Composite dot-matrix interlayer double-skin cylindrical shell structure with metal liner for bearing inner pressure and preparation process thereof

A composite material, metal lining technology, applied in the direction of metal layered products, synthetic resin layered products, lamination, etc. Complexity and other problems, to achieve the effect of large-scale production and automated production, less defects, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

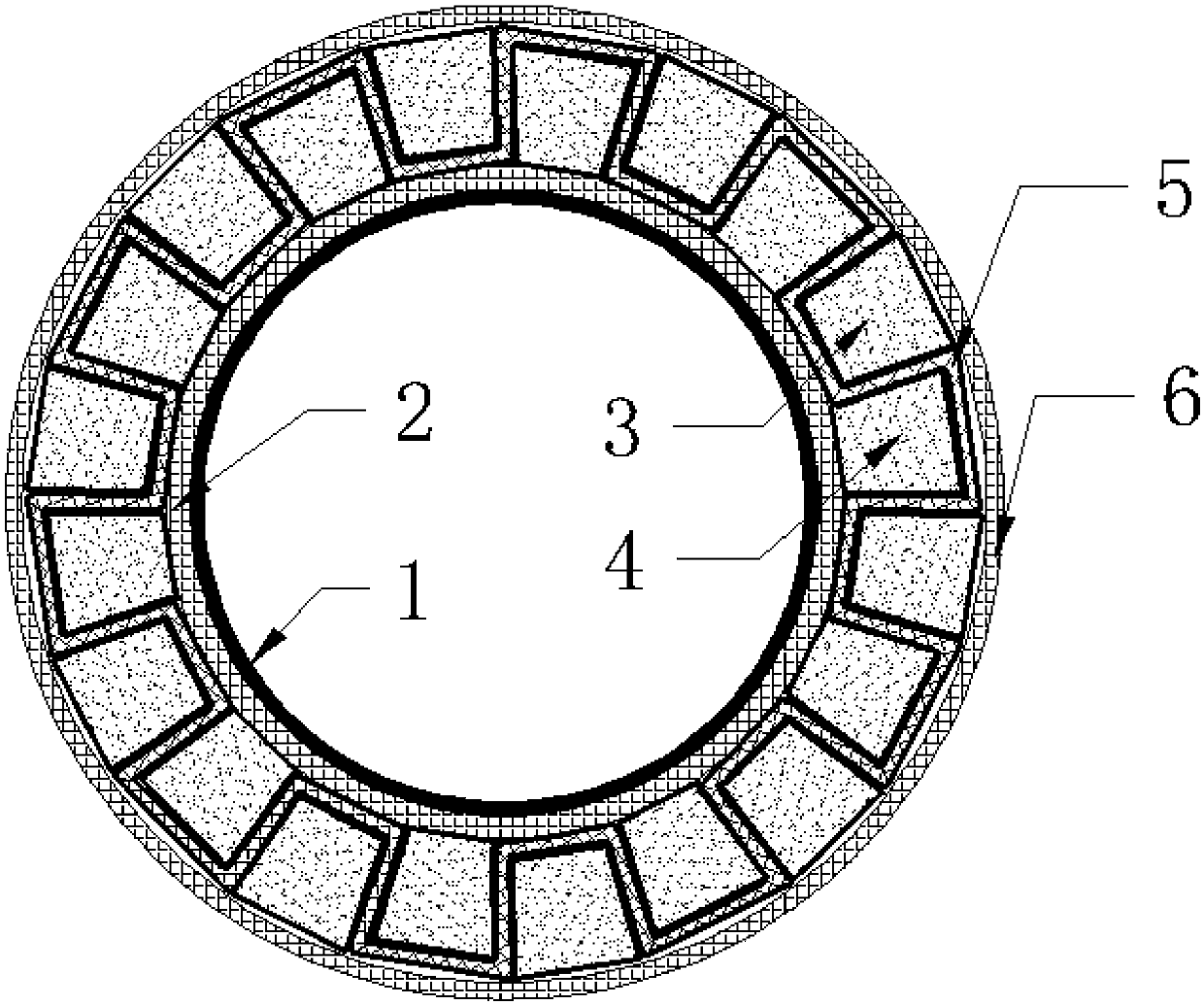

[0045] The composite material lattice interlayer double-skinned cylindrical shell structure containing metal lining under internal pressure of the present invention comprises: a thin-walled cylindrical metal lining, an inner skin, a lattice core and an outer skin, wherein the inner skin Both the outer skin and the outer skin are made of composite materials; according to the strength of the thin-walled metal-lined cylindrical shell under internal pressure, the inner skin is made of fiber winding; the lattice core includes corrugated ribs and isosceles trapezoidal foam strips, corrugated ribs The foam strips are evenly circled along the outer wall of the inner skin, and then fixed by the outer skin to meet the rigidity requirements of the internal pressure thin-walled cylindrical shell metal-lined composite material cylindrical shell; the corrugated ribs are made of composite materials; the foam strips and corrugated ribs The cavities fit without clearance; two adjacent foam stri...

Embodiment 2

[0057] The preparation process of a metal-lined composite material lattice sandwich double-skin cylindrical shell structure that withstands internal pressure in this embodiment includes the following steps:

[0058] Step 1: Wrap the thin-walled metal liner pipe 1 with a predetermined fiber layer on a winding machine to form an inner skin 2;

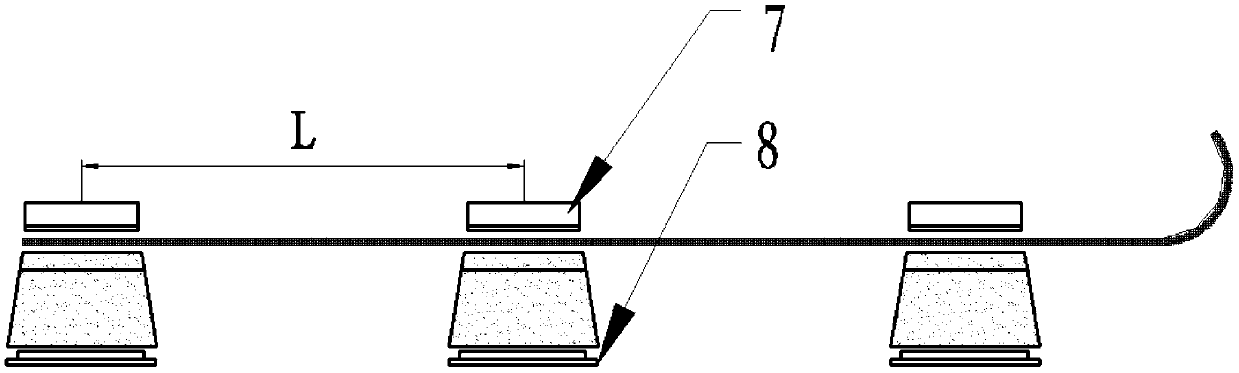

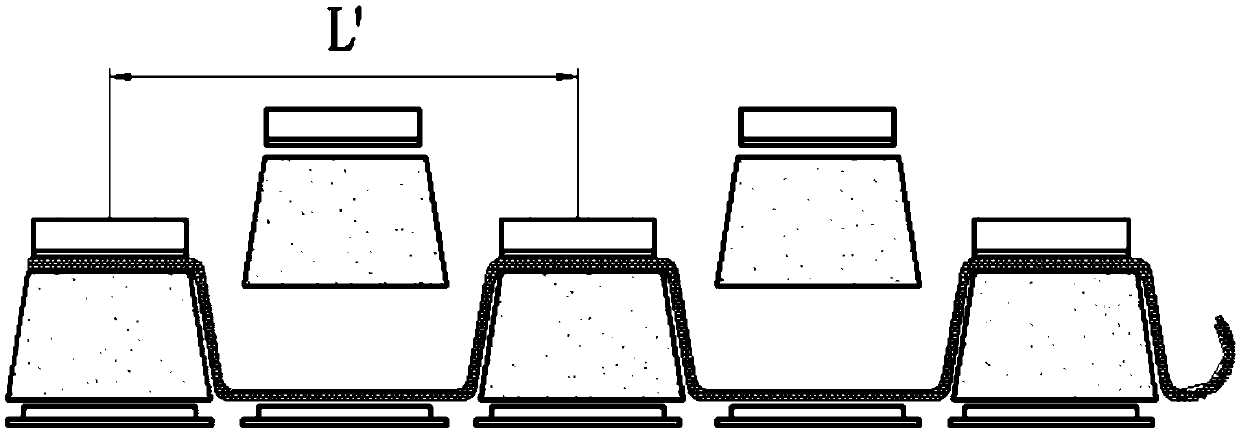

[0059] Step 2: Prepare a dot matrix interlayer. The interlayer is mainly composed of foam strips of two specifications and fiber cloth 5 arranged alternately, and five special tools are used to cooperate with each other and lay a circle along the inner skin 2. The specific process of interlayer preparation is as follows :

[0060] 1) Two types of isosceles trapezoidal foam strips 3 and 4 with equal numbers and different upper and lower bottoms are processed by a sawing machine, a total of N pieces (specification 1 and specification 2, N is an even number and N≧16)

[0061] 2) Fix the upper bottom of the foam strip 3 of specification one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com