Patents

Literature

211 results about "Cellulose diacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose diacetate, sometimes simply called diacetate, is a synthetic polymer made by treating cellulose with acetic acid. It consists of two acetyl functional groups on each unit of D-anhydroglucopyranose of the cellulose molecule. It was first developed in the United States.

Asymmetric Gas Separation Membranes with Superior Capabilities for Gas Separation

InactiveUS20080143014A1Excellent permeation fluxHigh selectivityMembranesSemi-permeable membranesCellulose diacetatePolymer science

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

Cellulose acetate and dope containing the same

InactiveUS7122660B1Good release effectSatisfactory optical propertyArtificial filaments from cellulose derivativesCarboxyl radicalCellulose diacetate

Using the dope containing the following cellulose acetate (1), (2), or (3), a film is prepared by the casting process:(1) a cellulose acetate having carboxyl groups binding to at least one member selected from the group consisting of a cellulose acetate and a hemicellulose acetate, wherein at least a part of said carboxyl groups are in an acidic form;(2) a cellulose acetate containing at least one member selected from the group consisting of an acid having an acid dissociation exponent pKa of 1.93 to 4.50 in water, an alkali metal salt of said acid and an alkaline earth metal of said acid; or(3) a cellulose acetate containing an alkali metal or an alkaline earth metal wherein the total content of an alkaline metal and an alkaline earth metal in 1 gram of the cellulose acetate is from an effective amount to 5.5×10−6 equivalent (in terms of ion equivalent). The above cellulose acetate is also useful for spinning process. The cellulose acetate includes a cellulose diacetate and a cellulose triacetate. The cellulose acetate of the present invention has high film-releasability from a support and excellent optical characteristics.

Owner:DAICEL CHEM IND LTD

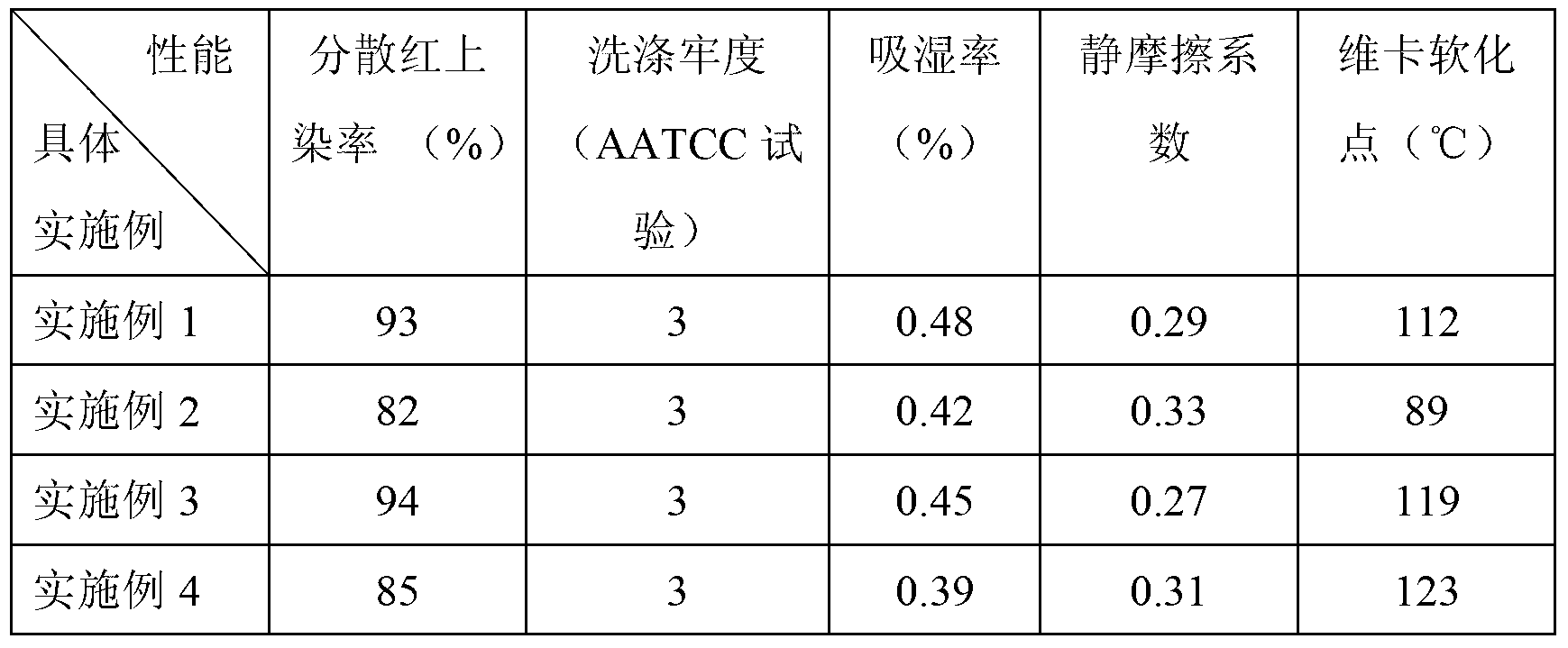

Modified polylactic acid fiber and preparation method thereof

ActiveCN103225125ASave raw materialsRich sourcesMelt spinning methodsMonocomponent polyesters artificial filamentEnvironmental resistanceCellulose diacetate

The invention discloses a modified polylactic acid fiber and a preparation method thereof. The modified polylactic acid fiber is prepared through blending polylactic acid, a cellulose derivative, a cellulose diacetate grafted polylactic acid copolymer, a lubricant, inorganic nanoparticles, a nucleating agent and an antioxidant. The preparation method comprises the following steps: adding partial polylactic acid slices and all other raw materials to a high speed mixer according to a mass component ratio, carrying out high speed dispersion, and carrying out melt blending and extrusion through a double screw extruder to obtain modified polylactic acid master batch slices; and carrying out dry mixing of the modified polylactic acid master batch slices and residual polylactic acid slices in the high speed mixer, carrying out melt spinning through a melt spinning machine, and stretching to obtain the modified polylactic acid fiber. The prepared polylactic acid fiber has the advantages of low cost, complete biodegradation, environmental protection, good spinning performance, stable filament bundle quality, excellent flexibility, excellent antifriction, excellent dyeing property and excellent comfortableness, and is a very good high-performance environmentally-friendly fiber material. The preparation method has the advantages of simplicity, low equipment requirement, and environmental protection in the production process, and is in favor of the industrialized production.

Owner:长沙乐远化工科技有限公司

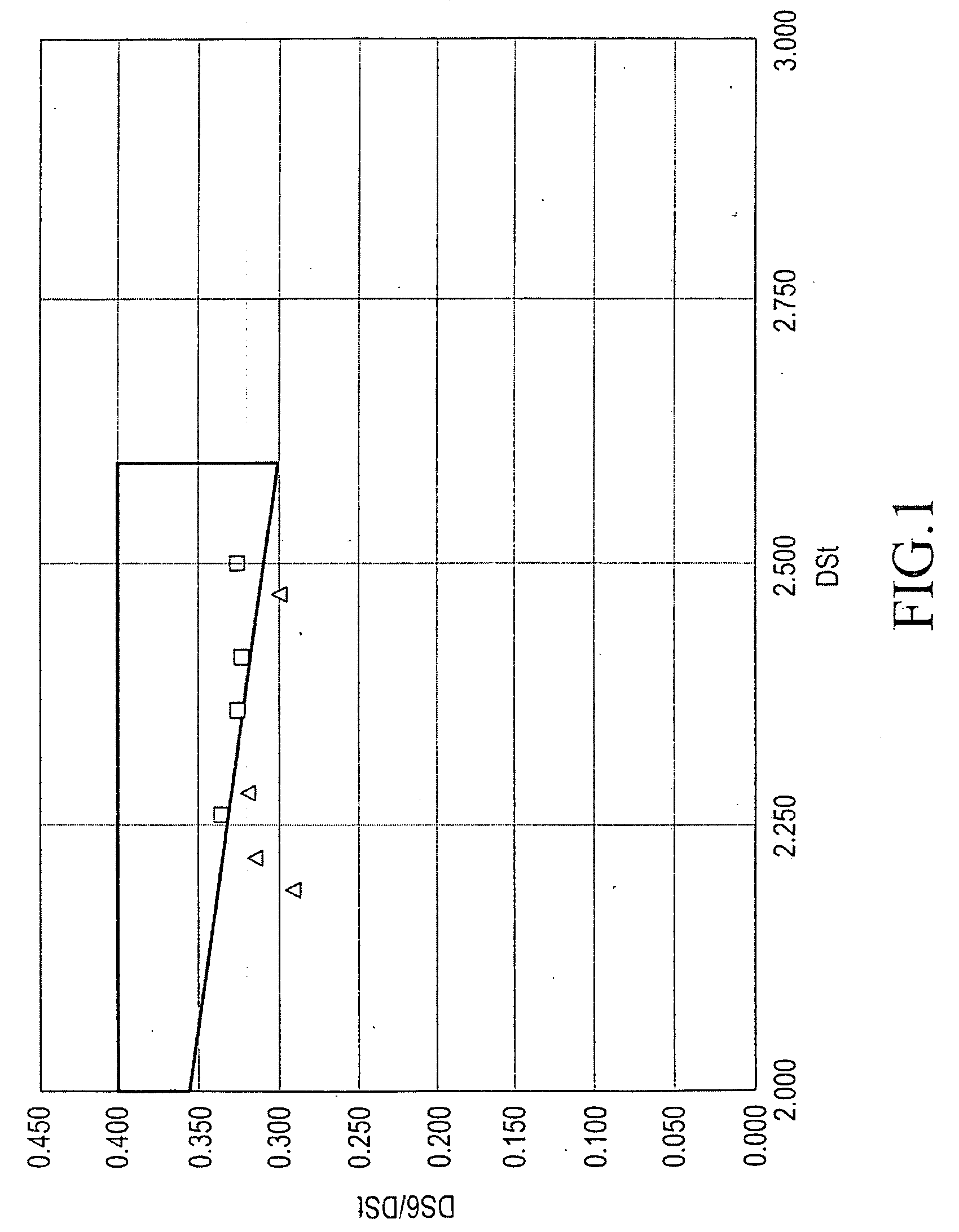

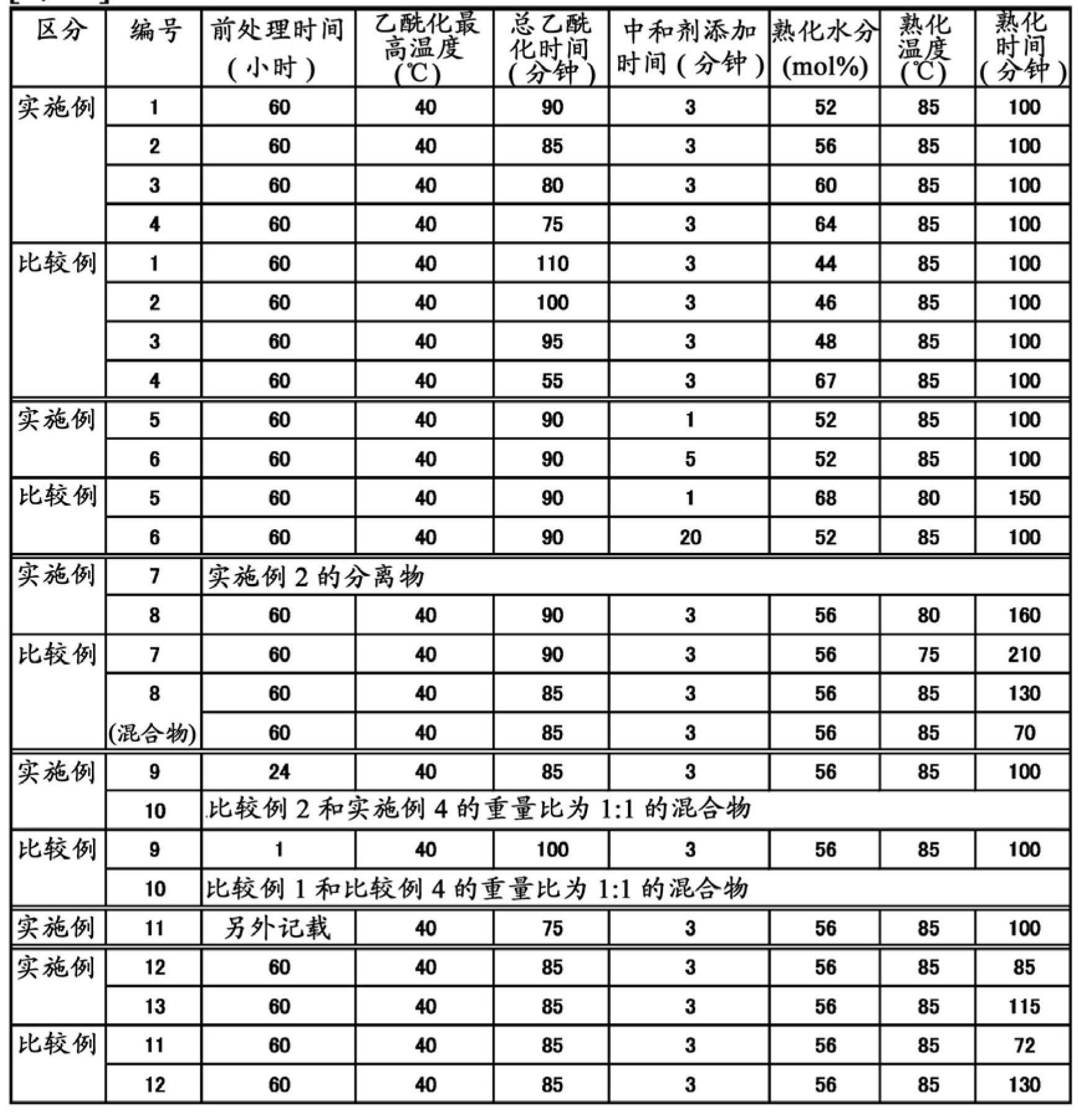

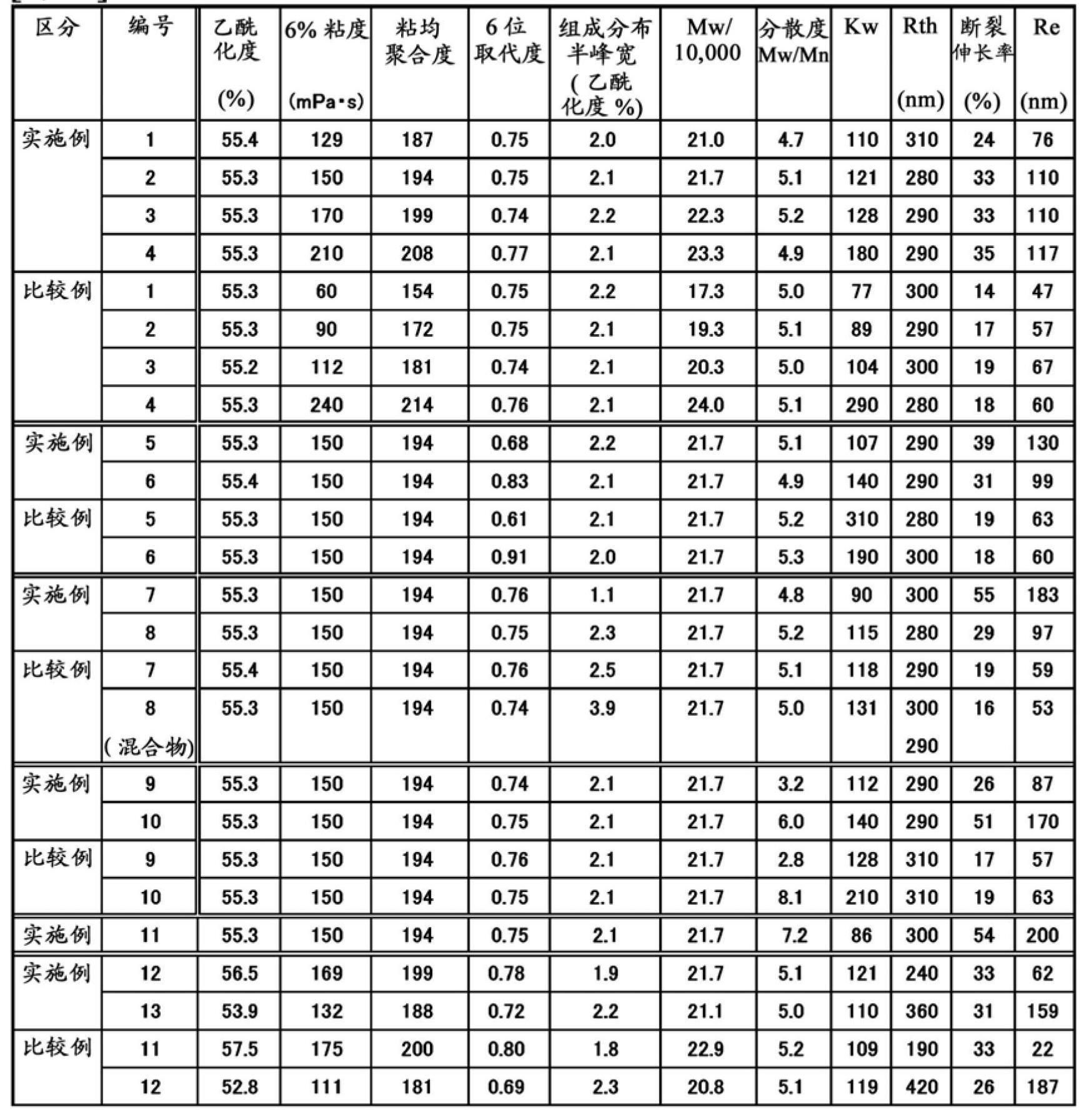

6-position highly acetylated cellulose diacetate and process for producing the same

ActiveUS20090171079A1Good optical performanceHigh degree of acetyl substitutionCellulose diacetateChemistry

Disclosed is a cellulose diacetate comprising a 6-position highly acetylated cellulose diacetate having a 6-percent viscosity of 40 to 600 mPa·s, and having a total degree of acetyl substitution of DSt and a degree of acetyl substitution at the 6-position of DS6, wherein DSt and DS6 satisfy following Conditions (1) and (2):2.0≦DSt<2.6 (1)0.400≧(DS6 / DSt)≧0.531−0.088×DSt (2)The cellulose diacetate is usable typically as a starting material for cellulose acylates of different acyl groups, which have a high total degree of acyl substitution, have superior optical properties, and usable typically as photographic materials and optical materials.

Owner:DAICEL CHEM IND LTD

Preparation method of cellulose diacetate fiber

InactiveCN102251302AAvoid pollutionImprove production environmentArtificial filaments from cellulose derivativesWet spinning methodsFiberCellulose diacetate

The invention relates to a preparation method of cellulose diacetate fiber, in particular to a preparation method of cellulose diacetate fiber for carrying out dry-jet wet spinning with ionic liquid serving as a solvent. The preparation method comprises the following steps of: 1, dissolving the cellulose diacetate in the ionic liquid to form a uniform and stable spinning stock solution, and 2, carrying out dry-jet wet spinning on the spinning stock solution to obtain the cellulose diacetate fiber. According to the preparation method of the cellulose diacetate fiber, provided by the invention, the problems of low tensile strength of fiber and poor mechanical performance existed in the cellulose diacetate dry spinning process, and low degree of substitution of the cellulose acetate fiber prepared by using the ionic liquid as the solvent, lower strength of the prepared fiber, and the like in the prior art are solved.

Owner:DONGHUA UNIV

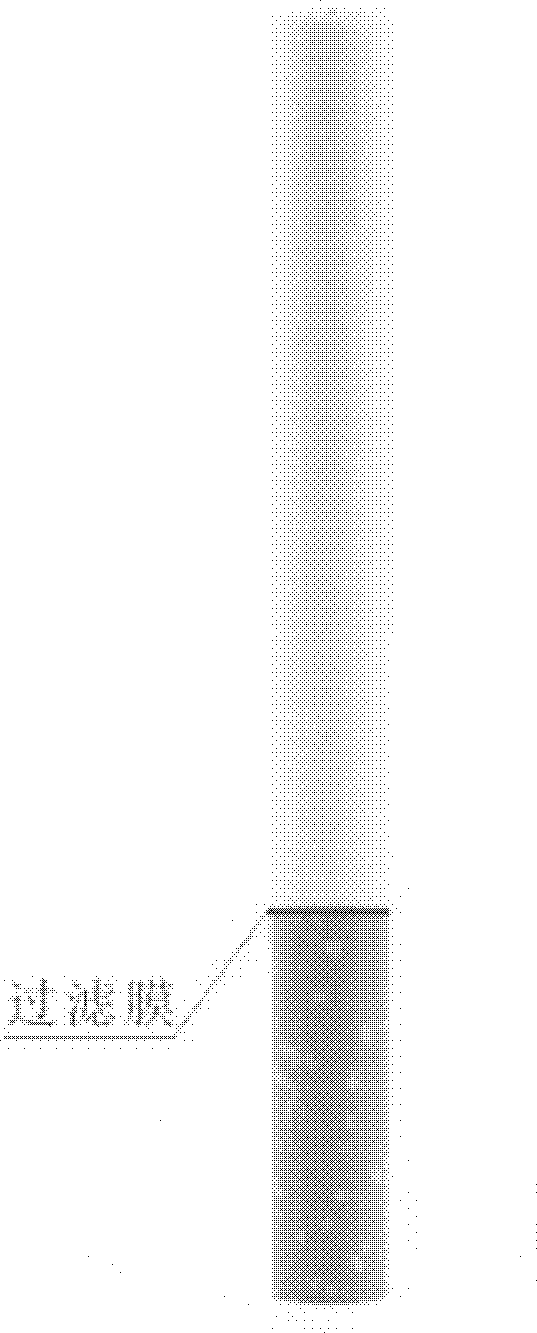

Double layered forward osmosis membrane and preparation method thereof

InactiveCN103055713AIncrease effective water fluxAvoid enteringSemi-permeable membranesPolyesterPolymer science

The invention discloses a double layered forward osmosis membrane which is characterized by comprising an intermediate porous support layer and ultrathin layers at both sides. A support material such as screen cloth or nonwoven is further embedded in the middle of the porous support layer. The material of the porous support layer and the ultrathin layers is cellulose triacetate fiber, cellulose diacetate fiber or a mixture thereof; and the support material is cotton, polyester or nylon. The preparation method of the double layered forward osmosis membrane includes immersing the processed support material in the film casting solution of cellulose triacetate fiber, cellulose diacetate fiber or the mixture thereof, pulling out from the middle of both sides of a blade, and forming the double layered forward osmosis membrane via a phase inversion method. The advantage of the present invention is that the forward osmosis membrane having two layers can effectively prevent a solute entering into the porous support layer, and reduce the concentration polarization within the support layer, thereby significantly improving the effective water flux of the forward osmosis membrane.

Owner:XIAN HHJ WATER TREATMENT TECH

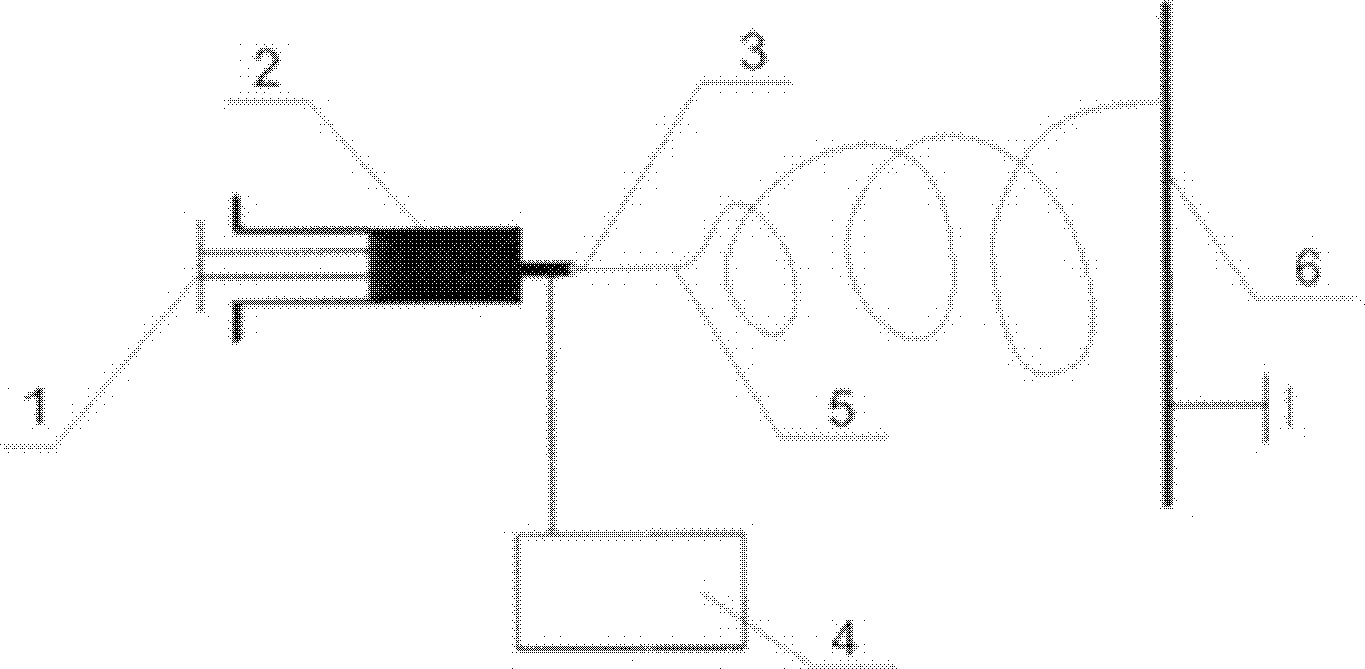

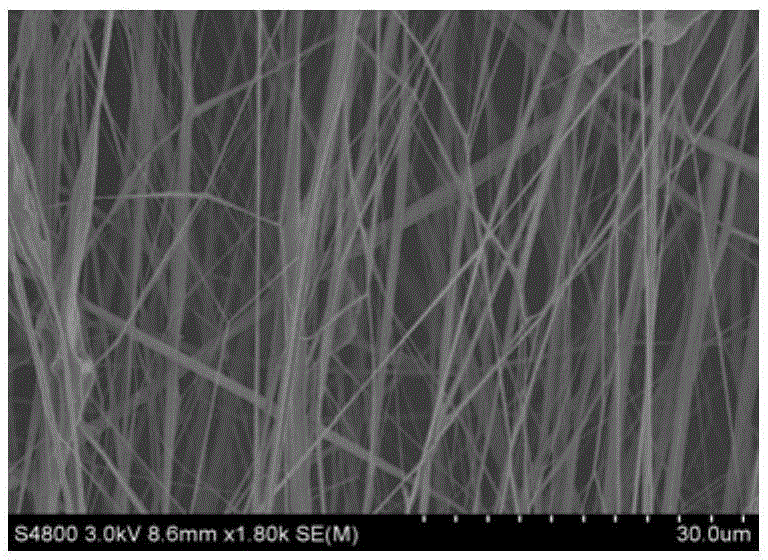

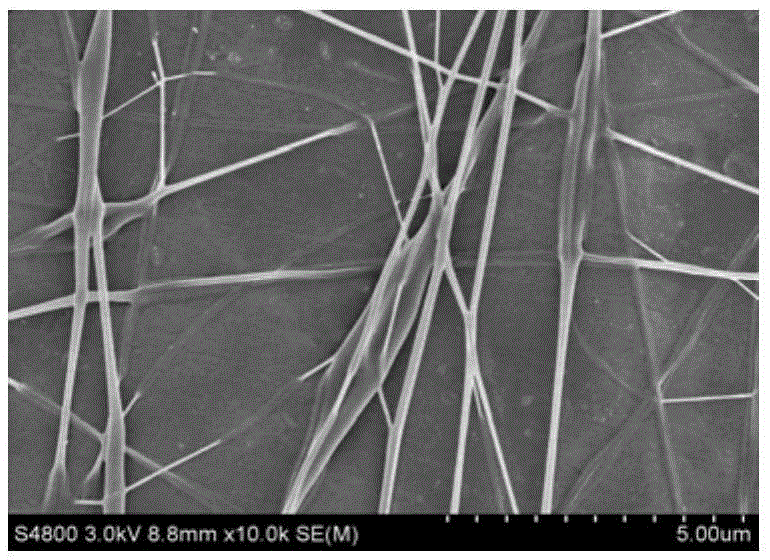

Preparation method for cigarette filter tip adopting electrostatically spun cellulose acetate membrane

InactiveCN102423141AEasy to cutEasy to sampleCigarette manufactureCellulose diacetateElectrospinning

The invention relates to a preparation method for a cigarette filter tip adopting an electrostatically spun cellulose acetate membrane, and the method includes the following steps: (1) cellulose diacetate is dissolved in the mixture of acetone and dimethylacetylamide, electrostatic spinning is carried out, and thereby the nano cellulose acetate membrane is obtained; (2) cellulose acetate tows in a cigarette are pulled out, the nano cellulose acetate membrane is laid between the filter tip and the cigarette along the cross-sectional direction of the filter tip, the cellulose acetate tows which are originally pulled out are then put into the cigarette, the part of the filter tip, which exceeds connecting paper, is cut off, and thereby the improved cigarette filter tip is fabricated. The preparation method uses the electrostatic spinning technology to fabricate the nano cellulose acetate membrane and adds the nano cellulose acetate membrane into the cigarette filter tip, the nano cellulose acetate membrane not only can be perfectly combined with the cigarette filter tip, but also can enhance the harmful gas-filtering performance of the cigarette filter tip, meanwhile, the preparation method is easy to operate, the efficiency is relatively high, and the cigarette filter tip can remarkably reduce the contents of various harmful components, and has a good market prospect.

Owner:DONGHUA UNIV +1

Modified polylactic acid fiber excellent in performance

ActiveCN104818543AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentCellulose diacetateCellulose acetate

The invention discloses a modified polylactic acid fiber excellent in performance. The modified polylactic acid fiber is prepared by use of a method and the method comprises the steps of adding such raw materials as PDLLA polylactic acid, PLLA polylactic acid, hydroxypropyl starch, cellulose diacetate, nano tourmaline powder, nano talcum powder, chitosan powder and nano montmorillonoid powder to a high-speed mixer, and dispersing at a high speed to obtain a modified polylactic acid mixture, forming a modified polylactic acid master batch from the evenly mixed modified polylactic acid mixture by virtue of melt blending and extruding in a twin-screw extruder, and drying in vacuum, feeding the modified polylactic acid functional master batch slices and the vacuum-dried common polylactic acid slices into the high-speed mixer for evenly mixing, and spinning the mixture by use of a quinquangular spinneret orifice on a melt spinning machine, thereby obtaining the modified polylactic acid fiber.

Owner:CHANGXING YONG XIN TEXTILE PRINTING DYEING

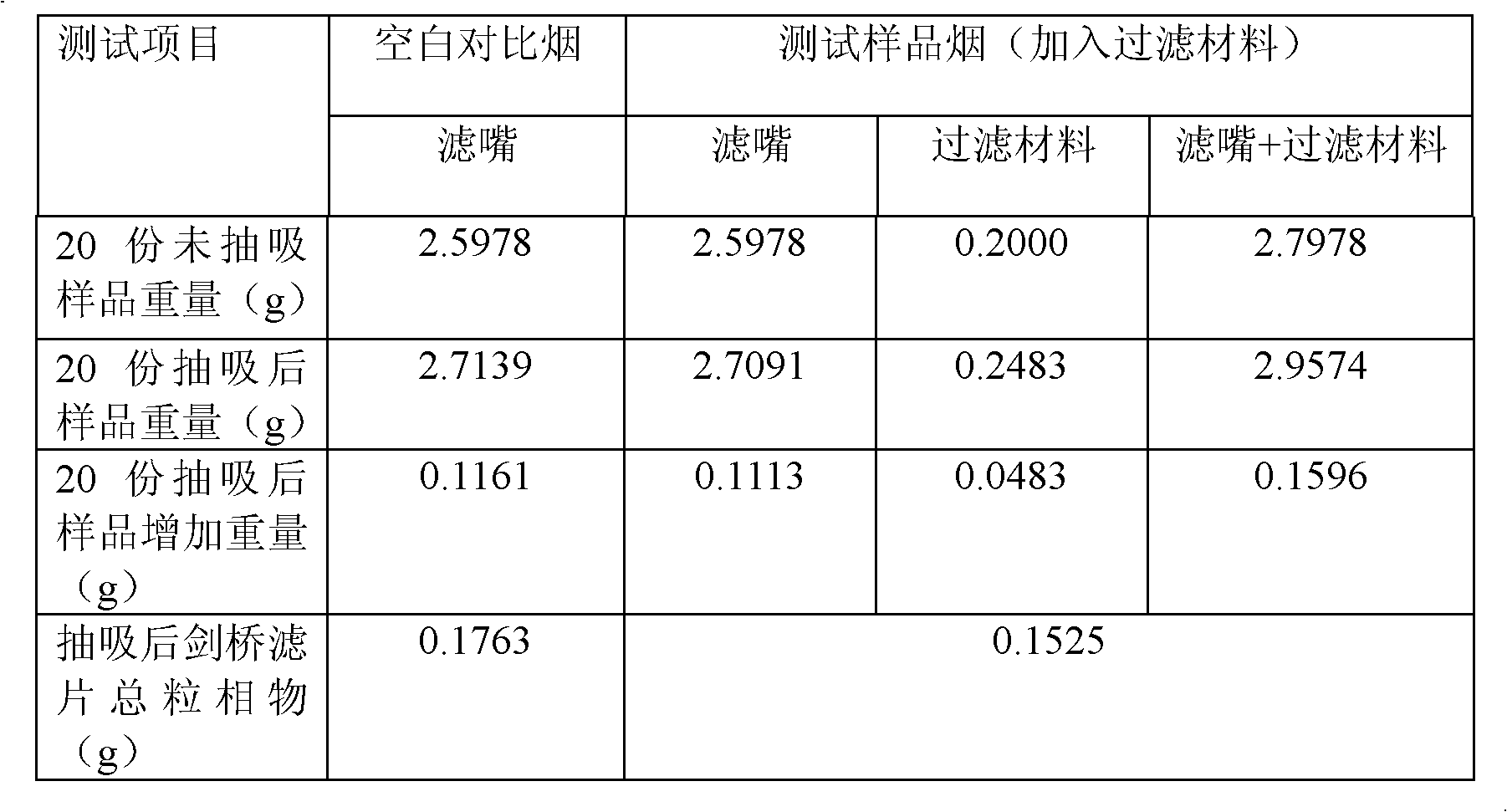

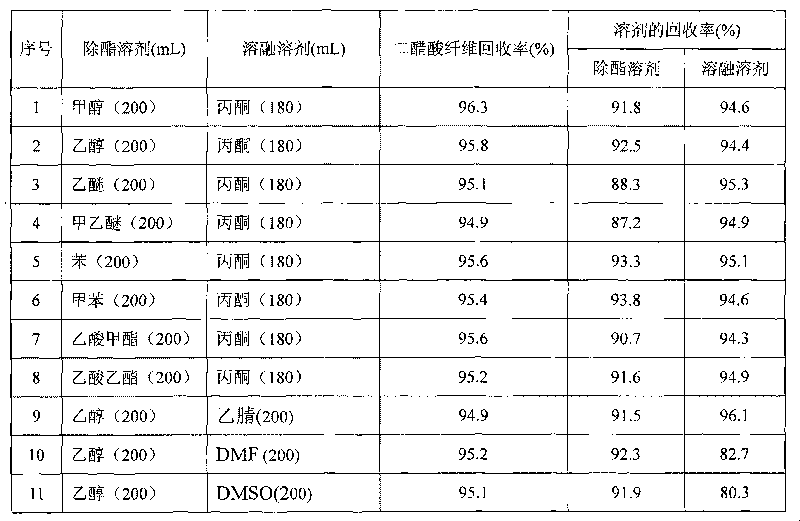

Recycle method of acetate fiber in waste acetate fiber tow filter rod leftovers

InactiveCN101717524ASimple reaction conditionsShort processCigarette manufacturePlastic recyclingFiberCellulose diacetate

The invention discloses a recycle method of acetate fiber in waste acetate fiber tow filter rod leftovers. The method is characterized by comprising the following steps: firstly, soaking the waste acetate fiber tow filter rod leftovers in an ester-removing solvent; removing and recycling the ester-removing solvent in a filtration or centrifugalization mode to obtain a material to be processed; then, adding acetone, N, N-dimethylformamide DMF, acetic acid, acetonitrile, or dimethyl sulfoxide DMSO as melting solvents to the material to be processed to obtain an emulsion; removing undissolved paper and rubber impurities in the emulsion in the filtration or centrifugalization mode; and steaming and recycling the solvent at normal pressure or reduced pressure to solid high-purity cellulose diacetate. The invention has simple and practical production process, environmental protection, no emission, short flows, low cost, high yield and good product quality.

Owner:HEFEI UNIV OF TECH

Method for preparing antibacterial fiber membrane

ActiveCN105839295AUniform pore sizeExcellent stable membrane fluxHollow filament manufactureElectro-spinningYarnCellulose diacetate

The invention discloses a method for preparing an antibacterial fiber membrane. The method comprises the following steps: preparing a complex antibacterial agent by using N-(4-hydroxy-3-methoxybenzyl)acrylamide, 2-hydroxypropyl methacrylate, N, N- (dimethylamino)ethyl methacrylate, and vinyltriethoxysilane-modified nano zinc oxide; adding polyacrylonitrile, cellulose diacetate and glucose to a mixed solvent to obtain a mixed solution; adding the complex antibacterial agent, poly vinyl alcohol, laponite, silver ion loaded zeolite molecular sieve, nano titanium dioxide, alumina sol, calcium chloride and dilauryl thiodipropionate to water to be uniformly mixed, adding the mixed solution and then conducting electrostatic spinning to obtain a raw yarn, putting the raw yarn in water to be soaked and dried. The method for preparing the antibacterial fiber membrane provided by the invention has the advantages of simple process, mild conditions, good antibacterial properties, excellent stain resistance, high mechanical strength and toughness, and long service life.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

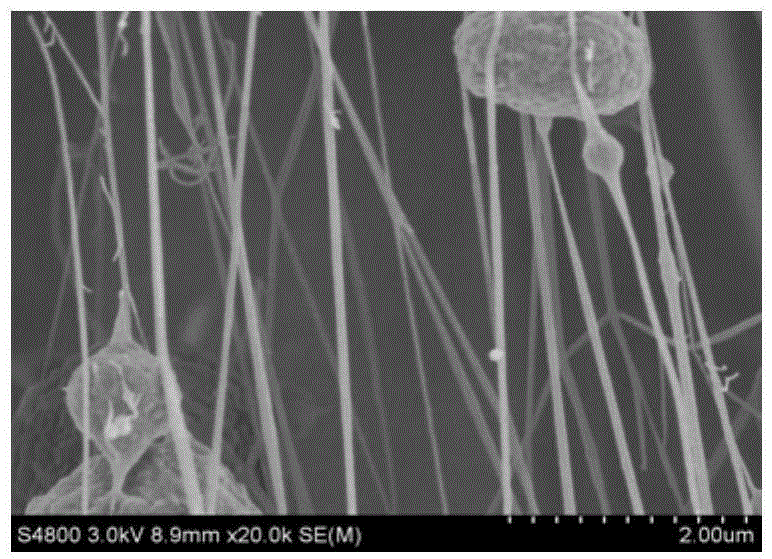

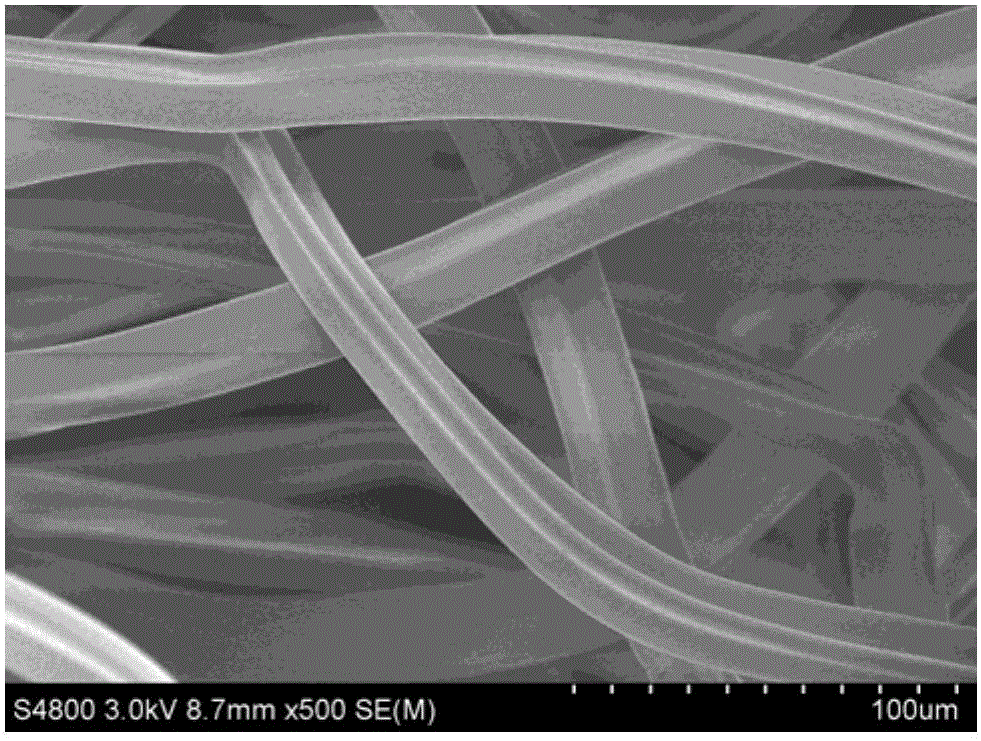

Preparation method of high-adsorbability cellulose diacetate composite electrostatic spinning nanofiber ordered porous film

ActiveCN105396563ACreate pollutionSmall fiber diameterOther chemical processesDispersed particle filtrationElectrospun nanofiberPolymer science

The invention discloses a preparation method of a high-adsorbability cellulose diacetate composite electrostatic spinning nanofiber ordered porous film. The preparation method comprises the following steps: dissolving cellulose diacetate and polycaprolactone, or cellulose diacetate and a lactic acid-glycolic acid copolymer, or cellulose diacetate and polyvinylpyrrolidone into an organic solvent so as to prepare a spinning solution, and preparing the cellulose diacetate composite electrostatic spinning nanofiber ordered porous film by adopting an electrostatic spinning method. The method disclosed by the invention is simple, and cannot pollute the environment in the preparation process. The prepared cellulose diacetate composite electrostatic spinning nanofiber ordered porous film has tiny fiber diameter, good pore diameter and order degree, is good in dry and wet state adsorption performances, is high in water absorption, can be applied to the flue gas and tobacco industry of the dry state and wet state adsorption and filtration separation industry, is wide in market application prospect, and has relatively high application value.

Owner:ZHEJIANG UNIV

Asymmetric gas separation membranes with superior capabilities for gas separation

InactiveUS20100244306A1Excellent permeation fluxHigh selectivityProductsSemi-permeable membranesCellulose diacetatePolyimide membrane

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes having a skin thickness of less than 100 nm, exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

Novel fragrant heat-not-burn cigarette and preparation method thereof

PendingCN109793274AReduce the temperatureEnhance sensory experienceTobacco smoke filtersFiberCellulose diacetate

The invention provides a novel fragrant heat-not-burn cigarette and a preparation method thereof. The novel fragrant heat-not-burn cigarette comprises a tobacco material segment, a tobacco shred end hollow filter rod segment, a cooling segment, a fiber tow filter segment and a hollow segment. The cooling segment is a hollow chamber composed of a paper tube and a polylactic acid sheet layer wound on the inner wall of the paper tube; fragrant fiber tows are arranged in the tobacco shred end hollow filter rod segment, in the cooling segment or in both the tobacco shred end hollow filter rod segment and the cooling segment; the fragrant fiber tows are made by mixing fragrance-containing capsules and cellulose diacetate in a ratio of (0.1-0.2):1, dissolving the mixture in a solvent to obtain aspinning solution with mass percent of 15-25%, and coagulating the spinning solution in a coagulating bath which is made with a solvent and water through a dry-wet process spinning machine. The fragrant fiber tows are added to the tobacco shred end hollow filter rod through a filter rod former; high-temperature smoke may release fragrant odor when passing by; therefore, the fragrant odor of the heat-not-burn cigarette can last long, the temperature of the smoke is reduced, and a user can gain better sensory experience.

Owner:HUBEI CHINA TOBACCO IND

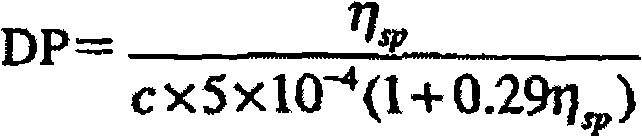

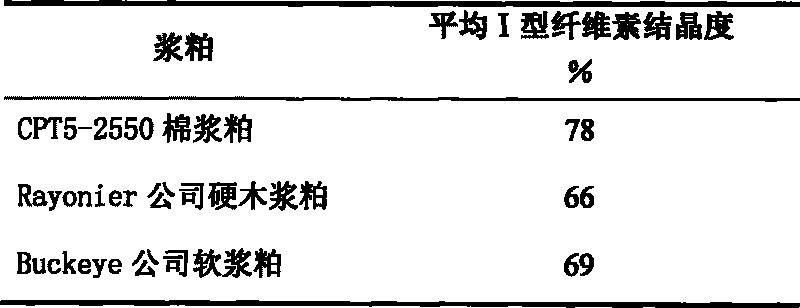

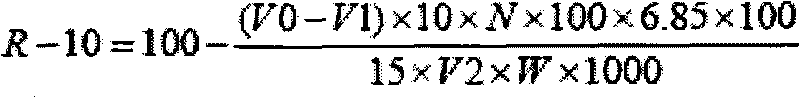

Cellulose pulp and production method thereof

InactiveCN101691407AChemical/chemomechanical pulpNon-woody plant/crop pulpCellulose diacetateCellulose acetate

The invention discloses cellulose pulp and a production method thereof, mainly used for producing cellulose diacetate and cellulose triacetate. In the invention, category II cotton linter, or category III cotton linter with ripeness being 60-70%, or a mixture of category II cotton linter and category III cotton linter are used as the raw material, I type cellulose crystallity of cellulose pulp is within the range of 60-74%, the acetifying reaction has good performance and low cost, and the invention is suitable for commercialized production of cellulose diacetate.

Owner:NANTONG CELLULOSE FIBERS CO LTD +1

Preparation method of cellulose diacetate

The invention discloses a preparation method of cellulose diacetate. The method prepares the cellulose diacetate by synchronously adding cellulose, acetic acid, an ionic liquid, a catalyst and an acetylation reagent in a reaction device to perform acetylation reaction, wherein the reaction time is 2-12 hours; the reaction temperature is 60-120 DEG C; the catalyst is sulfonation solid acid Amberlyst15; the acetylation reagent is acetic anhydride or acetic chloride; the dosage ratio of the cellulose to the ionic liquid is (0.025-0.05) g / ml; the mol ratio of the catalyst to the cellulose is (0.05-0.1):1; the mol ratio of the acetylation reagent to the cellulose is (3-6):1; solid catalyst is recovered through solid-liquid separation; after supernate is finished, the product can be separated and the ionic liquid is recovered. The method can synthesize the cellulose diacetate with excellent dissolving performance by one step; the catalyst and the reaction medium both can be recovered and recycled, so that the corrosion due to the traditional strong acid catalysis and the environmental pollution caused by the organic volatility solvent are overcome.

Owner:WUHAN POLYTECHNIC UNIVERSITY +1

Cellulose acetate and dope containing the same

InactiveUS20050187385A1Good release effectSatisfactory optical propertySugar derivativesArtificial filaments from cellulose derivativesAcetic acidCarboxyl radical

Using the dope containing the following cellulose acetate (1), (2), or (3), a film is prepared by the casting process: (1) a cellulose acetate having carboxyl groups binding to at least one member selected from the group consisting of a cellulose acetate and a hemicellulose acetate, wherein at least a part of said carboxyl groups are in an acidic form; (2) a cellulose acetate containing at least one member selected from the group consisting of an acid having an acid dissociation exponent pKa of 1.93 to 4.50 in water, an alkali metal salt of said acid and an alkaline earth metal of said acid; or (3) a cellulose acetate containing an alkali metal or an alkaline earth metal wherein the total content of an alkaline metal and an alkaline earth metal in 1 gram of the cellulose acetate is from an effective amount to 5.5×10−6 equivalent (in terms of ion equivalent). The above cellulose acetate is also useful for spinning process. The cellulose acetate includes a cellulose diacetate and a cellulose triacetate. The cellulose acetate of the present invention has high film-releasability from a support and excellent optical characteristics.

Owner:DAICEL CHEM IND LTD

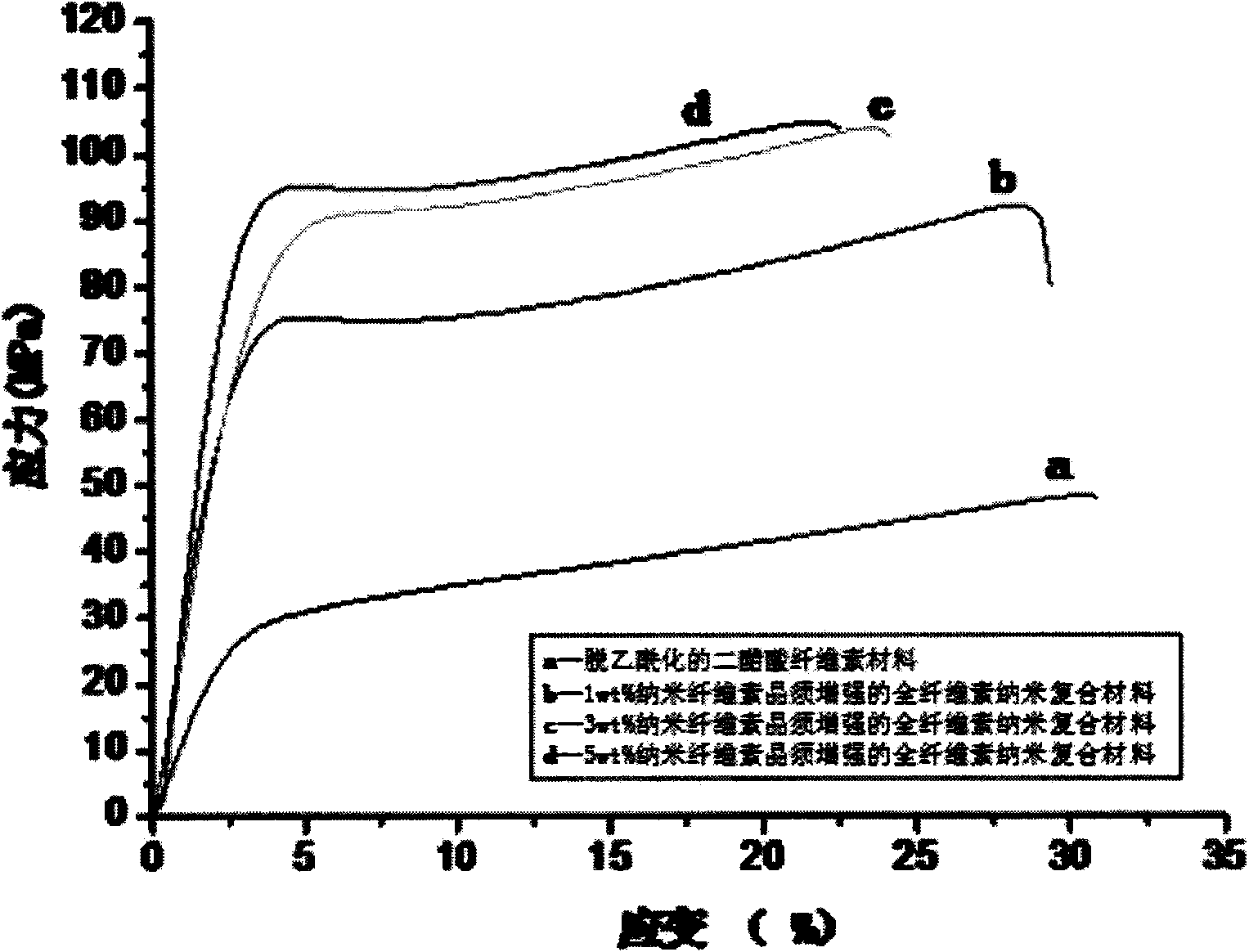

Preparation method for holocellulos nano composite film

The invention relates to a preparation method for a holocellulos nano composite film. The preparation method comprises the following steps: utilizing a cellulose diacetate solution as a matrix phase, uniformly dispersing nano cellulose into a matrix solution, casting moulding, and realizing film forming after solvent volatilization under a vacuum negative-pressure condition; performing alkaline treatment on a composite film at normal pressure and under a closed condition, and removing acetyl of cellulose diacetate to produce regenerated cellulose so as to prepare the holocellulos nano composite film. The holocellulos nano composite film has good biphase compatibility, favorable transparency and oxygen insulation performance, and excellent mechanical property, the problems of solvent selection and process complexity in the preparation process of the holocellulos nano composite film are solved, and the preparation method can be widely applied to the fields of material processing, food packaging, degradable environmental-friendly materials and the like.

Owner:JIANGNAN UNIV

Cellulose diacetate for retardation film

ActiveCN102597824ATaking into account the visibilityConsider filterabilityPolarising elementsNon-linear opticsPolymer scienceOptical property

Disclosed is a cellulose acetate that enables a cellulose acetate optical film, which expresses optical properties when stretched, to achieve excellent stretchability and excellent optical properties after being stretched. Specifically disclosed is a cellulose diacetate for a retardation film, which has a total degree of substitution of acetyl groups of 2.27-2.56. The cellulose diacetate for a retardation film is characterized by having a degree of dispersion (Mw / Mn) of more than 3.0 but 7.5 or less, a degree of substitution at the 6-position of 0.65-0.85, a half width of the distribution of the degree of acetylation of 1.0-2.3 and a viscosity average degree of polymerization of 182-213 (inclusive). It is preferable for the cellulose diacetate for a retardation film to have a 6% viscosity of 120-230 mPas and a weight average molecular weight (Mw) of 205,000-235,000 (inclusive).

Owner:DAICEL CORP

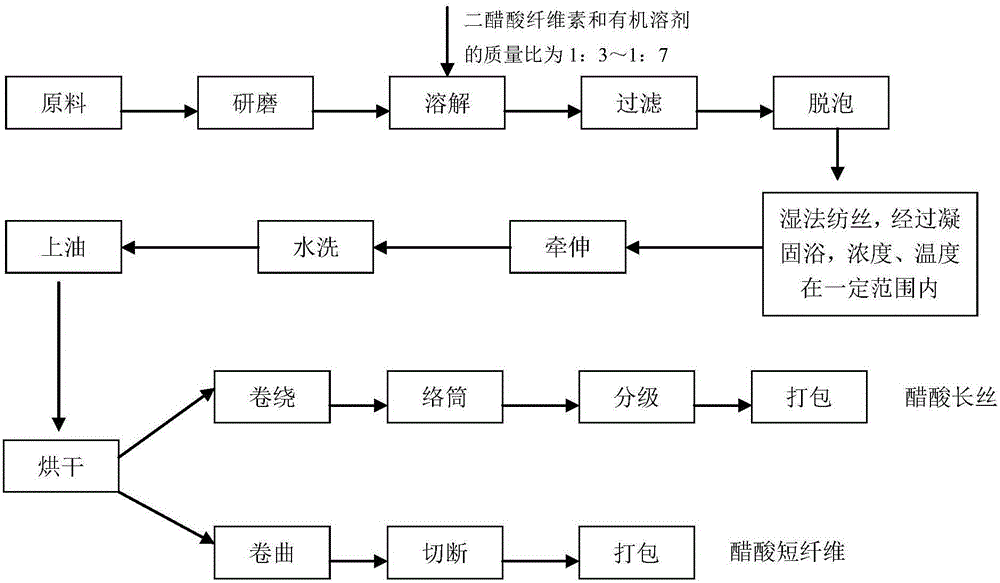

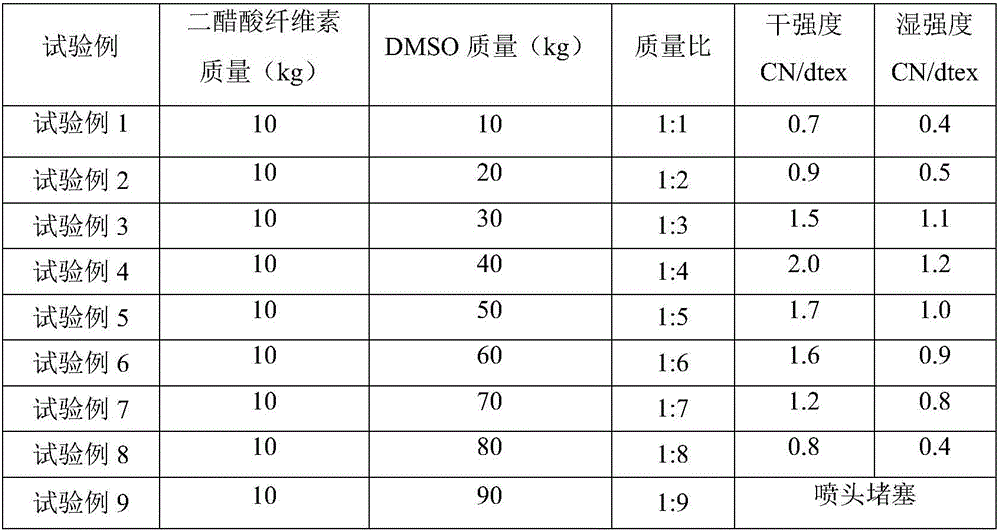

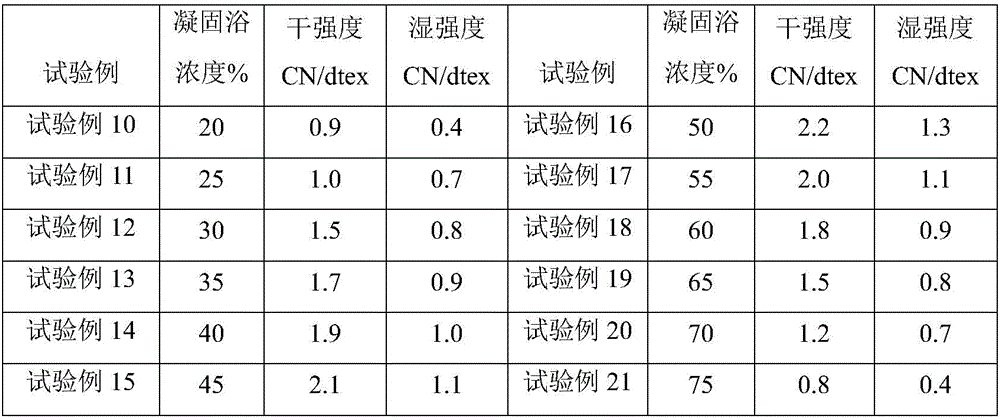

Wet spinning method for preparing cellulose acetate fiber

ActiveCN106012076AReduce pollutionImprove production environmentArtificial filaments from cellulose derivativesFiberCellulose diacetate

The invention discloses a wet spinning method for preparing cellulose acetate fiber. The wet spinning method comprises the following steps: grinding solid cellulose diacetate, of which the degree of acetylation is 2.1 to 2.8 and the water content is 1 to 7 percent, into powder; adding the cellulose diacetate powder and an organic solvent into a dissolving tank, and carrying out sufficient stirring for mixing, and raising the temperature for dissolution, wherein the mass ratio of the cellulose diacetate powder to the organic solvent ranges from 1:3 to 1:7, the dissolving time is 0.5 to 8 hours, and the dissolving temperature is 35 to 120 DEG C; filtering and deforming a dope obtained after dissolution to obtain a spinning dope; after the spinning dope passes through a metering pump and a filter, spraying the filtered spinning dope from spinneret orifices to enter a coagulation bath to obtain nascent fiber, wherein the concentration of the coagulation bath is 25 to 70%, and the temperature is 20 to 90 DEG C; preparing a finished acetate fiber product from the nascent fiber through drafting, washing, oiling and drying. The cellulose acetate fiber prepared according to the method disclosed by the invention has excellent indexes, good mechanical properties, and remarkably improved dry strength and wet strength; the preparation process is simple, feasible, and easy to control; the solvent cost is low.

Owner:吉林富博纤维研究院有限公司

Hydrophilic polyethylene hollow fiber membrane and preparation method thereof

ActiveCN102068918ACreate pollutionNot easy to fall offSemi-permeable membranesSolventCellulose diacetate

The invention discloses a hydrophilic polyethylene hollow fiber membrane and a preparation method thereof. The hollow fiber membrane is prepared by the following method of: (1) previously preparing a hydrophobic primary polyethylene hollow fiber membrane; (2) preparing cellulose diacetate solution, wherein the concentration of the cellulose diacetate solution is 20 to 50 percent; and (3) soaking the primary polyethylene hollow fiber membrane into the cellulose diacetate solution prepared in the step (2), making the cellulose diacetate solution fully soak into pores of membrane yarns, and thenremoving the solvent of the cellulose diacetate solution to obtain the hydrophilic polyethylene hollow fiber membrane. The method is simple, feasible and easy to apply in the industry, can be continued, and can also reduce the cost; and the obtained hydrophilic polyethylene hollow fiber membrane can keep hydrophilic property for long time.

Owner:盐城海普润科技股份有限公司

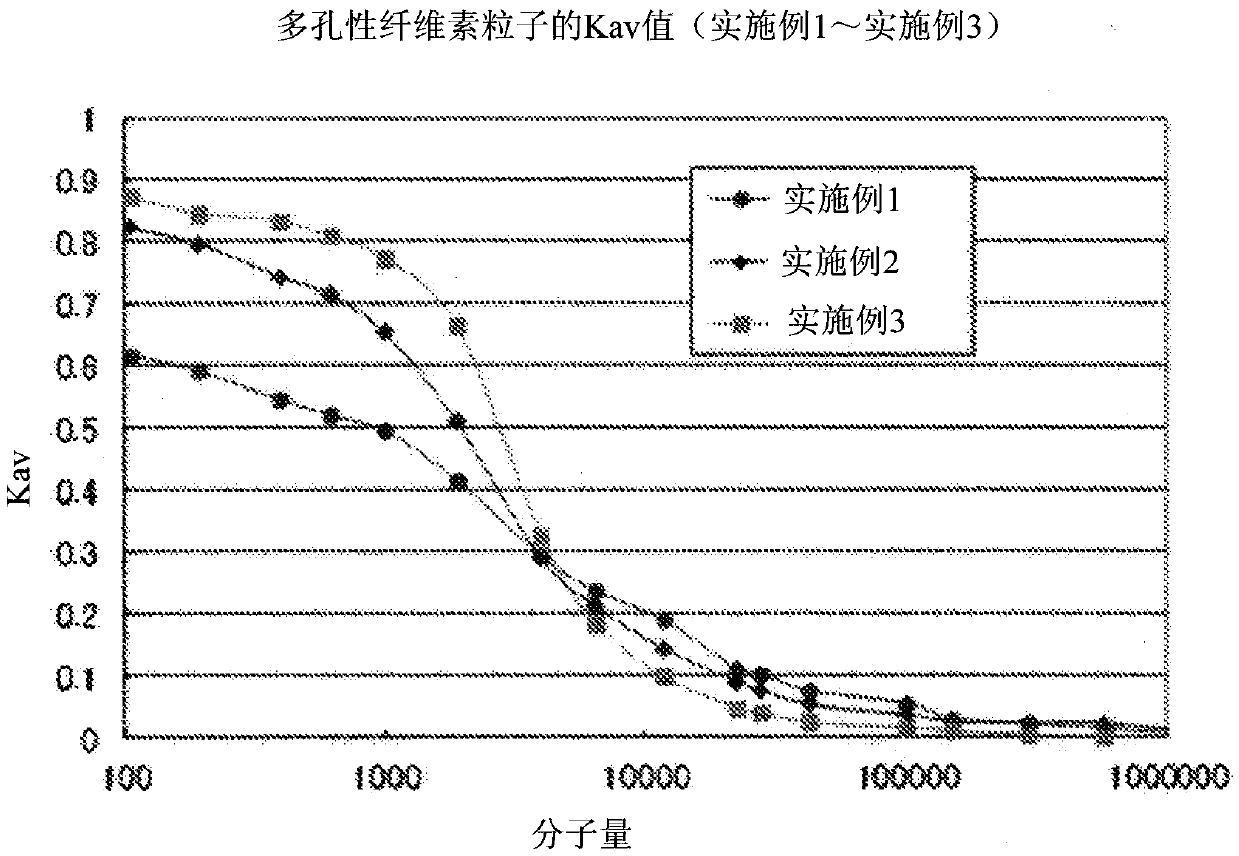

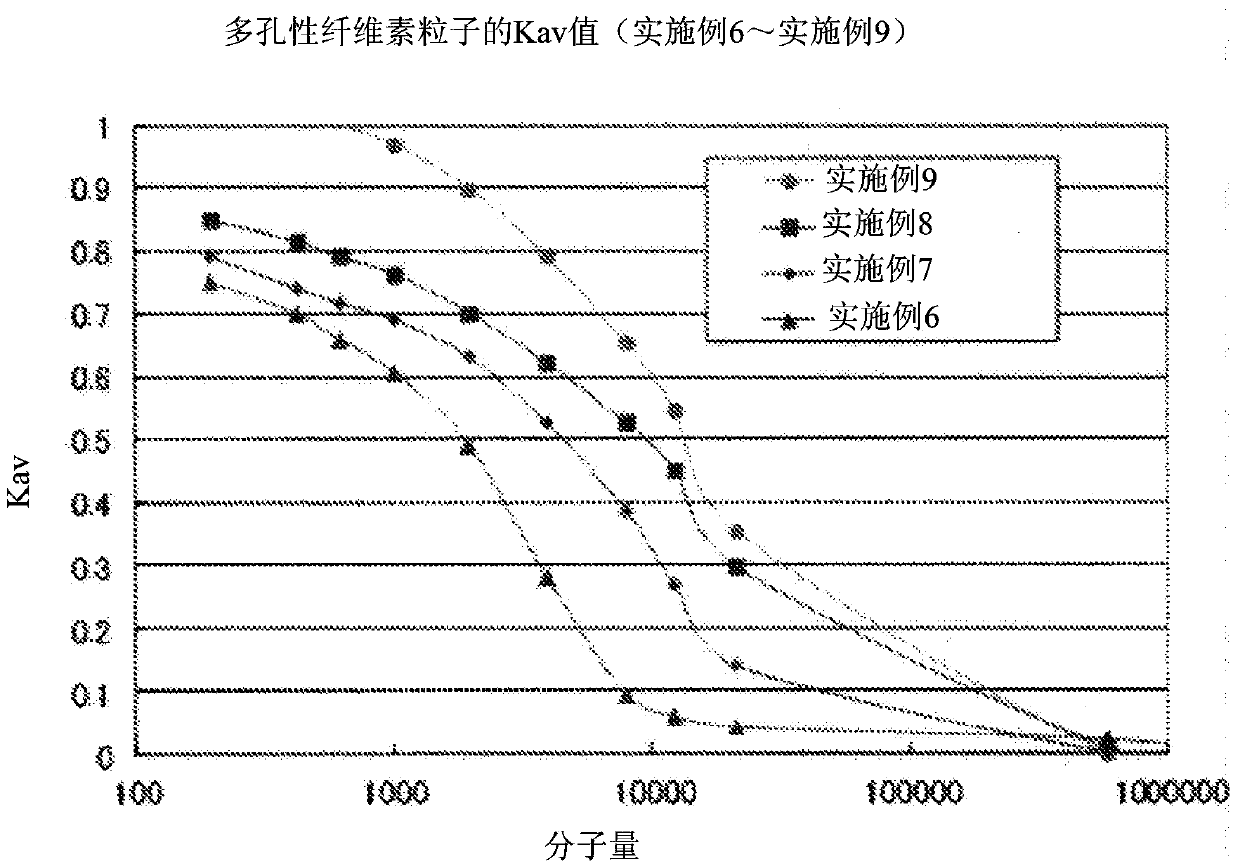

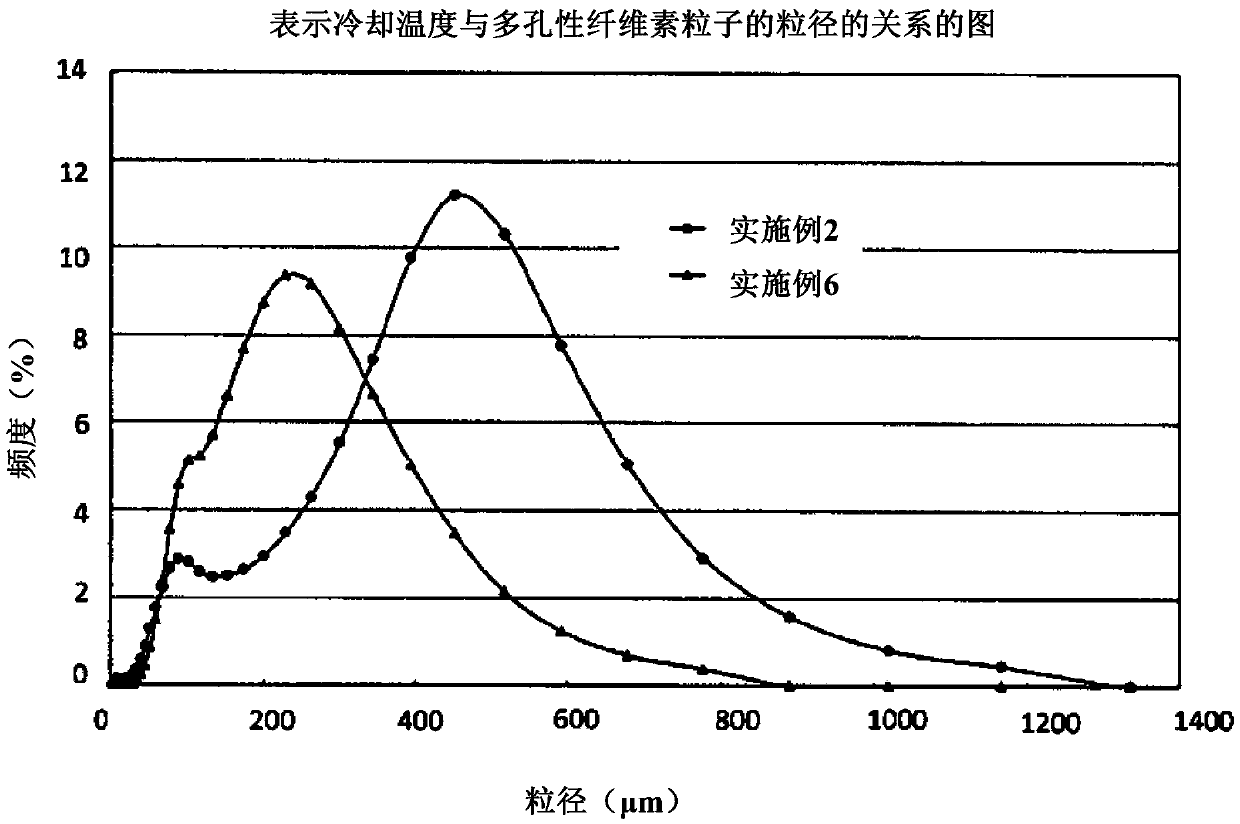

Method for producing porous cellulose particles, and porous cellulose particles

ActiveCN105518059AChromatographic cation exchangersCation exchanger materialsCellulose diacetateCellulose acetate

According to one embodiment, a method for producing porous cellulose particles is provided. The method comprises: (a) dissolving cellulose diacetate in a solvent to prepare a cellulose diacetate solution, (b) dispersing the cellulose diacetate solution in a medium that is immiscible with the cellulose diacetate solution to produce a dispersion system, (c) cooling the dispersion system, (d) adding a poor solvent to the cooled dispersion system to cause cellulose diacetate particles to precipitate, and (e) saponifying the cellulose diacetate particles.

Owner:JNC CORP

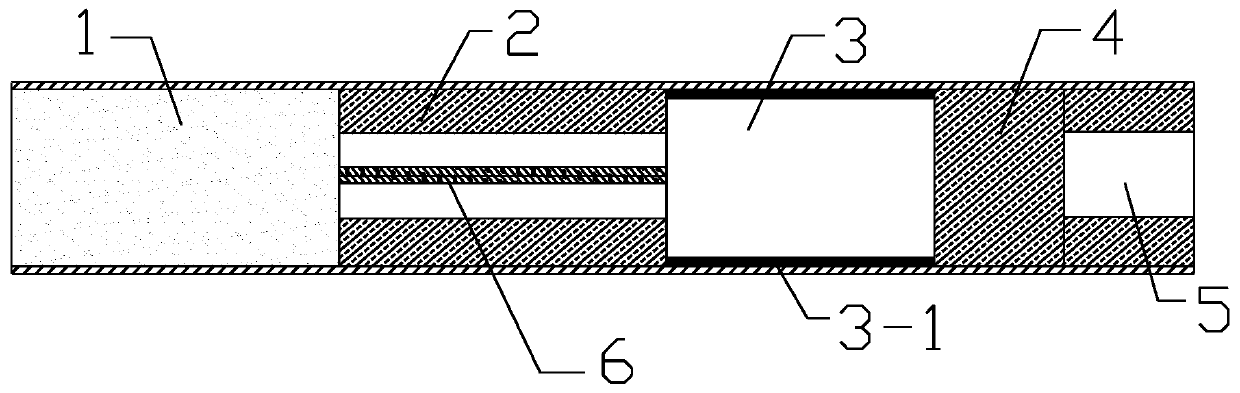

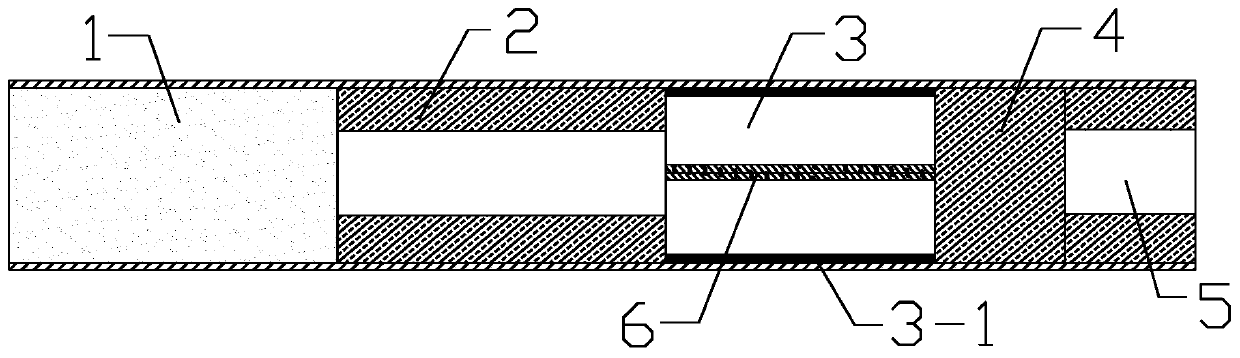

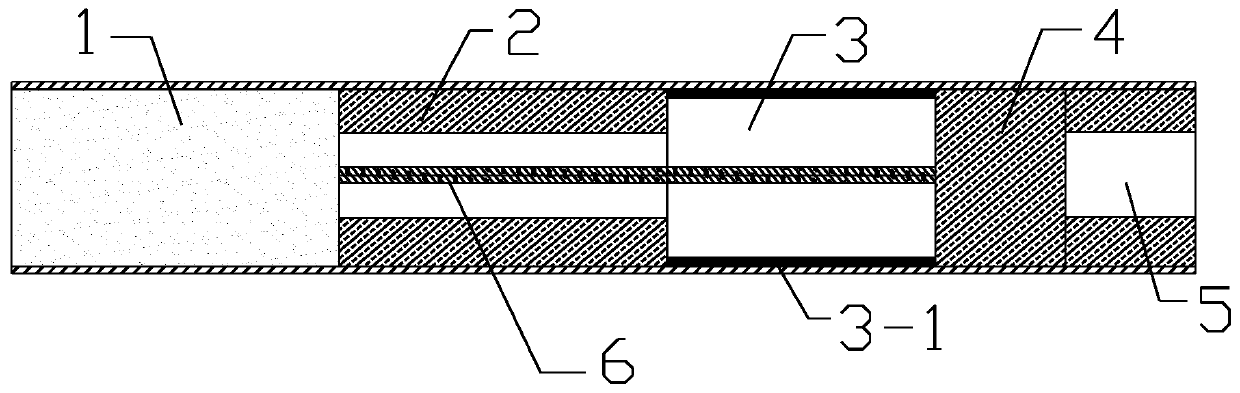

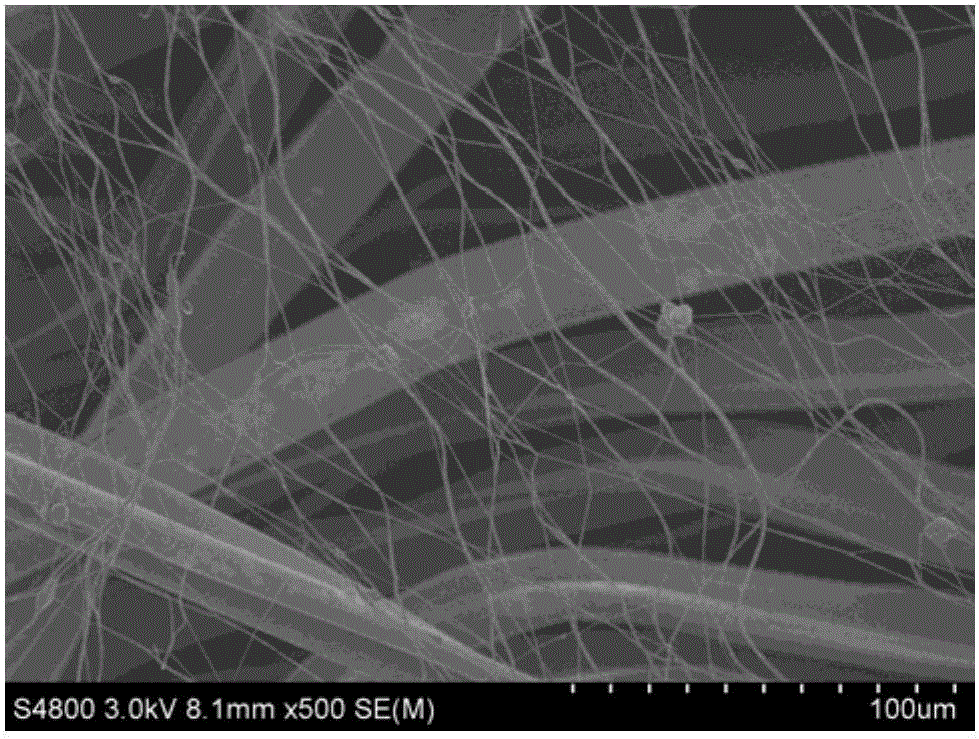

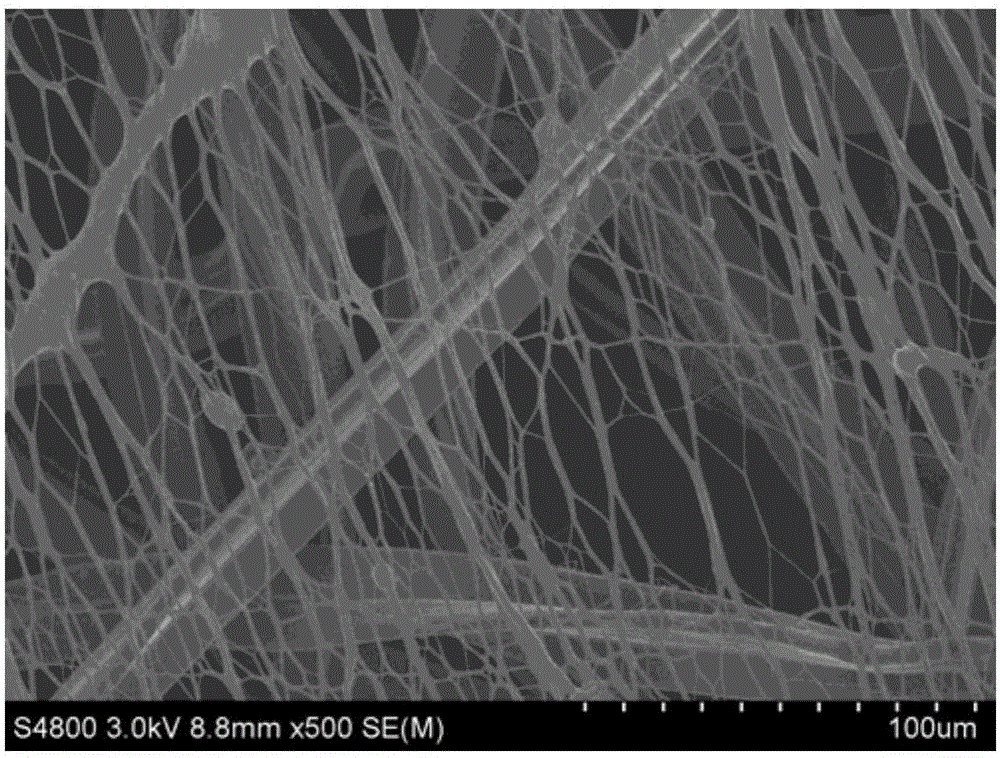

High interface adhesion strength nanofiber composite filament bundle and preparation method and application thereof

ActiveCN105088376AHigh viscosityHigh boiling pointTobacco smoke filtersArtificial filaments from cellulose derivativesCellulose diacetateCellulose acetate

The invention discloses a high interface adhesion strength nanofiber composite filament bundle and a preparation method and application thereof. The preparation method comprises the following steps: 1, preparing a spinning solution with polymer, additives and solvent, wherein the polymer comprises one or more ingredients out of cellulose diacetate, cellulose triacetate, hydroxyethyl cellulose, polyving akohol and polyving akohol, and the additives comprise one or more ingredients out of ethanediol, glycerol, pentaerythritol, diacetin, glycerol triacetate, glycerol trioleate, glycerol palmitate and glyceryl stearate; 2, taking a cigarette-used filament bundle as base materials, conducting electrostatic spinning on the spinning solution which is obtained in step 1, and obtaining the high interface adhesion strength nanofiber composite filament bundle. By means of the high interface adhesion strength nanofiber composite filament bundle, the phenol release amount and NNK release amount in mainstream smoke of a cigarette can be effectively reduced, the phenol release amount is reduced by 16-30%, and the NNK release amount is reduced by 12-36%.

Owner:CHINA TOBACCO ZHEJIANG IND

Copolymer monolithic column and preparation method and application thereof

InactiveCN104107687AImprove permeabilitySufficient enrichment capacityOther chemical processesComponent separationPolymer scienceCellulose diacetate

The invention relates to a macroporous copolymer monolithic column of a novel pipettor sucker and a preparation method and application of the copolymer monolithic column. The copolymer monolithic column is prepared by adopting an in-situ thermal initiation polymerization method by taking cellulose diacetate as a pore-forming agent. The preparation method particularly comprises the following steps: (1) pretreating the inner wall of the pipettor sucker; (2) preparing the copolymer monolithic column in the pipettor sucker; and (3) washing the monolithic column. The sucker monolithic column prepared by the preparation method disclosed by the invention has relatively large through hole size and large column bed volume, can be used by cooperating with a pipettor, can complete the SPE operation under the liquid discharge pressure of the pipettor, and can achieve the aim of enriching to-be-test target components rapidly and efficiently.

Owner:GUANGDONG PHARMA UNIV

Production method for reproducing colloidal particles of cellulose diacetate by using cellulose diacetate waste shred

The invention discloses a production method for reproducing the colloidal particles of cellulose diacetate by using cellulose diacetate shred for tobacco, pertaining to the field of waste shred chemical fiber reutilization technology. The method includes the following steps: the waste shred of the cellulose diacetate for tobacco is dissolved in an acetone solvent and then an enzyme preparation and deionized water are added; additives adhered on the waste shred are hydrolyzed by means of biocatalysis at temperature of 30-55 DEG C to generate glycerin and an acetic acid; and after steps including filtration, granulation, water rinse, drying and the like, the granular cellulose diacetate is prepared. The colloidal particles of the processed cellulose diacetate can be reutilized by acetate fiber enterprises to change waste into valuable, thereby improving economic benefit, saving cost and having relatively good application prospect.

Owner:HENAN ZHENGTONG CHEM

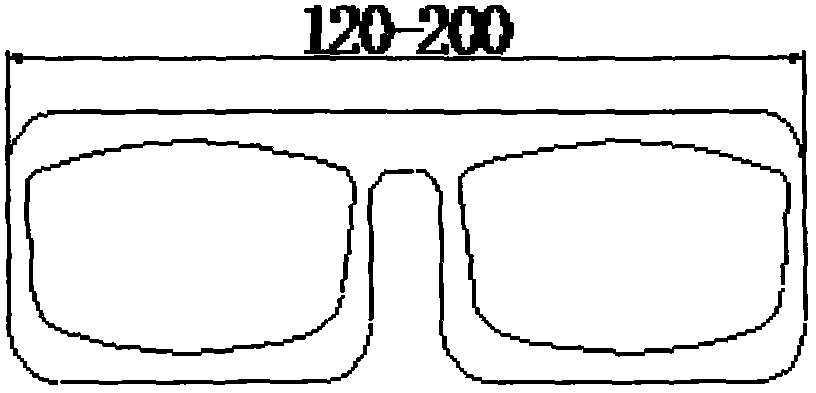

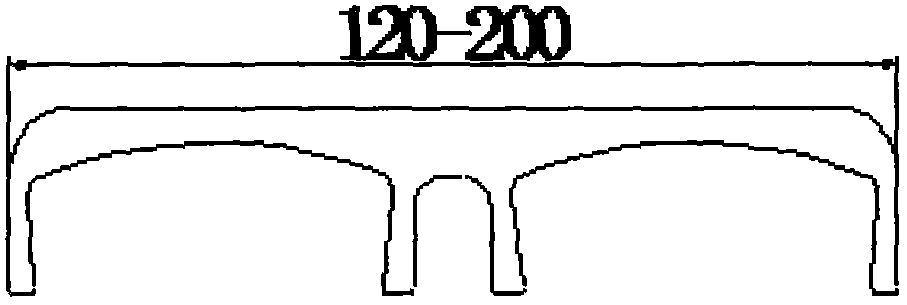

Multi-color glasses frame blank and shell profile shapes blank as well as molding equipment thereof

InactiveCN102692727AReduce wasteReduce one cutting production processNon-optical partsElastomerCellulose diacetate

The invention provides a multi-color glasses frame blank and a shell profile shapes blank as well as molding equipment thereof. The multi-color glasses frame blank is a long-strip profile shapes; the width of the multi-color glasses frame blank is 120-200 mm and the thickness of the multi-color glasses frame blank is 20-66 mm; the length of the multi-color glasses frame blank can be designed and set according to a shearing machine; and the blank can be made of cellulose diacetate, TR90 (Thio Rubber 90) or other nylon materials which are similar with the TR90, a nylon elastic body or a nylon alloy material. According to the multi-color glasses frame blank and the shell profile shapes blank as well as the molding equipment thereof disclosed by the invention, the blank with the width of the glasses frame with the needed shape is molded for one time under other related material profile molding process conditions of using the plastified cellulose diacetate, the TR90 or the other nylon materials which are similar with the TR90, the nylon elastic body or the nylon alloy material, so that a primary cutting production procedure can be reduced and the material waste is reduced; working hours can be saved by flat-bottom and arc-shaped profile shapes and the product quality is improved; and the working hours and the material waste can be saved by hollow and solid shell rods.

Owner:钟沿东 +1

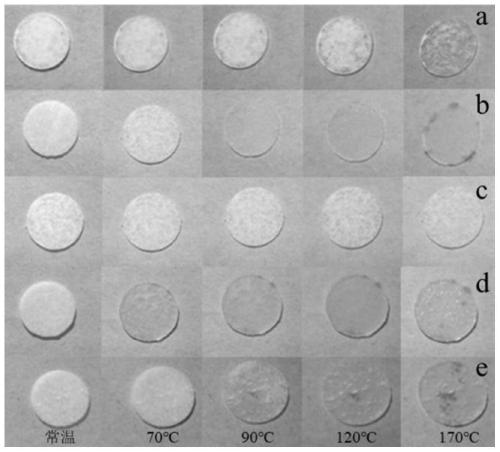

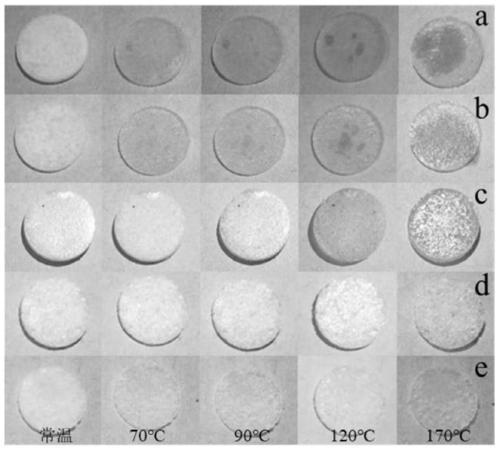

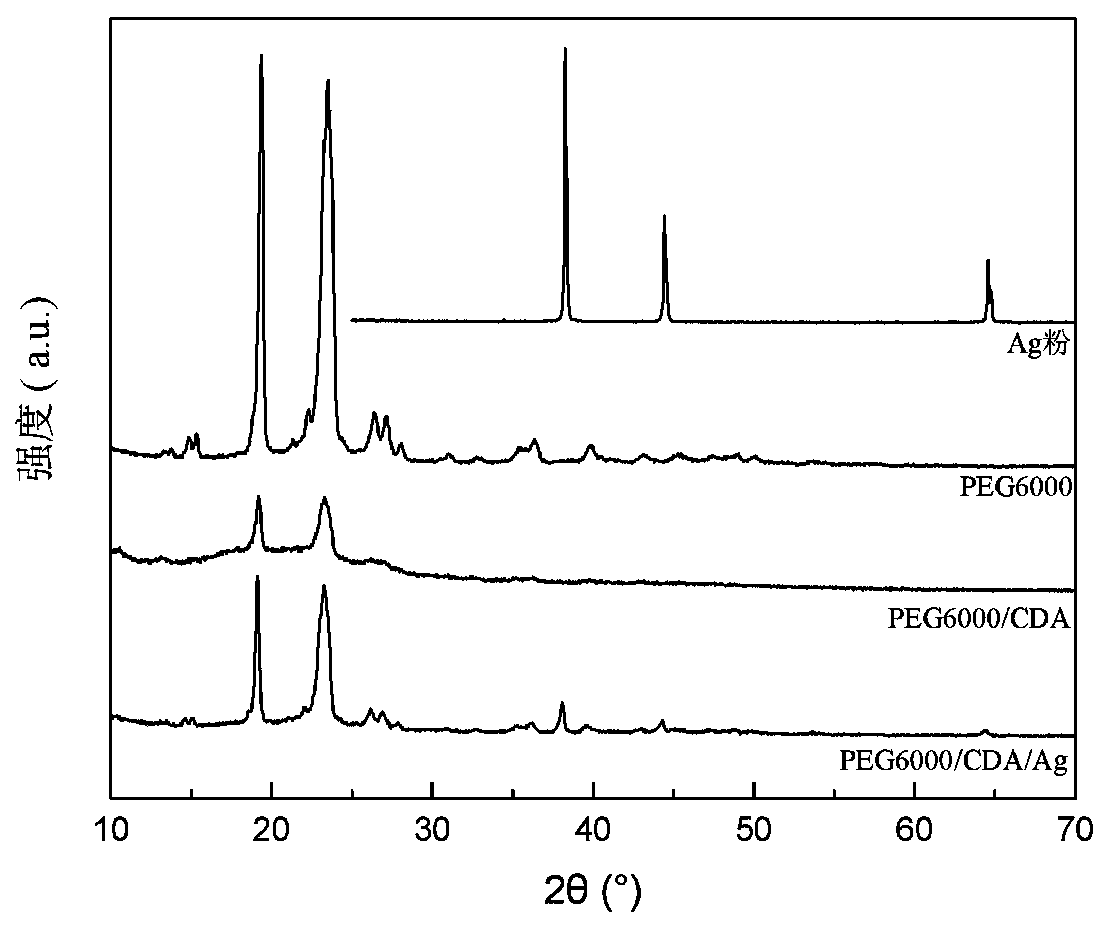

Cellulose diacetate composite shape-stabilized phase-change material, and preparation method and application thereof

InactiveCN111218099ARealize the function of heat absorption and energy storageHigh thermal conductivityTobacco smoke filtersHeat-exchange elementsCellulose diacetateCellulose acetate

The invention discloses a cellulose diacetate composite shape-stabilized phase-change material for reducing the smoke temperature of a heat-not-burn cigarette, and a preparation method and an application thereof. The cellulose diacetate composite shape-stabilized phase-change material is prepared from, by mass, 10-50% of cellulose diacetate, 50-90% of a phase-change material and 1-5% of a heat conduction material through a solvent blending method. The cellulose diacetate composite shape-stabilized phase-change material has a rigid net structure and high-melting-point cellulose diacetate, so that the cellulose diacetate composite shape-stabilized phase-change material has excellent thermal stability and solid-solid phase change characteristics; phase transformation from a PEG branched chaincrystalline state to an amorphous state enables the material to achieve the functions of heat absorption and energy storage; and by adding the heat-conducting metal powder, the heat-conducting property of the material is improved, and the effect of rapid cooling is achieved. The smoking resistance of the cellulose diacetate composite shape-stabilized phase-change material is similar to that of iQOS raw tobacco, the temperatures of first to fourth puffs of smoke can be remarkably reduced, and the temperature of the first puff of smoke can be reduced to 36 DEG C at most.

Owner:NANTONG UNIVERSITY

Method for preparing low-acetification natural fiber filter stick

InactiveCN102247013AMature technologyIncrease production capacityTobacco smoke filtersCellulose diacetateAdditive ingredient

The invention discloses a method for preparing a low-acetification natural fiber filter stick, which comprises: selecting one or several of wood pulp fibers, cotton pulp fibers and jute pulp fibers; preparing a raw material for making low-acetification fibers by using tobacco cellulose diacetate vinegar sheet production equipment, washing and drying the raw material for making low-acetification fibers, and thus obtaining low-acetification finished fibers with a water content of 5 to 20 percent; making paper pulp by using 100 percent of low-acetification finished fibers, or mixing not less than 10 percent of low-acetification finished fibers with one or several of wood pulp fibers, cotton pulp fibers and jute pulp fibers to make paper pulp, making low-acetification fiber special paper, and making low-acetification natural fiber unitary filter stick by using the special paper; or mixing 100 percent of low-acetification finished fibers or not less than 10 percent of low-acetification finished fibers with one or several of wood pulp fibers, cotton pulp fibers and jute pulp fibers, spraying a glycerol triacetate plasticizer, coiling to make the low-acetification natural fiber unitary filter stick; or combining the unitary filter stick with an acetate fiber white stick to obtain a low-acetification natural fiber combined filter stick. The method can solve the moisture absorption deformation problem of the filter stick, effectively lower tar and the harmful ingredients of main smoke of cigarettes and improve the perceptual effect of the cigarettes.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

Cellulose diacetate for retardation film

ActiveUS20120172585A1Satisfactory stretchabilityImprove filtering effectPolarising elementsAcetic acidPolymer science

To provide a cellulose acetate which gives a cellulose acetate optical film exhibiting optical properties as a result of stretching, in which the film shows excellent stretchability and gives a stretched film having excellent optical properties.Disclosed is a cellulose diacetate for a retardation film, having a total degree of acetyl substitution of from 2.27 to 2.56, in which the cellulose diacetate has a polydispersity Mw / Mn of more than 3.0 and 7.5 or less, a degree of substitution at the 6-position of from 0.65 to 0.85, a half height width of acetylation distribution of from 1.0 to 2.3, and a viscosity-average degree of polymerization of 182 or more and 213 or less. The cellulose diacetate for a retardation film preferably has a 6-percent viscosity of from 120 to 230 mPa·s and preferably has a weight-average molecular weight Mw of 205,000 or more and 235,000 or less.

Owner:DAICEL CHEM IND LTD

Toughened and modified cellulose diacetate material and preparation method thereof

The invention discloses a toughened and modified cellulose diacetate material and a preparation method thereof. By means of the preparation method, granulates are extruded through a twin-screw extruder; the material is prepared from, by mass, 100 parts of cellulose diacetate, 5-50 parts of epoxy resin, 5-20 parts of camphor and 0.1-1 part of antioxidant. On the premise that certain strength and hardness are ensured, toughness is remarkably improved, transparency is good, cellulose diacetate thin film products can be formed through blow molding or solution plastic flow casting, and cellulose diacetate plastic products can also be produced through fusing. The material is simple in preparation method and beneficial to industrialization and can be widely used for spectacle frames, child toys, table tennis balls, thin films, 3D printing supplies, automobiles and domestic consumed materials and other daily plastic products.

Owner:JIANGNAN UNIV +1

Method for preparing polyaniline nanofiber/cellulose diacetate composite conductive material

The invention discloses a method for preparing a polyaniline nanofiber / cellulose diacetate composite conductive material. The method comprises the following steps: (1) adding a dopant dodecylbenzene sulfonate into polyaniline nanofibers, then adding a plasticizer into the polyaniline nanofibers in a doped state, uniformly stirring the mixture to obtain a suspension, and placing the suspension in a ball mill to be subject to ball milling to obtain a plasticizer slurry containing the polyaniline nanofibers; (2) placing cellulose diacetate powder and a heat stabilizer calcium stearate in a high-speed mixer, stirring uniformly and adding the plasticizer slurry obtained in the step (1) to enable the cellulose diacetate powder to fully absorb the plasticizer so as to obtain a premix; (3) melting the premix melt for granulation to obtain a polyaniline nanofiber / cellulose diacetate composite particulate material; (4) placing the particulate material obtained in the step (3) into a mould. The method is simple in process, low in cost and easy to implement industrial production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com