Patents

Literature

1216results about How to "High boiling point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

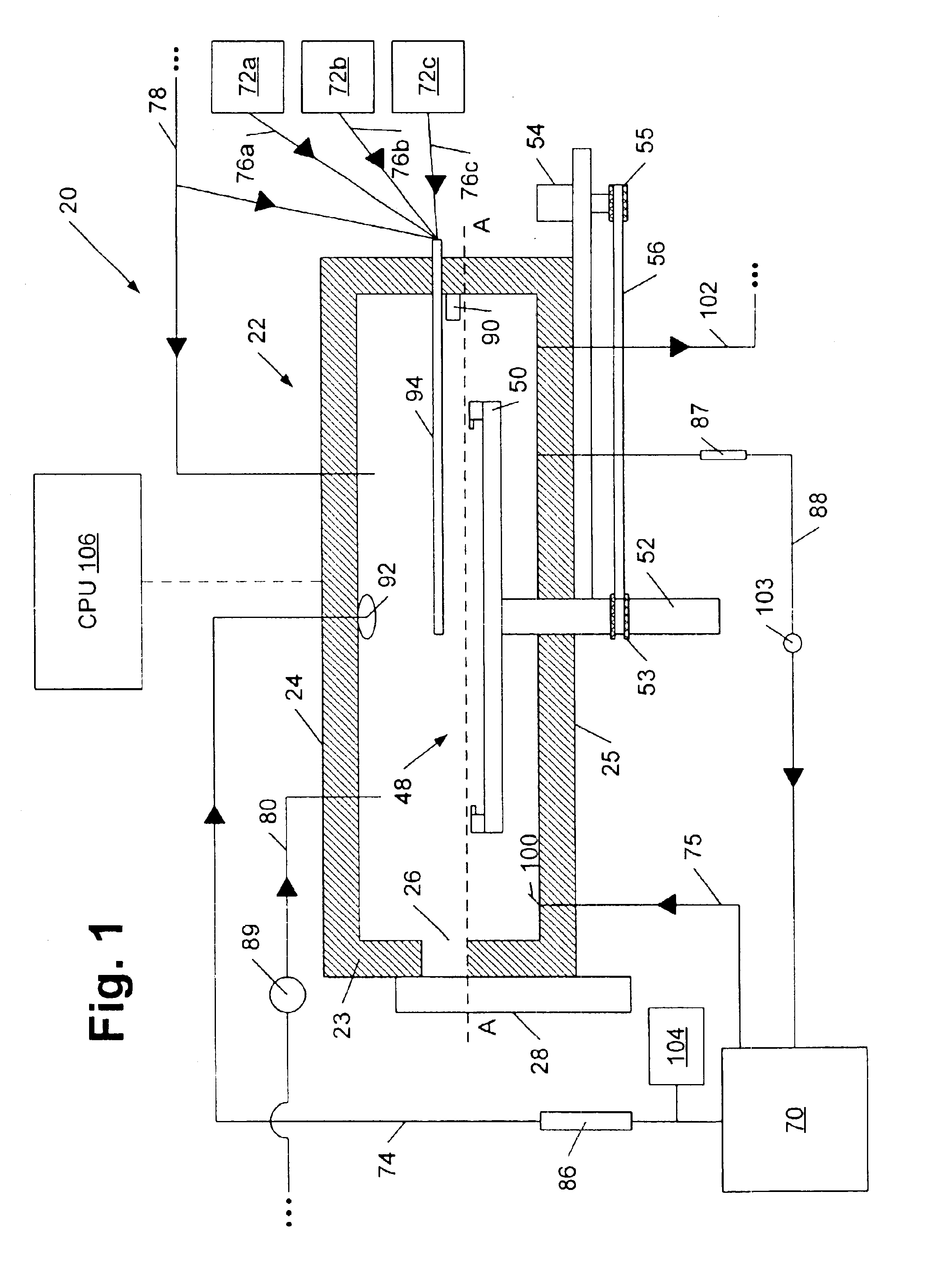

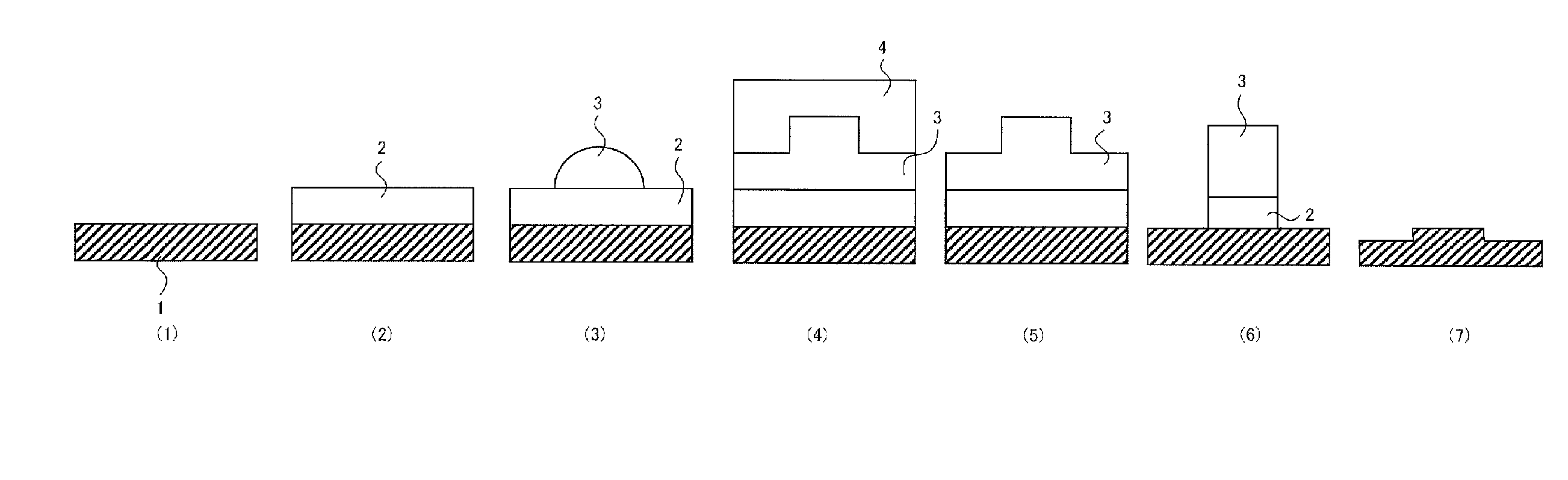

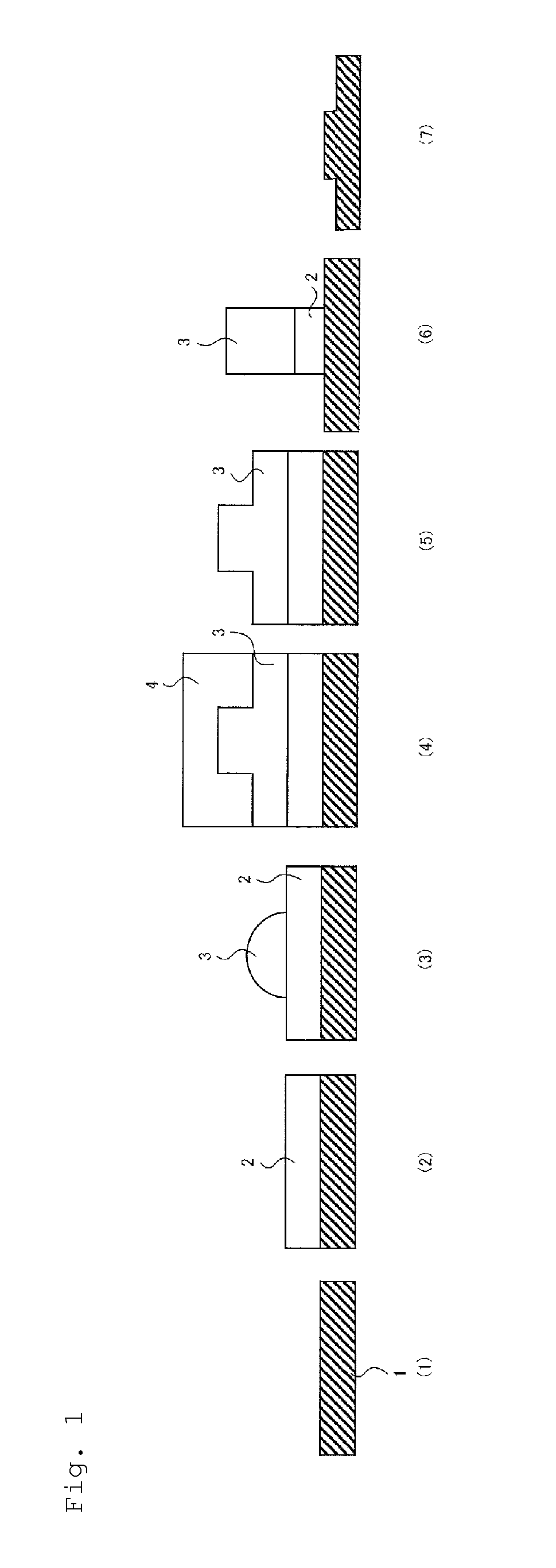

Methods and system for processing a microelectronic topography

InactiveUS6881437B2Avoid flowHigh boiling pointSemiconductor/solid-state device manufacturingPretreated surfacesElectroless depositionTopography

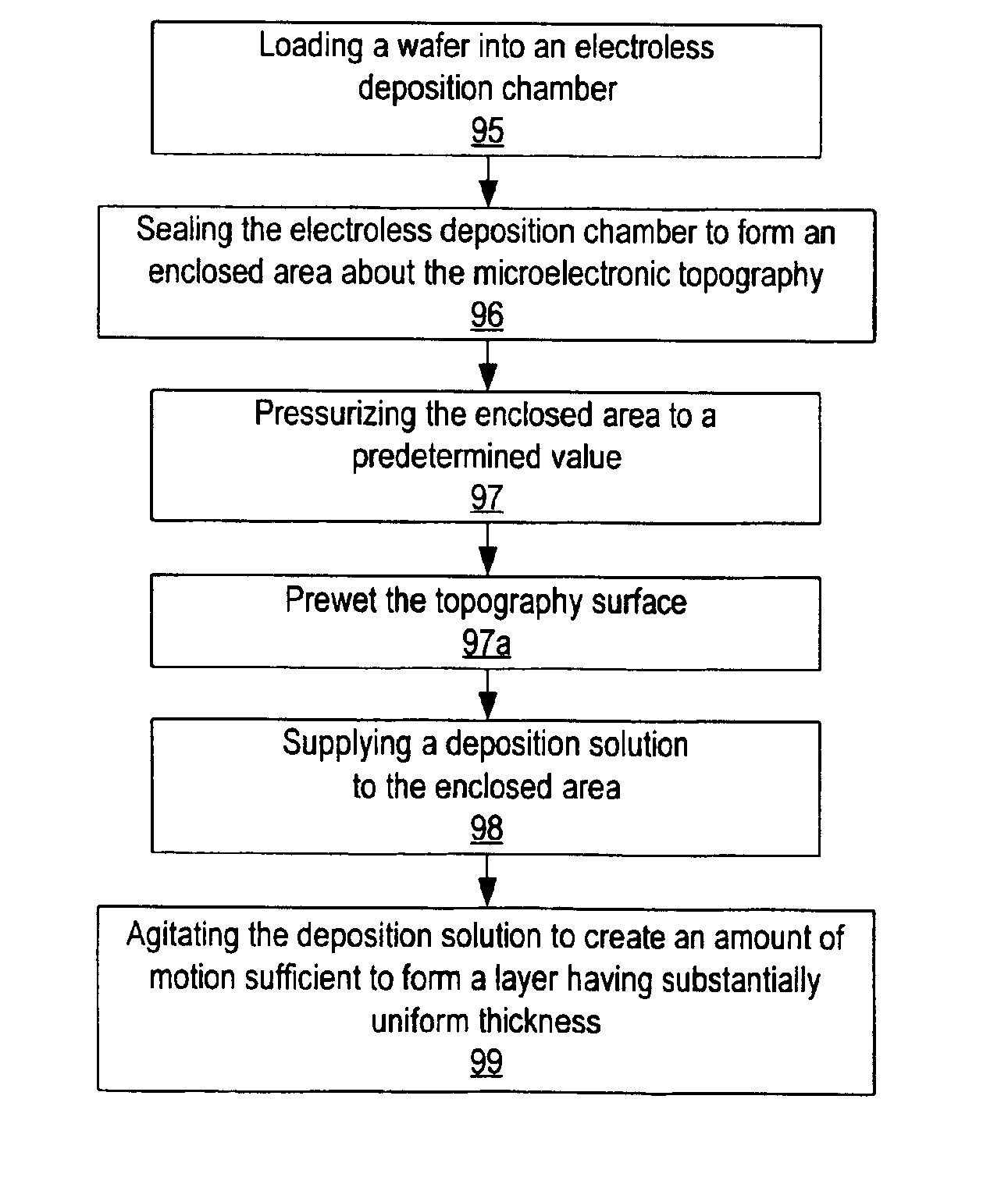

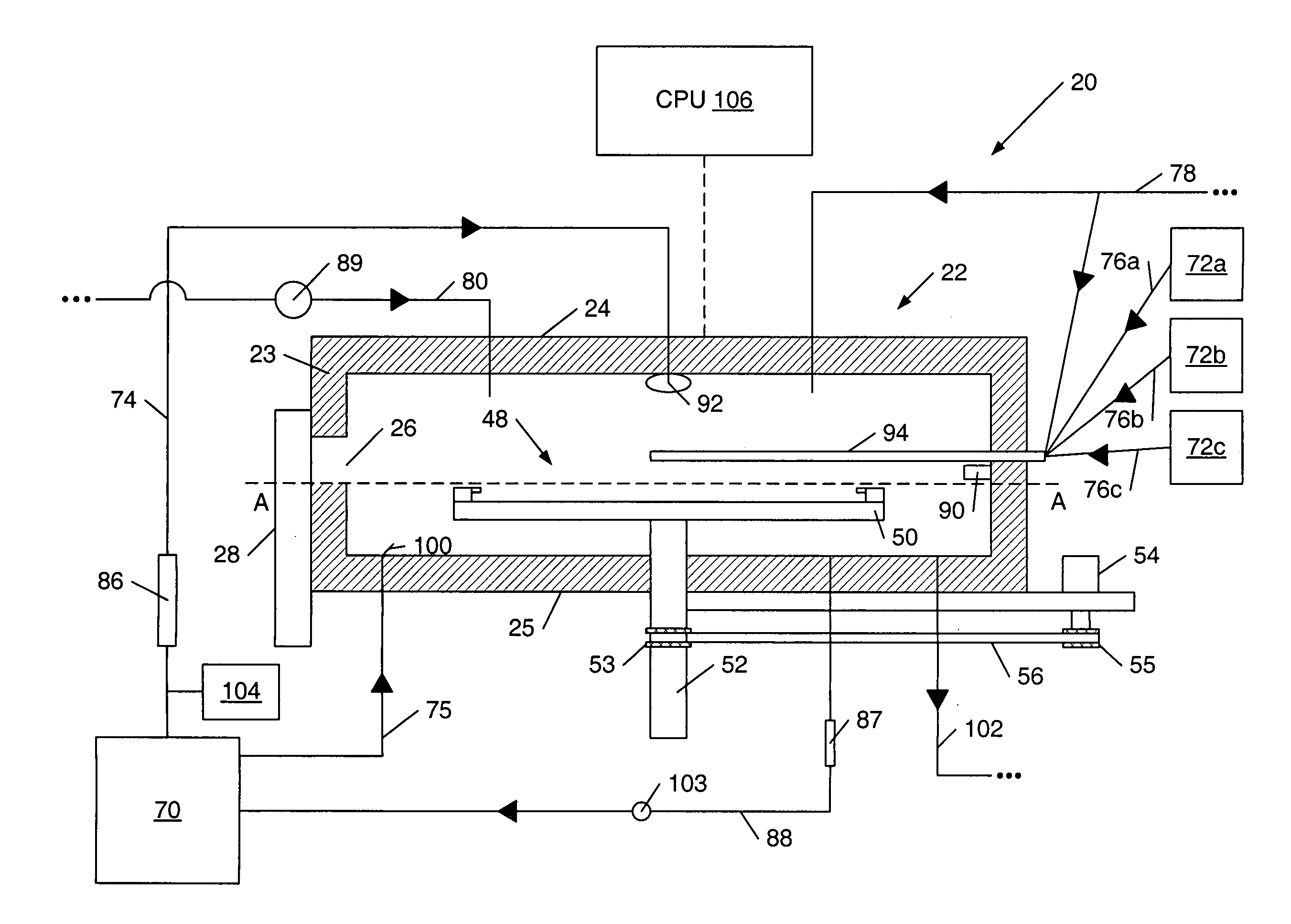

Methods and systems are provided which are adapted to process a microelectronic topography, particularly in association with an electroless deposition process. In general, the methods may include loading the topography into a chamber, closing the chamber to form an enclosed area, and supplying fluids to the enclosed area. In some embodiments, the fluids may fill the enclosed area. In addition or alternatively, a second enclosed area may be formed about the topography. As such, the provided system may be adapted to form different enclosed areas about a substrate holder. In some cases, the method may include agitating a solution to minimize the accumulation of bubbles upon a wafer during an electroless deposition process. As such, the system provided herein may include a means for agitating a solution in some embodiments. Such a means for agitation may be distinct from the inlet / s used to supply the solution to the chamber.

Owner:LAM RES CORP

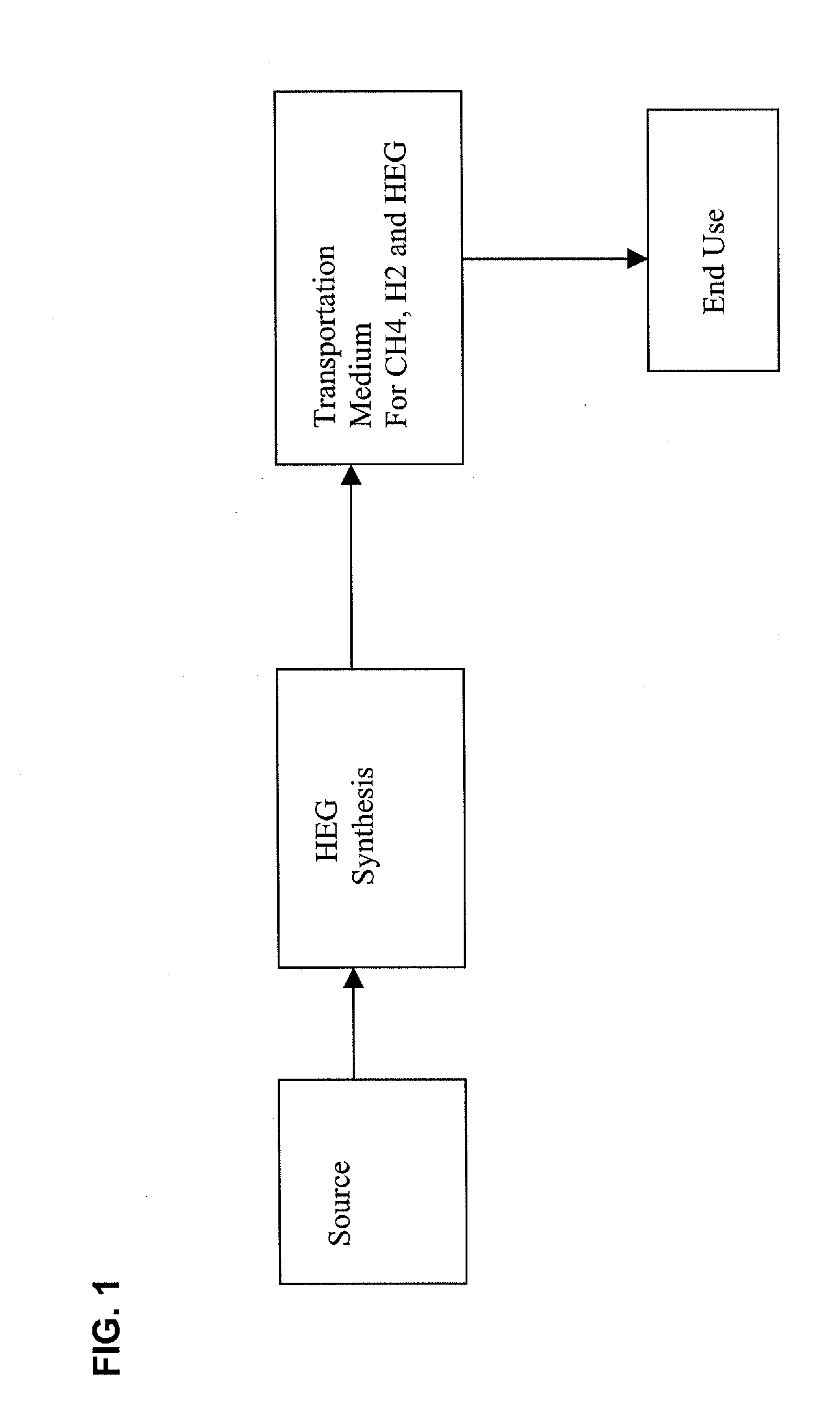

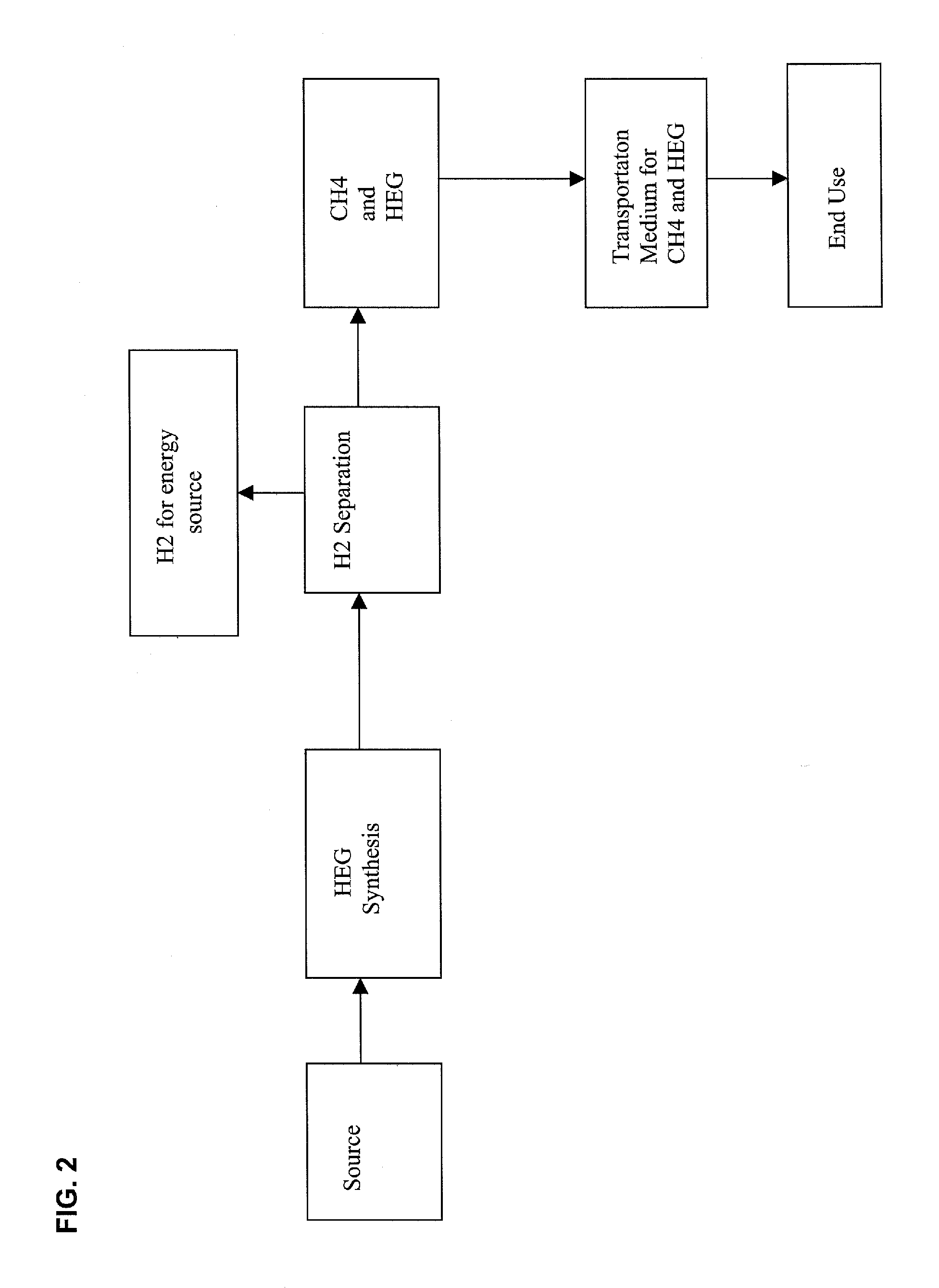

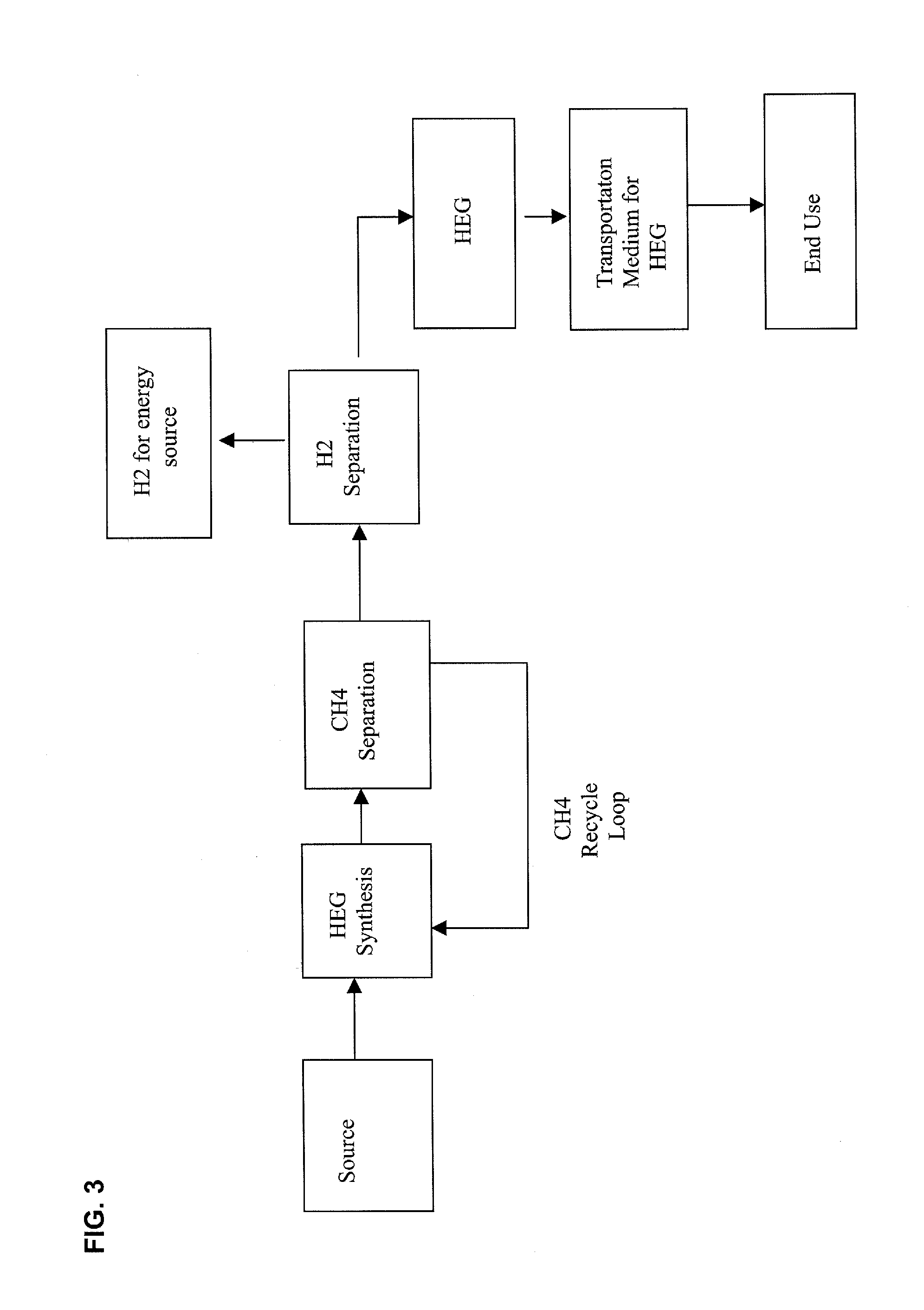

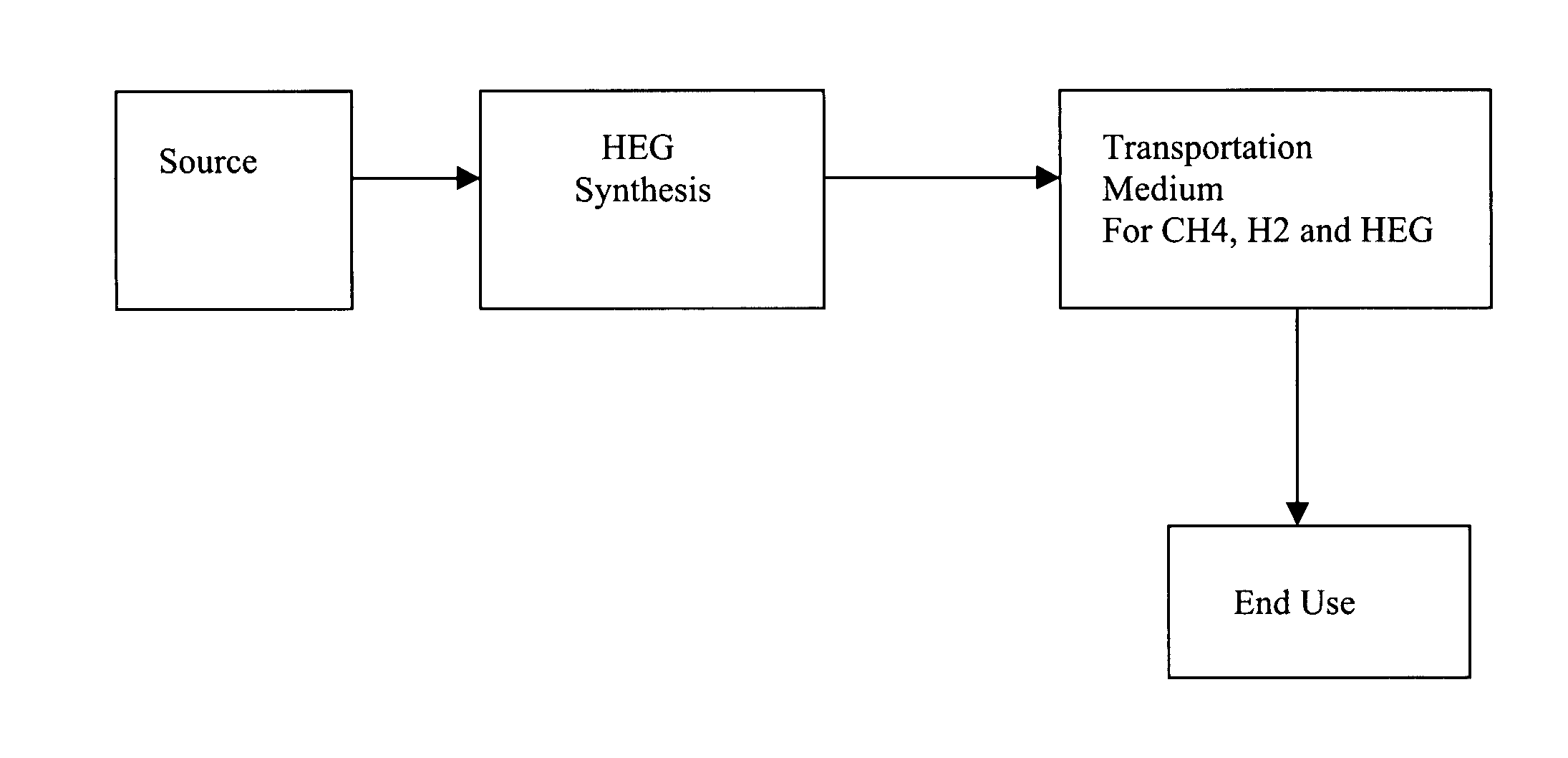

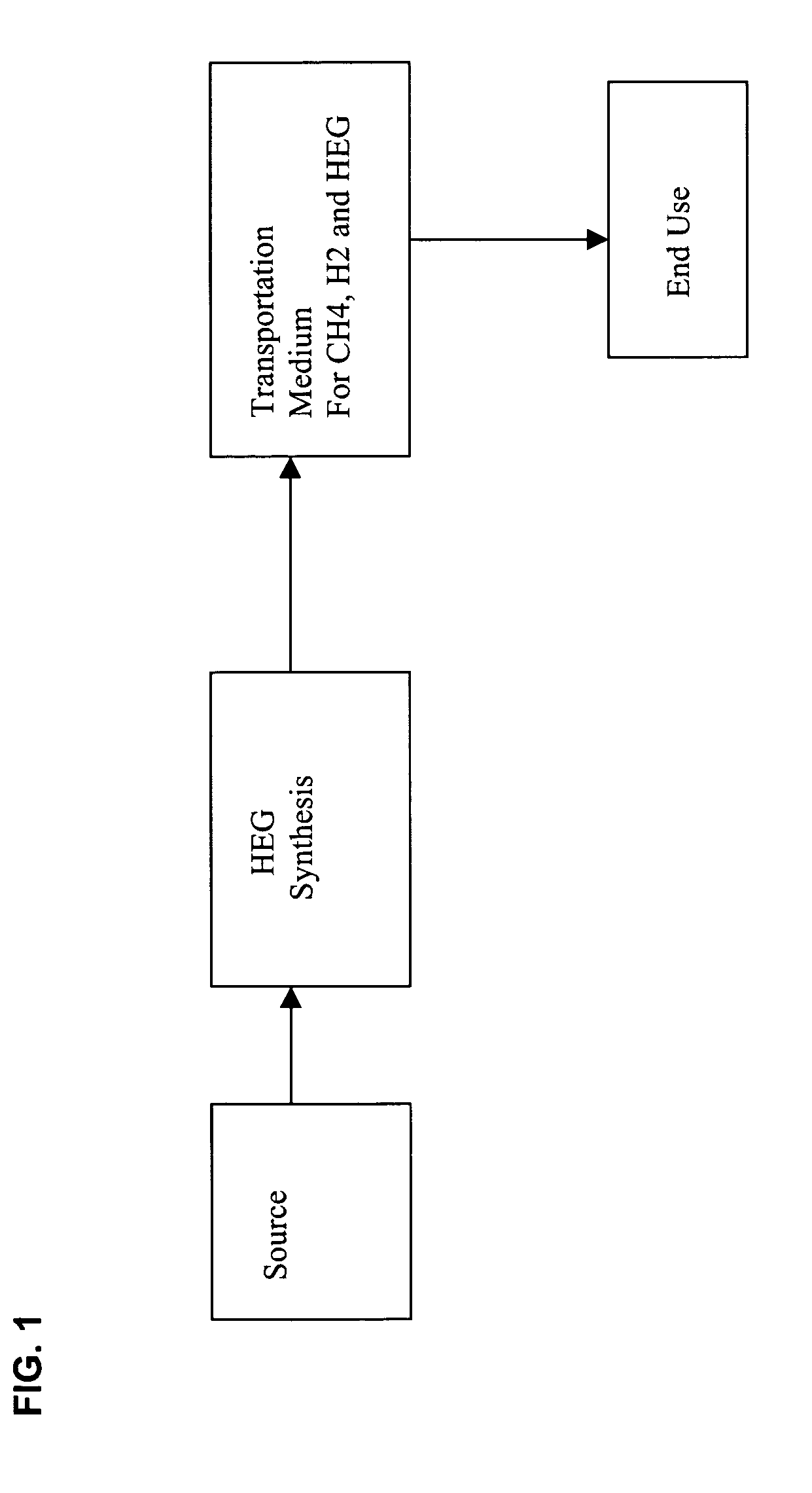

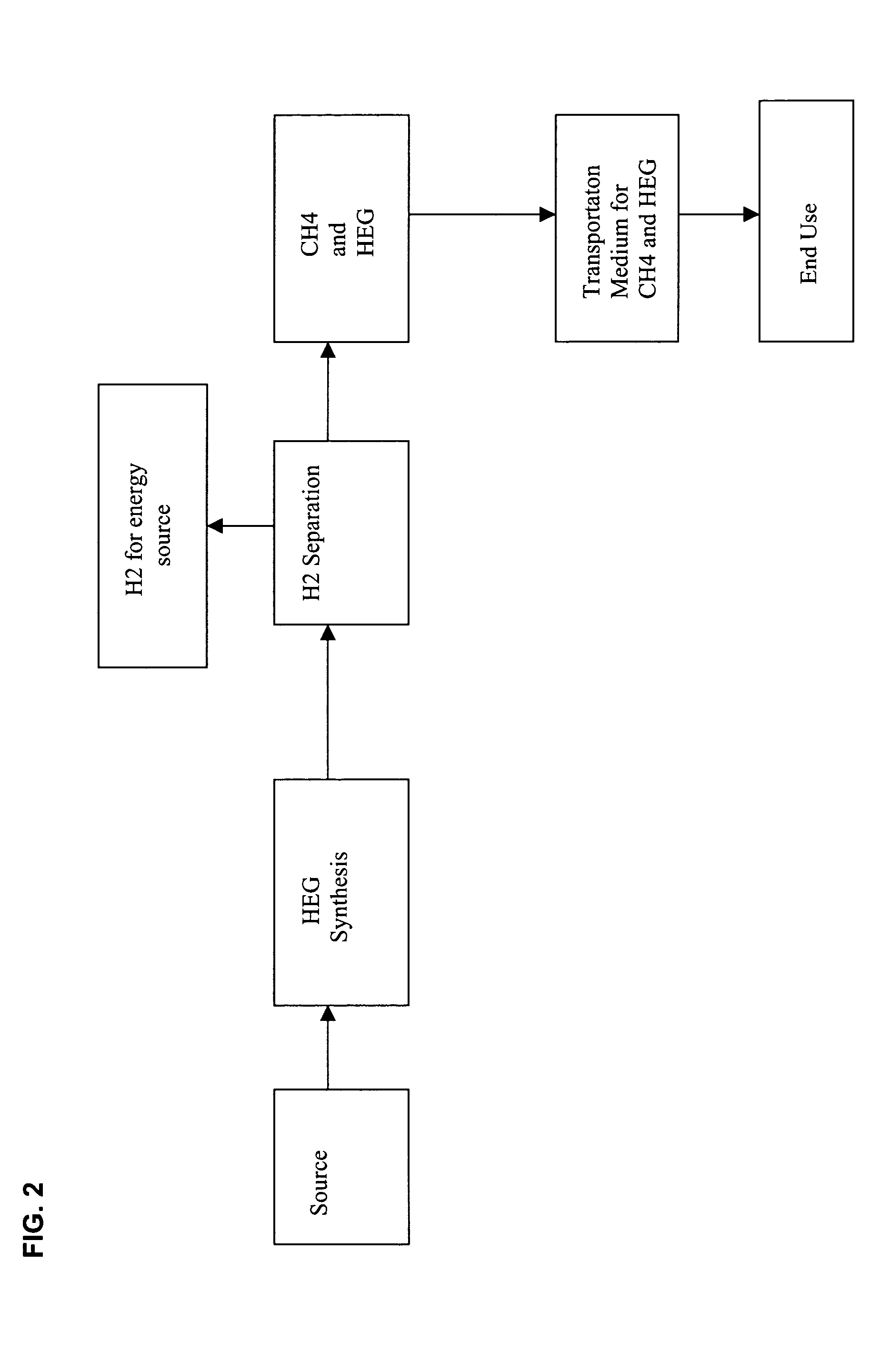

High energy transport gas and method to transport same

A high energy transport gas and a method to transport the high energy transport gas are used to increase the energy content of a pipeline and other vessels that are designed to carry natural gas under ambient conditions, in a compressed state or in a liquefied state. Methane and other gases are used as the feedstock, with methane from natural gas fields, coal beds or derived from hydrogen reacting with coal being primary energy sources. Also, this gas and method can provide an abundant source for hydrogen production, and the energy from hydrogen can be used for fuel cell applications that generate electricity and power motor vehicles. This gas and method are capable of increasing the energy capacity of current natural gas pipelines and other storage and transport vessels.

Owner:DALTON ROBERT C

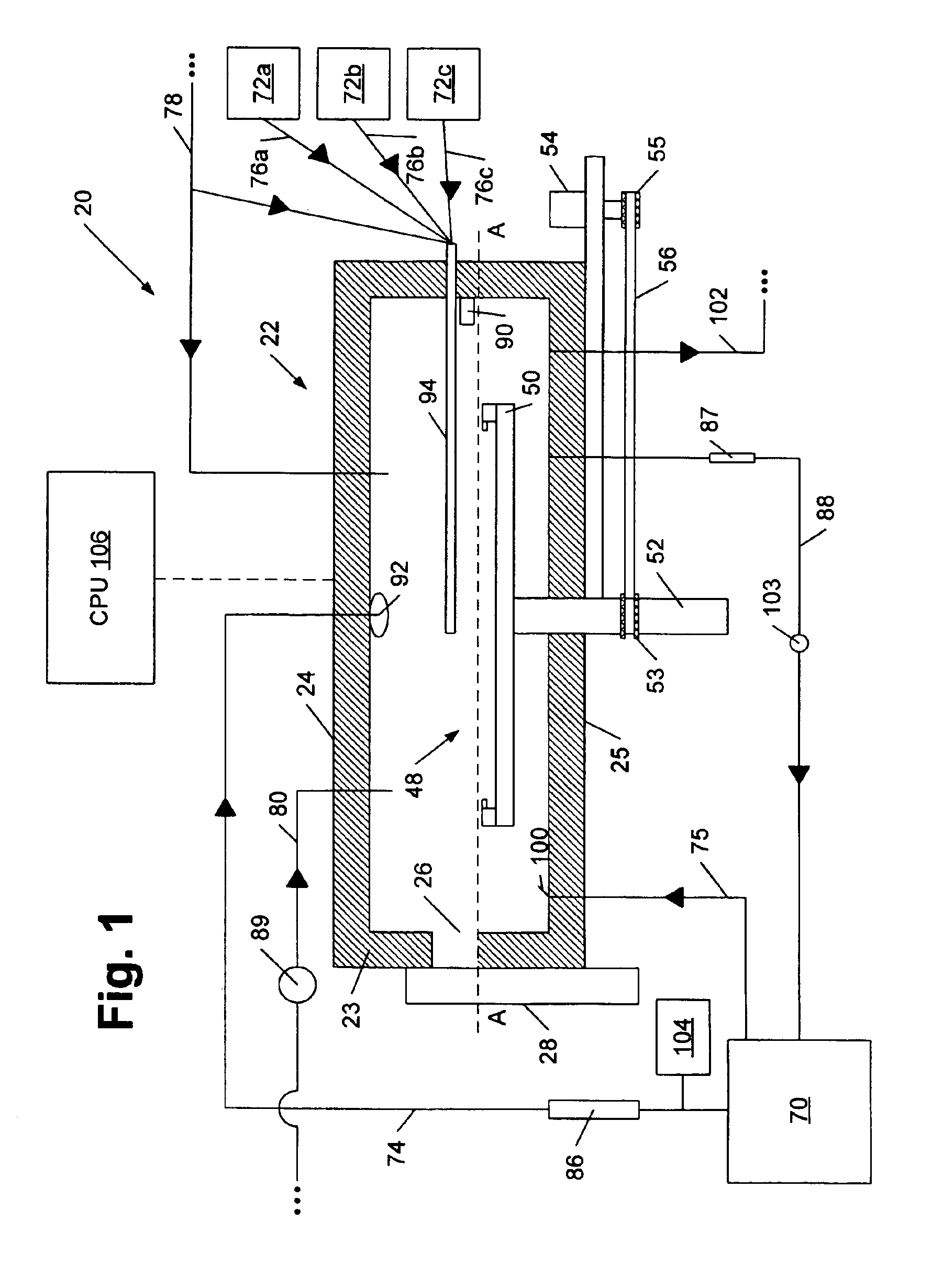

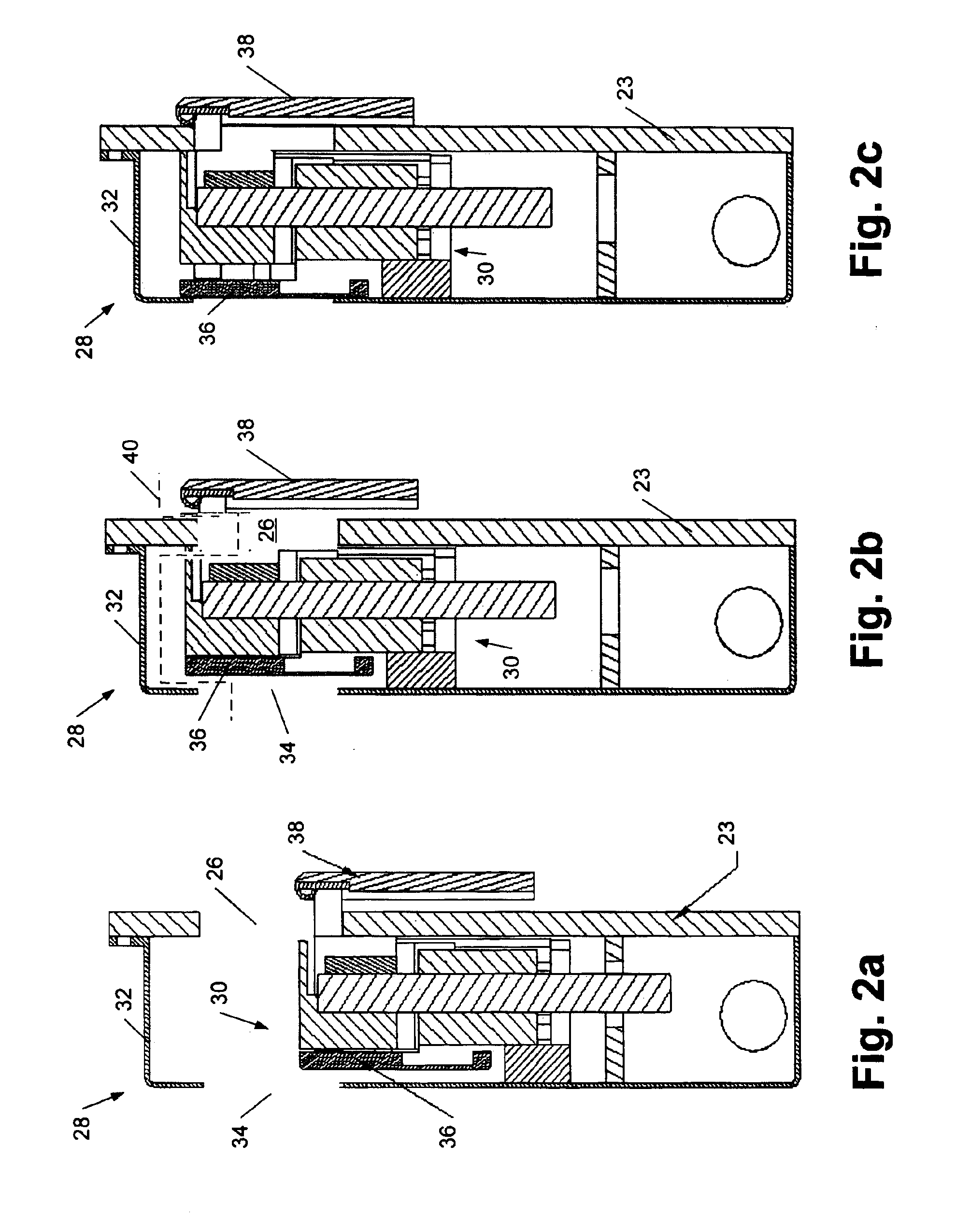

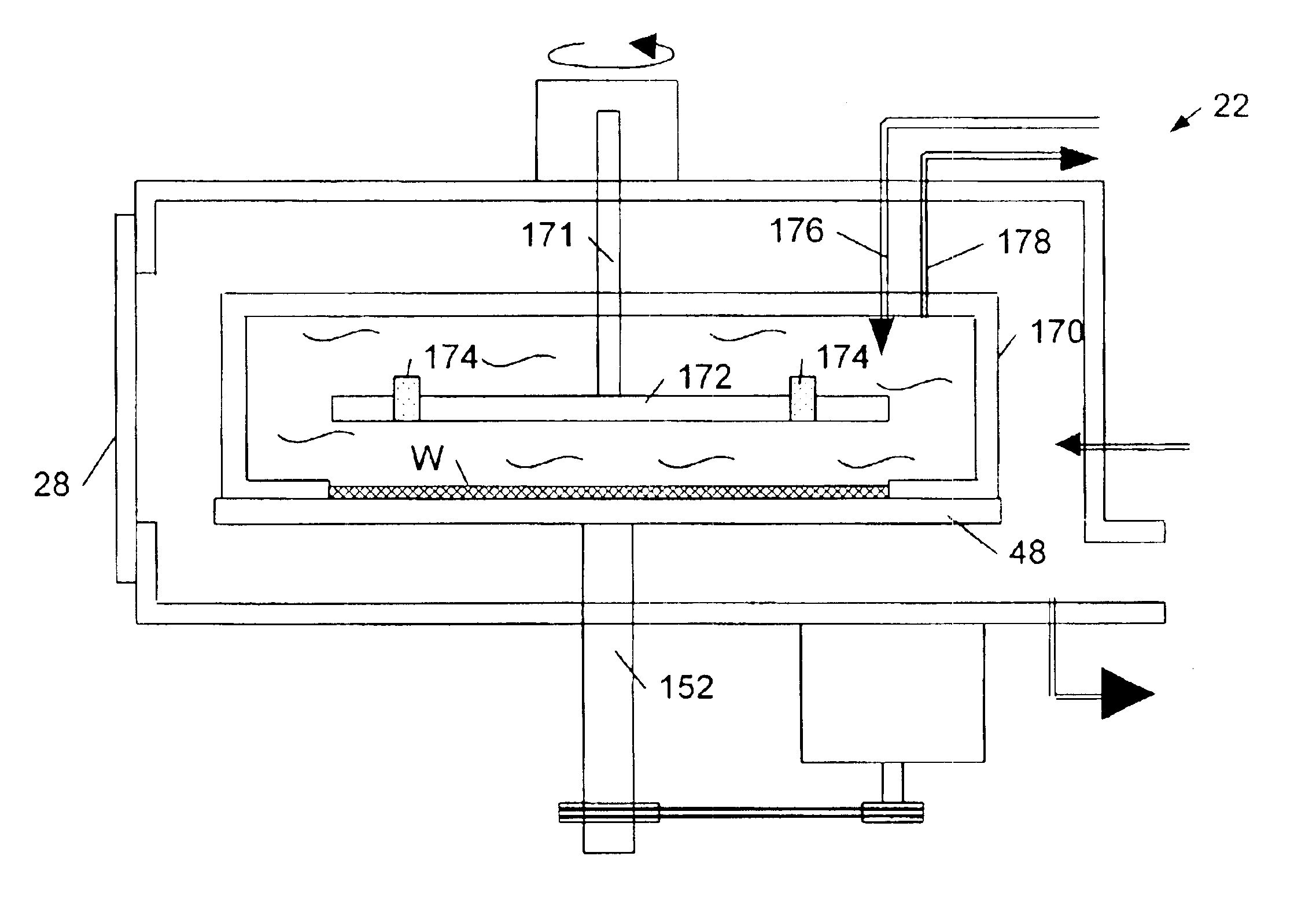

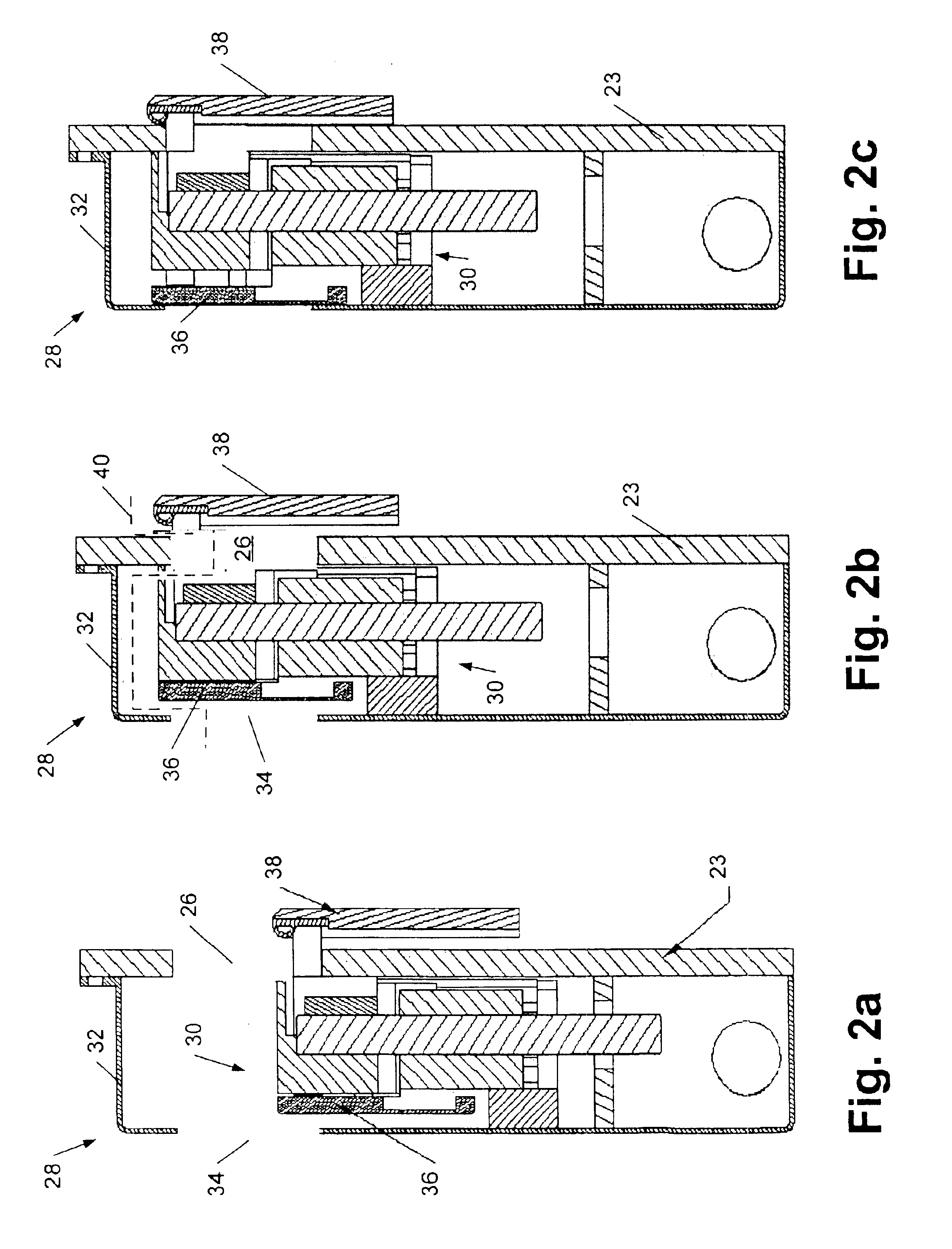

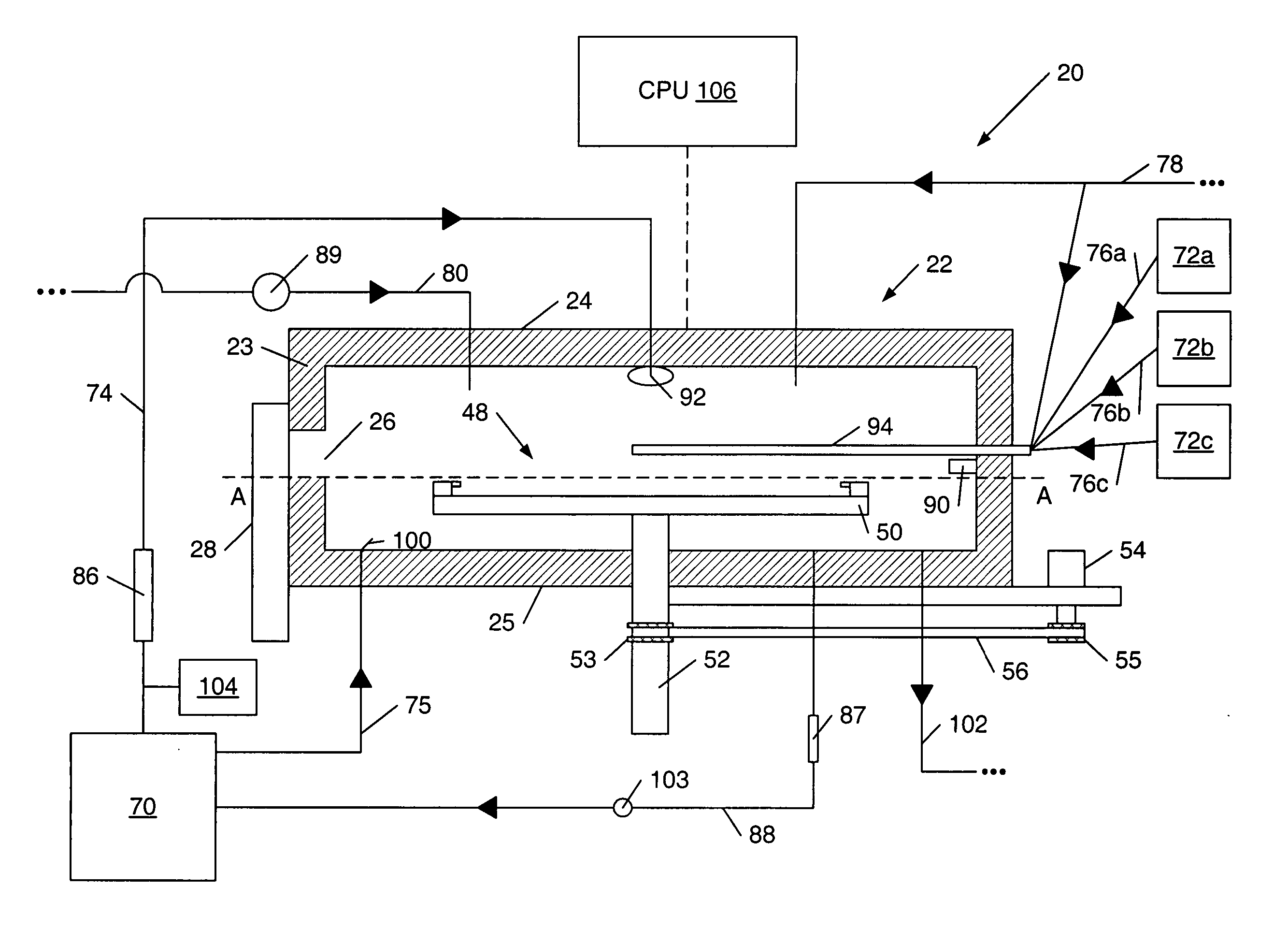

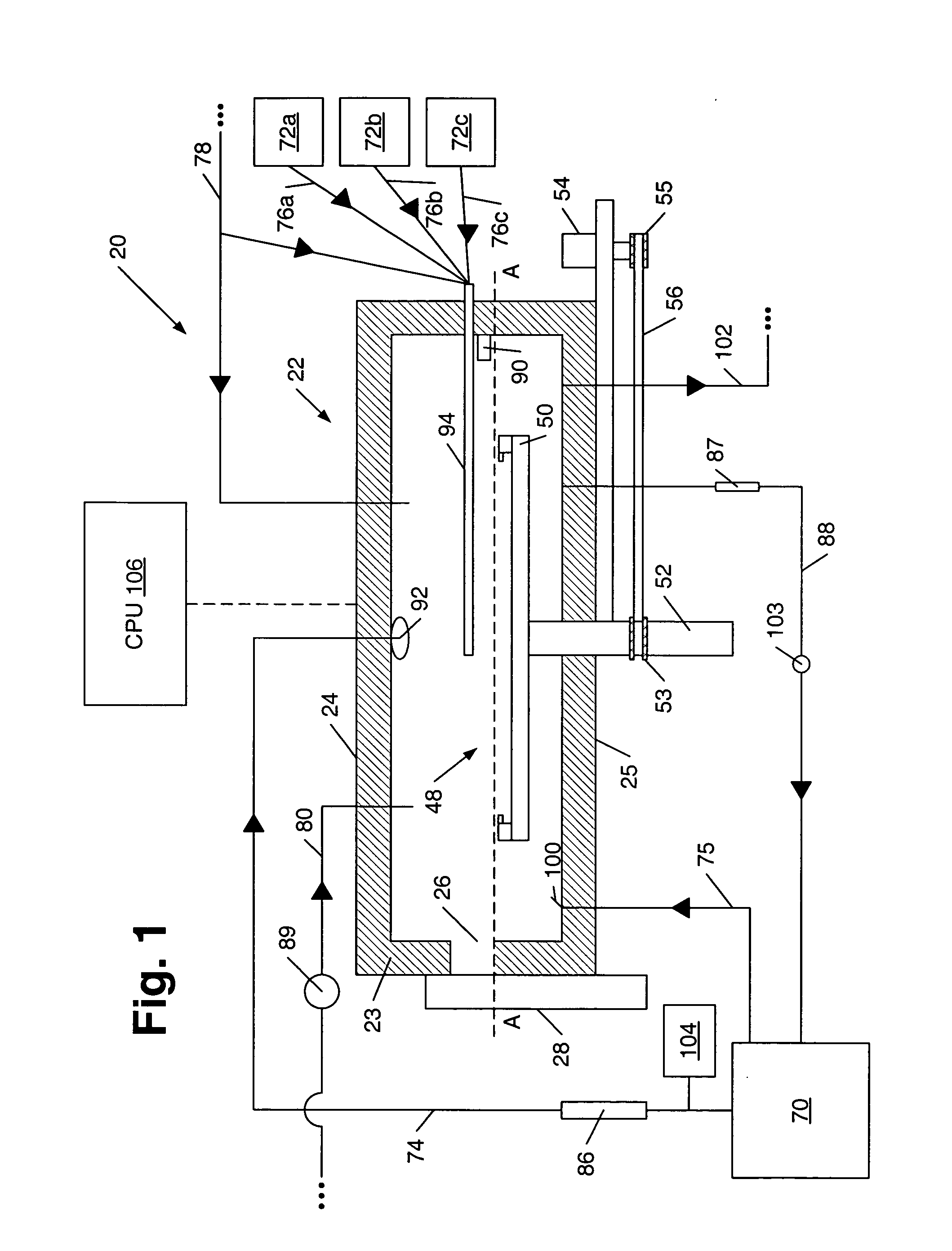

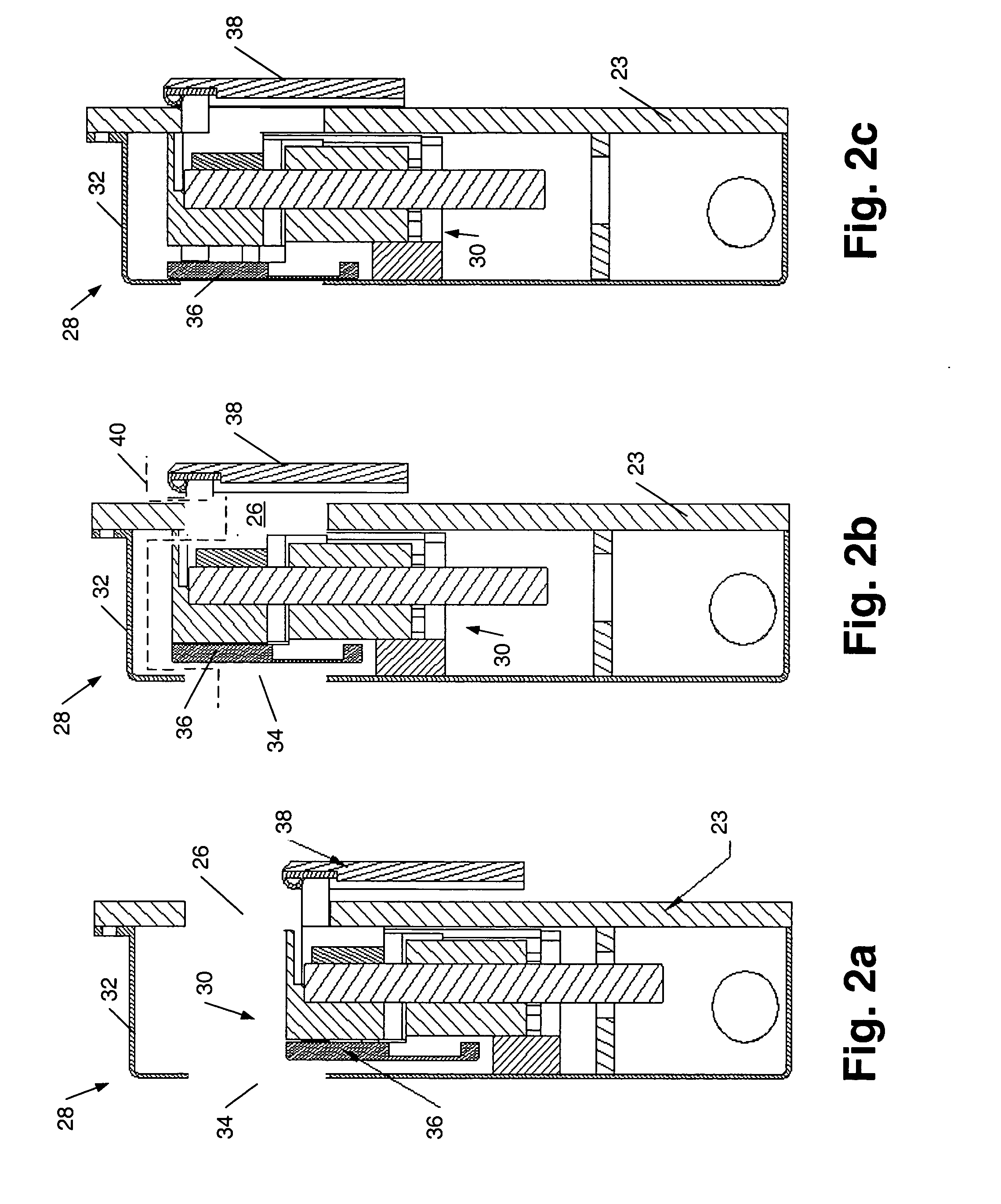

Microelectronic fabrication system components and method for processing a wafer using such components

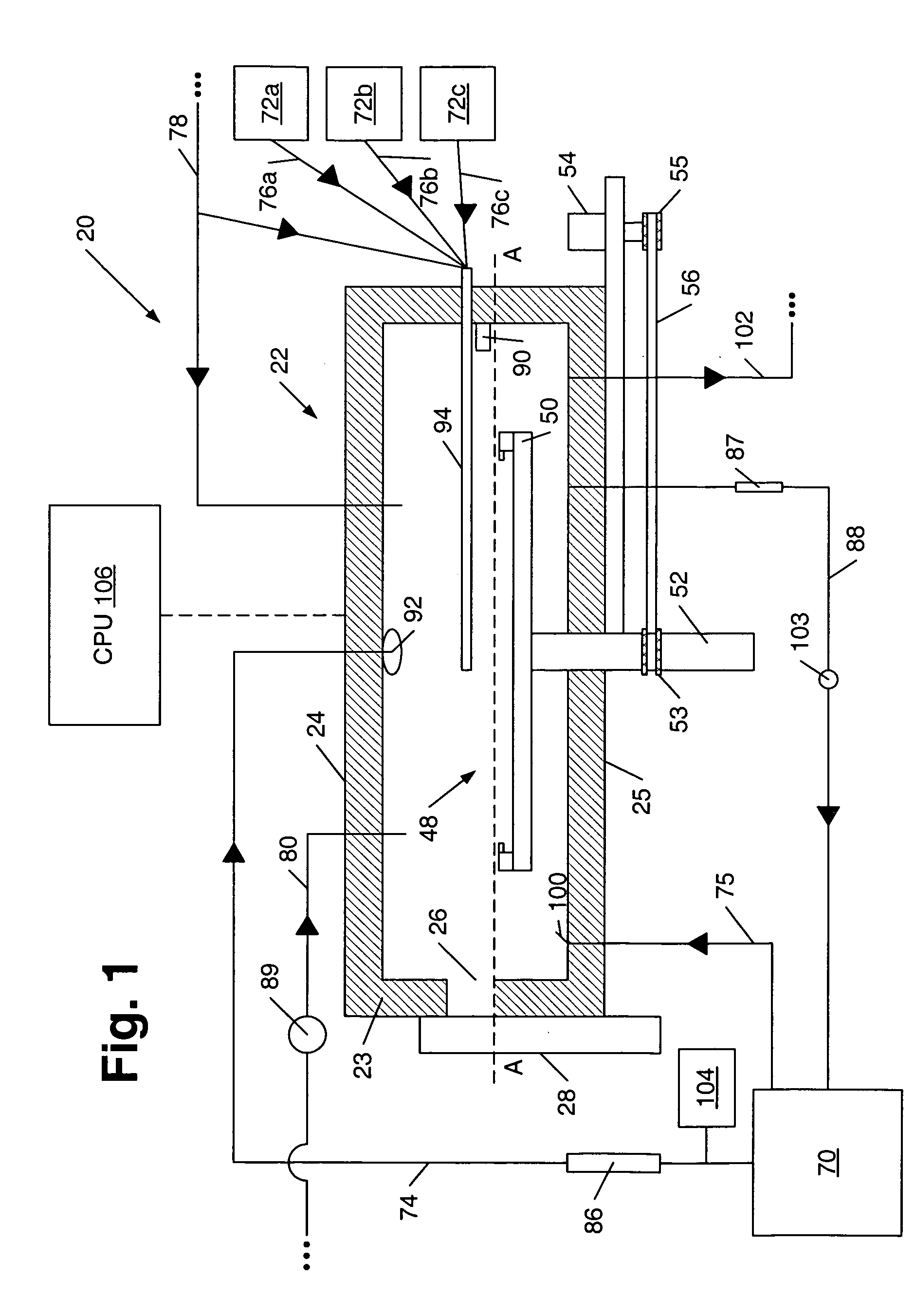

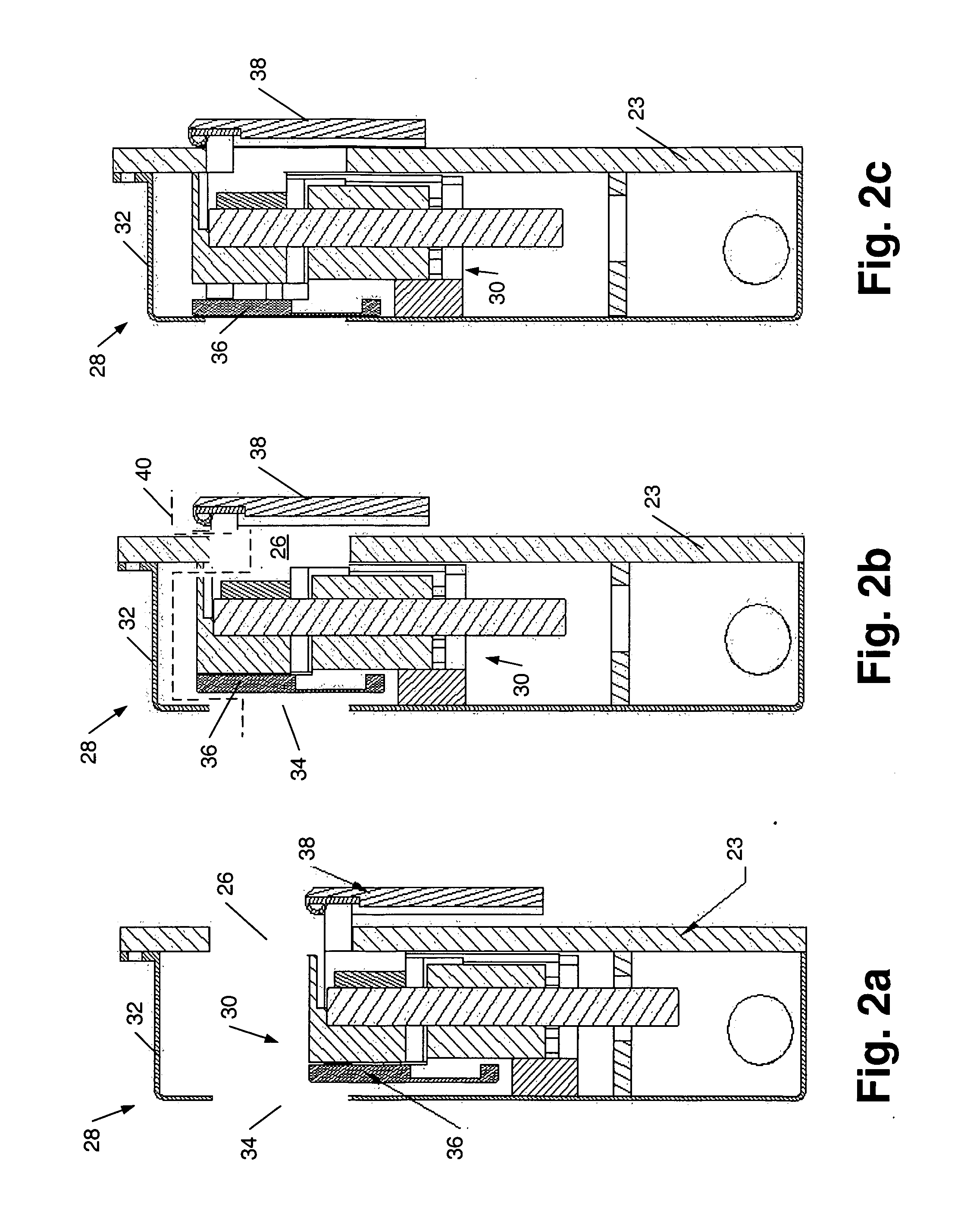

InactiveUS6860944B2Prevent oxidationInhibited DiffusionLiquid surface applicatorsSpraying apparatusEngineeringTopography

A process chamber is provided which includes a gate configured to align barriers with an opening of the gate and an opening of the process chamber such that the two openings are either sealed or provide an air passage to the chamber. A method is provided and includes sealing an opening of a chamber with a gate latch and exposing a topography to a first set of process steps, opening the gate latch such that an air passage is provided to the process chamber, and exposing the topography to a second set of process steps without allowing liquids within the chamber to flow through the air passage. A substrate holder comprising a clamping jaw with a lever and a support member coupled to the lever is also contemplated herein. A process chamber with a reservoir arranged above a substrate holder is also provided herein.

Owner:LAM RES CORP

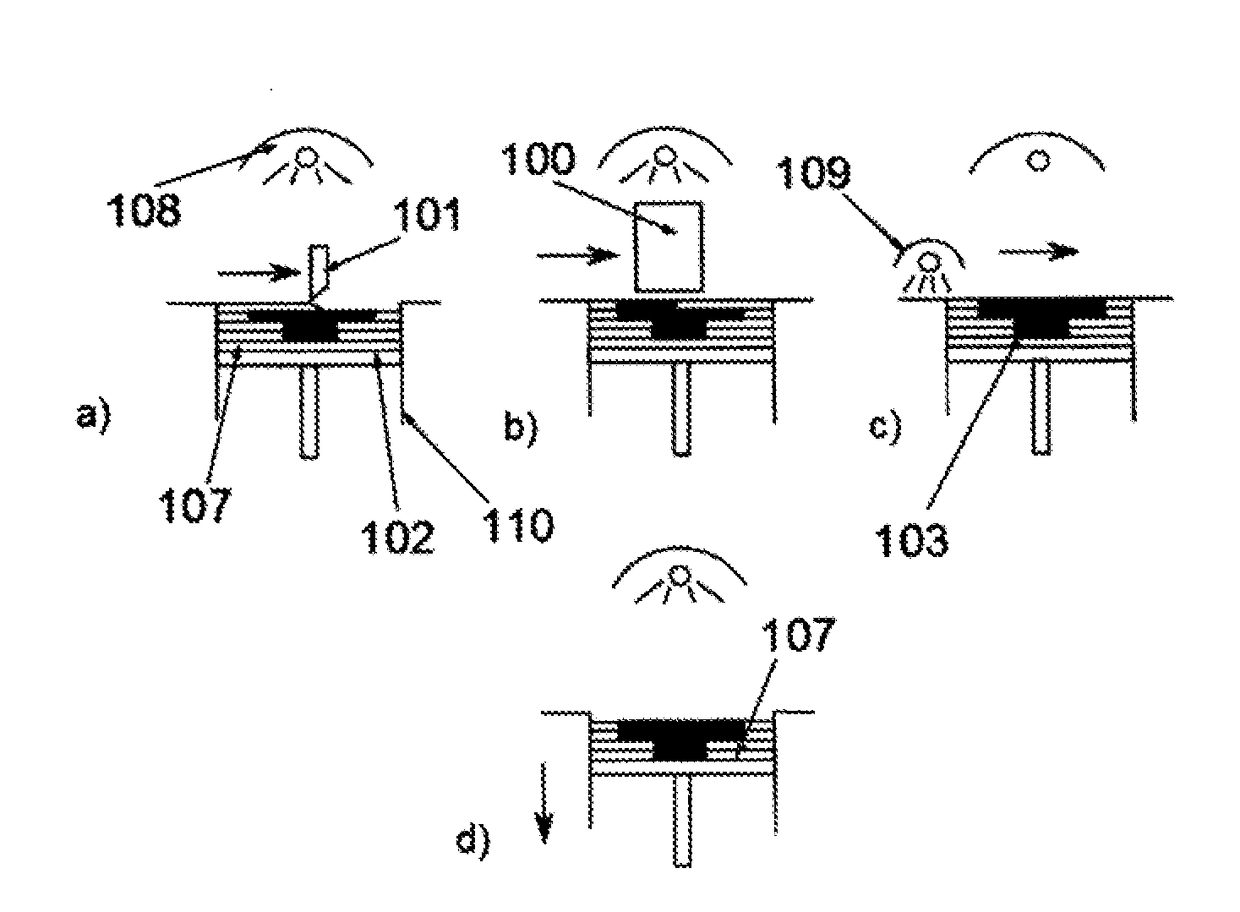

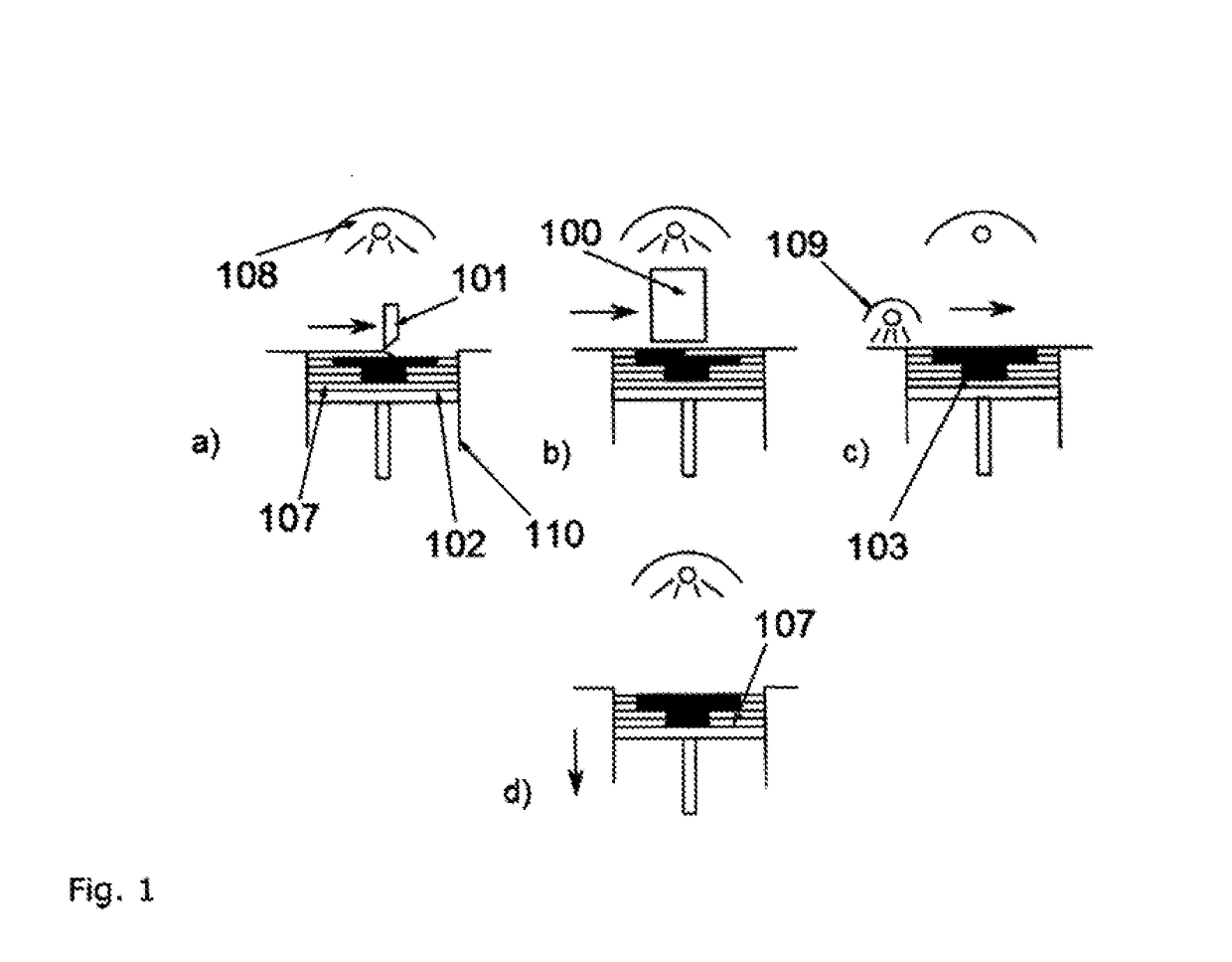

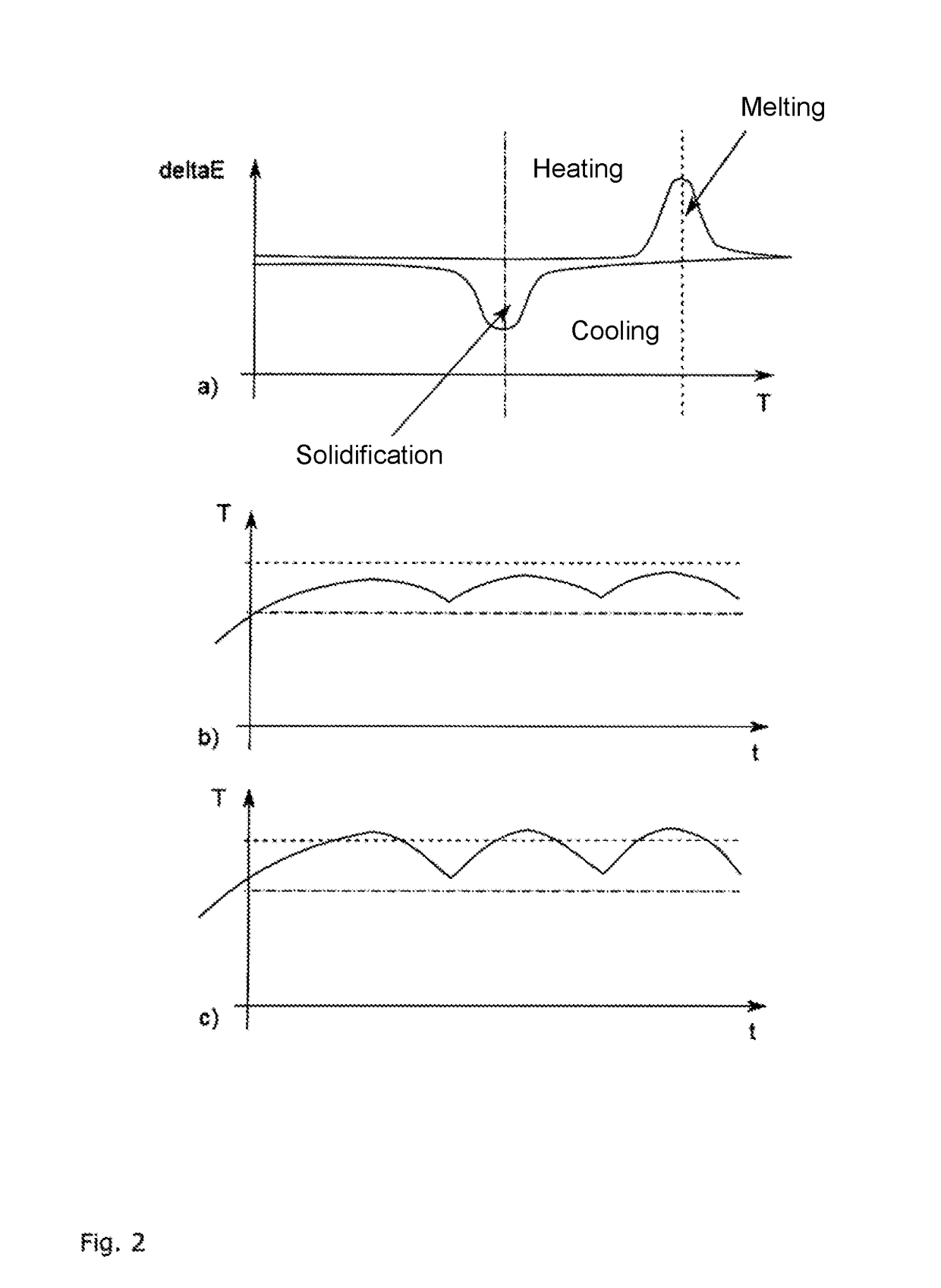

Method and device for producing 3D moulded parts by means of a layer construction technique

ActiveUS20170355137A1High boiling pointAdjustable temperatureManufacturing heating elementsManufacturing recyclingMaterials scienceThree dimensional model

The invention relates to a method and an apparatus for producing three-dimensional models by layering in a high-speed sintering process.

Owner:VOXELJET AG

High energy transport gas and method to transport same

InactiveUS8277525B2Increase volumeHigh boiling pointGas modification by gas mixingIndirect heat exchangersThermodynamicsFuel cells

Owner:DALTON ROBERT C

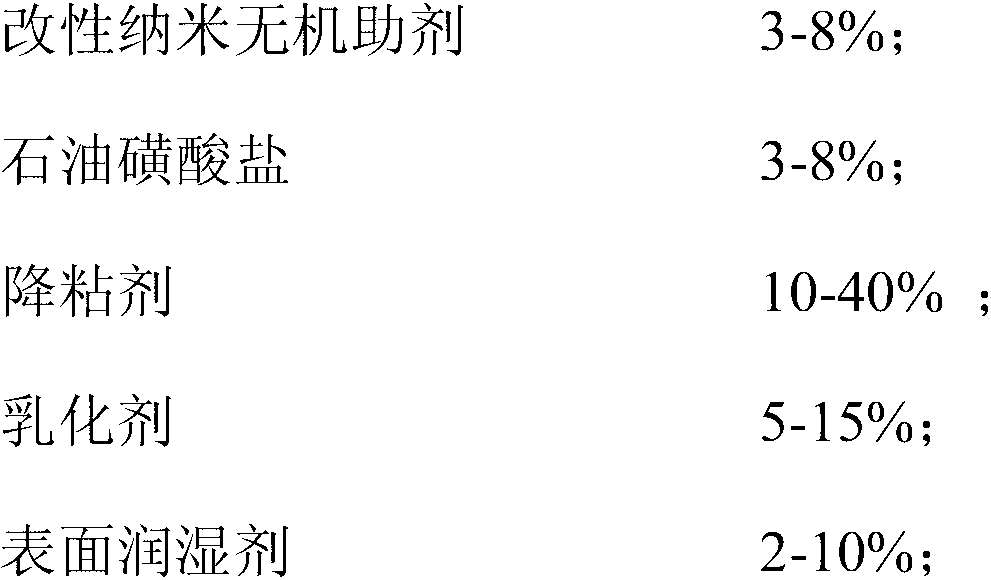

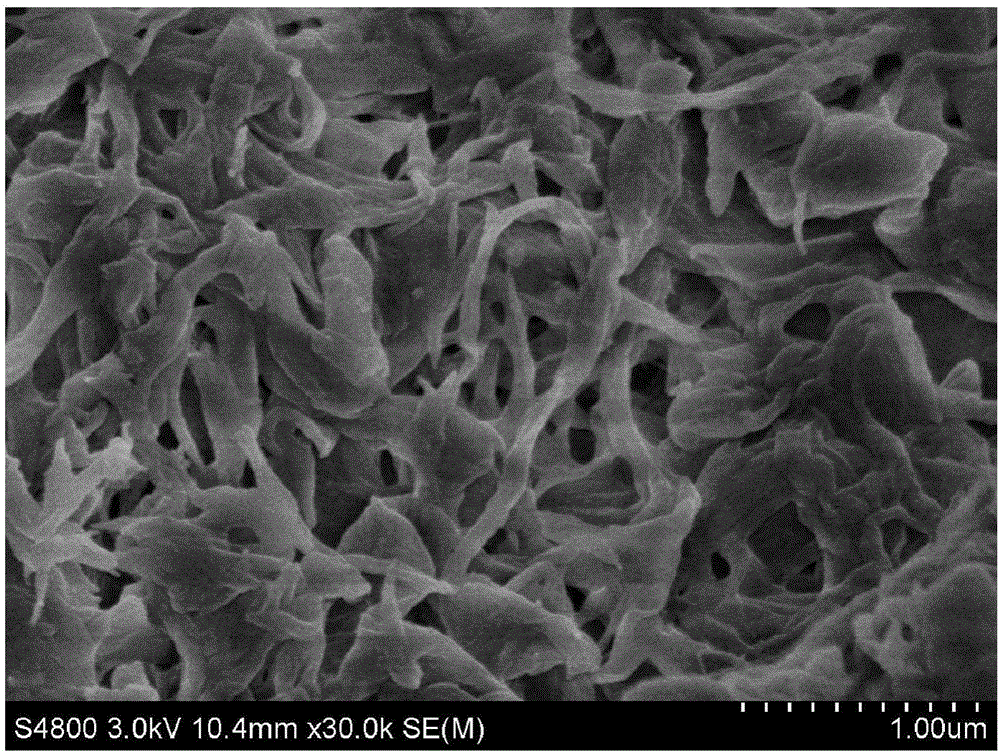

Nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery and preparation method thereof

ActiveCN103320110AGood viscosity reductionReduce dosageDrilling compositionSalt resistanceTemperature resistance

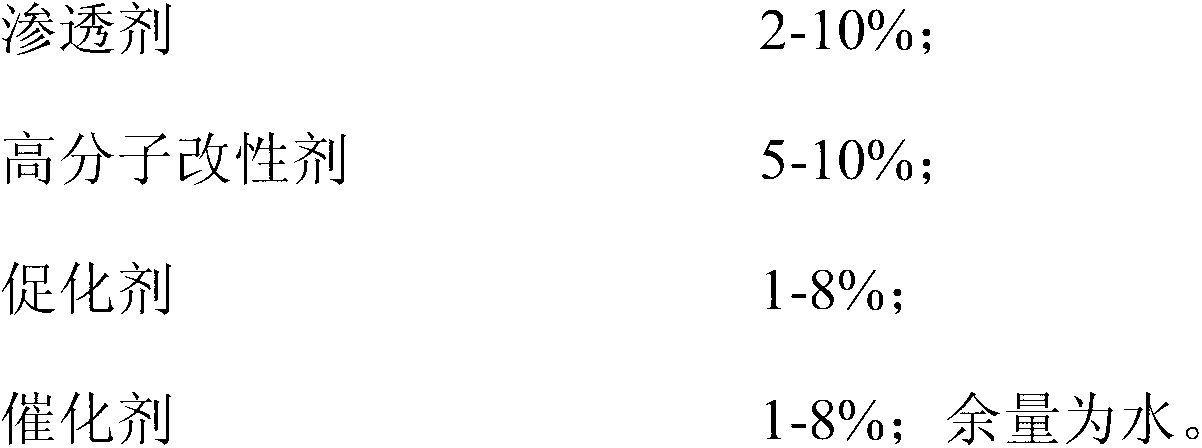

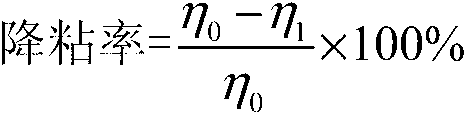

The invention discloses a nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery. The nano composite high-temperature-resistant extraction aid is prepared from 3-8 weight percent of modified nano-silica, 3-8 weight percent of petroleum sulfonate, 10-40 weight percent of a viscosity reducer, 5-15 weight percent of an emulsifier, 2-10 weight percent of a surface wetting agent, 2-10 weight percent of a penetrating agent, 5-10 weight percent of a high polymer modifier, 1-8 weight percent of a catalyst and the balance of water. The preparation method comprises the following steps: polymerizing the petroleum sulfonate, viscosity reducer, a promoting agent and the catalyst at the temperature of 60-150 DEG C for 2-6 hours according to a ratio, adding the modified nano inorganic aid, and uniformly mixing; and finally, adding the emulsifier, surface wetting agent, penetrating agent, high polymer modifier and water according to the ratio, and mixing for 1-2 hours. The nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery has high high-temperature resistance and excellent emulsification and salt resistance, the production efficiency can be greatly improved, and the recovery rate is reduced.

Owner:GUNGHO CHARGE TIANJIN REFINED PETROLEUM TECH DEV

Nano metal fluid with high heat-transfer performance

ActiveCN1955252AImprove thermal conductivityFast absorption and deliveryDigital data processing detailsSemiconductor/solid-state device detailsLiquid metalSolvent

This invention provides a high heat transfer performance liquid nano-metal. It relates to cooling fluid working medium, and especially it can be used under high rush density condition which need high intensity cooling fluid working medium for heat exchanging and cooling, such as computer array and reactor. The solvent of this invention is liquid metal, and the soluble of this invention is nanometer particle. This invention solve the problem of high price of present metal liquid cooling working medium and the limited performance of common metal liquid, leaking out easily taken place using common liquid and easy forming sediment of present nanometer cooling agent.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

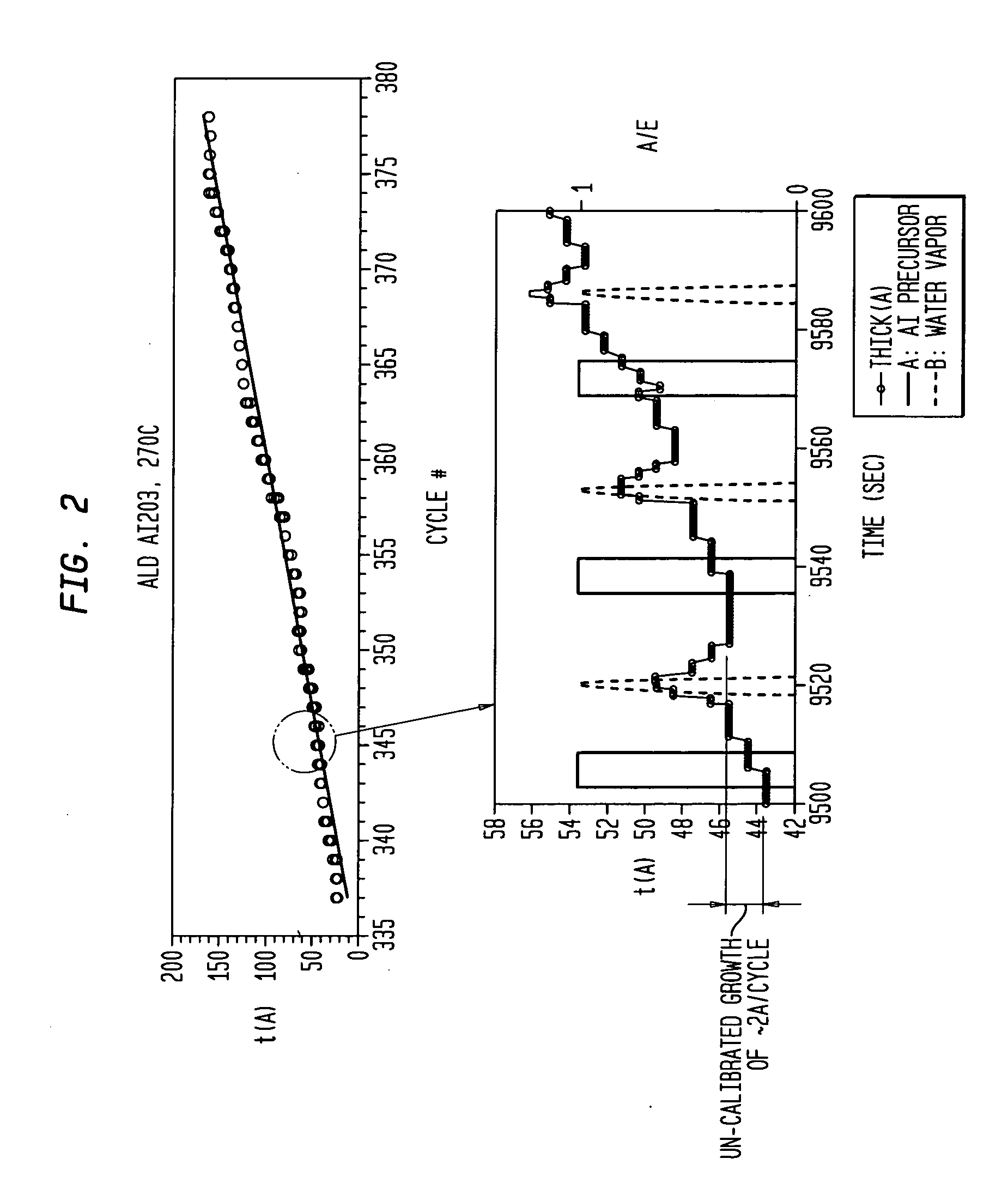

Method and apparatus for using solution based precursors for atomic layer deposition

InactiveUS20060269667A1High boiling pointPoint become highLayered productsSemiconductor/solid-state device manufacturingSolventVapor phase

A unique combination of solution stabilization and delivery technologies with special ALD operation is provided. A wide range of low volatility solid ALD precursors dissolved in solvents are used. Unstable solutes may be stabilized in solution and all of the solutions may be delivered at room temperature. After the solutions are vaporized, the vapor phase precursors and solvents are pulsed into a deposition chamber to assure true ALD film growth.

Owner:LINDE GAS NORTH AMERICA LLC +1

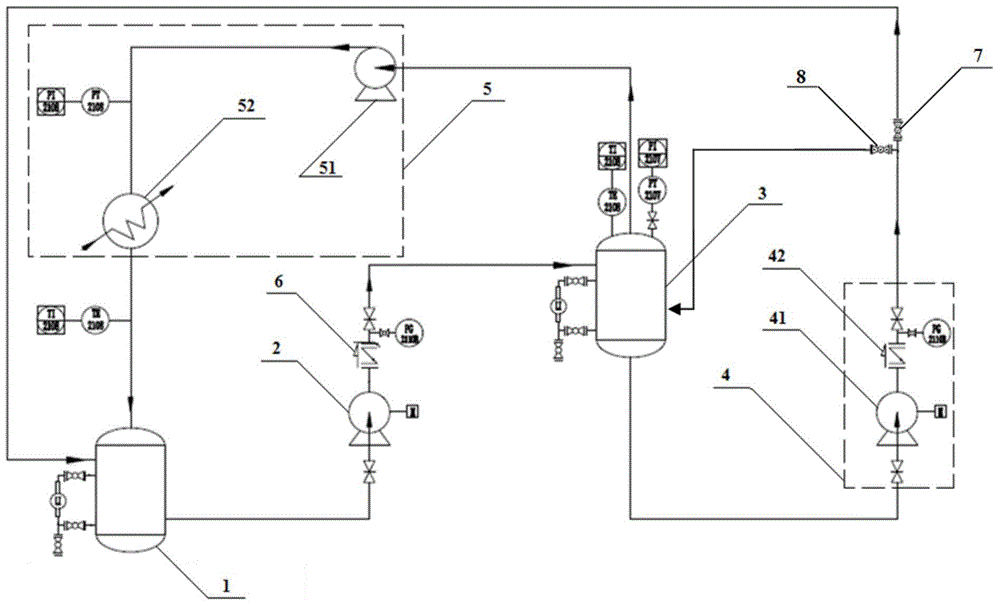

Paper deacidification agent, and paper deacidification system and method thereof

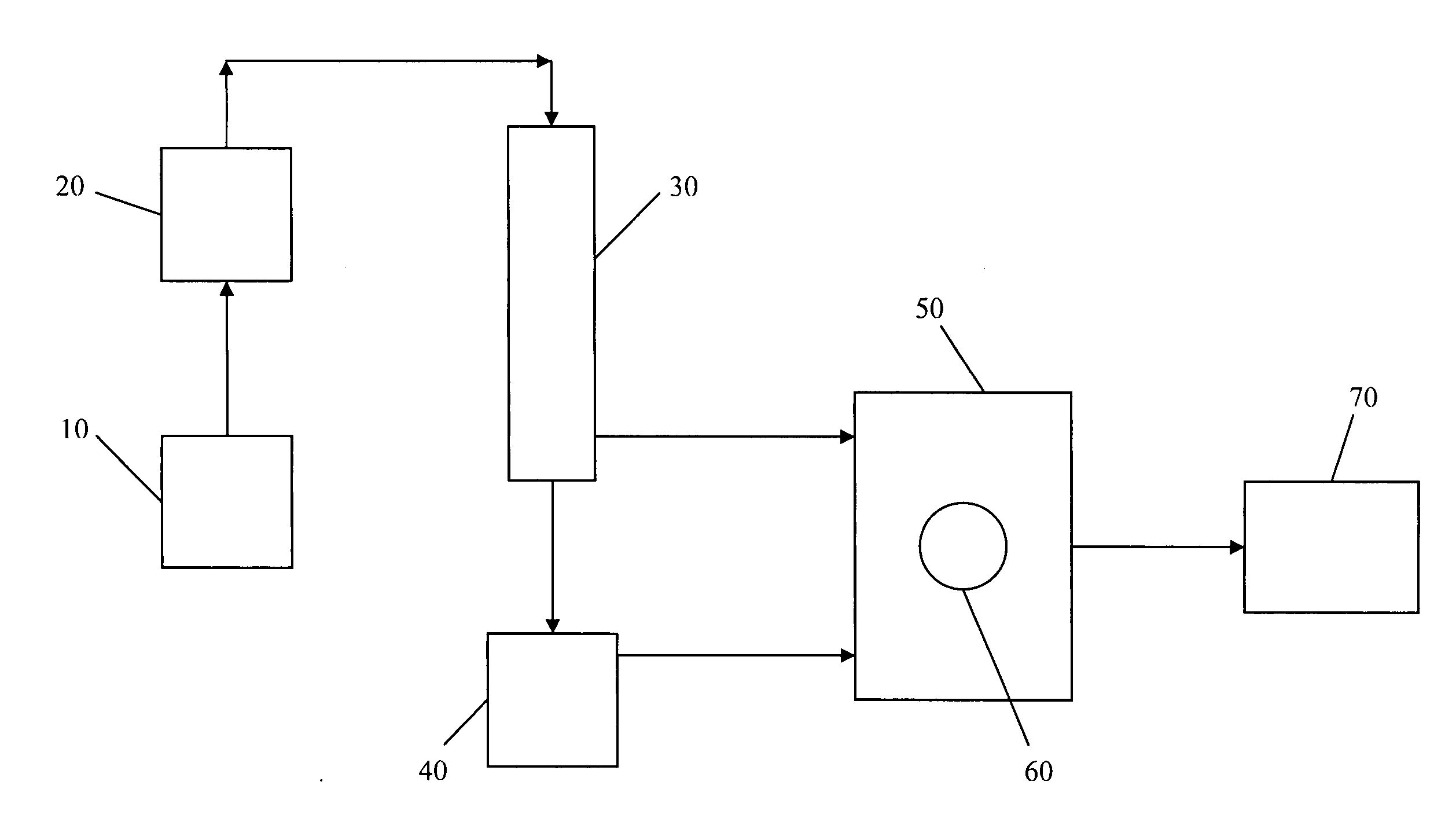

The invention belongs to the technical field of paper deacidification, and specifically relates to a paper deacidification agent, and a paper deacidification system and a paper deacidification method thereof. The paper deacidification agent comprises nanometer oxide particles, a silane coupling agent and n-perfluorooctane liquid, wherein the nanometer oxide particles are suspended in the n-perfluorooctane liquid after coated by the silane coupling agent, and the nanometer oxide particles can also be replaced by nanometer magnesium hydroxide particles. The paper deacidification system comprises a deacidification liquid storage tank, a centrifugation pump, a deacidification device and a circulation device which are in successive connection, wherein the outlet of the circulation device is respectively connected with the inlet of the deacidification liquid storage tank and the inlet of the deacidification device; a circulation loop is formed between the deacidification device and the circulation device; and the deacidification device is also connected with the deacidification liquid storage tank via a deacidification liquid recovery device. The paper deacidification method comprises the following steps: putting a literature into the deacidification device, then pumping the paper deacidification agent into the deacidification device, shaking the literature, subjecting deacidification liquid to circulation, pumping the deacidification liquid back, and carrying out condensation recovery. According to the invention, safety and effectiveness are obtained; and the paper deacidification agent has the advantages of easy recovery, good effects and low cost.

Owner:NAT LIBRARY OF CHINA

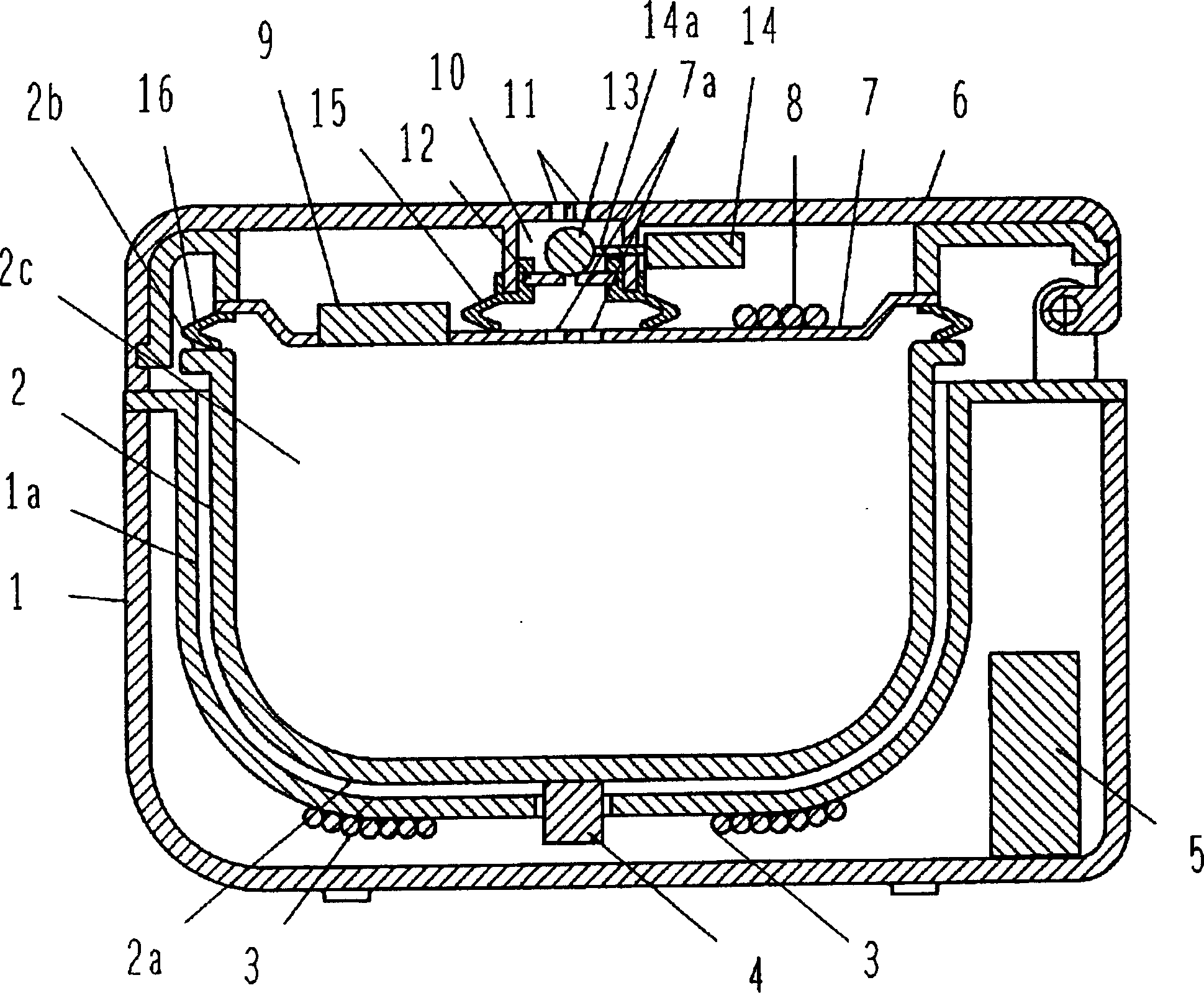

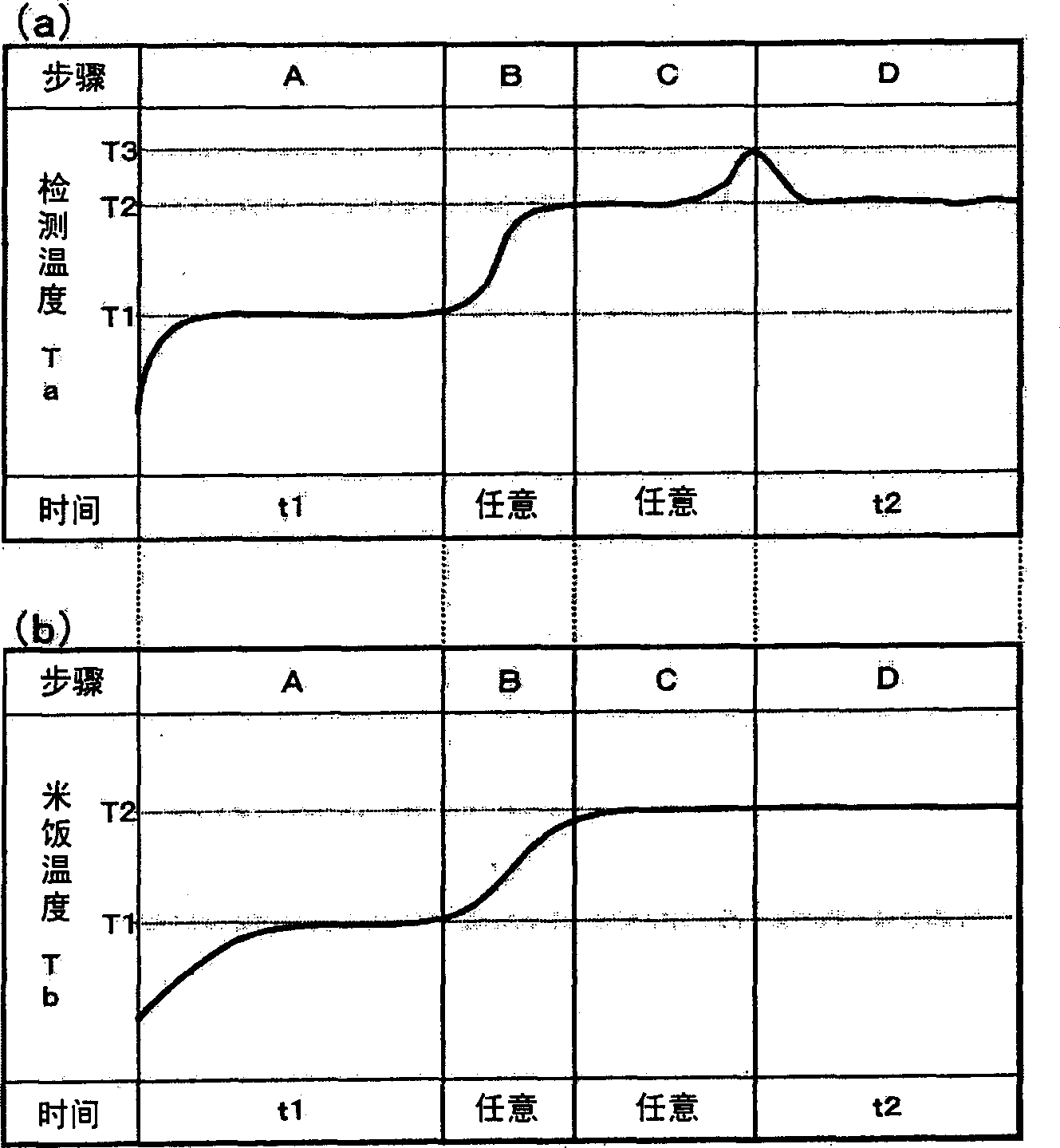

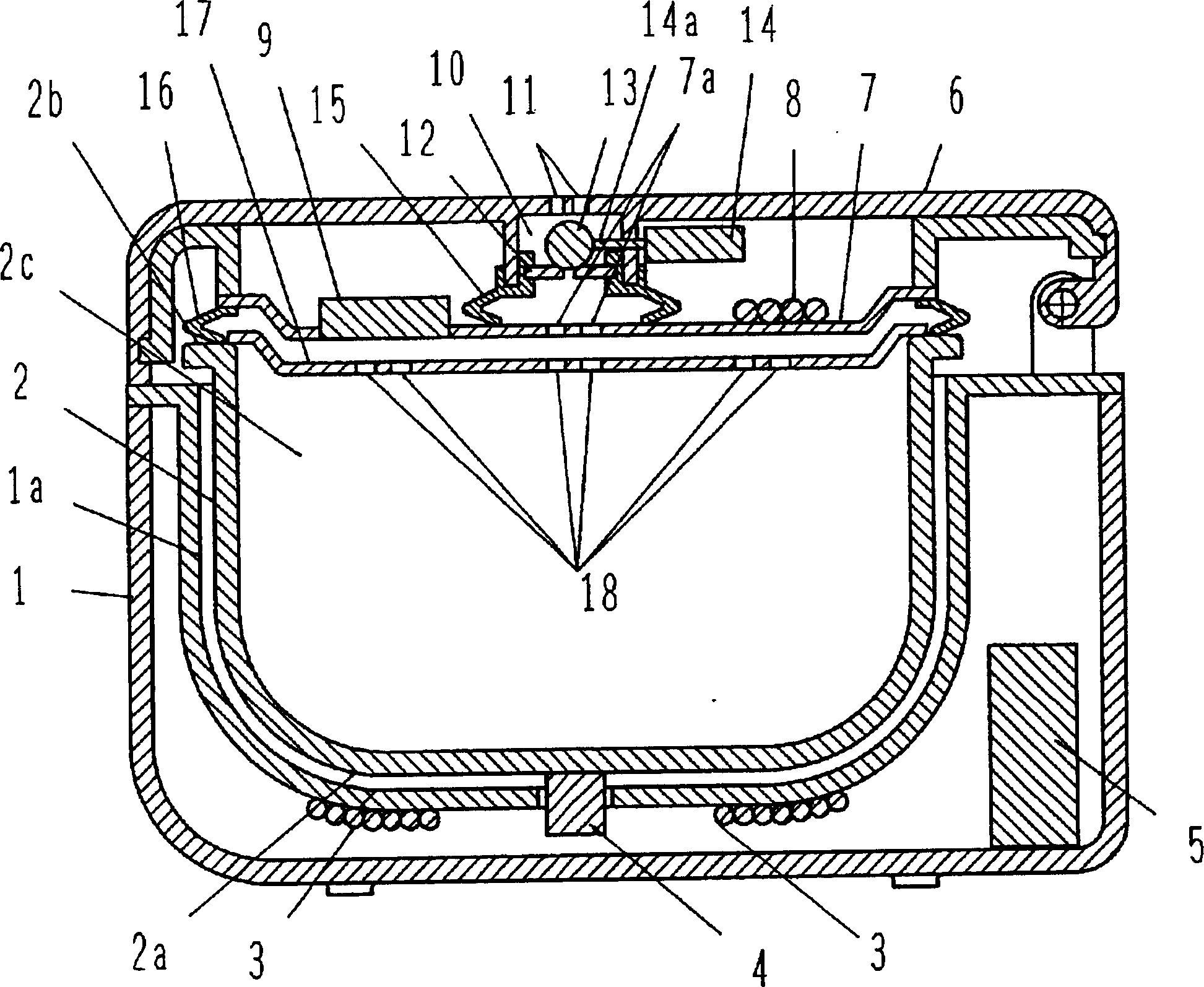

Electric cooker

InactiveCN1820685AImprove gelatinizationReduce power consumptionPressure-cookersEngineeringElectric power

The electric rice cooker includes one cooker body, one detachable pot, one cover, one pressure regulator for maintaining certain pressure inside the pot, one sealing unit to seal the opening of the pot, and one steam heater to heat the generated steam into high temperature steam for cooking rice. The electric rice cooker has reduced steam heating time, capacity of cooking delicious rice and effect of promoting water absorption. In addition, it has no special steam generator, and this results in reduced cooker size, low power consumption for generating steam and reduced total power consumption.

Owner:PANASONIC CORP

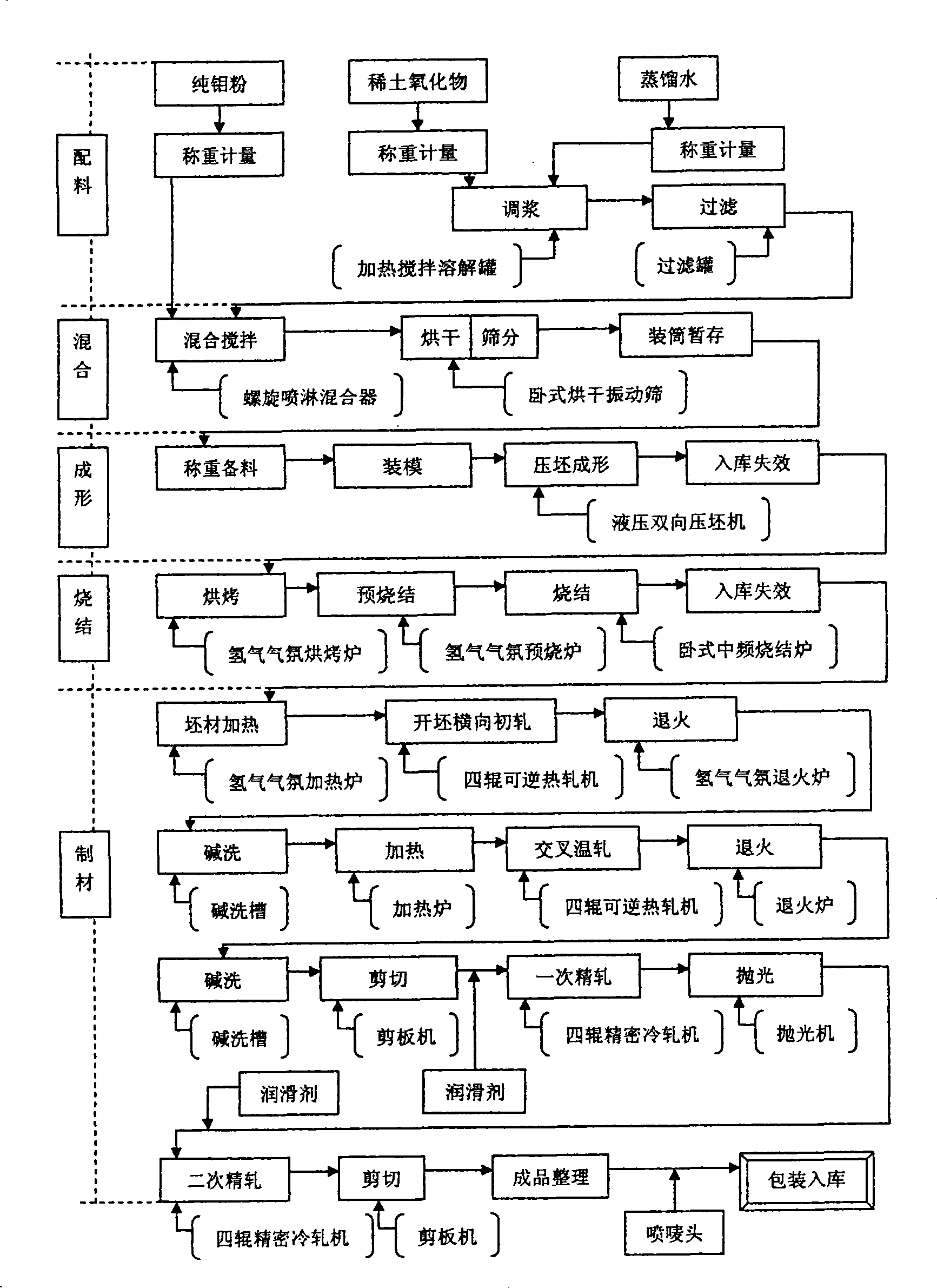

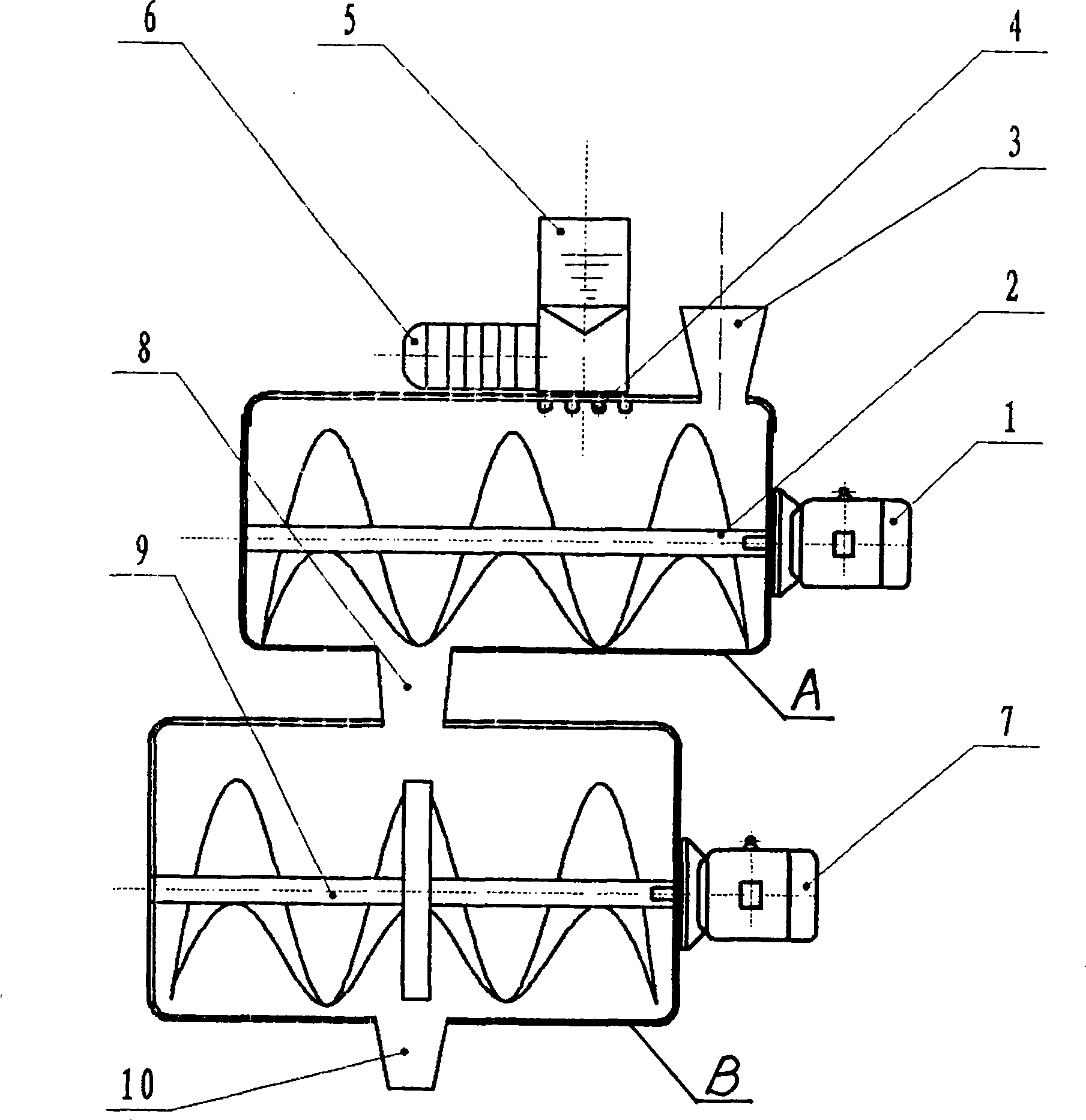

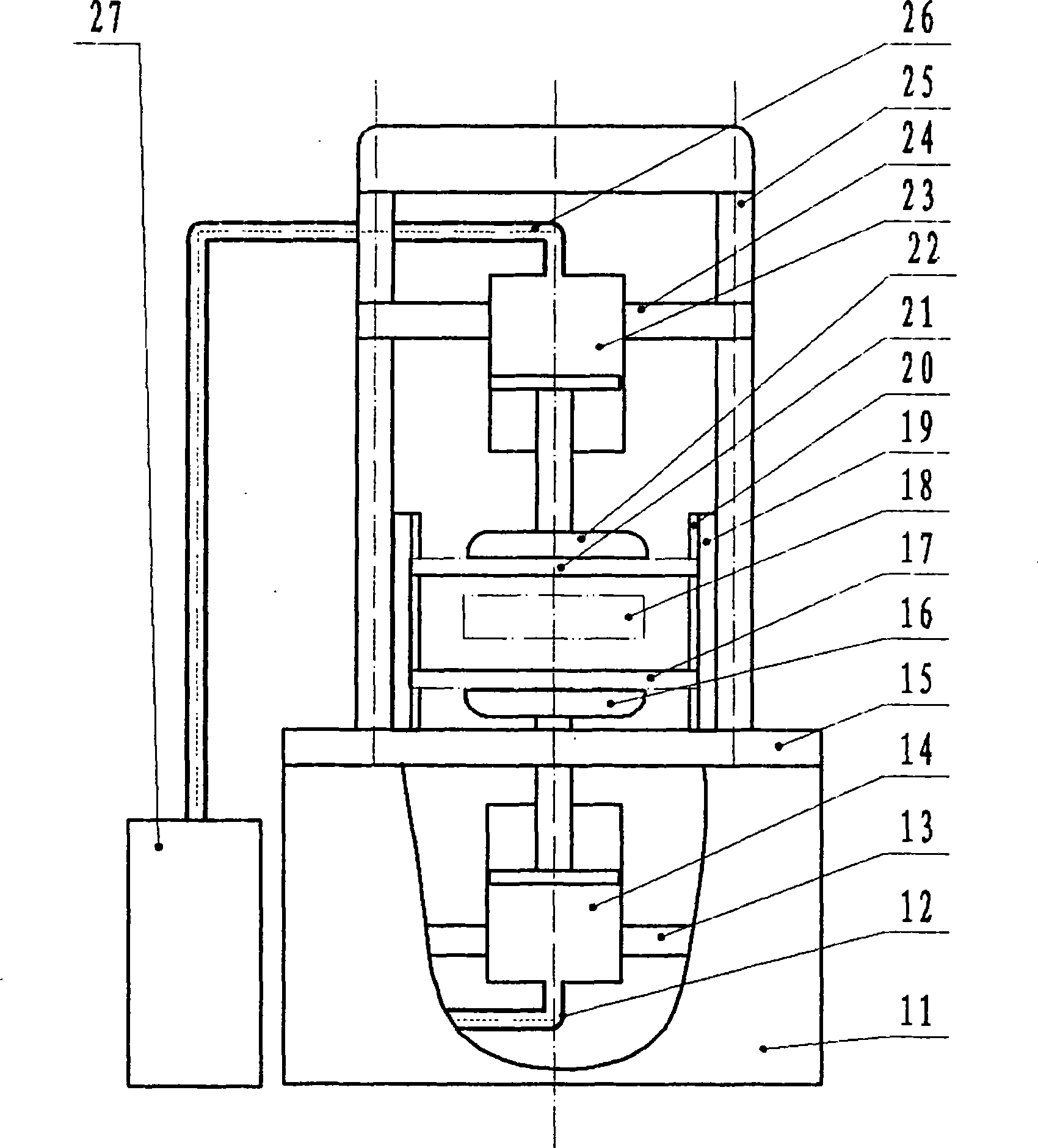

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

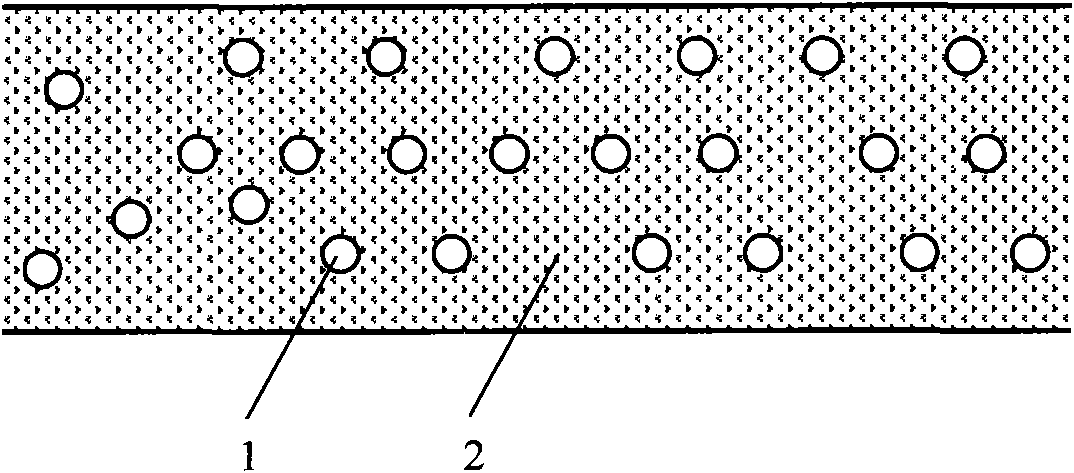

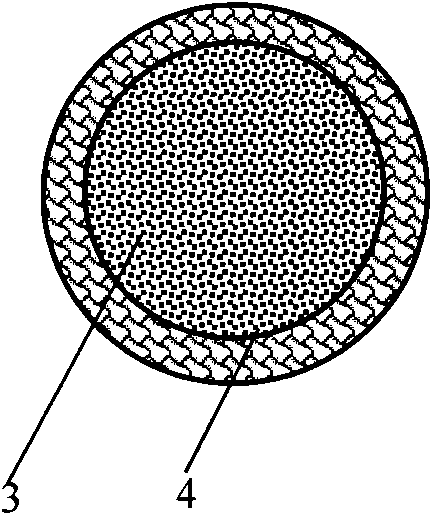

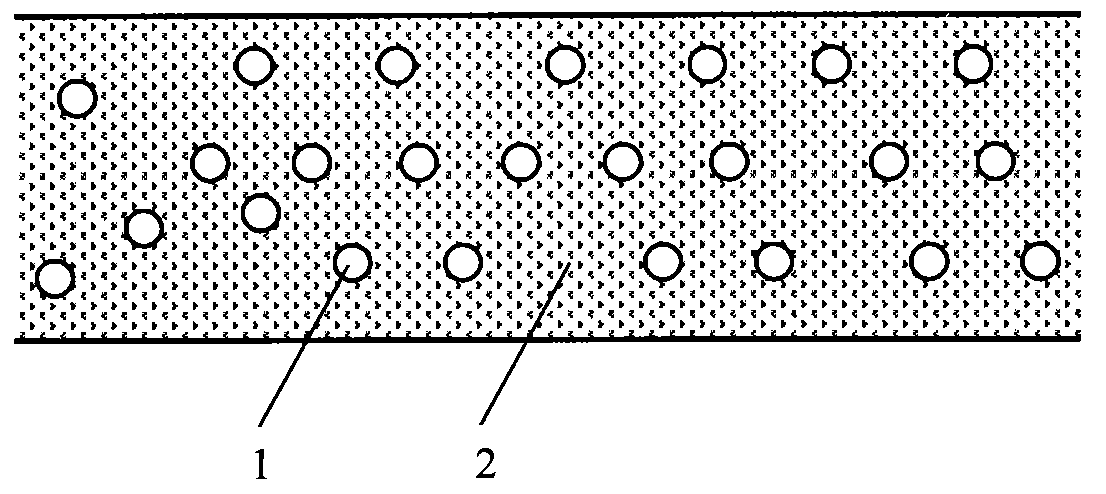

Liquid metal fluid containing phase-change microcapsules

InactiveCN101775270AHigh apparent specific heatIncrease surface tensionHeat-exchange elementsMicroballoon preparationIndiumIn situ polymerization

The invention discloses a liquid metal fluid containing phase-change microcapsules, which adopts phase-change microcapsules (1) as a solute and liquid metal (2) as a solvent, wherein the phase-change microcapsules (1), which are prepared by using an in-situ polymerization method or other methods to embed a phase-change material (3) into an outer casing (4), are spherical and has the diameter of 1nm-1mm; and the liquid metal (2) can be mercury, gallium, gallium-indium alloy or gallium-indium-tin alloy. The invention has the advantages that the liquid metal fluid containing the phase-change microcapsules has a large apparent ratio in the phase-change temperature area of a phase-change material, the phase-change microcapsules (1) are difficult to be deposited or aggregated, the liquid metal fluid has favorable performances in the aspects of calorifics, electrics, magnetics, and the like, and the thermal properties of traditional liquid metals can be enhanced greatly. The liquid metal fluid is a cooling medium suitable for various heat radiating occasions with high heat flux density, and can be widely applied to the fields of computer chips, satellites, rocket propulsion booster and lasers.

Owner:CHONGQING UNIV

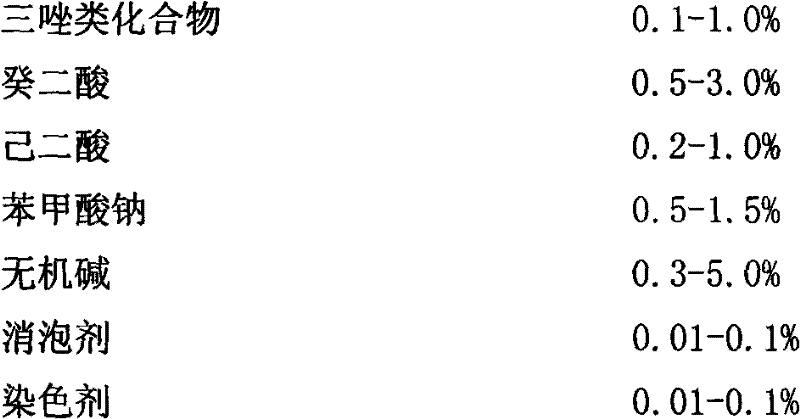

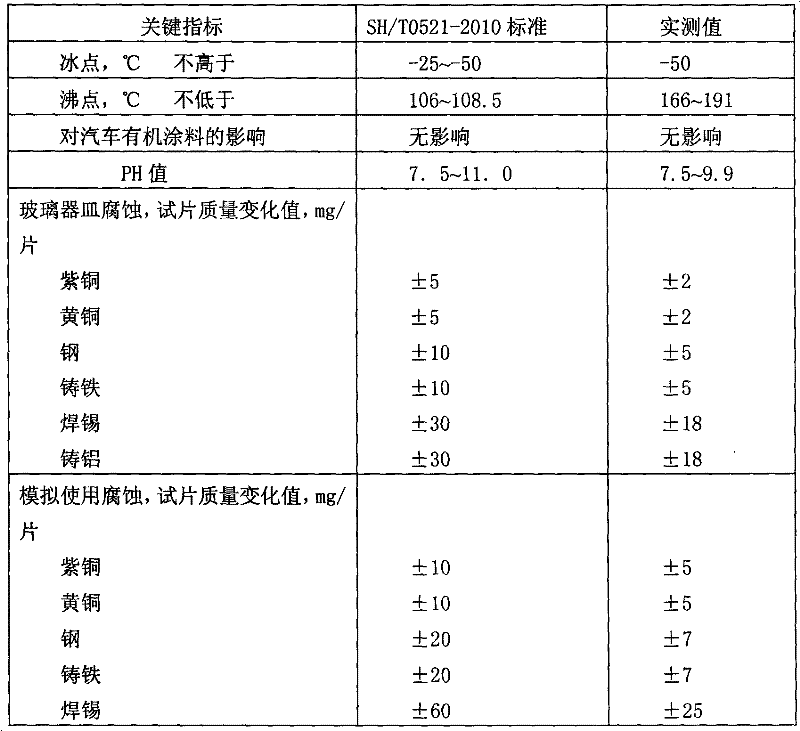

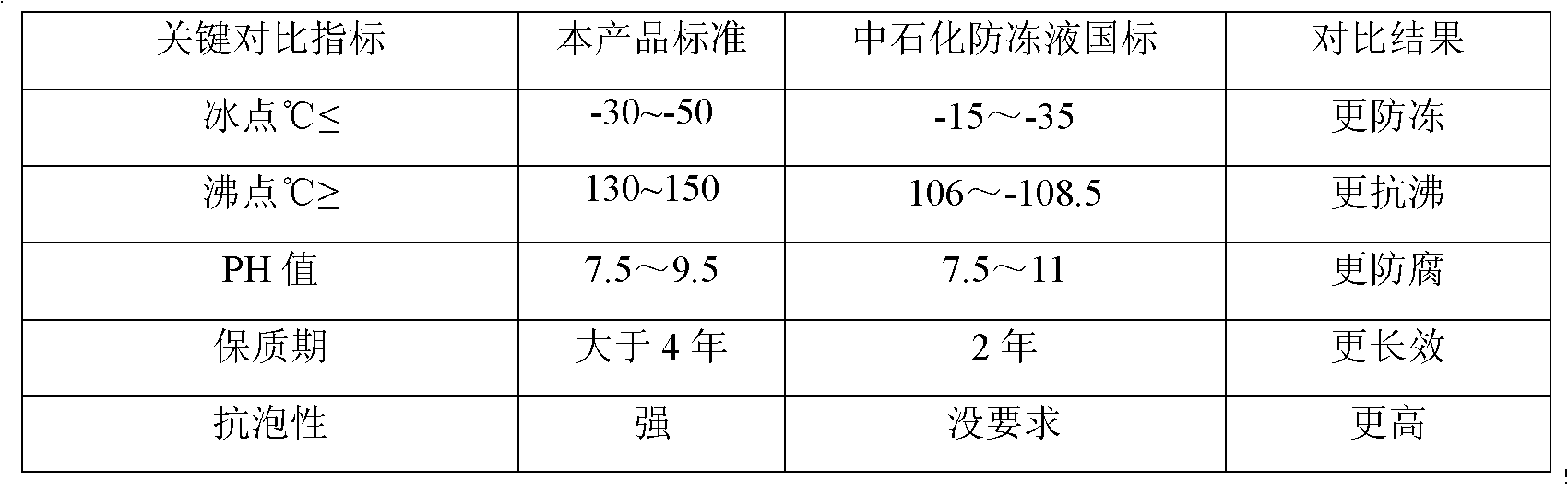

Life-cycle water-free cooling solution

The invention relates to a life-cycle water-free cooling solution which is characterized by comprising the following components in percent by weight: 10-50 percent of propylene glycol, 50-80 percent of ethylene glycol, 0.1-10 percent of triazole compounds, 0.5-3.0 percent of sebacic acid, 0.2-1.0 percent of adipic acid, 0.5-1.5 percent of sodium benzoate, 0.3-5 percent of inorganic base, 0.01-0.1 percent of antifoaming agent and 0.01-0.1 percent of colouring agent. The cooling solution has a freezing point of below -50 DEG C and a boiling point of 166-191 DEG C; and because the cooling solution does not contain water, problems of boiling, gas etching, evaporating, scaling, rusting and the like caused by water existing in the cooling solution are thoroughly eliminated, a steam air resistance layer seriously influencing heat radiation is avoided from generating, power of an engine can be effectively improved and fuel is saved. Because the cooling solution does not contain water and has a reasonable corrosion inhibition system, the problem of corrosion is thoroughly solved; and the cooling solution has a service life of reaching up to 8 hundred thousand kilometers, is added once without replacement, is a life-cycle cooling solution, is especially suitable for military vehicles, high-end vehicles and high-power heavy-loading trucks and passenger cars, and can ensure that the vehicles safely run under extremely hot weather, severe cold weather, and severe environments such as desert, plateau, snowfield and the like.

Owner:JIANGXI CHEPU IND CO LTD

Non-aqueous coolant for engine

ActiveCN102002347AStable pHImprove antifreeze effectHeat-exchange elementsOctanoic AcidsPhosphoric acid

The invention relates to a non-aqueous coolant for an engine, which is characterized by comprising the following components in percent by weight: 10-80 percent of ethylene glycol, 10-80 percent of propylene glycol, 5-20 percent of polyol, 0.1-0.8 percent of phosphate-molybdate, 0.2-0.9 percent of silicate ester, 0.1-1 percent of 4-methyl 1H-benzotriazole, 0.2-0.8 percent of citric acid, 0.2-1 percent of sebacic acid, 0.1-1 percent of octanoic acid, 0.4-1.2 percent of citrate and 0.01-0.2 percent of cosolvent. The non-aqueous coolant has freezing point of -30--50 DEG C and boiling point of 130-150 DEG C, and ensures that the cold start of the engine is realized in cold weather; meanwhile, the working temperature of the engine is improved to 95-150 DEG C from the original 85-95 DEG C. The non-aqueous coolant belongs to a non-aqueous system, avoids electrochemical corrosion, and is a buffer system with pH of 7.5-9.5; and the added relevant auxiliaries have active corrosion resistance on aluminum and aluminum alloy and copper.

Owner:HEFEI UNIV OF TECH

Method for producing aluminium and aluminium alloy by low temperature electrolysis

InactiveCN1664170ALight in massNon-volatilePhotography auxillary processesProcess efficiency improvementMetallic materialsIonic liquid

The invention relates to a method of making aluminum and aluminum alloy through electrolyzing in low temperature, which belongs to the metal material field, characterized in that it uses the alumina or silicate mineral containing aluminum as raw materials, and gets anhydrous aluminum chloride after chloridization, then prepares AlCl3 ionic liquid with anhydrous aluminum chloride, and uses the AlCl3 ionic liquid as ionogen, the aluminum will be produced in the cathode while the chlorine will be discharged from the anode. When producing the aluminum alloy, preparing the alloy elements chloridate-AlCl3 ionic liquid through adding alloy elements chloridate MeCln to the AlCl3 ionic liquid, Using the direct current to electrolyzing, wherein the voltage is above the higher decomposition voltage of the aluminium chloride and chloridate and below the electrochemistry window of the ionic liquid, and the aluminum will be produced in the cathode while the chlorine will be discharged from the anode.

Owner:UNIV OF SCI & TECH BEIJING

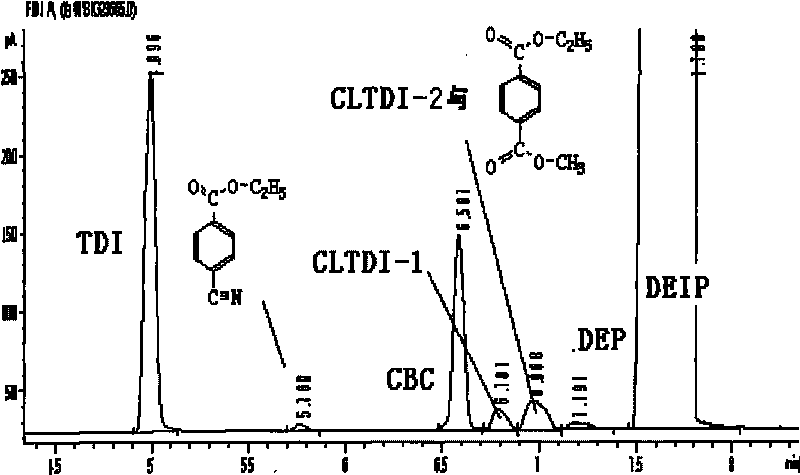

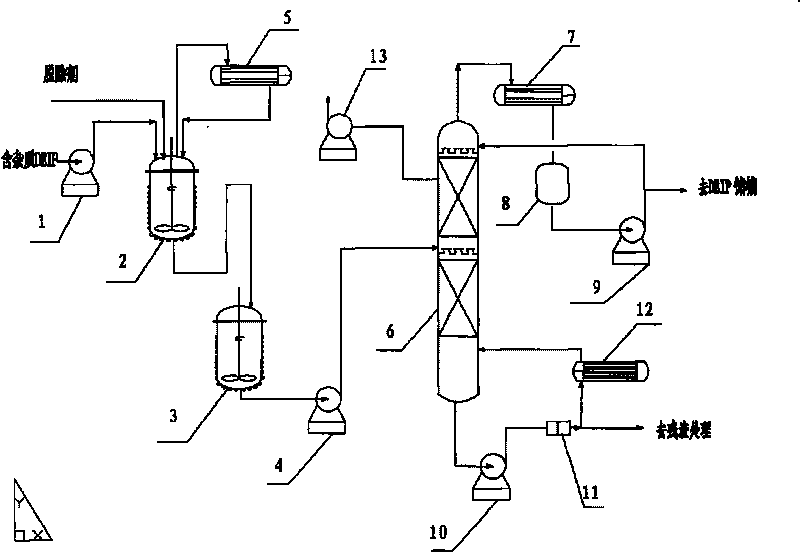

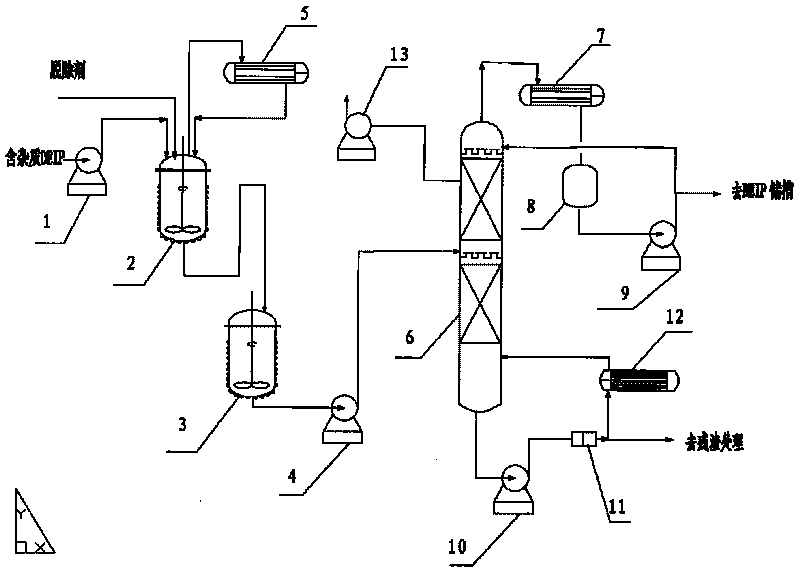

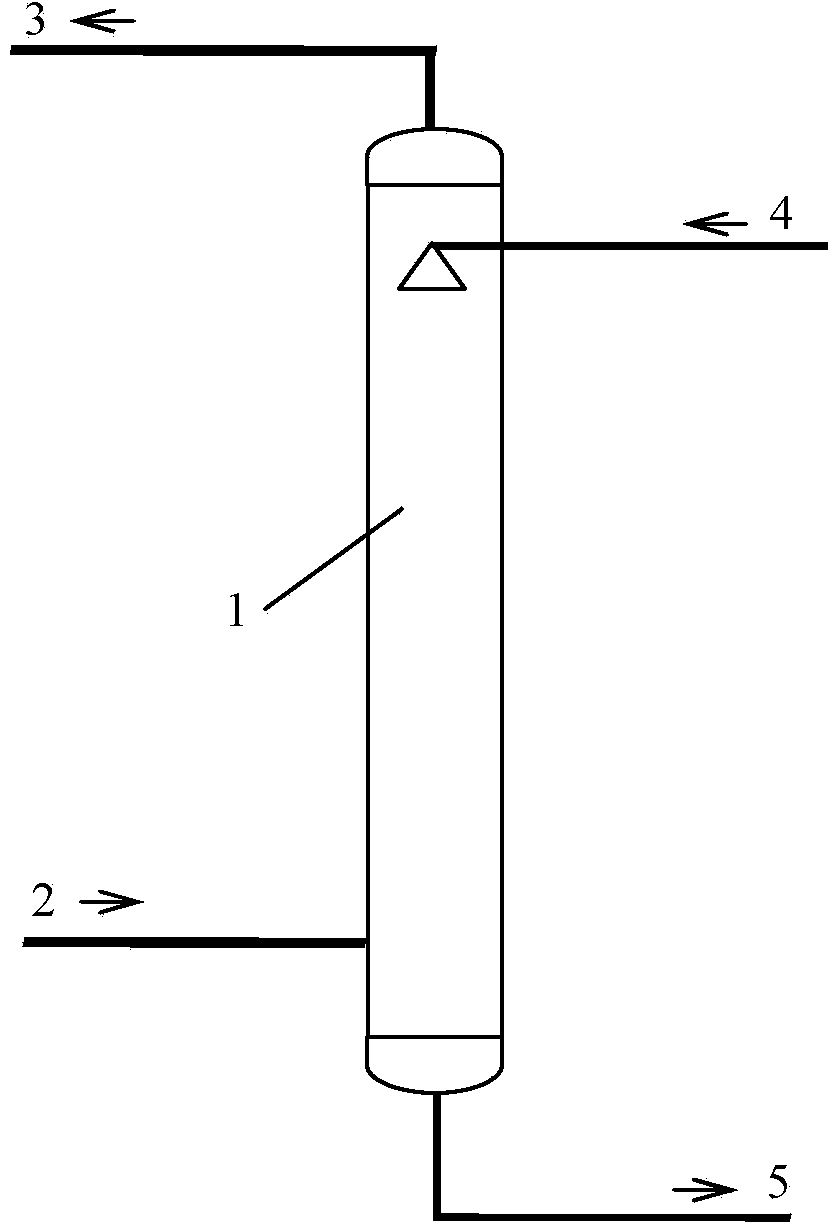

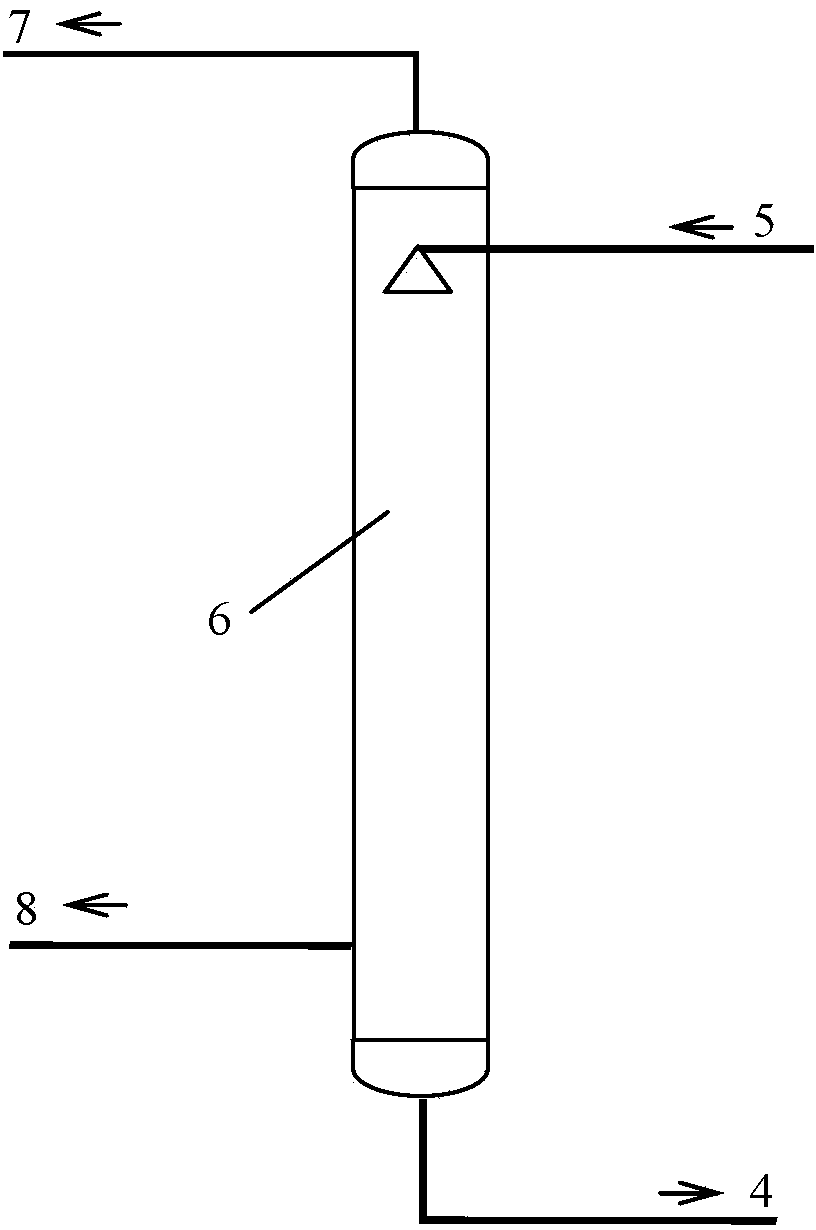

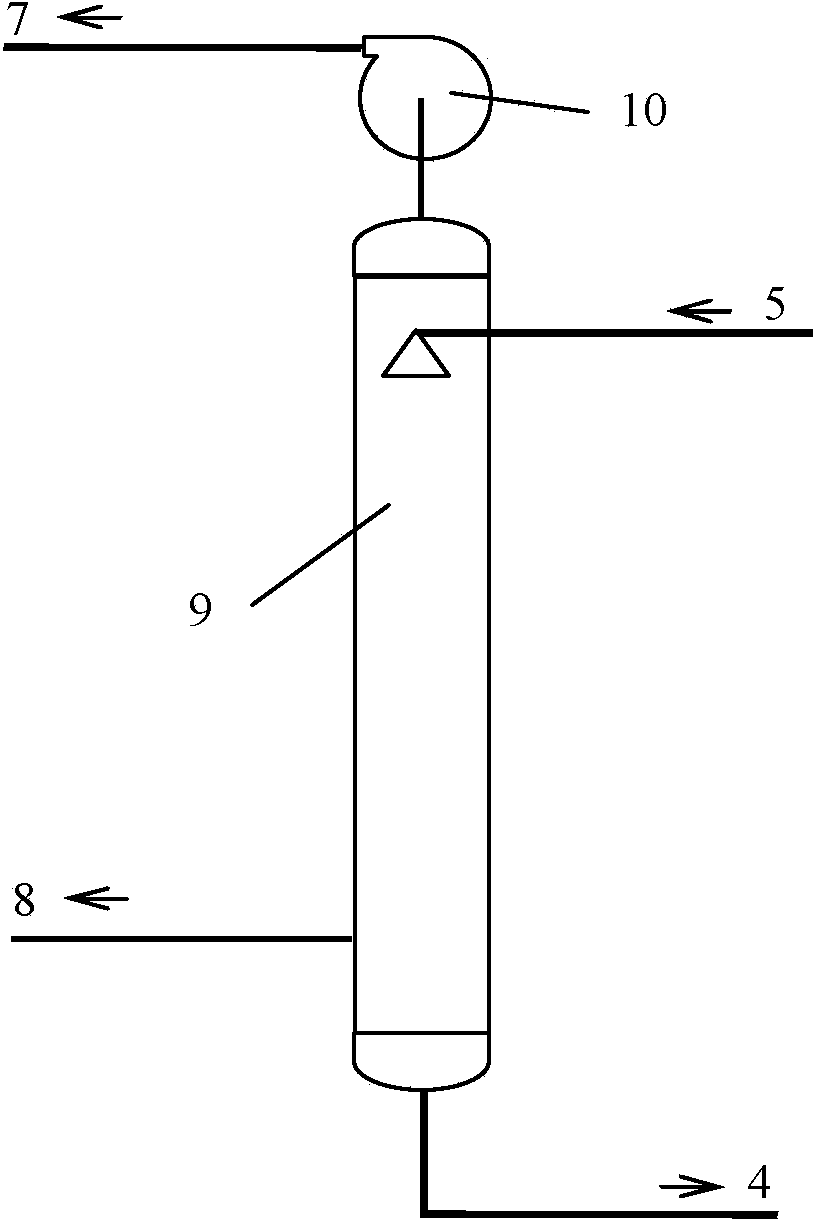

Method for purifying cyclic solvent in producing TDI

InactiveCN101698652AHigh removal rateLess removal rateIsocyanic acid derivatives preparationOrganic compound preparationPolyethylene glycolBenzoyl chloride

The invention relates to a method for purifying cyclic solvent in producing TDI, particularly relates to the case that if the abnormal condition that group impurities containing -NCO such as TDI, CI-TDI, m-CBC and the like are carried by the cyclic solvent DEIP occurs in producing toluene diisocynate (TDI) by a heavy solvent phosgene method, the -NCO group impurities react with TDA and phosgene in a photochemical process to lower TDI yield and generate urea and acid amides residual substances to lead to the problem that production is stopped to clean away obstruction due to the blocking of pipelines and device. The invention uses a processing method of reacting PEG or C2H5OH with -NCO group impurities, adopts rectification to separate the generated heavy components from DEIP to obtain pure DEIP at the tower top to return to a storing bank of the cyclic solvent, and the tower bottom obtains the reacted NCO components and original heavy component residual removal system, thus ensuring smooth operation of the device.

Owner:甘肃银光聚银化工有限公司 +1

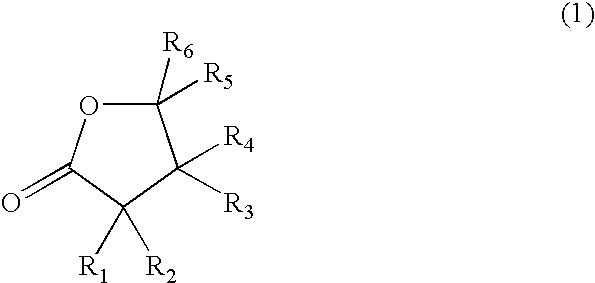

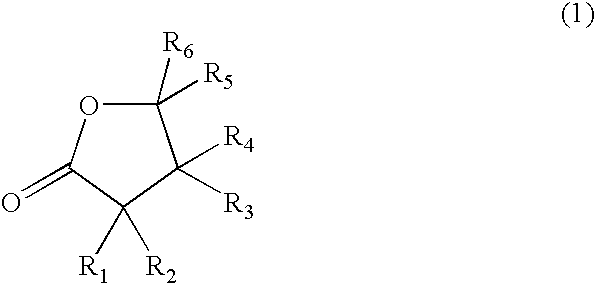

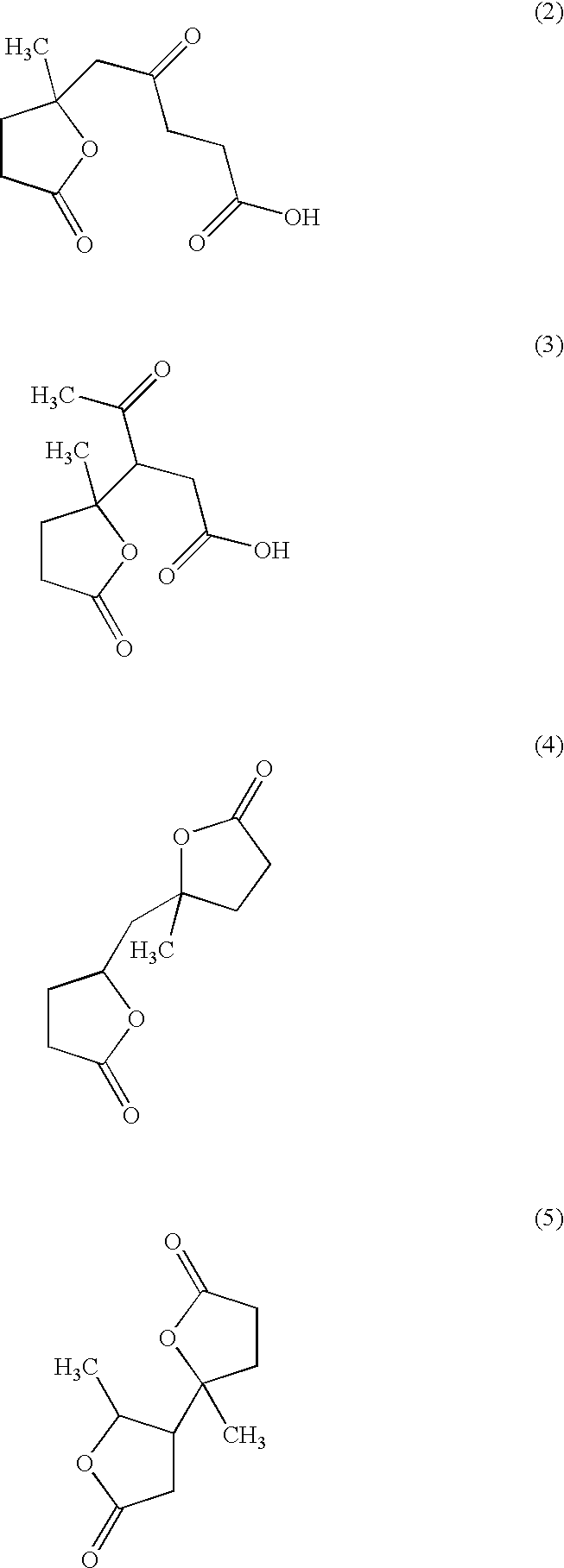

Process for organosolv pulping and use of a gamma lactone in a solvent for organosolv pulping

InactiveUS20070034345A1High boiling pointReduce stressPulp properties modificationPulp bleachingHydrogen atomOrganic group

The invention provides a process for organosolv pulping, wherein solid lignocellulosic feed material is heated at a temperature in the range of from 50 to 210° C. in a solvent to obtain a solid cellulosic fraction comprising at least 50 wt % of the cellulose present in the feed material and a liquid fraction, wherein the solvent comprises at least 10 wt % of a compound according to general molecular formula wherein R1 to R6 each represent, independently, a hydrogen atom or an organic group connected with a carbon atom to the lactone group. The invention further provides the use of a compound according to general molecular formula (1) in a solvent for organosolv pulping.

Owner:SHELL OIL CO

Microelectronic fabrication system components and method for processing a wafer using such components

InactiveUS20050160974A1Avoid flowHigh boiling pointVacuum evaporation coatingSemiconductor/solid-state device manufacturingTopographyElectrical and Electronics engineering

A process chamber is provided which includes a gate configured to align barriers with an opening of the gate and an opening of the process chamber such that the two openings are either sealed or provide an air passage to the chamber. A method is provided and includes sealing an opening of a chamber with a gate latch and exposing a topography to a first set of process steps, opening the gate latch such that an air passage is provided to the process chamber, and exposing the topography to a second set of process steps without allowing liquids within the chamber to flow through the air passage. A substrate holder comprising a clamping jaw with a lever and a support member coupled to the lever is also contemplated herein. A process chamber with a reservoir arranged above a substrate holder is also provided herein.

Owner:LAM RES CORP

Methods and systems for processing a microelectronic topography

InactiveUS20050181135A1Avoid flowHigh boiling pointPretreated surfacesSemiconductor/solid-state device manufacturingElectroless depositionTopography

Owner:LAM RES CORP

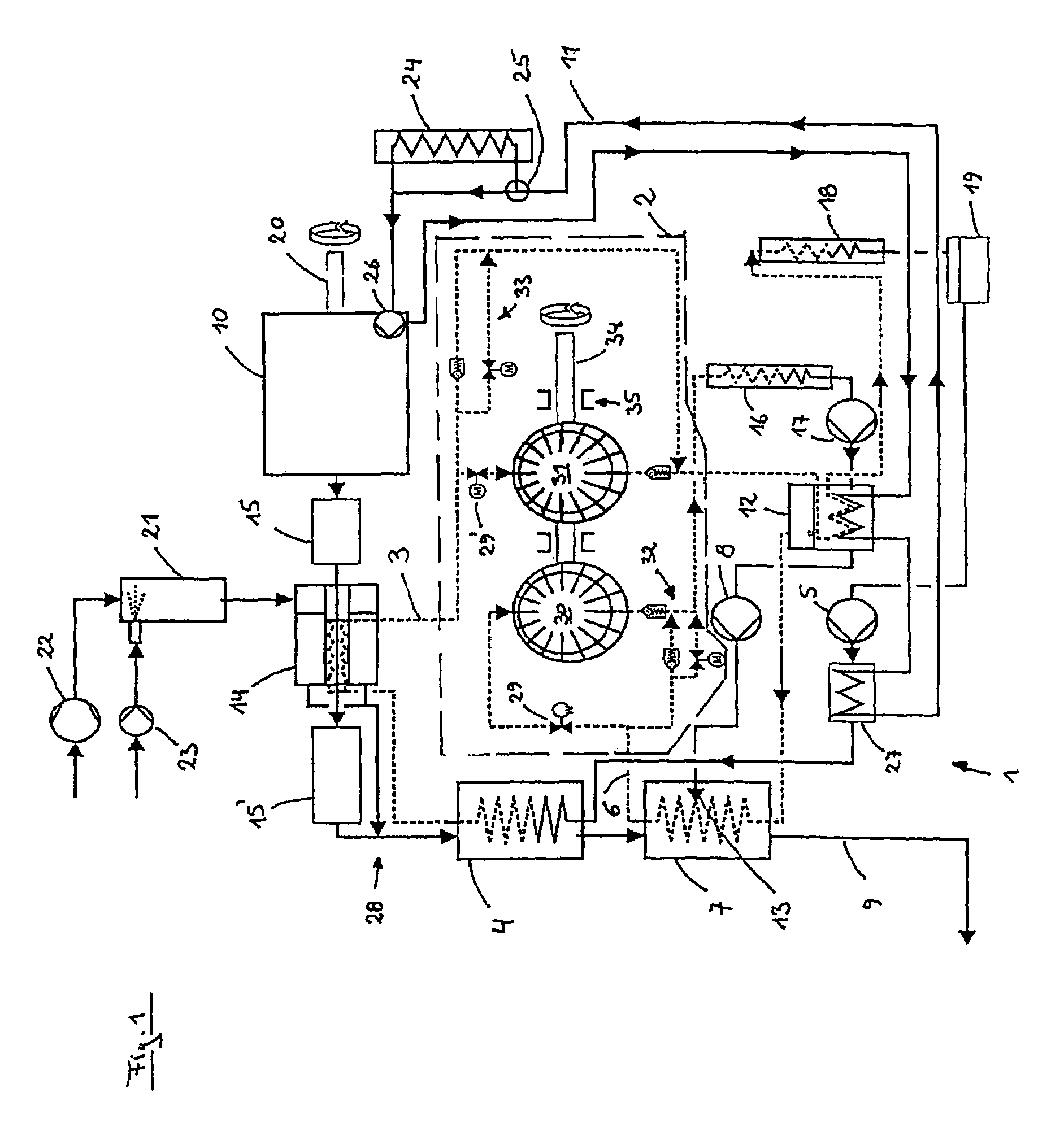

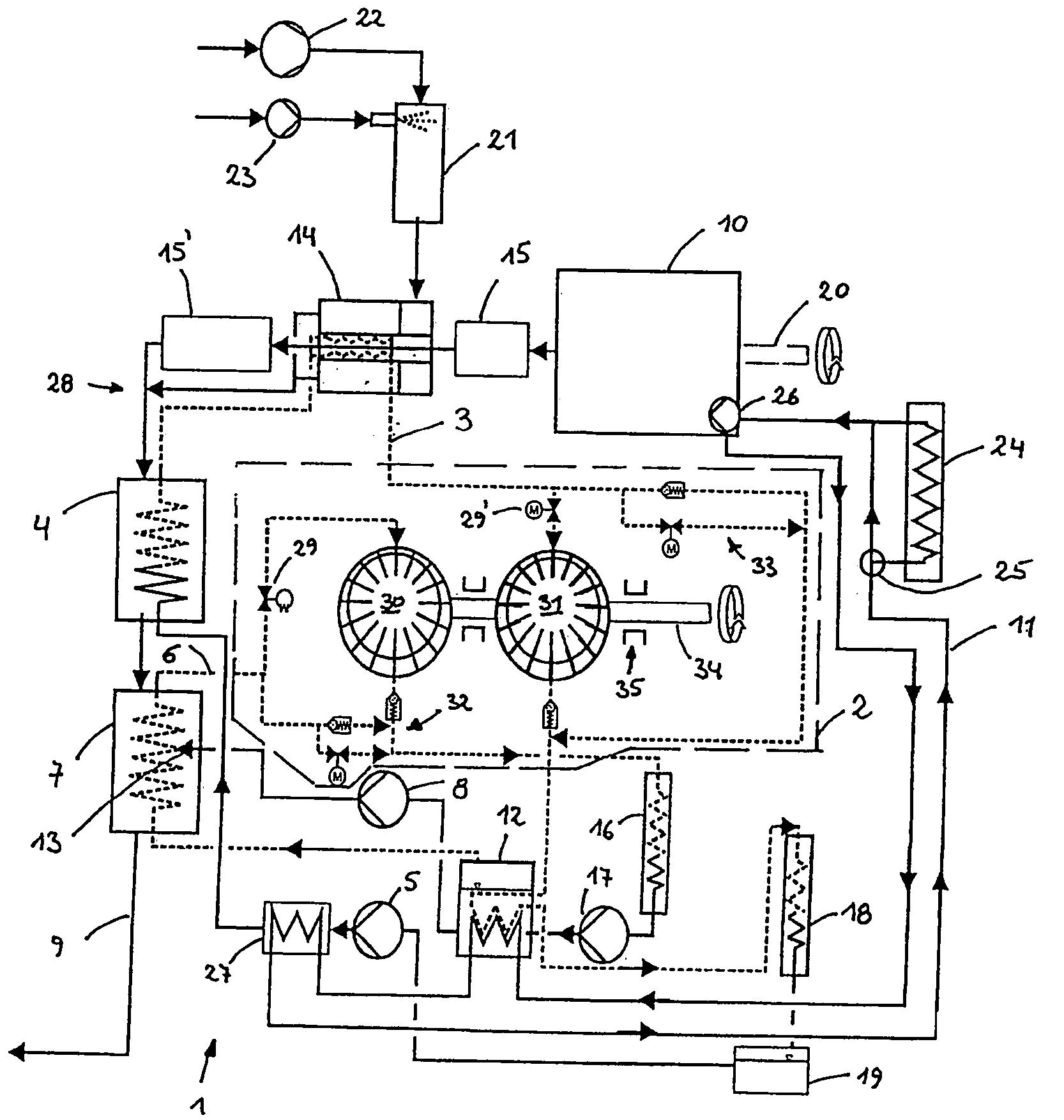

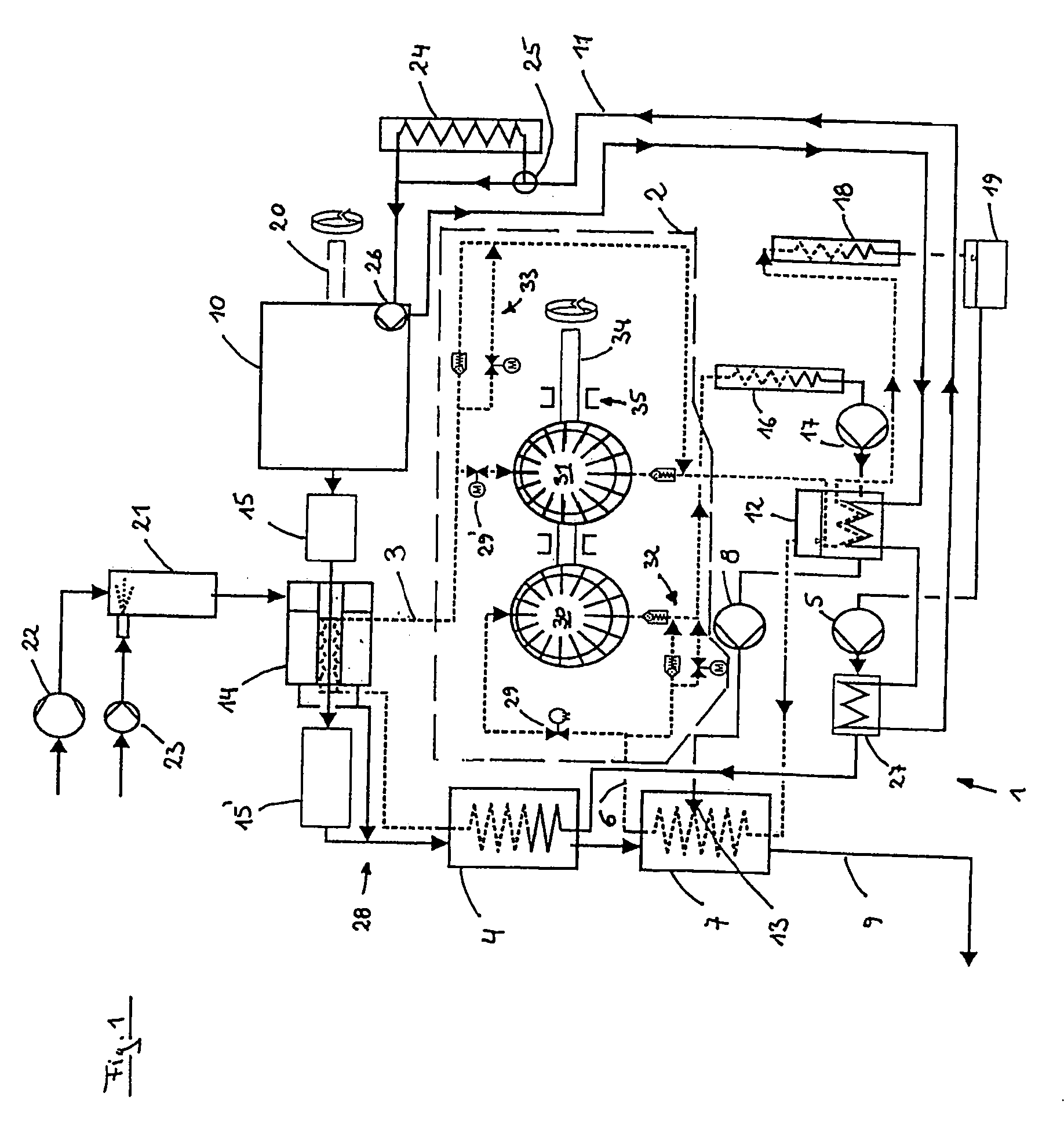

Thermodynamic engine

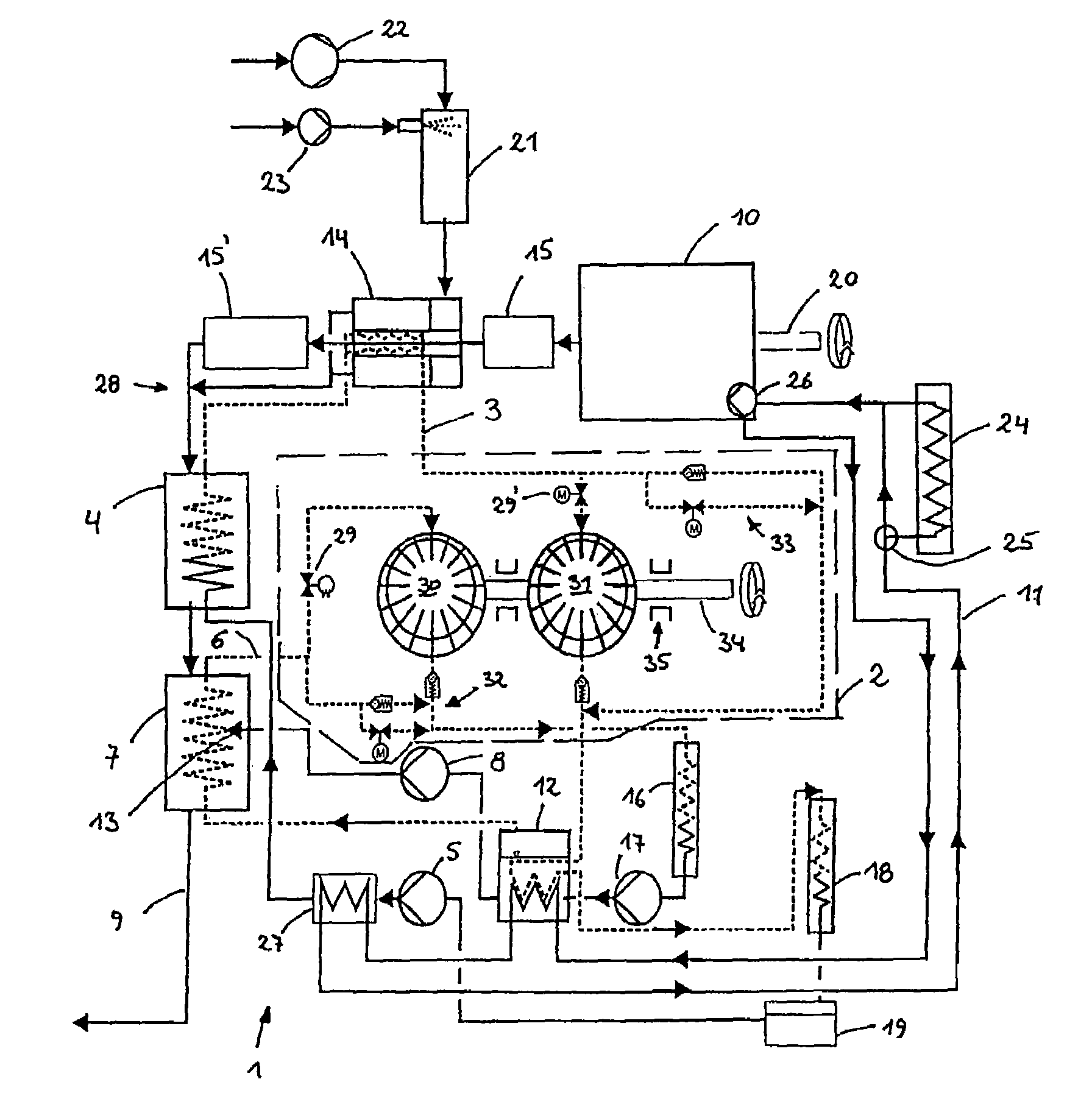

InactiveUS7520133B2Improve efficiencyMaintain efficiencyInternal combustion piston enginesEngine componentsPlate heat exchangerExternal combustion engine

A thermodynamic engine converts the superheated steam of at least one working medium into kinetic energy using a decompression device. Said engine includes a low-temperature circuit, in which a first working medium is transported through a first heat exchanger and subsequently through the decompression device and a high-temperature circuit, in which a second working medium is transported through a second heat exchanger and subsequently through the decompression device. The first heat exchanger and the second heat exchanger are located in the exhaust system of an internal combustion engine, and the internal combustion engine a coolant circuit can be used to heat the working mediums in separate collection containers.

Owner:BAYERISCHE MOTOREN WERKE AG

Thermodynamic engine

InactiveUS20050229595A1Avoid overall overheatingEasy to useInternal combustion piston enginesEngine componentsEngineeringInternal combustion engine

A thermodynamic engine converts the superheated steam of at least one working medium into kinetic energy using a decompression device. Said engine includes a low-temperature circuit, in which a first working medium is transported through a first heat exchanger and subsequently through the decompression device and a high-temperature circuit, in which a second working medium is transported through a second heat exchanger and subsequently through the decompression device. The first heat exchanger and the second heat exchanger are located in the exhaust system of an internal combustion engine, and the internal combustion engine a coolant circuit can be used to heat the working mediums in separate collection containers.

Owner:BAYERISCHE MOTOREN WERKE AG

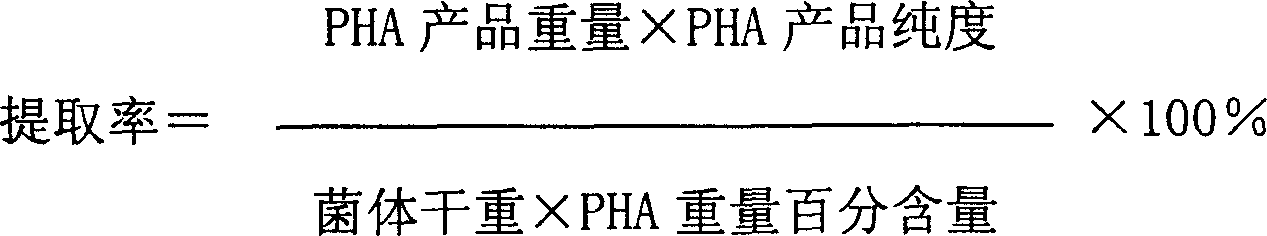

Method for extracting intracellular poly hydroxy fatty acid in microbe

This invention is extraction method of cellular hydroxy fatty acid esters from microorganism. The procedure is as followings: 1) ferment to get enough microorganisms, collect it. 2) Dry to powder, add esterlike organic solvents. React at 80-120deg C for 1-4hours. Extract hydroxy fatty acid esters. 3) Restore the organic phase. 4) Precipitate hydroxy fatty acid esters from the organic phase with esterlike organic solvents. 5) Separate, wash and precipitate. 6) dry to obtain hydroxy fatty acid esters. This invention could be used in high quality PHA industrialization. It's time-reduced, energy-saving, environment-friendly and highly-efficient. It has a large application scale.

Owner:TSINGHUA UNIV

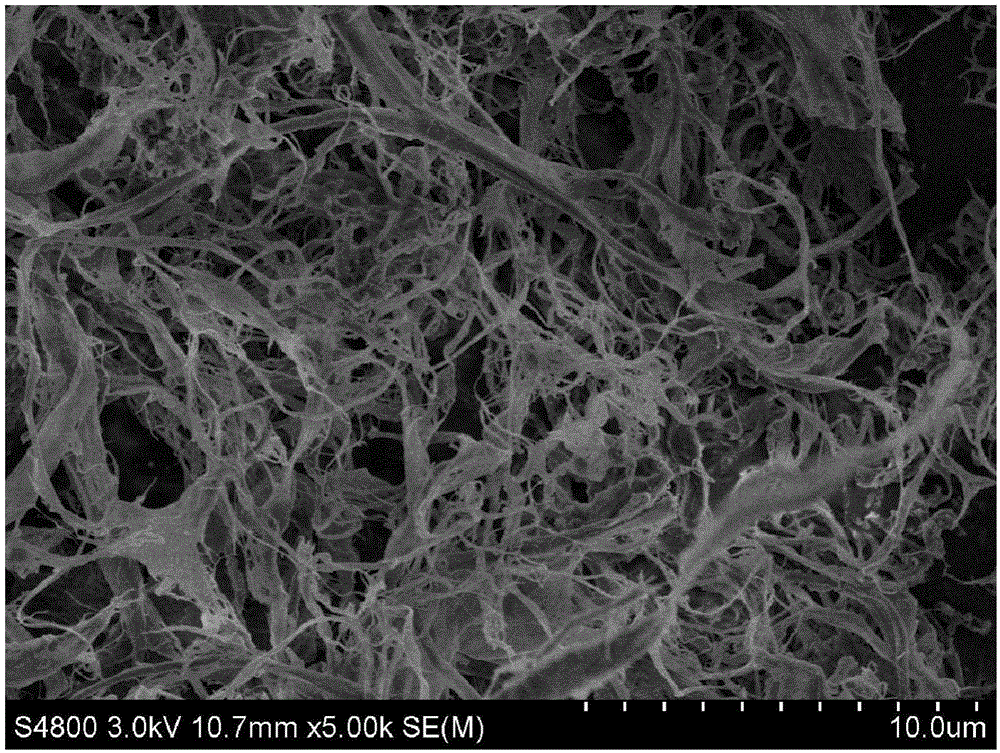

Method for sustainably preparing nanometer cellulose

The invention discloses a method for sustainably preparing nanometer cellulose in an environment-friendly and economic mode. The preparing method includes the following steps that 1, cellulose raw materials and organic acid are hydrolyzed and esterified; 2, the treated cellulose is prewashed in a centrifugal sedimentation mode, the organic acid is separated to be continuously recycled, washed cellulose suspension liquid is dialyzed, and then reacted acid and accessory substances are removed; 3, the dialyzed suspension liquid is separated to obtain small-particle cellulose nanometer crystals; 4, cellulose solid precipitated on a lower layer of the suspension liquid is treated through a high-pressure homogenizer or an ultrasonication physical machine to obtain colloidal cellulose nanometer fibrils. According to the method, in the preparing process, the modified cellulose raw materials are synchronously hydrolyzed and esterified through relative-safety and environment-friendly food-grade organic acid; compared with inorganic strong acid, the used organic acid is low in corrosion performance, high in boiling point, small in reaction pressure and easy to control and operate, and the cellulose nanometer crystals with the stable quality and the cellulose nanometer fibril products with the stable quality can be obtained at the same time.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

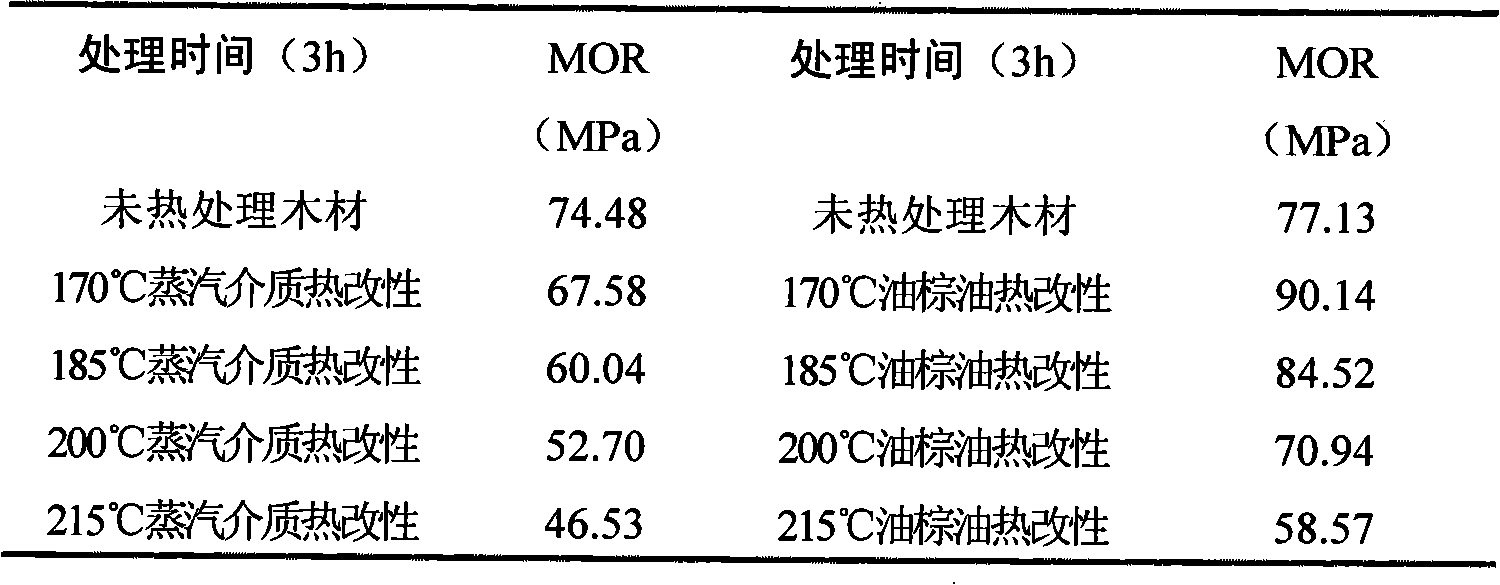

Method for thermally modifying wood by oil palm oil

ActiveCN102152361AFast heat transferHigh boiling pointWood treatment detailsIncrease sizeRoom temperature

The invention relates to a method for thermally modifying wood by oil palm oil. The method comprises the following steps of: stacking the wood stably, and then placing the wood stack in a treating tank; heating up the oil palm oil and then filling to the treating tank, completely covering the wood by the oil palm oil, heating up the wood, and keeping the temperature for 0.5-3 hours for thermally modifying the wood when the temperature of the wood reaches 200-215 DGE C; and stopping heat supply, then discharging the oil palm oil immediately, filling atomized water into the treating tank to gradually cool the wood, and then naturally cooling the wood to the room temperature (30 DEG C) so as to complete the treatment. The method in the invention is simple in process; the wood is isolated from the air by the oil palm oil; the wood is effectively prevented from oxidation and degradation; the thermal treatment features in fast heating speed, short treating period and low cost; the treated wood features in increased size stability, small bending resistance intensity loss, high corrosion resistance, high intensity, good durability and the like; and the wood is convenient for industrial application, and can be widely used for the indoor and outdoor furniture, landscapes, finishing materials and the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Water-based extinguishing agent and preparing method

The invention discloses a water-based extinguishing agent. The water-based extinguishing agent is prepared by raw materials including, by mass percent, 20% to 50% of a composite coagulant reduction agent, 0.5% to 2.0% of a thickening agent, 7% to 20% of a fire retardant, 4% to 10% of a stabilizing agent, 4% to 16% of a micro-foaming agent, 0.5% to 4% of a hardness-resisting agent, 0.2% to 5% of a solubilizing agent, 0.1% to 0.5% of a corrosion remover and the balance water. According to the water-based extinguishing agent, a food additive serves as a main raw material, a fluorocarbon surfactant is not contained, and the agent has the beneficial effects of being low in solidifying point, high in fire extinguishing cooling speed, capable of rapidly extinguishing fires of solids, liquid, gas and electrified and cooking objects, high in after-combustion resistance capacity, meanwhile, free of harms and pollutions to plants, animals, soil and water, capable of achieving complete biodegradation, energy-saving and environment-friendly.

Owner:浙江环亚消防新材料股份有限公司

Method for removing SOx in gas by using ethylene glycol complex solution

ActiveCN103611391ADecreased sulfur absorption capacityBroad marketGas treatmentDispersed particle separationMicrowave methodPolyethylene glycol

The invention discloses a method for SOx in a gas by using ethylene glycol complex solution. Ethylene glycol and / or polyethylene glycol is mixed with organic acid or organic acid salt without containing nitrogen atoms in molecules to form the ethylene glycol complex solution, and the ethylene glycol complex solution is in contact with the gas containing Sox to absorb SOx in the gas, wherein x is equal to 2 and / or 3; the ethylene glycol complex solution in which SOx is absorbed is regenerated by using one or more ways of a heating method, a vacuum method, a gas stripping method, an ultrasonic method, a microwave method and a radiation method, sulfur dioxide and sulfur trioxide byproducts are released, and the regenerated ethylene glycol complex solution is recycled. The method can be applied to desulfurization of flue gases, incineration gases, coke furnace gases, synthetic waste gases in a dyestuff plant and sewage disposal gases in a chemical fibre factory, and other industrial raw material gases or waste gases containing SOx.

Owner:BEIJING BOYUAN HENGSHENG HIGH TECH +2

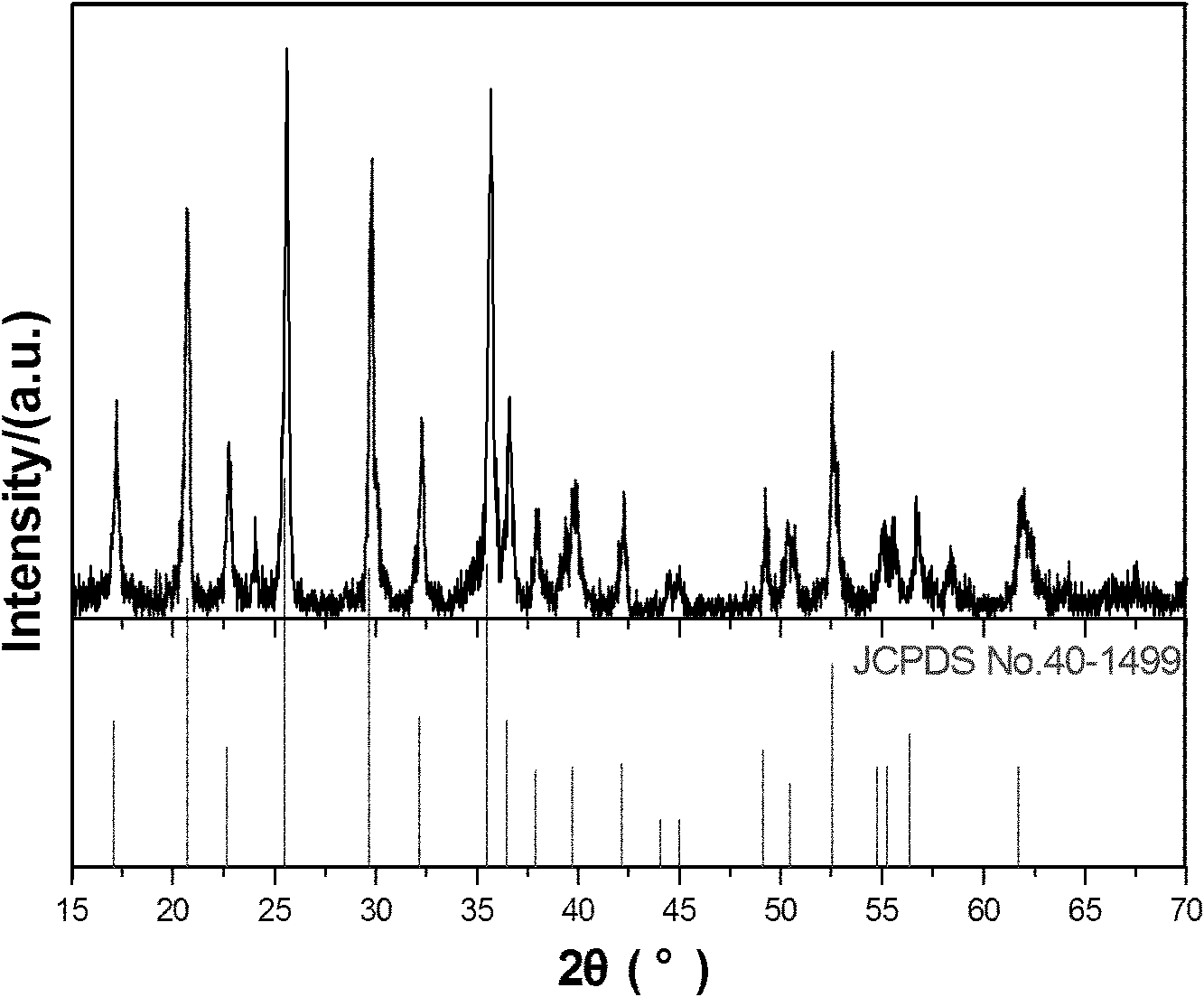

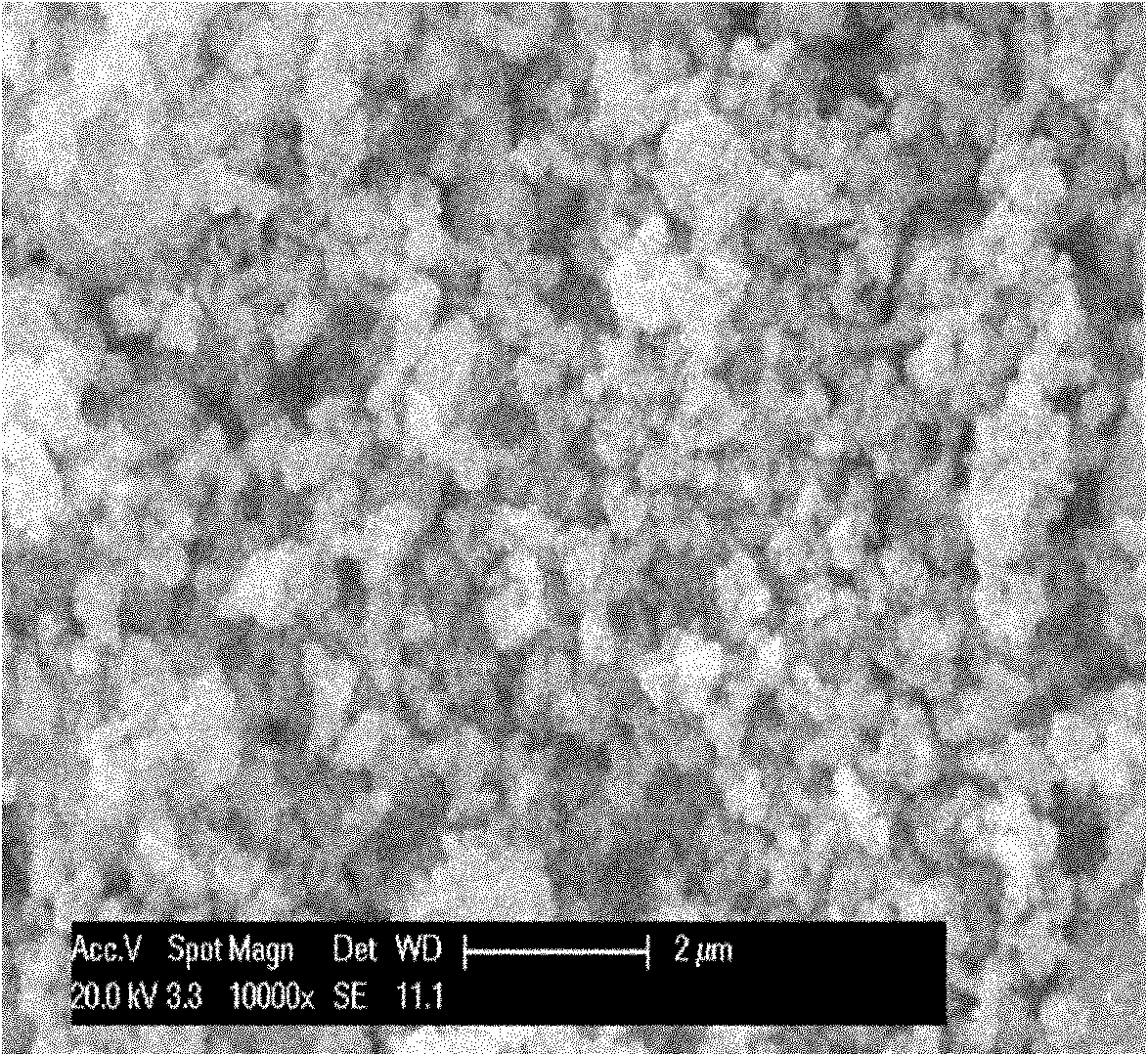

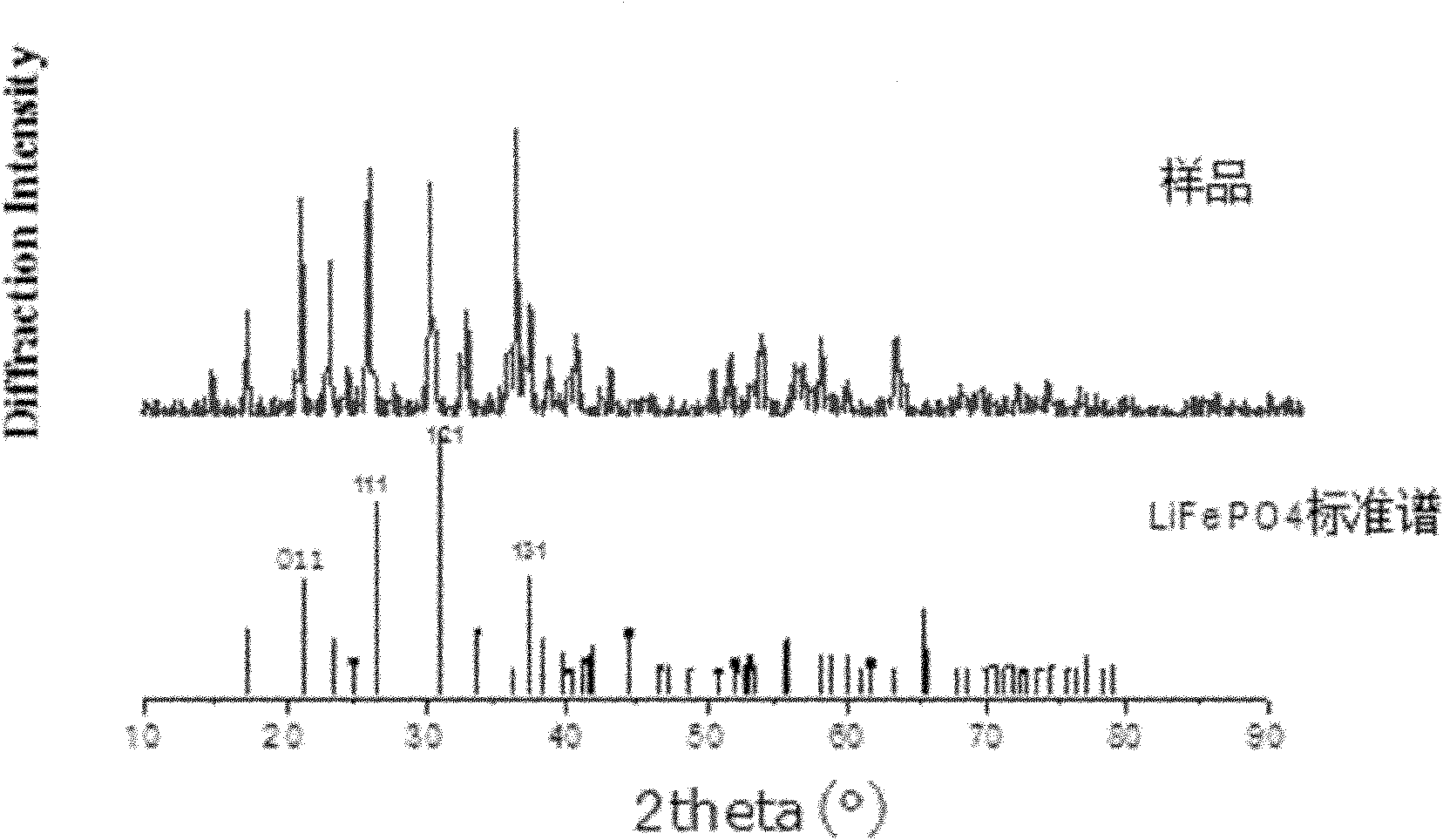

Hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate

InactiveCN102074687AShort tripIncrease the speed of diffusionCell electrodesReaction temperatureMolecular level

The invention discloses a hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate, which belongs to the field of lithium-ion battery anode materials and comprises the following steps of: sequentially adding a phosphorus-source solution, an iron-source solution, a carbon source, a lithium-source solution and a boiling-point elevator into a reaction device in sequence, mixing, then heating to the temperature of 60-180 DEG C for reaction under inert gas, cooling after the reaction, filtering precipitates to obtain a nano-scale lithium iron phosphate precursor, and then sintering the nano-scale lithium iron phosphate precursor at the temperature of 400-600 DEG C under the protection of the mixed gas of the inert gas and hydrogen gas. The combination of lithium, iron, phosphorus and the like on a molecular level is realized by the method, and the grains of a product are quite fine and are uniformly distributed; because the boiling-point elevator is adopted, the reaction temperature and pressure of the reaction kettle are decreased; and the hydrothermal synthesis method has the advantages of simple preparation process, short flow, easiness in operational control, low reaction temperature, short time, low energy consumption and easiness in realizing large-scale industrialized production.

Owner:JIANGSU DELI CHEM

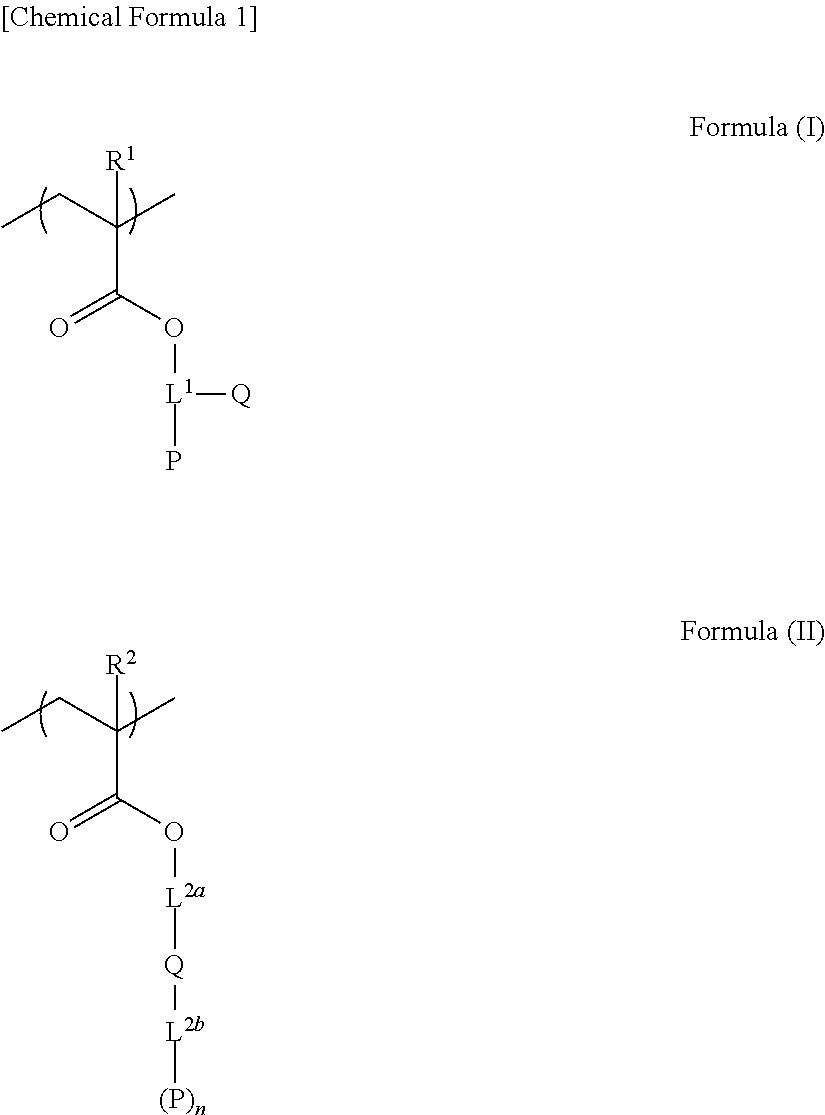

Composition, cured article, laminate, method for manufacturing underlying film, method for forming pattern, pattern and method for manufacturing a resist for semiconductor process

InactiveUS20160009945A1Improve adhesionSmall defect densityPretreated surfacesSemiconductor/solid-state device manufacturingResistIn plane

Provided is a composition capable of producing an underlying film which demonstrates a good adhesiveness between a substrate and a layer to be imprinted, showing a good in-plane uniformity of the thickness, and a small defect density. The composition includes a polymerizable compound, a first solvent, and a second solvent, the first solvent having a boiling point at 1 atm of 160° C. or higher, the second solvent having a boiling point at 1 atm of lower than 160° C., and the content of the polymerizable compound in the composition being less than 1% by mass.

Owner:FUJIFILM CORP

Vinyl trimethoxysilane oligomer preparation method

The invention relates the method for preparation of ethenyl trimethoxy silane low-molecular polymer, comprising the following steps: 1 adding the ethenyl trimethoxy silane into the reactor, adjusting the PH at 4-7 by adding the acid; 2 adding the metallic catalyst, the dosage of which is 10-1000ppm, stirring; 3 at 60-160 DEG C, making them hydrolytic polycondensation reaction for 6-12 hours by adding water, the weight ratio of water and ethenyl trimethoxy silane being 0.05-0.15; 4 distilling and removing the by-product carbinol; 5 neutralizing the acid by adding the alkali, using the suction and getting the product. The invention possesses the characters of simple technology and easy accomplishment. Because the boiling point and flash point of the said ethenyl trimethoxy silane low-molecular polymer are high, the security and operability is better. The alcohol of releasing by using the method is less, so it is more propitious to environmental protection.

Owner:南京市化学工业研究设计院有限公司

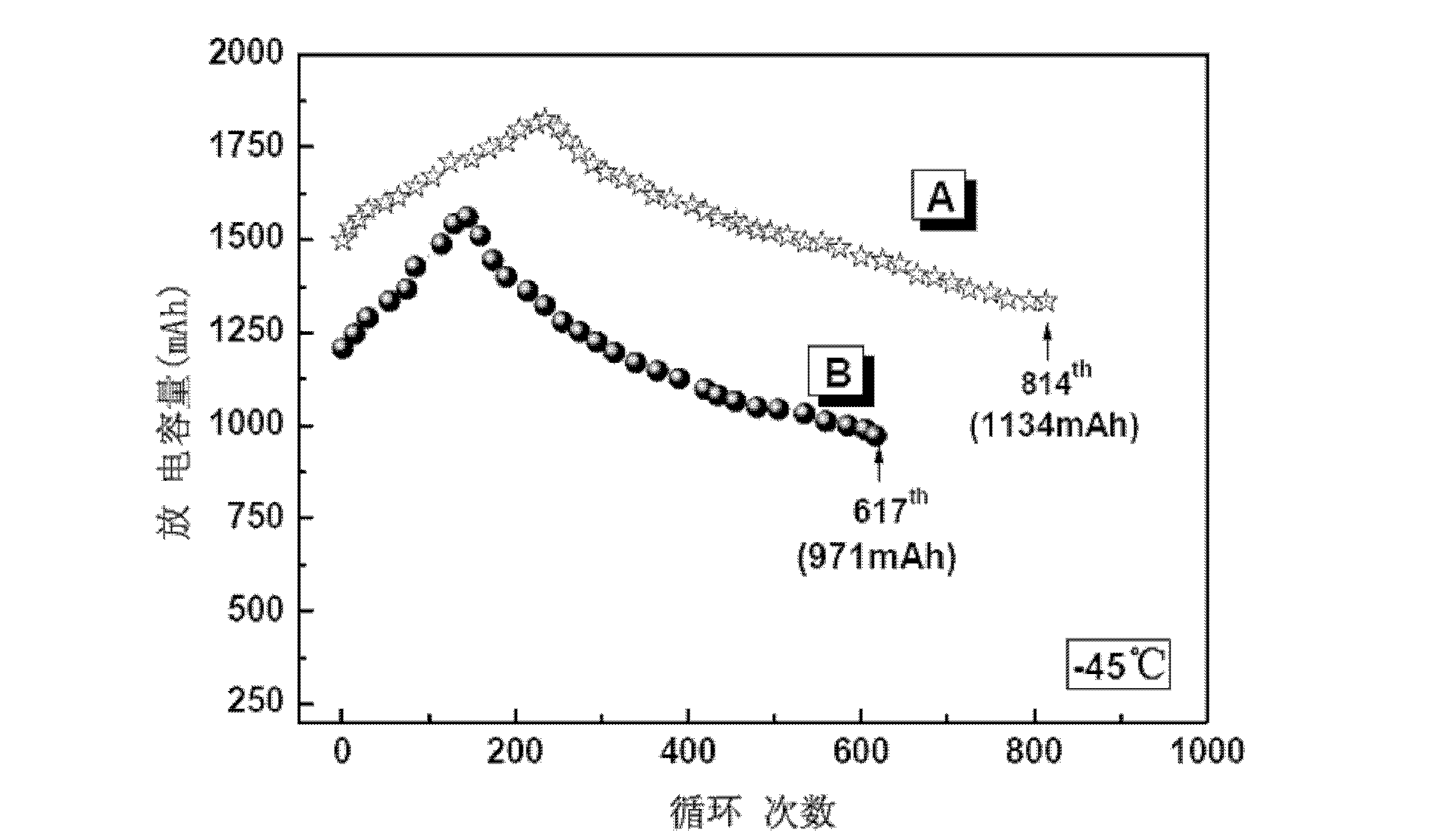

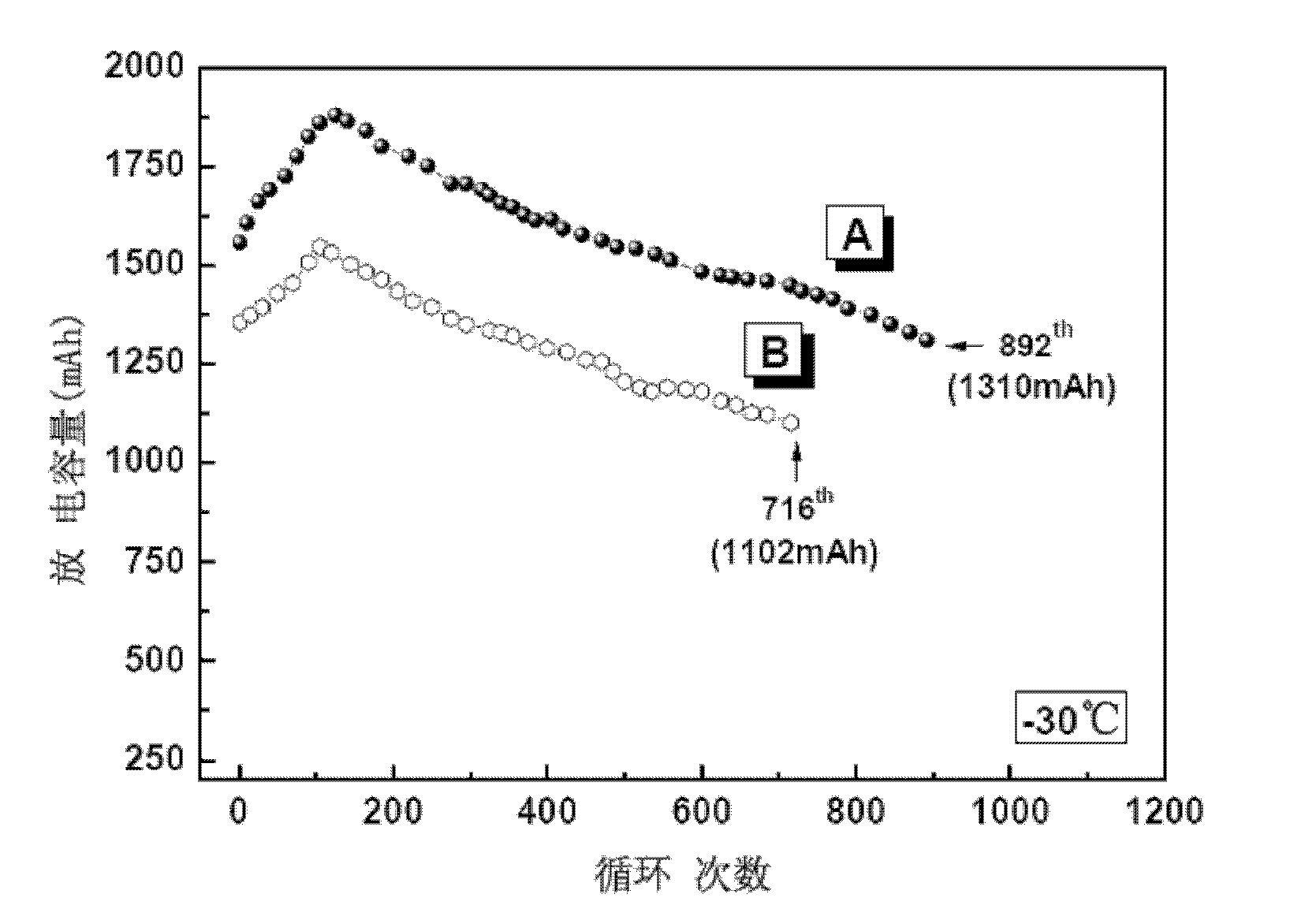

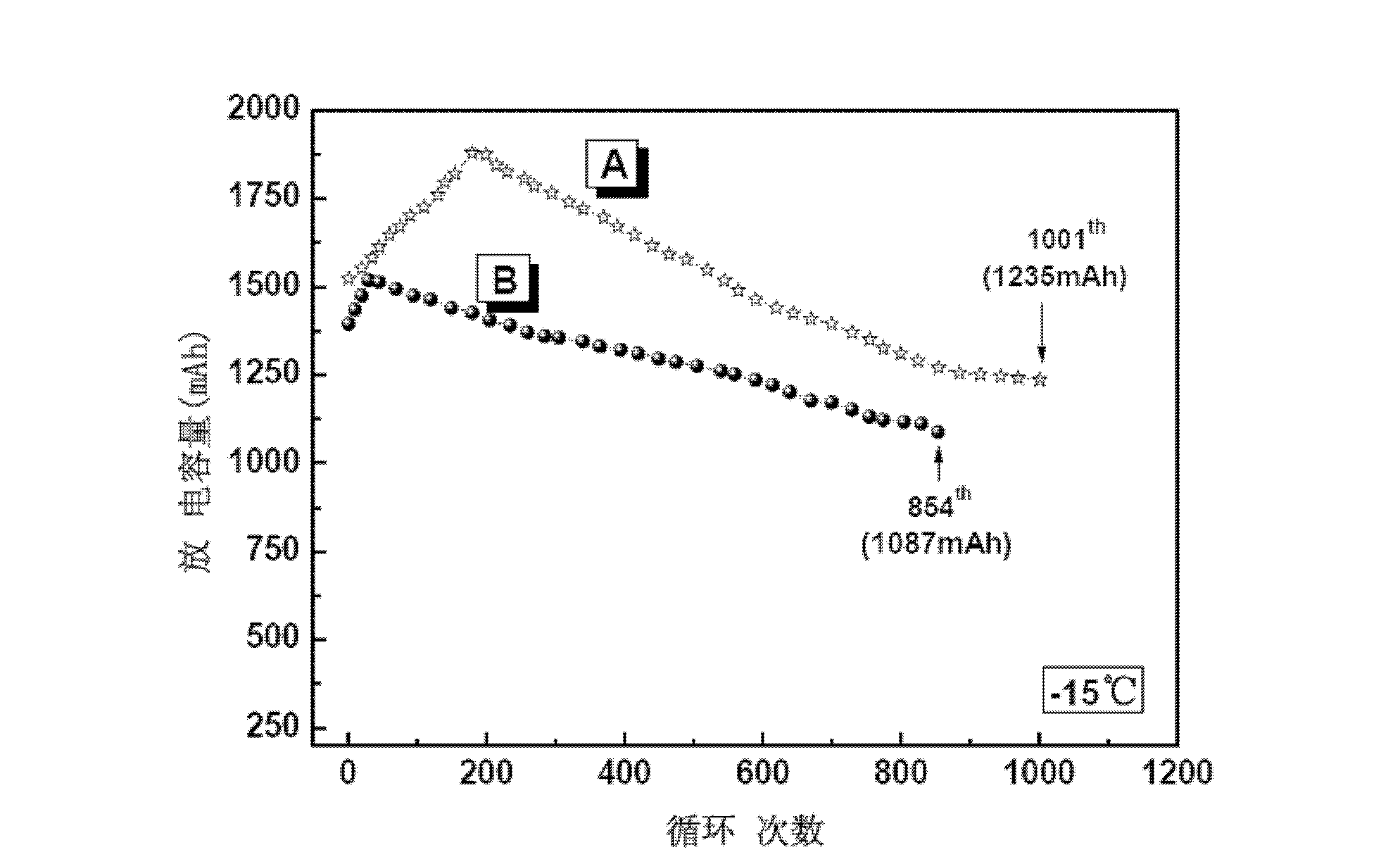

Electrolyte for lithium ion battery and preparation method thereof

ActiveCN102637901AGood effectImprove charge and discharge efficiencySecondary cellsLithium oxideLithium hydroxide

The invention discloses an electrolyte for a lithium ion battery and a preparation method thereof. The electrolyte consists of a main electrolyte, an electrolyte additive, a main solvent and a solvent additive. The preparation method comprises the following steps of: A. under the condition of vacuum or inert gas protection, respectively mixing the main solvent and the solvent additive with a drying agent (lithium oxide) which is dried to be at constant weight in advance, and mixing and filtering to remove the lithium oxide and lithium hydroxide sediment; B. uniformly mixing the dried main solvent and the dried solvent additive from the step A; and C. adding a main electrolyte mixture and an electrolyte additive into the solvent mixed in the step B, and agitating and dissolving under the vacuum and inert gas protection to prepare a solution with the mass mol concentration of the main electrolyte of 0.5-1.5 M. The electrolyte has the advantages of abundant resources, low price and no toxin, effectively improves the work temperature range of the battery and effectively prolongs the circulating service life of the battery, so that various types of the lithium ion batteries are manufactured; and the electrolyte is particularly suitable for manufacturing a lithium ion power battery with high power capacity and high multiplying power charging and discharging capacity.

Owner:广州云通锂电池股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com