Patents

Literature

8619 results about "Sodium Bentonite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bentonite usually forms from weathering of volcanic ash, most often in the presence of water. However, the term bentonite, as well as a similar clay called tonstein, has been used to describe clay beds of uncertain origin. For industrial purposes, two main classes of bentonite exist: sodium and calcium bentonite.

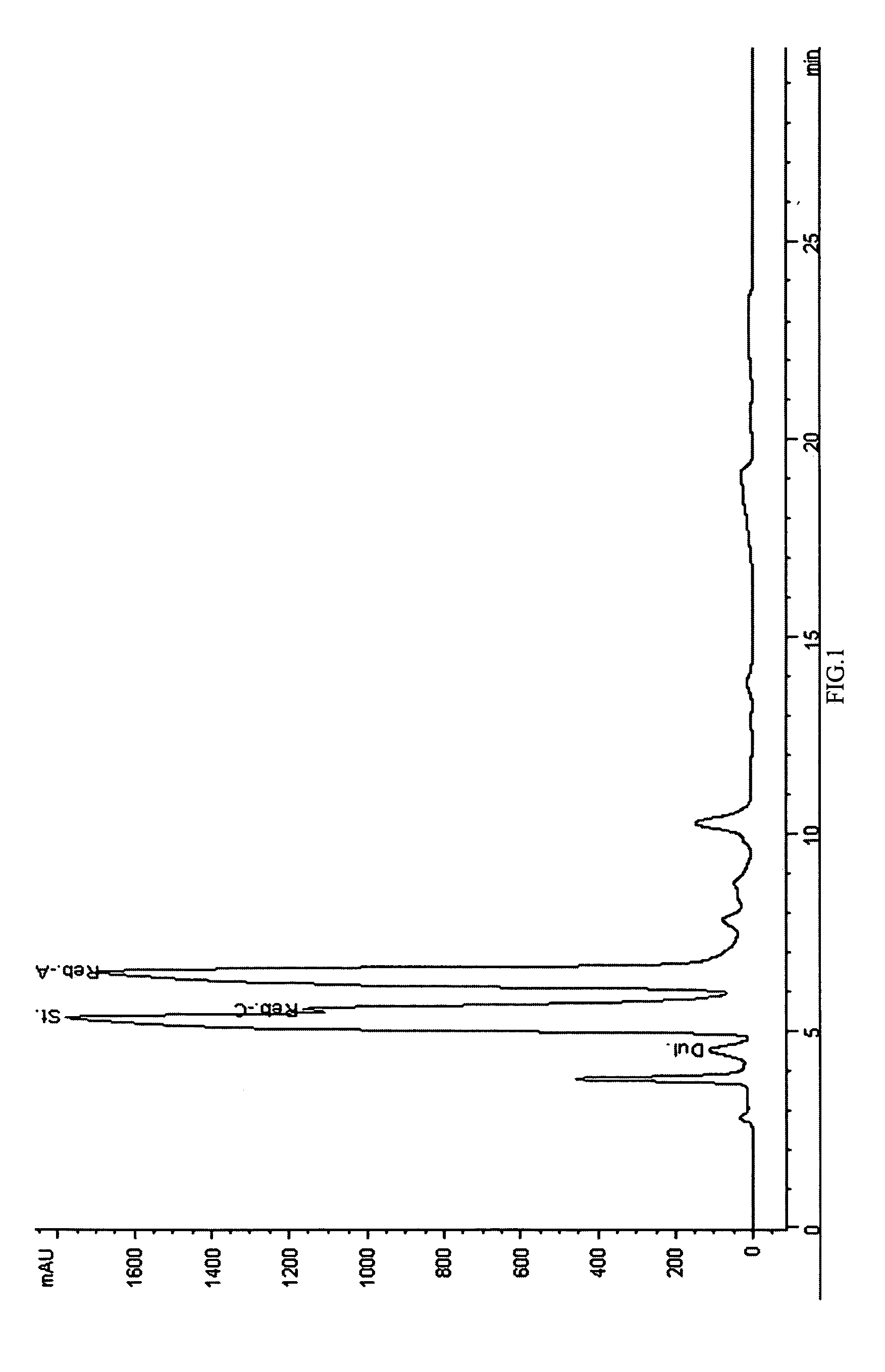

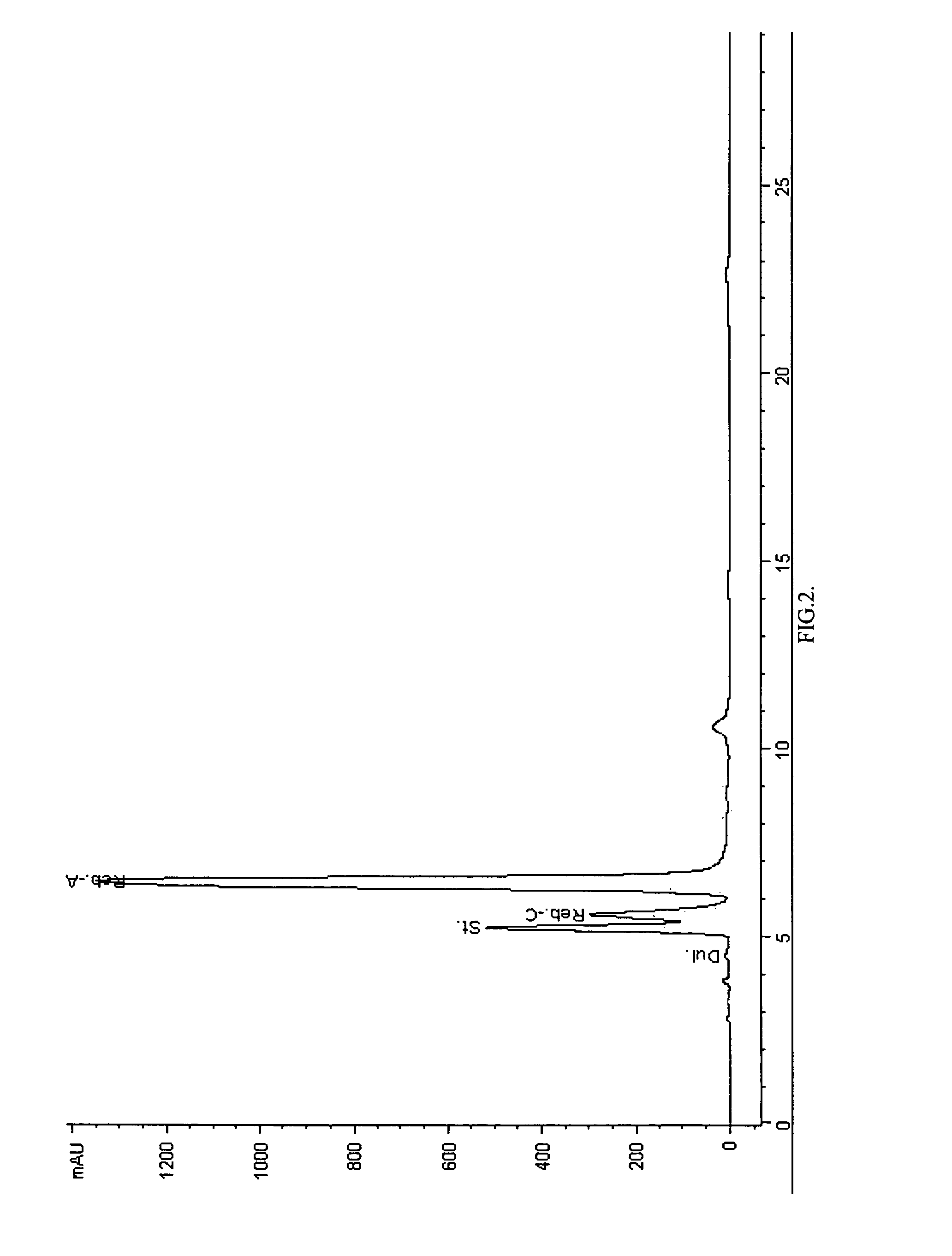

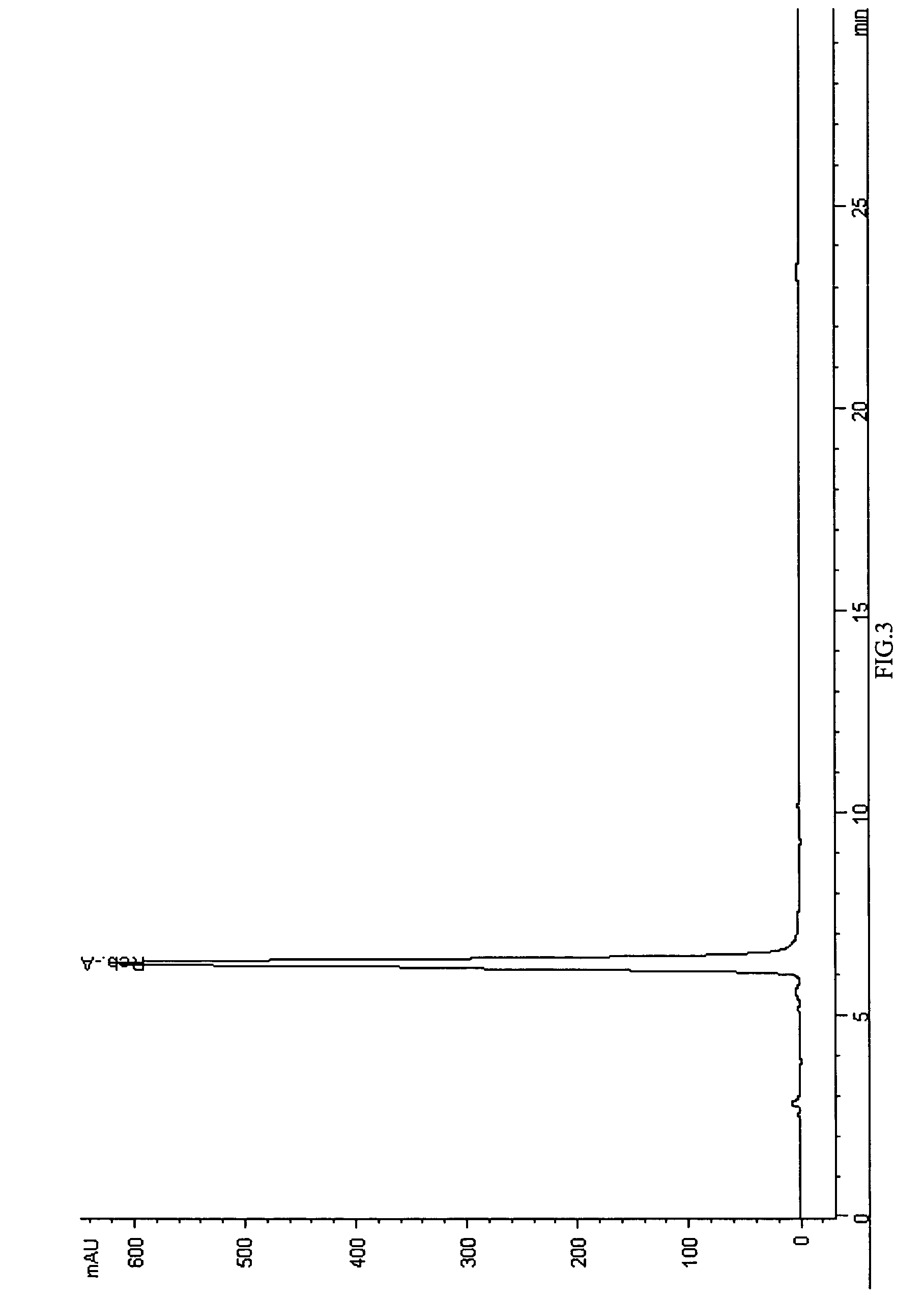

Extraction, separation and modification of sweet glycosides from the stevia rebaudiana plant

ActiveUS20060134292A1Increasing of degree of transglycosylationDelayed reaction timeBiocideAnimal repellantsPectinaseSodium Bentonite

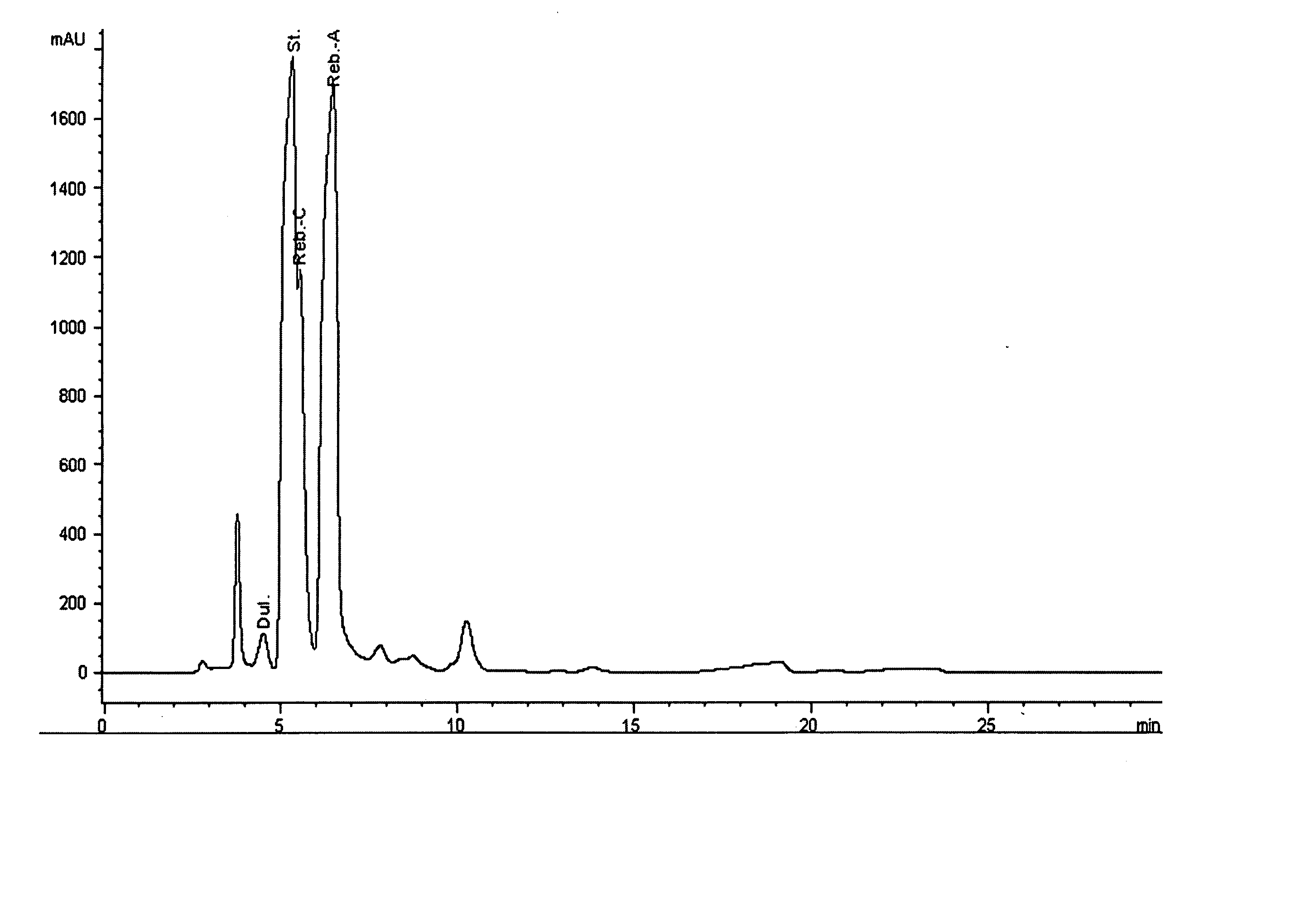

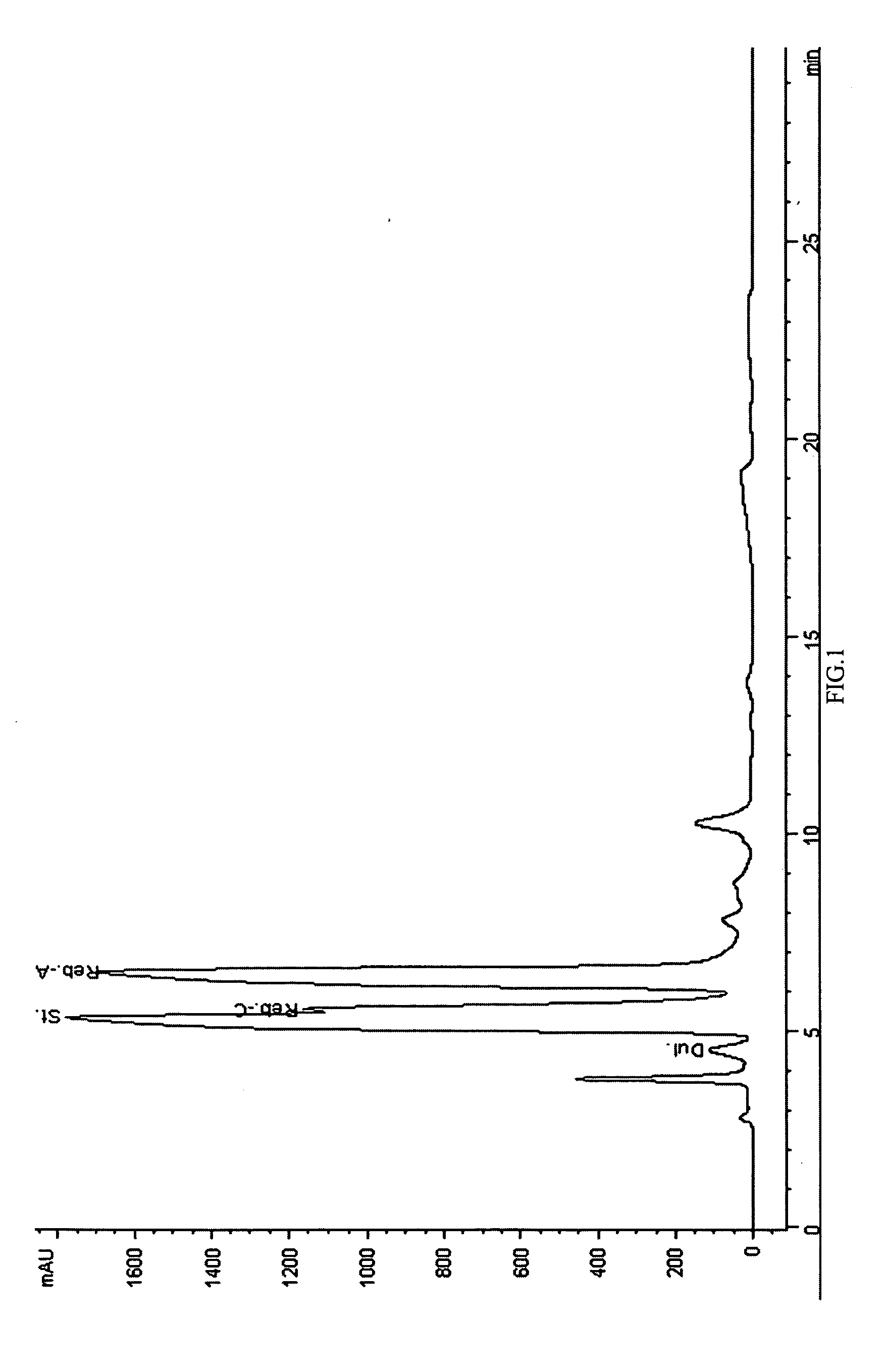

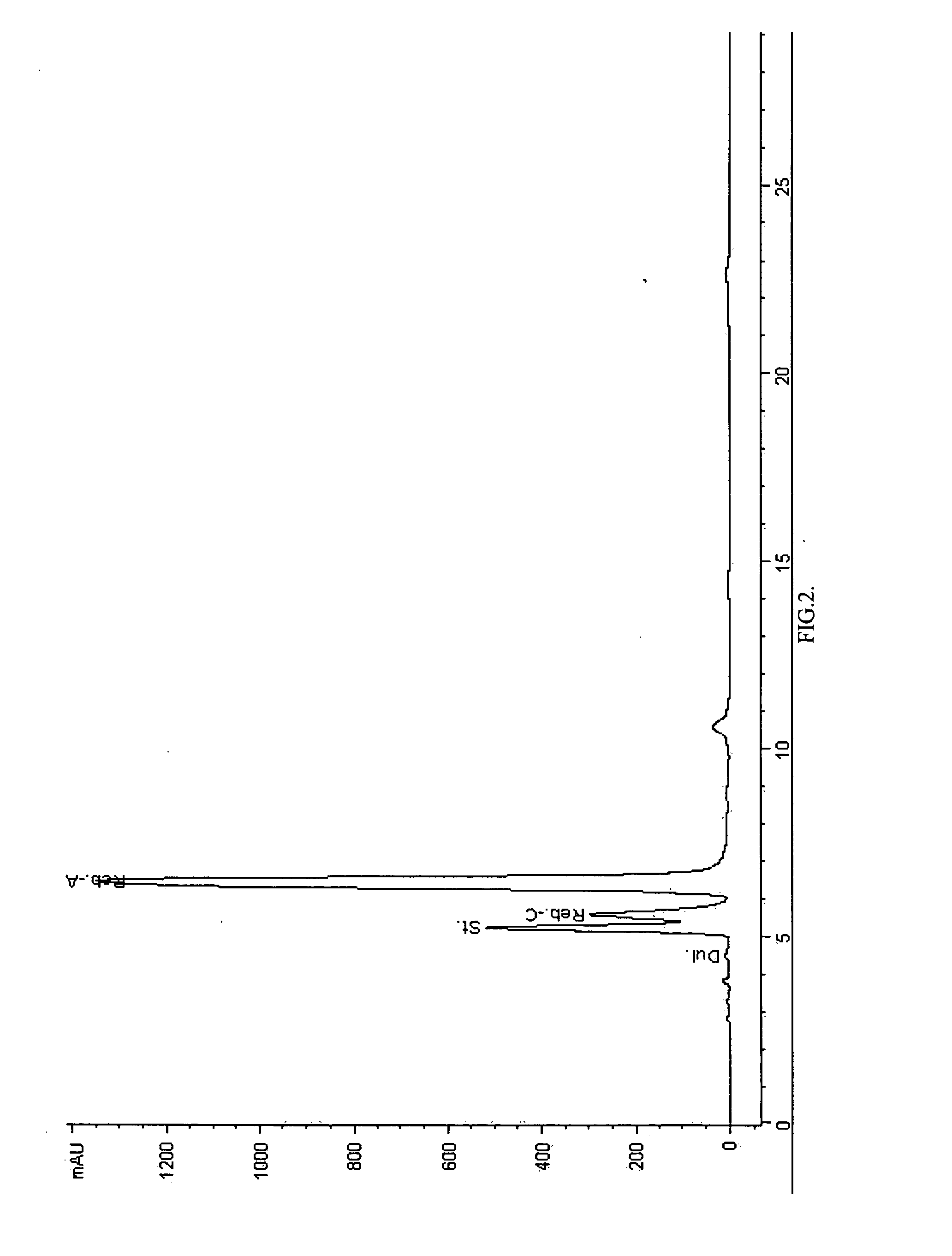

The invention disclosed relates to a method for the extraction of sweet glycosides from the Stevia rebaudiana Bertoni plant and recovery of individual rebaudioside A and stevioside. The extraction is developed in the presence of pectinase, and the extract is purified using cyclodextrin and bentonite. High purity rebaudioside A is obtained by crystallization and recrystallization from ethanol. High purity stevioside is prepared from the filtrate by purification with cyclodextrin, bentonit, and ion exchange resins. The enzymatic modification of the rebaudioside A, stevioside and the purified extract is carried out using the transferring enzymes derived from Thermoactinomyces vilgaris and Bacillus halophilus.

Owner:PURECIRCLE SDN BHD

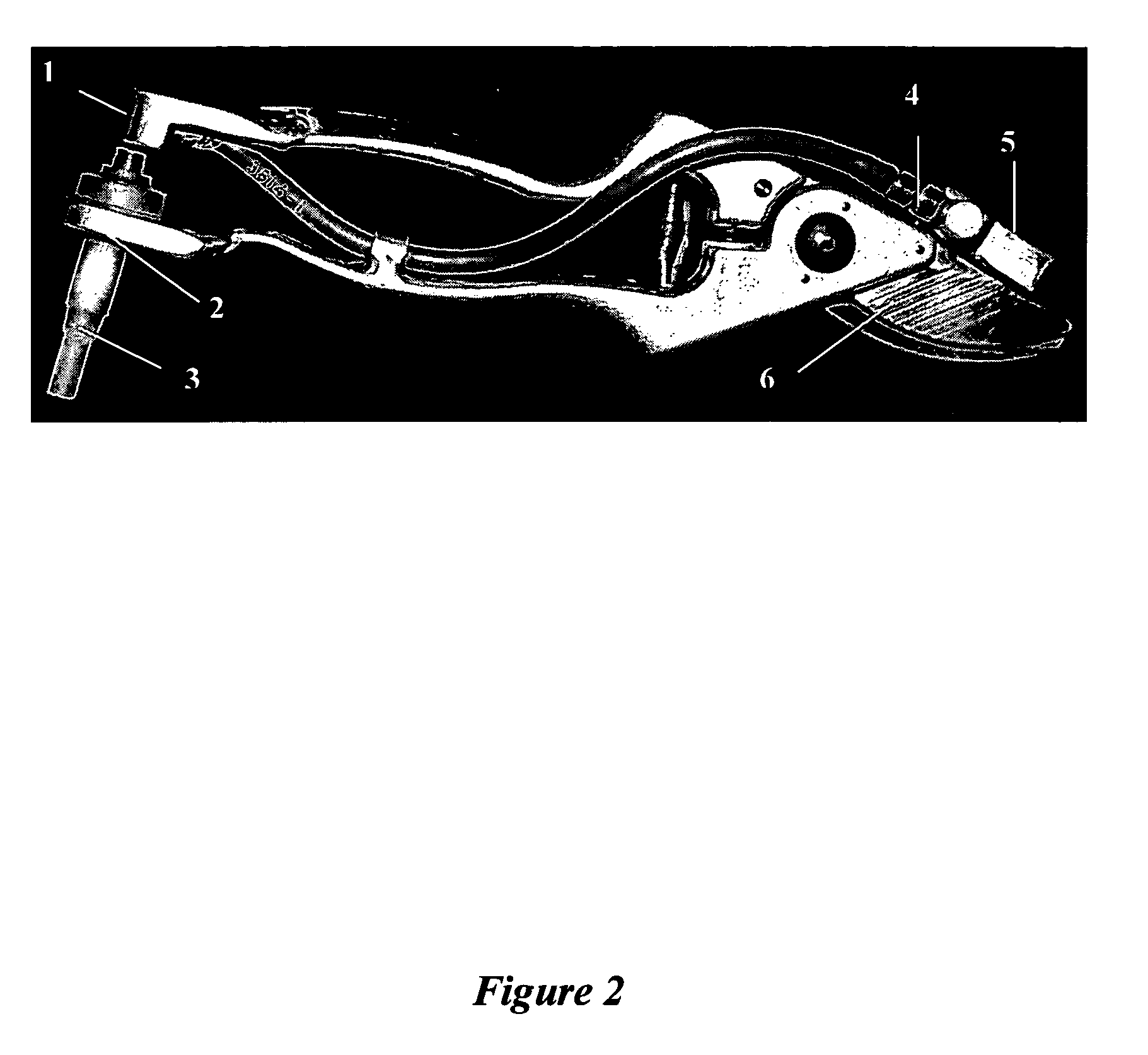

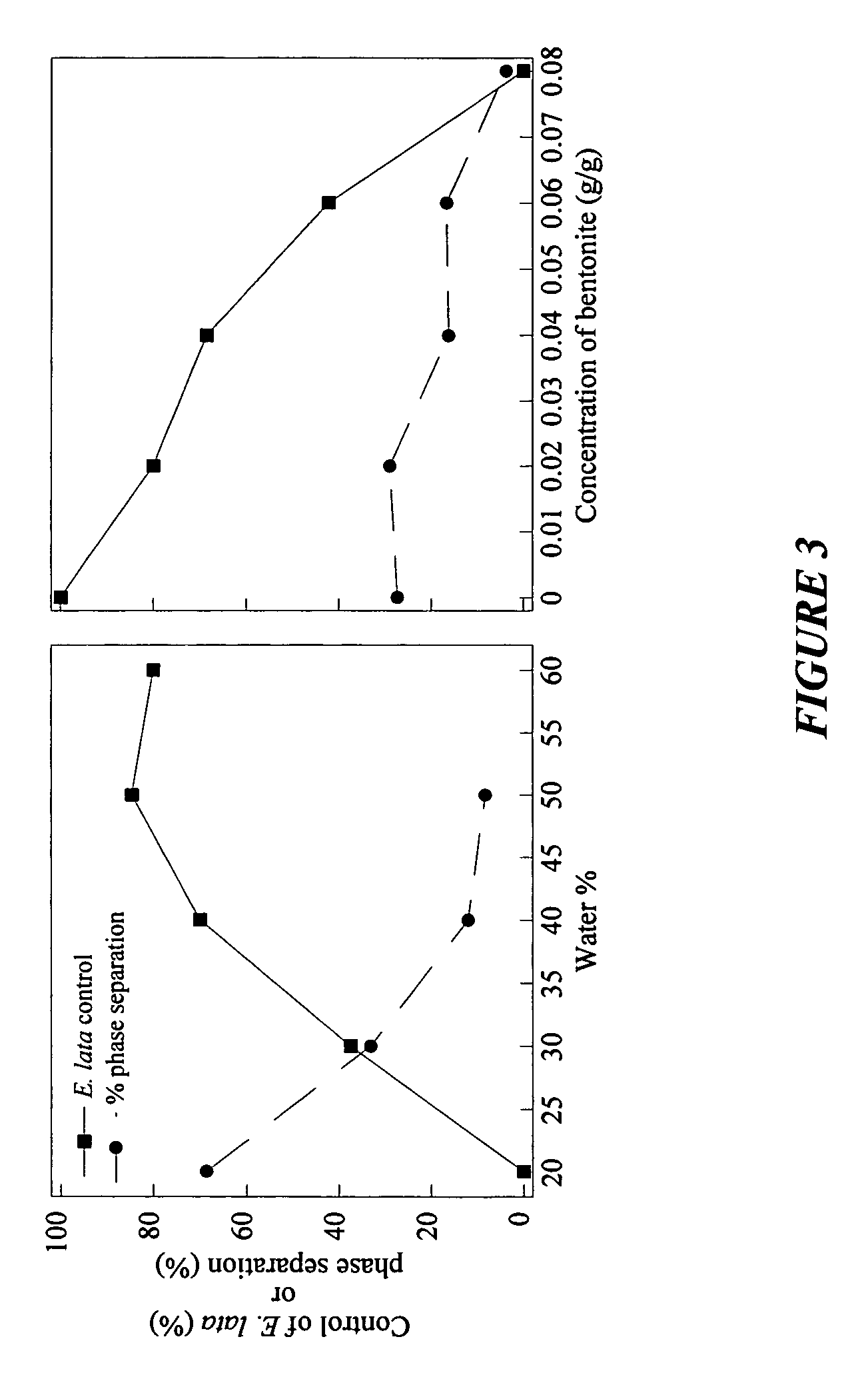

Storage stable compositions of biological materials

Storage stable compositions of biological materials, including bioactive biological materials are provided in the form of a water-in-oil emulsion, comprising:(a) cellular material selected from living and / or dormant prokaryotic and / or eukaryotic cells and tissues, the cellular material being compatible with water-in-oil emulsions;(b) one or more oils selected from vegetable oils and fish oils;(c) an oil-soluble nonionic polymeric surfactant having a molecular weight of from about 2500 to about 15000; and(d) water.The compositions may also contain a thickener such as a hydrophobic fumed silica or bentonite.Compositions may be used for various purposes, depending on the contained biological material. Specific examples include compositions containing Fusarium lateritium control of Eutypa lata in plant wounds made by cutting or pruning, and compositions containing Lagenidium giganteum for control of mosquitoes.

Owner:RGT UNIV OF CALIFORNIA

Extraction, separation and modification of sweet glycosides from the Stevia rebaudiana plant

ActiveUS7838044B2High extraction rateSimple processBiocideAnimal repellantsPectinaseSodium Bentonite

The invention disclosed relates to a method for the extraction of sweet glycosides from the Stevia rebaudiana Bertoni plant and recovery of individual rebaudioside A and stevioside. The extraction is developed in the presence of pectinase, and the extract is purified using cyclodextrin and bentonite. High purity rebaudioside A is obtained by crystallization and recrystallization from ethanol. High purity stevioside is prepared from the filtrate by purification with cyclodextrin, bentonit, and ion exchange resins. The enzymatic modification of the rebaudioside A, stevioside and the purified extract is carried out using the transferring enzymes derived from Thermoactinomyces vulgaris and Bacillus halophilus.

Owner:PURECIRCLE SDN BHD

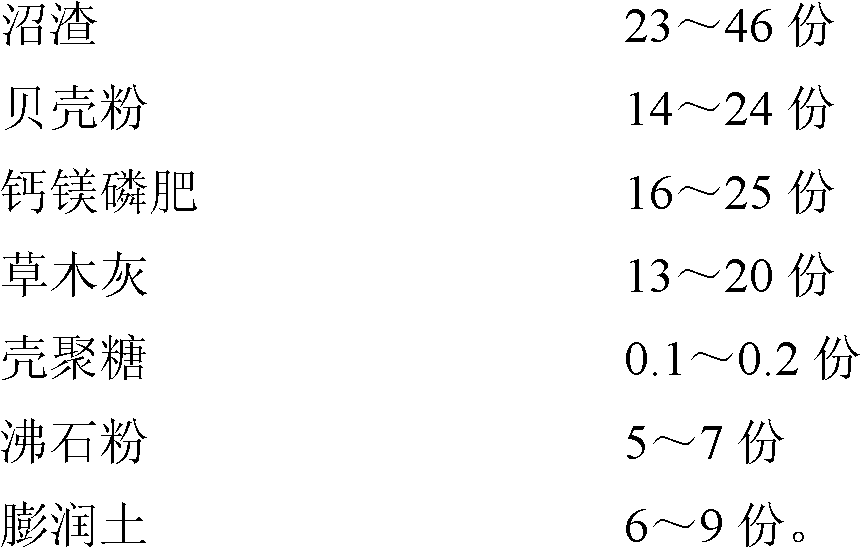

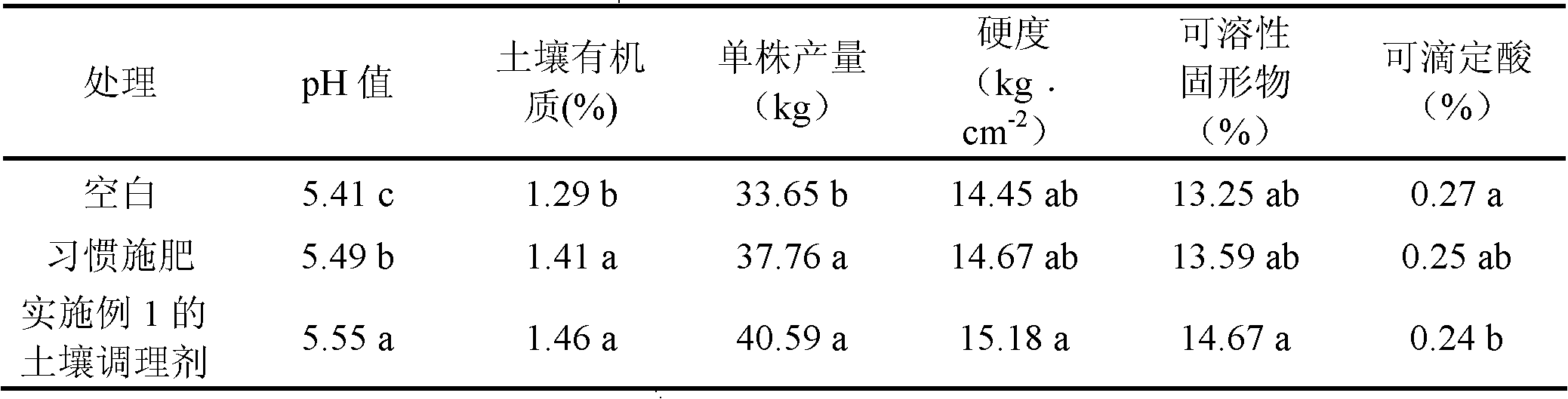

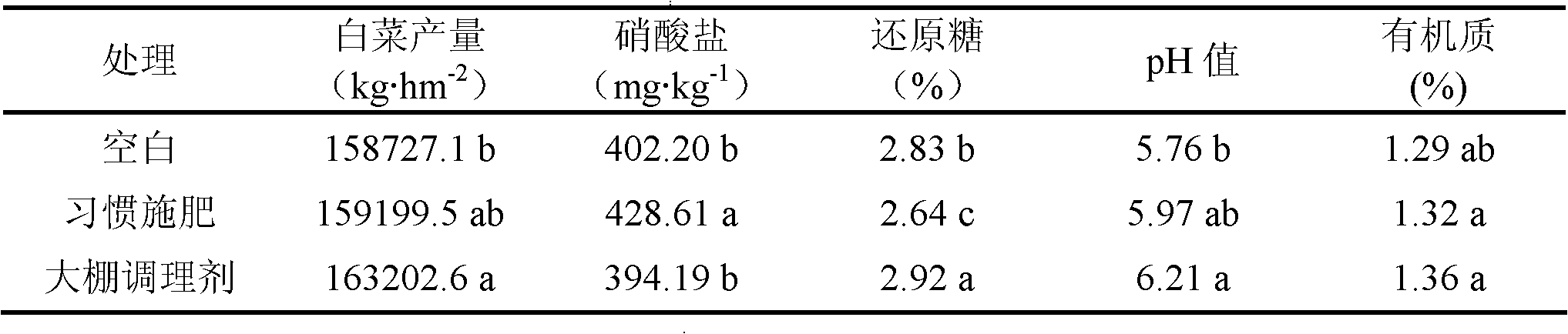

Organic environmentally-friendly soil conditioner for improving acidified or acid soil

ActiveCN102321484ARaw material safetyEfficient use ofOrganic fertilisersSoil conditioning compositionsSodium BentoniteHeavy metal poisons

The invention relates to an organic environmentally-friendly soil conditioner for improving acidified or acid soil and a preparation method thereof. The soil conditioner is prepared from the following raw materials in parts by weight: 23-46 parts of biogas residue, 14-24 parts of shell powder, 16-25 parts of calcium magnesium phosphate fertilizer, 13-20 parts of plant ash, 0.1-0.2 part of chitosan, 5-7 parts of zeolite powder and 6-9 parts of bentonite. The soil conditioner is prepared through pretreatment of the biogas residue, pretreatment of the shell powder and the like; through the produced soil conditioner, the pH value of soil can be increased; nutritive elements such as calcium, magnesium, phosphorus, potassium and the like in the soil are increased; the organic matter content in the soil is increased; the water retention and fertilizer retention capacity of the soil is improved; the physicochemical property of the soil is improved; the antiretroviral (diseases, pests, drought and the like) capacity of crops is improved; heavy metal poison is reduced; and the soil conditioner is convenient to apply, is not influenced by wind power and is suitable for mechanical working.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Inorganic putty powder with function of governing humidness

ActiveCN101368014AEffective regulation of relative humidityGood environmental protectionFilling pastesCement coatingsSodium BentoniteMetallurgy

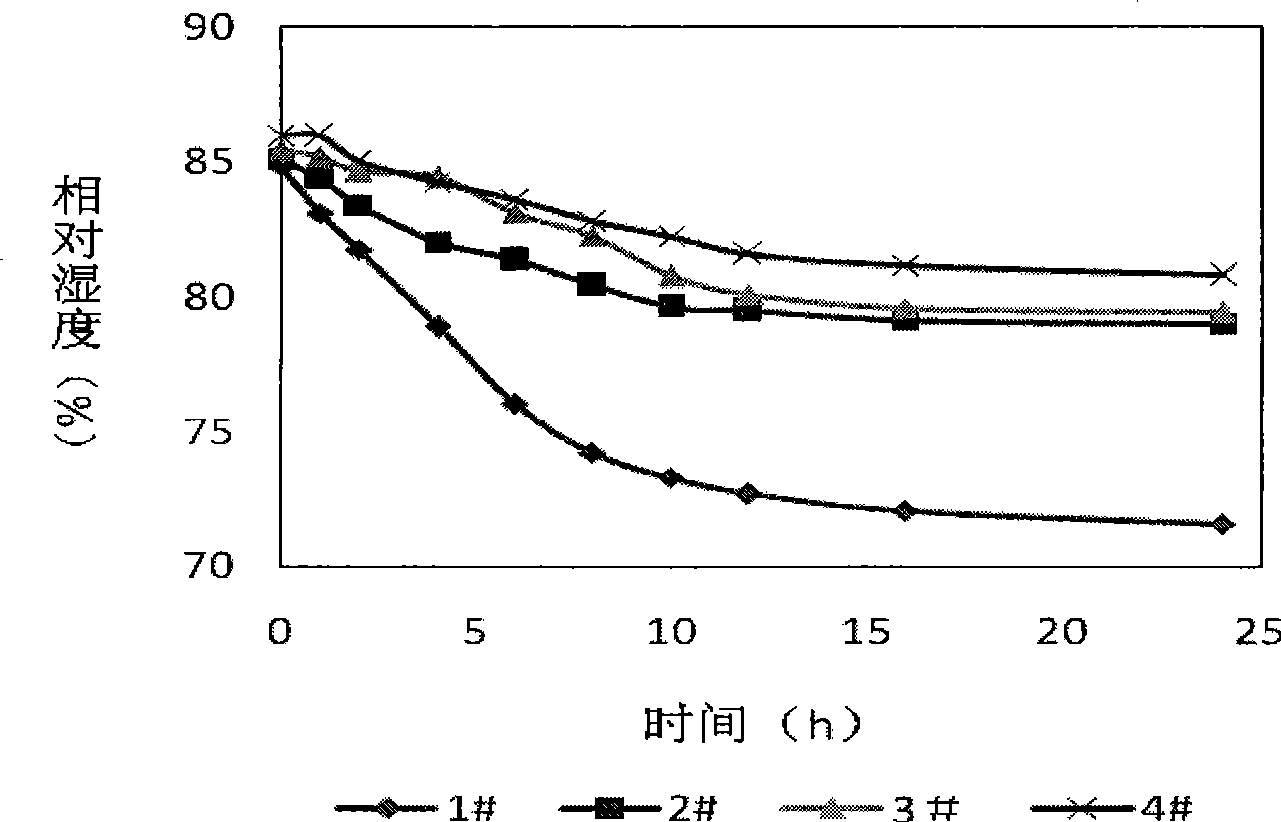

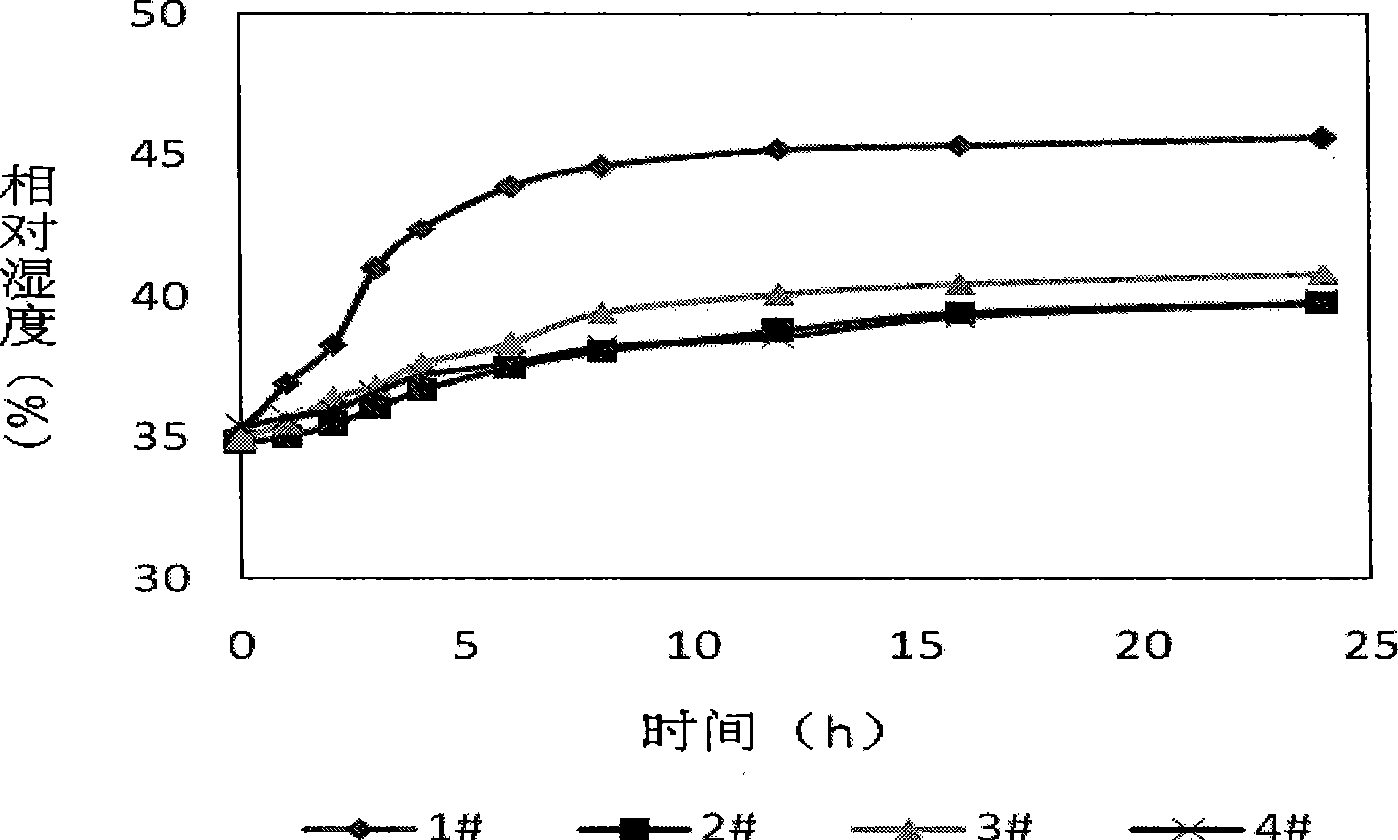

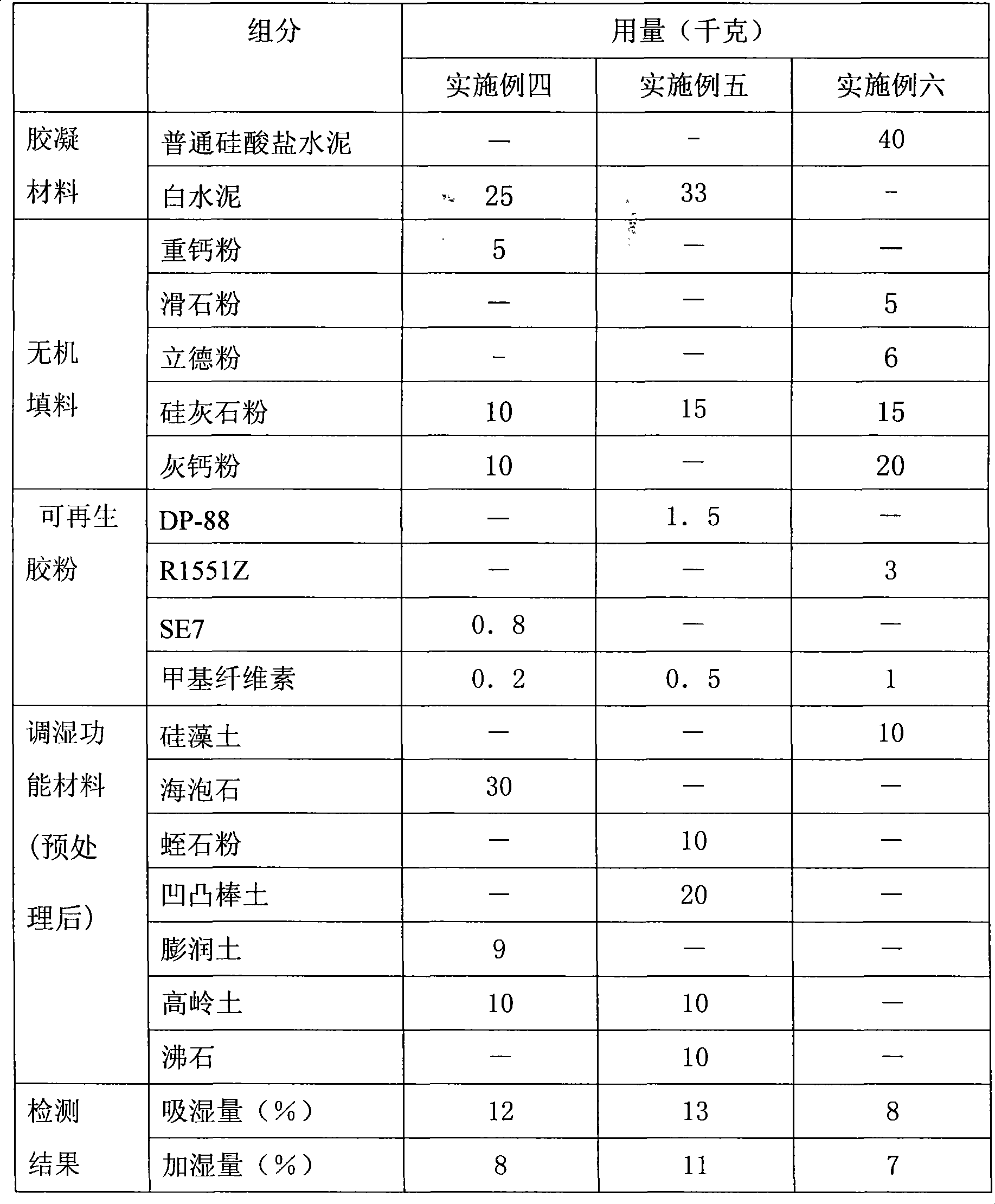

The invention relates to interior wall putty powder with air humidity regulating function, which belongs to the field of building materials. The putty powder is composed of 10 to 50 weight portions of humidity regulating material, 15 to 50 weight portions of inorganic binding material, 15 to 50 weight portions of inorganic filler, and 1 to 5 weight portions of sub divisible rubber powder; the humidity regulating material comprises one type or more than one type of diatomite, sepiolite, attapulgite, vermiculite, zeolite powder, kaolin and bentonite. Because of the environment protection and humidity regulating functions, the multi-pore inorganic mineral material is taken as humidity regulating material and applied in the building interior wall putty powder. With water added in, the putty powder is mixed into lacquer putty and applied on the wall surface, which can effectively regulate the indoor air humidity, so that the indoor air humidity is controlled within the scope which is beneficial to the health of human body; meanwhile, the putty powder has no pollution, no VOC released and can be directly used for decoration.

Owner:CHINA BUILDING MATERIALS ACAD

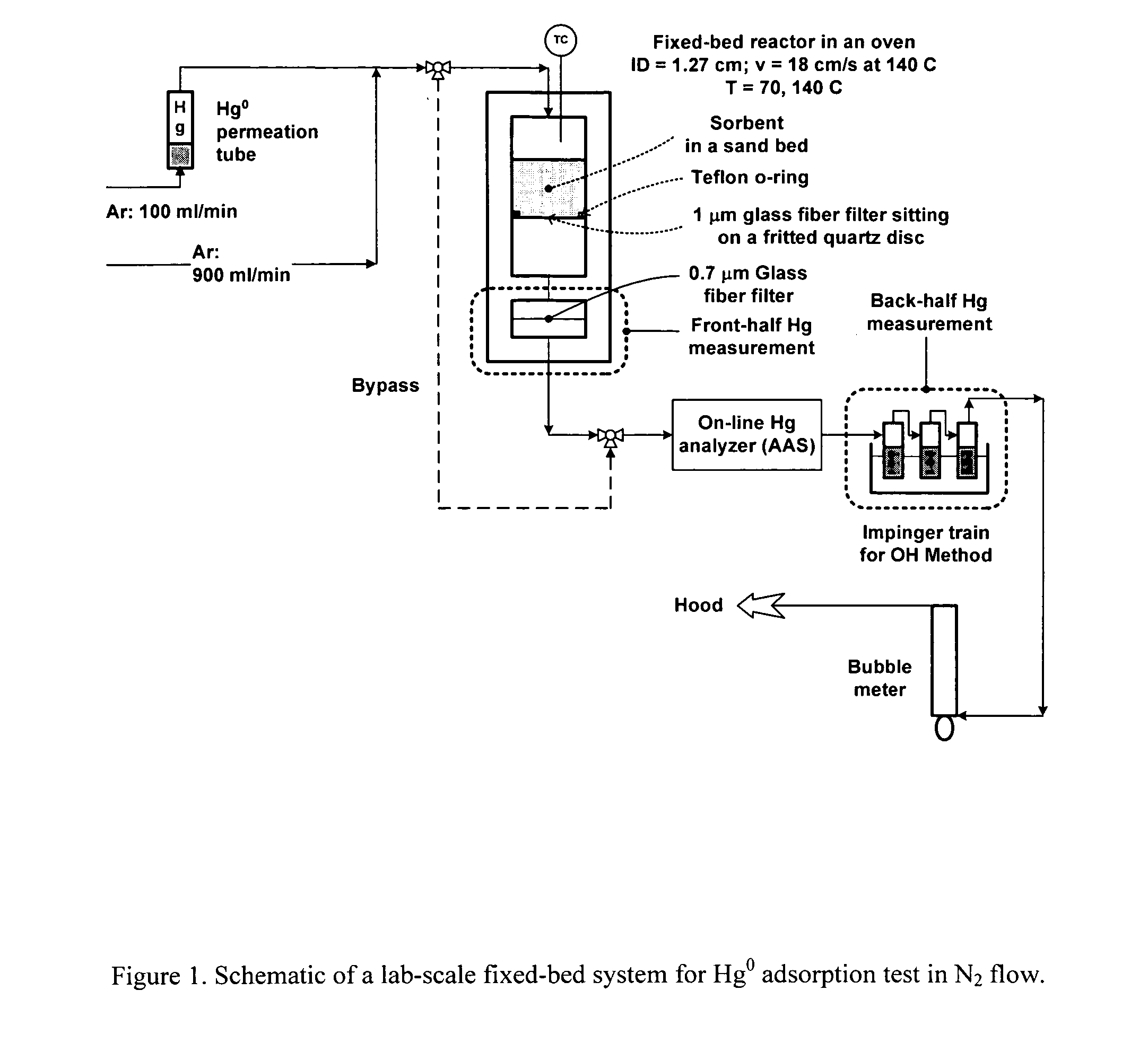

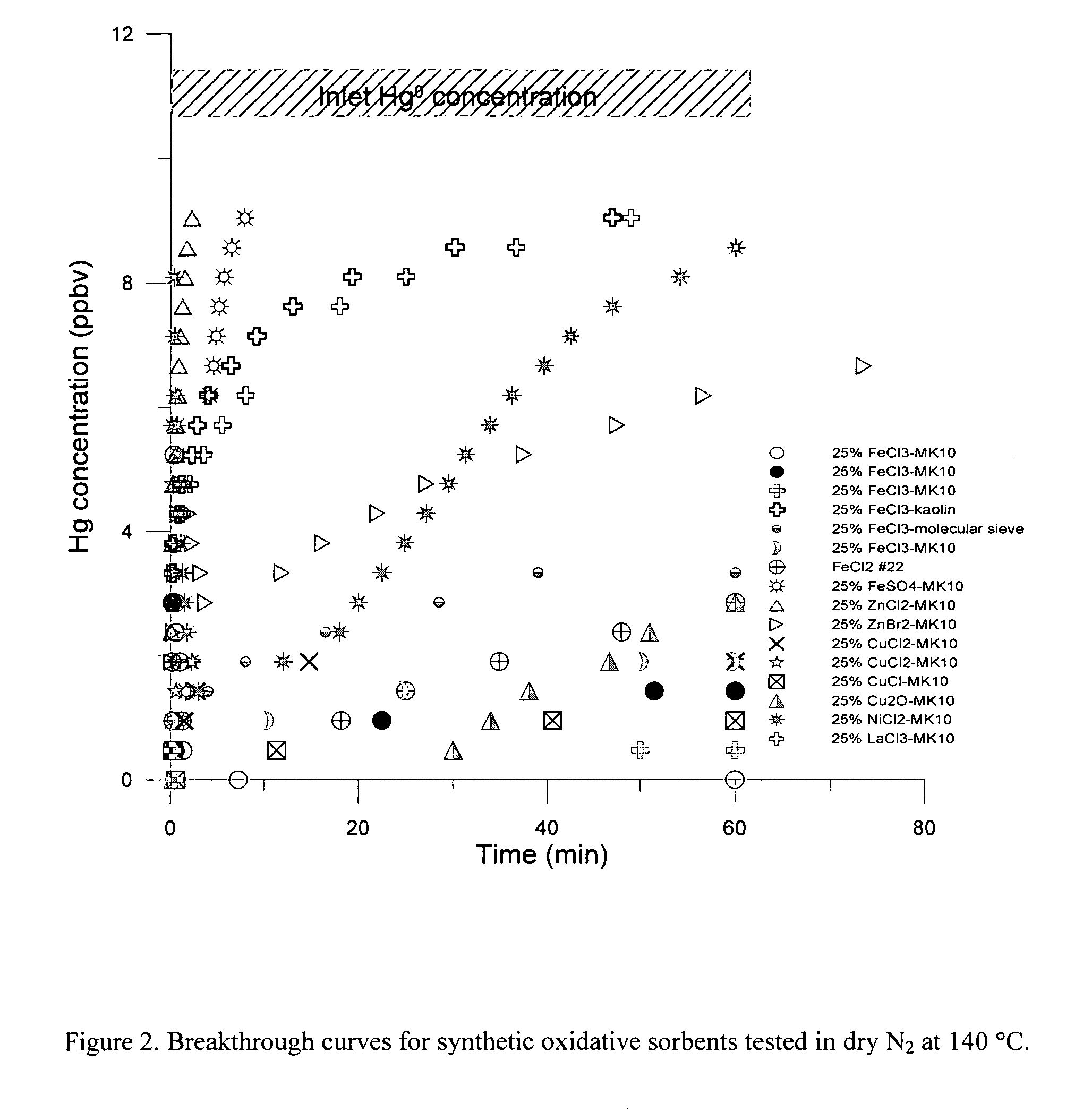

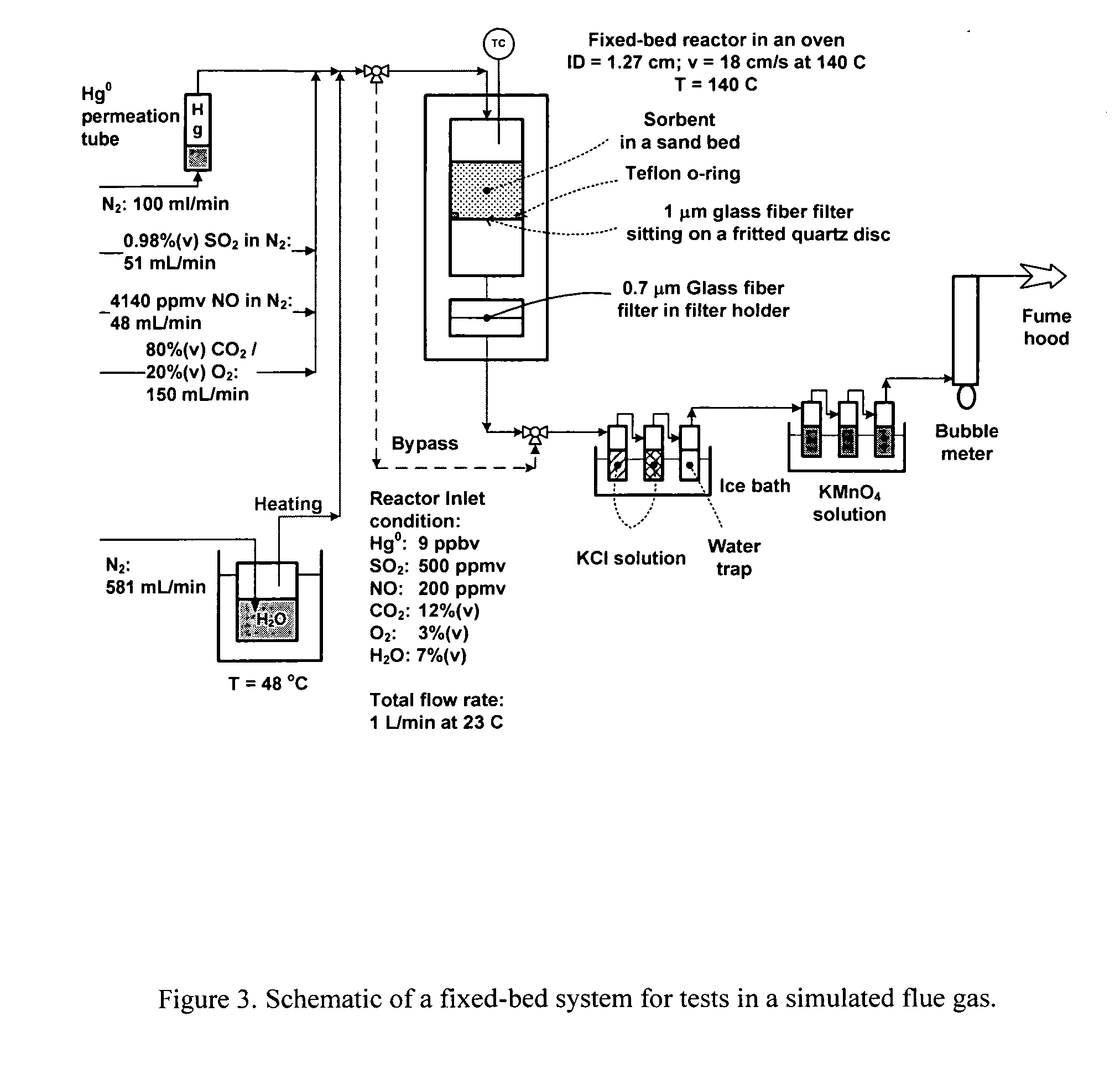

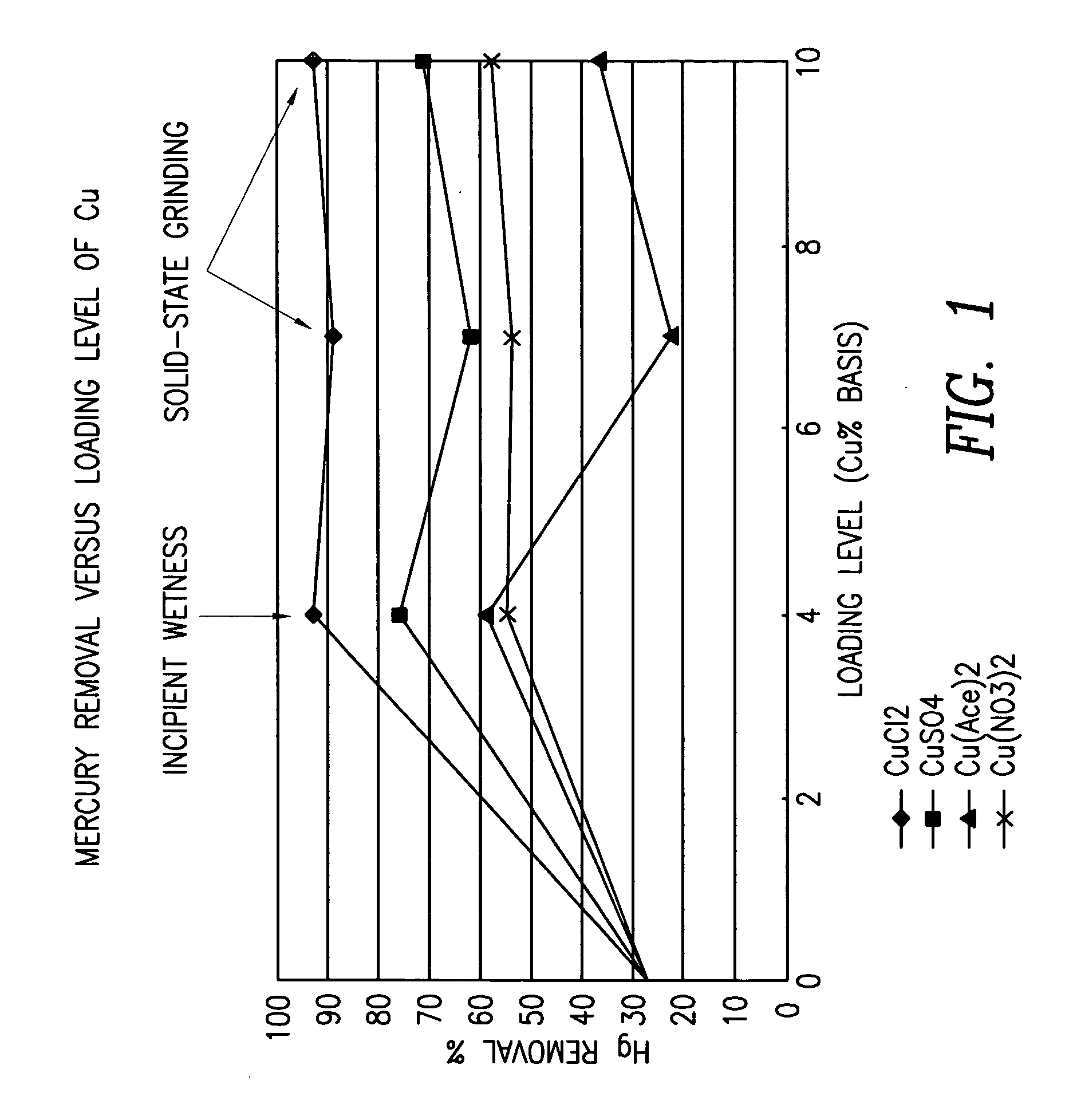

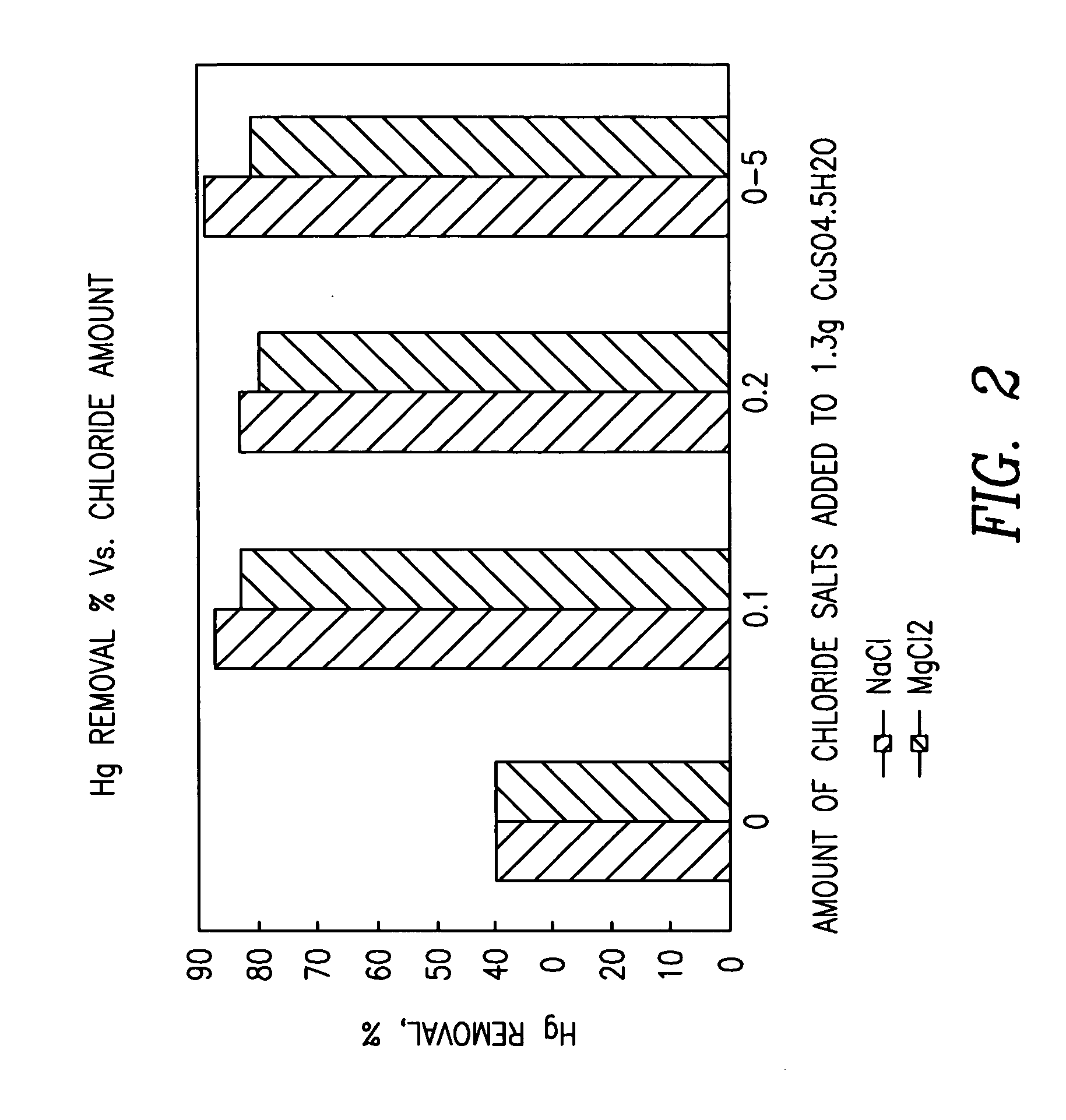

Compositions and methods for removing mercury from mercury-containing fluids

InactiveUS20070140940A1Facilitate mercury removalThe material is lowGas treatmentDispersed particle filtrationSodium BentoniteSorbent

Oxidative sorbents are provided for adsorbing elemental or oxidized mercury from mercury-containing fluids such as flue gas from a coal-burning power utility or the like at a temperature range of about 50 to 350 ° C. The method of preparing and using the oxidative sorbents is also provided. The oxidative sorbent compositions include one or more silicates capable of cation exchange with a plurality of active metal cations and their counter anions. The silicates may include those selected from clays such as montmorillonite, laumonite, bentonite, Mica, vermiculite and kaolinite, and from silica gels, natural and synthetic molecular sieves, zeolites, and ashes from stoker- and pulverized coal-fired boilers. The one or more oxidative metal halides and / or sulfates may be selected from the group consisting of CuCl, CuBr, CuCl2, CuBr2, CuSO4, FeCl2, FeCl3, FeSO4, Fe2(SO4)3, ZnCl2, ZnBr2, NiCl2, and NiSO4. The oxidative sorbents may also include activated carbon.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA THE AS REPRESENTED BY THE ADMINISTATOR

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

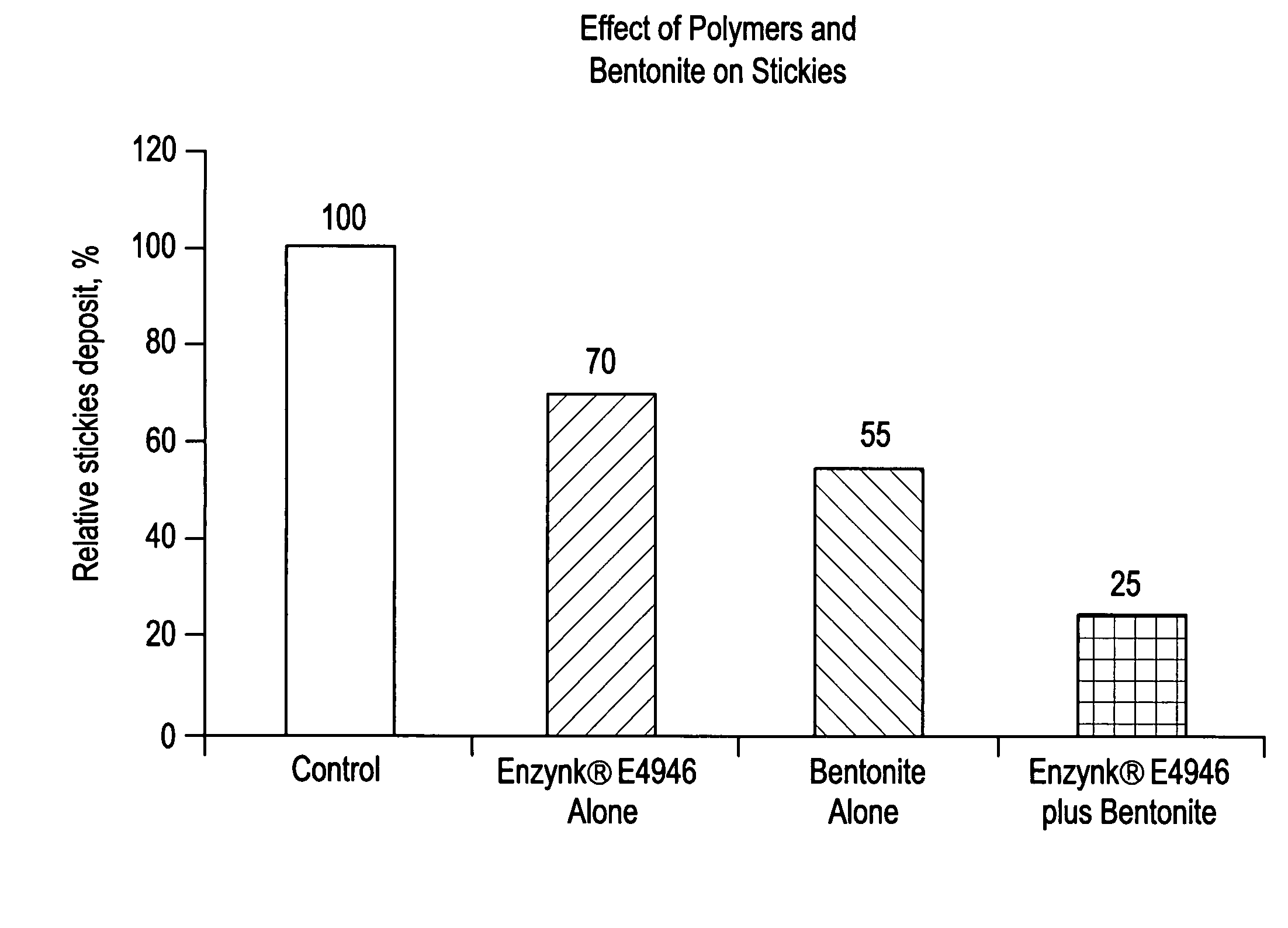

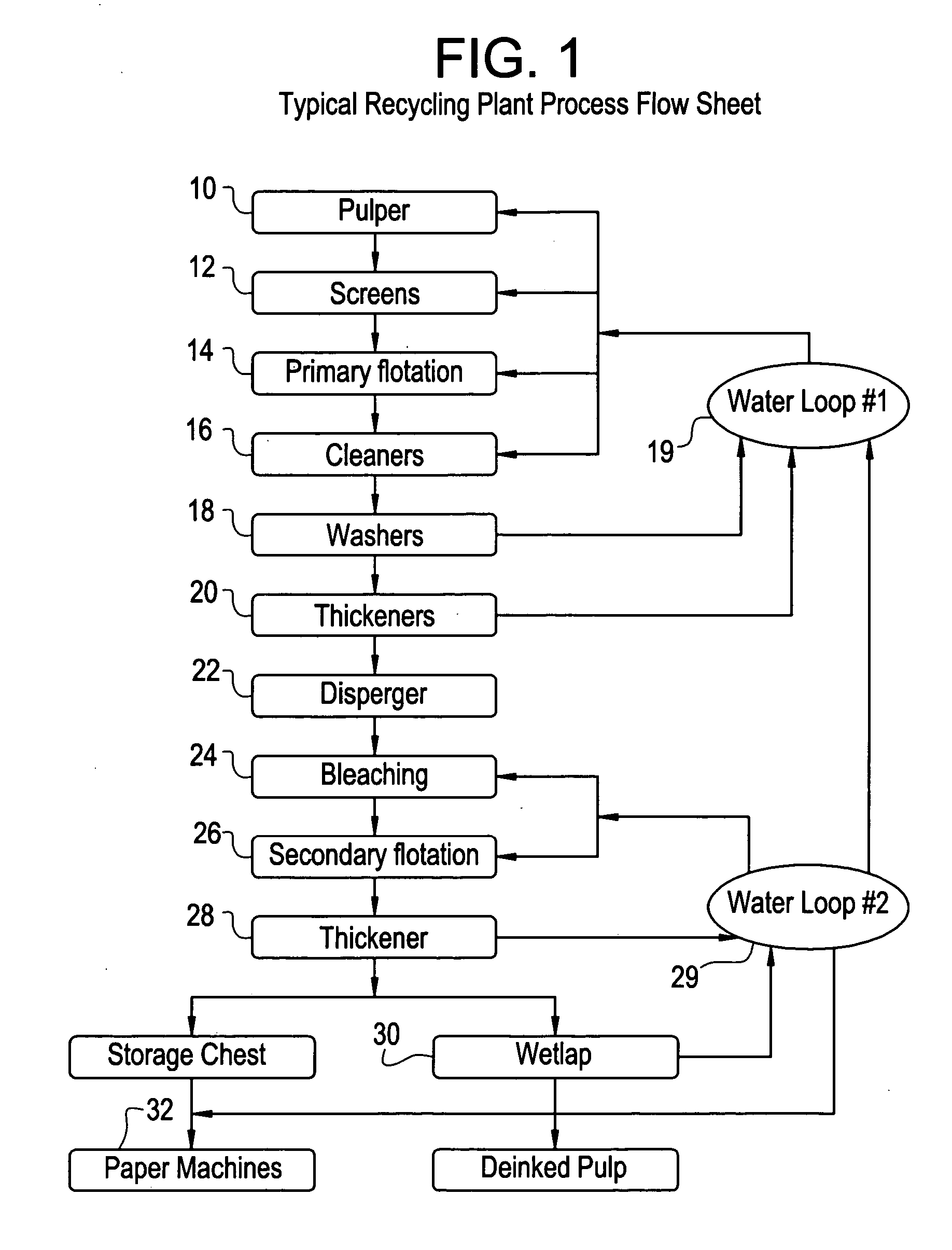

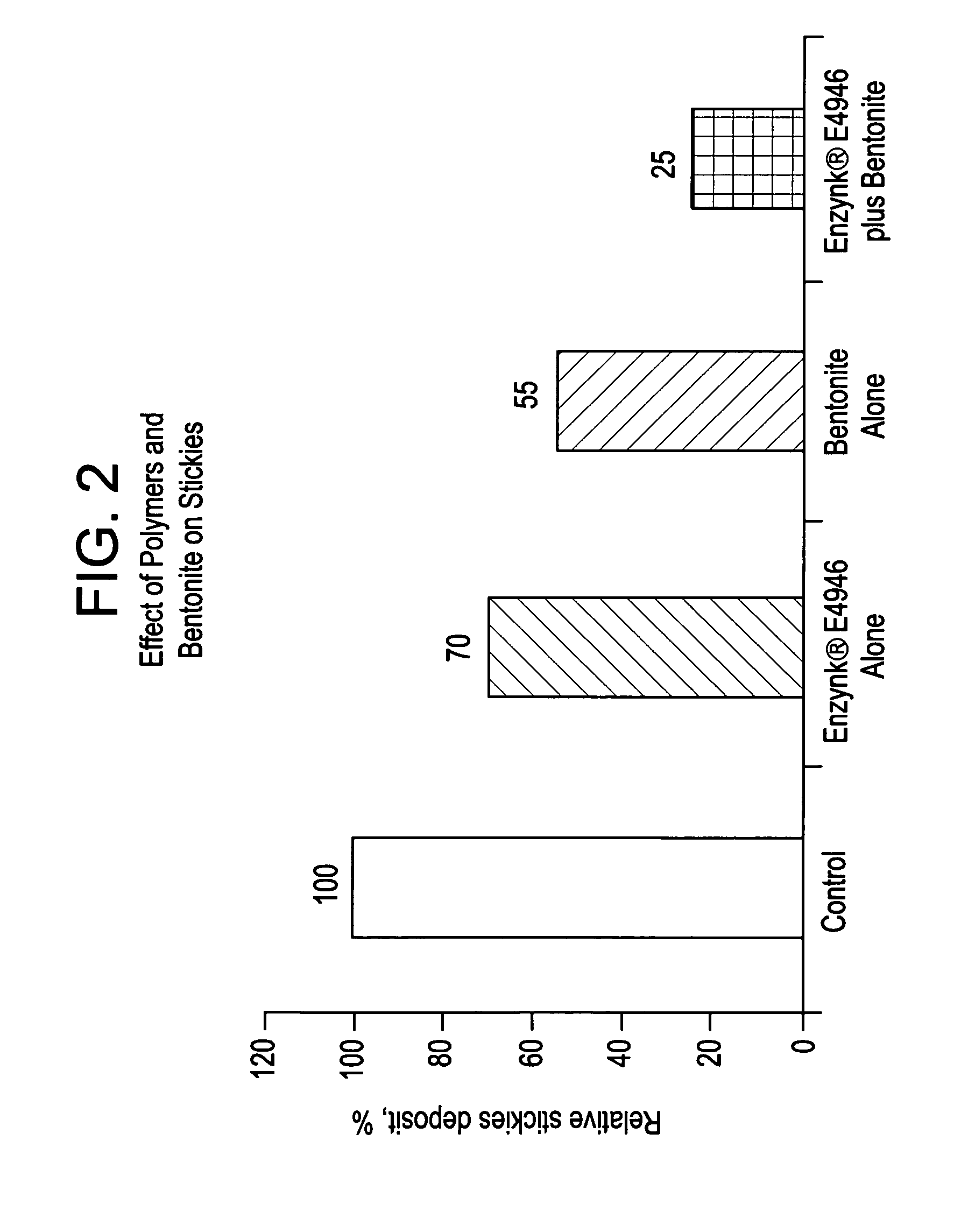

System for control of stickies in recovered and virgin paper processing

InactiveUS20060048908A1Good removal effectEasy to controlFats/resins/pitch/waxes removal in pulpMachine wet endPectinaseAmylase

Enhanced removal and / or control of adhesives or sticky materials, “stickies”, from recovered paper stock or virgin pulp fibers is achieved using a combination of enzyme treatment with adsorbents and / or absorbents. Pulp stock to be treated is typically obtained from old magazines, newspapers, household waste, but may include corrugated boxes and office waste. Virgin pulps may include mechanical, chemical, or semi-chemical pulps. Enzymes typically include hydrolases such as cellulases, hemicellulases, pectinases, amylases, and lipases such as esterases, lyases such as pectate lyases, and oxidoreductases. Adsorbents include activated bentonite, microparticles, talc, clay and modified silica. Absorbents typically include water soluble polymers, dispersants, coagulatants and agglomerants.

Owner:ENZYMATIC DEINKING TECH LLC

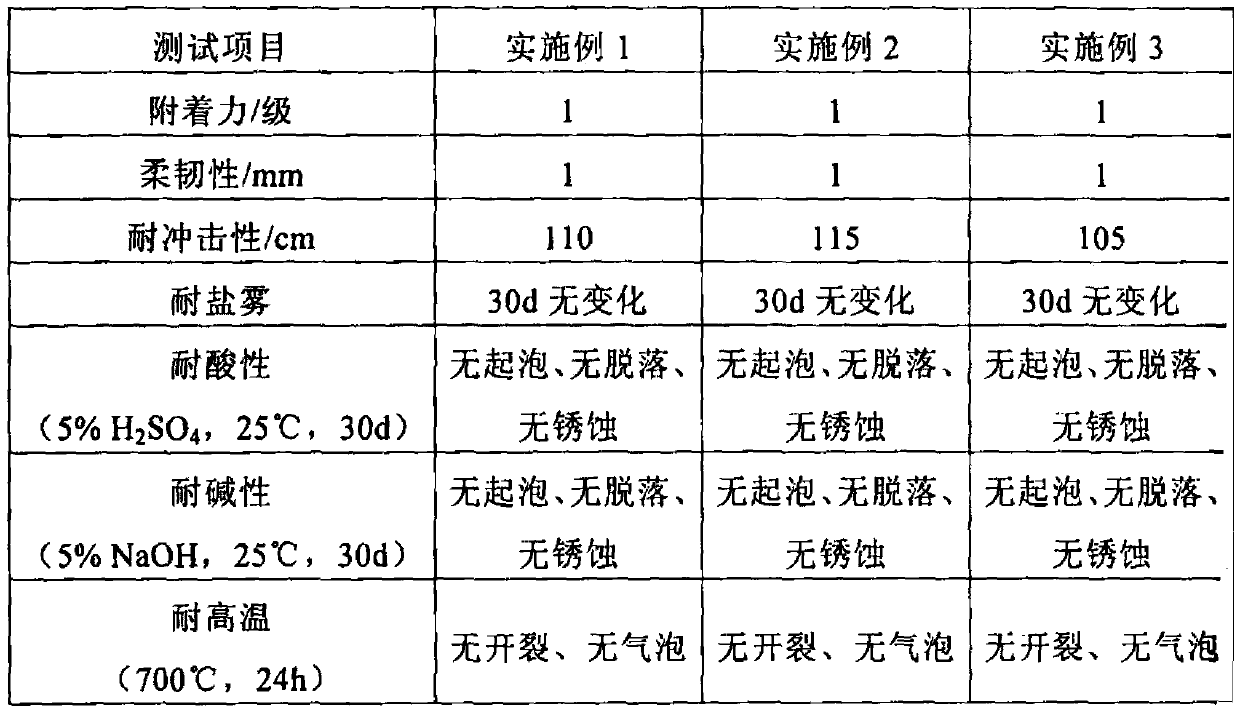

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

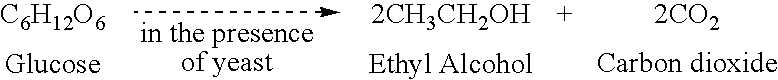

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Methods of manufacturing bentonite pollution control sorbents

InactiveUS20070119300A1Small particle sizeLiquid surface applicatorsGas treatmentSodium BentoniteSorbent

Methods of manufacturing bentonite sorbents for removal of pollutants including mercury from gas streams, such as a flue gas stream from coal-fired utility plants are disclosed. The methods include mixing bentonite sorbent particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the bentonite sorbent particles.

Owner:BASF CATALYSTS LLC

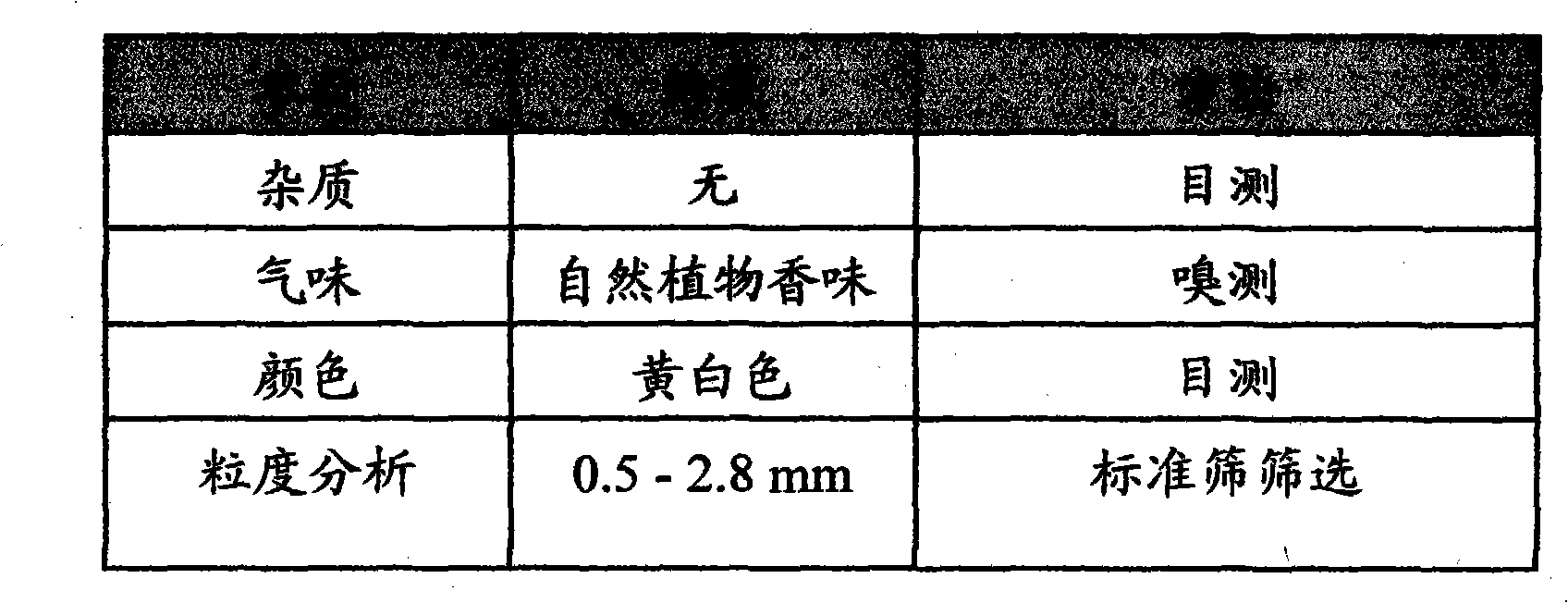

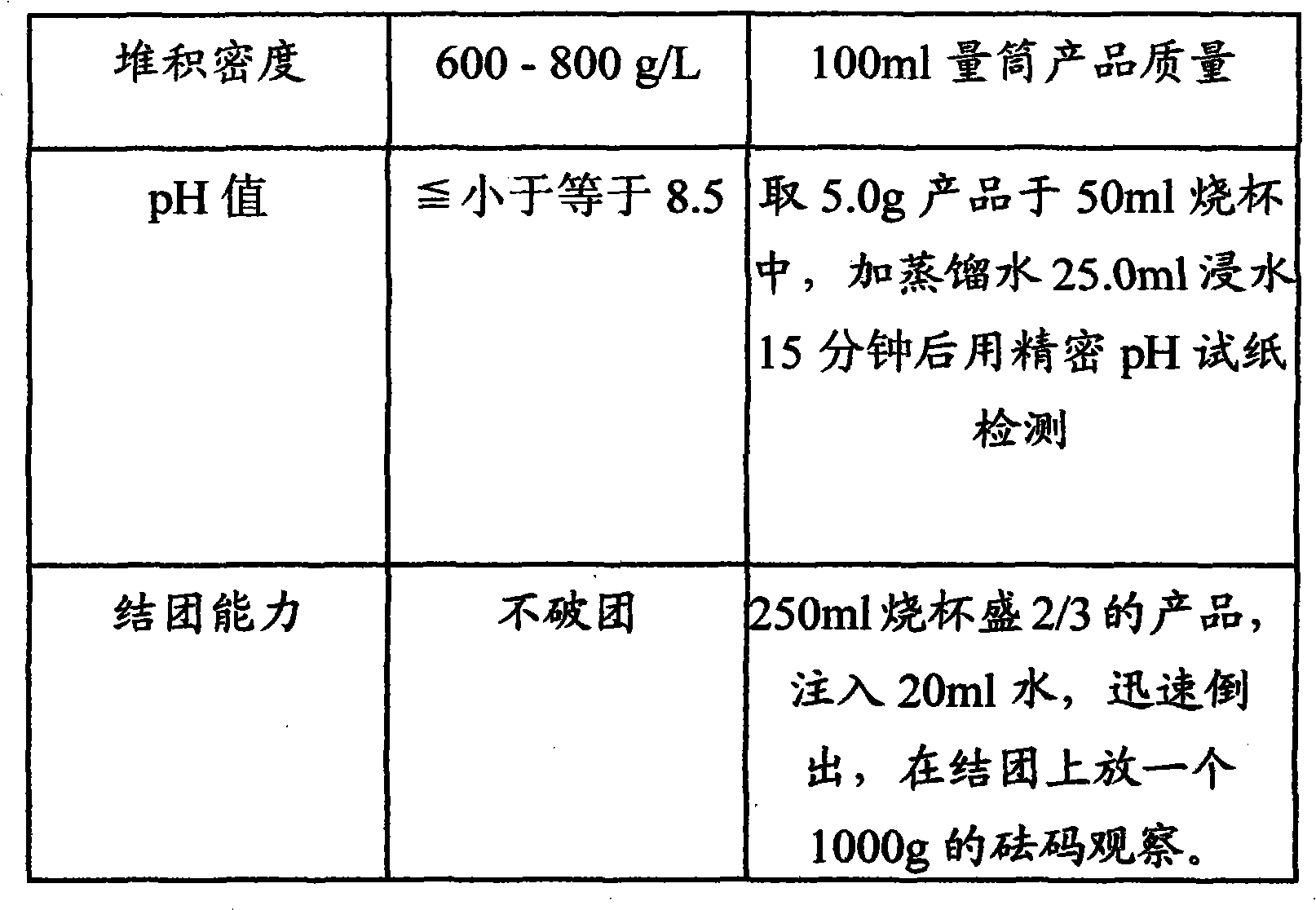

Cat litter and making method thereof

InactiveCN102150627AEnhanced adsorption and deodorization abilityImprove deodorization abilityAnimal housingSodium BentoniteSilica gel

The invention discloses cat litter comprising a composition prepared from the following components in percent by weight: 50-80% of inorganic clay, 5-15% of silica gel, 5-20% of organic substrate and 8-20% of mineral matter, wherein the inorganic clay is selected from one or a mixture of attapulgite, bentonite, kaolinite and sepiolite; the organic substrate is selected from one or a mixture of corncob, corn, wheat, clover, peanut hull, walnut shell, pine wood shavings and broadleaved tree wood shavings; and the mineral matter is selected from one or a mixture of perlite, diatomite, pumice and other low-density mineral matters. The cat litter disclosed by the invention has the following advantages of largely strengthened adsorption deodorization capacity due to the addition of the silica gel component, stronger deodorization capacity by utilizing the adsorbability of natural materials, natural fragrance, small weight and strong caking capability, in particular no dust and easiness for treatment; and the cat litter disclosed by the invention is 40% lighter than the traditional bentonite cat litter.

Owner:QINGDAO FRANK FINE CHEM

In-situ restoration method for heavy metal polluted soil

The invention discloses an in-situ restoration method for heavy metal polluted soil, which comprises the following steps of: uniformly mixing submicron or nano iron, coal ash, a magnesium-containing preparation and bentonite in proportion by weight of (5-25): (40-50): (1-10): (15-50) to obtain a heavy metal polluted soil restoration agent, after applying the heavy metal polluted soil restoration agent on the surface of the heavy metal polluted soil at the thickness of 1-4cm, uniformly mixing a 20cm thick polluted soil surface layer with the applied restoration agent by plowing, and after 3-6 months, reducing heavy metals such as cadmium, chromium, mercury, lead, arsenic, nickel, zinc, copper, magnesium and vanadium in the heavy metal polluted soil into low-valence immobilized heavy metals to lose biological effectiveness and realize the in-situ restoration for the heavy metal polluted soil. However, the environmental quality of restored soil satisfies the requirements of second-level standard values in Environmental Quality Standards for Soils (GB 15618-1995) in China.

Owner:刘阳生

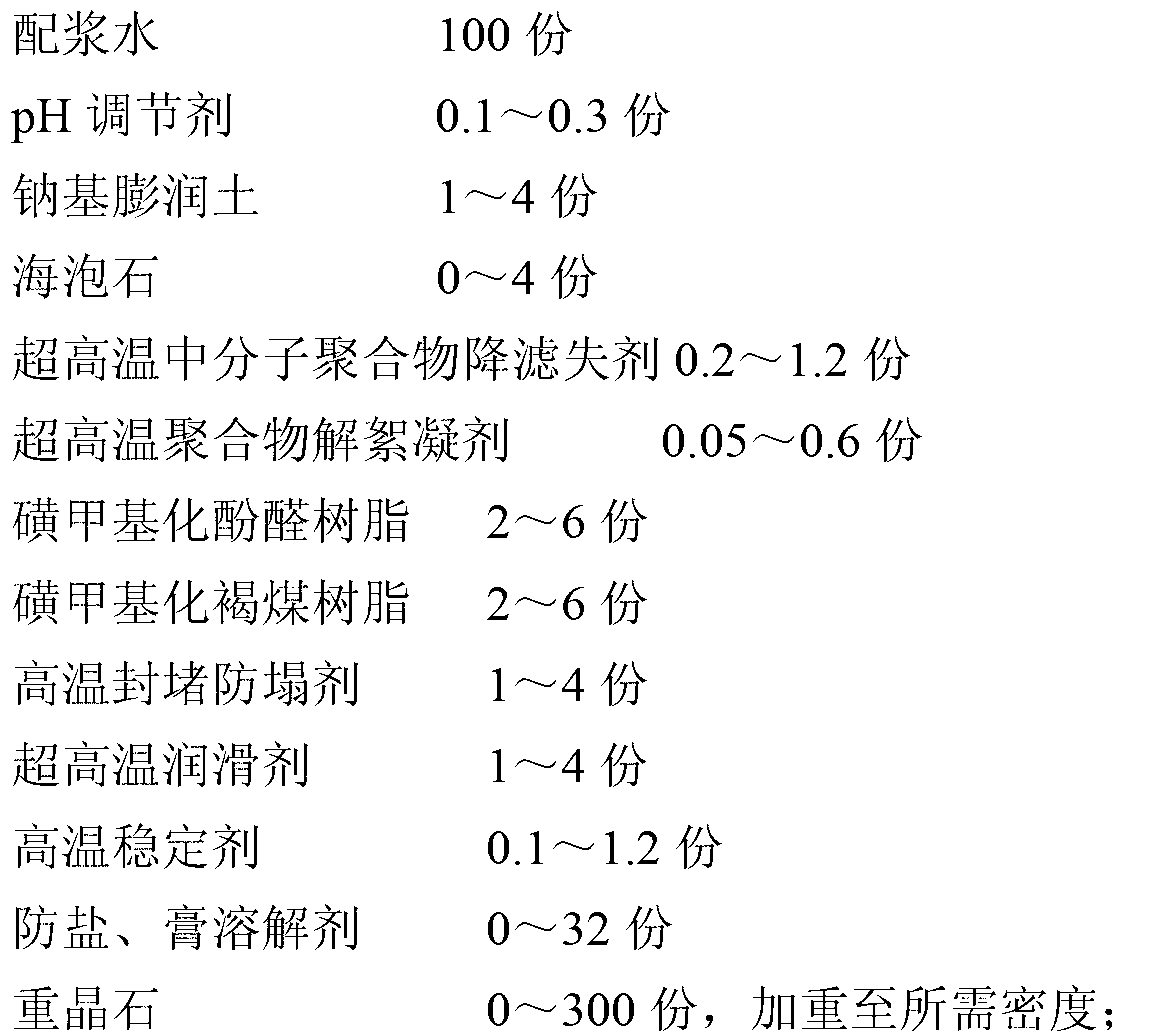

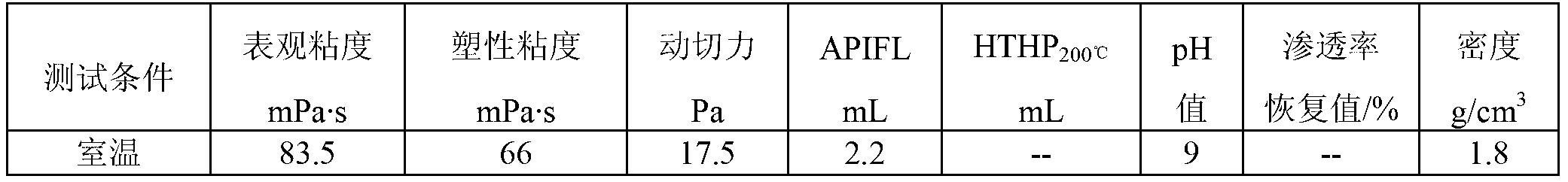

255 DEG C superhigh temperature resistant water-based drilling fluid and construction process thereof

ActiveCN103160259AHas ultra-high temperature stabilityGood plugging and anti-collapse performanceFlushingDrilling compositionWater basedSodium Bentonite

The invention relates to a 255 DEG C superhigh temperature resistant water-based drilling fluid and a construction process thereof. The drilling fluid comprises the following raw material in parts by weight: 100 parts of blending water, 0.1-0.3 part of a pH regulator, 1-4 parts of sodium bentonite, 0-4 parts of sepiolite, 0.2-1.2 parts of a superhigh-temperature middle-molecule polymer filtrate reducer, 0.05-0.6 part of superhigh-temperature polymer deflucculating agent, 2-6 parts of sulfomethylated phenolic resin, 2-6 parts of sulfomethylated walchowite, 1-4 parts of high-temperature plugging anti-collapse agent, 1-4 parts of a superhigh-temperature lubricant, 0.1-1.2 parts of a high-temperature stabilizer, 0-32 parts of an anti-salt / cream dissolving agent,and barites added to a required density. The invention also provides a construction process of the drilling fluid in the process of application. The 255 DEG C superhigh temperature resistant water-based drilling fluid disclosed by the invention is applied to deep well and ultra deep well drilling, and the applicable temperature is 245-255 DEG C. The drilling fluid is strong in stability under superhigh temperature conditions, good in rheological property and easy to control.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190BStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberSodium Bentonite

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

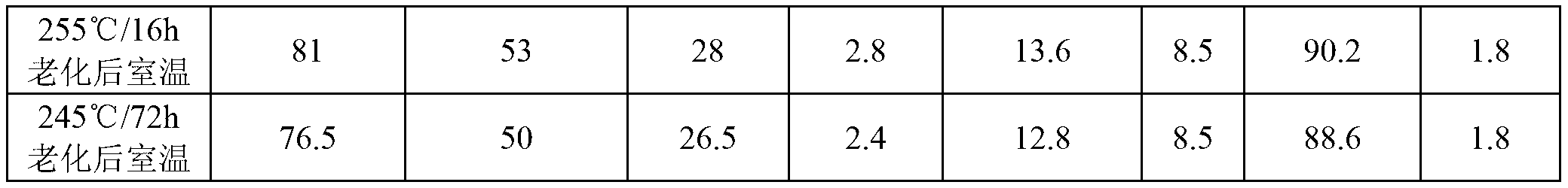

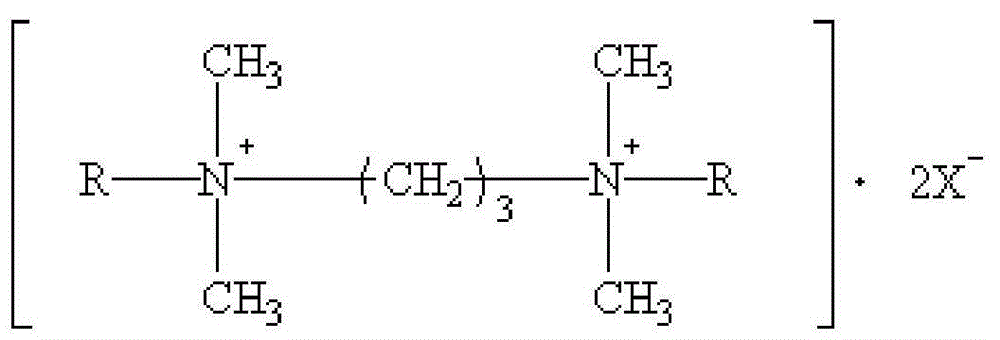

High-efficiency hydrate inhibitive environment-friendly drilling fluid

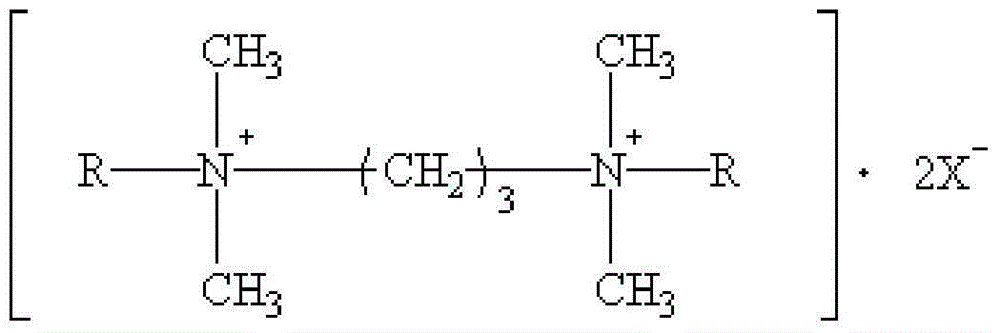

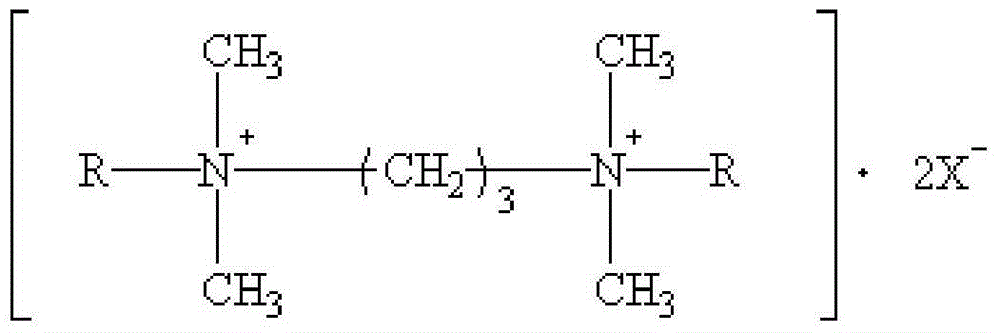

ActiveCN104531106AGenerate good effectLow cloud pointDrilling compositionInorganic saltsSodium Bentonite

The invention relates to high-efficiency hydrate inhibitive environment-friendly drilling fluid, and particularly relates to the drilling fluid containing water, bentonite, hyamine dimeric surfactant, inorganic salt, sodium carboxymethyl starch, cationic polyacrylamide and solid anti-sloughing lubricating agent GFRH. The high-efficiency hydrate inhibitive environment-friendly drilling fluid can be used for exploiting continental or ocean oil-gas resources and can effectively inhibit the generation of hydrate; moreover, the components of the drilling fluid are small in environment harm, and the drilling fluid has the advantages of high efficiency and environmental protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Extended curable compositions for use as binders

The present invention provides low-cost formaldehyde-free curable aqueous compositions comprising 100 weight parts of one or more than one binder chosen from (i) mixtures of one or more than one polycarboxylic acid or polymeric polyacid and one or more than one polyol compound comprising at least two hydroxyl or epoxy groups, (ii) copolymers or copolymeric polyacids bearing carboxylic acid groups or anhydride groups and hydroxyl groups, and (iii) mixtures thereof, and 10 to 40 weight parts of one or more than one extender having an average particle size ranging from 0.5 μm or more and as high as 45 μm or less, preferably chosen from microcrystalline silica, diatomaceous silica, kaolin, bentonite, and anhydrous aluminosilicate clay delaminated. In the inventive binder compositions, the ratio of the wet over dry tensile strength of said composition is about 0.5 or greater. The present invention further provides products coated or impregnated with the binder, such as heat-resistant fiberglass nonwovens used for insulation. The aqueous binder may further comprise one or more phosphorous-containing accelerator.

Owner:ADAMO JOSEPH ROBERT +3

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Cement compositions comprising improved lost circulation materials and methods of use in subterranean formations

The present invention relates to subterranean cementing operations and, more particularly, to cement composition that include improved lost circulation materials, and methods of using such cement compositions in subterranean formations. In certain exemplary embodiments, the improved lost circulation materials include inelastic particles of polyethylene, polystyrene and / or polypropylene. Optionally, the cement compositions also may include additives such as fly ash, a surfactant, a dispersant, a fluid loss control additive, a conventional lost circulation material, an generator, a retarder, a salt, a mica, fiber, a formation-conditioning agent, fumed silica, bentonite, expanding additives, microspheres, weighting materials, or a defoamer.

Owner:HALLIBURTON ENERGY SERVICES INC

Integral honeycombed catalyst for SCR flue-gas denitration and preparation method therefor

ActiveCN101444727AImprove catalytic performanceIncrease contact areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSodium BentoniteFlue gas

The invention relates to an integral honeycombed catalyst for SCR flue-gas denitration and a preparation method therefor. Titanium dioxide, bentonite and meerschaum are taken as carries, soaked for loading active components, formed, dried and baked to prepare the integral honeycombed catalyst. The carries comprise titanium dioxide 60-90%, bentonite 0-20% and meerschaum 0-10% by weight; the active components comprise WO3 5.0-10.0% OR MoO3 5.0-9.0%, V2O5 0.3-5.0%, and CeO2 0.0-2.0% or Nb2O5 0.0-1.0% by weight; and the total of the components is 100%. The catalytic activity is high, the denitration efficiency is high, and the service life is long; titanium dioxide, bentonite and meerschaum are taken as the carries, soaked for loading the active components, formed, dried and baked to prepare the integral honeycombed catalyst; and the preparation method is scientific, reasonable, simple and feasible.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

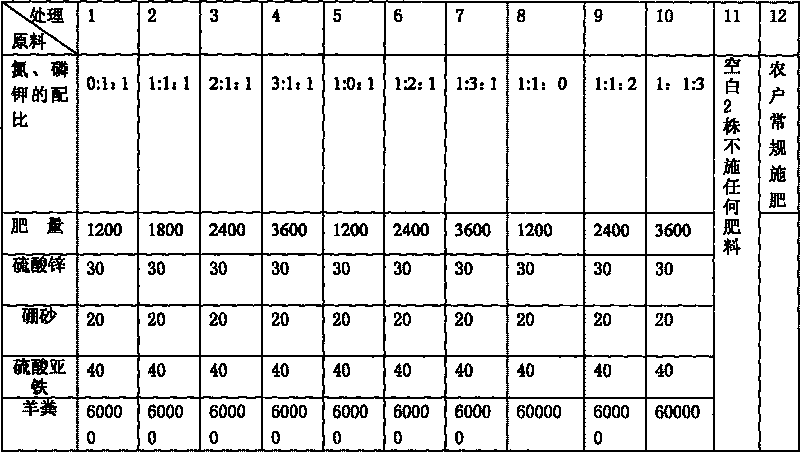

Preparation method and application method of grape special fertilizer

ActiveCN101693639AIncrease productionImprove qualityClimate change adaptationAlkali orthophosphate fertiliserSodium BentoniteAdditive ingredient

The invention relates to preparation method and application method of a grape special fertilizer, wherein the preparation method comprises the following steps: preparing an I-type fertilizer by taking the following ingredients in parts by weight: 30-40 parts of urea, 20-30 parts ammonium phosphate, 15-30 parts of potassium sulphate, 1-3 parts of humic acid, 1-3 parts of excrement, 1-5 parts of synergist, 0.1-1.0 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 3-7 parts of plaster and 3-13 parts of bentonite; preparing an II-type fertilizer by taking the following ingredients in parts by weight: 7-15 parts of urea, 25-35 parts ammonium phosphate, 35-45 parts of potassium sulphate, 1-3 parts of humic acid, 1-5 parts of excrement, 2-5 parts of synergist, 0.1-1.0 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 3-7 parts of plaster and 3-13 parts of bentonite; and blending, spraying, pelleting and drying at lower temperature to obtain the product. The application method of the fertilizer comprises the following steps: taking an organic fertilizer and the II-type fertilizer as a base fertilizer; applying the I-type fertilizer before blossom, applying the II-type fertilizer in the young fruit development period, and meanwhile, respectively spraying monopotassium phosphate and rare earth mixed liquid once on the leaf surfaces; and spraying calcium nitrate or calcium acetate to enhance the storage resistance property before picking.

Owner:新疆满疆红农资化肥科技有限公司

Granular activated carbon filler for paper mill sludge and preparation method thereof

InactiveCN102205964AWell-developed pore structureHigh strengthOther chemical processesSolid waste disposalSodium BentoniteFluidized bed

The invention relates to a granular activated carbon filler for paper mill sludge and a preparation method thereof. The preparation method comprises the following steps: mixing 70-90 parts by weight of anhydrated paper mill sludge and 10-30 parts by weight of bentonite, performing granulation in a granulator, drying at room temperature, performing carbonization of the raw balls at a low temperature, modifying the carbonized material balls with hydrochloric acid, and activating the balls in an activation furnace. The sludge granular activated carbon filler prepared by the invention has the characteristics of large specific surface area, developed pores, high intensity, and the like. Fillers sintered at different process conditions can be respectively used as reactor fillers for sewage treatment, biological aerated filters, fluidized beds, and the like, have wide application range and low cost.

Owner:SHANDONG UNIV

Simulated rock and method of making same

A simulated rock and a method of producing it, using Portland Cement, Bentonite or lime, polystyrene, and water. Ground polystyrene is mixed with cement, Bentonite or lime, and water, to form a settable cement formulation which is poured into removable forms. Reinforcing members are included in the mold, and a lifting hook is provided for later lifting and transporting of the resultant simulated rock. One or more base coats can be applied using a different formula, and a color coat can be applied. The method is use for making landscaping rocks, rock fountains, stone barbecues, light pillars, planters, room dividers, artificial masonry panels, and any structure which uses rocks or masonry.

Owner:CALLAHAN HARVEY J

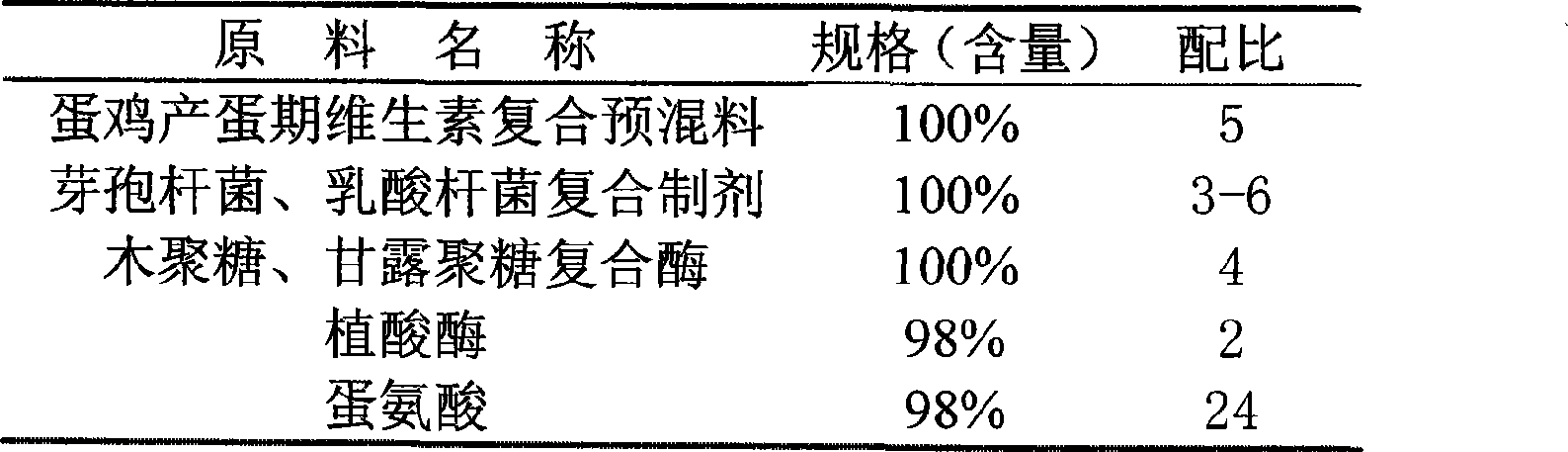

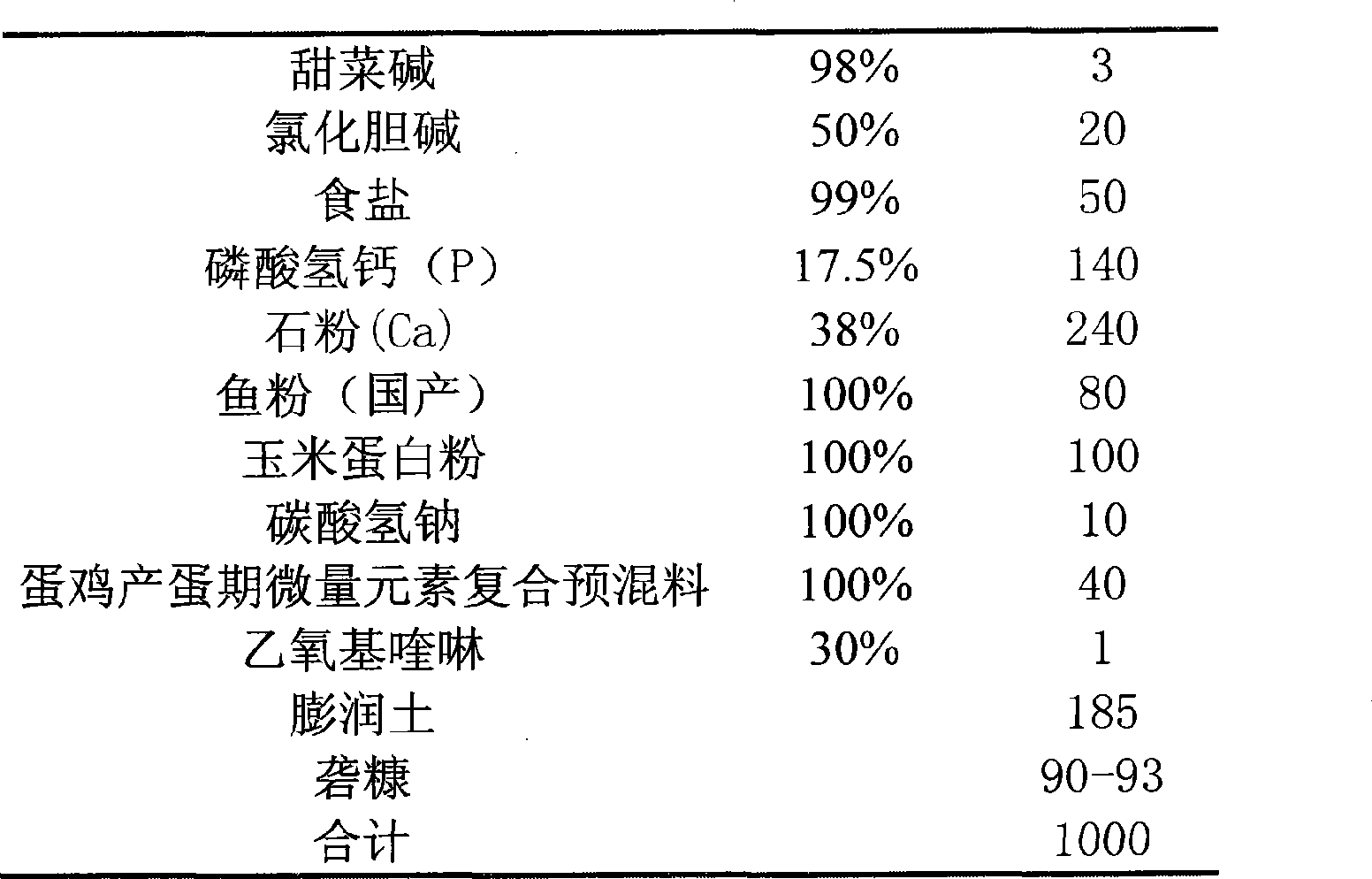

Premix feed with probiotics for laying hen

InactiveCN101485397AInhibition of reproductionReduce generationAnimal feeding stuffSodium bicarbonateSodium Bentonite

The invention discloses probiotic type premix feed for laying hens, which is prepared from vitamin compound premix feed for the laying hens in laying period, a bacillus and lactobacilli compound preparation, xylan and mannan complex enzyme, phytase, methionine, lycine, choline chloride, common salt, calcium hydrophosphate, stone dust, fish meal, corn gluten meal, sodium bicarbonate, trace element compound premix feed for the laying hens in the laying period, ethoxyquinoline, bentonite, and rice chaff by mixing in proportion. Compared with the common compound feed for the laying hens, the compound feed prepared by the premix feed reduces discharge of harmful substances such as nitrogen and phosphorus in chicken manure by more than 20 percent, reduces the concentration of harmful gases such as ammonia in a hen house by more than 40 percent, improves the feed utilization rate by 5 to 10 percent and the laying rate by 3 to 5 percent, averagely prolongs the laying period by 25 days, and reduces feeding cost by 5 to 8 percent and the death-cull rate of the laying hens.

Owner:山东众成饲料科技有限公司

Method for preparing organic sustained release fertilizer synergist

InactiveCN101591208AHigh calorific valueIncrease temperatureAgriculture gas emission reductionFertilizer mixturesMonosodium glutamateSodium Bentonite

The invention provides a method for preparing an organic sustained release fertilizer synergist. The synergist comprises the following components in portion by weight: 25 to 60 portions of organic component, 3 to 15 portions of synergistic component, 10 to 13 portions (solid) and 3.5 to 9 portions (liquid) of sustained release component, 0.5 to 5 portions of trace elements, 18 to 30 portions of inorganic nutrient, and 2 to 7 portions of additive. The synergist is prepared by the method of weighing, mixing, spray granulation and low-temperature drying, wherein the organic component contains 2 to 5 portions of humic acid, 25 to 45 portions of mature garbage or barnyard manure, and 2 to 5 portions of residue of monosodium glutamate and sugar; the synergistic component contains 1 to 3 portions of zeolite, 1 to 5 portions of fly ash, and 2 to 5 portions of synergistic agent; the sustained release component contains 10 to 13 portions of bentonite, 0.02 to 0.1 portion of nitrification inhibitor, and 4 to 8 portions of urease inhibitor (liquid); the trace elements contain 0.1 to 1 portion of zinc sulfate, 0.1 to 1 portion of manganese sulfate, 0.1 to 1 portion of borax, 0.1 to 1 portion of copper sulfate, and 0.1 to 1 portion of ferrous sulfate; the inorganic nutrient contains 6 to 9 portions of urea, 7 to 9 portions of ammonium phosphate, and 5 to 7 portions of potassium sulfate; and the additive contains 2 to 7 portions of plaster. The synergist is suitable for the planting of field crops and forest fruits.

Owner:新疆满疆红农资化肥科技有限公司

Chemical composition for treatment of nitrate and odors from water streams and process wastewater treatment

InactiveUS20020011447A1Efficient processSolid sorbent liquid separationWater softeningSodium BentoniteBisulfide

Owner:MAXICHEM

Method for preparing organic fertilizer by fermenting cow dung compost

InactiveCN103449864AGrow fastIncrease productionBio-organic fraction processingWaste based fuelSodium bicarbonateSodium Bentonite

Owner:六安亿牛生物科技有限公司

Green powdered paint and its prepn

The present invention discloses one kind of green powdered paint and its preparation process. The green powdered paint consists of re-dispersible polymer latex powder 5-20 wt%, white cement 20-40 wt%, calcium carbonate 20-45 wt%, titanium white powder 5-25 wt%, diatomite 2-8 wt%, bentonite 1-2 wt%, cellulose ether 0.2-0.5 wt%, defoaming agent 0.2-0.5 wt% and coloring pigment 0-4 wt%. It is prepared through mixing all the components in a stirrer, and packing. It is used after mixing with water in construction site. It has the combined decoration functions of both putty and emulsion paint and may be used widely for decorating inner and outer wall.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com