Preparation and forming integrated three-dimensional printing method and preparation and forming integrated three-dimensional printing device for amorphous alloy materials

An amorphous alloy and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of crystallization behavior warping and deformation, and achieve the effect of ensuring amorphous characteristics, saving the preparation process, and avoiding crystallization behavior and warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

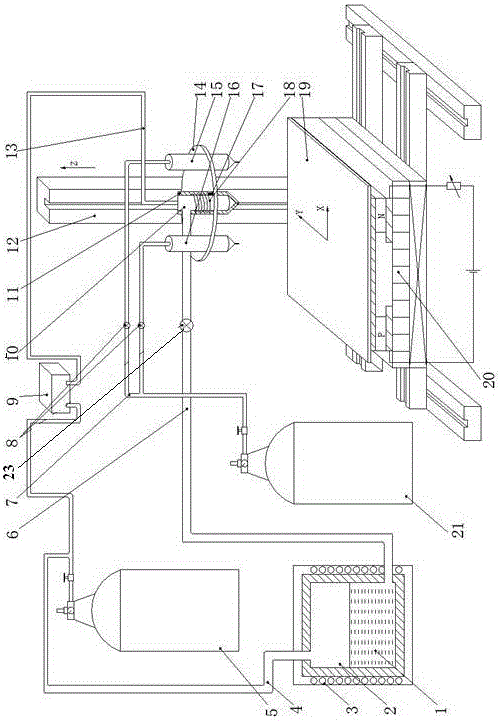

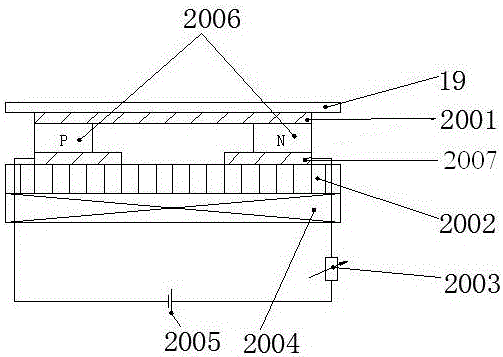

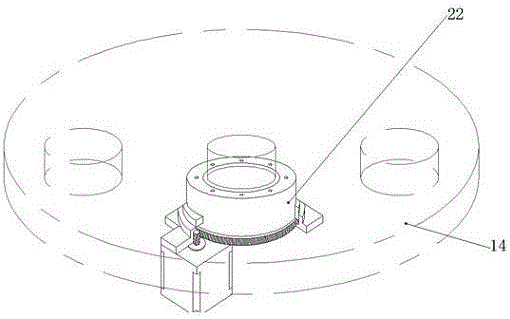

[0033] A 3D printing device that integrates the preparation of amorphous alloy materials and structural forming. The high-pressure liquid nitrogen tank 21 is connected to the liquid nitrogen nozzle 15 and the liquid nitrogen nozzle 16 through the liquid nitrogen tube 7, which is the liquid nitrogen nozzle 16 and the liquid nitrogen nozzle. 215 provides high-pressure liquid nitrogen, and the liquid nitrogen pipe 7 is provided with a switch 8 to control the opening and closing of the liquid nitrogen nozzle 7 to realize spraying on demand, "point-to-point" precise cooling, and the inert gas pressure storage bottle 5 passes through the inert gas pipe 1 4 is connected to the crucible 2 to provide feeding power. The molten metal 1 is placed in the crucible 2, and an annular heating furnace 3 is arranged outside the crucible 2 to heat the crucible 2 to maintain the fluidity of the molten metal 1. The crucible 2 passes through the feeding pipe 6 and the metal The droplet nozzle 10 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com