Patents

Literature

40results about How to "Realization of high value-added utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

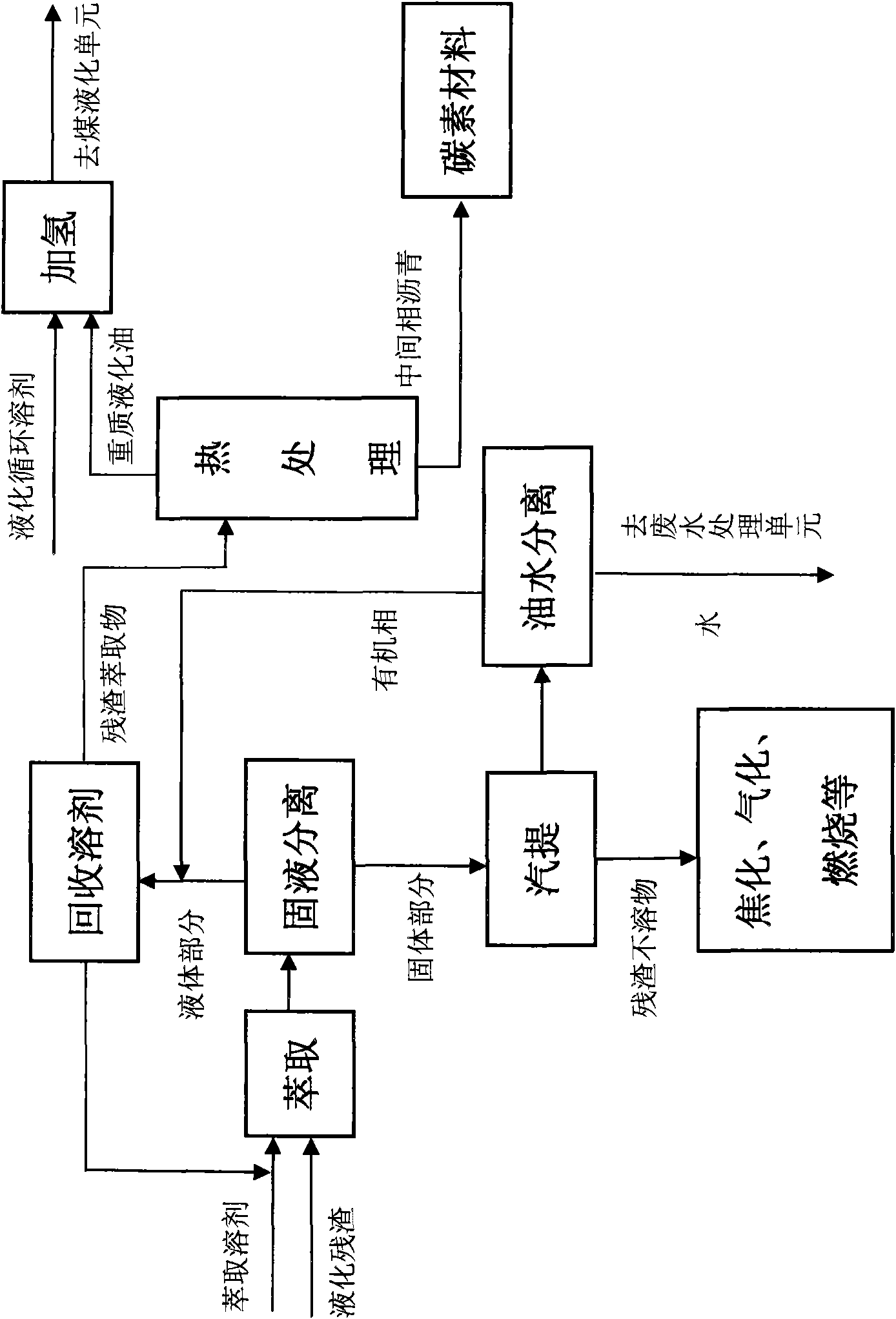

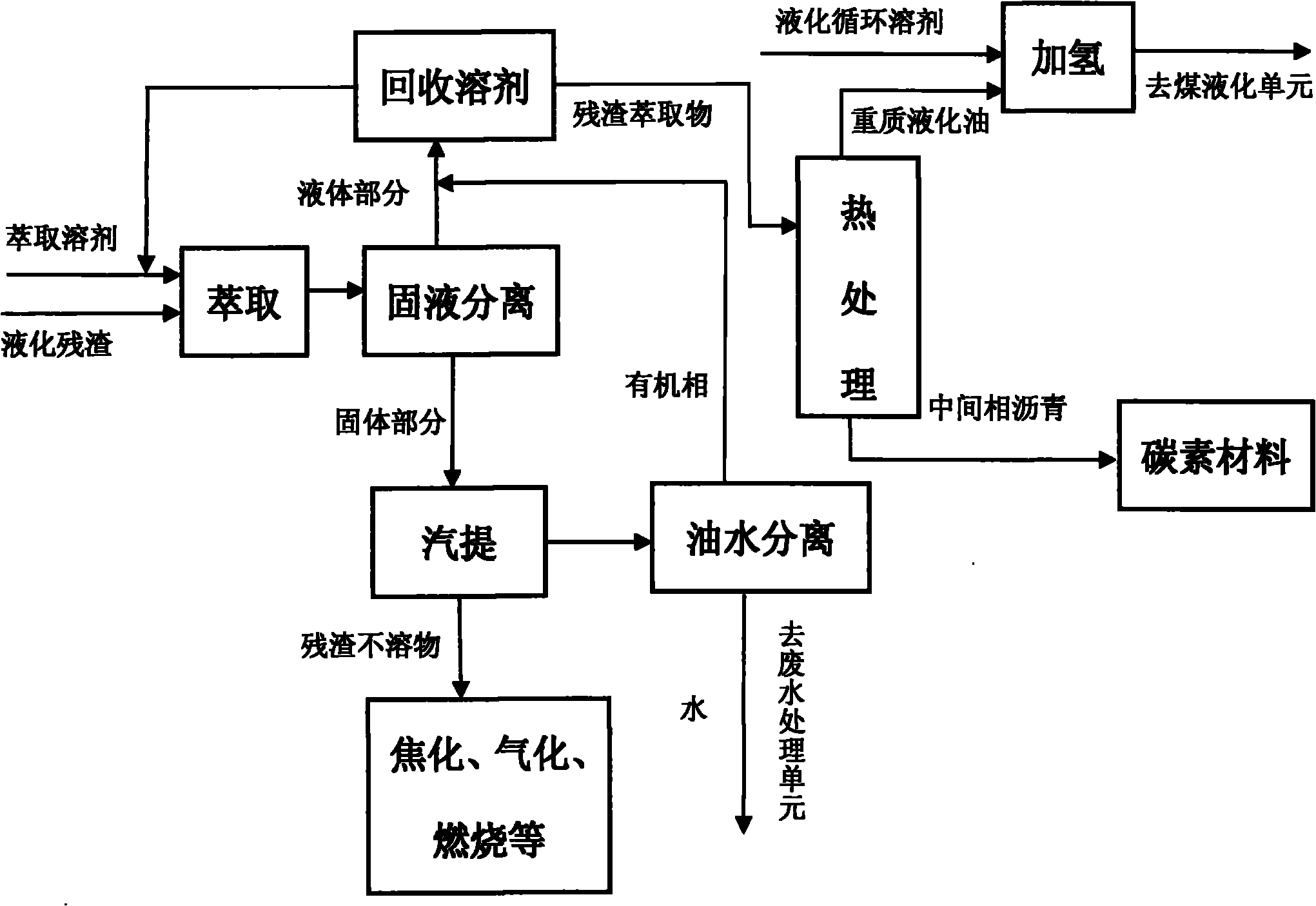

Method for extracting heavy liquefaction oil and intermediate-phase bitumen matter from coal liquefaction residuals and application thereof

ActiveCN101885976ARealize rationalityRealization of high value-added utilizationThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionEvaporationOil water

The invention provides a method for extracting heavy liquefaction oil and an intermediate-phase bitumen matter from coal liquefaction residuals and application thereof. The method comprises the following steps of: adding coal liquefaction residual powder and an extraction solvent to a stirring kettle together for extraction to obtain extraction liquid and extraction residues; carrying out solid-liquid separation on the obtained extraction liquid and extraction residues; carrying out steam stripping on the obtained extraction residues, and recovering an organic phase after oil-water separation; mixing the extraction liquid with the organic phase, and then delivering into a solvent recovery unit; recovering the extraction solvent for recycling use or being returned to a liquefaction productprocessing unit by using a distillation method and / or an evaporation method, wherein residuals obtained after the extraction solvent is recovered are liquefaction residual extractives; delivering theobtained liquefaction residual extractives into a heat treatment unit, and separating the heavy liquefaction oil from the intermediate-phase bitumen matter by using a heating dry distillation method;and adding the obtained heavy liquefaction oil and other recycling solvents in a direct liquefaction process to a coal liquefaction solvent hydrogenation unit together.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

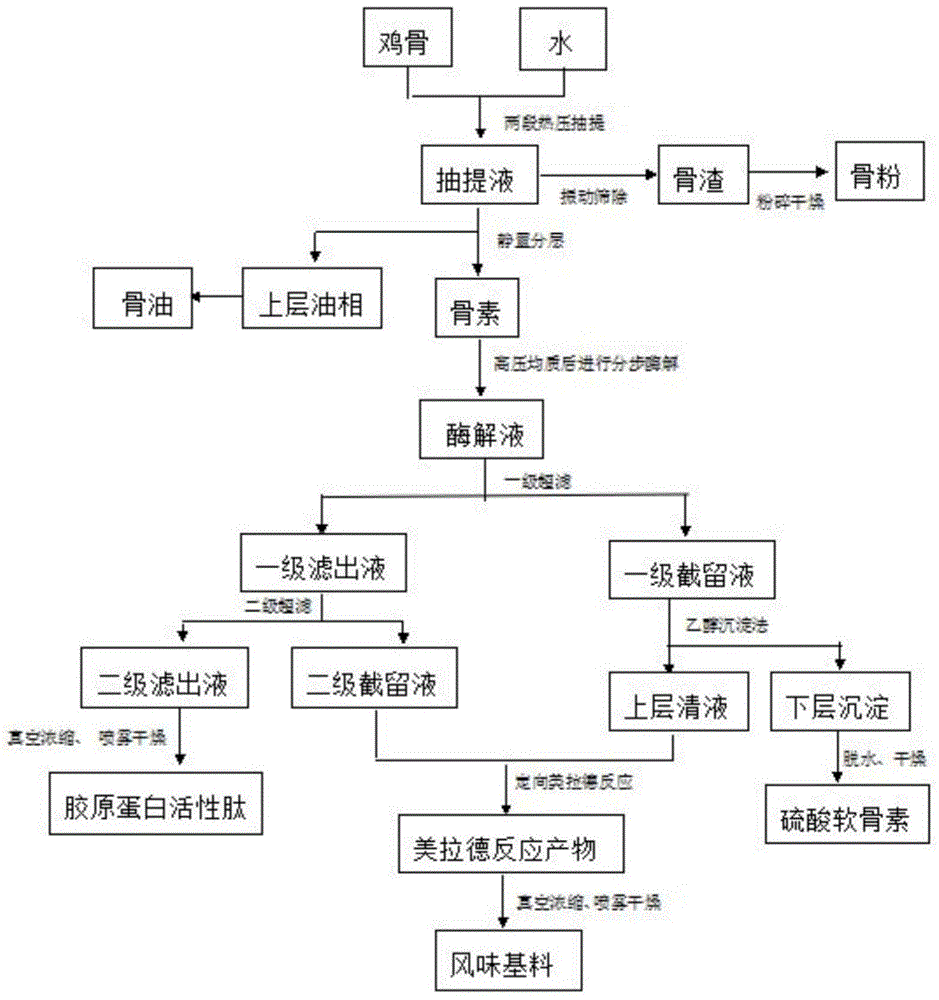

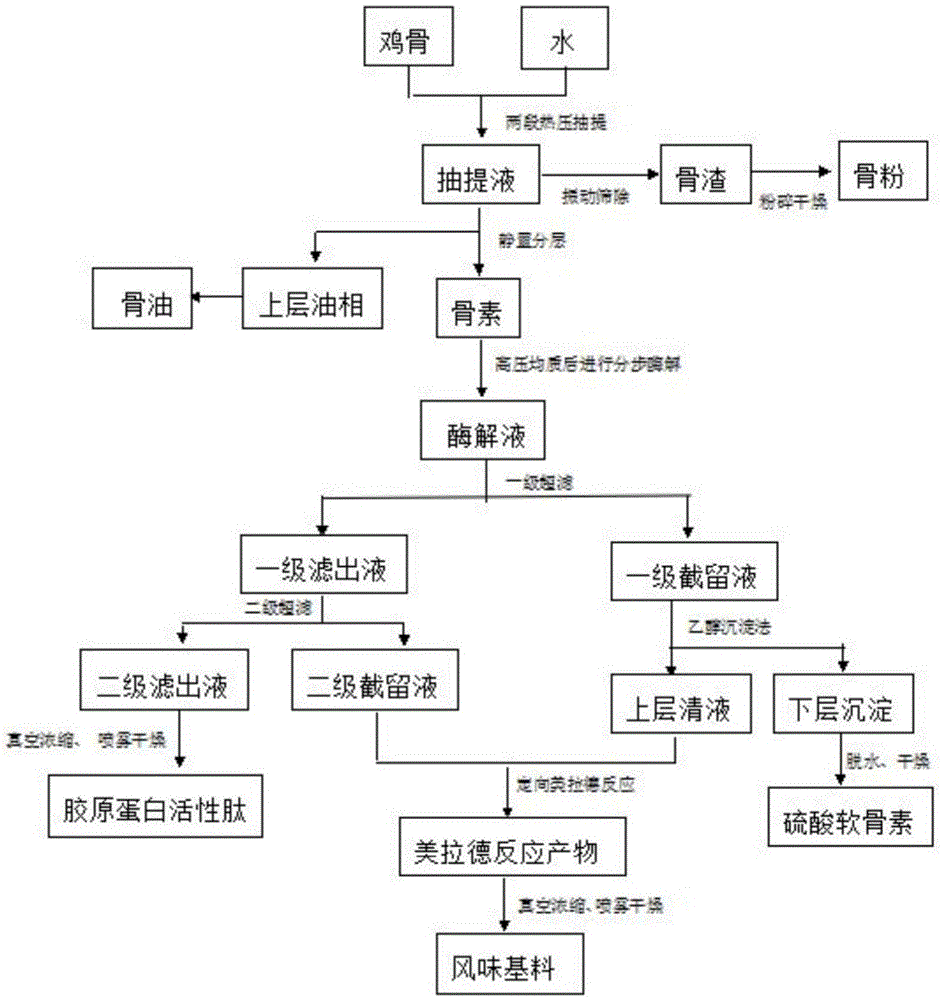

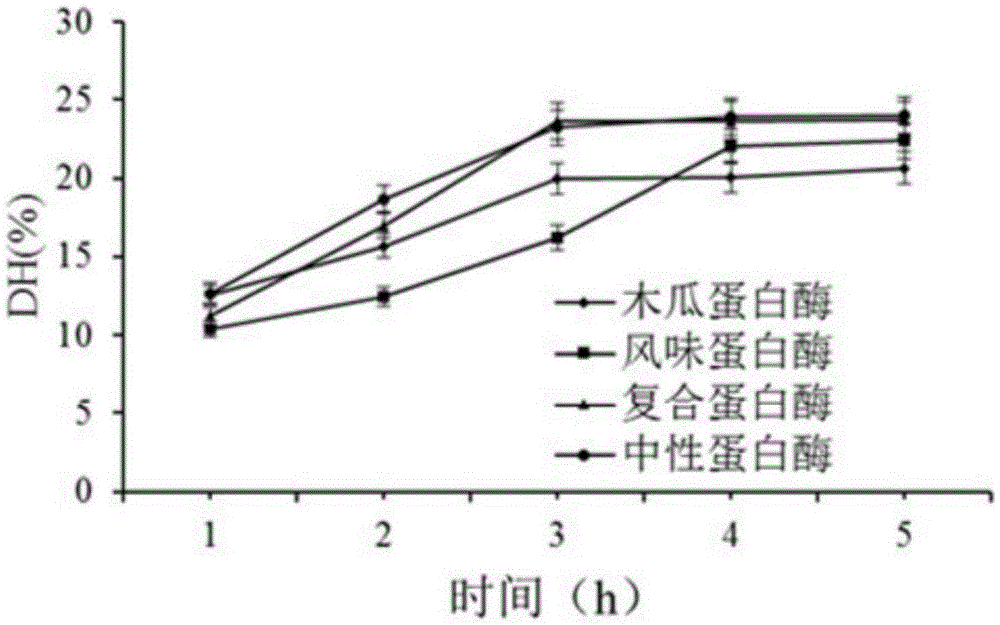

Method for coproducing collagen activity peptides and flavoured base materials with chicken bones

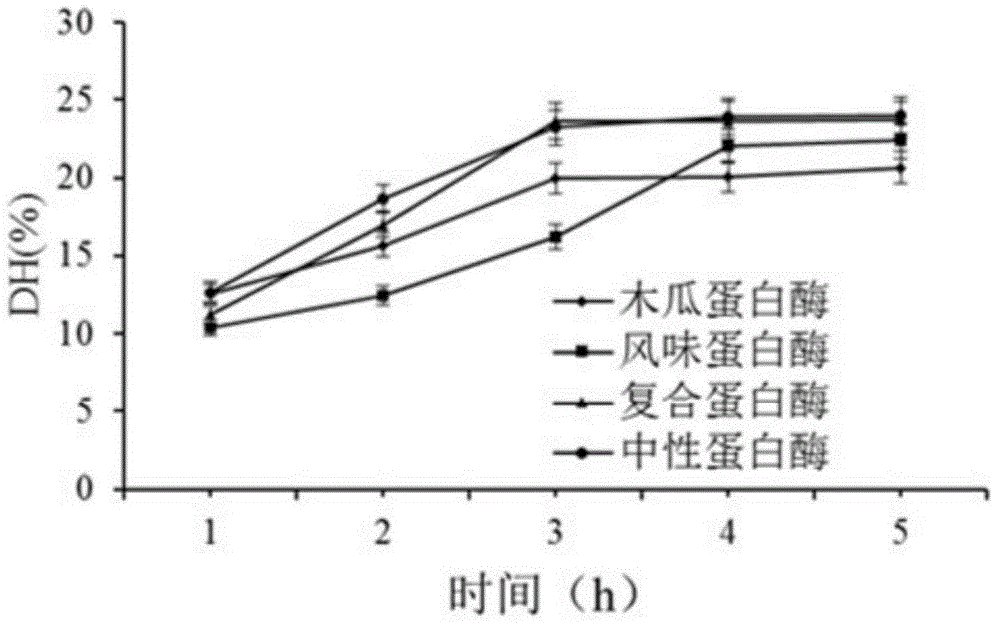

ActiveCN104095141AFacilitate physical disaggregationIncrease the degree of hydrolysisProtein foodstuffs working-upMaillard reactionFiltration

The invention discloses a method for coproducing collagen activity peptides and flavoured base materials with chicken bones. Through a two-step hot pressing and extracting method, and through slight pressure relief and pressure supplementation treatment, the yield of extracting the collagen activity peptides from the chicken bones is substantially increased. Through high-pressure homogenizing of osseins in extracting solutions before a step-by-step enzymolysis reaction of the osseins, the degree of hydrolysis of enzymolysis solutions is increased. In addition, two-step ultra filtration is performed on the enzymolysis solutions, and separation and purification of different products in the enzymolysis solutions are realized. Follow-up processing is performed aiming at the products of each molecule segment, different products of bone polysaccharide containing chondroitin sulfate, macromolecule polypeptide, micromolecule polypeptide and the like are obtained, making full use of ossein enzymolysis solutions is realized, and especially a Maillard reaction is performed on the macromolecule polypeptide, xylose, cysteine and thiamin to obtain the flavoured base material with a rich flavour.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for preparing inorganic mixture by using waste concrete recycled aggregate

InactiveCN102838306ALow costRealize harmless disposalSolid waste managementConstruction aggregateMaterials science

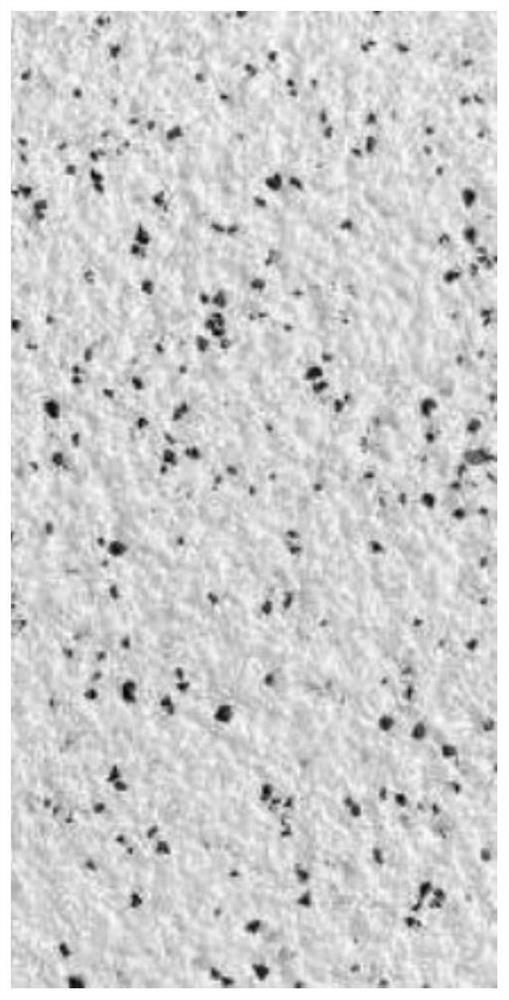

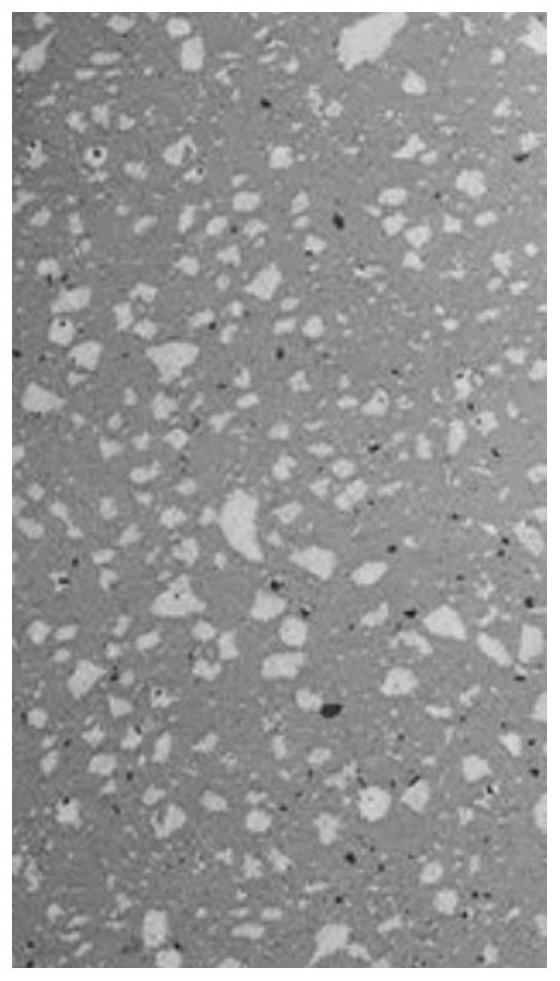

The invention provides a method for preparing inorganic mixture by using waste concrete recycled aggregate. The method comprises mixing, by mass percentage, 65-75% of the recycled aggregate with the grain diameter of 0-5 millimeters, 5-15% of the recycled aggregate with the grain diameter of 5-10 millimeters, and 20-30% of the recycled aggregate with the grain diameter of 10-31.5 millimeters, wherein the recycled aggregate is prepared by crushing waste concrete; and then adding cement to obtain the inorganic mixture, wherein the mass percentage of the mixed aggregate is 95.5-97%, and the mass percentage of the cement is 3-4.5%. The method for preparing the inorganic mixture by using the waste concrete recycled aggregate achieves grading design of the inorganic mixture by combination of the characteristics of the waste concrete aggregate and proportioning design, effectively utilizes part of activity of the waste concrete aggregate, reduces the proportion of the added cement, utilizes a large proportion of fine aggregate raw materials of the waste concrete recycled aggregate, and reduces cost.

Owner:SHOUGANG CORPORATION

Steel slag powder producing method employing roller press

InactiveCN103041904ARealization of high value-added utilizationReduced use of high added valueGrain treatmentsSlagClosed loop

The invention relates to the technical field of recycling of steel slag, in particular to a steel slag powder producing method employing a roller press. The method is characterized in that a closed loop formed by a high-pressure roller press, a bucket elevator, a static powder concentrator and a dynamic powder concentrator produces the steel slag powder; and the specific surface area of an obtained steel slag powder product is larger than 450m<2> / kg, the iron content is lower than 0.1% after the steel slag powder passes through a plurality of magnetic separation devices, and the negative pressure operation is adopted inside the static powder concentrator. Compared with the prior art, the method has the benefits that the closed loop and the negative pressure operation are adopted, therefore dust is little, the energy is saved, and the environment is protected; partial hot gas is recovered, and the heat energy utilization rate is improved; only the high-pressure roller press is adopted for grinding, so that the technological process is simple, and the investment is small; and the iron content is lower than 0.1%, the product quality is improved, the high value-added utilization of steel tailings is achieved, land-occupation stacking of the steel tailings is reduced, the environmental pollution is reduced, and the circular economy is developed.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION

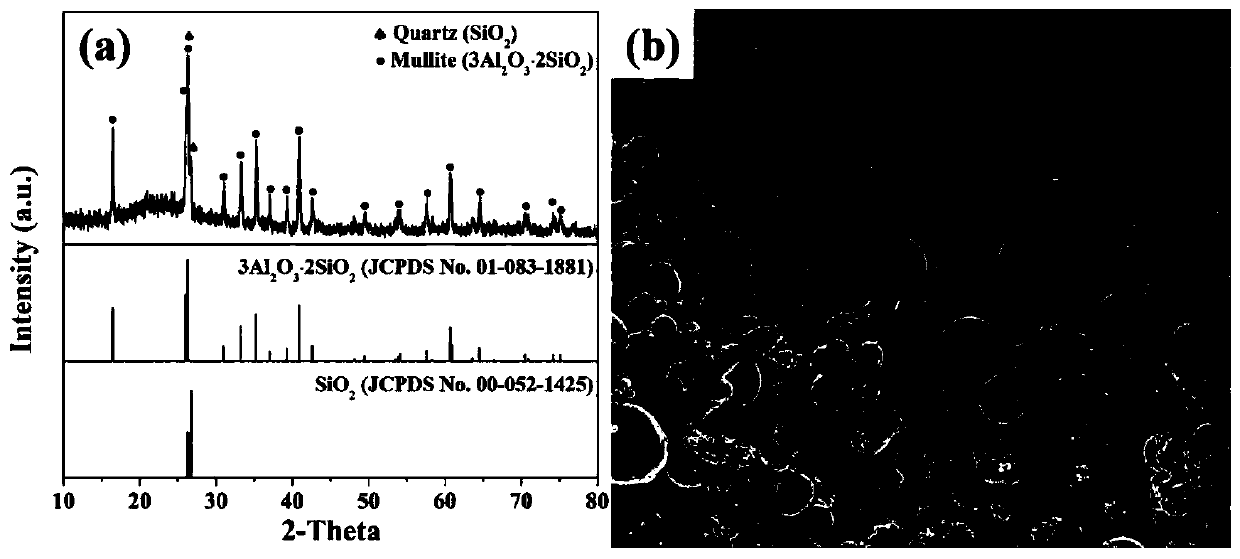

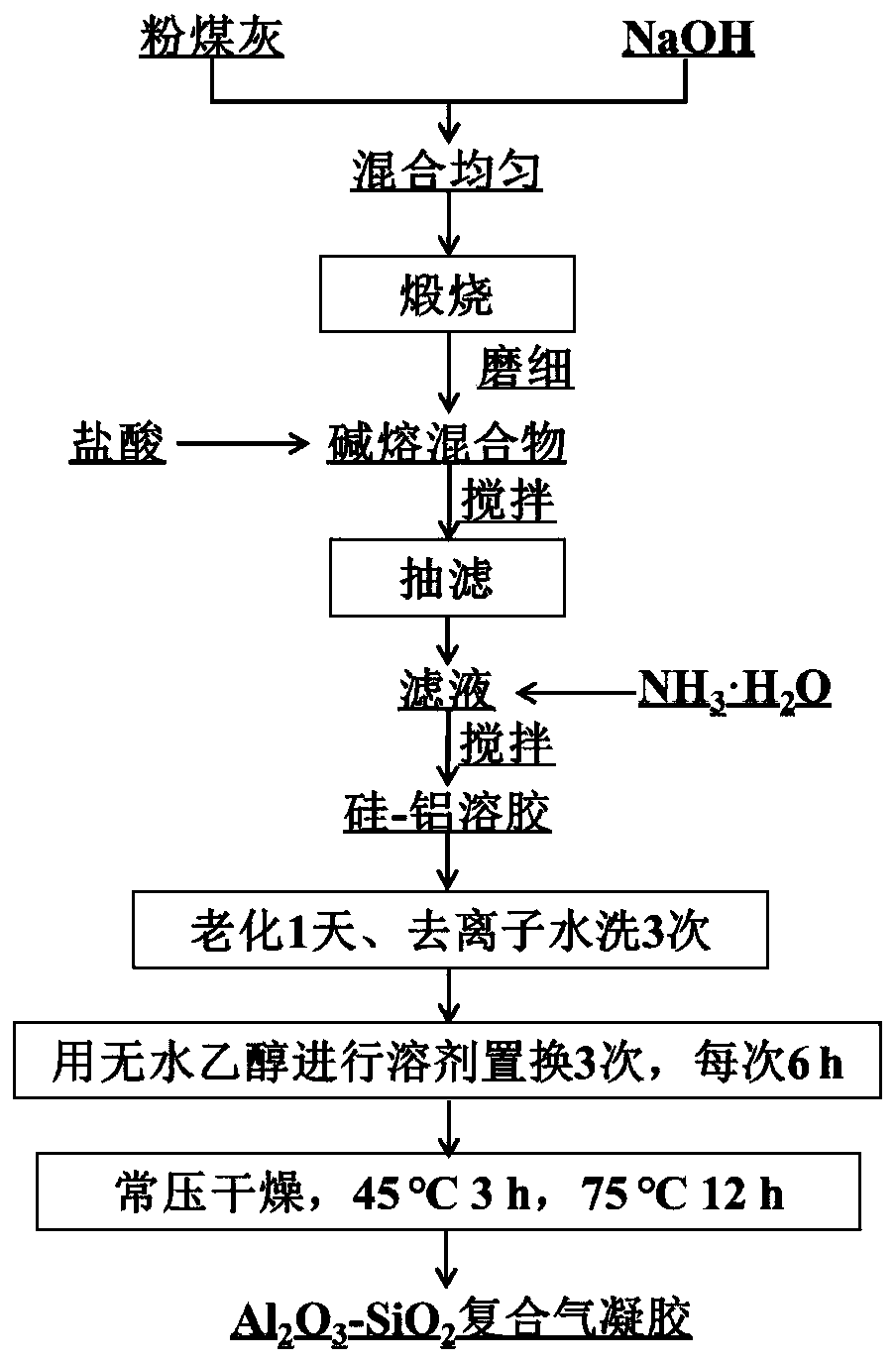

Method for preparing SiO2-Al2O3 composite aerogel material from fly ash

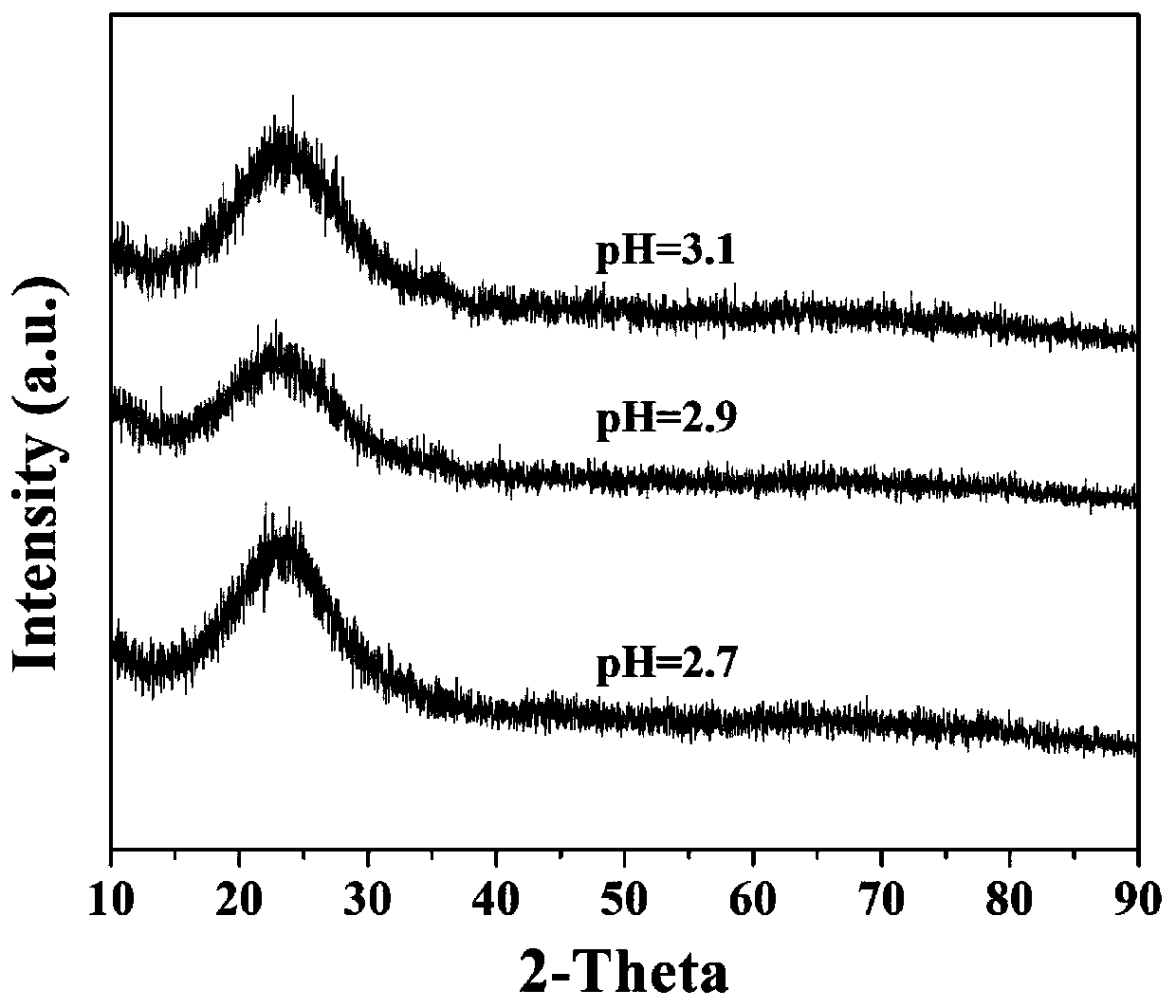

ActiveCN110668452ARealization of high value-added utilizationLarge specific surface areaSilicon compoundsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFluid phaseMesoporous material

The invention discloses a method for preparing SiO2-Al2O3 composite aerogel from fly ash, and belongs to the field of mesoporous materials. The preparation method comprises the following steps: uniformly mixing fly ash, used as a raw material, with sodium hydroxide, calcining the obtained mixture in a muffle furnace for a certain time to obtain an alkali fusion mixture, mixing and stirring the alkali fusion mixture and a hydrochloric acid solution, and carrying out solid-liquid separation to obtain a liquid phase containing silicon and aluminum; dropwise adding ammonia water into the liquid phase containing silicon and aluminum at normal temperature under a continuous stirring condition to promote a gel reaction of the liquid phase in order to obtain a wet gel; and ageing the wet gel, washing the aged wet gel with deionized water, and carrying out solvent replacement and normal-pressure drying to obtain the SiO2-Al2O3 composite aerogel. The whole technological process has the advantages of realization of high-added-value utilization of solid waste fly ash, low cost, short process, and realization of the whole preparation period of only 3 days; the specific surface area of the synthesized SiO2-Al2O3 composite aerogel is about 900 m <2> / g; and after the composite aerogel is calcined at 900 DEG C for 2 h, the amorphous structure is still maintained, and the good thermal stabilityis achieved.

Owner:UNIV OF SCI & TECH BEIJING

Fast flocculating agent and its preparation method

InactiveCN102745787AHigh activityRealize resource utilizationWater/sewage treatment by flocculation/precipitationFlocculationChemical composition

The invention discloses a fast flocculating agent and its preparation method. The flocculating agent comprises the following chemical components by weight: 75-85% of mixed sedimentation tank sludge, 5-15% of blast furnace slag powder, 2-10% of aluminium ammonium sulfate, 2-10% of polymeric ferric sulfate and 1-2% of an additive. According to the preparation method of the invention, the aluminium ammonium sulfate, the polymeric ferric sulfate, the mixed sedimentation tank sludge, and the blast furnace slag powder are successively stirred in proportion under the condition of 80-200r / min so as to obtain the fast flocculating agent. The flocculating agent of the invention is composed of the mixed sedimentation tank sludge and the blast furnace slag powder, the surface of which has great activity and can speed up flocculation, thus reaching the purpose of fast flocculation and realizing resource utilization and high value-added utilization of solid waste.

Owner:武钢集团有限公司

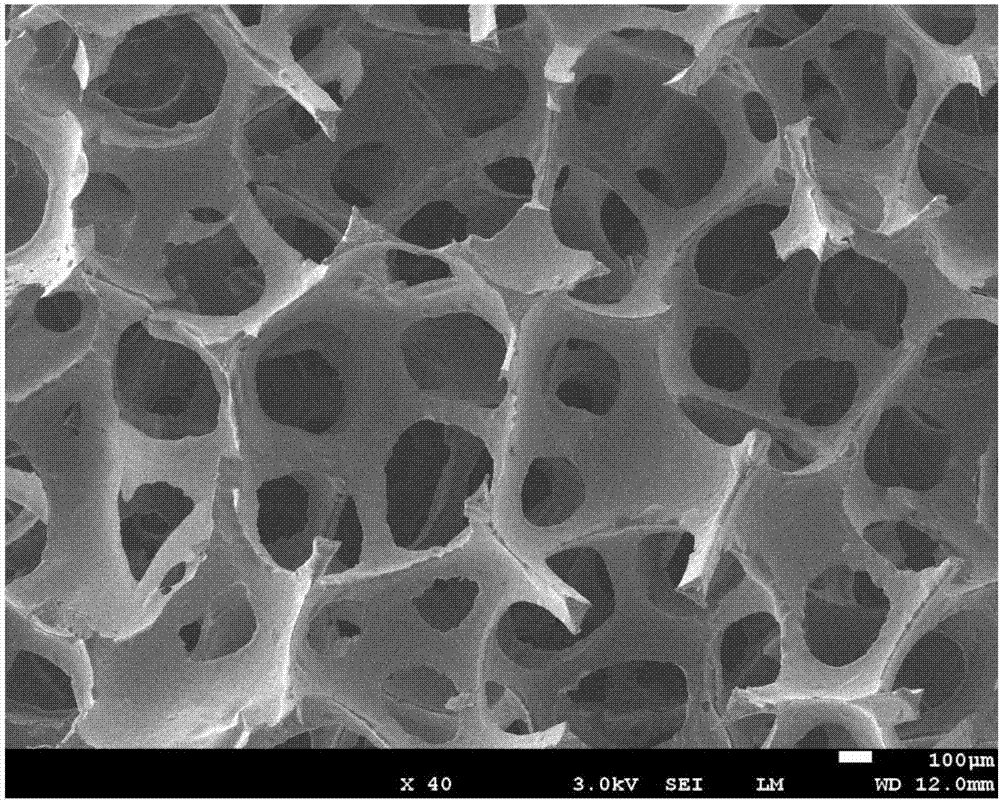

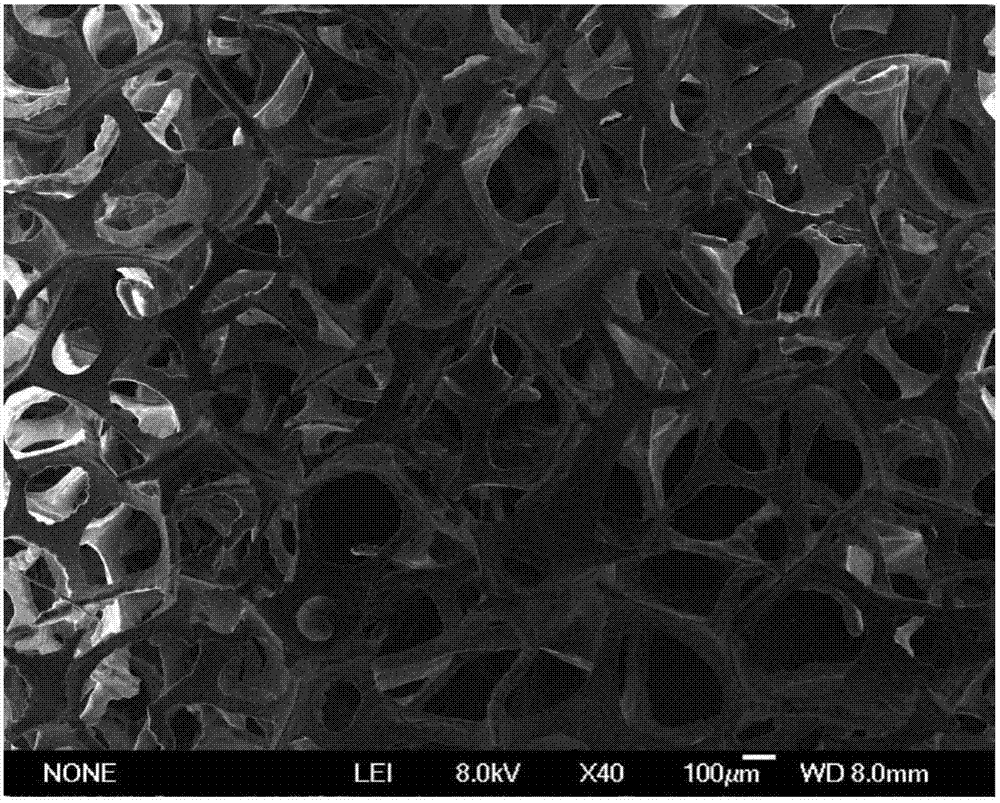

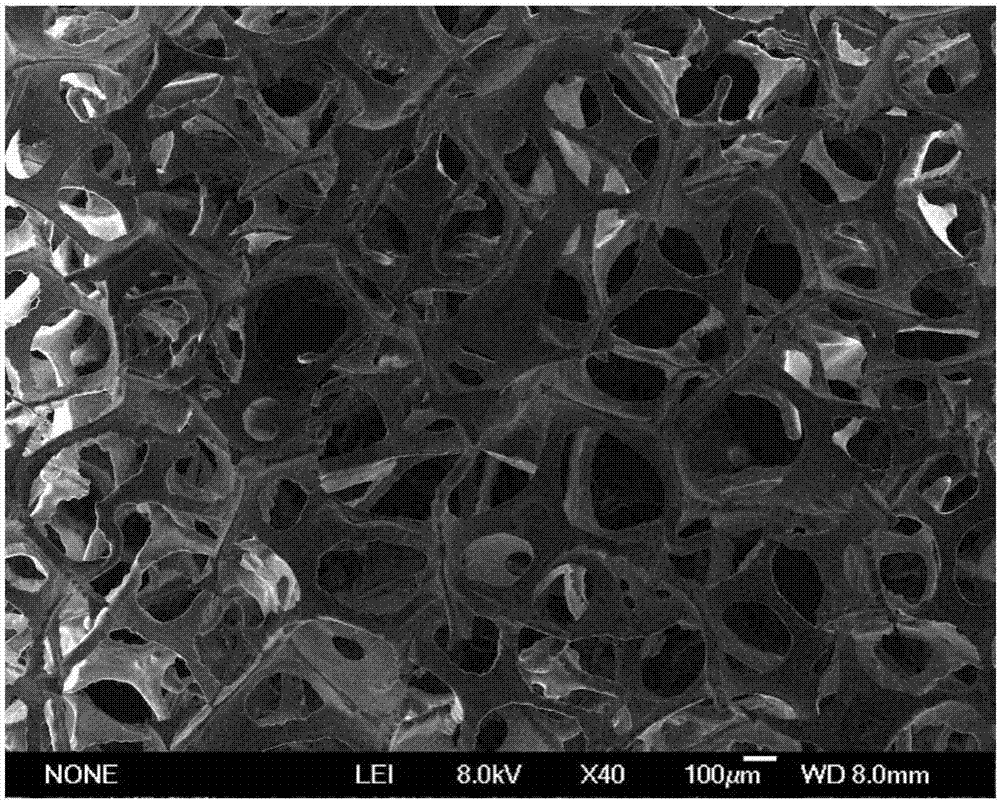

High-aperture-ratio biomass-based rigid polyurethane foam and preparation method thereof

ActiveCN107353389ARealization of high value-added utilizationImprove sustainabilityGrowth substratesCulture mediaHalogenChemistry

The invention provides high-aperture-ratio biomass-based rigid polyurethane foam and a preparation method thereof. The high-aperture-ratio biomass-based rigid polyurethane foam is prepared from, by mass, 100 parts of bio-based polyol mixture, 105-160 parts of polyisocyanate, 1.05-1.4 parts of composite catalyst, 2-6.5 parts of compound foaming agent and 1.5-3.0 parts of foam stabilizer. The obtained product has high aperture ratio, the used foaming agent does not contain halogen, the polyol is the bio-based polyol and is friendlier to the environment, and an auxiliary foaming agent is a boiling range type substance, so that the foaming process is milder and more stable. The polyurethane foam is suitable for making of flower soil and other materials having the higher requirements for the aperture ratio and water absorbability of foam. Steps are simple, operation is easy, and the practicability is high.

Owner:QINGDAO UNIV OF SCI & TECH

3D (Three Dimensional) printing material formula taking wood chemical component as main raw material

InactiveCN108178845AImprove mechanical propertiesRealization of high value-added utilizationAdditive manufacturing apparatusPolymer chemistryCompound (substance)

The invention provides a 3D (Three Dimensional) printing material formula taking a wood chemical component as a main raw material, belongs to the technical field of 3D printing and in particular relates to the technical field of a 3D printing formula taking the wood chemical component as the raw material. The 3D printing material formula taking the wood chemical component as the main raw material,provided by the invention, is prepared from the following components in parts by weight: 10 to 30 parts of high polymer plastic, 2 to 10 parts of cellulose, 40 to 60 parts of hemicellulose, 30 to 50parts of lignin, 2 to 5 parts of a lubricant and 5 to 8 parts of a coupling agent. The formula provided by the invention can take the wood chemical component as the main raw material for carrying out3D printing.

Owner:BEIJING FORESTRY UNIVERSITY

Method for carrying out reinforcing and sealing-protection on wood by using nano cellulose

ActiveCN110181632AImproved dimensional stabilityImprove wood quality and added valueWood treatment detailsPretreatment apparatusElastic modulusFiber

The invention belongs to a method for carrying out reinforcing and sealing-protection on wood by using nano cellulose. The method comprises the following steps: classifying the wood according to waterpermeability of the wood, and performing brushing or immersion treatment on the wood according to classification with a nano-cellulose sealing-protection liquid prepared by a carboxymethyl celluloseor hydroxypropyl cellulose or hydroxyethyl cellulose polymer solution with a concentration of 0.5-2.5%, a cellulose nano crystal with a concentration of 0.5-1.5%, a nano cellulose dispersion liquid ofTEMPO oxidized nano fibers with a concentration of 0.2-0.7%, and a modification liquid of a silica sol with a concentration of 0.5-1.5%. The method can improve dimensional stability, density, flexural modulus and compressive strength of the wood, and has the advantages of significantly improving quality and added values of the wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

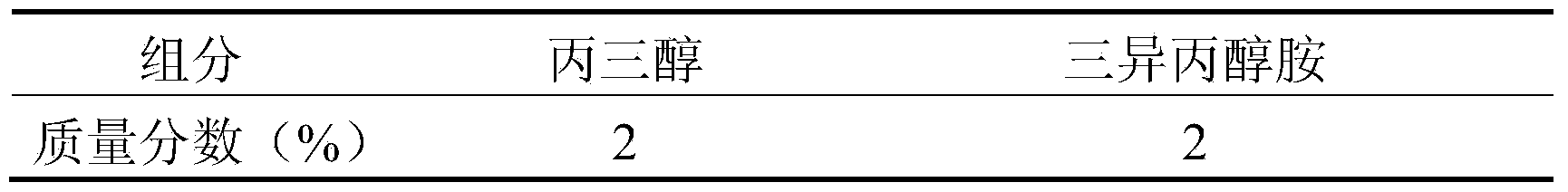

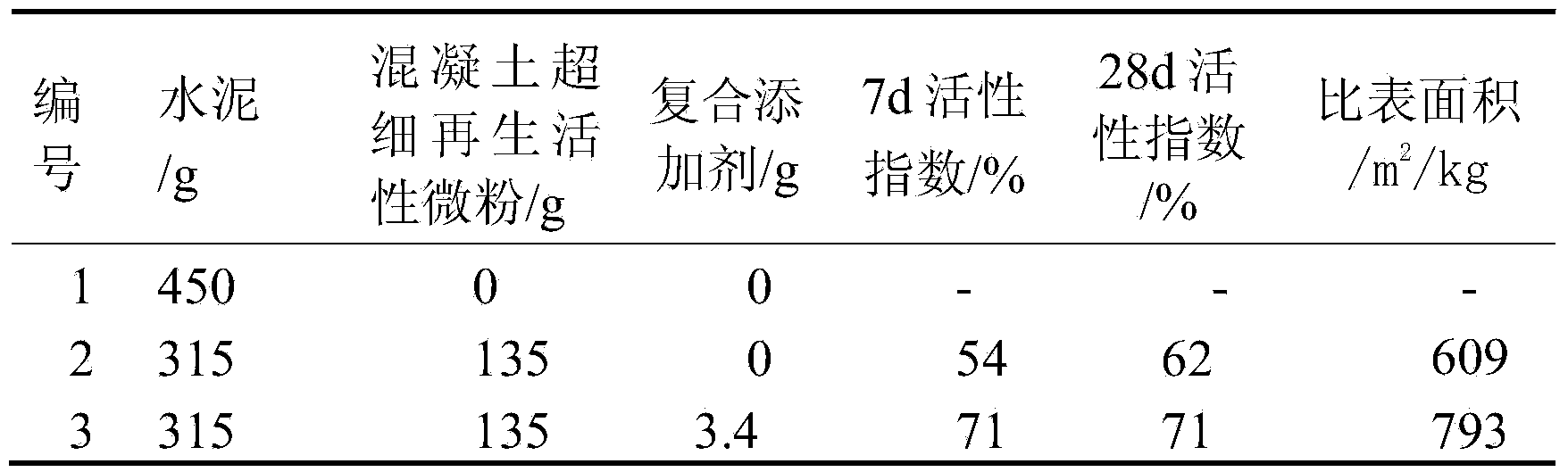

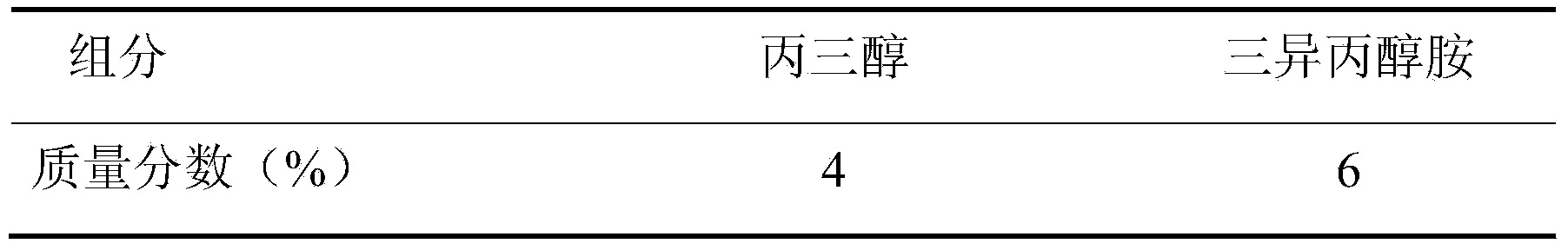

Waste concrete superfine regenerated active micro-powder and preparation method thereof

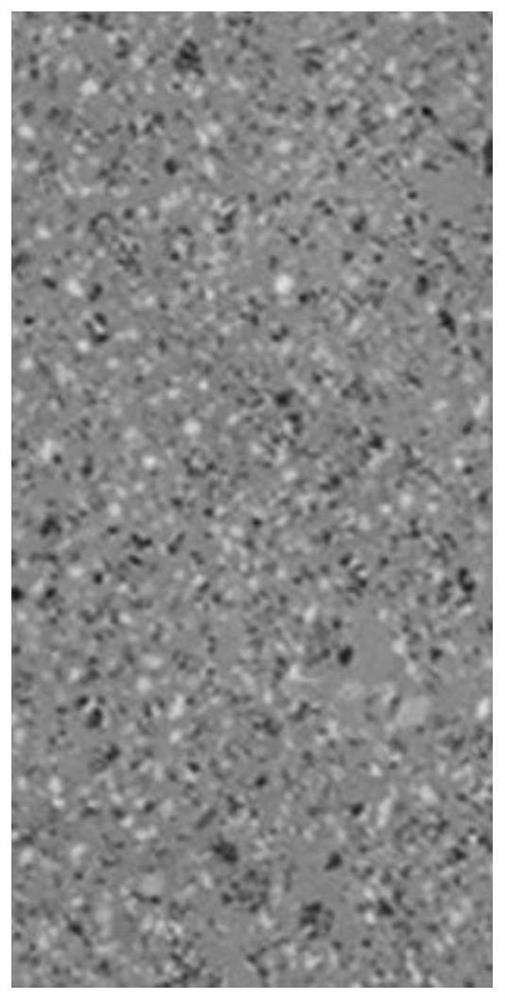

ActiveCN103466973ARealization of high value-added utilizationGood modification effectClinker productionConstruction aggregateMaterials science

The invention discloses a waste concrete superfine regenerated active micro-powder and a preparation method thereof. The specific surface area of the micro-powder is larger than 750m2 / kg, and the 28d activity index of the micro-powder reaches more than 70%. The micro-power can be used as admixture for mortar and concrete. The micro-powder is obtained in a mode that 0-5mm tailing obtained at the time that waste concrete is broken for production of recycled aggregate is used as raw materials, and a rough grinding process and a fine grinding process are conducted. Composite additives are added in the fine grinding process for assisting grinding and modifying. According to the micro-powder and the preparation method thereof, super fine grinding and efficient activity of the waste concrete tailing are realized, and a utilization mode with high value-added is provided for waste concrete.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

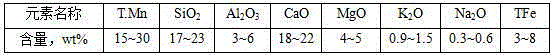

Method for preparing manganese-iron alloy based on low-grade manganese ore

The invention discloses a method for preparing a manganese-iron alloy based on low-grade manganese ore. The method comprises four processes, namely ball milling of raw materials, pelletizing, quick reduction and slag-metal separation. The method comprises the following steps: mixing low-grade manganese ore and iron ore powder; milling the mixed ore, and screening with a 150-300 meshes screen; mixing the screen underflow with the pulverized coal, lime, bentonite and water, and pelletizing on a disc type pelletizer, wherein the diameter of the green balls is 10-16mm; drying the green balls at 105 DEG C for 4h; reducing the dried pellets at 1,450-1,550 DEG C for 8-15min; and after the reaction, crushing the raw material, and performing simple magnetic separation to obtain granular manganese iron, wherein the manganese content is 45-70%, the iron content is 25-45%, the carbon content is 2-5%, and the balance is impurities. According to the method disclosed by the invention, the manganese-iron alloy is prepared by the one-step process of the quick reducing technology, the slag and metal are easily separated, the process is pollution-free, the manganese recovery rate is high, and high value-added utilization of the low-grade manganese ore is realized.

Owner:SUZHOU UNIV

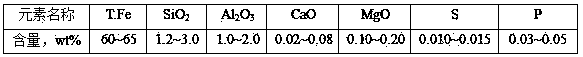

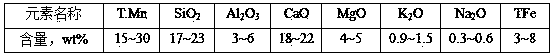

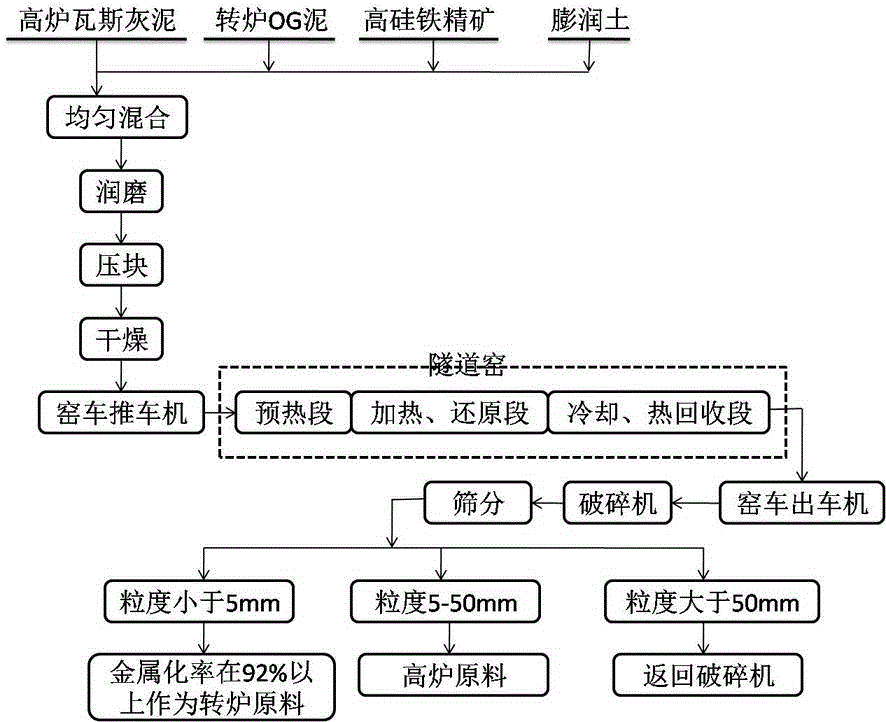

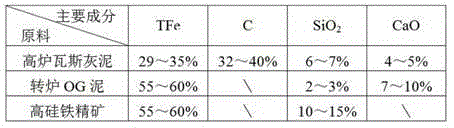

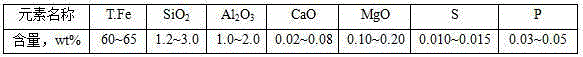

Technology for producing metallized furnace charge from iron-containing dust and high-silicon iron concentrate

ActiveCN103952540ARealization of high value-added utilizationMeet metallurgical performance requirementsTunnel kilnSludge

The invention discloses a technology for producing metallized furnace charge from iron-containing dust and high-silicon iron concentrate. The technology comprises the following steps of mixing blast furnace gas plaster, converter OG sludge, high-silicon iron concentrate and bentonite according to a weight ratio of 100: 20-30: 60-70: 2-3 to obtain a uniform mixture, wherein the blast furnace gas plaster has water content less than 8%, carrying out wet-grinding, briquetting and drying on the mixture to obtain raw pressed blocks, feeding the raw pressed blocks into a tunnel kiln, and carrying out pre-heating and reduction calcination to obtain the metallized furnace charge. The technology realizes reasonable matching of all the raw materials, realizes reasonable utilization of iron oxide, carbon and calcium oxide components in the iron-containing dust and has a product iron grade more than 55% and a metallization rate more than 85%. The technology has the advantages of simple processes, large treatment amount, full resource recovery utilization and less pollution.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

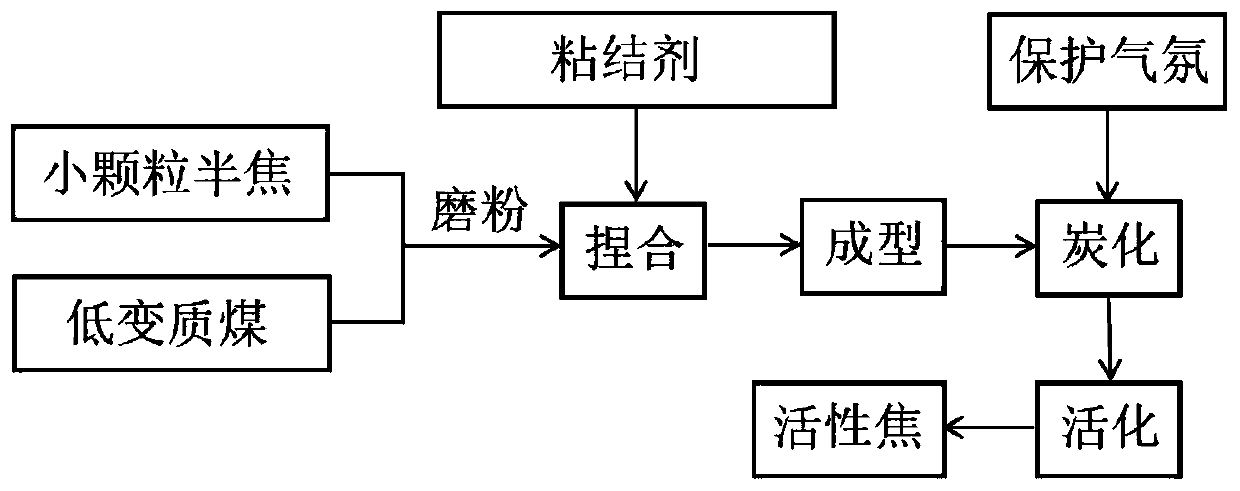

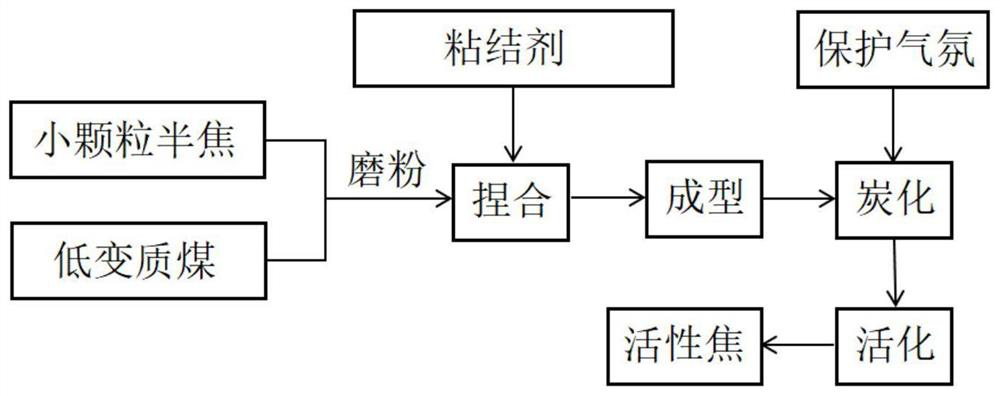

Active coke for flue gas desulfurization, and preparation method thereof

ActiveCN111054310AImprove adsorption capacityReduce manufacturing costGas treatmentCarbon compoundsSodium BentoniteCoal

The invention belongs to the technical field of comprehensive utilization of resources, and relates to an active coke for flue gas desulfurization, and a preparation method thereof. The preparation method comprises the following steps: mixing low metamorphic pulverized coal, semicoke powder, phenolic resin, sodium humate and sodium bentonite to obtain a mixture A, wherein the mixture Acontains, bymass, 35-42.5% of the low metamorphic pulverized coal, 35-42.5% of the semicoke powder, 5-15% of the phenolic resin, 5-15% of sodium humate and 5-15% of sodium bentonite; adding an ethanol solution of which the solute mass is 8-10% and deionized water into the mixture, uniformly mixing, and performing compression molding under the pressure of 5-7 MPa to obtain formed material strips; drying the formed material strips; carbonizing and activating the dried formed material strips in a protective atmosphere; and carrying out activation treatment to obtain the active coke material for flue gas desulfurization. The method is simple in process and low in cost, and opens up a new development and application way for high-added-value utilization of the low-rank coal.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

A process of using blast furnace titanium slag to absorb and regenerate waste lubricating oil

InactiveCN105255575BRealization of high value-added utilizationProfitableLubricant compositionSorbentEconomic benefits

Owner:CHONGQING TECH & BUSINESS UNIV

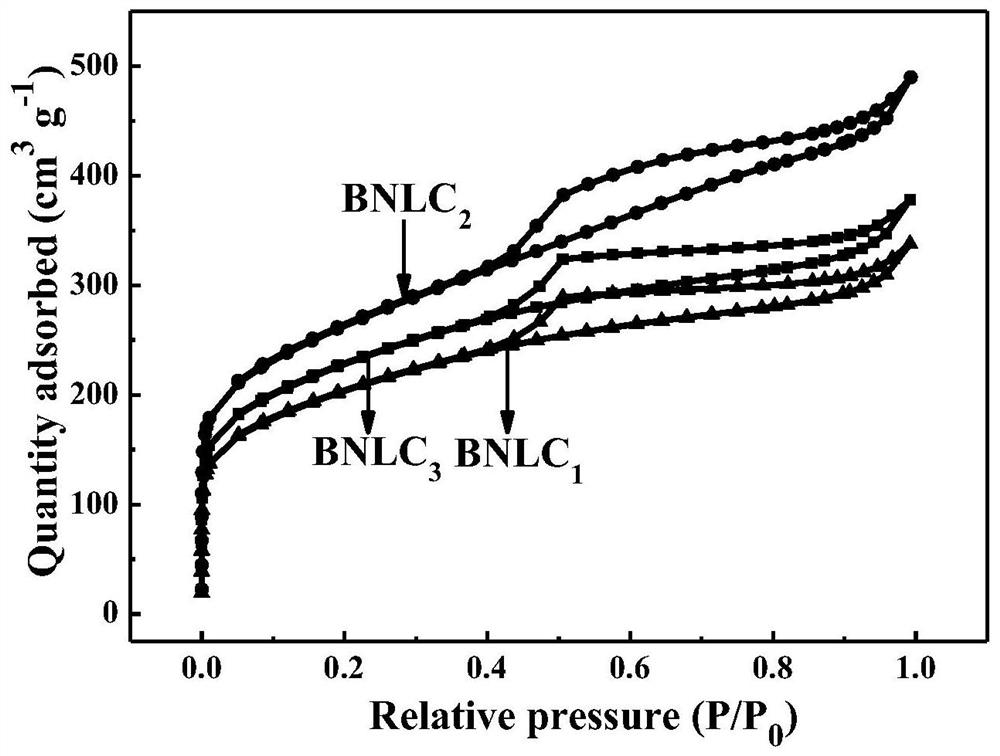

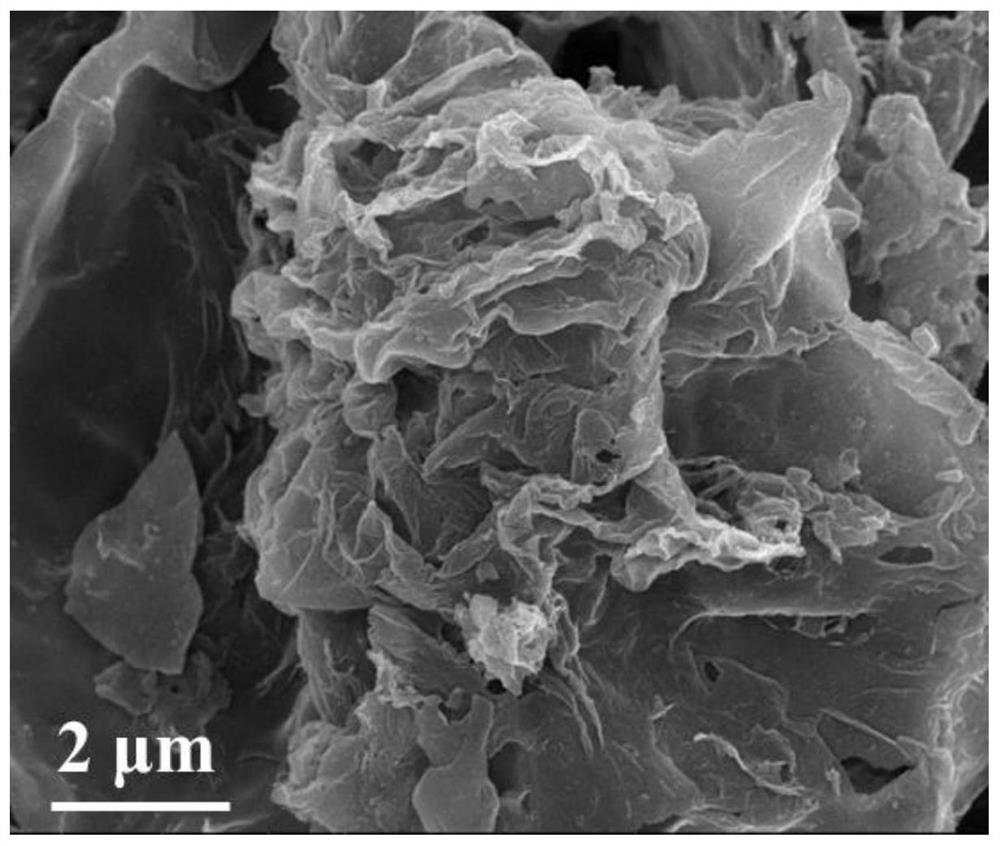

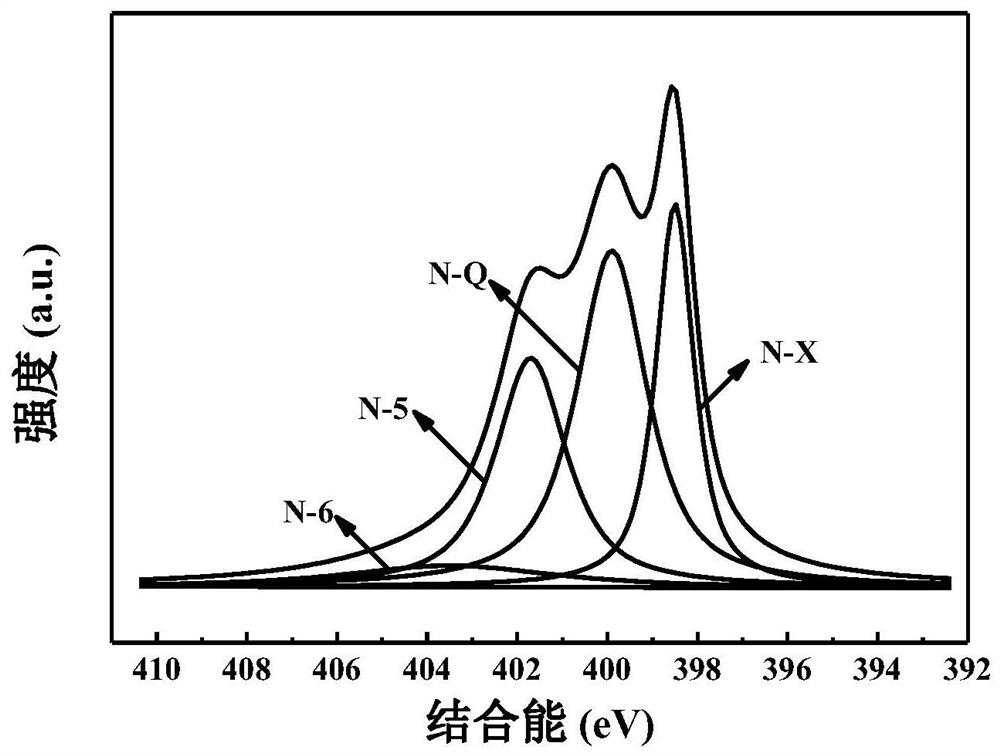

Preparation method of three-dimensional boron-nitrogen co-doped layered carbon for water system high-voltage supercapacitor

ActiveCN112374486ARealization of high value-added utilizationRaw materials are cheap and easy to getHybrid capacitor electrodesCarbon preparation/purificationFreeze-dryingArgon atmosphere

The invention discloses a preparation method of three-dimensional boron-nitrogen co-doped three-dimensional layered carbon for a water system high-voltage supercapacitor, and belongs to the technicalfield of carbon material preparation. According to the method, osmanthus fragrans is used as a carbon source, a potassium borate activator and 2-methylimidazole are used as a nitrogen doping agent; the method comprises the following steps: dissolving osmanthus fragrans in a mixed solution of potassium borate and 2-methylimidazole, heating, freeze-drying, transferring the obtained mixture to a corundum boat, placing the corundum boat in a horizontal tubular furnace, and heating in an argon atmosphere to prepare the three-dimensional boron-nitrogen co-doped layered carbon. The specific surface area of the obtained three-dimensional boron-nitrogen co-doped layered carbon is high, and when the three-dimensional boron-nitrogen co-doped layered carbon is used as a supercapacitor electrode material, the three-dimensional boron-nitrogen co-doped layered carbon shows ultrahigh capacity and excellent rate capability. The three-dimensional boron-nitrogen co-doped layered carbon for a supercapacitor is directly prepared by adopting a one-step method, and has the advantages that the raw materials are cheap and easy to obtain, the process route is simple and convenient, acid and alkali are not used in the preparation process, and the obtained product is good in performance.

Owner:CHUZHOU UNIV

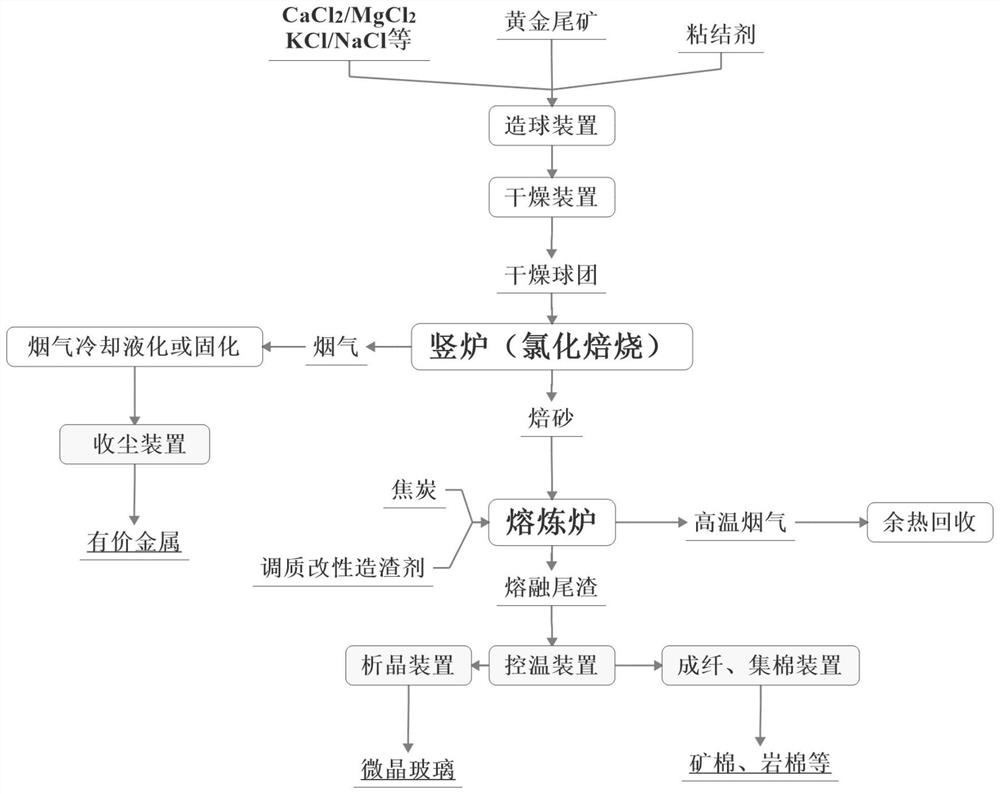

Treatment method of gold tailings

PendingCN113106249ARealization of high value-added utilizationEfficient recyclingProcess efficiency improvementPollutantMineralogy

The invention relates to the field of comprehensive utilization of solid waste resources and particularly relates to a treatment method of gold tailings. The treatment method comprises the following steps: mixing the gold tailings to be treated with a chlorinating agent and a binder, rolling and forming, drying, and then chloridizing and roasting to obtain metal flue gas and roasted sand, wherein the chlorinating agent is selected from one or several of CaCl2, MgCl2, NaCl and KCl. The problem that pollutants contained in the gold tailings are complex and are difficultly treated is solved; the treatment method of the gold tailings is provided; the method can effectively recycle valuable metals (especially precious metals) in the gold tailings; the problem that the extracted tailings are difficultly used after the valuable components are separated and extracted is solved; high value-added utilization of the tailings is realized; and the method has a wide application prospect.

Owner:PEKING UNIV

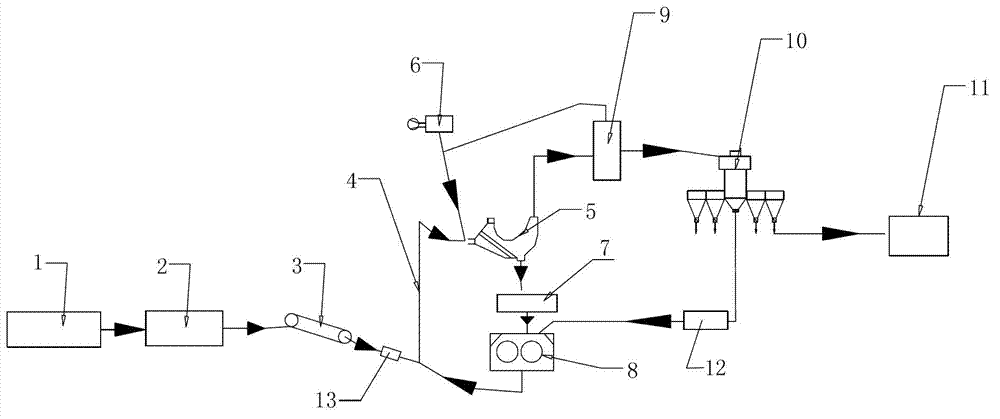

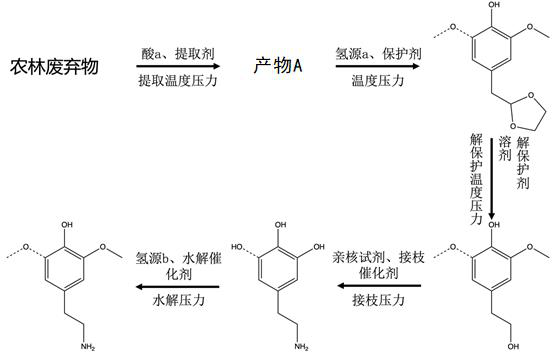

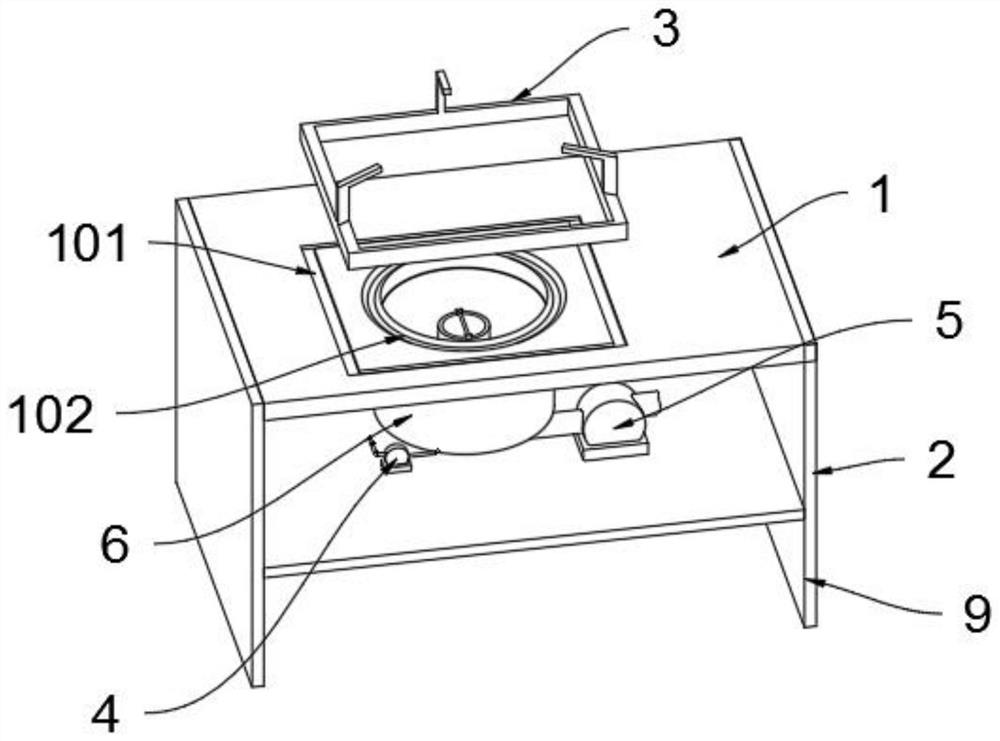

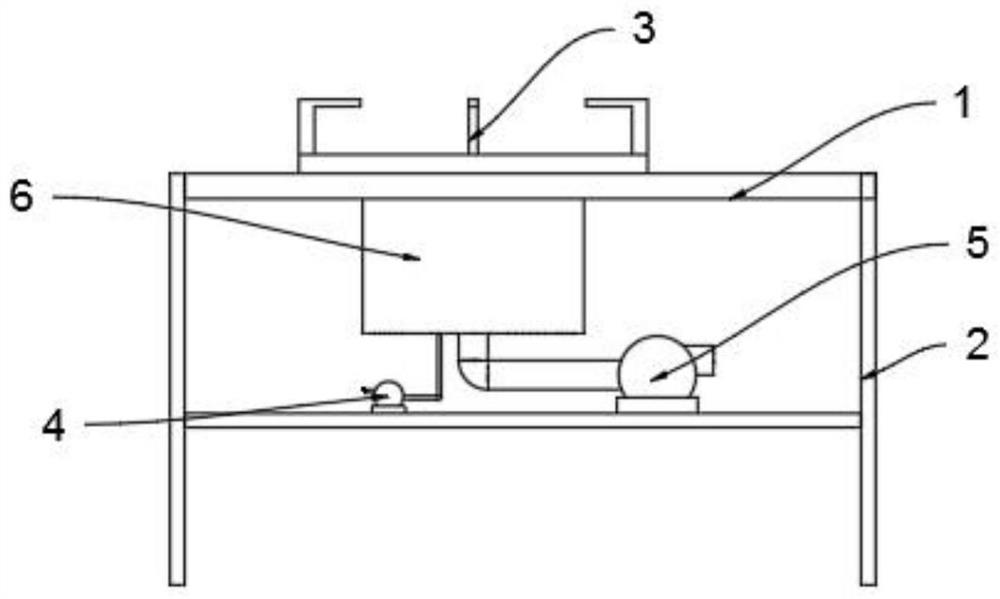

Method for preparing dopamine and derivative thereof by utilizing agricultural and forestry wastes and special equipment thereof

InactiveCN113999124AHigh purityHigh yieldOrganic compound preparationWaste based fuelGraft reactionAgricultural engineering

The invention discloses a method for preparing dopamine and a derivative thereof by utilizing agricultural and forestry wastes and special equipment thereof, and belongs to the field of medicine preparation. The method comprises the following steps: mixing the forestry and agricultural residues with an acid a and an extracting agent, and reacting to obtain a product A; mixing the product A with a hydrogen source a and a protective agent, and reacting to obtain a product B; mixing the product B with a de-protecting agent, and reacting to obtain a product C; adding a nucleophilic grafting reagent into the product C, and carrying out nucleophilic grafting reaction to obtain a product D; and hydrolyzing and hydrogenating the product D to obtain the dopamine or the dopamine derivative. The agricultural and forestry waste is used as the main raw material and is prepared into the dopamine and the derivative thereof so that high value-added utilization of the agricultural and forestry waste is realized, the yield of the prepared dopamine and the derivative thereof is relatively high, and a new thought is developed for high-value utilization of the agricultural and forestry waste.

Owner:NANJING FORESTRY UNIV

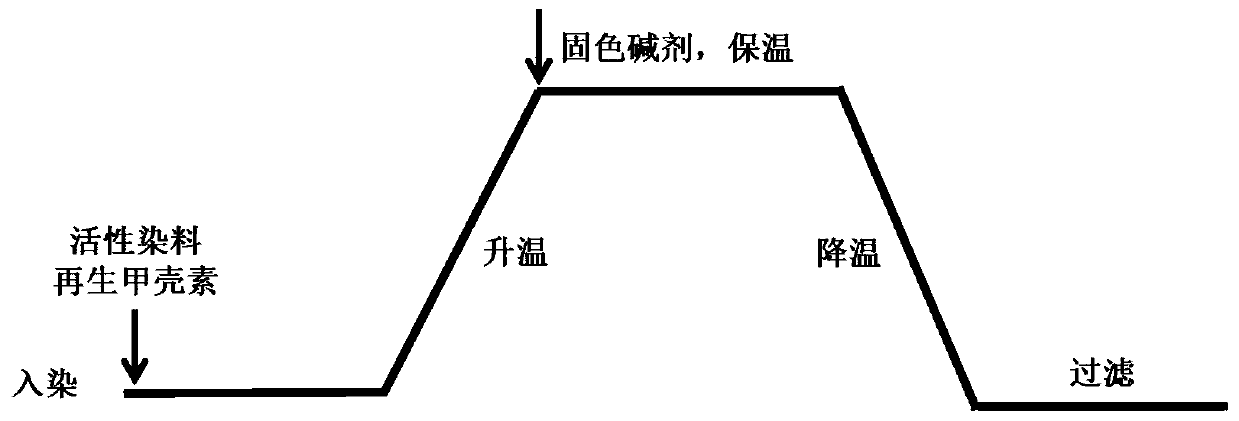

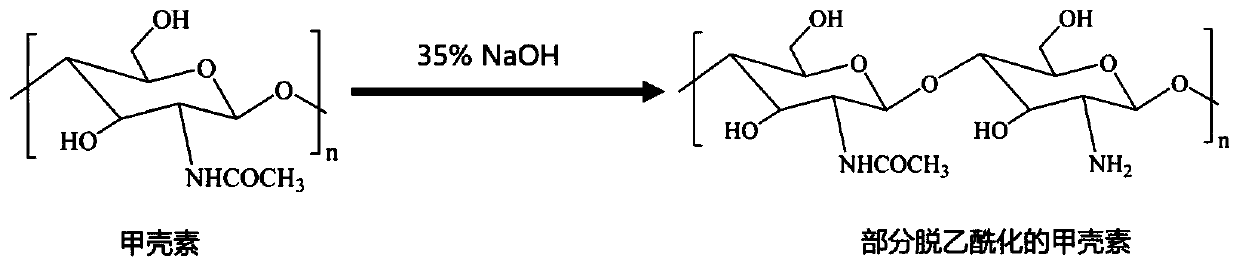

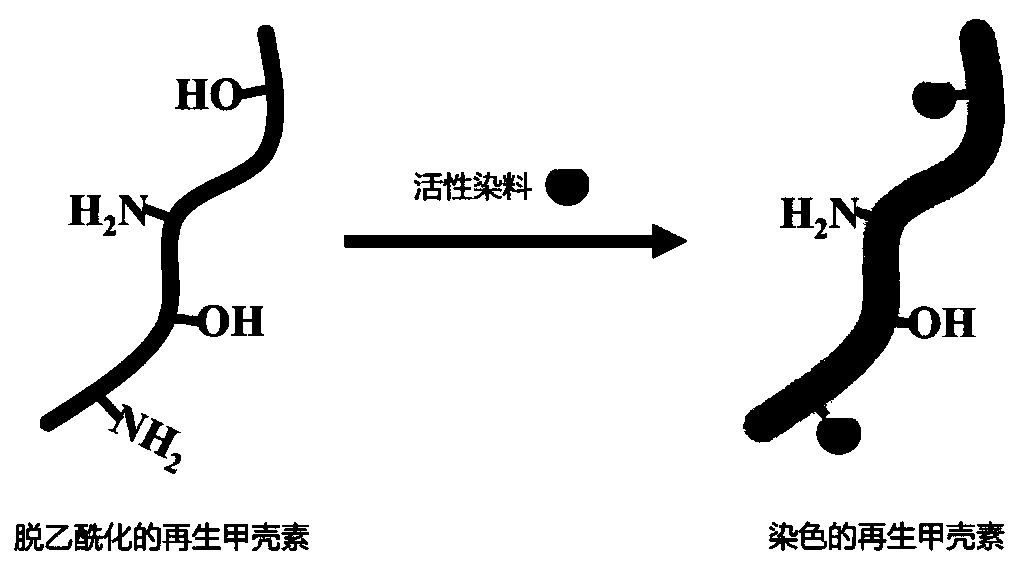

Preparation method of regenerated chitin color pastes

The invention relates to a preparation method of regenerated chitin color pastes. The method includes the steps of mixing regenerated chitin suspensions with different deacetylation degrees with reactive dyes, dyeing obtained mixed solutions to obtain dye liquors, adding a fixation alkali agent for color fixation, performing cooling, adding water to obtained dyed regenerated chitin suspensions fordilution, performing filtration, and then dispersing colored regenerated chitin in water. According to the method, the reactive dyes are used for performing colorization modification on the regenerated chitin, and by regulating and controlling the types of the dyes and the deacetylation degrees of the regenerated chitin, the regenerated chitin color pastes with different colors and color depths can be obtained; and the obtained regenerated chitin color pastes inherit the characteristics of the regenerated chitin.

Owner:DONGHUA UNIV

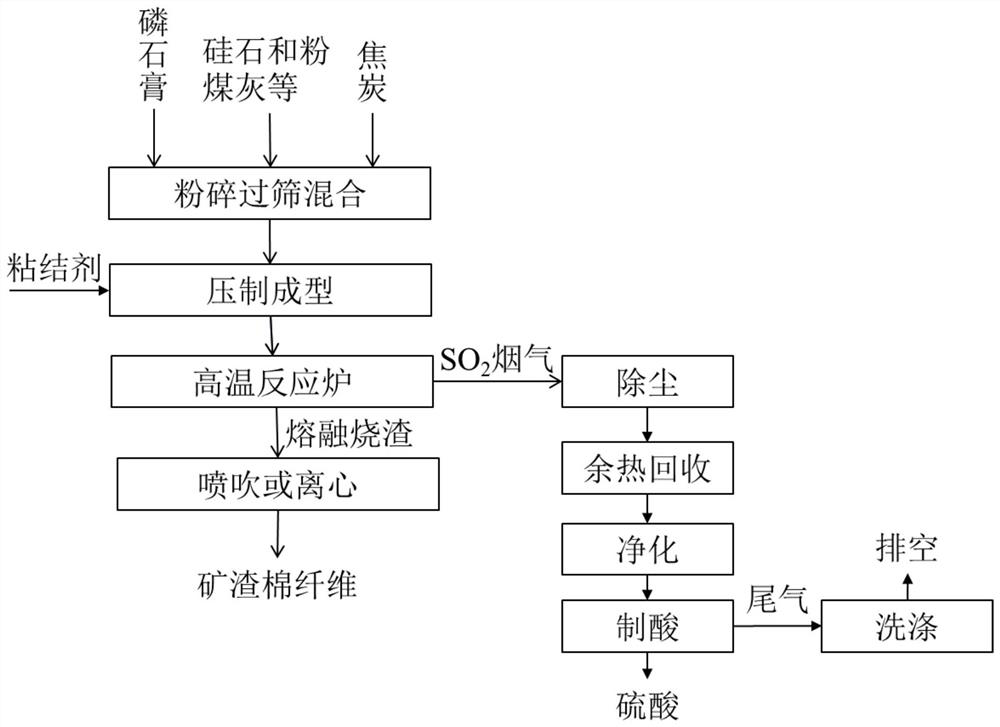

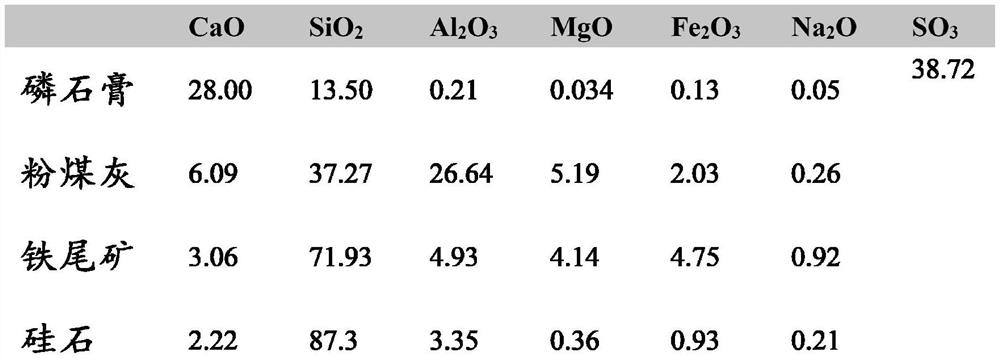

Method for preparing sulfuric acid and co-producing slag cotton fiber from high-impurity phosphogypsum

ActiveCN113753864ABeneficialRealization of high value-added utilizationGlass furnace apparatusSulfur compoundsCotton fibrePhosphogypsum

The invention provides a method for preparing sulfuric acid and co-producing slag cotton fiber from high-impurity phosphogypsum. According to the characteristics of phosphogypsum with high content of silicon, aluminum, magnesium and other impurities, calculation and burdening optimization are carried out, sulfur contained in the phosphogypsum is reduced into SO2 through reduction, roasting decomposition and melting, and when the phosphogypsum is used for preparing sulfuric acid, the obtained byproduct molten slag can be directly prepared into a slag cotton fiber product with high added value through a wire drawing, blowing or centrifuging process; the S element in the phosphogypsum is recycled, and the high silicon, aluminum, magnesium and other impurity components contained in the phosphogypsum are converted into the slag wool preparation raw material, such that the silicon, calcium and other raw materials required by the slag wool can be saved, the high value-added utilization of the phosphogypsum cinders is achieved, and the phosphogypsum acid production technology has advantages of economy and competitiveness; and the technical effect is prominent.

Owner:云南云天化环保科技有限公司 +1

A method for co-producing collagen active peptide and flavor base material from chicken bone

ActiveCN104095141BFacilitate physical disaggregationIncrease the degree of hydrolysisProtein foodstuffs working-upMaillard reactionUltrafiltration

The invention discloses a method for co-producing collagen active peptides and flavor base materials from chicken bones. By adopting a two-stage hot-pressing extraction method and undergoing slight pressure relief and pressure supplementation, the extraction of collagen from chicken bones is greatly improved. The yield of active peptides; the degree of hydrolysis of the enzymolysis solution is improved by homogenizing the osteotin in the extract solution under high pressure before performing the step-by-step enzymatic hydrolysis reaction. In addition, by performing two-stage ultrafiltration on the enzymatic hydrolysis solution, the separation and purification of different products in the enzymatic hydrolysis solution are realized, and subsequent processing is carried out on the products of each molecular segment to obtain osteopolysaccharides, macromolecular polypeptides and small molecules including chondroitin sulfate. Polypeptides and other products can make full use of bone enzymatic hydrolyzate, especially through the Maillard reaction of macromolecular polypeptides with xylose, cysteine and thiamine to obtain rich-flavored flavor bases.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

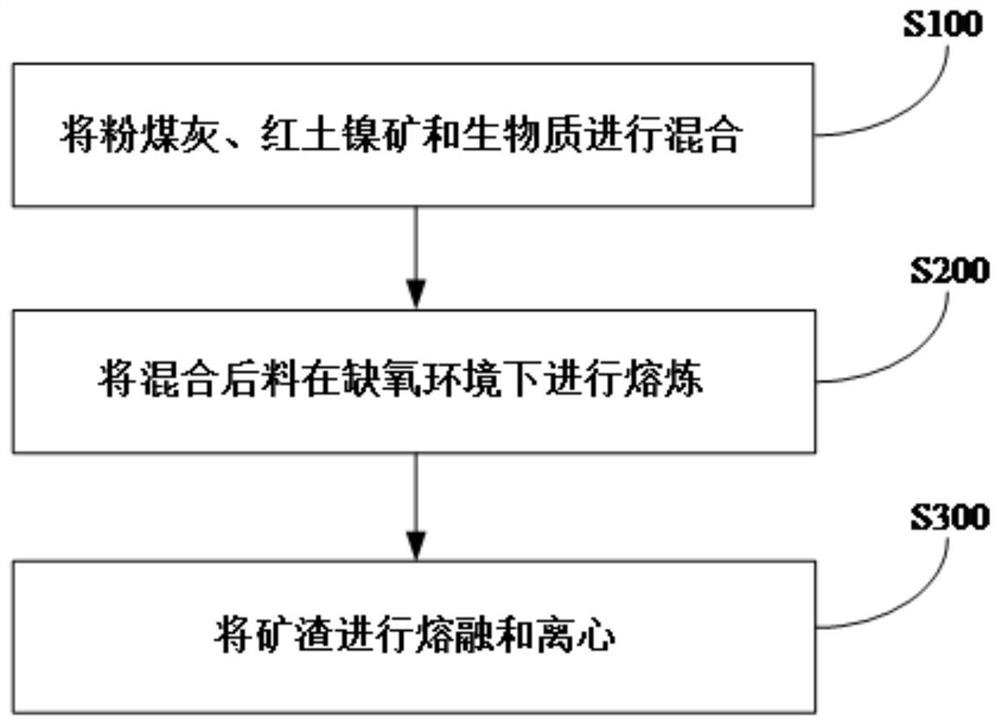

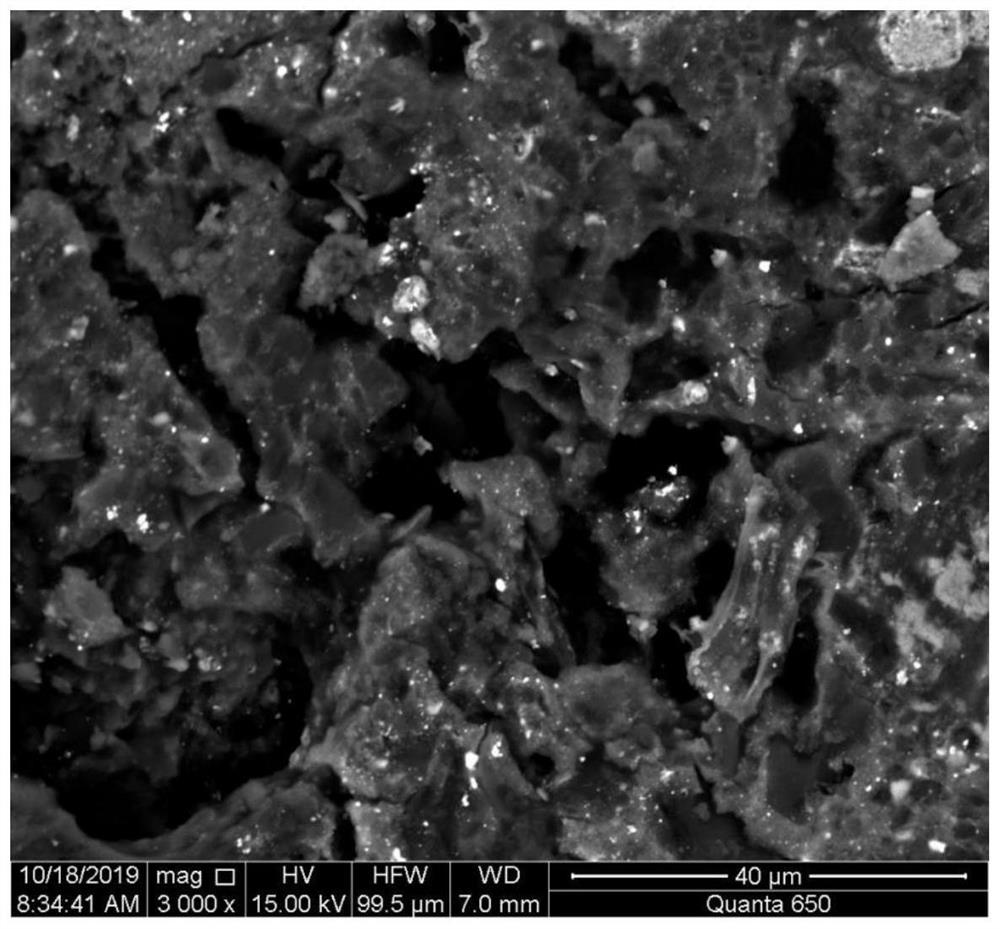

Method for preparing inorganic fiber and ferro-nickel alloy and inorganic fiber

The invention discloses a method for preparing an inorganic fiber and a ferro-nickel alloy and the inorganic fiber. The method comprises the steps that 1, fly ash, laterite-nickel ore and biomass are mixed so as to obtain a mixed material; (2) the mixed material is smelted in an anoxic environment to obtain the ferro-nickel alloy and slag; and (3) the slag is melted and centrifuged to obtain the inorganic fiber. With adoption of the method, high value-added utilization of the fly ash and biomass solid waste is realized, and the method has remarkable environmental benefits and economic benefits.

Owner:山西华清能创环境科技有限公司

Activated coke for flue gas desulfurization and preparation method thereof

ActiveCN111054310BImprove adsorption capacityReduce manufacturing costGas treatmentOther chemical processesSodium BentoniteFlue gas

The invention belongs to the technical field of comprehensive utilization of resources, and relates to an active coke for flue gas desulfurization and a preparation method thereof. The mixture is obtained by mixing low-modified pulverized coal, semi-coke powder, phenolic resin, sodium humate and sodium bentonite; In terms of percentage, the mixture A contains 35%-42.5% of low-modified pulverized coal, 35%-42.5% of semi-coke powder, 5%-15% of phenolic resin, 5%-15% of sodium humate, 5%- 15% sodium-based bentonite; add ethanol solution and deionized water with a solute quality of 8%-10% to the mixture, mix uniformly and press under a pressure of 5-7MPa to obtain a molding strip; dry the molding strip Carrying out carbonization and activation treatment on the dried molding strips under a protective atmosphere; obtaining the active coke material for flue gas desulfurization after the activation treatment. The invention has simple process and low cost, and opens up a new development and application path for the utilization of low-rank coal with high added value.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Method and system for preparing hydrocarbon-rich carbon-based fuel gas by driving carbon dioxide/water synergistic conversion through molten salt electrochemical method

InactiveCN112391643AHarmlessRealization of high value-added utilizationCellsElectrolytic organic productionIridiumNickel electrode

The invention relates to a method and system for preparing hydrocarbon-rich carbon-based fuel gas by driving carbon dioxide / water synergistic conversion through a molten salt electrochemical method, and the method comprises the following steps: carrying out pre-oxidation film-forming treatment on a nickel electrode to obtain a modified nickel electrode; taking mixed molten salt formed by carbonateand hydroxide as a molten salt medium, taking the modified nickel electrode as an anode, and taking nickel, platinum, titanium, iridium, ruthenium, palladium, iron, tungsten, chromium, copper, gold,graphite or stainless steel materials as a cathode to form a molten salt electrochemical reactor; and carrying water vapor by using a mixed gas of carbon dioxide and argon, and introducing the water vapor into the molten salt electrochemical reactor to carry out electrochemical reduction reaction so as to drive CO2 / H2O to synergistically convert and prepare the hydrocarbon-rich carbon-based fuel gas. The method can continuously drive CO2 / H2O to synergistically convert and prepare the hydrocarbon-rich carbon-based fuel gas for a long time, has the advantages of high gas product conversion rate,high gas product current efficiency and the like, and opens up a new green, environment-friendly and efficient CO2 resource utilization way.

Owner:NORTHEAST GASOLINEEUM UNIV

Novel process of utilizing blast furnace titanium slag for adsorbing and regenerating waste lubricating oil

InactiveCN105255575AProfitableRealization of high value-added utilizationLubricant compositionTitanium slagSocial benefits

The invention discloses a novel process of utilizing blast furnace titanium slag for adsorbing and regenerating waste lubricating oil. The process is characterized by comprising the steps of crushing, grinding and screening the blast furnace titanium slag, then adding the blast furnace titanium slag into an adsorption and regeneration reactor filled with the waste lubricating oil, stirring the waste lubricating oil with a stirrer, making the waste lubricating oil be subjected to an adsorption and regeneration reaction at the reaction temperature of 80-120 DEG C filtering the blast furnace titanium slag after the reaction is ended, and obtaining regenerated lubricating oil. The novel process is simple in process condition, little in investment, lower in operation cost and capable of effectively lowering cost of adsorption and regeneration of the waste lubricating oil. Meanwhile, activity of TiO<2> in the blast furnace titanium slag is utilized, blast furnace titanium slag serves as adsorbent, adsorption and regeneration of the waste lubricating oil are conducted, high added-value utilization of the blast furnace titanium slag can be achieved, and social benefits and economic benefits are fairly remarkable.

Owner:CHONGQING TECH & BUSINESS UNIV

Blast furnace low-carbon ironmaking process

ActiveCN114561500ARealization of high value-added utilizationRealize low-carbon smeltingBlast furnace detailsProcess efficiency improvementKryptonHot air oven

The invention relates to a blast furnace low-carbon ironmaking process, and belongs to the technical field of blast furnace ironmaking production in the metallurgical industry. According to the technical scheme, after oxygen-enriched inert gas is heated through a hot blast stove, blast furnace blast smelting is conducted, the oxygen-enriched inert gas is mixed gas of inert gas and oxygen, and the oxygen accounts for 21%-35% of the volume of the mixed gas. The inert gas is one or more of helium (He), neon (Ne), argon (Ar), krypton (Kr) and xenon (Xe), and the air temperature is 1050-1250 DEG C. The method has the beneficial effects that the oxygen-enriched inert gas is used for replacing air for blast smelting of the blast furnace, so that the difficulty that N2 and CO in the blast furnace gas are not easy to separate can be solved from the source, and high-added-value utilization of the blast furnace gas and low-carbon smelting of the blast furnace are realized.

Owner:HEBEI IRON AND STEEL

Method for producing radiation resisting plates

ActiveCN105439520ARealization of high value-added utilizationAchieve absorptionSolid waste managementBrown iron oxideRadiation

The invention provides a method for producing radiation resisting plates. The method comprises the following steps: processing a red mud-containing aqueous dispersion by using an acid, adding a reducing agent, adjusting the pH value of the aqueous dispersion to 8-9 by using an alkali, and mixing the obtained aqueous dispersion with a material for making heat insulation plates to make the heat insulation plates. The heat insulation plates made of a magnetic iron oxide wave absorbing material and having magnetic properties are produced from red mud through corresponding acid and alkalization treatment, so electromagnetic waves are absorbed to realize indoor electromagnetic radiation resistance, and wastes are changed into valuables to realize high added value utilization of solid wastes.

Owner:BEIJING NEW BUILDING MATERIAL

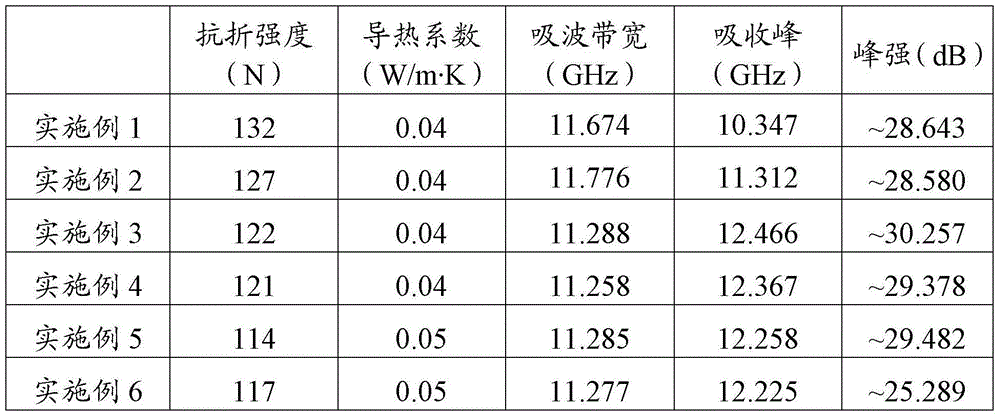

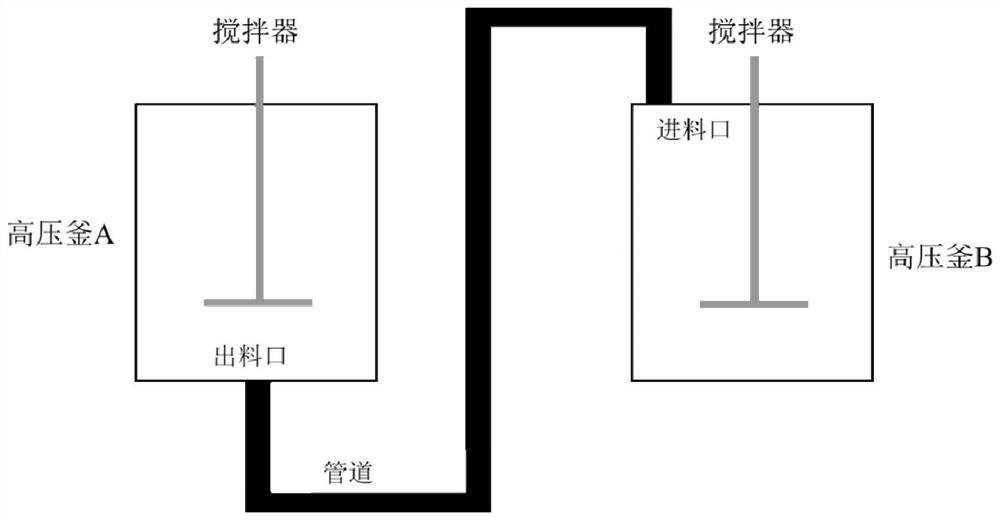

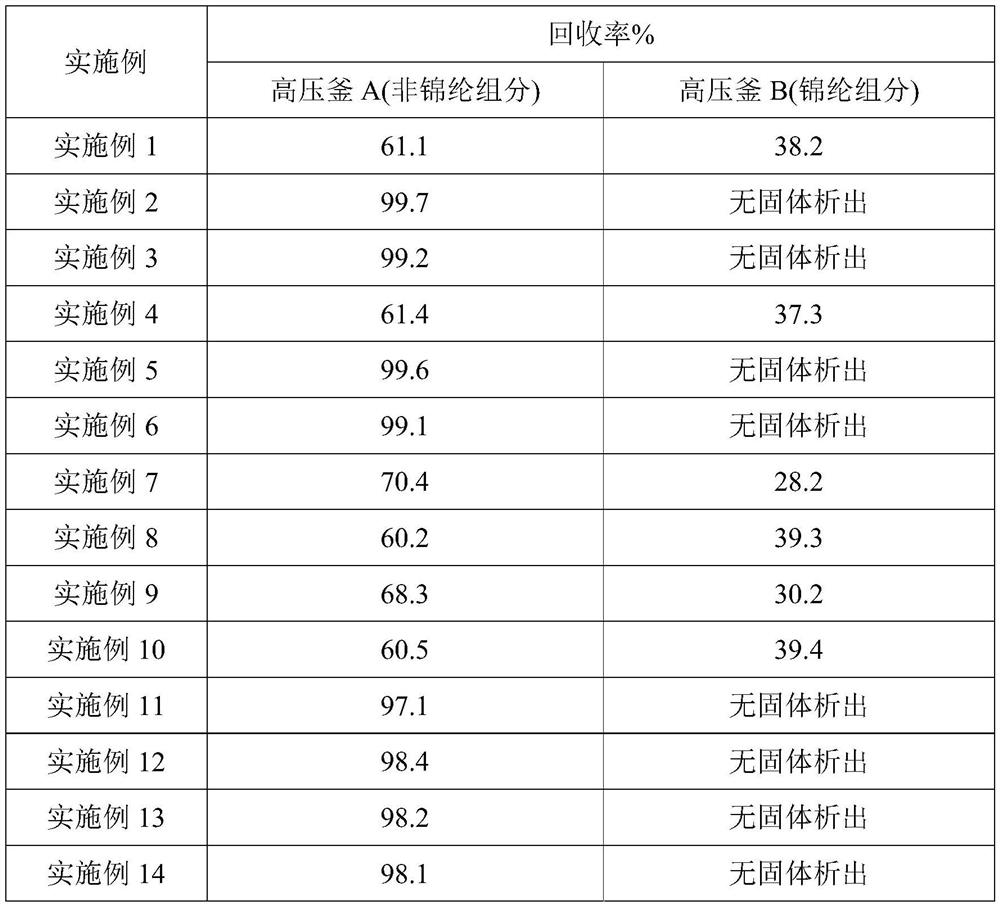

Process for recycling chinlon from waste chinlon blended fabric and recycled product

ActiveCN113717433AEfficient separationHigh recovery ratePlastic recyclingOrganic solventProcess engineering

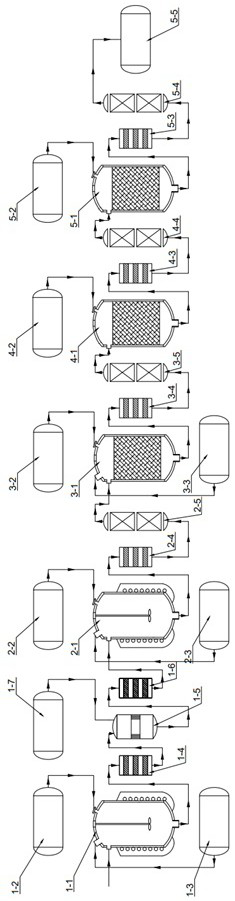

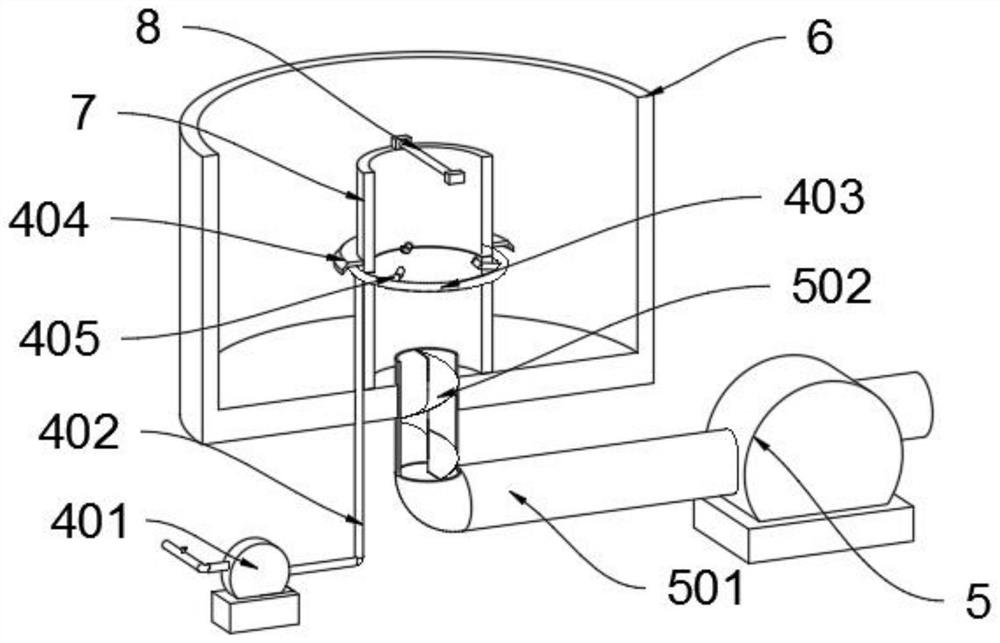

The invention relates to the field of IPC D01G11 / 00, and in particular, relates to a process for recycling chinlon from waste chinlon blended fabric and a recycled product. The process comprises the following steps: extracting the waste chinlon blended fabric by using an organic extracting agent to obtain an extracting solution; reducing the temperature of the extracting solution, and collecting solids separated out in the cooling process; and purifying the collected solid to obtain a chinlon recycled product. According to the method, effective separation of chinlon and non-chinlon components in the chinlon blended fabric is realized by adopting the alcohol extractant, a pure textile product with high recycling rate is obtained, and the method has important significance on recycling of textiles (especially chinlon); a specific recycling device is matched with the extractant, separation is carried out while extraction is carried out, and the recycling efficiency is improved on the basis of a simple and practical process; in the recycling process, the organic solvent with high toxicity and high cost is abandoned, and a safe, environment-friendly, efficient and high-selectivity chinlon recycling process is realized.

Owner:FUJIAN SAILON TECH CO LTD

A kind of method for preparing manganese ferroalloy based on low-grade manganese ore

The invention discloses a method for preparing a manganese-iron alloy based on low-grade manganese ore. The method comprises four processes, namely ball milling of raw materials, pelletizing, quick reduction and slag-metal separation. The method comprises the following steps: mixing low-grade manganese ore and iron ore powder; milling the mixed ore, and screening with a 150-300 meshes screen; mixing the screen underflow with the pulverized coal, lime, bentonite and water, and pelletizing on a disc type pelletizer, wherein the diameter of the green balls is 10-16mm; drying the green balls at 105 DEG C for 4h; reducing the dried pellets at 1,450-1,550 DEG C for 8-15min; and after the reaction, crushing the raw material, and performing simple magnetic separation to obtain granular manganese iron, wherein the manganese content is 45-70%, the iron content is 25-45%, the carbon content is 2-5%, and the balance is impurities. According to the method disclosed by the invention, the manganese-iron alloy is prepared by the one-step process of the quick reducing technology, the slag and metal are easily separated, the process is pollution-free, the manganese recovery rate is high, and high value-added utilization of the low-grade manganese ore is realized.

Owner:SUZHOU UNIV

Method for producing biomass oil from straws

PendingCN111849534AMild production conditionsLow equipment requirementsLiquid hydrocarbon mixture productionHydrocarbon oils treatmentOrganic acidDepolymerization

The invention discloses a method for producing biomass oil from straws. The method is characterized by comprising the following steps: (1) washing and drying a straw material; (2) crushing the straw material; (3) preparing a straw depolymerization solvent, wherein the volume ratio of organic acid to hydrogen peroxide is 24: 1-22: 3; (4) depolymerizing the straw powder in a solvent under the conditions that the pressure is normal, the temperature is 30-70 DEG C, the solid-to-liquid ratio of the straw powder to the depolymerizing solvent is 1: 12-1: 60, the mechanically stirring rotating speed of 90-150rpm, and the depolymerizing time is 12-48h; (5) filtering a depolymerizing product at normal temperature and normal pressure, and carrying out solid-liquid separation; and (6) rectifying the separated liquid to remove the organic acid solvent, and adding ethanol to prepare the biomass oil.

Owner:GUIZHOU INST OF TECH

Construction waste regenerated imitation stone brick and preparation method thereof

PendingCN114835448ARealization of high value-added utilizationHarmlessSolid waste managementBrickConstruction engineering

The invention relates to a construction waste recycled imitation stone brick, the structure of the recycled imitation stone brick comprises a surface layer and a base layer, the base layer comprises the following raw materials: ash cement, a compound of 0-5mm recycled tile aggregate and recycled concrete aggregate, a compound of 5-10mm recycled tile aggregate and recycled concrete aggregate, and an auxiliary agent, the surface layer is prepared from the following raw materials: grey cement or white cement, 0-5mm and 5-10mm recycled concrete aggregate compounds, pigment and auxiliaries. According to the construction waste recycled imitation stone brick developed by the invention, construction waste recycled bricks and tiles and concrete aggregate are used as the base layer and the surface layer aggregate, all indexes meet the requirements of the national standard GB28635-2012 Concrete Pavement Brick through the design of the base layer mix proportion, the product strength is not lower than 40MPa, the cost of the imitation stone brick is greatly reduced, and the production cost is reduced. And high value-added utilization of the construction waste in high-end imitation stone products is realized.

Owner:BCEG RESOURCES RECYCLING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com