Patents

Literature

1236 results about "Maximum pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

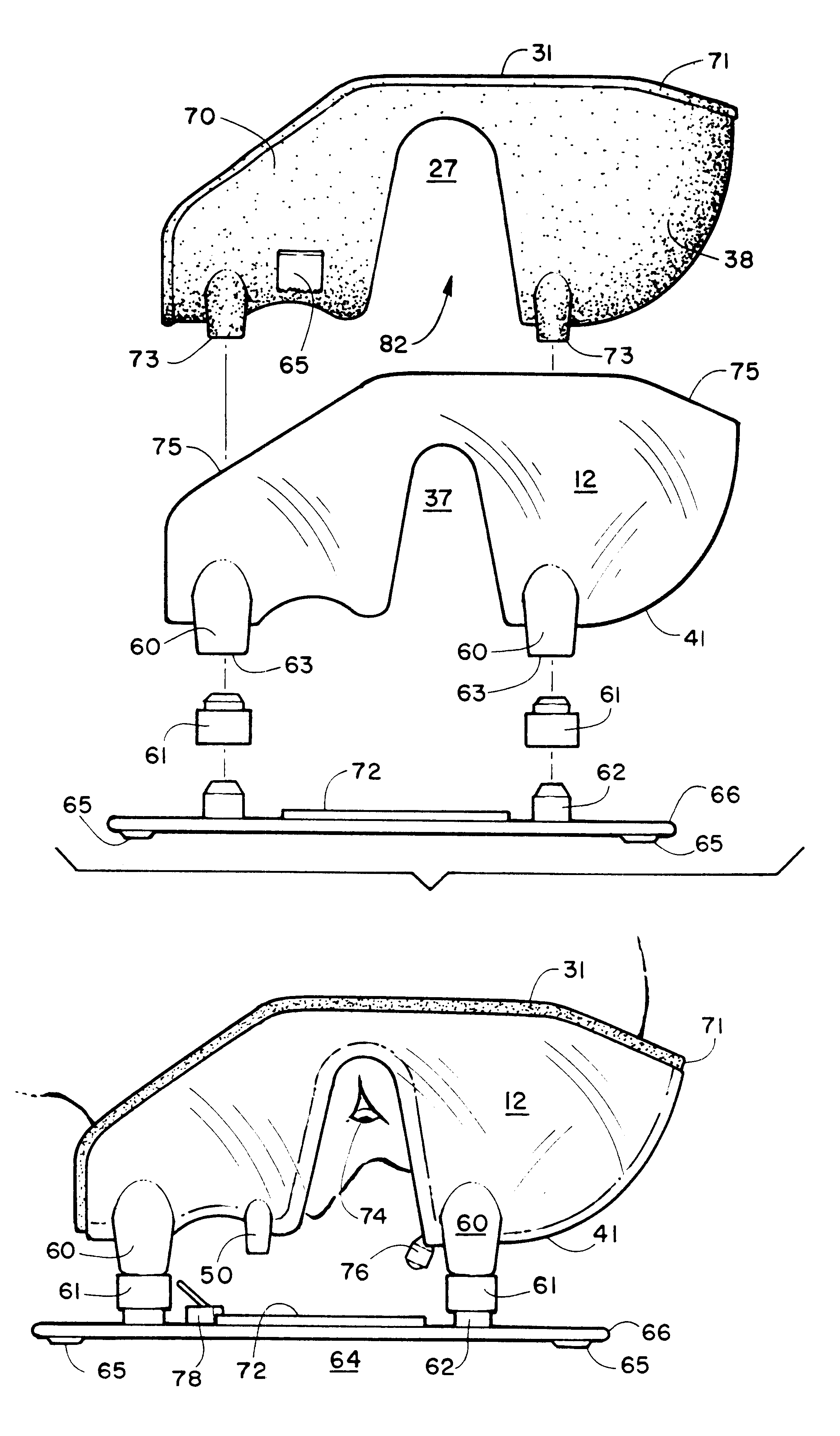

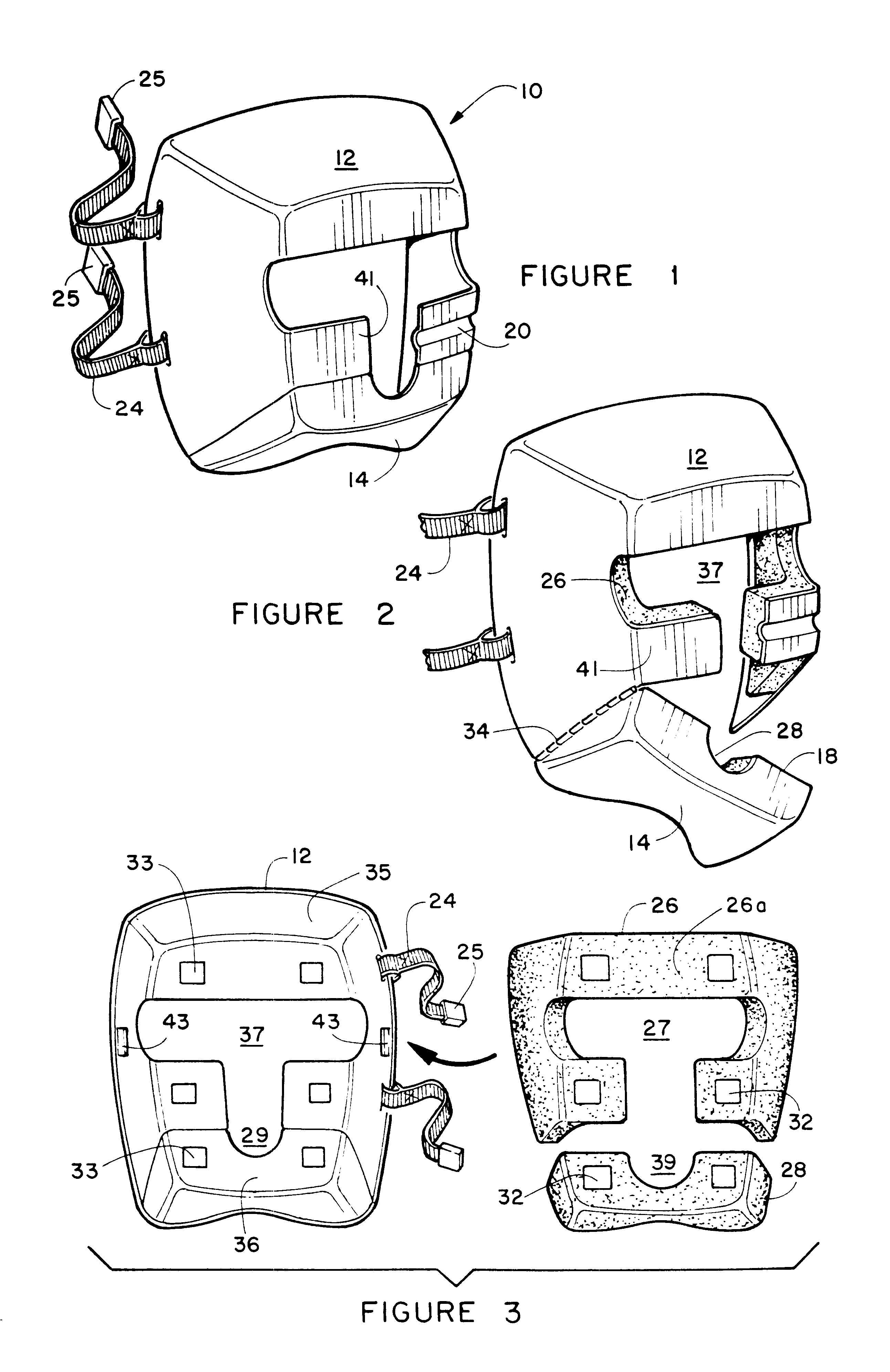

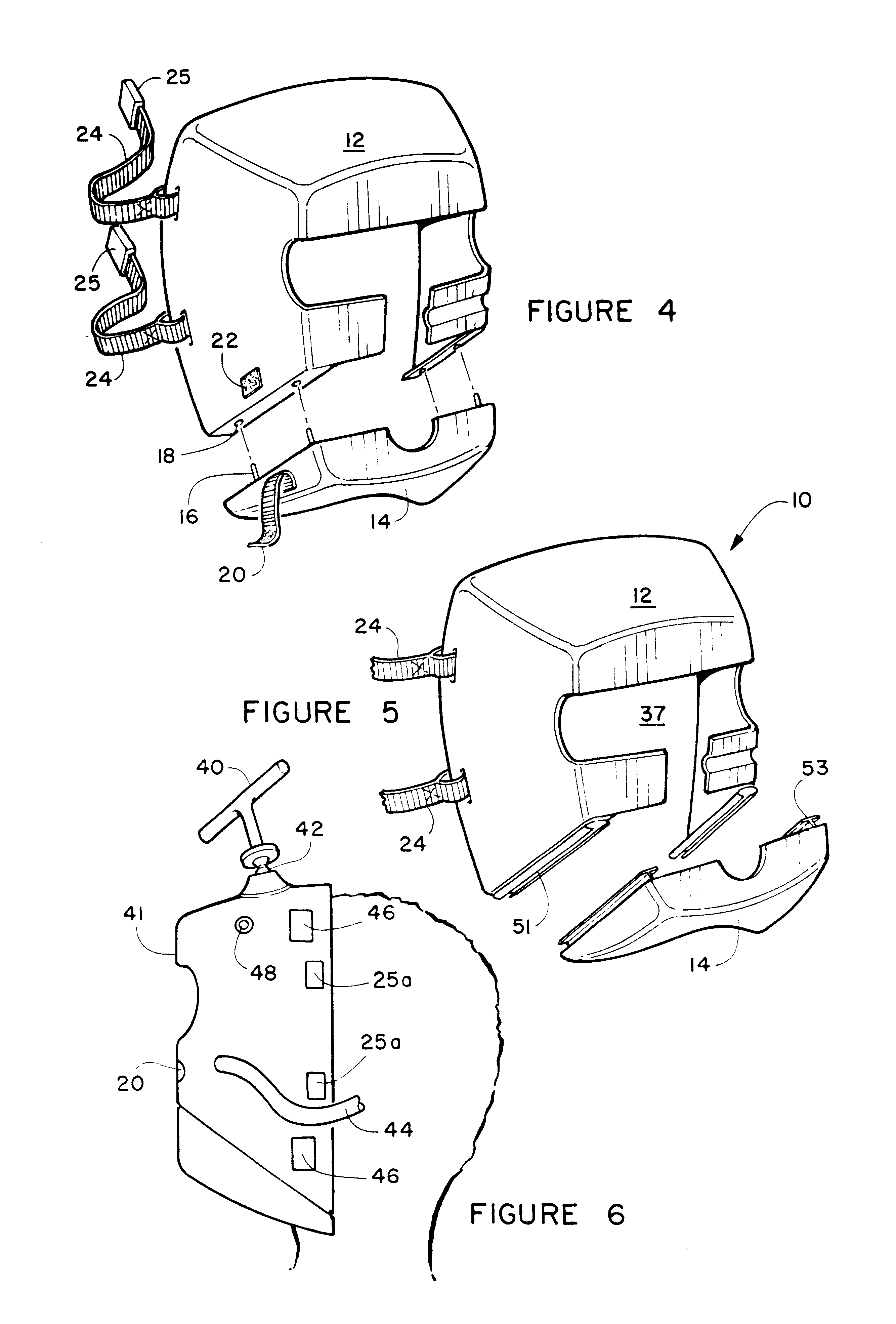

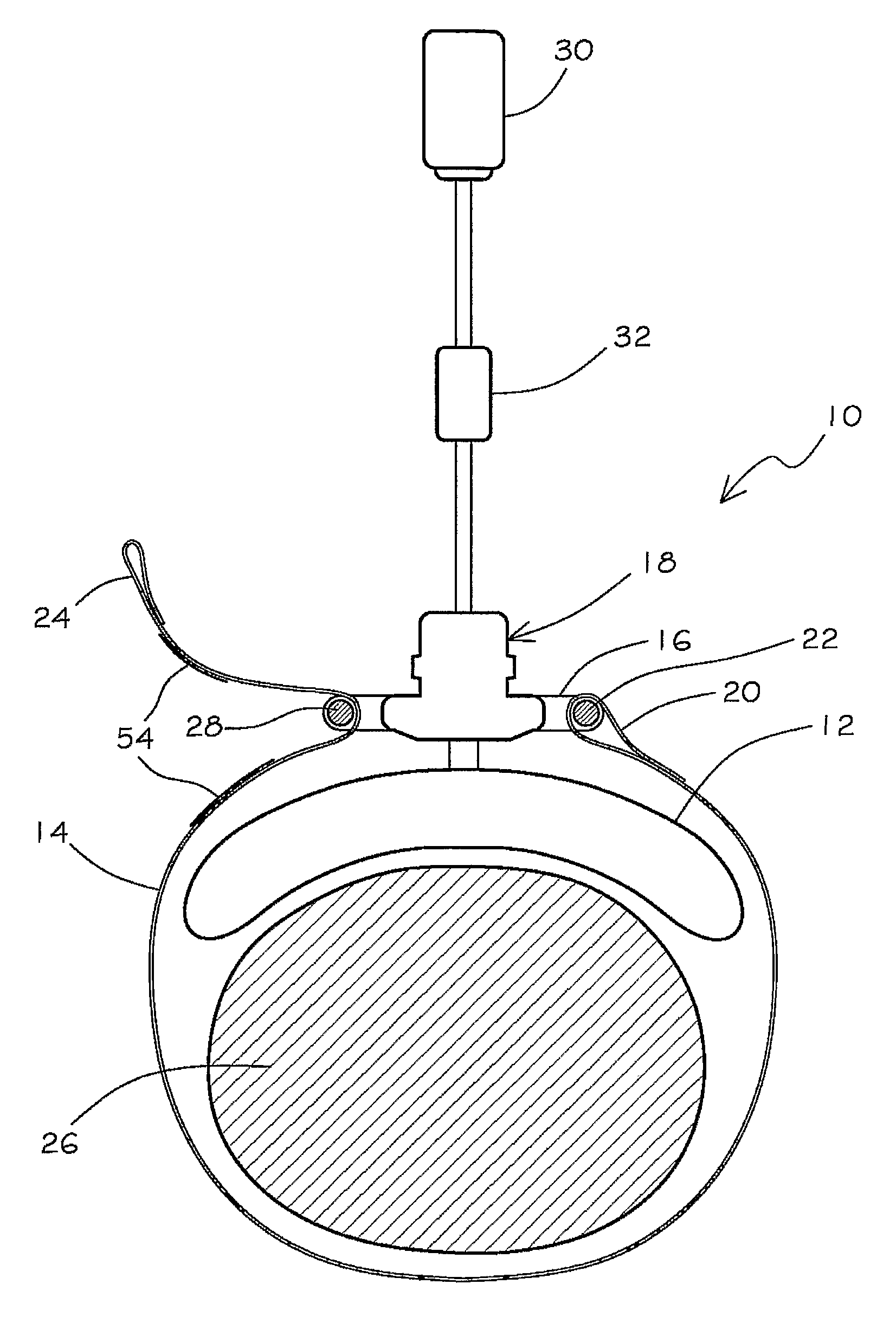

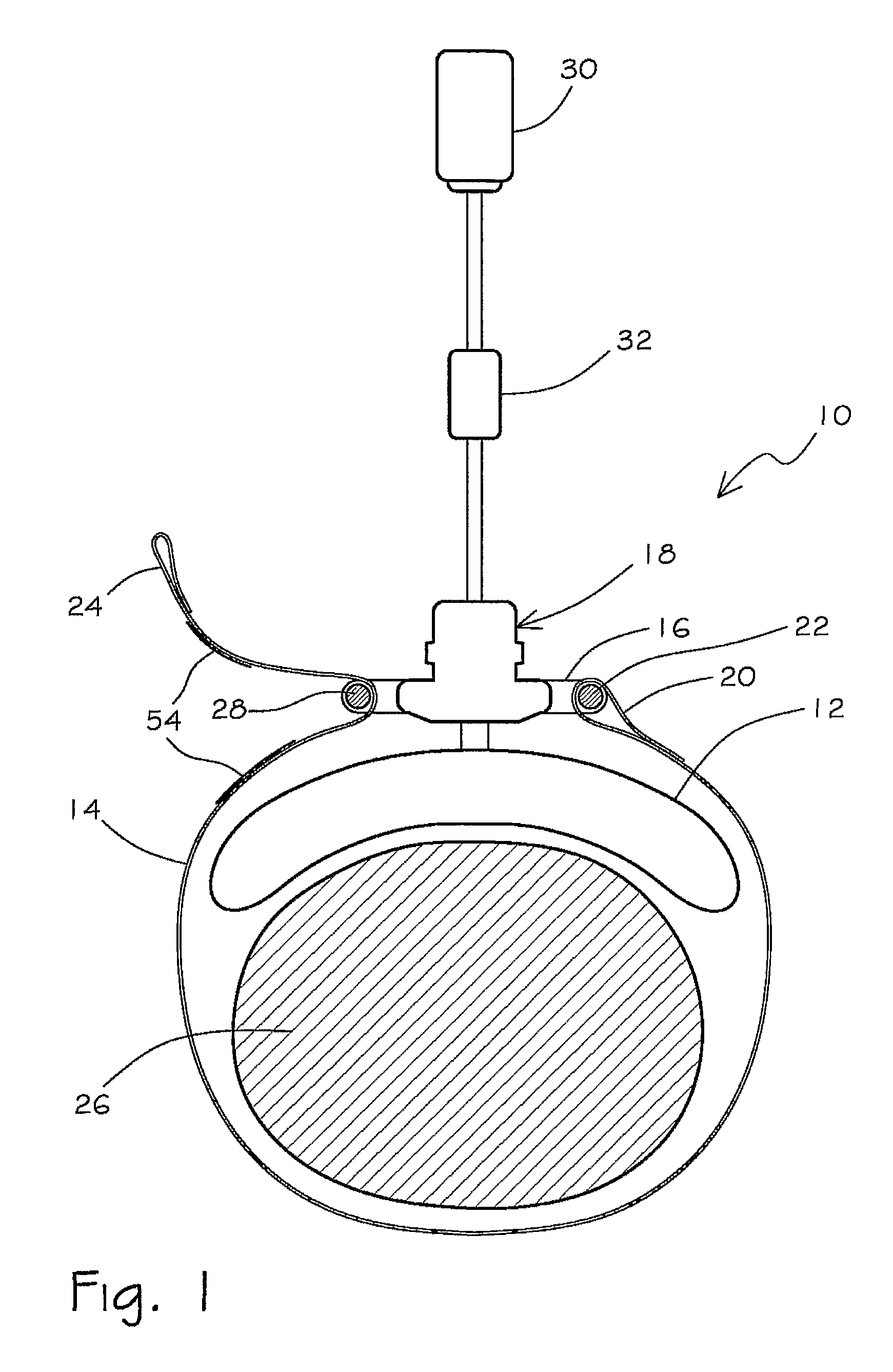

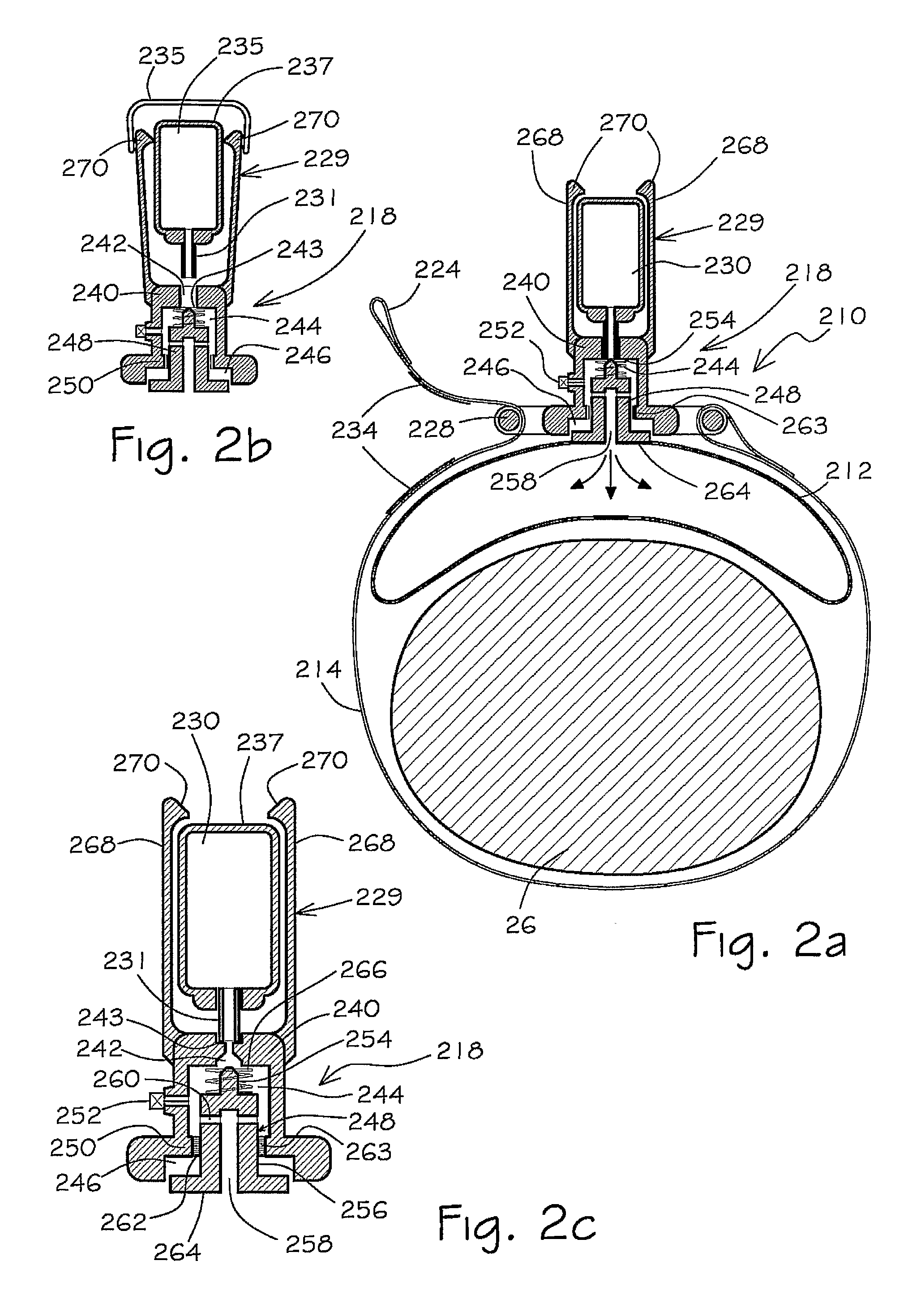

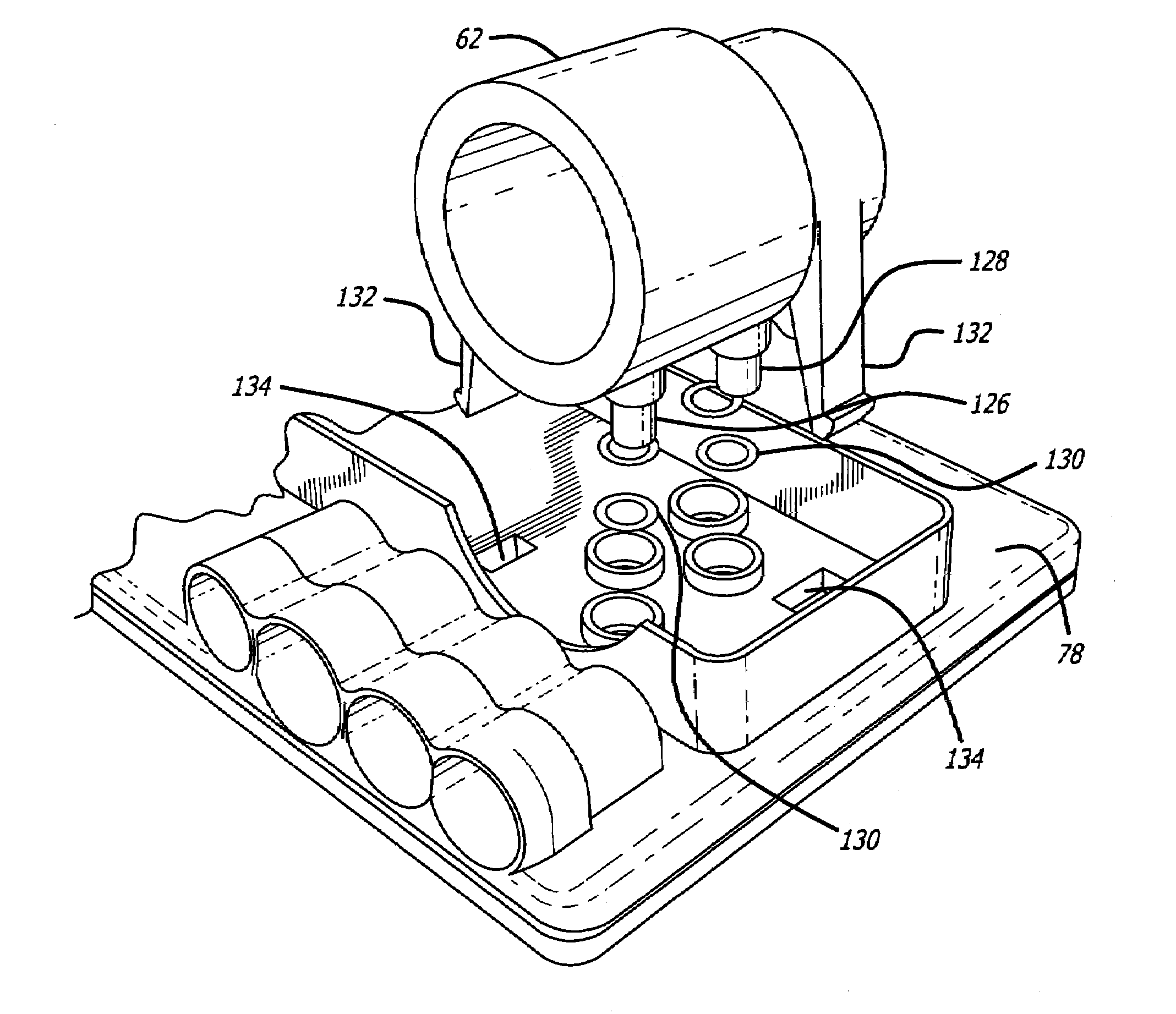

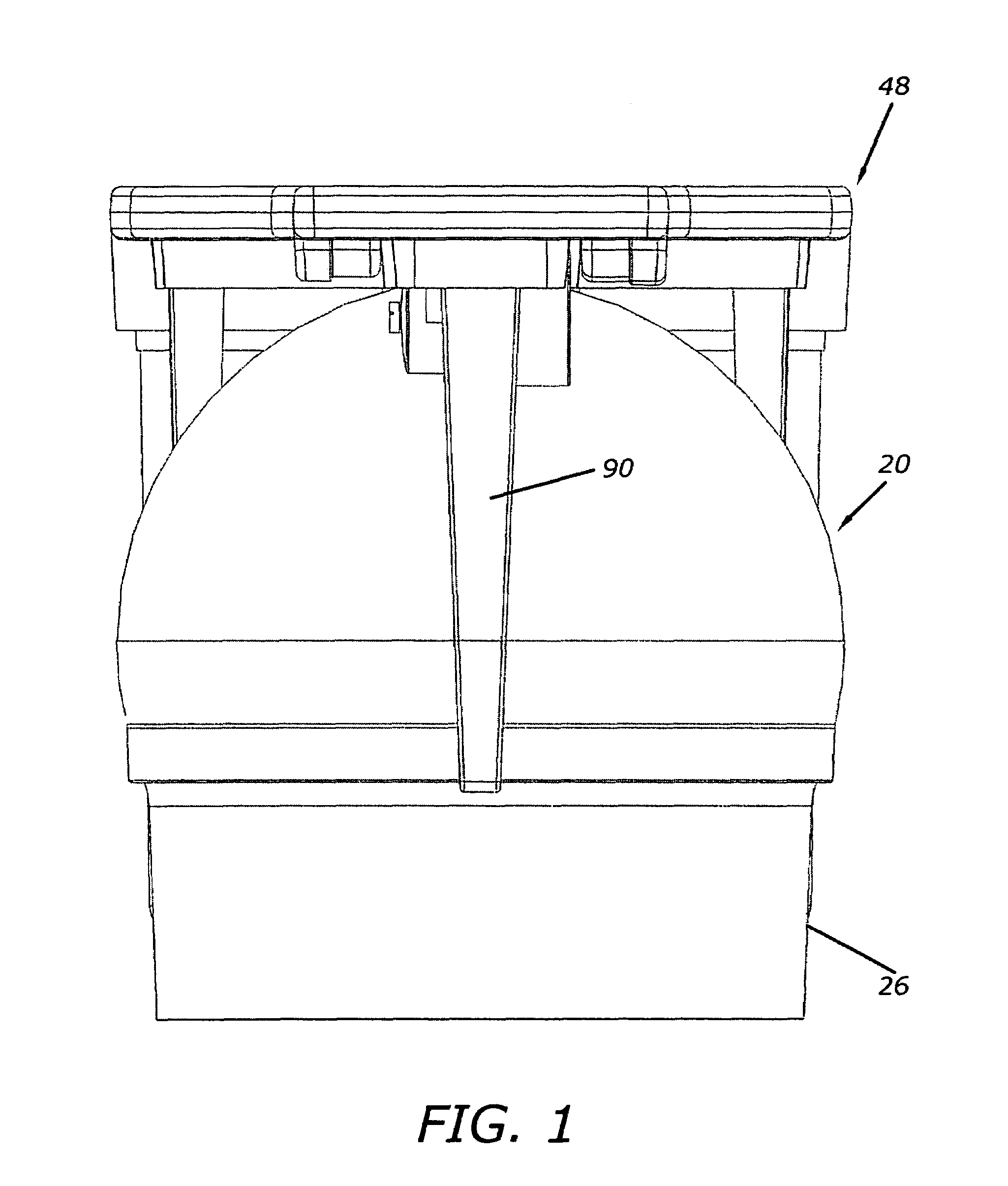

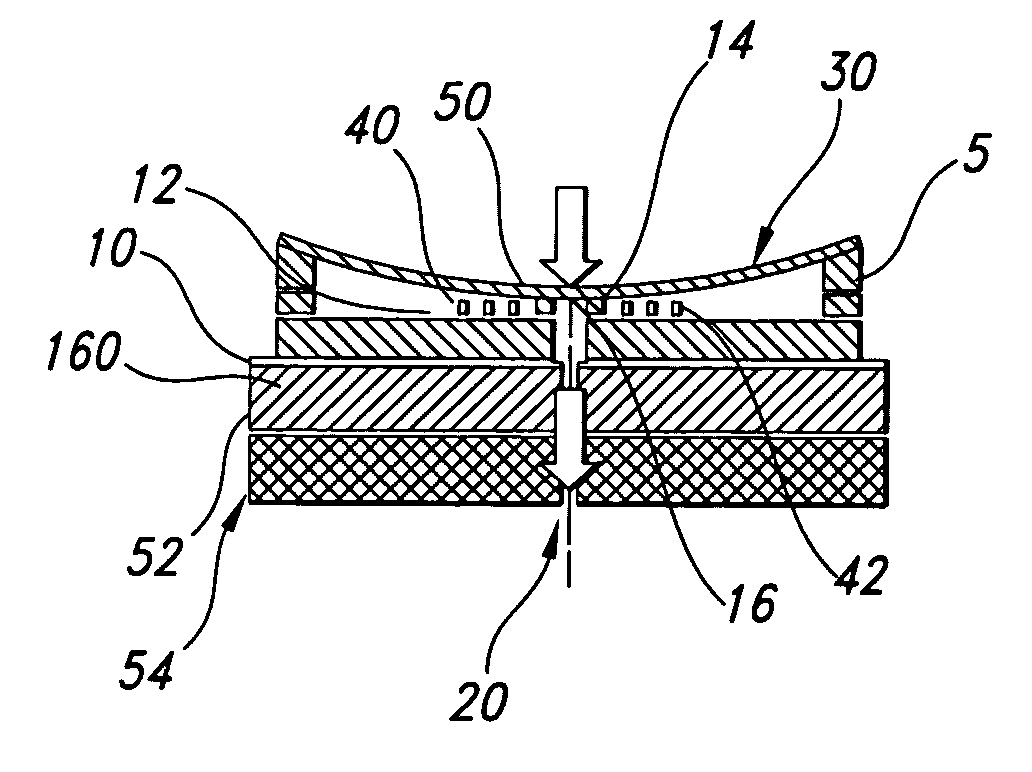

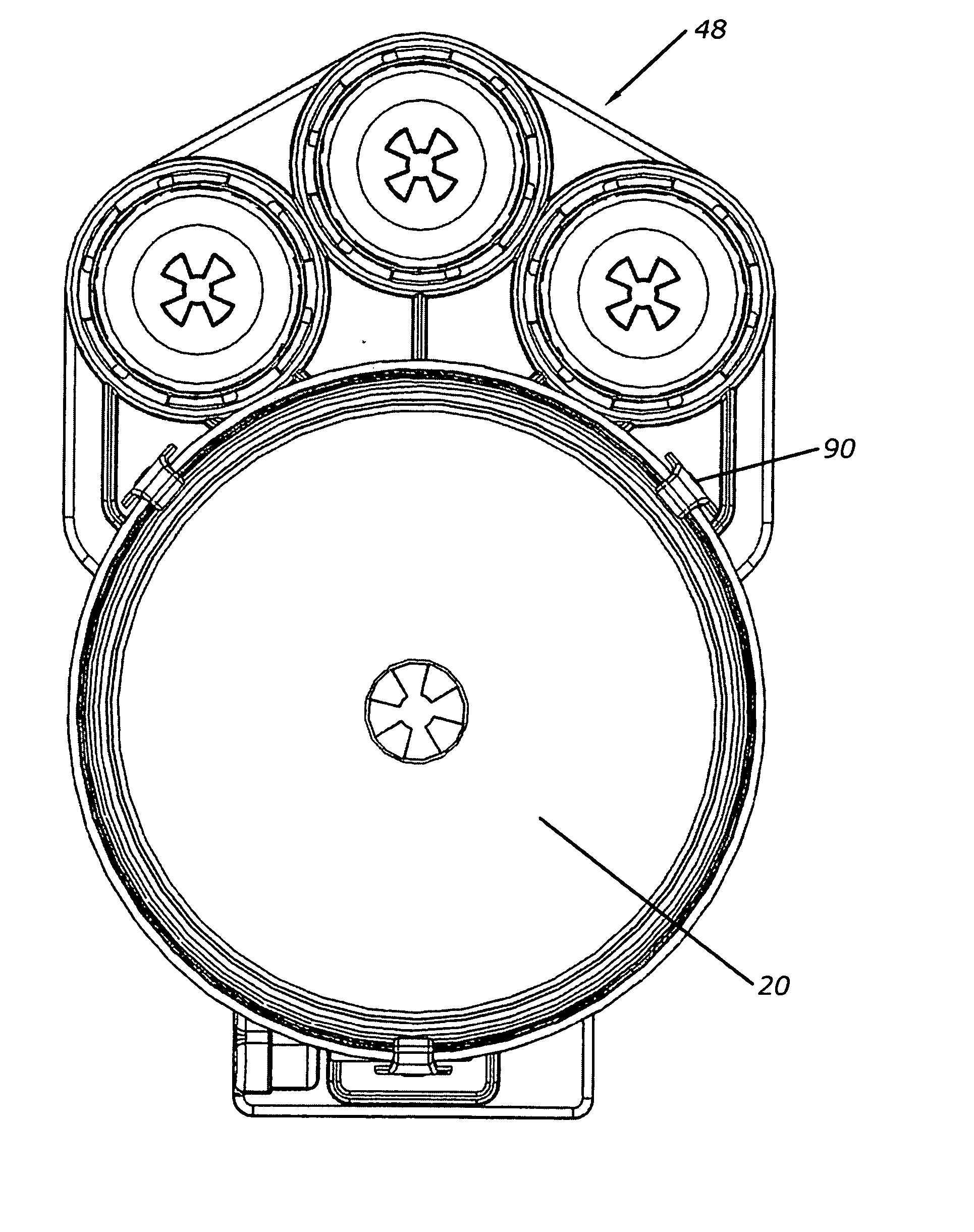

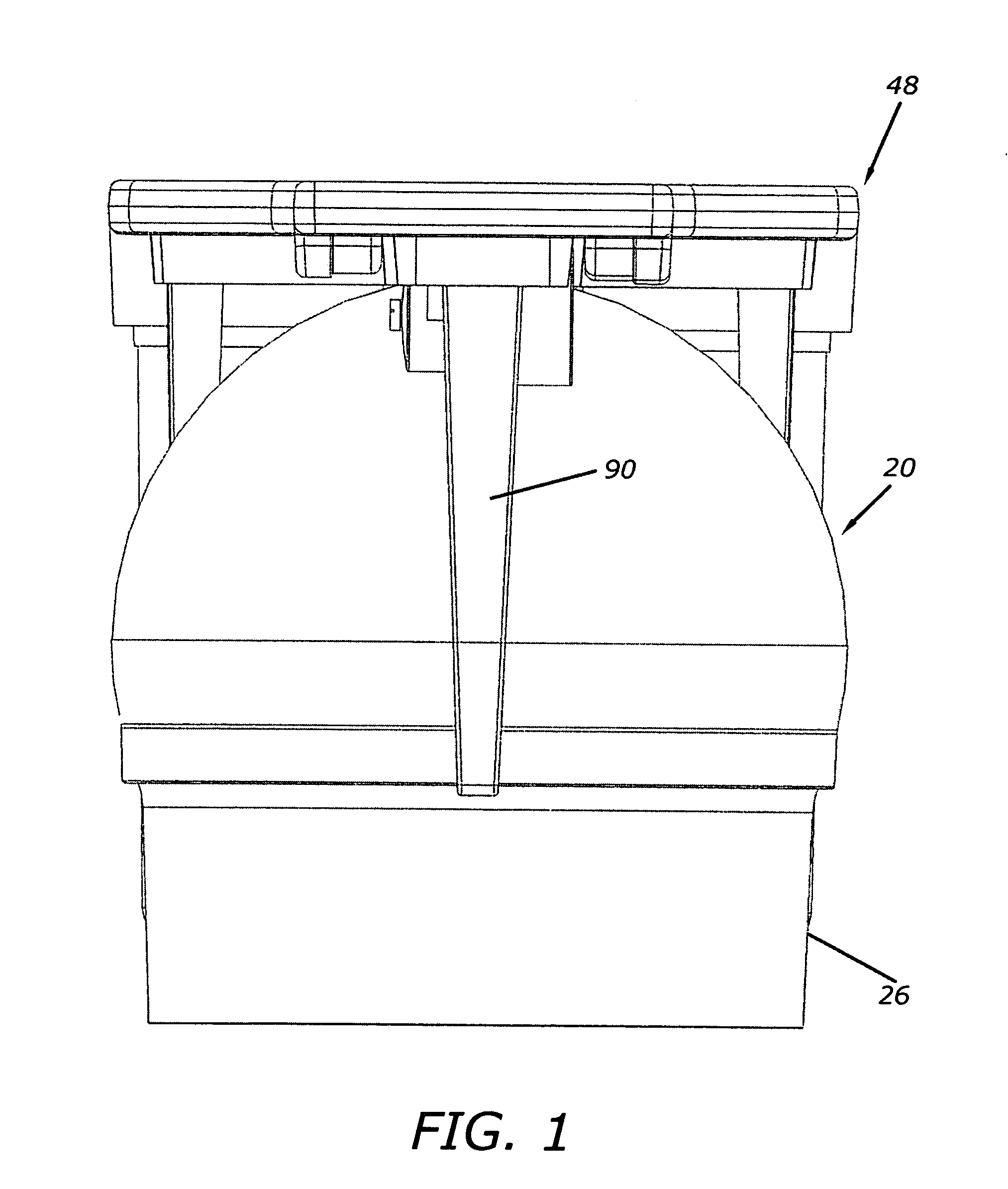

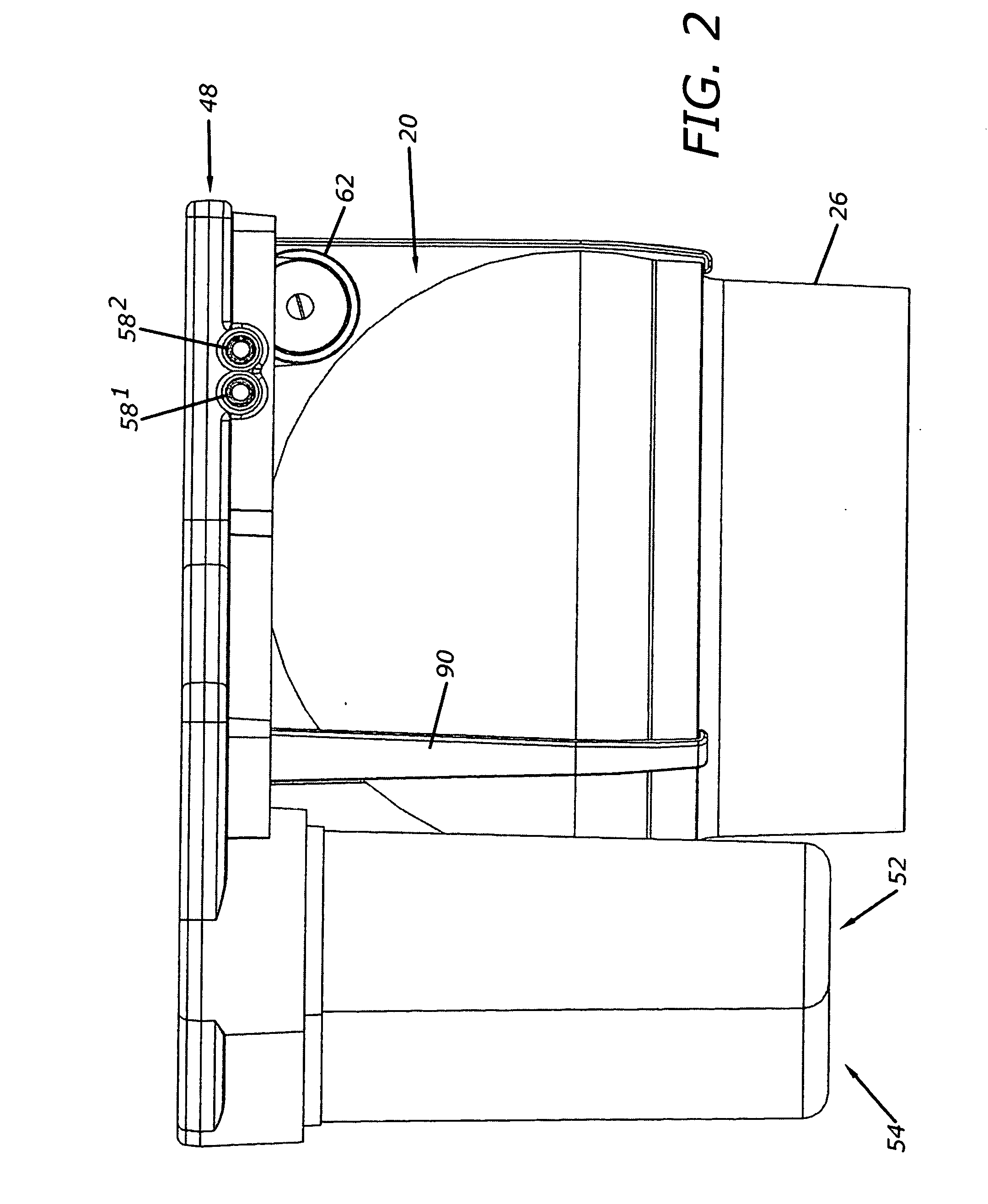

Protective cushion and cooperatively engageable helmet casing for anesthetized patient

InactiveUS6490737B1Aid in temperature controlEasy to viewOperating tablesEye treatmentTemperature controlChin

A protective helmet apparatus of modular construction to be worn by anesthetized patients for facial support during surgery. The helmet apparatus is assembled using one of a plurality of interchangeable, substantially transparent helmet casings, which are removably attachable to a plurality of dismountable facial cushions providing even support to the facial surface of a patient. The removable facial cushions are dimensioned on and interior surface to accommodate different sized facial structures of different patients to yield maximum pressure diffusion on the face and chin of the patient and are replaceable when worn. The exterior surface of the facial cushions are dimensioned for cooperative engagement with the interior surface of the helmet casing. A plurality of different facial cushions and helmet casings are modular in design and dimension to be interchangeable with each other thus providing accommodate the broad differences in facial structure and size of patients using them for surgery. The cushions may be marked with printed or color coded indicia to designate size. A view of the patients eyes and surrounding area is afforded through in line ocular apertures extending around a front surface area and up at least one sidewall. The ocular aperture is in line with a cushion ocular aperture when the cushion is engaged with the casing thereby allowing a view of the patent eye and surrounding face through the ocular aperture from the side of the device. Additional utility is provided by variable elevation above a registered engagement with a mount which also may provide a mirrored surface to reflect the patent facial features for viewing by upright doctors and operating staff. An optional integral heating element aids in temperature control of the patient's head during surgery.

Owner:DUPACO

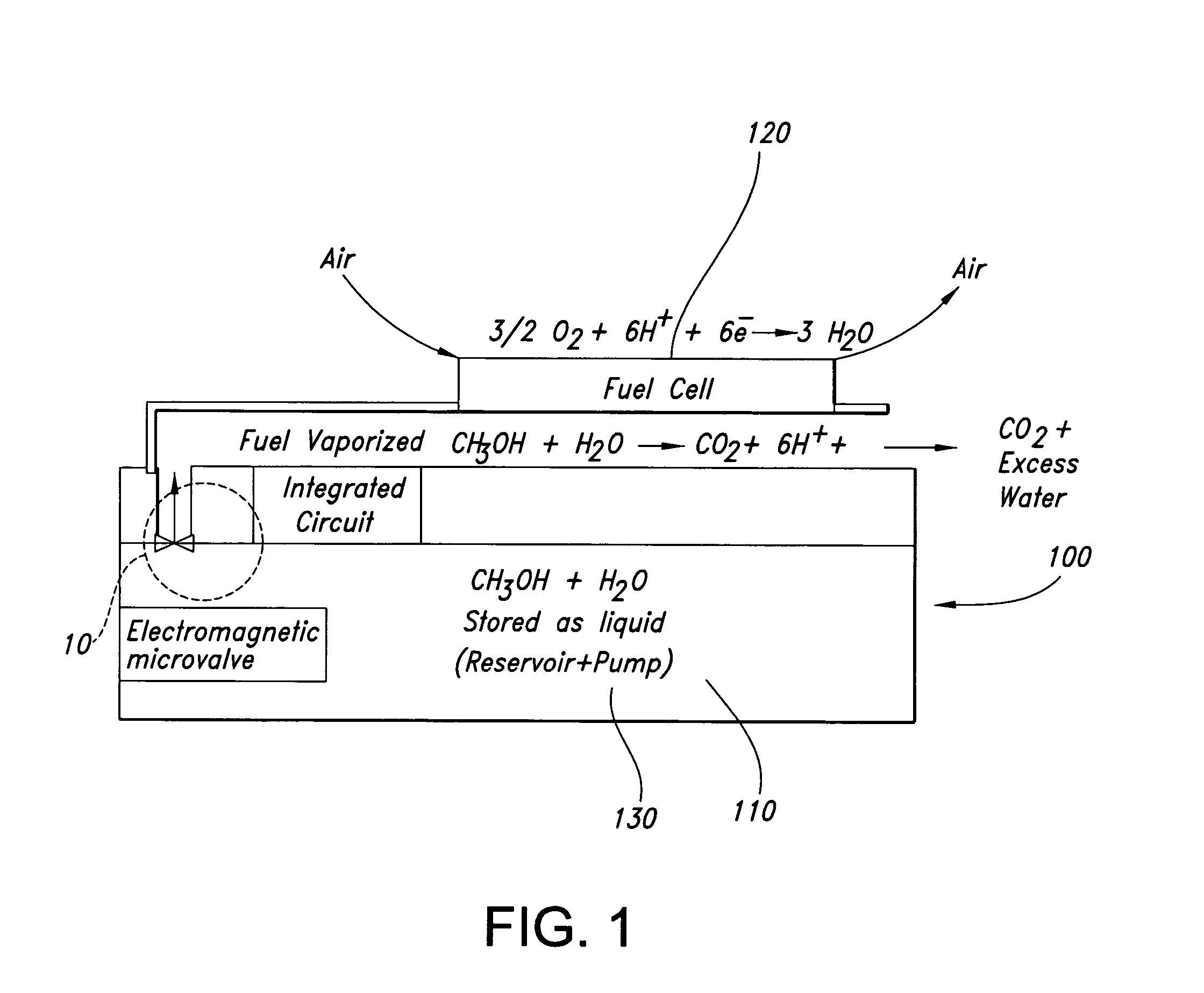

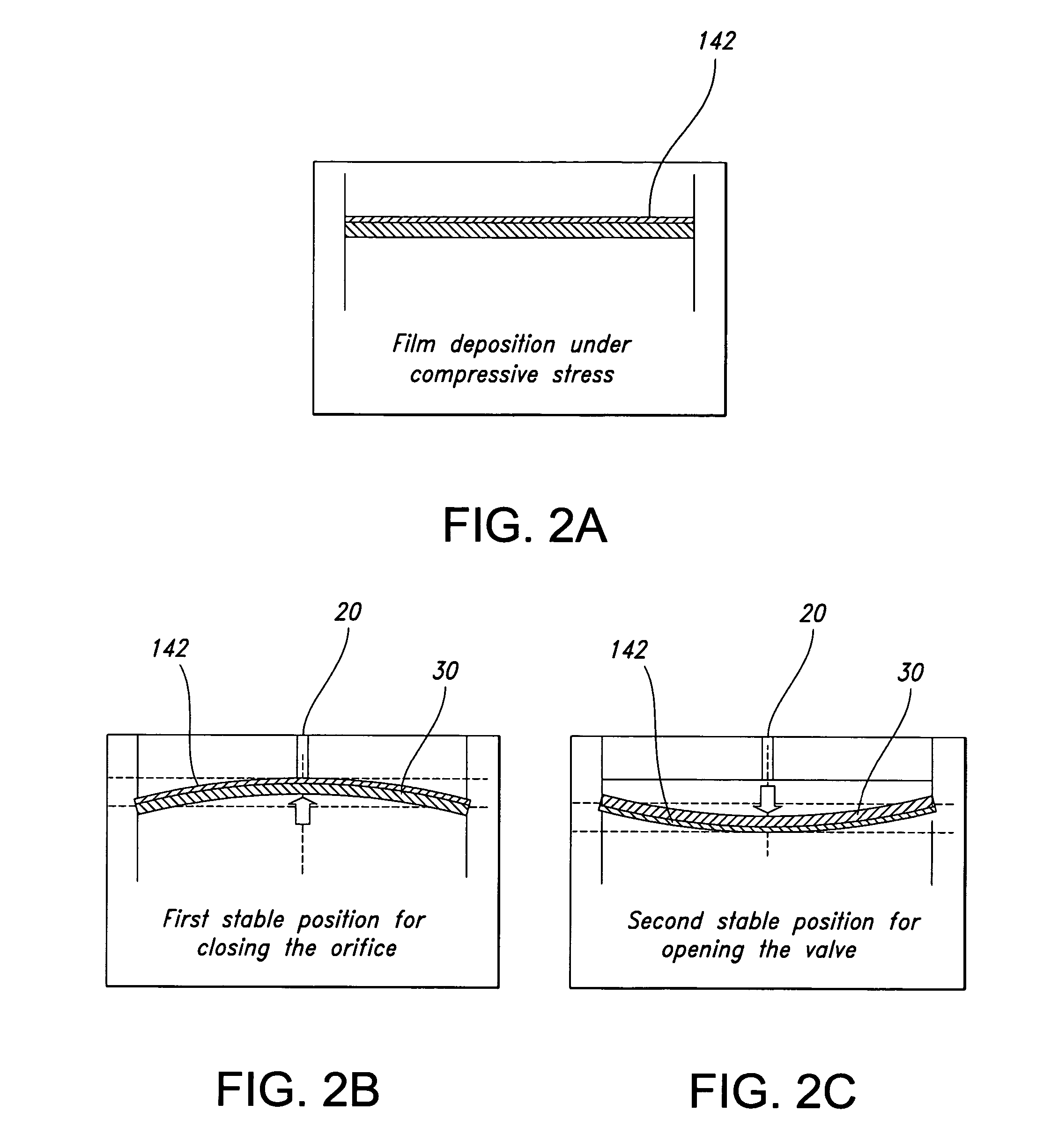

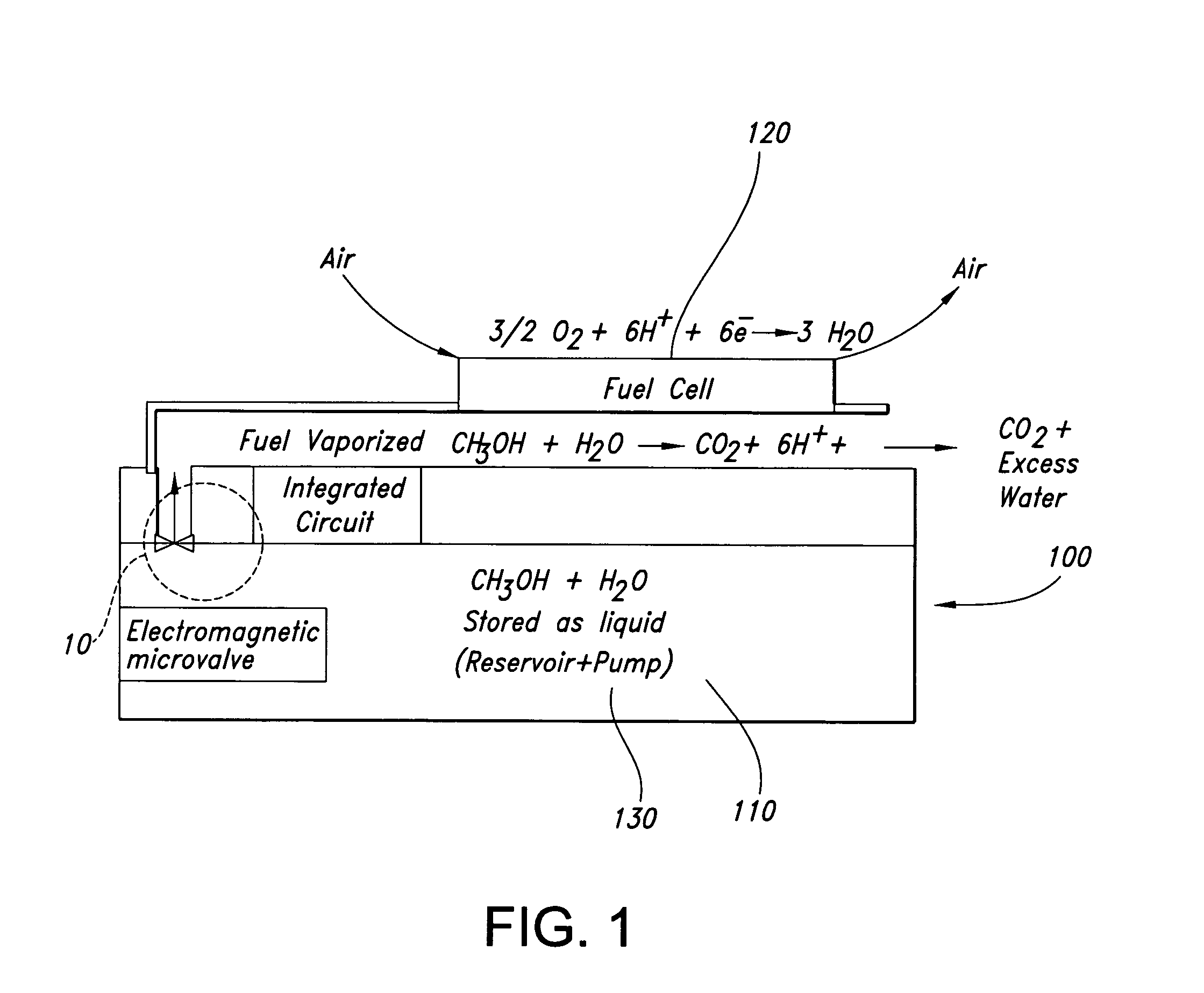

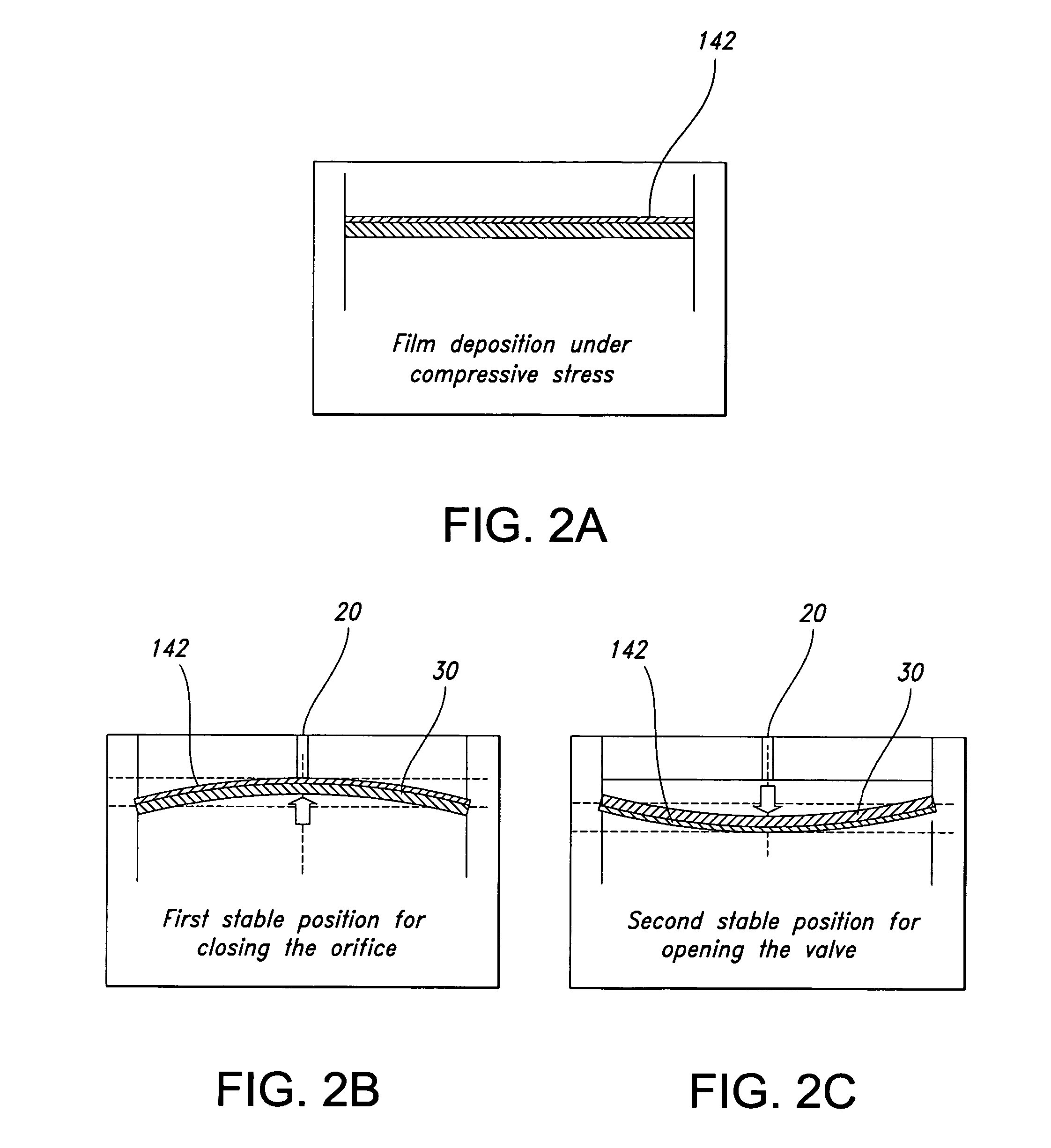

Single substrate electromagnetic actuator

InactiveUS20050116798A1Improve dynamic operation of valveLower average currentValve arrangementsAdditive manufacturing apparatusManufacturing technologyEngineering

A microvalve which utilizes a low temperature (<300° C.) fabrication process on a single substrate. The valve uses buckling and an electromagnetic actuator to provide a relatively large closing force and lower power consumption. A buckling technique of the membrane is used to provide two stable positions for the membrane, and to reduce the power consumption and the overall size of the microvalve. The use of a permanent magnet is an alternative to the buckled membrane, or it can be used in combination with the buckled membrane, or two sets of micro-coils can be used in order to open and close the valve, providing the capability for the valve to operate under normally opened or normally closed conditions. Magnetic analysis using ANSYS 5.7 shows that the addition of Orthonol between the coils increases the electromagnetic force by more than 1.5 times. At a flow rate of 1 mL / m, the pressure drop is <100 Pa. The maximum pressure tested was 57 kPa and the time to open or close the valve in air is under 100 ms. This results in an estimated power consumption of 0.1 mW.

Owner:AIR FORCE THE US SEC THE +1

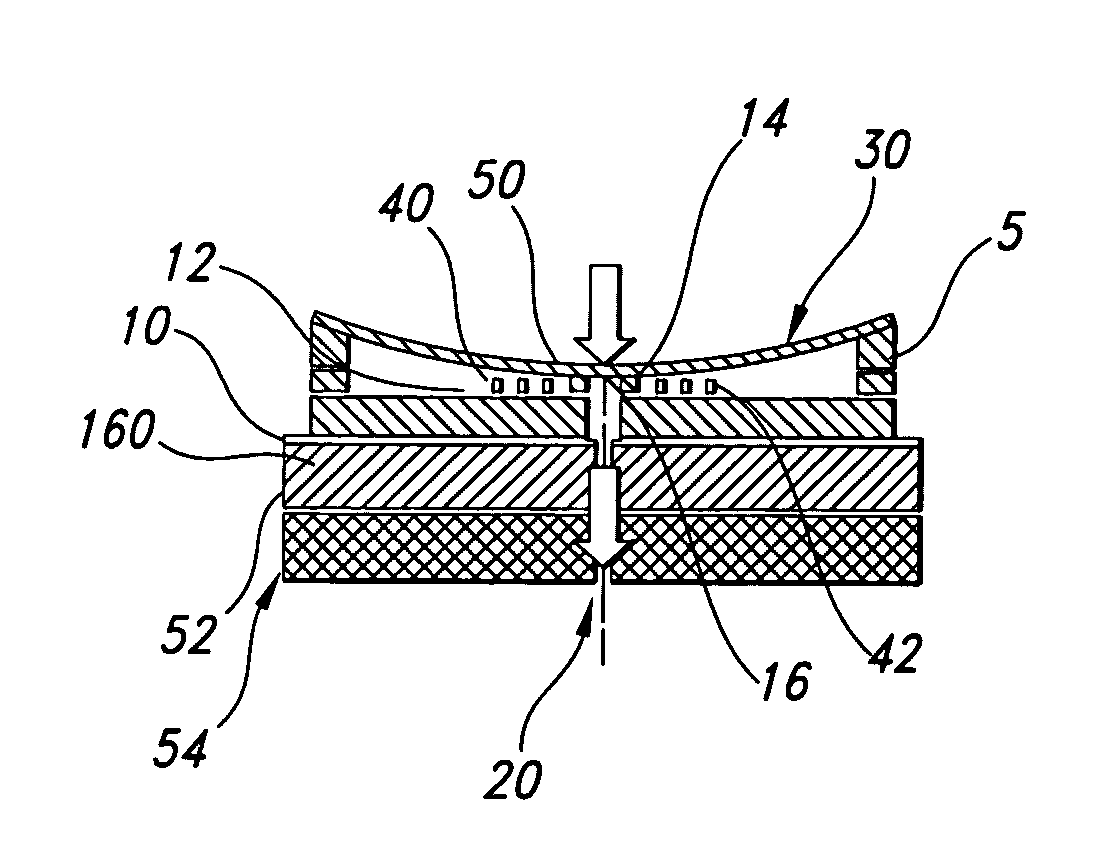

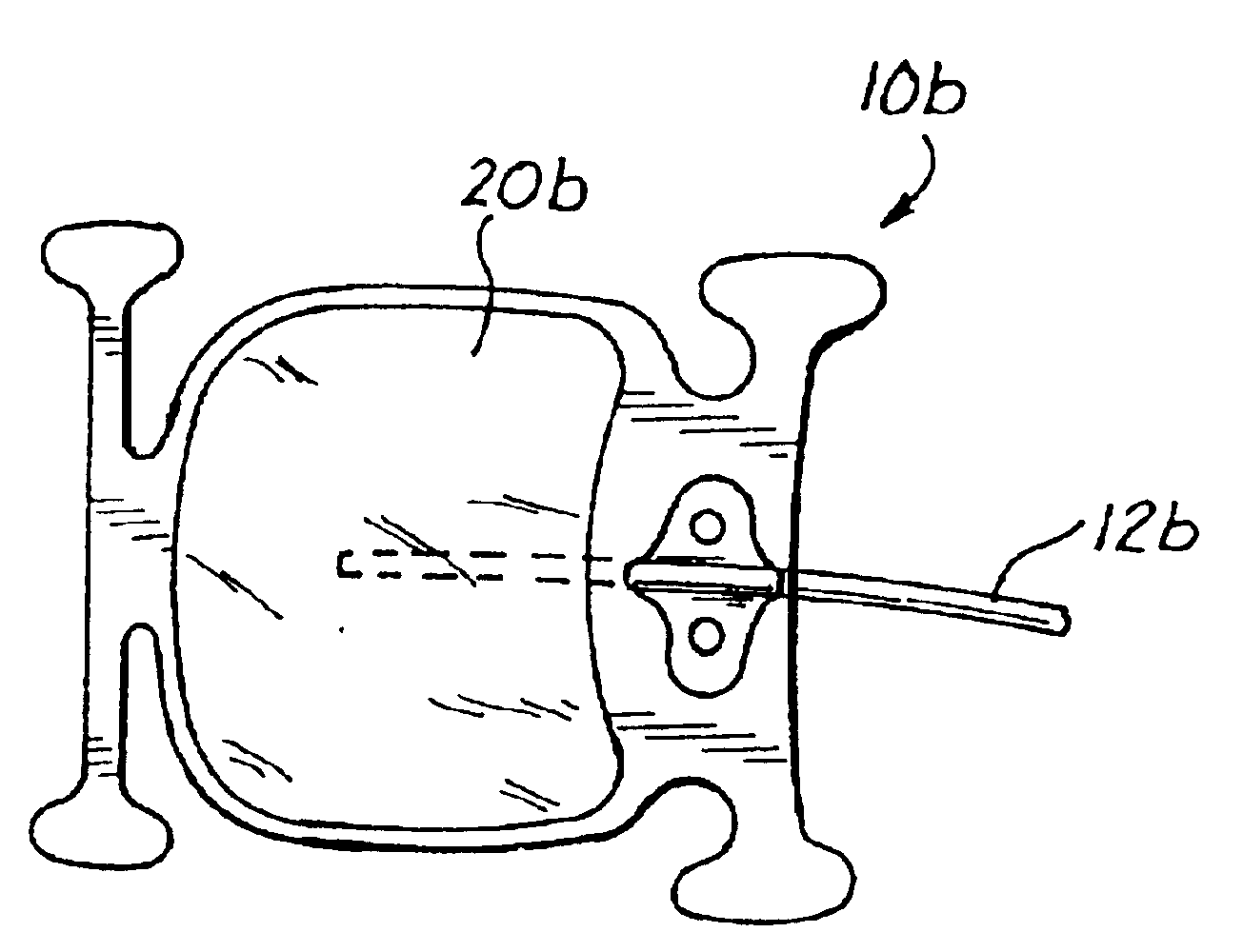

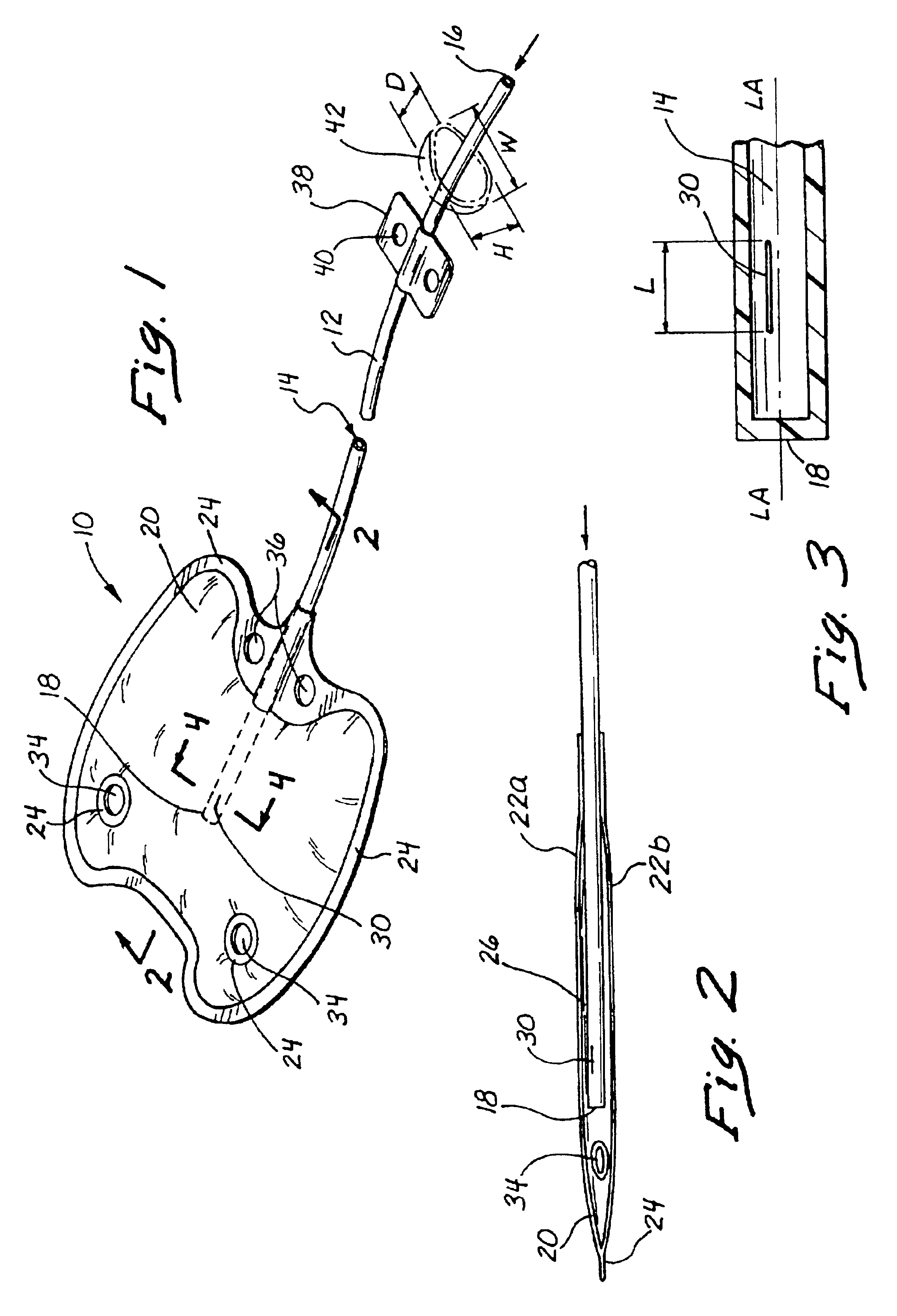

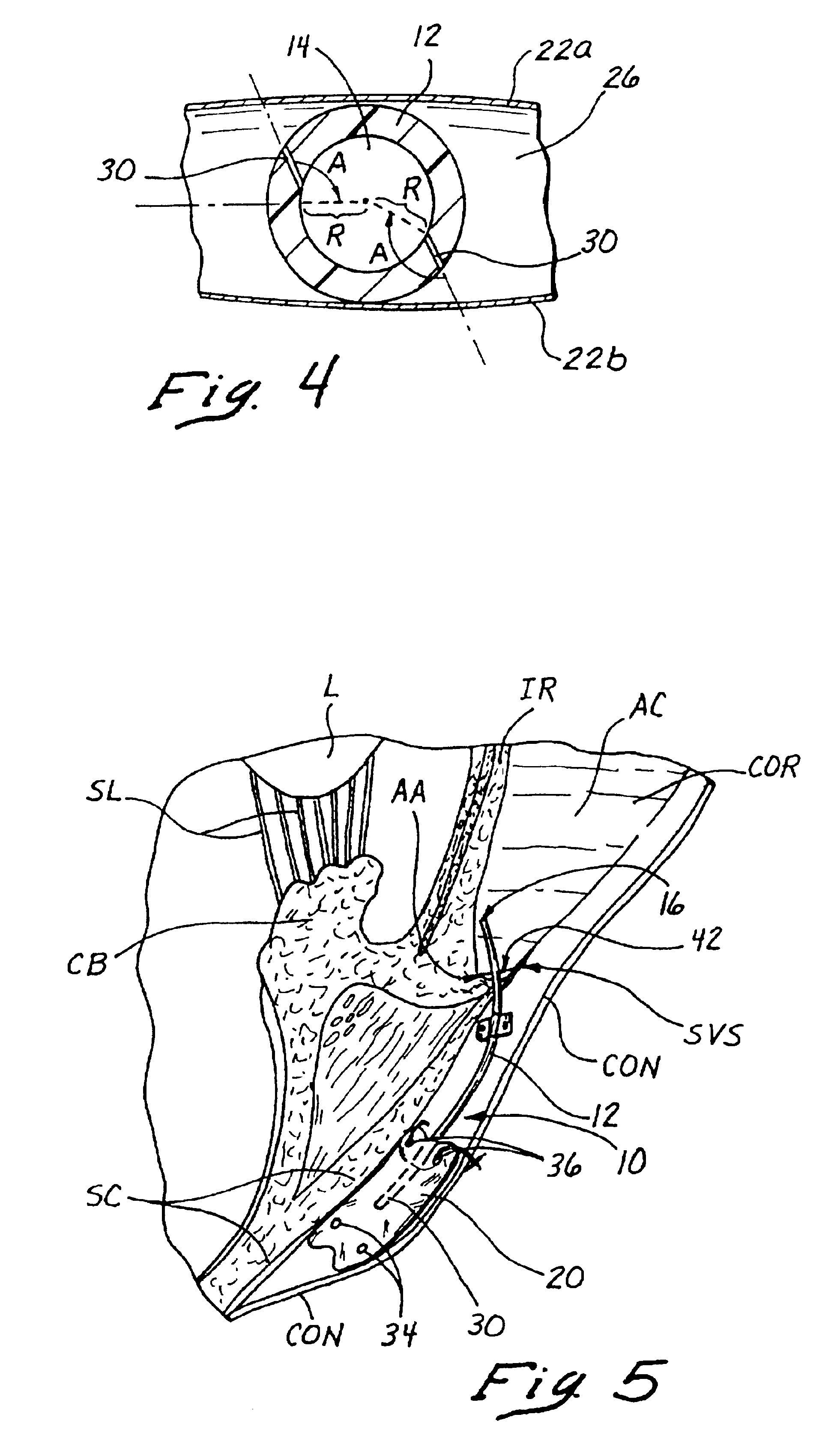

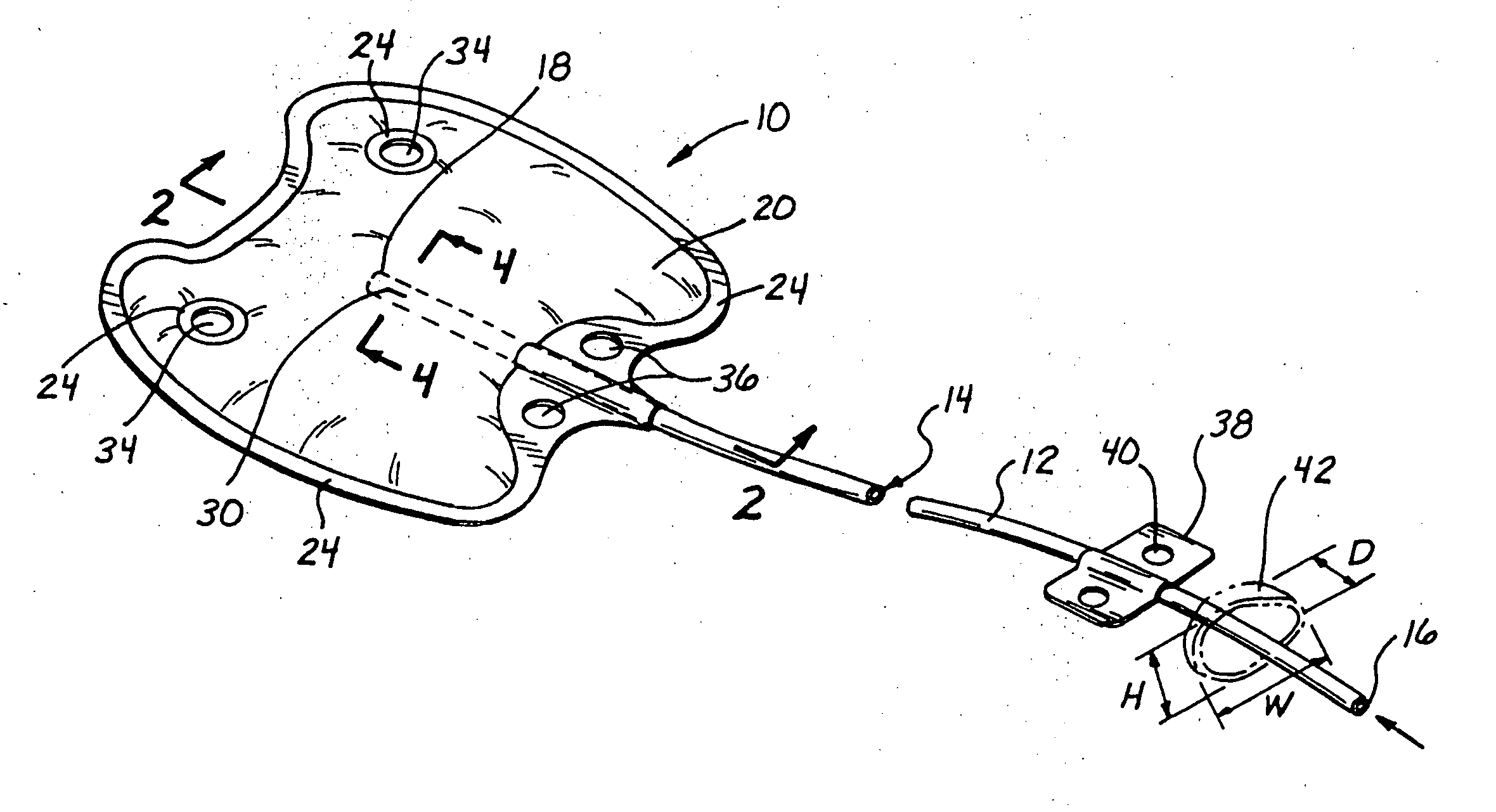

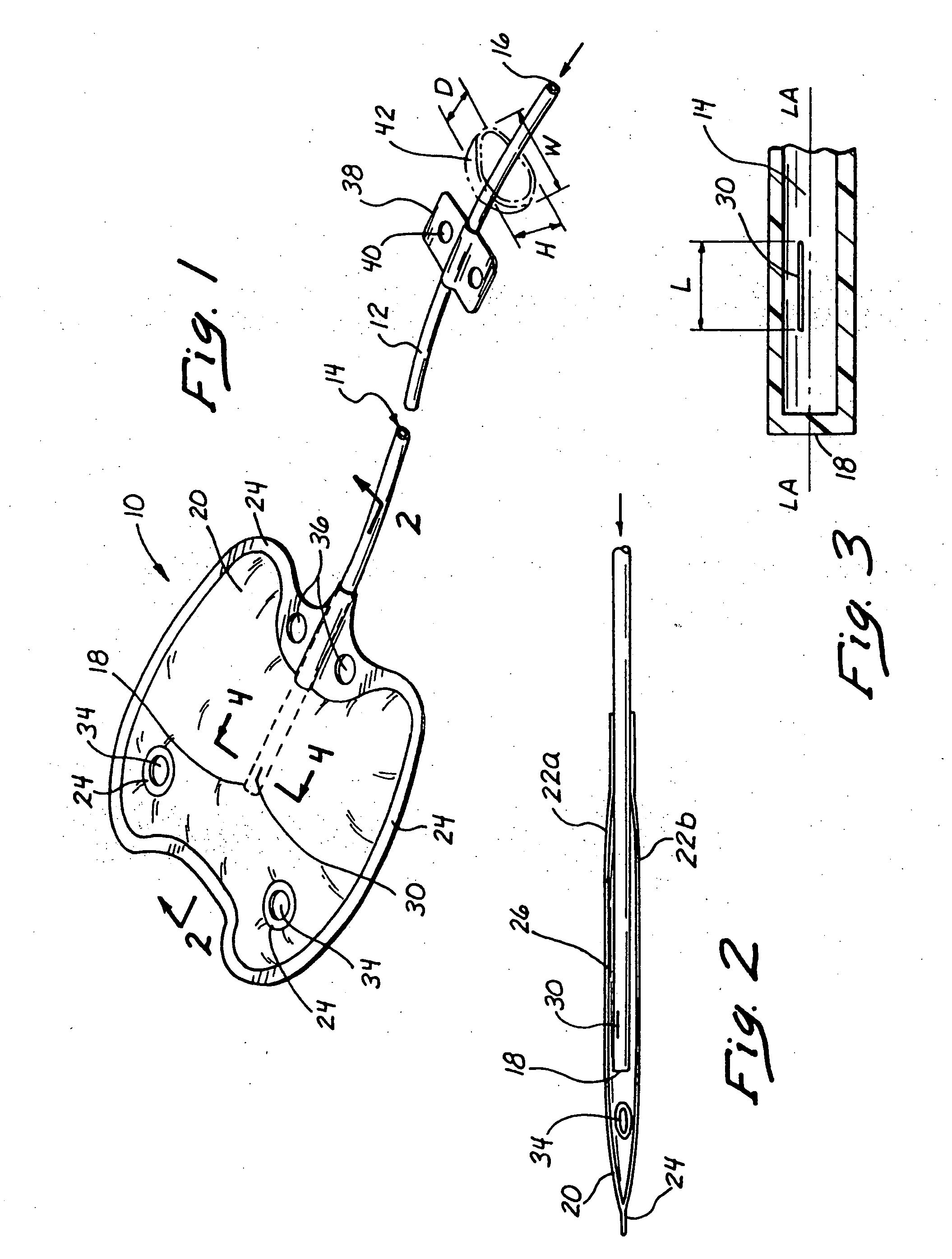

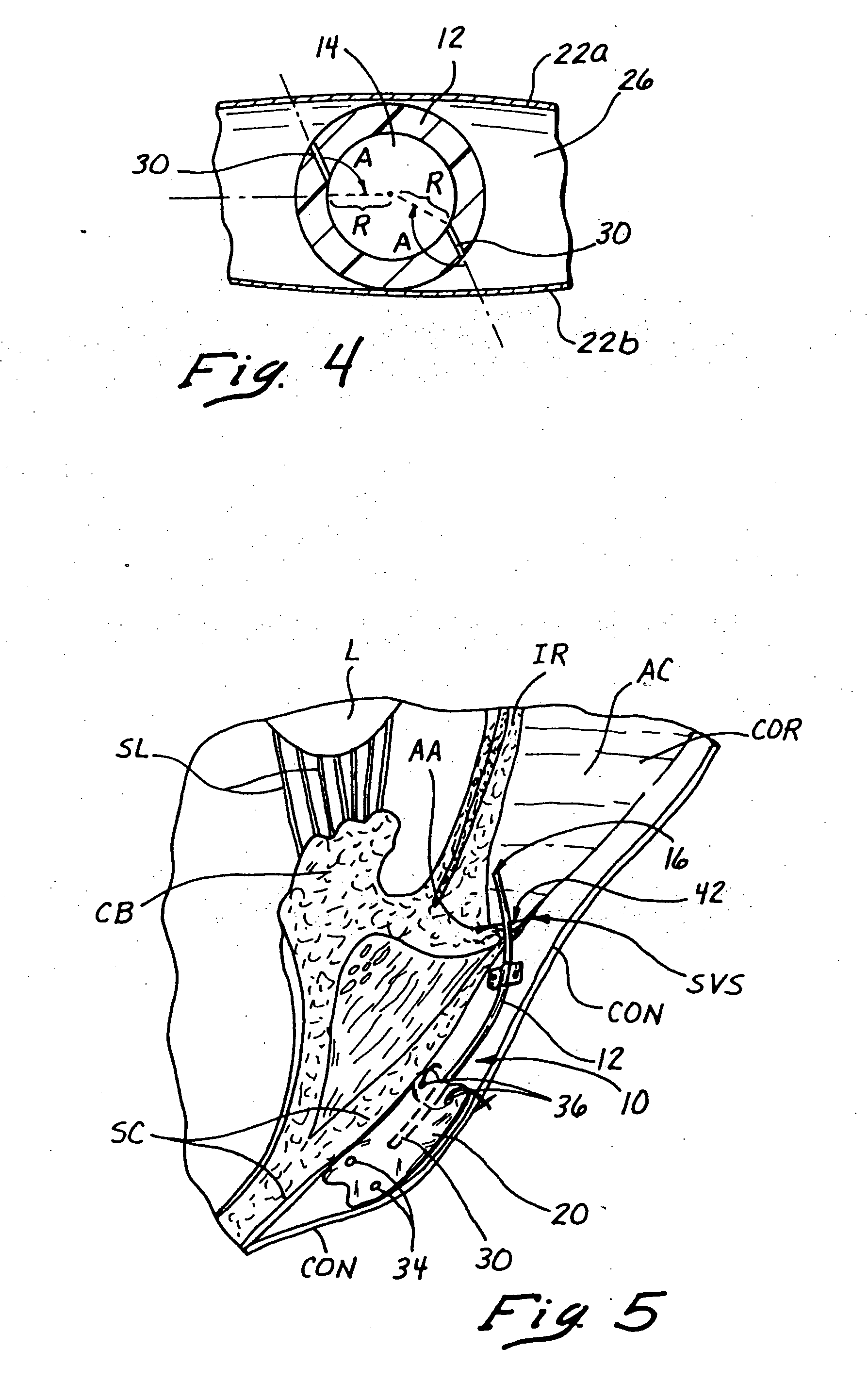

Sutureless implantable device and method for treatment of glaucoma

InactiveUS6881197B1Easy to installControl pressureEye surgeryWound drainsDiffusion barrierMaximum pressure

Sutureless, implantable fluid shunting devices and associated methods for controlling the pressure of fluids within anatomical spaces or cavities of the body. The device generally comprises a tube having a diffusion barrier (e.g., diffusion chamber) formed on a proximal end thereof. Fluid which flows through the tube will collect within the diffusion chamber and will diffuse outwardly therethrough. However, the presence of the diffusion chamber will prevent microbes, cells or other matter from interfering with or backflowing through the tube. Additionally, the tube may be provided with a pressure-openable aperture through which fluid from the tube may flow into the diffusion chamber. Such pressure-openable aperture will remain closed, until the pressure of fluid within the tube exceeds a predetermined maximum pressure PMAX. In this manner, the pressure-openable aperture will limit the amount of fluid drained from the anatomical space or cavity of the body, thereby avoiding hypotony within such anatomical space or cavity. The diffusion barrier of the device is preferably configured to fit between, and to be engaged by, adjacent recti muscles of the eye. Such engagement of the diffusion barrier with the adjacent recti muscles serves to prevent unwanted migration or post-implantation movement of the device, without the need for suturing of the device to the tissue of the eye.

Owner:REVISION OPTICS

Sutureless implantable device and method for treatment of glaucoma

InactiveUS20050182350A1Easy to installMinimal discomfort to the patientEye surgeryWound drainsDiffusion barrierMaximum pressure

Sutureless, implantable fluid shunting devices and associated methods for controlling the pressure of fluids within anatomical spaces or cavities of the body. The device generally comprises a tube having a diffusion barrier (e.g., diffusion chamber) formed on a proximal end thereof. Fluid which flows through the tube will collect within the diffusion chamber and will diffuse outwardly therethrough. However, the presence of the diffusion chamber will prevent microbes, cells or other matter from interfering with or backflowing through the tube. Additionally, the tube may be provided with a pressure-openable aperture through which fluid from the tube may flow into the diffusion chamber. Such pressure-openable aperture will remain closed, until the pressure of fluid within the tube exceeds a predetermined maximum pressure PMAX. In this manner, the pressure-openable aperture will limit the amount of fluid drained from the anatomical space or cavity of the body, thereby avoiding hypotony within such anatomical space or cavity. The diffusion barrier of the device is preferably configured to fit between, and to be engaged by, adjacent recti muscles of the eye. Such engagement of the diffusion barrier with the adjacent recti muscles serves to prevent unwanted migration or post-implantation movement of the device, without the need for suturing of the device to the tissue of the eye.

Owner:REVISION OPTICS

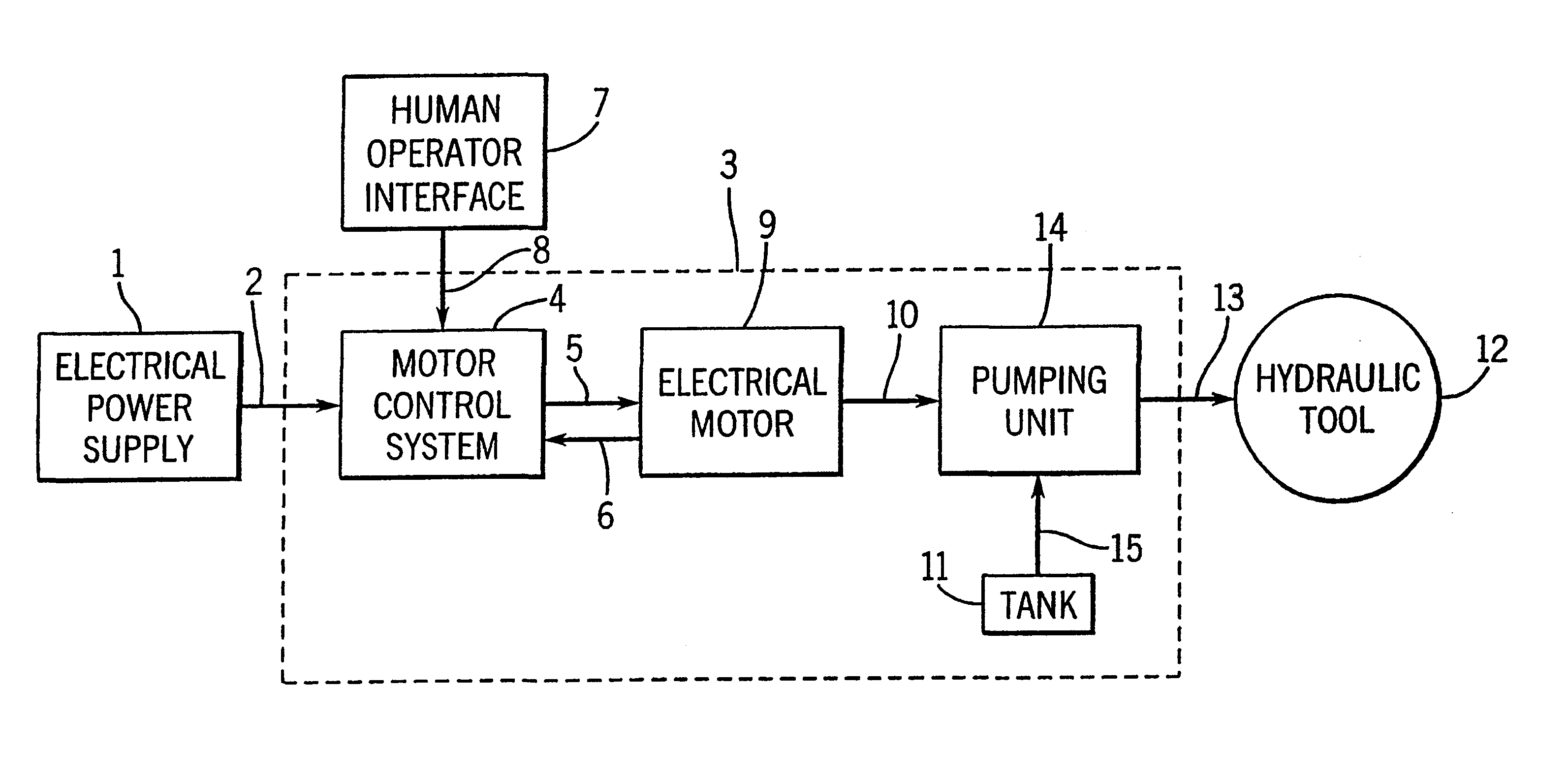

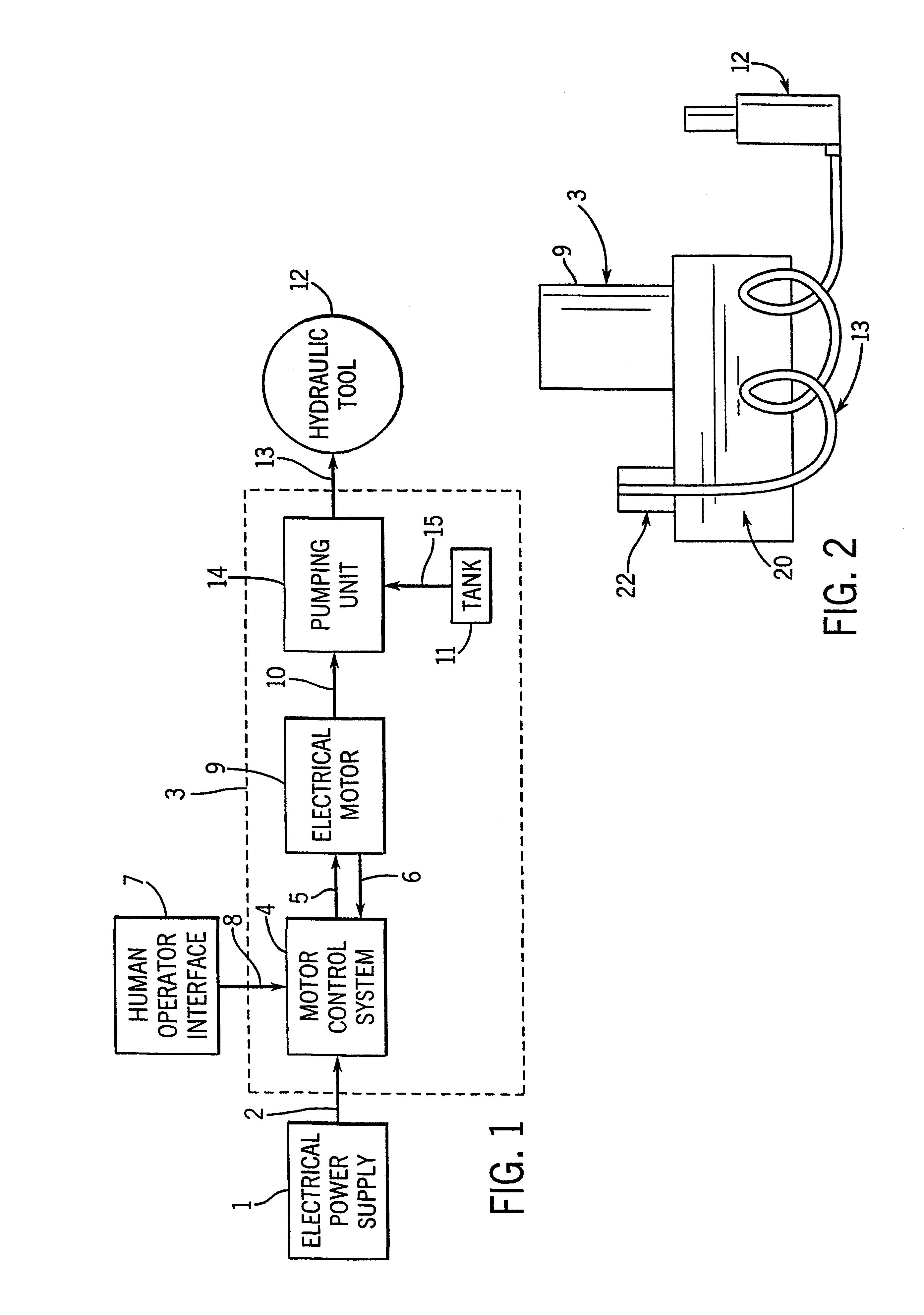

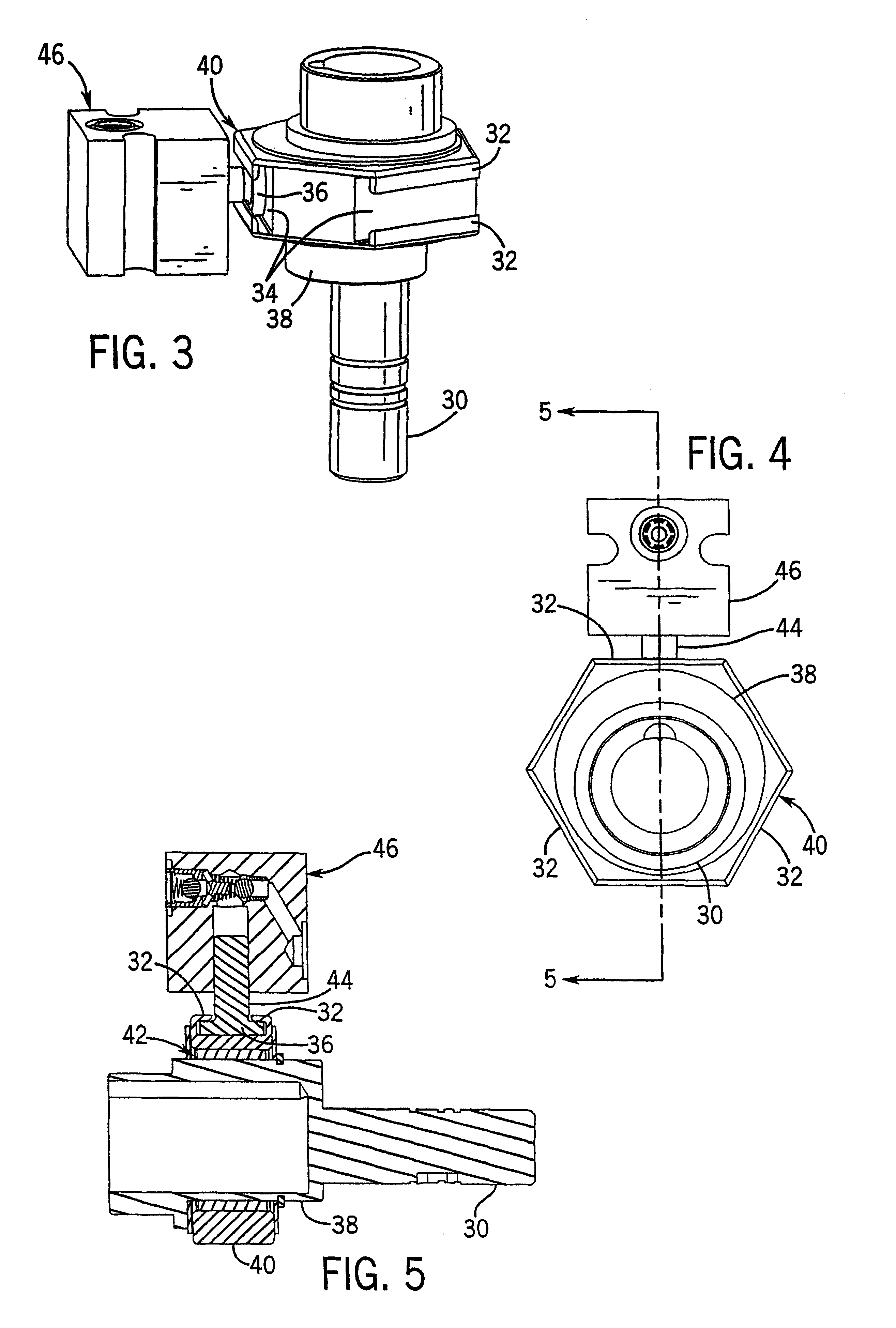

Variable speed hydraulic pump

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

Tourniquet

A self-regulating tourniquet has a pressure source, a pressure applicator apparatus associated with the pressure source and operative to apply pressure therefrom to a limb and a pressure regulator associated with the pressure source and the pressure applicator operative to restrict the pressure transferred from the pressure source to the limb to a designated maximum pressure applied to the limb. The pressure source and the pressure applicator may be separate modules that are adapted to be engaged by connecting means and establish gas passage from the pressure source to the pressure applicator.

Owner:AMISAR SHAI +1

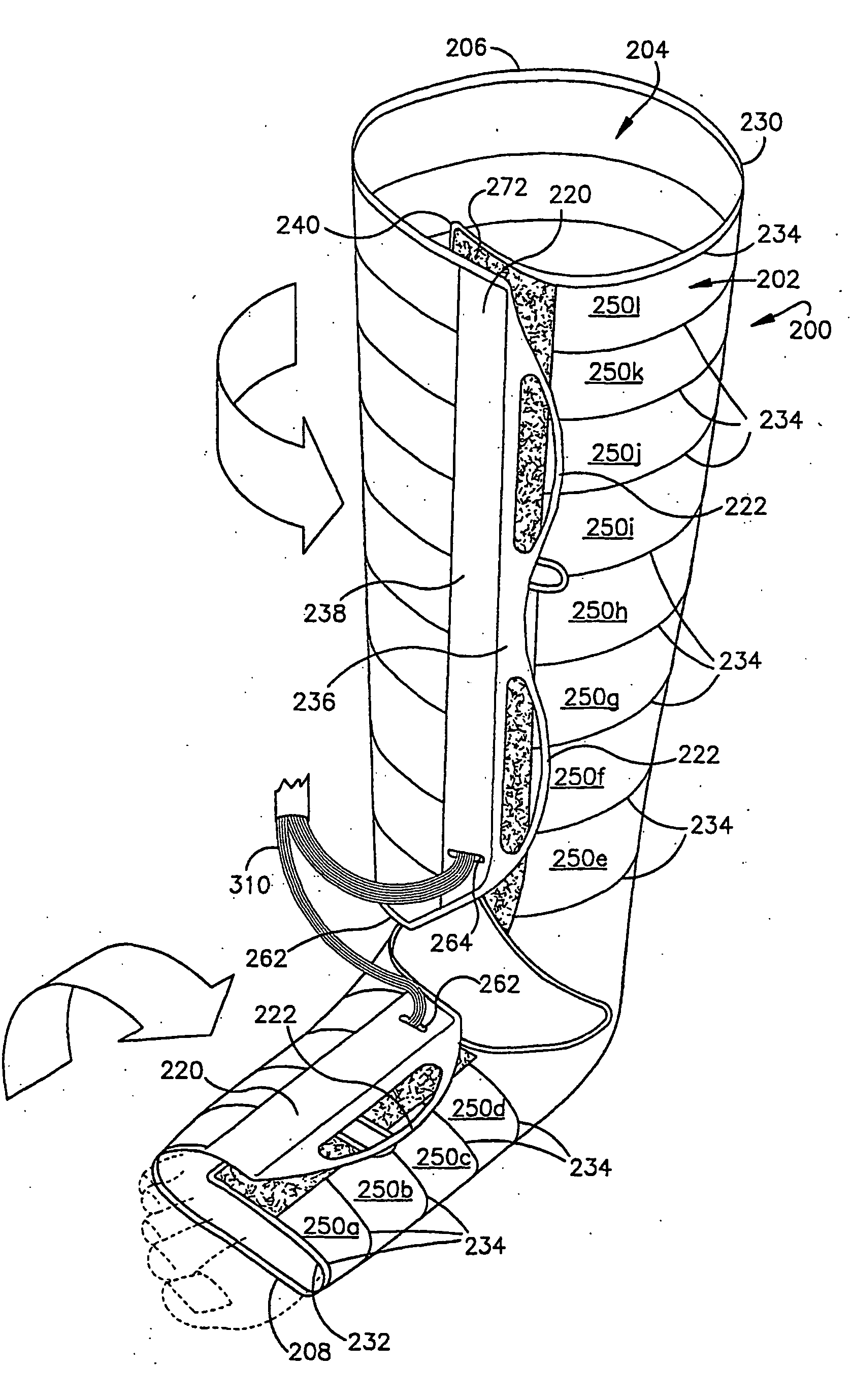

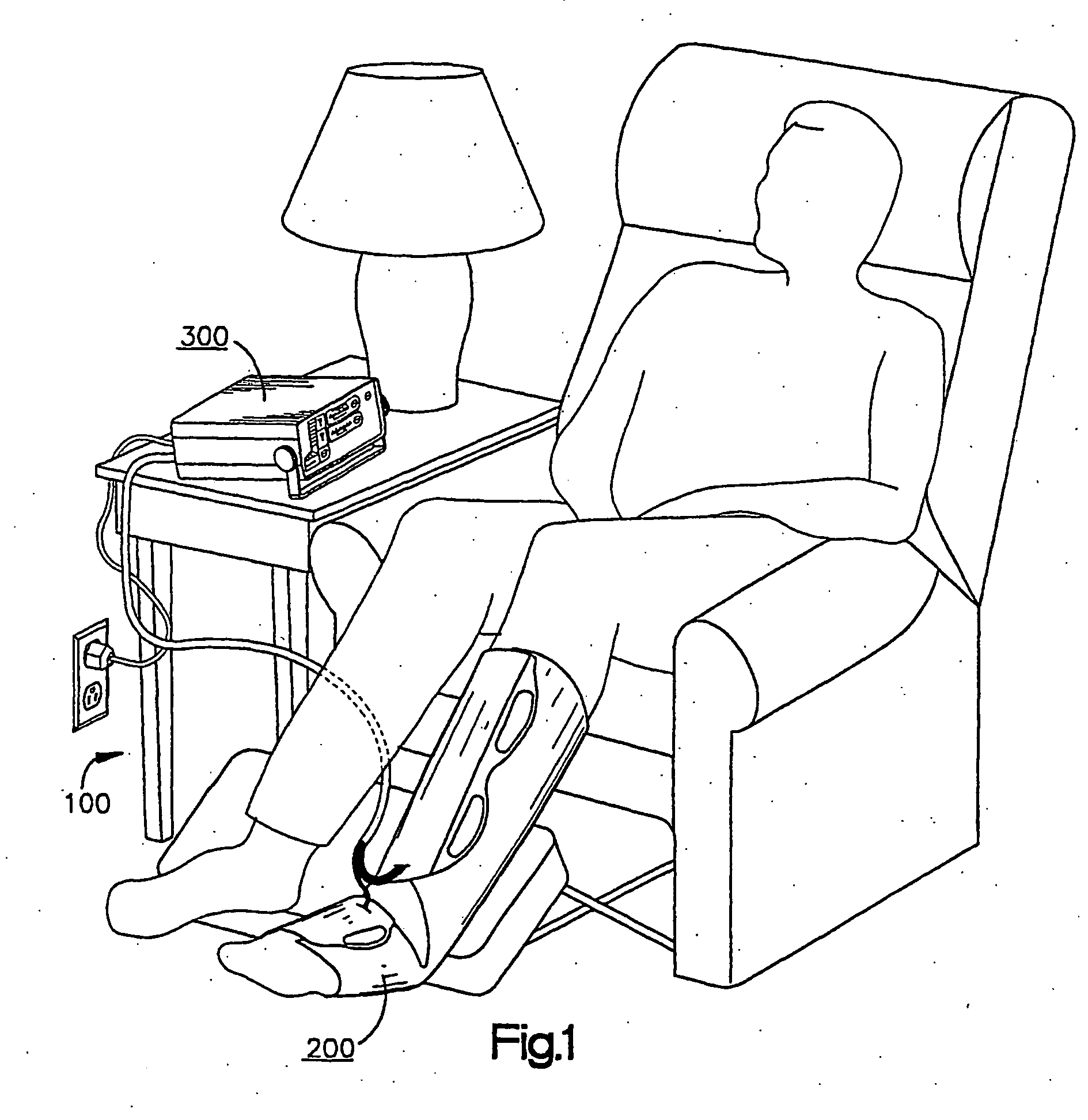

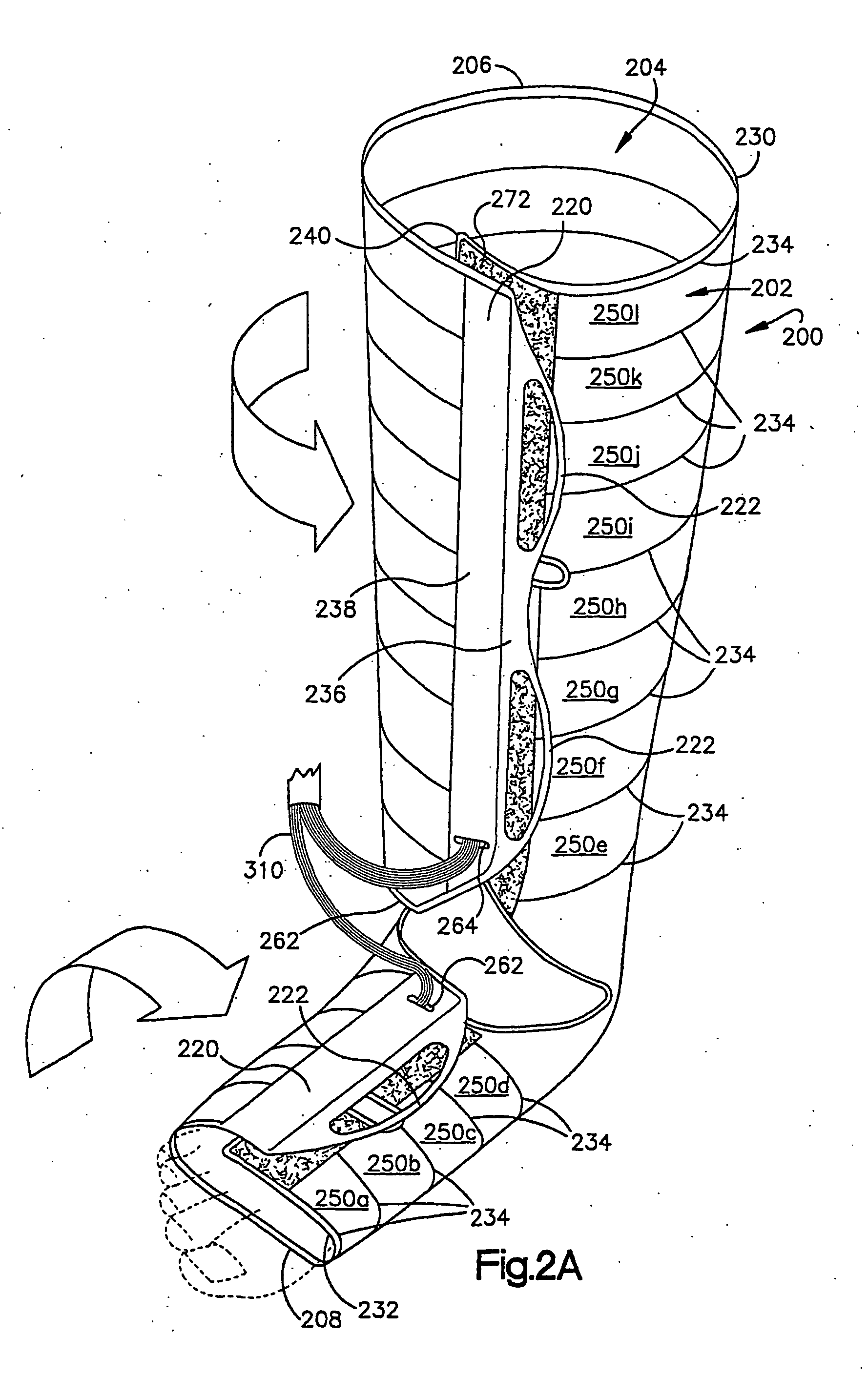

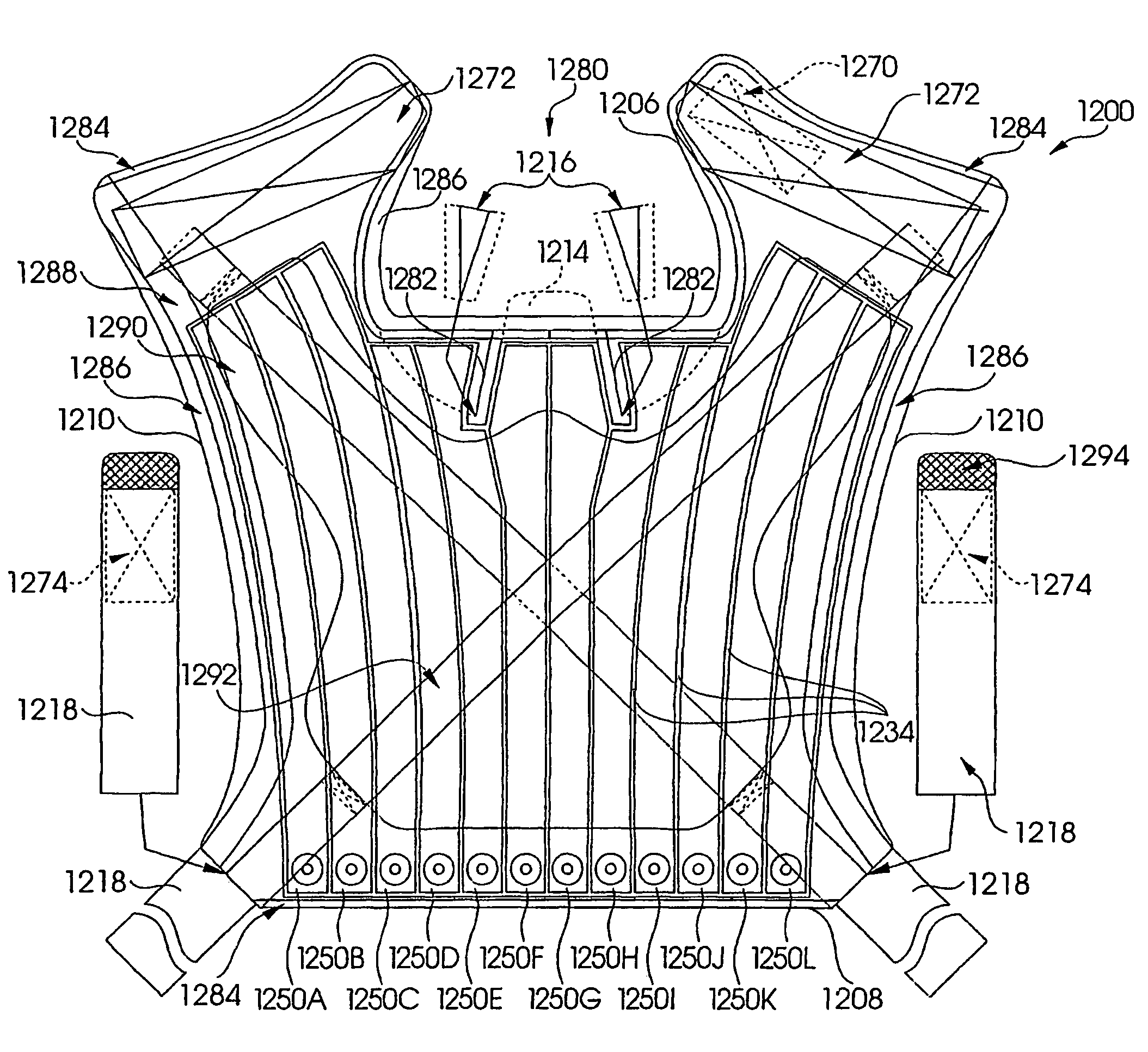

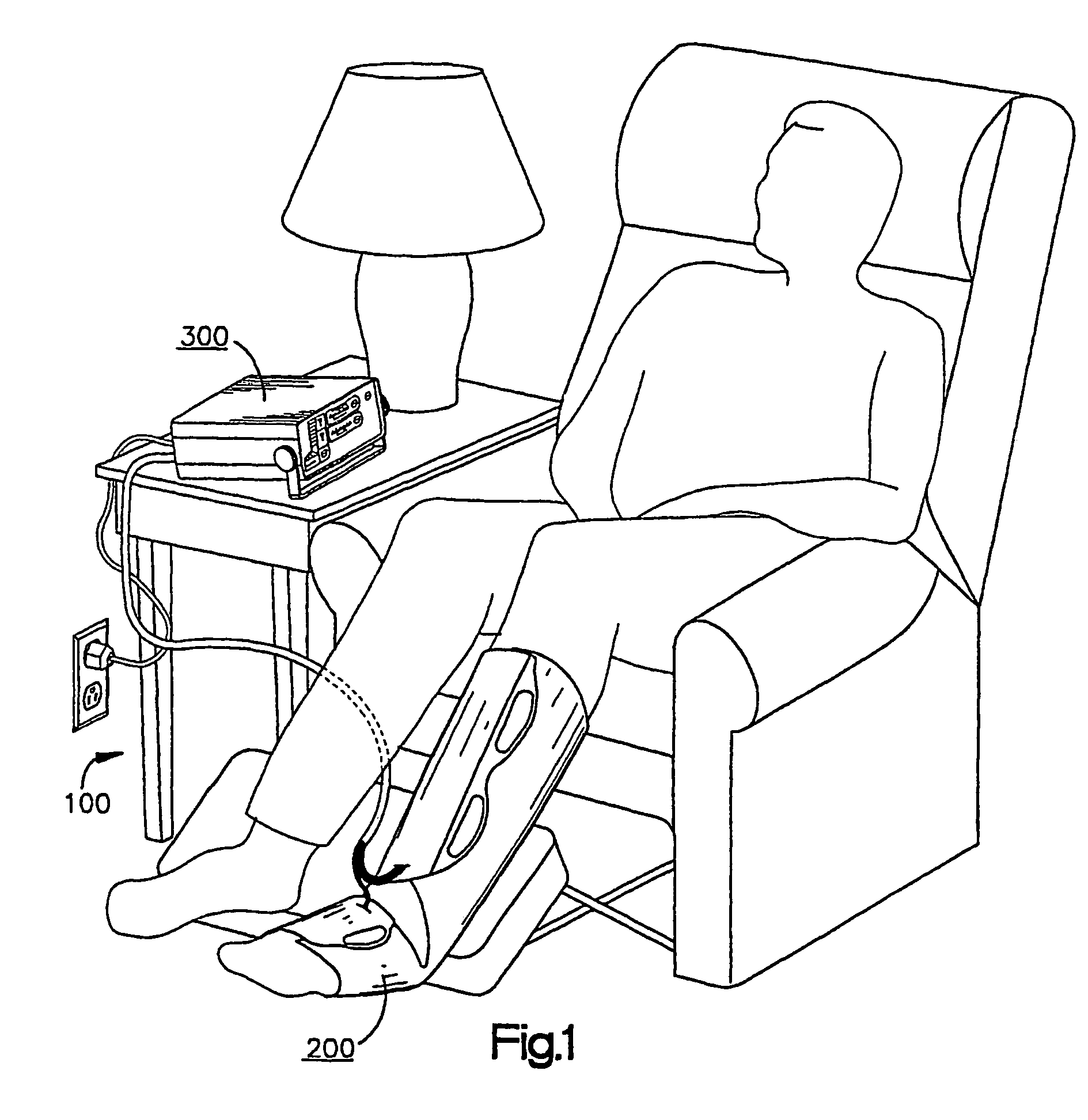

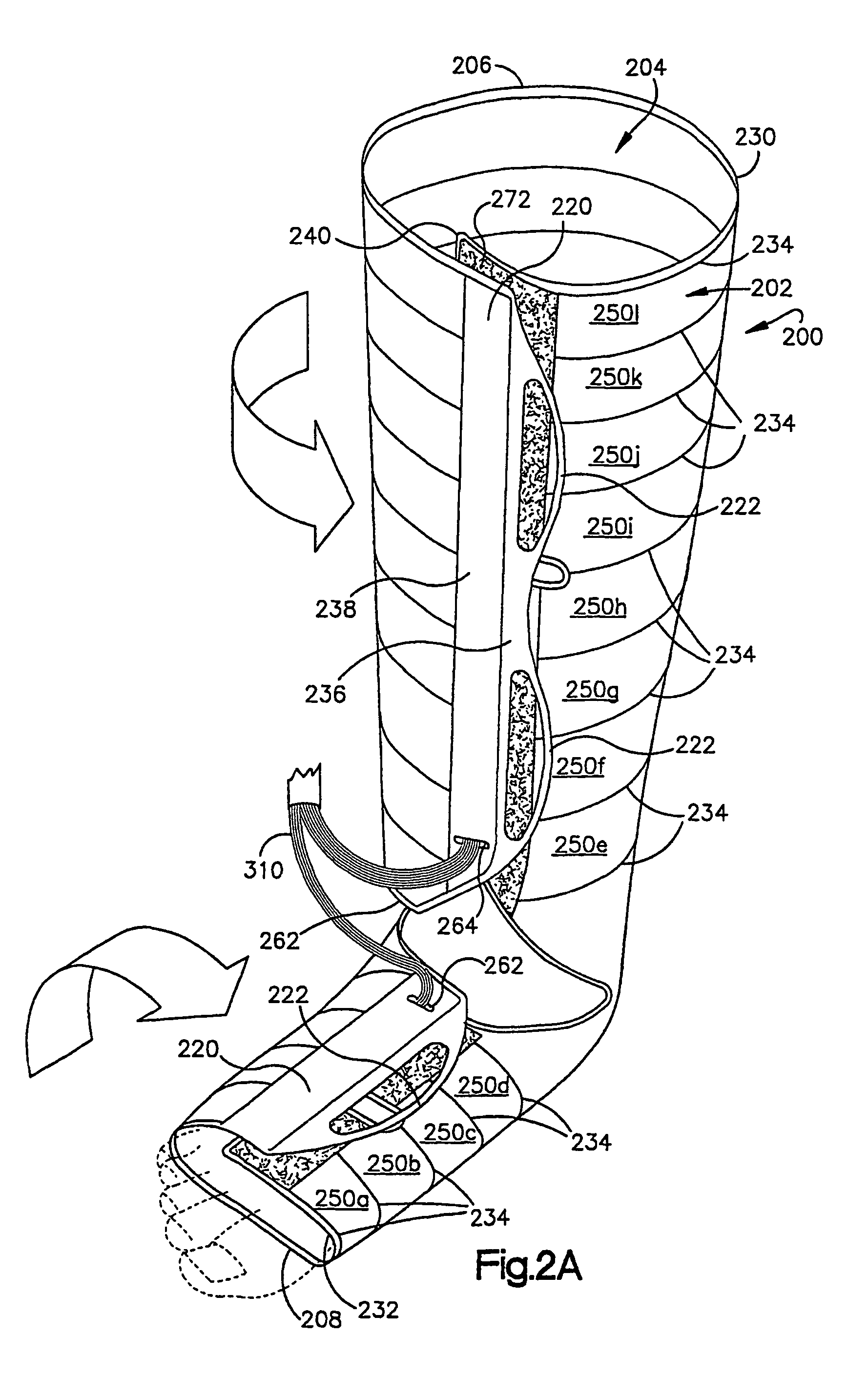

Inflatable massage garment

InactiveUS20070088239A1Simple and inexpensiveBlood stagnation preventionPneumatic massageMassageBladder size

A massage device for massaging a body part of a person in an unsupervised and unattended setting is provided. In a preferred embodiment, the massage device comprises an inflatable garment (200) having a plurality of inflation bladders (250), to apply pressure to the body part, and an inflation assembly (300) includes a manifold (324) into which the pressurized fluid flows, a plurality of inflation valves (326) which control the flow of fluid from the manifold to the bladders, and a manifold valve for controlling the maximum pressure level within the bladders. The inflation assembly may have a predeterminated inflation capacity which defines a maximum bladder size as well as an array in which the bladders are arranged. The massage device may further comprise a connector for connecting tubes from the bladders to the inflation assembly, wherein the connector includes a garment-identifying component for identifying the type of garment connected to the inflation assembly.

Owner:MIDTOWN TECH

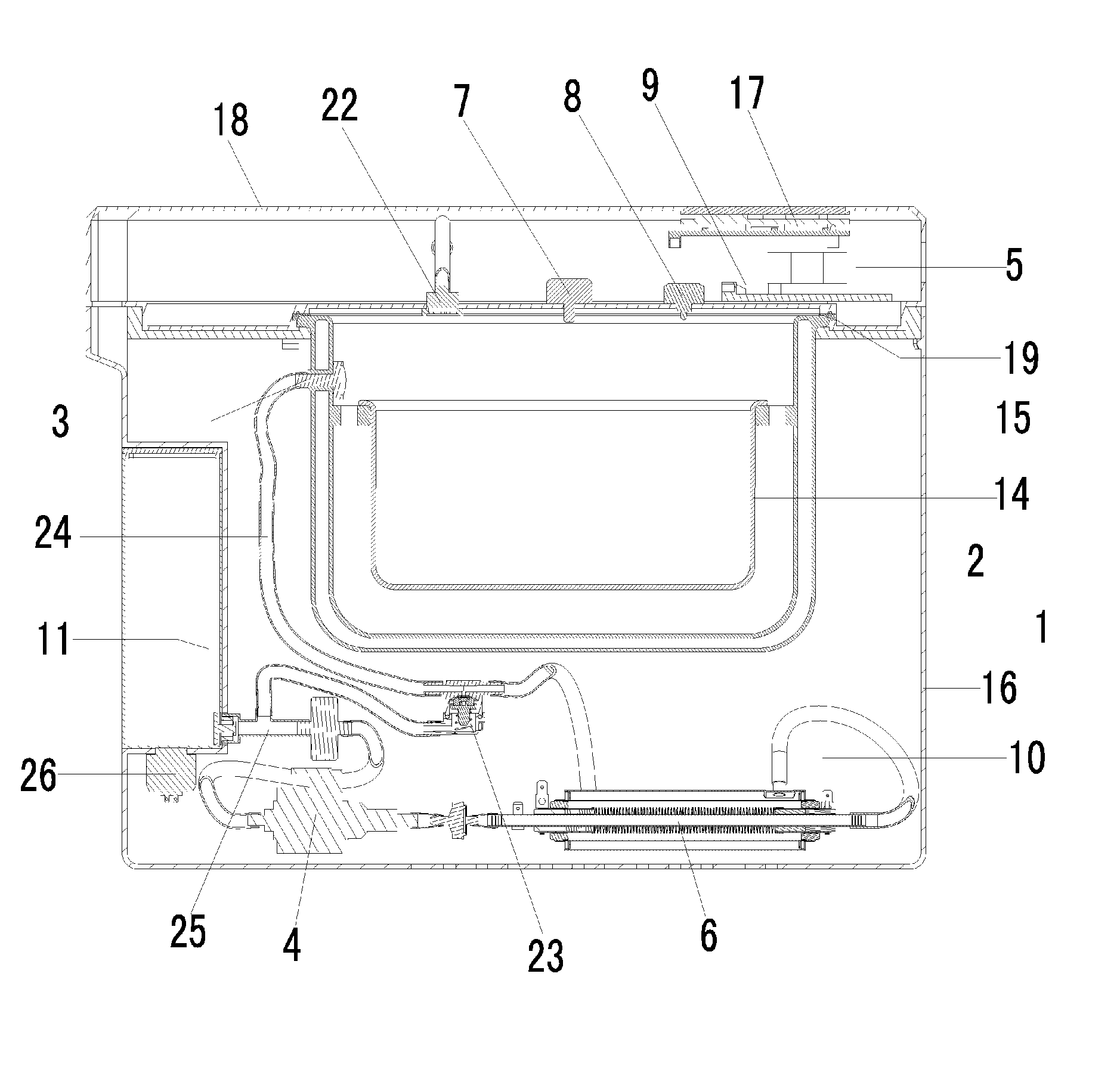

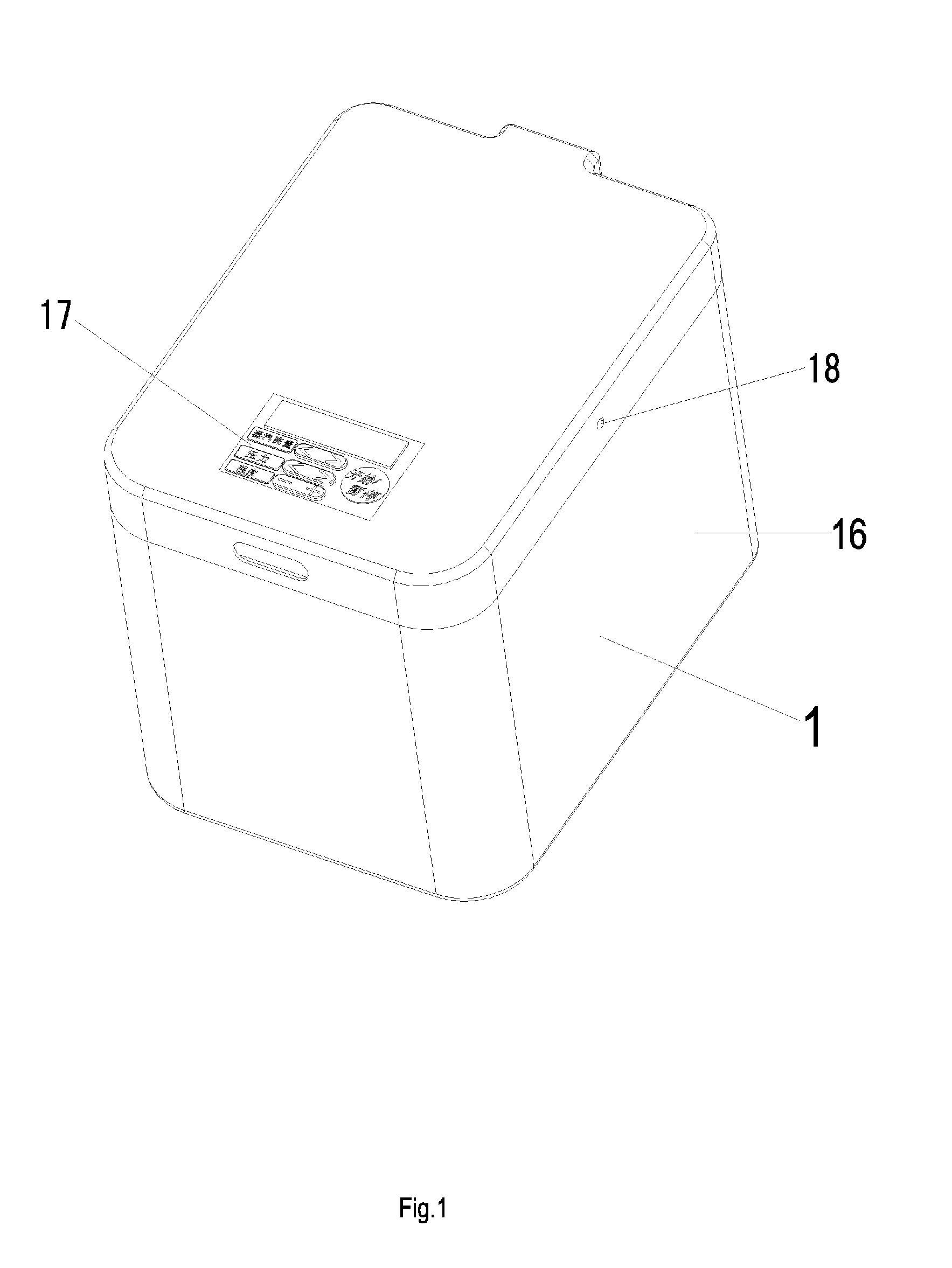

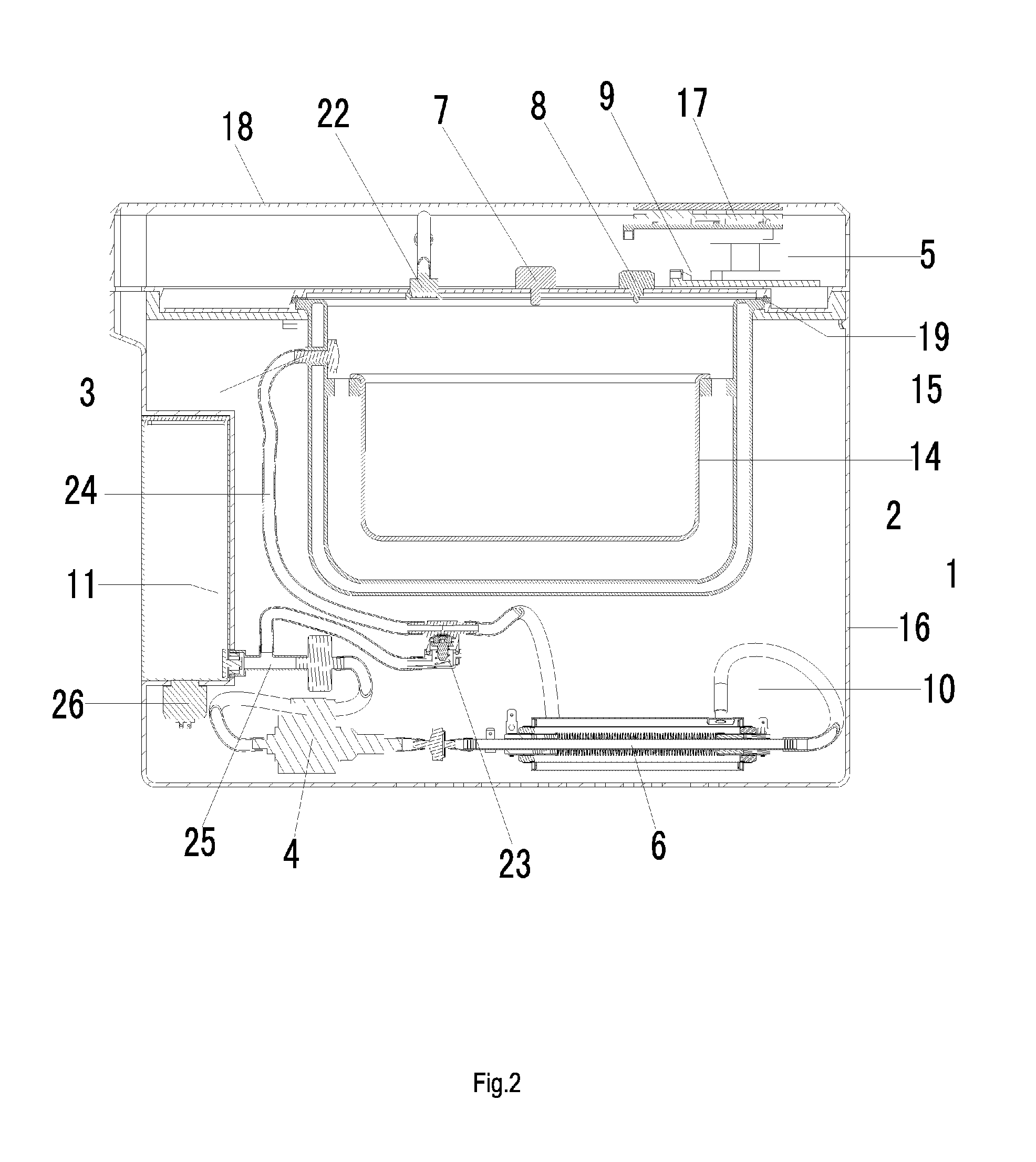

Pressure cooker

A pressure cooker (1) comprises: a pressure vessel (2) for containing items to be cooked; an inlet (3) in a wall of the pressure vessel (2) for receiving steam from a steam source; and a pump (4) for pumping the steam from the steam source into the pressure vessel (2) through the inlet (3), wherein the pump (4) produces a maximum pressure below a maximum safety pressure for the pressure vessel (2).

Owner:TOP ELECTRICAL APPLIANCES IND

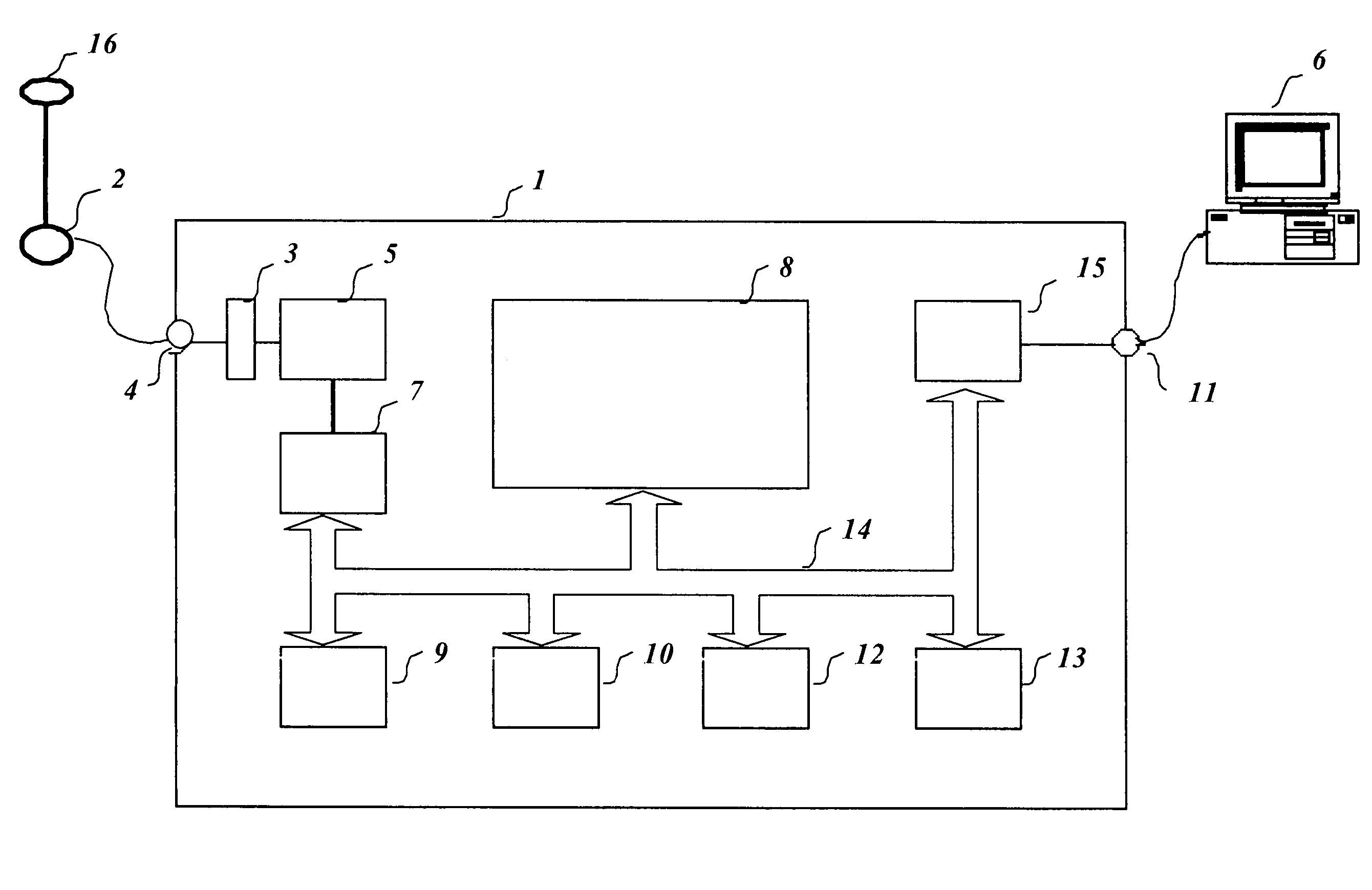

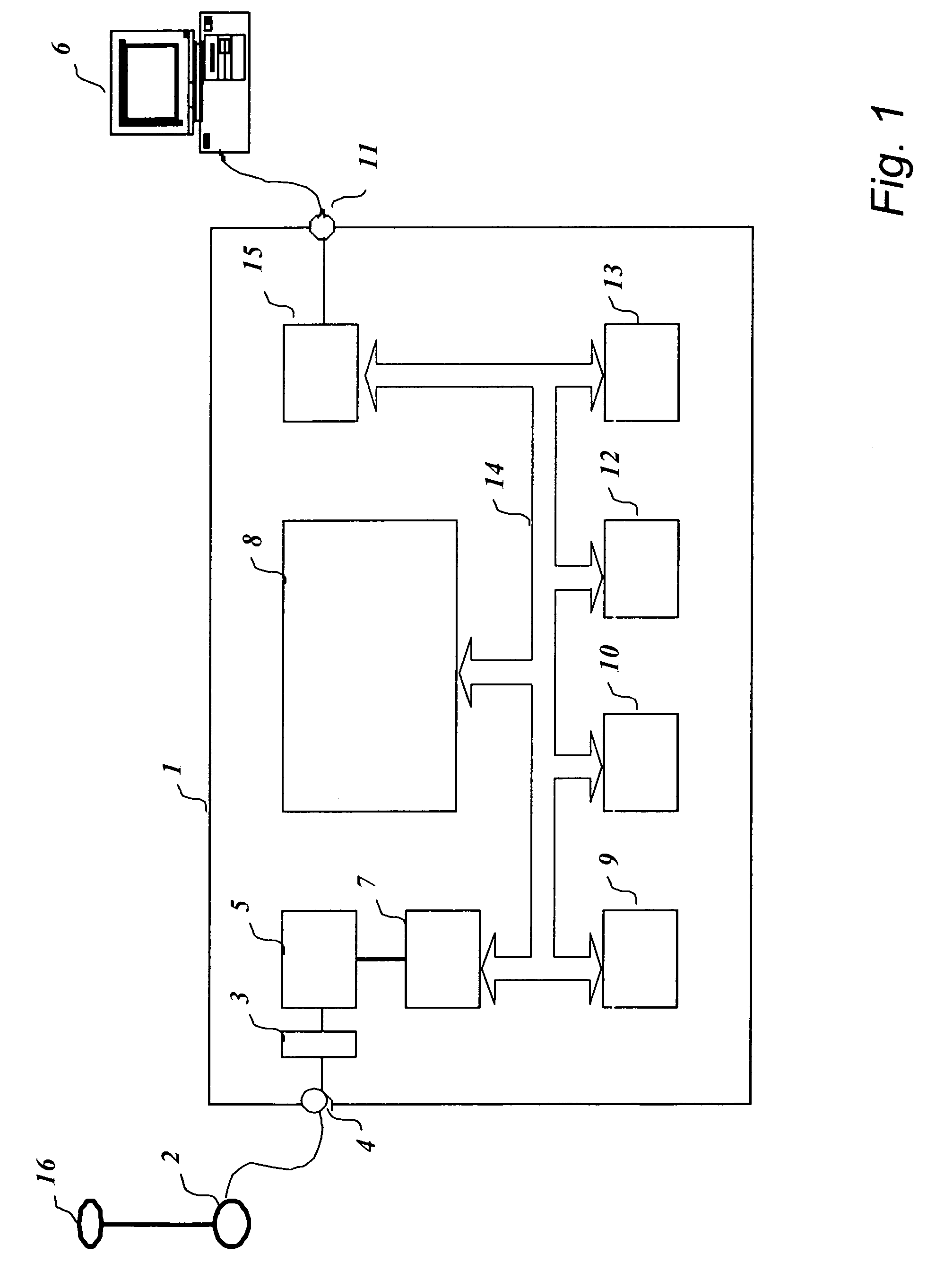

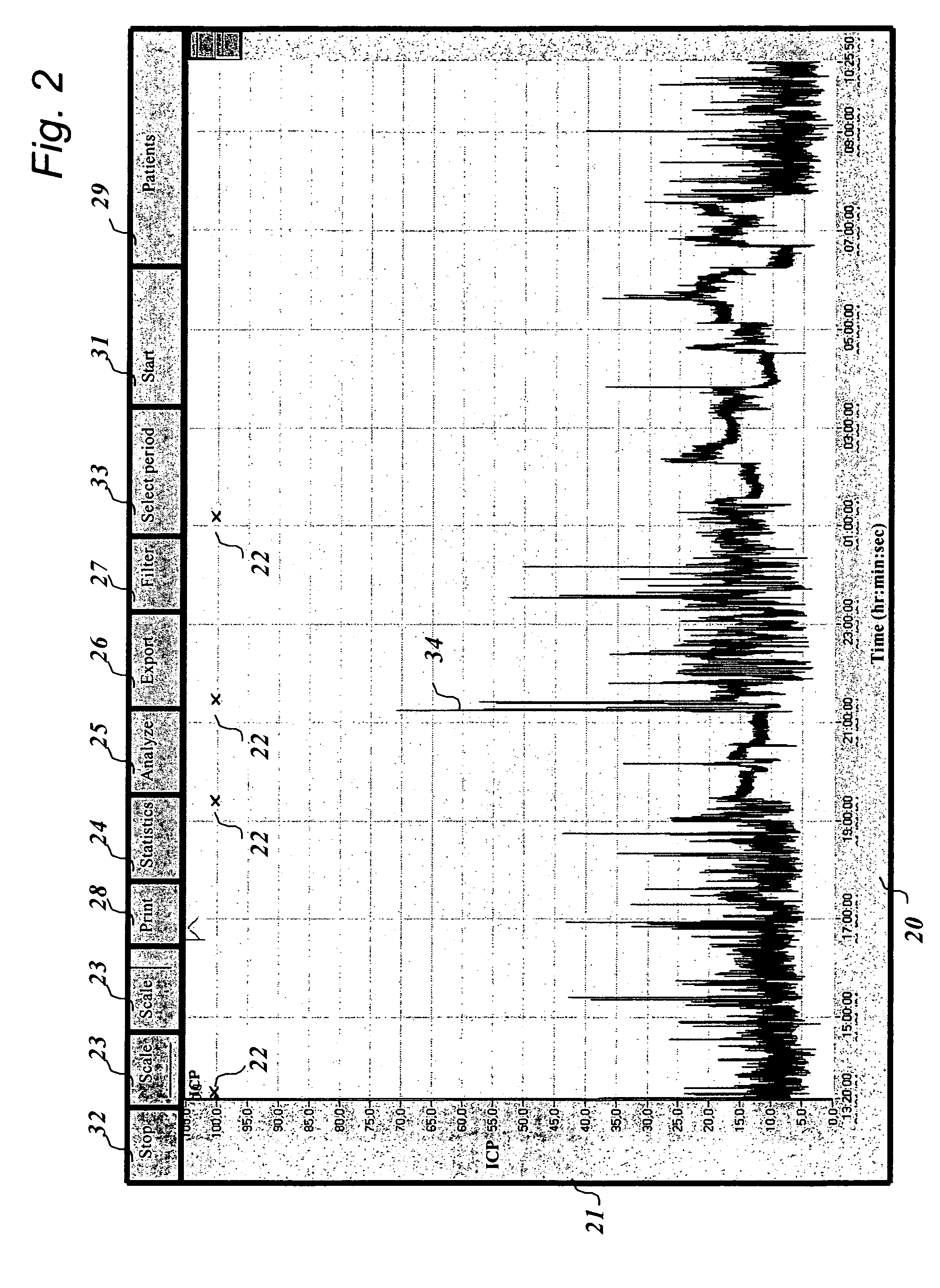

System for performing an analysis of pressure-signals derivable from pressure measurements on or in a body

InactiveUS7335162B2Reduce pressureEvaluation of blood vesselsCatheterDigital dataVisual presentation

A system for performing an analysis of pressure-signals derivable from pressure measurements on or in a body of a human being or animal, includes a communication interface for receiving a set of digital pressure sample values, a memory for storing these values, and a processor capable of performing the analysis, the processor having means to identify features related to single pressure waves in the pressure signals based on input of the digital data into the processor, and the processor further having determination means which based on the features is configured to a) determine a minimum pressure value related to diastolic minimum value and a maximum pressure value related to systolic maximum value, b) determine at least one parameter of the single wave parameters elected from the group of: pressure amplitude=ΔP=[(maximum pressure value)−(minimum pressure value)], latency (ΔT), rise time or rise time coefficient=ΔP / ΔT, and wavelength of the single wave, c) determine number of the single pressure waves occurring during a given time sequence, including determination of the number of single pressure waves with pre-selected values of one or more of the single pressure wave parameters during the given time sequence, and d) determine number of single pressure waves with pre-selected combinations of two or more of the single pressure wave parameters during the given time sequence. Further, the system has a display for visual presentation of the result of analysis performed by the processor.

Owner:SENSOMETRICS AS (NO)

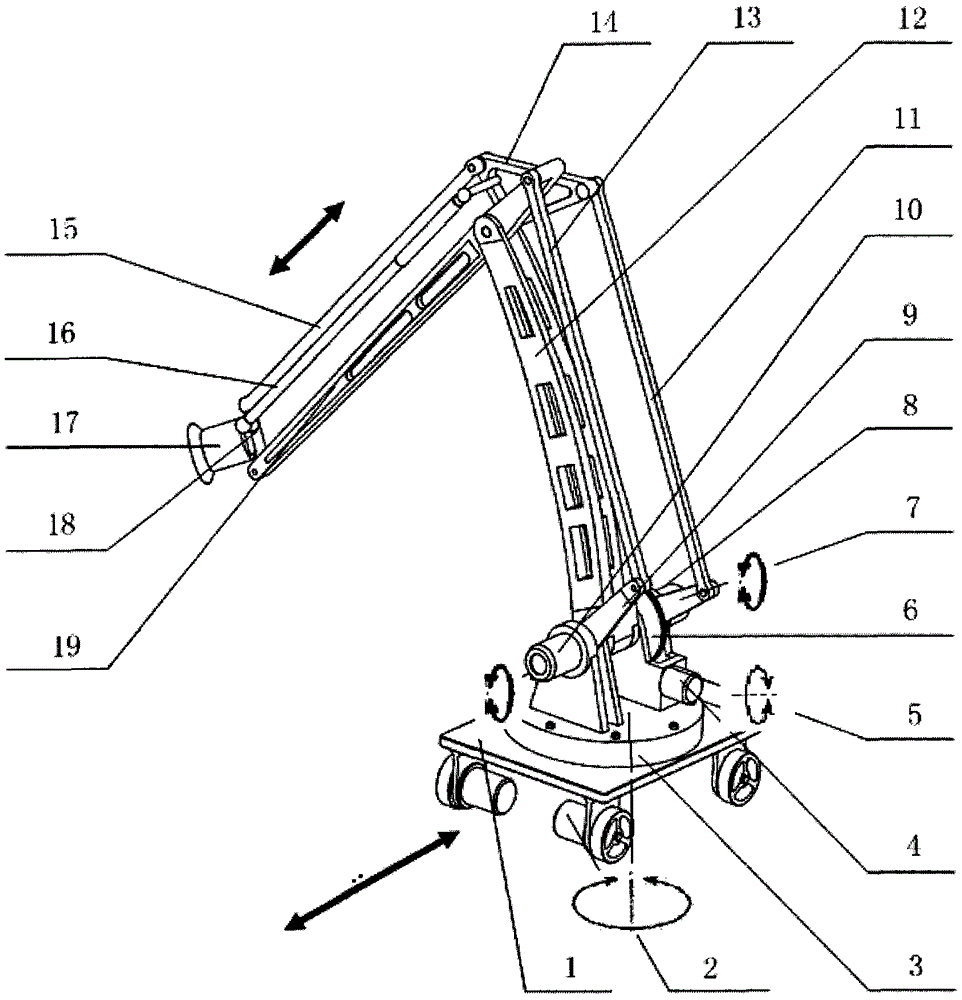

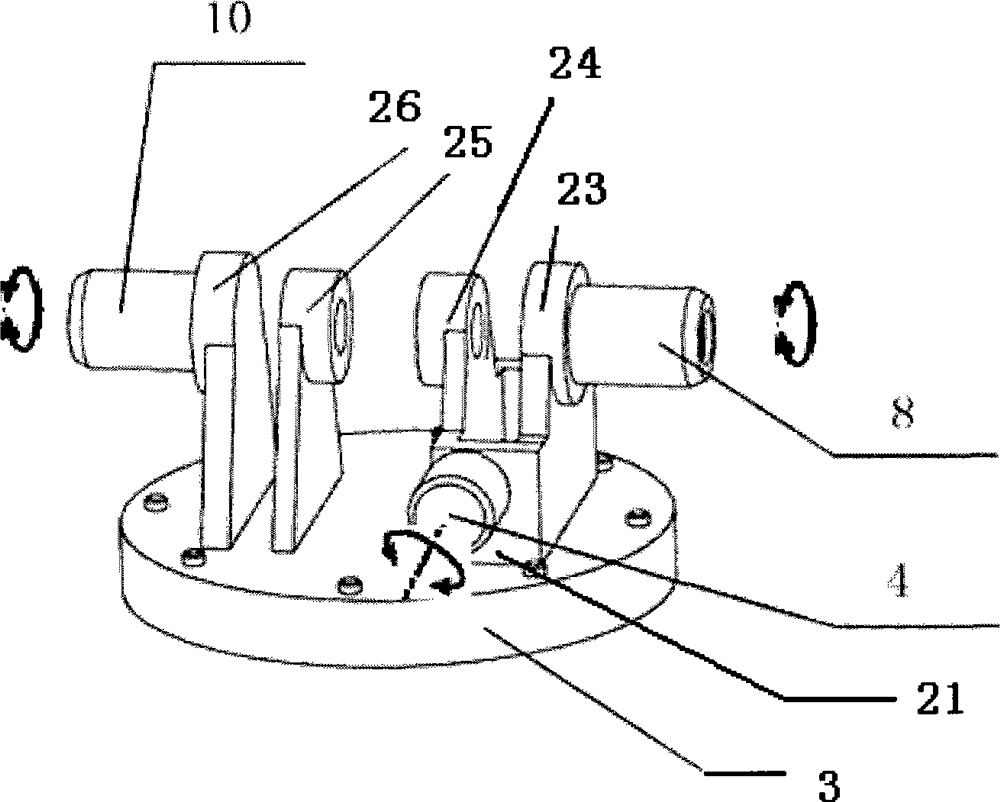

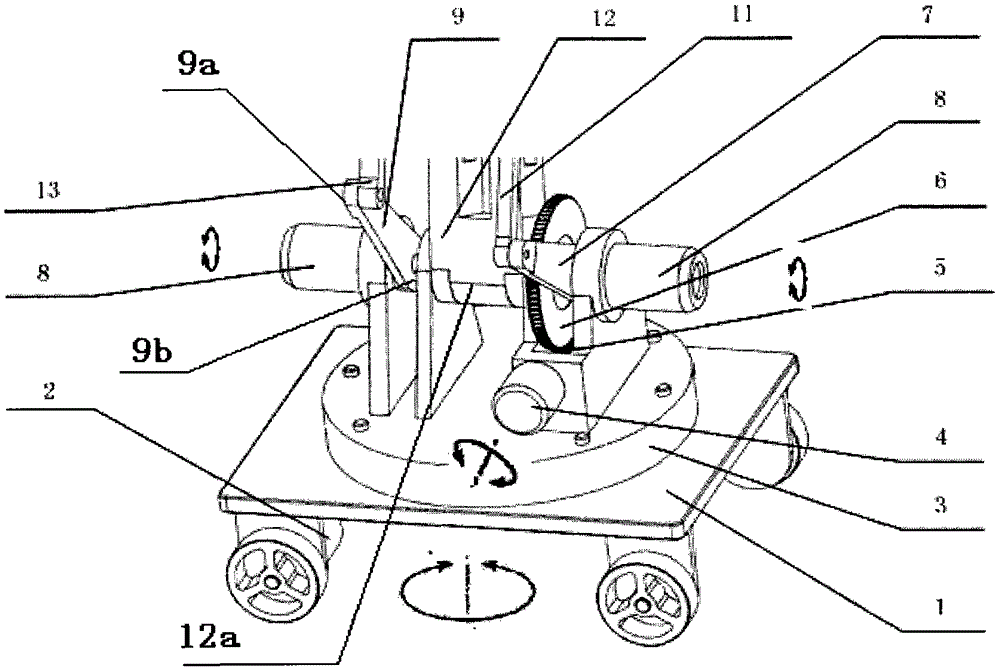

Spraying robot driven by multiple parallelogram links in parallel

InactiveCN104923431AReduce the safety of useImprove the safety of useProgramme-controlled manipulatorSpraying apparatusEngineeringMaximum pressure

The invention provides a spraying robot driven by multiple parallelogram links in parallel. The spraying robot comprises a pedestal (3), a big-arm driving motor (4), a small-arm driving motor (10), a pitch adjusting motor (8), a movable platform (18) and three paralleled parallelogram link mechanisms. The spraying robot is characterized in that the big-arm driving motor (4), the small-arm driving motor (10), and the pitch adjusting motor (8) are all arranged on one end of the pedestal (3), and the three paralleled parallelogram link mechanisms cooperate with one another to drive the movable platform (18). According to the invention, a three-parallelogram-link driving manner is employed, when the three parallelogram link mechanisms are designed, the maximum pressure angle is limited, in the working range, no matter the robot rotates to any position, the transmission performance of movements and forces can remain excellent.

Owner:SHANGHAI AIRCRAFT MFG +1

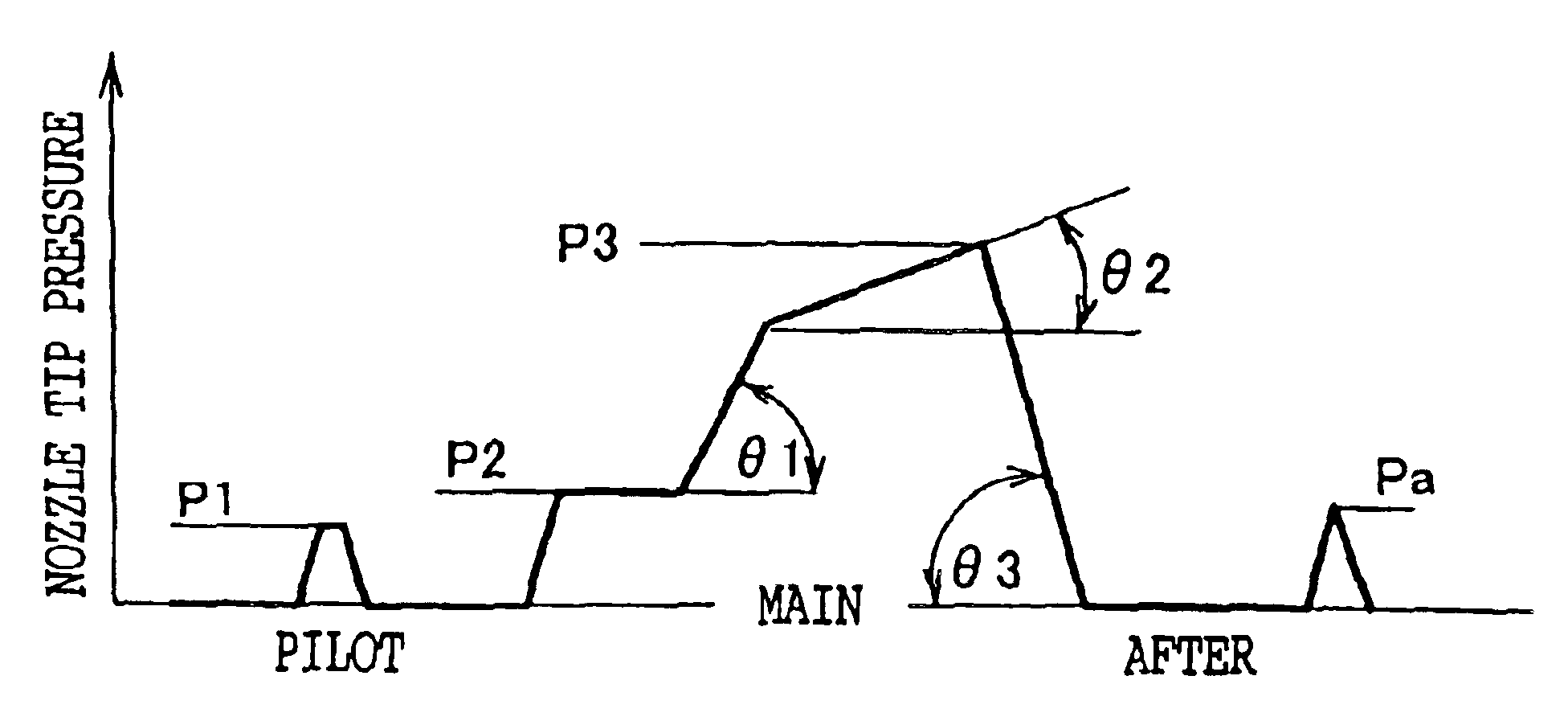

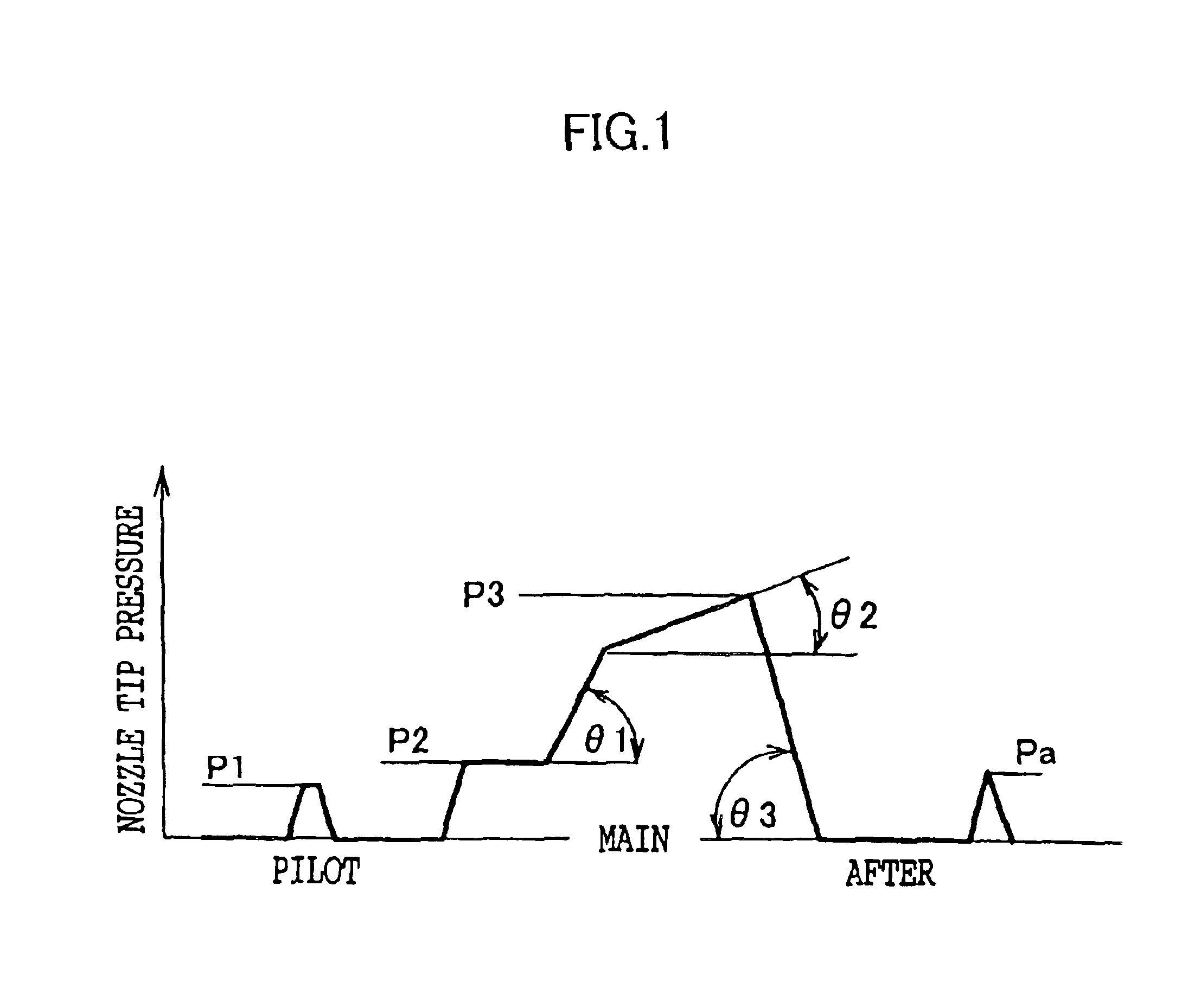

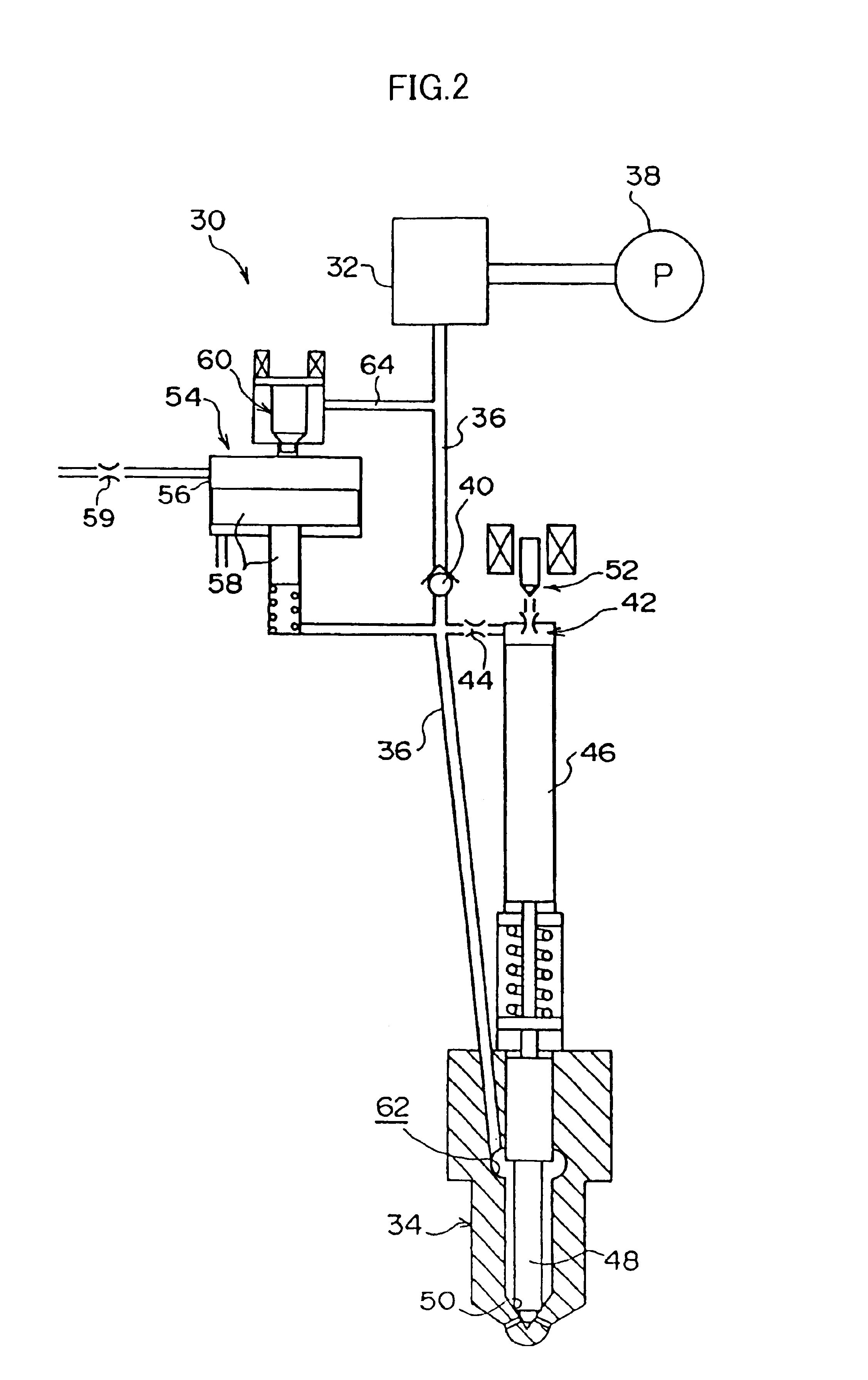

Fuel injection method in fuel injector

InactiveUS6904893B2Increase freedomRealize the structureElectrical controlInternal combustion piston enginesPhase differenceEngineering

In fuel injector including an accumulator and an intensifier, fuel is injected such that an injection control valve and a piston control valve are individually controlled, an operational phase difference therebetween is regulated, and at least one of a maximum injection pressure, a rate of increase of an injection pressure at the start of an increase of pressure, a rate of decrease of the injection pressure at the completion of injection, a pilot injection pressure, and an after injection pressure of fuel injected from a fuel injection nozzle is arbitrarily changed. Namely, a pressure during a movement from a base common rail pressure of the accumulator to a static maximum pressure statically determined by an operation of the intensifier is positively used as a control factor of injection, whereby a fuel injection pattern can be implemented with an extremely high degree of freedom.

Owner:TOYOTA JIDOSHA KK

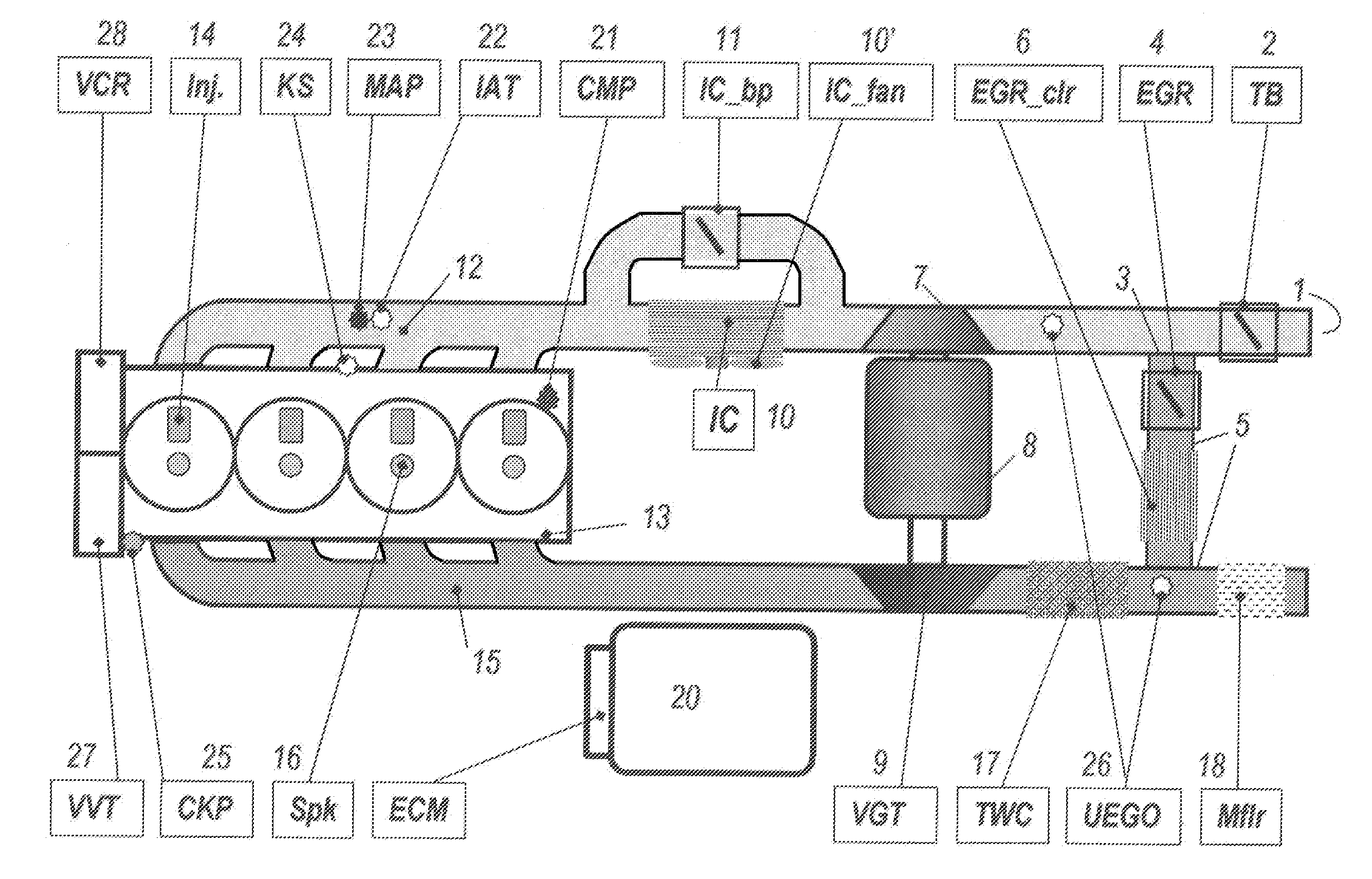

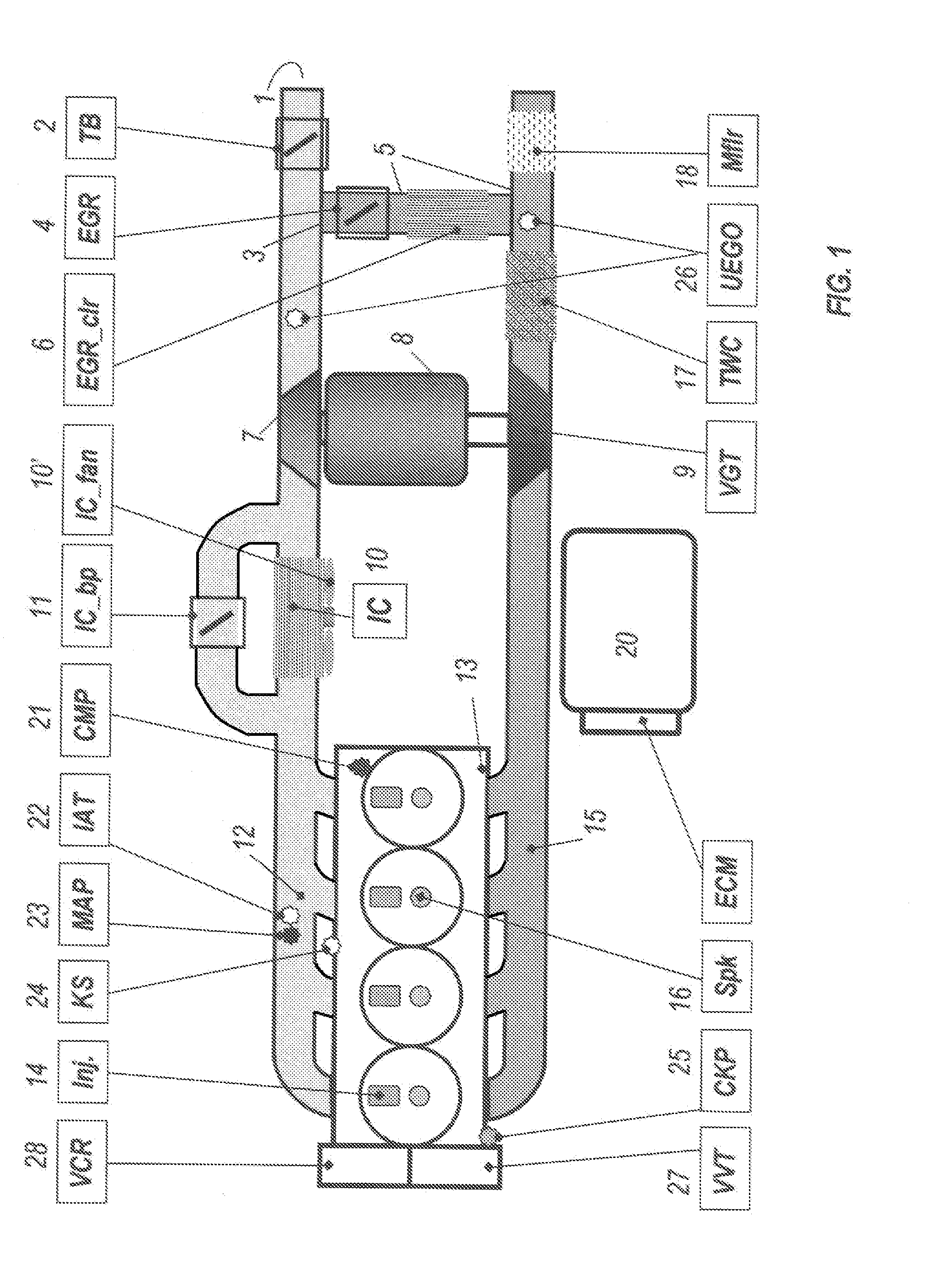

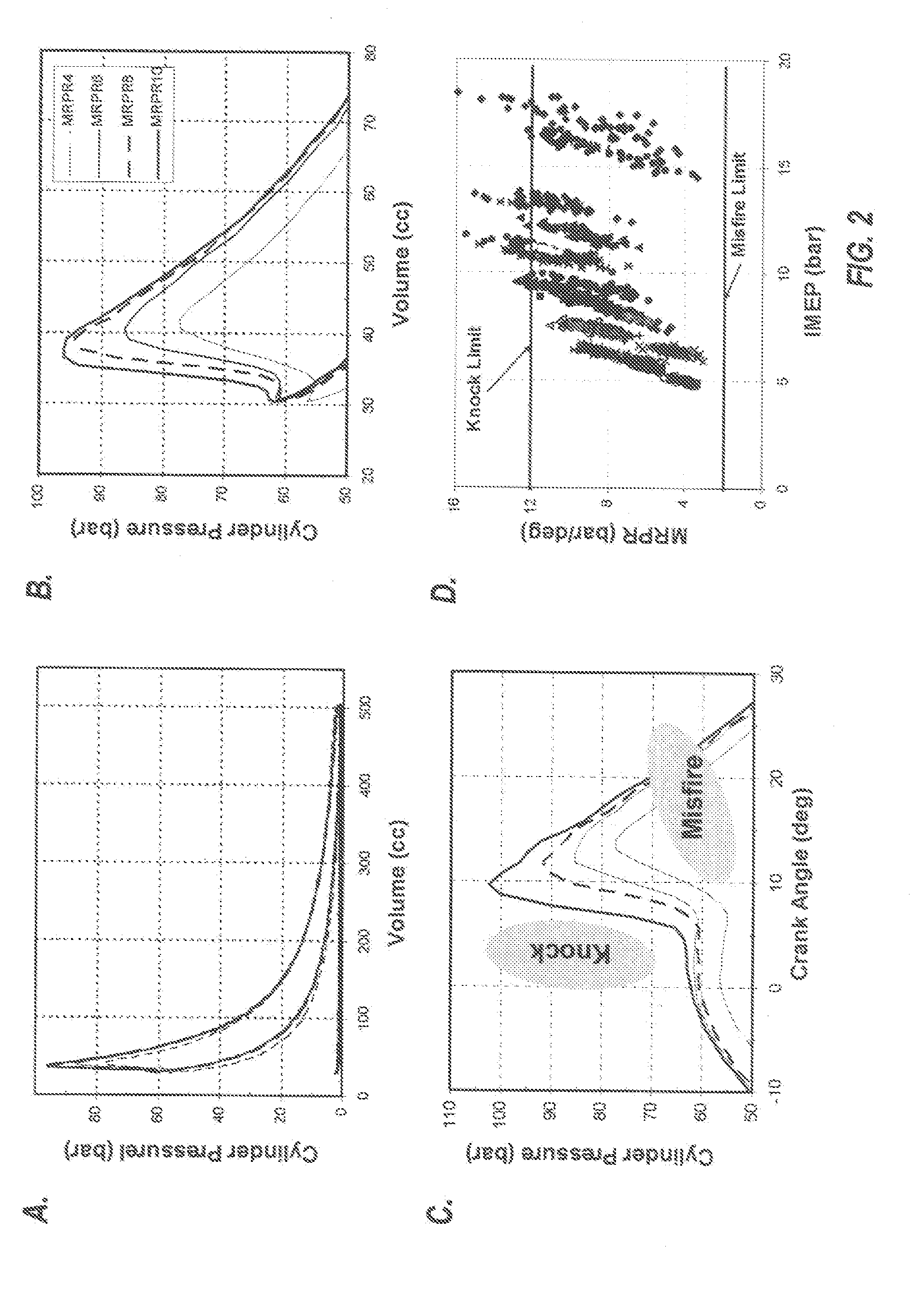

Method and system of transient control for homogeneous charge compression ignition (HCCI) engines

InactiveUS20100031924A1Reduce computing loadRobust engine controlElectrical controlInternal combustion piston enginesApplying knowledgeHcci combustion

A HCCI engine with a model reference adaptive feedback control system maintains stable HCCI combustion during speed / load transitions by: (1) estimating the maximum rate of pressure rise (MRPR), for each cycle, from an extra-cylinder sensor metric, such as a crankshaft dynamics or knock sensor metric, via statistical vector-to-vector correlation; (2) periodically self-tuning the vector-to-vector correlation; (3) applying knowledge base models to guide cycle-to-cycle adjustments of fuel quantity and other engine parameters, to maintain a target MRPR value.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA AS REPRESENTED BY THE

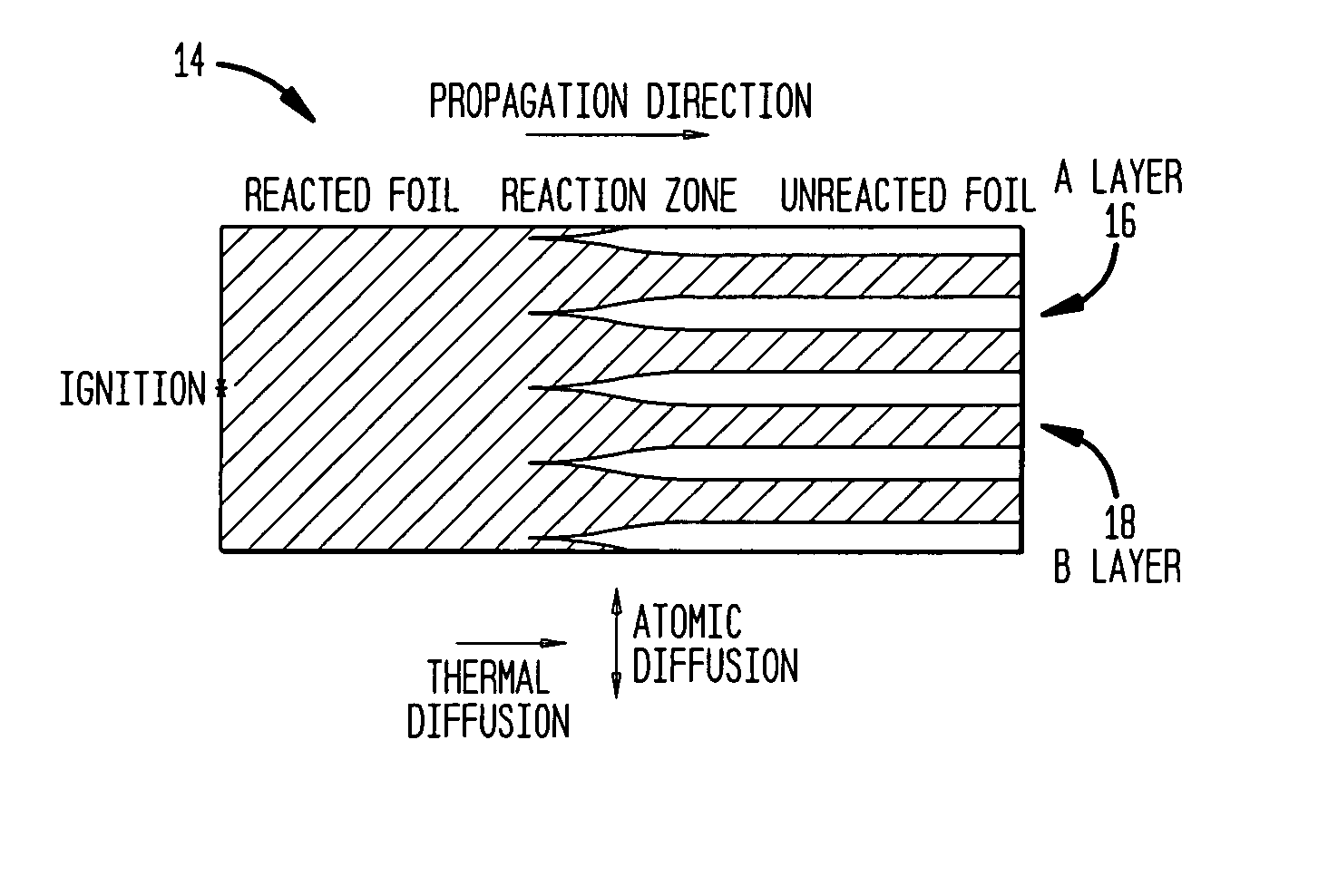

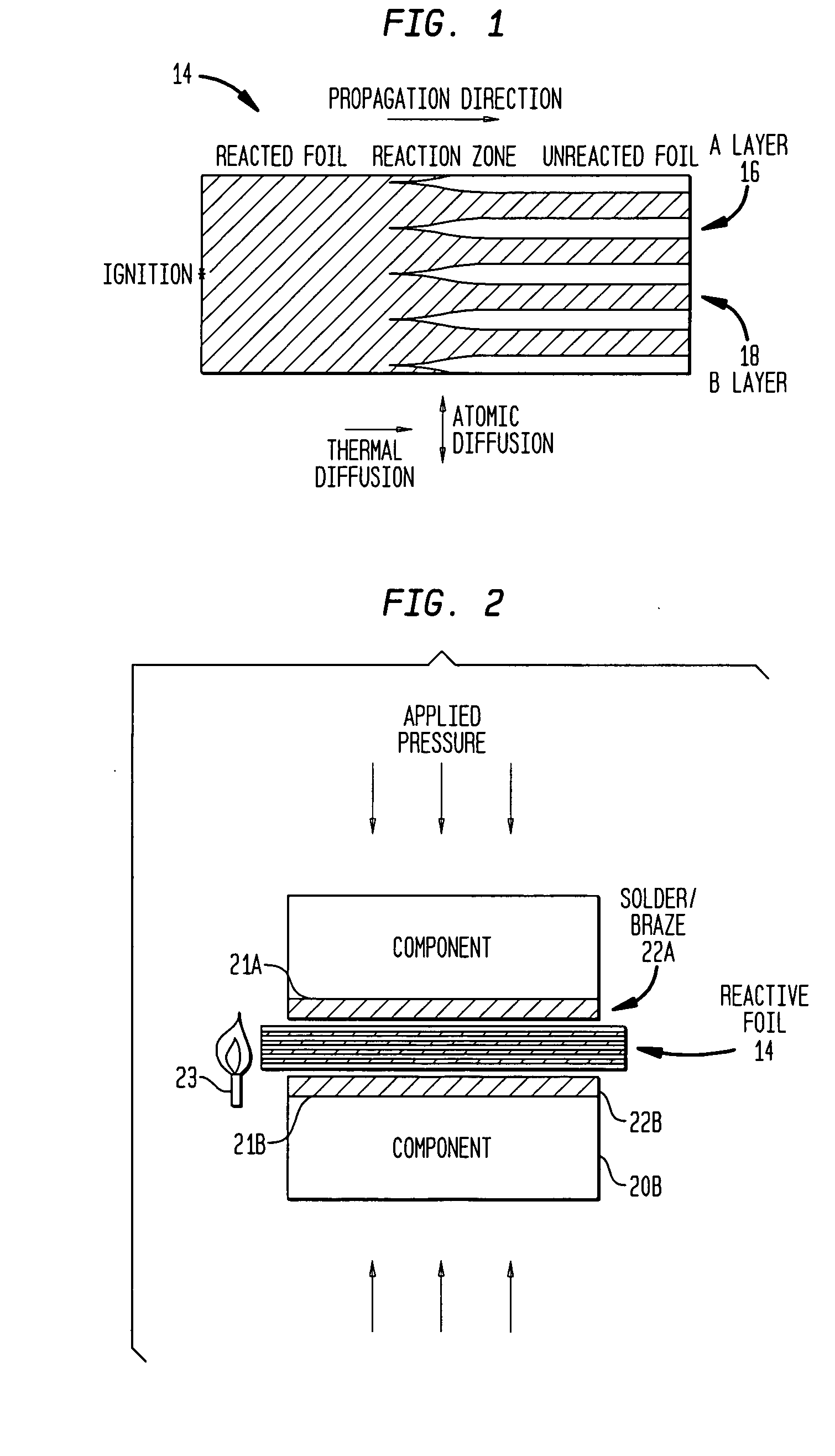

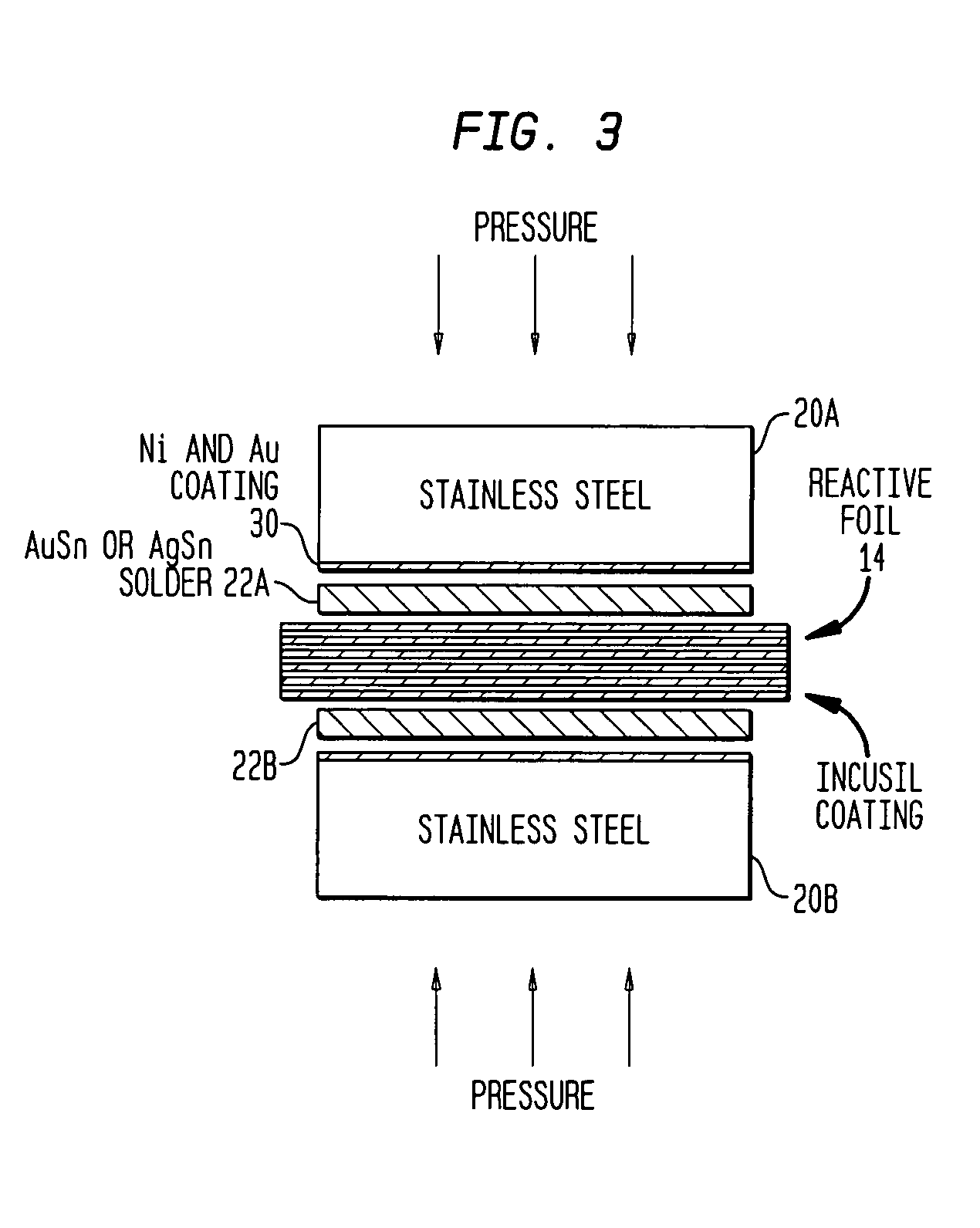

Method of joining using reactive multilayer foils with enhanced control of molten joining materials

InactiveUS20050082343A1Reducing applied pressureExtended durationExothermal chemical reaction heat productionVacuum evaporation coatingCopperMaximum pressure

In accordance with the invention, bodies of materials are joined by disposing between them a reactive multilayer foil and one or more layers of meltable joining material such as braze or solder. The bodies are pressed together against the foil and joining material, and the foil is ignited to melt the joining material. The pressing is near the critical pressure and typically produces a joint having a strength of at least 70-85% the maximum strength producible at practical maximum pressures. Thus for example, reactively formed stainless steel soldered joints that were heretofore made at an applied pressure of about 100 MPa can be made with substantially the same strength at a critical applied pressure of about 10 kPa. Advantages of the process include minimization of braze or solder extrusion and reduced equipment and processing costs, especially in the joining of large bodies.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

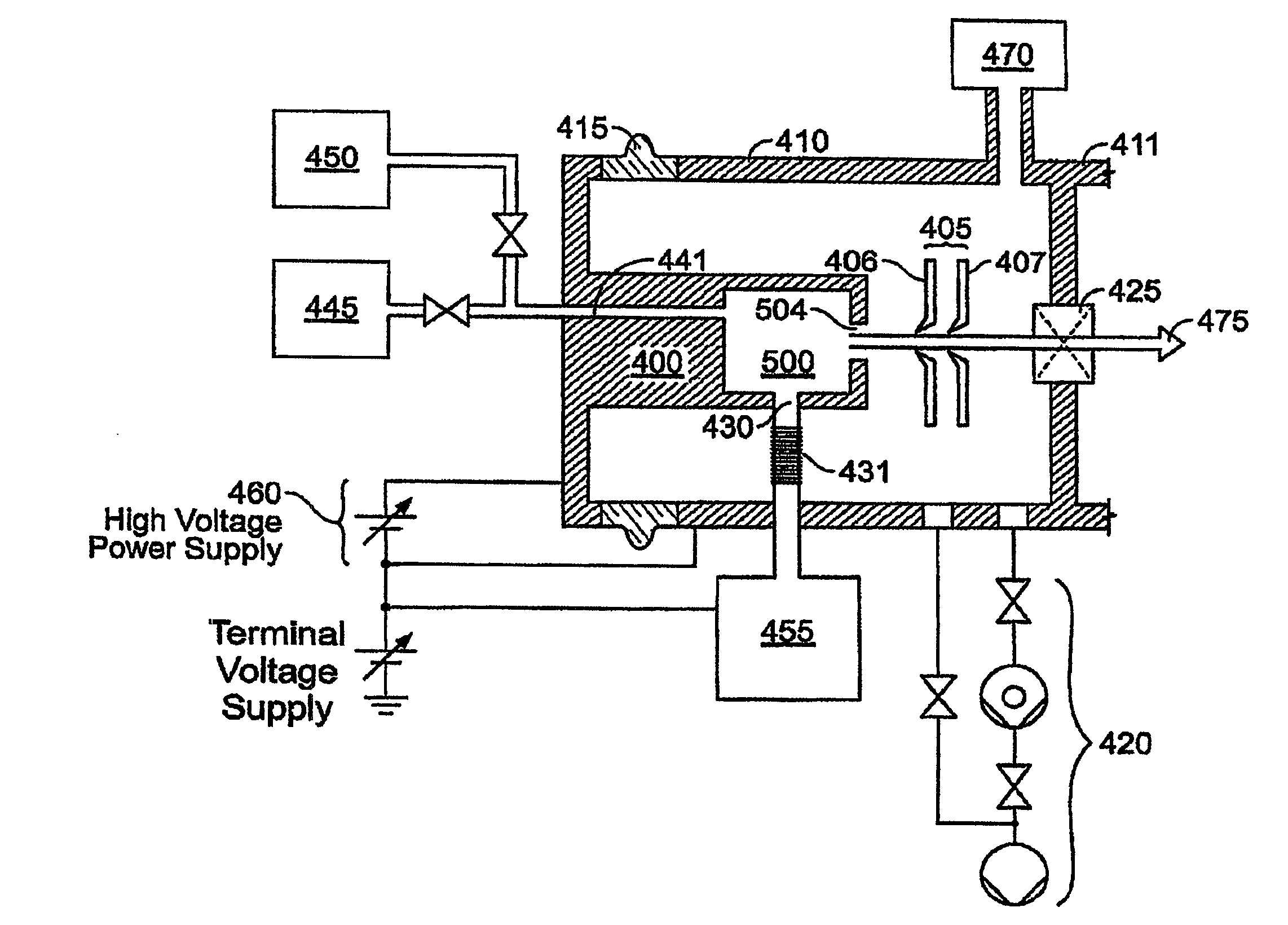

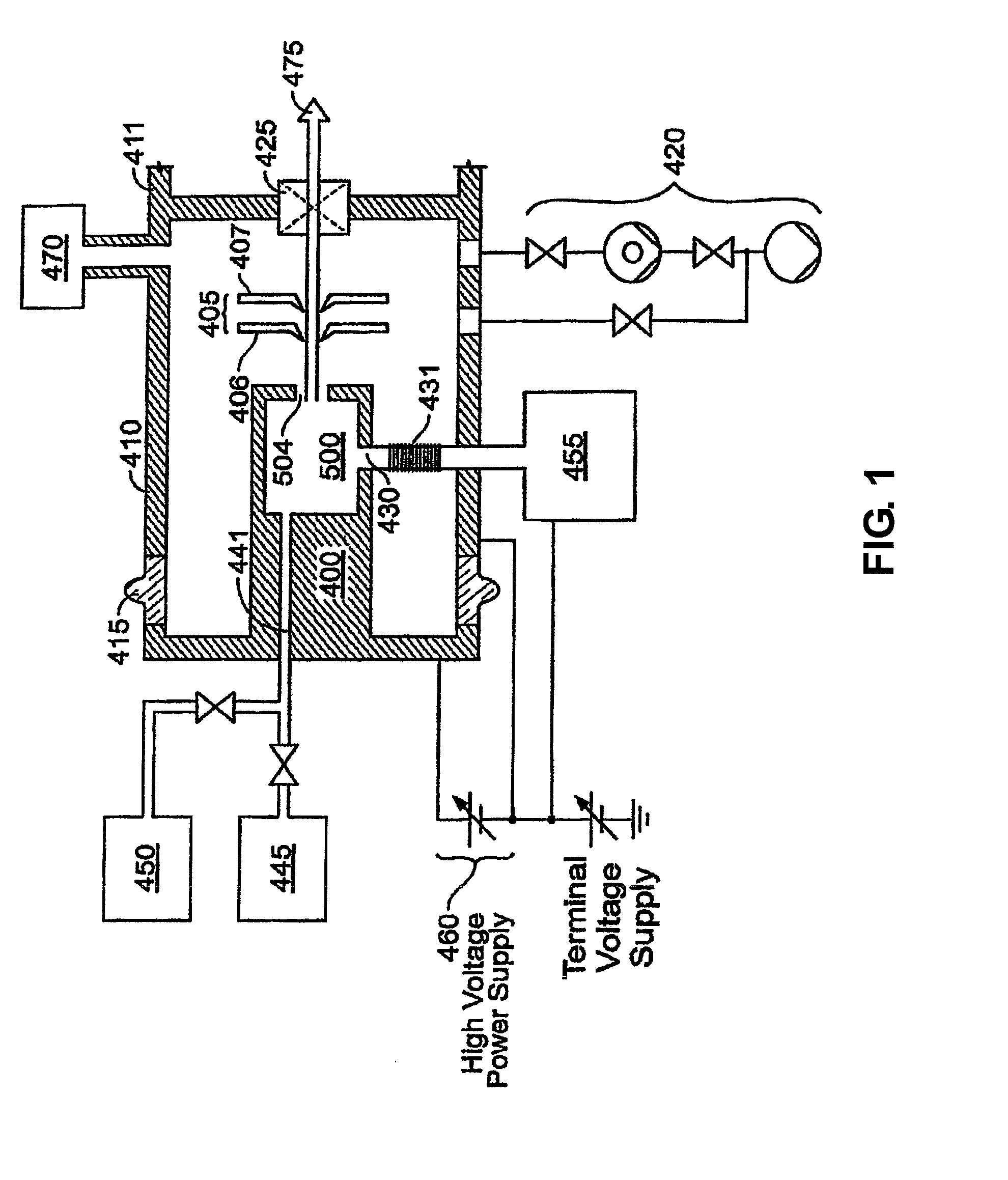

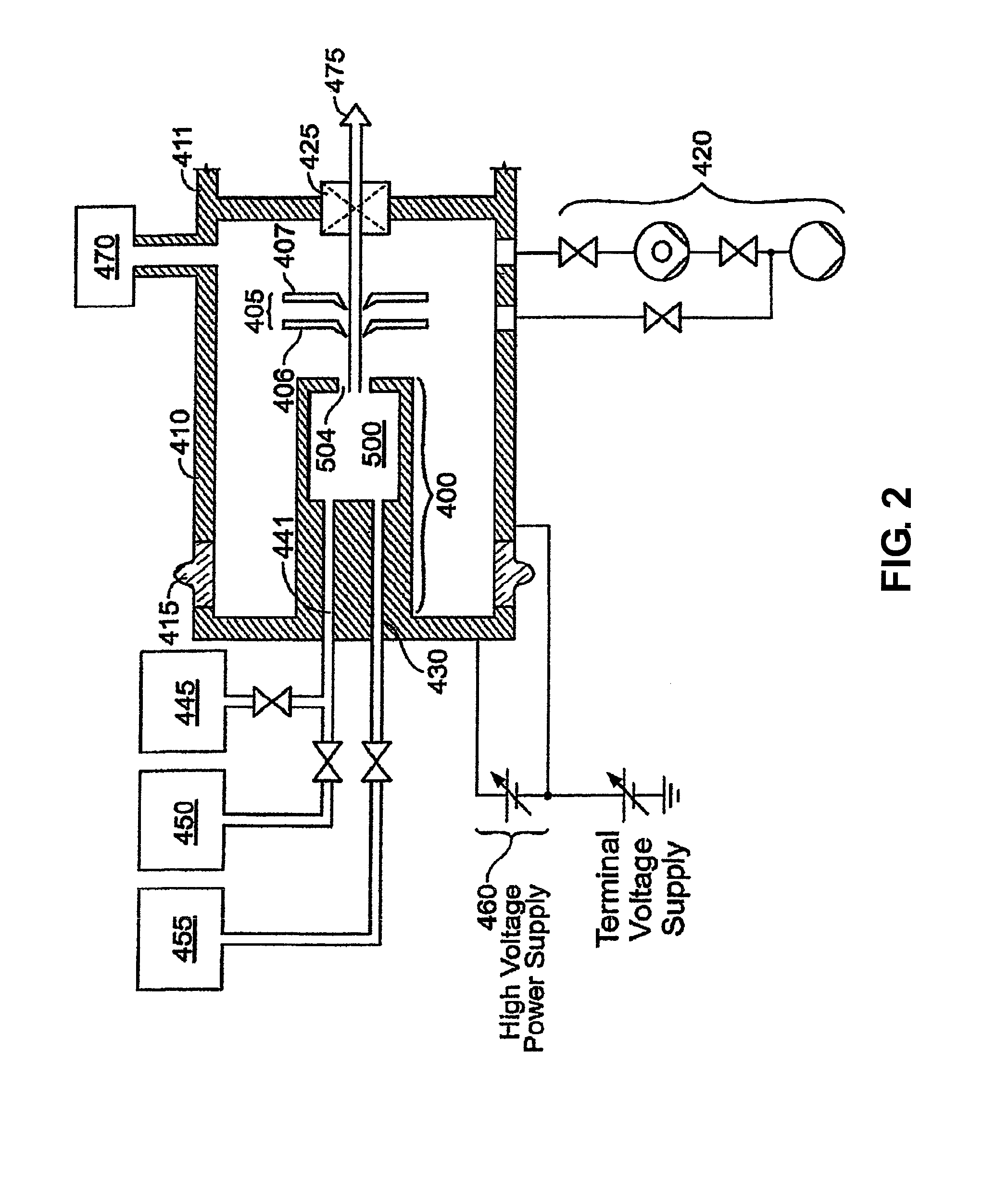

Method and apparatus for extending equipment uptime in ion implantation

InactiveUS20080223409A1Increasing effective reaction rateReduce pressureElectric discharge tubesHollow article cleaningPressure cycleReaction rate

An in situ cleaning system is disclosed for use with semiconductor processing equipment. In accordance with an important aspect of the invention, the cleaning system provides for dynamic cleaning of the semiconductor processing system by varying the pressure of the cleaning gas over time during a cleaning cycle. In particular, the cleaning gas is applied to the semiconductor processing system in repeated pressure cycles. Each pressure cycle begins with the pressure of the cleaning gas at PMIN. The pressure of the cleaning gas is increased to a maximum pressure PMAX during a fill portion of the pressure cycle and maintained for a dwell time selected to allow the available reactants to generate the desired end products. The pressure in the chamber to be cleaned is then reduced during a vent portion of the pressure cycle to permit venting of the reaction products. As such, each time the chamber to be filled is vented and re-filled, reaction products are removed and new reactants are introduced into the chamber to be cleaned, increasing the effective reaction rate.

Owner:SEMEQUIP

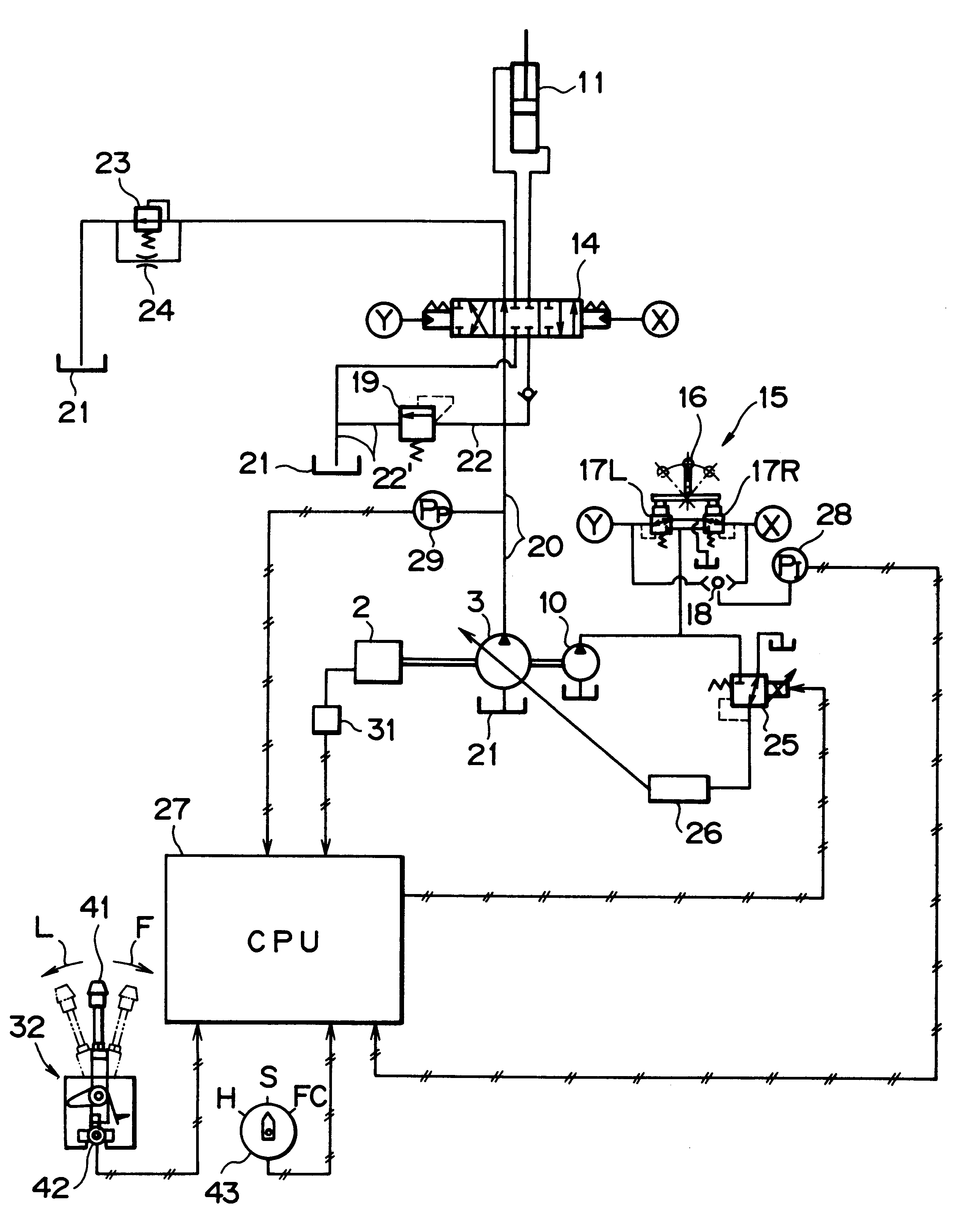

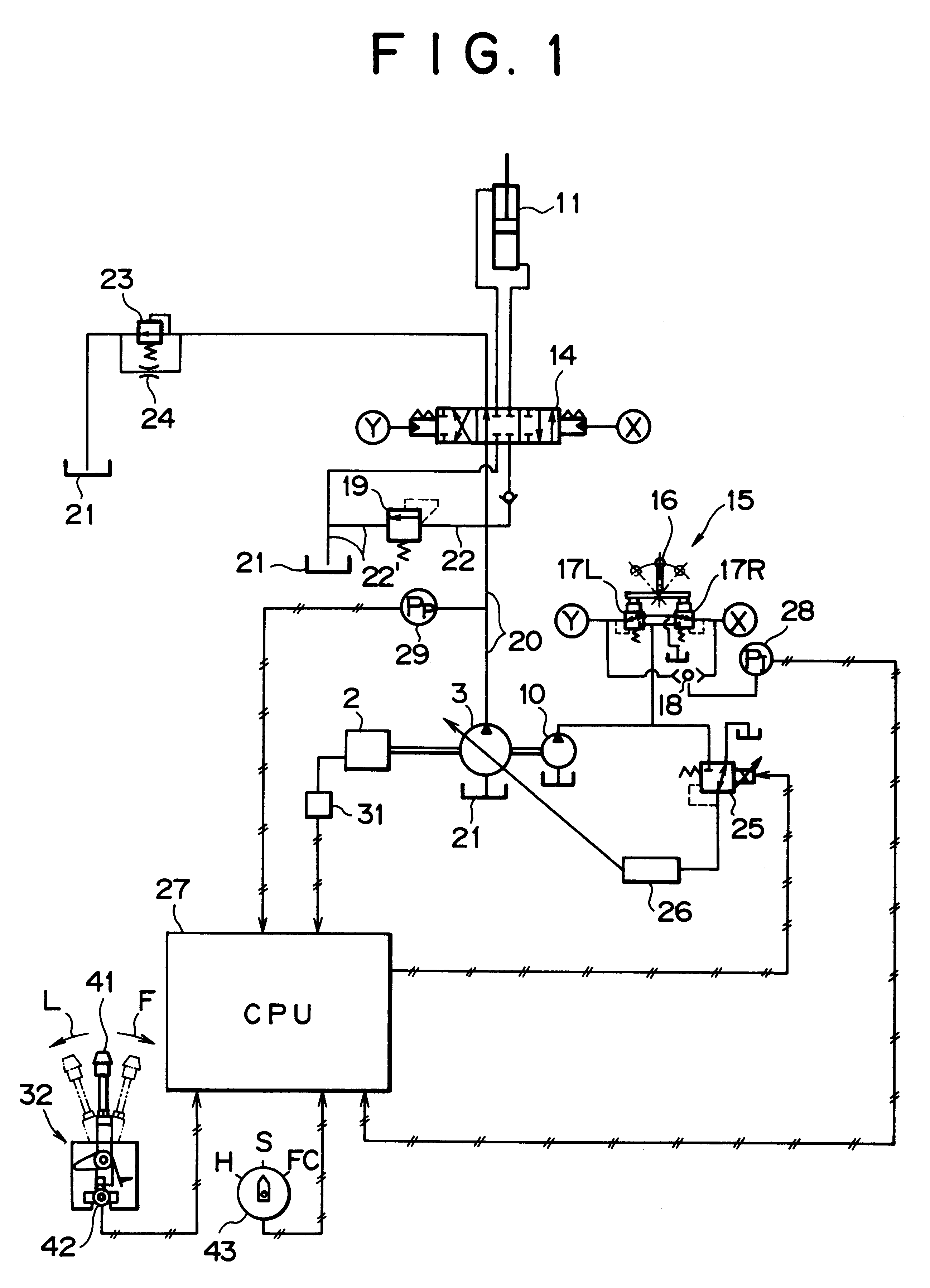

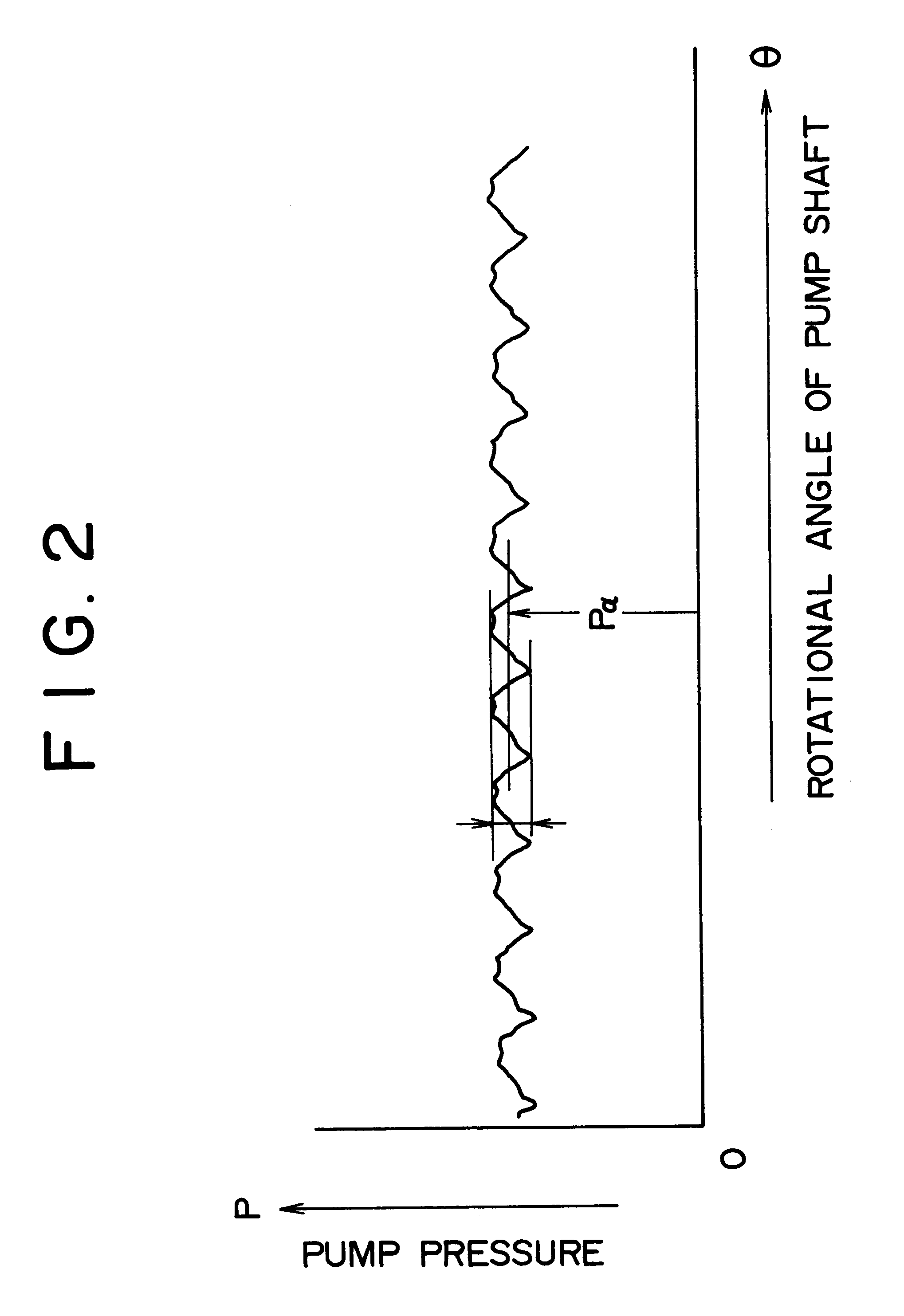

Flow rate control device in a hydraulic excavator

InactiveUS6202411B1Eliminate `` sense of incongruity ''Reduce rateFluid couplingsServomotorsHydraulic pumpActuator

A flow rate control device in a hydraulic excavator, comprising a hydraulic pump which is driven rotatively by an engine, a hydraulic actuator which is driven by a hydraulic oil discharged from the hydraulic pump, a control valve which controls the supply of the hydraulic oil to the hydraulic actuator, an operating means which operates the control valve so as to change over the valve from one position to another, a relief valve disposed in a discharge oil path extending from the hydraulic pump to limit the maximum pressure in the discharge oil path, an operational condition detecting means for detecting an operational condition of the hydraulic actuator, a pump pressure detecting means for detecting the discharge pressure of the hydraulic oil discharged from the hydraulic pump, a flow rate adjusting means for adjusting the discharge flow rate of the hydraulic oil discharged from the hydraulic pump, and a control means to which are inputted detection signals from both the operational condition detecting means and the pump pressure detecting means. When a specific operational condition of the hydraulic actuator is detected and when the said discharge pressure is held at a predetermined relief cut-off pressure or higher for a predetermined period of time, the control means makes control so that the discharge flow rate of the hydraulic oil discharged from the hydraulic pump is decreased to a relief cut-off pressure by the flow rate adjusting means. According to this construction, the relief cut-off control can be made only where required for each of various works of different conditions which the hydraulic excavator performs, such as excavating work, crushing work and land readjusting work. That is, even when the discharge pressure is held at a predetermined relief cut-off pressure or higher for a predetermined period of time, the relief cut-off control is made if the hydraulic actuator is in the specific operational condition.

Owner:KOBELCO CONSTR MASCH CO LTD

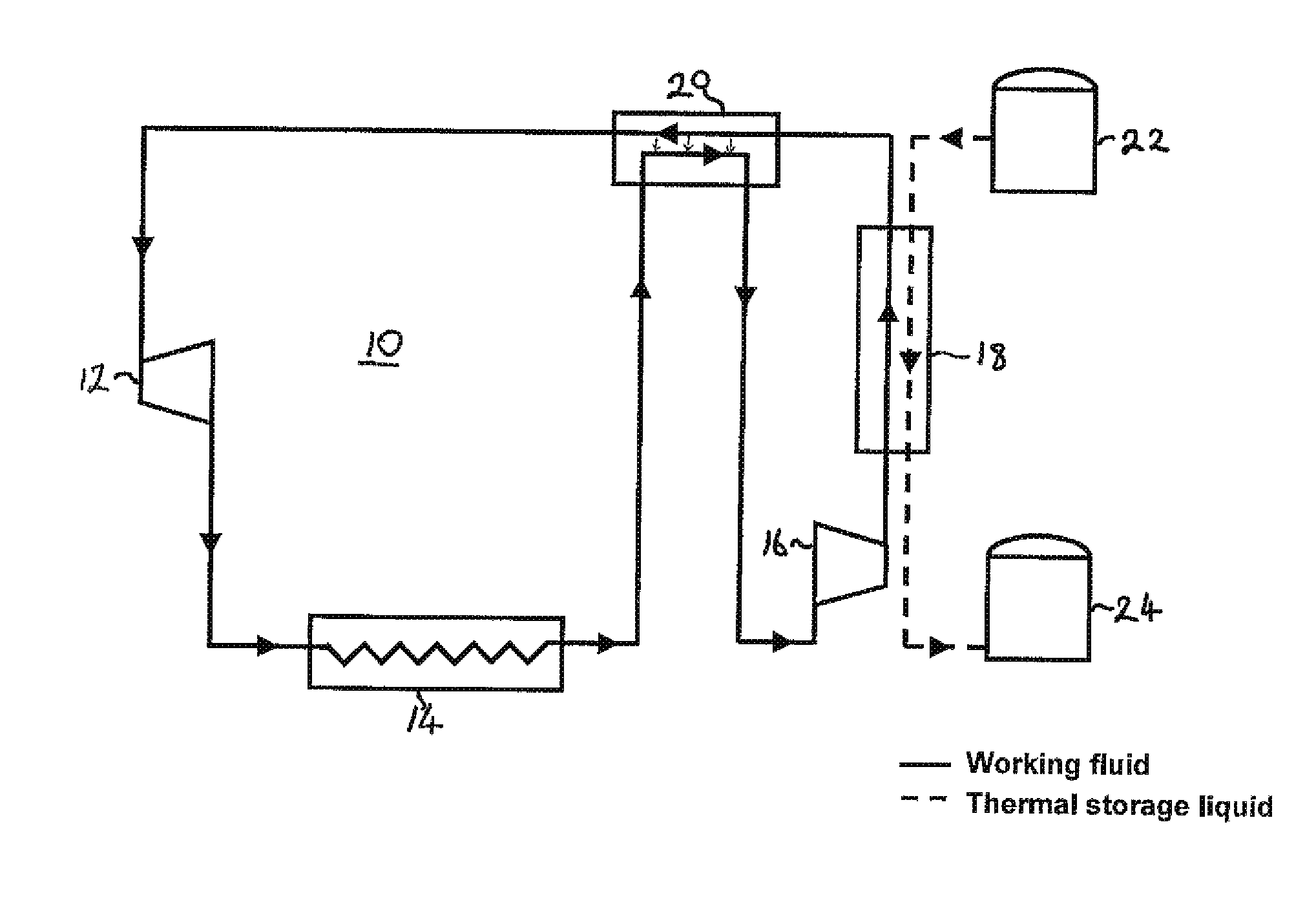

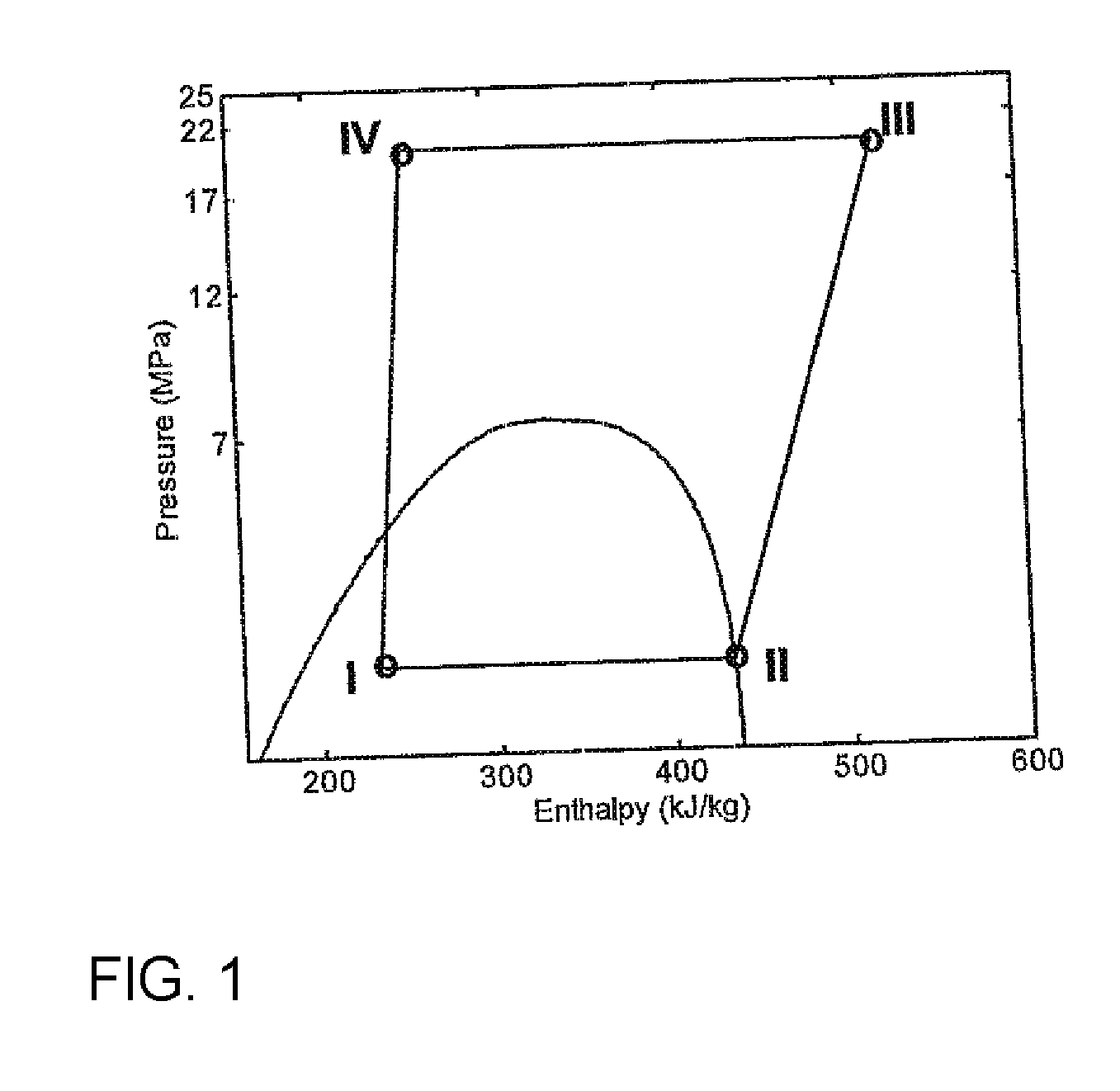

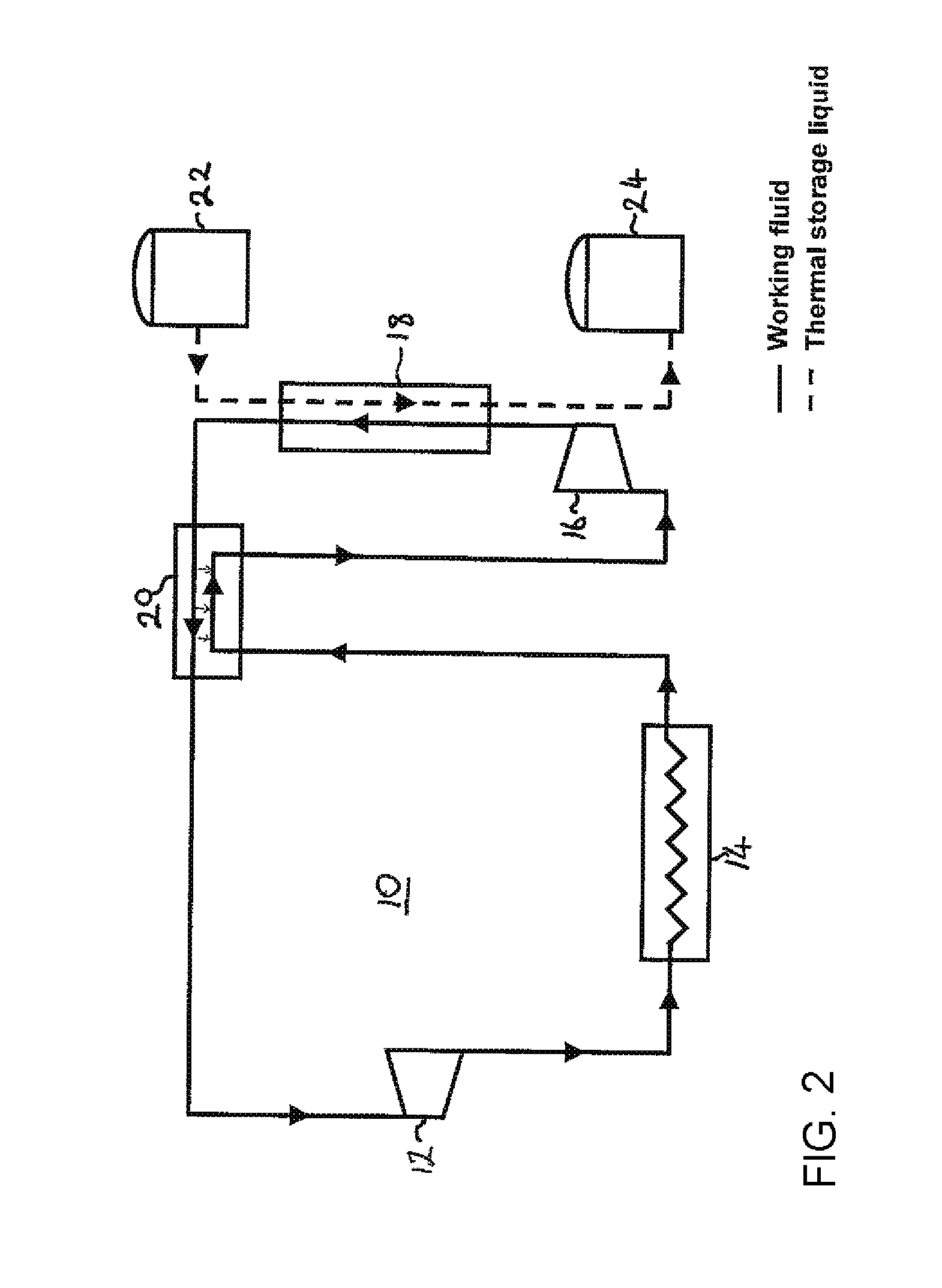

Thermoelectric energy storage system having an internal heat exchanger and method for storing thermoelectric energy

InactiveUS20120222423A1Minimized in sizeMaximizes workFeed water supplySteam accumulatorsThermal energyWorking fluid

Exemplary embodiments are directed to a thermoelectric energy storage system (TEES) and method for converting electrical energy into thermal energy to be stored and converted back to electrical energy with an improved round-trip efficiency are disclosed. The TEES includes a working fluid circuit for circulating a working fluid through a first heat exchanger and a second heat exchanger, a thermal storage medium circuit for circulating a thermal storage medium, the thermal storage medium circuit having at least one hot storage tank coupled to a cold storage tank via the first heat exchanger. The arrangement maximizes the work performed by the cycle during charging and discharging for a given maximum pressure and maximum temperature of the working fluid.

Owner:ABB RES LTD

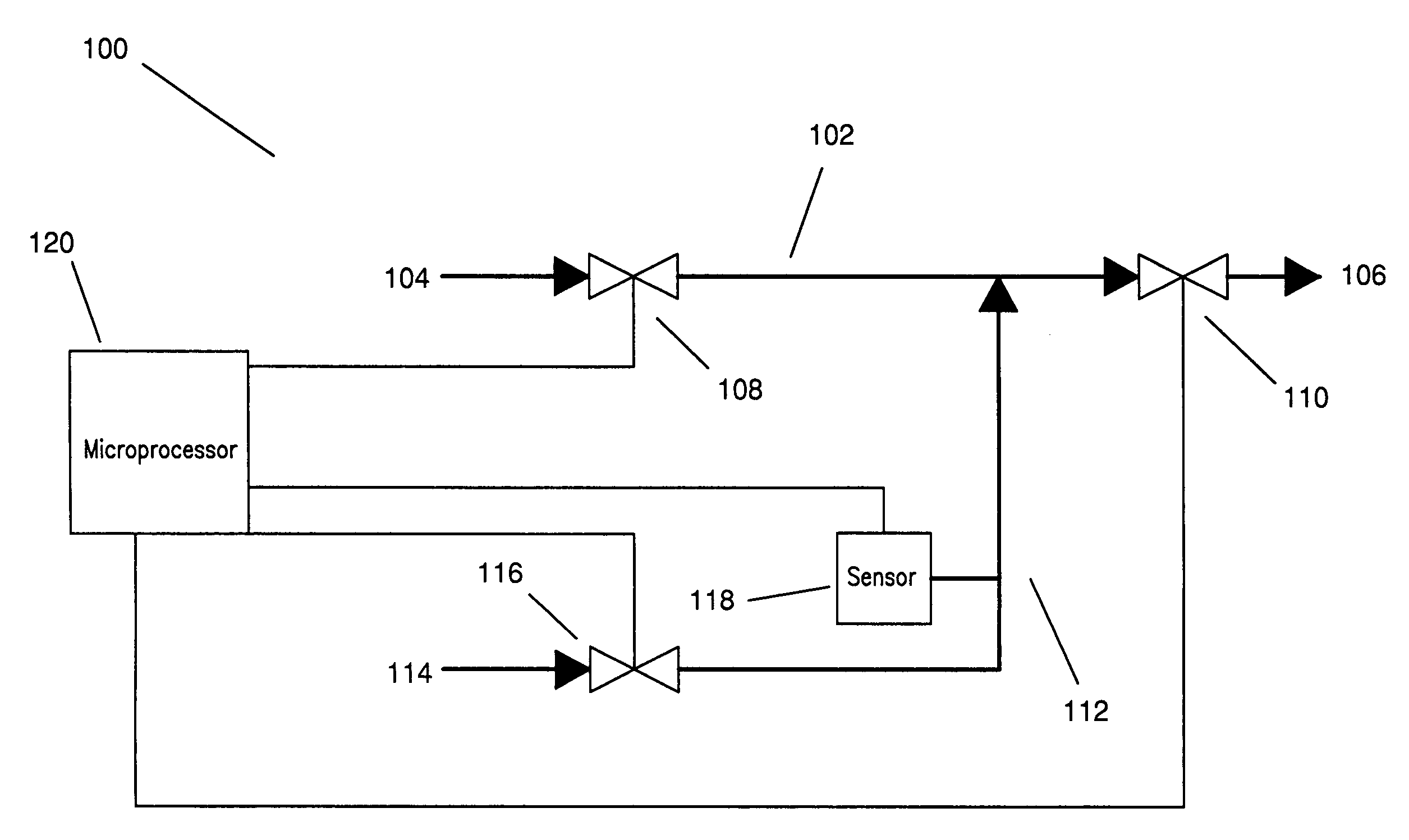

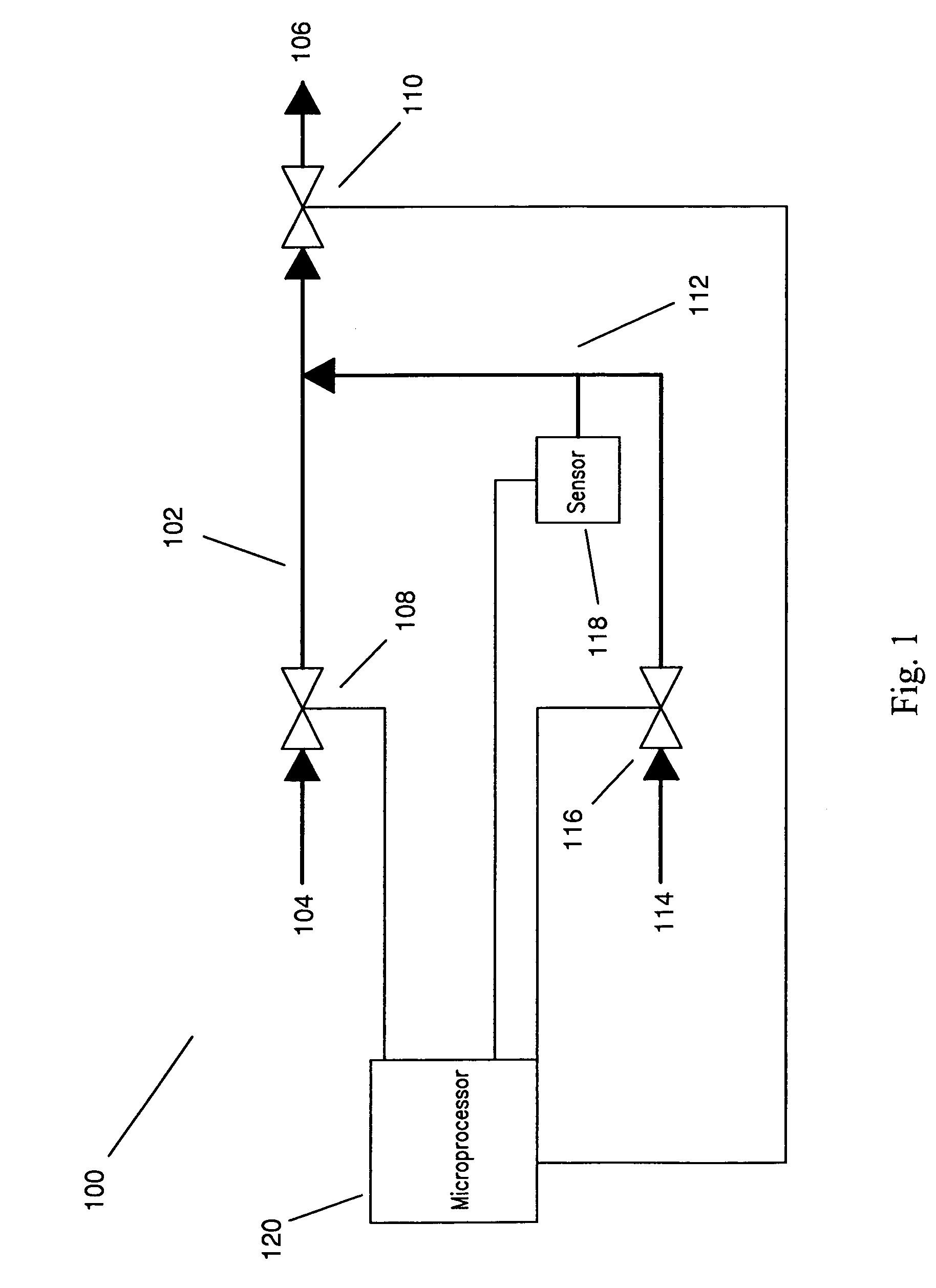

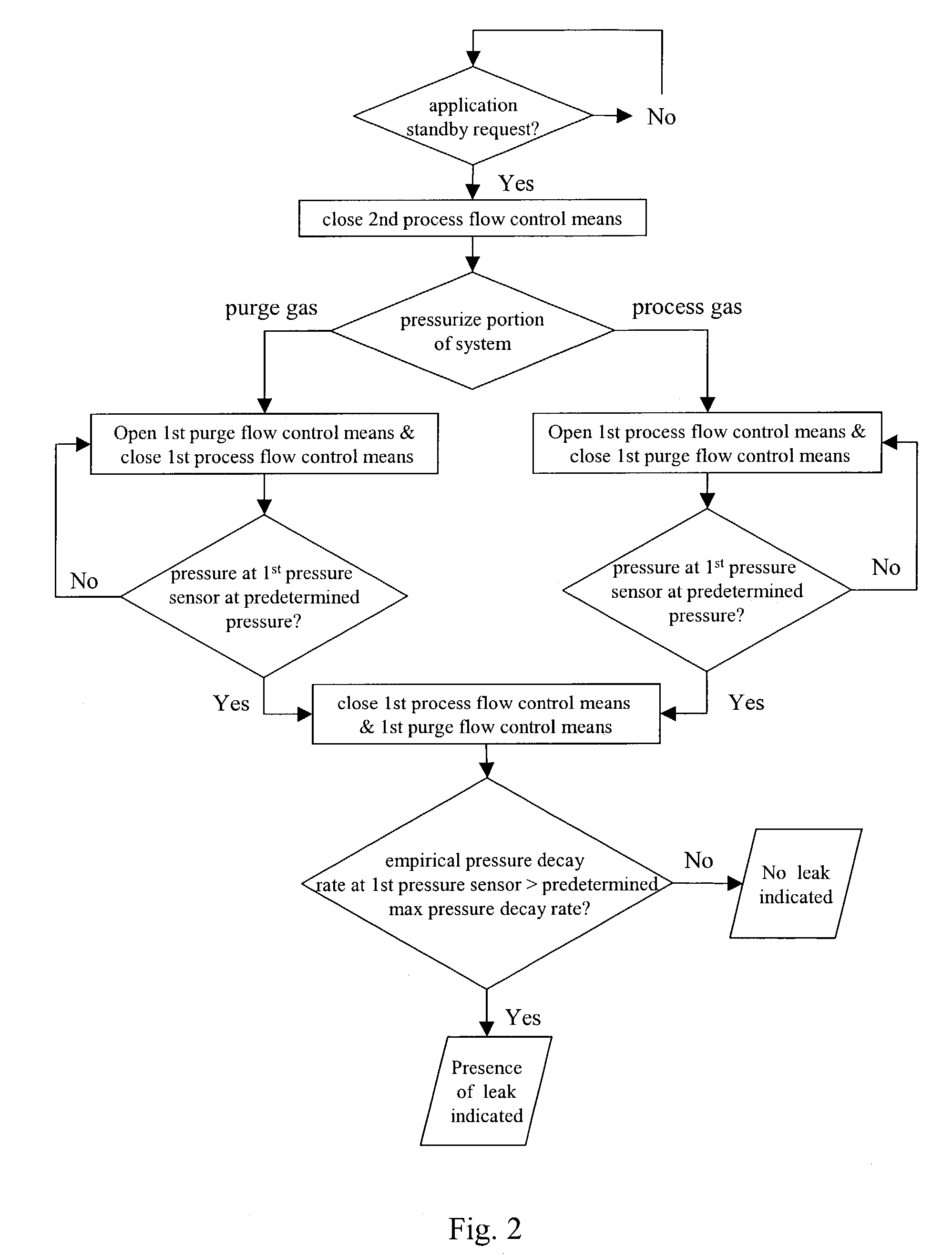

Integrated gas supply and leak detection system

InactiveUS7107820B2Reduce complexityLow costDetection of fluid at leakage pointMeasurement of fluid loss/gain rateElectronic communicationEngineering

The invention generally relates to a system and method for integrated gas delivery and leak detection to one or more applications. The system includes at least one application site, a process conduit extending from a process gas source site to the application site, a first and second process flow control at the process conduit, and a first pressure sensor.Also included in the system is a microprocessor that is in electronic communication with the flow controls and the first pressure sensor, wherein the microprocessor is programmed to respond to an application standby request by performing a pressure decay test, including closing the second process flow control and pressurizing a portion of the system by opening the first process flow control. Further included in the pressure test is closing the first process flow control when the pressure at the first pressure sensor is at a minimum pressure, and comparing an empirical pressure decay rate at the first pressure sensor with a maximum pressure decay rate, whereby an empirical pressure decay rate that exceeds the maximum pressure decay rate indicates the presence of a leak.

Owner:PRAXAIR ST TECH INC

Reverse osmosis filtration systems

Owner:TOPPER MFG CORP

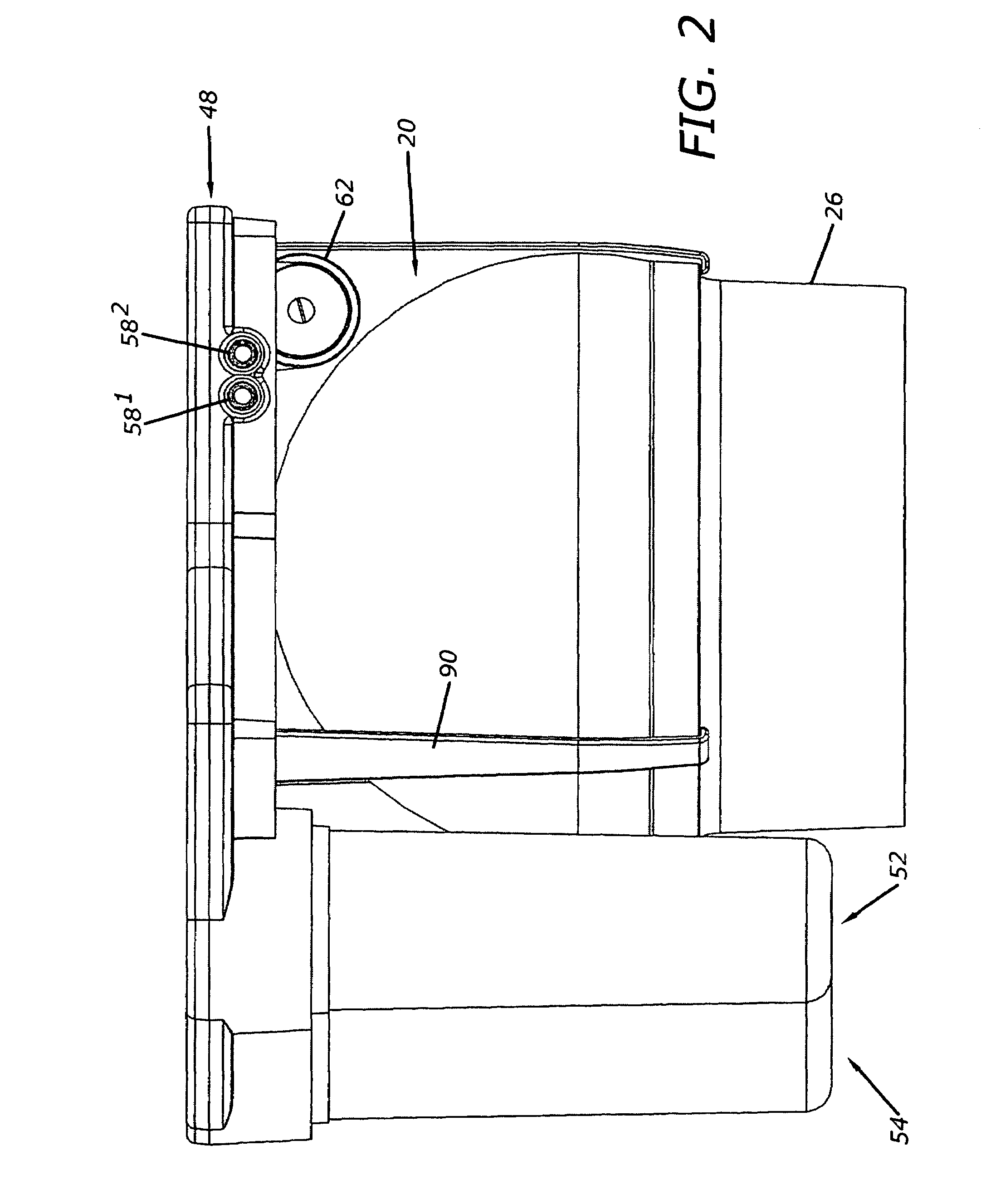

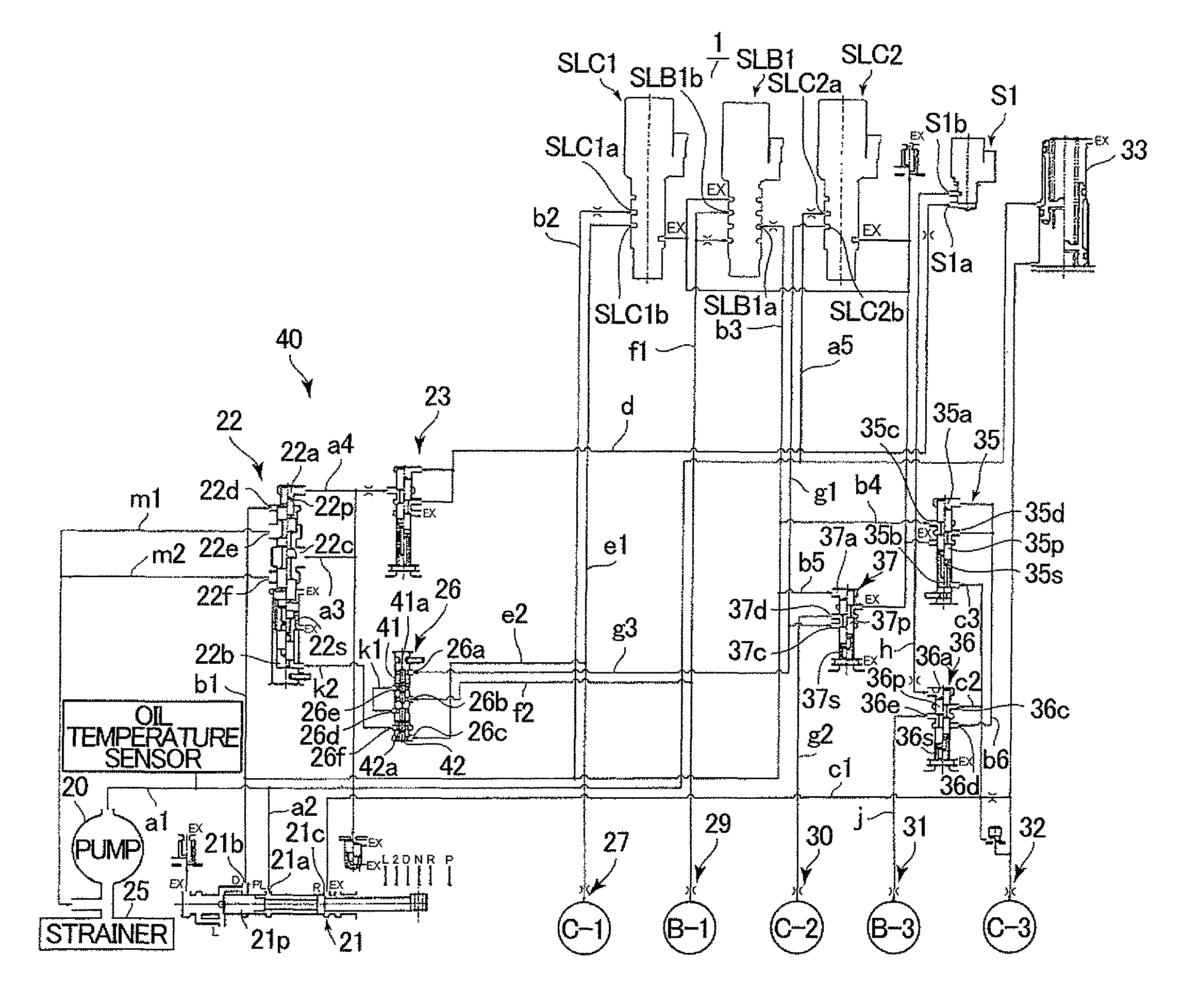

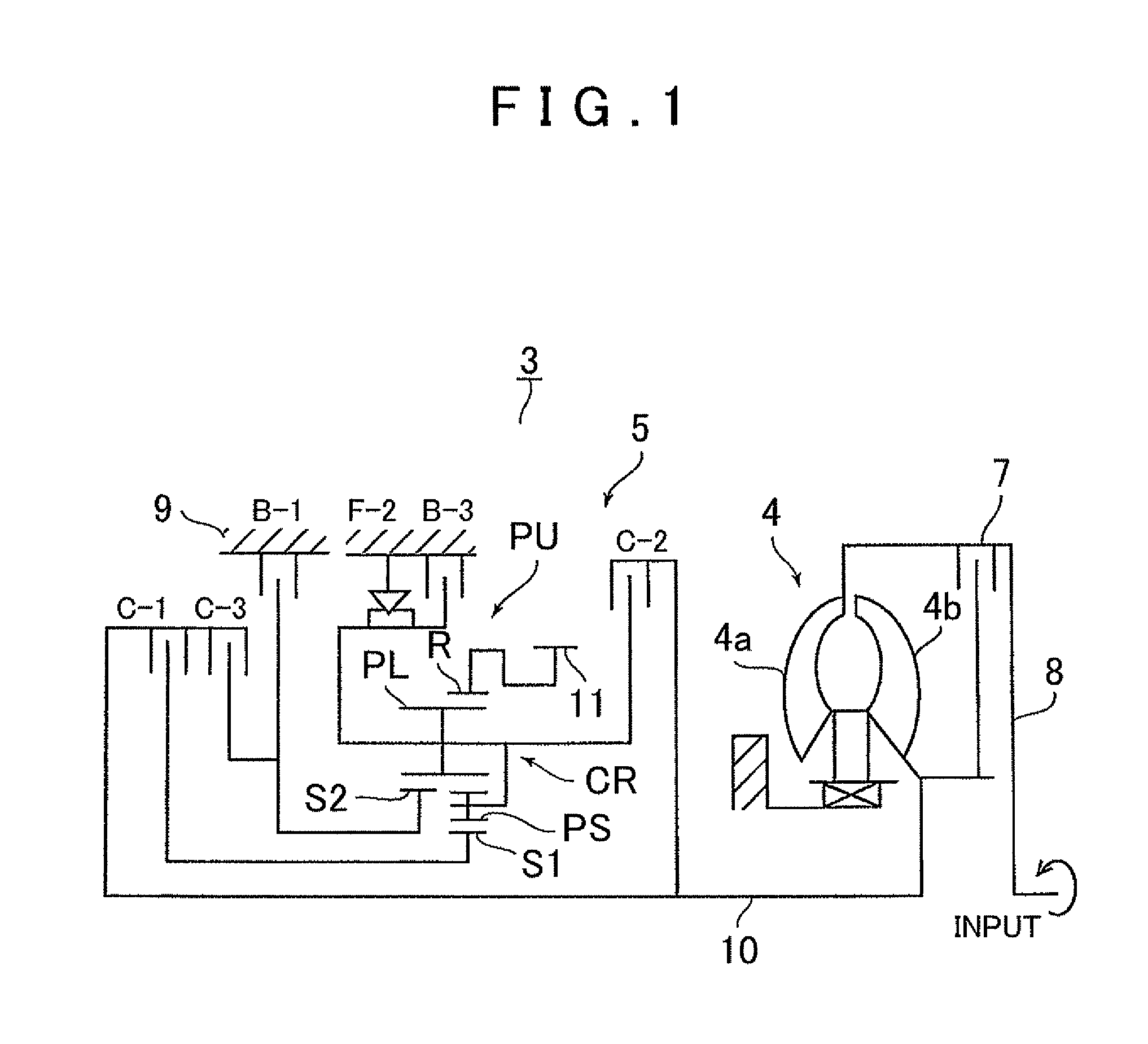

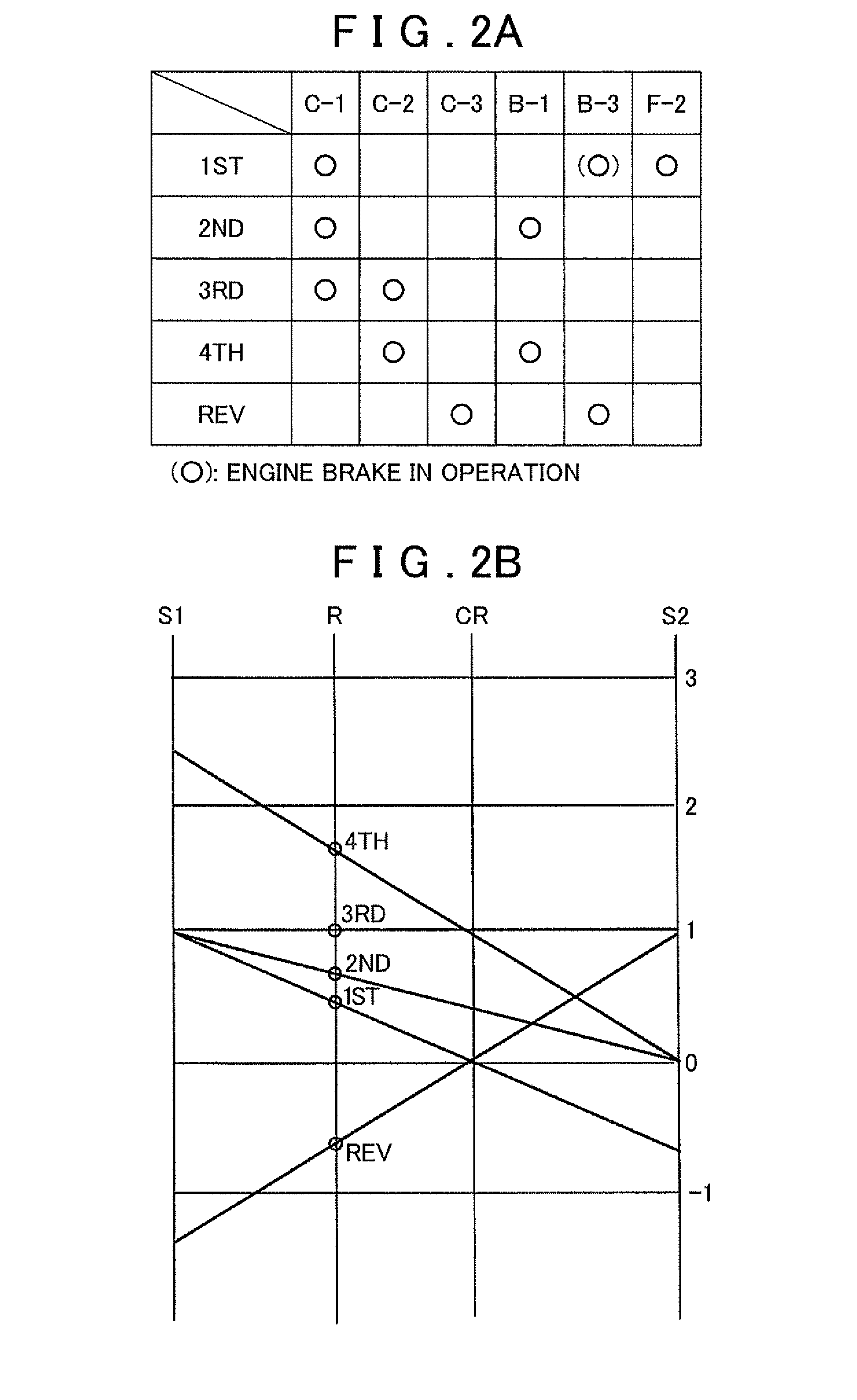

Hydraulic control device for automatic transmission

ActiveUS8123642B2Avoiding unnecessary increase to line pressureIncrease pressureFluid couplingsToothed gearingsAutomatic transmissionEngineering

A hydraulic control device for an automatic transmission, including: a hydraulic pressure source; a plurality of friction engagement elements; a line pressure regulating valve that regulates hydraulic pressure from the hydraulic pressure source to a predetermined line pressure; a plurality of operation pressure regulating valves that regulate the line pressure as operation pressure for a hydraulic servo operating a friction engagement element; a maximum pressure conducting circuit that feeds a maximum pressure, among the operation pressures, to the line pressure regulating valve, wherein the friction engagement elements are engaged and released to achieve a plurality of forward speeds and a reverse speed, and the line pressure regulating valve regulates the line pressure during forward travel based on the maximum operation pressure, and regulates the line pressure during reverse travel based on the operation pressure input from a specific operation pressure regulating valve.

Owner:AISIN AW CO LTD

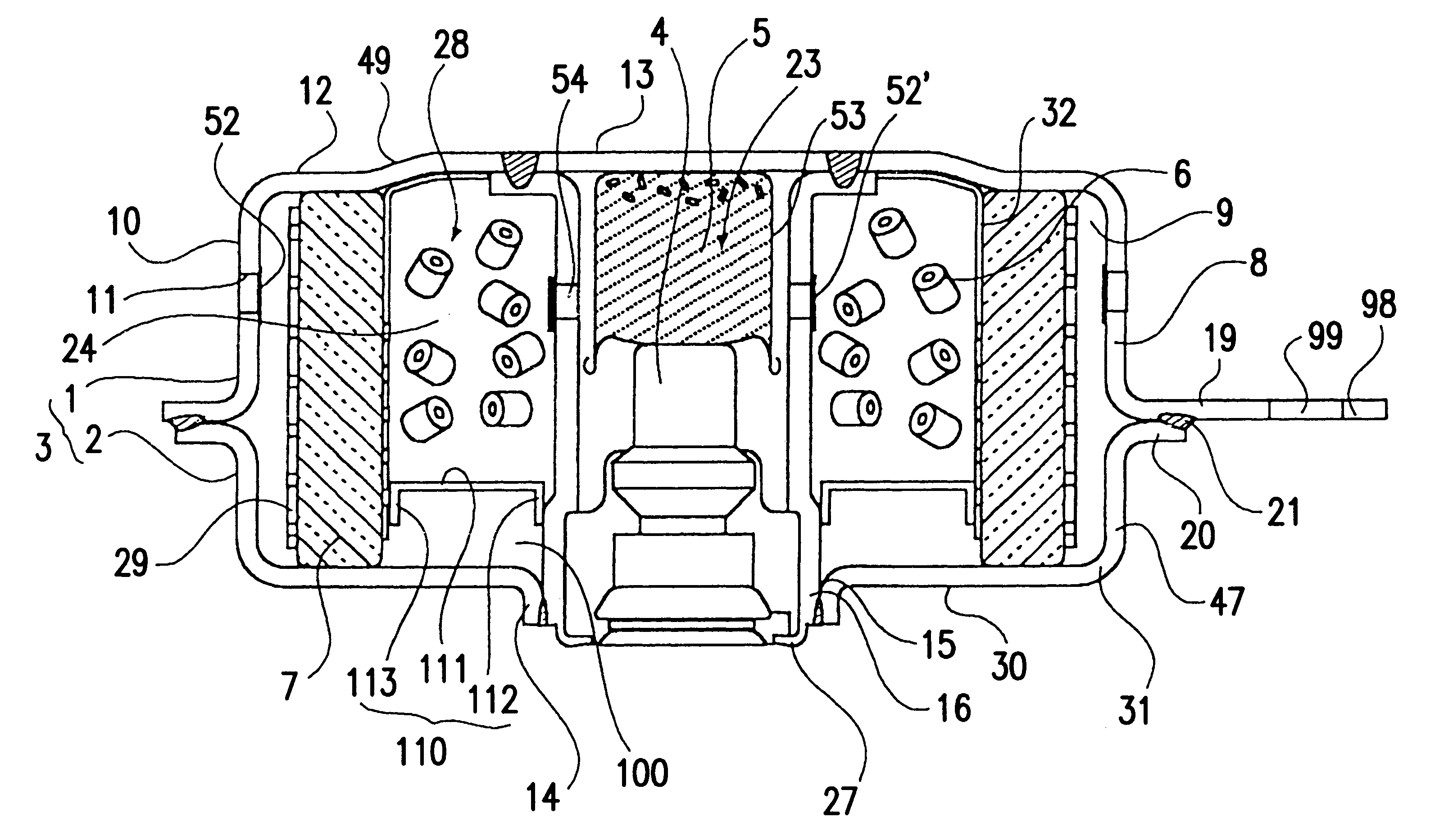

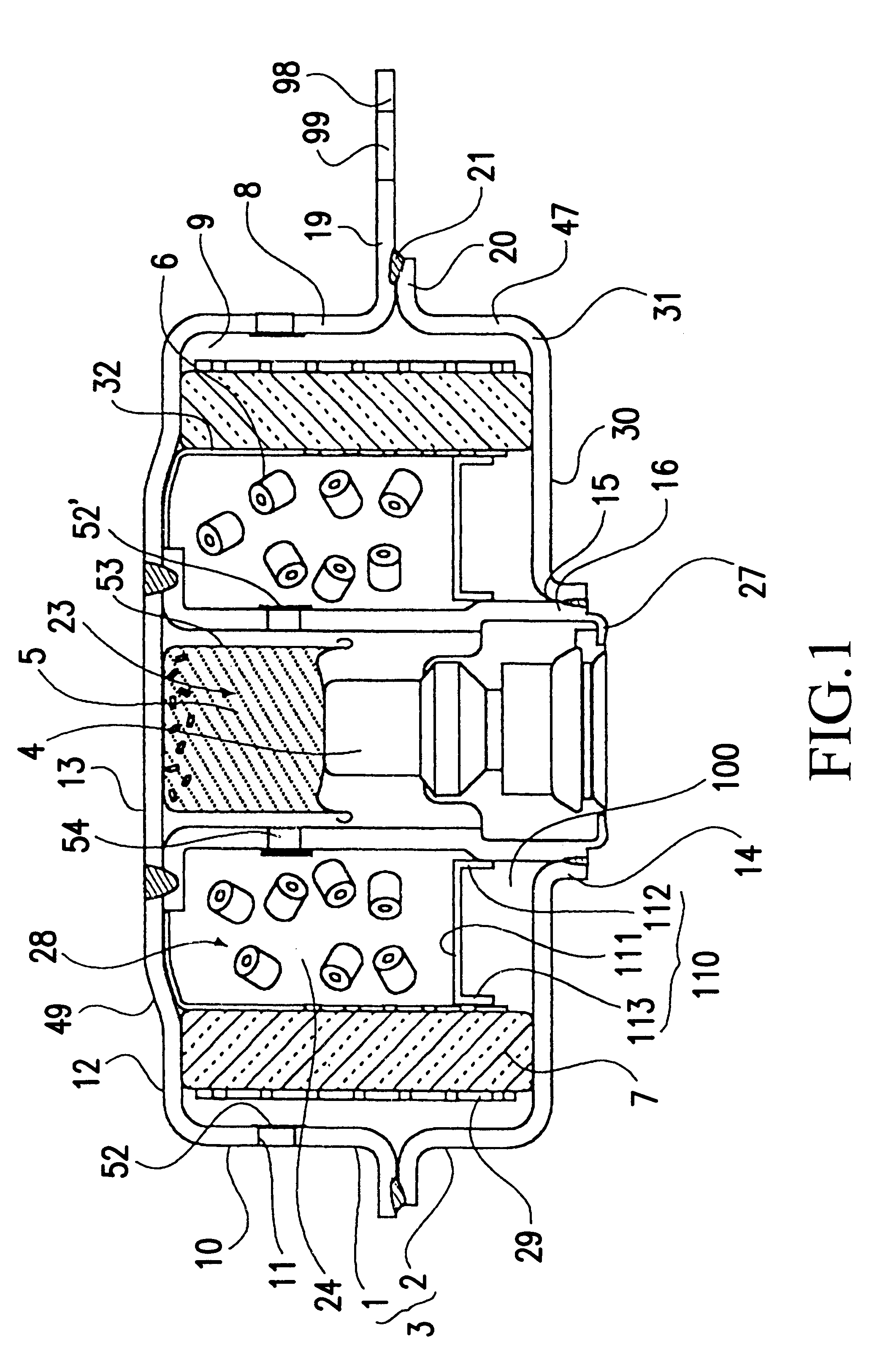

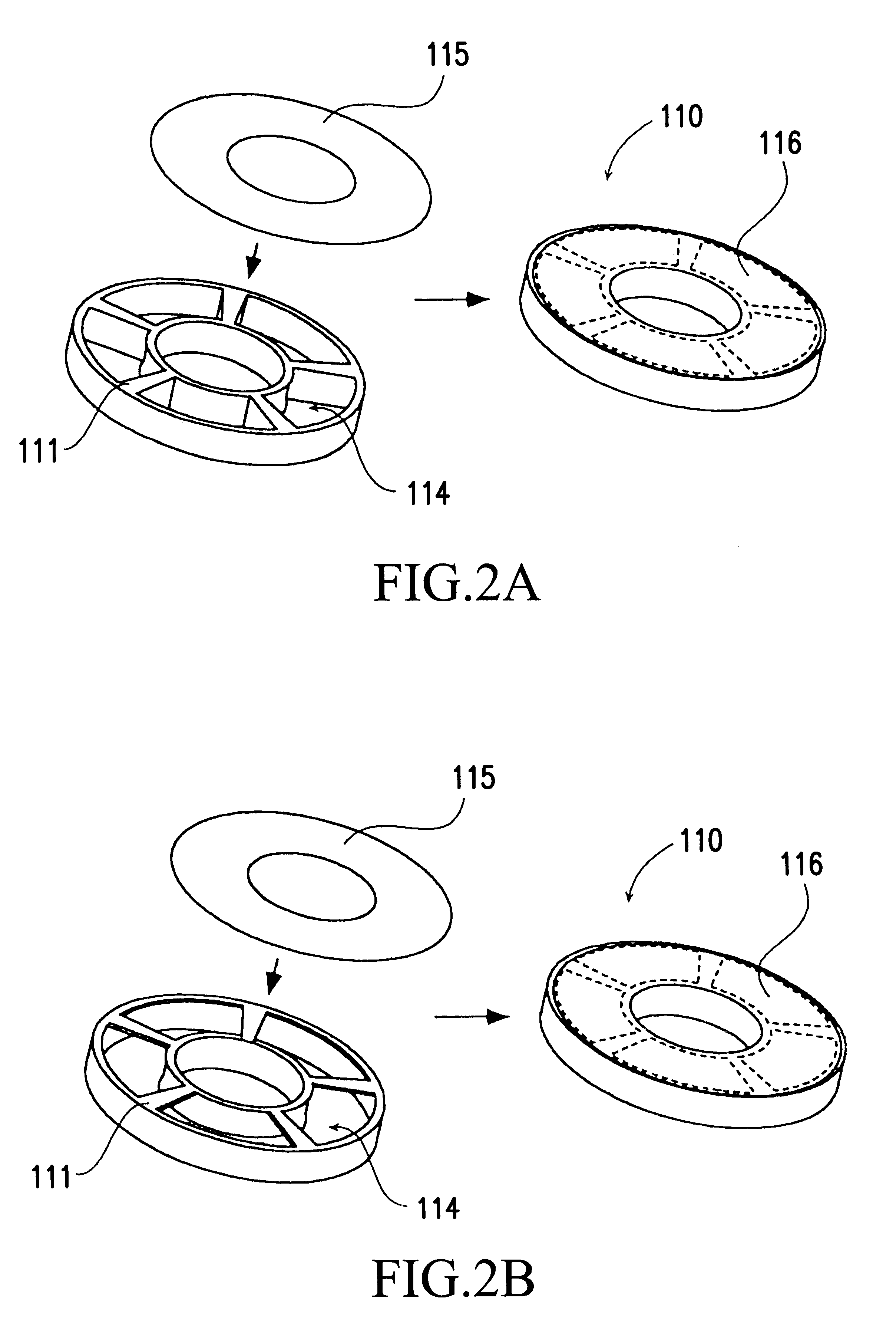

Airbag gas generator and an airbag apparatus

InactiveUS6540256B2Easy constructionImprove protectionPedestrian/occupant safety arrangementExplosivesGas-discharge lampCombustion

Owner:DAICEL CHEM IND LTD

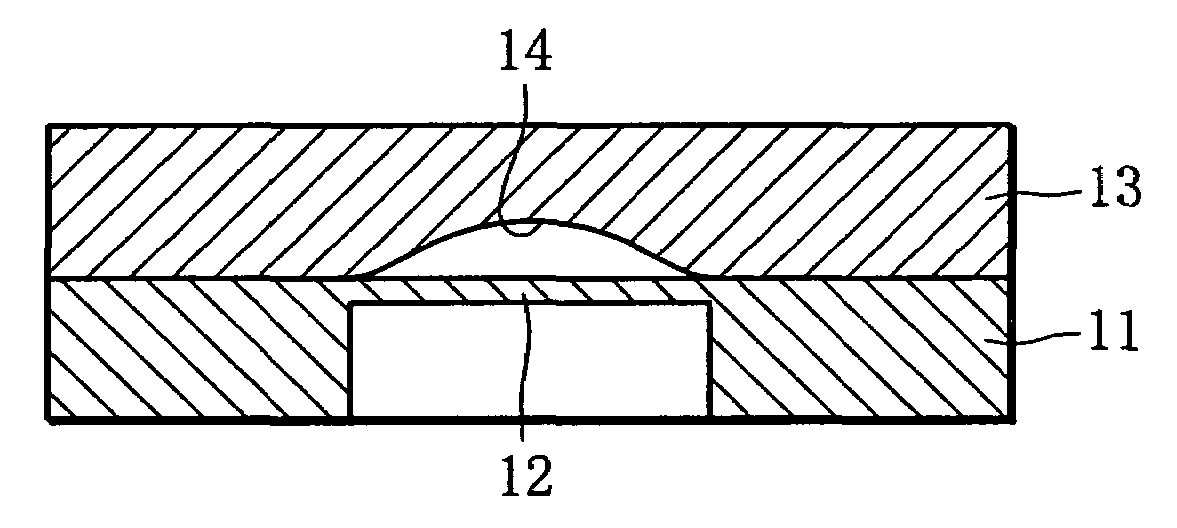

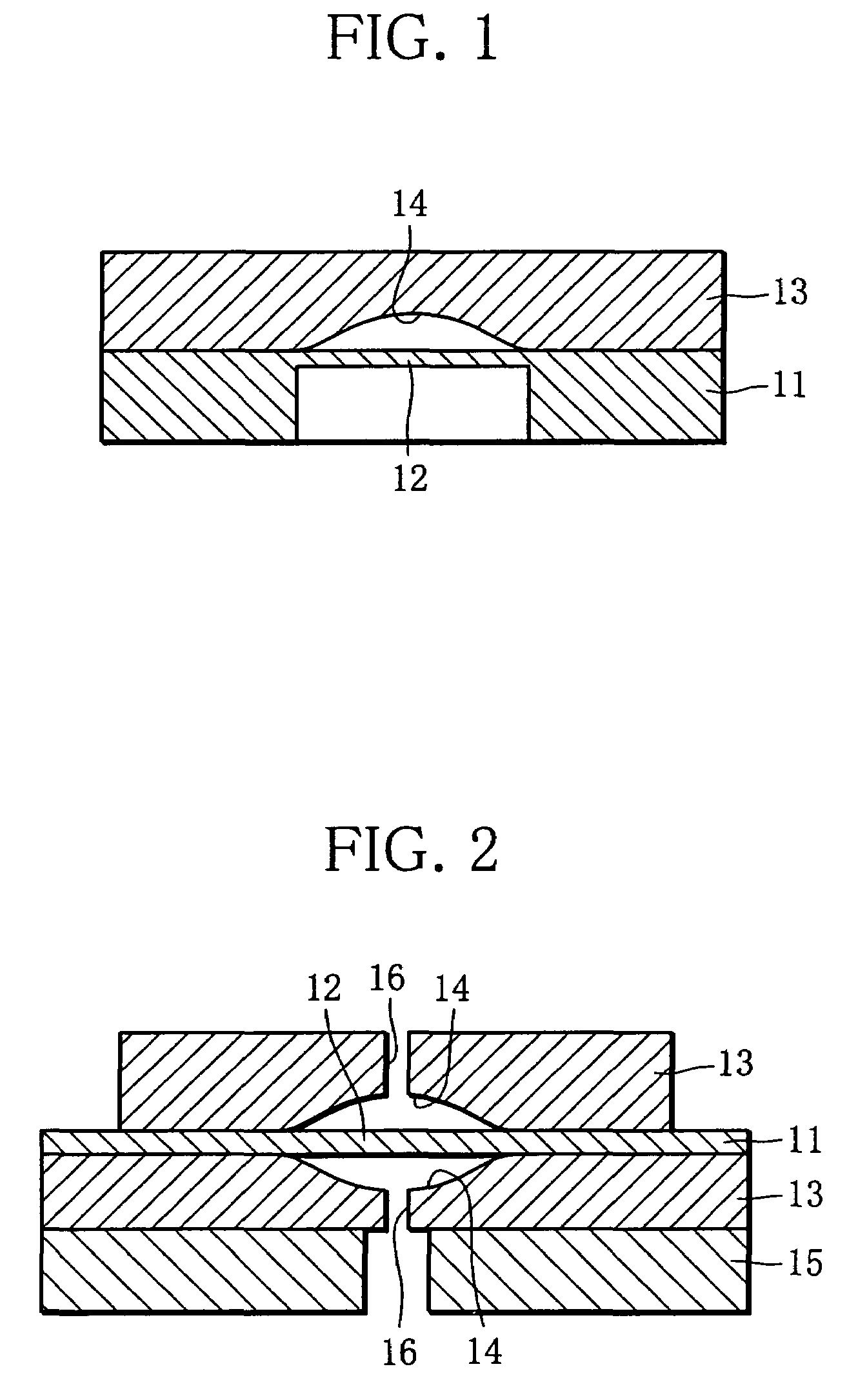

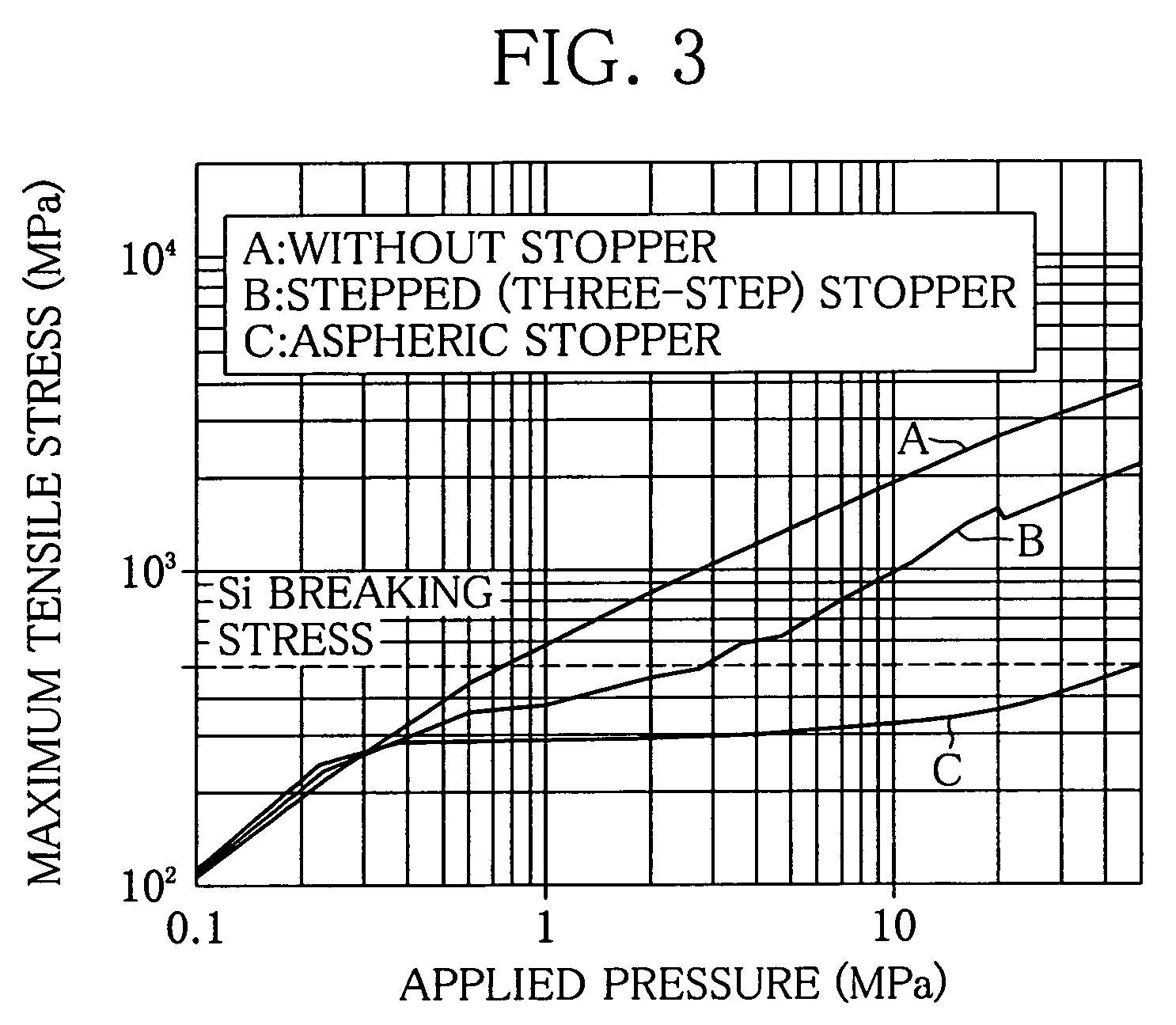

Pressure sensor device including a diaphragm and a stopper member having a curved surface facing the diaphragm

ActiveUS7360431B2Increase operating pressureSimple structureFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringMaximum pressure

The pressure sensor device has a laminated diaphragm (12) in which a strain resistance gauge is formed in a surface and a stopper member (13) including a concave portion forming a curved surface parallel to a surface formed by displacement of the diaphragm, the concave portion being disposed to face the diaphragm. Specifically, the concave portion of the stopper member is formed into a curved surface in which depth y at a distance x from the center of the diaphragm is expressed by a quartic function [y=pr4(1−x2 / r2)2 / 64D] in relation to the operating pressure for protection against maximum pressure p when the diaphragm has a radius of r, a thickness of t, and a flexural rigidity of D.

Owner:YAMATAKE HONEYWELL CO LTD

Inflatable massage garment

A massage device for massaging a body part of a person in an unsupervised and unattended setting is provided. In a preferred embodiment, the massage device comprises an inflatable garment (200) having a plurality of inflation bladders (250), to apply pressure to the body part, and an inflation assembly (300) includes a manifold (324) into which the pressurized fluid flows, a plurality of inflation valves (326) which control the flow of fluid from the manifold to the bladders, and a manifold valve for controlling the maximum pressure level within the bladders. The inflation assembly may have a predeterminated inflation capacity which defines a maximum bladder size as well as an array in which the bladders are arranged. The massage device may further comprise a connector for connecting tubes from the bladders to the inflation assembly, wherein the connector includes a garment-identifying component for identifying the type of garment connected to the inflation assembly.

Owner:MIDTOWN TECH

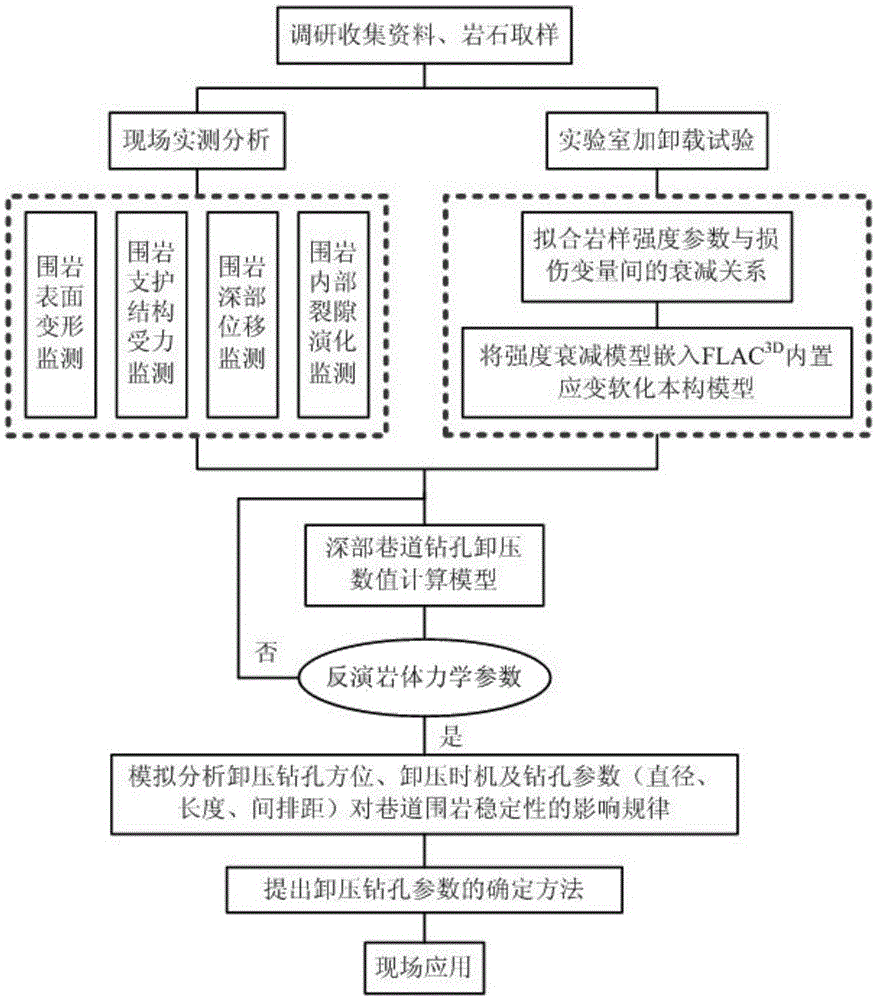

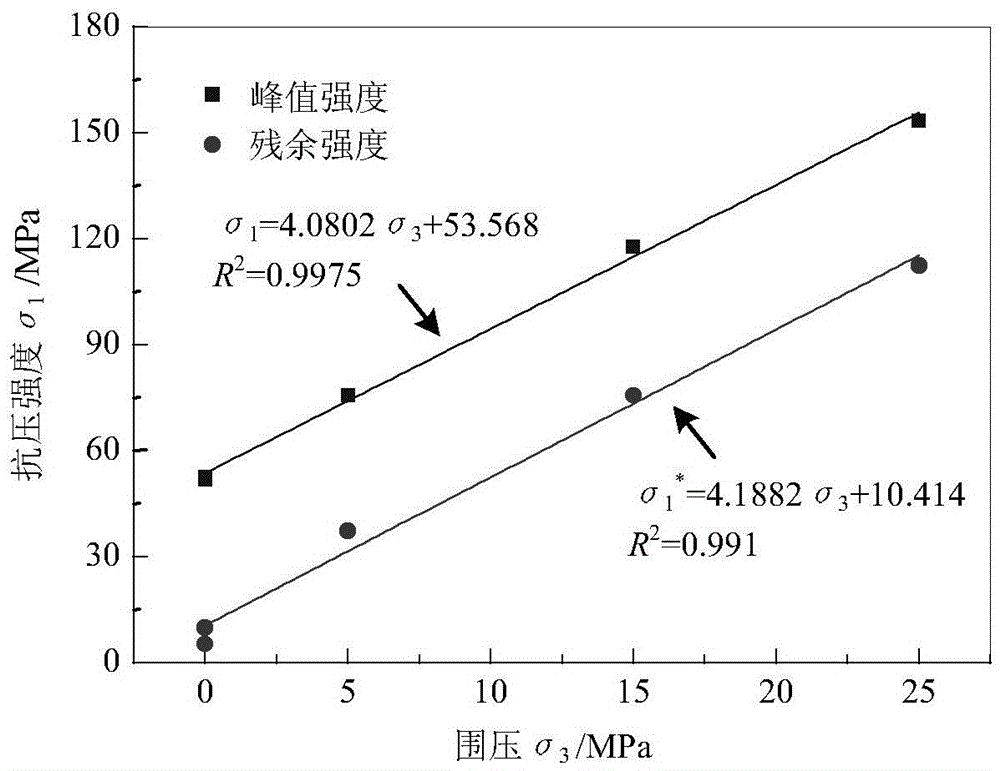

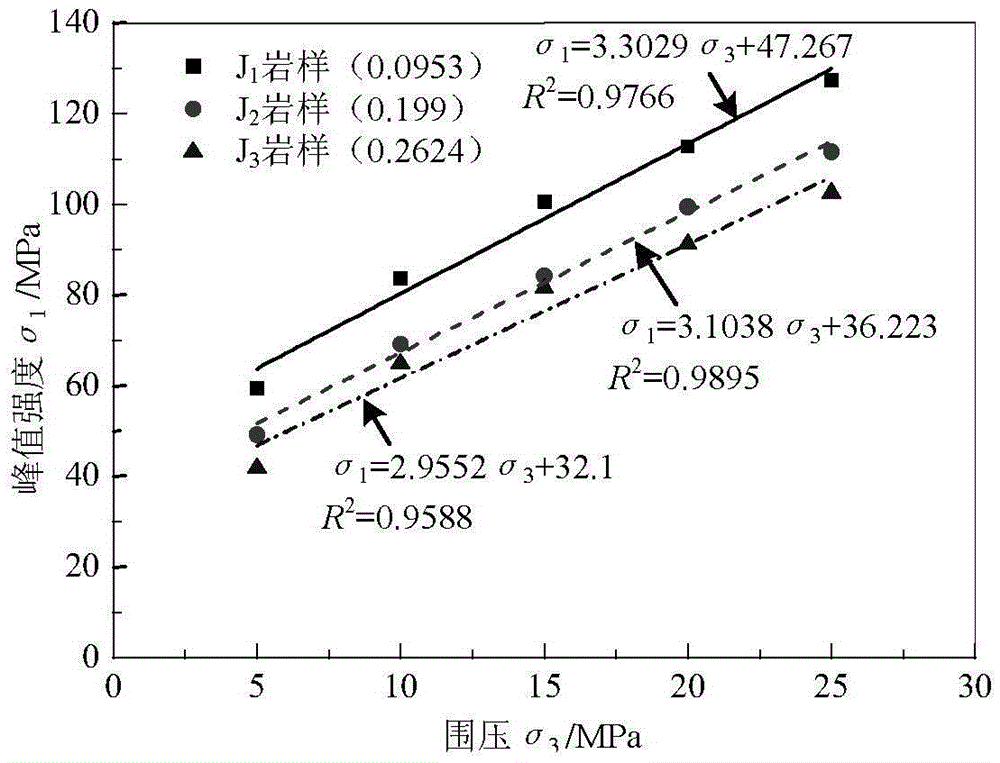

Numerical simulation determination method of deep high-stress roadway drilling pressure relief parameter

ActiveCN105631102AGood pressure relief effectStrong innovation significanceGeometric CADSpecial data processing applicationsModel parametersHigh stress

The invention discloses a numerical simulation determination method of a deep high-stress roadway drilling pressure relief parameter. Before simulation is carried out, a test roadway surrounding rock sample is firstly subjected to a loading and unloading test in a laboratory, an attenuation relationship between a rock sample strength parameter and a damage variable is obtained by fitting and is embedded into a FLAC<3D> (Fast Lagrangian Analysis of Continua) built-in strain softening constitutive model, and an actual measurement mine pressure expression law of a test roadway is taken as a known characteristic value to carry out inversion on the numerical calculation model parameter of a rock mass. A deep roadway drilling pressure relief numerical calculation model is established to simulate and analyze the influence law of a pressure relief drilling orientation, pressure relief opportunity and drilling parameters (diameter, length and inter-row spacing) on the stability of roadway surrounding rock, and a determination method of each factor which affects a pressure relief effect is put forward, and a drilling pressure relief technology system is perfected. The numerical simulation determination method considers the mutual action relationship of a pressure relief degree and the stability of the surrounding rock while pressure relief drilling parameters are determined, and the designed pressure relief drilling can perform a maximum pressure relief effect on a premise that the stability of the surrounding rock is guaranteed. The method is simple and exhibits high application value.

Owner:HENAN POLYTECHNIC UNIV

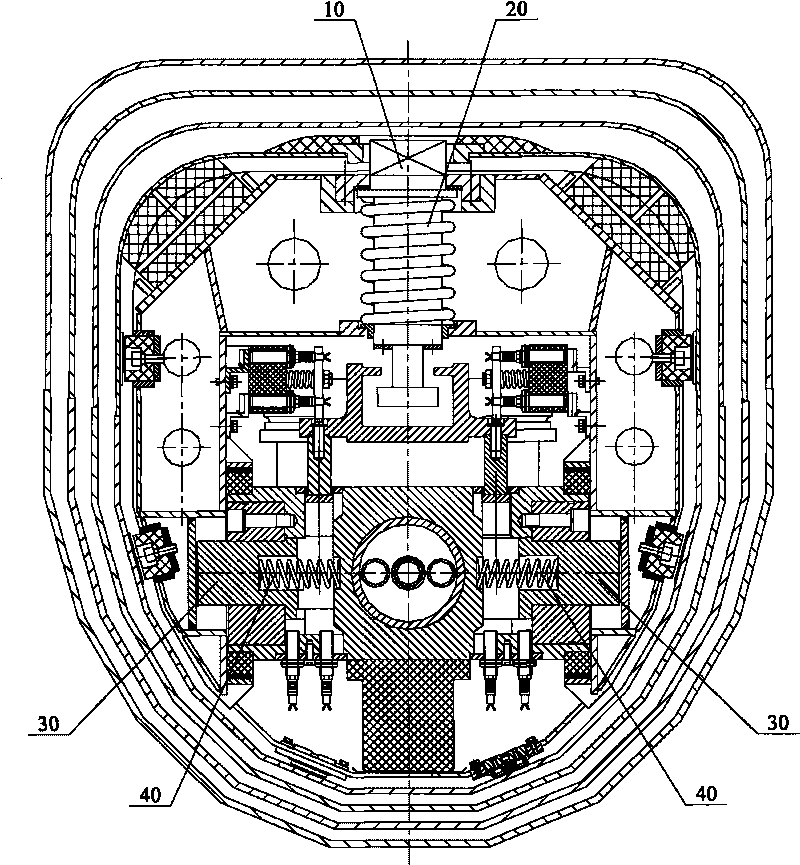

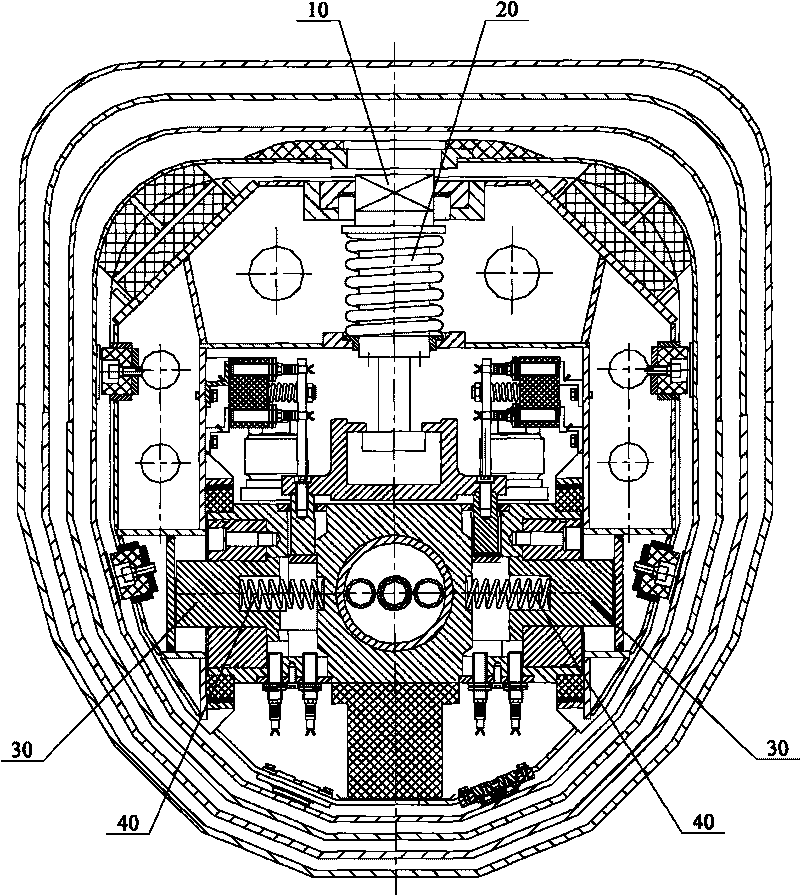

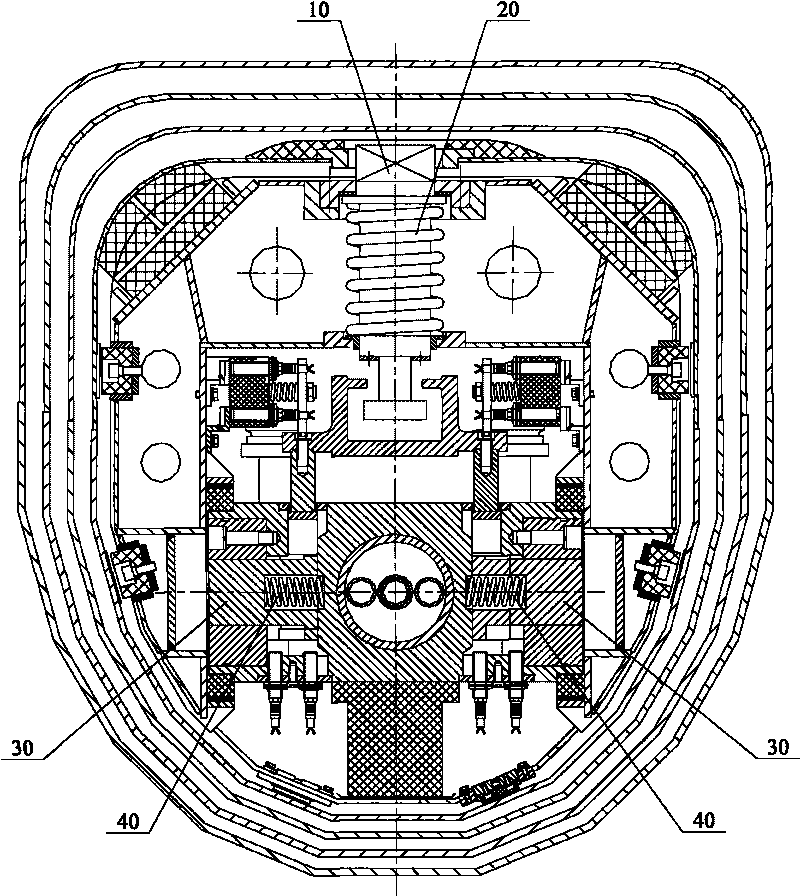

Control system of telescopic boom bolt mechanism

The invention discloses a control system of a telescopic boom bolt mechanism, which comprises an oil tank, a hydraulic pump, a motor and a second directional control valve which are arranged on a telescopic boom, wherein the oil tank is used for storing hydraulic oil; the hydraulic pump is used for outputting the hydraulic oil in the oil tank into a hydraulic circuit; the motor is used for driving the hydraulic pump; and the second directional control valve is used for controlling the route between the hydraulic circuit and the hydraulic pump or the oil tank to be turned on. Preferably, the control system also comprises a third one-way valve, an energy accumulator and a pressure relay; when a pressure value detected by the pressure relay is more than a preset maximum pressure value, the pressure relay outputs control signals to the motor, and the motor is switched off; and when a pressure value detected by the pressure relay is less than the maximum pressure value, the pressure relay outputs control signals to the motor, and motor is switched on. The system has simple and reasonable design, and can effectively avoid the problem that hydraulic volume in a large chamber influences the control response speed, so as to ensure the sensitive and reliable motions of an arm pin hydro cylinder and a cylinder pin hydro cylinder.

Owner:XUZHOU HEAVY MASCH CO LTD

Single substrate electromagnetic actuator

InactiveUS7474180B2Reduce power consumptionEasy to integrateValve arrangementsAdditive manufacturing apparatusElectromagnetic interferenceMicro coil

A microvalve which utilizes a low temperature (<300° C.) fabrication process on a single substrate. The valve uses buckling and an electromagnetic actuator to provide a relatively large closing force and lower power consumption. A buckling technique of the membrane is used to provide two stable positions for the membrane, and to reduce the power consumption and the overall size of the microvalve. The use of a permanent magnet is an alternative to the buckled membrane, or it can be used in combination with the buckled membrane, or two sets of micro-coils can be used in order to open and close the valve, providing the capability for the valve to operate under normally opened or normally closed conditions. Magnetic analysis using ANSYS 5.7 shows that the addition of Orthonol between the coils increases the electromagnetic force by more than 1.5 times. At a flow rate of 1 mL / m, the pressure drop is <100 Pa. The maximum pressure tested was 57 kPa and the time to open or close the valve in air is under 100 ms. This results in an estimated power consumption of 0.1 mW.

Owner:AIR FORCE THE US SEC THE +1

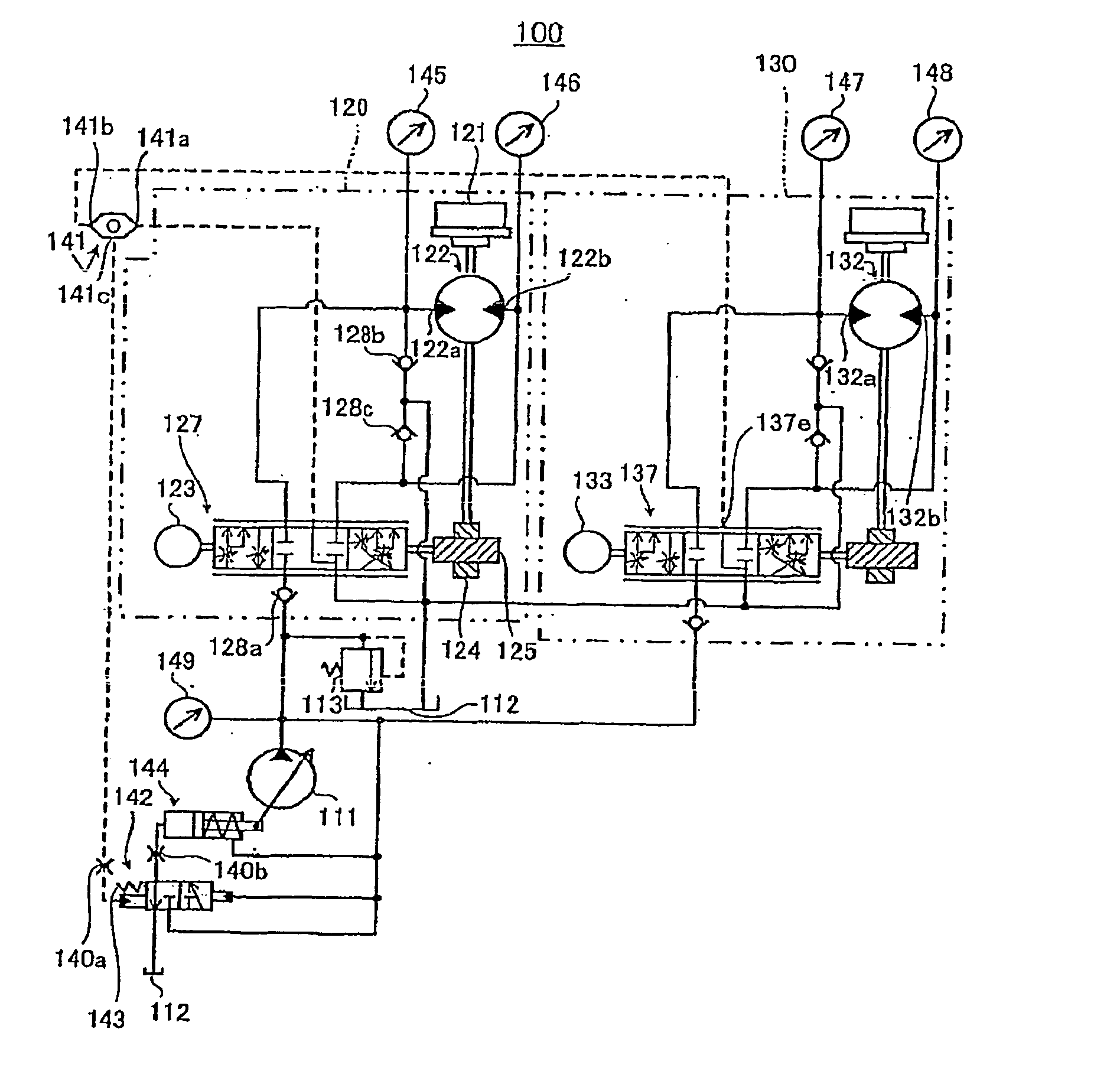

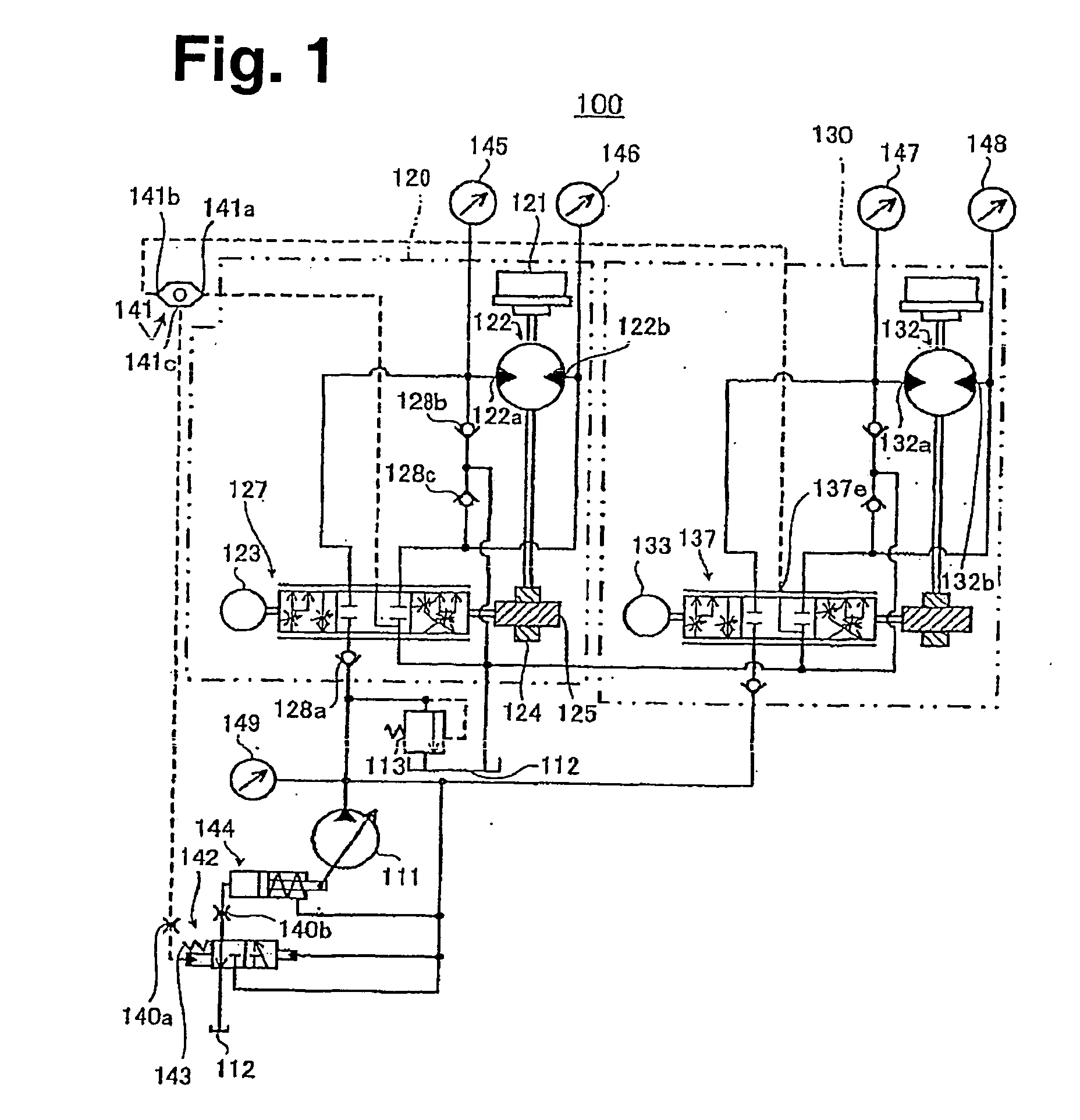

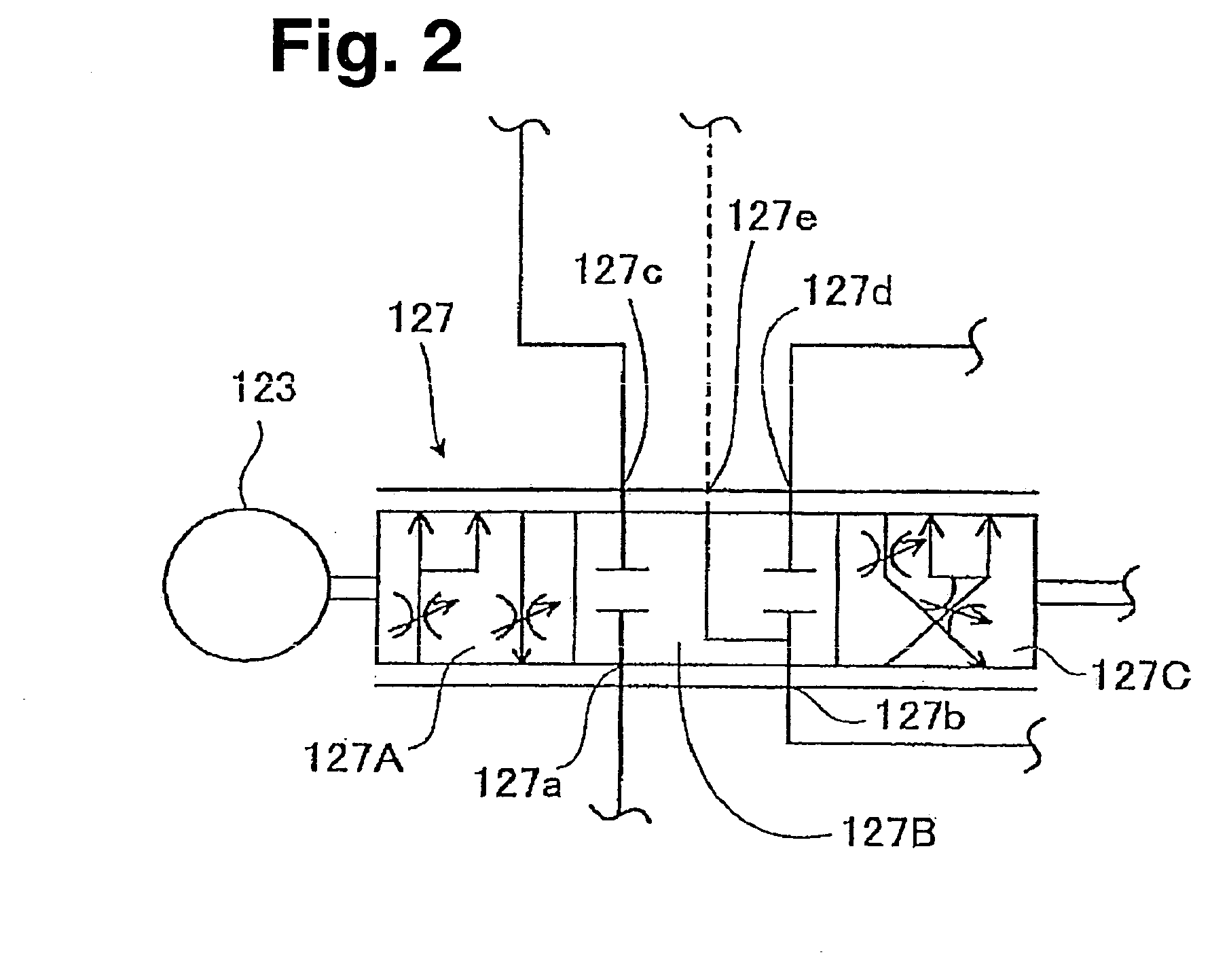

Electro-hydraulic actuation system

InactiveUS20050115234A1Lower the volumeAvoid shortageFluid couplingsServomotorsHydraulic cylinderHydraulic pump

An electrohydraulic actuation system in which the quantity of fluid being fed to hydraulic actuators under higher load pressure among those of a plurality of electrohydraulic actuators can be prevented from becoming deficient. In the electrohydraulic actuation system (100), a selection valve (141), a two-position valve (142), a spring (143) and a hydraulic cylinder (144) for altering delivery alter delivery of the working oil of a variable delivery hydraulic pump (111) based on the maximum pressure of the working oil being fed to hydraulic motors (122, 132) and the delivery pressure of working pump (111), and pressure gauges (145, 146, 147, 148, 149) and a computer (not shown) alter the rotatim speeds of motors (123, 133) at a substantially same rate for them.

Owner:NABLESCO CORP

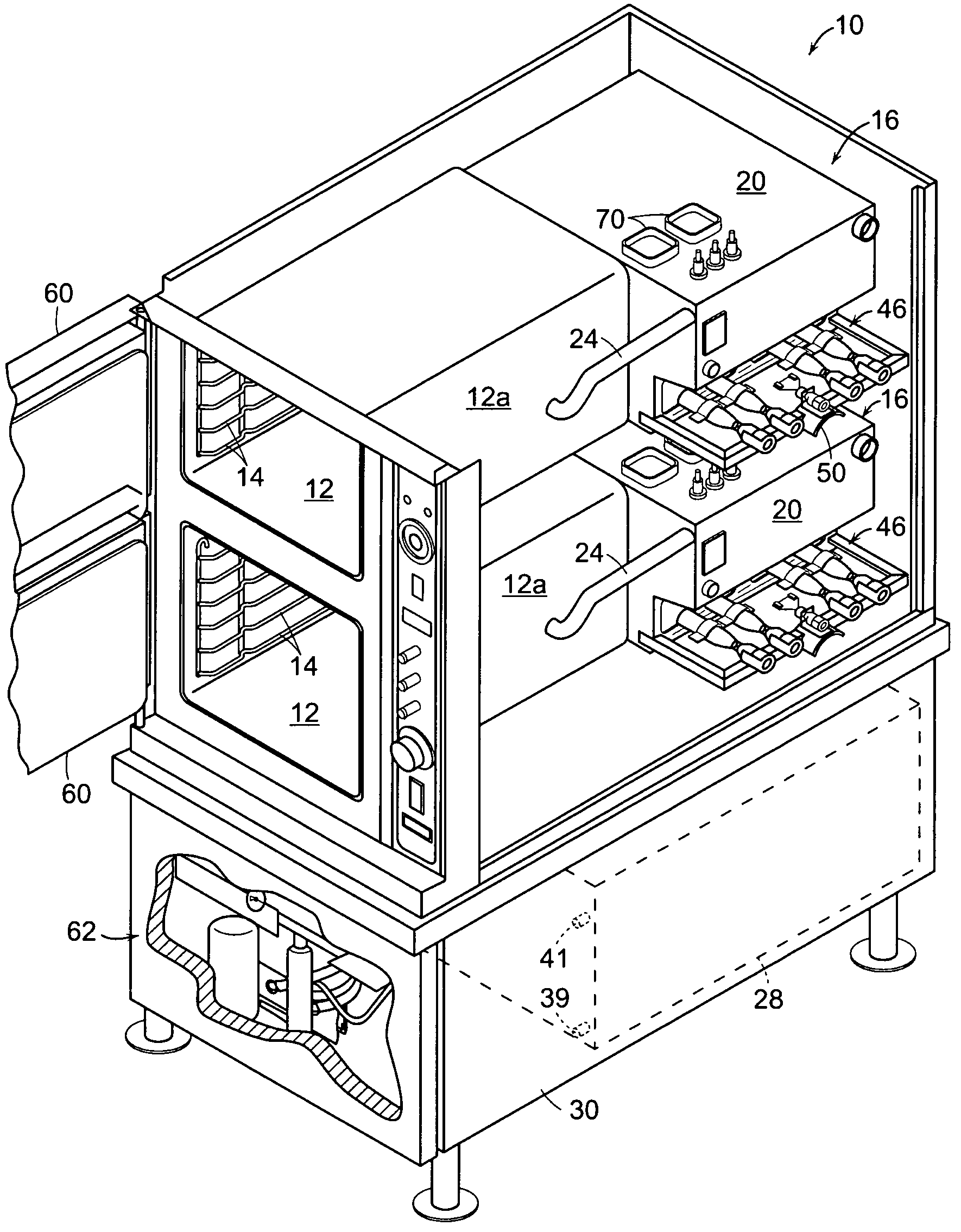

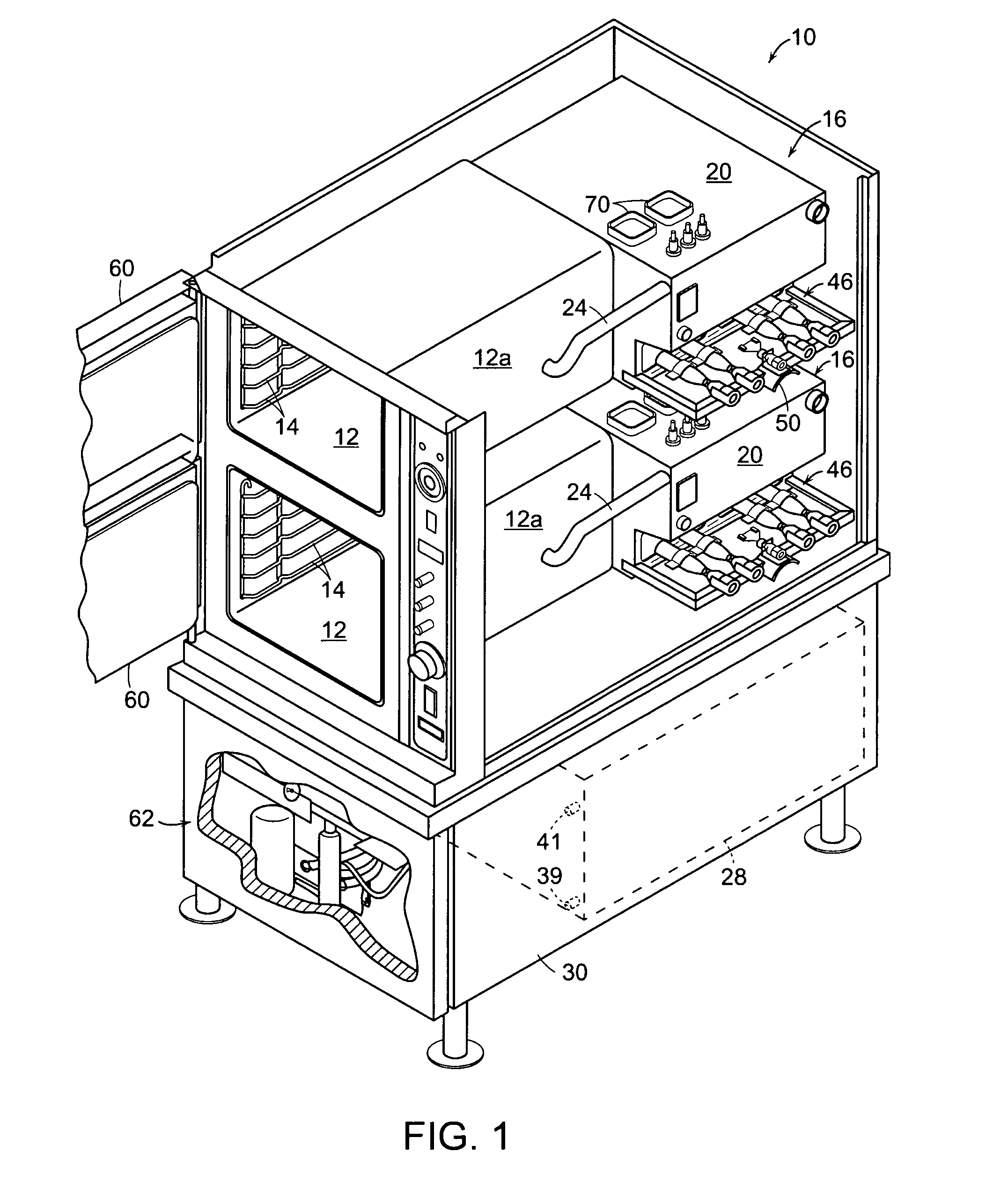

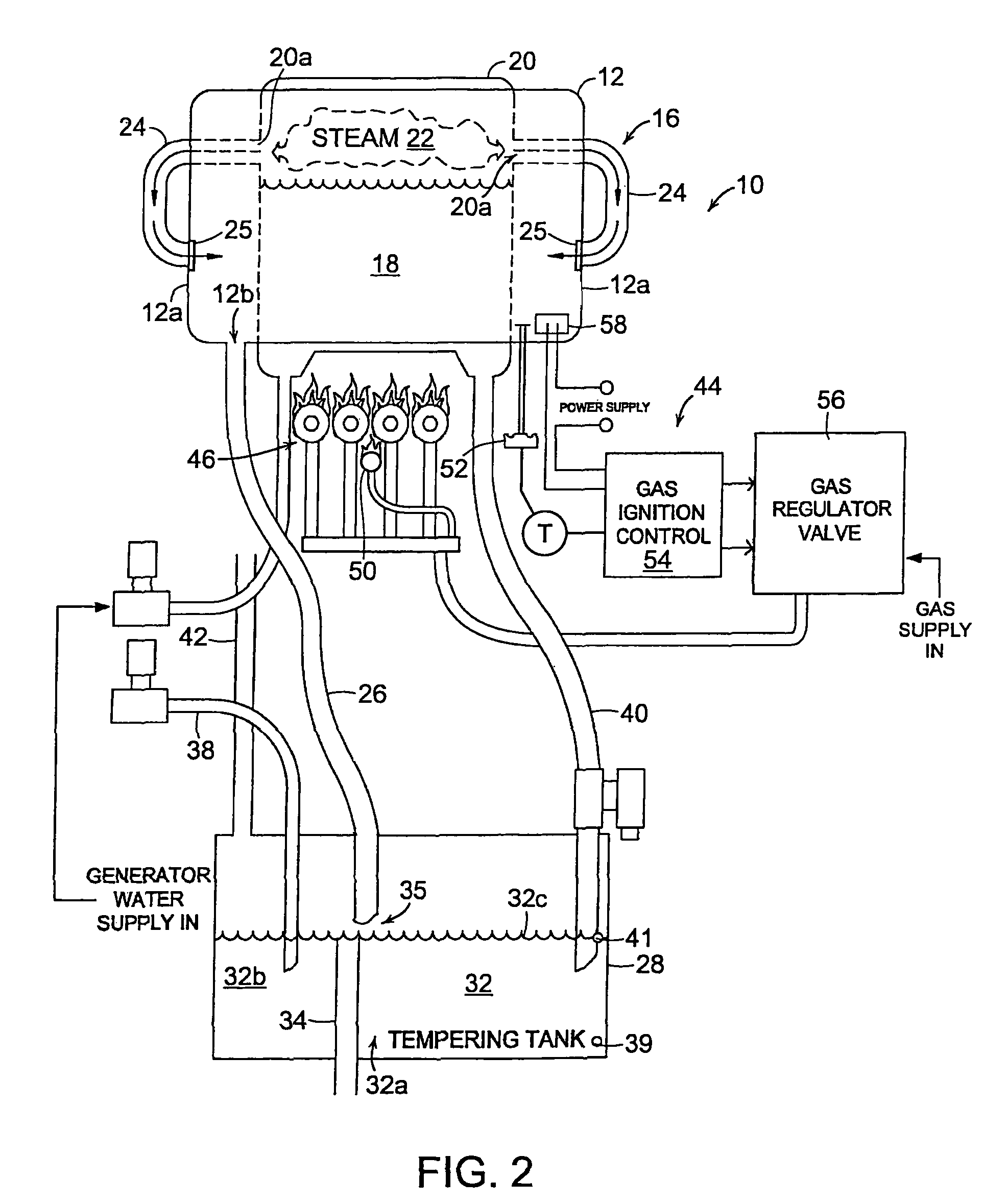

High efficiency atmospheric steamer

ActiveUS7810488B2Temperature control without auxillary powerDomestic stoves or rangesSteam pressureFiltration

A pressureless or atmospheric steamer for cooking food with a high cooking efficiency has a cooking compartment with an outlet for steam and condensate that feeds to a tempering tank via an outlet conduit. The outlet conduit is spaced closely from the controlled water level in the tempering tank, and is in fluid communication with the atmospheric vent to create an open steam cooker. A steam generator is adjacent the cooking compartment and has a water reservoir, a heat exchanger secured within the reservoir in a heat-transferring relationship at an exterior surface of the heat exchanger with the water held in the reservoir, and a heater that supplies heat to the interior of the heat exchanger. The tempering tank has a drain and level controls for a water supply held in the tempering tank. A pressure-sensitive device is disposed to measure the steam pressure in the cooking compartment and to generate electrical output signals indicative of minimum and maximum pressure values to control the operation of the heater to maintain the steam pressure in the cooking compartment within that operating range. The steamer has an in-built water filtration system for water supplied to the water reservoir.

Owner:MARKET FORGE INDS

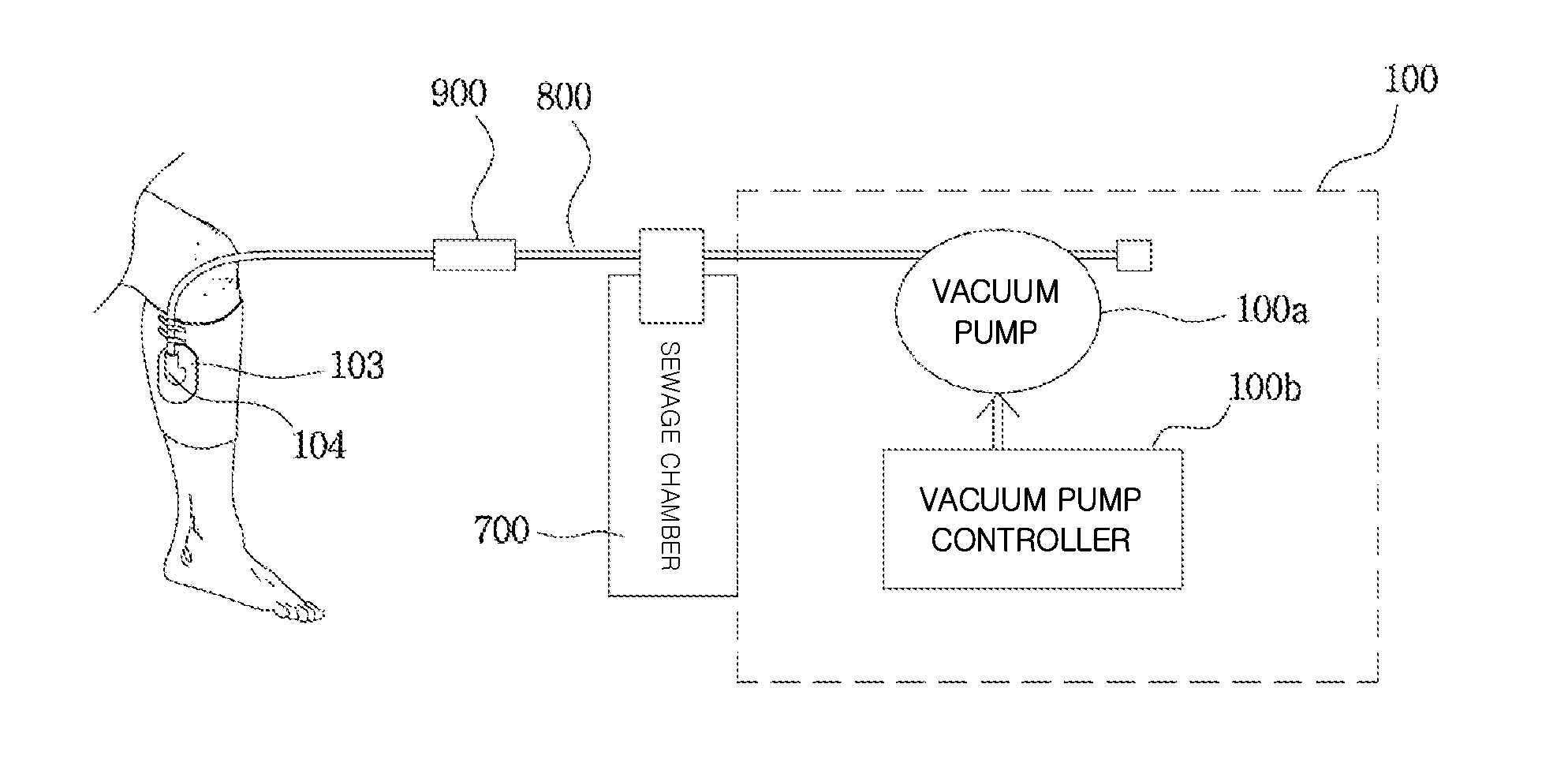

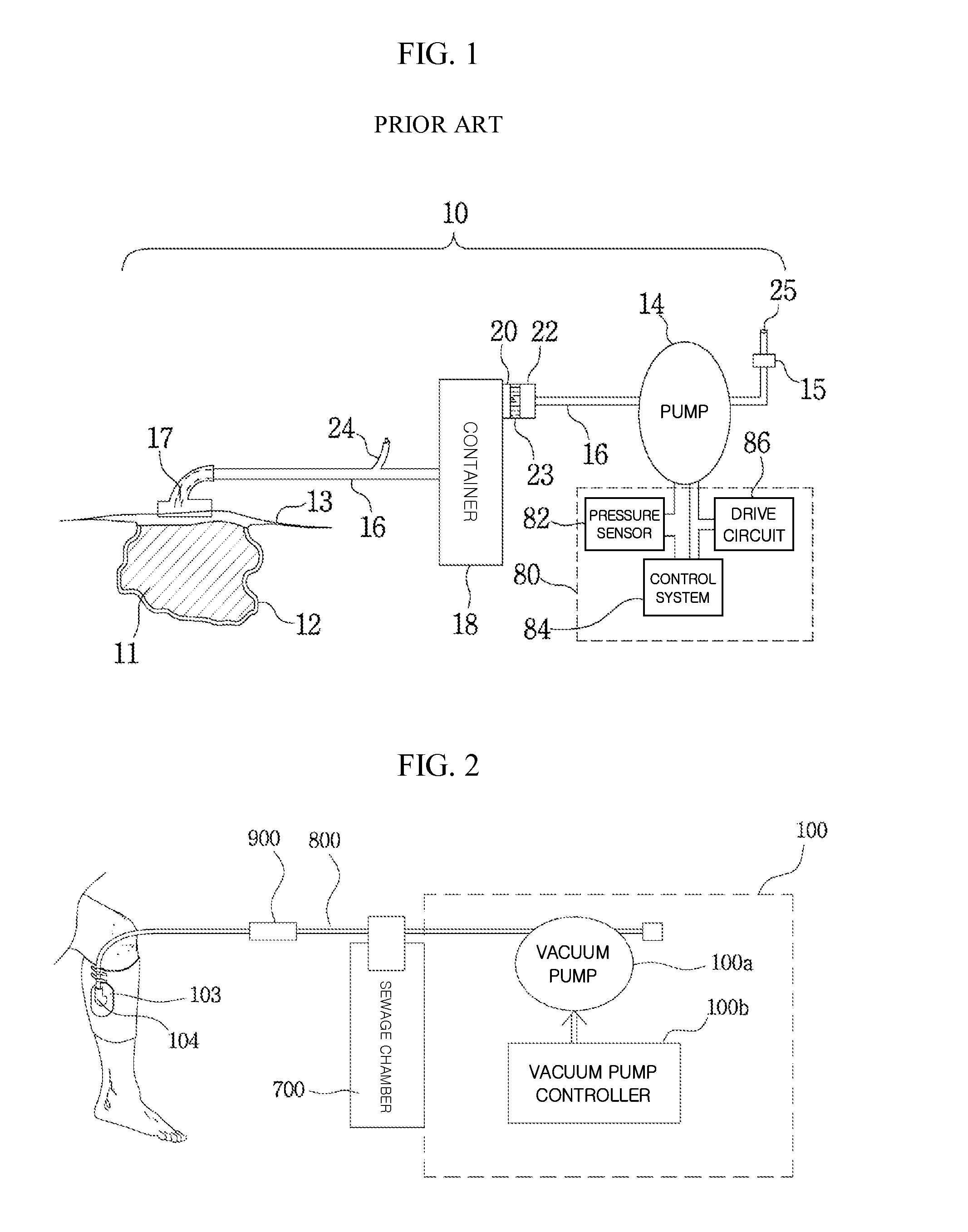

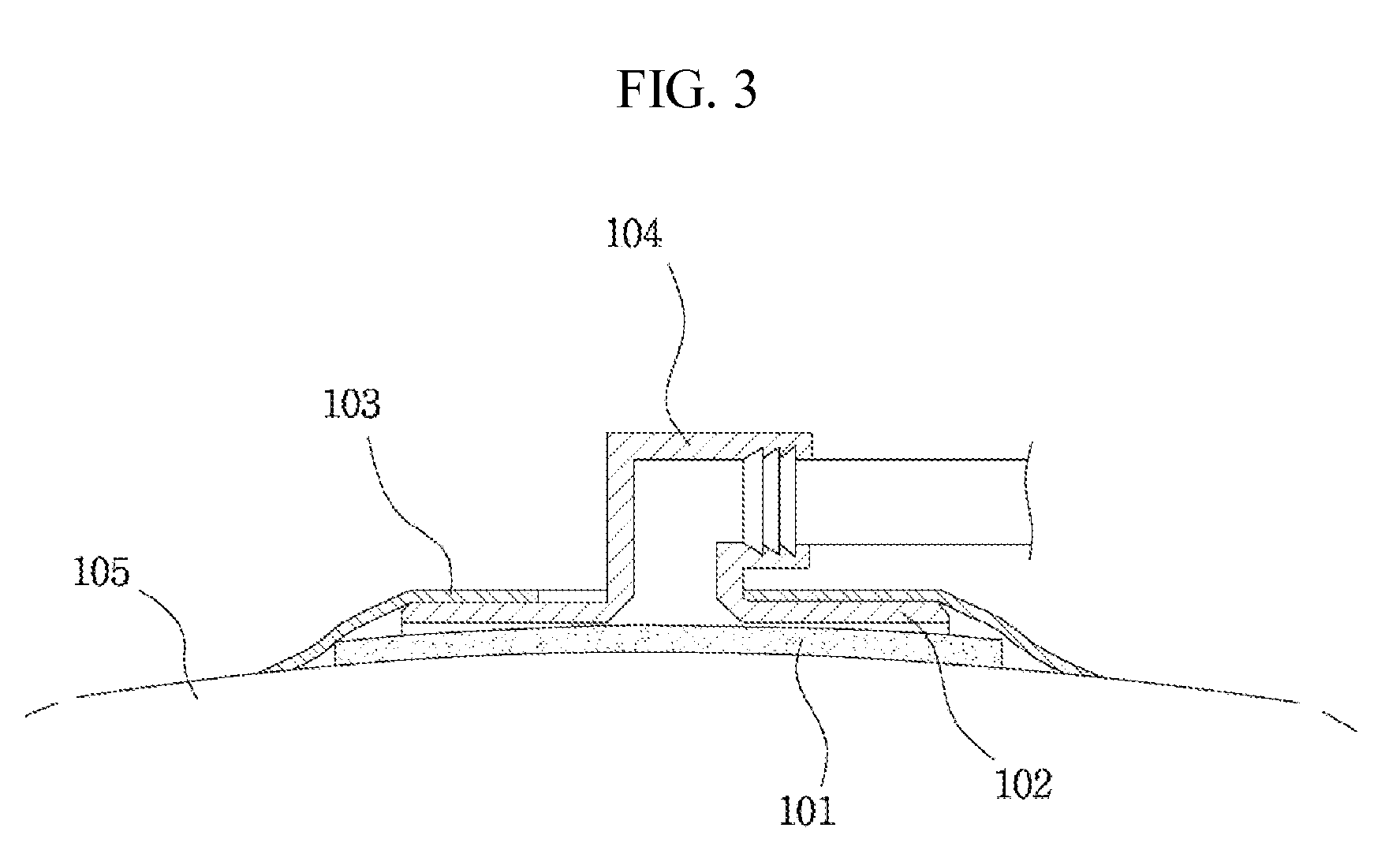

Portable vacuum generation device, and medical suction device using same

ActiveUS20120259299A1Extend battery lifeMinimize operation of pumpWound drainsMedical devicesEngineeringMaximum pressure

Provided is a portable vacuum generator that can effectively save battery power of a vacuum pump for absorbing exudates from a suction head that is connected to a tube, and a medical suction device using the same. The medical suction device includes: a connection tube whose one end is connected to a connector of the suction head; and a vacuum generator including a vacuum pump that is connected to the other end of the connection tube and having a motor for generating negative pressure, and a vacuum pump controller that controls a power supply for the vacuum pump so as to maintain a vacuum state, in which the vacuum pump controller blocks the power supply for the vacuum pump until pressure of the vacuum pump falls down to preset minimum pressure in the case that the current pressure that is applied to the vacuum pump reaches preset maximum pressure, and drives the vacuum pump until pressure of the vacuum pump reaches the preset maximum pressure in the case that the current pressure falls down to the preset minimum pressure.

Owner:CG BIO CO LTD

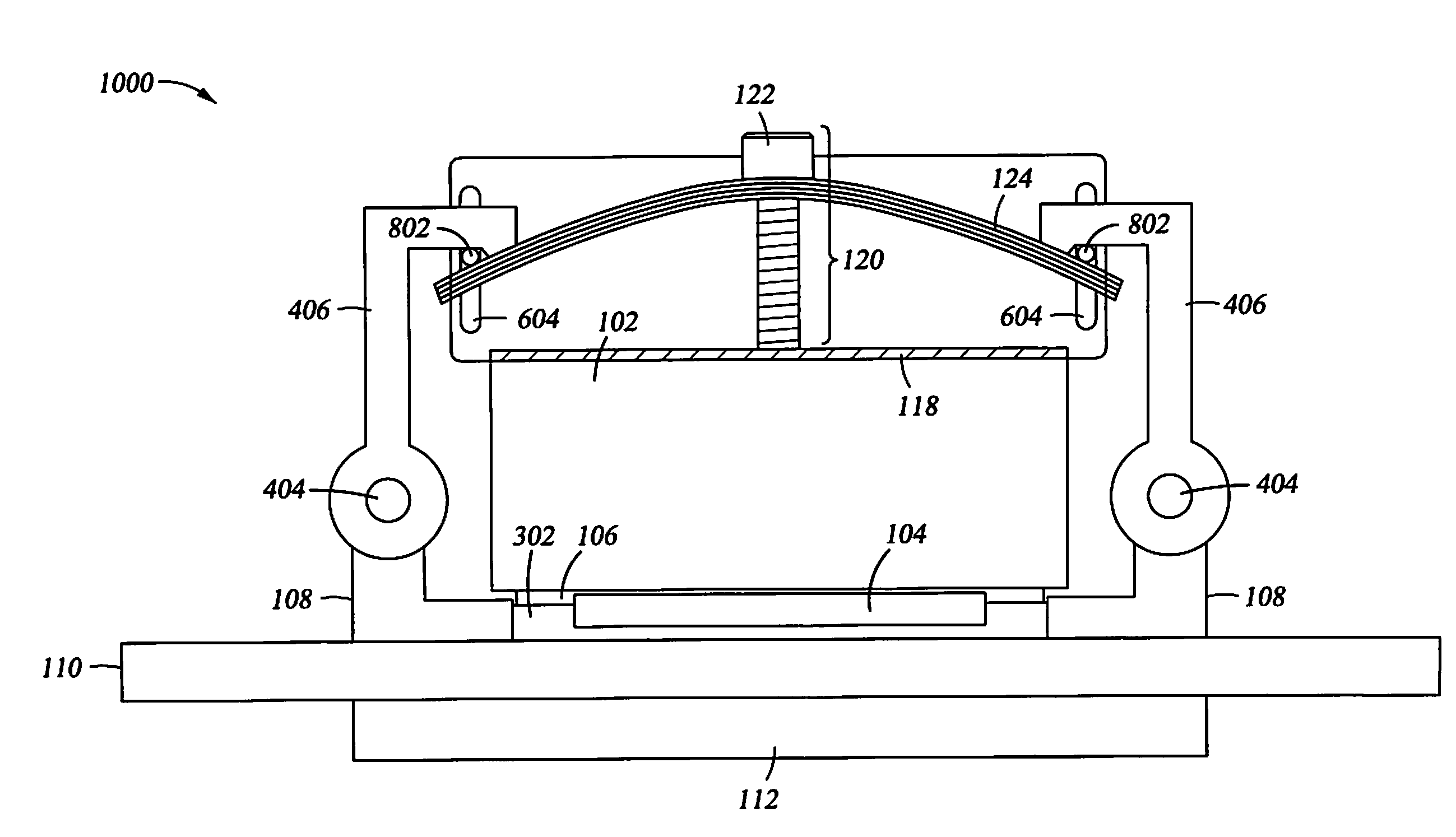

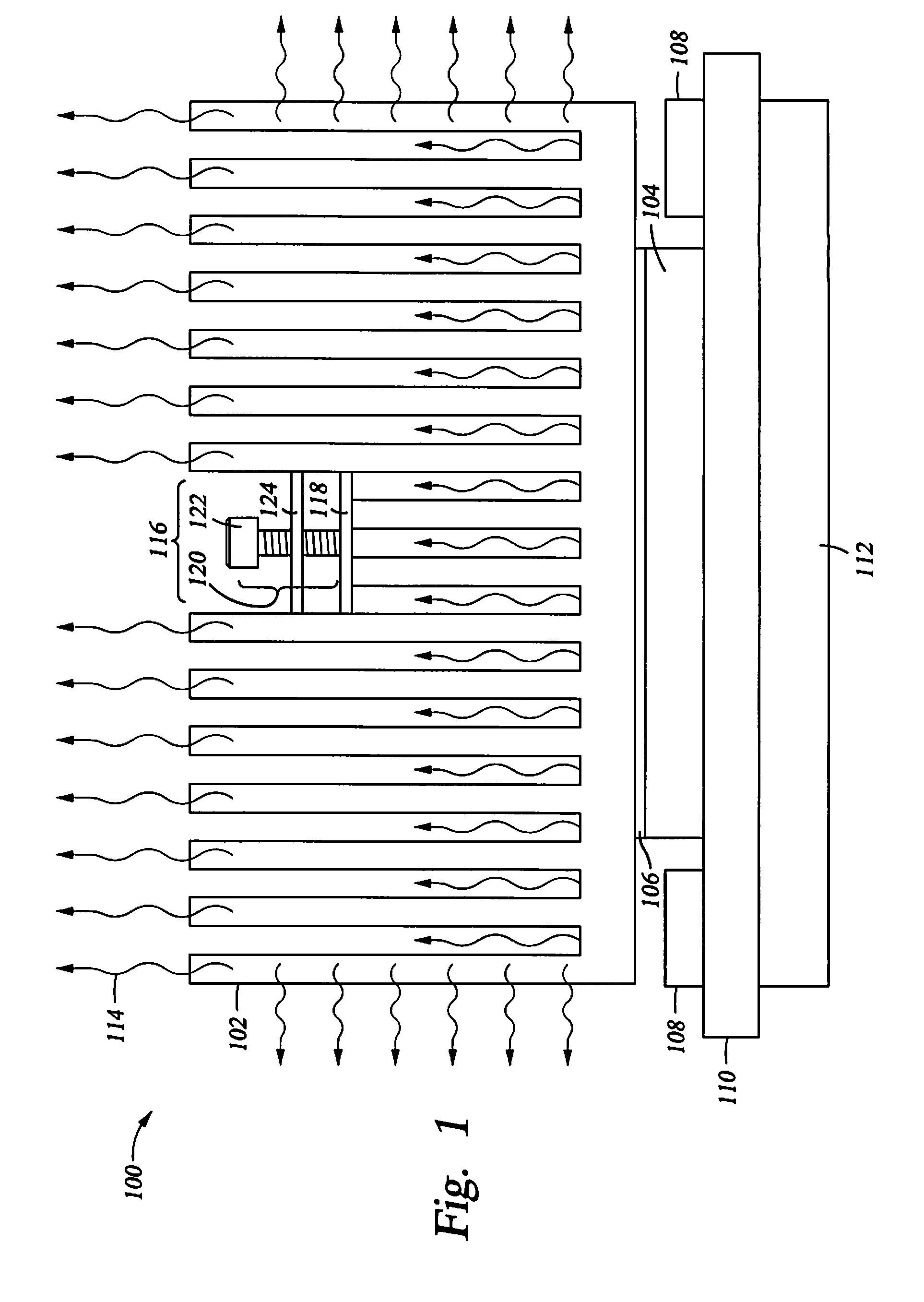

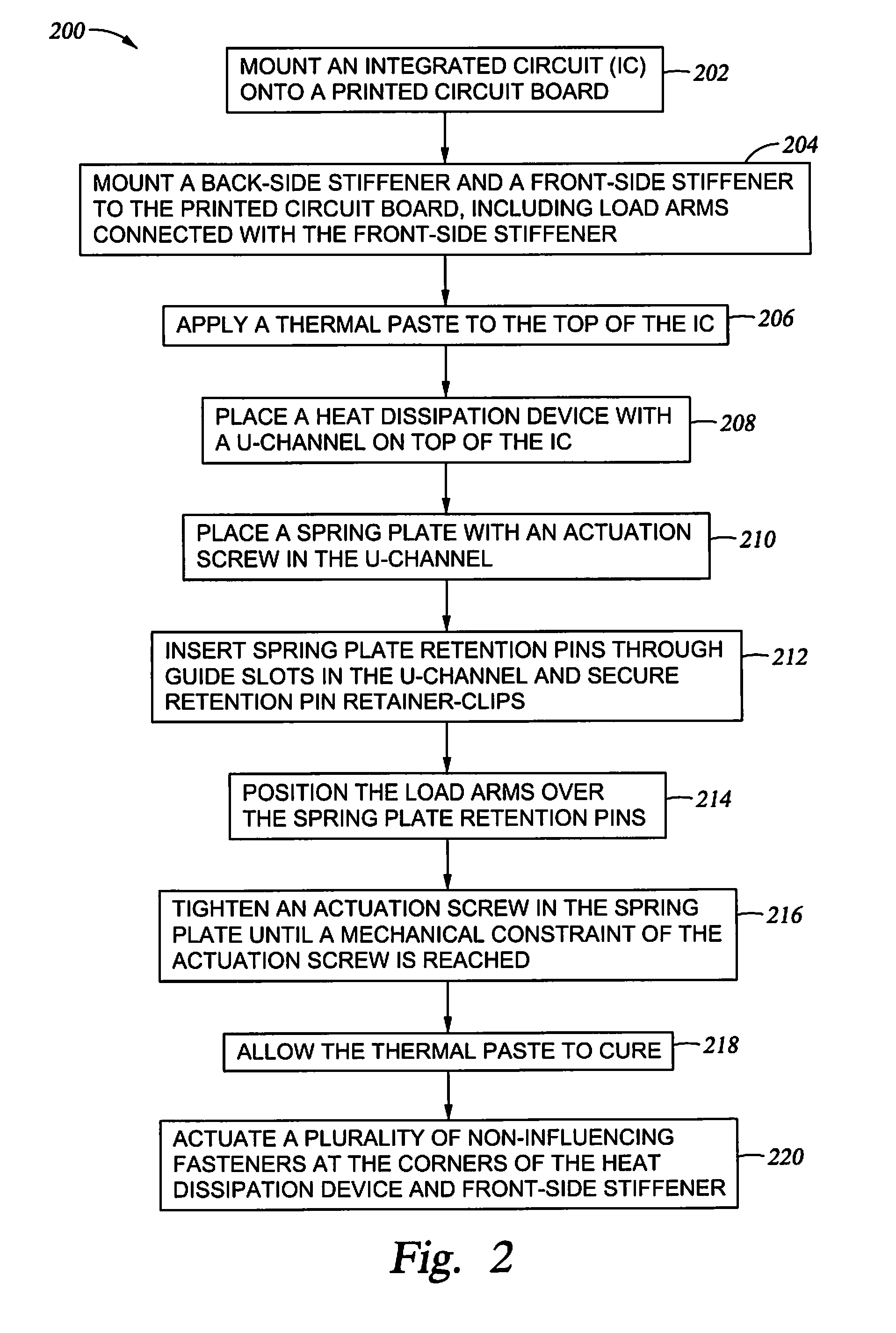

Heatsink Apparatus for Applying a Specified Compressive Force to an Integrated Circuit Device

ActiveUS20080024991A1Avoid tighteningSemiconductor/solid-state device detailsSolid-state devicesMaximum pressureMinimal contact

A method and apparatus for applying a specified compressive force by a heat dissipation device for an integrated circuit are given, including placing the integrated circuit device onto a printed circuit board and then placing the heat dissipation device onto the integrated circuit device. The method includes tightening an actuation screw in a spring plate against a portion of the heat dissipation device. The actuation screw may be prevented from being tightened beyond a mechanical constraint corresponding to a pre-set calibration for the specific compressive force, which may be greater than or equal to a minimum compressive force corresponding to the greater of a minimum thermal interface pressure and a minimum contact interface pressure. Additionally, the specific compressive force may be less than or equal to a maximum pressure which may be exerted on the integrated circuit device.

Owner:IBM CORP

Reverse osmosis filtration systems

Reverse osmosis filtration systems that are self contained and easily converted from above the counter use to below the counter use. The systems feature a simple construction, including a two piece manifold assembly to which filters, including a reverse osmosis filter, a product water storage tank and a control valve connect, all without separate fasteners. The manifold assembly provides all water connections within the system, and includes connections to connect to a water supply, a drain, two dispensers and to an auxiliary water storage tank. The system pressurizes squeeze water for product water dispensing, providing maximum efficiency, maximum storage capacity for a given tank size and maximum pressure for dispensing product water. Various embodiments are disclosed.

Owner:TOPPER MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com