Patents

Literature

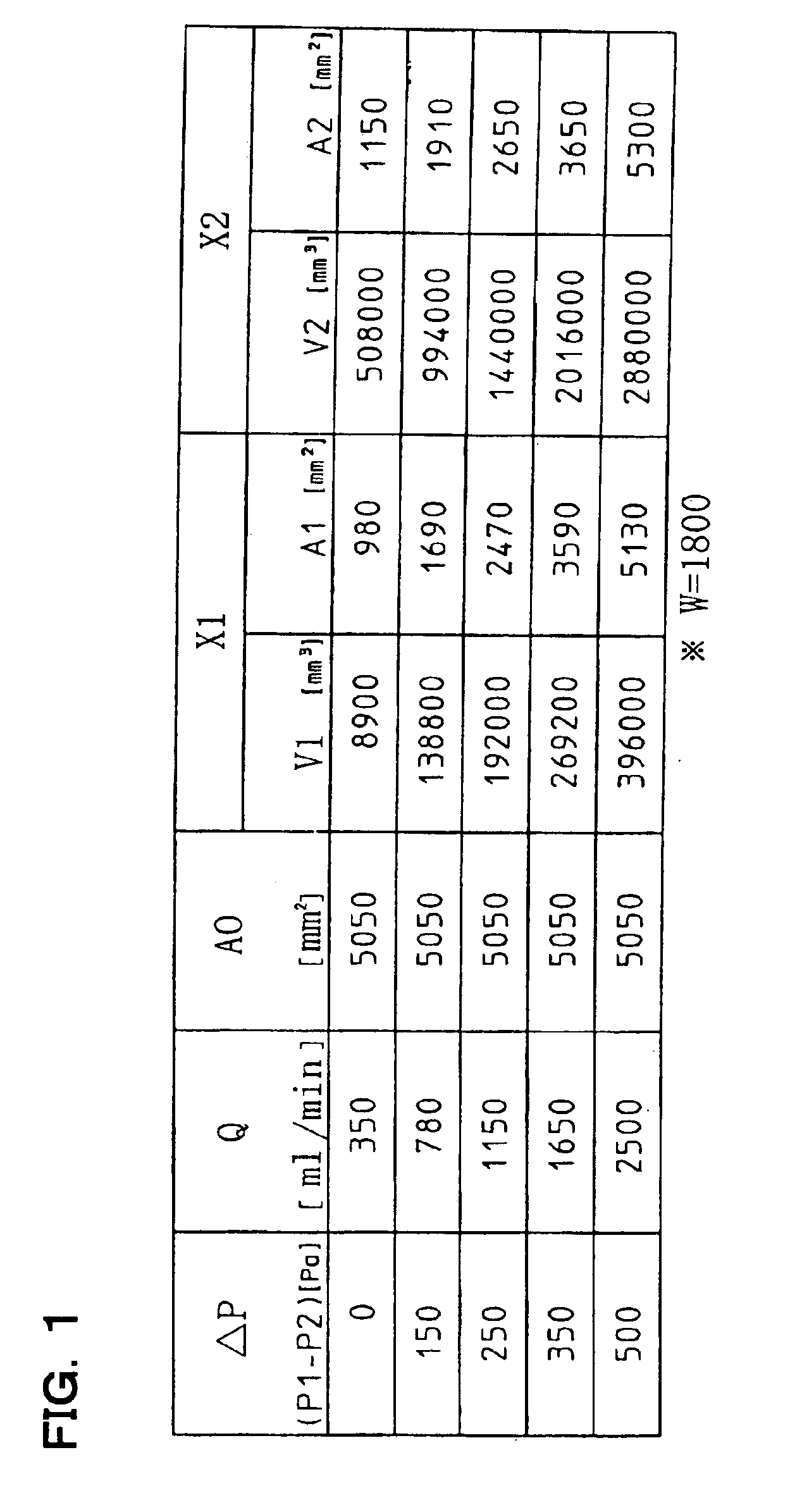

138results about How to "Ensure strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

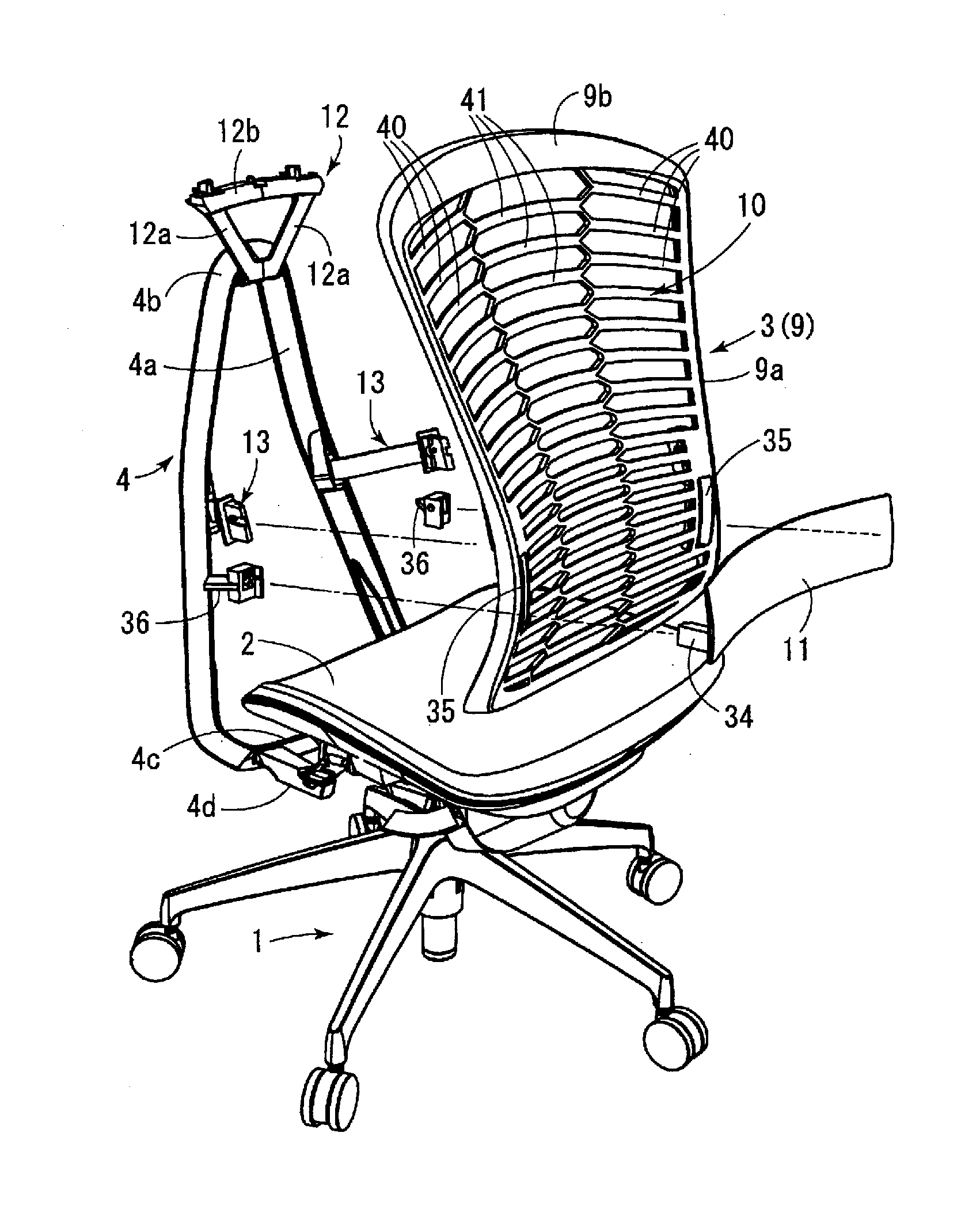

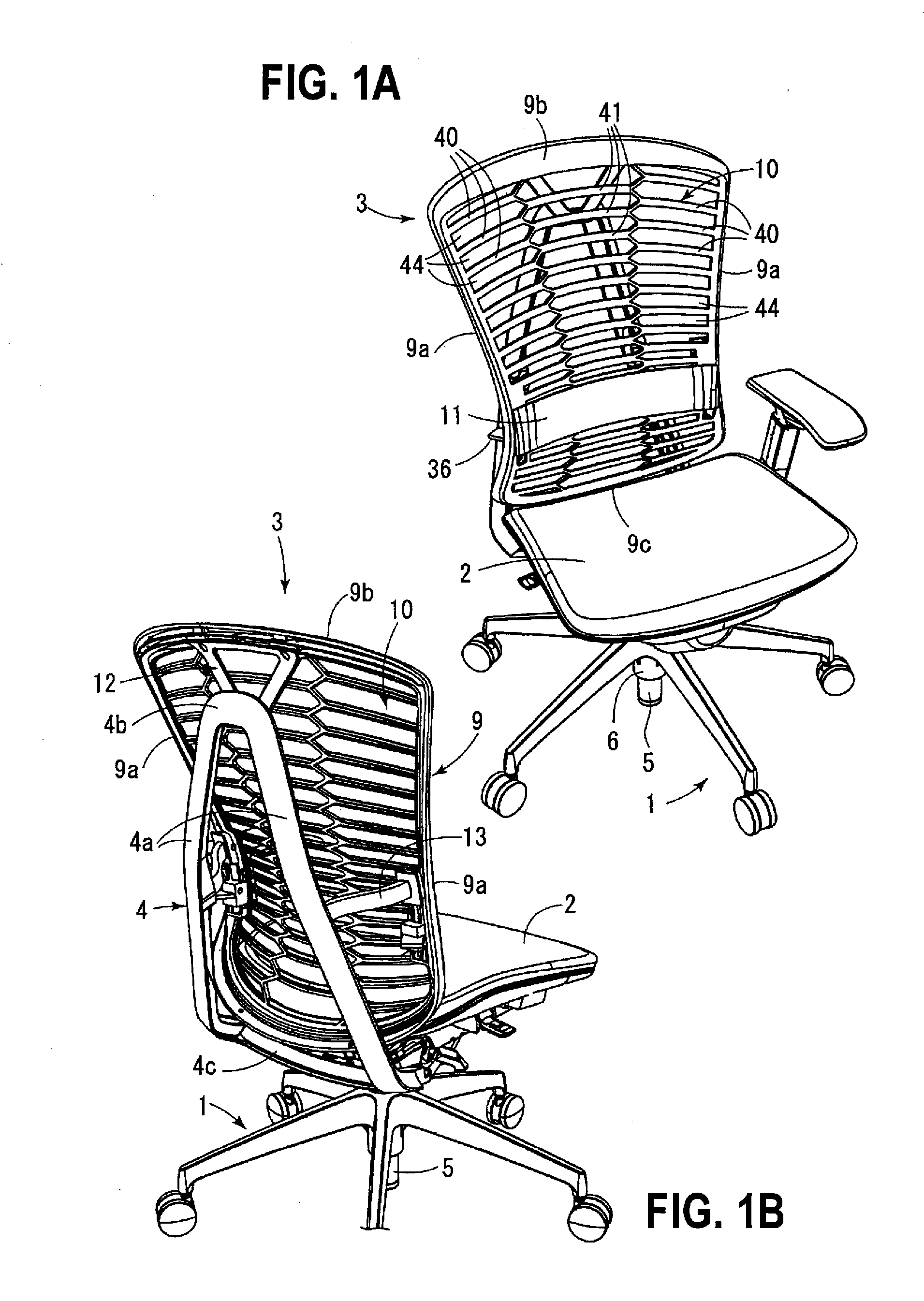

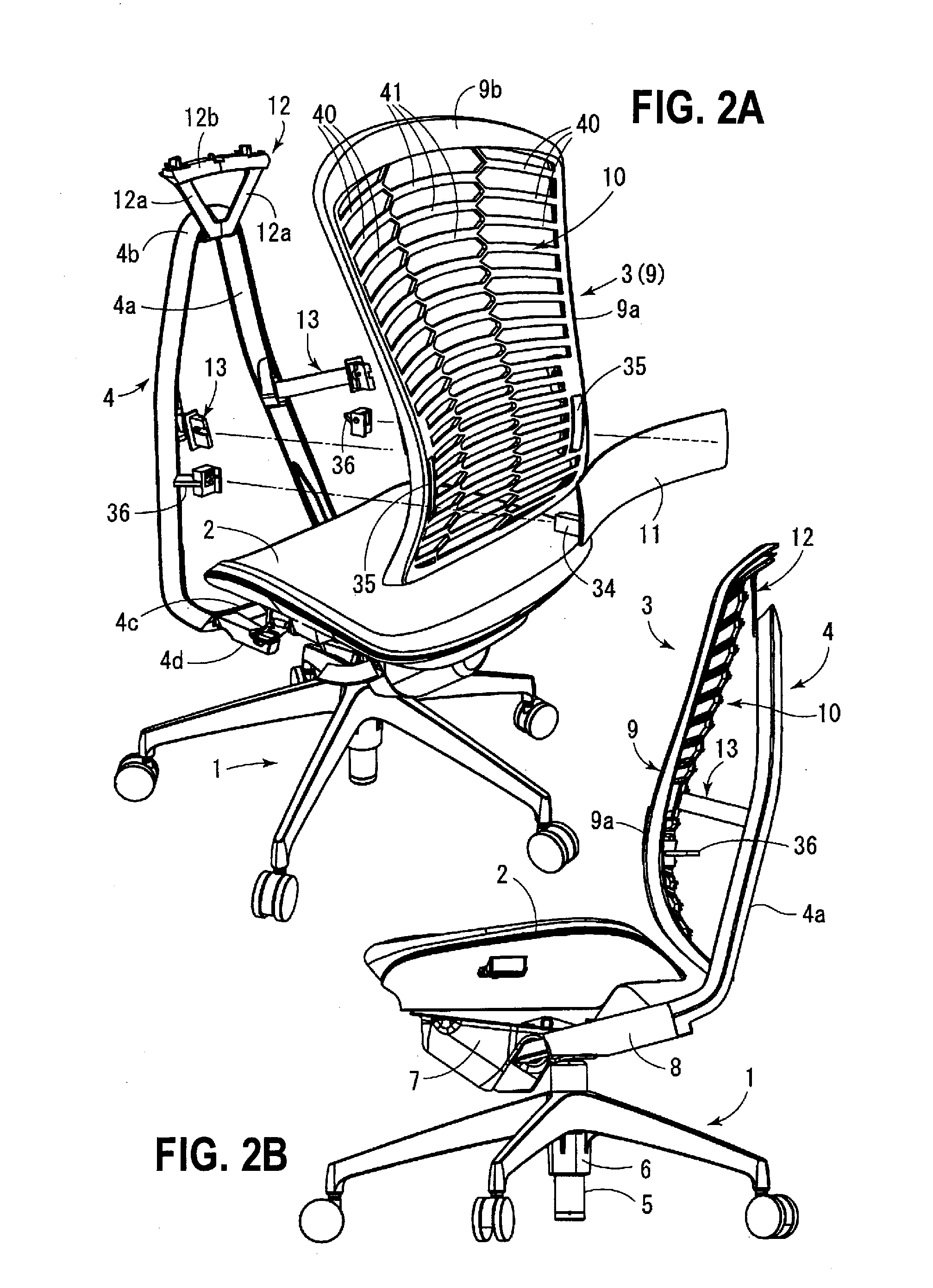

Chair

InactiveUS20160135603A1Improve stateEnsure strengthStoolsAdjustable chairsEngineeringRigid structure

A chair includes a seat, a backrest and a back frame having a rigid structure and arranged behind the backrest with an interval in between. The backrest is attached to the back frame by a first support device arranged at a height position close to an upper end of the backrest and by a second support device arranged at a position lower than the first support device and higher than a seat surface. The first support device is attached to a part close to a right-left middle part of the upper end part in the backrest. The second support device is attached to a left end part and a right end part of the backrest.

Owner:ITOKI CORP

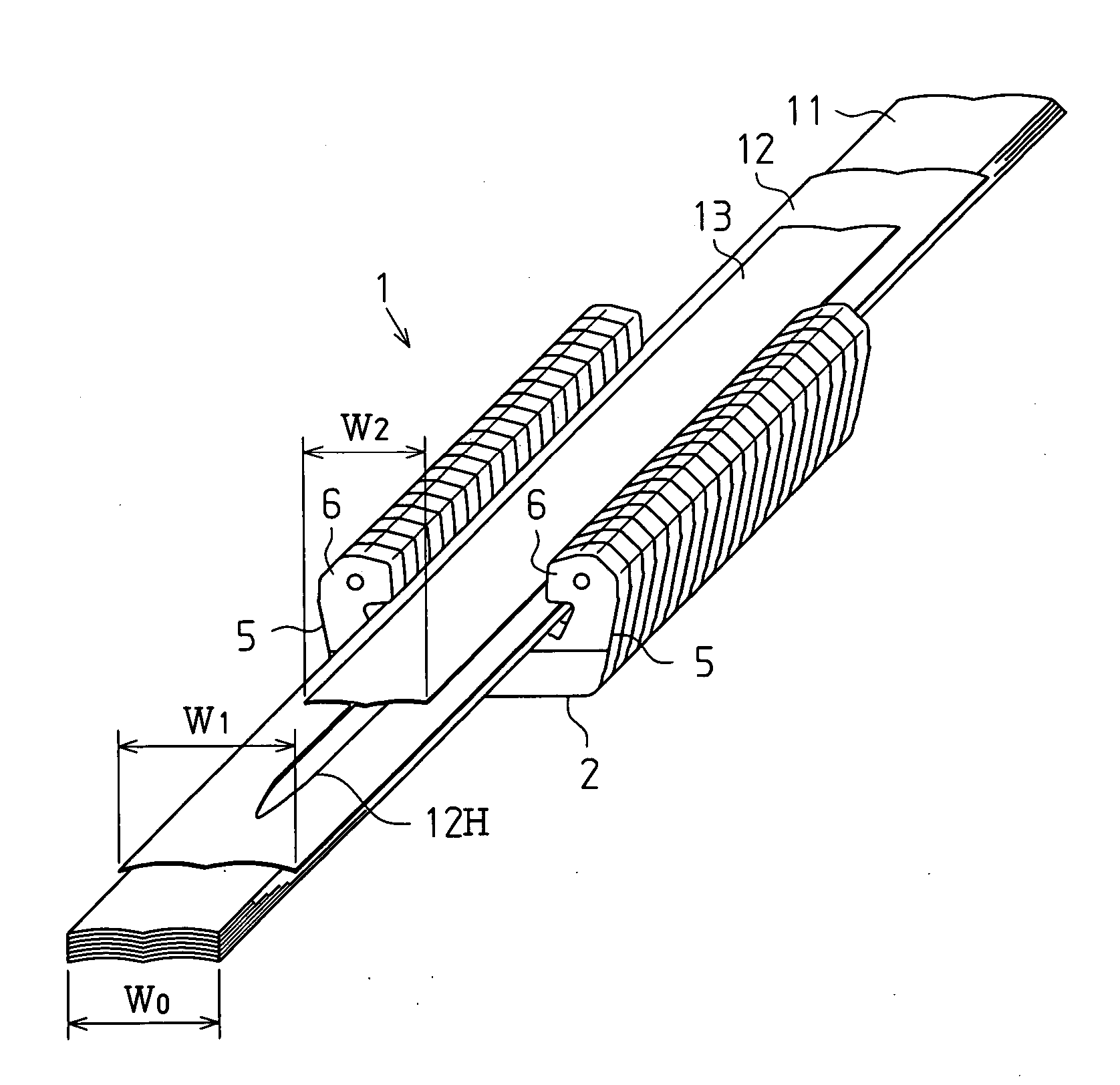

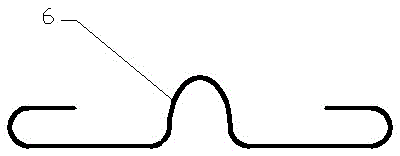

Metallic belt and push block used therefor

A single-band type metallic belt wound between annular V-grooves of a drive pulley and a driven pulley is provided. The metallic belt includes a metal endless band having at least one layer, and a plurality of metal push blocks engaged and superimposed on the band in a manner enabling sliding in a longitudinal direction of the band. The push block includes a body formed by bending a single wire material and subsequently performing pressing so as to have two outer side surfaces defining side contact surfaces that are inclined to respectively make frictional contact with two inner surfaces of the annular V-grooves. A pair of pillars respectively extend along extensions of the two contact surfaces of the body and have an outer surface that is continuous with the side contact surfaces of the body. A pair of opposed hooks extend. The outer side surface of the push block that makes frictional contact with the V-grooves include an oil film breaking portion. An opening is defined by the pair of hooks, and a band holding surface is formed on the body in the opening. The band is inserted in the opening of each push block and held on the band holding surface. A metal retainer is arranged on an outer surface of the band in a manner engageable with the pair of hooks to ensure engagement between the band and the push blocks. A ring is attached to the outer surface of the retainer to prevent deformation of the retainer.

Owner:FUKUJU INDS

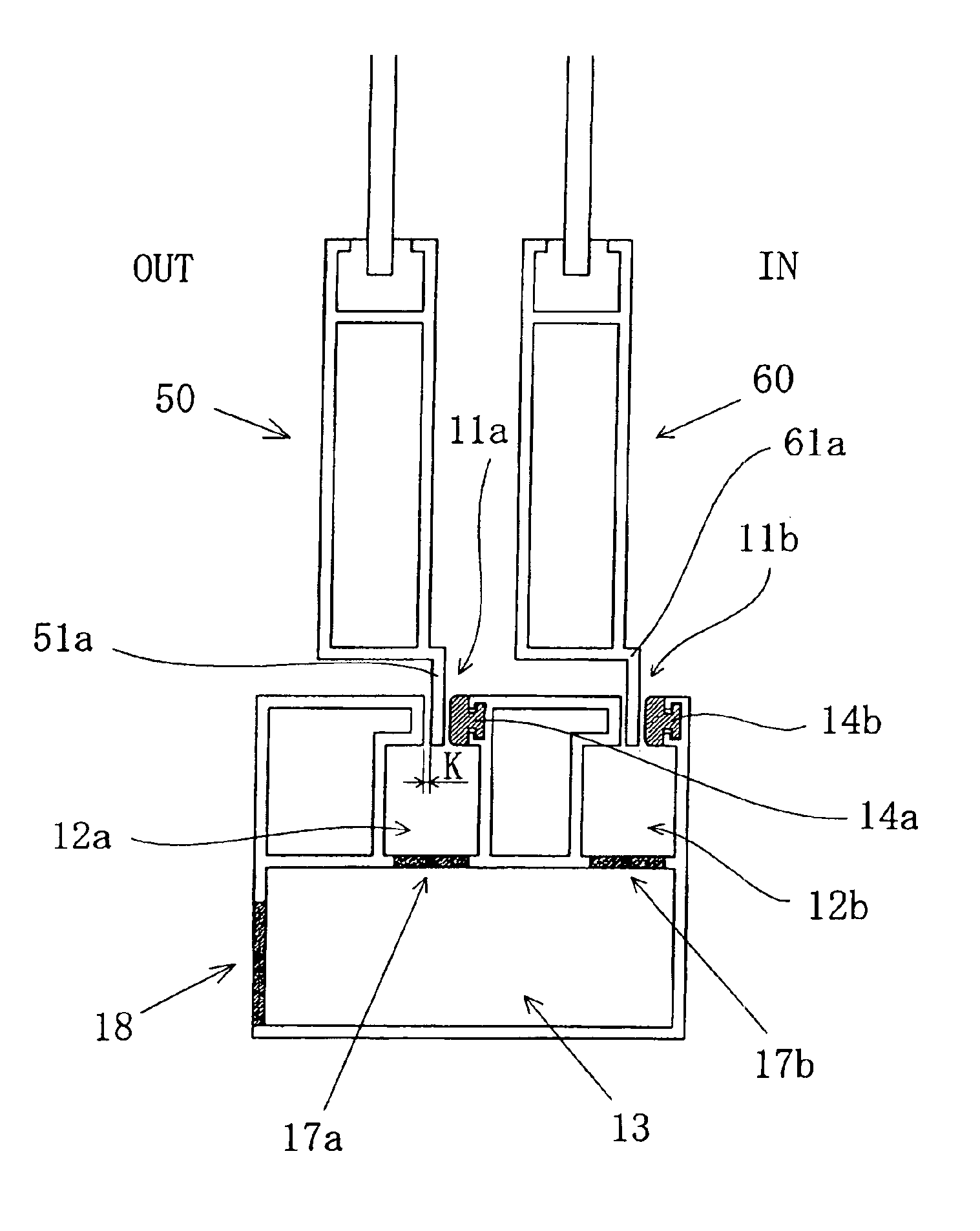

Outdoor window

InactiveUS6883279B2Superior in drainage of rainwaterHigh in watertightness against indoor water leakageCondensed water drain-offSealing arrangementsSash windowEngineering

Owner:TATEYAMA ALUMINUM IND

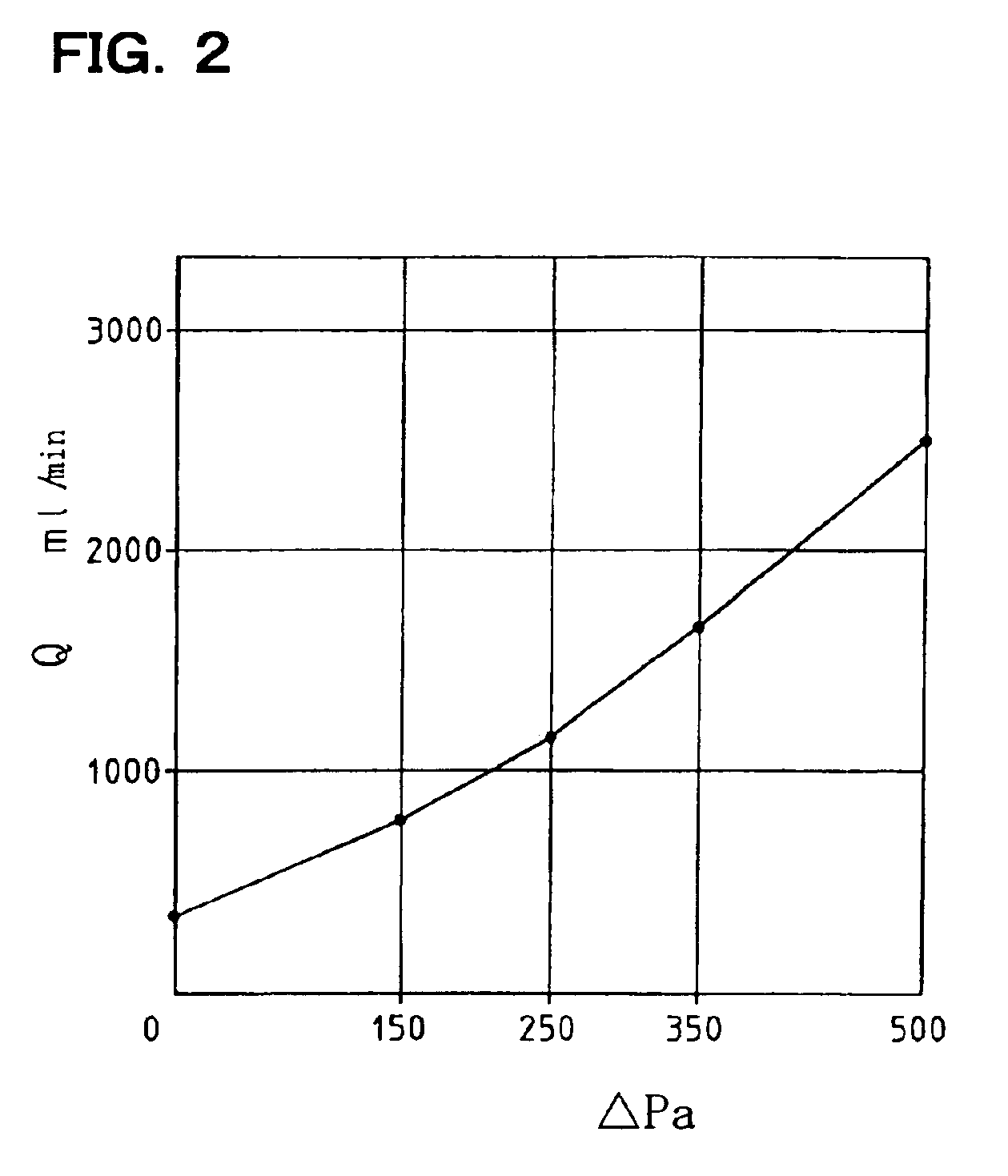

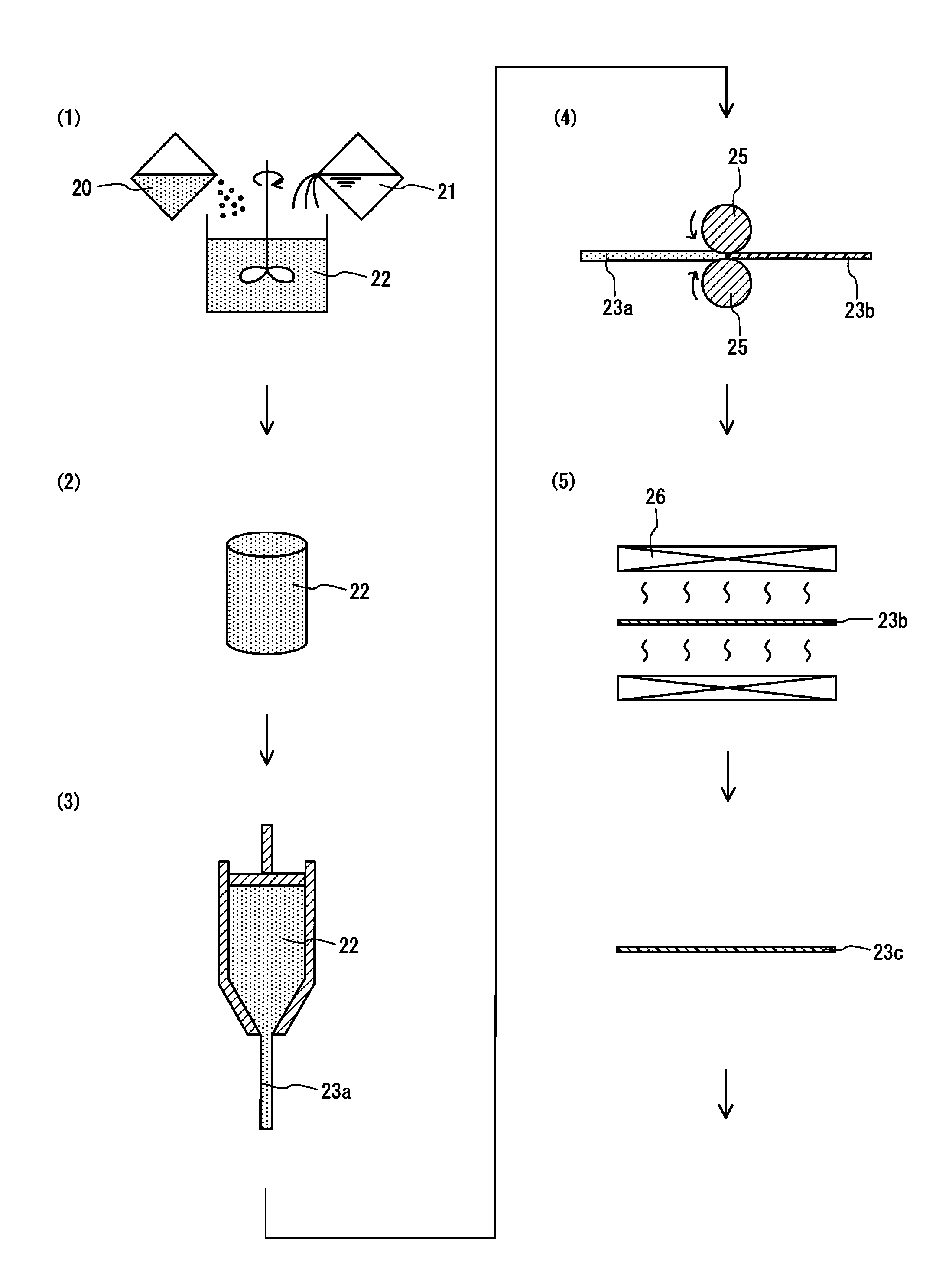

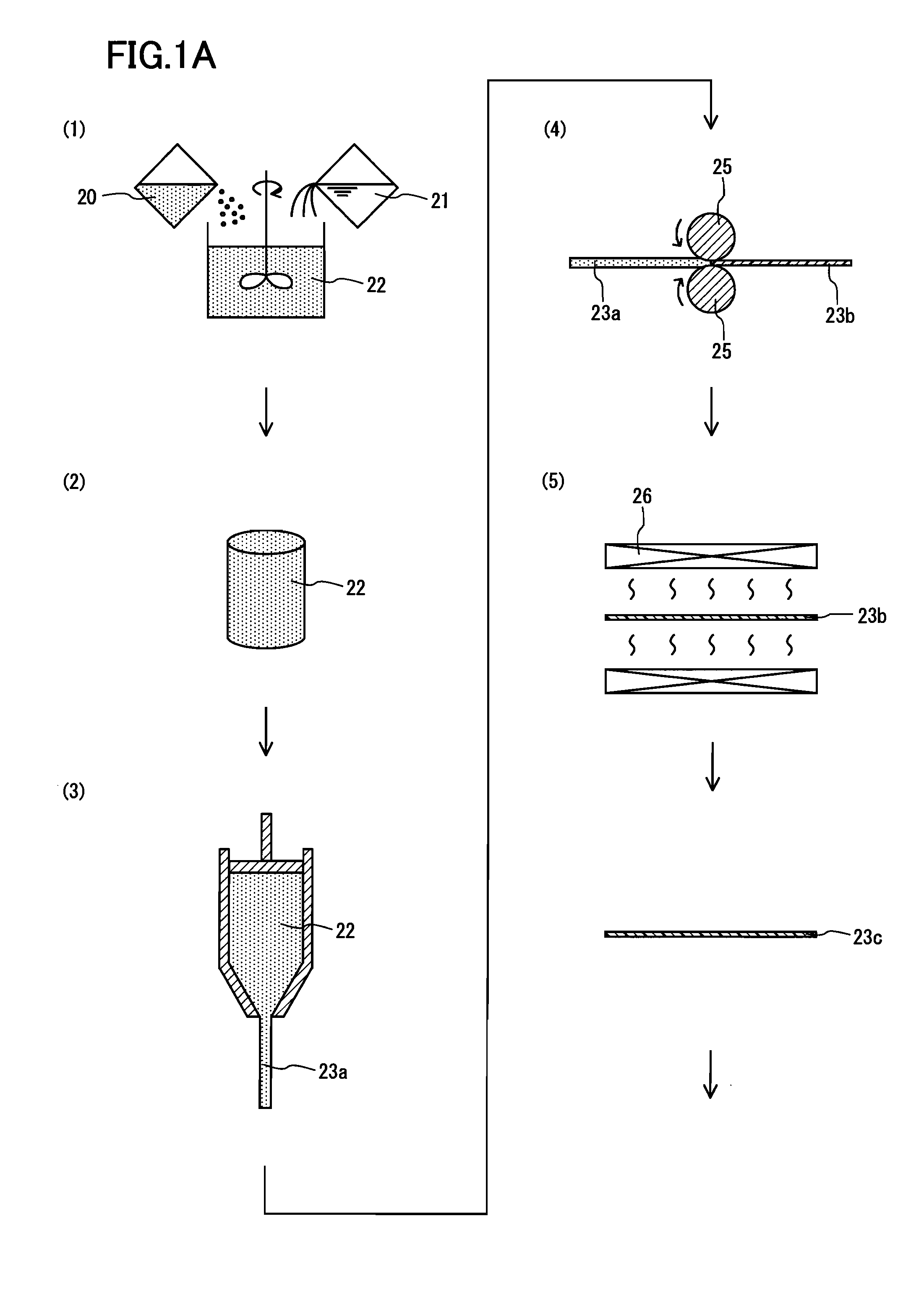

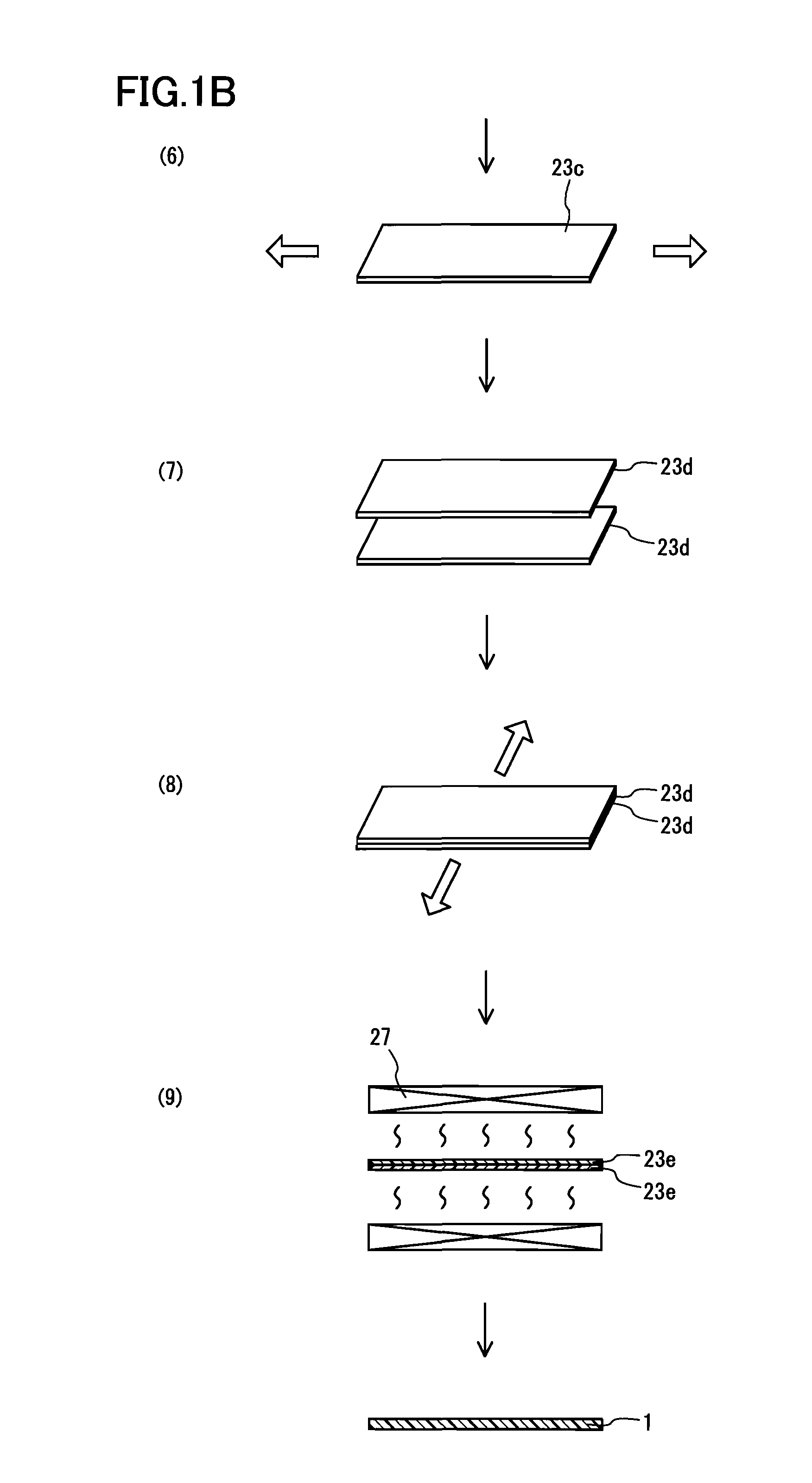

Water-proof sound-transmitting membrane, method for producing water-proof sound-transmitting membrane, and electrical appliance using the membrane

ActiveUS20100206660A1Ensure strengthGood transmittanceSynthetic resin layered productsLaminationPorous membraneBinding force

A water-proof sound-transmitting membrane 10 includes a polytetrafluoroethylene porous membrane 1 and has a surface density of 1 to 20 g / m2. The polytetrafluoroethylene porous membrane 1 includes a first porous layer 1a, and a second porous layer 1b stacked on and integrated with the first porous layer 1a by a binding force acting between polytetrafluoroethylene matrices.

Owner:NITTO DENKO CORP

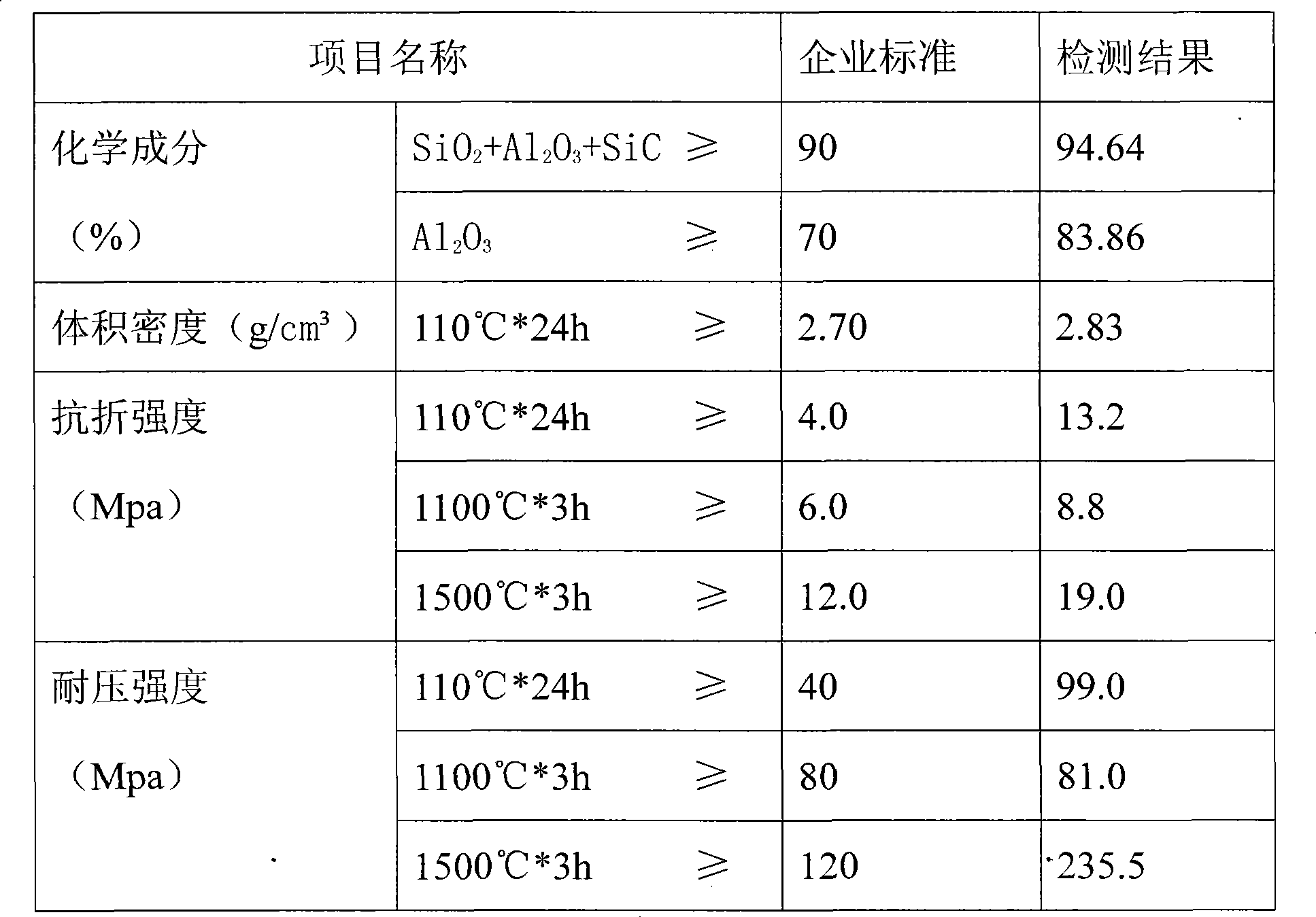

Corundum-mullite self-flow refractory castable

The invention discloses a corundum mullite artesian fireproof casting material, which comprises 30-35% of plate-shaped corundum, 5-8% of carborundum powder material, 4-5% of pure calcium aluminate cement, 35-45% of mullite, 10-15% of alpha-Al2O3 micropowder and 3-5% of bonite by mass percentage. The casting material is characterized by good fluidity, good resistance to thermal shock, low porosity rate of entity after casting, good chemical resistance, high intensity and long service life.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

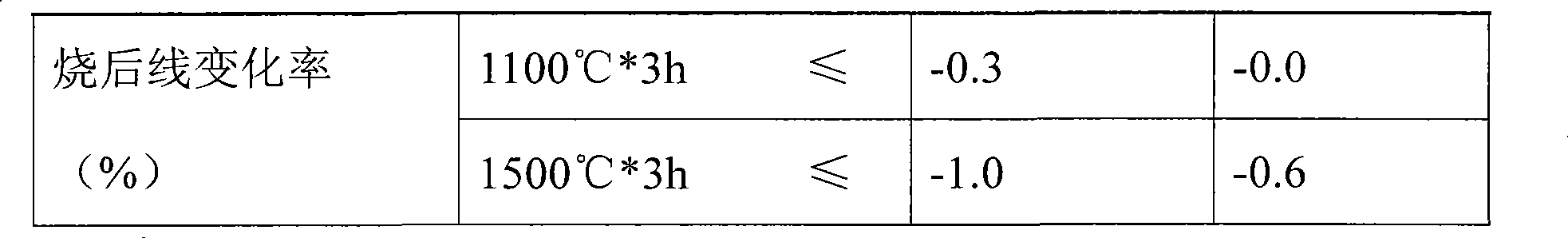

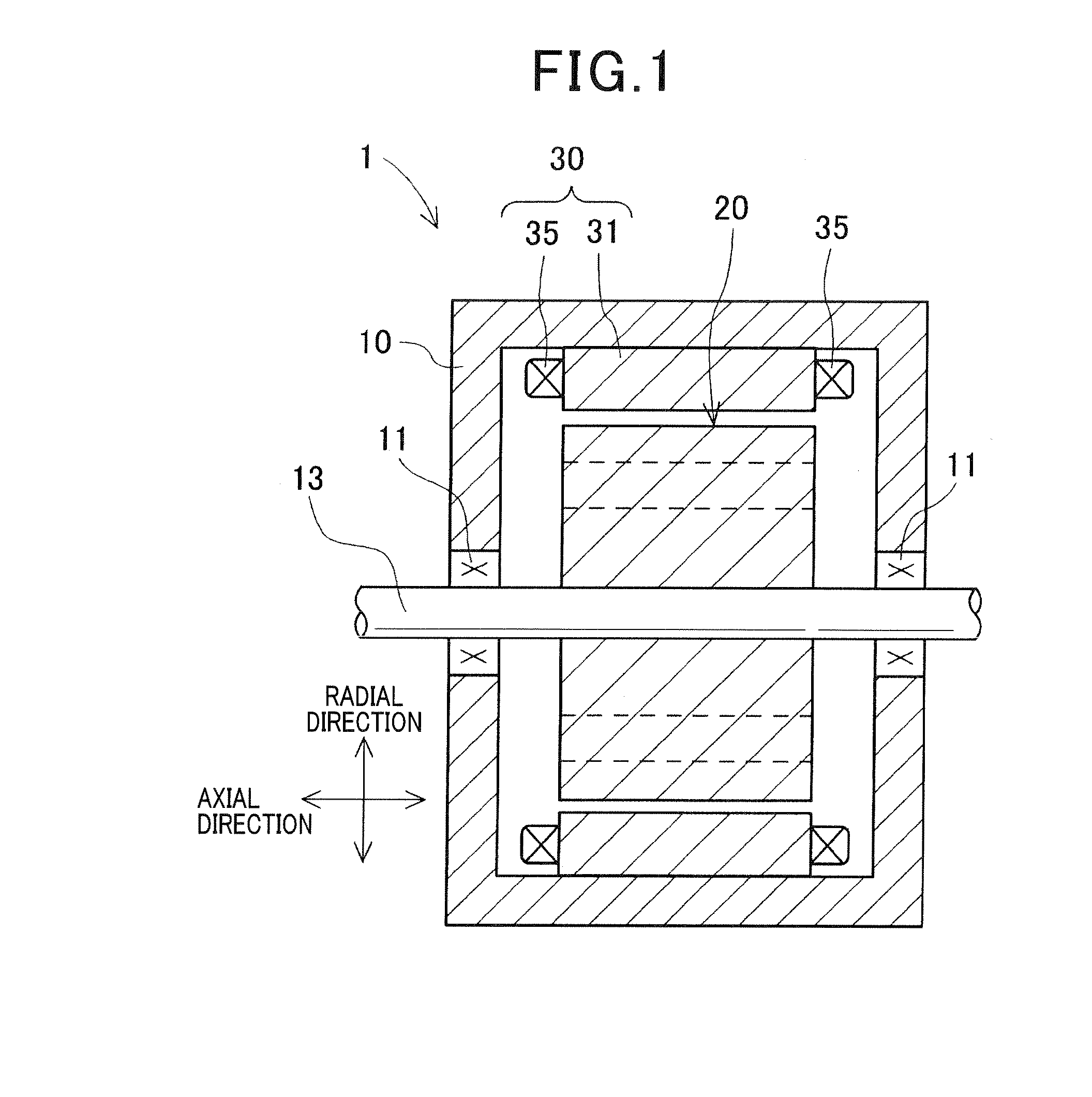

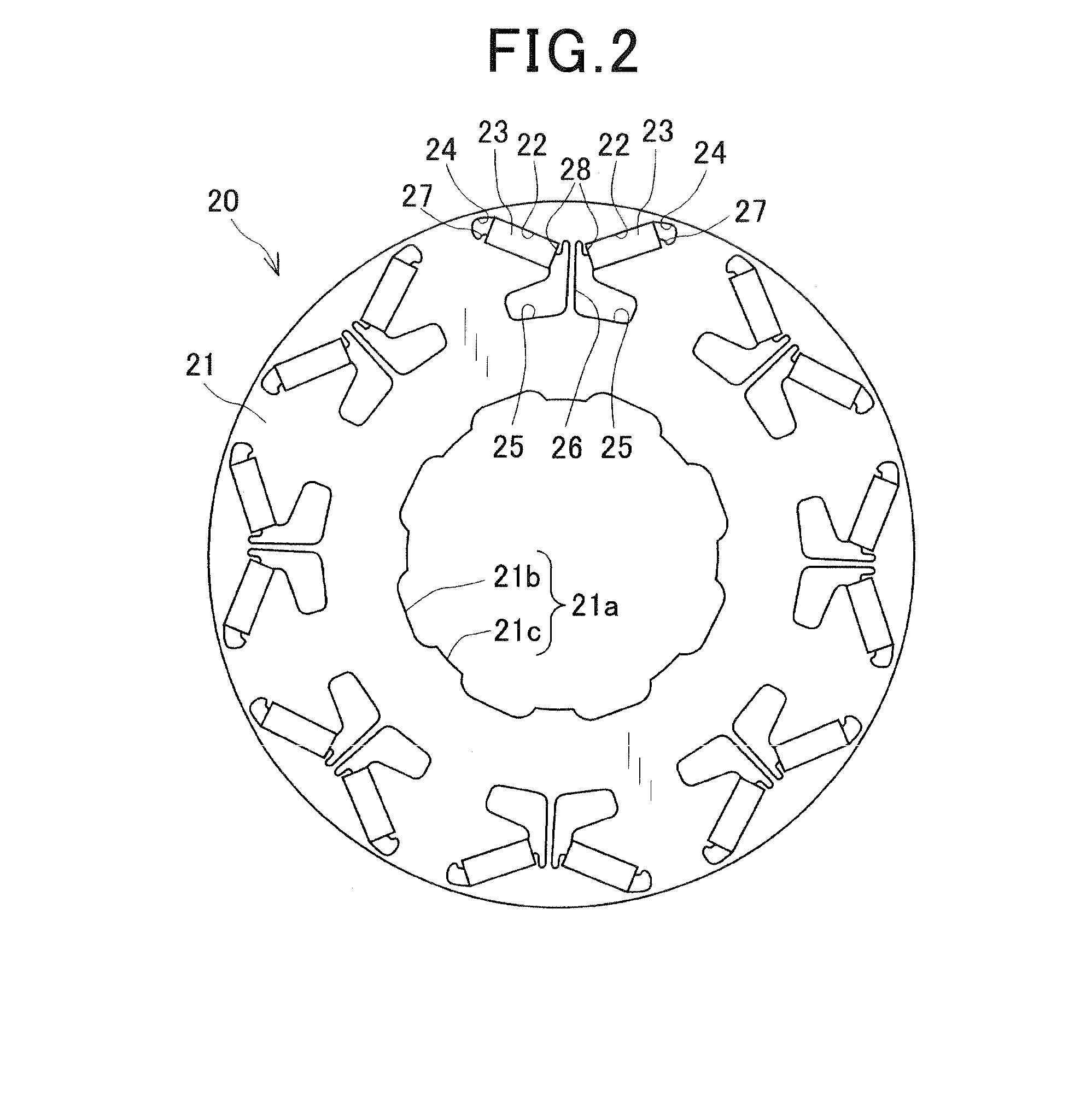

Rotor for rotating electric machine

ActiveUS20150137650A1High strengthEnsure strengthMagnetic circuit rotating partsCooling/ventillation arrangementMagnetic fluxMagnet

A rotor includes a rotor core that has magnet-receiving holes in each of which is received a corresponding permanent magnet. The rotor core also has, for each of the magnet-receiving holes, first and second supporting portions. The first supporting portion supports a radially inner end portion of a first magnetic flux barrier-side face of the corresponding permanent magnet. The second supporting portion supports a radially outer end portion of a second magnetic flux barrier-side face of the corresponding permanent magnet. A second magnetic flux barrier-side end portion of a radially outer wall surface of the magnet-receiving hole is planar in shape and parallel to a radially outer side face of the corresponding permanent magnet. A second magnetic flux barrier-side end portion of a radially inner wall surface of the magnet-receiving hole is planar in shape and parallel to a radially inner side face of the corresponding permanent magnet.

Owner:DENSO CORP

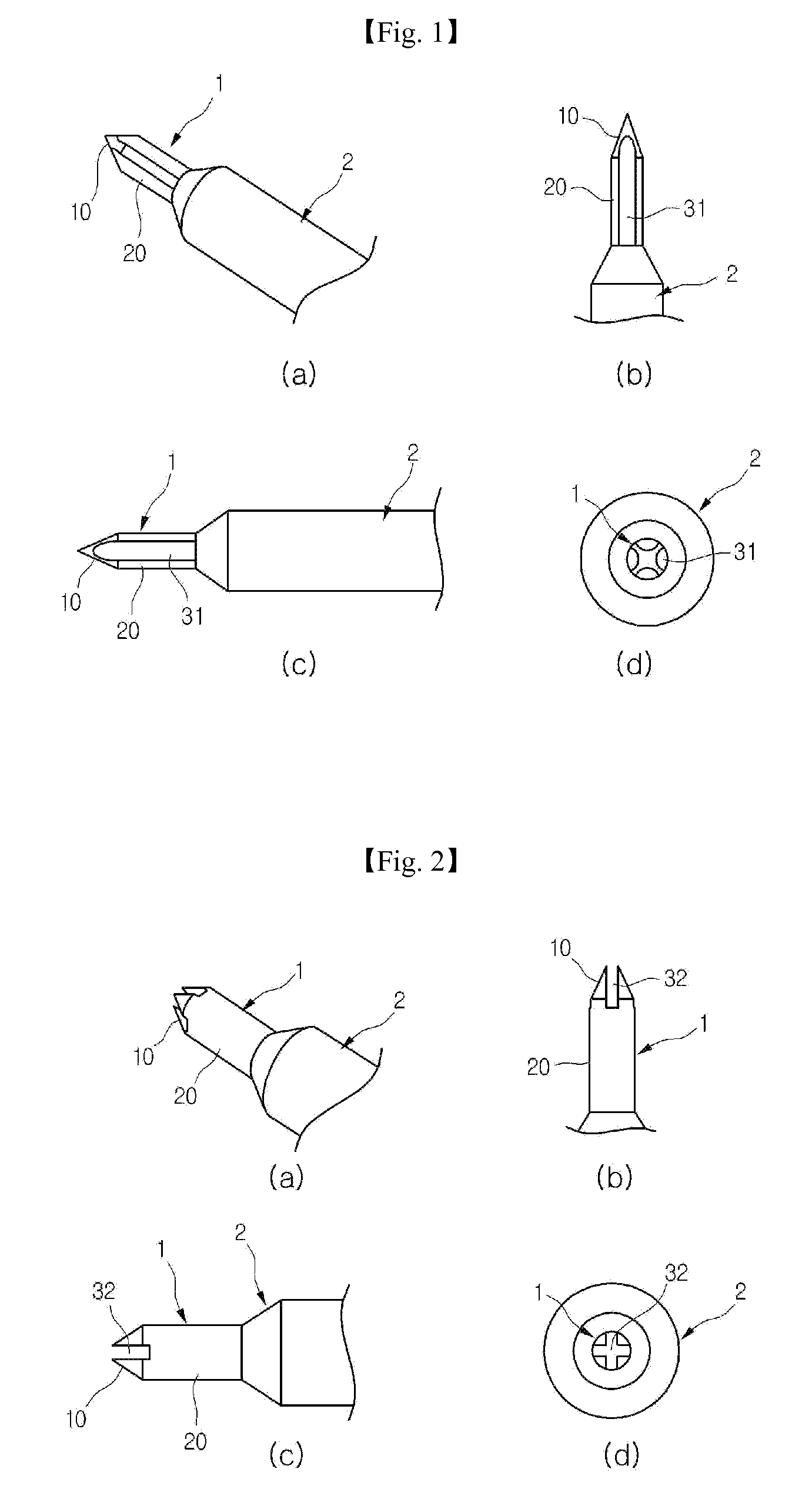

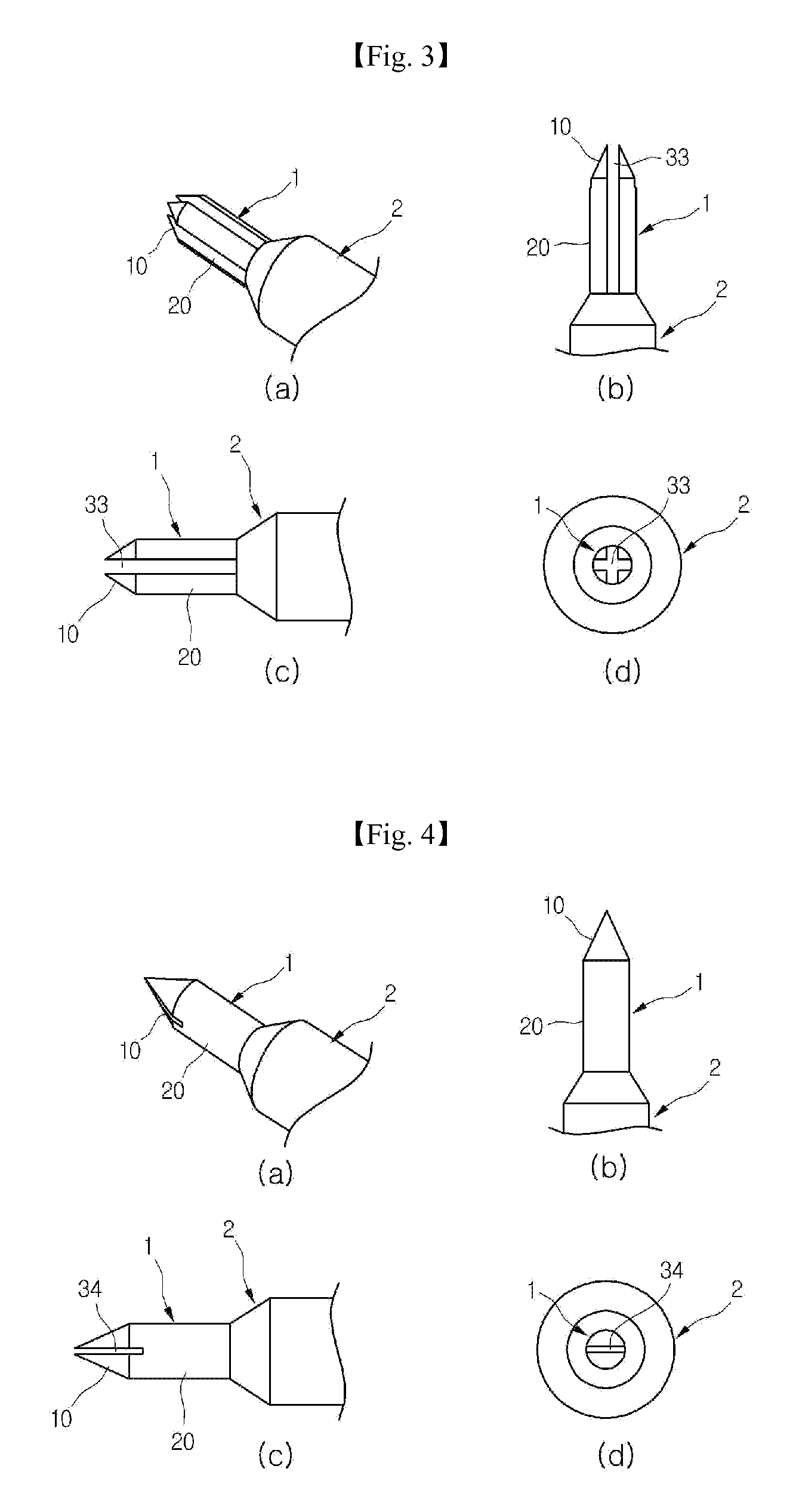

Micro needle and micro needle device

The micro needle includes a needle and a body. The needle includes an inclined part including an inclined outer wall, a straight part including a straight outer wall, and a recess having a certain depth along the inclined or straight outer wall. The body is coupled to the needle to move or support the needle. The micro needle apparatus includes a micro needle head part, an infrared generator part, and a power supply part. The micro needle head part includes a plurality of micro needles having front ends protruding out of the micro needle head part. When the micro needles are pressed against a skin, the micro needles arrive at a dermis of the skin. The infrared generator part generates an infrared or far infrared ray to the skin through an inside or outside of the micro needle. The power supply part supplies energy required for the infrared generator part.

Owner:UBIOMED

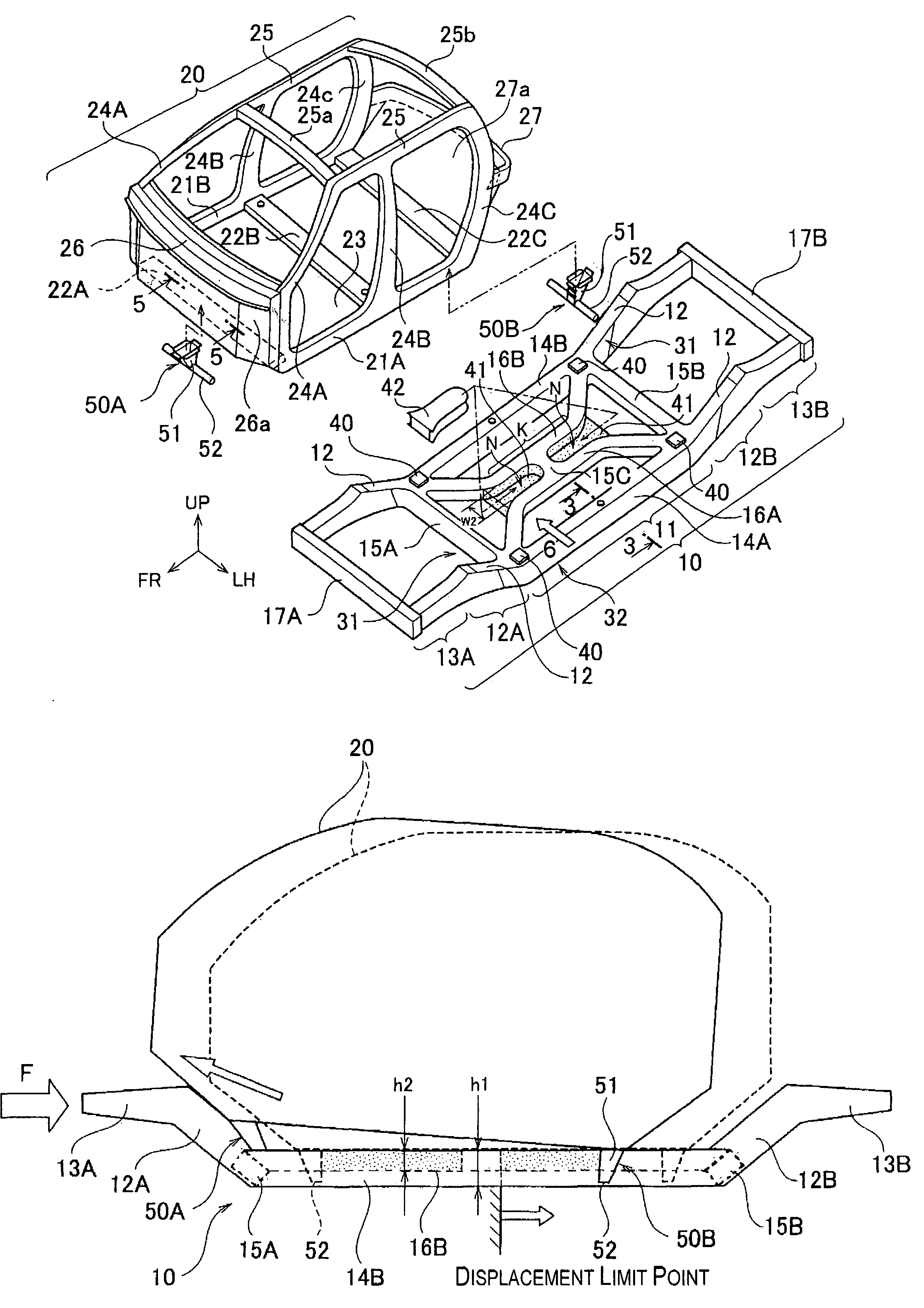

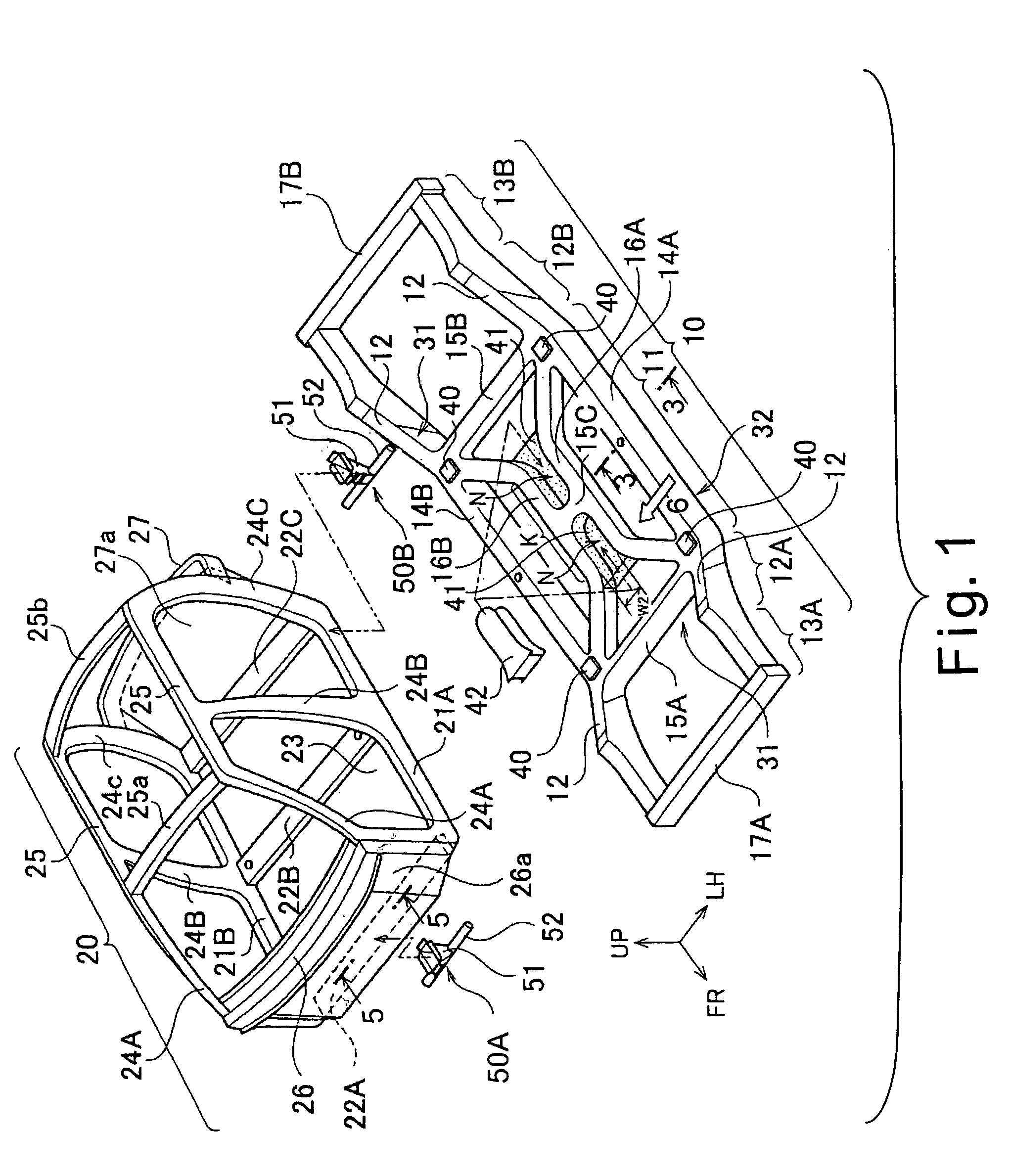

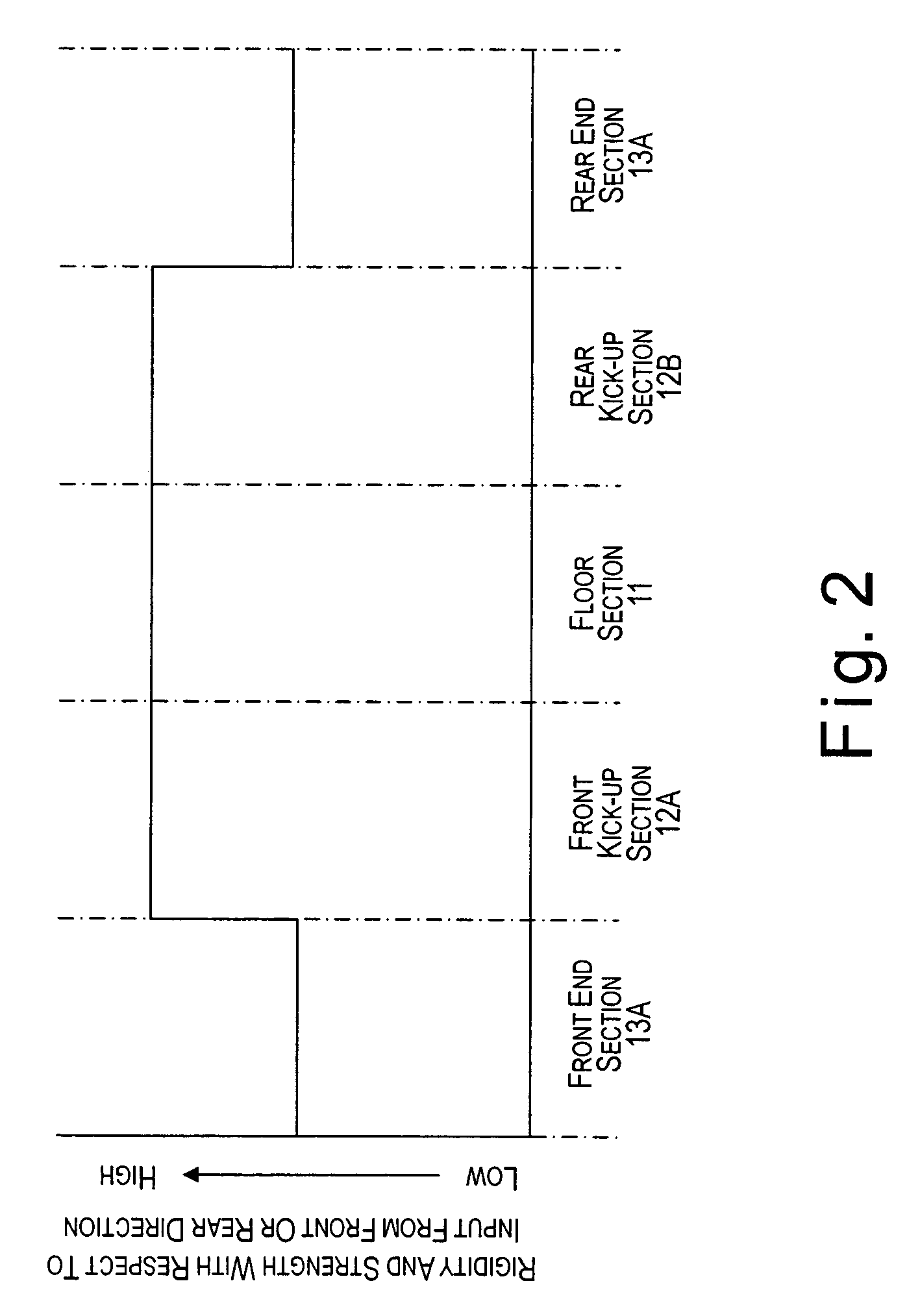

Vehicle body structure

InactiveUS7185934B2High strengthHigh impact energy absorption capacityVehicle body-frame connectionsElectric propulsion mountingVehicle frameEngineering

A vehicle body structure is configured that enables a cabin section and a chassis frame to move relative to each other and enables both strength of the vehicle body and the safety of the occupants during a collision to be ensured with good efficiency. The cabin section serves as the space in which the passengers reside. The chassis frame and cabin section are separate, independent structures connected through a displacement mechanism in such a manner that the chassis frame and cabin section can move separately relative to each other, when a collision occurs. As a result, transmission of the collision impact to the cabin section is alleviated in an effective manner and the strength of the cabin section and chassis frame can be increased.

Owner:NISSAN MOTOR CO LTD

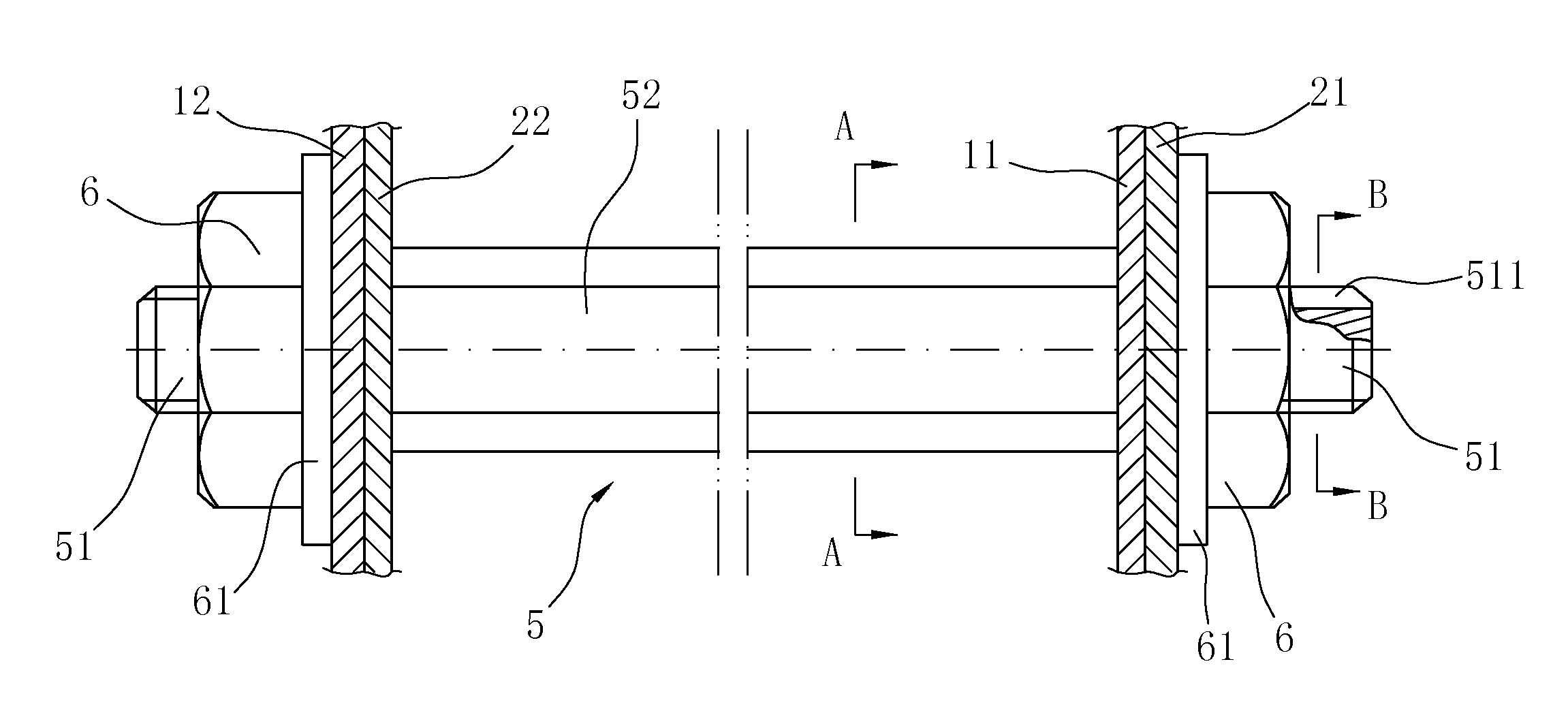

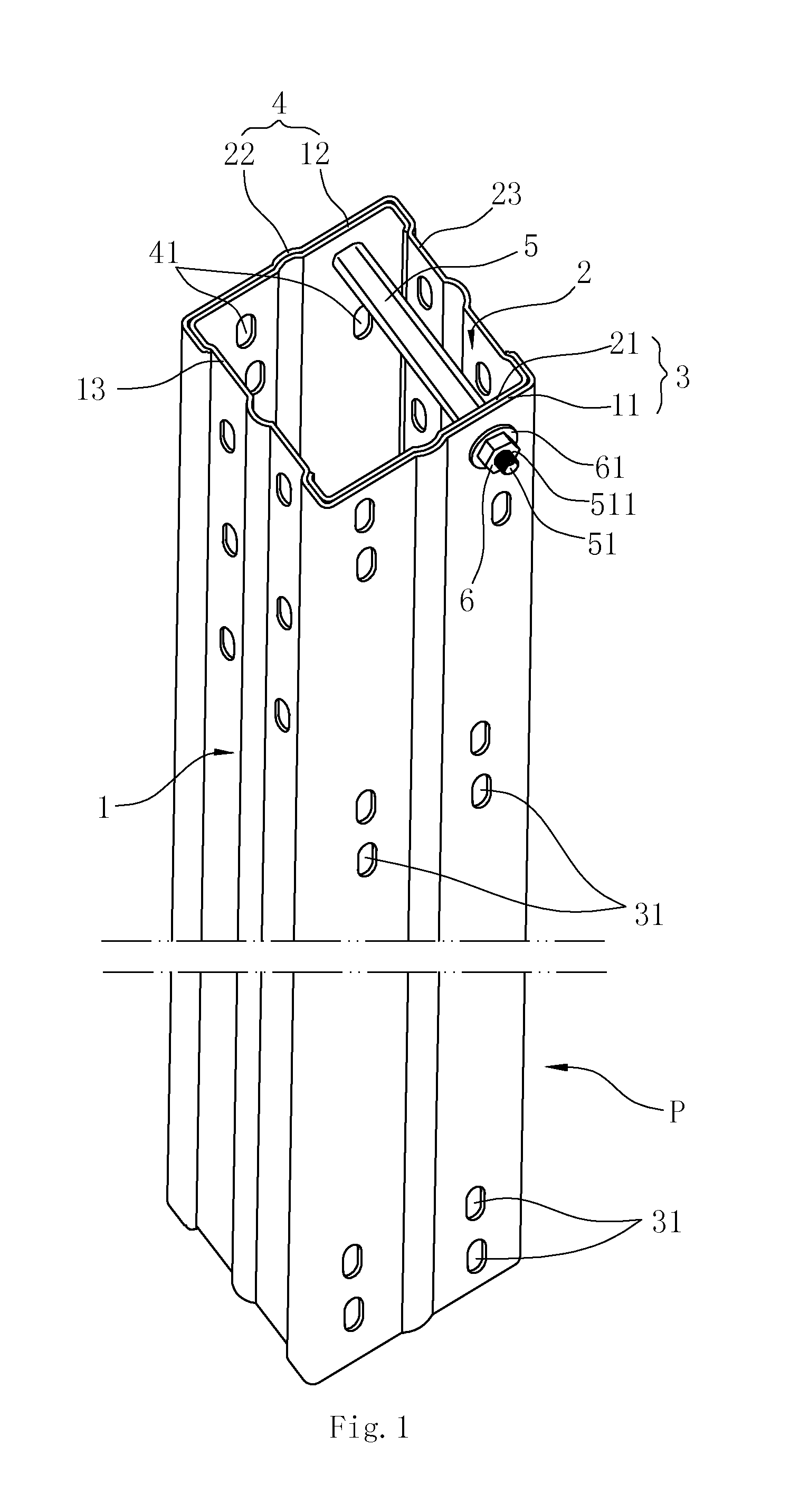

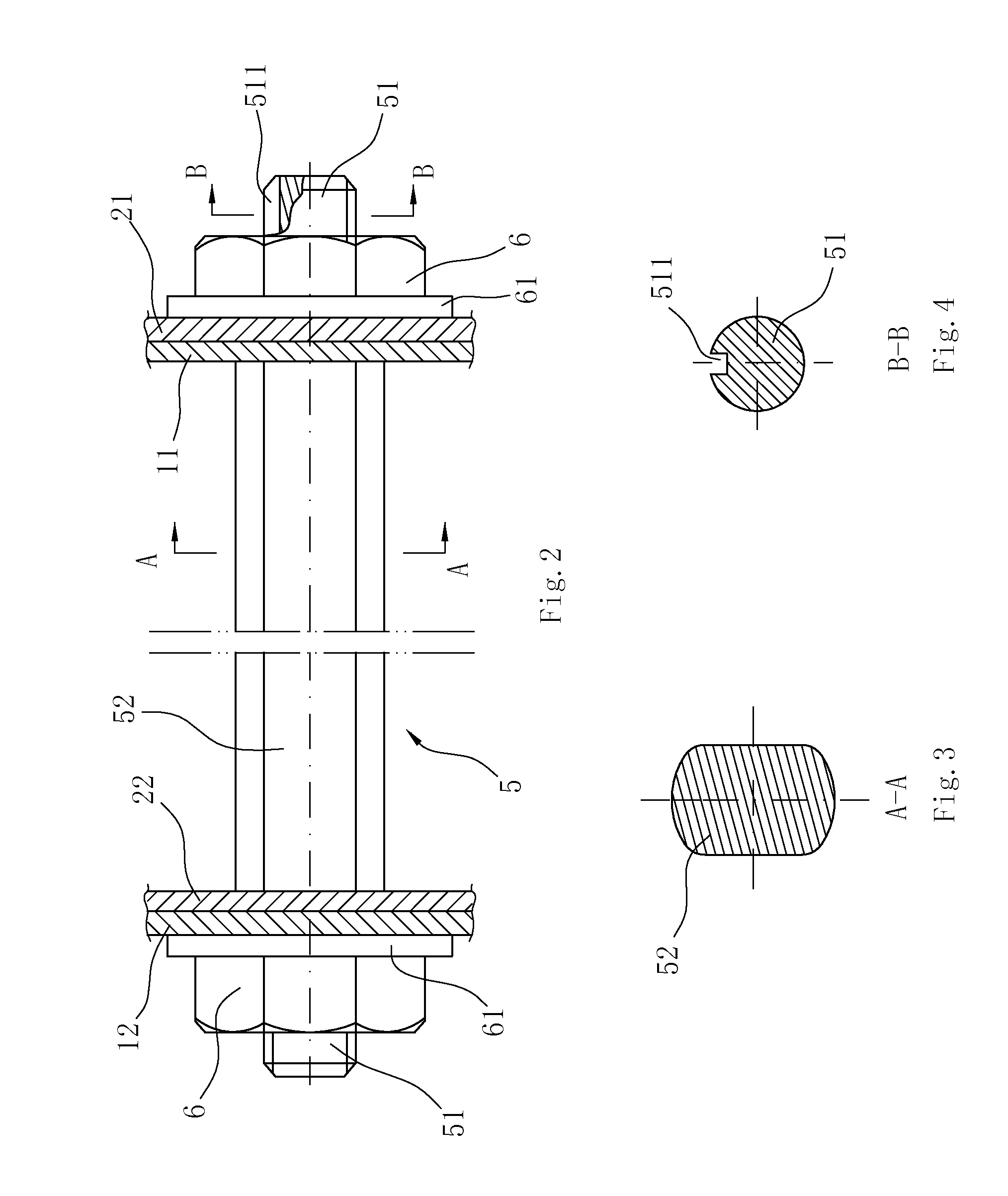

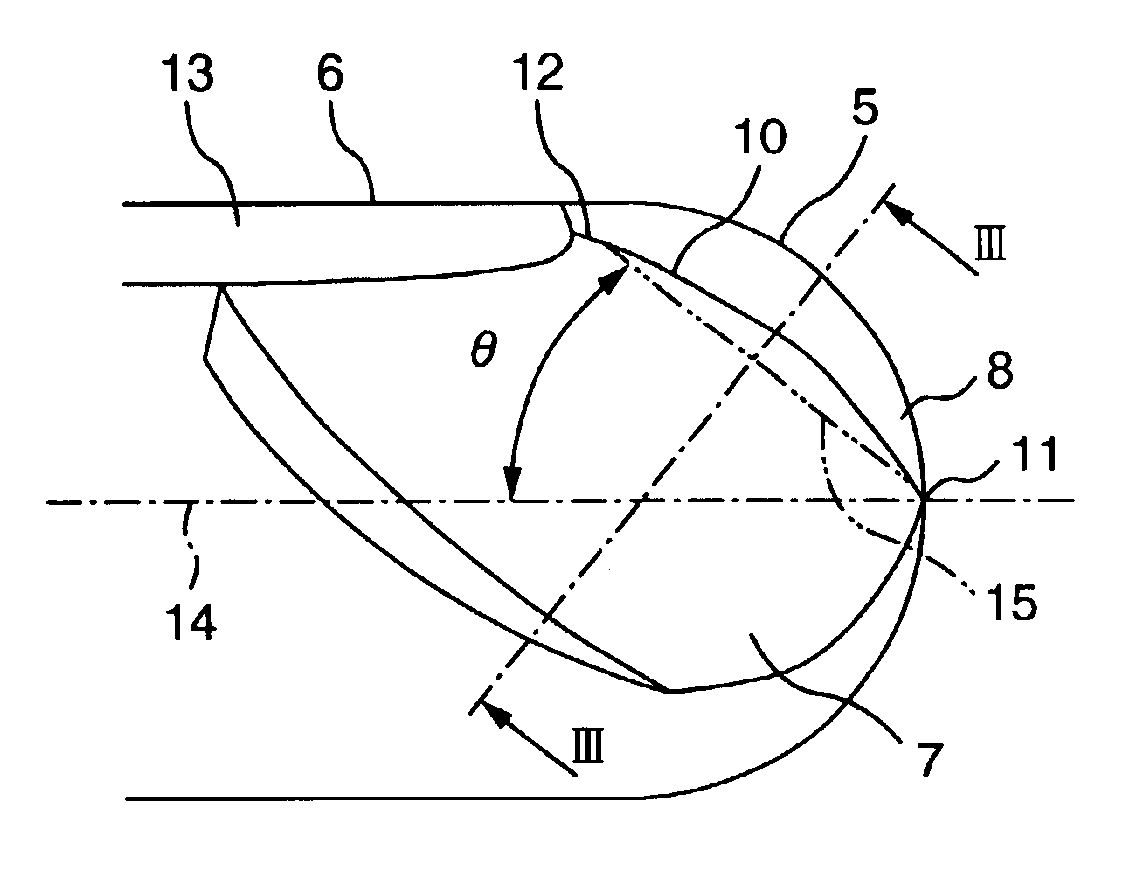

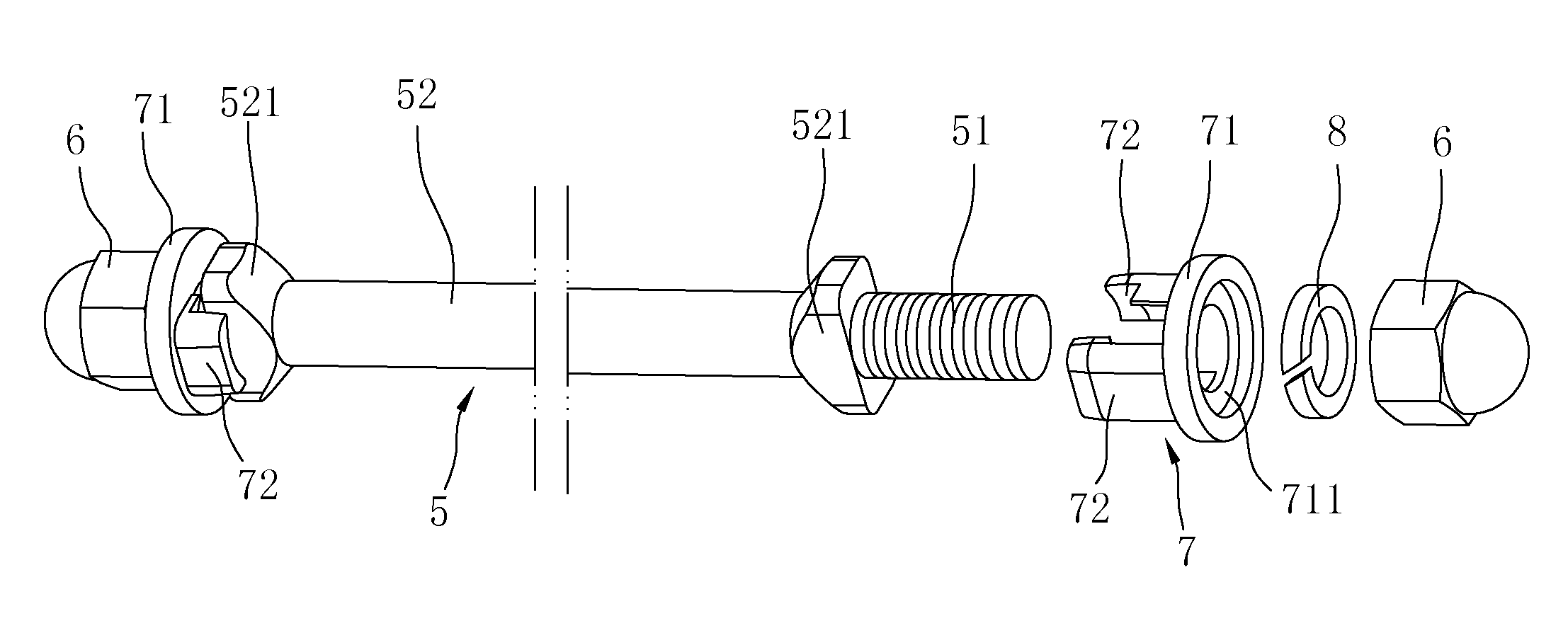

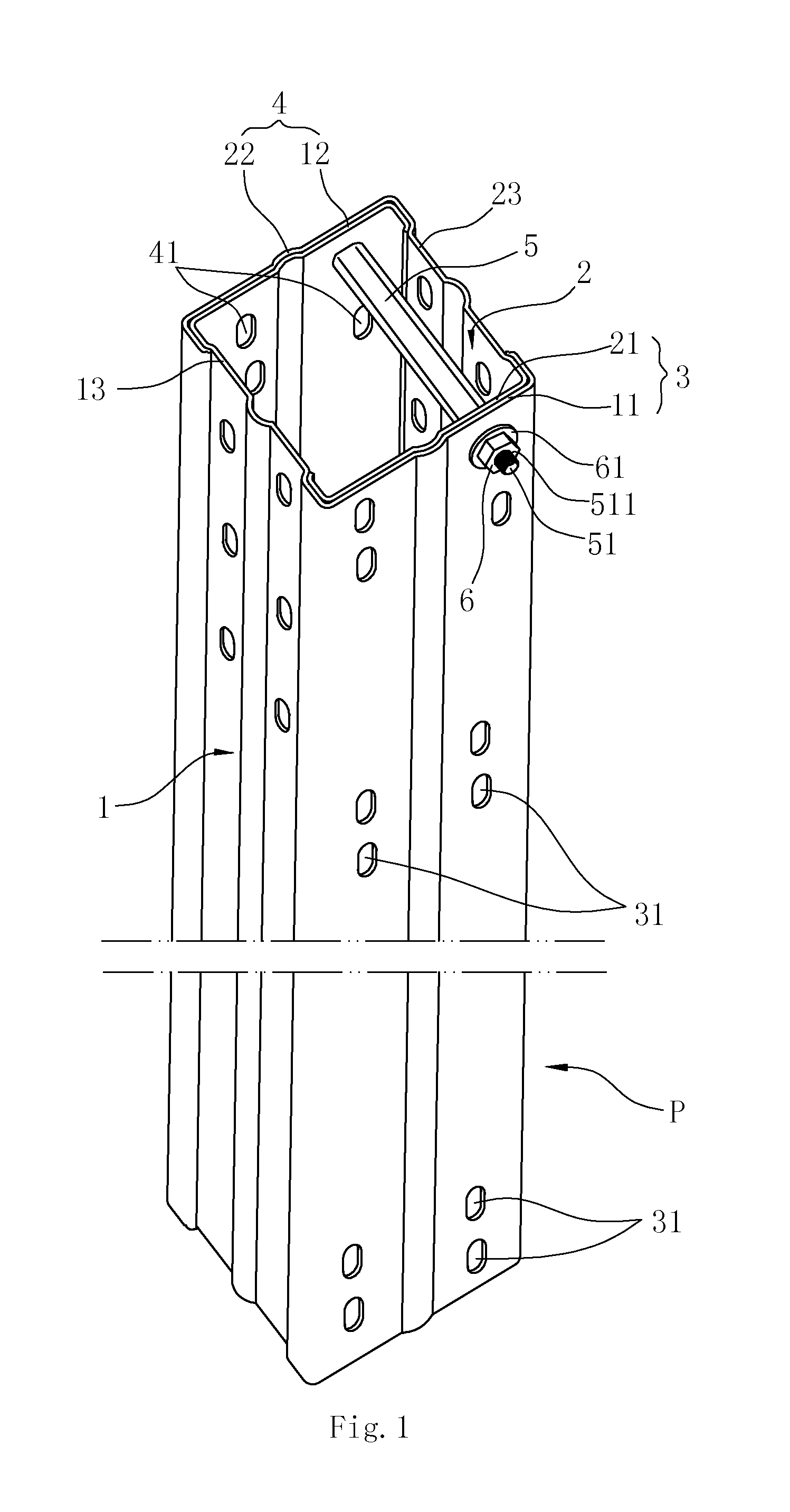

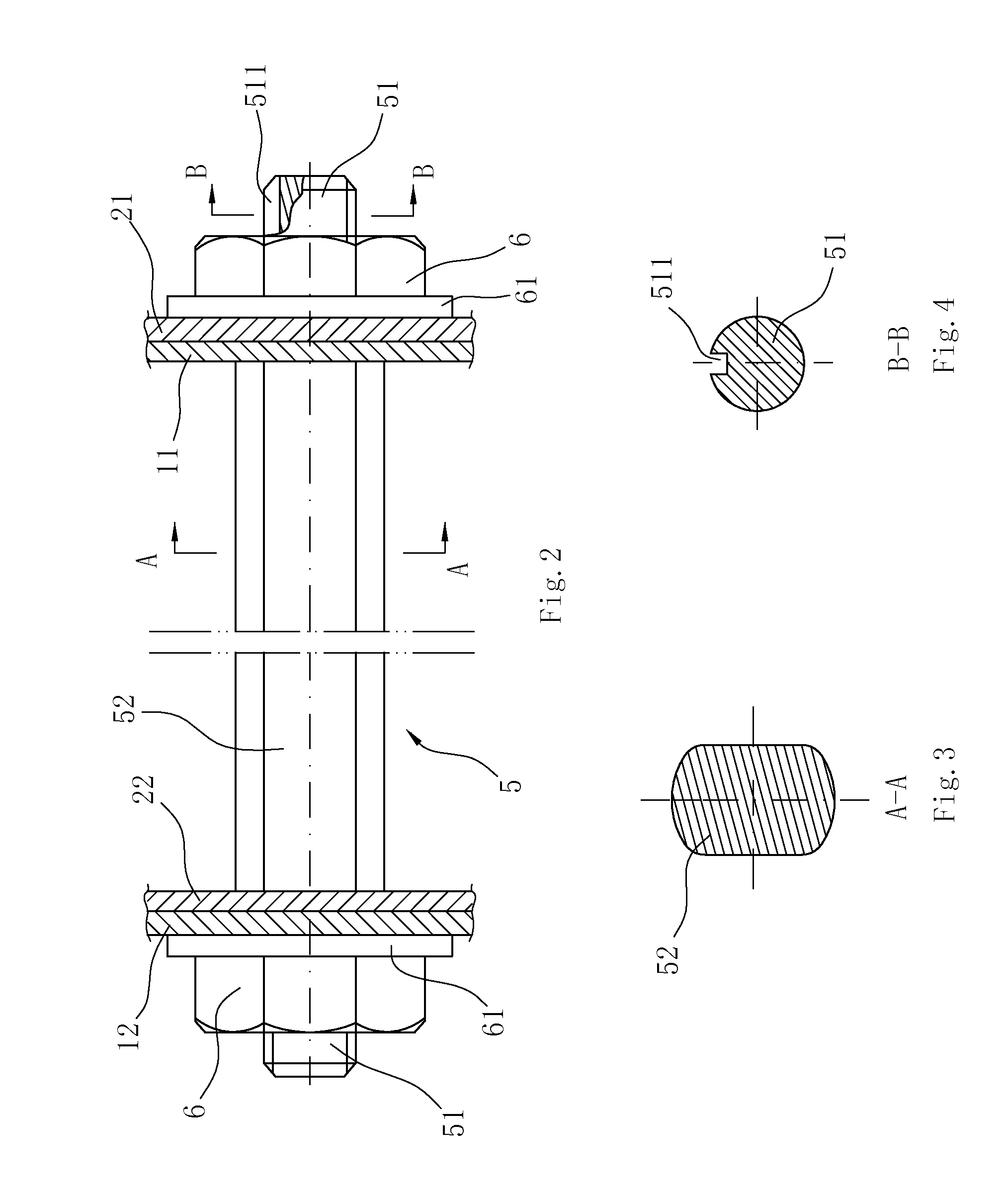

Unconventional Bolt and a Fastening Device Using the Unconventional Bolt Thereof

An unconventional bolt includes a main body having two heads, and two threaded rods respectively formed at the external surface of each head coaxially with the main body, wherein the cross section of each head has a noncircular shape, and the axial projection of the cross section of the middle of the main body is located in the noncircular axial projection of each head of the main body. The unconventional bolt has a simple structure and a convenient assembly, and can improve the strength and rigidity of the nested profiled components after the connection; and the fastening device using the unconventional bolt can not only support the component but also reinforce it, thus effectively preventing the nested profiled components from transforming.

Owner:NINGBO BANGDA INDAL

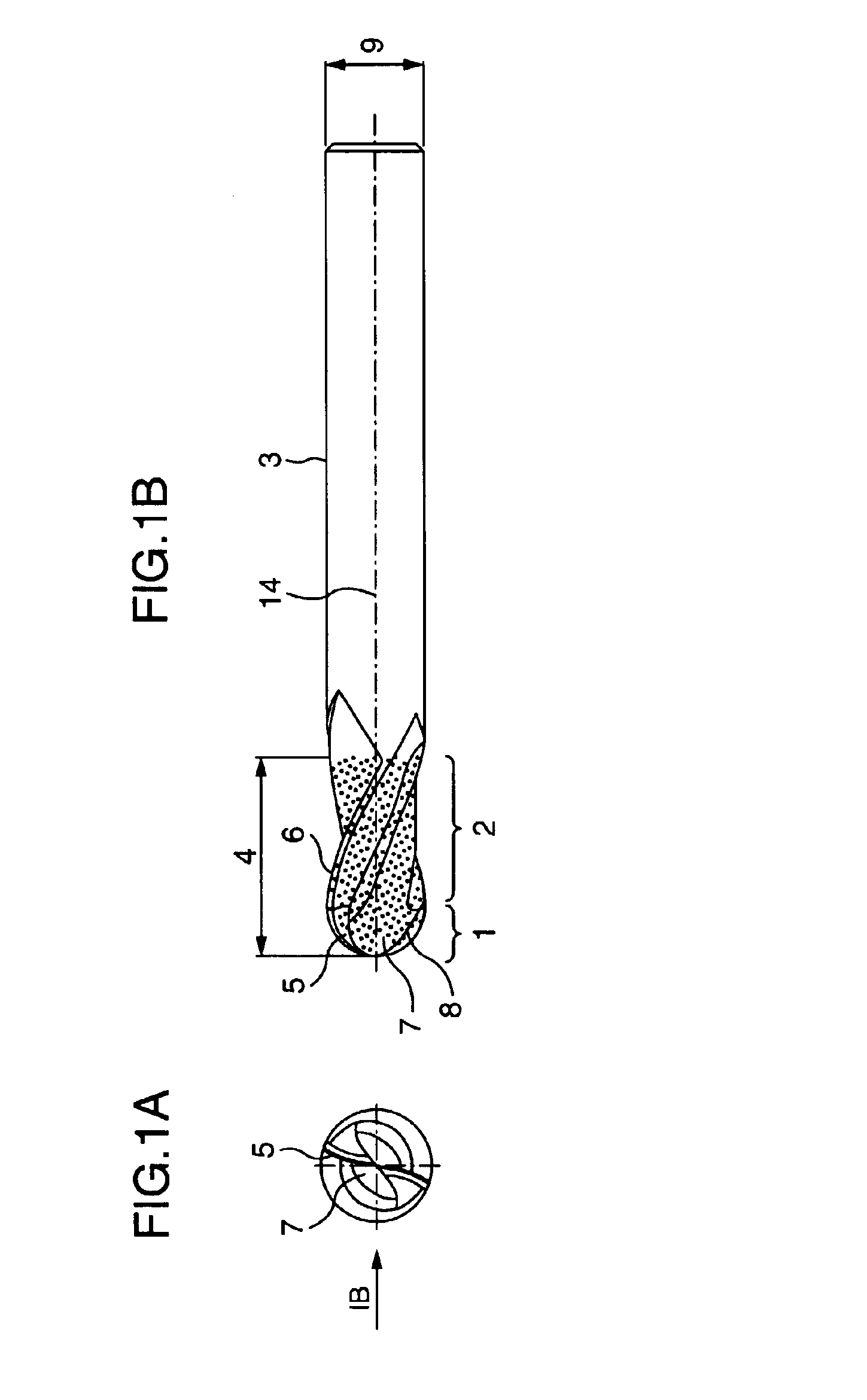

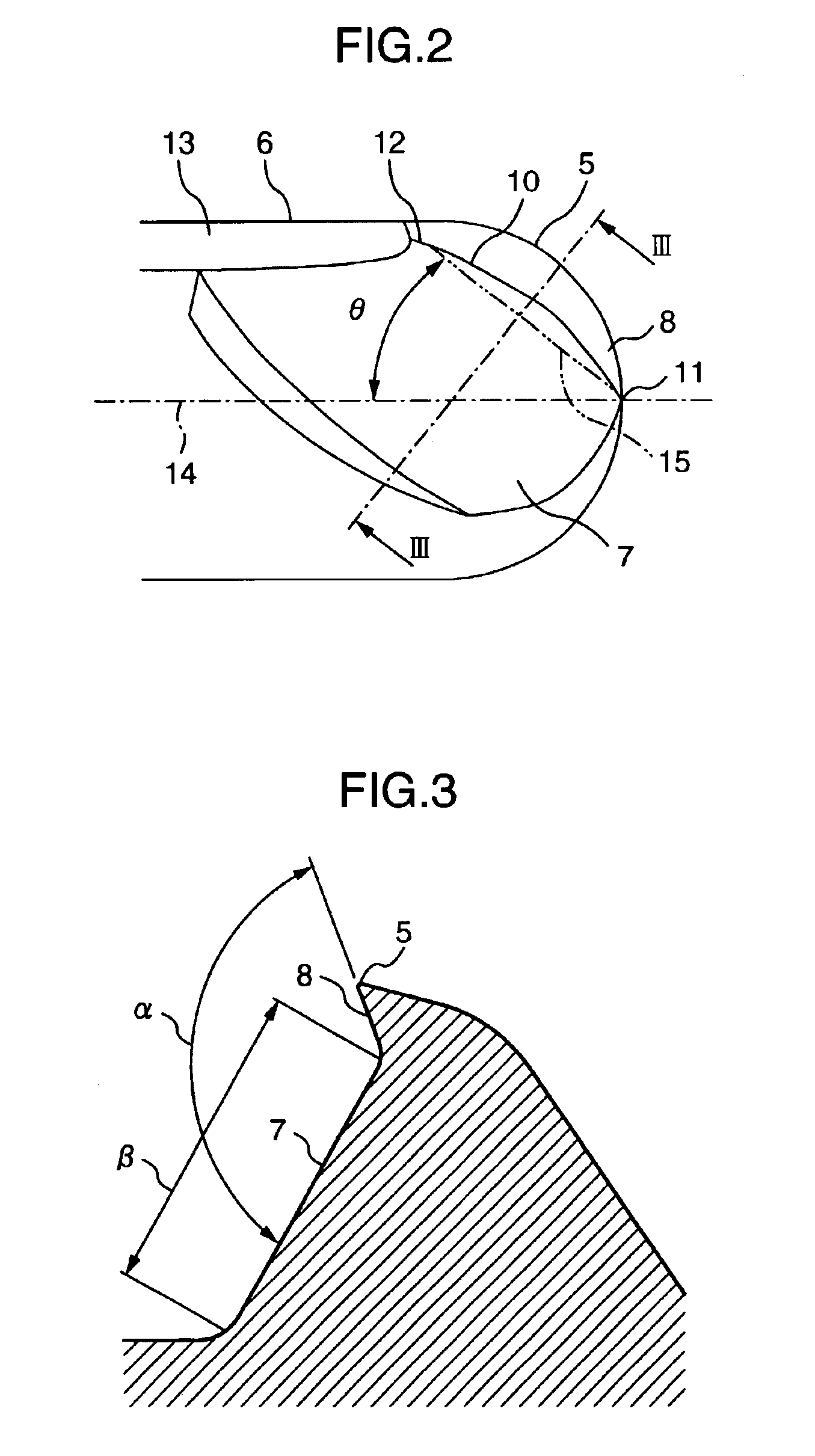

Cemented carbide ball end mill

InactiveUS6953310B2Improve machine performanceImprove performanceMilling cuttersWorkpiecesFluteCemented carbide

A cemented carbide ball end mill comprises a cutting portion with a semi-spherical ball portion at a tip thereof. The cutting edge portion has a cutting edge rake face and a chip evacuating flute at the ball portion. An angle formed by a straight line connecting a vertex of the ball portion, where an intersection line passes through, and another end of the intersection line with respect to the central axis, is from 30° to 50°. Further, and angle formed by the rake face and the chip evacuating flute is from 100° to 150°, and a width of the chip evacuating flute is 0.5 to 5 times as large as a radius of the ball portion.

Owner:NACHI-FUJIKOSHI

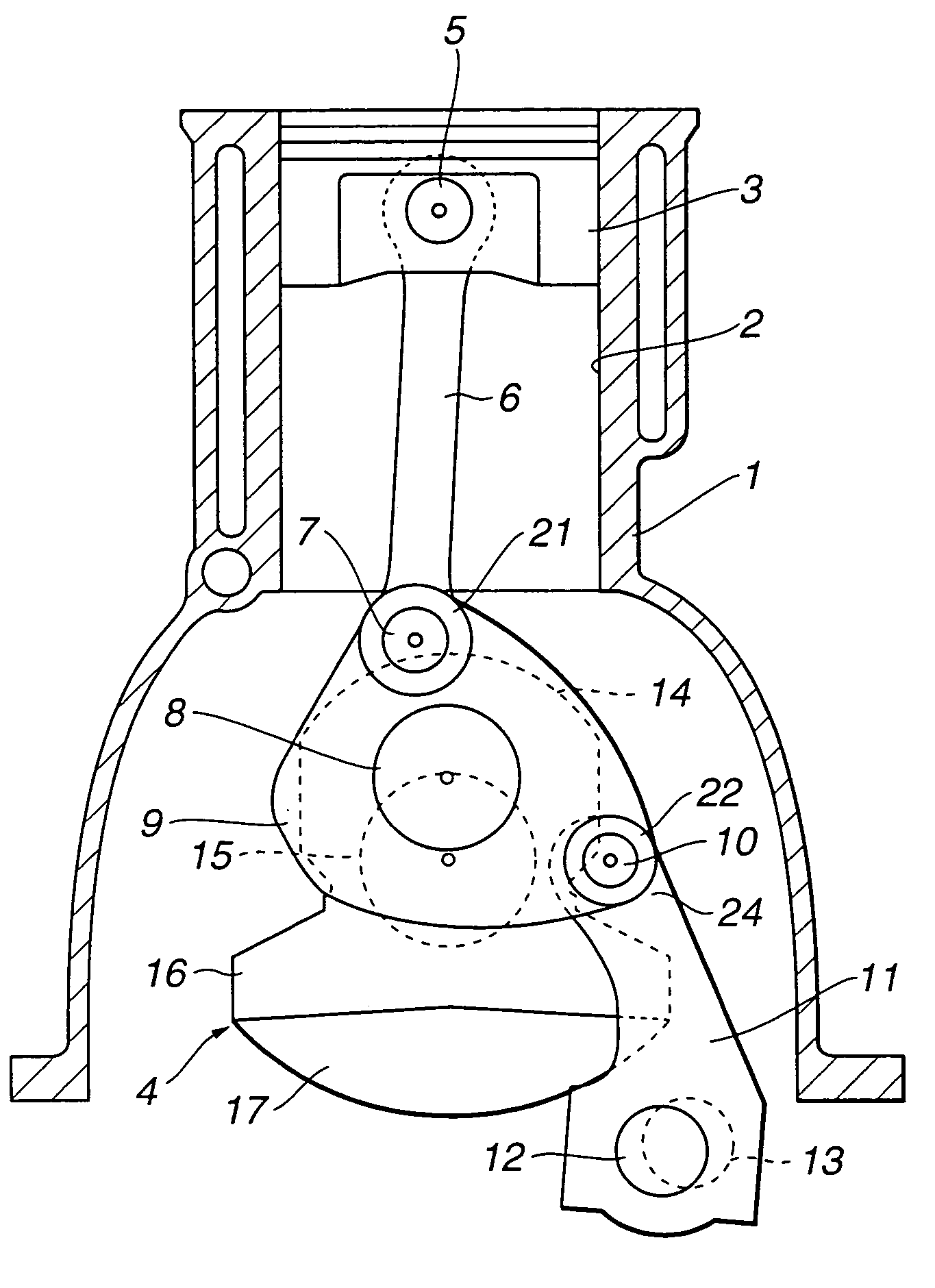

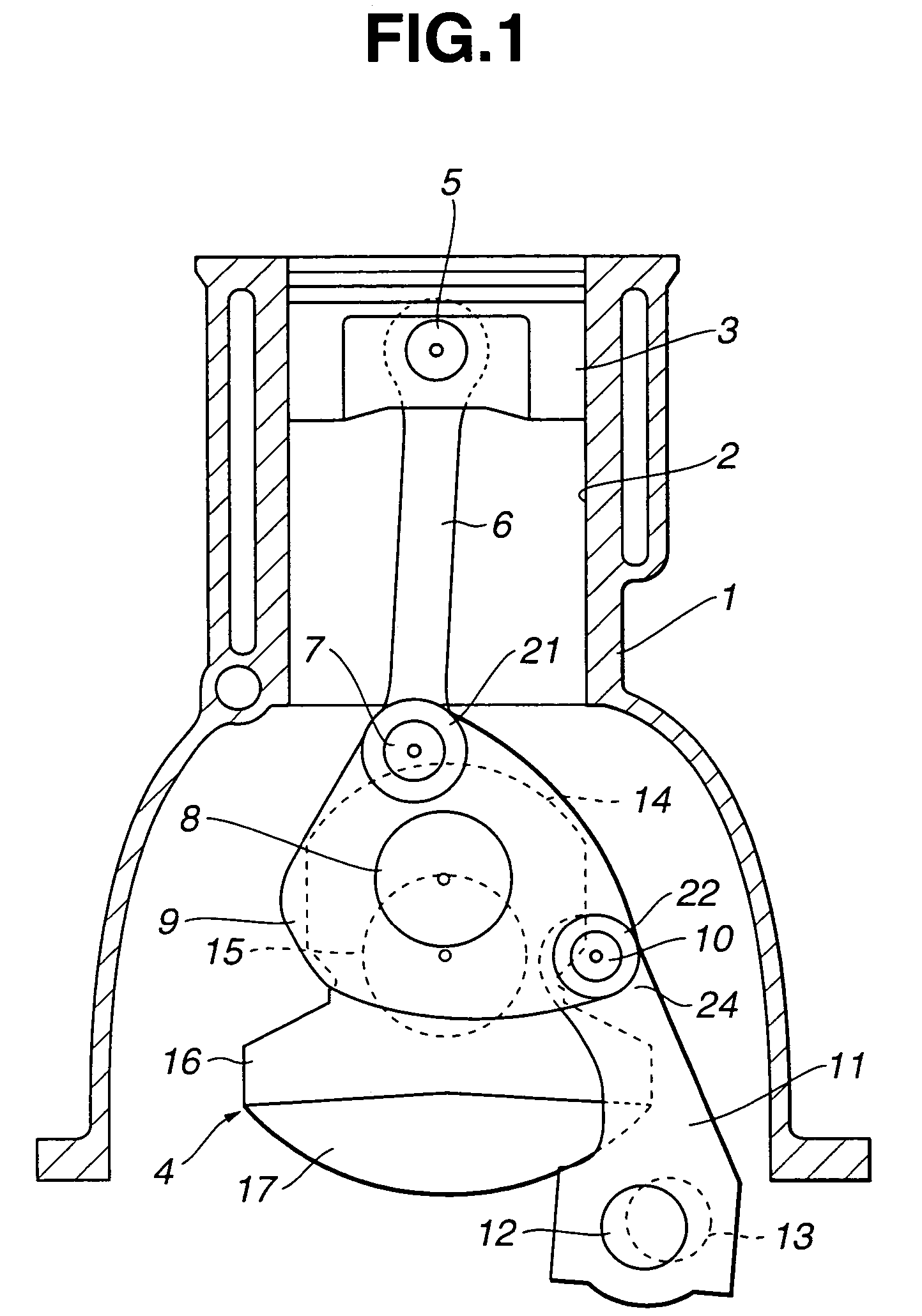

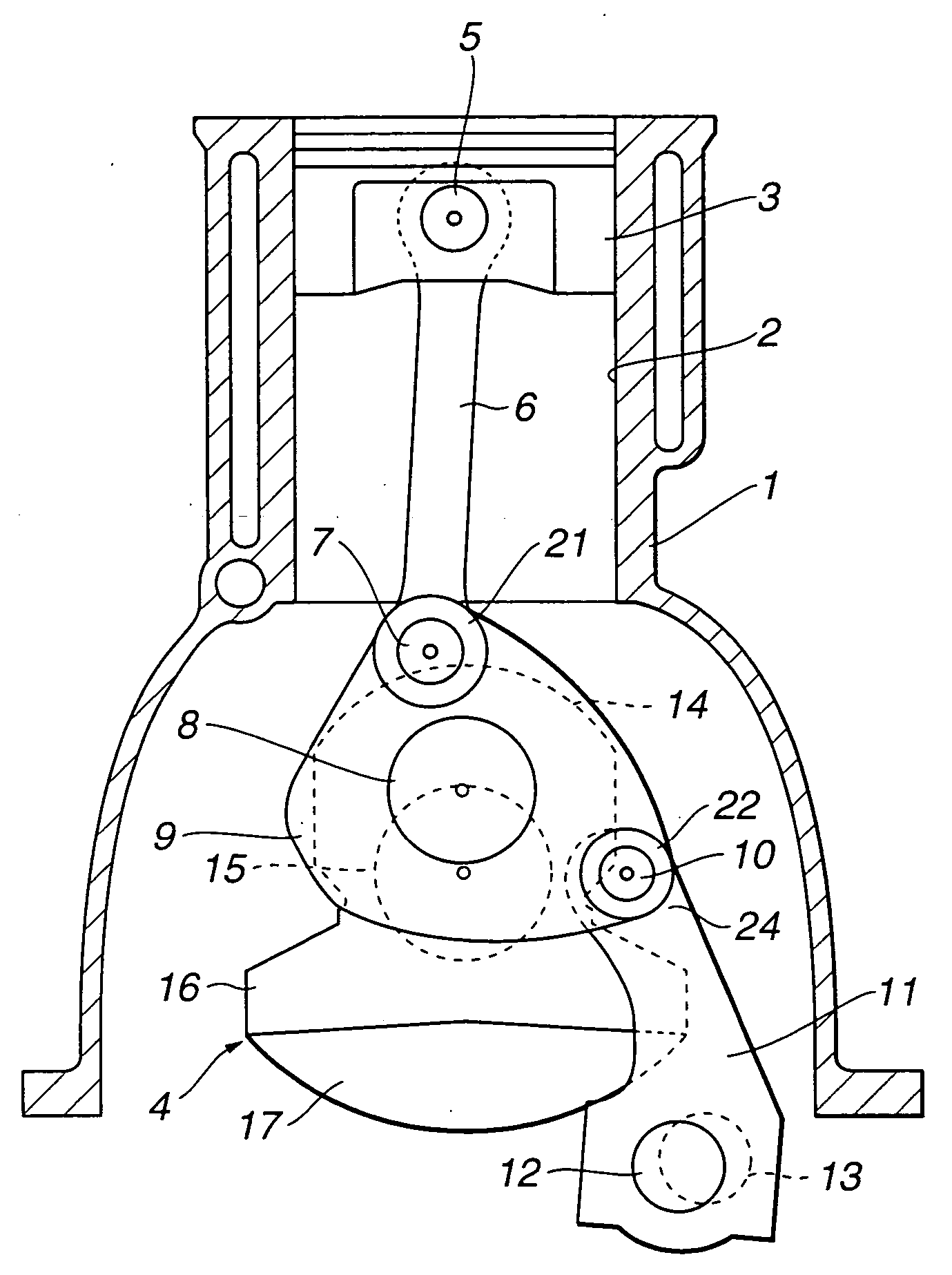

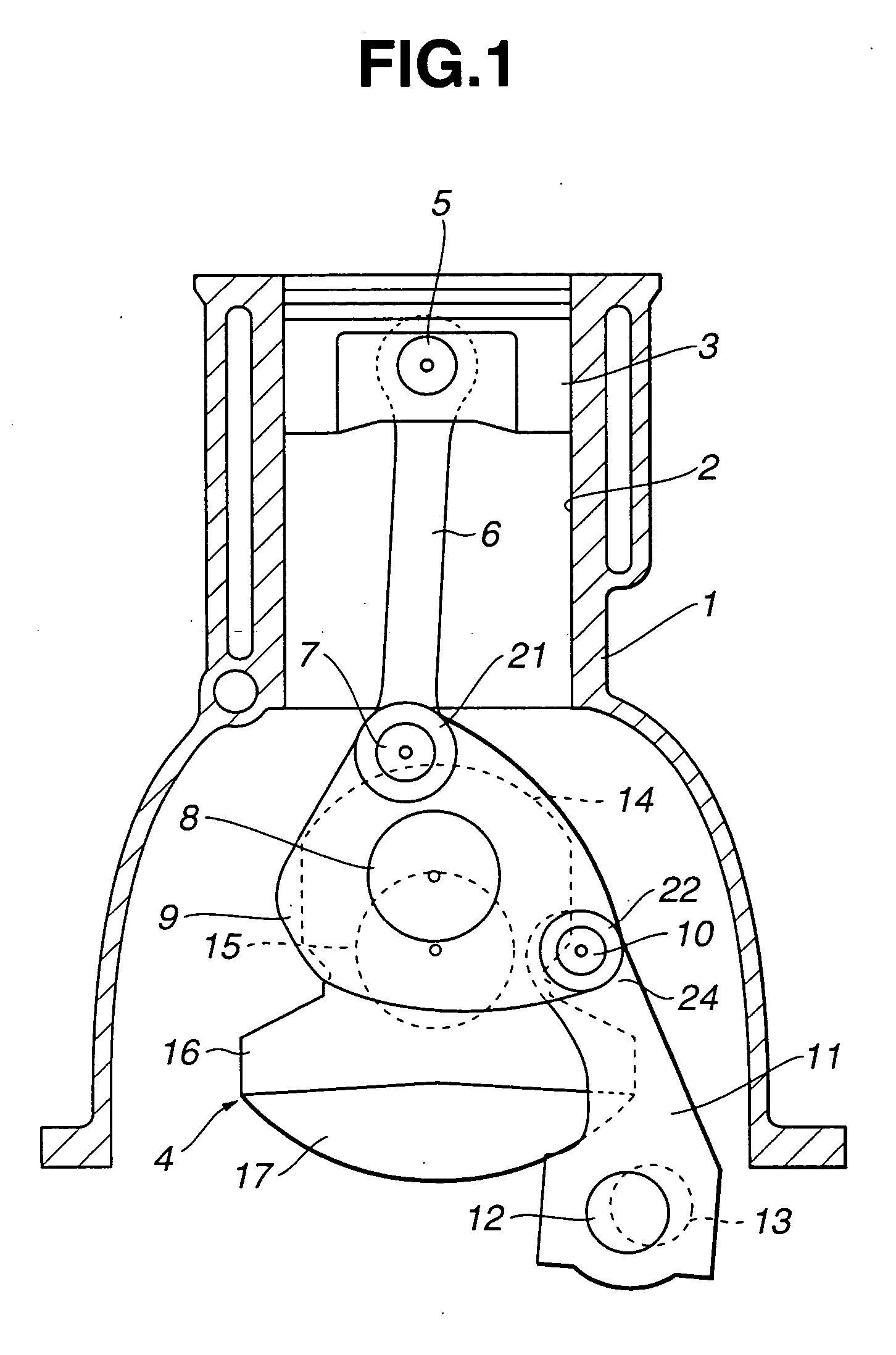

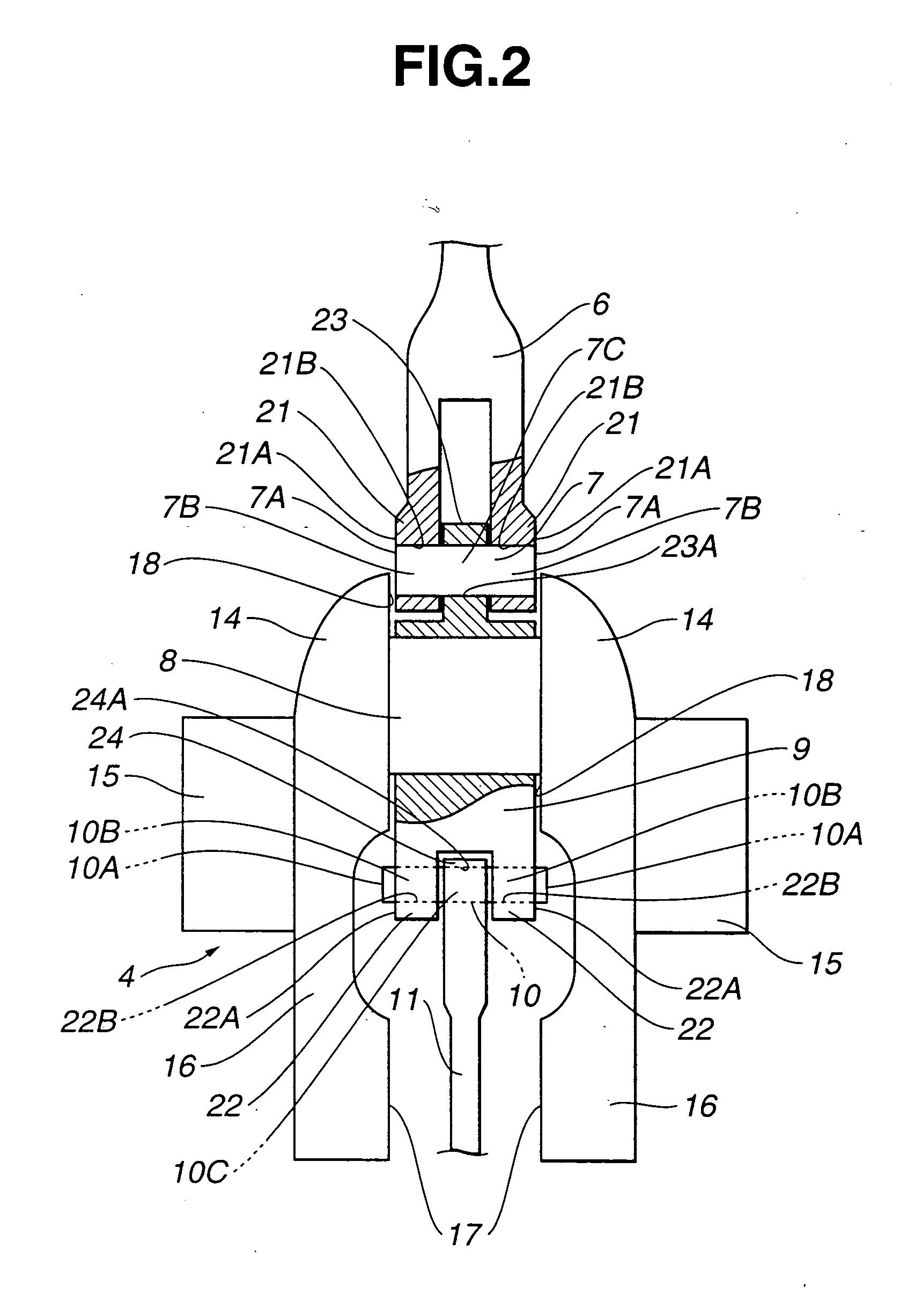

Multi-link piston crank mechanism for internal combustion engine

ActiveUS7121251B2Optimization mechanismAvoid interferenceConnecting rodsGearingMulti linkInternal combustion engine

A multi-link piston crank mechanism for an internal combustion engine, including a crankshaft having a crank pin, and crank webs connected with each other through the crank pin. A pair of thrust surfaces are formed on the crank webs so as to be opposed in a direction of a center axis of the crank pin. A first link pivotally supported on the crank pin is coupled to a second link through a connection pin located in a space between the thrust surfaces. The connection pin is moveable about the crank pin to form a circular trace along which the thrust surfaces extend. The end surfaces of the connection pin and the thrust surfaces come into mutual contact to prevent the connection pin from falling out of the space between the thrust surfaces.

Owner:NISSAN MOTOR CO LTD

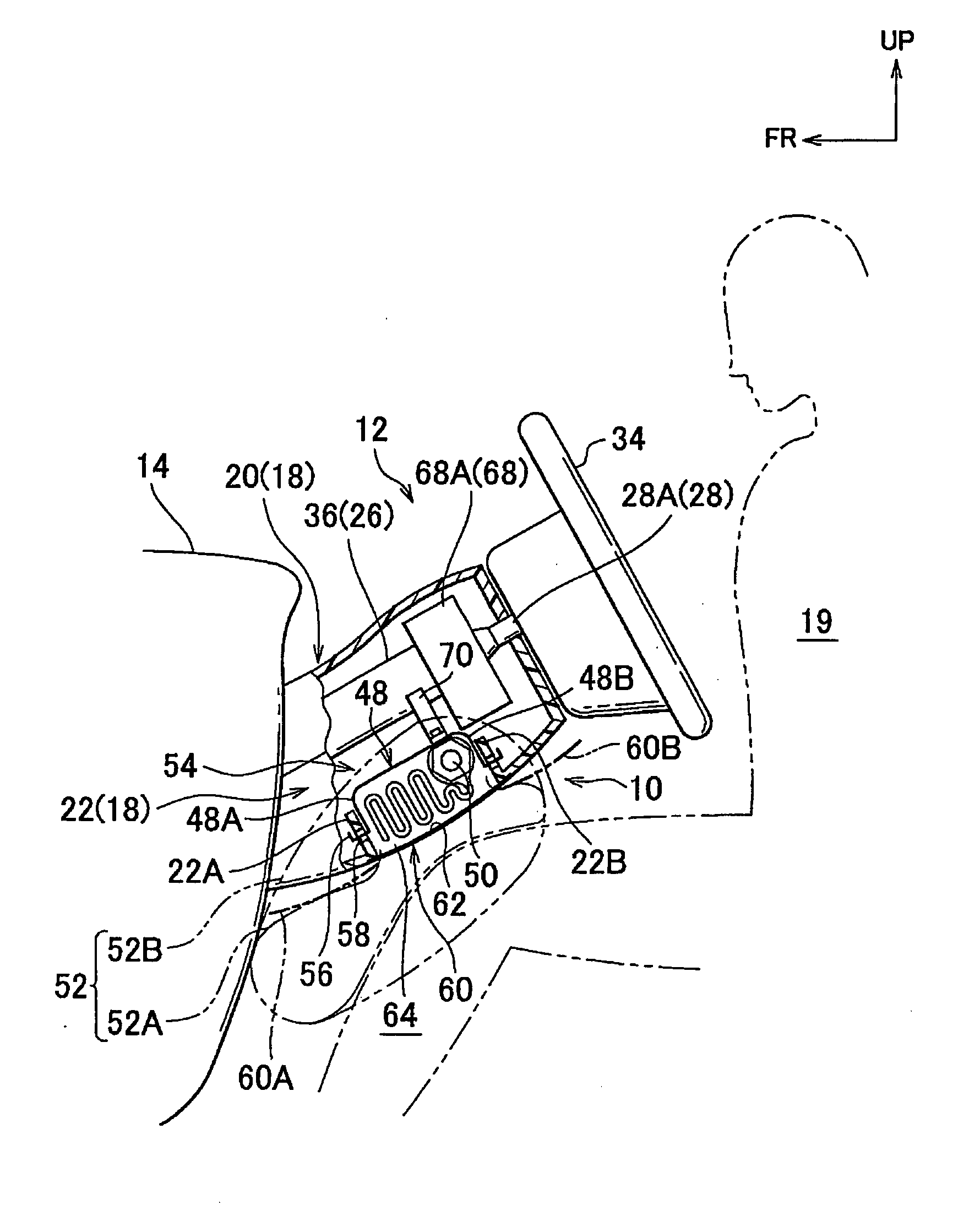

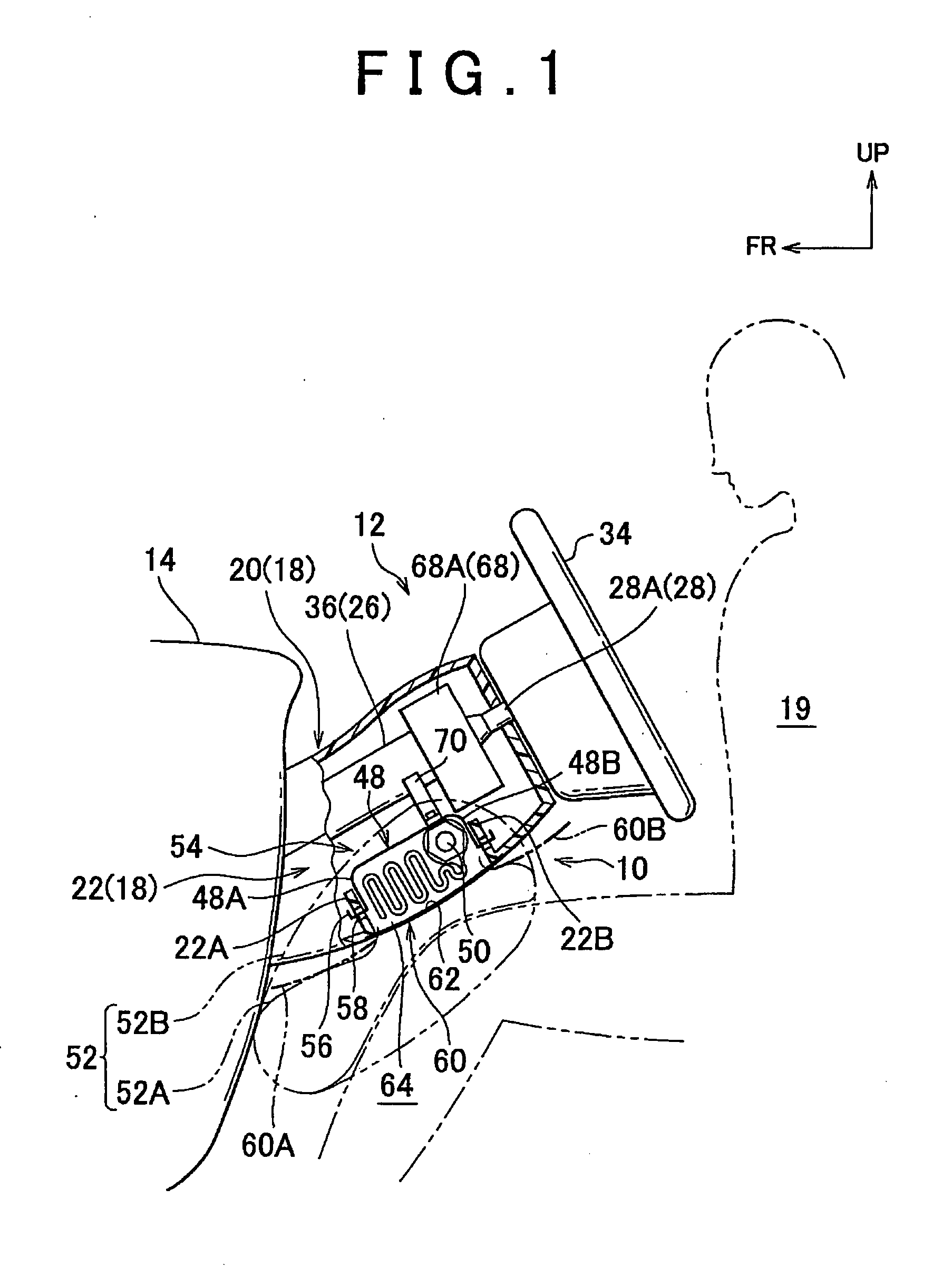

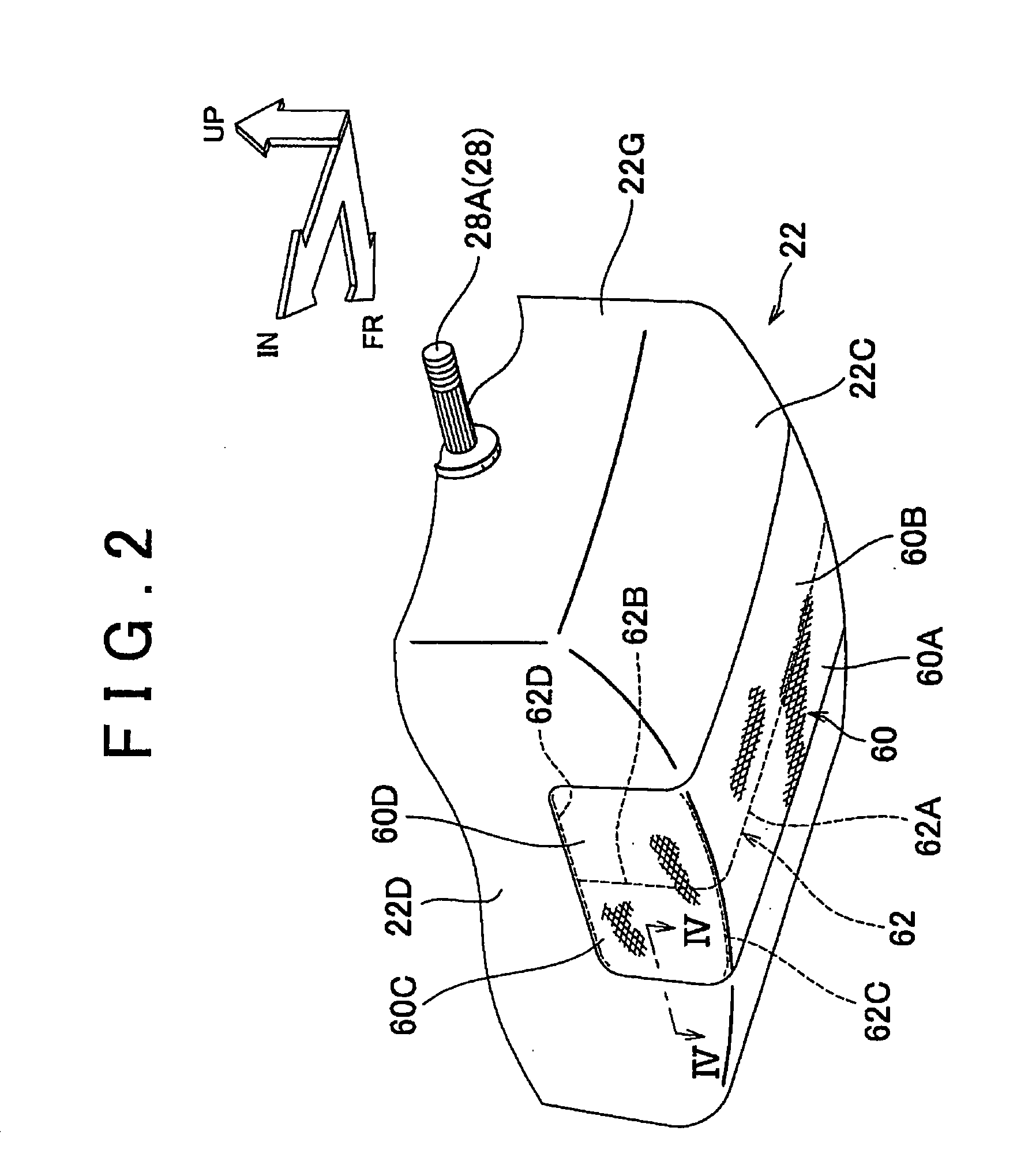

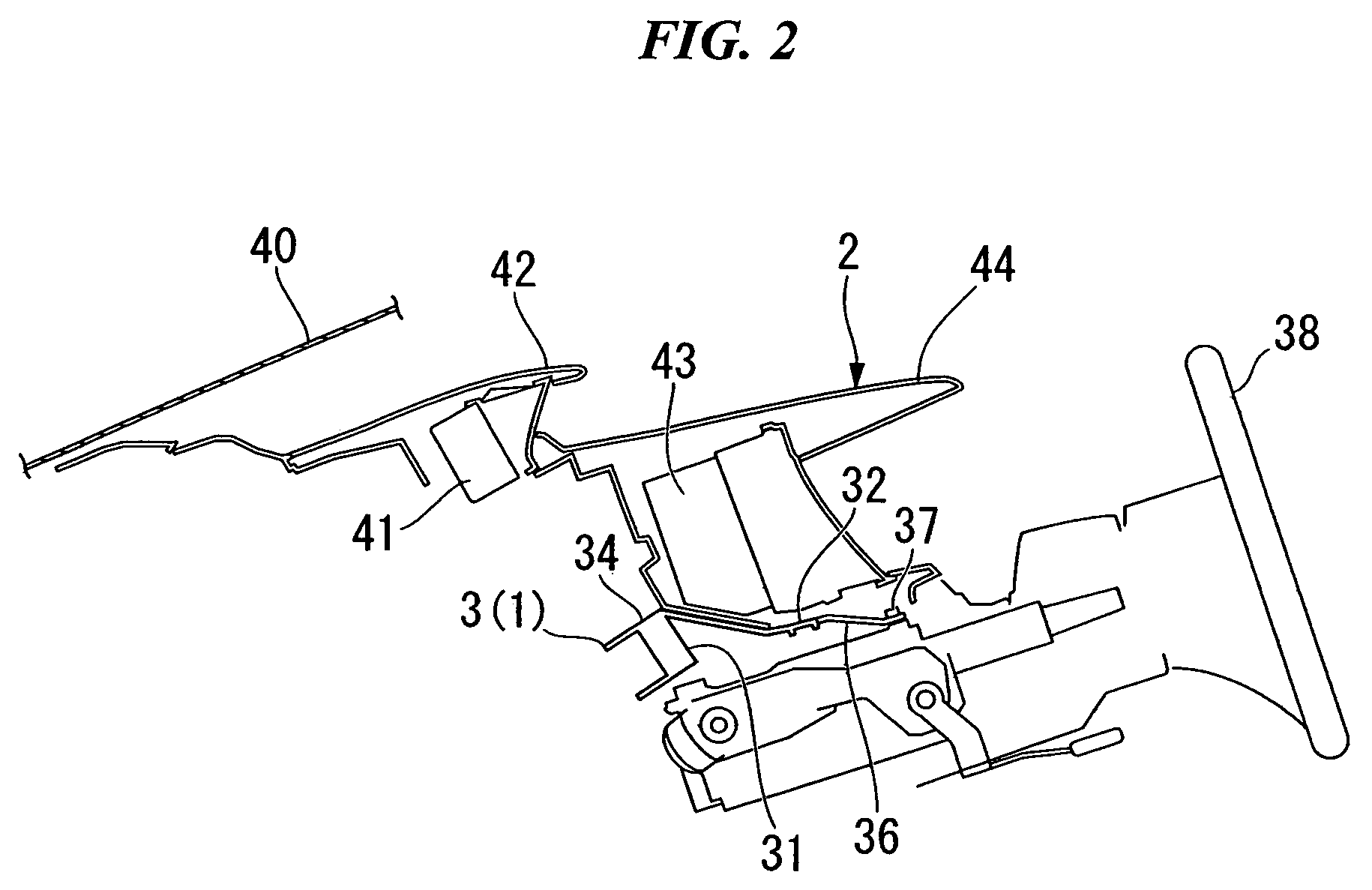

Knee airbag device

InactiveUS20080122204A1Ensure strengthReduced strengthPedestrian/occupant safety arrangementEngineeringAirbag

A knee airbag device includes an airbag module and an airbag door. The airbag module includes a gas generation device that is operated when the knee airbag device is operated, and a knee airbag that is stored in a folded state inside a column cover that covers the rear end portion of a steering column. When the knee airbag receives gas from the gas generation device, the knee airbag is inflated and deployed toward the knee of an occupant. The airbag door, provided in the lower portion of the column cover, is made of a flexible material. When the knee airbag is inflated and deployed, the airbag door is opened toward the knee of the occupant due to an airbag inflation pressure.

Owner:TOYOTA JIDOSHA KK

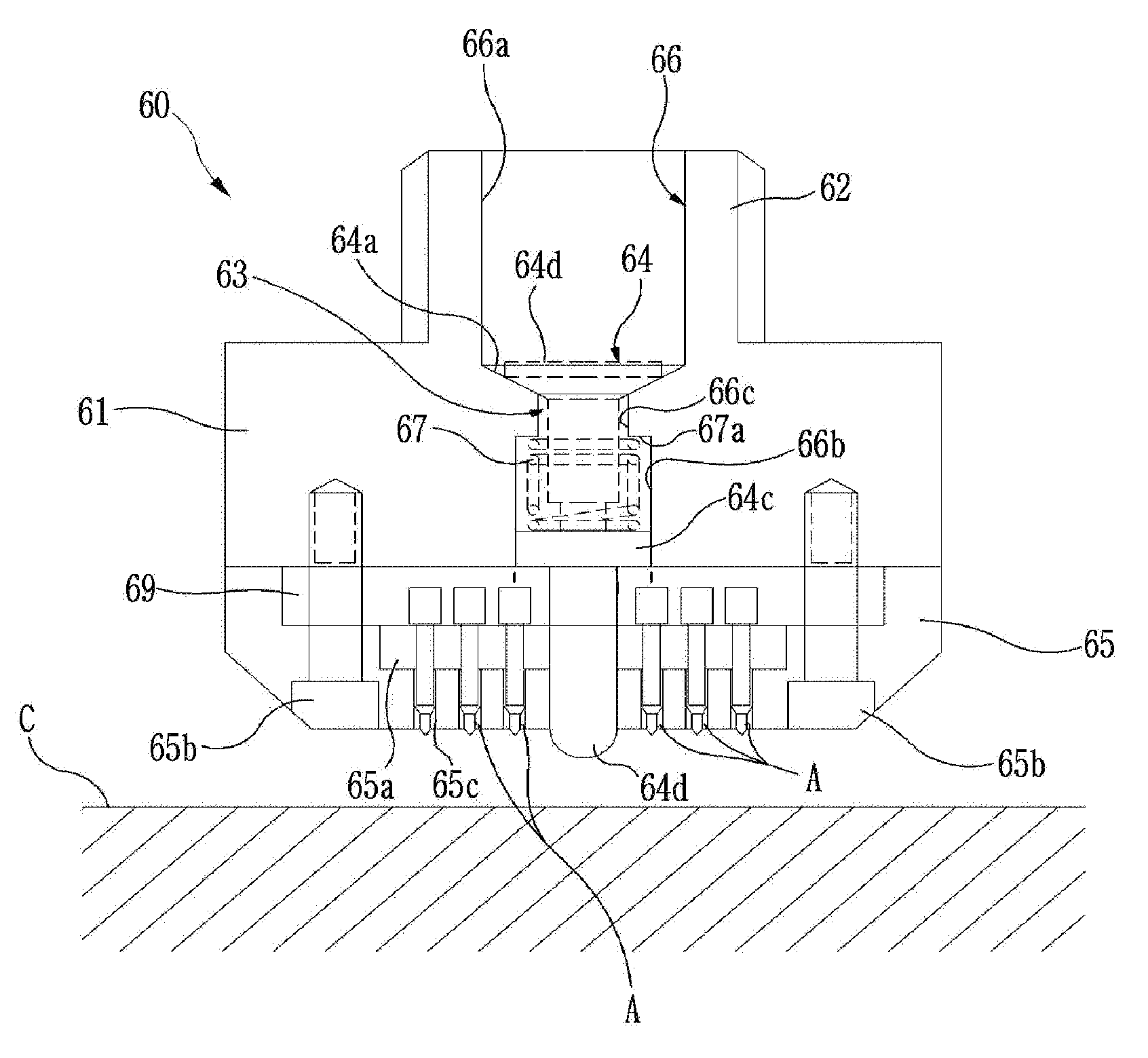

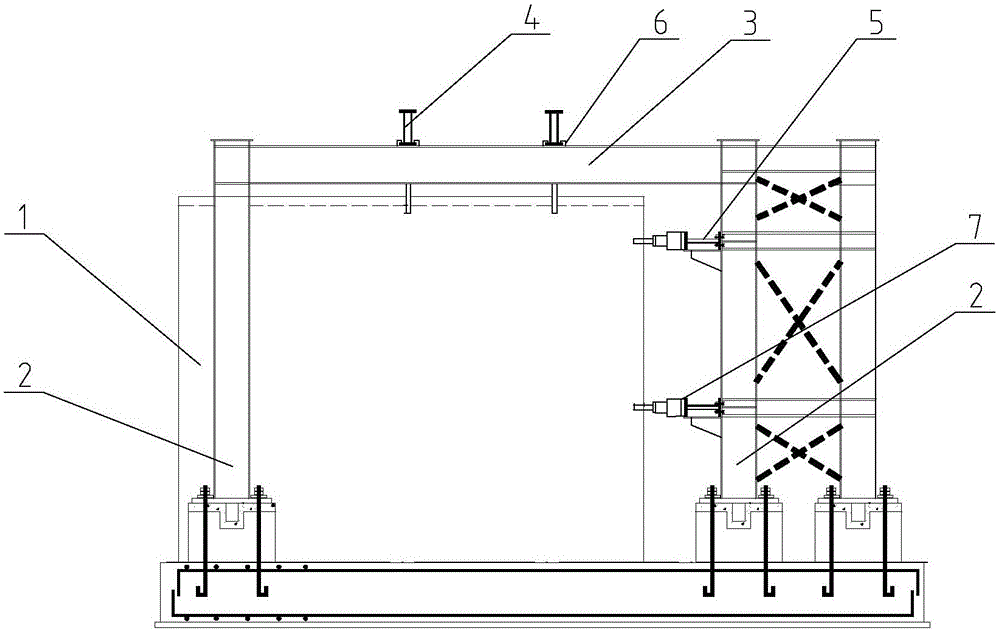

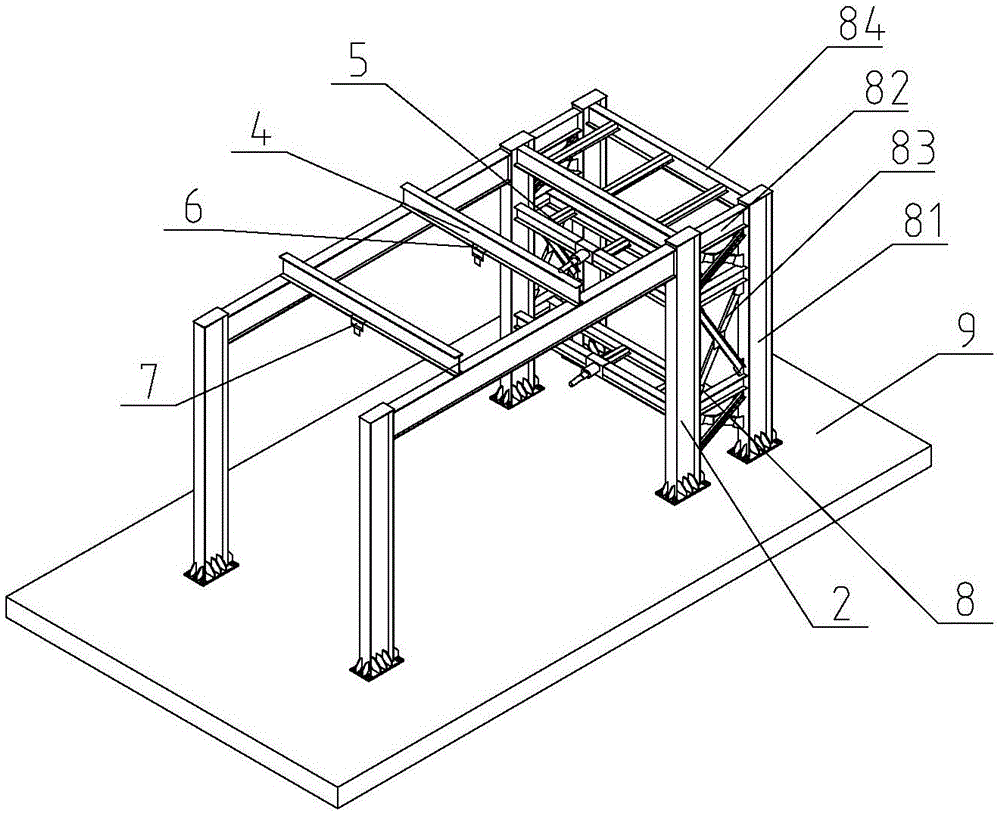

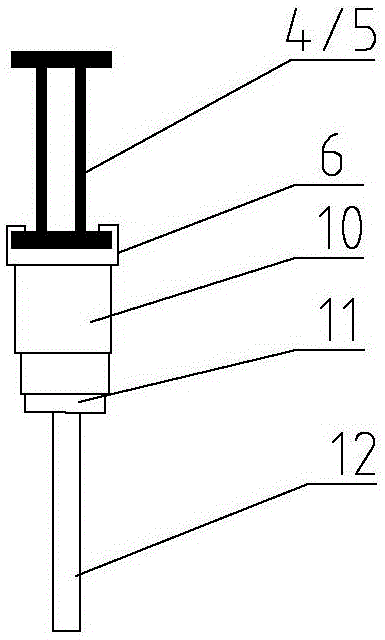

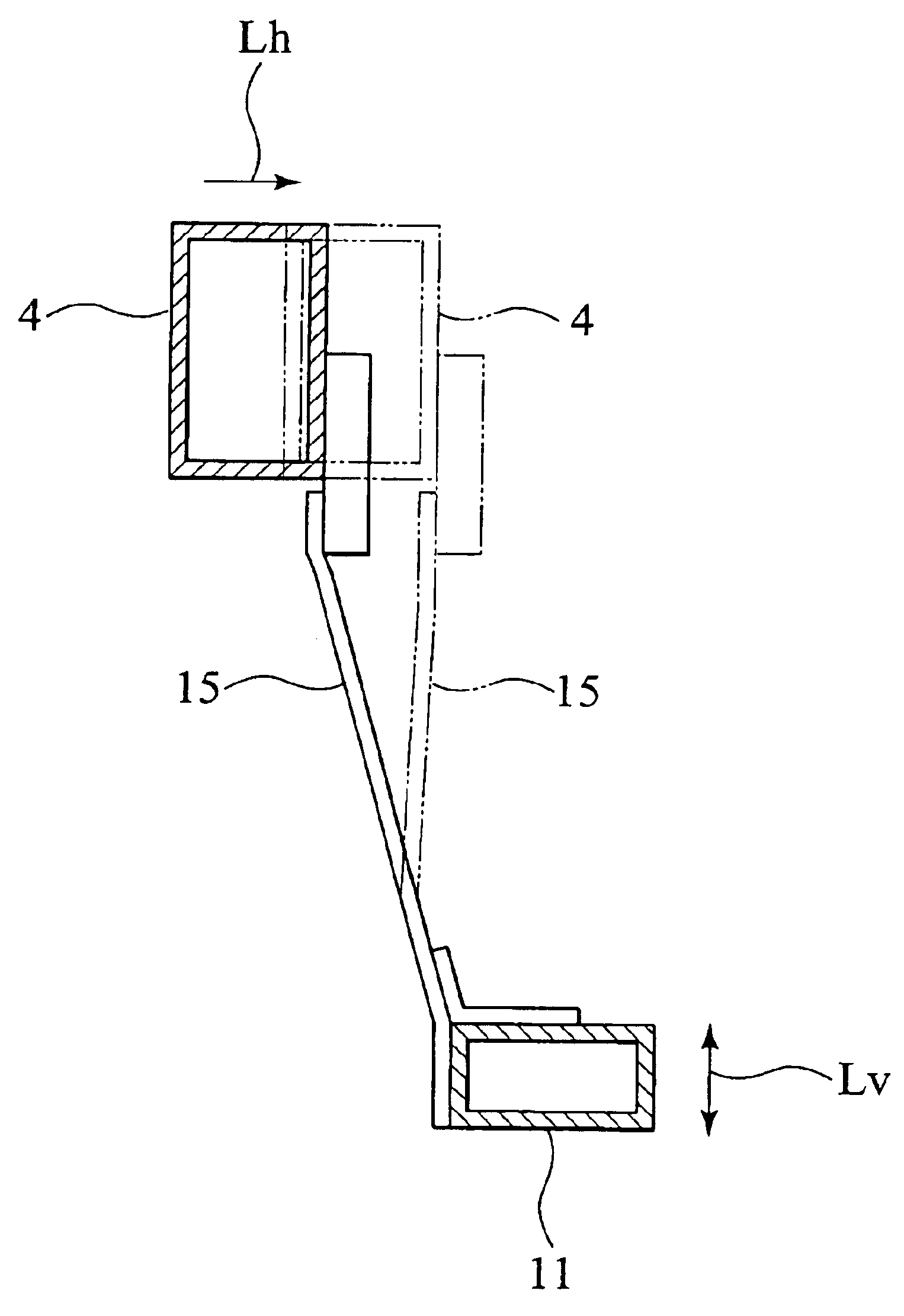

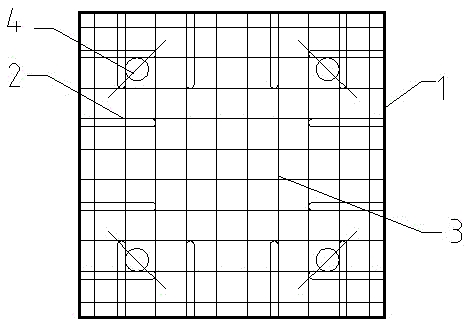

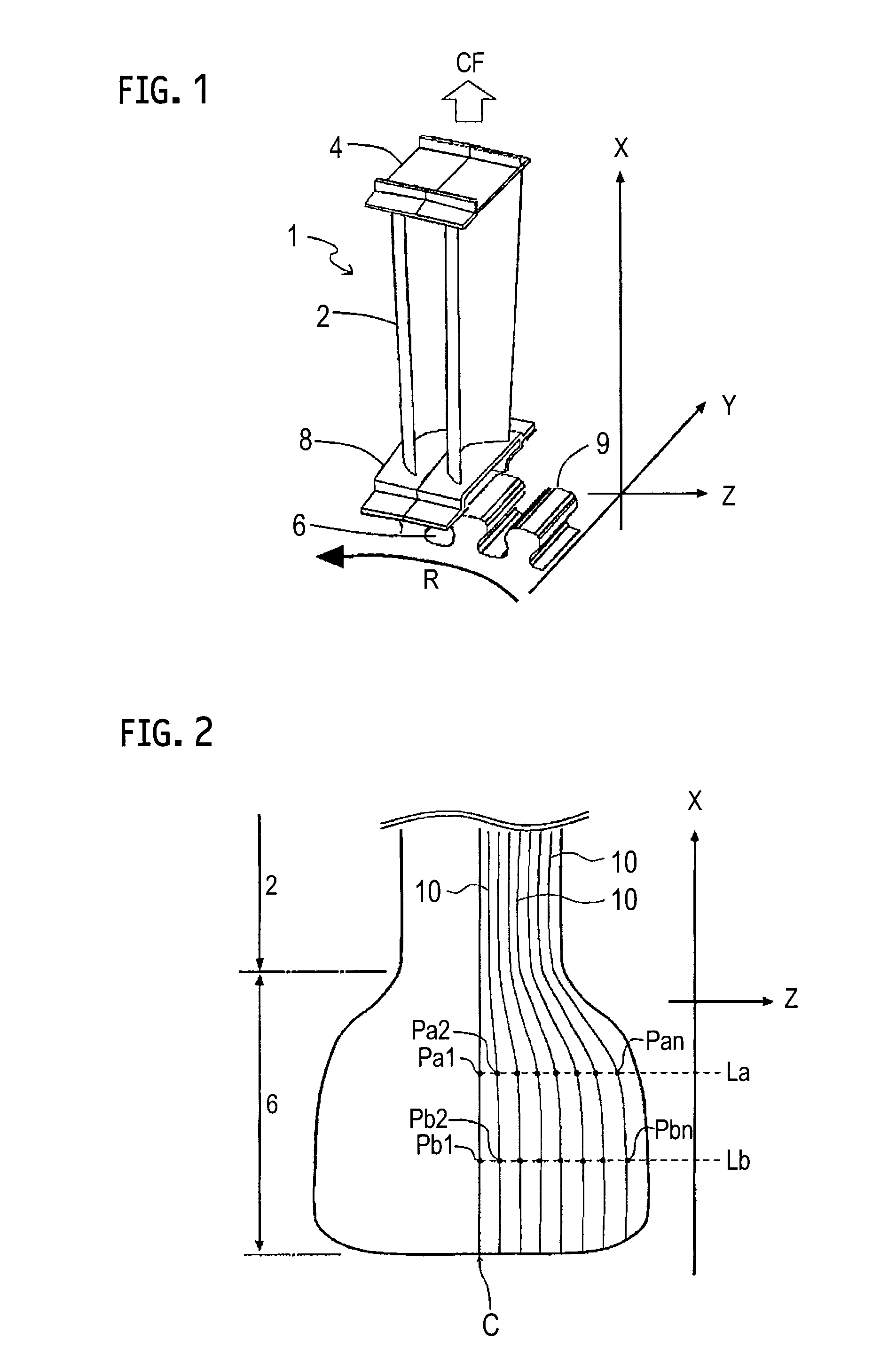

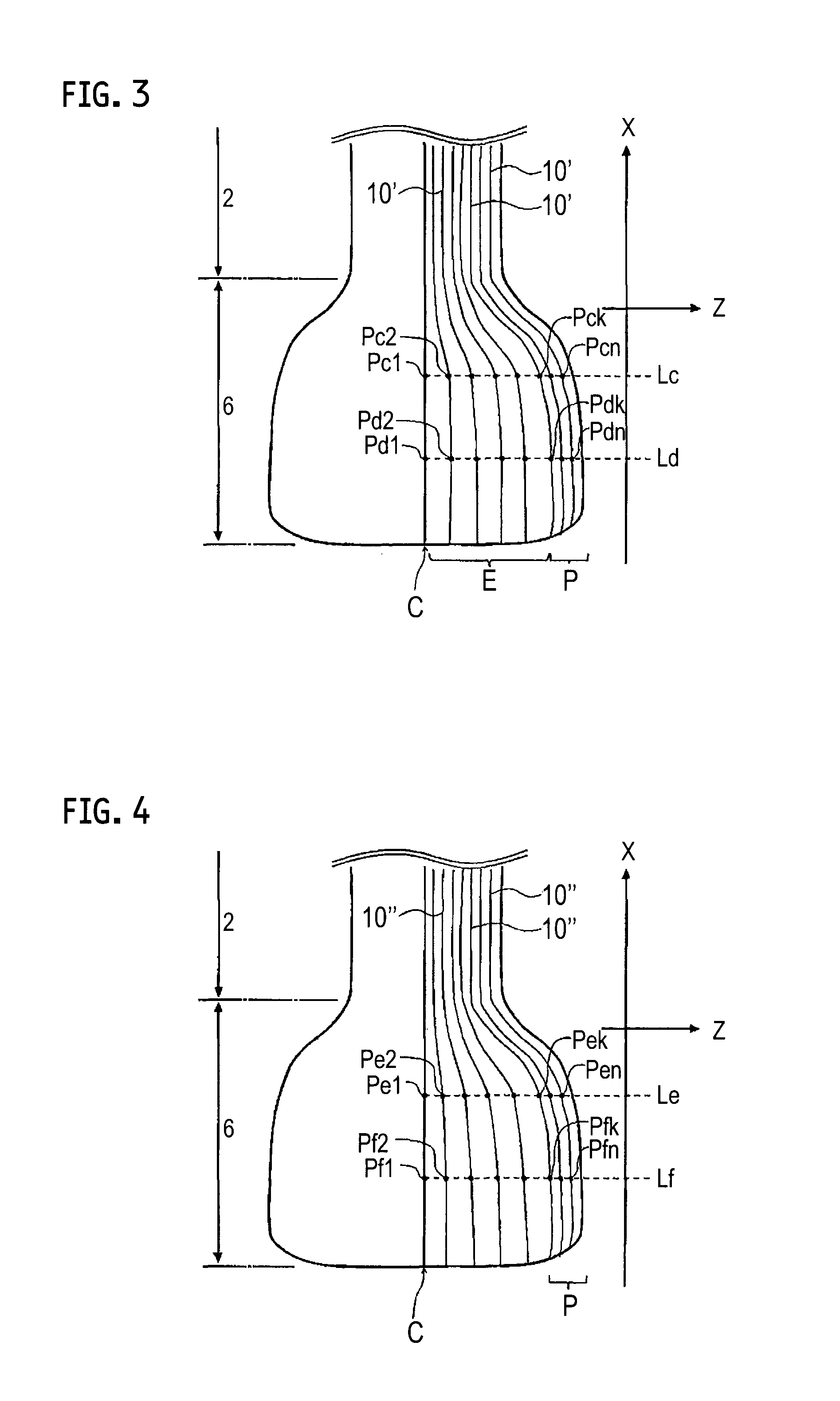

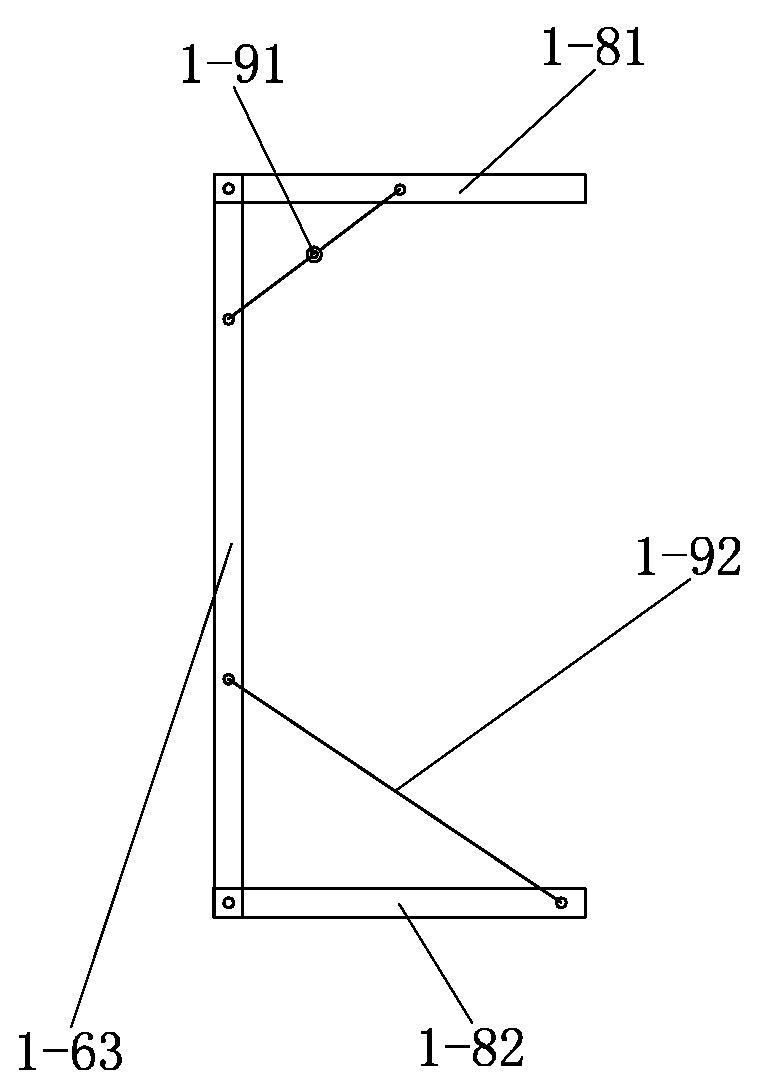

Fire test furnace loading device

InactiveCN105043851ARealize the vertical loadFulfillment requirementsMaterial strength using tensile/compressive forcesFire testEngineering

The invention discloses a fire test furnace loading device which comprises stand columns located at four corners of a fire test furnace. Beams are connected between the stand columns transversely adjacent respectively. At least one vertical loading beam is vertically connected between the beams. At least one horizontal loading beam is vertically connected between the stand columns longitudinally adjacent. The vertical loading beams and the horizontal loading beams are each provided with sliding blocks facing the fire test furnace. The sliding blocks have freedom degrees allowing the sliding blocks to move in the length direction of the vertical loading beams and the length direction of the horizontal loading beams. Detecting devices used for detecting performance of members, to be detected, in the fire test furnace are arranged at the bottoms of the sliding blocks. As the vertical loading beams, the horizontal loading beams and the sliding blocks capable of moving in the length direction of the vertical loading beams and the length direction of the horizontal loading beams are utilized, the requirements for vertical loads and transverse loads of the loading device can be met individually or together, the result accuracy of fire tests of a building structure is improved, and convenience of test operation is improved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

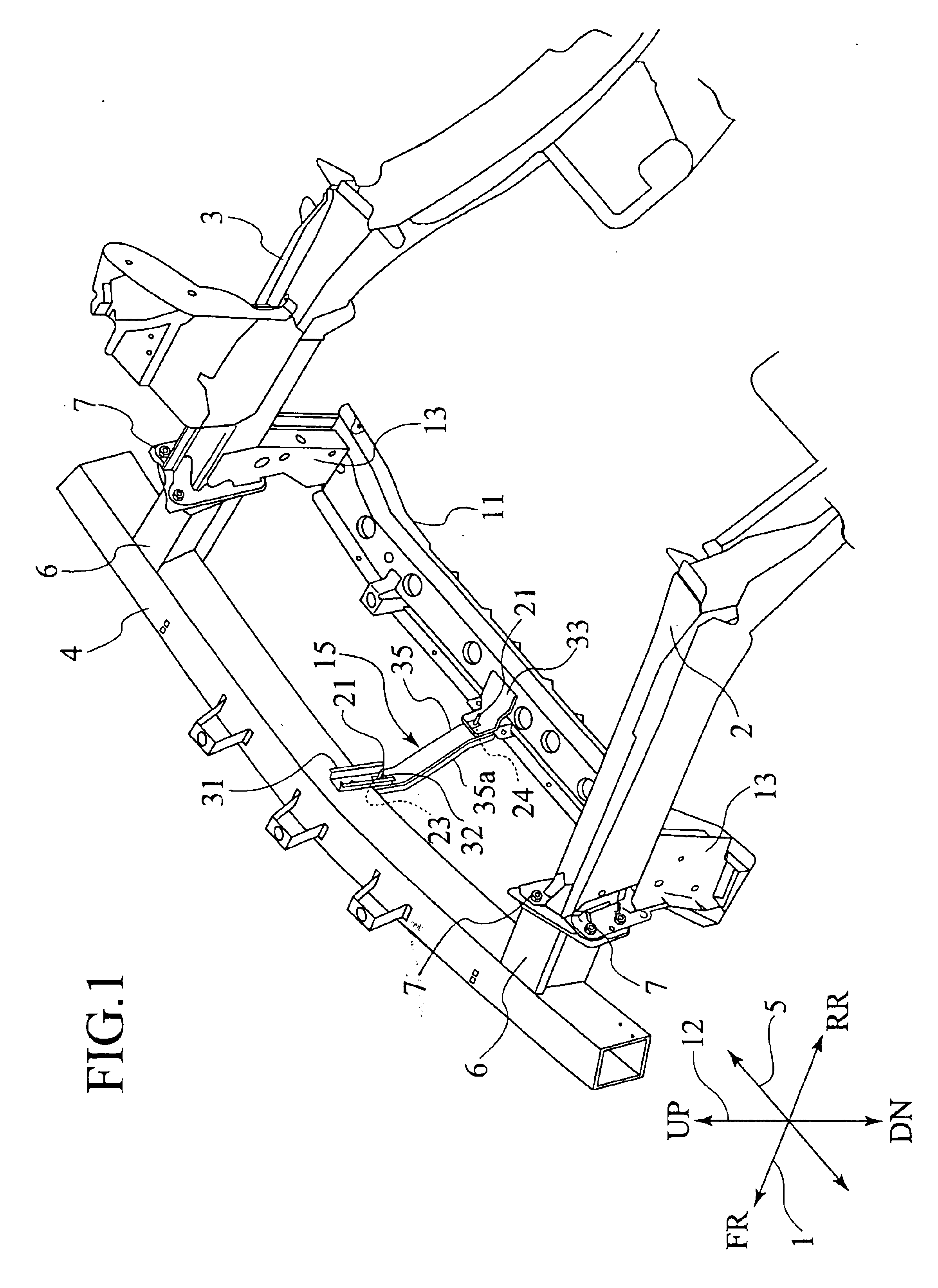

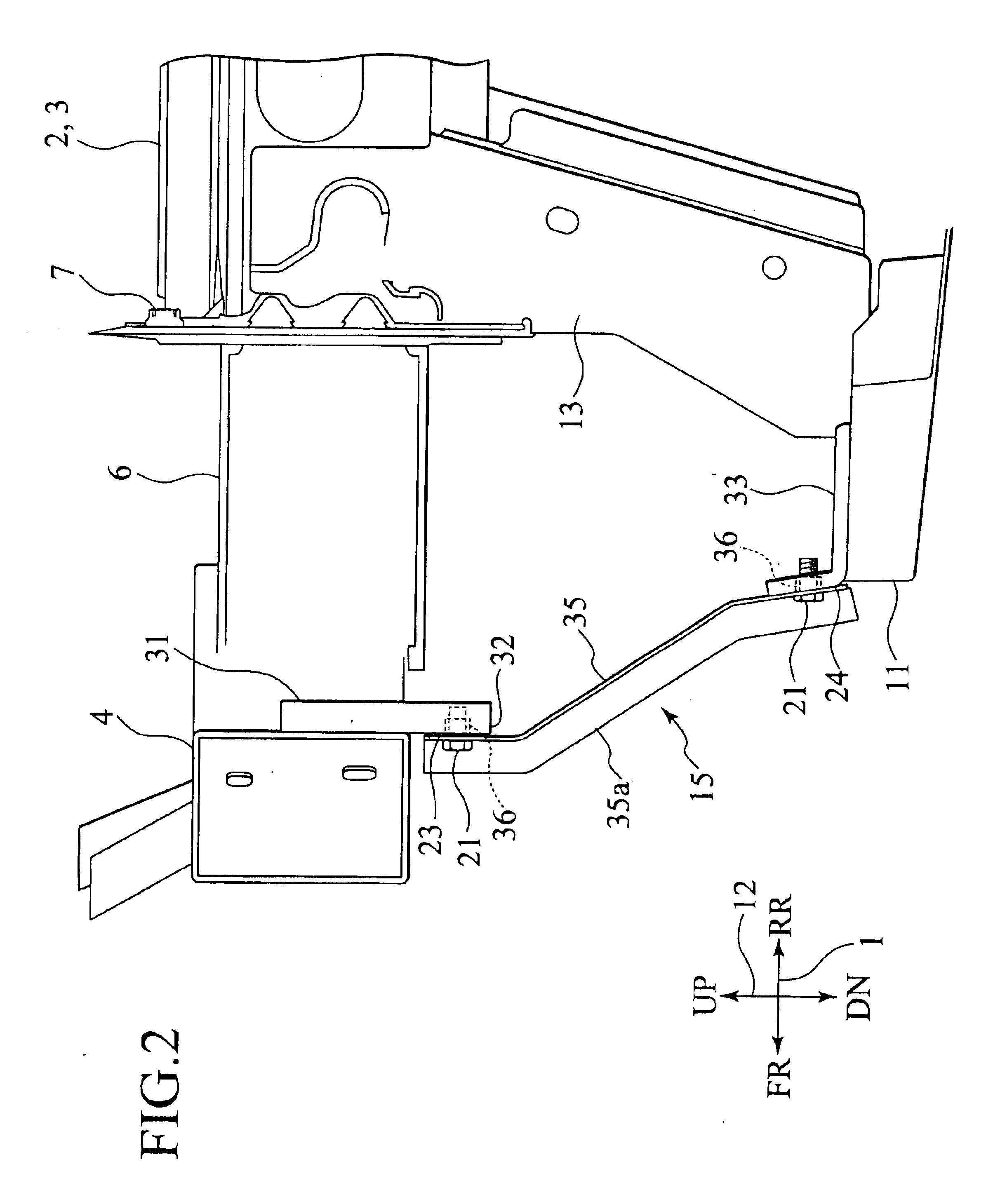

Vehicle front body structure

ActiveUS6866333B2Ensure strengthEnsure rigidityVehicle seatsUnderstructuresFlexural strengthEngineering

A vehicle front body structure which includes: a pair of side members extending in a vehicle longitudinal direction; a bumper reinforcing member connected to front ends of the side members; a cross member connected to bottoms of the side members in the vicinities of the front ends thereof; and a connecting member connected to the bumper reinforcing member and the cross member. Connection strength between the connecting member and the bumper reinforcing member in the vehicle longitudinal direction is lower than a flexural strength of the cross member in the vehicle longitudinal direction.

Owner:NISSAN MOTOR CO LTD

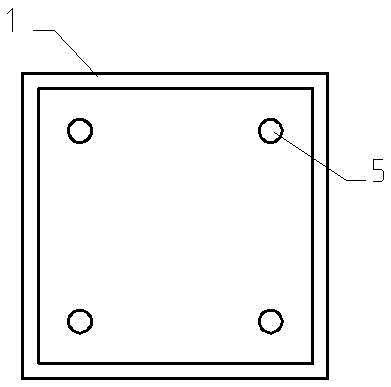

Manufacturing process for environment-friendly construction modularization tool type temporary road plate block

InactiveCN105563640AIncrease profitGuaranteed load capacityCeramic shaping apparatusTemporary pavingsArchitectural engineeringSteel frame

The invention discloses a manufacturing process for an environment-friendly construction modularization tool type temporary road plate block. The specific manufacturing process comprises the steps of 1, surveying and lining; 2, manufacturing of U-steel frames; 3, welding of frame reinforced reinforcing steel bars; 4, assembling of reinforcing steel bars; 5, pre-burying and installing of lifting rings; 6, installing of lifting ring hole die sleeves; 7, concrete pouring; and 8, maintenance. The environment-friendly construction modularization tool type temporary road plate block applying the manufacturing process comprises the U-steel frames, the frame reinforced reinforcing steel bars, the inside assembling reinforcing steel bars, the lifting rings and pouring concrete plate block bodies. According to the manufacturing process for the environment-friendly construction modularization tool type temporary road plate block, U-steel cantilever beams used for cantilever scaffolds in former projects are adopted as frame materials, and the advantage of environmental protection is achieved; the process of double-layer reinforcement distribution is adopted, and thus the bearing capacity of the road plate block is ensured; laying of the modularization tool type temporary road plate block is flexible through factory-like manufacturing, and the temporary road plate block can be laid or folded according to the requirements of an engineering site and are widely applied; the temporary road plate block can be reused for many times, so that environmental pollution is reduced, the effects of energy conservation and environmental protection are achieved, and the purpose of environment-friendly construction is achieved.

Owner:江海燕

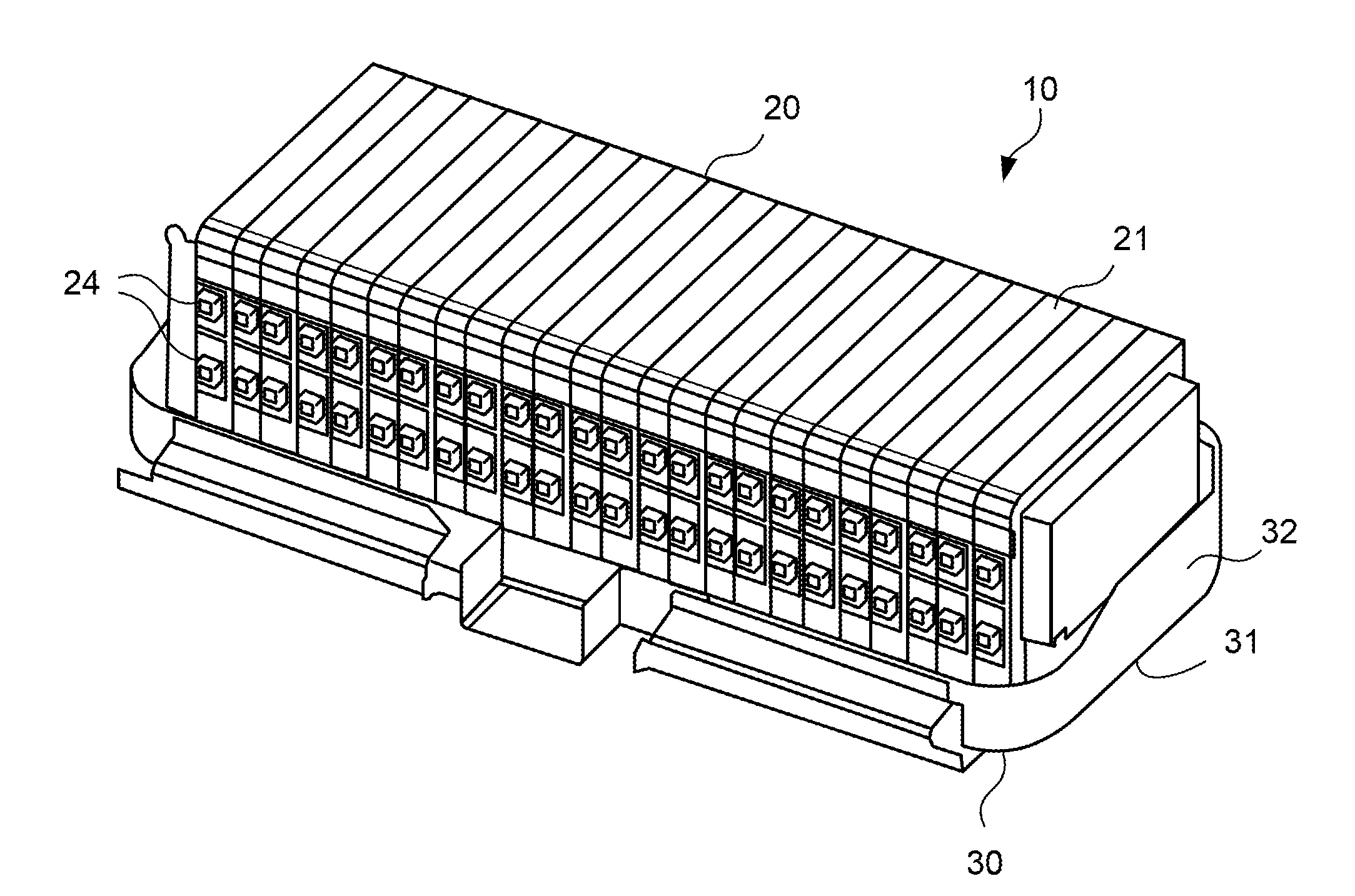

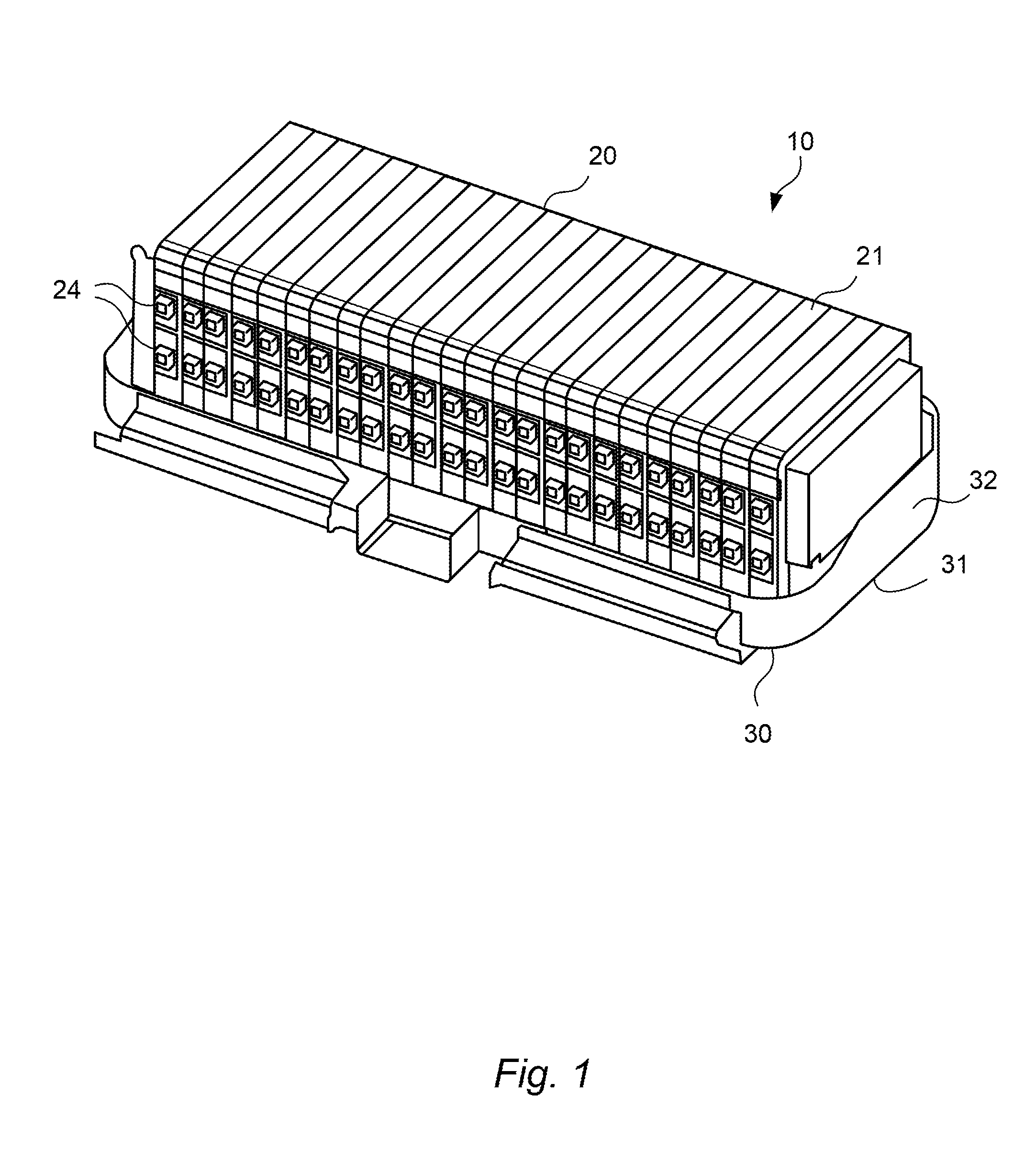

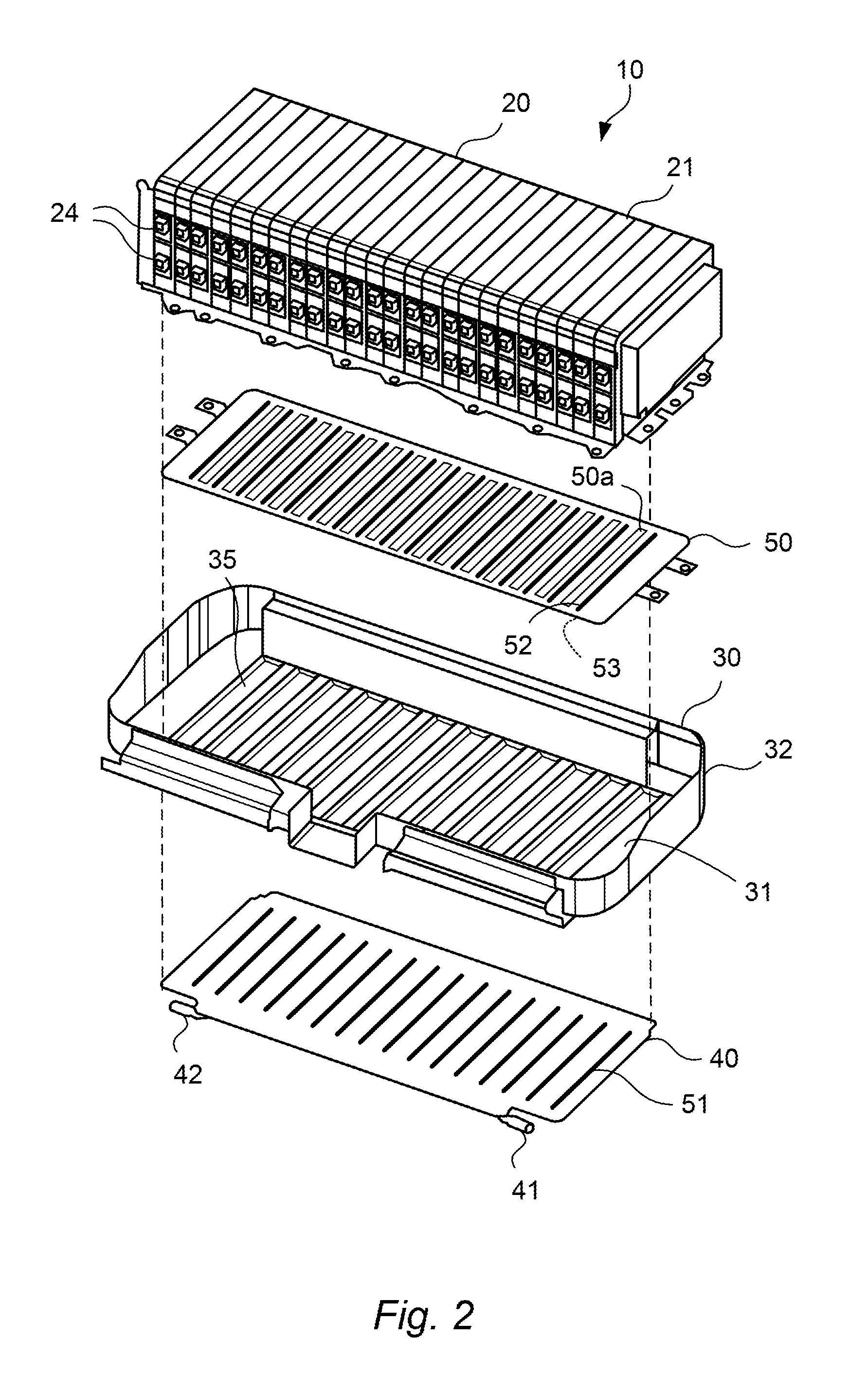

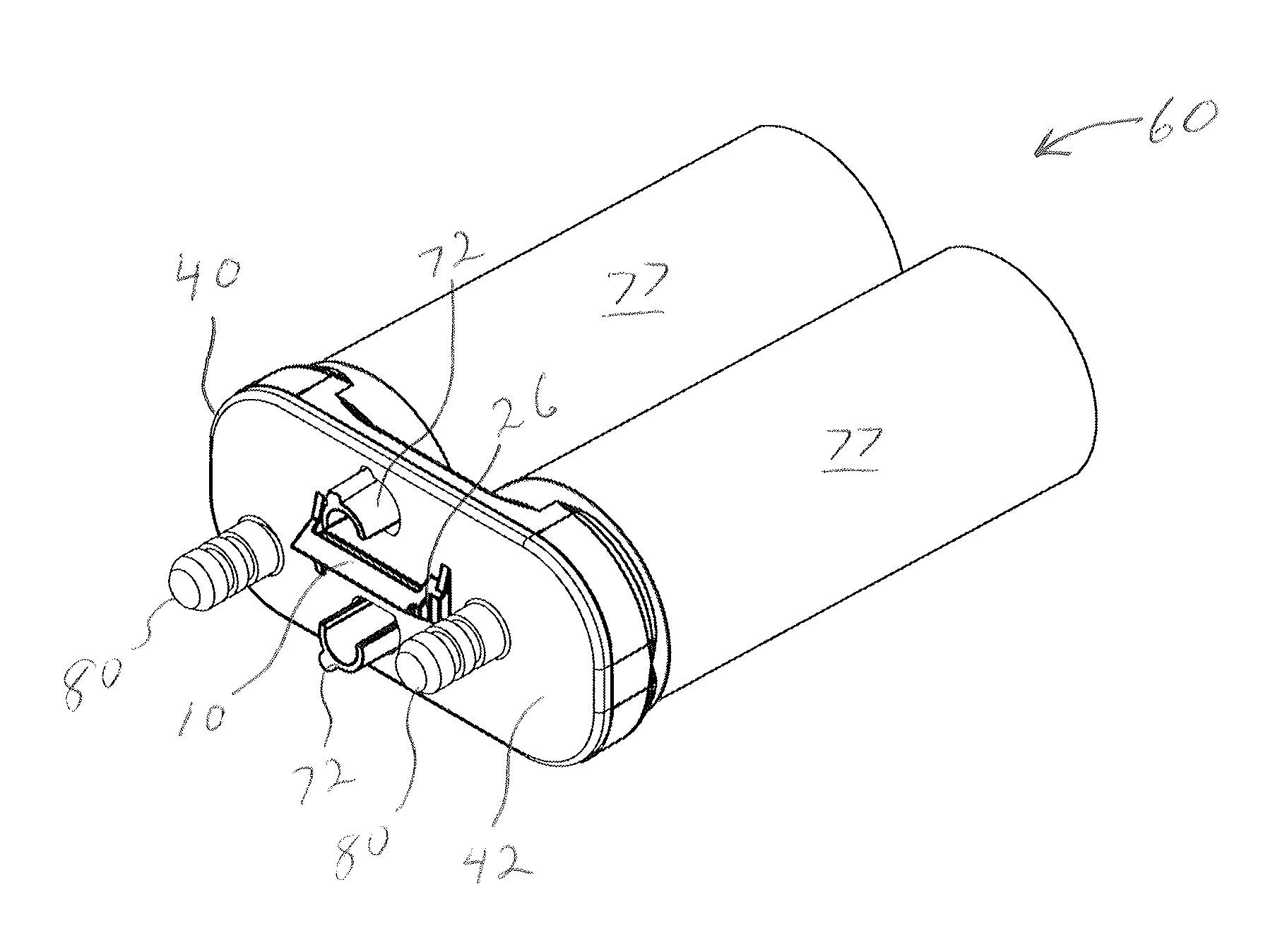

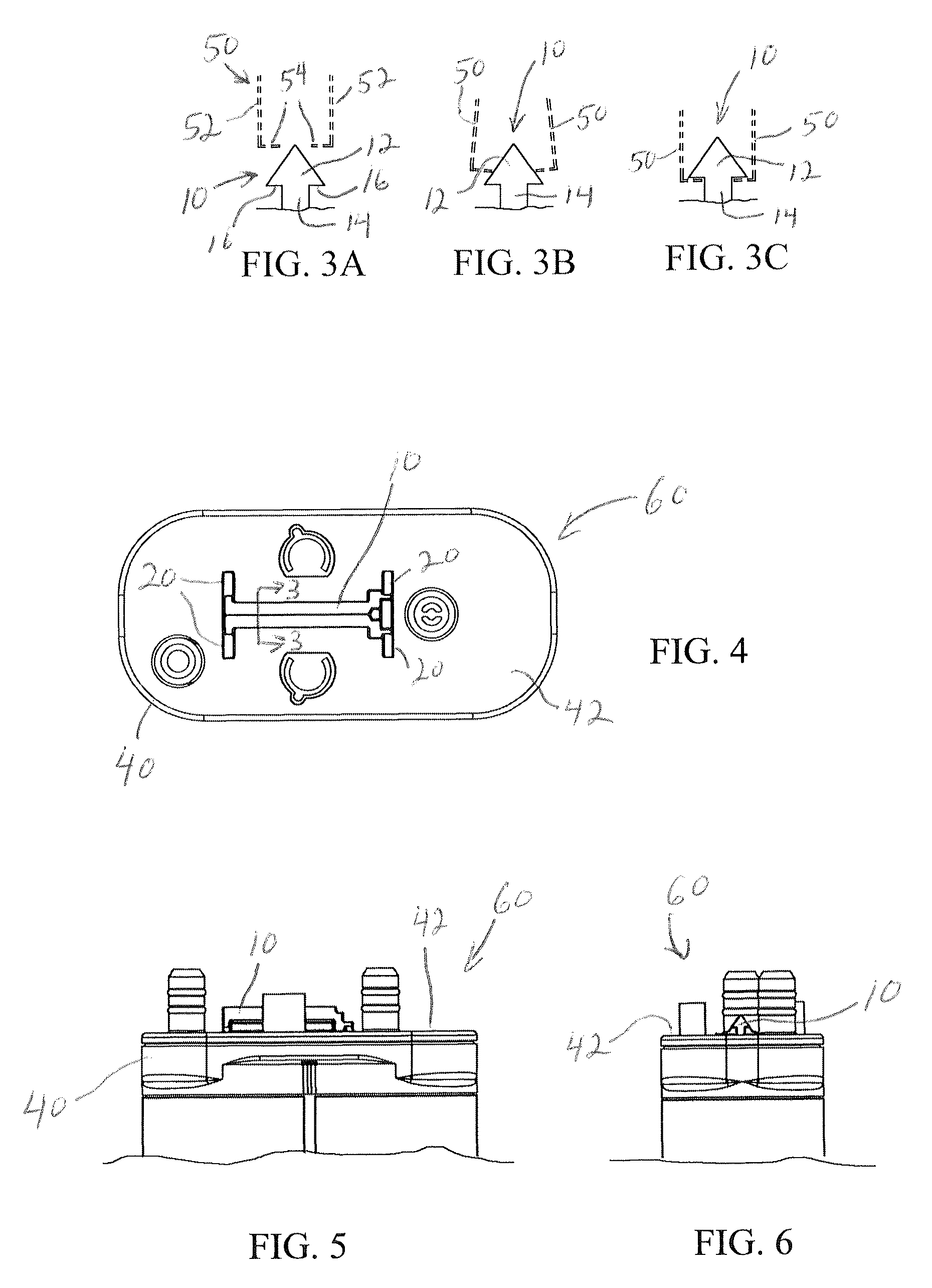

Assembled battery

InactiveUS20160141735A1Ensure durabilityEnsure strengthCell temperature controlCell component detailsEngineeringMechanical engineering

A battery unit, a bottomed case, a plate-shaped cooling plate, and first heat transfer material are included. The cooling plate is fastened to a bottom part of the case from the outside of the case, and can cool the battery unit via the bottom part of the case. The first heat transfer material have a plastic property and are held between the bottom part of the case and the cooling plate. The bottom part of the case has heat transfer material housings that house excess first heat transfer material therein when the cooling plate has been fastened to the case.

Owner:CALSONIC KANSEI CORP

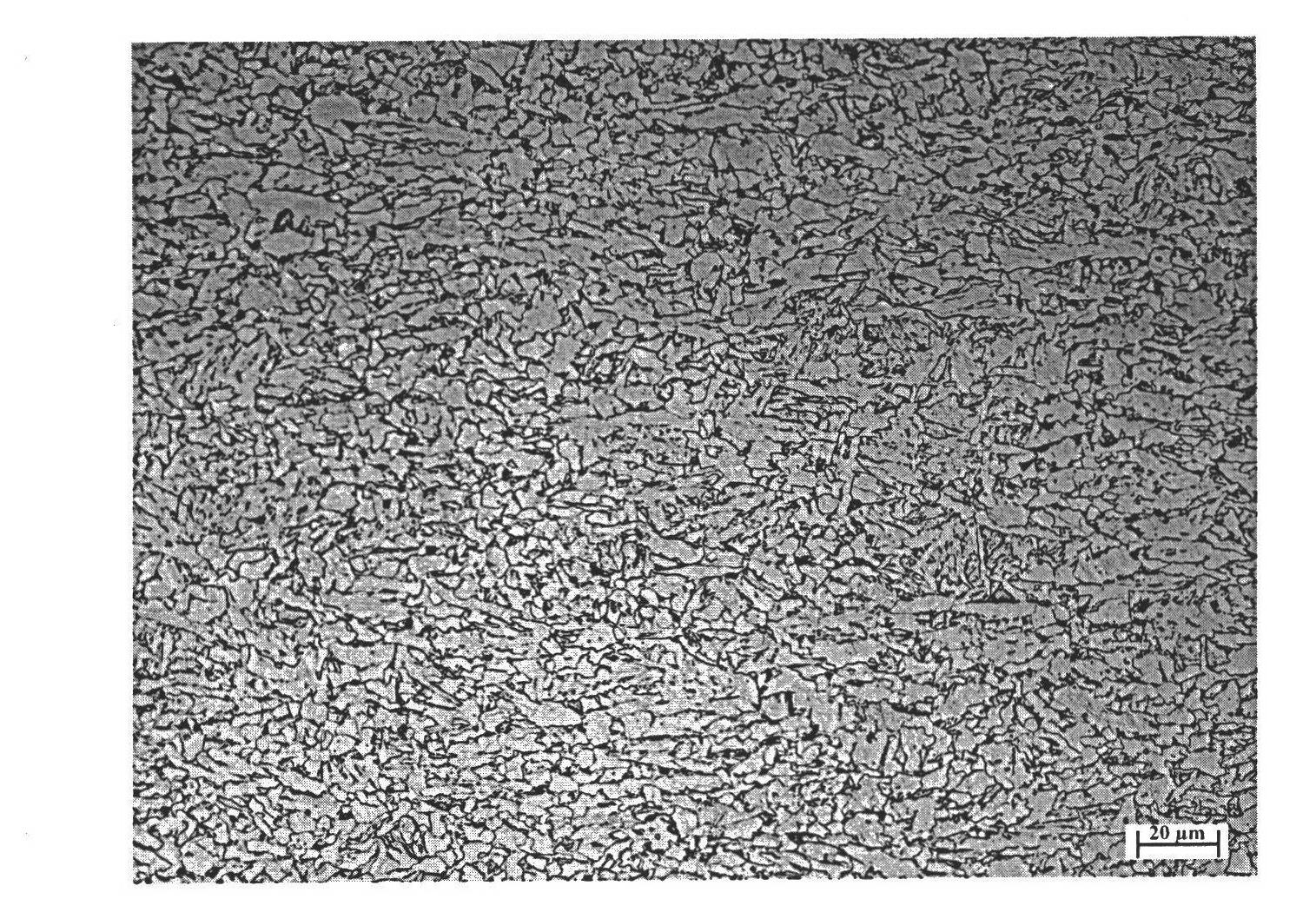

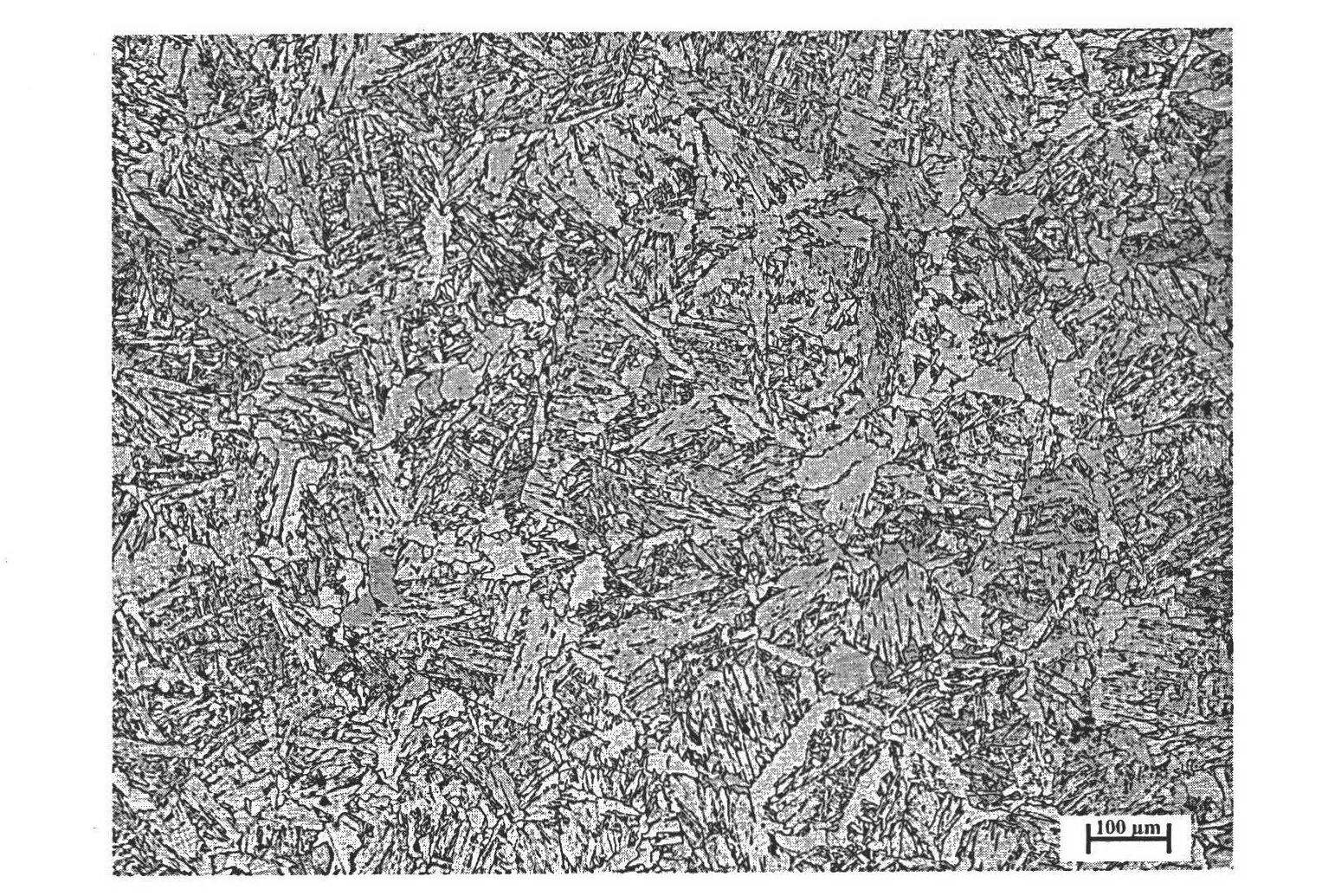

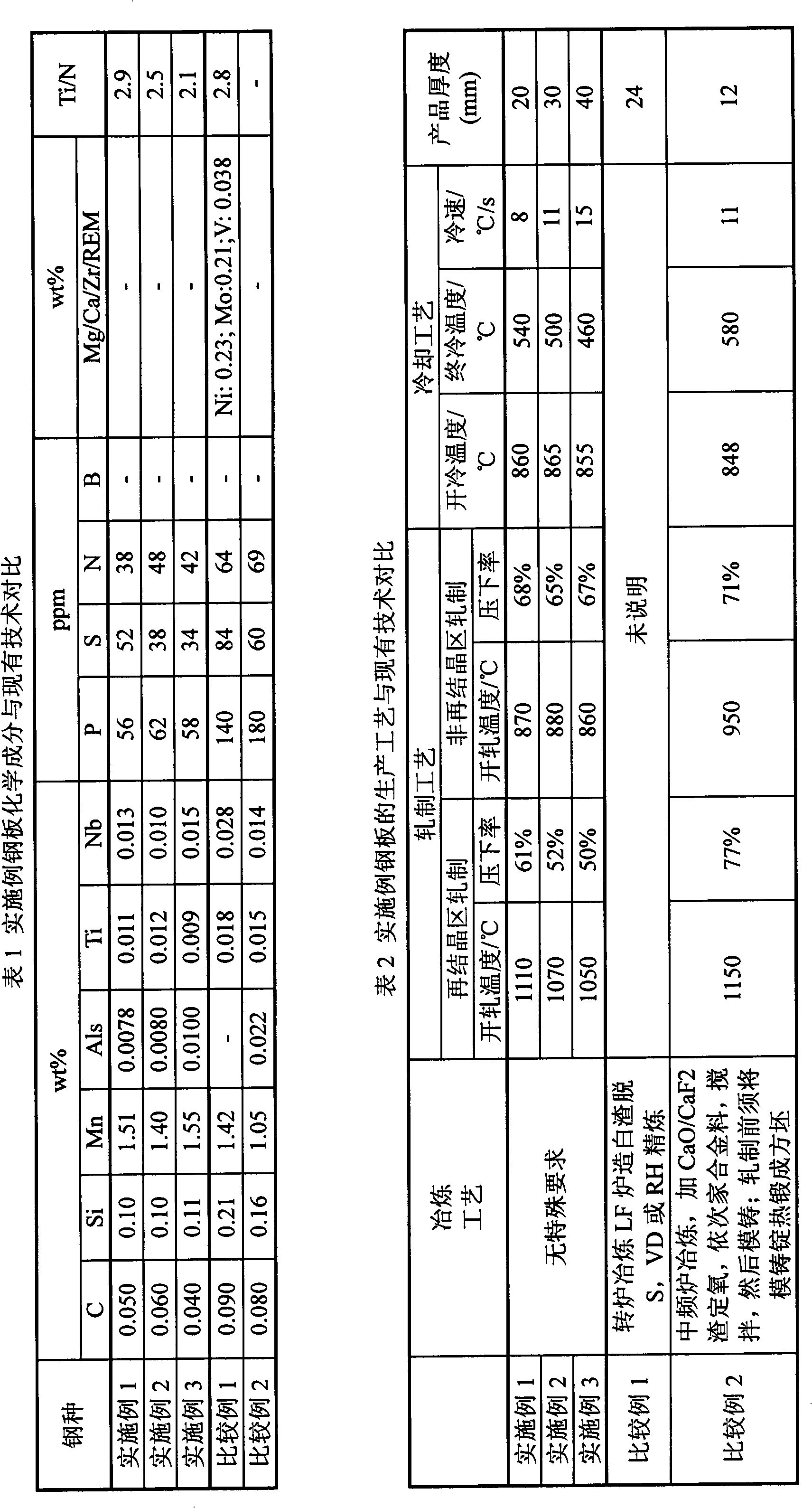

Steel plate with excellent low-temperature toughness in large heat-input weld heat affected zone and production method thereof

The invention discloses a steel plate with excellent low-temperature toughness in a large heat-input weld heat affected zone, which comprises the following chemical components in percentage by weight: 0.03-0.06% of C, 0.05-0.12% of Si, 1.30-1.60% of Mn, 0.007-0.015% of Nb, 0.007-0.015% of Ti, at most 0.01% of Al, 0.0035-0.0060% of N, at most 0.009% of P, at most 0.0052% of S and the balance of Fe and inevitable impurities. The invention adopts a low-C low-Si low-Al high-Mn-Nb microalloy composition, and the Ti / N ratio is 2.0-3.0. The production method adopts an advanced TMCP-AcC technique, so that the steel plate microstructure is an acicular ferrite of which the dimension is at most 10 mu m, and has excellent strength and low-temperature toughness; under the condition that the weld heat input is up to 200kJ / cm, the Charpy impact work of the weld heat affected zone at -20 DEG C is at least 179J; and the invention is applicable to ships, low-temperature pressure containers, ocean platforms and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

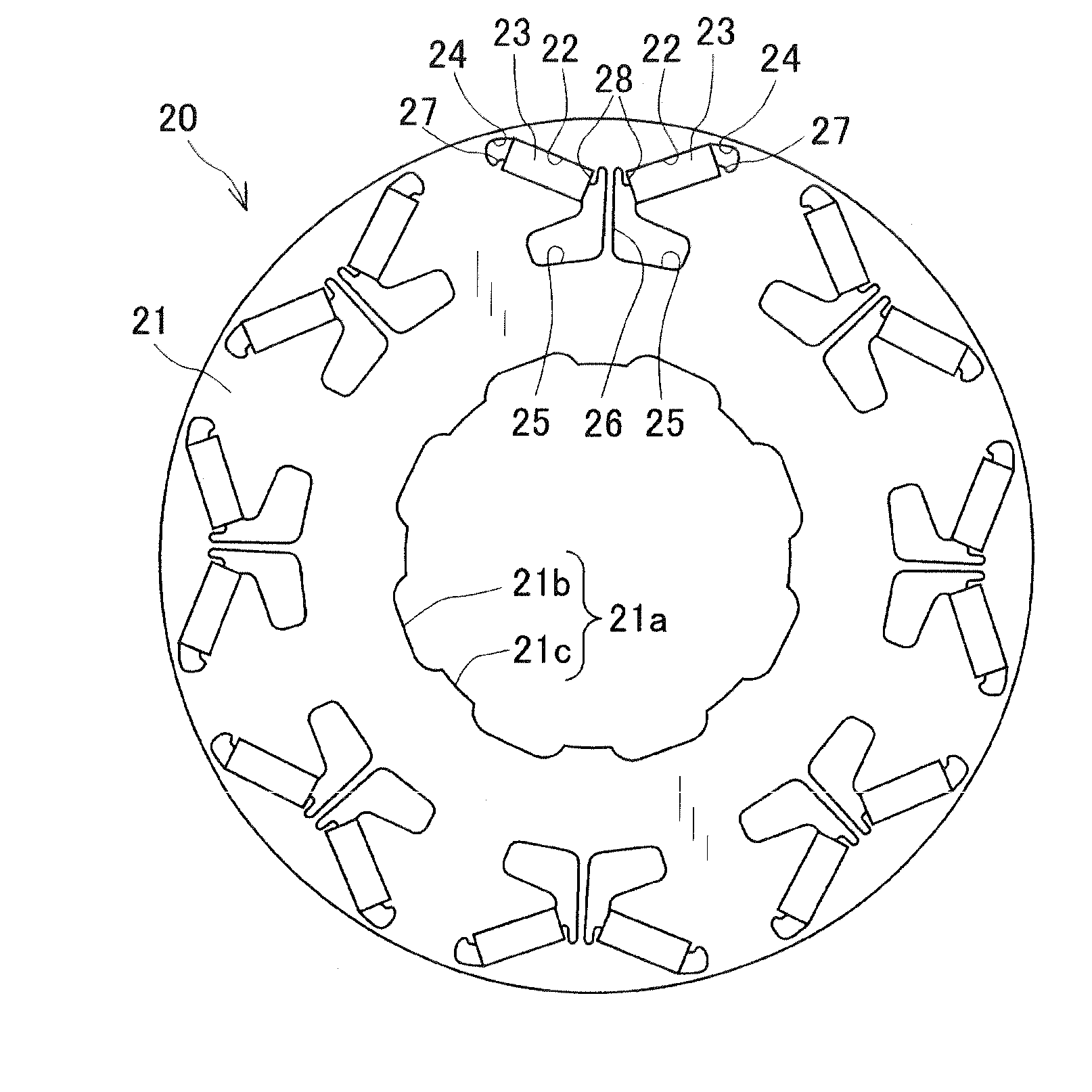

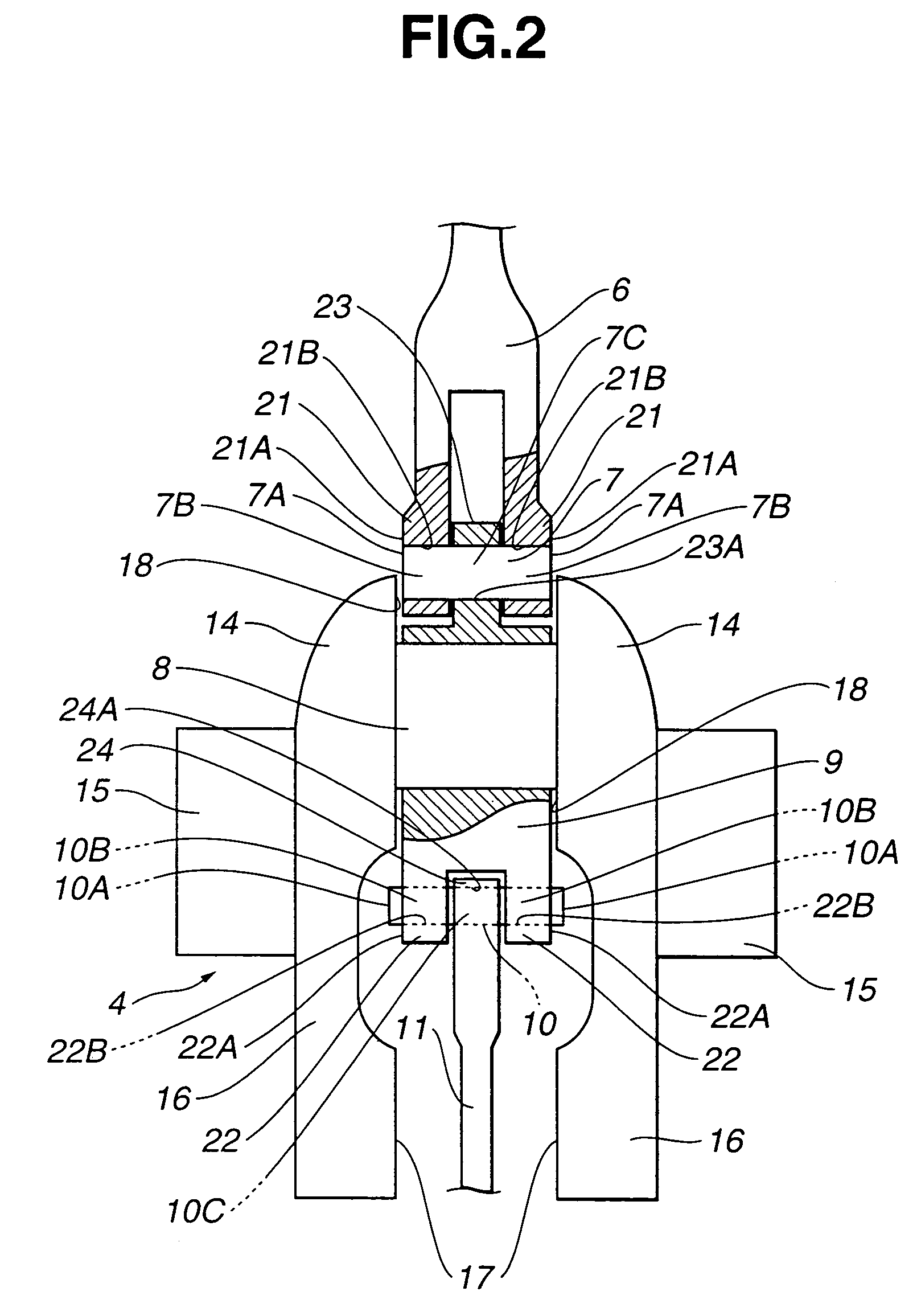

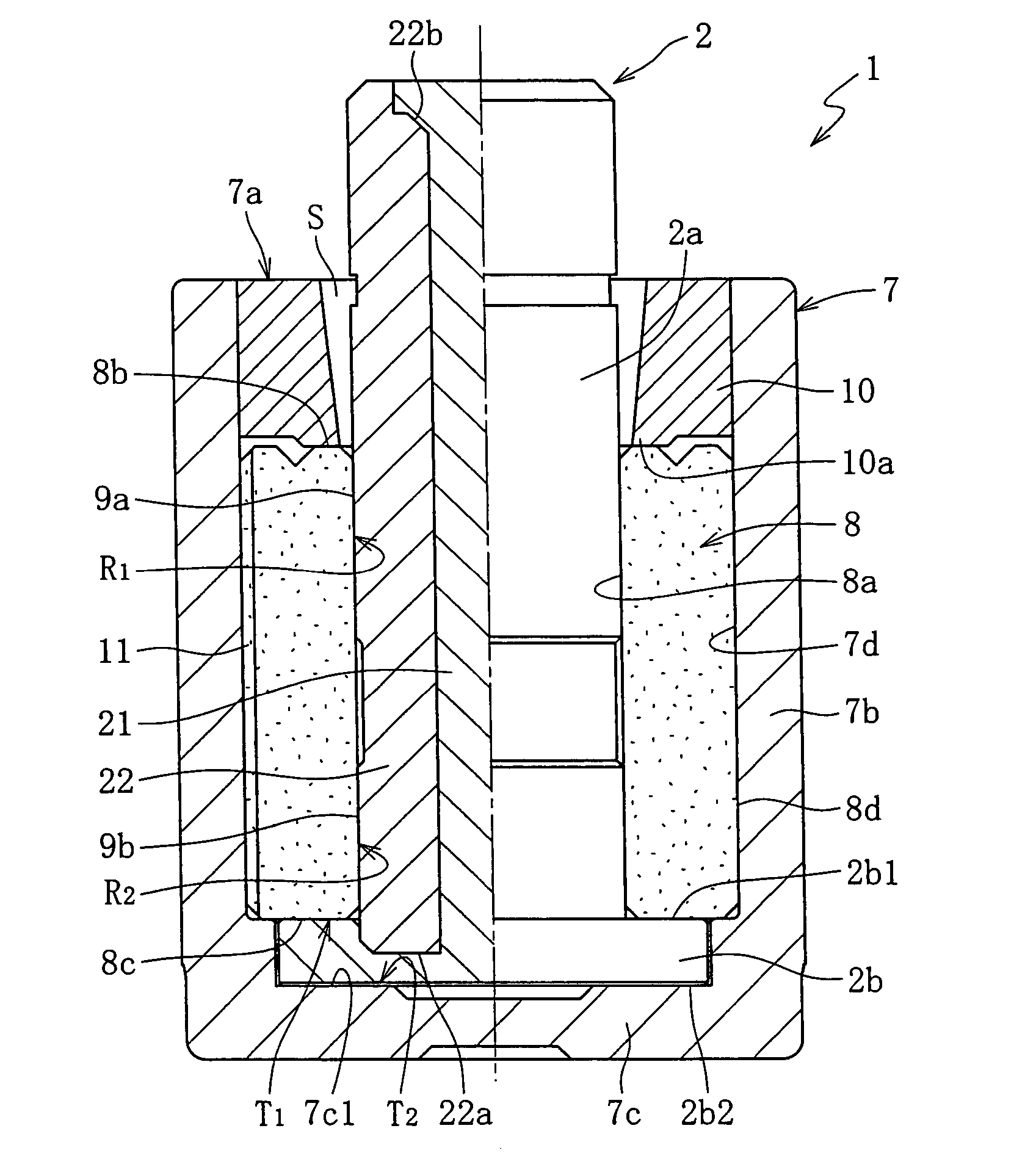

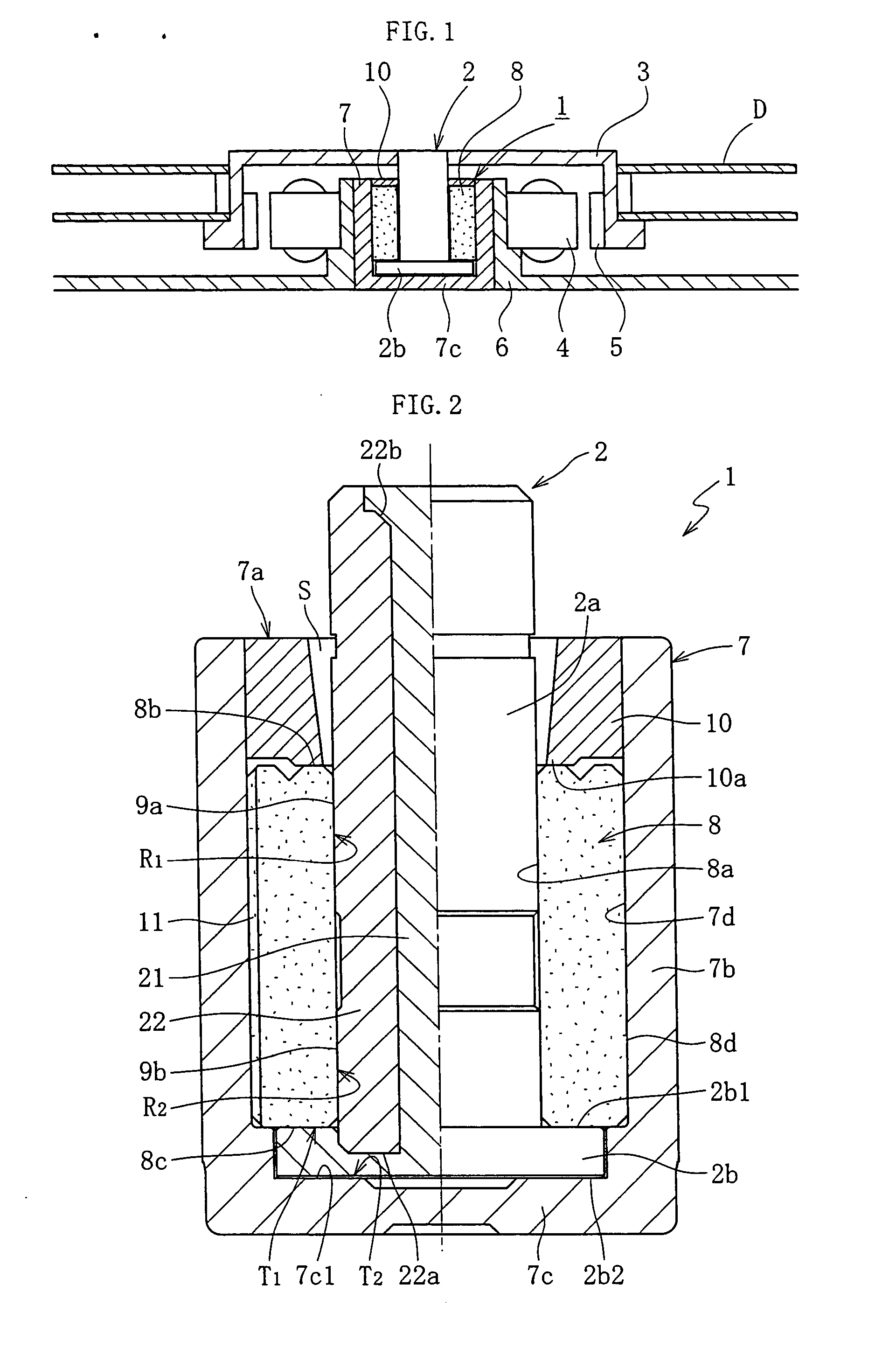

Dynamic bearing device

InactiveUS20070104400A1Ensure strengthEnsure rigidityShaftsRecord information storageThrust bearingEngineering

It is an object to improve bearing rigidity in a thrust direction at high temperatures and reduce a torque at low temperatures. An axial member 2 is arranged in such a manner that an outer circumferential surface of an axial part 2a is opposed to an inner circumferential surface of a bearing sleeve with a radial bearing gap interposed therebetween, and both end faces 2b1 and 2b2 of a flange part 2b are opposed to one end face of the bearing sleeve and a bottom face of a housing with thrust bearing gaps interposed therebetween, respectively. In this manner, the axial member 2 is supported by dynamic pressures generated in the respective bearing gaps in the thrust direction in a non-contact manner. The flange part of the axial member 2 is formed of a resin in such a manner that its linear expansion coefficient in its axial direction is equal to or larger than that of the housing 7.

Owner:NTN CORP

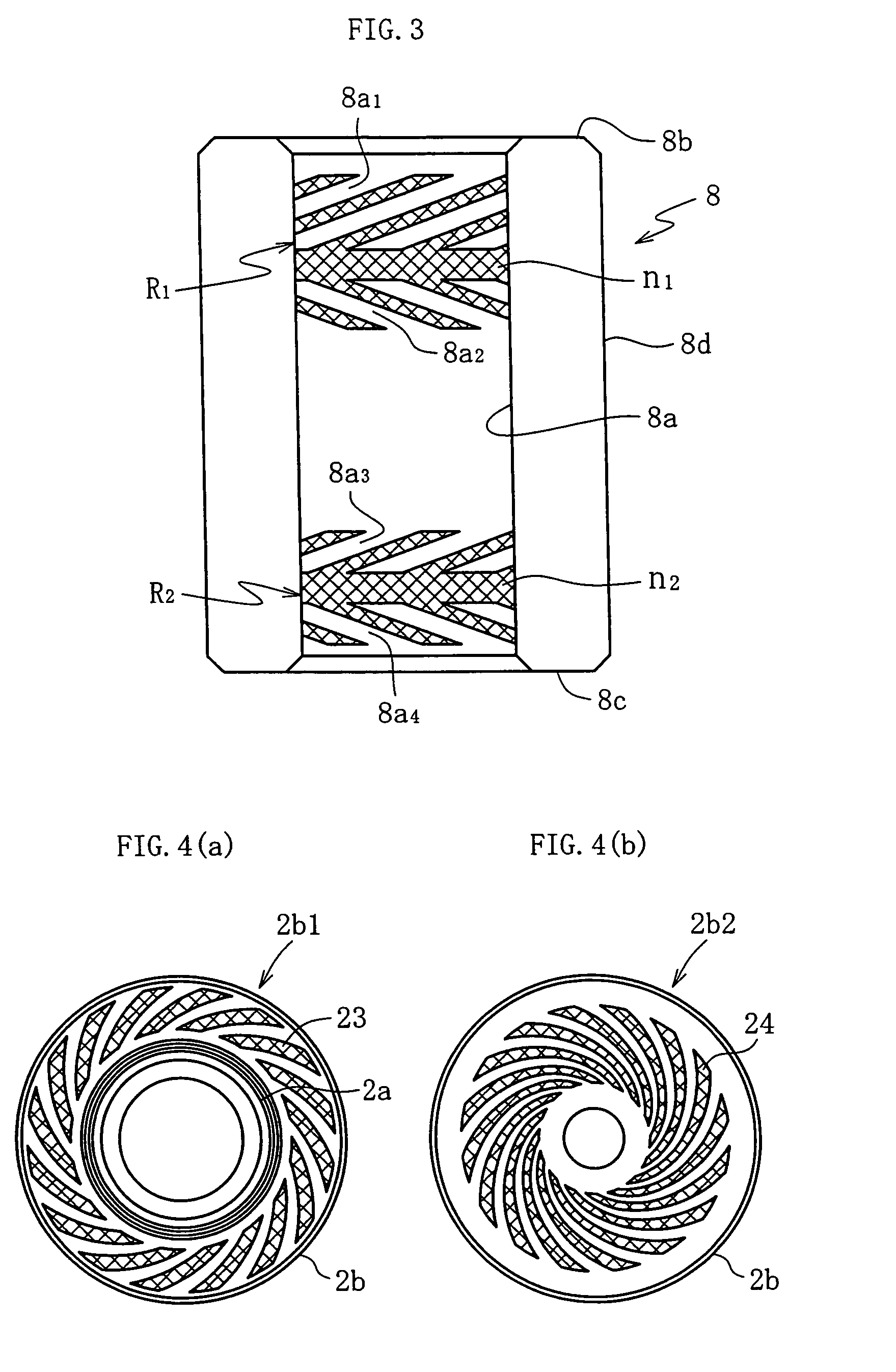

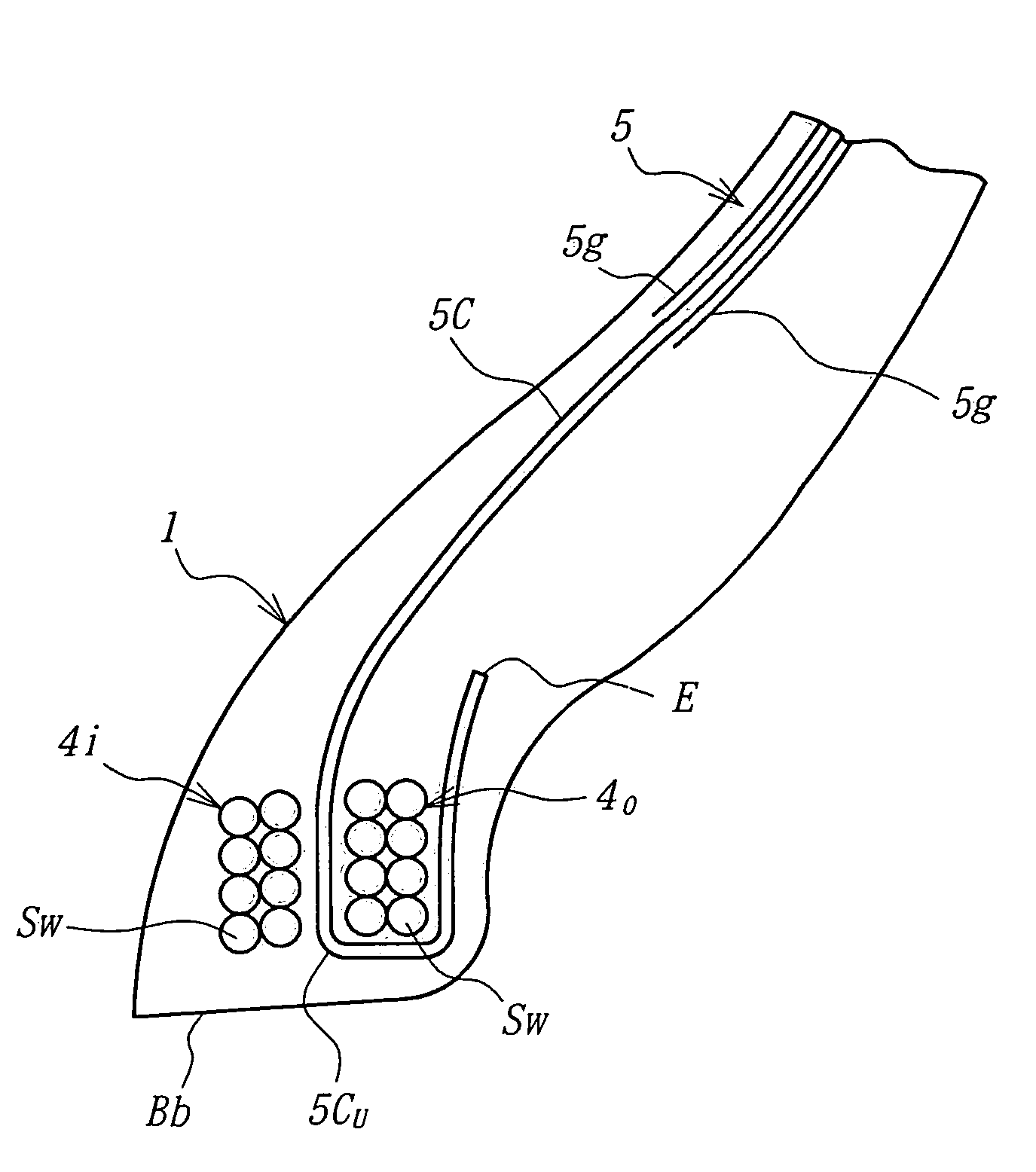

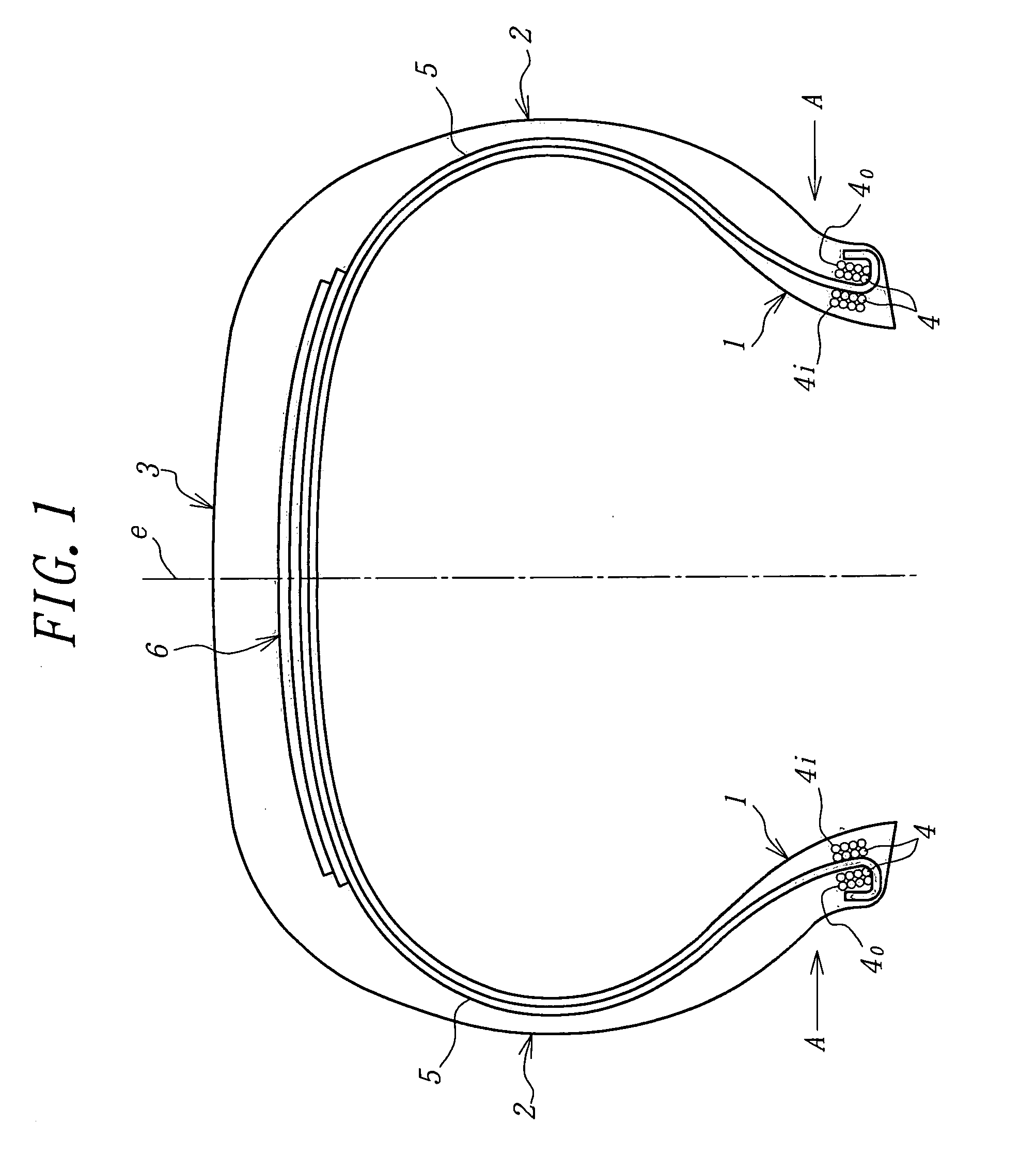

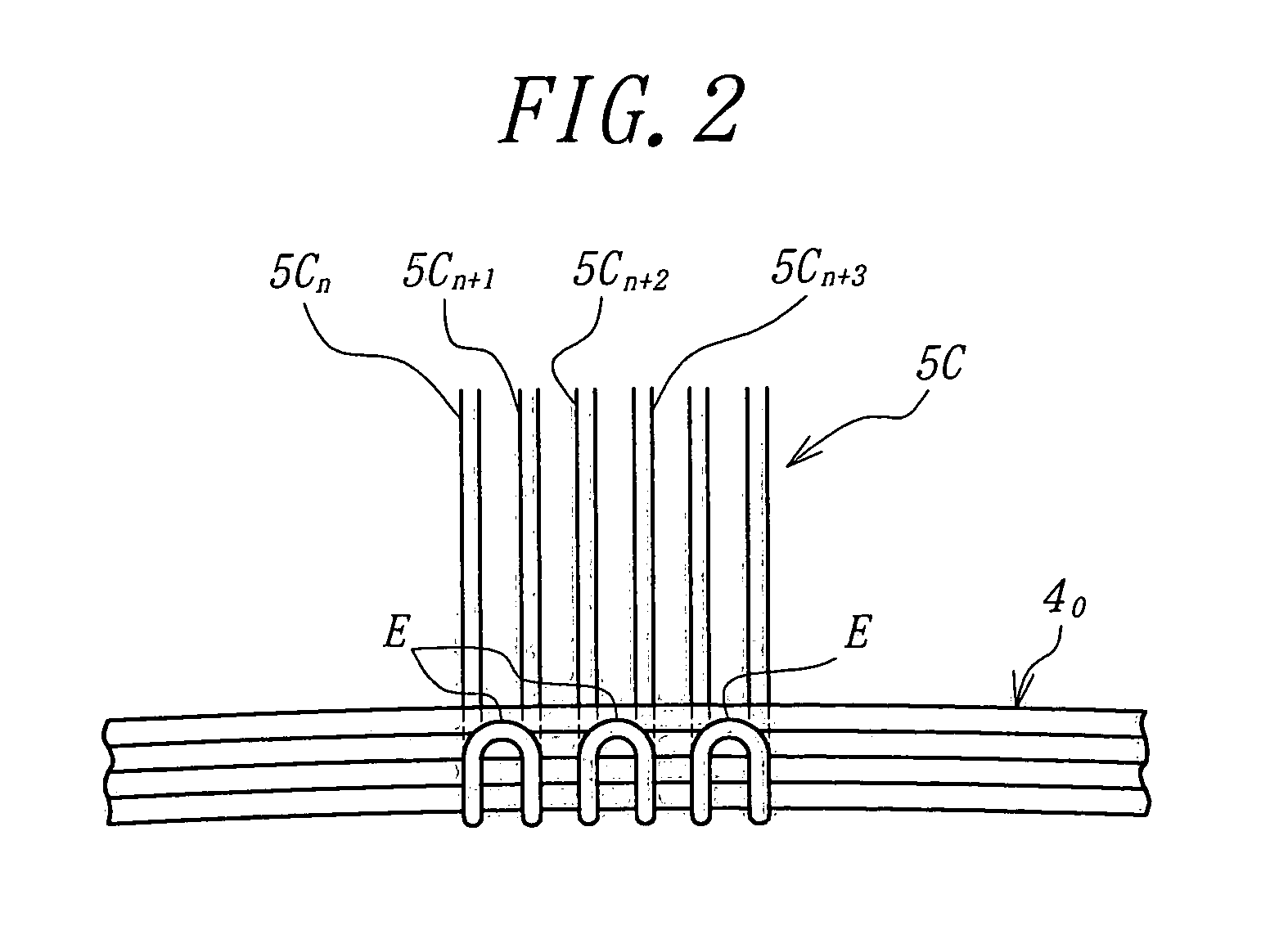

Pneumatic radial tires

InactiveUS6929045B1Ensure rigidityEnsure strengthPneumatic tyre reinforcementsTyre beadsMechanical engineeringRadial tire

A pneumatic radial tire comprises a radial carcass extending between a pair of bead portions each including two bead cores therein and reinforcing a pair of sidewall portions and a tread portion, wherein the radial carcass is comprised of a rubberized ply of a continuous cord successively repeating round trip in at least one of the two bead cores as a pair between the pair of the bead portions along a circumference of the bead portion and a roundtrip return portion of the cord is existent in both the bead portions. In this case, at least one of the two bead cores has such a structure that one or more steel wires are arranged lengthwise and widthwise in radial and widthwise directions of the tire, and the cord of the carcass ply has a roundtrip return portion located through a side face of the bead core having the above structure so as to cover at least an innermost steel wire arrangement in the radial direction from an inner side in the radial direction of the tire.

Owner:BRIDGESTONE CORP

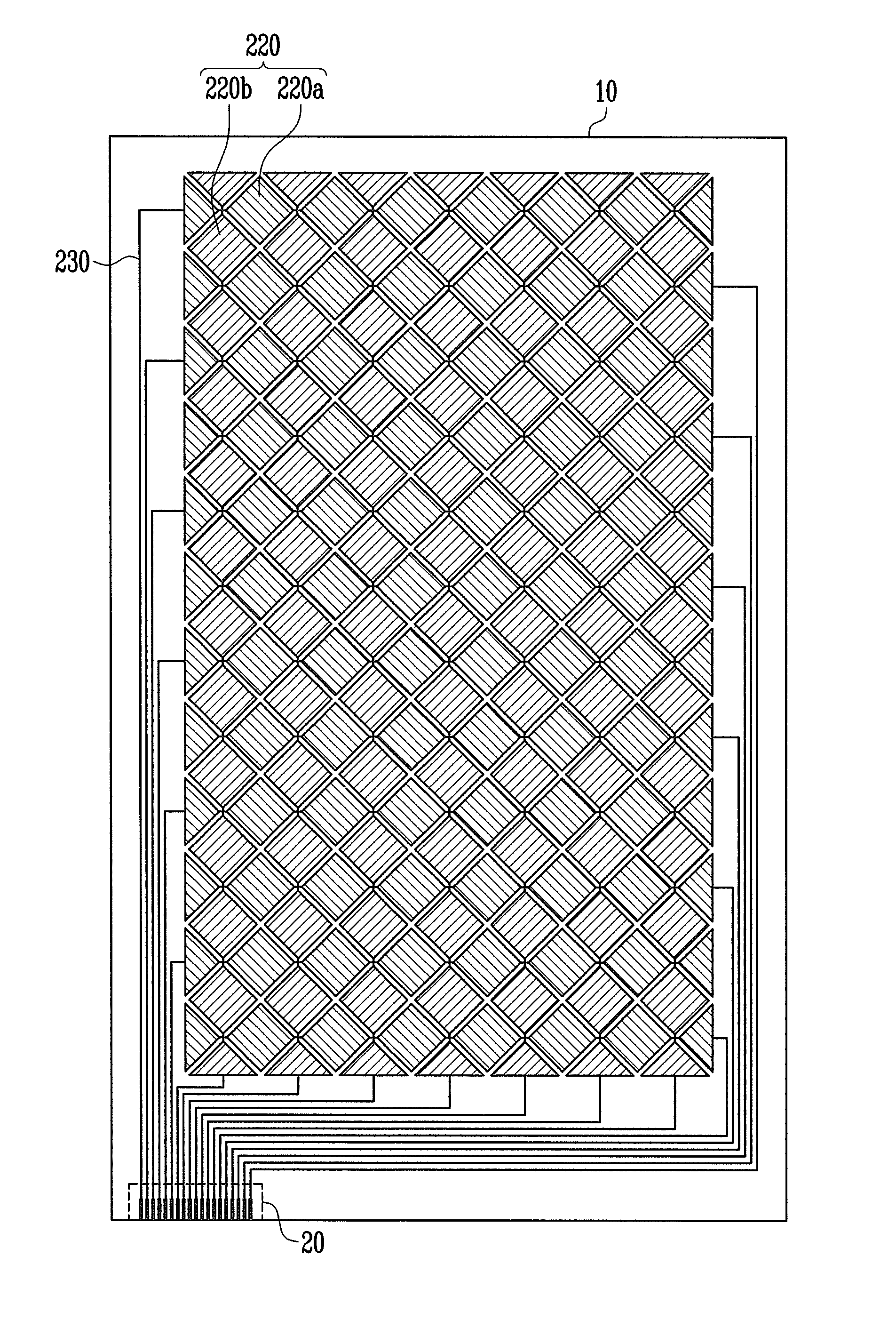

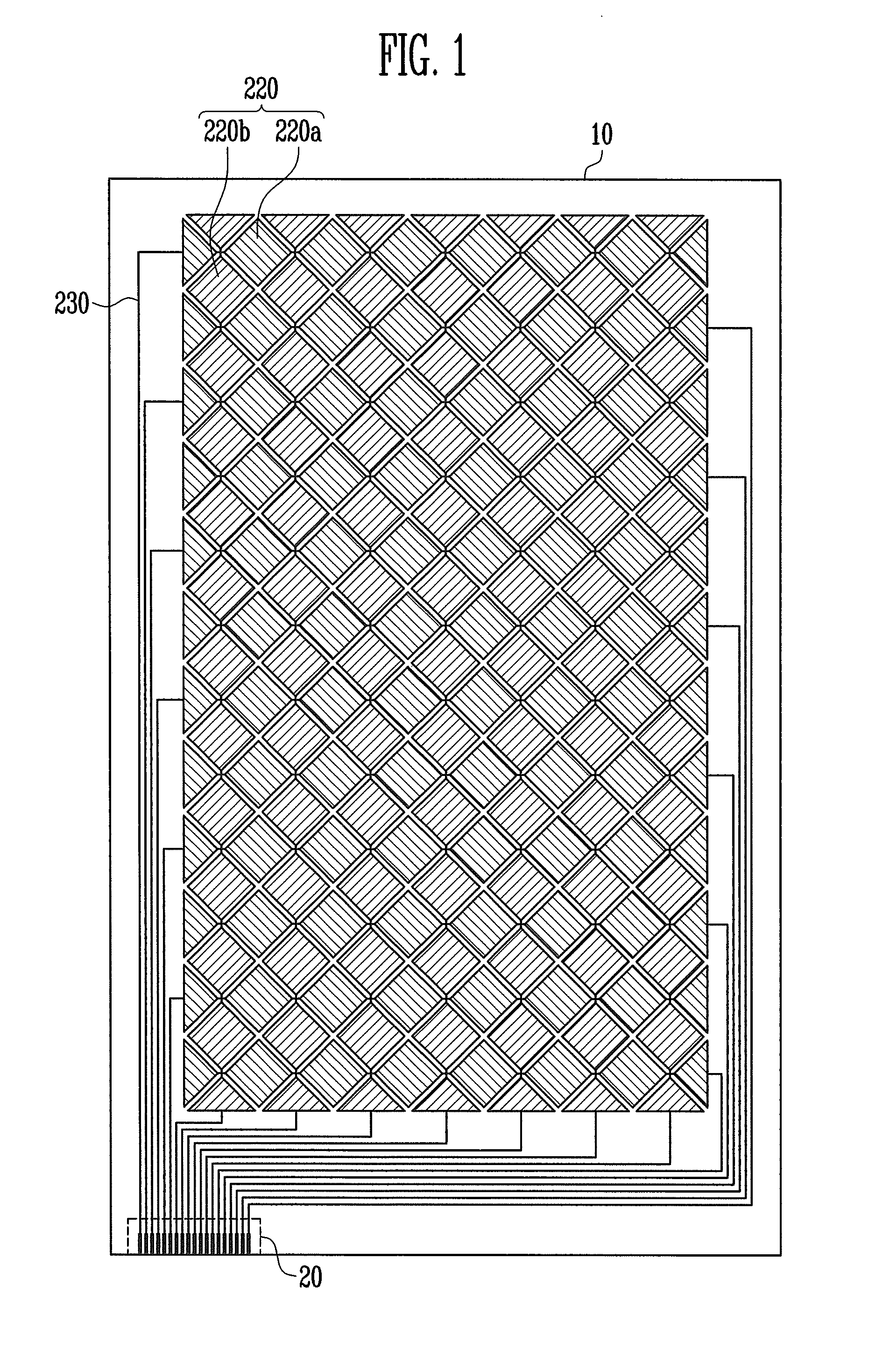

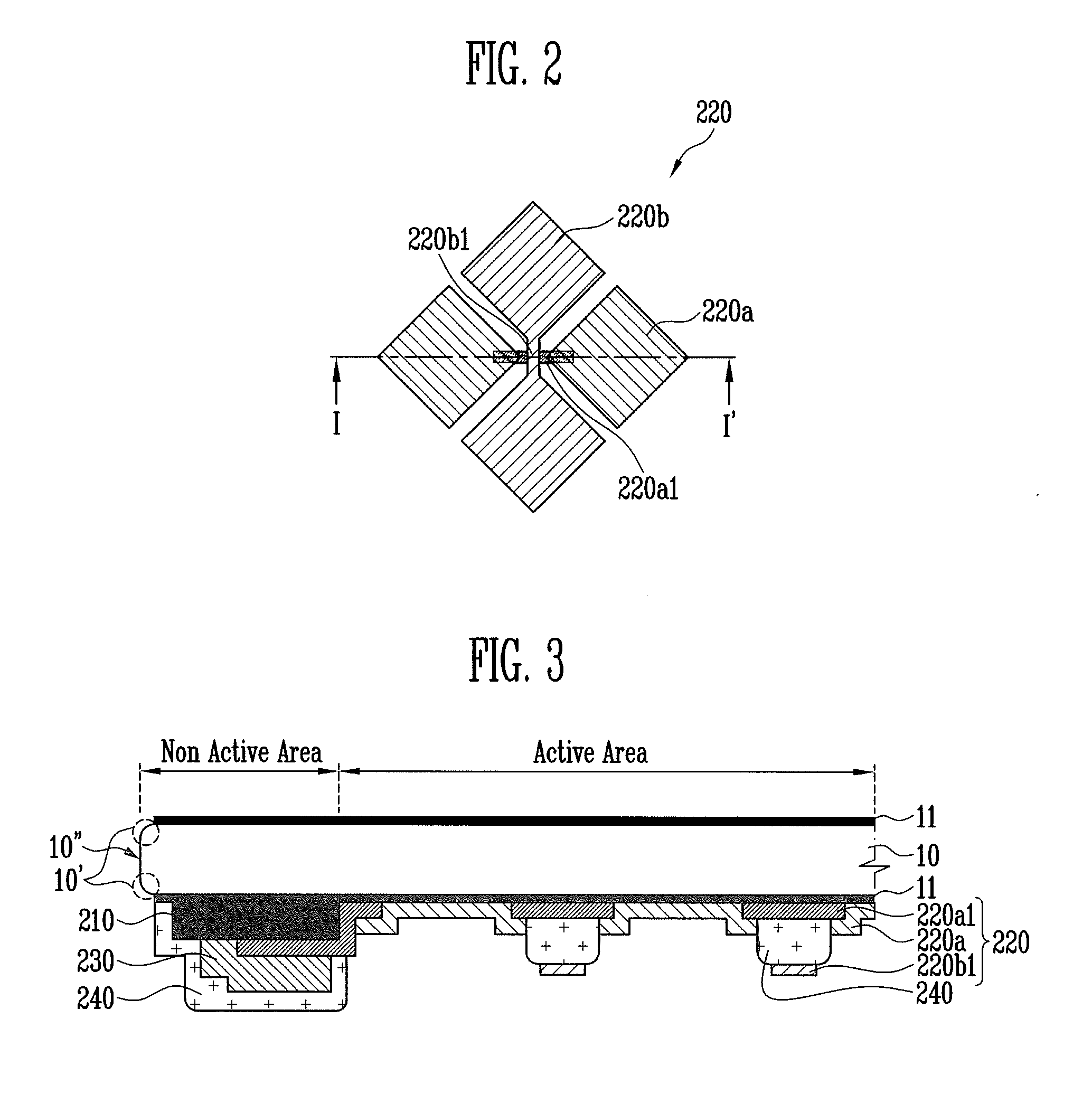

Touch screen panel and fabricating method for the same

ActiveUS20120120003A1Increase productivityHigh strengthLamination ancillary operationsControlling laminationCell regionTouchscreen

A method of fabricating a touch screen panel according to an embodiment of the present invention includes: forming a reinforcing layer on the top and the bottom of a glass substrate by reinforcing the entire surface of the glass substrate defining a plurality of unit cell regions; forming the touch screen panels in the unit cell regions on a side of the glass substrate with the reinforcing layers; cutting the reinforced glass substrate into the touch screen panels; forming passivation layers on the outer surfaces of the touch screen panels and sequentially stacking the touch screen panels; and simultaneously with the stacking, performing healing on the non-reinforced cut-sides of the stacked touch screen panels.

Owner:SAMSUNG DISPLAY CO LTD

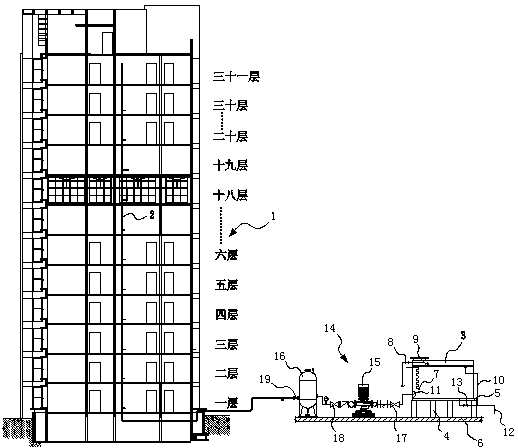

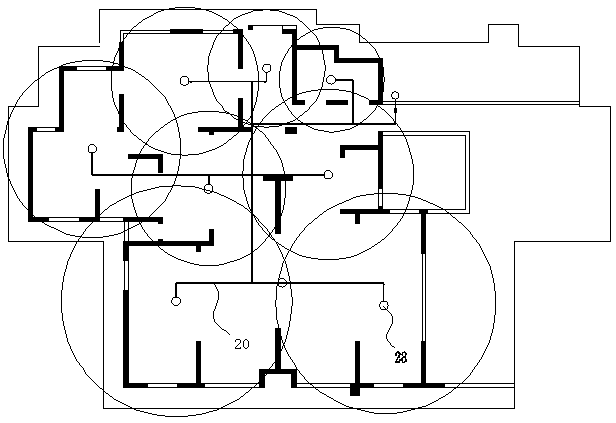

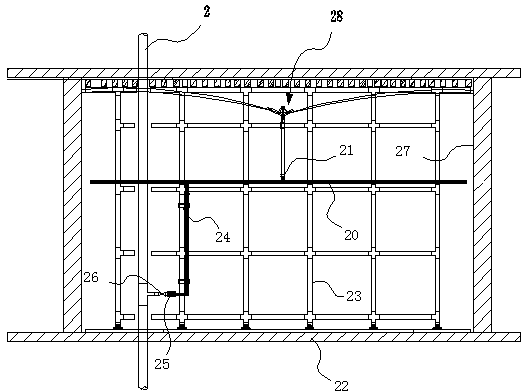

Automatic spraying conservation system for high-rise building shear wall structure

ActiveCN104264995AEffective protectionAvoid damageBuilding material handlingWater sourceWater storage tank

The invention discloses an automatic spraying conservation system for a high-rise building shear wall structure. The automatic spraying conservation system for the high-rise building shear wall structure comprises a water supply main pipeline which extends from the bottom layer of a high-rise building to the top layer; the water supply main pipeline is connected with a water storage tank which is used for providing water sources for the high-rise building; a power device which is used for conveying the water sources inside the water storage tank inside the water supply pipeline is arranged between the water supply main pipeline and the water storage tank; water supply branched pipelines which extend to floors are connected to the water supply main pipeline; spraying heads which are used for spraying water towards concrete wall surfaces between the floors are connected to the water supply branched pipelines. The automatic spraying conservation system for the high-rise building shear wall structure solves wall body conservation of an irregular concrete shear wall and the technical problem that the concrete solid intensity cannot be guaranteed increasing and the surface of the concrete is easy to generate shrinkage cracks if the conservation is not proper.

Owner:青岛东建建设有限公司

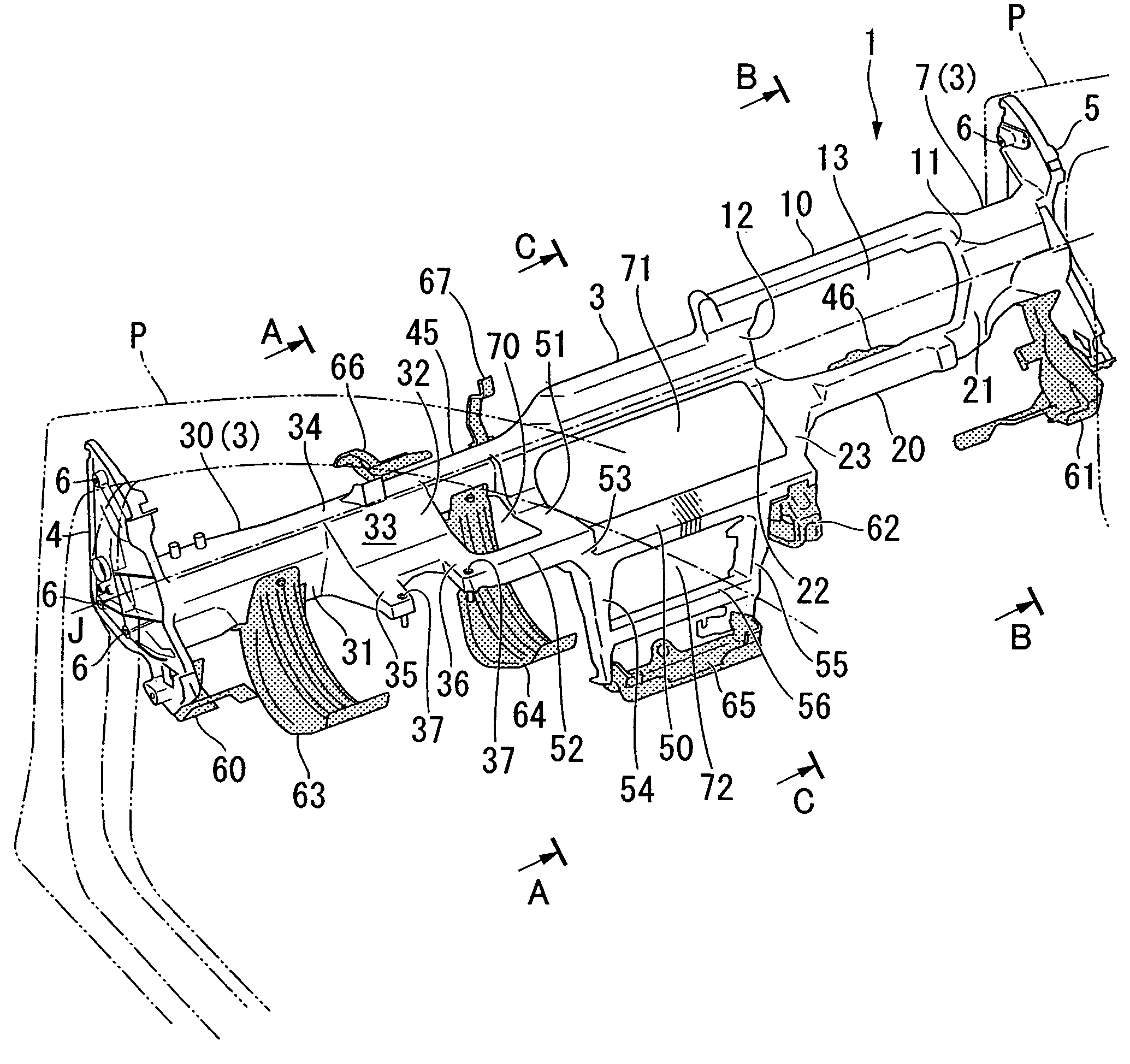

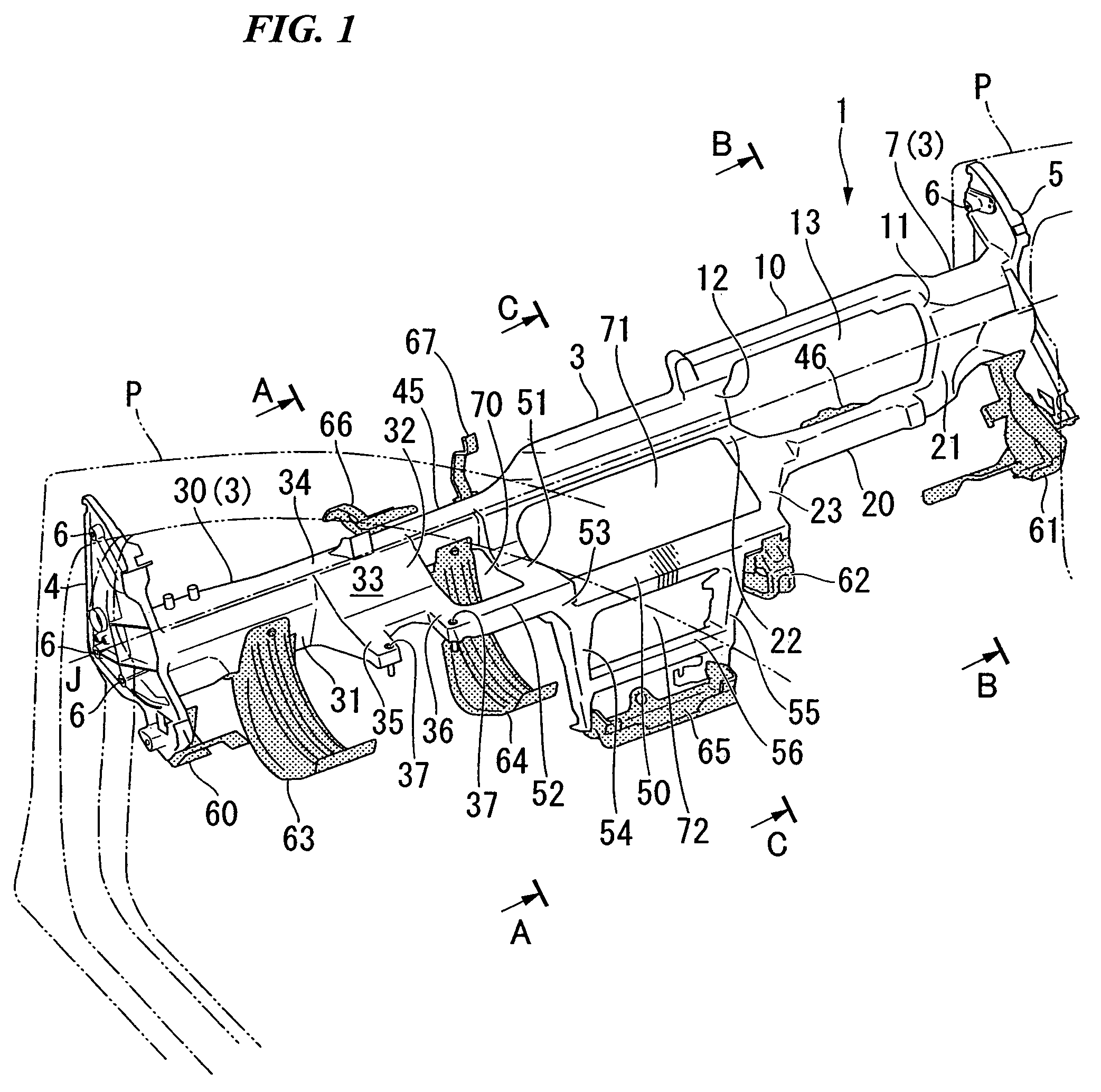

Steering hanger beam

InactiveUS7891707B2Reduce the overall heightIncrease freedomVehicle seatsUnderstructuresEngineeringMechanical engineering

The steering hanger beam extending in a width direction of a vehicle and connected to left and right vehicle-body members, is provided with: a main member which supports a steering device; a pair of front and rear transverse beam portions connected to the main member in the width direction of the vehicle so as to be offset from an axis of the main member to front and rear; and an opening which is formed between the pair of front and rear transverse beam portions so as to penetrate in substantially a vertical direction.

Owner:HONDA MOTOR CO LTD

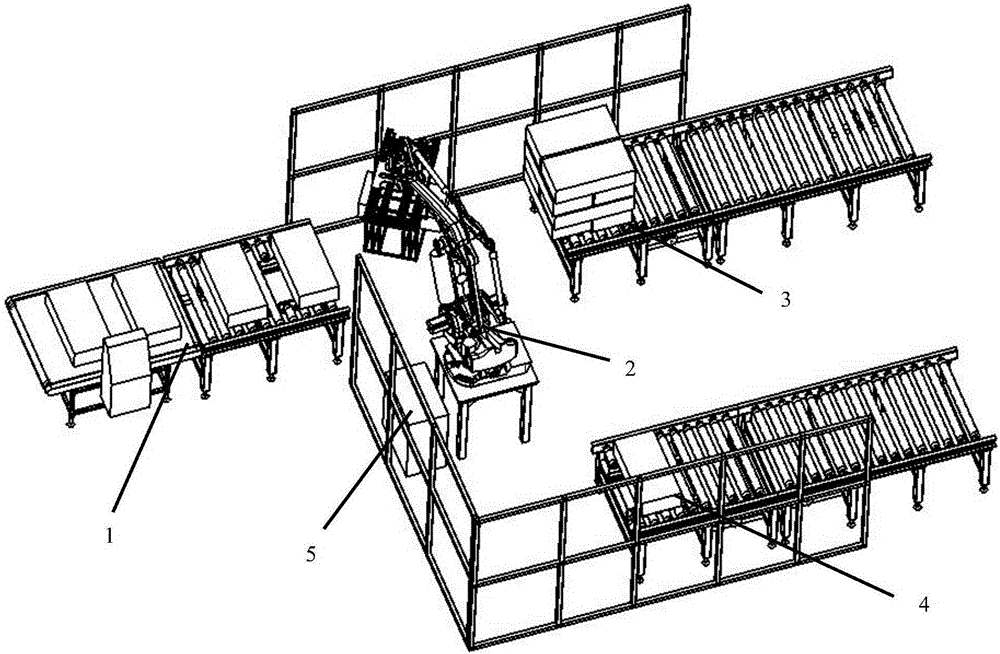

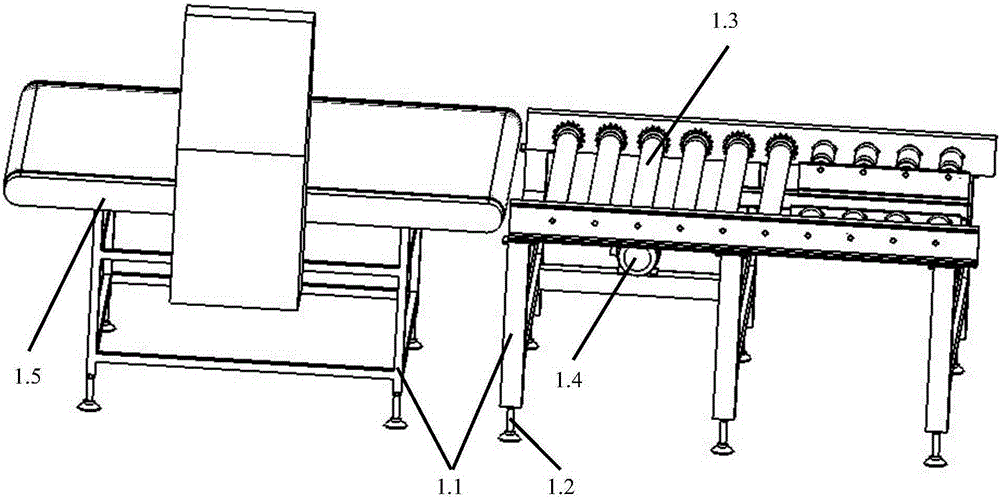

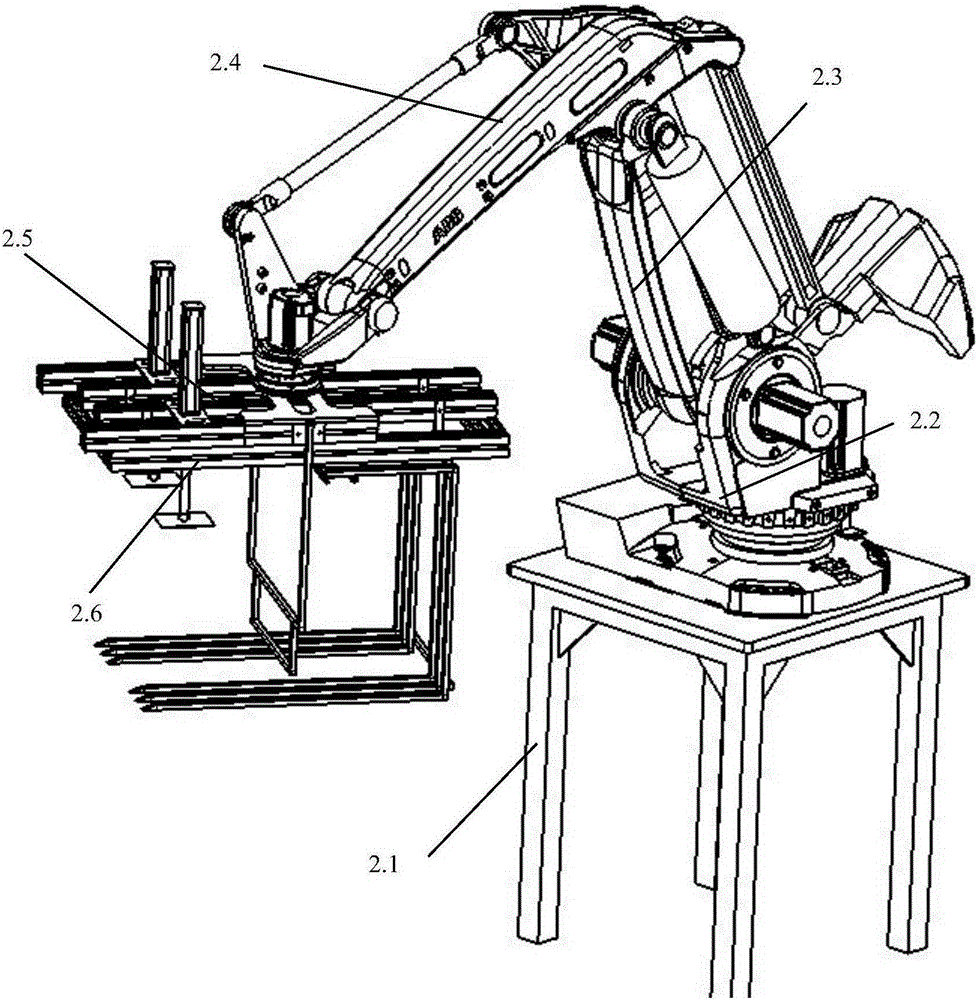

Device used for automatically stacking mineral wool products

InactiveCN105173764ASimplify auxiliary equipmentEnsure strengthStacking articlesDe-stacking articlesMechanical engineeringAutomatic testing

The invention discloses a device used for automatically stacking mineral wool products. The device comprises an automatic weighing conveying line, an automatic four-axis stacking robot, a first roller conveying line, a second roller conveying line and a central controller, wherein the automatic weighing conveying line, the automatic four-axis stacking robot, the first roller conveying line and the second roller conveying line are all in communication connection with the central controller; the automatic weighing conveying line is arranged on the front working procedure of the automatic four-axis stacking robot; the first roller conveying line and the second roller conveying line are arranged on the rear working procedure of the automatic four-axis stacking robot and located on the two sides of the automatic four-axis stacking robot respectively. The device used for automatically stacking the mineral wool products is simple in structure, auxiliary devices in a robot stacking system are simplified, and the manufacturing cost is reduced. The functions of automatic detection, processing, stacking, transportation and the like can be achieved, and full-automatic operation is achieved. The quality of the mineral wool products can be detected, and unqualified products can be automatically rejected by the stacking robot after being detected out.

Owner:SINOMA SCI & TECH

Multi-link piston crank mechanism for internal combustion engine

ActiveUS20050045120A1Optimization mechanismAvoid interferenceConnecting rodsGearingMulti linkEngineering

A multi-link piston crank mechanism for an internal combustion engine, including a crankshaft having a crank pin, and crank webs connected with each other through the crank pin. A pair of thrust surfaces are formed on the crank webs so as to be opposed in a direction of a center axis of the crank pin. A first link pivotally supported on the crank pin is coupled to a second link through a connection pin located in a space between the thrust surfaces. The connection pin is moveable about the crank pin to form a circular trace along which the thrust surfaces extend. The end surfaces of the connection pin and the thrust surfaces come into mutual contact to prevent the connection pin from falling out of the space between the thrust surfaces.

Owner:NISSAN MOTOR CO LTD

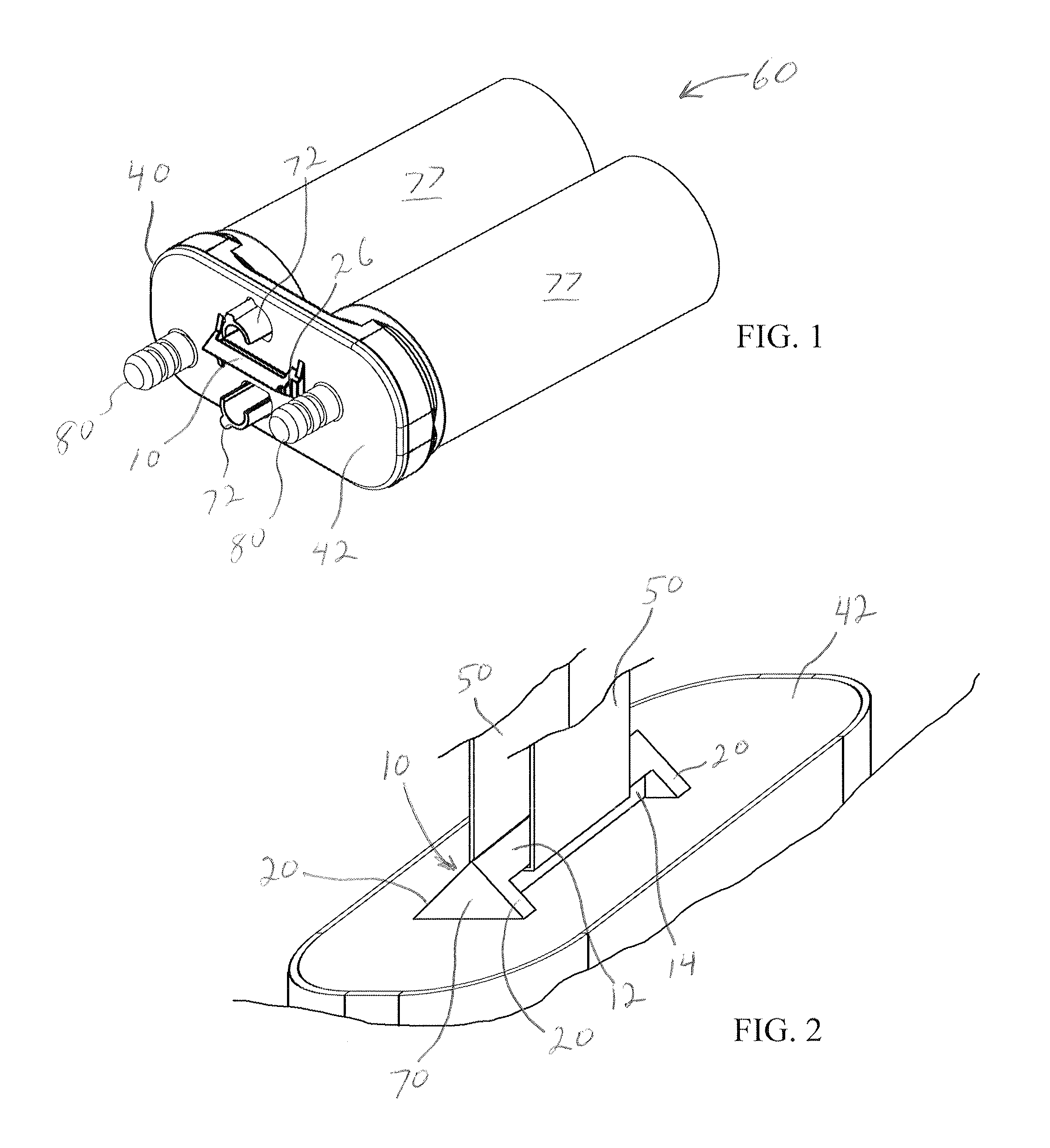

Reinforced receiver for cassette filter locking clip

ActiveUS9061225B2Sufficient supportEnsure reliabilityMembrane filtersCartridge filtersEngineeringMechanical engineering

A receiver for a cassette filter housing having an upper housing surface. The receiver comprises an arrow shaped elongated member having ends. The elongated member may be parallel with an upper surface of the cassette and may include a base portion attached to the upper housing surface the cross-section of which is a substantially planer segment extending to the upper surface. The elongated member includes an upper receiver portion having at least one cavaliered retaining surface. The receiver includes a first reinforcement member extending outward from the base portion adjacent one of the ends of the elongated member and perpendicular to the elongated member, and a second reinforcement member extending outward from the base portion adjacent the opposite end of the elongated member and perpendicular to the elongated member the reinforcement members affixed to the base portion and the upper housing surface.

Owner:KX TECH LLC (DW US)

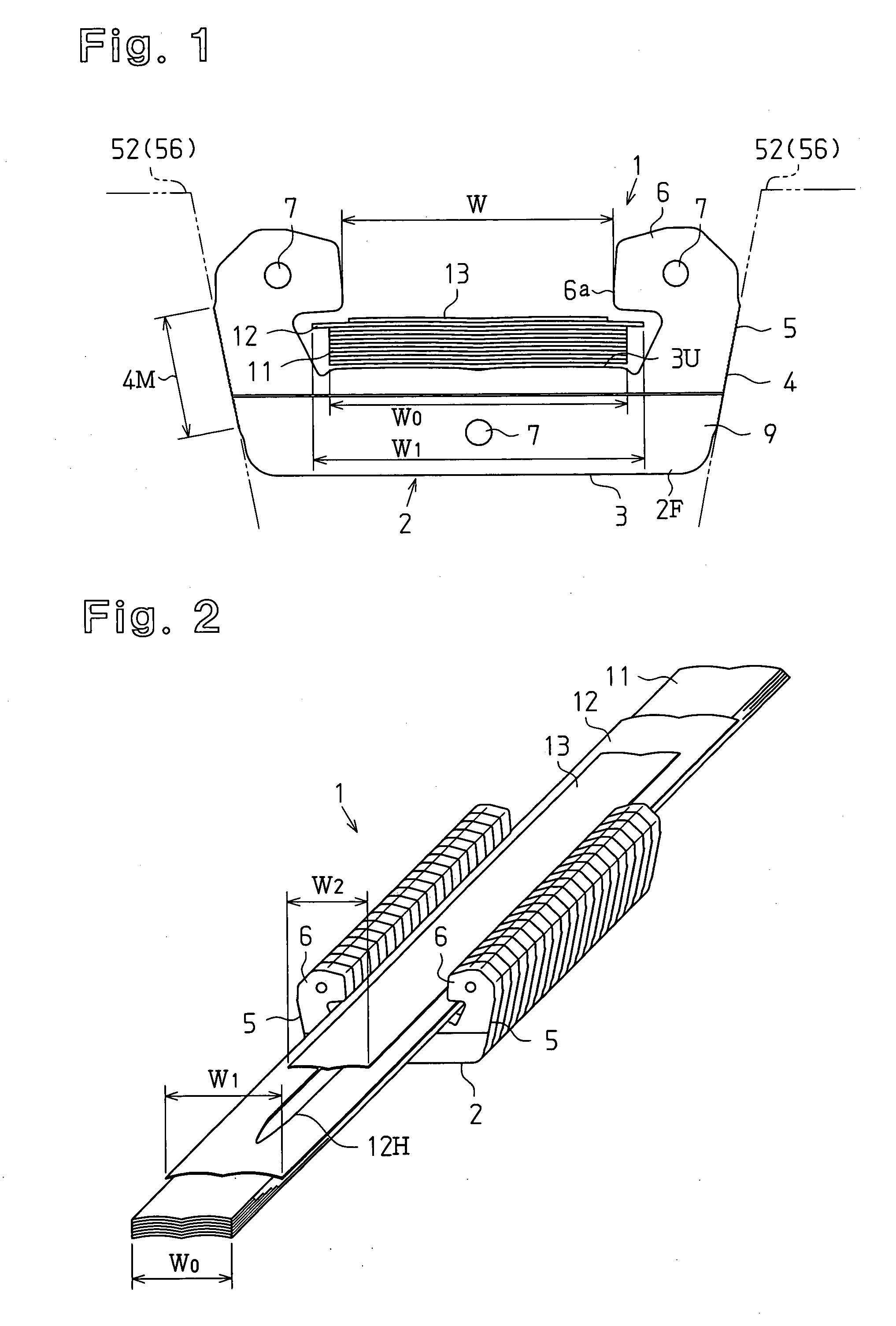

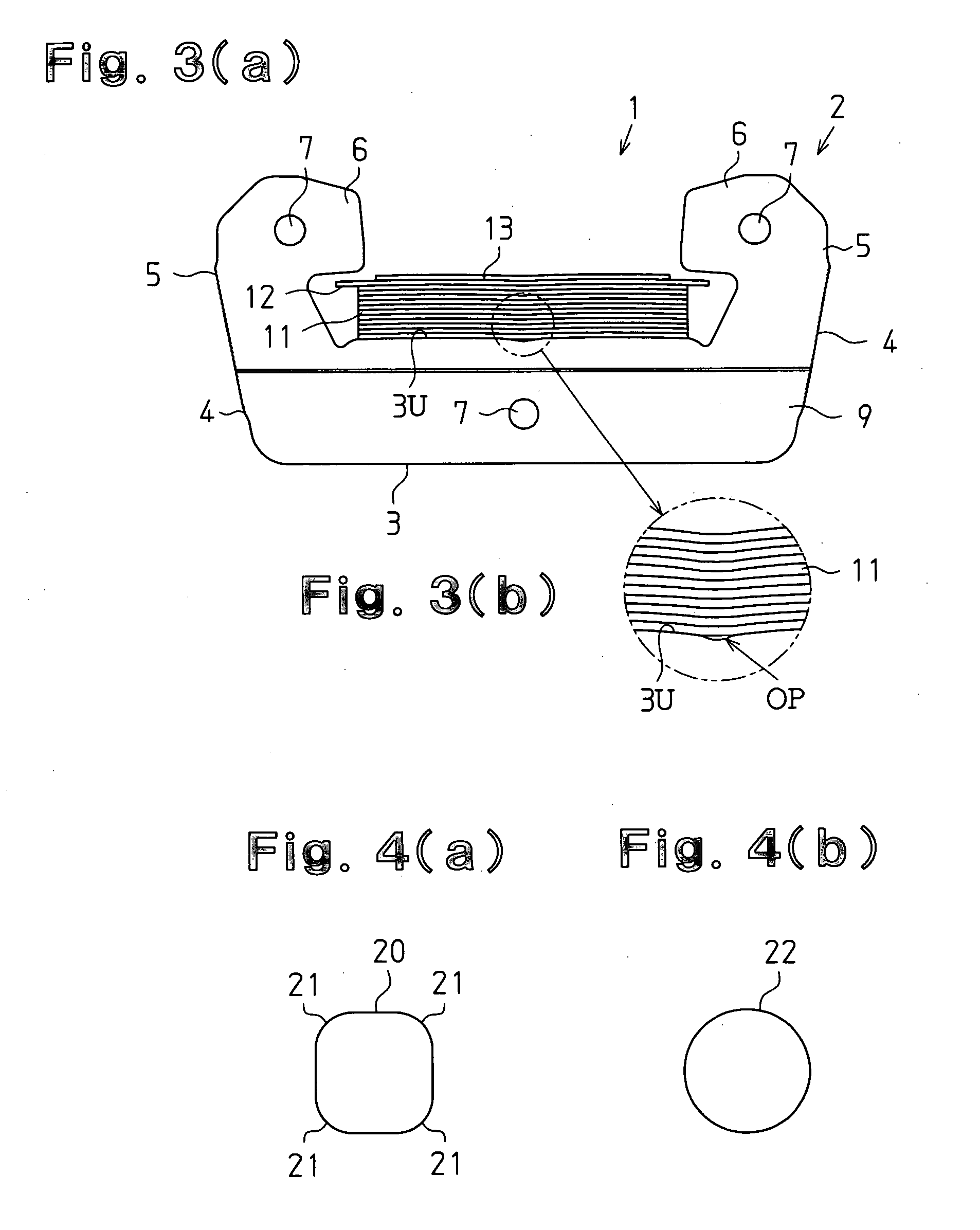

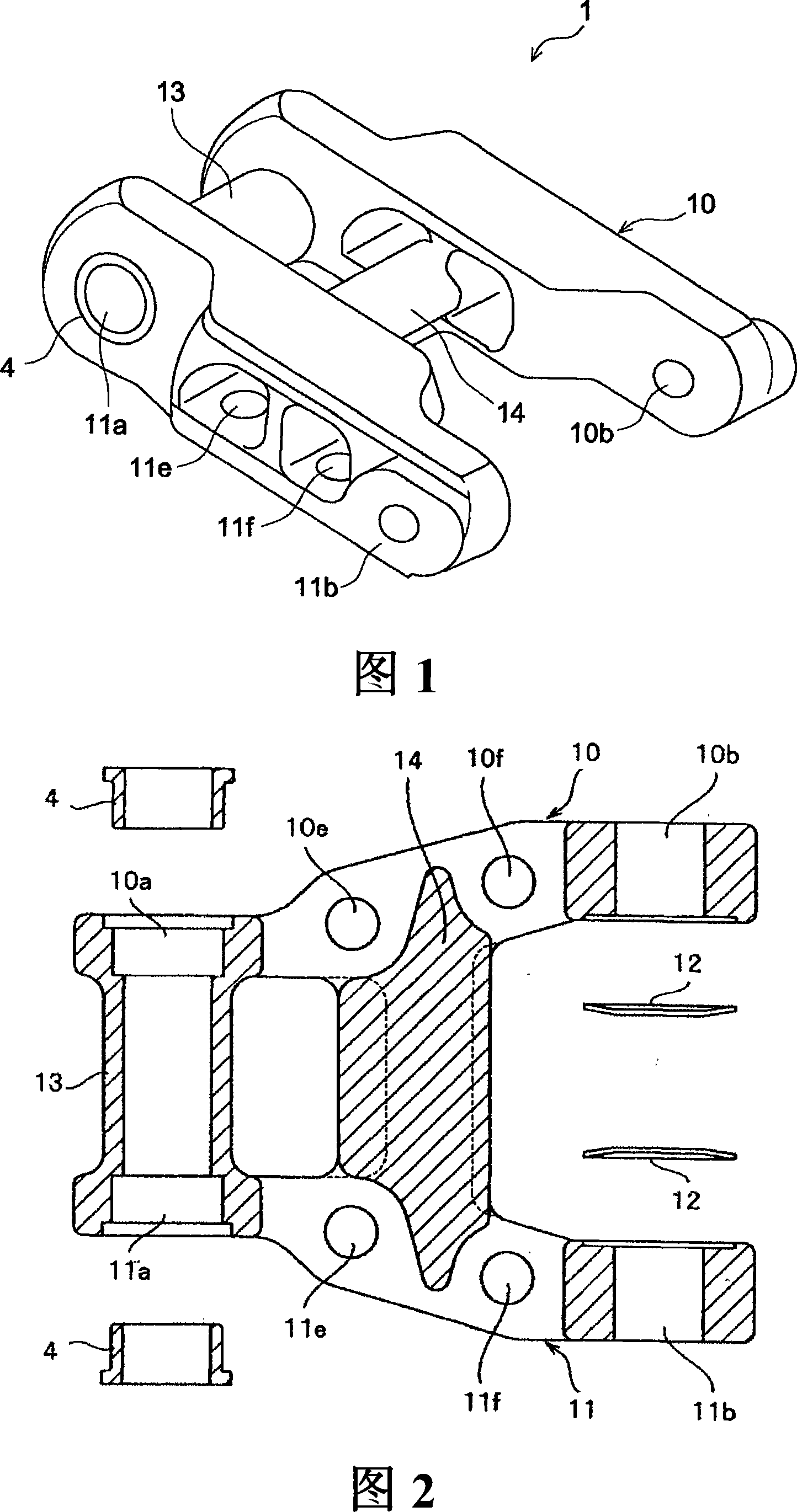

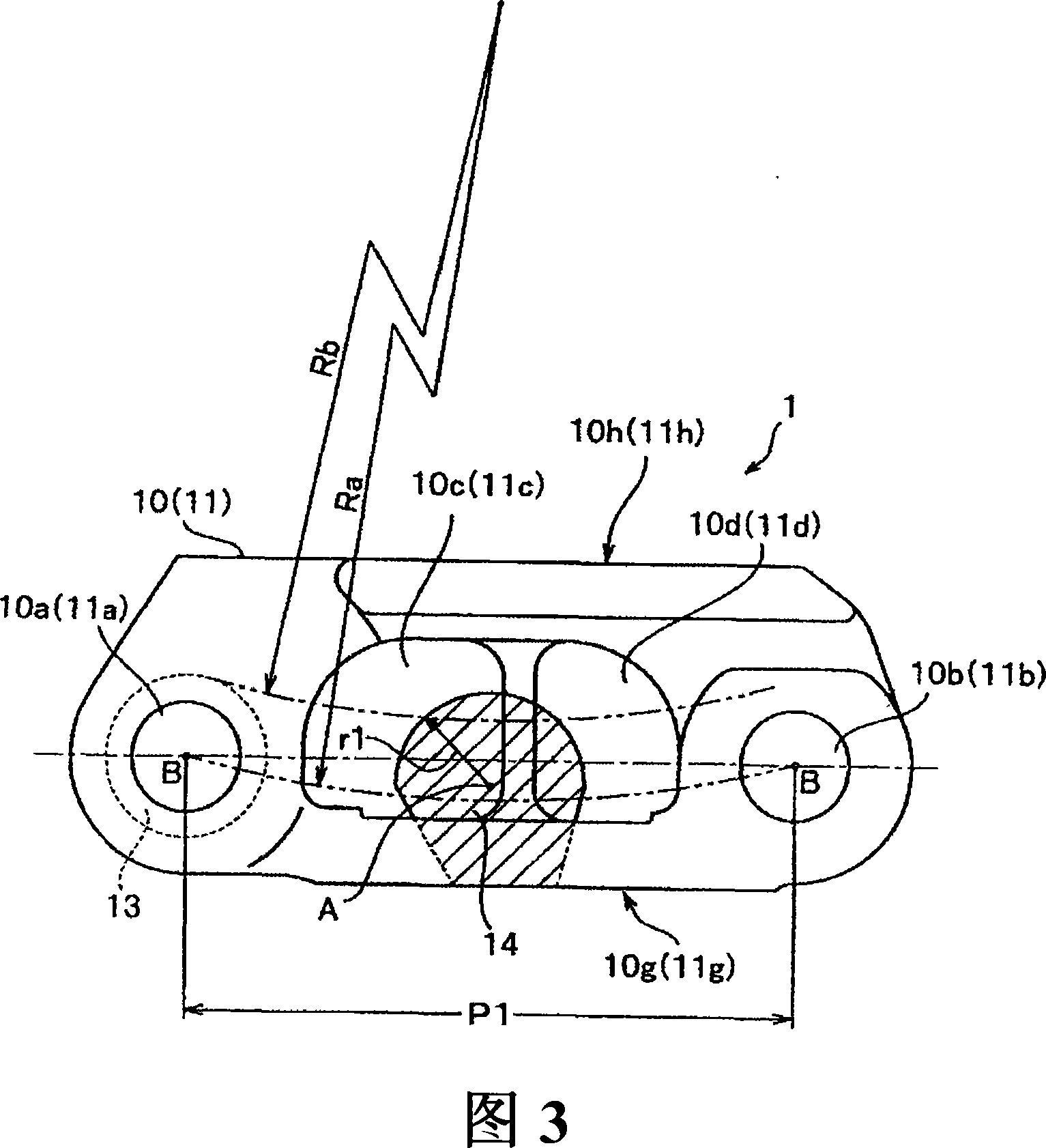

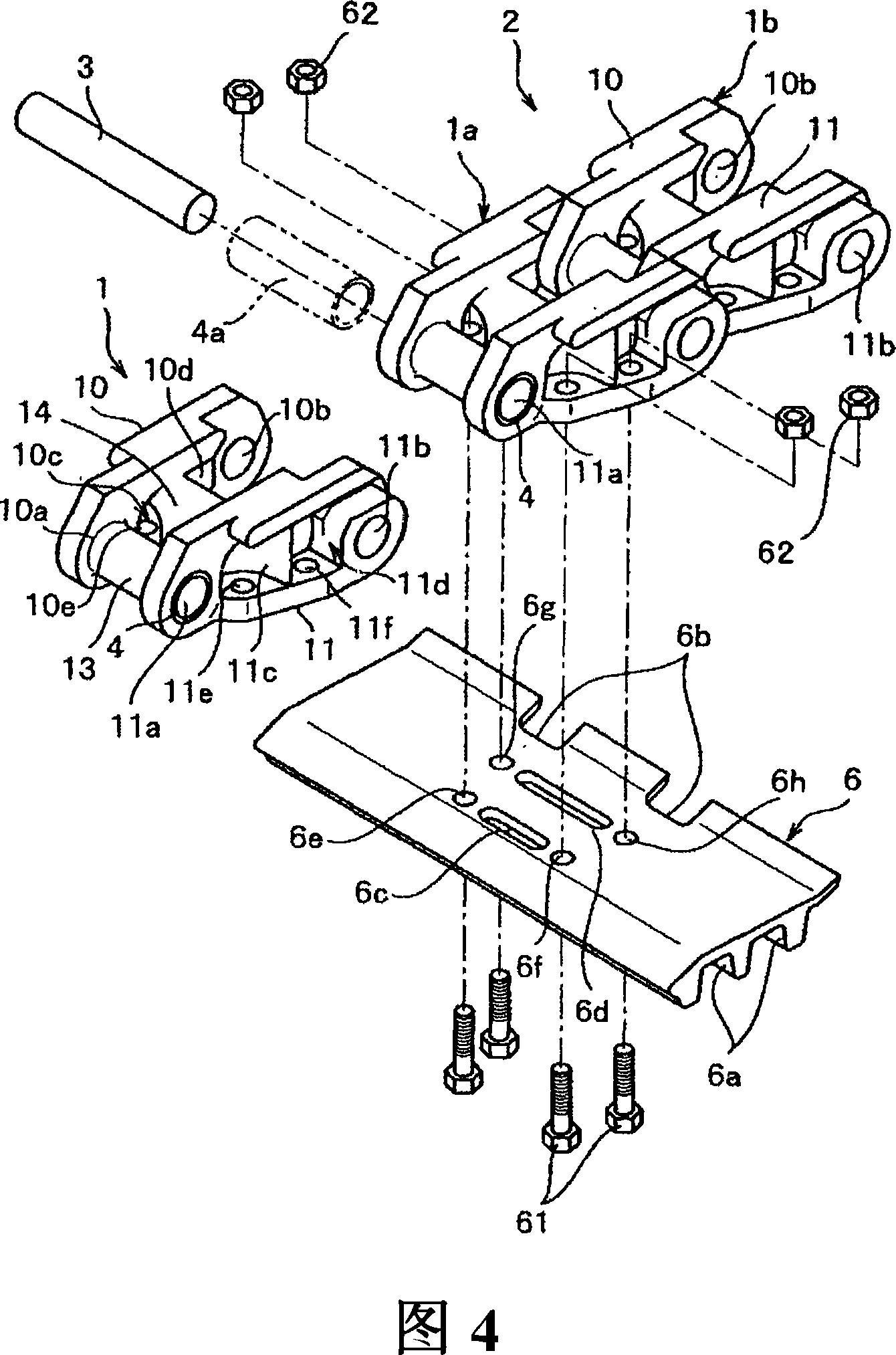

Link structure bodies for track belt and link chain formed by connecting the link structure bodies

InactiveCN101072706AEasy to assembleReduce the cross-sectional areaEndless track vehiclesSprocketEngineering

Link structure bodies for a track belt, which link structure bodies each can be easily assembled, reduced in cost, and is highly durable, and a link chain using the link structure bodies. Each link structure body is constructed by integrally forming the following: a left and right pair of link sections (10, 11) having, at their front and rear sections, first and second through-holes (10a, 11a, 10b, 11b); a tubular first connection section (13) for communicating the first through-holes (10a, 11a) of the pair of link sections (10, 11) with each other and connecting them; and a solid second connection section (14) for connecting to each other the center sections in the longitudinal direction of the pair of link sections (10, 11). A cross-sectional shape of the second connection section (14) is designed so that only the second connection section (14) carries all the sprocket load with the hollow first connection section (13) carrying no sprocket load.

Owner:KOMATSU LTD

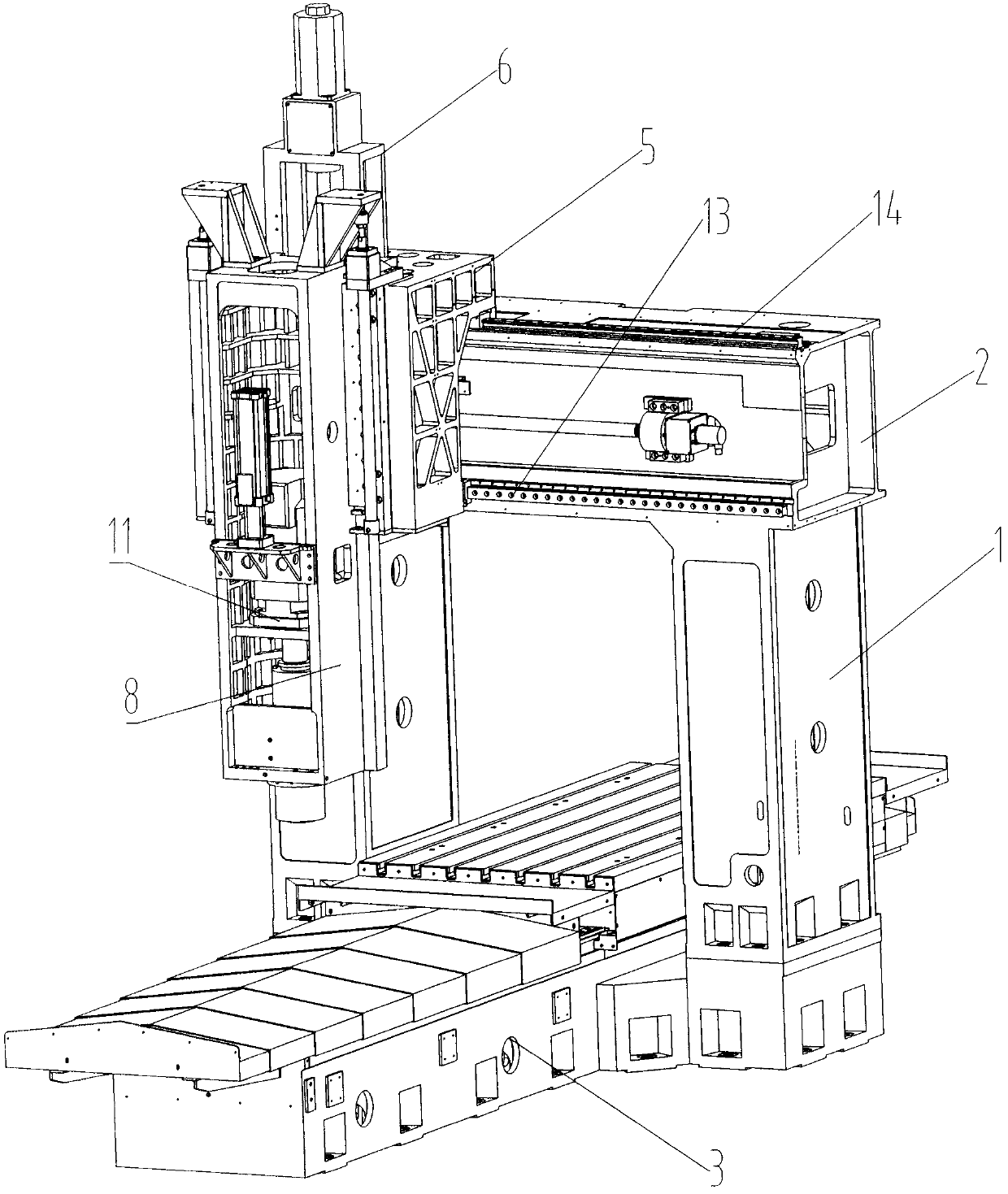

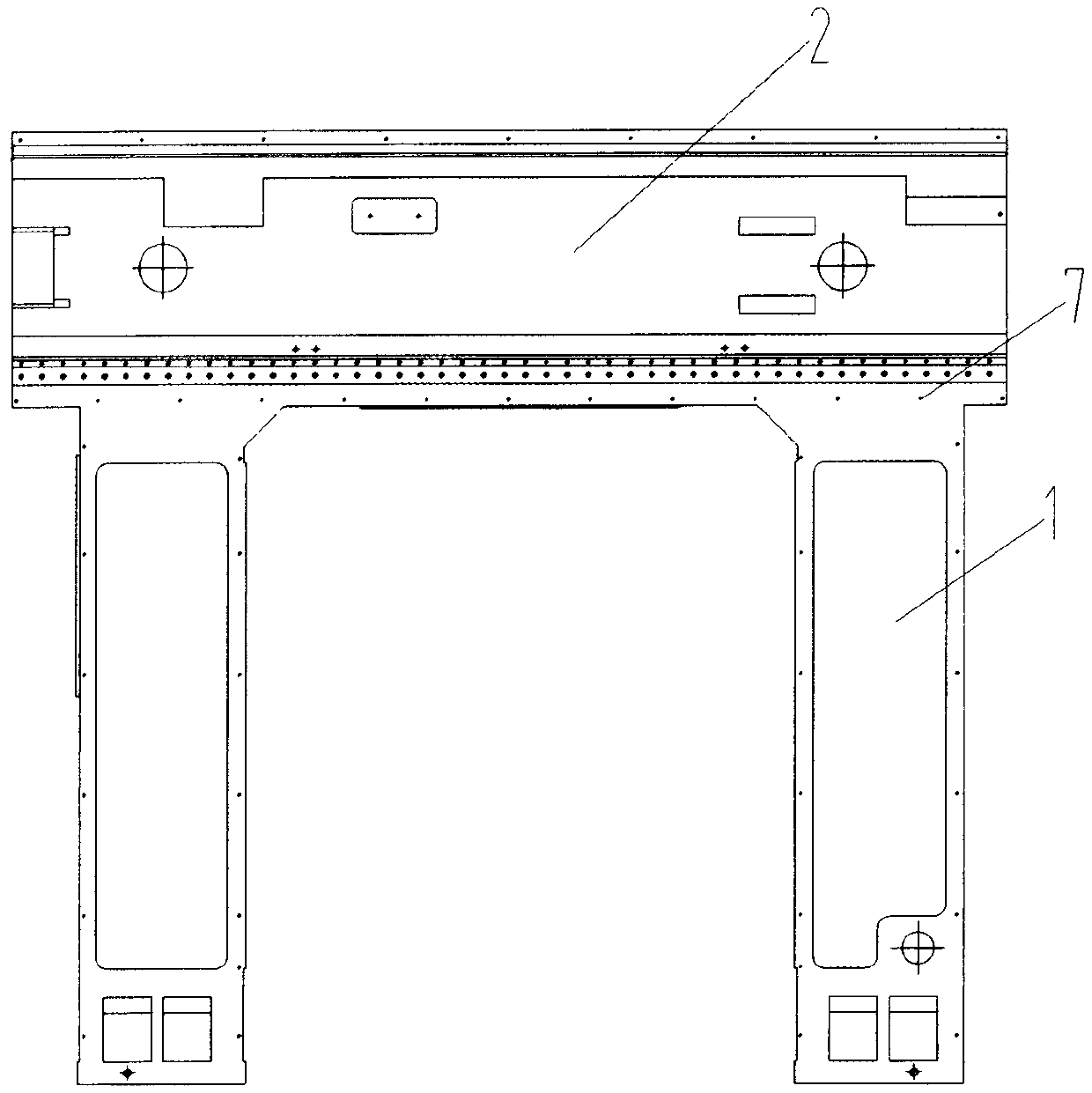

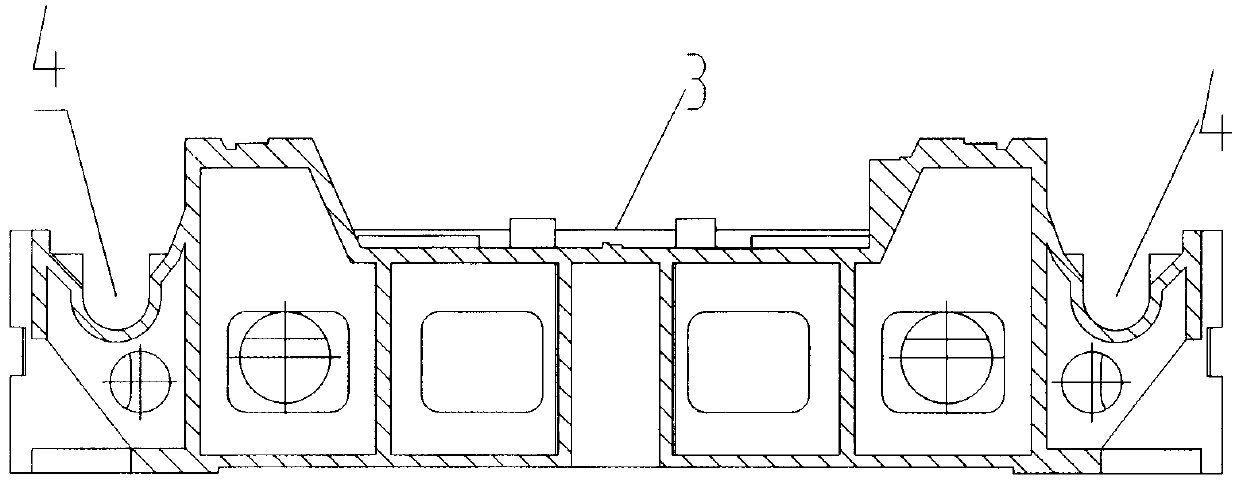

Novel gantry machining center

InactiveCN103624553AEnsure rigidityEnsure strengthLarge fixed membersDriving apparatusEngineeringUltimate tensile strength

The invention discloses a novel gantry machining center which comprises a stand column, a beam, a lathe bed body, casting chip removal device grooves, a sliding base body, a sliding base support and the like. The novel gantry machining center is characterized in that the stand column and the beam are of an integrated structure which is one-time formed by cast iron, the casting chip removal device grooves are formed in the two sides of the lathe bed body, the casting chip removal device grooves and the lathe bed body are of an integrated structure which is one-time formed by castings, the sliding base body and the sliding base support are of a split structure and are fixedly connected together through bolts. According to the novel gantry machining center, the partial integrated structure or the split structure is adopted, the rigidity and strength of the whole gantry machining center are improved, and assembling efficiency and production efficiency are improved.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

Unconventional bolt and a fastening device using the unconventional bolt thereof

An unconventional bolt includes a main body having two heads, and two threaded rods respectively formed at the external surface of each head coaxially with the main body, wherein the cross section of each head has a noncircular shape, and the axial projection of the cross section of the middle of the main body is located in the noncircular axial projection of each head of the main body. The unconventional bolt has a simple structure and a convenient assembly, and can improve the strength and rigidity of the nested profiled components after the connection; and the fastening device using the unconventional bolt can not only support the component but also reinforce it, thus effectively preventing the nested profiled components from transforming.

Owner:NINGBO BANGDA INDAL

Fiber-reinforced turbine component

InactiveUS20150292340A1Sufficient strengthEnsure strengthPropellersRotary propellersFiber reinforcementTurbine

A turbine component includes an airfoil section elongated in a longitudinal direction; a dovetail section continuous with an end of the airfoil section and bulging in a width direction across the longitudinal direction; a plurality of first reinforcement fibers running continuously from the airfoil section to the dovetail section; a plurality of second reinforcement fibers running at least partly in the width direction in the airfoil section; and a matrix joining an entirety of the first reinforcement fibers and the second reinforcement fibers. In the airfoil section, the second reinforcement fibers are woven into the first reinforcement fibers to form a three-dimensional fabric. In the dovetail section, the first reinforcement fibers are not gathered in the width direction by other fibers but deploy in the width direction.

Owner:IHI CORP

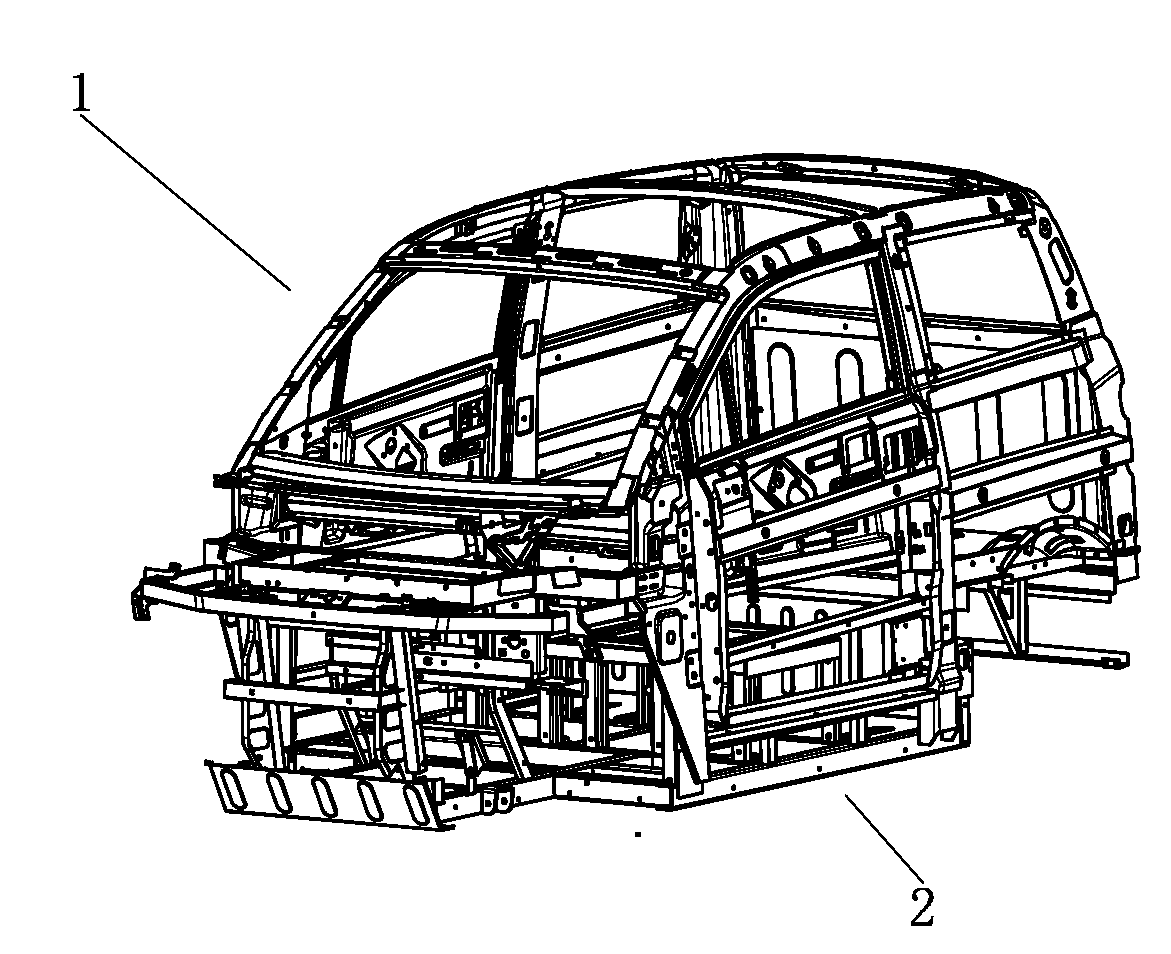

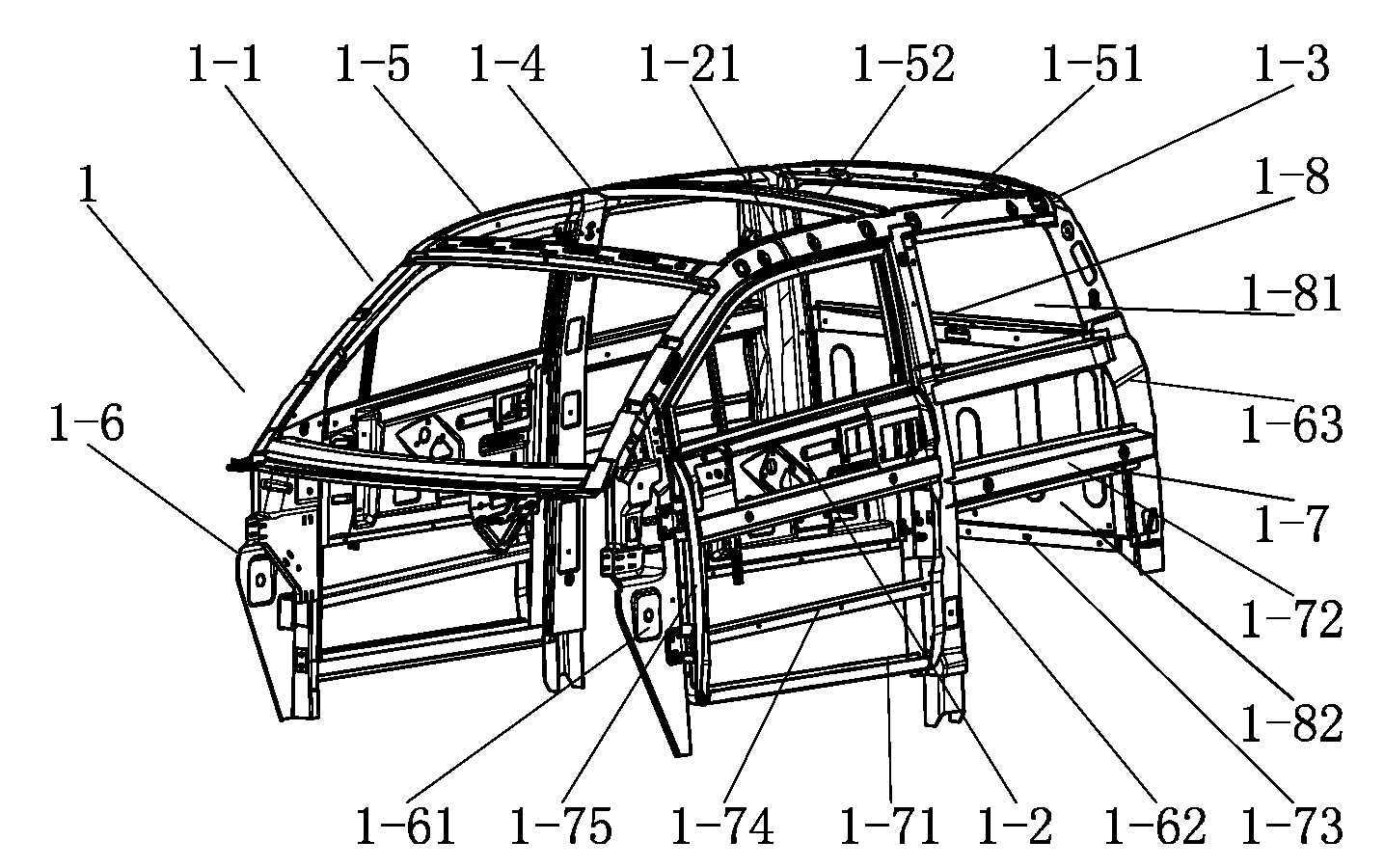

Lightweight electric vehicle

InactiveCN103318263AGuaranteed StrengthGuaranteed stiffnessMonocoque constructionsVehicle frameElectrical battery

The invention discloses a lightweight electric vehicle which comprises a vehicle body structure of the electric vehicle and a frame structure connected with the lower portion of the vehicle body structure. The vehicle body structure comprises a vehicle body and a vehicle door, wherein the vehicle body and the vehicle door are composed of a skeleton and thermoplastic boards, wherein the thermoplastic boards cover the inner surfaces and the outer surfaces of the skeletons. The skeleton is composed of a plurality of stamping rod parts which are welded to form a cage-shaped vehicle body skeleton in an integral mode. The surface of the cage-shaped vehicle body skeleton is provided with threaded fixing holes for fixing the thermoplastic boards which are fixedly connected with the cage-shaped vehicle body skeleton through screws and form a whole closed vehicle body. A body of the vehicle frame structure is composed of a crossbeam frame. A battery bin is arranged in the middle of the crossbeam frame. According to the lightweight electric vehicle, strength, rigidity and safety of the vehicle body and the vehicle door can be ensured, the weight of the vehicle body and the weight of the vehicle door can also be obviously relieved, strength and rigidity of a chassis can be effectively improved, when four wheels are stressed unevenly, the vehicle body will not deform, and batteries can be arranged in the most safe position.

Owner:北京宏瑞汽车科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com