Method for preparing polymer micro balls with uniform grain diameter and controllable size

A polymer, homogeneous technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of complex experimental equipment and high cost, and achieve the effects of simple equipment, smooth appearance and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

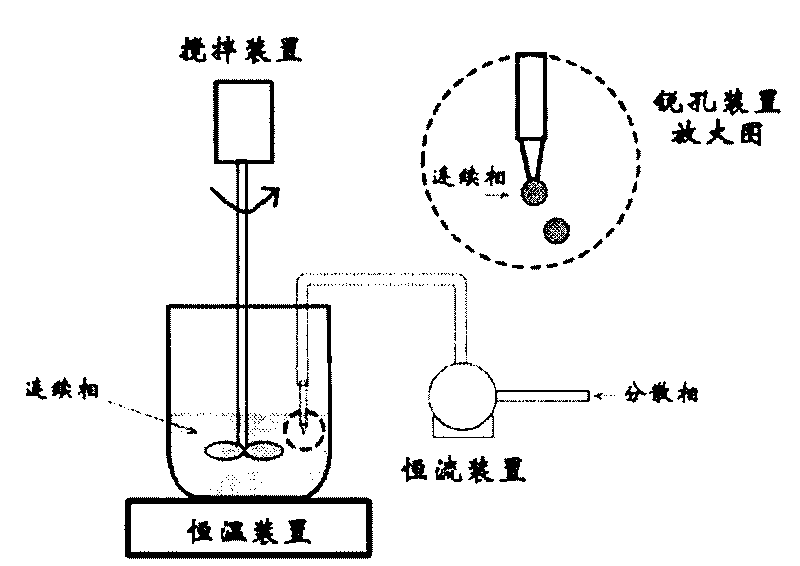

[0018] Embodiment 1: Preparation of polylactic acid microparticles

[0019] A certain mass of polylactic acid (molecular weight: 22,000) was weighed and dissolved in methylene chloride to obtain a dispersed phase with a concentration of 0.5% g / ml. A certain mass of polyvinyl alcohol-124 was weighed and dissolved in water to obtain a continuous phase with a concentration of 0.1% g / ml. Measure 250ml of the continuous phase into the reactor, and adjust the temperature of the continuous phase to 20°C with a constant temperature device. Turn on the stirring device and adjust the rotating speed to 100 rpm. Turn on the constant flow device, so that the injection rate of the dispersed phase is 0.5ml / min, the injection volume of the dispersed phase is 10ml, and the inner diameter of the orifice is 10μm. After the injection of the dispersed phase is completed, the stirring is continued for 0.5 hour, so that the droplets of the dispersed phase are solidified into polylactic acid micros...

Embodiment 2

[0020] Embodiment 2: Preparation of polylactic acid microparticles

[0021] A certain mass of polylactic acid (molecular weight 8000) was weighed and dissolved in ethyl acetate to obtain a dispersed phase with a concentration of 10.0% g / ml. A certain mass of polyvinyl alcohol-124 was weighed and dissolved in water to obtain a continuous phase with a concentration of 5.0% g / ml. Measure 1000ml of the continuous phase into the reactor, and adjust the temperature of the continuous phase to 50°C with a constant temperature device. Turn on the stirring device and adjust the rotating speed to 1000rpm. Turn on the constant flow device so that the injection rate of the dispersed phase is 10.0ml / min, the injection volume of the dispersed phase is 10ml, and the inner diameter of the orifice is 300μm. After the injection of the dispersed phase is completed, the stirring is continued for 4.0 hours, so that the droplets of the dispersed phase are solidified into polylactic acid microspher...

Embodiment 3

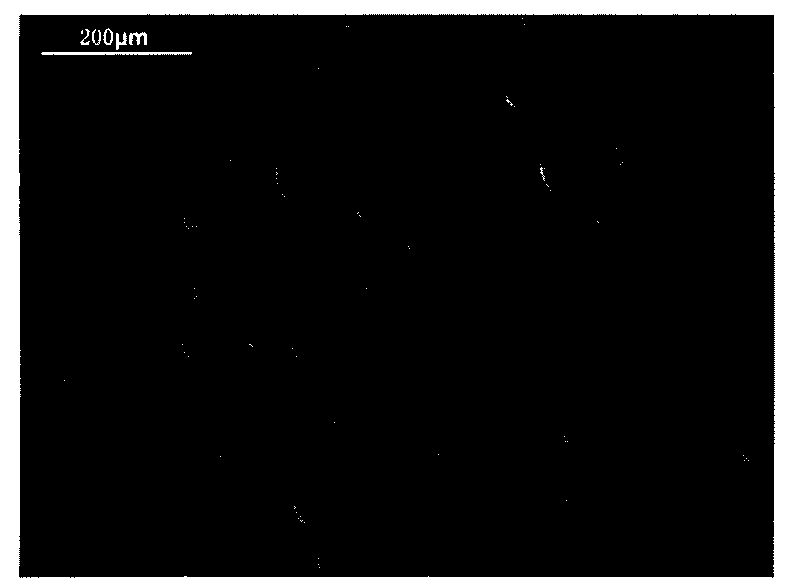

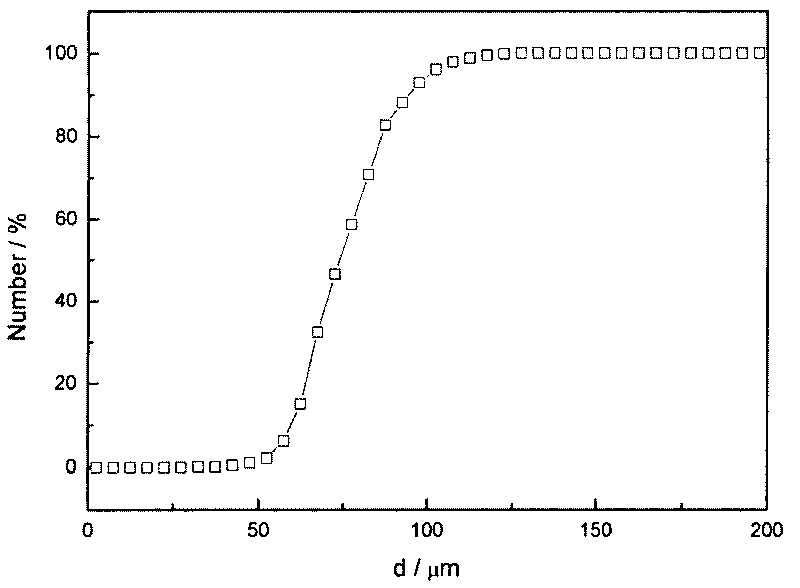

[0022] Embodiment 3: Preparation of polylactic acid microparticles

[0023] A certain mass of polylactic acid (molecular weight: 22,000) was weighed and dissolved in methylene chloride to obtain a dispersed phase with a concentration of 4.0% g / ml. A certain mass of polyvinyl alcohol-124 was weighed and dissolved in water to obtain a continuous phase with a concentration of 1.0% g / ml. Measure 600ml of the continuous phase into the reactor, and adjust the temperature of the continuous phase to 35°C with a constant temperature device. Turn on the stirring device and adjust the rotating speed to 300rpm. Turn on the constant flow device so that the injection rate of the dispersed phase is 1.0ml / min, the injection volume of the dispersed phase is 10ml, and the inner diameter of the orifice is 200μm. After the injection of the dispersed phase is completed, the stirring is continued for 1 hour, so that the droplets of the dispersed phase are solidified into polylactic acid microsphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com