Patents

Literature

592results about How to "Realize the structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

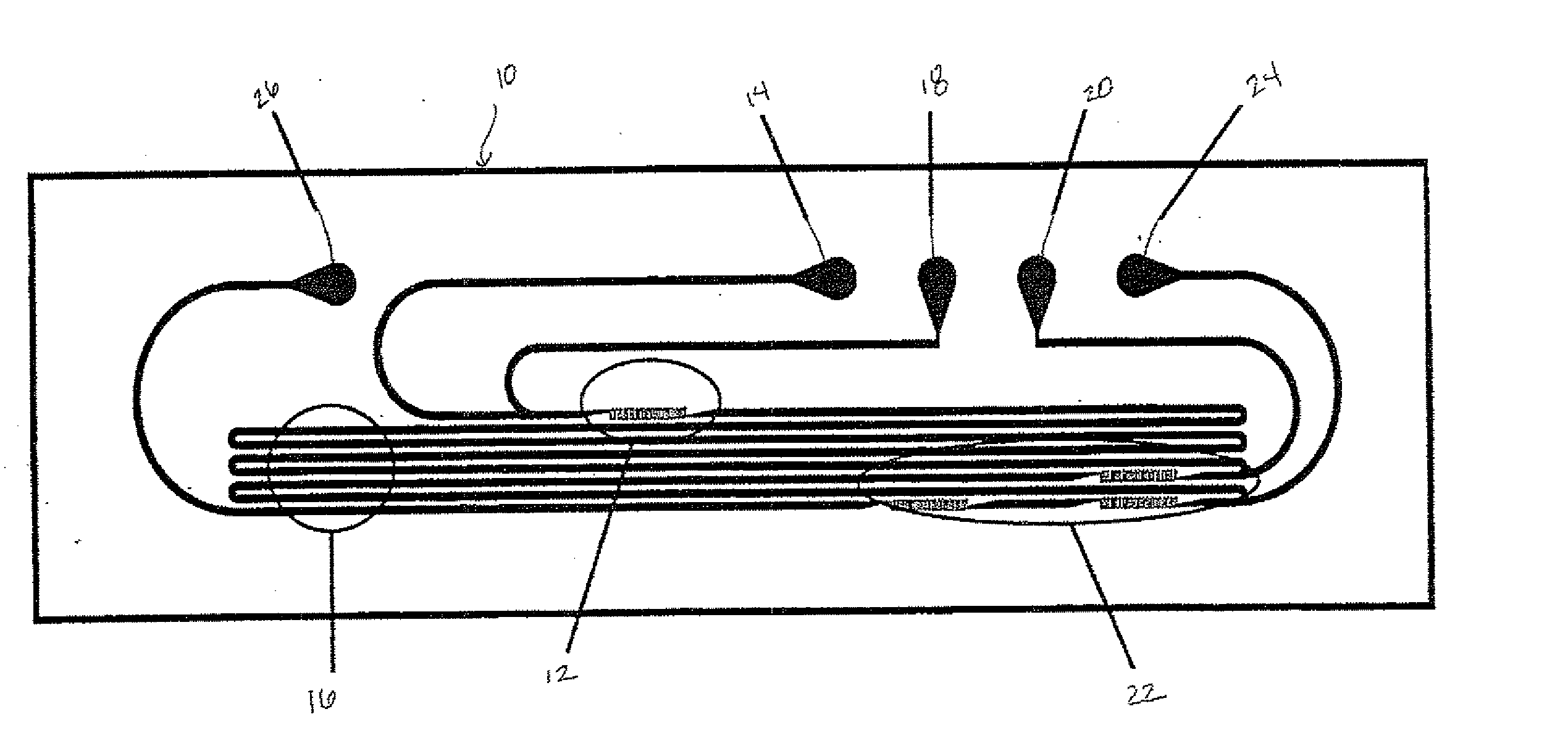

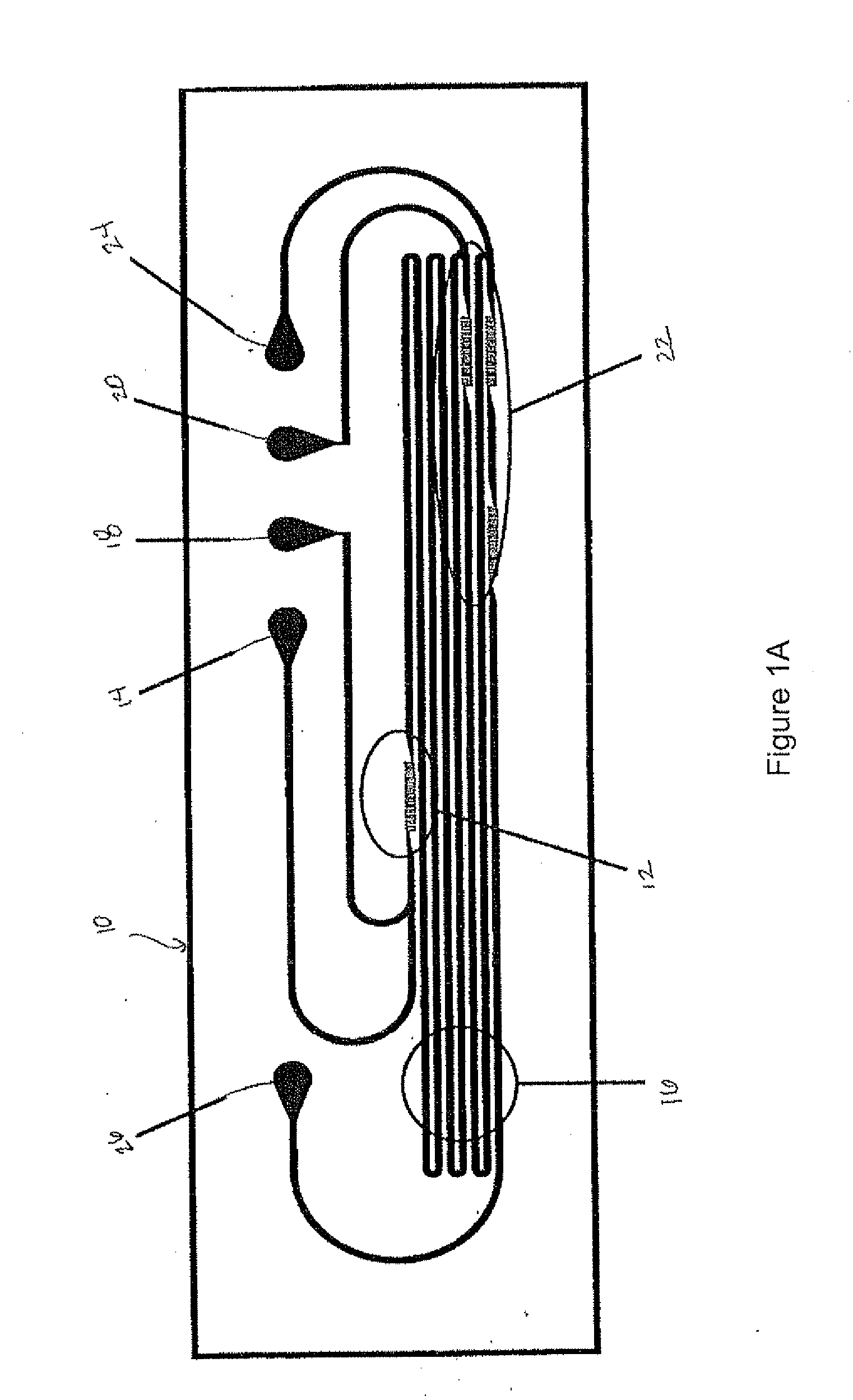

Microchemical method and apparatus for synthesis and coating of colloidal nanoparticles

InactiveUS20080087545A1Aggressive processing conditionsRealize the structureFlow mixersVolume/mass flow measurementCrystallographyBatch processing

The present invention represents a radical departure from most conventional macro-scale batch processing methods employed to synthesize and coat colloidal nanoparticles. Synthesis and coating are in series and in-situ, obviating the need for numerous cumbersome, and often expensive intermediate-processing steps. In one embodiment, the invention is a method and apparatus for synthesizing colloidal nanoparticles. In another embodiment, the invention is a method and apparatus for enabling coating of colloidal nanoparticles using an electrophoretic switch for contacting and separating said colloid nanoparticles.

Owner:MASSACHUSETTS INST OF TECH

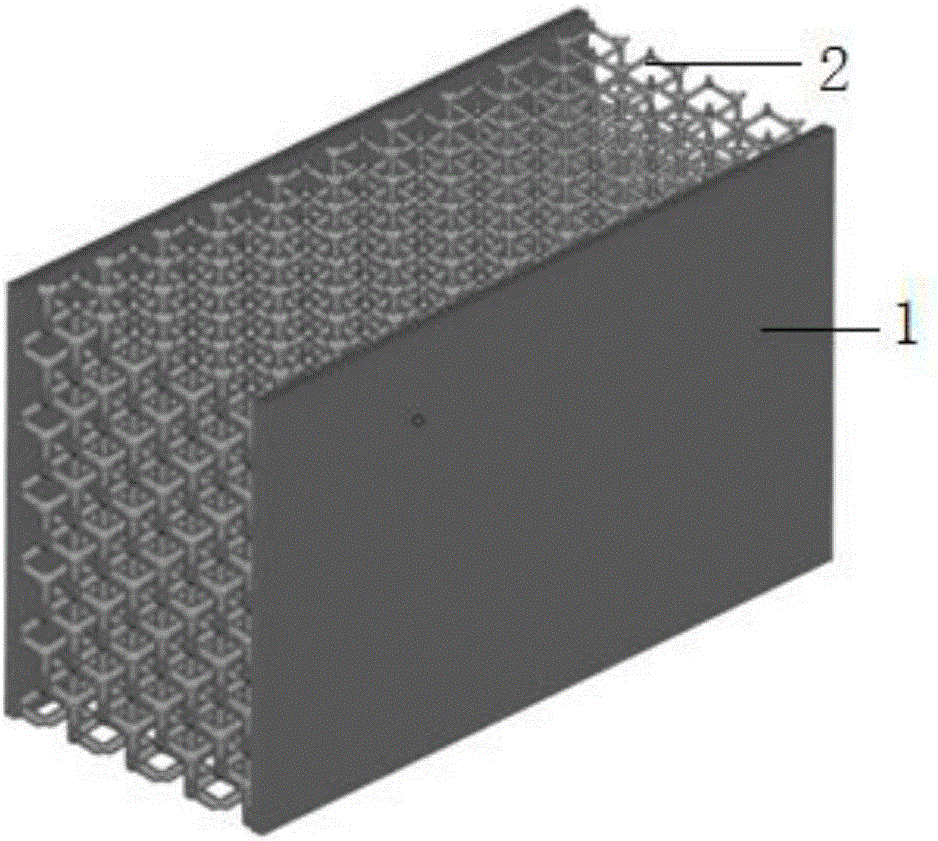

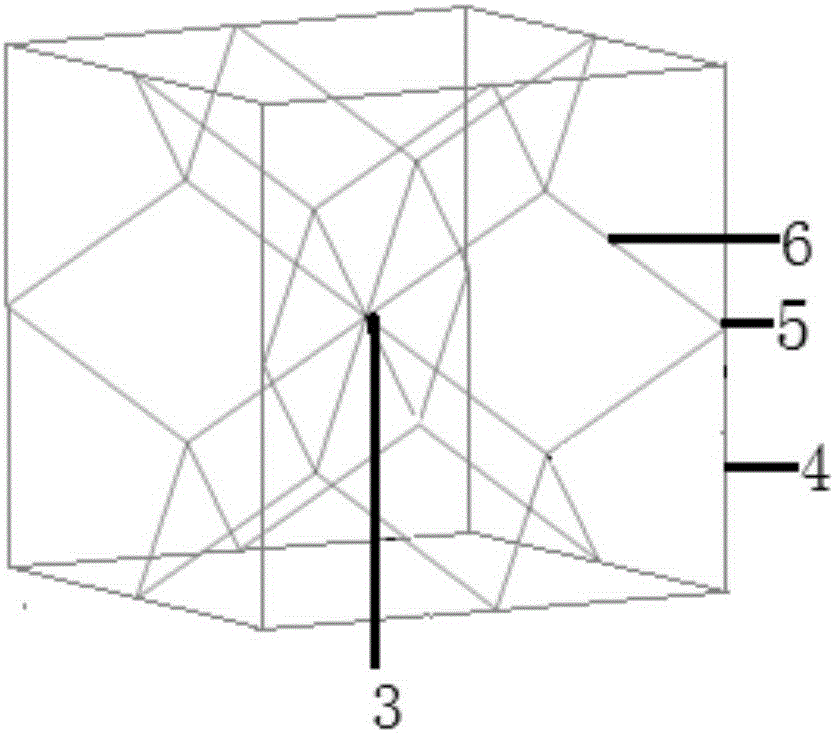

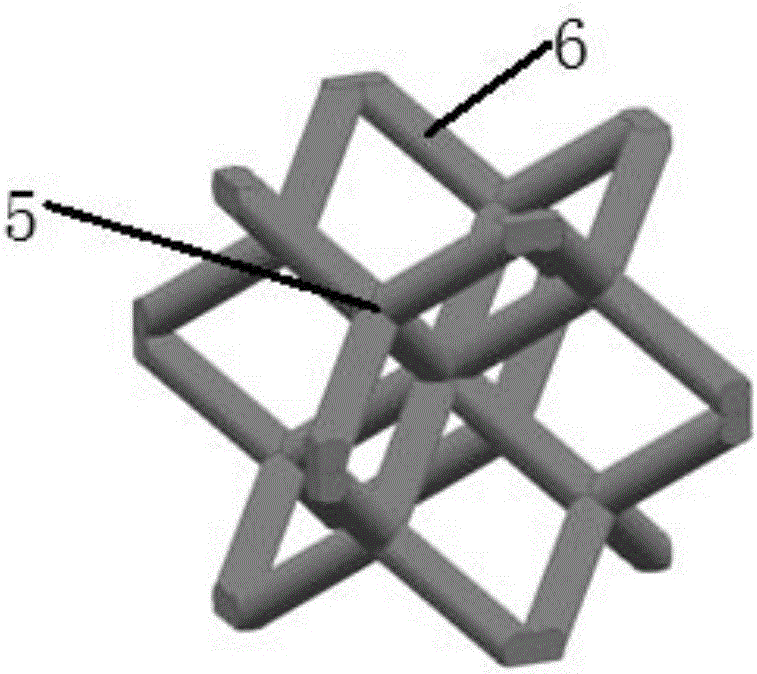

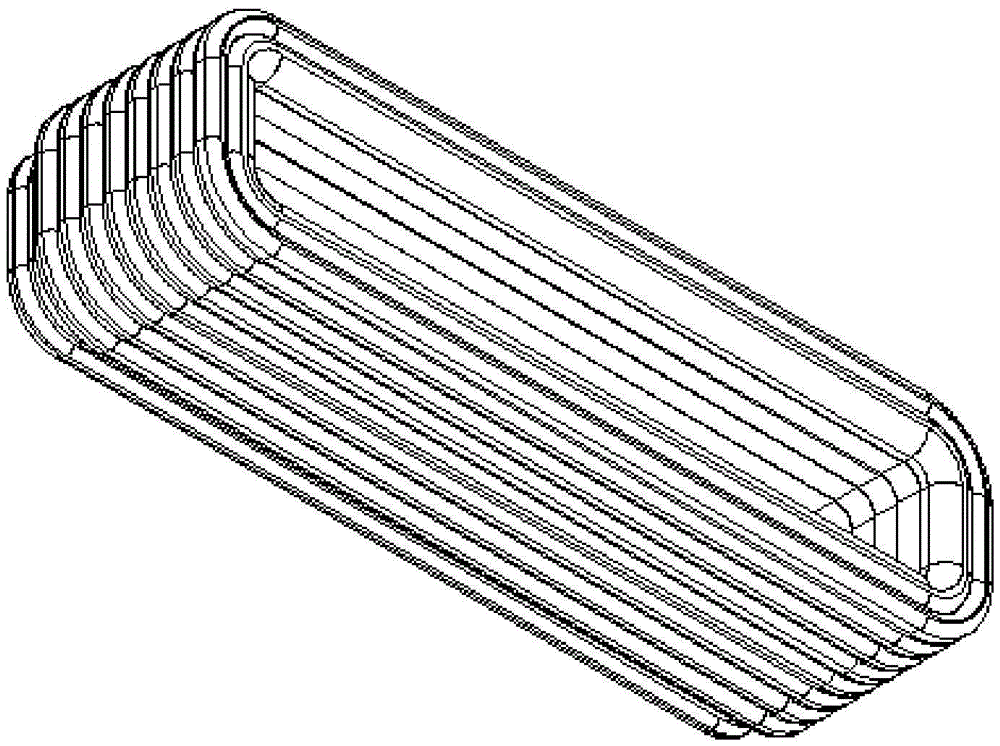

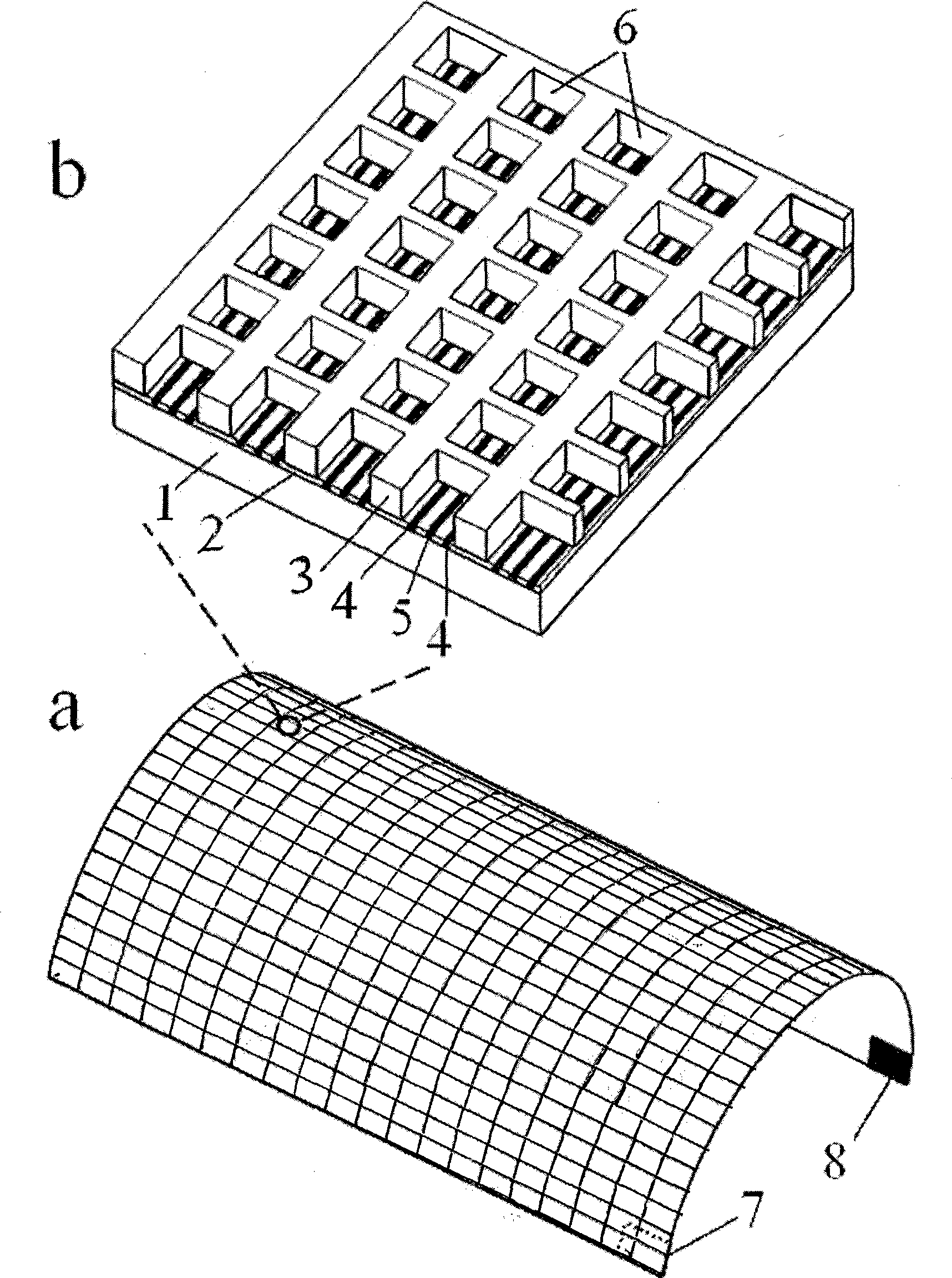

Hollowed-out lattice sandwich layer with gradient functionality and manufacturing method of hollowed-out lattice sandwich layer

ActiveCN106694884ALightweight structureHigh specific strengthAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSandwich board

The invention discloses a hollowed-out lattice sandwich layer with gradient functionality. The hollowed-out lattice sandwich layer with gradient functionality comprises two cladding plates, wherein a core sandwich layer is arranged between the cladding plates and comprises a plurality of hollowed-out lattice filling units which are connected with one another; and each hollowed-out lattice filling unit consists of a plurality of tiny dense hollowed-out base cells. The hollowed-out sandwich layer is formed by the hollowed-out lattice filling units, and is light in structure weight and high in specific strength, the maximum weight reduction benefit can reach 85% or above, and meanwhile, the hollowed-out lattice sandwich layer has functional benefits such as heat insulation and sound insulation; comprehensive benefits of structure light weight and functionalization are improved, property mismatching of a sandwich board with the single structure in the application field under various working conditions is avoided, and finally, the gradient function is fulfilled; and meanwhile, a selective laser melting technology is adopted, the risk of reduction of strength of a connecting region between a traditional sandwich layer and an outer cladding plate and complicated multi-process flow can be avoided, and therefore, the use value is quite high.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

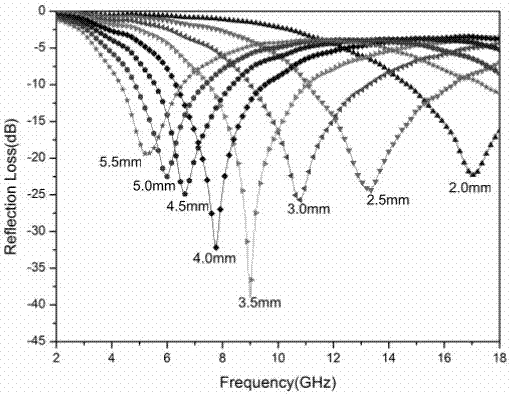

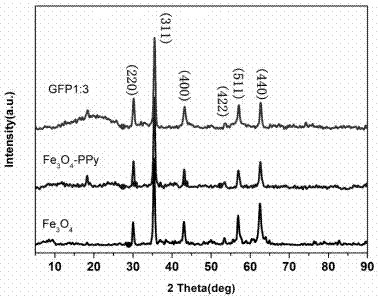

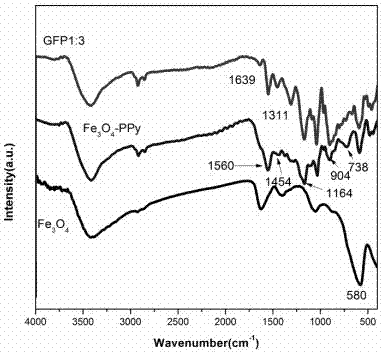

Preparation method of graphene composite aerogel absorbing material and application thereof

ActiveCN107399735ALow densityMild experimental conditionsMagnetic/electric field screeningGrapheneWave bandOxide

The invention discloses a preparation method of a graphene composite aerogel absorbing material and application thereof. The material is obtained by one-step reduction self-assembled reaction on reduced graphene oxide, a polymer A and magnetic nano particles which wrap a polymer B. The absorbing material is low in density and high in absorbing strength, effectively absorbs bandwidth, and has excellent absorbing property on an X wave band. In the absorbing material, the content of graphene is low, the cost is low, and therefore, the graphene composite aerogel absorbing material has wide application potential and market prospect in the field of invisibility of aircrafts, electromagnetic shielding of radar and communication equipment, and electromagnetic safety protection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

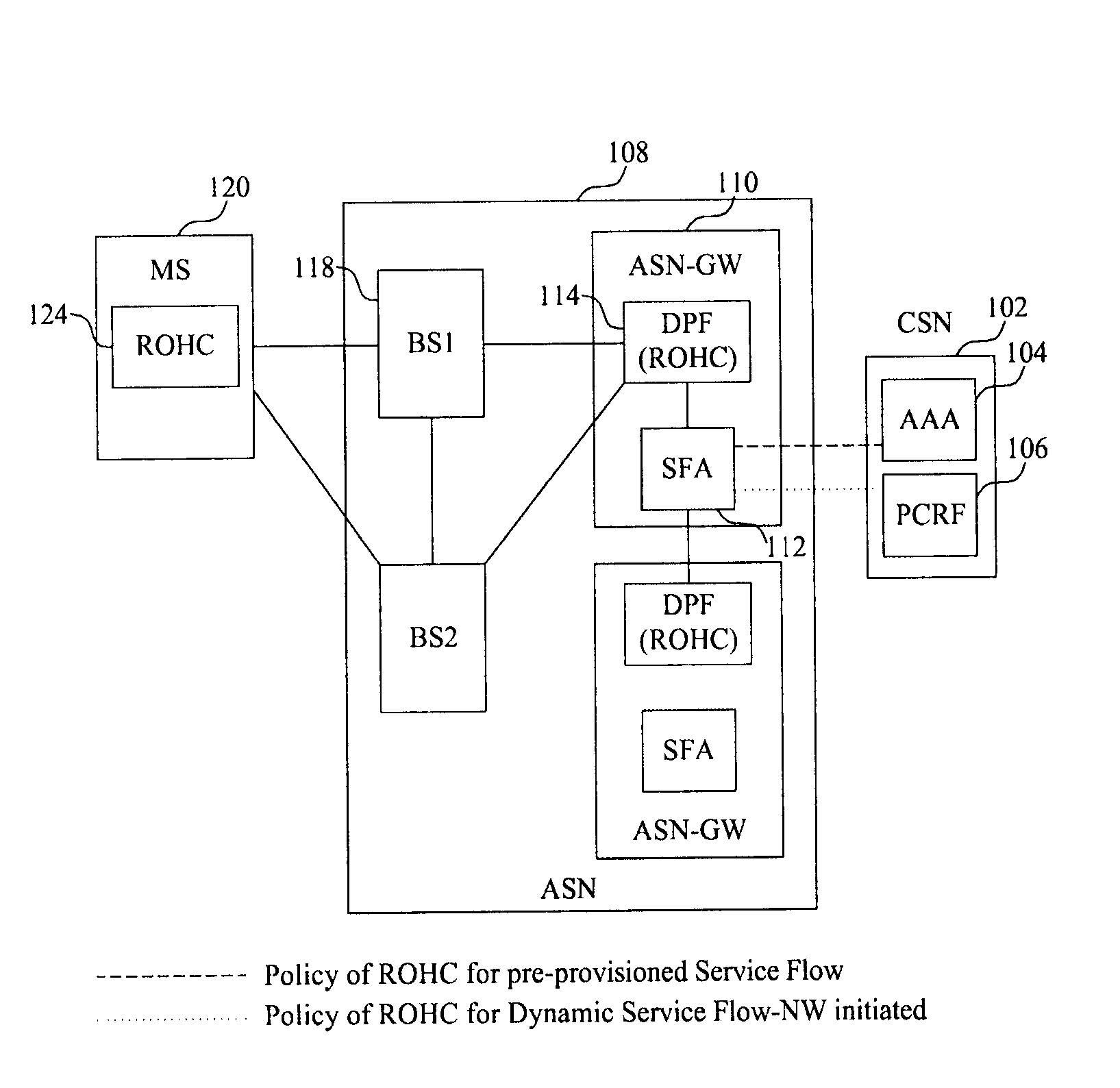

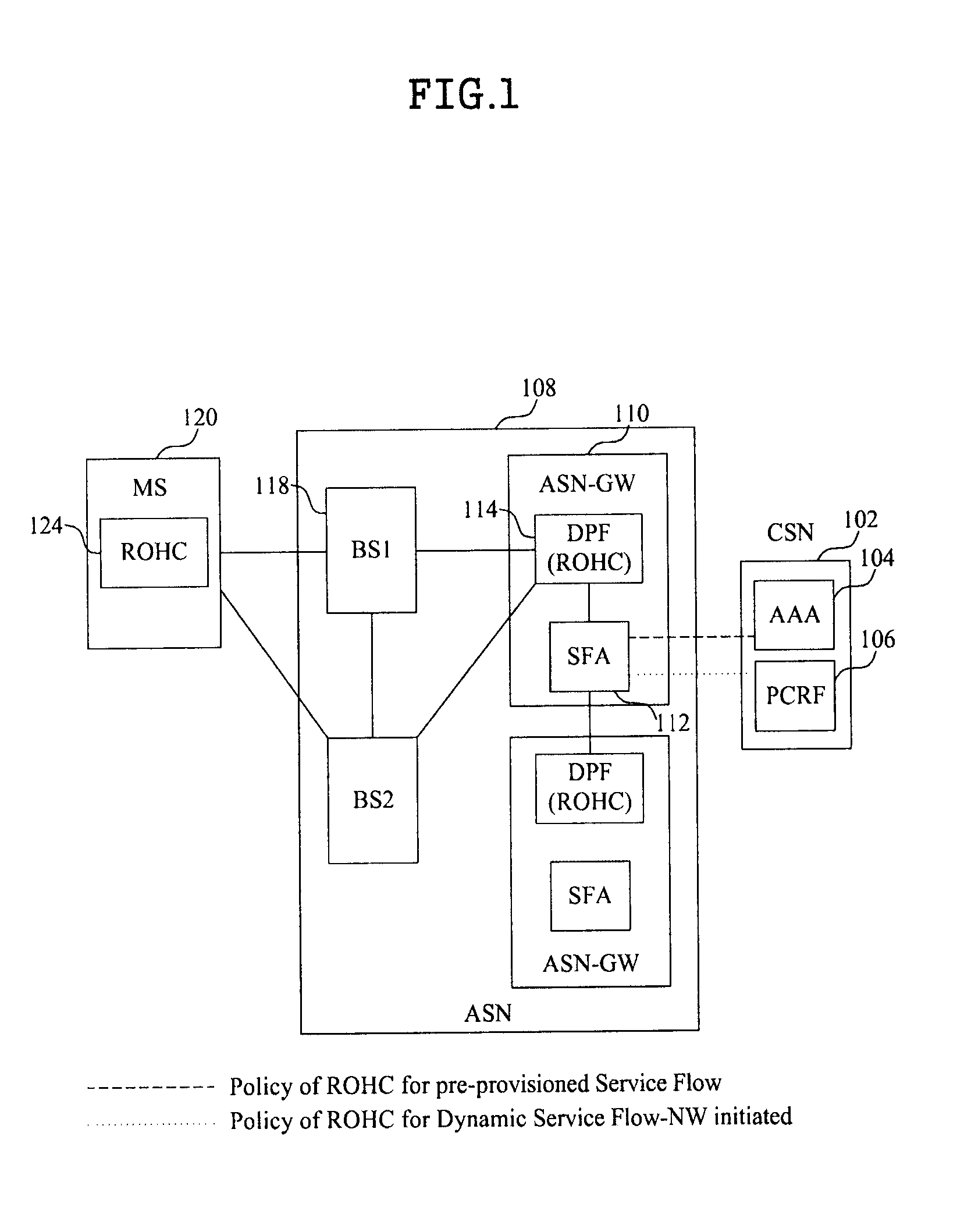

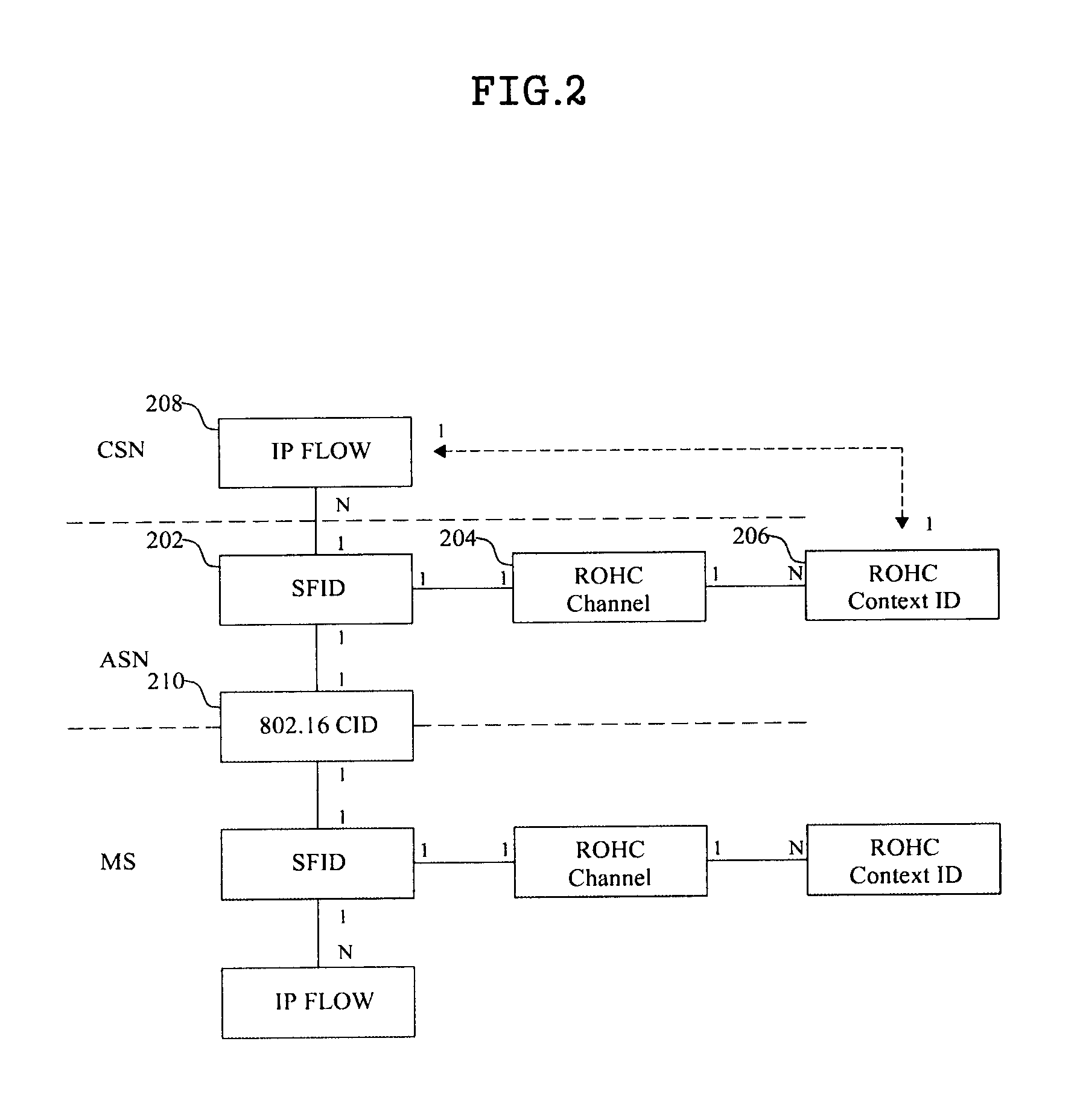

Method of creating and deleting service flow for robust header compression, and wireless communication system supporting the same

ActiveUS20090080374A1Realize the structureNetwork traffic/resource managementConnection managementService flowCommunications system

A method of creating a service flow for ROHC in a control station is disclosed, which can establishes a ROHC channel between ROHC entities, the method comprising obtaining a first ROHC parameter from a ROHC entity of the control station, upon receiving a subscriber profile to which ROHC is applied; and transmitting a first message including the first ROHC parameter for requesting the creation of service flow to a mobile station related with the subscriber profile and a base station performing a dynamic service addition (DSA) procedure through the use of a second message including the first ROHC parameter.

Owner:WIRELESS ALLIANCE LLC

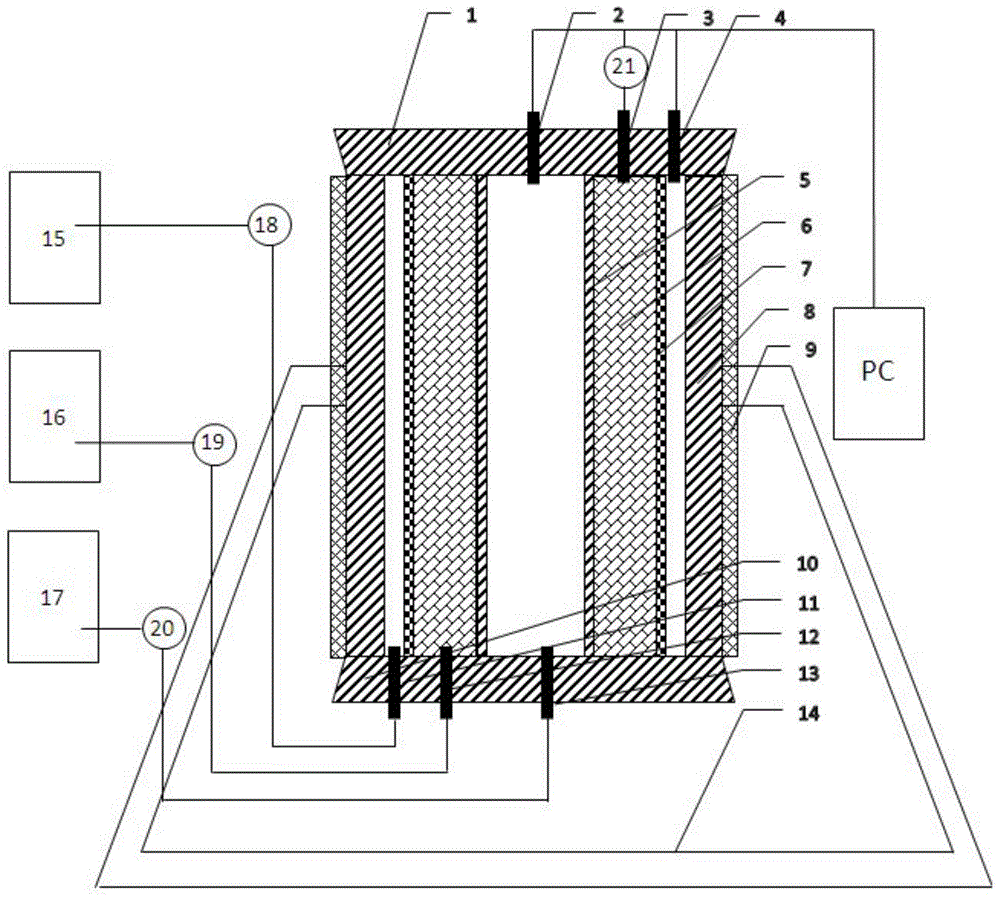

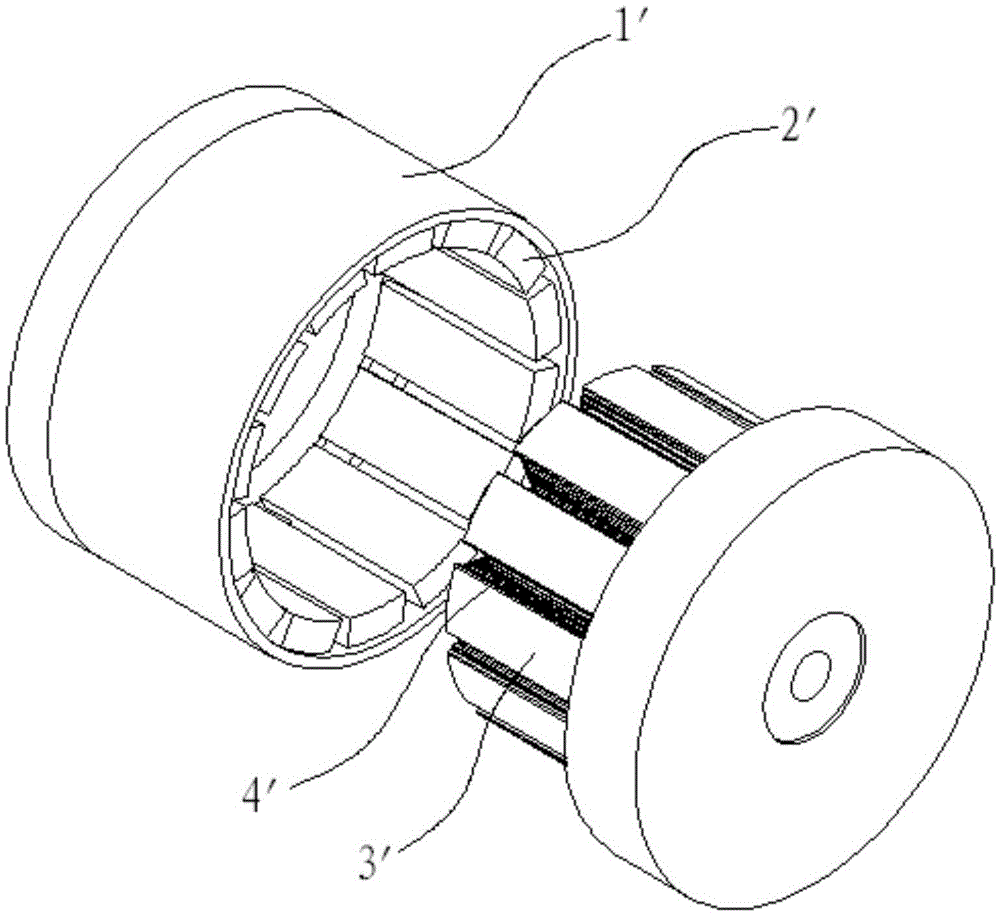

Device and method for testing mechanical integrity of high-temperature high-pressure well cementation cement sheath

ActiveCN104405366AAchieve high temperature and high pressureRealize the structureConstructionsMechanical integrityInternal pressure

The invention discloses a device and a method for testing the mechanical integrity of a high-temperature high-pressure well cementation cement sheath. The device comprises a cement sheath maintenance mould and a test working platform. The method comprises the following steps of (1) arranging an internal pressure casing into a hollow column formed by connecting left and right moulds, filling cement paste, and sealing upper and lower ends of the hollow column; (2) maintaining the cement sheath maintenance mould, taking the cement sheath and the internal pressure casing out, and putting the cement sheath and the internal pressure casing on the test working platform; (3) injecting water into an annular space of an annular pressure sleeve and a pressure bearing cylinder through an annular pressure inlet, injecting water into the casing through an internal pressure inlet, controlling the temperature at the target temperature, adjusting the annular pressure and the internal pressure to target pressure, recording the change of reading of a rotor flow meter, and showing that the mechanical integrity of the cement sheath is damaged at a time point that flow is obviously increased; (4) taking the cement sheath out, observing and detecting. The device and the method are suitable for simulating the damage and degradation of the cement sheath under different string structures in the later production process of an oil-gas well.

Owner:SOUTHWEST PETROLEUM UNIV

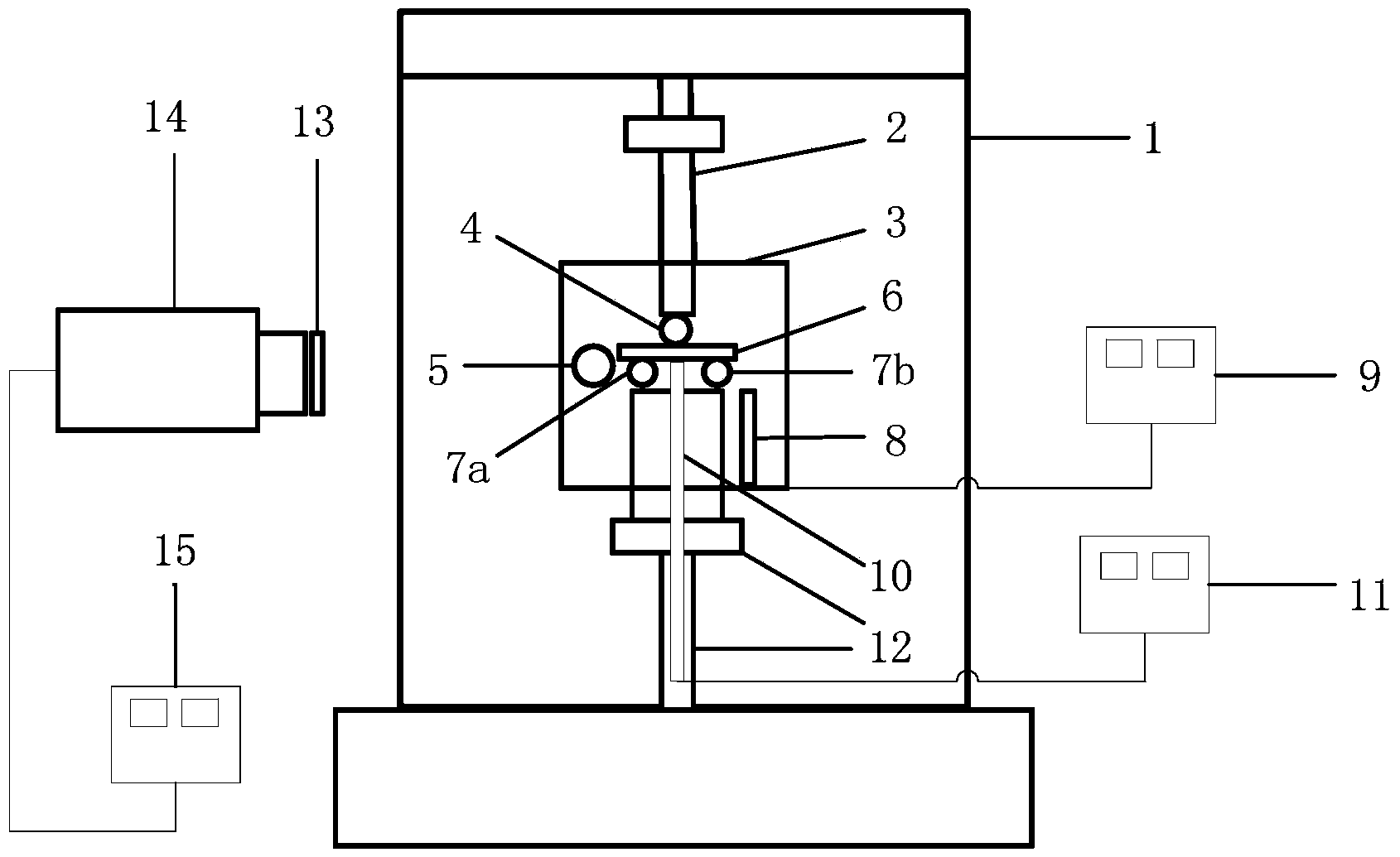

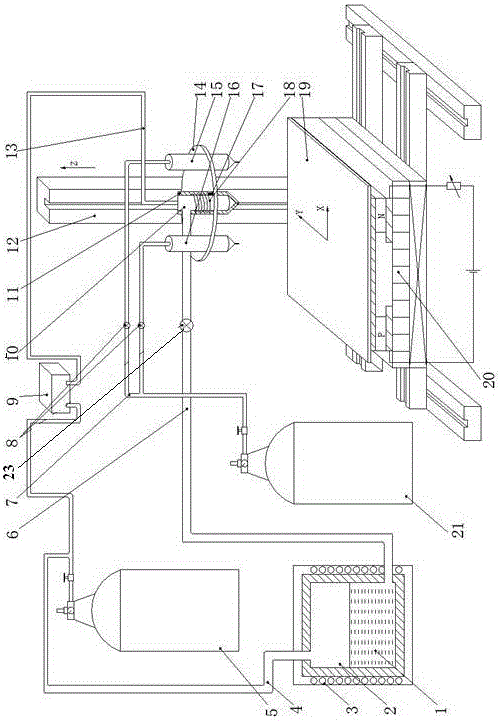

On-line observable high-temperature three-point bend test system

InactiveCN103728186ARealize online observationRealize surface topography observationMaterial strength using steady bending forcesStructural deformationMeasurement device

An on-line observable high-temperature three-point bend test system belongs to the technical field of engineering materials, structural deformation and mechanical experiments. The test system comprises a three-point bend load applying device, a high-temperature heating furnace, a deflection measurement device, a temperature measurement device and an on-line observation device. The invention relates to the high-temperature three-point bend test device integrating the on-line real-time observation function, and the surface of a test piece for the three-point bend test device in the high-temperature heating furnace is observed on line by a high-precision industrial camera with filters; the changes of microcosmic morphology, changes of crystal phase and crack propagation on the surface of the test piece in the three-point bend test process are recorded, so as to provide on-line observable test support for studying the deformation and crack of materials at high temperature.

Owner:TSINGHUA UNIV

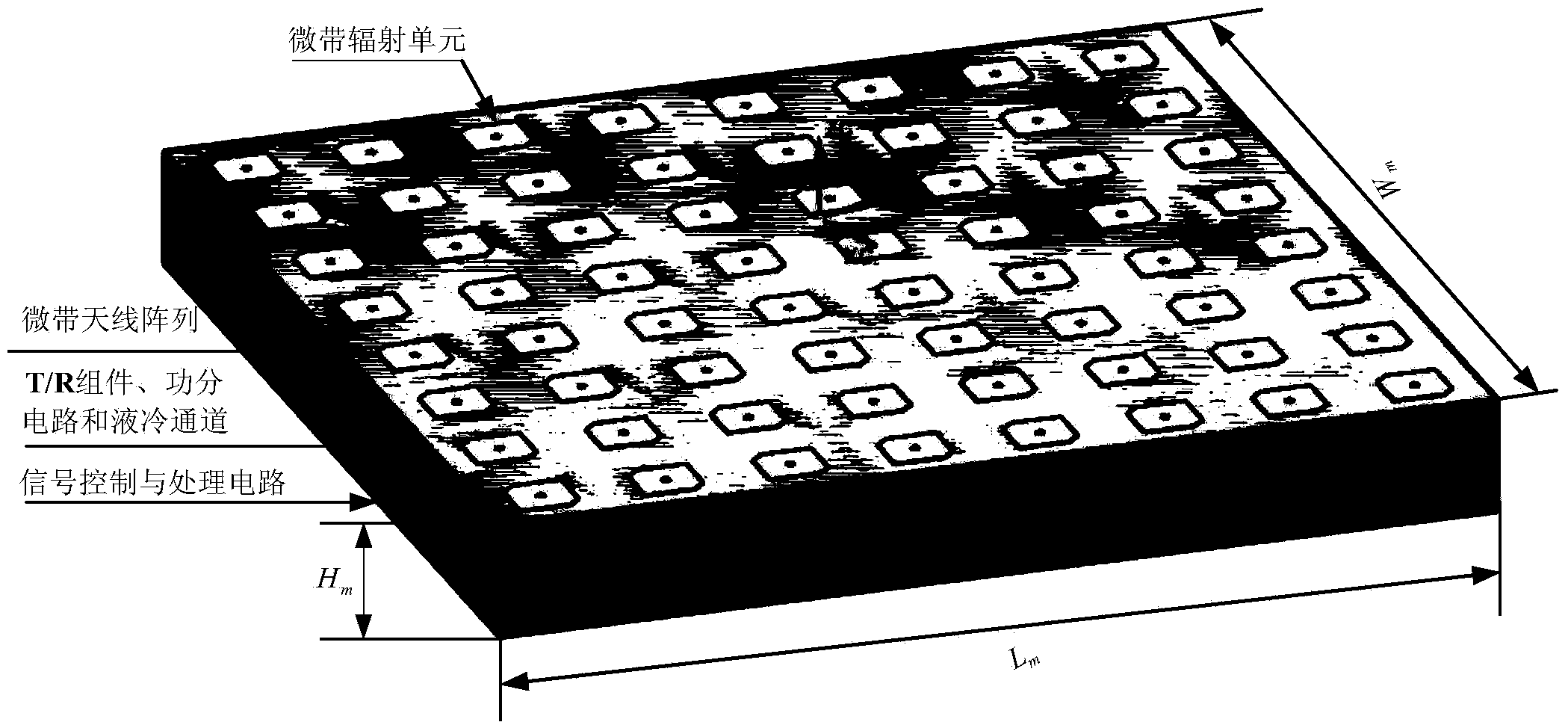

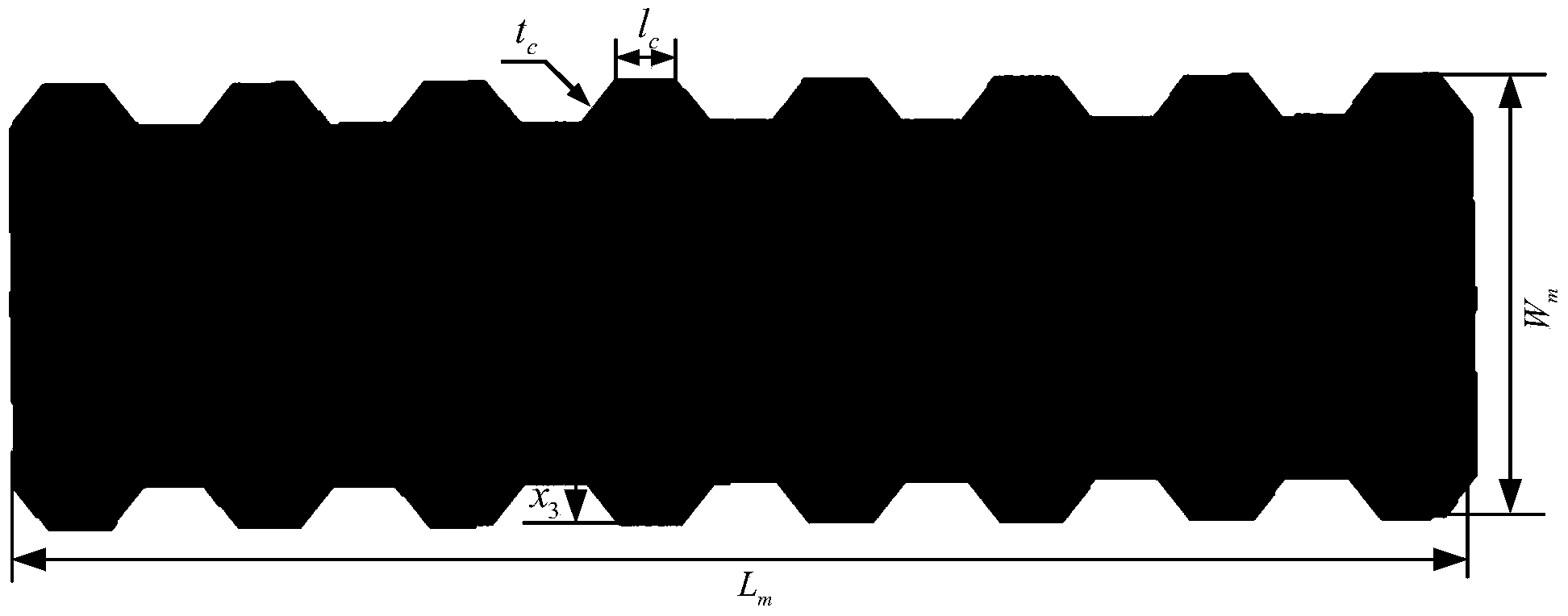

Data-driven design method integrating active interlayer microstrip antenna structure and electromagnetism and antenna

ActiveCN103353904ATo overcome the difficulty in realizing the design of electromechanical integrationRealize the structureSpecial data processing applicationsInformation technology support systemEngineeringRadio frequency

The invention discloses a data-driven design method integrating an active interlayer microstrip antenna structure and electromagnetism and an antenna, and solves the problem that the prior art can not realize the integrated design of the structure and electromagnetism. The method comprises the following steps: firstly, fixing the material, size, panel and cellular size of a radio frequency function layer according to electrical property indexes, secondly, obtaining front deformation data and stress data of the antenna structure through mechanical analysis, thirdly, preprocessing the front deformation data, so as to obtain the position error of each radiating element, fourthly, calculating a far-field pattern of an interlayer microstrip antenna according to a data-driven coupling model, fifthly, calculating and considering the wave-transparent performance influenced by the panel and cellular, sixthly, establishing an optimization design model integrating the interlayer microstrip antenna structure and electromagnetism, and seventhly, solving the optimization design model, so as to obtain an optimal integrating result. The method can realize the simultaneous optimal design of the active interlayer microstrip antenna structure and electromagnetism, shortens the development period, and improves force-electricity properties of products.

Owner:XIDIAN UNIV

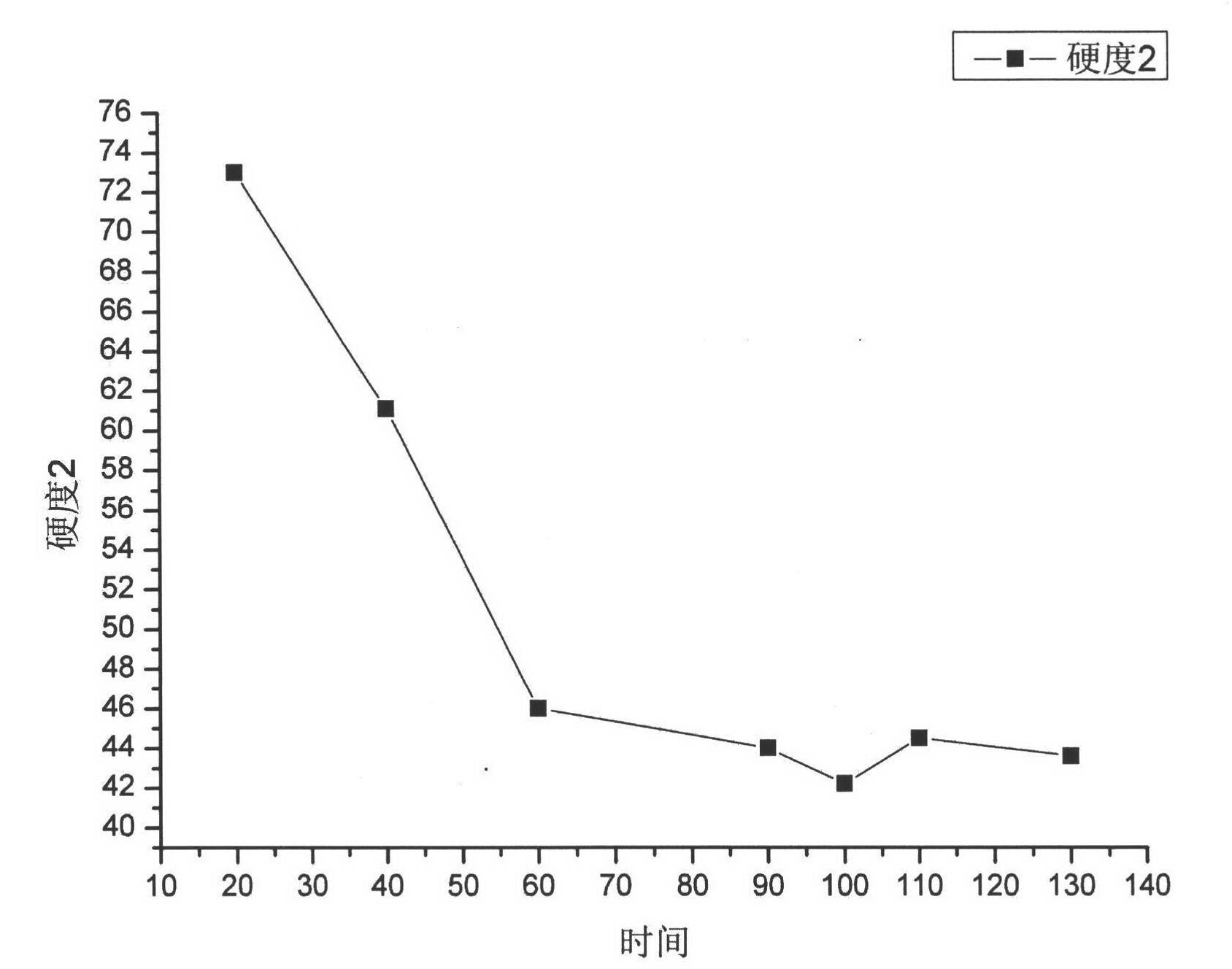

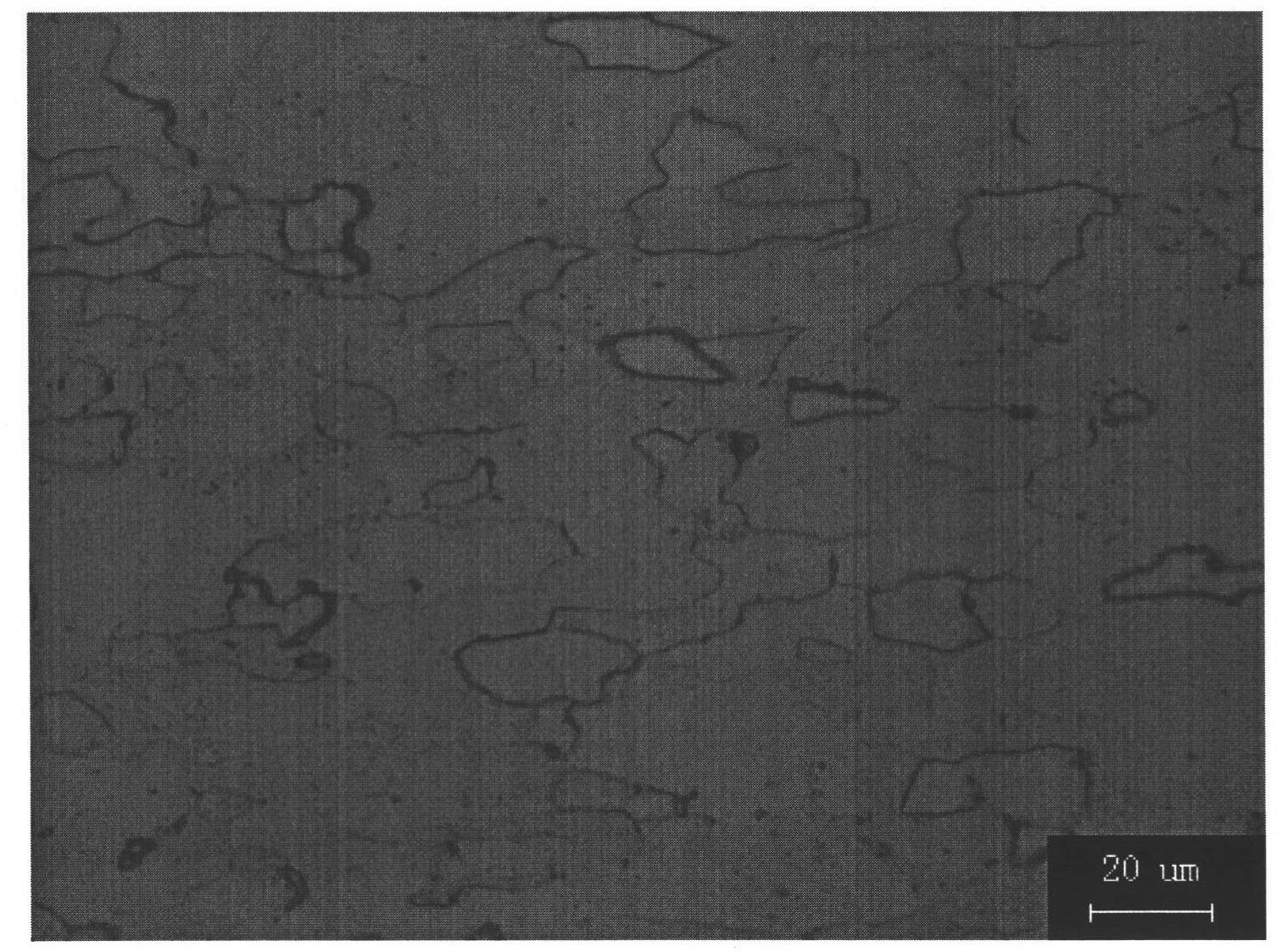

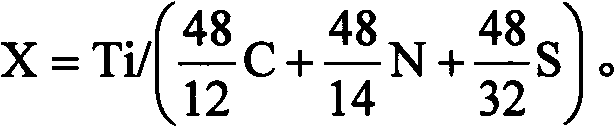

Low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and production method thereof

ActiveCN102653839ALower recrystallization temperatureRealize the structureChemical compositionReduction ratio

The invention relates to a low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and a production method thereof and belongs to the technical field of iron-based alloys. The production method of the cold-rolled steel plate comprises the following steps of: controlling the components of the cold-rolled steel plate in percentage by mass: 0.0005-0.0025% of C, less than or equal to 0.03% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, less than or equal to 0.0025% of O, less than or equal to 0.0025% of N, 0.015-0.050% of Al, 0.03-0.07% of Ti, and the balance of Fe and inevitable mixed elements; and meanwhile, controlling the continuous-annealing temperature of the cold-rolled steel plate to be 710-740 DEG C, and controlling the cold-rolling reduction ratio to be not less than 80%. According to the cold-rolled steel plate and the production method thereof, the reasonable chemical components and the suitable control of cold-rolling reduction are adopted, the recrystallization temperature is lowered, full-old-rolled microstructures are formed, and a lower continuous-annealing temperature can be adapted, so that the equipment cost and energy consumption are reduced, the control difficulty of a production process is reduced, the product defects and production accidents are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Process of obtaining composite brazed seam with ultrasonic brazed aluminium-base composite material

InactiveCN101088691ARealize weld compoundingRealize the structureWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloyUltrasonic vibration

The present invention relates to relates to welding method, and is especially ultrasonic brazing process of obtain composite brazed seam in aluminum-base composite material. The process includes the following steps: 1. filling brazing alloy; 2. primary brazing; and 3. ultrasonic vibration treatment to obtain composite brazed seam in aluminum-base composite material. The said brazing process can obtain brazed joint with greatly improved mechanical performance and heat expansion performance, low heat expansion coefficient, and high strength near that of the mother material.

Owner:HARBIN INST OF TECH

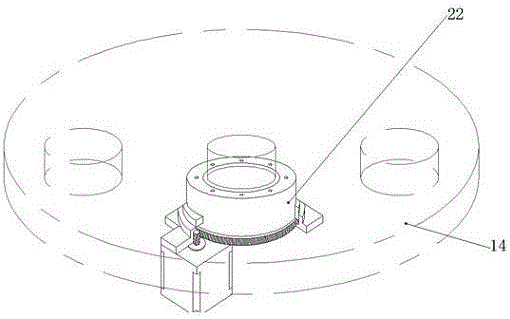

Preparation and forming integrated three-dimensional printing method and preparation and forming integrated three-dimensional printing device for amorphous alloy materials

ActiveCN105728728AGuaranteed amorphous propertiesAchieve preparationAdditive manufacturing apparatusSelective laser meltingManufacturing technology

The invention relates to a preparation and forming integrated three-dimensional printing method and a preparation and forming integrated three-dimensional printing device for amorphous alloy materials, belonging to the technical field of micro-droplet jetting material increase manufacturing and amorphous alloy preparation. Crystalline molten metal is directly jetted by using a metal droplet jetting material increase manufacturing technology; environmental cooling of a substrate before metal droplet jetting and deposition droplet cooling after the metal droplet jetting are realized by adopting a method of combining a rotatable double-jetting liquid nitrogen cooling device with a cold substrate; and by using a point-to-point cooling method for two times, the molten metal can be quenched and amorphized, and further the integration of preparation of the amorphous alloy materials and three-dimensional forming of a large-size complex structure are realized. According to the preparation and forming integrated three-dimensional printing method and the preparation and forming integrated three-dimensional printing device disclosed by the invention, the limit of a traditional preparation method of an amorphous alloy in a forming critical dimension of a bulk amorphous alloy is overcome; the defects of crystallization behavior and buckling deformation generated in the selective laser melting three-dimensional printing process of amorphous alloy powder are avoided; and the problem that the amorphous alloy materials are difficult to machine is solved, and the preparation and structure forming integrated three-dimensional printing of the amorphous alloy materials is realized.

Owner:JILIN UNIV

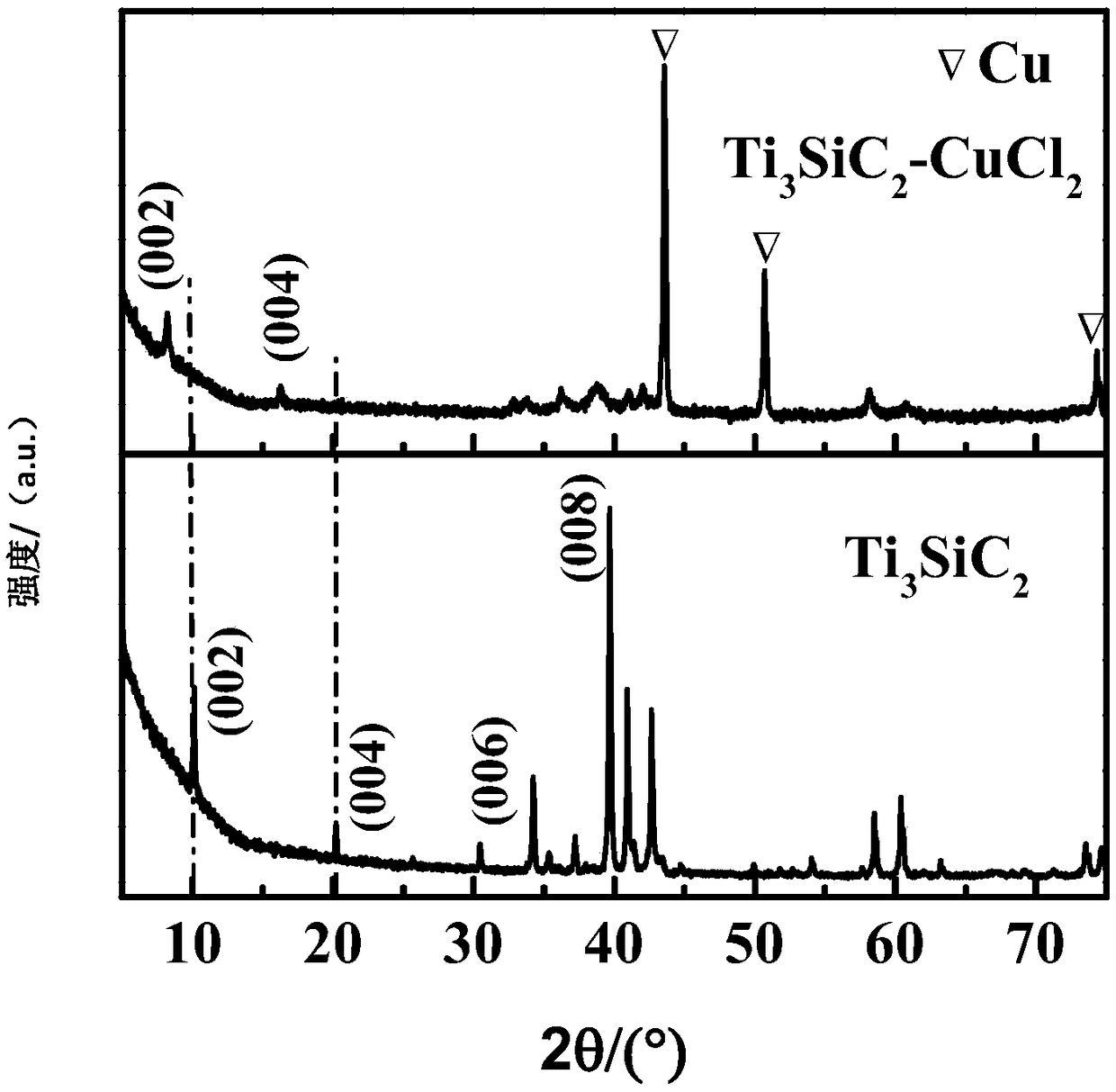

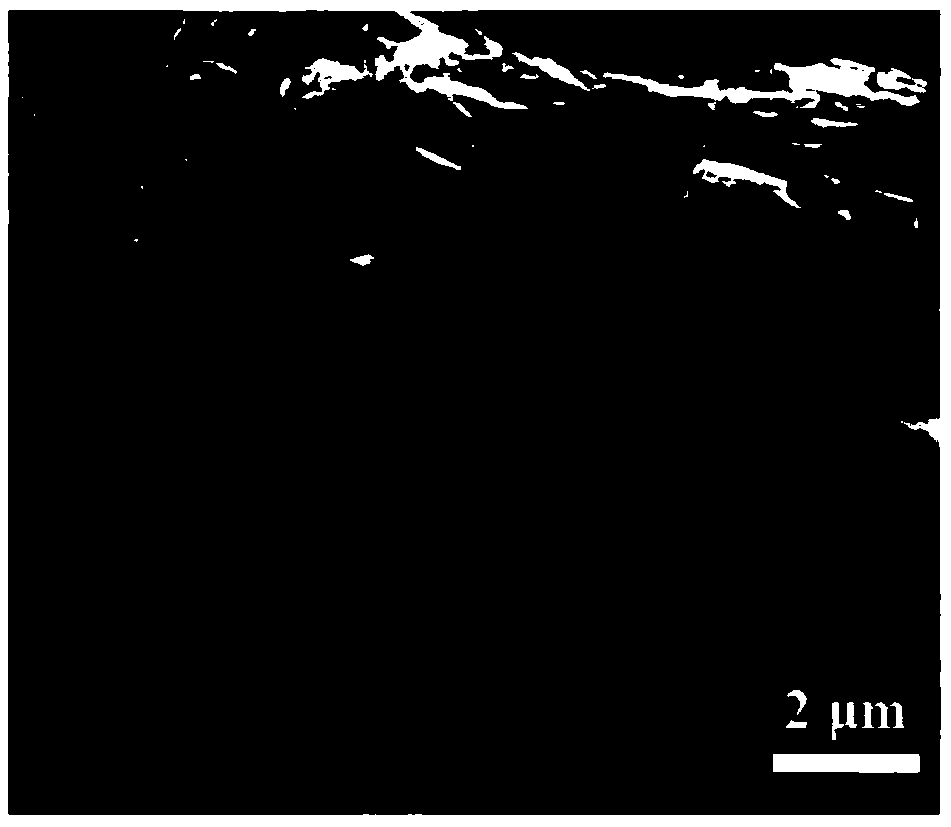

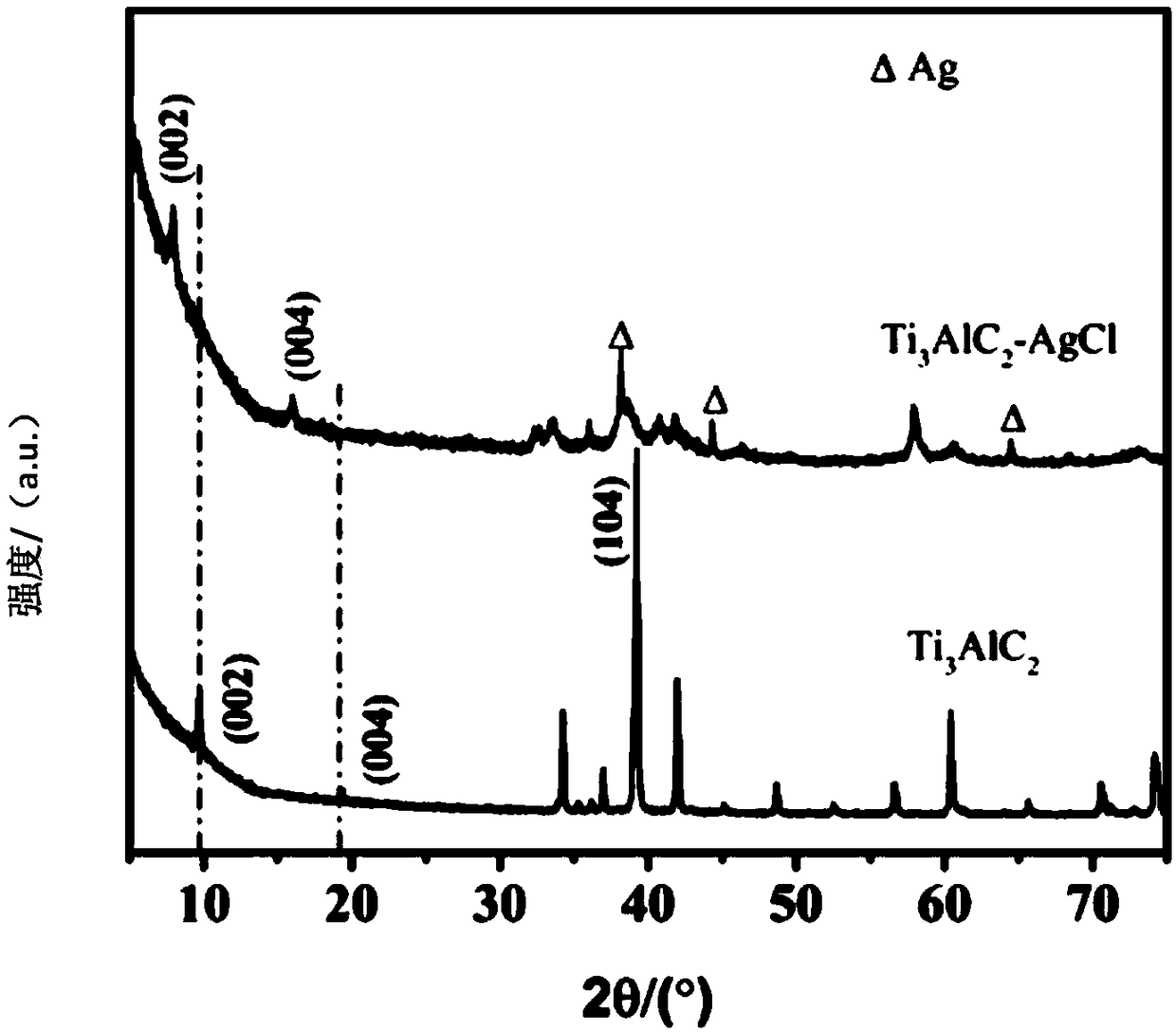

Composite material of sub-group metals compounded with MXenes and preparation method and application of composite material

ActiveCN108793166ARealize the structureRealize functionTitanium carbideMetal/metal-oxides/metal-hydroxide catalystsInorganic saltsMolten salt

The invention discloses a composite material of sub-group metals compounded with MXenes and a preparation method of the composite material. The composite material of sub-group metals compounded with MXenes is prepared from MXenes materials and sub-group metals, wherein the surfaces of the MXenes materials are coated with the sub-group metals in situ, and the sub-group metals are also distributed among layers of the MXenes materials. The preparation method comprises the following steps: grinding precursor Mn+1AXn-phase materials, sub-group metal salts and inorganic salts for 5-60min by adoptinga molten salt method, enabling the obtained mixture to react for 1-48h at 300-800 DEG C in inert atmosphere, and then, performing post-treatment to obtain the composite material of the sub-group metals compounded with the MXenes. The composite material disclosed by the invention has the advantages of adjustable and uniform components, low cost, environmental protection, high efficiency and the like, and has application prospects in the fields of electrode materials for electrochemical energy storage, wave absorption materials, electromagnetic shielding materials, catalysts and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

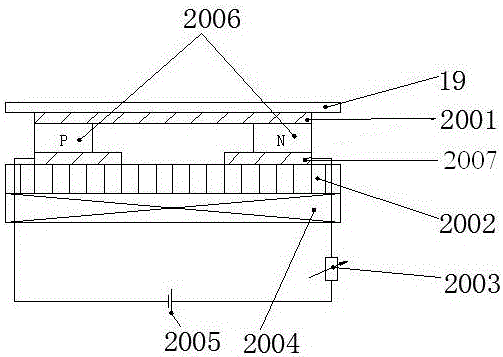

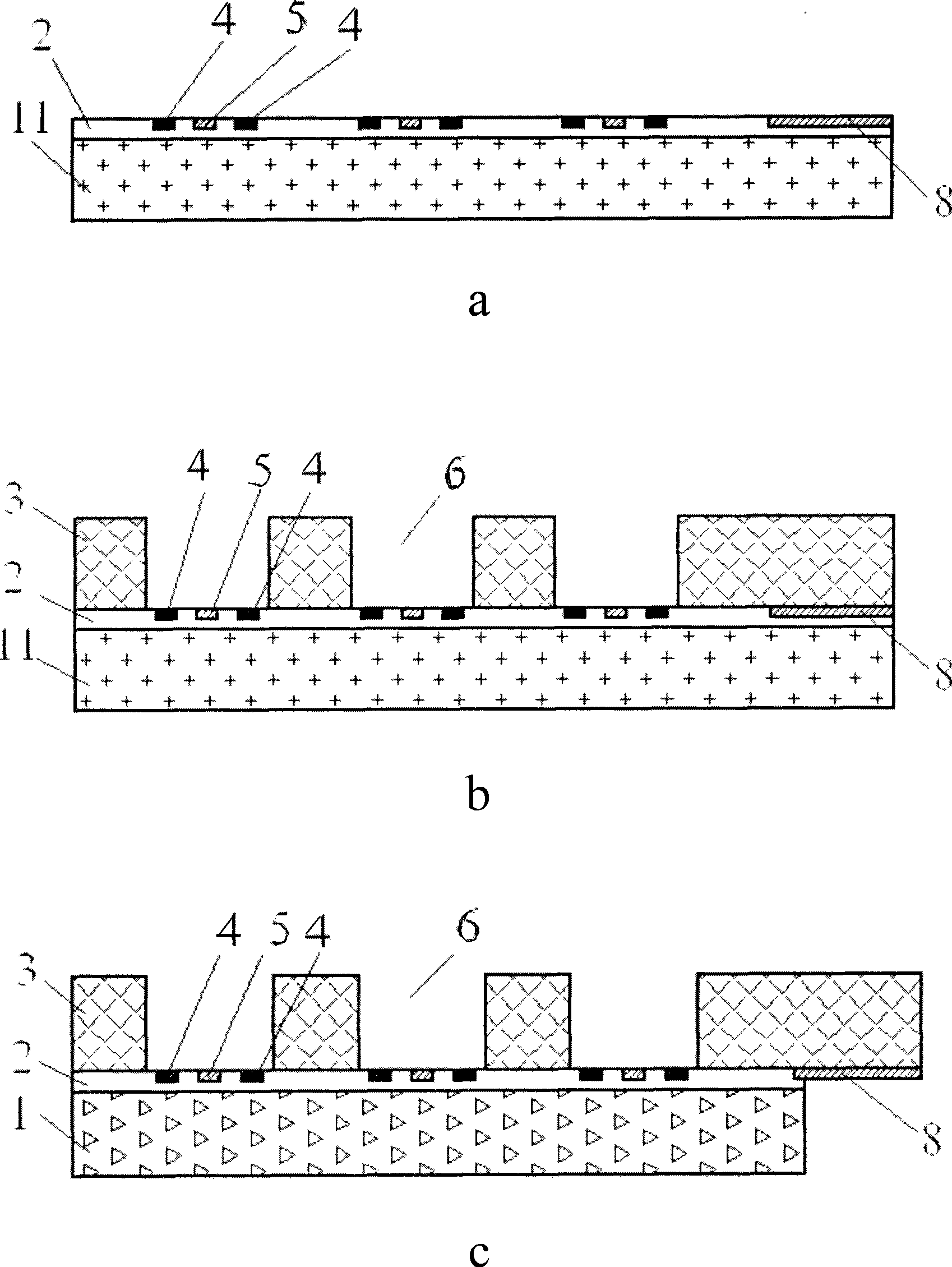

Technology for manufacturing selective emitter junction solar cell by printed phosphorous source one-step diffusion method

ActiveCN101937940ARealize the structureGood diffusion uniformity controlFinal product manufactureSemiconductor devicesDiffusion methodsScreen printing

The invention relates to technology for manufacturing a selective emitter junction solar cell by a printed phosphorous source one-step diffusion method. The method comprises the following steps of: cleaning and texturing a silicon wafer, performing screen printing of phosphorous-containing nano Si slurry, drying at the temperature of between 200 and 350 DEG C for about 20 minutes, and removing the solvent to obtain a phosphorous-containing oxidation layer with the thickness of 30 to 100nm; implementing BOE and RCA cleaning to remove 70 percent of surface phosphorous slurry before diffusion; putting the silicon wafer into a diffusion furnace, adding a POCL3 air source, heating to between 800 and 1,000 DEG C, forming re-diffusion at a grid line of the phosphorous-containing nano slurry on the silicon wafer to form a higher surface concentration-heavily doped region, and forming a shallow diffusion region in other areas. By adopting the screen printing of the phosphorous-containing nano slurry, the phosphorous-containing nano slurry is heated at high temperature for diffusion, forms the heavily doped region at a contact position with the grid line and forms a lightly doped region in other areas. The technology has the efficiency of over 18.5 percent on the premise of better controlling the diffusion uniformity.

Owner:TRINA SOLAR CO LTD

Single-phase winding coiling method used for p axial magnetic field motors and winding structures thereof, printed circuit board and motor

ActiveCN105490476ALow costIncrease profitManufacturing dynamo-electric machinesSynchronous machines with stationary armatures and rotating magnetsSingle phasePrinted circuit board

The invention provides single-phase winding structures used for axial magnetic field motors and a coiling method thereof, a printed circuit board and a motor. The windings are arranged on 2N layers of PCB. The windings arranged on all layers of PCB except for the first layer of PCB are provided with winding cycle rings of which the number is the same with that of motor magnetic poles. The adjacent winding layers are serially connected via connecting holes arranged at the central parts of the winding cycles. The head end and the tail end of the winding end parts are arranged on the first layer of PCB. Cost of the windings is relatively low; the motor coefficient of the windings is relatively high; and the windings are realized through the mode of the PCB so that the shape of the 2D windings can be arbitrary, and the size and the thickness of the windings can be accurately controlled. The aforementioned is important for realization of the thin motor structure and enhancement of motor performance; and the lines of a motor driving circuit, a Hall sensor circuit and other electronic devices can be manufactured on the same PCB forming the motor windings so that utilization rate of motor space can be enhanced.

Owner:FORTIOR TECH SHENZHEN

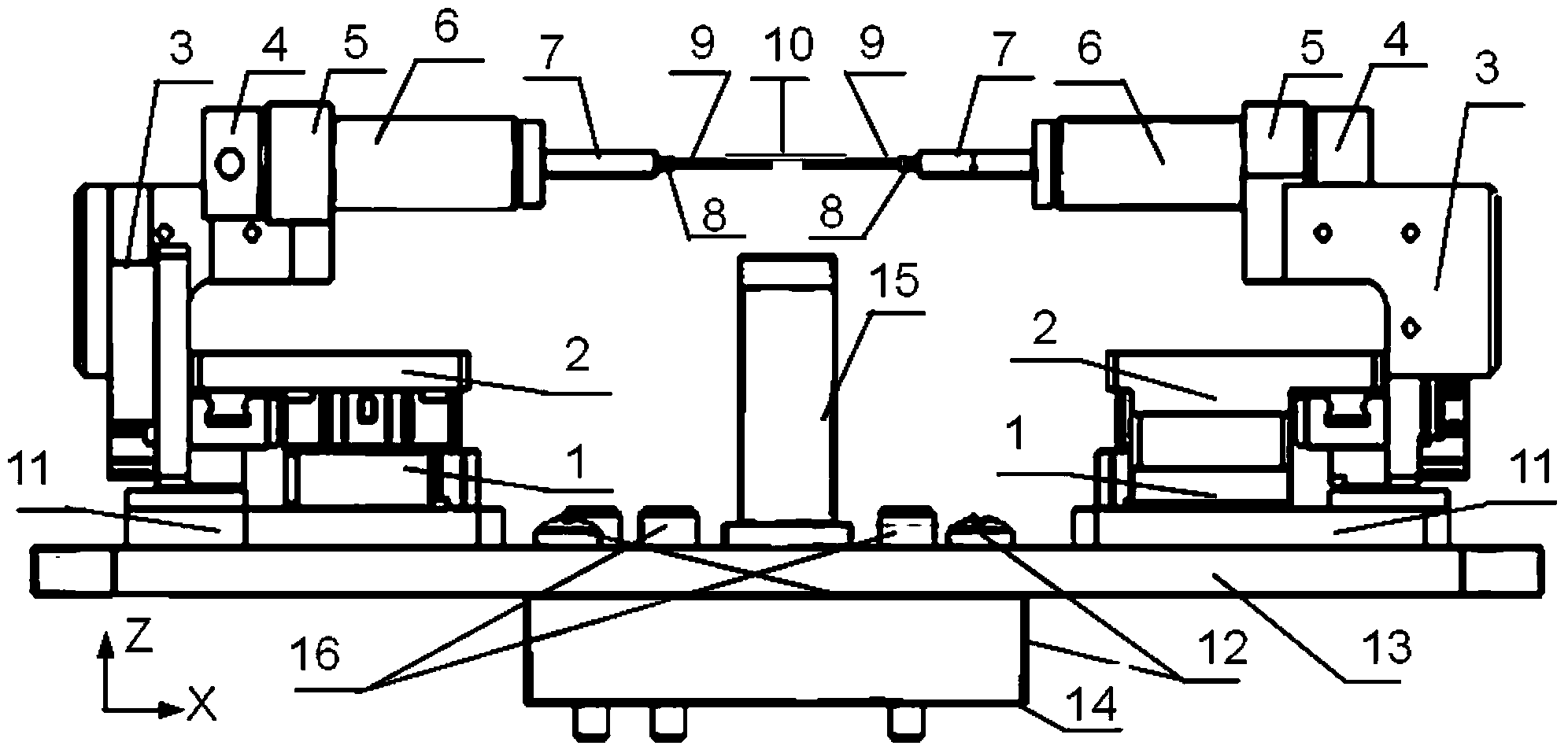

Uniaxial two-way micro mechanical measurement device and method for scanning micro environment

ActiveCN103471905ASchema Loading GuaranteeGuaranteed normal loadingMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMeasurement deviceSpeckle correlation

The invention belongs to the fields of micro-nano mechanics and precision machinery, and in particular relates to a uniaxial two-way micro mechanical measurement device and method for a scanning micro environment. According to the device, symmetrical coordinate type three-dimensional coarse-tuning translation stages, symmetrical fine-tuning three-dimensional moving precision platforms and a sample platform are installed on a main support unit. Through the control operation of a control system and a manipulation unit, the device can be used for detecting micro-nano characteristic scale materials and a structural mechanical property, and can realize one-way centering stretch, compressing, bending and vibration measurement and micro-nano scale sample surface deformation and micro-structural evolution detection. The device can be repeatedly used and can combine a digital image / speckle correlation technique, an image processing technique or a micro-labeling technique to detect the in-situ deformation and mechanical property of samples in a high-spatial-discrimination scanning microscopic environment.

Owner:TSINGHUA UNIV +1

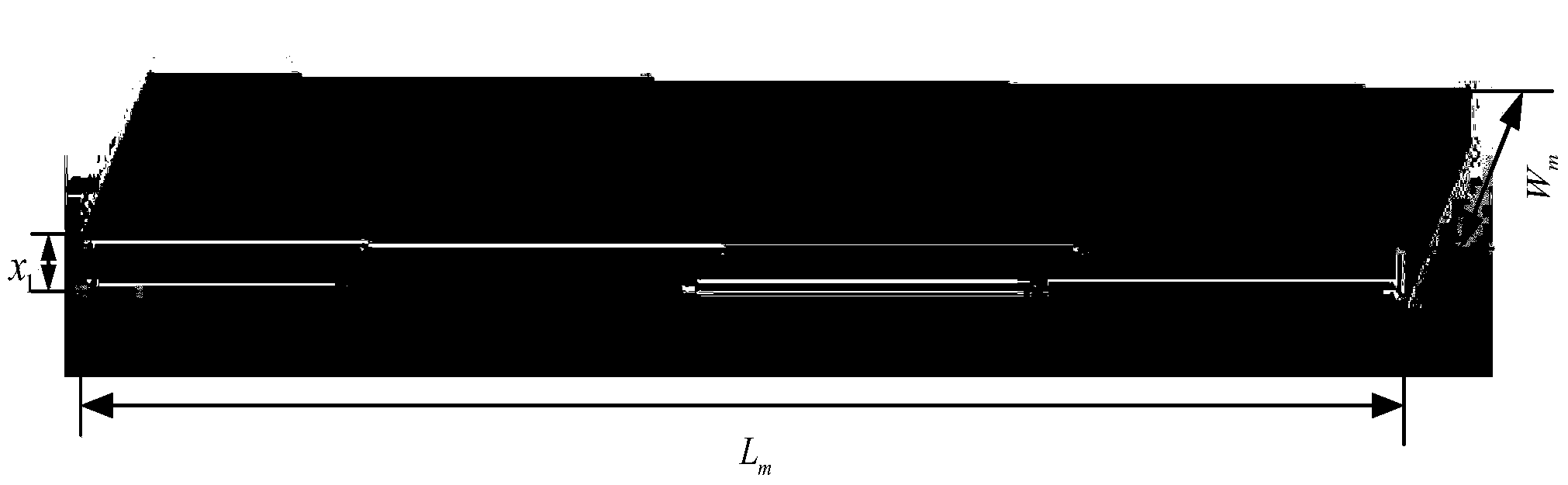

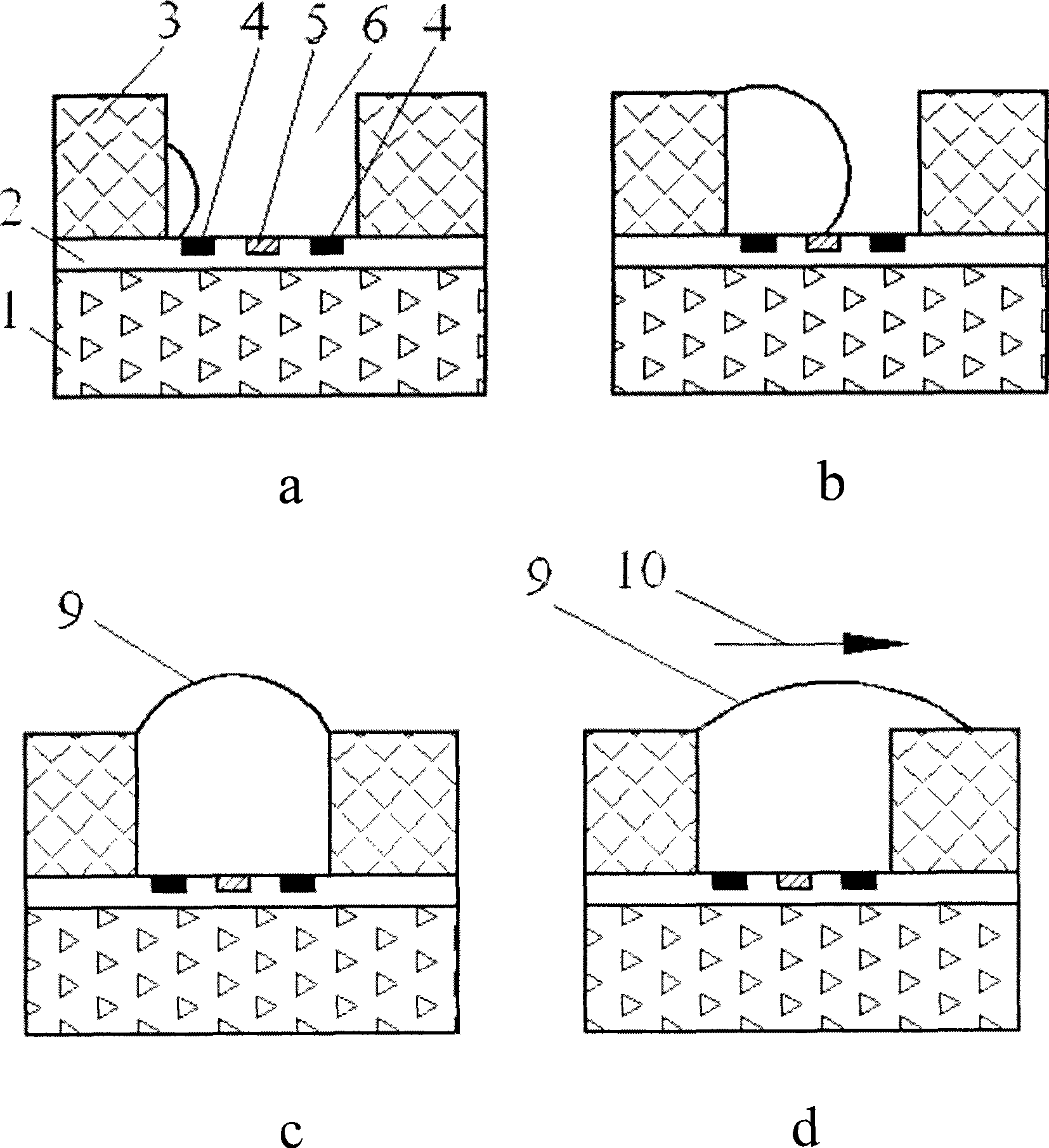

Flexible MEMS resistance reducing covering and method of manufacturing the same

InactiveCN101486438AAchieve residencyImplement auto-replenishmentTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrolysisMicrobubbles

The invention discloses a flexible MEMS resistance-reducing skin and a manufacturing method thereof used for reducing skin friction resistance during the advancing of on-water or underwater vehicles, which employs micro-fine resident bubbles to reduce resistance and belongs to the fields of micro-machinery and fluid dynamics. The upper surface of the skin is a surface layer coated with micro-pit arrays and processed by surface soakage; electrolytic anodes and cathodes of comb-shaped micro-fine planar metal, which are attached on an insulating layer, are arranged at the bottom of the micro-pits; a flexible substrate is positioned below the insulating layer; wire leading terminals for electrodes are arranged on the lower surface of the skin; and both the surface layer and the substrate are made by flexible materials. The overall thickness of the resistance reducing skin is at sub-millimeter level, and the skin is in the status of flexible film. The manufacturing method is an MEMS micro machining technique compatible with the flexible MEMS technology. The flexible MEMS resistance-reducing skin is coated on the outer surfaces of the on-water or underwater vehicles, with power thereof supplied by the on-water or under-water vehicles. Micro-bubbles stably residing in the micro-pits are formed by water electrolysis reaction to coat most parts of the surfaces of the on-water or under-water vehicles, thus realizing the function of reducing skin friction resistance.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

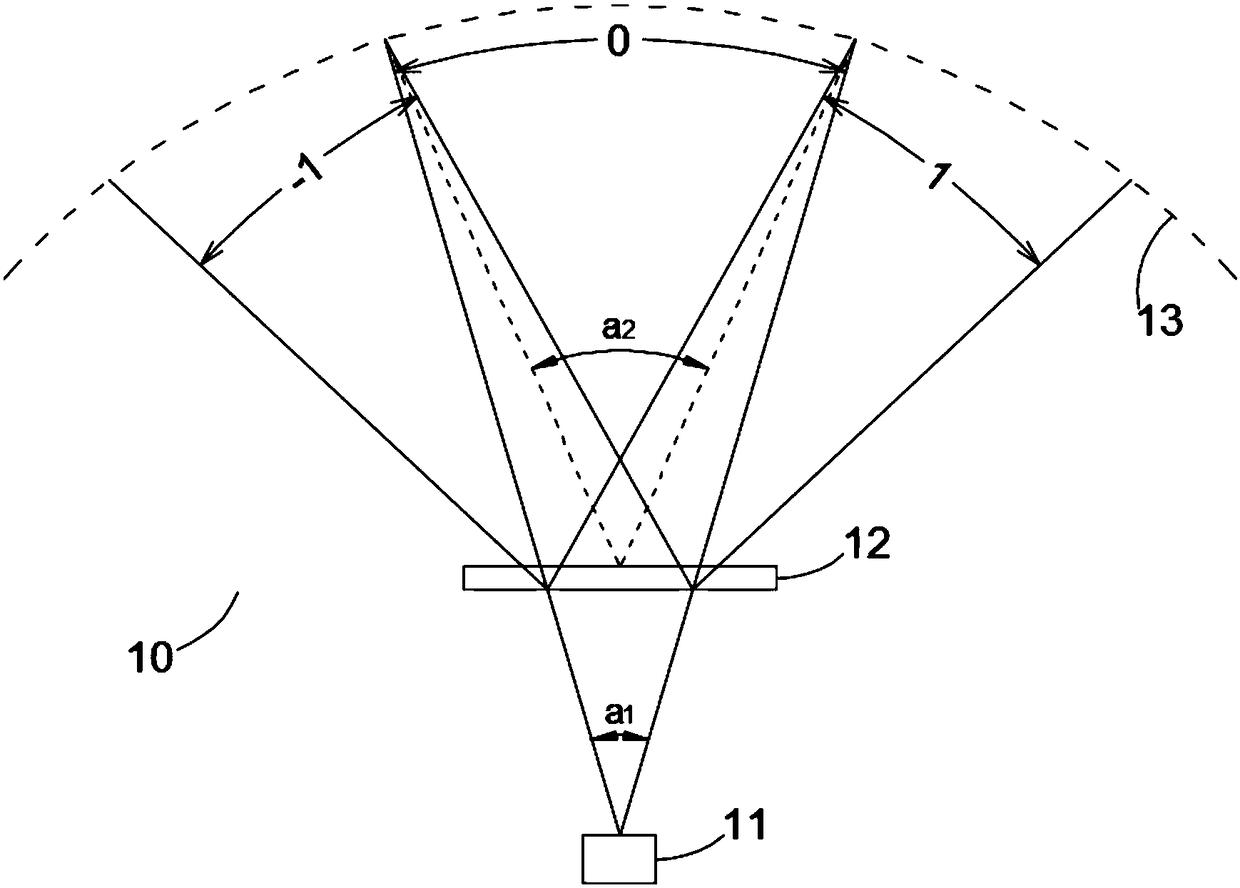

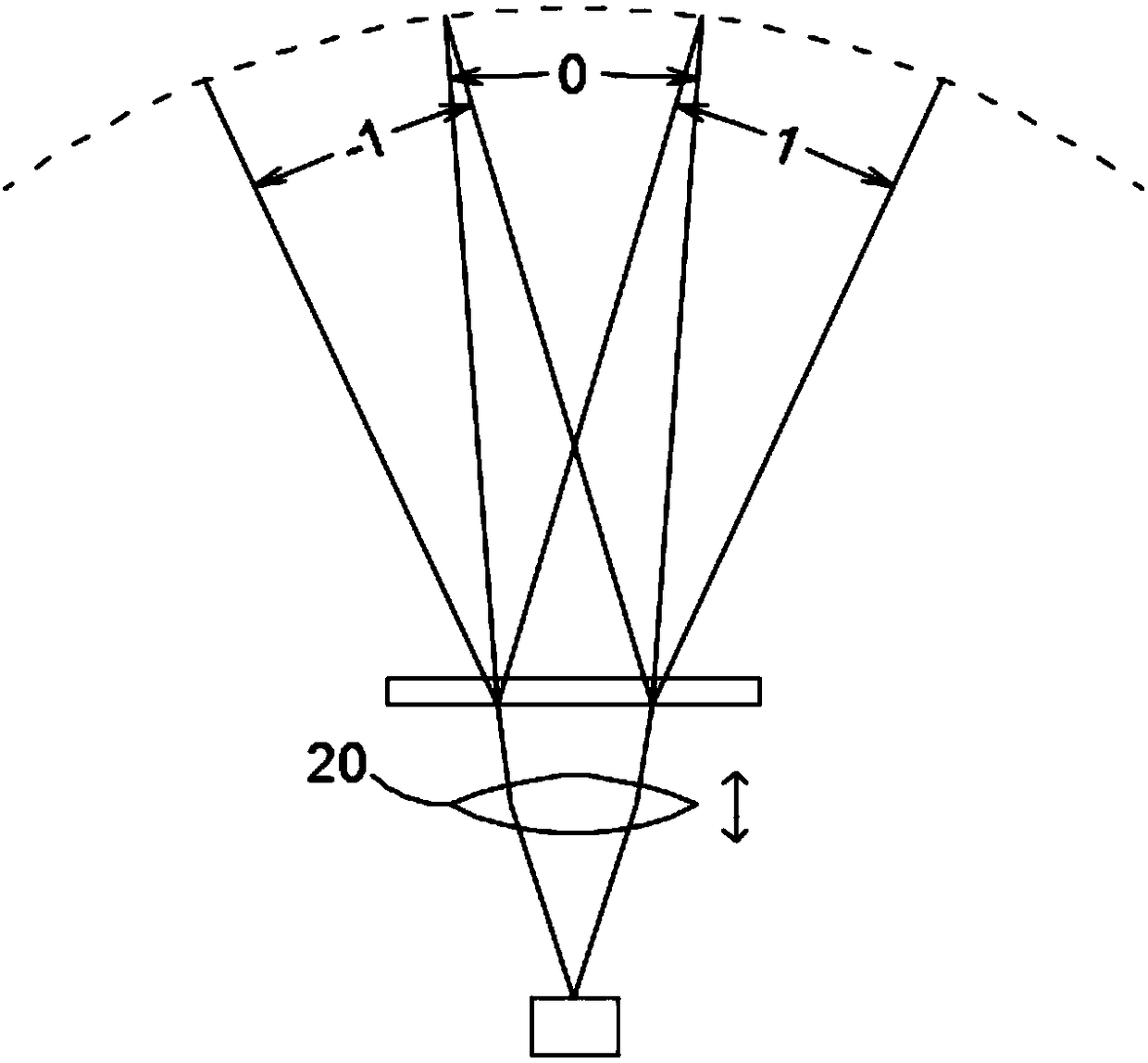

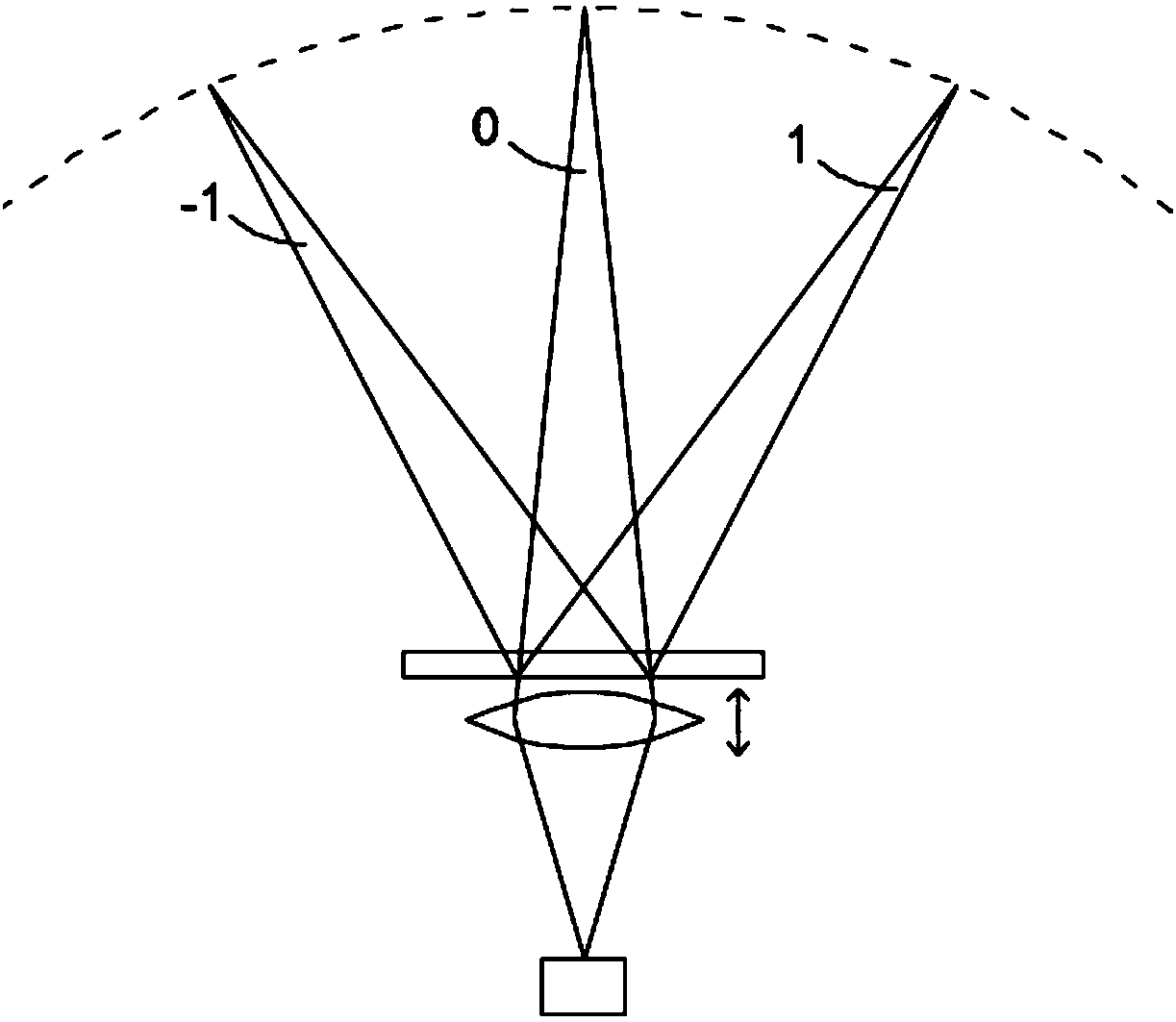

Illumination module

ActiveCN108332082ARealize the structureReduce volumeElectric circuit arrangementsElectric lightingLight beamOptoelectronics

The invention provides an illumination module which comprises a light source, a lens, a diffractive optical element and a processor, wherein the light source is used for transmitting light beams; thelens is used for diverging or converging the light beams; the diffractive optical element is used for duplicating and spreading the light beams to an illuminated space; and a processor is connected with and used for controlling one or more of the light source, the lens and the diffractive optical element, thereby achieving floodlight illumination or structured light illumination. According to theillumination module, one or more of the light source, the lens and the diffractive optical element can be regulated through the processor, thereby meeting the floodlight illumination or structured light illumination conditions, and achieving floodlight illumination or structured light illumination; the floodlight illumination function and the structured light projection function are integrated into one module and can be switched over as required at any time, thereby achieving floodlight illumination or structured light illumination; and furthermore, the illumination module has the characteristics of being small in size and low in power consumption, and is beneficial to the integration into intelligent equipment.

Owner:SHENZHEN ORBBEC CO LTD

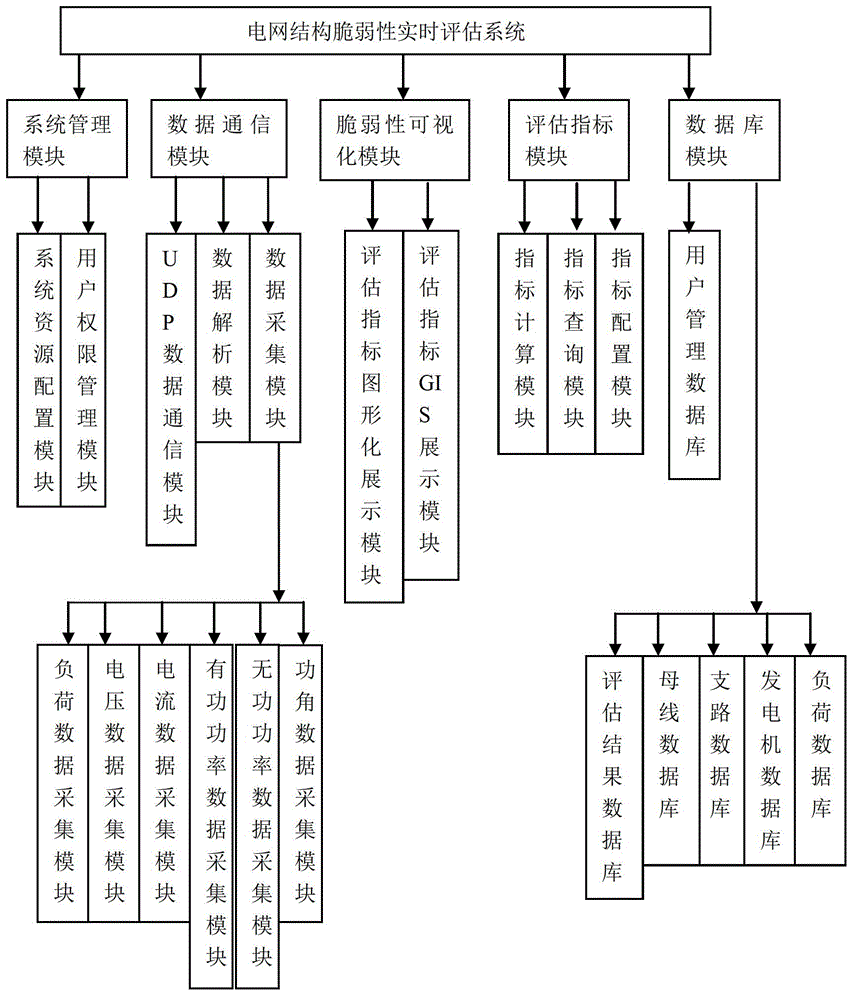

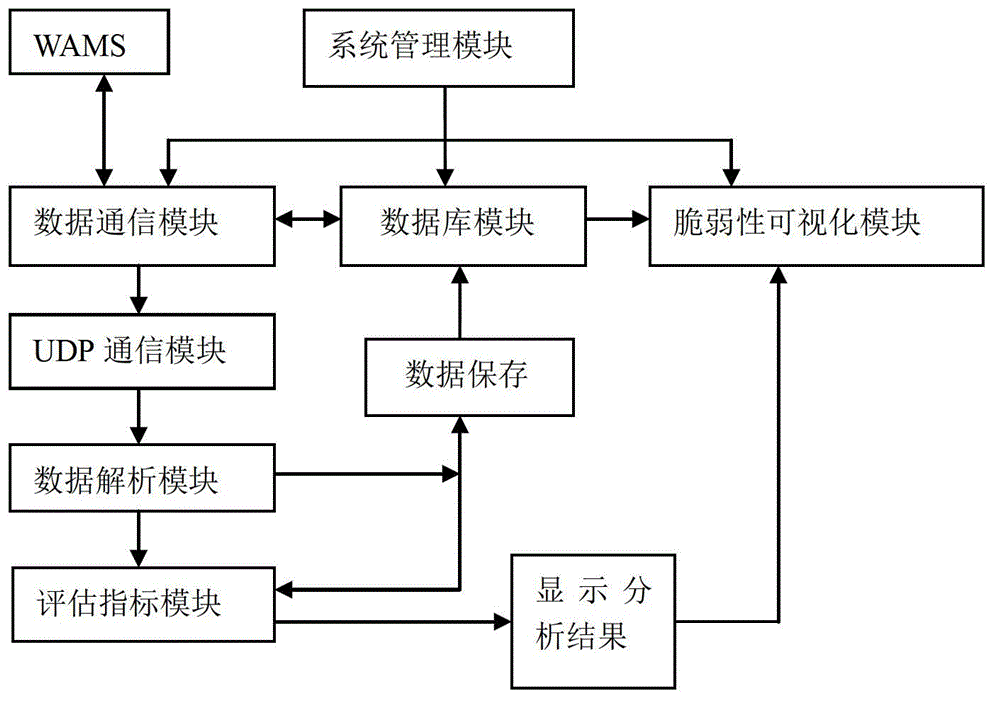

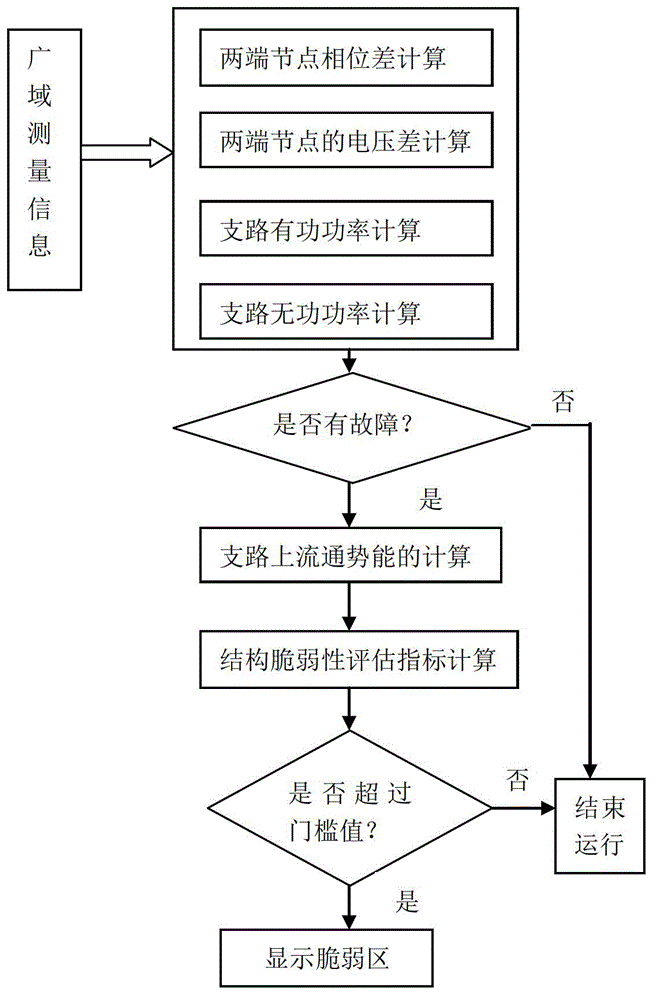

Electric network structure vulnerability real-time evaluation system

InactiveCN103150687ARealize the structureAchieve real-time recordingData processing applicationsState parameterSystems management

The invention relates to an electric network structure vulnerability quantification and visualization display technology and discloses an electric network structure vulnerability real-time evaluation system for carrying out real-time evaluation and analysis on the electric network structure vulnerability. The electric network structure vulnerability real-time evaluation system has the technical scheme that the electric network structure vulnerability real-time evaluation system comprises a system management module, a data communication module, a vulnerability visualization module, an evaluation indicating module and a database module. The electric network structure vulnerability real-time evaluation system is based on the wide area measurement information, the electric network structure vulnerability is evaluated in real time, and the functions of the structure vulnerability evaluation, the real-time display, the real-time recording and the like of operation parameters in an electric network are realized. On one hand, the receiving of dynamic data transmitted by a WAMS (wide area measurement system) is realized, in addition, the dynamic structure and the state information are analyzed, and the real-time recording of the electric network operation state parameter is realized; and on the other hand, the electric network structure vulnerability evaluation and result display is realized, and basis is provided for improving the safe operation of the electric network.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Antenna structure of electronic product with rotational structure

ActiveCN103682621ARealize the structureDoes not affect the development of thin and lightAntenna supports/mountingsAntenna equipments with additional functionsResonanceEngineering

The invention discloses an antenna structure of an electronic product with a rotational structure. The antenna structure comprises a mainboard and a rotational structure, wherein the mainboard is arranged in an electronic product shell; the rotational structure is coupled with the electronic product shell through a revolving shaft, and comprises a metal part which can be taken as an antenna radiator; the antenna radiator is connected with a radiofrequency connector arranged on the mainboard through a revolving shaft. The metal part in the rotational structure is taken as the antenna radiator, and the antenna radiator and the radiofrequency connector arranged on the mainboard of the electronic product are connected with a feed signal, thereby forming an antenna and producing resonance. The antenna radiator is arranged by fully utilizing an existing metal structure in the rotational structure of the electronic product without influencing the lightening and thinning development of the electronic product. Different types of antennae can be arranged under the condition that the rotational structure is a metallic or nonmetallic structure without being limited by the material of the rotational structure.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

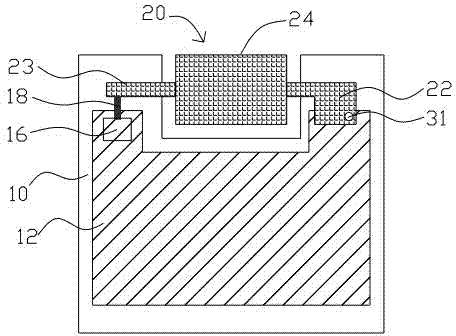

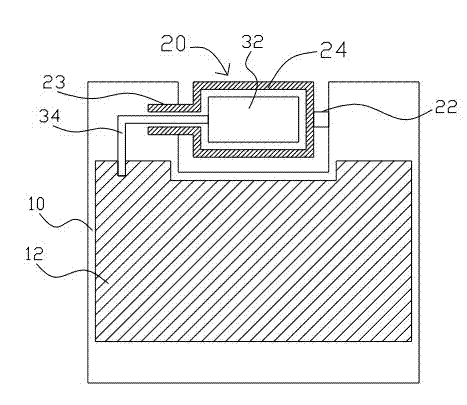

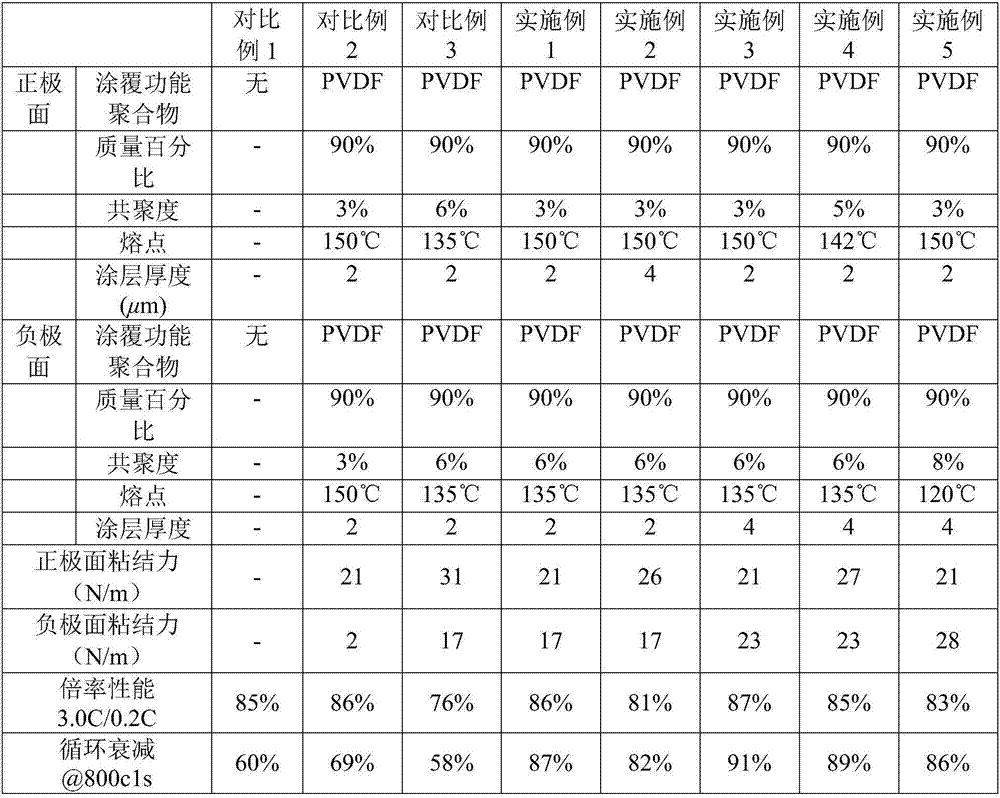

Organic functional porous isolating membrane, preparation method and lithium ion battery

ActiveCN107123767AImprove adhesionExcellent rate performanceCell seperators/membranes/diaphragms/spacersSecondary cellsSodium-ion batteryLong term cycling

The invention discloses an organic functional porous isolating membrane, a preparation method and a lithium ion battery, and aims to the solve the problem that a function of a coating layer is influenced caused by different binding effects when the surfaces of two coating layers of the same specification of an isolating membrane are laminated and glued with positive and negative plates of different physical properties of a battery. According to the main points of the technical scheme, the organic functional porous isolating membrane comprises a porous base material and organic functional coating layers attached to two surfaces of the porous base material; and each organic functional coating layer comprises organic functional polymer polyvinylidene fluoride, an aqueous polymer thickening agent, and an aqueous polymer binder. According to the different characteristics of the positive and negative electrode materials of the lithium ion battery corresponding to the two surfaces of the porous base material, the organic functional polymer polyvinylidene fluoride with different copolymerization degrees and fusing temperatures can be selected on the surfaces of the isolating membranes of the corresponding positive and negative electrodes, so that the safety performance and the long-term cycling stability of the battery can be improved.

Owner:深圳市旭然电子有限公司

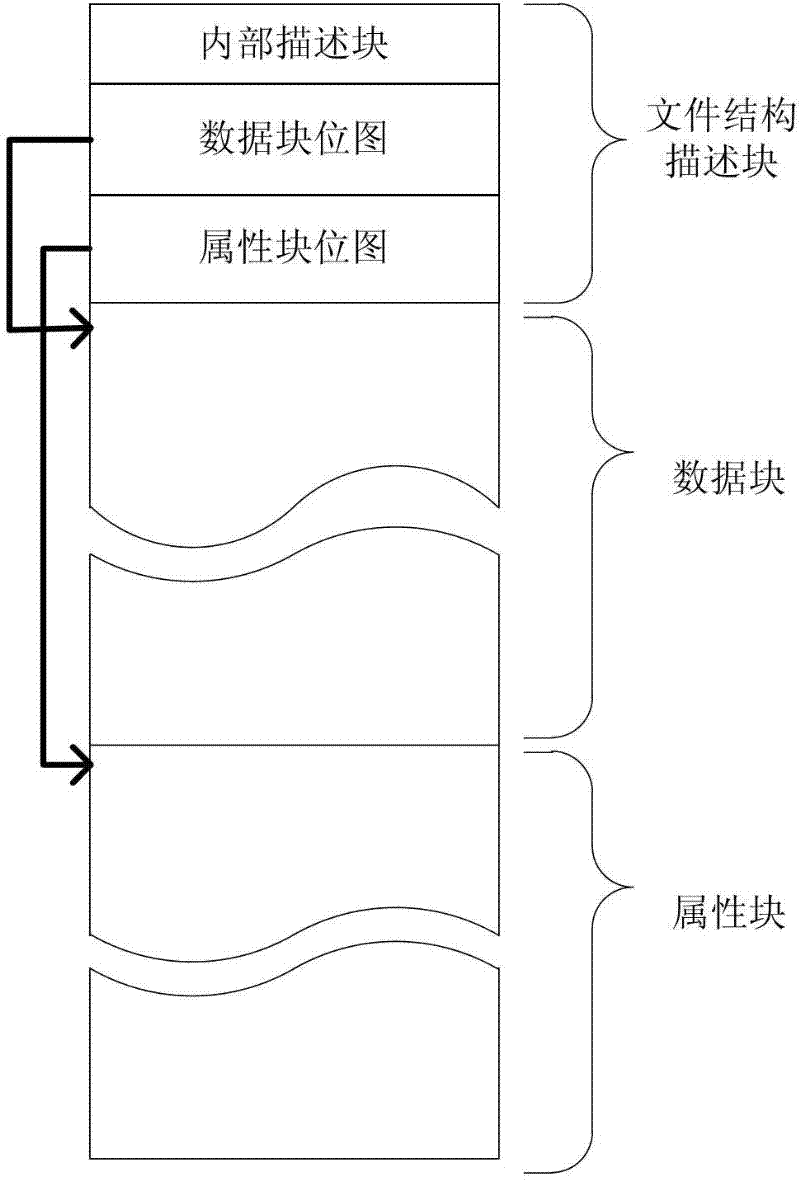

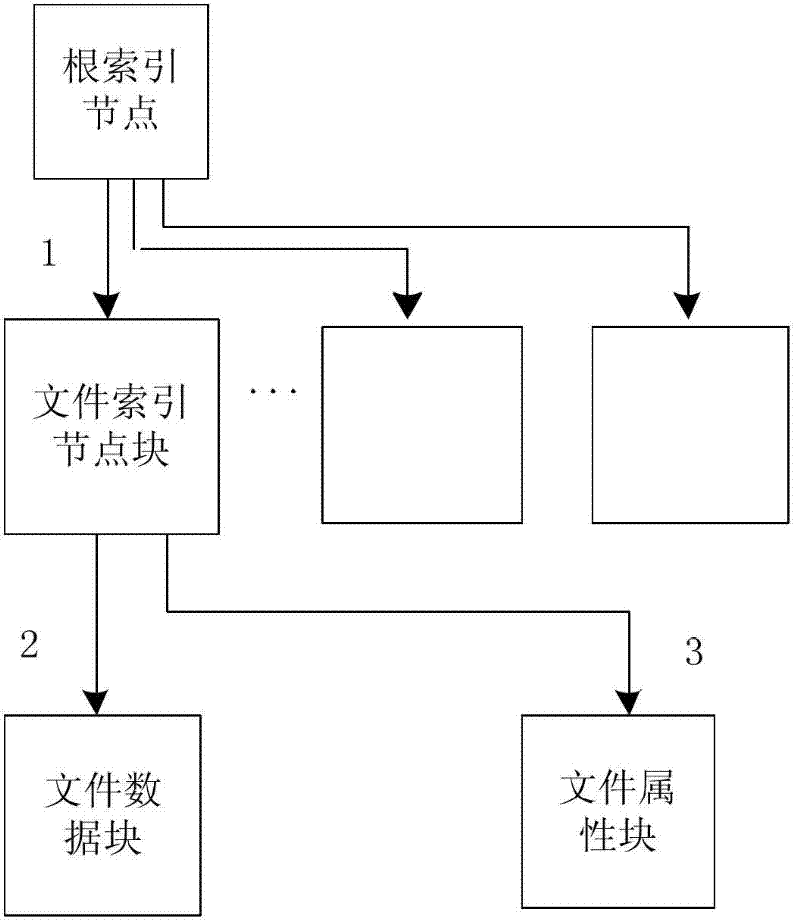

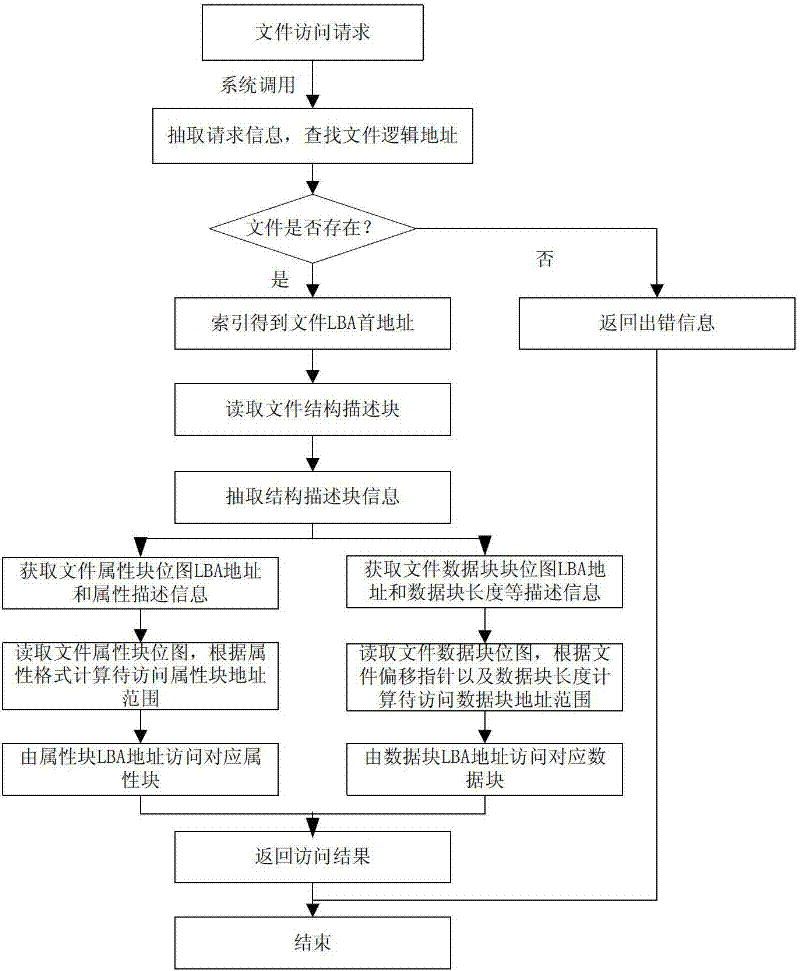

Method for organizing and managing file content and metadata

ActiveCN102693286ASupport storageSupport scalabilitySpecial data processing applicationsComputer data storageUnstructured data

The invention belongs to the field of computer data storage, and particularly relates to a method for organizing and managing file content and metadata. The method is characterized in that the self organization and the self management of the metadata are realized in a file, so that the file has a self-describing property, and trust on a specific format, a database and the like is eliminated. Compared with an original file, the file in the method is additionally provided with a file structure description block and a file attribute block. A user sends a file access request to find a corresponding target file. The information of the file structure description block is extracted, and the file content or the file attribute is read or written by a data block bitmap and an attribute block bitmap in the information of the file structure description block according to the choice of the user. With the method disclosed by the invention, attribute extension and semantic association can be conveniently supported to provide support for information retrieval and a semantic structure is supported, and therefore the efficient file retrieval of a huge quantity of unstructured data can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

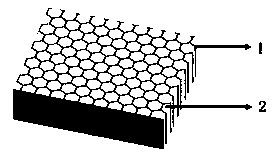

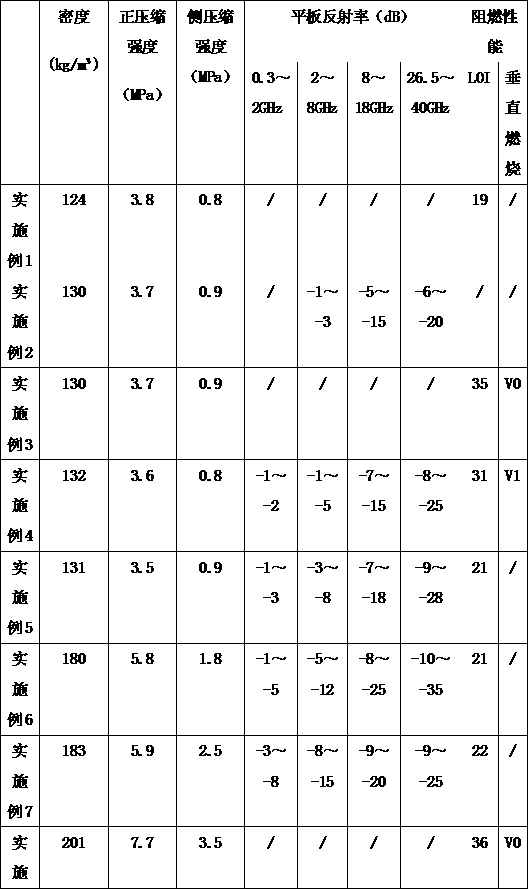

A method for preparing a reinforced polymethacrylimide foam composite material

The invention relates to the field of novel material preparation and particularly relates to a method for preparing structure-function integrated foam. The objective of the invention is to provide a honeycomb reinforced polymethacrylimide foam composite material. The composite material includes polymethacrylimide prefoam particles, a functional filler, a guanidine-based impregnating agent, an adhesive and honeycomb. Through filling with particle fillers having different functions and honeycomb having different specifications and different materials, mechanical properties of the composite material are enhanced, and the composite material is endowed with electric conduction, wave absorption, flame retardance, shock absorption and other functions. Mechanical properties of foam can be enhanced, and the composite material is endowed with excellent temperature resistance, excellent mechanical properties, electric conduction, wave absorption, flame retardance, shock absorption and other functions.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

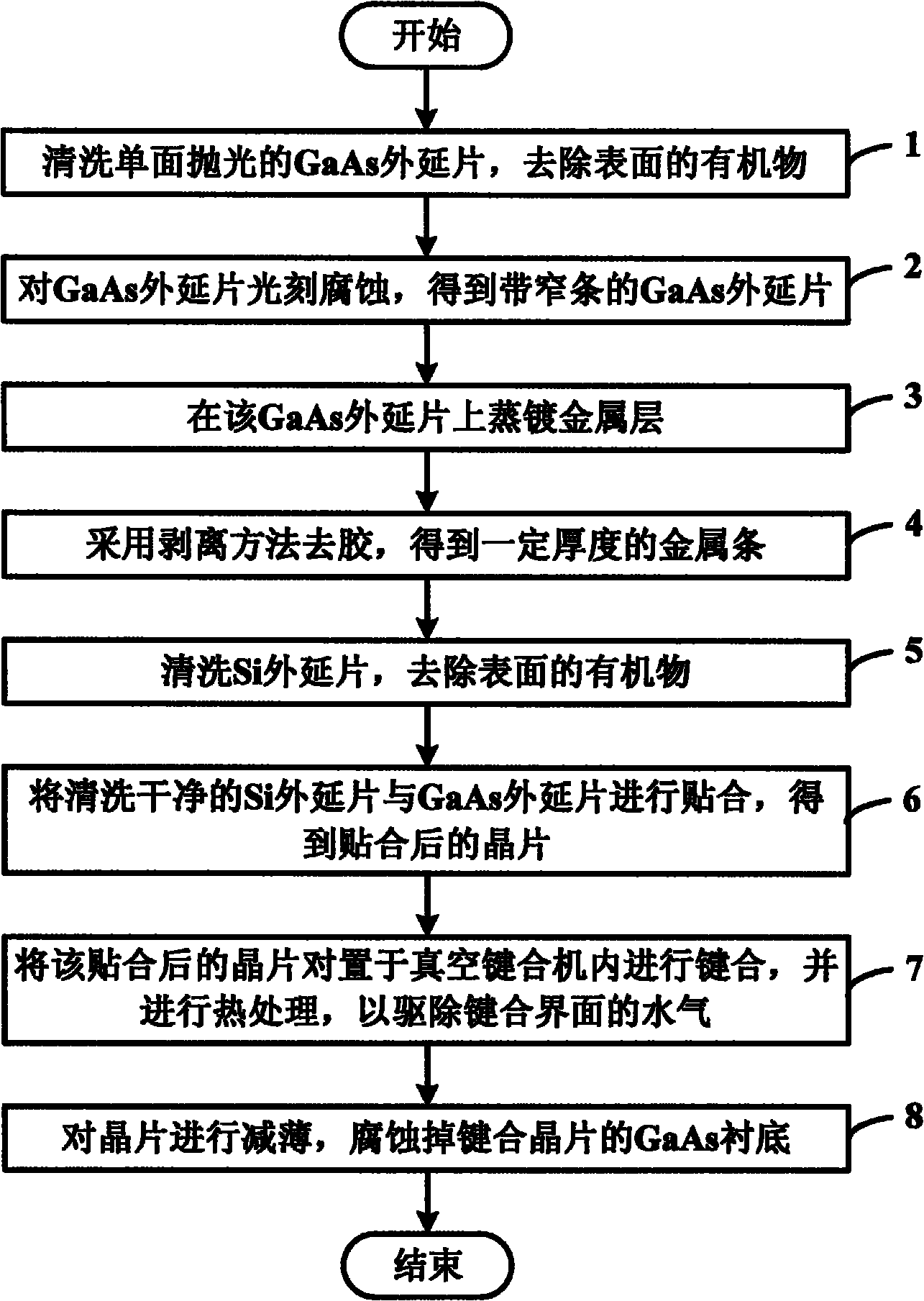

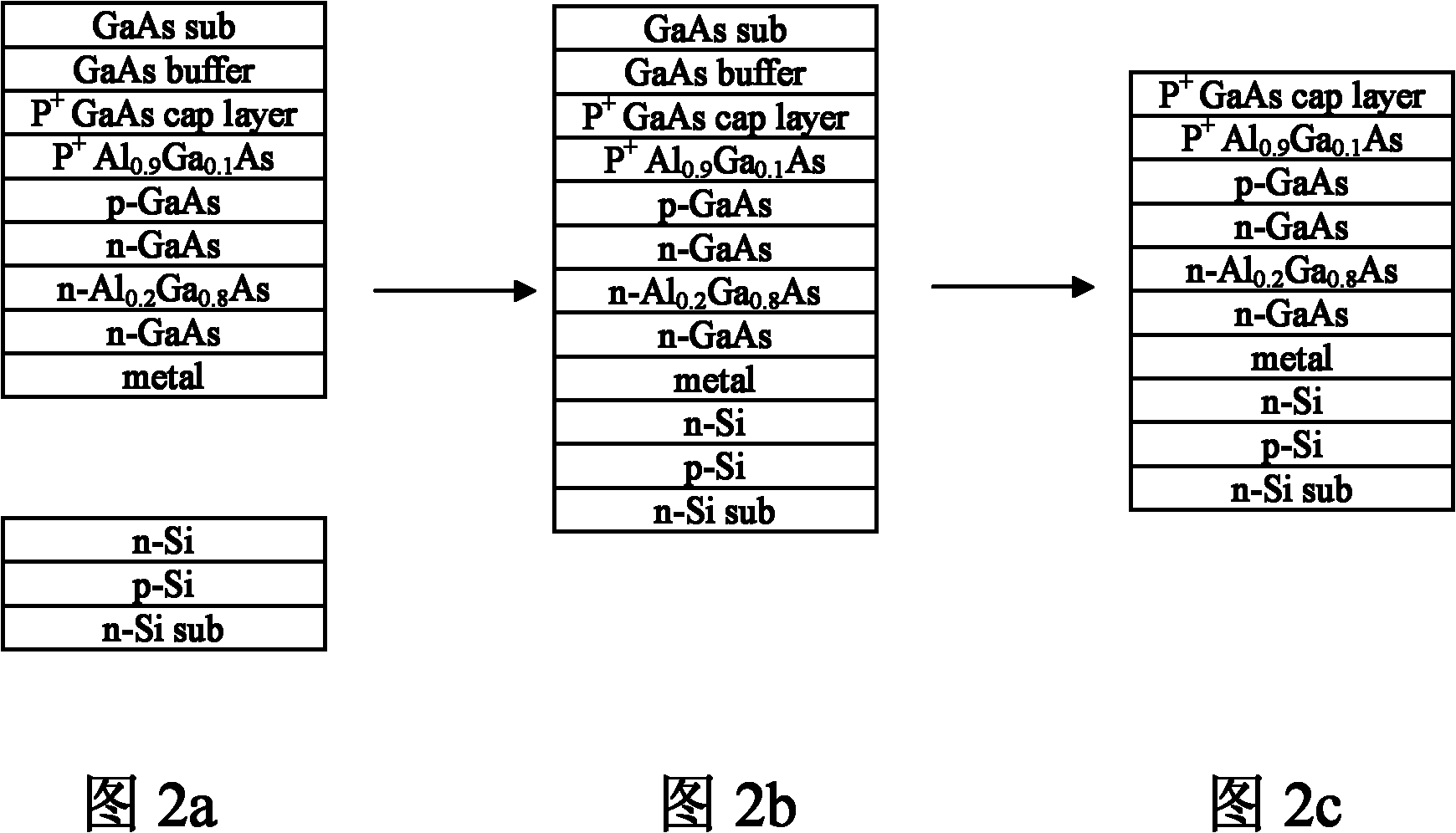

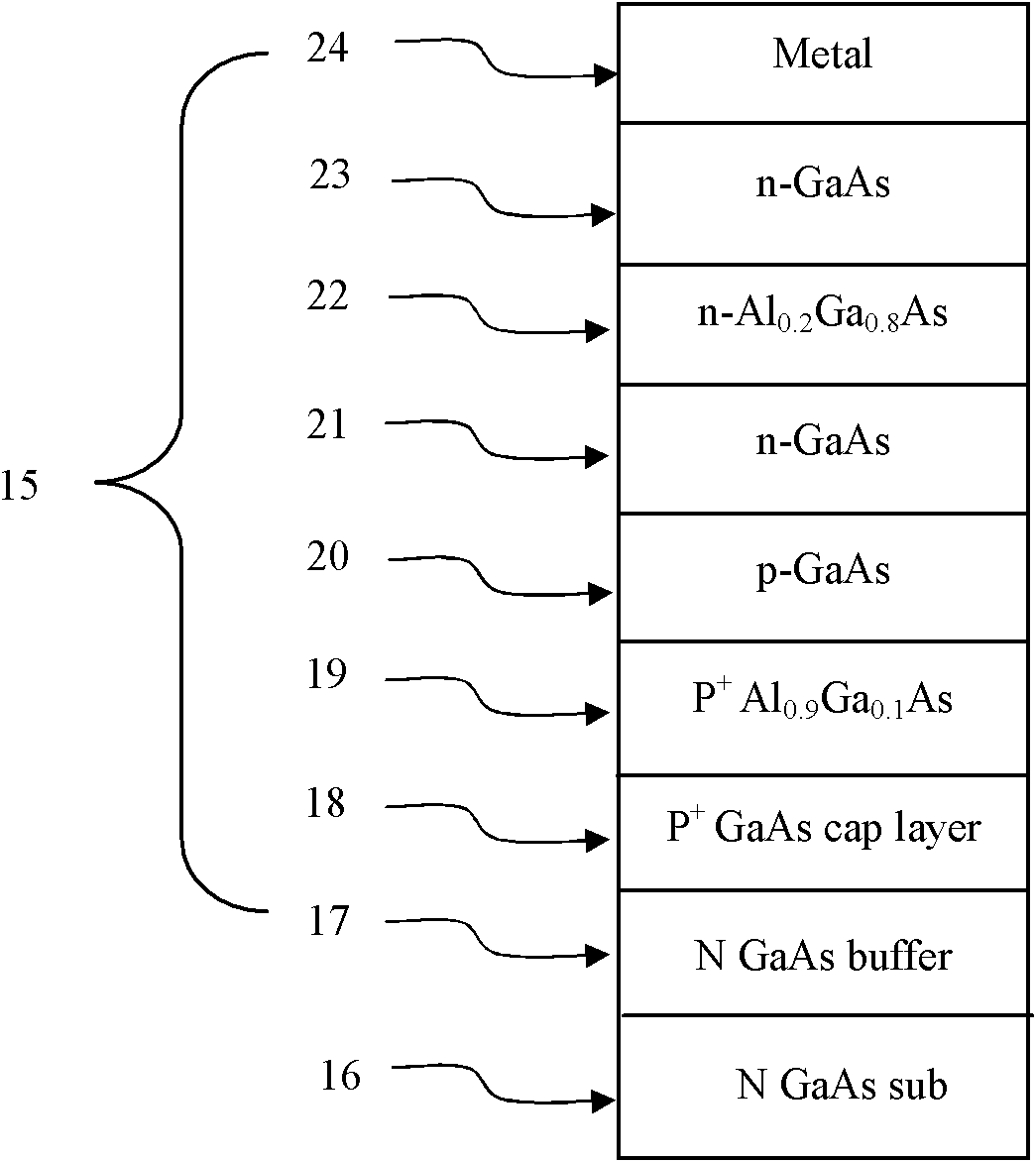

Method for performing low-temperature metal bonding on GaAs and Si

InactiveCN102110594ARealize the structureAchieve bondingFinal product manufactureSemiconductor/solid-state device manufacturingMetal stripsBond interface

The invention discloses a method for performing low-temperature metal bonding on GaAs and Si. The method comprises the following steps of: cleaning a single-side polished GaAs epitaxial wafer to remove organic substances on the surface of the wafer; performing photoresist etching on the GaAs epitaxial wafer to obtain the GaAs epitaxial wafer with a narrow strip; performing evaporation on the GaAs epitaxial wafer to form a metal layer; removing a photoresist by a stripping method to obtain a metal strip with a certain thickness; cleaning a Si epitaxial wafer to remove organic substances on the surface of the wafer; treating the surface of the Si epitaxial wafer by using H2SO4 solution and RCAl solution and attaching the cleaned Si epitaxial wafer to the GaAs epitaxial wafer so as to obtain an attached wafer; oppositely arranging the attached wafer in a vacuum bonding machine for bonding and performing thermal treatment to remove vapor of a bonding interface; and thinning the bound wafer and corroding off the GaAs substrate of the bound wafer. By the method, the low-temperature metal bonding of the GaAs and the Si is realized; and the method can be extended to the bonding between two III-V groups (or materials such as Si, Ge and the like of an IV group).

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

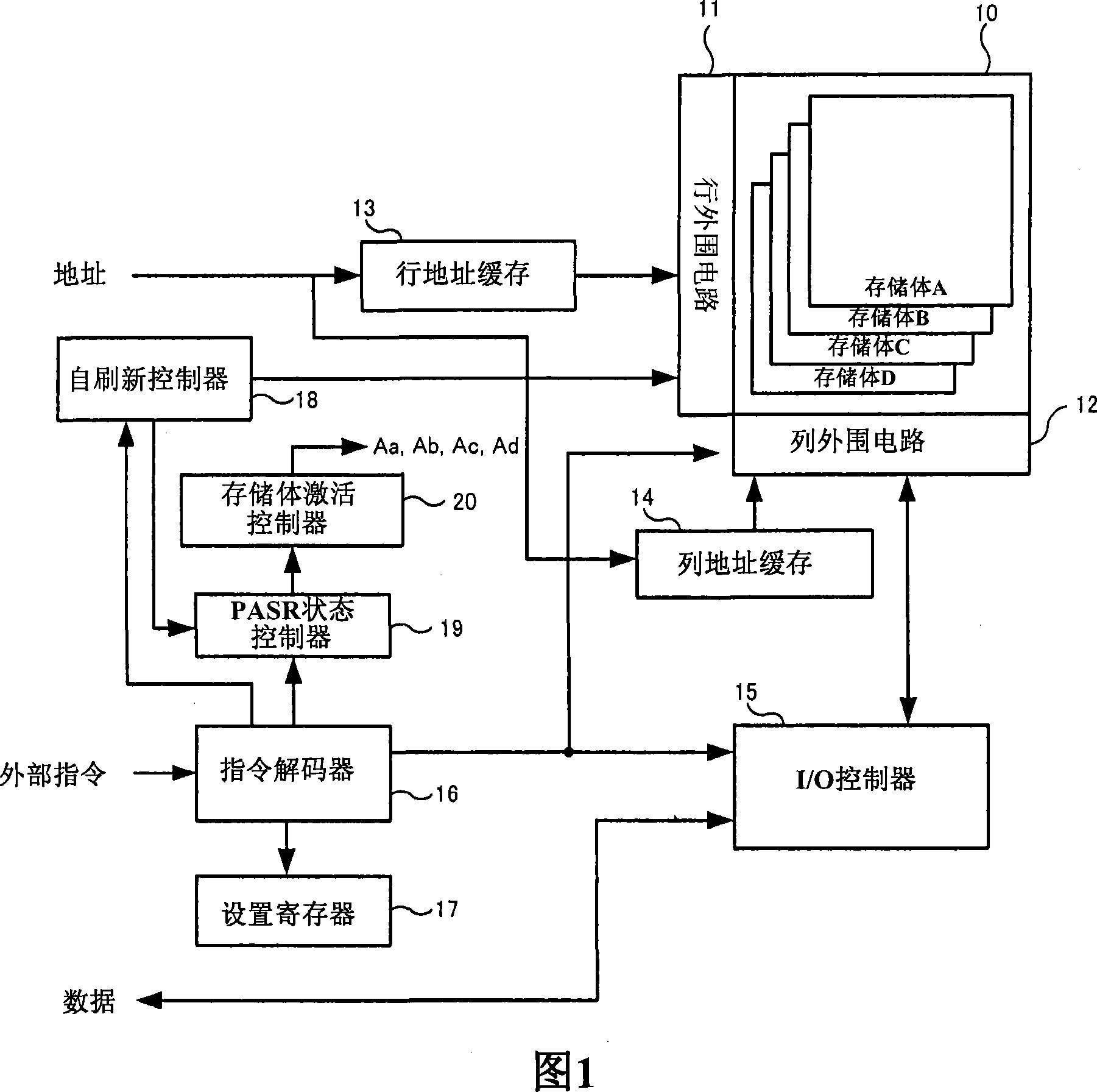

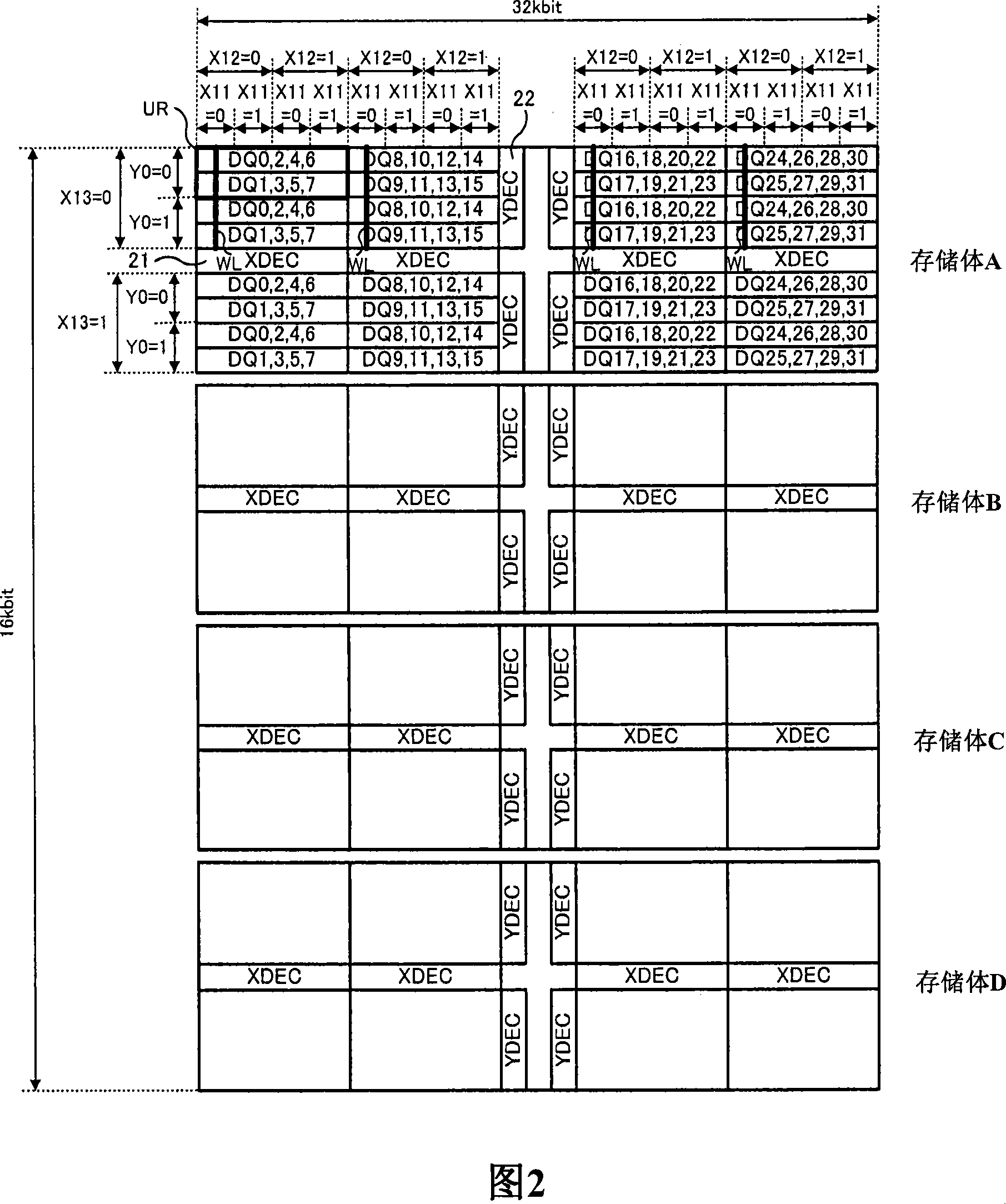

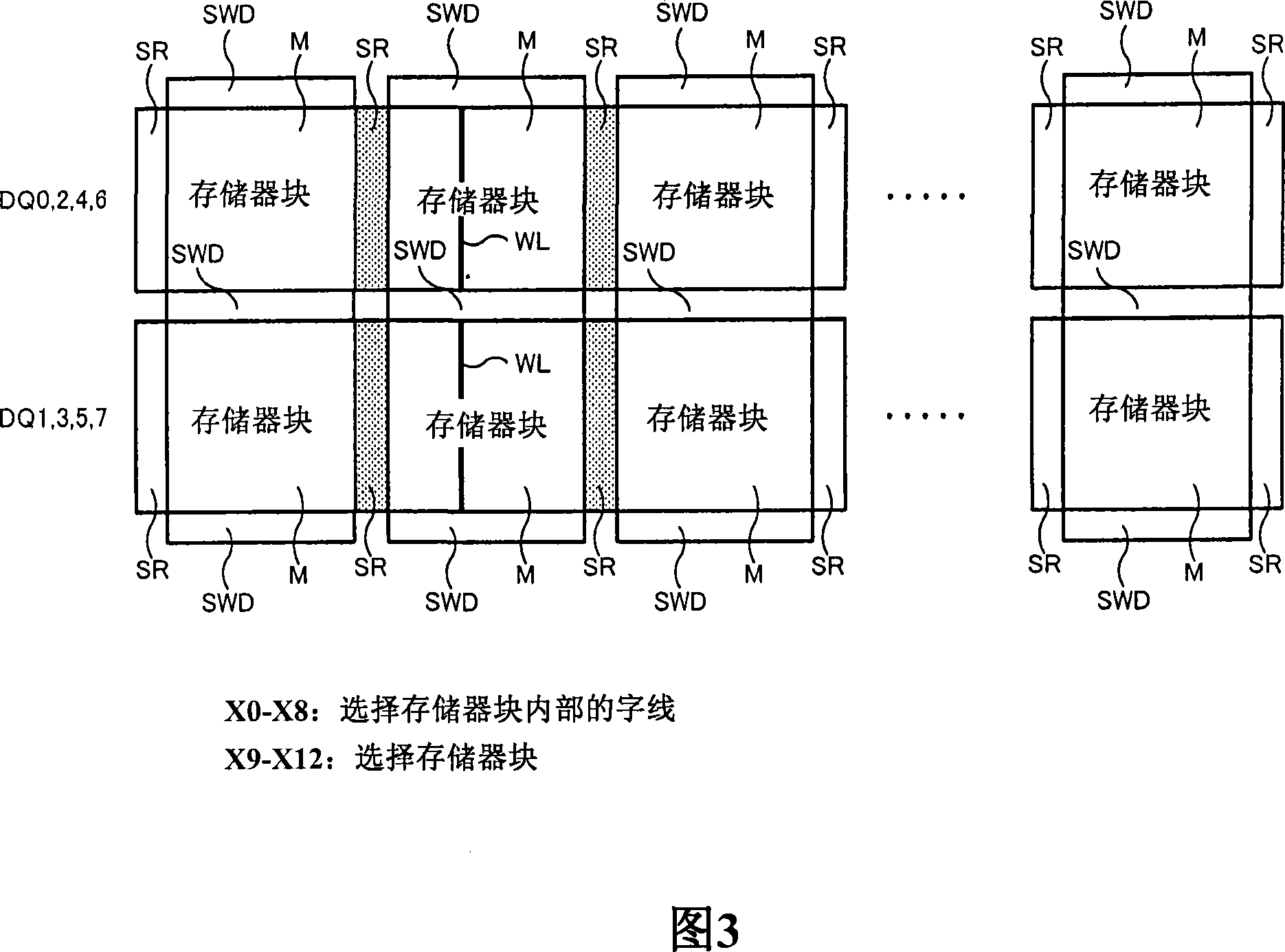

Semiconductor storing device, semiconductor device, storing system and renovating control method

A semiconductor memory device includes a memory cell array, wherein the memory cell is divided into a plurality of memory bodies; caches, each of which is used to store data of word line selected by line address; set registor, for setting data retention capacity so as to ensure a retention region for storing data during self-refresh cycle and a non retention region for non storing data during self-refresh cycle locate in a same memory bank; a refresh controller, for exporting refreshing line address with prescribed distance during self refreshing cycle and implementing refreshing operation to selective word line corresponding to the line address in enabled memory bank; and memory bank controller, for activating the memory bank when the selected work line is included in the retention region, and activating all memory banks when the selected work line is included in the non retention region.

Owner:ELPIDA MEMORY INC

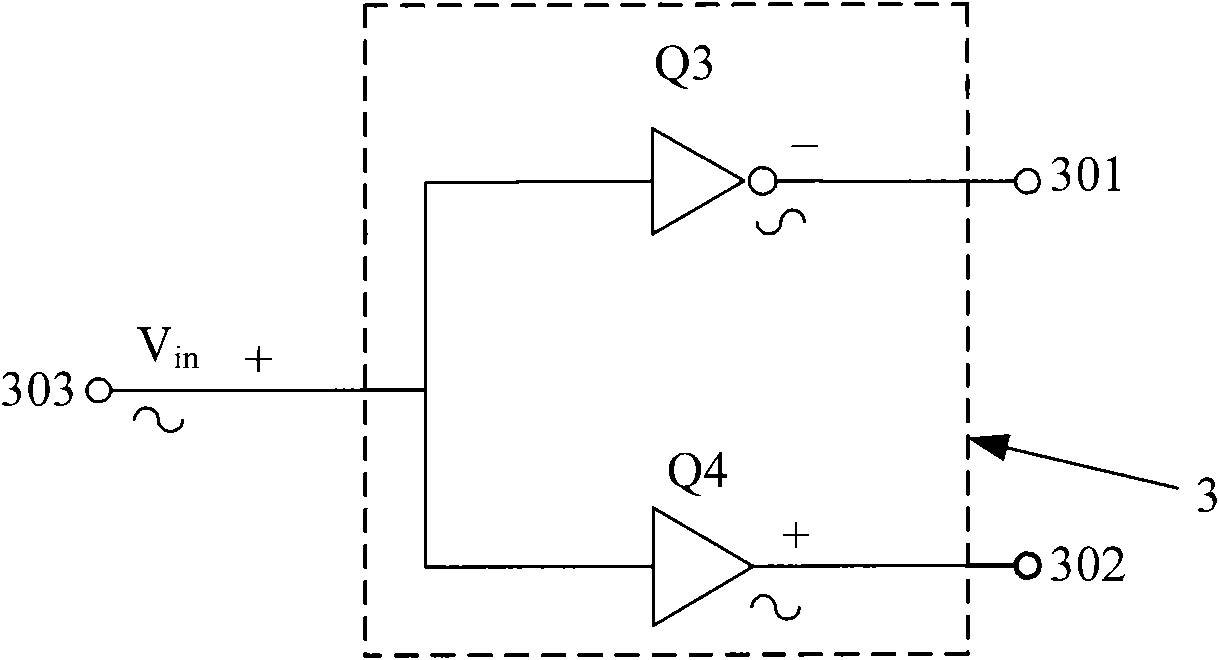

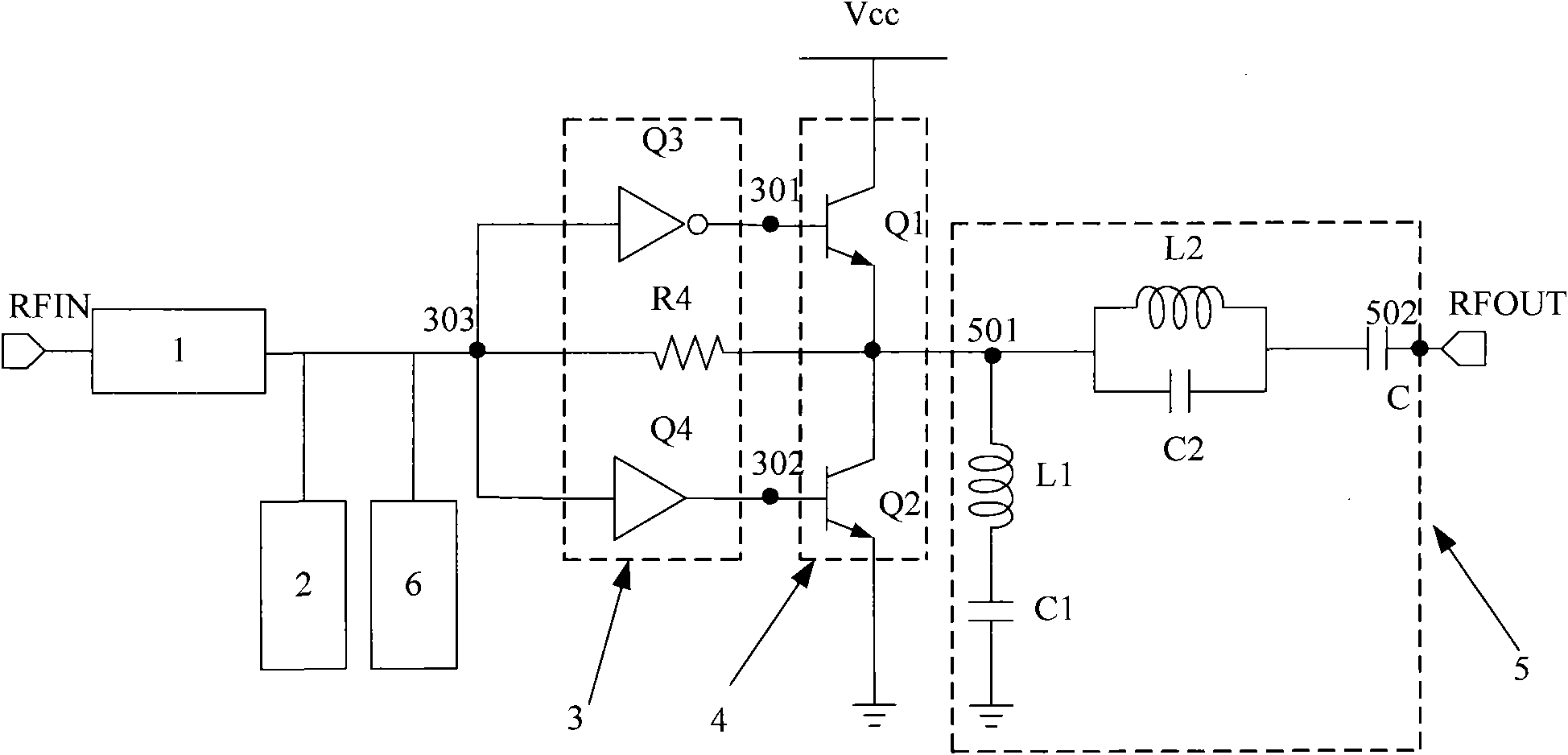

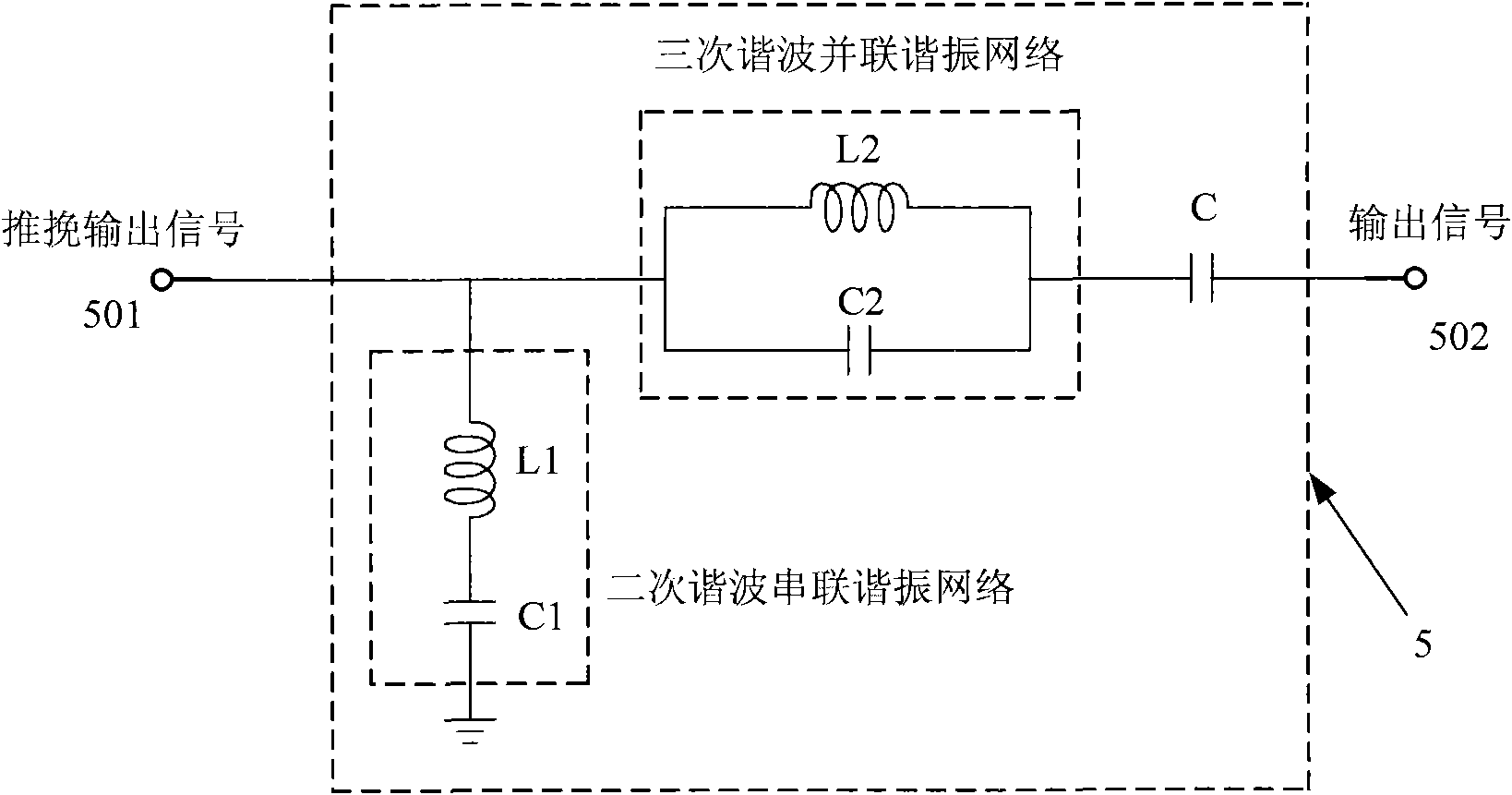

Push-pull radio-frequency power amplifier with improved linearity and efficiency

InactiveCN101888213ARealize the structureImprove power added efficiencyAmplifier modifications to reduce non-linear distortionHigh frequency amplifiersCapacitanceCommon emitter

The invention discloses a push-pull radio-frequency power amplifier with improved linearity and efficiency, comprising an input matching network, an output matching network and a power amplification circuit, wherein the power amplification circuit comprises a first-stage amplification circuit and a second-stage amplification circuit, the first-stage amplification circuit is connected with the input matching network, the second-stage amplification circuit is connected between the first-stage amplification circuit and the output matching network, and the second-stage amplification circuit is an NPN-NPN push-pull amplification circuit composed of a second common collector amplifying tube and a second common-emitter amplifying tube. The output matching network is an output filter matching network which comprises a secondary harmonic series resonance network, a third harmonic series resonance network and a stopping condenser, wherein the secondary harmonic series resonance network is connected between the output end of the second-stage amplification circuit and the ground, the third harmonic series resonance network is connected between the output end of the secondary harmonic series resonance network and the stopping condenser, and the stopping condenser is connected between the third harmonic series resonance network and the power amplifier. The invention improves the additional efficiency of the radio-frequency power amplifier and improves the linearity of the radio-frequency power amplifier.

Owner:SUZHOU INNOTION TECH

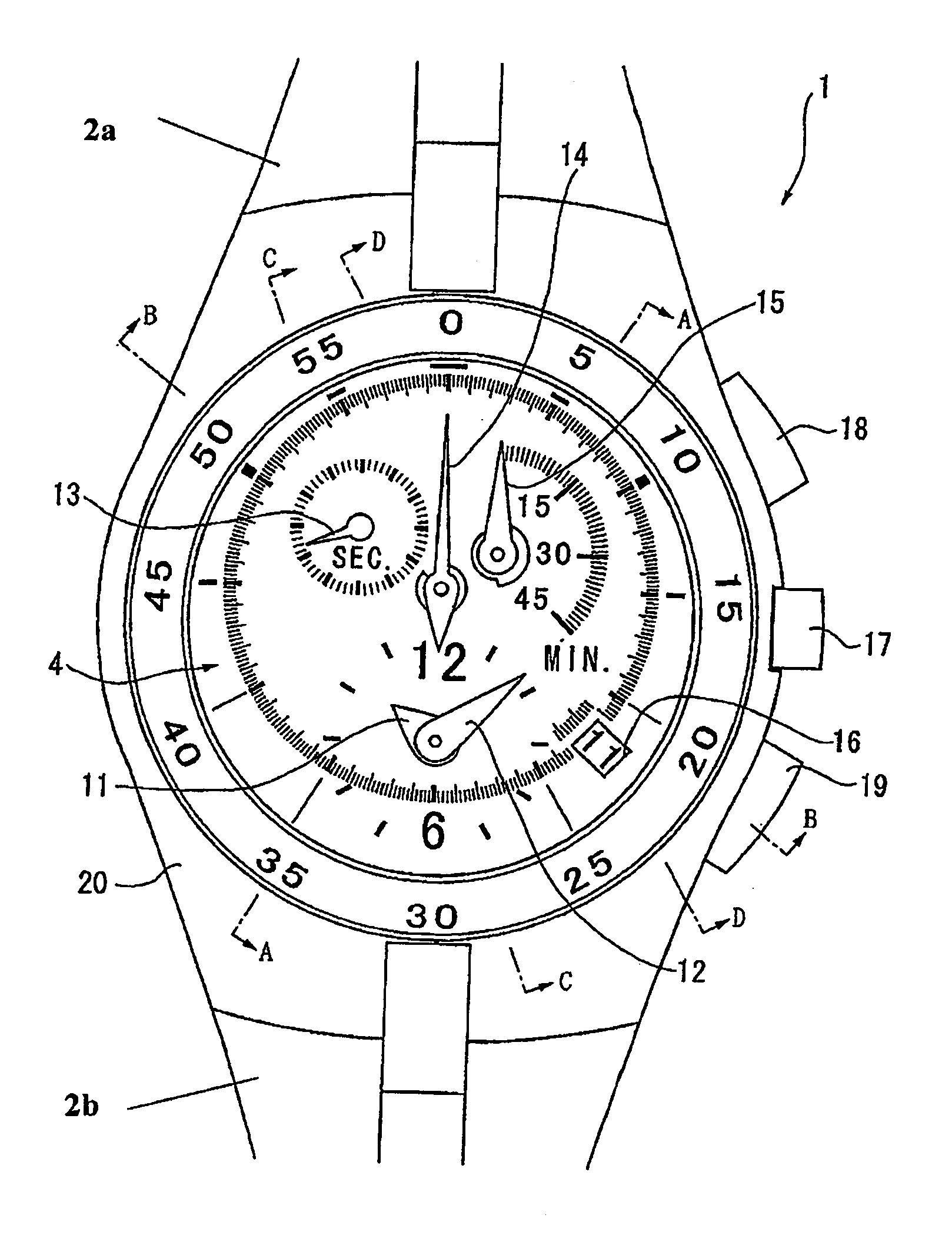

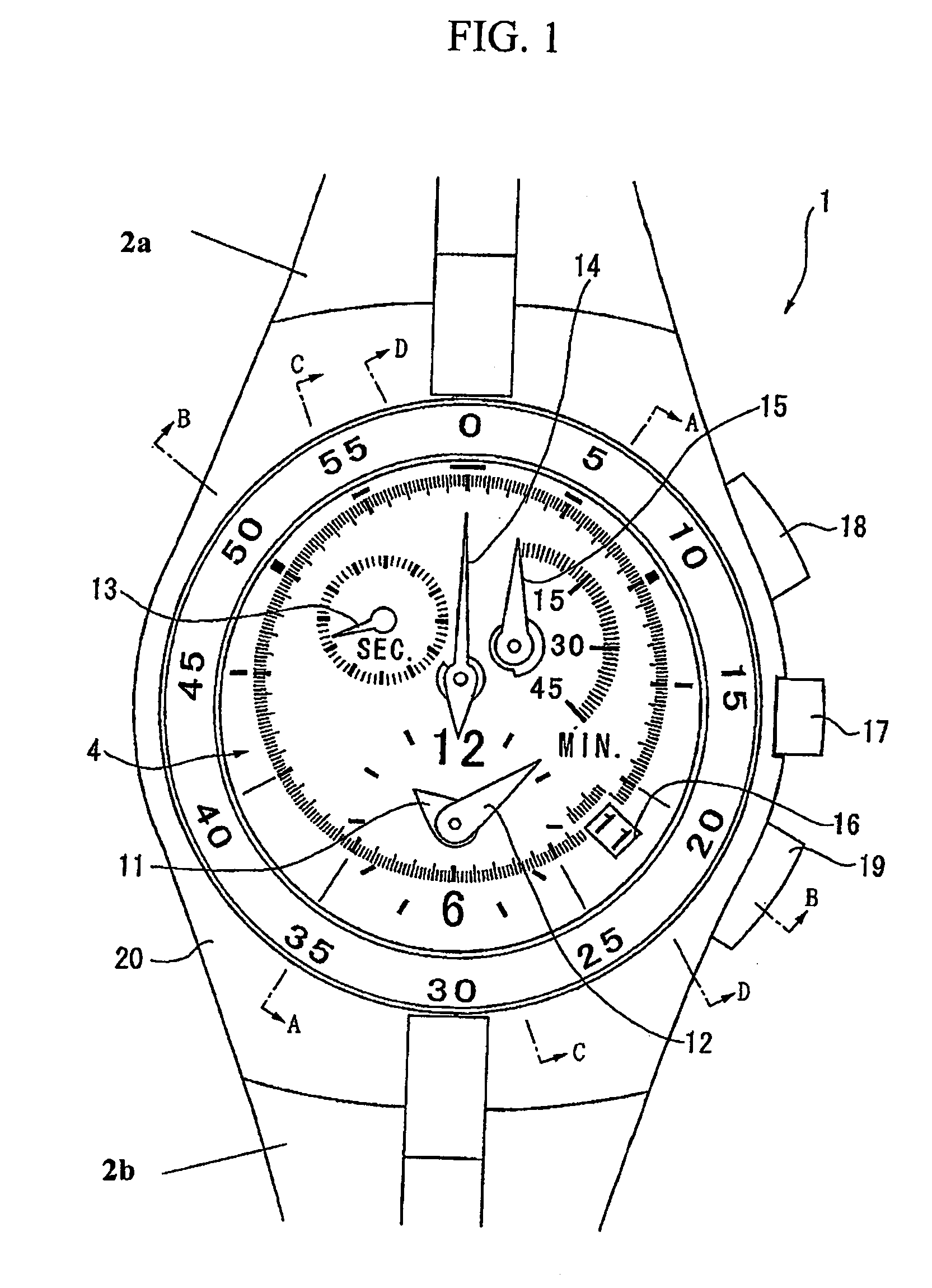

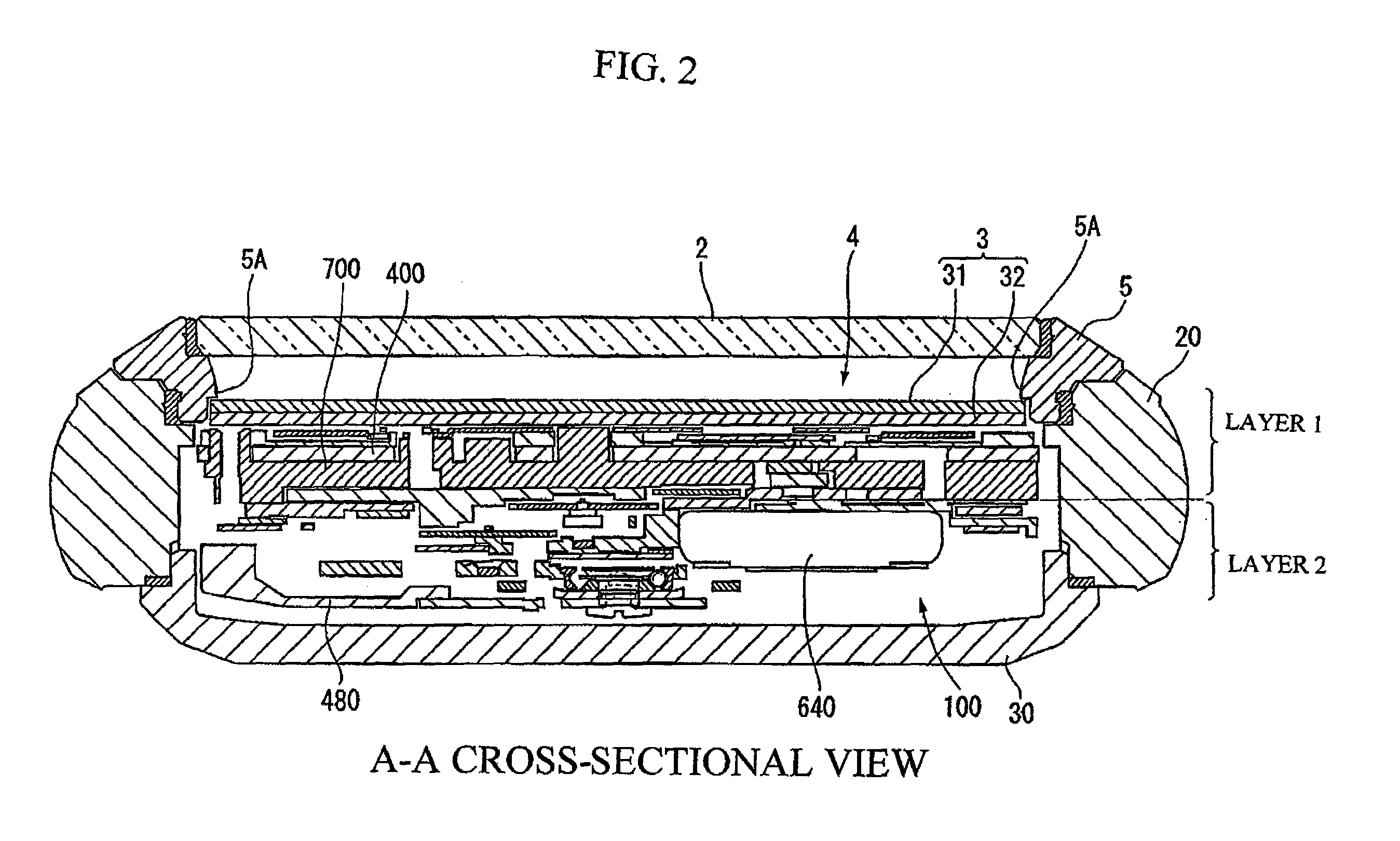

Multifunctional watch

InactiveUS7170826B2Increase awarenessEasy to assembleVisual indicationElectric indicationVisibilityEngineering

There is provided a multifunction timepiece wherein the visibility of pointers can be improved, and increases in the thickness of the timepiece can be reduced. This timepiece includes a dial, an hour hand, a minute hand, a pointer, and a movement. The dial has a dial cover and a time display section on the inner periphery thereof. The hour hand is mounted on the time display section and has an hour hand rotating shaft disposed at a different position from the center position of the time display section. The minute hand is mounted on the time display section and has a minute hand rotating shaft disposed at a different position from the center position of the time display section. The pointer is mounted on the time display section and has a pointer rotating shaft. The dimension A from the pointer rotating shaft to the tip of the pointer is greater than the dimension B from the minute hand rotating shaft to the tip of the minute hand. The pointer rotating shaft is disposed at a position away from the hour hand rotating shaft by a distance less than dimension A and greater than dimension B. The movement drives the hour hand, the minute hand, and the pointer.

Owner:SEIKO EPSON CORP

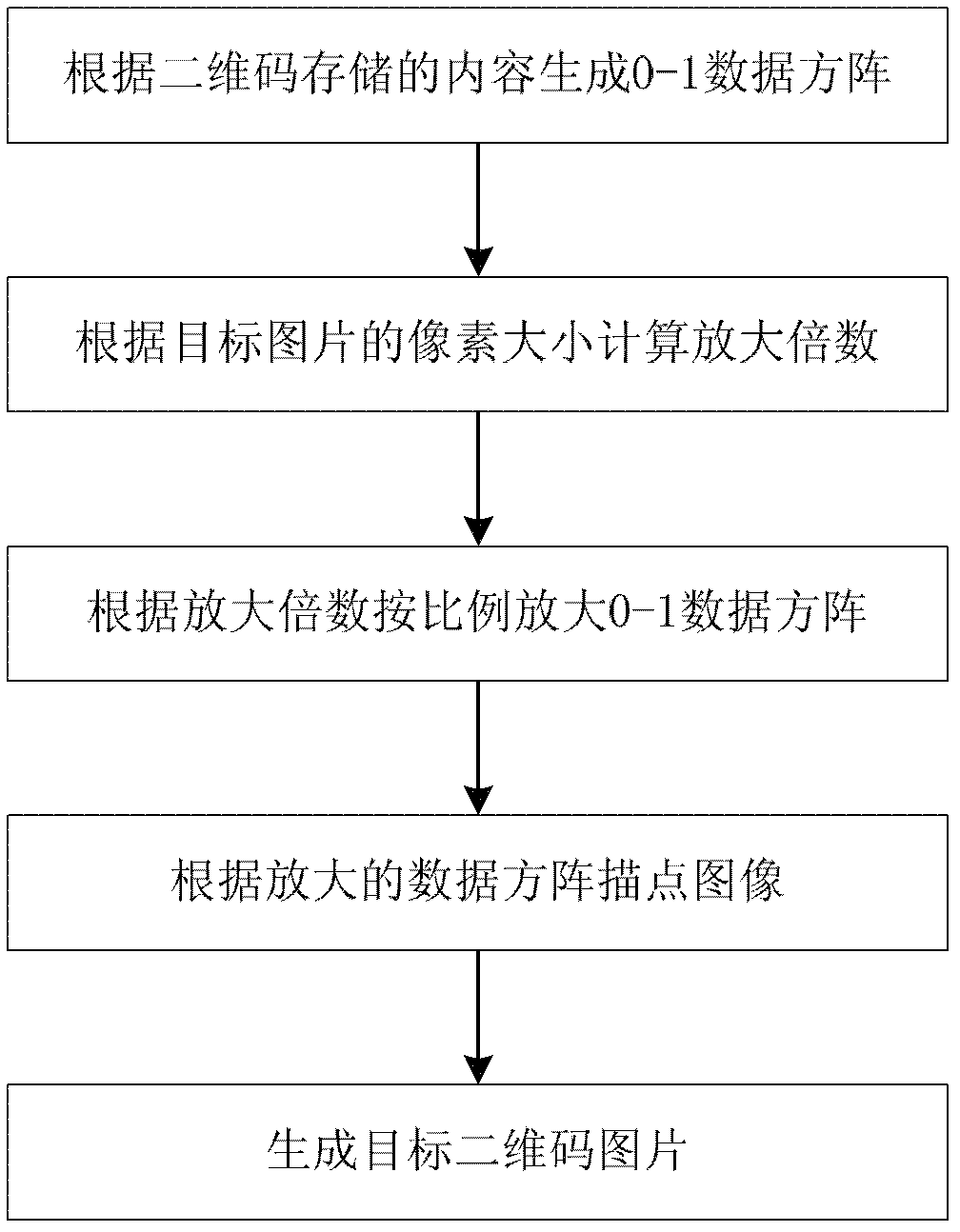

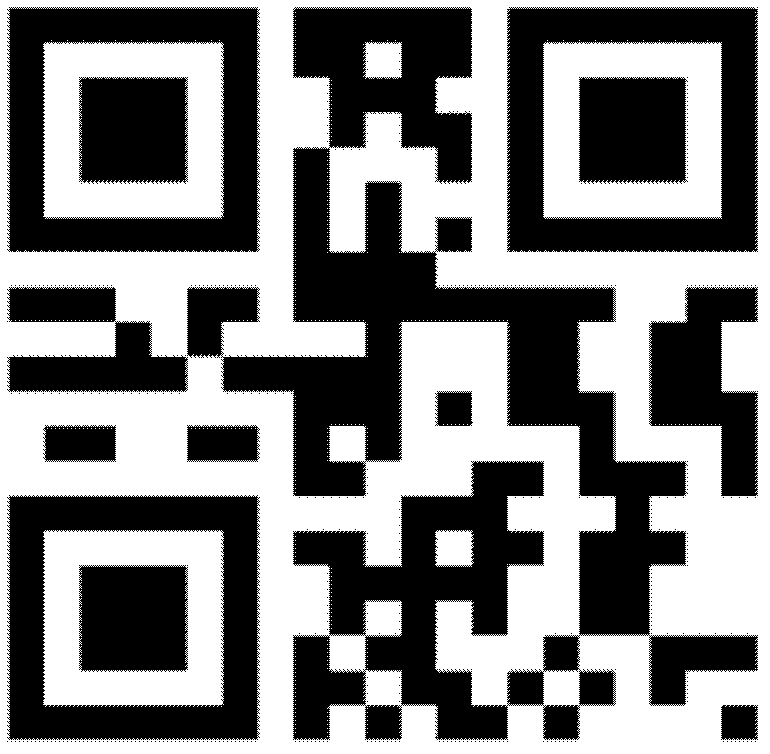

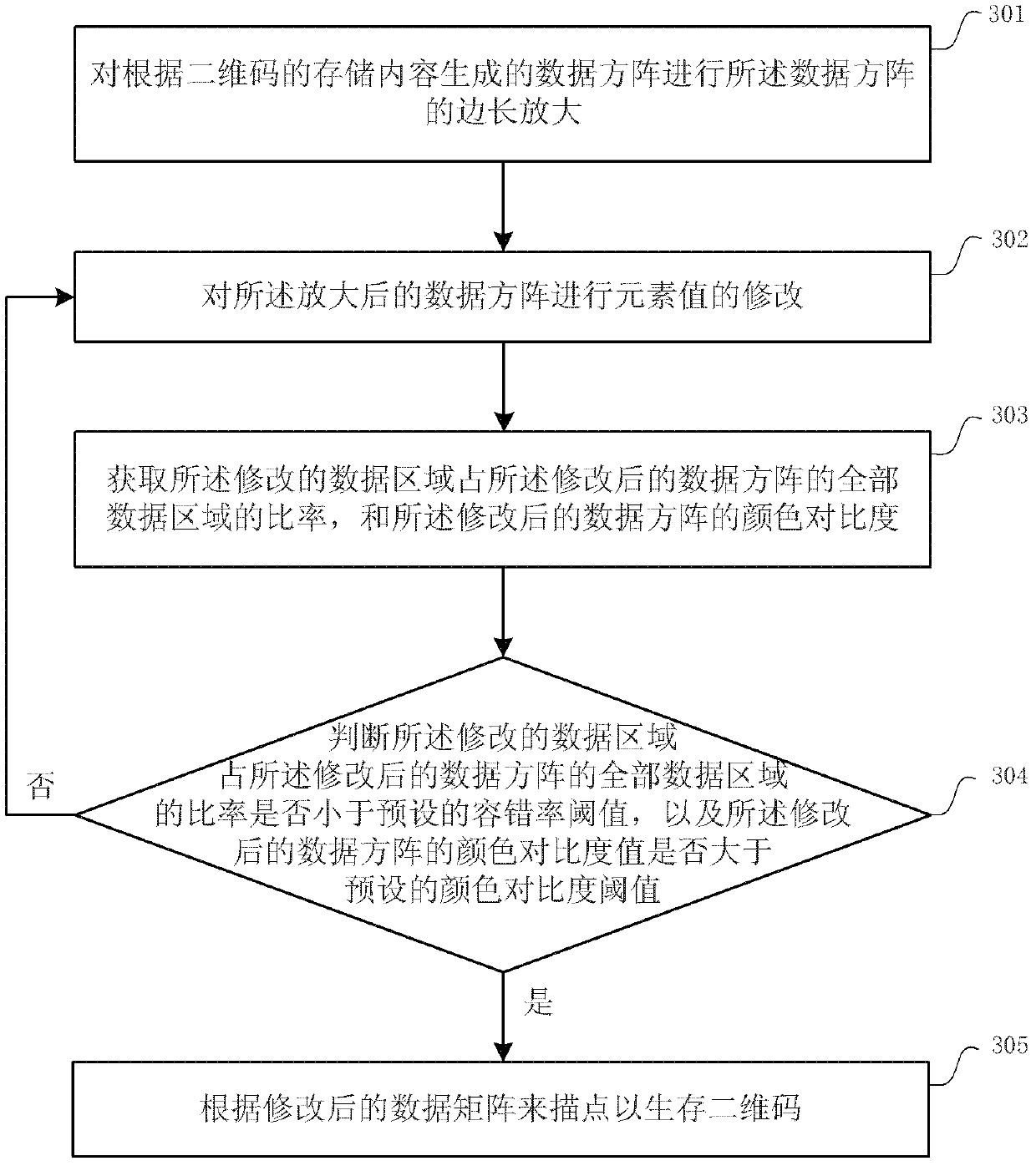

Method and device for generating and recognizing two-dimension code

ActiveCN103377390AAchieve colorRealize the structureRecord carriers used with machinesSensing by electromagnetic radiationComputer scienceColor contrast

The invention relates to a method and device for generating and recognizing a two-dimension code. Specifically, according to the method, a data matrix generated according to the memory content of the two-dimension code is amplified; element value modification is carried out on the amplified data matrix; the rate of a modification area in all areas and the color contrast of the modified data matrix are obtained; whether the rate of the modification area in all the areas is smaller than a preset error-tolerant rate threshold value or not is judged, and whether the color contrast value of the modified data matrix is larger than a preset color contrast threshold value or not is judged; when the rate of the modification area in all the areas is smaller than the preset error-tolerant rate threshold value, and the color contrast value of the modified data matrix is larger than the preset color contrast threshold value, dotting is carried out to generate the two-dimension code according to the modified data matrix. Therefore, the method and device for generating and recognizing the two-dimension code achieves the color and structure change of the two-dimension code, and therefore the two-dimension code is more attractive and more practical, and is convenient for users to recognize, and meanwhile the coding use of the two-dimension code is not affected.

Owner:ALIBABA GRP HLDG LTD

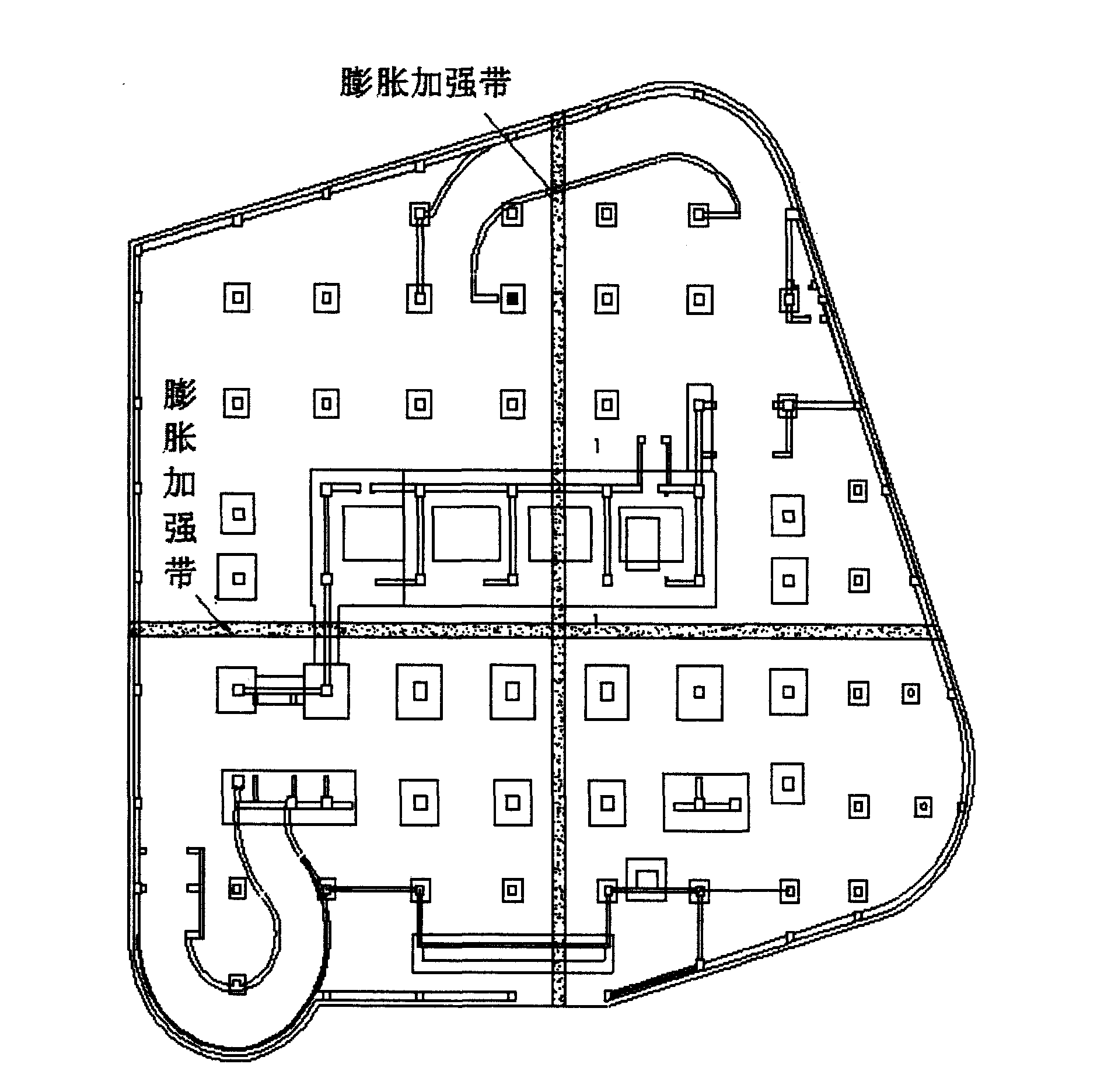

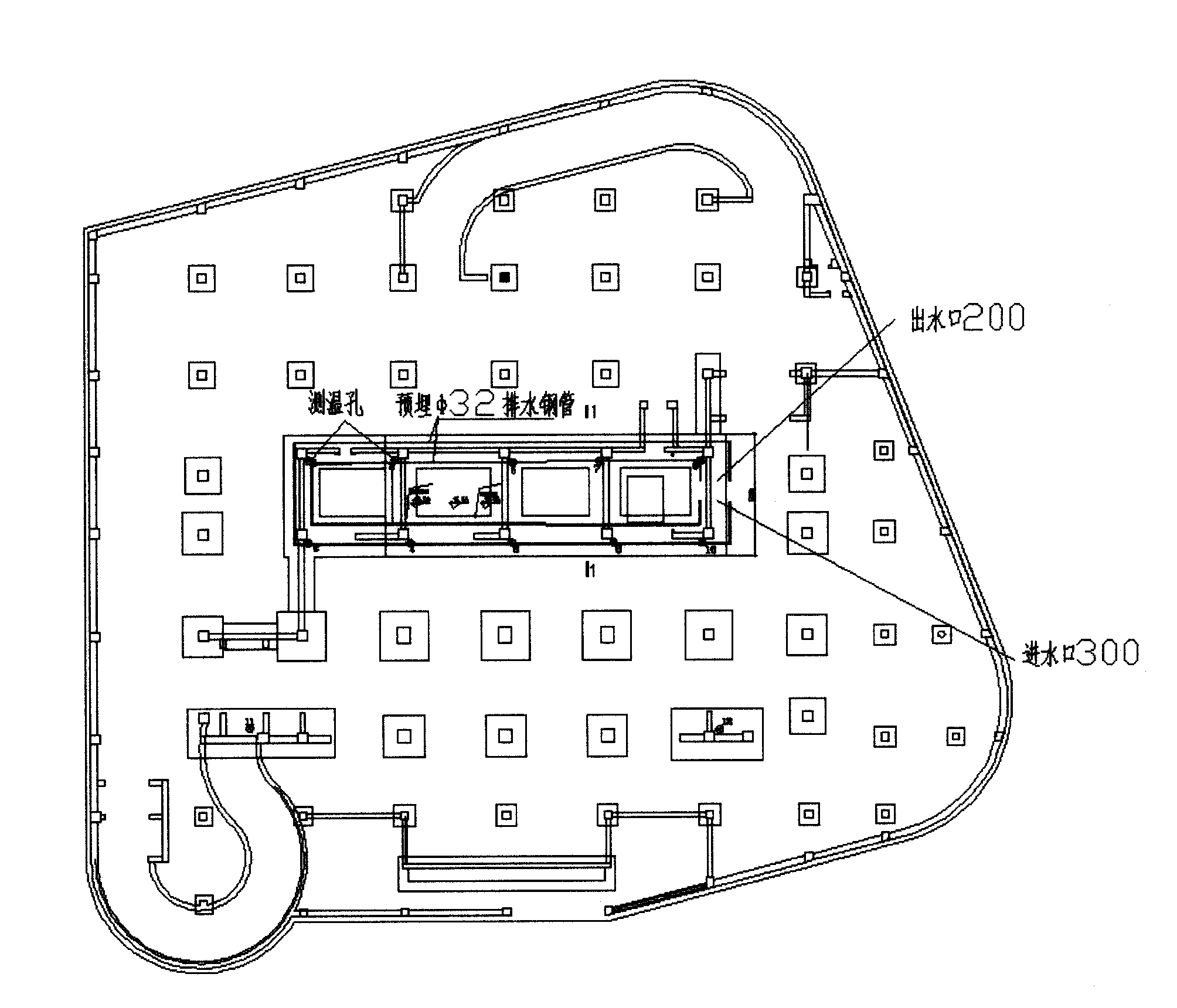

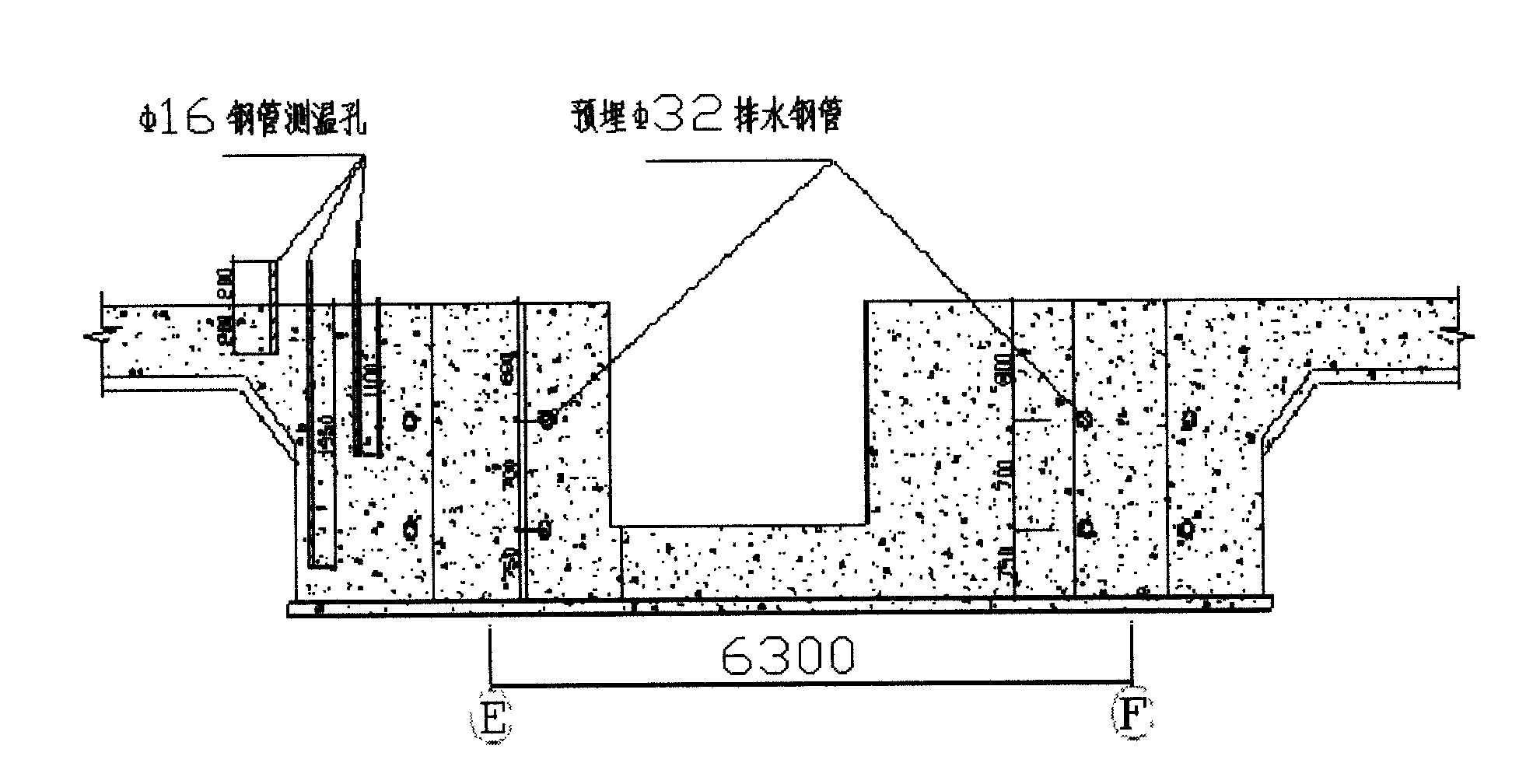

Large plate mass concrete seamless construction method

InactiveCN101638940ARealize the structureBuilding material handlingWater circulationConstruction aggregate

The invention relates to a large plate mass concrete seamless construction method which can be used for forming seamless large plate mass concrete structure without being provided with post-poured strips. The method comprises the following steps: (a) selecting cement: low-heat or medium-heat cement can be used; (b) adding adulterating agent: the FS-102 adulterating agent is added into the cement;(c) selecting aggregate, when fine aggregate is selected, medium-coarse sand with larger average grain diameter can be adopted; (d) pouring the concrete: the concrete is poured for once without cold seam in a construction section, and is sequentially vibrated and thickened; meanwhile, thermometer holes and cooling water circulation pipes with prescriptive number can be arranged inside the concrete; (e) maintaining the concrete: after the concrete is poured, an insulating layer is covered in time; (f) the surface of the concrete is flattened and trimmed for twice, and water is sprayed on the concrete for maintenance; (g) cooling water is filled into the laid cooling water circulation pipes, so as to lower the temperature inside the concrete.

Owner:CHINA HUAYE GROUP

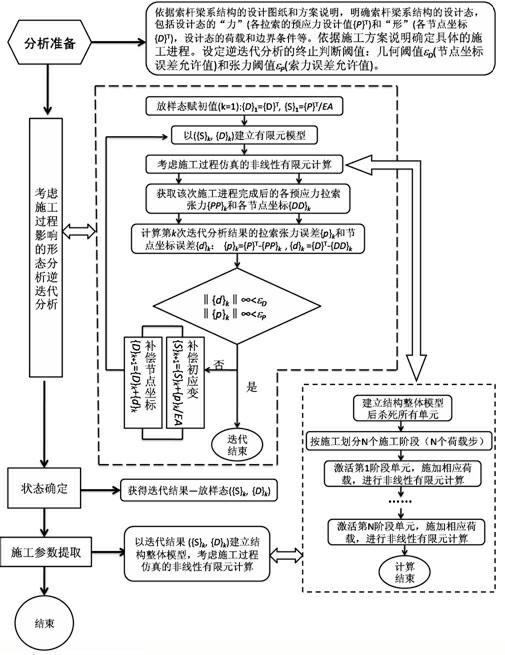

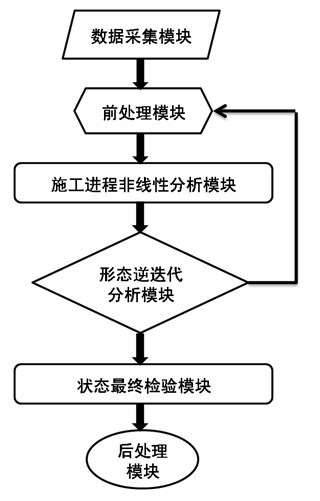

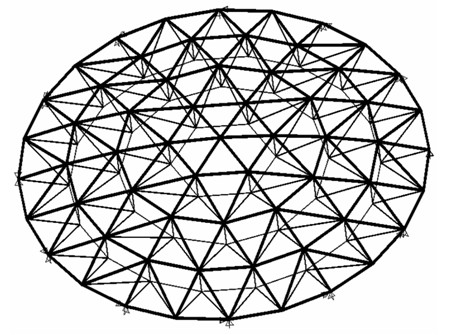

Morphological analysis inverse iteration method for determining space structural lofting states of cable-strut-beam system

InactiveCN102622485ASolving Morphological Analysis ProblemsGuaranteed accuracySpecial data processing applicationsSpatial structureEngineering

The invention provides a morphological analysis inverse iteration method for determining space structural lofting states of a cable-strut-beam system. The method includes: using a nonlinear finite element inverse iteration method with construction process considered, using an inactivating-activating unit method to positively simulate construction process influences based on assumption of the lofting similar state, using a morphological compensation method to inversely correct a lofting state geometrical configuration and pretension scheme, gradually astringing a positive tension analysis result of a lofting similar state to a preset design state through positive-inverse loop iteration, and finally obtaining a precise lofting state geometrical configuration and pretension control scheme.

Owner:SOUTHEAST UNIV

Flashing light wool-simulating hemp-simulating surfacing material and process technique thereof

InactiveCN101109125AImprove comfortSpecial glossHeating/cooling textile fabricsDyeing processPolyesterPolymer science

The invention discloses a sparkling fur- / hemp-imitated shell fabric and the processing process for the shell fabric. Wherein, a warp and a weft are woven together, the warp takes blend yarn of bamboo fiber and polyester microfiber as raw materials, the weft uses blended yarn of sparkled and various color from modified polyester and viscose as raw materials. The invention is soft, of good drapability, highly resistant to wear, with good air permeability, resistance to static, good resilience and antibiotic property.

Owner:洪桂焕

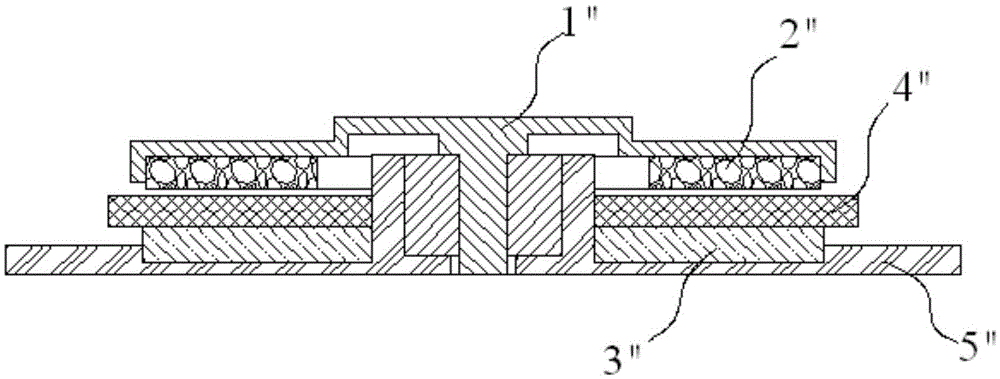

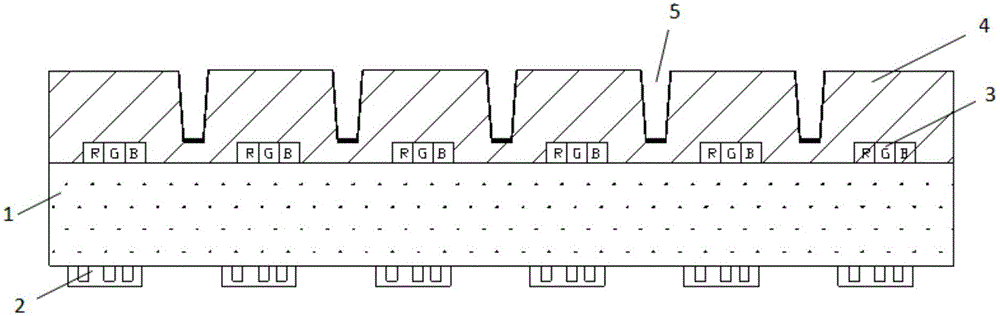

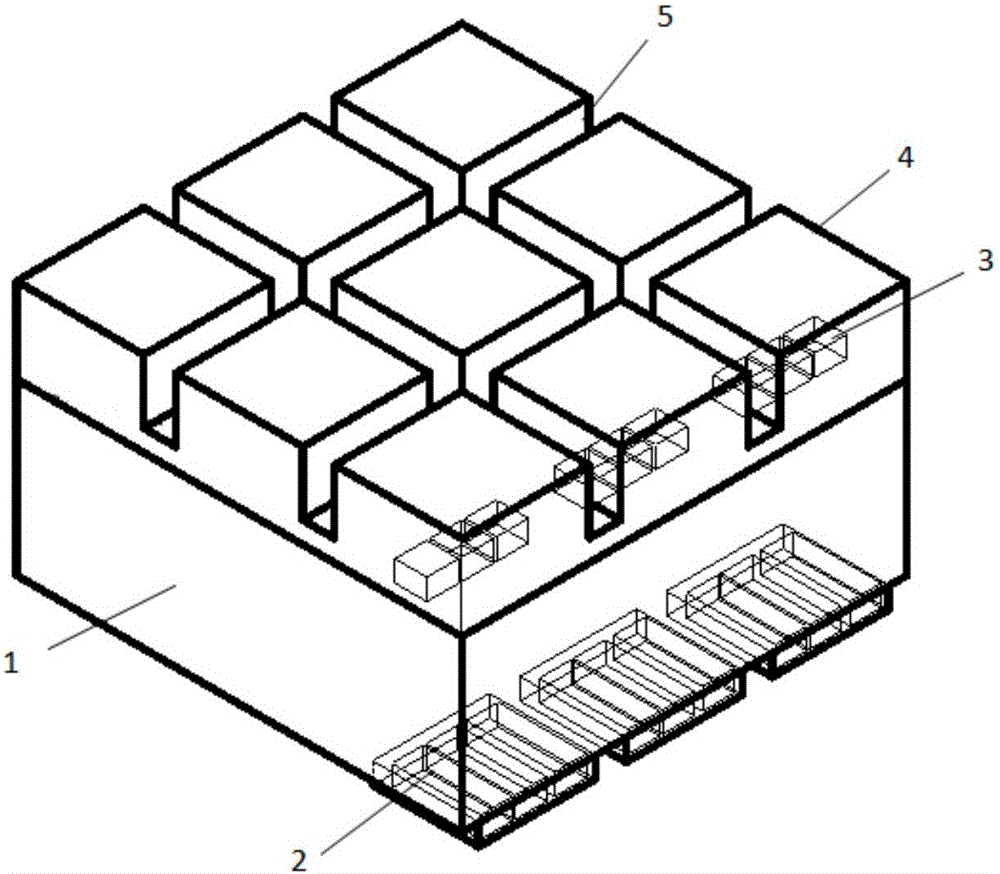

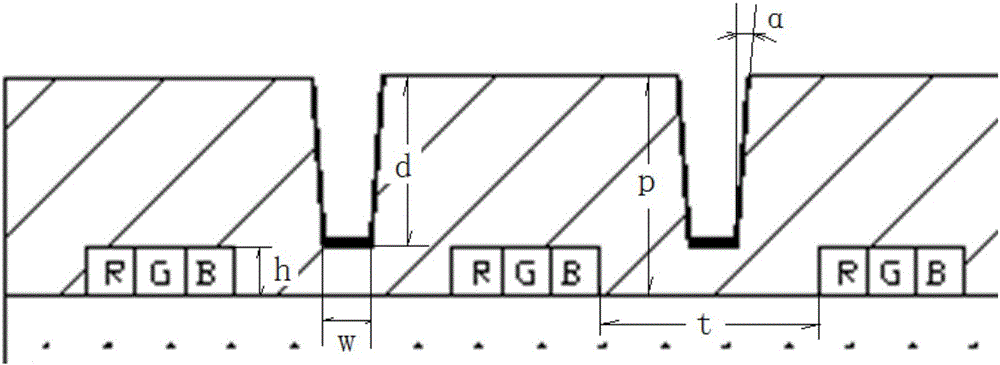

Integrated packaged LED display module and manufacturing method thereof

InactiveCN106205401AEnable direct encapsulationSolving Consistency IssuesIdentification meansMicro nanoLED display

The invention relates to an integrated LED display packaged module and a manufacturing method of the integrated LED display packaged module. A drive IC of the packaged module is welded to the back of a drive circuit board, and LED lamp modules are fixed to the front of the drive circuit board; packaging glue covers the drive circuit board, and grooves are formed in the packaging glue among the LED lamp modules; a micro-nano-scale filler capable of absorbing light rays is uniformly mixed in the packaging glue; the cross sections of the grooves are trapezoid-shaped, and coatings are arranged on the side walls of the grooves. According to the integrated LED display packaged module, the packaging glue is filled with the micro-nano-scale filler being in black or other colors and being capable of absorbing the light rays, therefore, the light flee problem is solved under the premise that certain brightness of an LED screen is consumed, so that the LED display screen has the clear display effect. With the packaged device, the filling and packaging of the packaging glue are realized in the vacuum environment is realized, therefore, the consistency of the packaging glue is effectively realized, the packaging efficiency is promoted, and the yield and the optical effect of the product are improved.

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com