Paper deacidification agent, and paper deacidification system and method thereof

A deacidification method and technology of deacidification agent, which are applied in the post-processing of waste paper, etc., can solve the problems of low deacidification effect, high risk, and less alkali residue, and achieve remarkable deacidification effect, low equipment manufacturing cost, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A paper deacidifying agent comprises nano oxide particles, a silane coupling agent and a perfluorooctane liquid. The nano oxide particles are coated with a silane coupling agent and then suspended in the perfluoro octane liquid.

[0043] The nano-oxide particles are nano-magnesia particles, and the silane coupling agent is KH-570 (γ-(methacryloyloxy)propyltrimethoxysilane).

[0044] The average diameter of the nano oxide particles is 50nm.

[0045] The mass percentage of the nano-oxide particles is 0.5%.

[0046] The mass percent of the silane coupling agent is 6%.

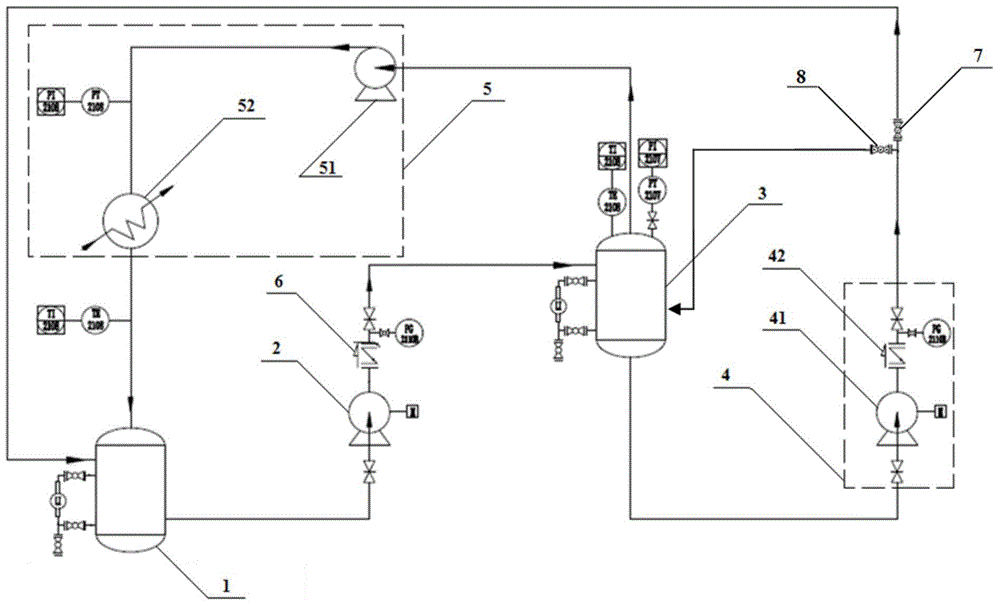

[0047] like figure 1 Shown, a kind of paper deacidification system using described paper deacidification agent, comprises deacidification liquid storage tank 1, centrifugal pump 2, deacidifier 3 and circulation device 4 that are connected in sequence, the outlet of described circulation device 4 The first switch valve 7 is connected to the inlet of the deacidification liquid storage tank 1, the outlet of...

Embodiment 2

[0065] A paper deacidifying agent comprises nano magnesium hydroxide particles, a silane coupling agent and a perfluorooctane liquid. The nano magnesium hydroxide particles are coated with a silane coupling agent and then suspended in the perfluoro octane liquid.

[0066] The silane coupling agent is KH-570 (γ-(methacryloyloxy)propyltrimethoxysilane).

[0067] The average diameter of the nano magnesium hydroxide particles is 50nm.

[0068] The mass percentage of the nano magnesium hydroxide particles is 0.8%.

[0069] The mass percent of the silane coupling agent is 5%.

[0070] Such as figure 1 Shown, a kind of paper deacidification system using described paper deacidification agent, comprises deacidification liquid storage tank 1, centrifugal pump 2, deacidifier 3 and circulation device 4 that are connected in sequence, the outlet of described circulation device 4 The first switch valve 7 is connected to the inlet of the deacidification liquid storage tank 1, the outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com