Method for designing swinging follower cylindrical cam contour line

A technology of cylindrical cam and design method, applied in the field of mechanical design, can solve problems such as inability to be practically applied, complex analytically, difficult to master, etc., and achieve the effect of simple design process, broad application prospects, and easy mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples, but the present invention is not limited to the following specific examples.

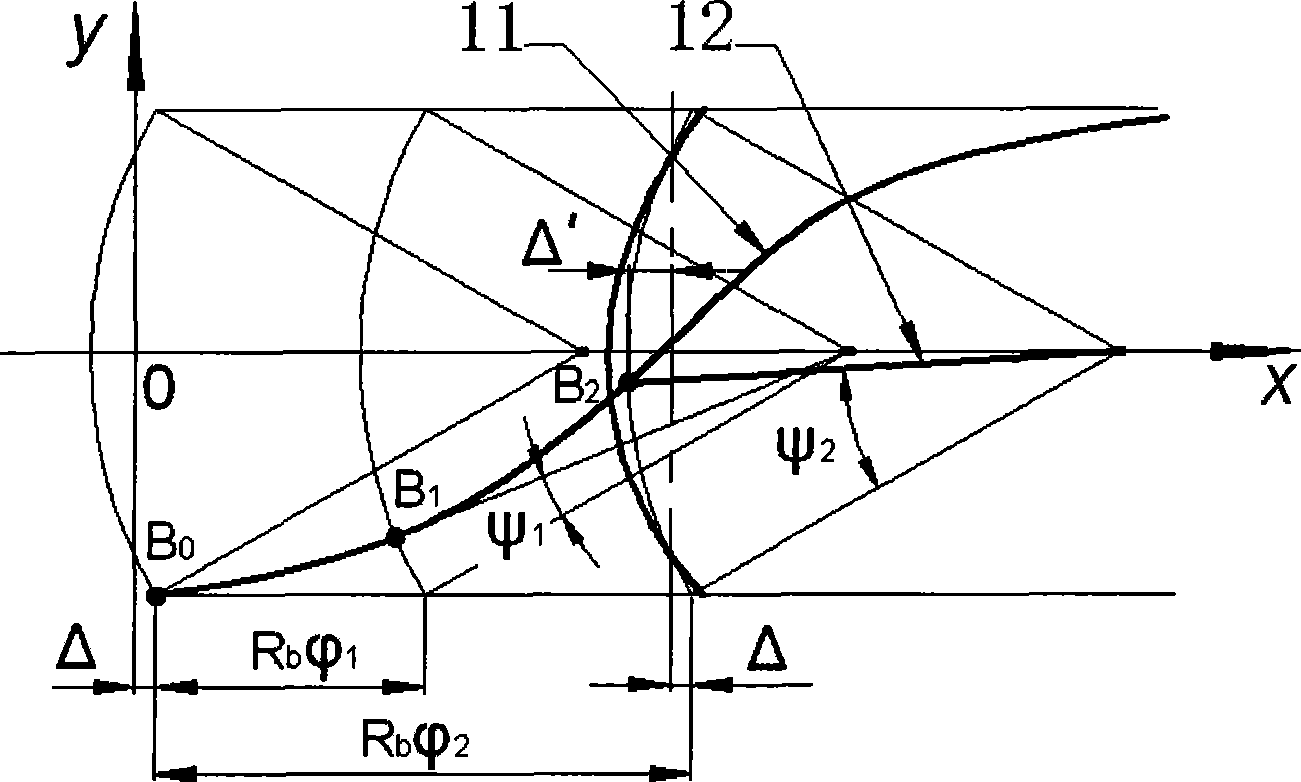

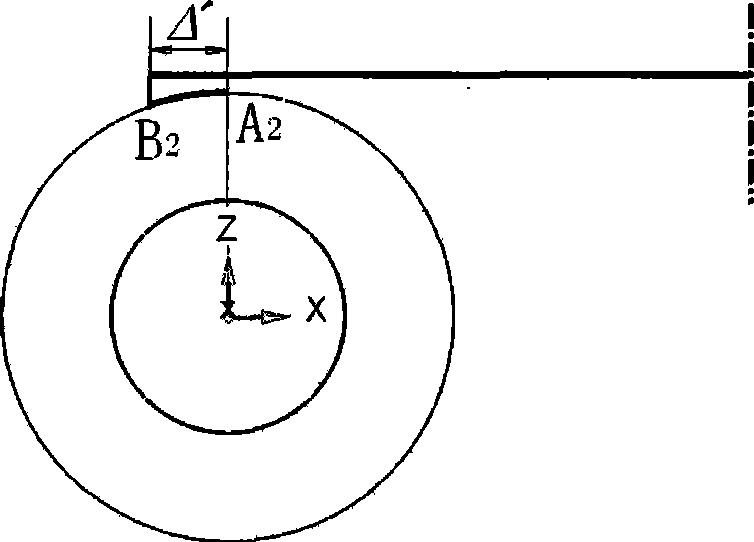

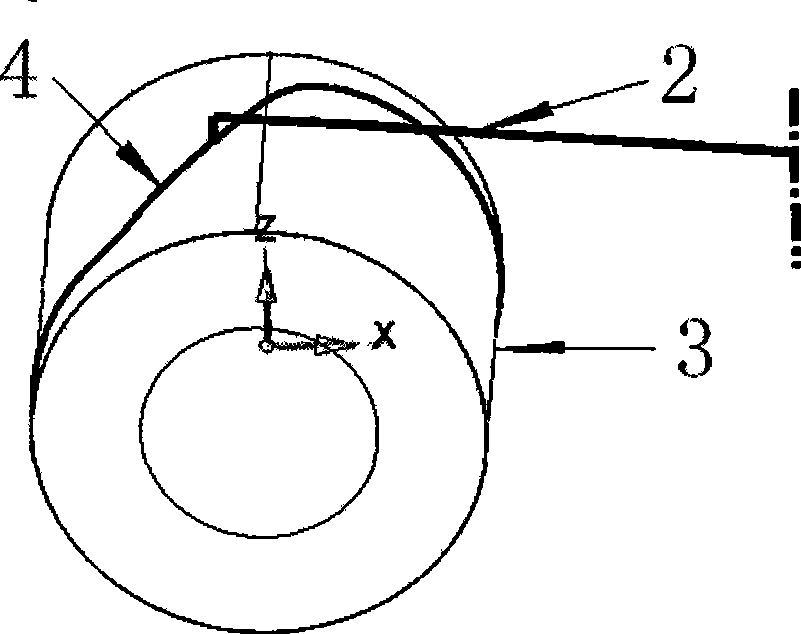

[0045] (1) Establish the curve equation of the contour expansion line

[0046] ① Introduce the coordinate expression of swinging from the 3D expansion of the moving part

[0047] That is to introduce the coordinate expression of the 3D development line of the displacement curve of the swing follower obtained in the applicant's previous patent "Processing Method of the Cylindrical Cam Groove of the Swing Follower" (Patent No.: ZL200610154488.9):

[0048]

[0049] In the formula: S is the displacement of the follower, the unit is mm; l is the length of the pendulum rod, the unit is mm; is the rotation angle of the cylindrical cam, in degrees (°); a is the distance from the swinging axis of the pendulum rod to the rotating axis of the cylindrical cam, in mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com