A niobium-based bulk amorphous alloy and its preparation method

An amorphous alloy and niobium-based technology, applied in the field of niobium-based amorphous alloy materials, can solve problems such as weak forming ability and limited application fields, and achieve the effects of improving processing technology, expanding applications, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the molecular formula of the niobium-based bulk amorphous alloy is Nb 42 Ni 39co 18 B 1 .

[0046] The preparation method of the niobium-based bulk amorphous alloy is as follows:

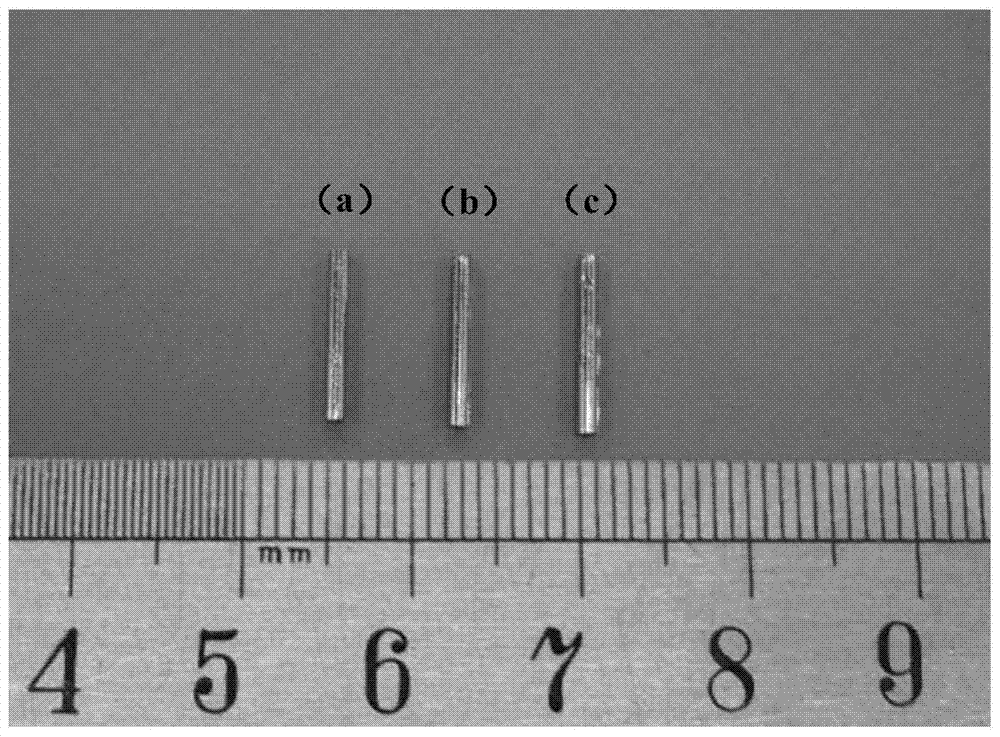

[0047] Use raw materials Nb, Ni, Co, and B with a purity of more than 99.5%, and prepare them in a molar ratio of 42:39:18:1; put the prepared raw materials into an electric arc furnace with an argon atmosphere adsorbed by titanium, and melt for 4 More than one time, to ensure that the composition of the master alloy is uniform, and the master alloy ingot of the Nb-Ni-Co-B quaternary alloy is obtained after cooling; The suction casting device sucks the master alloy melt into the water-cooled copper mold to obtain the composition of Nb 42 Ni 39 co 18 B 1 , a niobium-based bulk amorphous alloy with a diameter of 1 mm, such as figure 1 In (a) shown.

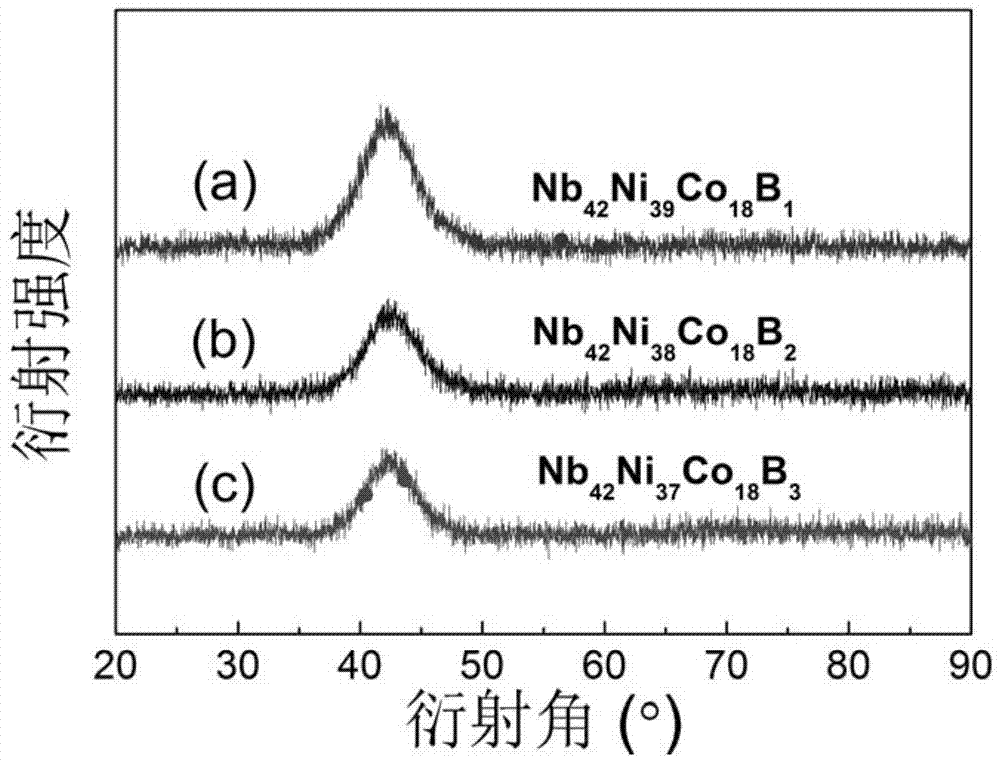

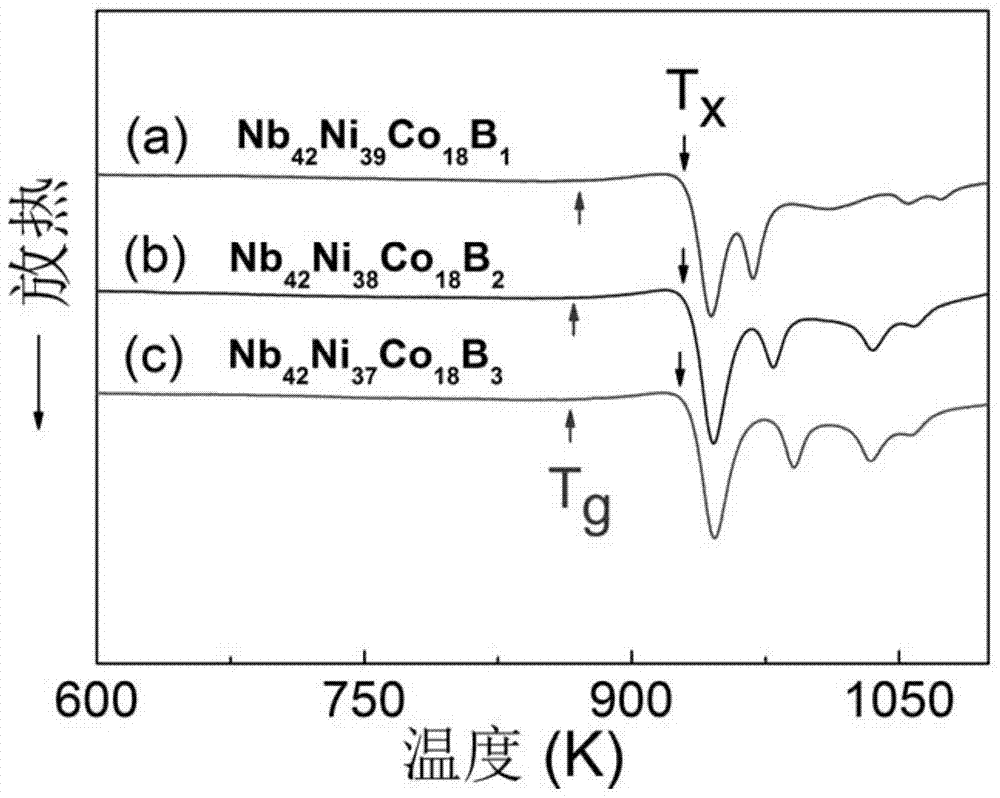

[0048] The X-ray diffraction (XRD) pattern of the niobium-based bulk amorphous alloy is shown in figure 2 In (a) s...

Embodiment 2

[0053] In this embodiment, the molecular formula of the niobium-based bulk amorphous alloy is Nb 42 Ni 38 co 18 B 2 .

[0054] The preparation method of the niobium-based bulk amorphous alloy is as follows:

[0055] Use raw materials Nb, Ni, Co, and B with a purity of more than 99.5%, and prepare them in a molar ratio of 42:38:18:2; put the prepared raw materials into an electric arc furnace with an argon atmosphere adsorbed by titanium, and melt for 4 More than one time, to ensure that the composition of the master alloy is uniform, and the master alloy ingot of the Nb-Ni-Co-B quaternary alloy is obtained after cooling; In the suction casting device, the master alloy melt is sucked into the water-cooled copper mold, and the composition is Nb 42 Ni 38 co 18 B 2 , a niobium-based bulk amorphous alloy with a diameter of 1 mm, such as figure 1 In (b) shown.

[0056] The X-ray diffraction (XRD) pattern of the niobium-based bulk amorphous alloy is shown in figure 2 As s...

Embodiment 3

[0061] In this embodiment, the molecular formula of the niobium-based bulk amorphous alloy is Nb 42 Ni 37 co 18 B 3 .

[0062] The preparation method of the niobium-based bulk amorphous alloy is as follows:

[0063] Use raw materials Nb, Ni, Co, and B with a purity of more than 99.5%, and prepare them in a molar ratio of 42:37:18:3; put the prepared raw materials into an electric arc furnace with an argon atmosphere adsorbed by titanium, and melt for 4 More than one time, to ensure that the composition of the master alloy is uniform, and the master alloy ingot of the Nb-Ni-Co-B quaternary alloy is obtained after cooling; In the suction casting device, the master alloy melt is sucked into the water-cooled copper mold, and the composition is Nb 42 Ni 37 co 18 B 3 , a niobium-based bulk amorphous alloy with a diameter of 1 mm, such as figure 1 In (c) shown.

[0064] The X-ray diffraction (XRD) pattern of the niobium-based bulk amorphous alloy is shown in figure 2 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com