Manufacture die for carbon fiber composite integrative multipass joint and preparation method thereof

A technology of composite materials and multi-way joints, applied in the field of composite material space trusses, can solve the problems of artificial weaving, heavy weight of metal connectors, low efficiency, etc., and achieve the effect of improving bearing capacity, reducing stress concentration, and good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

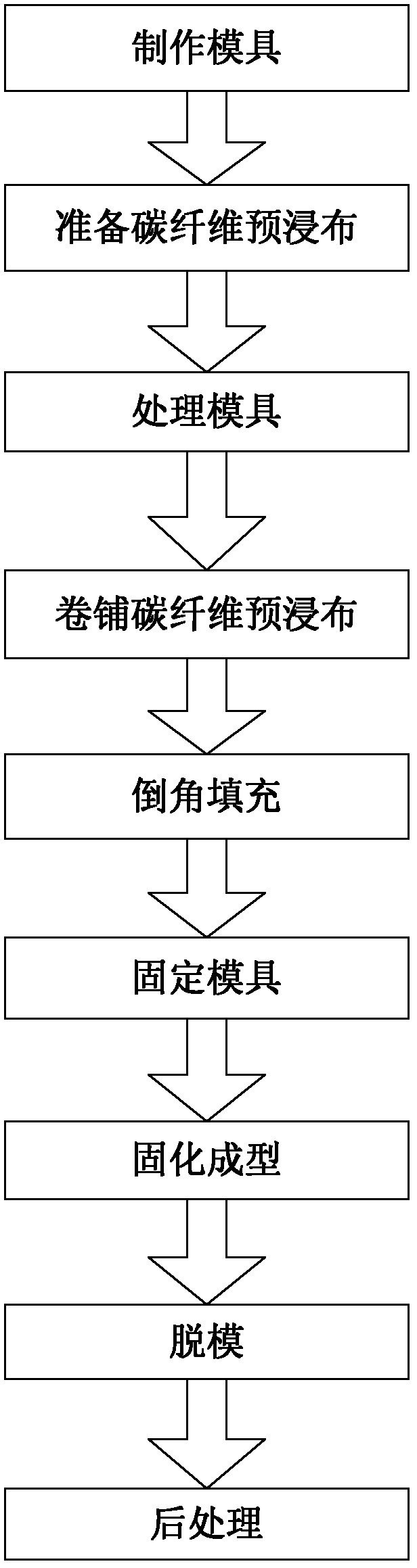

[0042] The preparation method of the carbon fiber composite material integrated multi-way joint of the present invention, such as figure 1 shown, including the following steps:

[0043] Step 1: Make a mold according to the design requirements of the carbon fiber composite integrated multi-way joint, and the mold includes a female mold and a male mold;

[0044] The male mold is made of silica gel, and the female mold is made of steel. The coefficient of thermal expansion of silica gel is greater than that of the material steel of the female mold. Therefore, the use of silica gel can increase the pressure of the mold on the carbon fiber product during the production process and improve the quality of the product.

[0045] At the sudden change in the section of the carbon fiber composite joint, make chamfers to reduce the local stress, but because the thickness of the carbon fiber cloth at the chamfers changes greatly, the chamfers need to be filled with carbon fiber filaments to...

Embodiment

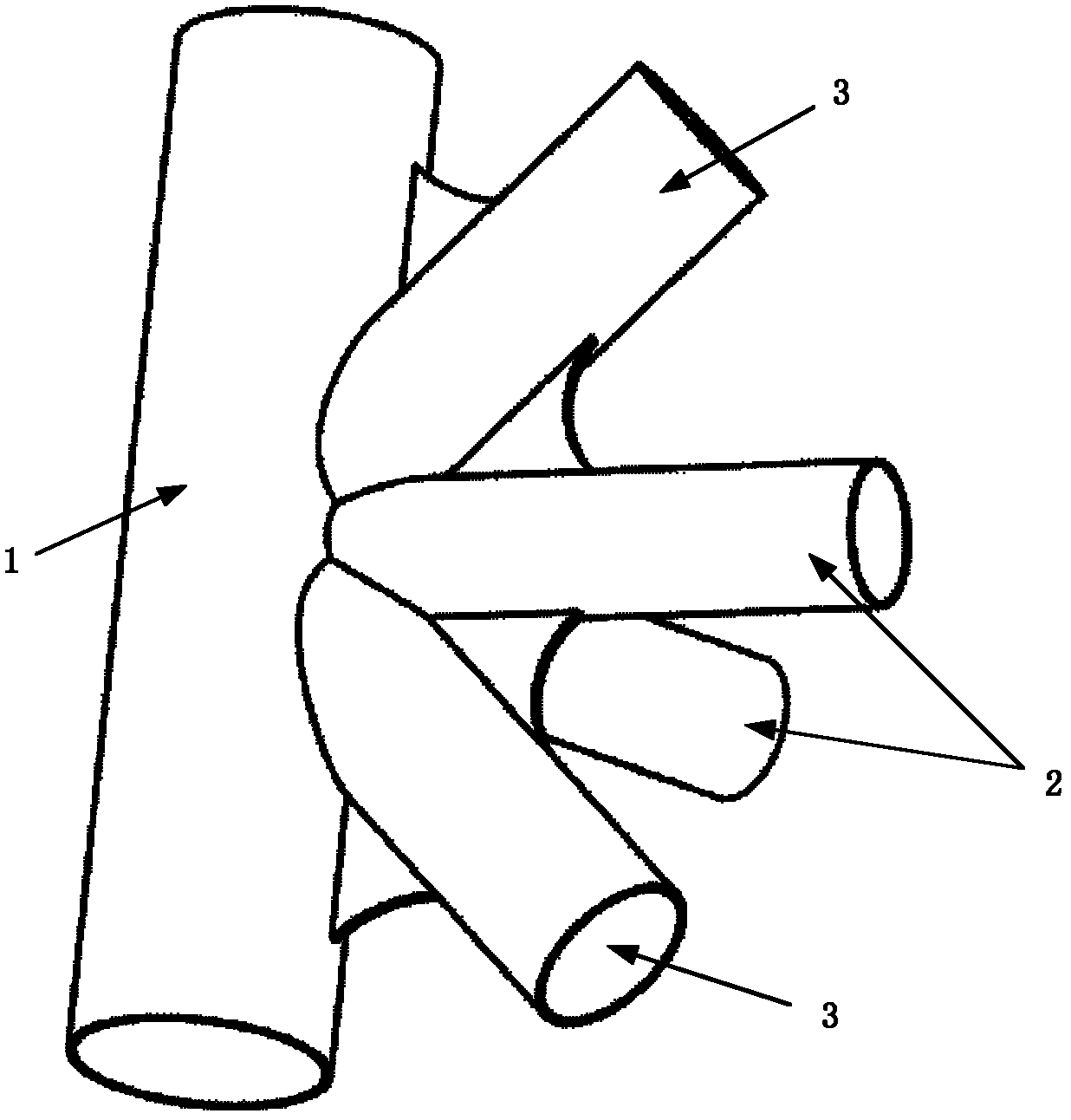

[0056] The carbon fiber composite material integrated joint in this embodiment, such as figure 2 As shown, it includes one main sleeve 1, two oblique sleeves 2 and two straight sleeves 3, the angle between the main sleeve 1 and the oblique sleeve 2 is 45°, the main sleeve 1 and the straight sleeve The angle between 3 is 90°.

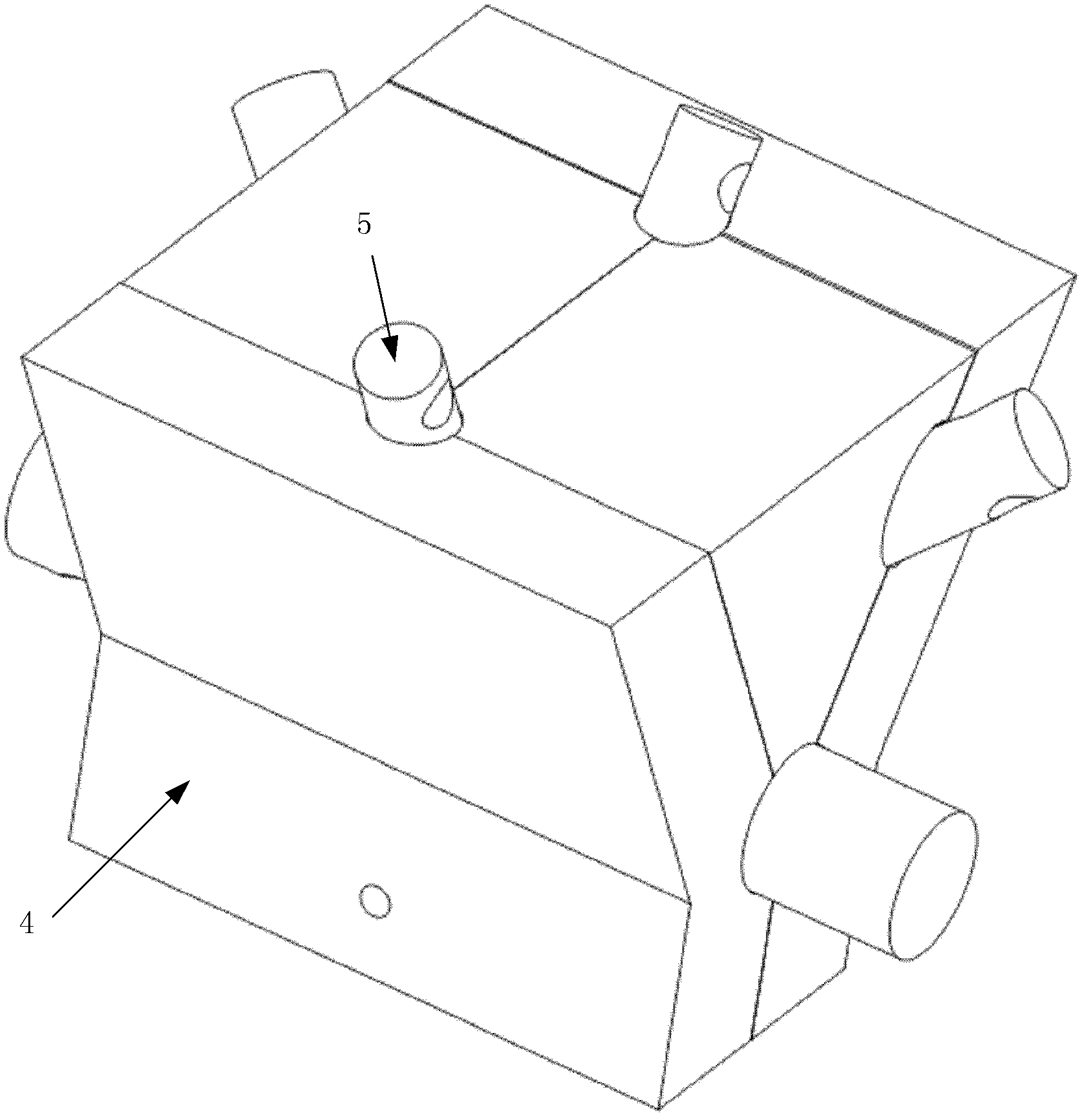

[0057]The production mold of the integrated joint of carbon fiber composite material is as follows: image 3 As shown, including the female mold 4 and the male mold 5, the female mold 4 as a whole is as Figure 4 As shown, it is made of steel and consists of 4 parts, including upper female mold 401, lower female mold 402, left female mold 403 and right female mold 404, as Figure 5 shown. The whole male mold 5 is as Figure 6 As shown, the male mold 5 is made up of 5 silicone parts, including the main rod male mold 501, two oblique rod male molds 502 and two bulkhead rod male molds 503, as Figure 7 shown. The mold is fastened by bolts.

[0058] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com