Fixed bed-fluidized bed coupled gasification method and apparatus

A technology of fixed-bed gasifier and fluidized-bed gasifier, which is applied in joint combustion mitigation, combustible gas production, petroleum industry, etc. It can solve the problems of high carbon content and low carbon conversion rate, and reduce tar content , Improve the conversion rate of carbon, the effect of quality increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

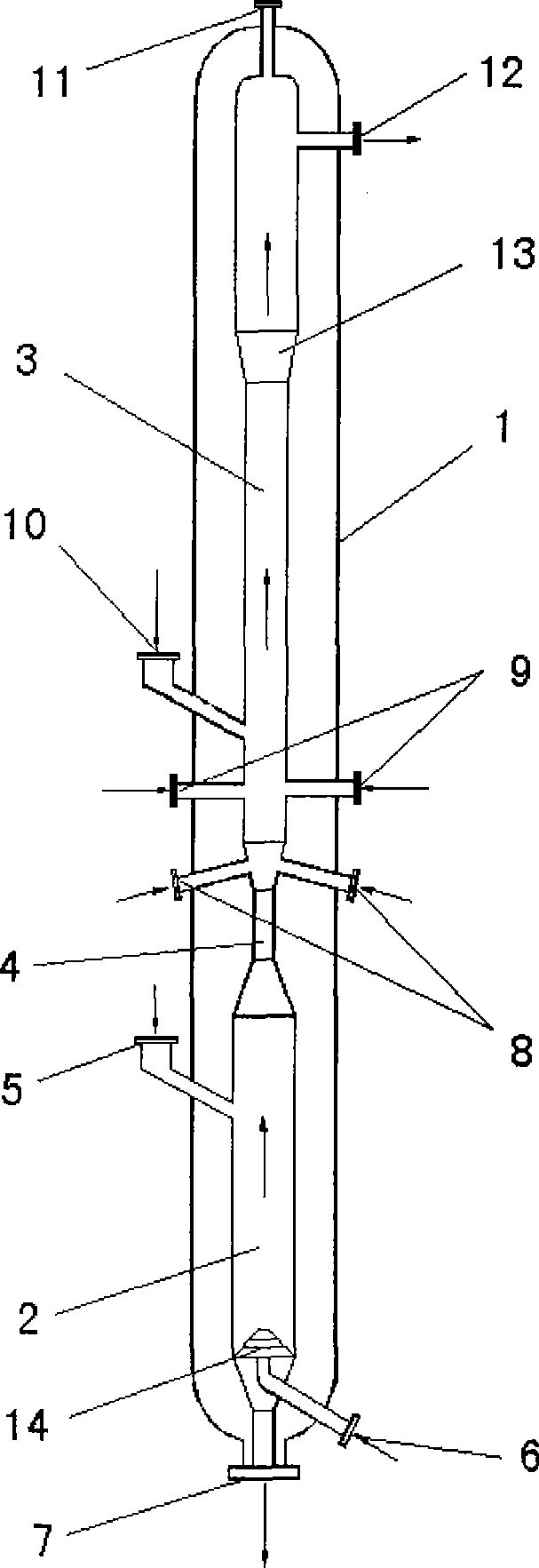

[0019] Such as figure 1 As shown, the device of the present invention includes an integral shell 1, the inner chamber of the integral shell 1 is a fixed bed gasifier 2 and a fluidized bed gasifier 3, the top of the fixed bed gasifier 2 is connected with the fluidized bed gasifier The bottom of 3 communicates with a throat 4, and a refractory and heat insulating material is arranged between the overall shell 1 and the inner cavity.

[0020] The upper part of the fixed bed gasifier 2 is provided with a fixed bed feed inlet 5, the lower part of the fixed bed gasifier 2 is provided with a fixed bed gasification agent inlet 6, and the bottom of the fixed bed gasifier 2 is provided with a fixed bed ash outlet 7 .

[0021] The lower cone of the fluidized bed gasifier 3 is provided with a water vapor inlet 8 in the circumferential direction, and the fluidized bed gasifier 3 above the water vapor inlet 8 is provided with a fluidized bed oxygen inlet 9, and the fluidized bed oxygen inl...

Embodiment 2

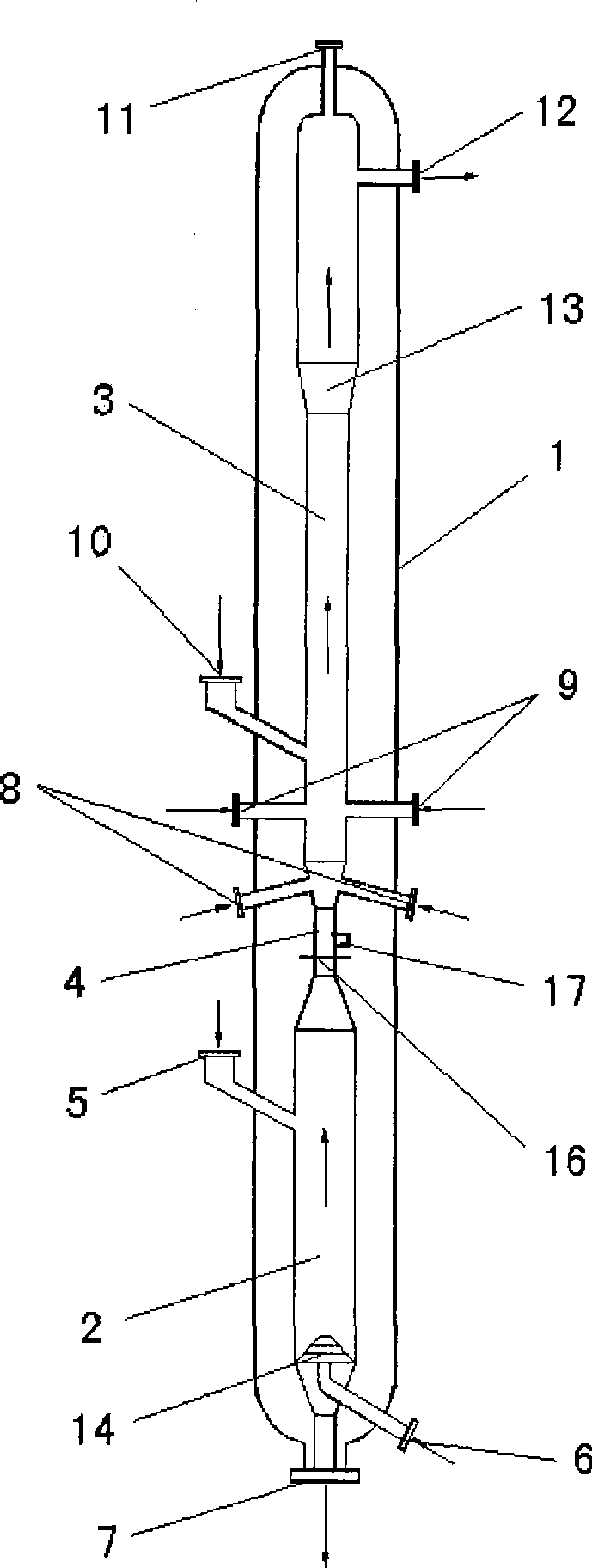

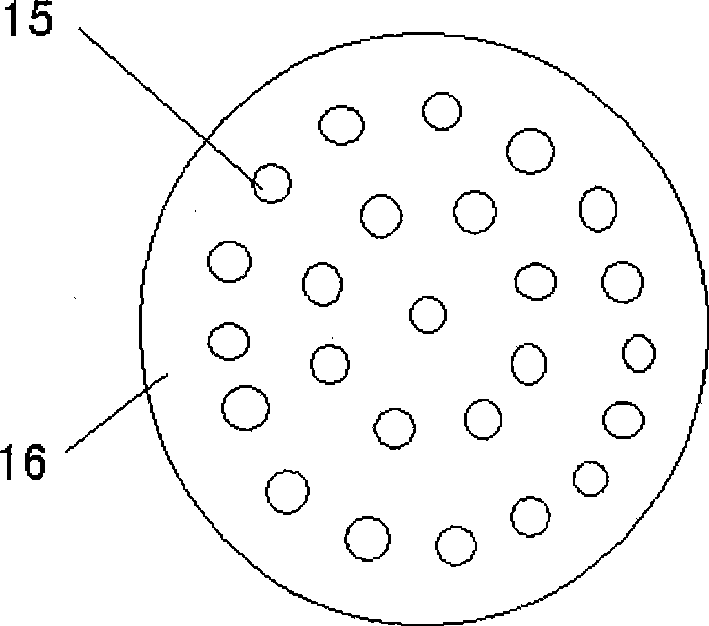

[0025] Such as figure 2 As shown, the structure of this embodiment is basically the same as that of the above-mentioned embodiment, the difference is that: on the throat pipe 4 connected between the fixed bed gasifier 2 and the fluidized bed gasifier 3, a valve with several ventilation holes is arranged. 15 sieve plates 16 (such as image 3 shown), the throat 4 above the sieve plate 16 is separately provided with a fluidized bed ash outlet 17 (such as figure 2 shown), the ash can be discharged from the fluidized bed ash outlet 17 through the ash discharge screw. Concrete ash discharge screw etc. are prior art, no longer repeat them.

Embodiment 3

[0027] The fixed bed-fluidized bed integrated gasification method of the present invention comprises the following steps:

[0028] 1) The gasification raw material with a particle size of 10-50 mm is fed into the fixed bed gasifier 2 in normal operation through the fixed bed feed port 5 of the fixed bed gasifier 2, and at the same time, water vapor is mixed with pure oxygen or oxygen-enriched The gas is used as a gasification agent to enter the fixed-bed gasification furnace 2 from the lower fixed-bed gasification agent inlet 6, so that the gasification raw material and the gasification agent are contacted and gasified in the fixed-bed gasification furnace 2 in countercurrent, and the gasification raw material and gasification agent are gasified. A gasification reaction occurs to produce gas and ash.

[0029] 2) The ash generated in the fixed bed gasifier 2 is discharged from the fixed bed ash outlet 7 at the bottom, and the gas generated in the fixed bed gasifier 2 rises and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com