Patents

Literature

991results about How to "Expand the scope of processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilayer coated corrosion resistant article and method of production thereof

InactiveUS20050031894A1Increase heightImprove heat resistanceSynthetic resin layered productsCoatingsPhosphateZinc

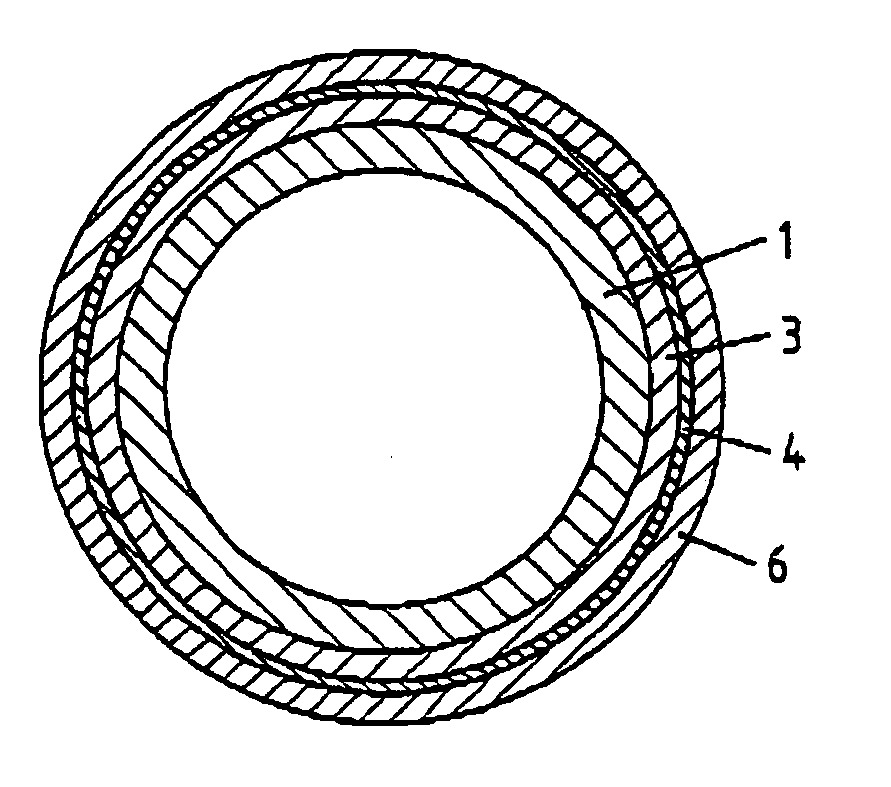

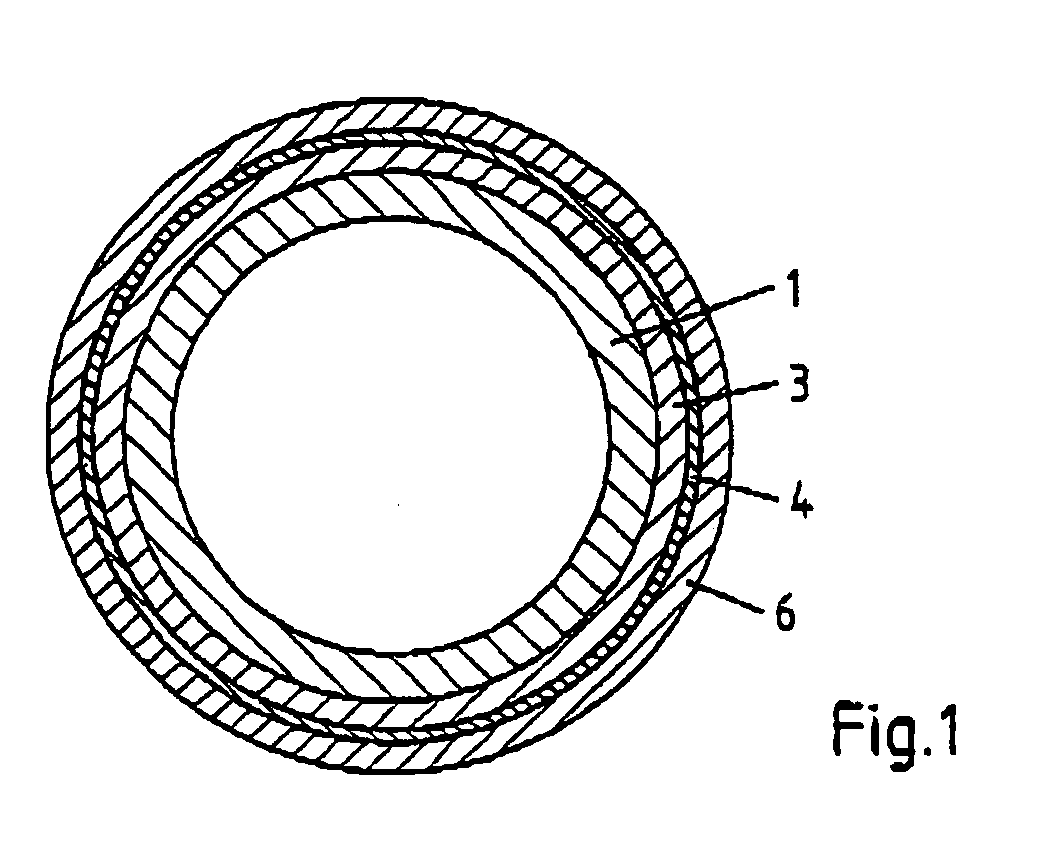

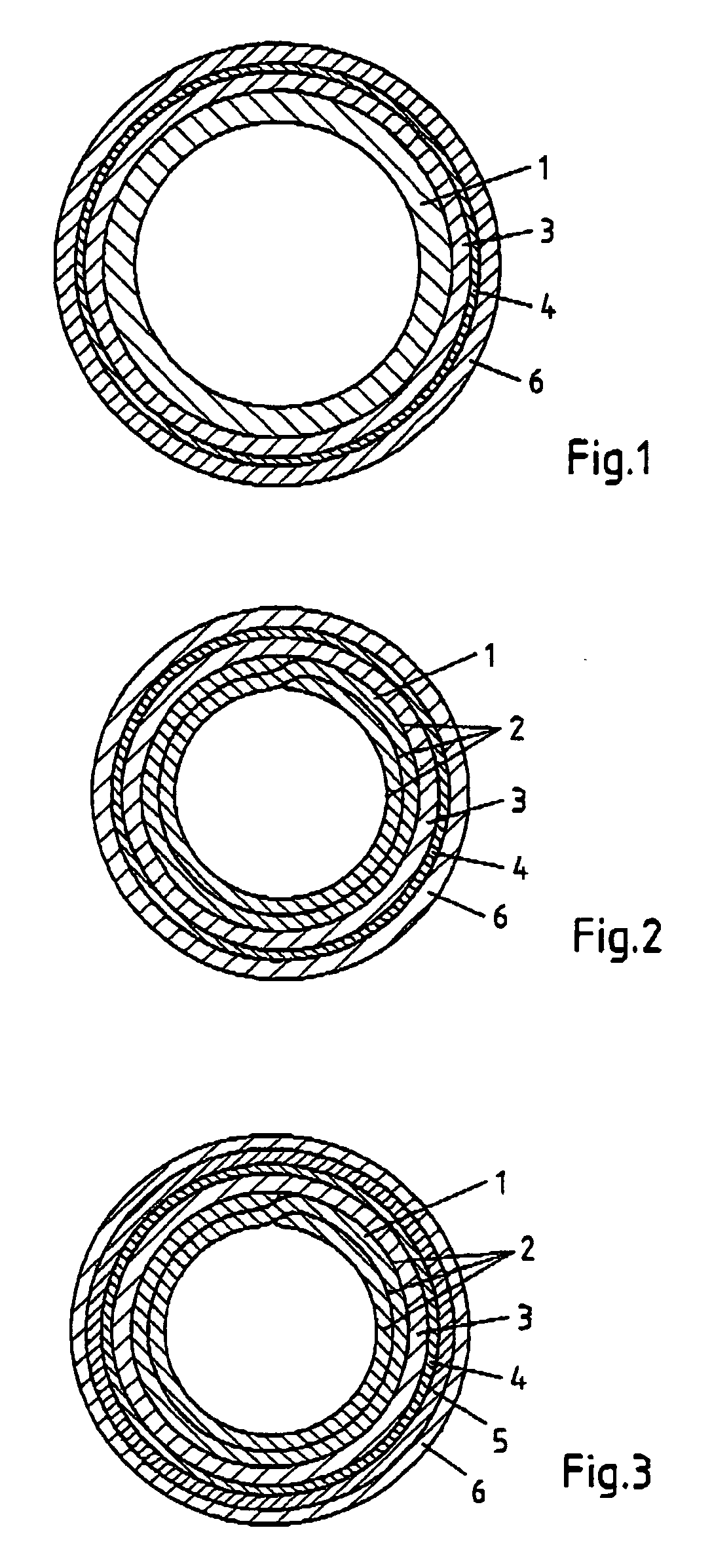

The disclosure relates to a corrosion resistant article comprising a metal body 1 and a protective coating applied on at least one surface of said metal body 1, said protective coating comprising: (a) a zinc layer 3 comprising metallic zinc; (b) a silicate layer 4 comprising at least one silicate; and (c) a synthetic resin layer 6 comprising at least one fluoroplastic material such as, for example, polyvinylfluoride. In particular, the disclosure relates to a corrosion resistant brake pipe or fuel pipe having a protective coating for use in motor vehicles. The protective coating is substantially free of chromates and phosphates and, hence, environmentally acceptable.

Owner:ELISHA HLDG LLC

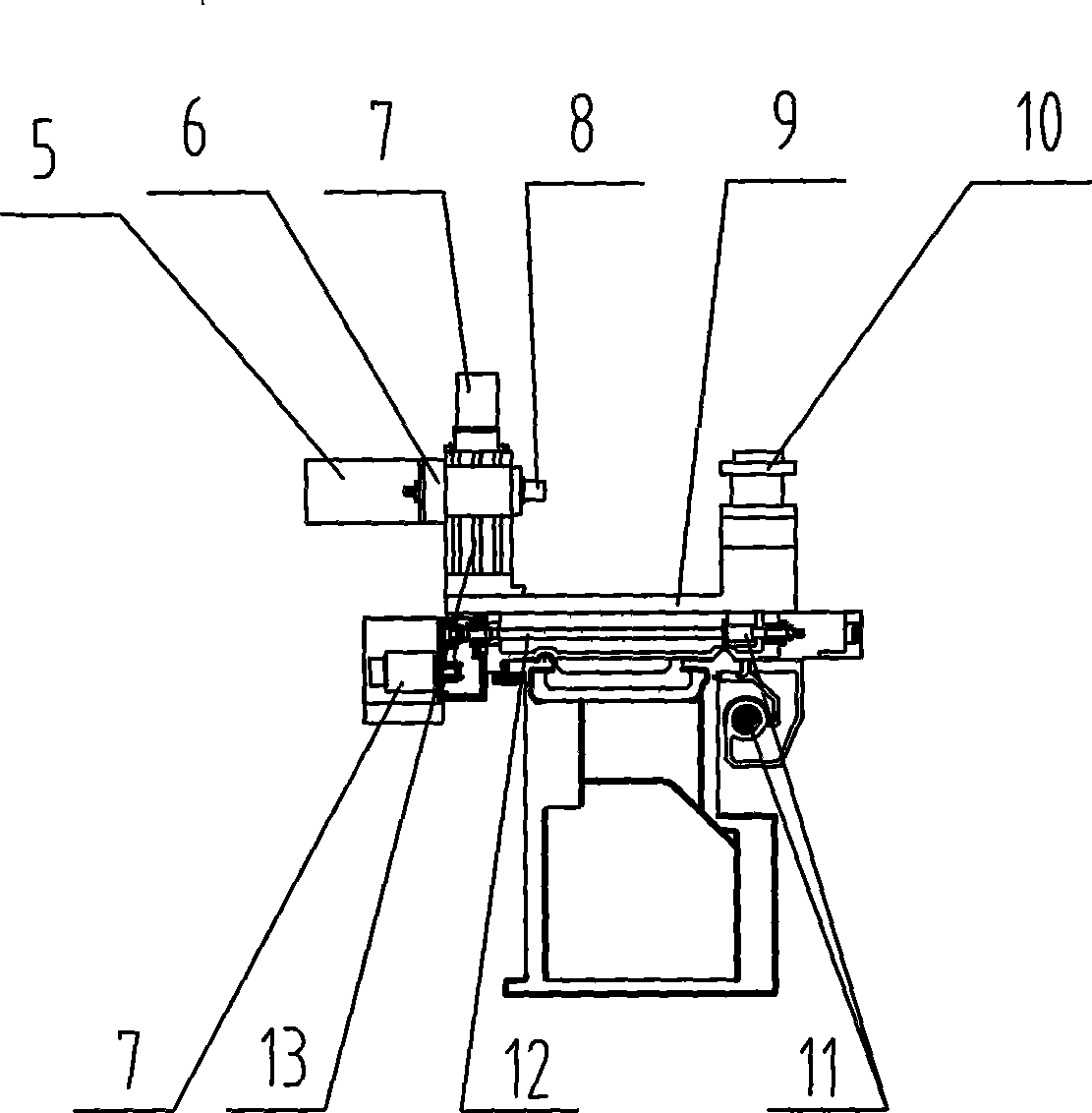

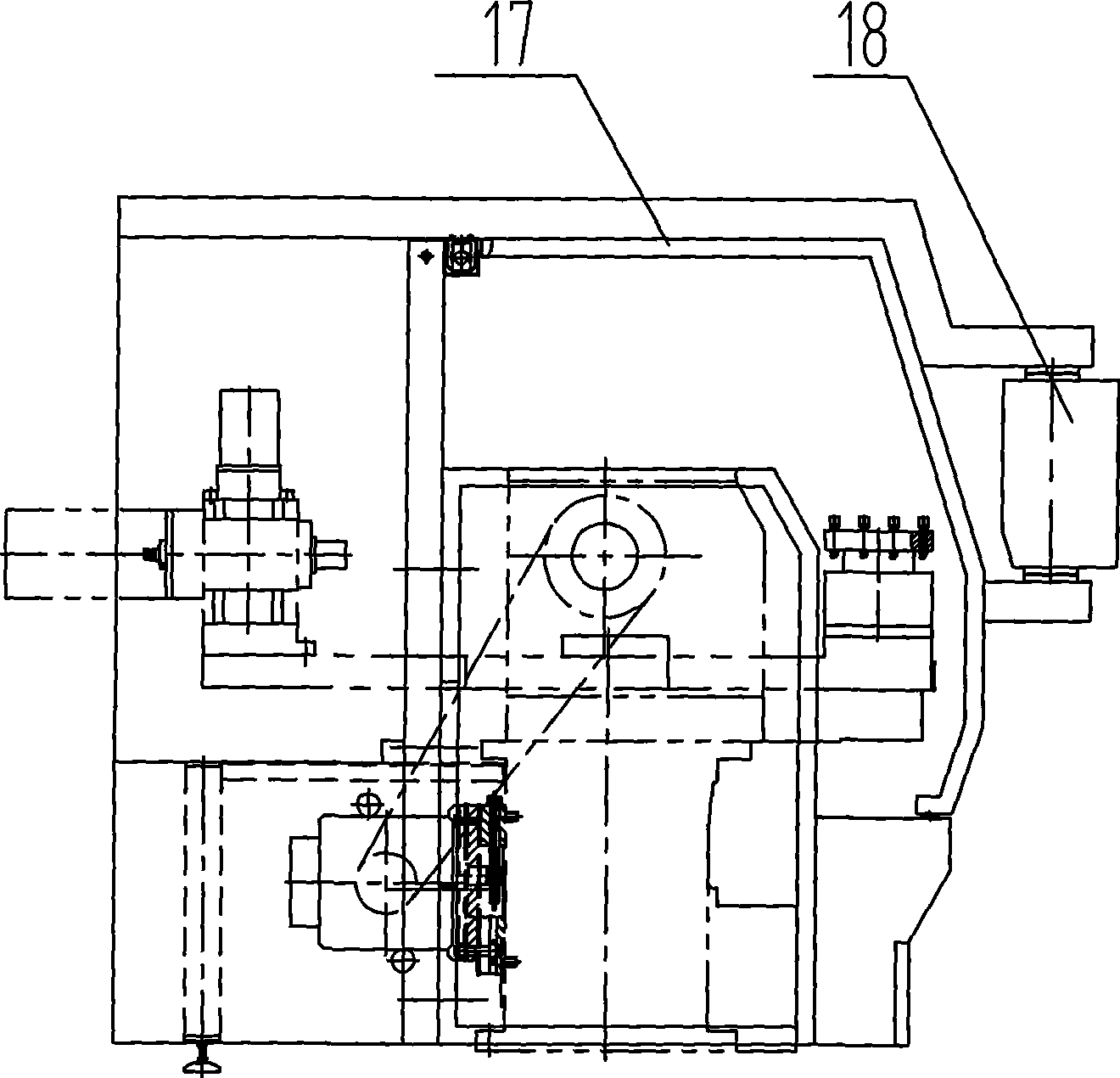

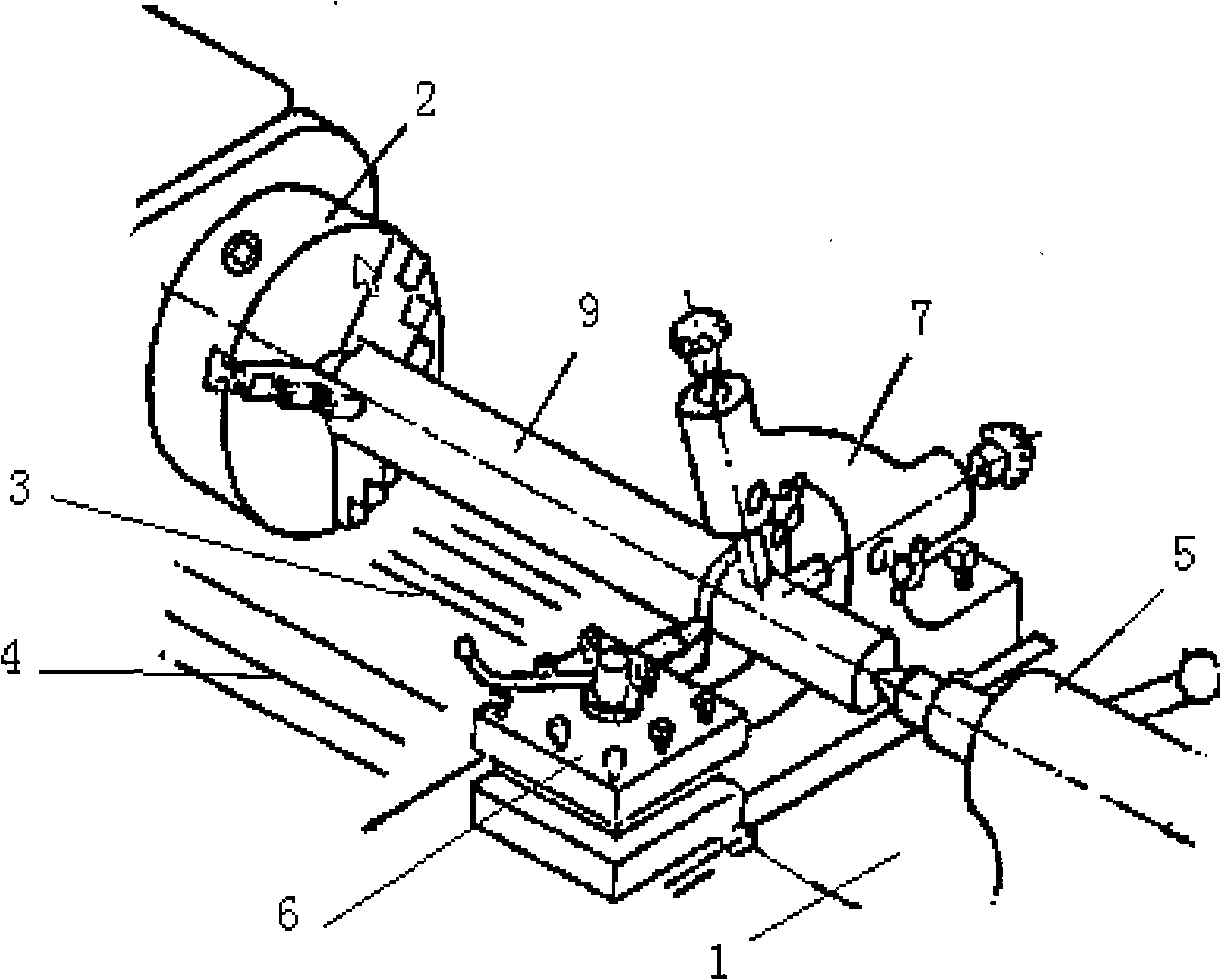

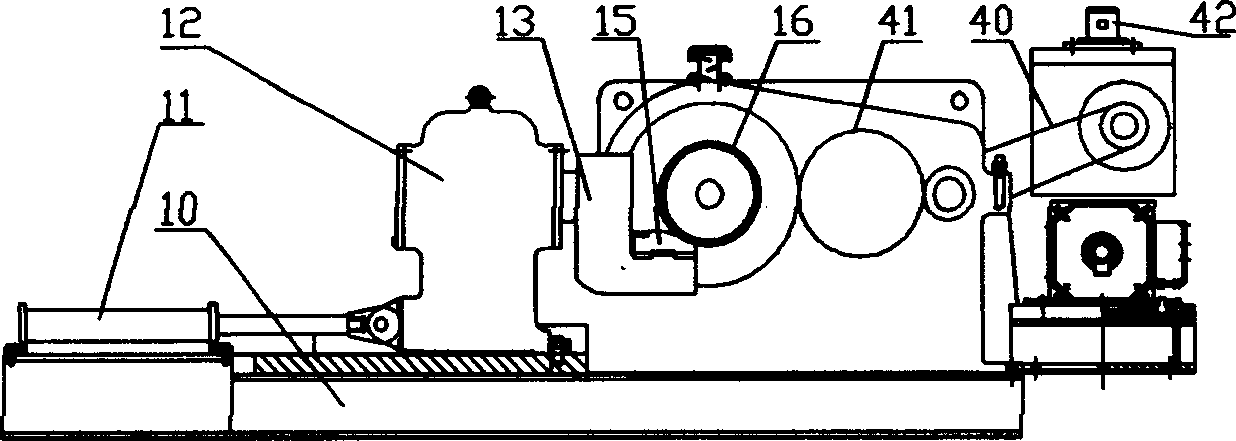

Numerically-controlled milking composite machine tool

InactiveCN101508069ASmall temperature rise and thermal deformationOperational securityTailstocks/centresOther manufacturing equipments/toolsDimensional precisionMotor drive

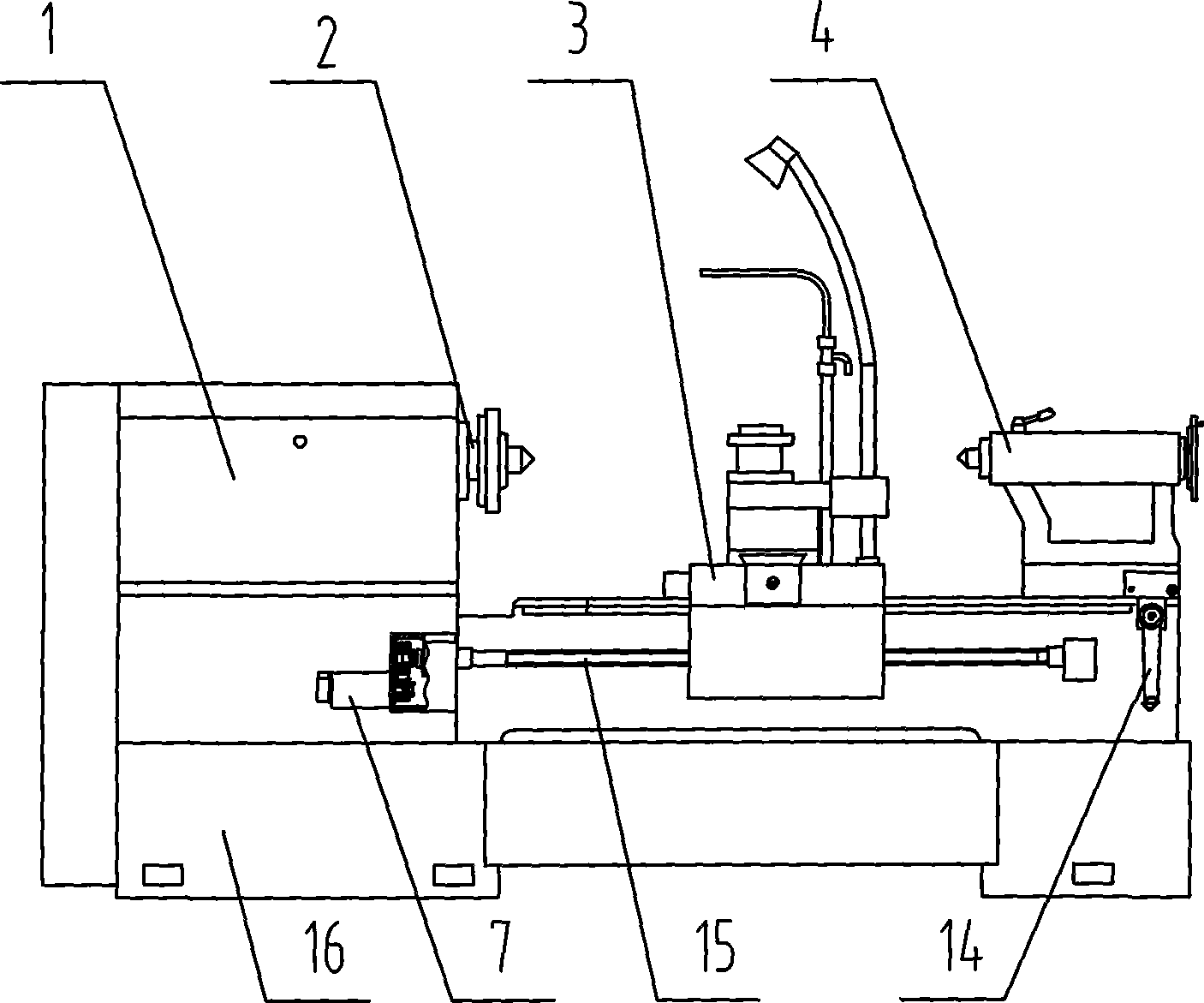

The invention discloses a digital control turning-milling complex machine tool, which comprises a digital control machine tool body, a spindle system, a milling unit head, a cutting off tool rest, a tailstock, a longitudinal and horizontal feed system and a lubricating system, and is characterized in that a lower slide block is arranged on a saddle of the machine tool; the front end of the lower slide block is provided with the four-station electric cutting off tool rest; the back end of the lower slide block is provided with the milling unit head capable of lifting; a mill head spindle of the milling unit head is provided with a milling cutter or a drill bit; the lifting of the milling unit head is realized by a servo motor driving a ballscrew pair to rotate; and a variable-frequency motor drives the mill head spindle to rotate, and the rotating speed of the mill head spindle is changed through adjustment of the frequency of the variable-frequency motor. Through once clamping, the digital control turning-milling complex machine tool can realize turning-milling complex processing to achieve the aim of multiple functions of one machine; the machine tool realizes four-axis linkage controlled by four axes combined by an X axis, a Y axis, a Z axis and a C axis together through a digital control system; and the whole machine has good rigidity, and the dimensional precision of processed parts reaches IT 7 and the surface roughness Ra is less than or equal to 3.2 mu m.

Owner:CHANGSHA JINLING MACHINE TOOL

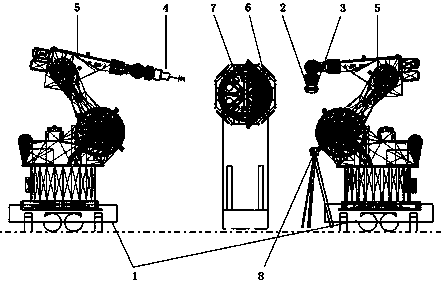

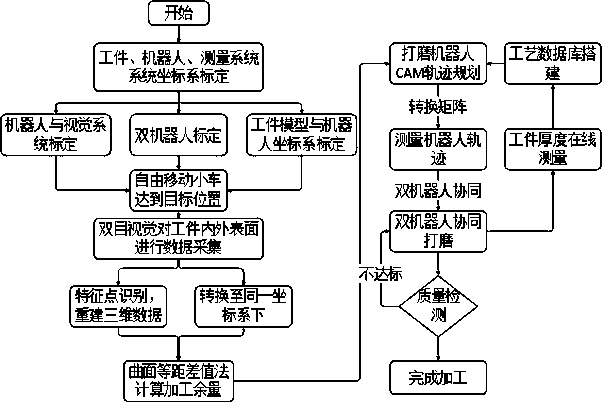

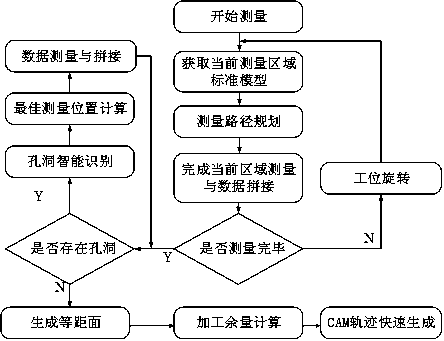

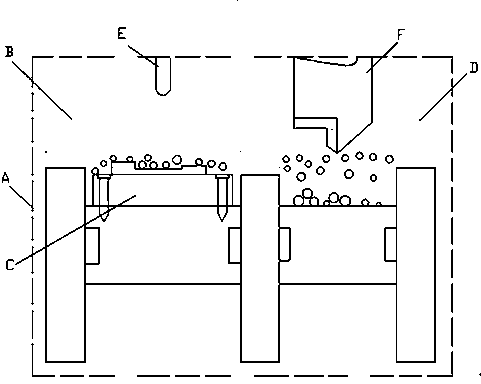

Moving double-robot cooperative grinding device and method based on online thickness detection

ActiveCN109623656ARealize online awarenessRealize regulationGrinding feed controlGrinding machinesConstant forceThree dimensional measurement

The invention provides a moving double-robot cooperative grinding device and method based on online thickness detection. In order to meet the intelligent development trend of the world and raise the automation level of traditional machining, and with regard to the problems of multiple machining stations, complex working procedures, the need of repeated loading and unloading, low machining accuracy, low efficiency and the like of traditional grinding machining for medium and large parts, the invention discloses a machining system composed of double robots, a free movement platform, a free moving platform, a floating constant-force grinding electric spindle, binocular vision, an electromagnetic thickness meter, a laser tracker, a rotary fixture and other key equipment, and discloses an integrated grinding method combining double-robot cooperative control, three-dimensional measurement, offline programming, process database, and online detection and machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

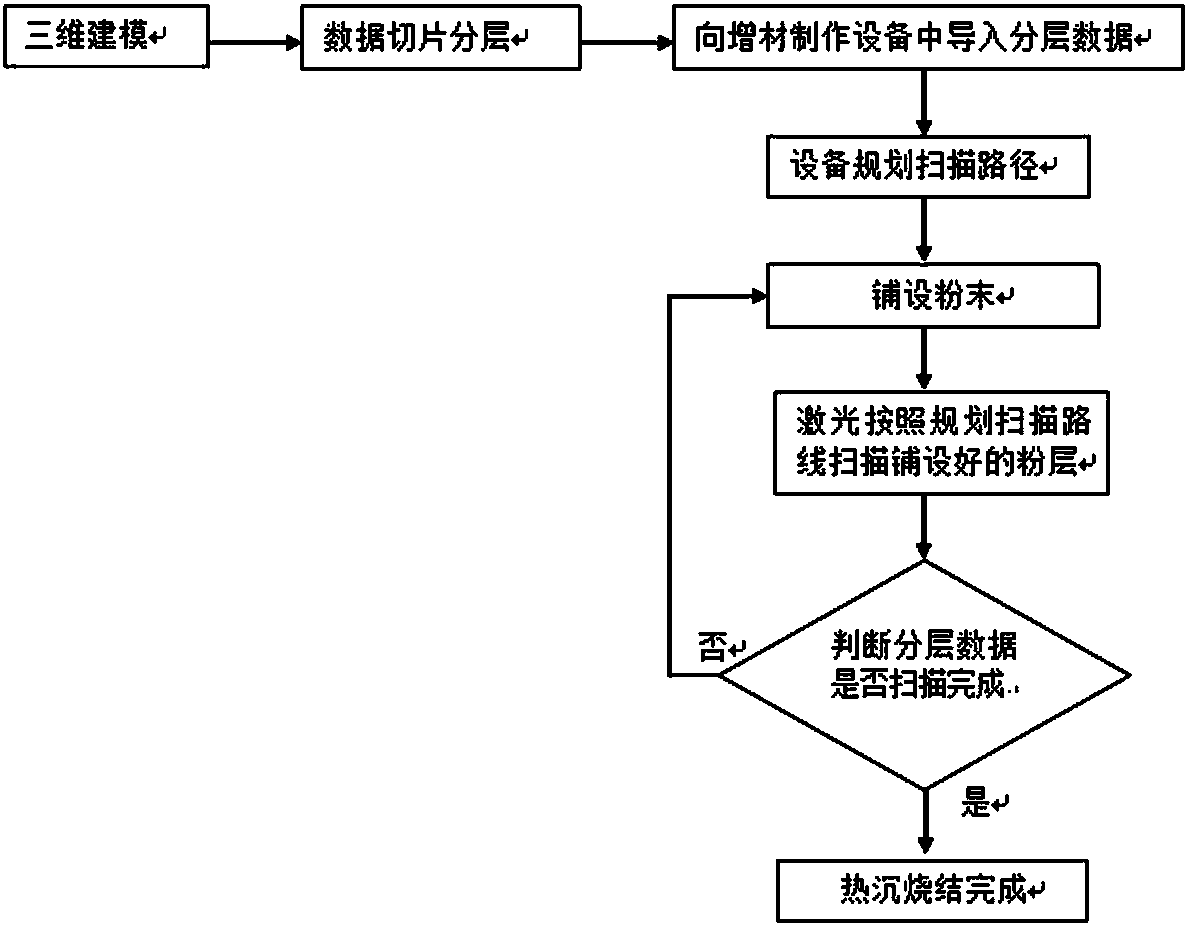

Method for manufacturing heat sink body

ActiveCN104028758AReduced time for structural optimization and product manufacturingImprove thermal performanceIncreasing energy efficiencyThree dimensional modelHeat sink

The invention discloses a method for manufacturing a heat sink body. The method aims at solving the problems that in the traditional heat sink manufacturing process, heat resistance is increased due to multilayer welding, and a heat sink body needs to be manufactured through multiple processes and is short in service life. The method includes the steps that three-dimensional modeling is conducted on the whole structure of the heat sink body; a three-dimensional model is guided to a workbench computer, and the printing angle and positions are set according to the structure of a three-dimensional pattern; a powder layer laid on a base plate of a workbench in advance is sintered into two-dimensional shapes corresponding to the powder layer through high-energy laser beams according to the scanning path; powder as thick as the powder layer is laid on the workbench on which one layer of pattern is sintered, and lasers scan the powder according to the scanning path of the layer until the whole three-dimensional pattern is finished. Through the structure, the heat sink body has the advantages that pressure distribution is uniform and the service life of the heat sink body is prolonged.

Owner:CHENGDU 3D CHANGE TECH

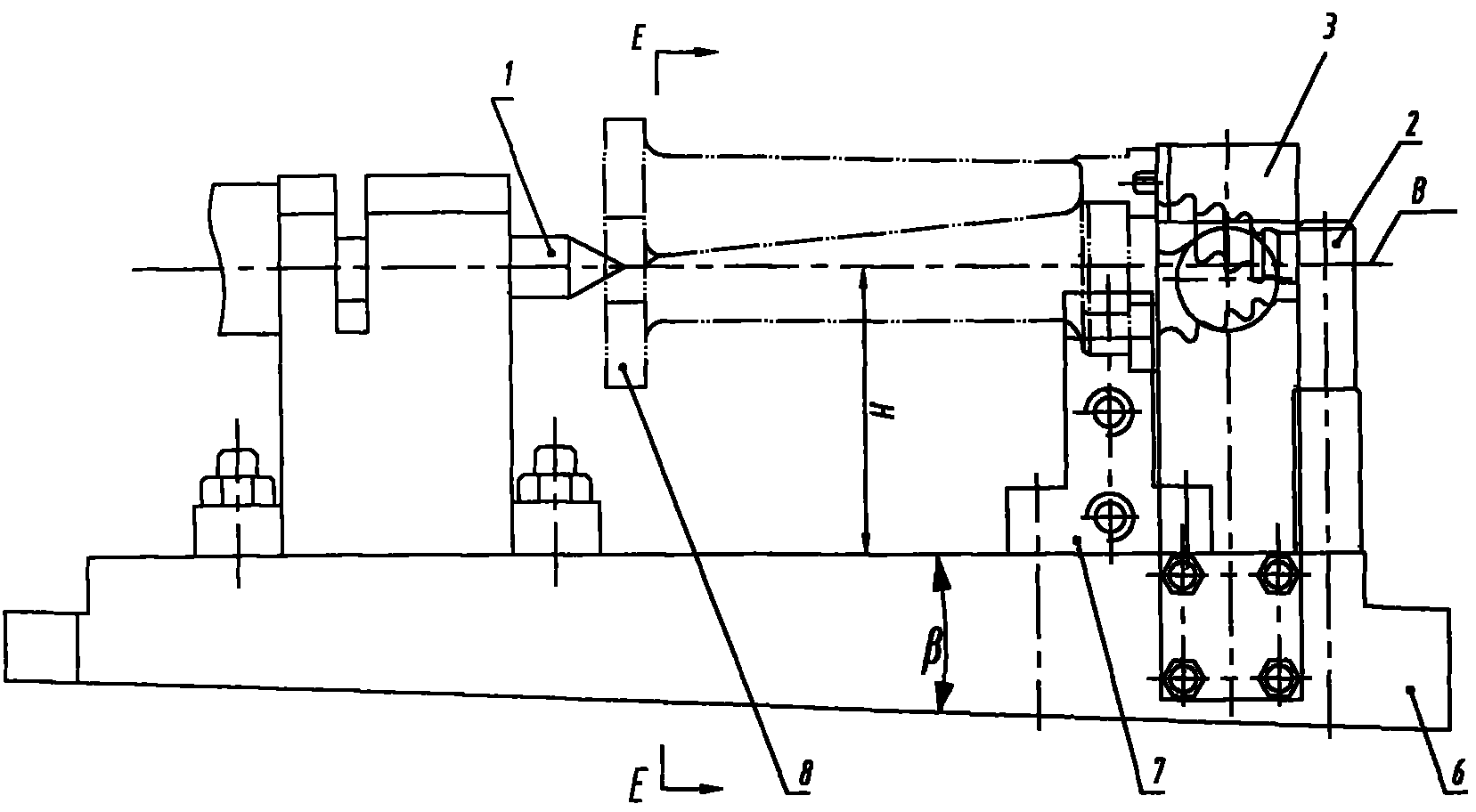

Machine tool and method for machining over-long diameter ratio shaft exceeding machine tool standard

InactiveCN101574743AIncrease profitIncrease travelLarge fixed membersTurning machinesFinialLongest Diameter

The invention discloses a machine tool and a method for machining an over-long diameter ratio shaft exceeding the machine tool standard. The method comprises the following steps: firstly, leaving a section of chuck dock with an effective length respectively at two ends of a workpiece in advance, and drilling central holes on two end surfaces of the workpiece; secondly clamping one end of the workpiece on a chuck of a headstock, and supporting the other end by a finial on a tailstock; thirdly, coarsely turning the excircle of each section of the workpiece, and reversing the workpiece for turning when a knife rest feeds to the tail end of a knife rest lead rail; fourthly, finely turning the excircle of each section of the workpiece, and reversing and clamping the workpiece for turning when the knife rest feeds to the tail end of the knife rest lead rail; and finally, milling the chuck docks at the two ends and the chamfer angle on a boring lathe, a milling machine or other machine tools. The machine tool and the method for machining an over-long diameter ratio shaft exceeding the machine tool standard achieve the purpose of machining long-shaft parts over 15 m on a common machine tool for machining long shaft parts, thereby reducing the production cost.

Owner:SHANGHAI HEAVY MACHINERY PLANT

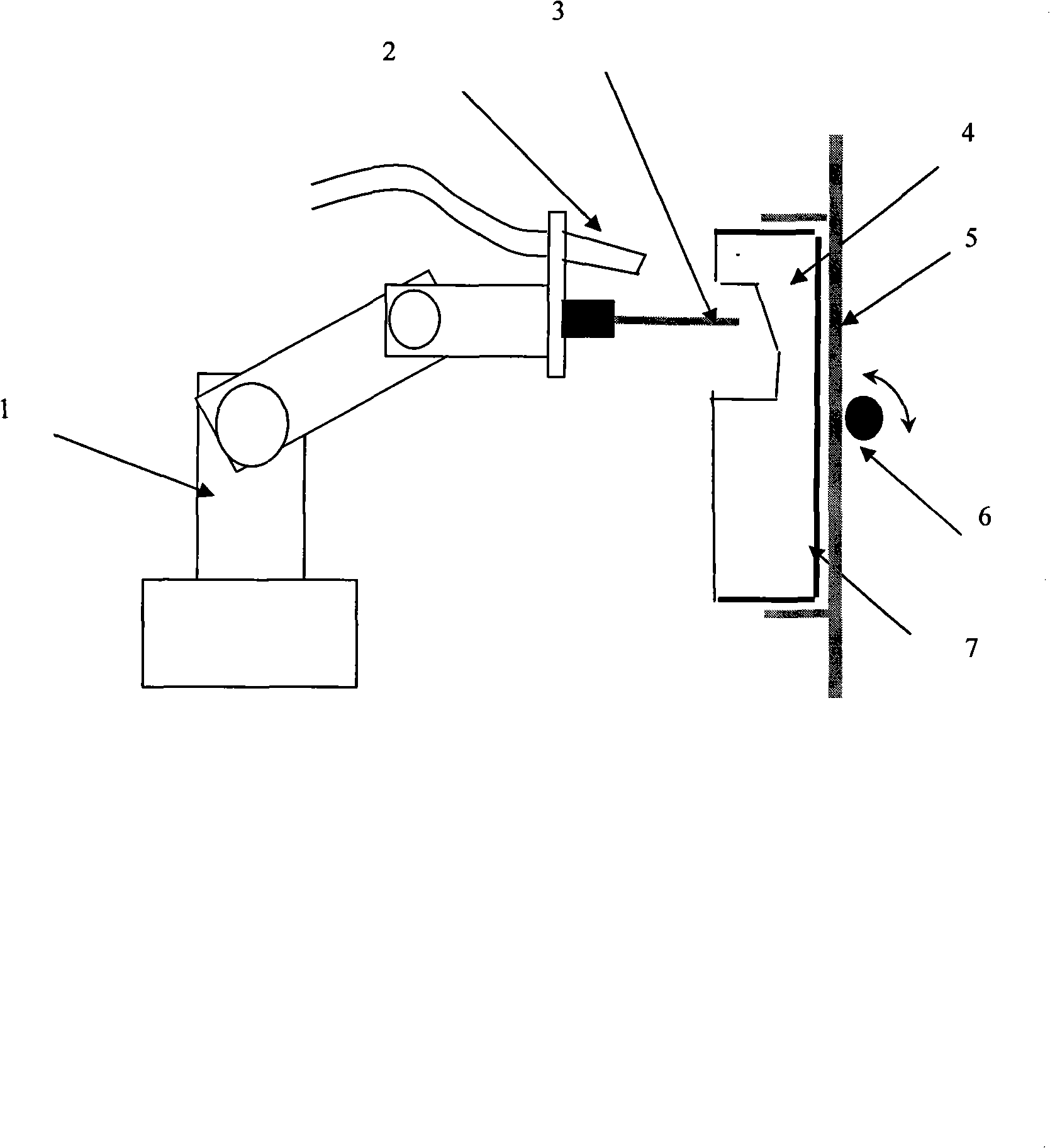

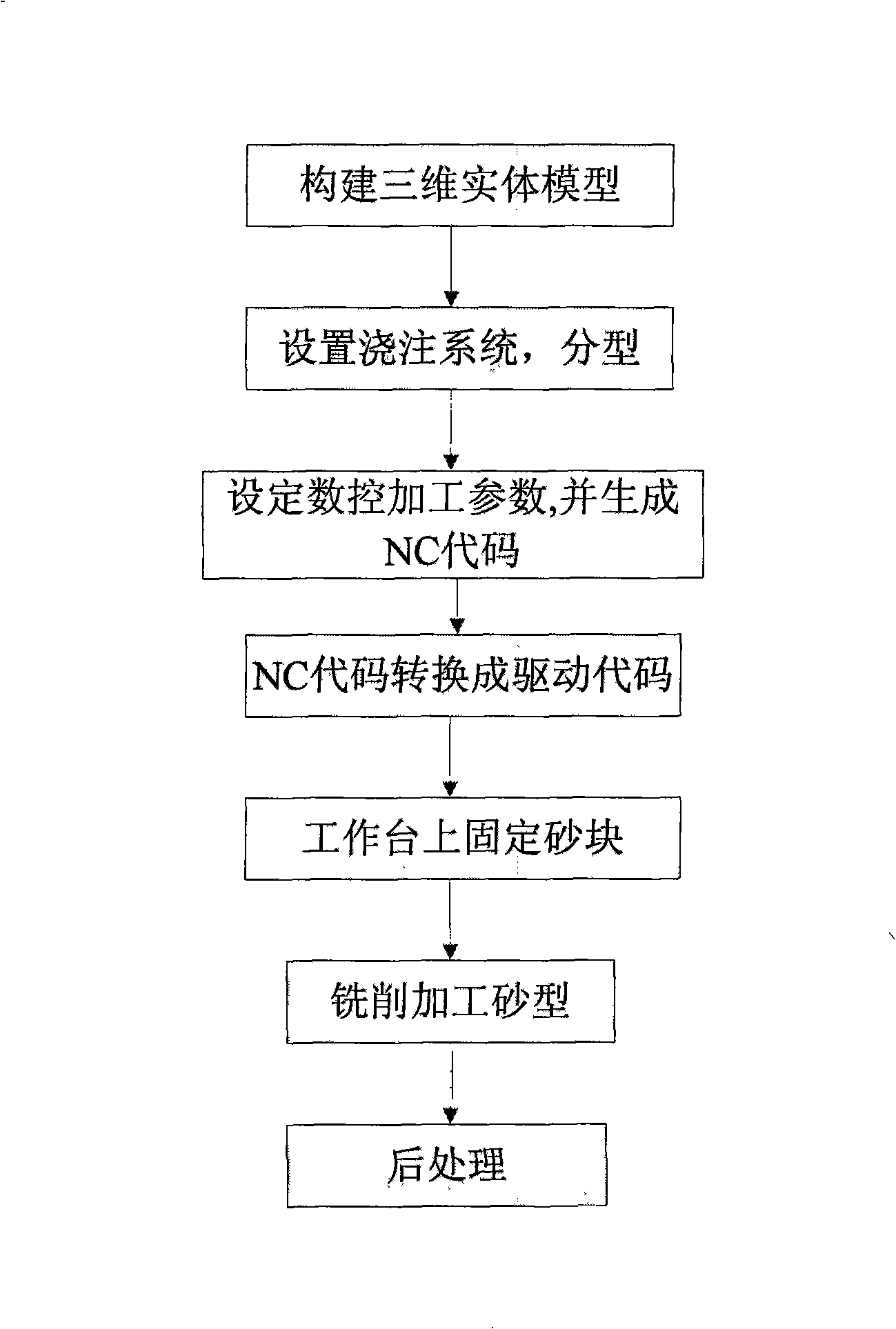

Sand mold milling method based on industrial robot

InactiveCN101279357AReduce preparationQuick cutFoundry mouldsFoundry coresBatch processingAttitude control

The invention relates to a method for adopting an industrial robot to carry out the ordinary sand mold milling processing, which pertains to the filed of the cross technology of casting, numeric control processing and the industrial robot. The steps of the method of the invention are that: a tool and a planned milling path are selected according to the shape of a sand mold to be processed, the generated NC code is translated into a control code of the robot according to a motion model of the industrial robot, thus realizing the gesture control of the robot during the processing process, carrying out the milling of a sand lump and finally carrying out the post-processing of the sand lump after the processing. Compared with the existing traditional casting mold processing method, the processing method of the invention can save the manufacturing link of the mold, reduce the processing procedure, shorten the production period and reduce the production cost; compared with the machine tool-based sand mold milling processing method, the processing method of the invention has larger processing range and higher processing flexibility, in particular to a motion guide track without the need of carrying out the strict sand control protection. The method of the invention is especially applicable to the single and small-batch processing and manufacturing of the large-scale sand mold.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

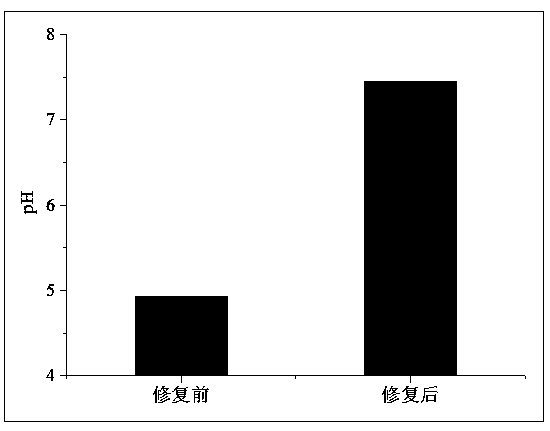

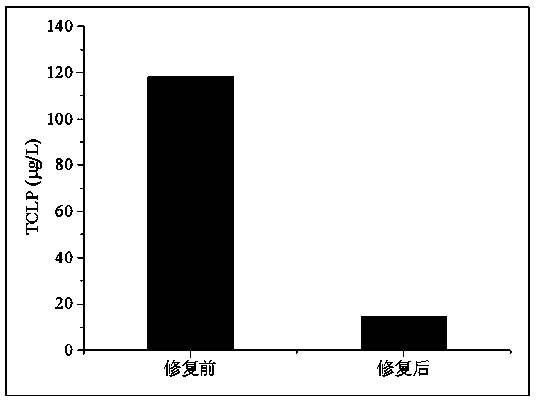

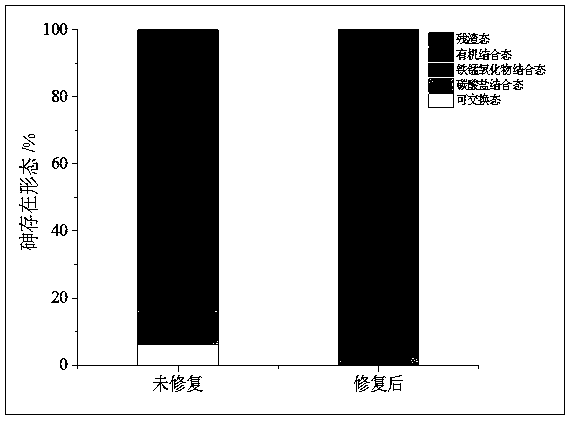

Method for remedying acidified arsenic contaminated soil by biochar-loaded nano-scale zero-valent iron cooperated with bacteria

ActiveCN109570227AReduce dosageAvoid destructionContaminated soil reclamationChemical reactionPseudomonas putida

The invention relates to a method for remedying acidified arsenic contaminated soil by biochar-loaded nano-scale zero-valent iron cooperated with bacteria. The method includes selecting Pseudomonas putida strain MnB1 (ATCC23483); carrying out enrichment culture on the Pseudomonas putida strain in enrichment culture media; inoculating strains in culture media with divalent manganese and carrying out culture on the strains to obtain active metabolites; adding the active metabolites and the green synthetic biochar-loaded nano-scale zero-valent iron into the acidified arsenic contaminated soil anduniformly stirring the active metabolites, the biochar-loaded nano-scale zero-valent iron and the acidified arsenic contaminated soil; carrying out a series of physical-chemical reaction on active manganese oxide, zero-valent iron, biochar and trivalent arsenic or pentavalent arsenic in the soil; converting the arsenic in exchangeable forms into arsenic in residual forms. The method has the advantages that the arsenic in the soil can be effectively immobilized, the pH (potential of hydrogen) of the soil can be increased, and the double purposes of remedying soil acidification and arsenic contamination can be simultaneously achieved; the method is short in remediation time, high in efficiency, wide in treatment range and free of secondary pollution, and stable effects can be realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

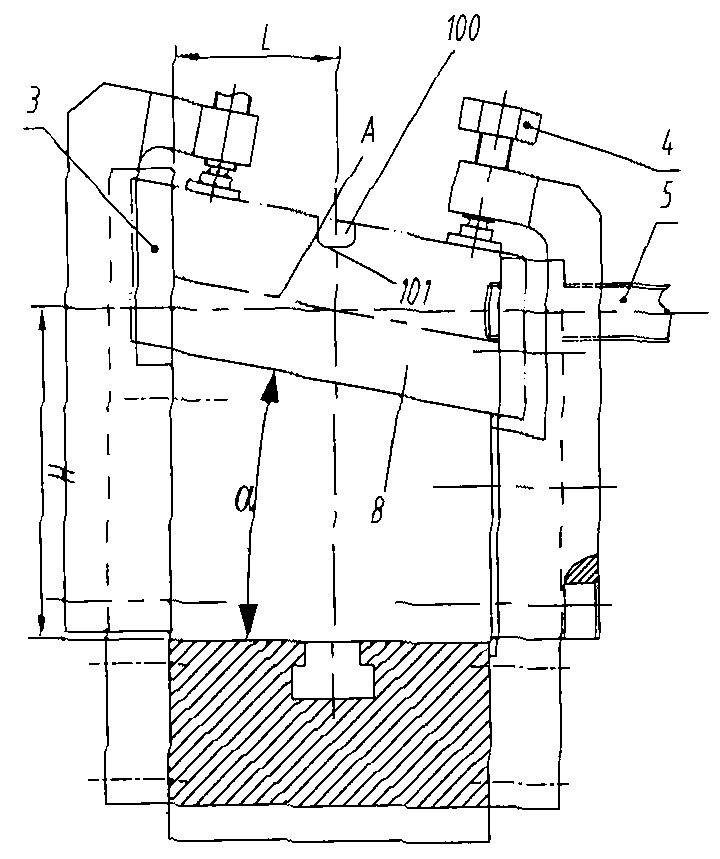

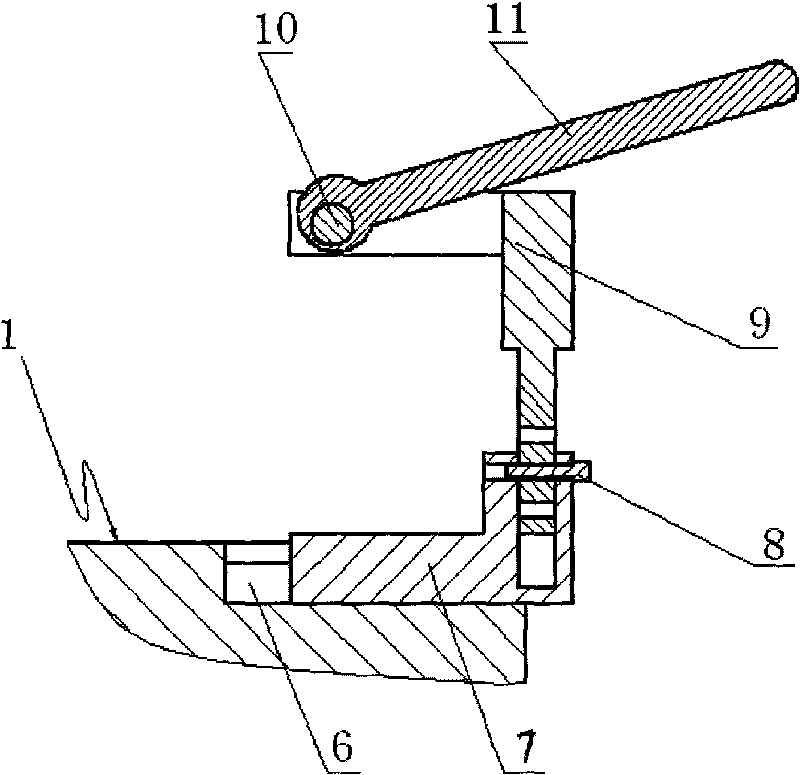

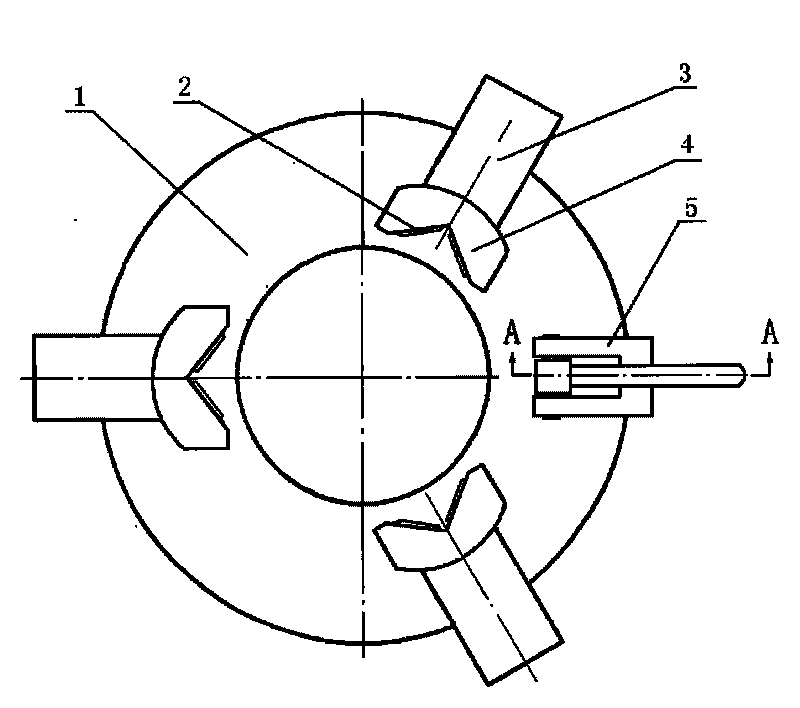

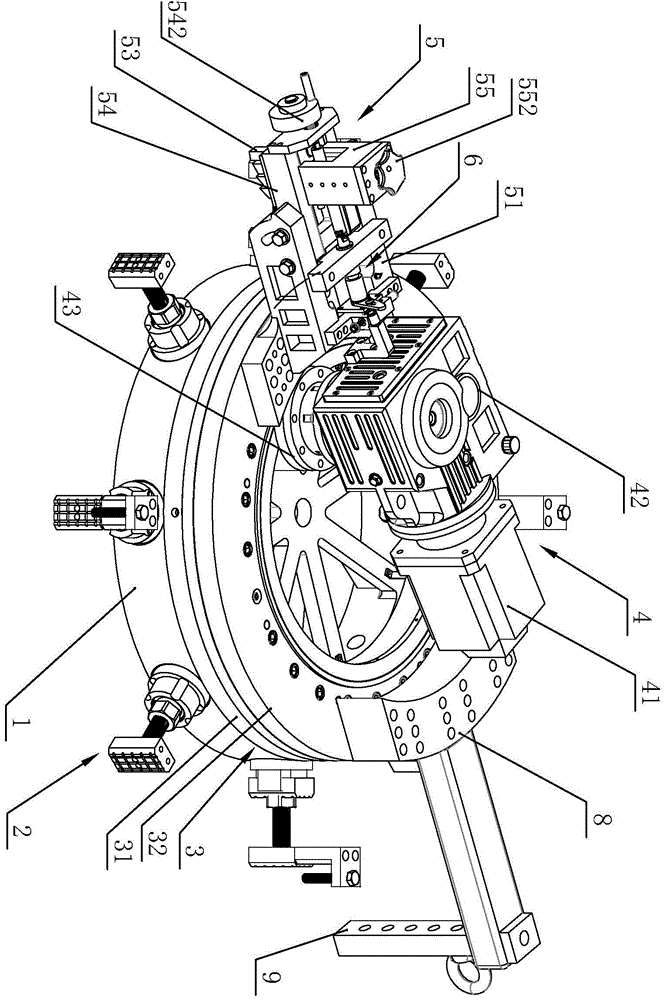

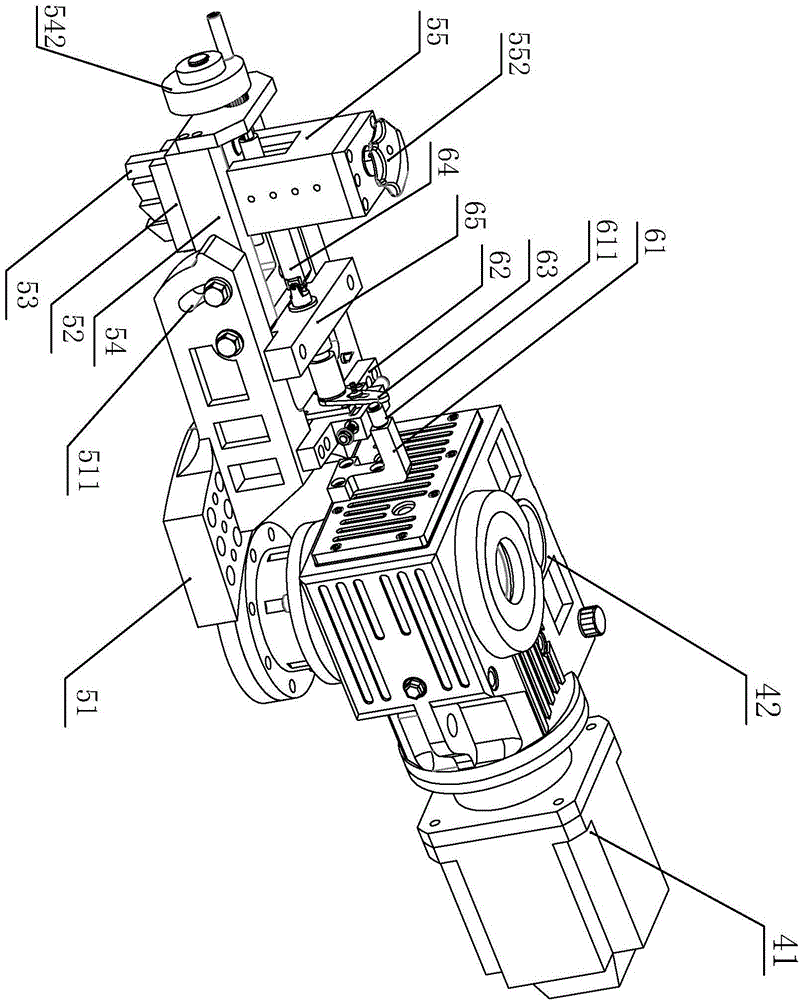

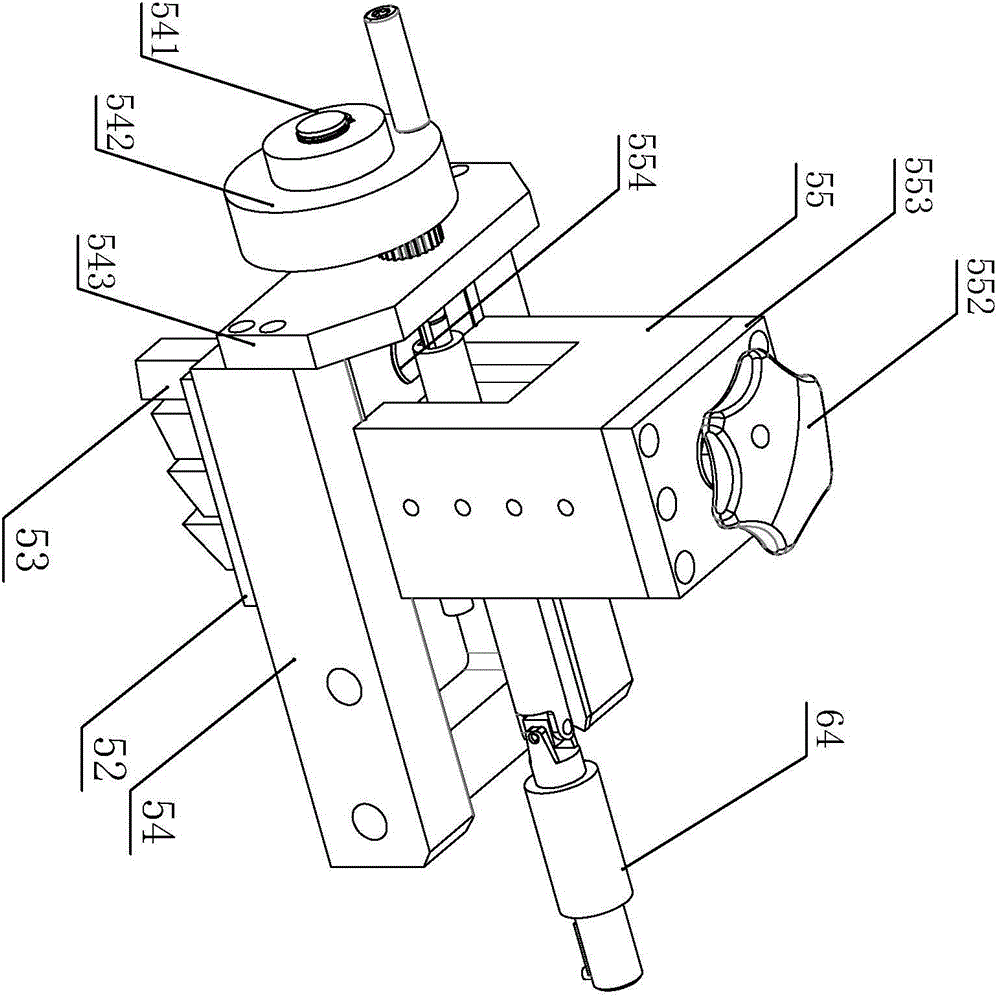

Special fixture used for processing open slot on spatial dihedral angle slope of turbine blade

ActiveCN102371491AExpand the scope of processingComply with positioning installation requirementsPositioning apparatusMetal-working holdersSurface finishBaseboard

The invention provides a special fixture used for processing an open slot on a spatial dihedral angle slope of a turbine blade, and the special fixture is characterized by comprising a slope baseboard component capable of adjusting a radial gradient, wherein a tailstock tip component and an end face positioning component are oppositely arranged at two radial ends of the slope baseboard component; a slope cushion component which is capable of adjusting an axial gradient and a height is arranged on the slope baseboard component between the tailstock tip component and the end face positioning component; a side wall positioning component is also arranged on the slope baseboard component; the side wall positioning component can axially feed a side wall positioning element which is contained in the side wall positioning component; a clamping component is also arranged on the slope baseboard component; and a pressing head capable of feeding downward is arranged at the tail end of the clamping component. The fixture provided by the invention can firmly and accurately position a device, can quickly and efficiently process the open slot meeting a design demand on a size precision and a position precision, and has ultrahigh surface glossiness.

Owner:四川省自贡市海川实业有限公司

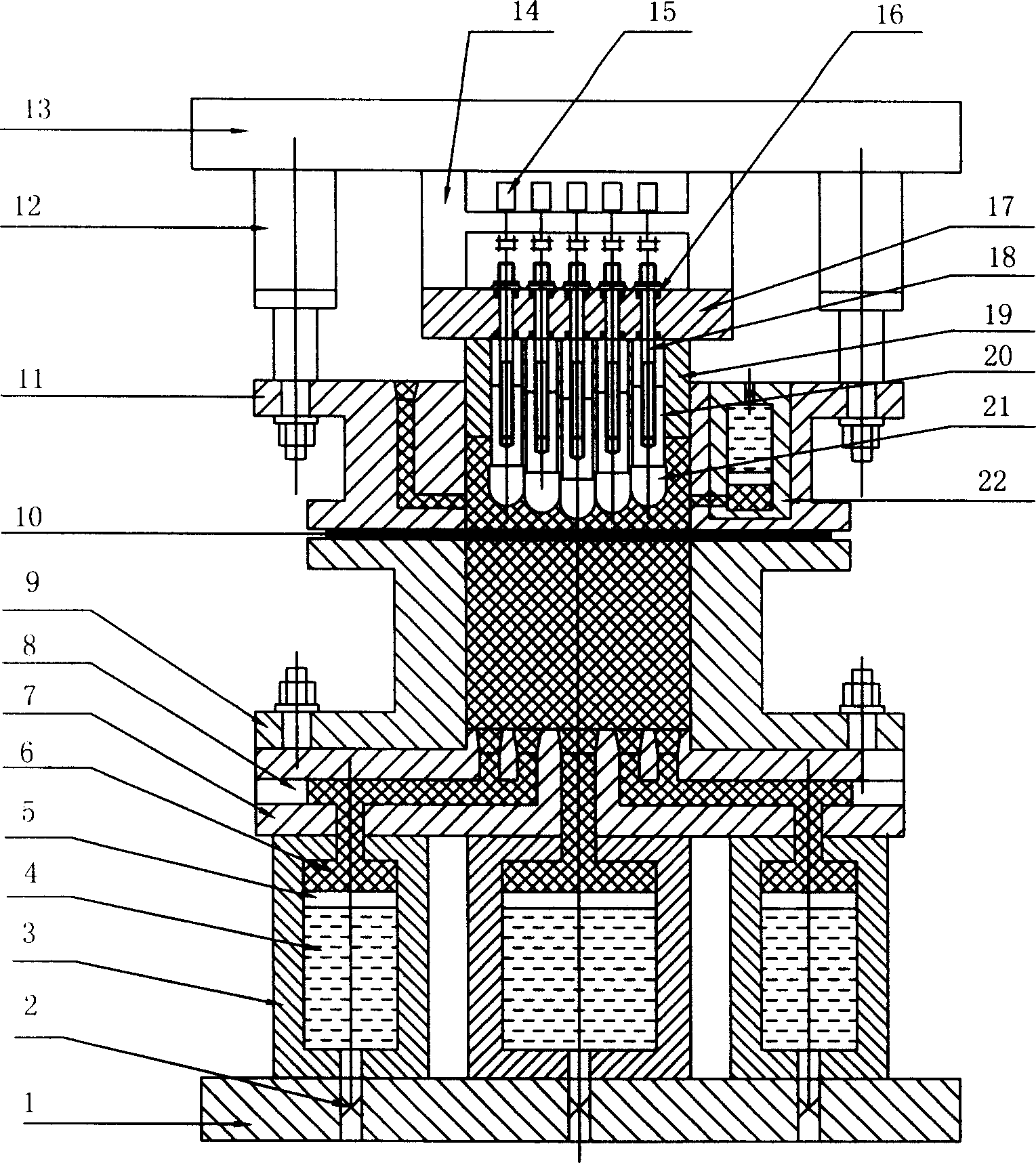

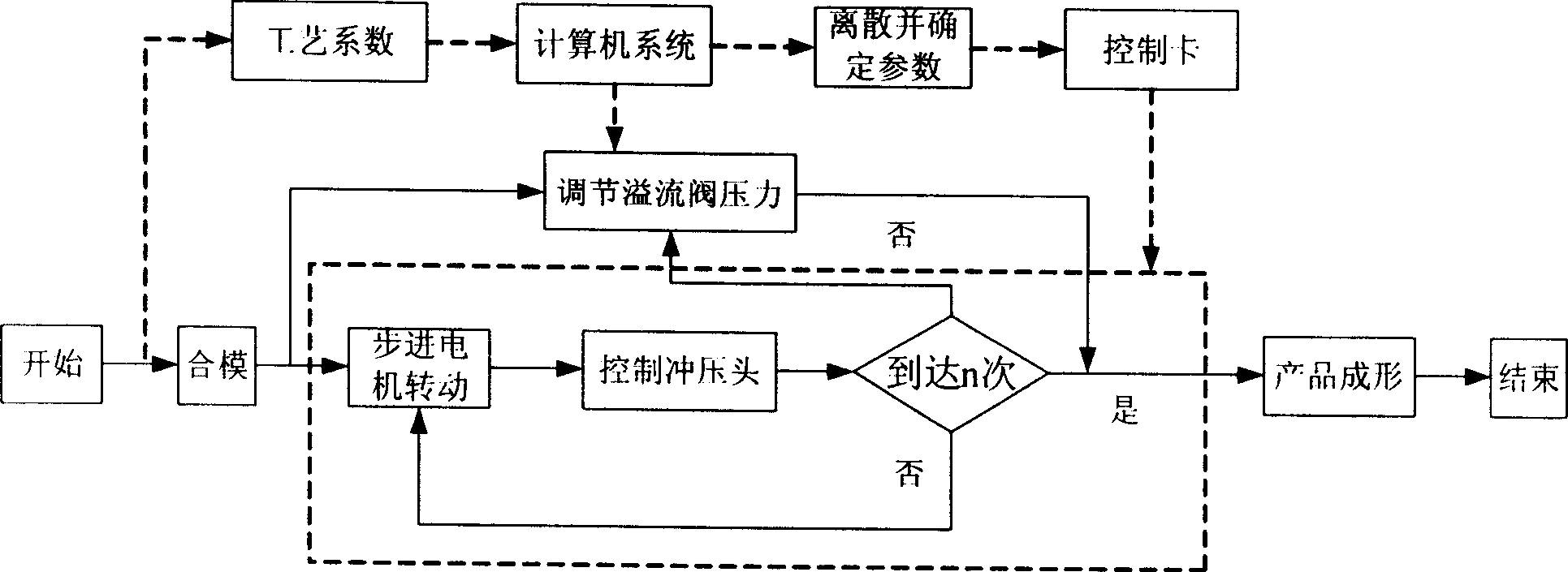

Sheet material mold-free multi-point forming device based on viscous medium transfer force and method

The invention relates to a sheet multipoint molding device and relative method, based on adhesive medium force transmission. Wherein, the lower die cavity is formed by concave mould and the bottom plate of concave mould; the bottom of concave mould has the discharge hole of adhesive medium, which is connected to the cylinder via the channel inside the bottom plate; the fixing compress device is formed by the upper mould, motor, mounting element, convex mounting plate and the punch head connected to the flexible sheath; the flanging ring, convex mould fixing plate, flexible sheath and the punch head form the upper die chamber; the sheet compress device is formed by the upper edge of concave mould and the flanging ring. The invention uses adhesive medium with uniform force transmission, to reduce the producing period, the producing cost, avoid the surface crack caused by rigid mould, while the thickness is uniform.

Owner:重庆工学院

Method for brewing fermentation of olive wine with fruit juice and residue of olive

InactiveCN101319183AHas nutritional and health effectsPrevent cardiovascular and cerebrovascular diseasesAlcoholic beverage preparationYeastFruit juice

The invention relates to a method for preparing fermenting olive wine from olive fruit juice and olive fruit pomace. The fermenting olive wine mainly comprises the olive fruit juice, the olive fruit pomace, citric acid, an additive A and wine microzyme in different percentages by weight, wherein the olive fruit juice is mixed concentrated solution of a fruit juice generated in the oil extraction of olive and a water juice obtained after fruit pomace leaching, and the olive fruit pomace is the remaining fruit pomace which remains after oil exaction of the olive and is subjected leaching, drying and smashing. The olive fruit juice after removal of bitter taste and the de-oiling olive fruit pomace is stirred evenly, predistilled, mixed with yeast, fermented, reserved, blended, and processed by other preparation methods to obtain the fermenting olive wine. The fermenting olive wine prepared by the method combines the sweetness and fragrance of olive fruit and rice wine, has pure taste, is rich in nutrition, and has the health care functions of building up a sound body, preventing cardiovascular disease, treating bronchitis and chronic pharyngolaryngitis disease.

Owner:罗建军

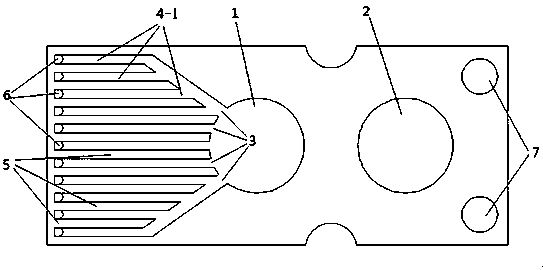

Design and manufacturing method of porous grid structure material

InactiveCN105499575AManufacturing flexibilityImprove performance qualityAdditive manufacturing apparatusTissue regenerationLaser scanningSize ratio

The invention discloses a design and manufacturing method of a porous grid structure material and aims to solve the problems of blindness and uncertainty in traditional manufacturing of a porous material and apply an effective design concept for the porous material to practical manufacturing. The design and manufacturing method comprises the following steps: obtaining a data image based on topological optimization simulation; performing three-dimensional rebuilding on the data image on Solid Works; importing to magics software as a unit grid structure; filling into various three-dimensional models of specific parts which need to adopt the grid structure at any size ratio; afterwards manufacturing the parts. According to the design and manufacturing method, firstly, the three-dimensional model of each part is imported to a computer on a worktable; the printing angle and the printing position are set according to the three-dimensional graph structure; a powder layer is sintered into a corresponding two-dimensional shape on the layer; powder with the same thickness is repeatedly laid on the worktable on which one layer of graph is sintered; laser scanning is still performed according to the scanning route of the layer until the overall three-dimensional graph is completed. The design and manufacturing method disclosed by the invention has the advantages of reducing the elasticity modulus of the part and realizing good mechanical properties.

Owner:BEIJING UNIV OF TECH

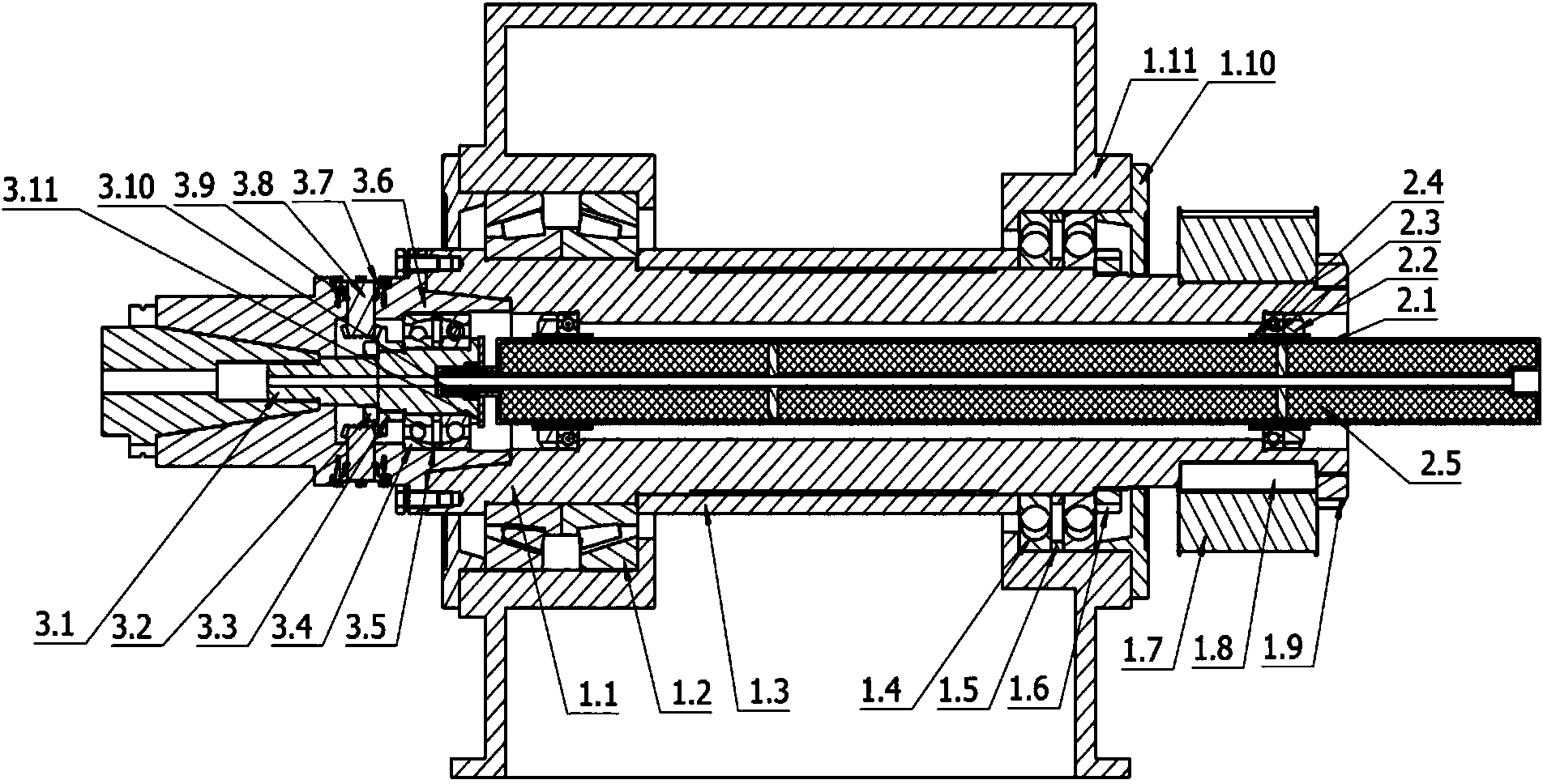

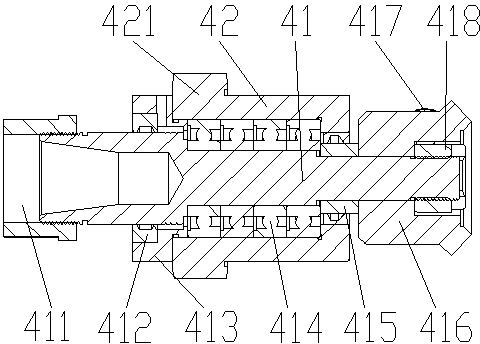

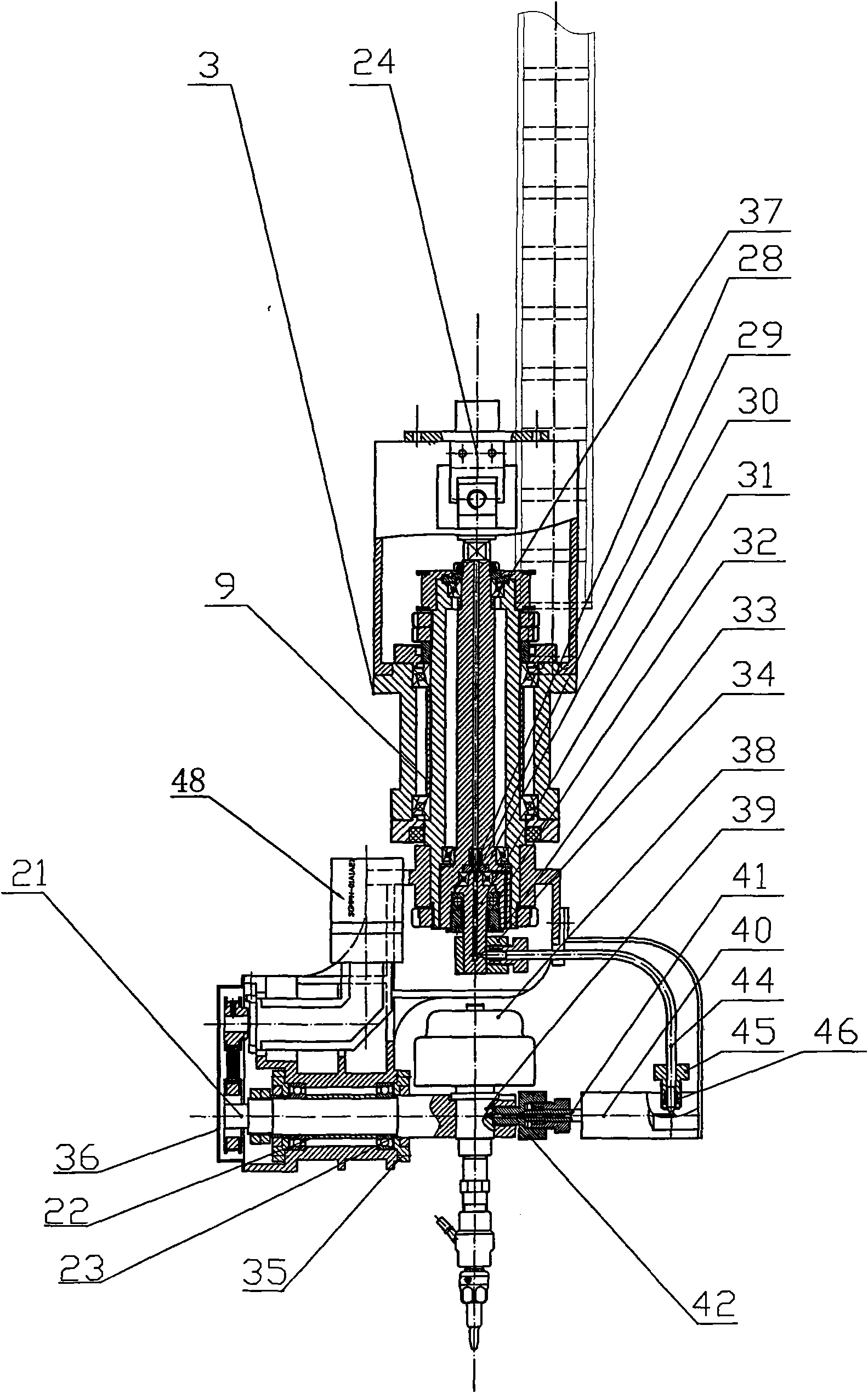

Liquid nitrogen inner spraying type numerical control drilling and milling machine main shaft device

ActiveCN103962584ASolve the problem of inconvenient transportation of liquid nitrogenSolve the problem of realizing internal spray liquid nitrogen cutting fluidLarge fixed membersMaintainance and safety accessoriesNumerical controlLiquid nitrogen

The invention discloses a liquid nitrogen inner spraying type numerical control drilling and milling machine main shaft device, belongs to the field of numerical control machine tool main shaft design and relates to a numerical control drilling and milling machine main shaft device. According to the numerical control drilling and milling machine main shaft device, liquid nitrogen flows in an inner cavity of a main shaft to positions near a hollow cutter cutting edge and is sprayed out through thin holes, and therefore copious cooling and low temperature cutting are achieved. The liquid nitrogen inner spraying type main shaft device is composed of a main shaft assembly, a liquid nitrogen heat insulation pipe assembly and a rivet assembly. A main shaft in the main shaft assembly is in a hollow shape, two bearings in the liquid nitrogen heat insulating pipe are arranged on two bearing adapter sleeves respectively in a sleeved mode, and two clamp nuts are screwed to conical face external threads of the two bearing adapter sleeves respectively. Two bevel gears in the rivet assembly are symmetrically installed in two outer round holes of a cutter connection frame, and rotation and limiting of axial moving are achieved through inner groove balls. A vacuum heat insulating hard pipe is composed of an inner steel pipe set and an outer steel pipe set. According to the liquid nitrogen inner spraying type numerical control drilling and milling machine main shaft device, the machining precision and the cutter durability of materials which are difficult to cut are reduced, liquid nitrogen losses are reduced, the machining range of a complicated structural workpiece is expanded, and the liquid nitrogen inner spraying type numerical control drilling and milling machine main shaft device can be used for machining in different working conditions and high in practicability.

Owner:DALIAN UNIV OF TECH

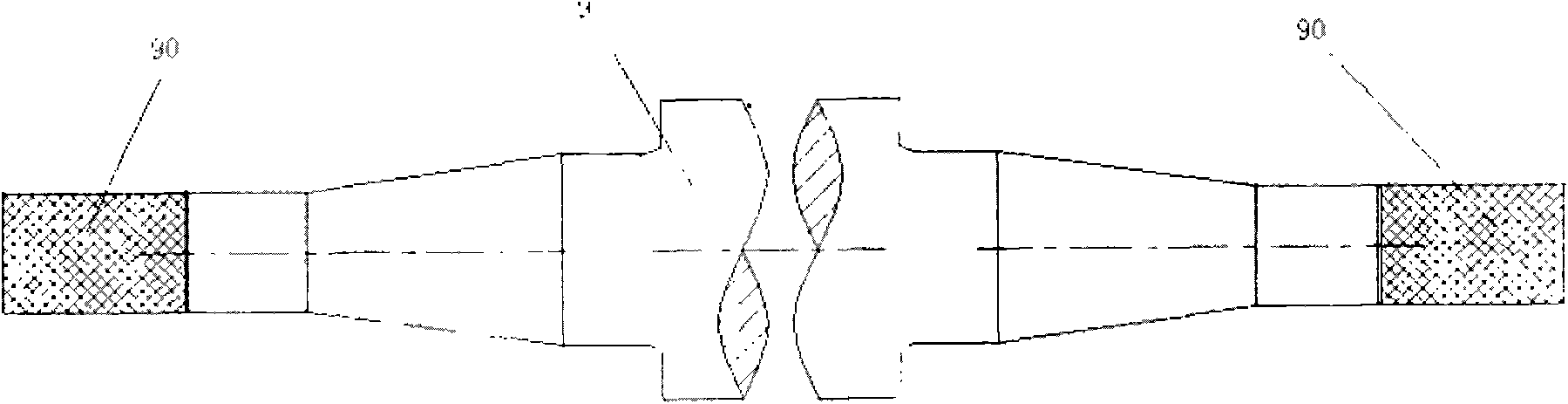

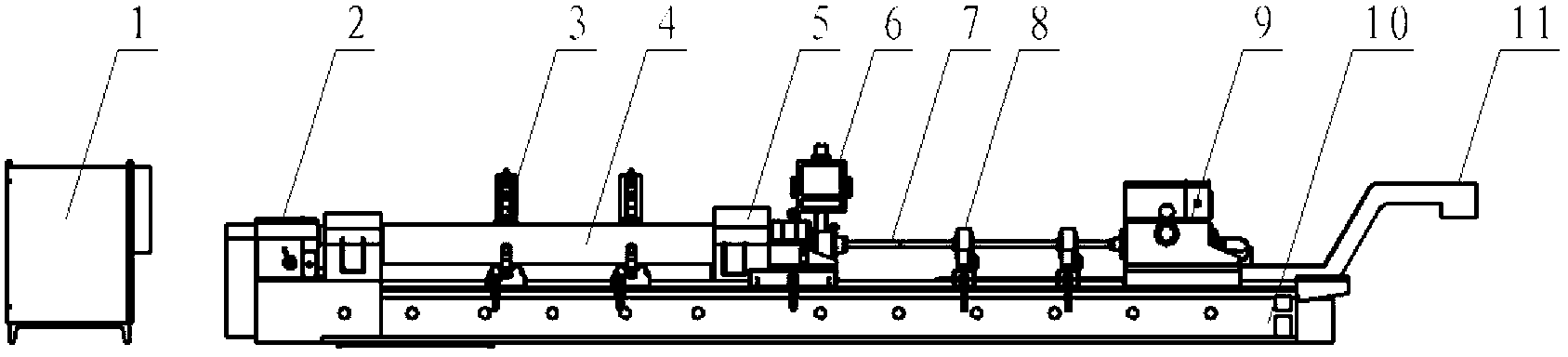

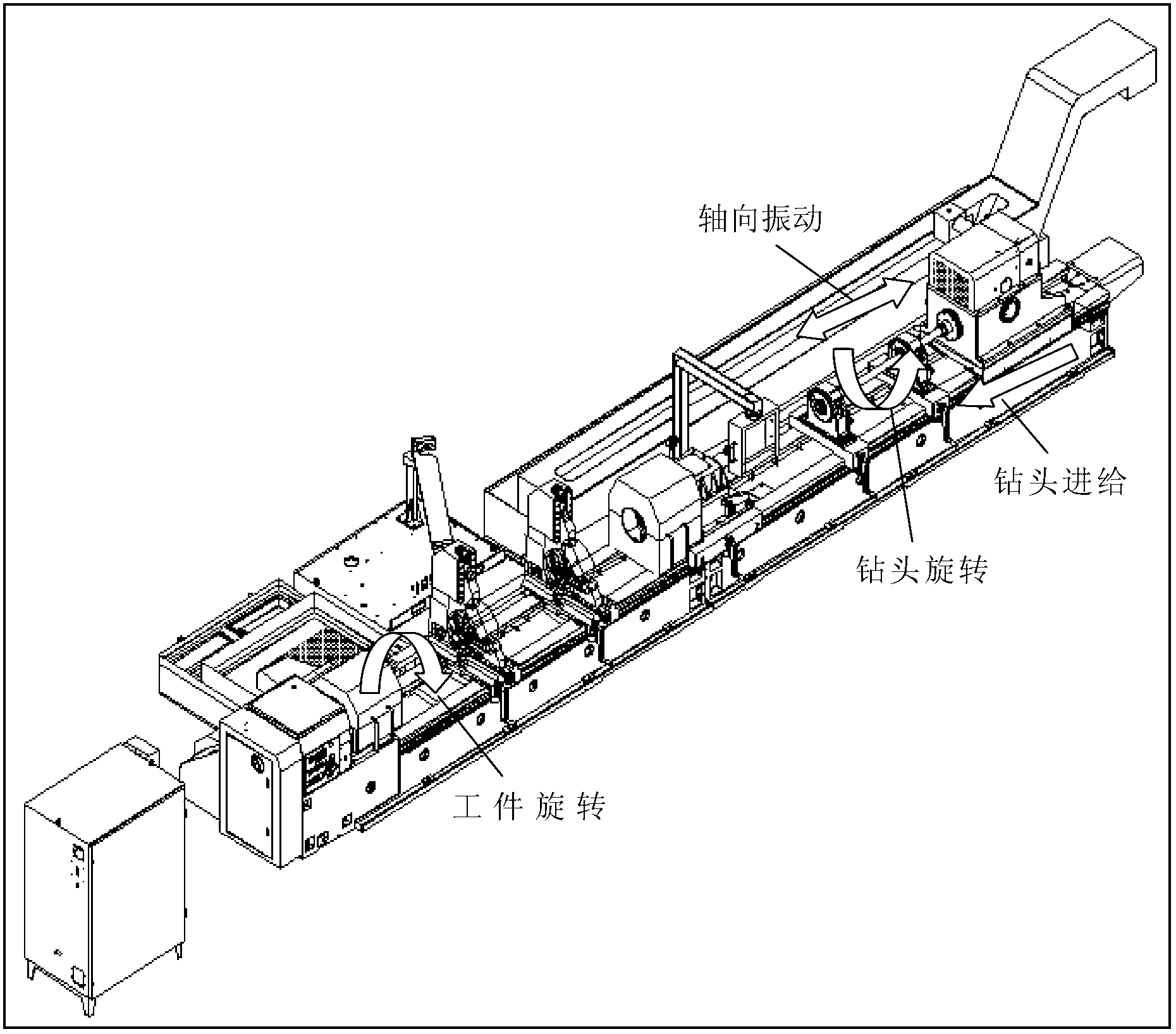

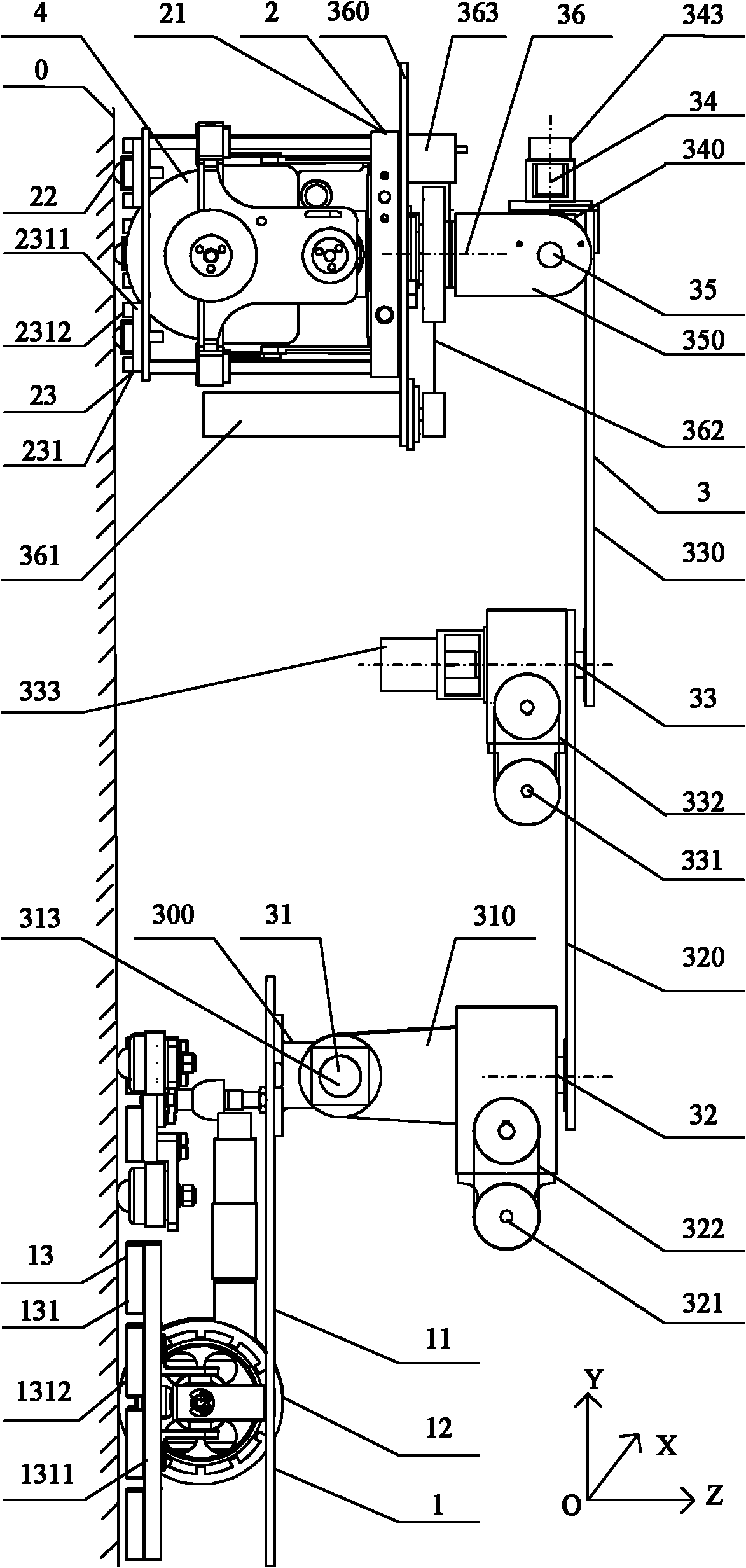

Numerical control vibration deep-hole drilling and boring machining equipment and method

InactiveCN102699375AImprove roundnessImprove straightnessBoring/drilling componentsMaintainance and safety accessoriesNumerical controlAxial vibration

The invention discloses numerical control vibration deep-hole drilling and boring machining equipment, which is characterized by comprising a workpiece arranged on a machine tool body, a drill bit and a drill stem, wherein the workpiece is driven by a main motor to rotate; and the drill bit is driven by the motor to rotate along with the drill stem and is simultaneously driven by a servo reducing motor and a vibration motor to make numerical control feed movement and axial reciprocating vibration. By the deep-hole drilling and boring equipment, the functions of rotating the workpiece and the drill bit in a bidirectional mode and axial vibration drilling can be realized, the severe working conditions and the lubricating effect of a cutting area of the drill bit are improved, the cuttings are automatically controlled, the process range of the equipment is greatly widened, the machining precision indexes of the holes such as roundness and straightness are improved, and the hole machining quality and efficiency are improved further; and moreover, the problem of chip breakage and removal in the prior art is solved, the cuttings can be automatically separated, collected and conveyed, automation of the drilling process is realized, and the equipment can be widely applied to the field of machining of rotary deep-hole parts.

Owner:XIAN UNIV OF TECH

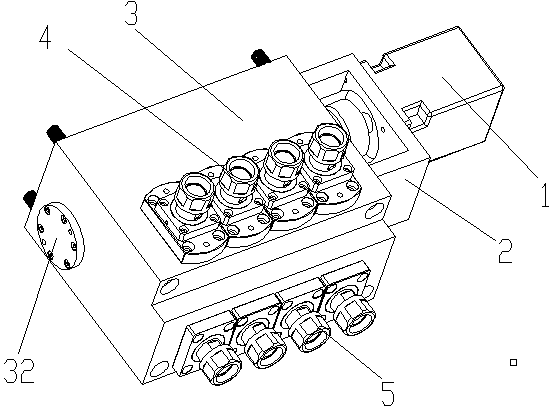

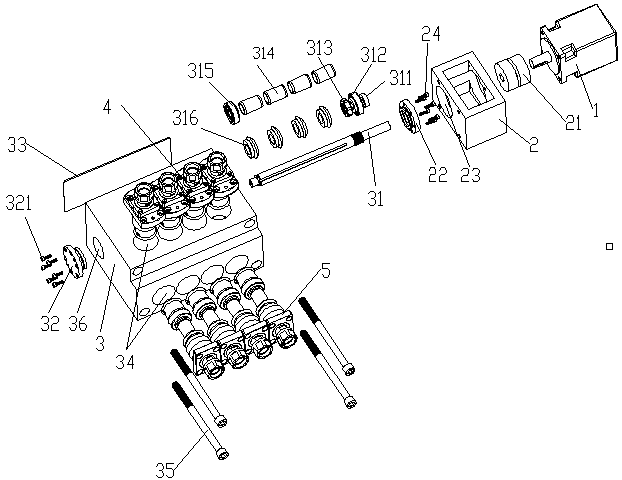

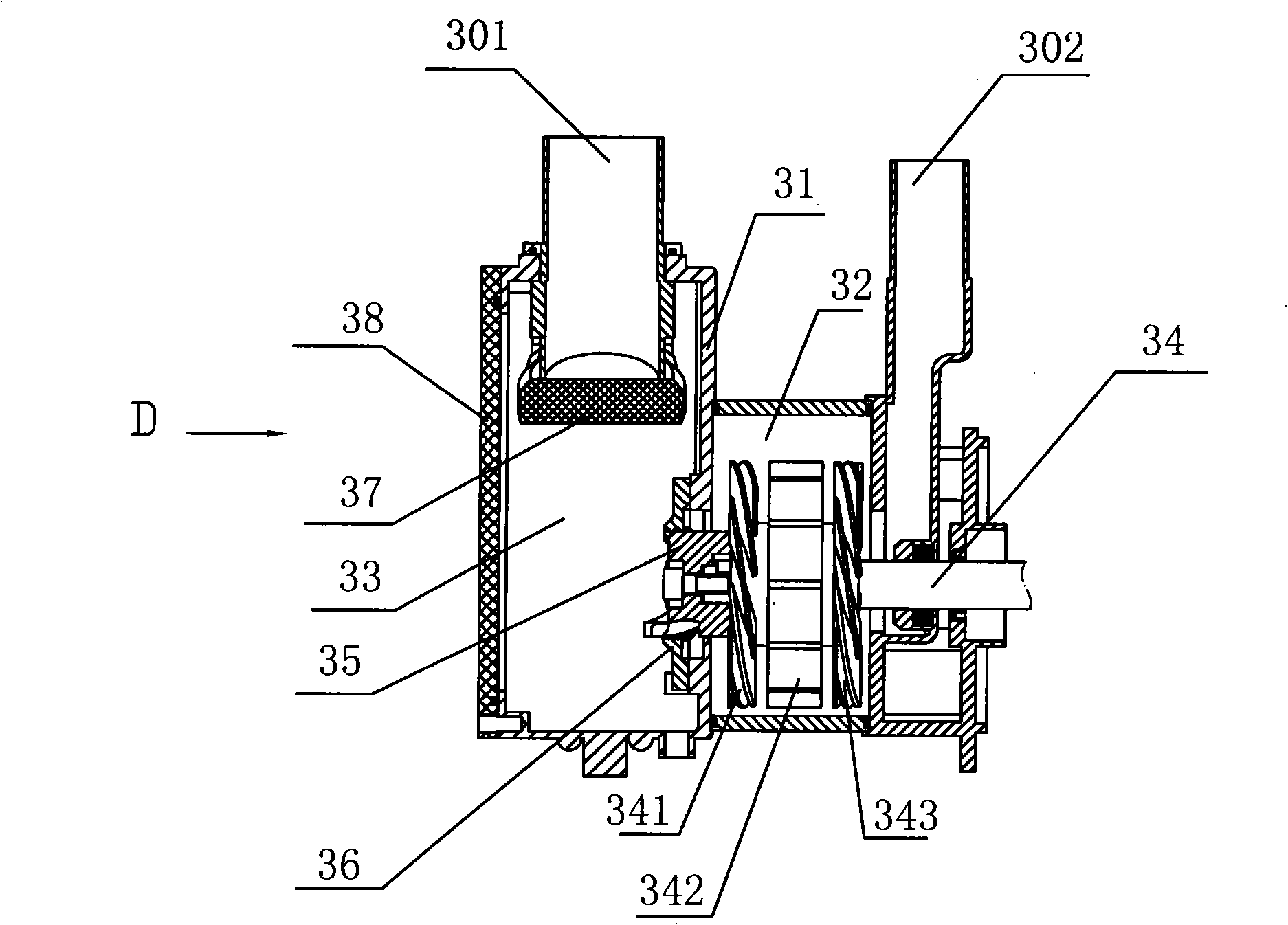

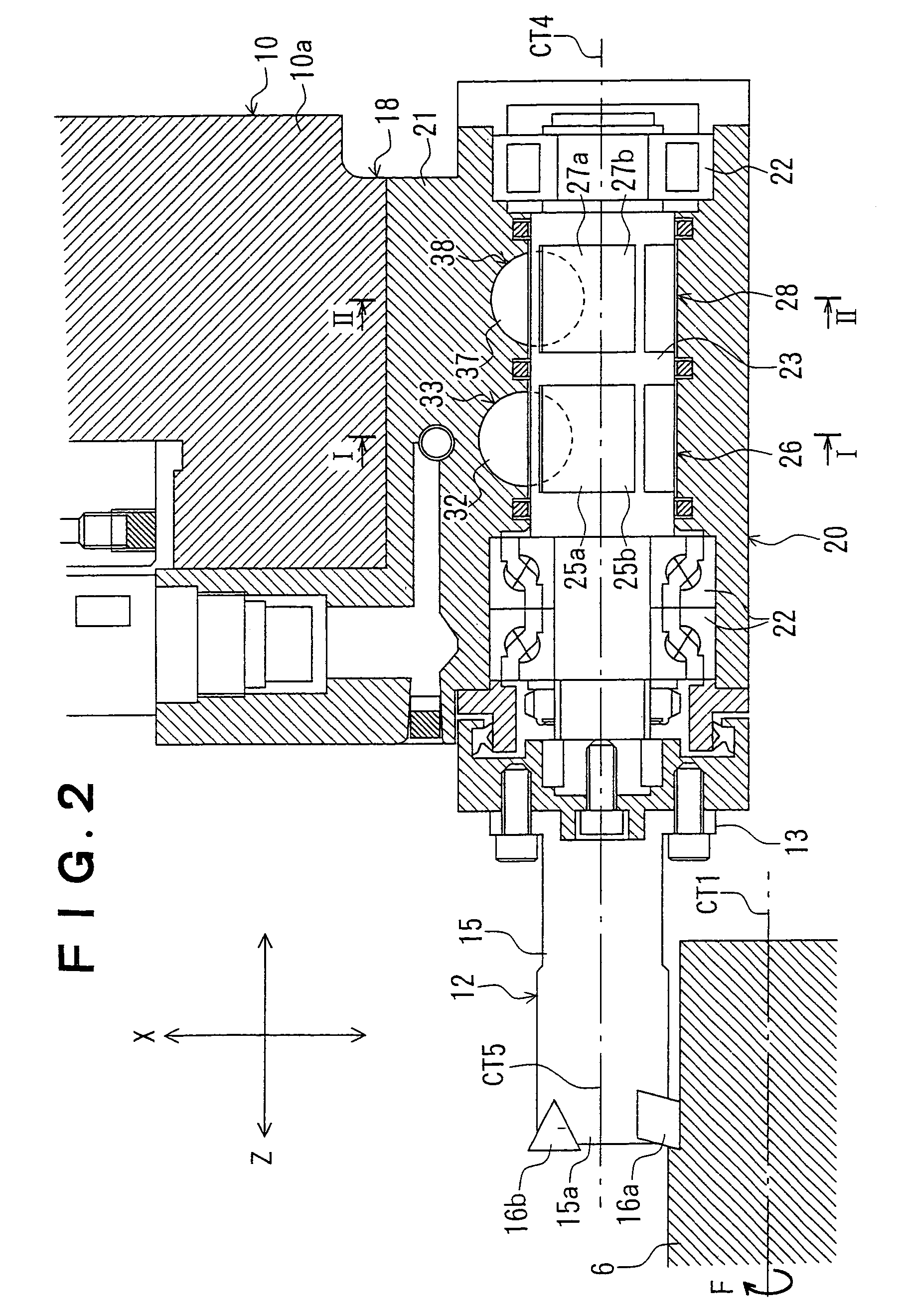

Turning and milling compound multi-shaft power head device

ActiveCN103692271ACompact structureSmall footprintLarge fixed membersDriving apparatusEngineeringBevel gear

The invention relates to a turning and milling compound multi-shaft power head device comprising a servo motor, a motor seat and a gearbox. The servo motor is mounted on one side of the motor seat, and the motor seat is mounted on the right side wall of the gearbox. Two linkage shafts are mounted in the motor seat in parallel, and one of the linkage shafts is mounted on a revolving shaft of the servo motor. Multiple mounting holes are formed uniformly on two vertical surfaces of the gearbox, front shaft assemblies or side shaft assemblies are respectively mounted in the mounting holes. A mold cavity is reserved at the back of the gearbox, a power bearing is arranged in the mold cavity, and a bearing II, a bevel gear I, a spacer bushing, a radial locking nut, a bearing I and a frame oil-seal I are sequentially arranged on the power bearing. The turning and milling compound multi-shaft power head device has compact structure, occupies small space, and is convenient to assemble. The shaft assemblies on the two surfaces can be controlled to rotate to complete processing simultaneously. A power motor is omitted due to connection of the synchronous movement structure, and thus cost is saved.

Owner:GUANGZHOU LONGBANG AUTOMATIC CONTROL EQUIP

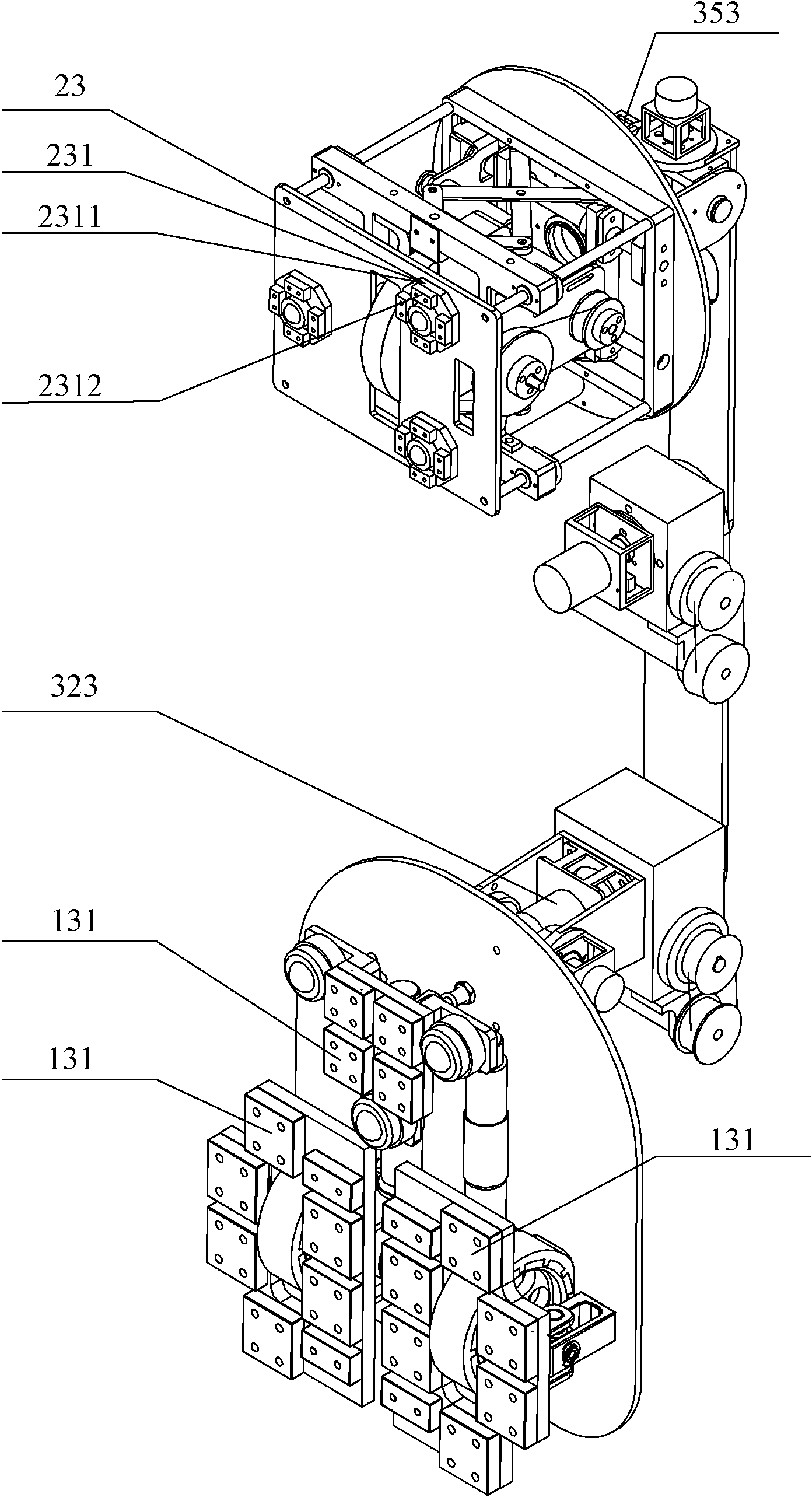

Multi-body magnetic adsorption type adaptive wall climbing robot

ActiveCN102039592AExpand the scope of processingIncrease load capacityArmsCarrying capacityEngineering

The invention discloses a multi-body magnetic adsorption type adaptive wall climbing robot and belongs to the technical field of special robots. The robot comprises a main body device, at least one slave body device, at least one mechanical arm and a working tool arranged on each slave body device, wherein the main body device comprises a main body frame, a movable mechanism and a main body magnetic adsorption device; the slave body device comprises a slave body frame, a slave body magnetic adsorption device and at least one auxiliary supporting wheel; and each mechanical arm comprises at least five connecting rods, at least two active joints and at least two passive joints. The invention provides a wall climbing robot which flexibly moves and steers on a magnetized wall surface at full positions spatially, is adaptive to a spatial curved surface and can perform welding, gouging, cutting, grinding, milling, detecting, cleaning or spraying work. The robot has wide processing range, high carrying capacity, high flexibility of movement and high working efficiency.

Owner:TSINGHUA UNIV +1

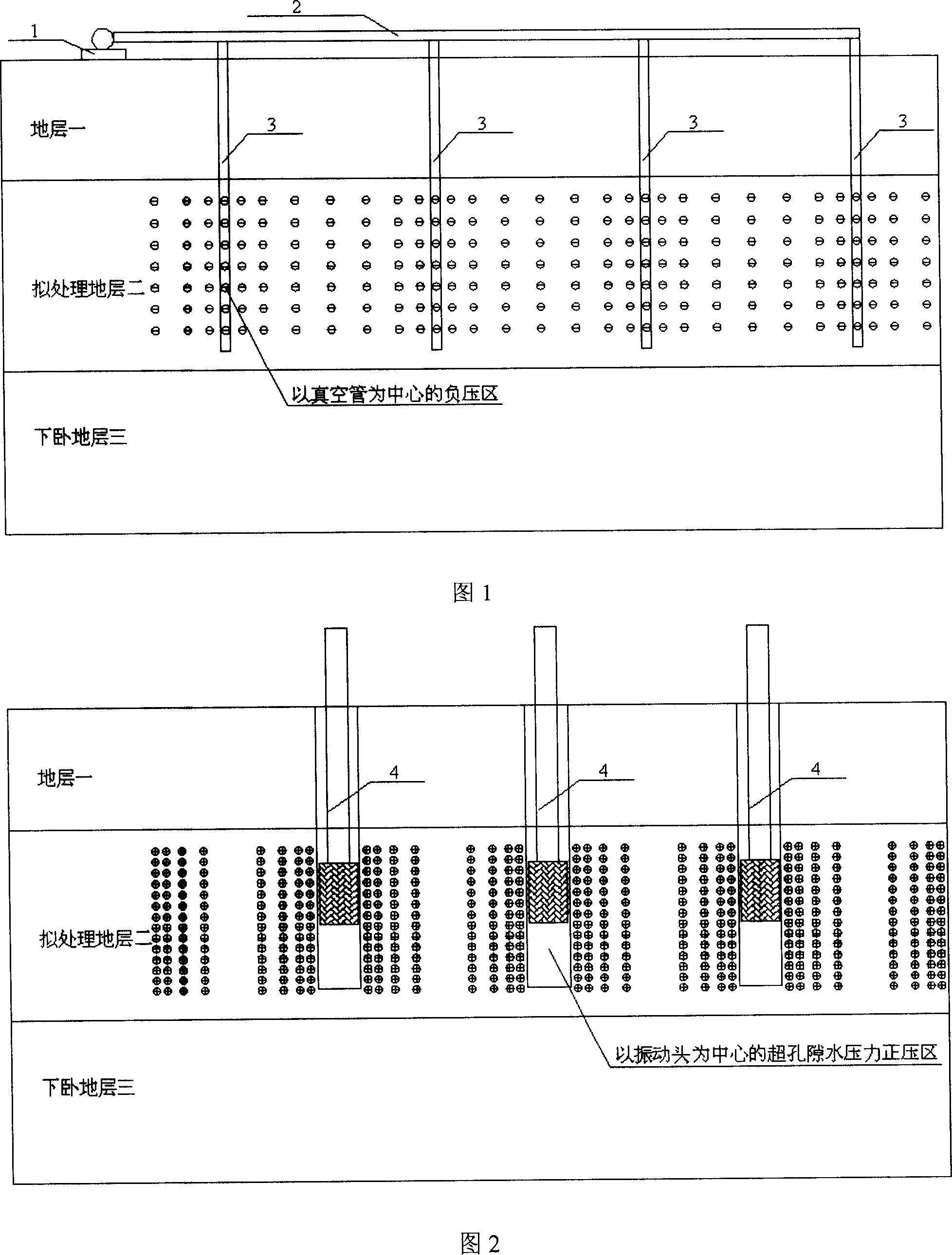

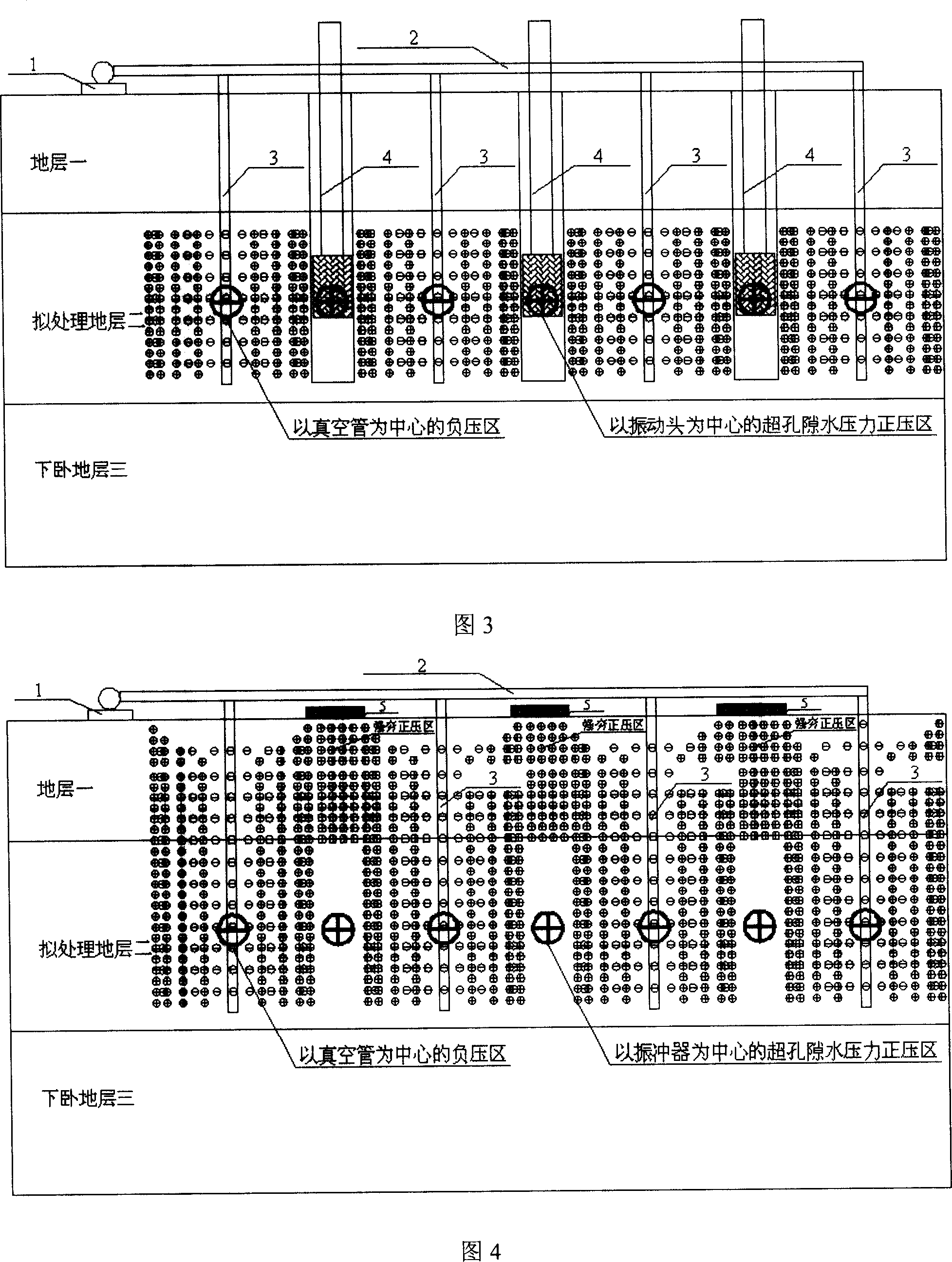

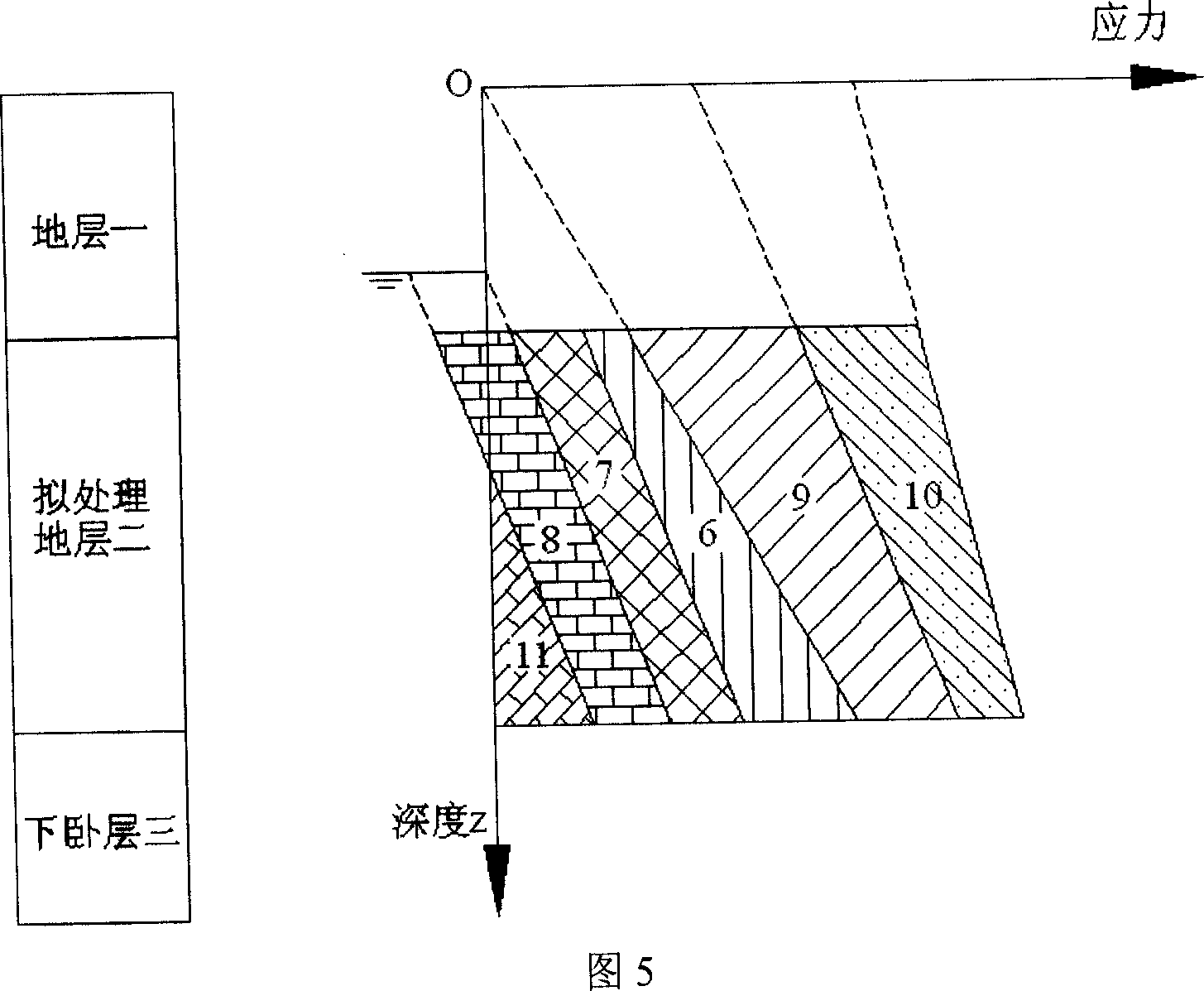

Multiple pressurizing fast consolidated compacting soft earth foundation treatment method

InactiveCN101016740AIncreased excess pore water pressureExpand the scope of processingSoil preservationSoil sciencePresent method

The invention in a technical sphere of soft soil ground treatment in geotechnical engineering relates to a soil ground treatment method in the areas along the sea, the river and the lake. The invention combines a vacuum drainage, a compaction via vibration supercharging, and a compaction via dynamic consolidation supercharging, wherein a higher kinetic head gradient which is consisted of a positive pressure of excess pore water by vibration excitation and a vacuum negative pressure firstly discharges the water in soil and increases the water content in the soil, thereby compacting the soil to a certain extend, and then the dynamic consolidation action is proceeded to improve the excess pore water pressure and form the higher kinetic head gradient thereby draining and compacting the soil. All the steps are proceeded many times to eliminate the settling of the worked deep layer soft soil and to improve surface consolidation degree, intensity, and stiffness until up the design requirement. Compared with the present method, the invention not only has a short time for a project, lower manufacturing cost and settling after work, and a good effect of consolidating and compacting, but also is extensive used in the soft soil ground treatment of various projects in the area along the sea, the river, or the like.

Owner:武亚军

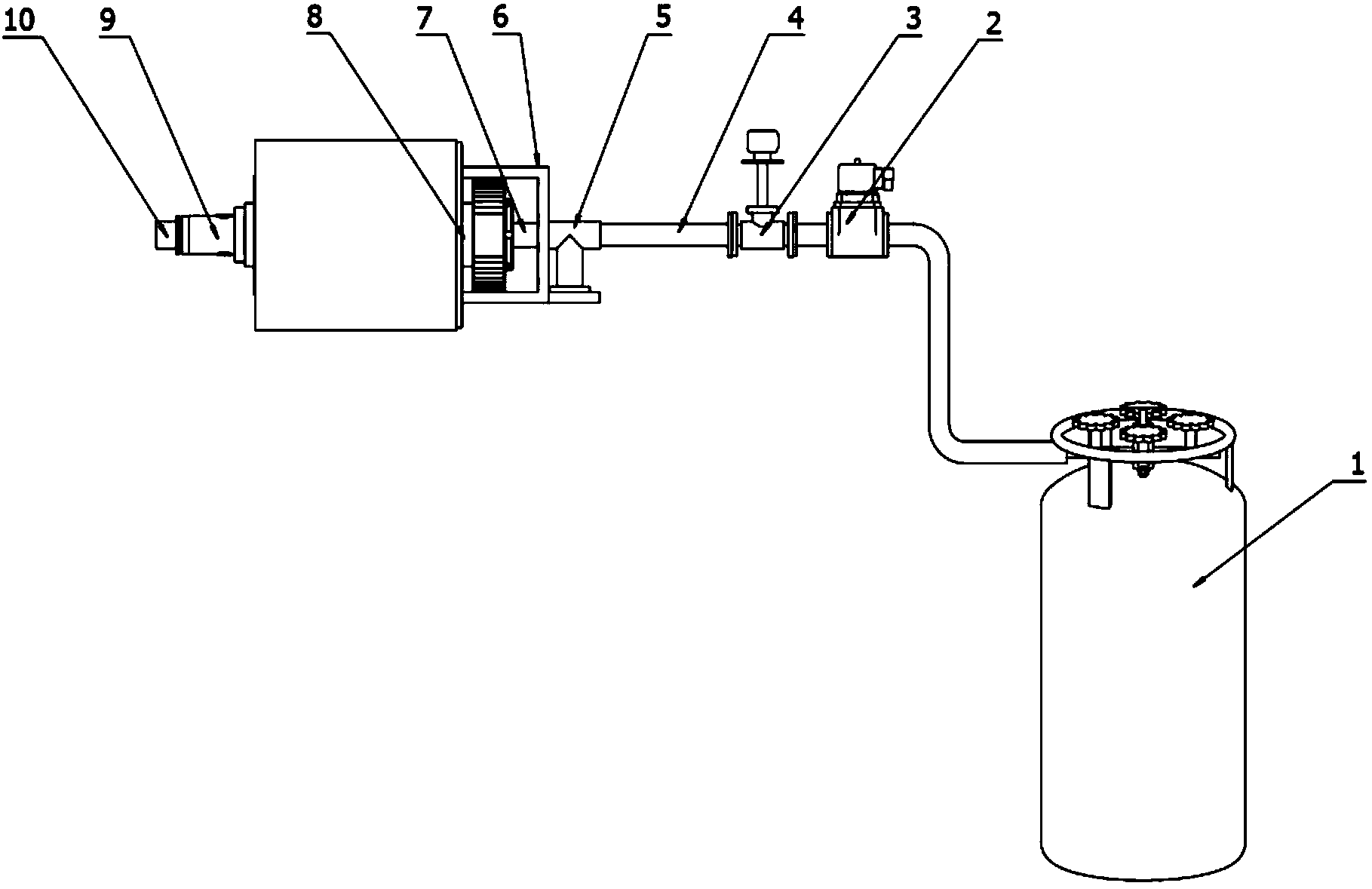

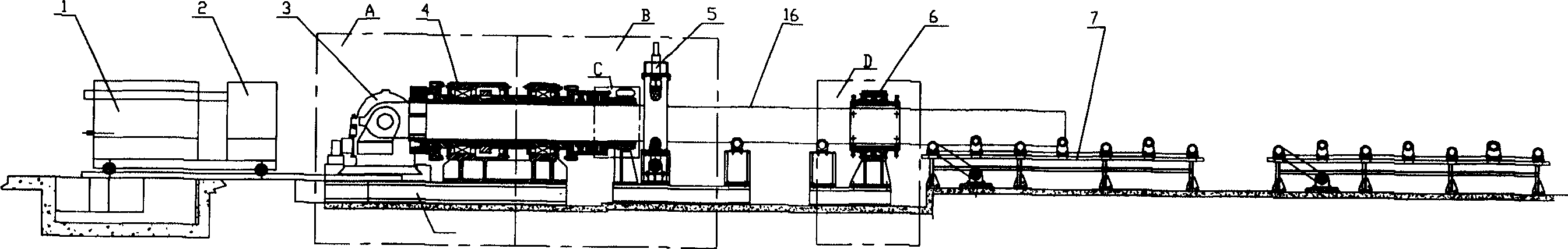

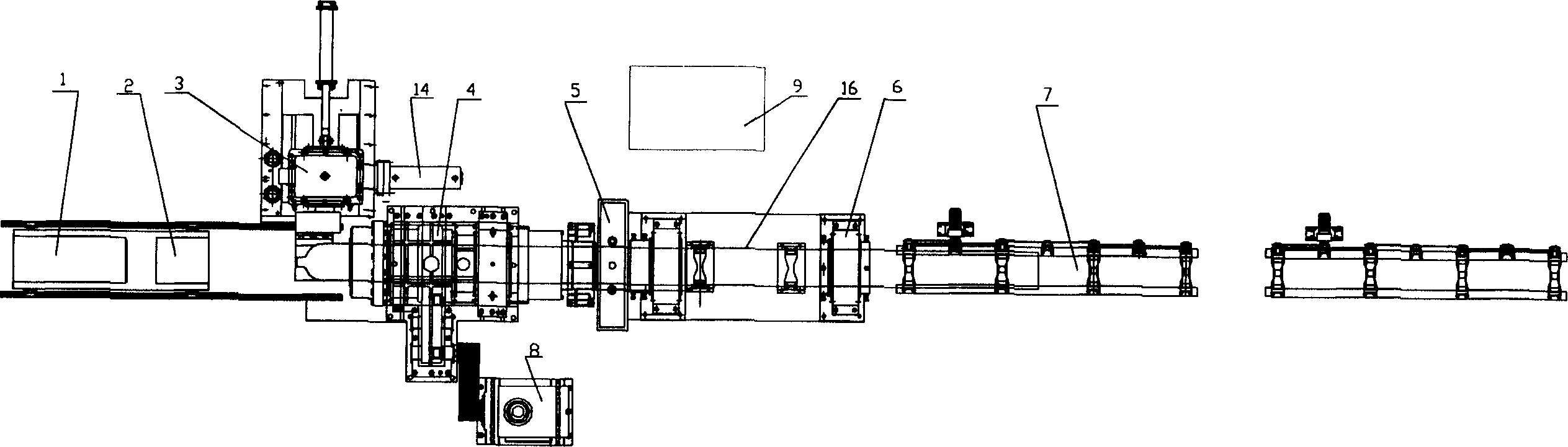

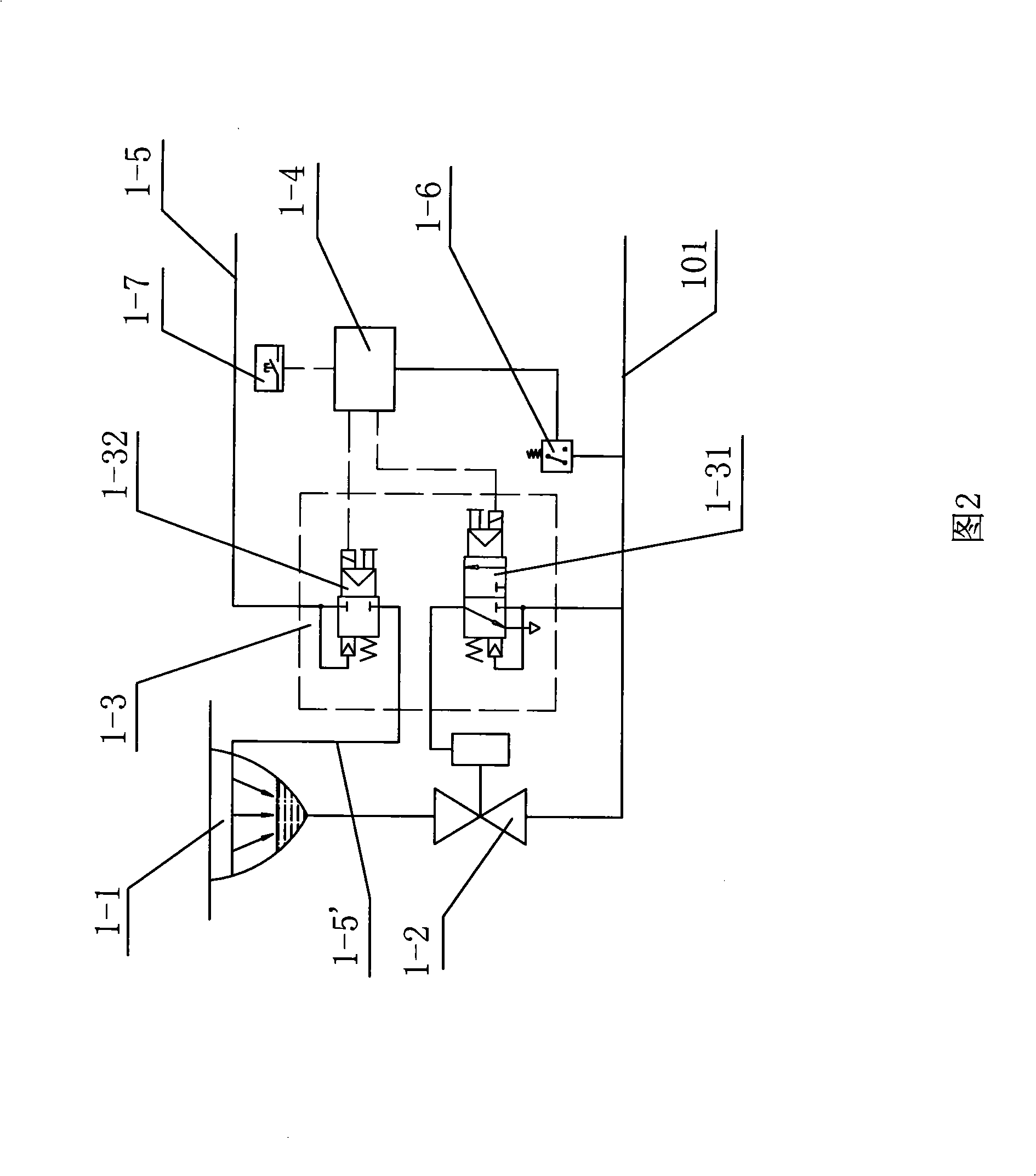

Special closing-in machine for high-pressure seamless gas cylinder

InactiveCN1775408AEasy to adjustReduce the number of startsMetal-working feeding devicesPositioning devicesGas cylinderMedium frequency

The present invention relates to a special-purpose neck-reducing machine for high-pressure seamless gas cylinder manufacture. It includes holding device, feeding roller way, power device, forming device, medium-frequency heating furnace, hydraulic system, lubricating station, electric control box and base seat. Said invention also provides the concrete structure of above-mentioned every component, and provides their connection mode and working principle of said special-purpose neck-reducing machine.

Owner:XINXING DUCTILE IRON PIPES CO LTD

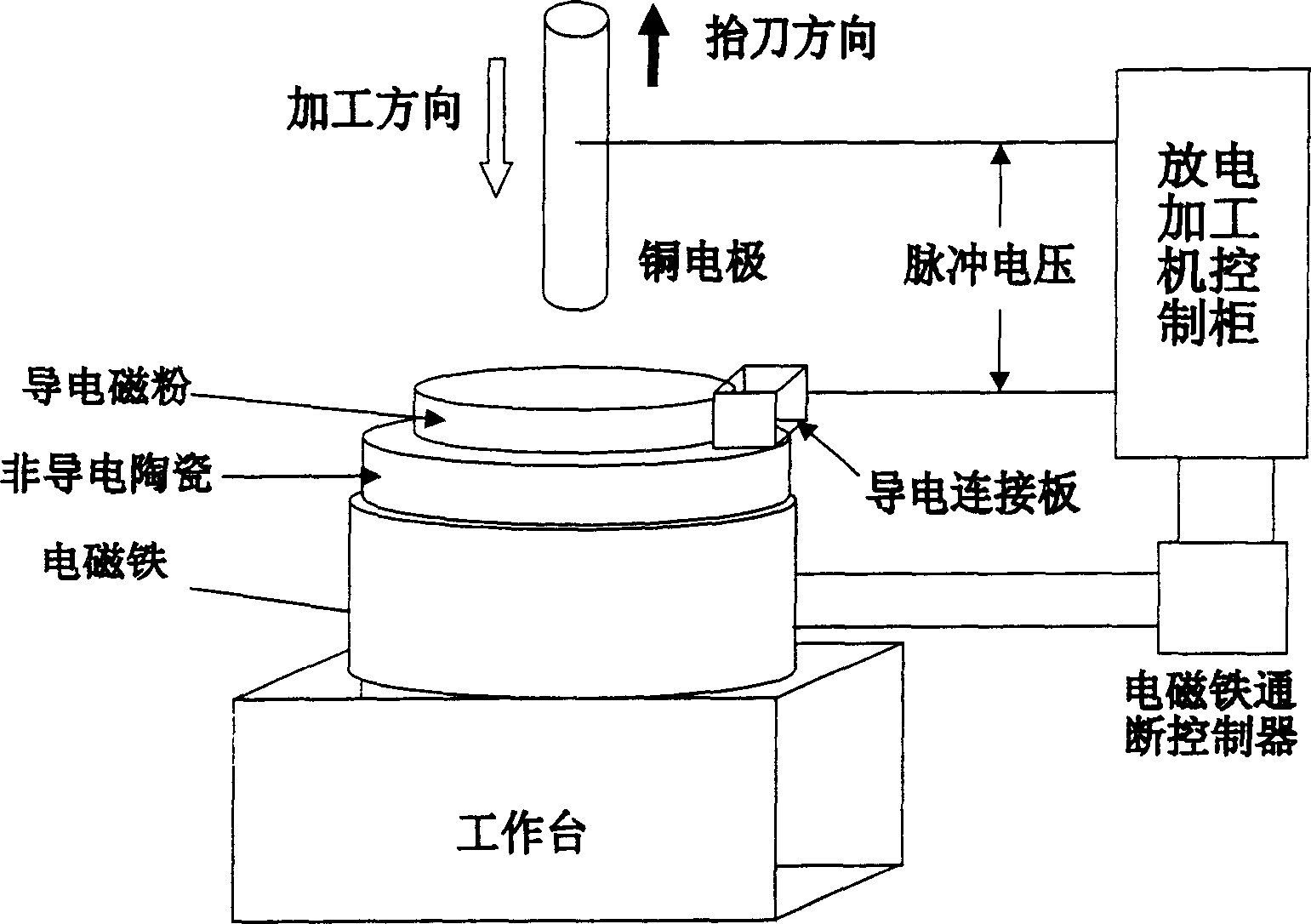

Electrodischarge machining method for working non-conductive ceramic utilizing conductive magnetic powder

InactiveCN1775441AEasy to operateExcellent machinabilityElectrical-based auxillary apparatusCeramicSurface spreading

The electro-discharge machine method for preparing nonconducting ceramics by utilizing conductive magnetic powder includes the following steps: (1) placing electromagnetic iron device on working table of electro-discharge machining machine, form of electromagnetic iron is identical to that of workpiece; (2) on the electromagnetic iron mounting and holding nonconducting ceramics; (3) on said ceramics surface spreading conductive magnetic powder; (4) using conductive magnetic powder as one end of electrode and making it and metal electrode be formed into electrode pair; (5) switching on the power supply of electromagnetic iron, the conductive magnetic powder can be adsorbed on the ceramics surface; (6) setting main electro-discharge machining parameter; and (7) making electro-discharge machining process.

Owner:SHANGHAI JIAO TONG UNIV

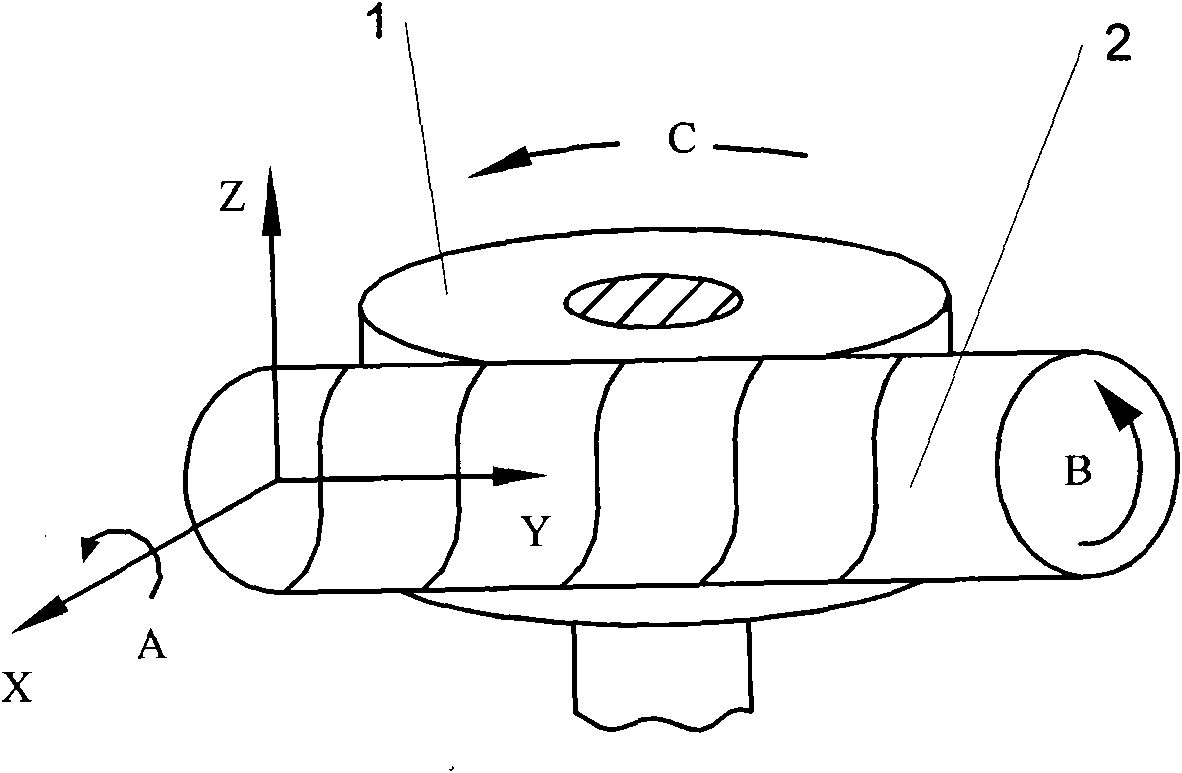

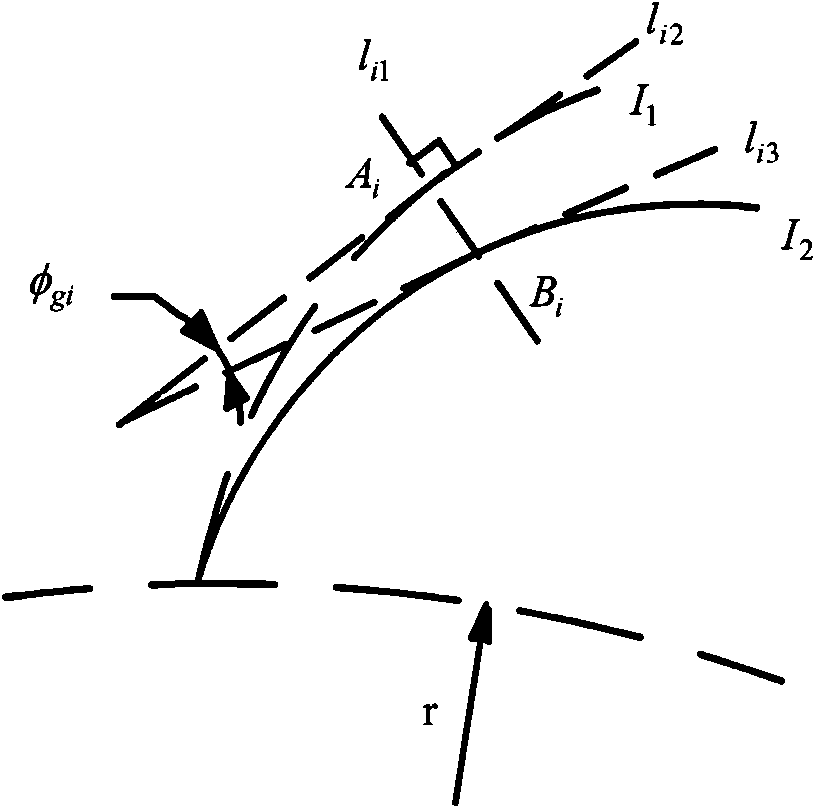

Numerical control grinding and machining method of stepwise variable pressure angle involute gear

InactiveCN101875139ARealize continuous grindingImprove processing efficiencyGear teethInvolute gearGear wheel

The invention discloses a numerical control grinding and machining method of a stepwise variable pressure angle involute gear. The numerical control grinding and machining method is characterized in that: by utilizing a radial and tangential linkage displacement principle of a grinding wheel, a linkage control model for grinding the stepwise variable pressure angle involute gear by adopting an Archimedes worm wheel on the basis of a six-axis five-linkage numerical control system and a real-time interpolation pulse value calculation method directly used for actual design machining of a machine tool are provided. The invention fills a blank of the technology for grinding and machining the stepwise variable pressure angle involute gear by adopting a fix-axis five-linkage numerical control method and can provide the technical basis for high-precision machining of the stepwise variable pressure angle involute gear.

Owner:HEFEI UNIV OF TECH

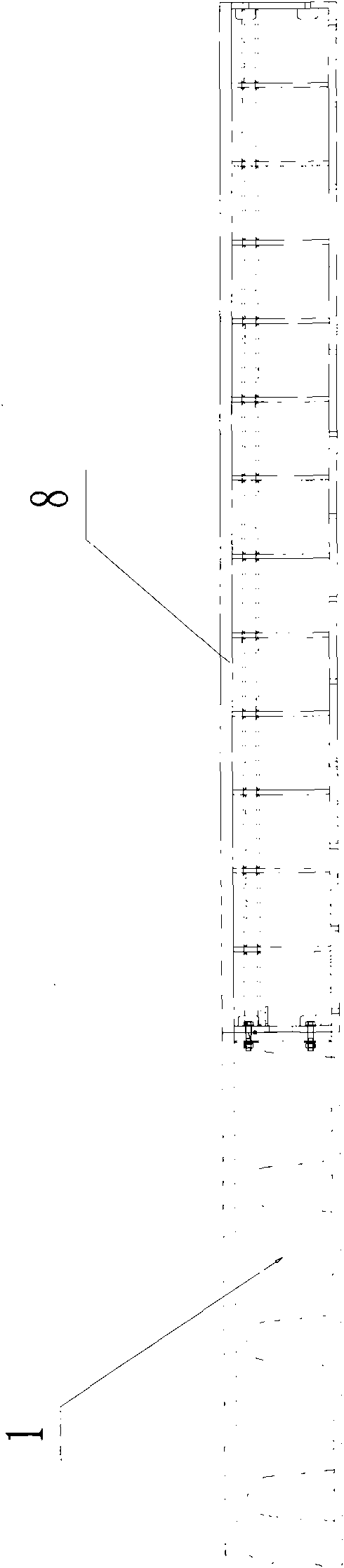

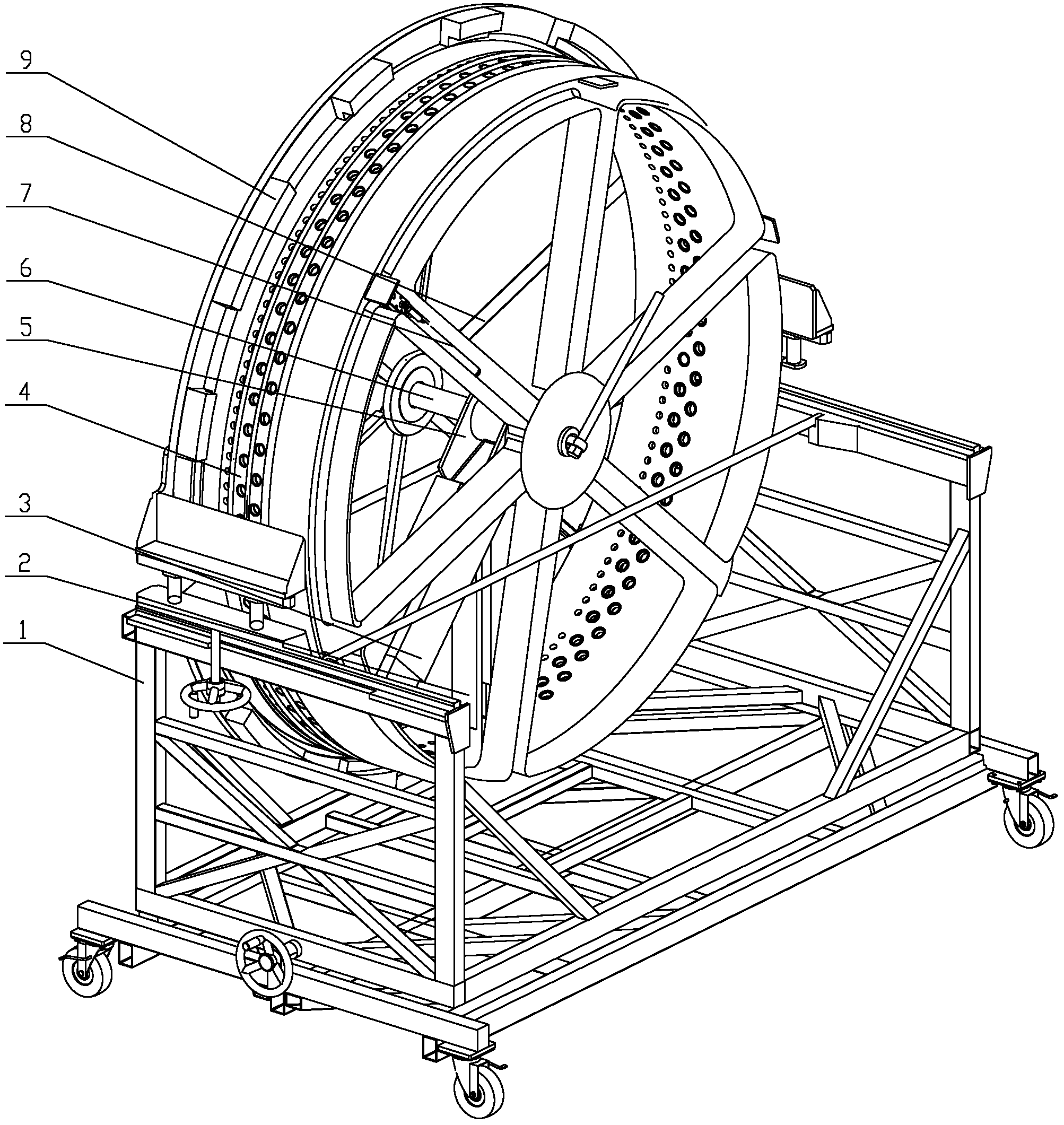

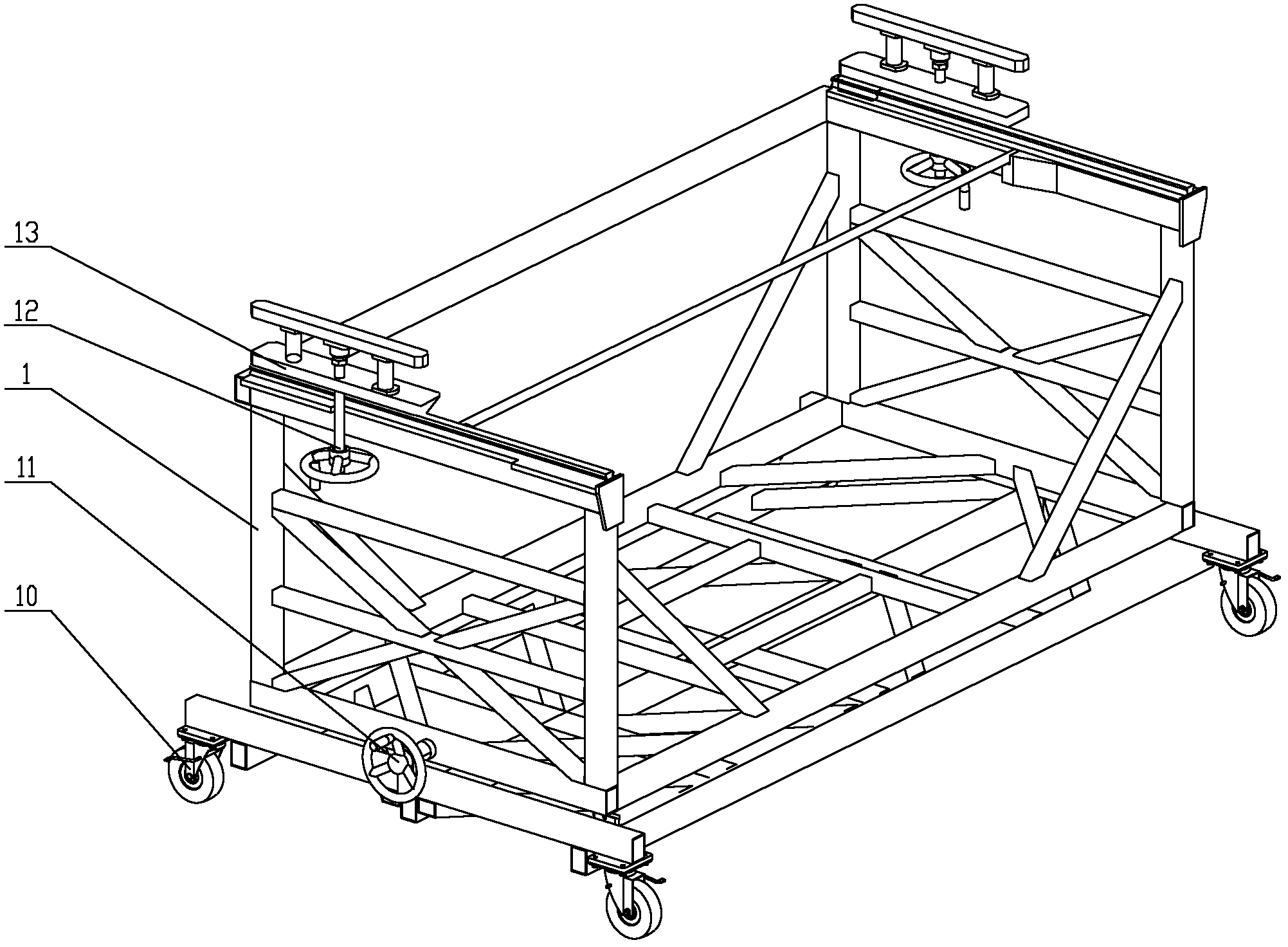

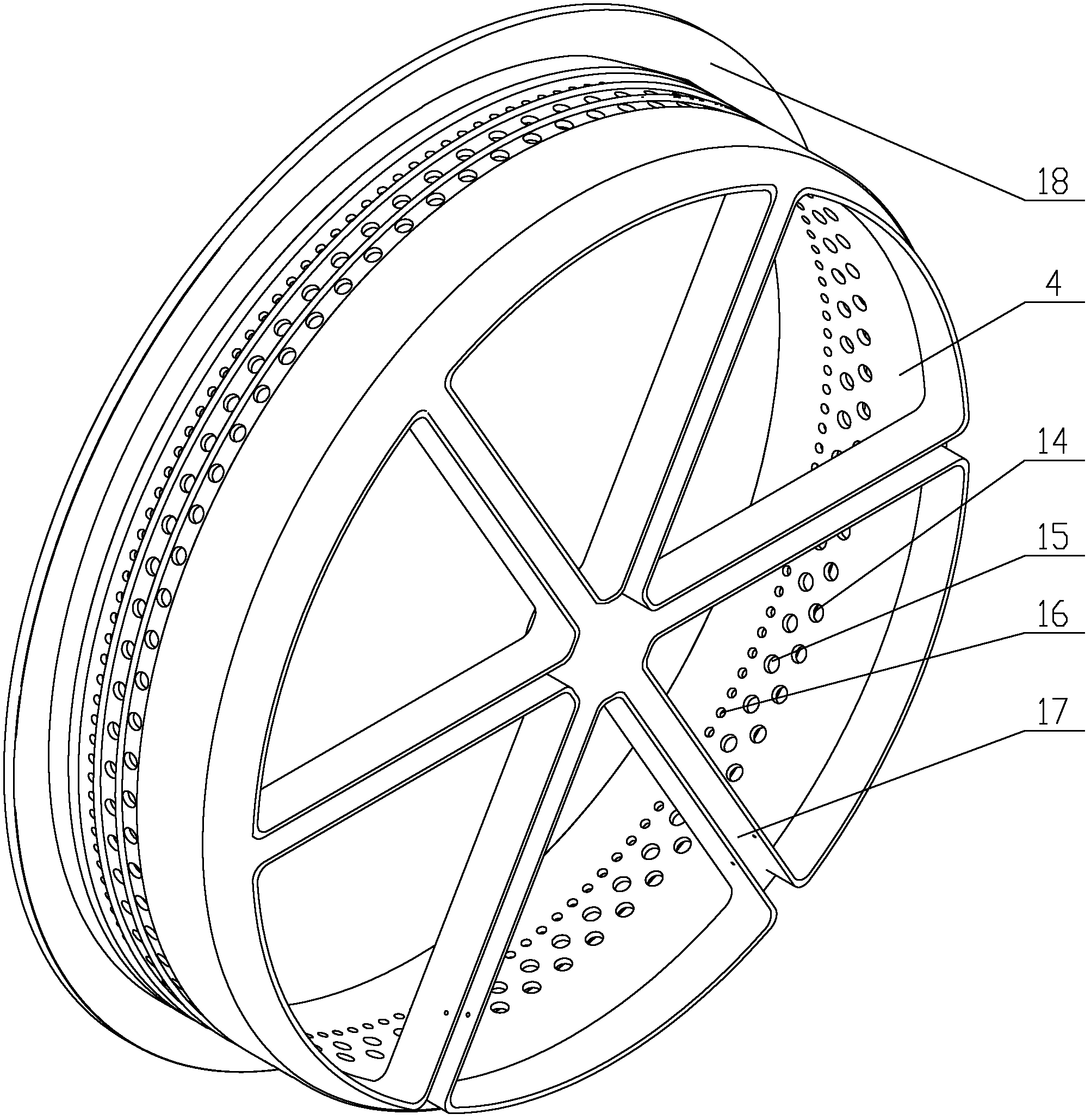

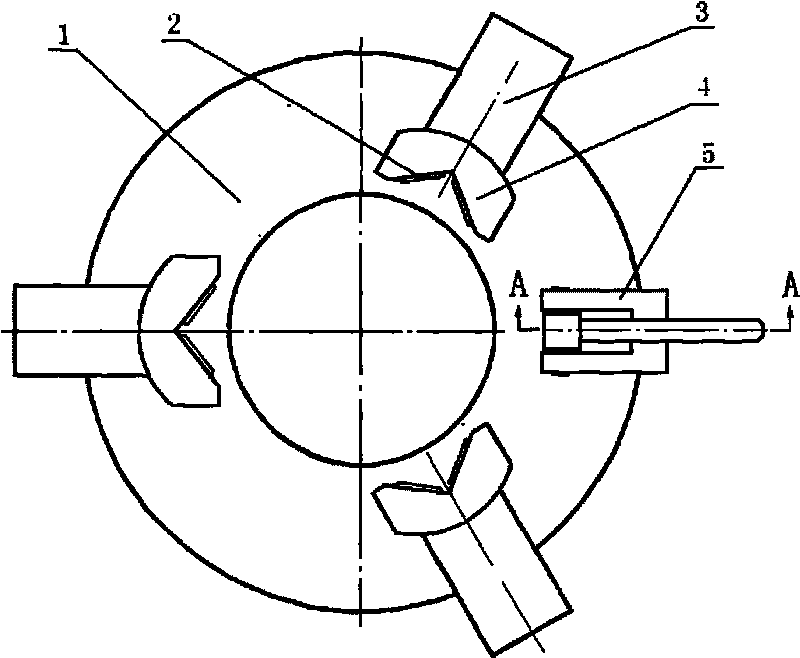

Radial automatic drilling device for large-size compound cylinder

The invention provides a device which has a simple structure and can be used for automatically drilling a large-size compound cylinder in batches along a radial direction aiming at the problems of difficulty in tool setting and low drilling efficiency in the process of drilling the large-size compound cylinder along the radial direction. A processing mode of processing from inner to outer is adopted in the drilling device, thereby avoiding the fiber tearing and layering on the inner wall of a cylinder made of compound materials. By using a double-power head for drilling, first and second rows of holes can be processed at the same time. In order to change a drilling position, a drilling unit is rotated without moving the large-size compound cylinder, thereby widening the processing range. And meanwhile, a drilling device bracket is designed for storing and mounting the drilling device and avoiding the rubbing between the drilling device and the inner wall of the cylinder.

Owner:DALIAN UNIV OF TECH

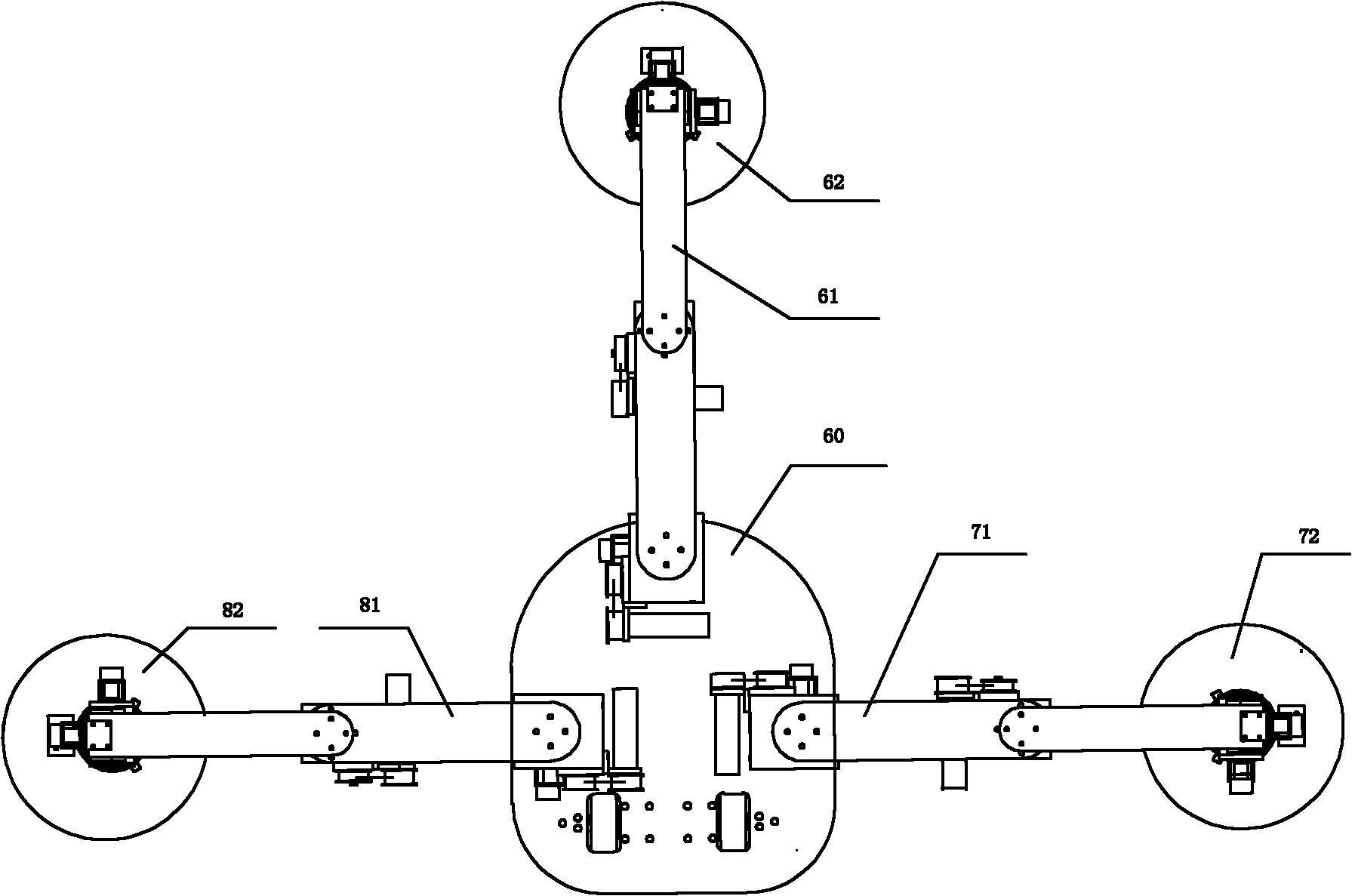

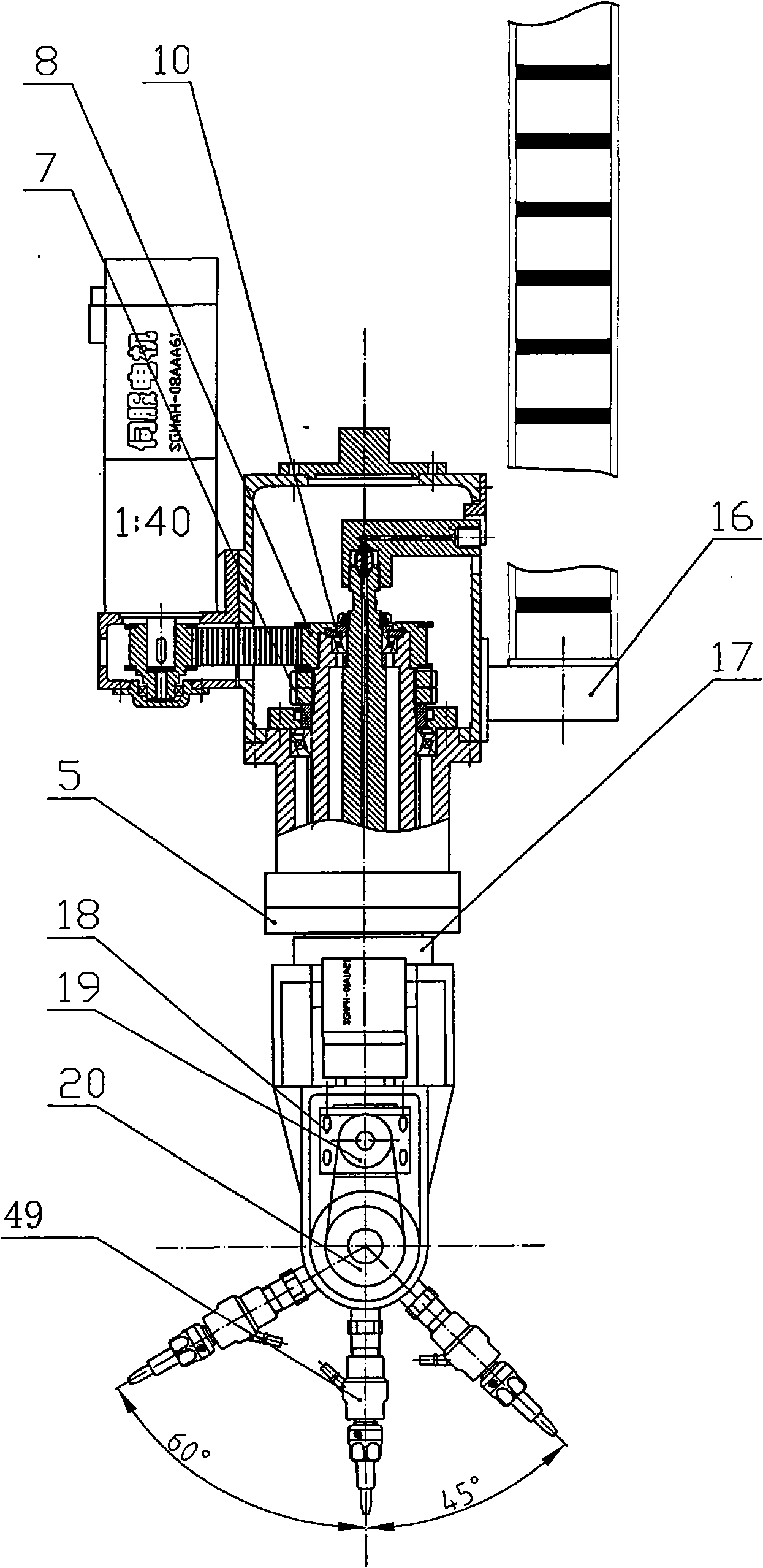

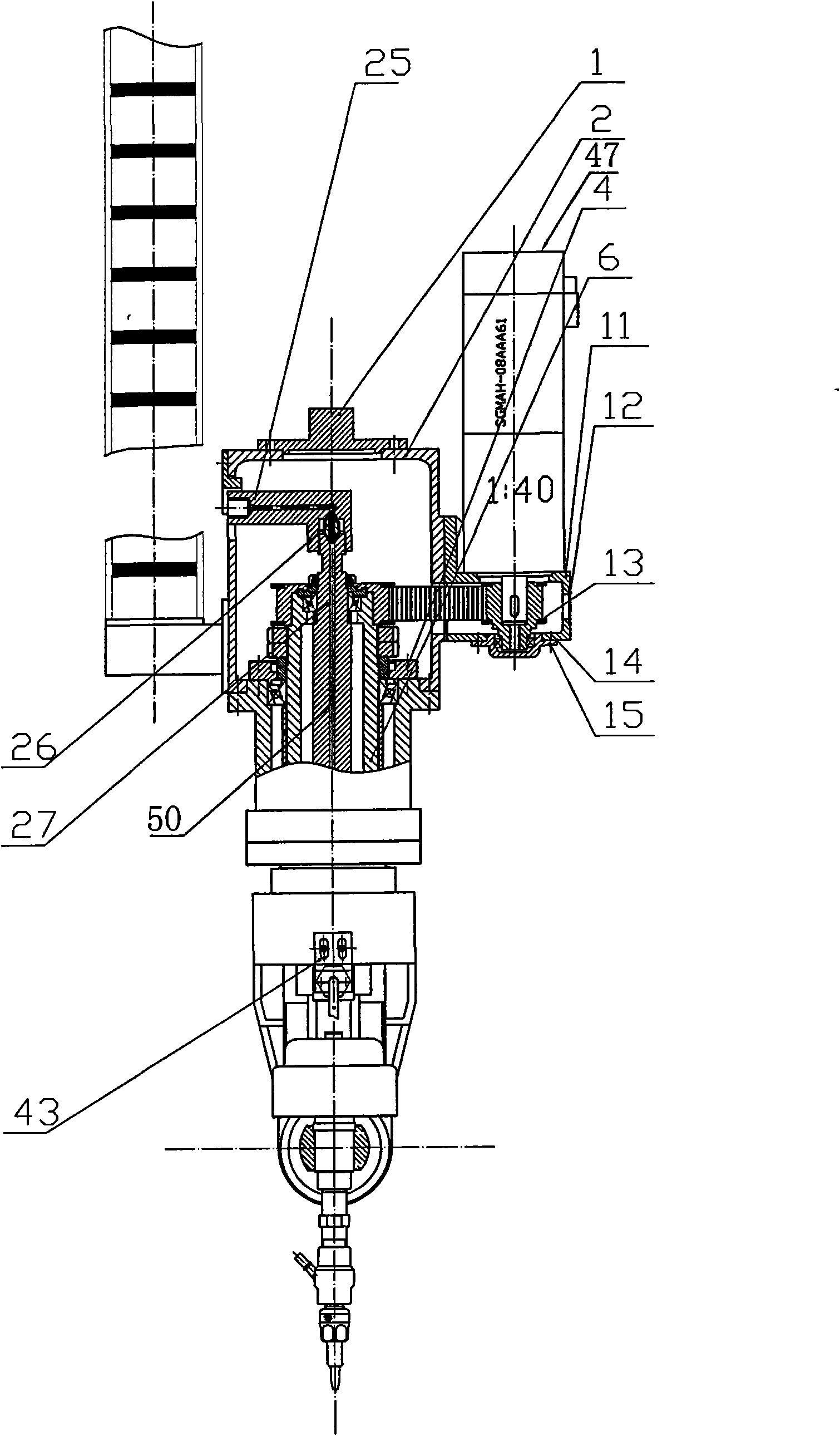

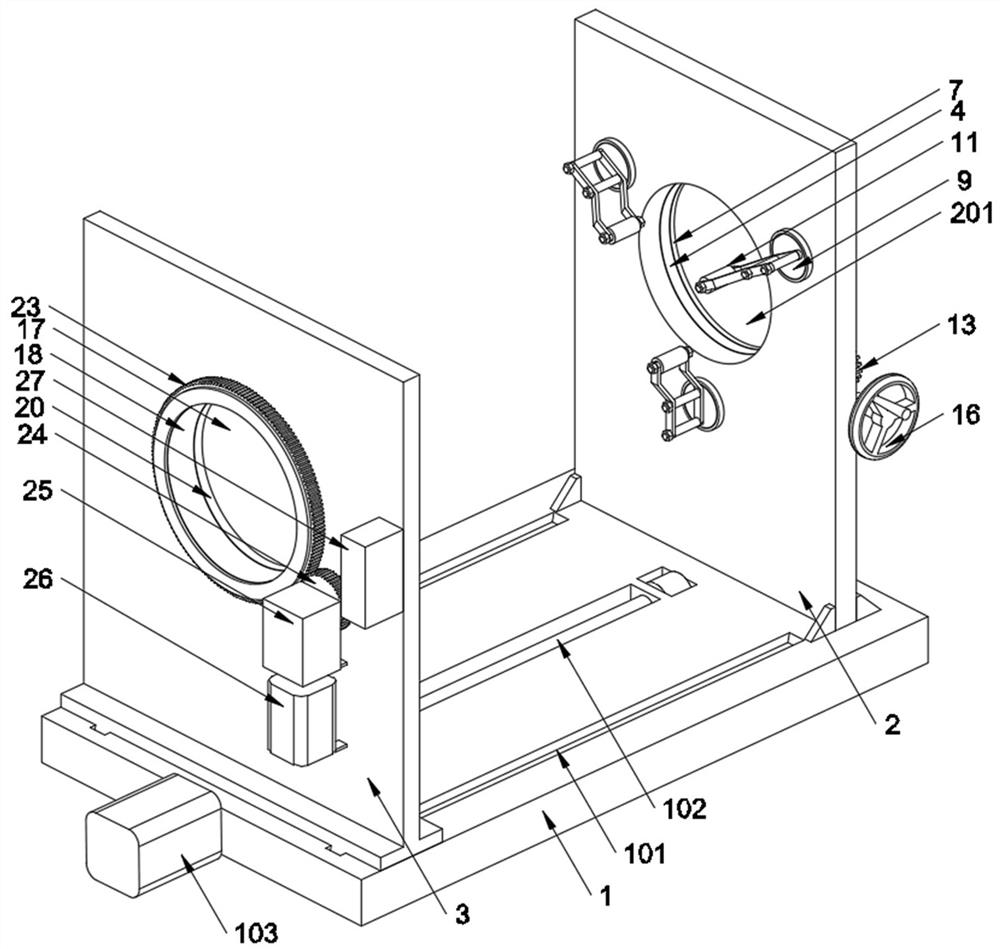

Five-axis controlled motion control mechanism of water cutting head with functions of rotation and swing

ActiveCN101659067AExpand the scope of processingAchieve tiltMetal working apparatusElectric machineryWater cut

The invention relates to a five-axis controlled motion control mechanism of a water cutting head with the functions of rotation and swing, which comprises a connecting flange (1) and a connecting frame (2) of a rotating shaft. The mechanism is characterized in that a rotating motor support (11) is mounted on the connecting frame (2) of the rotating shaft, a small synchronizing wheel (13) is mounted on an output shaft of a rotating motor (47), the small synchronizing wheel (13) is connected with a big synchronizing wheel (8), the big synchronizing wheel (8) is mounted at the upper end of a hollow main shaft (6), and the lower end of the hollow main shaft (6) is connected with a swing connecting frame (17); and a swing motor (48) is mounted on the swing connecting frame (17), the swing motor(48) is connected with the small synchronizing wheel (19), the small synchronizing wheel (19) is connected with the big synchronizing wheel (20) through a synchronizing belt, the big synchronizing wheel (20) is mounted on a swing shaft (21), and the water cutting head (49) is mounted on the swing shaft (21). As the mechanism increases the control with two degrees of freedom of rotation and swing,the mechanism is conductive to improving the precision and the efficiency of processing of water cutting, simultaneously expands the application range of the water cutting and realizes the five-axiscontrol in the true sense.

Owner:DARDI INT CORP

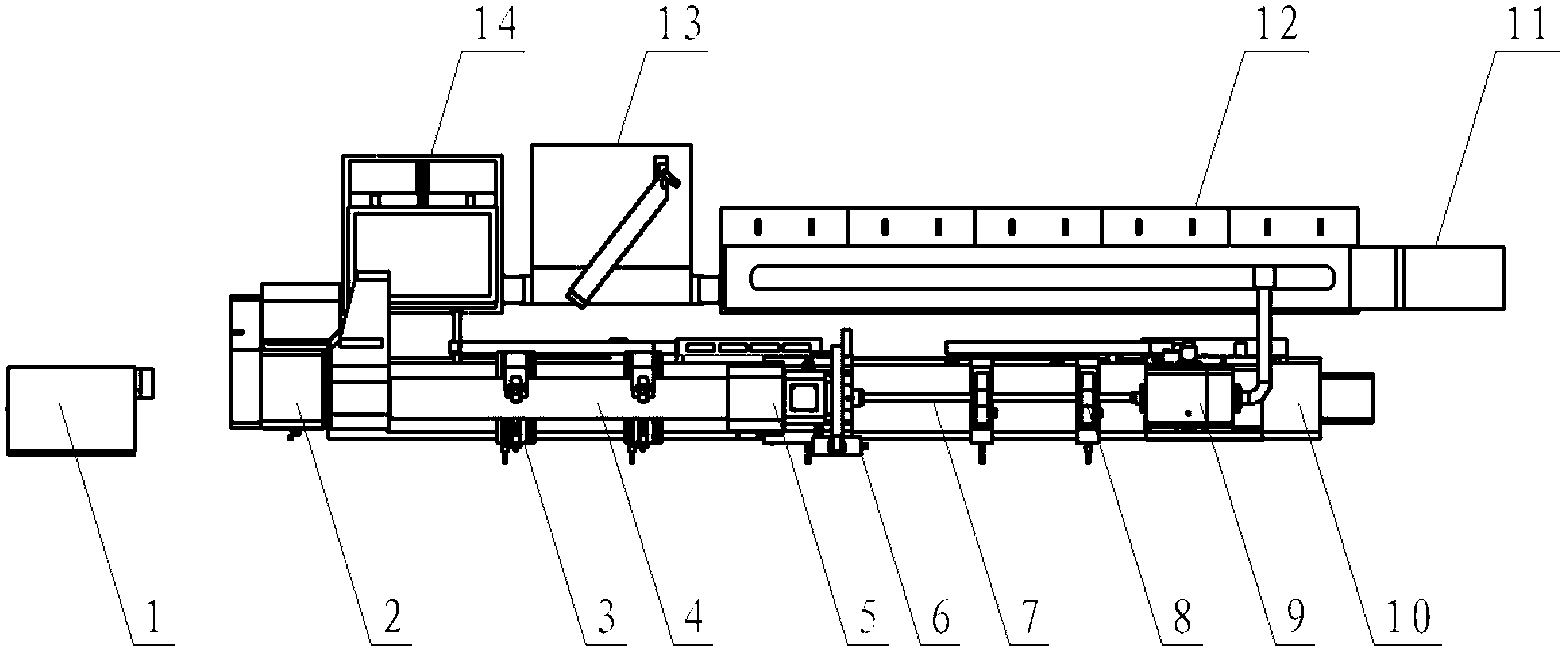

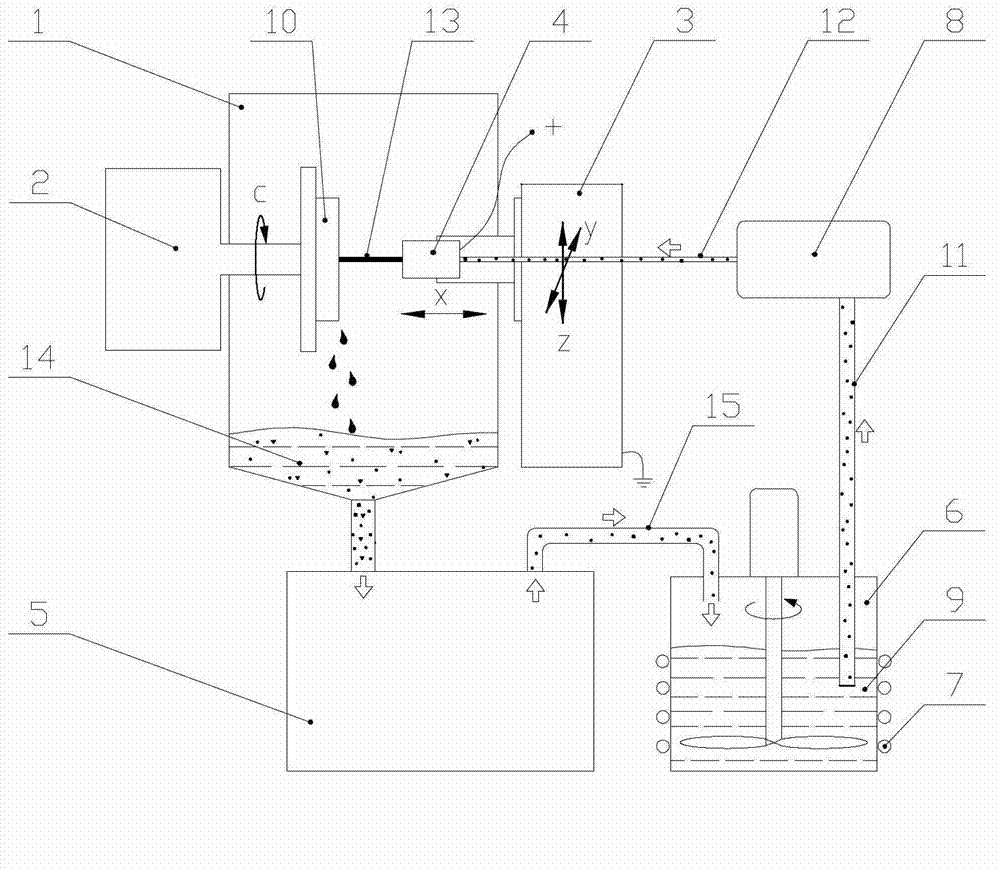

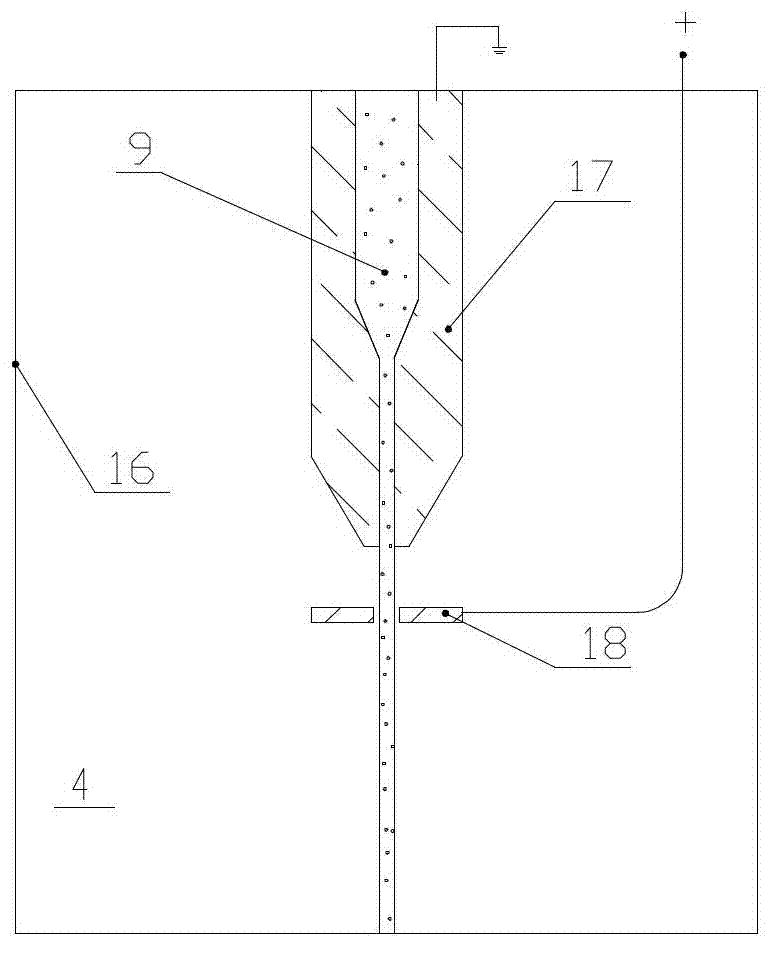

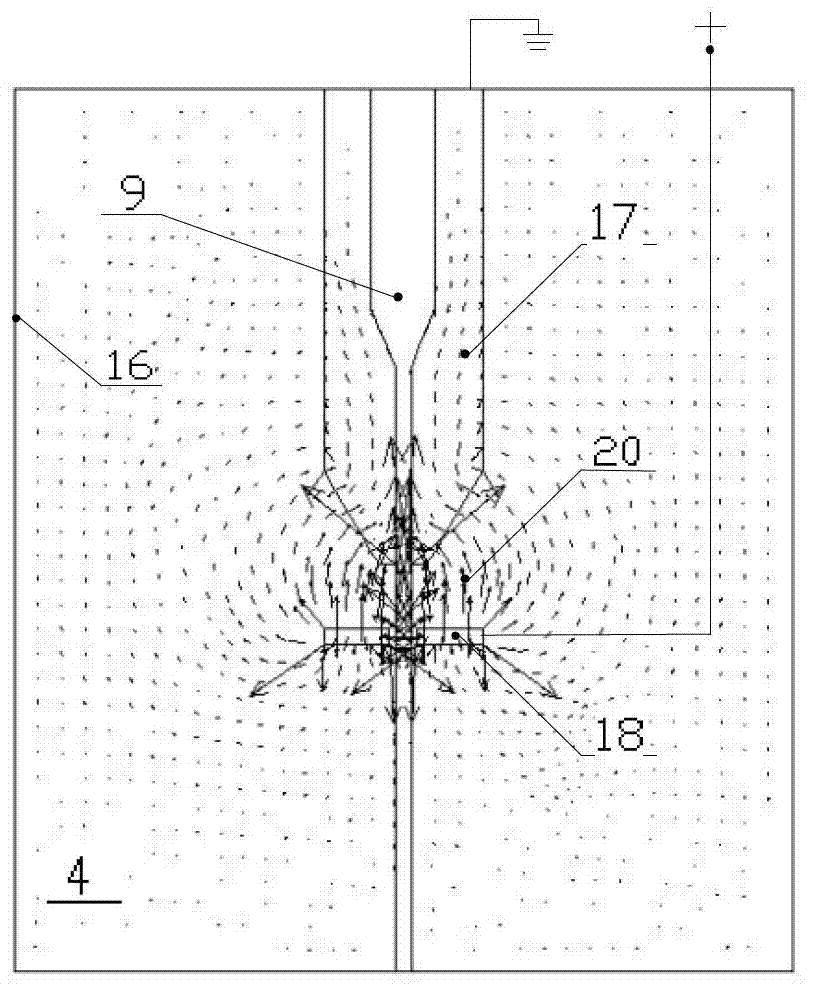

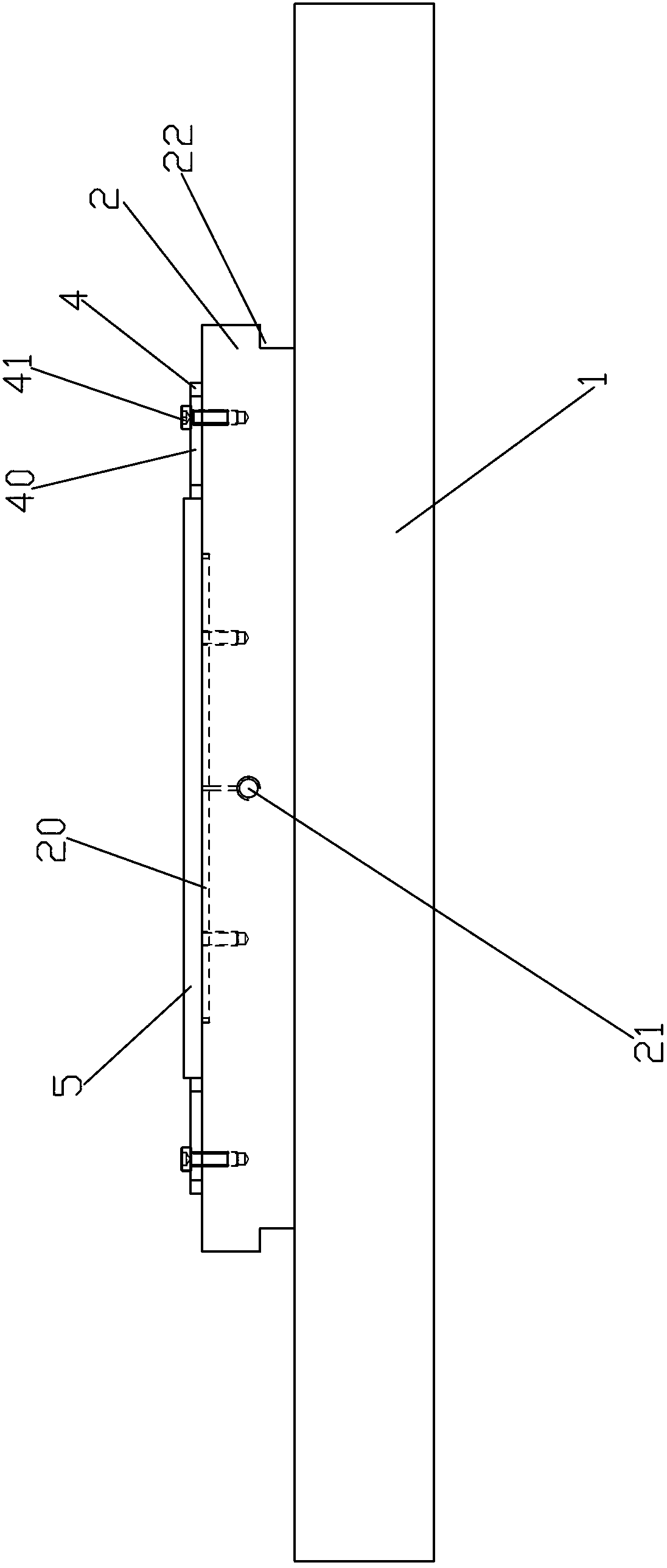

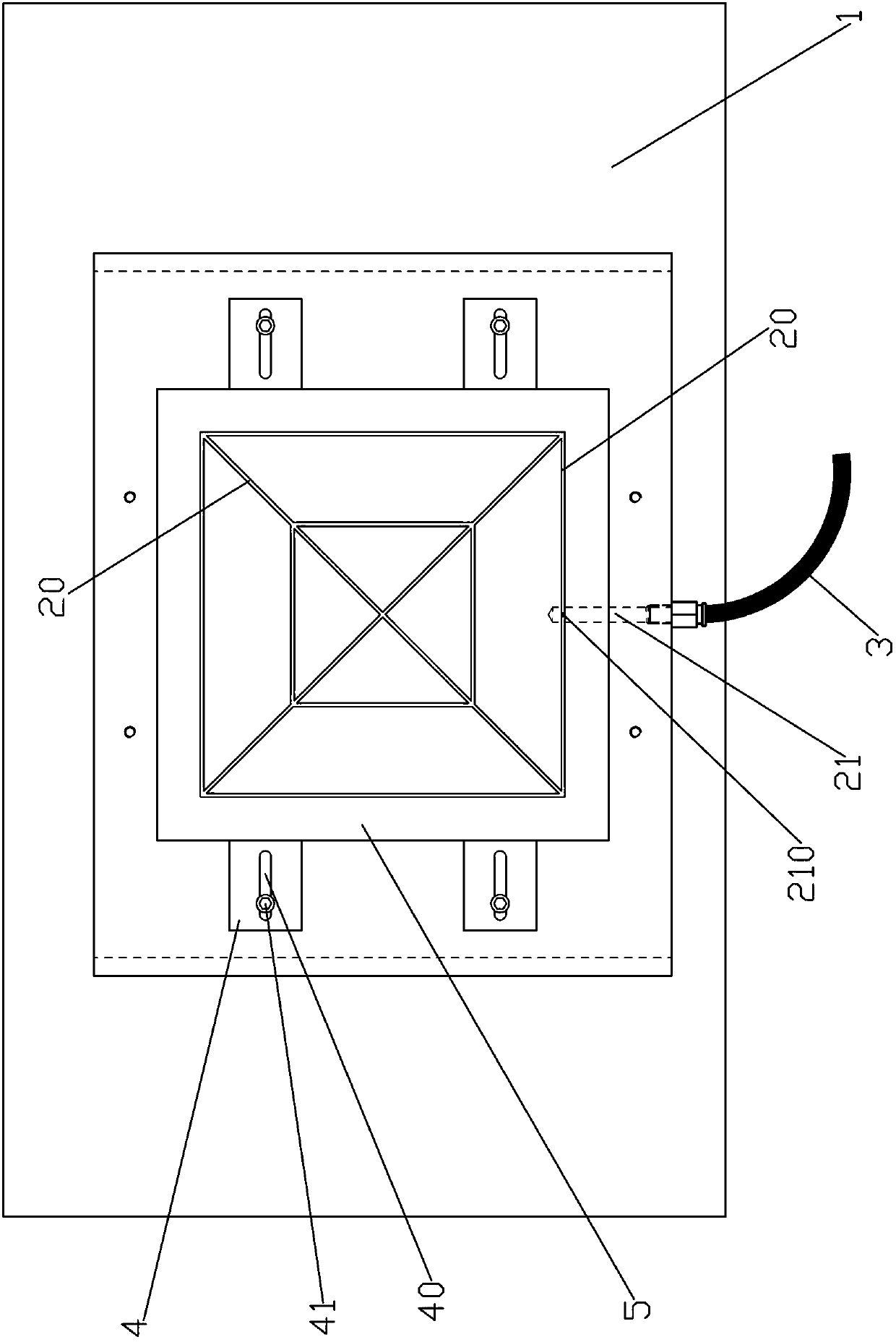

Electric field electrorheological jet polishing device

InactiveCN102962776AWide range of changesImprove stabilityBlast gunsAbrasive machine appurtenancesAfter treatmentPower flow

The invention discloses an electric field electrorheological jet polishing device. The electrorheological jet polishing device comprises a work chamber, a rotary table, a machine tool, a jetting device, a filter, a stirring tank, a cooling device, a boosting device, flow guide pipes and an electrorheological polishing liquid. The machine tool does three-dimensional linear movement; the jetting device is fixed on a horizontal moving shaft driving device and faces the object carrying tabletop of the rotary table; the jetting device and the object carrying table of the rotary table are sealed by the work chamber; the filter is arranged between the work chamber and the stirring tank; the cooling device is arranged on the outer wall of the stirring tank; a boosting system is arranged between the jetting device and the stirring tank; and all parts of a system are connected through the flow guide pipes to form a liquid loop. When the electrorheological jet polishing device is in work, the electrorheological polishing liquid is boosted by the boosting device, input into the electrified jetting device, shaped by the jetting device and subjected to an electrorheological effect to form stable standard straight jets for polishing a workpiece; and waste liquid can be recycled for use after treatment. The electric field electrorheological jet polishing device combines an electrorheological polishing technology and a jet polishing technology and belongs to the domain of optical fine machining.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Flat grinder using vacuum chuck

InactiveCN103341820AExpand the scope of processingGrinding work supportsPulp and paper industryVacuum pump

The invention discloses a flat grinder using a vacuum chuck. The flat grinder using the vacuum chuck comprises a grinder base which is fixedly provided with the vacuum chuck with the smooth and flat surface. The upper surface of the vacuum chuck is provided with a bare groove, one side face of the vacuum chuck is provided with a through hole which is communicated with the groove, and the through hole is connected with a vacuum pump through a vacuum suction tube. Due to the facts that a vacuum chuck structure used for sucking workpieces is arranged on the upper surface of the flat grinder, and metal or non-metal workpieces can be sucked through the vacuum chuck, the flat grinder is suitable for machining non-metal workpieces, and meanwhile enlarges the machining range of the flat grinder.

Owner:KAIPING YINGGUANG ELECTROMECHANICAL TECH

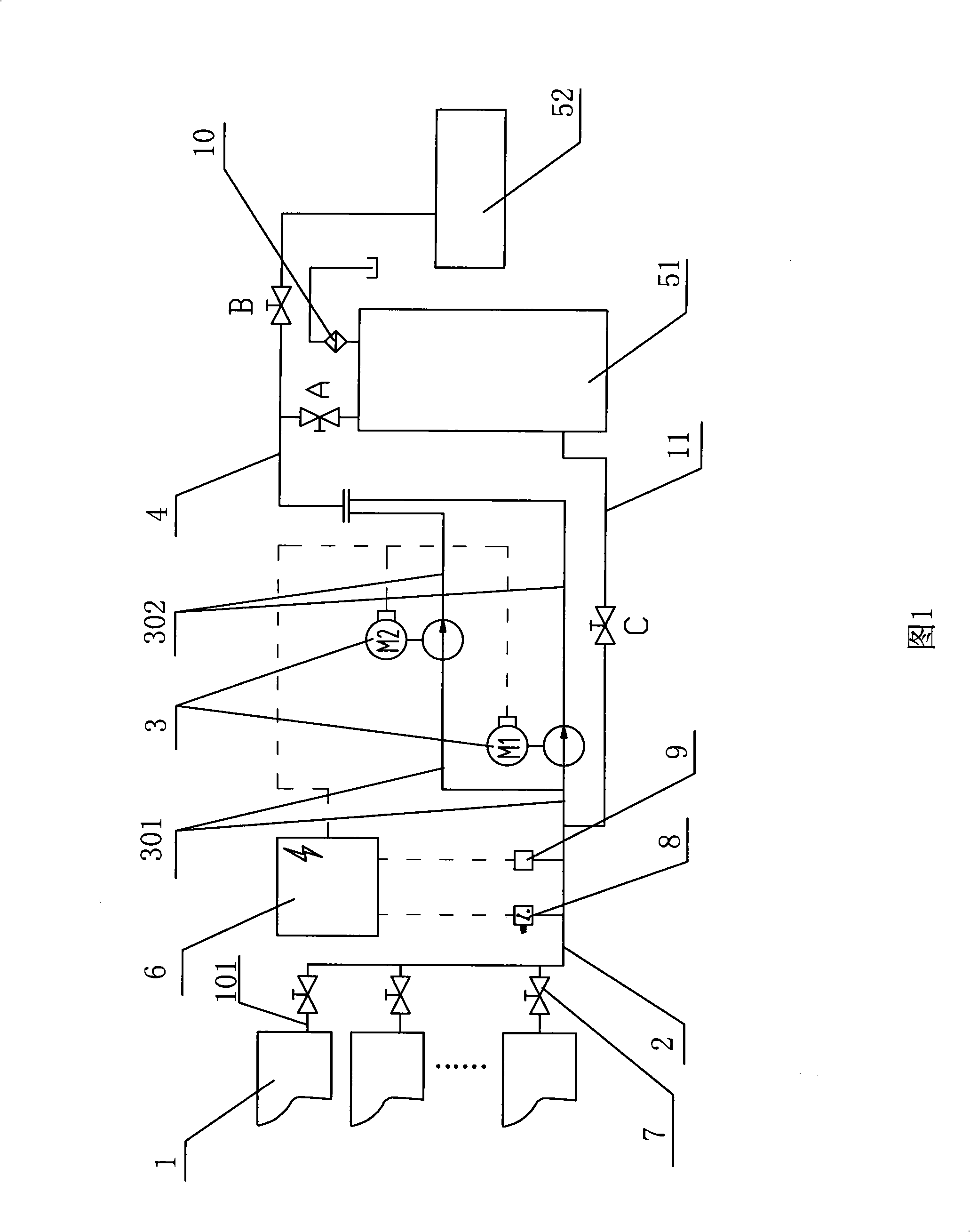

Vacuum system

ActiveCN101349072AGuaranteed vacuumOptimize layoutRotary piston pumpsSewage drainingElectricityWater source

The invention relates to a vacuum system which comprises a plurality of drainage sources, a plurality of vacuum conveying pumps, a sewage collecting part and a control center. Each sewage source comprises a drainage pool with a sewage outfall, a vacuum release valve, a vapor integrated double electromagnetic valve and a control device; and the sewage outfall of the drainage pool is connected with a discharge pipe of the sewage source by the vacuum release valve. The discharge pipe of the sewage source is connected with a sewage suction pipe by an isolation ball valve; the sewage suction pipe is connected with an inlet pipe of each vacuum conveying pump; and an outlet pipe of each vacuum conveying pump is connected with a sewage discharge pipe which is connected to the sewage collecting part. A pressure detection device in electric connection with the control center is arranged on the sewage suction pipe; and the vacuum conveying pump and the control center are in electric connection. In the vacuum system, the control center carries out intelligent control that one or a plurality of the vacuum conveying pumps are opened according to the detected vacuum degree of the sewage suction pipe; the vacuum system can ensure the vacuum degree of the sewage suction pipe to make sewage discharging smooth, effectively saves energy, has simple control, reduces cost, improves the reliability of the system and is convenient to maintain.

Owner:湖南真创环保科技有限公司

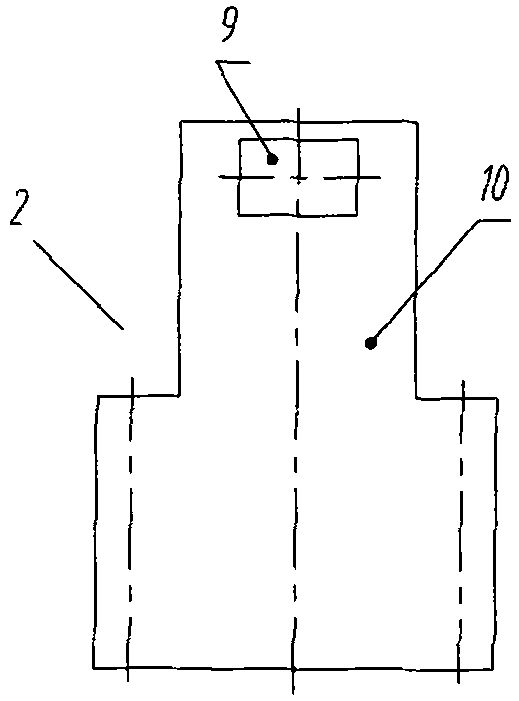

Three-jaw chuck

The invention discloses a three-jaw chuck, which comprises a chuck body and three jaws with the same structure, wherein the chuck body is provided with a workpiece pressing structure; the workpiece pressing structure comprises a frame-shaped sliding seat, a small shaft and an eccentric hand wheel rotating around the small shaft; the frame-shaped sliding seat is provided with an upper opening plate and a lower sliding strip which is parallel to and connected into a whole with the upper opening plate; the small shaft is fixed on the upper opening plate of the frame-shaped sliding seat; the lower sliding strip makes reciprocating displacement along a track groove arranged on the chuck body; and an extended line of a centre line of the track groove on the chuck body is intersected with a centre line of the chuck body. The three-jaw chuck adopting the structure is convenient to use, can prevent a held workpiece blank from loosening when workpiece blanks are clamped, improves the acceptability of lathe machining and increases the range of the lathe machining.

Owner:芜湖长胜机械制造有限公司

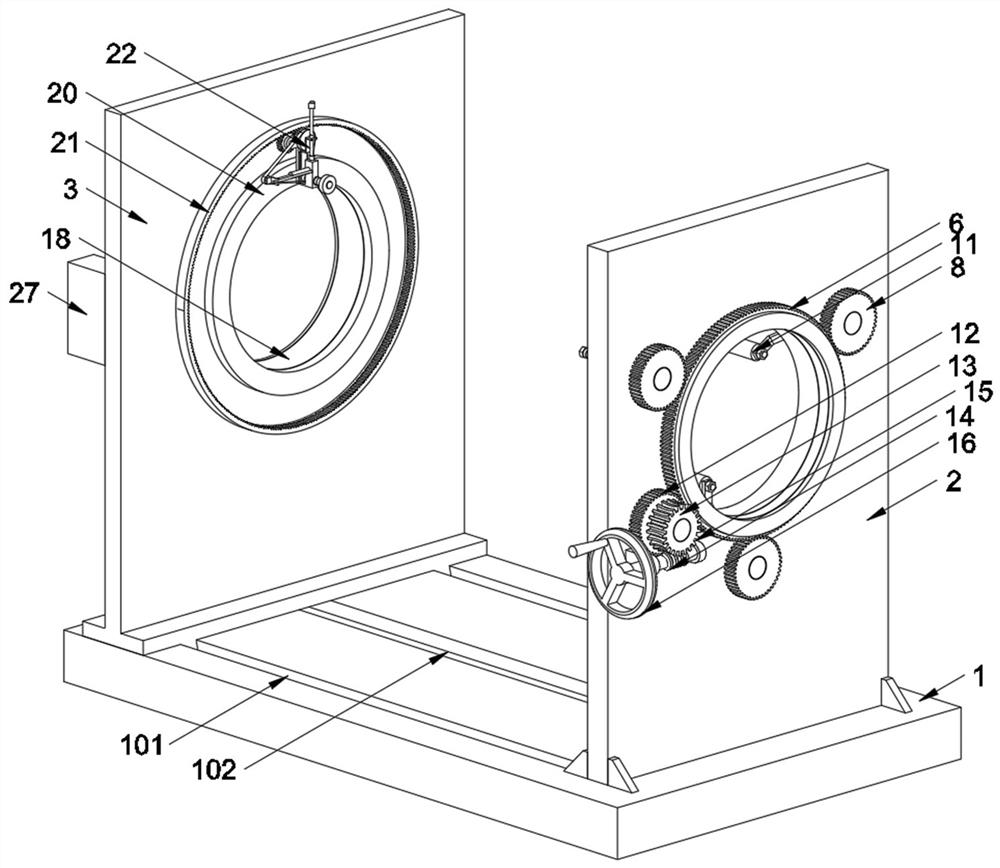

Internal-swelling pipe beveling machine

ActiveCN104785833AFlexible adjustmentEquipped with feed and retract functionFeeding apparatusMilling equipment detailsTool holderEngineering

The invention discloses a novel internal-swelling pipe bevelling machine which comprises a machine base, a tensioning device, a rotating device, a power device, a tool holder adjusting device and a tool holder progressive device, wherein the tool holder adjusting device comprises a cutter, a radial feed supporting plate, an axial feed supporting plate, a radial feed screw rod, an axial feed screw rod and a tool holder, wherein the cutter is fixedly arranged on a mounting plate, one end of the radial feed supporting plate is hinged to the cutter, the radial feed supporting plate is matched with the axial feed supporting plate in a guiding and sliding manner, a tool holder outer side is arranged on the axial feed supporting plate in a sleeving manner, the axial feed supporting plate is matched with the tool holder in a guiding and sliding manner, a long strip shaped radial through hole is formed in the tool holder, the radial feed screw rod penetrates through the long strip-shaped radial through hole in the tool holder, the radial feed supporting plate is matched with the axial feed supporting plate in a linked manner, the axial feed screw rod is matched with the tool holder of a beveling cutter in a linked manner, and the novel internal-swelling pipe bevelling machine provided by the utility model solves the problem of inflexibility in tool holder adjusting in a conventional internal-swelling pipe bevelling machine.

Owner:ZHEJIANG AOTAI MACHINE MFG

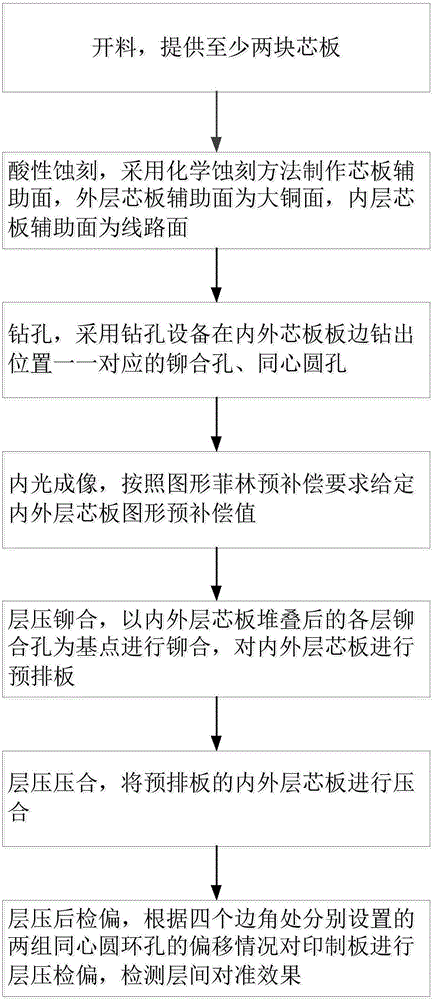

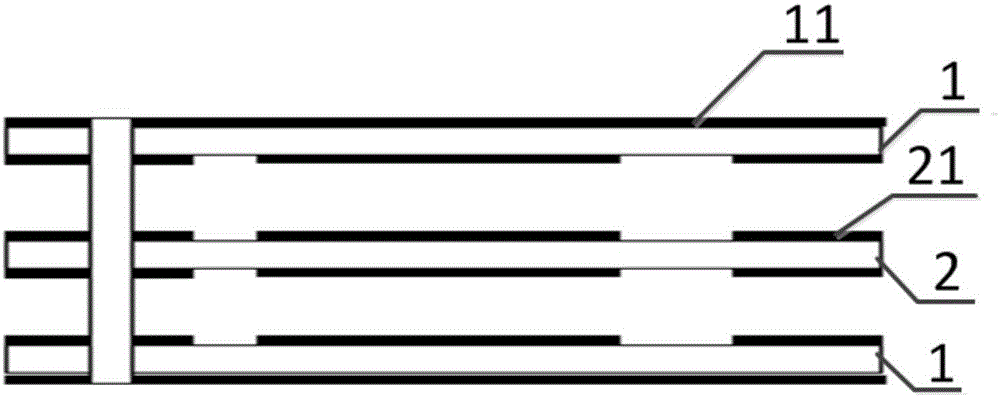

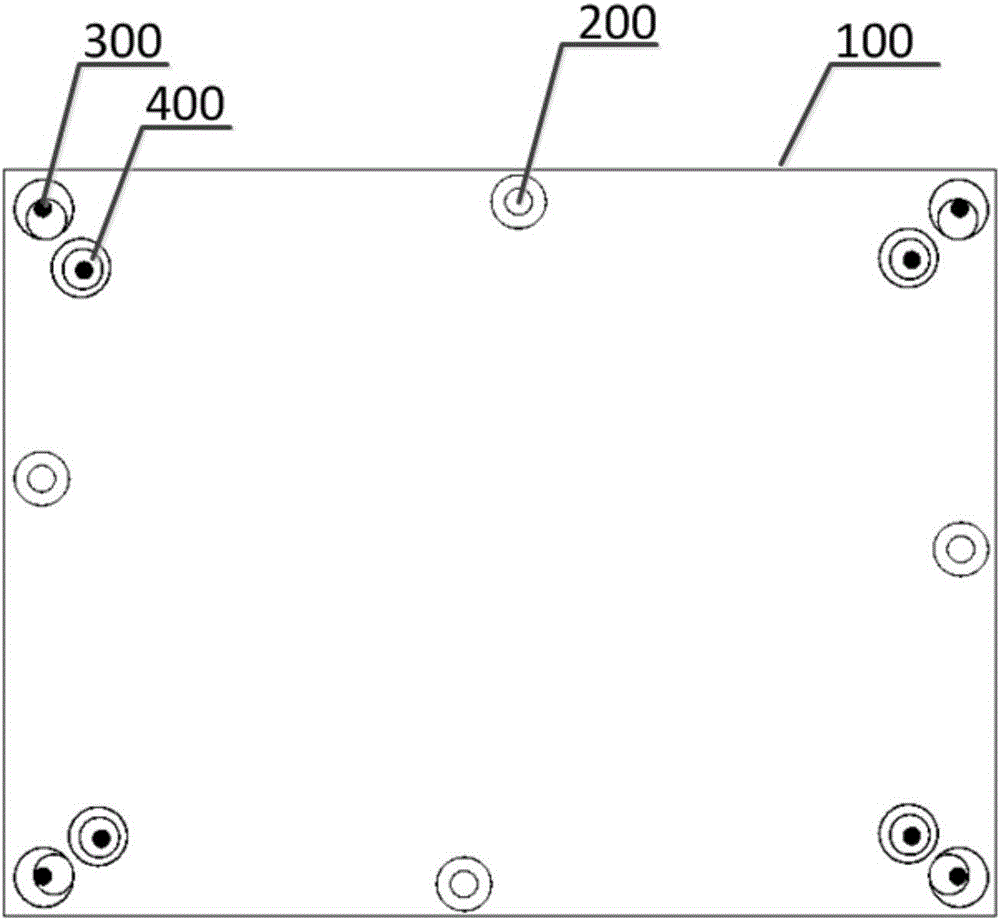

Method for optimizing laminated structure printed board expanding and shrinking matching and laminated structure printed board

PendingCN106413292AControl expansion and contraction differencesEasy alignmentInspection/indentification of circuitsMultilayer circuit manufactureGraphicsAcid etching

The invention provides a method for optimizing laminated structure printed board expanding and shrinking matching and a laminated structure printed board. The method comprises the following steps of material cutting: at least two core boards are provided; acid etching: a core board auxiliary surface is manufactured by using a chemical etching method; hole drilling: riveting holes are drilled at the side of the board; internal optical imaging: internal and external layer core board graphic pre-compensation values are given according to the graphic film pre-compensation requirements; laminating and riveting: riveting is performed with the riveting holes of each layer after stacking of the internal and external layer core boards acting as basic points, and pre-arrangement of the internal and external layer core boards is performed; and laminating and pressing: the pre-arranged internal and external layer core boards are pressed. The core board graphic pre-compensation values are optimized based on statistical analysis of a large volume of expanding and shrinking data, and the expanding and shrinking difference generated in pressing of the internal and external layer core boards is controlled so that the alignment of the pressing layers of the laminated structure core board can be effectively enhanced, the quality of the printed board can be ensured, and the processing technical capacity of the printed board can be enhanced and the processing range can be expanded.

Owner:珠海杰赛科技有限公司

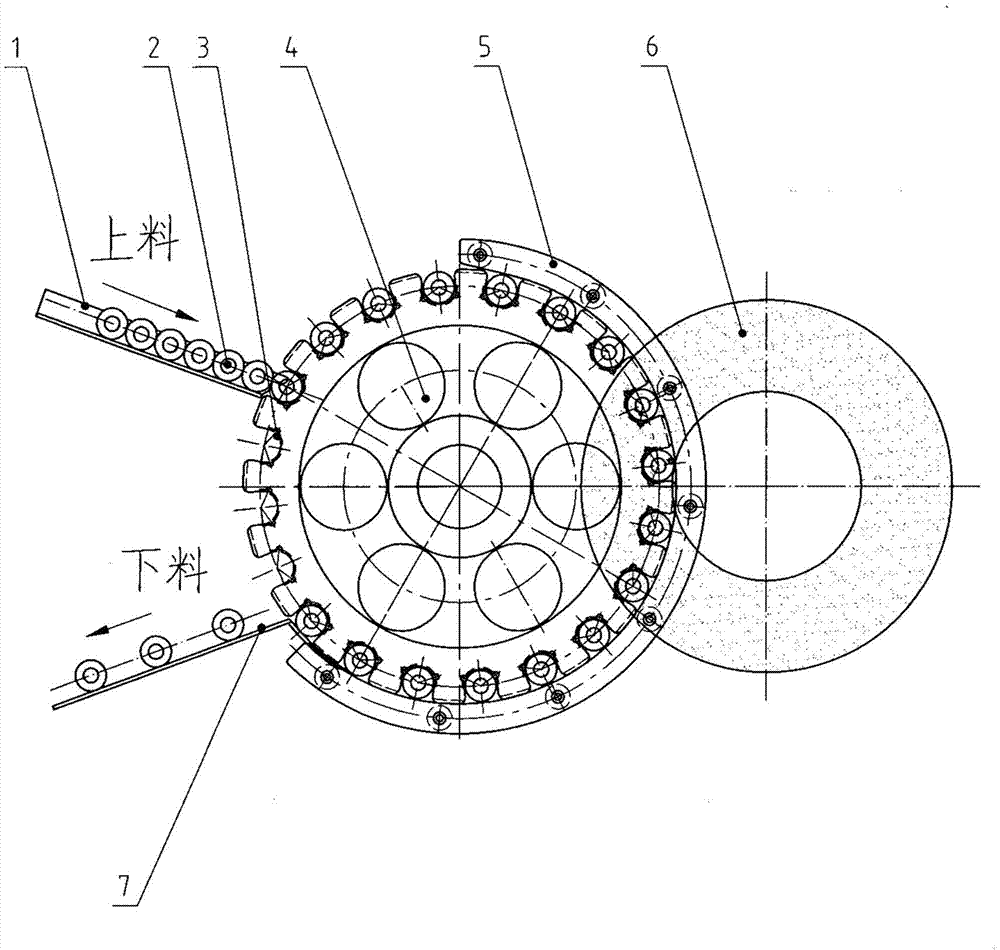

Special disk type feeding device of double-ended grinding machine

InactiveCN103878652AExpand the scope of processingImprove processing efficiencyGrinding feedersPlane surface grinding machinesEngineeringGuard ring

The invention relates to a special disk type feeding device of a double-ended grinding machine. The special disk type feeding device of the double-ended grinding machine is composed of a feeding support, an arc base, a feeding disk, a grinding guard ring, a workpiece, an abrasive wheel and the like. The special disk type feeding device of the double-ended grinding machine is characterized in that the feeding disk is arranged at the right end of the feeding support, the arc base is arranged on the feeding disk, the grinding guard ring is arranged on a grinding region on the right side of the feeding disk, the workpiece enters in the arc base on the feeding disk from the feeding support, and grinding of the workpiece is completed along with rotation of the feeding disk. The special disk type feeding device of the double-ended grinding machine has the advantages of being reasonable in design, simple in structure, convenient to use and practical.

Owner:RUSHAN HONGYUAN MACHINE MFG

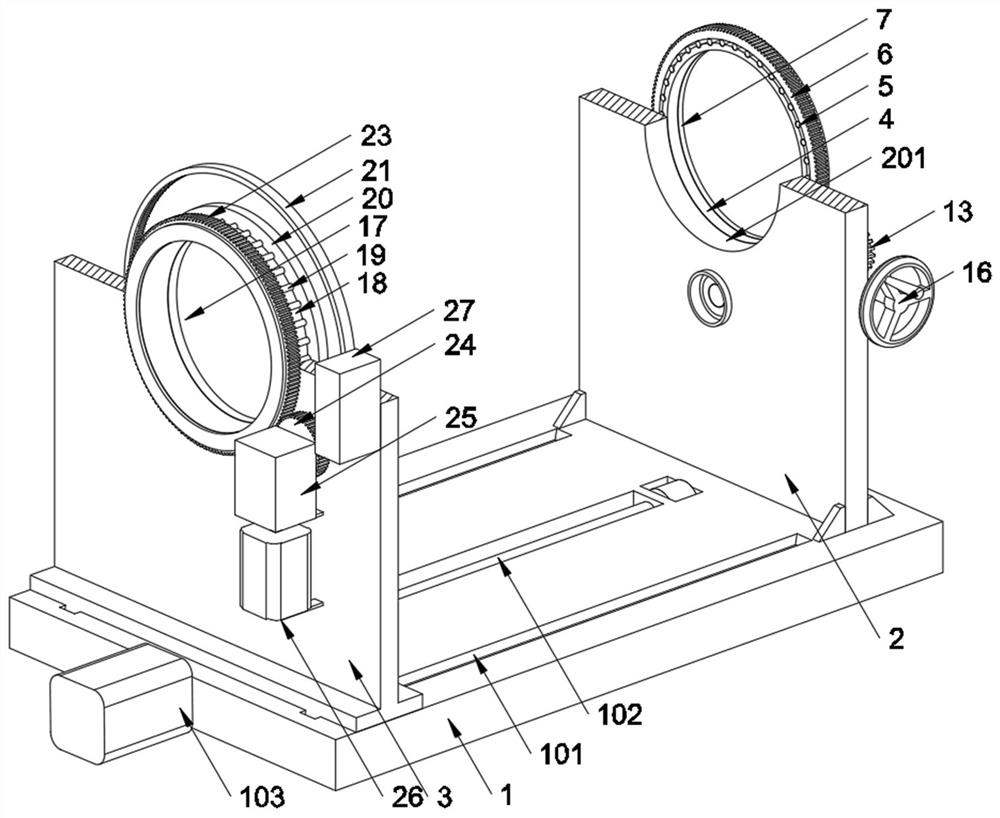

Surface pretreatment device for steel member welding

InactiveCN112658583AGuaranteed stabilityReduce laborGrinding carriagesRevolution surface grinding machinesGear wheelClassical mechanics

The invention belongs to the technical field of steel member machining, and particularly relates to a surface pretreatment device for steel member welding. The device comprises a fixed base, wherein a sliding frame is slidably mounted on the top face of the fixed base, a fixed frame fixedly mounted on the top face of the fixed base, a fixed ring is fixedly mounted on the right end face of the fixed frame, a right outer gear ring rotationally connected to the fixed ring through a right roller is connected with a planetary gear and a driving gear in a meshed mode, the planetary gear is connected with a self-centering clamping jaw through a connecting shaft, a worm wheel fixedly mounted on the driving gear is connected with a worm in a meshed mode, a rotating ring is rotationally mounted in a left through hole formed in the sliding frame through a left roller, a grinding mechanism is fixedly mounted in a connecting ring connected to the right end of the rotating ring, an inner gear ring is mounted on the right end face of the sliding frame, and a left outer gear ring connected to the left end face of the rotating ring is connected with a drive gear in a meshed mode. The self-centering clamping jaw is convenient to replace and can clamp workpieces of different sizes in a self-centering mode, so that the grinding mechanism revolves around the axis of a workpiece to circumferentially grind the workpiece, and the position of a grinding wheel can be linearly adjusted to grind workpieces with different diameters.

Owner:安徽宇艳智能机械科技有限公司

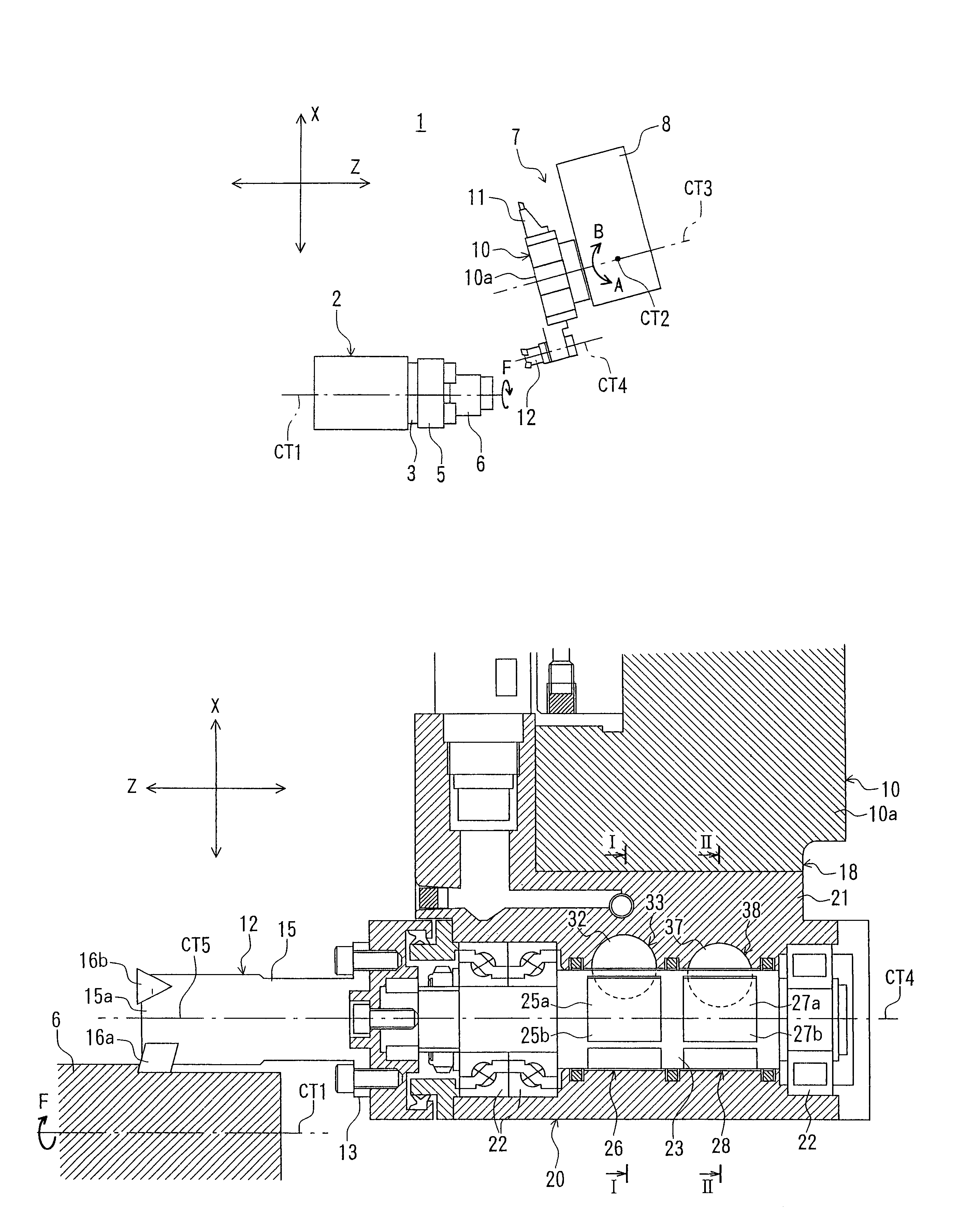

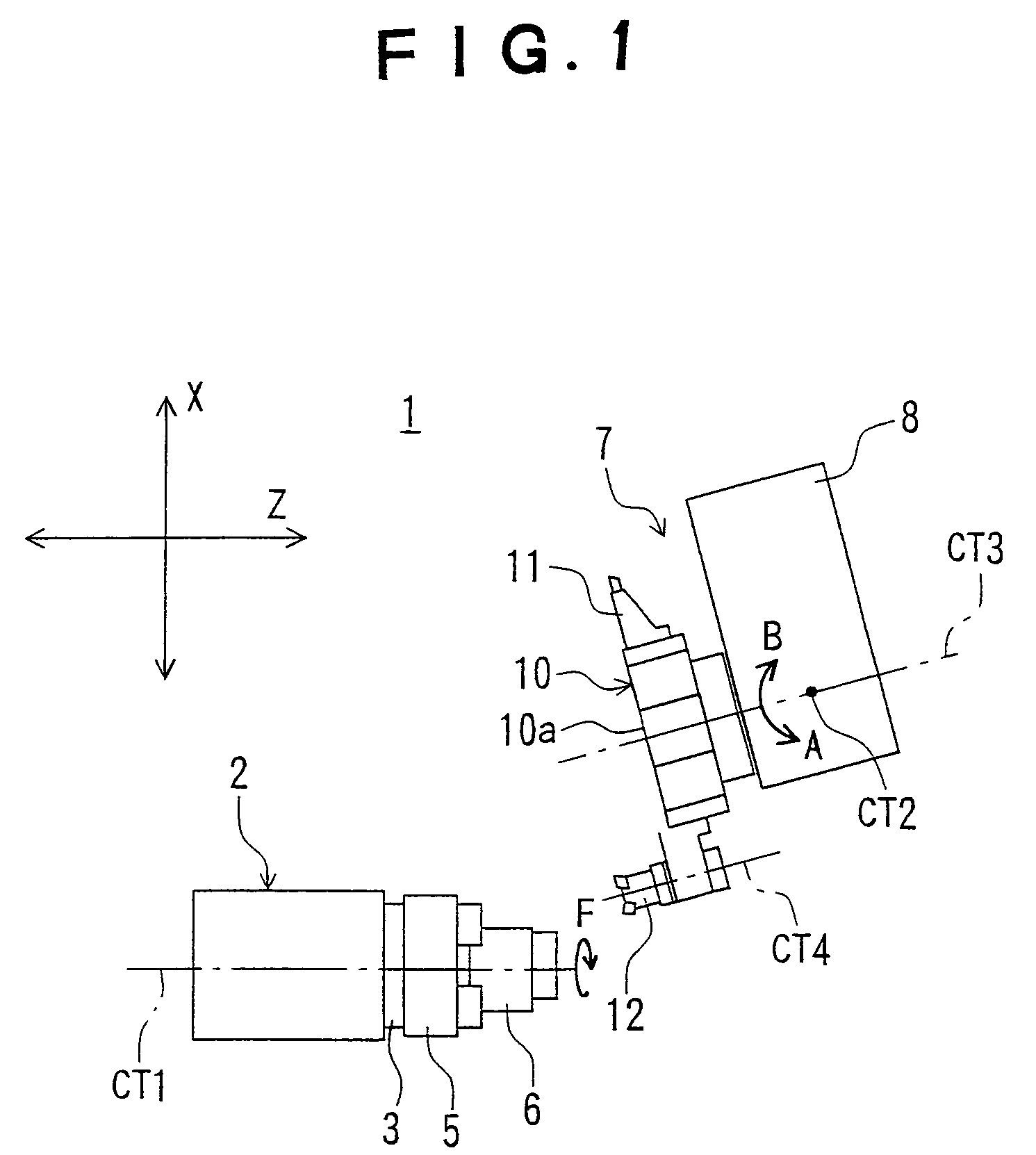

Turret for turret lathe

InactiveUS7117773B2Improve machine efficiencyAvoid long exchangesLathesAutomatic/semiautomatic turning machinesEngineeringTurret

A turret body is provided with a tool spindle for detachably attaching a complex tool so as to be freely rotated with an axial center as its center. The turret body is provided with indexing means for indexing the tool spindle, and clamping means for clamping the tool spindle at an indexed position indexed by the indexing means. The turret body has a function for indexing the tool spindle for attaching the complex tool thereto and a function for clamping, thereby using the complex tool in a turret lathe.

Owner:YAMAZAKI MAZAK KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com