Patents

Literature

31results about How to "Simple equipment and process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for disposing residues produced by fermentation of cephalosporin C through alkaline hydrolysis process

ActiveCN102488997ASimple equipment and processLow costClimate change adaptationBioloigcal waste fertilisersCephalosporin CChemistry

The invention relates to a method for disposing residues produced by fermentation of cephalosporin C through an alkaline hydrolysis process, which comprises the following steps: putting the disposing residues produced by the cephalosporin C in aqueous alkali so as to be heat and hydrolyzed, wherein the working pressure is 0.4-0.7 Mpa, the hydrolysis temperature is 150-220 DEG C, and the hydrolysis time is 1-3h; and filtering after hydrolysis, and respectively collecting filtrate and filter residues. The process and equipment provided by the invention are simple, has low cost, high efficiency, less pollution, and is easy to industrial production; and the obtained filtrate and filter residues realize full degradation of antibiotics and intermediate products thereof, so that higher ecological safety is realized.

Owner:天津市裕川环境科技有限公司

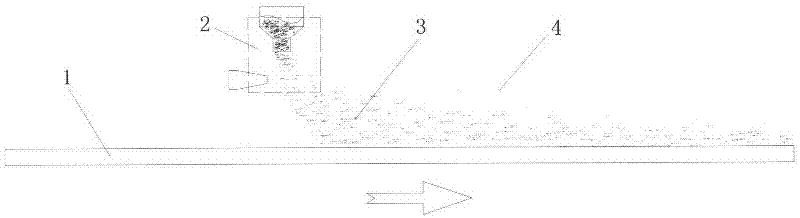

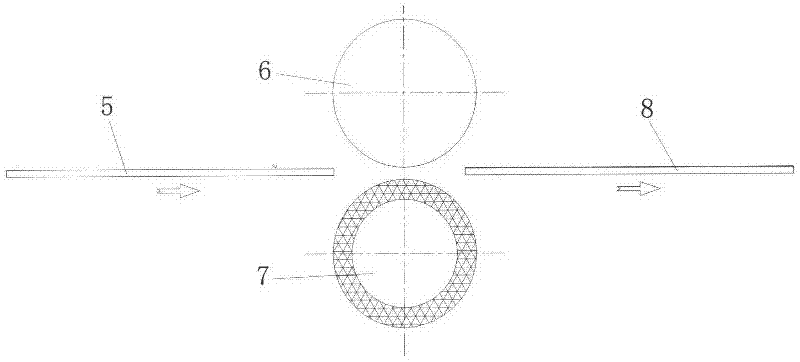

A kind of self-wearing wood decoration material and its manufacturing method

InactiveCN102294722ARich sourcesSimple equipment and processCovering/liningsWood working apparatusWear resistantHeat press

The invention provides a manufacturing method of self-wear-resisting wooden decorative material with simple process and equipment. Pressing will not wear out the polishing pad of the heat press. It includes the following steps: immersing the substrate suitable for impregnation into the impregnating resin and then taking it out; drying the impregnated substrate to make the surface of the substrate slightly sticky to the touch; putting the wear-resistant material of more than 100 meshes through the air-laid The loading machine is paved on the upper surface of the pre-dried substrate, and the paving amount of the wear-resistant material is 5-25g / m2; the substrate on which the wear-resistant material is paved is passed through a pair of round rollers to press the wear-resistant material. Firmly and firmly adheres to the surface of the substrate; the substrate is re-dipped in the impregnating resin and then placed in a dryer to dry again.

Owner:NANJING FORESTRY UNIV

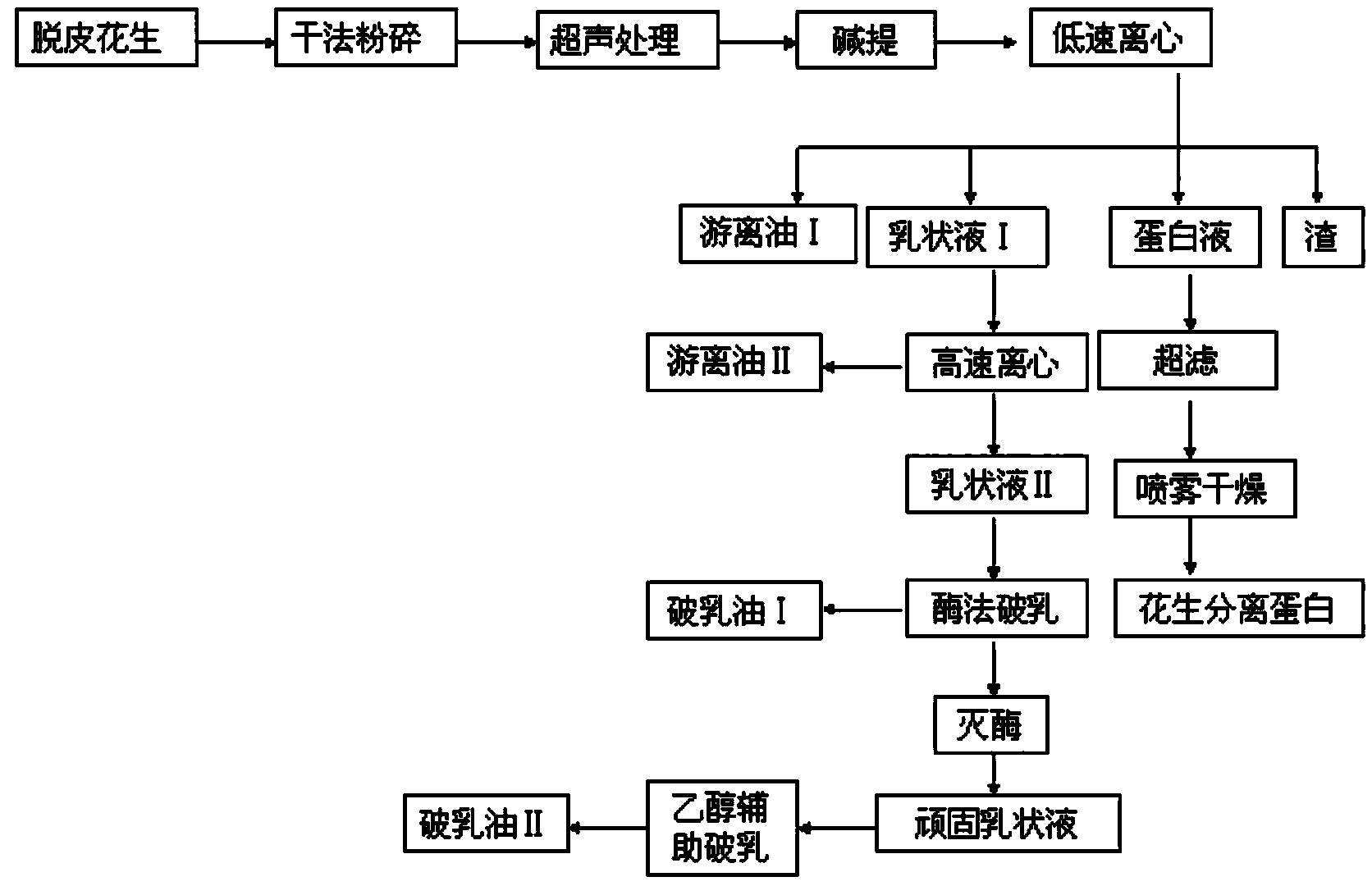

Method for extracting peanut oil and fat and protein with ultrasonic assisted aqueous enzymatic method

ActiveCN103588856ASimple equipment and processReduce energy and resource consumptionPeptide preparation methodsFatty-oils/fats productionUltrafiltrationChemistry

The invention discloses a method for extracting peanut oil and fat and protein with an ultrasonic assisted aqueous enzymatic method, belonging to the technical field of fine processing of agricultural products and comprehensive utilization of by-products. The method comprises the following steps: after grinding blanched peanuts with a dry method, adding water to adjust alkali for ultrasonic-assisted extraction, and digesting after adjusting alkali at the second time; low-speed centrifuging to obtain free oil I and emulsion I, and high-speed centrifuging the emulsion I to obtain free oil II and emulsion II; causing the emulsion II to carry out complex enzyme breaking to obtain demulsification oil I, and causing stubborn emulsion to carry out ethanol-assisted breaking to obtain demulsification oil II; ultra-filtering and desalting protein fluid, and then spray drying to obtain peanut isolate protein powder. Finally, the extraction ratio of free oil is 83 percent, the extraction ratio of total oil is 92 percent, the protein recovery ratio is 91.6 percent, the peanut protein purity is 89 percent, and the breaking ratio of emulsion can achieve 97-98 percent. Compared with the traditional aqueous enzymatic method, the method has the advantages that the extraction ratio of free oil is increased, the dosage of enzyme is greatly reduced, the residual oil ratio of emulsion is significantly reduced, and meanwhile, the peanut protein powder with high purity and good functionality is obtained.

Owner:JIANGSU JOILK GRAIN & OIL

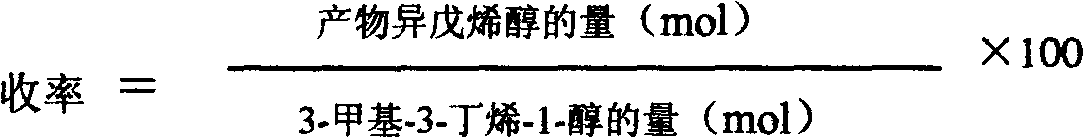

Method for preparing prenol by isomerizing 3-methyl-3-butene-1-ethanol

InactiveCN102701910AStable compositionSimple equipment and processPreparation by isomerisationHigh pressureEnergy consumption

The invention relates to a method for preparing prenol by isomerizing 3-methyl-3-butene-1-ethanol. The novel catalyst is advantaged in stable component, simple apparatus and process, and high-pressure hermetic operation, no hydrogen atmosphere is needed, so that the safety is high, and the energy consumption is low, and the industrialized implementation is facilitated.

Owner:NANKAI UNIV

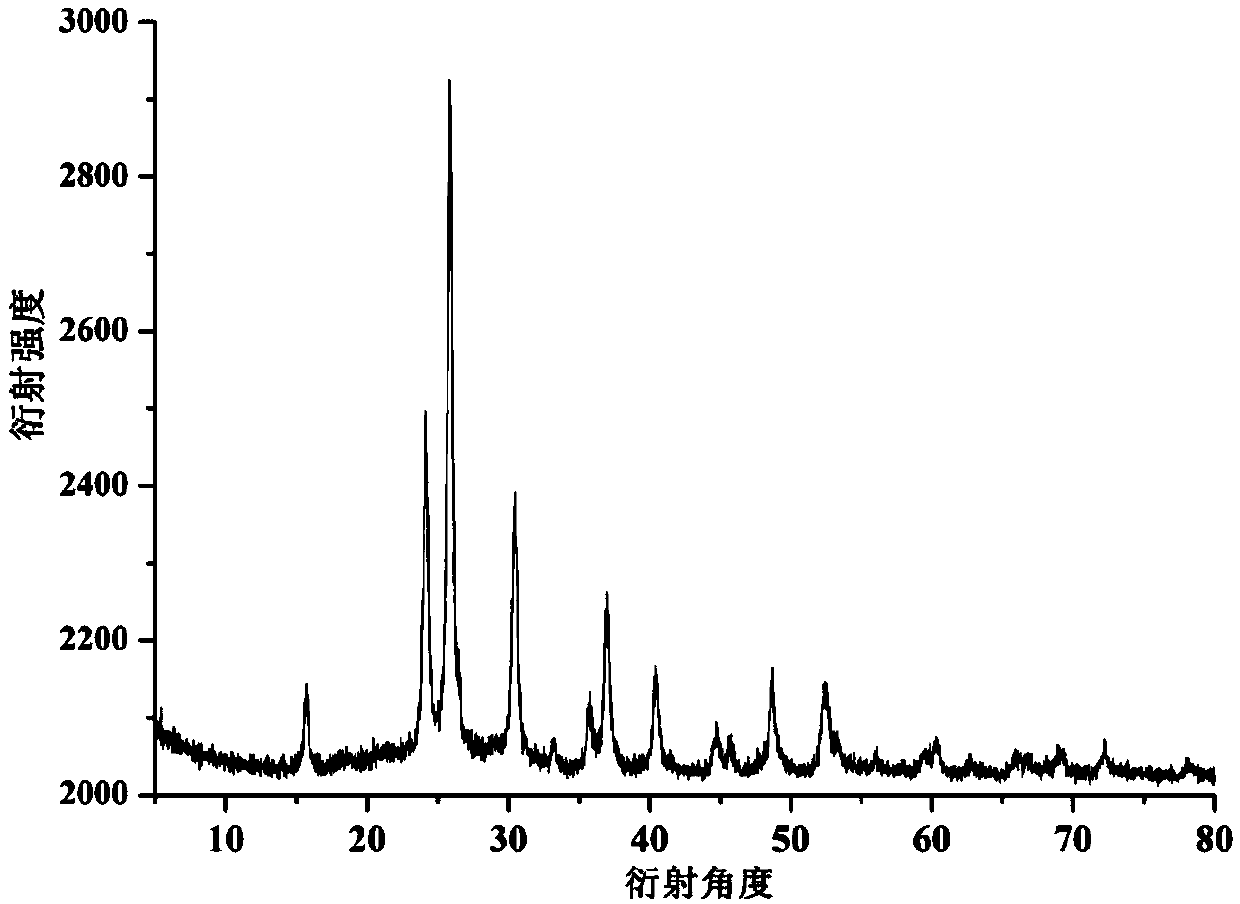

Method for preparing high-purity high-density WO3/S core-shell structure nano-particles

InactiveCN103469155ASimple equipment and processIncrease productionVacuum evaporation coatingSputtering coatingSingle crystalNanoparticle

The invention relates to a method for preparing high-purity high-density WO3 / S core-shell structure nano-particles, and belongs to the technical field of material preparation. The high-density WO3 / S core-shell structure nano-particles can be prepared by one-step synthetic deposition on a silicon chip, a gallium arsenide chip, a sapphire chip or a silicon carbide chip with flat and smooth surface in the protection of a carrier gas by virtue of a thermal evaporation method by adopting a vacuum tubular furnace and taking tungsten oxide and sulfur powder as evaporation sources, wherein the core is single-crystal WO3, and the shell is amorphous simple substance S. The method has the advantages of strict and controllable deposition condition, simple equipment and process, high yield, low cost and the like. The product with a nano-structure has high purity, the diameters of the core and the shell are uniformly distributed, and the particle size is controllable; the nano-particles have a wide application prospect in piezoresistors, gas sensors, catalysts and other fields.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

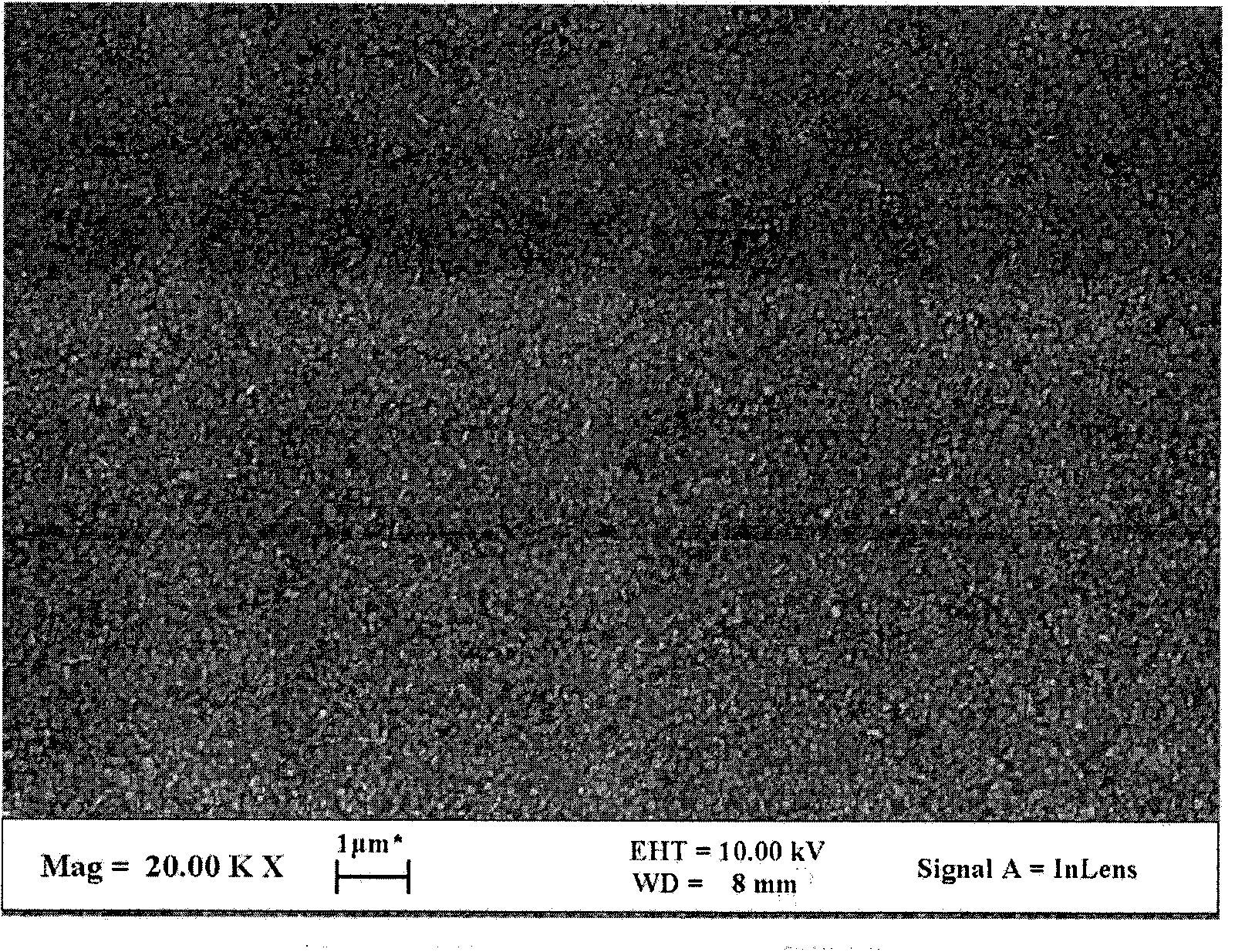

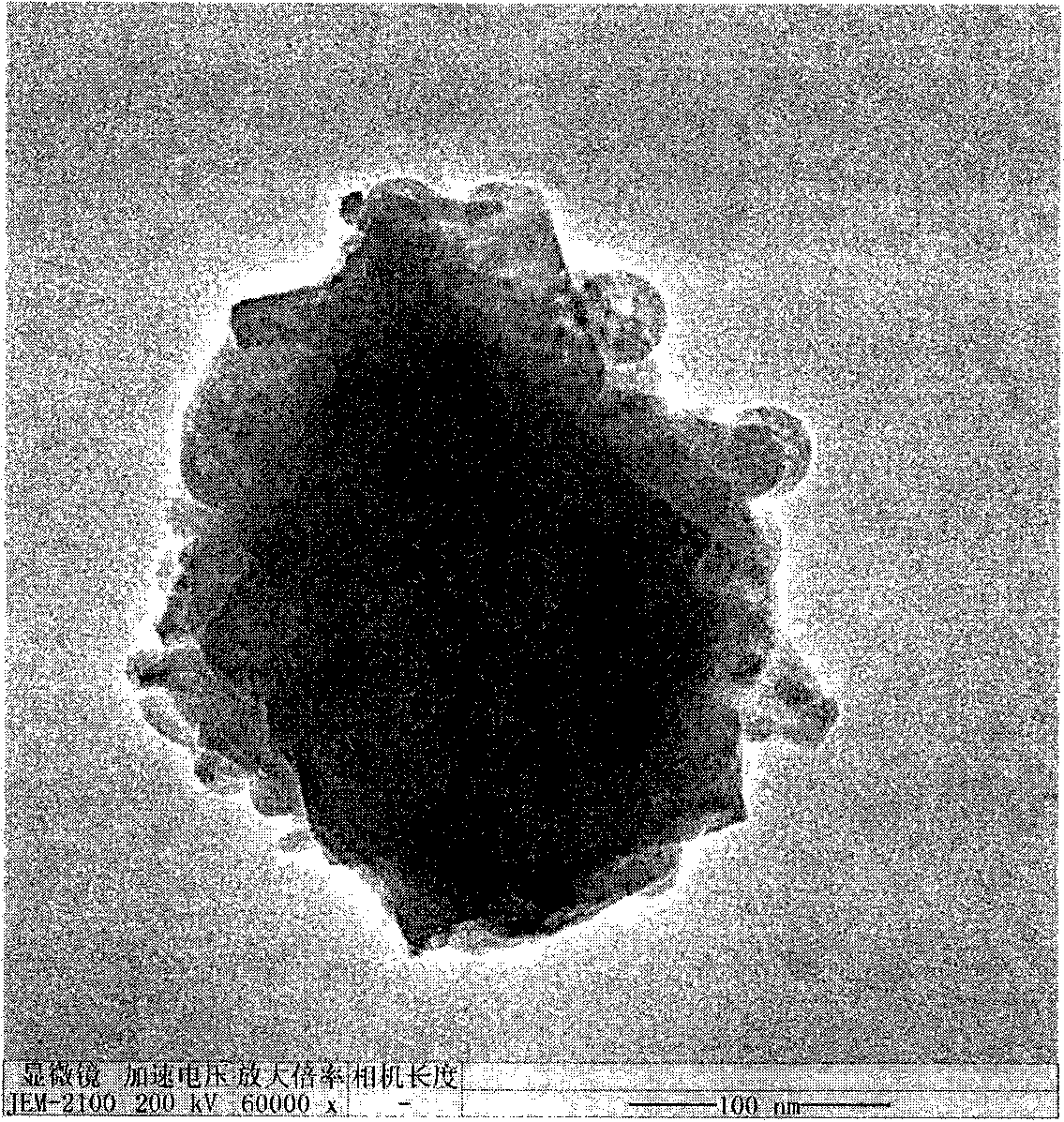

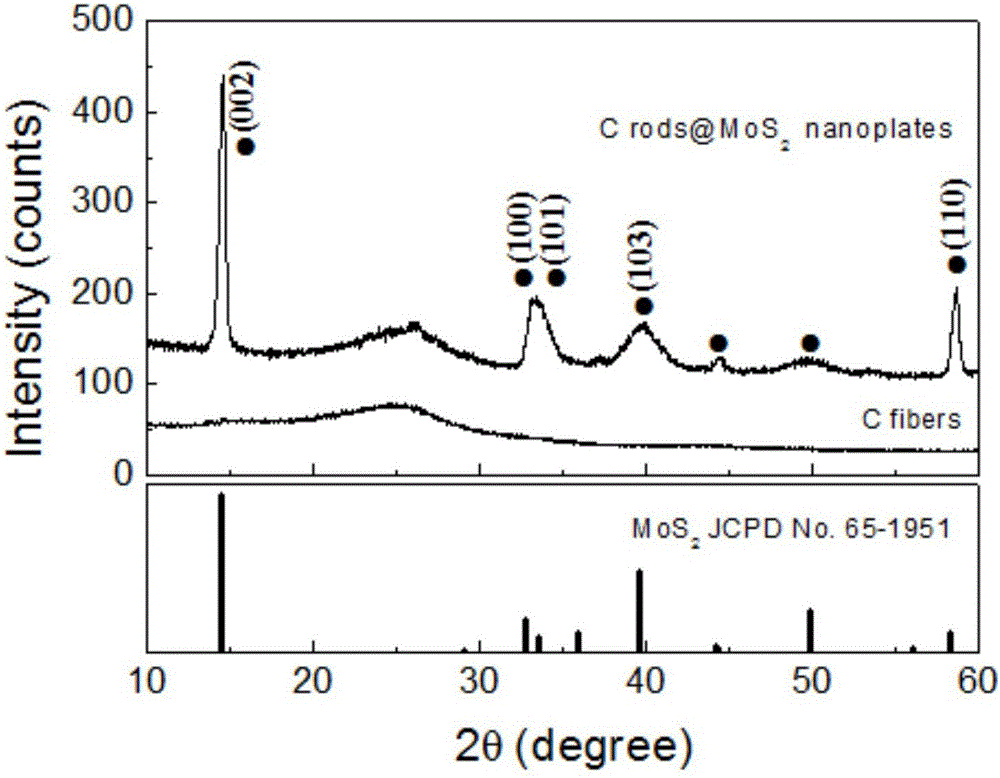

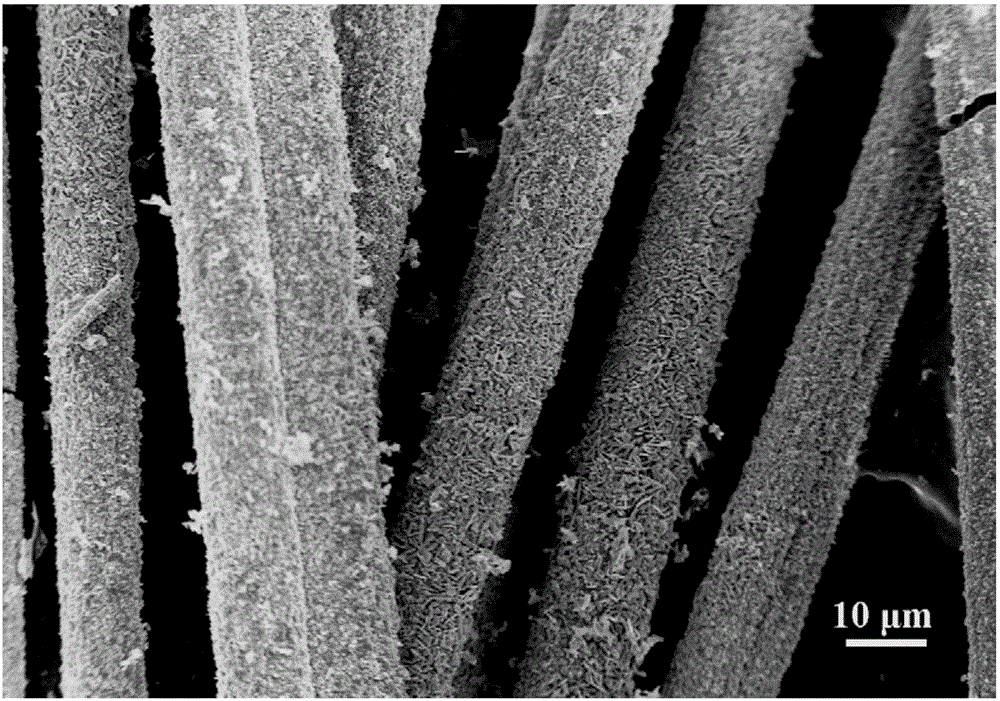

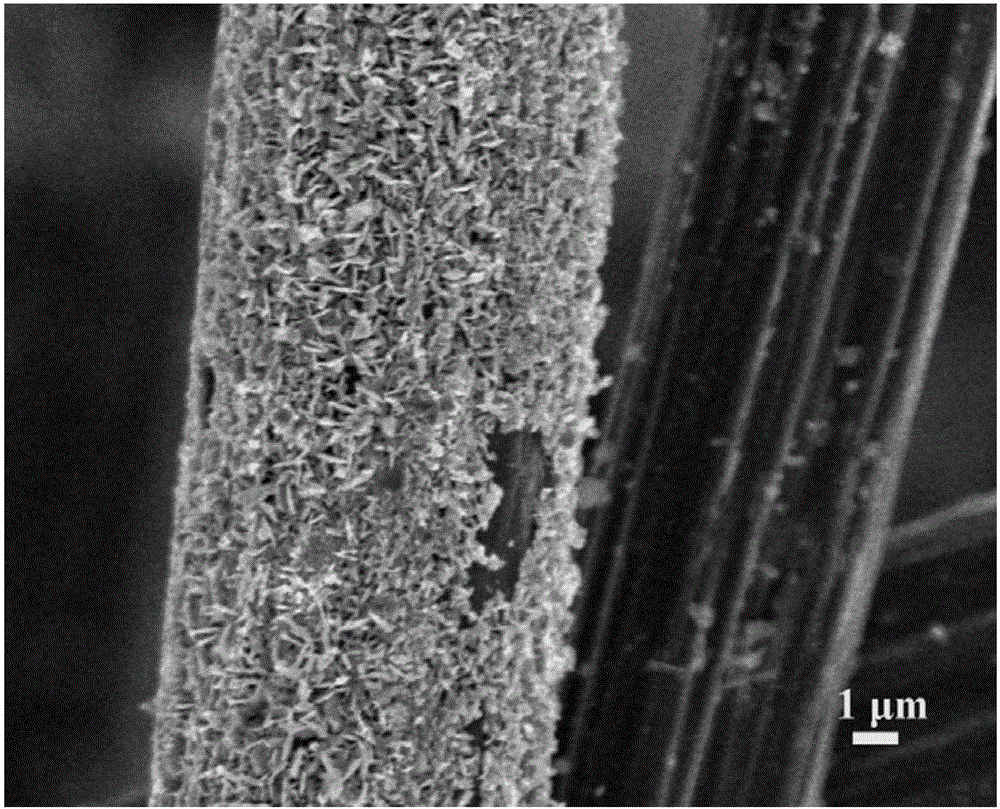

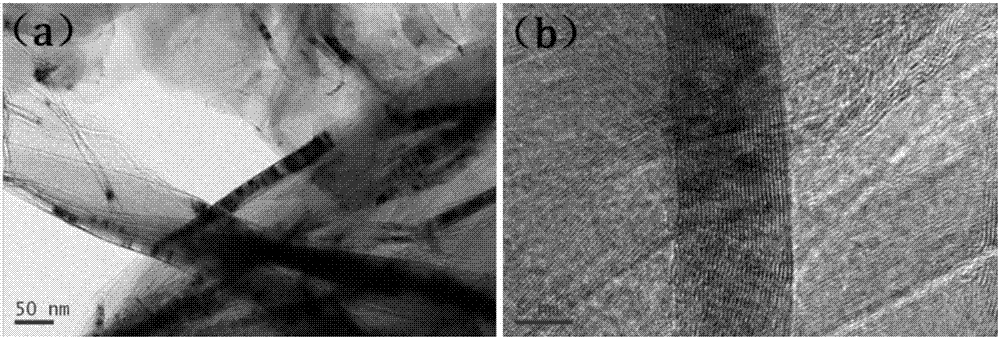

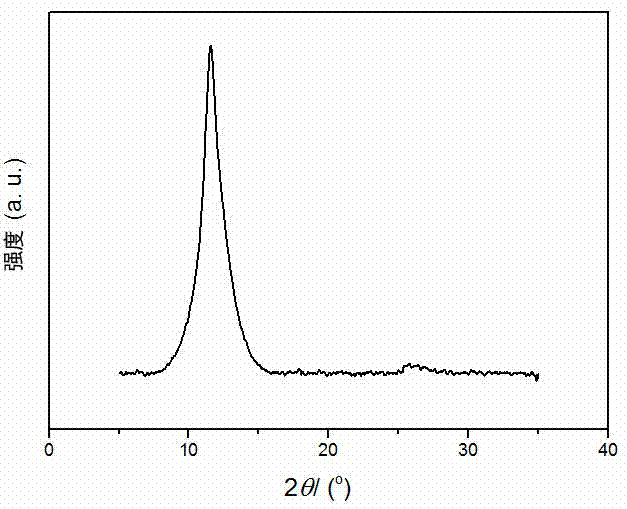

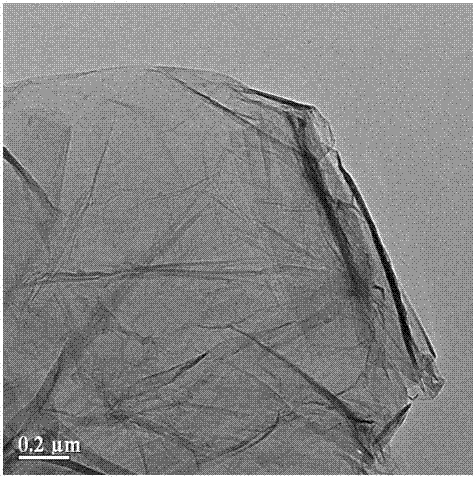

Carbon fiber@molybdenum disulfide nanosheet core-shell composite structure and preparation method thereof

InactiveCN106238077ASimple equipment and processSynthetic growth conditions are tightly controlledPhysical/chemical process catalystsElectrolysis componentsTube furnaceLithium electrode

The invention relates to a carbon fiber@molybdenum disulfide nanosheet core-shell composite structure and a preparation method thereof, and belongs to the technical field of material preparation. Carbon fibers serve as an inner core of the composite structure, and molybdenum disulfide nanosheets which are arranged in an array mode serve as a shell of the composite structure. The preparation method comprises the steps that in a vacuum tubular furnace, sulfur powder is directly evaporated through a thermal evaporation technique to serve as a sulfur source, pre-oxidized polyacrylonitrile fibers soaked with MoO3 turbid liquid are fumigated at high temperature under the action of carrier gas, simultaneous synthesis of the carbon fibers and the molybdenum disulfide nanosheets is achieved, and the carbon fiber@molybdenum disulfide nanosheet core-shell composite structure can be prepared at high yield. The product prepared through the method is high in yield, density and purity and controllable in morphology and does not need aftertreatment; the method has the advantages that equipment and the process are simple, the synthesis growth conditions are strict and controllable, the product yield is high, the cost is low, and the production process is clean and environmentally friendly; the obtained material is an excellent visible light catalyst, hydrogen desulfurization catalyst, electrocatalyst, lithium ion battery electrode material and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

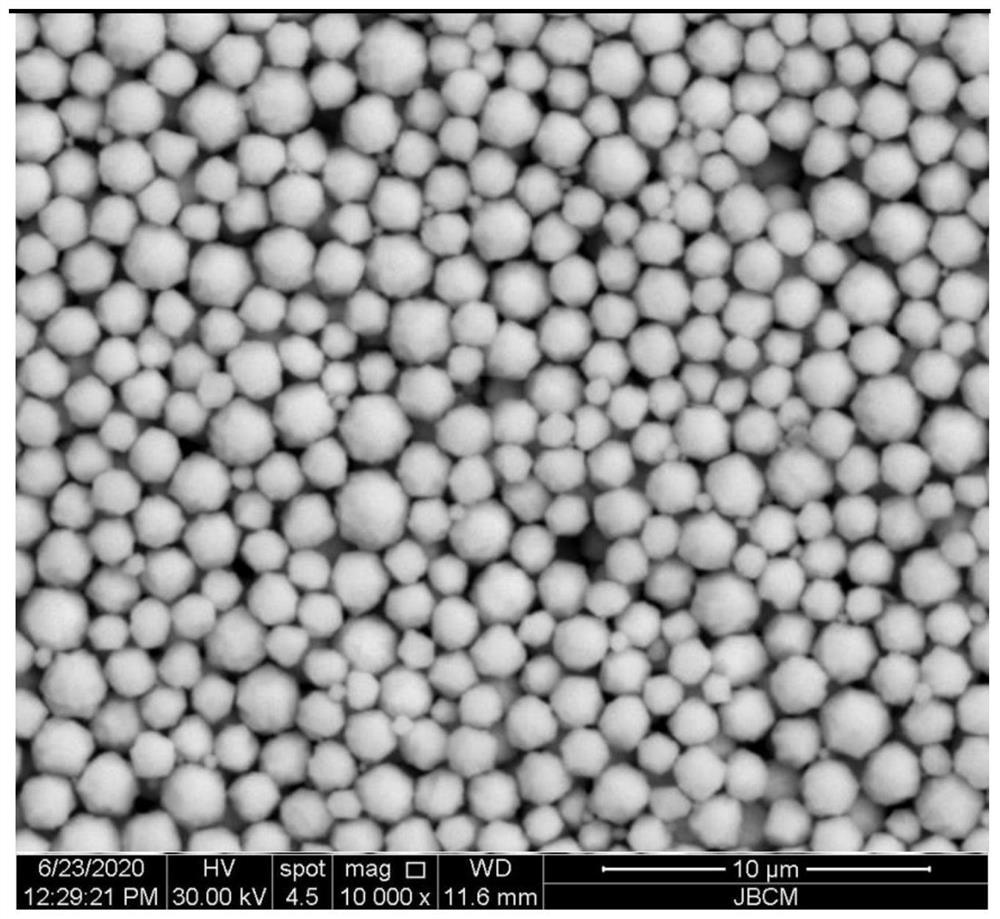

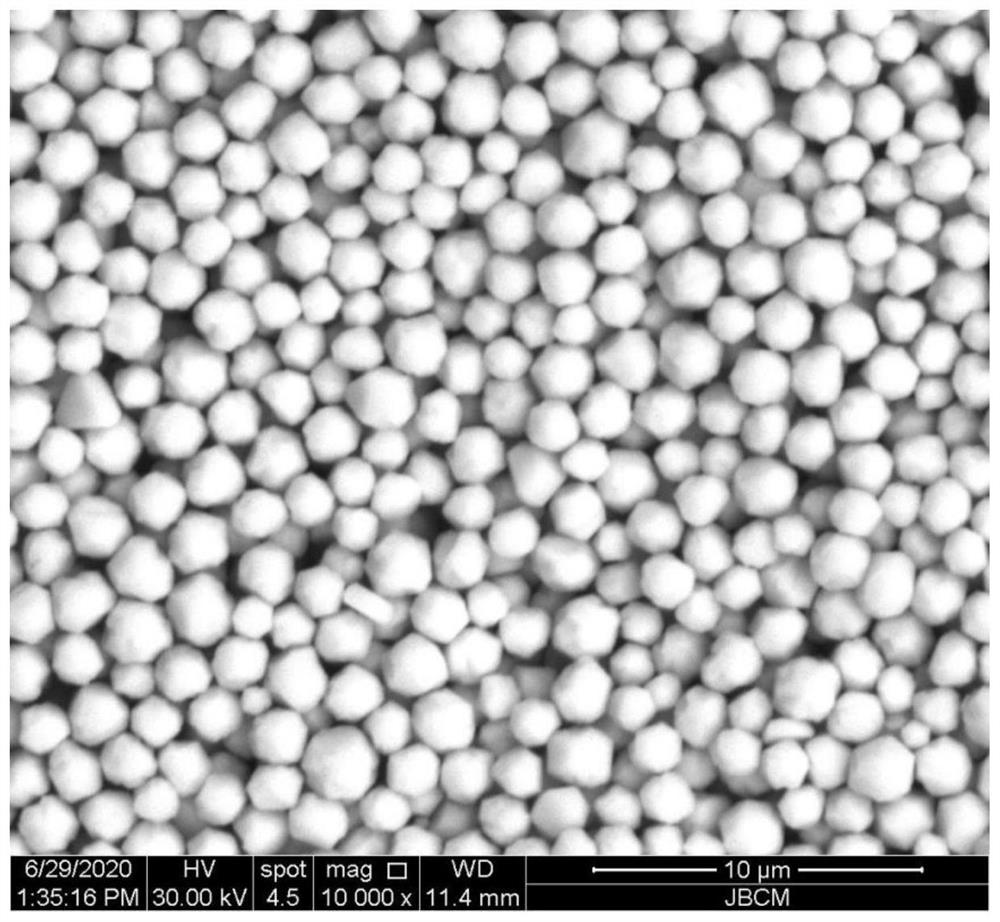

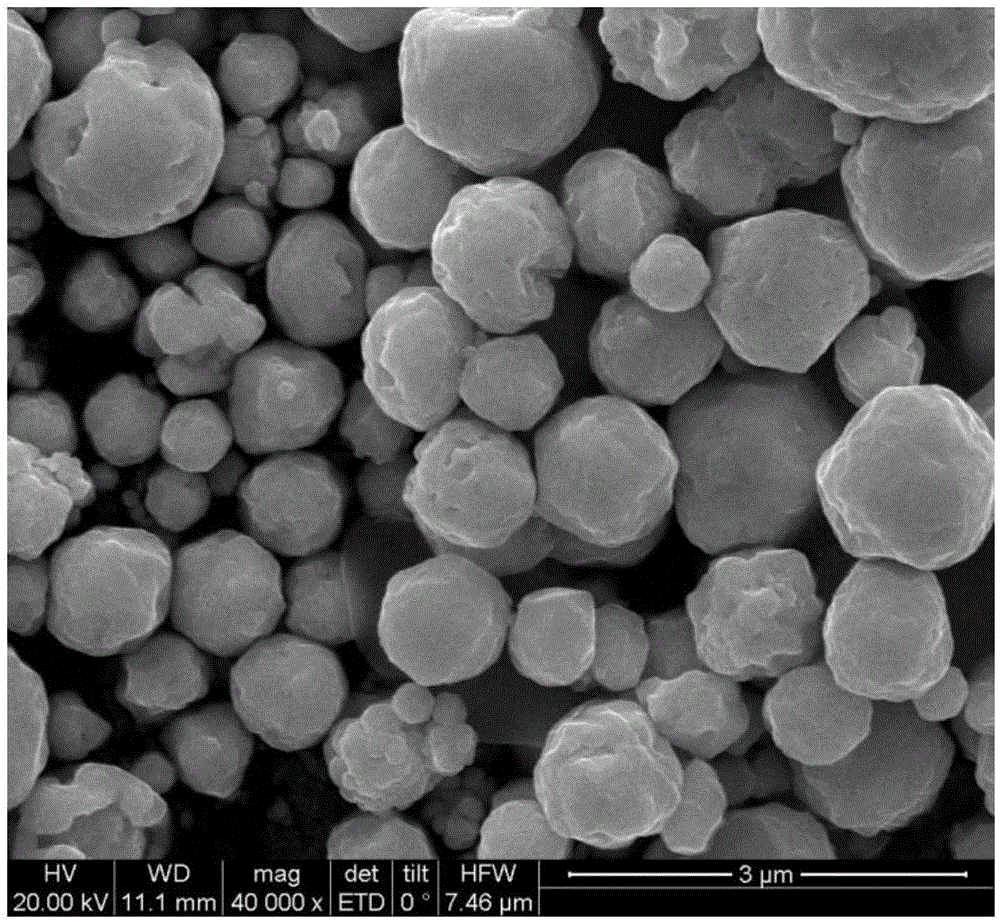

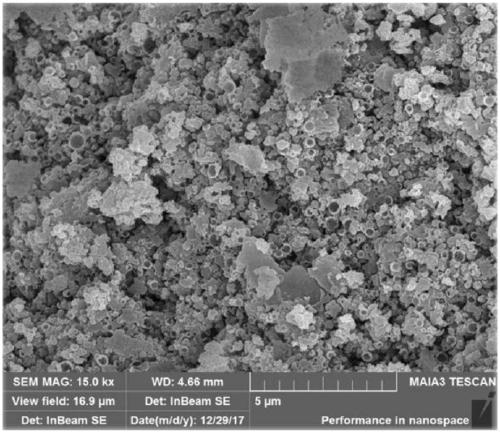

Microcrystal silver powder with nano-silver surface structure, and preparation method thereof

ActiveCN111922356ASimple process controlSimple equipment and processMaterial nanotechnologyTransportation and packagingActive agentSilver nitrate

The invention provides microcrystal silver powder with a nano-silver surface structure, and a preparation method thereof. The preparation method comprises the following steps: (1) obtaining a silver nitrate solution, a reducing agent solution and a dispersing agent solution through separate preparation; (2) adding 70-95% of the total mass of the silver nitrate solution and all the reducing agent solution into the dispersing agent solution at the same time under a stirring condition to prepare a silver powder suspension; (3) adjusting a pH value of the silver powder suspension, adding a surfaceactive agent for mixing, and then adding the left silver nitrate solution for stirring and a reaction; and (4) treating above reaction reagents with solid-liquid separation, washing and drying to obtain the microcrystal silver powder with the nano-silver surface structure. Through control of the reaction pH and an addition amount of the silver nitrate solution, compound modification of a nano surface of the microcrystal silver powder is realized, and the obtained microcrystal silver powder has a controllable particle diameter of 0.5-3.0 mu m and has a spherical or near-spherical uniform shape.

Owner:山东建邦胶体材料有限公司

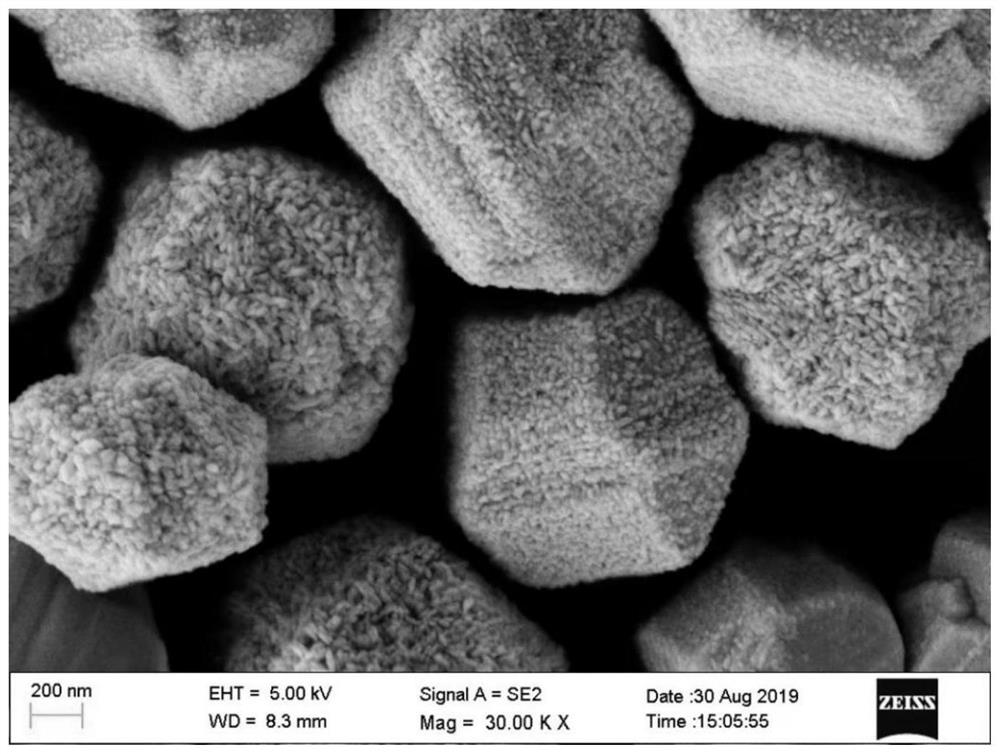

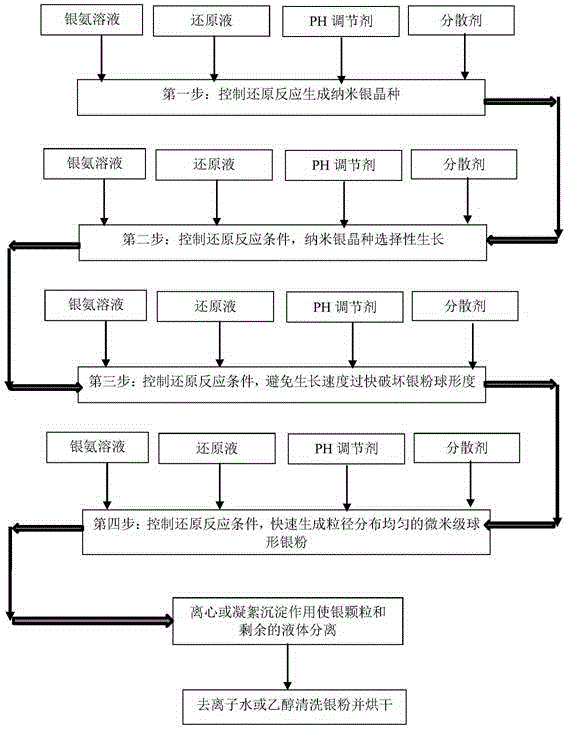

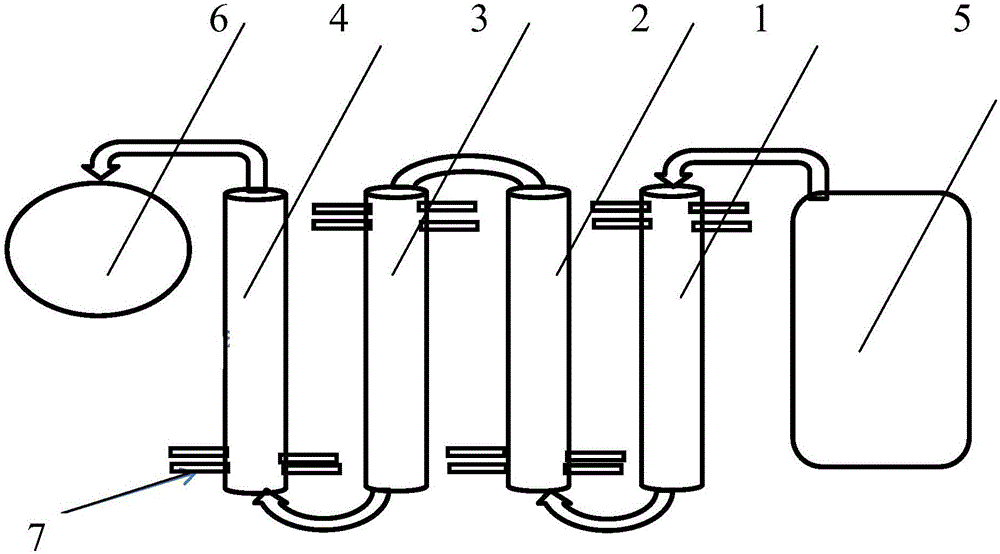

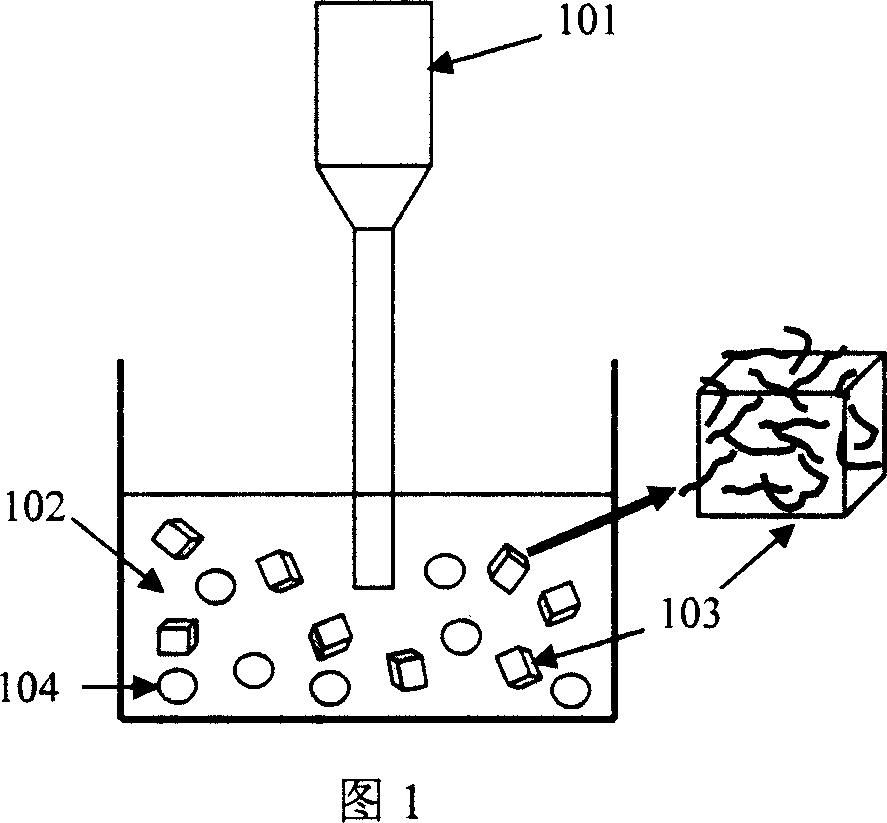

Method and device for preparing spherical silver powder by fractional step method

The invention discloses a method for preparing spherical silver powder by a fractional step method. Reducing liquid, silver ammonium solution, a PH adjusting agent and a dispersing agent are respectively added in multiple serially connected reaction devices in sequence in a jet manner, and are fully mixed in sequence in different reaction containers for fraction step reaction. (1) a nanosilver seed crystal is generated by controlling a reducing reaction; (2) the nanosilver seed crystal is selectively grown by controlling reducing reaction conditions; (3) the damage of sphericity of silver powder due to quicker growth speed is prevented by controlling the reducing reaction conditions; and (4) micron-grade spherical silver powder with uniformly distributed particle sizes is quickly grown by controlling the reducing reaction conditions. Finally, the generated high-dispersibility spherical silver particles and the remained liquid are conveyed into a separation system; silver particles are separated from the remained liquid by a centrifugation or floculation precipitation effect to obtain the high-dispersibility spherical silver particles; the spherical silver particles are cleaned by de-ionized water or ethanol for drying to obtain the spherical silver powder. The method is simple and stable in production process, and is higher in quality of the spherical silver powder.

Owner:珠海德晶光电科技有限公司

Lithium ion capacitor and preparation method therefor

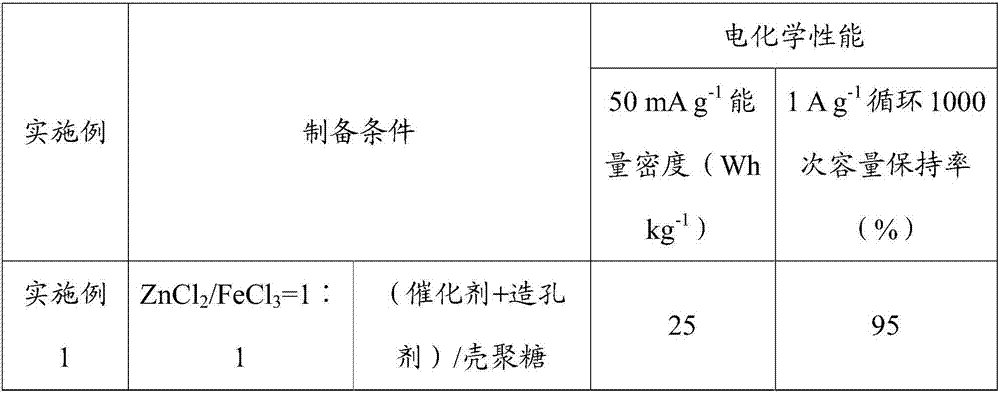

ActiveCN106952736ASimple equipment and processLow cost of preparationGraphiteHybrid capacitor electrodesLithium-ion capacitorElectrical battery

The invention provides a lithium ion capacitor and a preparation method therefor. The lithium ion capacitor comprises a positive electrode material and a negative electrode material, wherein the positive electrode material is a porous carbon material, and the negative electrode material is a graphitized carbon material. The porous carbon material and the graphitized carbon material take a pore forming agent and / or catalyst and a carbon source as the raw materials, and are prepared through thermal treatment. The preparation method comprises the steps: assembling the negative electrode material and a lithium piece into a semi-battery, performing the circulation for three times under the condition of a 50 mA / g current, and carrying out the discharging till the voltage is 0.01V; disassembling the semi-battery to obtain a graphitized carbon negative electrode piece, in which lithium is embedded in advance; enabling the negative electrode piece with the lithium and the porous carbon positive electrode material to respectively serve as the negative electrode and the positive electrode of the lithium ion capacitor, and carrying out the assembling with electrolyte and a diaphragm to form the lithium ion capacitor. According to the invention, the positive electrode material is large in capacity, and the negative electrode material has a certain voltage platform, is large in capacity, is better in multiplying performance, and enables the performance of the capacitor to be excellent.

Owner:CENT SOUTH UNIV

Nano or micron-scale gold disk and preparation method thereof

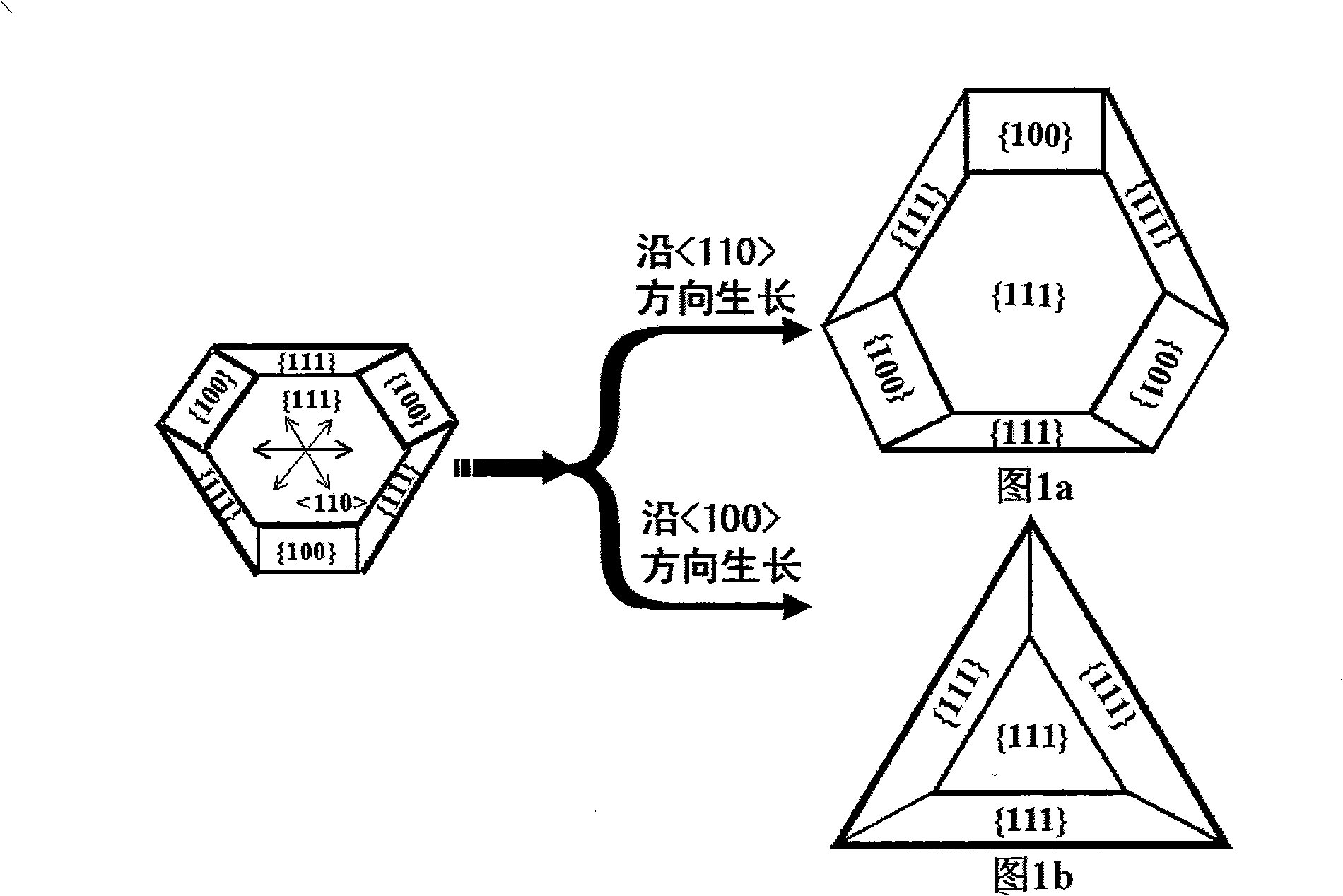

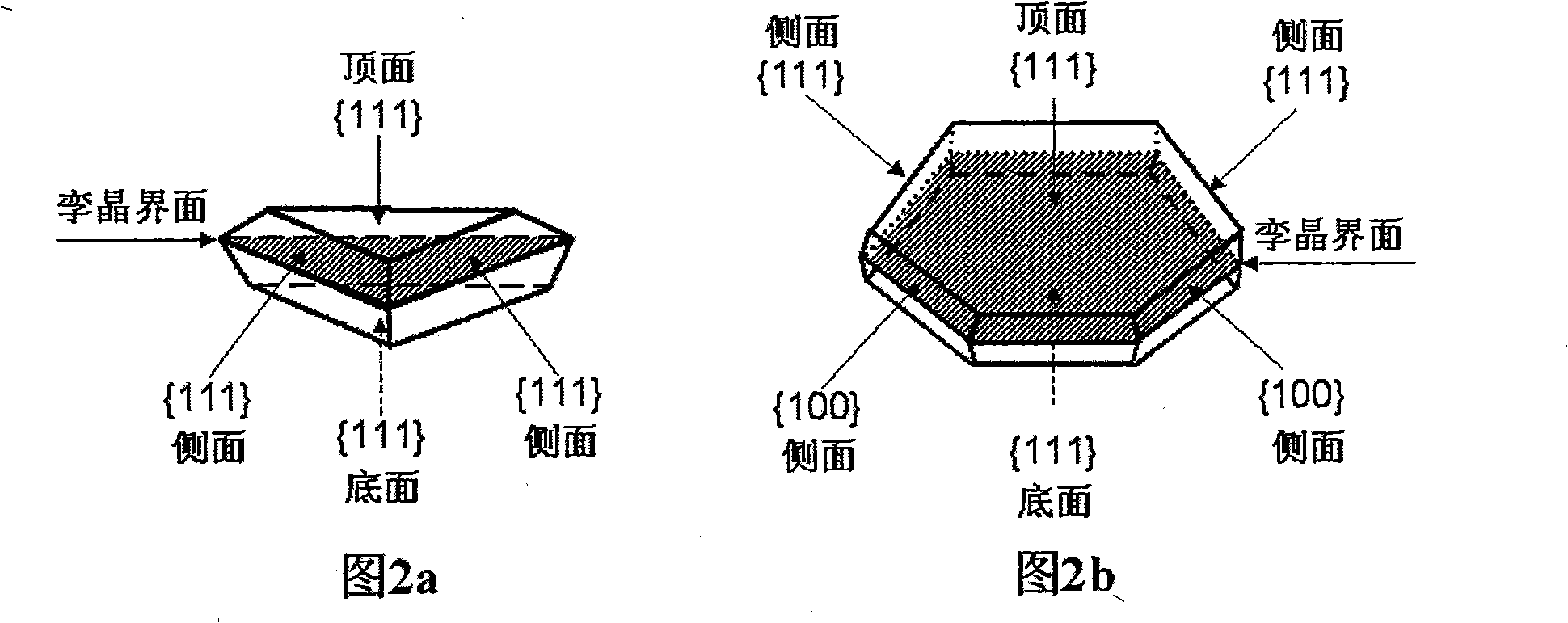

InactiveCN101538735ASimple equipment and processStrong maneuverabilityPolycrystalline material growthSingle crystal growth detailsSolventPolytetrafluoroethylene

The invention relates to a nano or micron-scale gold disk and a preparation method thereof. The shape of the gold disk is a triangle or a hexagon. The middle of the gold disk is provided with a twin-plane boundary. The preparation method comprises the following steps of: selecting chloroauric acid or chloraurate and a polyvinylpyrrolidone capping agent in the same volume; adding the chloroauric acid or chloraurate and the polyvinylpyrrolidone coating agent into a solvent of ethylene glycol and obtaining a mixed solution of reactants after mixing; transferring the obtained solution to a polyfluortetraethylene container and sealing the polyfluortetraethylene container in a metal high pressure autoclave; heating the solution for 2 to 12 hours and allowing the solution to cool naturally to room temperature to obtain orange red sol; subjecting the orange red sol to natural settling by using ethanol or acetone for 24 hours or to centrifugal settling in a centrifuge for 30 minutes; removing supernatant liquid to obtain orange yellow precipitate; continuing to wash the orange yellow precipitate with ethanol or acetone, and settling for times to remove excess PVP and EG solvent by washing; and finally, obtaining the polyvinylpyrrolidone-coated nano and micron-scale gold disk. The method is simple and safe in equipment and process, strong in commonality and manageability, and capable of realizing large-scale production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing rare earth fluorescent fiber

InactiveCN101838860AAvoid reunionSimple equipment and processMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentPolyvinylidene fluorideSolvent

The invention discloses a method for preparing rare earth fluorescent fiber. A flash vaporization process is adopted. The method comprises the following steps of: putting a polymer and a nano rare earth fluorescent material into a high-pressure autoclave in a mass ratio of 100:0.5-5 for uniform mixing; adding a solvent into the mixture, wherein 50 to 200ml of the solvent is added into every 10g of the polymer; fully and uniformly stirring the mixture; heating to raise the temperature; fully dissolving the polymer at the temperature of between 150 and 350 DEG C under the pressure of between 5 and 25MPa; continuously stirring the mixture for 10 to 30 minutes; opening the high-pressure autoclave for discharging and controlling the valve to make the spinning solution eject from a nozzle; and performing high stretching on the cured polymer by high-speed air flow to obtain the rare earth fluorescent fiber, wherein the polymer is polyolefin, polyethylene terephthalate, polysulfone or polyvinylidene fluoride; the nano rare earth fluorescent material is Ln2M1(M2)R and has a grain diameter of 30 to 100nm; and the solvent is 1,2-dichloroethane, chloroform or hexamethylene.

Owner:TIANJIN POLYTECHNIC UNIV

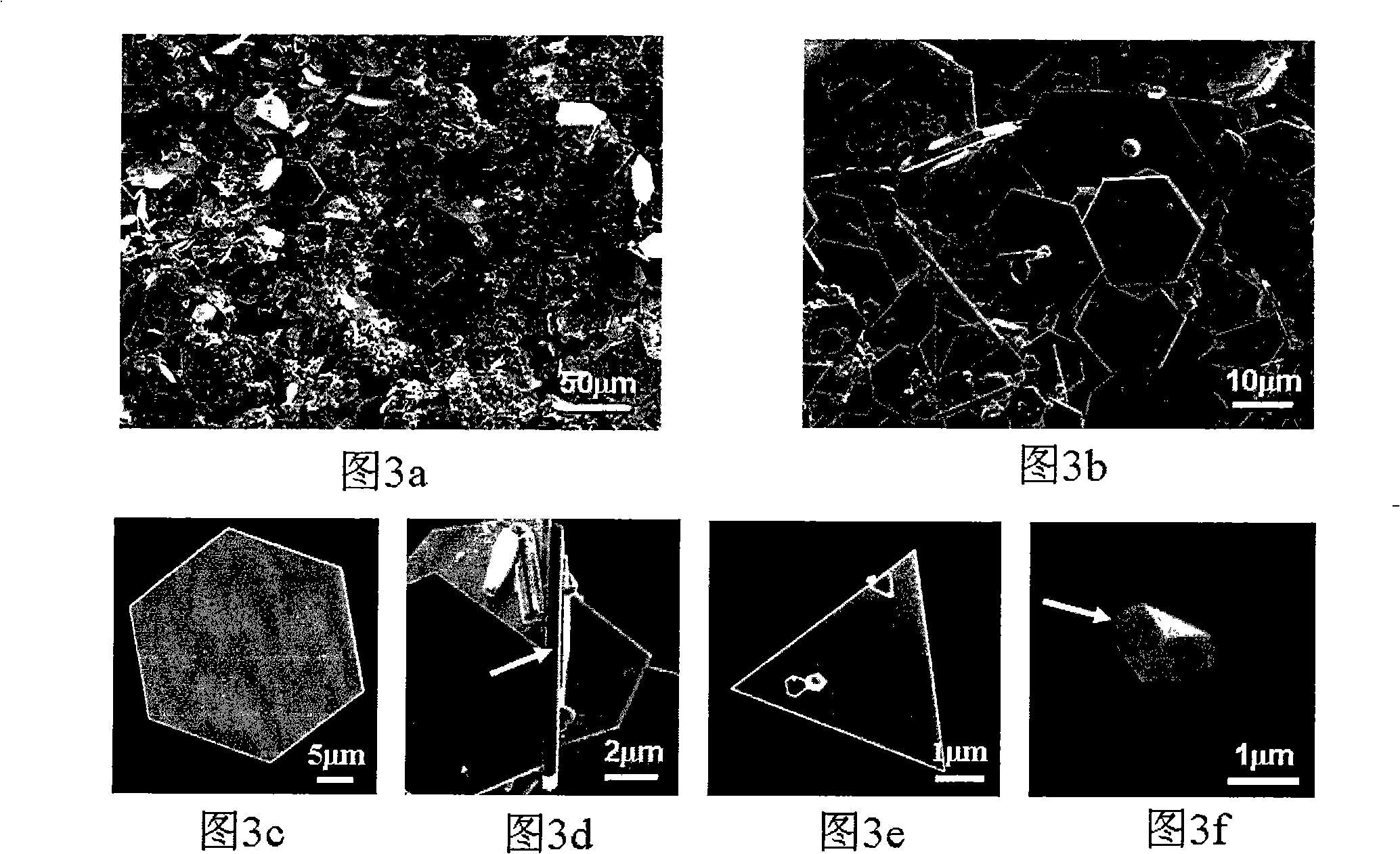

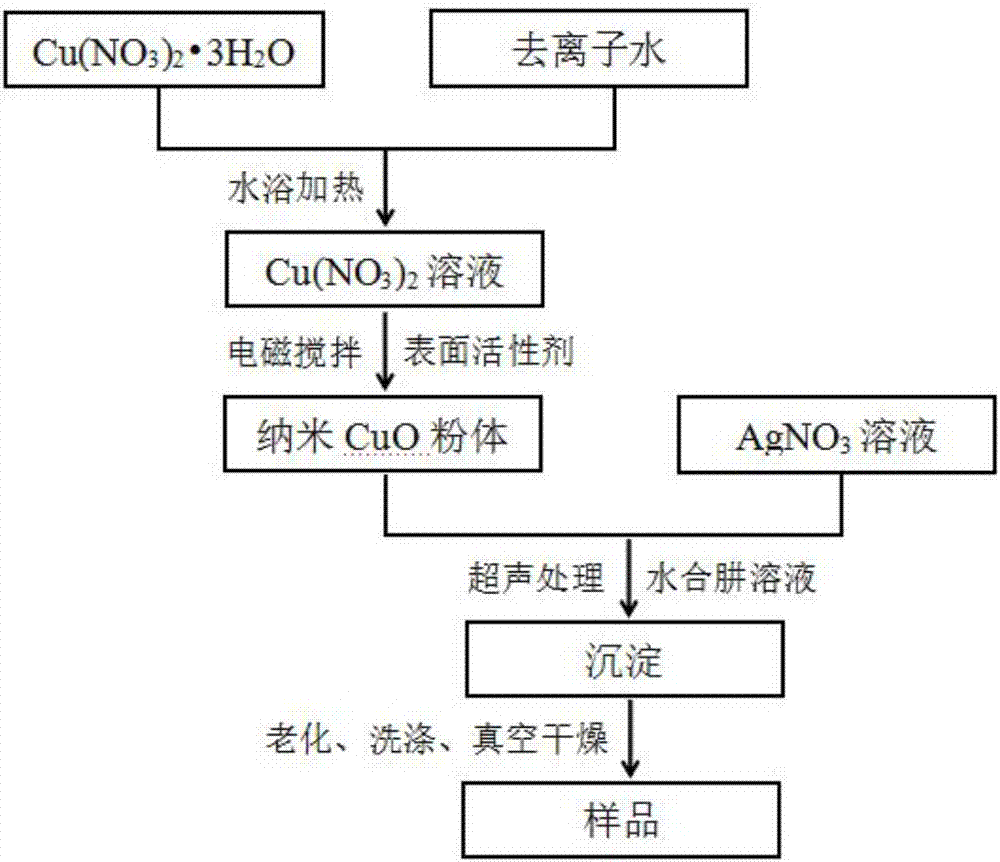

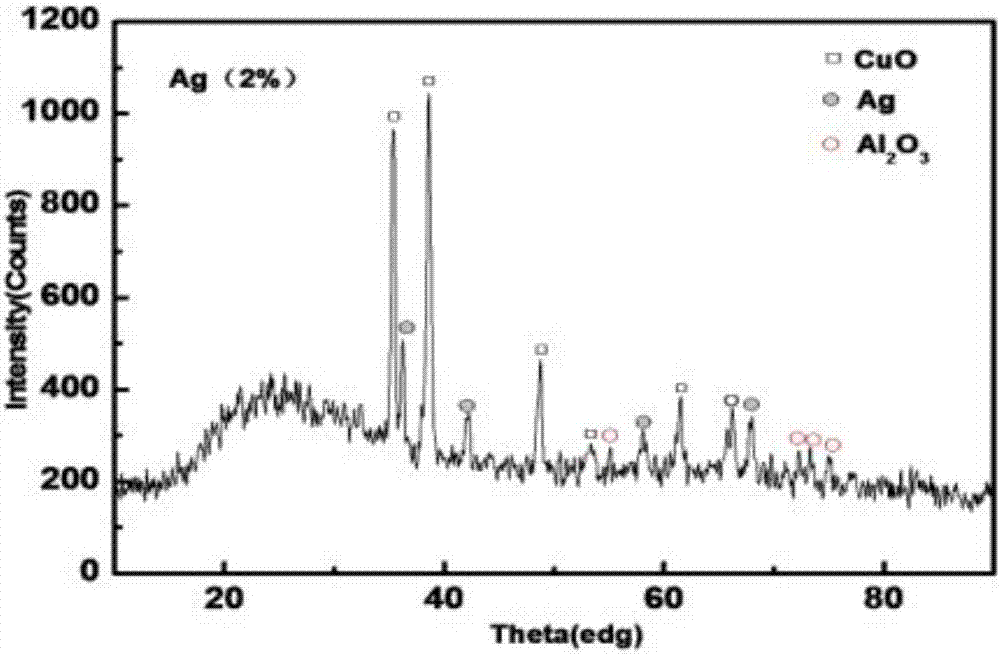

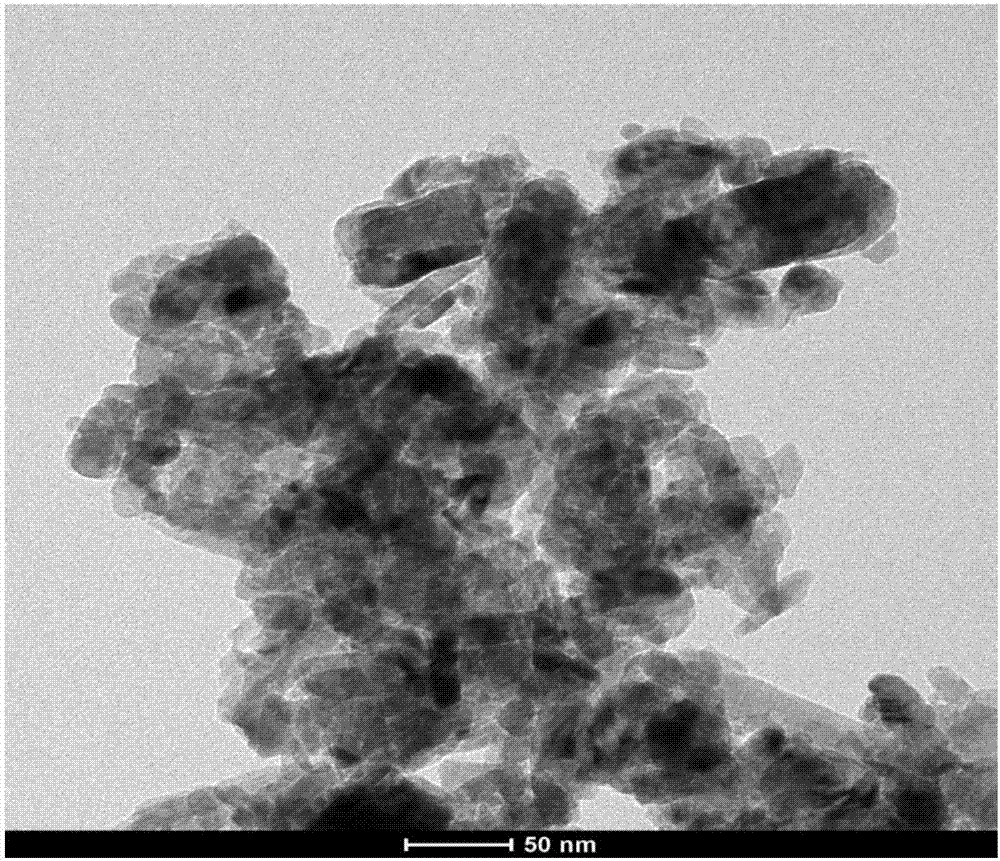

Silver-loaded copper oxide nano composite material preparation method

ActiveCN107413354ALow costSimple equipment and processMetal/metal-oxides/metal-hydroxide catalystsMaterials preparationVacuum drying

The invention discloses a silver-loaded copper oxide nano composite material preparation method which is applied to the field of catalysis. The method includes steps: taking copper nitrate trihydrate as a copper source and sodium hydroxide solution as a precipitant, adding a surfactant, electromagnetically stirring to obtain a precipitate, washing and drying to obtain nano CuO powder; under the condition of ultrasonic treatment, taking silver nitrate solution as a silver source and hydrazine hydrate as a precipitant to obtain a silver-loaded copper oxide nano composite material through aging, washing and vacuum drying. The preparation method is simple in process, low in cost and low in equipment requirement, an obtained product is small in particle size being about 50nm, large in specific surface area, close in combination of nano silver particles and a copper oxide matrix and great in catalysis performance, problems of complex preparation process, long production period, high production cost and the like of the nano copper oxide composite material are solved, and a promising industrial application prospect is achieved.

Owner:SHANDONG NORMAL UNIV

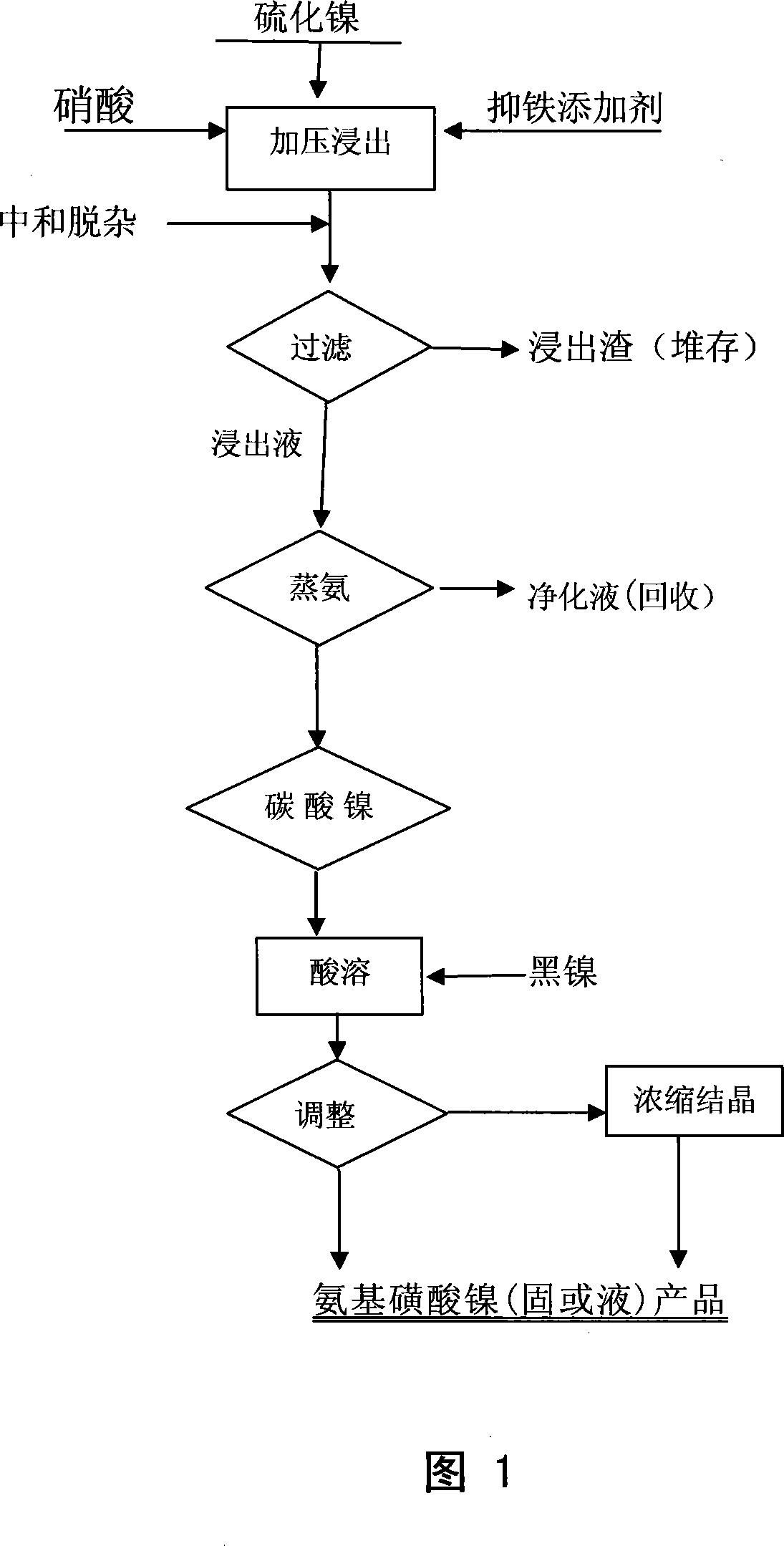

Process for preparing amino-sulfonic acid nickel by nickel sulfide concentrate

InactiveCN101134566ALarge amount of nickel lossSimple equipment and processAmidosulfonic acidSulfur compoundsSal ammoniacDiammonium carbonate

The present invention belongs to the field of wet treating process of nickel sulfide material, and is especially wet process of preparing nickel sulfamate with concentrated nickel sulfide ore. The process includes the following steps: pressure leaching the material with nitric acid; neutralizing and purifying with ammonium carbonate or ammonia water to eliminate Fe, Mn, Zn and other impurities; distilling ammonium nickel carbonate to eliminate ammonia; drying refined nickel carbonate; dissolving refined nickel carbonate in sulfonic acid; depurating nickel sulfamate with black nickel; and regulating nickel sulfamate solution. The present invention has simple technological process, low nickel loss, capacity of recovering Co and other valuable metals, low power consumption, low cost and other advantages.

Owner:YUNNAN TIN GROUP HLDG

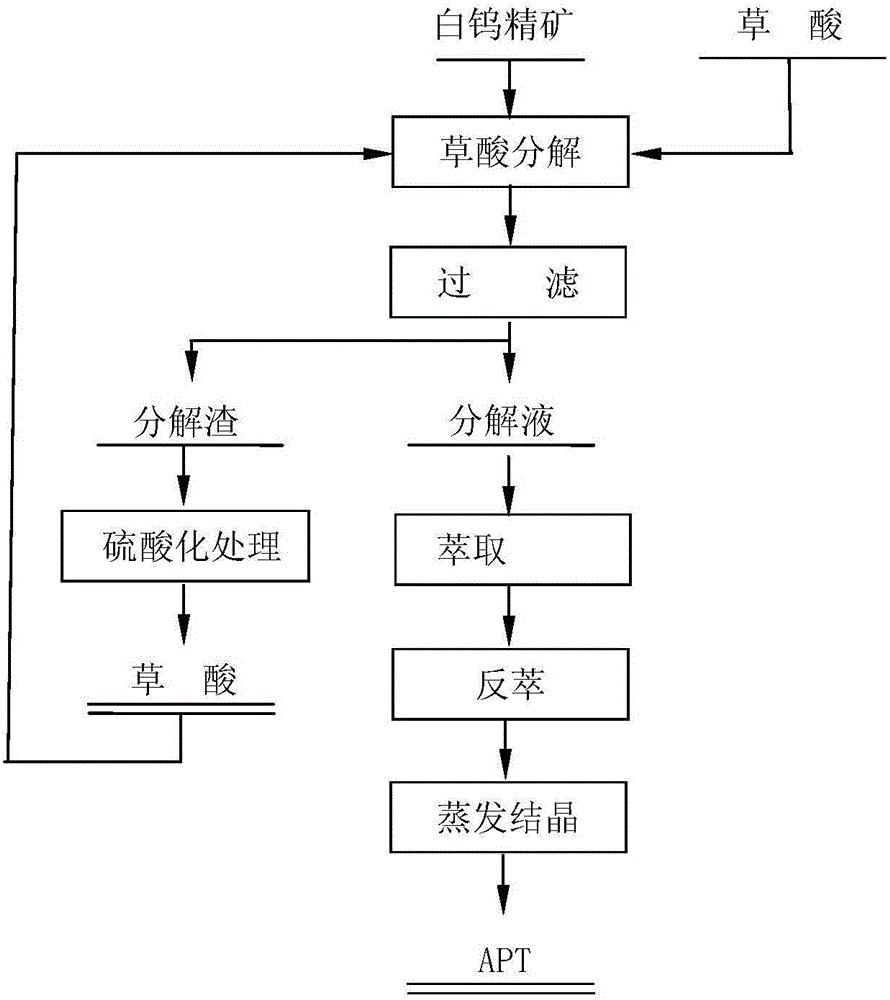

Method and system for decomposing scheelite concentrate

ActiveCN105925797ASimple equipment and processStrong maneuverabilityProcess efficiency improvementSlagScheelite

The invention discloses a method for decomposing scheelite concentrate. The scheelite concentrate is decomposed through oxalic acid, and decomposing liquid and decomposing slag are obtained through filtration; the decomposing liquid is subjected to extraction, reverse extraction and evaporative crystallization, and APT products are obtained; and the decomposing slag is treated through sulfuric acid, regenerated oxalic acid is obtained, and the regenerated oxalic acid can return to decompose the scheelite concentrate and can be repeatedly used. According to the method, the oxalic acid is adopted to directly decompose the scheelite concentrate under the normal pressure condition, and the decomposing rate of tungsten trioxide in the scheelite concentrate can reach 99% or above; and after the decomposing liquid is subjected to extraction, the tungsten extraction rate can reach 99% or above, and the zero-level APT products can be obtained in the whole process. By means of the method, the scheelite concentrate decomposing cost can be remarkably reduced, decomposing equipment is simplified, and operation is convenient.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

Nano carbon pipe composite field-emission source and manufacturing method thereof

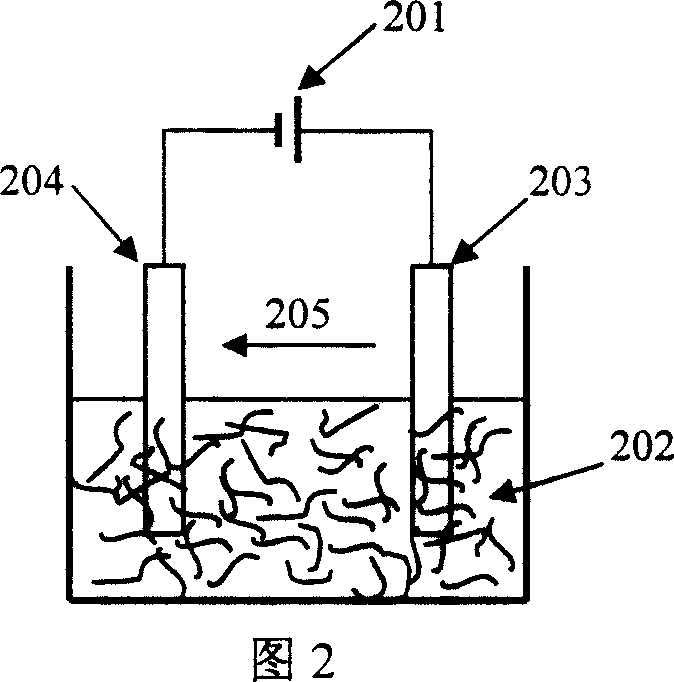

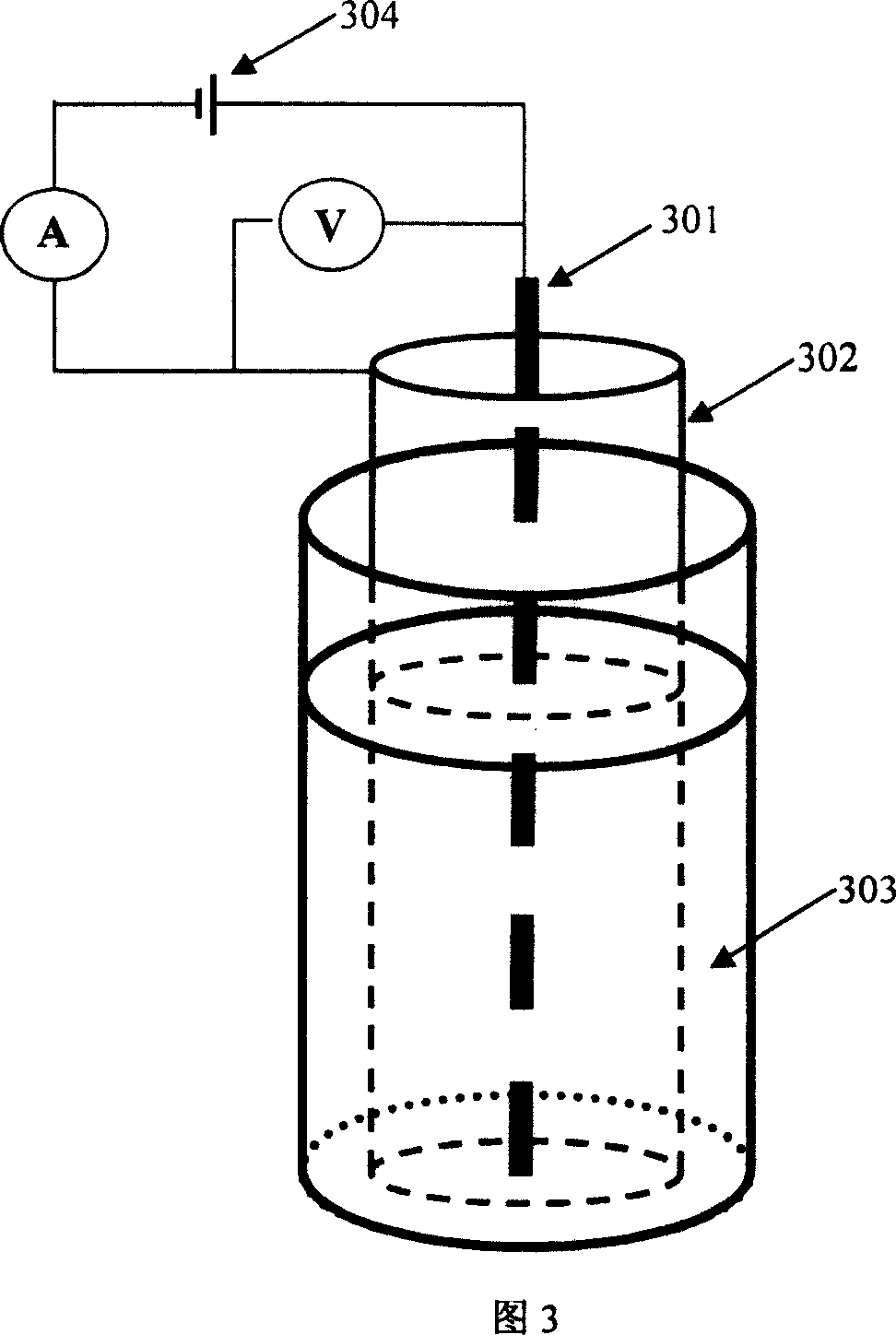

ActiveCN101047086ASimple equipment and processImprove efficiencyCathode ray tubes/electron beam tubesDischarge tube/lamp detailsElectrophoretic depositionEtching

The present invention relates to a nano carbon tube composite field emission source. It includes nano carbon tube membrane which is grown on the substrate and can be used as electronic field emission source. The described substrate is of conductive fibre braided rope or braided fabric, its fibre diameter range is 1-20 microns. The preparation method of said composite field emission source includes the following steps: under the condition of normal temperature and normal pressure utilizing phonochemical method to prepare nano carbon tube; adopting the processes of centrifugal separation, filtration, surface active ultrasonic dispersion, chemical corrosion, selective oxidation and ultrasonic etching, etc. to purify and shear nano carbon tube; then utilizing electrophoretic deposition process to make the purified and sheared nano carbon tube be firmly deposited on the conductive fibre braided rope or braided fabric so as to form the invented nano carbon tube composite field emission source.

Owner:北京汉纳源纳米科技有限公司

Method for preparing adipic acid by oxidizing cyclohexene with air under catalysis of non-metal carbon

InactiveCN103193616ASimple equipment and processHigh catalytic activityOrganic compound preparationCarboxylic compound preparationEnvironmental chemistryCyclohexenes

The invention belongs to the technical field of catalysis and synthesis and in particular relates to a method for preparing adipic acid by oxidizing cyclohexene with air under catalysis of non-metal carbon. The method adopts cyclohexene as a raw material, a non-metal carbon material as a catalyst, molecule oxygen as an oxygen source, and the adipic acid is catalyzed and synthesized in one step. According to the method, the adipic acid is prepared by oxidizing cyclohexene with air under catalysis of non-metal carbon, the used equipment and process are simple, the catalyst is low in price and easy to prepare and has high catalysis activity and high selectivity, no pollution is caused, the system is environmental-friendly, and the method is an environment-friendly process.

Owner:FUDAN UNIV

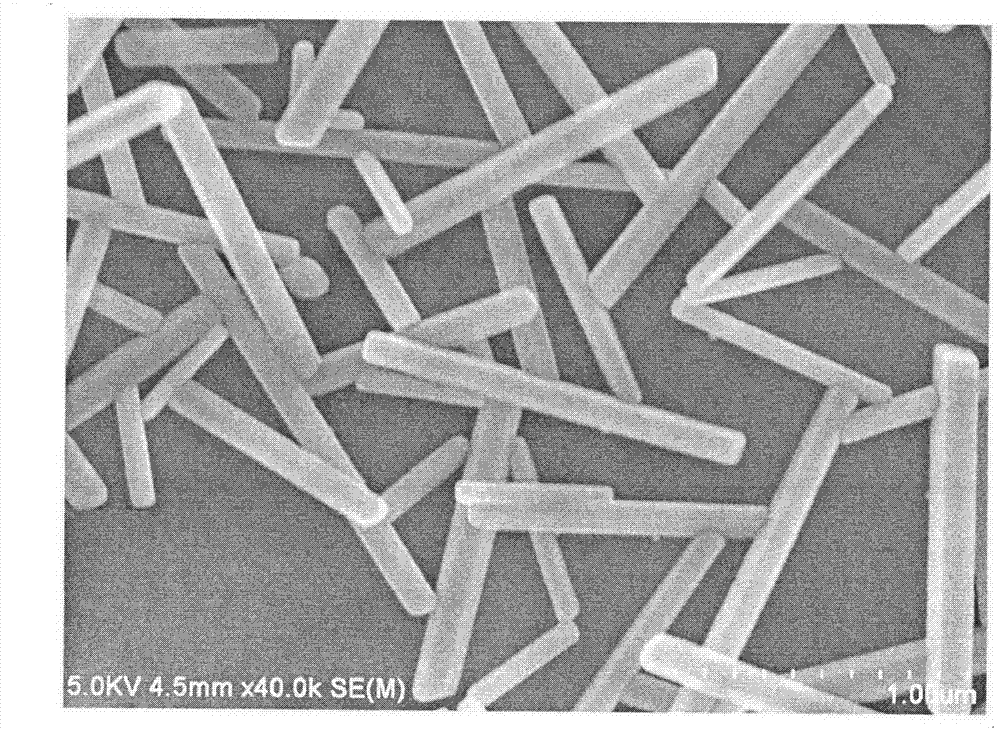

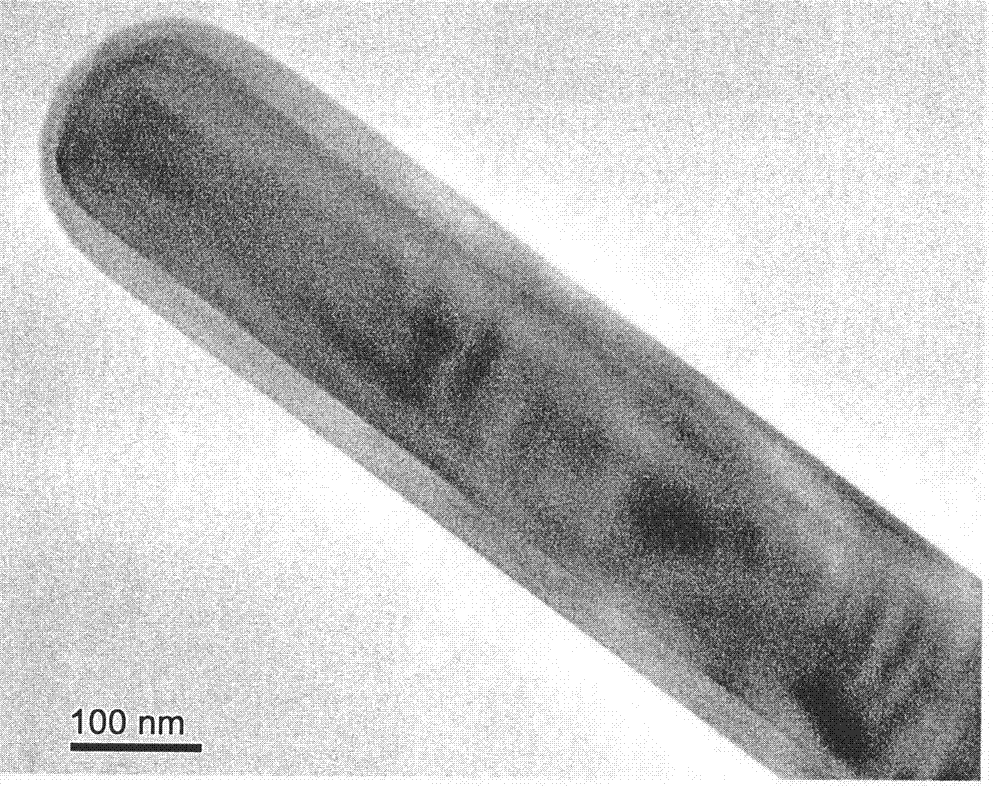

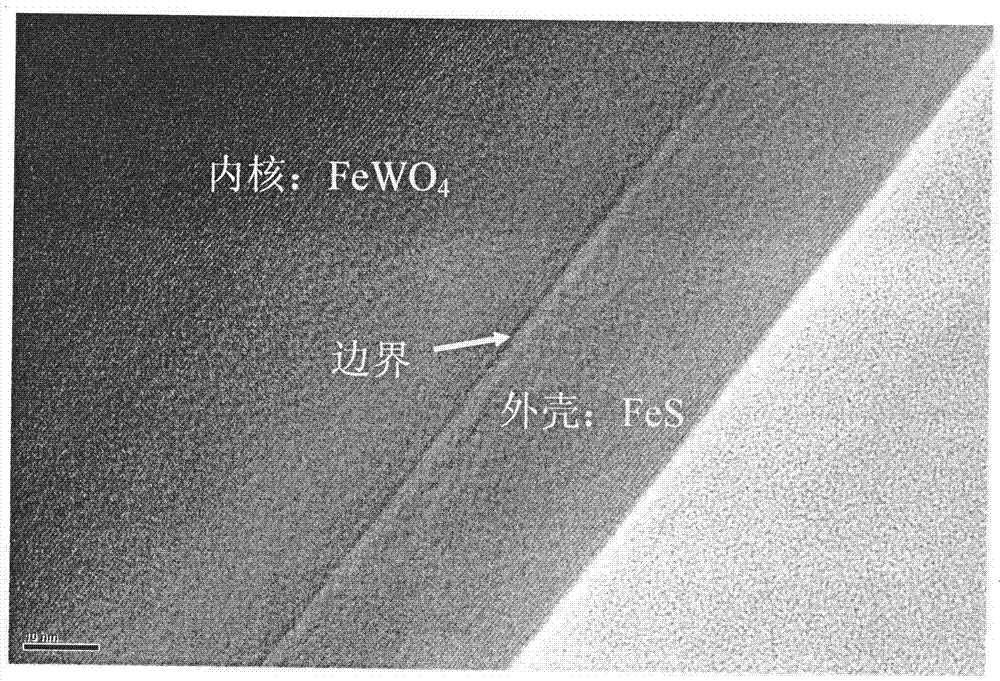

Preparation method of high-purity short-rod-like crystalline FeWO4/FeS core-shell nano structure

InactiveCN103498191ASimple equipment and processSynthetic growth conditions are stringentMaterial nanotechnologyPolycrystalline material growthSingle crystalMaterials preparation

The invention relates to a preparation method of a high-purity short-rod-like crystalline FeWO4 / FeS core-shell nano structure, belonging to the technical field of material preparation. According to the method, a vacuum tube furnace is adopted, tungsten oxide and sulfur powder are used as evaporation sources, and a thermal evaporation method is adopted to prepare the short-rod-like crystalline FeWO4 / FeS core-shell nano structure on a substrate coated with an iron film under the protection of carrier gas, wherein the core is single crystal FeWO4, and the shell is single crystal FeS. The method has the advantages of strict and controllable synthesis and growth conditions, simple equipment and technique, high product yield, low cost and the like. The obtained nano structure has the advantages of high product purity, uniform diameter distribution of the core and shell, and controllable diameters and lengths. The synthesized nano structure has wide application prospects in the fields of optical fibers, sensors, catalysts and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

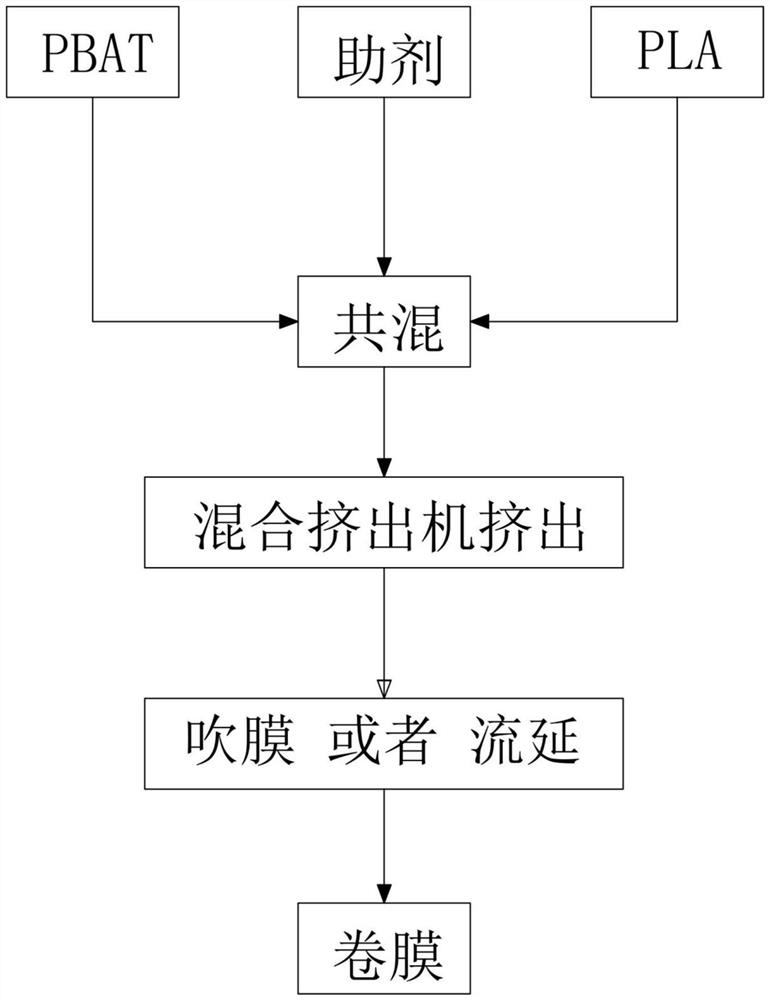

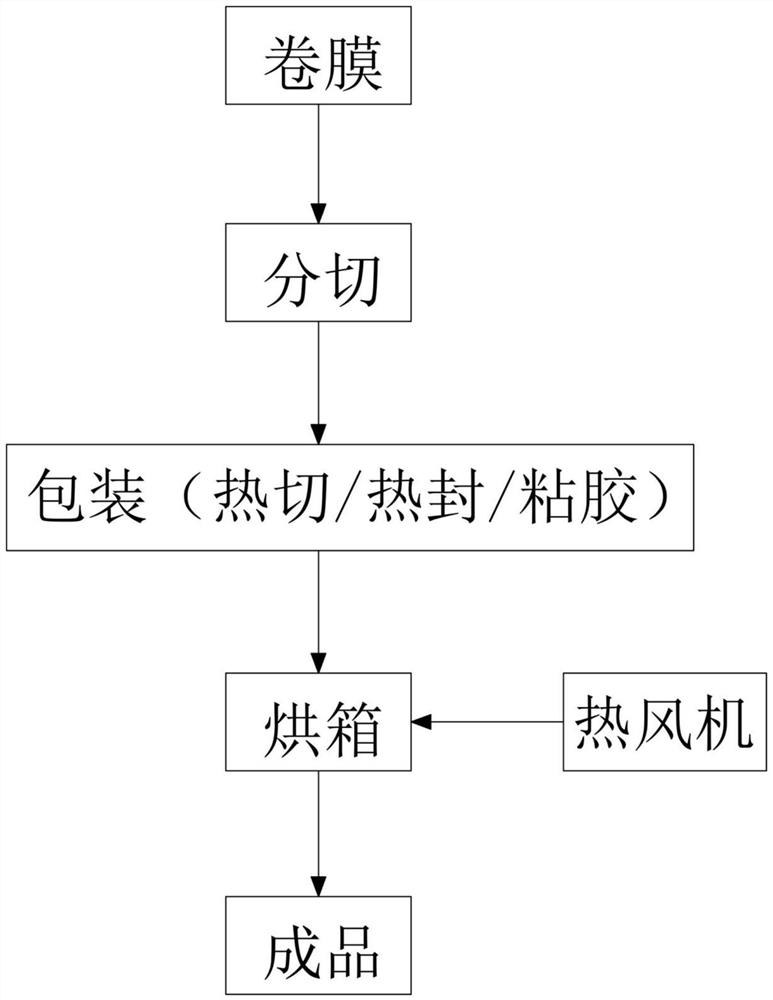

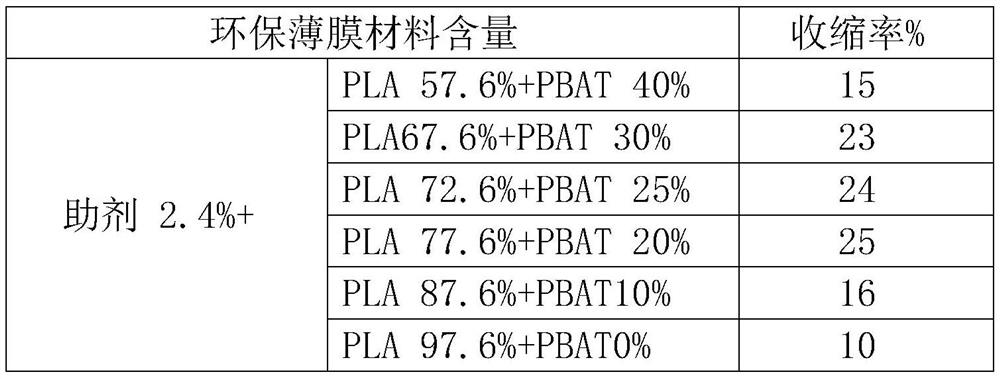

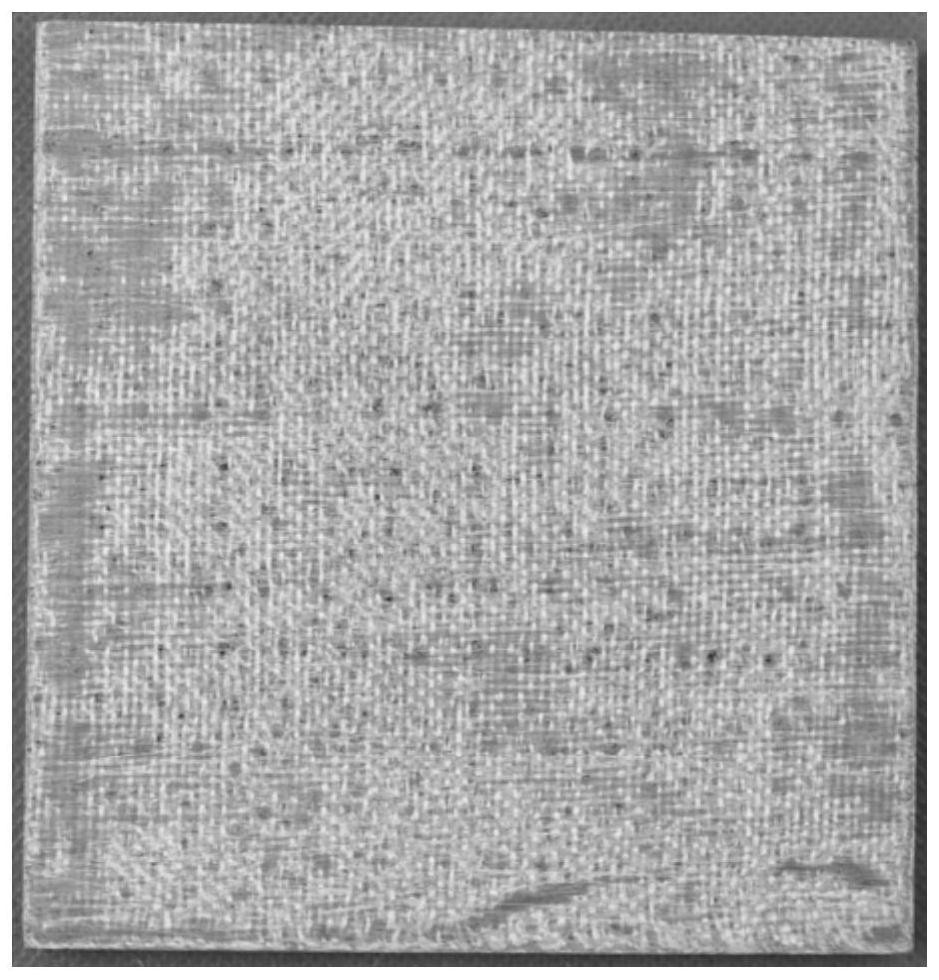

Heat-shrinkable degradable environment-friendly film material as well as preparation method and application method

PendingCN113045881ASimple equipment and processSuitable for large-scale industrial productionWrappers shrinkageFlexible coversThin membraneFilm material

The invention provides a heat-shrinkable degradable environment-friendly film material which is prepared by blending and modifying PBAT and PLA in proportion under the action of auxiliaries, wherein the auxiliaries comprise wax, a coupling agent, a chain extender, an anti-blocking agent and a slipping agent. According to the invention, the PBAT material with good biodegradability, biocompatibility and high elongation at break and the PLA material with high hardness, high transparency and low elongation rate are modified and mixed under the action of the auxiliaries to obtain the biodegradable compostable environment-friendly film material with thermal shrinkage performance. The process and equipment for preparing the environment-friendly film material are simple, and are very suitable for large-scale industrial production. The heat-shrinkable degradable environment-friendly film material can be used to prepare a packaging film with good blow molding effect, good thermal shrinkage, good stiffness and good toughness, and can also be applied to packaging films, industrial materials and the like.

Owner:珠海横琴辉泽丰包装科技有限公司

Resin-based heat-proof composite material with surface coated with high-temperature infrared stealth coating and preparation method thereof

ActiveCN112920442ASimple equipment and processImprove infrared stealth performanceFireproof paintsCamouflage paintsSilicone resinQuartz fiber

The invention relates to the field of high-temperature stealth materials, and particularly discloses a resin-based heat-proof composite material with the surface coated with a high-temperature infrared stealth coating and a preparation method thereof. The resin-based heat-proof composite material takes high silica fiber, Shi Ying fiber, aluminosilicate fiber or basalt oxide fiber as reinforcements, the resin matrix is one or a mixture of phenolic aldehyde and silicon resin, and the hollow microspheres are additives in the resin matrix; according to the high-temperature infrared stealth coating, precious metal serves as low-emissivity filler, lead-free glass serves as a binder, and the glass softening point temperature is 400-1100 DEG C. The composite material has good thermal insulation and infrared stealth properties, and a glass phase in the high-temperature infrared stealth coating on the surface of the composite material can be quickly melted in a medium-low heat flow high-temperature environment, so that the surface of the decomposed composite material is effectively sealed and filled; and the glass melt and oxide fibers in the composite material are sintered to be firmly attached to the surface of the material so that falling and stripping of the coating caused by decomposition of the composite material are avoided.

Owner:NAT UNIV OF DEFENSE TECH

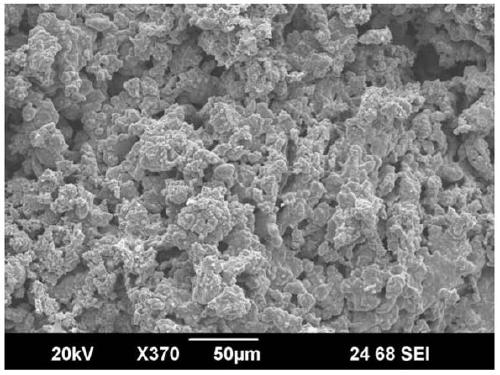

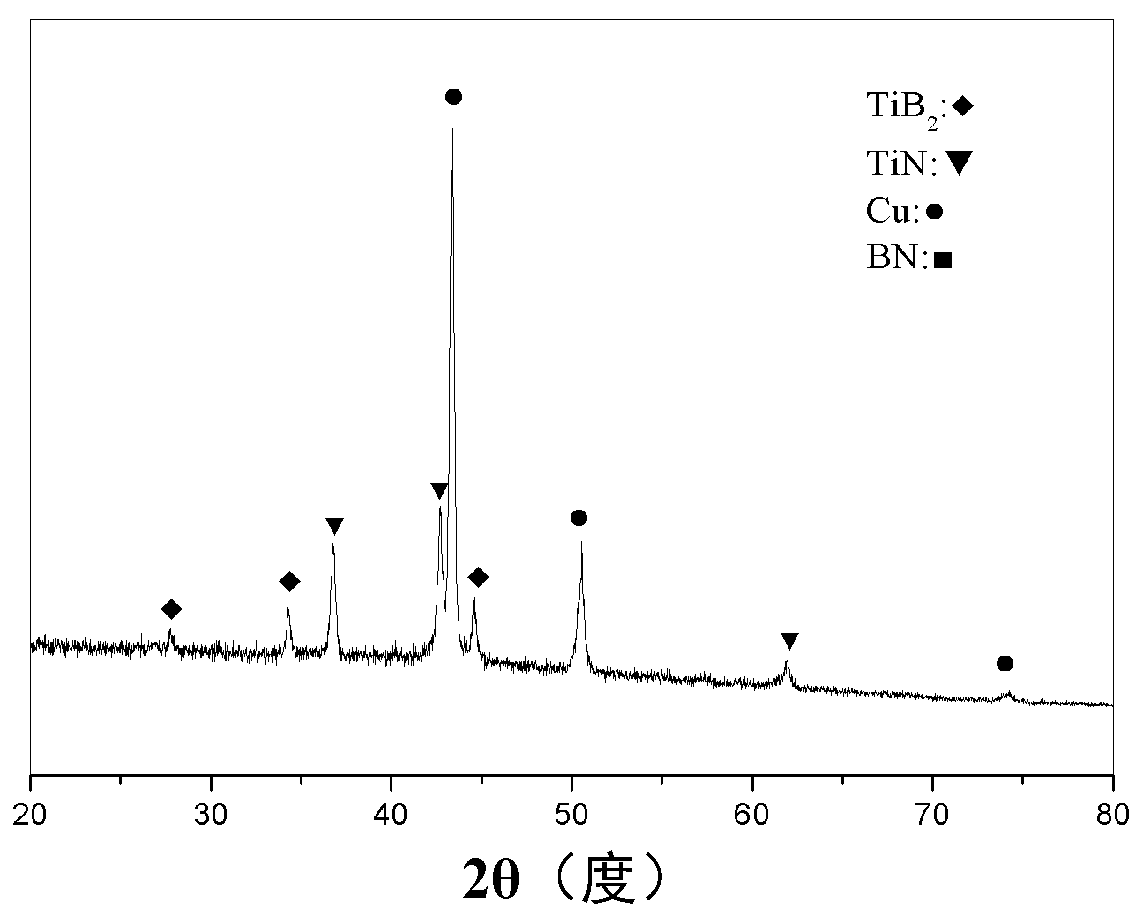

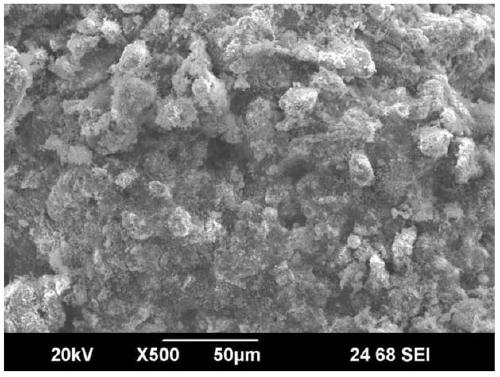

Enhanced self-lubricating copper-based composite material and preparation method and application thereof

ActiveCN109136606ASimple equipment and processLow cost of preparationPressureless sinteringBoron nitride

The invention relates to an enhanced self-lubricating copper-based composite material and a preparation method and application thereof. The preparation method comprises the steps that titanium powder,boron nitride powder, copper powder and / or copper-based alloy powder serve as raw materials and are uniformly mixed, and then self-propagating sintering is adopted to prepare precursor powder; the precursor powder is subjected to pressureless sintering or hot-pressing sintering to obtain the reinforced self-lubricating copper-based composite material. Compared with the prior art, the enhanced self-lubricating copper-based composite material with TiB2 / TiN as a binary reinforced phase and BN as a self-lubricating medium is provided, and the material has the high hardness and high abrasion resistance characteristics of TiB2 / TiN and the high heat conductivity characteristic of pure copper or copper-based alloy.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Process for synthesizing p-aminophenol through nitrobenzene hydrogenation

ActiveCN104326925ASimple equipment and processStable performance for repeated useOrganic compound preparationChemical recyclingNitrobenzeneChemistry

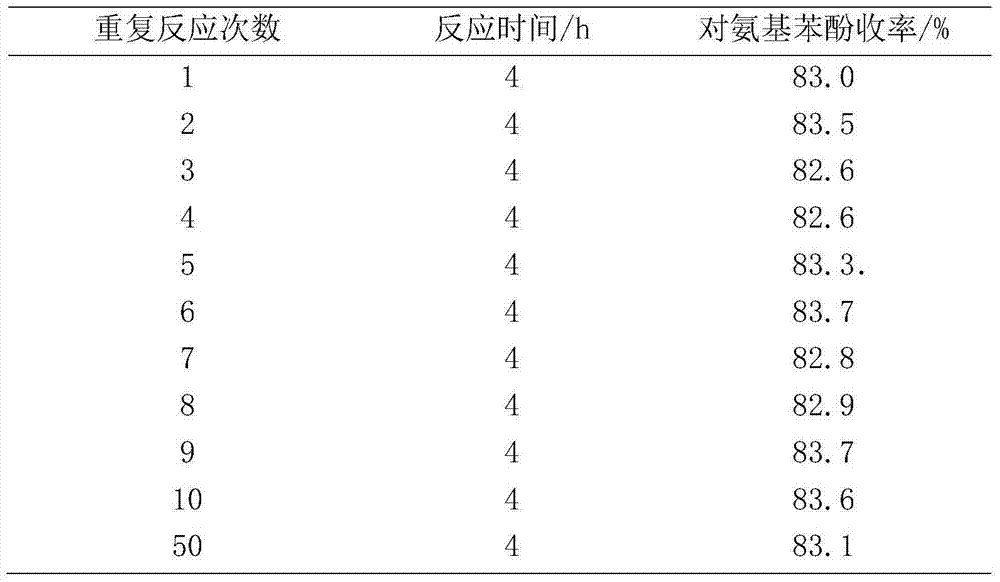

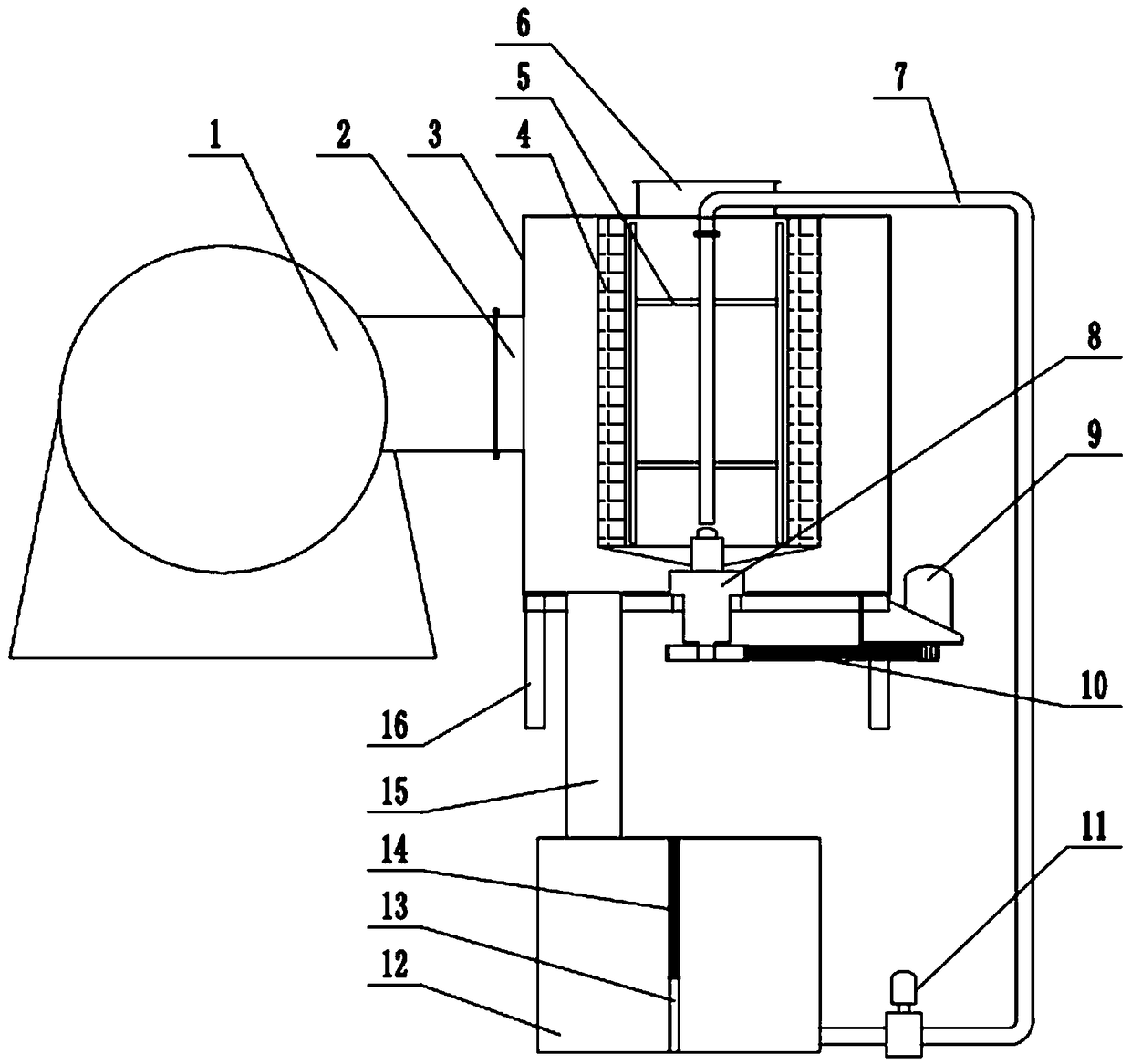

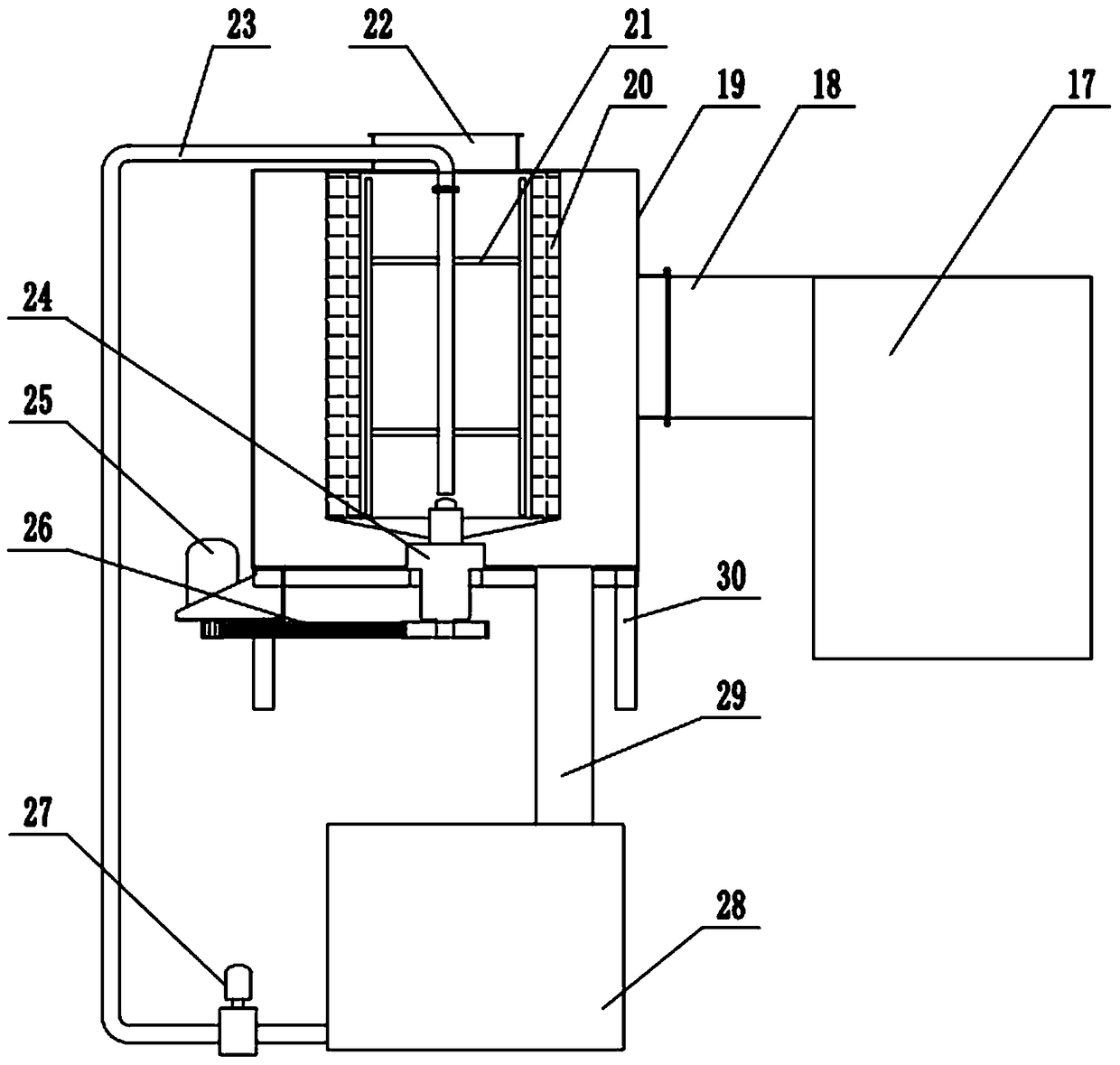

The present invention relates to a process for synthesizing p-aminophenol through nitrobenzene hydrogenation. The process comprises: adding water, concentrated sulfuric acid, zinc sulfate, nitrobenzene and a surfactant hexadecyl trimethyl ammonium bromide to a reactor provided with an active reaction member according to a mass ratio of concentrated sulfuric acid to zinc sulfate to nitrobenzene to hexadecyl trimethyl ammonium bromide to water of 0-20:0-2:2-20:0.01:100; and adopting N2 to replace air for 8-12 min, heating to a reaction temperature of 80-200 DEG C, introducing H2 to achieve a hydrogen partial pressure of 0.1-2.0 MPa, and carrying out a reaction for 3-8 h to make the nitrobenzene convert into the p-aminophenol. According to the present invention, the active reaction member is adopted to synthesize the p-aminophenol through nitrobenzene hydrogenation, wherein the highest p-aminophenol yield is 83.7%, the repeated use performance is stable, the reaction result does not significantly change after repeating the reaction more than 50 times, and the catalyst loss and regeneration problems are not produced during the reaction process.

Owner:HEBEI UNIV OF TECH

Method for producing iron oxide red by utilizing titanium dioxide byproduct ferrous sulfate heptahydrate

ActiveCN109437321ASimple equipment and processLow costCalcium/strontium/barium sulfatesFerric oxidesGypsumFerrous sulfate heptahydrate

The invention relates to a method for producing iron oxide red by utilizing titanium dioxide byproduct ferrous sulfate heptahydrate. The method comprises the production steps of (1) dissolving the byproduct ferrous sulfate heptahydrate obtained by the production of titanium dioxide into a water solution with the mass percent concentration being 8 percent, and filtering to obtain liquid for standbyuse; (2) feeding 8 percent of water solution into a mixed reactor, feeding ammonia gas, carrying out reaction of the 8 percent of water solution and the ammonia gas to generate mixed liquor of (NH4)2SO4 and Fe(OH)2; (3) heating the mixed liquor, pumping into a high gravity reactor, feeding air, carrying out reaction to obtain Fe(OH)3 and (NH4)2SO4, and carrying out solid-liquid separation; (4) washing the Fe(OH)3 obtained through separation, then calcining, and finally smashing and packaging to obtain a product; (5) adding lime into the (NH4)2SO4 obtained through separation to obtain gypsum and ammonia gas, and recycling the ammonia gas. The method is high in efficiency on producing the iron oxide red, the product quality is stable, and the production cost is greatly reduced.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

Heating furnace radiation area collecting pipe surface high temperature corrosion resistant coating and preparation method thereof

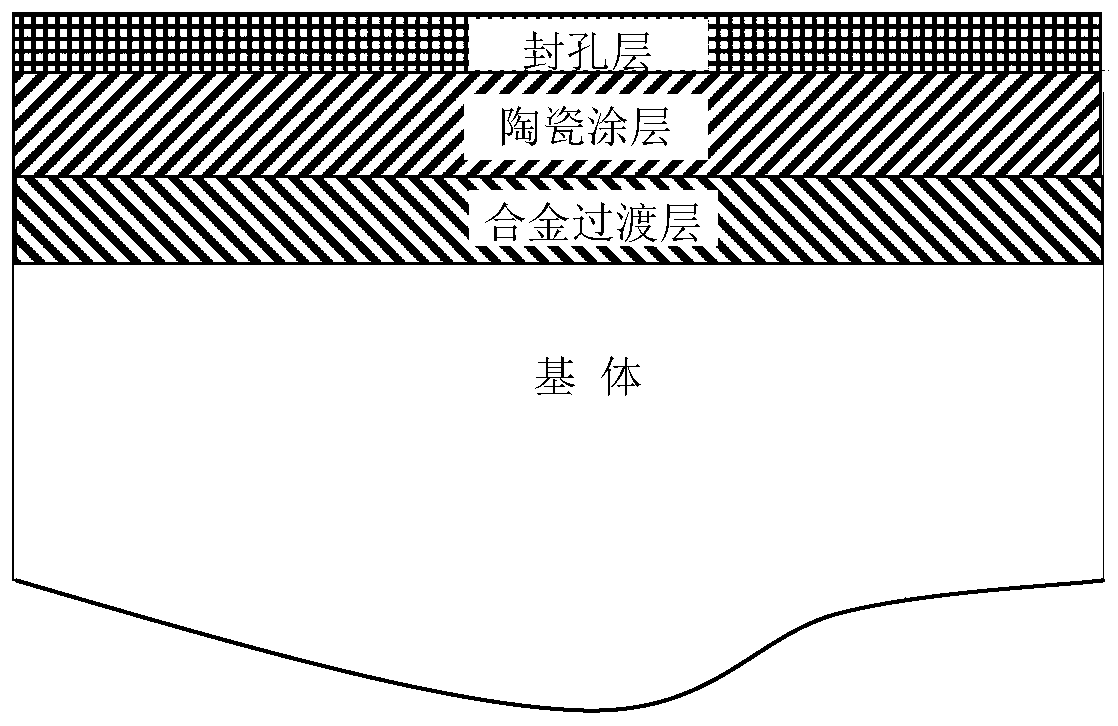

InactiveCN110965005AExtended service lifeSimple equipment and processMolten spray coatingOxideBonding strength

The invention discloses a heating furnace radiation area collecting pipe surface high temperature corrosion resistant coating and a preparation method thereof. The method is characterized in that heatresistant steel is taken as a base material, and cleaning, oil removing, rust removing and surface roughening are carried out on the heat resistant steel, firstly, an alloy transition layer and a ceramic coating are prepared on a surface of a base body through thermal spraying, and then hole sealing treatment is conducted through an inorganic hole sealing agent containing trace metal elements (Al, Ni, Ti, Mg and the like); in the high-temperature oxidation process, metal elements in the hole sealing agent are diffused to the position near an interface of microcracks and pores of the ceramic coating firstly, moreover, most of metal is subjected to an oxidation reaction to generate a metal oxide film, the microcracks and the pores in the ceramic coating can be filled up, and the coating isprevented from being further oxidized. The method is advantaged in that a heat-resistant steel base body is protected against high-temperature oxidation and corrosion through the ceramic coating, stress concentration in the coating is relieved through the alloy transition layer, the bonding strength of the heat-resistant steel base body and the ceramic coating is improved, and the service life ofthe heating furnace radiation area collecting pipe can be remarkably prolonged; and the required equipment and process are relatively simple, operation is easy, production efficiency is higher, cost is lower, the production process is pollution-free, and the industrialization prospect is wide.

Owner:江阴市东泰管件有限公司

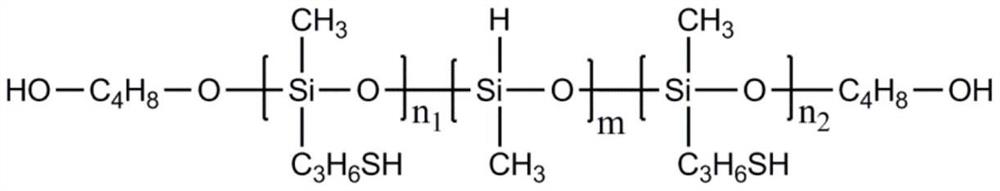

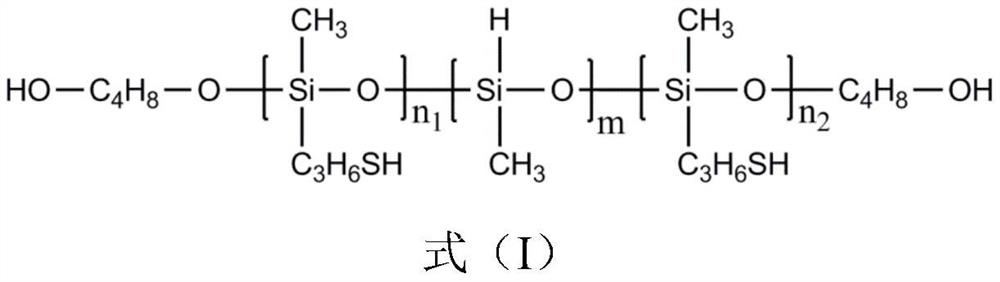

Polysiloxane dihydric alcohol, thermoplastic organic silicon polyurethane elastomer, cross-linked polyurethane elastomer and application of polysiloxane dihydric alcohol, thermoplastic organic silicon polyurethane elastomer and cross-linked polyurethane elastomer

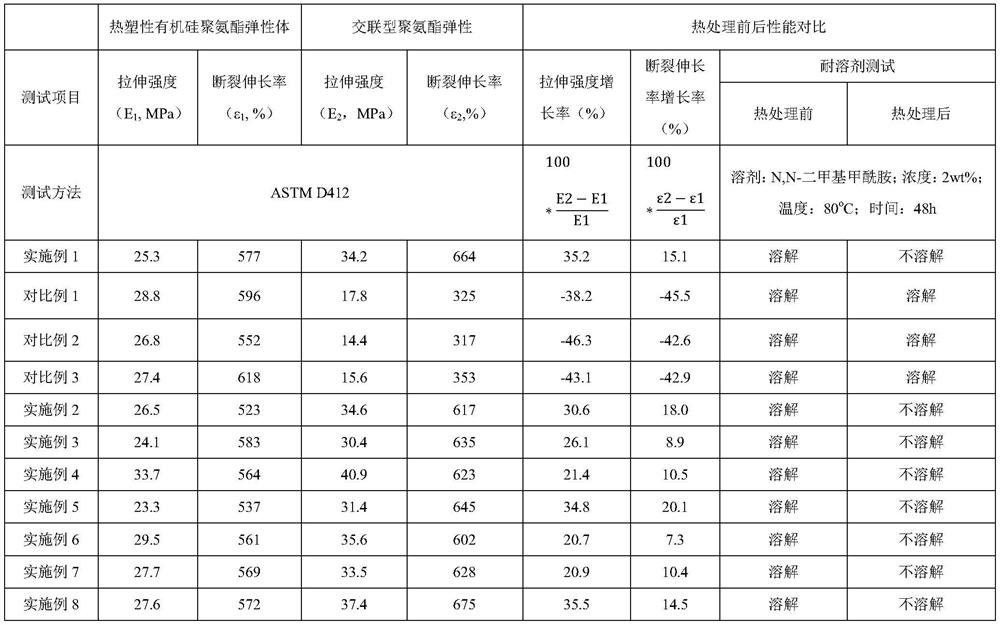

The invention discloses polysiloxane dihydric alcohol, a thermoplastic organic silicon polyurethane elastomer, a cross-linked polyurethane elastomer and application of the polysiloxane dihydric alcohol, the thermoplastic organic silicon polyurethane elastomer and the cross-linked polyurethane elastomer. The structural formula of the polysiloxane dihydric alcohol is as follows: the polysiloxane dihydric alcohol is adopted to prepare a thermoplastic organic silicon polyurethane elastomer, and then thermal oxidation treatment is performed to prepare the cross-linked polyurethane elastomer. The cross-linked polyurethane elastomer material has better comprehensive performance, especially has obvious advantages in the aspects of mechanical property, chemical resistance, oxidation resistance, creep resistance and the like, and can be applied to the field with harsh environmental conditions.

Owner:WANHUA CHEM GRP CO LTD

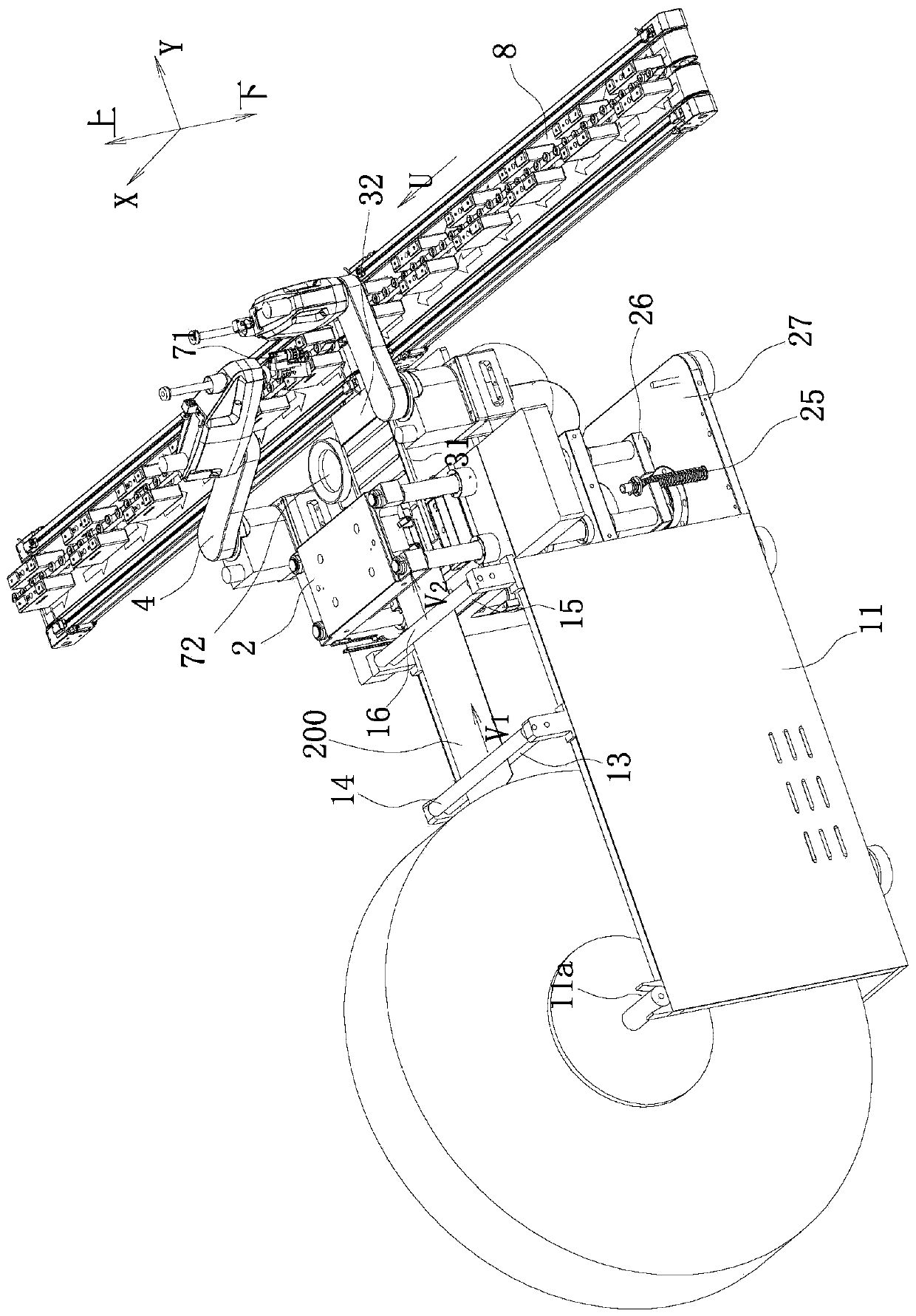

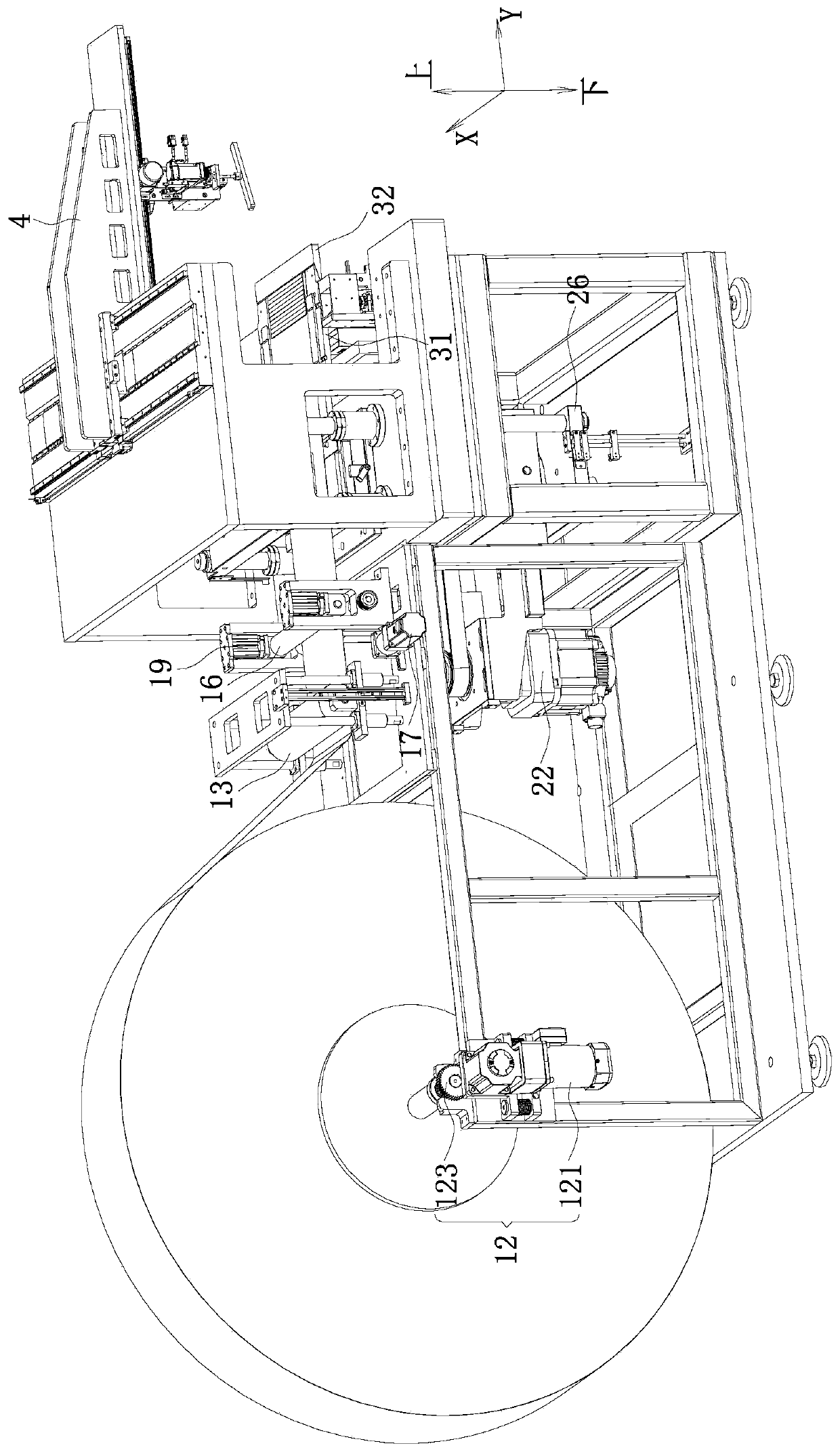

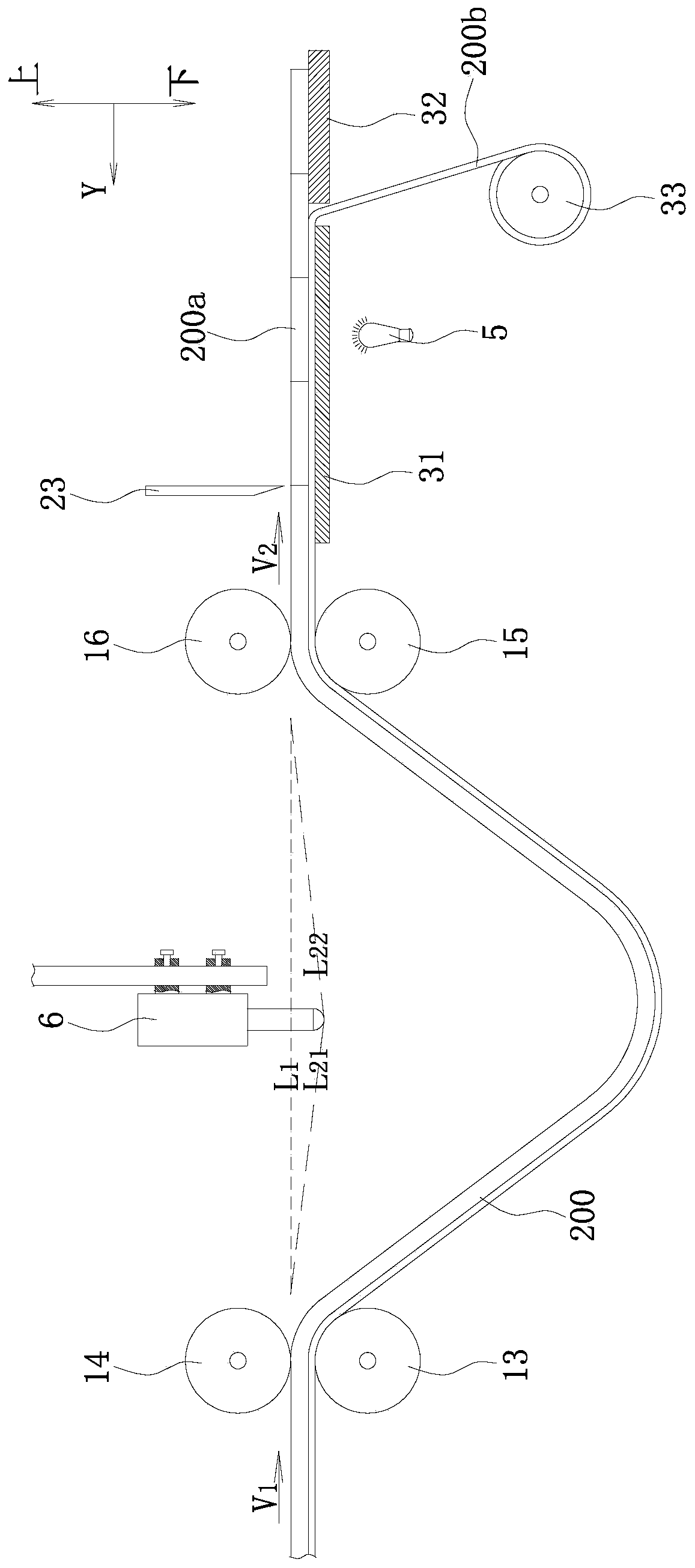

Cutting and laminating machine and application method thereof

The invention discloses a cutting and laminating machine and an application method thereof. The cutting and laminating machine comprises a feeding device, a blanking assembly, a first platform, a second platform, a transfer device, a first imaging detection device and a conveying assembly. The feeding device, the blanking assembly and the first platform are arranged in the material conveying direction in sequence. The blanking assembly can cut off a raw material band into membrane pieces. A gap between the first platform and the second platform allows a master band of the raw material band topass through. The second platform can slowly store the membrane pieces of the raw material band. The transfer device can transfer the membrane pieces on the second platform onto products on the conveying assembly. The cutting and laminating machine conducts material feeding in a raw material band form. Compared with the manner that the membrane of each single membrane piece needs to be torn off, the cutting and laminating machine is simpler in process, and the burden of a designer is reduced; and the cutting and laminating machine conducts mechanical and continuous feeding on the raw materialband, conducts membrane cutting, membrane tearing and transfer pasting, facilitates achievement of automation, has higher production efficiency and productivity and can reduce the labor cost and othercost.

Owner:ZHUHAI RUIXIANG ELECTRONICS

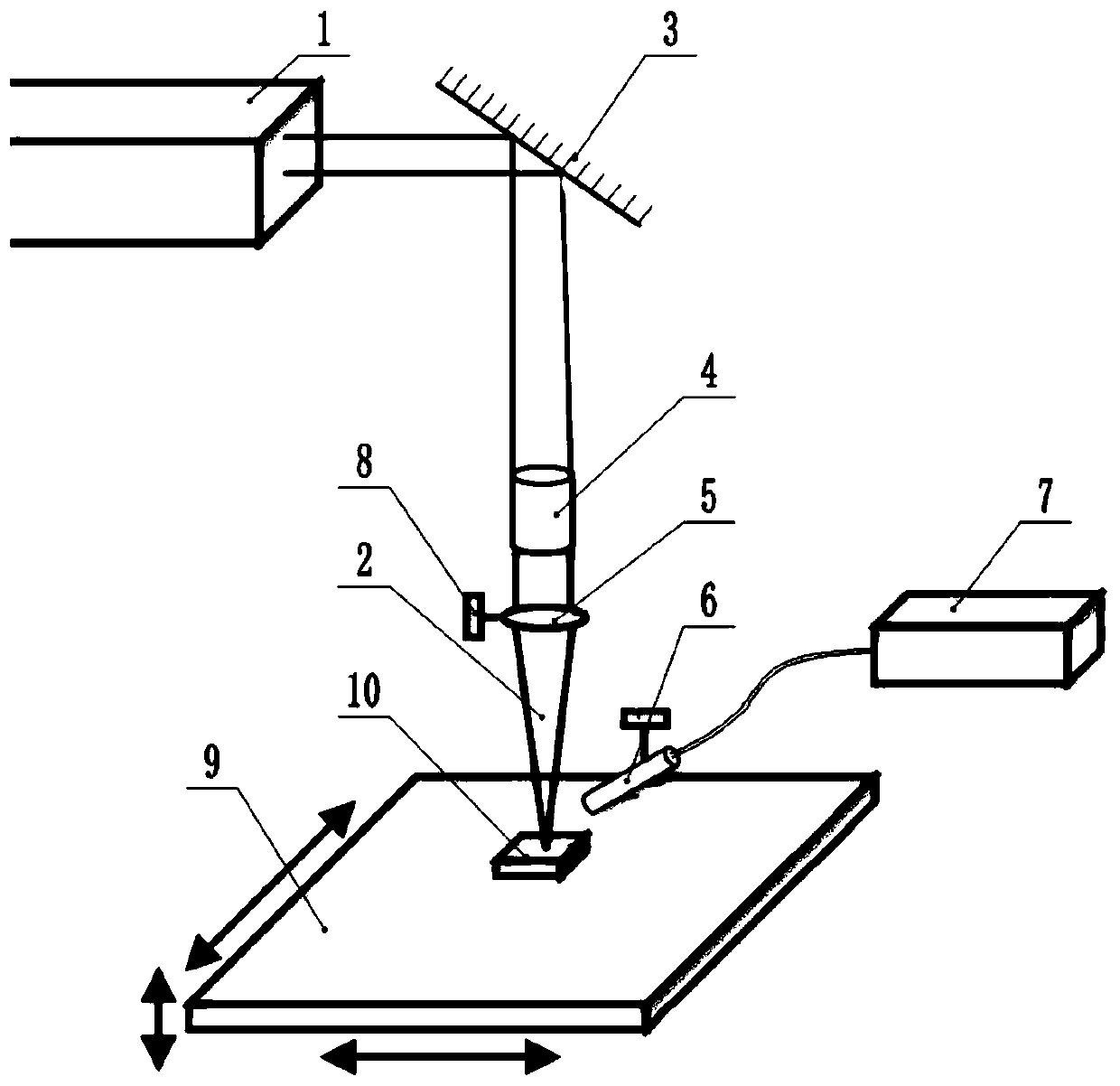

Micro-lens manufacturing method based on CO2 laser melting assisted by high-pressure gas

ActiveCN111045120ASimple equipment and processExpand the scope of processingLensMicrolensErbium lasers

The invention relates to the technical field of optical material processing equipment, and especially relates to a micro-lens manufacturing method based on CO2 laser melting assisted by a high-pressure gas. The method comprises the following steps of 1, manufacturing a preform, and manufacturing the preform by using a machining method; 2, carrying out CO2 laser reshaping, emitting a CO2 laser to asurface of the preform by using a CO2 laser to generate a high-temperature region at a temperature higher than a melting temperature or softening temperature of a material, and then injecting a high-pressure gas to a softening region by using a nozzle to reshape the preform; and 3, carrying out multi-area remodeling, making a CO2 laser focus and the nozzle keep moving consistently, generating linear motion, spiral motion, rotation motion, sawtooth vibration motion and other relative motion between the CO2 laser focus and the nozzle and an optical material, making the optical material, the CO2laser focus and the nozzle generate relative three-dimensional motion, and carrying out high-temperature melting and shaping on the optical materials in different areas. According to the method, a rapid forming property of laser melting is utilized, high-pressure gas forming is assisted, and efficient machining of an optical material micro lens is achieved.

Owner:北京理工大学重庆创新中心

Preparation method of porous pollucite profile

The invention discloses a preparation method of a porous pollucite profile. The preparation method is characterized by comprising the following steps: taking and mixing 100 weight parts of metakaolin,75-210 weight parts of an amorphous form spherical silicon dioxide ultrafine powder, 145 weight parts of cesium hydroxide monohydrate at the weight ratio; taking and adding water of which the weightis 20% of the total weight of the metakaolin, the amorphous form spherical silicon dioxide ultrafine powder and the cesium hydroxide monohydrate, and stirring evenly to obtain a slurry; injecting theslurry into a steel mold, sealing, processing in an air dry oven of 50-100 DEG C for 24 hours, then demolding to obtain a solid profile; putting the solid profile in an autoclaving reaction kettle, hydrothermally reacting in a water vapor environment of 160-220 DEG C for 12-24 hours, taking out the solid profile and drying to obtain the porous pollucite profile. By adopting the preparation method,the porous pollucite profile having the advantages of excellent mechanical property and high porosity is directly obtained, and the porous pollucite profile can be used as a catalytic reactor, a high-temperature resistant catalyst carrier and a high-temperature resistant thermal insulating layer in the fields like chemical engineering and environments.

Owner:SOUTHWEAT UNIV OF SCI & TECH

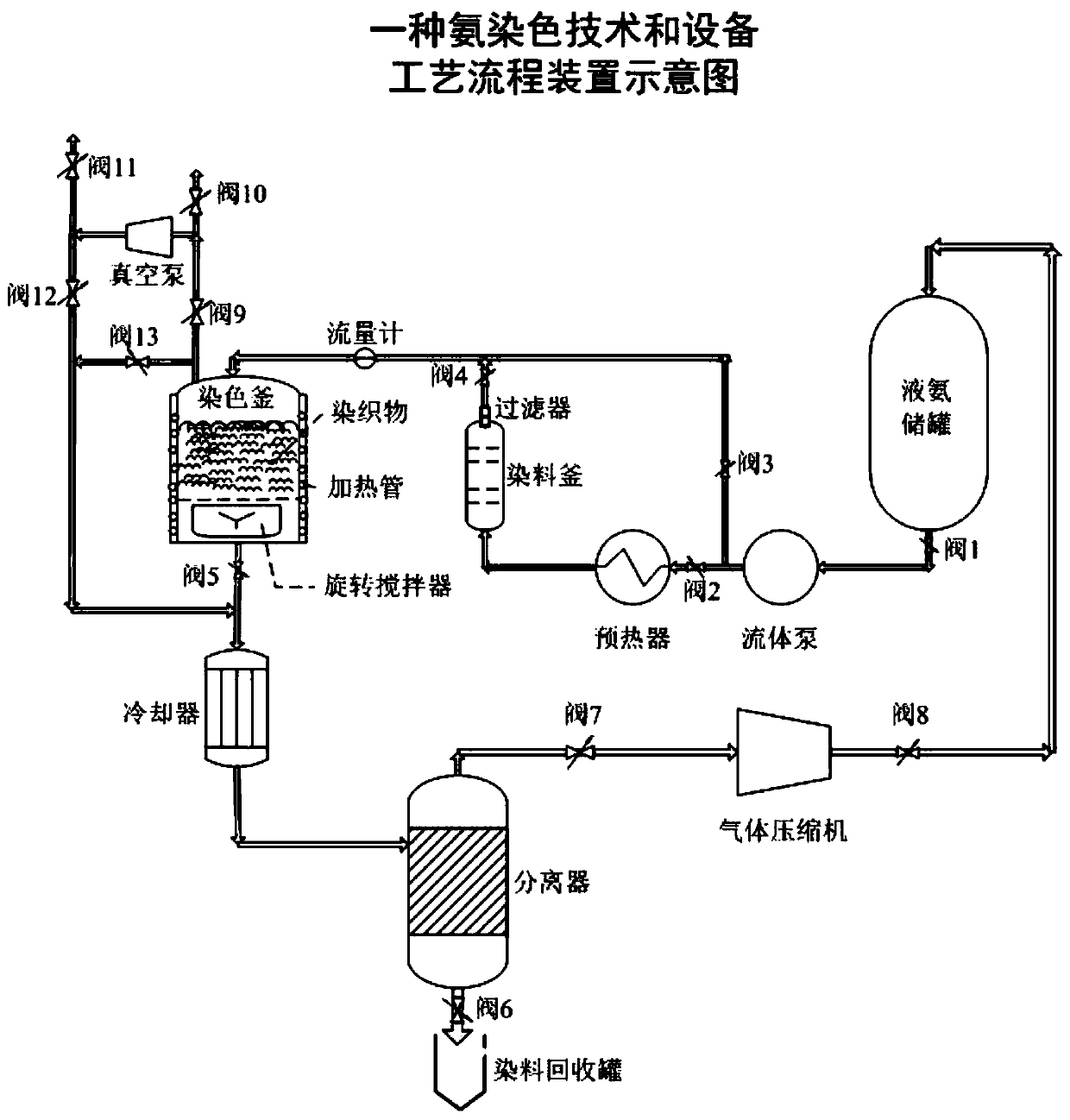

Ammonia dyeing technology and equipment

PendingCN111074448ASimple equipment and processReduce manufacturing costTextile treatment machine arrangementsTextile/flexible product manufactureHemp fiberChemistry

The invention relates to equipment and method adopting a technology of dyeing various cellulosic fibers including cotton fibers and linen fibers with a reactive dye or a direct dye by using ammonia asa medium, and belongs to the technical field of textile dyeing. Liquid ammonia, a dye and cellulosic fibers are placed in a pressure container, three technical process steps of dyeing, heating colorfixing and removal of floating color of the dyed cellulosic fibers are implemented on the cellulosic fibers, all the steps are completed in one set of device, and the technology belongs to a green andpollution-free dyeing technology.

Owner:代勇 +1

Diesel engine chemical additive

InactiveCN103773515ALow priceSimple equipment and processLiquid carbonaceous fuelsFuel additivesPetroleum sulphonateTruck

A diesel engine chemical additive is composed of the following raw materials in parts by weight: 40 to 50 parts of ethanol, 20 to 30 parts of cyclohexanone, 5 to 10 parts of silicone oil, 10 to 15 parts of n-butanol, 1 to 5 parts of benzyl alcohol, 10 to 15 parts of S80, and 1 to 5 parts of petroleum sulfonate. The addition amount of the chemical additive is 0.1% of diesel oil, the chemical additive is suitable for passenger trucks, cargo trucks, trains, ships and tractor which take the diesel oil as the fuel, the oil saving rate of the chemical additive in trains and locomotives is 2% to 3%, and the oil saving rate of the chemical additive in automobiles and ships can reach 8% to 20%. The diesel engine chemical additive has the advantages of available raw material, low price, simple equipment and technology, good product stability, and easy promotion; has a prominent effect on strengthening the power, improves the cetane value, triggers the complete combustion, improves the thermal efficiency, and reduces the oil consumption. The oil consumption is more effectively saved for long-distance high-speed driving, and people can directly sense the oil-saving effect. Moreover, the discharging of CO, hydrocarbon compounds, NOx, and solid particles in the tail gas is greatly reduced, the environmental pollution is reduced, and thus the chemical addictive has a prominent economic benefit and social benefit.

Owner:XIAN RUNDA CHEM TECH

Preparation method of fiber-base-fabric foamed epoxy resin cloth

InactiveCN104099736ASimple equipment and processLess investmentFibre treatmentLiquid/gas/vapor textile treatmentTextileFiber

The invention discloses a preparation method of fiber-base-fabric foamed epoxy resin cloth. The preparation method is characterized in that raw materials include fiber base fabric, foaming agent, epoxy resin, auxiliaries and organic solvent. The preparation method comprises the following steps: respectively adding the foaming agent, the epoxy resin and auxiliaries into organic solvent to be stirred and mixed until the foaming agent, the epoxy resin and the auxiliaries are completely dissolved to form a mixed solution, then impregnating the fiber base fabric into the mixed solution, and drying, reeling, packaging and warehousing the fabric after the fiber base fabric is fused with the mixed solution. The preparation method is convenient to operate and has the advantages of less investment, high efficiency, low cost and the like.

Owner:杨贤斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com