Patents

Literature

994results about How to "Good sphericity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of mesophase carbon microspheres from coal liquefaction residues

InactiveCN102225755ANarrow particle size distributionSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansMicrosphereQuinoline

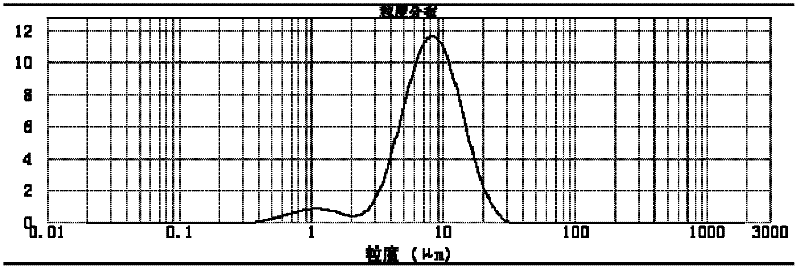

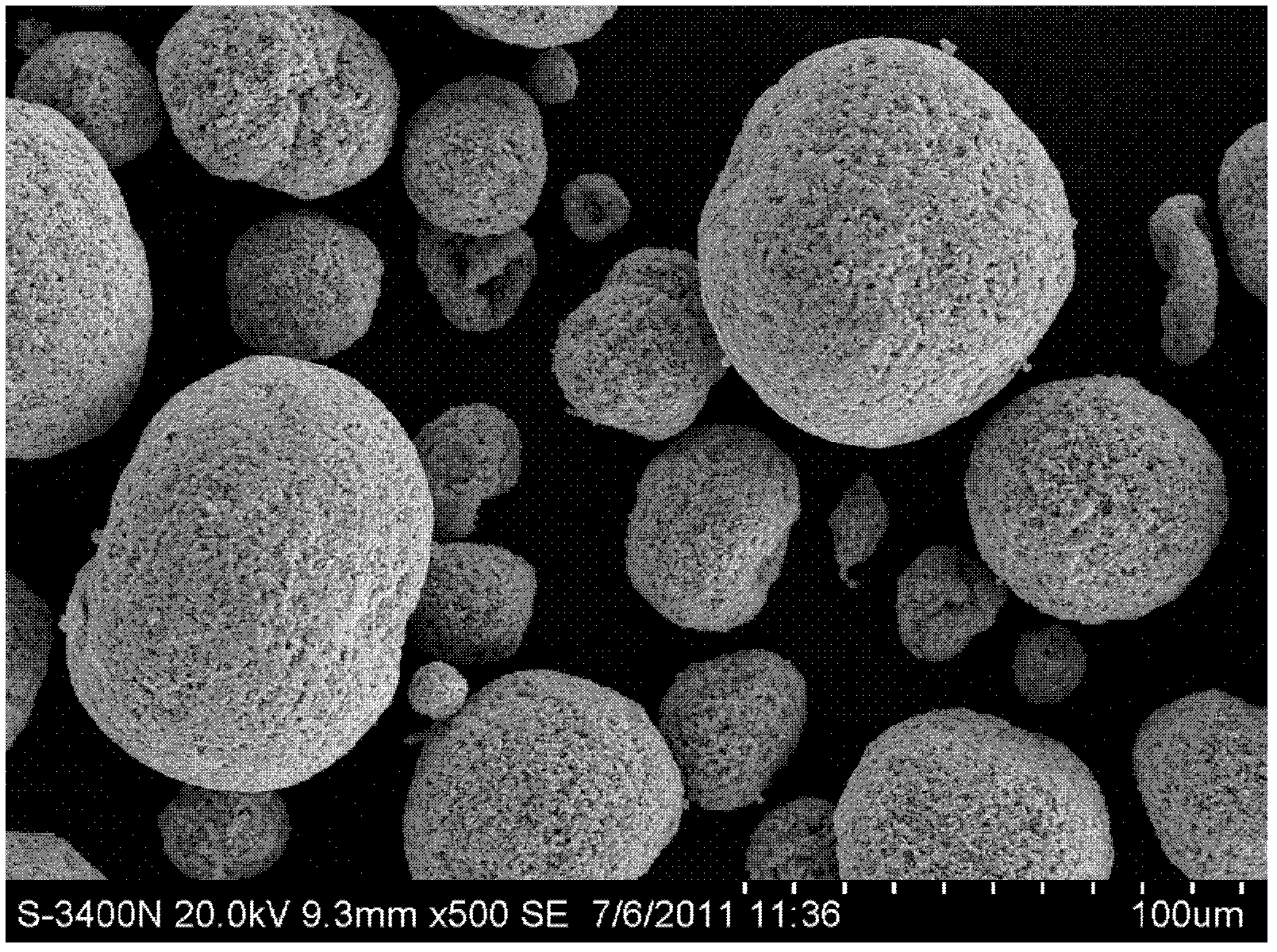

The invention discloses a preparation method of mesophase carbon microspheres from coal liquefaction residues serving as raw materials, which comprises the following steps of: firstly carrying out solvent extraction on the coal liquefaction residues, then carrying out a series of processing to obtain refined asphalt with different contents of quinoline insoluble substances, and carrying out thermal polycondensation reaction on the refined asphalt in the presence of a chemical auxiliary agent and a nucleating accelerator at the temperature of 380-450 DEG C, the pressure of 0-5 MPa and the stirring rotation speed of 40-500 r / min for 1-20 hours to obtain the mesophase microspheres. According to the invention, the chemical auxiliary agent and the nucleating accelerator can be added during theheat treatment process to improve the yield and narrow the particle size distribution of the mesophase carbon microbeads, and the mesophase carbon microspheres are prepared from the coal liquefactionresidues serving as the raw materials and have the advantages of low cost, simple preparation process, high yield (up to 35%), narrow particle size distribution, good sphericity, etc.

Owner:ZIBO MINING GRP

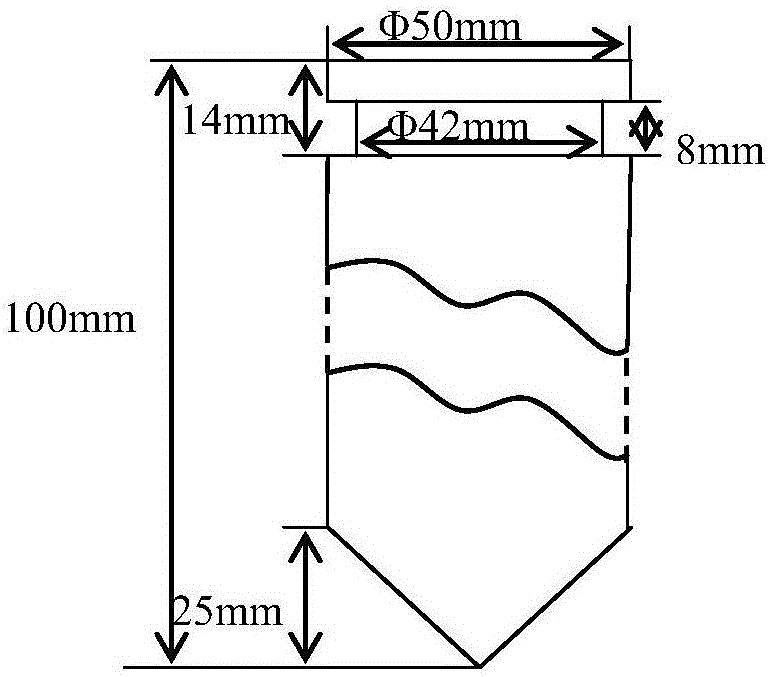

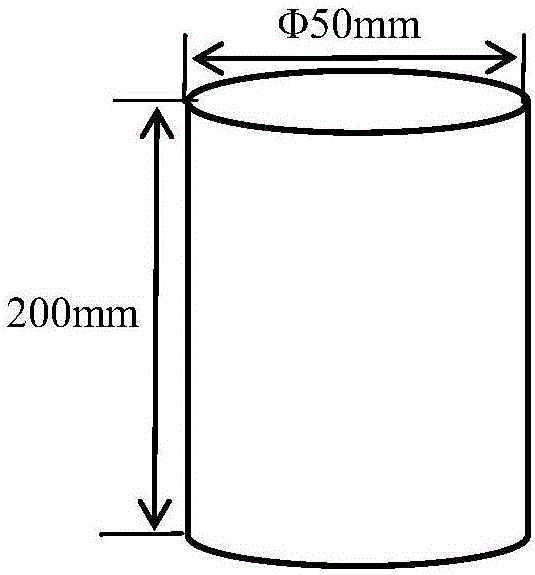

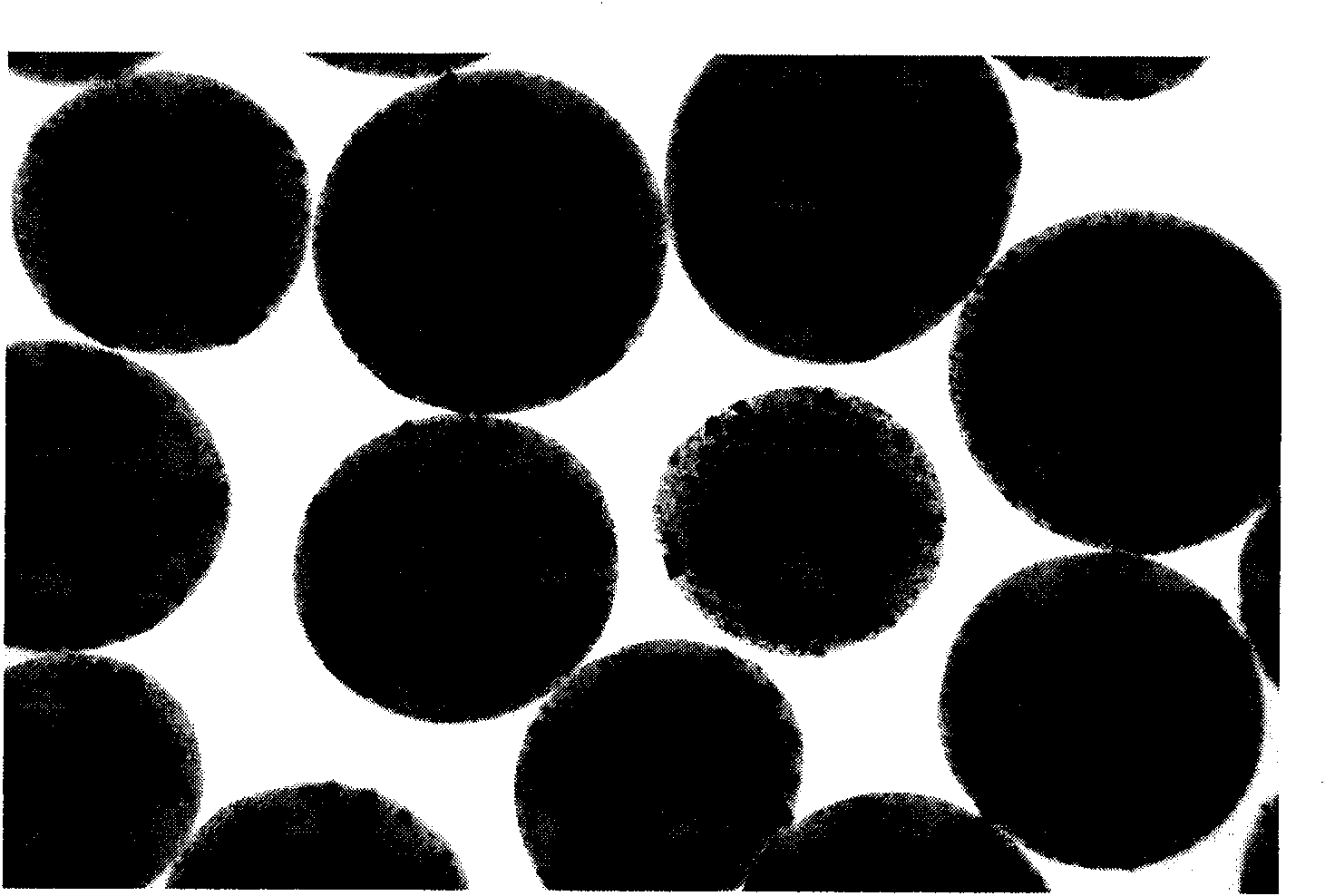

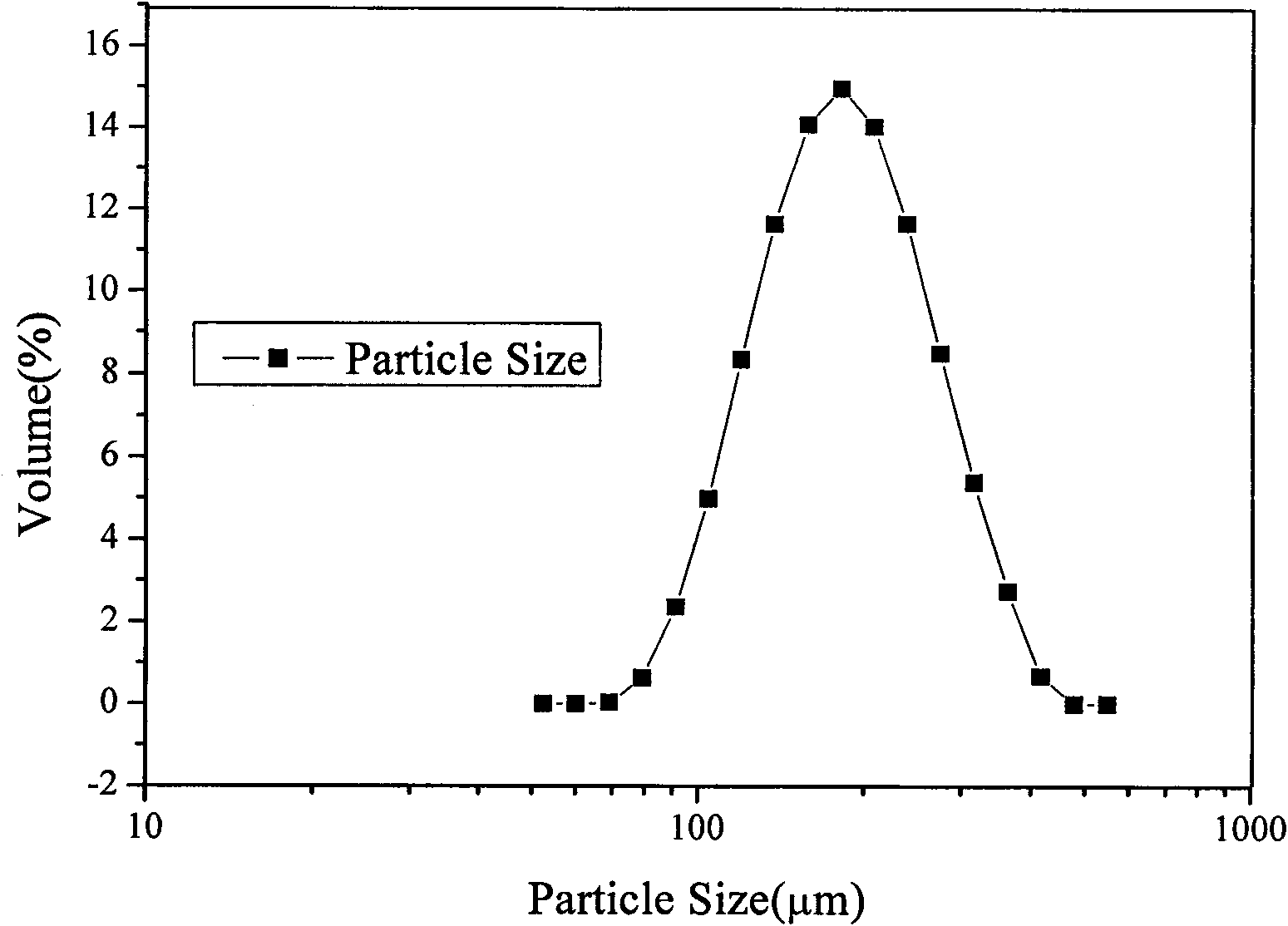

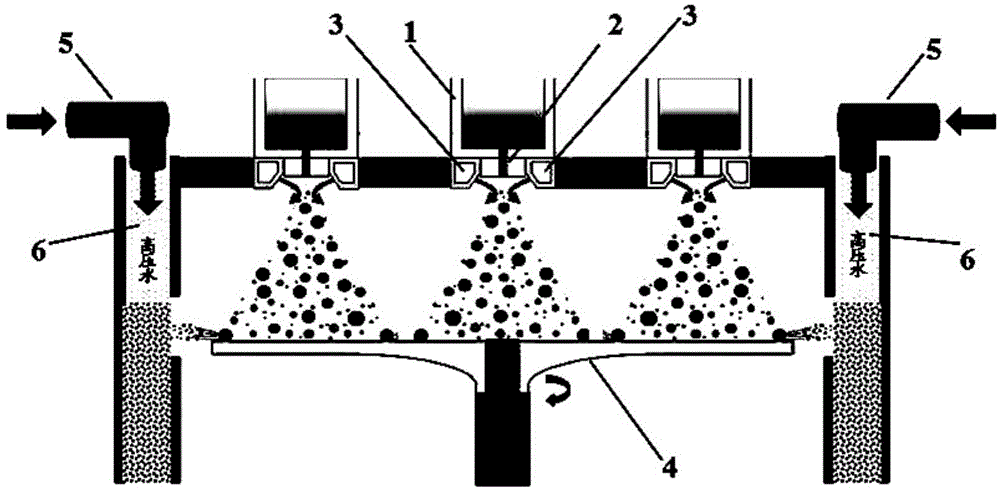

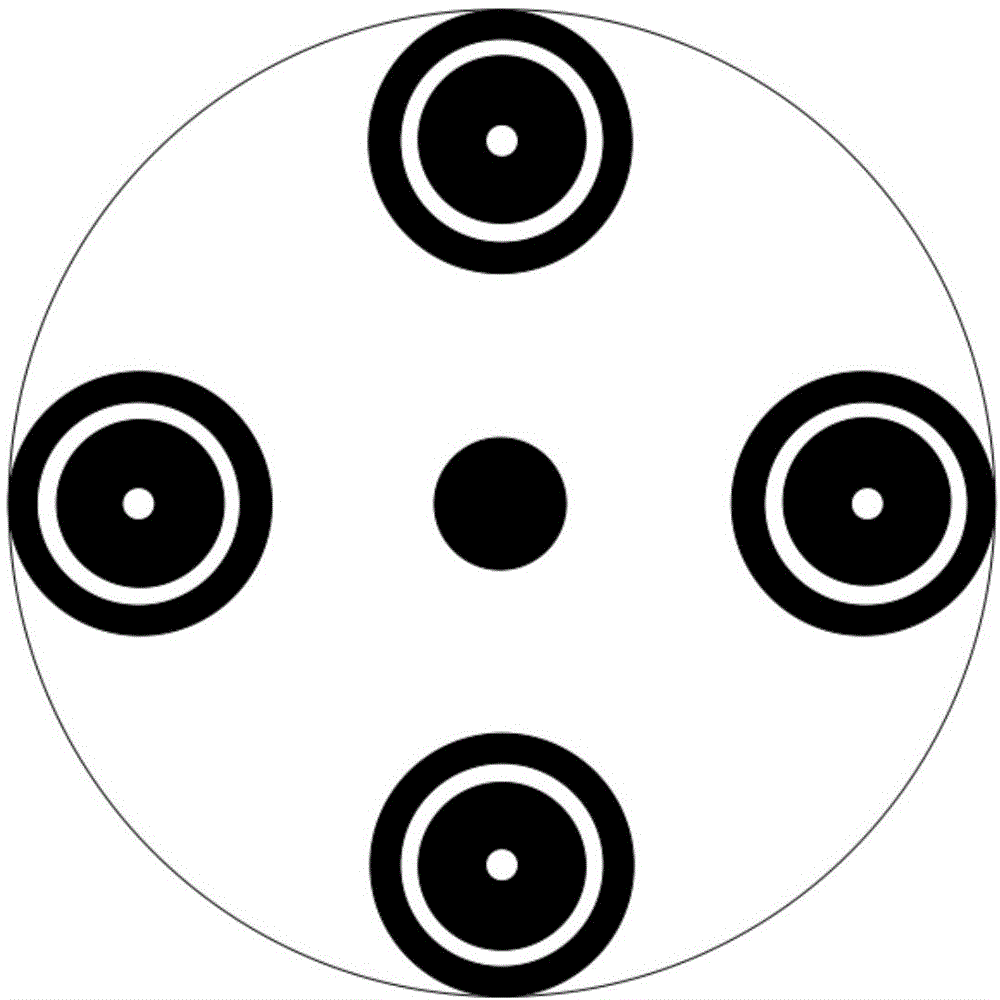

Method for preparing polymer micro balls with uniform grain diameter and controllable size

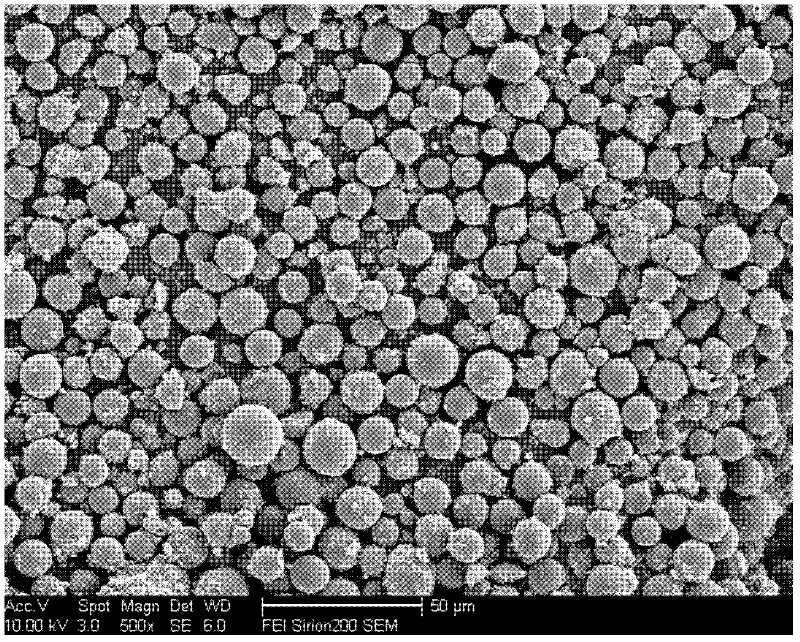

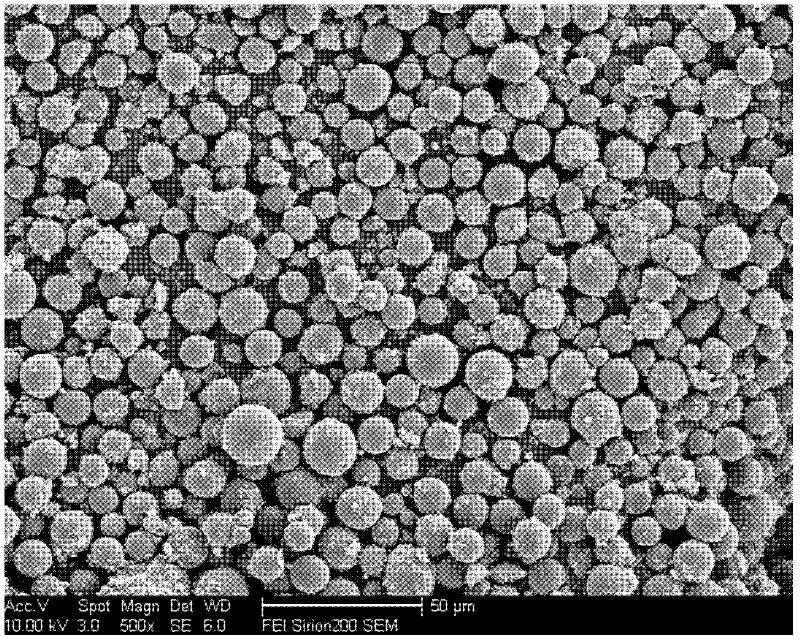

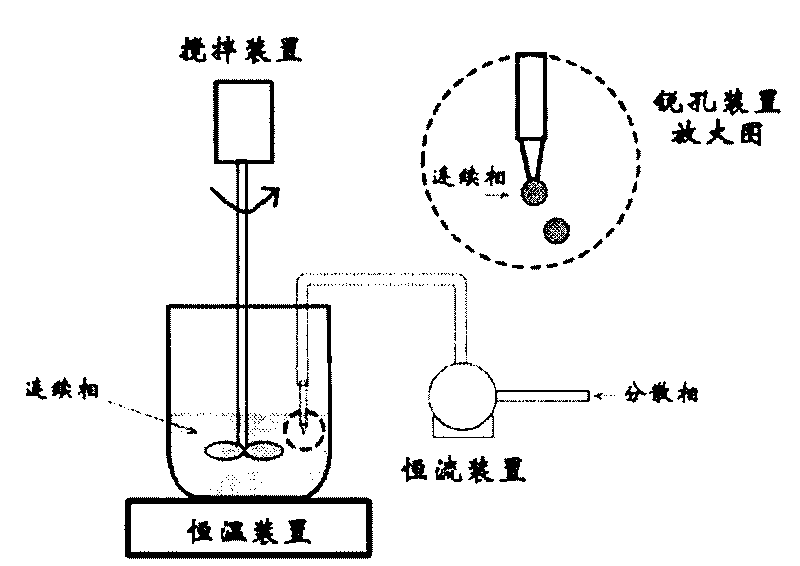

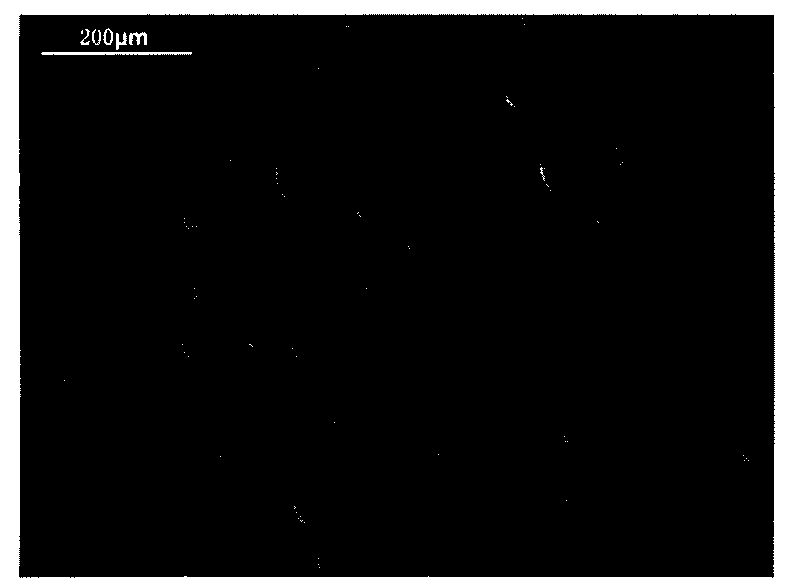

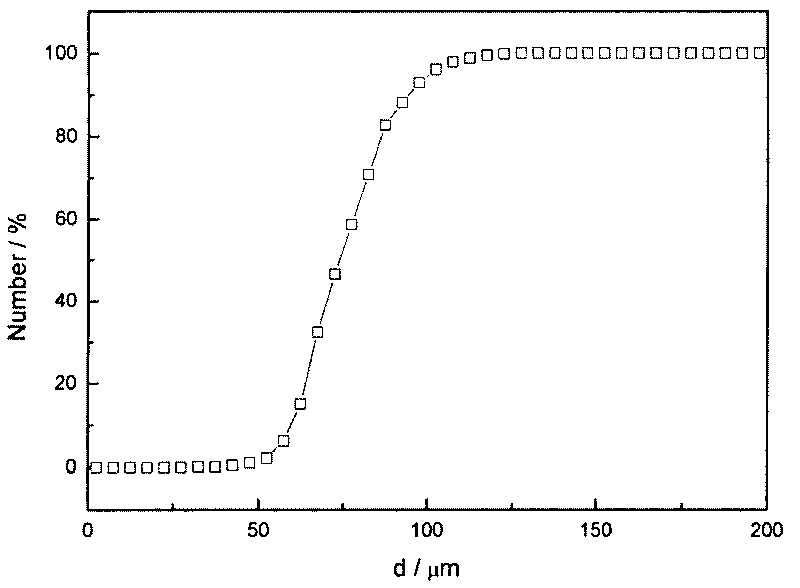

InactiveCN101690879AFlat shapeGood sphericityMicroballoon preparationMicrocapsule preparationPolymer scienceMicrometer

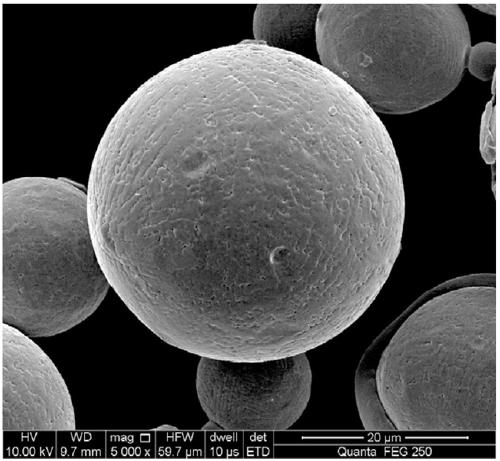

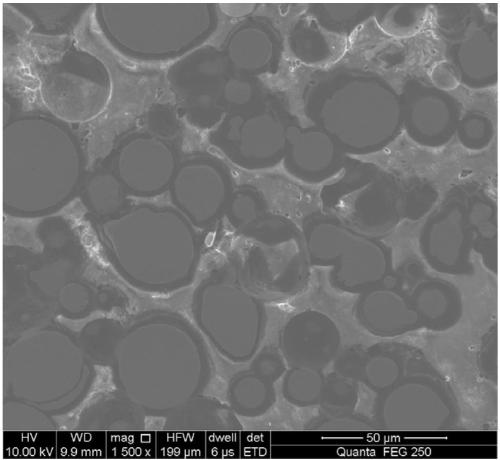

The invention discloses a method for preparing polymer micro balls with uniform grain diameter and controllable size, which comprises the following steps: a disperse phase (organic solution of polymers) is introduced into a continuous phase (water solution containing surfactant) through an orifice device; under the scouring action of the continuous phase, the disperse phase forms tiny liquid drops with uniform grain diameter; and after being solidified in the continuous phase without a solvent, the liquid drops form the polymer micro balls with uniform grain diameter. The invention is characterized in that the grain diameter of the polymer micro balls can be changed by adjusting the operation parameters to prepare the polymer micro balls with uniform grain diameter; and the average grain diameter of the polymer micro balls with uniform grain diameter can be adjusted within the range of 10-1000 micrometers, and the dispersion coefficient is smaller than 20%. The prepared polymer micro balls have the advantages of uniform grain diameter, low dispersion coefficient, smooth surface and no adhesion; and the method has the advantages of strong adjustability, simple equipment and stable operation.

Owner:ZHEJIANG UNIV

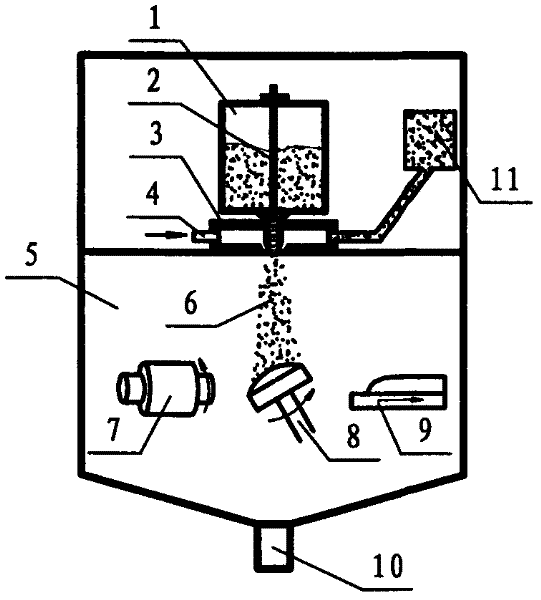

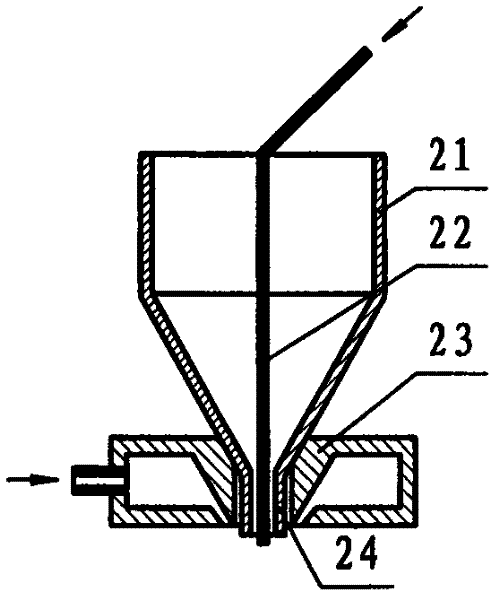

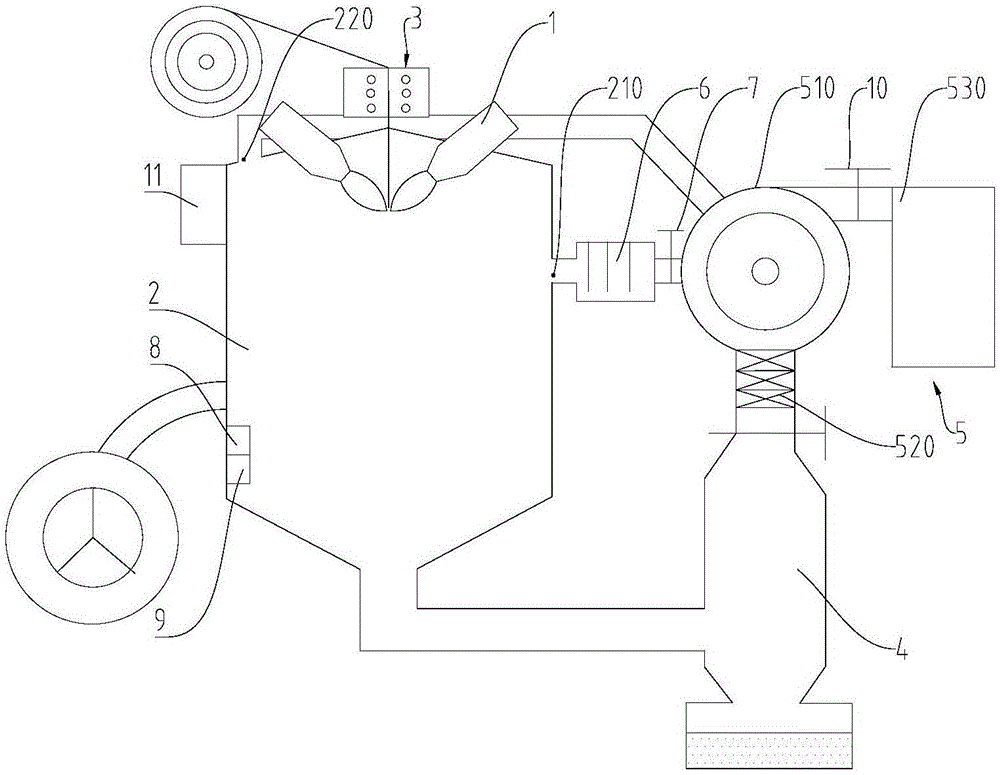

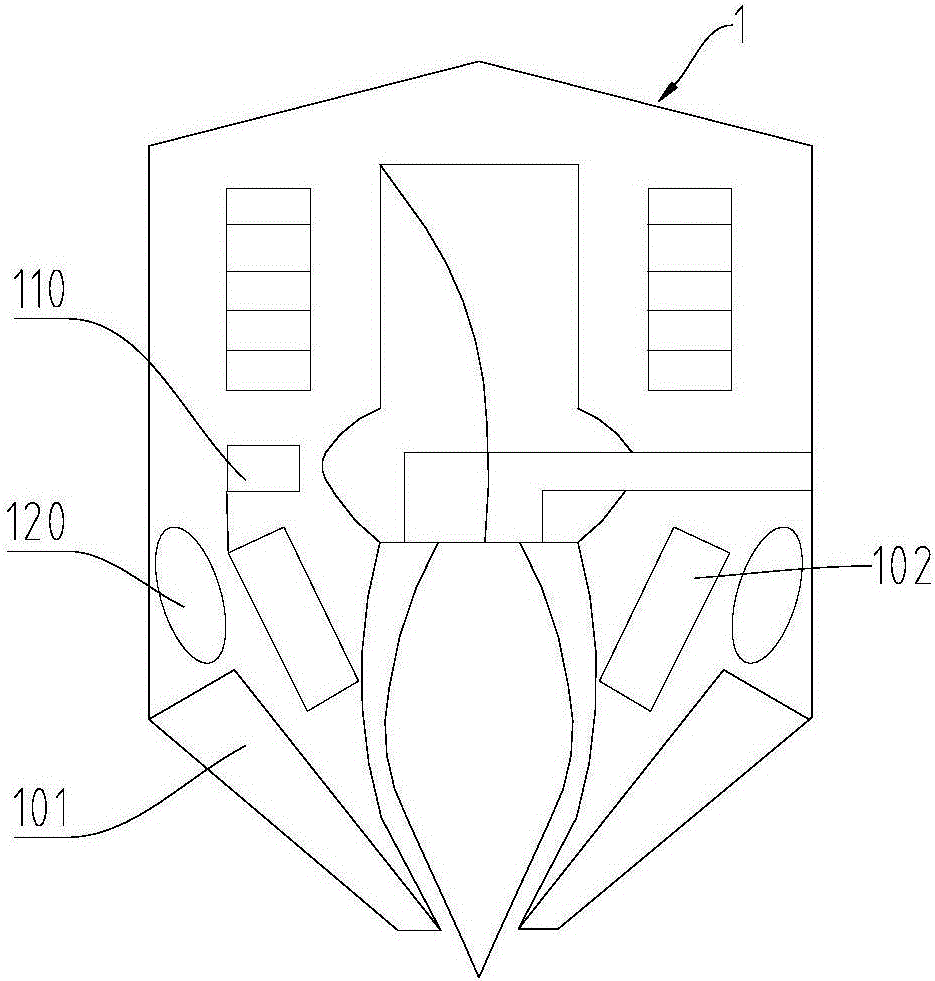

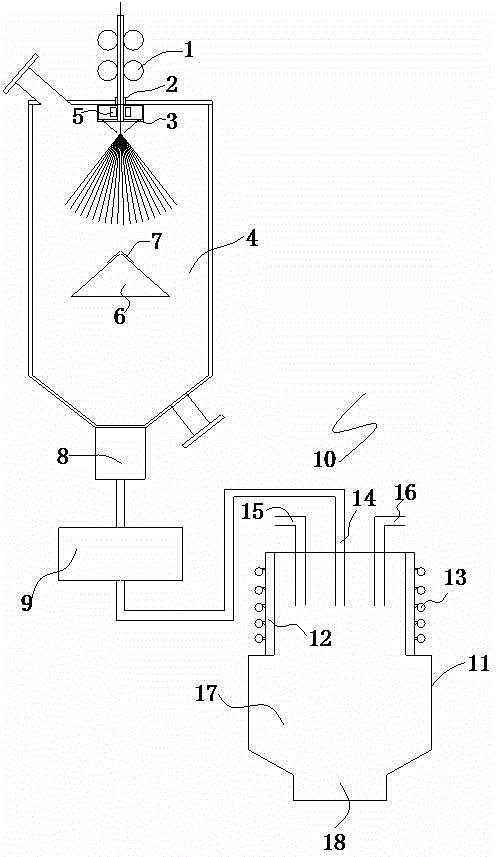

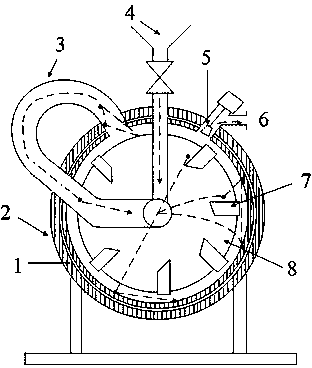

Method and system for preparing particle-reinforced metal-based composite material through injection molding

The invention relates to a method and system for preparing a particle-reinforced metal-based composite material through injection molding. Ceramic reinforced particles and high-pressure inert gas are uniformly mixed in an acceleration nozzle to be used as an atomizing medium, thereby improving the density, momentum and impact force of the atomizing medium, obviously enhancing the atomization effect and reducing the inert gas consumption as compared with the atomization based on the single use of inert gas. After atomization is completed, the ceramic particles are uniformly dispersed in atomized molten drops, and the molten metal drops doped with the reinforced particles are gradually solidified in the flying process and are ultimately deposited, solidified and molded on a receiver, thus obtaining the high-performance metal-based composite material of which the ceramic reinforced particles are uniformly distributed. In addition, the ceramic reinforcements used in the invention are prepared by a reaction and ball milling method, thereby ensuring that the reinforced particles better in strength, interface stability, high-temperature performance and other aspects can be prepared at a low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Recycled concrete and preparation method thereof

InactiveCN111039624AReduce porosityCompact structureSolid waste managementEpoxyCompressive resistance

The invention relates to recycled concrete and a preparation method thereof, and belongs to the technical field of concrete. The recycled concrete comprises (by weight): 150-280 parts of cement, 90-130 parts of water, 800-950 parts of modified recycled coarse aggregate, 400-530 parts of fine aggregate, 40-85 parts of fly ash, 80-100 parts of mineral powder, 50-140 parts of zeolite powder, 30-60 parts of epoxy resin, 4-10 parts of a water reducing agent and 2-6 parts of an air entraining agent. The preparation method of the modified recycled coarse aggregate comprises the following steps: S1, crushing and screening waste concrete to obtain recycled coarse aggregate; S2, soaking the recycled coarse aggregate obtained in the step S1 in an acetic acid solution with the mass concentration of 2-7%, and airing; S3, stirring 80-110 parts of polyvinyl alcohol, 60-110 parts of silica fume, 40-80 parts of sodium silicate and 800-1,000 parts of water to obtain a modified liquid; and S4, soaking the recycled coarse aggregate obtained in the step S2 in the modified liquid obtained in the step S3, taking out the soaked recycled coarse aggregate, and baking the recycled coarse aggregate to obtainthe modified recycled coarse aggregate. The recycled concrete provided by the invention has a good compressive strength effect.

Owner:泸州临港思源混凝土有限公司

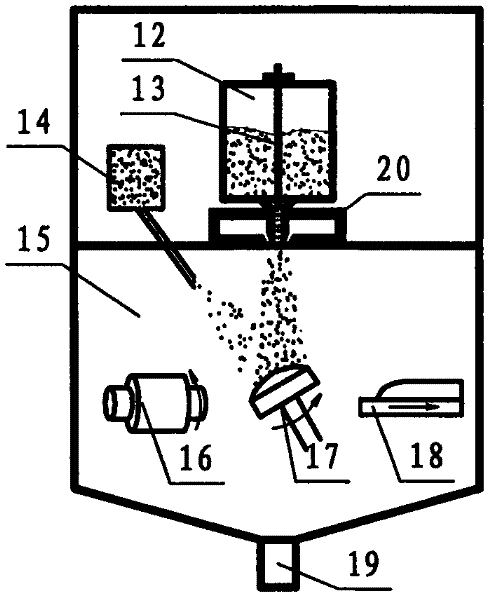

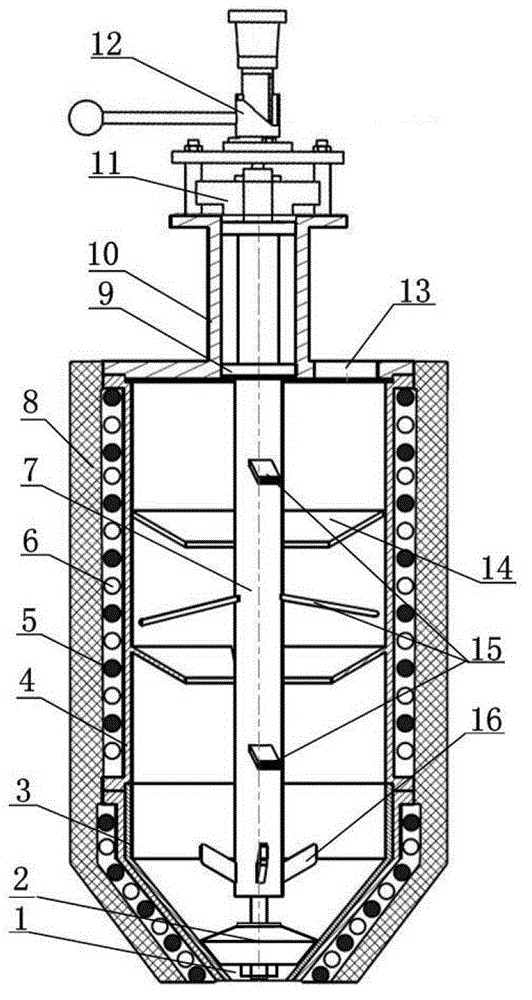

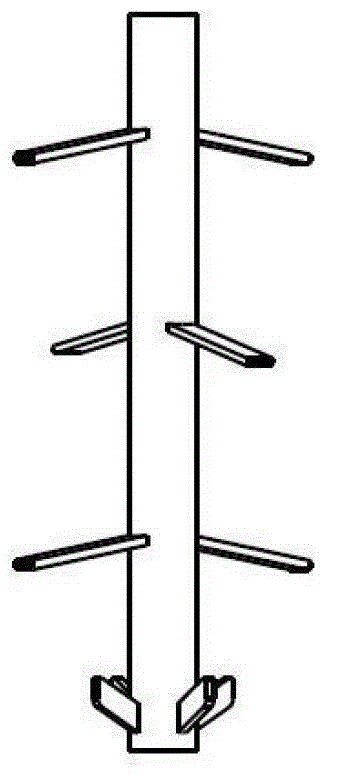

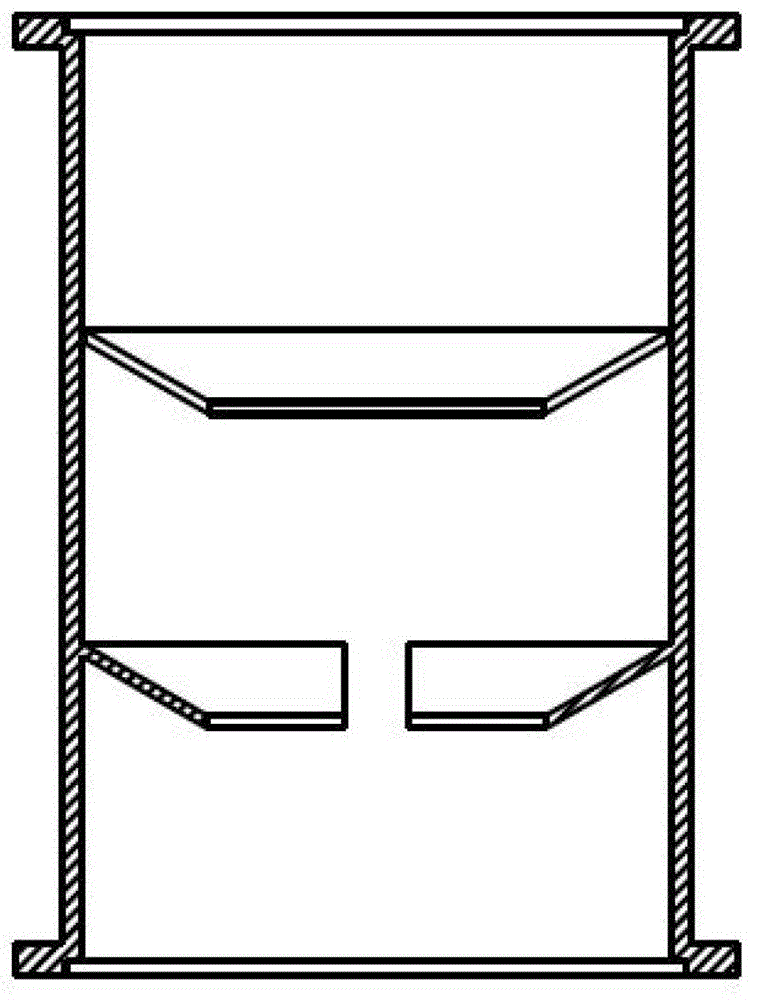

Continuous preparation device for composite stirred semi-solid slurry

The invention relates to a continuous preparation device for composite stirred semi-solid slurry, and belongs to the technical field of machining semi-solid metal machining. The device comprises a discharge outlet 1, a graphite plug 2, a graphite lining 3, a stainless steel tube 4, a heating element 5, a cooling element 6, a stirring shaft 7, a thermal insulating layer 8, a bearing 9, a bearing seat 10, a gear 11, a discharge handle 12, a feeding inlet 13, an oblique baffle 14, a rotary blade 15, a stirring blade 16 and the like. The semi-solid slurry is prepared through the following steps: after feeding an alloy fuse into the device, throwing onto the inner wall of a stirring chamber through the rotary blade rotating at high speed, enabling the fuse to flow downward along with the inner wall and flow downward along with the baffle when encountering the oblique baffle, then throwing the fuse on the inner wall of the stirring chamber by the rotary blade, after circulating the processes for two times, enabling the fuse to flow downward along the wall of the graphite lining at the lower part, carrying out convection at the bottom of a stirring bucket through driving of the stirring blade, generating a great deal of crystal nucleus in the fuse in the process, and directly growing into spheres. The flowing velocity of the slurry can be controlled through adjusting a gap between the graphite plug and the graphite lining, the semi-solid slurry can be subjected to rheoforming together with conventional equipment such as die casting, rolling and mold forging, and semi-solid ingot can also be continuously prepared.

Owner:UNIV OF SCI & TECH BEIJING

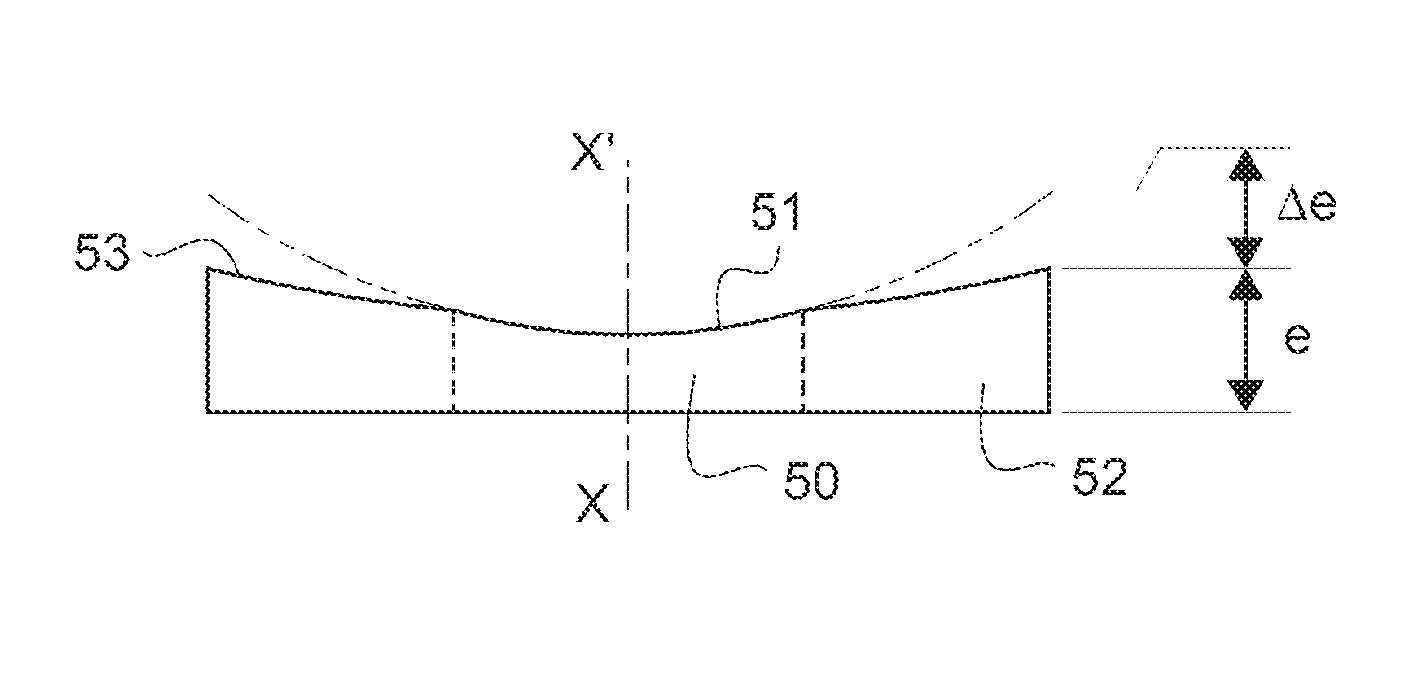

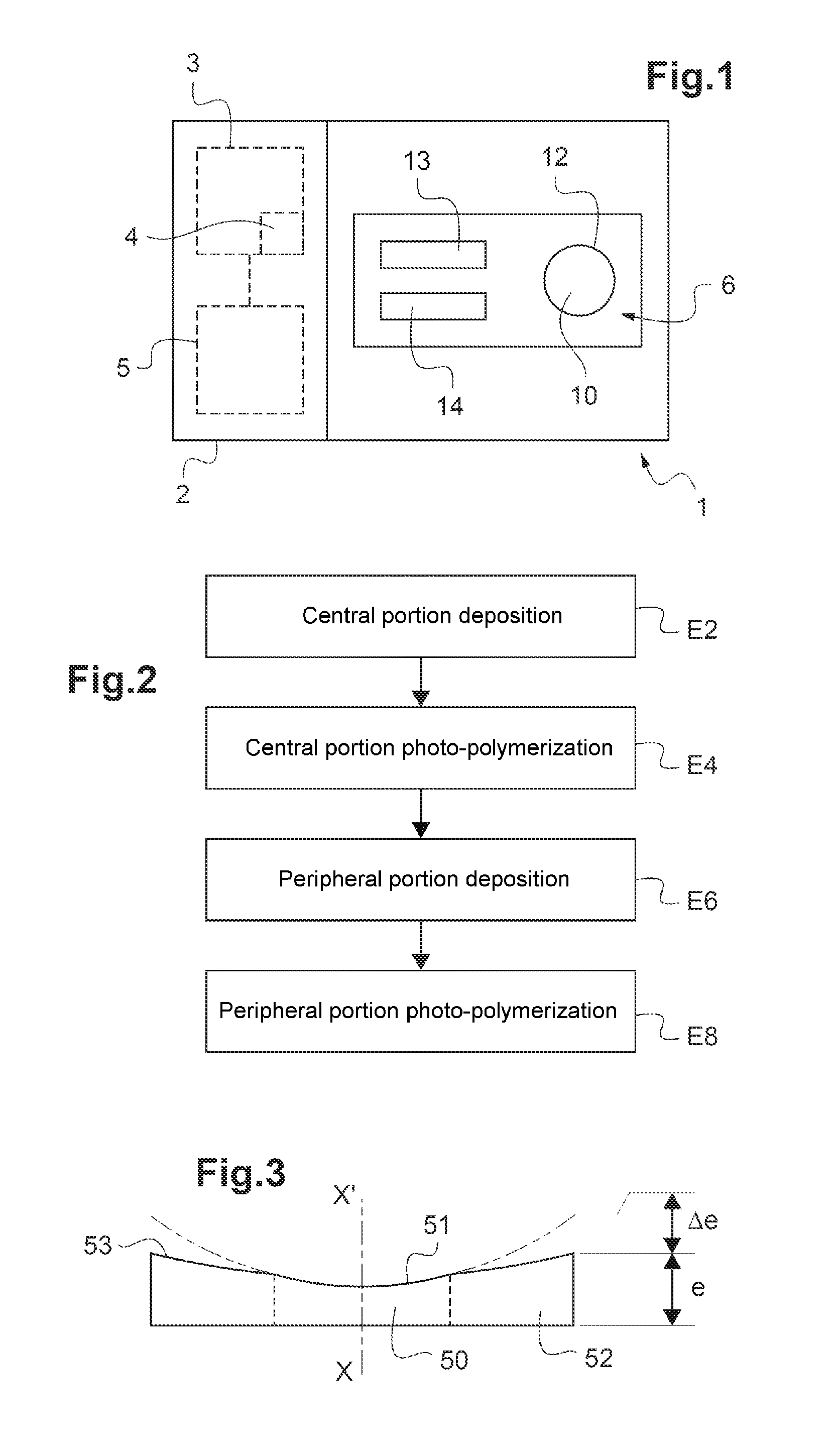

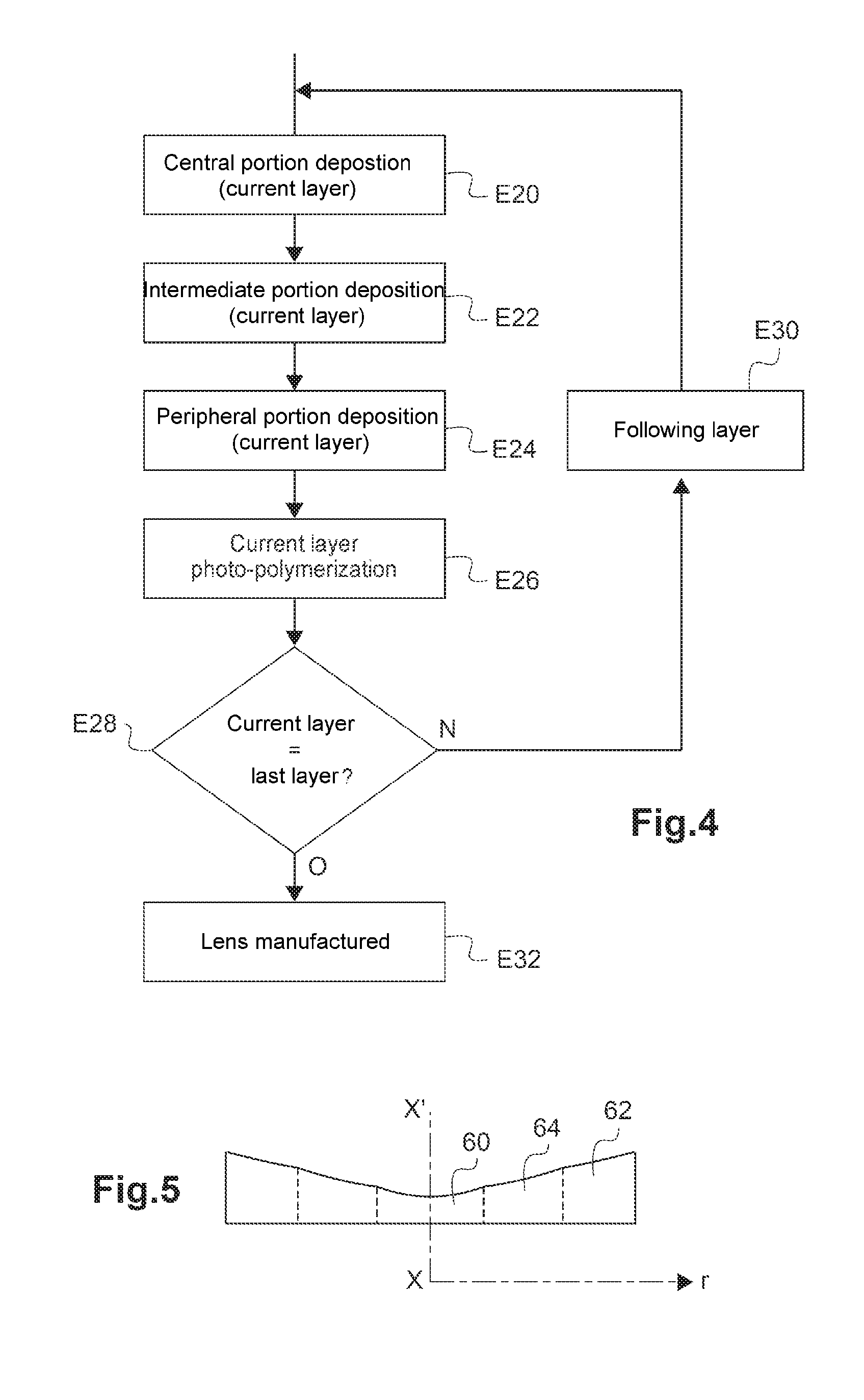

Ophthalmic lens and process for manufacturing such a lens

ActiveUS20150277150A1Good sphericityImprove optical qualitySpectales/gogglesAdditive manufacturing apparatusRefractive indexEye lens

A process for manufacturing a negative ophthalmic lens comprising a central portion (50) and a peripheral portion (52) comprises the following steps:forming the central portion (50) by forming voxels of a first material having a first refractive index, the central portion having a zone at its periphery; andforming the peripheral portion (52) from said zone and contiguous to the perimeter of said zone, by forming voxels of at least one second material having a second refractive index, the second refractive index being strictly higher than the first refractive index.

Owner:ESSILOR INT CIE GEN DOPTIQUE

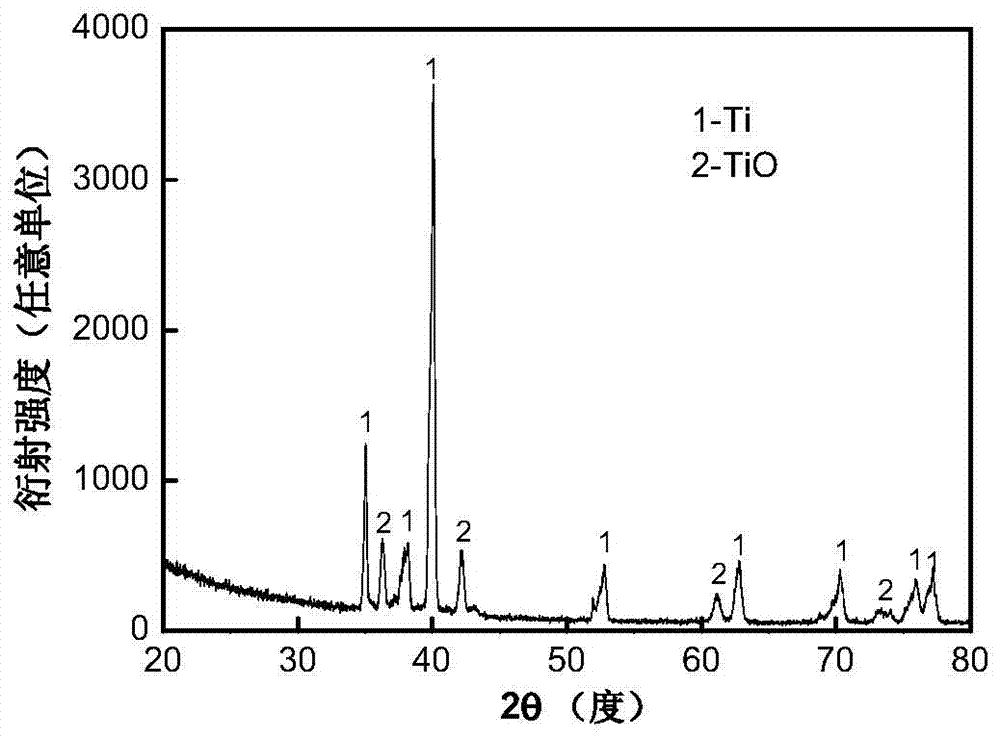

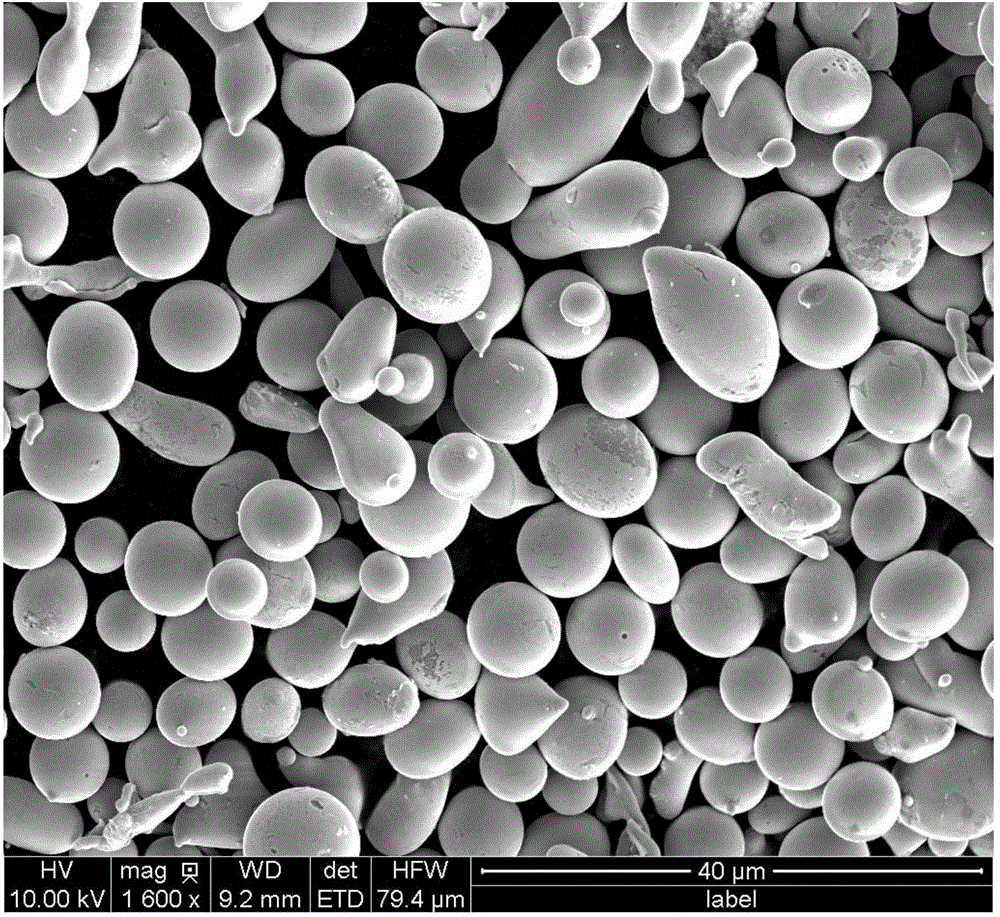

Plasma atomization method and apparatus for preparing pure titanium or titanium alloy powder

The invention relates to a plasma atomization method and apparatus for preparing spherical pure titanium or titanium alloy powder, and belongs to the technical field of preparation of titanium or titanium alloy powder. The plasma atomization method for preparing pure titanium or titanium alloy powder comprises the following steps of (1) preparing a titanium wire or titanium alloy wire with the diameter ranging from 3 millimeters to 20 millimeters, (2) using a plasma torch to fuse and atomize the titanium wire or titanium alloy wire in an atomization bin with an argon atmosphere to obtain atomized pure titanium particles or titanium alloy particles, and (3) feeding argon flow with the temperature ranging from 300 DEG C to 500 DEG C into the atomization bin, carrying out laminar cooling on the atomized pure titanium particles or titanium alloy particles to obtain pure titanium or titanium alloy powder. The obtained powder is good in degree of sphericity and low in the content of satellite balls, and has the advantages of being uniform in size distribution, high in purity and degree of sphericity, good in liquidity, low in oxygen content and impurity content, free of bond or cluster phenomenon and the like. The prepared titanium powder can be widely applied to the forming manners such as metal additive manufacturing, powder injection moulding and hot isostatic pressing for manufacturing parts with high precision.

Owner:OPTIMAL MATERIAL TECH CO LTD

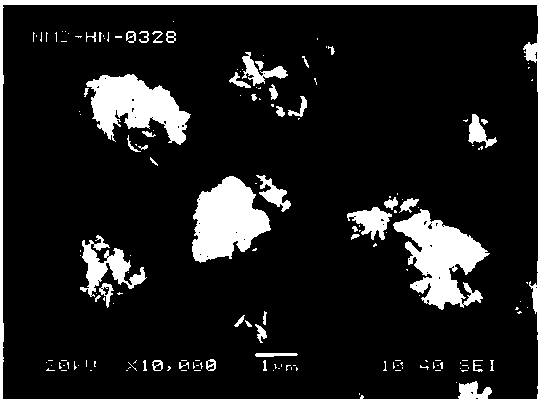

Method for preparing metal reinforced uranium dioxide nuclear fuel pellet

ActiveCN107256726ALow densityHigh strengthNuclear energy generationReactor fuel susbtancesMicro cellTwo step

The invention discloses a method for preparing metal reinforced uranium dioxide nuclear fuel pellets. The method mainly comprises two steps: firstly, preparing core-shell structure granules, namely performing low-temperature rapid pre-sintering on UO2 powder by using a Spark Plasma Sintering SPS technique, pelletizing, balling to obtain UO2 pellets, performing physical mixing on the UO2 pellets with metal (one of Mo, Cr, W and the like) micro powder to coat surfaces of the UO2 pellets by the metal micro powder, thereby obtaining metal coated uranium dioxide core-shell structure granules; secondly, preparing a nuclear fuel pellets, namely performing high-temperature liquidation on the metal powder on the surfaces of the UO2 pellets, thereby forming a micro cell structure continuous phase similar to a cytomembrane structure around the UO2 pellets, and obtaining the special metal reinforced UO2 nuclear fuel pellets with a UO2 substrate.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

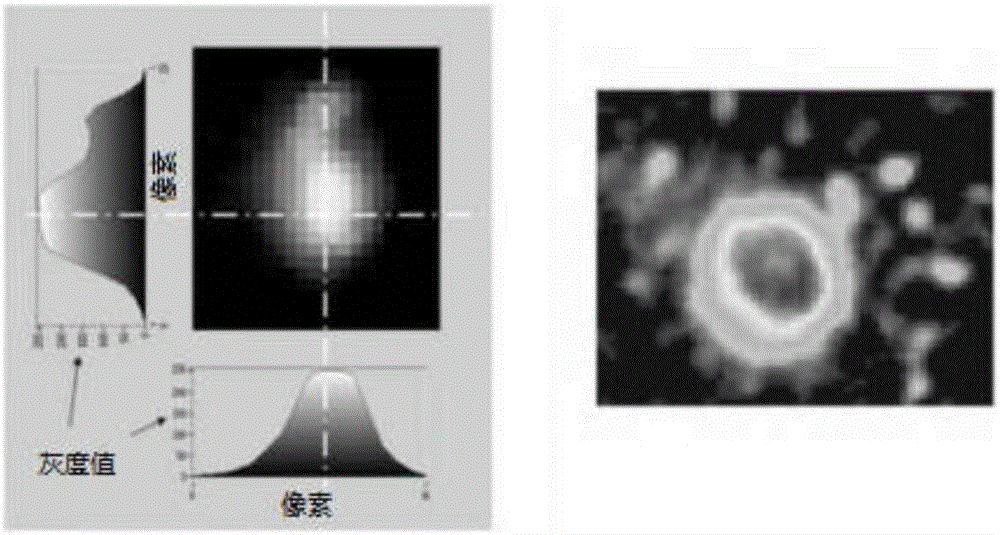

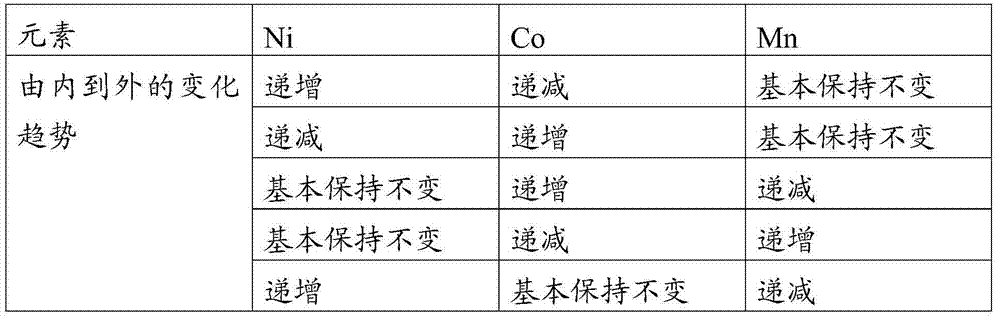

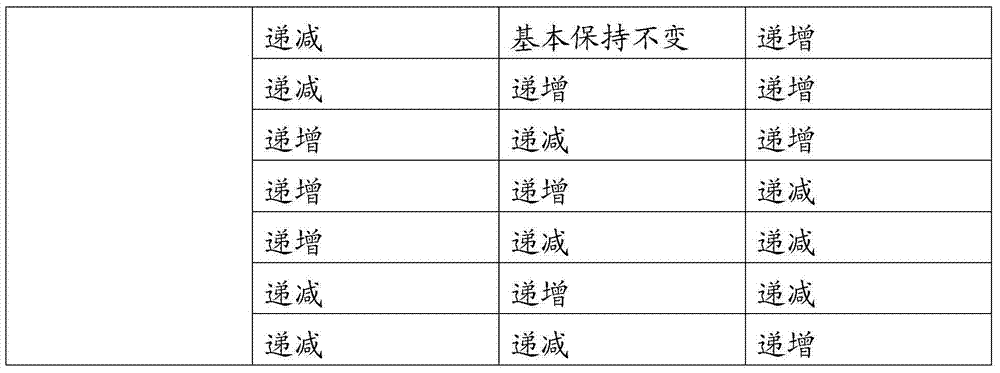

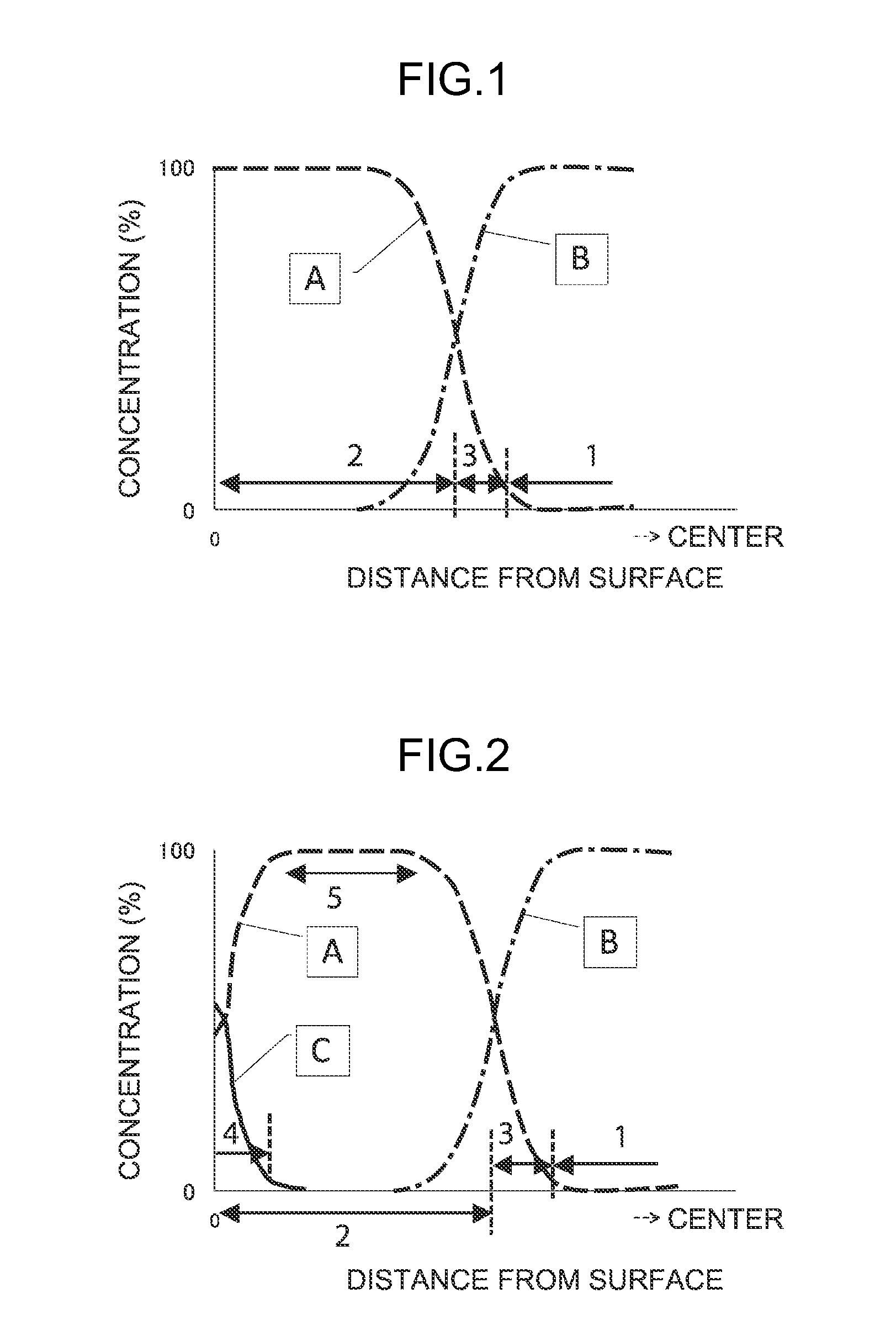

Lithium-ion-battery gradient cathode-material precursor and preparation method thereof

The invention relates to a preparation method for a lithium-ion-battery gradient cathode-material precursor, and belongs to the technical field of preparation of lithium ion batteries cathode materials. The concrete steps of the method comprise; preparing a solution A and a solution B with different molar ratios from a nickel salt, a cobalt salt and a manganese salt, and controlling the volume of the solution A and the solution B to be same; employing a metering pump to gradually adding the solution A into the solution B, then adding the uniformly-mixed solution into a reaction kettle, and also adding an alkali solution and a complexing agent solution into the reaction kettle, and stabilizing synthesis technology parameters during reaction, stopping reaction once the solution A and the solution B are completely consumed, finally centrifuging, washing and drying, so as to prepare the spherical cathode material precursor with different-concentration gradient-distributed elements. The disclosed preparation method helps to improve the processing performance and the tap density of the cathode material, and overcome the disadvantages about capacity and stability of the material, and by controlling the morphology and the particle size of the cathode material, the physicochemical performances of the cathode material are controlled and the material stability is improved.

Owner:HUBEI RONGBAI LITHIUM BATTERY MATERIAL CO LTD

Method for preparing spherical carbon material

The invention relates to a method for preparing spherical porous carbon, wherein the spherical porous carbon is obtained through the following steps of taking commercialized spherical polyvinylidene fluoride (PVDF) resin as a raw material, carrying out defluorination stabilization at a low temperature below 150 DEG C, carrying out carbonization at high temperature, and activating. The commercial production of the spherical PVDF resin is realized, the particle diameter of the spherical PVDF resin is controllable, and the method for preparing the spherical porous carbon has the advantages that the method is simple, the degree of sphericity of a carbon sphere is good, the particle diameter is uniform, the size of the particle diameter is easy to regulate and control, and the like. The particle diameter of the spherical porous carbon is adjustable between 5 nm and 50 microns, the specific surface area is 50-3000 m<2> / g, and thus, the spherical porous carbon can be used for an electrode material of a super capacitor, an electrode material of a lithium ion battery, an electrode material of a capacitance-method desalination equipment, blood purification, a catalyst carrier, water treatment, gas purification, solvent recovery and the like.

Owner:NO 63971 TROOPS PLA

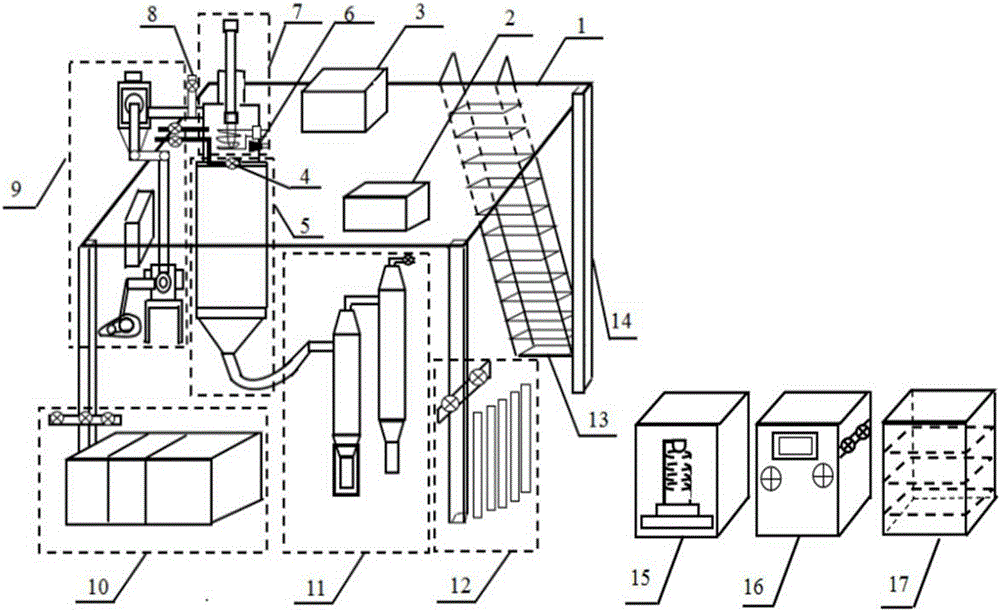

Alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing

InactiveCN106424748AWith mechanical controlWith automatic controlAdditive manufacturing apparatusTransportation and packagingAutomatic controlCollection system

The invention relates to a high-performance alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing. The device comprises a vacuum acquirement and inflation system, an induction smelting system, an atomization powder preparation system, a power collection system and a power system. The preparation method includes that: (1) the induction smelting system selects a non-crucible induction system or a crucible induction system; (2) alloy bars are fixed on a continuous feeder, or nickel-based / cobalt-based alloy bars are put in a smelting chamber; (3) the smelting chamber, an atomizing chamber and a power collection device are vacuumized prior to be fed with inert gas; (4) induction smelting is started, when alloy reaches preset temperature, alloy droplets are enabled to enter the atomization powder preparation system, and nozzles are started to perform atomization powder preparation; alloyed power prepared in the atomization chamber is collected through the powder collection device. The device can realize mechanical control, automatic control and real-time monitoring; the prepared alloy powder is high in yield, uniform in particle size distribution, good in degree of sphericity, uniform in chemical component, good in mobility, low in oxygen content and low in hollow sphere rate.

Owner:NORTHEASTERN UNIV

Method for preparing cellulose microsphere by taking ionic liquid as solvent

InactiveCN101612540ASolve forming problemsSolve the problem of sphericityOther chemical processesAlkali metal oxides/hydroxidesCelluloseLow speed

The invention discloses a method for preparing cellulose microspheres by taking ionic liquid as a solvent. The method comprises the steps of: 1) preparing cellulose solution as follows: dissolving the cellulose into the ionic liquid under low-speed stirring and proper temperature; 2) adding inert particles: adding proper amount of inert particles, and stirring evenly; 3) forming spheres by reversed phase suspension: adding oil phase and a surface active agent, leading the cellulose solution to be condensed into spheres by reversed phase suspension and program temperature reduction; 4) curving microspheres: adding a curving agent and curving to form the cellulose microspheres; 5) washing: using deionized water to wash and soak so as to obtain the cellulose microspheres; and 6) screening: screening in a wet state and obtaining the cellulose microspheres with a certain particle size range. The developed preparation process is simple and convenient, the used solvent is safe and non-toxic, the prepared cellulose micrsphere has porous structure and proper particle size, high sphericity and good hydropathy, can adjust density, can be used as substrate of an absorbent and has good biocompatibility.

Owner:ZHEJIANG UNIV

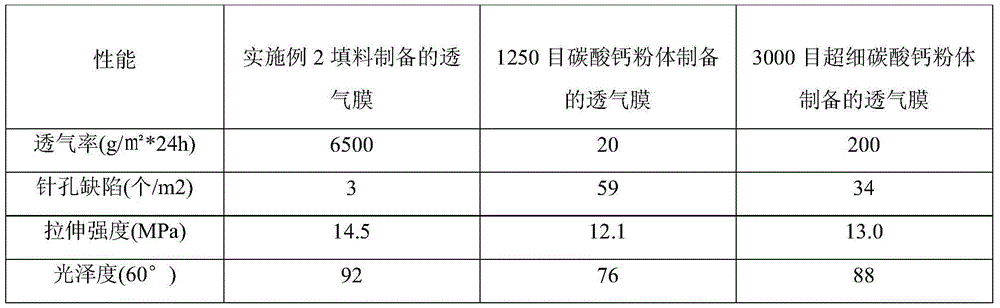

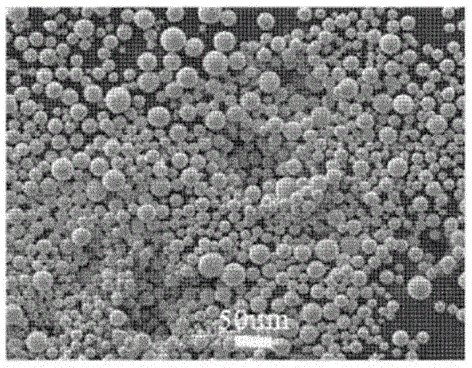

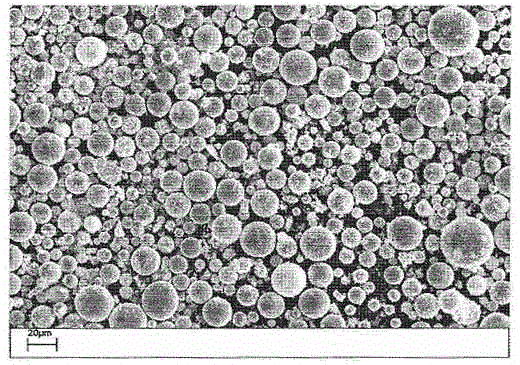

Coarse whiting filler for gas-permeable membrane and preparation method of coarse whiting filler

ActiveCN104530768AGood sphericityNo edges and cornersPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsMicrometerSURFACTANT BLEND

The invention belongs to the field of deep processing and utilization of nonmetal minerals, composite materials and functional materials, and particularly relates to coarse whiting filler for a gas-permeable membrane and a preparation method of the coarse whiting filler. The invention aims to provide the preparation method of the coarse whiting filler for the gas-permeable membrane. The preparation method comprises the following steps: crushing marble until the diameter is 40 to 70 micrometers; uniformly mixing marble powder, water and a high-molecular surfactant at a weight ratio of 1:(0.2-1.5):(0.001-0.1); ball-milling and filtering; dehydrating until the water content is not larger than 1%; dismissing gathered powder; drying until the water content is not larger than 0.2%; adding an activating agent of which the weight is 0.5% to 3% of the total weight of the dried powder material; fully reacting at the temperature of 110 to 140 DEG C; and cooling, uniformly mixing and packaging. The coarse whiting filler prepared by the method disclosed by the invention is good in performance and can be well applied to preparation of the gas-permeable membranes and relevant products.

Owner:SICHUAN SHIMIAN JUFENG POWDER

Device and method for preparing superfine micro-spherical titanium powder for 3D printing

InactiveCN105057689AGood sphericityHigh purityAdditive manufacturing apparatusPlasma torchRadio frequency plasma

The invention relates to a device for preparing superfine micro-spherical titanium powder for 3D printing. The device for preparing the superfine micro-spherical titanium powder for 3D printing comprises an automatic feeding system, an insulation dynamic seal unit, an annular gas atomization nozzle, an atomization chamber, an arc cathode smelting well, a radiating cover, a protection cover, a powder collection tank, a supersonic gas crushing mill and a radio frequency plasma reactor. The invention further relates to a method for preparing the superfine micro-spherical titanium powder for 3D printing. The method comprises the steps that firstly a gas atomization unit is used for performing initial powder production on raw titanium powder; then crushing is used for further reducing the granularity of the titanium powder; a plasma unit is used for further processing the titanium powder; the high-energy characteristic of radio frequency plasma is used for injecting carrying gas for irregular-shaped titanium powder particles into a plasma torch, the irregular titanium powder is heated rapidly and melted, the melted particles form drops with high sphericity degree under the action of surface tension, and the drops are solidified rapidly under an ultra-high temperature gradient to form the superfine micro-spherical titanium powder good in sphericity degree, high in purity and low in oxygen content.

Owner:SHANXI ZHUOFENG TITANIUM IND

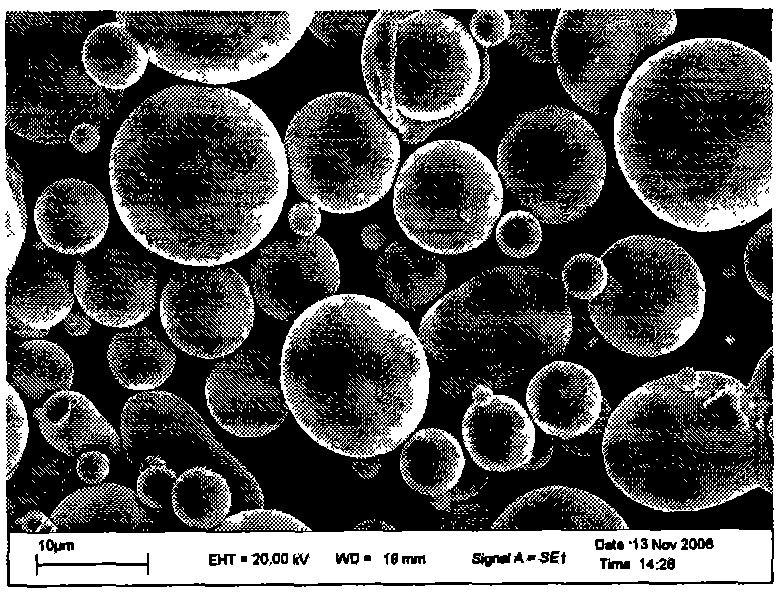

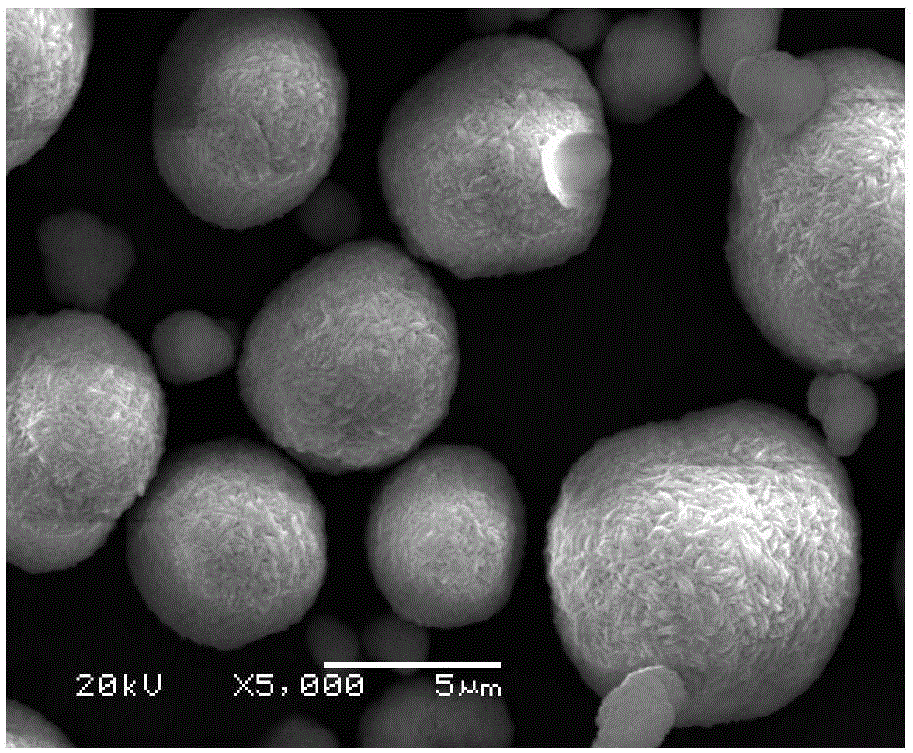

Preparation method of coating containing TiB2 metal ceramic composite powder for thermal spraying piston ring

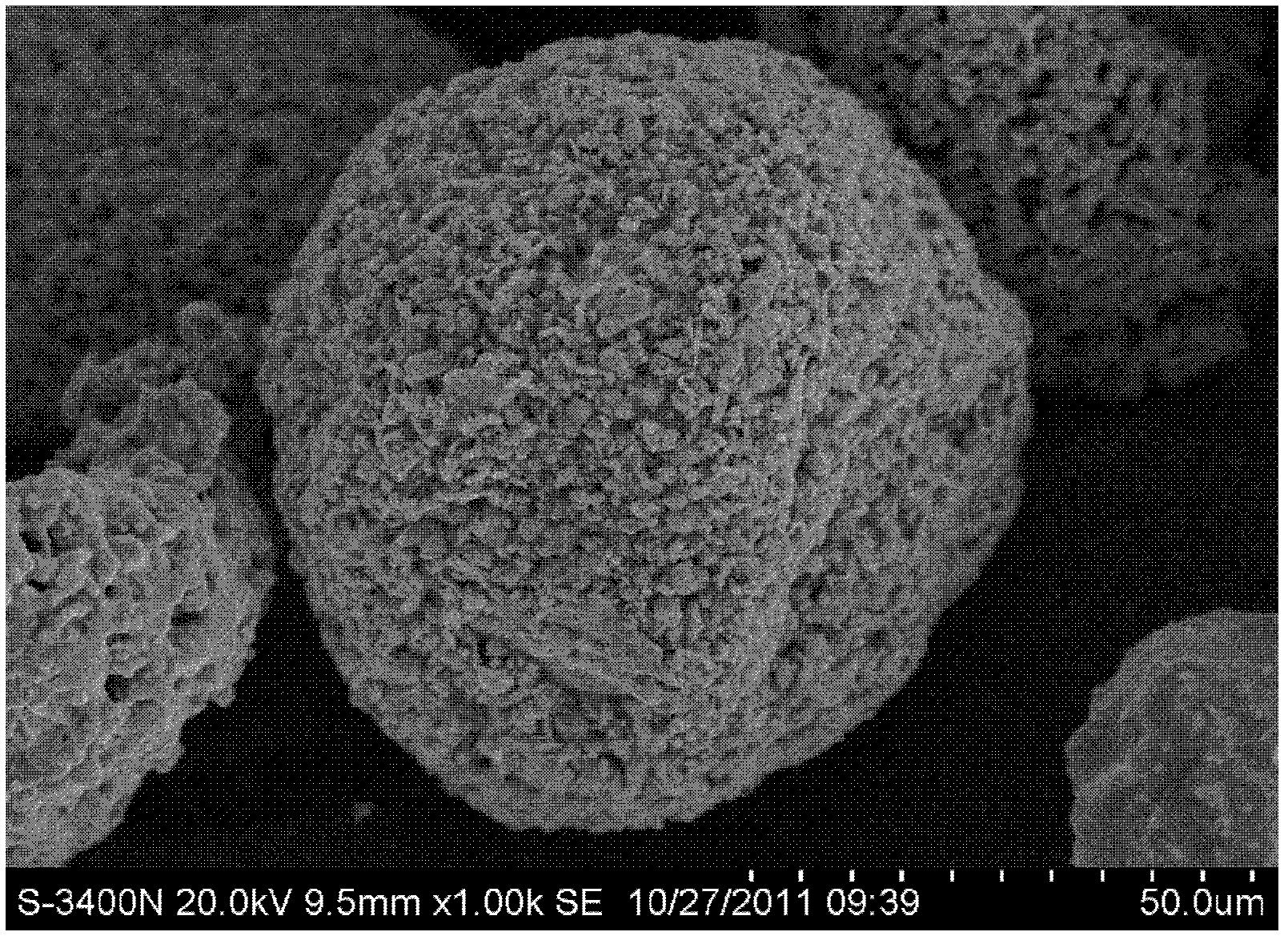

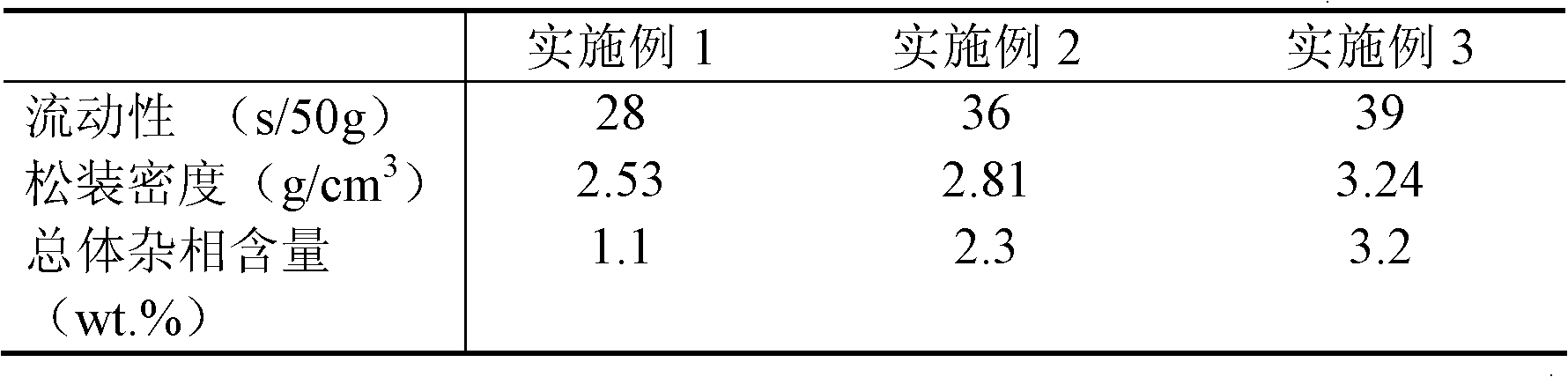

InactiveCN102581292AImprove deposition efficiencyGuaranteed contentMolten spray coatingThermal sprayingPolyvinyl alcohol

The invention relates to a preparation method of a coating containing TiB2 metal ceramic composite powder for a thermal spraying piston ring, belonging to the field of composite power body technology. The preparation method provided by the invention comprises the following steps: firstly, adopting a ball-milling method to perform mixing and wet grinding on 25-75wt.% TiB2 powder, 25-10wt.% NiCr alloy powder and 50-15wt.% Mo metal powder to obtain mixed powder with the particle size less than 3 micrometers; then mixing the mixed powder with adhesion agent PVA (Polyvinyl Alcohol), dispersing agent and deionized water in proportion in to slurry, performing atomization and granulation of the slurry at the drying temperature rang of 150-250 DEG C and under the atomizing disc frequency range of 140-190Hz through a spray drying device; and finally performing densification treatment on the powder through heat treatment technology and plasma balling technology. For the composite powder prepared by the preparation method of the invention, the particle size is uniformly distributed, the spherical degree, the densification degree and the mobility are good, the deposition efficiency of TiB2 can be improved, and the metal ceramic coating with good wear-resisting property can be prepared.

Owner:BEIJING UNIV OF TECH

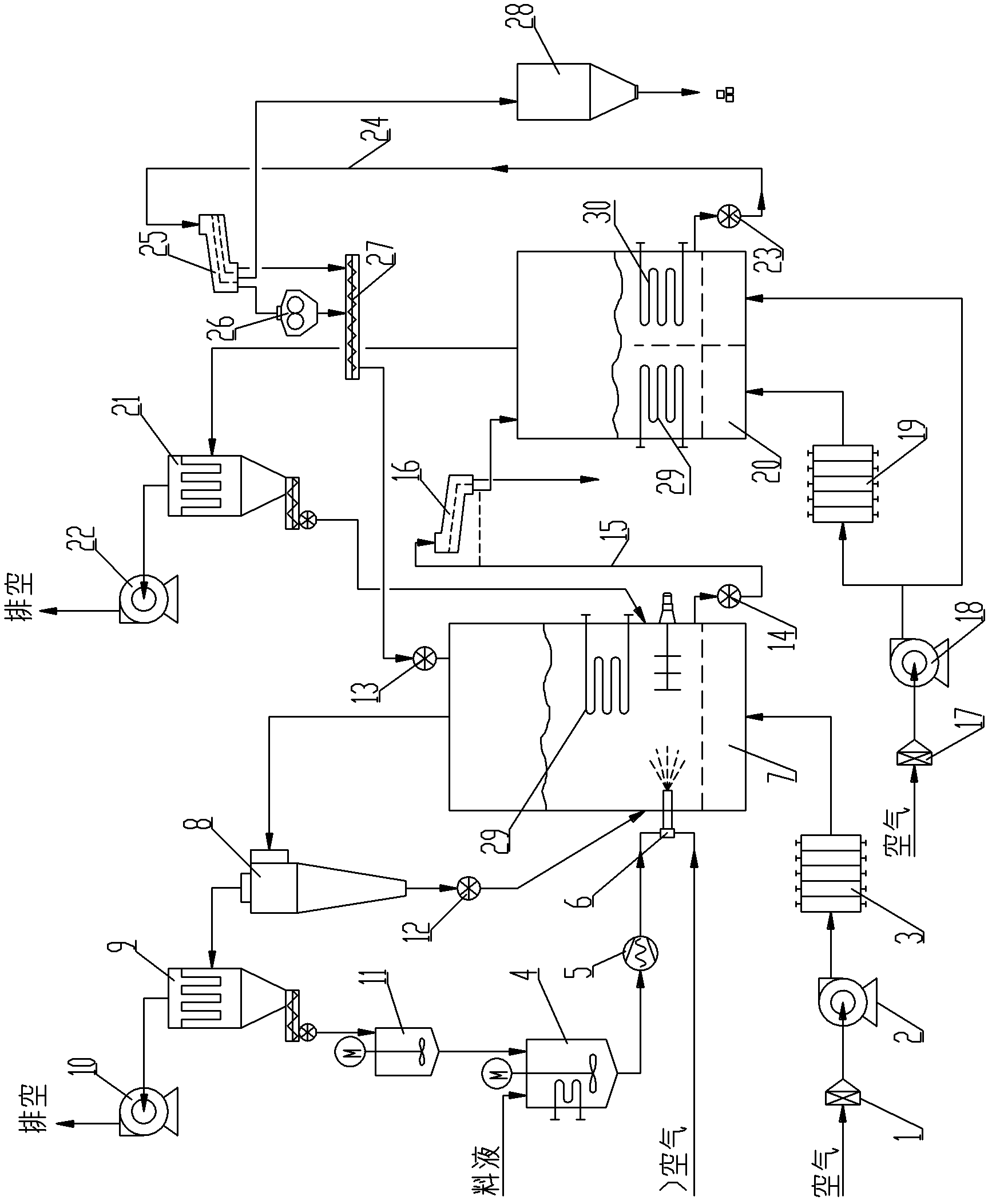

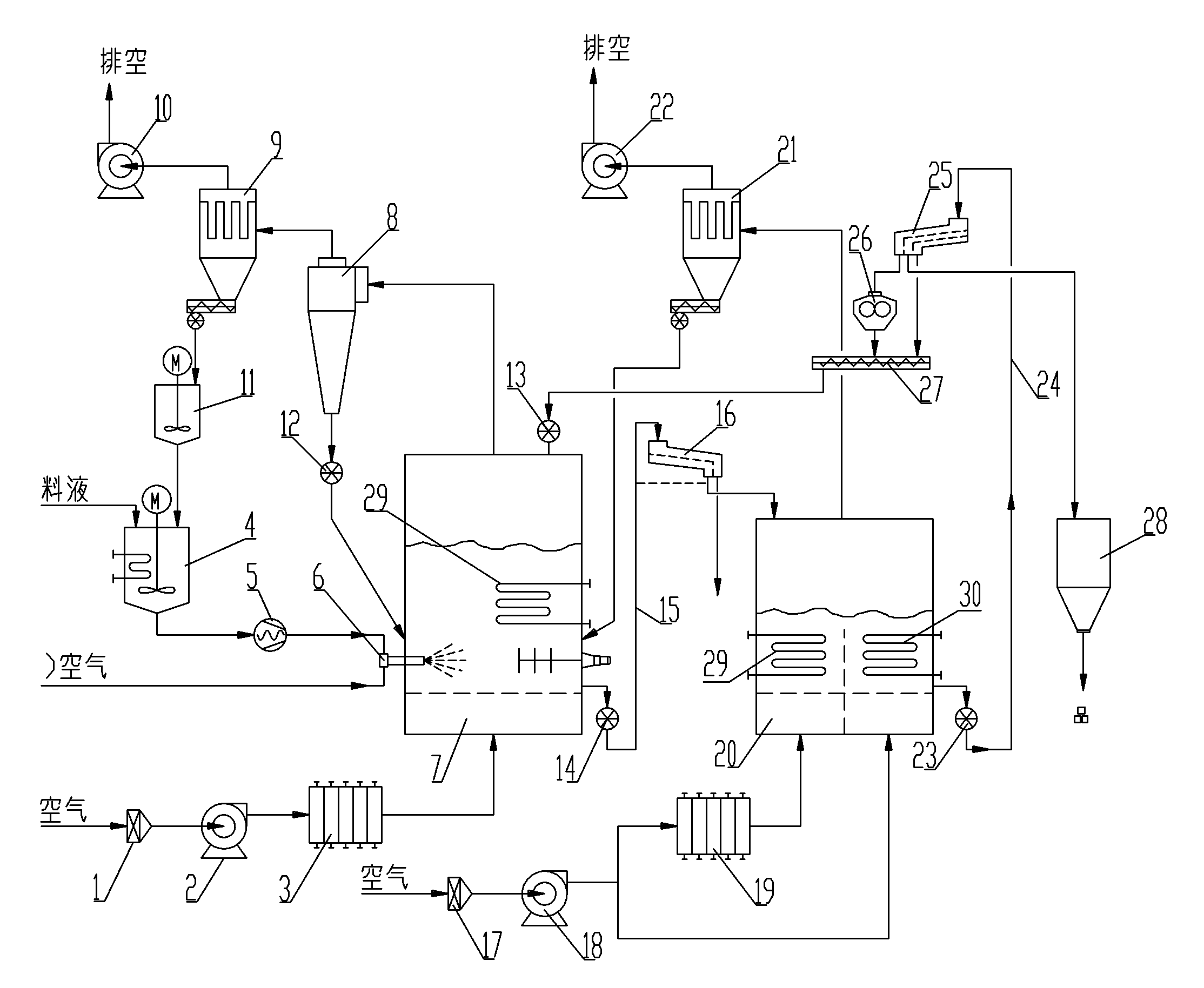

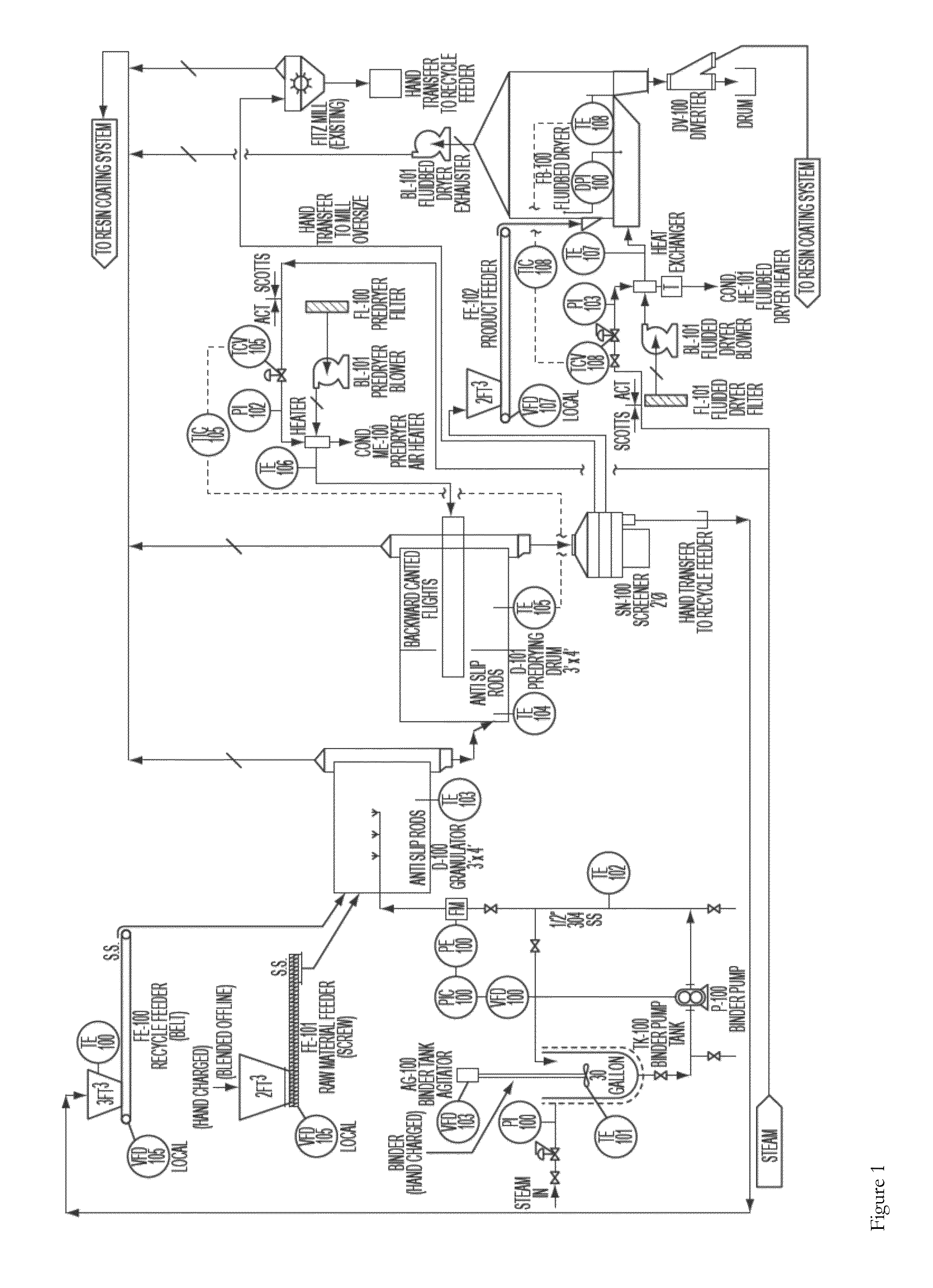

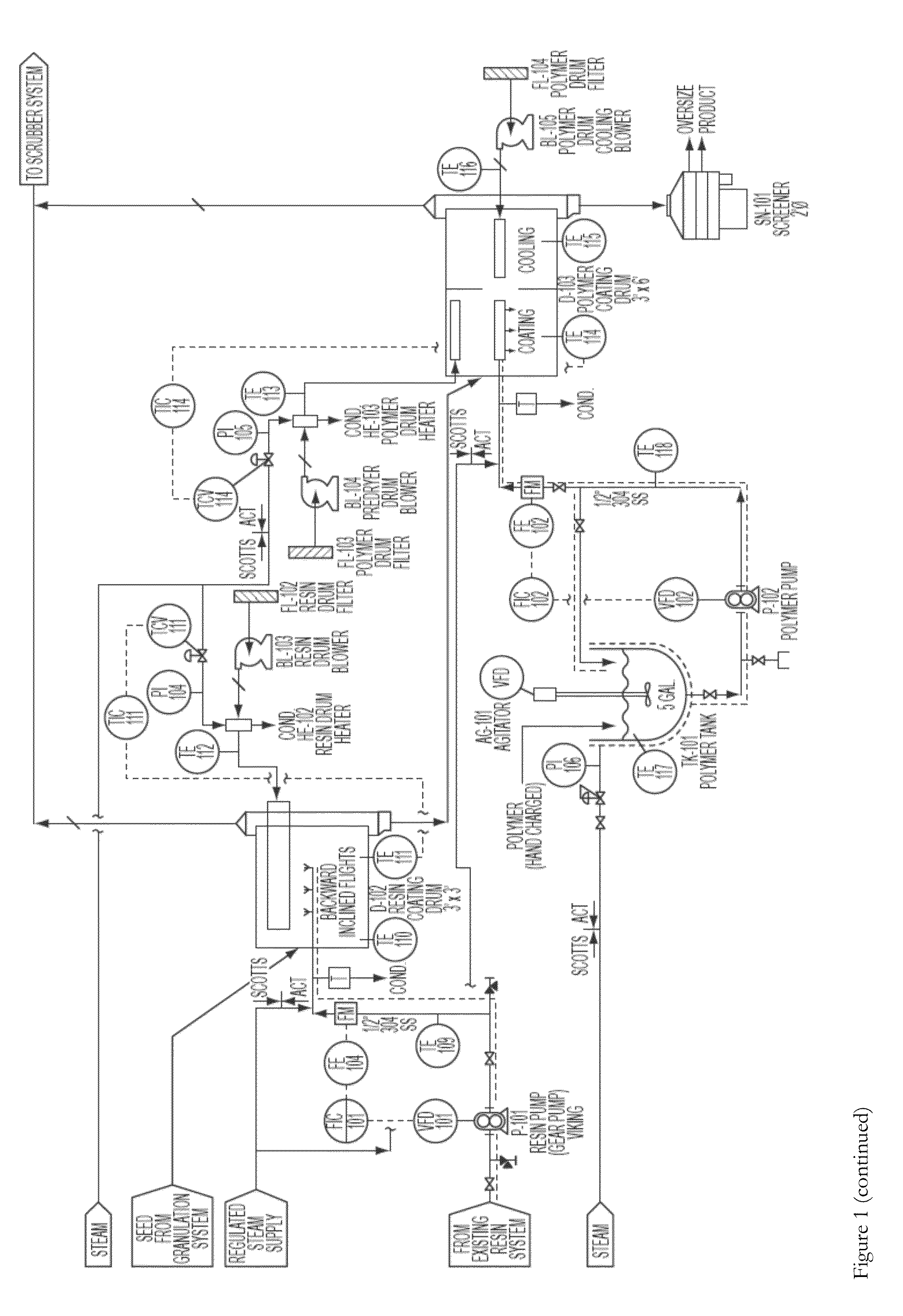

Large-scale continuous energy-saving fluidized bed spray granulation drying process

InactiveCN102274703AAdaptableNo pyrolysis problemsDrying solid materials with heatGranulation by liquid drop formationPrillEngineering

The invention discloses a large-scale continuous energy-saving fluidized bed spray granulation drying process, which belongs to the granulation drying technology. The surface of the seed crystal particles in the granulation fluidized bed is dried under the combined heating of the hot air and the built-in heater. The discharged materials are first screened out of lumps and oversized particles, and then sent to the cooling fluidized bed After the discharged materials are screened, the materials larger than the qualified particle size are crushed by the crusher, and then returned to the granulation fluidized bed together with the material smaller than the qualified particle size as crystal seeds for re-granulation, and the qualified particle size is sent to the into the finished product silo. The invention has strong material adaptability, can obtain granular products with large specific gravity, high strength, good sphericity, uniform particle size, and is not easy to absorb moisture, and realizes continuous large-scale production. Pollution and other characteristics.

Owner:山东奥诺能源科技股份有限公司

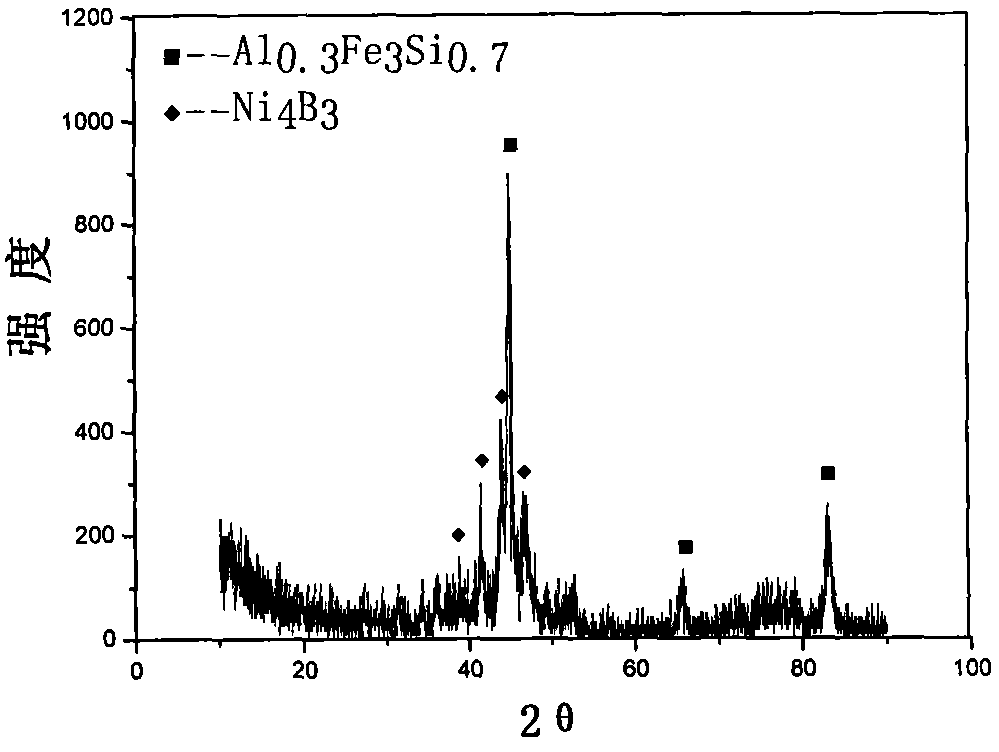

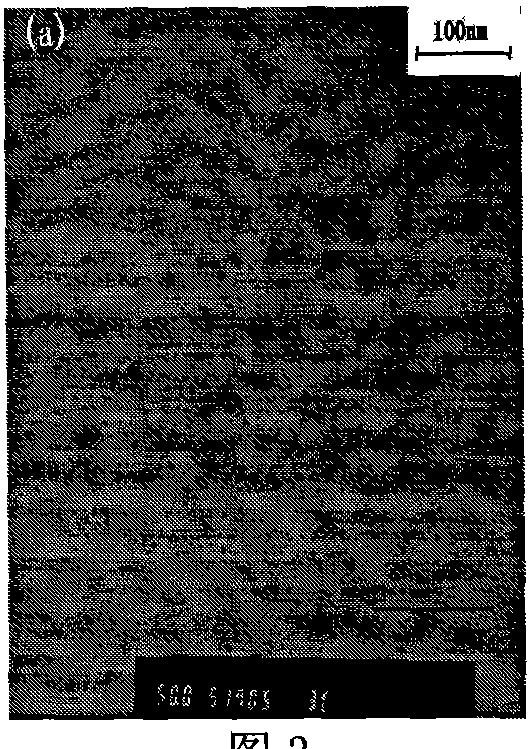

Fe-based amorphous nano-coating powder and its argon atomization production

A Fe-based amorphous nano-crystal spraying powder and its argon atomizing production are disclosed. The spraying powder consists of Cr 8-15wt%, Ni 8-16wt%, Si 2.8-5.7wt%, B 2.8-5wt%, W 2-8wt%, Mo 2-8wt%, Co 0.5-1wt%, Al 1-4wt% and Fe residues. The process is carried out by proportioning for ingredients, vacuum smelting, atomizing and screening powders. It has excellent fluidity and stability.

Owner:UNIV OF SCI & TECH BEIJING

Process For Producing Spherical Carbon Material

InactiveUS20070212610A1Good yieldGood sphericityAlkali metal halidesSecondary cellsNon aqueous electrolytesElectrode material

A process for producing a spherical carbon material, comprising: subjecting a spherical vinyl resin to an oxidation treatment in an oxidizing gas atmosphere to obtain a spherical carbon precursor, and carbonizing the spherical carbon precursor at 1000-2000° C. in a non-oxidizing gas atmosphere. The thus-obtained spherical carbon material exhibits excellent performances, including high output performance and durability, when used, e.g., as a negative electrode material for non-aqueous electrolyte secondary batteries.

Owner:KUREHA KAGAKU KOGYO KK

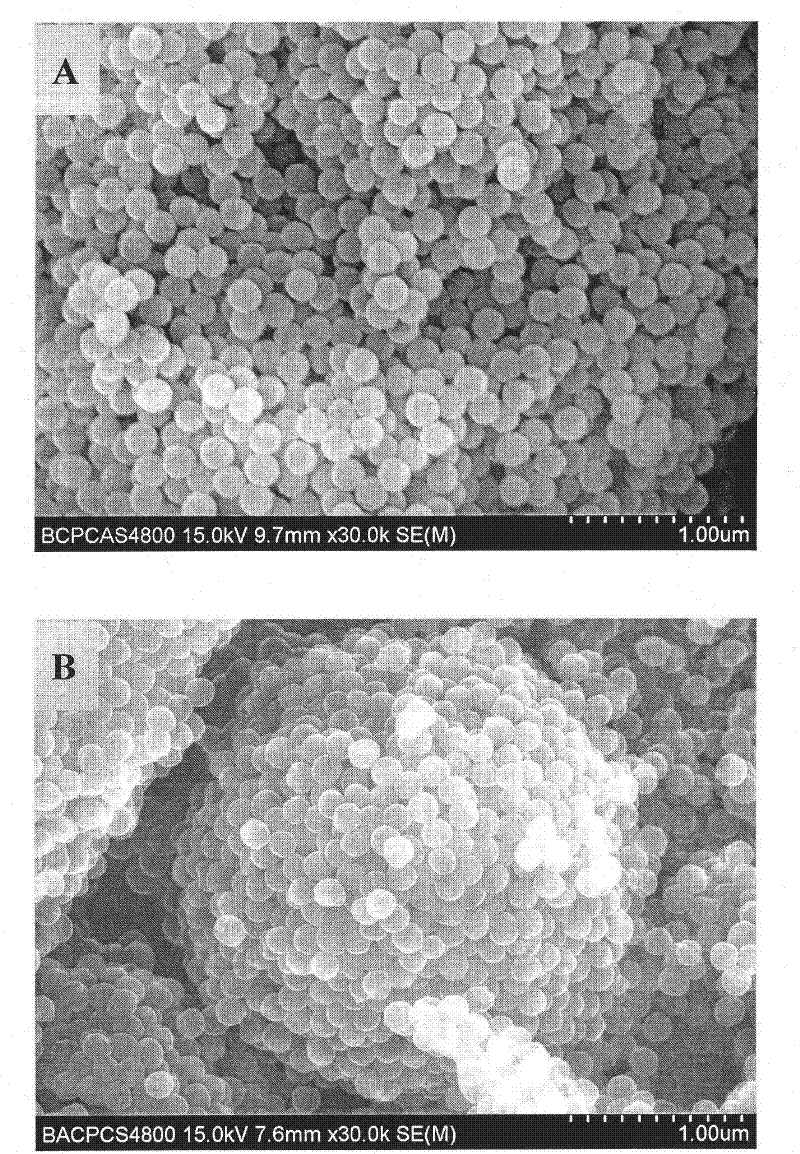

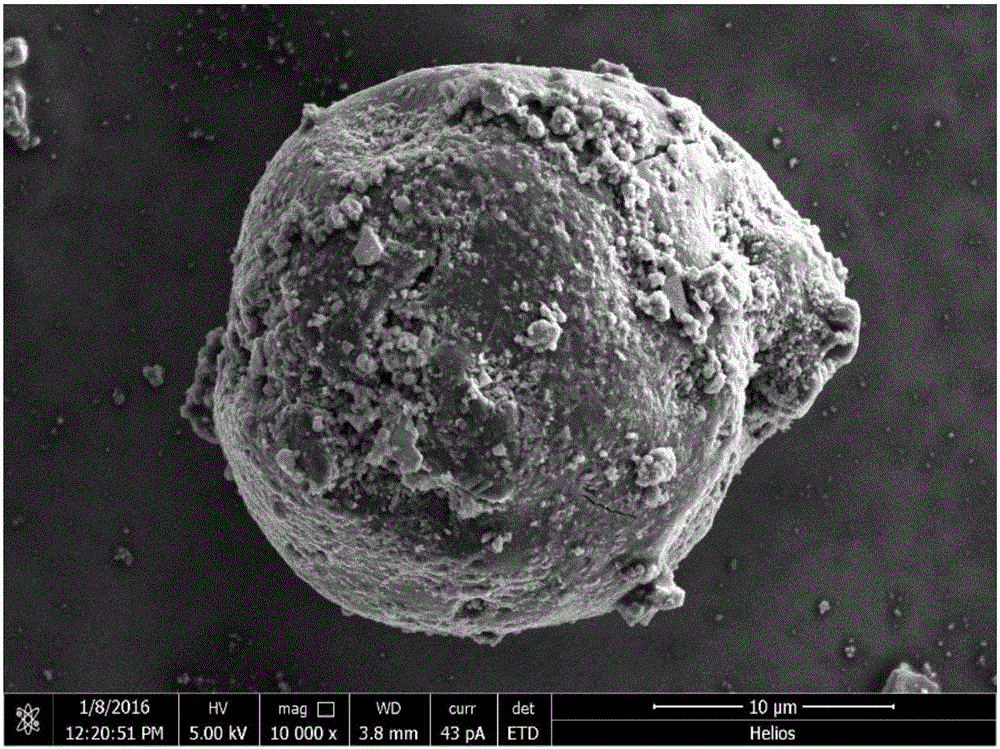

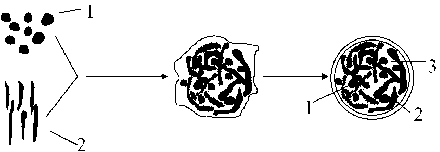

Silicon carbon composite microsphere, and preparation method and application thereof

ActiveCN106384825ASmall specific surface areaImprove cycle stabilityCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention provides a silicon carbon composite microsphere, and a preparation method and application thereof. The method comprises the following steps that (1) silicon dispersion liquid is prepared: 30 to 95 percent of asphalt and 5 to 70 percent of silicon are used as raw materials, and are dispersed in an organic solvent; ball milling is performed; (2) other carbon sources are added into grinding liquid; the ball milling is further performed; (3) the dispersion liquid obtained through the ball milling is added into a high-temperature high-pressure reactor; high-temperature high-pressure reaction is performed under the inert gas protection; (4) products obtained in the third step are subjected to suction filtration to obtain solid particles; (5) the solid particles obtained in the fourth step are subjected to high-temperature carbonizing treatment in inertia non-oxidizing atmosphere to obtain the silicon carbon composite microsphere. The method has the advantages that the asphalt and the micron silicon are used as raw materials; the raw materials are cheap and are easy to obtain; a dispersing agent is nontoxic and can be recovered; the process is simple; the sphericity degree of the obtained material is good; the tap density is high; the specific surface is small; a stable SEI membrane is favorably formed; the circulation stability is excellent.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

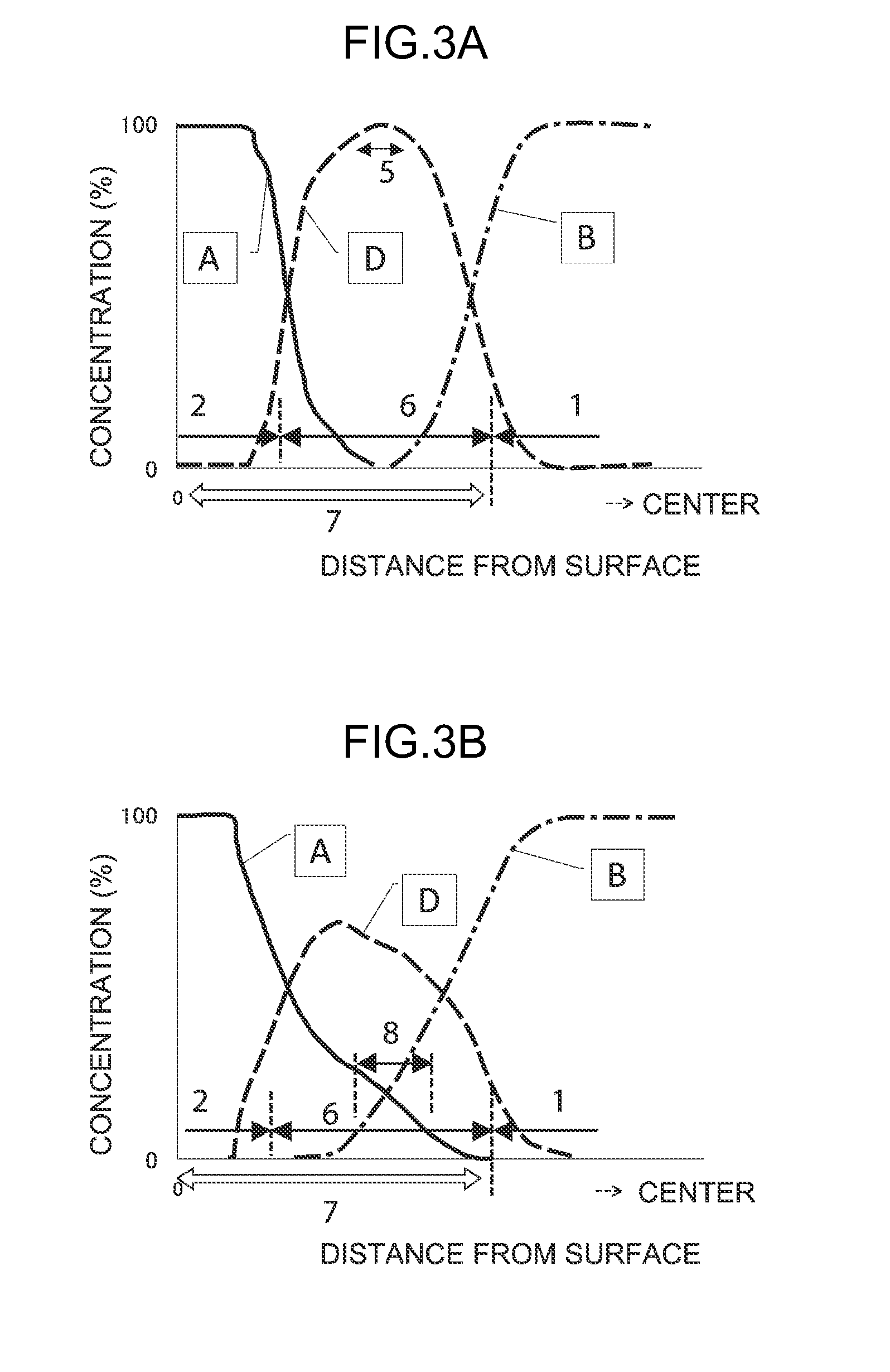

Bonding wire for semiconductor

ActiveUS20110120594A1Reduce tensionLarge spanSolid-state devicesWelding/cutting media/materialsWire rodHydrogen concentration

It is an object of the present invention to provide a multilayer wire which can accomplish both ball bonding property and wire workability simultaneously, and which enhances a loop stability, a pull strength, and a wedge bonding property. A semiconductor bonding wire comprises a core member mainly composed of equal to or greater than one kind of following elements: Cu, Au, and Ag, and an outer layer formed on the core member and mainly composed of Pd. A total hydrogen concentration contained in a whole wire is within a range from 0.0001 to 0.008 mass %.

Owner:NIPPON STEEL CHEMICAL CO LTD +1

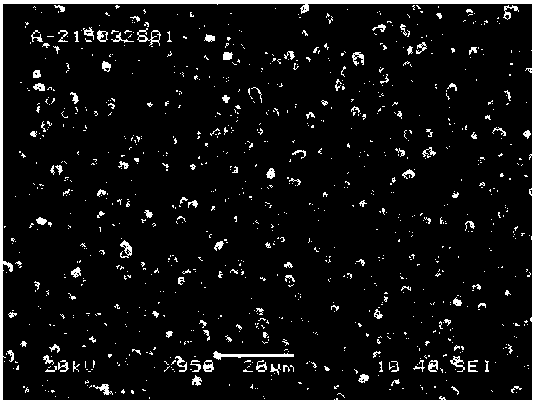

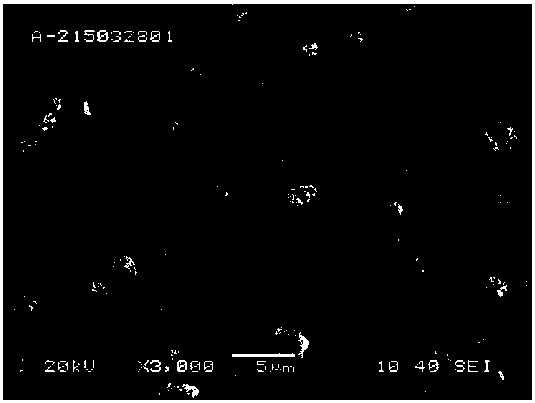

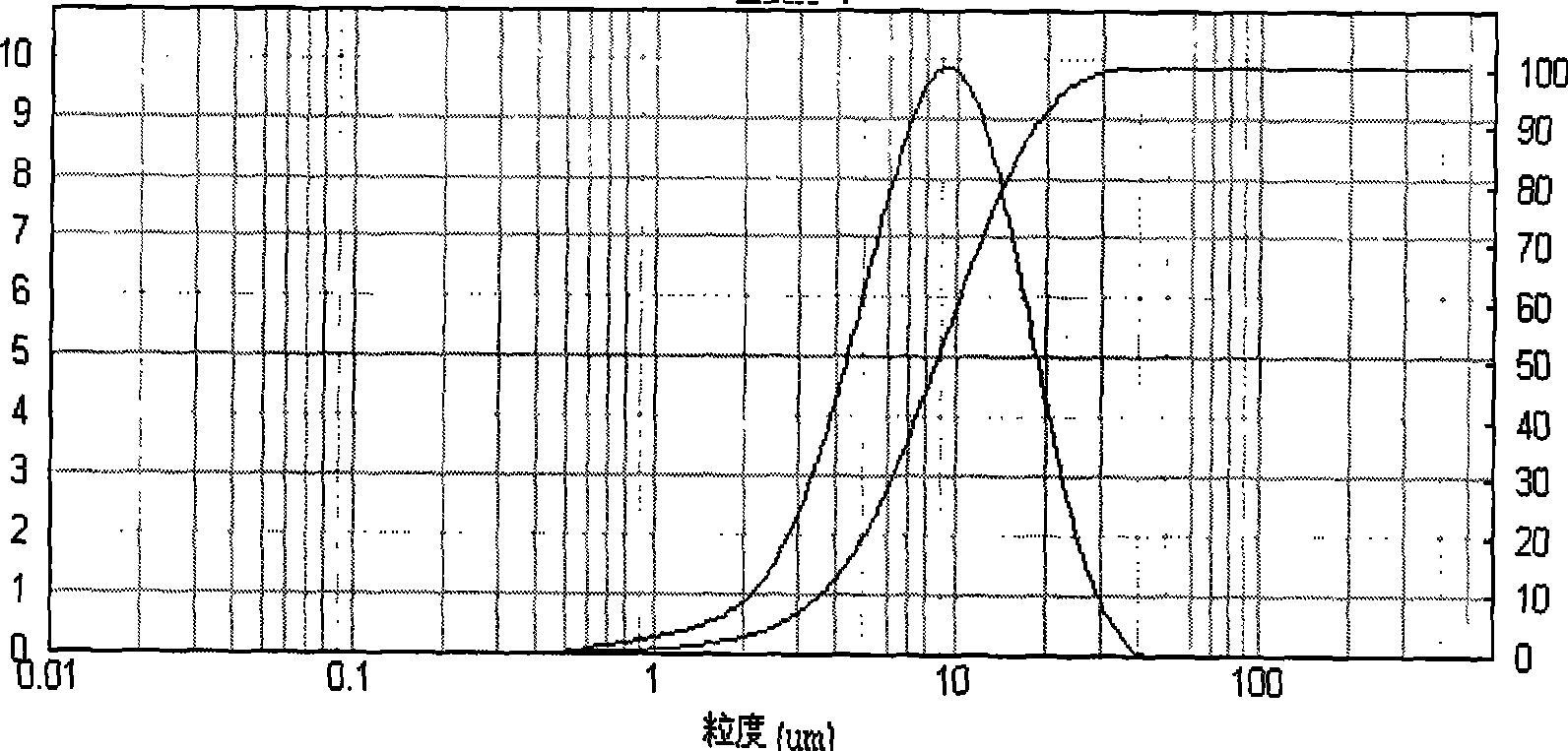

High-density and small-particle size nickel-cobalt-manganese hydroxide and preparation method thereof

InactiveCN107640792AHigh density and small tap densityLow tap densityCell electrodesSecondary cellsHigh densityManganese

The invention discloses a high-density and small-particle size nickel-cobalt-manganese hydroxide and a preparation method thereof. For the high-density and small-particle size nickel-cobalt-manganesehydroxide provided by the invention, a general chemical formula is NixCoyMnz(OH)2, wherein x+y+z=1, x is larger than or equal to 0.3 and smaller than or equal to 0.8, y is larger than or equal to 0.1and smaller than or equal to 0.4, and z is larger than or equal to 0.1 and smaller than or equal to 0.4; the particle sizes are d10 larger than or equal to 2 microns, d50 equal to 2.5-4 microns and d90 smaller than or equal to 6 microns, the tap density is larger than or equal to 1.4g / cm<3>, the specific surface area is 5-20m<2> / g, and the shape is spherical or spheroidal. The invention also discloses the preparation method of the high-density and small-particle size nickel-cobalt-manganese hydroxide. The preparation method is strong in controllability, can stably control the particle sizes ineach production batch without using a surfactant and is low in production cost, high in efficiency and good in physicochemical index of a final product.

Owner:ZHUJI PAWA NEW ENERGY

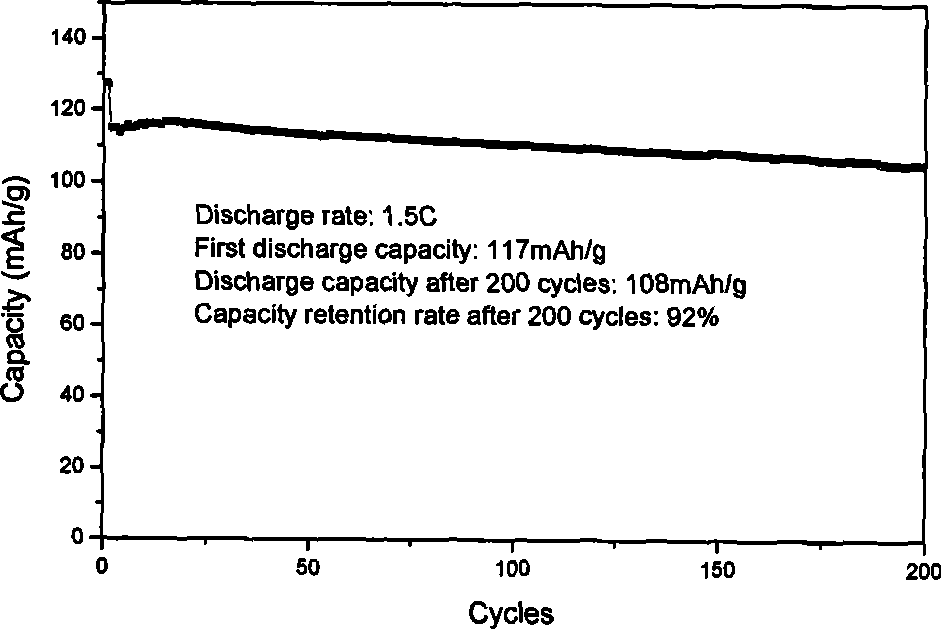

Method for preparing nickle lithium manganate material for lithium ion power battery anode

InactiveCN101465420AImprove electrochemical performanceGood sphericityElectrode manufacturing processesPower batteryManganate

The invention discloses a preparation method of nickel lithium manganate anode material LiNixMn2-xO4(x is more than 0 and is less than 1) and belongs to the preparing field of secondary battery materials. The preparing steps are that: nickel-source containing compound and manganese-source containing compound are firstly mixed according to chemometry, and then de-ionized water is added in the raw material mixture, and the solution is spray-dried for preparing the mixed powder; the mixed powder is mixed and sintered with the nickel-source containing compound, thus preparing the lithium ion battery anode material LiNixMn2-xO4(x is more than 0 and is less than 1). The method has simple and convenient process, short preparing time and low producing cost; the prepared product has stable structure, high specific capacity and good electrochemical performance; the method is suitable for large-scale industrial production of the lithium ion battery active material. The mean grain size of the product is 10mum and the initial discharge capacity thereof is 138mAh / g; after 200 times of 1.5C charge-discharge circulation, the capacity attenuation is less than 8 percent.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

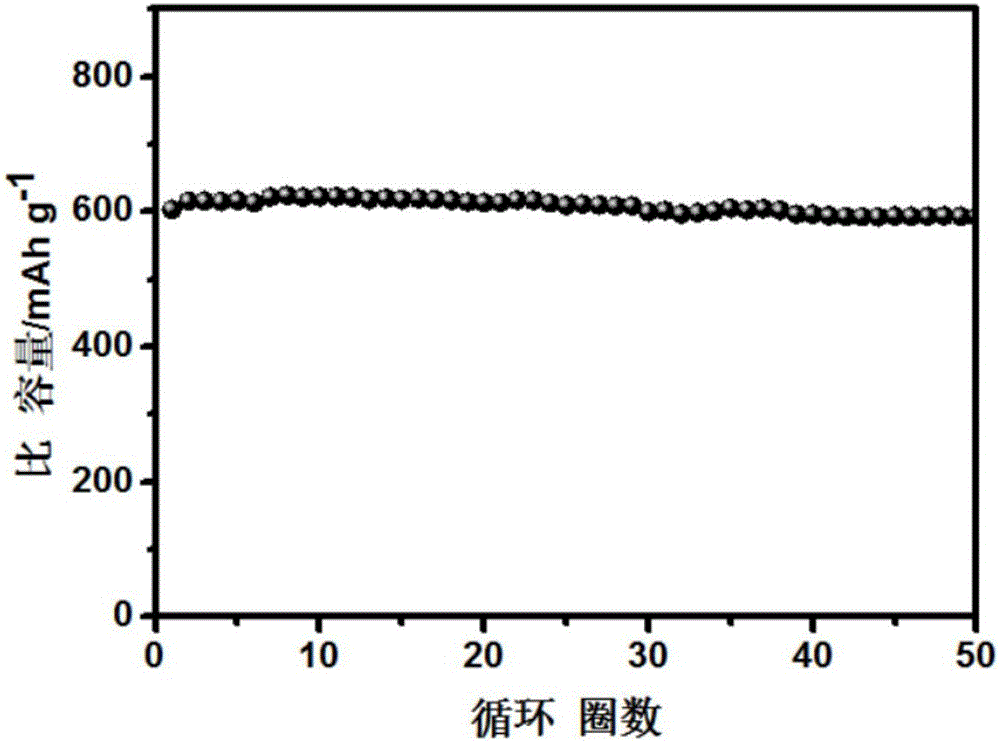

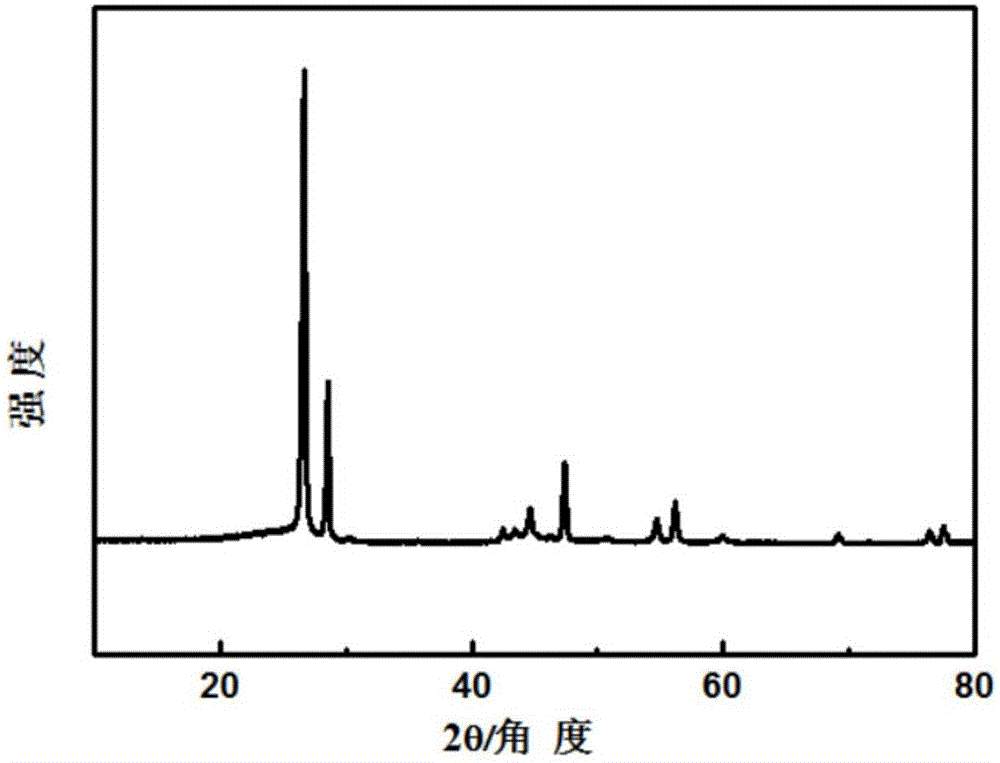

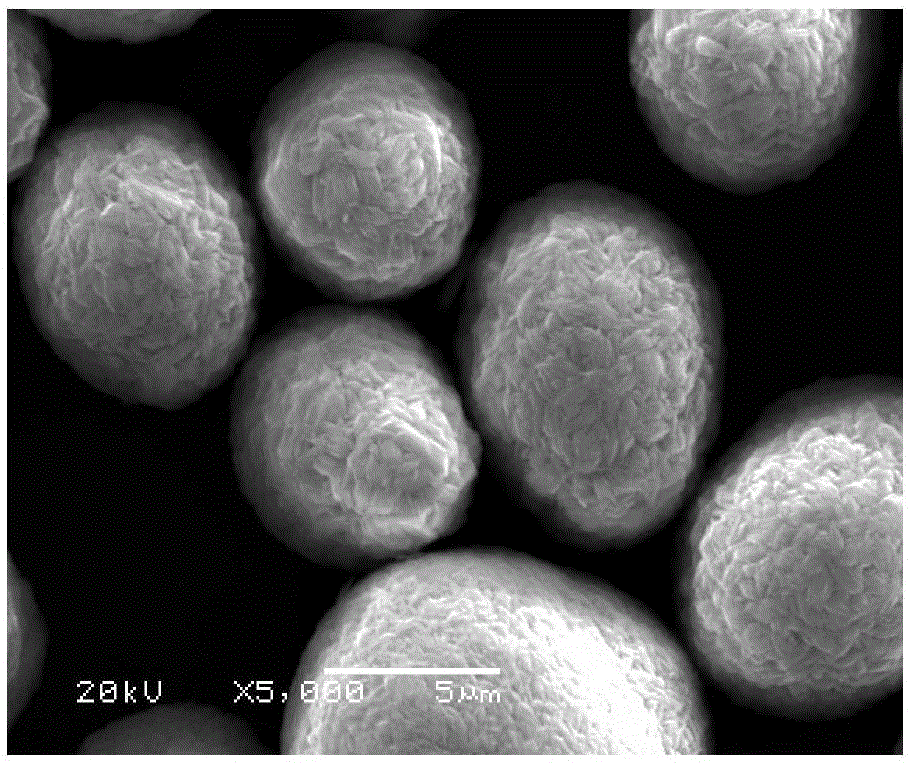

High-capacity nickel-cobalt-lithium manganate precursor and preparation method thereof

InactiveCN105118981AHigh tap densityConcentrated particle size distributionCell electrodesSecondary cellsManganateCharge discharge

The invention relates to a positive electrode material of a lithium ion battery, especially to a high-capacity nickel-cobalt-lithium manganate precursor and a preparation method thereof. The high-capacity nickel-cobalt-lithium manganate precursor is characterized by having a chemical formula of NixCoyMnz(OH)2, wherein x is no less than 0.5 and no more than 0.9, y is no less than 0.05 and no more than 0.2, z is no less than 0.05 and no more than 0.3, and x+y+z is equal to 1. The invention provides the high-capacity nickel-cobalt-lithium manganate precursor prepared through coprecipitation and the preparation method thereof; and the prepared precursor has concentratedly distributed particle size, high tap density, good sphericility, high specific capacity, low cost, long service life, higher discharge plateau and energy density, primary 1C charge-discharge specific capacity of 195 mA.h / g and 186.5 mA.h / g, and capacity retention ratio of 95.6% after 50 cycles.

Owner:NINGXIA ORIENT TANTALUM IND

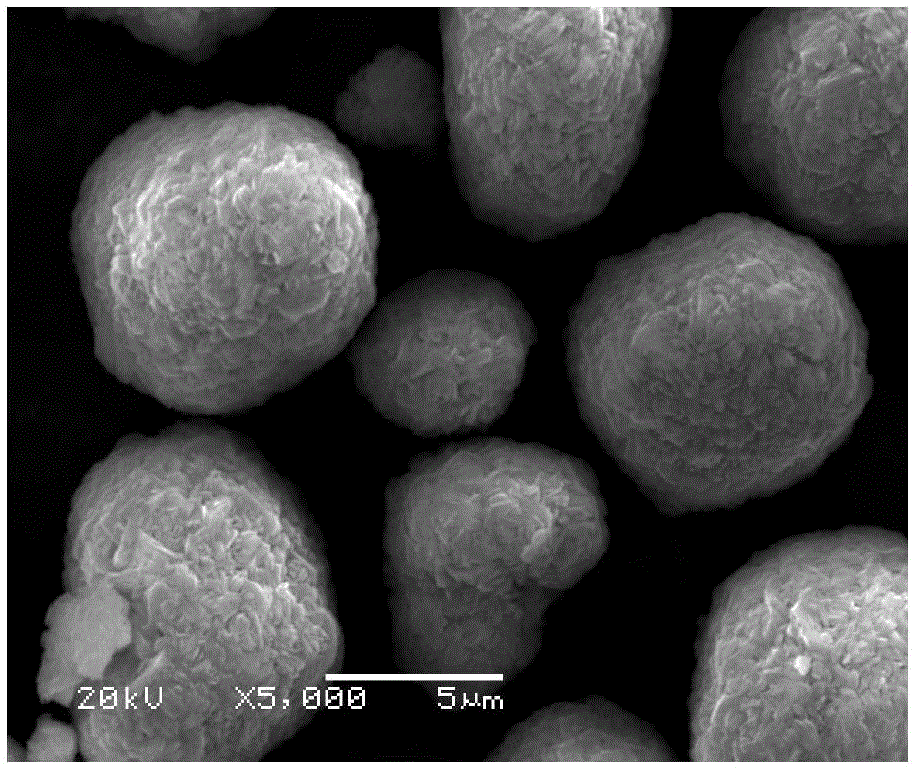

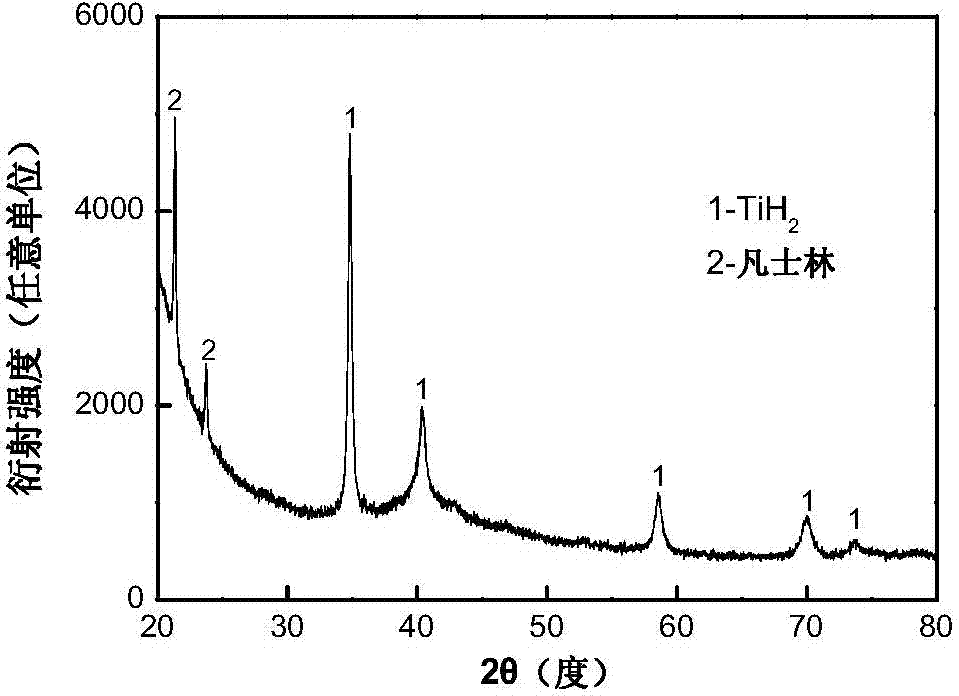

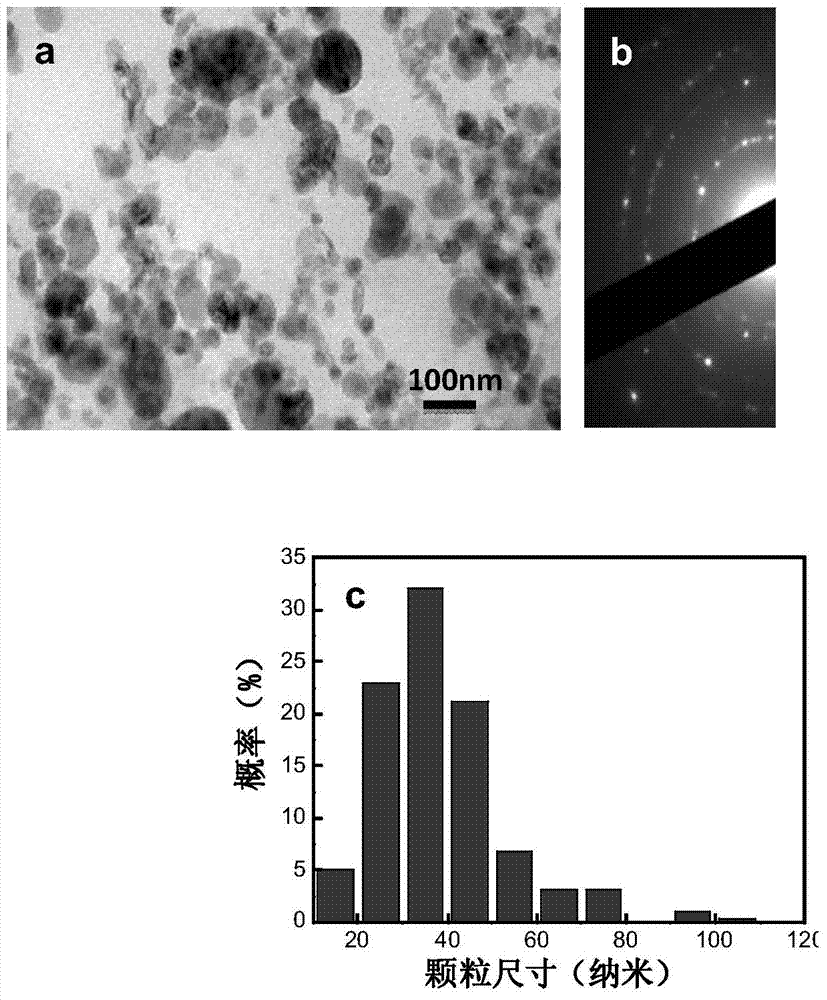

Preparation method of fine-particle spherical titanium powder for three-dimensional (3D) printing

The invention discloses a preparation method of fine-particle spherical titanium powder for three-dimensional (3D) printing and belongs to the technical field of preparation of metal powder. The method comprises the following steps: firstly, by using a high-purity titanium block material as a raw material, performing arc evaporation under an inert gas environment, and meanwhile, charging hydrogen to synthesize titanium hydride nano powder through a gas-phase reaction; secondly, agglomerating and granulating the titanium hydride nano powder to obtain micron-sized titanium hydride powder with higher density; finally, performing heat treatment on the granulated micron-sized titanium hydride powder, and performing degumming, dehydrogenation and compacted consolidation to obtain pure-titanium powder particles of which the particle size, the sphericity and the fluidity meet a 3D printing requirement. According to the method, the sphericity and the particle size distribution of the titanium powder particles are highly controlled; the process is simple, and the cost is low; metal titanium with great activity is stabilized in a new way of generating oxidation-resistant titanium hydride nano powder particles firstly, and the content of oxygen in the titanium powder particles which are finally prepared can be controlled.

Owner:BEIJING UNIV OF TECH

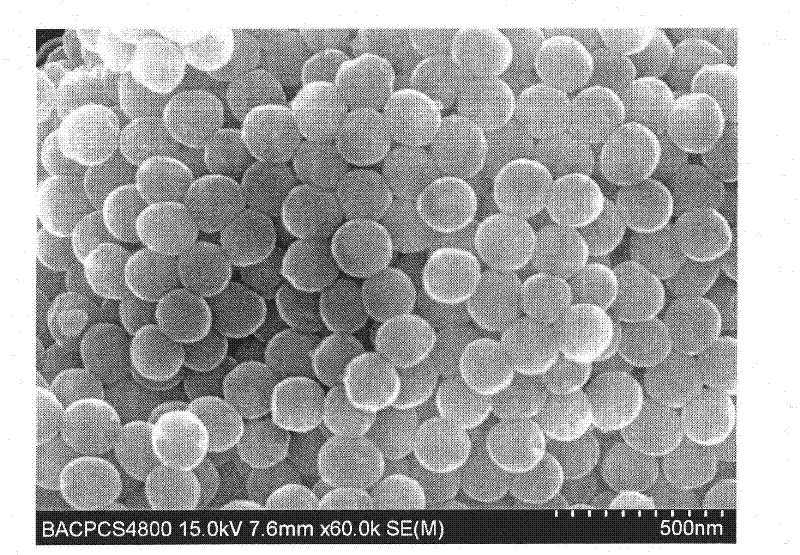

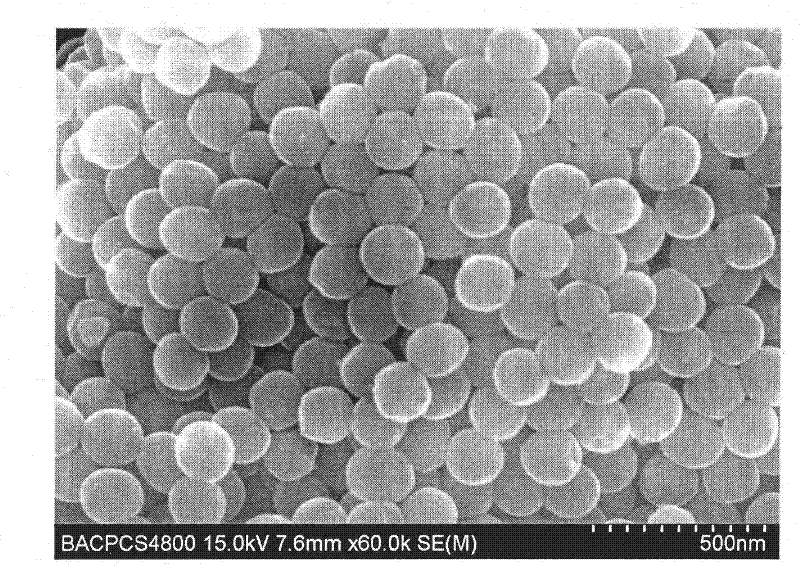

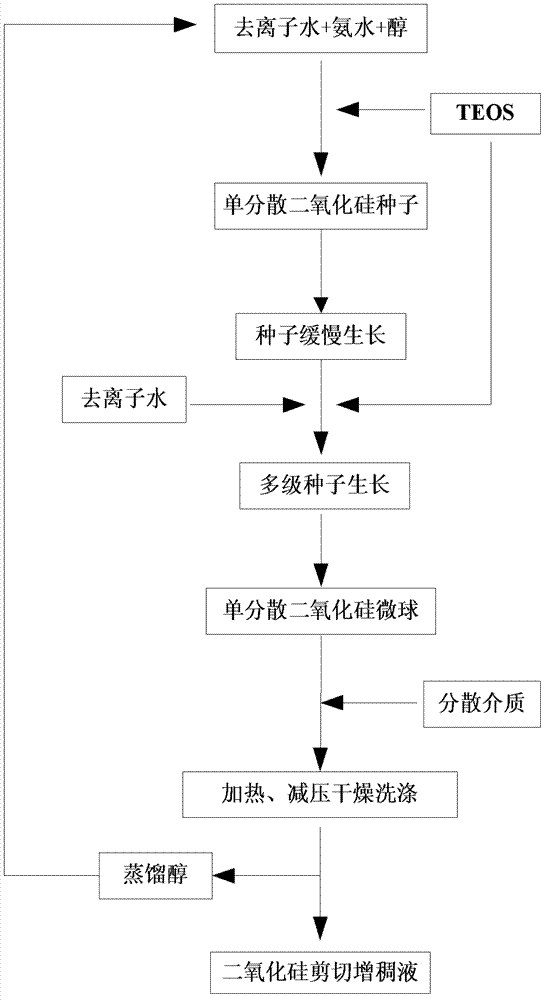

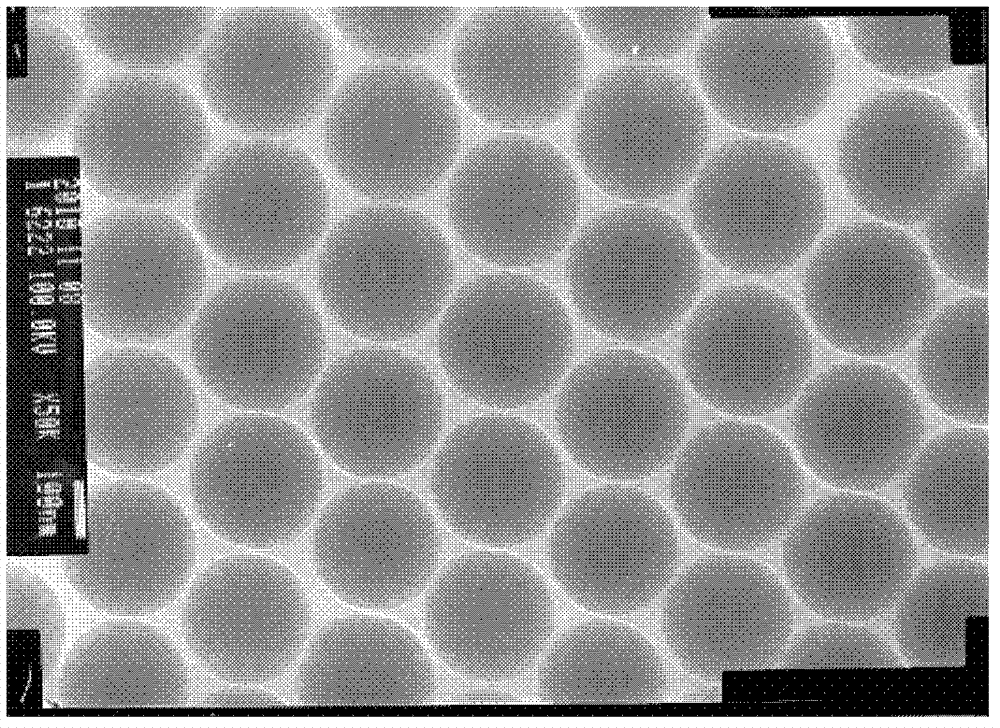

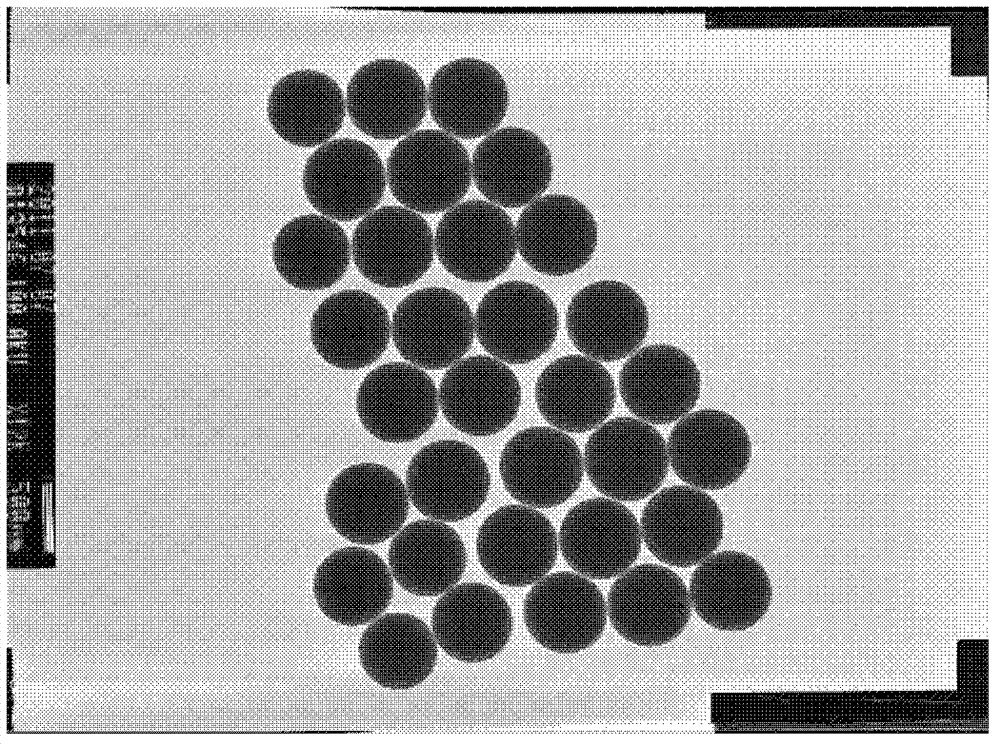

Preparation method of silica shear thickening liquid

The invention discloses a preparation method of a silica shear thickening liquid. The preparation method comprises the following steps of: preparing monodisperse silica microspheres with certain grain size in an alcohol-water mixed liquid according to a multi-level seed growth method by utilizing tetraethoxysilane serves as a raw material and ammonia as a catalyst; after reaction is finished, adding shear thickening liquid dispersion media (polyethylene glycol, glycerol and the like) into a SiO2 suspension liquid; after mixing uniformly, removing ethanol, water and ammonia from the mixed liquid by adopting a heating and pressure-reducing method to finally prepare the silica shear thickening liquid, wherein the ethanol which is collected under reduced pressure can serve as a solvent and can be reused. In the preparation method, the SiO2 microspheres exist in the form of a uniformly dispersed suspension liquid from the synthesis link to the preparation link of the shear thickening liquid, so the agglomeration phenomenon of powder in drying and redispersion processes is avoided, and the stability and rheological property of the shear thickening liquid are improved.

Owner:浩华科技实业有限公司

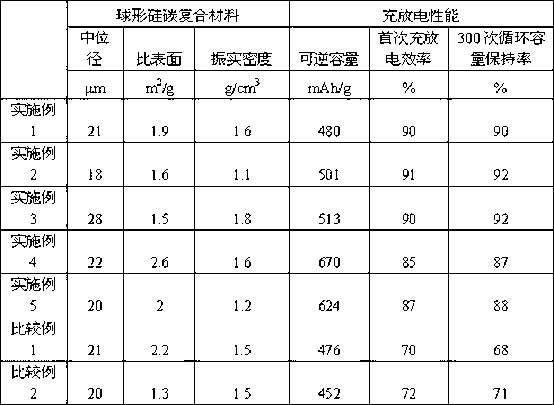

Spherical silicon carbon composite anode material of lithium ion battery and preparation method for spherical silicon carbon composite anode material

InactiveCN102709566AHigh specific capacityGood sphericityCell electrodesCarbon compositesElectrical battery

The invention provides a spherical silicon carbon composite anode material of a lithium ion battery and a preparation method for the spherical silicon carbon composite anode material. The spherical silicon carbon composite anode material comprises 5 to 12 percent of silicon, 68 to 90 percent of graphite and the balance of carbon material. A spherical precursor is prepared from silicon powder, flake graphite and the carbon source material by a constant-temperature mixing technology; and the spherical silicon carbon composite anode material is prepared by balling high-temperature thermal treatment, wherein the core of spherical silicon carbon composite anode material is anisotropically distributed and the surface of the flake / carbon is wrapped by the carbon material. In the spherical silicon carbon composite anode material, the reversible capacity can reach more than 480 Ah / g; the sequential efficiency at the first time can reach over 85 percent; and the capacity retention rate after circulation is performed for 300 times is more than 87 percent.

Owner:力芯(青岛)新能源材料有限公司

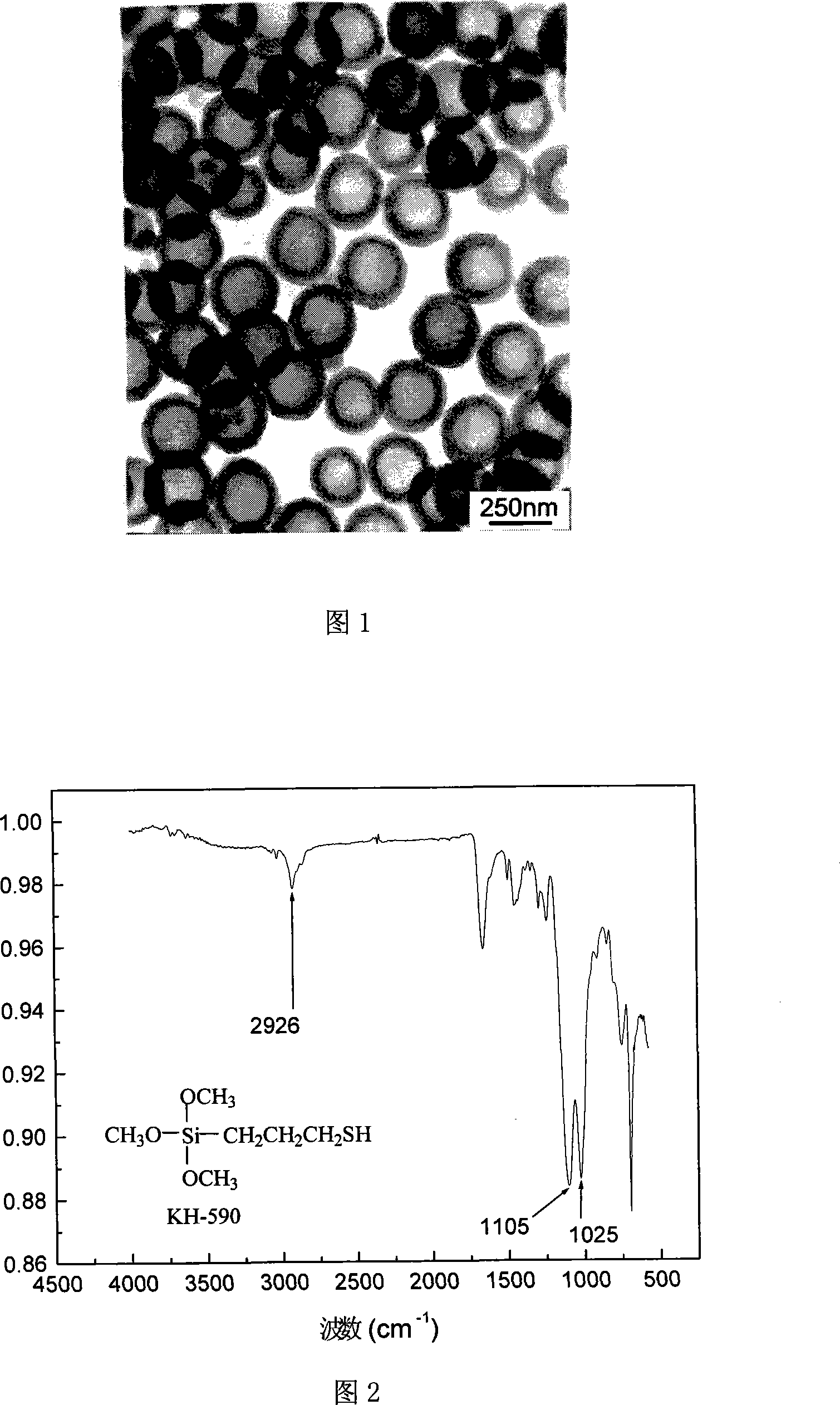

Method of producing hollow silicon dioxide microsphere with mercapto on internal and external surfaces

The invention belongs to the technical field of the polymeric material, in particular relates to a preparation method of hollow silicon dioxide spherical particles with mercapto on the internal and the external surfaces. The invention uses polystyrene spherical particles with positive charges on the surface as a module, under the system of ethanol or water and with ammonia as a catalyst and an etching agent, causing the hydrolytic condensation of a coupling agent with the mercapto on the surface of the polystyrene spherical particles, thus a silicon dioxide shell is formed and the polystyrene spherical particles are eliminated, finally the silicon dioxide shell with the mercapto is formed on the internal and the external surfaces. The invention has simple operation, avoids high-temperature calcinations and reagent etching in the traditional preparation process of inorganic and hollow spherical particles. Because the hollow silicon dioxide spherical particles have the mercaptos on the internal and the external surfaces, the hollow spherical particles with sulfonic groups on the internal and the external surfaces can be formed through oxidization with oxidizer, and can be not only a solid acid catalyst, but also be a modifier for a hydrated proton exchange membrane.

Owner:TONGJI UNIV

Preparation method for nickel-base superalloy powder for laser forming

ActiveCN108941588AHigh sphericityHigh yieldAdditive manufacturing apparatusTransportation and packagingOxygen contentHot Temperature

The invention discloses a preparation method for nickel-base superalloy powder for laser forming, and belongs to the field of superalloy and powder metallurgy. According to the preparation method, vacuum induction melting and argon atomization powder making technologies are adopted, and the nickel-base superalloy powder suitable for laser forming is prepared. The nickel-base superalloy powder prepared through the method is high in small grain size powder, high in degree of sphericity, low in oxygen content, good in flowing performance, free of hollow defects, less in satellite powder and capable of meeting the technical requirement for laser forming.

Owner:CENT SOUTH UNIV

Multi-purpose lignin-carbohydrate binding system

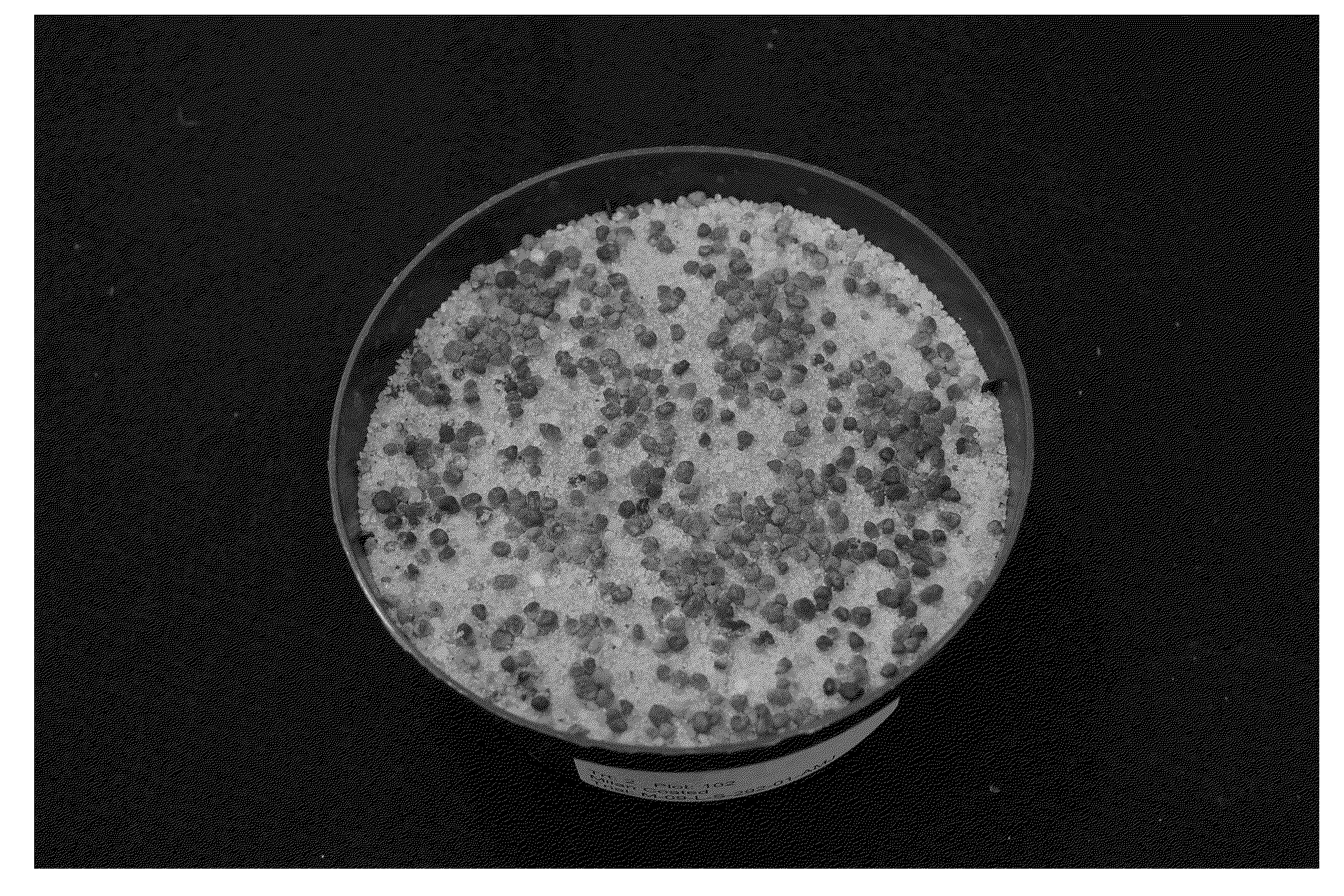

InactiveUS20140235438A1Improve crush resistanceHigh hardnessCalcareous fertilisersBiocideDual purposeGermination

The present invention relates to a novel, dual purpose binder formulation or system. The invention also relates to a process of agglomerating dispersed particles or fines into substantially spherical and crush resistant granules. The invention further relates to a method of covering a seed and binding the seed with a material mixture beneficial for seed germination. The invention also relates to an all-in-one seed agglomerated by the dual purpose binder formulation.

Owner:OMS INVESTMENTS INC

Preparation method for fine metal powder and equipment achieving method

The invention provides a preparation method for fine metal powder and equipment achieving the method. On the one hand, metal materials are fused and atomized into liquid drops to be sprayed to a high-speed rotation disc and smashed into small liquid drops, and the center spraying axis of the liquid drops is perpendicular to the rotation disc face; on the other hand, the liquid drops sprayed to the high-speed rotation disc are cooled after being smashed, and the metal powder is obtained. Compared with the prior art, the metal powder prepared through the method is fine in grain size, good in degree of sphericity and narrow in grain size distribution range and has good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com