Patents

Literature

1726 results about "Ti element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium is a chemical element with the symbol Ti and atomic number 22. Sometimes called the "space age metal", it has a low density and is a strong, lustrous, corrosion-resistant (including sea water, aqua regia and chlorine) transition metal with a silver color.

Composite refractory metal carbide coating on a substrate and method for making thereof

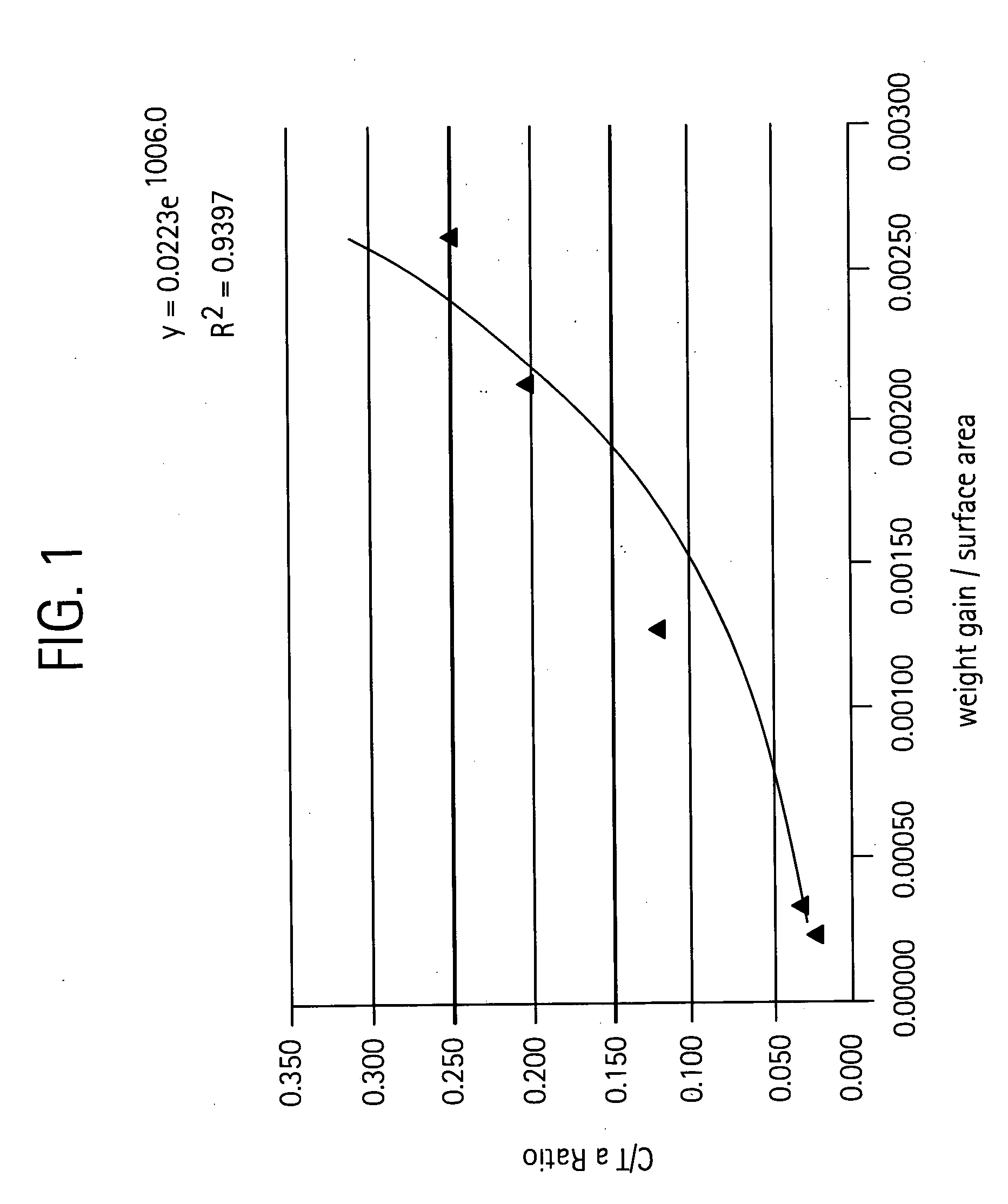

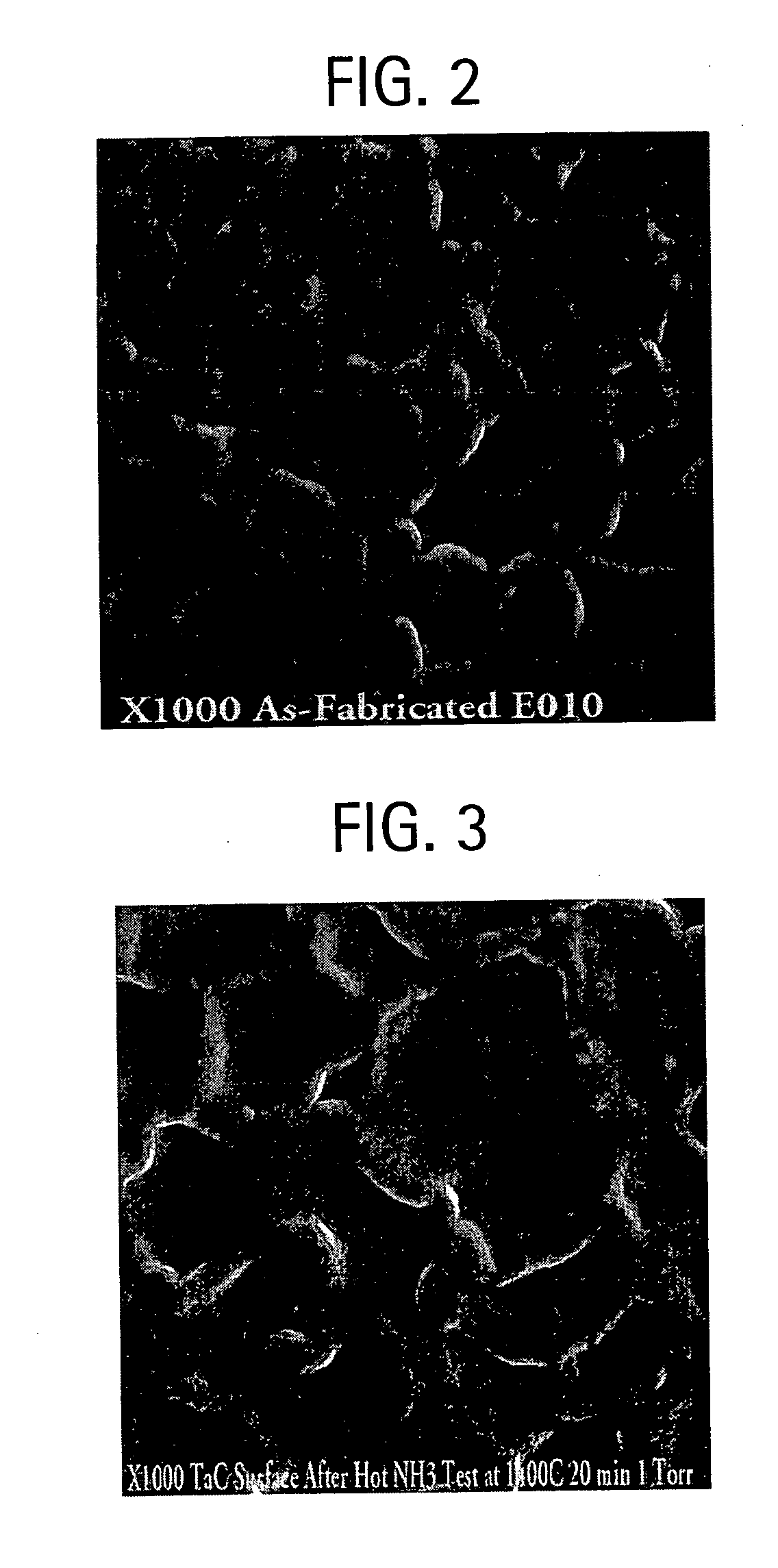

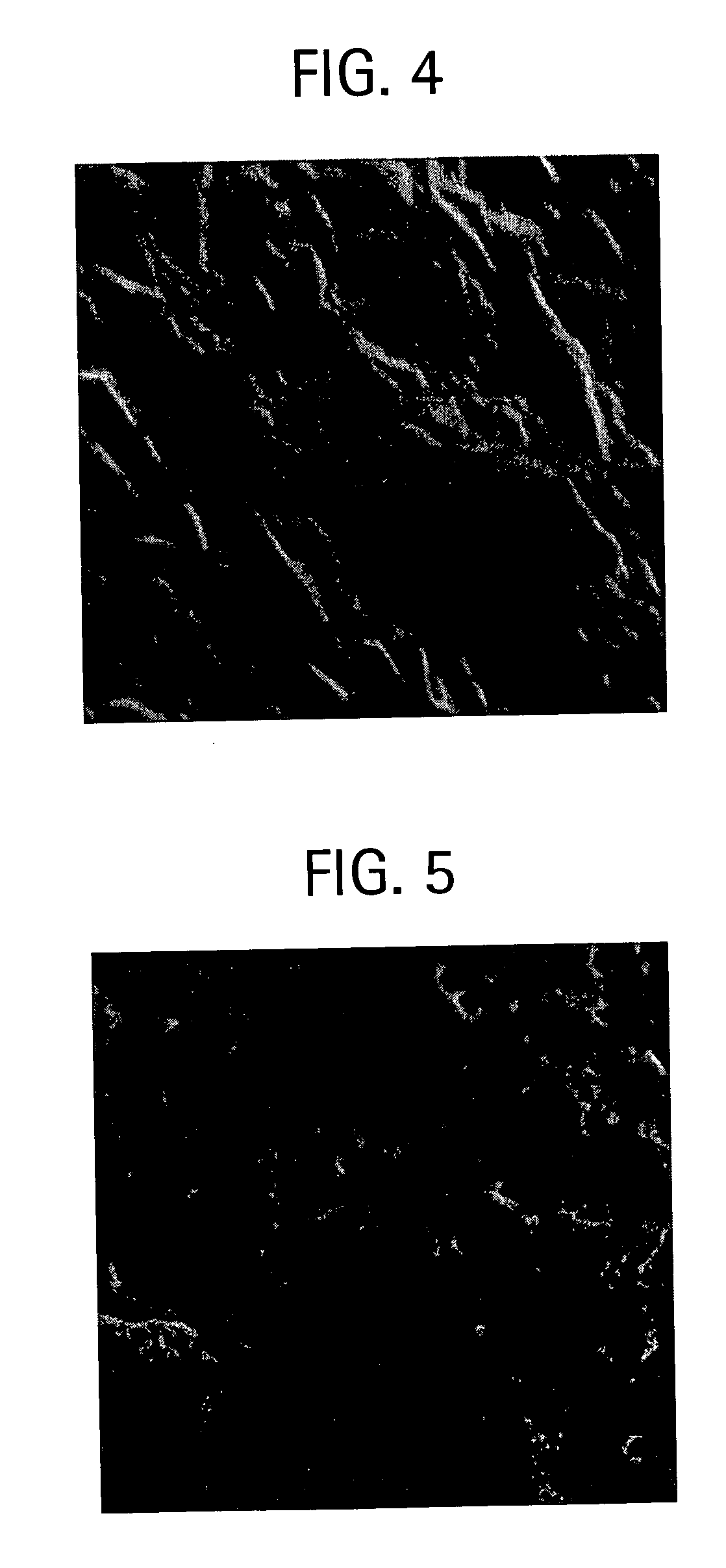

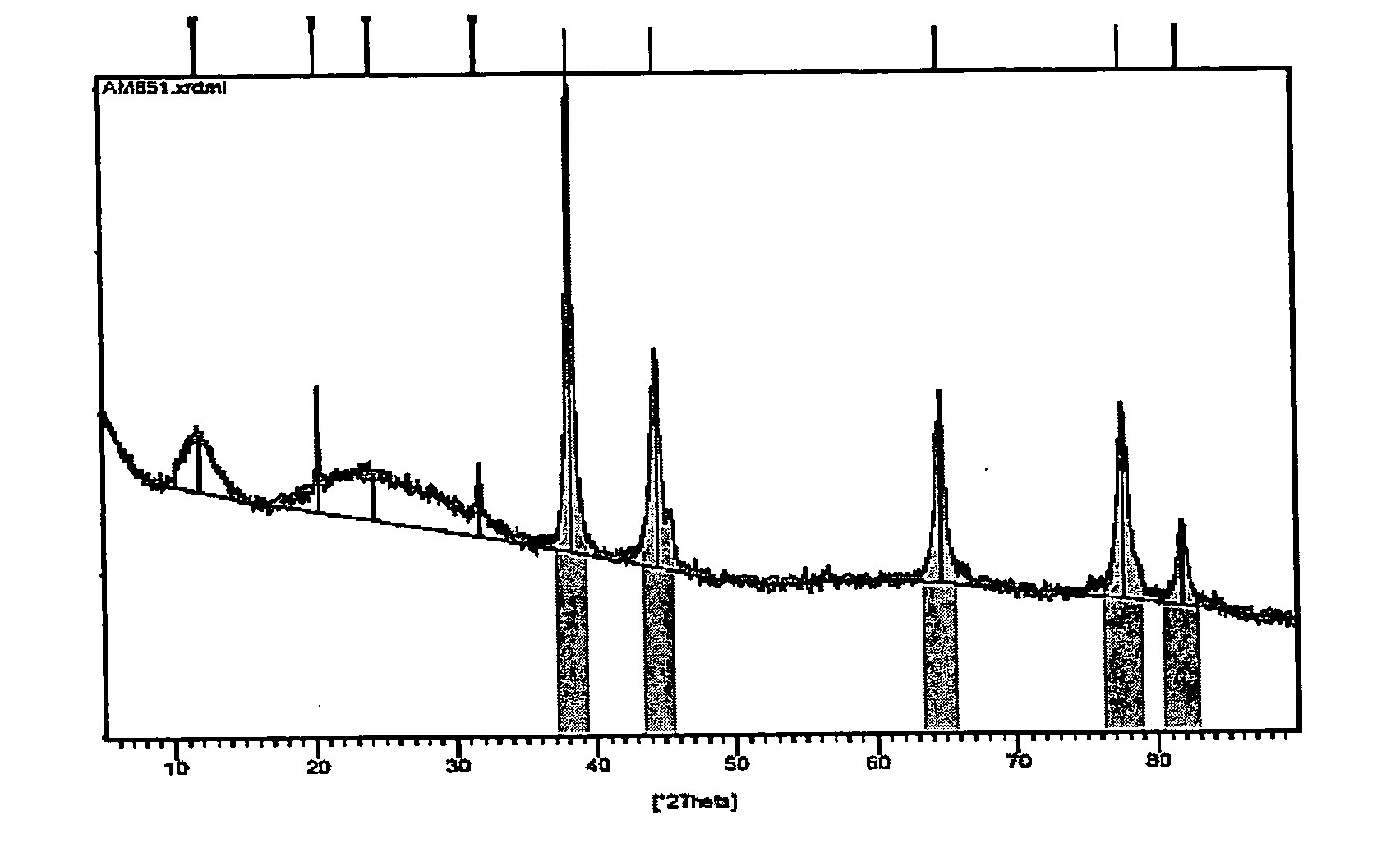

InactiveUS20050064247A1Improved corrosion resistance propertyIncreased emissivity insensitivityLiquid surface applicatorsSemiconductor/solid-state device manufacturingBeryllium carbideMagnesium

A composite coating for use on semi-conductor processing components, comprising a refractory metal carbide coating with its surface modified by at least one of: a) a carbon donor source for a stabilized stoichiometry, and b) a layer of nitride, carbonitride or oxynitride of elements selected from a group B, Al, Si, refractory metals, transition metals, rare earth metals which may or may not contain electrically conducting pattern, and wherein the metal carbide is selected from the group consisting of silicon carbide, tantalum carbide, titanium carbide, tungsten carbide, silicon oxycarbide, zirconium carbide, hafnium carbide, lanthanum carbide, vanadium carbide, niobium carbide, magnesium carbide, chromium carbide, molybdenum carbide, beryllium carbide and mixtures thereof. The composite coating is characterized as having an improved corrosion resistance property and little emissivity sensitivity to wavelengths used in optical pyrometry under the normal semi-conductor processing environments.

Owner:GENERAL ELECTRIC CO

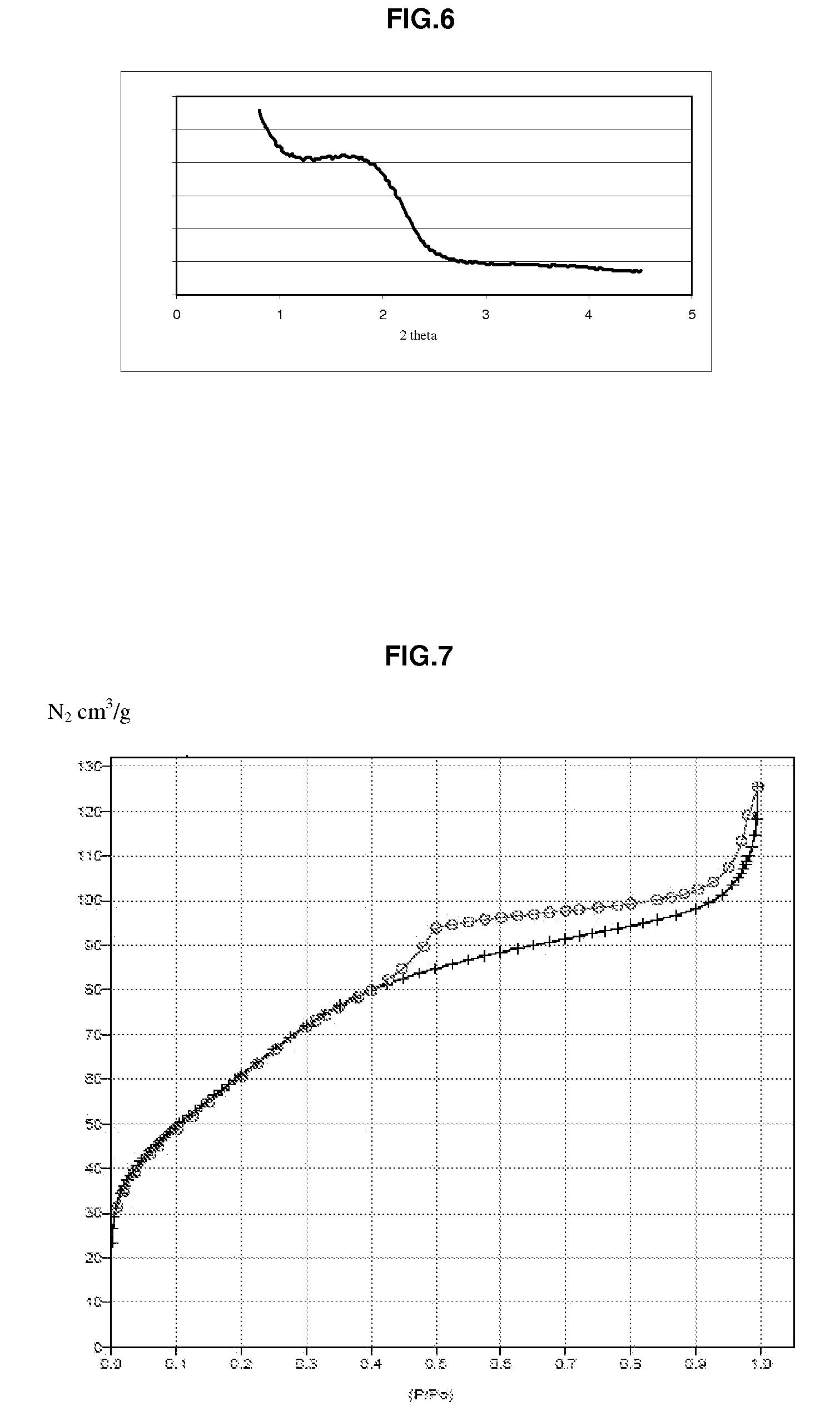

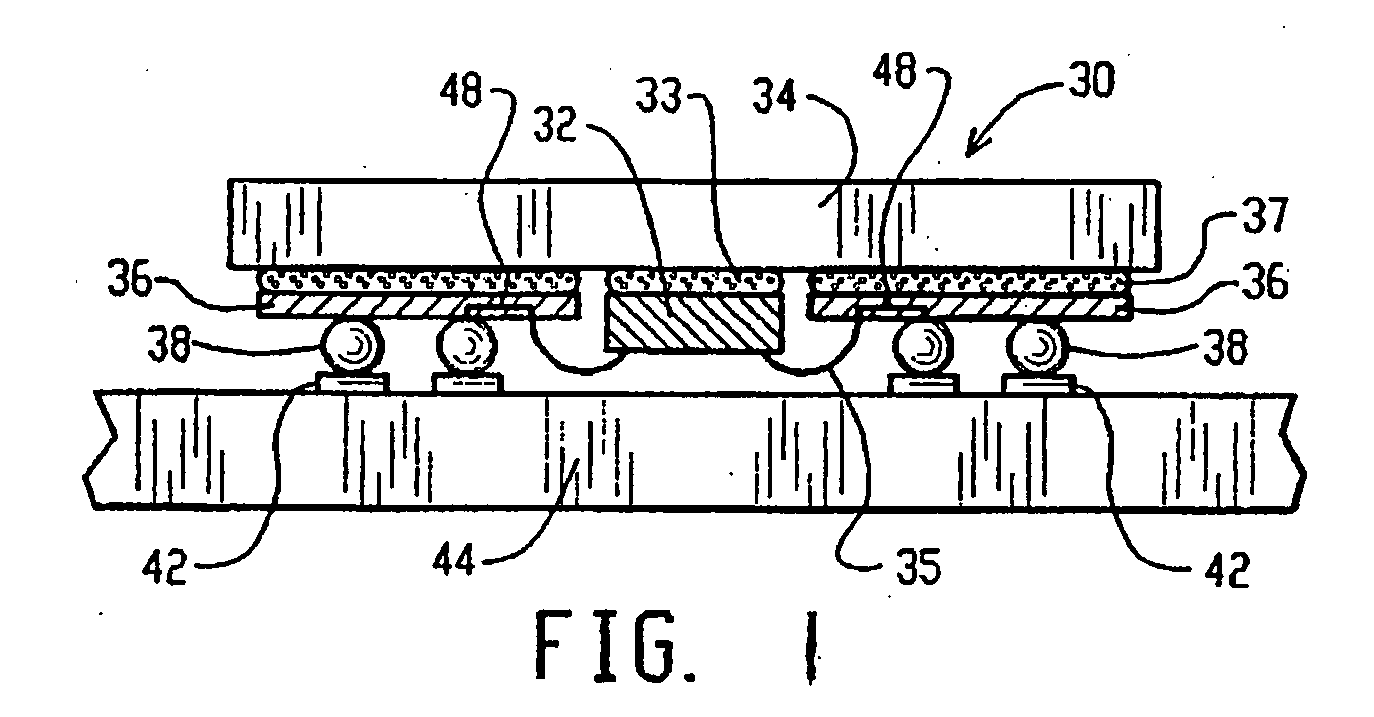

Inorganic material that has metal nanoparticles that are trapped in a mesostructured matrix

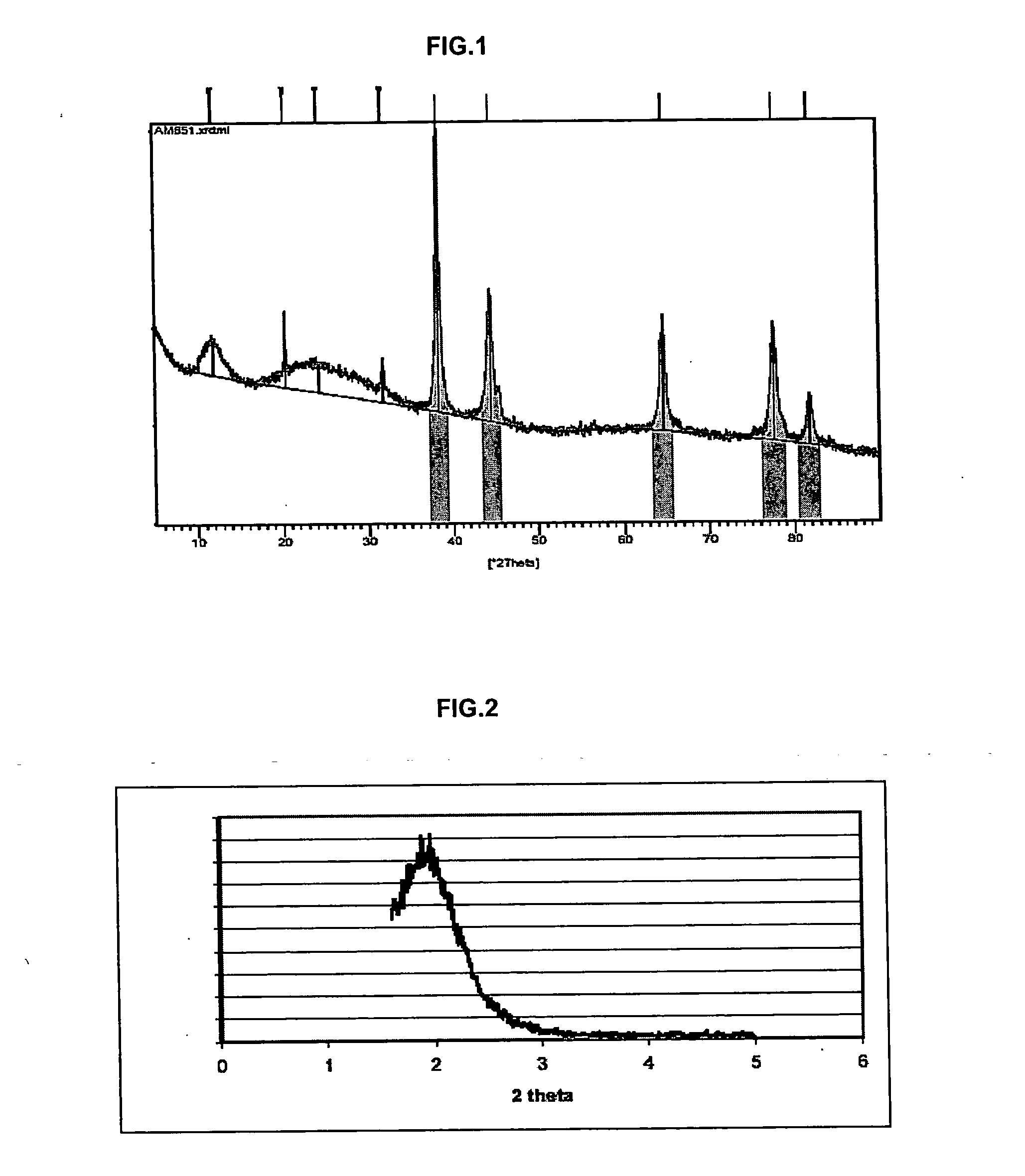

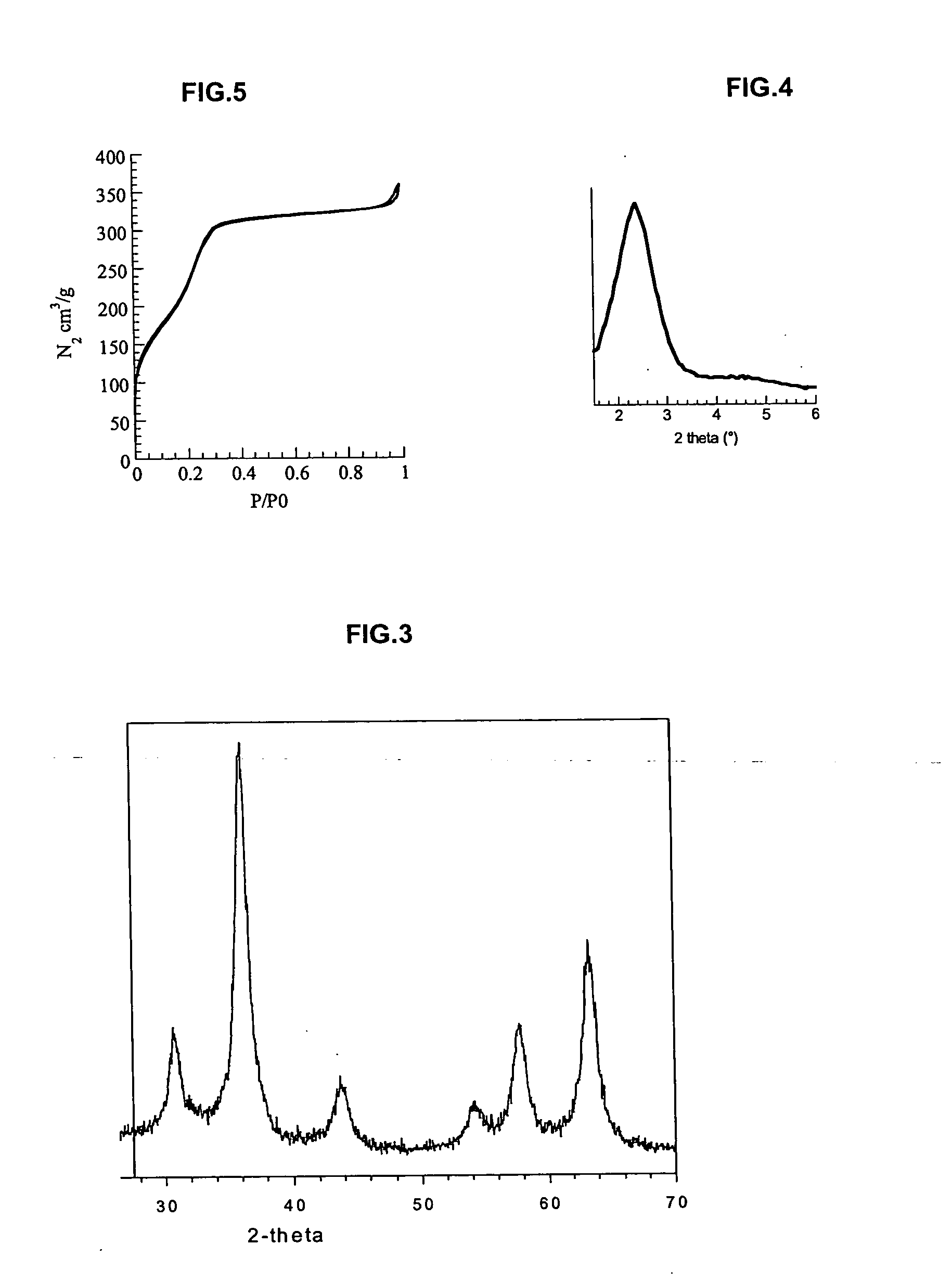

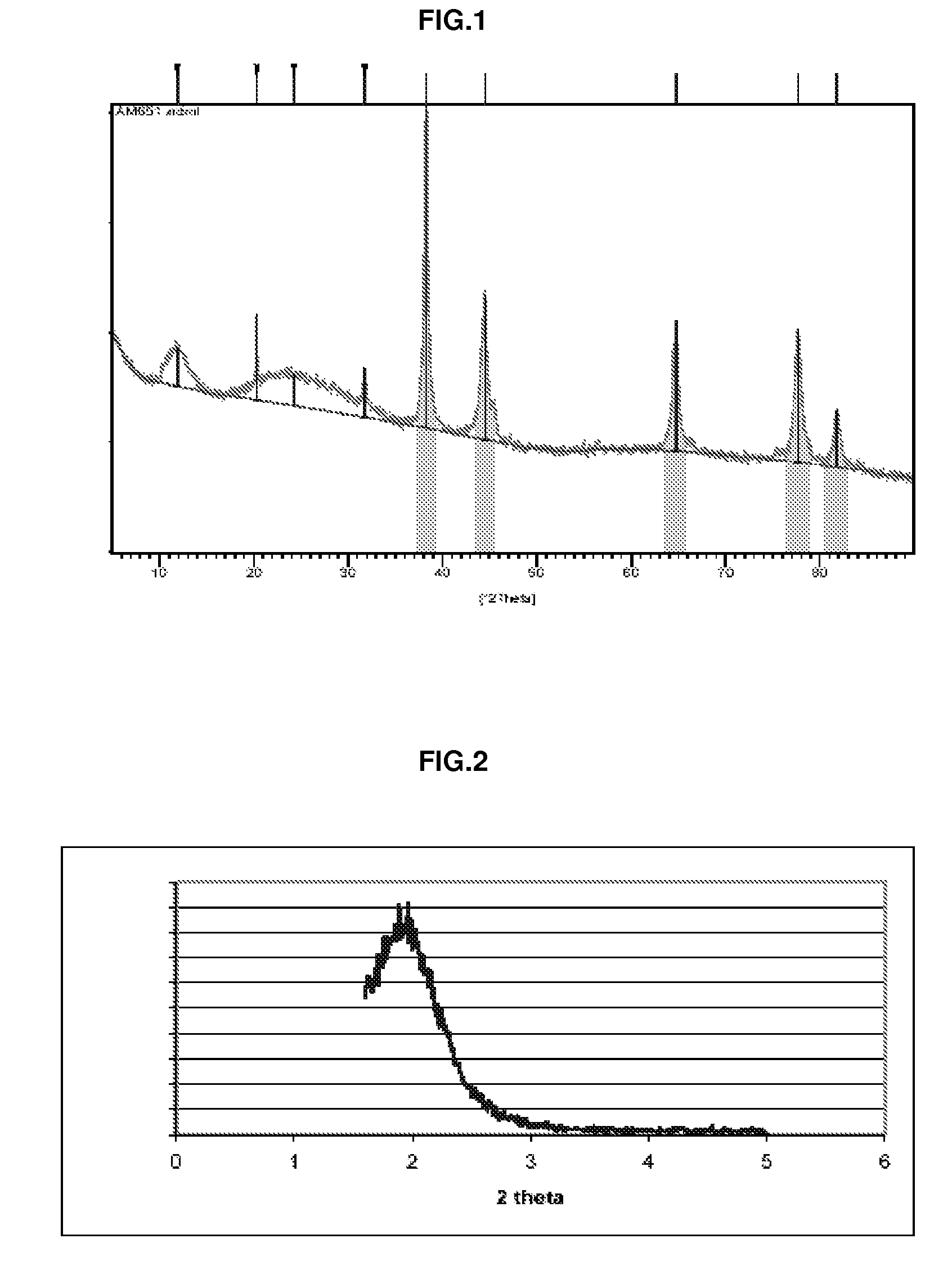

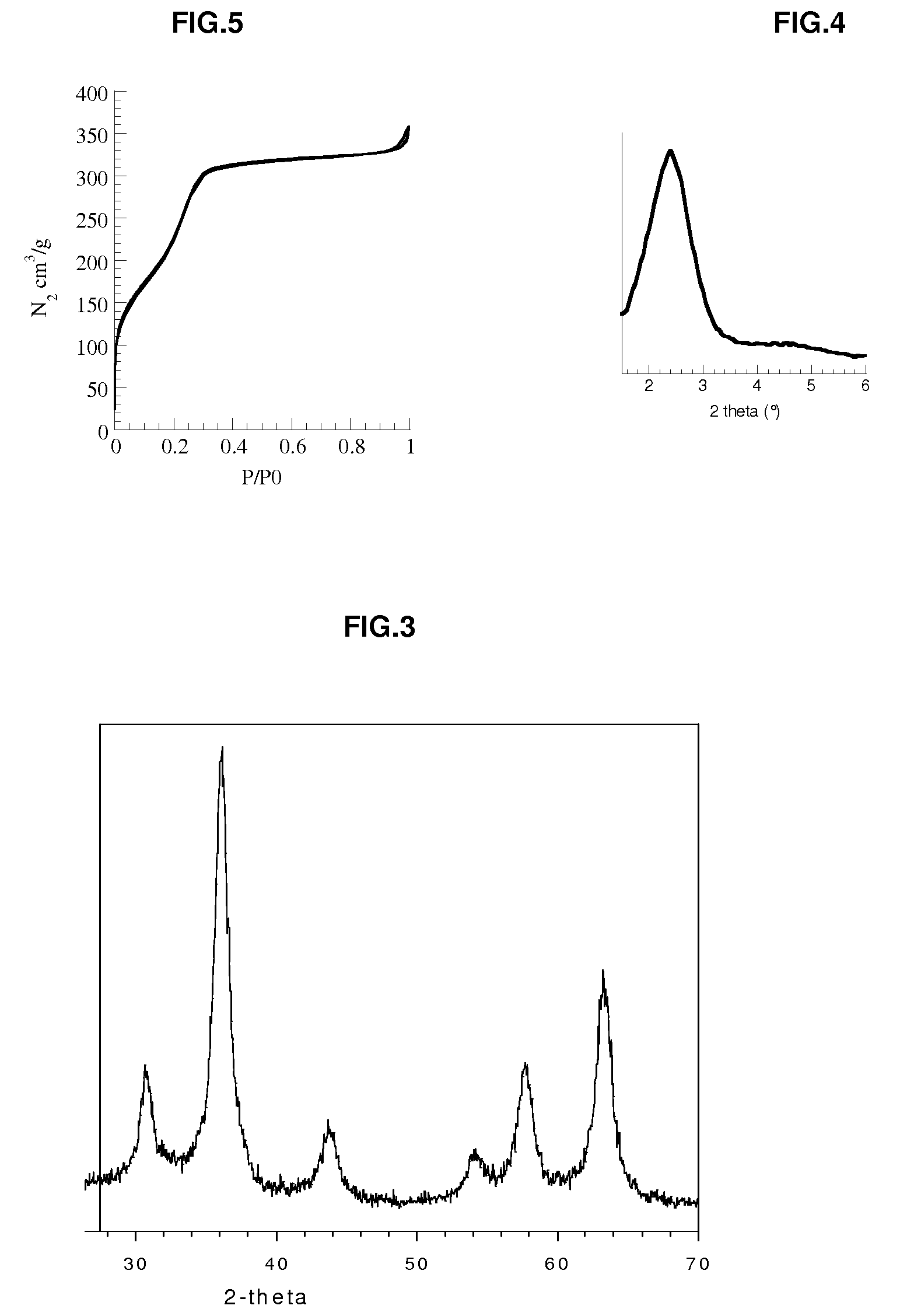

An inorganic material that consists of at least two elementary spherical particles, each of said spherical particles comprising metal nanoparticles that are between 1 and 300 nm in size and a mesostructured matrix with an oxide base of at least one element X that is selected from the group that consists of aluminum, titanium, tungsten, zirconium, gallium, germanium, tin, antimony, lead, vanadium, iron, manganese, hafnium, niobium, tantalum, yttrium, cerium, gadolinium, europium and neodymium is described, whereby said matrix has a pore size of between 1.5 and 30 nm and has amorphous walls with a thickness of between 1 and 30 nm, said elementary spherical particles having a maximum diameter of 10 μm. Said material can also contain zeolitic nanocrystals that are trapped within said mesostructured matrix.

Owner:INST FR DU PETROLE

Inorganic material that has metal nanoparticles that are trapped in a mesostructured matrix

An inorganic material that consists of at least two elementary spherical particles, each of said spherical particles comprising metal nanoparticles that are between 1 and 300 nm in size and a mesostructured matrix with an oxide base of at least one element X that is selected from the group that consists of aluminum, titanium, tungsten, zirconium, gallium, germanium, tin, antimony, lead, vanadium, iron, manganese, hafnium, niobium, tantalum, yttrium, cerium, gadolinium, europium and neodymium is described, whereby said matrix has a pore size of between 1.5 and 30 nm and has amorphous walls with a thickness of between 1 and 30 nm, said elementary spherical particles having a maximum diameter of 10 μm. Said material can also contain zeolitic nanocrystals that are trapped within said mesostructured matrix.

Owner:INST FR DU PETROLE

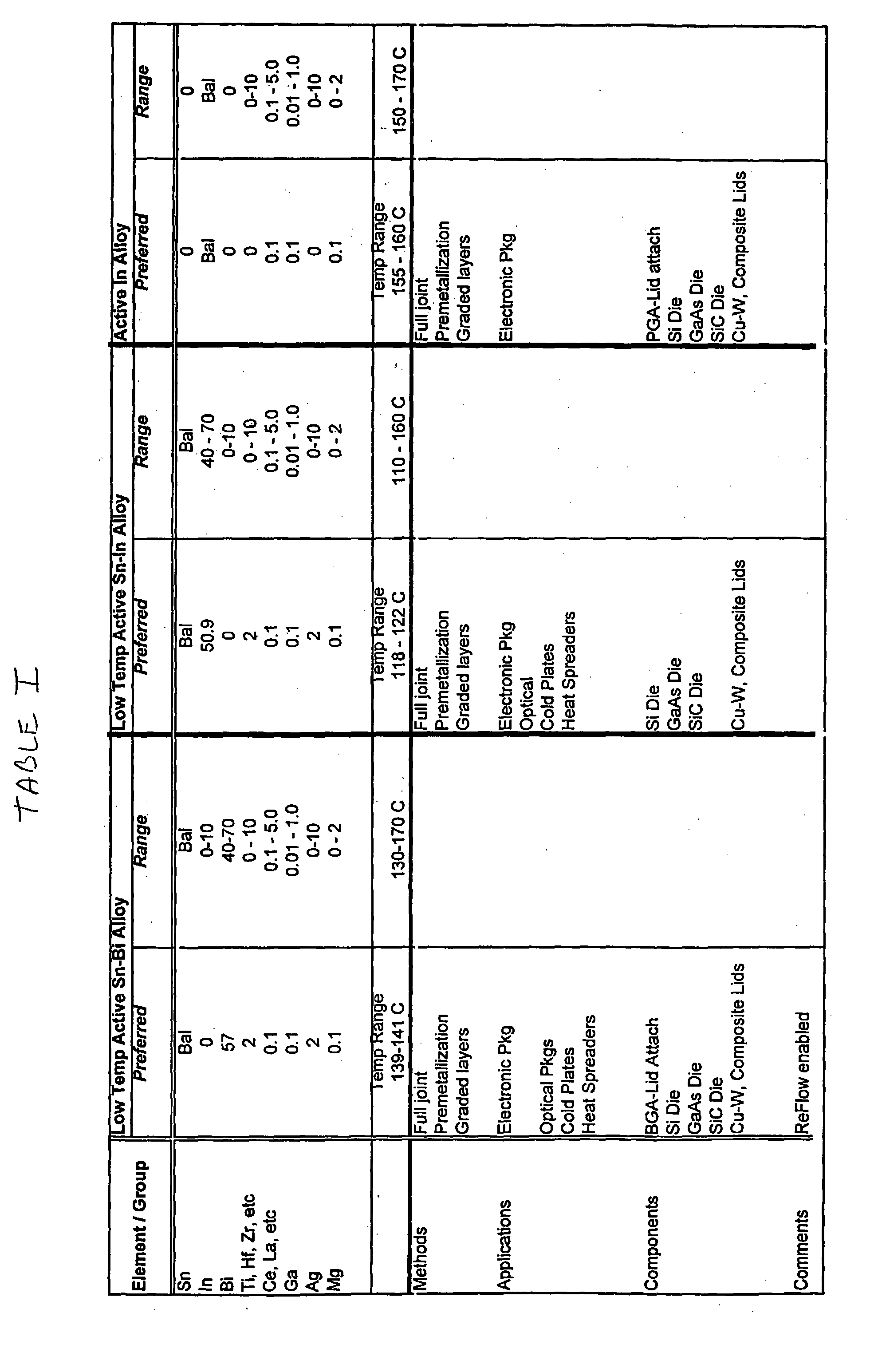

Electronic Package Formed Using Low-Temperature Active Solder Including Indium, Bismuth, and/or Cadmium

InactiveUS20070228109A1Increase concentrationHigh-strength, high-thermal conductivity jointsCooking-vessel materialsExhaust apparatusIndiumNiobium

An active solder alloy, an electronic device package including the active solder alloy bonding an electronic device to a substrate, and a method of forming high-strength joints by soldering using the solder alloy. The alloy contains up to about 10% by weight of an element or a mixture of elements selected from the group consisting of titanium, zirconium, hafnium, vanadium, niobium, or tantalum; between about 0.1 and 5% by weight of an element or a mixture of elements selected from the group of the lanthanides (rare earths); between about 0.01 and 1% by weight of gallium up to about 10% by weight of silver; up to about 2% by weight of magnesium; and a remainder consisting of tin, bismuth, indium, cadmium, or a mixture of two or more of these elements. The alloy enables low-temperature (less than about 180° C.) soldering within relatively narrow melting ranges (less than about 10° C.).

Owner:S BOND TECH

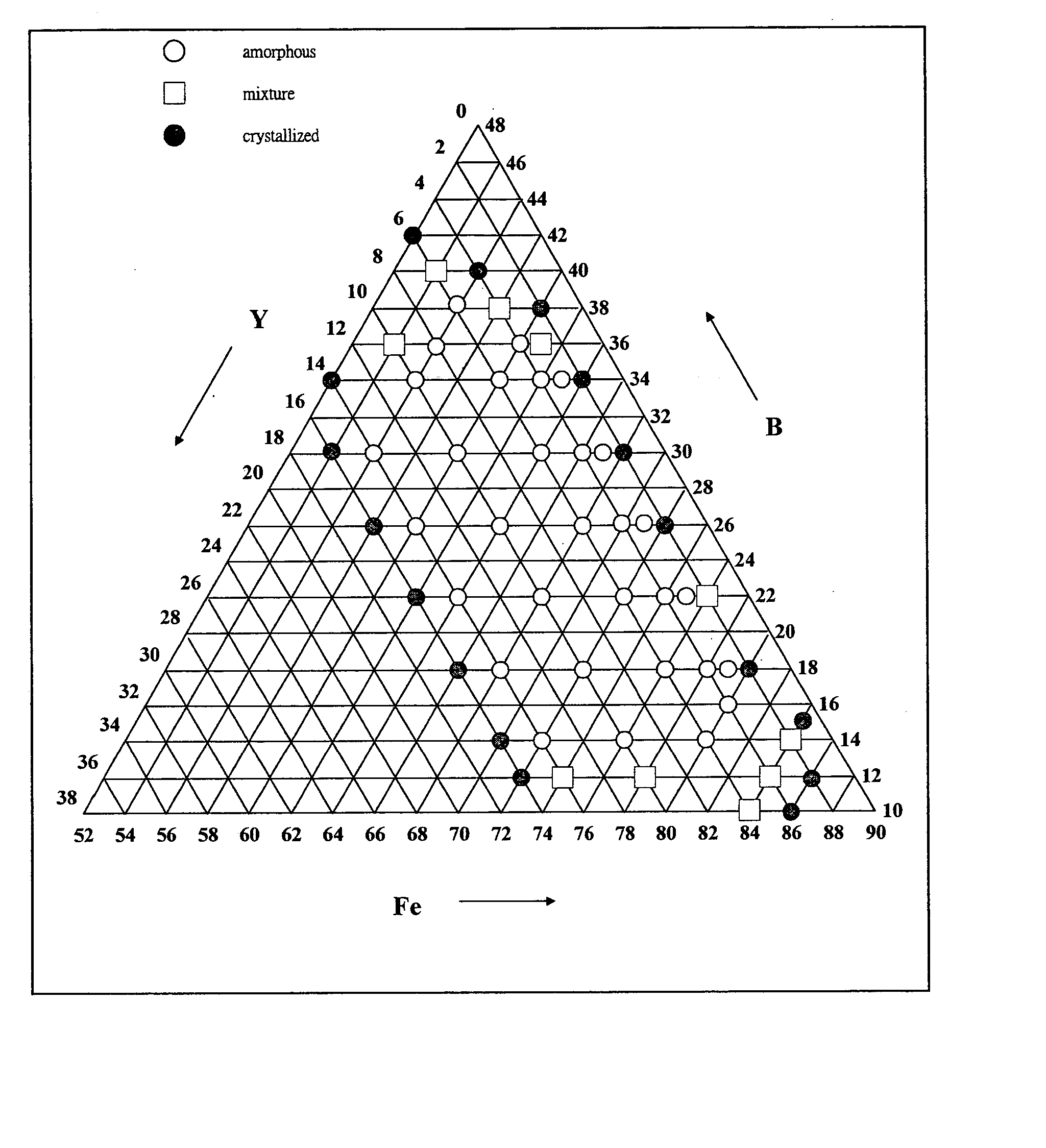

Ternary and multi-nary iron-based bulk glassy alloys and nanocrystalline alloys

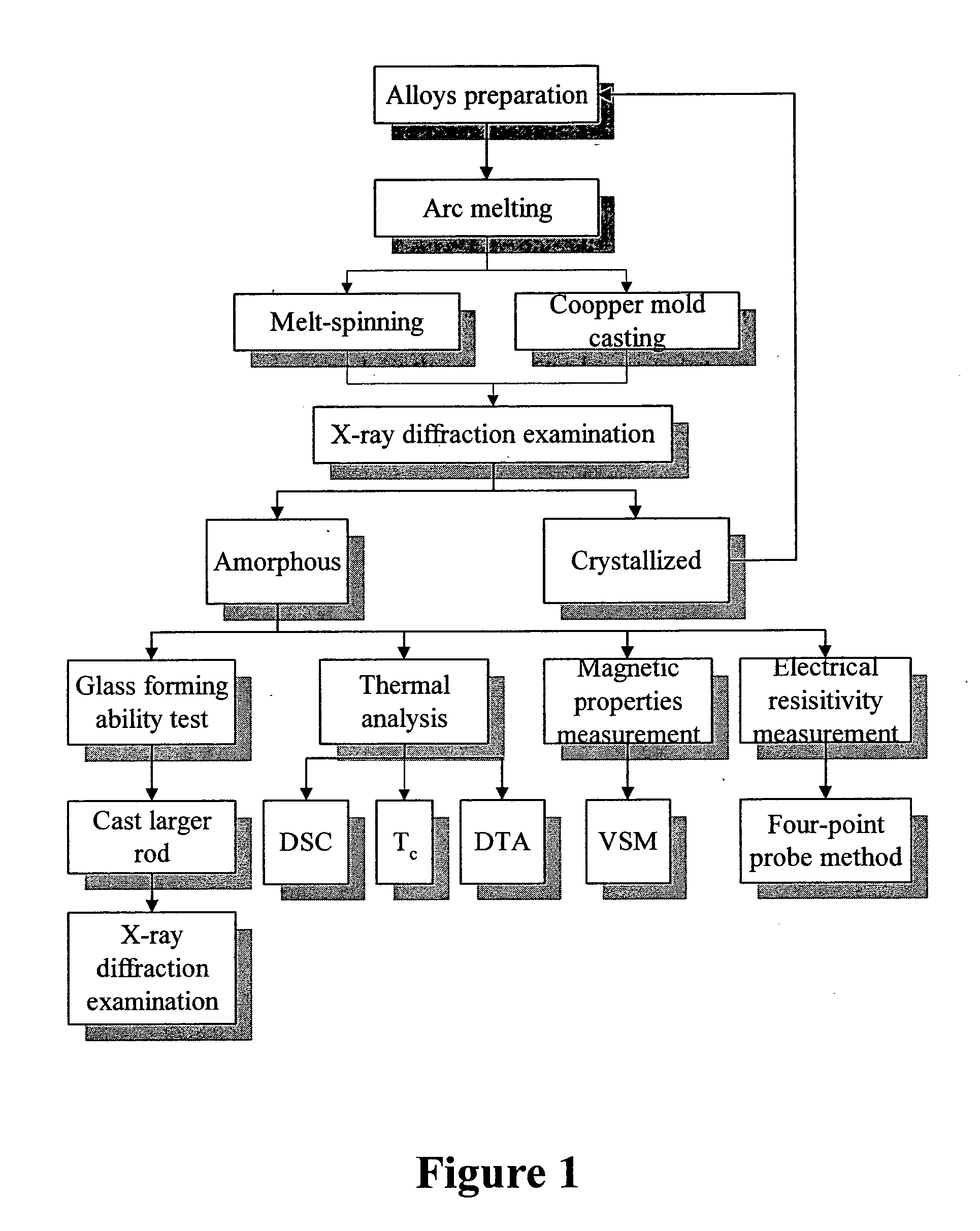

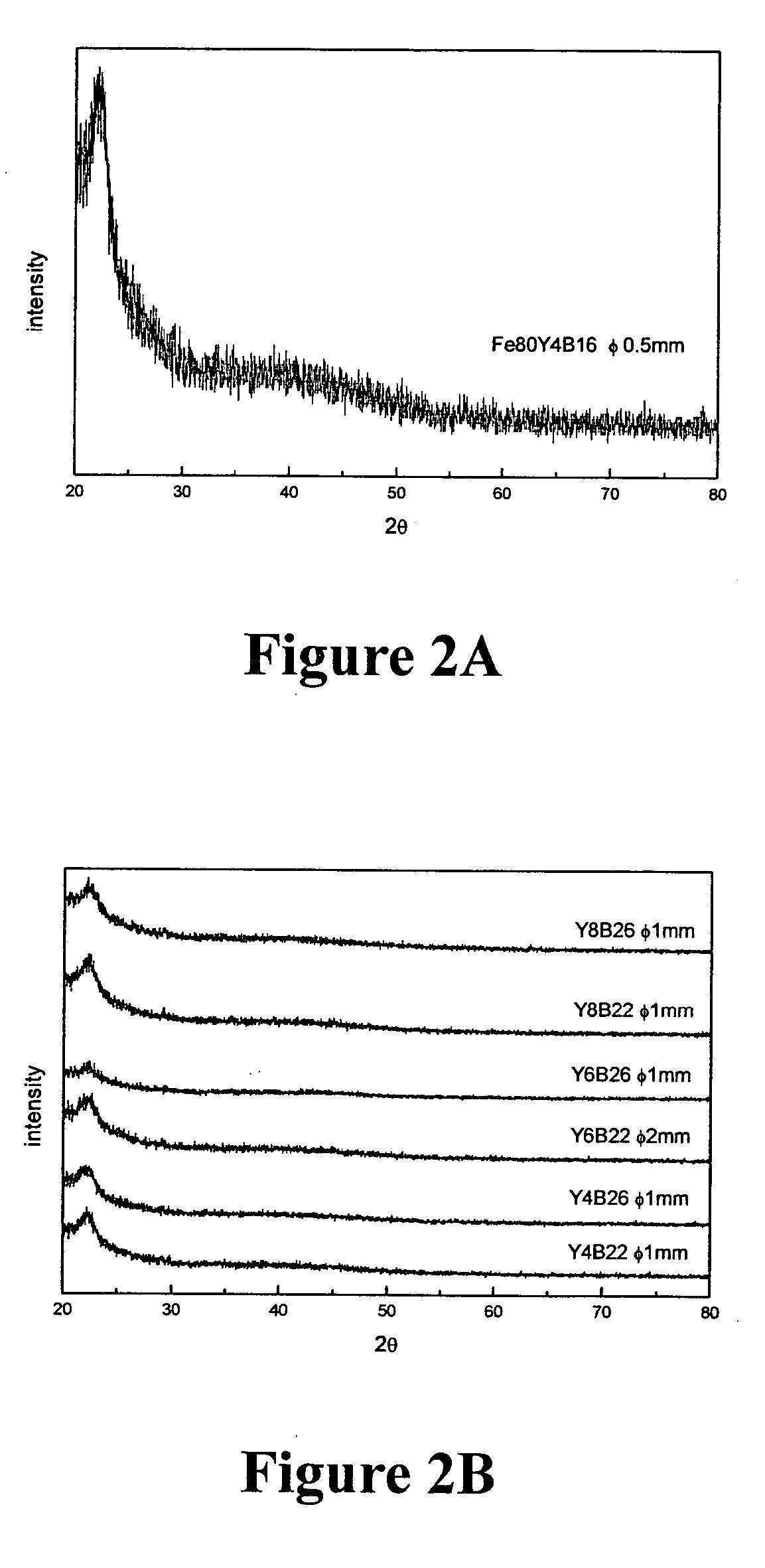

InactiveUS20050263216A1High glass forming abilityIncreased electrical resistivityMagnetic materialsAmorphous phaseAtomic radius

Disclosed in this invention is a family of ternary and multi-nary iron-based new compositions of bulk metallic glasses which possess promising soft magnetic properties, and the composition selection rules that lead to the design of such new compositions. The embodiment alloys are represented by the formula MaXbZc, where M represents at least one of ferromagnetic elements such as iron and may partly be replaced by some other substitute elements; X is an element or combinations of elements selected from those with atomic radius at least 130% that of iron and in the mean time is able to form an M-rich eutectic; and Z is an element or combinations of elements selected from semi-metallic or non-metallic elements with atomic radius smaller than 86% that of iron and in the meantime is able to form an M-Z eutectic; a, b, c are the atomic percentage of M, X, Z, respectively, and a+b+c=100%. When 1%<b<15% and 10%<c<39%, the alloys show a bulk glass forming ability to cast amorphous ribbons / sheets at least 0.1 mm in thickness. When 3%<b<10% and 18%<c<30%, the alloys show a bulk glass forming ability to cast amorphous rods at least 1 mm in diameter. The amorphous phase of these as-cast sheets / rods is at least 95% by volume. This invention also discloses the existence of nano-crystalline phase outside of the outer regime of the bulk glass forming region mentioned above.

Owner:NATIONAL TSING HUA UNIVERSITY

Tin coatings incorporating selected elemental additions to reduce discoloration

A method of introducing an anti-tarnish agent into the matrix of a tin coating to reduce oxidation and / or yellowing of the tin coating. The agent is preferably zinc, indium or phosphorous and can be deposited in a molten form to alloy with the existing tin coating. Alternatively, the existing tin coating may be exposed to a chemical bath including the agent and later heated to reflow the tin coating and agent thereby incorporating the agent into the matrix of the tin coating.

Owner:GBC METALS LLC

Weld joint and weld material thereof

InactiveCN1993488AIncreased durabilityImprove securityArc welding apparatusWelding/cutting media/materialsChemical compositionImpurity

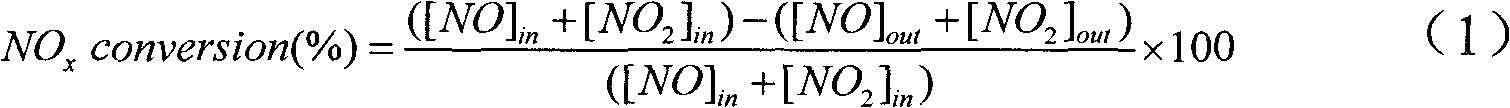

A weld joint, characterized in that both of a base material and a weld metal have a chemical composition that C: 0.01 to 0.45%, Si: more than 1 % and not more than 4 %, Mn: 0.01 to 2 %, P: 0.05 % or less, S: 0.01 % or less, Cr: 15 to 35 %, Ni: 40 to 78 %, Al: 0.005 to 2 %, N: 0.001 to 0.2 % and Cu: 0.015 to 5.5 %, Ti: a content satisfying the following formula (1): {(Si - 0.01) / 30} + 0.01Cu <= Ti <= 5 (1) wherein an element symbol in the formula (1) means the content (mass %) of the element, and the balance: Fe and impurities. The base material and the weld metal may further contain one or more of Co, Mo, Ta, W, V, Zr, Nb, Hf, B, Ca, Mg and REM.

Owner:SUMITOMO METAL IND LTD

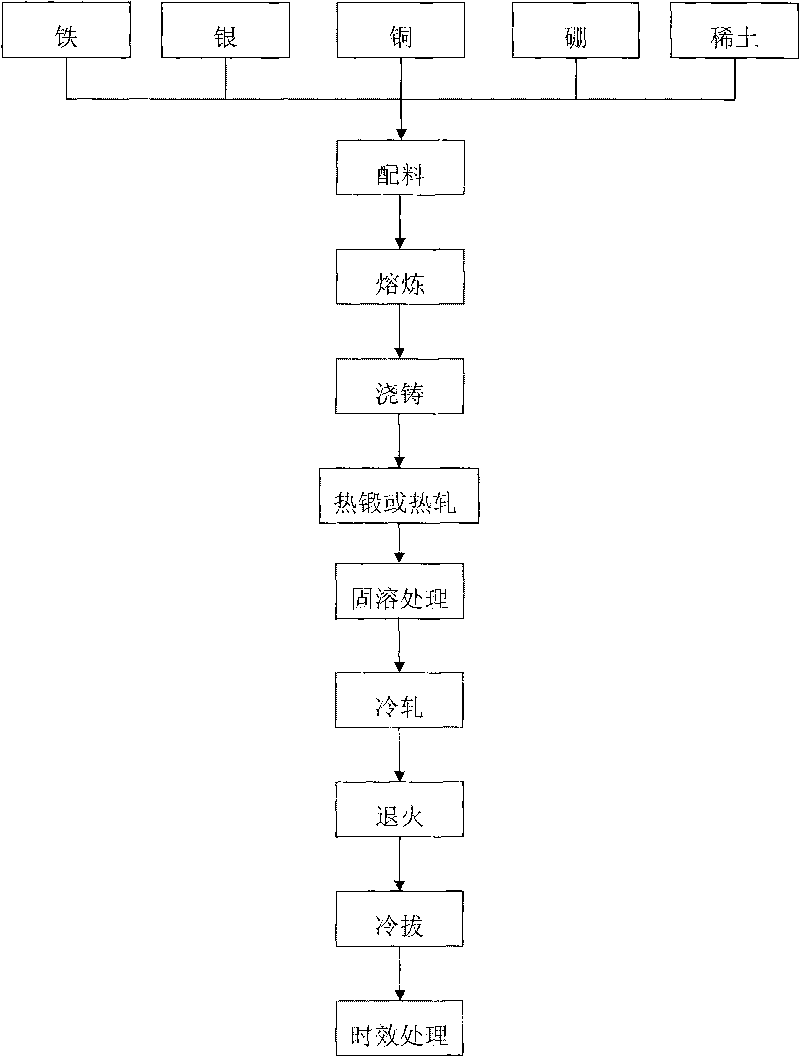

Cu-Fe in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Fe in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Fe and trace Ag and B, rare earth or rare earth compounds to prepare the high strength and high conductivity copper alloy material through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing wide application in the fields such as electronics, information, transportation, energy, metallurgy, electromechanics and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

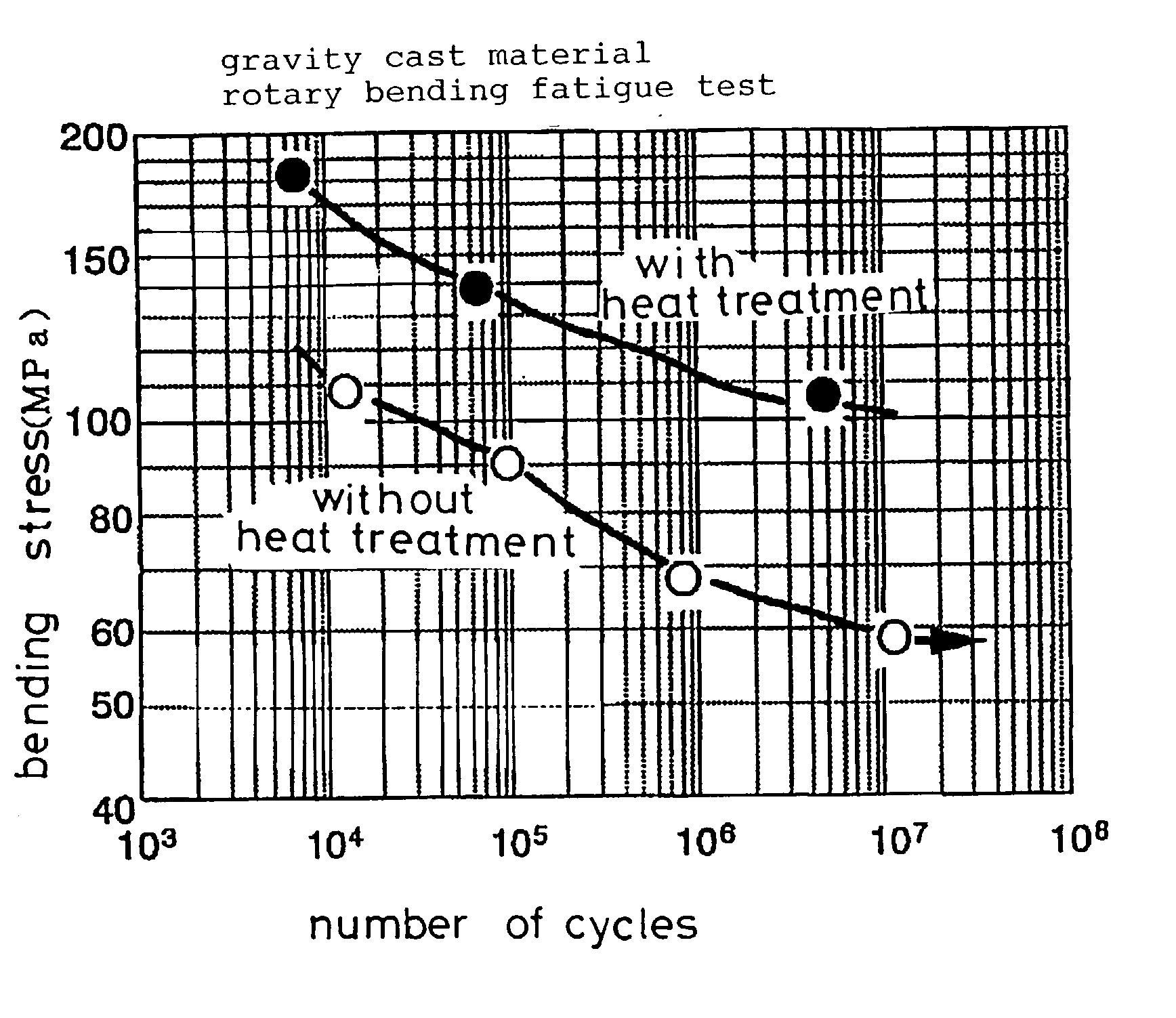

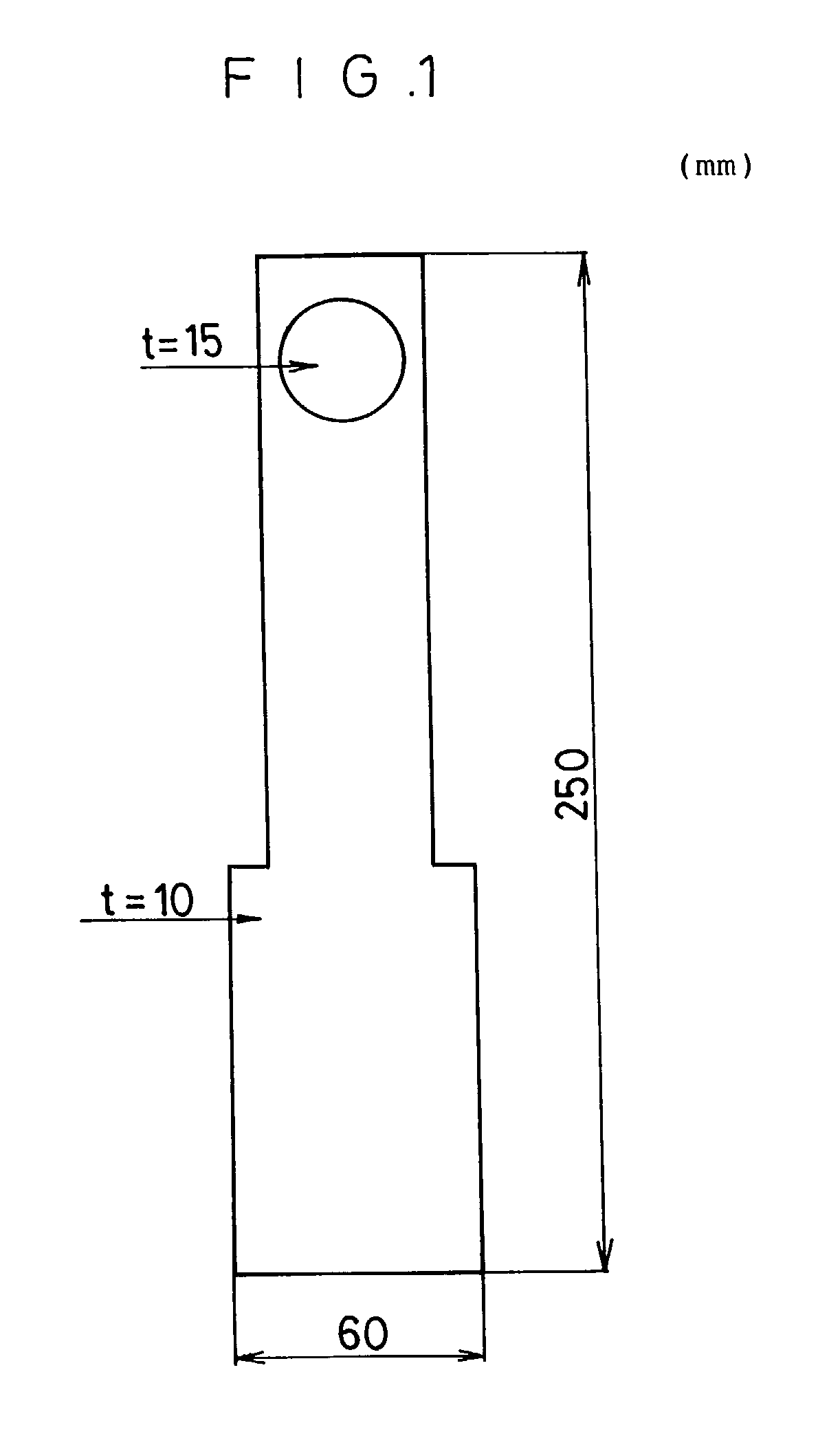

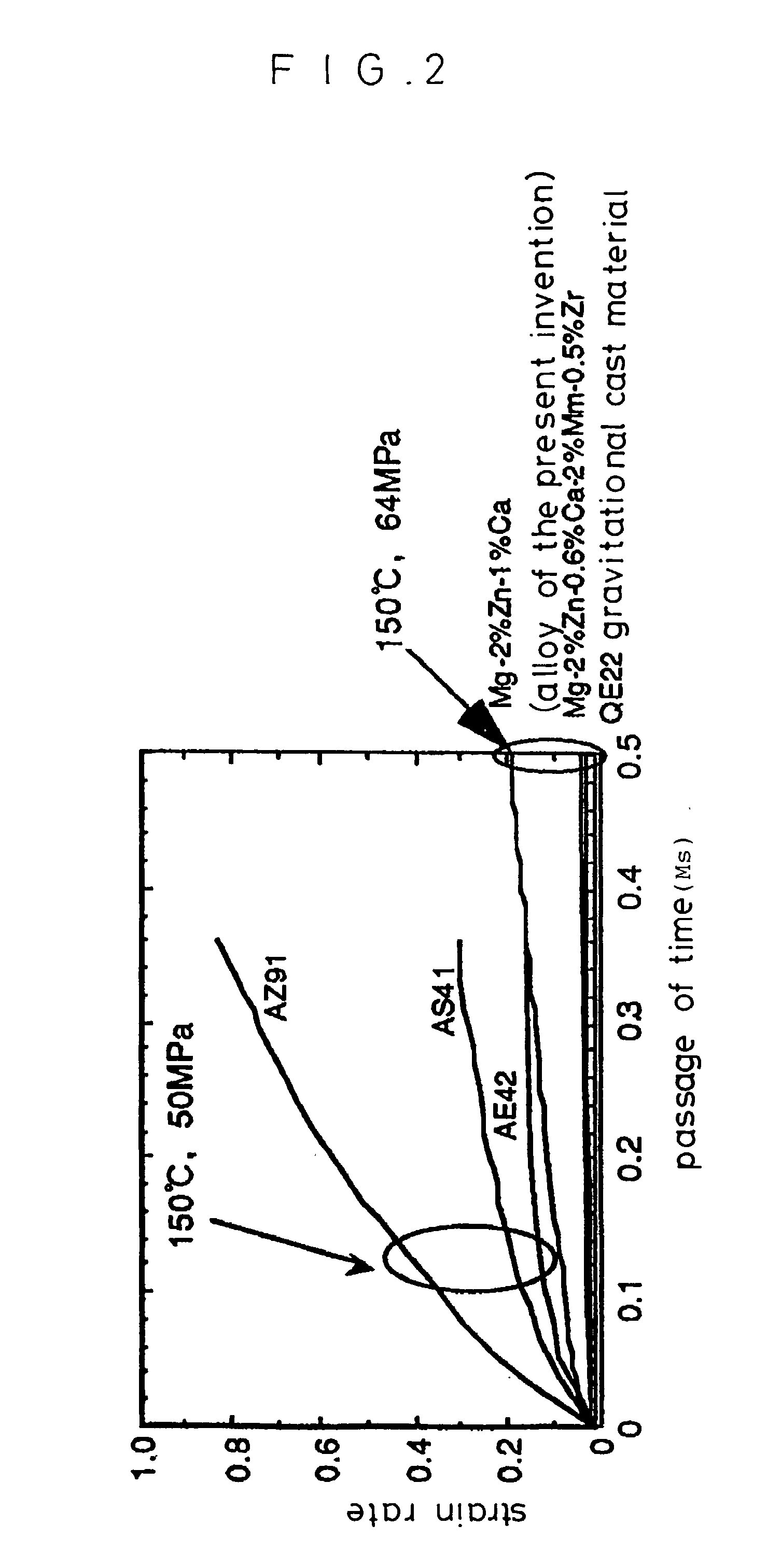

Magnesium alloy and heat treatment method thereof

InactiveUS20030000608A1Excellent high pressure die casting property and creep propertyExcellent high pressure die casting property and creep characteristicQuenchingMagnesium alloy

A magnesium alloy having excellent castability and creep properties has compositions of 1.0-6.0 wt % Zn, 0.5-3.0 wt % Ca, 1.0 wt % or less Zr, 1.0-5.0 wt % at least one lanthanoid, the remainder being Mg and unavoidable impurities. This magnesium alloy undergoes heat treatment of heating the magnesium alloy to 430-470 ° C., quenching, and then heating to 150-250 ° C. for aging. Hot tearing and temperature strength are improved by the addition of an element which is effective for causing eutectic reaction and peritectic reaction with Mg and making Mg particles divied finely.

Owner:TOYOTA CENT RES & DEV LAB INC

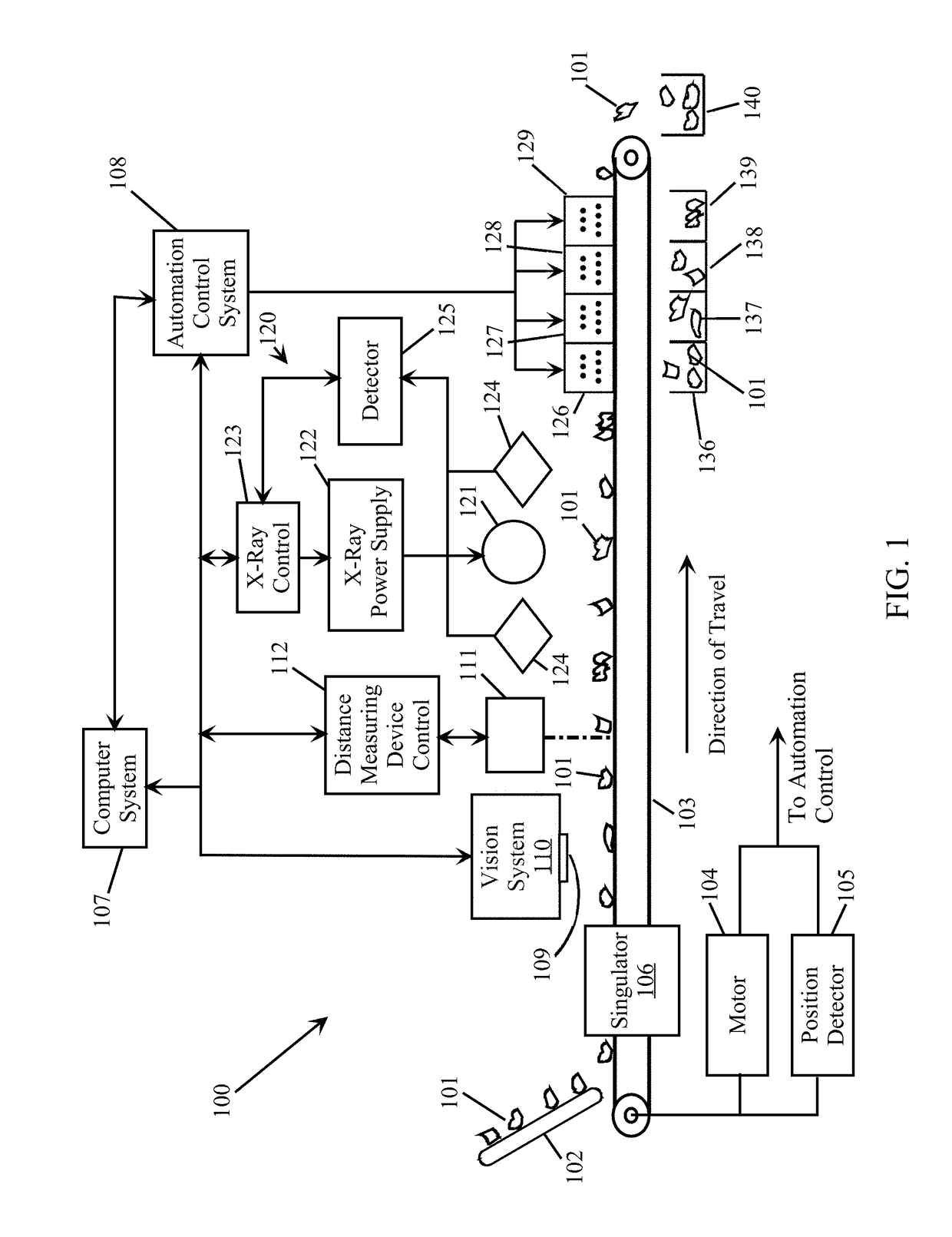

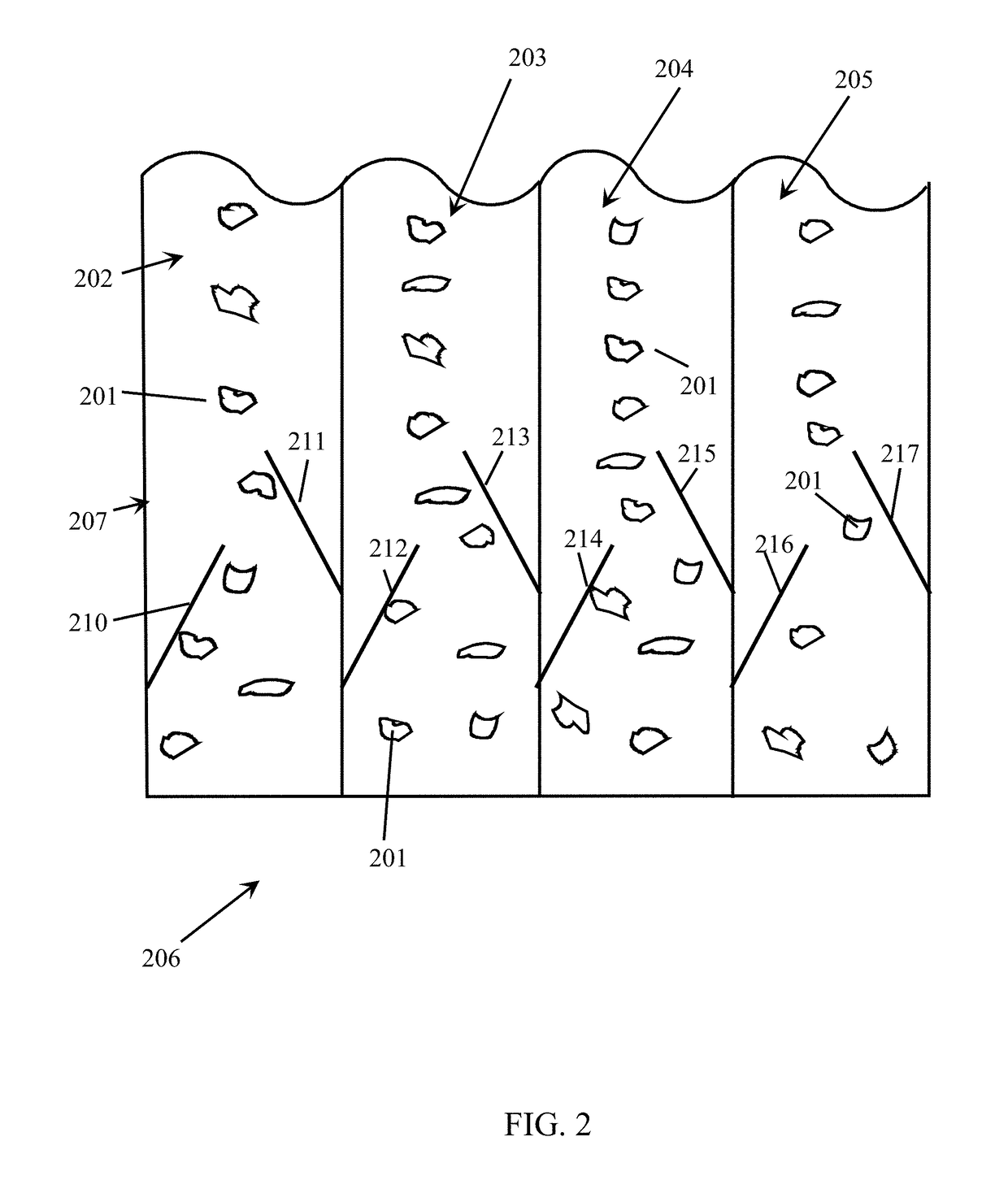

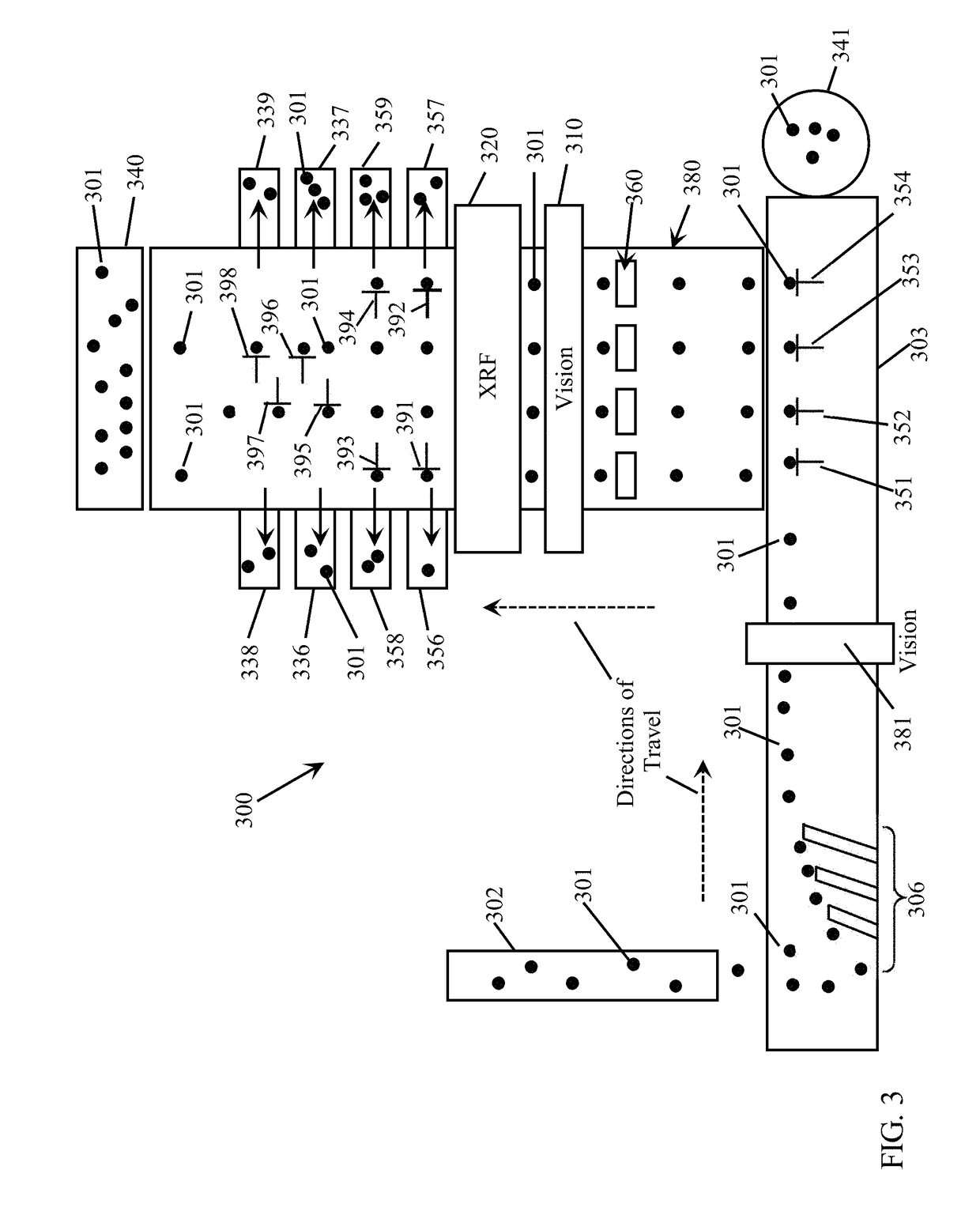

Material sorting system

ActiveUS10207296B2Material analysis using wave/particle radiationUsing optical meansMetal alloyFluorescence

A material sorting system sorts materials, such as scrap pieces composed of unknown metal alloys, as a function of their detected x-ray fluorescence. The x-ray fluorescence may be converted into an elemental composition signature that is then compared to an elemental composition signature of a reference material in order to identify and / or classify each of the materials, which are then sorted into separate groups based on such an identification / classification. The material sorting system may include an in-line x-ray tube having a plurality of separate x-ray sources, each of which can irradiate a separate stream of materials to be sorted.

Owner:SORTERA TECH INC

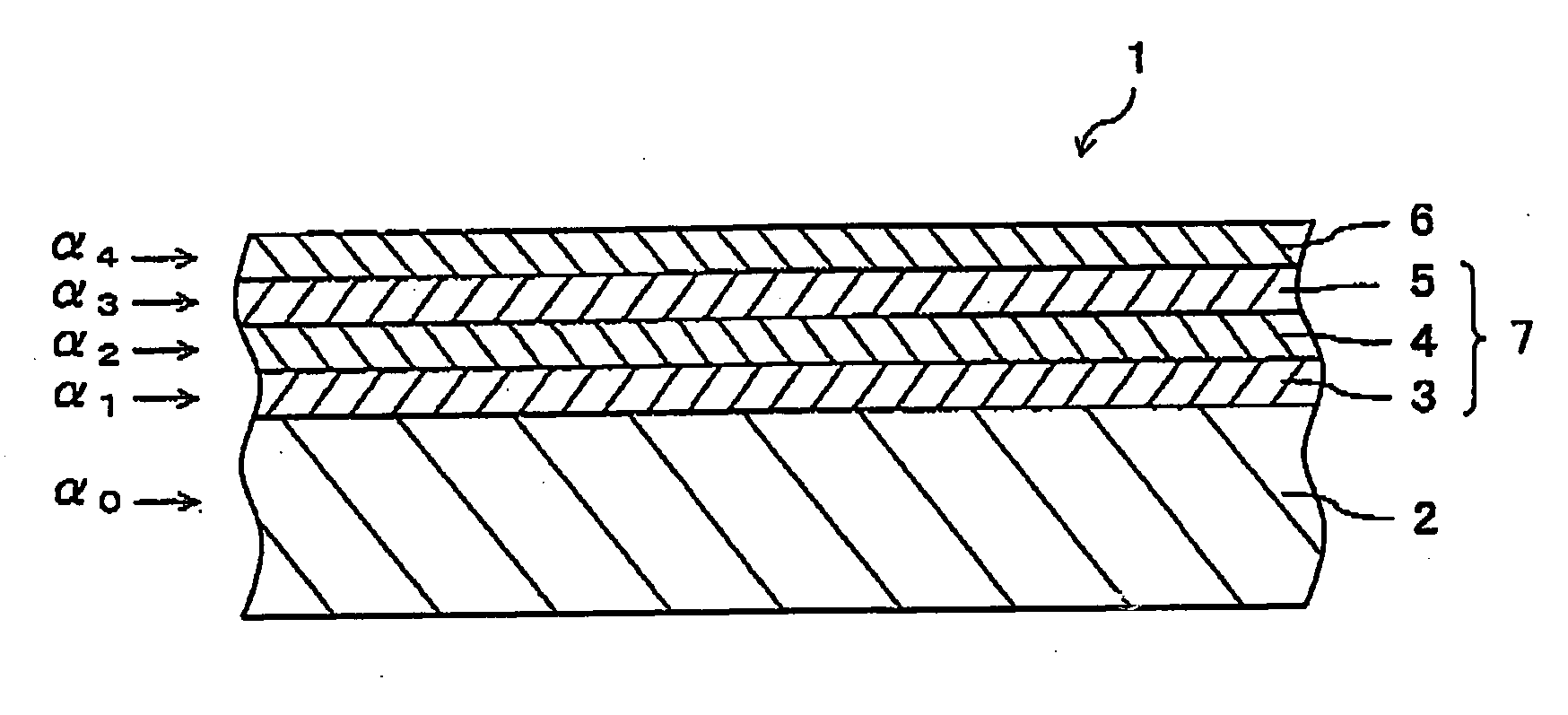

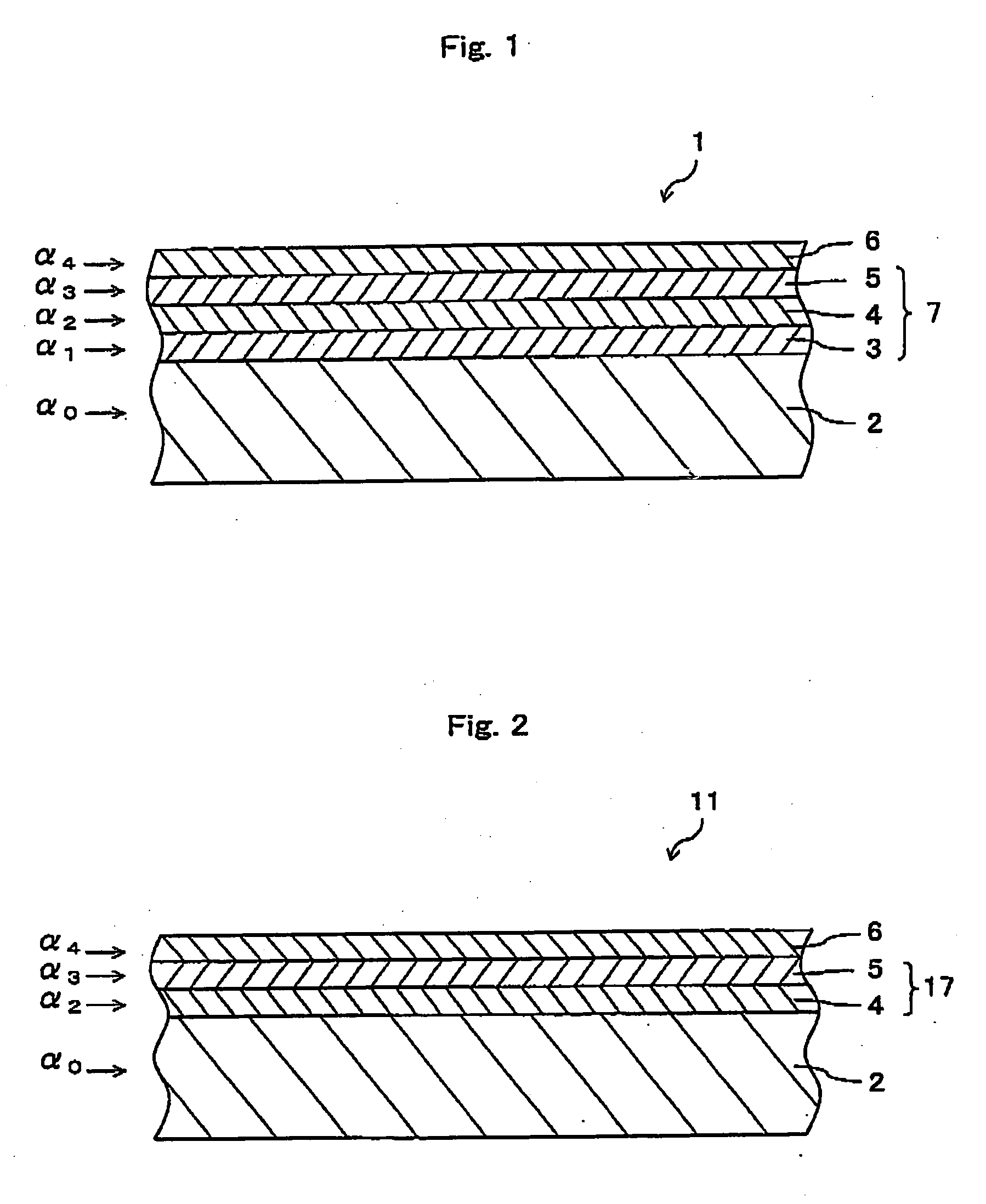

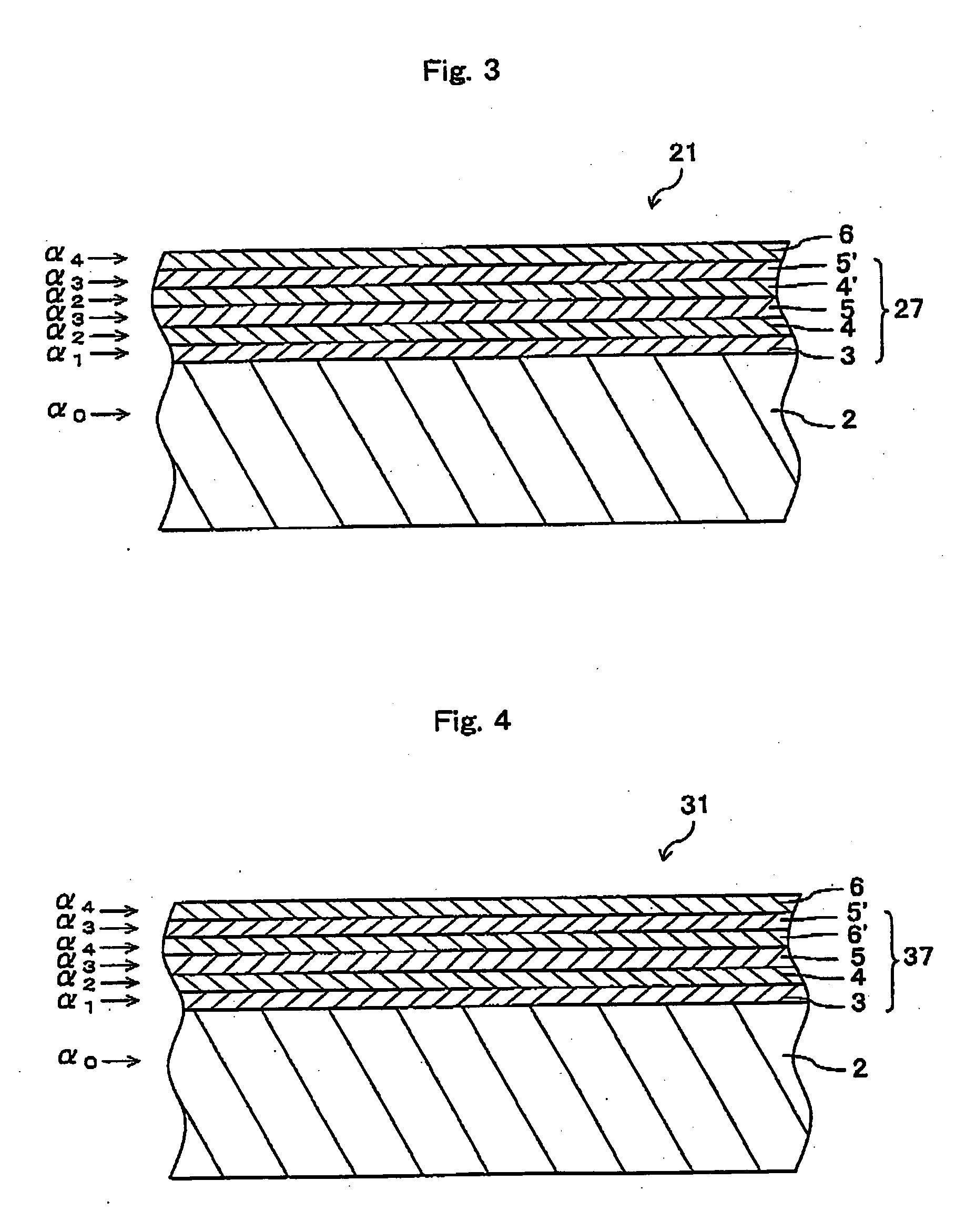

Corrosion-resistant silicon nitride ceramics

InactiveUS20060073361A1Prevent peelingLarge coefficientBlade accessoriesMachines/enginesThermal dilatationCrazing

A corrosion-resistant silicon nitride ceramics in which an adhesion enhancing layer (3), a stress relaxing layer (4) and a crack extension preventing layer (5) are laminated in this order on a ceramic substrate (2) composed mainly of silicon nitride, and a surface corrosion-resistant layer (6) composed mainly of zirconium oxide stabilized by an element of the group 3a of the periodic table is laminated. The thermal expansion coefficient (α0) of the ceramic substrate (2), the thermal expansion coefficient (α1) of the adhesion enhancing layer (3), and the thermal expansion coefficient (α2) of the stress relaxing layer (4), the thermal expansion coefficient (α3) of the crack extension preventing layer (5), and the thermal expansion coefficient (α4) of the surface corrosion-resistant layer (6) satisfy the following relational expressions (I) to (III): α0≈α1 (I) α3<α2 (II) α3<α4 (III)

Owner:KYOCERA CORP +2

Al-Mg-Si series alloy plate, method for manufacturing the same and Al-Mg-Si series alloy material

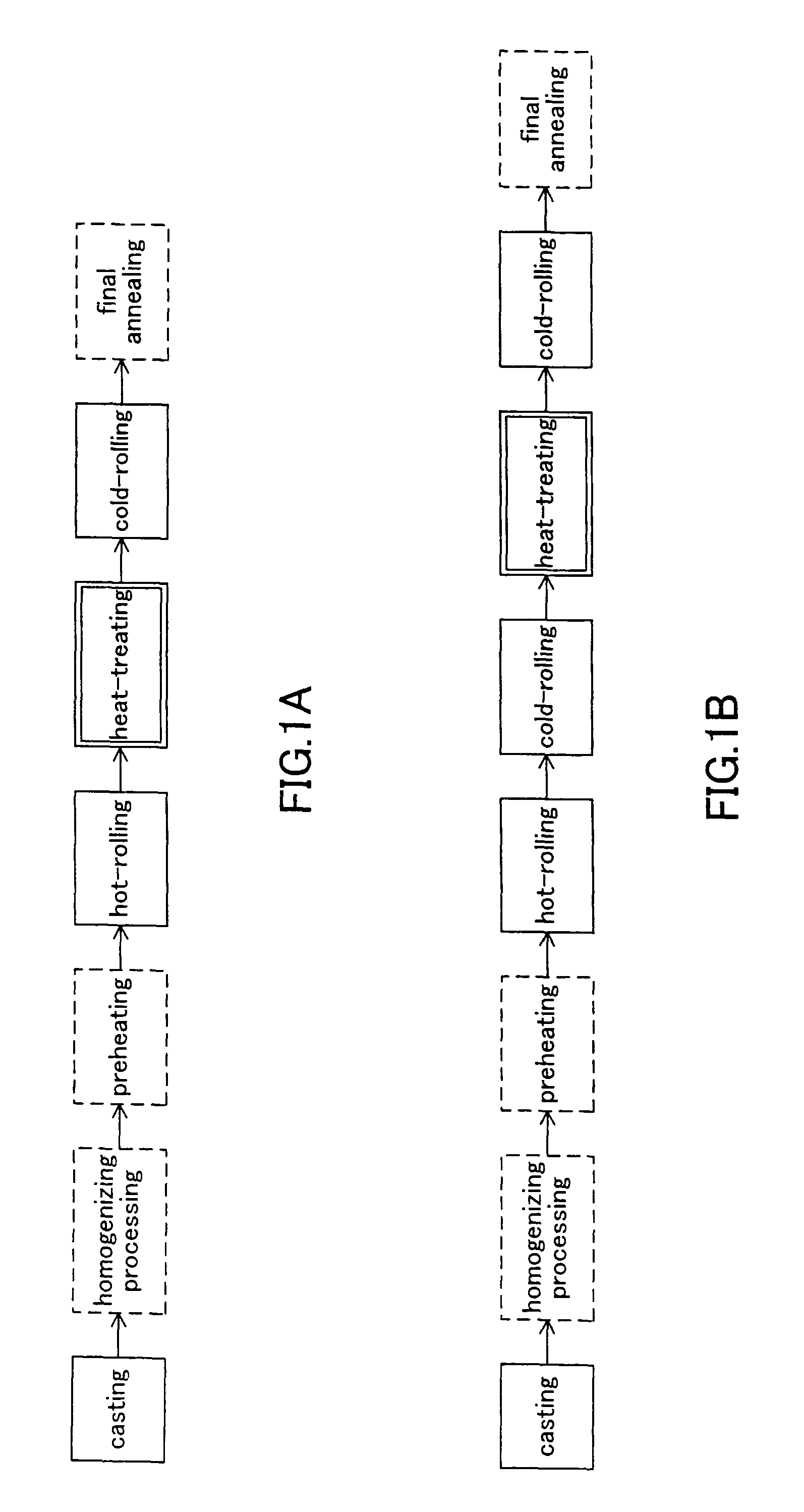

A method for manufacturing an Al-Mg-Si series alloy plate includes the steps of hot-rolling and subsequently cold-rolling an Al-Mg-Si series alloy ingot. The Al-Mg-Si series alloy ingot consists of Si: 0.2 to 0.8 mass %, Mg: 0.3 to 1 mass %, Fe: 0.5 mass % or less, Cu: 0.5 mass % or less, at least one of elements selected from the group consisting of Ti: 0.1 mass % or less and B: 0.1 mass % or less and the balance being Al and inevitable impurities. Heat-treating for holding a rolled ingot at 200 to 400° C. for 1 hour or more is performed after a completion of the hot-rolling but before a completion of the cold-rolling.

Owner:SHOWA DENKO KK

High-strength hot-corrosion-resistant Ni-based single crystal superalloy and preparation method

InactiveCN103966671AImprove high temperature mechanical propertiesExcellent hot corrosion resistancePolycrystalline material growthFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the field of single crystal superalloys, particularly to a high-strength hot-corrosion-resistant Ni-based single crystal superalloy and a preparation method, and is mainly applied to high-temperature components applied to various marine environments and turbine high-temperature components of ground industrial gas turbines. The superalloy comprises chemical components in percentage by weight as follows: 11-15% of Cr, 5-9% of Co, 0.5-2.0% of Mo, 3.0-5.0% of W, 4.5-7.0% of Ta, 3.5-5.6% of Al, 2.3-3.7% of Ti and the balance of Ni. A vacuum induction furnace is used for smelting, a mother alloy is cast firstly, and then the high-strength hot-corrosion-resistant single crystal superalloy is prepared according to a single crystal growth technology and a heat treatment system. The Cr and refractory metallic elements with higher content are selected, but the content of the Ti element is reduced. Meanwhile, the crystal boundary is eliminated through a single crystal technology, so that the hot corrosion resistance, the high-temperature mechanical property and the structure stability of the alloy are further improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

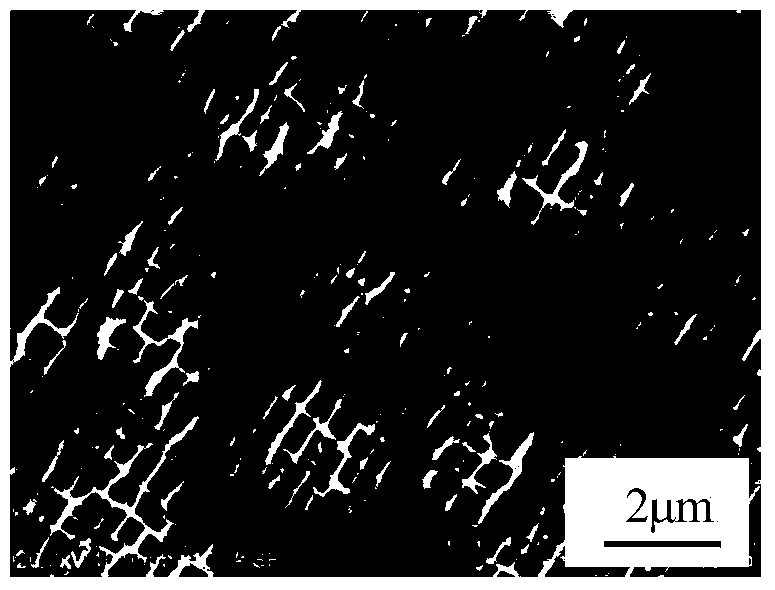

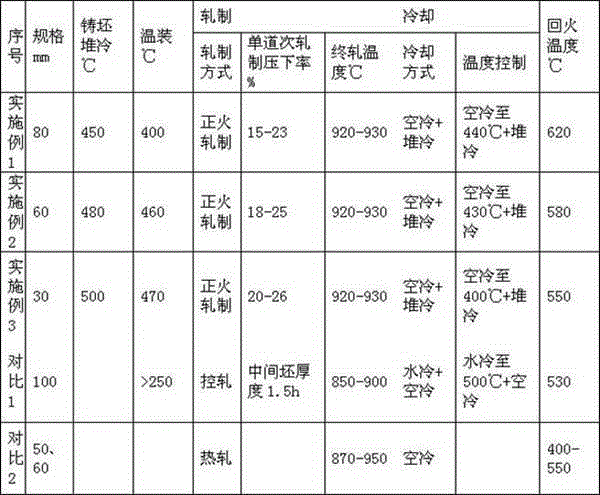

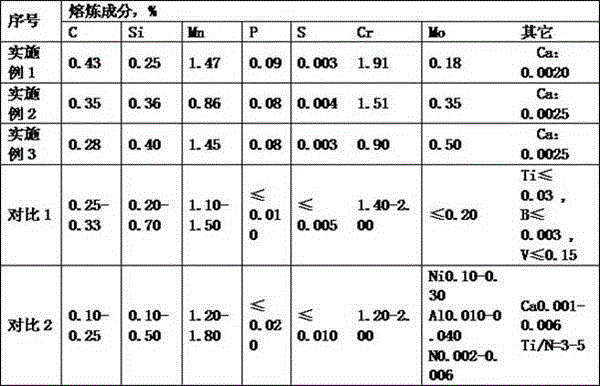

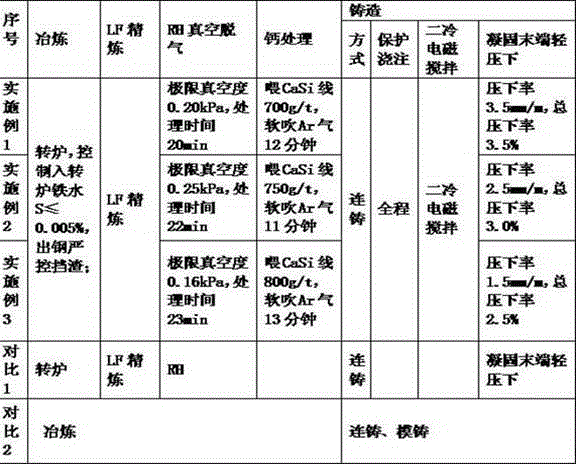

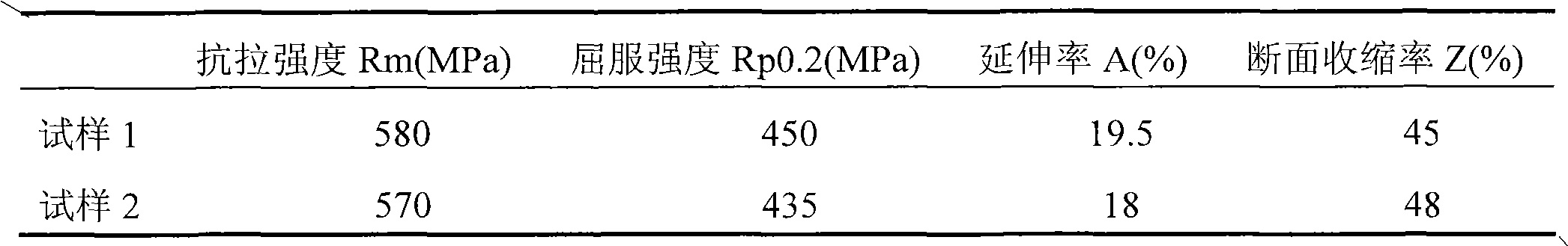

Production process of high-cleanliness non-quenched and tempered plastic mold thick steel plate

The invention relates to a production process of a high-cleanliness non-quenched and tempered plastic mold thick steel plate. The high-cleanliness non-quenched and tempered plastic mold thick steel plate is chemically composed of, by weight percentage, 0.25-0.45% of carbon, 0.20-0.50% of silicon, 0.70-1.50% of manganese, 0.70-2.00% of chromium, 0.15-0.55% of molybdenum, less than 0.01% of phosphorus, less than 0.005% of sulfur, 0.0010-0.030% of calcium, balanced iron and inevitable impurities. The chemical composition is simple in design; by means of the C-Mn-Cr-Mo alloying technology, the content of Mn and Cr can be improved;, by adding a certain amount of Mo, conversion of austenite to ferrite and pearlite can be inhibited, so that the high-cleanliness non-quenched and tempered plastic mold thick steel plate can have high hardenability and obtain a bainite structure; without the elements of Ti and V which are prone to generating inclusions, relatively clean steel can be obtained. The high-cleanliness non-quenched and tempered plastic mold thick steel plate has the advantages of being internally clean and compact, low in content of inclusions and capable of fundamentally eliminating pores, can meet the requirements of advanced plastic molds on internal high quality of steel and can be applied to the plastic mold industries such as automobile and electric appliances.

Owner:SGIS SONGSHAN CO LTD

Metal oxide

ActiveUS20100025617A1Satisfactory piezoelectricityIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyThin material handlingBi elementPiezoelectricity

Provided is a piezoelectric material excellent in piezoelectricity. The piezoelectric material includes a perovskite-type complex oxide represented by the following General Formula (1).A (ZnxTi1-x))yM(1-y)O3 (1)wherein A represents at least one kind of element containing at least a Bi element and selected from a trivalent metal element; M represents at least one kind of element of Fe, Al, Sc, Mn, Y, Ga, and Yb; x represents a numerical value satisfying 0.4≦x≦0.6; and y represents a numerical value satisfying 0.1≦y≦0.9.

Owner:CANON KK +6

Pure titanium wire for spectacle frame and manufacturing method thereof

The invention discloses a pure titanium wire for a spectacle frame and a manufacturing method thereof. 0 to 0.20 weight percent of O element and 0 to 0.26 weight percent of Fe element are added in the pure titanium cast ingot smelting process. The amount of Fe and O elements needed to be added during reinforcement is obtained according to the strength theta 0 of original spongy titanium, and the adding amount of Fe and TiO2 in the pure titanium material smelting process is determined further. Through forging, rolling, drawing and annealing processes, the strength controllable pure titanium wire is prepared and meets requirements on titanium wire properties of different parts of the spectacle frame. In the smelting process for preparing the pure titanium material, accurate amount of Fe element and O element are added, and chemical composition content in the pure titanium wire is controlled, so that the strength of the pure titanium wire is accurately controlled, the strength deviation of TA2 pure titanium wires produced in different batches is controlled within 40MPa, and the pure titanium wires meeting specific strength requirements are produced.

Owner:XIAN AEROSPACE NEW MATERIAL

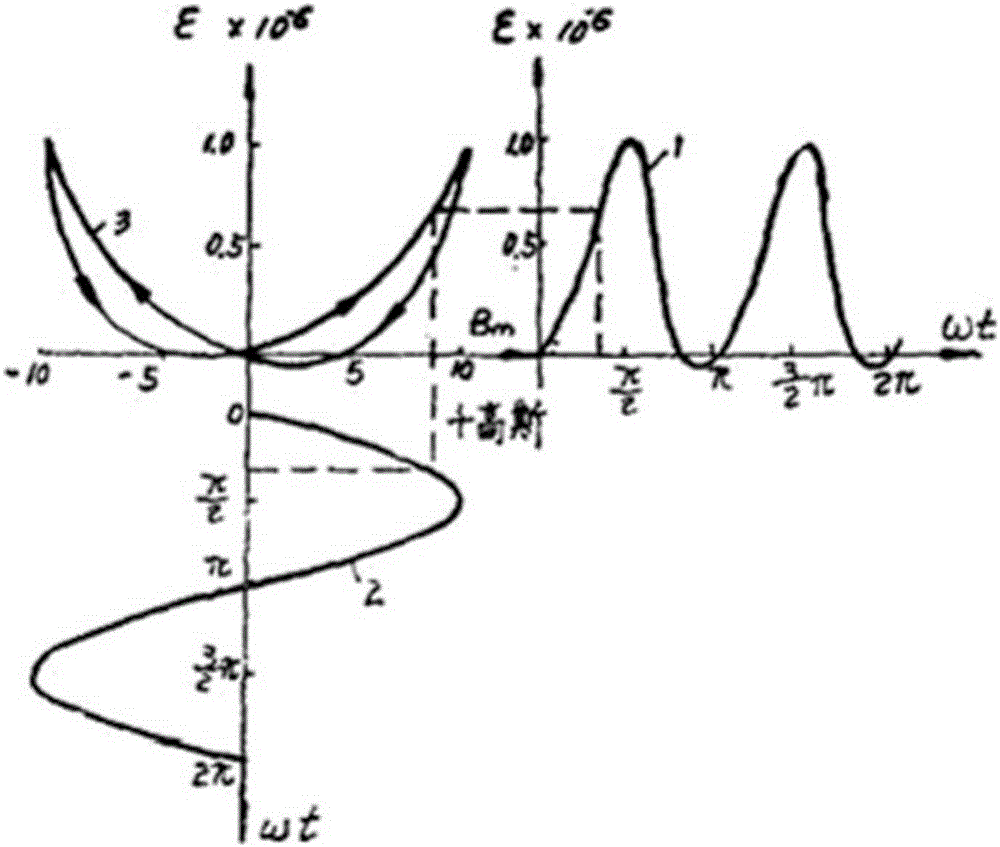

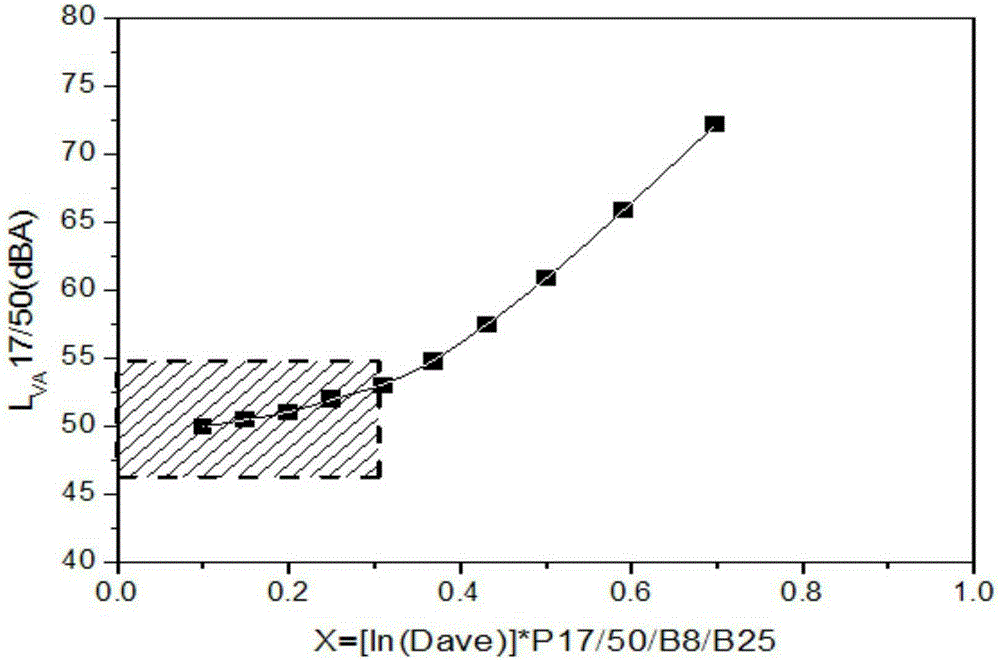

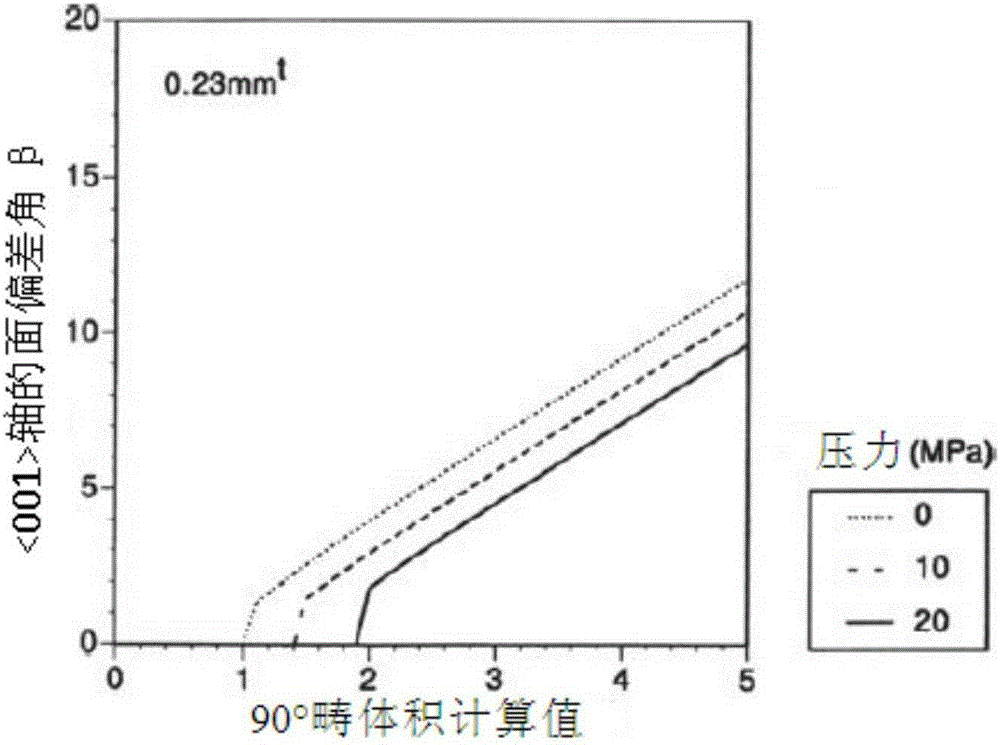

Low-noise feature oriented silicon steel and manufacturing method thereof

The invention discloses low-noise feature oriented silicon steel which comprises a silicon steel base plate and an insulating coating, wherein the silicon steel base plate is coated with the insulating costing. In addition, the tension range of the insulating coating ranges from 6 MPa to 8 MPa. The content of Cu in the silicon steel base plate satisfies the inequation that 0.1%<=Cu<=0.5%, the content of S in the silicon steel base plate satisfies the inequation that 0.01%<=S<=0.05%, and the atomic ratio of Cu / S satisfies the inequation that 5<=Cu / S<=10. The invention further discloses a manufacturing method for the low-noise feature oriented silicon steel. The method sequentially includes the steps of firstly, smelting and casting to form a plate blank, secondly, heating, thirdly, normalization, fourthly, cold rolling, fifthly, decarbonization annealing, sixthly, finished product annealing, and seventhly, thermal drawing annealing, wherein the surface of the silicon steel base plate is coated with the insulating costing, and the coating quantity is adjusted so that the tension range of the insulating coating can range from 6 MPa to 8 MPa. The low-noise feature oriented silicon steel is small in magnetostriction, vibration generated by an iron core made of the silicon steel is small, and therefore the overall noise level of a transformer is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Copper base alloy with improved punchin and impacting performance and its preparing method

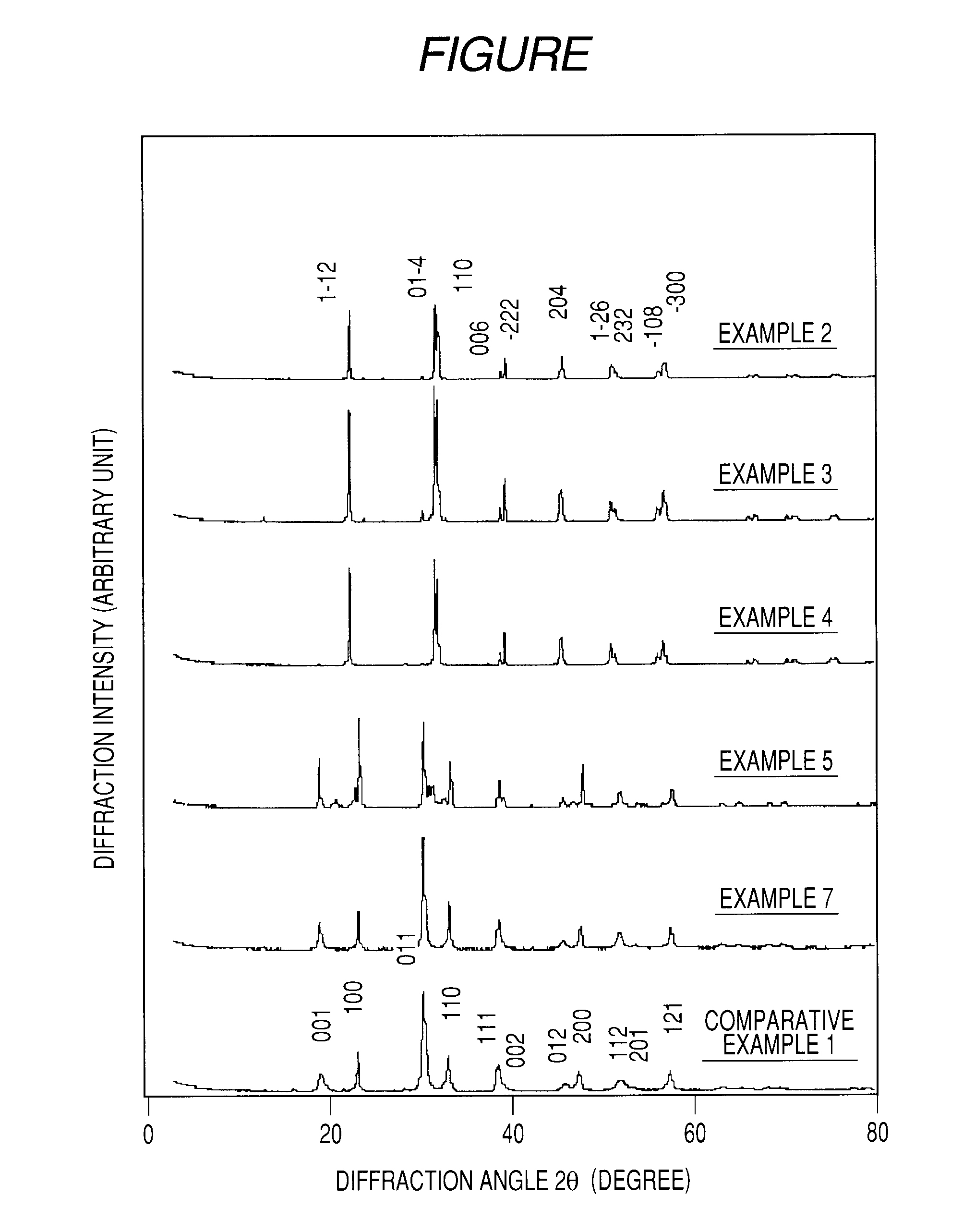

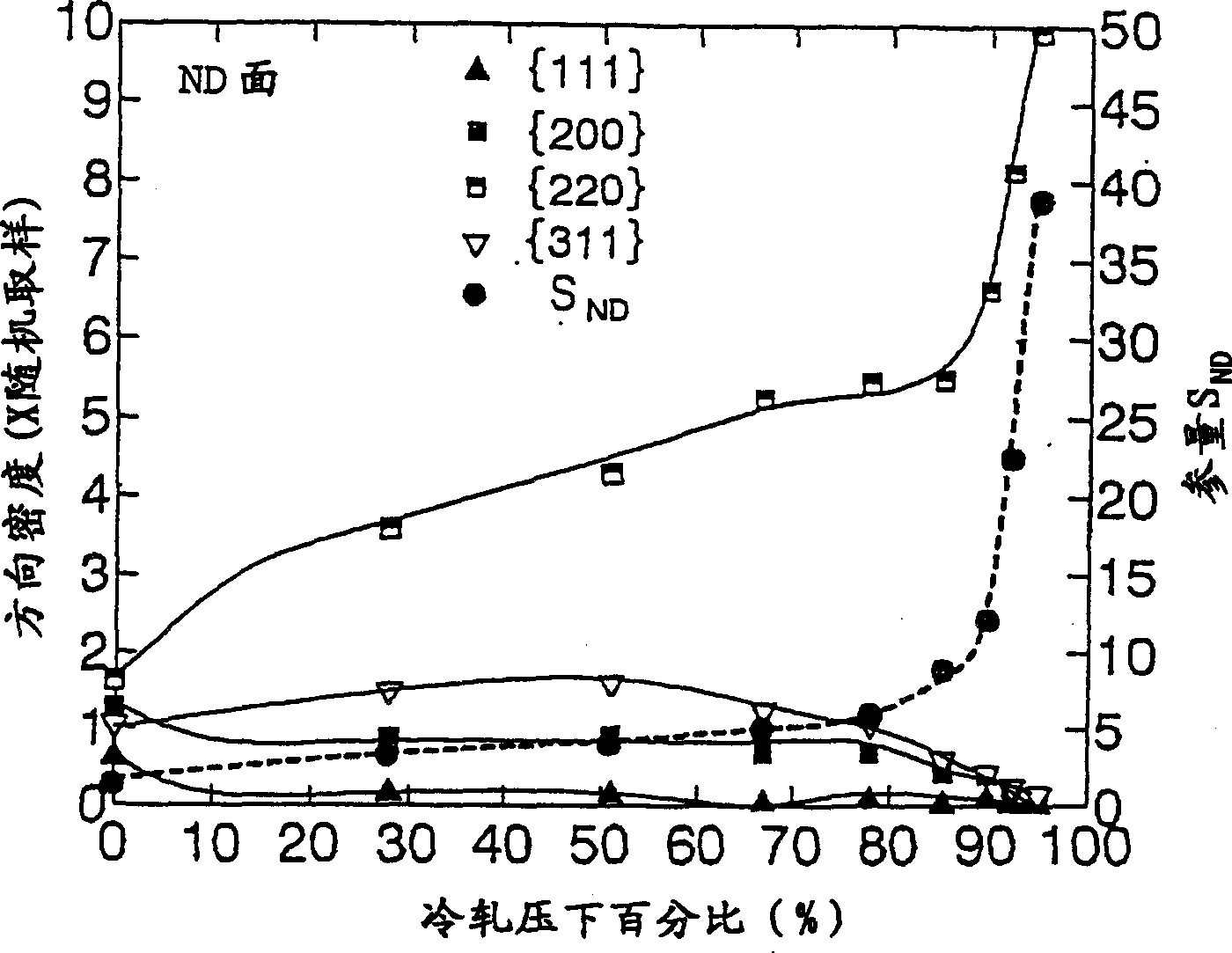

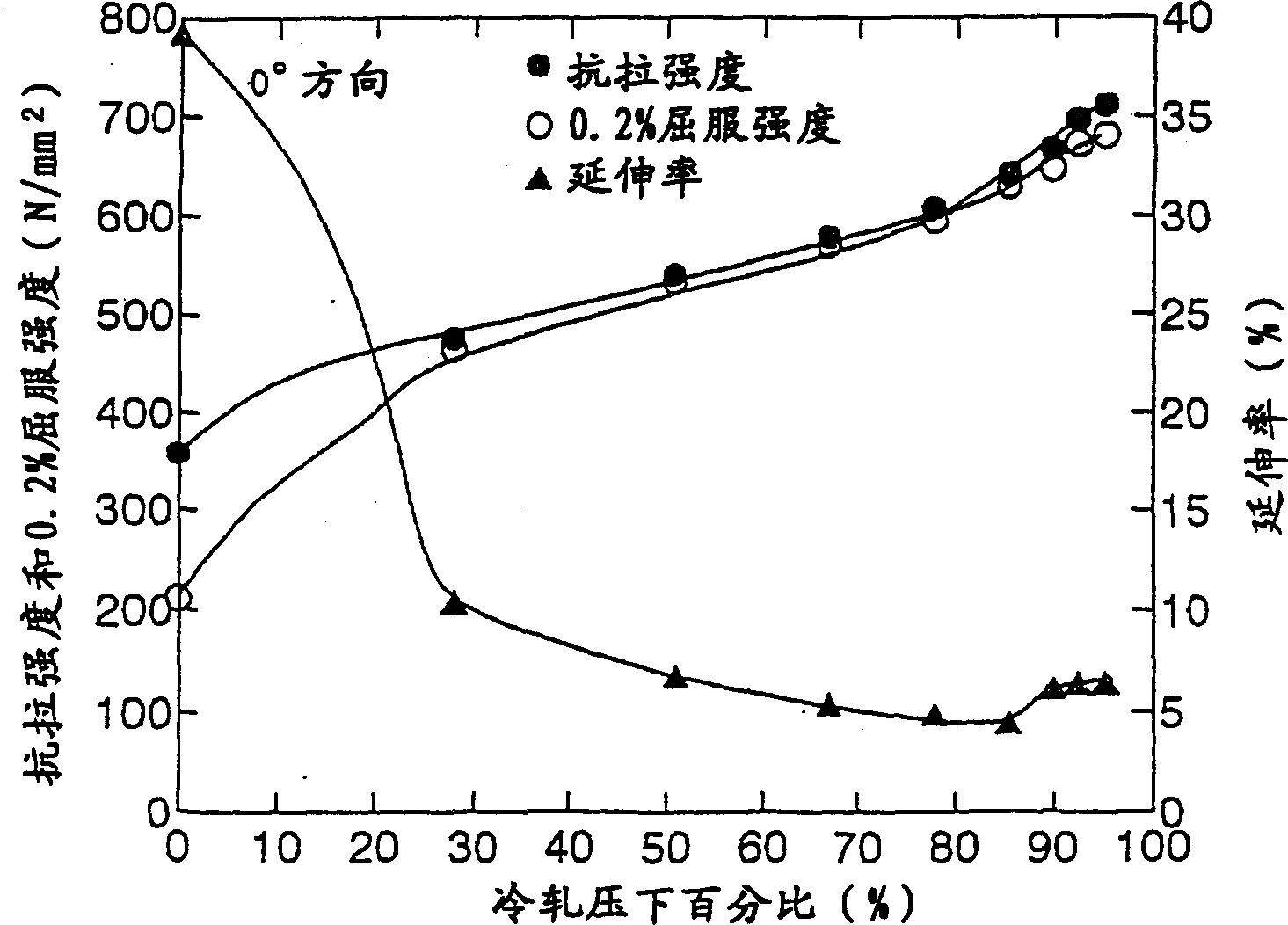

The present invention relates to a kind of copper-base alloy containing at least one element selected from Sn, Ni, P, Zn, Si, Fe, Co, Mg, Ti, Cr, Zr and Al in 0.01-30 wt% except Cu and impurities. The alloy has the X ray diffraction strength ratio SND of at least 10, where Snd=I{220} / I{200}, with I{220} is the X ray diffraction strength in {220} plane and I{200} is the X ray diffraction strength in {200} plane. At the same time, the alloy has balanced conductivity, strength, rebound elasticity, hardness and bending performance as well as improved punching performance. The present invention also relates to the preparation process of the alloy.

Owner:DOWA METALTECH CO LTD

Aluminium alloy strip for brazing

The invention relates to a method for assembling sheets of aluminium alloy, comprising a welding without flux, in a controlled atmosphere, at a temperature of 580 to 620° C. a rapid cooling and, optionally, reheating to a temperature of 80 to 250° C. in which at least one of the sheets has a core alloy comprising (wt. %), Si 0.3 1.0, Fe<1.0, Cu 0.3 1.0, Mn 0.3 2.0, Mg 0.3 3.0, Zn<6.0, Ti<0.1, Zr<0.3, Cr<0.3, Ni<2.0, Co<2.0, Bi<0.5, Y<0.5, other elements <0.05 each, to a total of 0.15, the remainder being aluminium and covered on at least one face with a welding aluminium alloy, comprising 4 to 15 % silicon and 0.01 to 0.5% of at least one of the elements Ag, Be, Bi, Ce, La, Pb, Pd, Sb, Y or a mixed metal. The method is particularly suitable for the non-flux welding of heat exchangers.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD +1

Al-Si-Cu-Mg cast aluminum alloy and preparation method thereof

InactiveCN104073699AImprove performanceAccurate element content control valuePressure castingAutomotive industry

The invention relates to metal smelting technology and particularly relates to a Al-Si-Cu-Mg cast aluminum alloy and a preparation method thereof. The cast aluminum alloy comprises 89.5-90.5wt% of aluminum (Al) and the balance of 6.5-7.5wt% of silicon (Si) and 0.02-0.04wt% of modificator strontium (Sr), wherein according to the alloy, the content of copper (Cu) is 1.5-2.5wt%, the content of magnesium (Mg) is 0.35-0.65wt% and 0.05-0.25wt% of zirconium (Zr) and 0.1-0. 5wt% of cadmium (Cd) are both added into the alloy. The preparation method comprises the steps of smelting, refining, carrying out modification treatment, adding 0.04wt% of Sr, standing for 40-60 minutes, carrying out low pressure casting by using an electromagnetic pump and carrying out T6 heat treatment on castings to obtain the corresponding castings. Since more accurate element content control values and reliable operation process parameters are provided by the scheme, the high-performance cast aluminum alloy, especially suitable for the automotive industry can be prepared based on the optimized configuration of trace elements in AlSi7Cu2Mg.

Owner:QUZHOU COLLEGE OF TECH

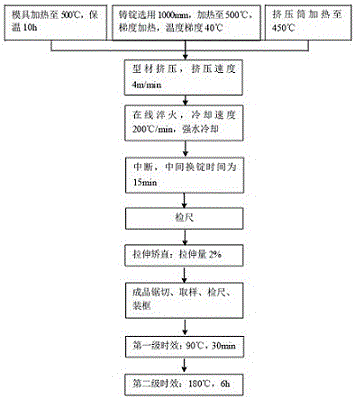

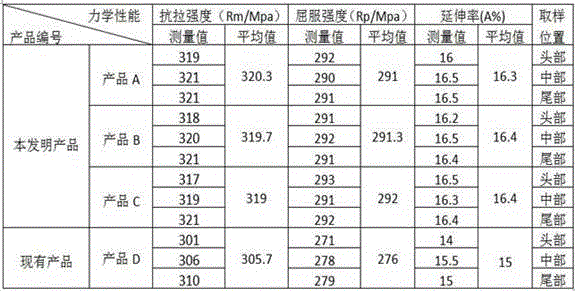

Al-Mg-Si aluminum alloy and extrusion method for sectional bar of Al-Mg-Si aluminum alloy

The invention discloses an Al-Mg-Si aluminum alloy and an extrusion method for a sectional bar of the Al-Mg-Si aluminum alloy. The Al-Mg-Si aluminum alloy comprises, by weight percent, 0.9%-1.25% of Mg, 0.5%-0.9% of Si, 0.2%-0.42% of Cu, smaller than or equal to 0.6% of Fe and 0.07%-0.35% of Cr and further comprises one or more elements of smaller than or equal to 0.15% of Mn, smaller than or equal to 0.22% of Zn, smaller than or equal to 0.15% of Ti, smaller than or equal to 0.05% of V, smaller than or equal to 0.5% of Hf, smaller than or equal to 0.25% of Sc, smaller than or equal to 1.0% of Ag and the balance Al. The aluminum alloy with the high mechanical performance is obtained by optimizing alloy components, the content of the alloy components and the sectional bar extrusion technology, and the production efficiency is effectively improved. The problems that in the prior art, conventional aluminum for transportation is low in strength and poor in ductility, the control range of the sectional bar extrusion technology link is wide, stability is poor, online quenching control difficulty is large, quenching uniformity is poor, and the production efficiency is low are solved.

Owner:广西南南铝加工有限公司

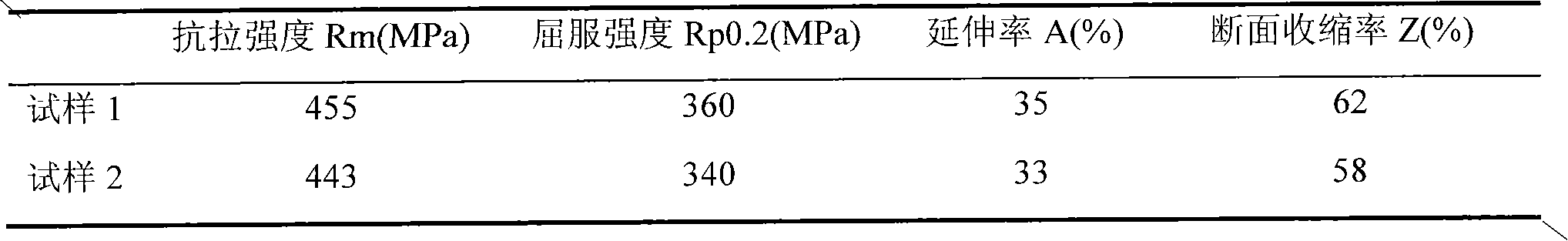

Steel plate for third-generation nuclear power station reactor containments and manufacturing method thereof

InactiveCN102776441AAchieve productionReduce carbon contentManufacturing convertersNiobiumNuclear power

The invention belongs to the field of steel plate smelting, and specifically relates to a steel plate for third-generation nuclear power station reactor containments and a manufacturing method for the steel plate. The steel plate for the third-generation nuclear power station reactor containments contains the following components by weight: 0.08-0.12% of carbon (C), 0.15-0.55% of silicon (Si), 0.9-1.5% of manganese (Mn), less than or equal to 0.007% of phosphorus (P), less than or equal to 0.004% of sulphur (S), 0.1-0.5% of nickel (Ni), 0.0-0.3% of chromium (Cr), 0.10-0.35% of molybdenum (Mo), 0.010-0.050% of vanadium (V), 0.010-0.030% of niobium (Nb), 0.008-0.035% of titanium (Ti), 0.020-0.050% of aluminum (Al), less than or equal to 0.006% of nitrogen (N), and less than or equal to 0.08% of Nb+V; and the balance of iron and unavoidable impurities. The steel plate has benefits that the steel plate, containing combinations of components by weight percentage mentioned above and being manufactured by the method provided by the invention, is characterized by low carbon content, high-temperature resistant performance against 200 degrees centigrade, low cost and excellent welding performance; and tensile strength of the steel plate is higher than 600MPa.

Owner:JIGANG GRP

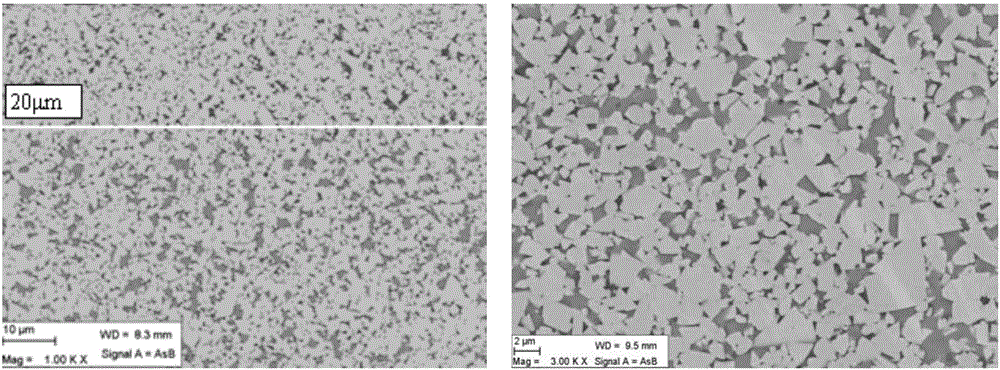

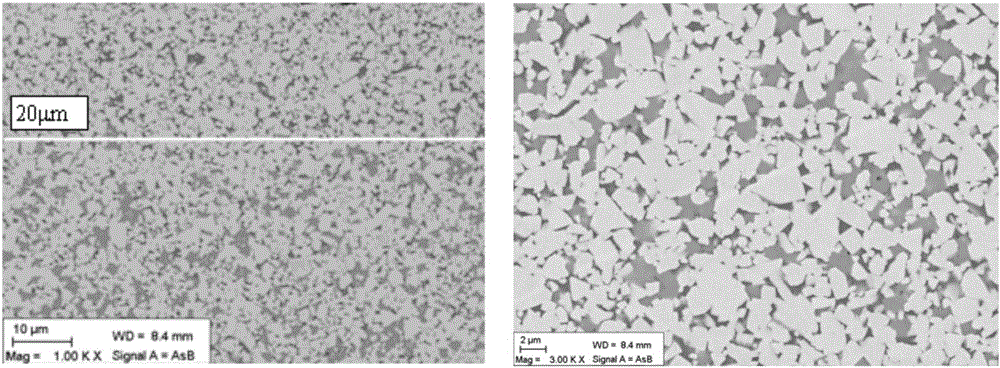

Hard alloy blade and preparation method thereof

ActiveCN105950937AHigh hardnessImprove high temperature performanceTurning toolsTi elementTungsten carbide

The invention discloses a hard alloy blade and a preparation method thereof. The hard alloy blade comprises a hard alloy blade basal body and a coating layer; the hard alloy blade basal body uses Co as a binding phase, and uses tungsten carbide and a titanium-contained cubic-phase compound as a hard phase; the solid solution is performed for a W element and a Cr element in the binding phase; the mass fraction of the W element in the binding phase is 2-10 wt.%; the mass fraction of the Cr element in the binding phase is 1-10 wt.%; the titanium-contained cubic-phase compound is a carbon-nitrogen compound containing one or two in a Ta element and a Nb element and a Ti element; and the grain distribution of tungsten carbide has a double-peak structure. The preparation method comprises batching, powder preparation by mixing, molding by pressing, sintering and preparation of a coating layer. The hard alloy blade has the advantages of high hardness, toughness and strength and excellent and stable cutting performance, and is high in generality, suitable for various processing fields, simple in preparation method and low in cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Mn alloy materials for magnetic materials, Mn alloy sputtering targets, and magnetic thin films

InactiveUS6270593B1High purityLower Level RequirementsVacuum evaporation coatingSputtering coatingThin membraneManganese

Mn alloy materials for magnetic materials contain 500 ppm or less, preferably 100 ppm or less, oxygen, 100 ppm or less, probably 20 ppm or less, sulfur, and preferably a total of 1000 ppm or less, more preferably 500 ppm or less, impurities (elements other than Mn and the alloying component). The alloying component that forms an alloy with Mn is one or two or more elements selected from the group consisting of Fe, Ir, Pt, pd, Rh, Ru, Ni, Cr and Co. Sputtering targets formed from the Mn alloy materials for use in depositing magnetic thin film, and the thin films so produced.

Owner:JX NIPPON MINING& METALS CORP

Al-zn-mg alloy product with reduced quench sensitivity

This relates to an aluminum alloy product, in particular an age-hardenable Al—Zn—Mg type alloy product for structural members, the alloy product combining a high strength with high toughness and reduced quench sensitivity, and having a chemical composition including, in wt. %: Zn about 3 to 11%, Mg about 1 to 3%, Cu about 0.9 to 3%, Ge about 0.03 to 0.4%, Si max. 0.5%, Fe max. 0.5%, balance aluminum and normal and / or inevitable elements and impurities. Furthermore, this relates to a method of producing such aluminum alloy products.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

Production method for reducing titanium content in high-carbon chromium bearing steel

The invention relates to a production method for reducing the titanium (Ti) content in high-carbon chromium (Cr) bearing steel. The production method comprises the following steps of: firstly, blowing oxygen into steel liquid in an electric furnace or a converter to remove Ti, pre-putting ferrochrome with Cr of 60 to 75 percent for smelting steel GCr15 into a steel ladle, and baking the steel ladle with the ferrochrome at the temperature of between 1,000 and 1,100 DEG C for 30 to 35 minutes; secondly, adding Si, Mn and Al for deoxygenation when the steel liquid enters 2 / 3 to 3 / 4 part of the steel ladle by using the characteristic of eccentric eriochrome black T (EBT) of the electric furnace, and then adding low-Ti and high-carbon ferrochrome; thirdly, blowing Ar and stirring during steel discharging, refining the steel liquid in a ladle furnace (LF) by adding the low-Ti ferrochrome, wherein the Ti content in the low-Ti ferrochrome is less than 0.12 percent; and finally, adjusting components of refined slag and adsorbing the Ti element in the steel liquid in a strengthening manner. The Ti content in the high-carbon Cr bearing steel prepared by using the method is 0.0016 to 0.0027 percent. The method is easy to operate, secure and high in Ti removing efficiency.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

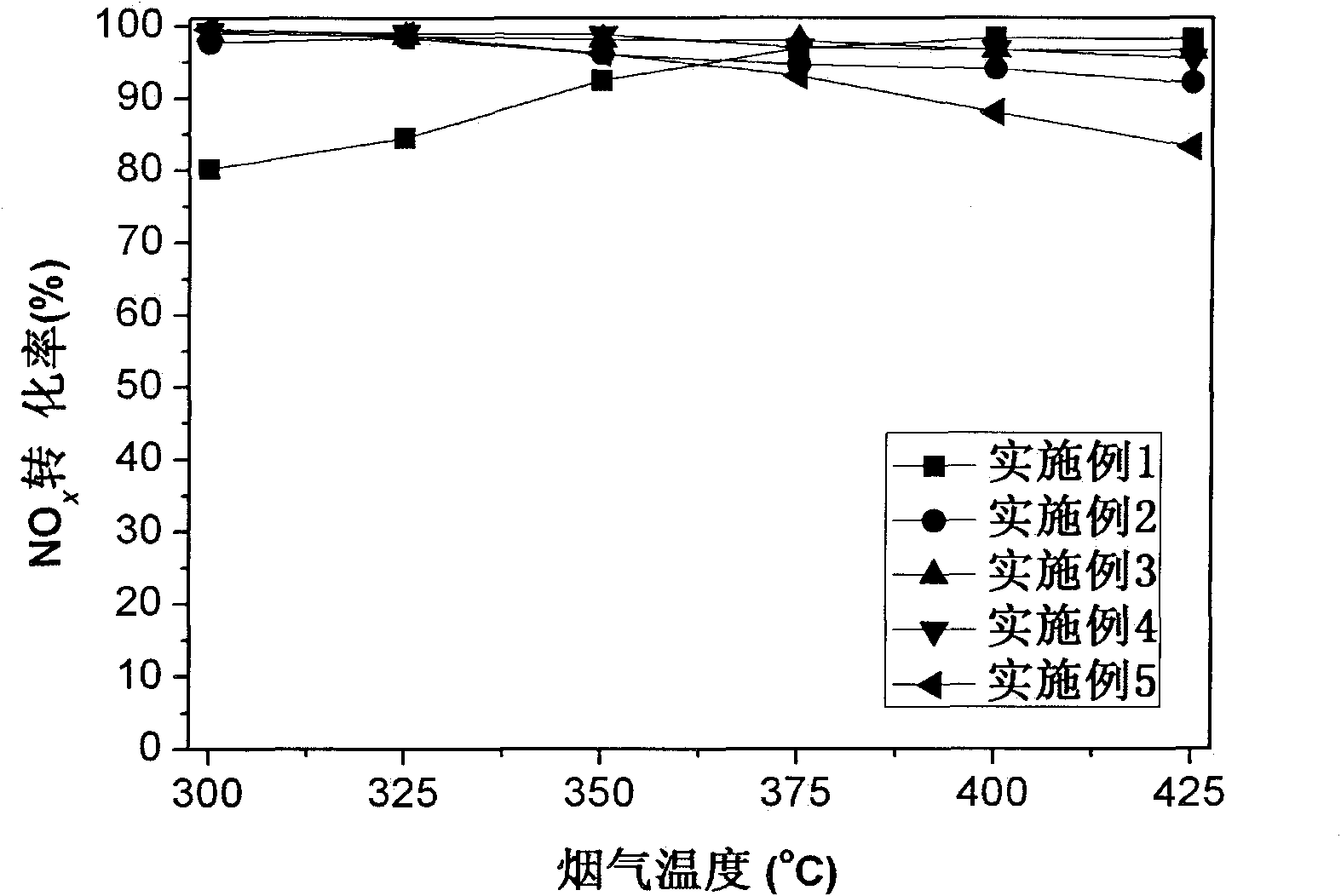

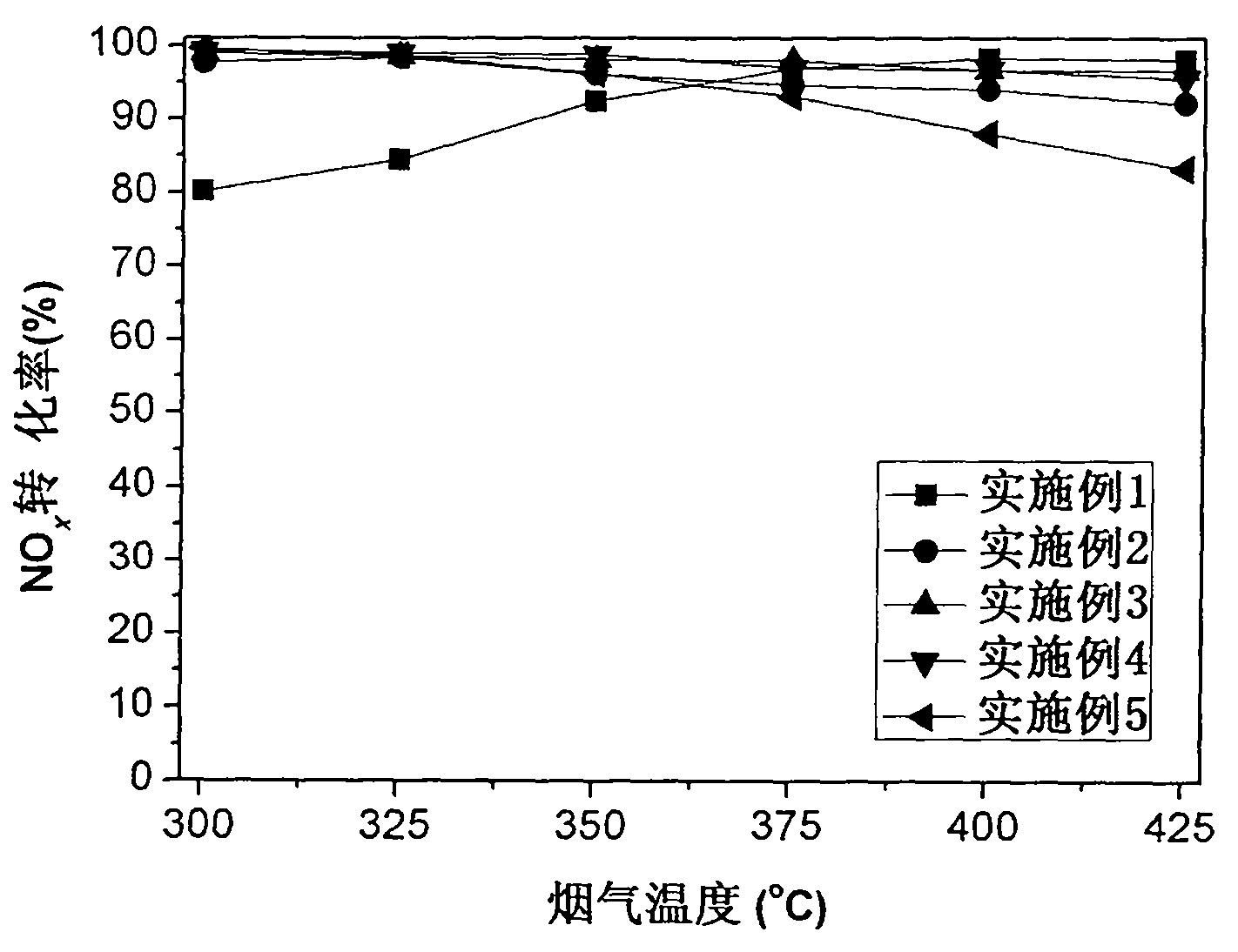

Composite oxidant SCR (Selective Catalytic Reduction) denitrating catalyst, preparation method and applications thereof

ActiveCN101829573ANon-toxicHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulphate IonHigh activity

The invention discloses a composite oxidant SCR (Selective Catalytic Reduction) denitrating catalyst for warm fume in boilers, a preparation method and application thereof. The catalyst comprises the components of transition metal element M and Ti element. As counted by the oxidant, the amount of the transition metal element M accounts for 6.8-20wt% of the total weight of the catalyst. As counted by TiO2, the amount of Ti accounts for 80-93.2wt% of the total weight of the catalyst. Compared with the widely used commercial catalyst, the catalyst decreases the cost by more than 20%, does not contain W, Mo, V and Ce, and has the advantages of low cost, no toxicity, high activity, good sulphate resisting property and the like.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

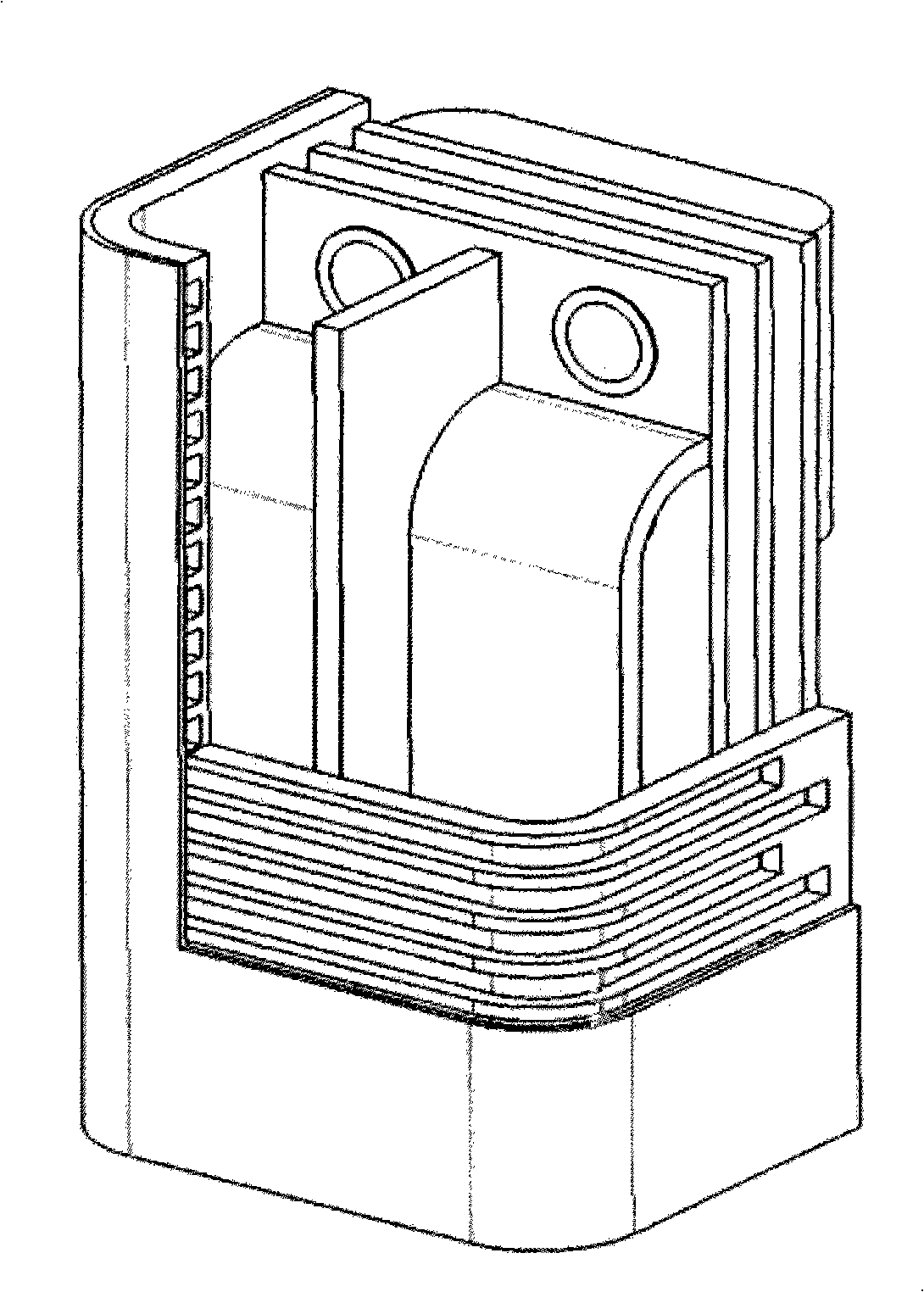

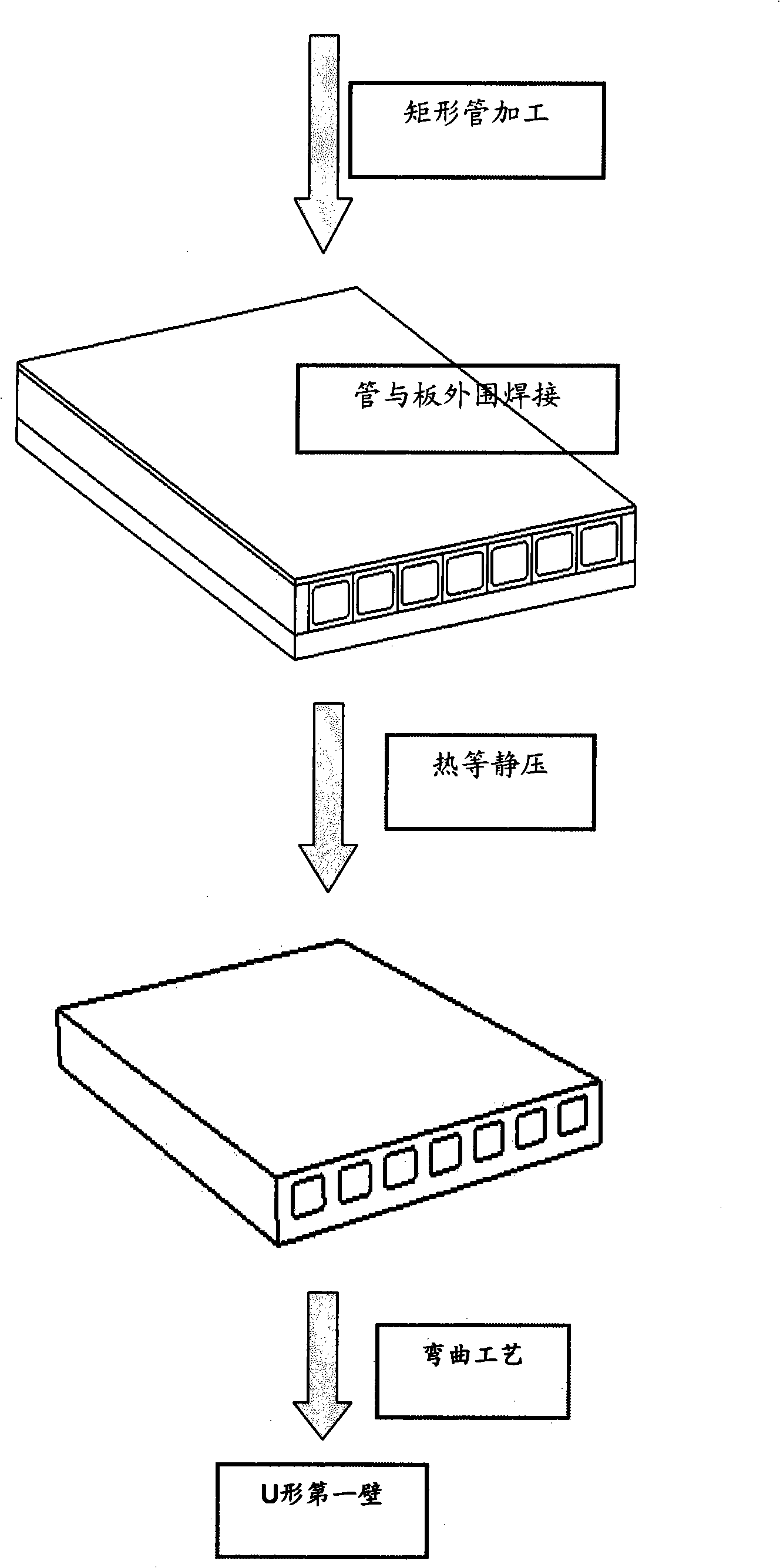

Manufacture technique for thermonuclear reactor flow-passage containing parts

InactiveCN101332557AImprove cleanlinessAvoid damageNon-electric welding apparatusAs elementHeat-affected zone

The invention discloses a production process applicable to runner-containing parts in a fusion reactor blanket. The production process includes the steps: first, a plate and a runner-containing rectangular tube are manufactured according to the design and undergo precision surface working, the roughness Ra is less than 6.3Mum; second, the runner-containing parts are cleaned and decontaminated and then heated in vacuum for degassing; third, the runner-containing parts are vacuumized in an electron beam welding machine and the periphery of the surface to be welded is hermetically welded; and then the runner-containing parts are put into a hot isostatic pressing furnace for forming by hot isostatic pressing diffusion welding; finally, bending forming, heat treatment and machining, and the like, are performed. By adopting the production process; the runner-containing parts manufactured by the production process have reliable and uniform comprehensive performance without the weak performance zones of the heat affected zone, and the like, resulting from the fusion welding process or the defects such as element segregation and air vent, and the like, existing in the similar casting parts, thereby, the production process is particularly applicable to the production of the runner-containing part with the fusion reactor blanket under the condition of intense neutron radiation.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

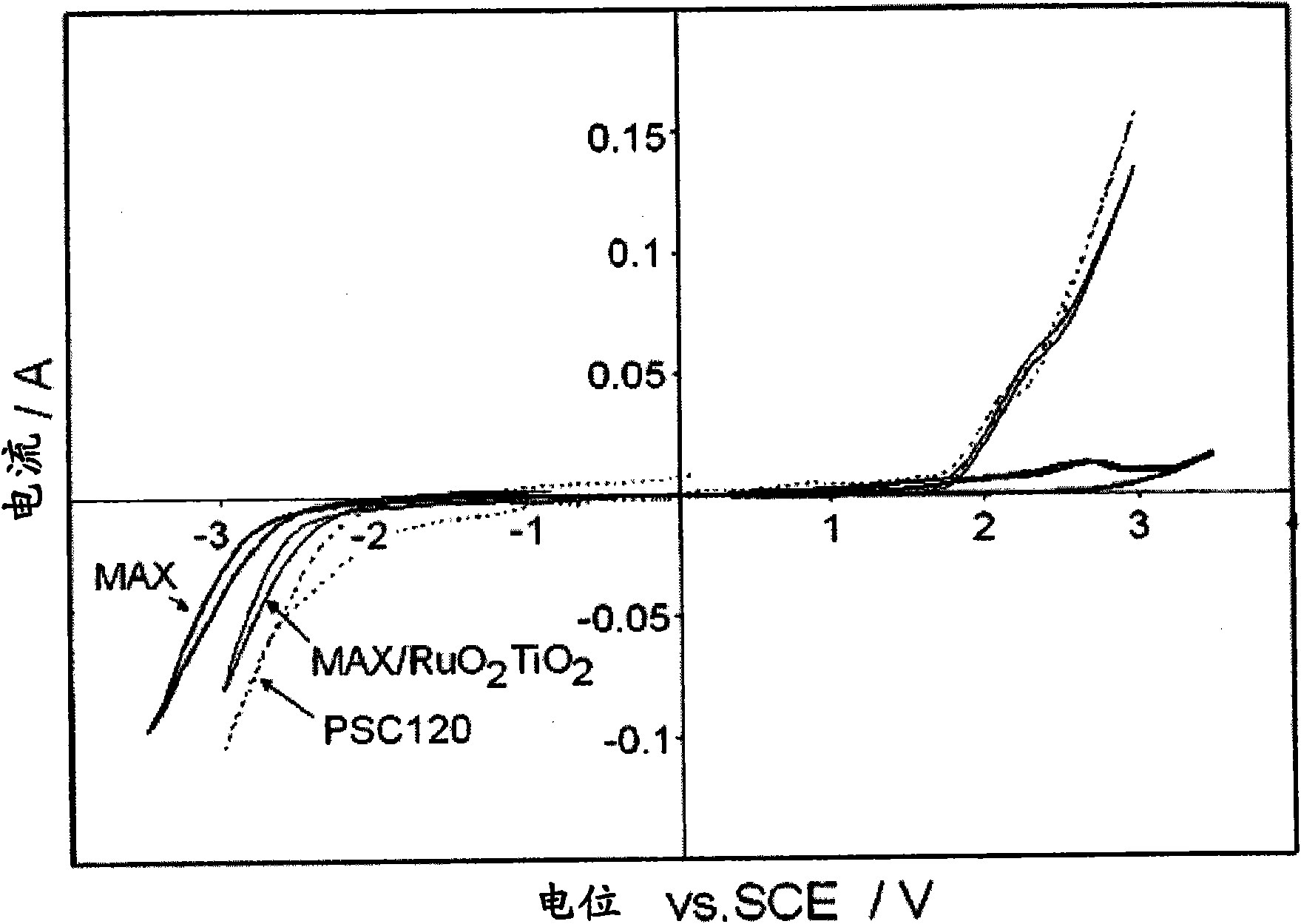

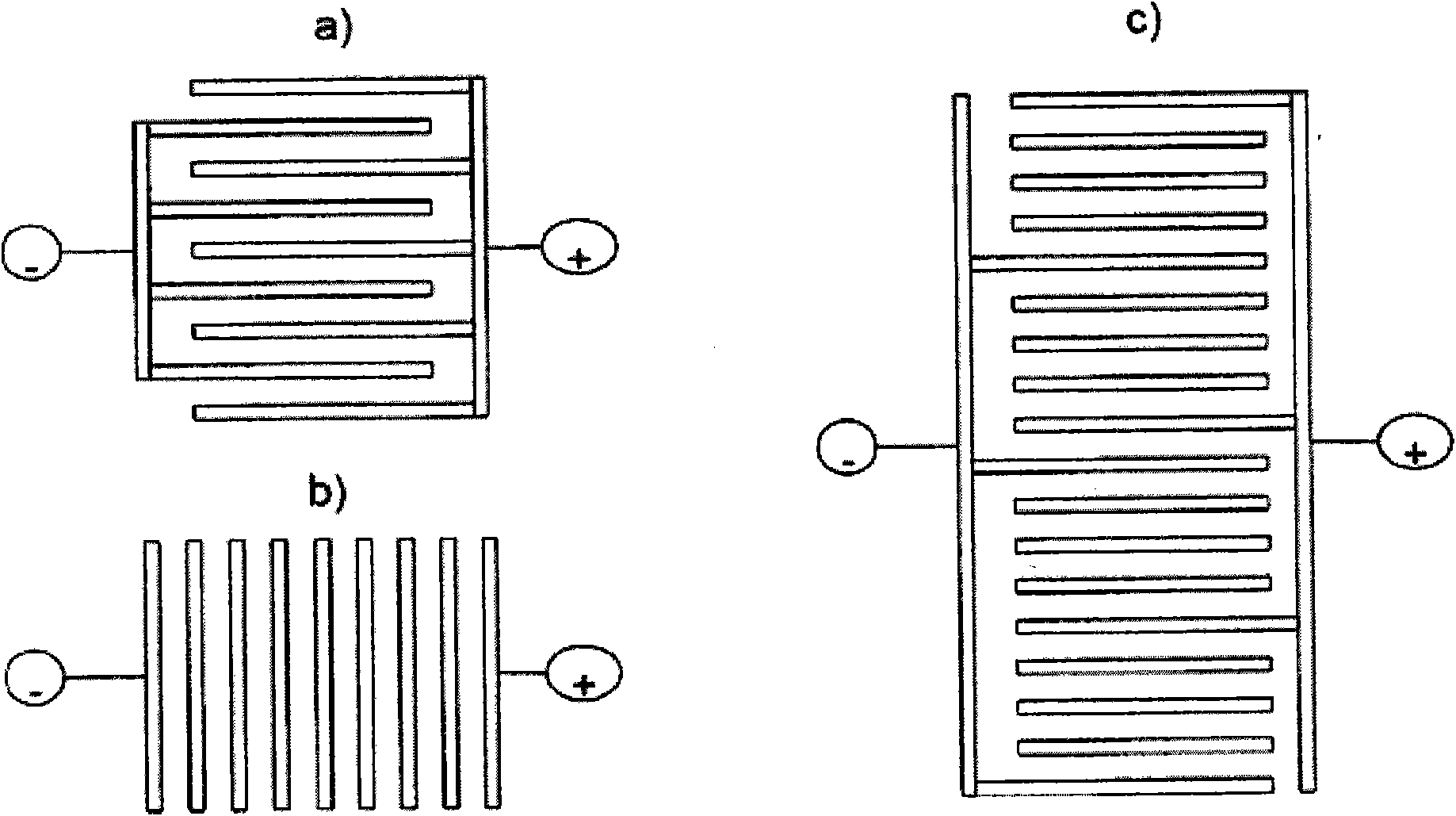

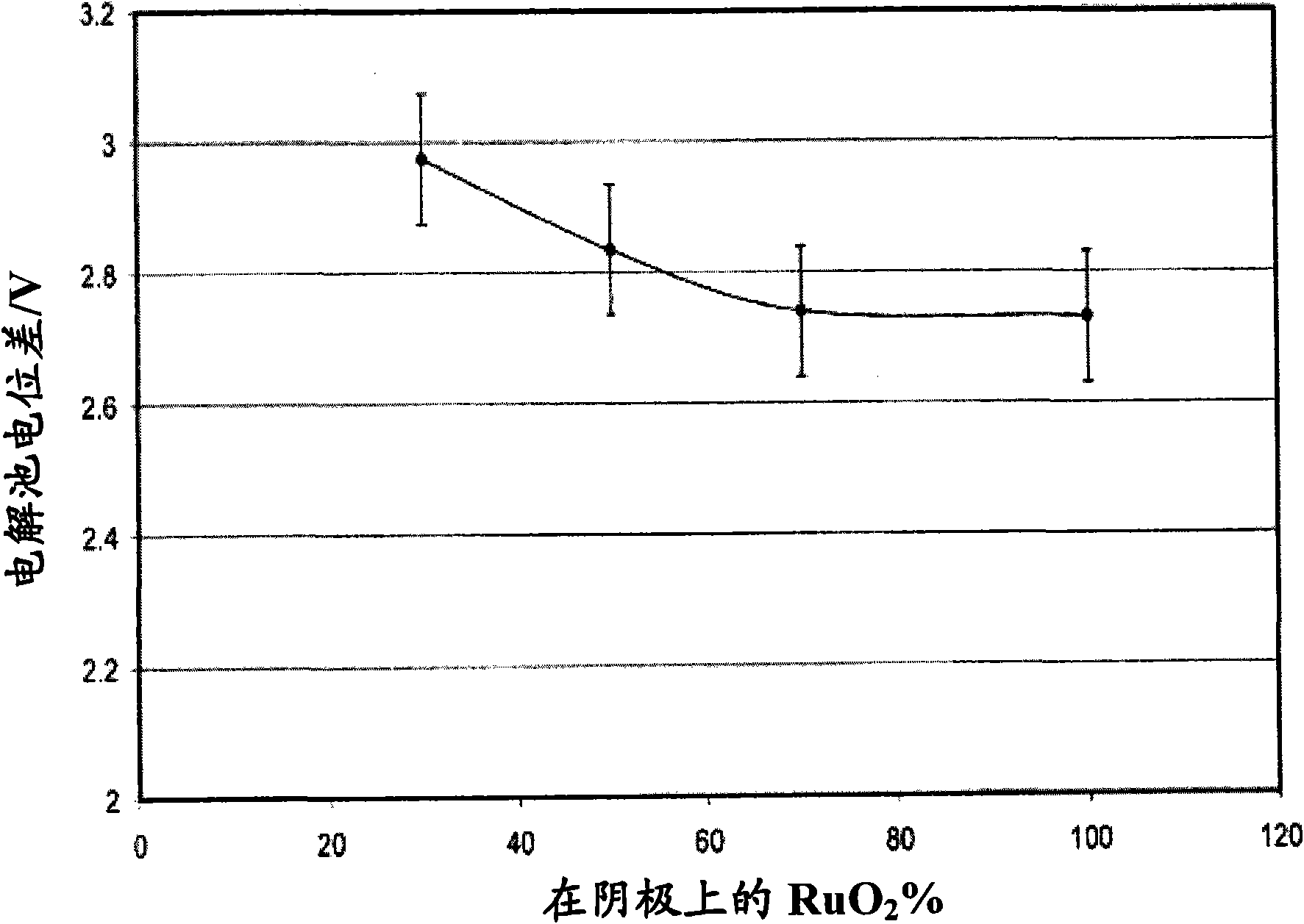

Electrode

An electrode substrate comprising M(n+1)AXn, where M is a metal of group IIIB, IVB,VB,VIB or VIII of the periodic table of elements or a combination thereof, A is an element of group IIIA, IVA, VA or VIA of the periodic table of elements or a combination thereof, X is carbon, nitrogen or a combination thereof, where n is 1, 2, or 3; and b) an electrocatalytic coating deposited on said electrode substrate, said coating being selected from at least one of b.1 ) a metal oxide and / or metal sulfide comprising ByC(1-y)Oz1Sz2, wherein B is at least one of ruthenium, platinum, rhodium, palladium, iridium, and cobalt, C is at least one valve metal, y is 0.4-0.9, 0 <= z1, z2 <= 2 and z1+z2=2; b.2) a metal oxide comprising BfCgDhEi, wherein B is at least one of ruthenium, platinum, rhodium, palladium, and cobalt, C is at least one valve metal, D is iridium, E is Mo and / or W, wherein f is 0-0.25 or 0.35-1, g is 0-1, h is 0-1, i is 0-1, wherein f+g+h+i=1; b.3) at least one noble metal; b.4) any alloy or mixture comprising iron-molybdenum, iron-tungsten, iron-nickel, ruthenium-molybdenum, ruthenium-tungsten or mixtures thereof; b.5) at least one nanocrystalline material. The electrode is used in an electrolytic cell for the production of alkali metal chlorate.

Owner:NOURYON CHEM INT BV

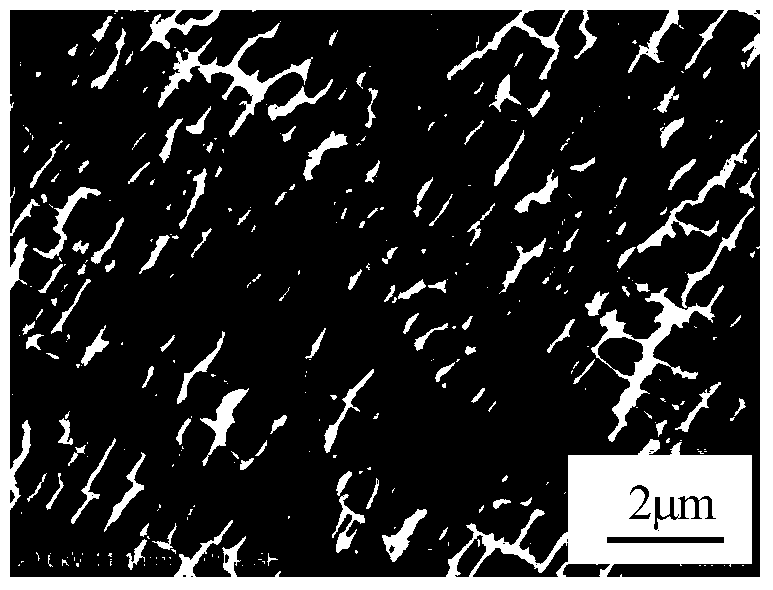

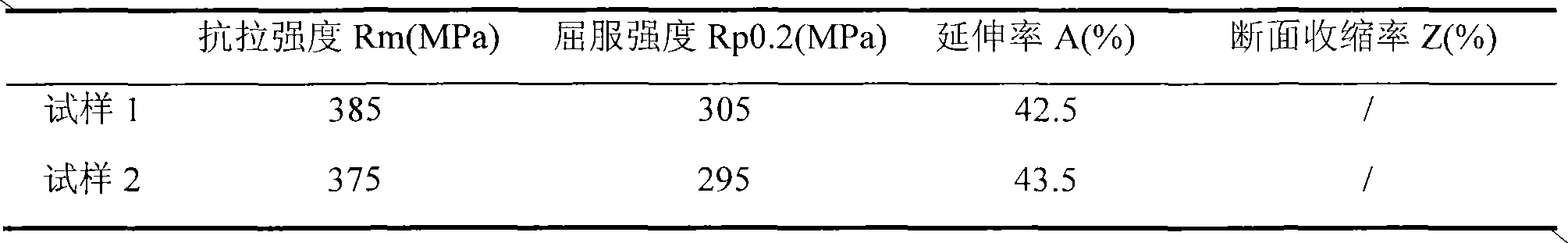

High tensile strength low carbon bainite thick steel plate and its production method

InactiveCN1786245AReduce carbon contentLow carbon content, low temperature toughnessOther manufacturing equipments/toolsChemical compositionHigh intensity

The invention offers a high tensile strength low carbon bainite coarse plate and its manufacturing method. Its compositions (Wt%) are C 0.052%-0.08%, Si 0.1%-0.5%, Mn1.65%-1.90%, Nb 0.015%-0.060%, Ti 0.005%-0.03%, B 0.0005%-0.003%, Mo 0.25%-0.50%, Cu 0.62%-0.85%, Ni 0.42%-0.80%, Al 0.015%-0.05%, and rest Fe and other inevitable impurity. The invention adopts low cost Mn element as the main additional element, fully applies the changing action of Cu, Mo, Ni, Nb, B to the bainite. The steel has low carbon, good low temperature toughness, welding performance, and forming performance. Its Nb and Ti element is low. And it is fit for large-scale industrialization continuous casting production. The TMCP+ RPC+T technique is adopted to make tensile strength over 900N / mm2 high intensity and tenacity steel. Adopting lower steel blank heating temperature can economize energy and improve steel low temperature toughness. The product can apply in engineering machinery, digging machinery, heavy-duty car, and marine facilities field, and etc.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com