Patents

Literature

179 results about "Double curvature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

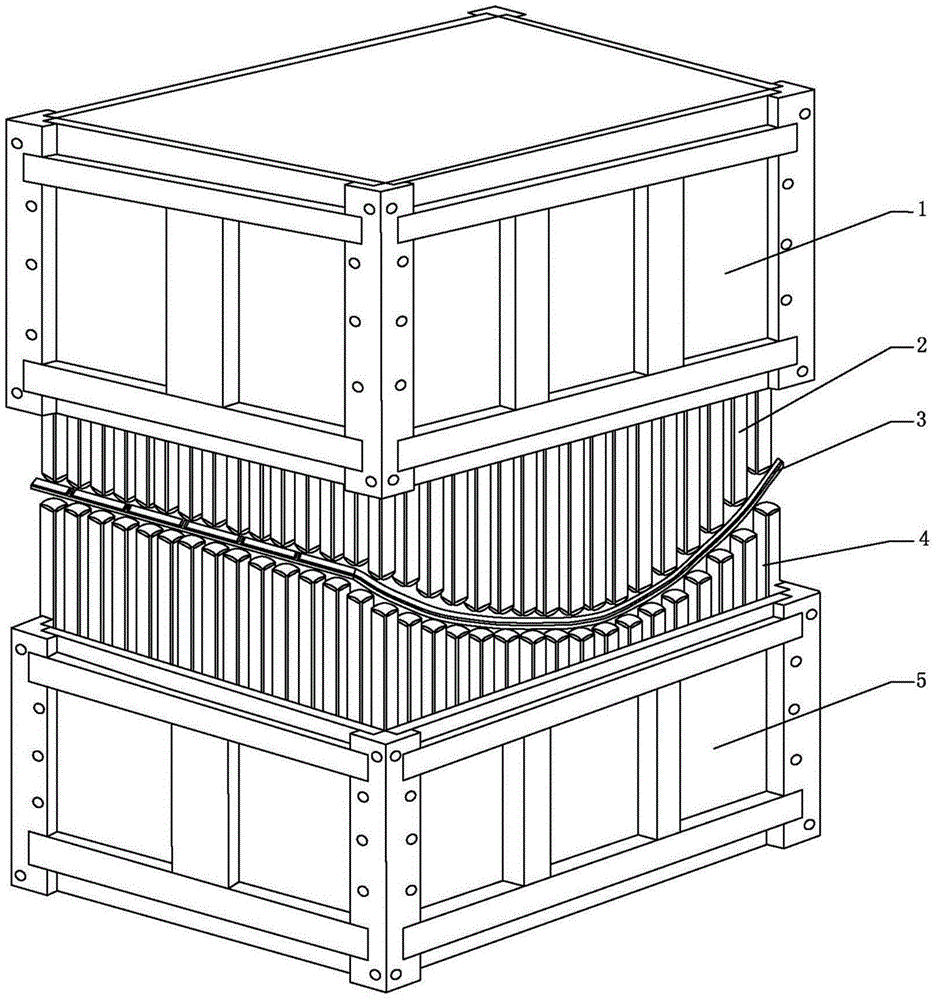

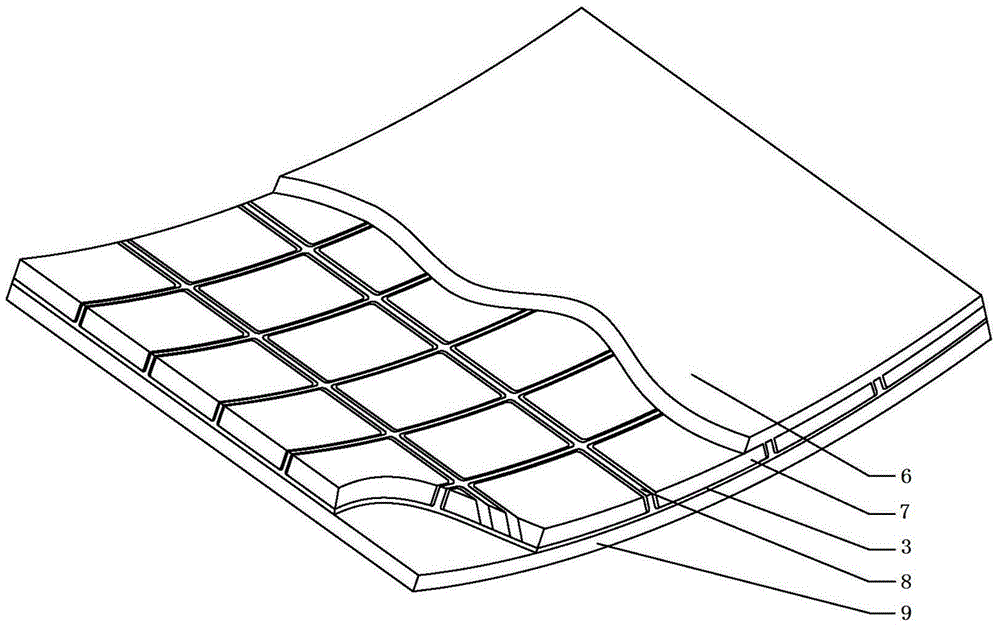

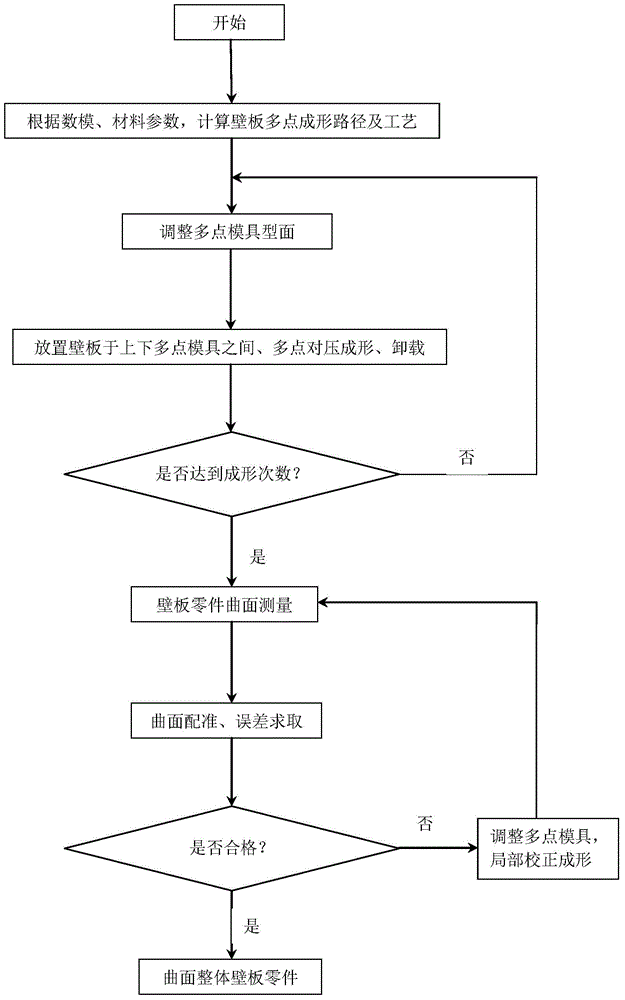

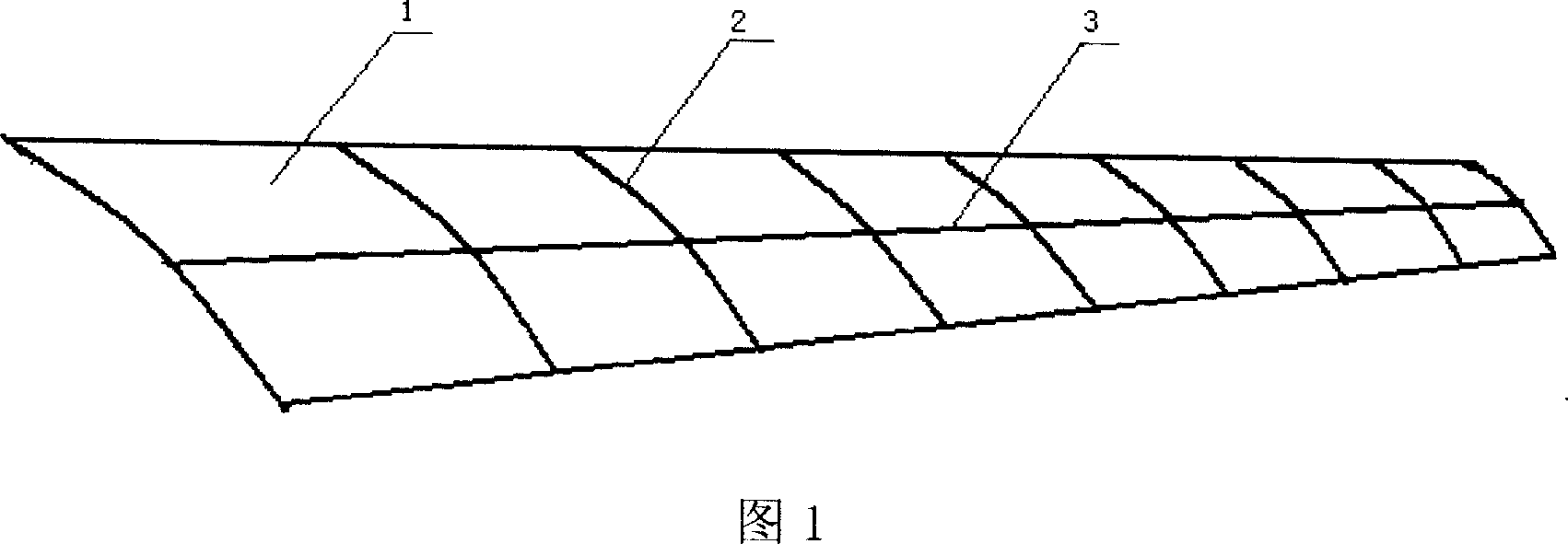

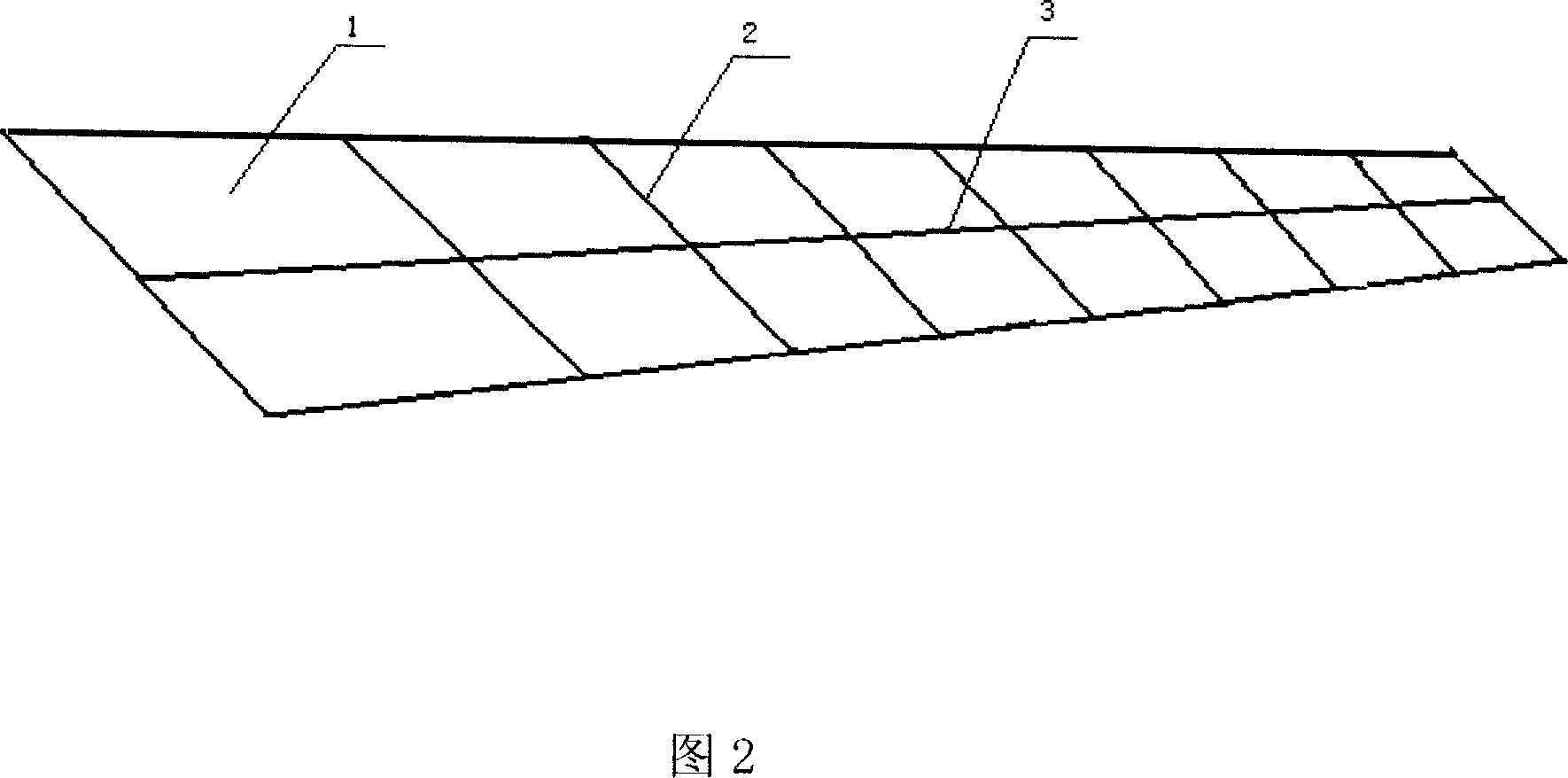

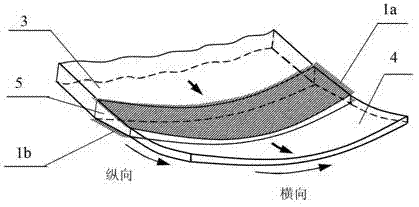

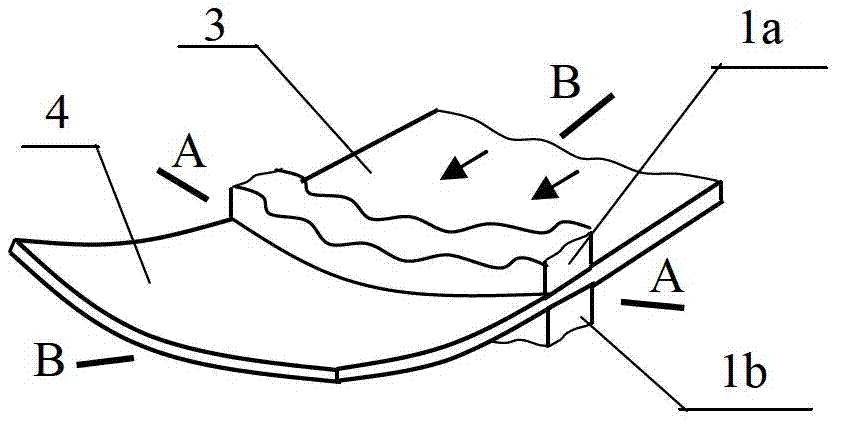

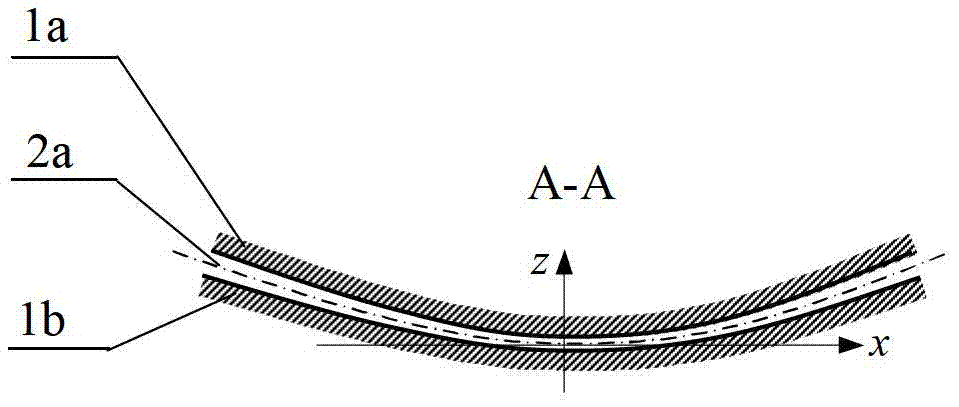

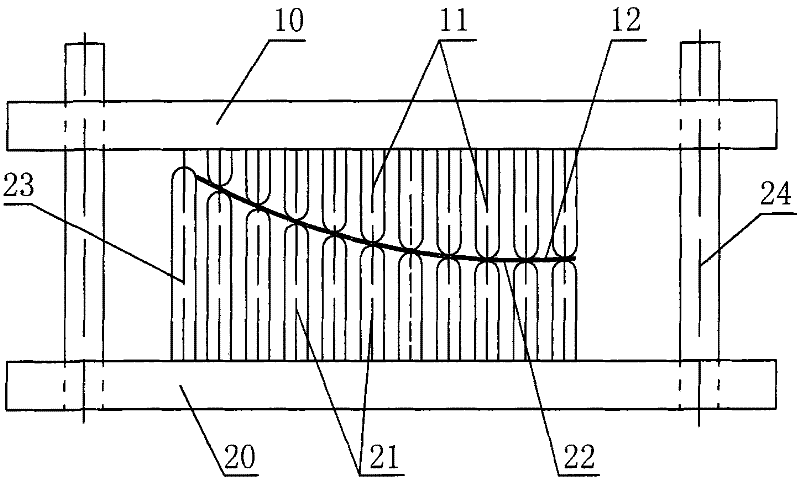

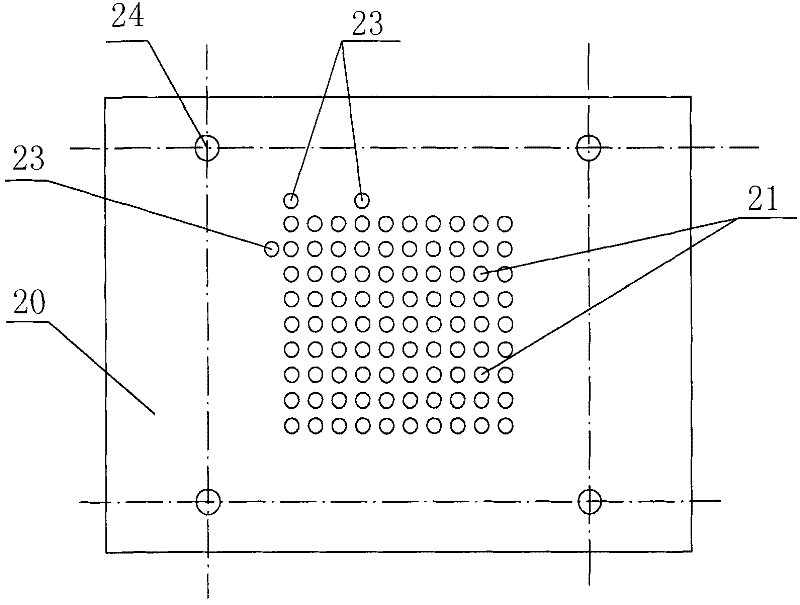

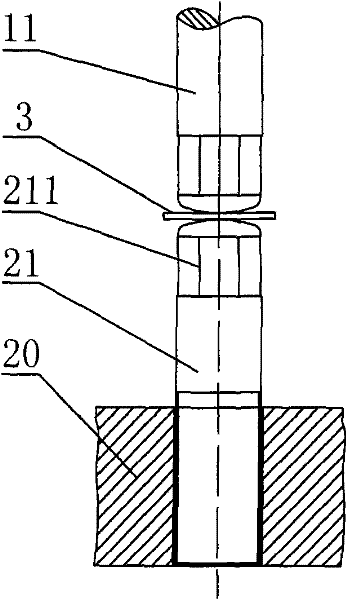

Multi-point forming method for whole aluminum alloy wall plate of aircraft

InactiveCN104646475ASolve efficiency problemsSolve the problem that cracks are prone to occur and cause the overall wall panel to be scrappedShaping toolsMetal working apparatusRocketDouble curvature

The invention discloses a multi-point forming method for a whole aluminum alloy wall plate of an aircraft. The multi-point forming method comprises the following steps of arranging the whole aluminum alloy wall plate with ribs between an upper multi-point die and a lower multi-point die of a quick reconstructing die surface, filling a filling material between the ribs, arranging an elastic cushion between the wall plate and the multi-point die, and gradually forming a whole aluminum alloy wall plate part with ribs by a die pressing method along a controllable deformation path. The multi-point forming method has the advantages that by utilizing the quick and adjustable characteristic of the reconstructing multi-point die surface, the wall plate parts with different geometric shapes and double curvatures can be processed by one set of equipment; compared with the traditional rolling and bending forming method and the pressing and bending forming method, the stress of the wall plate is uniform, and the forming quality can be guaranteed; compared with the shot peen forming method and the aging forming method, the deformation amount is large, and the forming efficiency is high; the method can be used for forming the whole aircraft wall plate with different rib structures and the double curvatures, the problems of large size and high rib in the whole wall plate forming process are solved, and the method can be applied to the manufacturing of other large ribbed curvature parts of aircrafts, rockets and the like.

Owner:JILIN UNIV

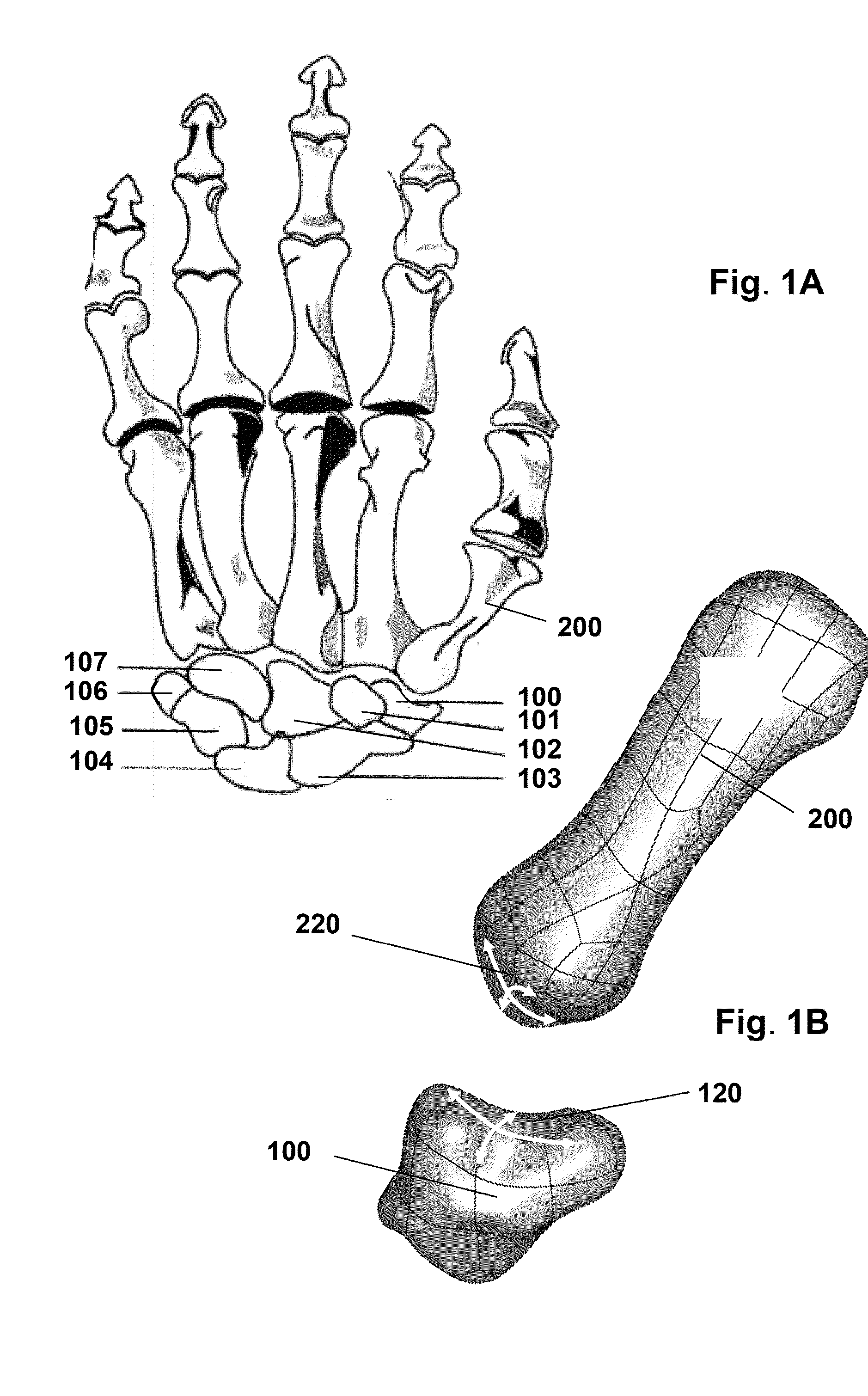

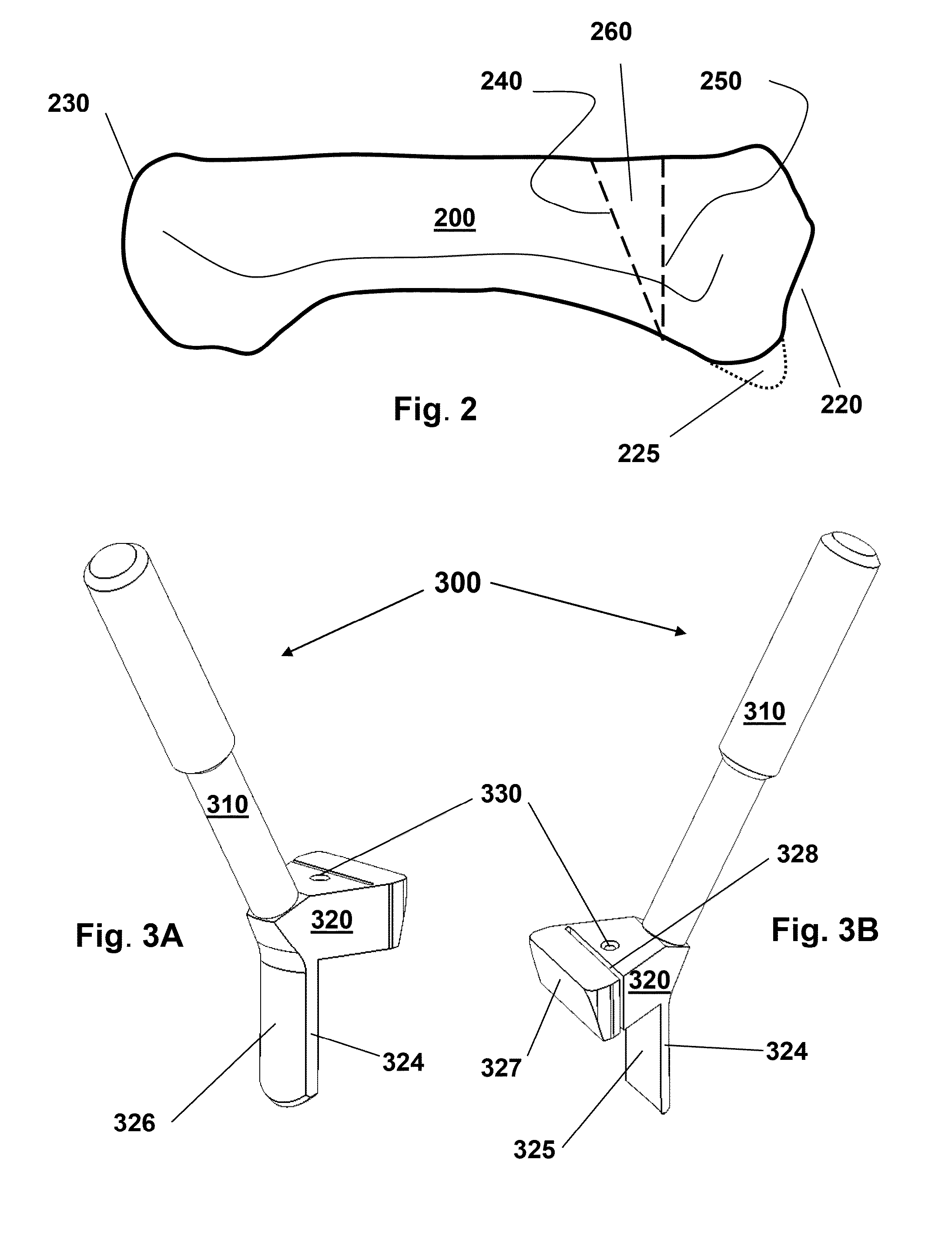

Devices, implements and methods for the treatment of a multi-axis joint

Devices, implements and methods are provided for performing trapezioplasty of the osteoarthritic trapezium. Once a palmar osteophyte has been removed from the trapezium bone, a trapezial rasp is used to shape the central portion of the trapezium bone into an initial saddle shape. A contouring tool having a double curvature reverse saddle shape is used to contour the trapezium bone into a final, smooth saddle shape.

Owner:SKELETAL DYNAMICS LLC (US)

Prestressing shot-blasting formation technique for double-curved wallboard

A pre-stressing and grit-blasting technique for shaping a double-curvature plate wall used as the thick jacket of large airplane features that a pre-stressing fixture unit is used to pre-bend a plate longitudinally and transversely and fix it for applying a pre-stress to it while the grits are blasted onto said plate for obtaining a needed shape.

Owner:XIAN AIRCRAFT IND GROUP

Unfoldable reflecting mirror body based on double-curvature negative poisson ratio honeycomb structure

InactiveCN102768377AAchieve lightweight designReduce stress concentrationMirrorsControl systemMetallic materials

The invention relates to an unfoldable reflecting mirror body based on a double-curvature negative poisson ratio chiral honeycomb structure. The unfoldable reflecting mirror body consists of a laying layer and a double-curvature negative poisson ratio chiral honeycomb structural layer; and the structural layer has a paraboloid shape, and the internal surface of the structural layer is the laying layer. The structural layer is made from shape memory polymer materials, and the laying layer is made from metal materials and carborundum or carborundum-based composite materials. The unfoldable reflecting mirror body is used for solving the problems that an aerospace reflecting mirror cannot meet the use requirement on the high ratio of the unfolded volume to the contraction volume, and has low light weight degree, a small caliber and a complicated control system. The unfoldable reflecting mirror body has the functions of obtaining a higher ratio of the unfolded volume to the contraction volume, and repeated folding and unfolding for a plurality of times, can be unfolded at one time, and has a simple structure, high light weight degree, high system reliability and strong stability.

Owner:HARBIN INST OF TECH

Double curvature plate cold press forming method and equipment thereof

The present invention relates to double curvature plate cold pressing formation method and apparatus. The formation process includes the following steps: determining the rebound elasticity of cold pressed steel plate, determining the curvature radius and size of upper and lower working plates, setting plate material, cutting, pressing, etc. The formation apparatus includes upper pressing mold, lower pressing mold, reinforcing ribbed plates welded onto the top plate, upper working plate, lower working plate and bottom plate, and oil press. The present invention makes it possible to produce high quality double curvature plate with smooth surface.

Owner:中国船舶集团渤海造船有限公司

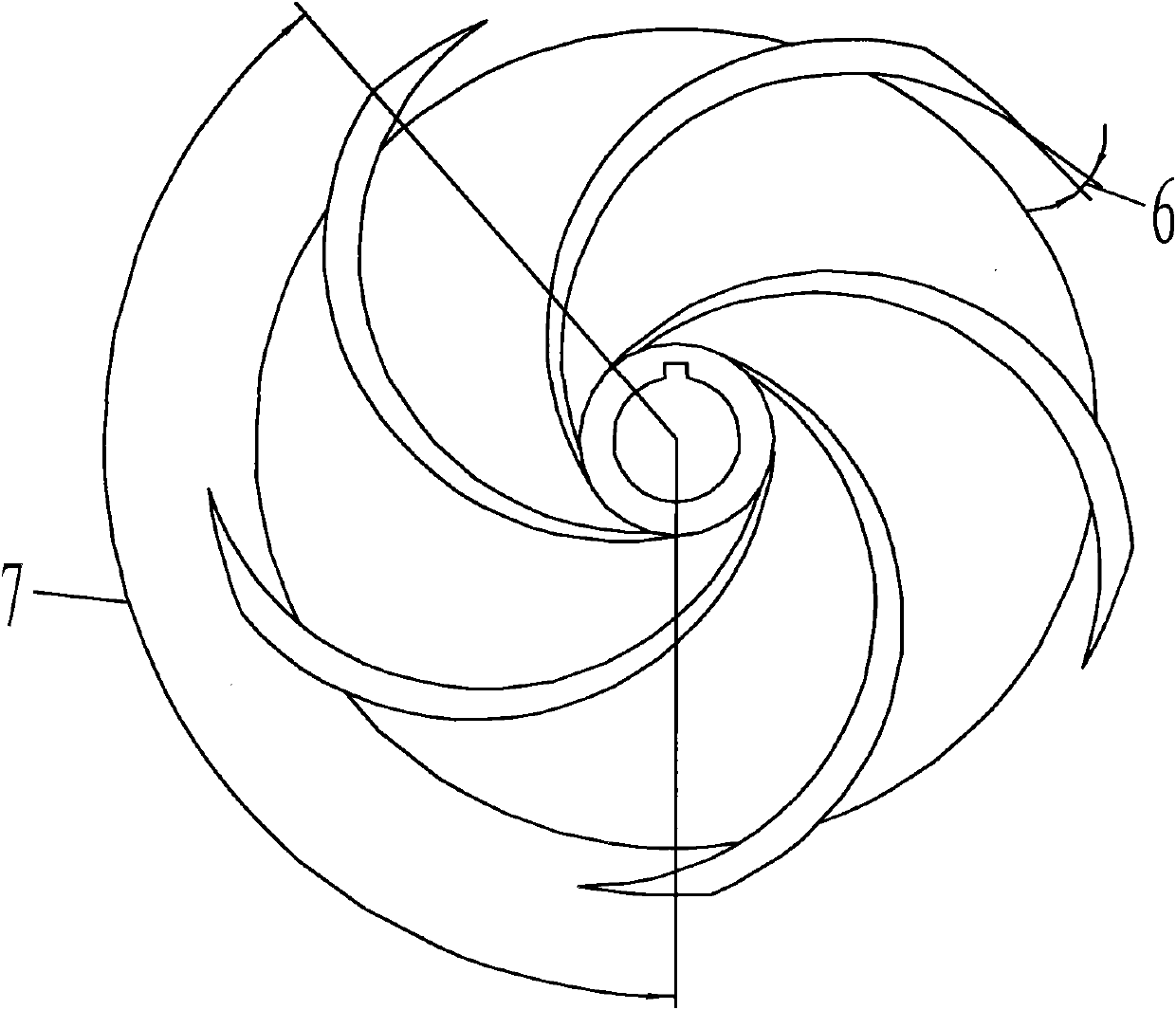

Design method for high-efficiency overload-free vortex pump impeller

InactiveCN102003407ASatisfy the requirement that there will be no overloadReduce eddy lossPump componentsPumpsImpellerEngineering

The invention relates to a design method for a high-efficiency overload-free vortex pump impeller. By designing blades of the impeller to be cambered blades with double curvature or single curvature and designing installation performance parameters of the outlet diameter of the blades, the outlet diameter of the blades changes according to a certain rule. The vortex loss of the impeller at the outlet can be reduced, and overload is not produced for the operation in a full-head range while the vortex pump runs at a high-efficiency region.

Owner:江苏振华海科装备科技股份有限公司

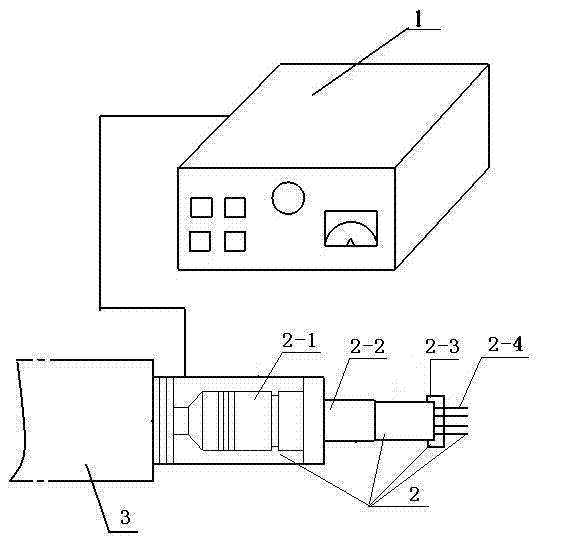

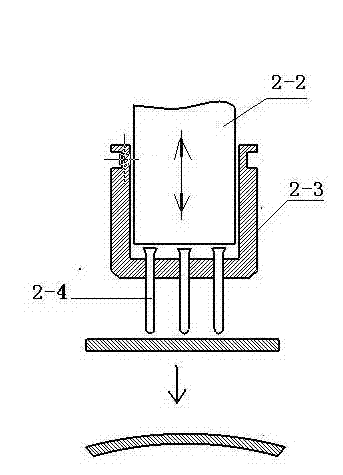

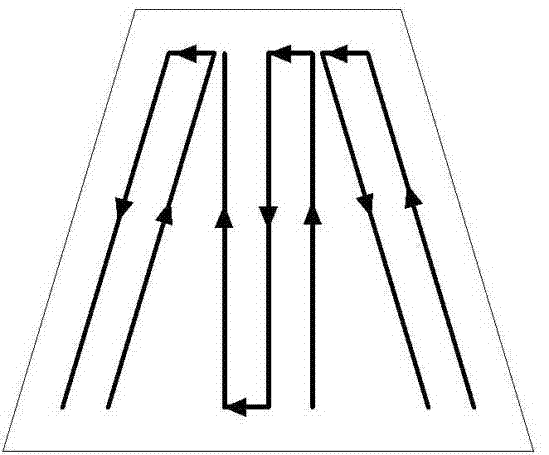

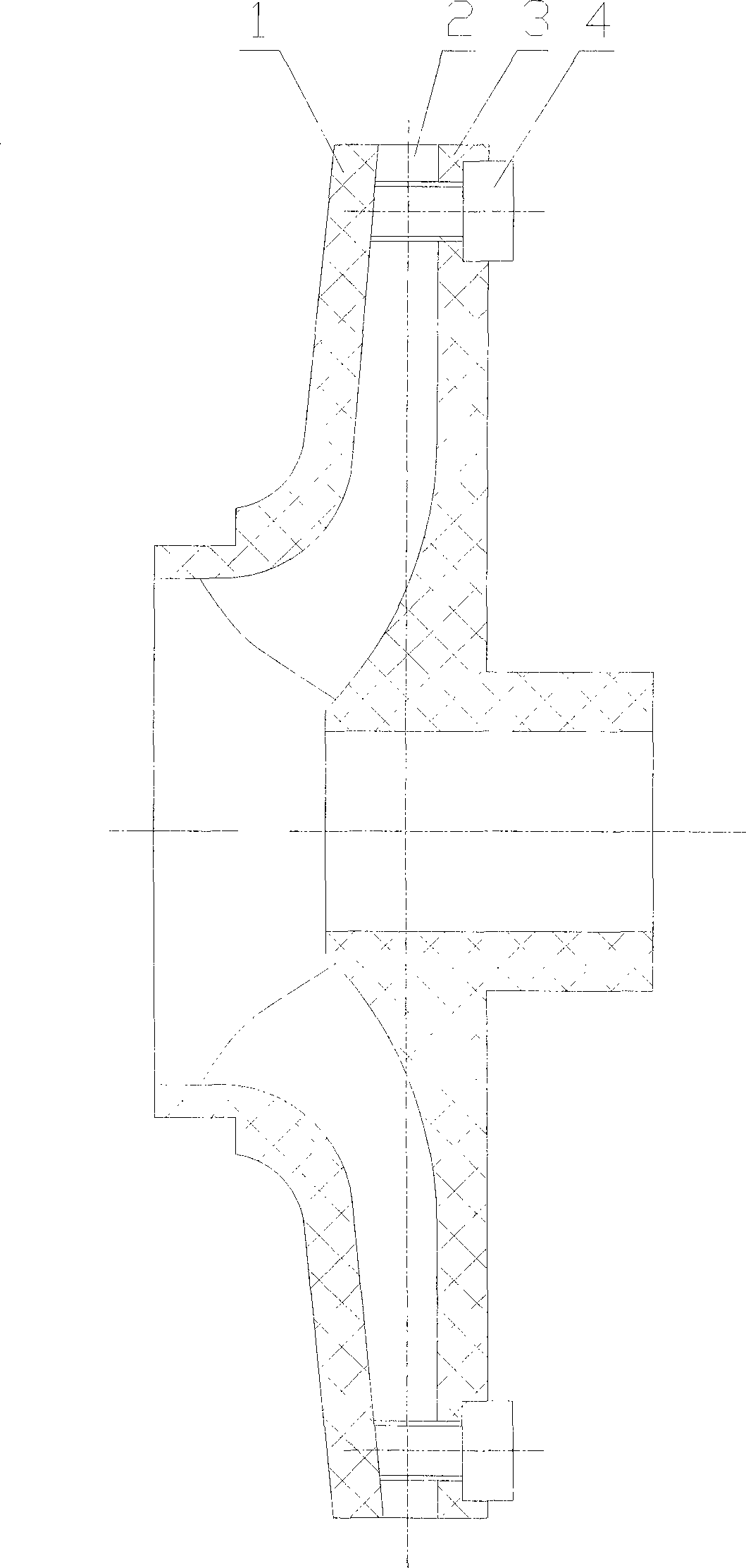

Supersonic shot-peening forming method for single or double curvature integral panels

InactiveCN102513942AHigh precisionStable structureAbrasive blasting machinesNumerical controlTransformer

The invention discloses a supersonic shot-peening forming method for single and double curvature integral panels. According to the invention, a supersonic shot-peening forming device is utilized, different forming loci are set according to integral panel forming shape demands, and a numerical control program corresponding to the forming loci is compiled on a numerical control machine tool to make the main shaft of the machine tool move according to the compiled numerical control program and control the movement of an impact gun (2). A supersonic transducer (2-1) is utilized to transmit oscillation electric signals generated by a supersonic generator (1) to longitudinal wave mechanical oscillation with the frequency same as the frequency of the signals, minimal amplitudes are amplified through an amplitude transformer (2-2), panel surfaces are impacted by means of firing pins (2-4) on an oscillation tool head (2-3) according to the forming loci to make the panels project, be bent and be formed in the impact direction to obtain the single or double curvature integral panels with different curvatures. The method which has the advantages of strong maneuverability, high working efficiency, high forming precision and wide application range can be used for processing the single or double curvature integral panels with different curvatures, different shapes and highly required precision in the aerospace industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

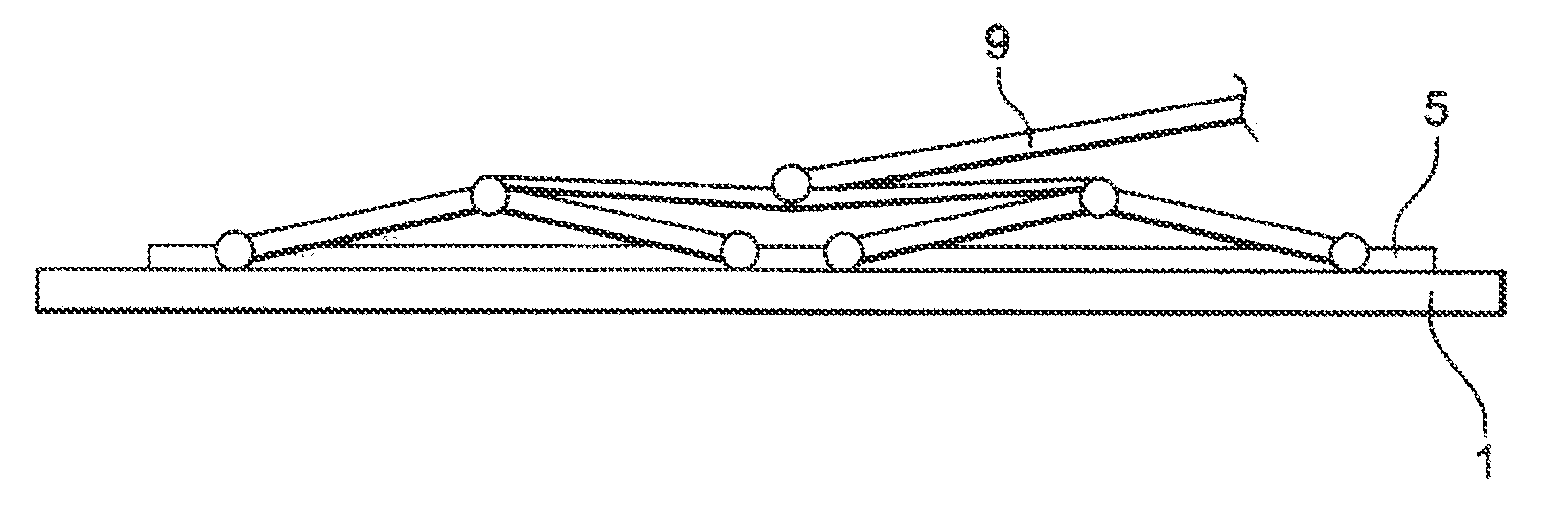

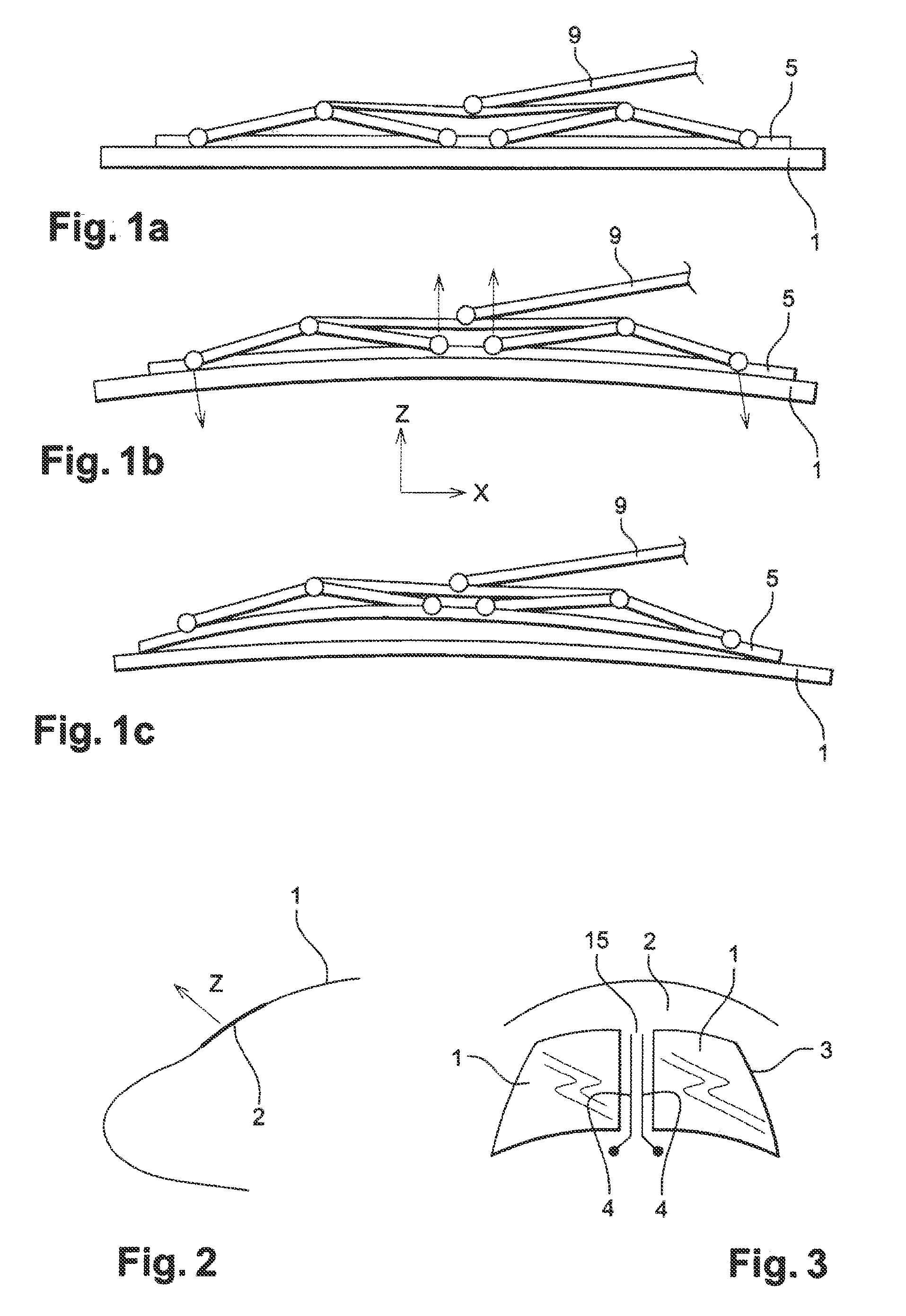

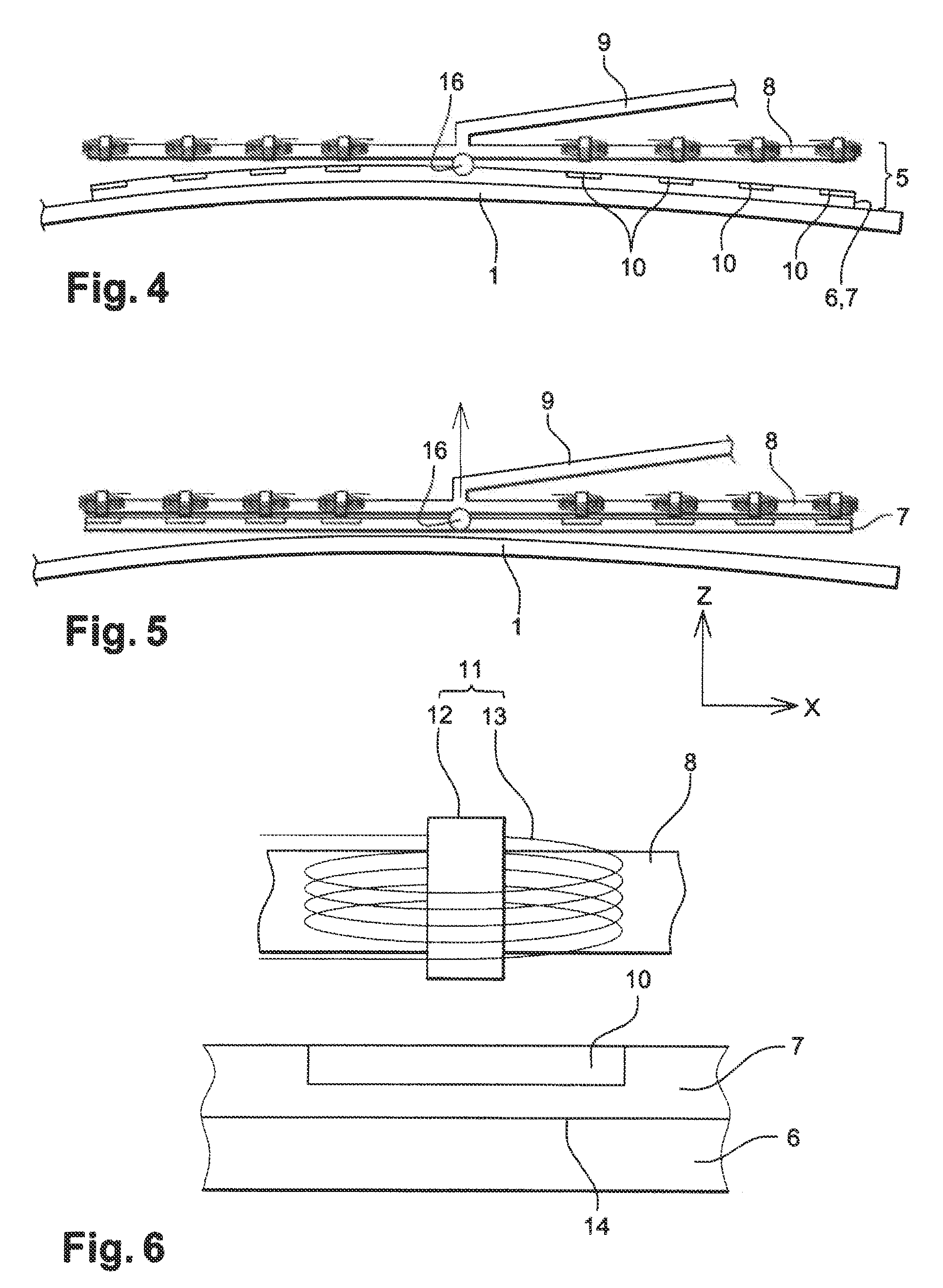

Wiper blade with electromagnetic command

ActiveUS20100125967A1Great contact forceWear minimizationWindow cleanersVehicle cleaningEngineeringLocal pressure

The wiper blade for a surface of the type with a dual curvature, the wiper blade including a flexible blade element and a means of applying a pressing force to at least one point of the blade element in a direction Z mostly normal to the surface, also including means of varying the pressing force over time, at least some of the points, between pre-chosen positive and negative limit values, and means of commanding the pressing force. These means for bringing about local pressure or lift are electromagnetic.

Owner:AIRBUS OPERATIONS (SAS)

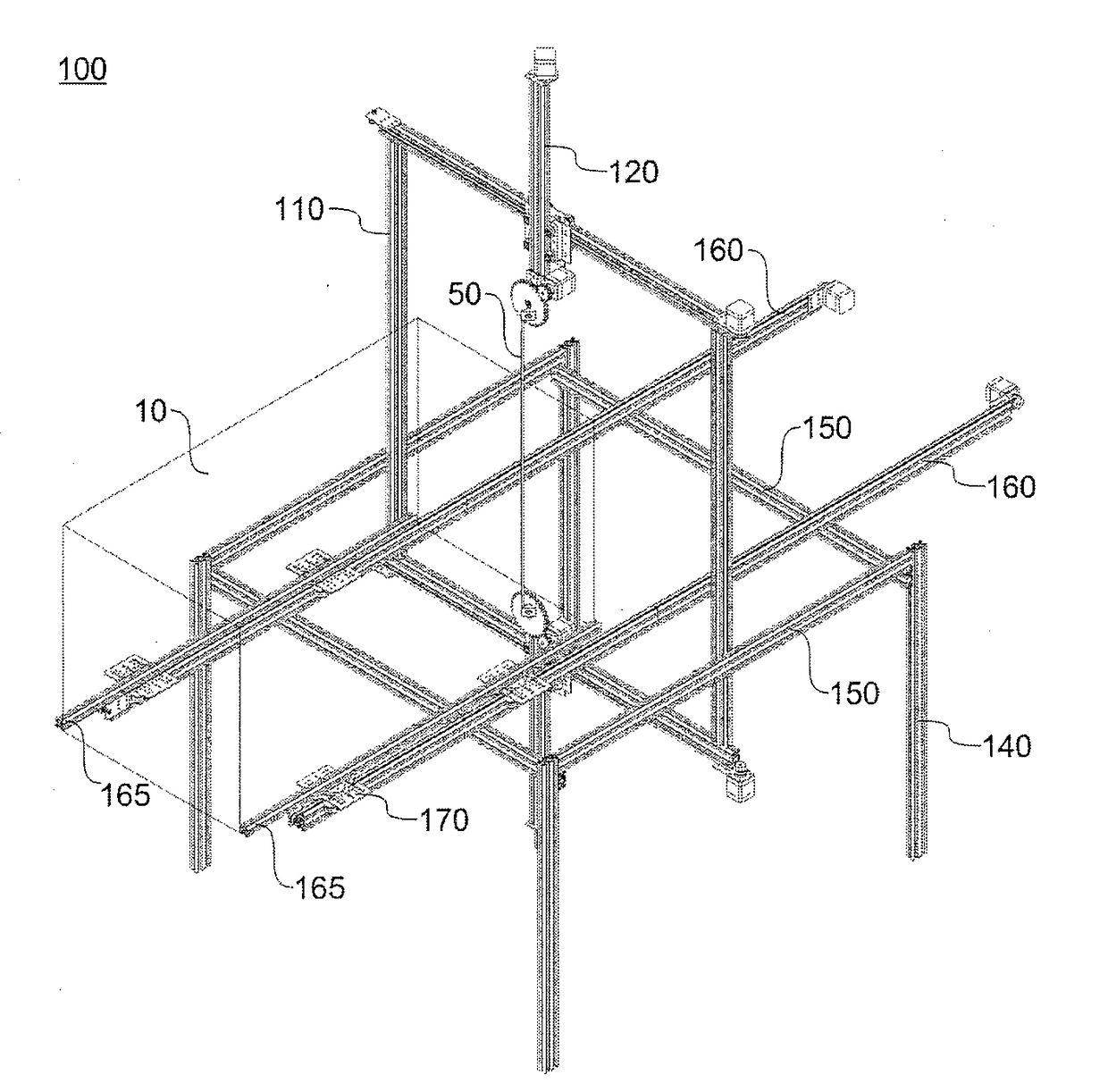

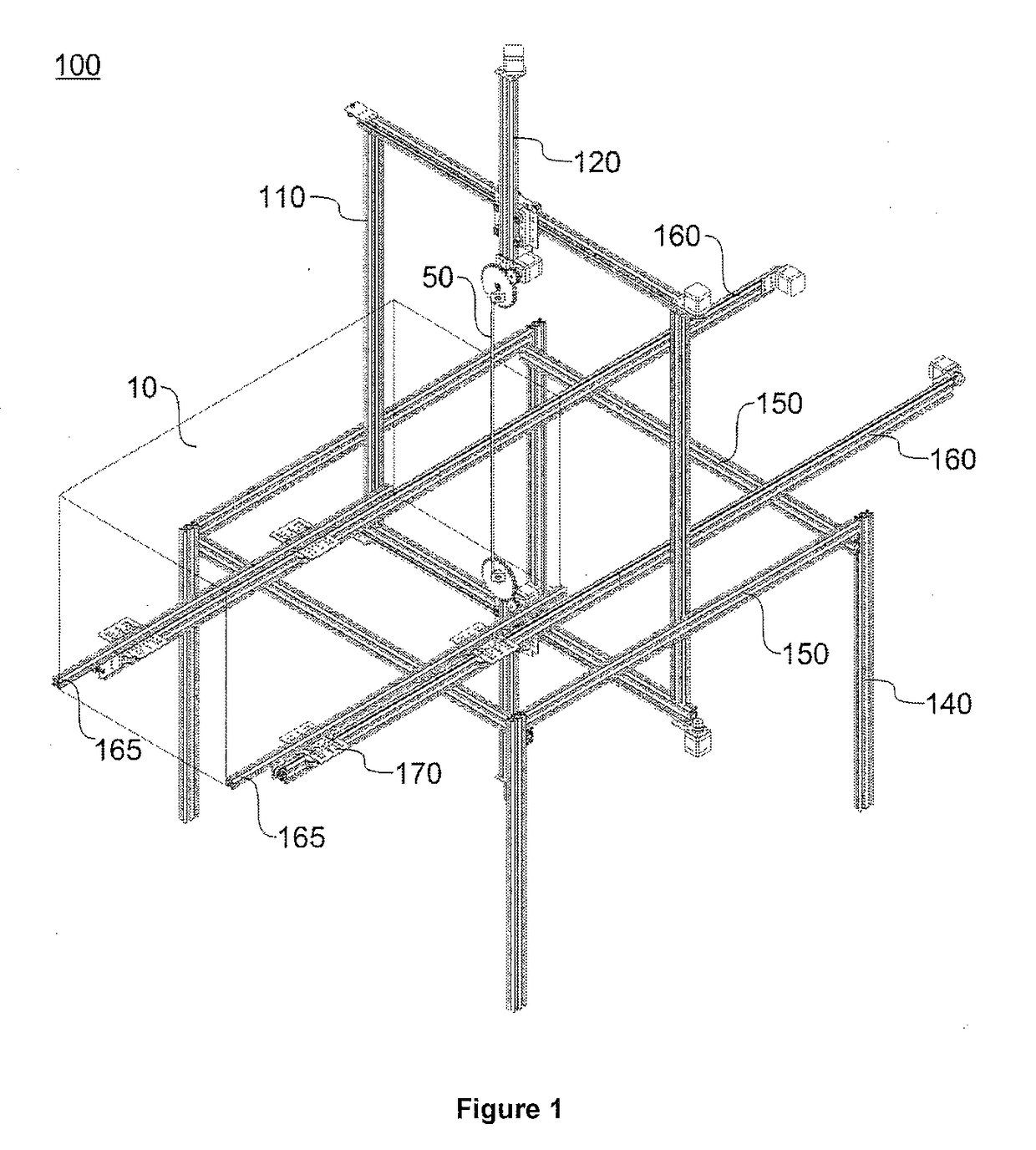

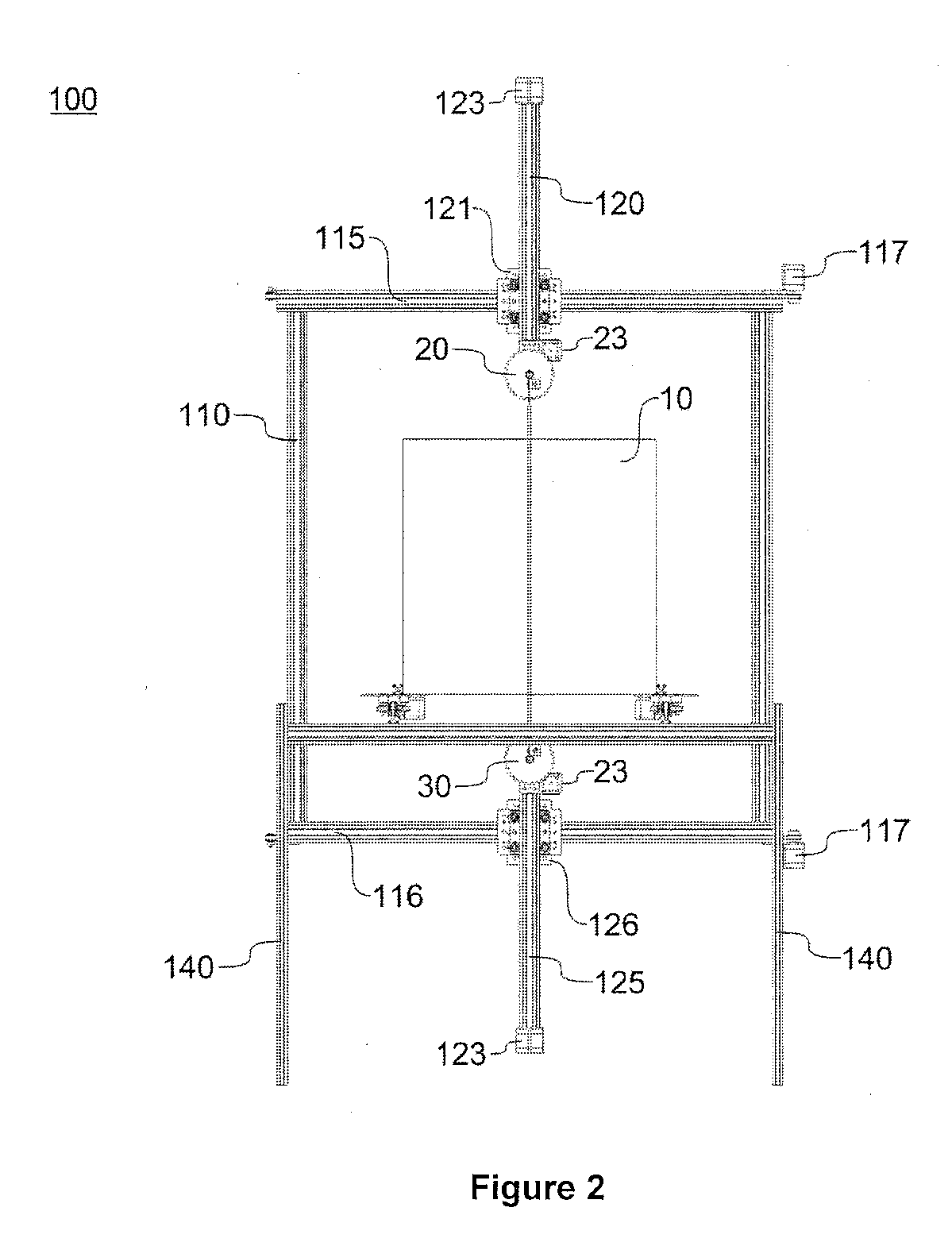

Device for cutting volumes of expanded polystyrene foam or similar, producing double-curvature surfaces

ActiveUS20180050460A1Automatic control devicesMetal working apparatusElectricityElectrical resistance and conductance

Device for cutting expanded polystyrene foam volumes or the like, obtaining double-curvature surfaces, comprising a first pair of linear guides; over each of the linear guides two pairs of plates arranged over skids are moving, where each pair of plates is connected by a horizontal beam; the two pairs of plates and the pair of horizontal beams allow supporting and fixing a block of material of expanded polystyrene foam or the like for cutting; the block of material supported on the plates is displaced by a first pair of synchronous belts and pulleys, which are driven by a first pair of step motors, which are simultaneously activated; where the block of material in its movement faces a rectangular frame which is arranged perpendicularly to the movement path of the block, with said rectangular frame having a fixed position and a flexible foil, which is covered with a sheath of thermal and electrical insulation, over which a resistive heating wire is helically wound, through which an electrical current circulates that heats the resistive heating wire and vaporizes the zone that is previous to physical contact with the block of material during the displacement thereof.

Owner:UNIV TECNICA FEDERICO SANTA MARIA

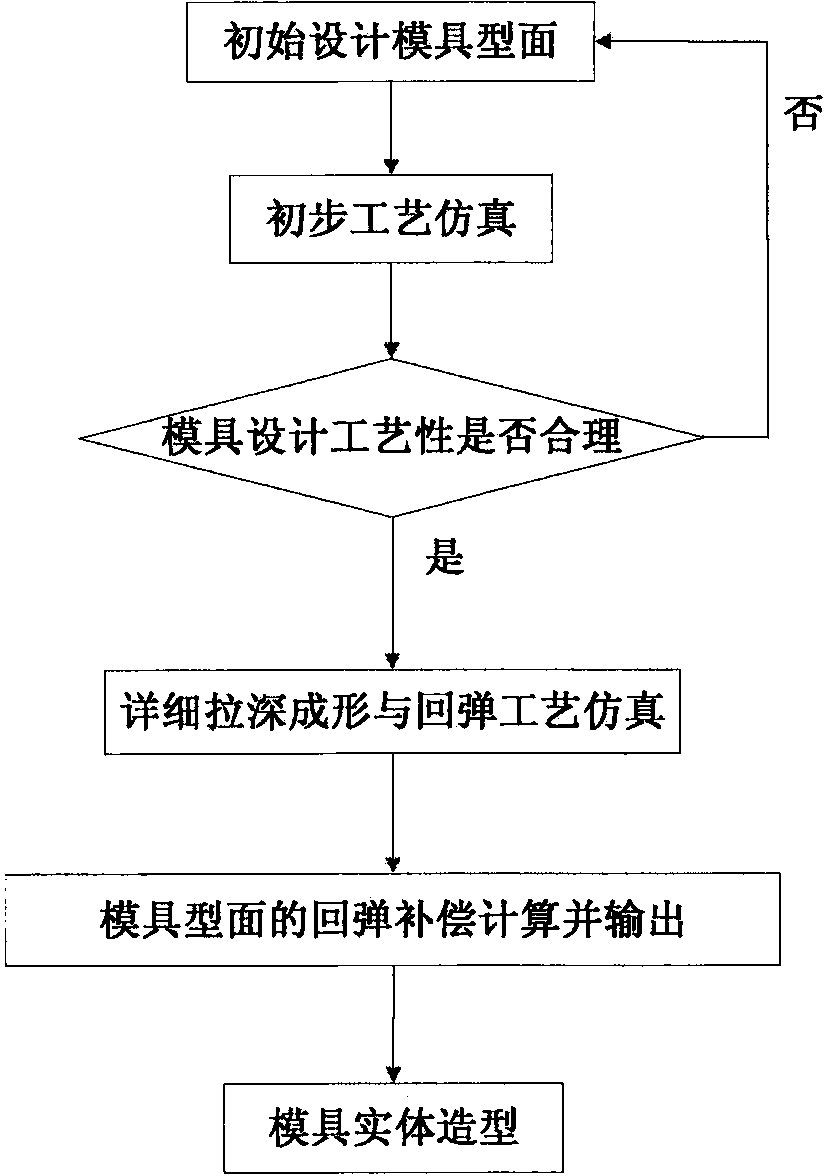

Method for designing forming dies for low-double-curvature sheet metal parts

ActiveCN104200037APrecise positioningLarge plastic deformationSpecial data processing applicationsDesign softwareEngineering

The invention relates to a method for designing forming dies for low-double-curvature sheet metal parts. The method includes steps of 1), initially designing four-piece integrated forming die profiles; 2), preliminarily simulating deep drawing forming technologies; 3), judging the rationality of die design technologies; 4), simulating deep drawing forming and spring-back technologies in detail; 5), computing and outputting spring-back compensation on the die profiles; 6), performing solid modeling on the dies in three-dimensional design software. The method has the advantages that all the four-piece double-curvature parts can be formed at one step by the aid of a deep drawing forming process, accordingly, the forming efficiency can be improved, the parts are low in spring-back rate, and the quality of the parts can be guaranteed.

Owner:SHENYANG AIRCRAFT CORP

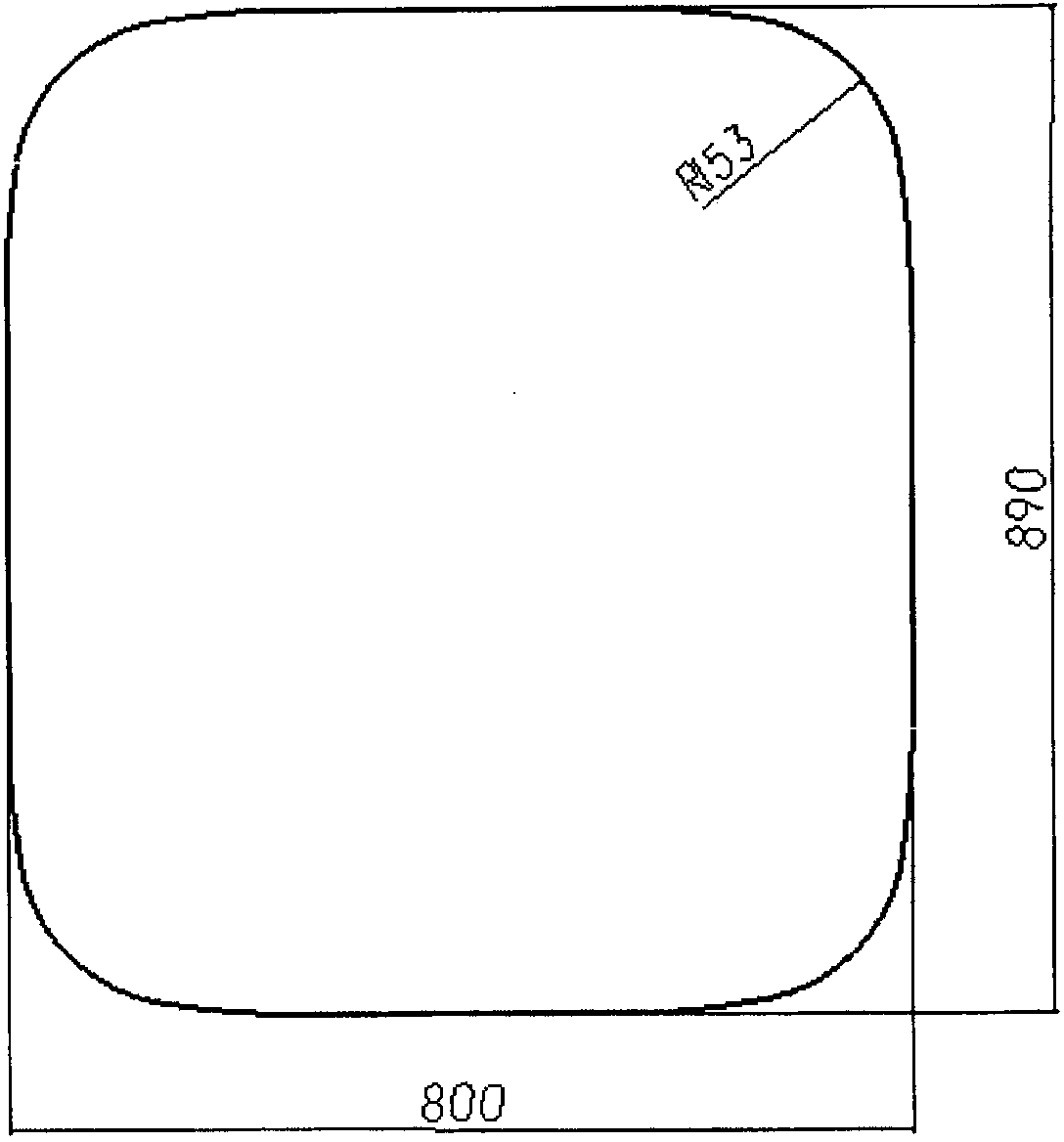

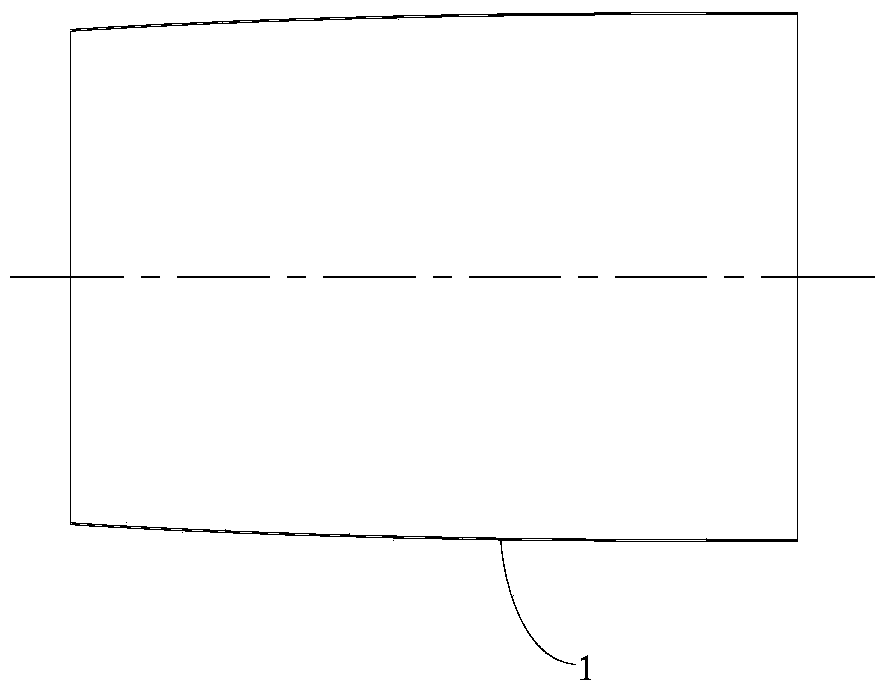

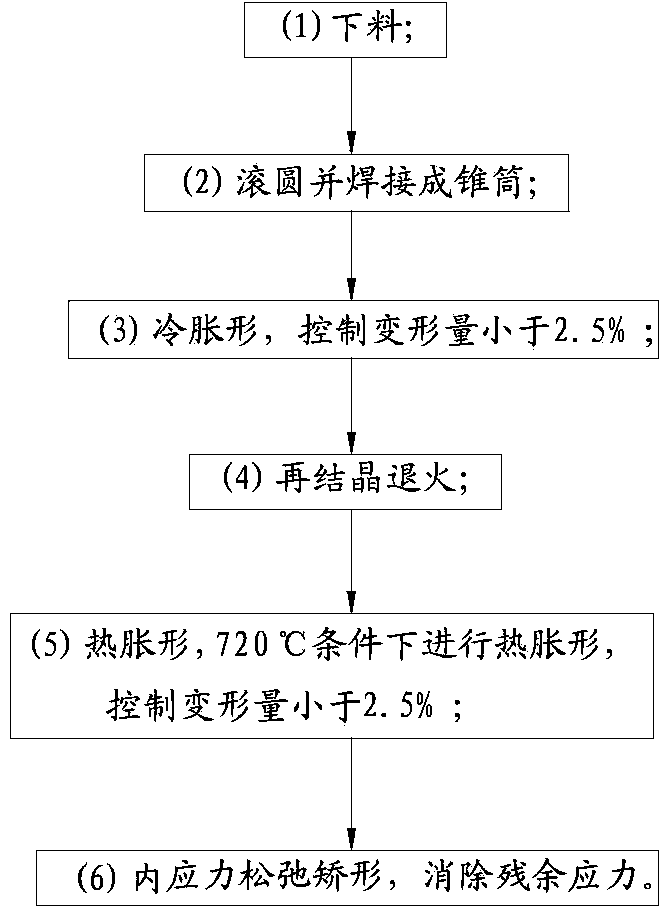

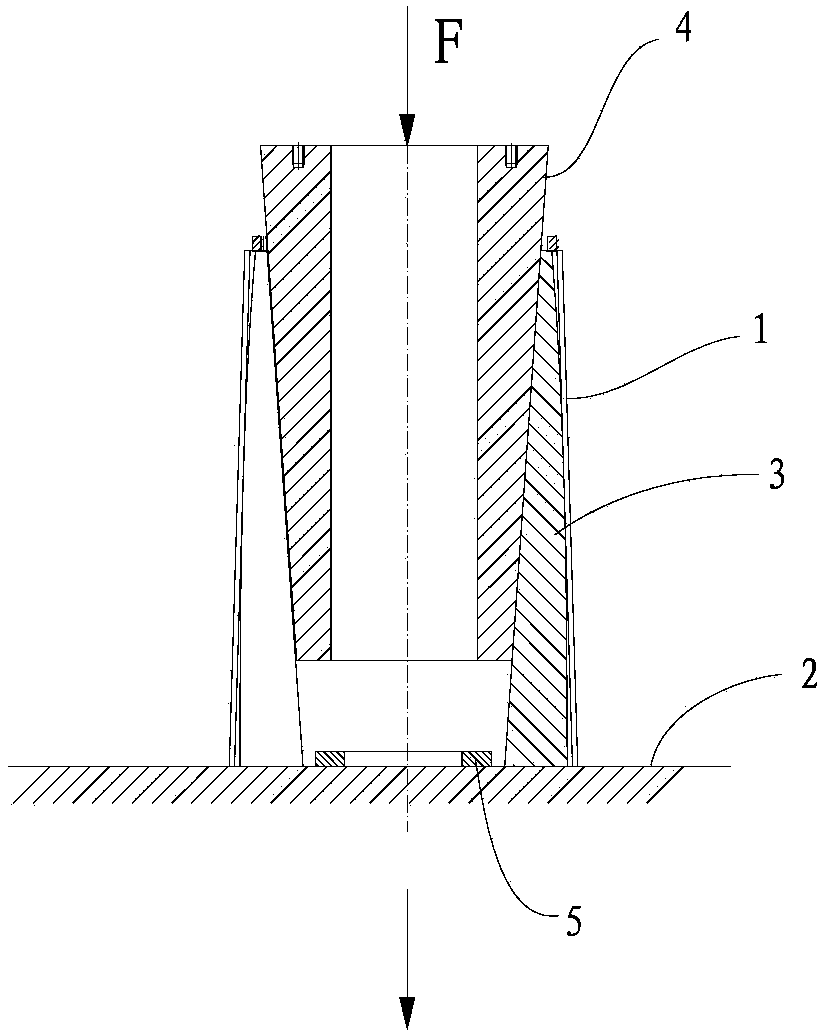

Processing method of titanium alloy double-curvature rotary drum

The invention belongs to the field of metal forming and processing and in particular relates to a processing method of a titanium alloy double-curvature rotary drum. The method comprises the following steps of (1) feeding materials; (2) rolling the materials and forming a conical drum through welding; (3) performing cold bulging and controlling the deformation quantity to be less than 25%; (4) performing recrystalization annealing; (5) performing hot bulging under the condition of 720 DEG C and controlling the deformation quantity to be less than 2.5%; (6) performing internal stress relaxed shaping to eliminate residual stress. The processing method of the titanium alloy double-curvature rotary drum ensures the maximum deformation rate to be approximate to and less than 6% to guarantee the strength of the titanium alloy double-curvature rotary drum and eliminates the residual stress after bulging as well as under stress removal temperature and time conditions to guarantee the dimensional accuracy of the titanium alloy double-curvature rotary drum and the uniformity of products.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

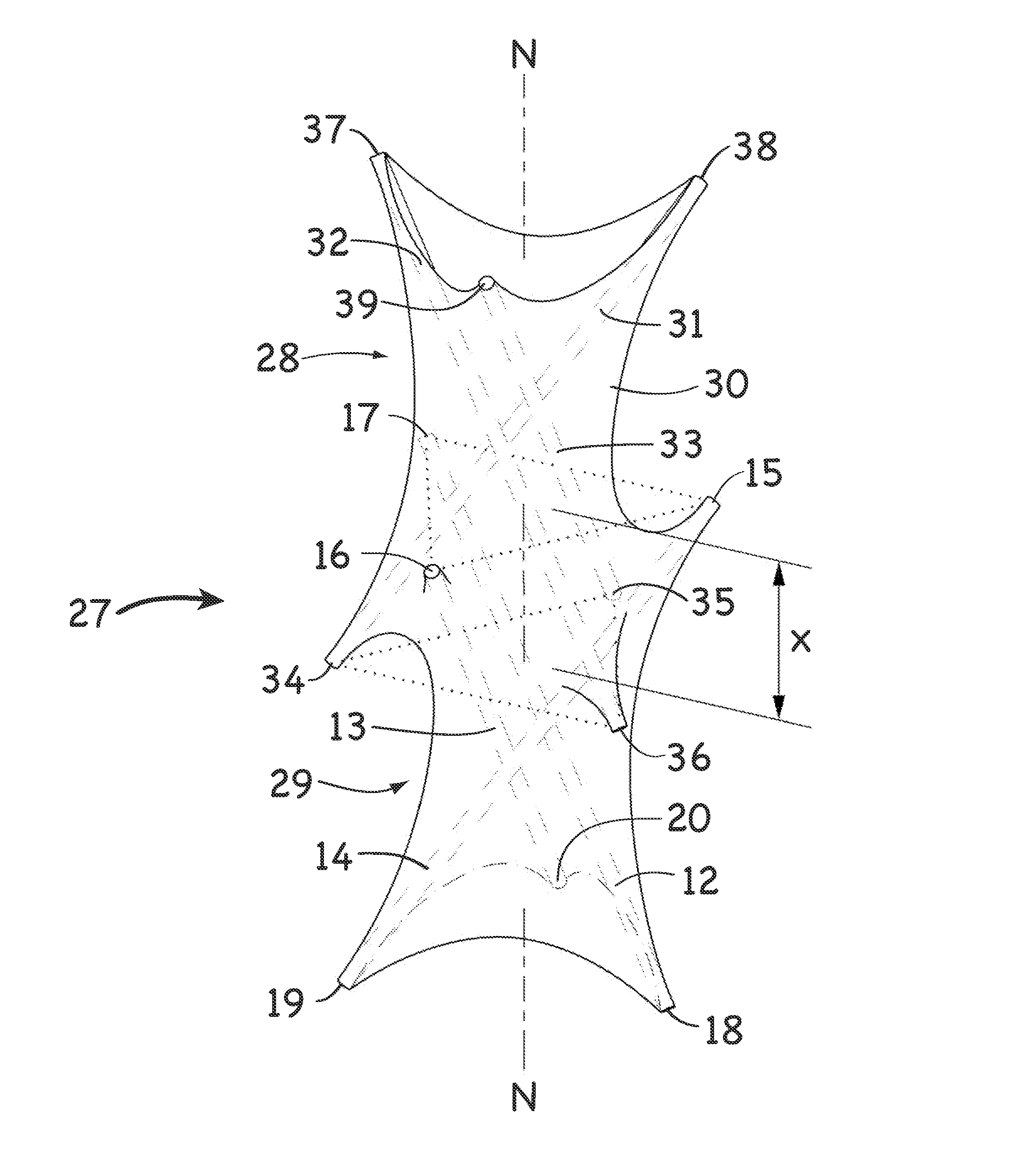

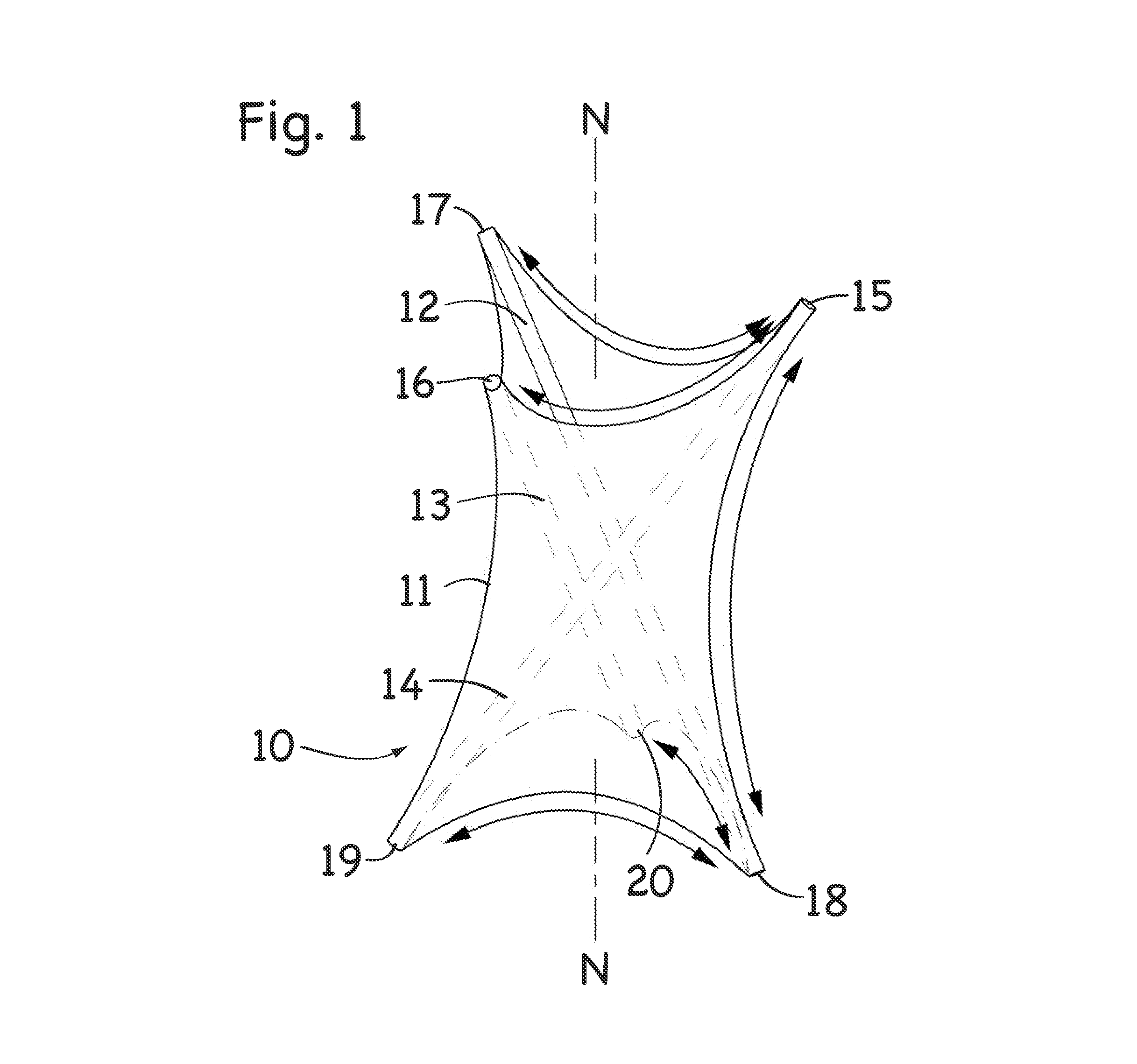

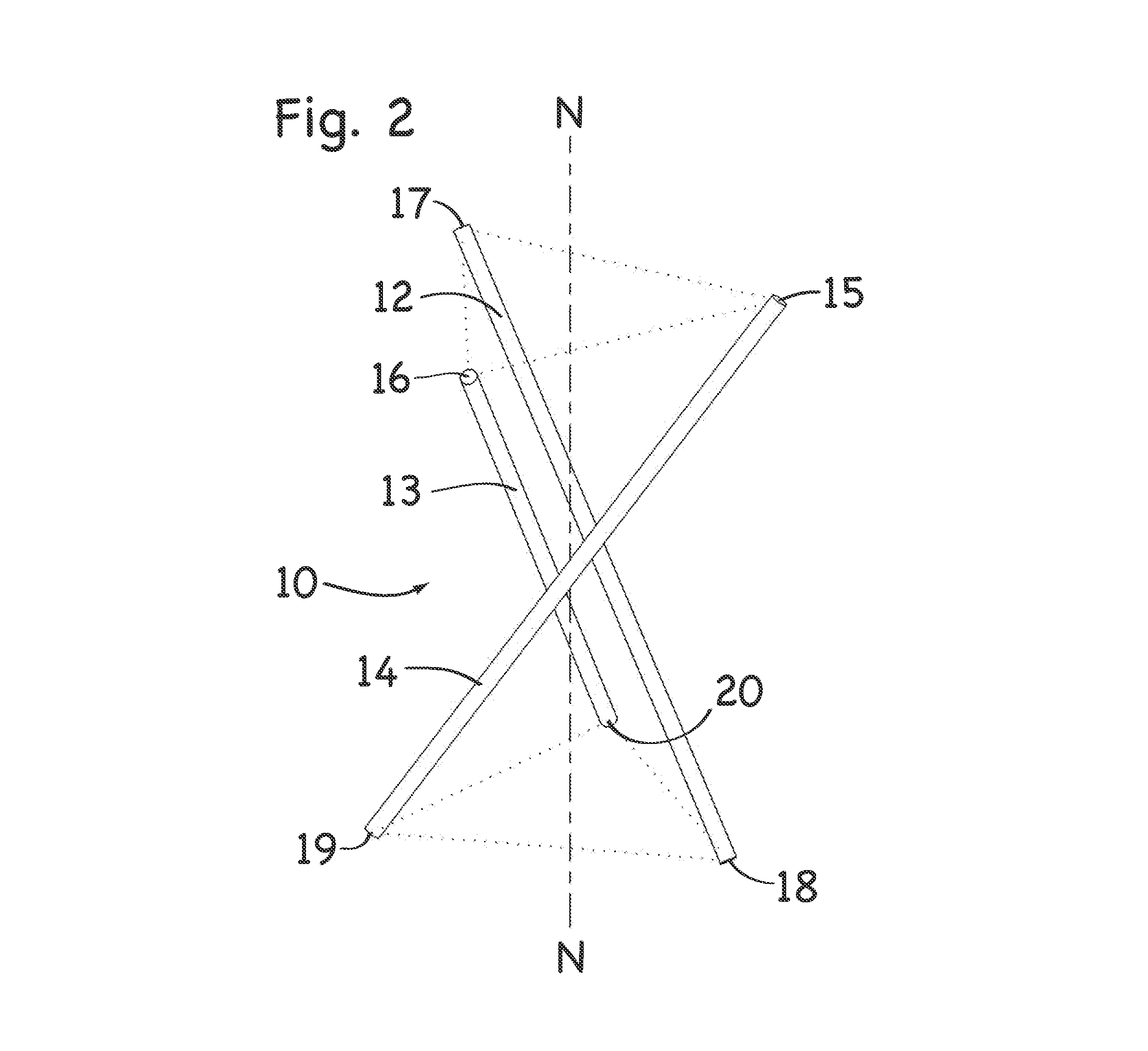

Continuous tension, discontinuous compression systems and methods

A tensegrity structure with one or more tensegrity units formed by a membrane in combination with three or more elongate compression members obliquely disposed in a spiral relationship in compression within the membrane. The ends of the compression members within each tensegrity unit and in adjacent tensegrity units are spaced from one another, and the compression members of adjacent tensegrity units overlap along a longitudinal dimension. The membrane forms anticlastic curves and has variable double curvature between ends of compression members. Multiple tensegrity units can form a column, which can be tapered, curved, or otherwise constructed.

Owner:NADEAU GERARD F

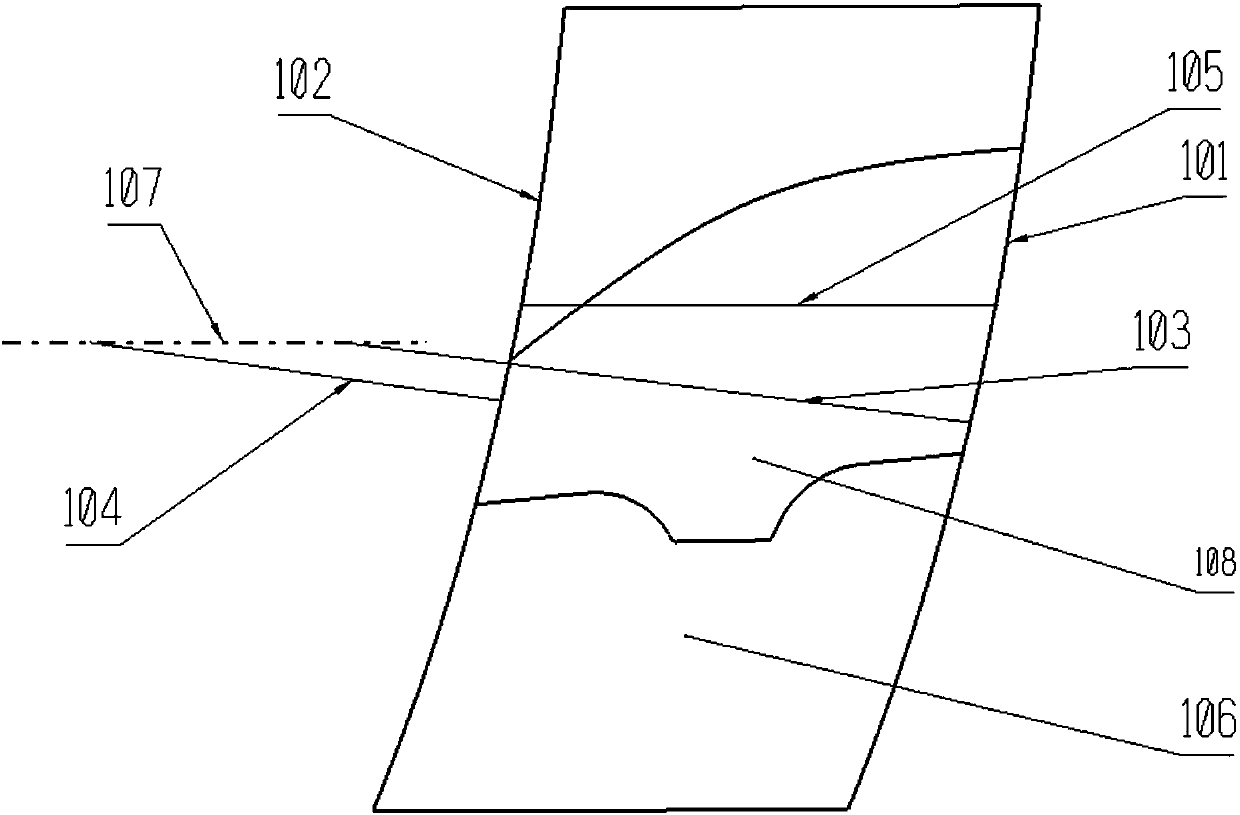

Design method of double-curvature glass for car doors and windows

The invention relates to the technical field of glass for car doors and windows, in particular to a design method of double-curvature glass for the car doors and windows. The design method of the double-curvature glass for the car doors and windows provided by the invention theoretically has no displacement error between the glass and guide rails when the glass is lifted and lowered and the lifting and lowering movement of the glass is stable. The word "theoretically" means that manufacturing errors are not taken into account. Theoretically, the displacement error between the glass and the guide rails is zero and a matching error with a class A surface can be controlled within 0.5 mm, so as to solve the problem that prior double-curvature glass theoretically has an error of the lifting andlowering movement of the glass, that is the prior double-curvature glass has the displacement error between the glass and the glass guide rails.

Owner:CHINA FIRST AUTOMOBILE

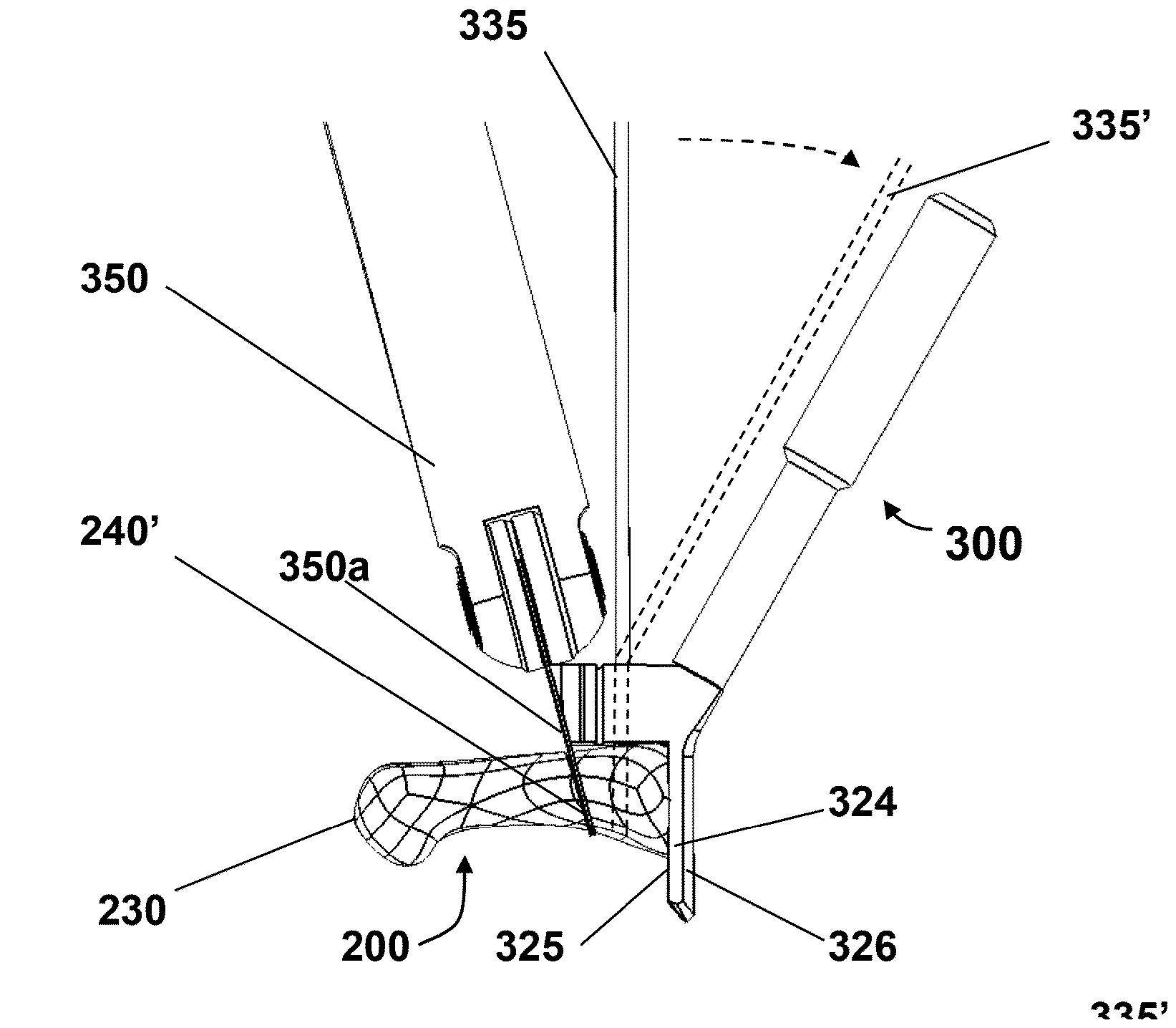

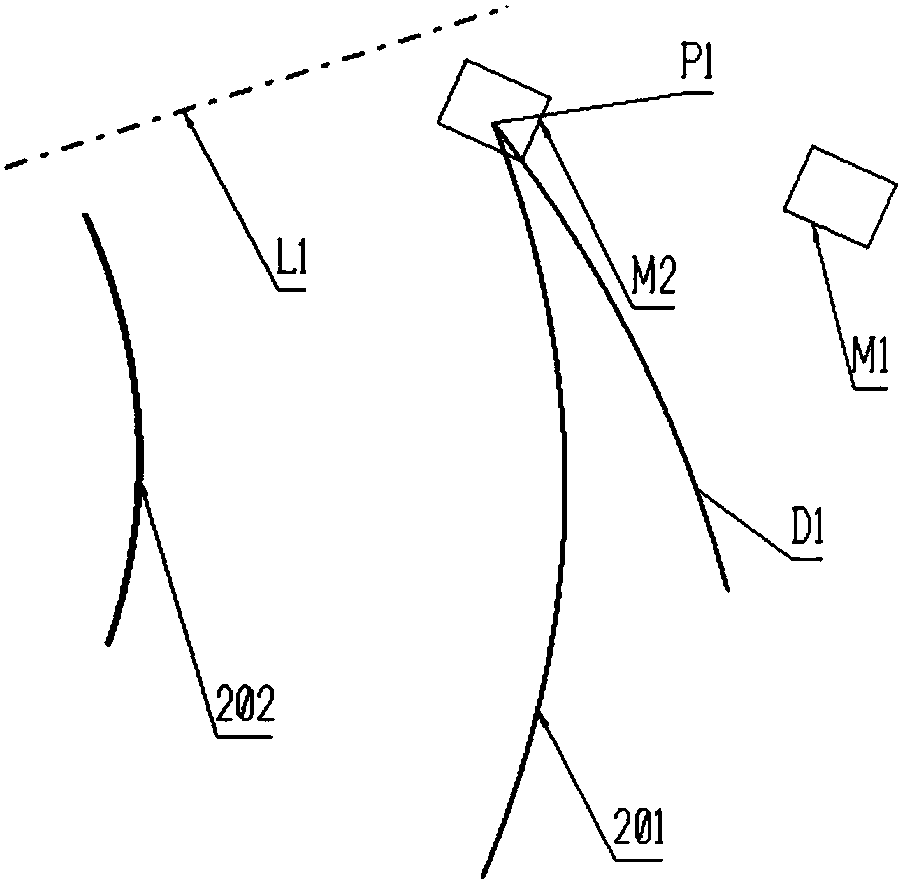

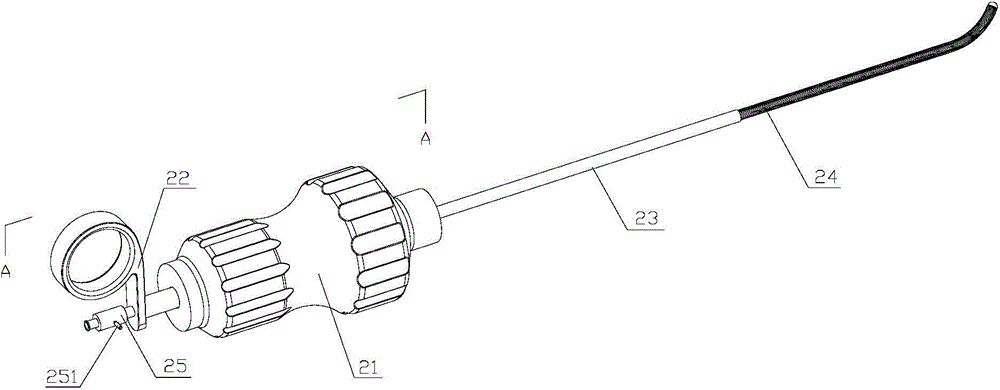

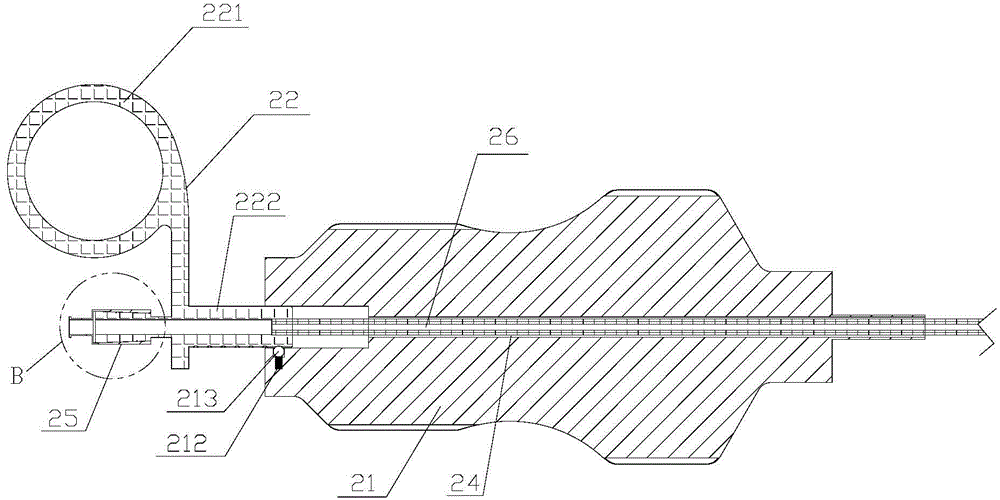

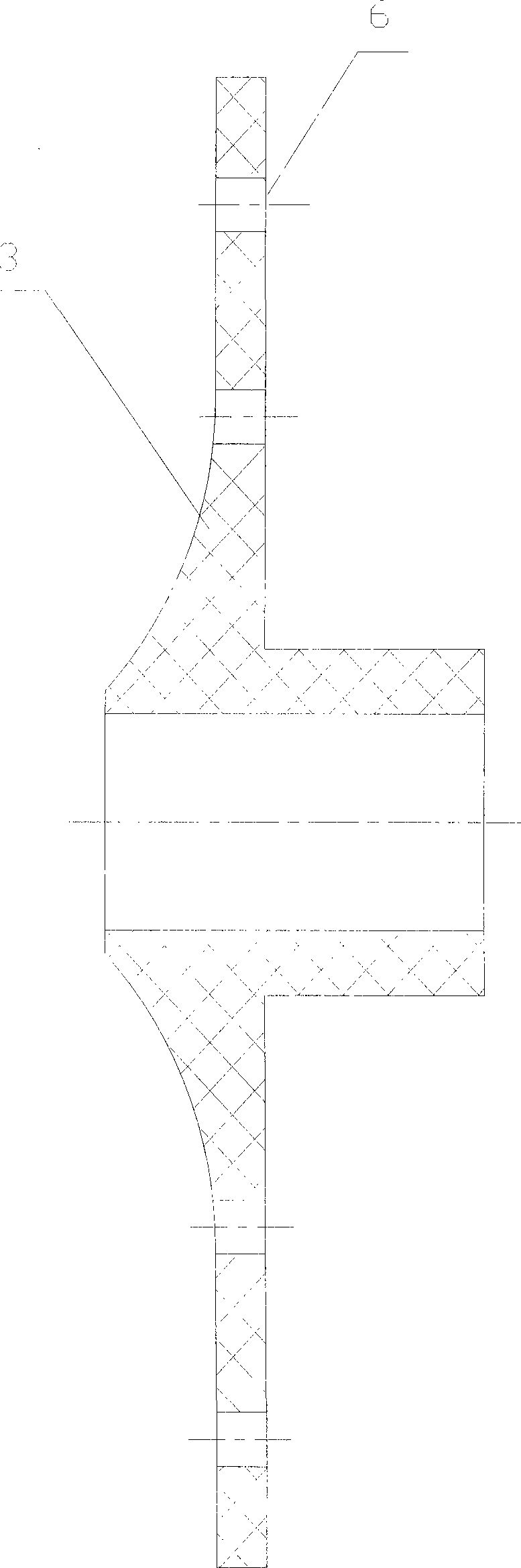

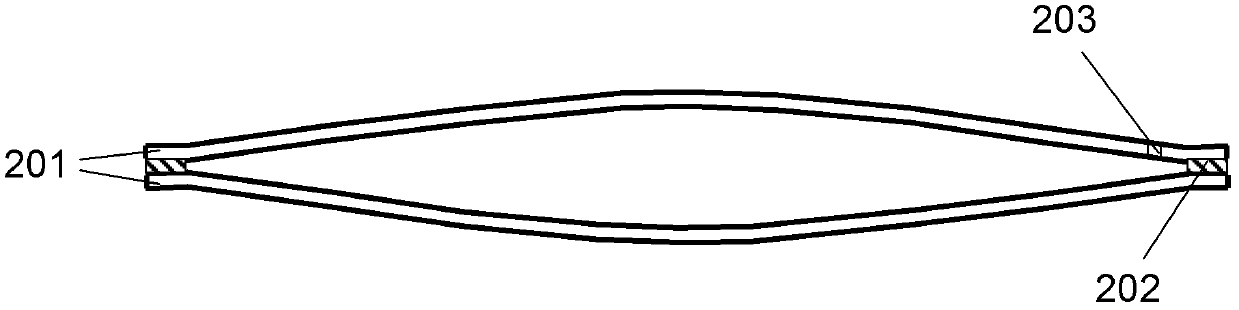

Bendable surgical instrument with pre-bending pipe structure

InactiveCN104473687AEasy resectionEasy to operateSurgical instruments for heatingAbnormal tissue growthPush pull

The invention relates to a bendable surgical instrument with a pre-bending pipe structure. The bendable surgical instrument is provided with a handle and an operating rod. A pre-bending pipes is disposed in the handle and the operating rod and assembled to the push-pull rod of a push-pull handle. The operating rod can move relative to the handle to adjust the extending length of the pre-bending pipe relative to the operating rod. The operating rod is communicated with the interior of the pre-bending pipe to form a built-in instrument channel. One or multiple embedded pre-bending pipes can be used. The bendable surgical instrument has the advantages that natural one-way bendable materials such as metal braided pipes are applied to the field of surgical instruments, the length of the metal braided pipes extending out of the far end of the operating rod is controlled through the push-pull handle, instrument tail ends of different shapes such as arc shapes and 'S' double-curvature bending shapes, the surgical instrument assembled into the built-in instrument channel can reach all parts of lesions, operation fineness is achieved, all angles are achieved, blind areas are avoided, and tumors of various forms and at various positions can be cut off conveniently, and the bendable surgical instrument is simple to operate and good in surgical effect.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY +1

Method for continuously and unevenly compressing and forming three-dimensional curved surface

InactiveCN102728706AReduce reboundSimple structureMetal-working feeding devicesPositioning devicesCurve shapeDouble curvature

The invention provides a method for continuously and unevenly compressing and forming a three-dimensional curved surface by using a sheet metal, belongs to the field of metal plastic processing and is especially suitable for the quick forming of a double-curvature three-dimensional curved surface part. The method is characterized in that the continuous forming of the curved surface is realized by paired upper and lower forming tools and the feeding motion of the sheet metal. When the sheet metal continuously passes by the forming tools, a plastic deforming area with a cross section having a curved shape and a thickness gradually reducing along the feeding direction of the sheet metal is formed at a gap of the upper and lower forming tools. The sheet metal is subjected to horizontal bending deformation and uneven compressing deformation along thickness direction in the deforming area; the uneven extension volume of the sheet metal along the horizontal direction is caused by the uneven compressing, so that an additional longitudinal bending moment is formed on the bent cross section and the sheet metal is longitudinally bent; and following the longitudinal continuous feeding of the sheet metal, a double-curvature three-dimensional curved surface is formed under the combined action of the horizontal and longitudinal bending deformation.

Owner:JILIN UNIV

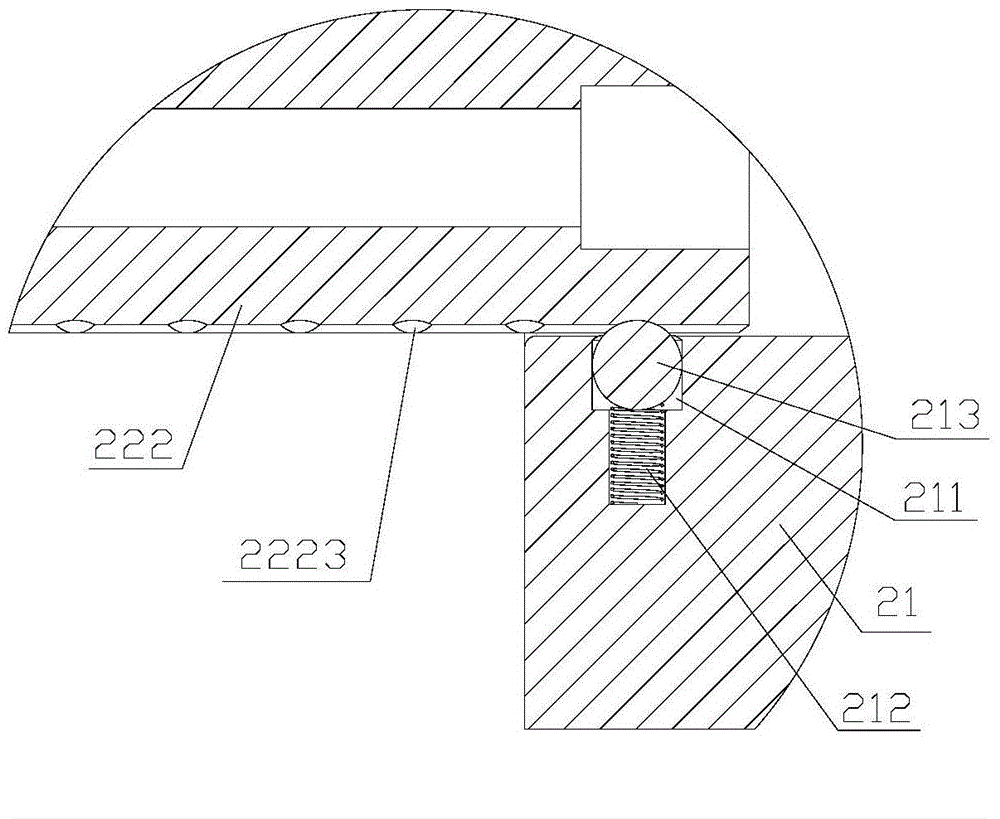

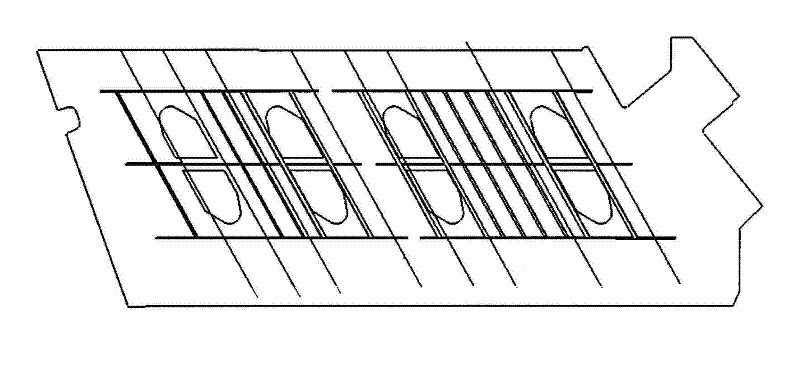

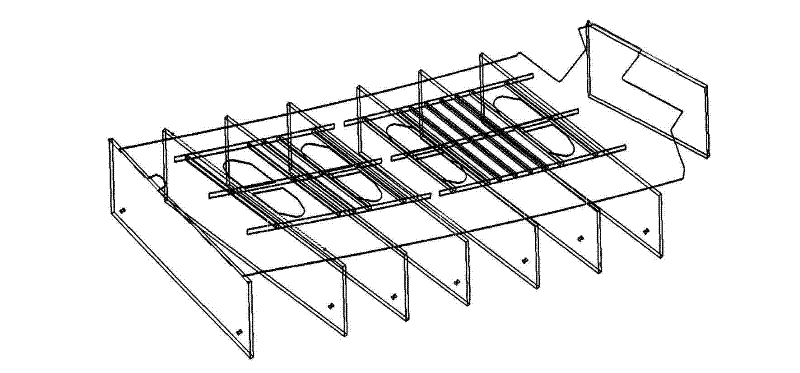

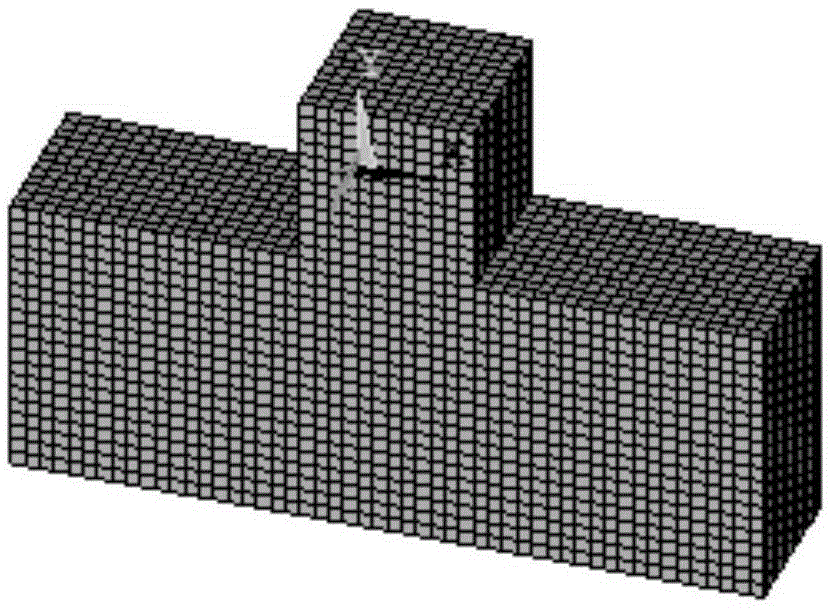

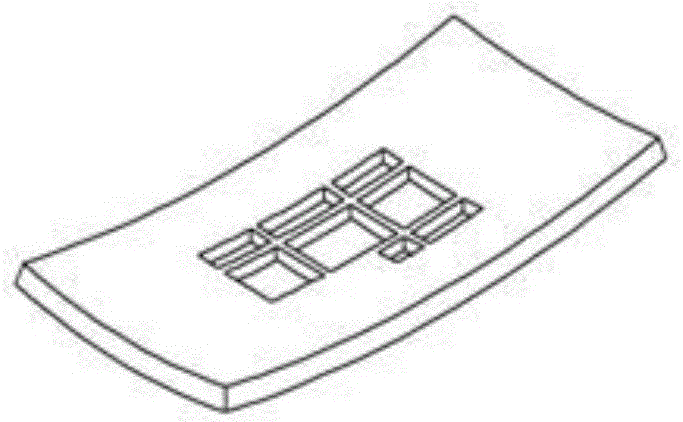

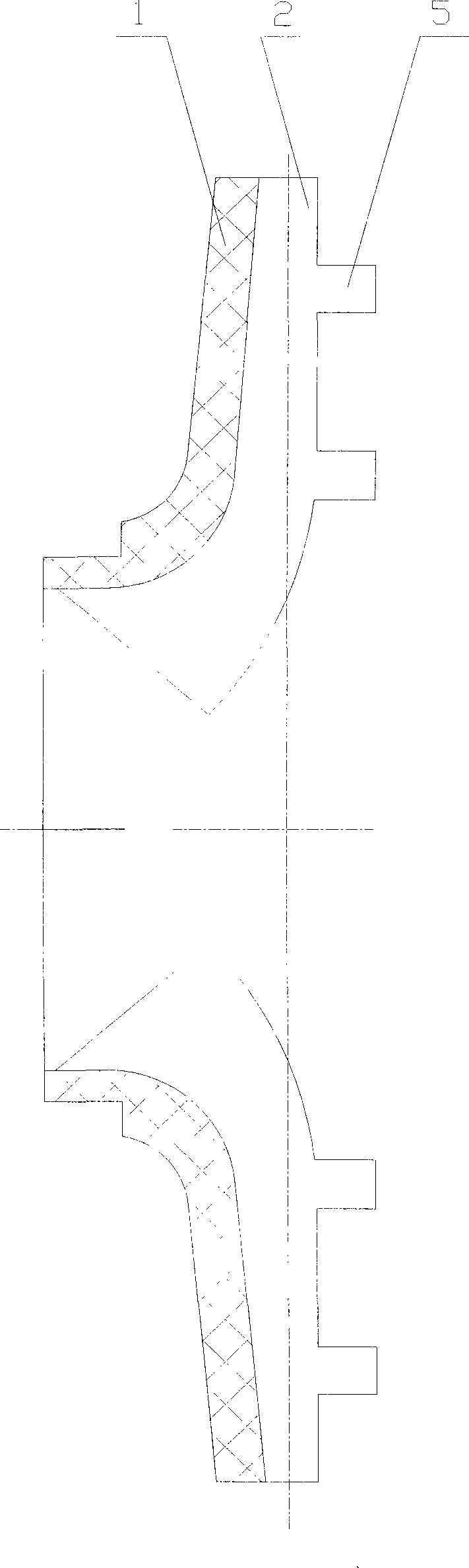

Multi-column regulation type pressing die and method for forming titanium alloy double-curvature plate by using same

InactiveCN102233383AFlexible shapeReduce manufacturing costShaping toolsDouble curvatureTitanium alloy

The invention discloses a multi-column regulation type pressing die and a method for forming a titanium alloy double-curvature plate by using the same. The multi-column regulation type pressing die comprises an upper die base plate, an upper molding surface, a lower die base plate and a lower molding surface, wherein a plurality of length adjustable upper die columns are fixed on the upper die base plate and extend vertically downwards from the upper die base plate; the upper molding surface consists of lower end faces of the plurality of upper die columns together; a plurality of length adjustable lower die columns are fixed on the lower die base plate and extend vertically from the lower die base plate upwards; the lower molding surface consists of upper end faces of the plurality of lower die columns together; and the upper die columns correspond to the lower die columns in a one-to-one mode. The multi-column regulation type pressing die can flexibly adjust the shapes of the molding surfaces by changing the lengths of the upper die columns and the lower die columns, has the advantages of multifunction and low manufacturing cost, and is suitable for pressing various plate materials singly or on a small scale.

Owner:JIANGNAN SHIPYARD GRP CO LTD

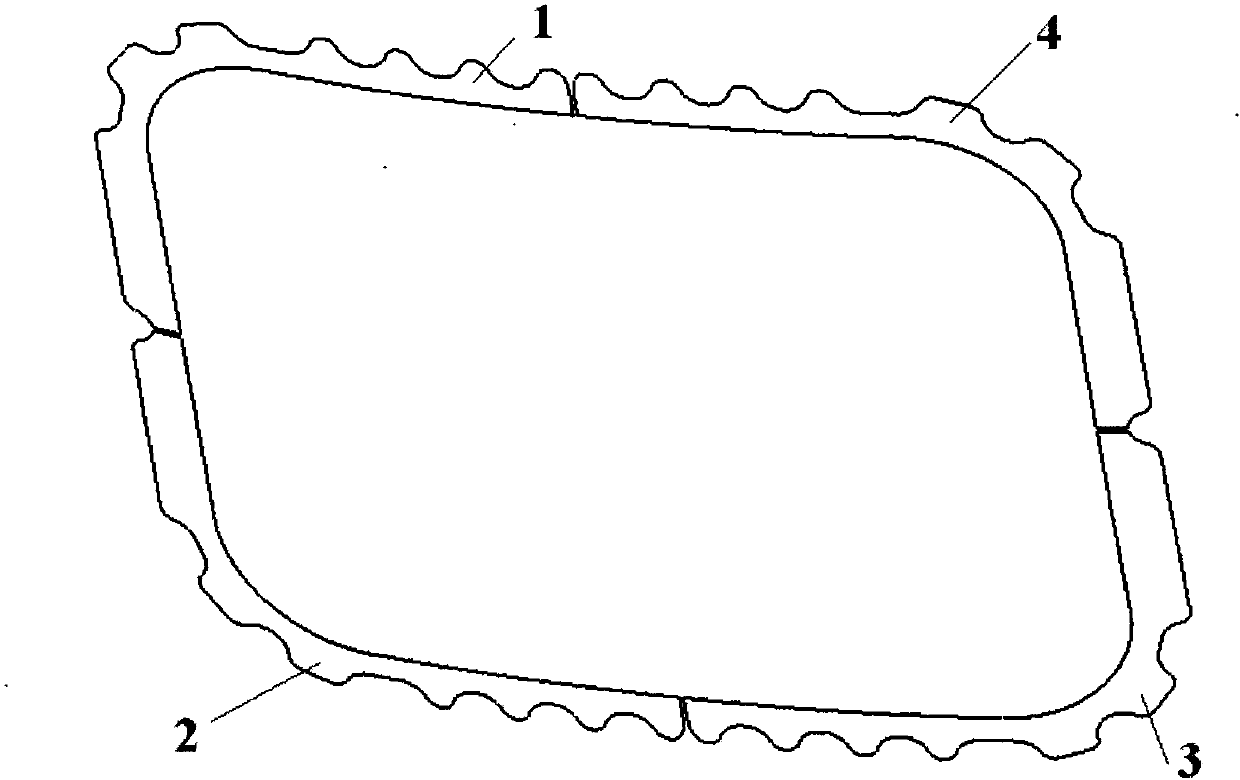

Testing method of integral panel parts with double curvatures

InactiveCN102338612AImprove accuracyShorten the production cycleMechanical counters/curvatures measurementsDouble curvatureElectrical and Electronics engineering

The invention relates to a testing method of integral panel parts with double curvatures; the testing method comprises the following steps of: (1) drawing a plurality of parallel lines which are vertical to the axes of the panel parts according to the positions of main force bearing structures of the panel parts and formulating positions put forward by manufactures; (2) collecting a data set of curvatures of each parallel line; (3) manufacturing a group of testing clamping plates, wherein bottom surfaces of the testing clamping plates are on the same horizontal surface, the testing clamping plates are vertical to the horizontal surface, and a curved surface which is consistent with the curvature of the corresponding parallel line is arranged on the upper end surface of each testing clamping plate; (4) fixing the testing clamping plates on the horizontal surface, ensuring gaps to be consistent with the positions of the corresponding parallel lines; (5) placing the integral panel parts with the double curvatures on the group of testing clamping plates, wherein the parallel lines are coincided with the corresponding testing clamping plates; and carrying out the curvature measurement on the parts by using a plug gauge. The testing method is used for testing the double curvature appearance surface of the parts by adopting the testing clamping plates and has the advantages of not only reducing the time required for production, but also increasing the accuracy of testing, being convenient for testing and saving time and labor.

Owner:SHENYANG AIRCRAFT CORP

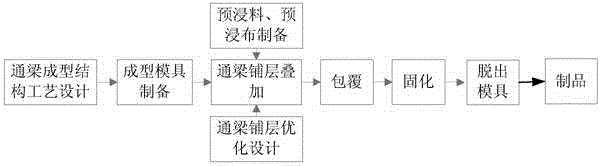

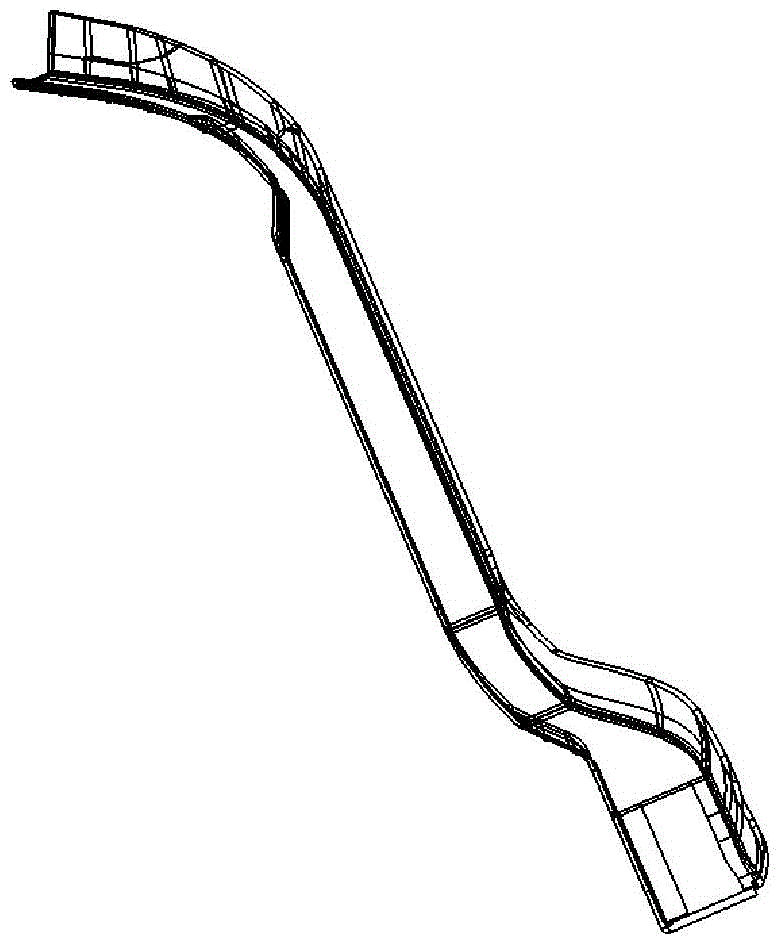

Molding method of double-curvature variable-section variable-thickness through beam

The invention discloses a molding method of a double-curvature variable-section variable-thickness through beam. The molding method comprises the steps that a molding die is manufactured according to the structural form of the double-curvature variable-section variable-thickness through beam; the molding die comprises a combined female die body and a limiting strip, and the combined female die body comprises a detachable side check block and a fixed block; prepared hot-melting prepreg and hot-melting prepreg cloth are shorn to the size of an unfolded section laying layer of the through beam, a hot-melting prepreg cloth laying layer is firstly laid on the surface of the female die body, and then vacuumizing compaction is carried out; laying layers are stacked according to the thickness of the through beam and the designed laying layer sequence, hot-pressing shaping is carried out in the laying layering stacking process according to the thickness of the laying layers, and finally a composite material prepreg lamination is manufactured; then coating, curing and combined female die body removal are carried out to obtain a product. The aerodynamic configuration requirement can be effectively guaranteed, the problems that the laying layers and size precision of a large-size double-curvature variable-section variable-thickness through beam are hard to control are solved, and finally the overall quality and size precision requirements of the through beam are guaranteed.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

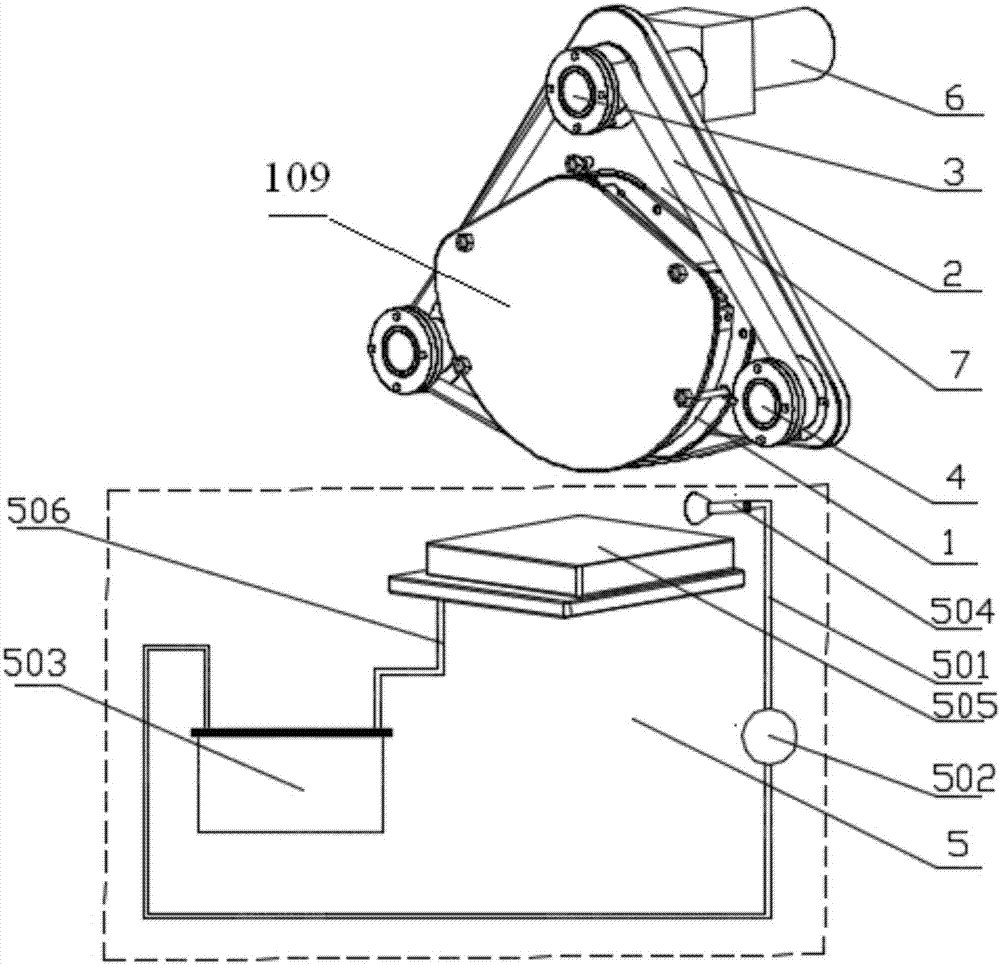

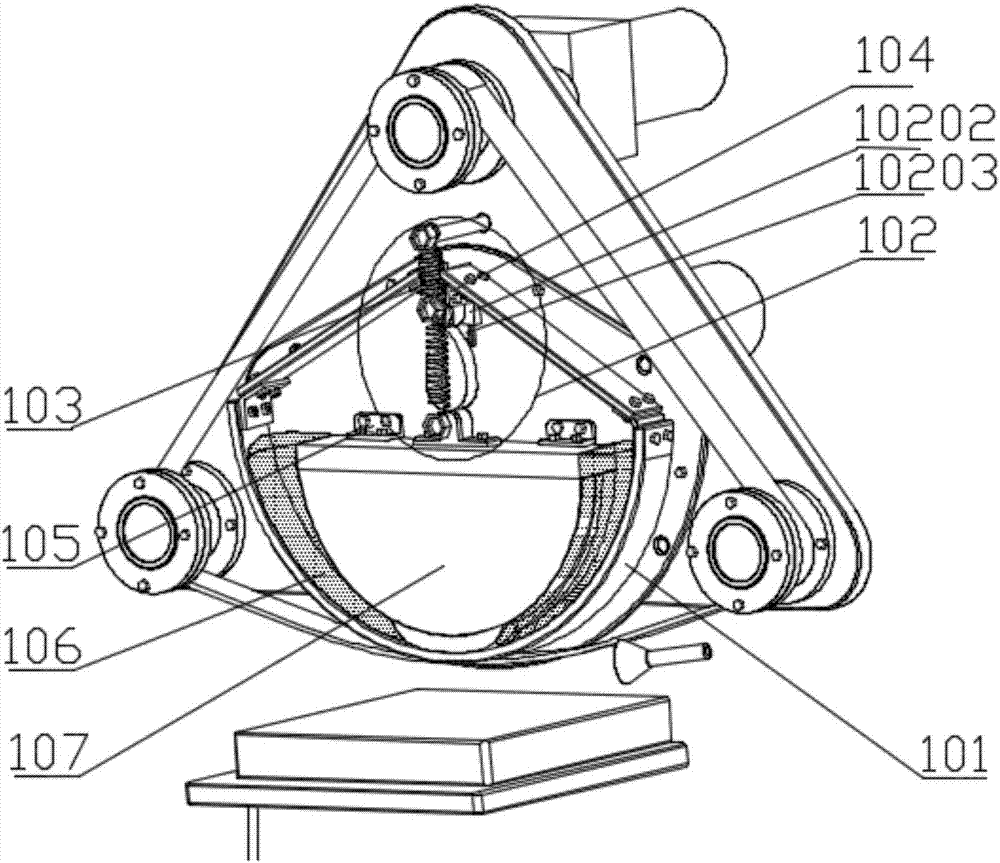

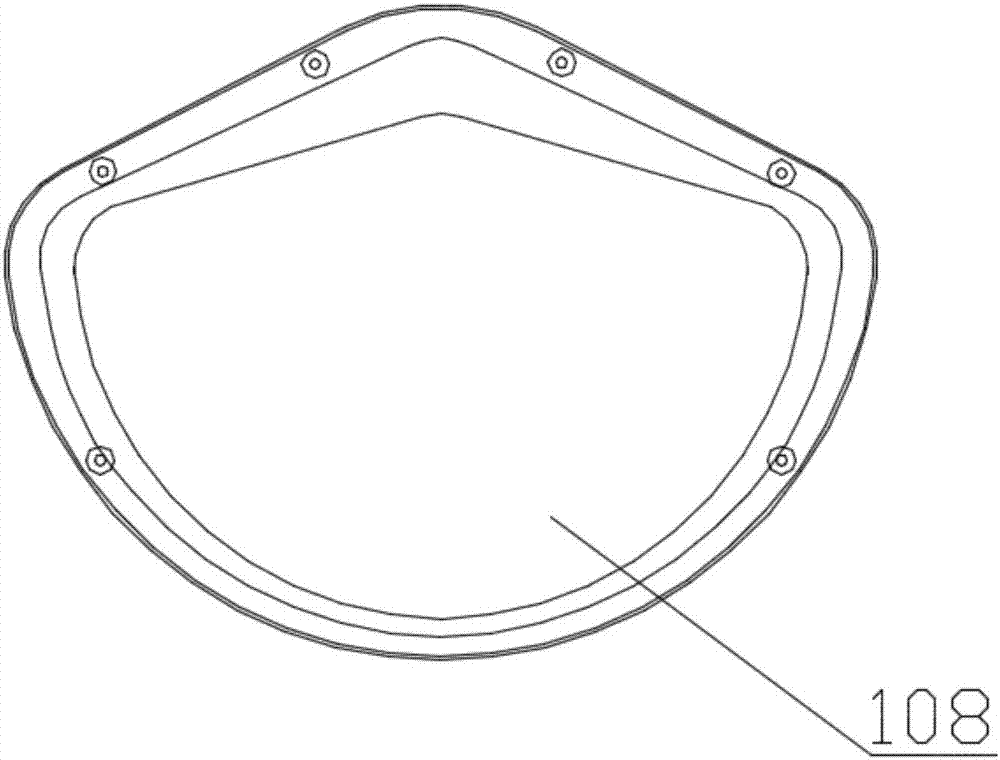

Abrasive band magnetorheological double curvature controllable composite finishing tool

ActiveCN106903586APreserve the advantages of micro-adaptive flexible deformationImprove processing efficiencyGrinding machine componentsBelt grinding machinesDrive wheelOptical processing

The invention relates to an abrasive band magnetorheological double curvature controllable composite finishing tool, and belongs to the technical field of precision optical machining. A macro curvature adjustment mechanism, a motor, a driving wheel and a tensioning wheel are fixed to a rack, wherein an output shaft of the motor is connected with the driving wheel, the driving wheel, the tensioning wheel and the macro curvature adjustment mechanism are wound by an abrasive band, and a magnetorheological fluid supply and recovery system is arranged below the abrasive band. The abrasive band magnetorheological double curvature controllable composite finishing tool has the following advantages: a microscope self-adapting flexible deformation advantage of magnetorheological finishing can be maintained, a macro active curvature controllable technical advantage of stress disc machining can be exerted, the problem that wide-range complete fitting machining can not be realized in the prior art can be solved, and the machining efficiency and the machining quality of a large workpiece are improved.

Owner:JILIN UNIV

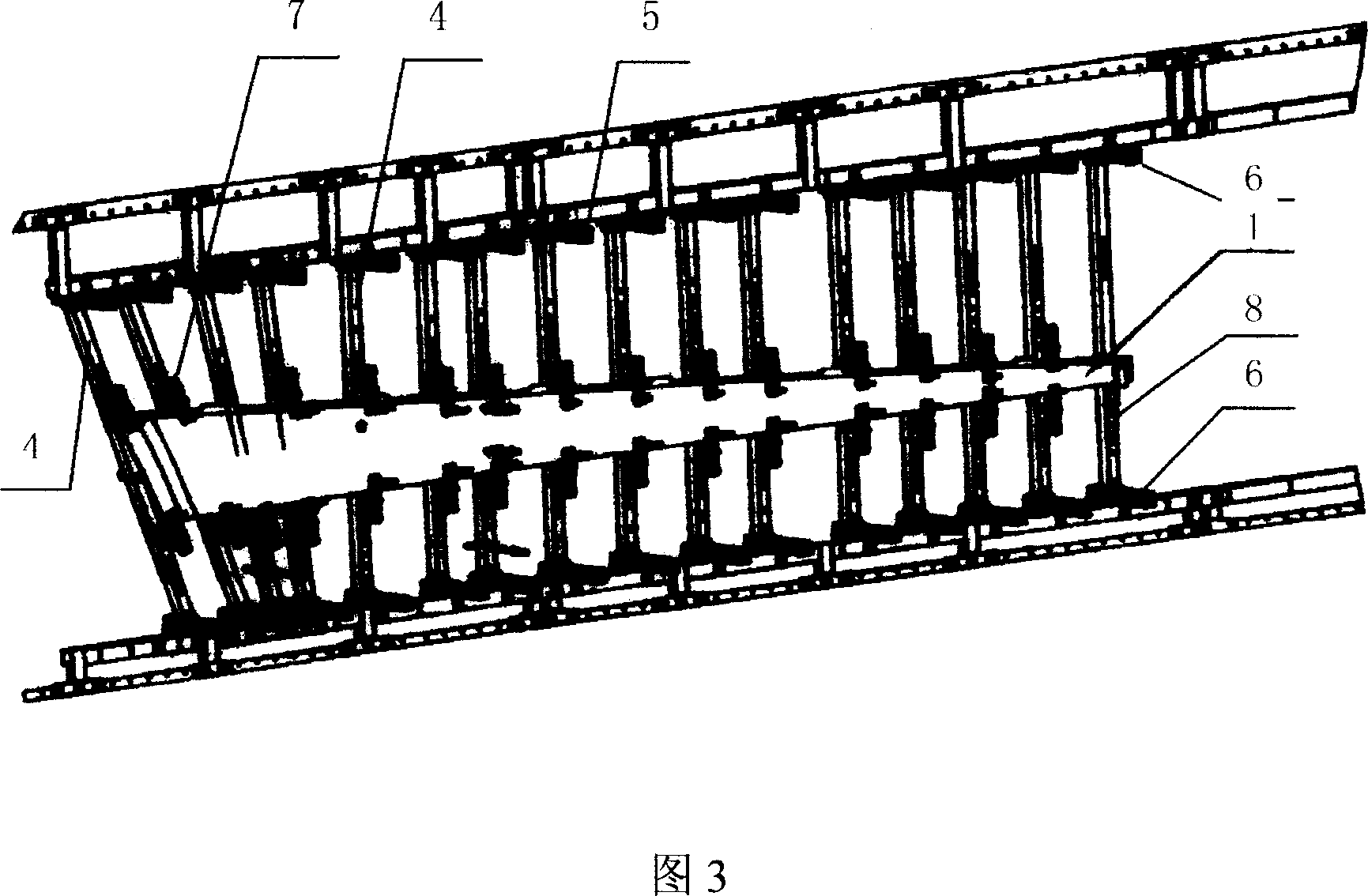

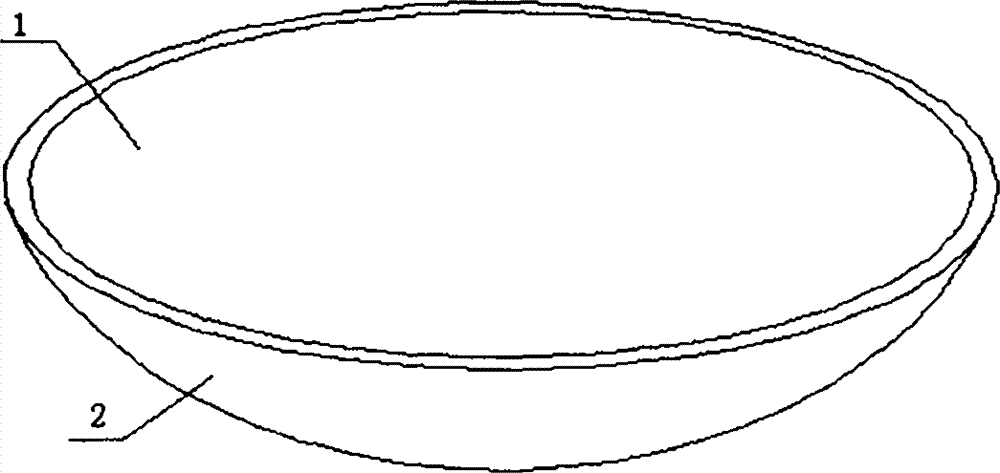

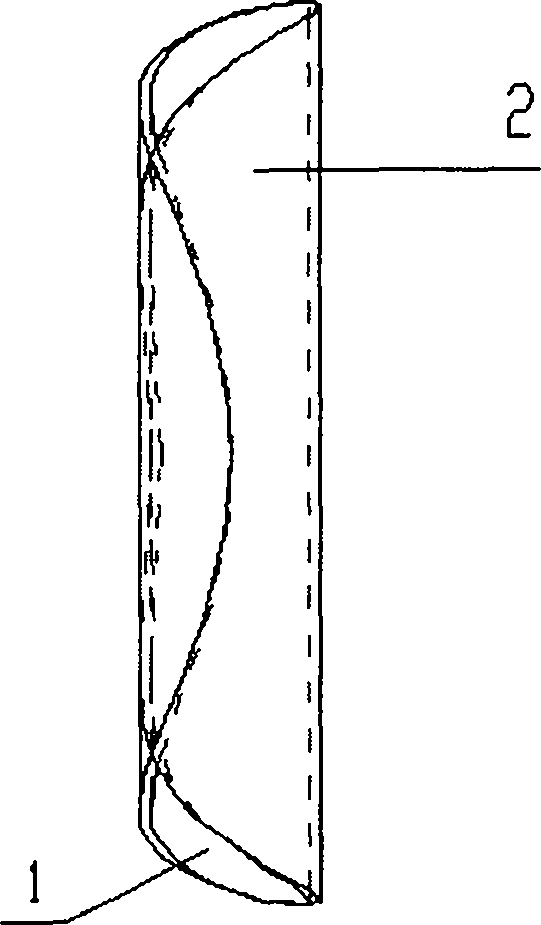

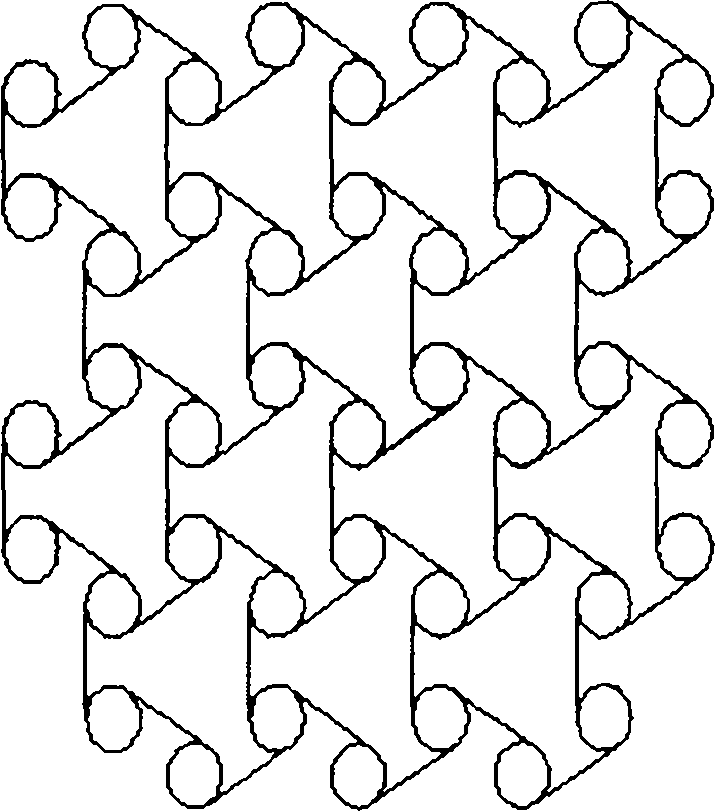

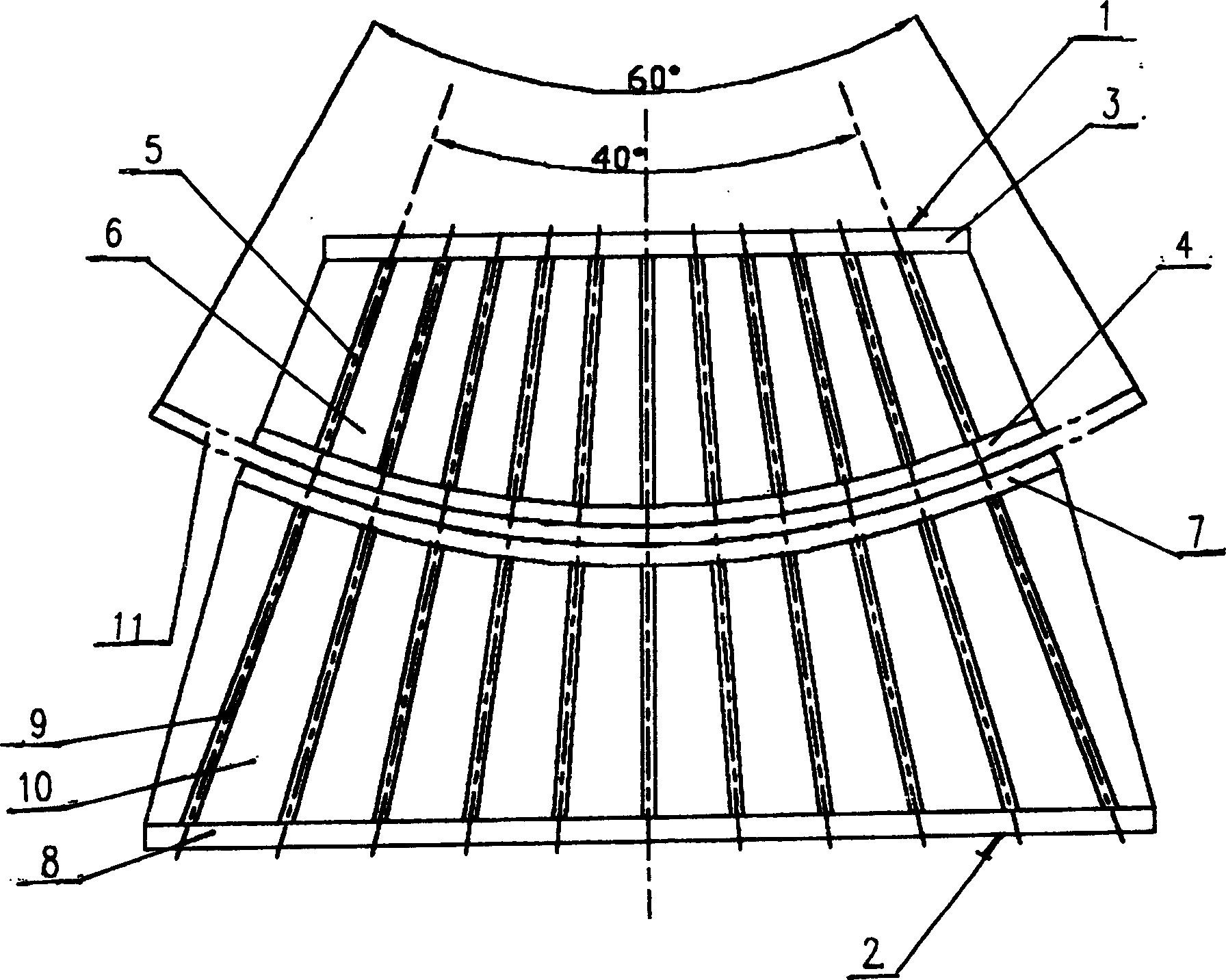

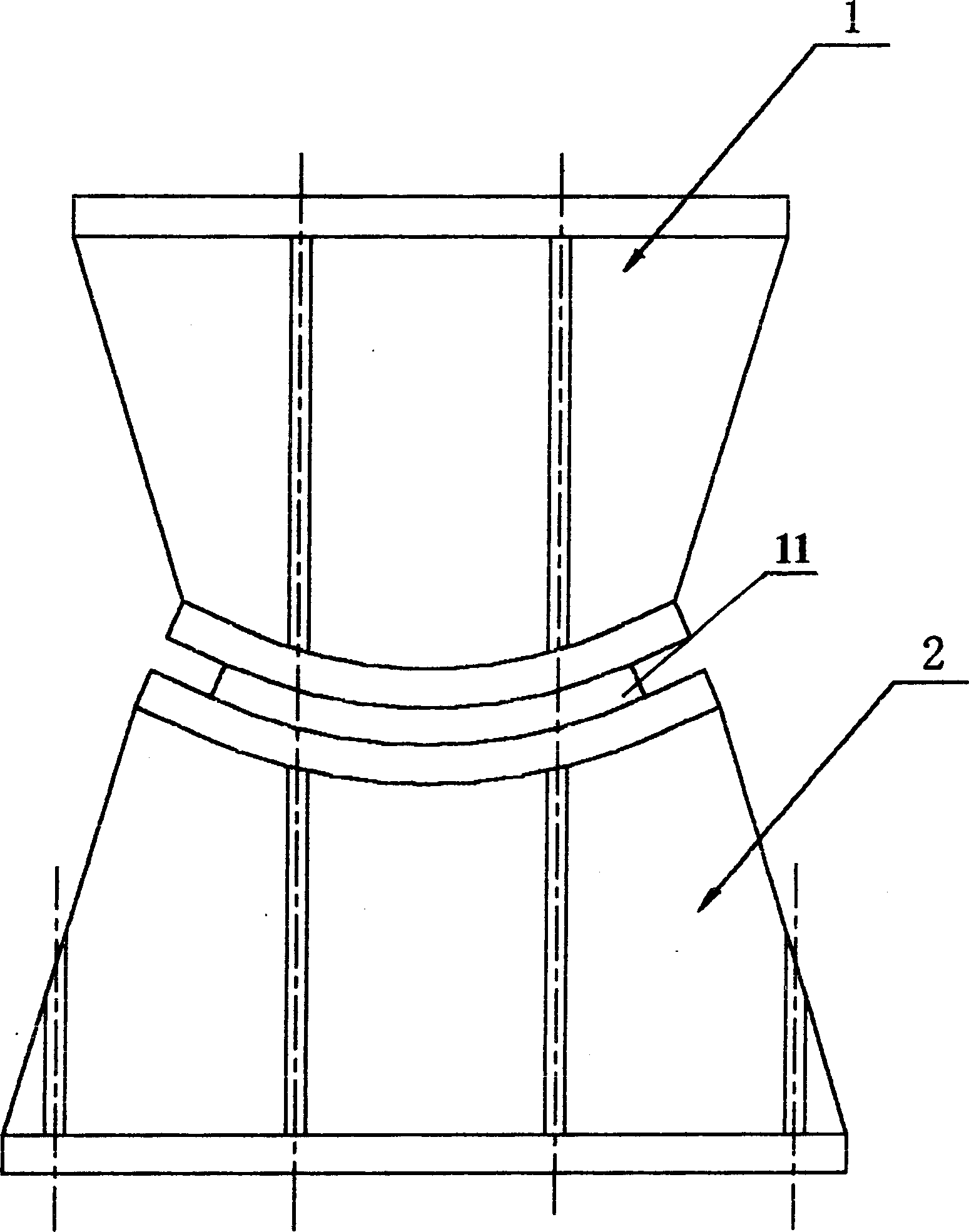

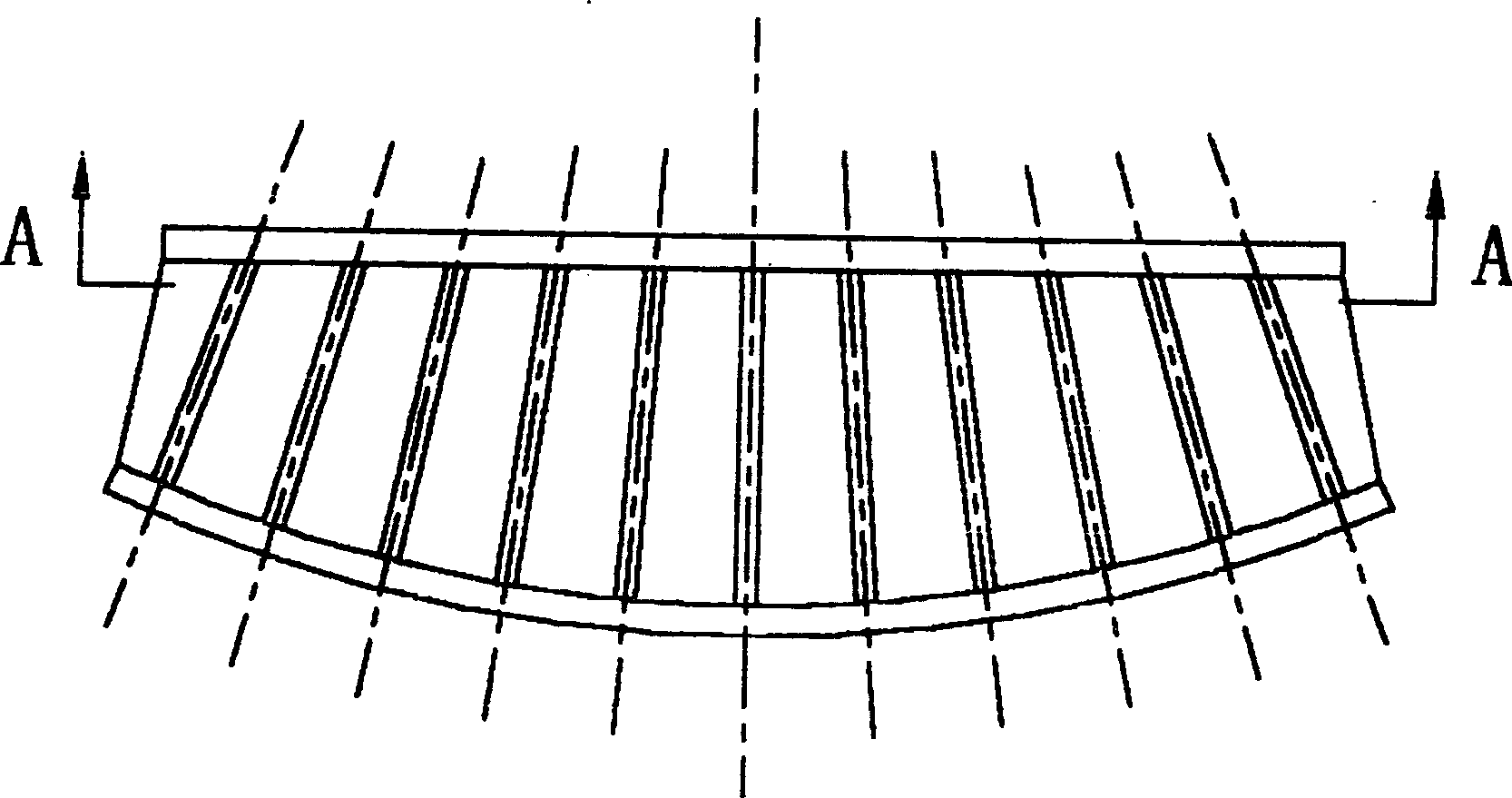

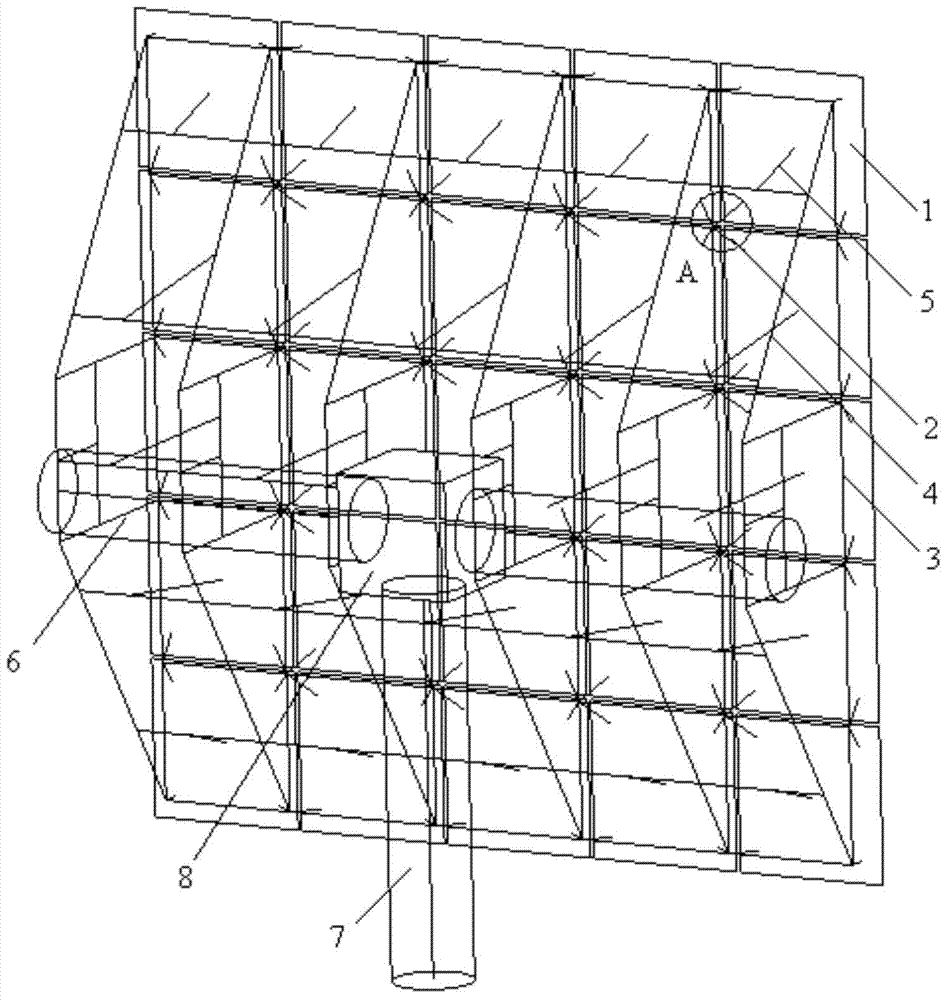

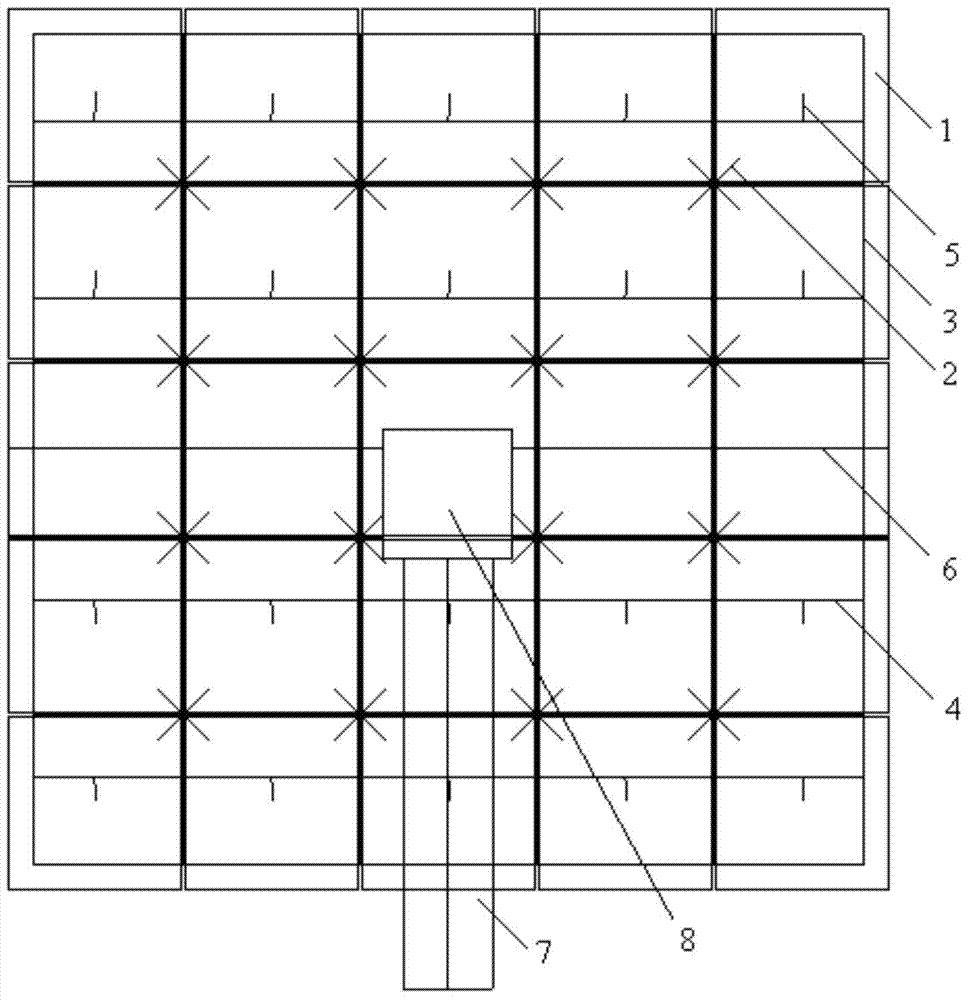

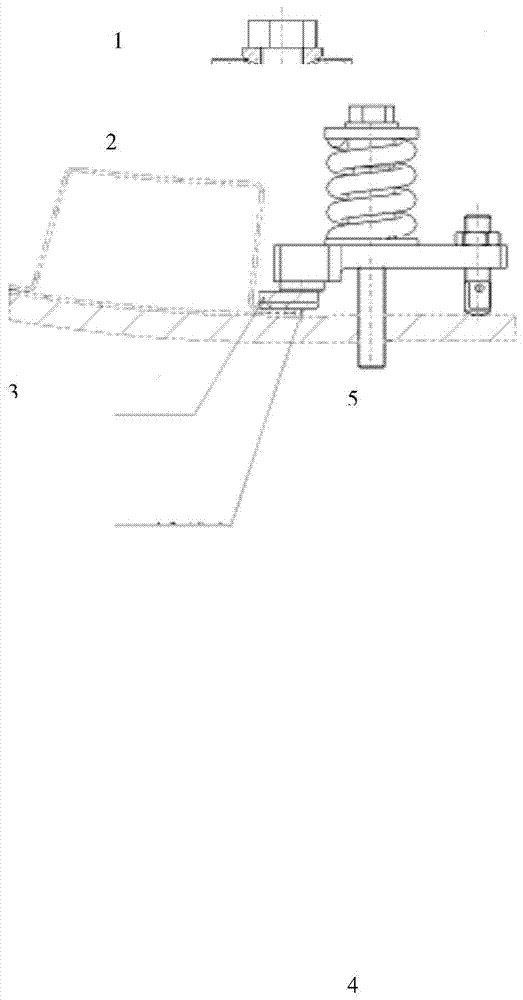

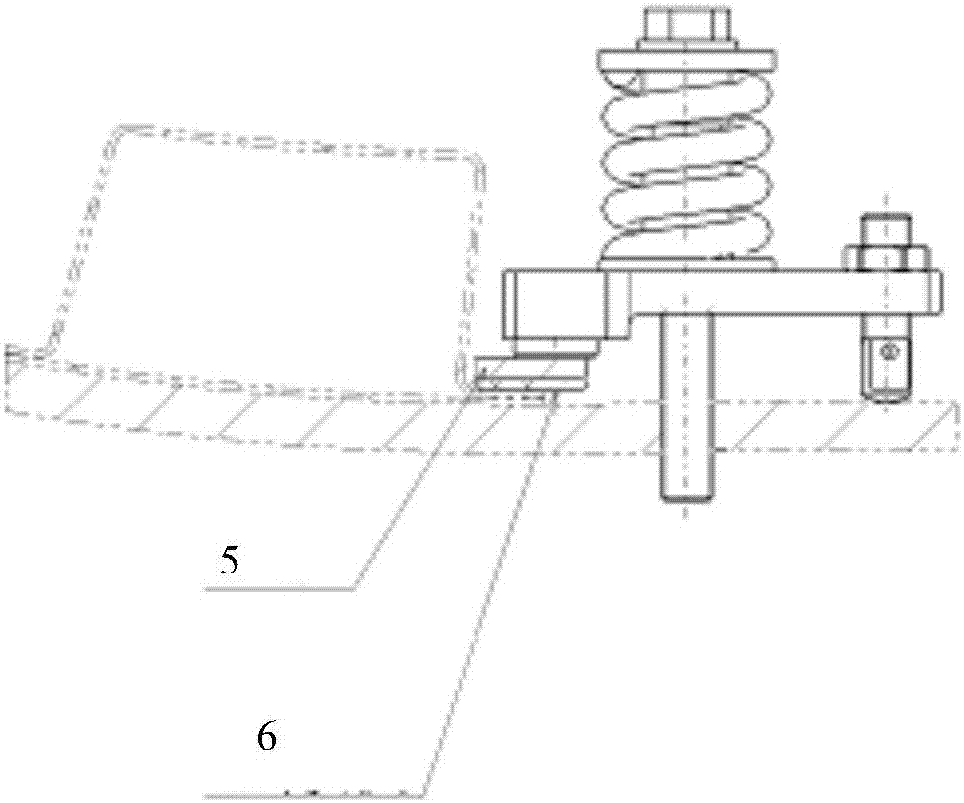

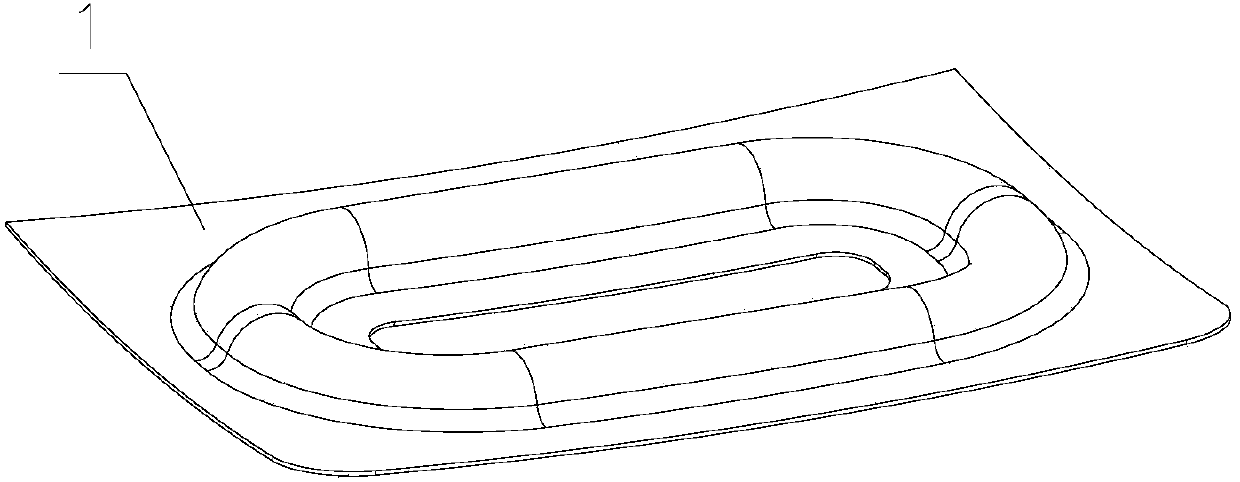

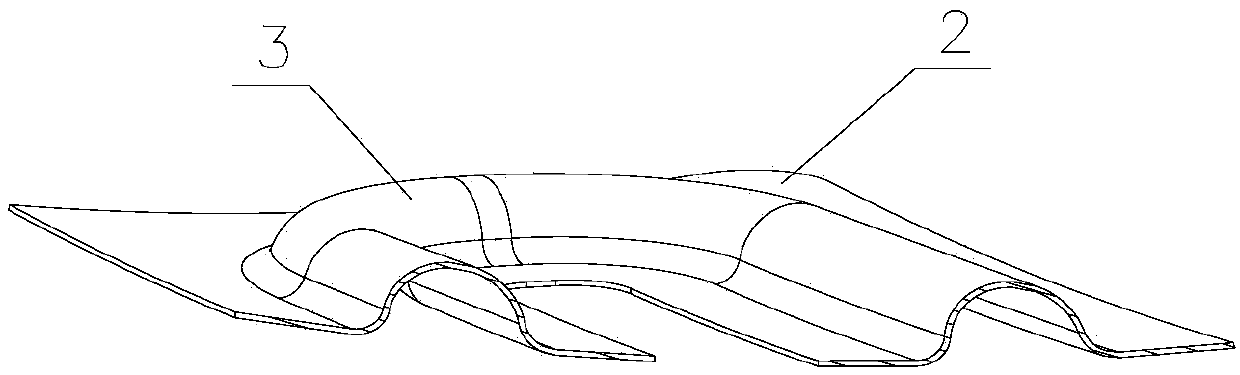

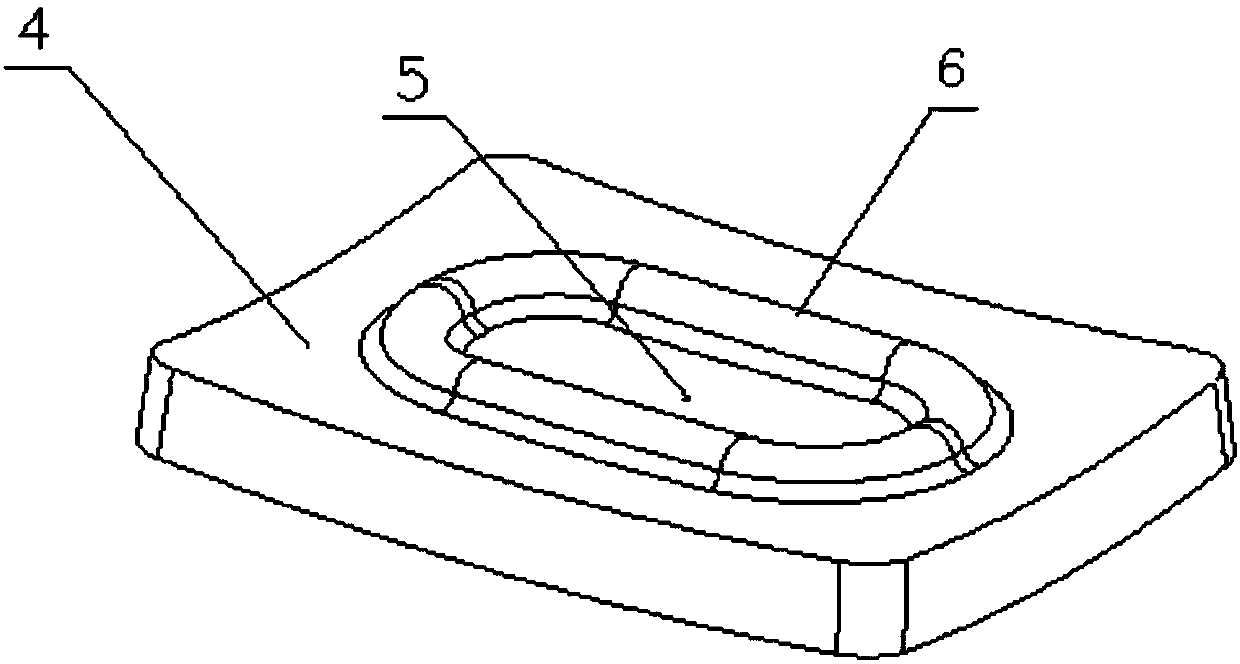

Cable truss type heliostat supporting device

A cable truss type heliostat supporting device comprises a reflector (1), connecting systems (2), a steel inhaul cable net (3), trusses (4), type adjusting steel inhaul cables (5), transverse shafts (6), a stand column (7) and a driving device (8). Through connection of the connecting systems (2) at the corner point positions and the center point positions of a plurality of sub-mirrors of the reflector (1), all the sub-mirrors are connected into a whole through the steel inhaul cable net (3). The plane face type of all the sub-mirrors is converted into a double-curvature condensation face type through the type adjusting steel inhaul cables (5). Each truss (4) is connected with the steel inhaul cable net (3) and the corresponding type adjusting steel inhaul cables (5) in a multi-point supporting mode. The two transverse shafts (6) are inserted into holes of the trusses respectively in a penetrating mode and connected with the trusses (4). The driving device (8) is installed at the upper end of the stand column (7) and connected with the two transverse shafts (6). Thus, the trusses (4), the transverse shafts (6), the driving device (8) and the stand column (7) are connected into a whole.

Owner:恒基能脉新能源科技有限公司

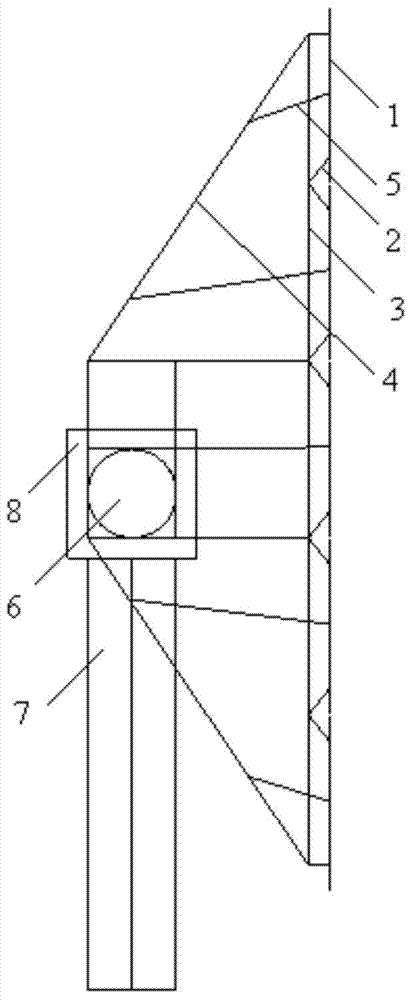

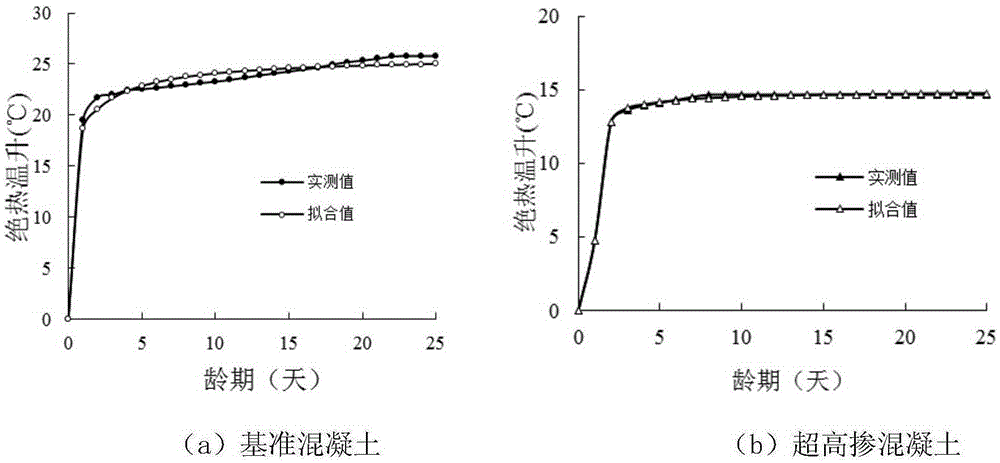

Method for determining temperature process curve of ultrahigh fly-ash content hydraulic massive concrete

InactiveCN105260509AIn line with the actual situationHigh precisionSolid waste managementDesign optimisation/simulationTemperature stressCrack resistance

The invention discloses a method for determining a temperature process curve of ultrahigh fly-ash content hydraulic massive concrete. The method comprises: using normal concrete and ultrahigh mixture concrete to perform an adiabatic temperature rise test, manufacturing an ultrahigh mixture concrete cubic large test block with side length of 1.2 m to carry out a temperature measuring test, combined with an internal point actual measured temperature record of a certain double-curvature arch dam which is established by using the normal concrete, providing an ultrahigh mixture concrete adiabatic temperature rise model, to improve temperature simulation calculation program, so as to simulate a temperature process curve of an ultrahigh mixture concrete dam which has no construction precedent. The method can be used for temperature-stress test evaluation and early-age crack resistance.

Owner:ZHEJIANG UNIV OF TECH

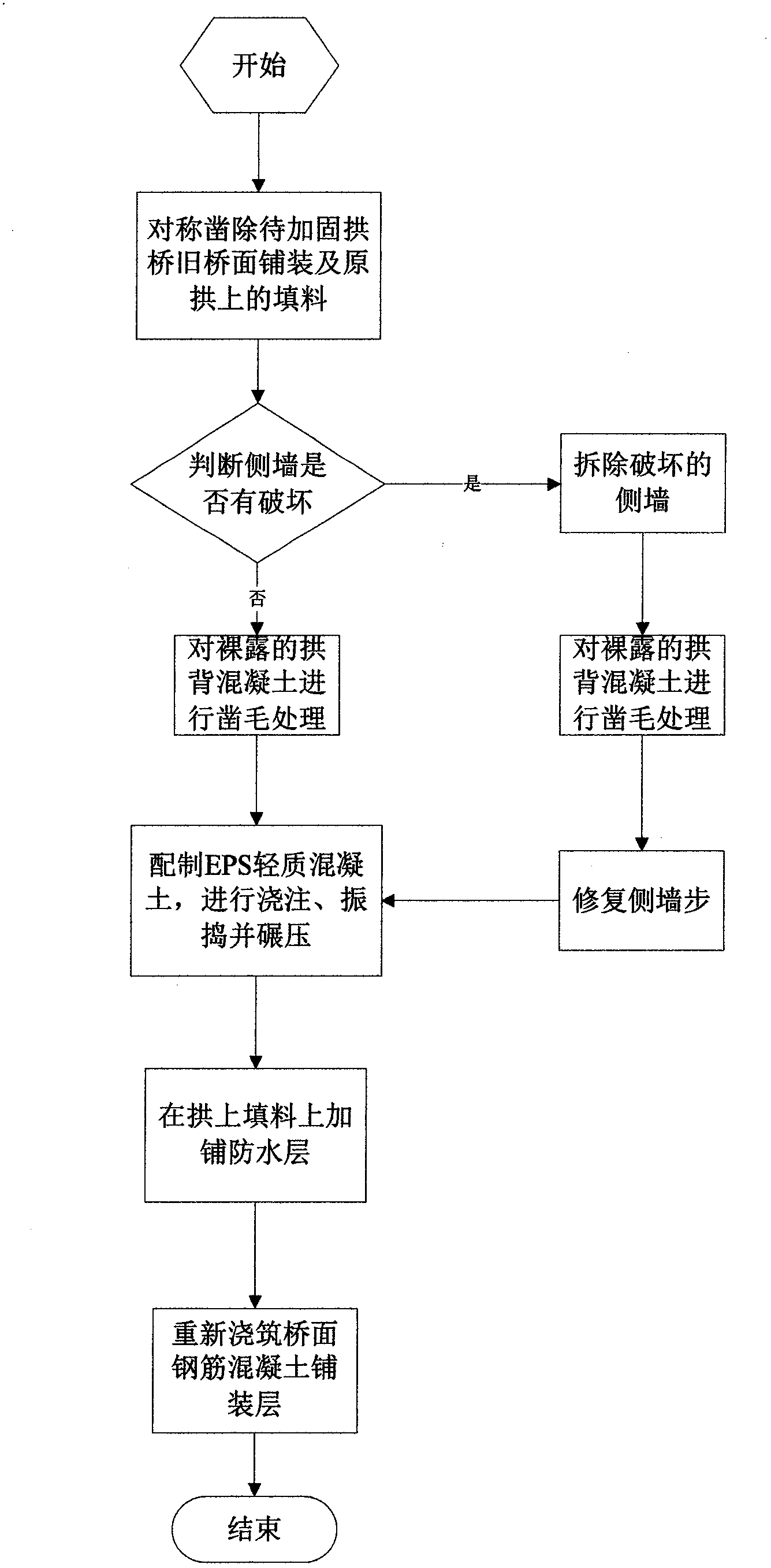

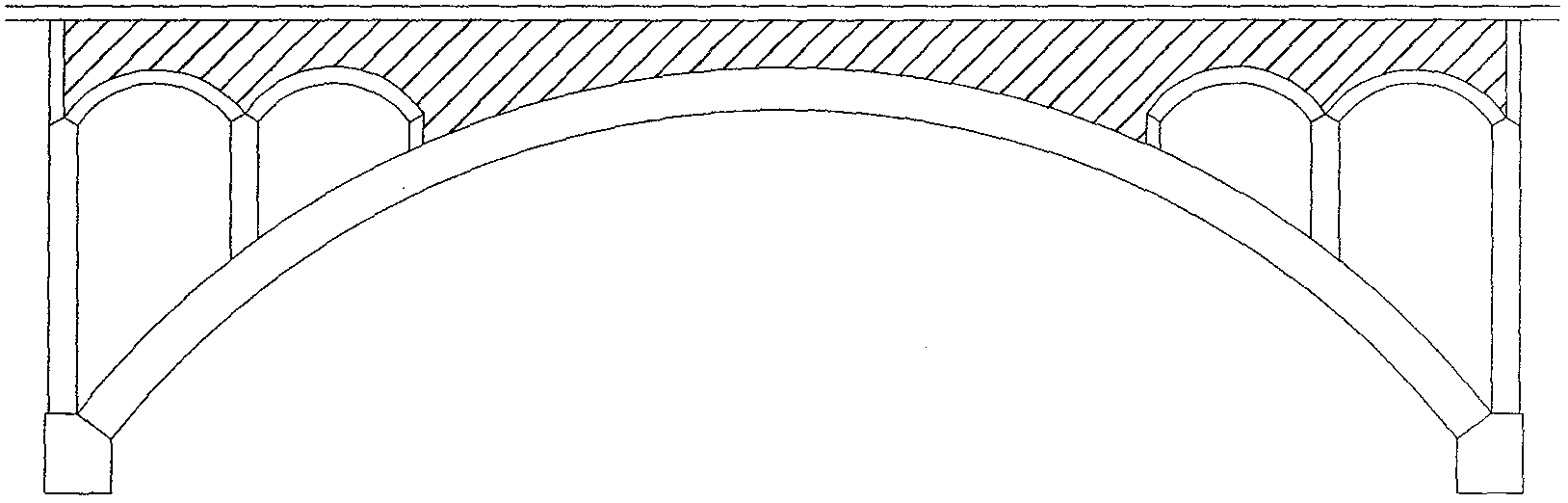

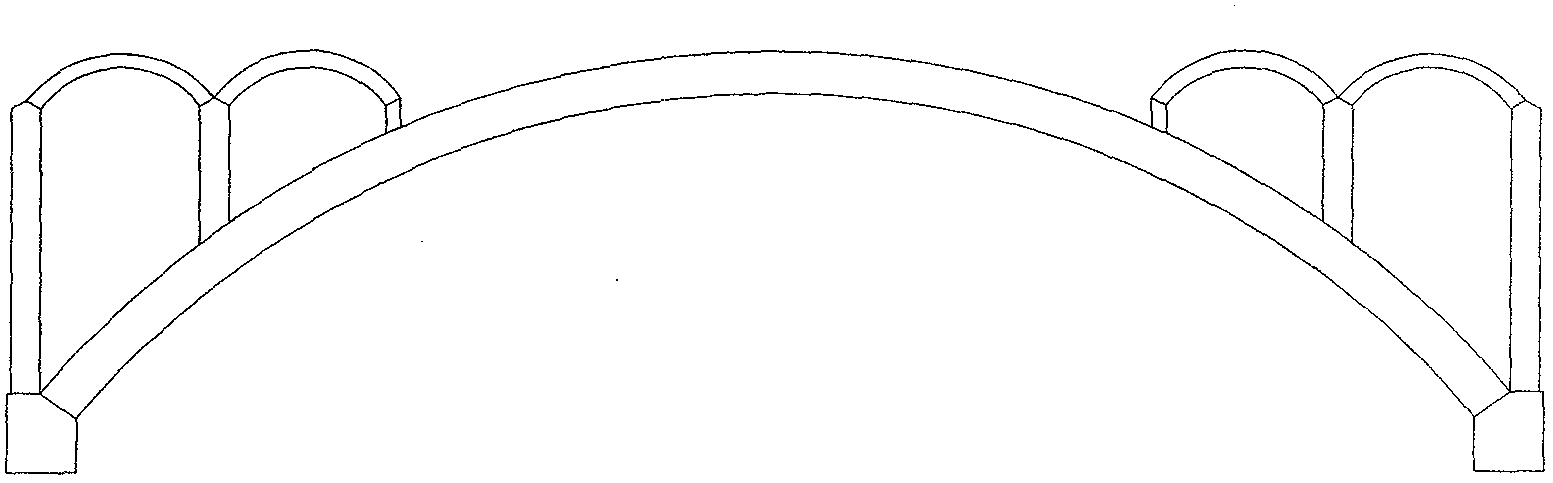

Method for reinforcing arch bridge with EPS Expandable Polystyrene light concrete

InactiveCN103184723AImprove carrying capacityCarrying capacity restored or improvedBridge erection/assemblyBridge strengtheningPolystyreneEngineering

The invention relates to a method for reinforcing an arch bridge with EPS Expandable Polystyrene light concrete. The method comprises the following steps: a, chipping away pavement on the old deck of the arch bridge to be reinforced and filling materials on original arches; b, preforming scabbling treatment on naked back arch concrete; c, preparing the EPS light concrete and performing casting, vibrating and rolling compaction; and d, pouring a new deck reinforced concrete pavement layer. Through the adoption of the method for reinforcing the arch bridge, the following benefits can be obtained: 1, the dead weight of the upper structure of the arch bridge can be reduced obviously, and the EPS light concrete has higher strength and thus can enhance the integrity of the construction on the arches and improve the load diffusion effect of the deck; 2, arch axis coefficients are regulated and optimized, so as to effectively improve the load-carrying capacity of a double curvature arch bridge; and 3, the EPS light concrete is low in manufacturing cost and can be made from recycled waste polystyrene material, thereby having favorable economic and environmental benefits.

Owner:金辉

High rib aluminum alloy wallboard manufacturing method

ActiveCN106180247AGuaranteed preparation efficiencyGuaranteed manufacturing accuracySheets/panelsThick plateDouble curvature

The invention relates to the field of metal molding, in particular to a high rib aluminum alloy wallboard manufacturing method. Firstly, upper and lower multipoint molds are adopted to oppositely press an aluminum alloy plane thick plate to mold a needed curved surface shape; and then, a high-speed milling method is used for milling a needed rib structure on the curved surface thick plate in a processing path parallel to the curved surface, so that a designed high rib aluminum alloy wallboard is obtained. The method applies the characteristic of quick and adjustable reconstruction of profile surfaces of the multipoint molds, uses one set of multipoint molds for molding double-curvature aluminum alloy thick plate parts with different geometric shapes, different thicknesses and different materials, and can control the rebound in molding of the aluminum alloy thick plate through multiple times of correction so as to improve the molding precision; and the high rib aluminum alloy wallboard manufacturing method can obtain high-precision high rib aluminum alloy wallboard parts without damaging fiber structures of the aluminum alloy plate materials, guarantees the strength requirements of the wallboard parts, solves the technical difficulties in large aircraft manufacturing, and can be popularized and applied to manufacturing of such other parts as spacecrafts and rockets.

Owner:JILIN UNIV

Plastic enclosed impeller manufacturing technique

InactiveCN103128974AOvercoming the problem of being unable to press and formImprove hydraulic performanceDomestic articlesImpellerManufacturing technology

The invention relates to a plastic enclosed impeller manufacturing technique of a plastic lining pump. The plastic enclosed impeller manufacturing technique is characterized by comprising the following processing steps: adding 720 grams of tetrafluoroethylene-hexafluoropropylene copolymer granules into the mold of a front shroud, heating the tetrafluoroethylene-hexafluoropropylene copolymer granules to 320 DEG C + / - 2DEG C in a heating box, carrying out heat preservation for 3 hours, then pressurizing 10 MPa in a pressing machine, maintaining pressure for 2 hours, carrying out natural cooling in air, and demoulding to take out a front shroud; adding 512 grams of tetrafluoroethylene-hexafluoropropylene copolymer granules into the mold of a back shroud, heating the tetrafluoroethylene-hexafluoropropylene copolymer granules to 320 DEG C + / - 2DEG C in the heating box, carrying out heat preservation for 2 hours, then pressurizing 10 MPa in the pressing machine, maintaining pressure for 1.5 hours, carrying out natural cooling in air, and demoulding to take out a back shroud; and using teflon bar materials to process screws to connect the front shroud and the back shroud. The manufacturing technique guarantees the separated pressing of the front shroud and the back shroud through a pressing technique, a blade can be made into a double curvature shape, and therefore the hydraulic performance of an impeller is improved, and a manufacturing technology is simple, production cost is low, and the plastic enclosed impeller manufacturing technique can meet the usability of the plastic enclosed impeller completely.

Owner:黄晓鹏 +1

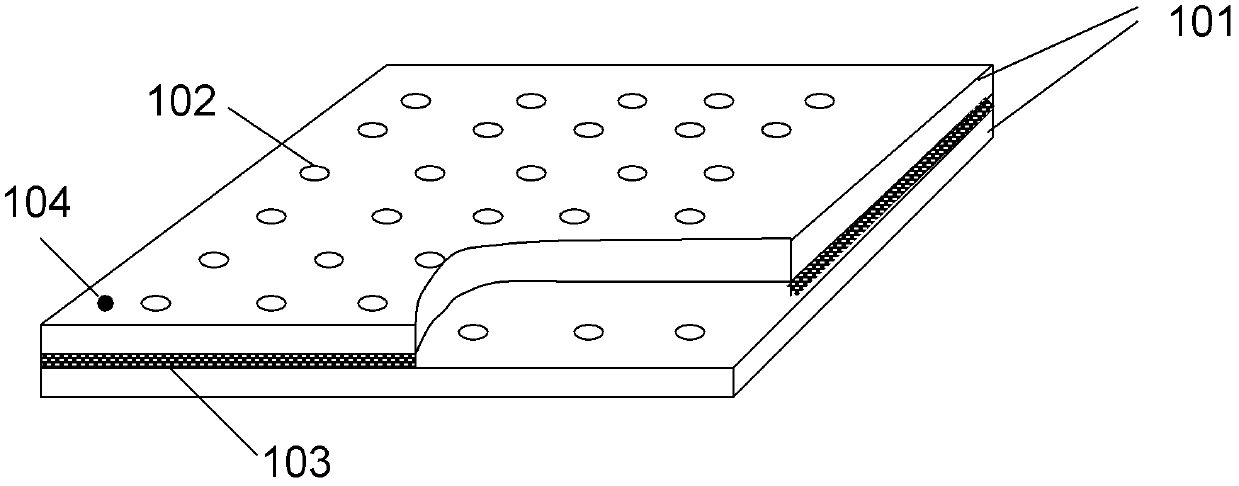

Secondary glue joint pressing method for thin composite material plate

The invention belongs to the technical field of composite materials, and particularly relates to a secondary glue joint pressing method for a thin composite material plate. According to the secondary glue joint pressing method for the double-curvature-surface thin composite material plate, the pressing method used as the drawing is adopted in secondary glue joint compression; and then curing and demolding are performed in a curing oven according to the curing parameters of the material, and accordingly secondary glue joint is completed. The process stability is high, a pressure application device can be prepared easily, and operation is easy. Meanwhile, helpful experience is provided for other plane types.

Owner:HARBIN

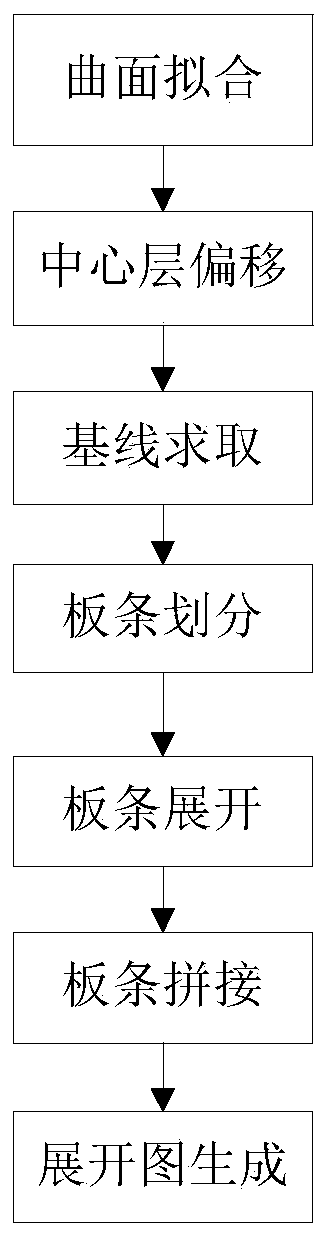

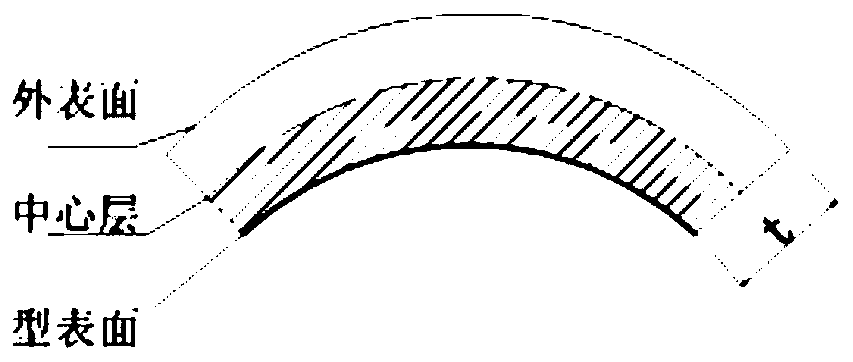

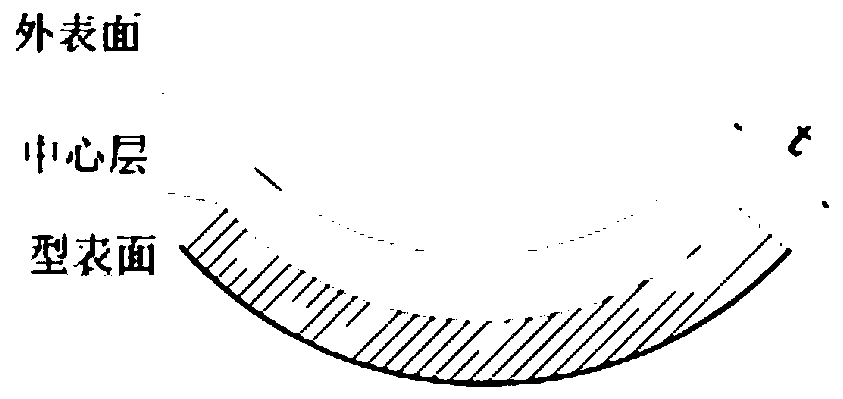

Unfolding method of double-curvature plate

ActiveCN110472291AImprove efficiencyGood precisionGeometric image transformationSpecial data processing applicationsEngineeringDiscretization

According to the unfolding method of a double-curvature plate, a geometric unfolding method is adopted. In the unfolding process, the influence of the plate thickness on the unfolding result is eliminated through deviation of a theoretical surface; meanwhile, a finite element discretization method is adopted, the bent plate is divided into a plurality of battens along a base line, then the battensare divided into small triangular bent plates, the bent plate is approximately replaced by a flat plate, and the battens are unfolded; and finally, different forming machining methods of the hyperbolic plate are considered, the battens are spliced in different modes, and the unfolding outline of the hyperbolic plate is formed. The hyperbolic plate unfolding method better reflects the actual deformation situation in the hyperbolic plate forming process, so that the unfolding result precision is high, and meanwhile the method can be suitable for unfolding of single curvature and thin plates.

Owner:WUHAN UNIV OF TECH

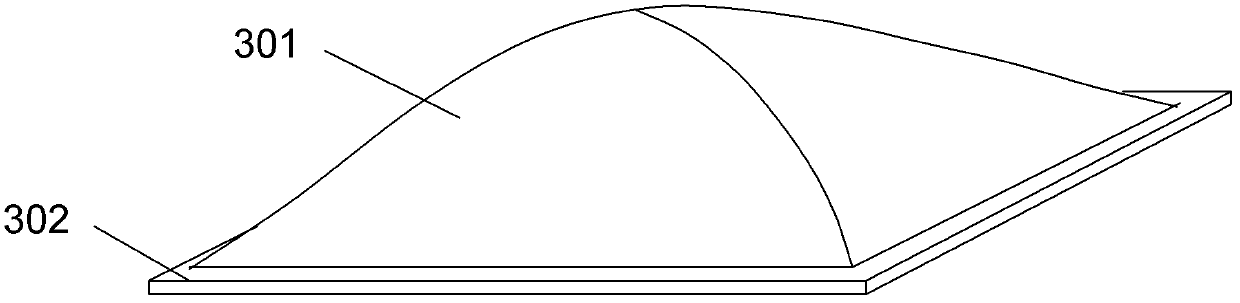

Support-free double bent vacuum glass and manufacturing method thereof

ActiveCN103288337AImprove carrying capacityReduce deflectionGlass reforming apparatusEngineeringDouble curvature

The invention discloses support-free double bent vacuum glass and a manufacturing method thereof. The glass consists of two pieces of hermetical bent glass relatively distributed, wherein the middle gap is vacuum. The two pieces of bent glass consist of arched curved surfaces and banding planes at the edges, wherein the arched curved surfaces can be spherical surfaces or double curvature arch-shaped surfaces, and the banding planes at the edges are 5-10mm wide. The periphery of the bent glass can be circular or rectangular. The bent vacuum glass can be used for forming vacuum glass in a vacuum furnace or bleeder holes are distributed on one piece of the bent glass to from vacuum through the bleeder holes. According to the double bent vacuum glass disclosed by the invention, indispensable support in common vacuum glass is cancelled, so that the vacuum glass is higher in strength and more excellent in heat and sound insulating function, and better in practical value, and can be used in building ceilings and some special parts.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

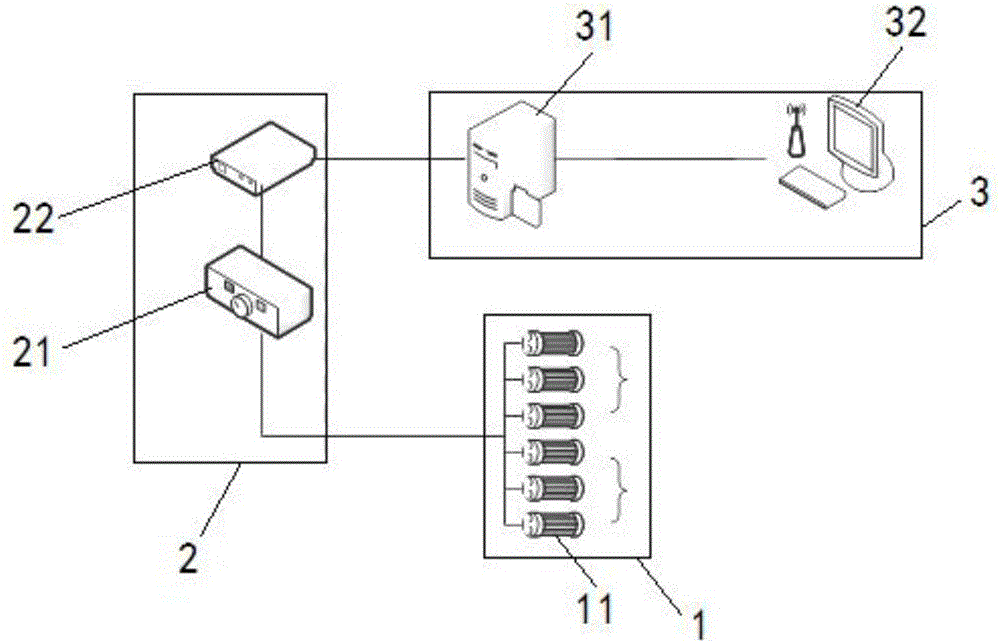

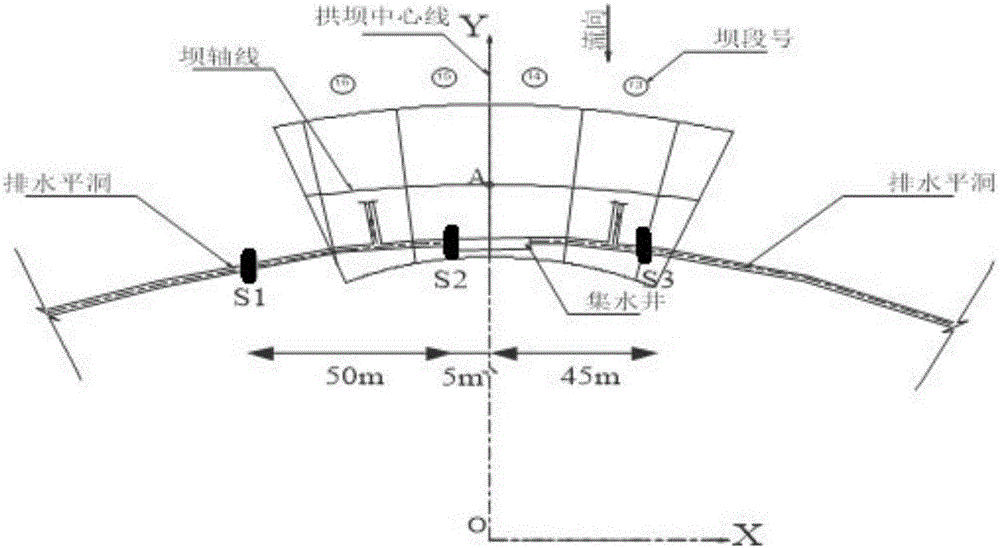

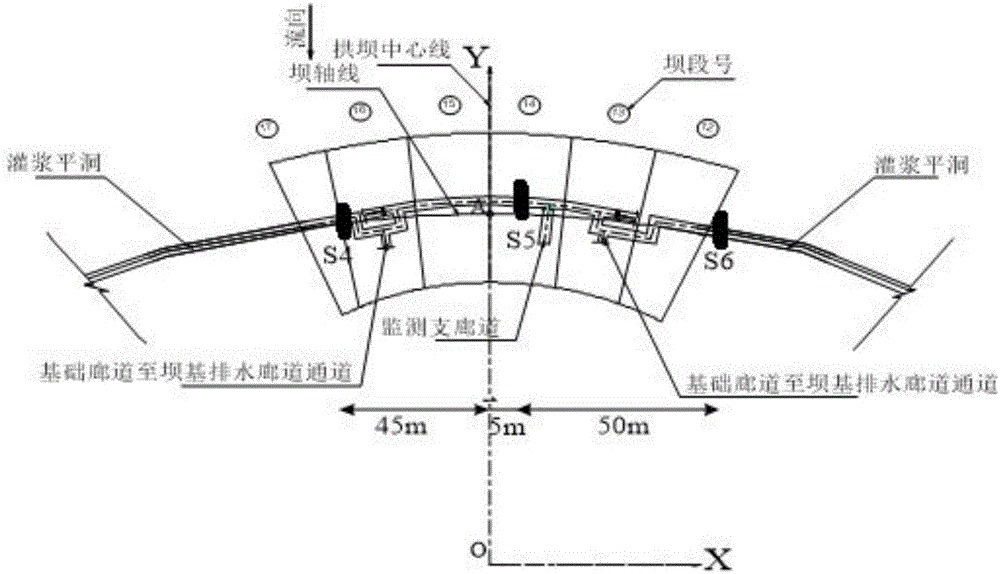

Slight shock monitoring system and method of double-curvature arch dam

The invention discloses a slight shock monitoring system and method of a double-curvature arch dam. The system comprises a slight shock sensing device, at least one signal collecting substation and a data processing terminal; the slight shock sensing device monitors slight shock signals of different areas of the double-curvature arc dam in real time in the water storage process of the double-curvature arch dam, and sends the slight shock signals to the signal collecting substation; the signal collecting substation carries out analog-to-digital conversion on the slight shock signals, stores the slight shock signals, and sends the converted signals to the data processing terminal; the data processing terminal analyzes the converted signals to obtain slight shock evolution data of the different areas of the double-curvature arc dam. A slight shock monitoring technology is applied to monitoring for the concrete double-curvature arch dam in water conservancy and hydropower, dangerous areas of the dam body of the double-curvature arc dam in the water storage period can be deduced according to an analysis result of slight shock monitoring, stable monitoring in the storage and operation period of the double-curvature arc dam is accumulated and completed, and the system and method have sustainable economical and social benefits.

Owner:DALIAN UNIV OF TECH

Double-curvature rectangular reinforcing inner skin rubber hydraulic forming method

InactiveCN108237173AQuality assuranceQuality improvementAircraft componentsShaping toolsWrinkle skinEngineering

The invention provides a double-curvature rectangular reinforcing inner skin rubber hydraulic forming method. The method involves a rubber hydraulic forming die, the edge covering allowance is increased along the edge of the die on the basis of the unfolding size of the die line, due to the fact that the compression type cushion layer plates are laid step by step, the deformation of the blank is gradually increased, and the purpose of gradually forming is achieved; and rubber hydraulic forming is carried out, an inner hole part is opened up, and forming is finished. According to the method, the rubber hydraulic forming technology is utilized to obtain the product which is stable in quality and meets the design requirements; and wrinkles caused by over-fast flowing of the materials can be effectively controlled, and manual knocking modification amount is greatly reduced.

Owner:XIAN AIRCRAFT IND GROUP

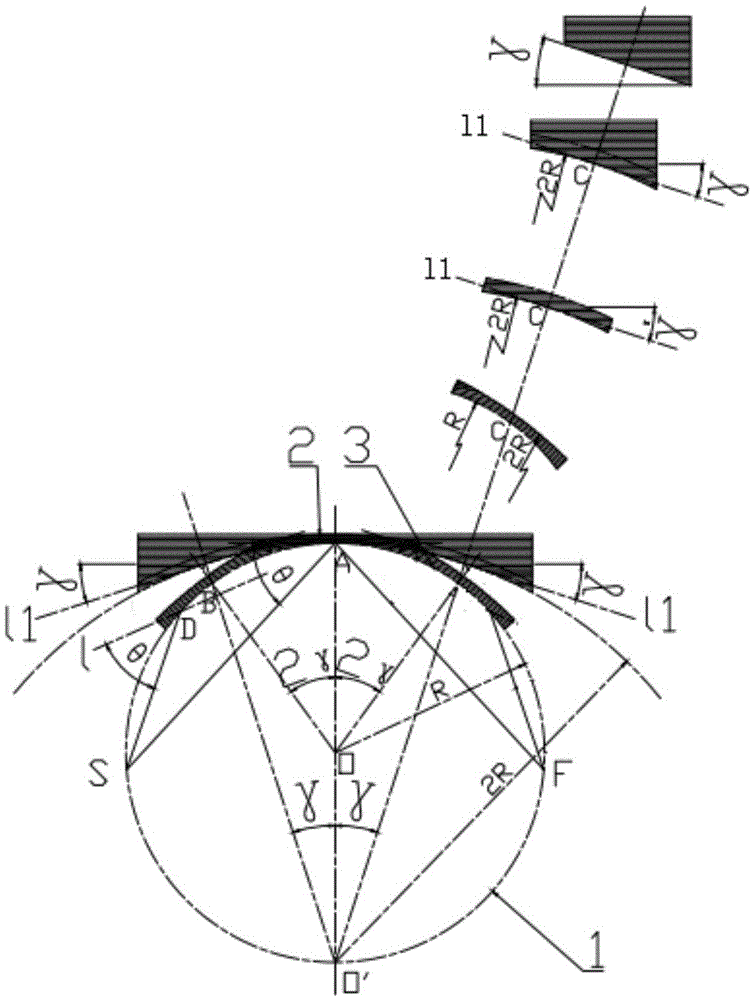

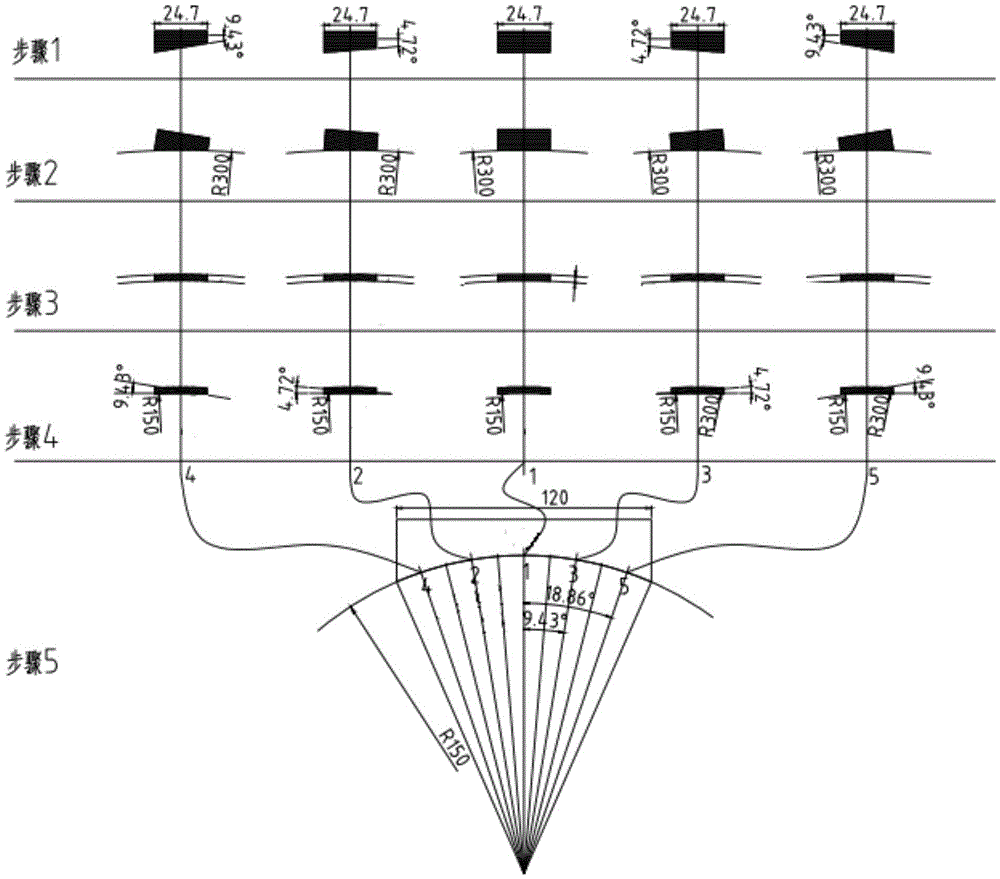

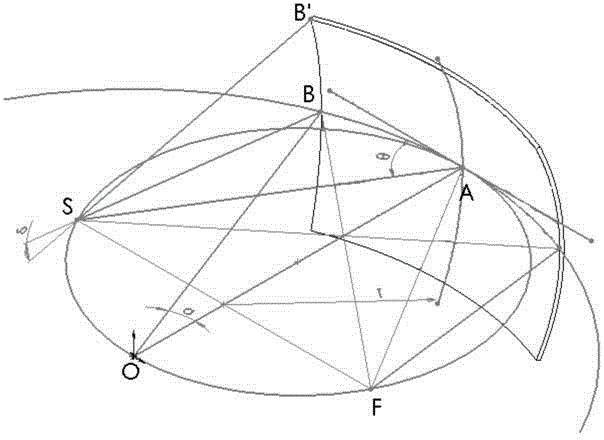

Manufacturing method of large-area total focusing type double curvature bent crystals

InactiveCN105575454AHigh diffraction efficiencyHigh strengthHandling using diffraction/refraction/reflectionOptical axisX-ray

The invention provides a manufacturing method of large-area total focusing type double curvature bent crystals. The manufacturing method is characterized by comprising the following steps that step one, in a Rowland circle direction: (1) a center chip is processed and manufactured; (2) chips of the two sides of the center chip are processed and manufactured; and step two, in an arc surface direction perpendicular to the Rowland circle: rotating radius r bending is performed on all the covering crystals in the Rowland circle direction completely manufactured in the step 1 in the original position along an optical axis formed by an incident focus S and an emergent focus F so that the double curvature bent crystals are formed. The beneficial effects of the manufacturing method of the large-area total focusing type double curvature bent crystals are that total focusing crystal diffraction can be realized in two directions in a segmented way by using a simple and feasible processing method of small crystals so that the large-area double curvature bent crystals on the designed total focusing curved surface can be realized and more incident intensity can be collected; and X-ray monochromatization and crystal light splitting in wavelength dispersion X-ray fluorescence analysis can be realized by utilizing the technology so that crystal diffraction efficiency and intensity can be greatly enhanced.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com