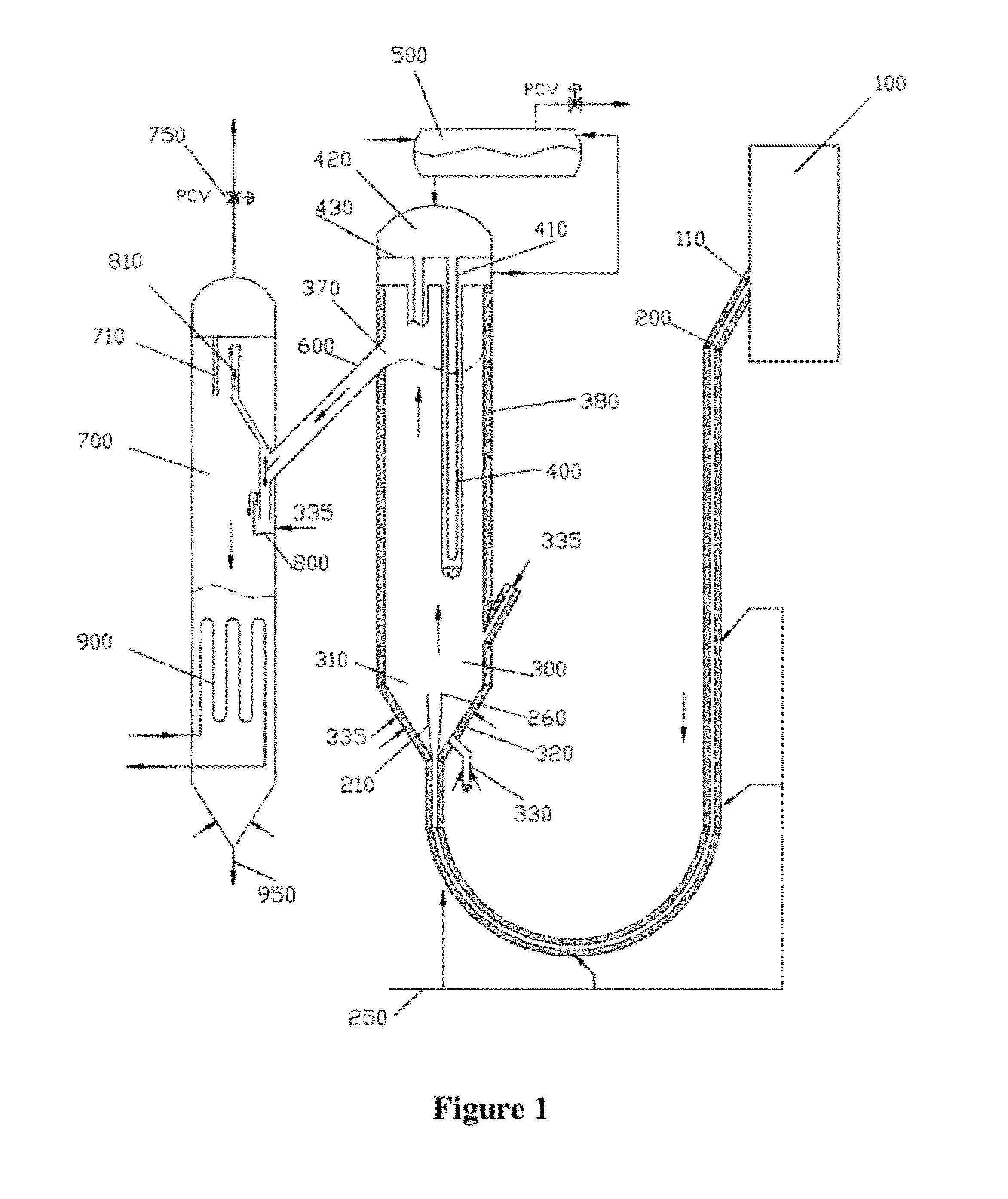

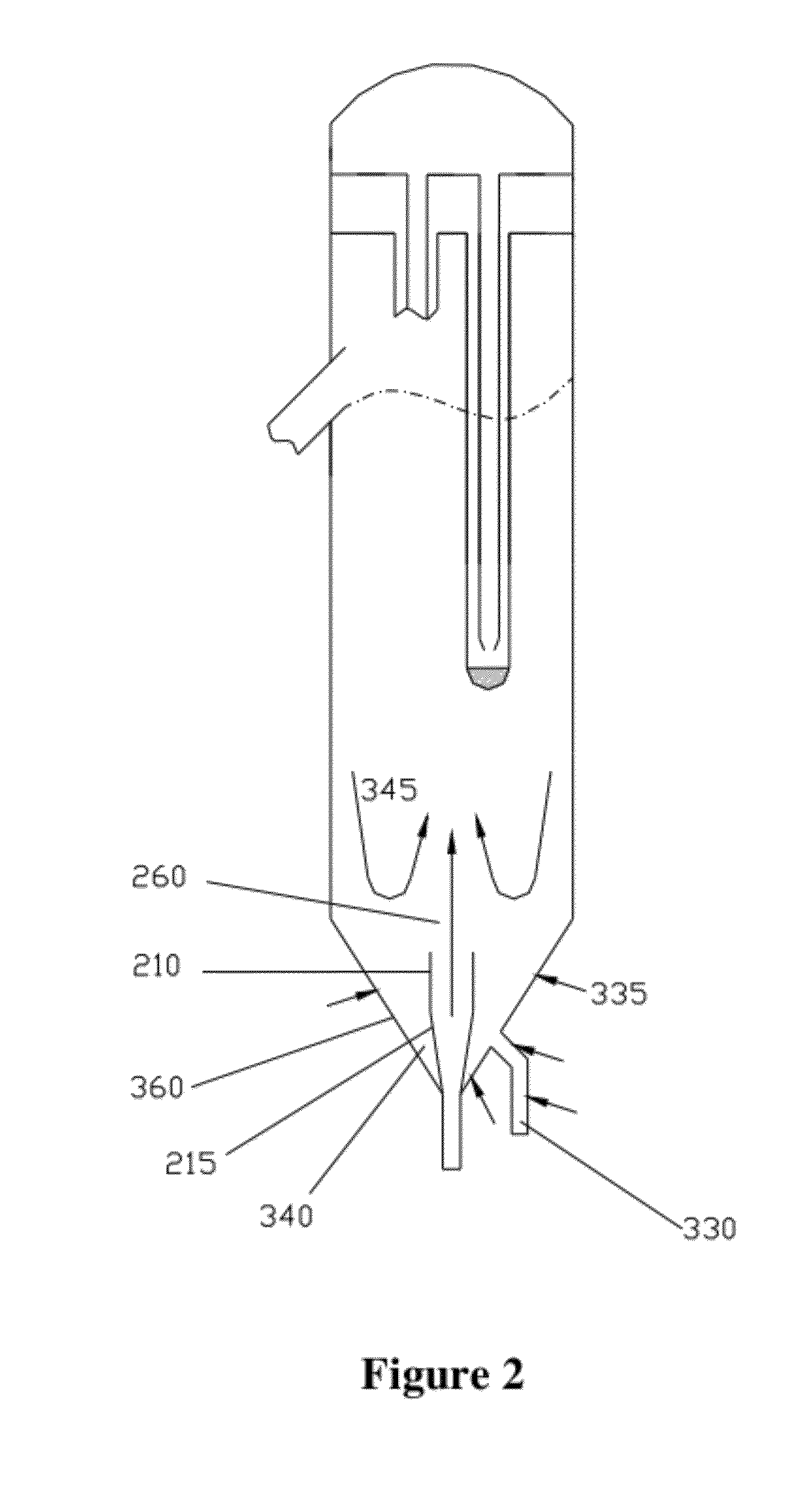

The invention provides systems and methods for converting biomass into syngas using a pressurized multi-stage progressively expanding fluidized bed gasifier to eliminate or reduce the formation of methane, volatiles such as BTX, and tars. The gasifier may include a reactive stage that may receive a biomass feed through a feed line and oxygen through an oxygen feed line. The gasifier may also include a fluidized bed section that may be configured to receive the reaction products from the first stage, mix them and perform fluidized bed activity. A gasifier may also have a disengagement section that may be configured to separate fluidized media and particulate matter from syngas product. A gasification system may also include oxyblown catalytic autothermal reactor and a cryogenic air separation unit.

Owner:SYNT

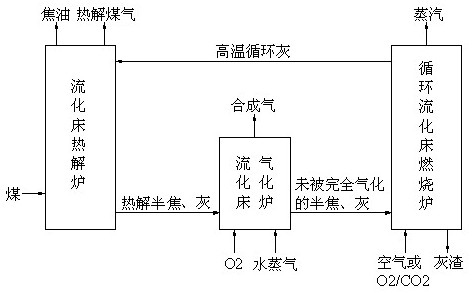

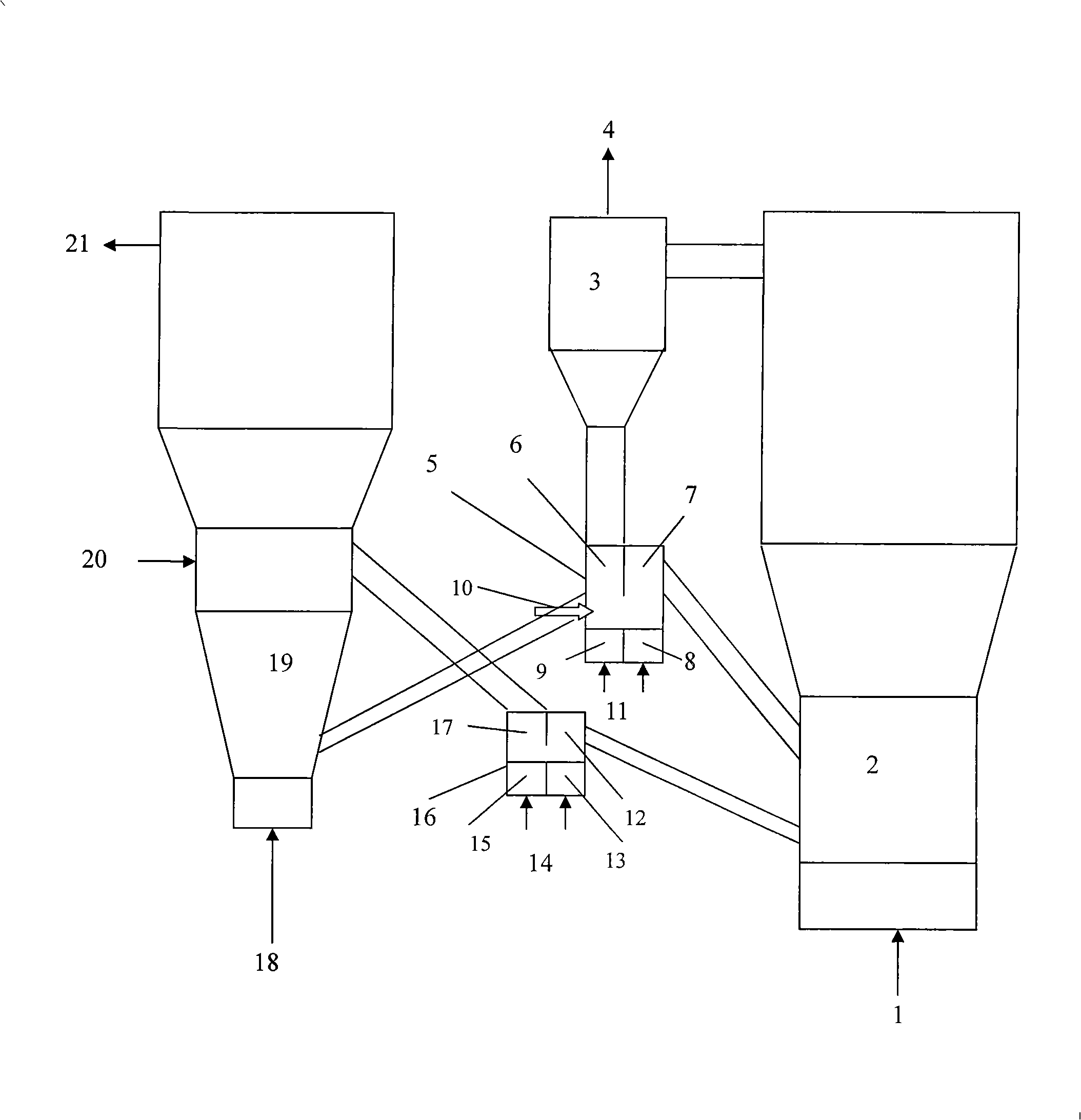

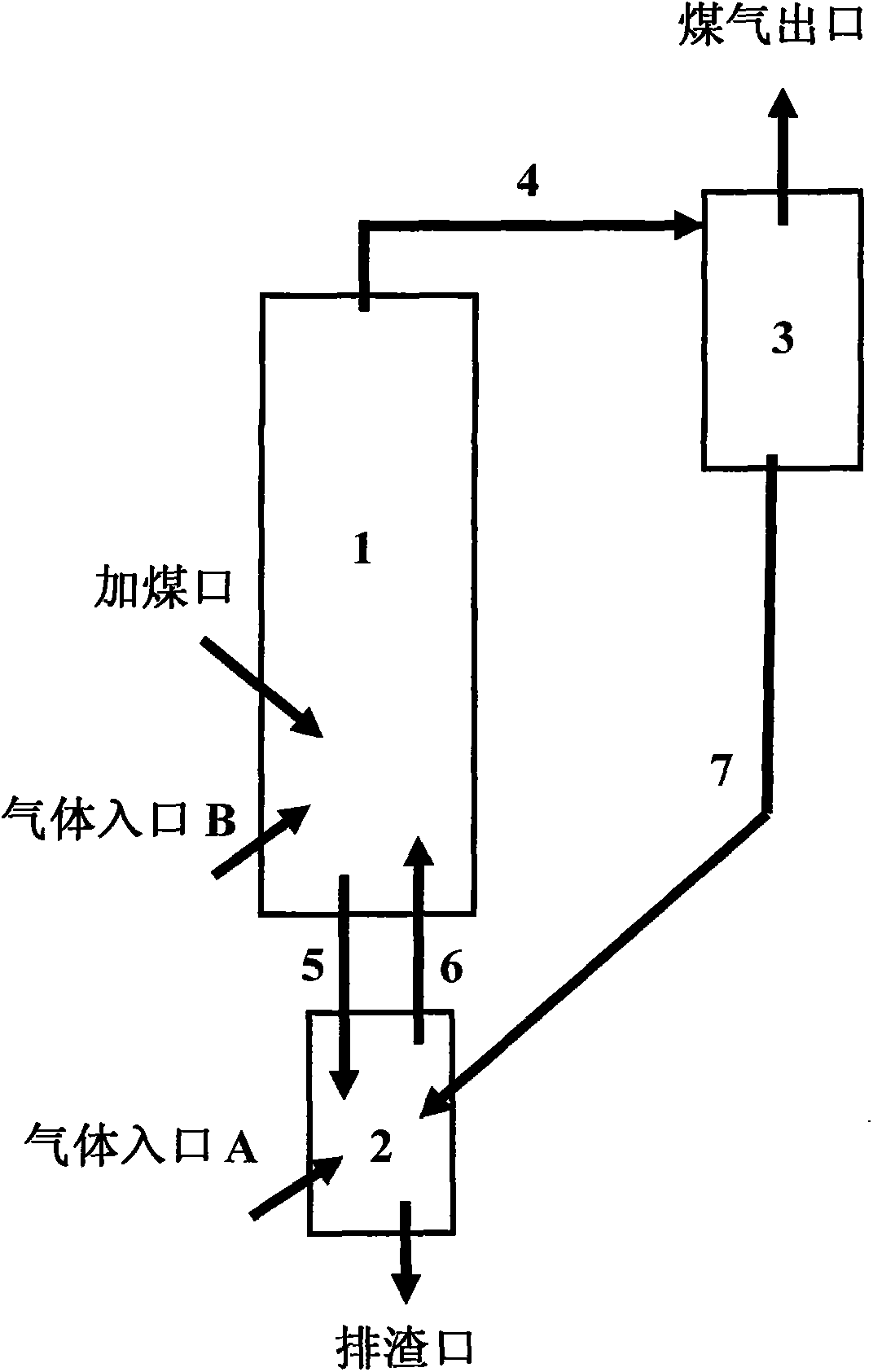

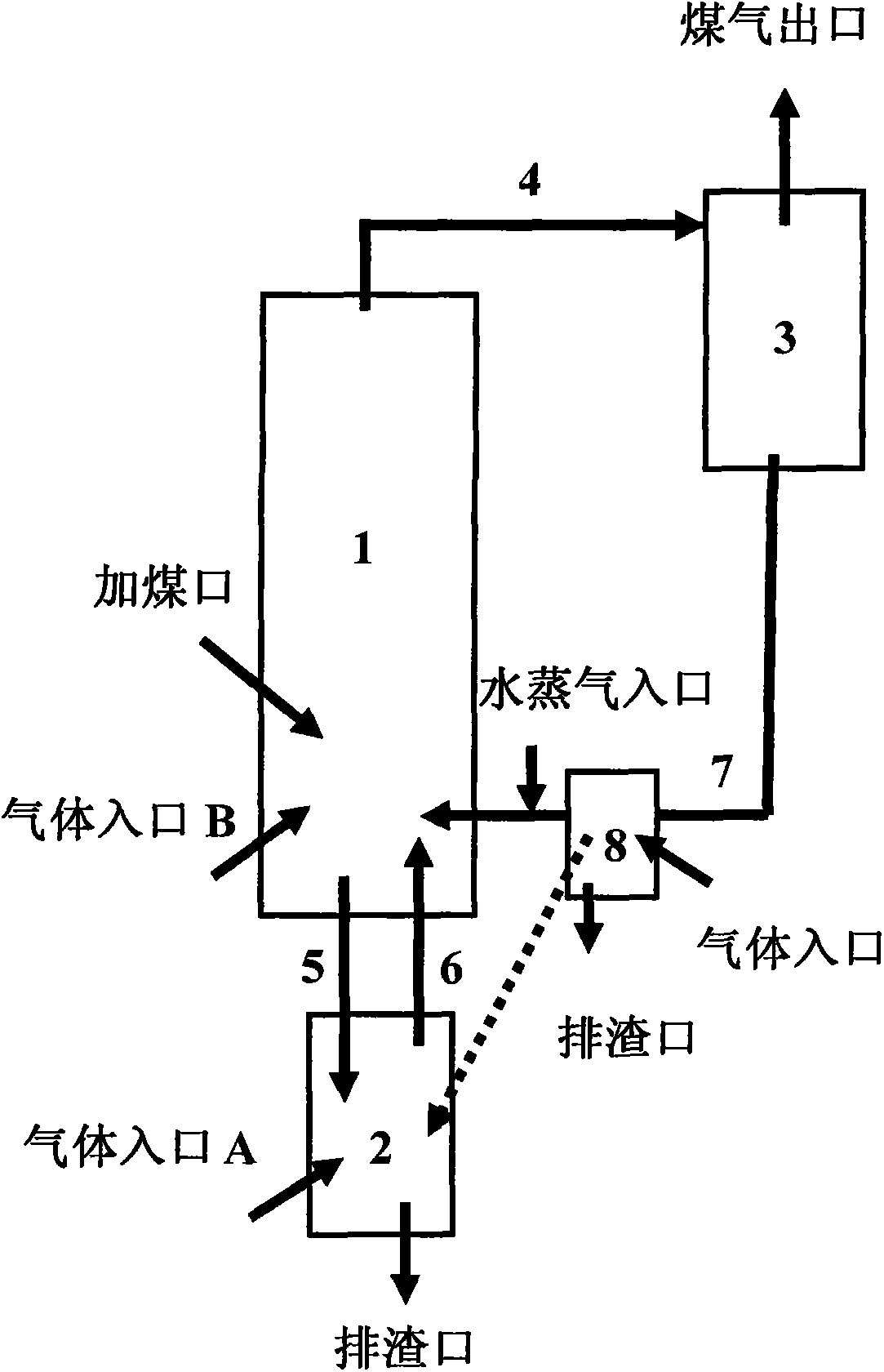

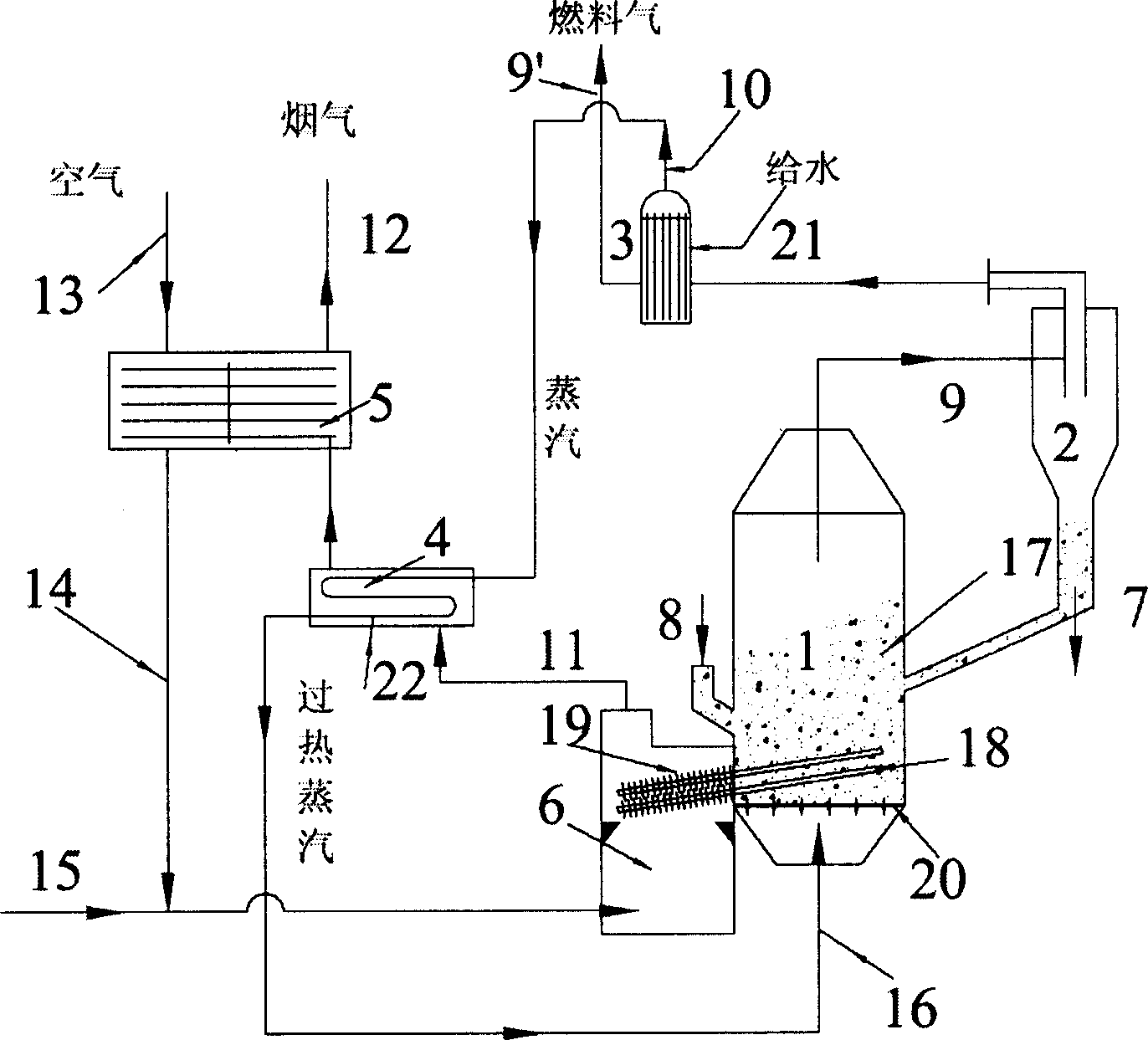

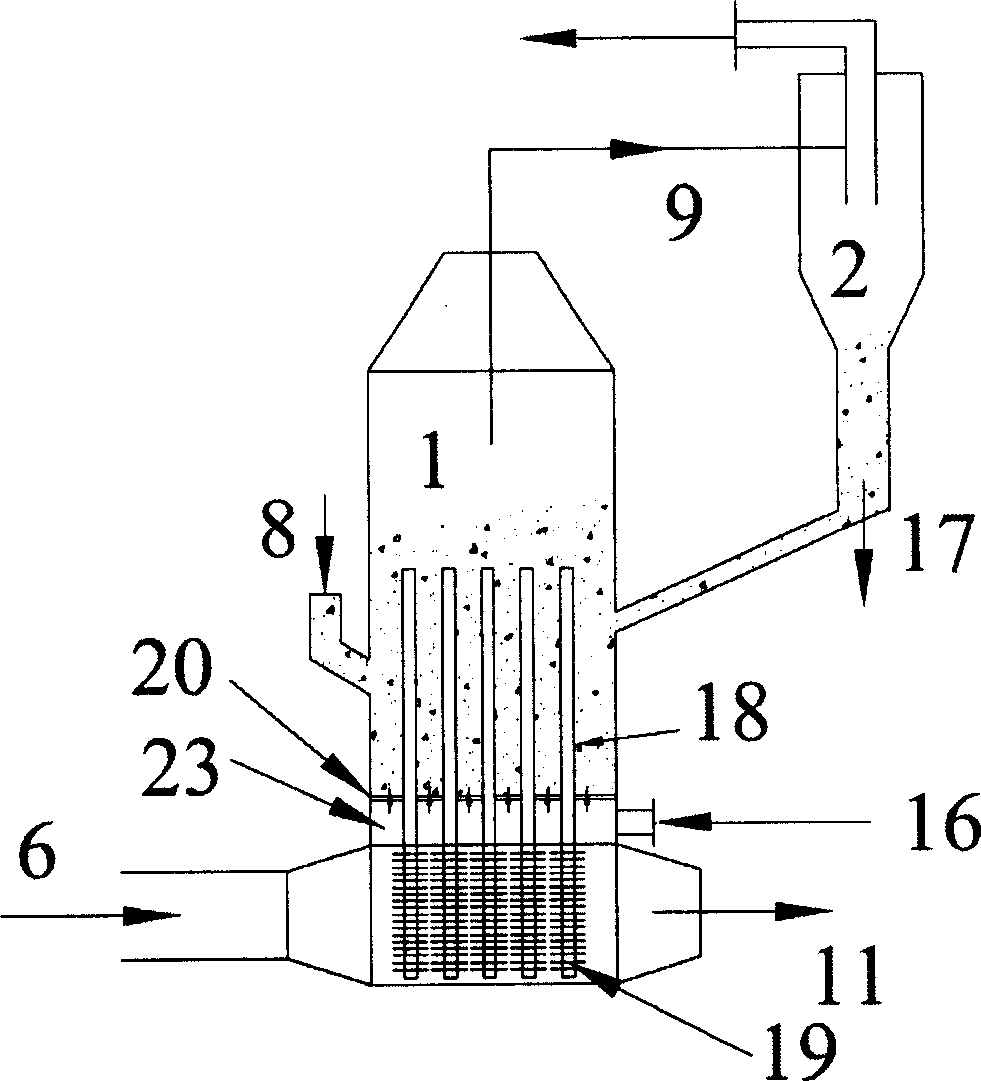

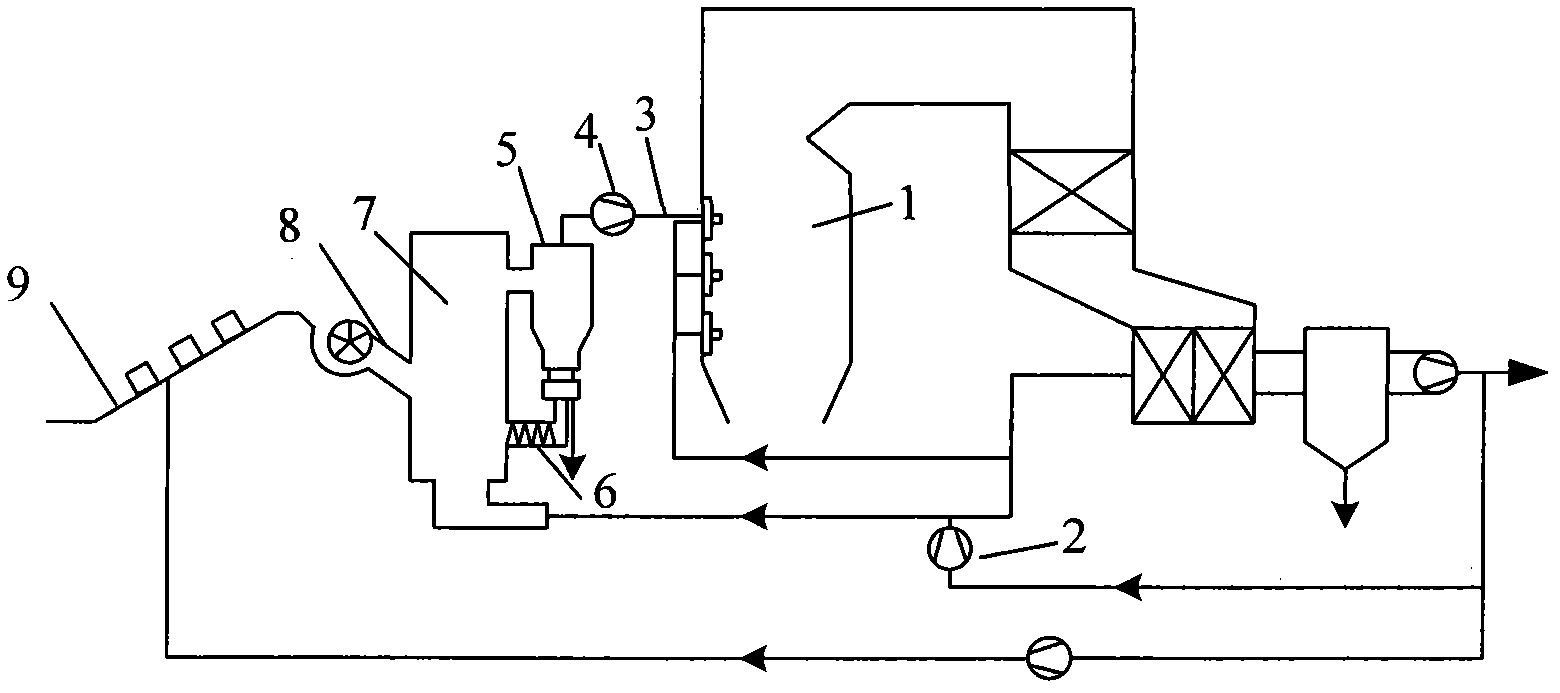

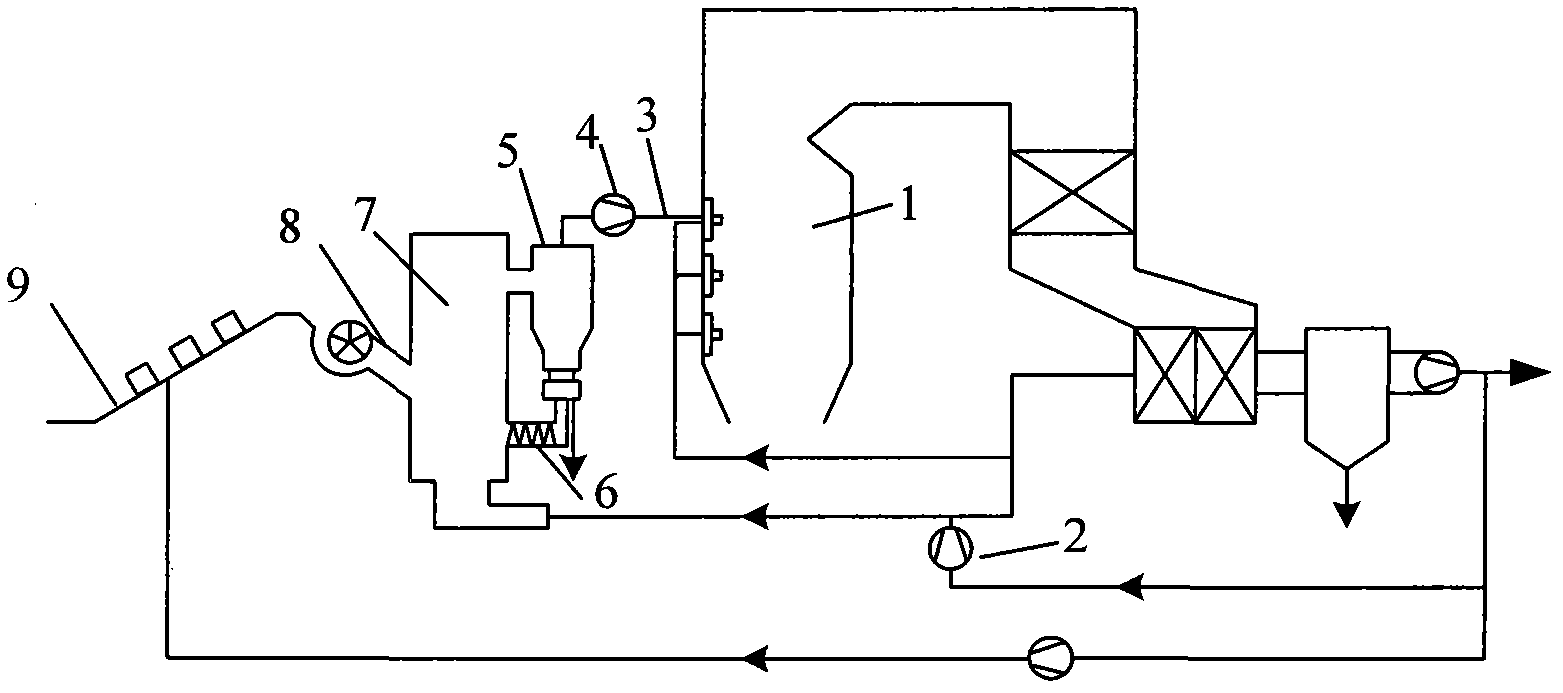

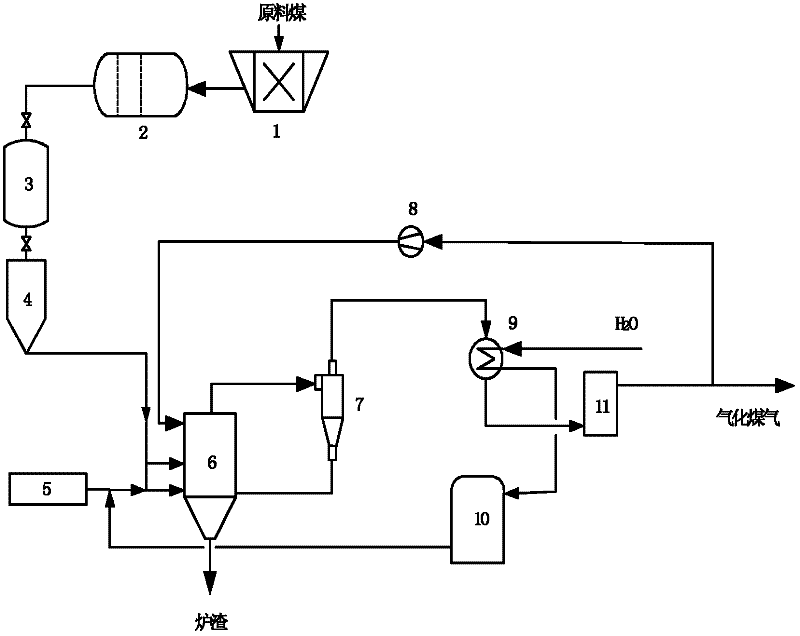

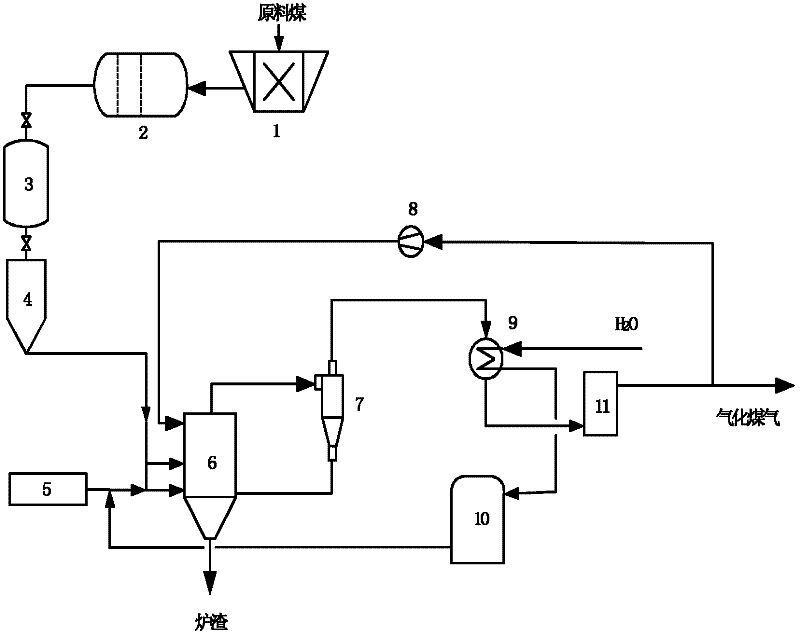

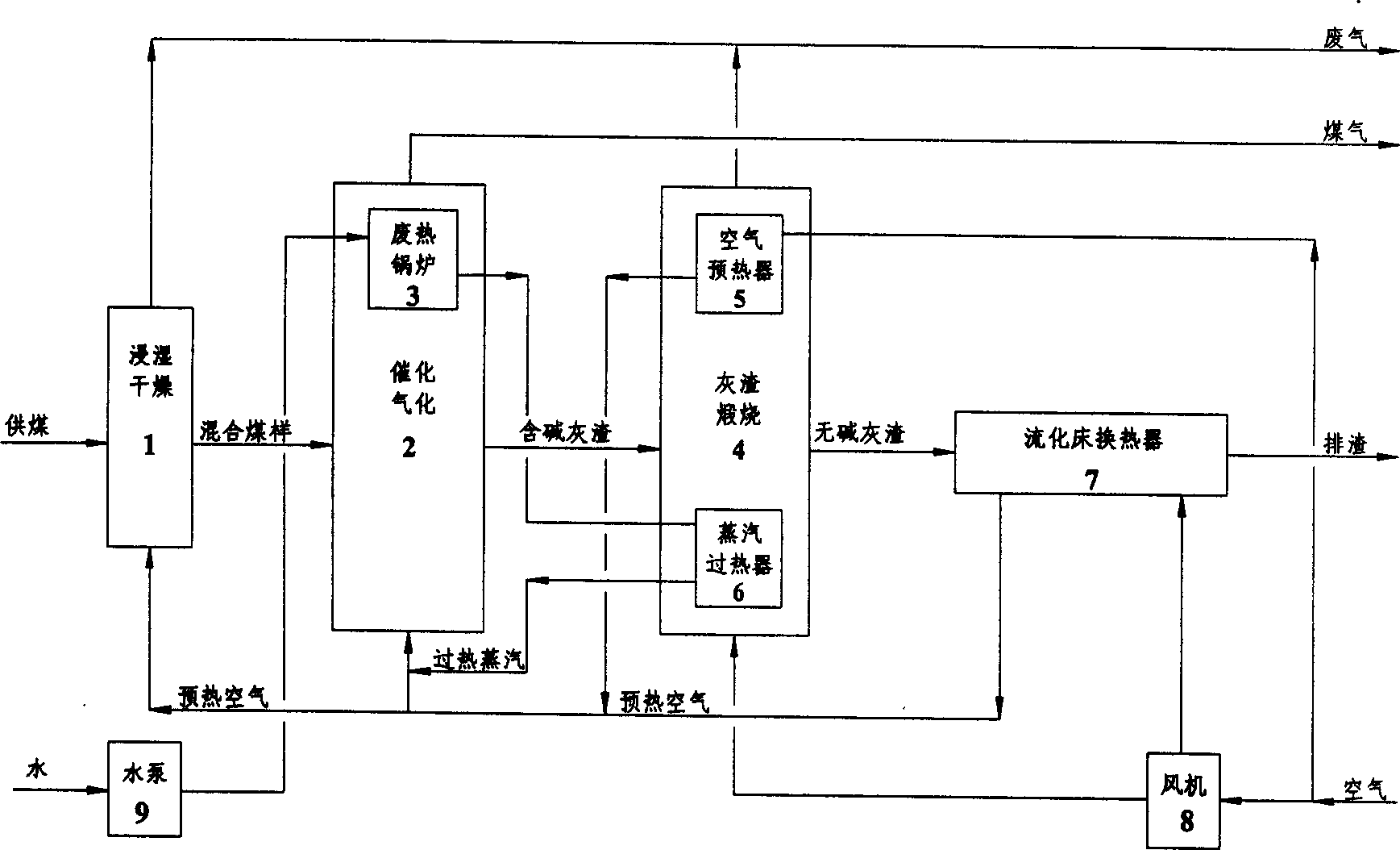

Three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method

InactiveCN102504842AImprove conversion efficiencyImprove utilization efficiencyDirect heating destructive distillationTreatment with hydrotreatment processesFluidized bed gasifierSyngas

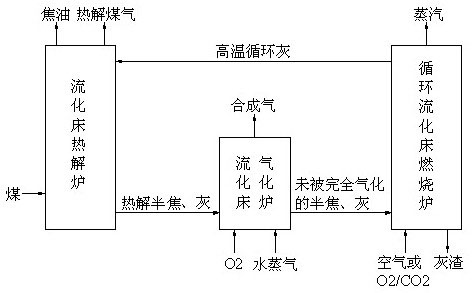

The invention discloses a three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method. The method comprises the following steps of: mixing coal and high temperature circulating ash serving as a solid heat carrier in a fluidized bed pyrolysis furnace, pyrolyzing to separate out volatile, cooling and separating the volatile to obtain tar and pyrolysis gas, conveying pyrolysis semi-coke generated by pyrolyzing the coal to a fluidized bed gasification furnace, performing gasification reaction by using water vapor and O2 as gasification agents to prepare synthesis gas, conveying the semi-coke which is incompletely gasified in the gasification furnace to a circulating fluidized bed combustion furnace, blowing air for the conventional combustion or blowing O2 / CO2 for oxygen-enriched combustion, heating the circulating ash serving as the solid heat carrier, and producing gasification agent vapor required by the gasification furnace by using high temperature flue gas generated by combustion. The method has the advantages that: the tar, the pyrolysis gas and the synthesis gas are co-produced through coal pyrolysis, gasification and combustion cascade utilization, the gasification condition of the semi-coke is reduced, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG UNIV

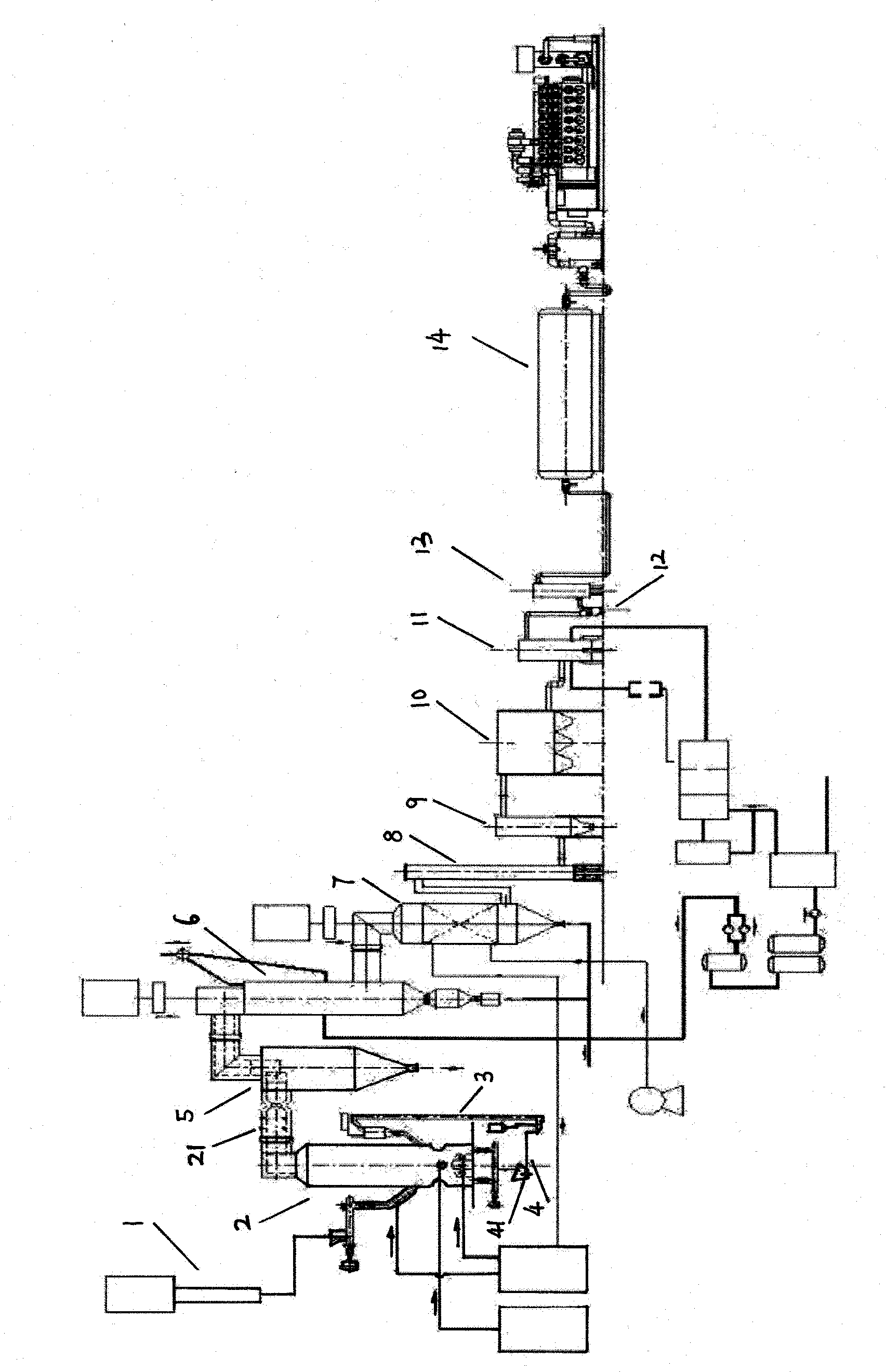

Apparatus and method for gasification of refuse and hyperthermia melt processing of flying ash

ActiveCN101201167AWith waste heat utilizationHigh heat intensity of combustionDamper arrangementIndirect carbon-dioxide mitigationAir preheaterEngineering

A device and method for garbage gasification and flying ash high temperature melting treatment relates to an integrated technology for garbage gasification and flying ash high temperature melting. The invention aims at solving the problem that the heavy metals and dioxins in the ash collected by a hop-pocket in an incinerator for garbage gasification exceeds the standard limits greatly. The device is formed in the way that a fluidized bed gasifier is communicated with a cyclone furnace; the cyclone furnace is communicated with a burnt chamber and the burnt chamber is communicated with a flue. The method includes that the smoke and gas generated by the gasification of the garbage in the fluidized bed gasifier enters the cyclone furnace and burns with the help of coal powder; the heavy metals in the flying ash are reduced to metals and recycled; the dioxins in the flying ash are decomposed; the exhaust smoke and gas enters a tail gas treatment device after entering the burnt chamber, a superheater, a coal saving device and an air preheater. The invention leads the smoke and gas generated by the gasification and burning of the garbage in the fluidized bed gasifier to enter the cyclone furnace for high temperature melting treatment so as to lead the dioxins in the tail gas collecting ash and in the tail gas to be respectively lower than 50ng-TEQ / kg, 0.1ng-TEQ / m{3}.

Owner:HARBIN INST OF TECH

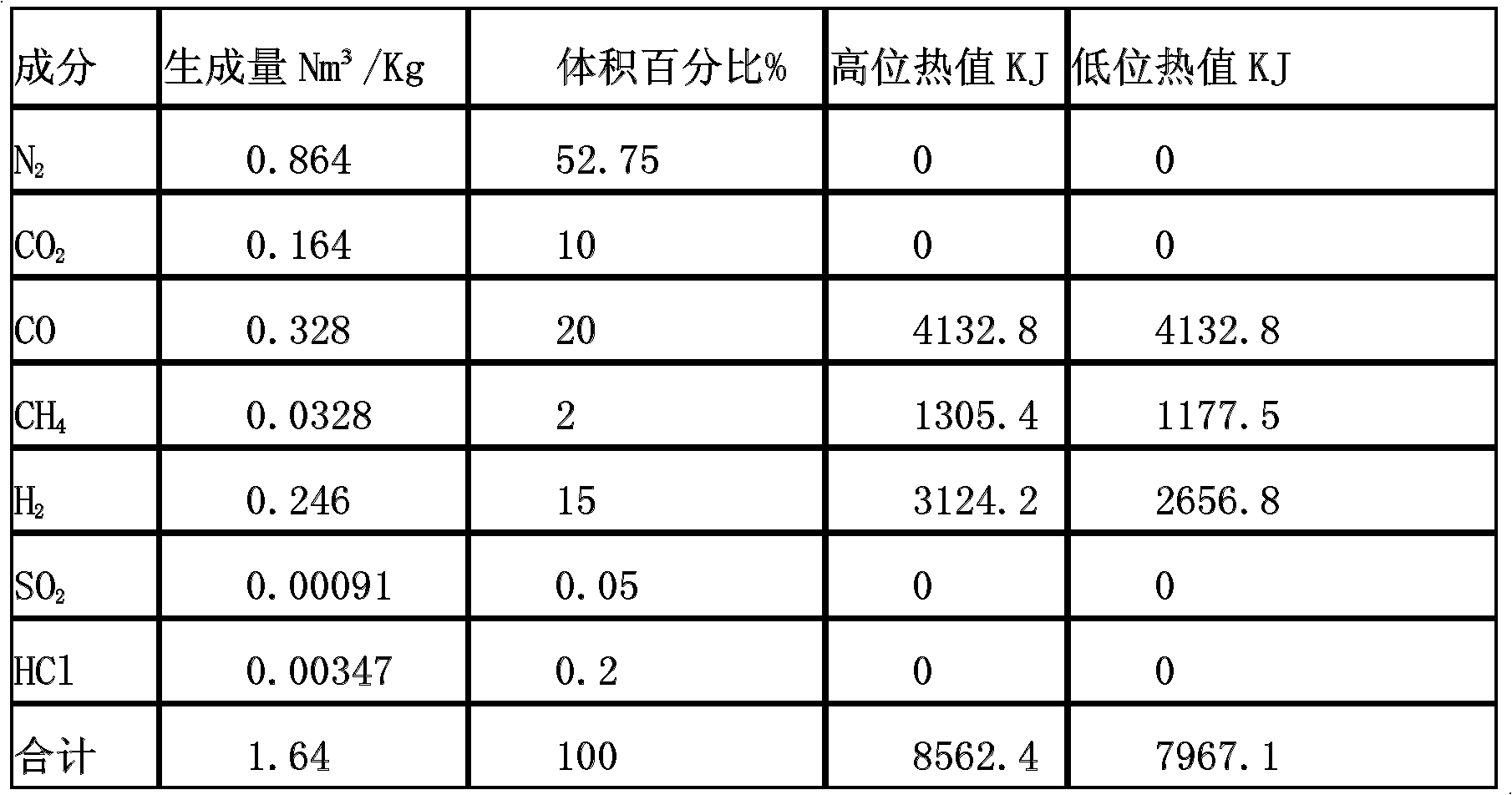

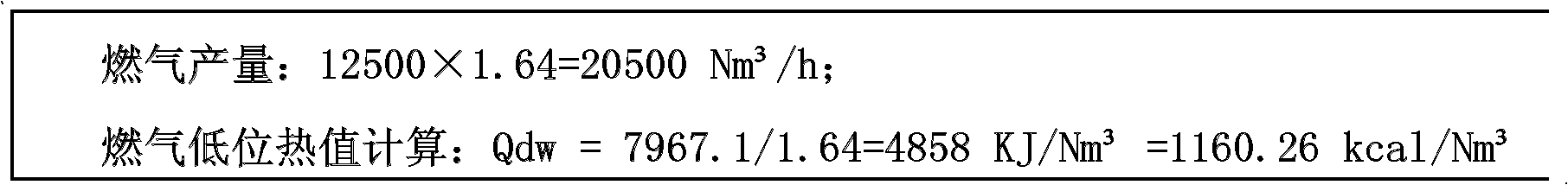

Gasification method and device for biomass and coal mixed fluidized-bed

ActiveCN1557919AEasy to makeRich sourcesGranular/pulverulent flues gasificationWater vaporProduced water

The present invention relates to energy source apparatus, and is one kind of simple biomass-coal mixture gasifying method and apparatus capable of producing high heat value gas and no tar. Inside fluidized bed gasifying furnace, biomass and coal as gasified material is burnt and gasified intermittently. In the burning stage, coal and blast are supplied to the furnace, so that coal is burnt in fluidizing state to produce heat; in the gasifying stage, vapor and biomass are supplied to the furnace, so that the high temperature carbon material layer produces water gas reaction in fluidizing state and biomass is dry distilled and pyrolyzed at high temperature to produce high heat value gas, which is cooled and made to enter the gas purifying system. By combining of biomass and coal with different advantages, the present invention produces high heat value fuel gas without tar.

Owner:JIANGSU UNIV

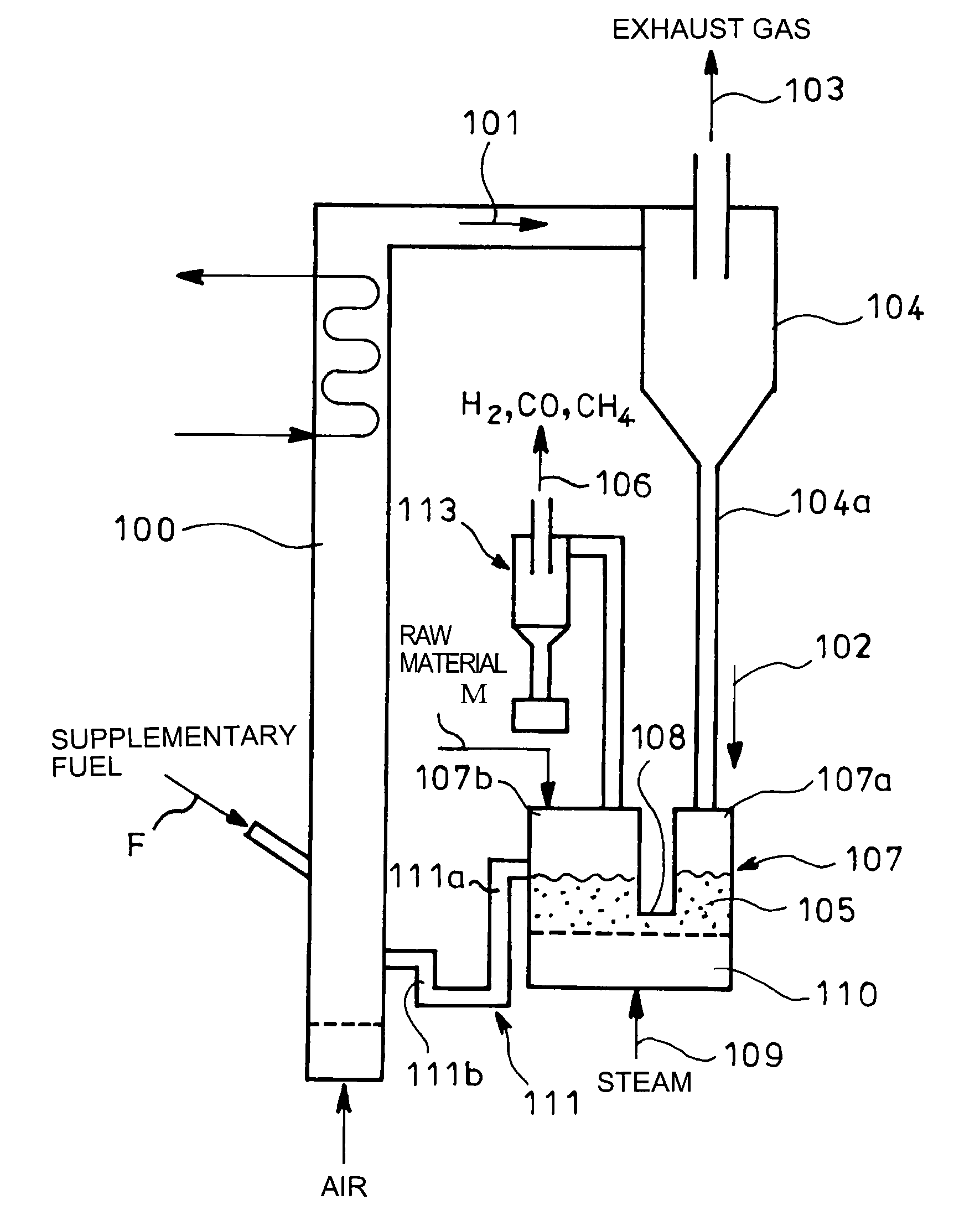

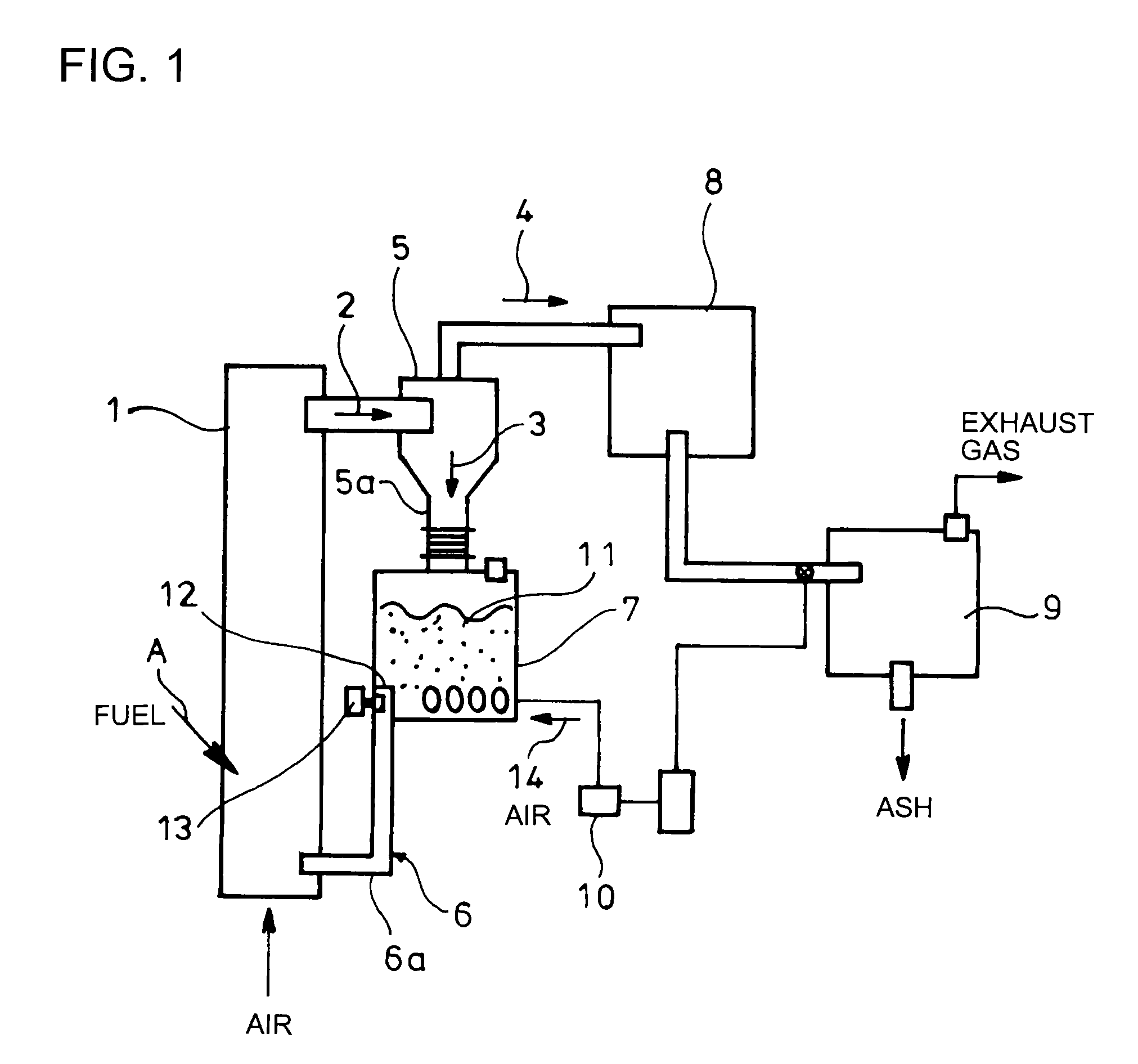

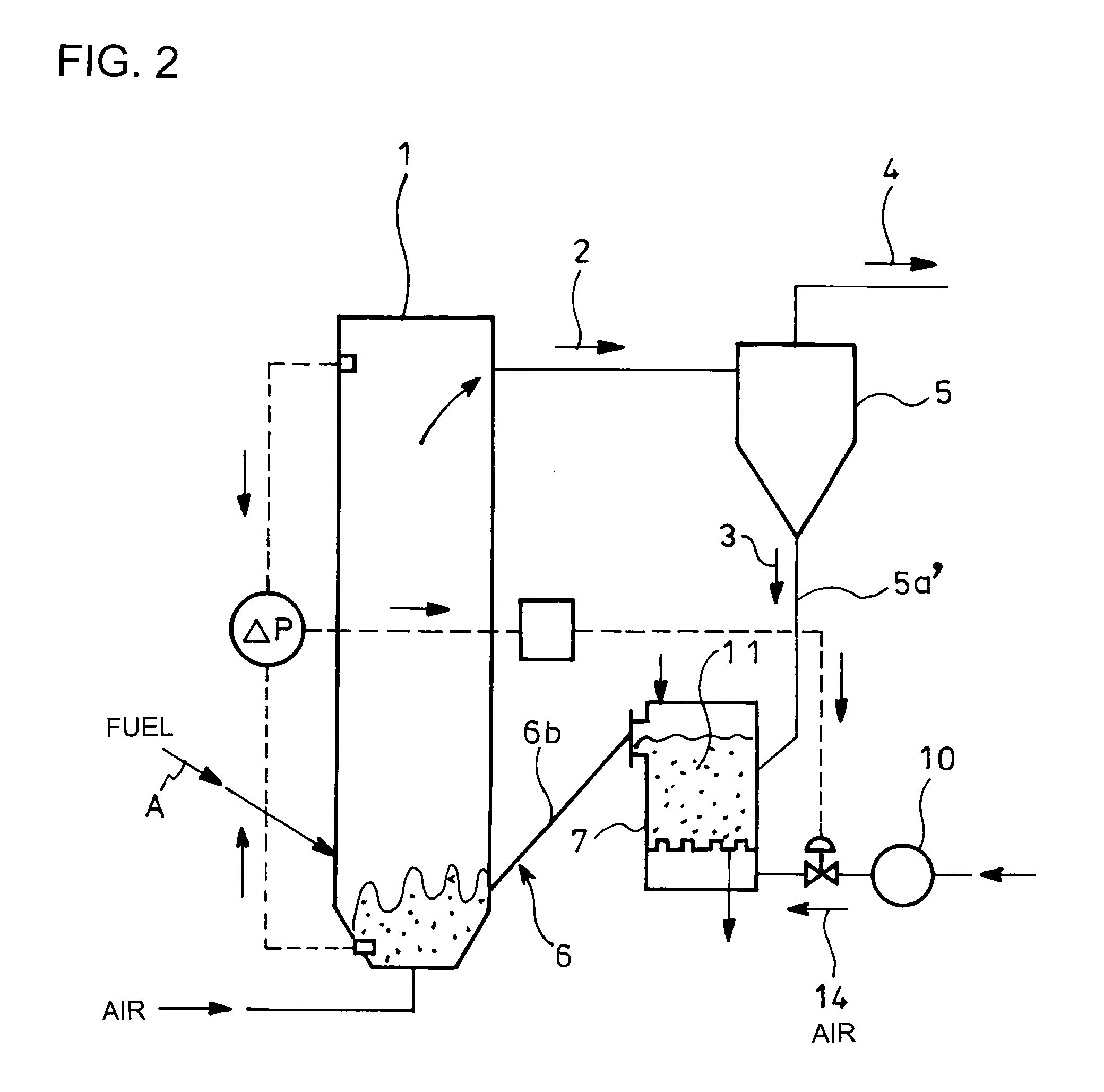

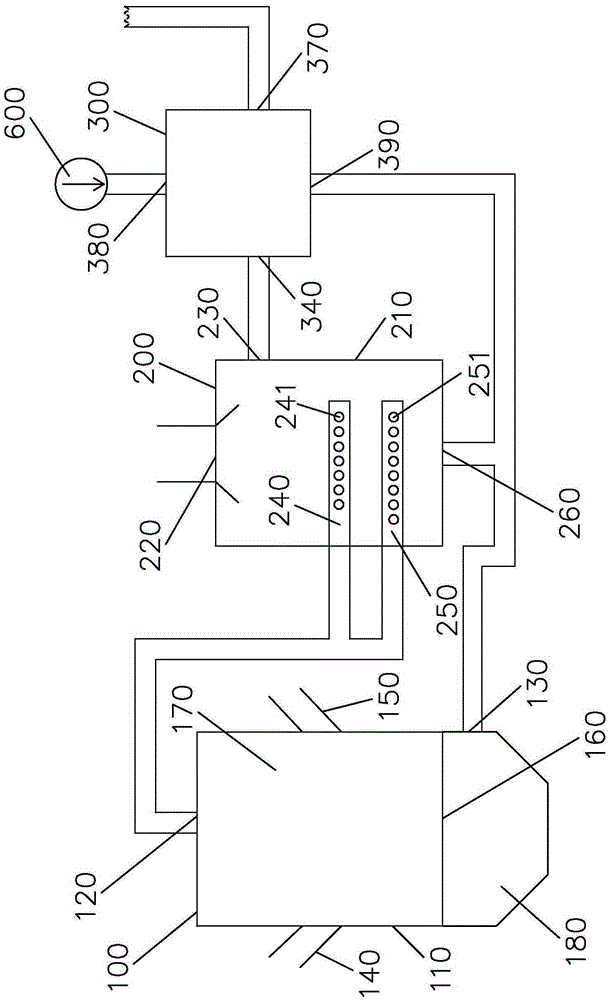

System for controlling circulatory amount of particles in circulating fluidized bed furnace

ActiveUS20100024297A1Improve gasification efficiencyFluidized bed combustionLevel controlFluidized bed gasifierDifferential pressure

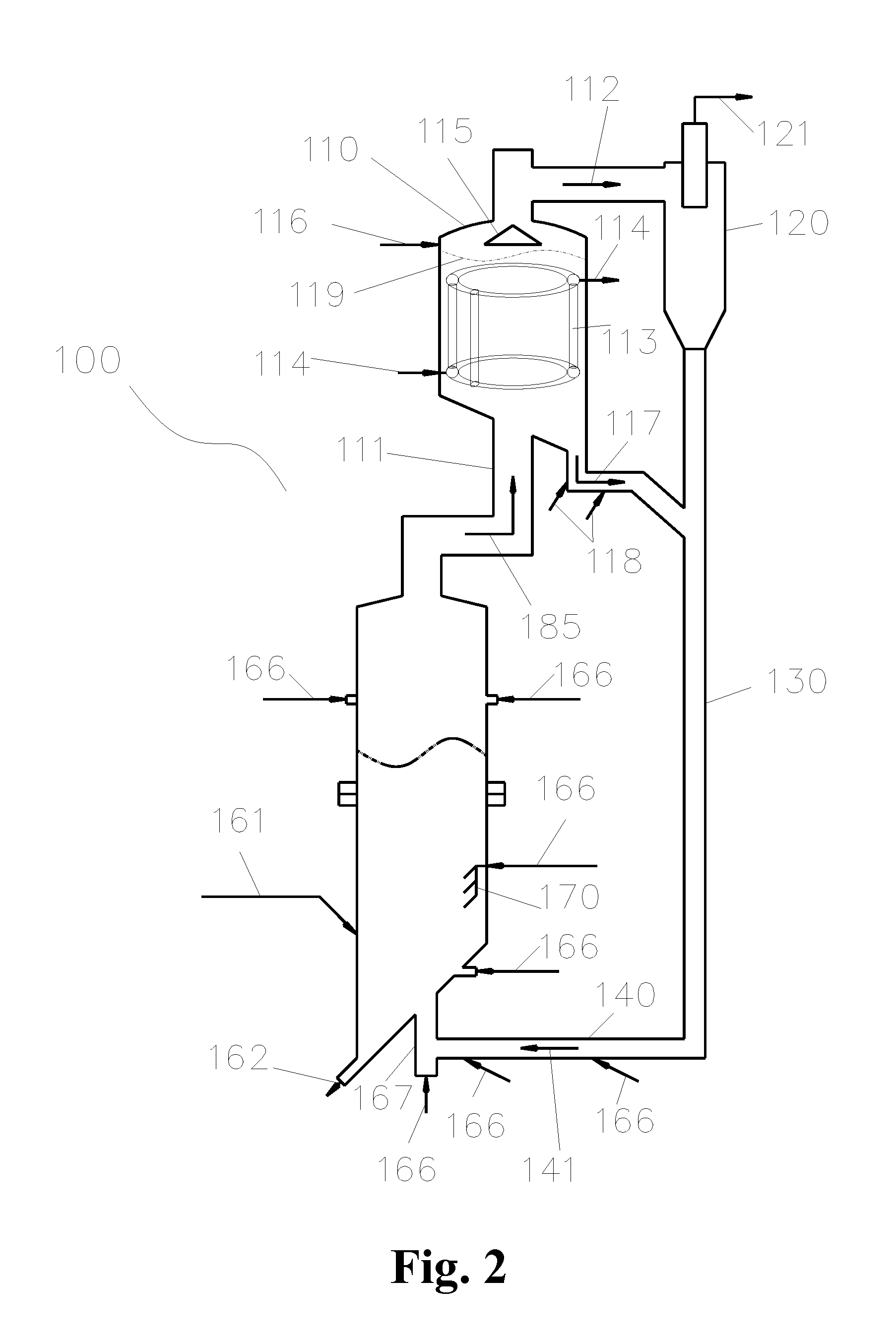

The invention has its object to arbitrarily adjust an amount of particles to be circulated without changing a flow rate of a gasification agent to thereby enhance gasification efficiency in a fluidized bed gasification furnace.The fluidized bed gasification furnace 107 comprises first and second chambers 113 and 114 in communication with each other in a fluidized bed 105. The hot particles 102 separated in the separator 104 and raw material M are introduced into the first chamber 113. The particles 102 introduced from the first chamber 113 through interior in the fluidized bed 105 to the second chamber 114 are supplied in an overflow manner to the fluidized bed combustion furnace 100. A first pressure controller 121 is provided to control the resultant gas induction means 116 such that the pressure in the first chamber 113 is kept to preset pressure 120; and a second pressure controller 124 is provided to control the exhaust gas induction means 118 such that difference between pressure in the first and second chambers 113 and 114 is equal to the preset differential pressure 123, so that the fluidized bed 105 in the first chamber 113 is controlled in height to control an amount of particles 102 to be circulated.

Owner:IHI CORP

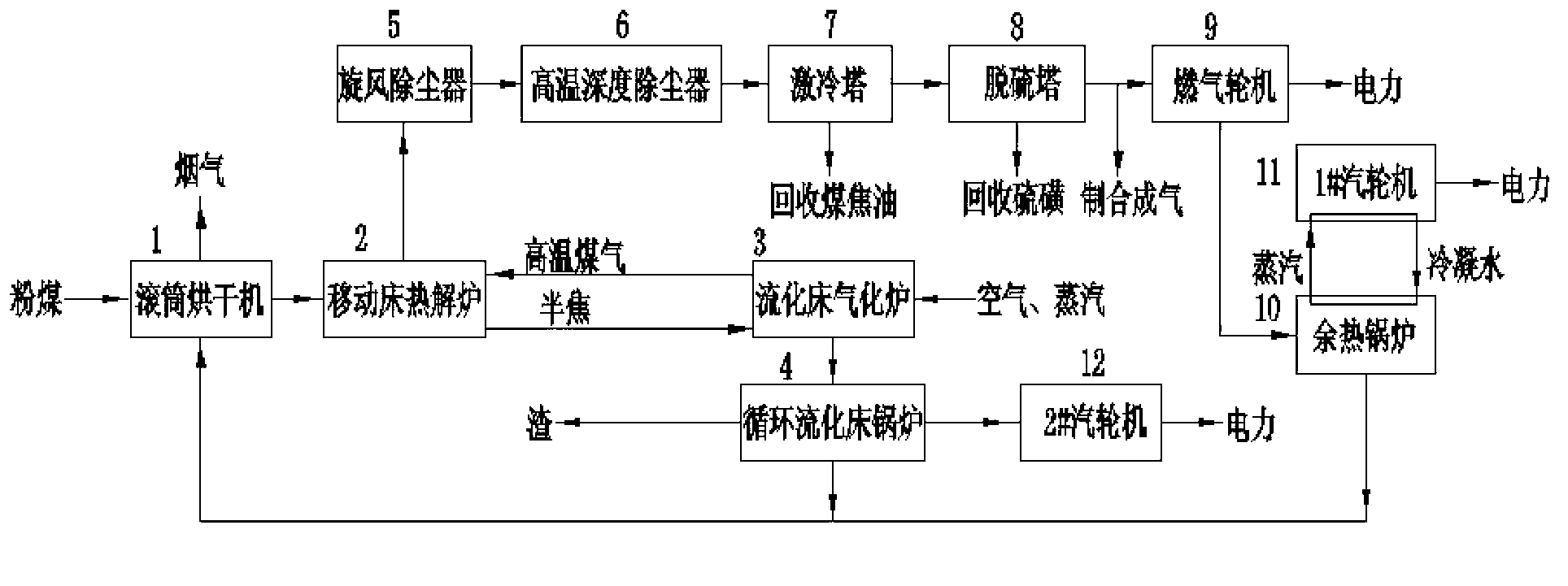

IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal

InactiveCN103013576ATake advantage ofAchieve integrationEnergy inputGas turbine plantsResource utilizationChemical products

The invention discloses an IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal. The device comprises a pyrolysis / gasification system, a coal gas purifying system, a circulating fluidized bed boiler and a gas turbine / steam turbine system. The method comprises the steps as follows: carrying out low temperature pyrolysis and partial air gasification on the low metamorphic powdered coal, grading and converting into coal gas, tar and semi-coke, and carrying out the IGCC poly-generation process by the semi-coke and the coal gas with high calorific value. According to the device and the method, the tar, sulphur and other chemical products can be produced while clean power is generated, the products obtained by grading and converting the low metamorphic powdered coal are fully utilized, the material conversion and energy conversion functions are integrated, the resource utilization rate is high, and the heat energy efficiency is high. The device and method are suitable for the low metamorphic powdered coal such as peat, brown coal, jet coal, non-sticking coal and the like, and the particle size of raw materials is 0-8 mm. The high-temperature coal gas generated in a fluidized bed gasification furnace contains a large amount of hydrogen, so that the powdered coal can be subjected to hydropyrolysis, and the tar recovery rate can reach more than 12%.

Owner:陕西华祥能源科技集团有限公司

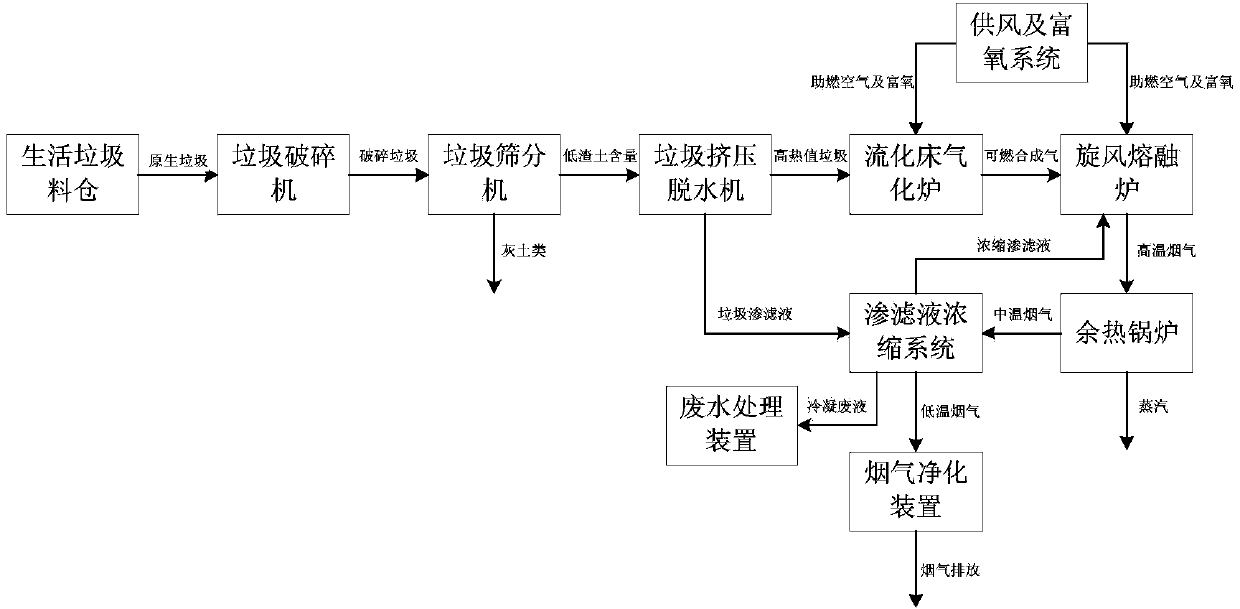

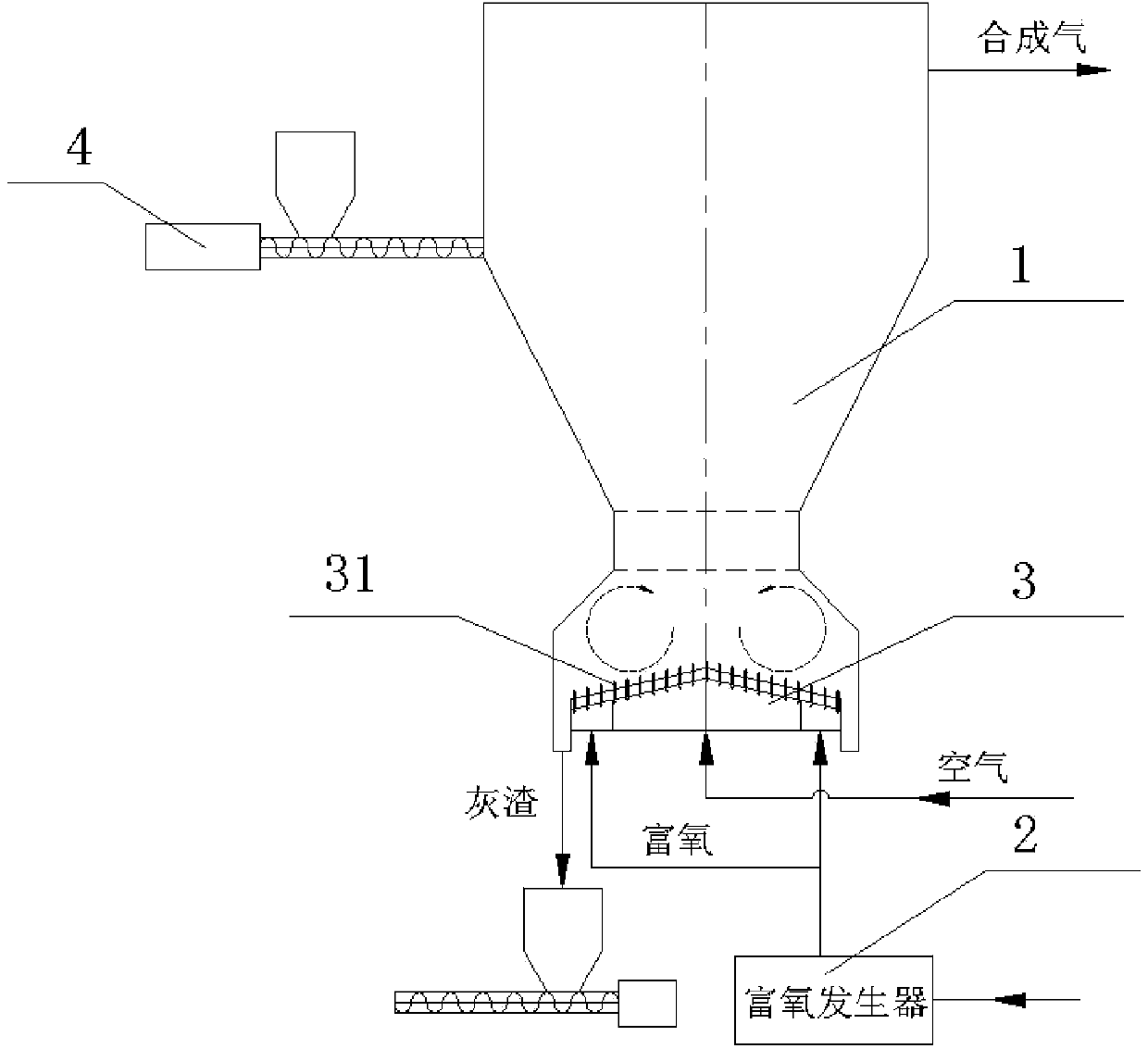

System and method for gasification melting of household refuse and treatment of household refuse leachate

ActiveCN103471105AHigh calorific valueAchieve enrichmentIndirect carbon-dioxide mitigationIncinerator apparatusCrusherTreatment system

The invention provides a system and a method for gasification melting of household refuse and treatment of household refuse leachate. The system comprises a household refuse pretreatment system, a refuse energy recovering system and a refuse leachate concentration and flue gas treatment system, wherein the household refuse pretreatment system comprises a household refuse stock bin, a household refuse crusher, a household refuse sieving machine and a household refuse extrusion dehydrator which are sequentially connected; the refuse energy recovering system comprises a fluidized-bed gasifier, a cyclone melting furnace, a waste heat boiler and an air-supplying and oxygen-enriching system matched with the fluidized-bed gasifier, the cyclone melting furnace and the waste heat boiler; the refuse leachate concentration and flue gas treatment system comprises a leachate concentrating system, a flue gas purifying device and a wastewater treatment device. According to the system, the heat value of the refuge is increased by a pretreatment process; an oxygen-enriching gasifier and a high-temperature cyclone melting furnace technology are used as a recovering system of refuge energy; the refuge leachate is concentrated by using medium-temperature flue gas exhausted by the waste heat boiler; the concentrated leachate is sprayed into the high-temperature cyclone furnace for harmless treatment.

Owner:陕西圣昊朗道科技有限公司

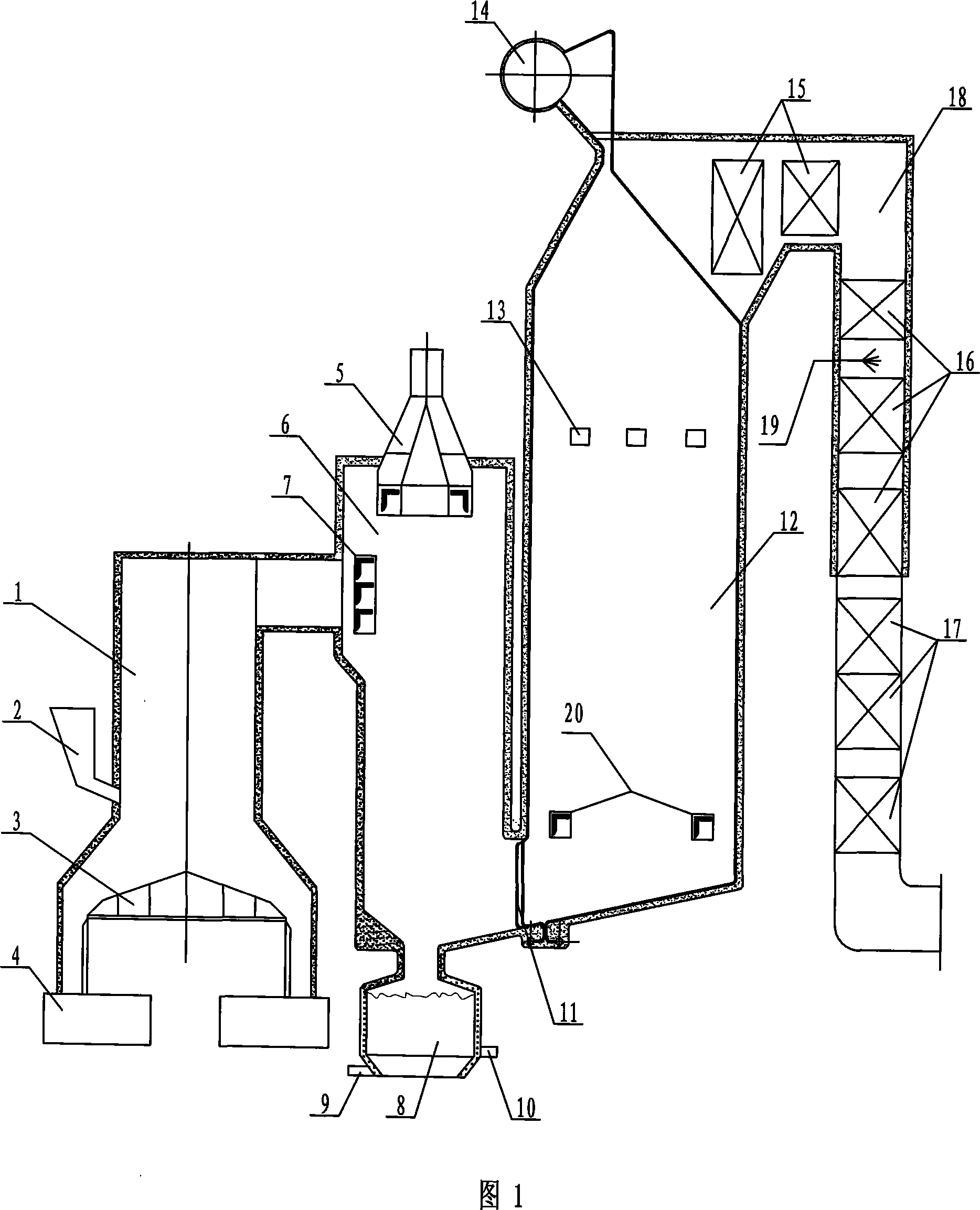

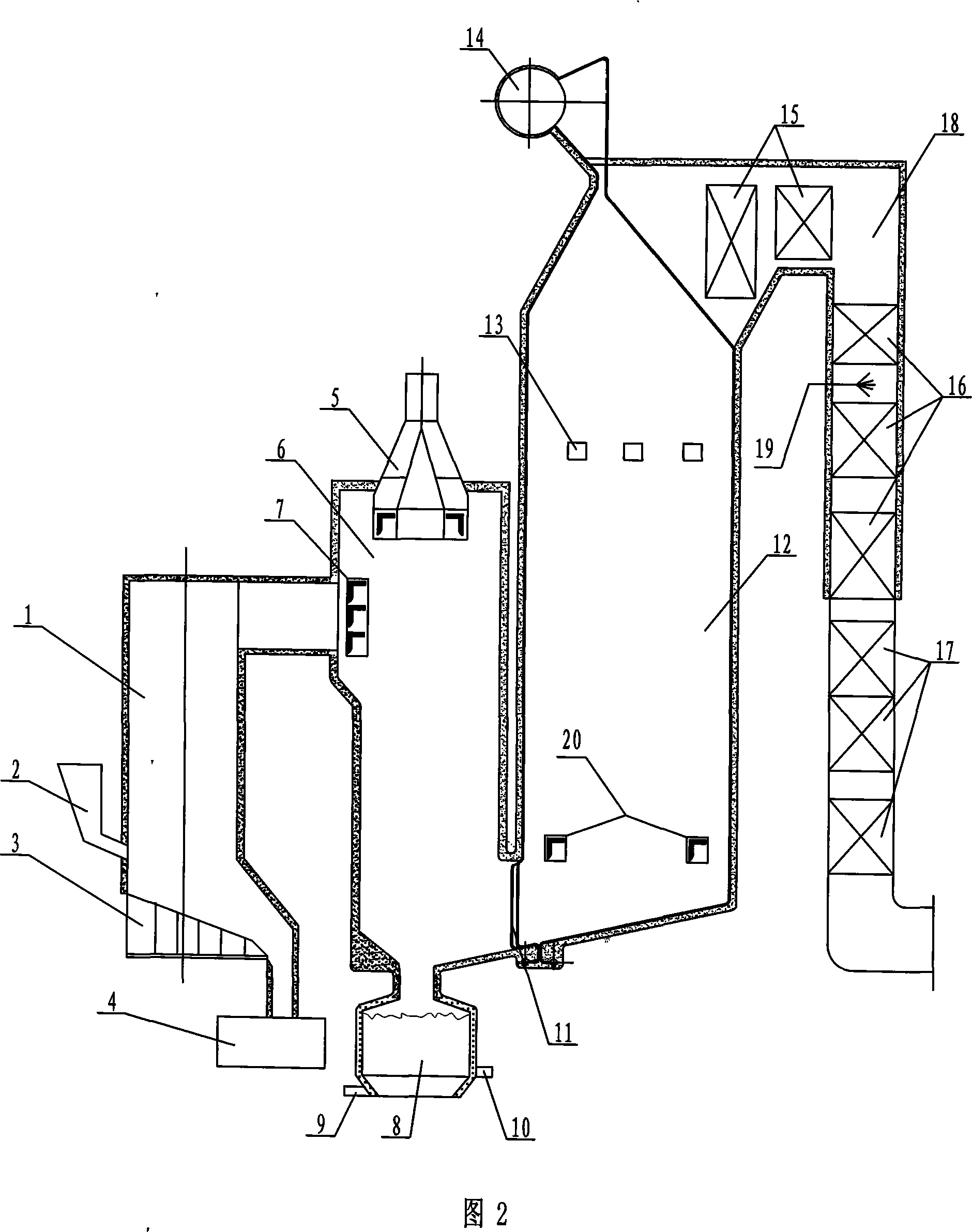

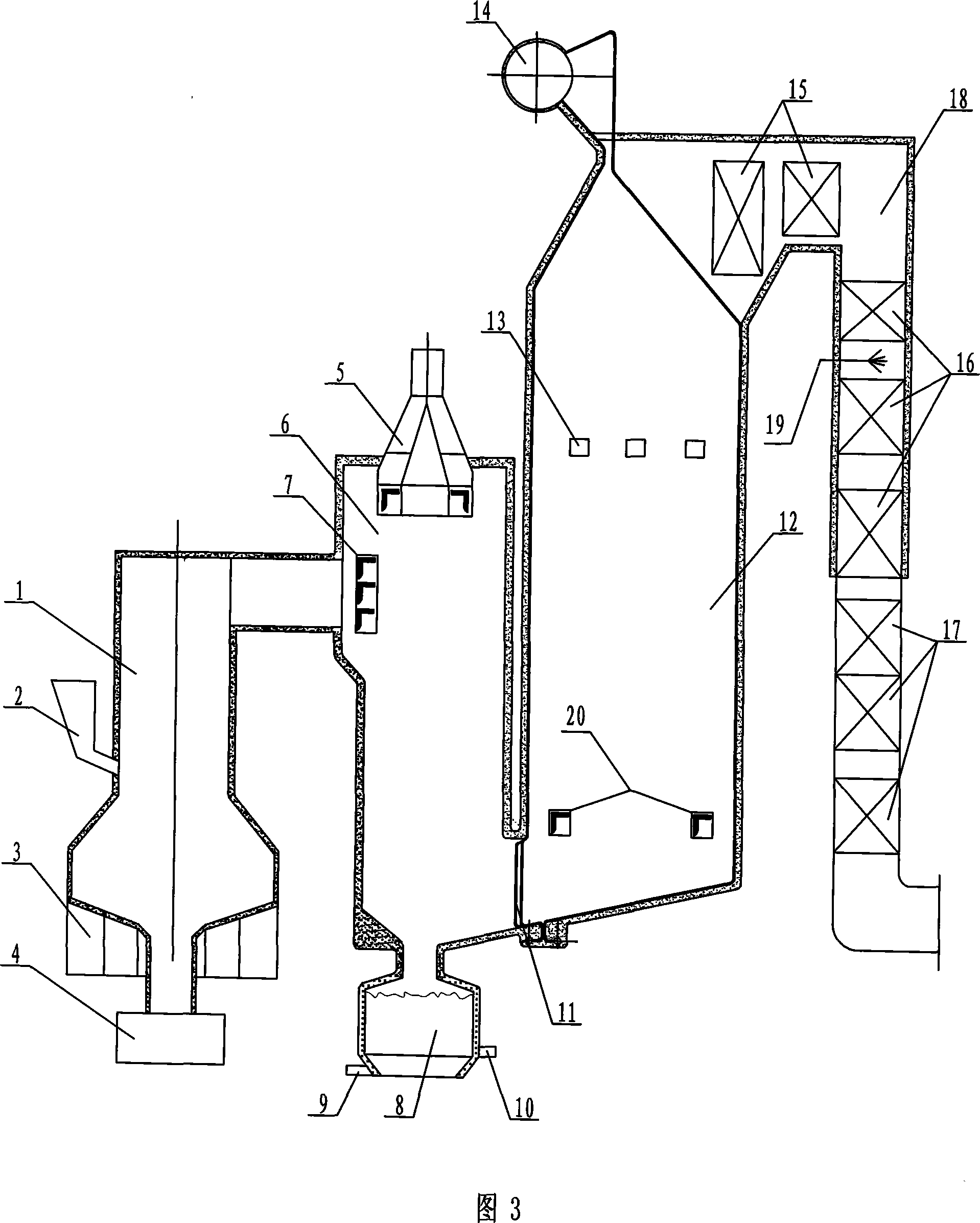

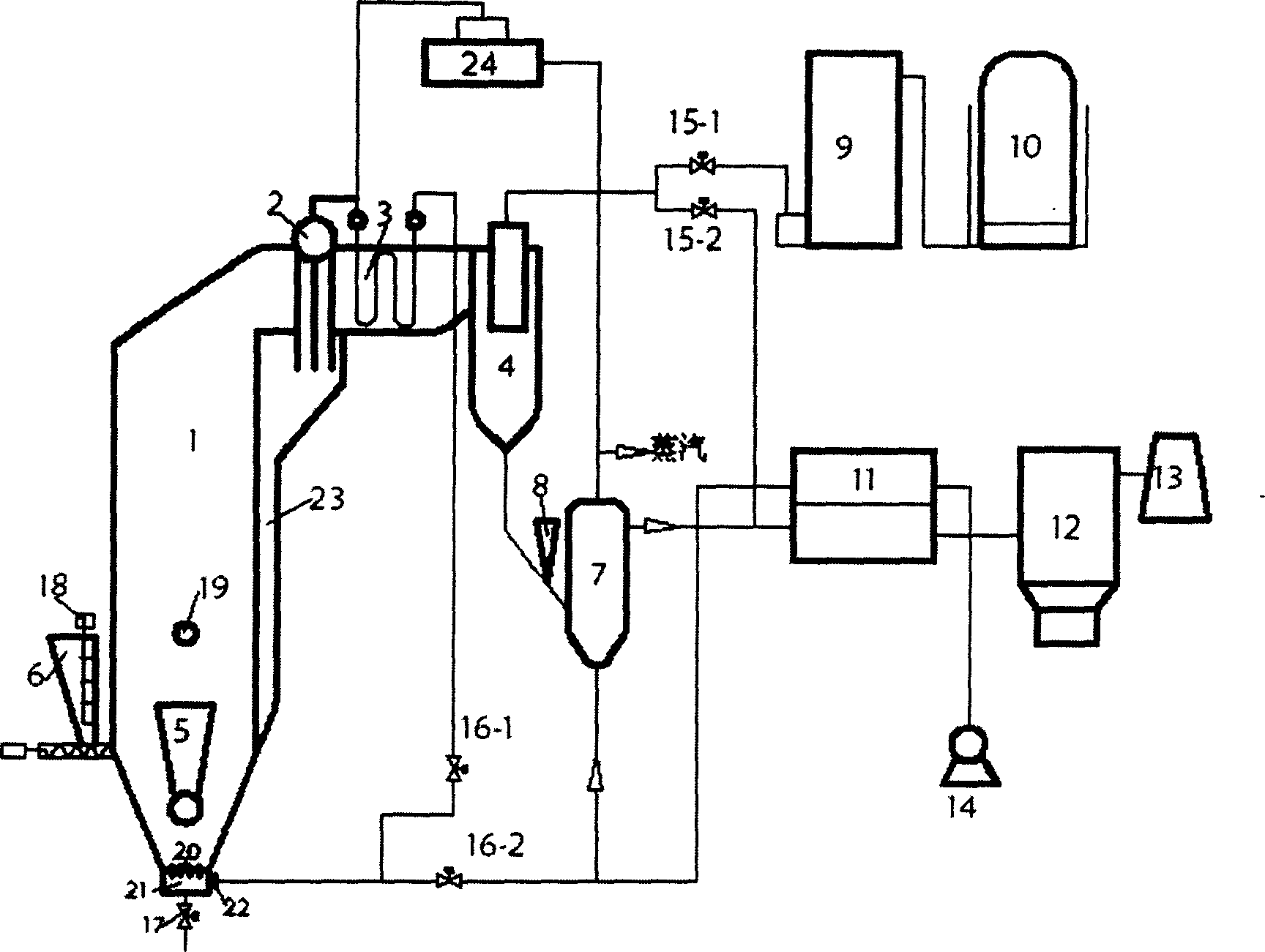

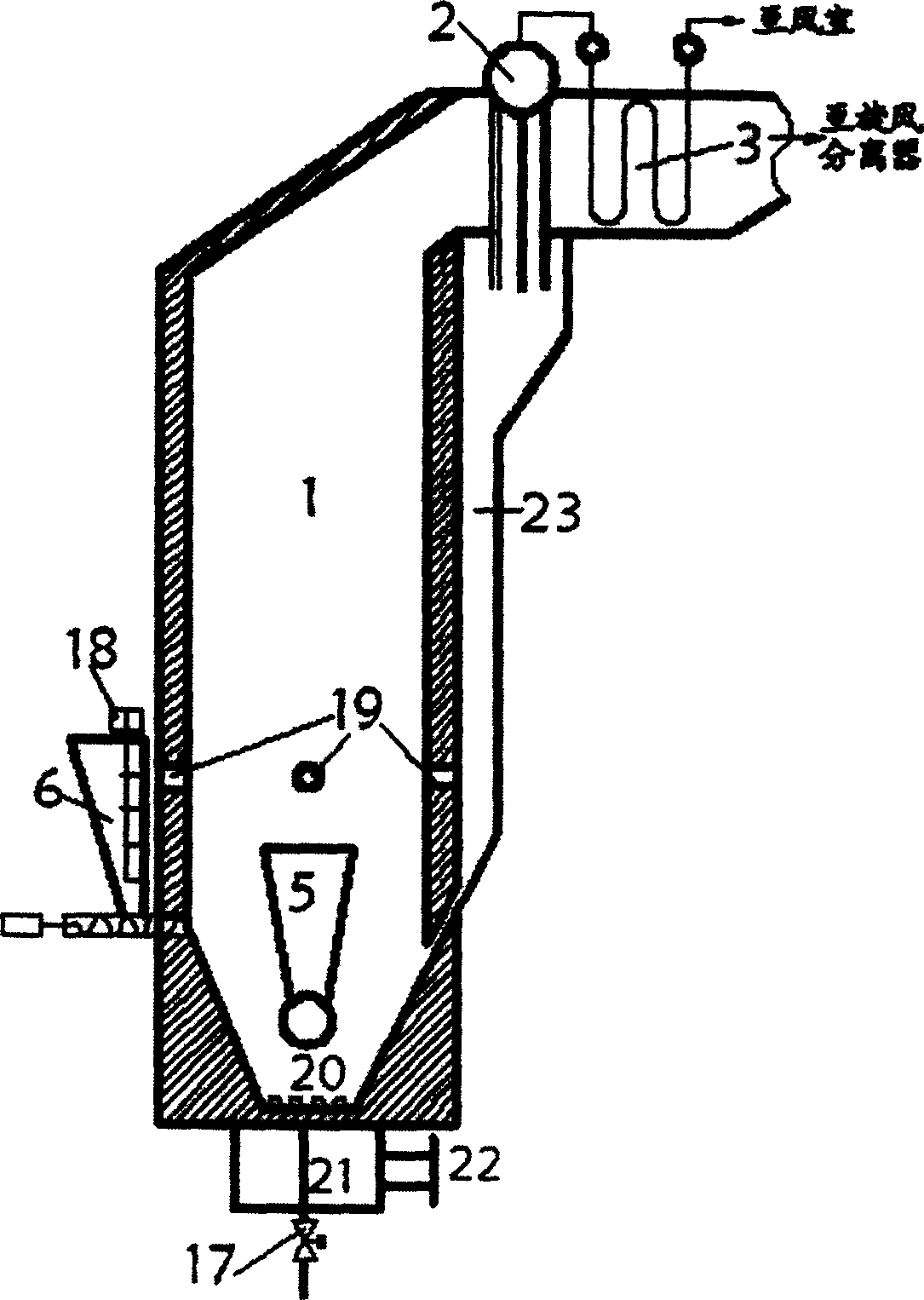

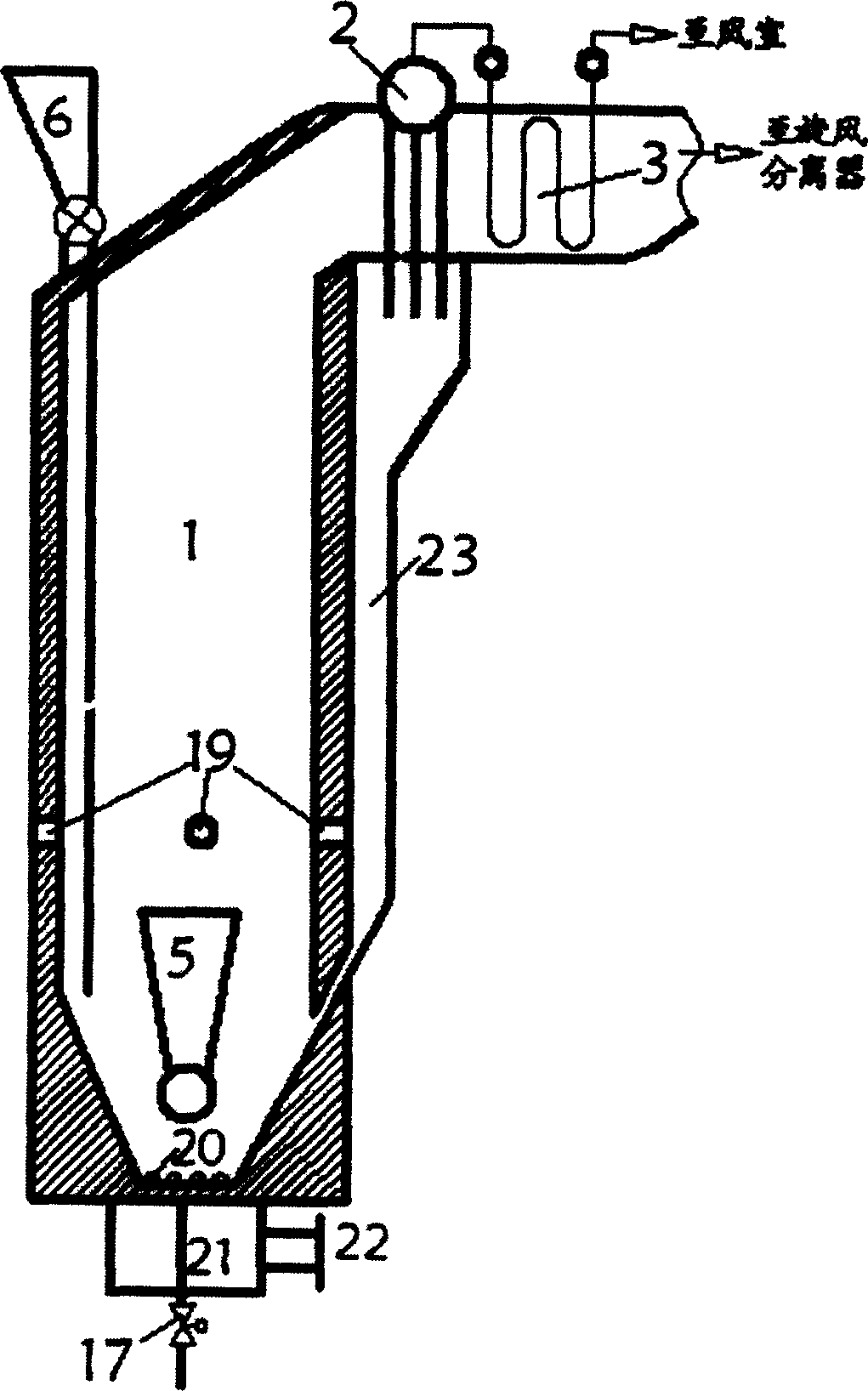

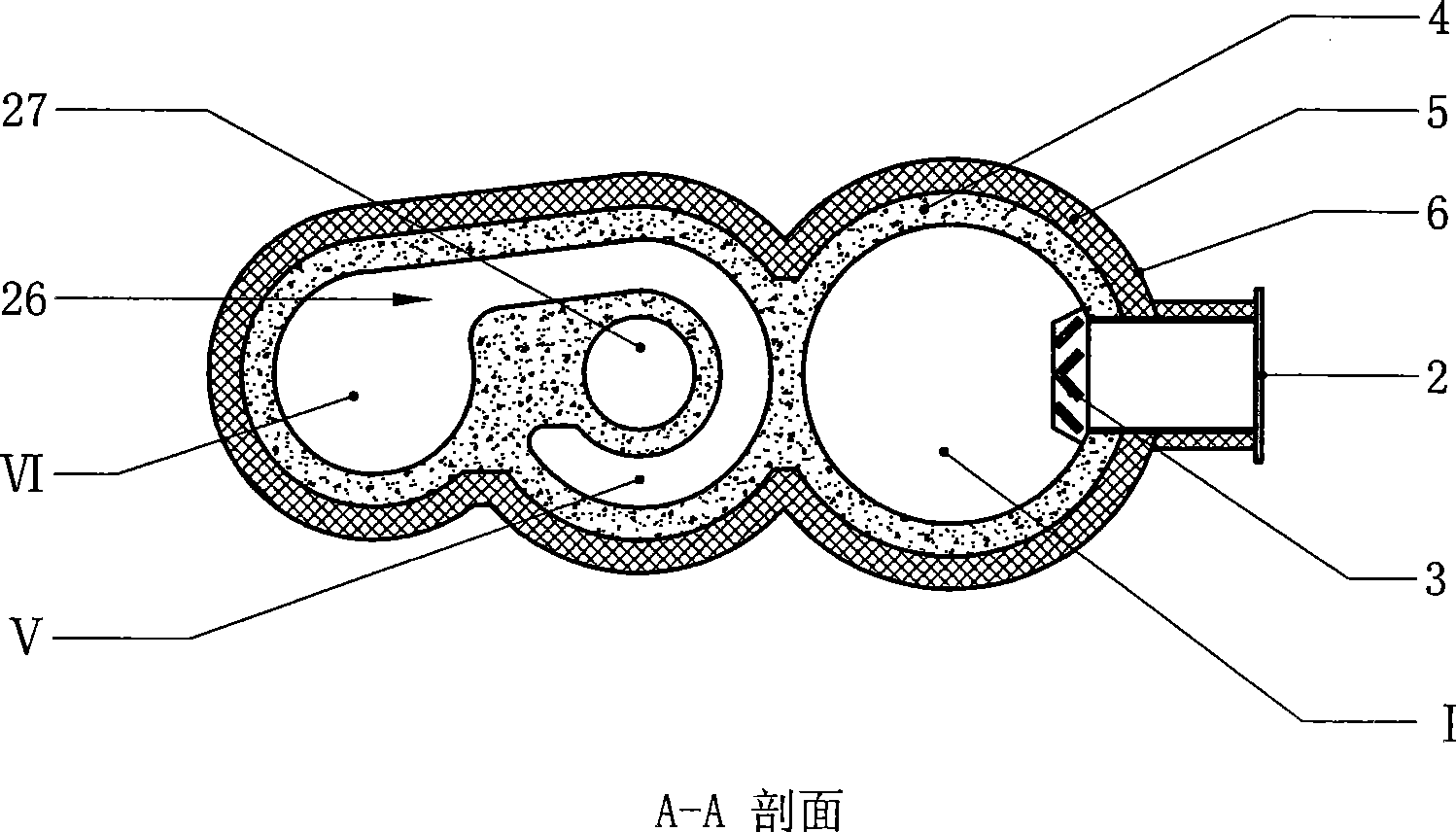

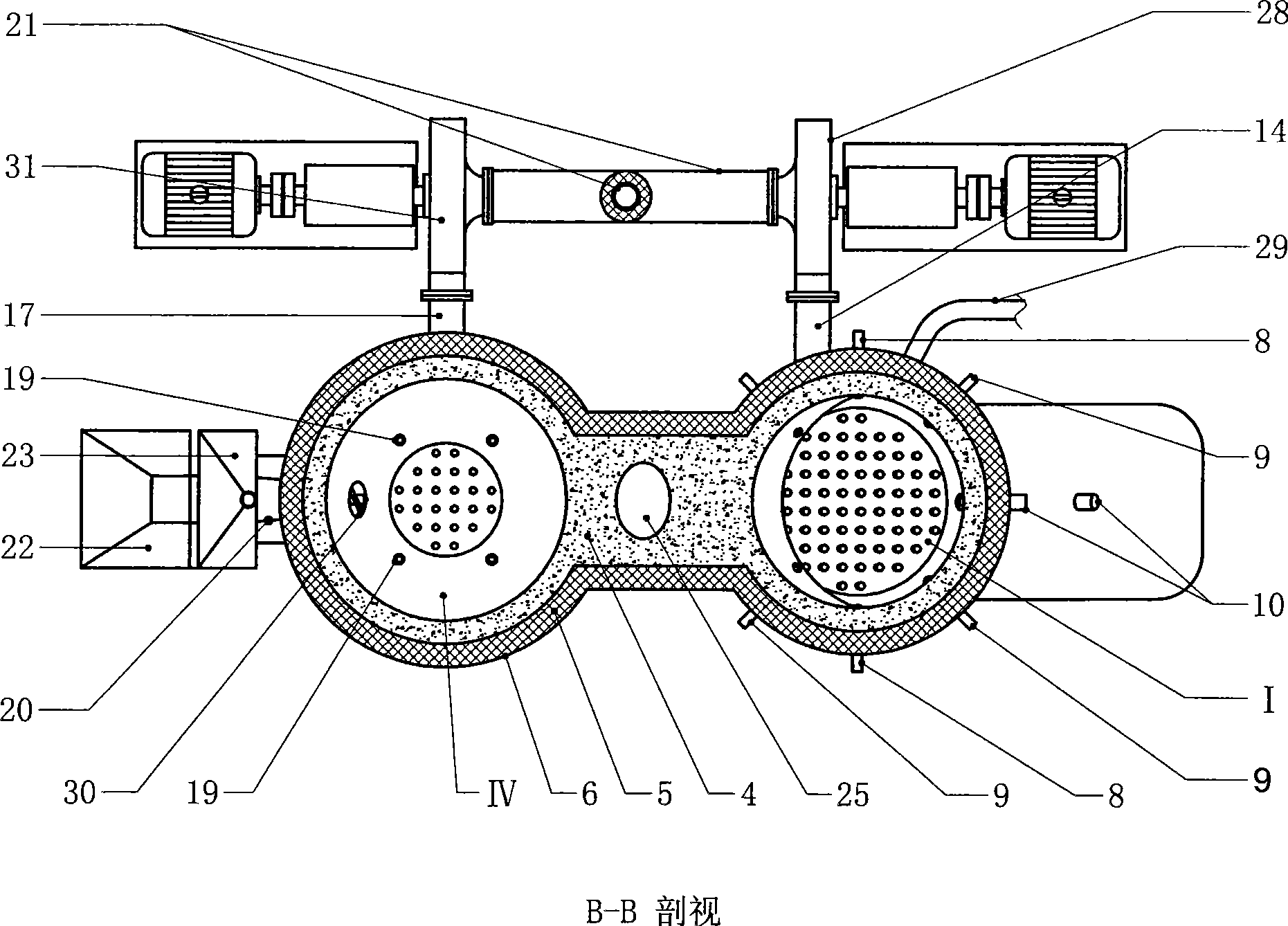

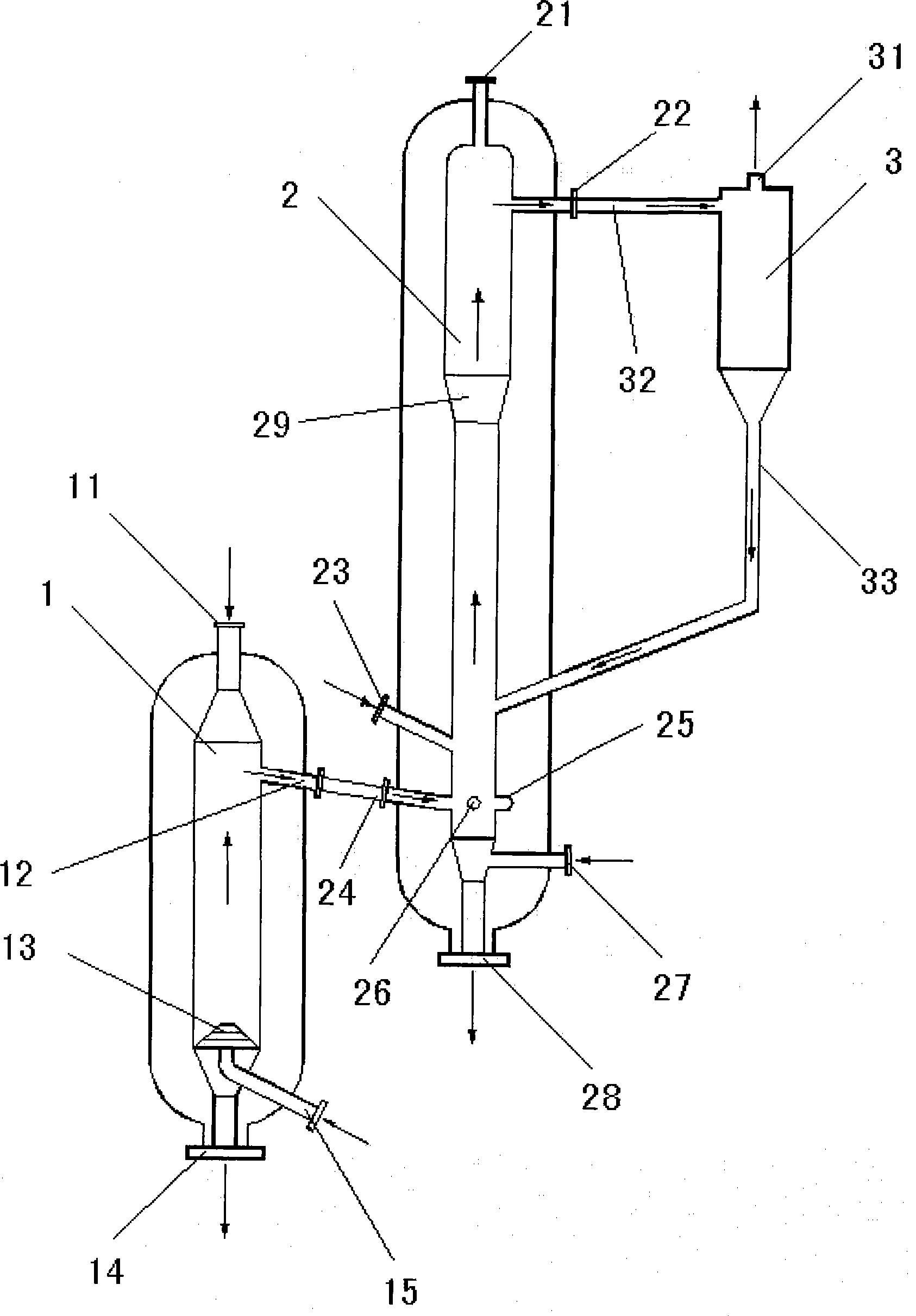

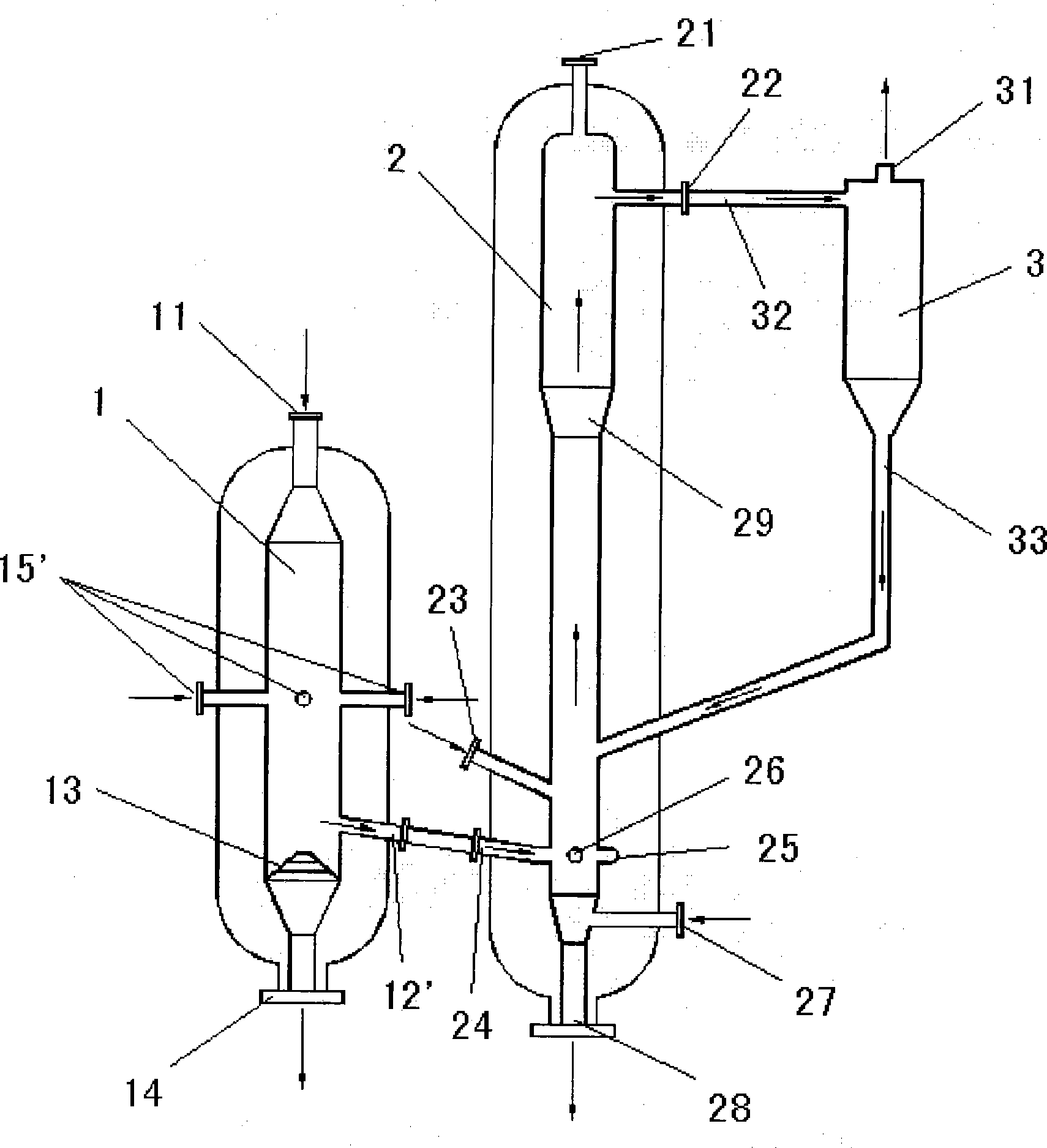

Circulating system for double fluidized bed combustion gasification materiel

ActiveCN101255987AReasonable useControl operating temperatureFluidized bed combustionApparatus for fluidised bed combustionFluidized bed gasifierEngineering

The invention discloses a double fluidized beds combustion-gasification material circulating system comprising a fluidized bed gasification furnace and a circulating fluidized bed combustion furnace; the middle portion of the fluidized bed gasification furnace is connected with a material charging chamber of a material returning chamber, and then is connected with the lower portion of the circulating fluidized bed combustion furnace through a material discharging chamber of the material returning device; the upper portion of the circulating fluidized bed is connected to a material charging chamber of a bi-directional material control device through a hyperthermia separator, then is divided into two paths, one path is connected with the lower portion of the fluidized bed gasification furnace through a hyperthermia conical valve on the side surface of the material charging chamber of the bi-directional material control chamber, and the other path is connected with the lower portion of the circulating fluidized bed combustion furnace through the material returning chamber of the bi-directional material control chamber. The circulating fluidized bed combustion furnace and the fluidized bed gasification furnace are combined tightly to implement gasification, combustion, classification and conversion of coal in one set of system, which leads to highly efficiency conversion of coal; the inventive system is also can be used broadly in combustion, gasification, catalysis and regeneration processes.

Owner:ZHEJIANG UNIV +1

Plasma and calcium oxide cooperation-gasified rubbish biomass gasification method and equipment

InactiveCN101469865AReduce contentHigh calorific valueSpecial form destructive distillationIncinerator apparatusNew energyWater vapor

A method and apparatus for gasifying a plasma and calcium oxide cooperating with gasified rubbish biomass, relating to the rubbish processing and new energy resource field, characterized in that, the rubbish biomass is fed into a suspending fluidized bed thermal decomposition furnace, meanwhile, the heated fluidization material is circularly fed into the thermal decomposition furnace and is mixed with the raw materials to transfer heat, so that the rubbish biomass raw material is heated to decompose, and then the thermal decomposed gas and solid carbocoal is fed into a turbulent fluidized bed gasification furnace, the water vapor is heated over 3100 DEG C and is sprayed into the gasification furnace by a plasma spray gun, the water vapor is reacted with the solid carbocoal to generate carbon monoxide and hydrogen gas, the required heat of the gasification reaction in the gasification furnace can be provided by the plasma spray gun and an exothermal reaction of the calcium oxide absorbing the carbon dioxide. According to the invention, synthesis gas can be produced by rubbish and biomass raw materials under the condition without air or oxygen, the main ingredients of the synthesis gas are hydrogen gas and carbon monoxide which can be directly used for city gas or producing hydrogen gas, methanol and dimethyl ether and so on clean energies.

Owner:衢州市广源生活垃圾液化技术研究所

Fixed bed-fluidized bed coupled gasification method and apparatus

ActiveCN101440307AReduce tar contentImprove effective componentsCombined combustion mitigationCombustible gas productionFluidized bed gasifierWater vapor

The invention relates to a method and a device for coupling gasification of a fixed bed and a fluid bed, wherein the method comprises the following steps: 1) connecting the fluidized bed gasifier with the top of a fixed bed gasifier through a hollow throat; 2) adding a gasification raw material with the particle size of between 10 and 50 millimeters to the fixed bed gasifier from the upper part of the fixed bed gasifier, and inputting a gasification agent to the fixed bed gasifier from the lower part of the fixed bed gasifier simultaneously; 3) raising coal gas generated through gasification reaction and introducing the coal gas into the fluidized bed gasifier through the hollow throat; 4) adding the gasification raw material with the particle size of less than 10 millimeters to the fluidized bed gasifier from a dense phase zone of the fluidized bed gasifier, and inputting water vapor and pure oxygen or enriched oxygen to the fluidized bed gasifier from the lower part thereof simultaneously; and 5) exhausting coal gas generated through the mixing gasification of the high temperature coal gas, the gasification raw materials, the water vapor and the pure oxygen or the enriched oxygen in the fluidized bed gasifier from a coal gas outlet of the fluidized bed gasifier. The method and the device have the advantages of simplified gas producing process, short flow, compact equipment, small occupied area, reduced amount of sewage emission, low cost and the like, and can be widely applied to medium and small-sized coal chemical enterprises in China.

Owner:CCTEG CHINA COAL RES INST

Second-level high-temperature gasification incineration system for rubbish

ActiveCN105333439AHandle a large number of efficientLow costIncinerator apparatusFluidized bed gasifierFluidized bed

The invention discloses a second-level high-temperature gasification incineration system for rubbish. The second-level high-temperature gasification incineration system comprises a fluidized bed gasification furnace and an incinerator. The fluidized bed gasification furnace comprises a gasified gas outlet formed in the top wall of a fluidized bed furnace body, a primary air inlet formed in the bottom of the fluidized bed furnace body, a first-level rubbish inlet and a first-level auxiliary fuel inlet. The interior of the fluidized bed furnace body is divided into a gasification room and an air room through an air distribution plate. The incinerator comprises a second-level rubbish and second-level auxiliary fuel feeding opening formed in the top wall of an incinerator body, a high-temperature smoke outlet formed in the side wall of the incinerator body, a first burning spray pipe arranged in the incinerator body and a secondary air inlet formed in the bottom wall of the incinerator body. The gasified gas outlet of the fluidized bed furnace body is communicated with the first burning spray pipe through a pipeline, and therefore gasified gas generated by first-level rubbish and first-level auxiliary fuel in the gasification room is conveyed into the incinerator, and second-level rubbish from the second-level feeding opening is incinerated at a high temperature under the assistance of second-level auxiliary fuel.

Owner:广东博业热能供应有限公司

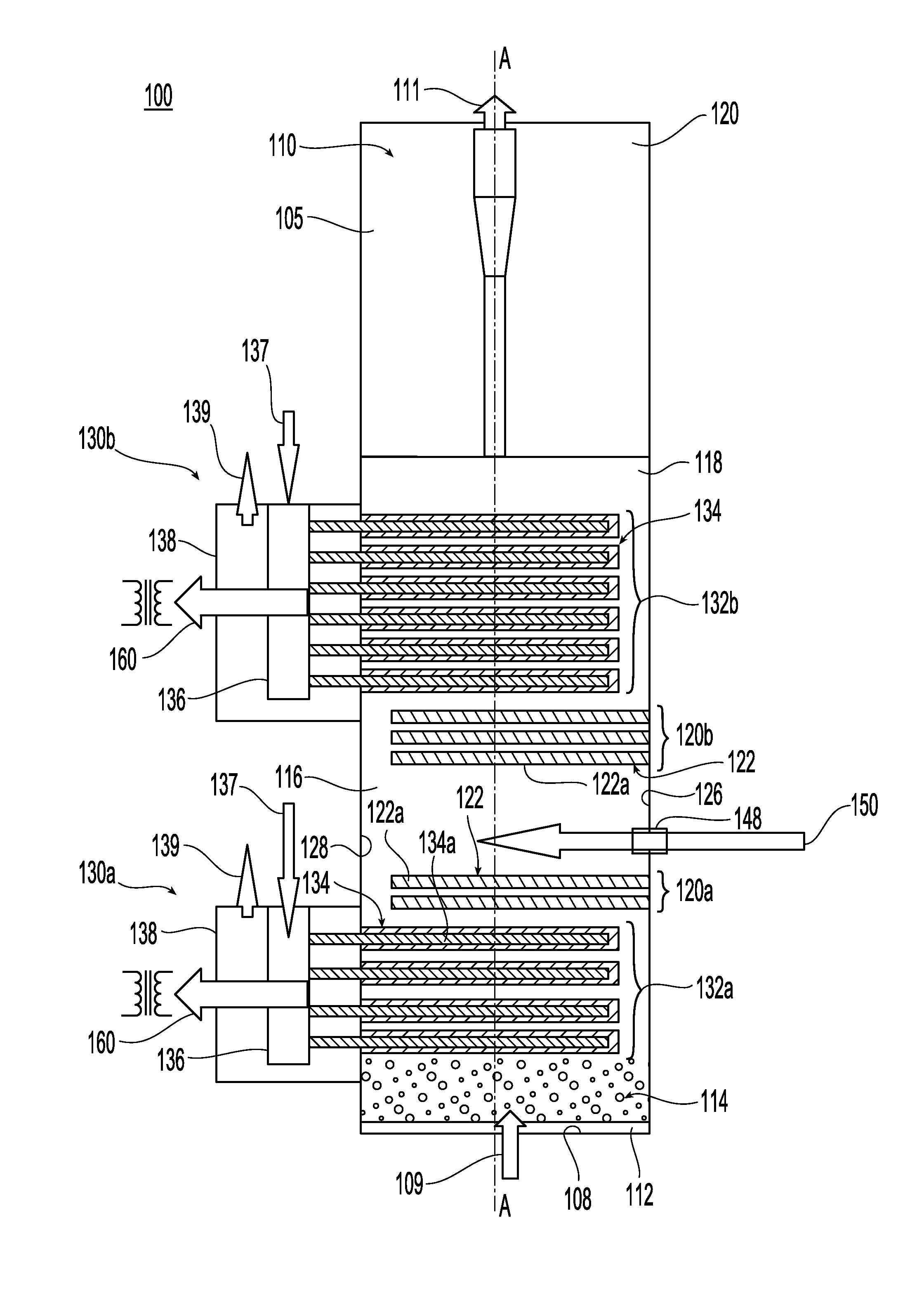

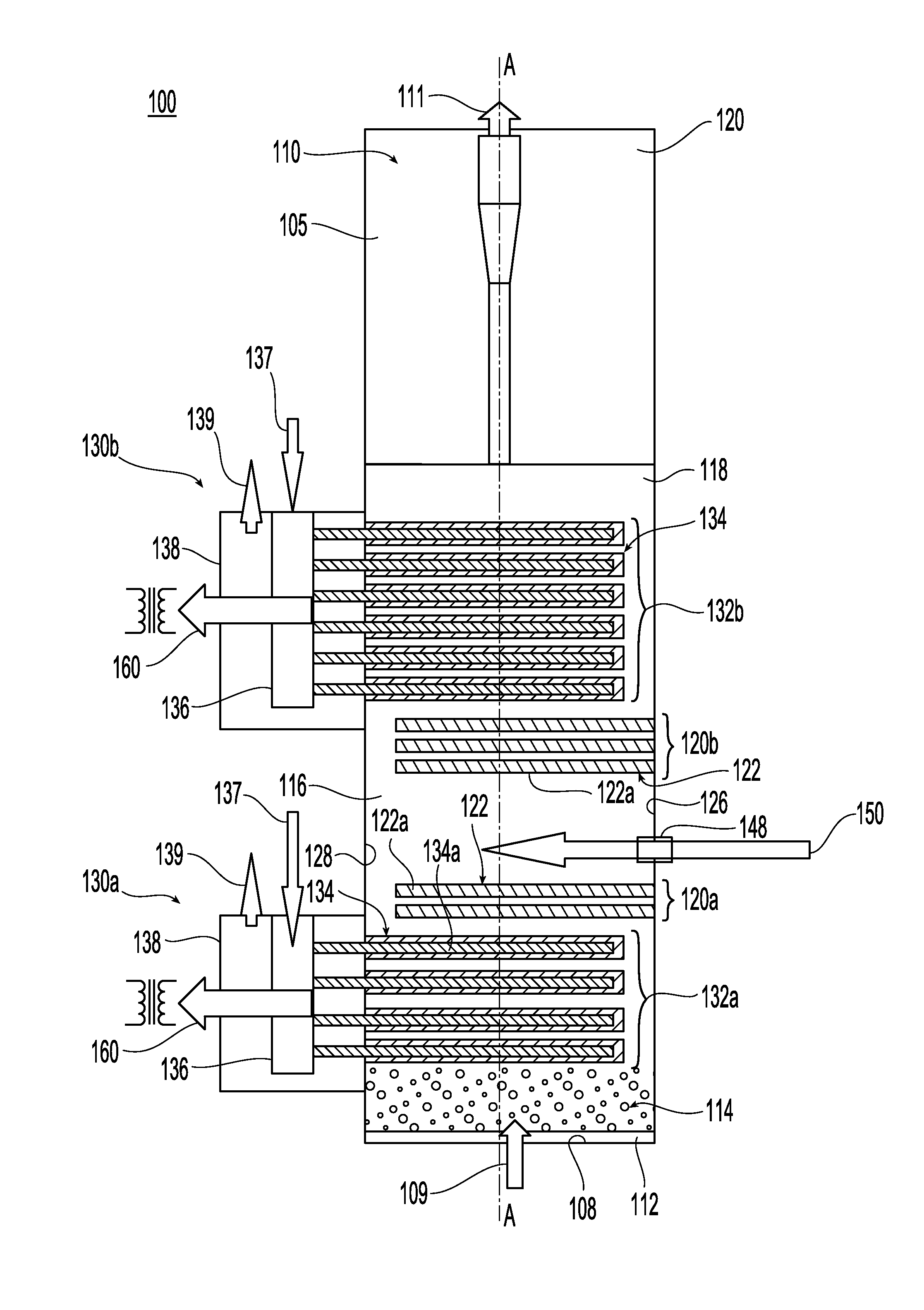

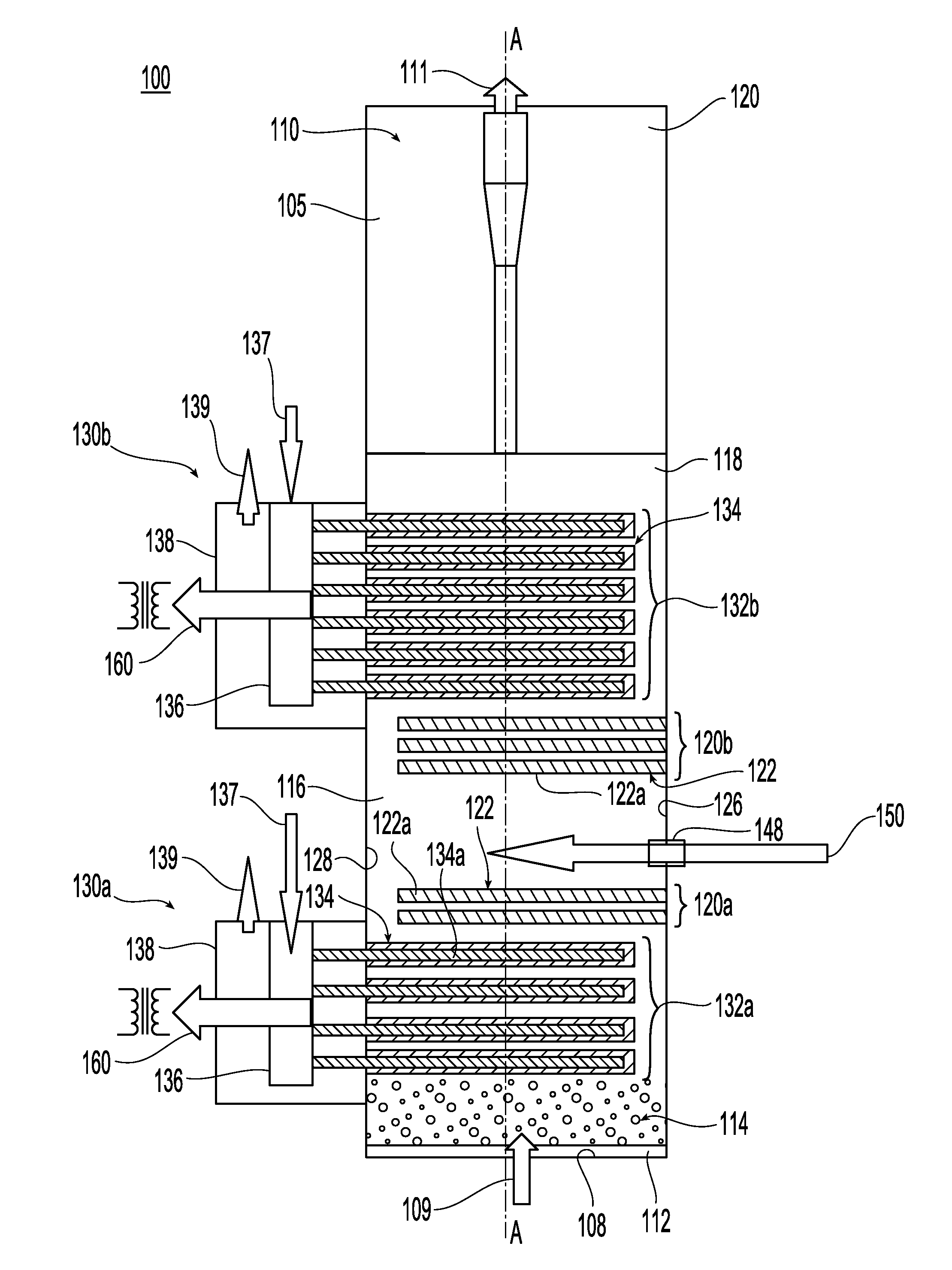

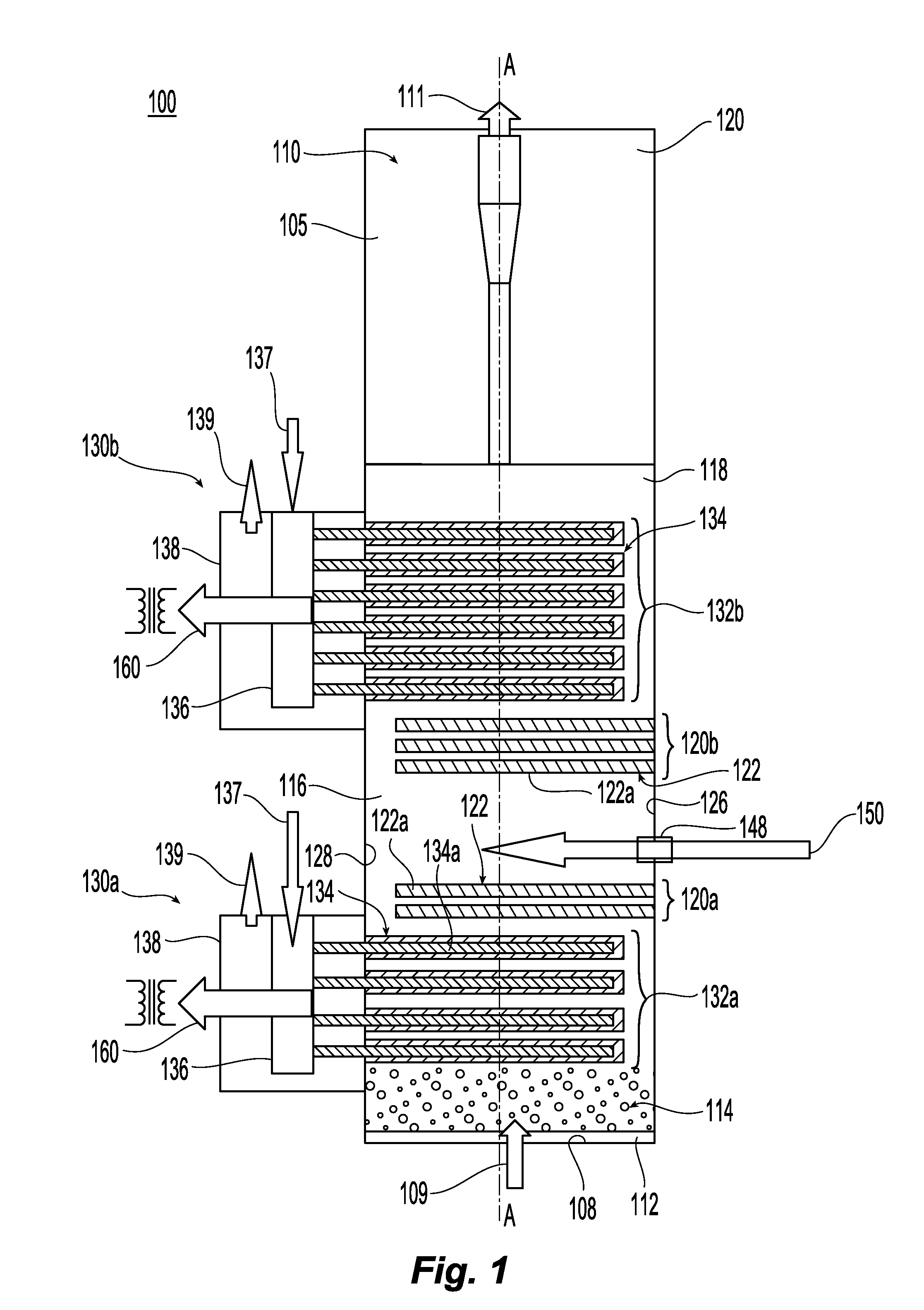

Gasifier having integrated fuel cell power generation system

A direct carbonaceous material to power generation system integrates one or more solid oxide fuel cells (SOFC) into a fluidized bed gasifier. The fuel cell anode is in direct contact with bed material so that the H2 and CO generated in the bed are oxidized to H2O and CO2 to create a push-pull or source-sink reaction environment. The SOFC is exothermic and supplies heat within a reaction chamber of the gasifier where the fluidized bed conducts an endothermic reaction. The products from the anode are the reactants for the reformer and vice versa. A lower bed in the reaction chamber may comprise engineered multi-function material which may incorporate one or more catalysts and reactant adsorbent sites to facilitate excellent heat and mass transfer and fluidization dynamics in fluidized beds. The catalyst is capable of cracking tars and reforming hydrocarbons.

Owner:THERMOCHEM RECOVERY INT

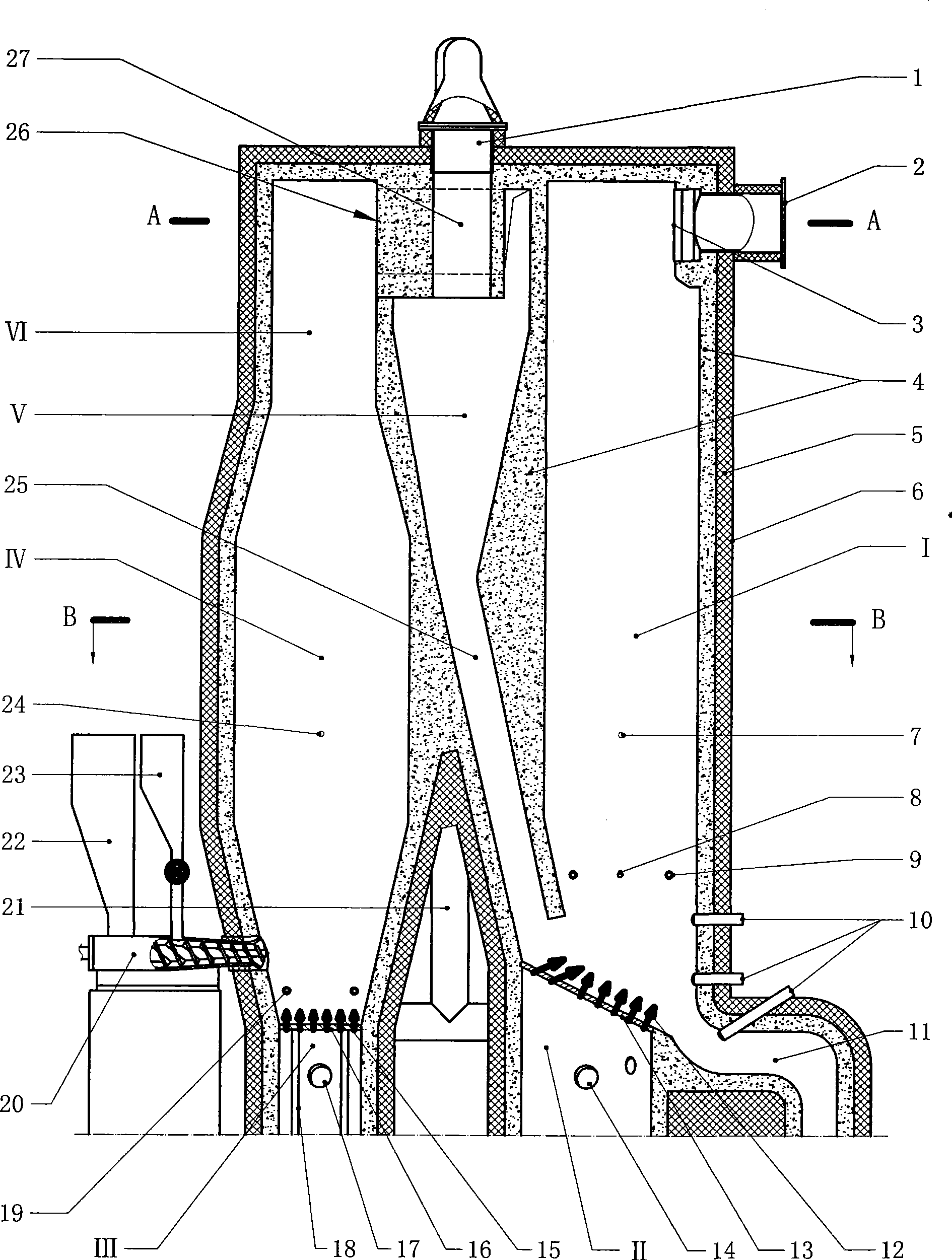

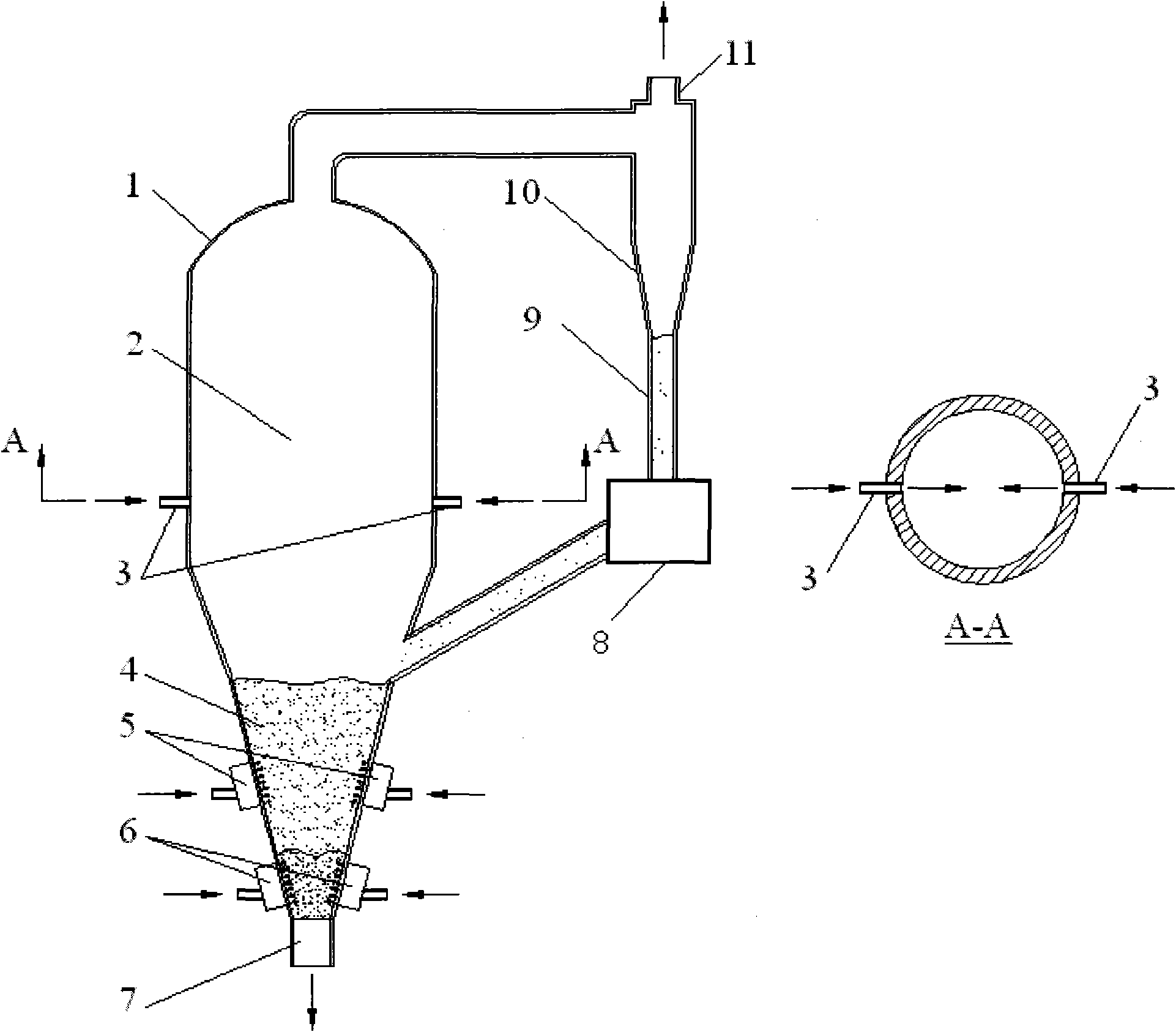

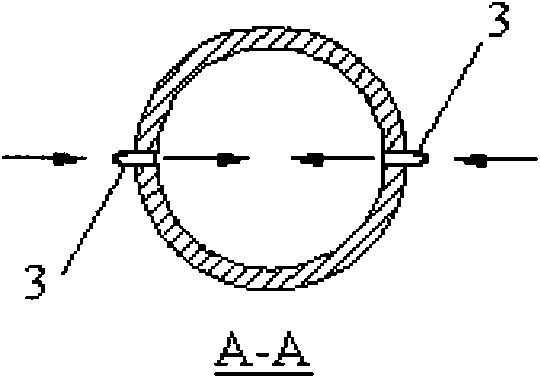

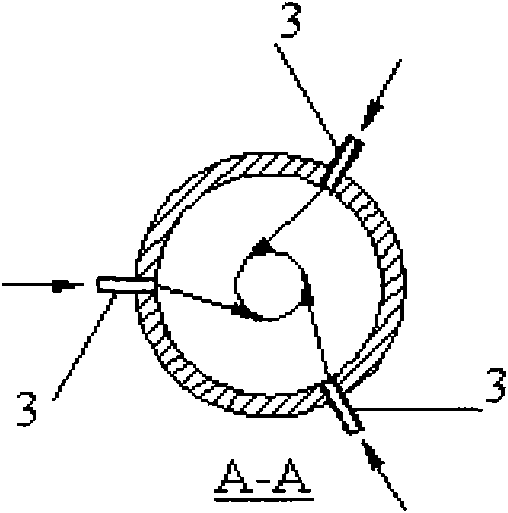

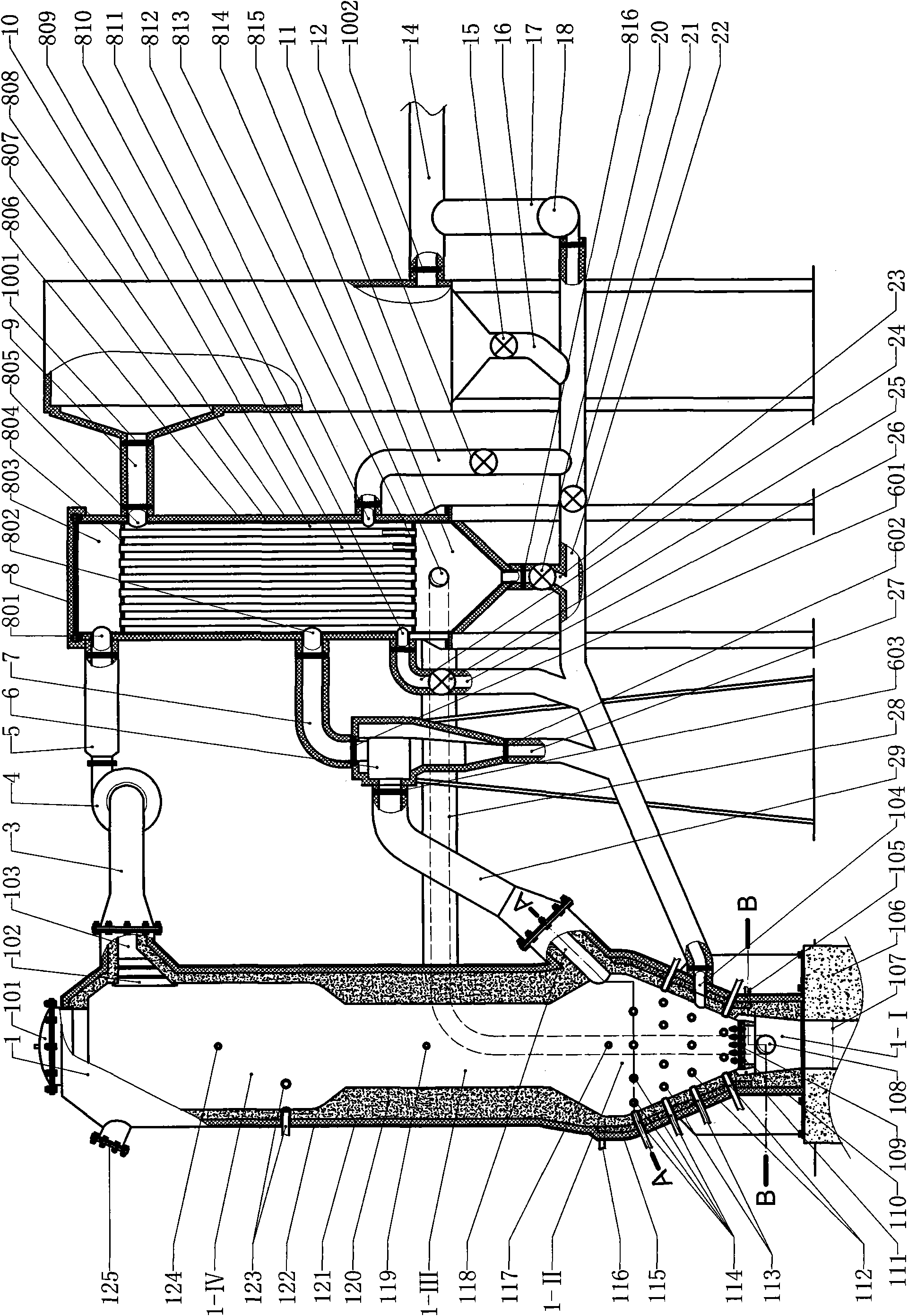

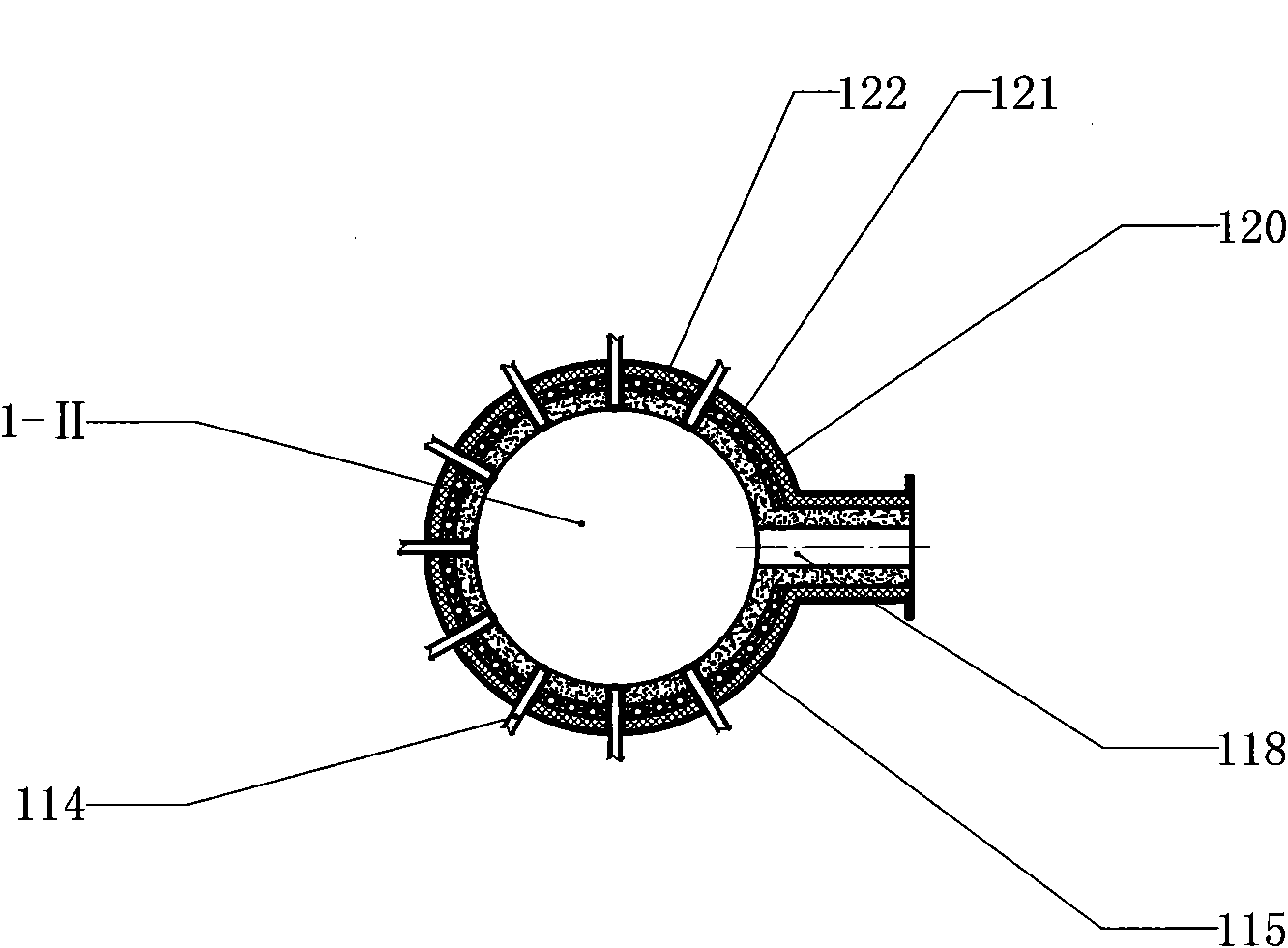

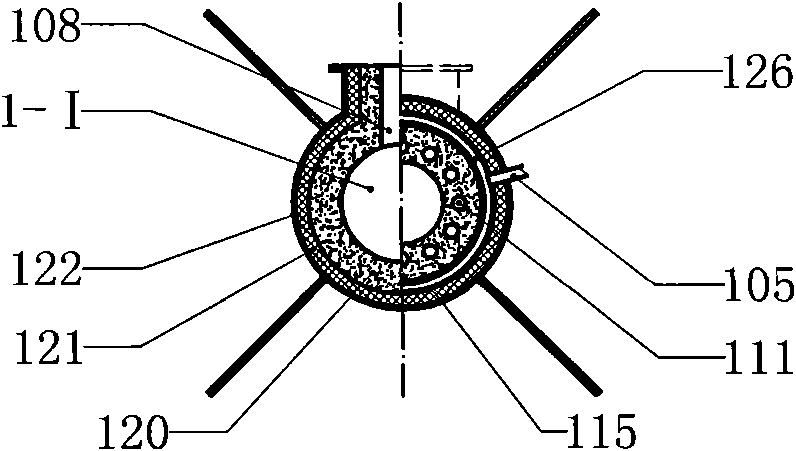

Method and device for jet/preoxidation/pyrolysis/fluidized bed gasification of carbon-containing solid fuel

ActiveCN102120936AReduce the possibility of sticking and cokingImprove adaptabilityGranular/pulverulent flues gasificationFluidized bed gasifierThumb opposition

The invention belongs to the field of energy utilization of a solid fuel, and relates to a method and gasifier for jet / preoxidation / pyrolysis / fluidized bed gasification of a carbon-containing solid fuel. The method provided by the invention comprises steps as follows: by using oxygen-containing gasifying agent gas as a carrier, carbon-containing solid fuel particles are fed into a fluidized bed gasification furnace in a high-speed jet mode, so that the fuel particles are previously subjected to oxidation and pyrolysis in the high-speed jet and are highly dispersed; and the carbon-containing solid fuel particles are subjected to intensified pyrolysis in a dilute-phase region of the fluidized bed gasification furnace, and then, the formed semicokes of the carbon-containing solid fuel particles are moved into a dense-phase bed of the fluidized bed gasification furnace to participate in burning gasification reaction so as to generate crude gas or synthetic gas accompanied with fine semicoke particles and hot ash of the carbon-containing solid fuel. The method provided by the invention can be widely applied to various kinds of coal. The body of the fluidized bed gasification furnace ofthe jet / preoxidation / pyrolysis / fluidized bed gasification device is provided with fuel nozzles which are arranged at the circumference of the fluidized bed gasification furnace in an opposition, diagonal opposition or tangential circle mode.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

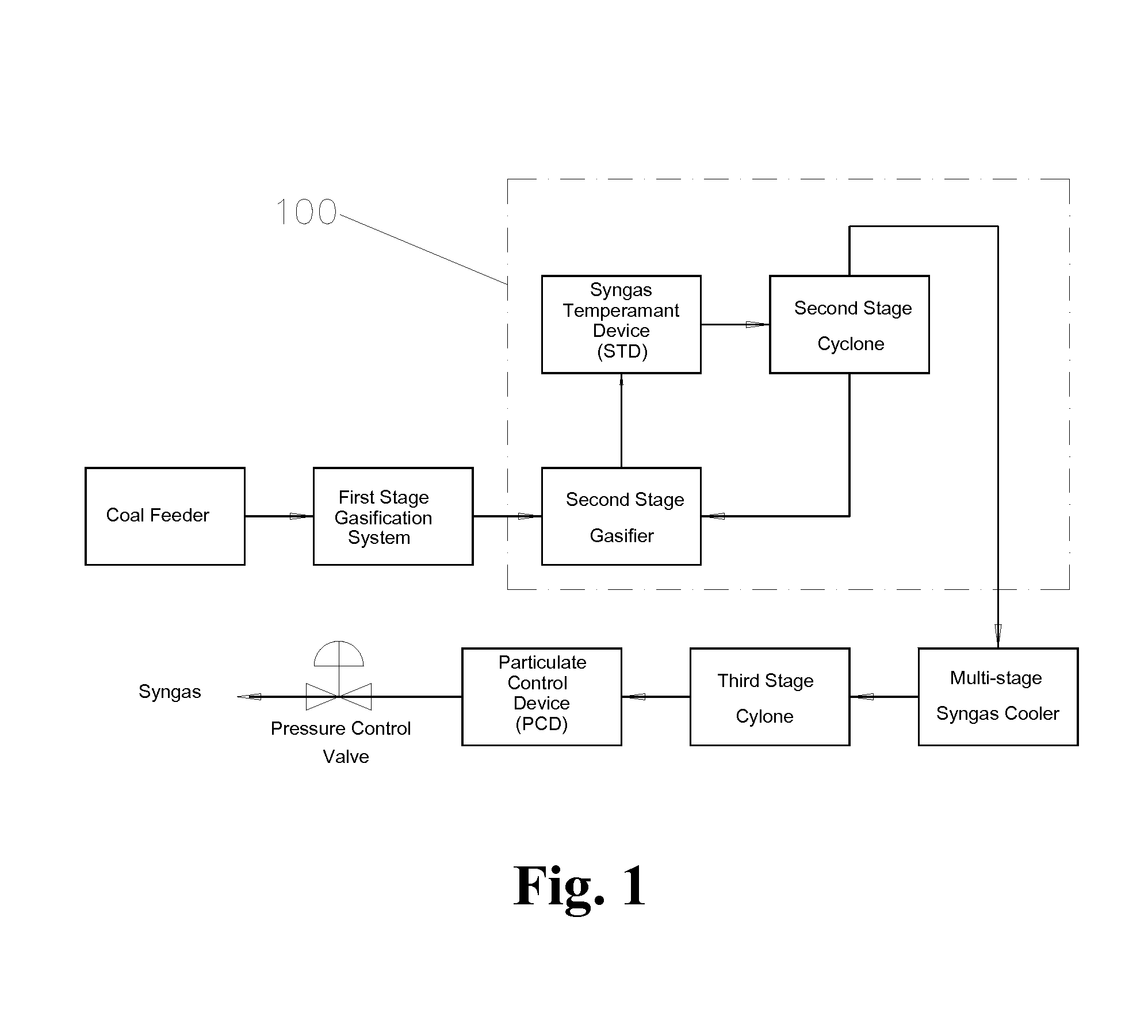

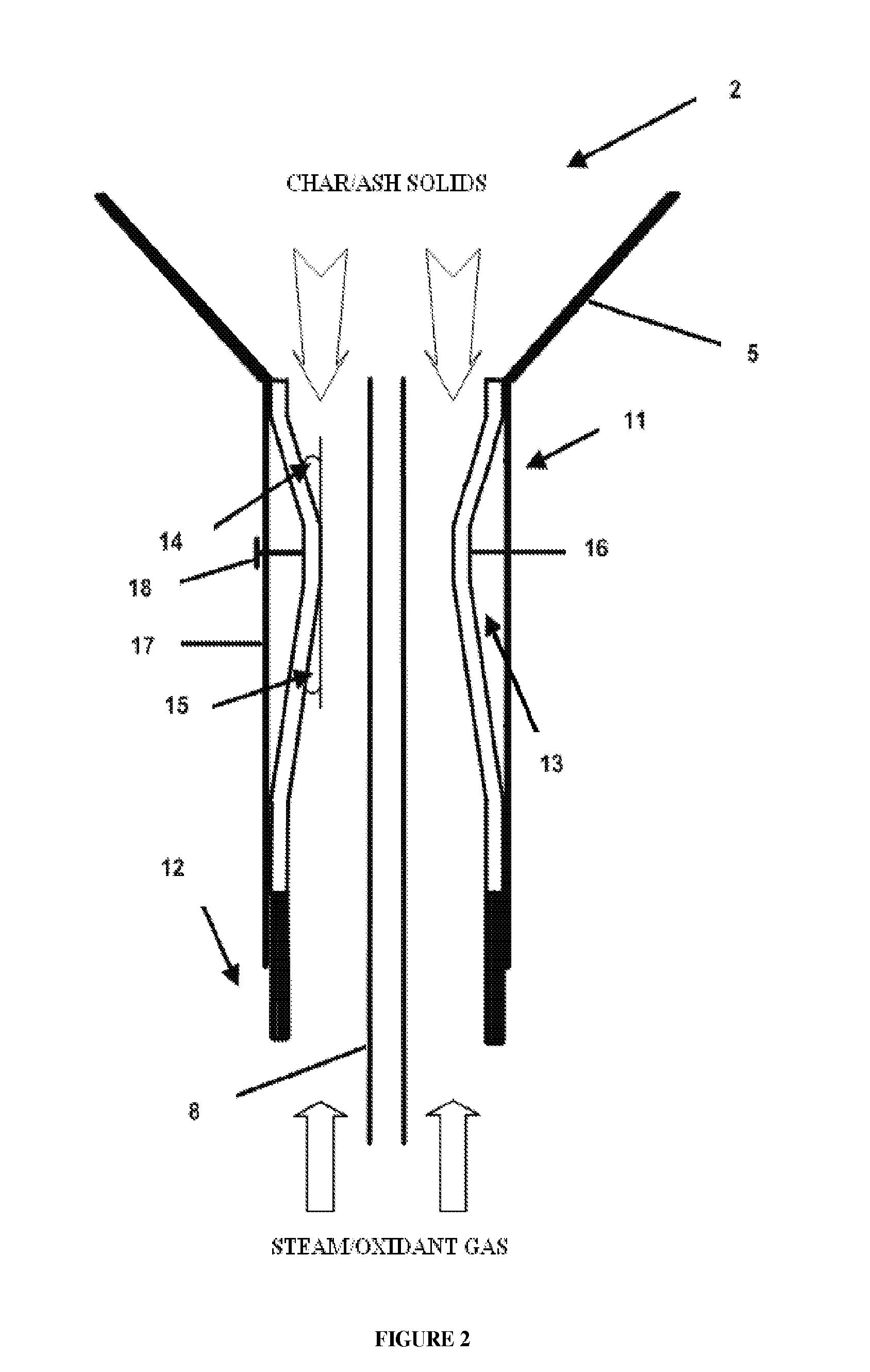

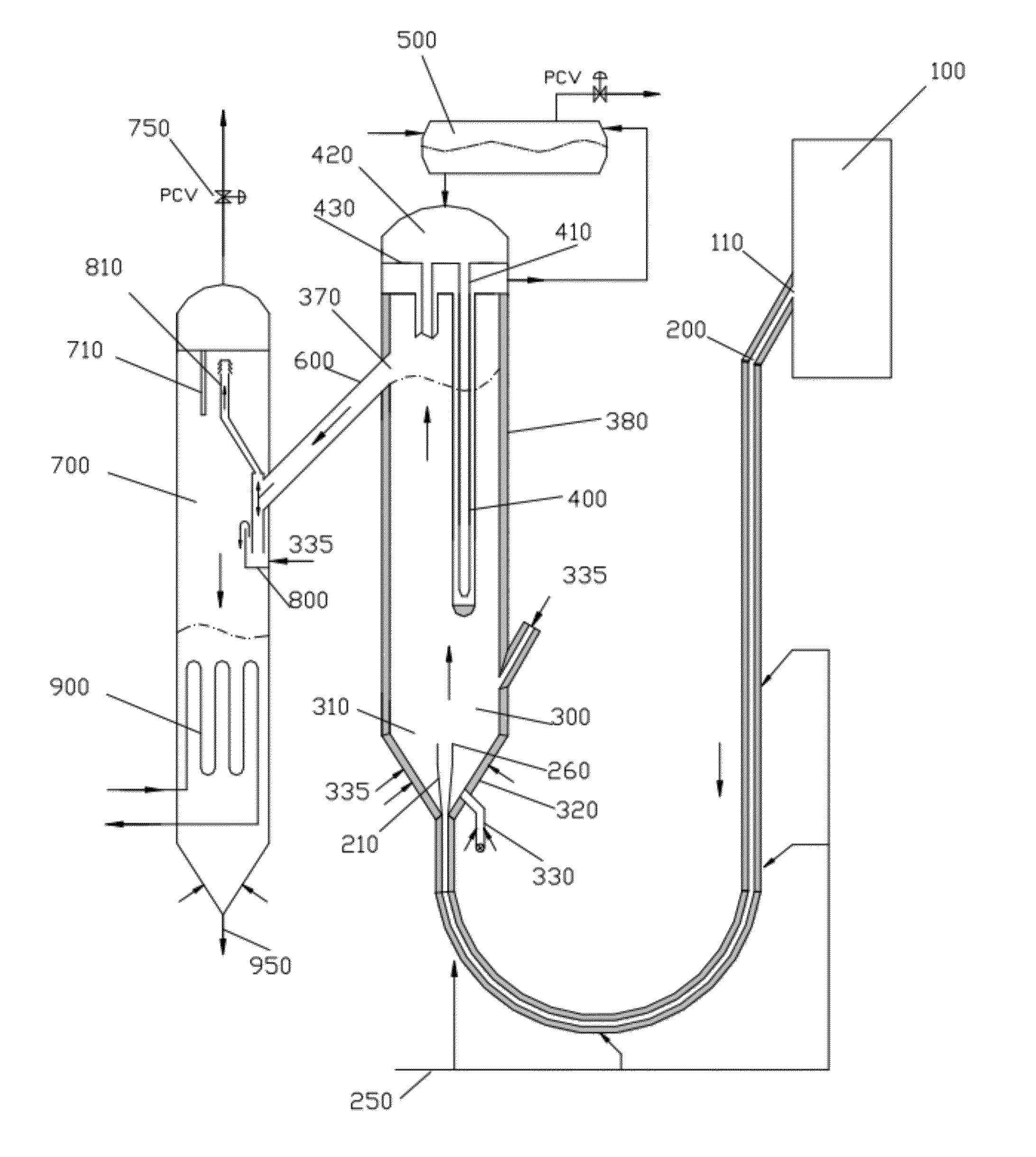

Second Stage Gasifier In Staged Gasification And Integrated Process

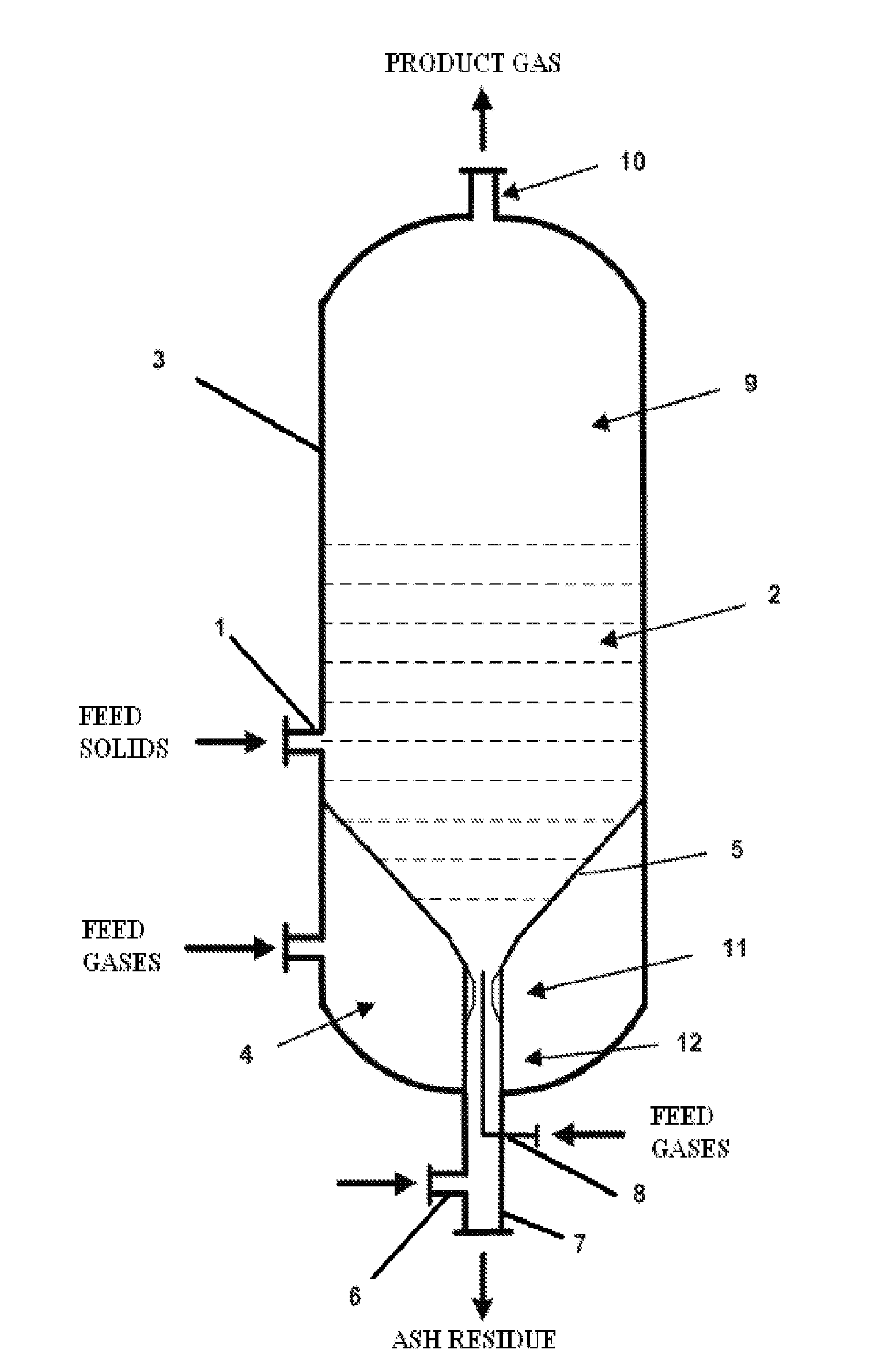

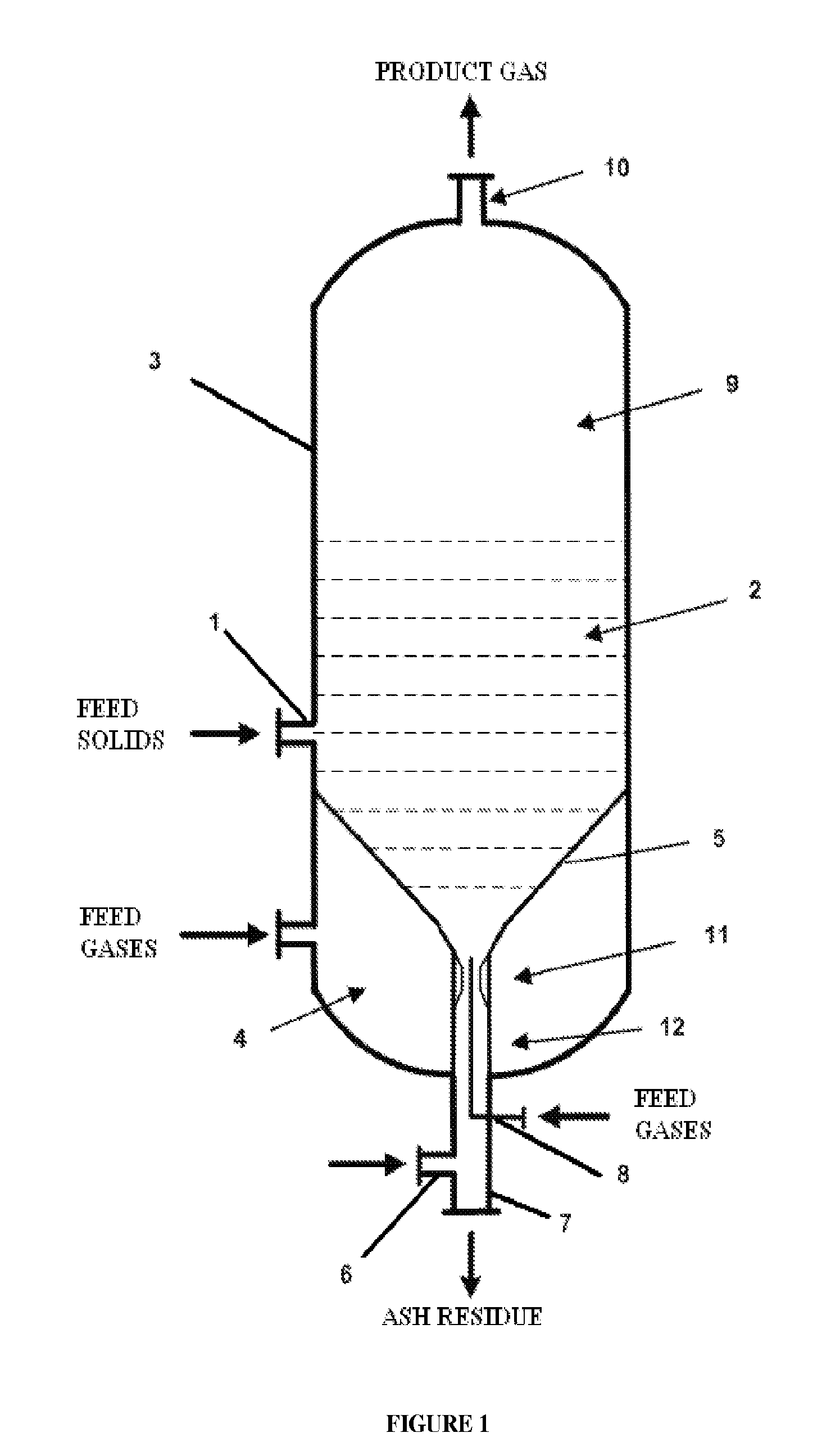

ActiveUS20140158941A1Energy efficient and cost-effectiveHydrogenHydrocarbon from carbon oxidesFluidized bed gasifierFluidized bed

A second stage gasification unit in a staged gasification integrated process flow scheme and operating methods are disclosed to gasify a wide range of low reactivity fuels. The inclusion of second stage gasification unit operating at high temperatures closer to ash fusion temperatures in the bed provides sufficient flexibility in unit configurations, operating conditions and methods to achieve an overall carbon conversion of over 95% for low reactivity materials such as bituminous and anthracite coals, petroleum residues and coke. The second stage gasification unit includes a stationary fluidized bed gasifier operating with a sufficiently turbulent bed of predefined inert bed material with lean char carbon content. The second stage gasifier fluidized bed is operated at relatively high temperatures up to 1400° C. Steam and oxidant mixture can be injected to further increase the freeboard region operating temperature in the range of approximately from 50 to 100° C. above the bed temperature.

Owner:THE SOUTHERN CO

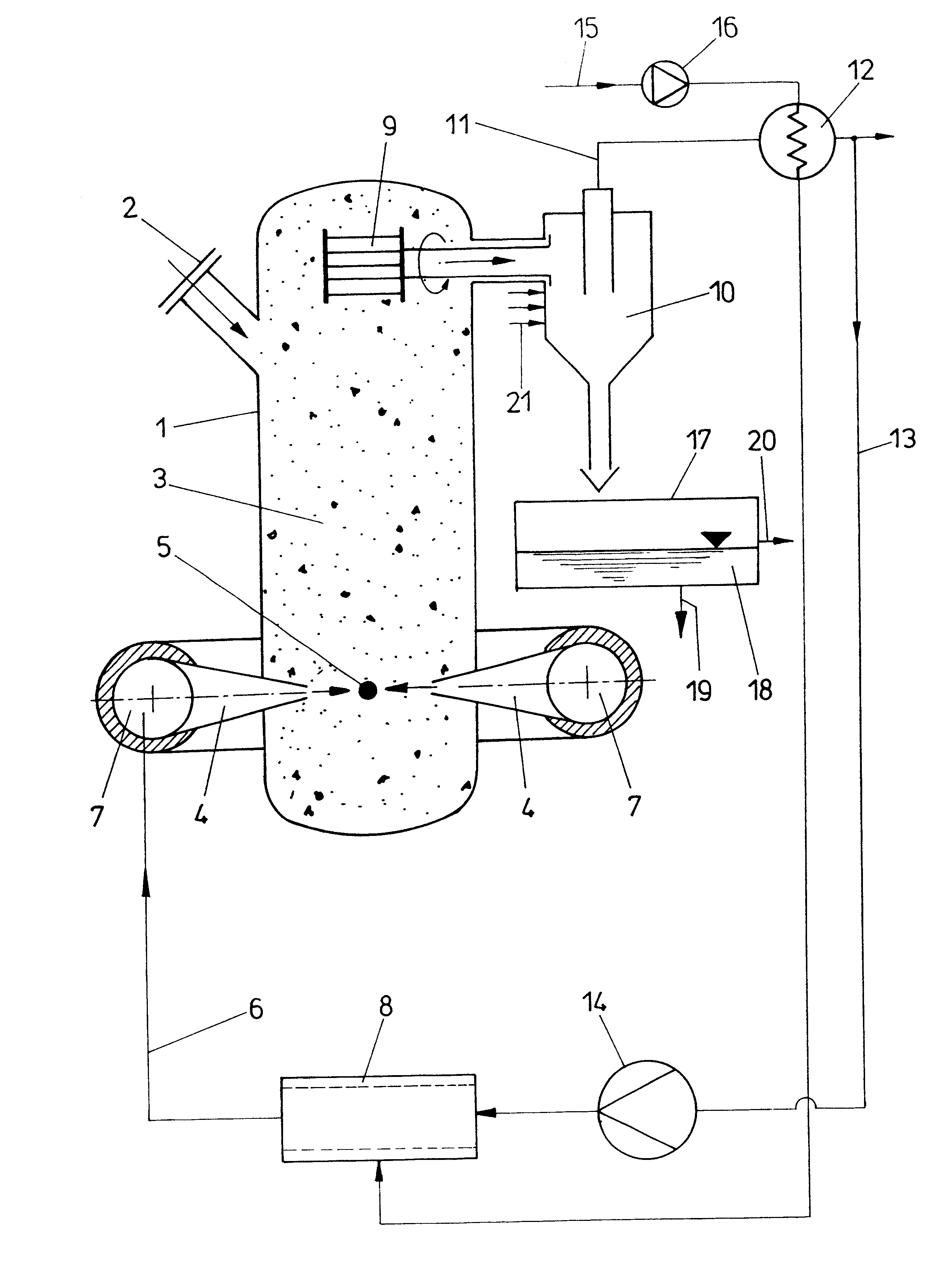

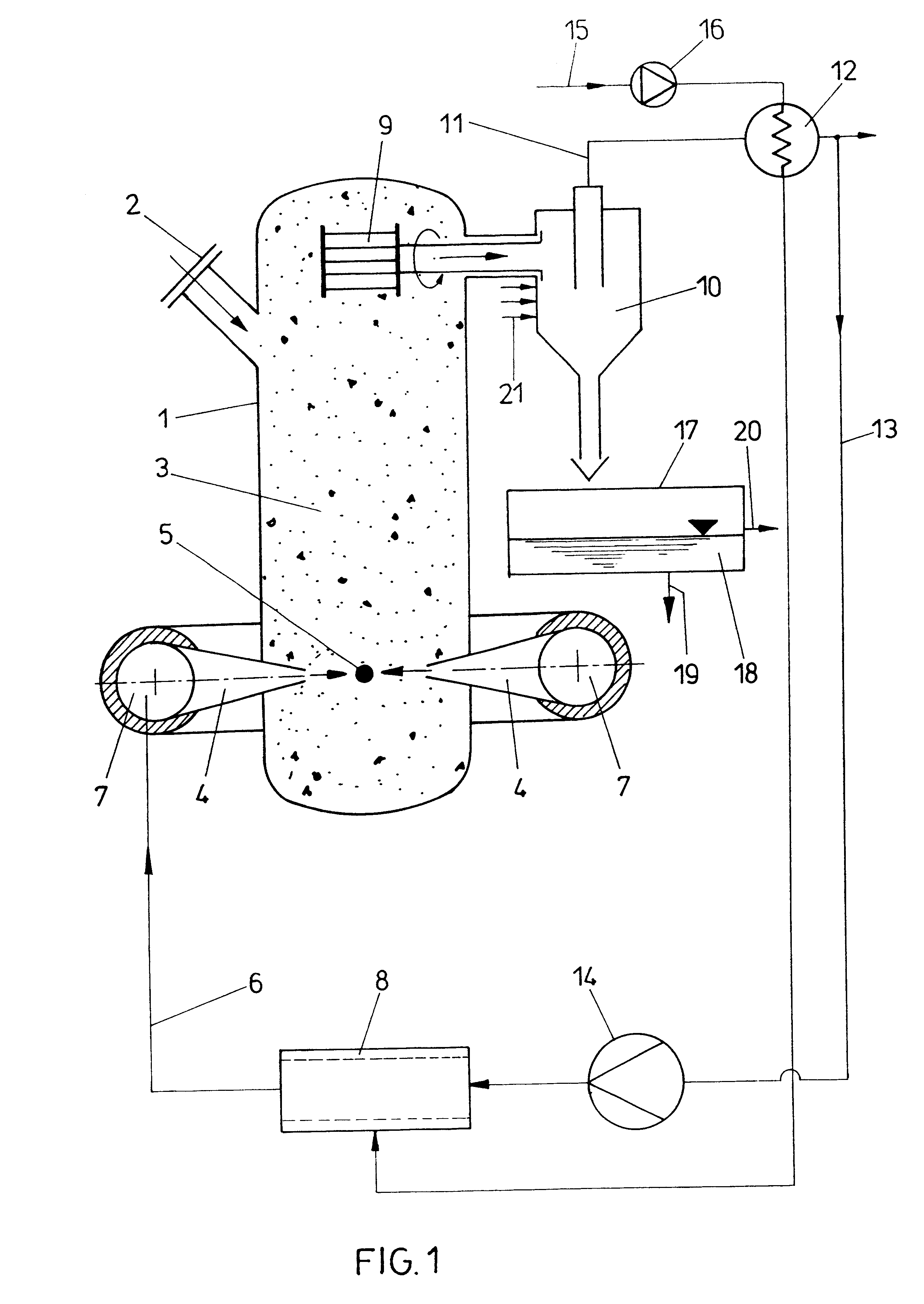

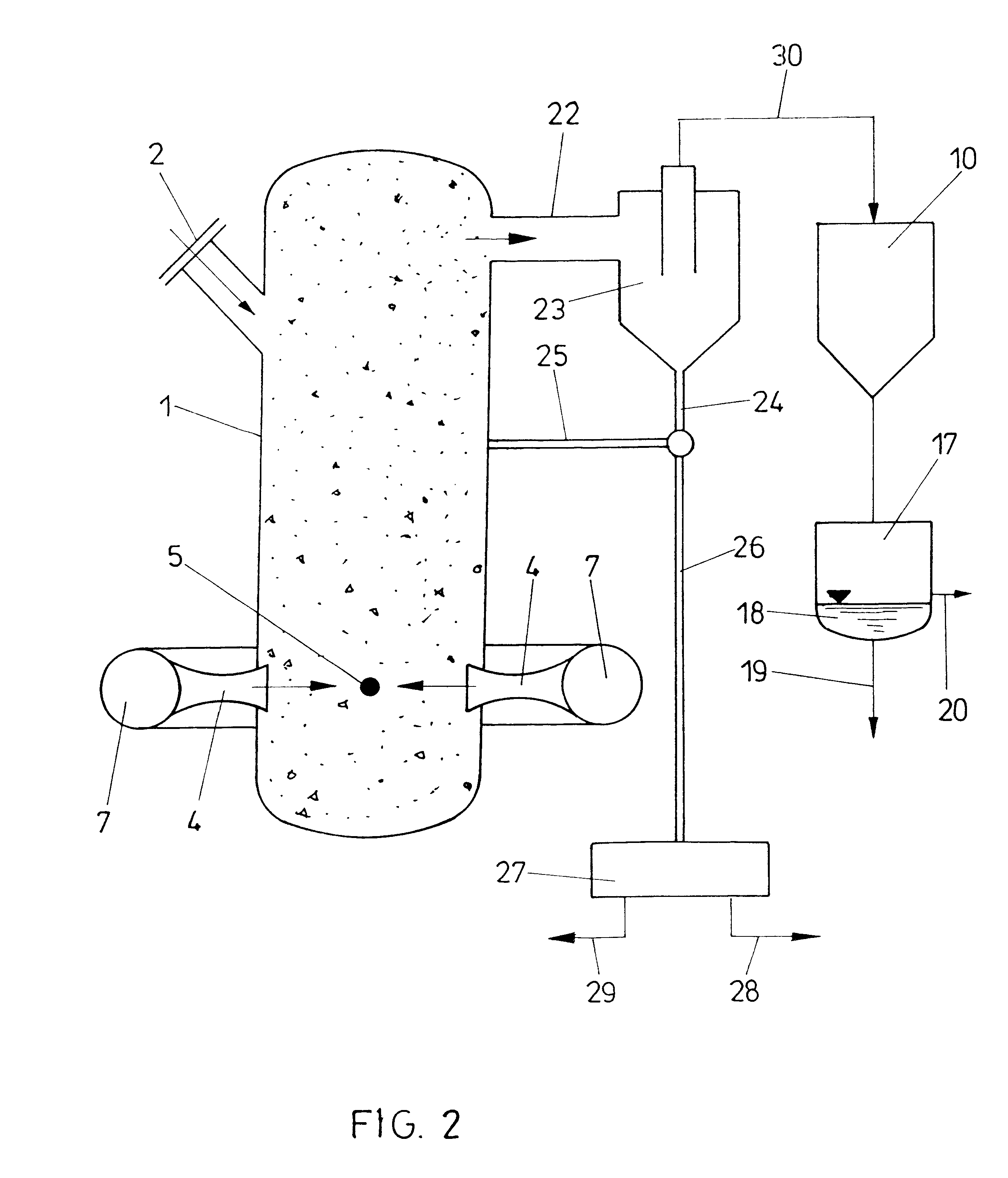

Fluidized bed gasifier with solids discharge and classification device

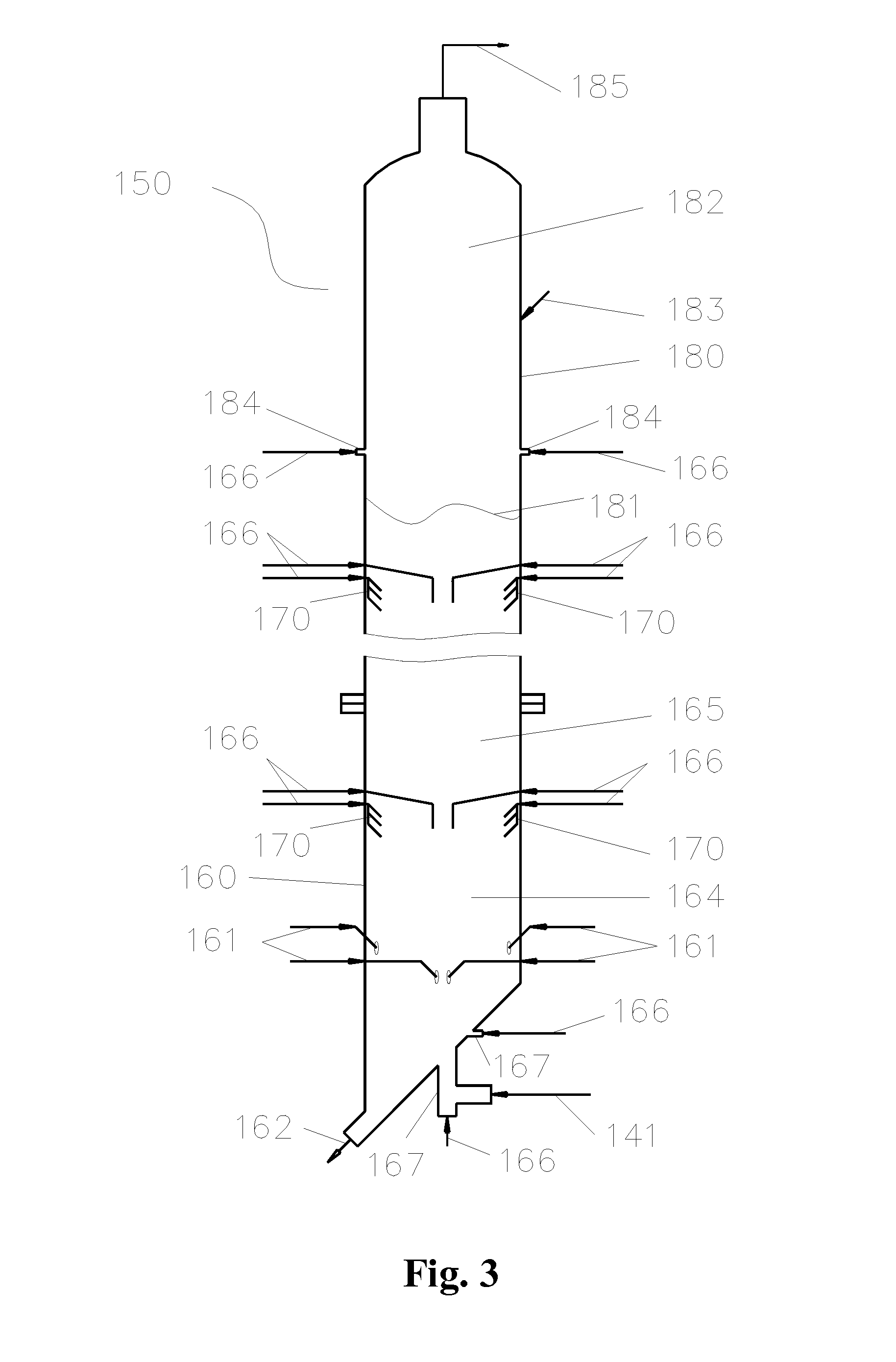

InactiveUS20110189054A1Speed up the conversion processKeep for a long timeGasifier feeding meansGasifier mechanical detailsFluidized bed gasifierFluidized bed

An apparatus for withdrawing solids from a fluidized bed reactor comprises a venturi tube connected to the stem end of a funnel-shaped distribution plate, and a center jet pipe enclosed within the venturi, wherein a jet stream of feed gas is delivered above the venturi throat. Preferably, the distribution plate is equipped with multiple horizontally- or downwardly-oriented grid holes through which the feed gases flow and enter the fluidized bed, which holes may be covered by metal plates to prevent solids from weeping through grid holes and falling into the plenum below the distribution plate. The venturi is preferably engineered to be readily removable from the rest of the gasifier reactor for repair or replacement. Also provided is a fluidized bed reactor comprising the above apparatus.

Owner:SYNTHESIS ENERGY SYST

Fluidized bed plasma garbage-gasifying equipment and gasifying process thereof

InactiveCN102627983AImprove gasification efficiencyImprove throughputGranular/pulverulent flues gasificationSlagQuenching

The invention relates to fluidized bed plasma garbage-gasifying equipment and a gasifying process thereof. A gasifying furnace of the gasifying equipment is a plasma gasifying fluidized bed. The gasifying equipment comprises a fluidized bed gasifying furnace, wherein a plasma torque is arranged at a smoke outlet at the top of the fluidized bed; the inner layer of the wall of the fluidized bed gasifying furnace is a corundum cast material layer; an ash plasma processing cabin is arranged on the tail part of a slag discharging system; and the inner layer of the fluidized bed gasifying furnace is a corundum cast material layer. The gasifying process comprises the following steps of: (a) generating mixed gas; (b) discharging slag and returning the materials; and (c) purifying and filtering gas. In the process, the mixed gas generated in the fluidized bed furnace is re-heated to more than 1,000 DEG C through plasma to perform tar recombination and eliminate dioxin on the surface of a part of ash, and the mixed gas is cooled from 800 DEG C to 180 DEG C within 0.6 second under the action of quenching, so a re-polymerization interval of the dioxin is completely avoided. The fluidized bed plasma garbage-gasifying equipment has the characteristics of harmlessness, environment friendliness, energy conservation and consumption reduction.

Owner:大连鑫宝生物质能有限公司

Fluidized-bed gasification reaction device with independent combustion chamber and fluidized-bed gasification reaction method

InactiveCN103450946ASpeed up the conversion processImprove conversion rateGranular/pulverulent flues gasificationFluidized bed gasifierCombustion chamber

The invention relates to a fluidized-bed gasification reaction device with an independent combustion chamber and a fluidized-bed gasification reaction method, belonging to the technical field of coal gasification. The fluidized-bed gasification reaction device mainly comprises a fluidized-bed gasification furnace and a combustion chamber which are separately arranged, wherein coal is gasified in the fluidized-bed gasification furnace, generated fly ash or bottom slag is subjected to high-temperature and oxidation treatment in the combustion chamber, so that the carbon conversion process is enhanced and the carbon conversion ratio is increased; the combustion chamber is at a higher operation temperature, the influence of high temperature on the fluidization state of the fluidized-bed gasification furnace can be eliminated just by simply treating high-temperature gas, entering the fluidized-bed gasification furnace, of the combustion chamber, and thus the fluidized-bed gasification furnace is easy to operate on the premise of ensuring high-efficiency conversion of the whole system. According to the fluidized-bed gasification reaction device and the fluidized-bed gasification reaction method have the advantages that the defect of low carbon conversion rate existing in the fluidized-bed gasification furnace is overcome, the environment is protected, the energy source utilization rate is increased and a wide application prospect is achieved.

Owner:张荣光

Gasifier Having Integrated Fuel Cell Power Generation System

A direct carbonaceous material to power generation system integrates one or more solid oxide fuel cells (SOFC) into a fluidized bed gasifier. The fuel cell anode is in direct contact with bed material so that the H2 and CO generated in the bed are oxidized to H2O and CO2 to create a push-pull or source-sink reaction environment. The SOFC is exothermic and supplies heat within a reaction chamber of the gasifier where the fluidized bed conducts an endothermic reaction. The products from the anode are the reactants for the reformer and vice versa. A lower bed in the reaction chamber may comprise engineered multi-function material which may incorporate one or more catalysts and reactant adsorbent sites to facilitate excellent heat and mass transfer and fluidization dynamics in fluidized beds. The catalyst is capable of cracking tars and reforming hydrocarbons.

Owner:THERMOCHEM RECOVERY INT

Process for working up resh or shredder light fractions, with CaCO3

InactiveUS6203595B1Simple magneticCalcium/strontium/barium carbonatesMagnesium carbonatesFluidized bed gasifierCombustion

In this process for working up RESH or shredder light fractions, the RESH or shredder light fractions are charged into a fluidized bed gasifier. Hot wind or combustion offgases having a temperature above 450° C. are blown into the fluidized bed through nozzles while forming a counterflow grinding space. CaCO3 is introduced into the fluidized bed and calcined in the grinding space to effect disintegration.

Owner:HOLCIM

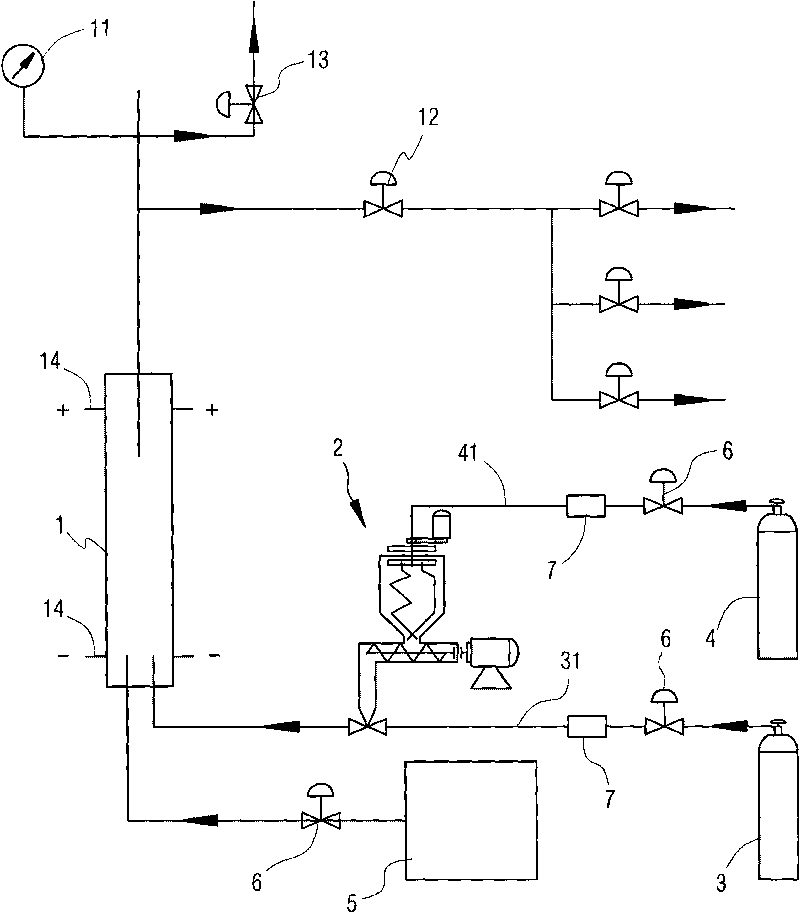

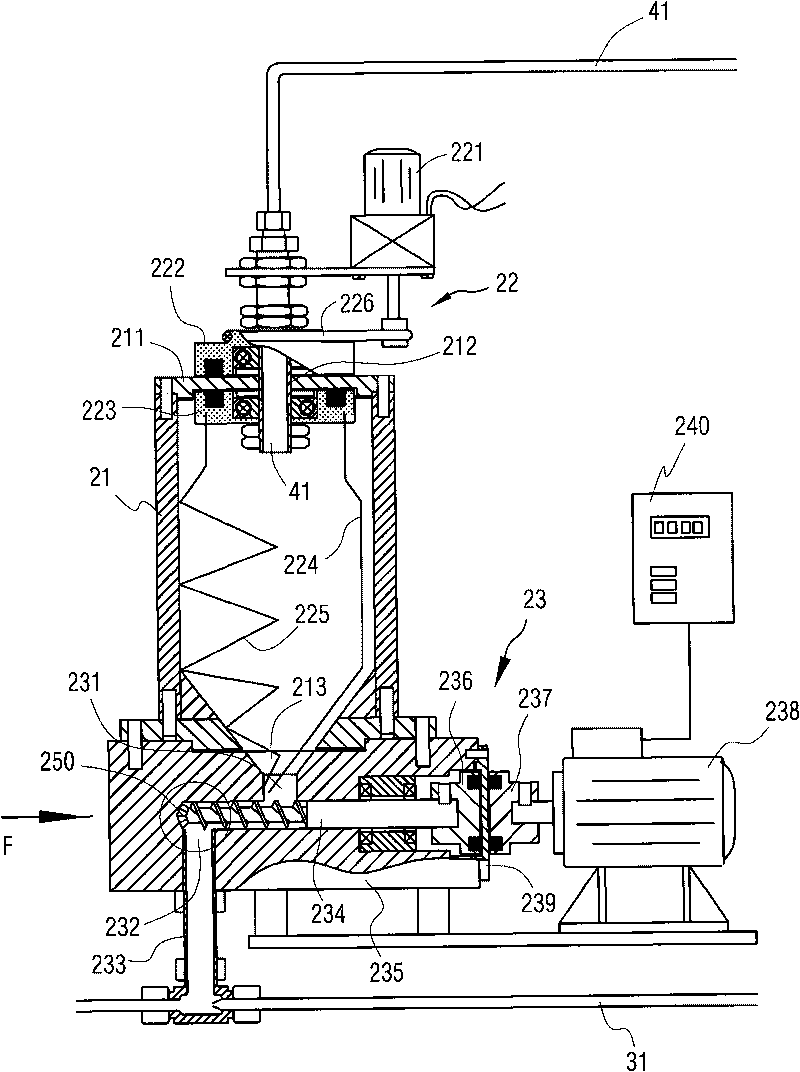

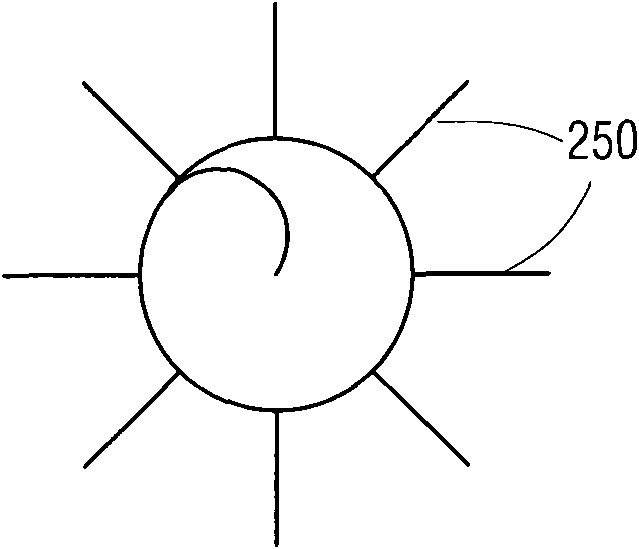

Biomass feeder for pressurized fluidized bed gasifier

InactiveCN101760246AInto continuous stabilityContinuous and stable feedingProductsReagentsFluidized bed gasifierEngineering

The invention provides a biomass feeder for a pressurized fluidized bed gasifier, which comprises a sealed hopper with a non-magnetic conductive top cover, a stirring device and a spiral feeding device. The invention draws lessons from the basic working principle of magnetic transmission, respectively improves the stirring device and the spiral feeding device, so as to achieve the purpose of sealed transmission. The biomass feeder for the pressurized fluidized bed gasifier of the invention is applicable in the feeding of biomass powder under high-pressure condition and gasification in the gasifier, particularly improves the stirring device and the sealed transmission of the spiral feeding device so that the spiral device and the spiral feeding device are applicable in the feeding of biomass powder in high-pressure environment, thereby solving the problems that the low-density fine powder is easy to be lapped, bridged, channeled and cohered into a group, and is not easy to enter the next stage of reactor, so as to disclose a technical scheme which can realize continuous and stable feeding at high pressure and lead the material to enter the reactor continuously and stably.

Owner:TAIYUAN UNIV OF TECH

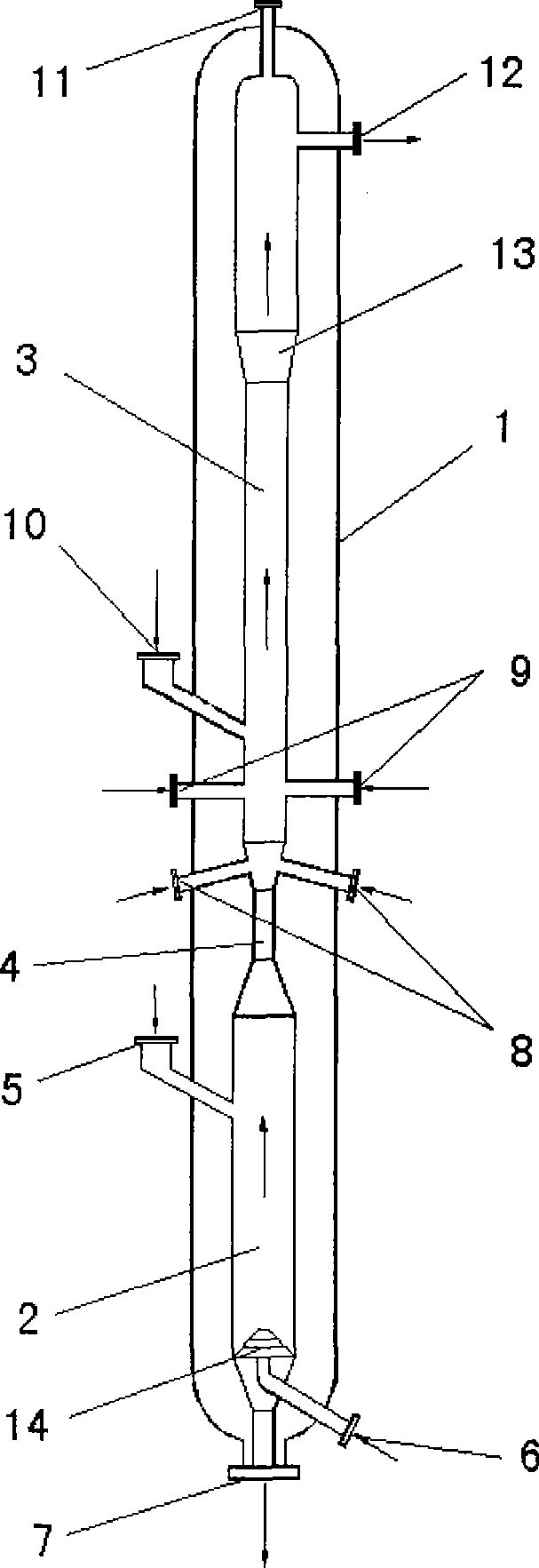

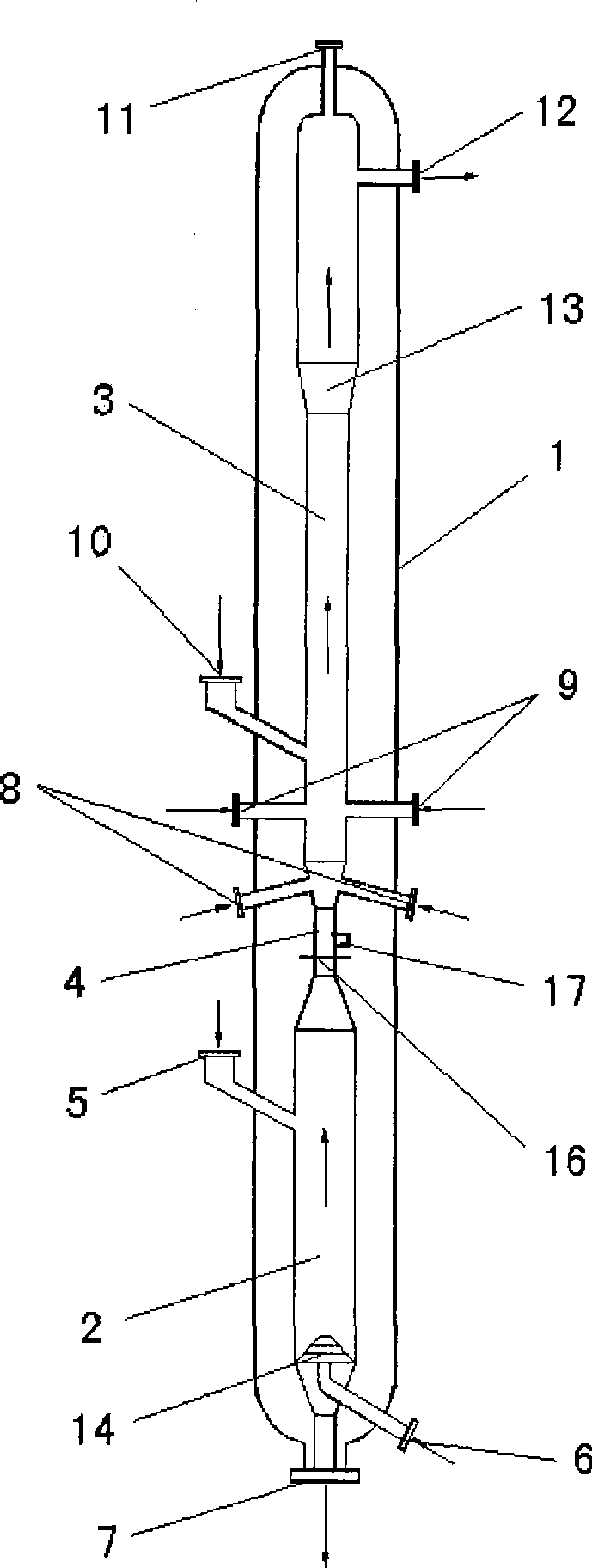

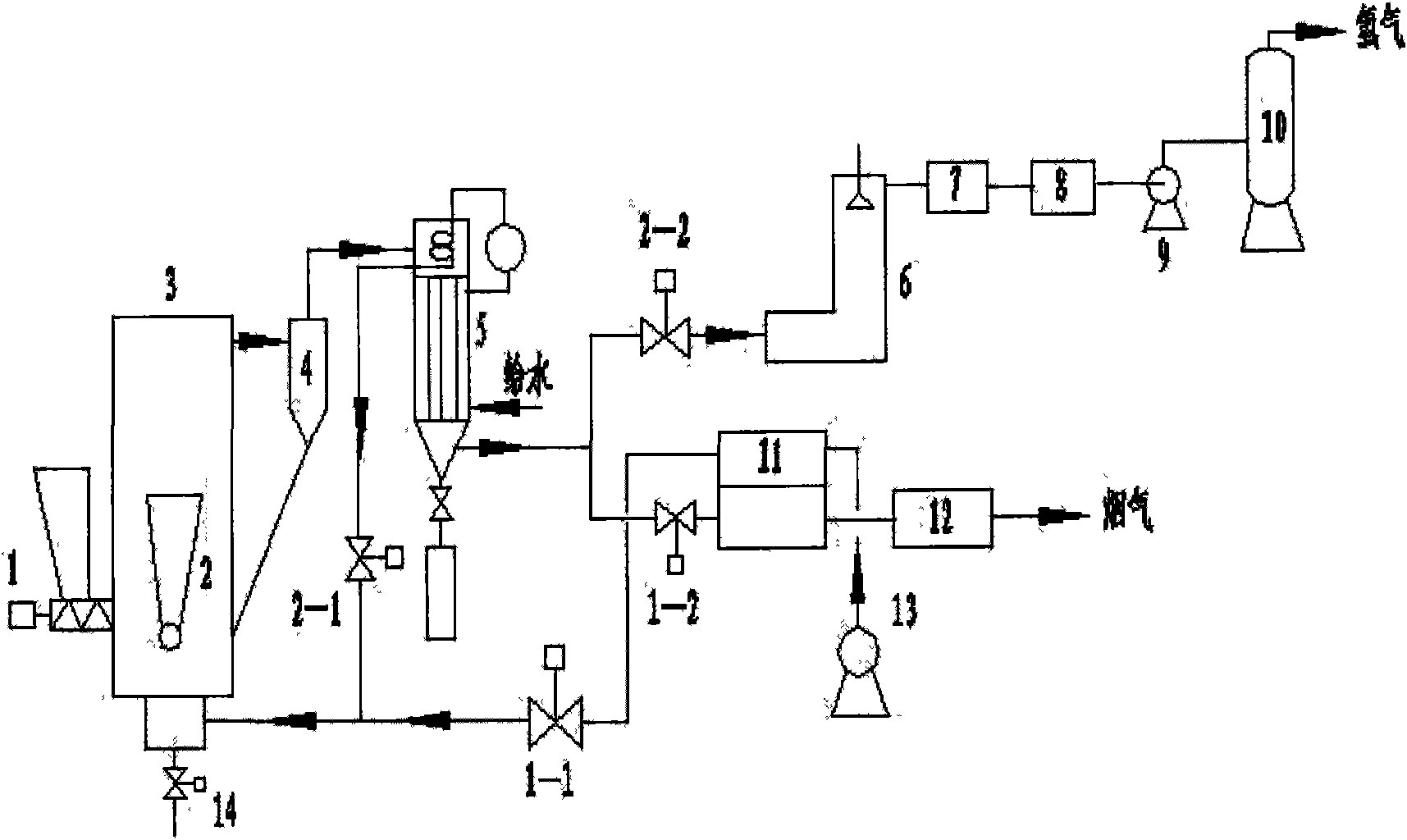

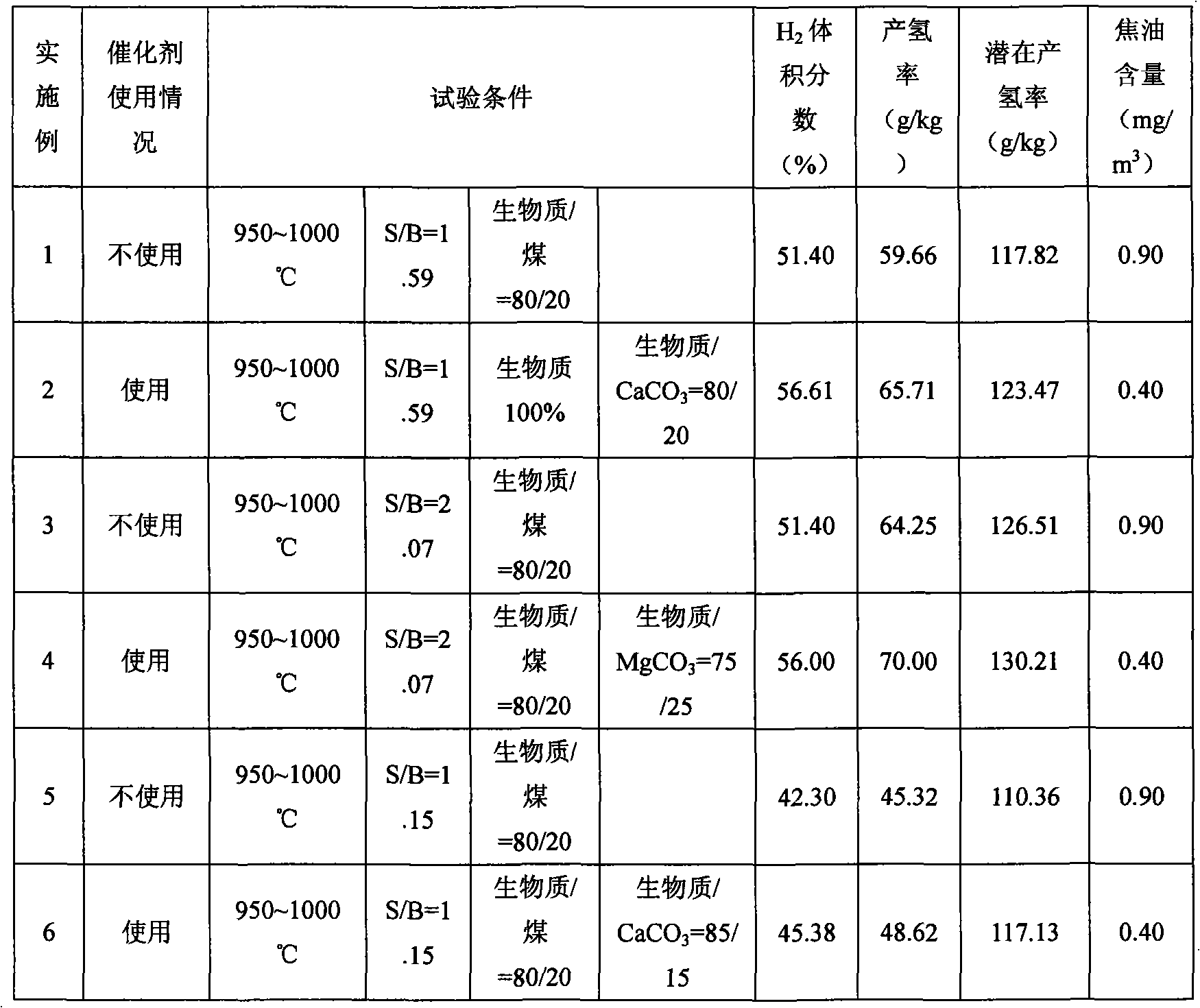

Method and device for producing hydrogen through biomass gasification by using single fluidized bed and two-step method

InactiveCN101570315AQuality improvementLess investmentHydrogen separationEnergy inputWater vaporVariable pressure

The invention belongs to the field of energy. Biomass is used as a raw material, and is added with catalyst calcium carbonate / magnesium carbonate of a carbonate system to react in a fluidized bed; a biomass gasification process is divided into two processes, namely a biomass burning process and a biomass pyrolysis and gasification process, and the two processes work alternately in turn, wherein the burning process comprises that catalyst calcium carbonate / magnesium carbonate granules are added into the fluidized bed, simultaneously air is supplied to the fluidized bed, the air supply to the furnace is stopped when the temperature of the bed layer is raised to a predetermined temperature, and the burning process is finished; then the biomass burning process turns to the gasification process, namely vapor and biomass are supplied to the fluidized bed to obtain hydrogen-rich gas with extremely low tar content; and after the hydrogen-rich gas is washed and purified by coal gas, the hydrogen-rich gas is converted into H2 and CO2 in a CO conversion device, then the gas is desulfurized and compressed, and the H2 is extracted from the gas in a variable pressure adsorption device. The method achieves that the gasification and burning two processes and the cyclic regeneration of a catalyst are finished in the same fluidized bed gasification furnace, the investment is saved, and the running cost is low.

Owner:JIANGSU UNIV

Biomass fluid bed gasification furnace using heat pipe supplying heat

The invention relates to a fluid bed biological mass gasification furnace employing heat pipe for heat supply, wherein superheated steam is loaded into a fluid bed as gasifying agent, a heat pipe is employed to supply the reaction heat needed by the reduction reaction between the biological mass and the steam, one segment of the heat pipe is arranged in the reactor as a heat output section, the other segment is arranged in the combustion chamber as a heat adsorption segment, and the residual heat of the fuel can produce gasifed steam.

Owner:NANJING UNIV OF TECH

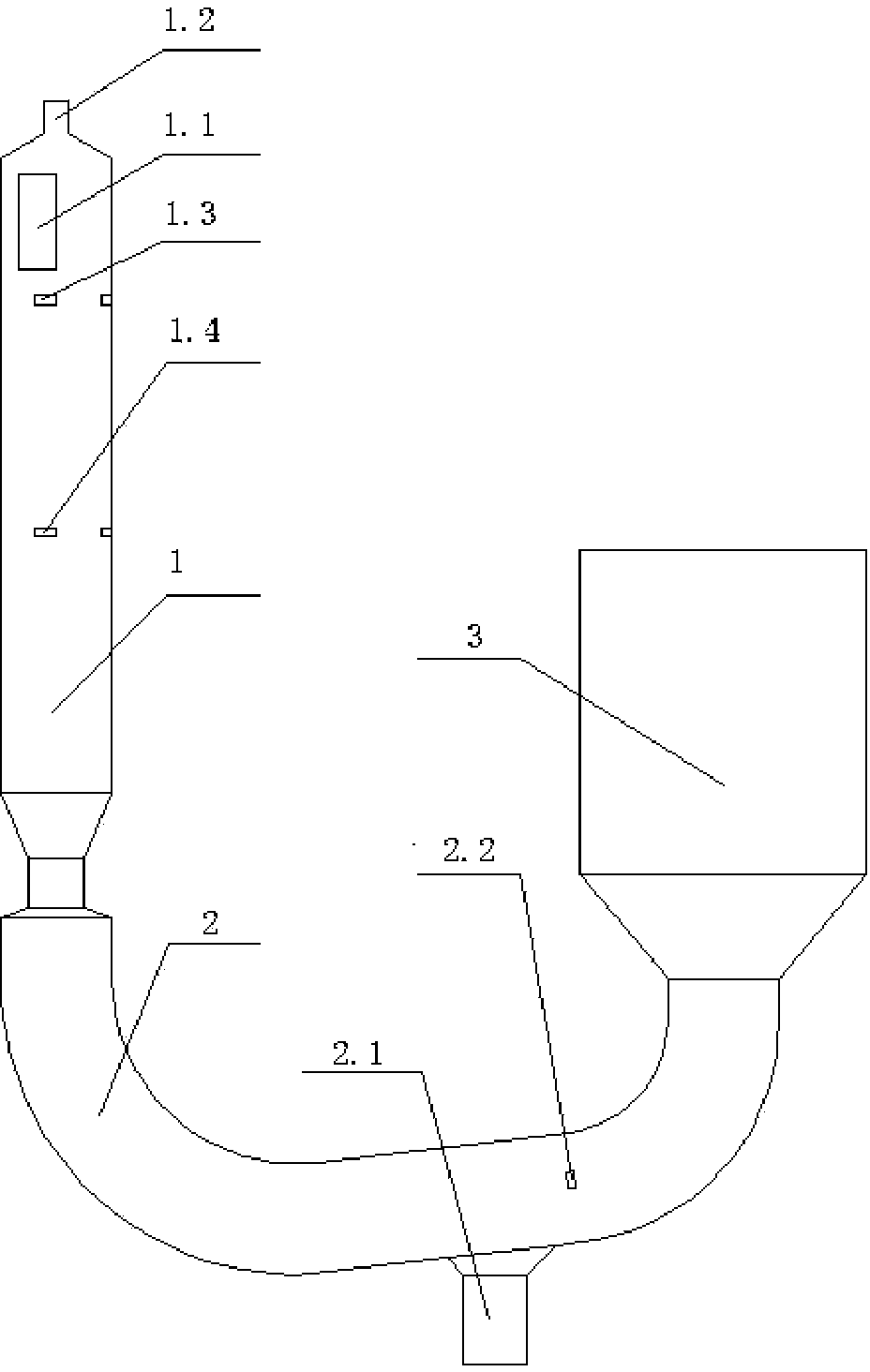

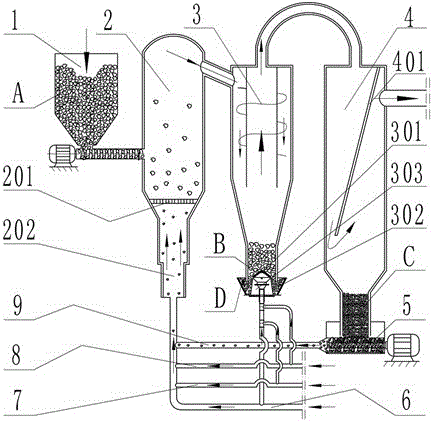

Circulating fluidized bed and pyrolysis bed combined gasification process and device

ActiveCN106635179AImprove conversion rateLarge adjustment rangeGasifier moving partsGasification processes detailsBurn outCoal gasification

The invention provides a circulating fluidized bed and pyrolysis bed combined gasification process and device, and relates to a coal gasification technology. The gasification process is characterized in that a fluidized bed technology is used for pyrolysis and gasification, and coal free of tar and other pollutants is converted into gas; semicoke coal and the like are gasified and burnt out by a pyrolysis bed; coal-containing fly ash is removed from the gas with a precipitation separation method and is returned to fluidized bed gasifier by a screw conveyor to be pyrolyzed and gasified circularly. The fluidized bed gasifier, a cyclone separator, the pyrolysis bed and a sedimentation chamber which are connected are used for combustion and transport of raw coal, the gas, the semi-coke and the coal-containing fly ash, and accordingly, the purpose of the invention is achieved. The gasification process and device have the beneficial effects that the gasification rate of the raw coal is high, and tar and other pollutants are not produced; the circulating fluidized bed is applicable to equipment with large, medium and small gasification rates, and regulation range of gas production capacity in unit time is broad.

Owner:JIANGSU HUAWEI MACHINERY MFG

Ash And Solids Cooling In High Temperature And High Pressure Environment

ActiveUS20120031584A1Avoid interferenceEnsure sufficient separationFluidized bed combustionCorrosion preventionSolid particleHigh pressure

Disclosed are cooling and depressurization system equipment, arrangement and methods to cool solid particles from a coal gasifier operating at high temperature and pressure. Ash from the coal needs to be continuously withdrawn from a circulating fluidized bed gasifier to maintain the solids inventory in the gasifier. The system disclosed enables use of conventional materials of construction for heat transfer surfaces. The supports for the cooling surfaces are located on the lower temperature upper section of the primary cooler. The cooled solids along with the fluidizing gas exits the primary cooler to a secondary receiving vessel where the solids can be further cooled by conventional means. The fluidizing and entrained gas entering the secondary vessel is filtered and vented through a vent pressure control valve. The column of cooled solids in the secondary vessel is depressurized by a continuous depressurization system to low pressures which are sufficient for conveying the solids to silos for disposal. The system and methods proposed are equally applicable to many high temperature, high pressure processes that require cooling and depressurization of process solids.

Owner:THE SOUTHERN CO

Method for generating power by gasifying integrated straws in supercritical coal-fired generator set

InactiveCN102010757AEasy to storeSmall footprintInternal combustion piston enginesEnergy inputBiomass gasifierBubbling fluidized bed

The invention discloses a method for generating power by gasifying integrated straws in a supercritical coal-fired generator set. The method comprises the following steps of: packing and forming biomass straws serving as a gasification raw material of a gasifier of a bubbling fluidized bed, wherein primary wind-heat air surplus in a power station and tail gas fume of a boiler are used as gasifying agents. A biomass gasifier is effectively integrated by simply modifying the conventional supercritical unit to make biomass gasified, combusted and generate power, so that the defect that the biomass is directly blended and combusted is effectively overcome, the influence of biomass ash on fly ash is avoided, and the problem that the conventional auger feeding equipment is easy to damage is solved; therefore, biomass energy can be efficiently utilized and pollutant emission of coal-fired power stations is further reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Fixed bed-fluidized bed serially connected gasification method and apparatus

ActiveCN101440308AReduce tar contentEmission reductionCombined combustion mitigationCombustible gas productionFluidized bed gasifierFluidized bed

The invention relates to a method and a device for gasification, in particular to the method and the device for serial gasification of a fixed bed and a fluidized bed, wherein the method comprises the following steps: 1) feeding a gasification raw material with the particle size of between 13 and 50 millimeters and a gasification agent to a fixed bed gasifier to perform gasification reaction so as to generate coal gas and ash content, discharging the ash content from an ash discharging opening of the fixed bed, and introducing the coal gas to the lower part of a dense phase zone of a fluidized bed gasifier; 2) feeding a thin particle shapeed coal gasification raw material with the particle size of between 0.5 and 8 millimeters and the gasification agent into a fluidized bed gasifier to perform gasification reaction with the vertically raising coal gas so as to generate the coal and the ash content, discharging the ash content from the ash discharging opening of the fluidized bed, and introducing the coal gas into a cyclone separator; and 3) performing gas-solid separation on the coal gas in the cyclone separator, outputting the coal gas from a coal gas outlet of the cyclone separator, and sending back solid particles carried by the coal gas to the fluidized bed gasifier through a dipleg of the cyclone separator to perform the gasification reaction continuously. The method and the device have quite important significance on improving the economic benefit and reducing the sewage treatment cost for the medium and small-sized coal chemical enterprises in China.

Owner:CCTEG CHINA COAL RES INST

Method for gasifying cyclone bed powder coal

InactiveCN102226111ALarge amount of processingSimple structureGasification processes detailsGranular/pulverulent flues gasificationCycloneFluidized bed gasifier

The invention discloses a method for gasifying cyclone bed powder coal, which comprises steps as follows: raw coal, of which the particle size is less than or equal to 3mm, is dried and preheated to 200-300 DEG C in a coal drying and preheating system; under the combined action of oxygen / steam mixed gasifying agent, the dried and preheated raw coal enters a cyclone bed gasifier through an upper route and a lower route to carry out gasifying reaction, thereby obtaining gasified coal gas; after being chilled on the top of the cyclone bed gasifier, the gasified coal gas enters a coal gas heat exchanger to be further cooled, and is purified by a coal gas purification system, wherein part of the purified coal gas is used as chilled gas after being compressed by a chilled gas compressor; and after being treated by a high pressure steam boiler, the steam generated by the coal gas heat exchanger is used as a gasified medium together with oxygen generated by an oxygen generation system. By integrating the advantages of the fluidized bed gasifier and the entrained flow gasifier, the invention has the advantages of simple equipment structure, low manufacturing cost and high material treatment capacity, and is easy to operate.

Owner:BEIJING HUAFU ENG

Low activity dust coal catalytic gasifying method

InactiveCN1570025AChange the traditional heating modeReduce pollutionSpecial form destructive distillationLow activityFluidized bed gasifier

The invention discloses a low activity dust coal catalytic gasifying method which consists of, spraying industrial alkali waste liquid to low active powered coal or coal carbonization coal coke, mixing and drying, then entering fluid bed gasification stove for catalyzed gasification with air / aqueous vapor or aqueous vapor, basic ash and slag can be automatically discharged from the bottom or lateral surface or the gasification furnace.

Owner:FUZHOU UNIV

Method and equipment for gasifying coal by using plasma

InactiveCN101781584AIncrease gasification rateReduce coal consumptionGranular/pulverulent flues gasificationChemical reactionWater vapor

The invention provides method and equipment for gasifying coal, relating to a coal chemical industry technique and gasification furnace equipment. The invention is characterized in that a fluidized bed gasification furnace is designed into a three-section working mode, the upper section is a suspended preheating section, the middle section is a turbulent flow pyrolyzing section, the lower section is a bubbled gasifying section, a plasma torch is arranged at the bubbled gasifying section, and water vapor is heated to be greater than 4000 DEG C in the plasma torch, is decomposed into active chemicals H., O., H2., HO., O2. and then is directly sprayed to carbon coke of the bubbled gasifying section for chemical reaction to generate synthesis gas of CO and H2 and release heat; and pyrolysis gas, the water vapor and fluidized gas in the furnace are mixed, are discharged out of the furnace through an outlet of the suspended preheating section and then return the bubbled gasifying section of the gasification furnace through a fluidized air pipe and a fluidized fan, and soot, gaseous tar, CmHn and CH4 in the pyrolysis gas react with the water vapor to generate the synthesis gas of the CO and the H2. Compared with the conventional coal gasification technique, the invention reduces the consumption of coal resources and the discharge of greenhouse gases.

Owner:周开根

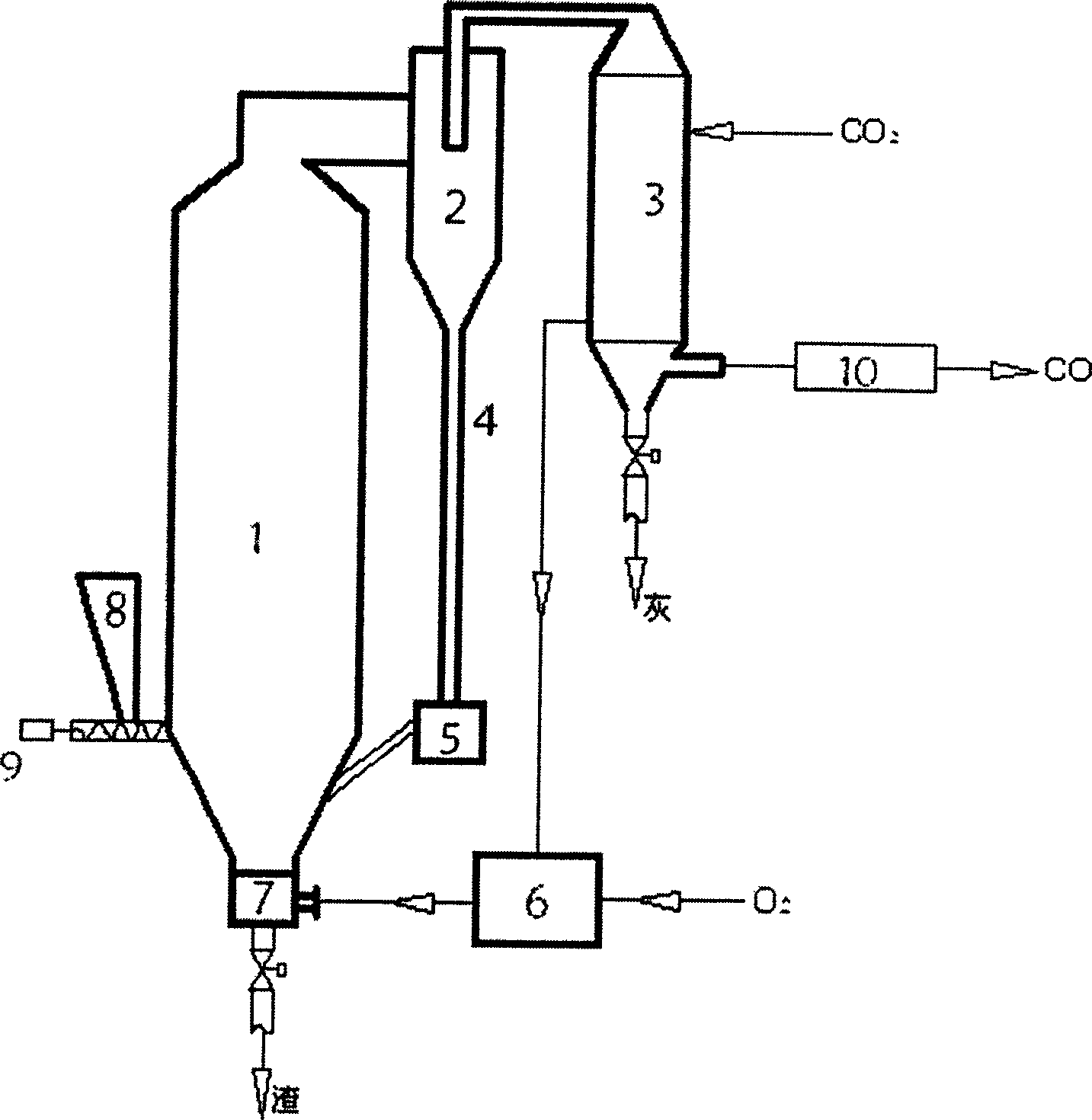

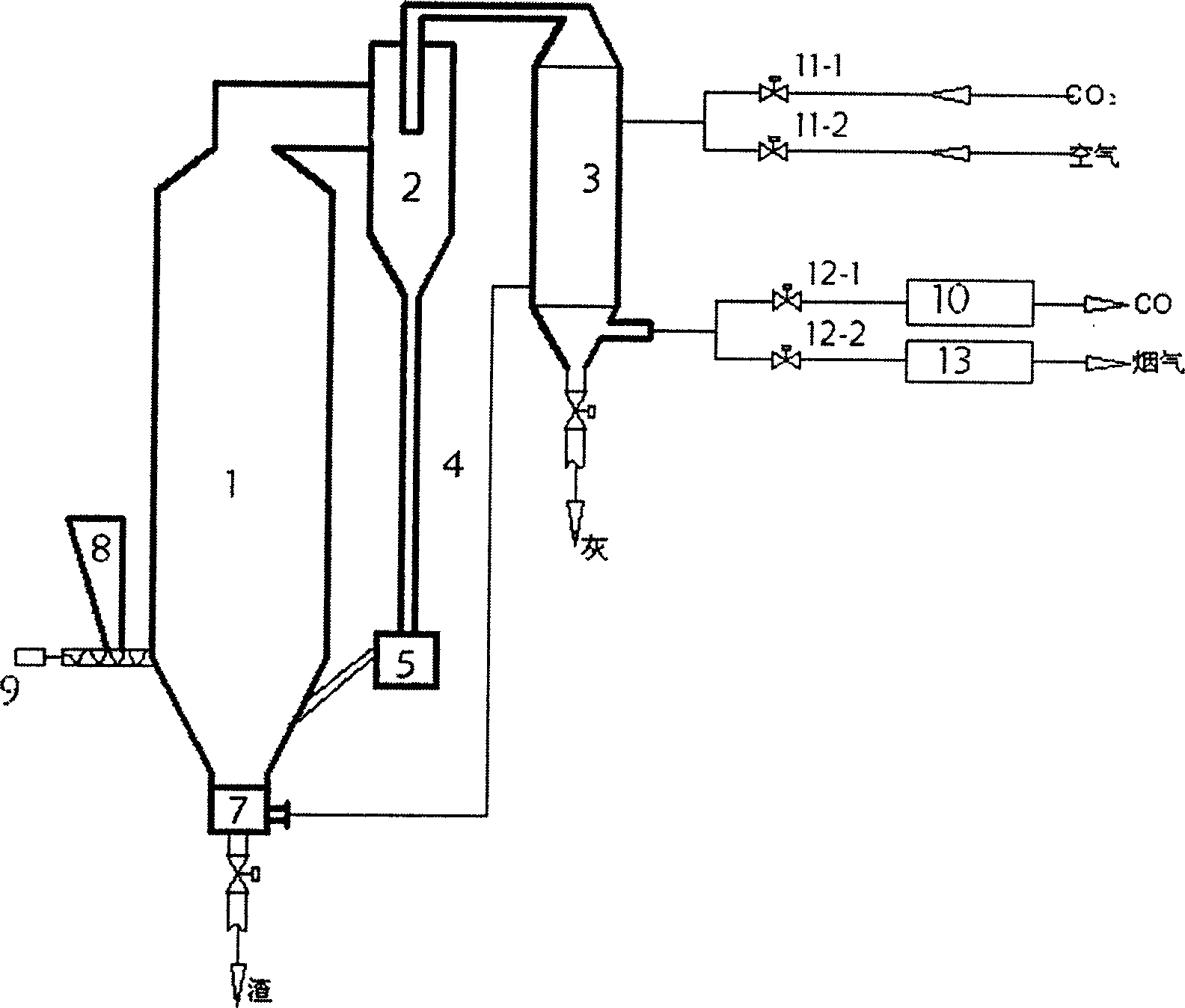

Technical process for gasification of fluidized-bed CO gasifying furnace and apparatus thereof

InactiveCN1597871ARich sourcesImprove the situationCombined combustion mitigationGranular/pulverulent flues gasificationFluidized bed gasifierFluidized bed

The invention relates to a gasification process which uses O2+CO2 or air+CO2 as a gasifying agent for fluidized bed CO gasification furnace, and its device, using O2 and CO2 as gasifying agent, and 0-10 mm-sized fine coke and blind coal as raw materials, adopting continuously-gasifying fluidized bed gasification furnace as a gasifier, namely adopting continuous gasification process; or using air and CO2 as gasifying agent, using 0-10 mm-sizd fine coke, blind coal, lean coal, long flame coal and wood coal as raw materials, adopting intermittently-gasifying fluidized bed gasification furnace as a gasifying device, namely adopting intermittent gasification process, reducing CO2 gas into CO gas to make highly pure CO gas as organic synthetic raw material. The advantage are the raw material source is rich, it retrieves and uses the CO2 gas to act as the gasifying agent.

Owner:JIANGSU UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com