Preparation of functional nanometer short fiber and its application in cigarette filter tip

A technology of functional nanometers and nanofibers, which is applied in the preparation of functional nanofibers and the application fields of cigarette filters, can solve the problems of particles entering the lungs, catalyst deactivation, particle leakage, etc., to reduce tar content, continuous operation, The effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention mainly uses cellulose acetate for cigarettes, cellulose diacetate and cellulose triacetate on the polymer material. It is best to use cellulose diacetate for tobacco use. The spinning solution uses acetone, acetone-water or acetone-dimethylacetamide as solvent, and the best solvent system is acetone-water (80:20 by volume). The concentration of cellulose acetate in the spinning solution is 4-16%, and the optimum concentration range is 8-12%. Catalysts such as heme, hemin, metal molybdate, and metal rubidium salt can be added to the spinning solution. The best catalyst is heme, and the concentration range is 0.5-2.5%.

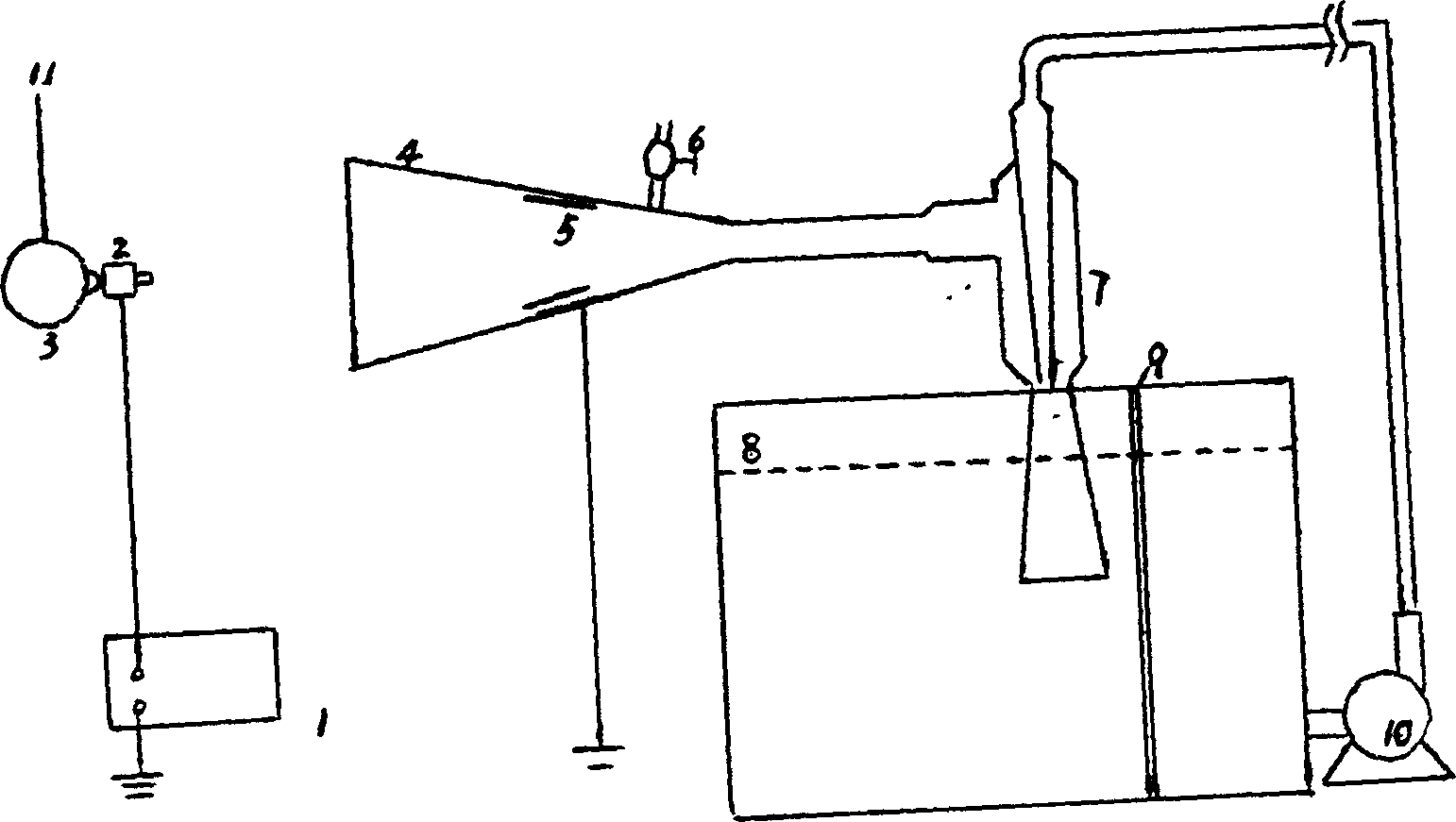

[0029] During the electrospinning process, a tubular multi-jet electrospinning device (see figure 1 ), the resulting nanofibers were directly deposited in circulating water. The voltage range for spinning is 12KV-32KV, and the optimum voltage range is 18KV-26KV. The polymer flow rate of each nozzle is 5-35 ml / hour, and the optimu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com