Patents

Literature

432results about How to "Reduce tar content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing synthetic gas by three-phase type biomass pyrolysis-gasification-catalytic reforming

ActiveCN102424359AImprove conversion utilizationHigh yieldHydrogenWaste based fuelCatalytic reformingChemical industry

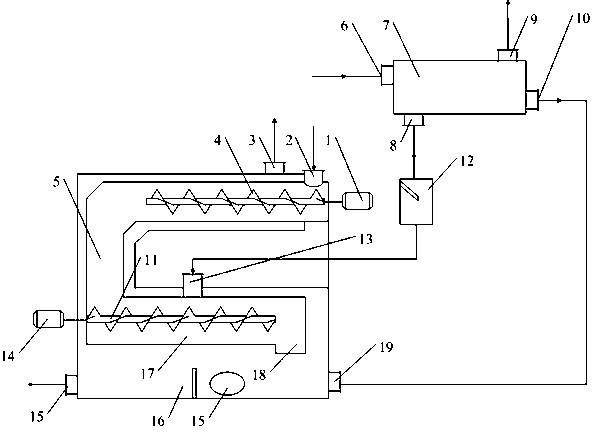

The invention belongs to the technical field of energy chemical industry. The process for preparing synthetic gas by biomass pyrolysis and gasification is divided into three steps of biomass low-temperature pyrolysis, coke or semi-coke high-temperature gasification and crude synthetic gas / tar catalytic reforming. The three reaction steps are successively and continuously carried out in three relatively independent spaces of an upper pyrolysis hearth, a lower gasification hearth and a catalyst bed inside the same gasification reaction device so as to finally obtain the high-quality synthetic gas. The method provided by the invention has high carbon conversion rate, produces no secondary pollution and is simple to realize. In addition, required biomass is rich in reserves and can be regenerated, thus realizing integrated sustainable utilization of resource, energy and environment.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

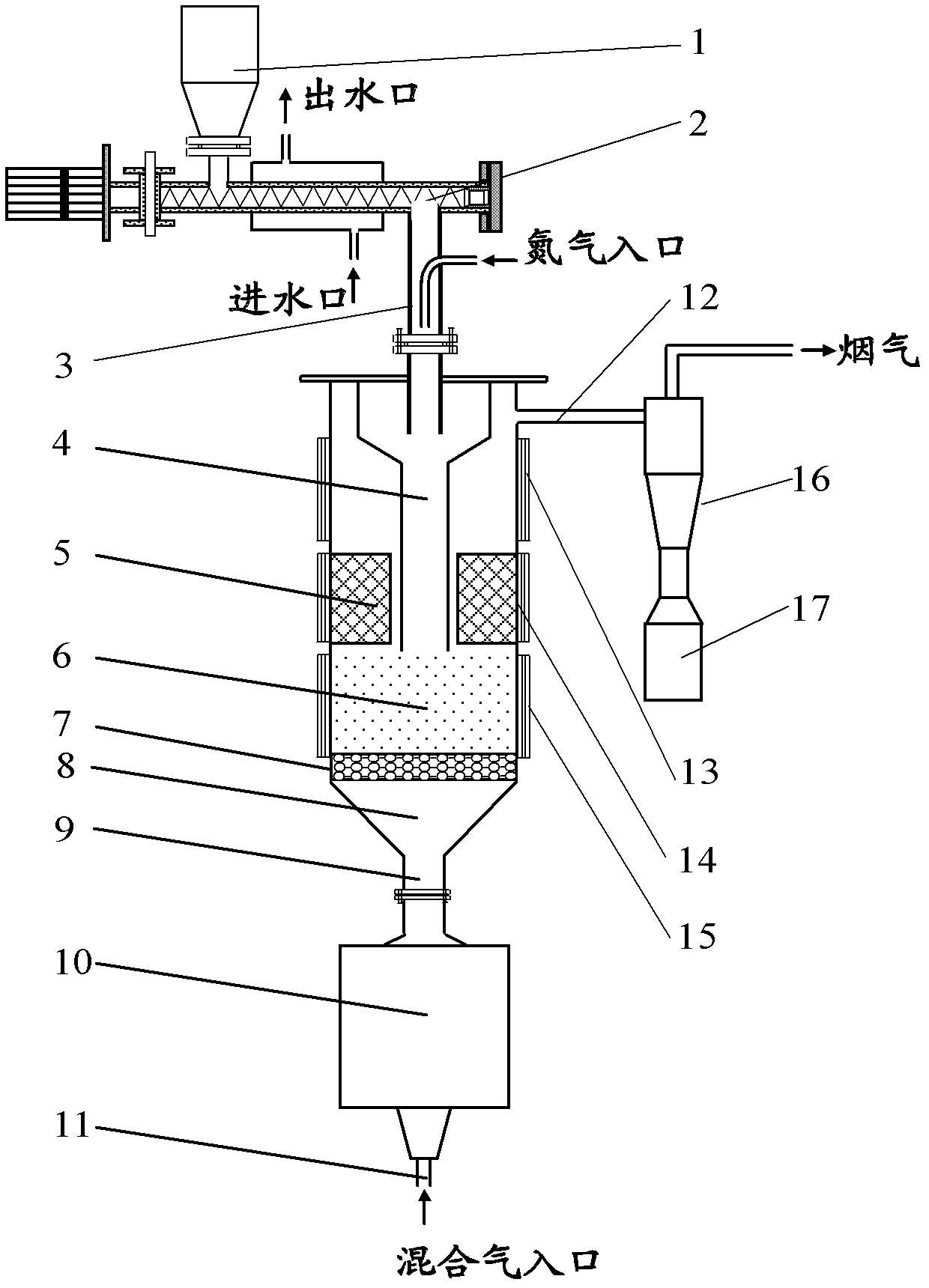

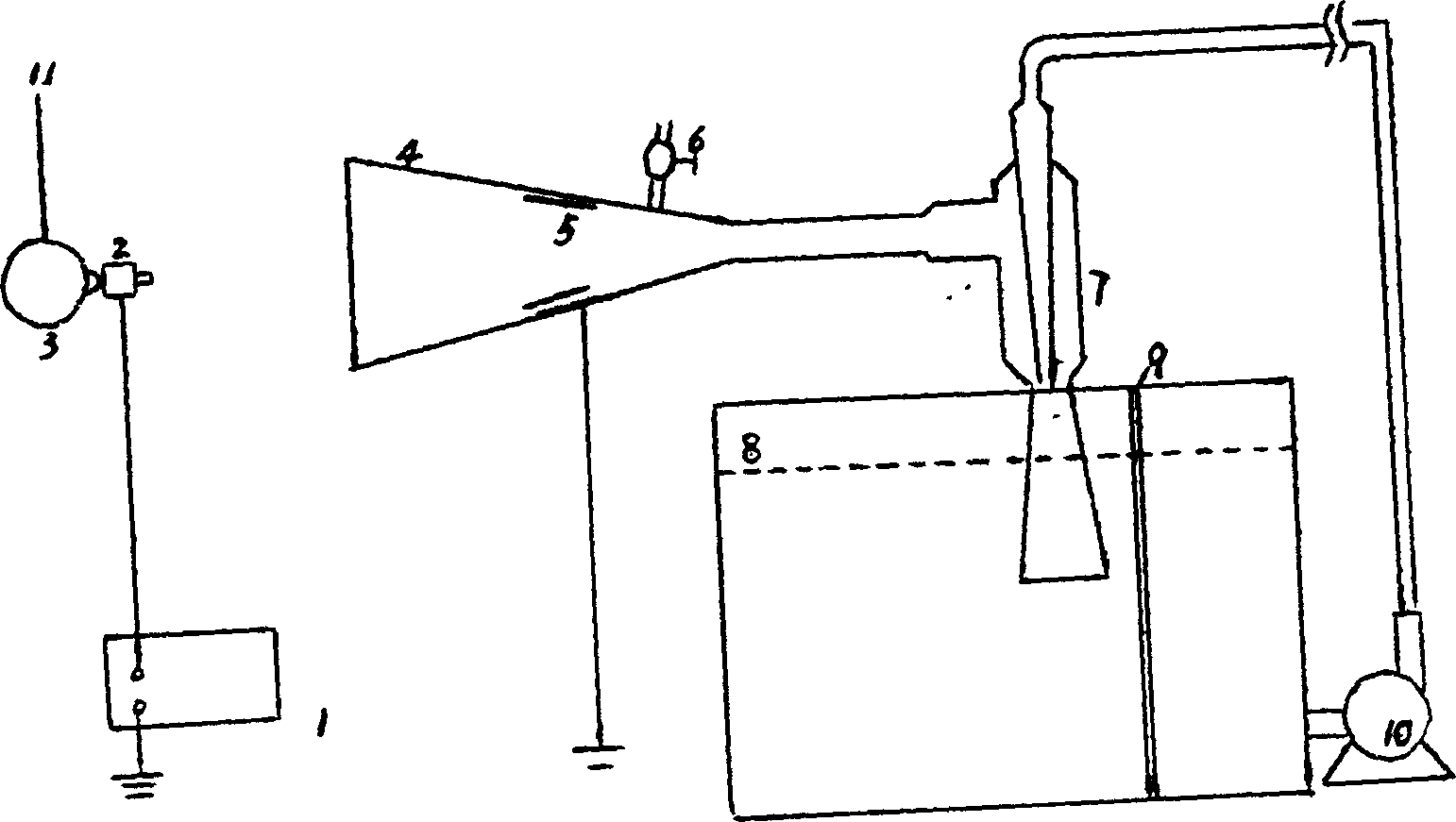

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

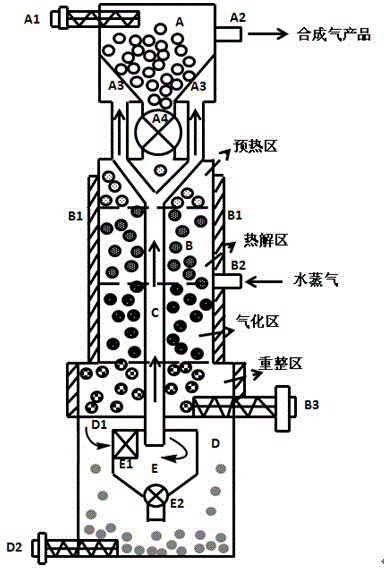

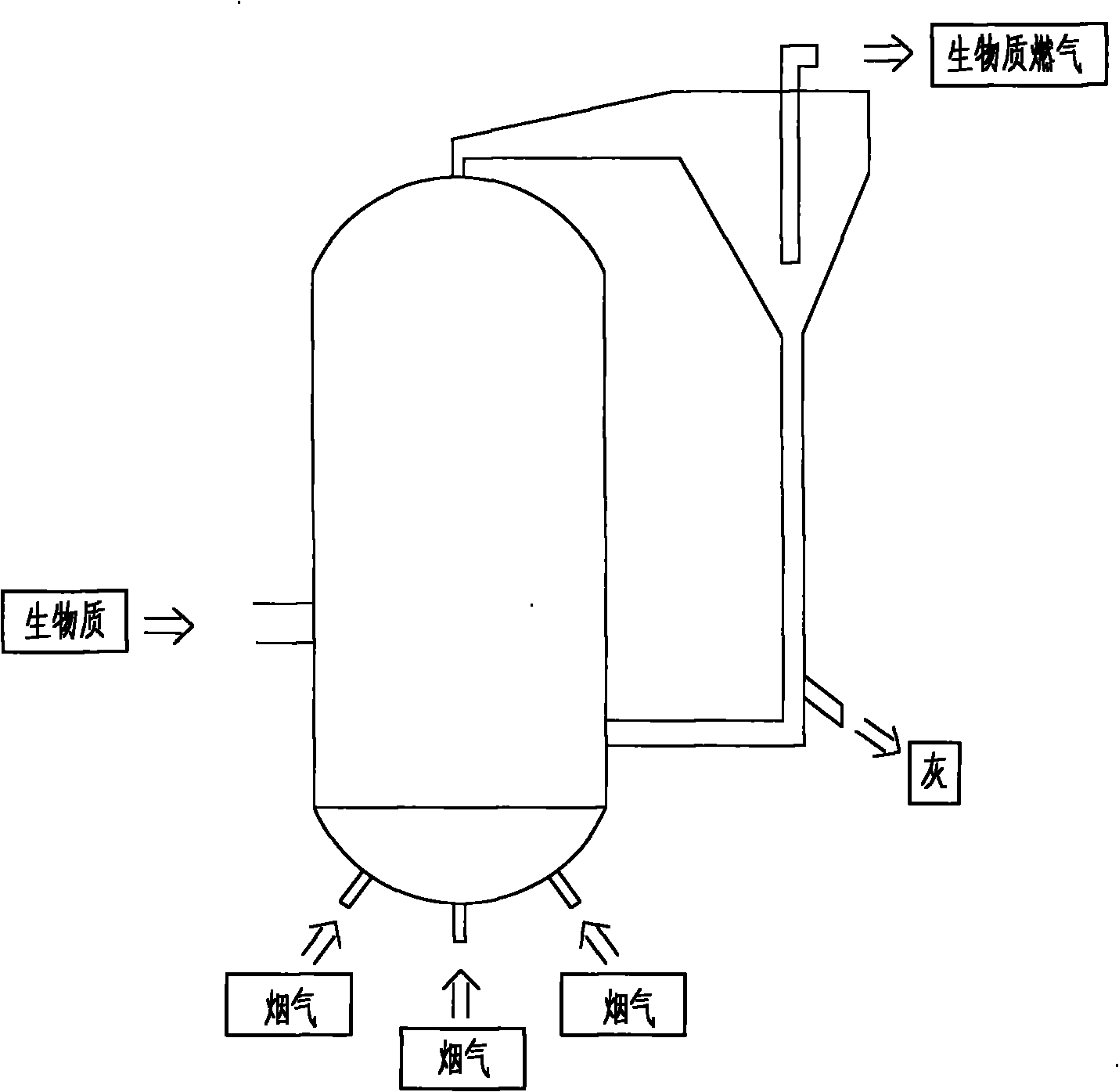

Biomass high-temperature flue gas gasification combination coal burning boiler and low-pollution combustion method thereof

ActiveCN101865451AReduce tar contentReduce contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHearthPollution

The invention belongs to the technical field of a coal burning boiler and particularly relates to a biomass high-temperature flue gas gasification combination coal burning boiler and a low-pollution combustion method thereof. Flue gas serving as a gasification agent enters a gasification furnace; a biomass to be gasified in a biomass bin also enters the gasification furnace; gasified biomass fuel gas enters a fuel gas purification chamber to be subjected to primary purification to remove H2S, HCl and oil tar impurities; after a pressure head of the purified biomass fuel gas is improved by a booster fan, the purified biomass fuel gas enters a fuel gas storage tank and then enters a hearth of the coal burning boiler by a fuel gas nozzle to be burnt; the content of the biomass in the total glue gas is in the range of 0 to 30 percent and the whole system can still operate stably. The use of the biomass effectively reduces discharge of CO2 and SO2. The high-temperature flue gas is used as a heat source to gasify the biomass so as to reduce the content of the oil tar in the biomass fuel gas. The generated biomass fuel gas has high CO2 concentration. The reducing effect of the fuel gas on NOX is far superior to that of the biomass solid on NOX. The NOX concentration is effectively reduced.

Owner:ZHEJIANG GUANGHAN ENVIRONMENTAL PROTECTION TECH

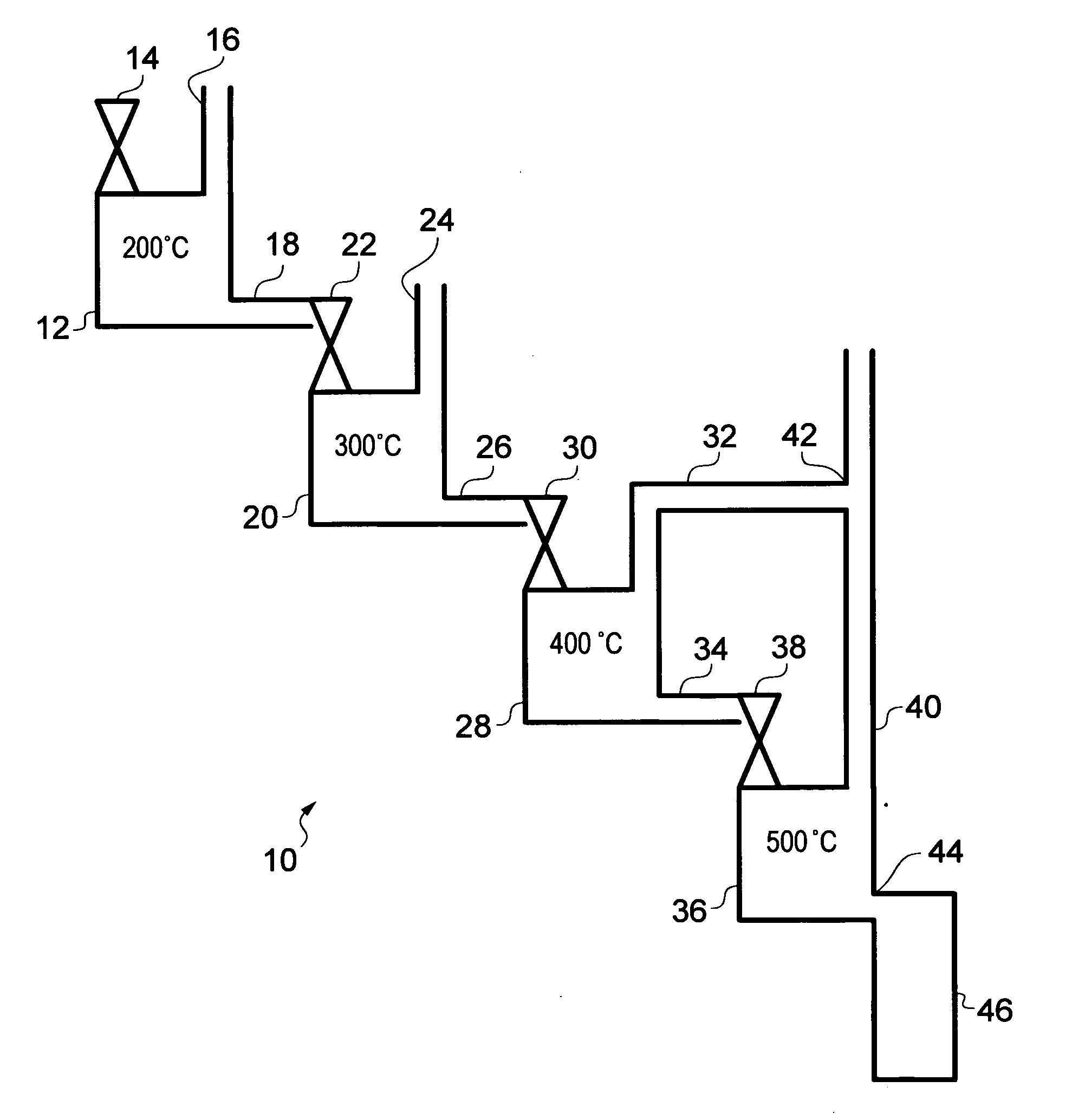

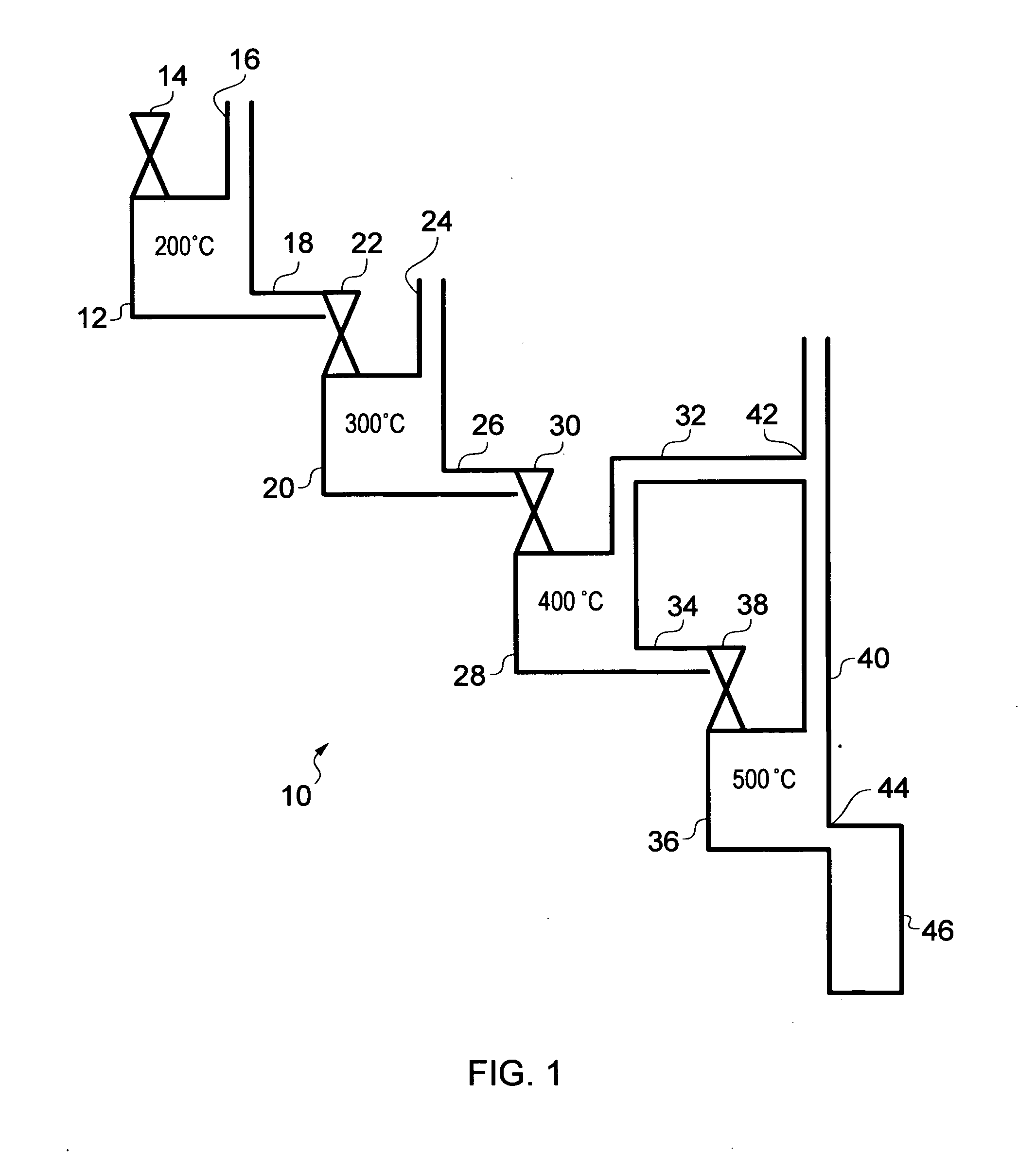

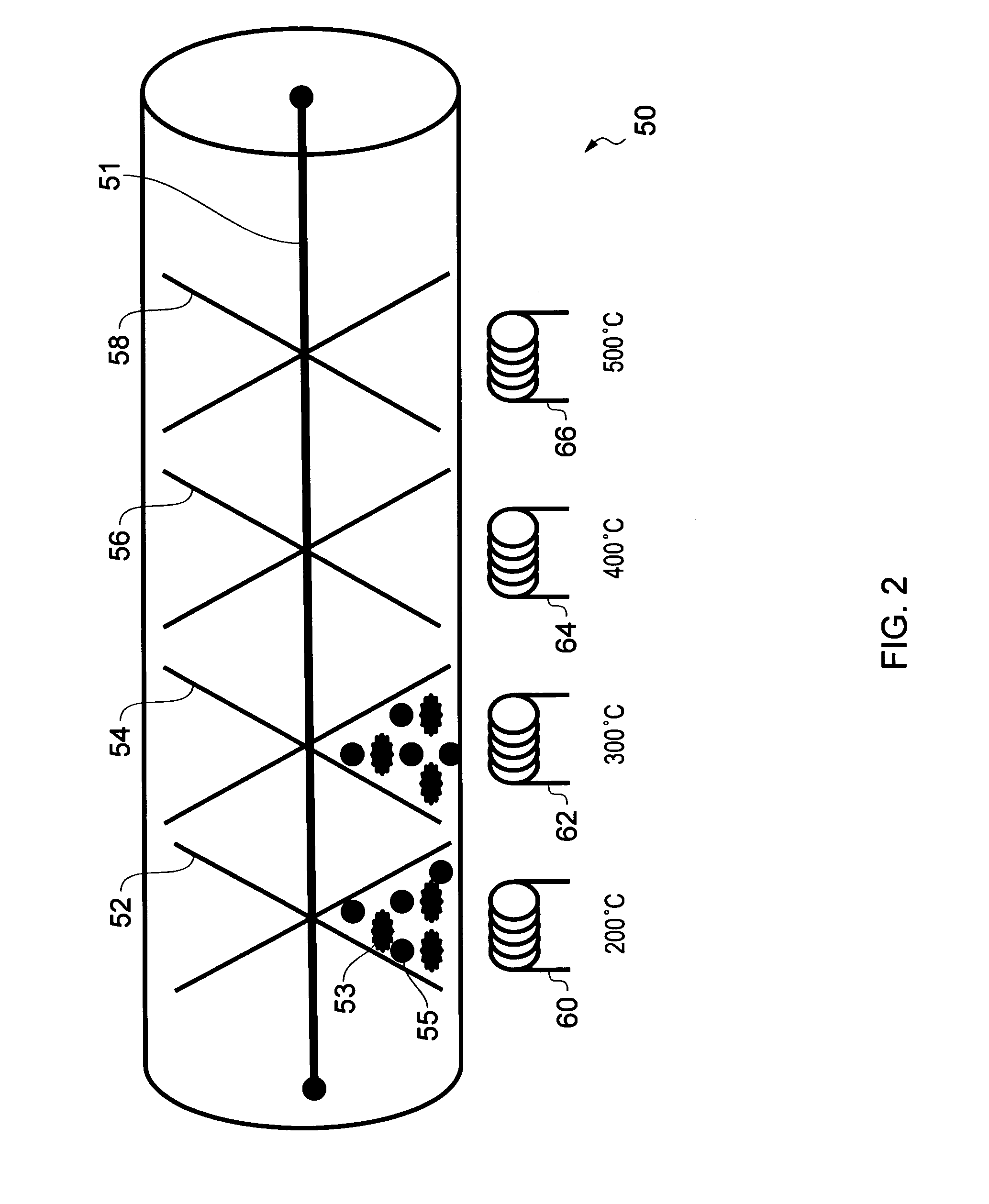

Staged biomass pyrolysis process and apparatus

InactiveUS20110278149A1Low heating rateReduce tar contentProductsBeehive ovensOxygenThermal treatment

Owner:ASTON UNIV

Additive for lowering harmful constituents in cigarette flue gas and cigarette thereof

InactiveCN101692934AImprove adsorption capacityLarge aspect ratioTobacco treatmentHazardous substanceCarbon nanotube

The invention relates to a cigarette additive and cigarette prepared by the additive. The additive can lower the tar contents in cigarette flue gas and can selectively absorb harmful substances such as polycyclic aromatics, phenols and the like in cigarette flue gas. The additive is carbon nanometer pipe preparation dispersed in water solution of surface active agent. The preparation is taken as cigarette cut tobacco additive and is sprayed on tobacco leaves in the cigarette production material feeding technique process according to 1 to 25% of the weight of the cut tobacco, and carbon nanometer pipes are evenly and dispersedly absorbed on the surface of the cut tobacco after silk drying processing. The additive can remove 6.2-38.8% of polycyclic aromatics such as Benzo(a)pyrene and the like and 3.0 to 28.3% of carbolic acid and catechol in cigarette main flow flue gas, and also can lower the tar contents in flue gas for 3.4 to 20.4%, and the original color and flavor of cut tobacco are not changed basically.

Owner:CHINA TOBACCO HUNAN INDAL CORP

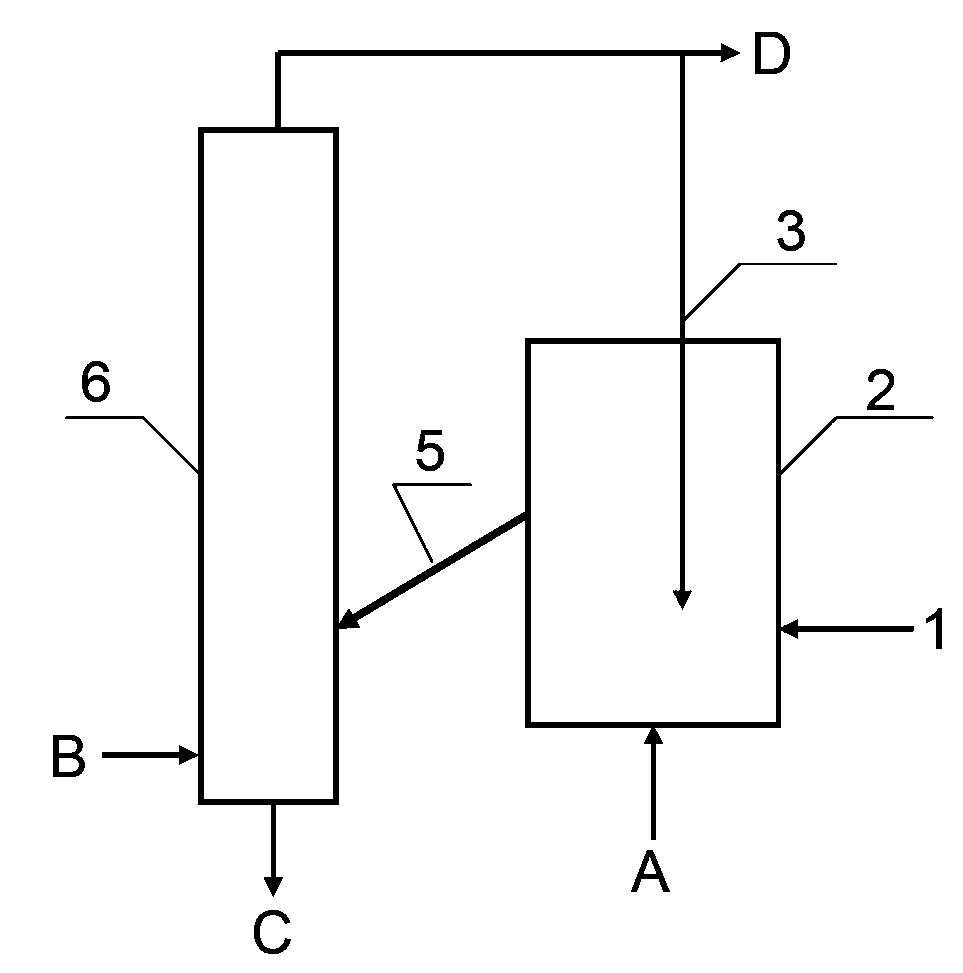

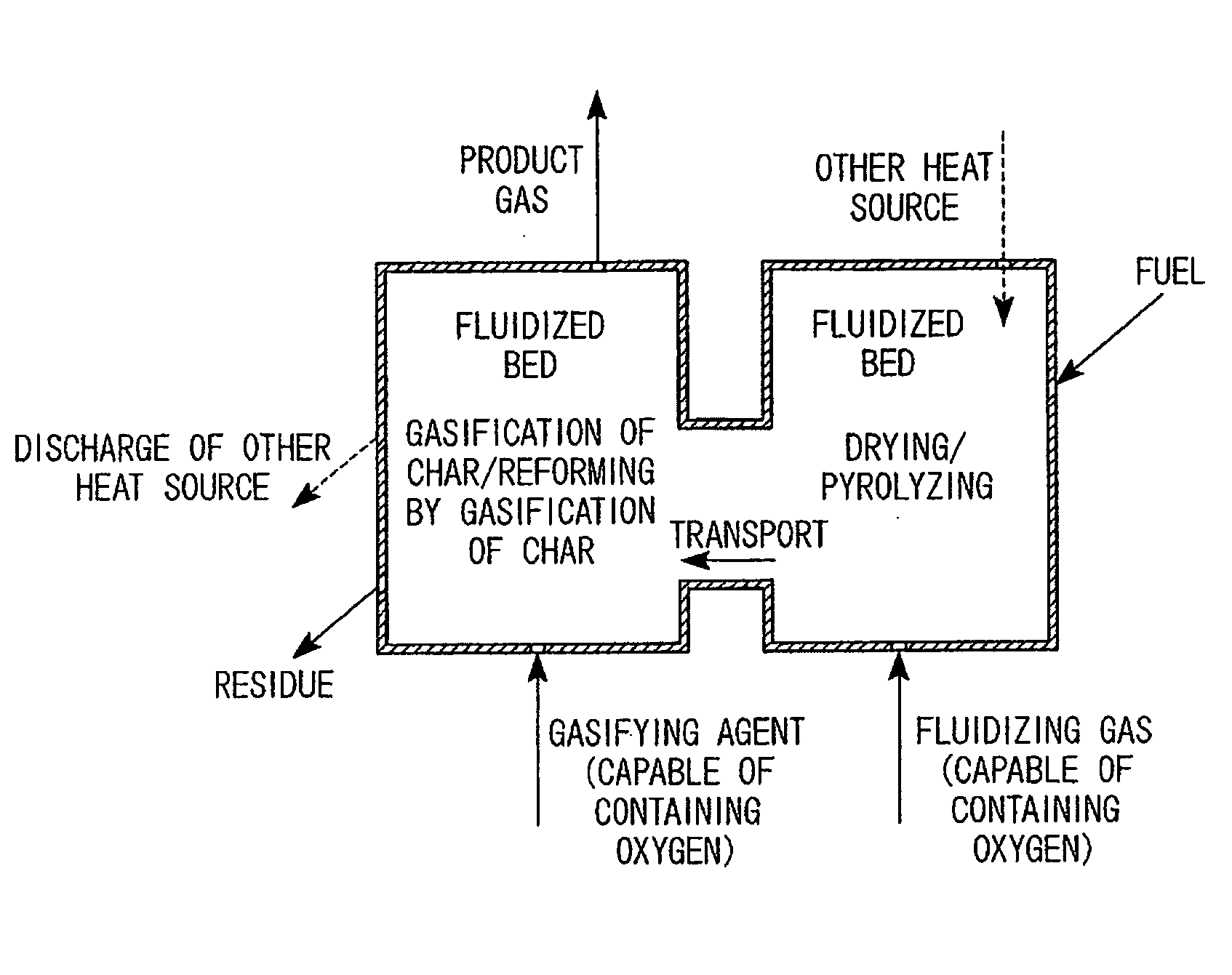

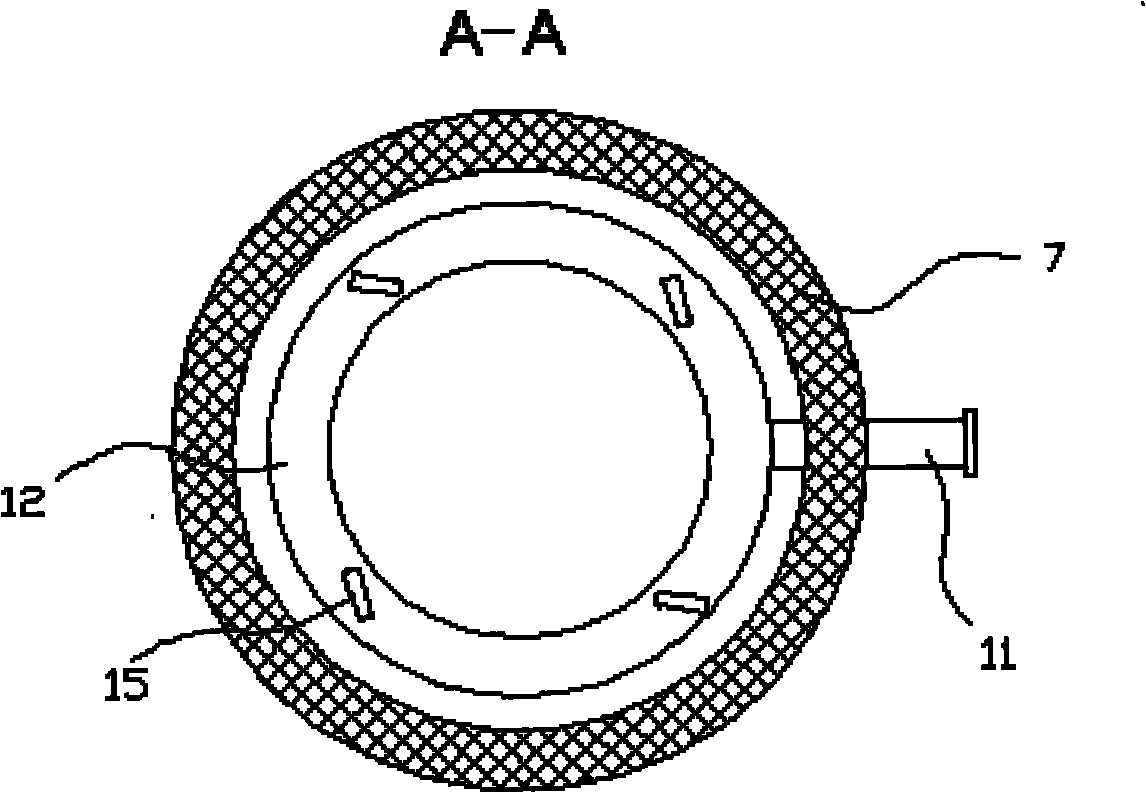

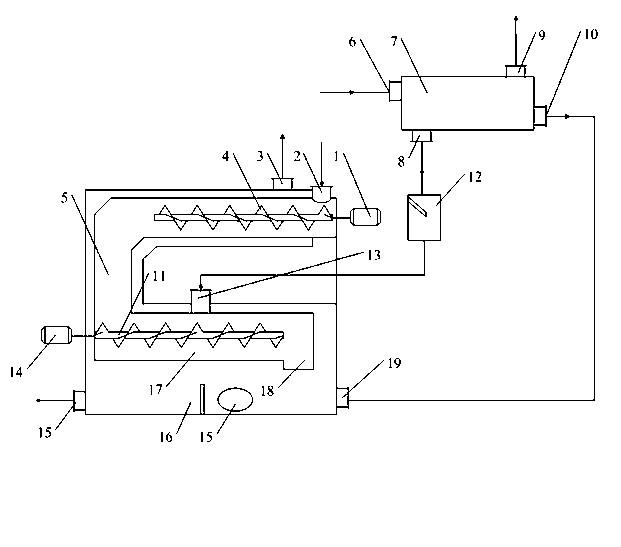

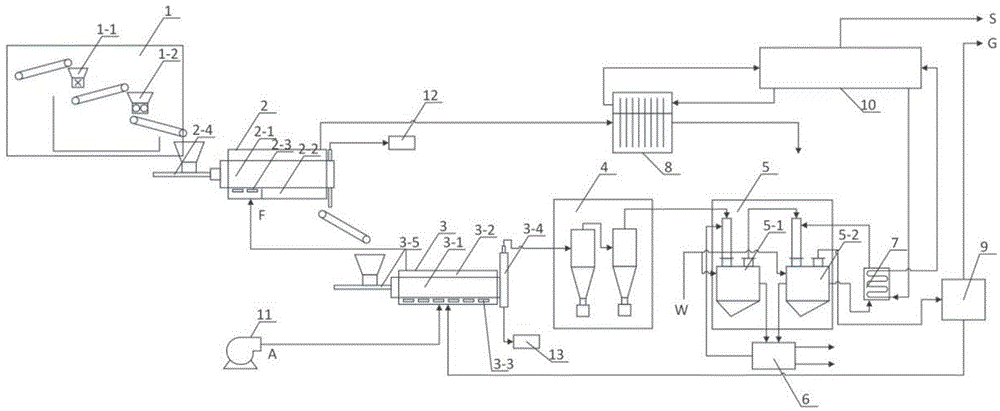

Two-stage gasification method and gasification device for fuels with wide size distribution

ActiveCN102703131AExtensive sources of raw materialsWide particle size distributionCombined combustion mitigationGranular/pulverulent flues gasificationTarProcess engineering

The invention relates to a two-stage gasification method and a gasification device for a fuel with wide size distribution. The two-stage gasification method for the fuel with wide size distribution comprises the steps of 1) adding the fuel to a fluidized bed pyrolyzer by a feeding device; adding a gasifying agent to the fluidized bed pyrolyzer; drying / pyrolyzing or partly gasifying the fuel under semicoking of the pyrolyzer and heating of the gasifying agent; and 2) sending the solid and gas generated in the step 1) to a fluidized bed gasification furnace, adding the gasifying agent to the fluidized bed gasification furnace, finishing complete gasification of semicoke; removing tar by high-temperature pyrolysis, part oxidization and semicoke catalytic reforming in the fluidized bed so as to produce clean gas. With the adoption of the method, the traditional fuel gasification process is divided into a material pyrolysis stage and a semicoke gasification stage, which are performed in an upper fluidized bed pyrolyzer and a lower fluidized bed gasification furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

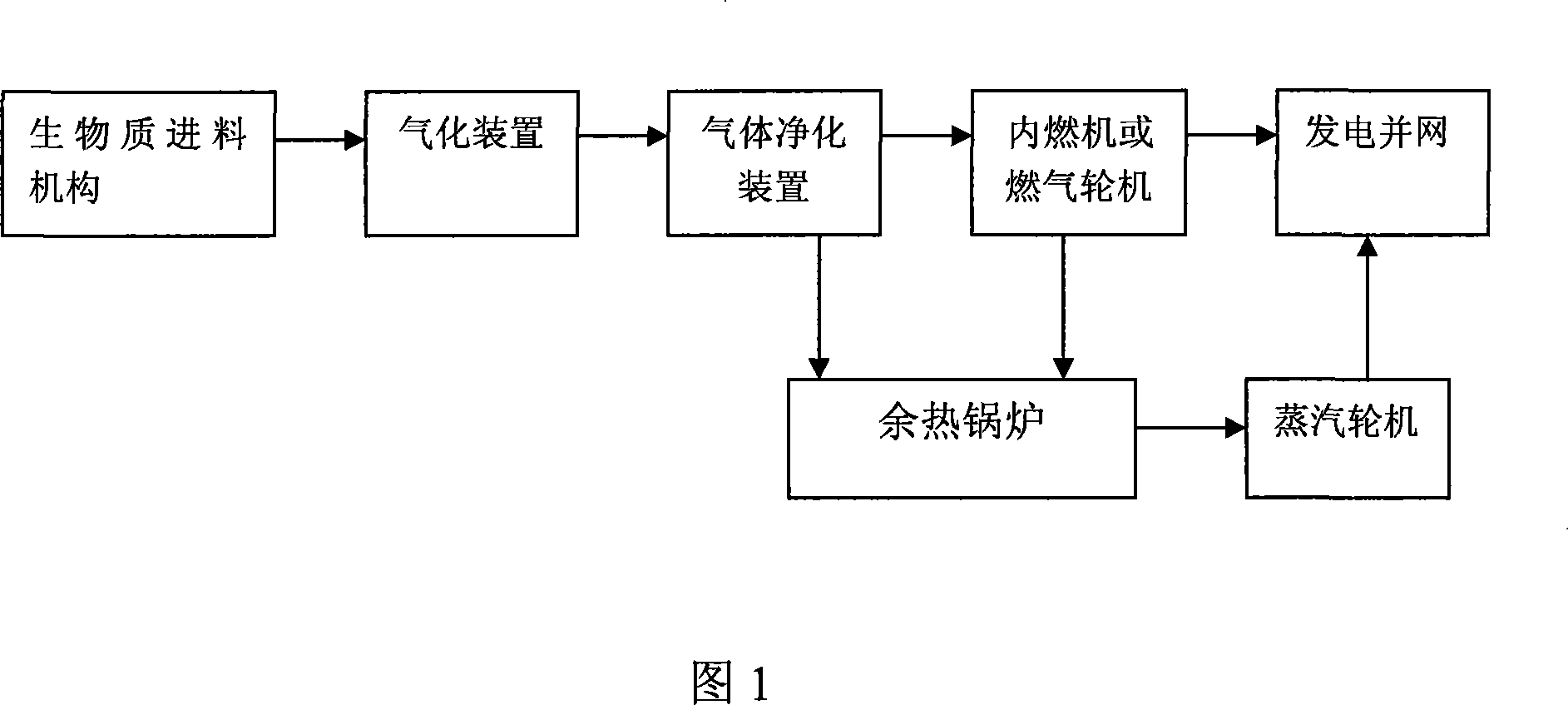

Power generation method using biomass

InactiveCN101158312AAdaptableStrong production intensityProductsInternal combustion piston enginesAgricultural residueInternal combustion engine

The invention relates to a method for generation by a biomass. The method utilizes the gasification technology, which converts the forestry and agricultural residues comprising wasted straws, sawdust, haulms, rice husks, bagasse, etc. into the flammable gas approaching the coal gas; after the dust and the tar of the flammable gas is removed by a purifier, the flammable gas is conveyed in a gas internal combustion engine or a gas turbine for generation. The invention has strong raw material adaptability, can dispose the biomass raw material of different types, and has the advantages of large production intensity, high gas heat value, little tar content, high gasification efficiency, strong load adaptability, easy start and stop, large adjustable range, stable operation, extremely high flexibility in scale. Furthermore, the generation scale depends on the quantity of the raw material and the requirement of the power, and can be designed and matched according to the requirement of the user.

Owner:WUHAN LIREN INVESTMENT

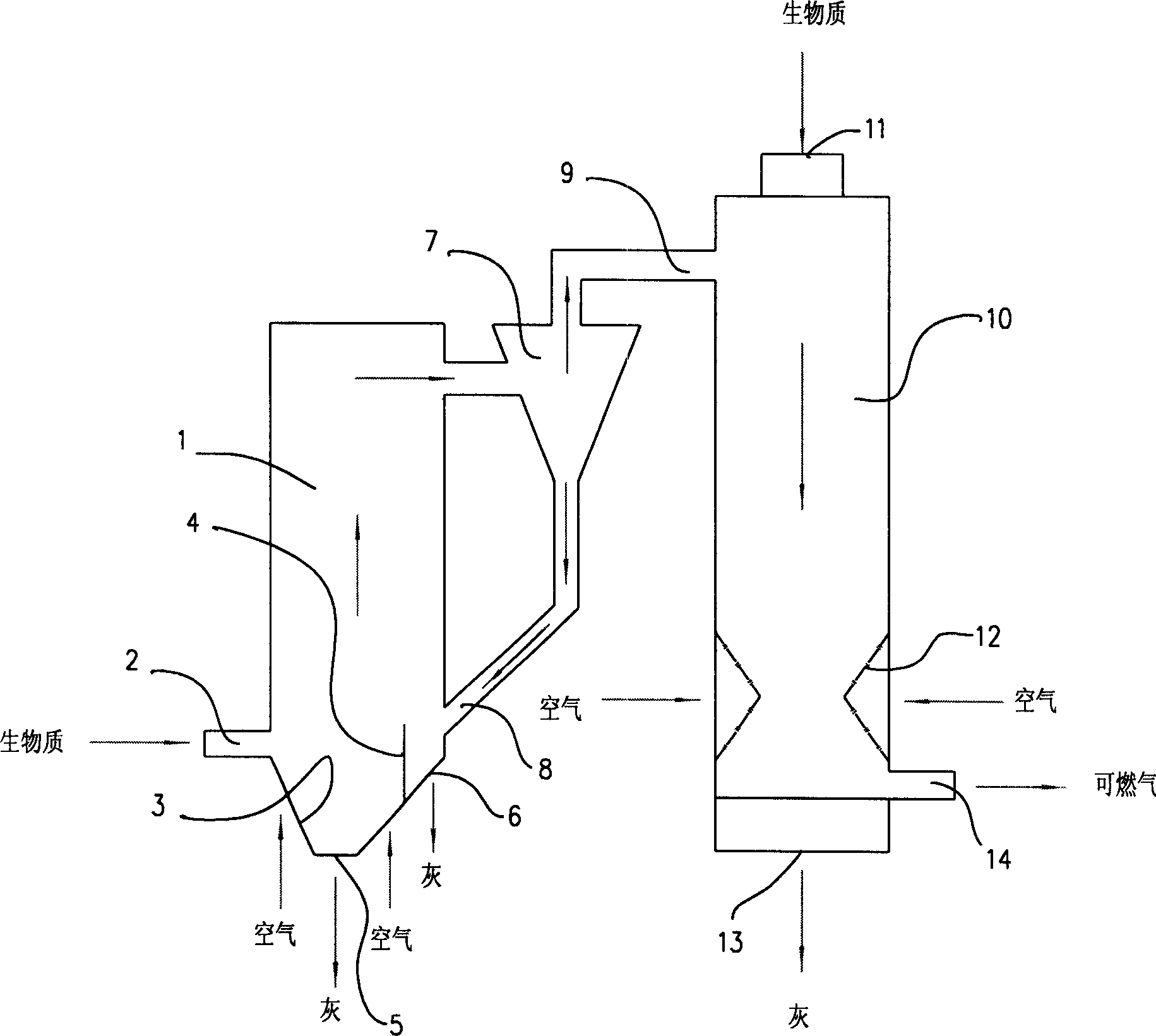

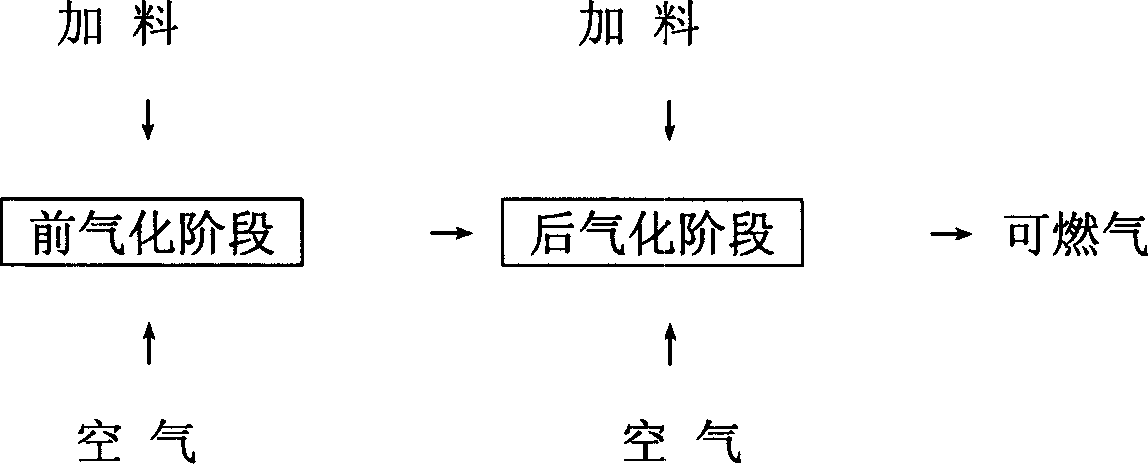

Biomass mixing and gasifying process and apparatus

ActiveCN1583956AExcellent thermal decompositionReduce loadSpecial form destructive distillationCombustible gas productionComplex typeFluidized bed

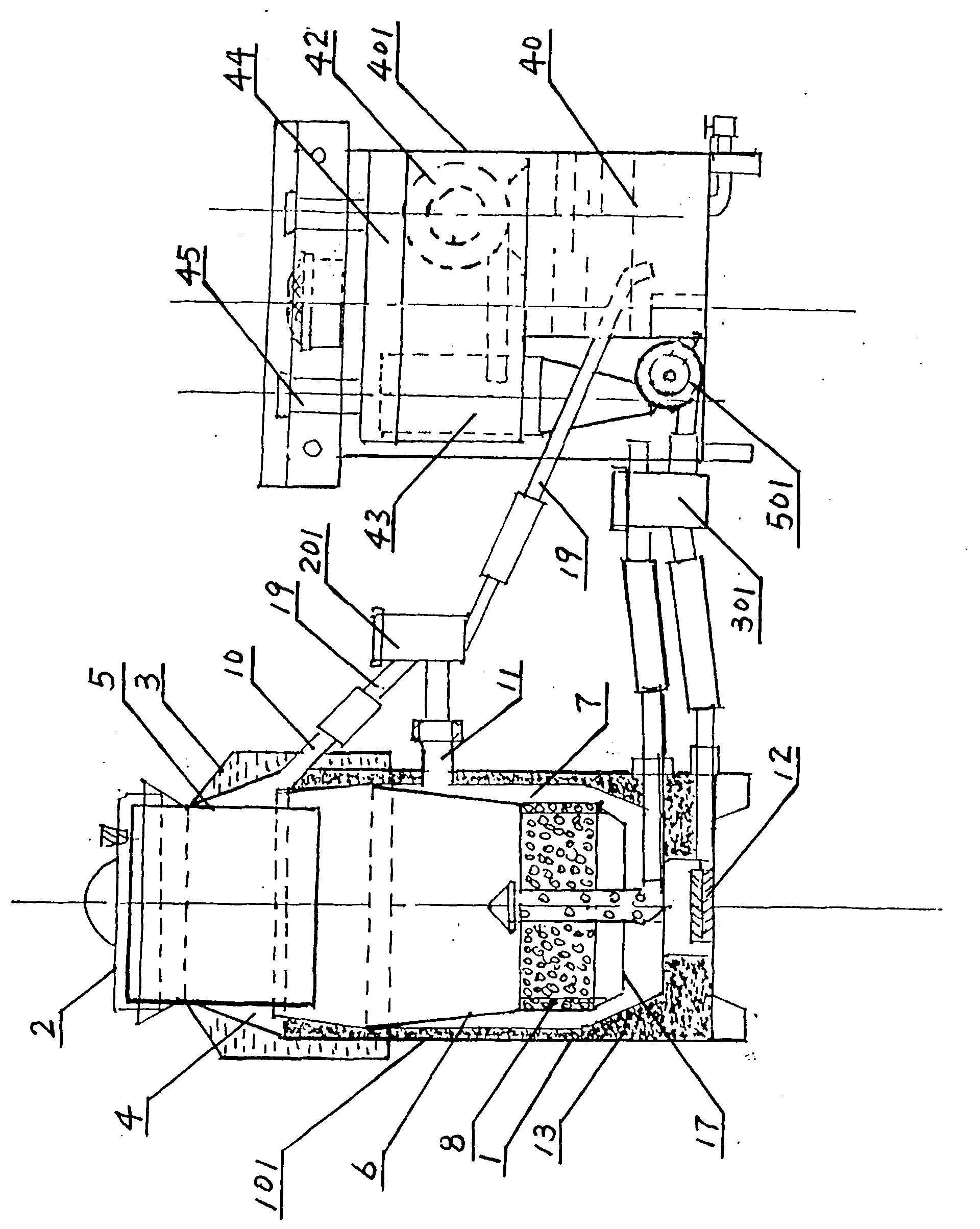

This invention offers a kind of bionass to mix and vaporize craft method and device, gasification stage before include its gasification course and after gasification stage, in before gasification stage, the biomass supplies adopt the circulation fluidized bed gasification craft to carry on hotly and vent one's spleen to melt, in after gasification stage, biomass adopt supplies down carry on the gasification crafts hot to it is take to vent one's spleen inhaling type. Gasification stage lay the inhaling type gasification device after gasification stage produce can gas enter before being, with add biomass supplies among them is it take gasification stage produce can gas enter before being, iwht add bionass supllies among them is it take gasification react altogether to go on together. Air that invention design this turn device into by circulation fluidized bed gasification stove with lay gasification complex type gasification stove gasification stove that stove made up of inhaliing etc.

Owner:GUANGZHOU DEVOTION THERMAL TECH

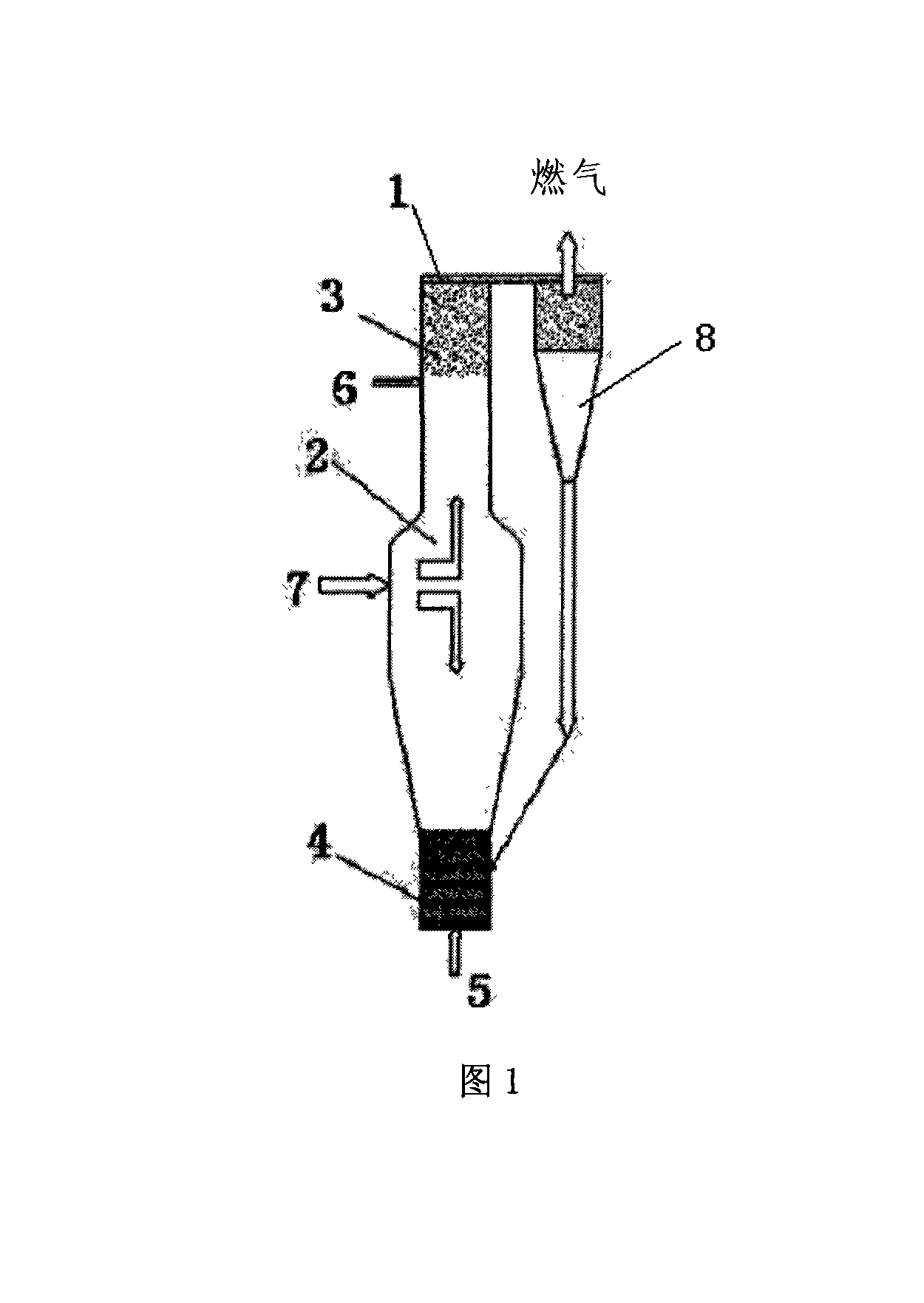

Method and device for biomass compound gasification

InactiveCN101225315AImprove gasification efficiencyReduce tar contentBiofuelsSpecial form destructive distillationTarBiomass

The invention discloses a biomass complex gasification method and a device of the gasification. The thermal decomposition, the gasification, part of the oxidation process are combined in one reactor by the integrating the fluidized bed and the airflow bed. Firstly, the biomass is decomposed at 500 to 600 degrees C and generates hard coke; secondly, the hard coke with large grain sizes are partly oxidized and gasified in the hard coke gasifying section, which provides heat and generates combustible gas for the thermal decomposition section; thirdly, the reaction gases with small hard coke grains discharged from the thermal decomposition section and the catalyst fast flows upwards through the macromolecular gasifying section, and the reaction gas are partly oxidized because of the function of the secondary gasifying agent, the heavy tar component is forced simultaneously through thermal cracking reaction and catalytic cracking reaction with the catalyst at the temperature over 1000 degrees C and transformed to lightweight combustible gas; at last, the unreacted hard coke is sent back to the furnace through the gas-solid separation device and the solid recycling device. The biomass complex gasification method has the advantages of high gasification efficiency, low tar content, high control ability of the gas component, stable operation and easy enlargement.

Owner:江苏中科龙城能源系统有限公司

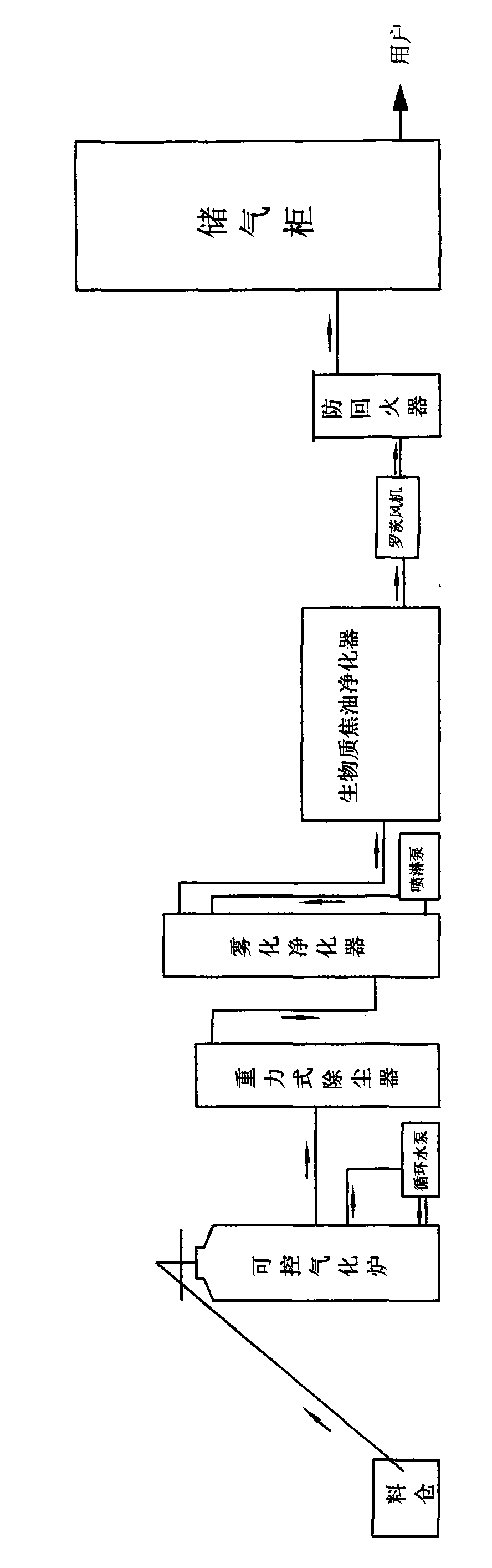

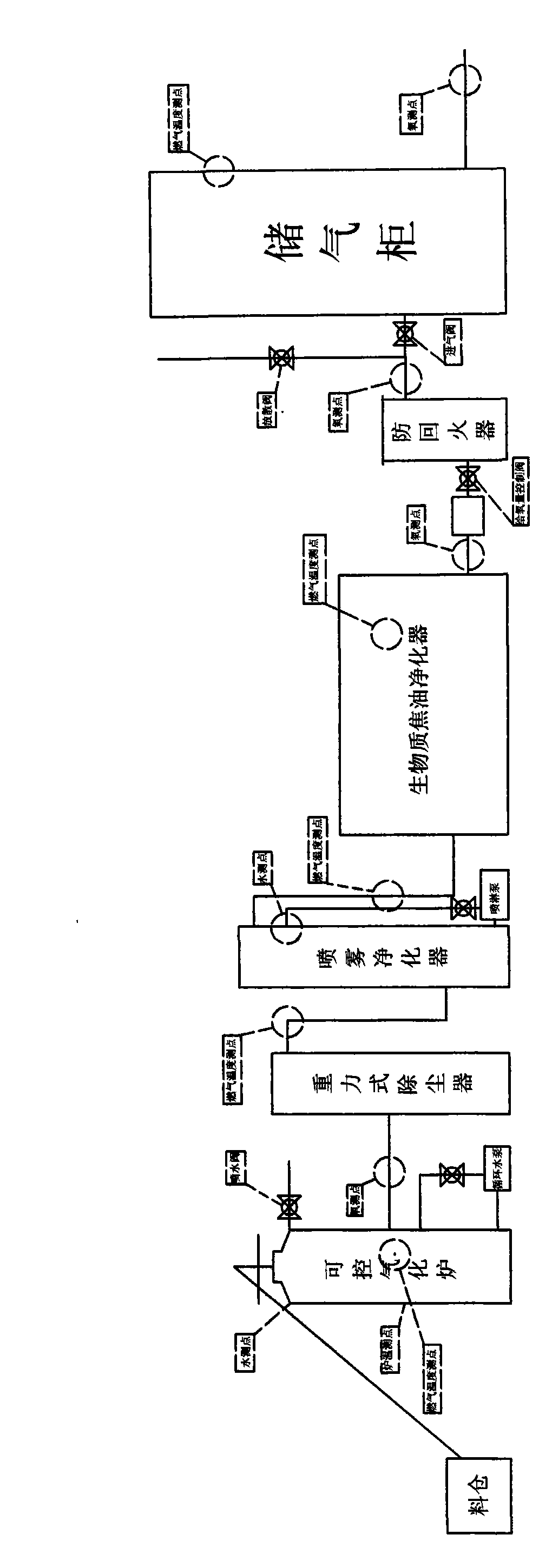

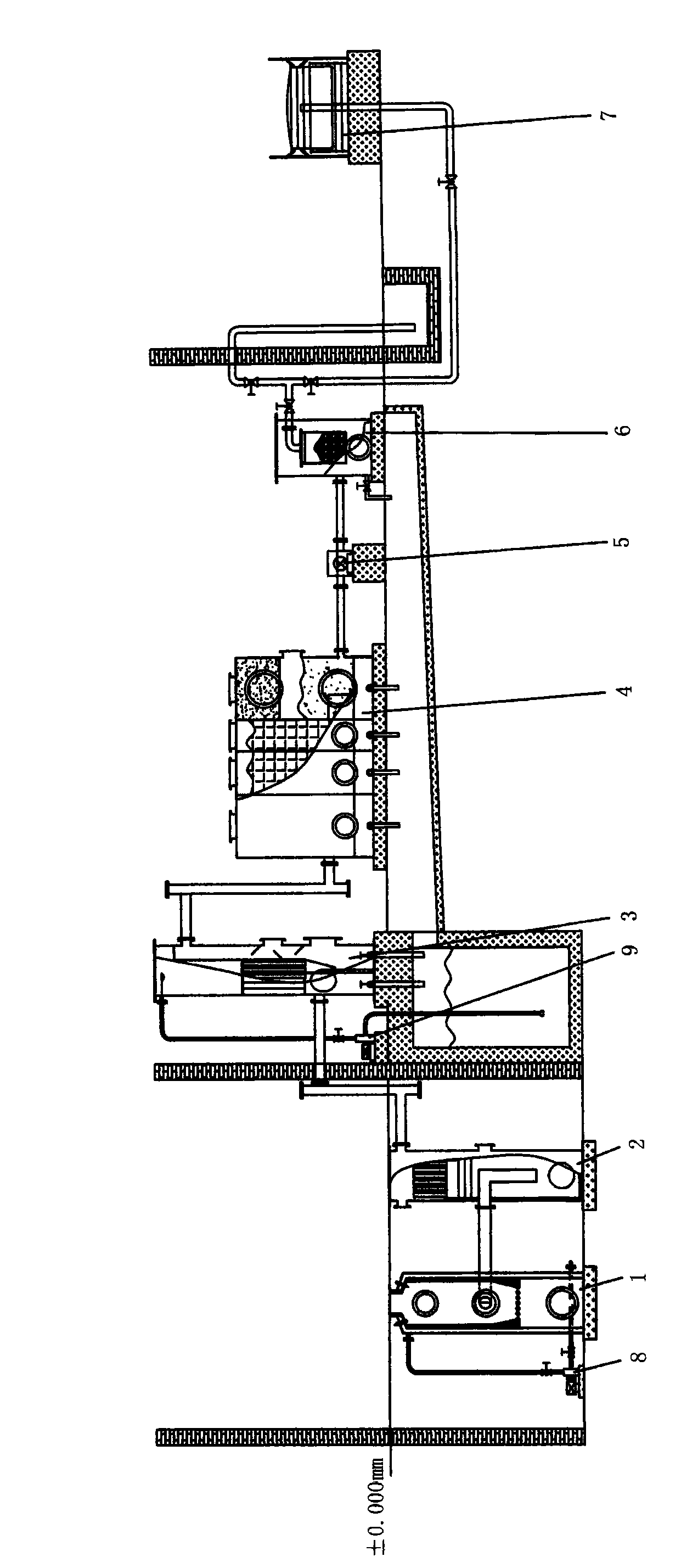

Method for preparing fuel gas by gasifying biomass materials and device thereof

InactiveCN101649226AReduce cloggingSolve the blockageCombined combustion mitigationCombustible gas productionTarProcess engineering

The invention relates to a method for preparing fuel gas by gasifying biomass materials and a device thereof, belonging to the technical fields of methods for preparing fuel gas by solid biomass materials in a gasifying process and the devices thereof. The method comprises the following steps: feeding, gasifying, dedusting, spraying and purifying, detarring, pumping front-end gases and conveying rear-end fuel gas by a Roots blower, and conveying the fuel gas to a fuel gas storage cabinet through a tempering preventing device. The device realizing the method comprises a feeding mechanism, a controllable gasifying furnace and a circulation water pump, a gravity deduster, a spraying purifier and a spraying pump, a biomass tar purifier, the Roots blower, the tempering preventing device and thefuel gas storage cabinet. The device is used for transforming the solid biomass materials of straws and the like into the fuel gas with less impurities and high heat value and supplying the fuel gasfor users centrally.

Owner:ZHENYU COMPLETE SET ELECTRIC EQUIP GROUP BEIJING

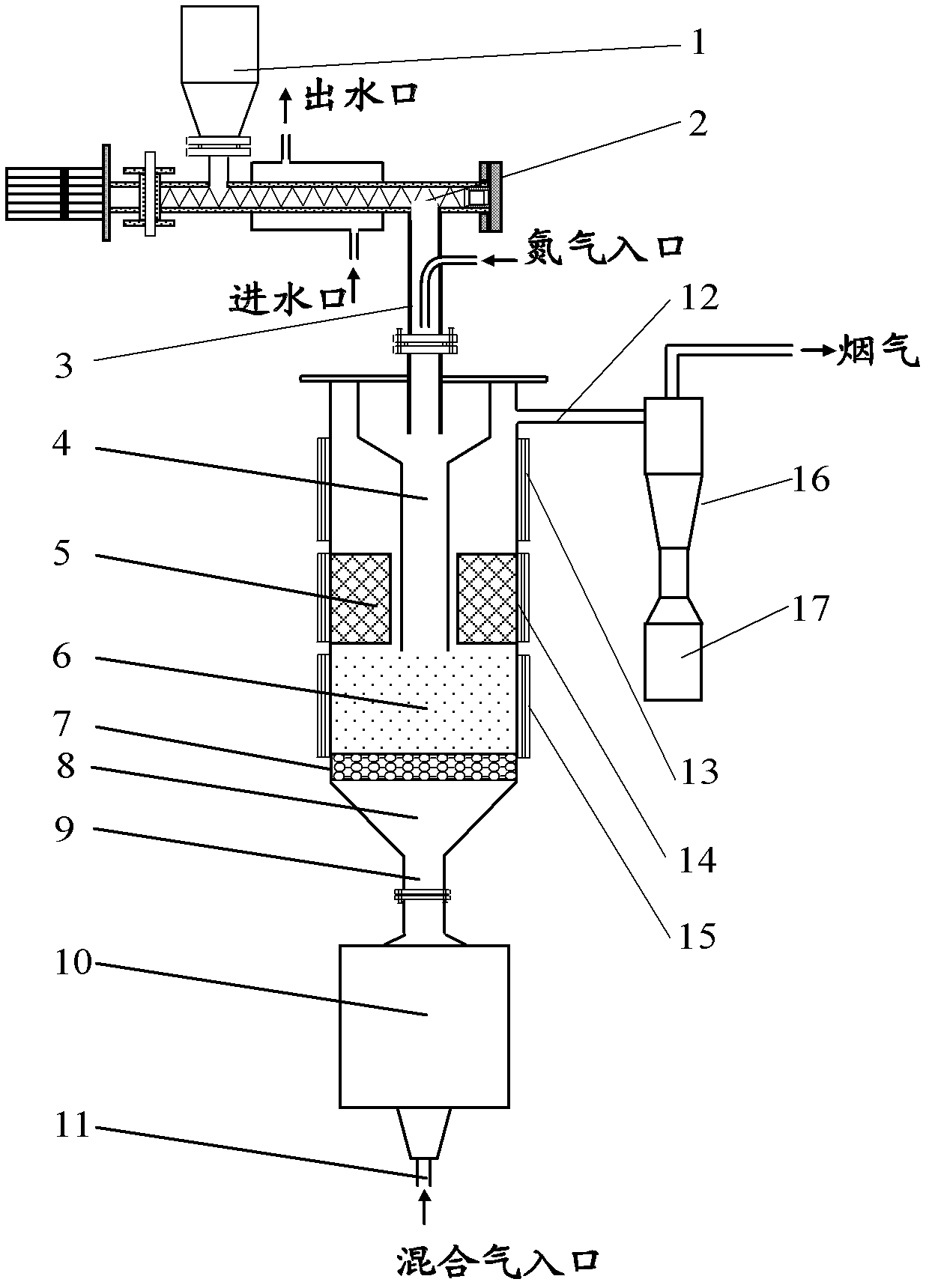

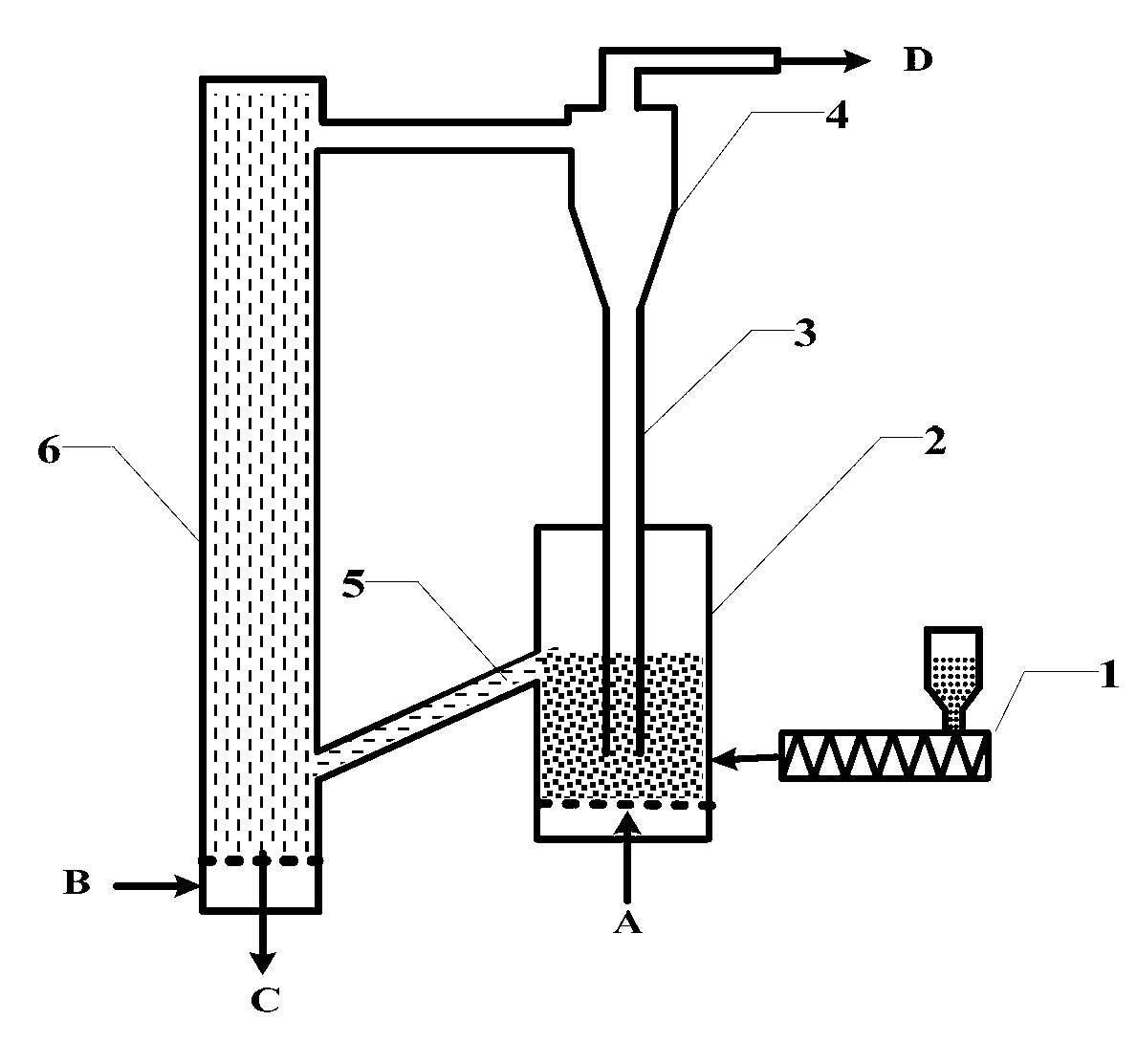

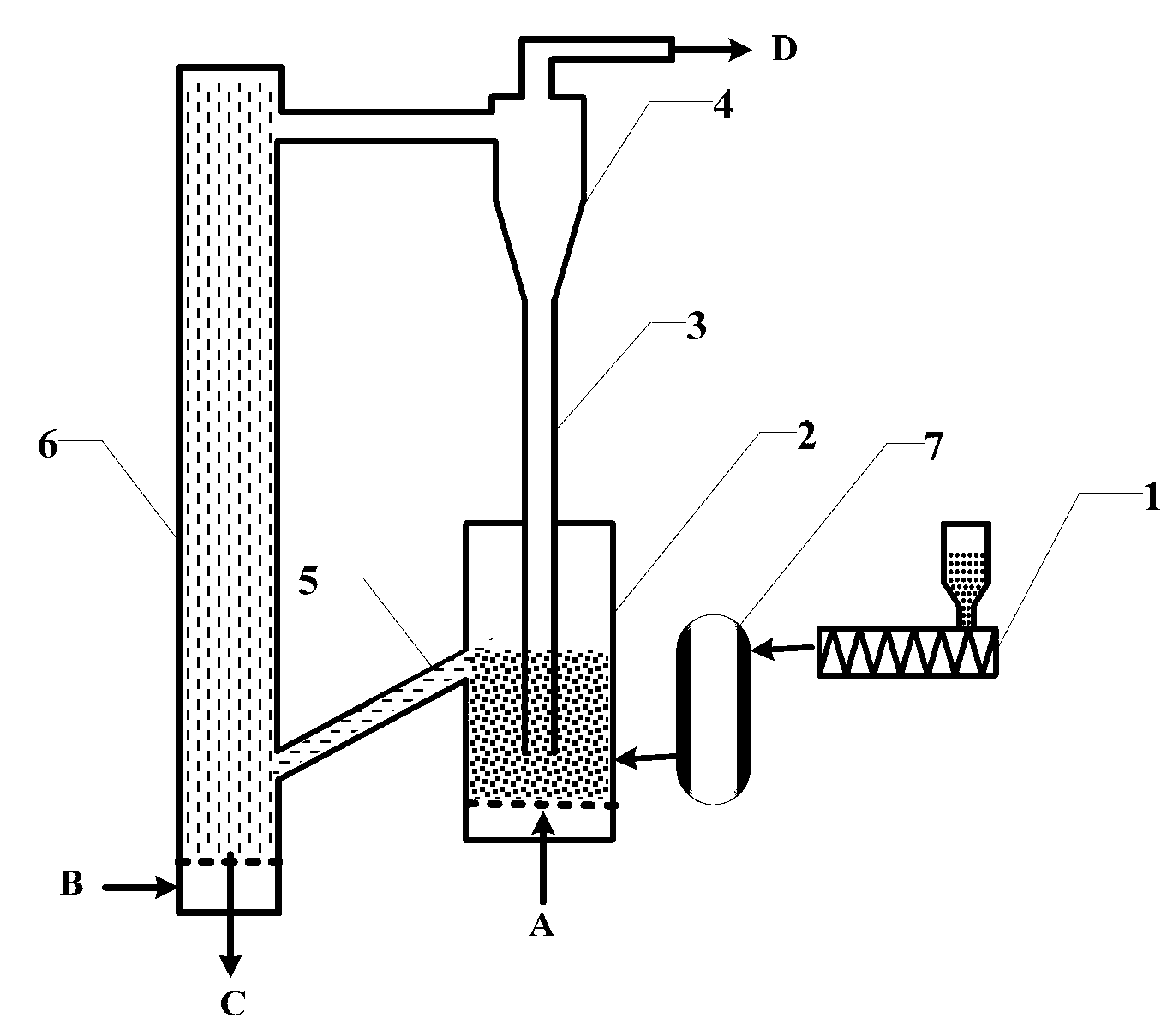

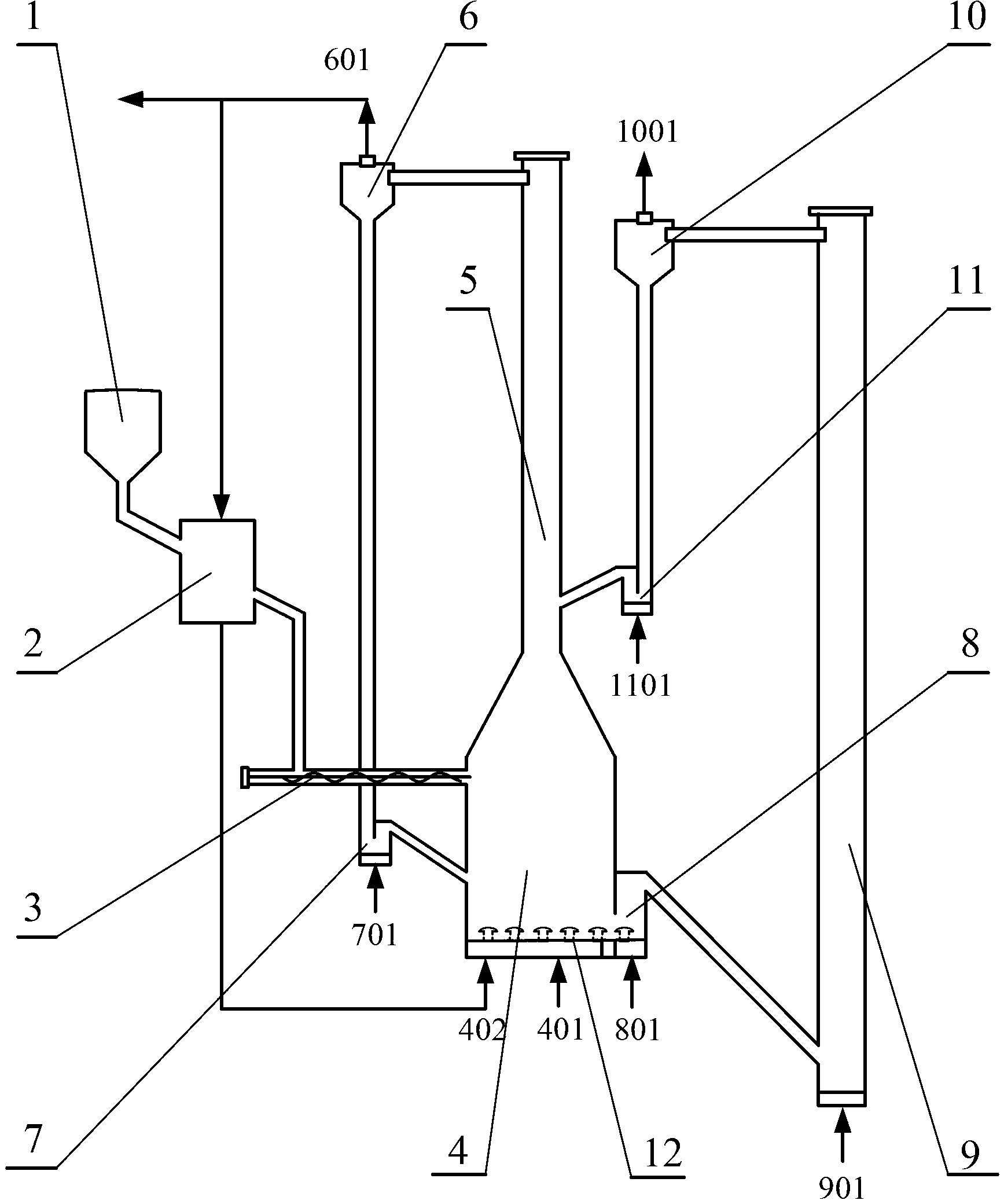

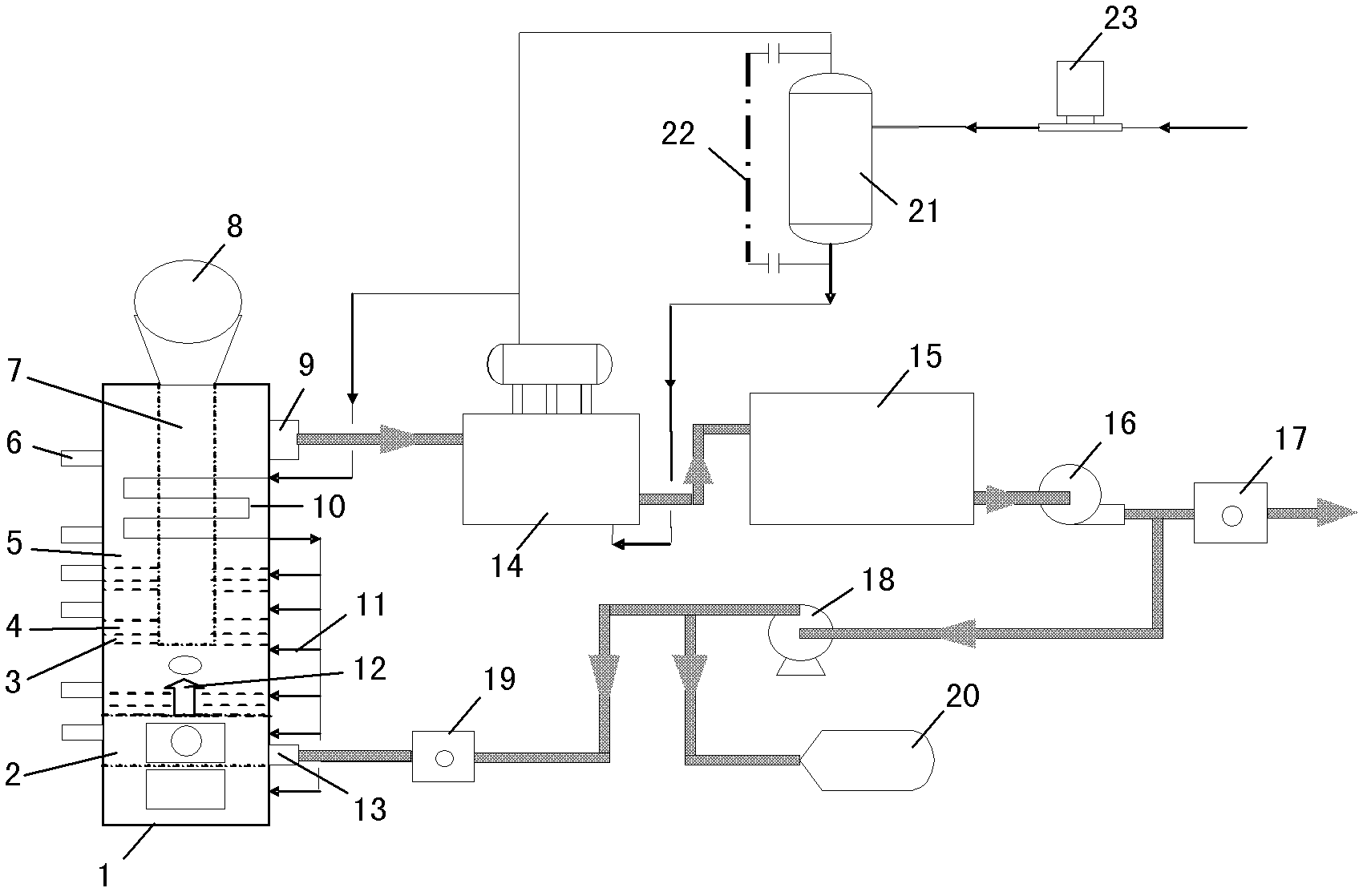

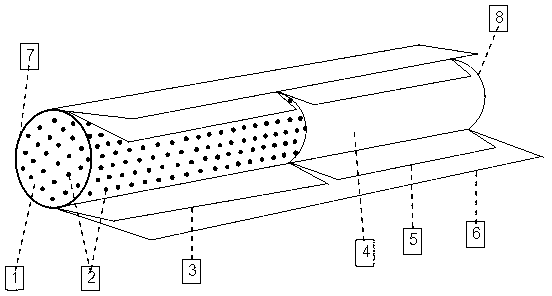

Apparatus for preparing synthesis gas based on dual fluidized bed biomass gasification and preparation method thereof

InactiveCN102977927AReduce outputHigh calorific valueBulk chemical productionGranular/pulverulent flues gasificationCycloneGas phase

The present invention discloses an apparatus for preparing synthesis gas based on dual fluidized bed biomass gasification, including a hopper, a dryer, a screw feeder, a pyrolysis fluidized bed, a reforming fluidized bed, a reforming cyclone separator, a calcination fluidized bed, a calcination cyclone separator, a first U-shaped refeeder, a second U-shaped refeeder and a third U-shaped refeeder. The method of the apparatus for preparing synthesis gas includes: feeding biomass into the hopper, feeding the dried biomass to the pyrolysis fluidized bed, pyrolyzing and gasifying, and feeding carbon residue into the calcination fluidized bed. In the calcination fluidized bed, the coke in solid residue is combusted with oxygen to decompose calcium carbonate. The products of gas phase and solid phase are separated by the calcination cyclone separator. The heat-carrying agent calcium oxide is fed into the reforming fluidized bed. The pyrolysis gas carries calcium oxide to increase to promote catalytic cracking of tar. The reformed gas is obtained by reforming the pyrolysis gas. The synthesis gas is obtained from a synthesis gas outlet. The apparatus for preparing synthesis gas can reduce the tar yield, and improve the synthesis gas heat value ?and gasification efficiency.

Owner:SOUTHEAST UNIV

Microwave plasma biomass gasification fixed-bed gasification furnace and process

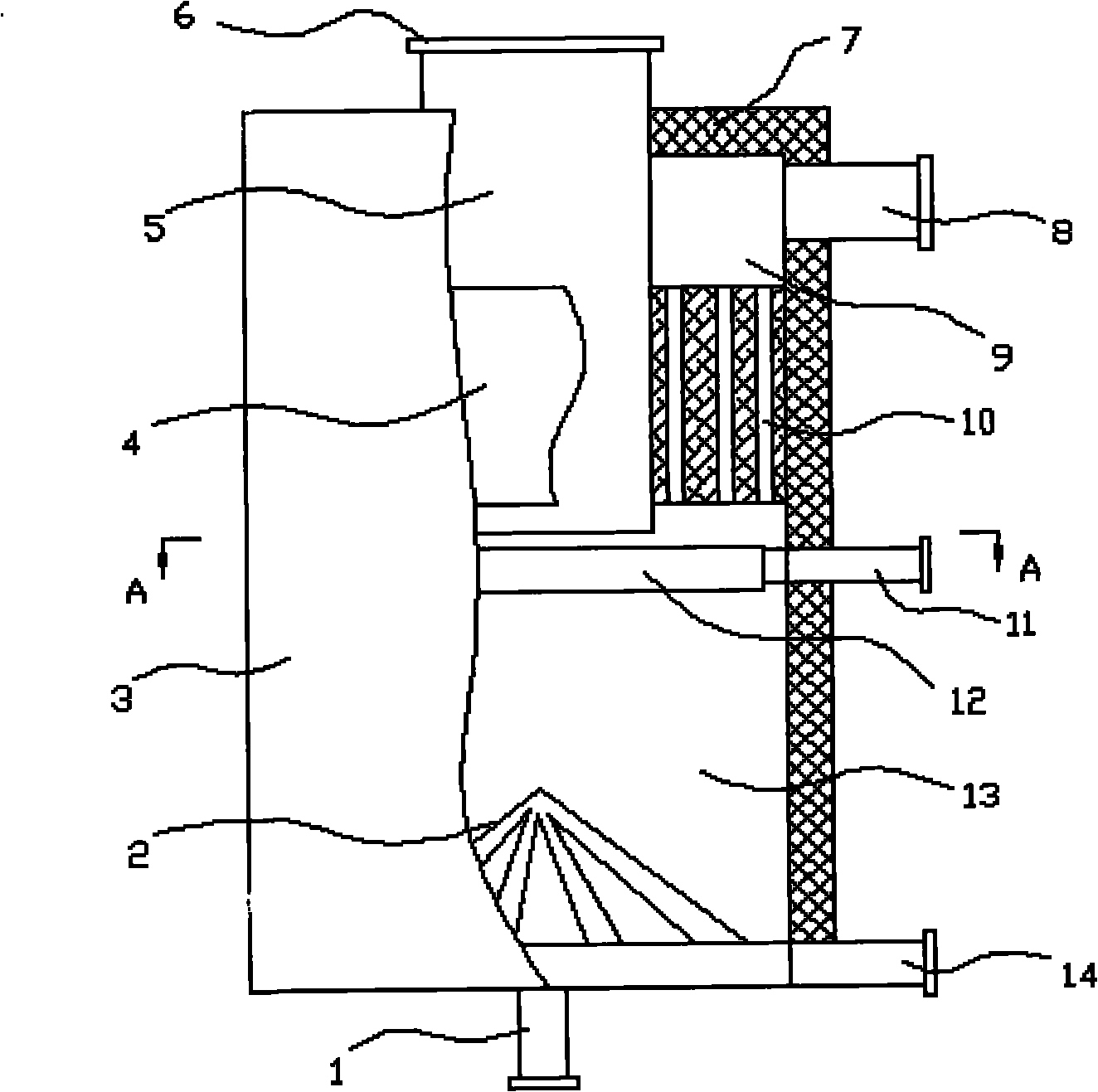

The invention relates to a microwave plasma biomass gasification fixed-bed gasification furnace and a process, comprising a vertically arranged furnace body; a gasification furnace clearance zone is arranged at the upper part of the furnace body; a fixed bed is arranged at the lowest part of the furnace body; an raw material and fuel inlet, a product gas outlet and an oxygen / steam inlet are arranged on the furnace body; a slag notch is arranged at the bottom of the furnace body, and a synthesis gas monitoring unit is arranged at the position of the product gas outlet. The gasification furnace and the process are characterized in that: at least one microwave plasma generating device is arranged on the furnace body, the characteristics of high dispersion degree and high ionization of microwave plasma are adopted to achieve high-efficiency conversion of biomass fuel chemical energy in the furnace. The cold gas efficiency can be significantly higher than that of the conventional biomass gasification process and can reach more than 85%. Non-equilibrium cleavage reaction is carried out to tar and the like in synthesis gas, so that tar content is very low, direct industrialization utilization can be achieved, and the follow-up process is simple and reliable. No special requirements on the fuel particle size are demanded, simple breaking operation is only needed without complex processing, and the economy is good.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

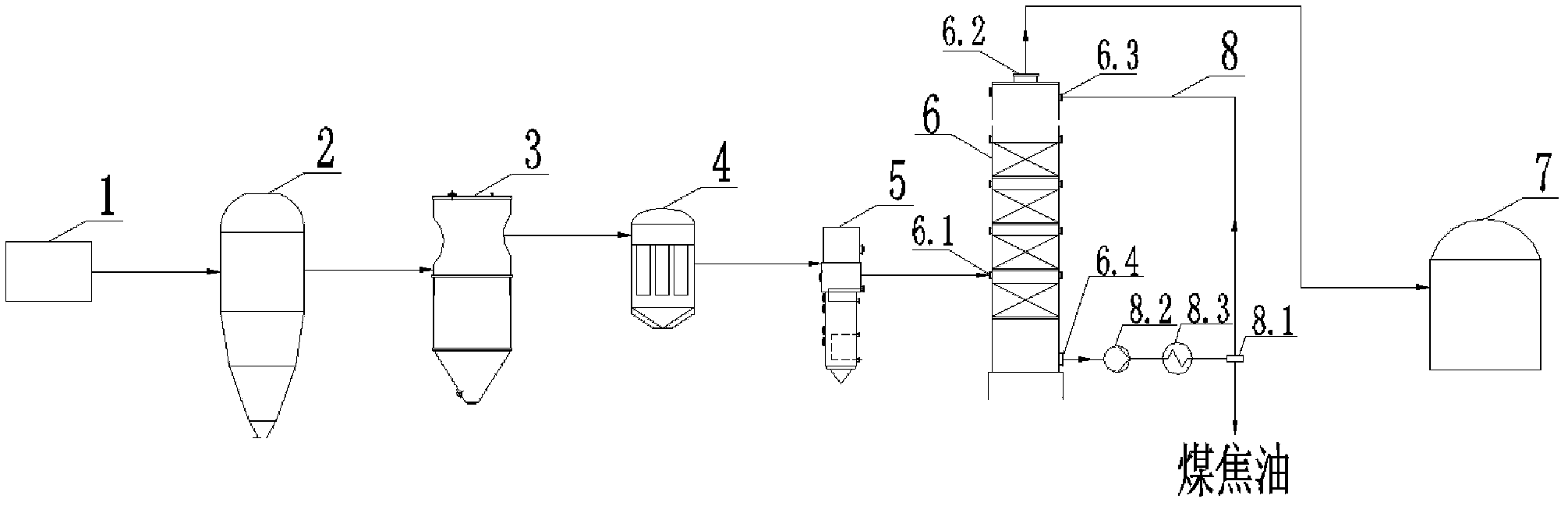

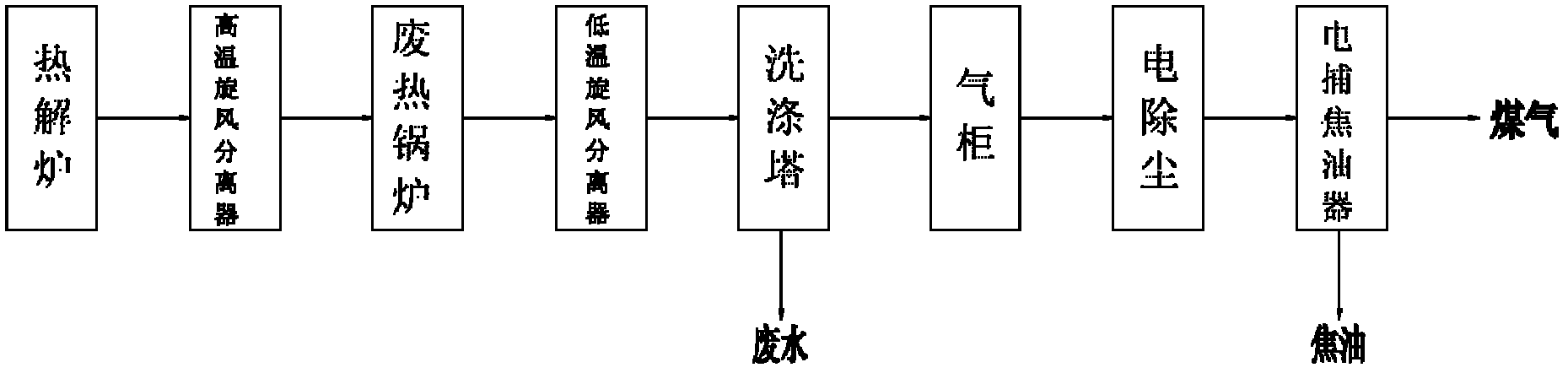

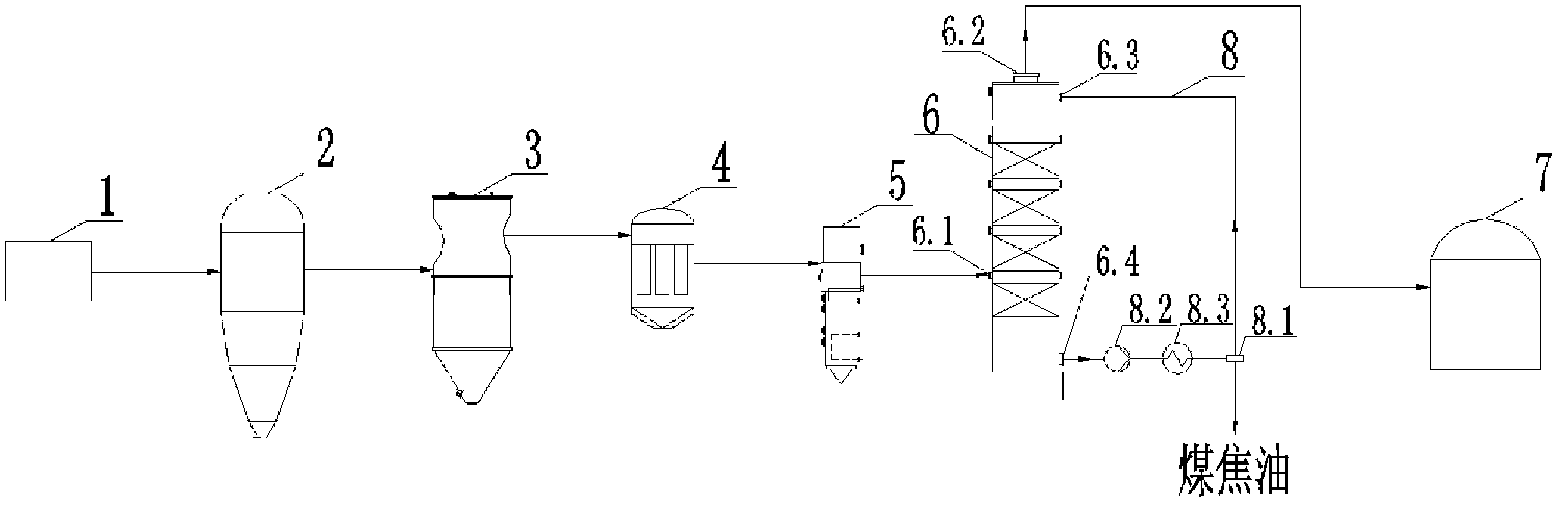

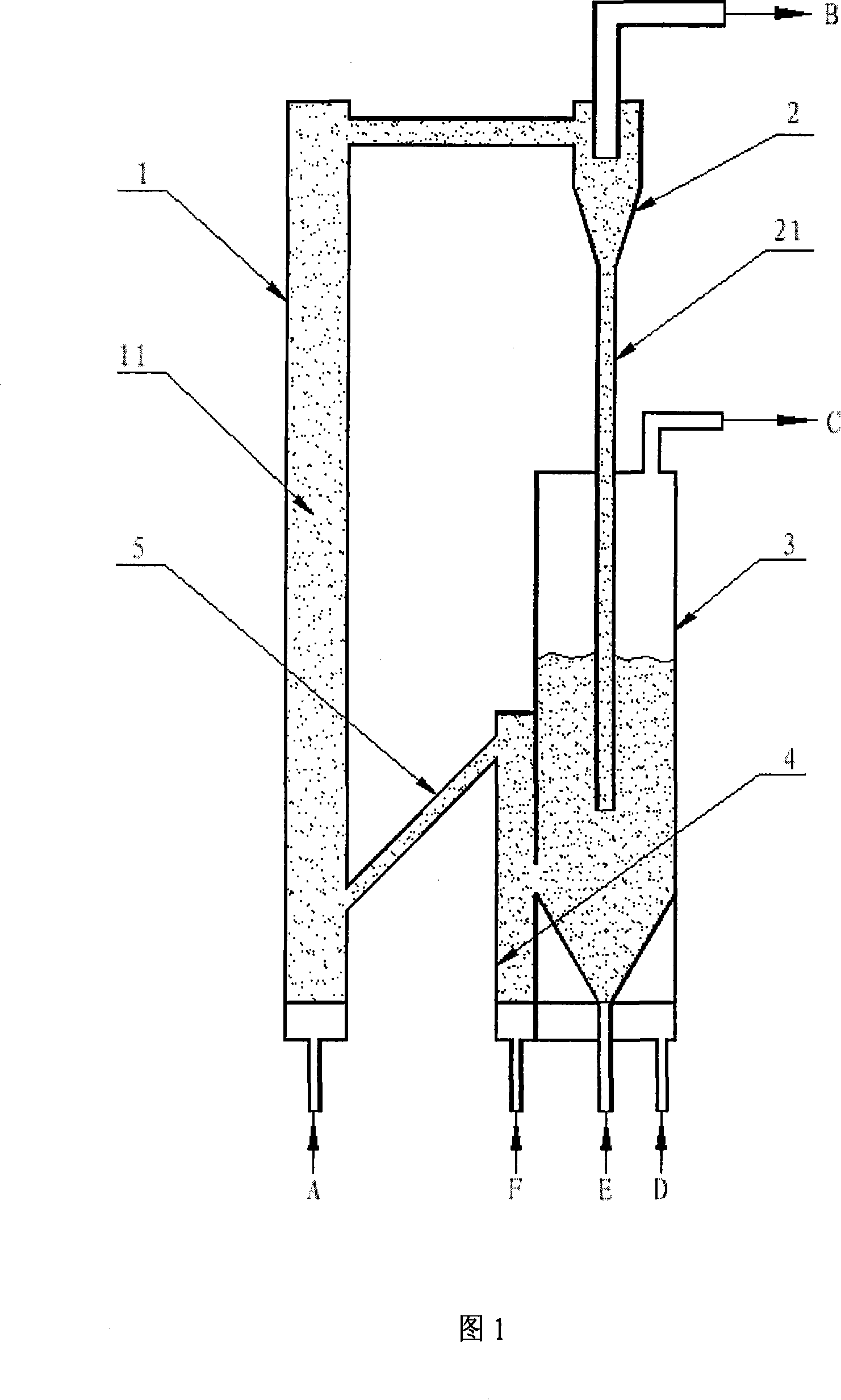

Gas purification process and system

InactiveCN102492490AReduce moisture contentImprove qualityCoke ovensEnergy inputCycloneProcess engineering

The invention relates to a gas purification process and a system, which solve the problem that the existing gas purification process is complex in process, large in waste water amount, high in production cost, poor in dedusting effect and low in coal tar quality. The technical scheme is that raw material coal is predried in a dryer and then sent to a high temperature pyrolysis furnace for pyrolysis, untreated gas containing ash and coal tar and produced through pyrolysis is sent to a high temperature cyclone separator to remove ash in large particles, dedusting of the untreated gas after removing the ash in large particles is further carried out through a high temperature filter, gas is carried out waste heat recovery through a waste heat boiler after dedusting, the gas which exchanges heat to the temperature of 300-350 DEG C enters a chilling tower and is contacted with coal tar oil at the temperature of 40-80 DEG C in an adverse current mode so as to conduct washing and cooling, the coal tar contained in the gas enters the coal tar oil and is discharged from a tower bottom, the gas is washed and cooled to 40-100 DEG C at the tower top to obtain clean gas, and the clean gas is sent to a gas cabinet. The gas purification process and the device are simple, free of waste discharge, good in gas dedusting effect, high in byproduct coal tar quality and low in production cost.

Owner:WUHUAN ENG

Indirect gasification device and method for solid fuel

InactiveCN101235321AReduce qualityExtended stayGranular/pulverulent flues gasificationHeat carrierFluidized bed

The invention relates to an indirect gasification unit solid fuel and method for separating gasification and combustion processes of solid fuel, gasification products with high quality can be got through gasifying solid fuel by the method, a circulating fluidized bed and a spout-fluid bed are kept communicated through an external separator and a refeed line, bed materials in the circulating fluidized bed, the spout-fluid bed and the external separator are high-temperature inert heat carrier particles, solid fuel, gasification medium and high-temperature inert heat carrier particle are mixed in the spout-fluid bed, solid fuel is pyrolized and gasified, residual coke particles and inert heat carrier particle of gasification reaction flow into a circulating fluidized bed through the external separator and the refeed line, coke particles and air / oxygen are combusted in the circulating fluidized bed, inert heat carrier particle is heated up, high-temperature inert heat carrier particle which is heated up returns to the spout-fluid bed after separating by a whirlwind separator, which provides heating source for pyrolysis and gasification of solid fuel.

Owner:SOUTHEAST UNIV

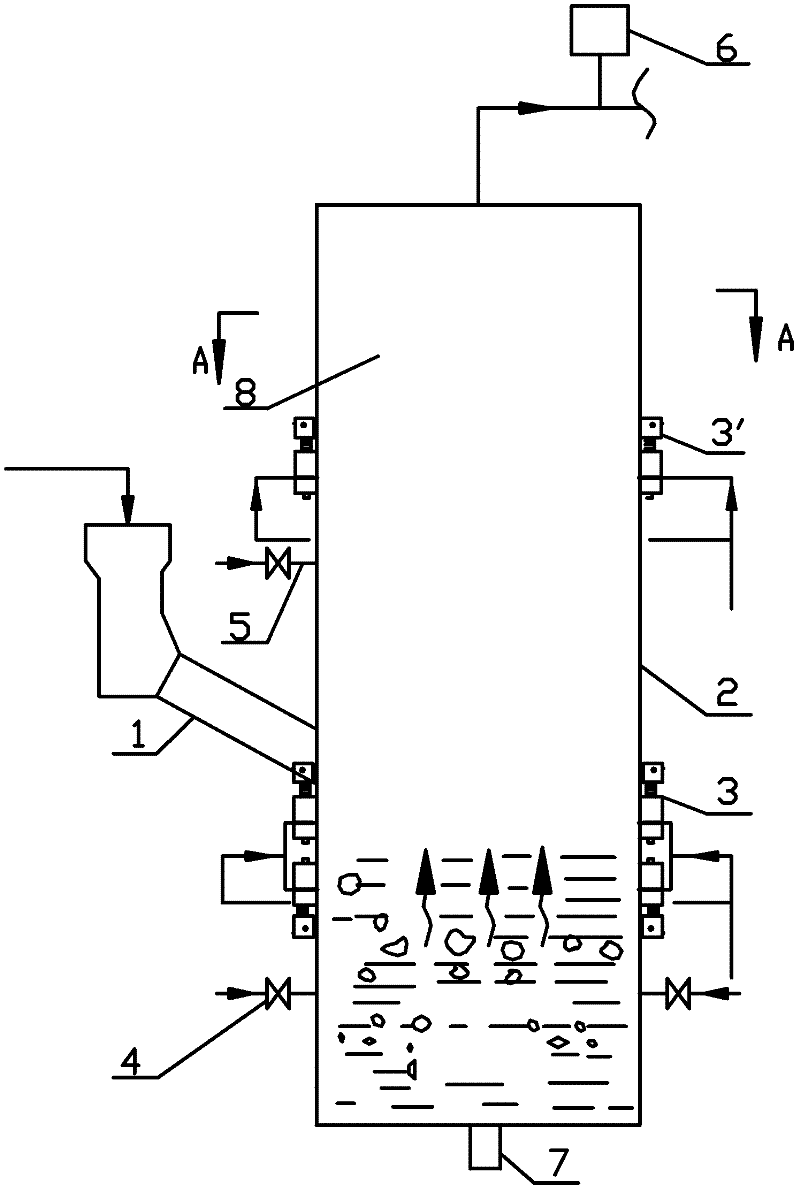

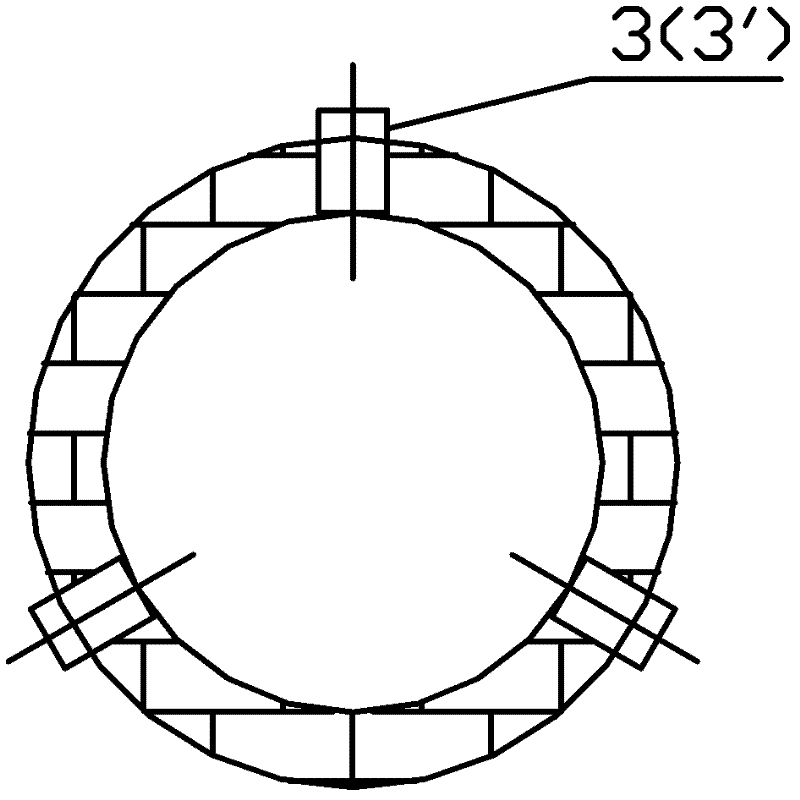

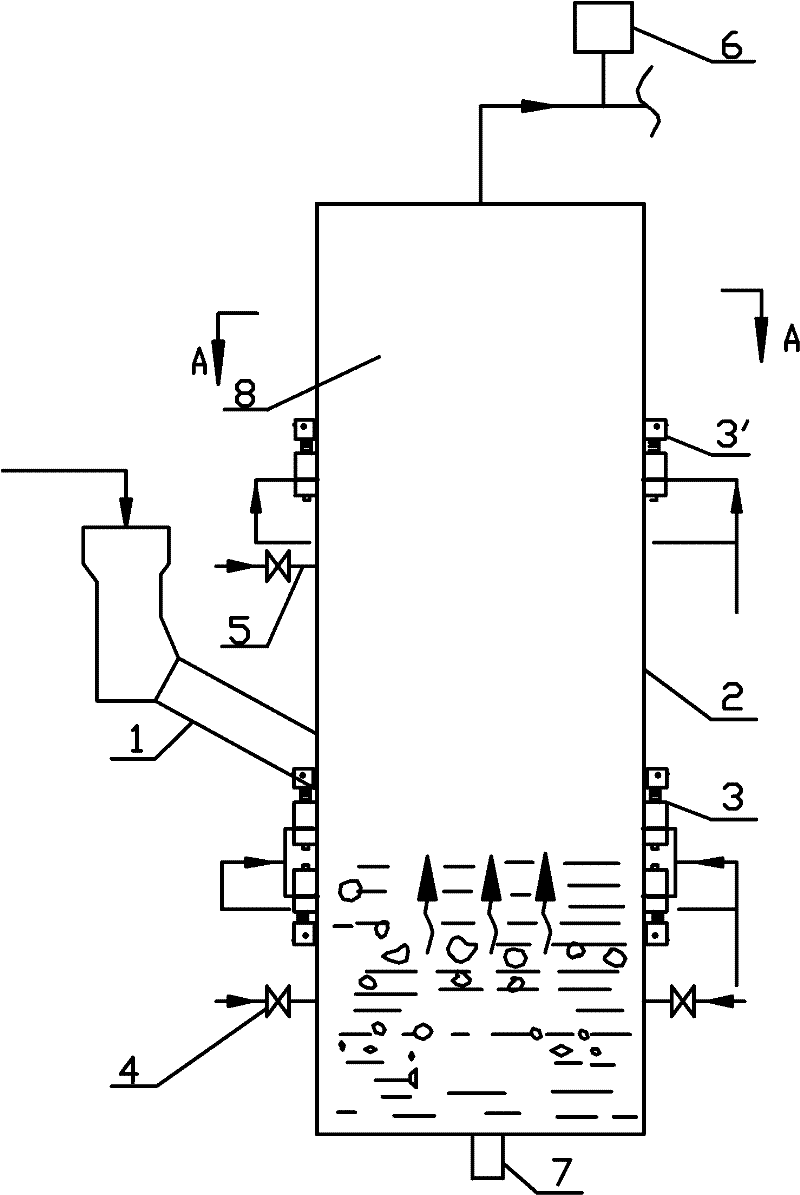

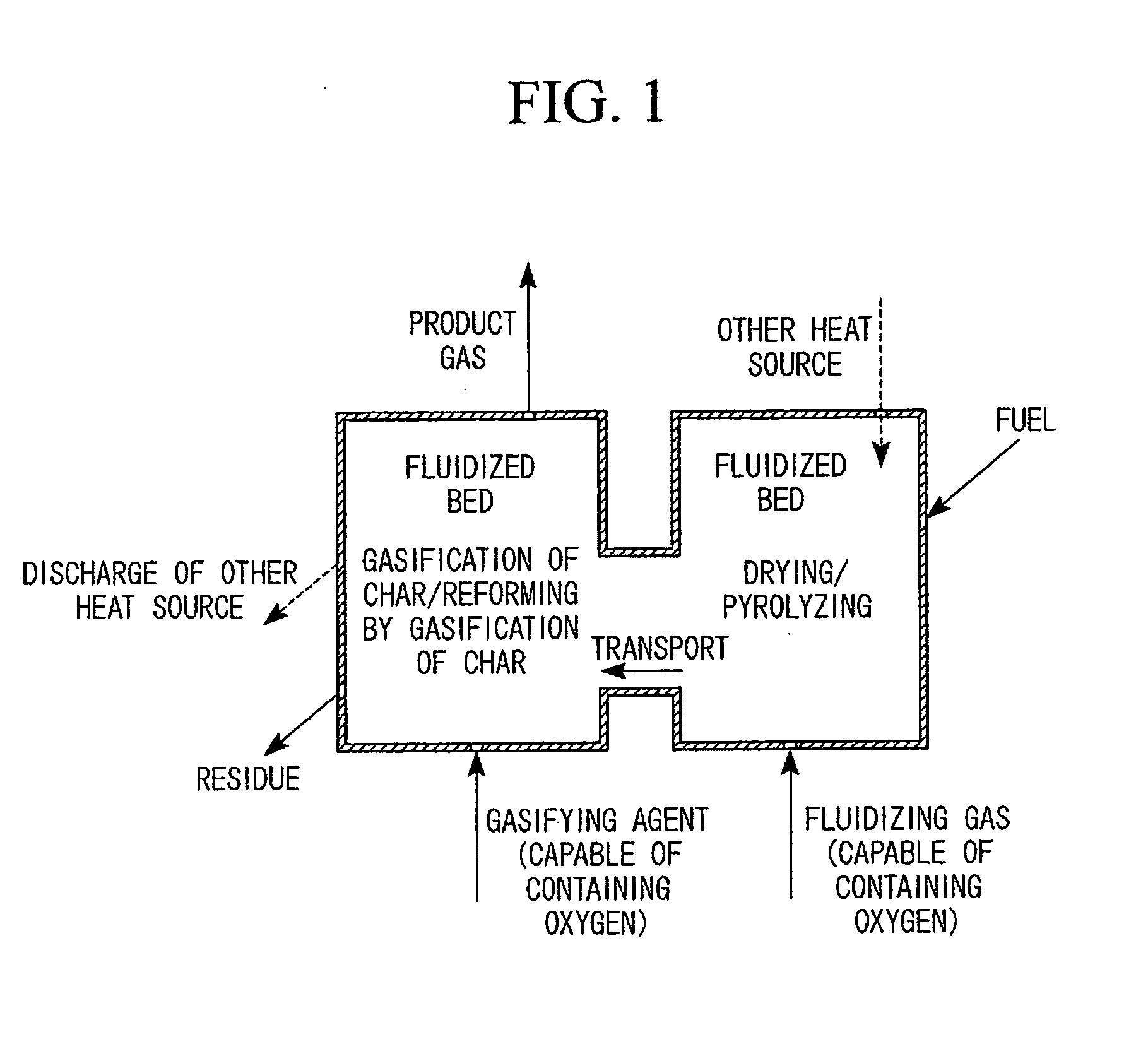

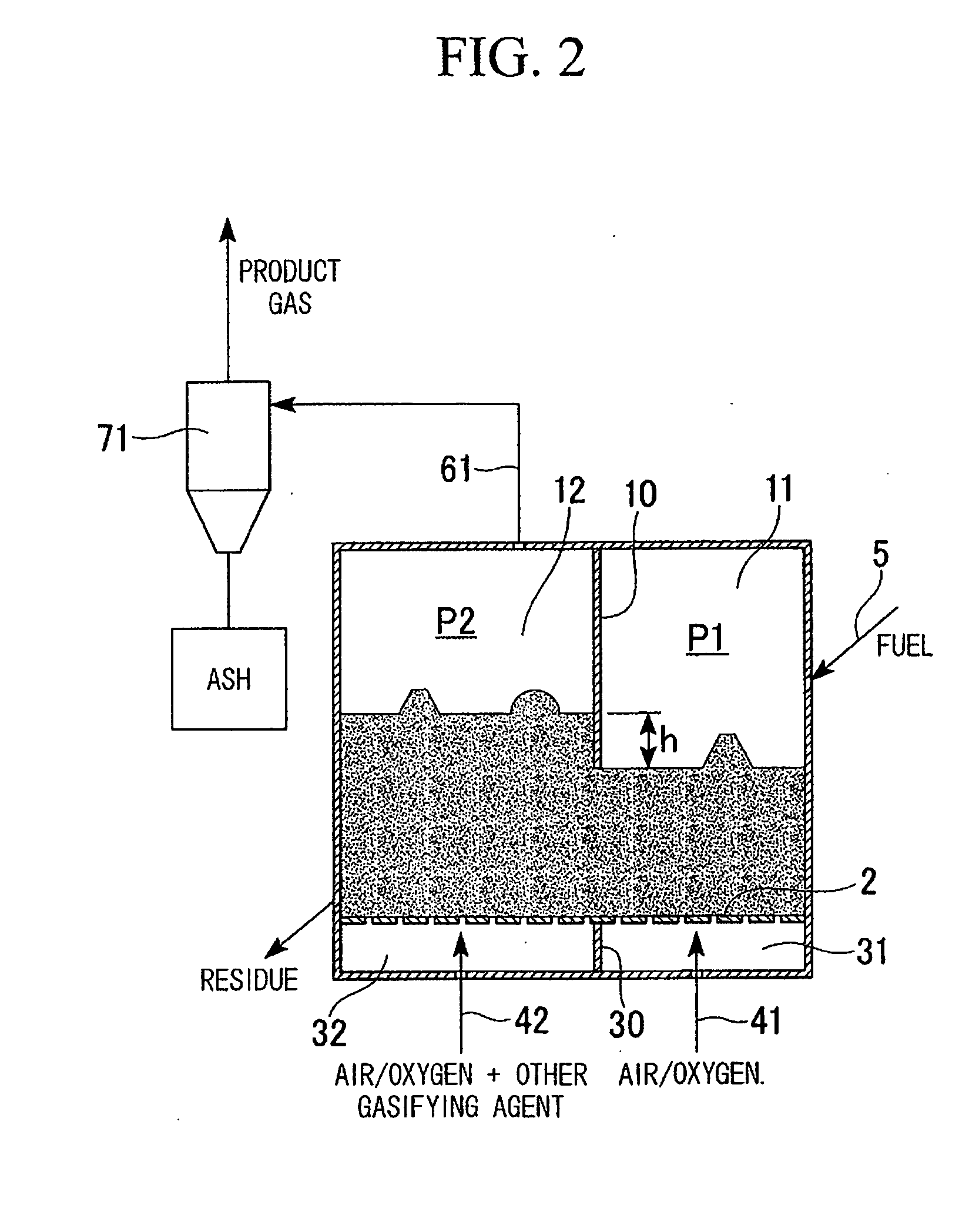

Decoupled fluidized bed gasifying method and gasifying apparatus of solid fuel

The invention relates to a solid fuel decoupled fluidized bed gasifying method and a gasifying apparatus. By physically separately performing drying and pyrolyzing of fuel, gasification of char, and tar / hydrocarbon reforming, the interactions between the separated chemical reactions and physical processes during fluidized bed gasification can be utilized. Specifically, in a fluidized bed reactor having two reaction chambers, drying and pyrolyzing of fuel, gasification of char, and tar / hydrocarbon reforming are performed, respectively, the reforming of tar / hydrocarbon is promoted through the catalytic effect of the char, and the evaporated fuel moisture is provided to the char gasification and tar / hydrocarbon reforming as an effective reaction agent. Accordingly, the tar content in product gas can be reduced, the use amount of external steam can be reduced, the overall efficiency of gasification can be improved, and this technique can also be applied to the processing of high water-containing fuel. This gasifying method not only can be applied to individual fluidized bed gasification, but can contribute to the design of a combustor that combusts unreacted char, and to advanced decoupled fluidized bed gasification.

Owner:IHI CORP

Preparation of functional nanometer short fiber and its application in cigarette filter tip

InactiveCN1603036AImprove filtration efficiencyReduce contentArtifical filament manufactureFiberCellulose acetate

The invention relates to a preparation of the function nanometer short fiber. It is mainly utilized the electrostatic spinning technique to quickly draw and transform the polymer solution to solid superfine fiber in high voltage electric field, produce nanometer fiber whose diameter is form fifty nanometers to one thousand nanometers. The fiber is directly collected in the water, and accelerated to collect by using the circulating water vacuum pump. It is utilized the shearing effect caused by the high velocity flow while the forming of the vacuum to quickly shear the collected nanometer long fiber into short one whose length is several millimeters. The catalyst is added in to the spinning liquid while the nanometer is preparing. The cellulose acetate nanometer short fiber and the filter tip fiber filament tow that is prepared by the above method are compounded to manufacture cigar filter. Not only can the compounded filter body effectively increase the filter efficiency of the inhalator grain with the submicron grade and nanometer grade, but also greatly increase the filter area at the same time to effectively reduce the content of the tar and other chemical composition in the smog.

Owner:林童 +2

Method for self-heating pyrolysis gasification of biomass by gas backflow combustion

InactiveCN102643676AKeep warmImprove gasification efficiencyEnergy inputCombustible gas productionWater vaporSelf heating

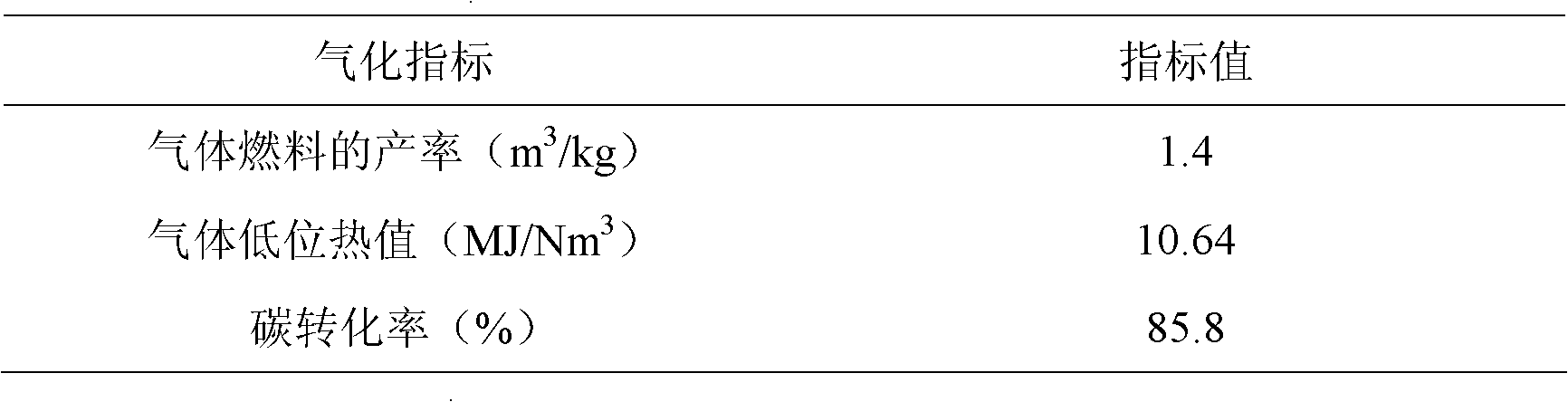

A method for self-heating pyrolysis gasification of biomass by gas backflow combustion includes using air and steam as gasifying agent for pyrolysis gasification of the biomass in a pyrolysis gasifier, making the steam generated by a vaporizer into super-heated steam to compensate heat for the interior of the gasifier by waste heat of produced gas, allowing part of the produced gas to flow back into the gasifier to be combusted for supplying heat for gasification, removing tar by high-temperature pyrolysis, ensuring the whole gasifier to be under high temperature, and allowing gasification of biological pyrolytic carbon and cracking of the tar to tend to be through. By the method using the waste heat of combustible gas, part of the gas flows back to supply heat required by the biomass for pyrolysis gasification, interior high temperature of the gasifier is guaranteed, reaction is accelerated, and gasifying efficiency is improved. The produced combustible gas is low-tar gas with caloric value reaching 10MJ / Nm<3>, combustion is isolated from other reactions, and accordingly operation control is facilitated.

Owner:GUANGXI UNIV

Double-flow biomass gasified gas purification device

InactiveCN102079998AHigh calorific valueIncrease contact areaBulk chemical productionCombustible gas productionReaction temperatureMoisture

The invention relates to a gasified gas purification device, in particular to a double-flow biomass gasified gas purification device, which solves the problems of low reaction temperature of a gasification furnace, abundant generated tar and wastewater, low gas-producing efficiency and abundant impurities and low heat value of output gas, resulted from unscientific structure of the gasification furnace. The gasified gas purification device comprises a gasification furnace, a gas flow control valve, a vortex flow oxidation-assisted control valve, a gas purifier and a fan. The gasified gas purification device provided by the invention has the advantages of increasing the reaction temperature of the furnace, wherein the temperature in oxidation, reduction and pyrolysis cylinders is between 1,300 and 1,600 DEG; increasing the gasification intensity; being capable of quickly separating moisture in biomass combustible gas so that gas quality is better; ensuring greatly reduced tar content in the combustible gas, less wastewater generated, high gas-producing efficiency and low environmental pollution due to the adoption of a mesh-type catalytic cracking device; and removing tar, moisture and ash in the gas through the gas purifier so that the heat value of the gas is improved. The gasified gas purification device is widely applied in industrial and civil fields.

Owner:林口信安建材板业有限公司

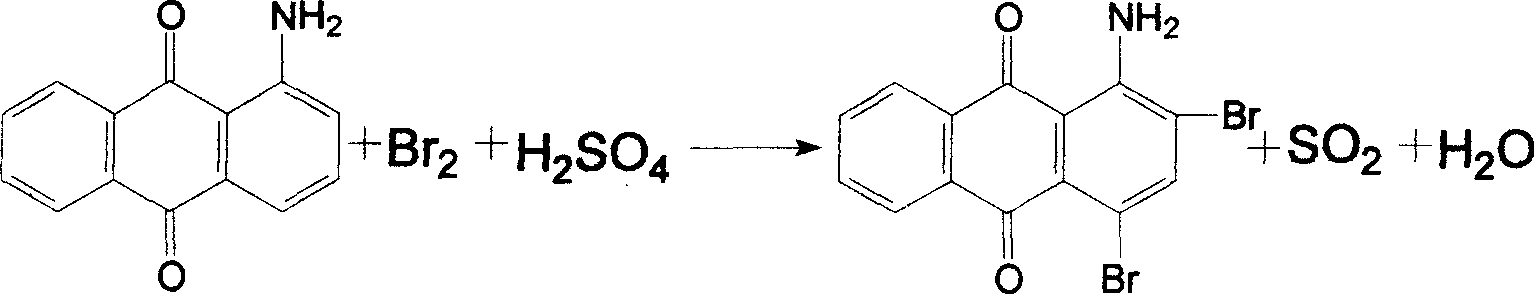

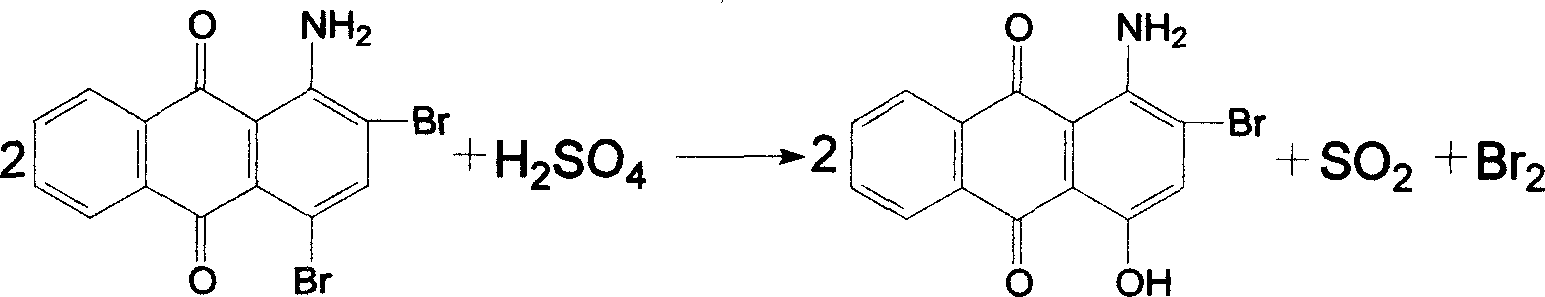

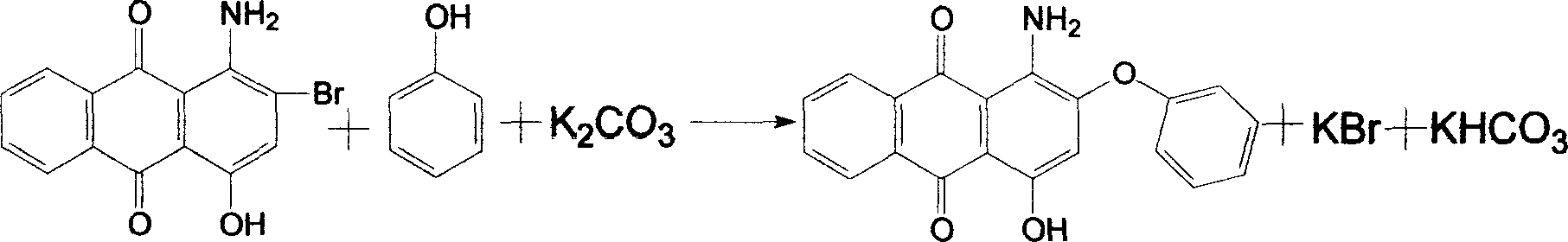

Method for producing modified disperse red 60

ActiveCN101003691AReduce dosageSave energyAmino-hydroxy-anthraquinone dyesAntioxidantImproved method

This invention relates to an improved method for producing disperse red 60. The method comprises: bromizing and hydrolyzing 1-aminoanthraquinone in sulfuric acid medium to obtain 1-amino-2-bromo-4-hydroxylanthraquinone wet filter cake, condensing in the presence of phenol medium and acid-attaching agent, cooling to 95-100 deg.C at the condensation end-point, adding water, dropping alkali solution, cooling to 50-52 deg.C, filtering, washing, and drying to obtain 1-amino-2-bromo-4-hydroxylanthraquinone (disperse red 60). The method directly utilizes disperse red 60 wet filter cake to avoid the drying procedure, thus simplifying the operation, lowering the equipment investment, improving the operation conditions, and reducing the labor intensity. Besides, the method also increases product yield and quality, as well as reduces phenol amount.

Owner:JIANGSU HUAER CHEM

Tobacco fiber paper filter stick and preparation method thereof

InactiveCN103829374AConsistent colorRealize visualizationCigarette manufactureTobacco smoke filtersTarPapermaking

The invention relates to the field of tobacco filter sticks, and discloses a tobacco fiber paper filter stick and a preparation method of the tobacco fiber paper filter stick. The paper filter stick is composed of a filter element and forming paper, wherein the filter element is obtained by coiling paper fiber, the paper fiber is tobacco fiber pulp and long fiber pulp which are obtained by grinding tobacco raw materials and long fiber raw materials into liquid, then the tobacco fiber pulp and the long fiber pulp are subjected to pulp matching, sheet making, squeezing and drying to be manufactured into a fiber paper base, and the tobacco fiber paper filter stick can be obtained through smearing, drying and rolling. On the basis of wet process papermaking, tobacco fiber and long fiber are mixed according to a proper proportion in the pulp matching stage of papermaking, and the obtained paper filter stick not only has higher tar and nicotine removing capacity than a cellulose acetate filter stick, but also can successfully eliminate wooden offensive odor of the long fiber. Raw materials of the filter stick come from natural plants, and therefore the filter stick only has the scent of tobacco and does not have the scent of paper or chemical fiber, the color of the filter stick is consistent to that of cut tobacco of cigarettes, and the filter stick has the texture of natural material of tobacco and guides a new direction for the technical field of cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND +1

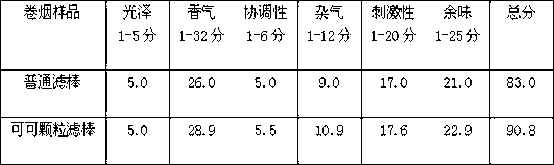

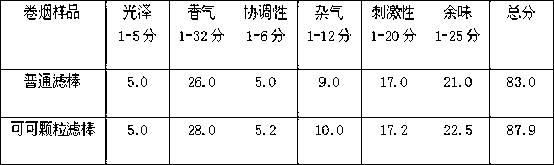

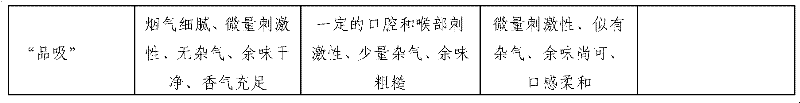

Coffee or cocoa composite particle filtering bar and manufacturing method thereof

ActiveCN103054181AAppropriate suction resistanceRemove irritants and impuritiesTobacco smoke filtersProcess engineeringCellulose acetate

The invention relates to the technical field of a filtering bar and discloses a composite particle filtering bar which comprises cellulose acetate base materials and shaping papers which are used for wrapping the cellulose acetate base materials. The cellulose acetate base materials contain the composite of processed coffee or cocoa particles. The cellulose acetate base materials of the filtering bar successfully contain the composite of the suitable ratio and processed coffee or cocoa particles. The suction produced by the filtering bar is suitable so that miscellaneous gases and irritation in smoke are removed effectively, the dedicate level of the smoke is improved and smoking tastes are improved. The smoke of cigarettes brings an agreeable smell of food solid particles to enrich cigarette agreeable smells and meanwhile to enable persons to have a variety of taste experiences in mouths.

Owner:CHINA TOBACCO GUANGDONG IND

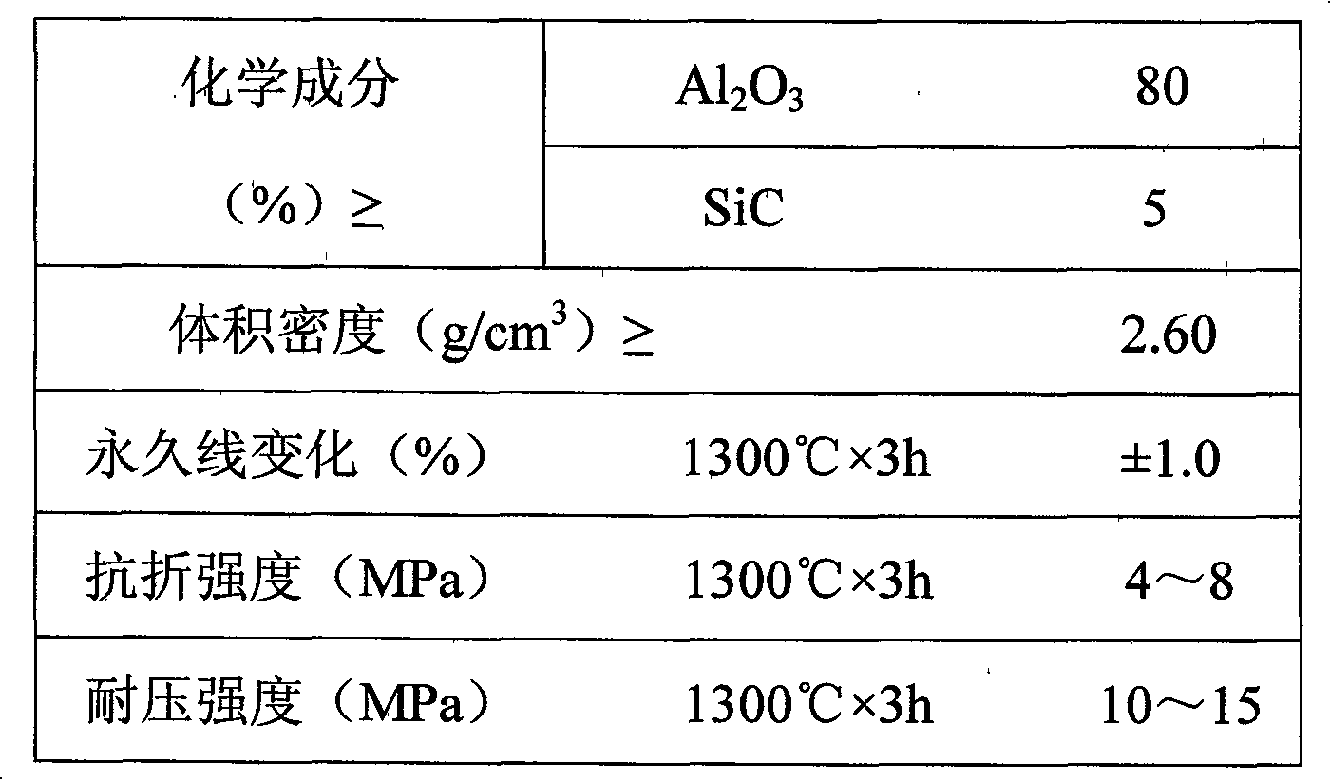

Environment-friendly stemming for blast furnace taphole and preparation method thereof

InactiveCN101613213AReduce tar contentImprove protectionBlast furnace componentsCeramic shaping apparatusInorganic phosphateSocial benefits

The invention discloses an environment-friendly stemming for a blast furnace taphole and a preparation method thereof, which is prepared by the following raw materials according to weight percentage content: 35-50% of bauxite or hard clay or fused alumina with thickness of 0.2-3mm, 1-5% of modified powder resin, 1-5% of high-temperature pitch, 3-8% of inorganic phosphate, 1-20% of silicon carbide, 10-20% of coke powder, 3-10% of sericite, 2-8% of cyanite and 3-8% of tar oil. The preparation method comprises the following steps: weighting each raw material according to the above formula, adding into a heating stirrer for stirring and mixing and molding by using a friction press after mixing. The invention adopts the mixture of organism and inorganic substance as a binder to prepare the stemming, thus greatly reducing the component content of tar oil which pollutes environment, being favor of environmental protection and having remarkable social benefit, and can be hardened quickly.

Owner:HENAN GENGSHENG REFRACTORIES

Method for fermenting tobacco leaf using Pu'er tea

InactiveCN101480274ALess irritatingImprove aftertasteTobacco preparationTobacco treatmentTarGreen tea

The invention relates to a method for fermenting tobacco leaves by Pu'er tea. Firstly, Pu'er tea zymotic fluid is prepared: Yunnan big leaf green tea is made into the Pu'er tea by the traditional process, the Pu'er tea is filtered after being immersed for 3-4h by hot water according to 5:10-15 weight ratio so as to obtain the Pu'er tea zymotic fluid. The Pu'er tea zymotic fluid is uniformly sprayed on tobacco leaves according to the proportion of 100 portions of redried tobacco leaves or fresh tobacco leaves and 10-20 portions of Pu'er tea zymotic fluid, and then the tobacco leaves are dried by hot air until the water content is about 12 percent. The invention is used for fermenting the tobacco leaves by using the Pu'er tea zymotic fluid as the ferment liquid so as to enable the irritation of the tobacco leaves to be reduced and the savor to be improved; in addition, the invention leads a nicotinamide component in the fermented tobacco leaves to be greatly lowered and changed, increases the effective odorous component and the tobacco pure taste, reduces the tar content, and improves the tobacco leaf grade.

Owner:王乐观

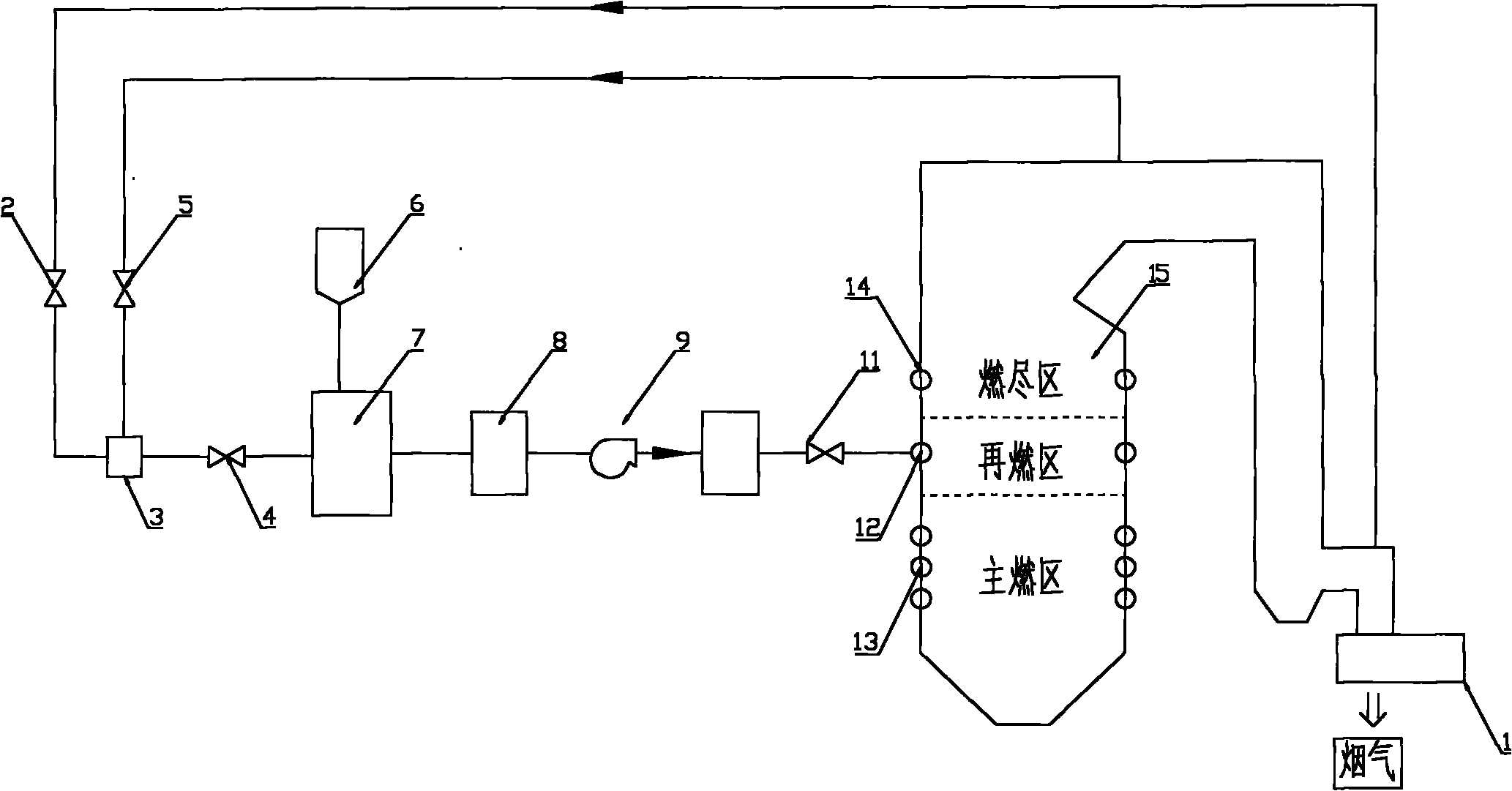

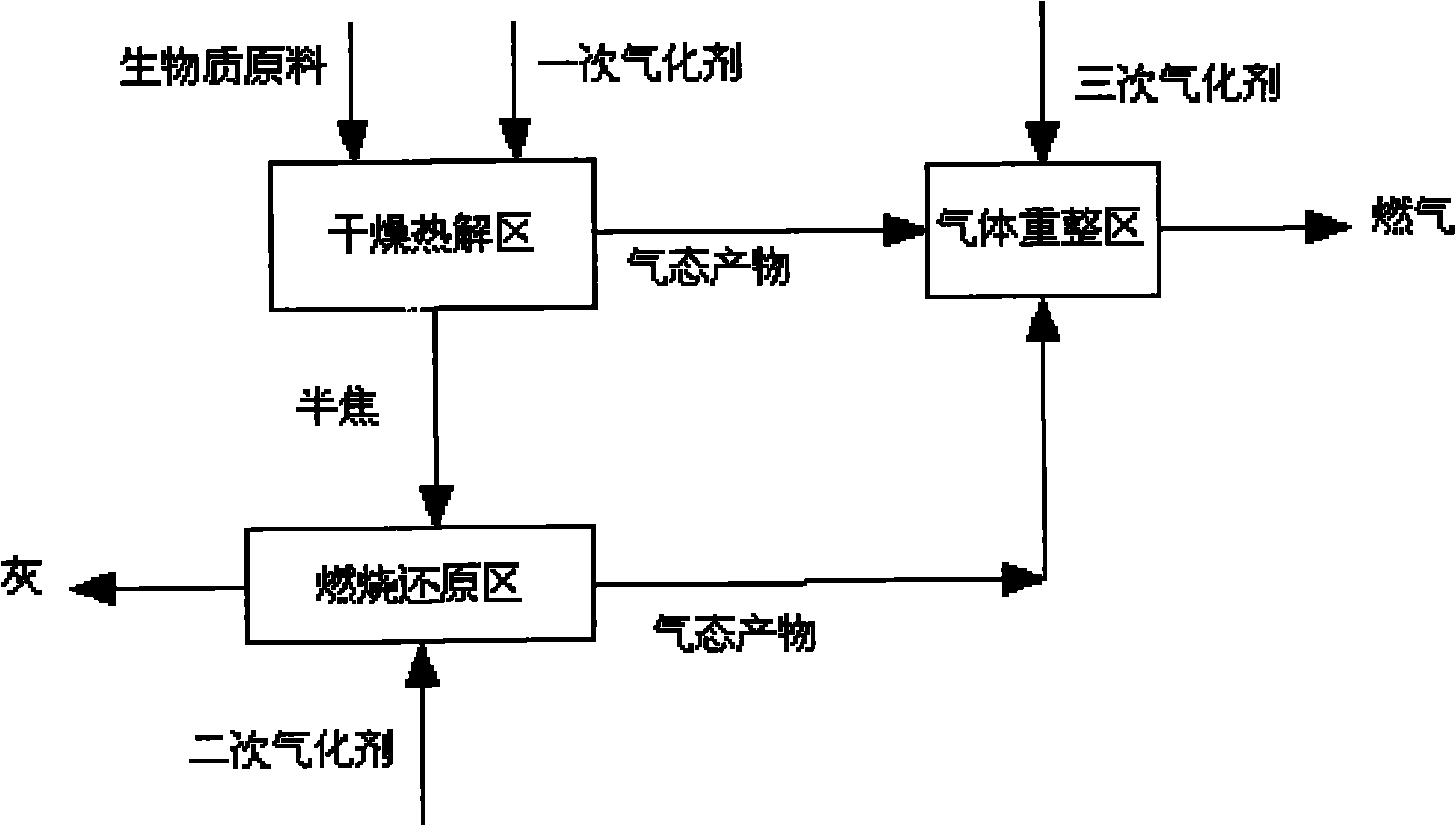

Biomass gasification method

ActiveCN101805638AReduce qualityAchieving directional gasificationCombustible gas productionCombustionMass ratio

The invention discloses a biomass gasification method. The method requires the steps of drying pyrolysis, combustion deoxidization and gas reforming in the gasification process to be relatively separated and continuously carried out in the same gasification furnace, simultaneously continuously gasification agent is introduced at three points in the whole gasification process and finally the cleanhigh quality product gas is obtained. In the invention, the equivalence ratio of the total gasification agent is 0.2-0.35, and the mass ratio of a first gasification agent, a second gasification agent and a third gasification agent is (0-0.8):(2-3.5):(0.7-1.5). The method controls the temperature and the reaction depth of each subarea in the furnace by controlling the mutual ratio of the biomass materials, the first gasification agent, the second gasification agent and the third gasification agent so as to control the quality of the final product gas. The obtained product gas can be used as the energy or the chemical engineering synthesis raw material gas. The method can generate clean product gas from the biomass, cannot generate secondary pollution and has high carbon conversion rate and simple implementation method.

Owner:山东山科环境资源有限公司

Biomass pyrolysis gasification multifunctional iron-based catalyst and preparation method thereof

ActiveCN103394356AImprove stabilityImprove anti-sintering and anti-carbon abilityGas purification with selectively adsorptive solidsMetal/metal-oxides/metal-hydroxide catalystsMuffle furnacePyrolysis

A biomass pyrolysis gasification multifunctional iron-based catalyst and a preparation method thereof are disclosed. The preparation method is characterized by comprising the following steps: (1) carrier pretreatment: placing CaO in a muffle furnace for calcining, then grinding and screening to prepare CaO carrier particles; (2) introduction of a main active component: mixing the CaO carrier particles with a Fe(NO3)3.9H2O solution, stirring and immersing, drying, calcining and grinding; (3) introduction of an auxiliary active component: mixing the sample prepared by the step (2) with a Ce(NO3)3.6H2O solution, stirring, immersing, drying, placing the obtained sample in a muffle furnace for calcining, placing the calcined sample in a dryer to cool to room temperature, grinding, then mixing the obtained powder with a Zr(NO3)4.5H2O solution, stirring, immersing, drying, then placing the sample in a muffle furnace for calcining, then placing the calcined sample in a dryer to cool to room temperature, and then grinding; and (4) shaping of the catalyst: performing shaping on the obtained catalyst, and screening to obtain the catalyst finished product.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

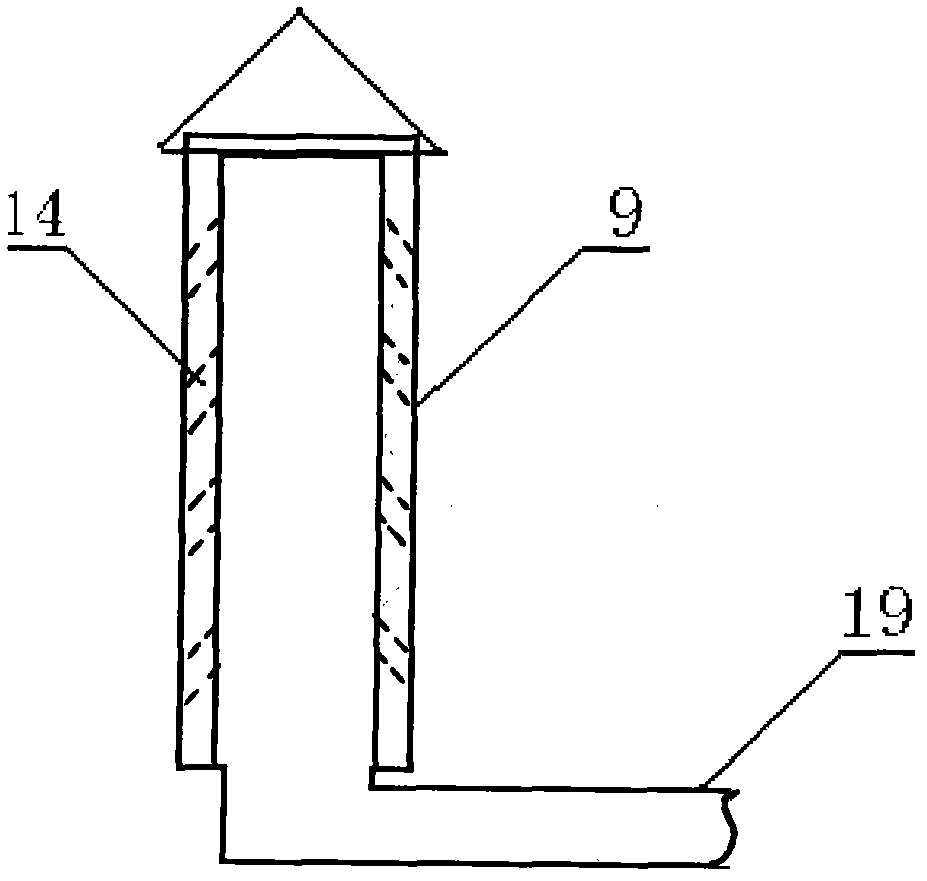

Method and device for three-stage separating biomass gasification

InactiveCN102676236AReduce oxygen consumptionHigh calorific valueEnergy inputCombustible gas productionAir preheaterGeneration rate

The invention discloses a method and a device for three-stage separating biomass gasification. The device mainly comprises a reacting furnace, a pyrolysis chamber which is a biomass pyrolytic reaction chamber is arranged on the upper portion of the reacting furnace, a gasification chamber and a combustion chamber are positioned in the reacting furnace, the gasification chamber is positioned inside the combustion chamber, the pyrolysis chamber and the gasification chamber are connected with a feeding pipe, a flue gas channel is arranged outside the pyrolysis chamber and the feeding pipe, a feeding device is arranged on the upper pyrolysis chamber, the lower gasification chamber is communicated with the combustion chamber, a high-temperature gas extraction outlet is arranged in the middle of the gasification chamber, flue gas rises up along the flue gas channel from the combustion chamber to the periphery of the pyrolysis chamber and then is exhausted via a flue gas outlet, and the exhausted high-temperature gas is separated and purified by a separator prior to entering an air pre-heater. Three processes of a biomass gasification generating system are completely separated, the length of a reduction area is increased, and time and temperature required by tar pyrolysis are guaranteed, so that content of tar in the gas is reduced, gas generation rate of the gasification furnace is increased, and quality of the biomass gas is improved. The device has the advantages of convenience for temperature control, energy saving, environmental protection, operating continuity and the like.

Owner:JINAN BAOHUA NEW ENERGY TECH

Method for tobacco leaf reforger for making cigarette using paper making method

InactiveCN1565284AImprove and tweak the physical structureImprove and adjust chemical compositionTobacco preparationCigarette useChemical composition

The invention discloses a method for tobacco leaf reforger for making cigarette using paper making method which comprises steeping the tobacco leaves with dissolvent, extracting, separating the tobacco extract, pulping and making substrates, modulating applying liquid, applying onto the substrate, throwing and rolling into cigarette end product.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

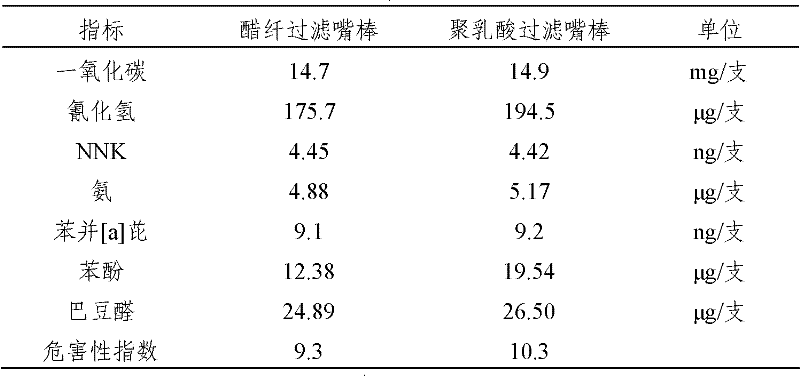

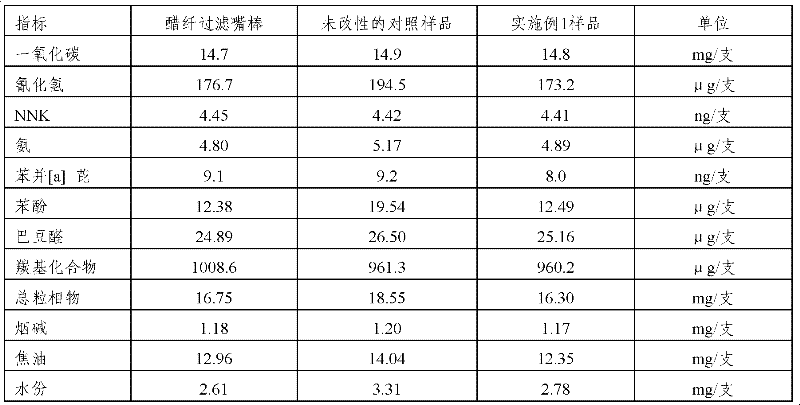

Modified polyactic acid composition for cigarette filter stick and preparation method thereof

ActiveCN102516728ASmall weight contentImprove adsorption capacityTobacco smoke filtersMonocomponent polyesters artificial filamentSODIUM PYRROLIDONE CARBOXYLATECellulose acetate

The invention relates to a modified polyactic acid composition for a cigarette filter stick and a preparation method thereof. The composition comprises following parts of raw materials, by weight, 100 parts of polyactic acid, 0.02-3 parts of polyactic acid-beta-cyclodextrin, 0.08-5 parts of sodium carbonate, 0.05-5 parts of sodium pyrrolidonecarboxylate, 0.01-4 parts of vitamin and 0.01-8 parts of polyacrylamide. The filter stick prepared through the polyactic acid composition is better in absorbing performance on smoke compared with the prior art and good in comprehensive performance, and a part of indexes of the filter stick exceed those of a cellulose acetate filter stick.

Owner:马鞍山同杰良生物材料有限公司

Household garbage internal circulation sealed low-temperature pyrolysis system and method based on decoupling combustion

ActiveCN105737163AIncreased pyrolysis capacityReduce heat lossIncinerator apparatusCombustorResource recovery

The invention discloses a household garbage internal circulation sealed low-temperature pyrolysis system based on decoupling combustion. A pyrolysis section comprises a drying drum and a pyrolysis drum. A scrubbing section comprises two stages of scrubber towers. A heat recovery section comprises a smoke and pyrolyzed gas waste heat recovery device. Household garbage is sent into the drying drum to be dried firstly and then sent into the pyrolysis drum to be pyrolyzed, so that pyrolysis gas and carbon residues are generated. The drying and pyrolysis process is divided into a starting stage and a normal operation stage. During the starting stage, air and gas output by a gas storage device are mixed, pass through a combustor of the drying drum and a combustor of the pyrolysis drum and burn in a cavity of the drying drum and a cavity of the pyrolysis drum correspondingly to supply heat, and accordingly high-temperature smoke is generated. During the normal operation stage, the high-temperature smoke in the cavity of the pyrolysis drum is sent into the cavity of the drying drum to be subjected to heat exchange and drying, and the combustor of the drying drum becomes an auxiliary heat source. The pyrolyzed gas sequentially enters the first stage of scrubber tower and the second stage of scrubber tower to be purified. According to the household garbage internal circulation sealed low-temperature pyrolysis system based on decoupling combustion, waste heat is sufficiently utilized to generate high-temperature steam, the smoke is exhausted after being cooled and purified, the generation of dioxin is effectively controlled, and resource recovery, reduction and low carbon of the household garbage are achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

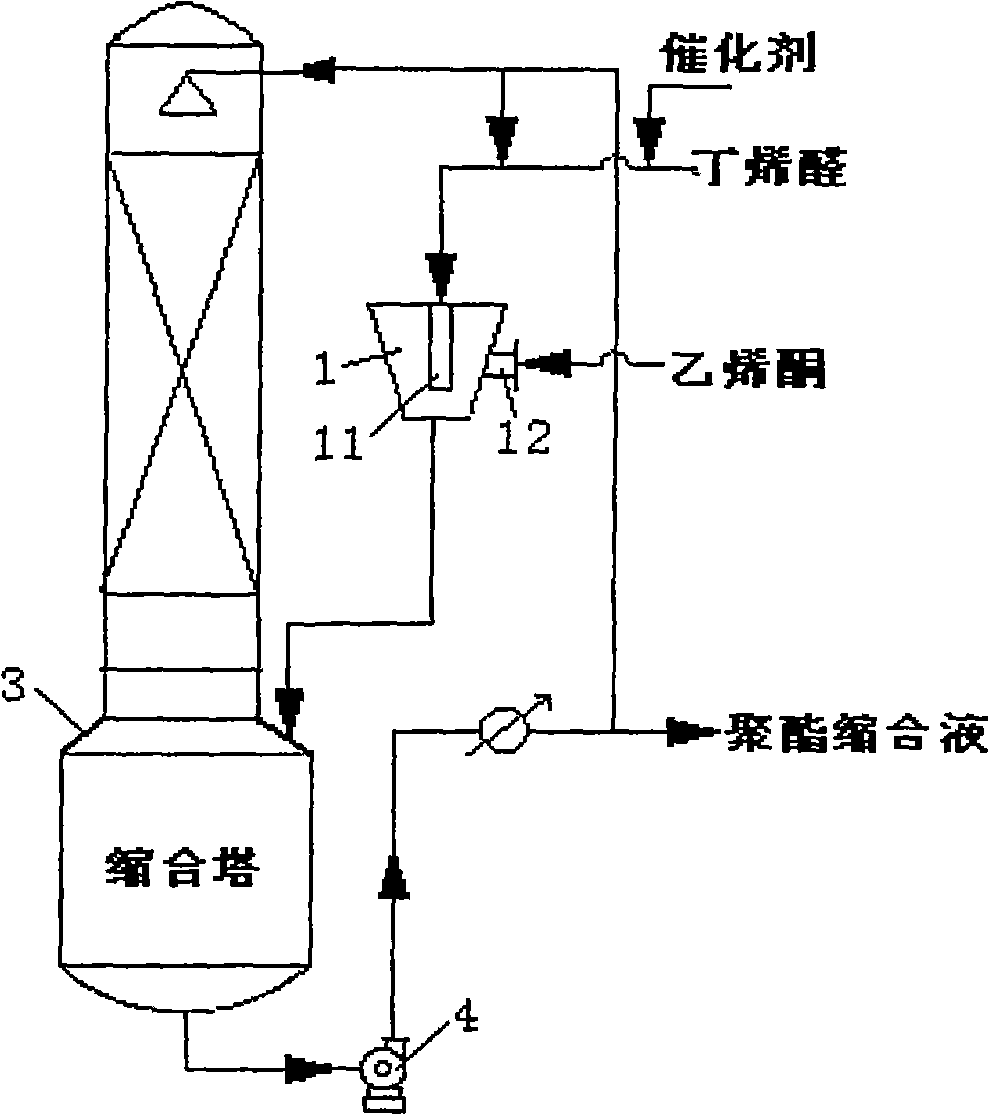

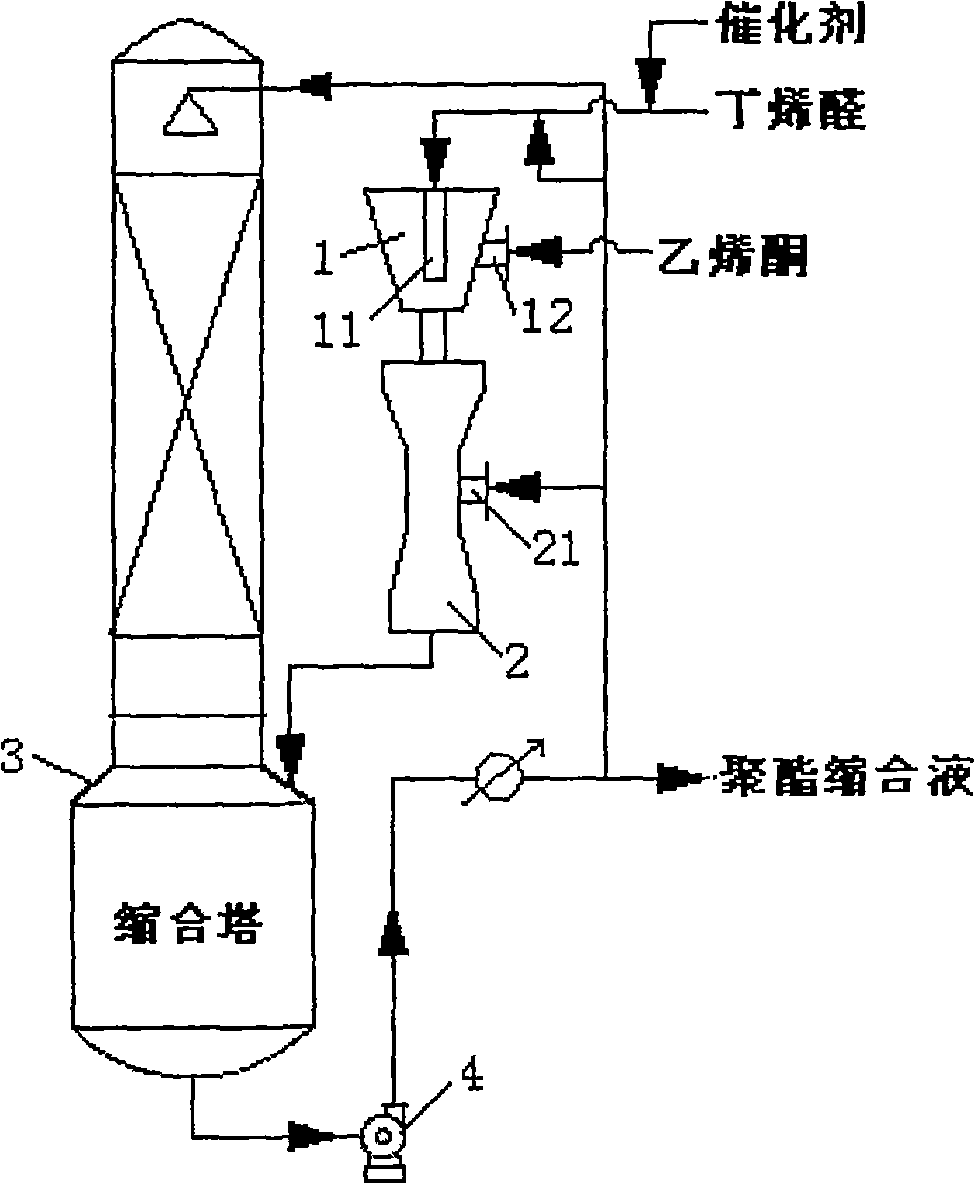

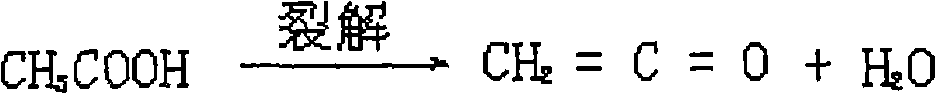

Process for preparing sorbic acid

ActiveCN101318891AQuality assuranceSmall molecular weightPreparation from carboxylic acid esters/lactonesChemical recyclingPolyesterAcetic acid

The invention provides a process for making a sorbic acid. The process comprises: pyrolysis of acetic acid for producing high purity ketene with coke oven gas as a heat source, polymerization reaction of butenoic aldehyde and ketene gas to give a sorbic acid polyester and acid decomposition of sorbic acid polyester to obtain the sorbic acid, wherein the polymerization reaction of the butenoic aldehyde and the ketene gas, which is performed in a combined polymerization reactor comprising at least of a spray absorption reactor and a packed tower provided with a recycle pump outside continuously, comprises the steps that: fresh butenoic aldehyde and recycle feed from a tower bottom of the packed tower are delivered to the spray absorption reactor to form a sprayed material flow and to react with a low-temperature ketene gas absorbed by formed negative pressure into the reactor; the reaction materials flow into the tower bottom of the packed tower circularly so as to conduct further polymerization reaction of the unreacted ketene and the butenoic aldehyde contained in the material flow; one part of the materials from the tower bottom of the packed tower is used for the inner circulation of a reactor system, while the other part is recovered constantly for use in the next process, thereby realizing continuous production.

Owner:JINNENG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com