Active coke for flue gas desulfurization, and preparation method thereof

A technology of activated coke and flue gas, which is applied in the field of comprehensive utilization of resources, can solve the problems of increasing the ash content of activated coke, achieve good adsorption performance, reduce production costs, and shorten the activation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

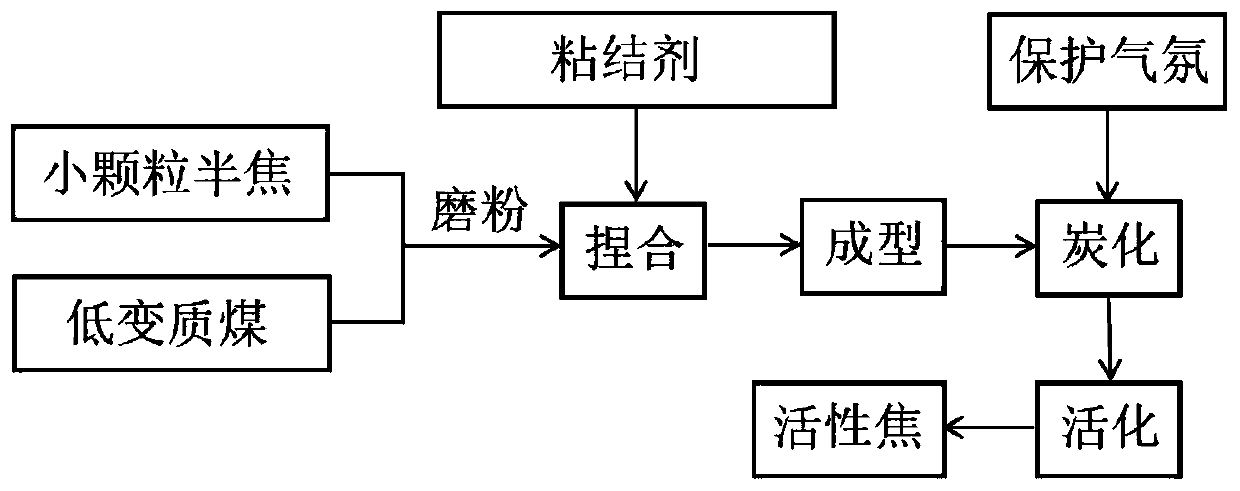

Method used

Image

Examples

Embodiment 1

[0043] The method for preparing activated coke for flue gas desulfurization from low-rank coal in this embodiment comprises the following steps:

[0044] Step 1, raw material preparation: take a certain amount of small particle semi-coke, wash it twice, dry it in a vacuum drying oven for 6 hours, put the dried small particle semi-coke into a pulverizer, and pass it through a 200-mesh sieve to obtain the required particle size semi-coke powder; dry low metamorphic pulverized coal and crush it through a 200-mesh sieve to obtain low metamorphic coal powder with the required particle size; prepare an ethanol solution with a solute mass percentage of 8% for later use; weigh the raw materials according to the required raw materials in different proportions Dry materials, raw materials, by mass percentage, contain 5% phenolic resin, 5% sodium humate, 5% sodium bentonite, 42.5% low-modified coal powder, 42.5% semi-coke powder;

[0045] Step 2, mix the above-mentioned dry materials of ...

Embodiment 2

[0051] The method for preparing activated coke for flue gas desulfurization from low-rank coal in this embodiment comprises the following steps:

[0052] Step 1, raw material preparation: take a certain amount of small particle semi-coke, wash it 3 times, dry it in a vacuum drying oven for 7 hours, put the dried small particle semi-coke into a pulverizer, and pass it through a 200-mesh sieve to obtain the required particle size semi-coke powder; dry the low-modified pulverized coal and crush it through a 200-mesh sieve to obtain the low-modified coal powder with the required particle size; prepare an ethanol solution with a solute mass percentage of 9% for later use; weigh the raw materials according to the required raw materials in different proportions Dry materials, raw materials, by mass percentage, contain 10% phenolic resin, 5% sodium humate, 10% sodium bentonite, 37.5% low-modified coal powder, 37.5% semi-coke powder;

[0053] Step 2, mix the above-mentioned dry materia...

Embodiment 3

[0059] The method for preparing activated coke for flue gas desulfurization from low-rank coal in this embodiment comprises the following steps:

[0060] Step 1, raw material preparation: take a certain amount of small particle semi-coke, wash it 4 times, dry it in a drying oven for 8 hours, put the dried small particle semi-coke into a pulverizer, and pass it through a 200-mesh sieve to obtain the desired particle size. Semi-coke powder; dry low metamorphic pulverized coal and crush it through a 200-mesh sieve to obtain low metamorphic coal powder with the required particle size; prepare an ethanol solution with a solute mass percentage of 10% for later use; weigh raw materials according to different proportions of raw materials required Material, in the raw material, by mass percentage, it contains 15% phenolic resin, 10% sodium humate, 5% sodium bentonite, 35% low metamorphic coal powder, and 35% semi-coke powder;

[0061] Step 2, mix the above-mentioned dry materials of ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com