Fire test furnace loading device

A technology of fire test furnace and loading device, which is applied in the direction of measuring device, applying stable tension/pressure to test the strength of materials, instruments, etc., which can solve problems such as the influence of test results, so as to ensure the strength and stability of the supporting structure and improve the results The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

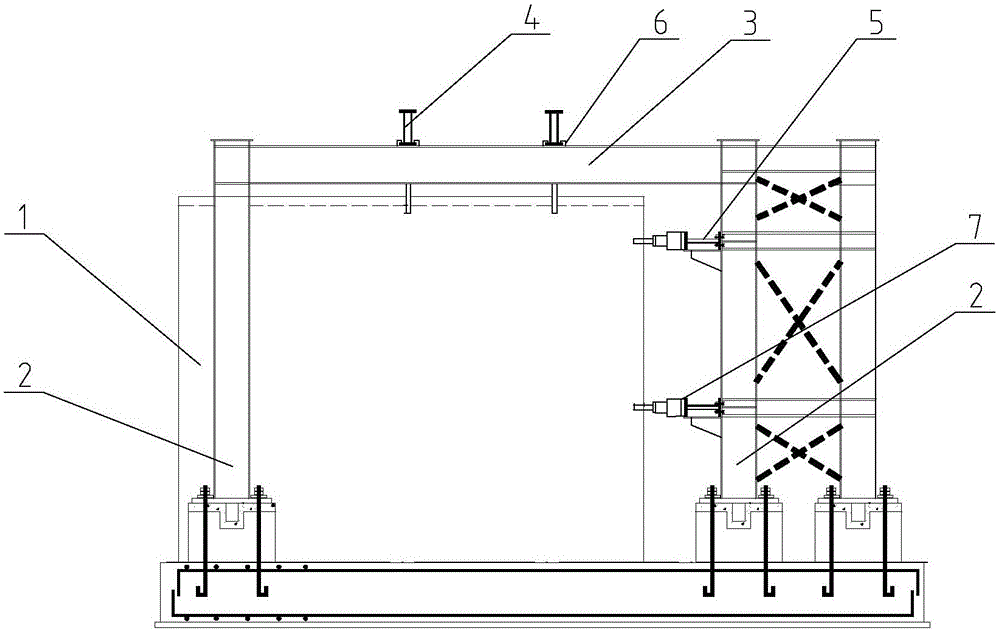

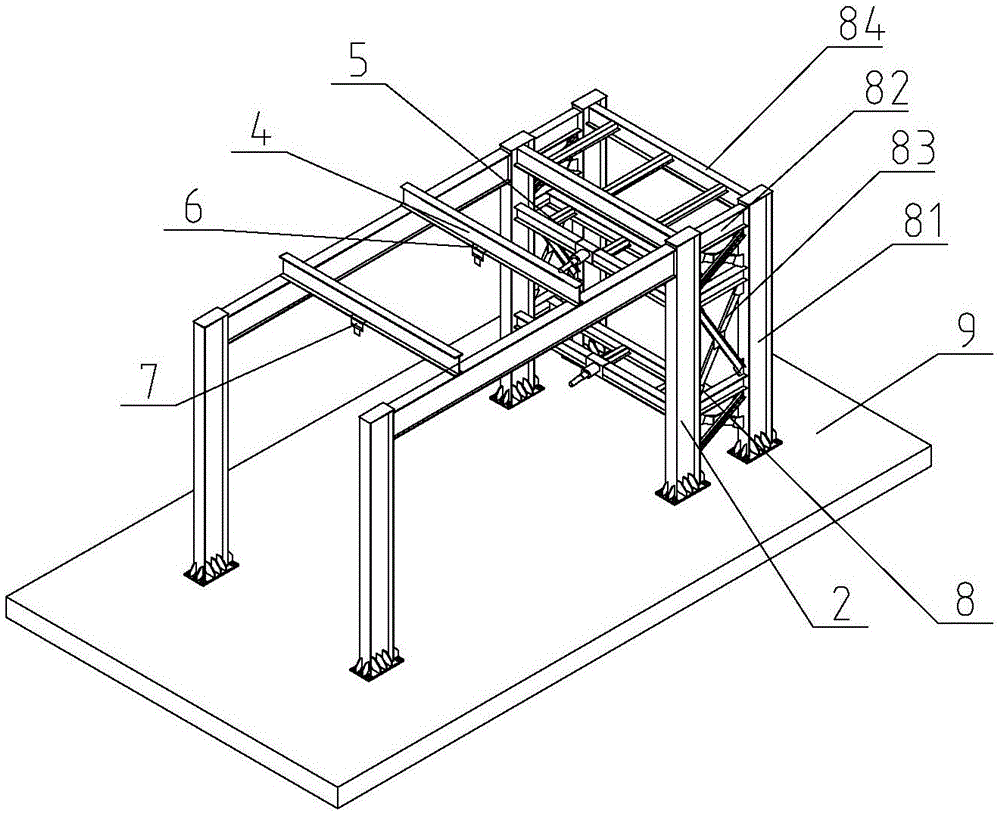

[0035] In this embodiment, the other side of the horizontal loading beam 5 is provided with a truss steel structure 8 connected with vertically adjacent columns 2 . The purpose is to improve the strength and stability of the supporting structure of the whole loading device. Specifically, the truss steel structure 8 includes steel columns 81 that are the same height as the columns 2 and are arranged parallel to and spaced apart from the columns 2. At least two short steel beams 82 are connected between the horizontally adjacent steel columns 81 and the columns 2. A support rod 83 is obliquely connected to the diagonal of the short steel beam 82 , and a long steel beam 84 is connected between the steel column 81 and the steel column 81 . The truss steel structure 8 adopting this structure has the advantages of high structural strength, strong stability, non-deformation and small occupied volume compared with the commonly used reaction frame loading frame in the past. In order t...

Embodiment 2

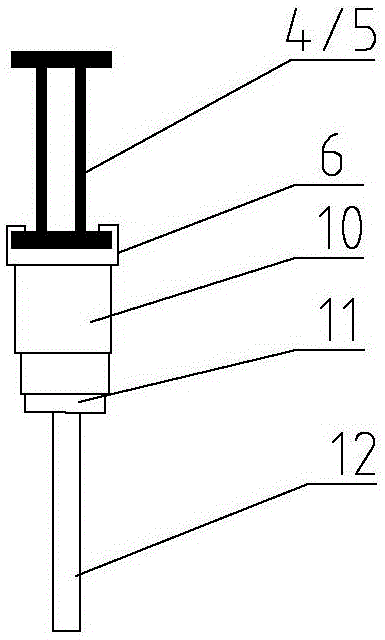

[0037] In this embodiment, the detection device 7 is a telescopic sensor detection mechanism, see image 3 , the telescopic sensing and detection mechanism includes an electro-hydraulic jack 10, the end face of the cylinder of the electro-hydraulic jack 10 is connected to the bottom of the slider 6, the end face of the piston at the other end is connected to the sensor 11, and the other end of the sensor 11 is connected to a high temperature resistant tungsten steel Connecting rod 12.

[0038] During use, utilize the expansion and contraction of electrohydraulic jack 10 pistons to apply force (because the slide block 6 that electrohydraulic jack 10 is connected is arranged on vertical loading beam 4 and horizontal loading beam 5, so can realize vertical and Lateral loading.) The effect of simulating multi-faceted force can be achieved on different faces of the component to be tested. The purpose of using high-temperature-resistant tungsten steel connecting rod 12 is that due ...

Embodiment 3

[0043] The slide block 6 is fixed on the vertical loading beam 4 and the horizontal loading beam 5 by fasteners. The purpose is to further limit the loading position of the loading front part and prevent the slide block 6 from being unable to be positioned accurately and stably due to failure of the power mechanism, resulting in failure of the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com