High interface adhesion strength nanofiber composite filament bundle and preparation method and application thereof

A nanofiber, interfacial adhesion technology, applied in the field of cigarettes, can solve the problems of not improving the adhesion strength of the nanofiber and tow interface, lack of strong interaction force or adhesion, hindering continuous production, etc. Time spinning, good adhesion, constant concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare 8g of cellulose diacetate, 8g of glycerol and 100g of acetone to form a uniform spinning solution, wherein the mass ratio of cellulose diacetate to acetone is 0.08:1, and the mass ratio of glycerol to cellulose diacetate is 1:1 . The spinning solution is placed in the liquid-carrying tank of the needleless electrospinning machine, the distance between the spinning electrode wire and the tow (that is, the receiving distance) is adjusted to 15cm, and the spinning voltage is adjusted to 32kV; The bundle is opened to a width of 25 cm, and the delivery speed of the tobacco tow is set to be 100 m / min.

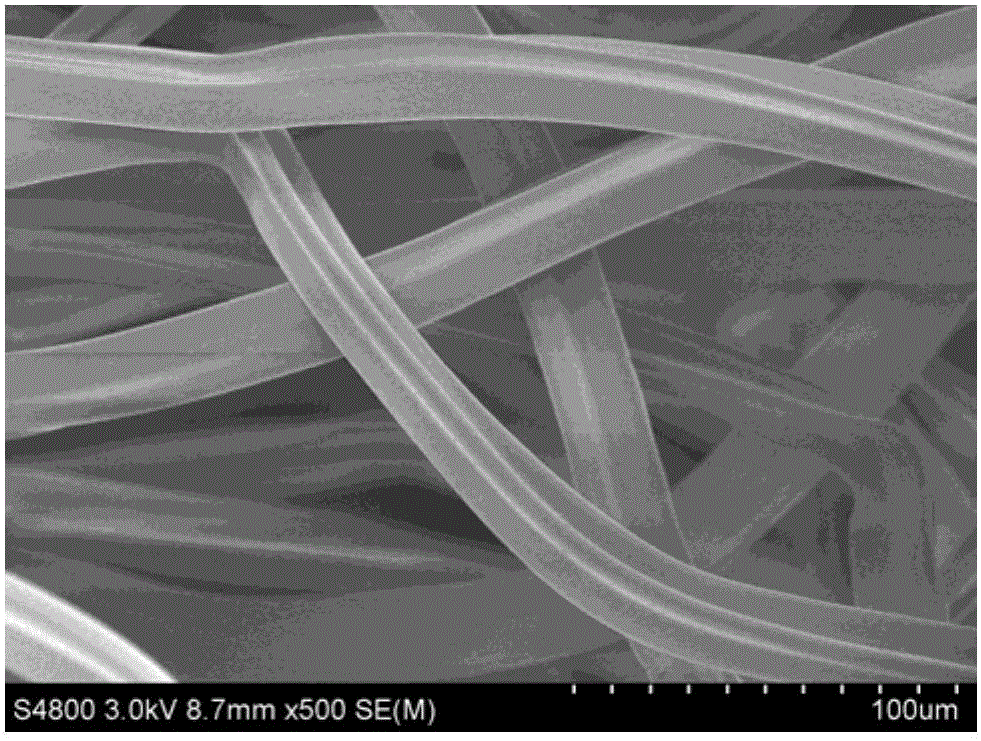

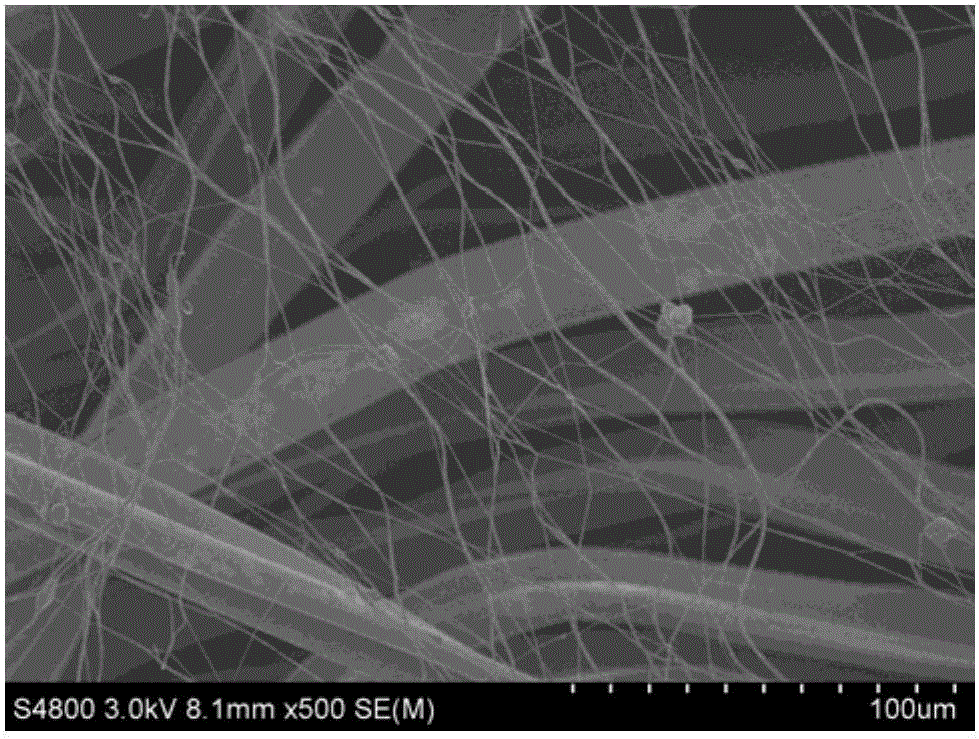

[0043] Turn on the power supply of the electrospinning machine to the set voltage, and the spinning solution forms nanofibers with a diameter of 110±32nm, and deposits on the surface of the continuously moving open tobacco tow to form a nanofiber composite tow; After the nanofiber composite tow passes through the electrospinning area, it enters the infrared lamp bakin...

Embodiment 2

[0047] Prepare 8g of cellulose triacetate, 8g of ethylene glycol and 100g of N,N-dimethylformamide into a uniform spinning solution, wherein the mass ratio of cellulose triacetate to N,N-dimethylformamide is 0.08:1, The mass ratio of ethylene glycol to cellulose triacetate is 1:1. Put the spinning solution in the liquid-carrying tank of the needleless electrospinning machine, adjust the distance between the spinning electrode iron wire and the tobacco tow to 15cm, and adjust the spinning voltage to 32kV; loosen the tobacco tow To a width of 25 cm, set the delivery rate of the tobacco tow to 100 m / min.

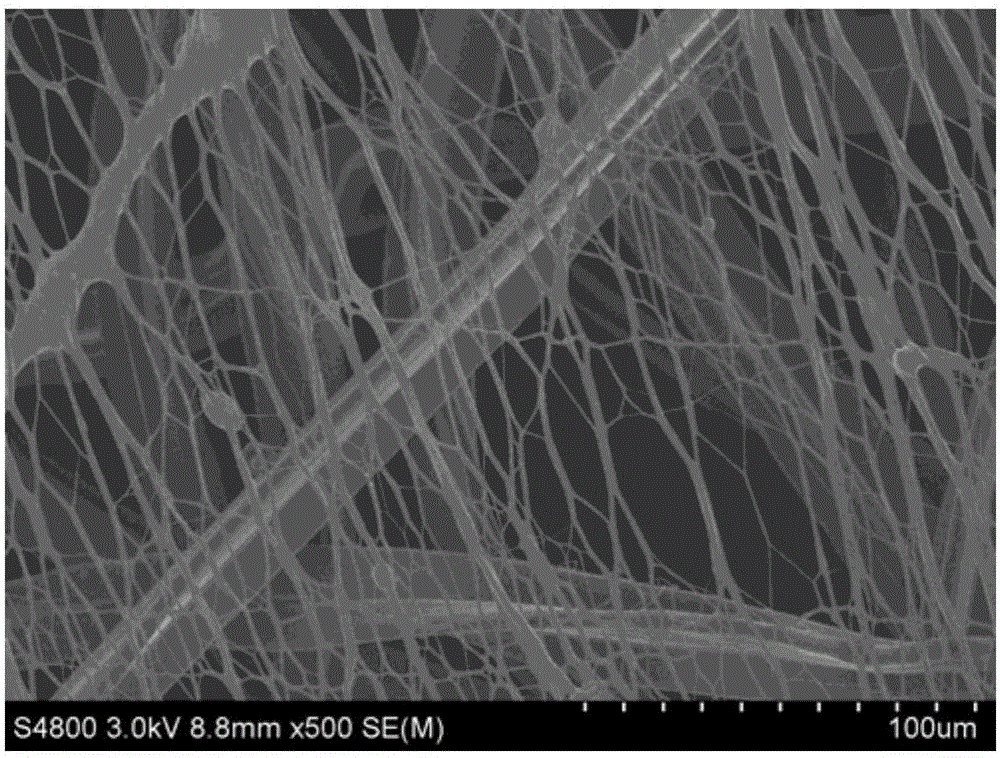

[0048] Turn on the power supply of the electrospinning machine to the set voltage, and the spinning solution forms nanofibers with a diameter of 120±32nm, and deposits on the surface of the continuously moving open tobacco tow to form a nanofiber composite tow; After the nanofiber composite tow passes through the electrospinning area, it enters the infrared lamp baking area an...

Embodiment 3

[0051] 4g of hydroxyethyl cellulose, 4.4g of pentaerythritol and 100g of acetone are configured into a uniform spinning solution, wherein the mass ratio of hydroxyethyl cellulose to acetone is 0.04:1, and the mass ratio of pentaerythritol to hydroxyethyl cellulose is 1.1: 1. Put the spinning solution in the liquid-carrying tank of the needleless electrospinning machine, adjust the distance between the spinning electrode iron wire and the tobacco tow to 15cm, and adjust the spinning voltage to 32kV; loosen the tobacco tow To a width of 25 cm, set the delivery rate of the tobacco tow to 400 m / min.

[0052] Turn on the power supply of the electrospinning machine to the set voltage, and the spinning solution forms nanofibers with a diameter of 95±20nm, and deposits on the surface of the continuously moving open tobacco tow to form a nanofiber composite tow; After the nanofiber composite tow passes through the electrospinning area, it enters the infrared lamp baking area and is ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com