Patents

Literature

1794results about How to "Improve finished product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

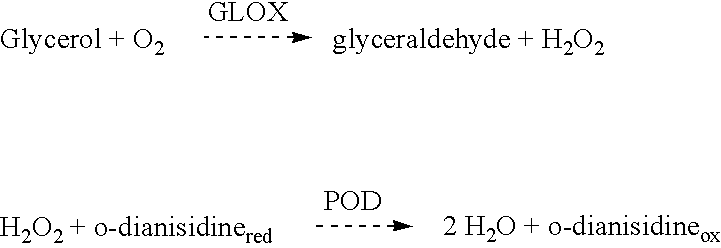

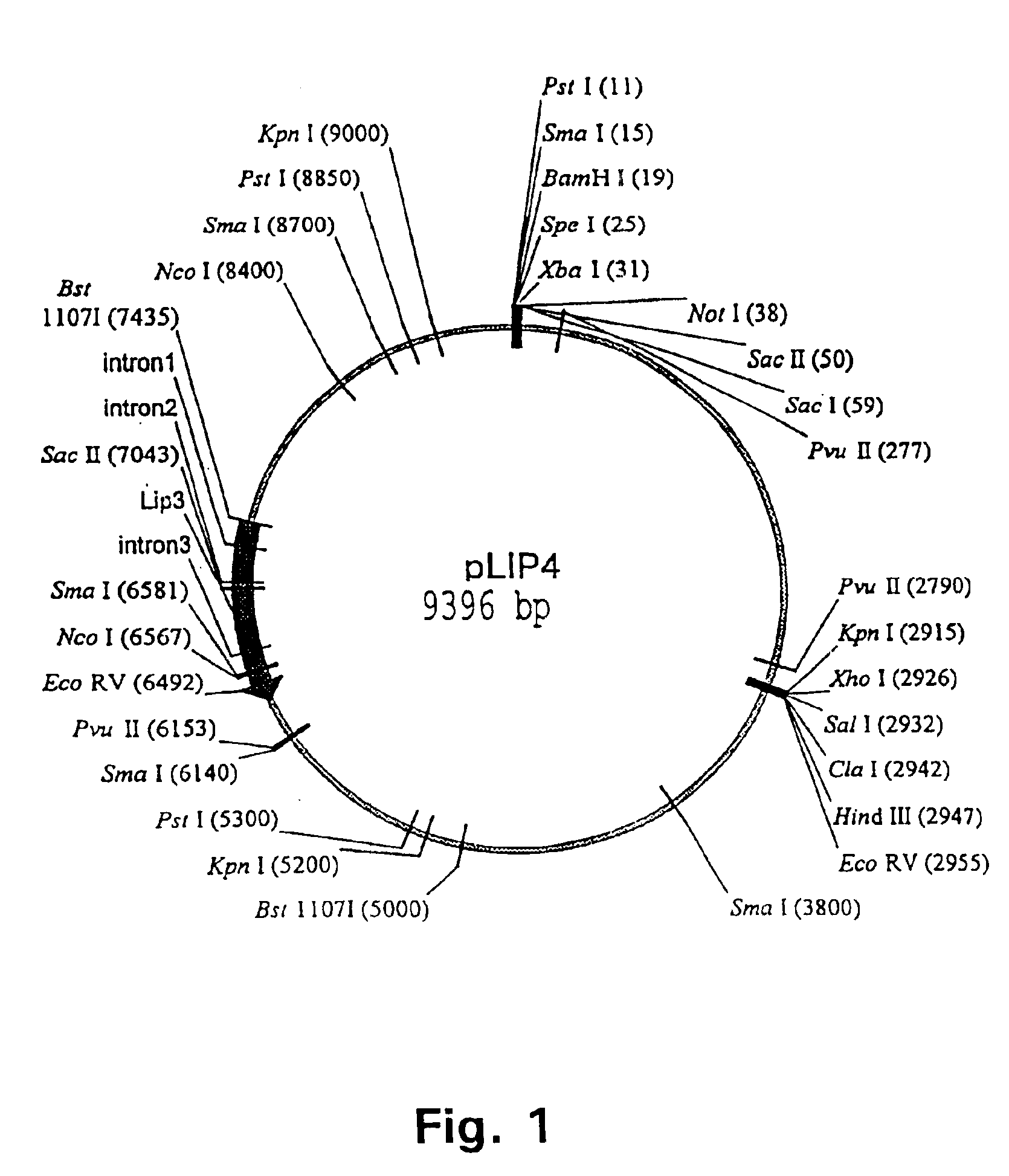

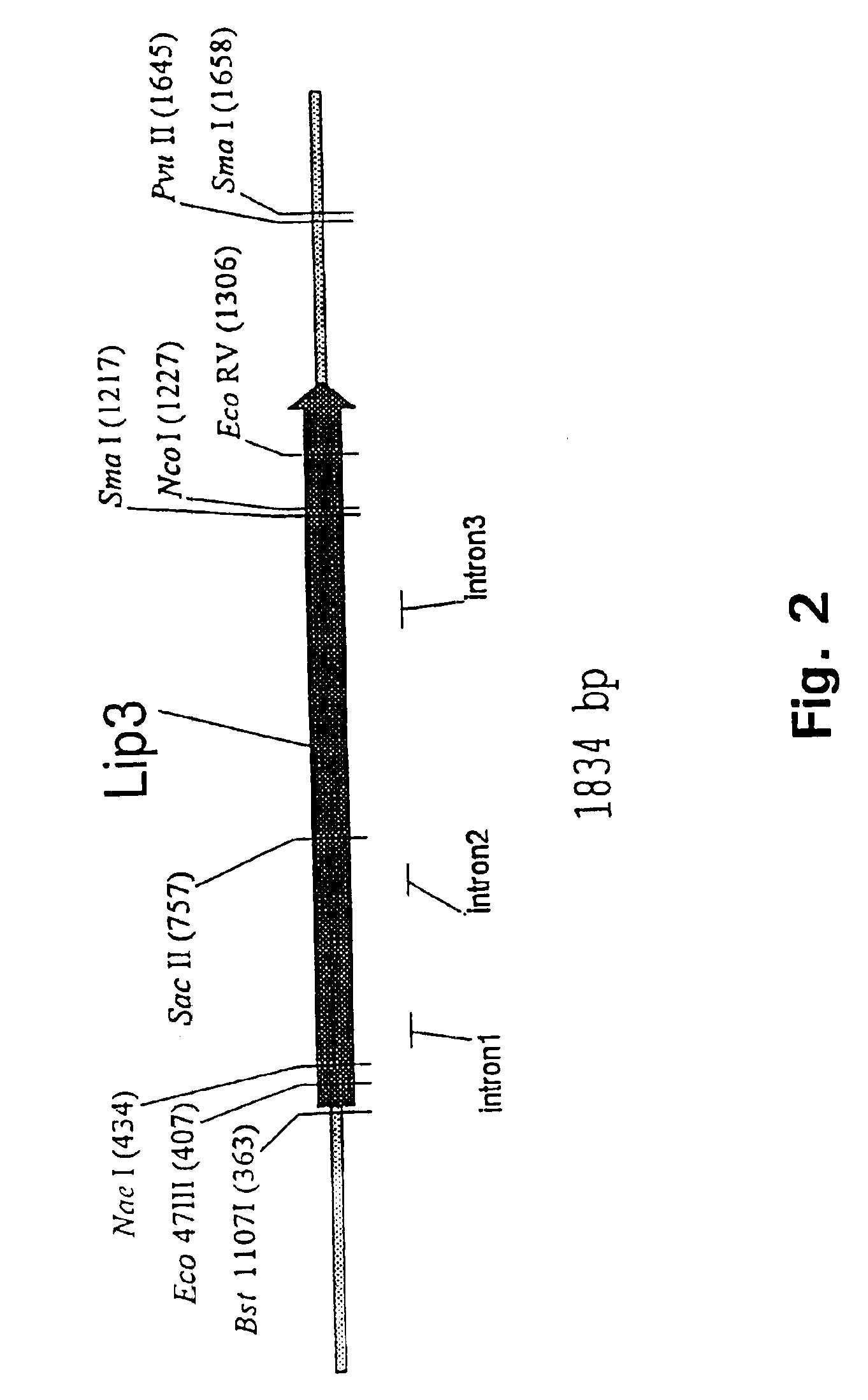

Method for preparing flour doughs and products made from such doughs using lipase

InactiveUS6852346B2Improve the immunityLess-prone to mechanical deformationFungiDough treatmentPore diameterSpecific volume

Owner:DUPONT NUTRITION BIOSCIENCES APS

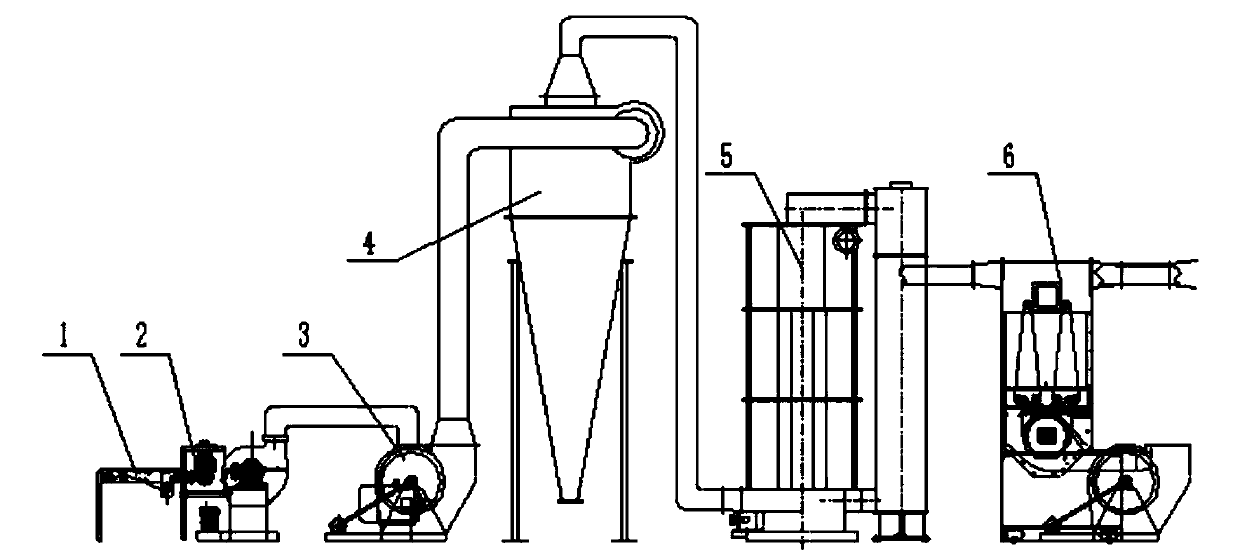

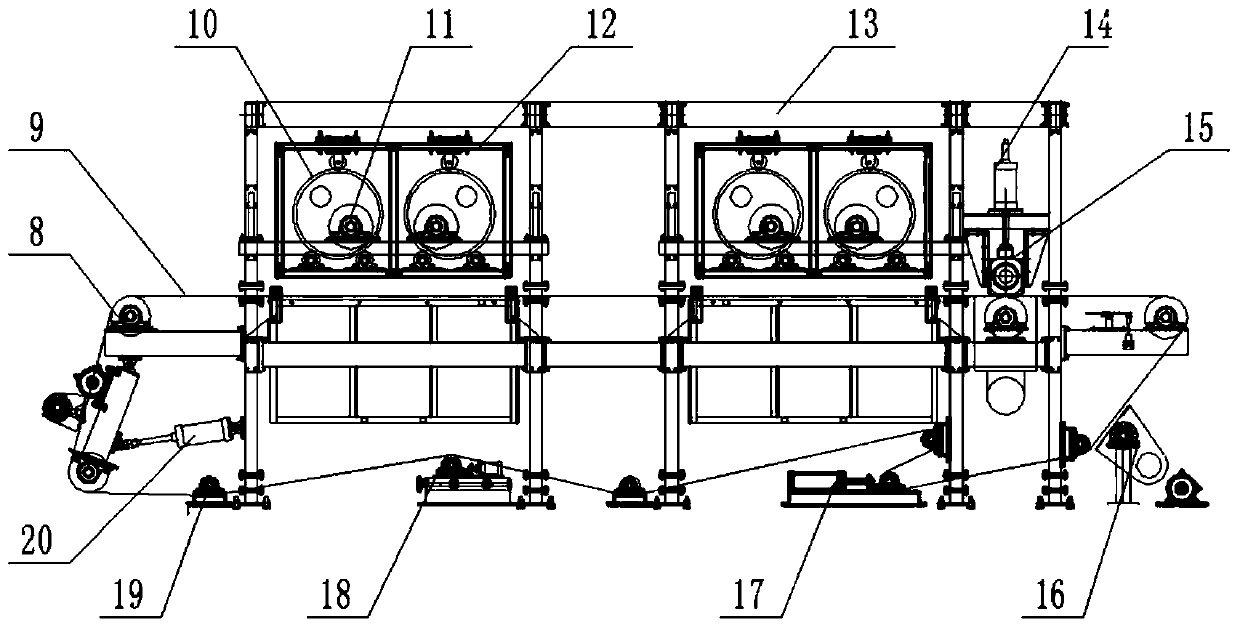

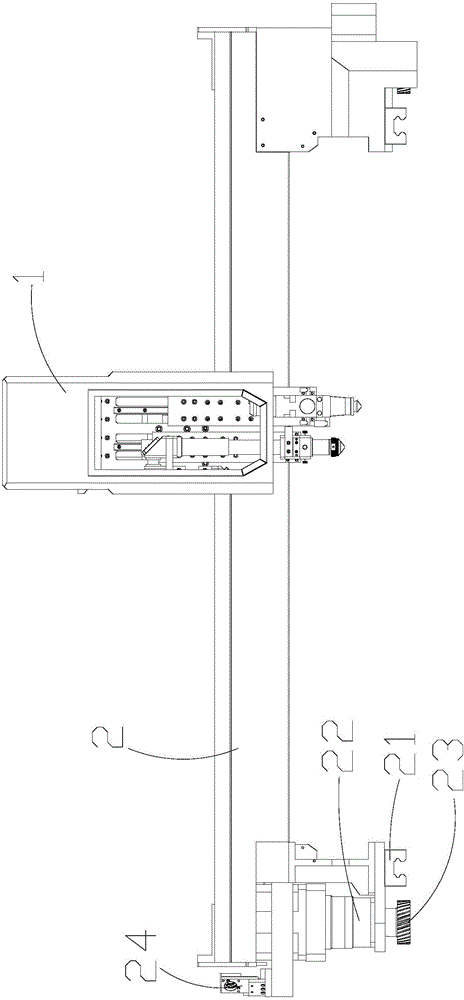

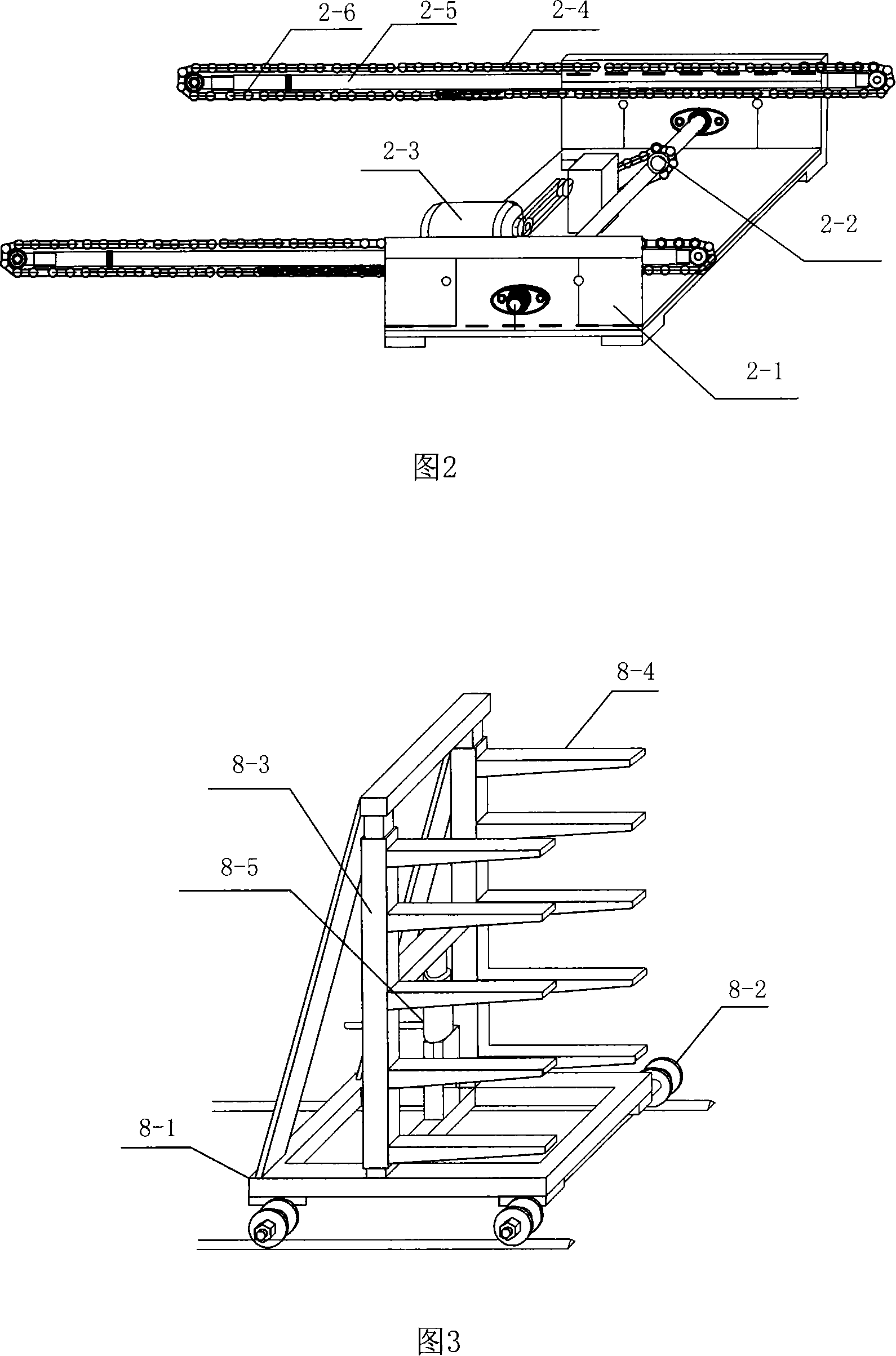

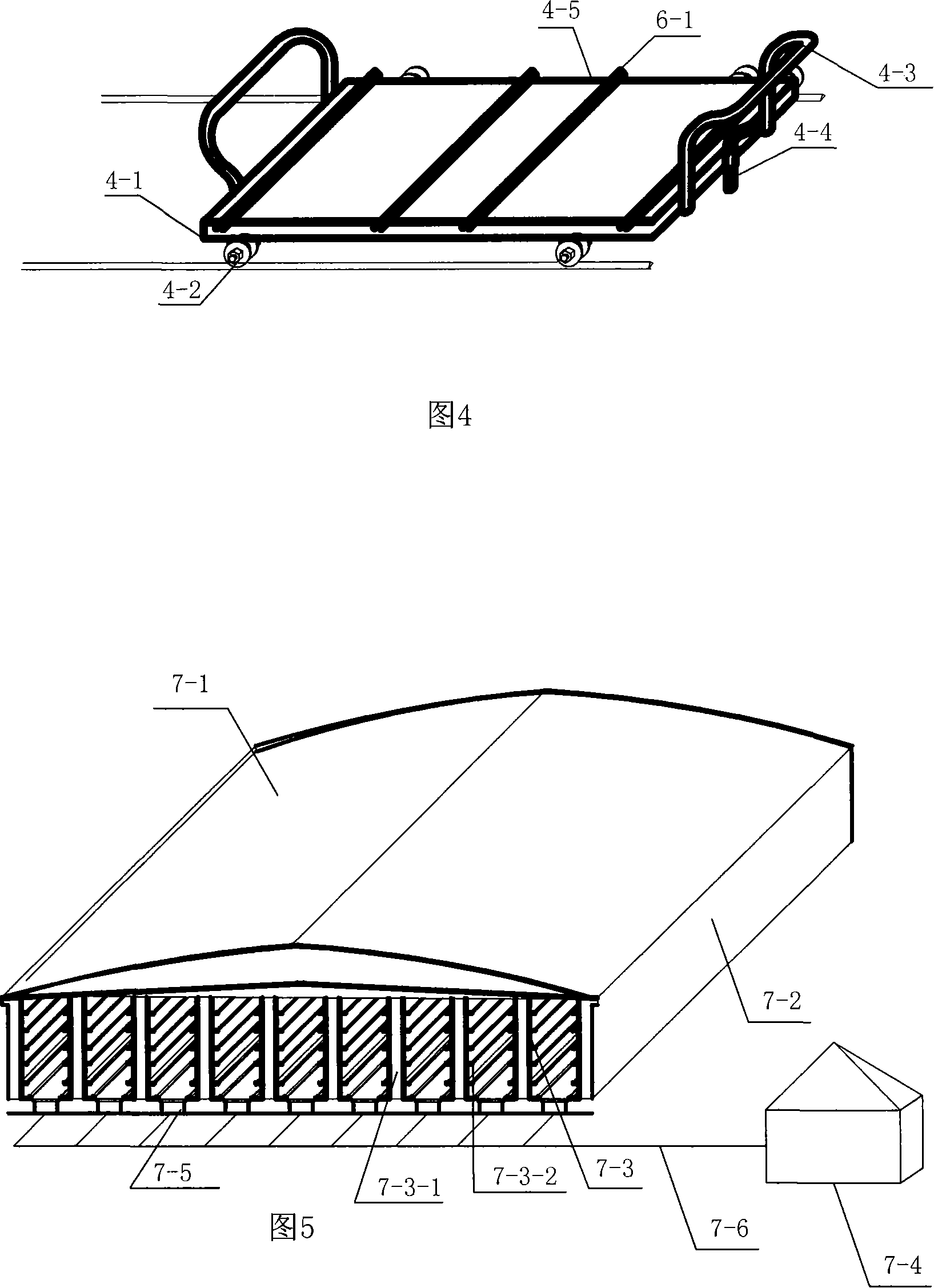

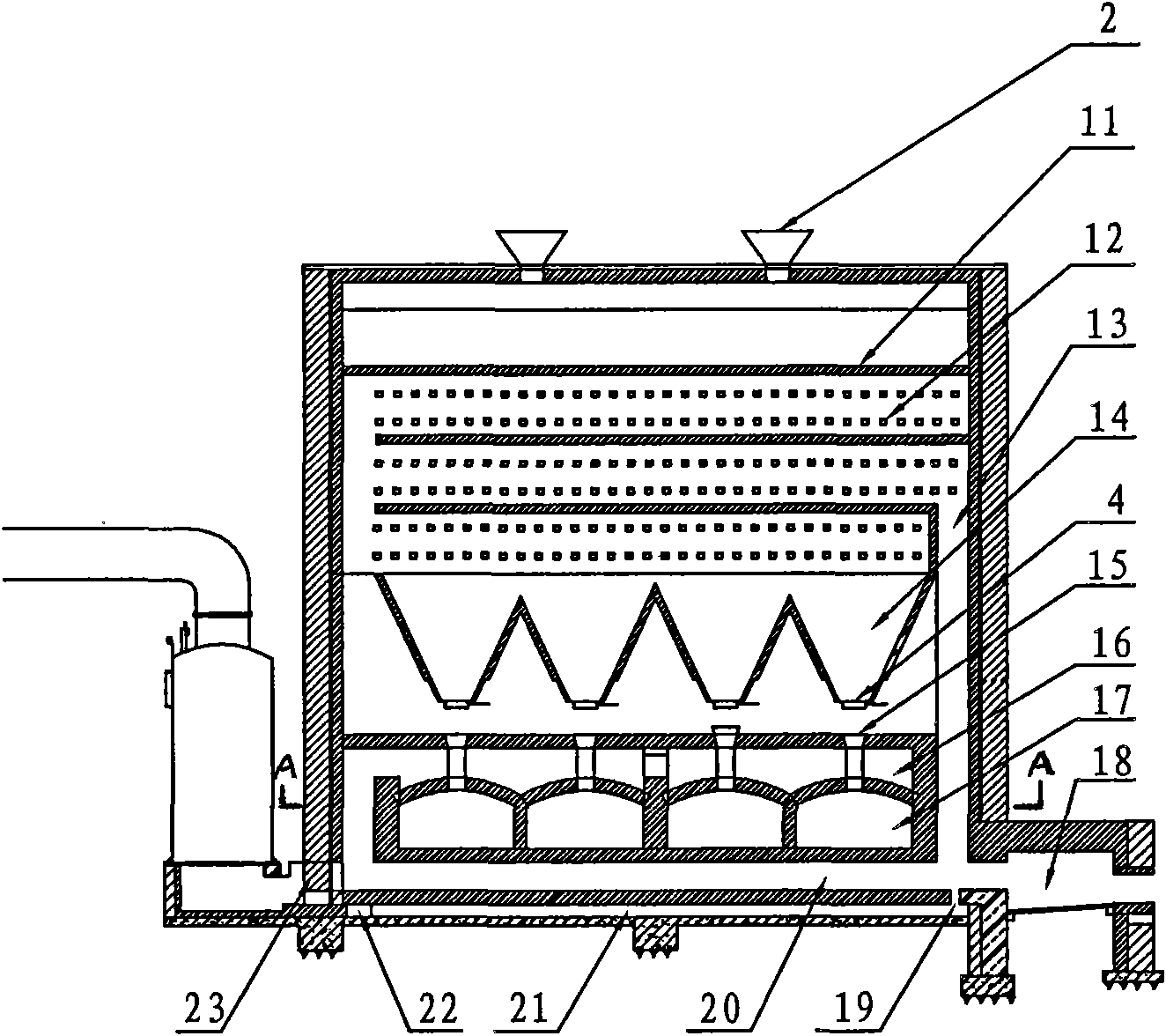

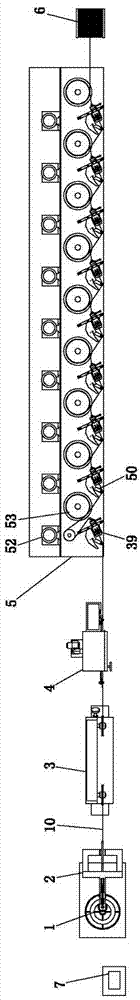

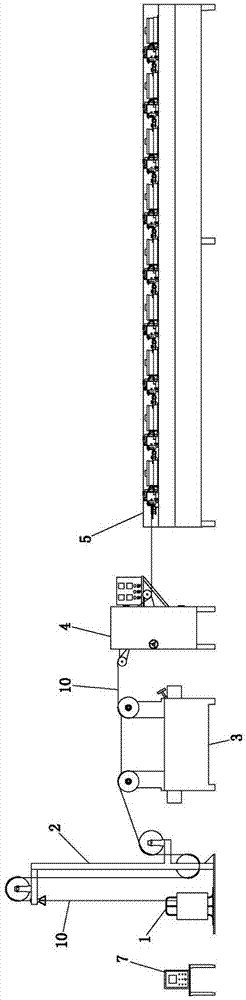

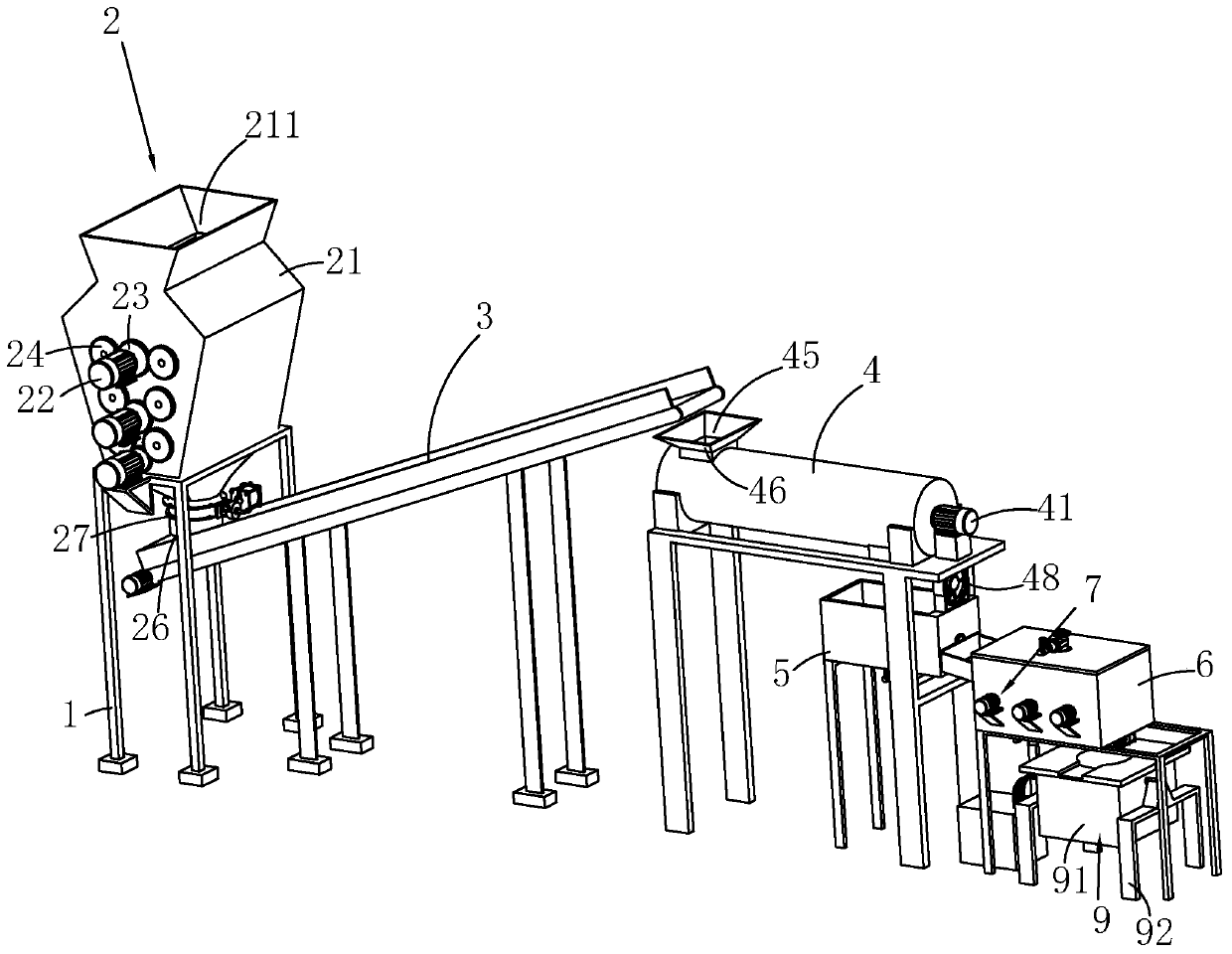

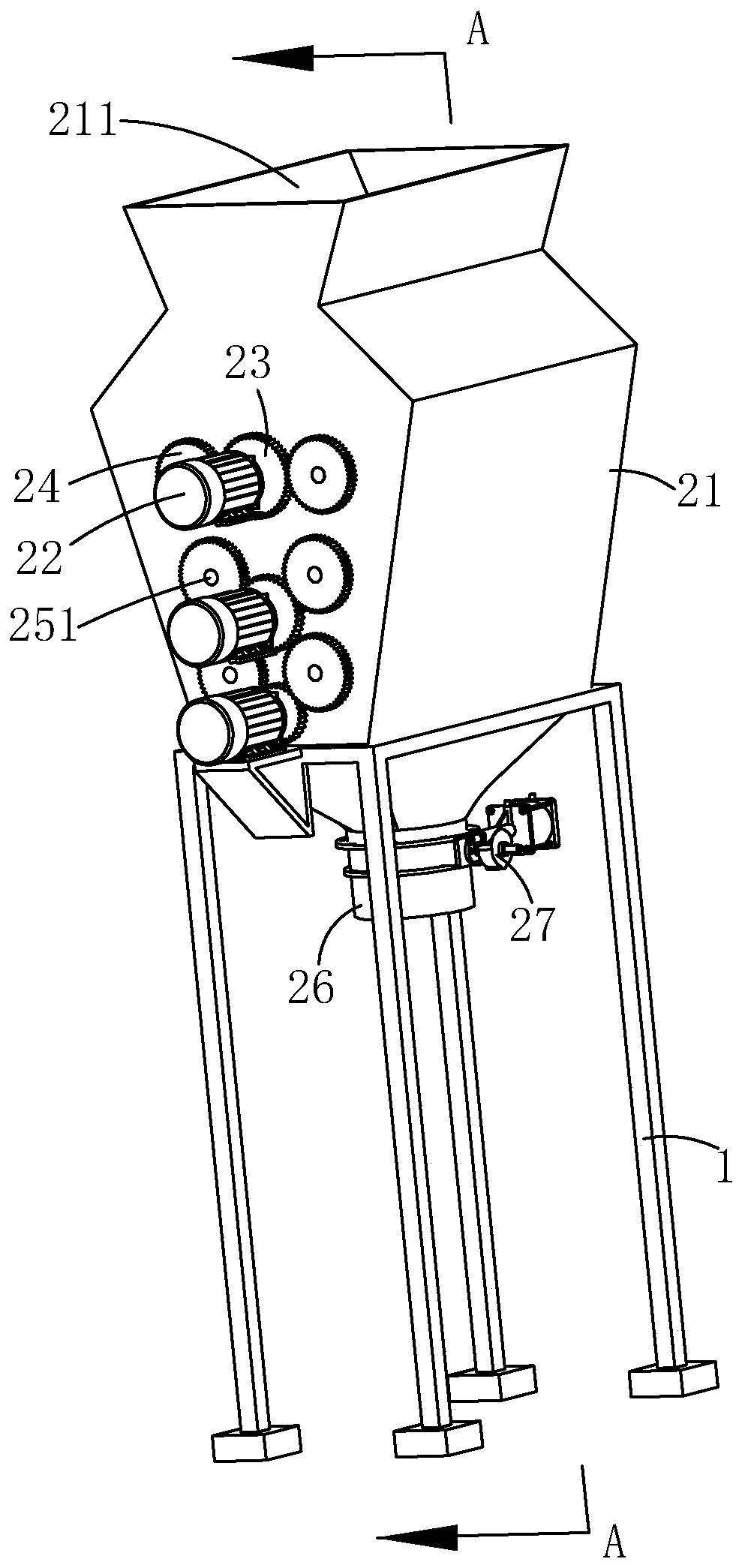

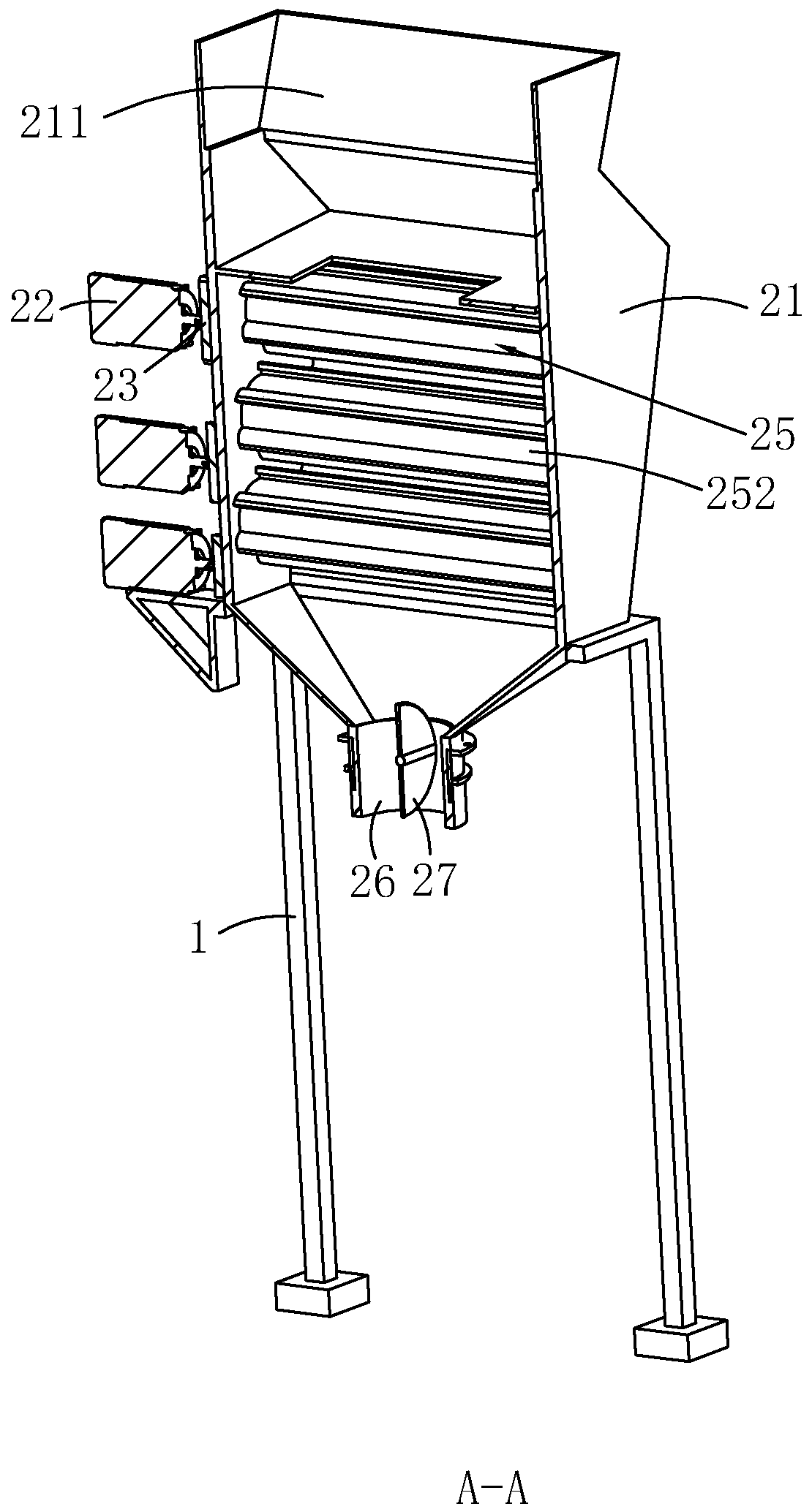

Bulk production line for reconstituted tobacco thin sheets by dry papermaking method

ActiveCN103431514AIncrease profitHigh degree of integration and automationTobacco preparationFiberProduction line

The invention discloses a bulk production line for reconstituted tobacco thin sheets by a dry papermaking method. The whole production line mainly comprises a raw material treatment part, a tobacco forming part and a thin sheet forming part, wherein material transportation is mainly executed through a carrying roller and a mesh belt, and is assisted through air flow of a fan; a conveying component of the whole production line is provided with a cleaning device, a tensioning device and a deviation correction device. According to the production line, wood pulp or tobaccos are smashed into fibers, then reconstituted tobaccos are produced through dry forming; finished products, namely the tobacco thin sheets, are produced through reconstituted tobacco treatment; the production requirements on the reconstituted tobacco thin sheet low sewage emission, low energy consumption and high quality are met.

Owner:SHANXI LIGONG MECHANICAL & ELECTRICAL TECH

Flavoring with beef flavor and preparation method thereof

The invention provides flavoring with beef flavor and a preparation method thereof. The flavoring is prepared from pure beef powder, refined butter, a yeast extract, hydrolyzed vegetable protein, bovine ossein, disodium 5'-ribonucleotide, salt, white sugar, glucose, dahurian angelica root powder, ginger powder, black pepper powder, white pepper powder, garlic powder, onion powder, tsaoko fruit powder, kaempferia galamga powder, anise powder, groud cinnamon, nutmeg seed powder, disodium 5'-inosinate, monosodium glutamate, maltodextrin and an anticaking agent. The flavoring with beef flavor prepared by mixing, heating, drying and crushing the above mentioned raw materials has rich meat flavor, natural and comfortable taste and a strong cooking property, is convenient to store, carry and utilize, is especially applicable as flavoring in the food industries of instant noodles, bibimbap, food and drink, leisure food and the like, and has the advantages of simple preparation, natural and rich flavor, high quality of a finished product, low production cost, etc.

Owner:天津市春升清真食品有限公司

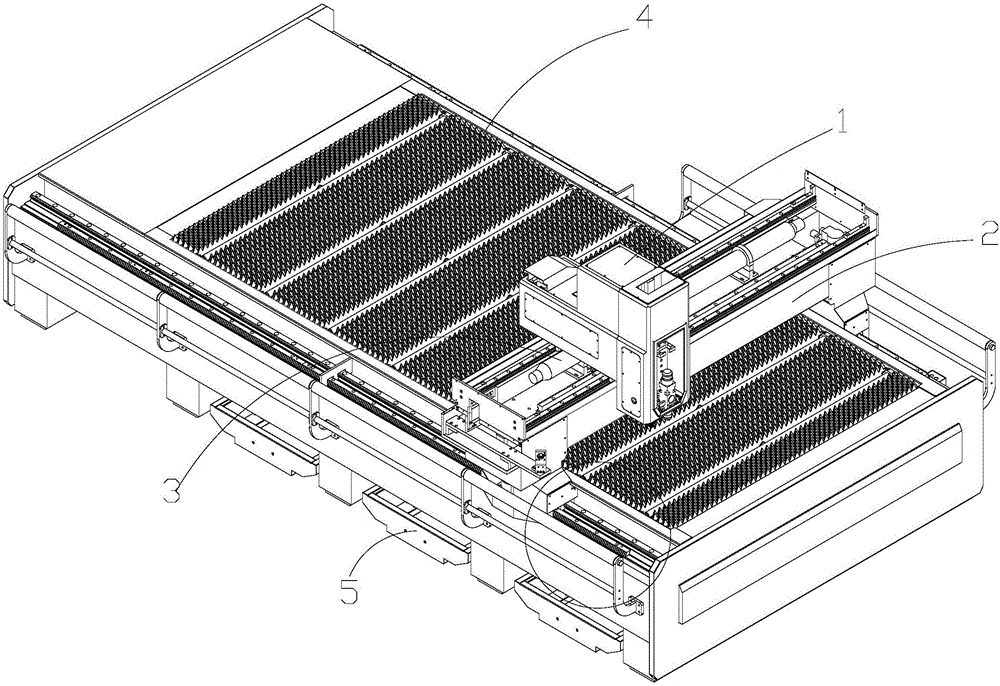

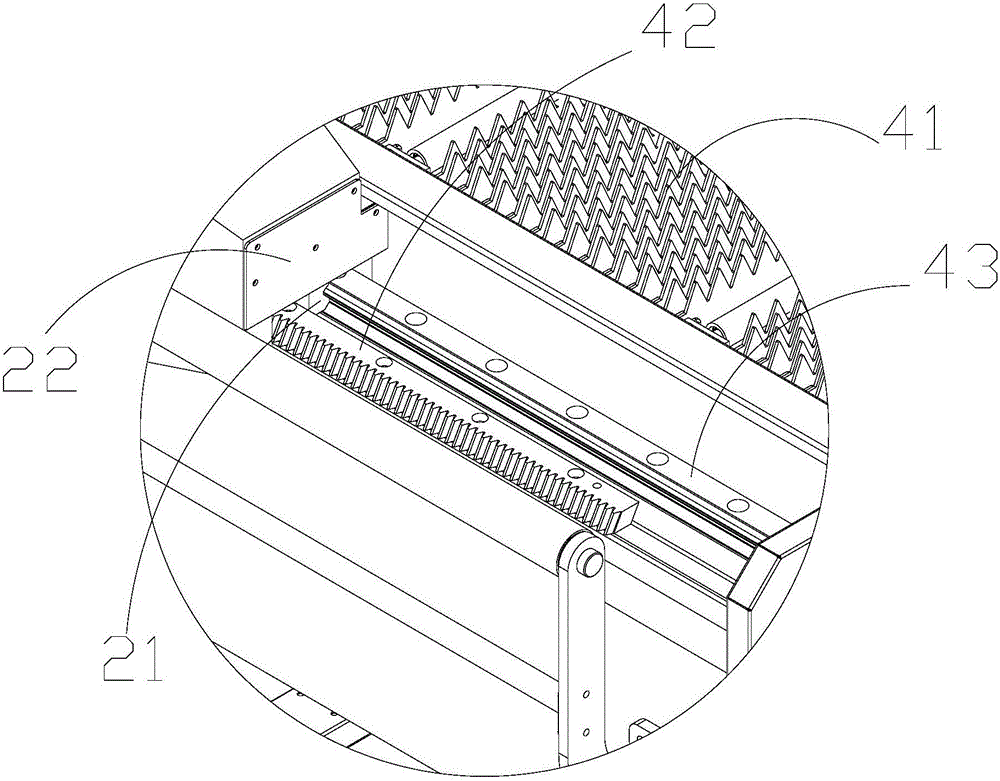

Multi-laser-head laser cutting machine

The invention provides a multi-laser-head laser cutting machine. The multi-laser-head laser cutting machine comprises a workbench, a laser cutting control system, a CO2 laser generator, a CO2 laser power supply, a CO2 laser reflector, at least one non-CO2 laser generator, for example, a fiber laser generator, a multi-laser-head cutting assembly, an X-axis movement assembly, a Y-axis movement assembly, a Z-axis movement assembly, a laser generator cooling system, an object carrying working table, a cutter console, a waste material collecting device and a dust collecting exhaust fan. Two or more than two laser sources are combined on the same laser cutting equipment by the multi-laser-head cutting assembly, so that the cutting processing of composites and the cutting processing of different single materials are realized.

Owner:GUANGZHOU GREAT YEAR LASER TECH CO LTD

Method for producing calcium hypophosphite

The invention relates to the production method of calcium hypophosphite; the production method includes the following technical steps: 1. material preparing which is detailed as follows: deionized water is firstly added in a mixer, unslaked lime powder, the weight of which accounts for 4% of the deionized water, is added under the stirring condition to prepare lime cream, and the lime cream is pumped into a reaction kettle by a pump, ready for use; 2. first neutralization reaction; 3. second neutralization reaction; 4. concentration which is detailed as follows: a vacuum pump of a concentration kettle is started, the filtrate from the second neutralization reaction is pumped into the concentration kettle in virtue of the vacuum in the kettle and is concentrated at vacuum condition after a steam valve is opened; 5. drying and packaging step is detailed as follows: the materials are put in a centrifuge for spin drying when the temperature of the feed liquid in a cooling kettle is below 60 DEG C to obtain the finished product with 92-95% of calcium hypophosphite, then the material is put into a dryer and dried for 20-25 min by the hot air with the temperature of 60-80 DEG C to obtain refined calcium hypophosphite finished product with the content of over 99.0 %. The production method has the advantages of low equipment investment, short process flow and simple production principle. Due to high quality, the finished product produced can be used as food additive, pharmaceuticals and chemical agents.

Owner:江苏和纯化学工业有限公司

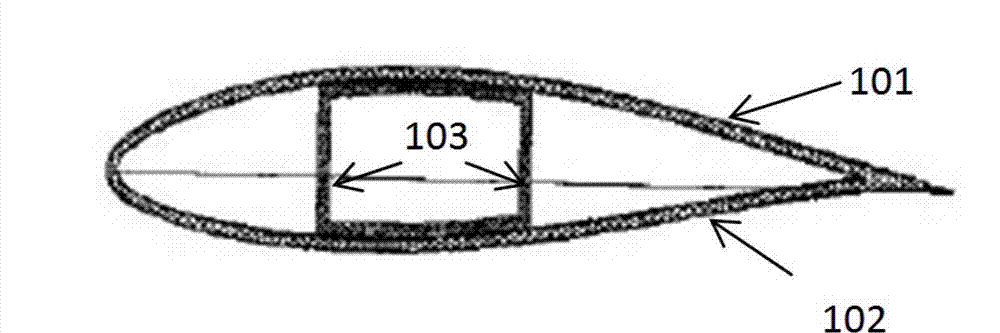

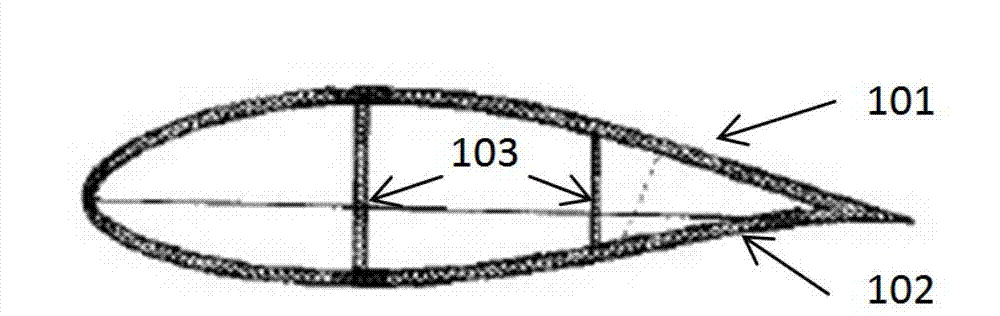

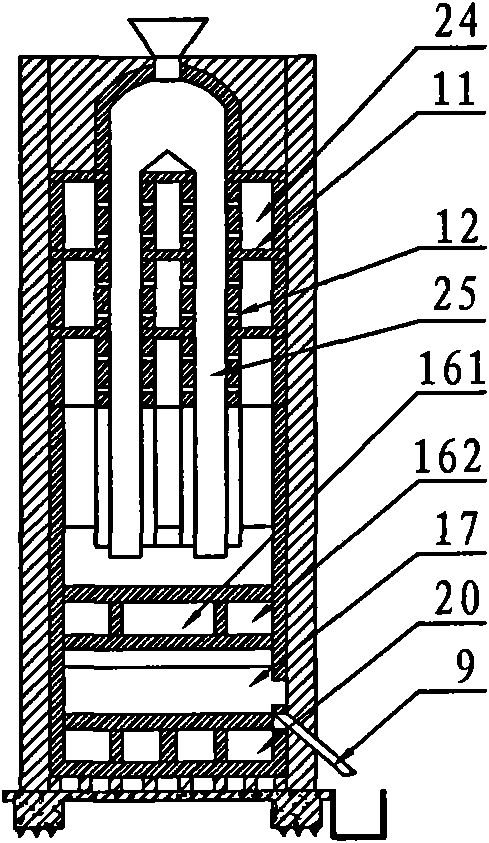

Integrated forming method and device for segmented blade

ActiveCN103042700ASolve the problem of integrated moldingImprove finished product qualityDomestic articlesElectricityPositive pressure

The invention relates to a manufacturing process method for integrated formation of a horizontal shaft segmented wind power blade and an integrated device applicable to the method. The wind power blade at least comprises two segments of composite material blade segments. A metal bolt sleeve is embedded into the connecting part of the two adjacent segments during manufacturing, and integrated formation is realized by a positive pressure auxiliary vacuum perfusion mode, so the defects of the traditional perfusion process are overcome, and the manufacturing problem of the segmented blade is solved. In addition, the integrated formation process avoids various disadvantages and risks caused by that the traditional process shell adopts adhesive to adhere.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

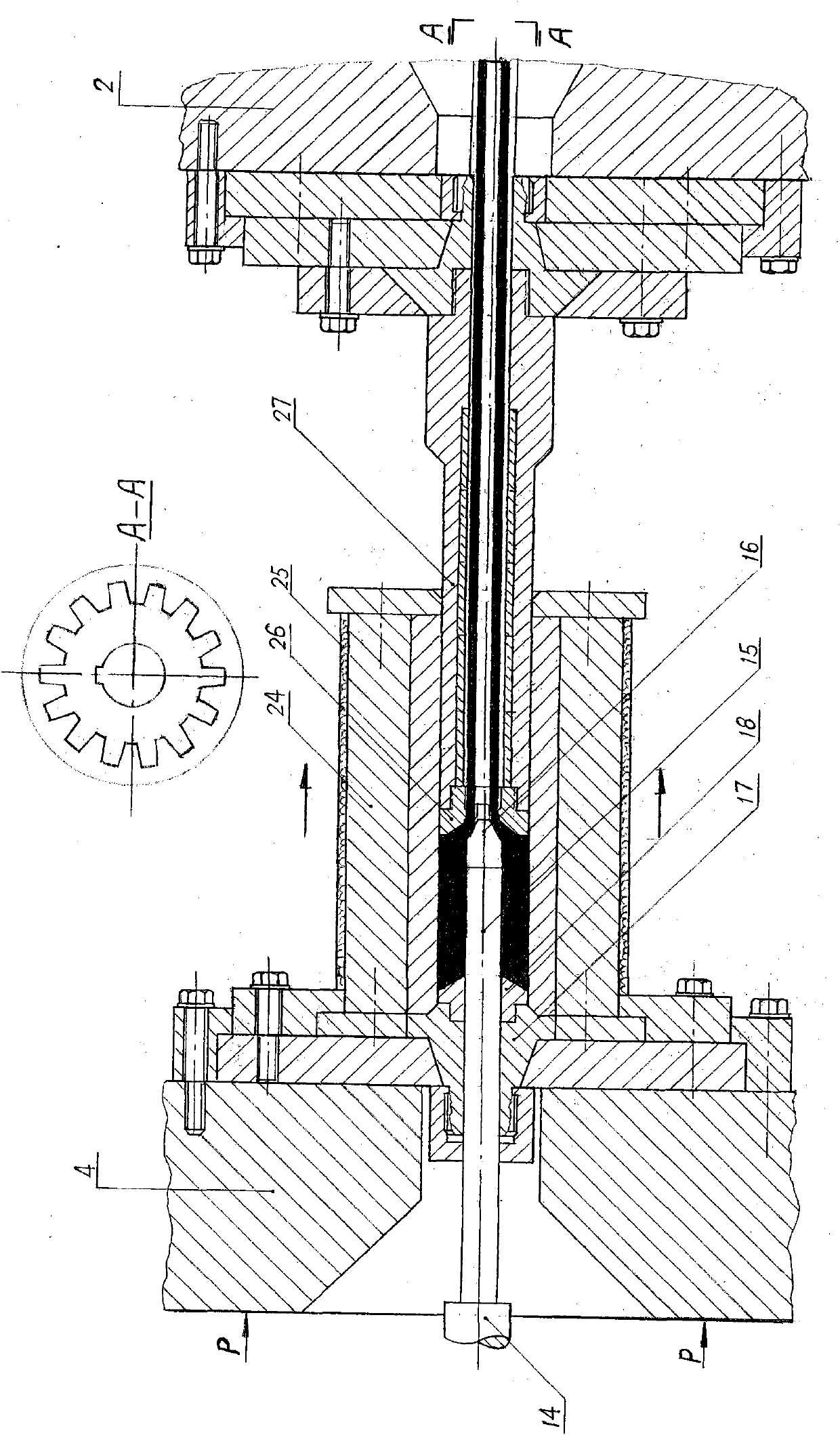

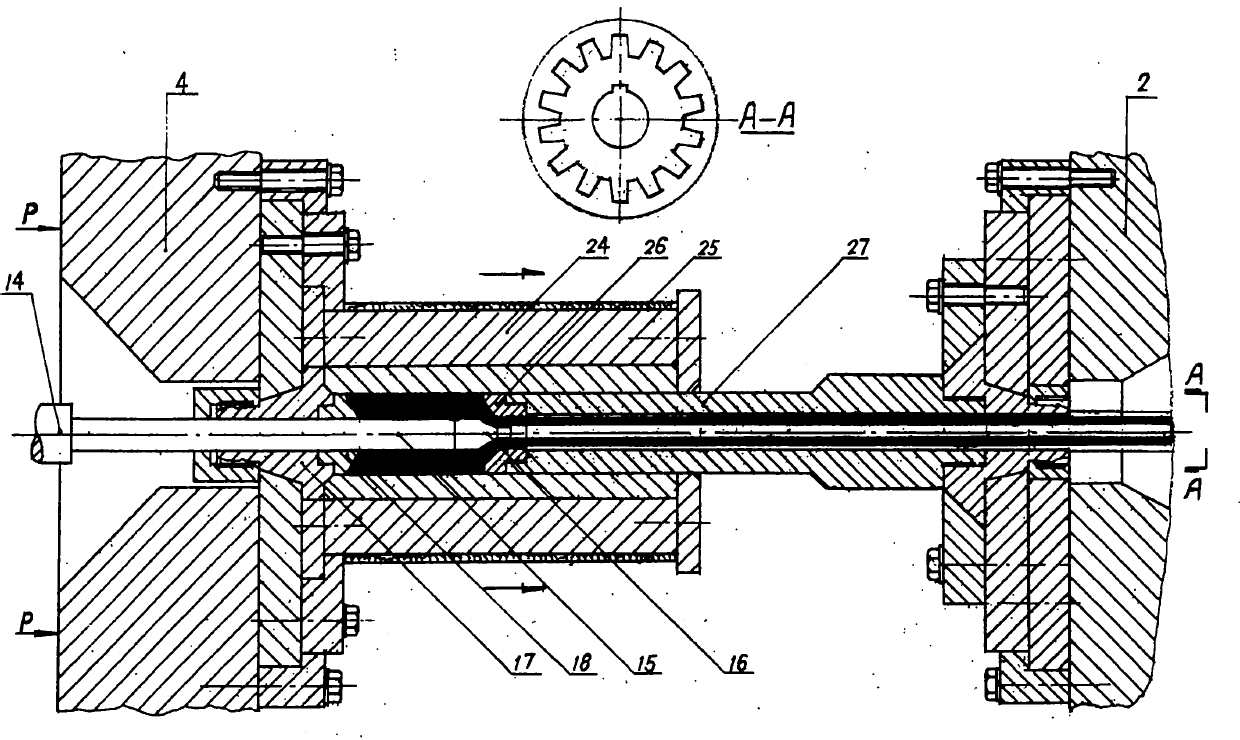

Chipless forming method for gear stick and section gear through hot extrusion

InactiveCN101905250AExtend your lifeImprove plasticityExtrusion diesFurnace typesEngineeringThick wall

The invention discloses a chipless forming method for a gear stick and a section gear through hot extrusion by utilizing an alloy steel horizontal type backward extruder, solving the problems that the existing gear cutting process has more working procedures, low efficiency, large metal loss, more operators for machine tool processing and high production cost and the like by utilizing the chip processes of lathing, milling, drilling, inserting and grinding. The method comprises the following steps: an inner cooling combined type double-conical surface gear squeezing die, a recipient and a floating pecker combined mandril are adopted by taking the producing principle of alloy steel thick wall special seamless steel tubes as an example; scale-free heating is rapidly carried out on the blank; lubricating warm-extrusion molding is carried out; center punching, shaft hole slotting and tooth surface extrusion are finished at a time; and the finished product of the gear stick is directly produced, then is subject to waste heat annealing, slicing by wire-electrode cutting and heating process to be manufactured into a finished product. Compared with a chip gear-cutting molding method, the invention has simplified working procedure, few labor, high efficiency, less metal loss, high gear strengthen and reduces the production cost, and then tooth surface precision reaches the standard. The method of the invention is a significant technological innovation of straight tooth and oblique tooth cylindrical gear process technologies.

Owner:周家镳

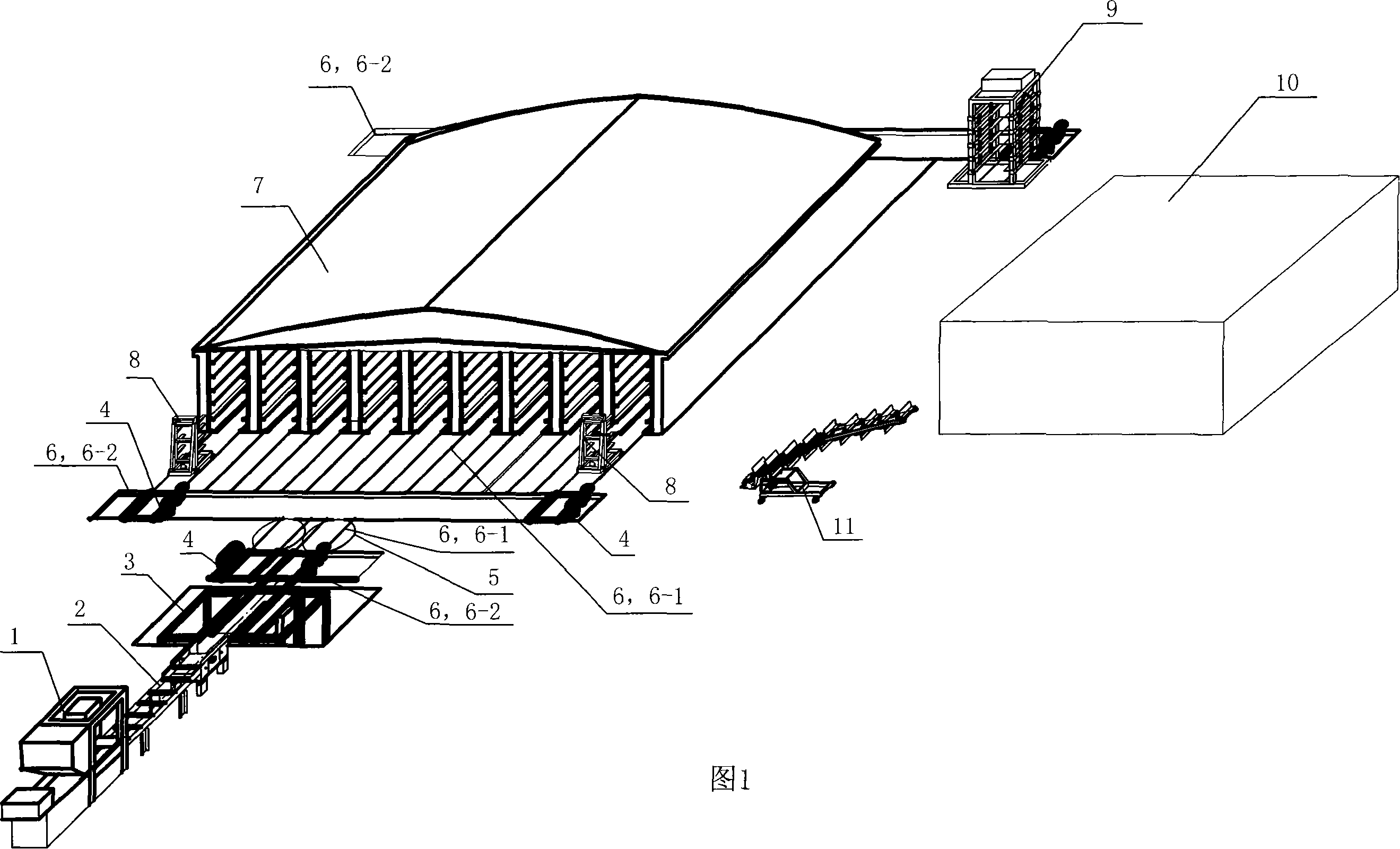

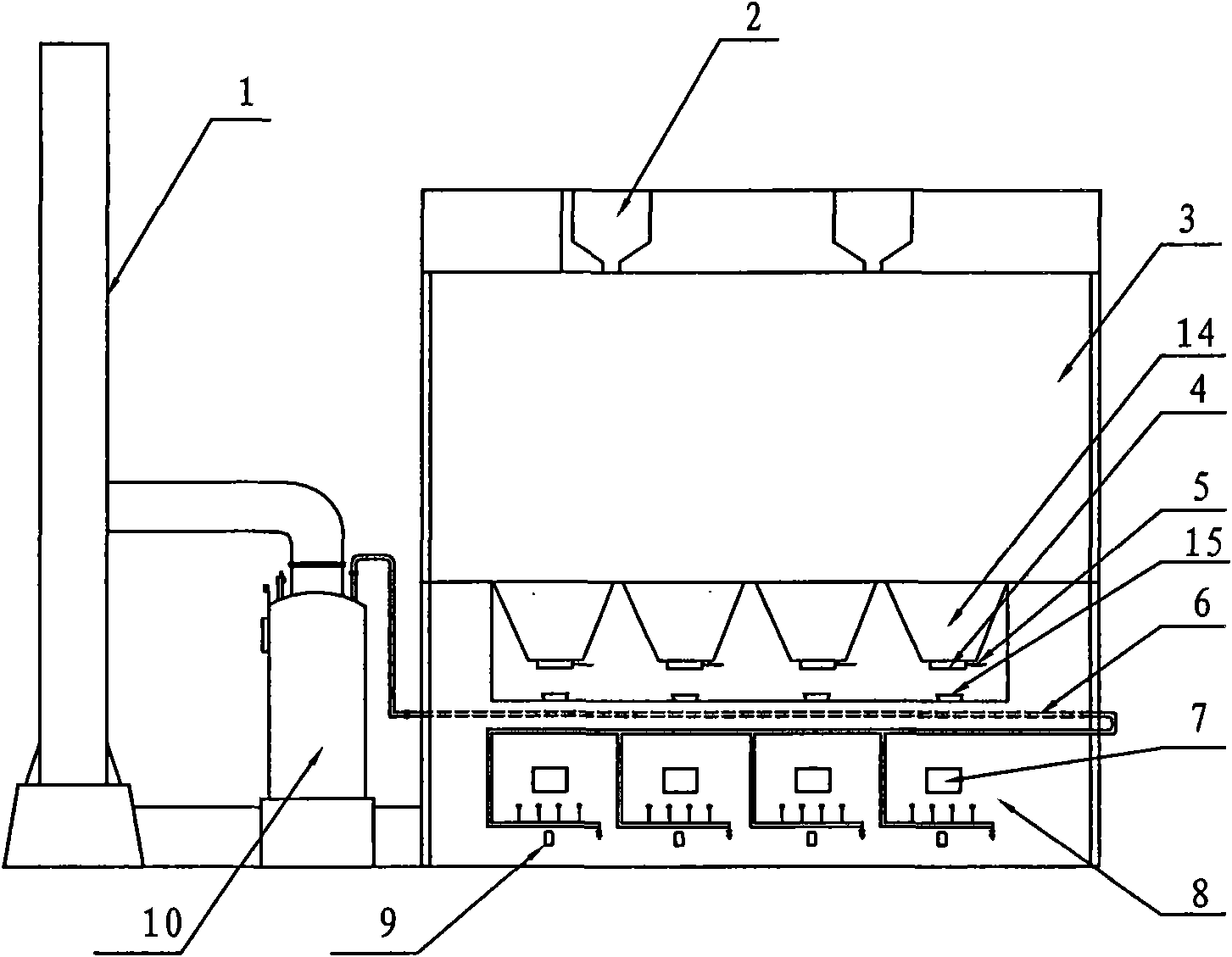

Fully-automatic building block forming machine mechanization production line

InactiveCN101148067ALess investmentSmall footprintDischarging arrangementCeramic shaping plantsEngineeringFully automatic

The semi-automatic mechanized brick producing line with automatic block forming machine includes one board feeding machine connected to one automatic block forming machine and one elevator, one rotary platform following the elevator and with fork lift tracks, one bogie on the bogie tracks perpendicular to the fork lift tracks, fork lift tracks stretching into the curing kiln, and one fork lift on the fork lift tracks and capable of returning to the elevator. The production line of the present invention has less investment, low power consumption, no pollution and other advantages, and is suitable for use in middle sized and small brick making enterprises.

Owner:袁森 +3

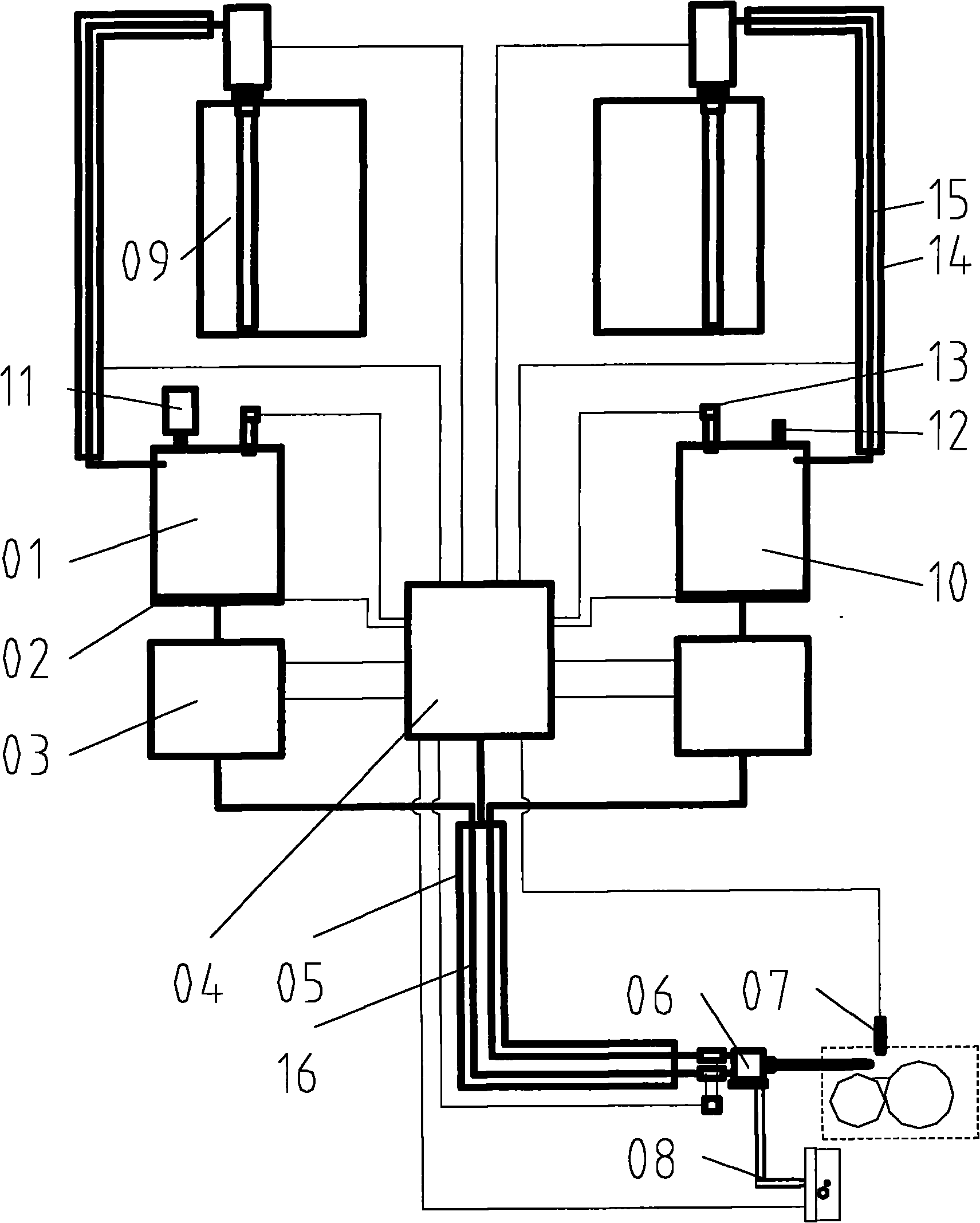

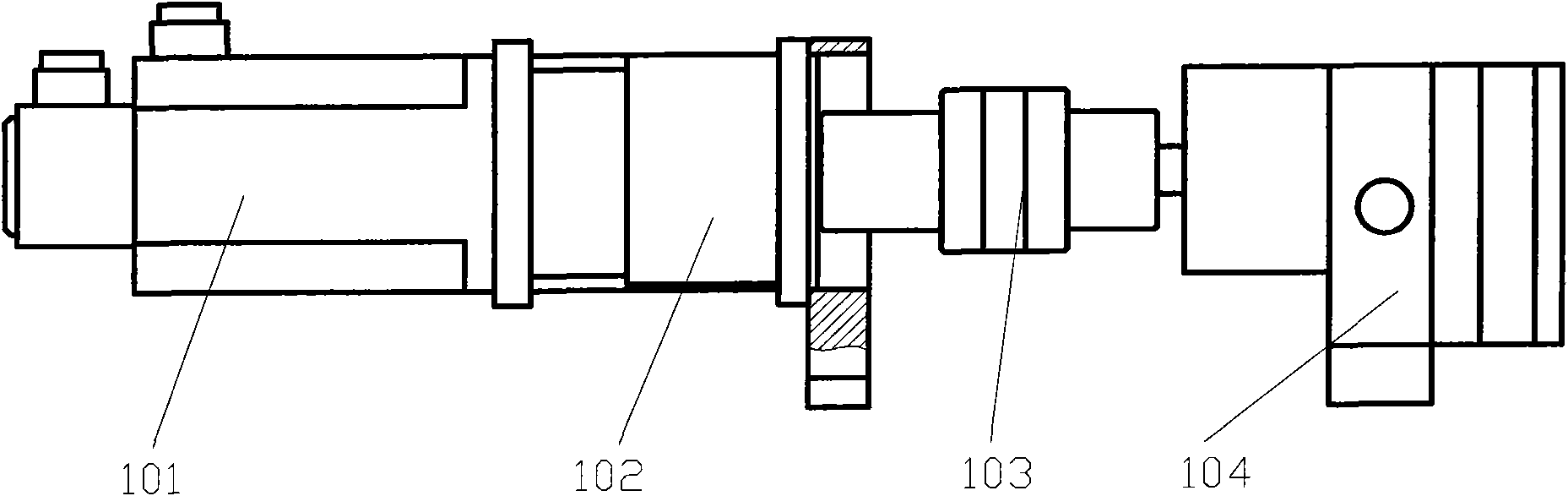

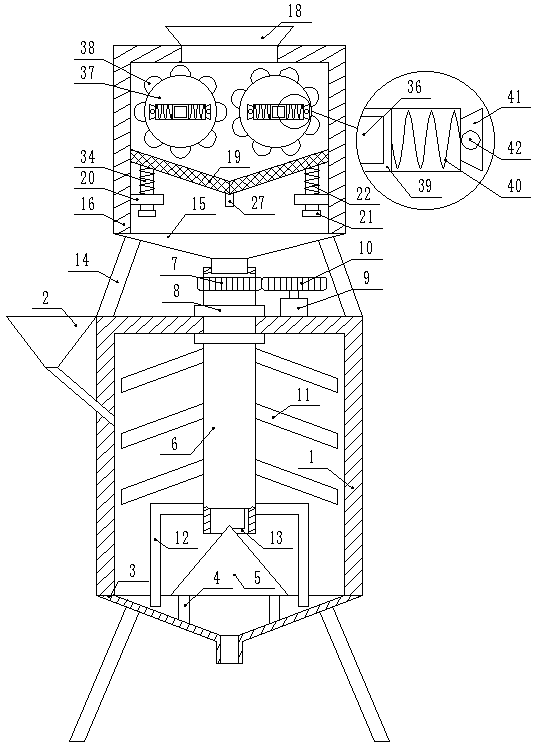

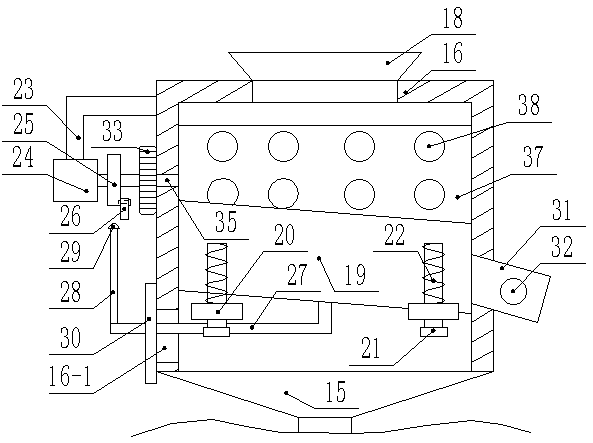

Double-component glue automatic glue mixer

InactiveCN102240514AImprove securityIncrease productivityRotary stirring mixersMixing methodsAutomatic controlReciprocating motion

The invention aims to provide a double-component glue automatic glue mixer with high safety performance, high production efficiency and good finished product quality. The automatic glue mixer comprises a glue storage mechanism, a glue transporting mechanism, a glue mixing mechanism, a reciprocating sizing mechanism, a heating insulation mechanism, a vat glue providing mechanism and a liquid level detection and electric control system. The glue storage mechanism employs a double glue storage barrel sealed structure. The glue transporting mechanism employs a structure of two motors connecting with the electric control system to ensure that an output glue proportion equals to a required glue proportion. The glue mixing mechanism employs a pneumatic performer to control two glues to enter into a mixing tube simultaneously and to mix fully through a double-spiral structured mixing core rod. The reciprocating sizing mechanism employs an automatic back-and-forth reciprocating motion apparatus. The heating insulation mechanism employs a multi-position heating to realize constant temperature of glue during an output process, so that an output proportion is more accurate. The vat glue providing mechanism realizes glue injection into the two glue storage barrels through the electric control system. The liquid level detection and electric control system realizes automatic control on an integral machine operation and controls glue proportion in a digitization approach with accurate proportion; besides the system can provide glue continuously to adapt high-speed automation production. The automatic glue mixer can ensure production efficiency, quality and safety; and compared with prior equipment, the automatic glue mixer is more convenient for operation, has a more reasonable structure and a more beautiful appearance.

Owner:SINOMECH CORP

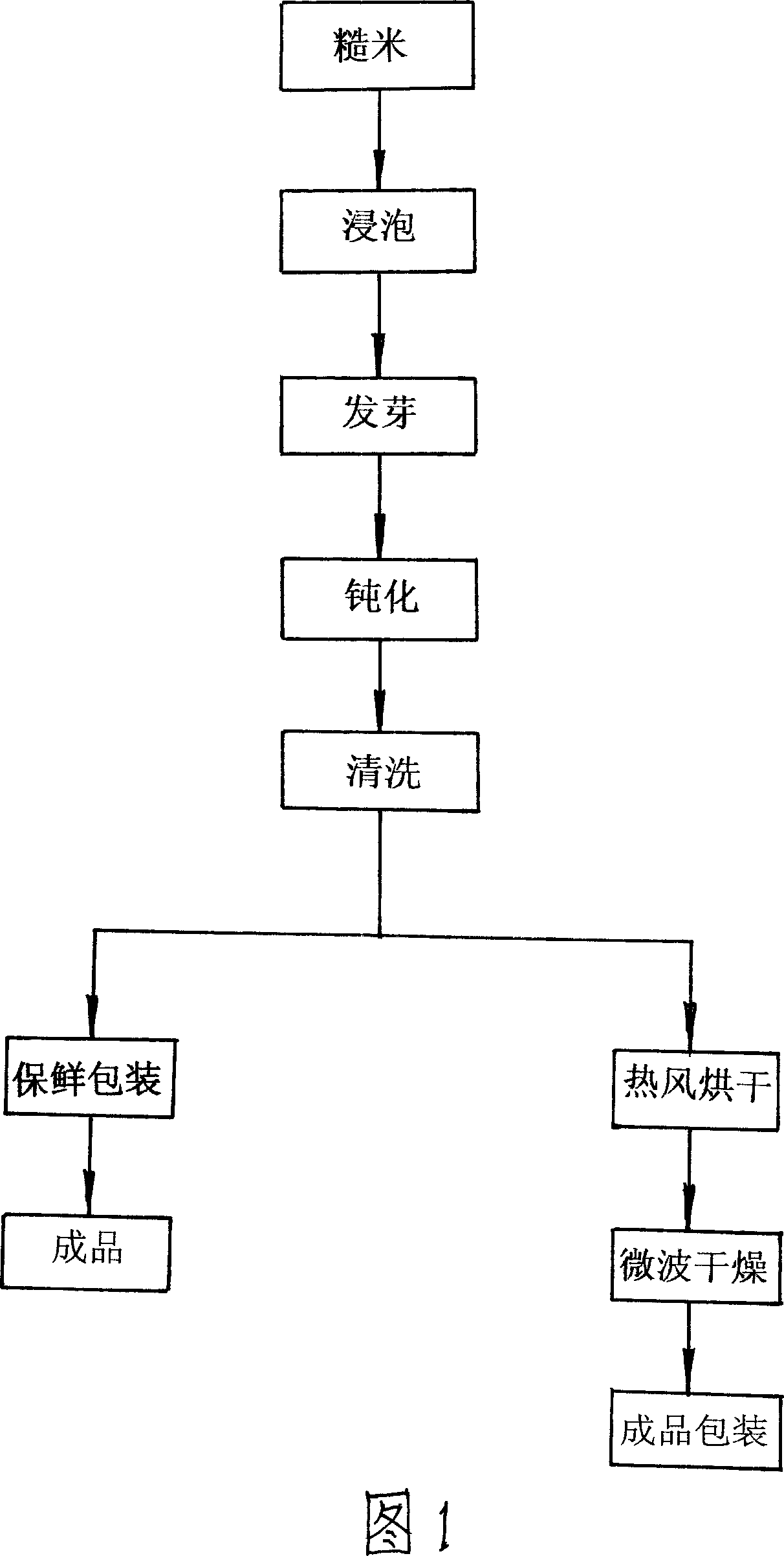

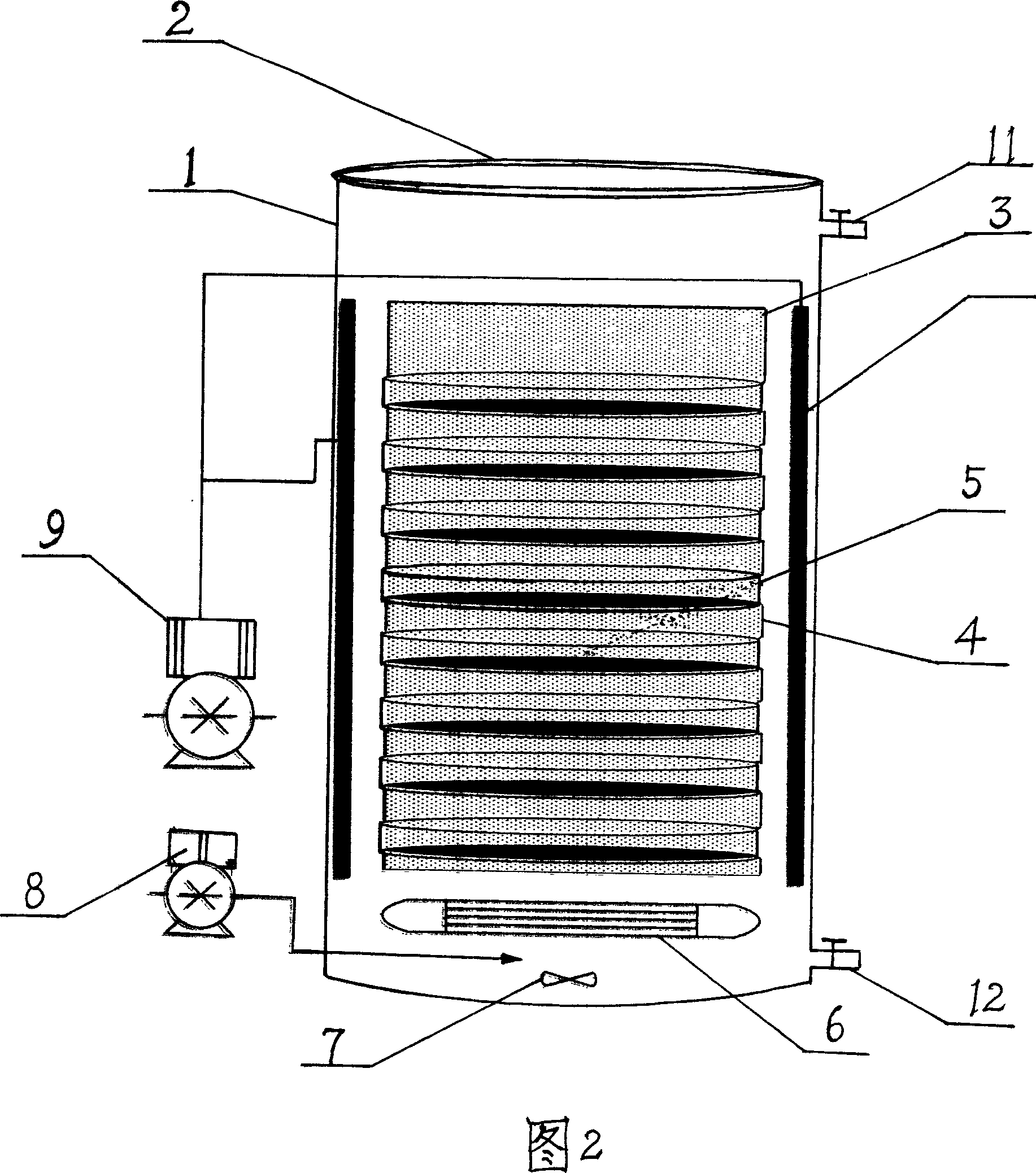

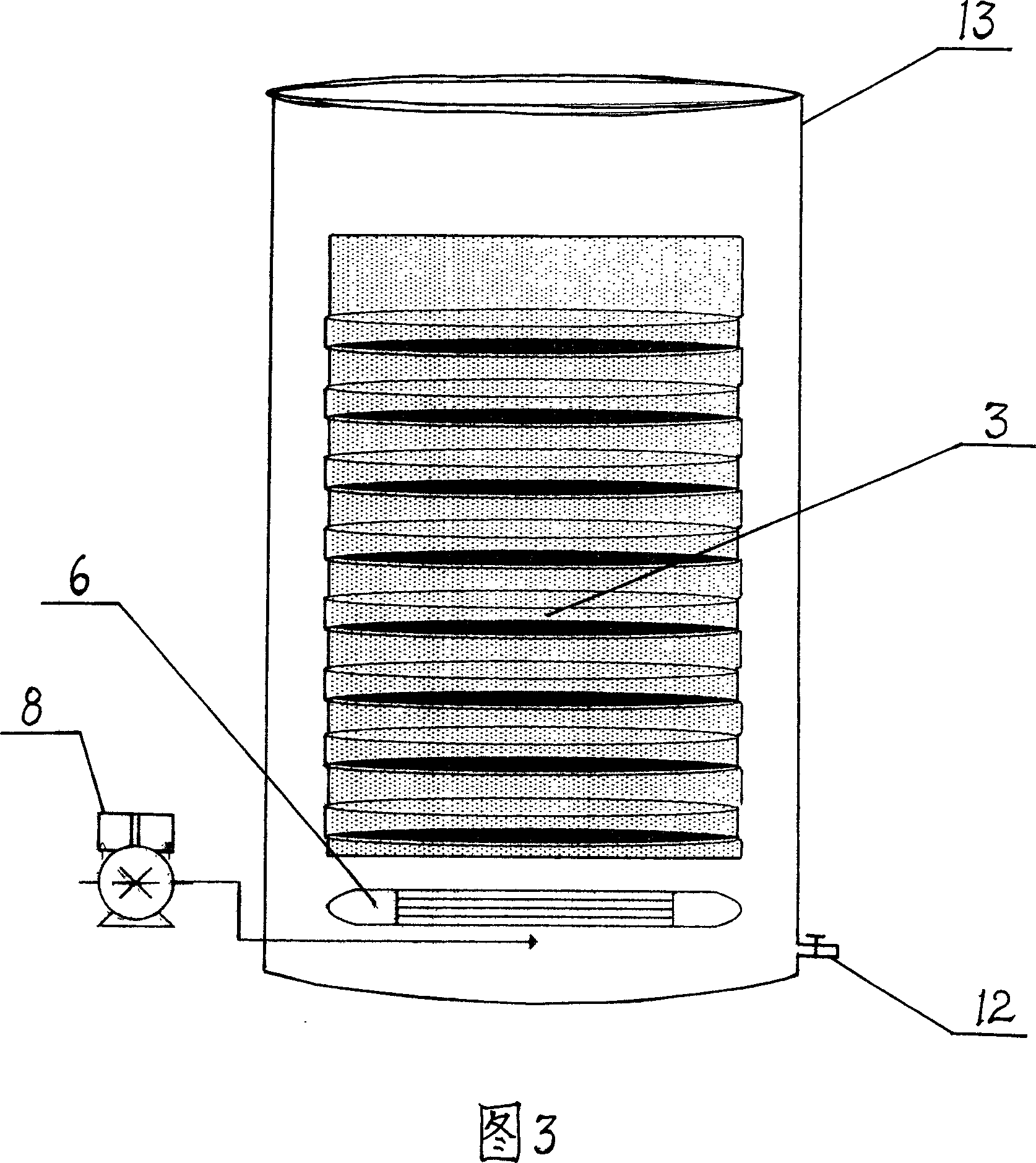

Method and equipment for producing sprouting half-polished rice

ActiveCN100998389AImprove whole bud rateHigh whole germination rateSeed preservation by heatingSeed preservation by dryingMicrowaveThin layer

A method for preparing the germinated embryo rice from non-glutinous rice includes such steps as spreading said rice to become thin layer, immersing in water, germinating, passivating in the water at 70-100 deg.C, washing, and antistaling packing or drying including hot air baking and microwave drying. Its apparatus is composed of container with openable cover or door, and rice spreading unit.

Owner:杨春华

Preparation method of water-based coating for lost foam casting

The invention discloses a preparation method of a water-based coating for lost foam casting. A coating prepared by the preparation method has excellent performances, good suspensibility, thixotropy and permeability, and high surface strength. The preparation method overcomes the defects that refractory powder adopted by the conventional casting coating preparation technology is very expensive and a coating production cost of the conventional casting coating preparation technology is high. A casting coating obtained by the preparation method is smooth and has appropriate viscosity. Through the preparation method, a high-quality casting coating can be prepared from cheap raw materials through simple production processes. Therefore, the preparation method reduces a coating production cost and realizes good finished product quality.

Owner:南通江海港建设工程有限公司

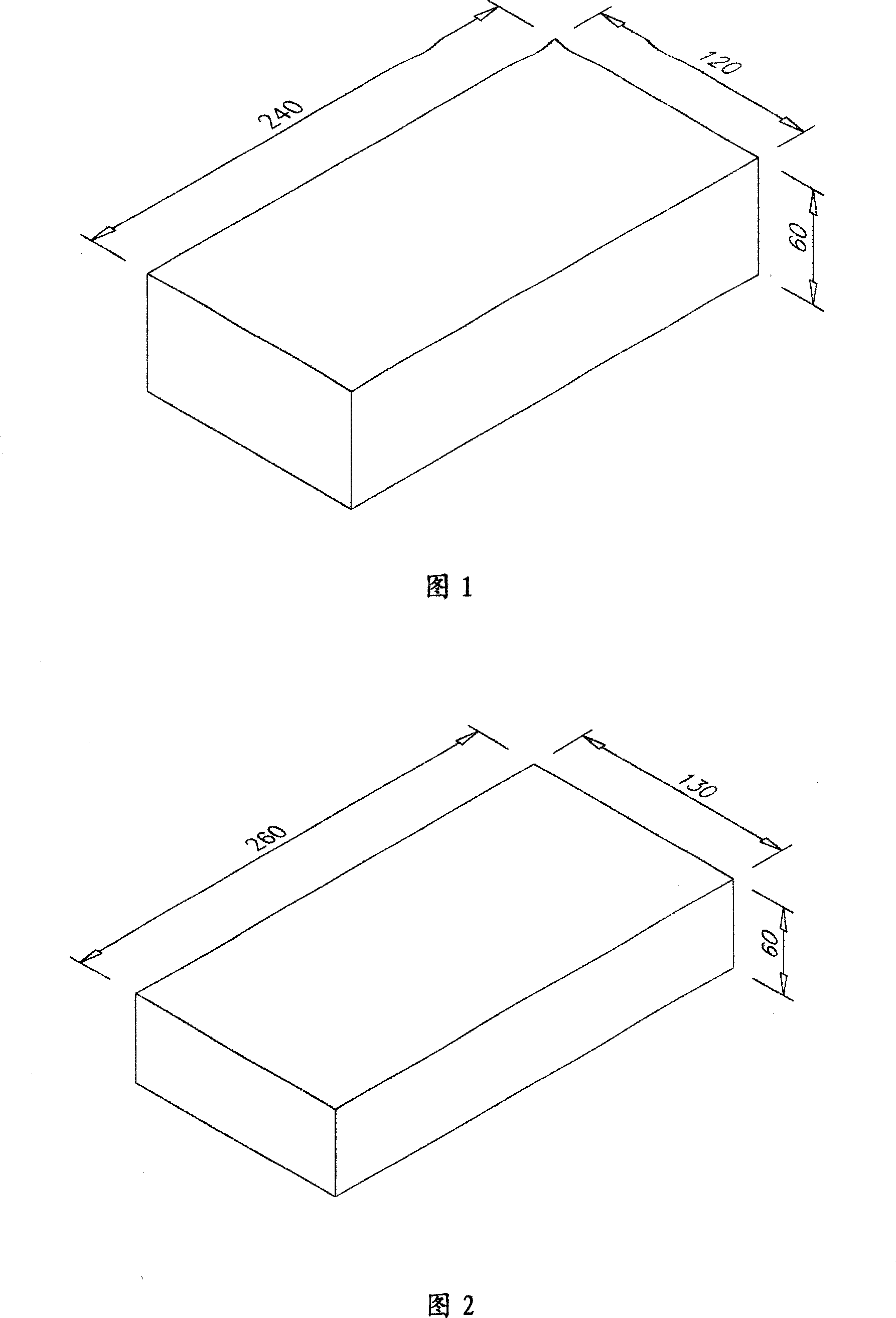

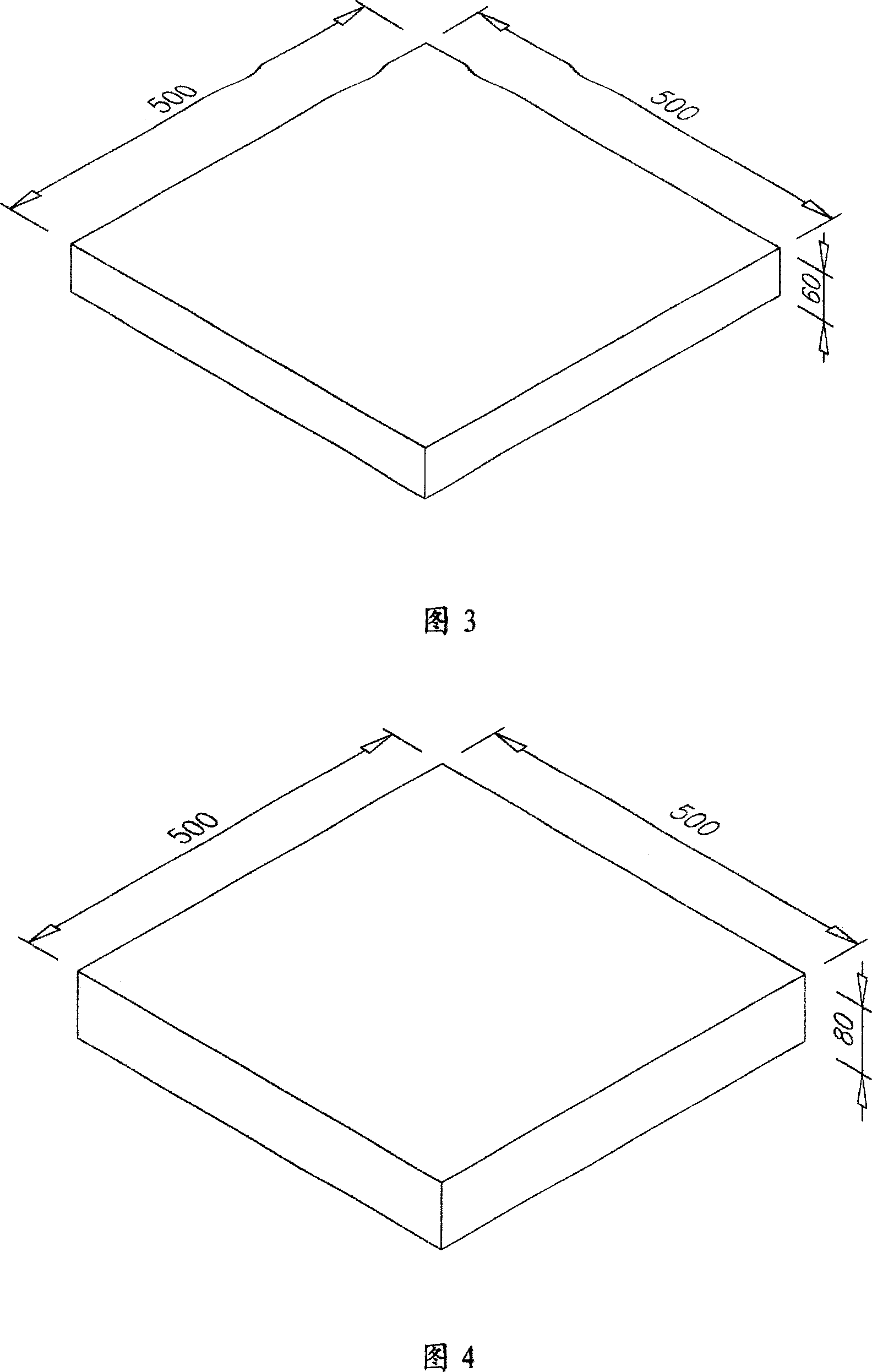

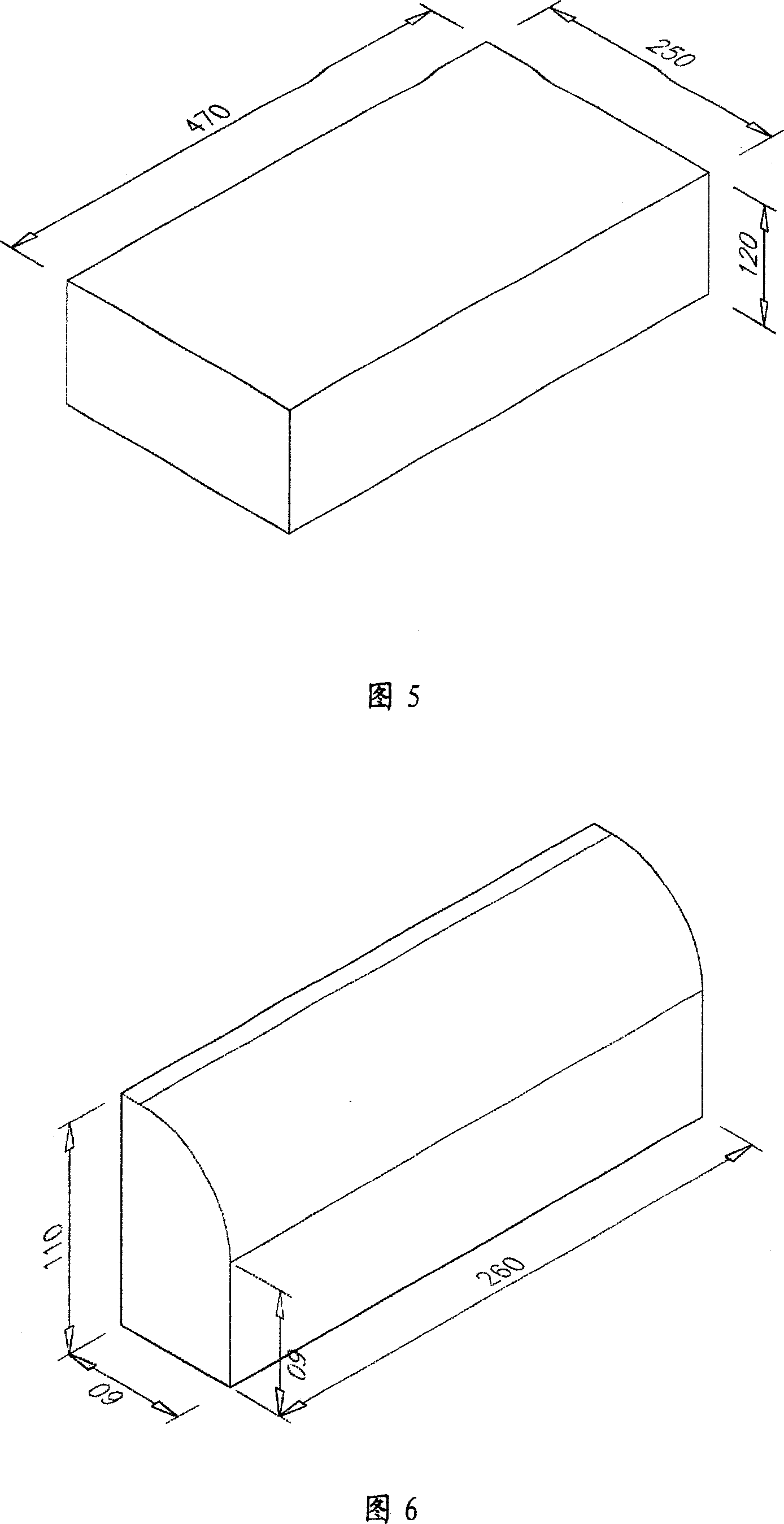

Machine-made archaized blue bricks

InactiveCN101003154ASolve processing problemsAvoid pollutionMixing operation control apparatusCeramic shaping apparatusBrickLitter

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

Method for producing active carbon

The invention discloses a method for producing active carbon, comprising the following steps: grinding corn cobs and cornstalks into flocculent corn cob materials and flocculent cornstalk materials bya grinder respectively, evenly mixing and then sending the materials into a particle forming machine to be extruded into particle materials; placing the particle materials into a carbonization kiln to be carbonized to obtain carbonized materials; directly sending the carbonized materials into an activation kiln to be activated without cooling to obtain activated materials; grinding and grading the activated materials to obtain the finished product of active carbon. Wood gas discharged from the flue of the carbonization kiln is introduced into a heating chamber on the lower part of an activation chamber to be ignited for heating the activation kiln; high temperature flue gases generated by combustion of the wood gas are introduced into the flue on the upper part of the activation chamber for carrying out secondary heating on the activation kiln; the flue gases discharged from the flue on the upper part of the activation chamber are introduced out to serve as the heat sources of a steamboiler, and the high temperature steam generated by the steam boiler enters the activation chamber to activate the carbonized materials. The active carbon produced by the method is good in quality and low in cost.

Owner:XIFENG DENGYUN JIEGAN COMPREHENSIVE UTILIZATION DEV

Chicken flavor seasoning and its preparation method

The invention provides a chicken flavor seasoning and its preparation method. The chicken flavor seasoning is prepared by the following raw materials of: by weight, 5-15% of a dry chicken powder, 2-5% of refined chicken oil, 3-10% of a chicken bone extract product, 3-10% of a chicken extract product, 0.3-0.8% of disodium 5'-ribonucleotide, 20-40% of salt, 5-10% of a granulated sugar powder, 3-10%of glucose, 0.1-0.3% of a turmeric powder, 0.5-2% of ginger juice, 0.5-2% of shallot juice, 1-2% of an onion powder, 0.1-1% of a white pepper powder, 3-10% of glutamic acid, 2-10% of maltodextrin, and 0.5-1% of an anticaking agent. The above raw materials are mixed, dried and crushed to obtain the chicken flavor seasoning which has a strong and natural taste and is a strong cooking seasoning. Thechicken flavor seasoning is simple to prepare; the production period is short; and the finished product has high quality, and is convenient and fast to store and use.

Owner:TIANJIN CHUNFA BIO TECH GRP

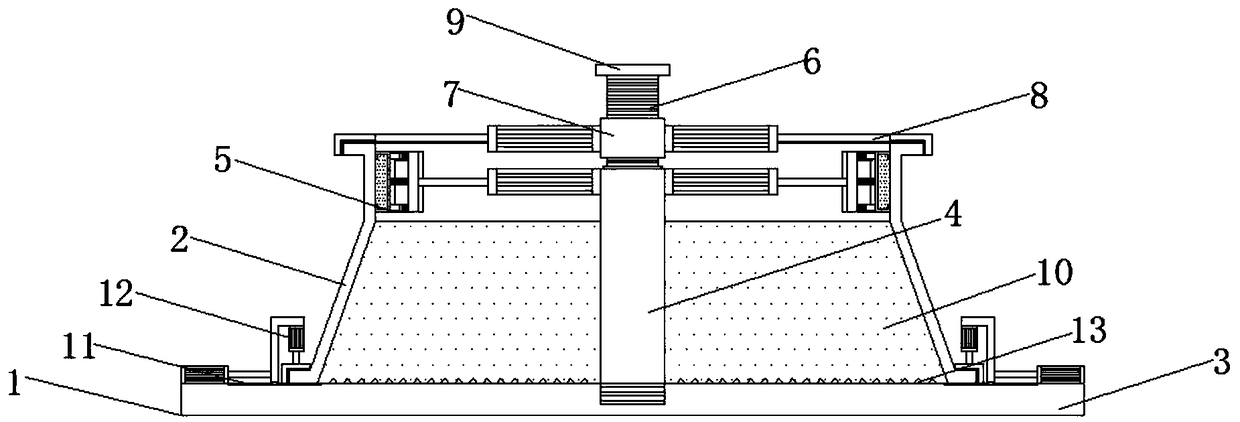

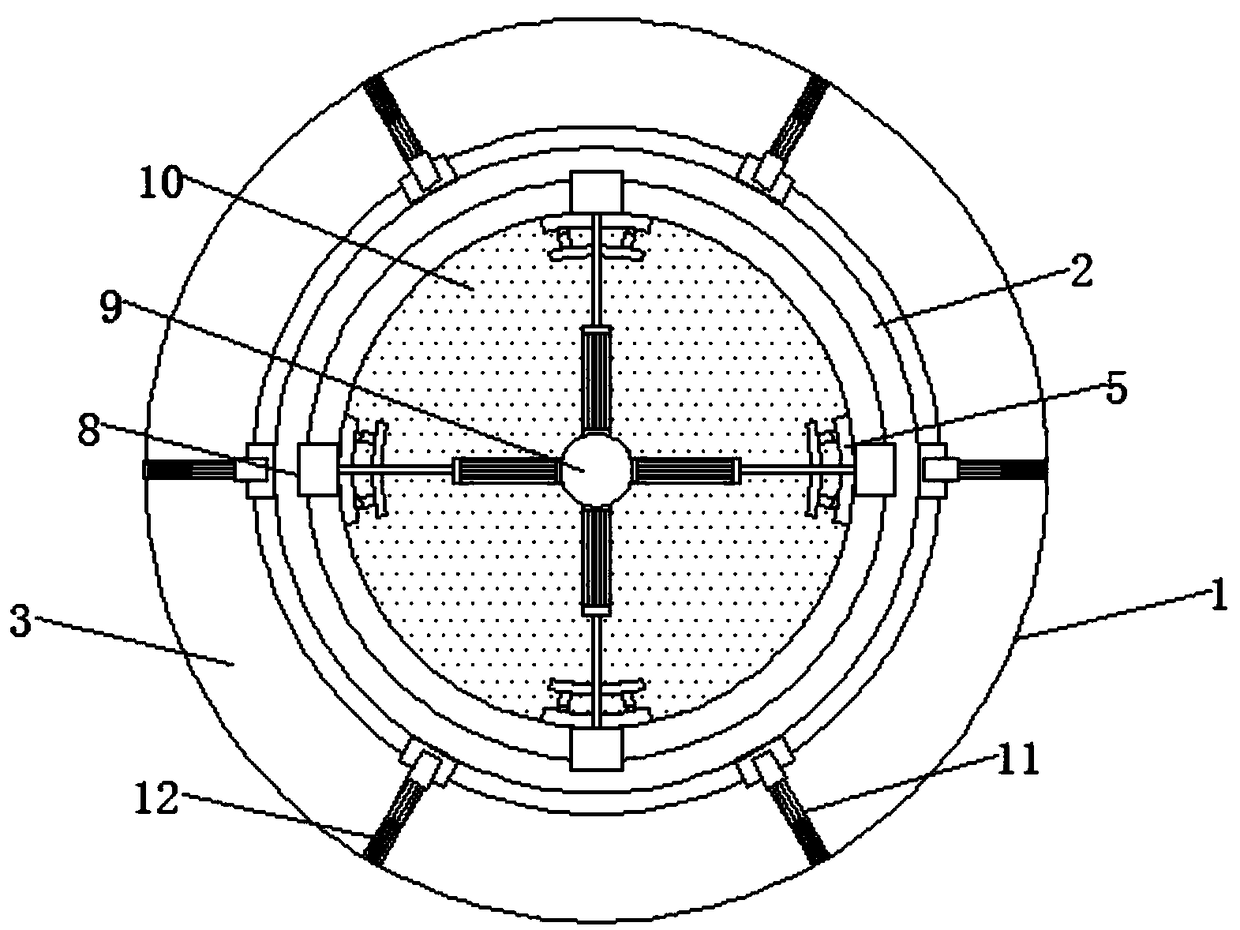

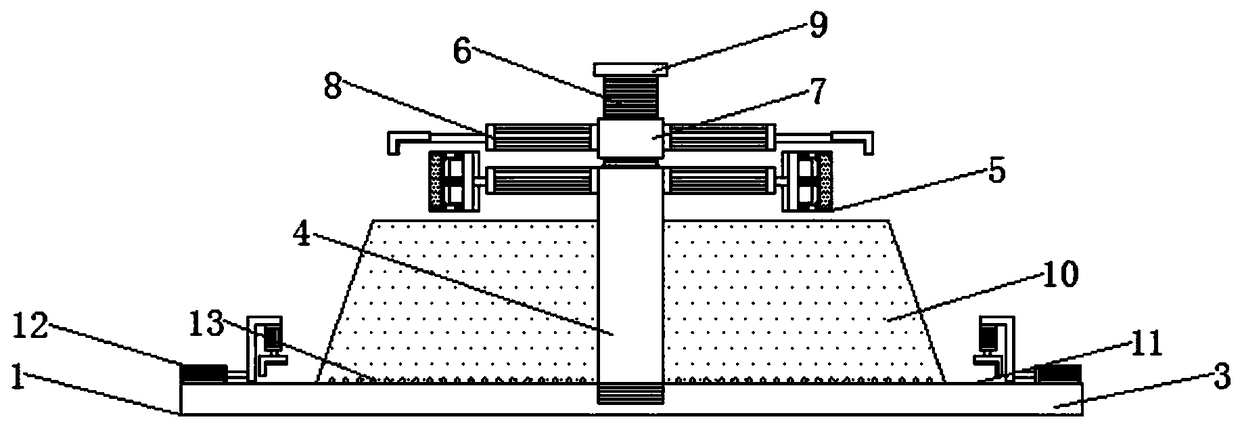

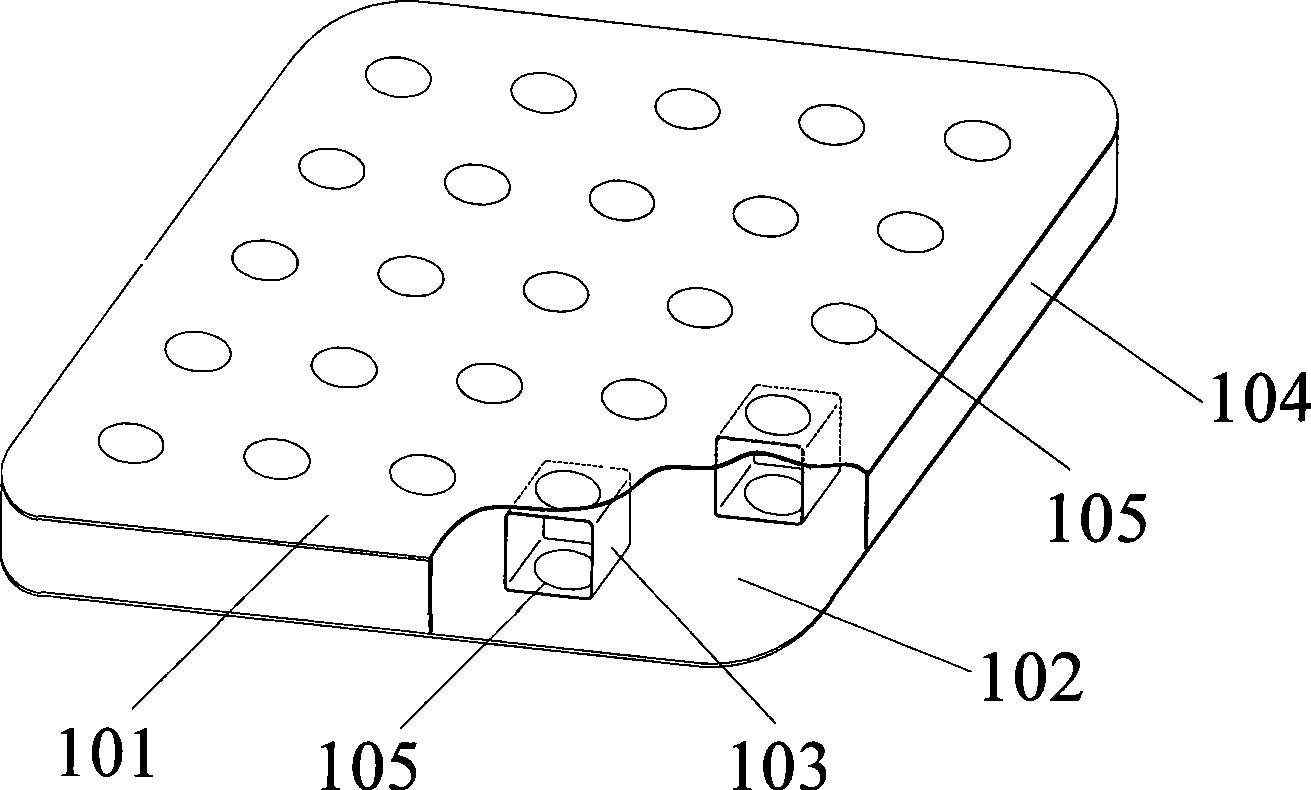

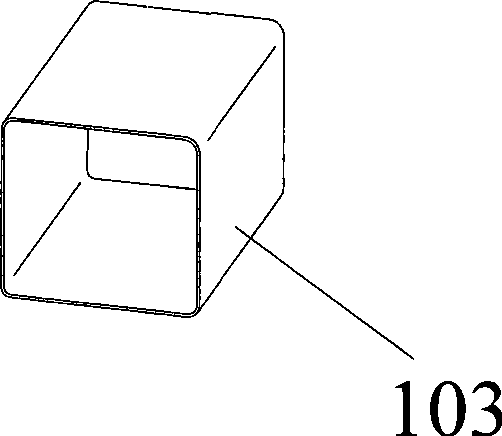

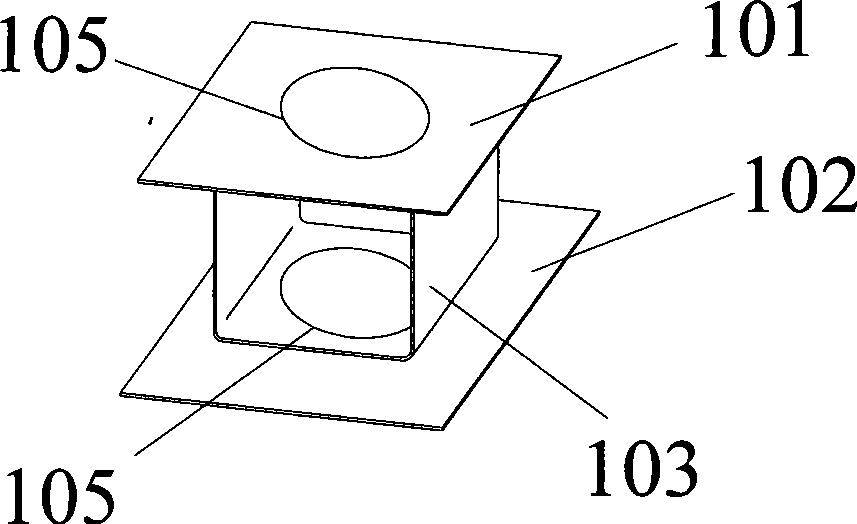

Precision hole processing equipment for thin-wall casing type part

ActiveCN109128904AAchieve fixationAvoid fixationPositioning apparatusMetal-working holdersEngineeringInternal Fixators

The invention discloses precision hole processing equipment for a thin-wall casing type part. An equipment body is installed on the outer side of the casing type part, a base is arranged on the bottomof the equipment body, a vertical rod is installed on the middle of the base, internal fixators are installed on the circumference of the top end of the vertical rod, a screw rod is installed on thetop of the vertical rod, and a convex edge is arranged at the top end of the screw rod. A sliding sleeve is arranged on the outer side of the screw rod in a sleeving mode, top fixators are installed on the circumference of the sliding sleeve, and bottom fixators are installed on the outer side of the base. According to the precision hole processing equipment for the thin-wall casing type part, thescrew rod and the sliding sleeve are cooperatively used, the sliding sleeve can drive the top fixators to move up and down on the screw rod, the top end of the casing part is fixed and prevented frommoving in the vertical direction, meanwhile, flexible adjustment can be carried out according to parts with different heights, simplification and practicality are achieved, and the application rangeof the equipment body is expanded.

Owner:贵州欣宇泰科精密科技有限公司

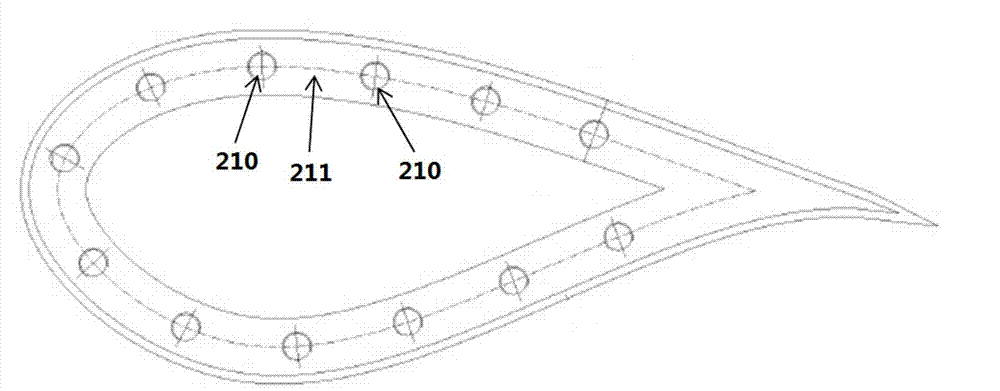

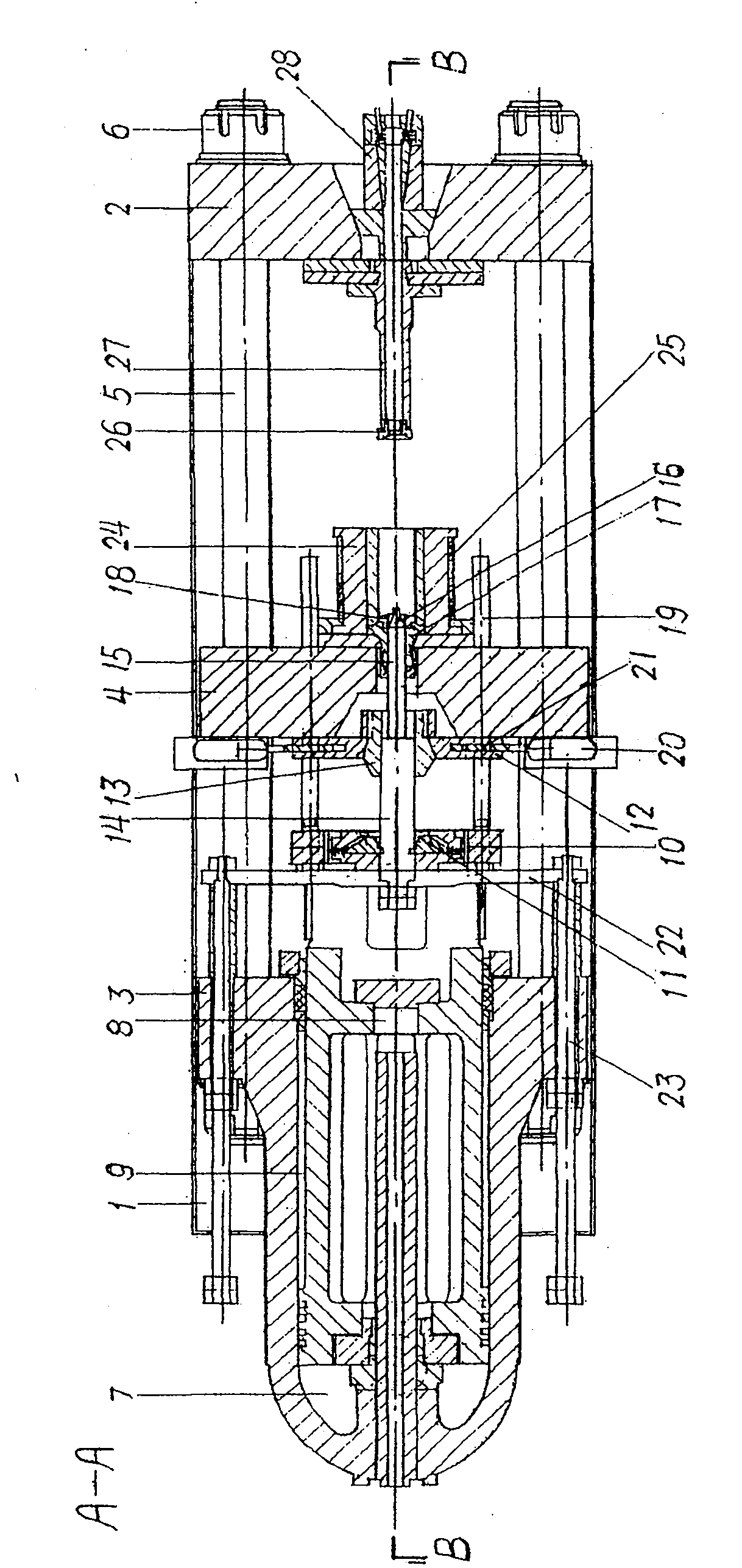

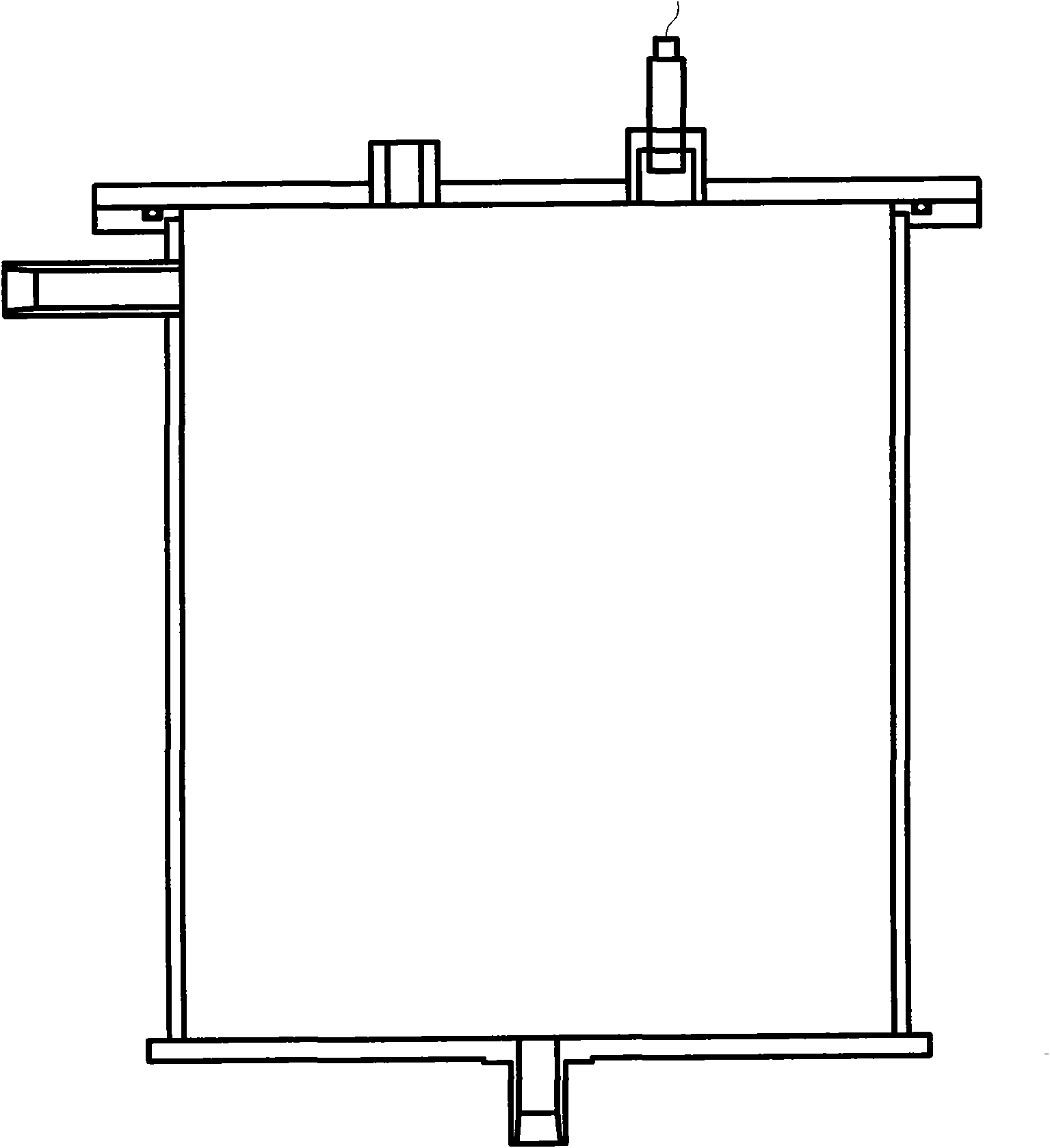

Fusion splicing technological process and equipment for hollow drawstring of air bed body

InactiveCN101439583AEasy to operateShort processing timeFluid mattressesDomestic articlesEngineeringFusion splicing

The invention discloses a heat-sealing technique for an airbed hole drawstring, comprising the following steps: (A) a plurality of hole drawstrings are positioned between the upper piece and the lower piece of a bed body in a certain position and in a certain arrangement mode; (B) lower heat transmission moulds are positioned at the bottom surface of the lower piece of the bed body and corresponding to hole drawstrings; upper heat transmission moulds are positioned at the superface of the upper piece of the bed body and corresponding to the hole drawstrings; the upper heat transmission moulds and the lower transmission moulds are clamped so that the upper piece and the lower piece of the bed body are tightly against each other; (C) a power supply is started to heat the upper heat transmission moulds and the lower heat transmission moulds; the upper heat transmission moulds heat-seal the upper piece and the hole drawstrings on the superface and the lower heat transmission moulds heat-seal the lower piece and the hole drawstring from the bottom surface; (D) the upper heat transmission moulds and the lower heat transmission moulds are separated and the bed body is taken out. The invention heat-seals the bed body and the hole drawstrings outside the bed body, thereby having the advantages of clear weld mark decorative patterns on the finished products, steady heat-sealing quality and fixed hole drawstring intervals. Meanwhile, the invention discloses heat-sealing equipment for the airbed hole drawstrings with high production efficiency.

Owner:ZHONGSHAN ZHANXIN PLASTIC PROD

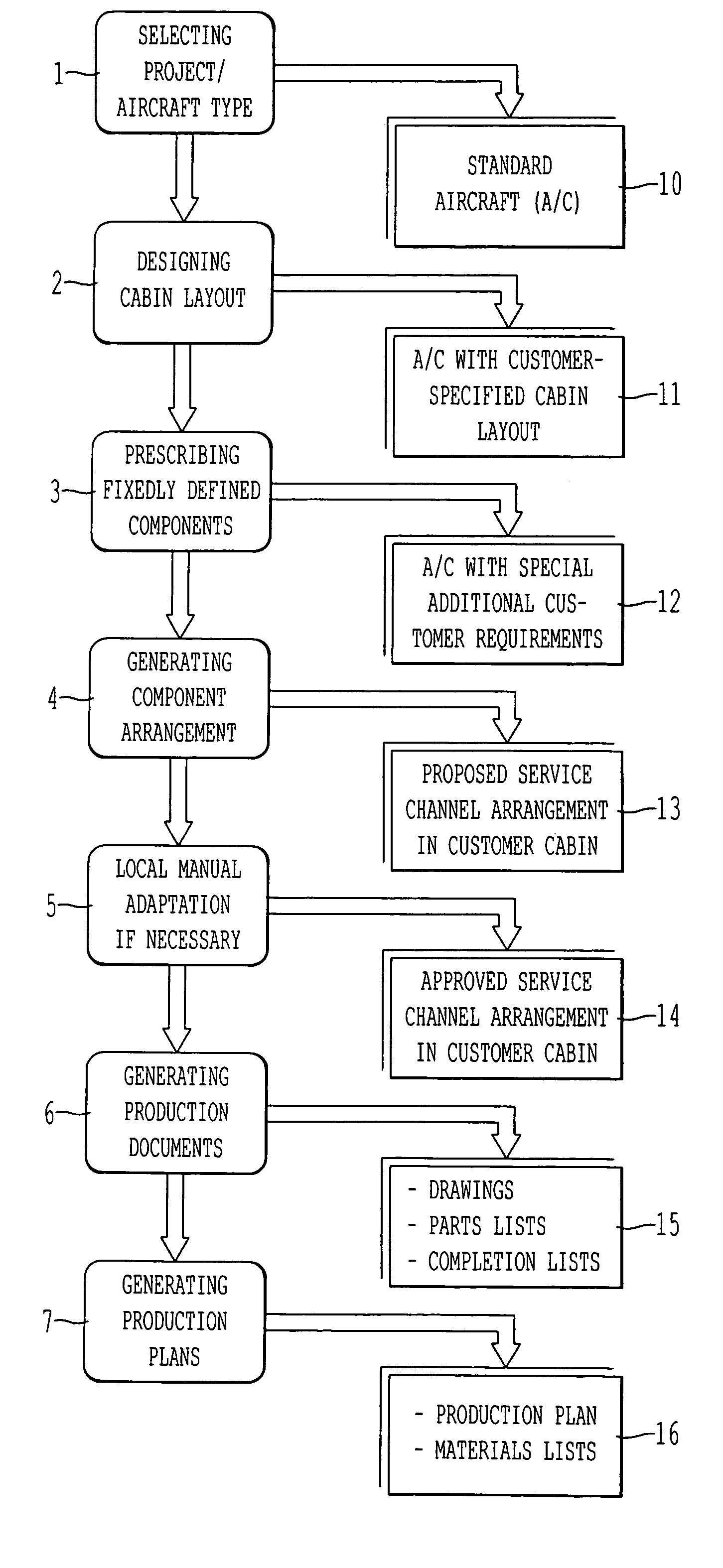

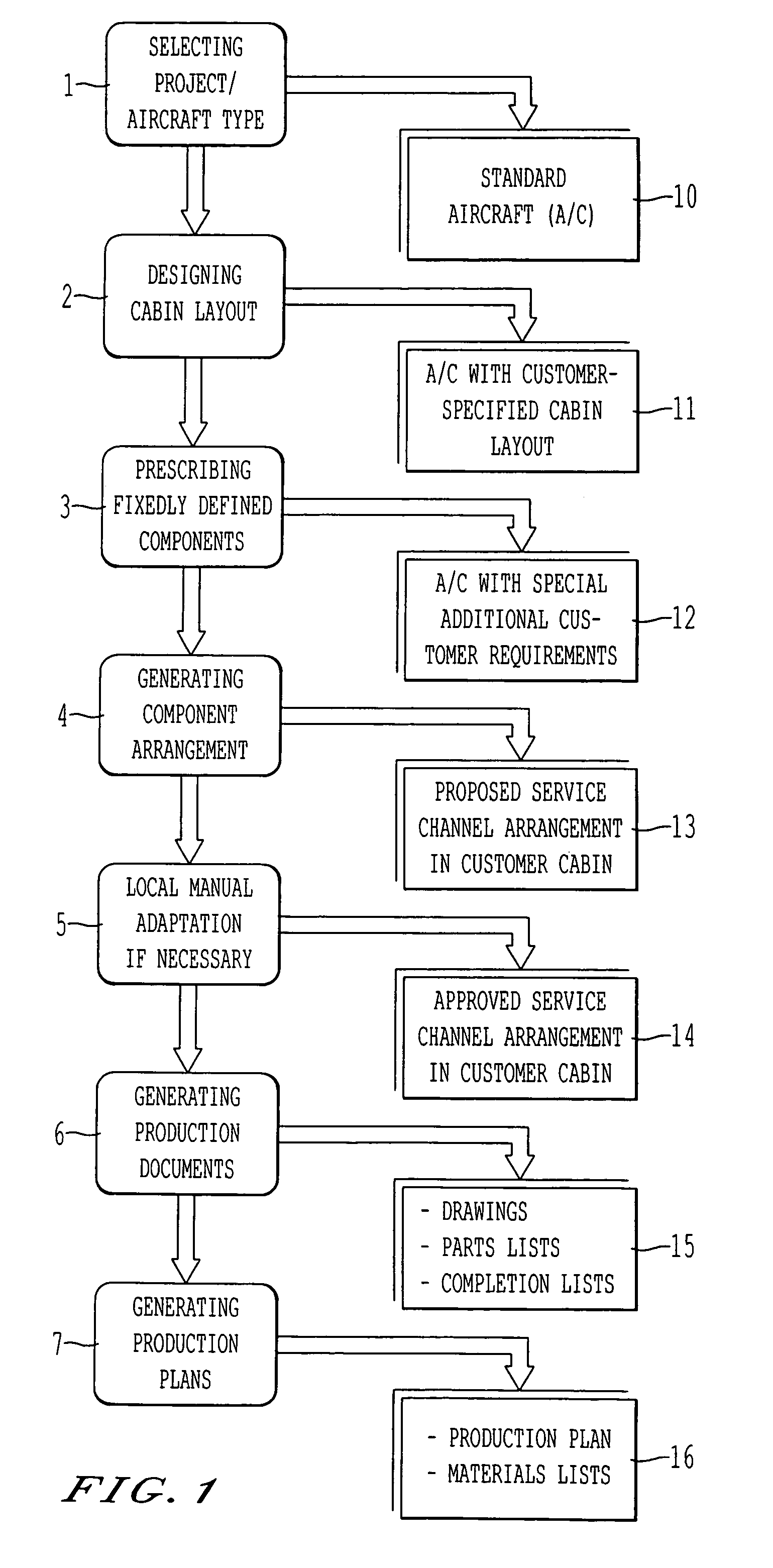

System for automatically configuring arrangements of components and automatically generating production documents

InactiveUS6968298B2Reduce the burden onEasy to investigateGeometric CADProgramme controlData processing systemCustomer requirements

A system for automatically defining the spatial arrangement of structural components and optimizing the functional positions and / or quantities thereof is useful for design and production of an aircraft cabin. The basic aircraft type is input into a configuration tool of a data processing system. The aircraft-specific geometry is stored in, loaded from and represented by a drawing module of the system. The required components are geometrically defined by stored data and position rules, and are combined with the aircraft-specific geometry in the drawing module. The components and the aircraft-specific geometry are spatially optimally configured relative to each other according to a rule set which accounts for specific customer requirements, in the configuration tool. Production documents such as drawings and parts lists are automatically generated by a document generating tool of the system after inputting project-related data.

Owner:AIRBUS OPERATIONS GMBH

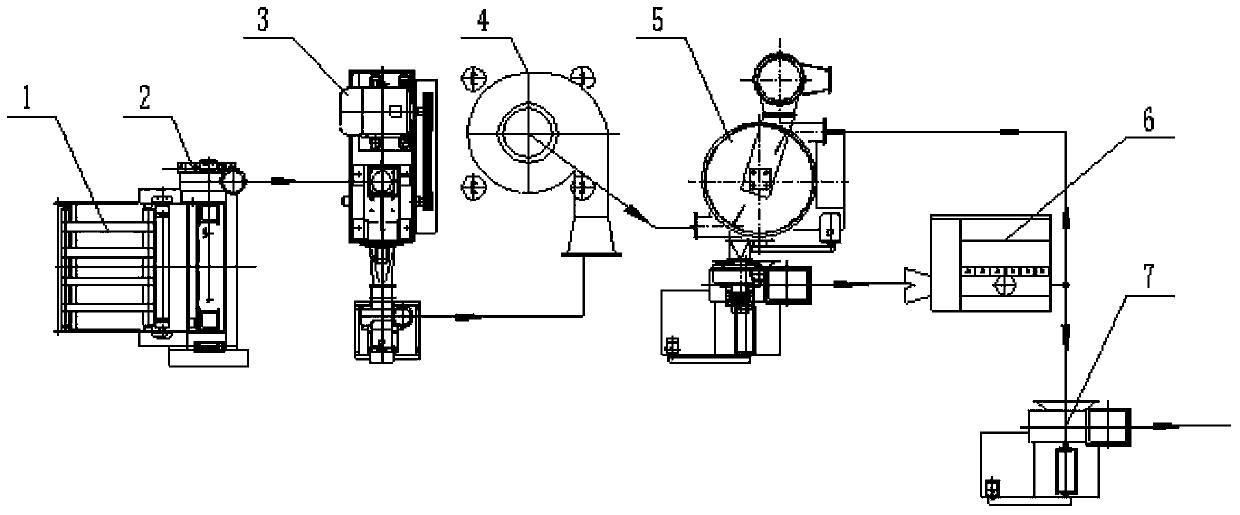

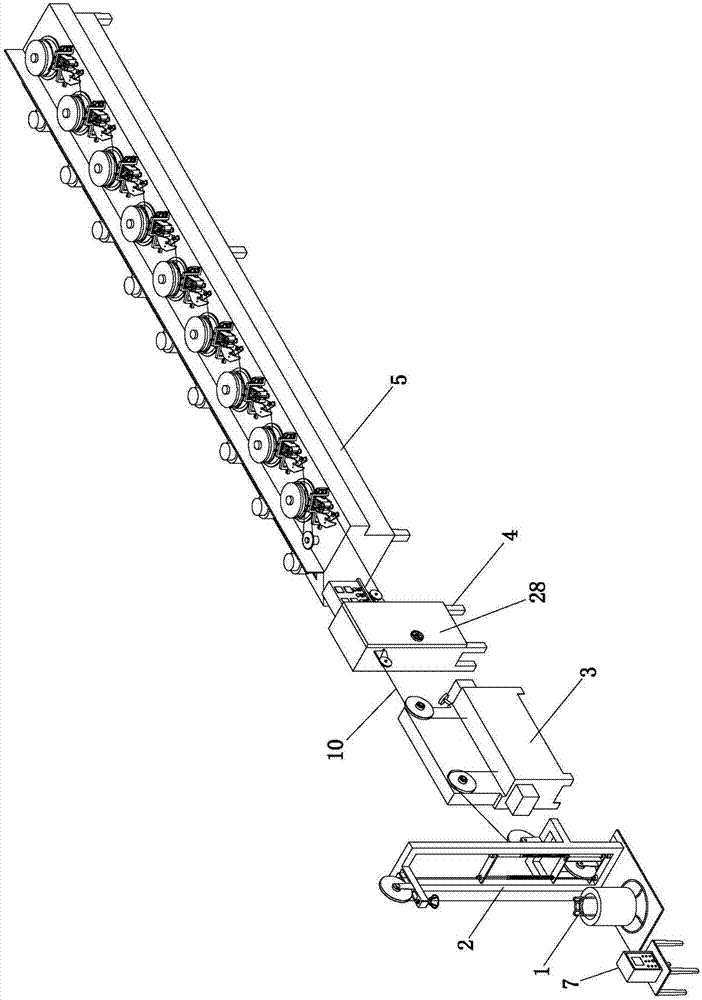

Wiredrawing system for steel wires

The invention discloses a wiredrawing system for steel wires. The wiredrawing system comprises a pay-off rack, a wire arrangement device, a single-line leather film device, an on-line leather film drying oven, a wiredrawing machine and a take-up rack, wherein the wire arrangement device, the single-line leather film device, the on-line leather film drying oven, the wiredrawing machine and the take-up rack are connected and controlled by an electric cabinet. With the reasonable arrangement of the components, when the whole system for wiredrawing steel wires runs, steel wire rods can be safely, efficiently and stably transported, the process of safe, efficient and high-quality steel wire drawing can be achieved, so that the quality of steel wire finished products and the efficiency of drawing the steel wires are effectively improved, and the production cost of enterprises is greatly reduced. The wiredrawing system for the steel wires is reasonable and compact in structure, reasonable in cost, and convenient in maintenance; when the system is operated, only the electric cabinet is operated; and one operator can simultaneously control a plurality of systems, so that time and labor are saved, the manpower resource is effectively saved, and thus the wiredrawing system for the steel wires is worth popularizing and applying.

Owner:GUANGTAI HLDG GRP

Stirring device for building construction

InactiveCN110861214AStir wellQuality improvementSievingScreeningRotational axisArchitectural engineering

The invention discloses a stirring device for building construction. The stirring device for building construction comprises a stirring barrel, the top end of a crushing barrel fixedly communicates with a feeding pipe, the two side walls of a barrel body are symmetrically and fixedly connected with second springs, two dovetail grooves are located on the two sides of a second through groove and communicate with the second through groove, a plurality of dovetail blocks are arranged in each dovetail groove in a attached and sliding mode, the other ends of the second springs are fixedly connectedwith the side walls of the dovetail blocks, one sides of the dovetail blocks are provided with blind holes, the other sides of the dovetail blocks are fixedly connected with inserting rods matched with the blind holes, the inserting rods are made of a Fe3O4 material, a first rotating shaft and a second rotating shaft are connected in a welded mode, and the model of a three-phase asynchronous motoris Y2-80M2-4S150. The device is diversified in function and high in practicability, concrete can be fully stirred and then can be uniformly mixed, the quality of the finished product is improved, stones with different hardness can be crushed and screened according to different requirements, so that the utilization rate of the stones is improved, then the quality of the concrete is indirectly improved, the labor intensity is reduced, and the building use requirement is met.

Owner:ZHEJIANG COLLEGE OF CONSTR

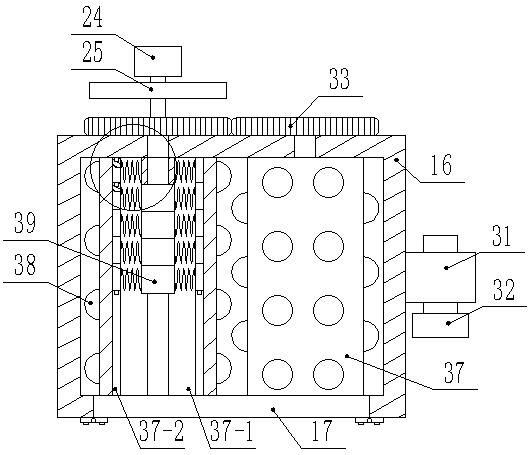

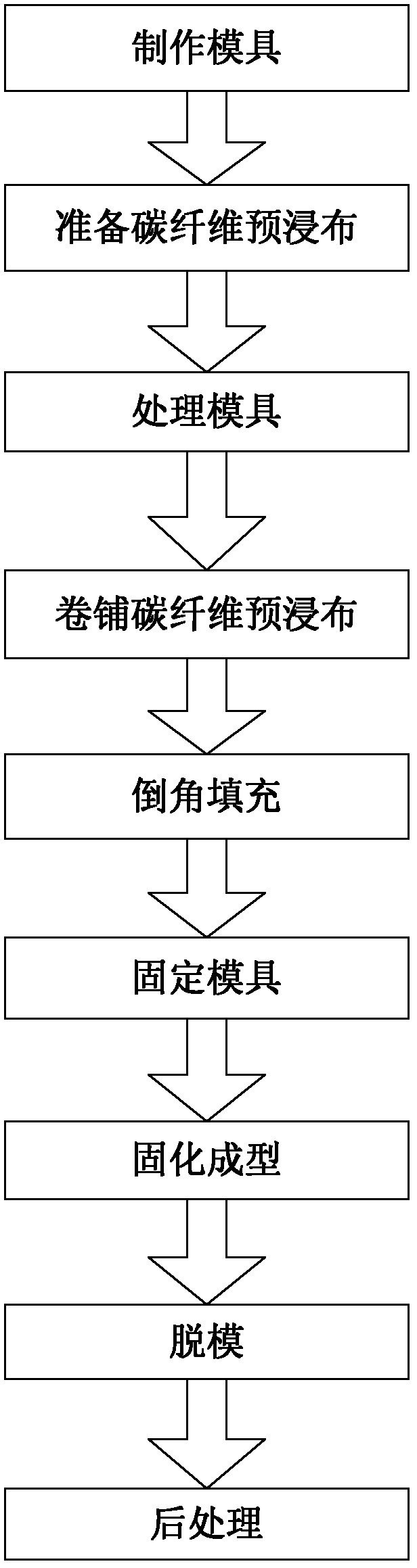

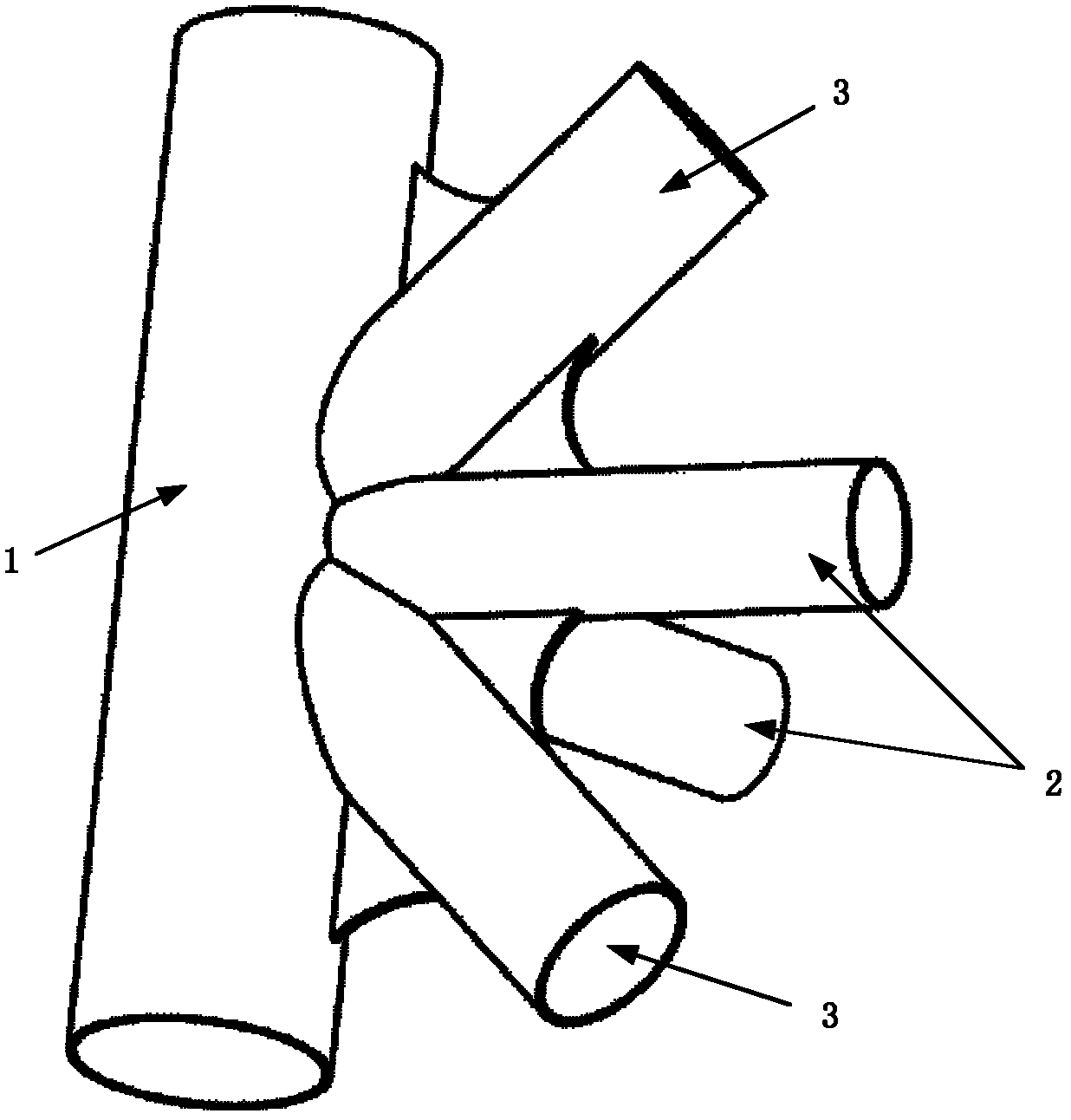

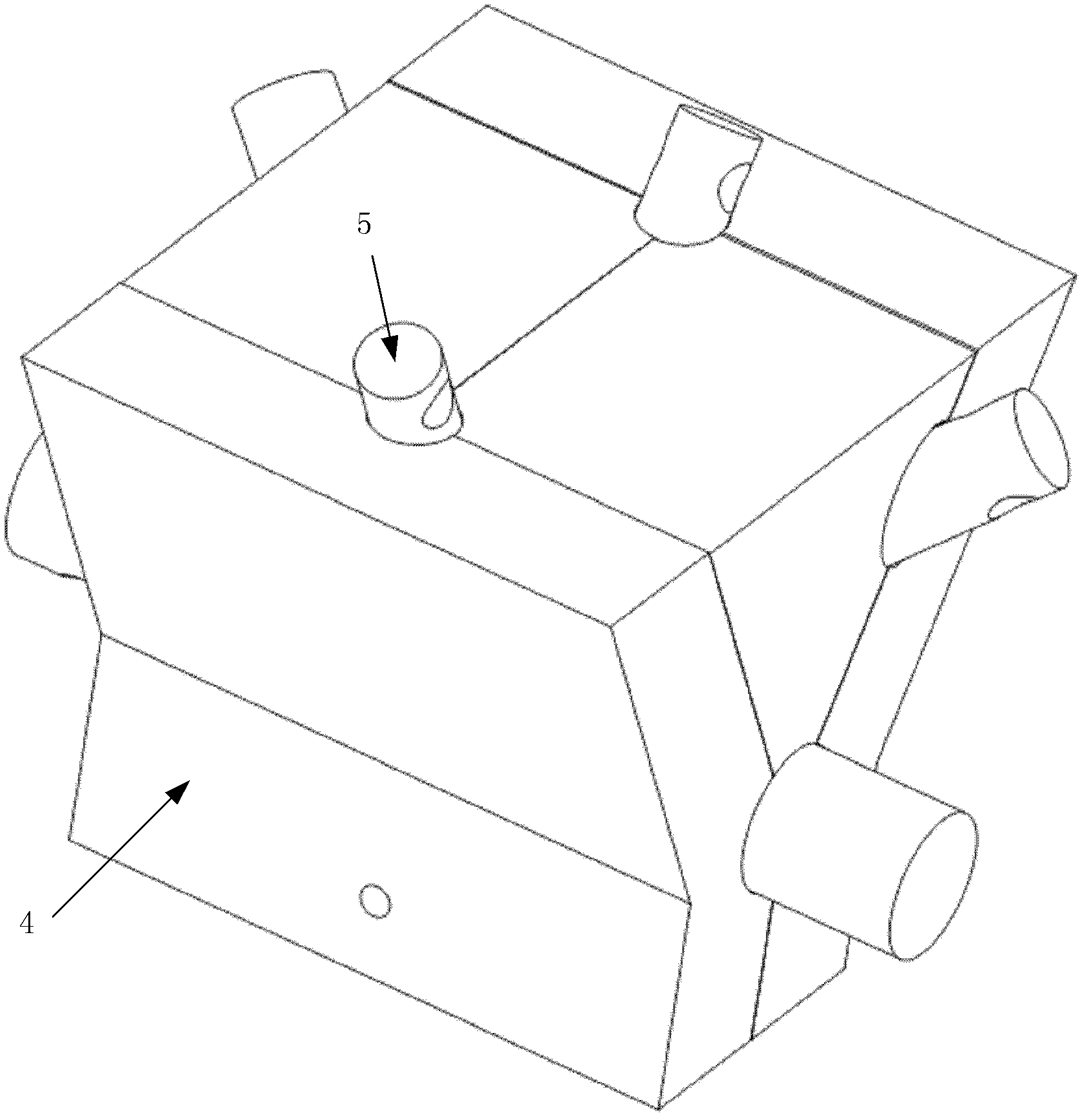

Manufacture die for carbon fiber composite integrative multipass joint and preparation method thereof

The invention discloses a manufacture die for a carbon fiber composite integrative multipass joint and a preparation method thereof. The manufacture die for a carbon fiber composite integrative multipass joint is manufactured according to the specific requirement of the integrative multipass joint and comprises a male die and a female die, wherein the male die is made of silica gel, and the female die is made of steel; and a section mutation of the integrative multipass joint is provided with a chamfer in which carbon fiber filaments are filled. In the manufacture die, a silica gel male die and a steel male die are combined, pressure on the carbon fiber composite material by the die is effectively improved, and the quality of the carbon fiber composite workpiece is improved. In addition, the manufacture die adopts the chamber filling technology, the stress concentration phenomenon on the shape mutation position of the joint is reduced, and the bearing capability of the joint is effectively improved.

Owner:BEIHANG UNIV

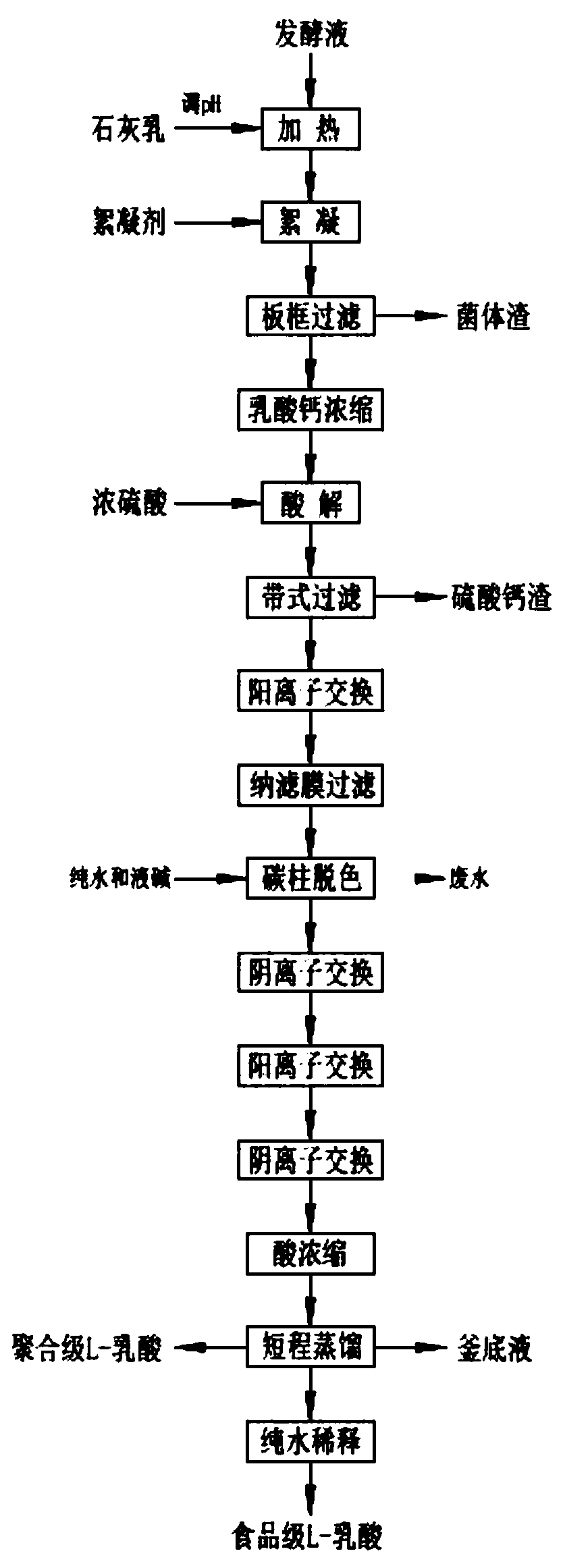

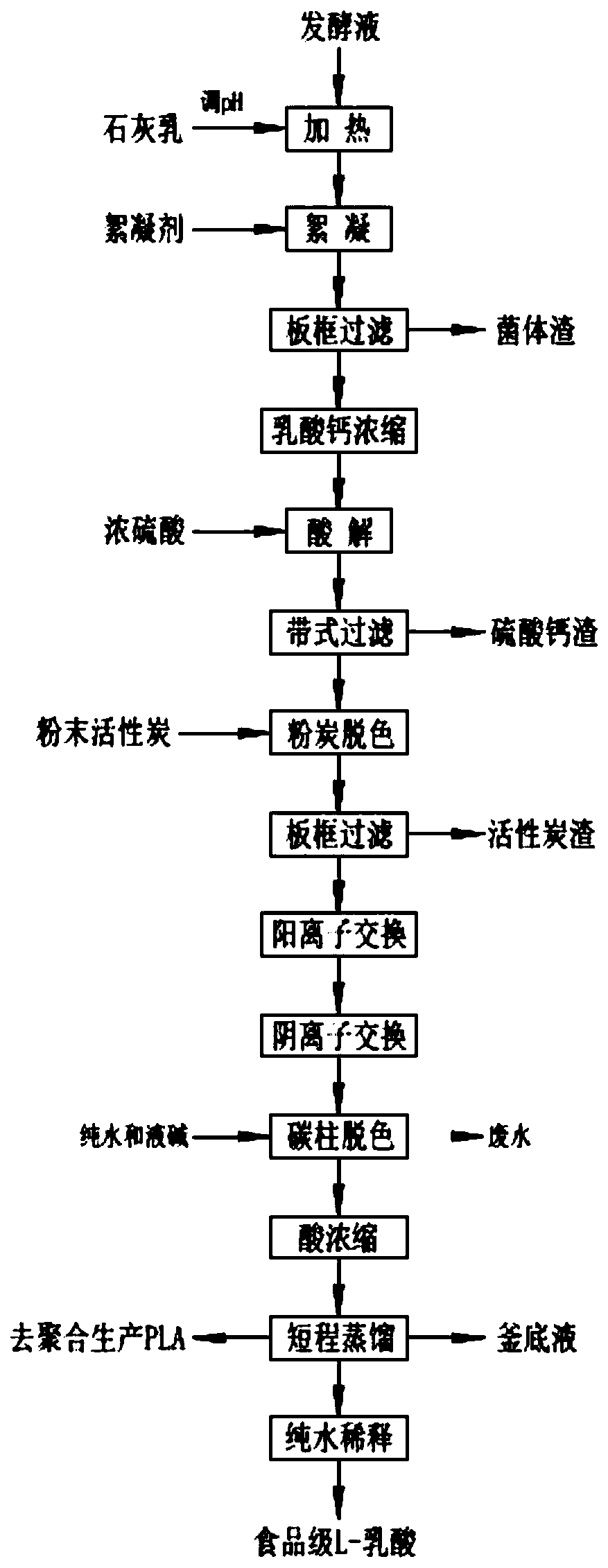

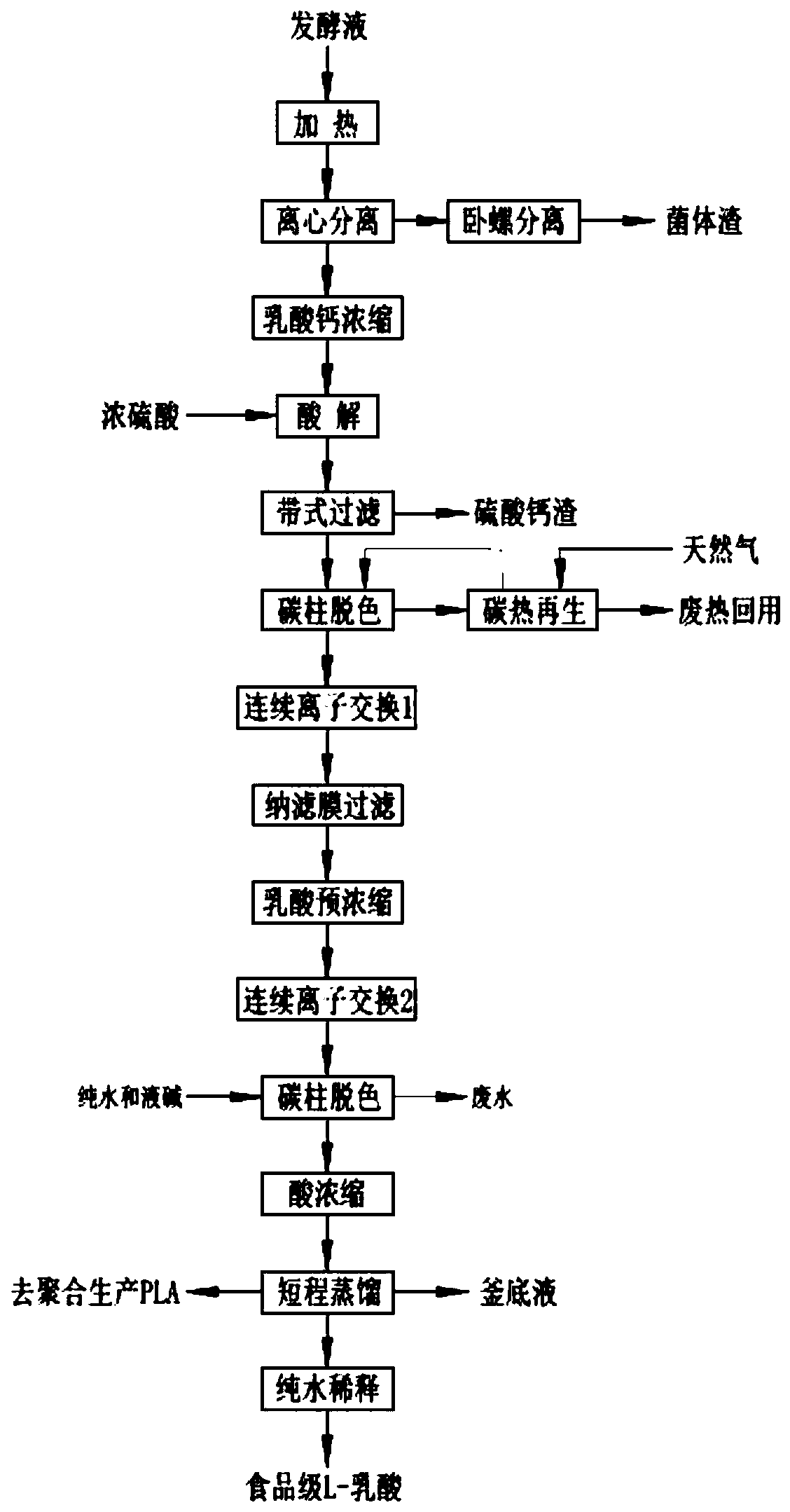

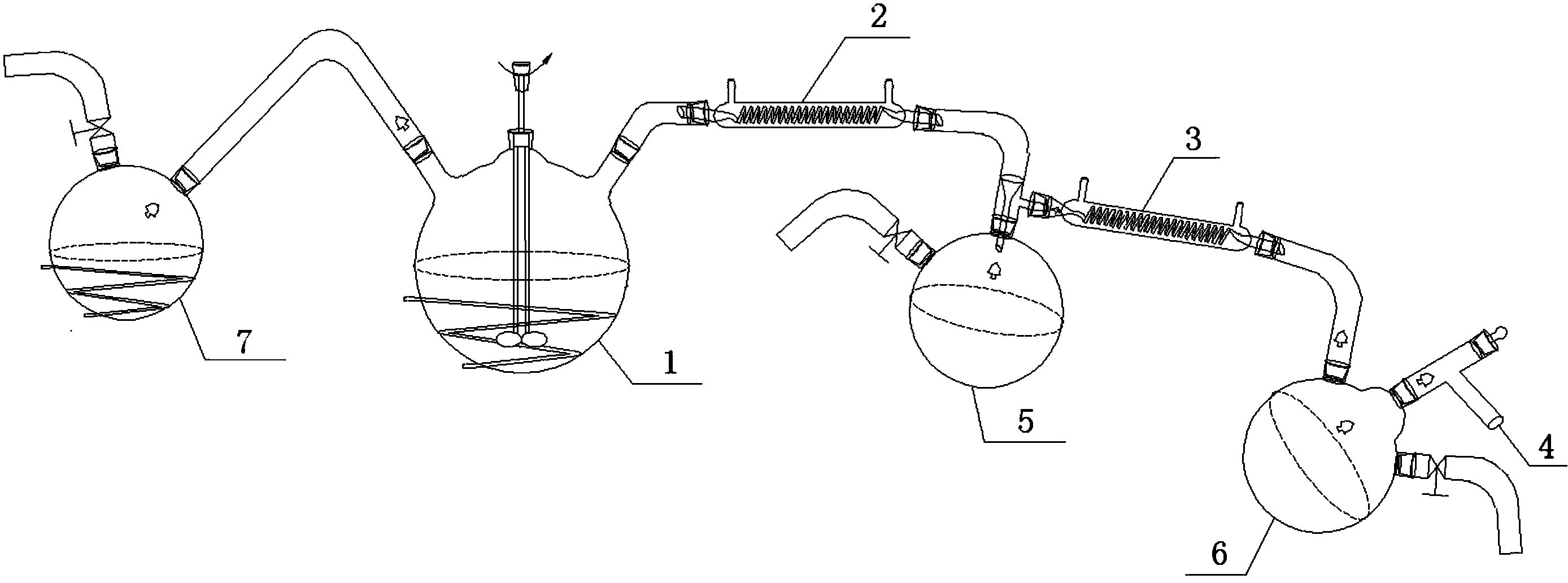

Method for purifying and refining L-lactic acid

ActiveCN111269107AOffset production costsReduce consumptionPreparation from carboxylic acid saltsCalcium/strontium/barium sulfatesBiotechnologyActivated carbon

The invention belongs to the technical field of L-lactic acid production, and particularly discloses a method for purifying and refining L-lactic acid. The method for purifying and refining L-lactic acid comprises the following steps: removing thalli in a fermentation liquor through separation to obtain thallus residues which can be used as a feed raw material; decolorizing an acidolysis filteredclear liquid by using activated carbon, feeding the decolorized acidolysis filtered clear liquid into a first ion exchange column, carrying out cation and anion exchange to obtain a primary ion exchange liquid, filtering the primary ion exchange liquid by using a nanofiltration membrane, carrying out pre-concentration, and sequentially carrying out cation and anion exchange to obtain a secondary ion exchange liquid; decolorizing the secondary ion exchange solution by adopting an activated carbon decolorizing column, and then concentrating to obtain a lactic acid concentrate with the L-lactic acid content of 80-90%; and carrying out short-path distillation and purification on the lactic acid concentrate to obtain high-purity food-grade lactic acid or produce polylactic acid. According to the L-lactic acid purification and refining method provided by the invention, the finished product quality of the L-lactic acid is improved, and the finally obtained L-lactic acid is good in quality andhigh in yield and particularly meets the quality requirement of the L-lactic acid serving as a PLA raw material.

Owner:安徽固德生物工程有限公司

Method and device for continuously producing isosorbide

ActiveCN103980286APromotes selective dehydration reactionSimple separation processOrganic chemistryIsosorbideDistillation

The invention relates to a method for continuously producing isosorbide, which comprises the following steps: (1) feeding: mixing sorbitol and a catalyst in a reactor; (2) reaction: under reduced pressure, controlling the temperature in the reactor to sequentially initiate first dehydration reaction and second dehydration reaction of the sorbitol so as to generate the isosorbide, and meanwhile, enabling the isosorbide and water to form a gaseous mixture; and (3) condensation separation: controlling the condensation temperature of the condenser to sequentially condense the isosorbide and water in the gaseous mixture from the reactor, thereby obtaining the isosorbide. The invention also relates to a device for the method.In the sorbitol dehydration reaction process, the isosorbide and water are separated in time by distillation, thereby promoting the selective dehydration reaction, simplifying the separation technique and implementing purification of the isosorbide.

Owner:长春鸿成生物化工材料技术开发有限公司

Drying method for Chinese medical extract

InactiveCN106123496AKeep the fragranceModerate colorDrying solid materials with heatDrying solid materials without heatMedicinal herbsMedicine

The invention relates to a drying method for Chinese medical extract, in particular to a vacuum drying method for Shouhui cathartic extract. The vacuum drying method adopts circulating hot water with the temperature being controlled automatically to serve as a medium for heating of the Chinese medical extract, and the purpose of low-temperature drying of the Chinese medical extract is achieved. Through the method, the defects, occurring to traditional vacuum drying and the like, that thermosensitive components of extract are decomposed due to high temperature, the energy consumption is high, the heat efficiency is low, the extract is dried and burnt, drying is insufficient can be overcome. According to the dried Chinese medical extract obtained through the drying method, the content of effective components is high, the quality of finished products is good, the water content is low, and preparation processing and storage of the finished products are facilitated; fresh scent of medicinal materials is maintained, the color and lustre are natural, the texture is loose and uniform, the extract is easy to crush; and continuous and automatic production can be achieved, and the method has quite high operability and practicability.

Owner:LUNAN PHARMA GROUP CORPORATION

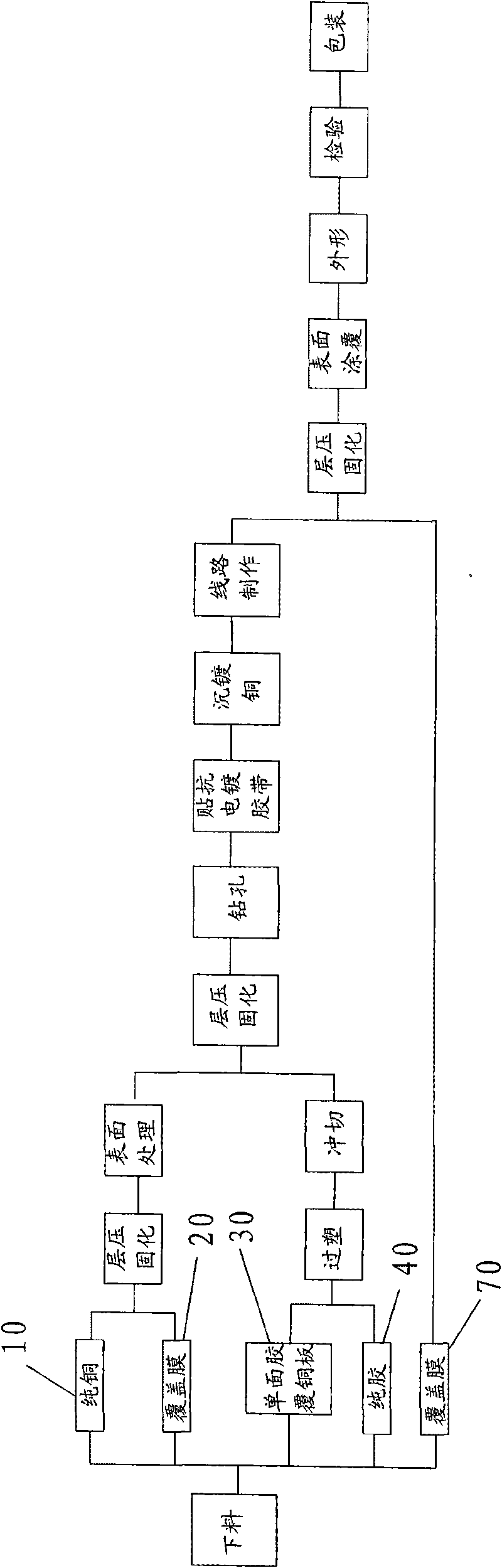

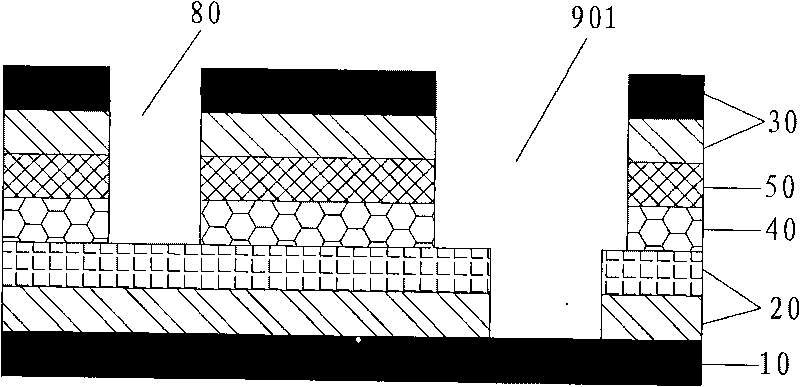

Productive technology of flexible printed circuit board

ActiveCN101742820AReduce usageReduce manufacturing costPrinted circuit manufactureFlexible circuitsWork in process

The invention discloses a productive technology of a flexible printed circuit board, comprising the following steps: (1) cutting pure copper 1, pure copper 3, a double faced adhesive tape cover layer and a single faced adhesive tape cover layer; (2) drilling out registration holes on pure copper 1 and pure copper 3, punching the single faced adhesive tape cover layer and the double faced adhesive tape cover layer to leave an opening; (3) assembling pure copper 1 on one side of the double faced adhesive tape cover layer; (4) assembling pure copper 3 on the other side of the double faced adhesive tape cover layer; (5) drilling pure copper 1 and pure copper 3 to form a through hole; (6) plating copper on the surface of a semi-finished printed circuit board; (7) etching copper at the openings of the bending area reserved by pure copper 3 and the conductive area corresponding to the double faced adhesive tape cover layer to manufacture required circuits; (8) respectively assembling the two single faced adhesive tape cover layers corresponding to the outer surfaces of pure copper 1 and pure copper 3; (9) coating noble metal at the reserved opening position of the single faced adhesive tape cover layer; and (10) punching to manufacture the appearance of products. The method has low manufacturing cost, simple process, high working efficiency and good cost and quality.

Owner:XIAMEN HONGXIN ELECTRON TECH

Aluminum alloy scrap recycling device and processing technology

InactiveCN110484750AImprove finished product qualityEasy to useMagnetic separationProcess efficiency improvementSpiral bladeDrive motor

The invention relates to an aluminum alloy scrap recycling device. The aluminum alloy scrap recycling device comprises a support and a crushing device; a conveying belt is arranged on one side of thecrushing device; a magnetic separation cylinder is arranged on one side of the conveying belt; a rotating shaft is arranged in the magnetic separation cylinder; a spiral blade is arranged on the rotating shaft; a plurality of magnets are arranged on the spiral blade; a driving motor is arranged on the rotating shaft; a first feeding opening is formed in the magnetic separation cylinder; a feedinghopper is arranged at the first feeding opening; a first discharging opening is formed in the magnetic separation cylinder; a fan is arranged at the first discharging opening; a receiving box is arranged below the first discharging opening; a first liquid outlet is formed in the bottom wall of the receiving box; a first liquid outlet pipe is arranged at the first liquid outlet; a first valve is arranged on the first liquid outlet pipe; a cleaning device and a drying device are arranged on one side of the receiving box; and a smelting device is arranged on one side of the driving device. An aluminum alloy scrap recycling technology sequentially includes crushing, magnetic separation, winnowing, acidification, cleaning, drying, smelting, raking and casting. By the aid of the device and the technology, scraps in secondary aluminum raw materials can be separated, and the finished product quality after reuse of the secondary aluminum raw materials can be improved.

Owner:陕西美泰节能科技有限公司

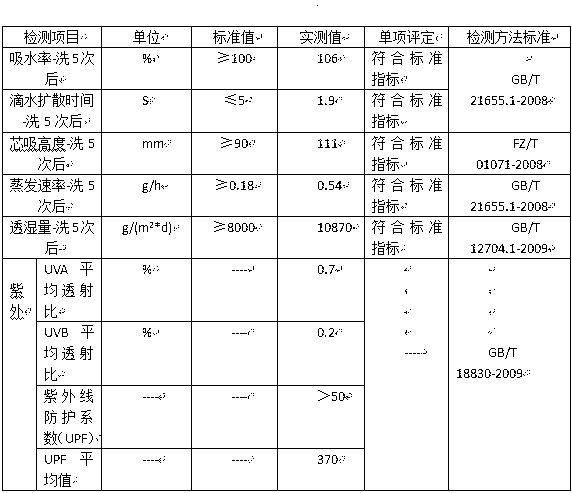

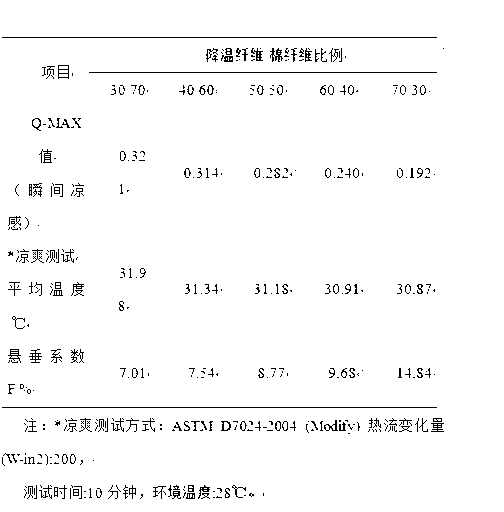

Tooling fabric with cooling function and uvio-resistant function

The invention relates to tooling fabric with a cooling function and an uvio-resistant function. A method for manufacturing the tooling fabric with the cooling function and the uvio-resistant function comprises a first step of using cooling master batch as raw materials and manufacturing the cooling master batch to slicing sheets, a second step of drying the slice sheets, a third step of carrying out spinning on the slicing sheets through a spinning box to manufacture nylon base cooling fibers, a fourth step of adopting a siro spinning technology to spin cotton fibers and the nylon base cooling fibers into blended yarn, and a fifth step of adopting technological measures of 'early opening, later weft insertion and on-machine tension slightly larger' to carry out weaving. A formula of the cooling master batch comprises PA6, bowlder powder, zirconium dioxide powder, silicon dioxide powder, stearic acid dispersants, polystyrene dispersants, low molecular wax dispersants and titanate coupling agents. The tooling fabric has functions of fast heat absorption and fast heat dissipation, and an everlasting cooling feature is guaranteed. Meanwhile, the tooling fabric further has a notable uvio-resistant feature.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

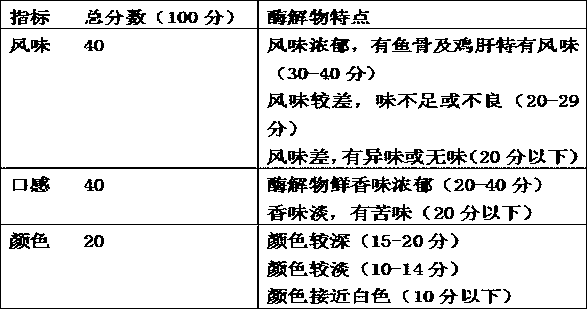

Fish bone pet attractant and preparation method thereof

InactiveCN103005167AReduce fishy smellPromote digestion and absorptionAnimal feeding stuffBiotechnologyMaillard reaction

The invention relates to a fish bone pet attractant and a preparation method thereof and belongs to the technical field of food resource comprehensive utilization. Fish bone leftovers are taken as a main ingredient, chicken liver is taken as an auxiliary material, the preparation method provided by the invention is adopted, step-by-step enzymolysis is carried out by virtue of compound protease and flavour protease, glucose and glycine are added, Maillard reaction is carried out, then white granulated sugar is added, mixed culture is inoculated, fermentation is carried out, then pH value is adjusted by virtue of critic acid and hydrochloric acid, and finally edible salt is added to prepare highly acidic semi-solid fish bone pet attractant. Fishbone waste is effectively utilized, economic value of the fishbone waste is increased, and a preparation method is simple, so that cost is greatly reduced, all the nutrients are contained, fishbone fishy smell is reduced, flavour is fresh and fragrant, and palatability and food calling property of a pet are greatly enhanced; high temperature treatment, appropriate pH value and addition of edible salt are adopted, so that the fish bone pet attractant can not decay or go bad in a longer time, and a quality guarantee period is prolonged; and the fish bone pet attractant provided by the invention is suitable for being purchased by vast of low-medium pet lovers and keeping pets by the vast of low-medium pet lovers, and the fish bone pet attractant is cheap and fine.

Owner:YANGTZE UNIVERSITY

Fruit and vegetable enzyme powder with weight reducing function and preparation method thereof

ActiveCN105249452AEasy to disinfectImprove finished product qualityLactobacillusStrepto/lacto-coccusWaxEnzyme

The invention discloses fruit and vegetable enzyme powder with a weight reducing function and a preparation method thereof. The fruit and vegetable enzyme powder is prepared from bananas, watermelons, pears, pineapples, apples, melons, dragon fruit, mulberries, celery, asparagus lettuce, white turnips, wax gourds, cucumbers, Chinese cabbages, bitter gourds, cherries, hawthorns, pawpaws, apricots, litchis, longan, jujubes, garlic, pepper, Chinese chives, spinach and asparagus. According to the fruit and vegetable enzyme powder, the scientific weight-reducing principle of eating less and consuming more is adopted, and after the fruit and vegetable enzyme powder is eaten for a long time according to the crowds with different habitus, the effects of reducing weight, slimming, detoxifying and beautifying skins are achieved, and malnutrition cannot be caused.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

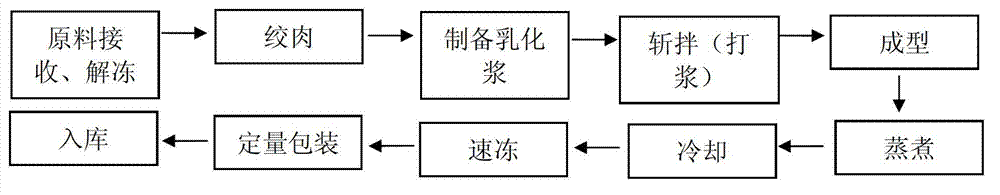

Dietary fiber fish ball and preparation method thereof

The invention provides a dietary fiber fish ball and a preparation method thereof. The fish ball is prepared from the following raw materials parts by weight: 80 to 100 parts of minced fillet, 3-5 parts of prime condition, 50-70 parts of modified starch, 4-6 parts of dietary fiber, 80-100 parts of emulsion paste, 0.1-0.25 part of phosphate, 10-15 parts of garlic, 5-6 parts of salt, 5-6 parts of white granulated sugar and 2.5-3.5 parts of condiment, wherein the emulsifier is prepared based on the mass ratio of the soy isolate protein to the water of 1:(3-4). The invention also provides a method for preparing the fish ball. The high-quality dietary fiber with a proper rate is added into the traditional fish ball, the traditional diet is not changed, the health-care effects of reducing the blood sugar, reducing the cholesterol, losing weight and preventing the intestinal cancer, constipation and cardiovascular diseases are achieved, and the dietary fiber fish ball meets the low-salt diet national health requirement.

Owner:天津市宽达水产食品有限公司

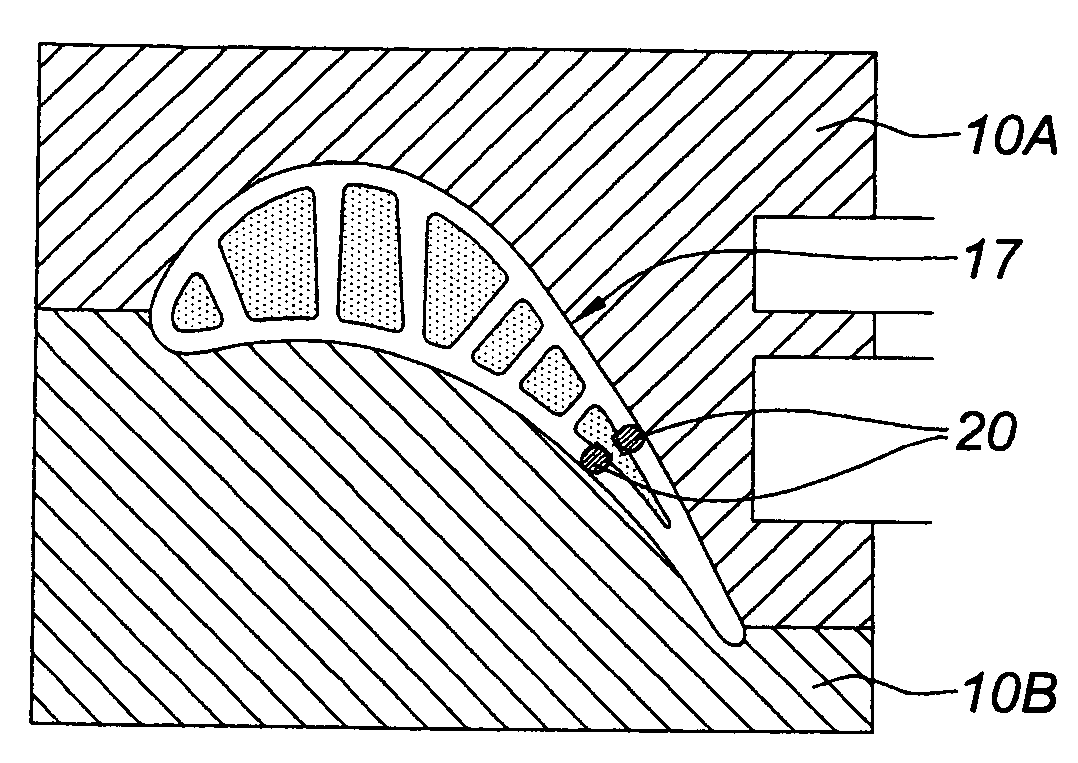

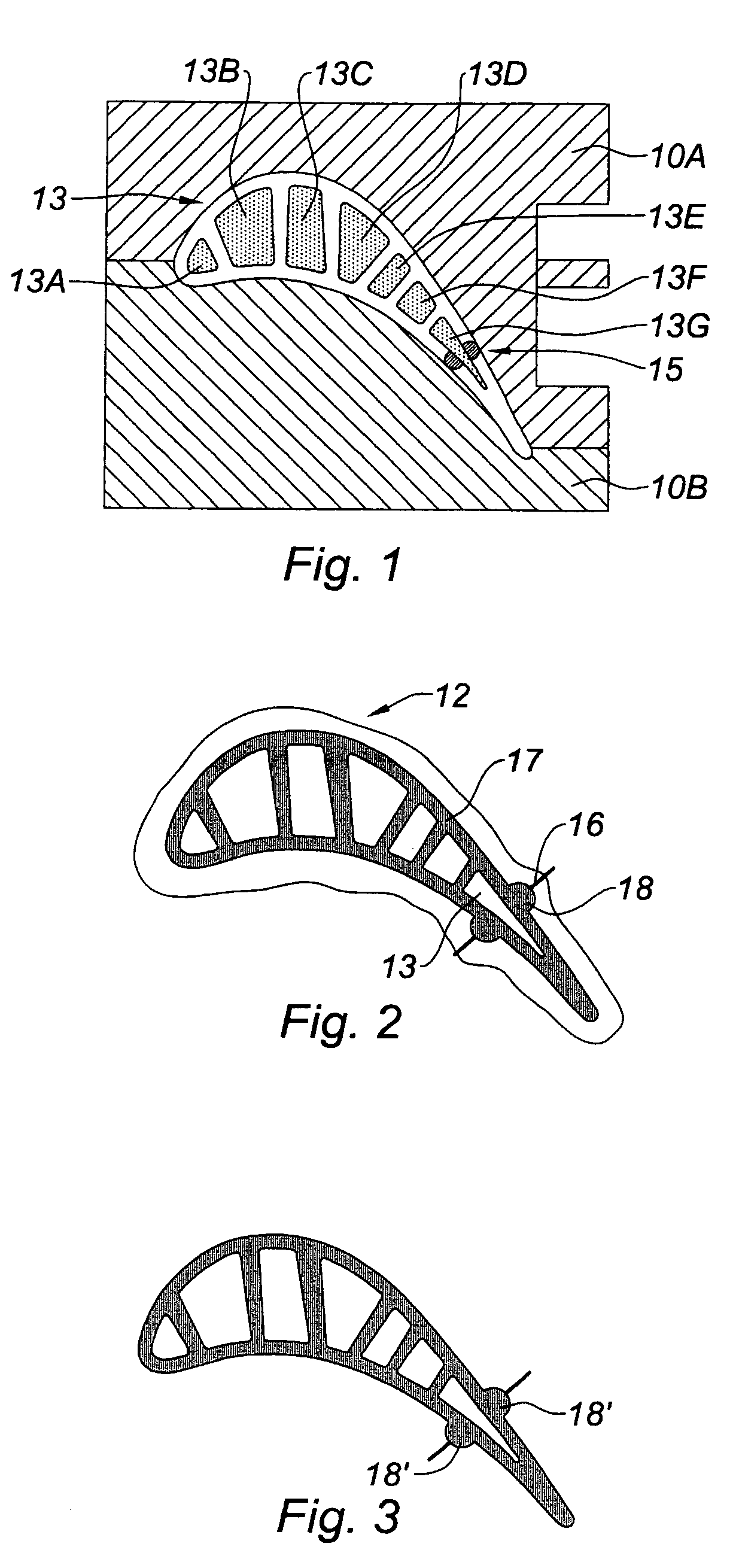

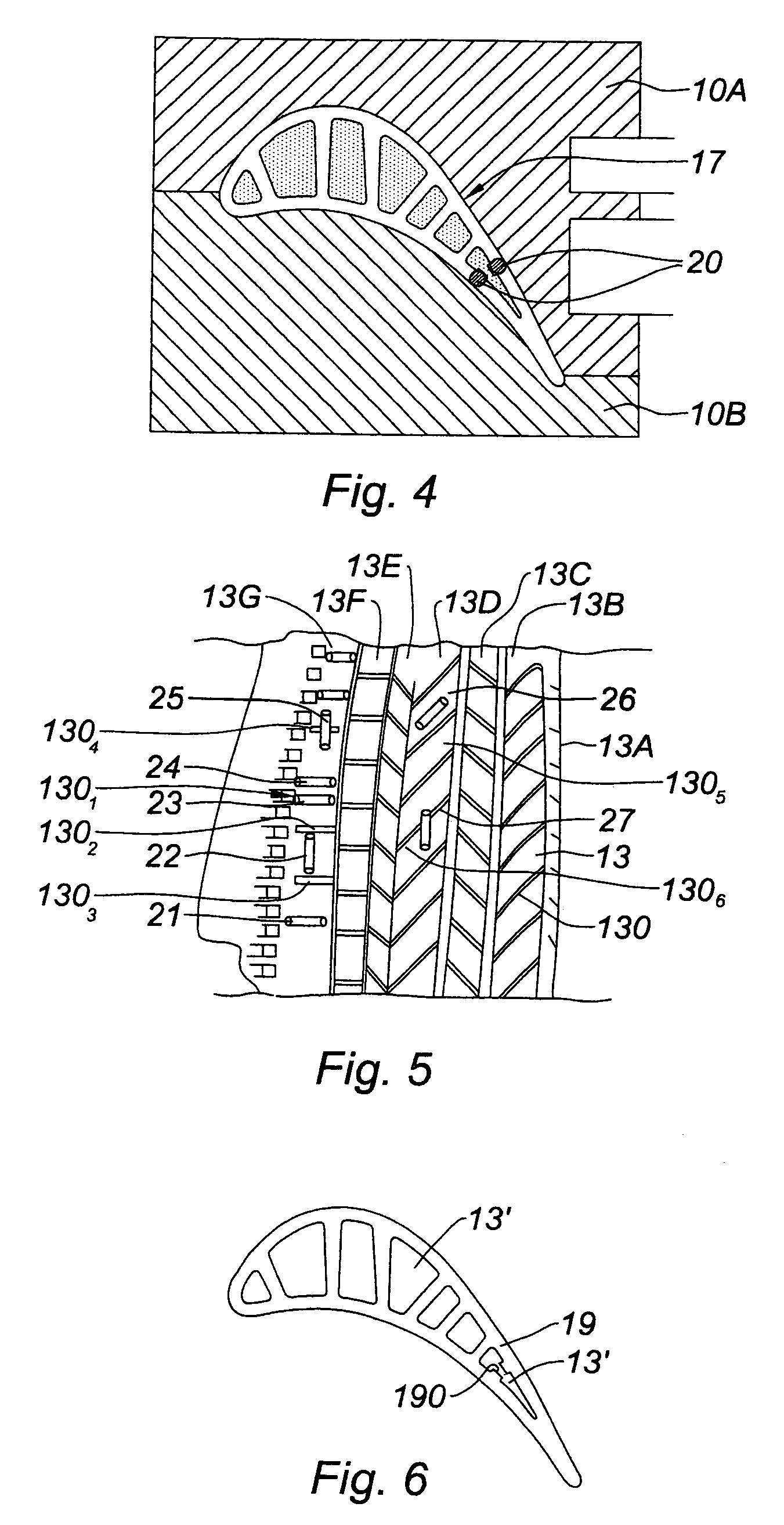

Process for the manufacture by lost wax moulding of parts that include at least one cavity

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com