Fully-automatic building block forming machine mechanization production line

A block forming machine, fully automatic technology, applied in ceramic forming machines, ceramic forming workshops, auxiliary forming equipment, etc., can solve the problems of high operation and maintenance costs, poor quality of finished products, high labor intensity, etc., and achieve investment and operating costs. High, poor product quality, low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

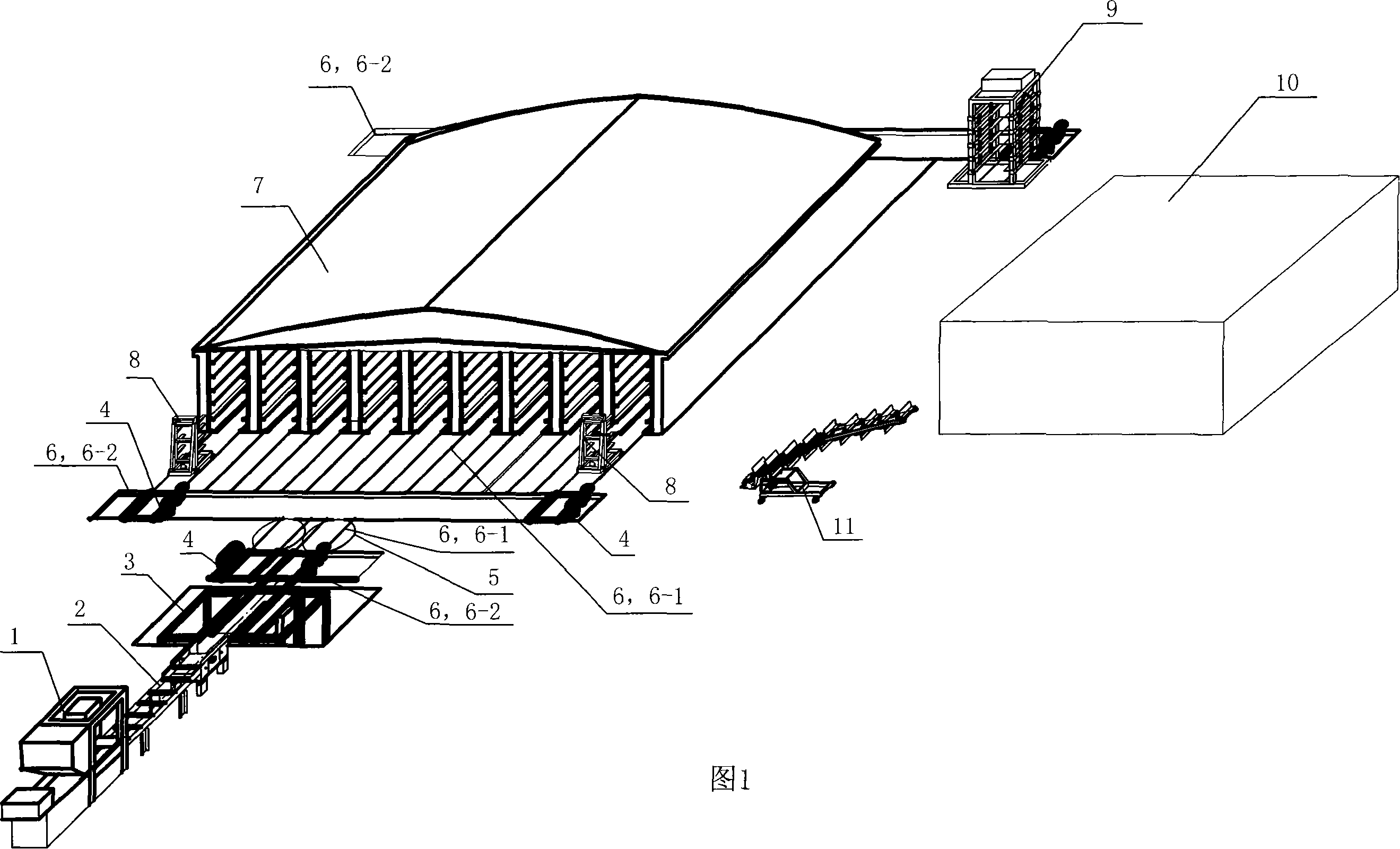

[0039] Below in conjunction with accompanying drawing 1 the present invention will be further described:

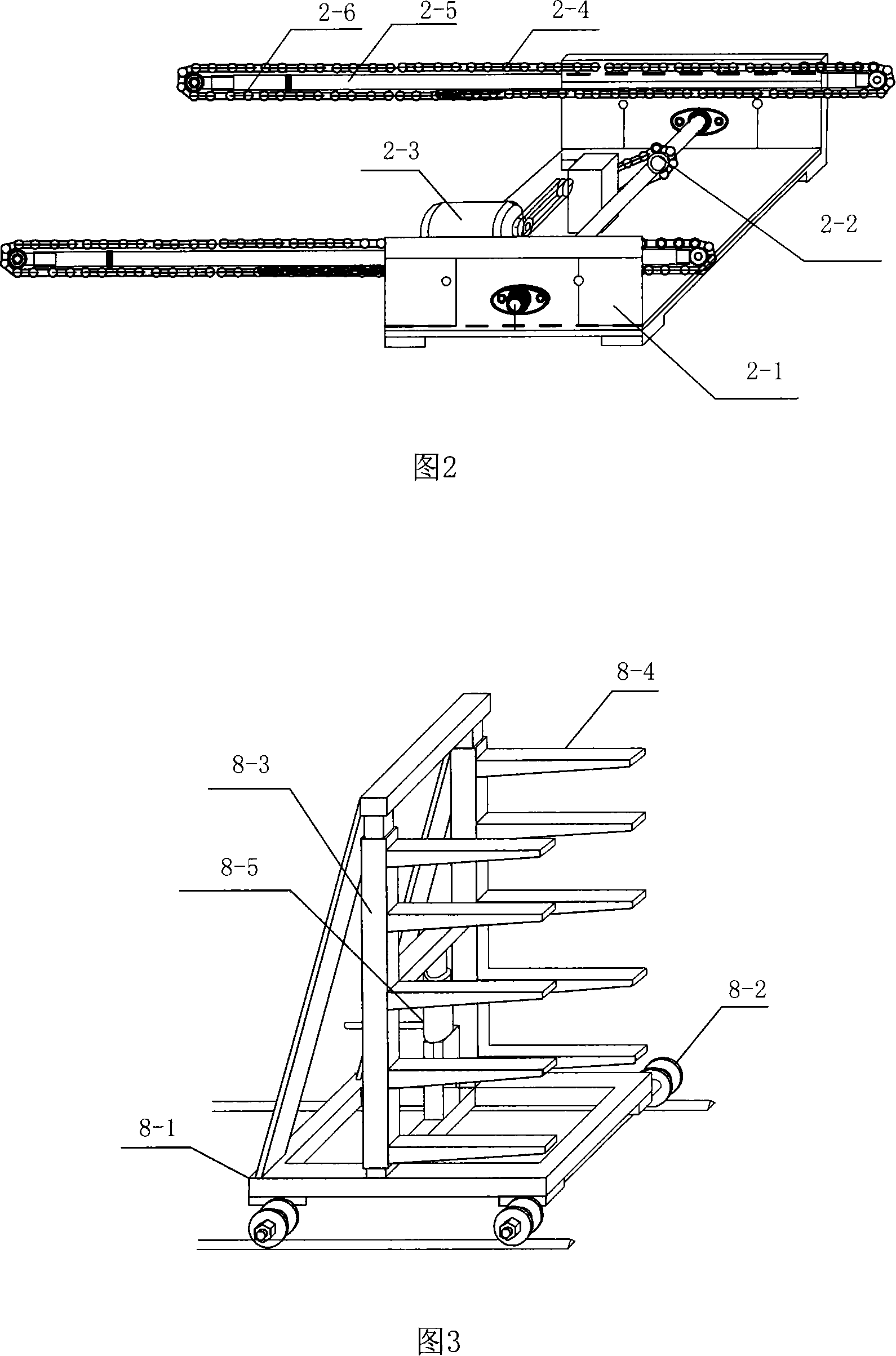

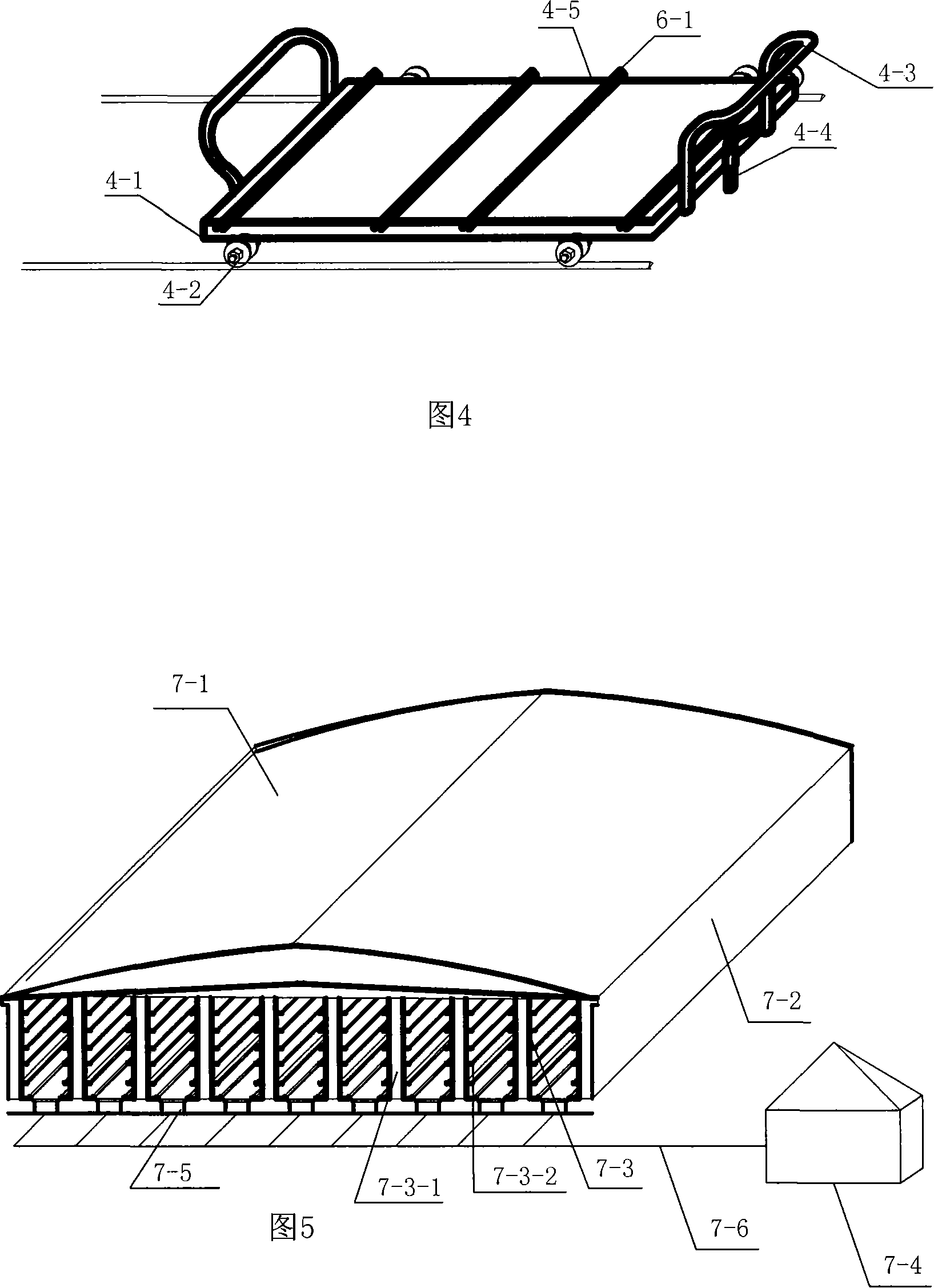

[0040]The automatic block forming machine forms every 25 seconds, and adopts a double-track mechanized production line. It is formed by the automatic block forming machine 1 and its supporting devices. The supporting devices mainly include the trigger 2, the elevator 3, the ferry car 4, and the rotating platform 5 , track 6, curing kiln 7, forklift 8, stacker 9, stacking yard 10, loading machine 11. The layout of the production line is that the automatic block forming machine 1, the trigger 2, and the elevator 3 are arranged along the central axis, and a ferry car track 6-2 perpendicular to the central axis is arranged behind the elevator 3, and two ferry cars 4 are installed on it, each The ferry car is correspondingly arranged with a rotating platform 5, forklift track 6-1 is set on the rotating platform 5, and a ferry car track 6-2 is arranged vertically with the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com