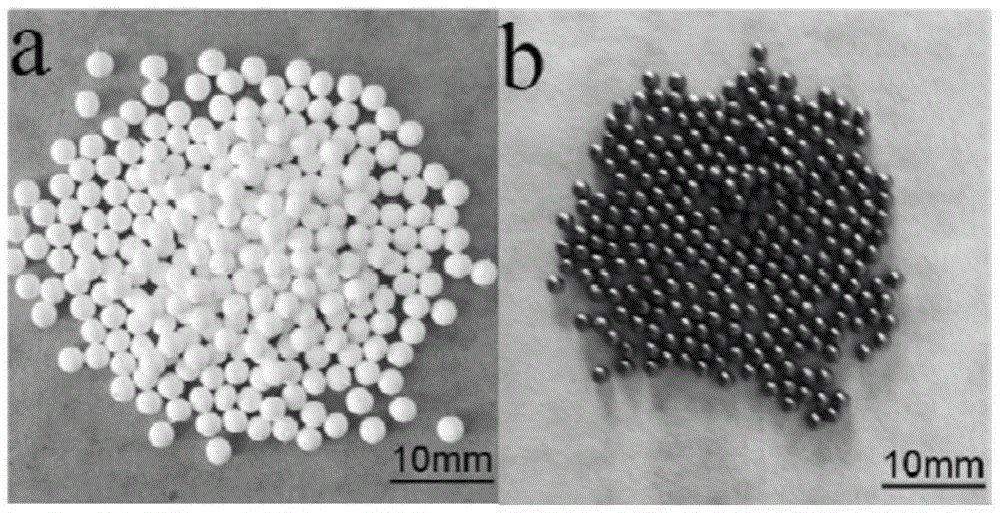

Preparation method of millimeter-scale hierarchical pore carbon balls

A multi-level hole and millimeter-scale technology, applied in the field of material preparation, can solve the problems of difficult industrialization and application, easy production of environmental waste, and complicated preparation process, and achieve the effects of easy industrial expansion of production, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

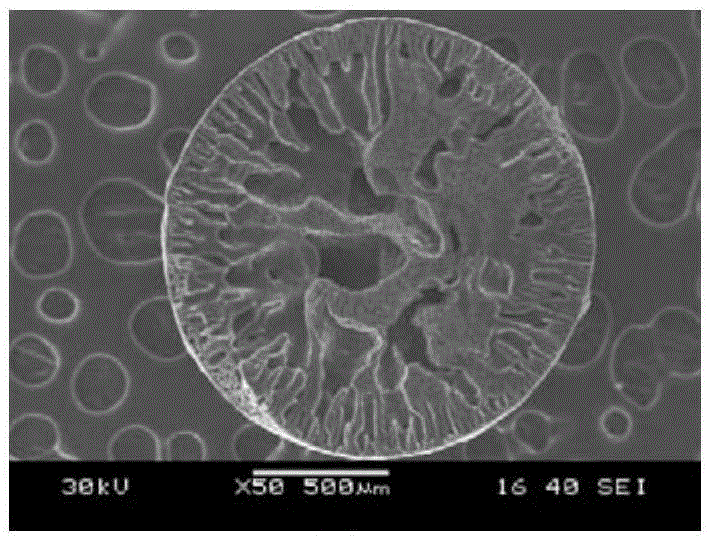

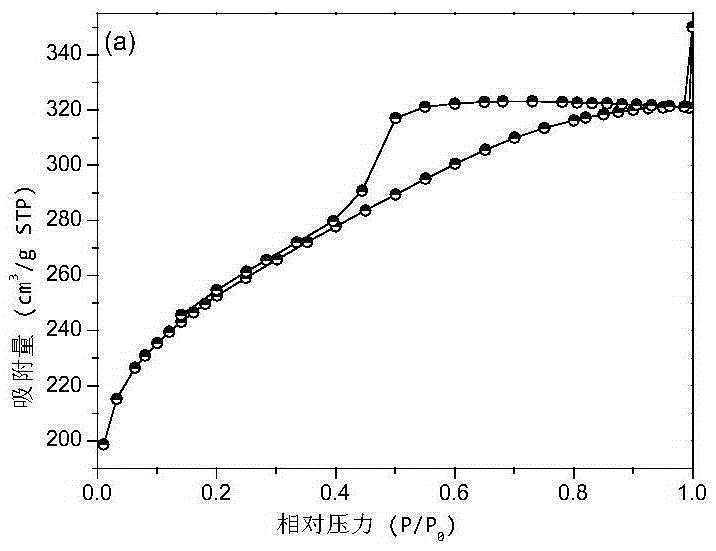

[0029] In the first step, accurately weigh 2.4g of PVDF and 0.3g of PVP, place them in a conical flask, add 12.5mL of N,N-dimethylformamide, and mechanically stir at 60°C until dissolved. In the second step, add 0.45g of phenolic resin and continue to stir until it dissolves evenly. In the third step, take 5mL of the above solution with a syringe and place it on the syringe pump, adjust the speed of the syringe pump to 0.5mL / min, squeeze out the droplet to 500mL of 5% volume isopropanol-95% volume deionized solution directly below the needle of the syringe Phase separation and gelation in water. In the fourth step, after 24 hours, the spherical polymer-based precursor is taken out and dried at room temperature. After drying, put it under a nitrogen atmosphere, raise the temperature to 900°C at a rate of 1°C / min, keep it for 3 hours, then cool it down to room temperature naturally, and take out the sample as a millimeter-scale hierarchical porous carbon sphere. The obtained m...

Embodiment 2

[0032] In the first step, accurately weigh 2.4g PES and 0.6g PVP, place them in a conical flask, add 12.2mL N,N-dimethylformamide, and mechanically stir at 60°C until dissolved. In the second step, add 0.45g of phenolic resin and continue to stir until it dissolves evenly. In the third step, take 5mL of the above solution with a syringe and place it on the syringe pump, adjust the speed of the syringe pump to 0.8mL / min, squeeze out the droplet to 500mL of 5% volume isopropanol-95% volume deionized Phase separation and gelation in water. In the fourth step, after 12 hours, the spherical polymer-based precursor is taken out and dried at room temperature. After drying, put it under a nitrogen atmosphere, raise the temperature to 600°C at a rate of 1°C / min, keep it for 3 hours, and then cool it down to room temperature naturally, and take out the sample as a millimeter-scale hierarchical porous carbon sphere. The obtained millimeter-scale hierarchical porous carbon spheres have ...

Embodiment 3

[0034] In the first step, accurately weigh 2.4g of PVDF and 0.3g of PVP, place them in a conical flask, add 12.5mL of N,N-dimethylformamide, and mechanically stir at 60°C until dissolved. In the second step, add 0.45g of phenolic resin and continue to stir until it dissolves evenly. In the third step, take 5mL of the above solution with a syringe and place it on the syringe pump, adjust the speed of the syringe pump to 1.0mL / min, squeeze out the droplet to 500mL of 25% volume isopropanol-75% volume deionized solution directly below the needle of the syringe Phase separation and gelation in water. In the fourth step, after 48 hours, the spherical polymer-based precursor is taken out and dried at room temperature. After drying, put it under a nitrogen atmosphere, raise the temperature to 900°C at a rate of 1°C / min, keep it for 3 hours, then cool it down to room temperature naturally, and take out the sample as a millimeter-scale hierarchical porous carbon sphere. The obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com