Processing method of titanium alloy double-curvature rotary drum

A technology of a rotating cylinder and a processing method, which is applied in the field of metal forming processing to achieve the effects of small springback, elimination of residual stress, and guarantee of dimensional accuracy and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

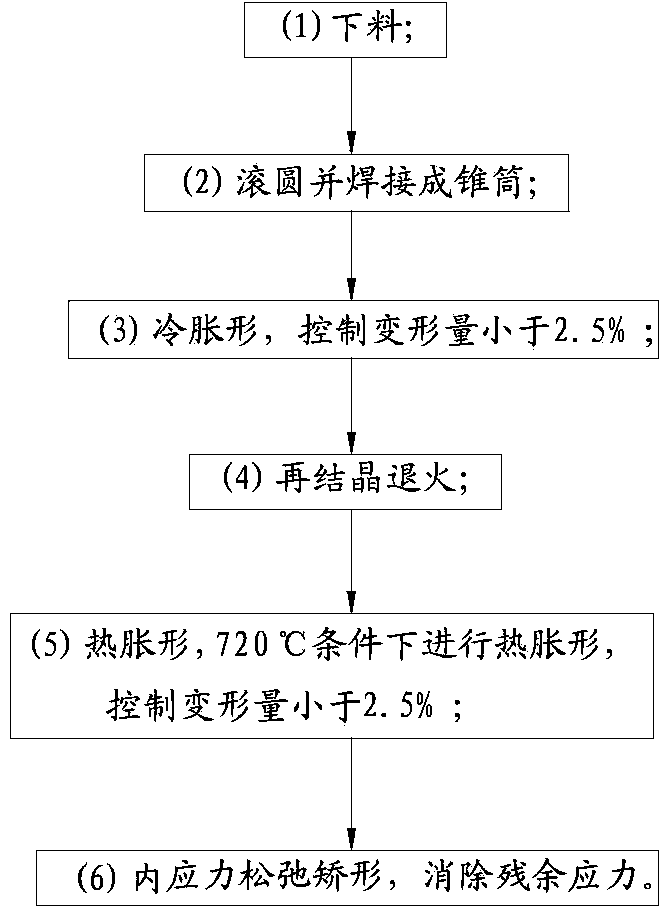

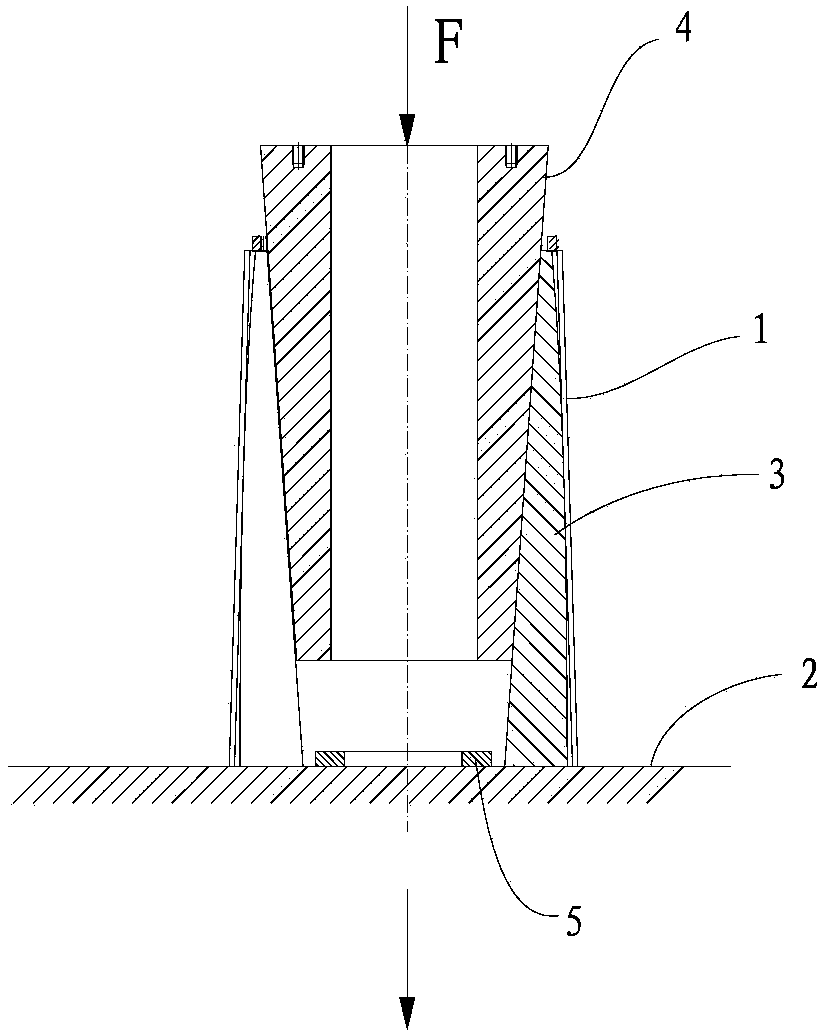

[0021] see figure 2 , shown in Fig. 3, the processing method of titanium alloy hyperbolic rotating cylinder of preferred embodiment of the present invention, comprises the following steps:

[0022] (1) For blanking, expand the cone into a fan shape; the arc length of the fan shape is negative work difference.

[0023] (2) Rolling and welding into a cone;

[0024] (3) Cold bulging. Under normal temperature conditions, cold bulging is carried out with expansion petal cold bulging tires, and the deformation is controlled to be less than 2.5%, that is, the diameter of the maximum deformation is expanded from 440mm to 450mm;

[0025] (4) Recrystallization annealing, 550 ℃, heat preservation for half an hour, cooling with the furnace;

[0026] (5) Thermal expansion. Under the condition of 720°C, thermal expansion is carried out with the expansion petal type thermal expansion tire, and the deformation is controlled to be less than 2.5%, that is, the diameter of the maximum deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com