Patents

Literature

566 results about "Pressure angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

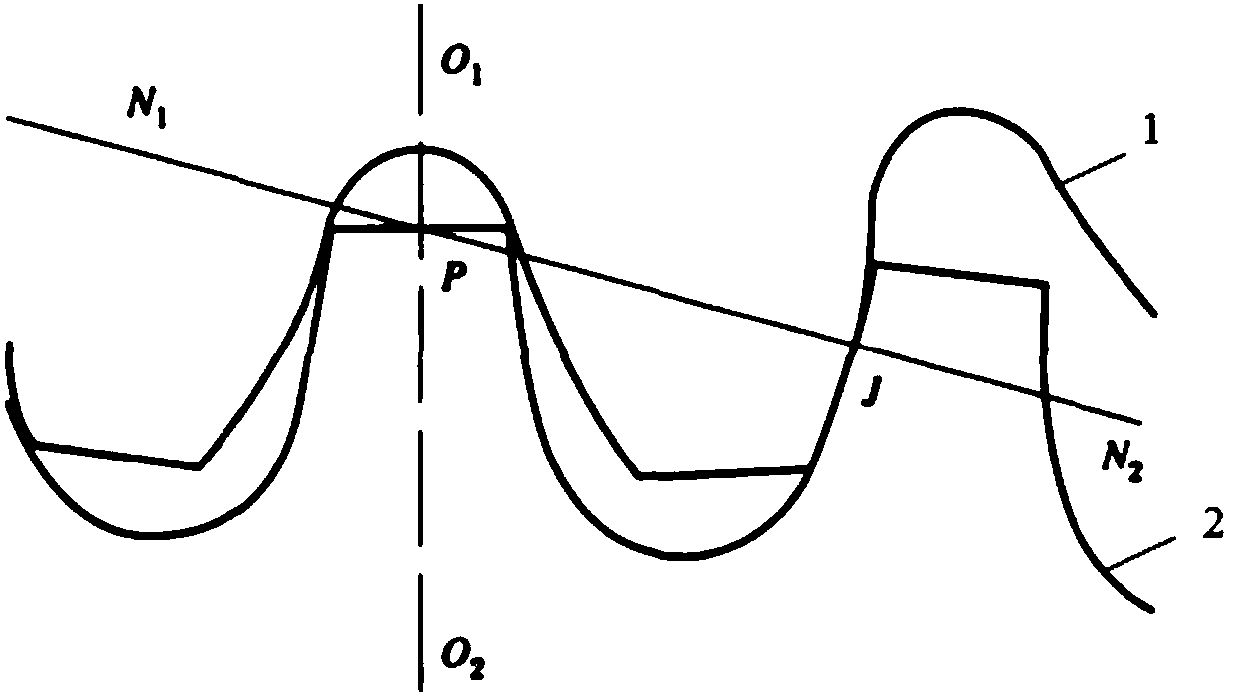

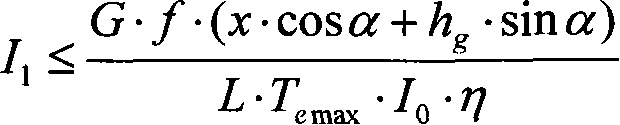

Pressure angle in relation to gear teeth, also known as the angle of obliquity, is the angle between the tooth face and the gear wheel tangent. It is more precisely the angle at a pitch point between the line of pressure (which is normal to the tooth surface) and the plane tangent to the pitch surface. The pressure angle gives the direction normal to the tooth profile. The pressure angle is equal to the profile angle at the standard pitch circle and can be termed the "standard" pressure angle at that point. Standard values are 14.5, 20 and 25 degrees. Earlier gears with pressure angle 14.5 were commonly used because the cosine is larger for a smaller angle, providing more power transmission and less pressure on the bearing; however, teeth with smaller pressure angles are weaker. To run gears together properly their pressure angles must be matched.

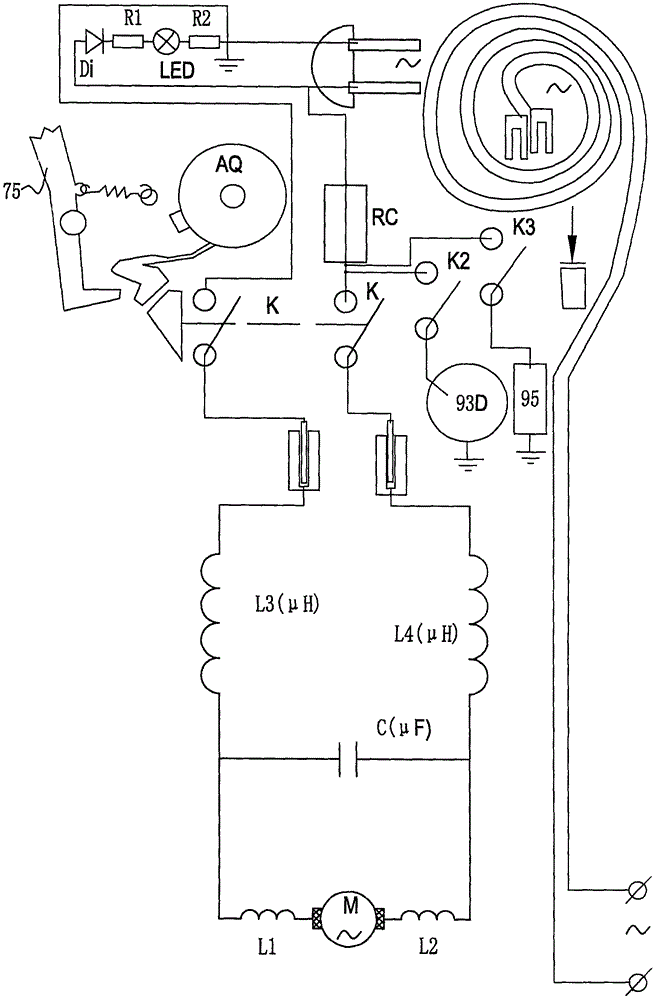

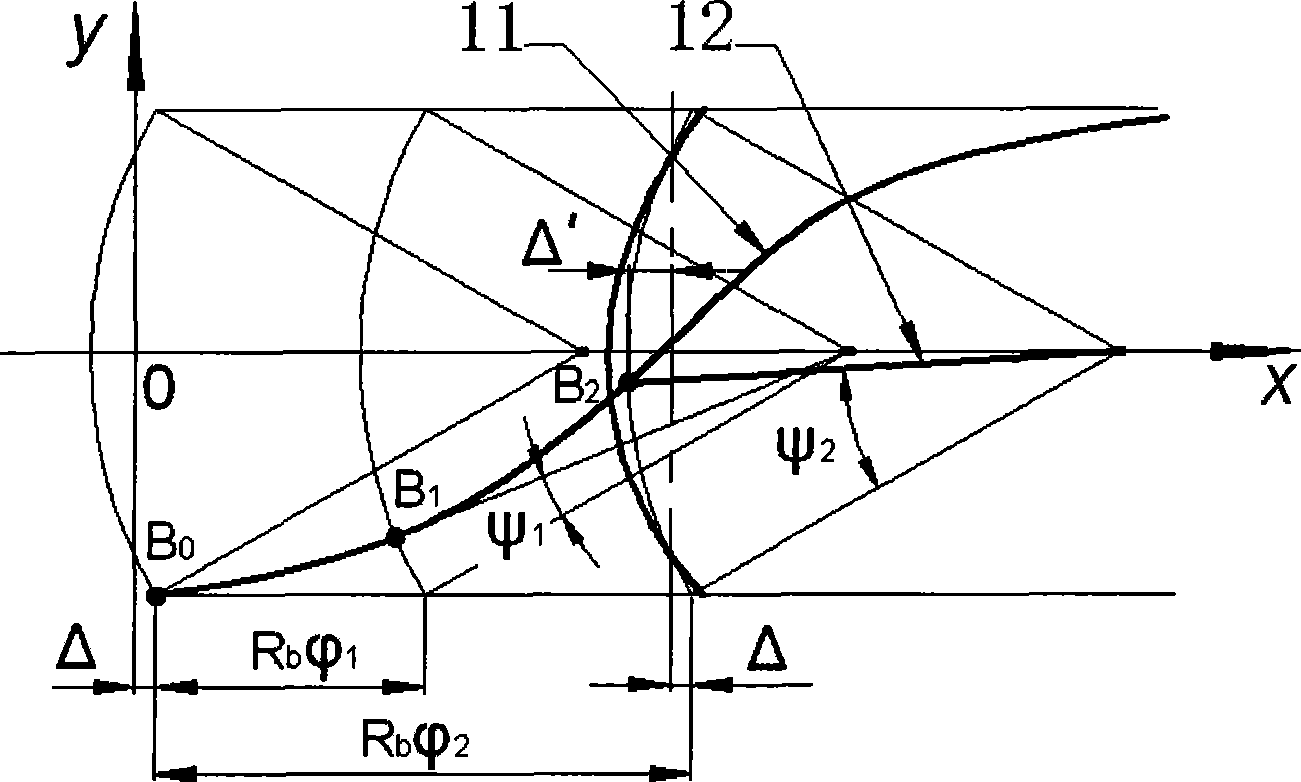

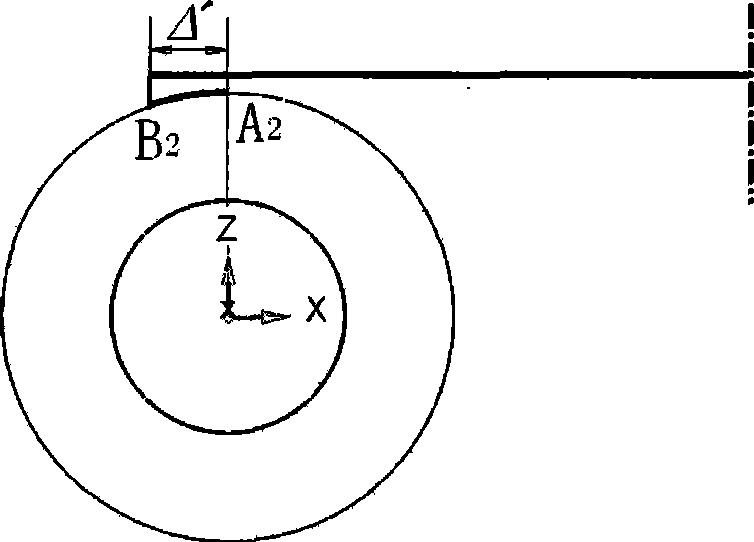

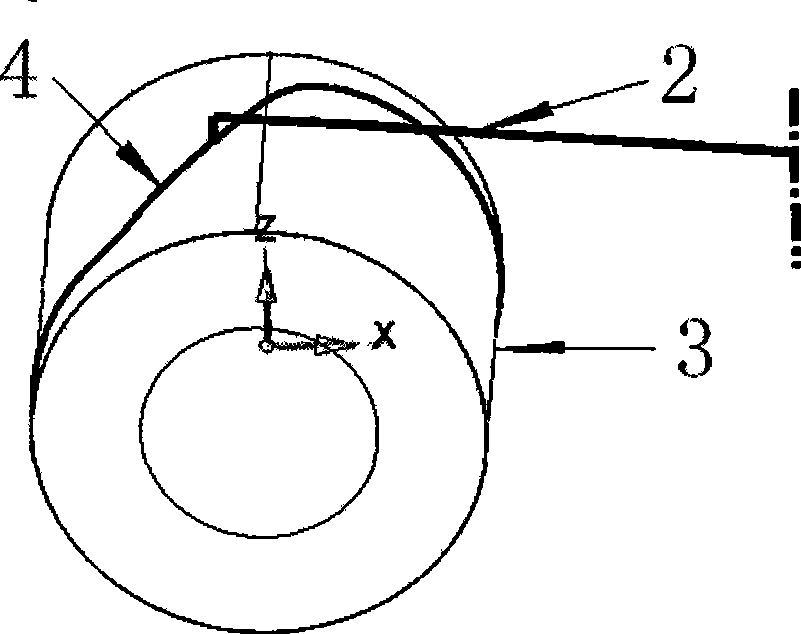

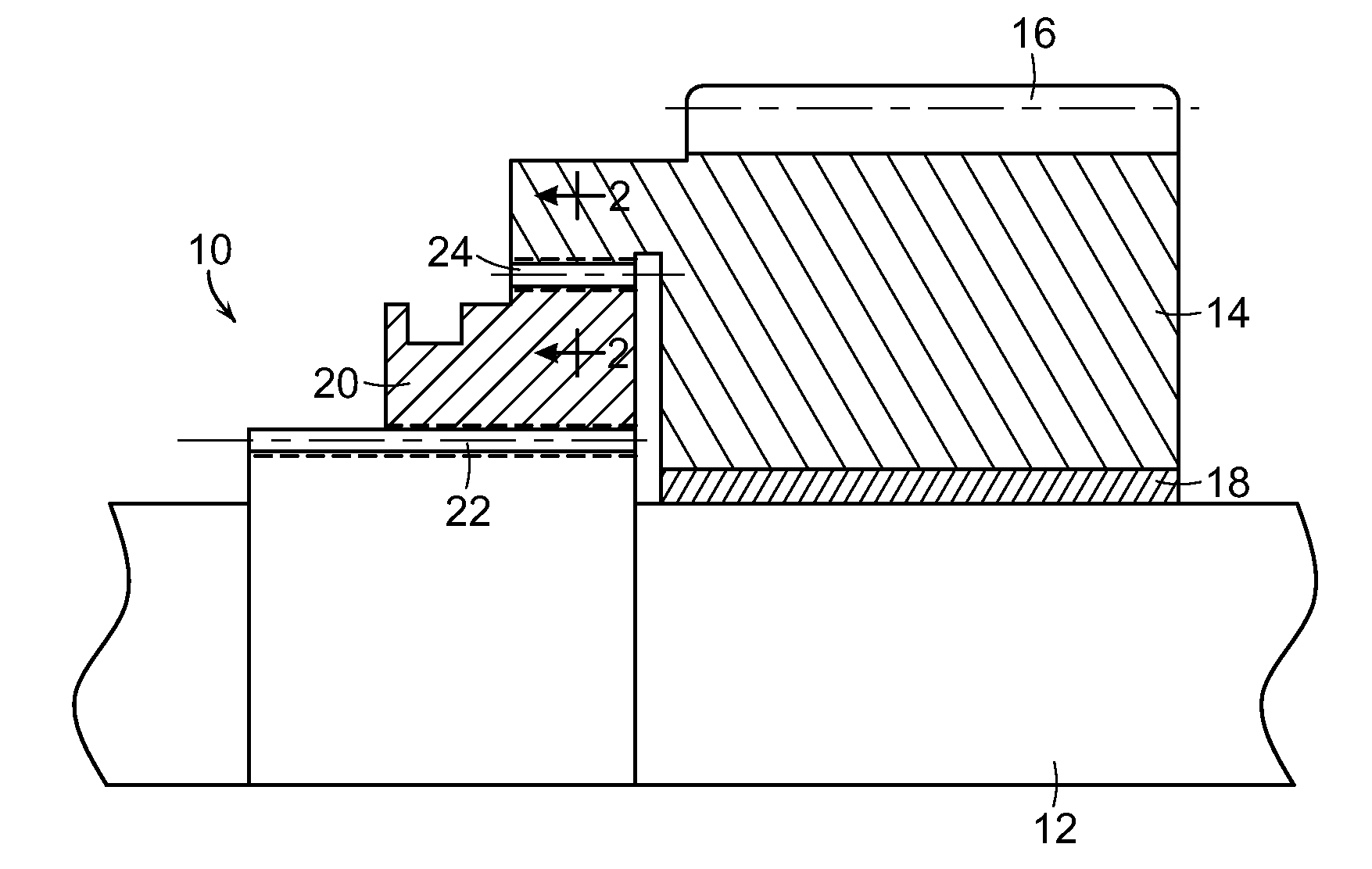

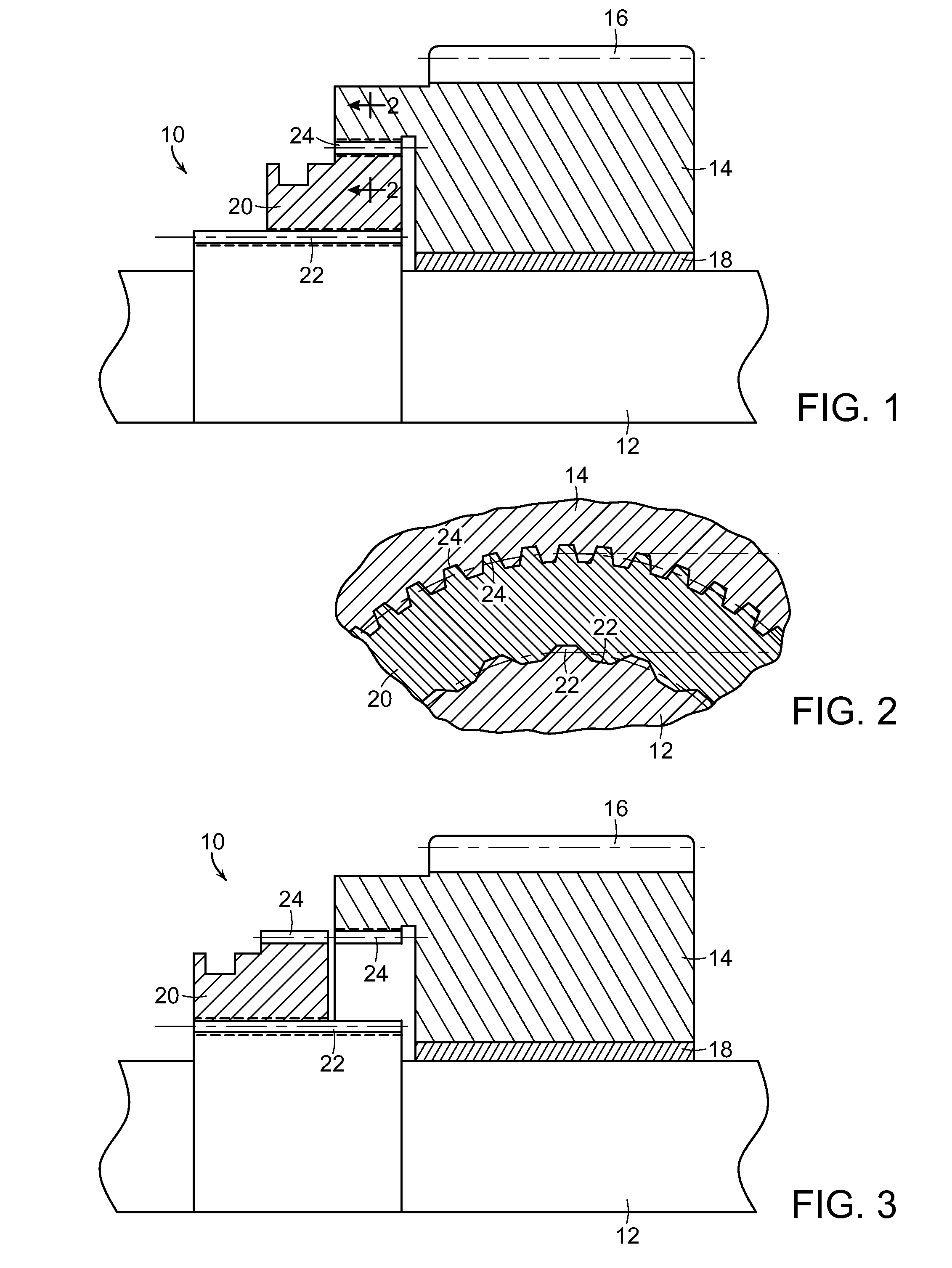

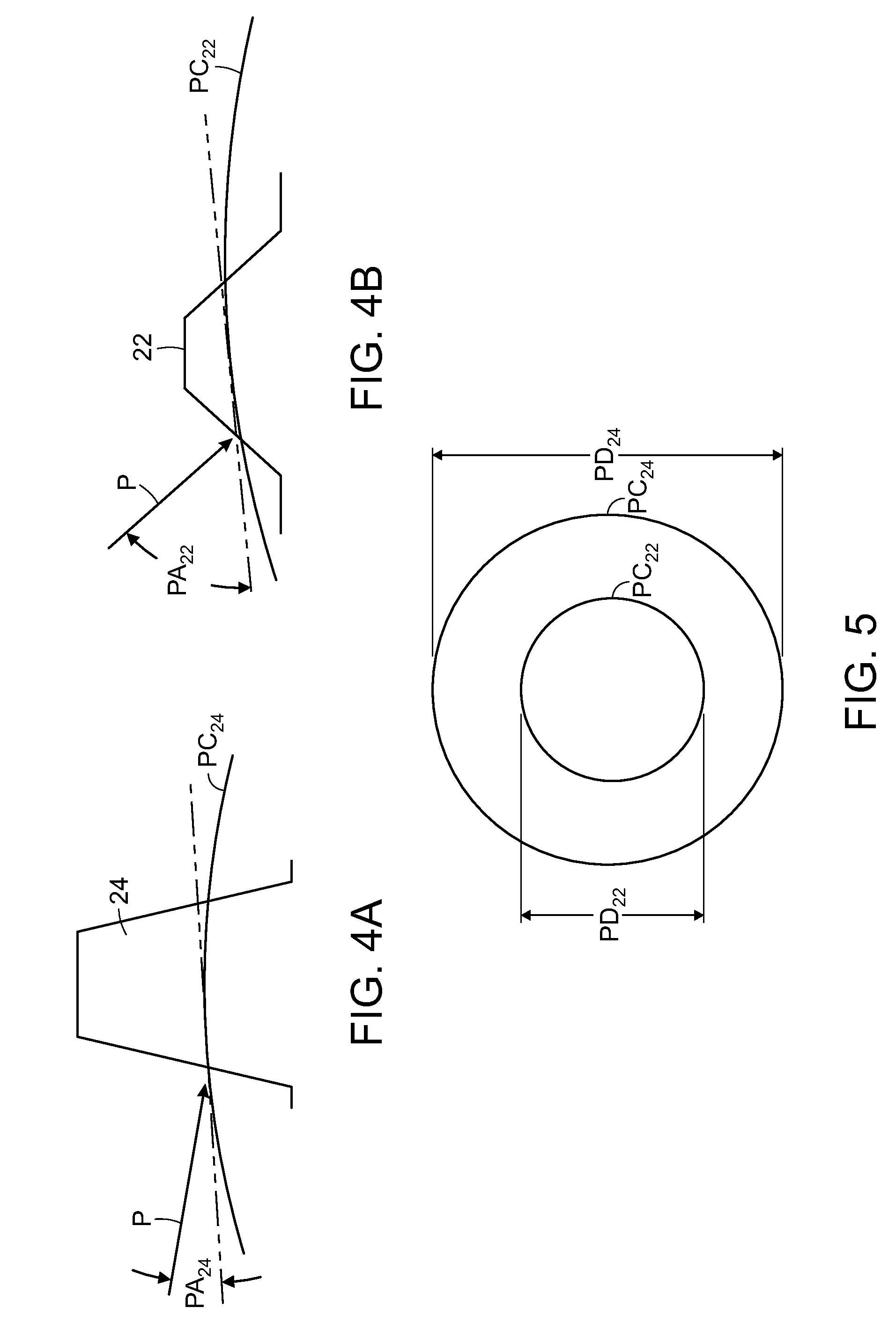

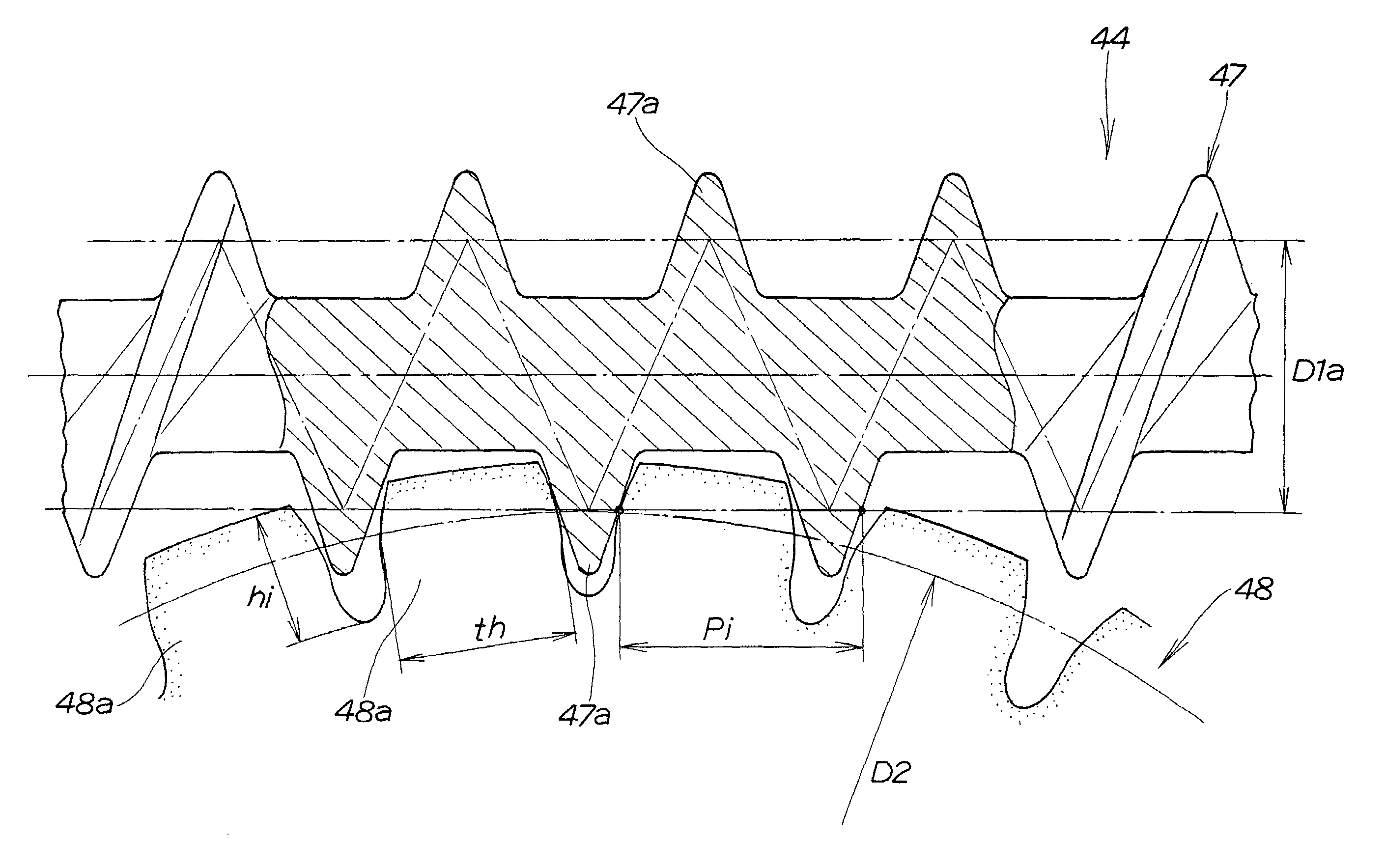

Random engagement roller chain sprocket and timing chain system including same

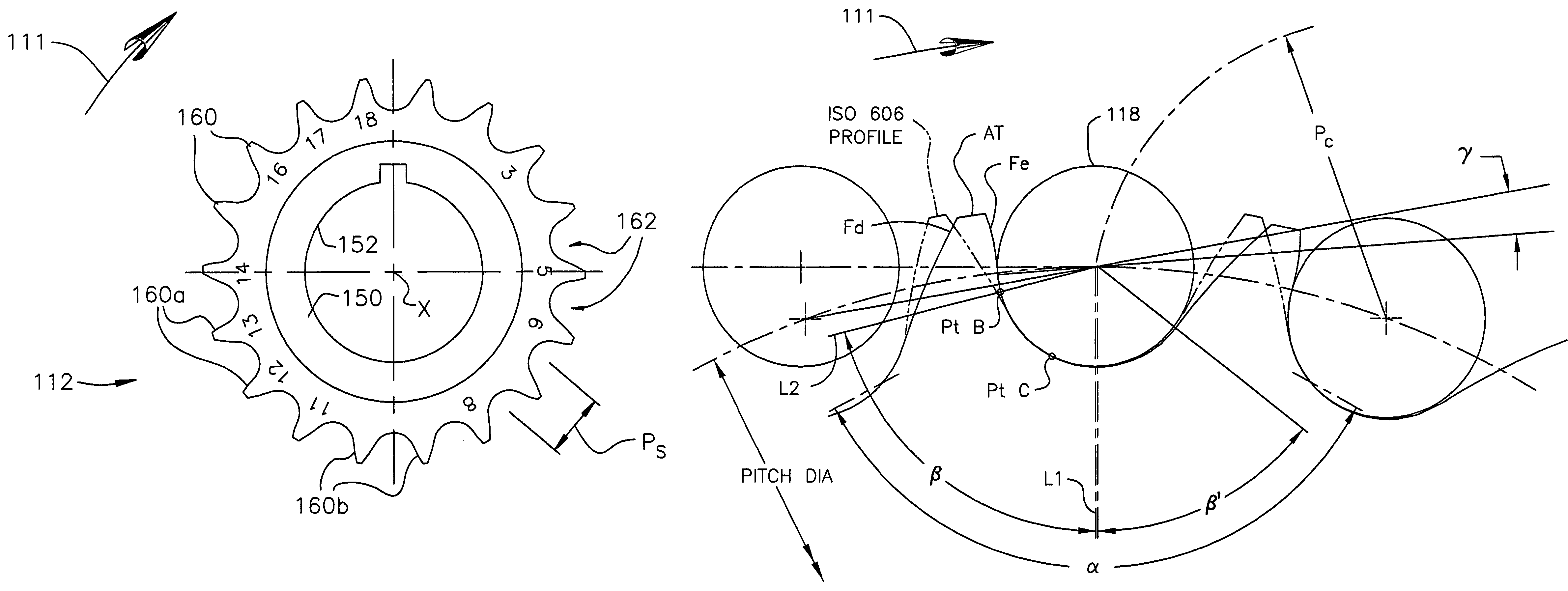

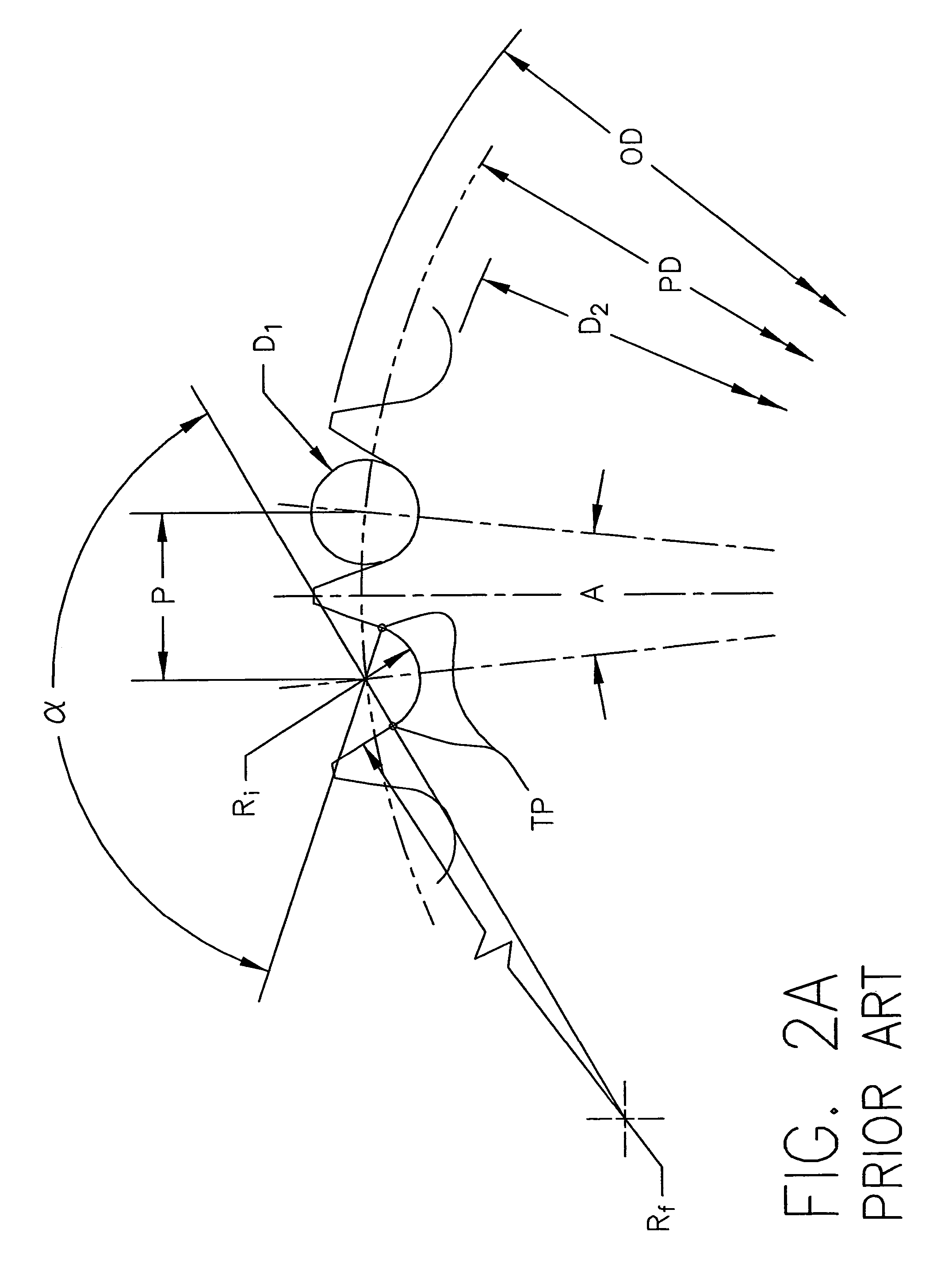

A sprocket and a roller chain drive system including same are disclosed. The sprocket is a random engagement sprocket comprising a first plurality of A-profile teeth formed with a first asymmetric profile and a second plurality of B-profile teeth formed with a second asymmetric profile. The A-profile teeth each define a first pressure angle and the B-profile teeth each define a second pressure angle that is at least 5 degrees greater than said first pressure angle so that a minimum separation Δ is defined. The sprocket is defined with added chordal pitch reduction of 0.2% up to 1% relative to the link pitch of the associated roller chain. The sprocket can be defined with root relief and / or can comprise resilient cushion rings. Initial roller contacts made with the A-profile and B-profile teeth are modulated owing to the pressure angle separation and added chordal pitch reduction.

Owner:HH CLOYES INC

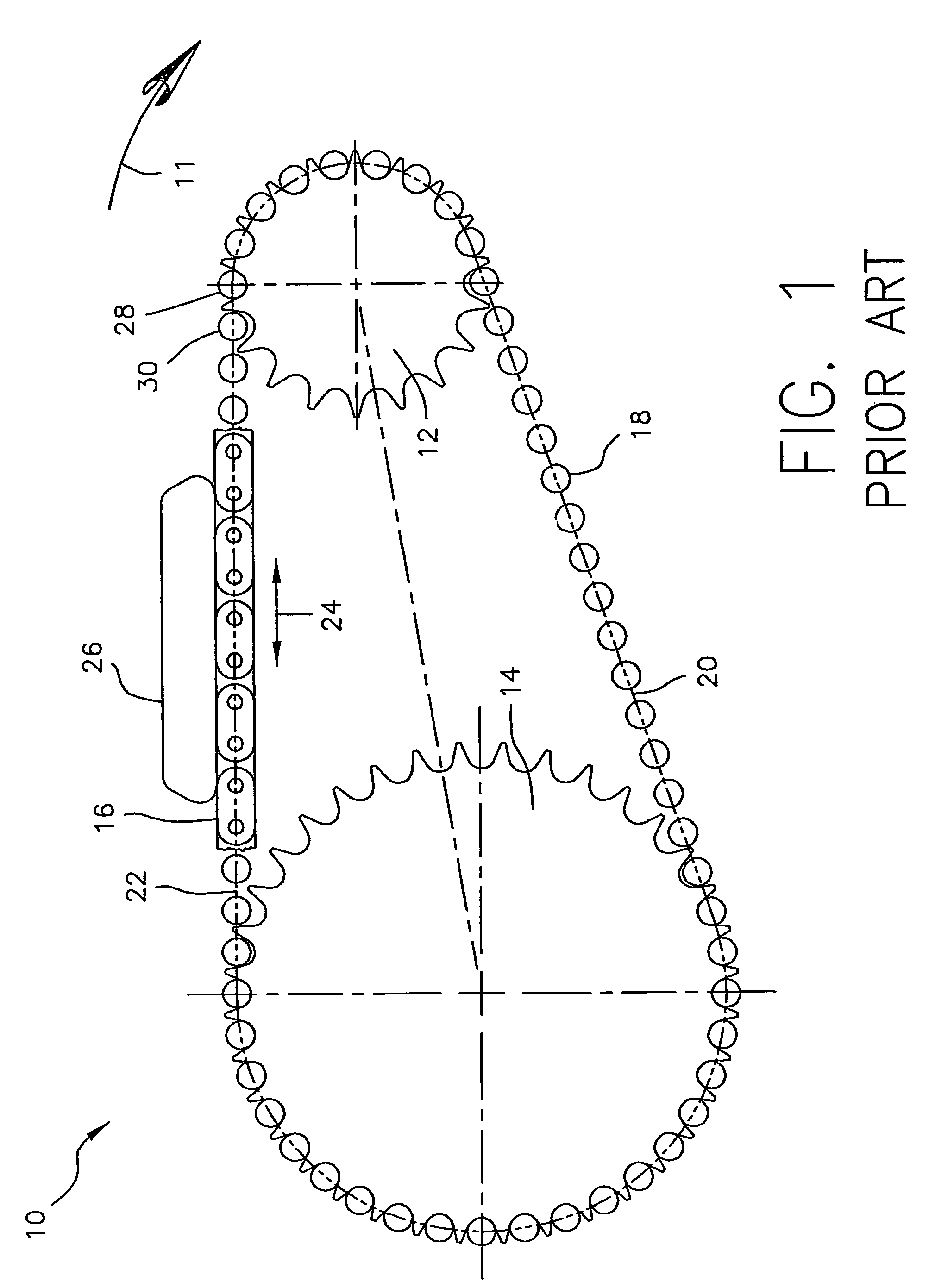

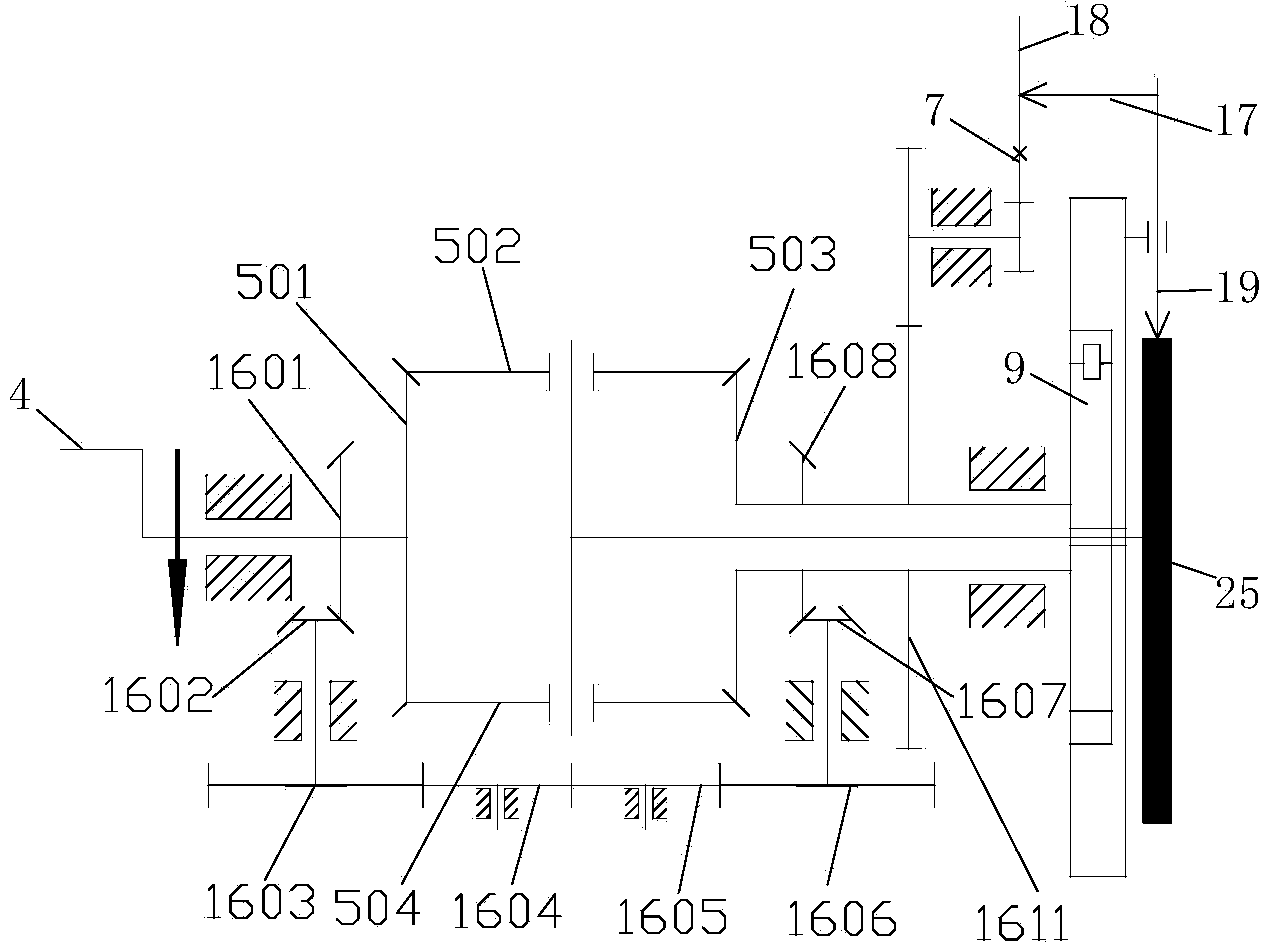

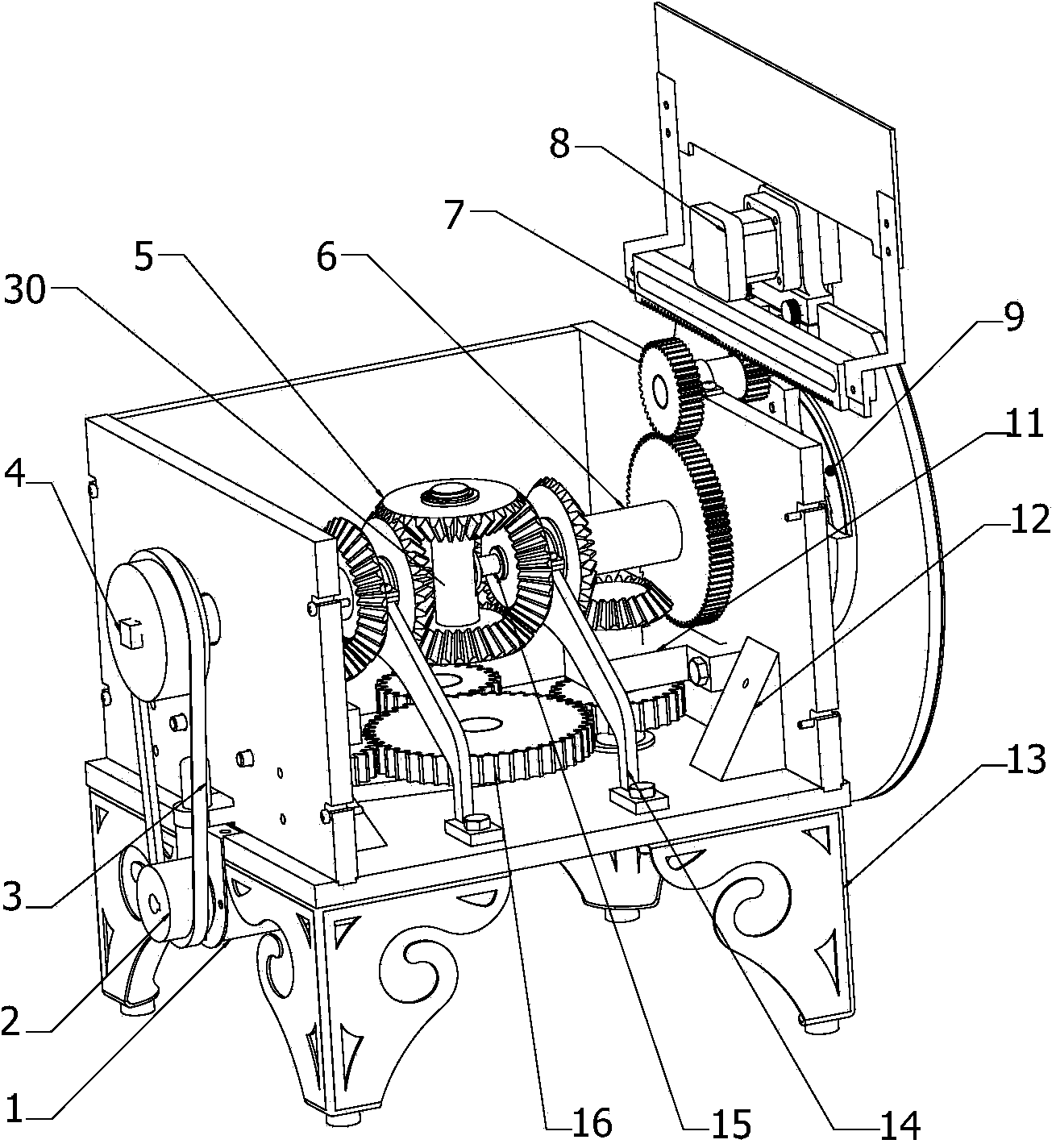

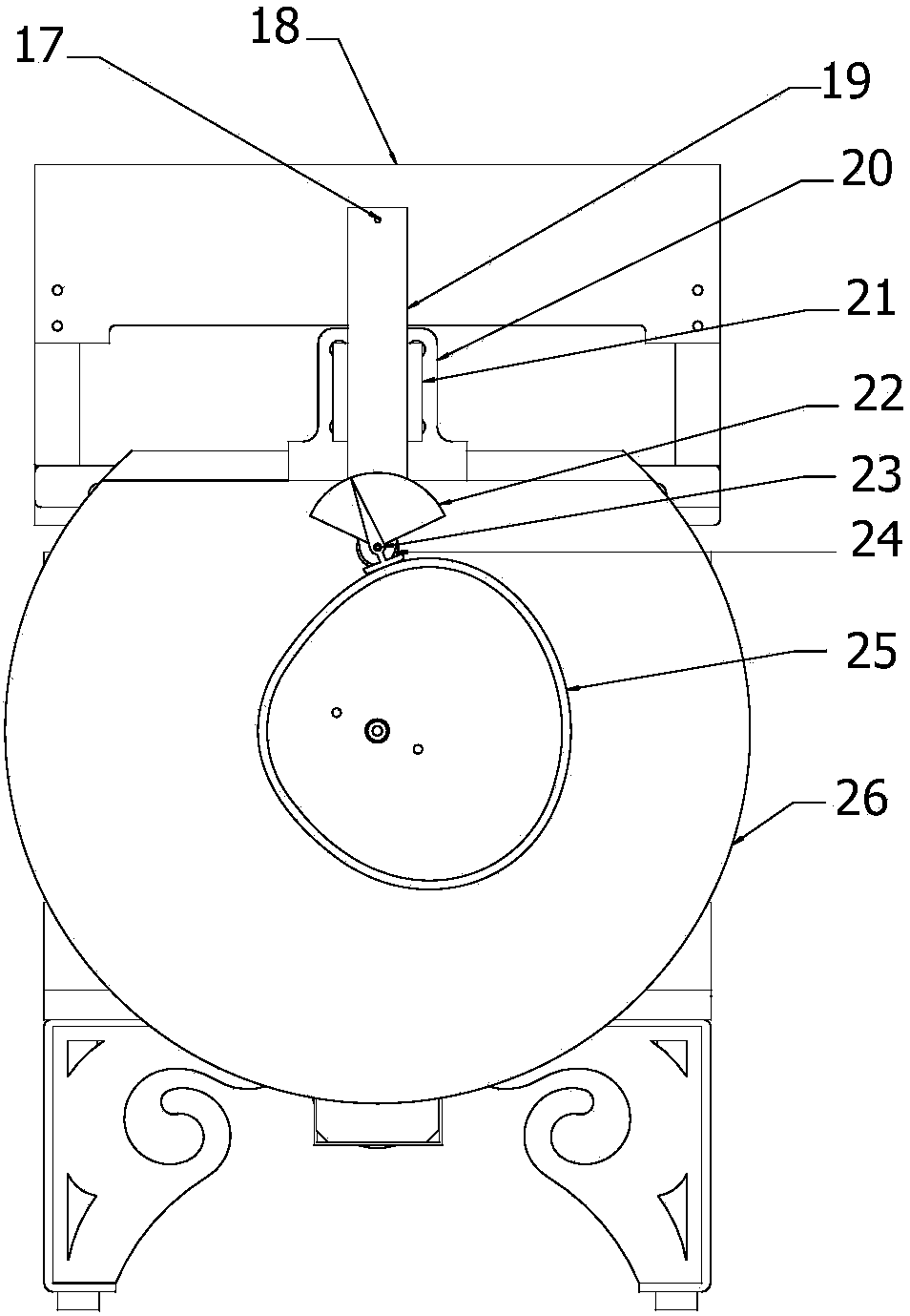

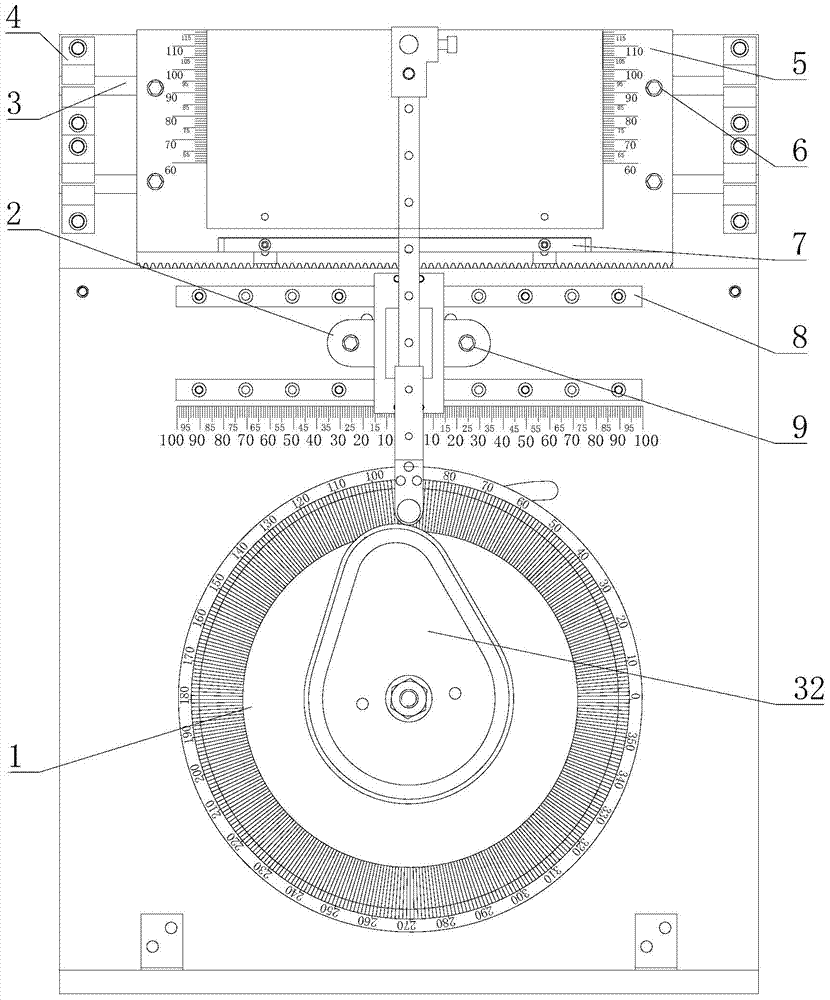

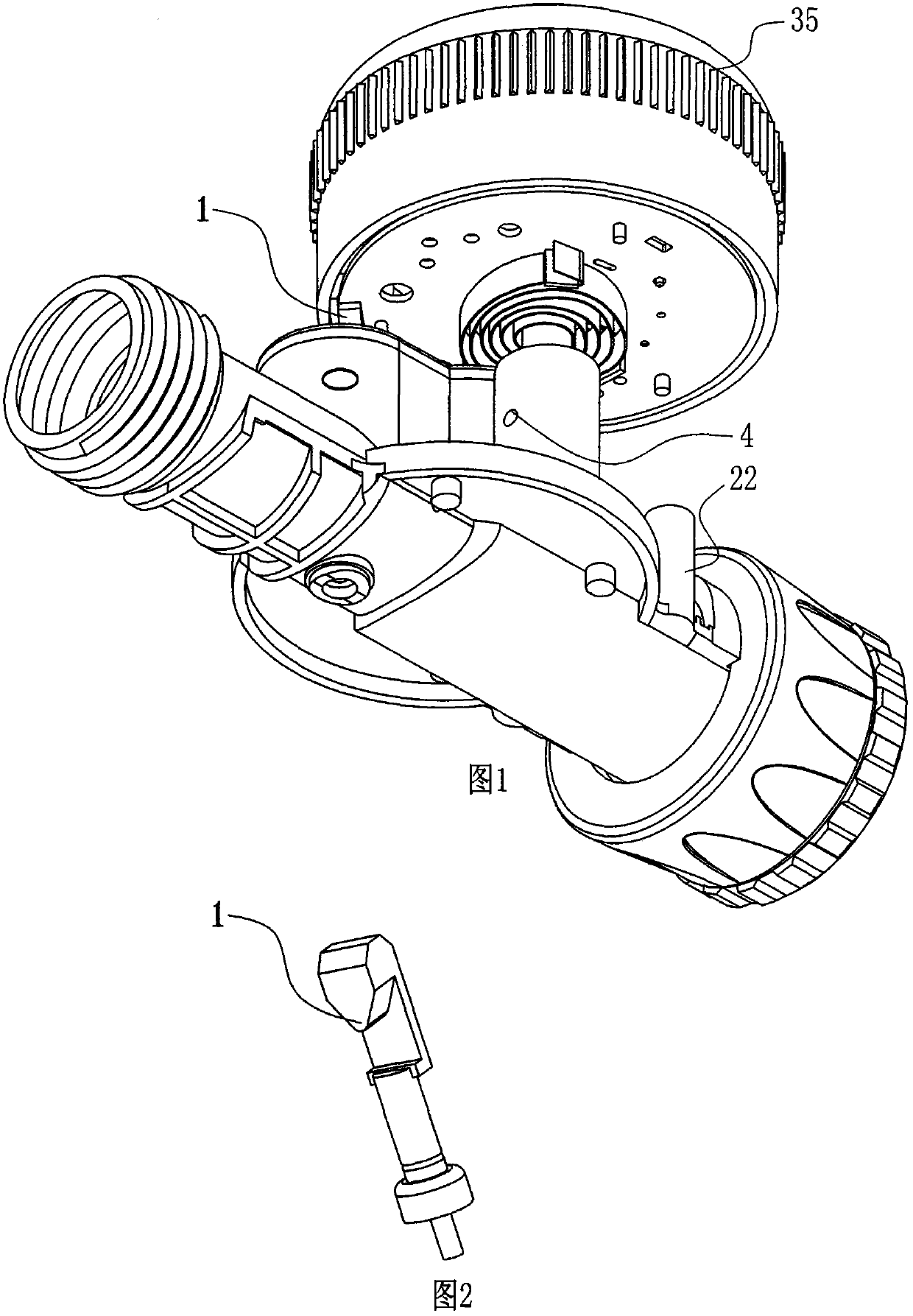

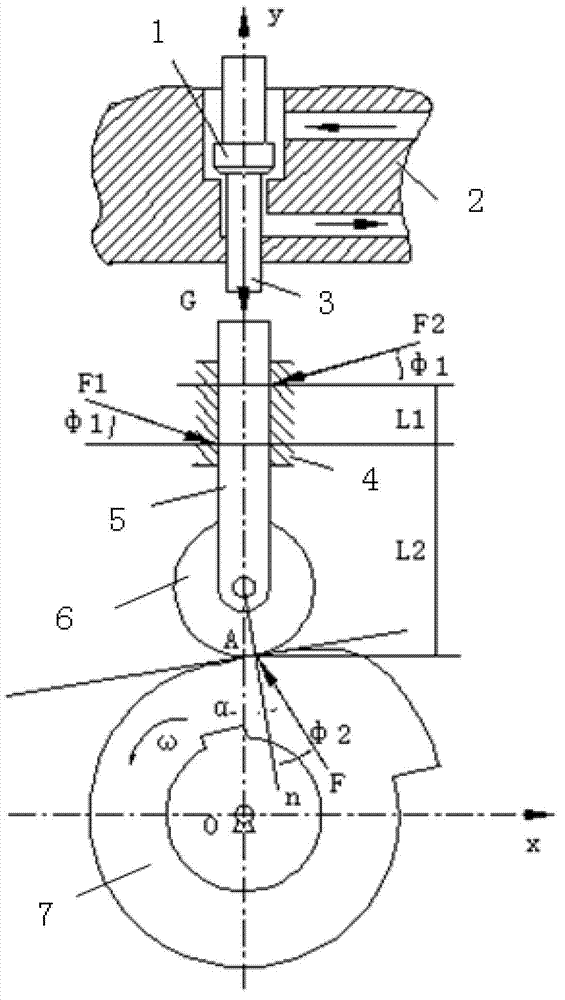

Comprehensive demonstrating teaching tool for cam mechanism

InactiveCN103971584AConvenient teachingIncrease enthusiasm for learningEducational modelsTeaching toolCam

The invention relates to a comprehensive demonstrating teaching tool for a cam mechanism. The comprehensive demonstrating teaching tool comprises a driving device, an ordinary gear train (16), an epicyclic gear train (5), a cam (25), a bottom plate (26), a ratchet mechanism (9) and a push rod (19). The ratchet mechanism (9) comprises an inner ratchet wheel (901), a ratchet wheel cover (904), a pawl (902) and a reset spring (903). The cam (25) is fixedly connected with the ordinary gear train (16) through a tie bar (15), and an output shaft (6) is arranged outside the tie bar (15) in a sleeved mode. The bottom plate (26) is provided with a sliding block (20), and the push rod (19) moves along the sliding block (20). The cam mechanism demonstrating teaching tool can vividly and visually demonstrate the reversal method, the cam profile design, the push rod motion law drawing, the cam mechanism pressure angle demonstration and other knowledge points, a teacher can teach conveniently, students can manually experience the characters of the cam after class, and the study enthusiasm of the students is improved to a maximum extent.

Owner:WUHAN UNIV OF TECH

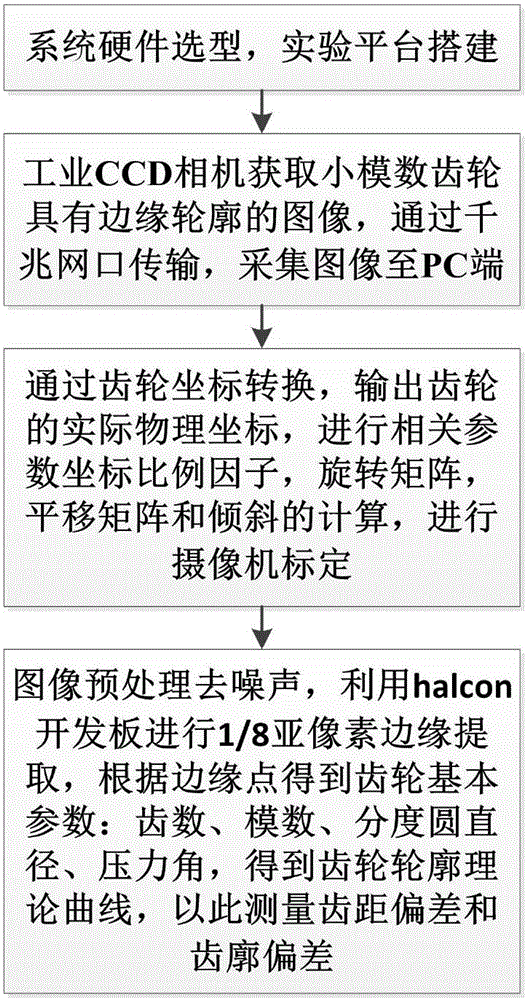

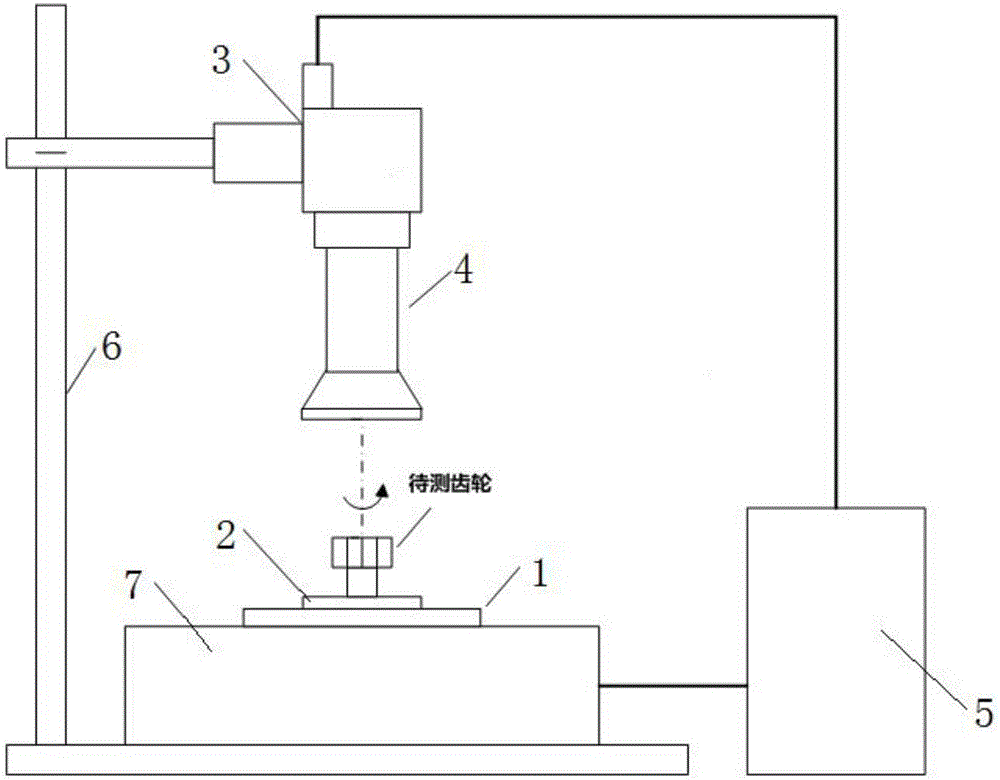

High-precision small modulus gear vision measurement method

A high-precision small modulus gear vision measurement method is disclosed. The method is characterized by after a CCD camera is calibrated, carrying out small modulus gear coordinate conversion, outputting an actual physical coordinate of a small modulus gear and calculating a correlation parameter coordinate scale factor, a rotation matrix and a translation matrix; reflecting a space position relation between a gear to be measured and a measurement system in the measurement system; carrying out image processing, wherein a processed object is a small modulus gear edge contour image acquired from a CCD camera 3; and carrying out denoising; then using and carrying out 1 / 8 sub-pixel edge extraction, extracting an edge point coordinate, carrying out center fitting and acquiring a center coordinate of the image; according to an edge point, acquiring a basic gear parameter, wherein the basic parameter is a tooth number, a mode number, a reference circle diameter and a pressure angle; fitting a standard gear contour curve; and comparing an actually-acquired edge contour curve with a theoretical contour curve so as to acquire a pitch deviation and a tooth profile deviation. The basic gear parameter and quality can be comprehensively analyzed and evaluated.

Owner:BEIJING UNIV OF TECH

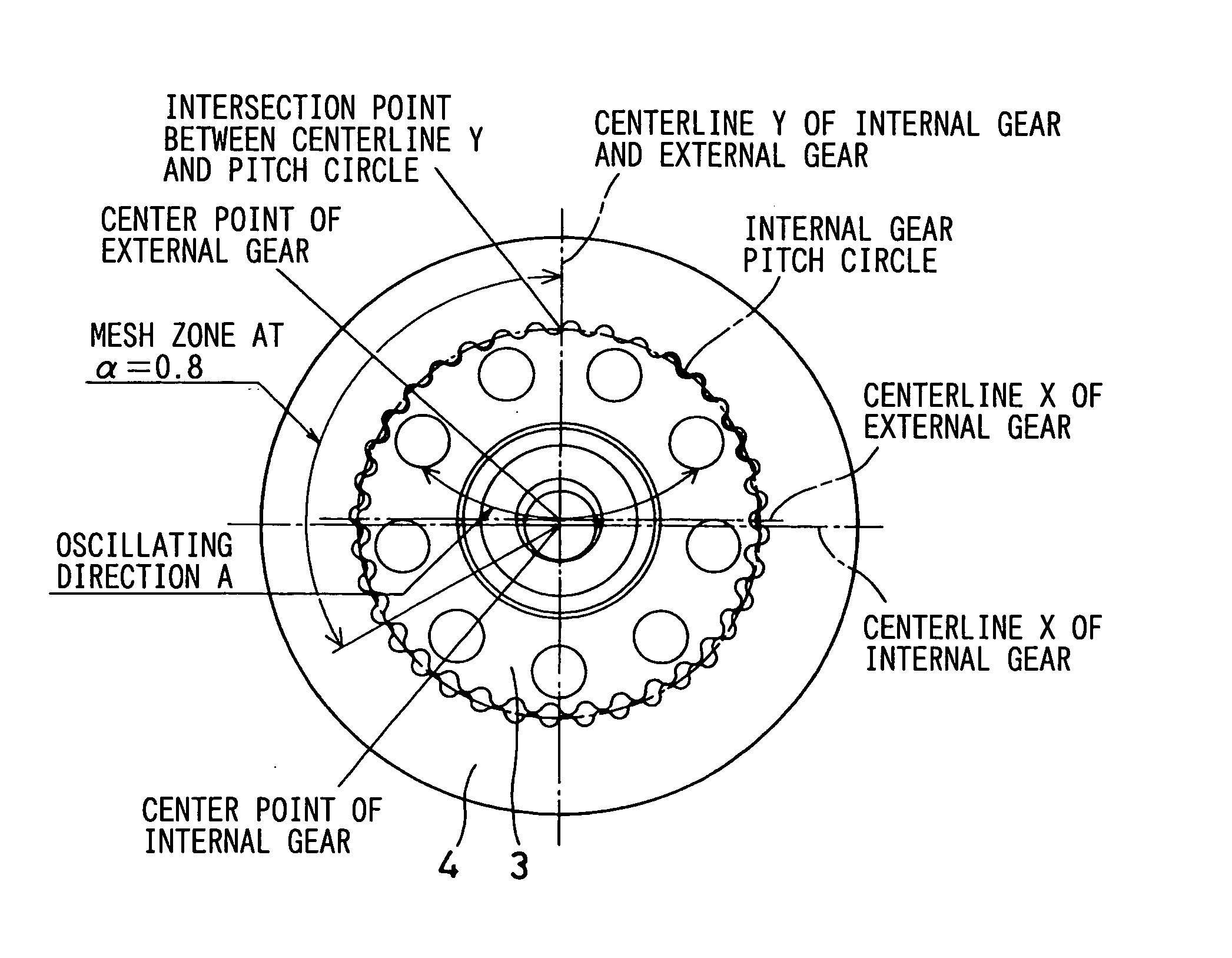

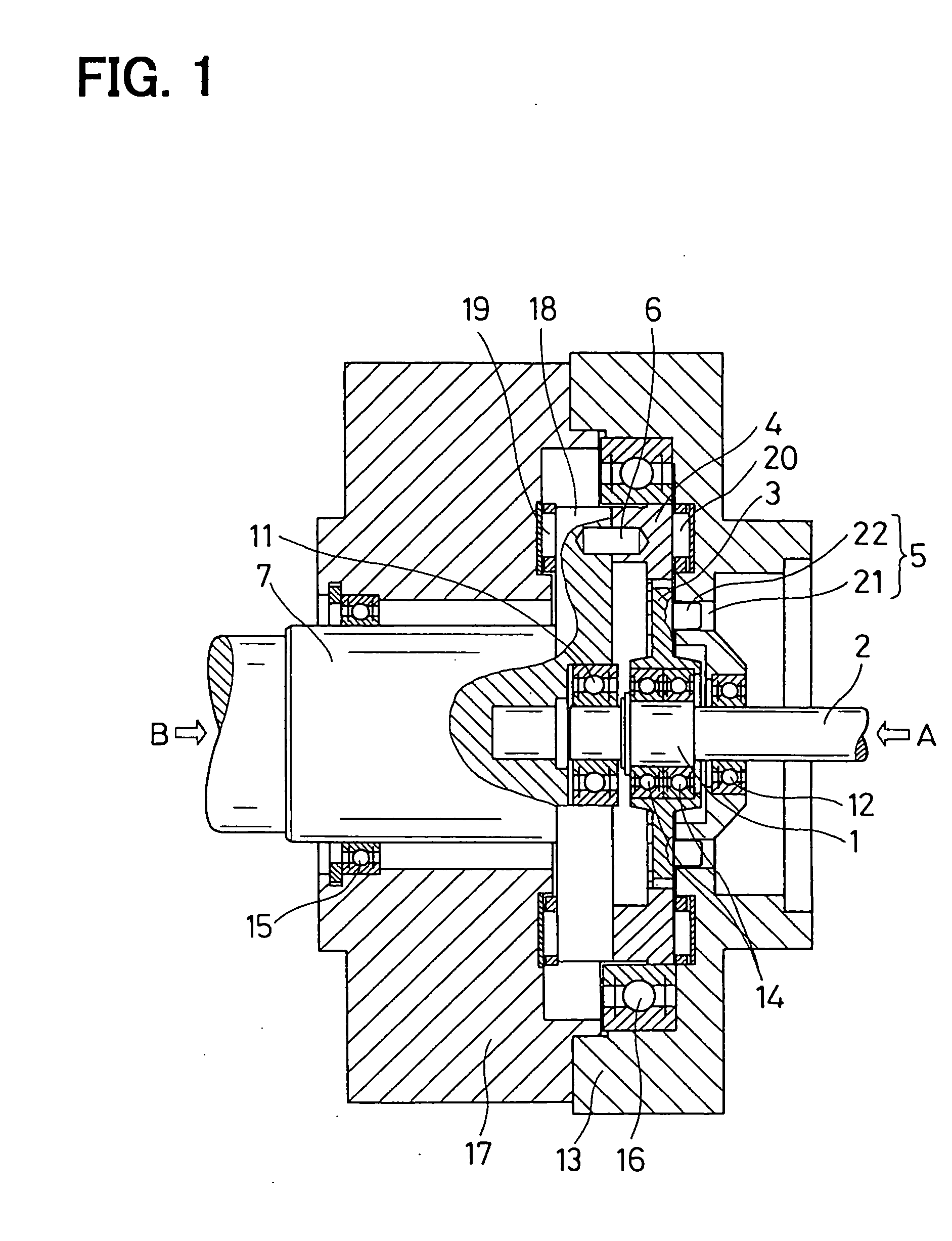

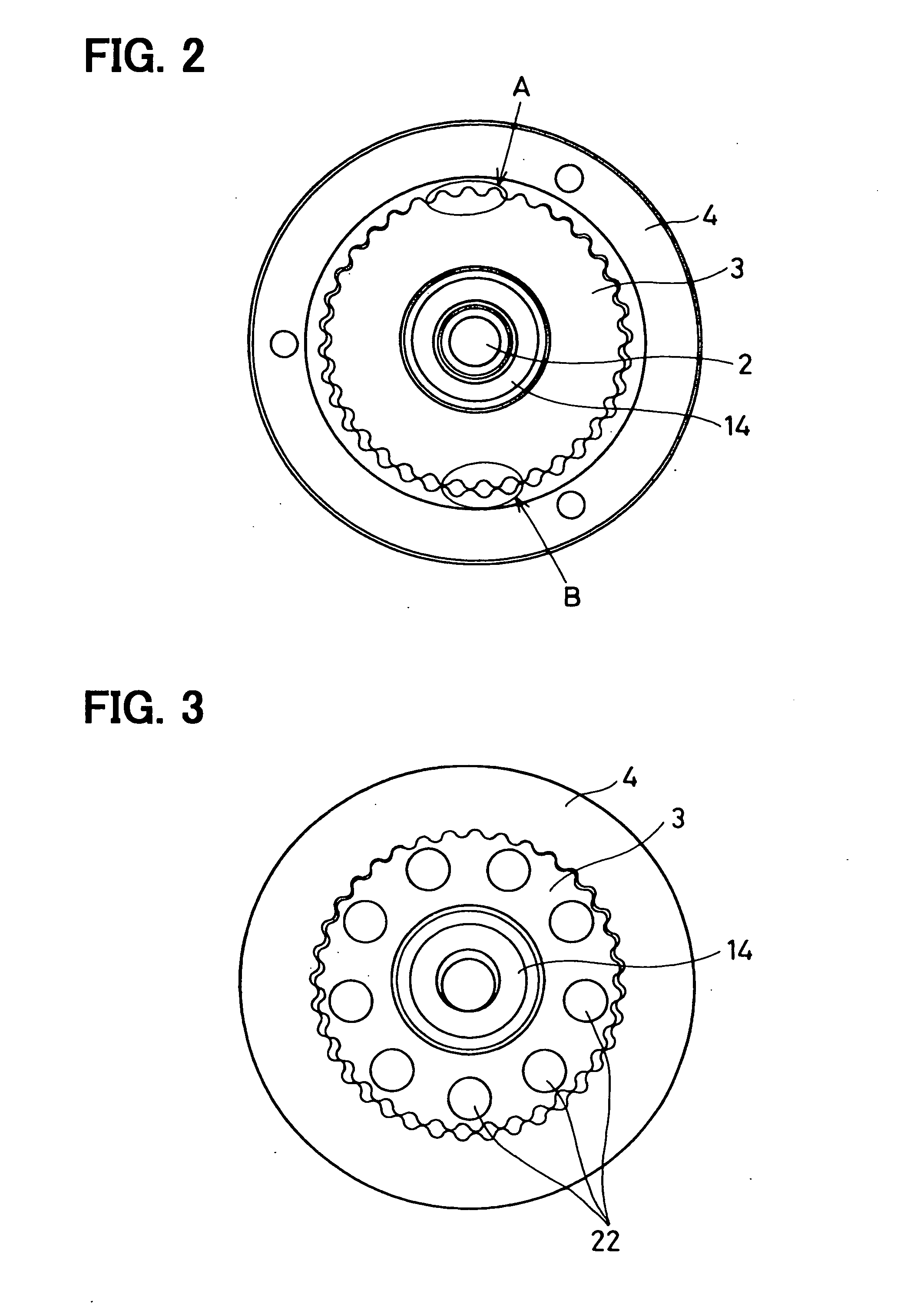

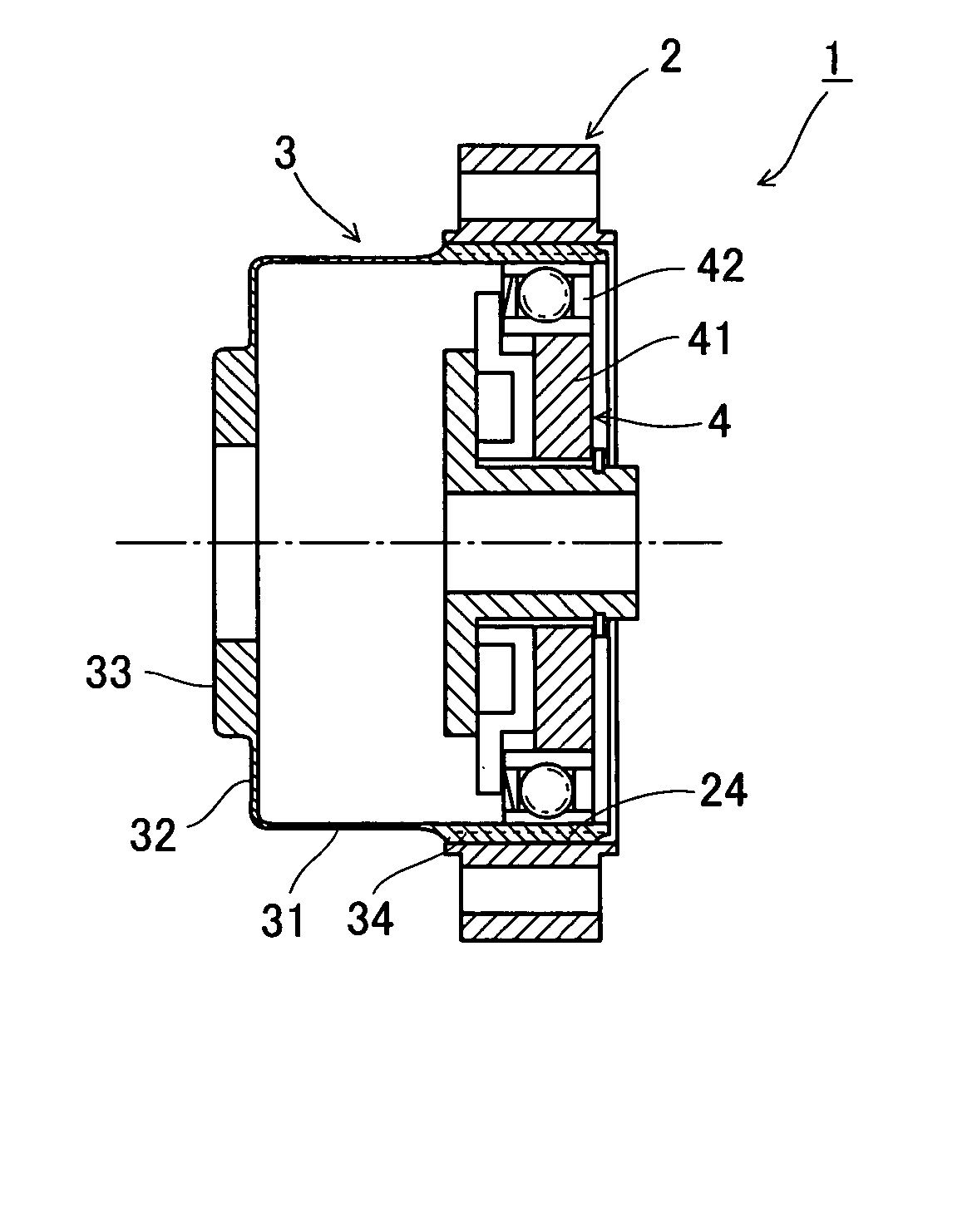

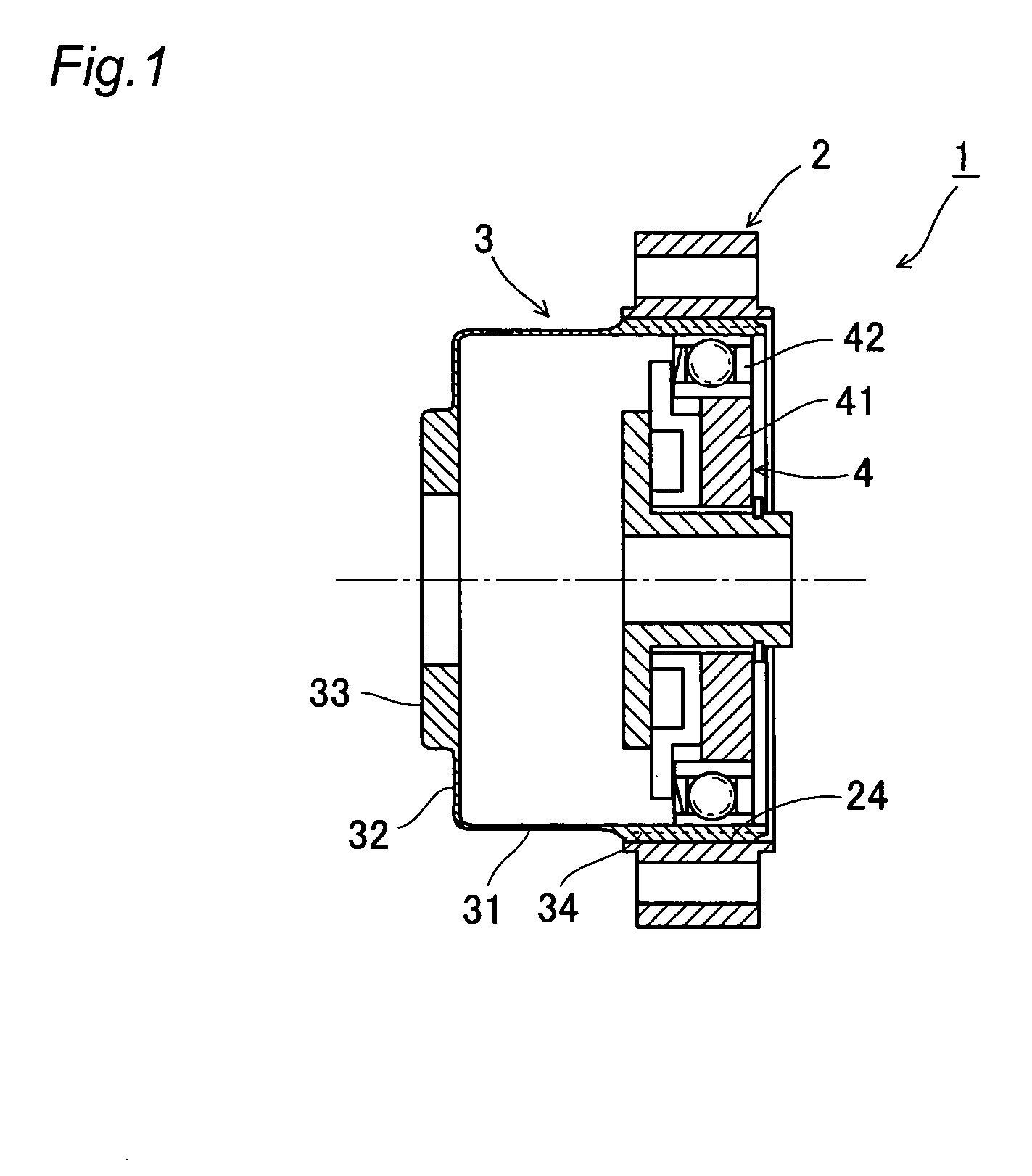

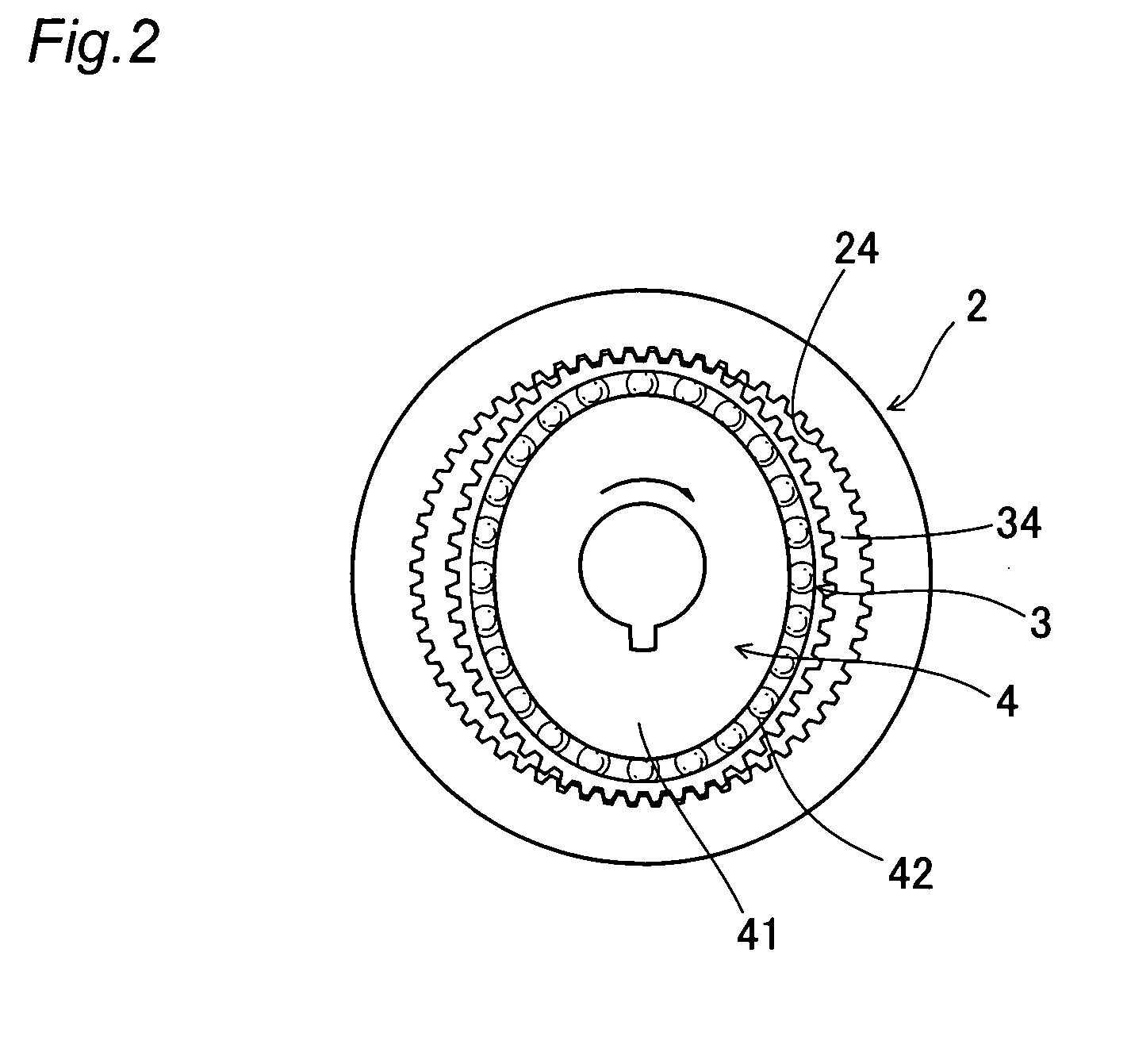

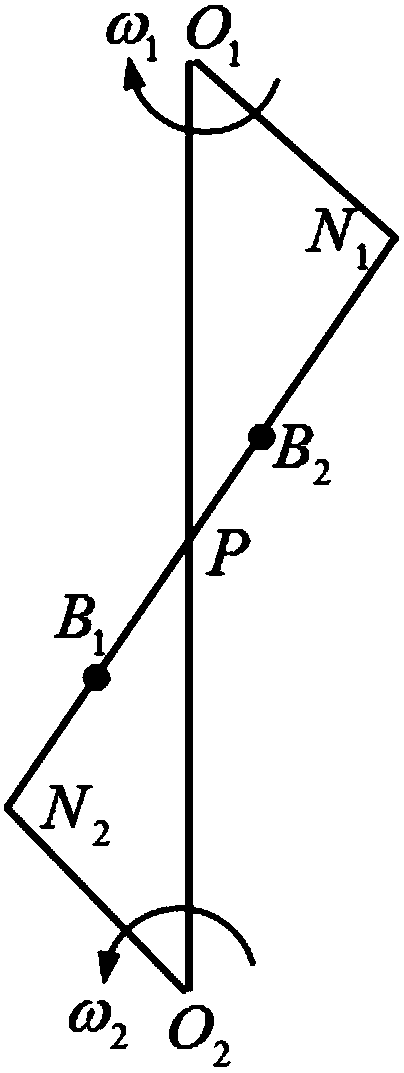

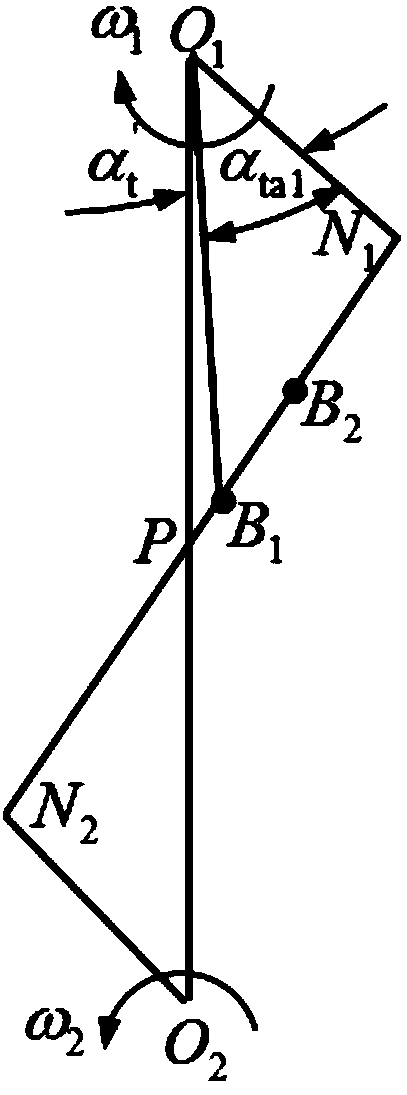

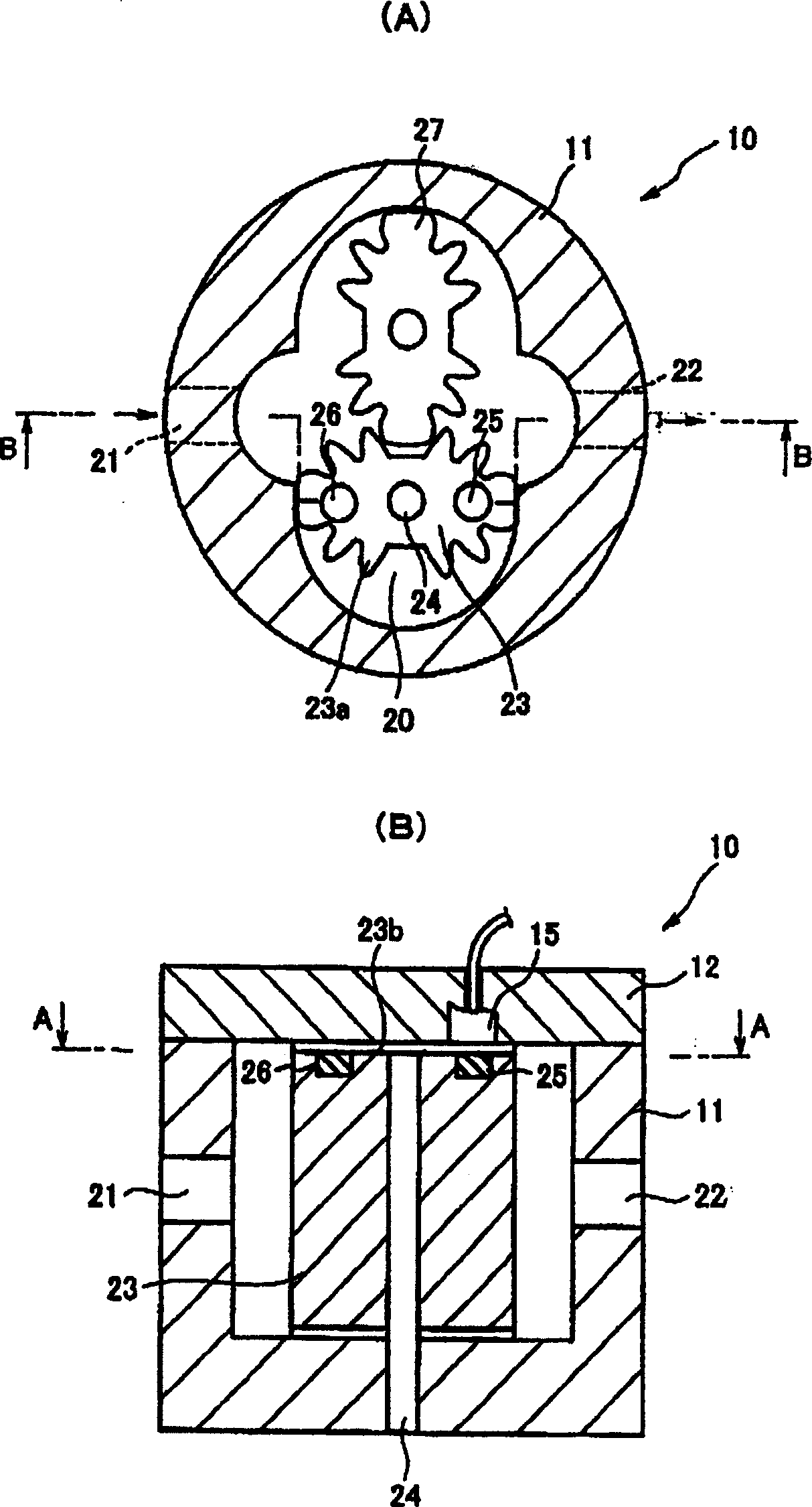

Internal planetary gear mechanism

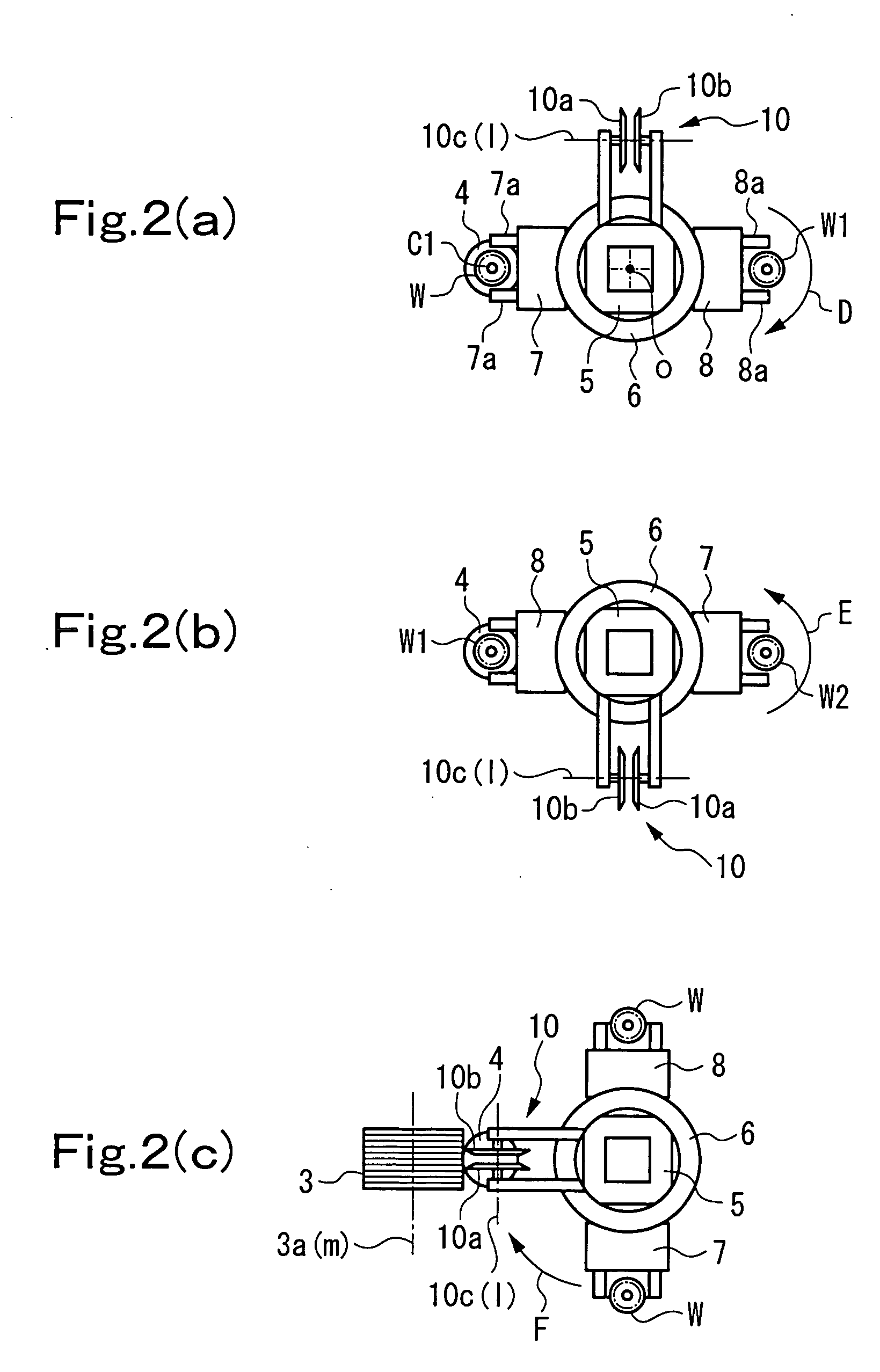

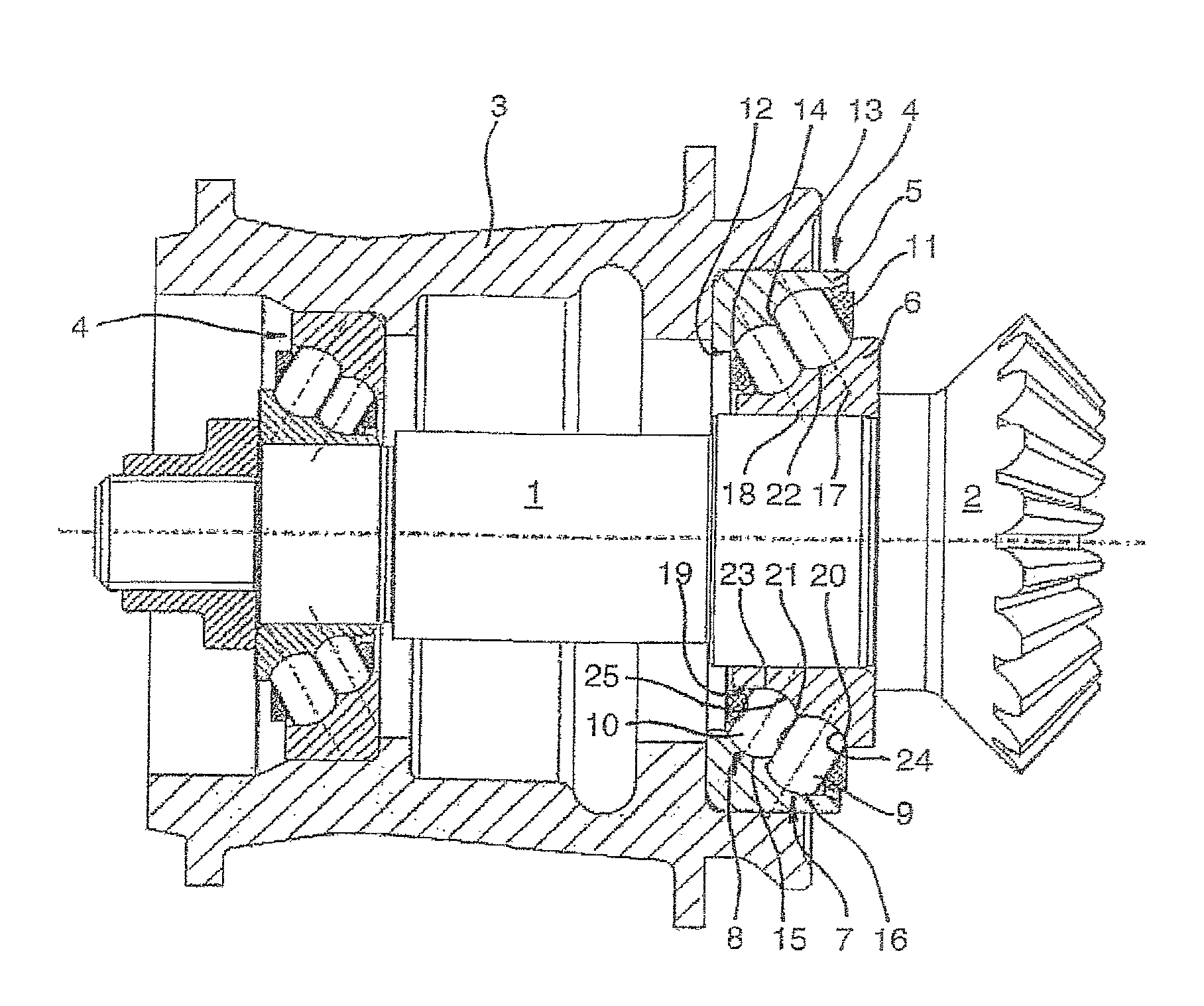

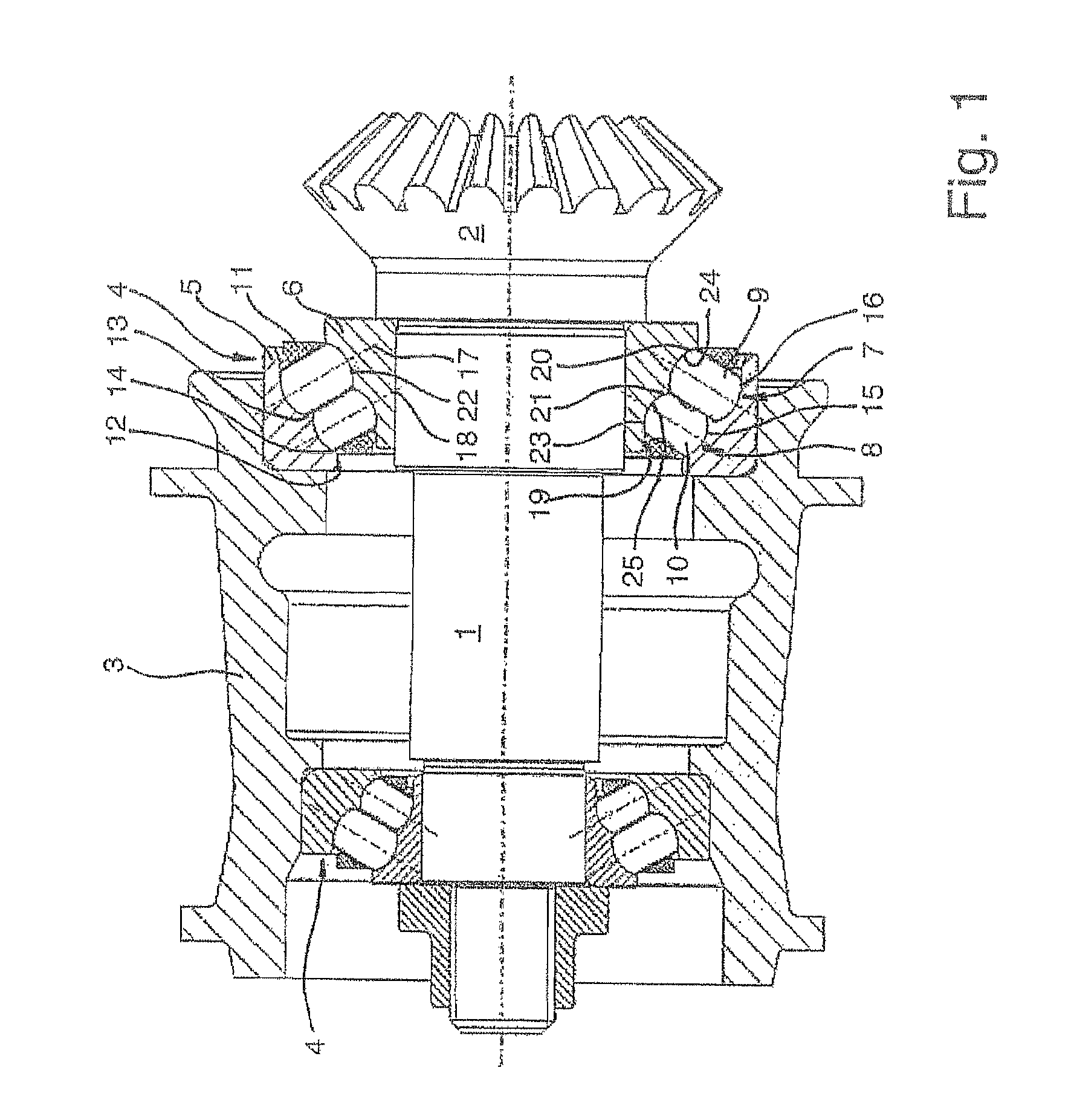

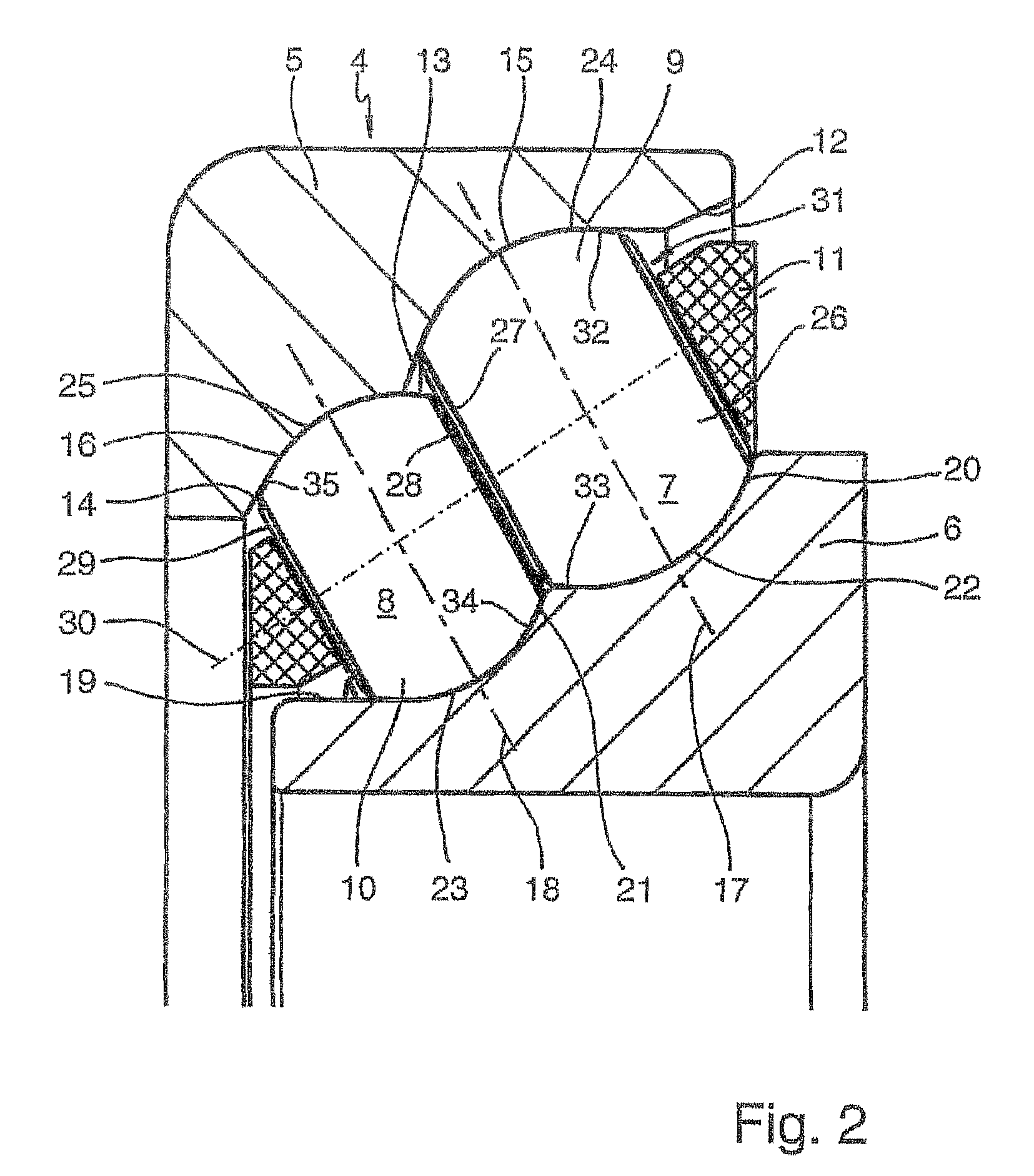

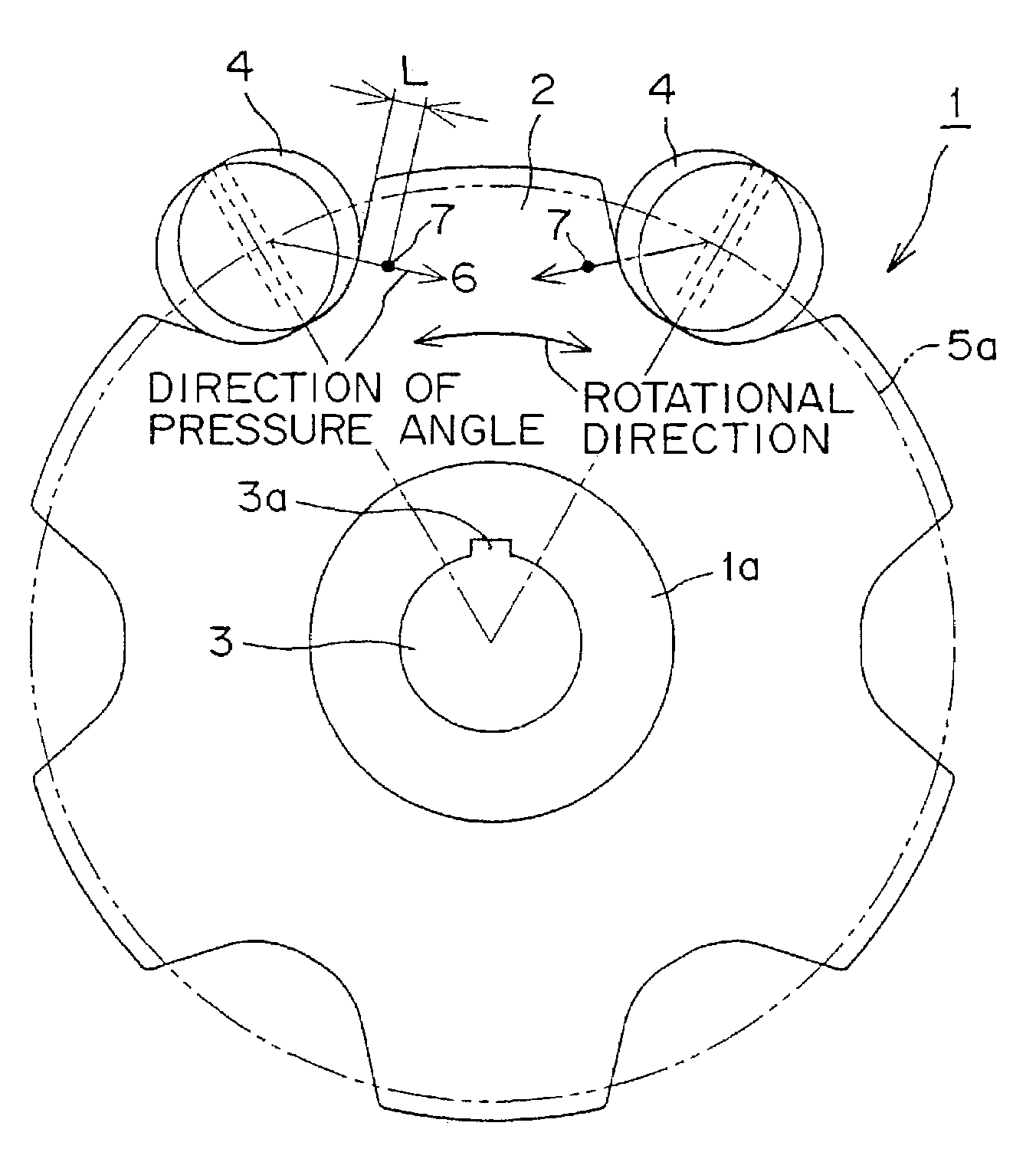

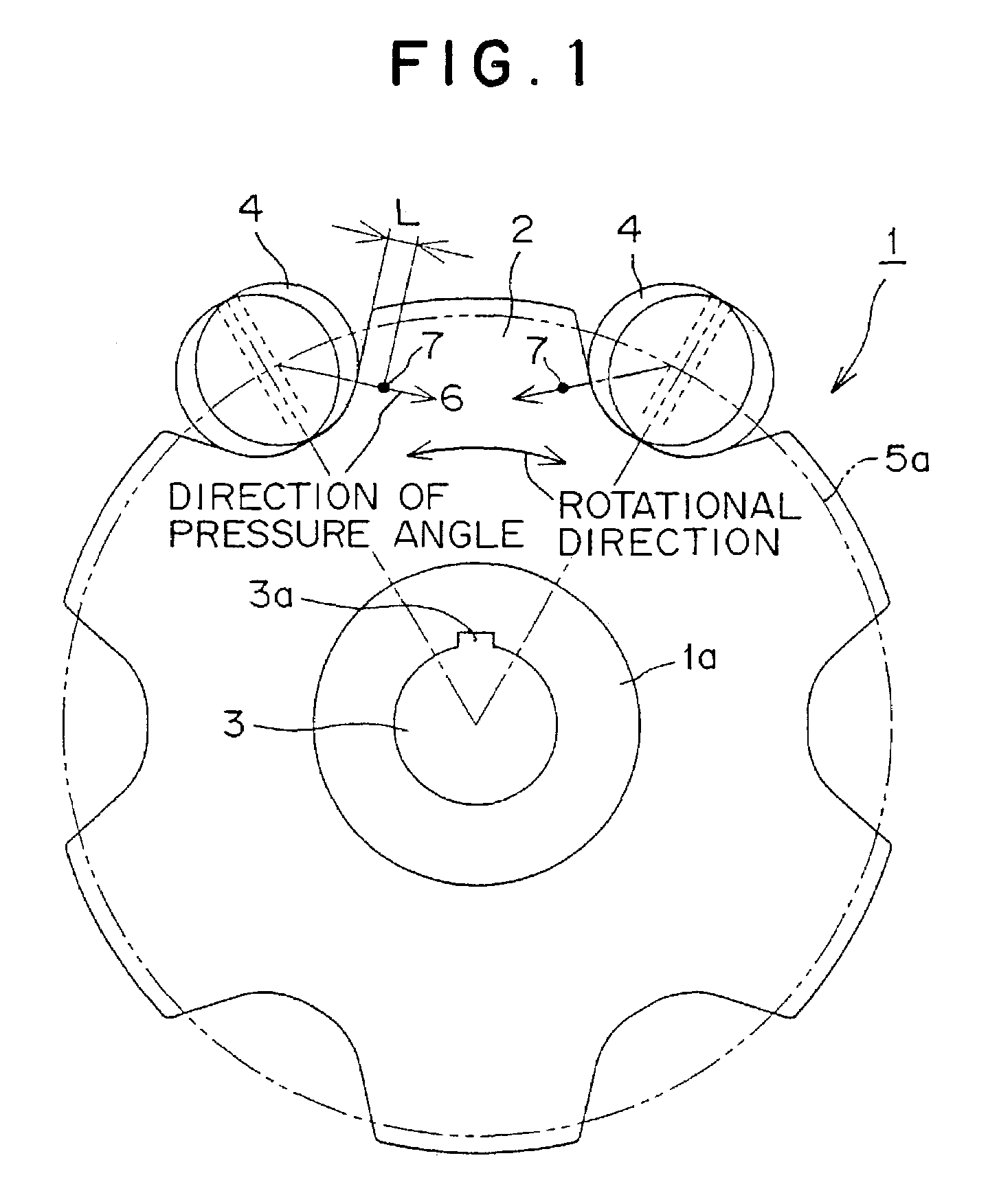

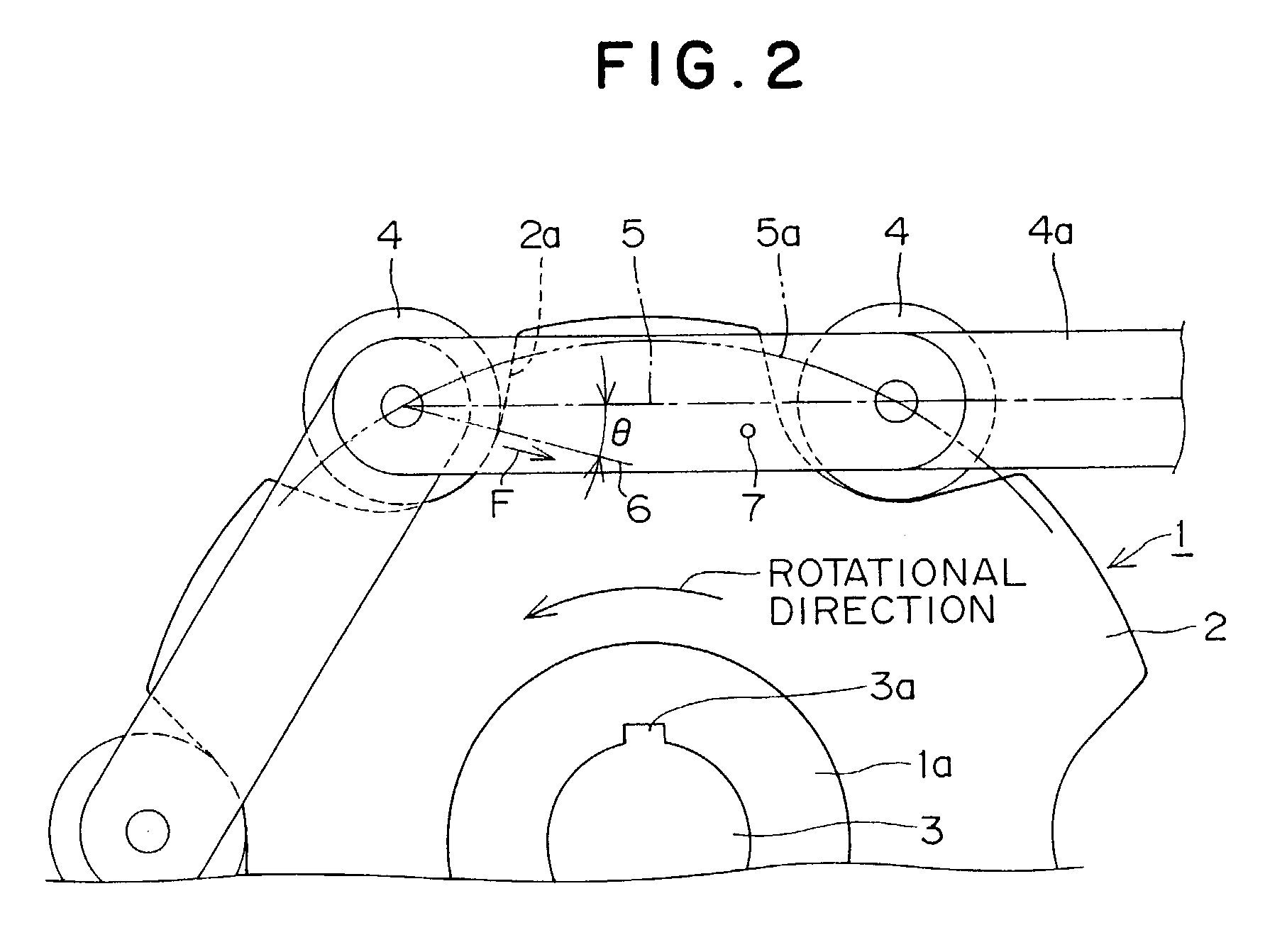

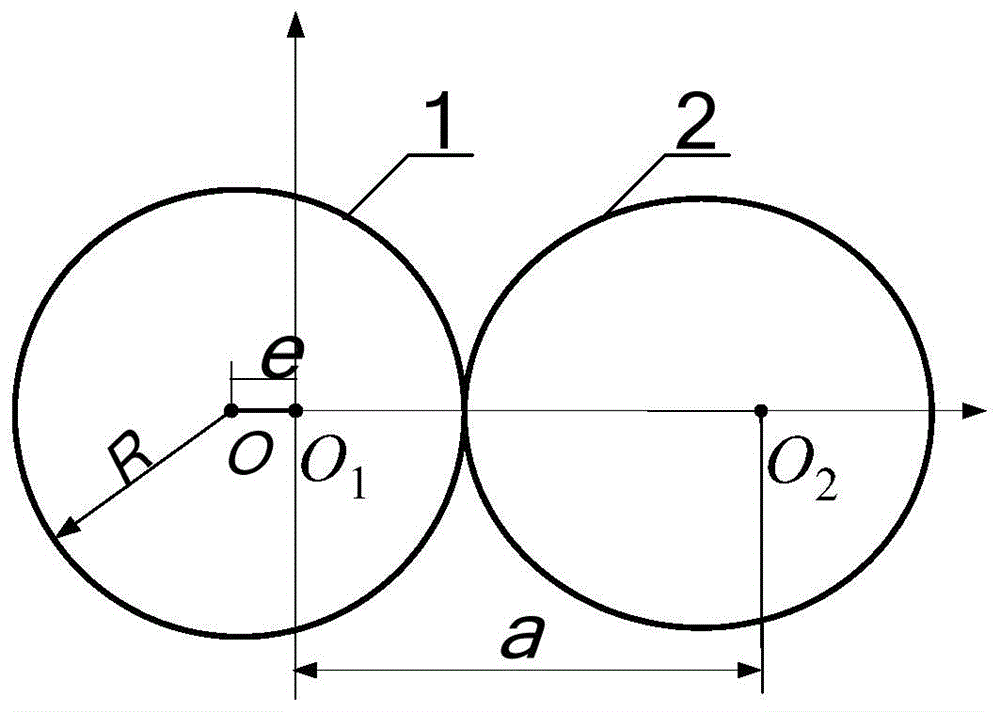

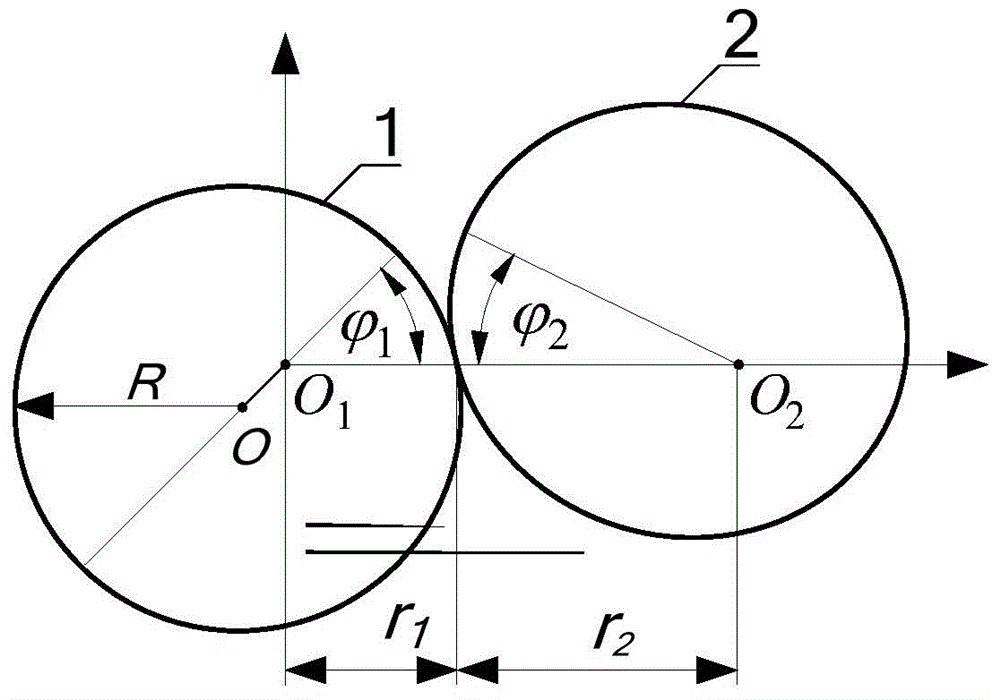

ActiveUS20050059524A1Improve mechanical efficiencyReduce loadToothed gearingsPortable liftingGear wheelPressure angle

An internal planetary gear mechanism reduces a load applied to tooth surfaces of an external gear and an internal gear, a sliding portion such as a bearing and the like. By setting the amount of eccentricity α of an eccentric part to be larger than a theoretical value, a distance between the center of the external gear and the center of the internal gear is increased to allow the reduction of a loss in the bearing and on the tooth surfaces of the gears, and a mesh zone between the internal gear and the external gear can be reduced to decrease a part at a large pressure angle, thereby reducing a loss generated by a large pressure angle. As a result of reduction in the mesh zone between the external gear and the internal gear, rolling contact of the gears is maintained.

Owner:DENSO CORP +2

Wave gear device

InactiveUS20050066769A1Increasing the thicknessPrevent degradationPortable liftingToothed gearingsGear wheelEngineering

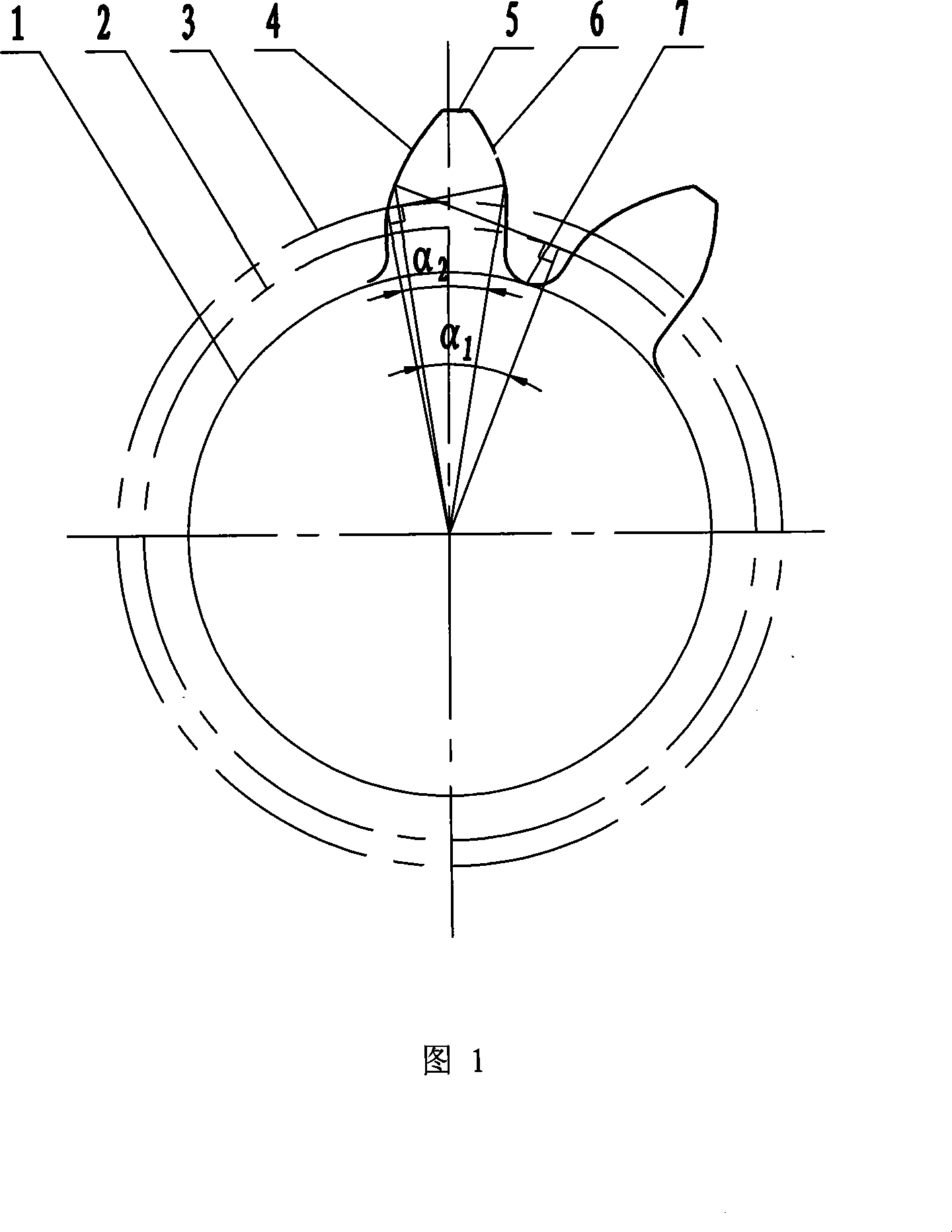

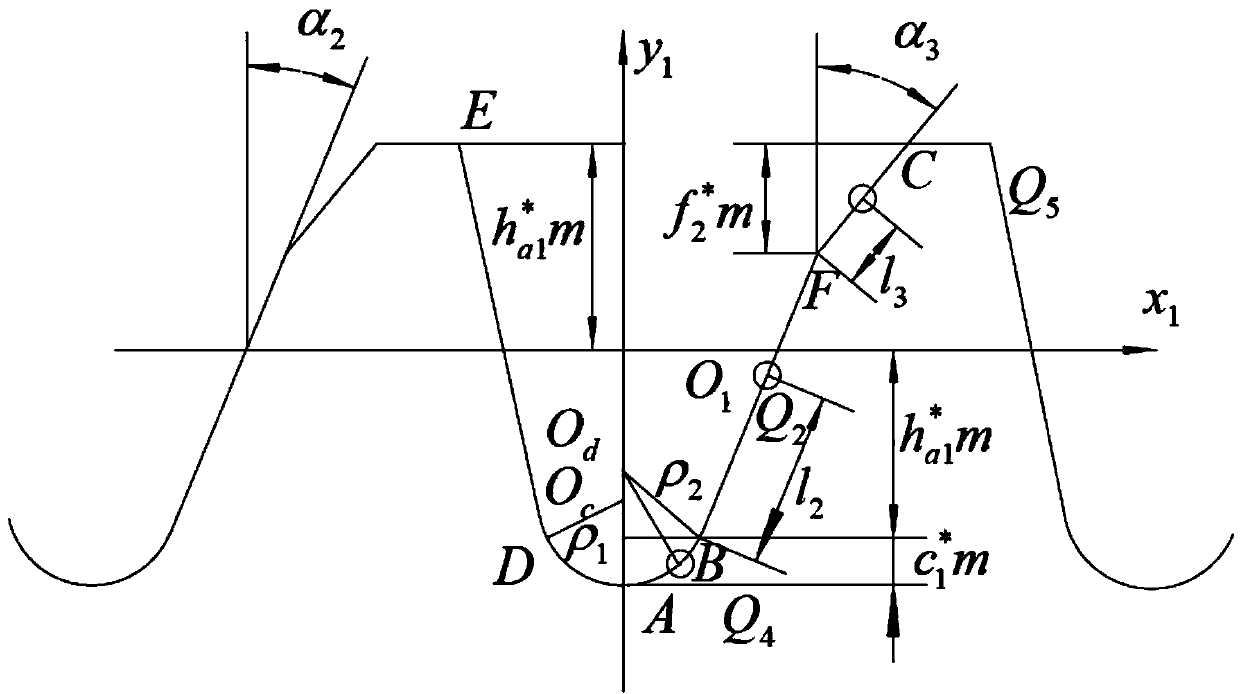

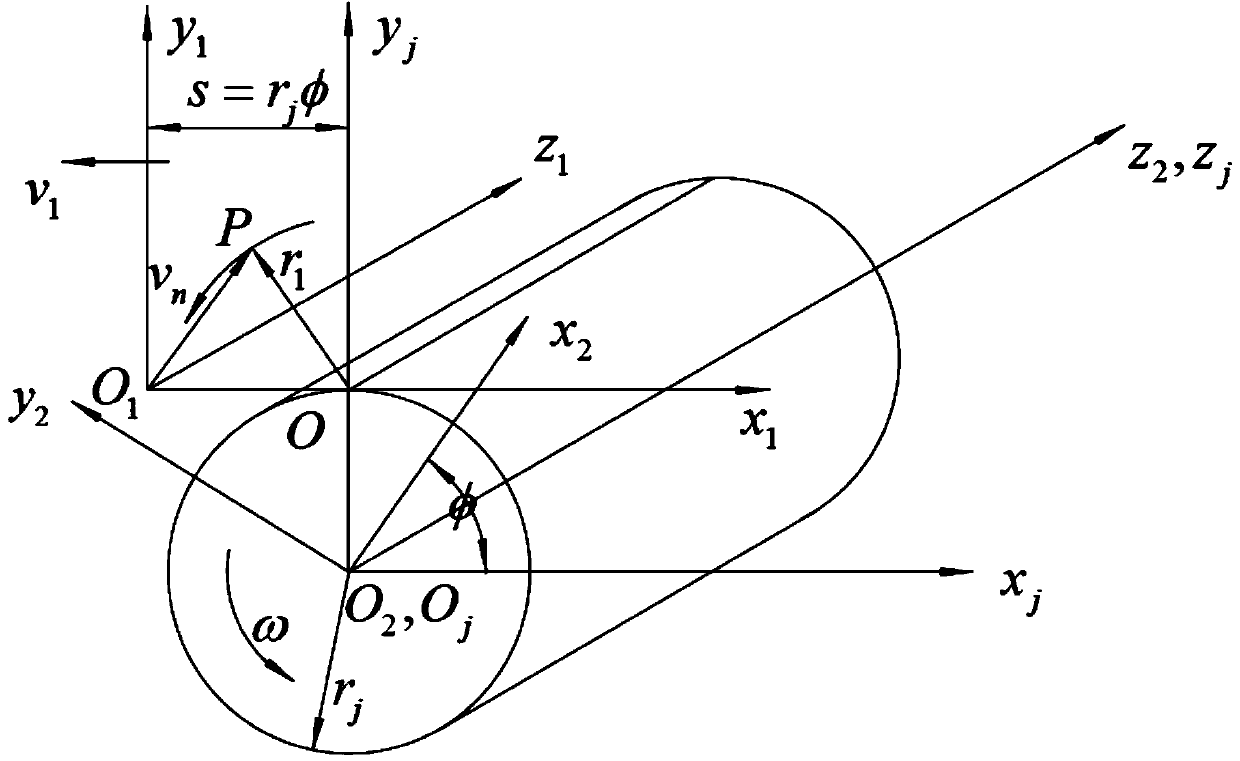

A wave gear device has a rigid internal gear, a flexible external gear, and a wave generator. The tooth profiles of both gears are initially defined by a basic rack tooth profile shape. The lower parts of the dedendum portions of these tooth profiles are modified by curves C2 and C3 having pressure angles α2 and α3 that are less than the standard pressure angle α1 of the basic rack tooth profile shape C1. An increase in thickness of the tooth bottom side can be minimized even if the tooth depth is increased and the tooth thickness / tooth space ratio changed to increase the tooth thickness. Hence, the ratcheting torque of a wave gear device having a high reduction gear ratio can be increased without reducing the service life and strength of a pinion cutter for the rigid internal gear, or the fatigue strength of the flexible external gear.

Owner:HARMONIC DRIVE SYST IND CO LTD

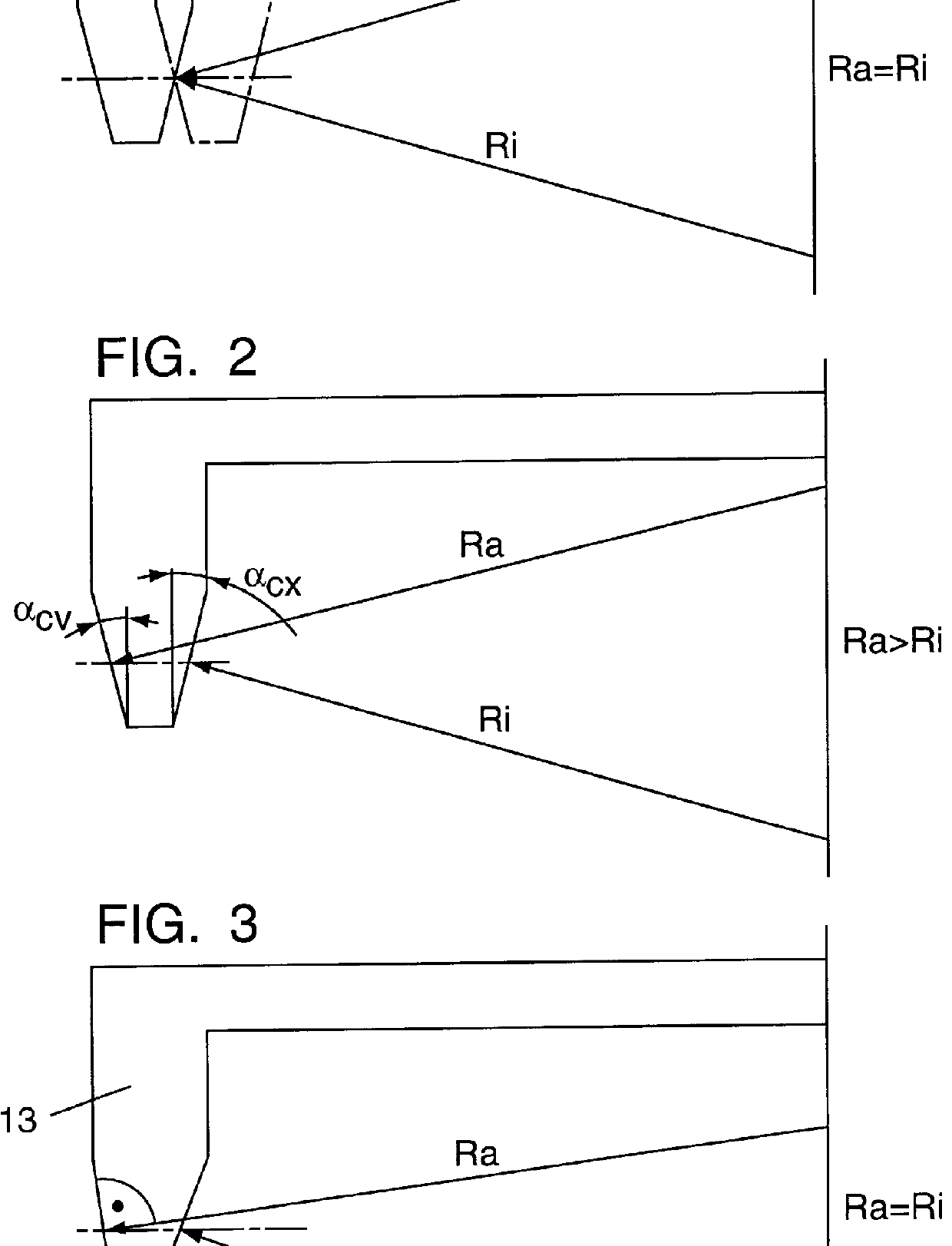

Method of grinding the teeth of spiral-toothed bevel gear wheels

PCT No. PCT / EP96 / 02020 Sec. 371 Date Nov. 5, 1997 Sec. 102(e) Date Nov. 5, 1997 PCT Filed May 10, 1997 PCT Pub. No. WO96 / 35541 PCT Pub. Date Nov. 14, 1996Disclosed is a method of grinding bevel gear teeth in an intermittent indexing process using a single grinding wheel provided with different bevel angles ( alpha ) to produce the desired grinding wheel radii (R): one flank is machined during grinding in downward generation as far as a first turning point, another flank is produced in upward generation as far as a second turning point, and machine settings are so adjusted in the turning points as to ensure a correct pressure angle and correct flank topography during the generating process, irrespective of the different bevel angles ( alpha ). The process combines the advantages of the known completing process, by which both flanks can be ground at the same time at the cost of imposing a particular wheel body geometry with conical teeth, with those of the known two-track process for grinding both flanks with a double grinding head, by which various additional correction factors can be introduced to optimize the flank shape for convex and concave flanks.

Owner:KLINGELNBERG AG

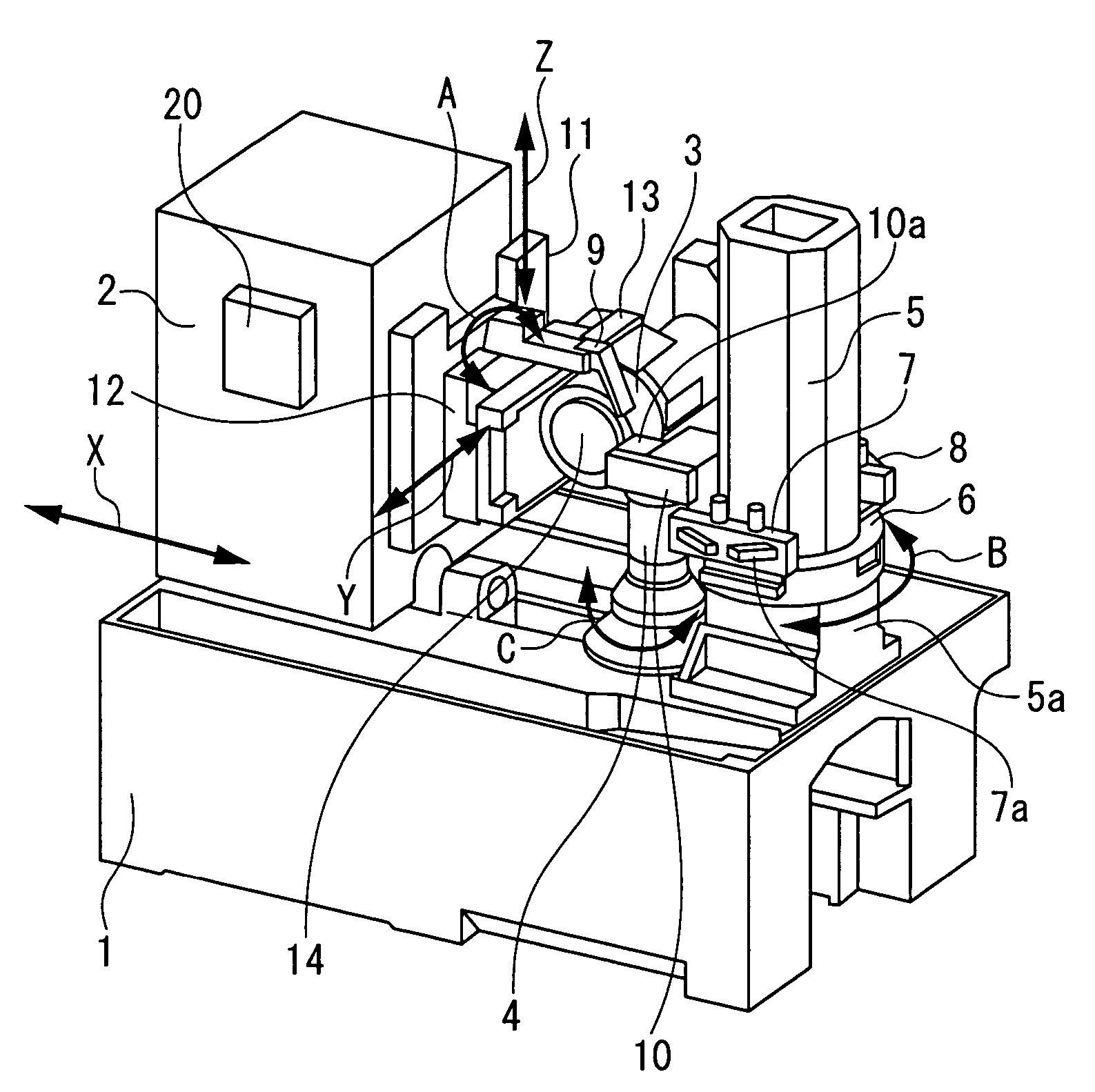

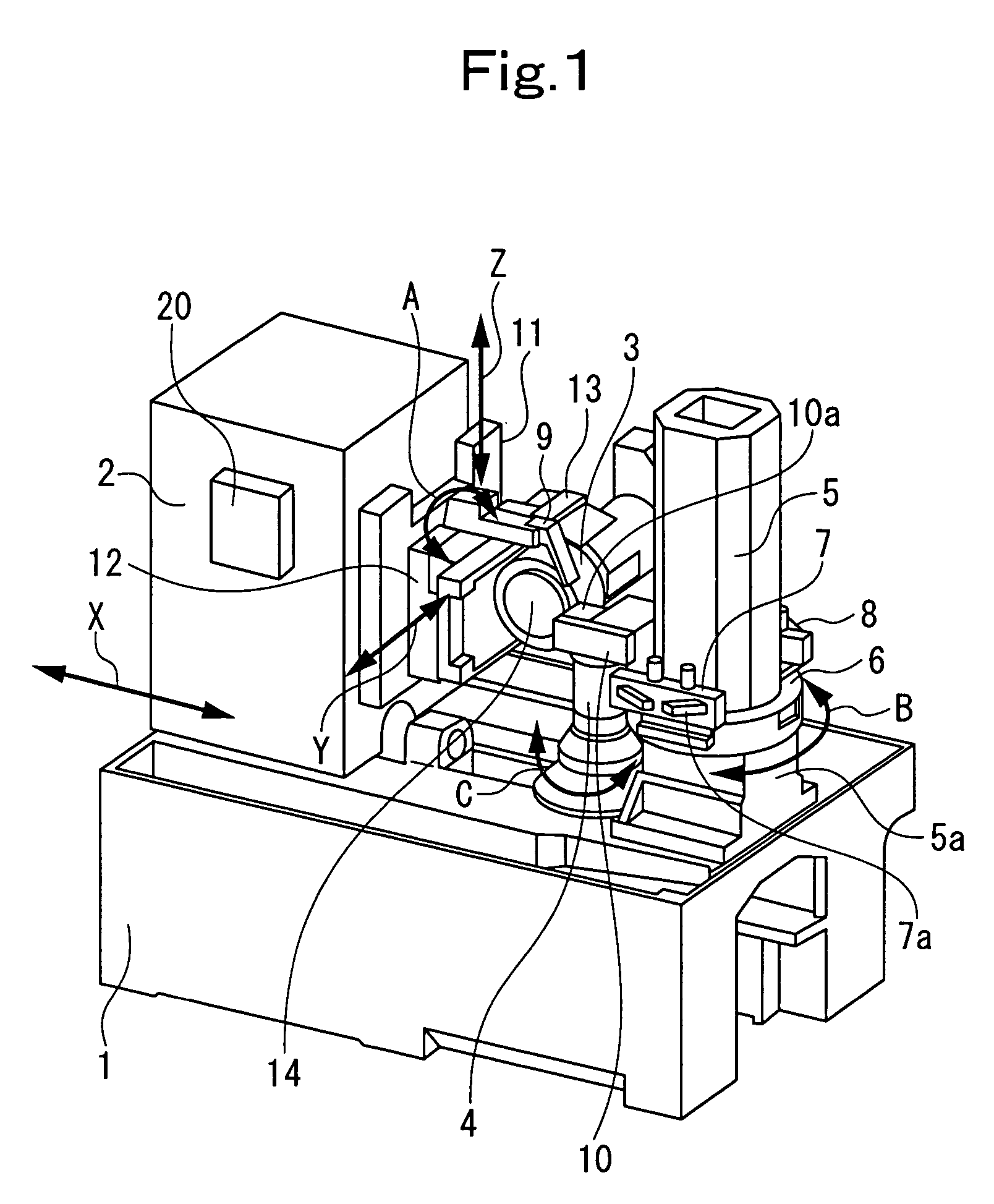

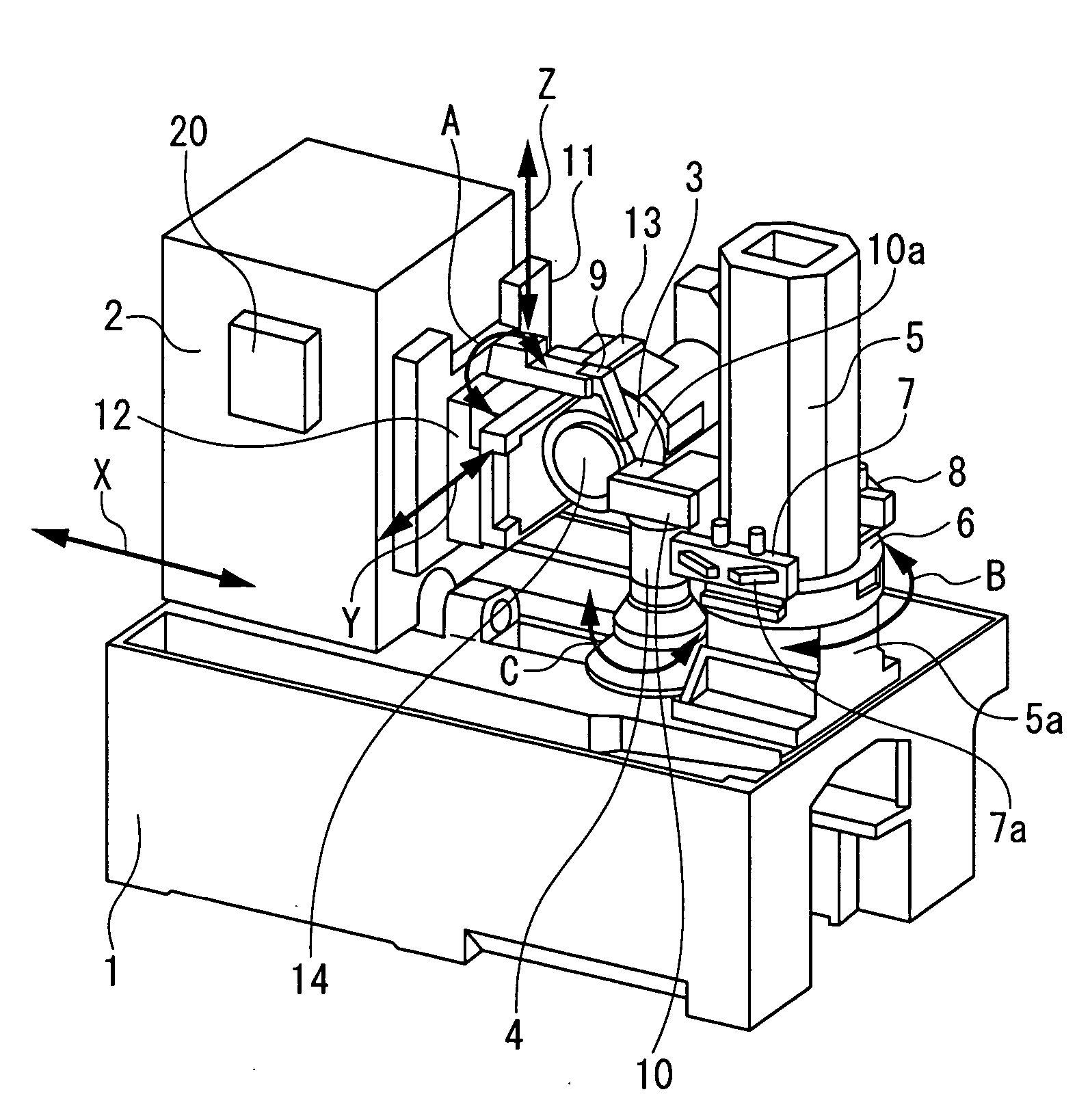

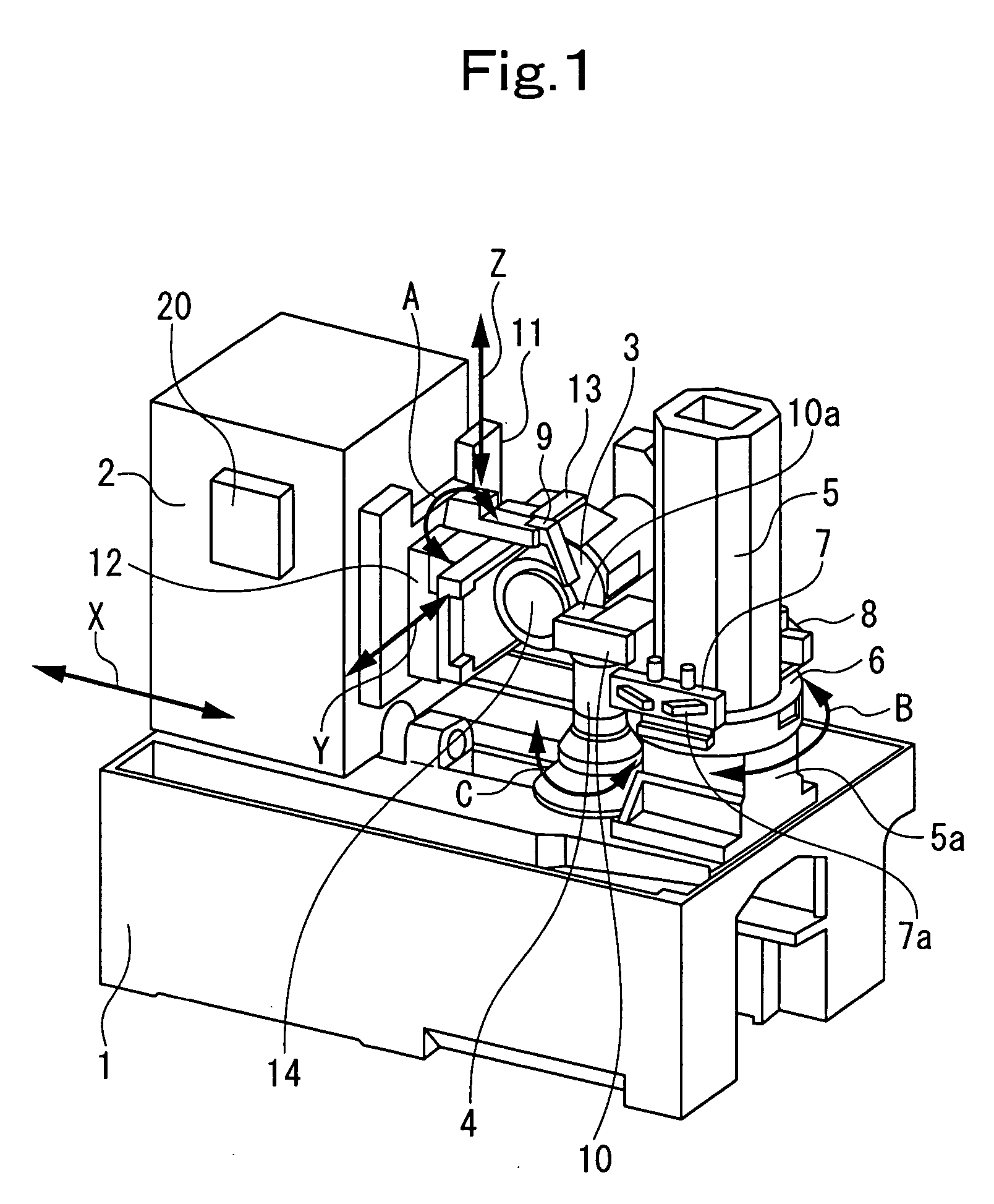

Gear grinding machine

A gear grinding machine comprises: a moving mechanism rotatably mounted with a threaded grinding wheel, and arranged to move the threaded grinding wheel along directions of X, Z, and Y, and to turn the threaded grinding wheel in a Y-Z plane; an NC device for controlling the position of the threaded grinding wheel; and a rotary dressing device having a dressing tool which contacts the flanks of the threads of the threaded grinding wheel, while rotationally driven, to perform dressing. The NC device numerically controls the moving mechanism so as to adjust the positions in the directions of X and Z, and the turning position in the Y-Z plane of the threaded grinding wheel, while keeping contact of the dressing tool with the flanks of the threads of the threaded grinding wheel, in order to modify the wheel pressure angle of the threaded grinding wheel.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

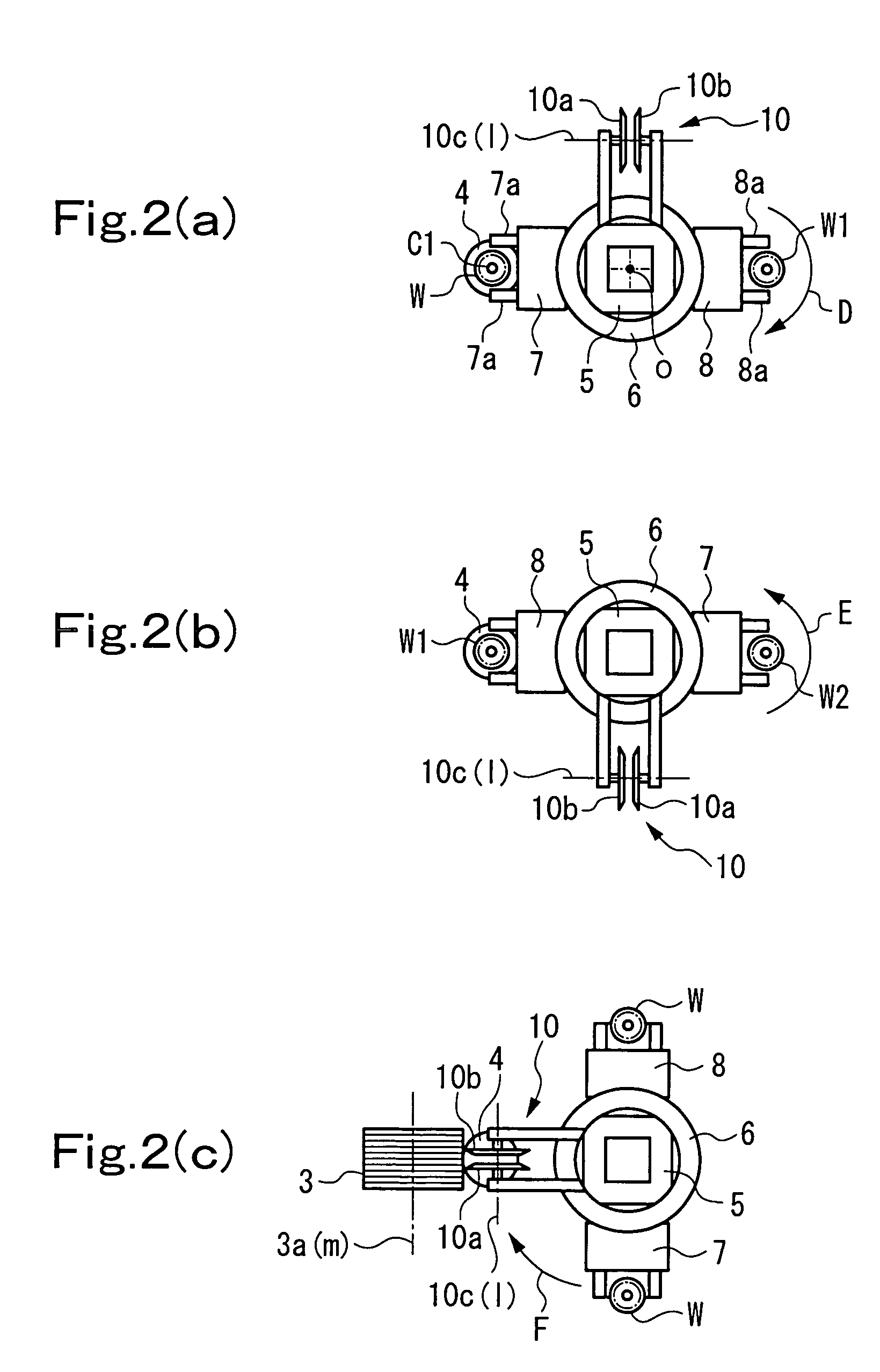

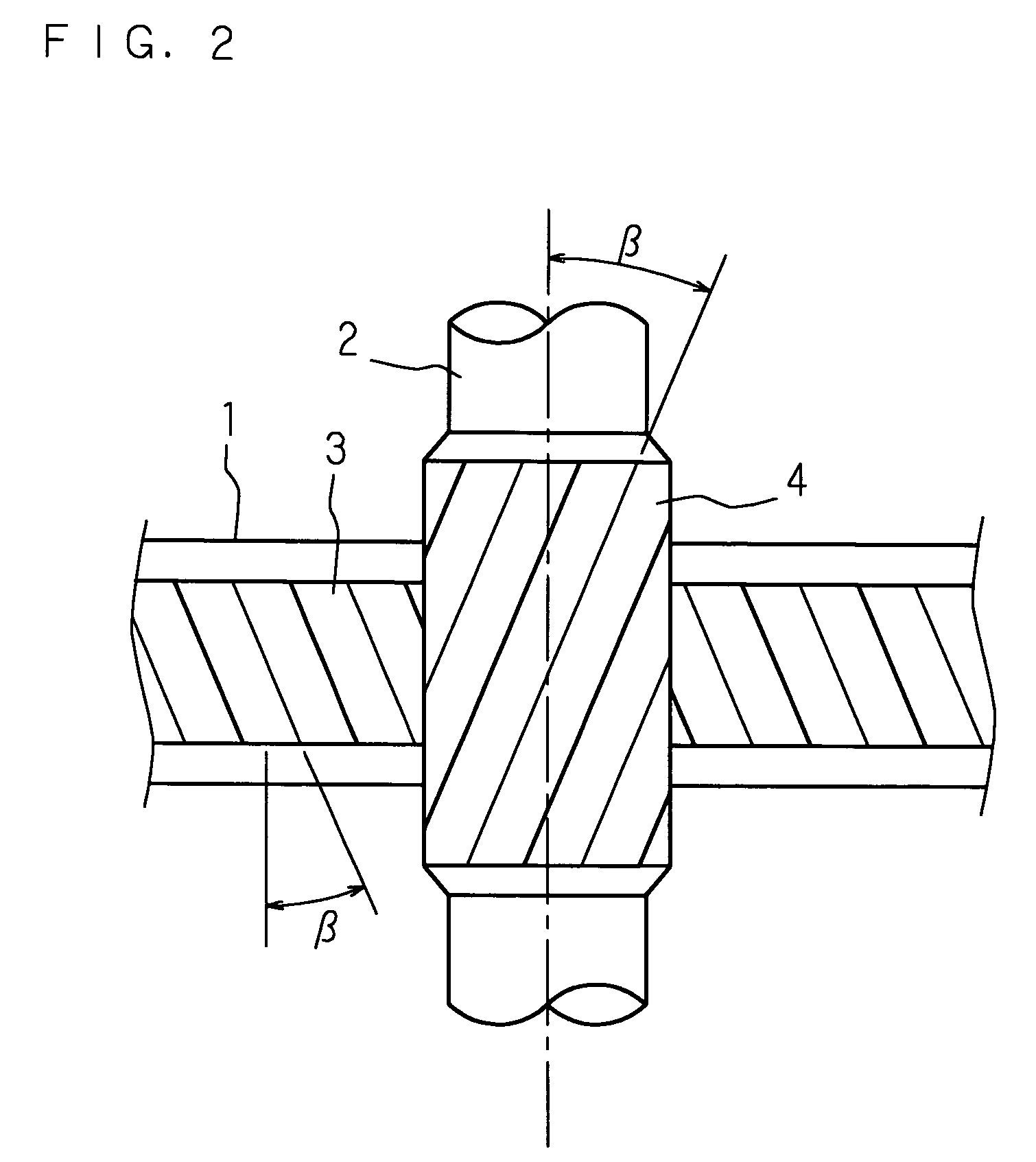

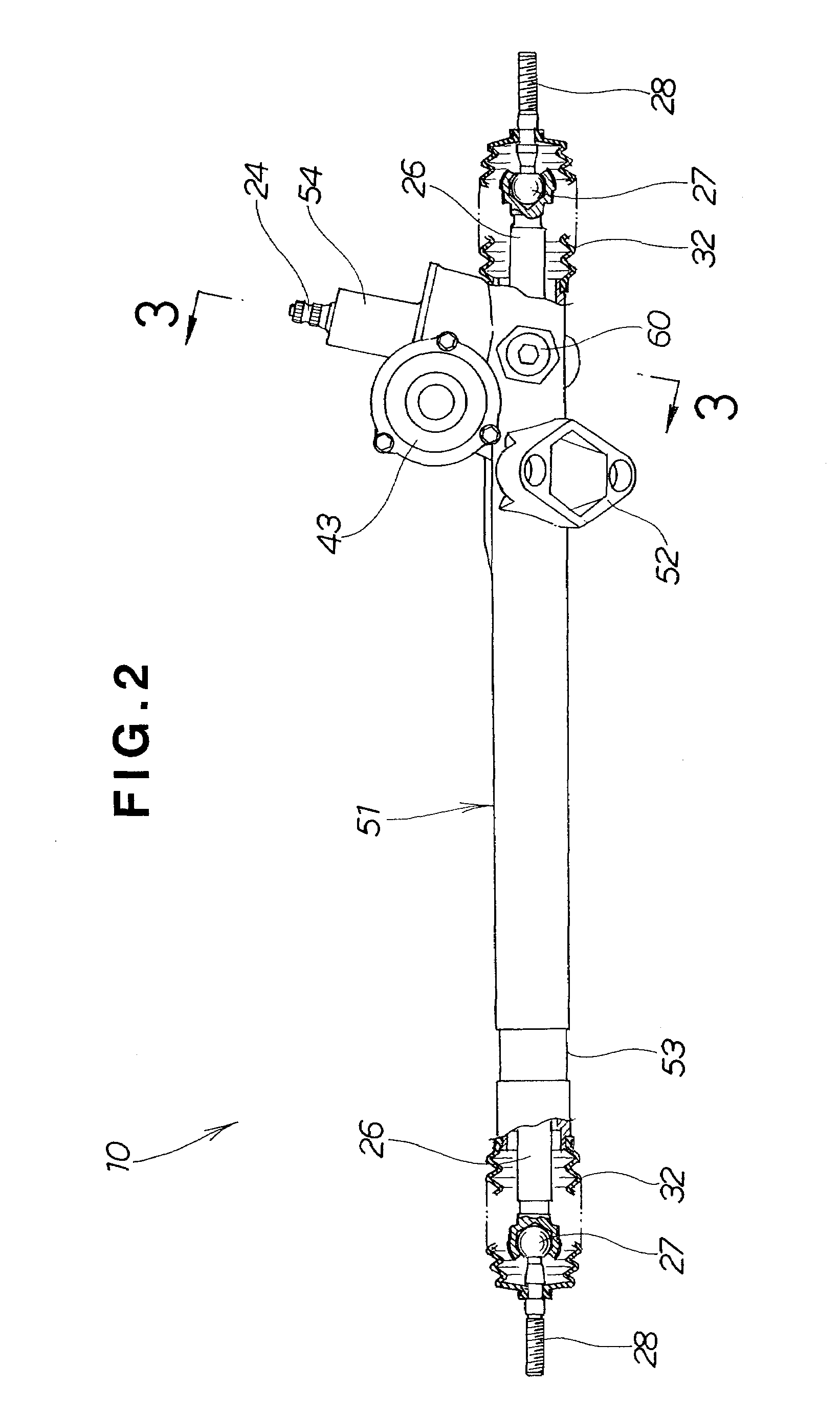

Rack-and-Pinion Steering Apparatus

InactiveUS20080223163A1Reducing meshing frictionStably offering smooth and comfortable steering feeling over a long timePortable liftingToothed gearingsEngineeringHelix angle

A rack-and-pinion steering apparatus comprises pinion teeth formed according to proper tooth specifications in other aspects under a larger pressure angle, thereby stably offering smooth and comfortable steering feeling over a long time. The module (m), number of teeth (z), tooth depth(h) and helix angle (β) of the pinion teeth (4) are set within the following ranges, under a pressure angle (α) set within a range of 24° to 30° and a given stroke ratio.module (m): 1.8 to 2.0number of teeth (z): 7 to 13tooth depth (h): 2 m to 2.5 mhelix angle (β): 350 or smaller

Owner:JTEKT CORP

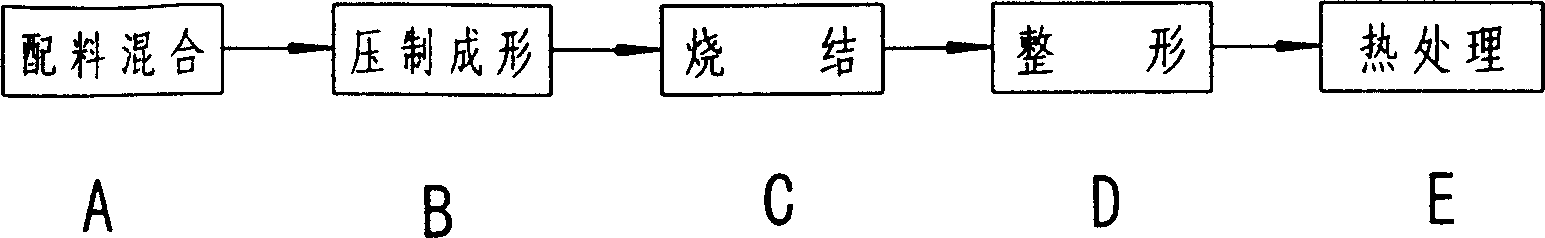

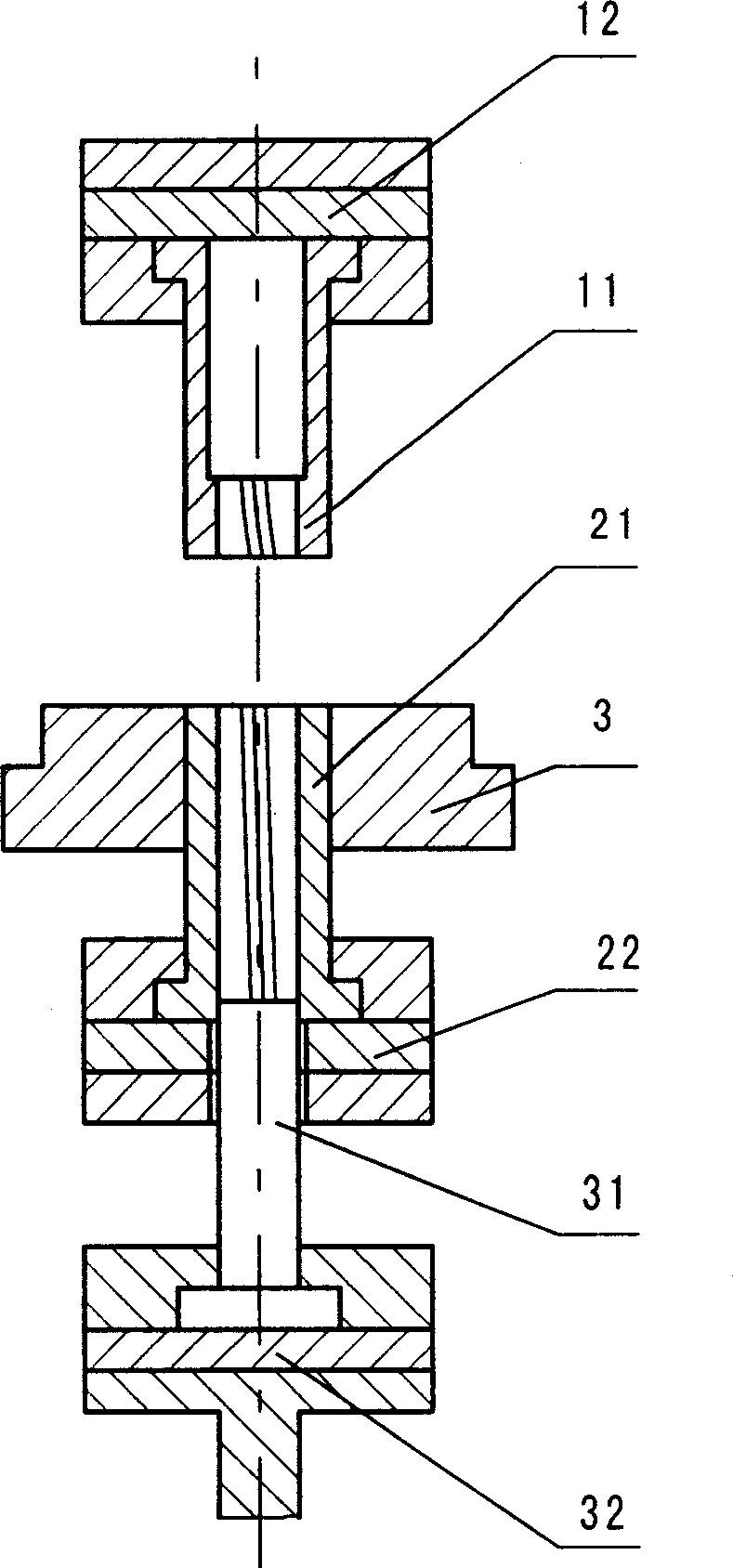

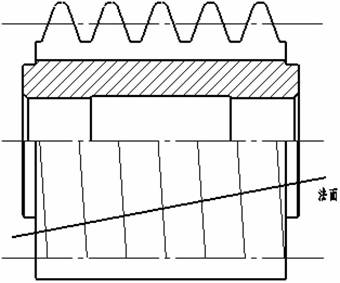

Powder metallurgy internal hilical gear, and its manufacturing method and die using same method

The invention discloses a powder metallurgical internal inclined gear, according to weight percent, containing elements Cu 1-3%, Ni 1-3%, Mo 0.1-1%, and the rest Fe and unavoidable component, where its spiral angle is not greater than 35 degrees, its pressure angle is 5-25 degrees, and its mode is 0.5-2.5 degrees. It mixes the alloy powder of Cu, Ni and Mo to make press molding, firing and shaping so as to make it. Its making mould is top, bottom and middle moulds and core stick. It gears stably and accurately, has small friction coefficient and low mechanical noise. It adopts special designed mould, presses by mould core's rotary ascending or descending along screw, which converts the rotary pressing into axial pressing, can press internal inclined gears of various spiral angles.

Owner:JIANGSU YINGQIU GRP CO LTD

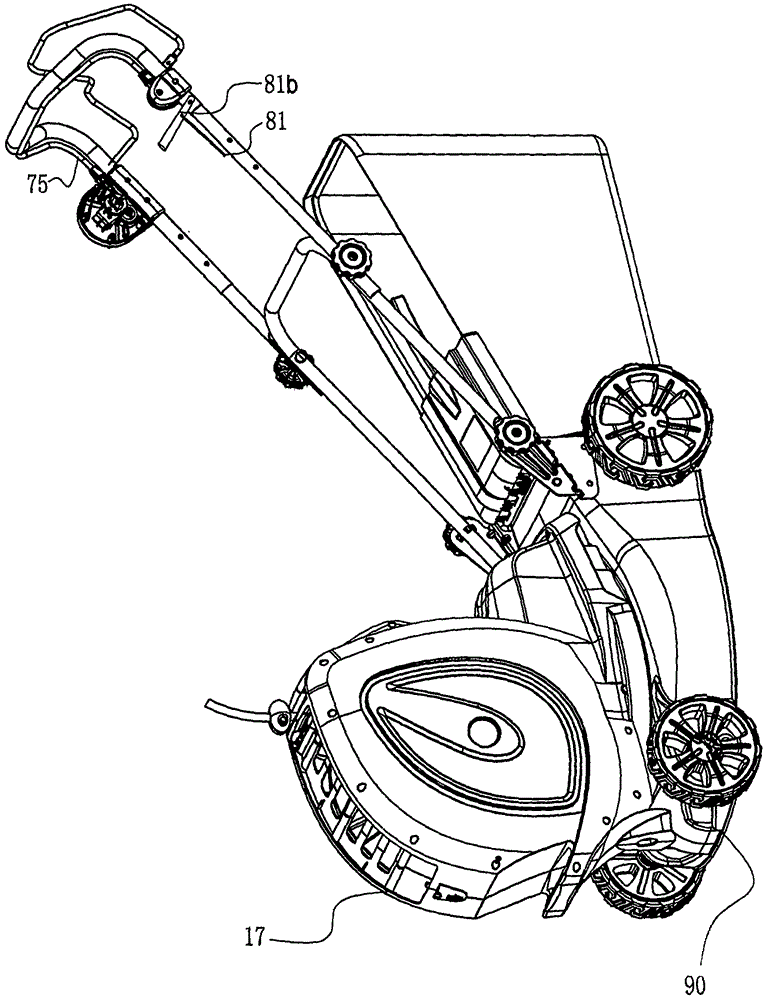

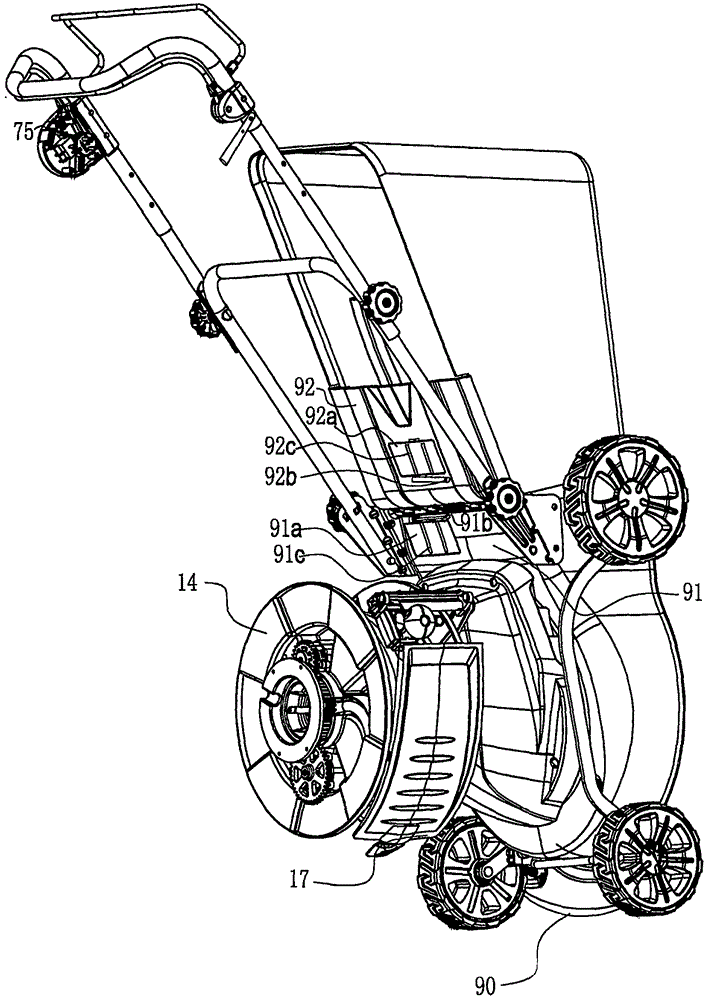

Blocked-grass lower-poking and upper-cutting mechanism for cleaning grass discharging passage of hand mower

InactiveCN106034538ASolve the problem of weed blockingSolving Worldwide Problems of MalfunctionMowersAgricultural undercarriagesLogarithmic spiralMower

The invention relates to a blocked-grass lower-poking and upper-cutting mechanism for cleaning a grass discharging passage of a hand mower. According to the blocked-grass lower-poking and upper-cutting mechanism, a lower poking mechanism is mounted on a rear shaft of the bottom of the mower, and meanwhile, an upper cutting mechanism is mounted at a grass discharging port of the grass discharging passage of the mower; the lower poking mechanism contains grass discharging blades (j1) and direction-changing bevel gears (j2), the rotating direction of a third direction-changing bevel gear is reverse to that of a first direction-changing bevel gear and that of the rear shaft, and thus, the rotating and direction changing of the grass discharging blades (j1), which are connected with the third direction-changing bevel gear and sleeve the rear shaft, are achieved; and the upper cutting mechanism contains upper cutting blades (j3) and a belt-pulley belt (j4), and a rotating shaft of the upper cutting blades (j3) is driven by the belt-pulley belt (j4). The direction-changing bevel gears are Klingen-Berg cycloidal-tooth hypoid gears. At least one of the upper cutting blades (j3) of the upper cutting mechanism of the blocked-grass lower-poking and upper-cutting mechanism for cleaning the grass discharging passage of the hand mower has a bent segment, and a curve of the bent segment is a logarithmic spiral which has the characteristic that pressure angles are equal everywhere.

Owner:NINGBO DAYE GARDEN EQUIP

Gear grinding machine

ActiveUS20060014474A1Adjustable positionGrinding drivesBelt grinding machinesGear grindingEngineering

A gear grinding machine comprises: a moving mechanism rotatably mounted with a threaded grinding wheel, and arranged to move the threaded grinding wheel along directions of X, Z, and Y, and to turn the threaded grinding wheel in a Y-Z plane; an NC device for controlling the position of the threaded grinding wheel; and a rotary dressing device having a dressing tool which contacts the flanks of the threads of the threaded grinding wheel, while rotationally driven, to perform dressing, and wherein the NC device numerically controls the moving mechanism so as to adjust the positions in the directions of X and Z, and the turning position in the Y-Z plane of the threaded grinding wheel, while keeping contact of the dressing tool with the flanks of the threads of the threaded grinding wheel, in order to modify the wheel pressure angle of the threaded grinding wheel.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

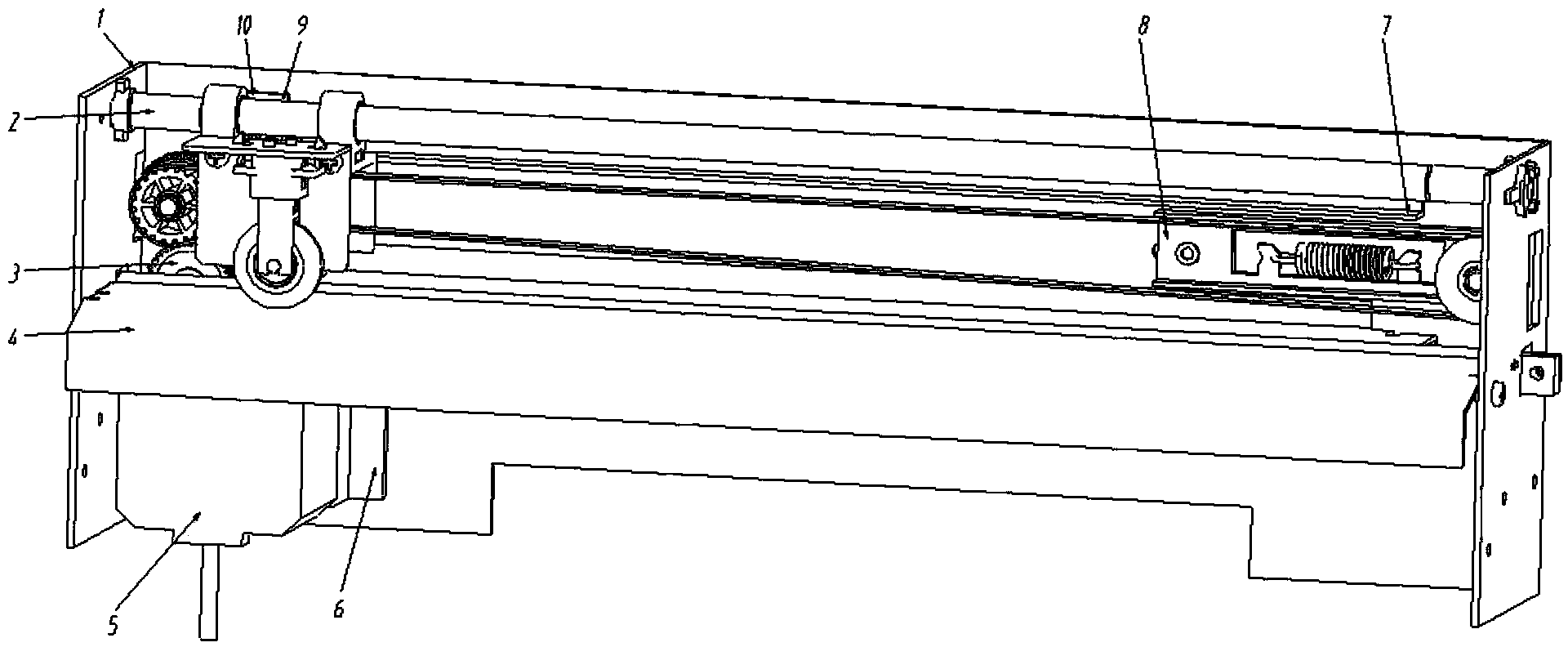

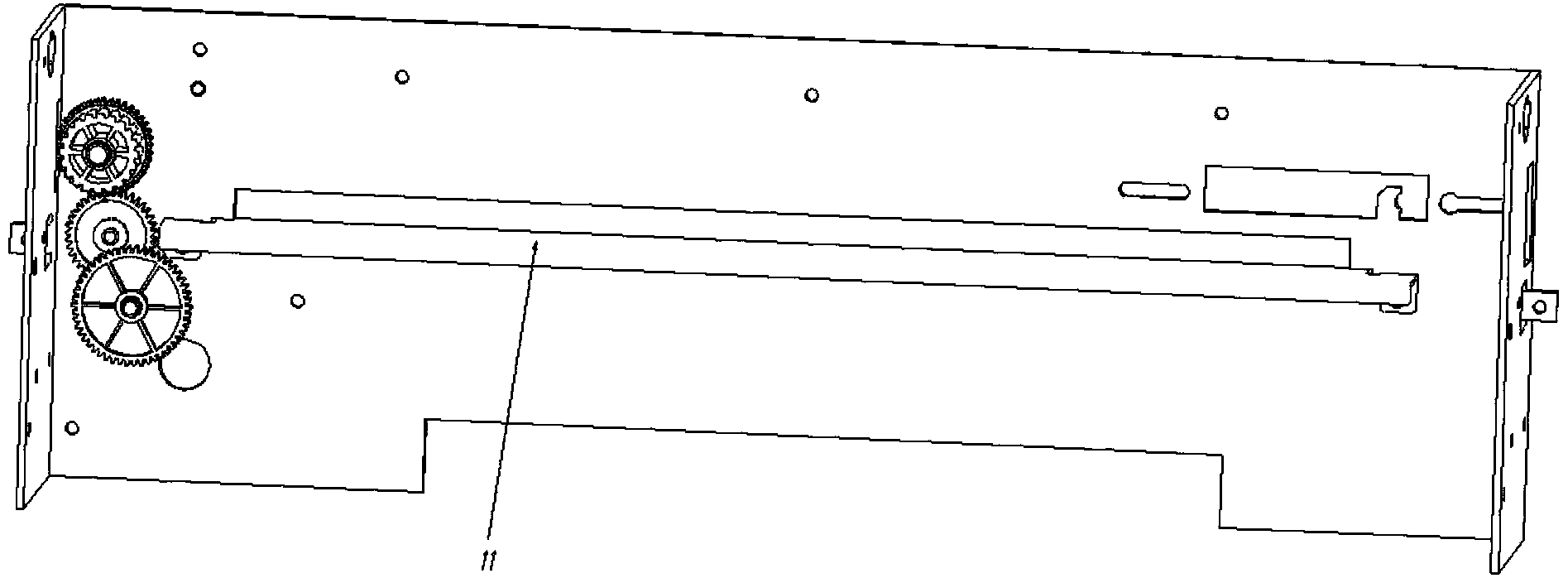

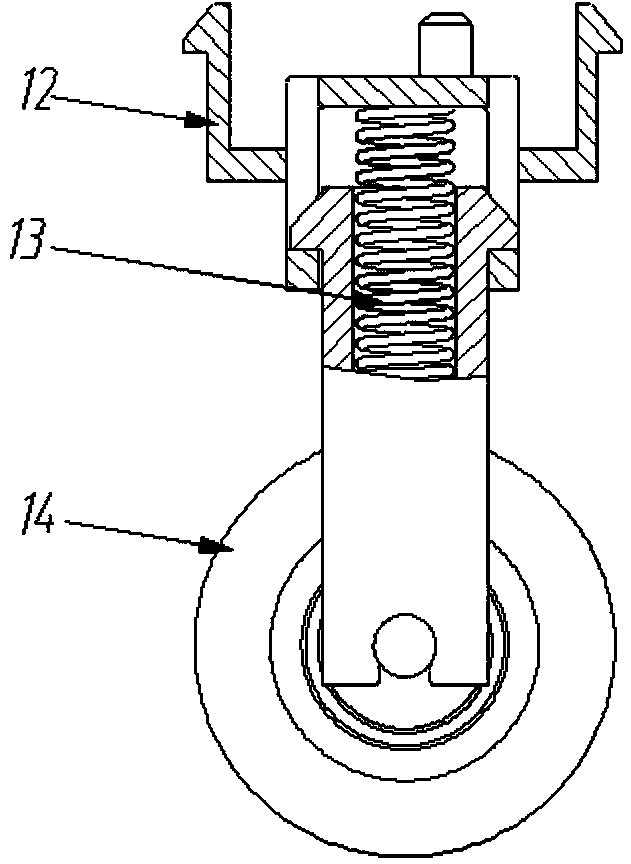

Hob type paper cutting device

ActiveCN104070841ASimple structureGood paper cutting reliabilityOther printing apparatusMetal working apparatusControl systemDrive motor

The invention discloses a paper cutting device, particularly relates to a hob type paper cutting device applied to a printer, and belongs to the field of computer communication technology. The hob type paper cutting device comprises a driving motor, a transmission mechanism, a rolling movable knife, a fixed knife, a holder, a paper pressing assembly, a guide support, a guide shaft, a guide plate, a position sensor, a tensioning support assembly, a control system and the like. The transmission mechanism transmits rotation movement of the driving motor to the rolling movable knife to perform automatic paper cutting. The hob type paper cutting device has the advantages that the hob type paper cutting device is modular in design manufacture, low in cost and convenient to maintain, assemble and disassemble; a pressure angle remains unchanged during paper cutting, so that paper is cut stably; a paper cutting assembly is simple in structure and good in paper cutting reliability.

Owner:NANJING FUJITSU ELECTRONICS INFORMATION TECH CO LTD

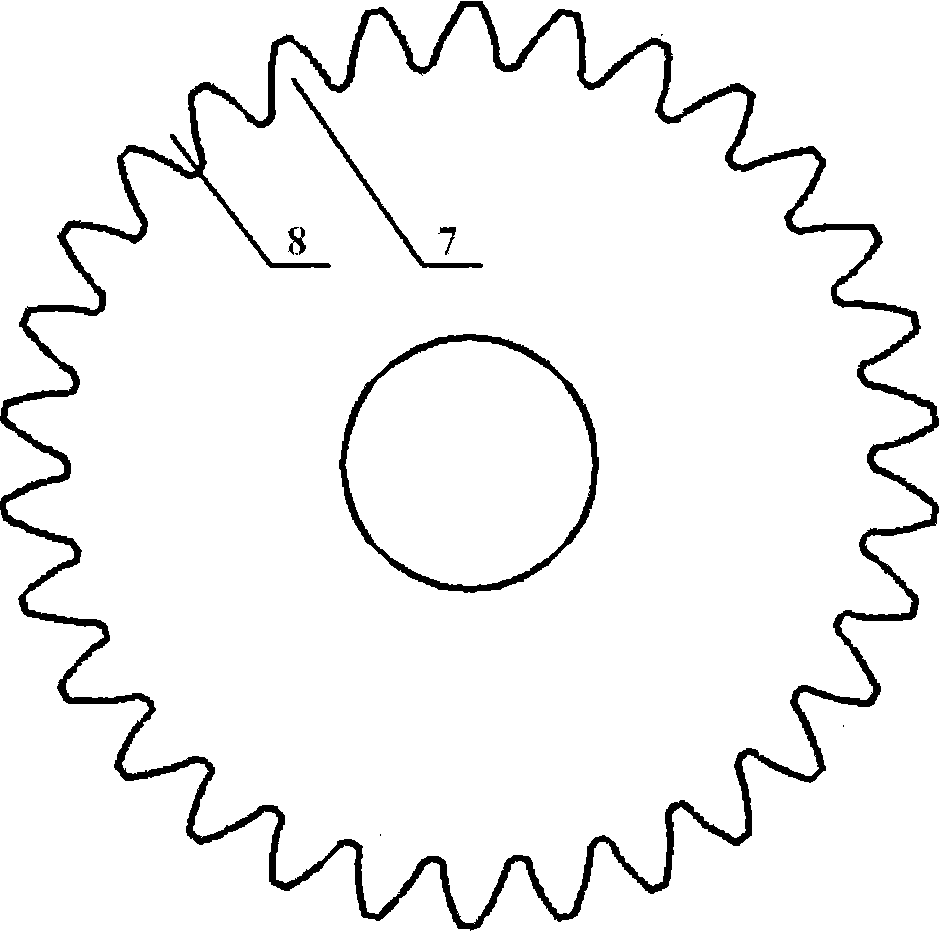

Antisymmetric involute plastic gear

InactiveCN101182879AImprove carrying capacityReduce the use temperaturePortable liftingGearing elementsCarrying capacityEconomic benefits

The invention provides a dissymmetrical involute plastic gear, which belongs to the machine manufacturing field. The invention is characterized in that the technical proposal of the invention is that unsymmetrical involute profiles are adopted on both sides of the gear teeth of the plastic gear, the pressure angles on both sides of the gear teeth are unequal and the involute profile 4 of the larger pressure angle is taken as the working side; the tooth of the gear consists of a dedendum circle 1, the larger pressure angle involute profile 4 generated by a minor diameter base circle 2, the small pressure angle involute profile 6 generated by a major diameter base circle 3, a tooth top 5 and a transition curve 7. By comparing with the prior symmetrical involute plastic gear, the carrying capacity of the invention is improved, the service temperature is reduced and the service life is prolonged. Accordingly, the invention has wide application prospect and considerable economic benefits.

Owner:TAIYUAN UNIV OF TECH

Multiple-Row Angular Contact Antifriction Bearing, Particularly For Mounting the Bevel Pinion Shaft in a Motor Vehicle Rear Axle Differential

InactiveUS20080166082A1Minimized axialMinimized radial installation spaceRoller bearingsShaftsTransverse axisGear wheel

The multiple-row angular contact antifriction bearing has an outer bearing ring, an inner bearing ring, and roll bodies, which are arranged at least in two rows next to one another between the bearing rings. The roll bodies are ball discs having two lateral surfaces that are symmetrically flattened from a spherical basic shape whose raceways are arranged inside the bearing rings, abutting against one another so that the respectively adjacent roll bodies of each row have their lateral surface pointing toward one another and arranged directly next to one another on a transversal axis situated at a right angle to the pressure angle axes. These lateral surfaces also provide mutual guide surfaces.

Owner:SCHAEFFLER KG

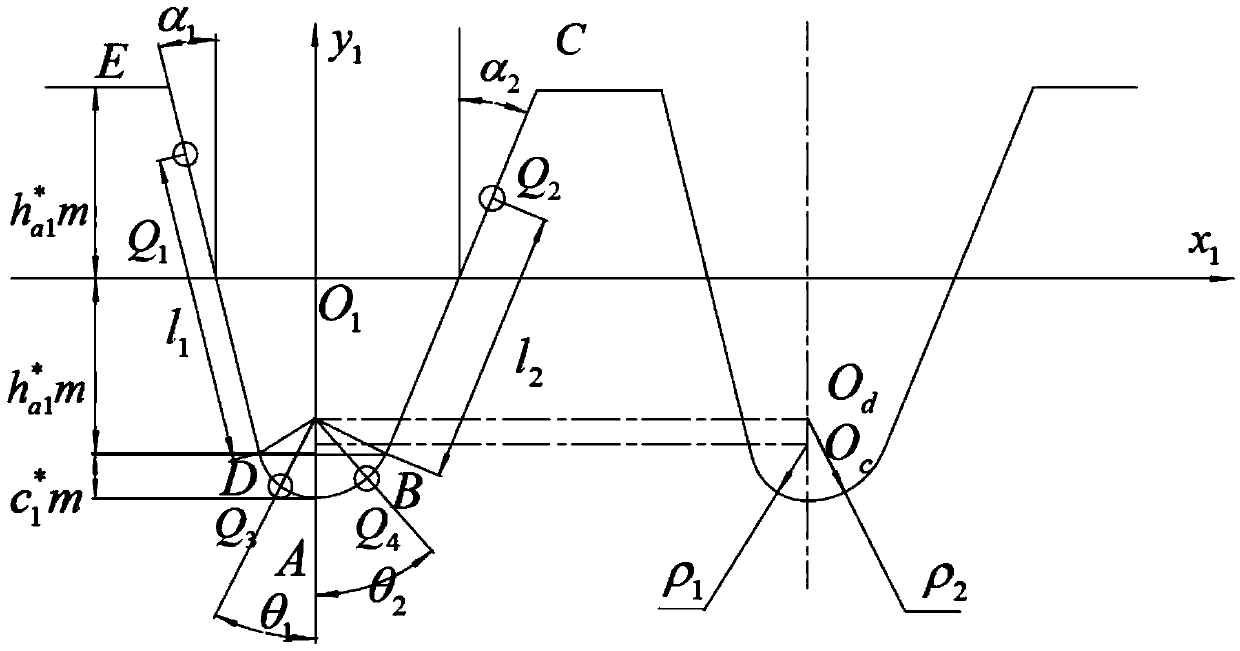

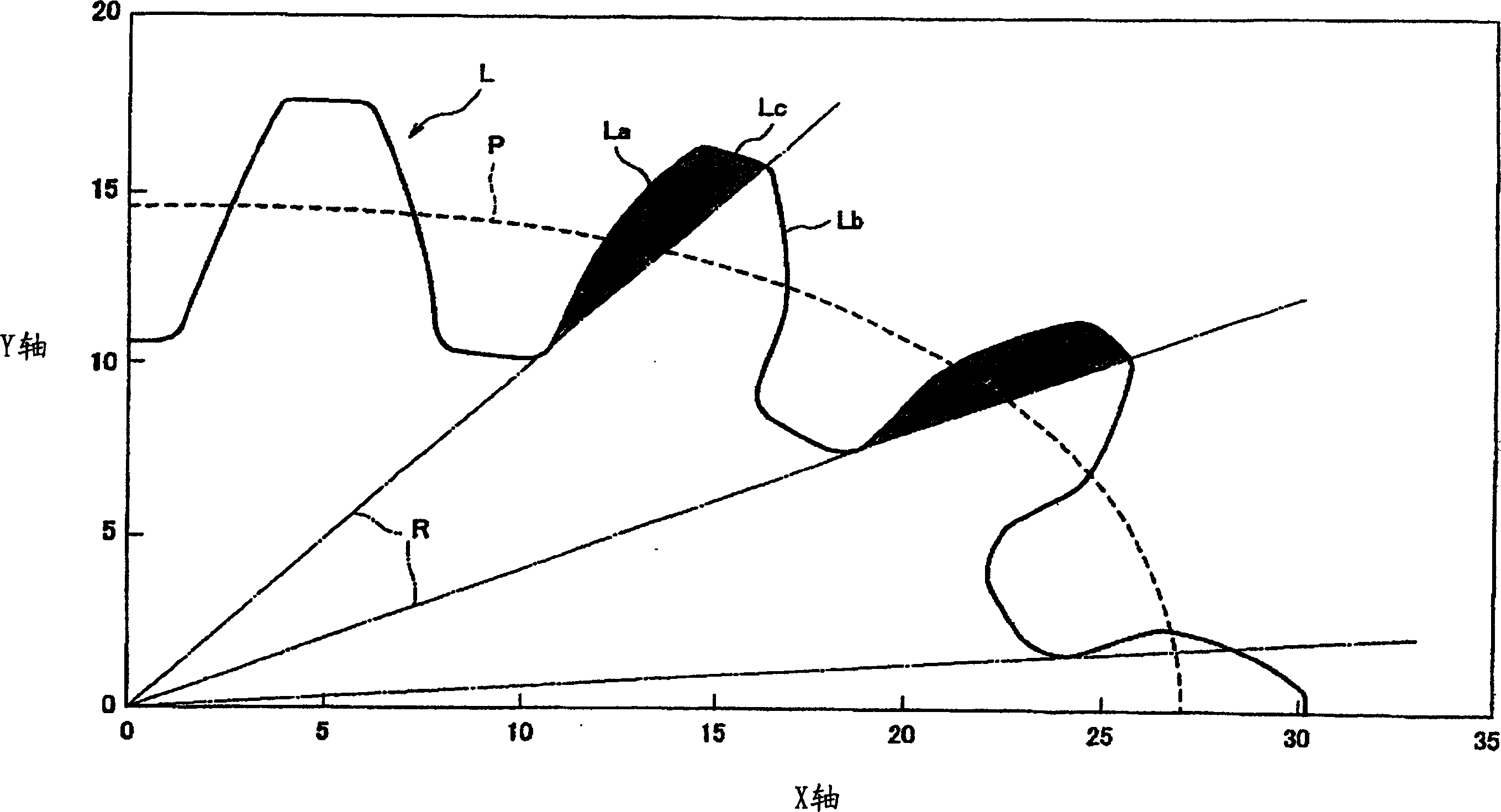

Method for designing swinging follower cylindrical cam contour line

The invention relates to a design method of a cylindrical cam profile of an oscillating follower. The method is characterized by comprising the following steps: introducing a coordinate expression of a 3D evolute of a displacement curve of the oscillating follower, putting forward a concept of a deviation angle, deducting the expression of the deviation angle according to a geometrical relation, and establishing a profile equation which is convenient for analyzing, designing and constructing the cylindrical cam of the oscillating follower; deducting an expression of a pressure angle according to the geometrical relation of the profile evolute, drawing a relation curve of a base radius R in relation to a maximum pressure angle alpha, and obtaining the minimum base radii which are corresponding to different allowable pressure angles; and programming an MATLAB program according to a known expression, namely, S=f(phi), 1, a and R, extracting coordinate values of the curve by MATLAB software after the operation of the program, pasting the coordinate values to AutoCAD software under a 'PLINE' command after processing, and then processing the coordinate values to 3D CAD software to obtain the profile. The solution process and the design process of the method are concise, visual, and easy to be controlled and practical, and have no design error.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Precise design and profile modification method for asymmetric gear

InactiveCN103593536AImprove processing efficiencySpecial data processing applicationsDimensional modelingEngineering

The invention relates to a precise design and profile modification method for an asymmetric gear. The method comprises the following steps that S1, the tooth profile equation of a rack tool is obtained according to the structure of the rack tool; S2, coordinate transformation is carried out on the tooth profile equation of the rack tool according to the movement rule of the rack tool to obtain a rack tool equation under a gear coordinate system; S3, a meshing equation is obtained according to the meshing rule of the rack tool and the gear; S4, the tooth profile equation of the asymmetric gear is determined according to the rack tool equation and the meshing equation; S5, three-dimensional modeling is carried out according to tooth profile data. The profile modification method directly carrying out pressure angle profile modification on the rack tool is disclosed, the tool after the profile modification can directly carry out machining to obtain the formed gear having the involute modified, the gear machining efficiency is improved, and the obtained formed gear through the profile modification is simple and practical.

Owner:WUHAN UNIV OF TECH

Sprocket with wear limit indication

In a sprocket for use with a roller chain, a wear limit marker, having a different color from that of the base material of the sprocket, is provided on side surface of a sprocket tooth adjacent to a keyway. The wear limit marker is disposed on an imaginary line extending in the direction of the pressure angle, and is located in a hole or groove provided in a side surface of the sprocket tooth. The marker makes it possible to determine easily and reliably whether or not wear at the location at which wear of a sprocket tooth proceeds most rapidly is within a predetermined limit, and the location of the marker makes it possible to evaluate wear conditions even when the sprocket is installed in a machine.

Owner:TSUBAKIMOTO SPROCKET

Clutch member adapted to remain engaged in a fixed position while under a heavy load

InactiveUS20120193185A1Simple designPrevent disengagementFriction clutchesInterengaging clutchesEngineeringHeavy load

A releasable gear type spline clutch can couple a shaft to a wheel rotatably mounted on the shaft. The clutch comprises an annular clutch member axially mounted on the shaft. Mating external and internal first splines are provided respectively on the shaft and the dutch member, and mating external and internal second splines are provided respectively on the clutch member and the wheel. The pitch diameter of the second splines is greater than the pitch diameter of the first splines, and the pressure angle of the first splines is greater than the pressure angle of the second splines. The clutch member is axially shiftable between a disengaged position at which the second splines are out of mesh, and an engaged position at which the second splines are meshed. The first splines are meshed in both the engaged and disengaged positions.

Owner:SIEMENS IND INC

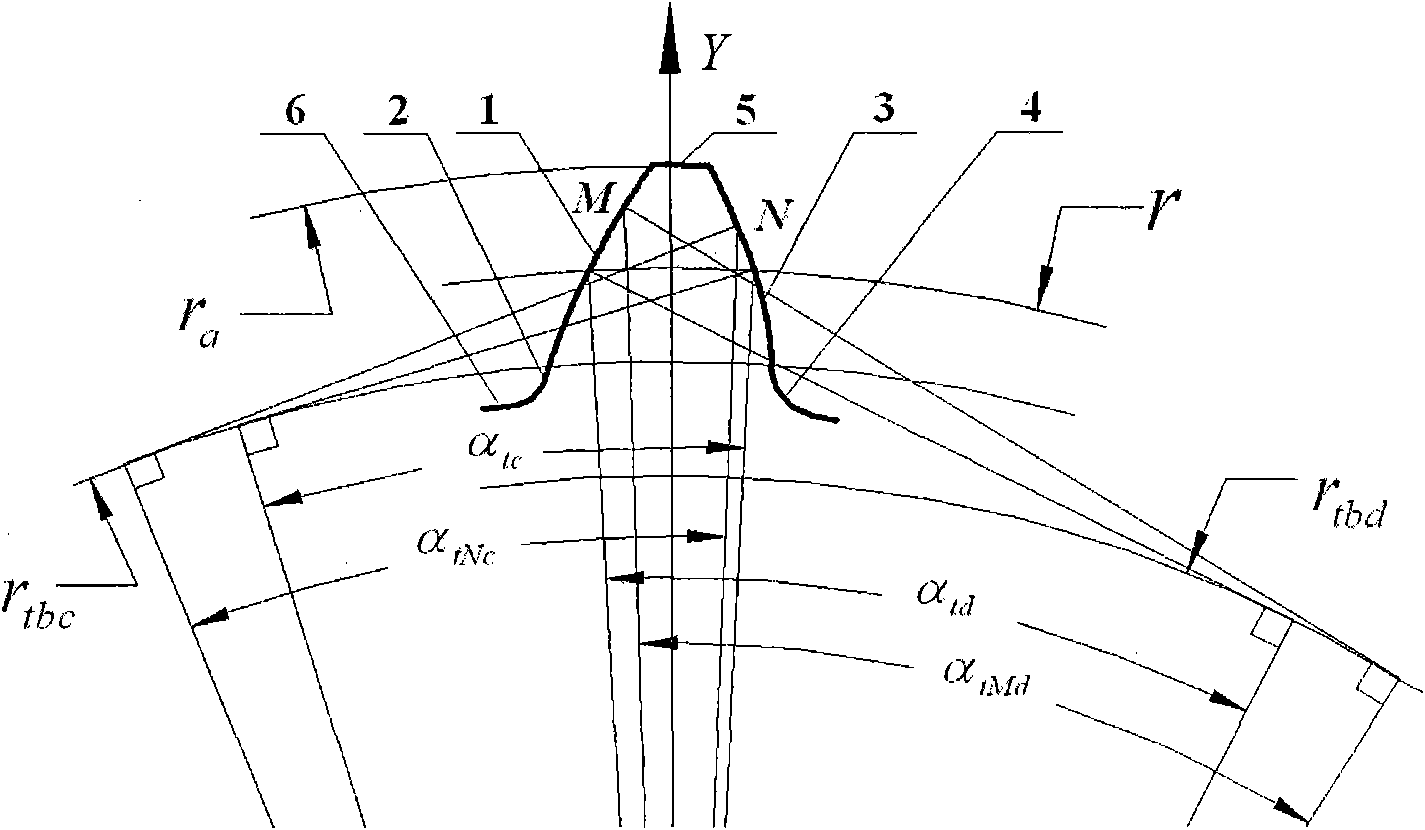

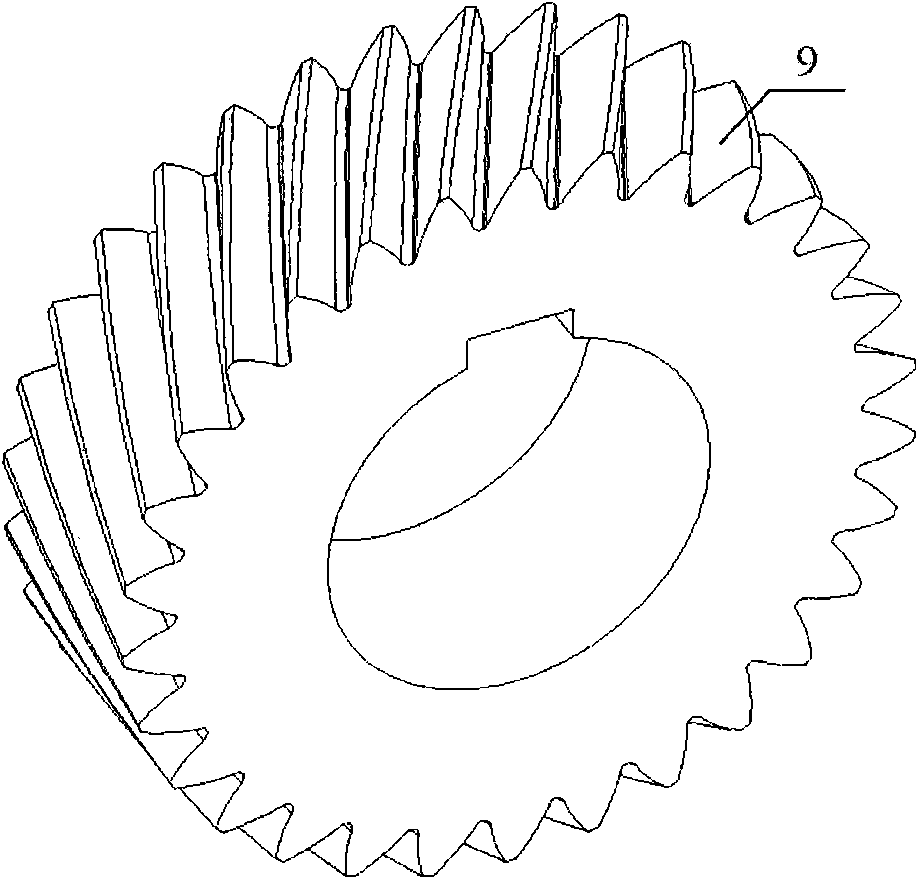

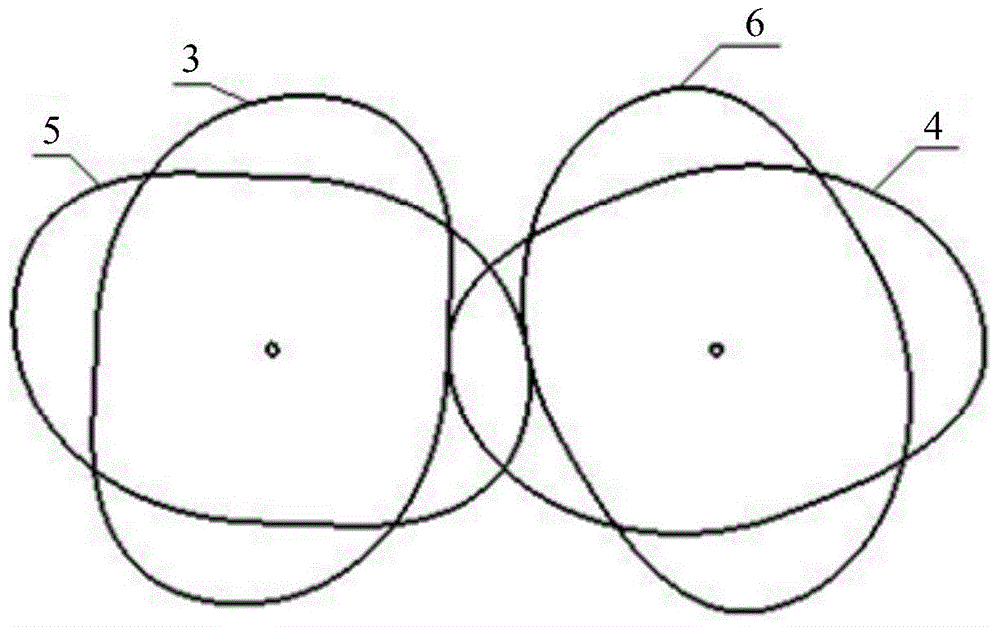

Tooth profile design of dual-pressure angle involute helical tooth externally-meshed cylindrical gear

The invention relates to a dual-pressure angle involute helical tooth externally-meshed cylindrical gear, and belongs to the technical field of gears. In the conventional involute helical tooth externally-meshed cylindrical gear, pressure angles at reference circles on two sides of involutes on the driving side and the driven side are equal to each other, but in the dual-pressure angle involute helical tooth externally-meshed cylindrical gear, a large pressure angle is formed at a reference circle of an involute on the driving side, and a small pressure angle is formed at a reference circle of an involute on the driven side, so the performance of the gear can be improved due to an asymmetrical design. A tooth profile on the end face of the gear comprises the involute (1) on the driving side, a tooth root transition curve (2) on the driving side, the involute (3) on the driven side, a tooth root transition curve (4) on the driven side, a tooth crest circular arc (5) and a tooth root circular arc (6); and the tooth profile on the end face moves along a spiral line to form the final dual-pressure angle involute helical tooth externally-meshed cylindrical gear.

Owner:李宁 +1

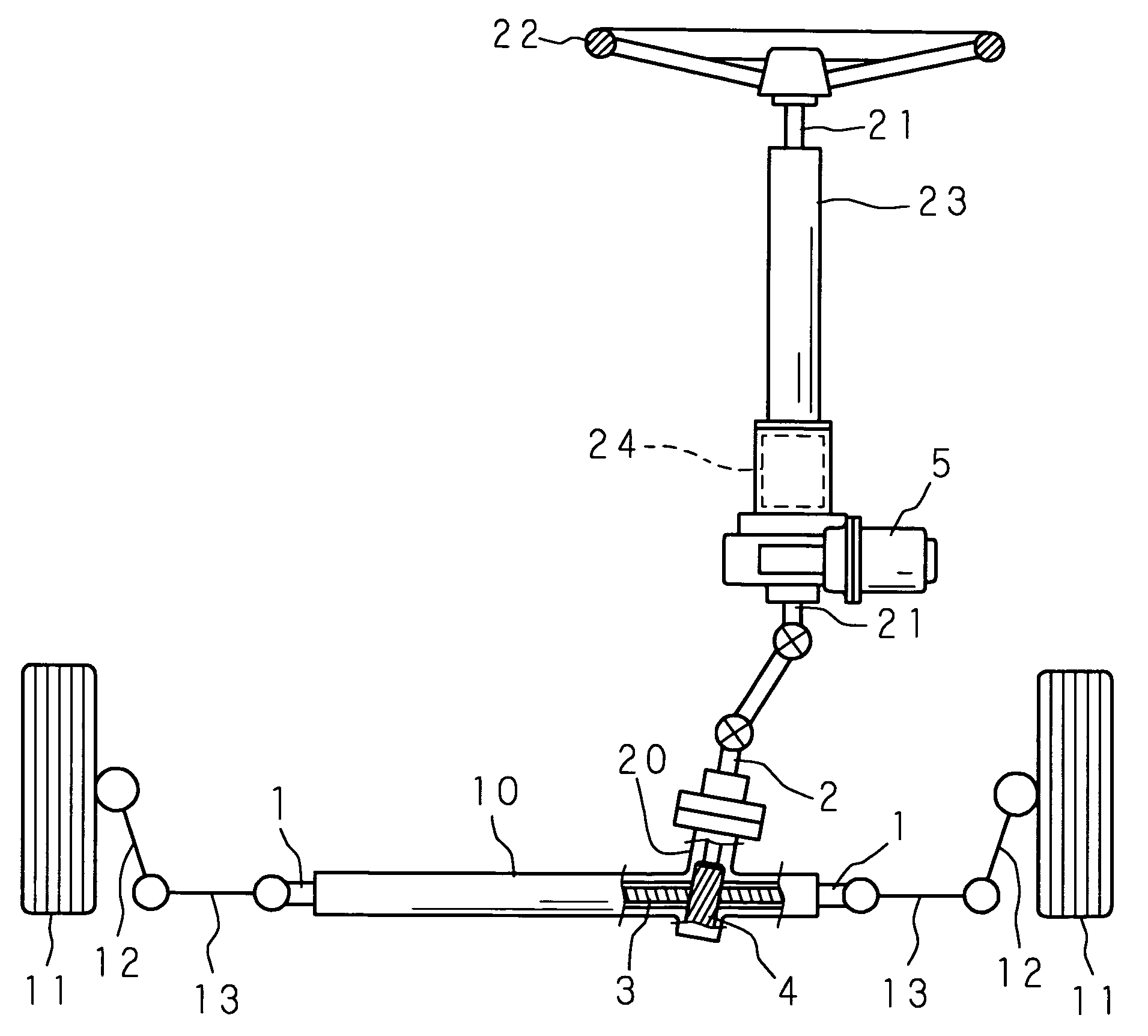

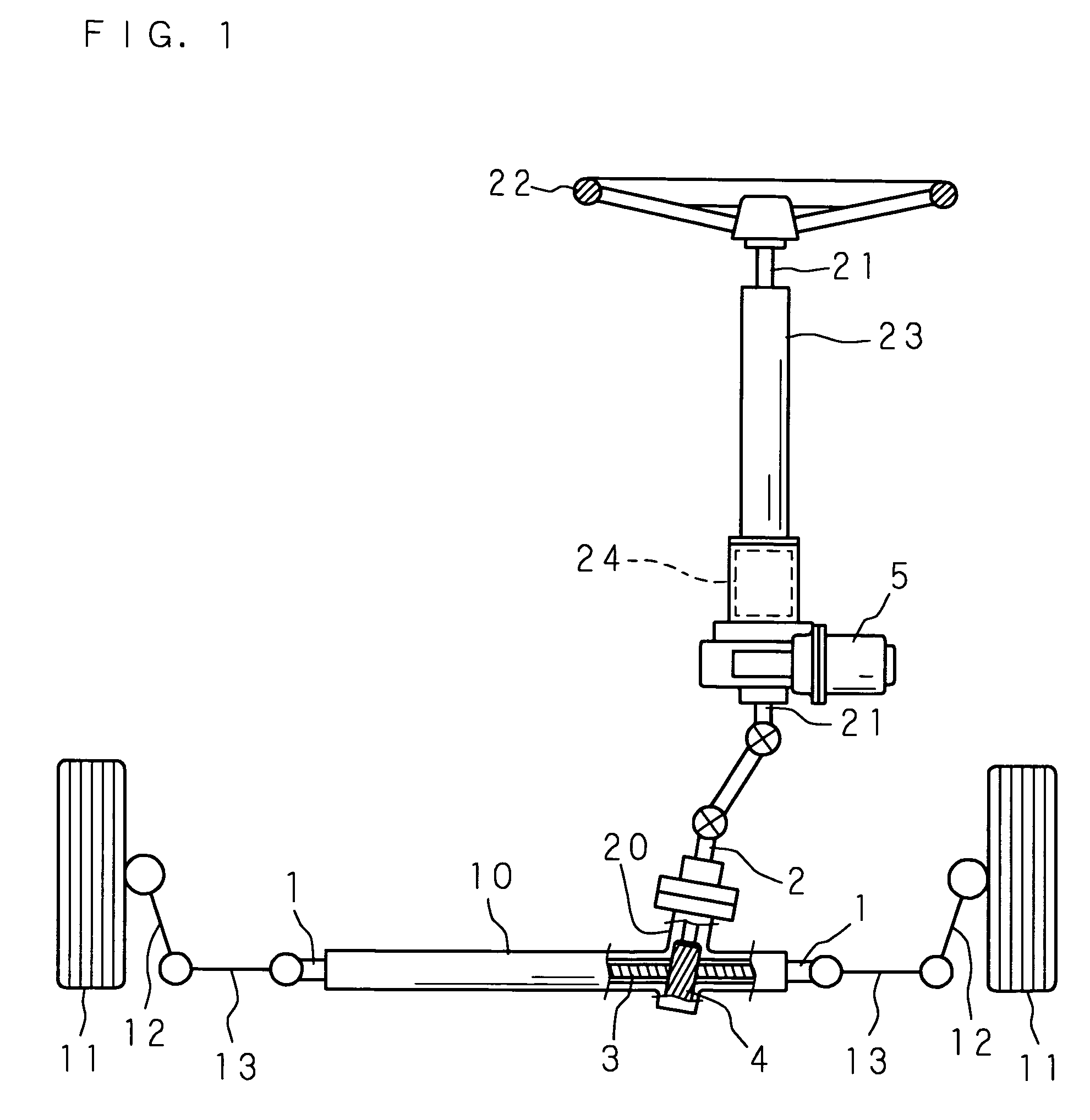

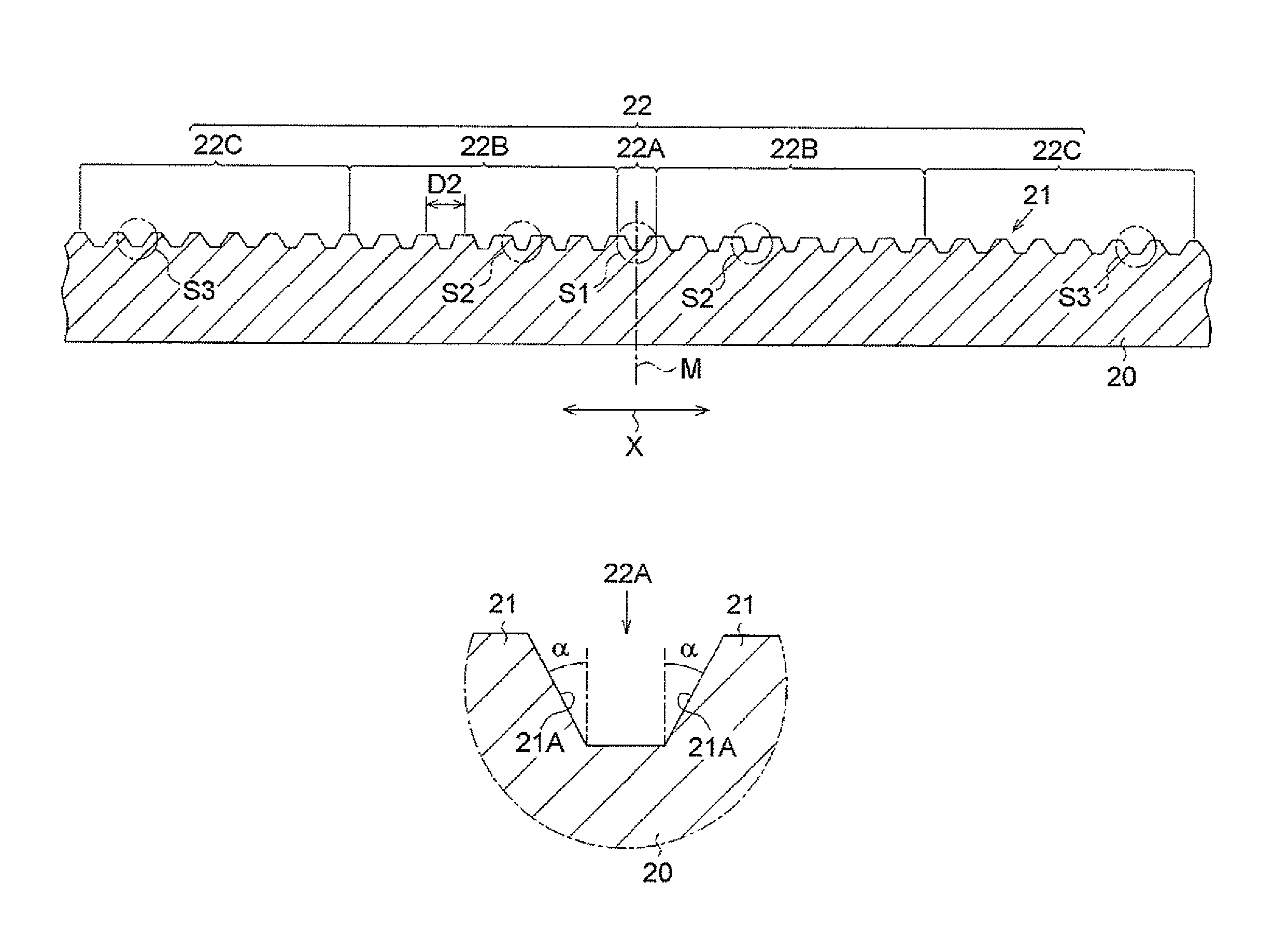

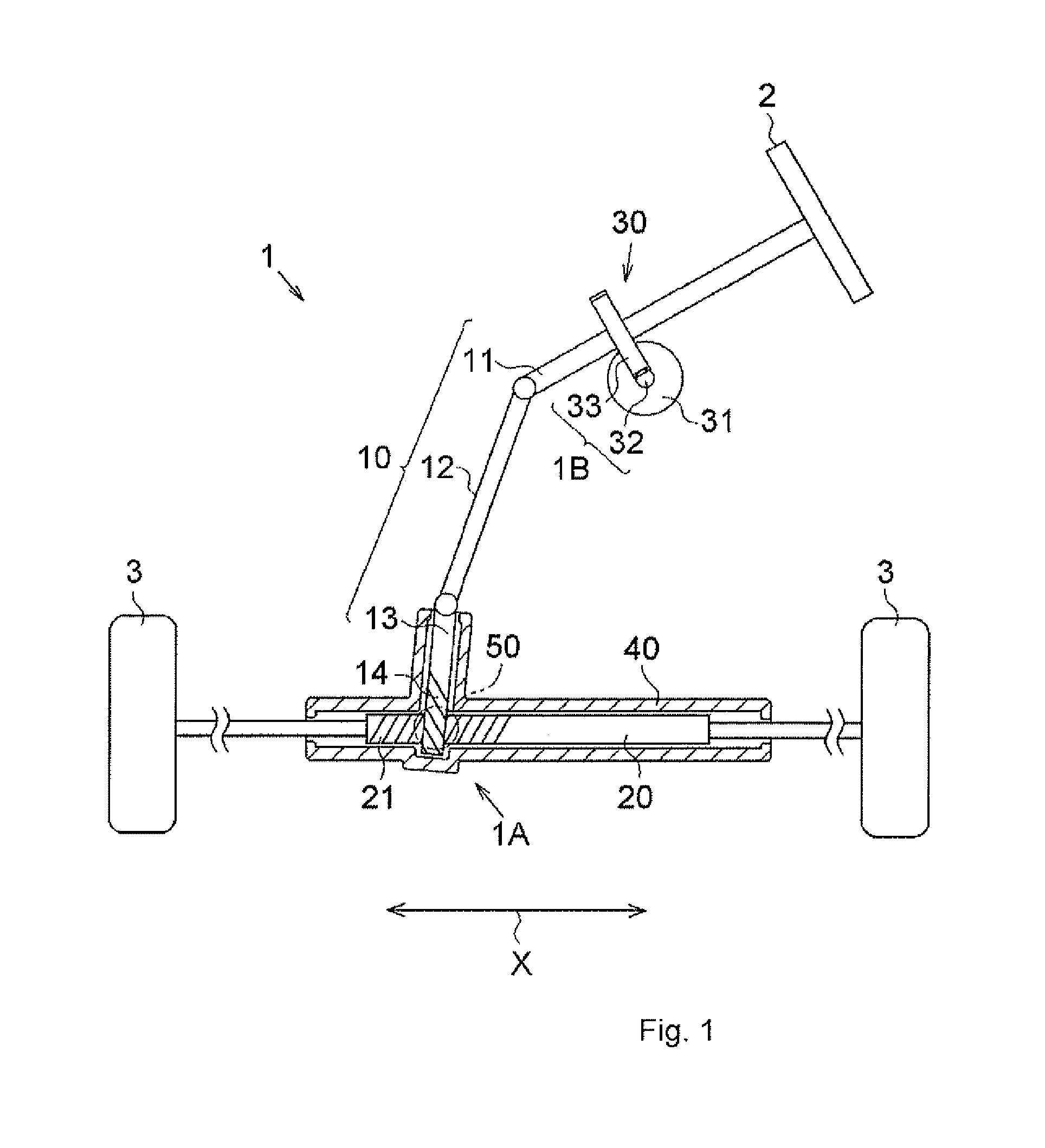

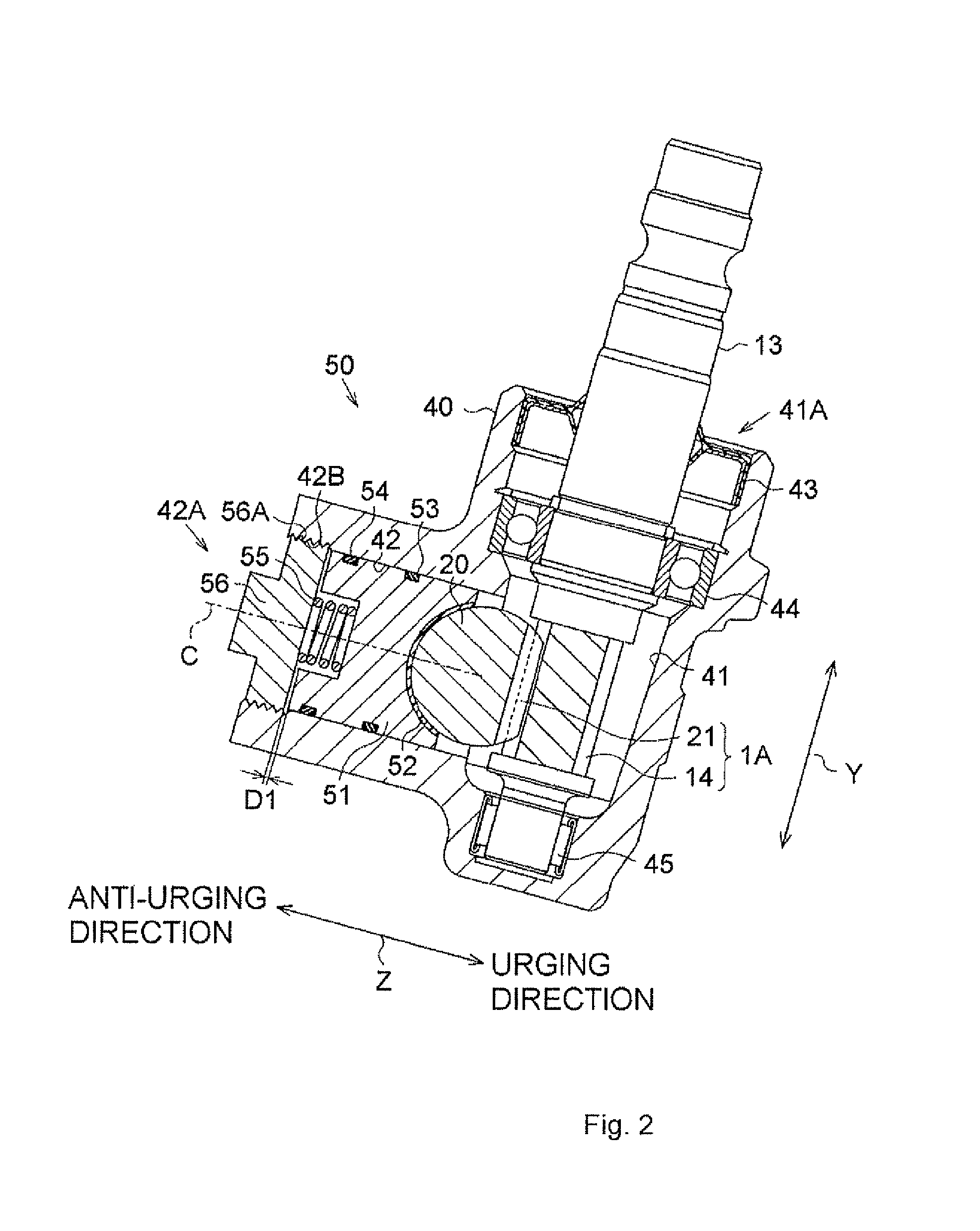

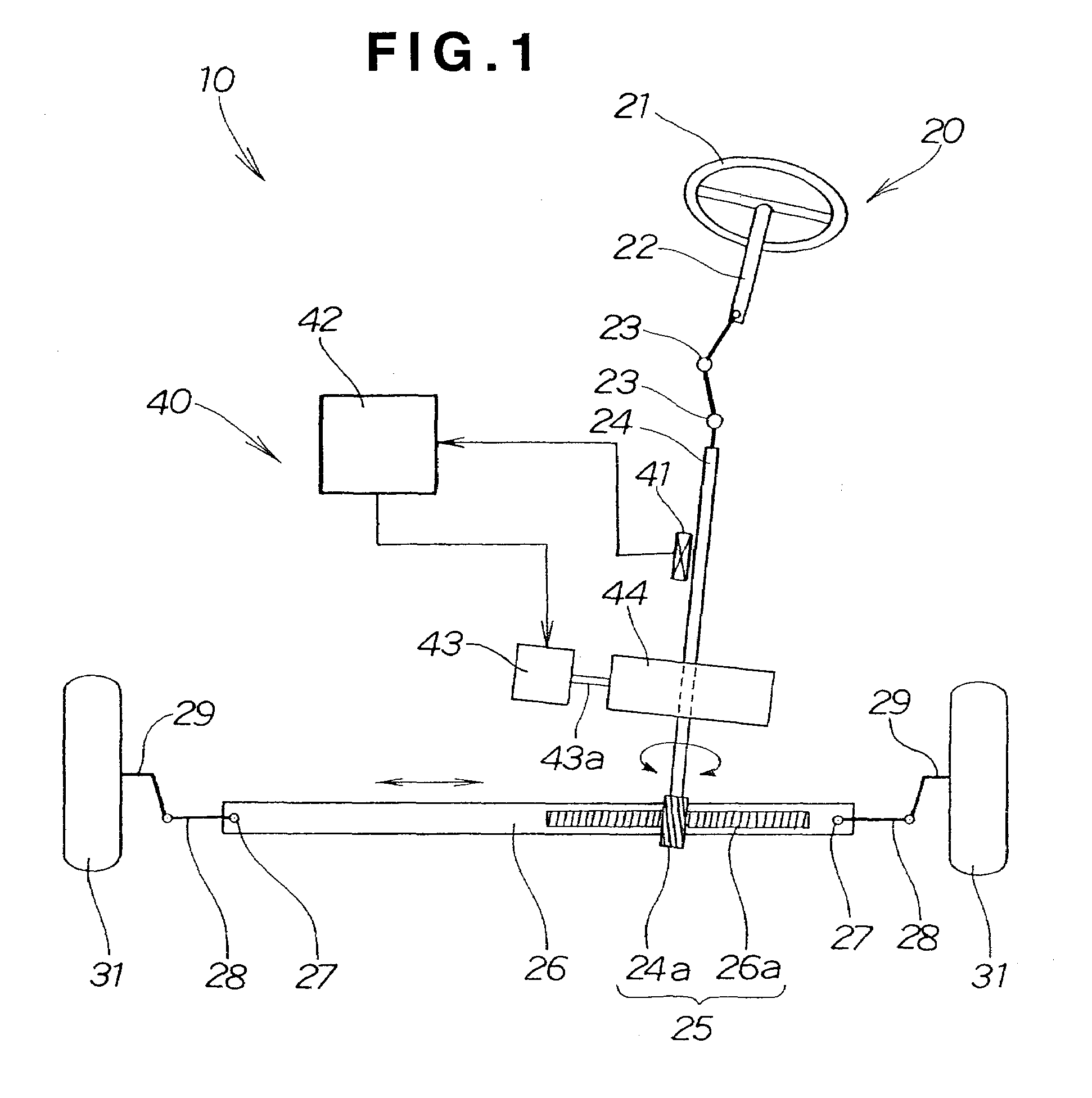

Steering system

ActiveUS8708357B2Steering feel is improvedSuppress generationMechanical steering gearsFluid steeringEngineeringPinion

A pinion shaft of a steering system has a plurality of pinion teeth. A rack shaft has a stroke region in which a plurality of rack teeth that mesh with the pinion teeth is formed. The stroke region includes a center region that includes a center position of the stroke region, end regions, each of which includes an end position of the stroke region, and intermediate regions, each of which is located between the center region and one of the end regions. A pressure angle of each rack tooth included in each of the intermediate regions is smaller than a pressure angle of each rack tooth included in each of the center region and the end regions.

Owner:JTEKT CORP

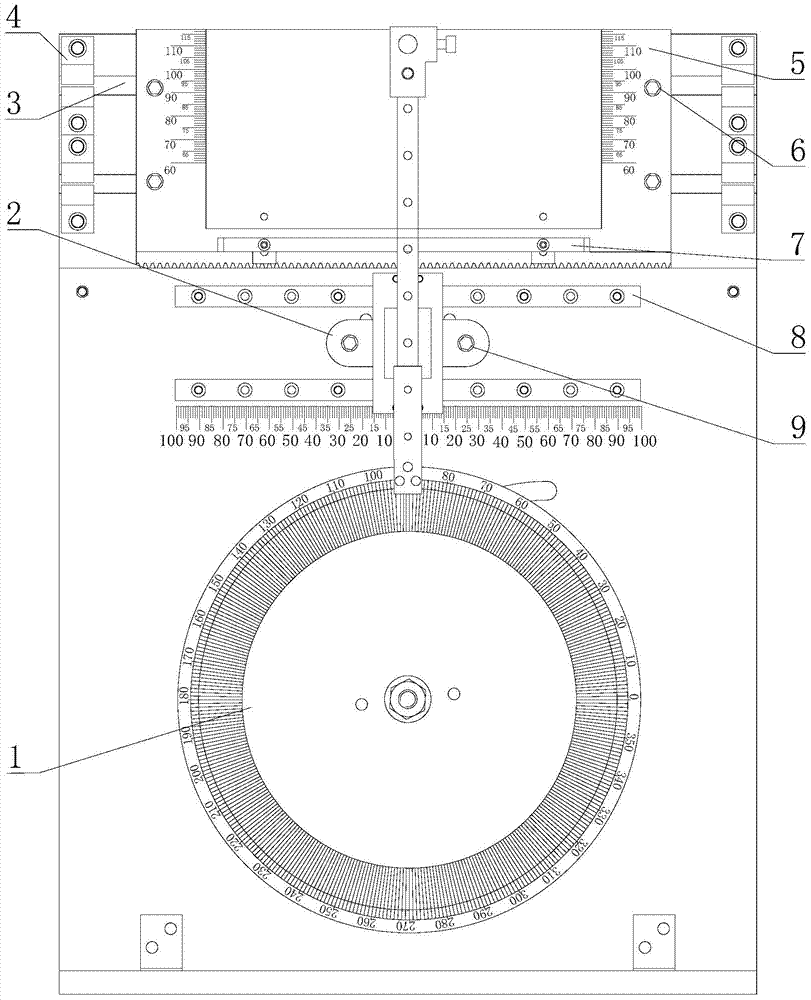

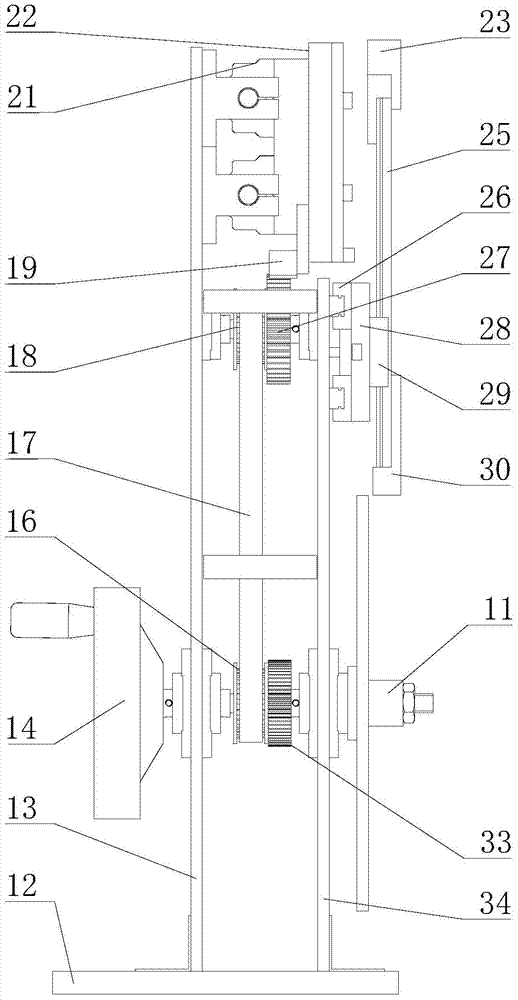

Cam analyzer

The invention discloses a cam analyzer. The cam analyzer comprises a frame, a main transmission part, a fixed disc, a translation plate, a synchronous tensioning mechanism, an eccentric mechanism, a follower mechanism, a pressure angle measuring mechanism and a contact head. According to the invention, almost all knowledge points related with a cam are covered. A motion curve of the formed cam can be drawn; the corresponding cam can be drawn from a follower displacement graph; and the pressure angle of each point on the contour of the cam can be measured, and the size and the corresponding position of the maximum pressure angle can be found. During drawing of the follower displacement graph, the shape of the head portion of a follower can be converted, the motion curve map of cams in any shapes can be drawn, and such parameters as a cam turn angle, a basic circle dimension, a return travel angle, a travel angle, a farthest dwell angle, a nearest dwell angle and the like can be effectively detected, the bias distance of the follower can be changed, and cam motion graphs under the condition of different bias can be drawn. The apparatus greatly deepens students' understanding of the cams, facilitates teaching and improves the teaching quality.

Owner:HANGZHOU DIANZI UNIV

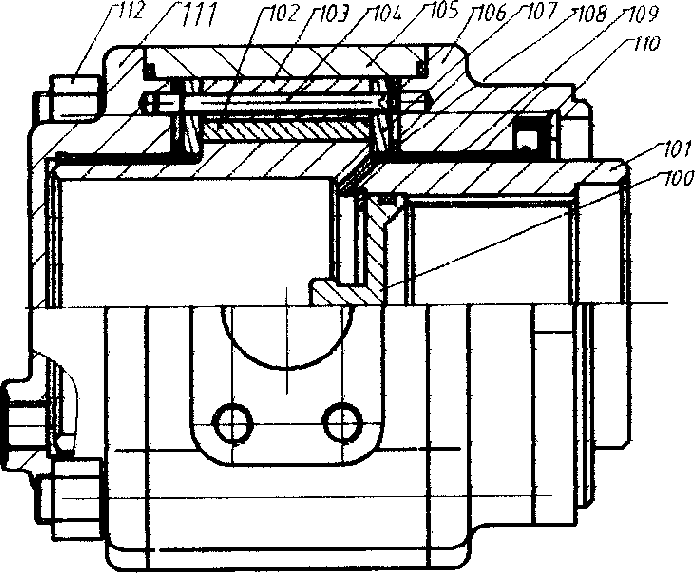

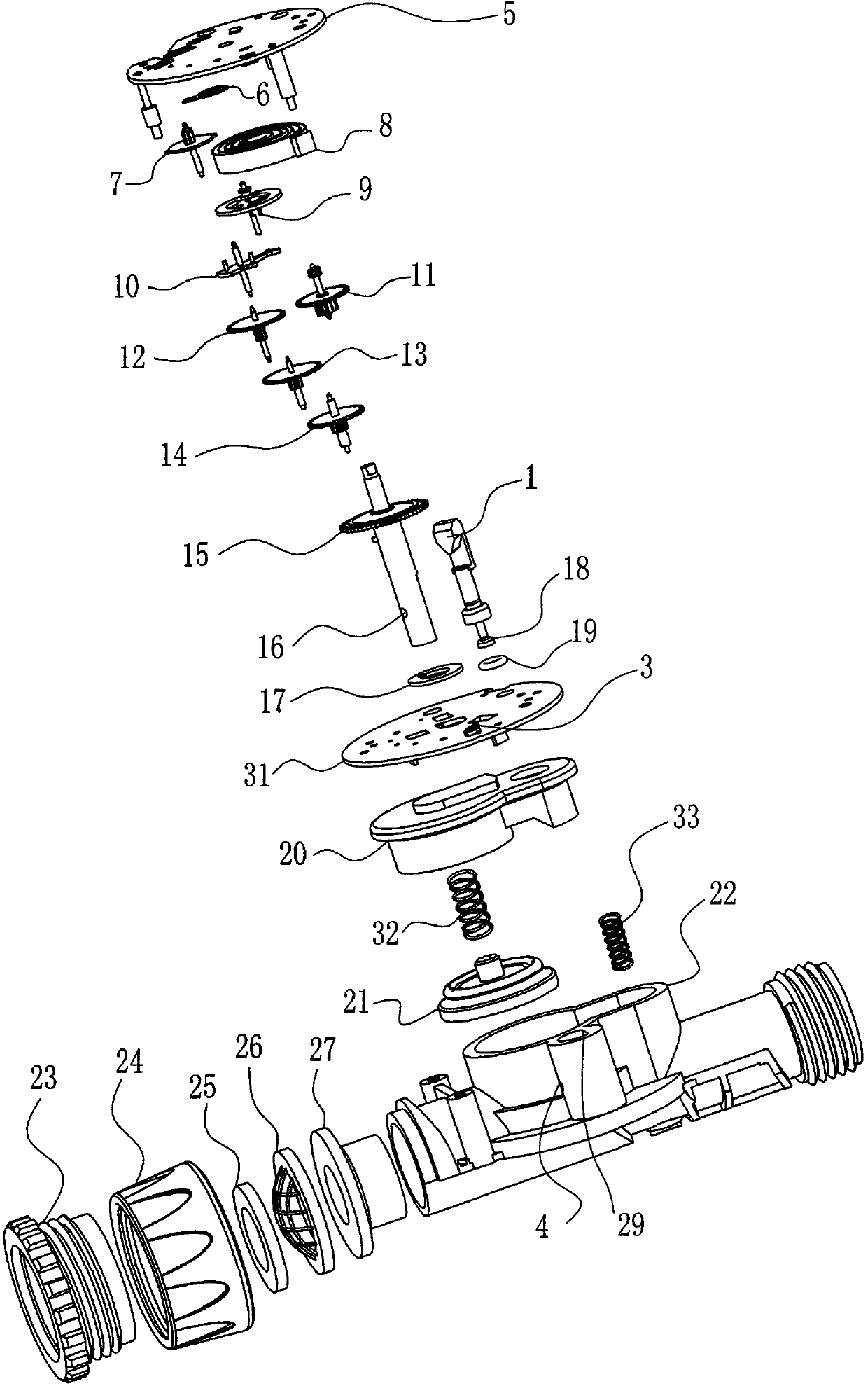

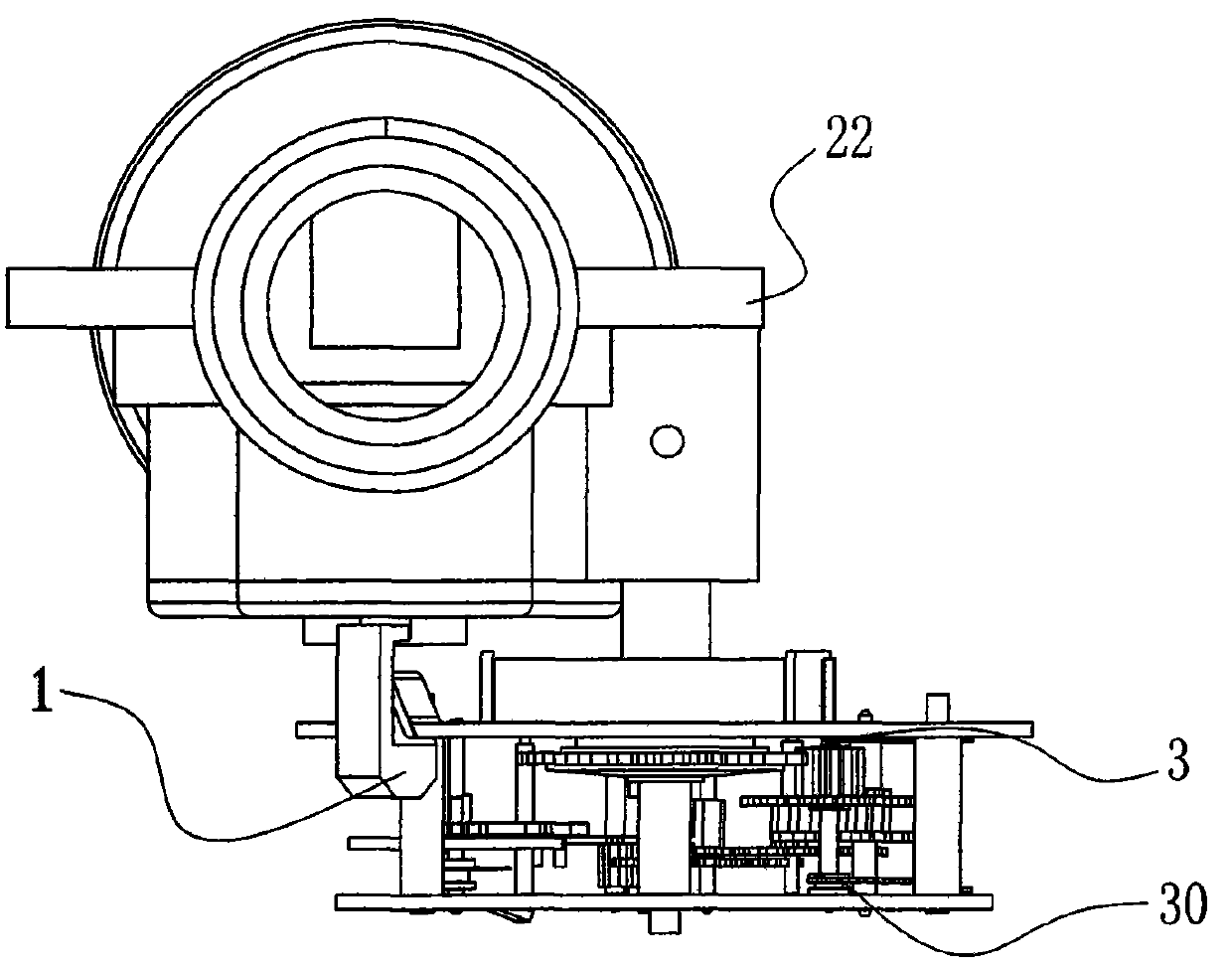

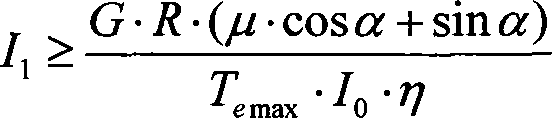

Rotary positive displacement hydraulic device

InactiveCN1673577AReduce the number of speciesSimple structureMachines/enginesFluid gearingsGear pumpAgricultural engineering

The rotary volumetric hydraulic mechanism includes block type hydraulic pump, motor and driver. The rotor block slot has profile curve of involute with pressure angle in the reference circle equal to 0 deg and geometrical parameters in modular system. Based on the specific application, the rotor bearing may be DU bearing or hydrostatic bearing. The present invention has the features of simple structure, easy manufacture, use and maintenance and low cost. The present invention has the adaptation range covering gear pump, blade pump, plunger pump and motor, and may form one new technology to develop serial products.

Owner:彭利

Dot-line engaged bevel gear pair high in bearing capability and low in vibration

ActiveCN107830116AImprove carrying capacityReduce vibrationPortable liftingToothed gearingsGear wheelTooth number

The invention belongs to the technical field of bevel gear design, and particularly relates to a dot-line engaged bevel gear pair high in bearing capability and low in vibration. The dot-line engagedbevel gear pair high in bearing capability and low in vibration comprises a first bevel gear and a second bevel gear which are engaged with each other; the tooth number of the first bevel gear and thetooth number of the second bevel gear are taken as z1 and z2 correspondingly, the normal module of the first bevel gear and the normal module of the second bevel gear are taken as m<n1> and m<n2> correspondingly, the normal pressure angle of the first bevel gear and the normal pressure angle of the second bevel gear are taken as alpha<n1> and alpha <n2>, and the reference circle spiral angle of the first bevel gear and the reference circle spiral angle of the second bevel gear are taken as beta1 and beta2 correspondingly, wherein z1 and z2 meet the transmission ratio requirement and the convenient machining principle, and the values of m<n1> and m<n2> are selected in reference to the bevel gear handbook or customized according to needs; the values of alpha<n1> and alpha<n2> are selected according to transmission requirements, following relations are met, A), when z1 is smaller than z2, alpha<n1> is larger than alpha<n2>, alpha<n2> is larger than 20 degrees, and m<n1> is larger than m<n2>; B), when z1 is larger than z2, alpha<n2> is larger than alpha<n1>, alpha<n1> is larger than 20 degrees, and m<n2> is larger than m<n1>; the values of beta1 and beta2 are selected according to work needs, meanwhile, beta1 is equal to + / -beta2, '-' is taken for outer meshing, and '+'is taken for inner meshing. The provided dot-line engaged bevel gear pair combines the beneficial effects of dot-line engaged bevel gear and bevel gear joint outer meshing transmission at the same time and has the beneficial effects of being low in vibration, low in noise, large in strength and long in service life.

Owner:JIANGSU UNIV OF TECH

Water saving method for rotary water sprayer with wide range

The invention relates to a water saving method for a rotary water sprayer with a wide range. The method is characterized by comprising a rotary water sprayer (59), a spraying head of the rotary water sprayer is rotary, and the heights from bottom to top of the groove bottoms of a right water spraying groove and a left water spraying groove in water spraying grooves of the rotary water sprayer are different to form the rotary water sprayer with the wide range. Arc grooves of the rotary water sprayer are respectively contour line grooves of which the parabolas are smoothly connected in a central arc equation manner and the cross sections are in wing shapes, the heights of the two groove bottoms are different, and the distance between two water throwing grooves is different, so that the rotary water spraying with axial flow and wide range is convenient. Function curves are adopted in multiple positions, so that the product quality is improved; an inner wall which is provided with a plurality of through holes and is arranged at the side part of a spraying head cap adopts a cube curve with the function of a buffering curve in the middles of a straight passage and a circular arc-shaped water passage, and the impact is alleviated when water flow turns; a rib is arranged between every two through holes, the rib is in an equal angle spiral shape, i.e. a logarithmic spiral shape, and the water can be uniformly sprayed because pressure angles are the same in any place; the batched quality of the product is further improved by the spraying head cap with a cube curve water passage and the equal angles spiral rib and a spraying head seat with a hyperbolic curve pipeline or a logarithmic spiral pipeline.

Owner:NINGBO DAYE GARDEN IND

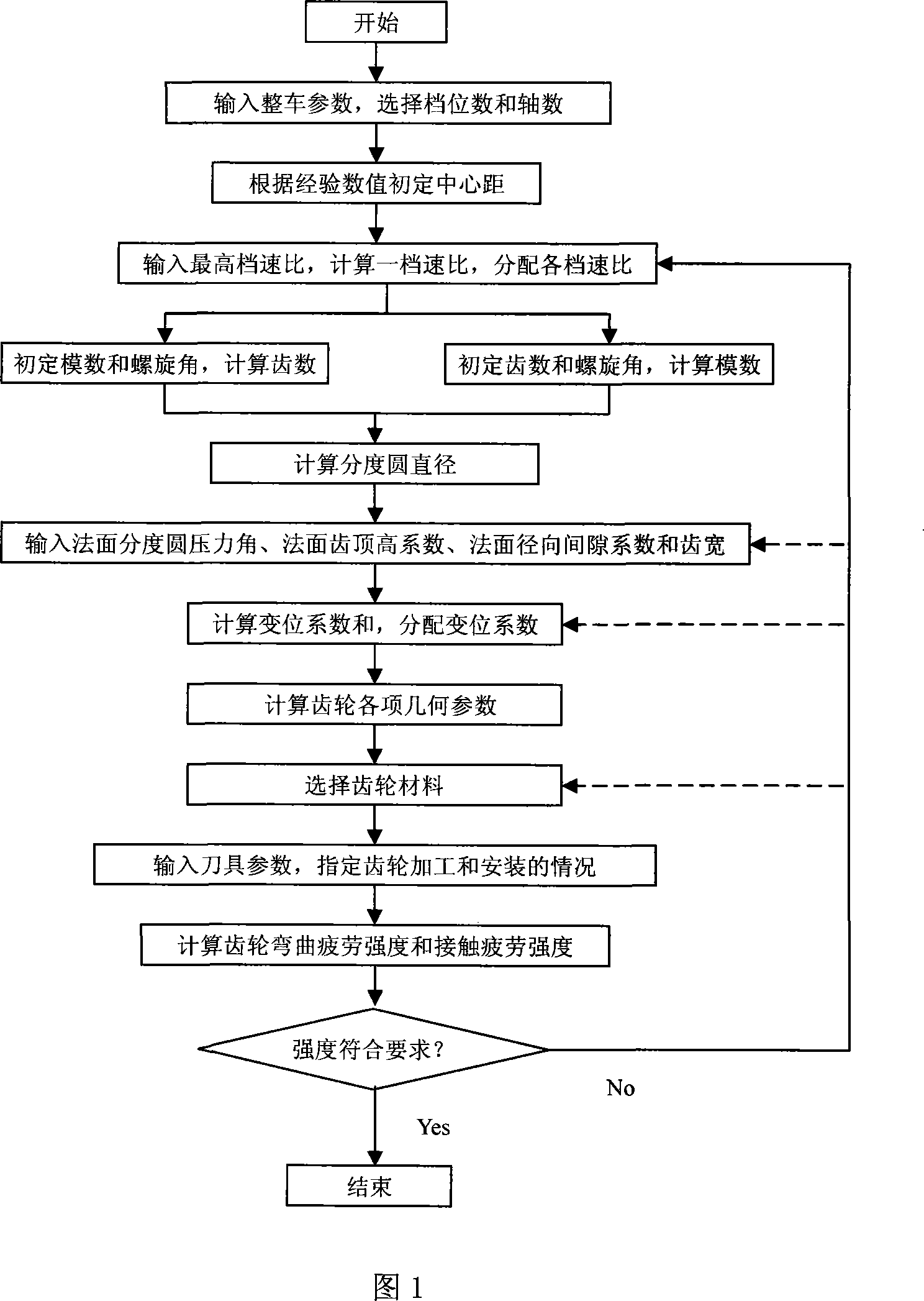

Design method of gear transmission system of automobile transmission based on Web technology

InactiveCN101196956AAchieve normalizationSolve the difficult problems of development and designSpecial data processing applicationsEngineeringTooth number

A design method of a Web technology-based automobile transmission gear drive system is provided, which belongs to the technology field of computer application. The steps are that: the system computes actual center distance or user directly gives the actual center distance; the system determines the range of lowest grade speed ratio and highest grade speed ratio value and allocates the grade speed ratio of the transmission; tooth number determination module is called to determine the tooth number, module number and helix angle; the system computes diameter of reference circle, inputs normal reference circle pressure angle, normal radial gap coefficient, normal tooth addendum coefficient and tooth width, calls addendum coefficient to compute and allocate the module, computer normal addendum coefficient sum and allocates the normal addendum coefficient; the system gives warning if the selected addendum coefficient is not in compliance with the requirement; the design result is checked. The invention can effectively solve the problem of difficult development and design of transmission gear drive system products and facilitate the design of the automobile transmission gear simple, convenient and fast and accurate.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS +1

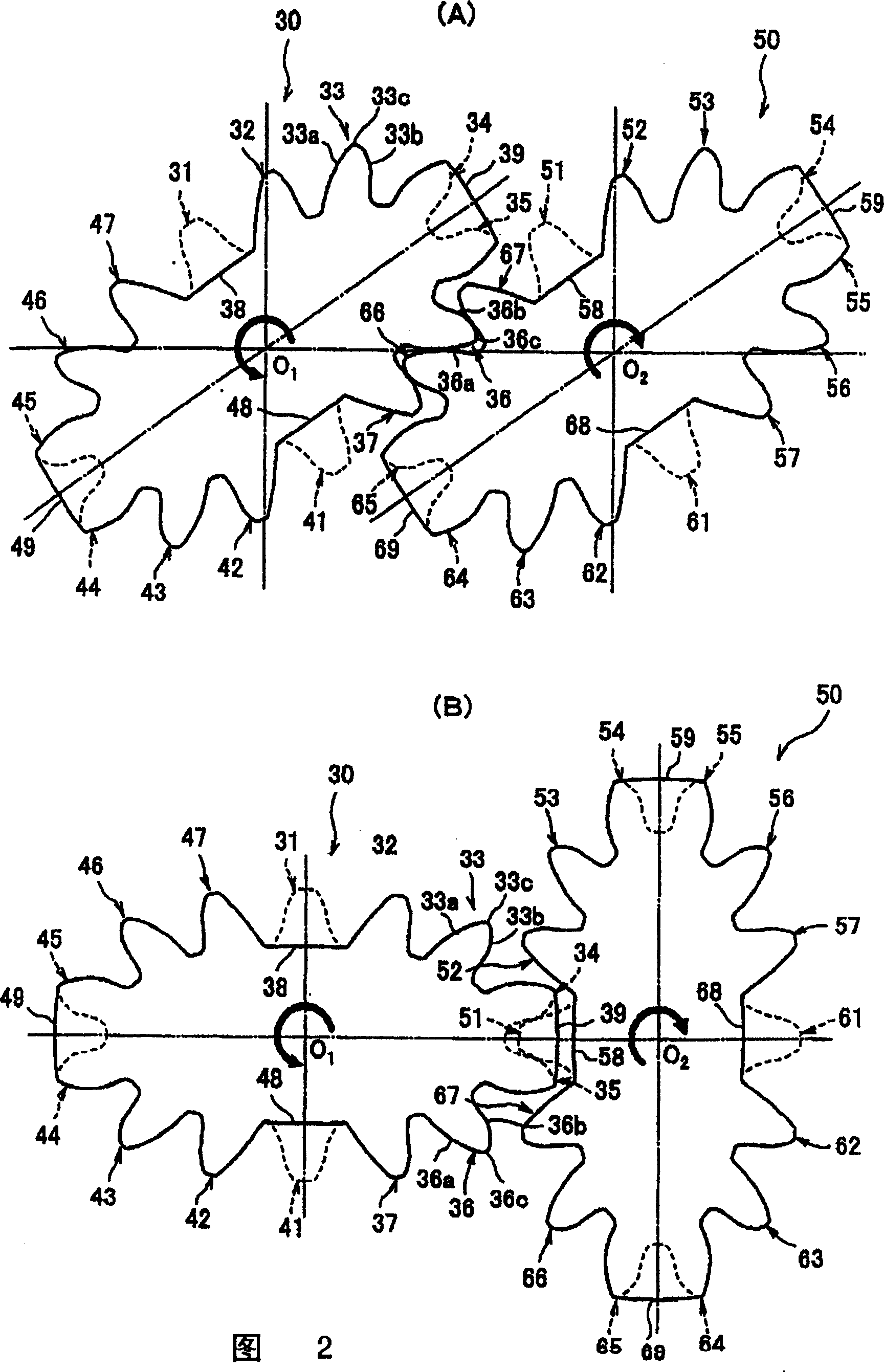

Non round gear and volumetric flowmeter using same

InactiveCN1573302ALittle changeEasy to set upVolume/mass flow measurementRotary piston pumpsEllipseEngineering

The number of teeth is set to 4n+2 (n is a natural number), both the ends on a long axis are set to be teeth grooves, both the ends on a short axis are set to be tips, a pitch curve is set to be, for example, an ellipse, and tooth marks 31-37, 41-47 are set to be basic tooth mark curves. With the tooth mark curve, the engagement teeth surface is set to be an involute curve, a non-engagement tooth surface is set to be a cycloid curve, and the tool pressure angle of each tooth mark is set by an undercut limit and a point limit. The non-circular gears 30, 50 bury the recess between two tooth marks, holding the tooth space located at both the ends on the long axis, based on the basic tooth mark curve, and have a shape, where the tooth section including the tip at both the ends on the short axis are scraped off, and the number of teeth completed is finally set to 4n-2. Accordingly, it is able to obtain a non-circular gear that reduces the change in an engagement pressure angle, is advantageous for setting the tool pressure angle of an engagement teeth surface, can reduce the number of teeth without forming an overhang section, and can fully secure the sealing performance with the inner wall of a casing to be installed.

Owner:OVAL CORP

Design method of high-order modified eccentric circular gear and non-circular gear pair conjugated with high-order modified circular gear

InactiveCN104455313AEasy programmingHigh solution accuracyPortable liftingToothed gearingsEngineeringMaximum pressure

The invention discloses a design method of a high-order modified eccentric circular gear and a non-circular gear pair conjugated with the high-order modified circular gear. There is no literature report on design and application research on a high-order modified eccentric circle-non-circular gear pair so far. The design method specifically comprises the following steps that firstly, a pitch curve equation of a high-order modified eccentric circle gear and a non-circular gear pair conjugated with the high-order modified eccentric circle gear is established, and a center distance is calculated through the numerical method; secondly, the concavity and convexity of a pitch curve are verified, the maximum modulus under the situation that undercutting is not carried out when a gear is machined through the gear shaping method is obtained, the pressure angle change range is calculated, the maximum pressure angle value is verified, and the contact ratio when the high-order modified eccentric circle gear and the non-circular gear pair conjugated with the high-order modified eccentric circle gear are meshed is calculated. According to the design method, a whole set of thorough design theoretical basis is provided for the high-order modified eccentric circle gear and the non-circular gear pair conjugated with the high-order modified eccentric circle gear in actual application, and the using and popularizing of the high-order modified eccentric circle gear and the non-circular gear pair conjugated with the high-order modified eccentric circle gear are promoted.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

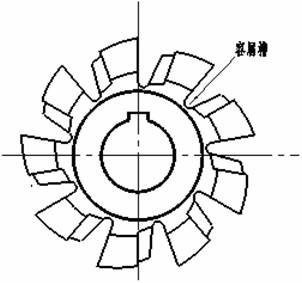

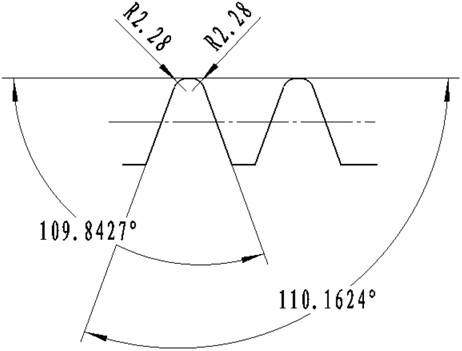

Processing method of tooth thickness-variable gear with intersecting axles and hob of tooth thickness-variable gear

InactiveCN102689054AOvercome the disadvantage of asymmetryImprovement of asymmetrical shortcomingsGear teeth manufacturing toolsGear teethFluteEngineering

The invention relates to the field of mechanical processing and manufacturing, in particular to a processing method of a tooth thickness-variable gear with intersecting axles and a hob of the tooth thickness-variable gear, and aims to improve the asymmetry of tooth forms of the left side and the right side of a processed tooth thickness-variable gear. Each cutting blade of the hob comprises a first straight line, a first circular arc, a second straight line, a second circular arc and a third straight line which are tangent to one another; the pressure angles of the cutting blades on the left side and the right side are not equal; the included angle between the first straight line and the second straight line of the hob is 110.1624 degrees; the included angle between the second straight line and the third straight line is 109.8427 degrees; the radius of the first circular arc is 2.28 mm, and the radius of the second circular arc is 2.28 mm as well; a chip flute is a straight flute parallel to the axle line of the hob; the processed tooth thickness-variable gear has a large-end modulus of 6 mm, a tooth number of 21, a helical angle of 11 degrees and a crossed axis angle of 2.18 degrees; and the two gears have same size and reversal rotation directions. The invention further discloses a method for processing the tooth thickness-variable gear. The asymmetry of tooth forms of the tooth thickness-variable gear can be greatly improved by using the method and the hob provided by the invention.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Electric power steering apparatus

InactiveUS6976556B2Reduce the amount of variationImprove smoothnessPortable liftingFluid steeringElectric power steeringTorque transmission

Electric power steering apparatus includes an electric motor for producing steering assist torque corresponding to steering torque applied to a steering system, and a worm gear mechanism for transmitting the steering assist torque to the steering system. The worm of the worm gear mechanism has a pressure angle greater than a pressure angle of the worm wheel, so as to reduce an actual meshing pitch circle diameter of the worm in the worm gear mechanism.

Owner:HONDA MOTOR CO LTD

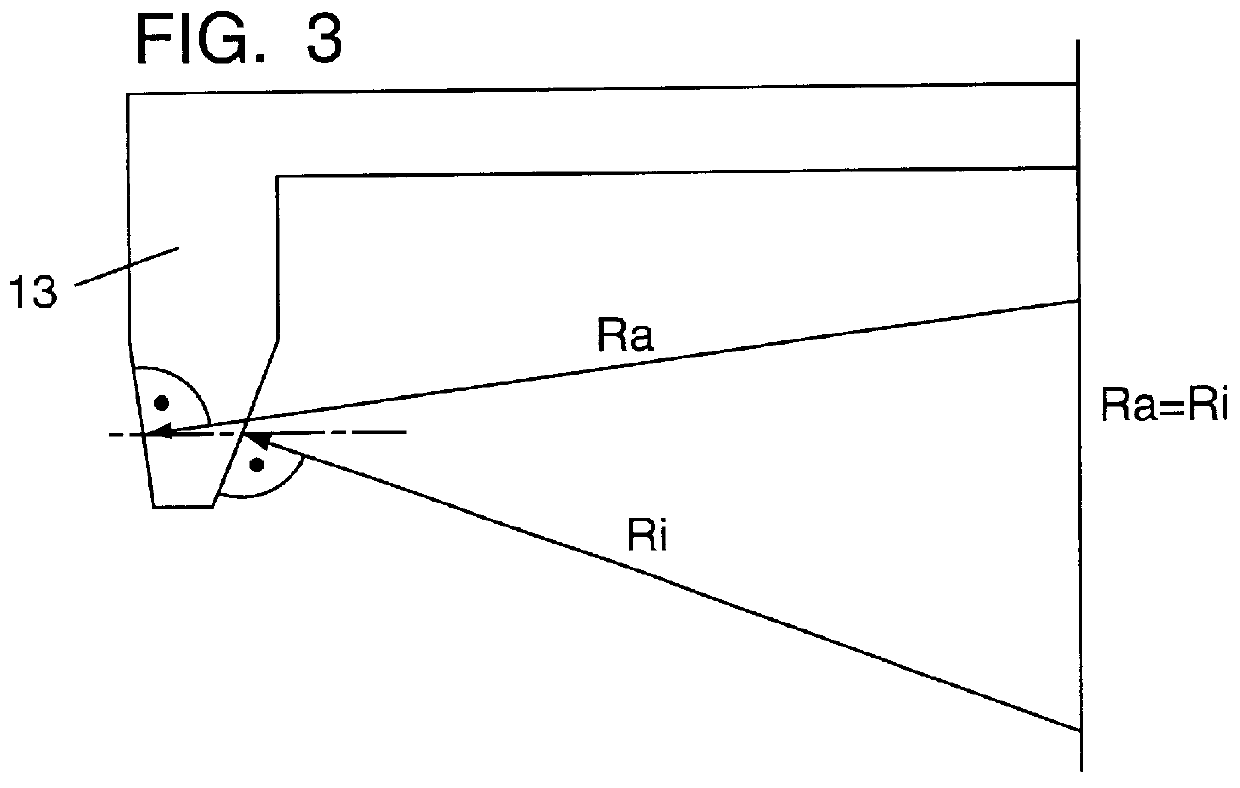

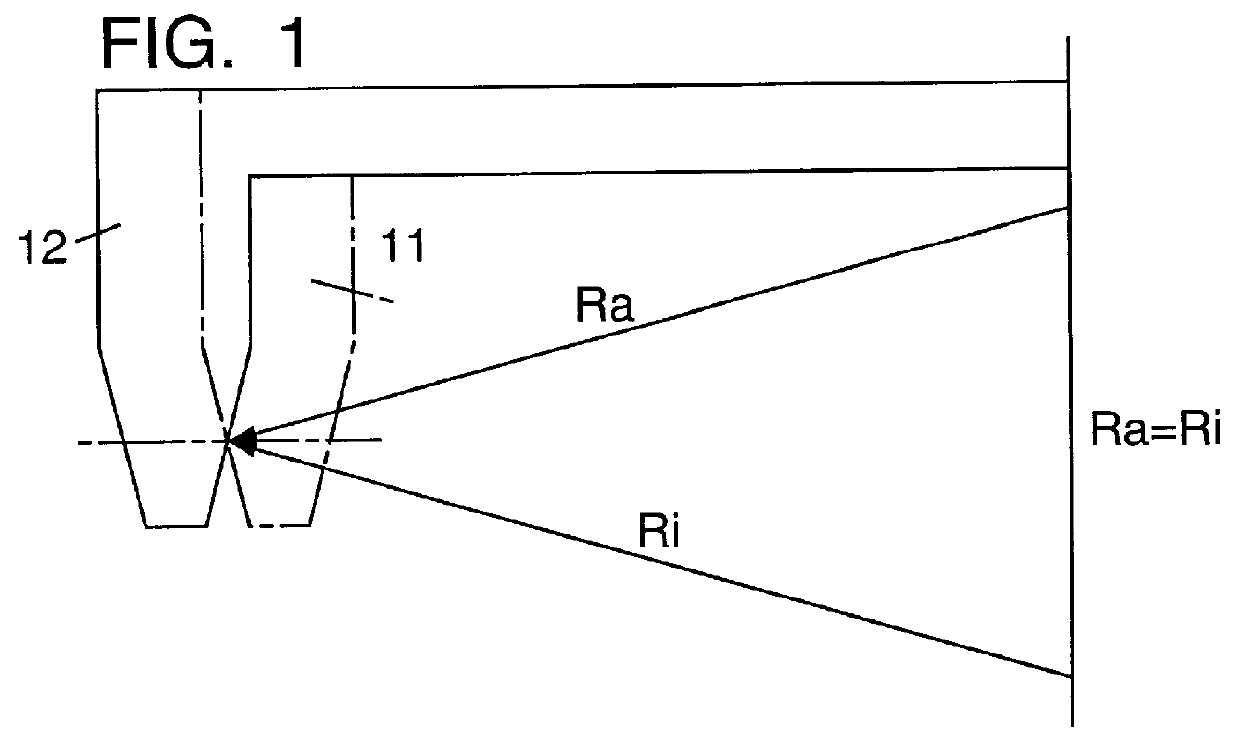

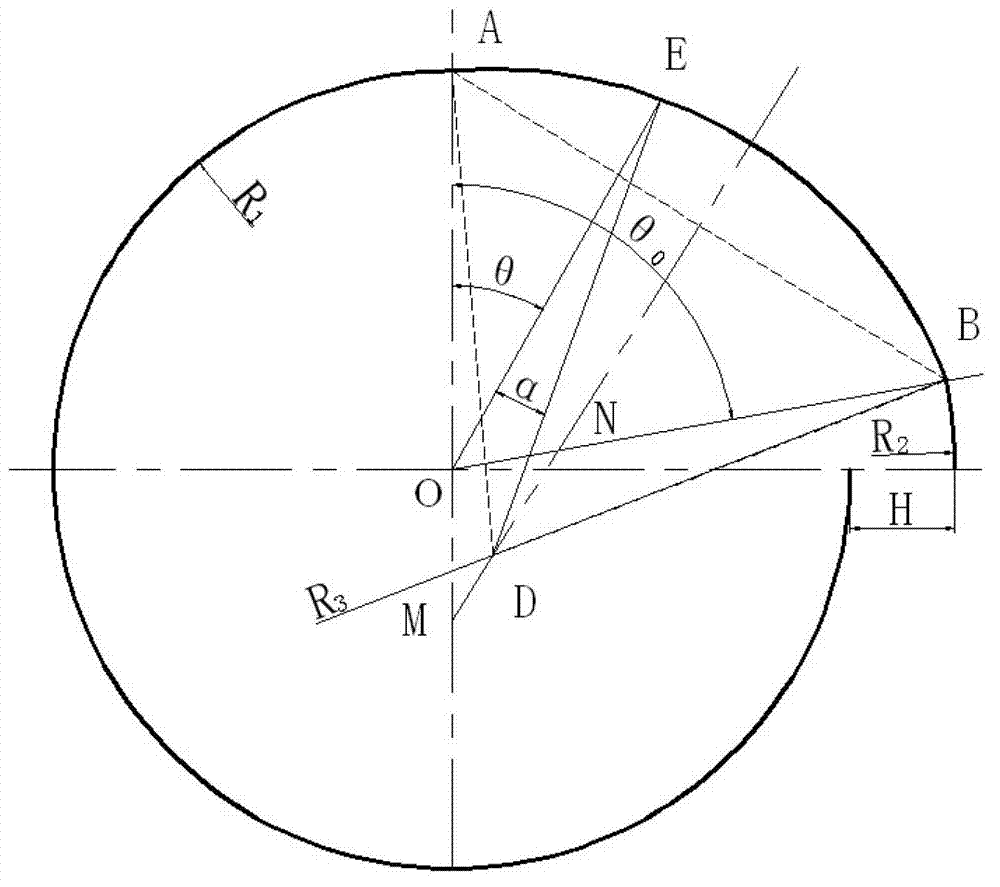

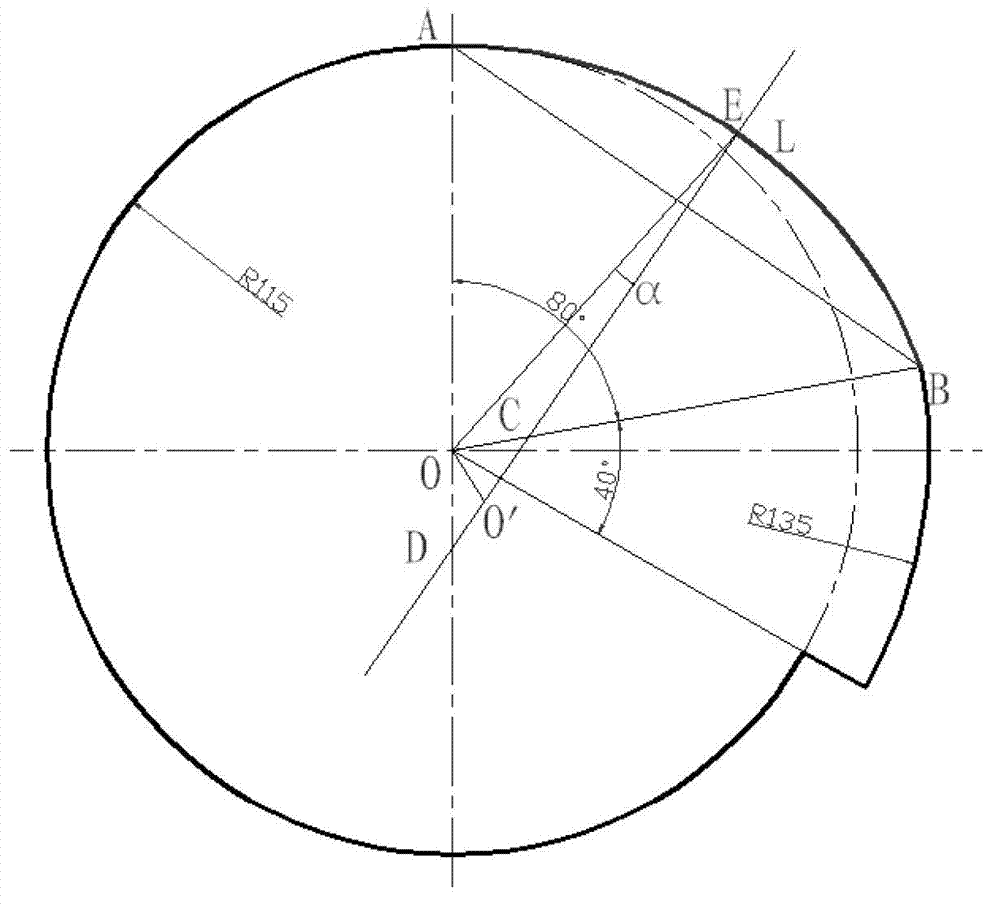

Variable pressure angle cam contour line design method applicable to sudden variable load

The invention discloses a variable pressure angle cam contour line design method applicable to sudden variable load. R1 refers to the radius of a base circle omicron, R2 refers to the farthest dwell arc radius, AB arc refers to a cam contour line with the radius of R3, and alpha refers to a theoretical working curve pressure angle. When the normal values R1 and R2 are given, a graph of relation between a lift range h and the pressure angle alpha can be determined under different R3 values. An optimal arc radius value R3 corresponding to the pressure angle alpha changed along with the lift range h under sudden variable load can be found through the graph. The variable pressure angle cam contour line design method applicable to sudden variable load has the advantages that the pressure angle is extremely small in an open stage of a main valve core during opening of a cam and matched with characteristics of loads, and additional force applied to a top rod can be decreased.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com