Granular activated carbon filler for paper mill sludge and preparation method thereof

A granular activated carbon and papermaking sludge technology, applied in the field of environmental science, can solve problems such as waste of land resources, high production costs, and application restrictions, and achieve the effects of developed pore structure, easy availability of raw materials, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Separately crush the dried papermaking sludge and bentonite, and pass through a 100-mesh sieve, with a particle diameter of ≤0.15mm;

[0029] (2) Mix the sieved dried papermaking sludge and bentonite evenly in a weight ratio of 90; 10, and use a composite binder to make raw meal balls in a granulator;

[0030] (3) Dry the raw meal balls at room temperature, and then carbonize at 400-500°C for 30-40 minutes without air;

[0031] (4) The carbonized raw meal balls are put into an activation furnace for activation treatment, and the activation temperature is 850-900°C.

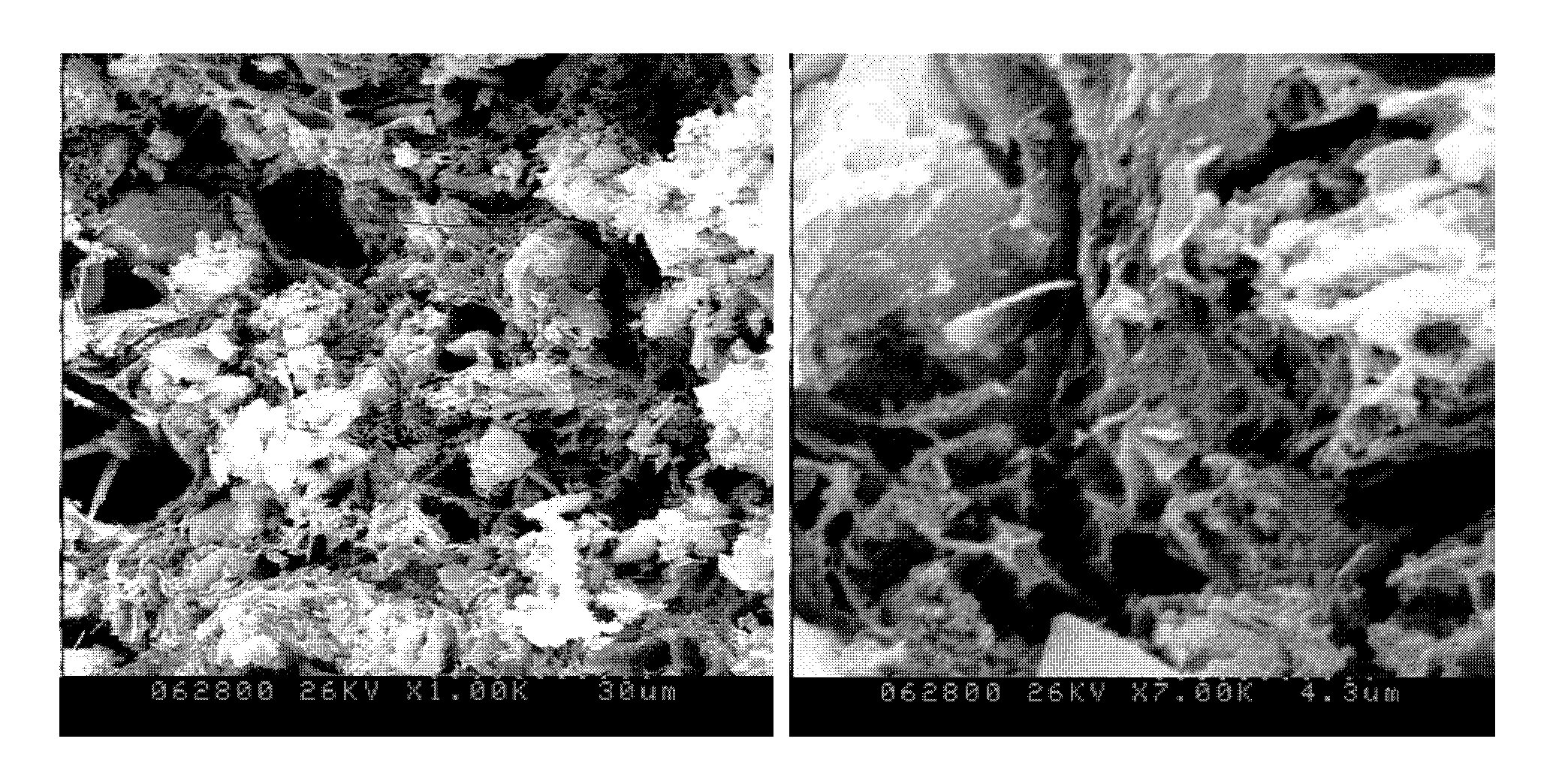

[0032] The particle density of the prepared sludge granular activated carbon filler is 1200-1300Kg / m 3 , the specific surface area is 120-150m 2 / g, its macrovoid, mesopore and microporous structure are developed, such as figure 1 As shown in the scanning electron microscope photos, and the production cost is far lower than commercial granular activated carbon, it can be used as a substitute in the a...

Embodiment 2

[0034] (1) Separately crush the dried papermaking sludge and bentonite, and pass through a 100-mesh sieve, with a particle diameter of ≤0.15mm;

[0035] (2) Mix the sieved dried papermaking sludge and bentonite evenly in a weight ratio of 80:20, and use a composite binder to make raw meal balls in a granulator;

[0036] (3) Dry the raw meal balls at room temperature, and then carbonize at 400-500°C for 30-40 minutes without air;

[0037] (4) putting the carbonized product into hydrochloric acid or 20% sulfuric acid with a mass fraction of 10% and soaking it for 6-9h to carry out modification treatment;

[0038] (5) Put the acid-soaked sphere into an activation furnace for activation treatment, and the activation temperature is 800-900°C.

[0039] The prepared sludge granular activated carbon filler particle density is 1050-1100Kg / m 3 , the specific surface area is 180-200m 2 / g, density close to water, easy to fluidize, well-developed pore structure, good for film formation...

Embodiment 3

[0041] (1) Separately crush the dried papermaking sludge and bentonite, and pass through a 100-mesh sieve, with a particle diameter of ≤0.15mm;

[0042] (2) Mix the sieved dry papermaking sludge and bentonite evenly in a weight ratio of 70:30, and use a composite binder to make raw meal balls in the granulator;

[0043] (3) Dry the raw meal balls at room temperature, and then carbonize at 400-500°C for 30-40 minutes without air;

[0044] (4) Put the carbonized raw meal balls into an activation furnace for activation treatment, and the activation temperature is 800-850°C.

[0045] The prepared sludge granular activated carbon filler particle density is 1250-1300Kg / m 3 , the specific surface area is 80-100m 2 / g, the pore structure is developed, which is conducive to film formation, and is suitable as a filler for biological aerated filters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com