Patents

Literature

1683 results about "Mischmetal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mischmetal (from German: Mischmetall – "mixed metal") is an alloy of rare-earth elements. It is also called cerium mischmetal, or rare-earth mischmetal. A typical composition includes approximately 55% cerium, 25% lanthanum, and 15-18% neodymium with other rare earth metals following. Its most common use is in the pyrophoric ferrocerium "flint" ignition device of many lighters and torches, although an alloy of only rare-earth elements would be too soft to give good sparks. For this purpose, it is blended with iron oxide and magnesium oxide to form a harder material known as ferrocerium. In chemical formulae it is commonly abbreviated as Mm, e.g. MmNi₅.

Method of forming mixed rare earth oxide and aluminate films by atomic layer deposition

InactiveUS20070237697A1Rare earth metal compoundsChemical vapor deposition coatingAluminiumAluminate

A method is provided for depositing a gate dielectric that includes at least two rare earth metal elements in the form of an oxide or an aluminate. The method includes disposing a substrate in a process chamber and exposing the substrate to a gas pulse containing a first rare earth precursor and to a gas pulse containing a second rare earth precursor. The substrate may also optionally be exposed to a gas pulse containing an aluminum precursor. Sequentially after each precursor gas pulse, the substrate is exposed to a gas pulse of an oxygen-containing gas. In alternative embodiments, the first and second rare earth precursors may be pulsed together, and either or both may be pulsed together with the aluminum precursor. The first and second rare earth precursors comprise a different rare earth metal element. The sequential exposing steps may be repeated to deposit a mixed rare earth oxide or aluminate layer with a desired thickness. Purge or evacuation steps may also be performed after each gas pulse.

Owner:TOKYO ELECTRON LTD

Catalytic dewaxing with trivalent rare earth metal ion exchanged ferrierite

InactiveUS6013171AMolecular sieve catalystsRefining to change hydrocarbon structural skeletonCation-exchange capacityIon exchange

A process for dewaxing waxy hydrocarbonaceous materials, such as hydrocarbon fuel and lubricating oil fractions to reduce their cloud and pour points comprises reacting the material with hydrogen in the presence of a dewaxing catalyst comprising at least one metal catalytic component and ferrierite in which at least a portion of its cation exchange positions are occupied by one or more trivalent rare earth metal cations. The rare earth ion exchanged ferrierite catalyst has good selectivity for lubricating oil production, particularly when dewaxing a Fischer-Tropsch wax hydroisomerate. Preferably at least 10% and more preferably at least 15% of the ferreirite cation exchange capacity is occupied by one or more trivalent rare earth metal cations.

Owner:EXXON RES & ENG CO

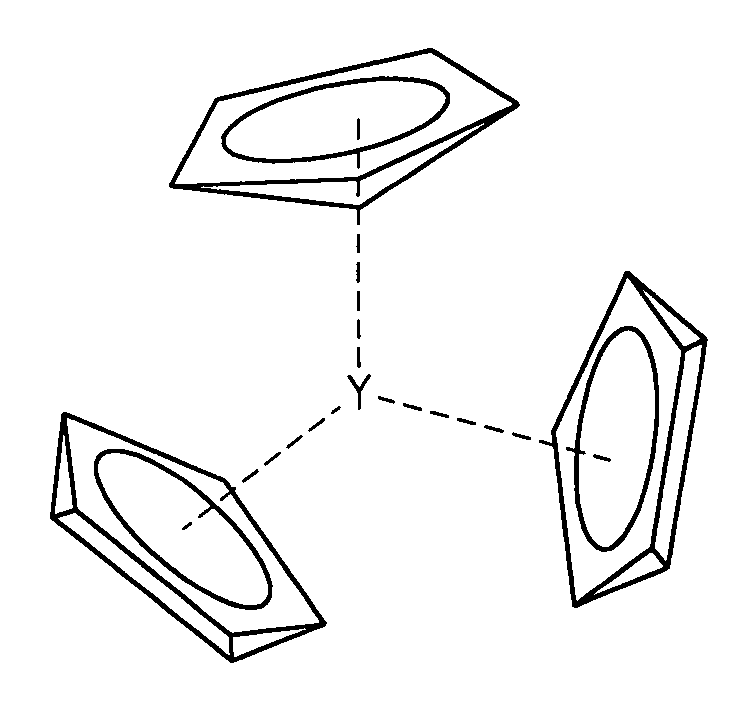

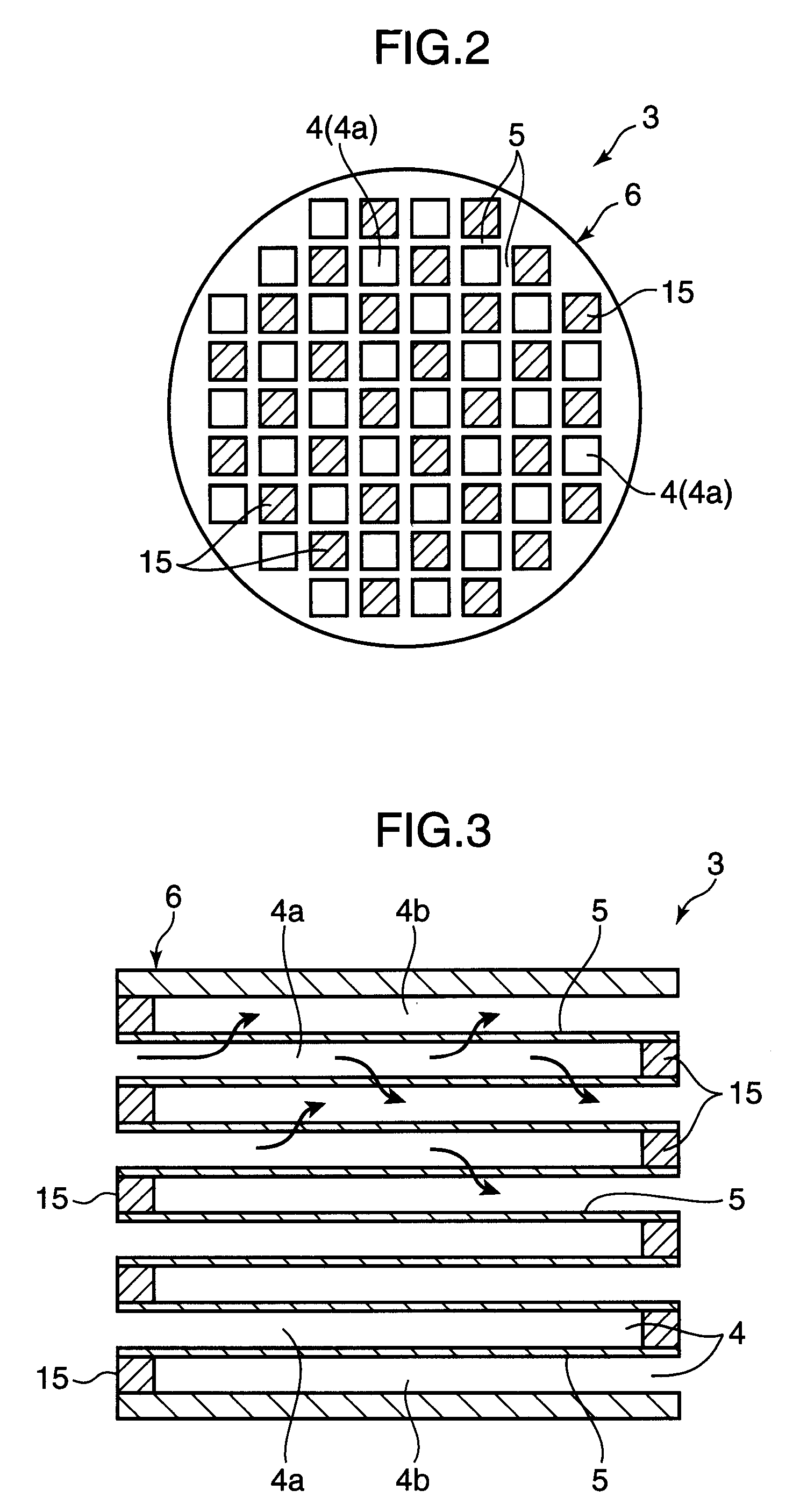

Single crystal and quasi-single crystal, composition, apparatus, and associated method

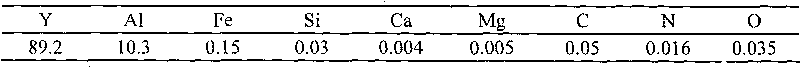

InactiveUS20060037529A1Material nanotechnologyPolycrystalline material growthMischmetalSource material

Owner:SORAA

Niobium powder and a process for the production of niobium and/or tantalum powders

InactiveUS6136062APrevent local overheating effectStirring speed is fastElectrolytic capacitorsTantalum compoundsMischmetalRare earth

The process comprises the reduction of niobium and / or tantalum oxides by means of alkaline earth metals and / or rare earth metals, wherein the first reduction stage is carried out as far as an average composition corresponding to (Nb, Ta)Ox where x=0.5 to 1.5 and before the second stage the reduction product from the first stage is freed from alkaline earth oxides and / or rare earth metal oxides which are formed (and optionally from excess alkaline earth metal and / or rare earth metal) by washing with mineral acids.

Owner:H C STARCK TANTALUM & NIOBIUM GMBH

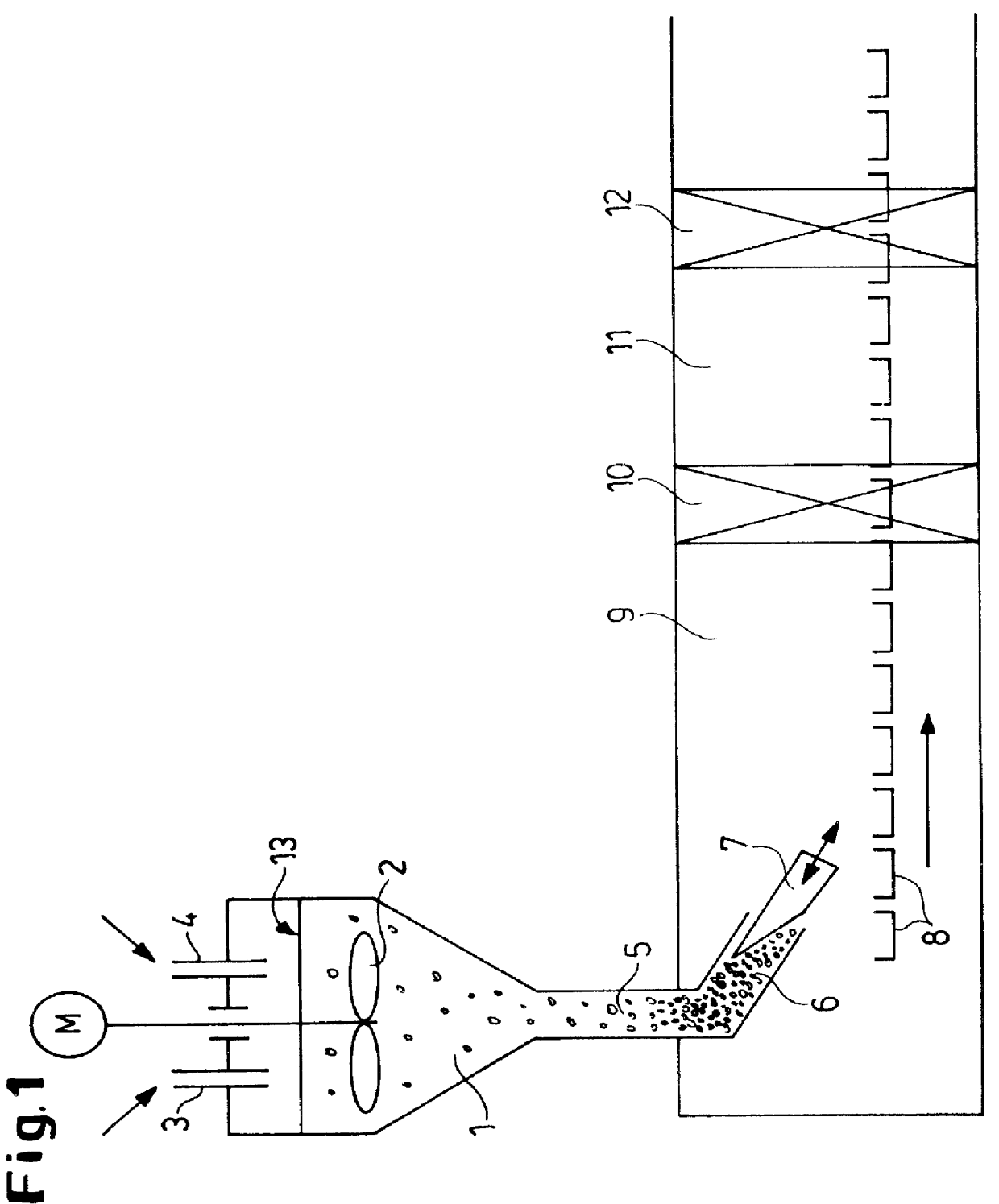

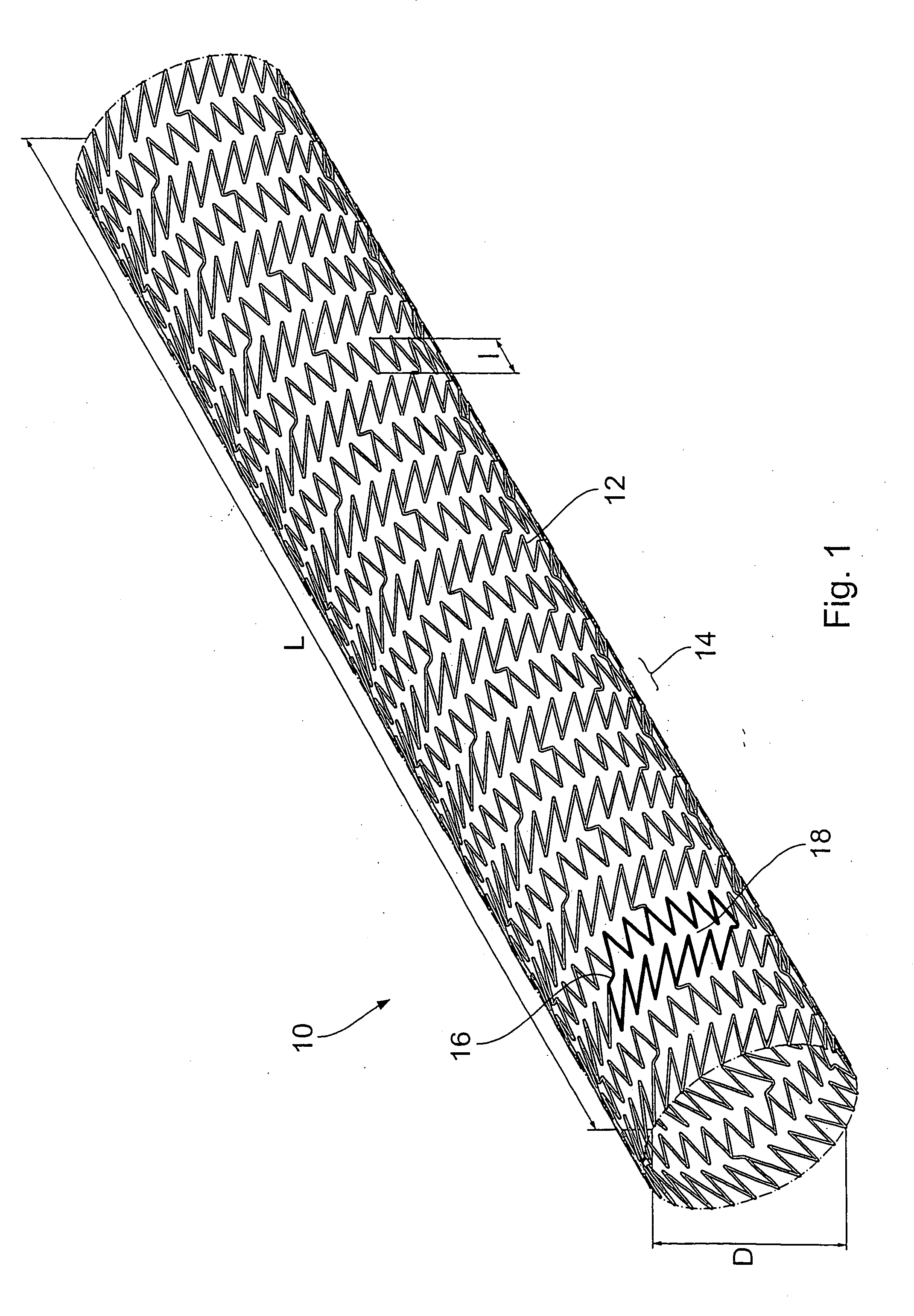

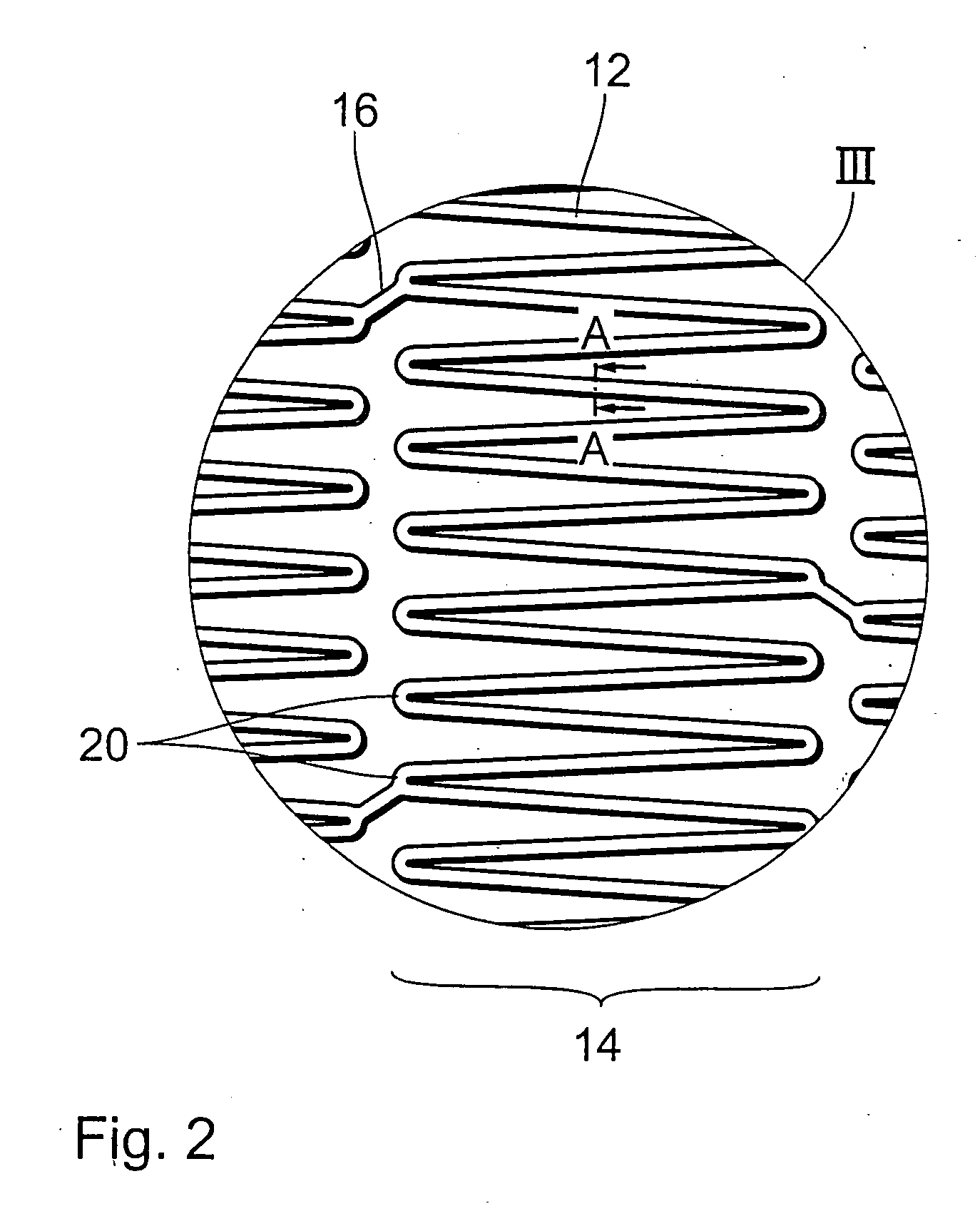

Endoprosthesis comprising a magnesium alloy

InactiveUS20060052863A1Improve mechanical stabilityLong degradation timeStentsSurgeryMischmetalInsertion stent

An endoprosthesis, in particular an intraluminal endoprosthesis such as a stent, comprises a carrier structure, which includes at least one component comprising a magnesium alloy of the following composition: Magnesium: between about 60.0 and about 88.0% by weight Rare earth metals: between about 2.0 and about 30.0% by weight Yttrium: between about 2.0% and about 20.0% by weight Zirconium: between about 0.5% and about 5.0% by weight Balance: between 0 and about 10.0% by weight wherein the alloy components add up to 100% by weight.

Owner:BIOTRONIK AG

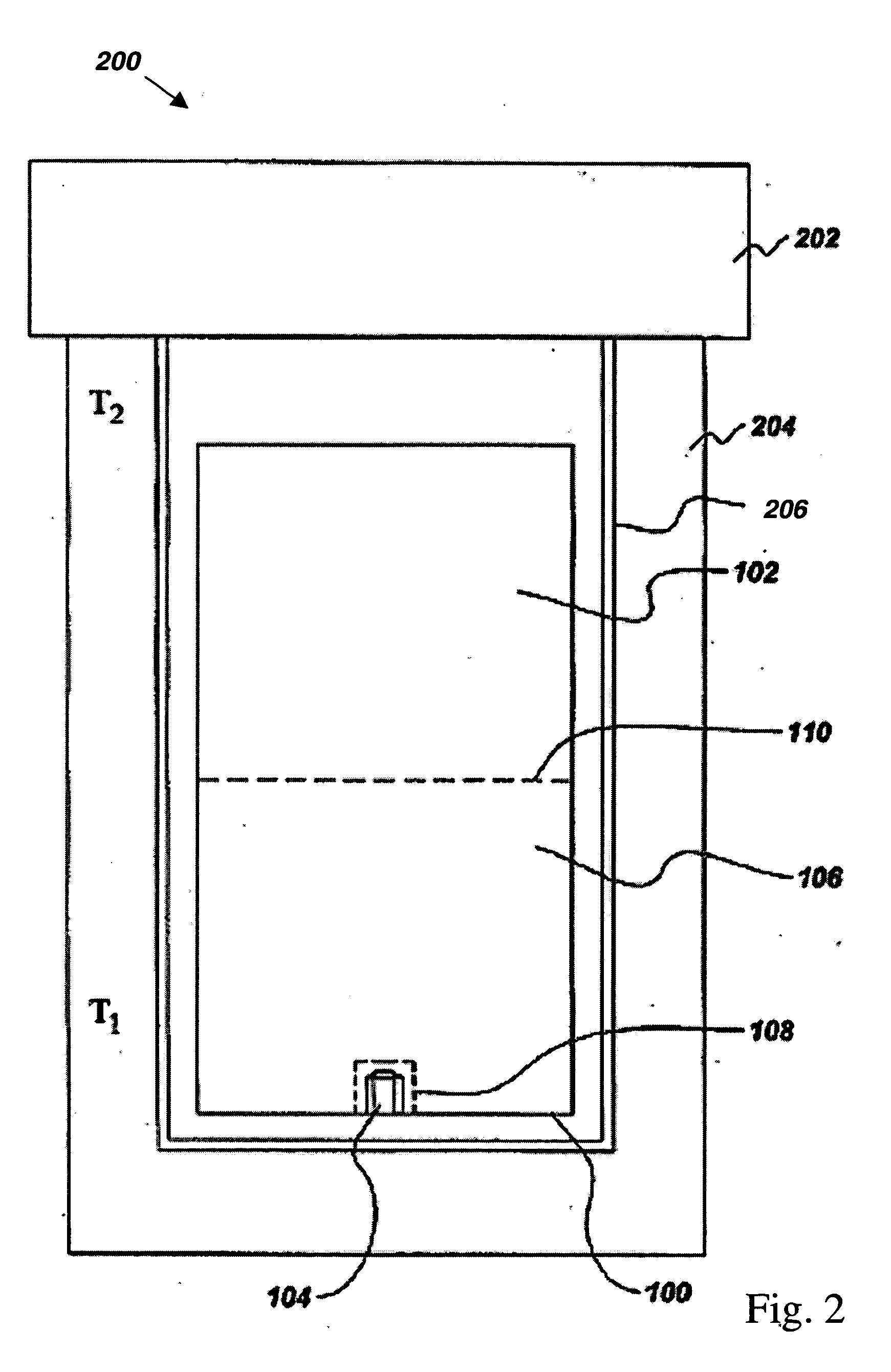

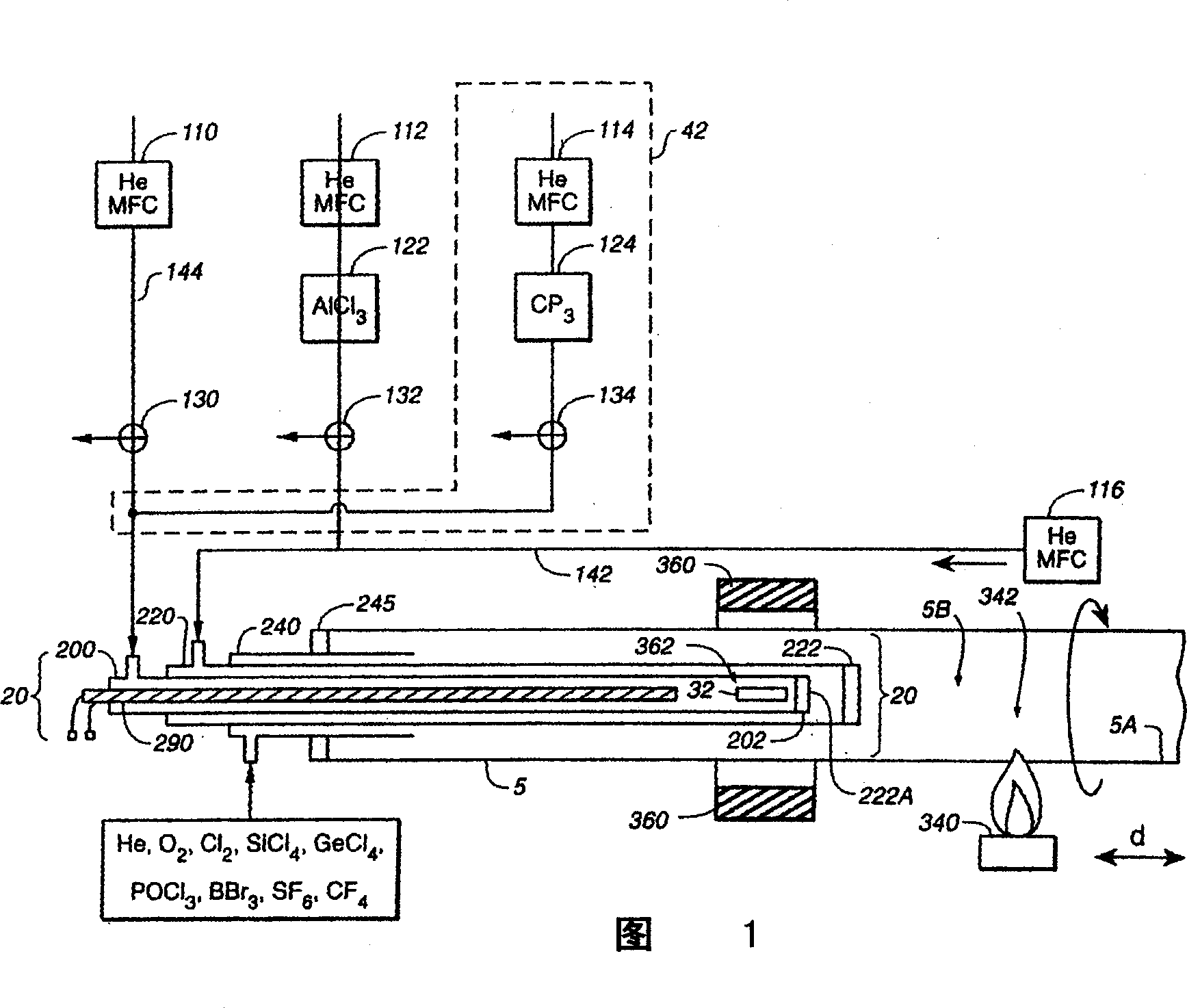

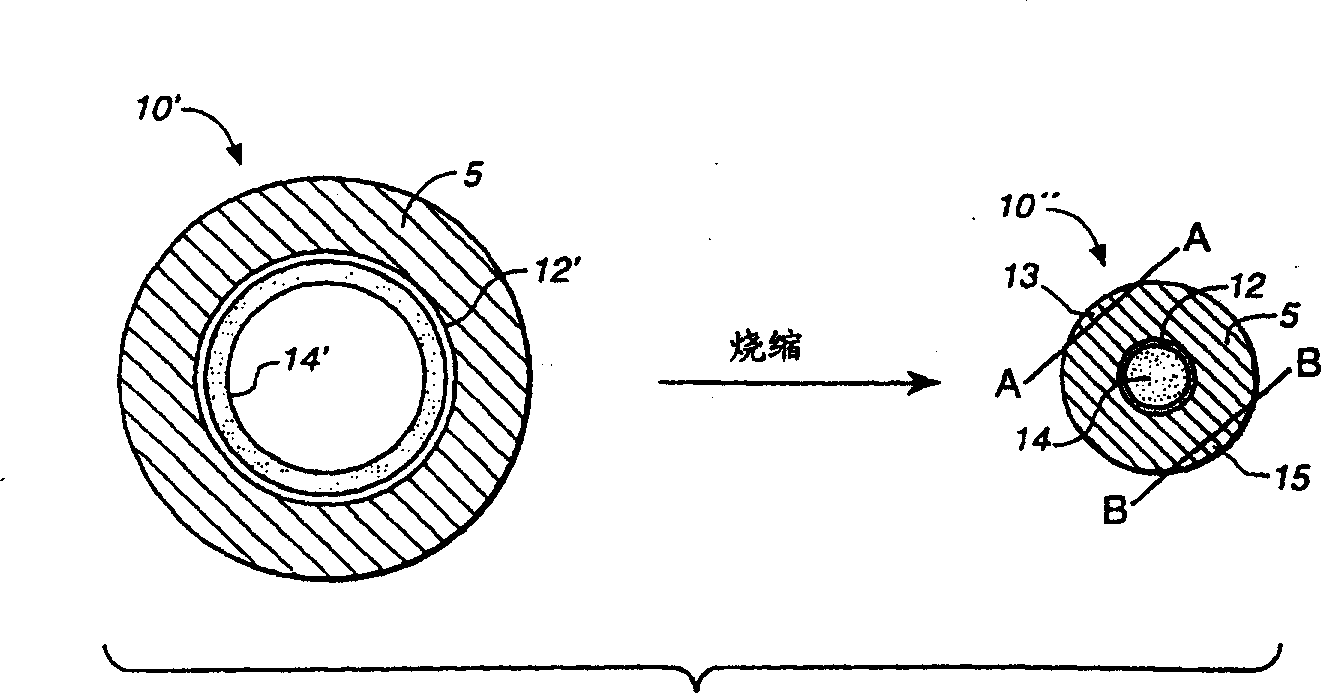

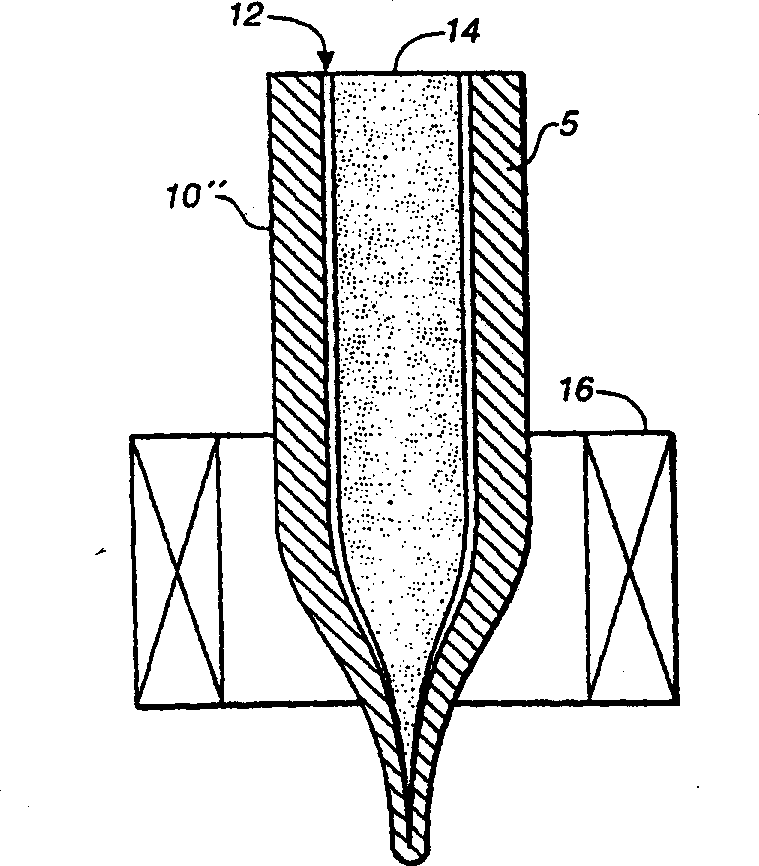

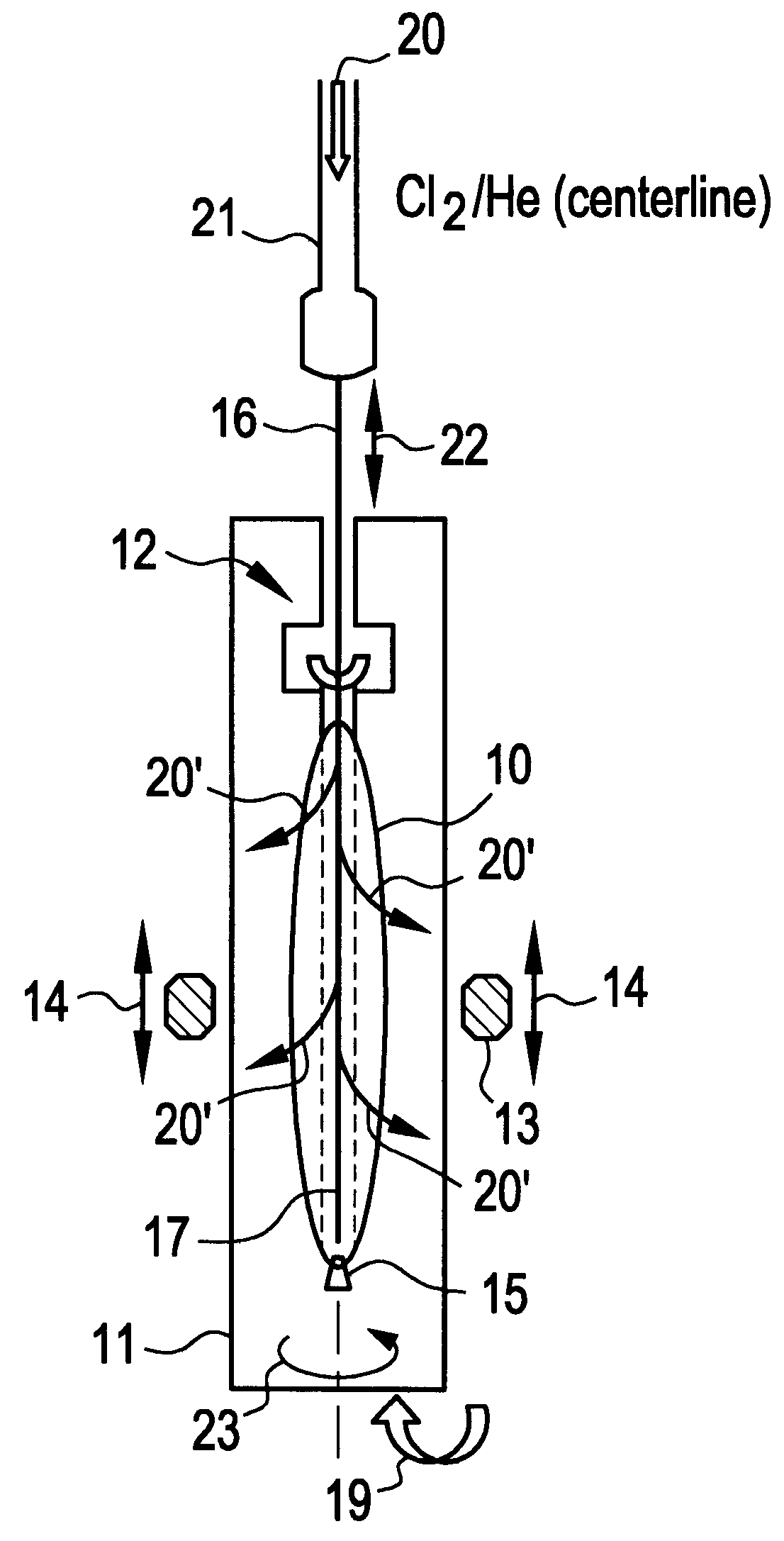

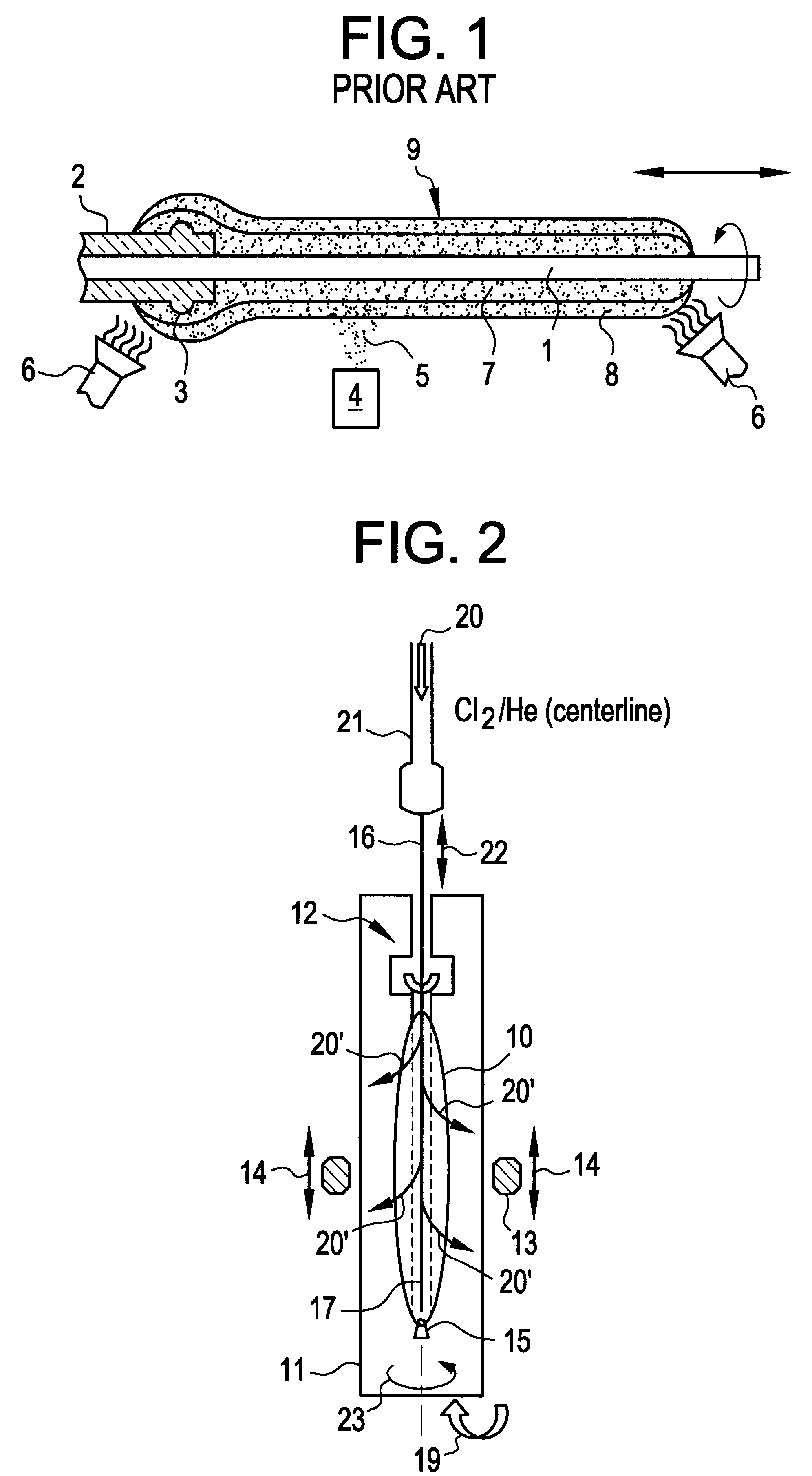

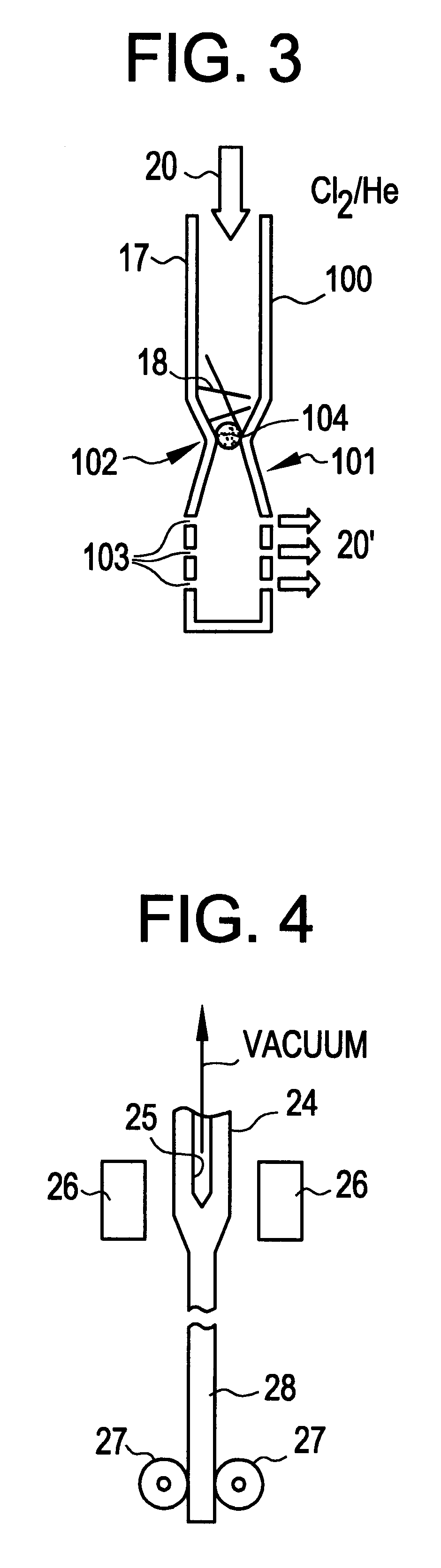

Method and apparatus for manufacturing a rare-earth metal doped optical fiber preform

InactiveCN1307544AHigh pump power absorptionSmall numerical apertureGlass deposition burnersOptical light guidesHigh concentrationGlass forming

A method and apparatus is disclosed for the manufacture of an optical fiber preform having incorporated therein a comparatively high concentration of rare earth metal dopant material, and which thus can be drawn and processed into an optical fiber having low numerical aperture, low core attenuation, and high pumping power absorption. The high concentrations of rare earth metal dopant material are accomplished through a ''hybrid vapor processing'' (HVP) method or a ''hybrid liquid processing'' (HLP) method, either being practiced in combination or independently of one another. The HVP method involves the vaporization of a rare earth metal halide by the exposure thereof to a sufficiently elevated temperature, independently, or contemporaneously with the transport of the resultant rare earth metal halide laden vapor, into a glass-forming oxidation reaction zone on a flowing stream of essentially an unreactive inert gas, such as helium. According to the HLP method, a first amount of rare earth metal dopant is provided according to the HVP method and / or other vapor source of rare earth metal dopant which is mixed with glass-forming vapors to form a deposited soot layer on the internal surface of a glass tube. The soot-deposited tube is then impregnated with a dopant solution comprising, a second amount of rare earth metal dopant. The tube is then thermally collapsed resulting in an optical preform with an enhanced amount of rare earth metal dopant incorporated at a comparatively high concentration. The apparatus comprises means, such as tubes, for introducing the rare earth metal dopant as a vapor, formed from a solid state form of the dopant, into the main glass deposition tube separately from glass-forming material vapors and oxygen for the reaction within the main tube.

Owner:JDS单相公司

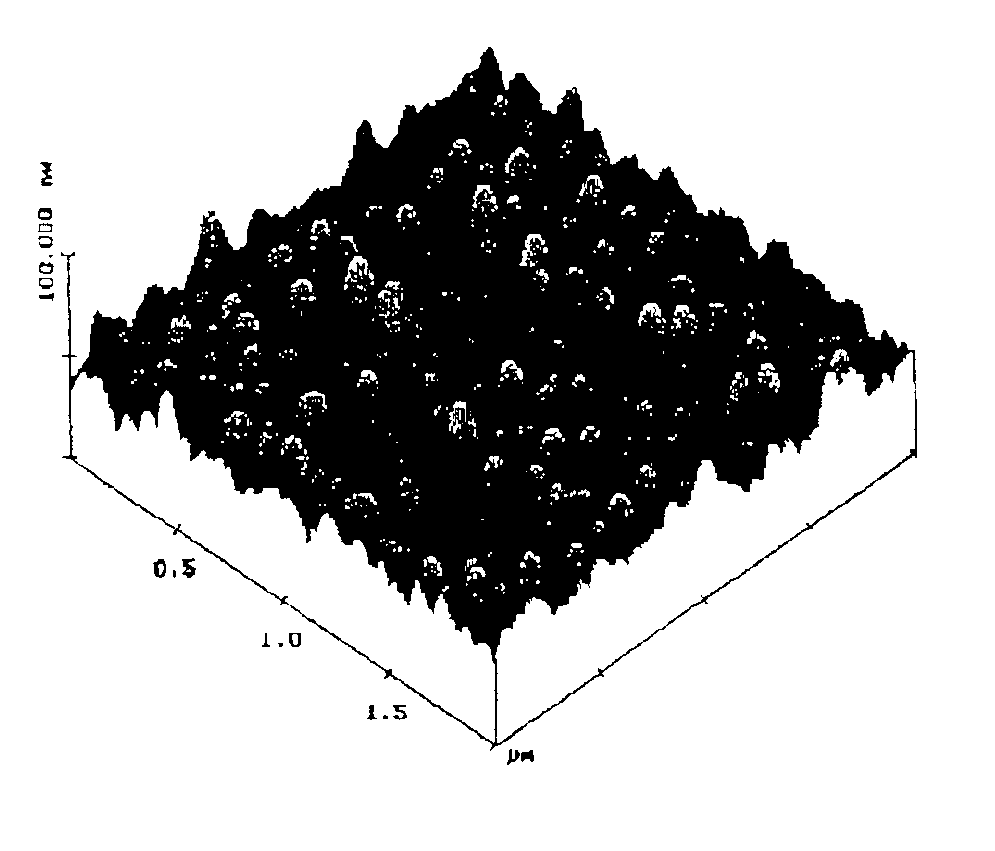

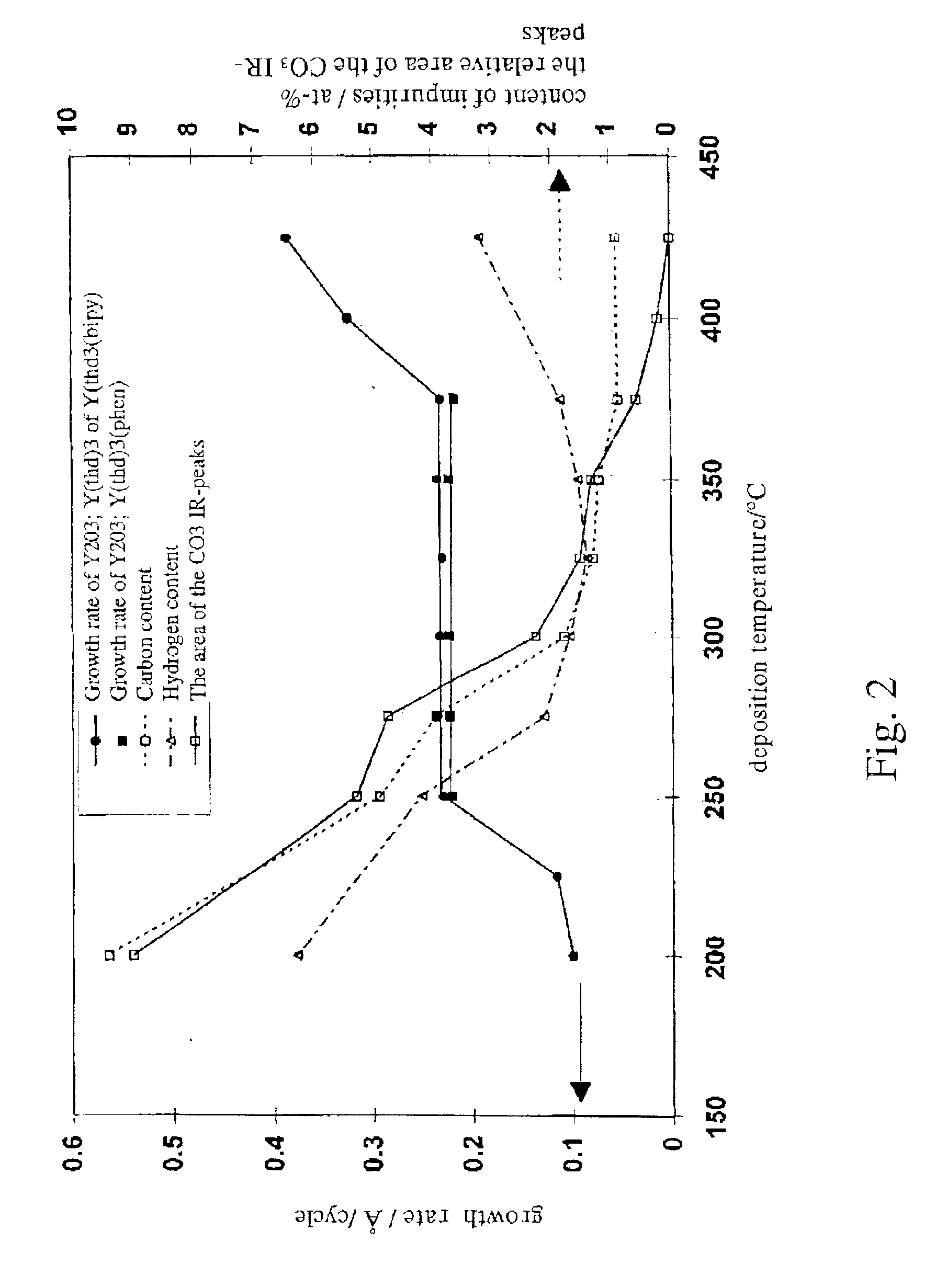

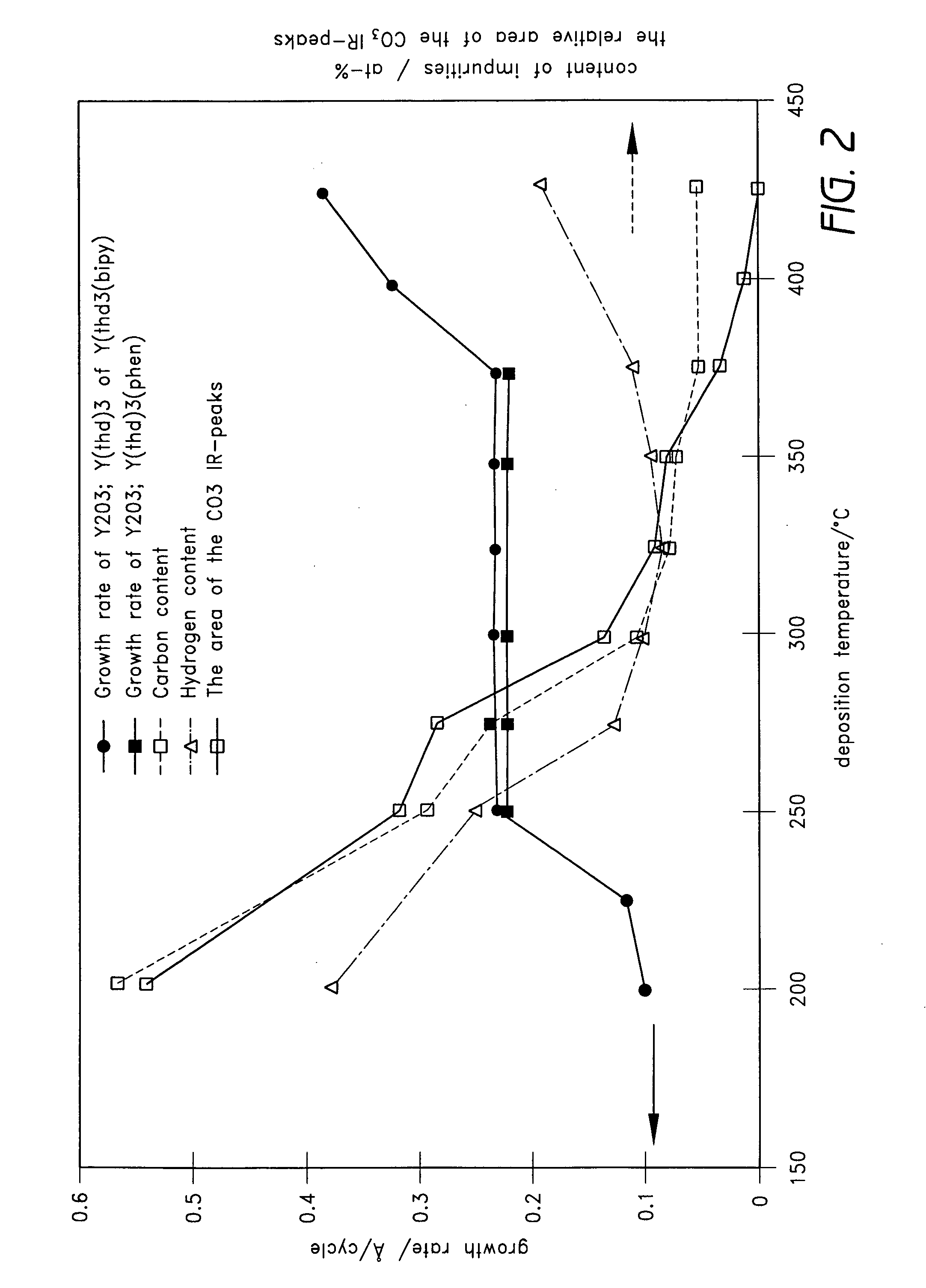

Method of depositing rare earth oxide thin films

InactiveUS6858546B2Increase probabilityIncrease ratingsPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureGadolinium

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds of rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

Selected processing for non-equilibrium light alloys and products

InactiveUS20030183306A1High valueEffectiveVacuum evaporation coatingSputtering coatingMagnesiumNet shape

A new class of light or reactive elements and monophase alpha'-matrix magnesium- and aluminum-based alloys with superior engineering properties, for the latter being based on a homogeneous solute distribution or a corrosion-resistant and metallic shiny surface withstanding aqueous and saline environments and resulting from the control during synthesis of atomic structure over microstructure to net shape of the final product, said alpha'-matrix being retained upon conversion into a cast or wrought form. The manufacture of the materials relies on the control of deposition temperature and in-vacuum consolidation during vapor deposition, on maximized heat transfer or casting pressure during all-liquid processing and on controlled friction and shock power during solid state alloying using a mechanical milling technique. The alloy synthesis is followed by extrusion, rolling, forging, drawing and superplastic forming for which the conditions of mechanical working, thermal exposure and time to transfer corresponding metastable alpha'-matrix phases and microstructure into product form depend on thermal stability and transformation behavior at higher temperatures of said light alloy as well as on the defects inherent to a specific alloy synthesis employed. Alloying additions to the resulting alpha'-monophase matrix include 0.1 to 40 wt. % metalloids or light rare earth or early transition or simple or heavy rare earth metals or a combination thereof. The eventually more complex light alloys are designed to retain the low density and to improve damage tolerance of corresponding base metals and may include an artificial aging upon thermomechanical processing with or without solid solution heat and quench and annealing treatment for a controlled volume fraction and size of solid state precipitates to reinforce alloy film, layer or bulk and resulting surface qualities. Novel processes are employed to spur production and productivity for the new materials.

Owner:HEHMANN FRANZ

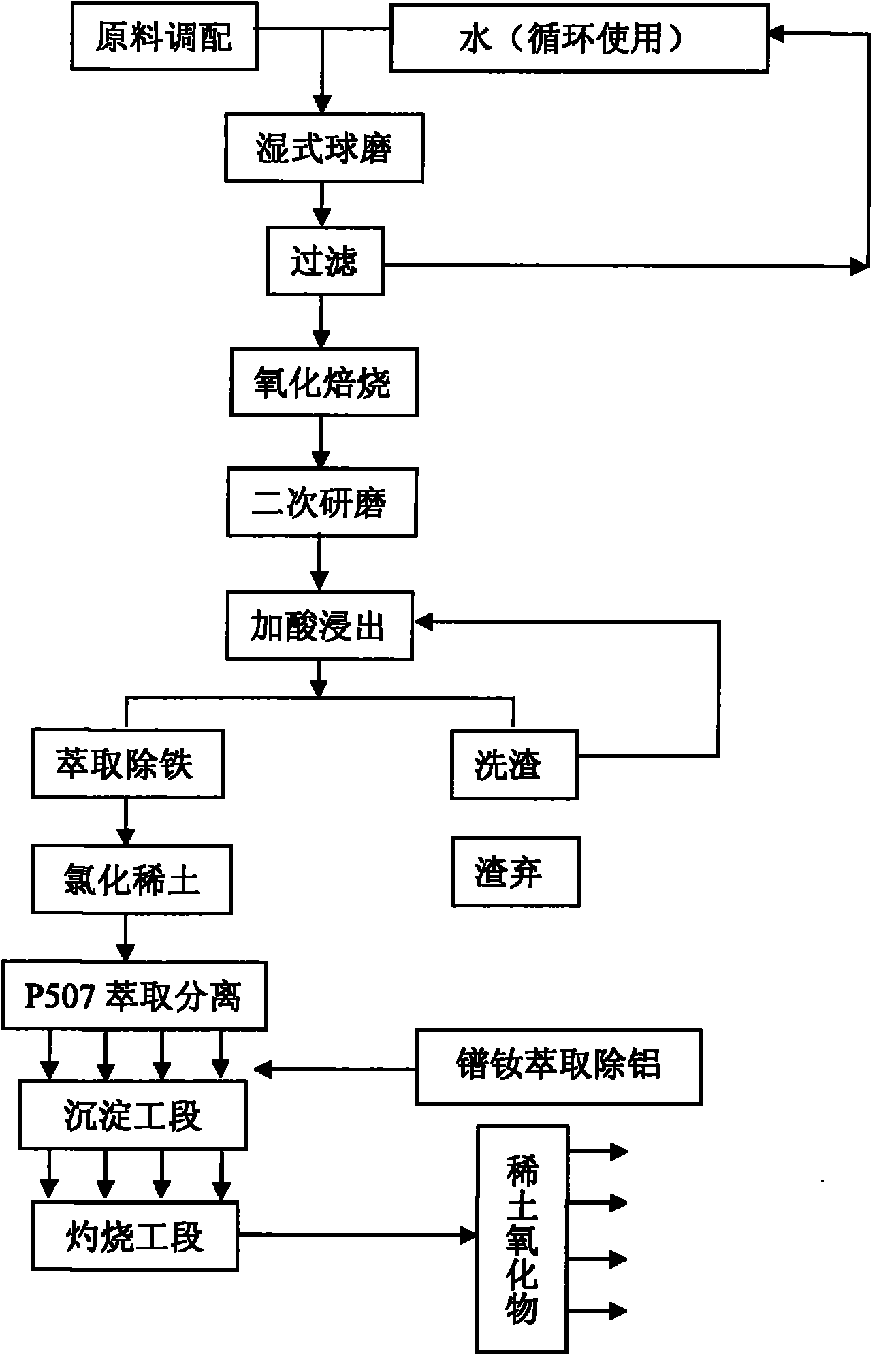

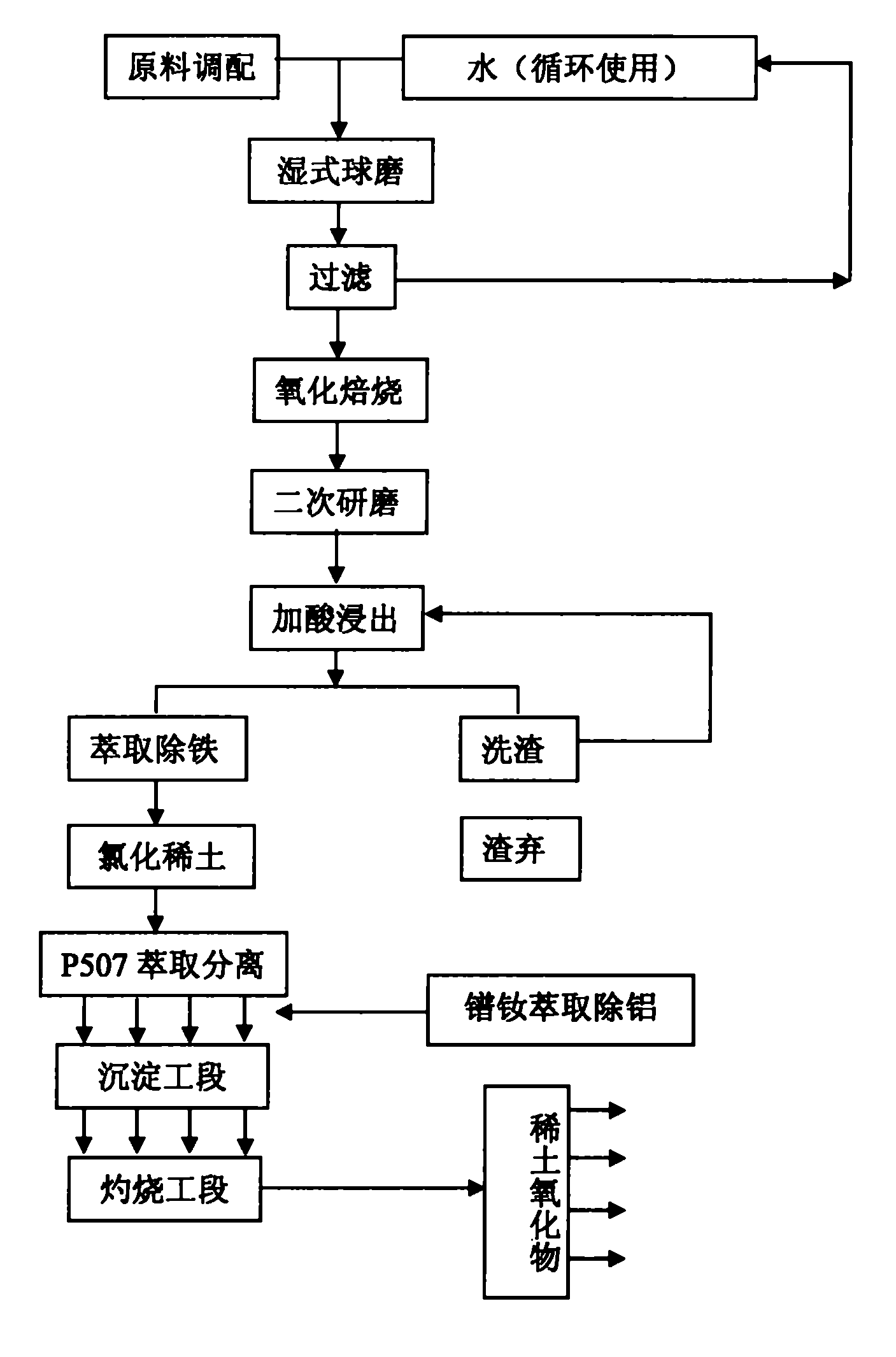

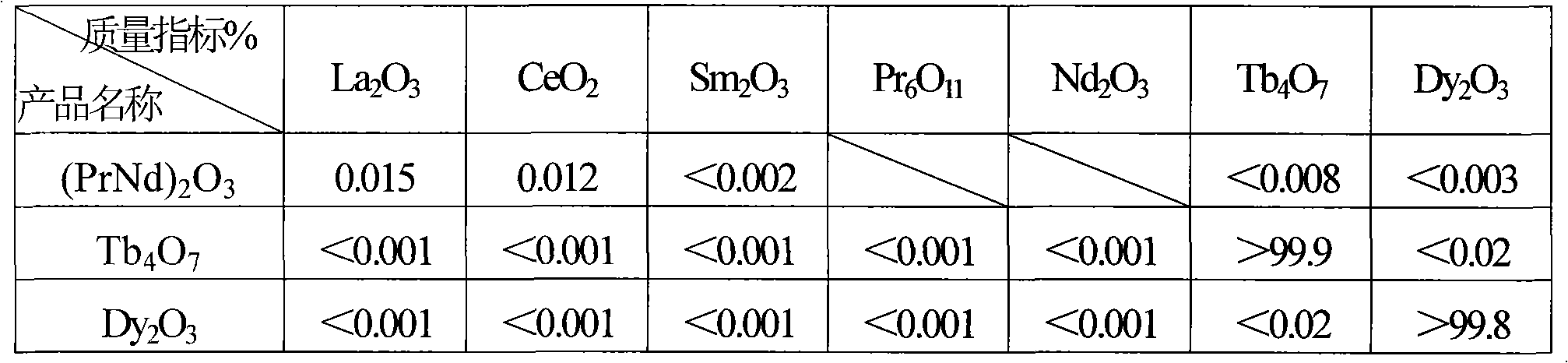

Method for recovering rare earth elements from neodymium-iron-boron wastes

InactiveCN102011020AHigh recovery rateImprove use valueProcess efficiency improvementMischmetalRare-earth element

The invention discloses a method for recovering rare earth elements from neodymium-iron-boron wastes, which comprises the steps of: mixing the neodymium-iron-boron wastes with water and then grinding; oxidizing the ground neodymium-iron-boron wastes; carrying out the secondary grinding for oxidation products; leaching by adding acid; separating solid from liquid; extracting to remove iron; chloridizing rare earth; separating the rare earth by extraction; extracting to remove aluminum; sedimenting; and firing. The method applied to recovery of the rare earth has the beneficial effects that the rare earth recovery rate is increased by 5-8%; the use value of the recovered rare earth is improved so that the production cost of further processing is reduced; the problem of puree fused salt in the electrolysis of single rare earth is solved, and the electrolytic efficiency of the rare earth metal during electrolysis is improved and energy consumption is effectively reduced; and the contents of non rare earth metals, such as C, S, O and the like are reduced.

Owner:BAOTOU XIJUN RARE EARTH

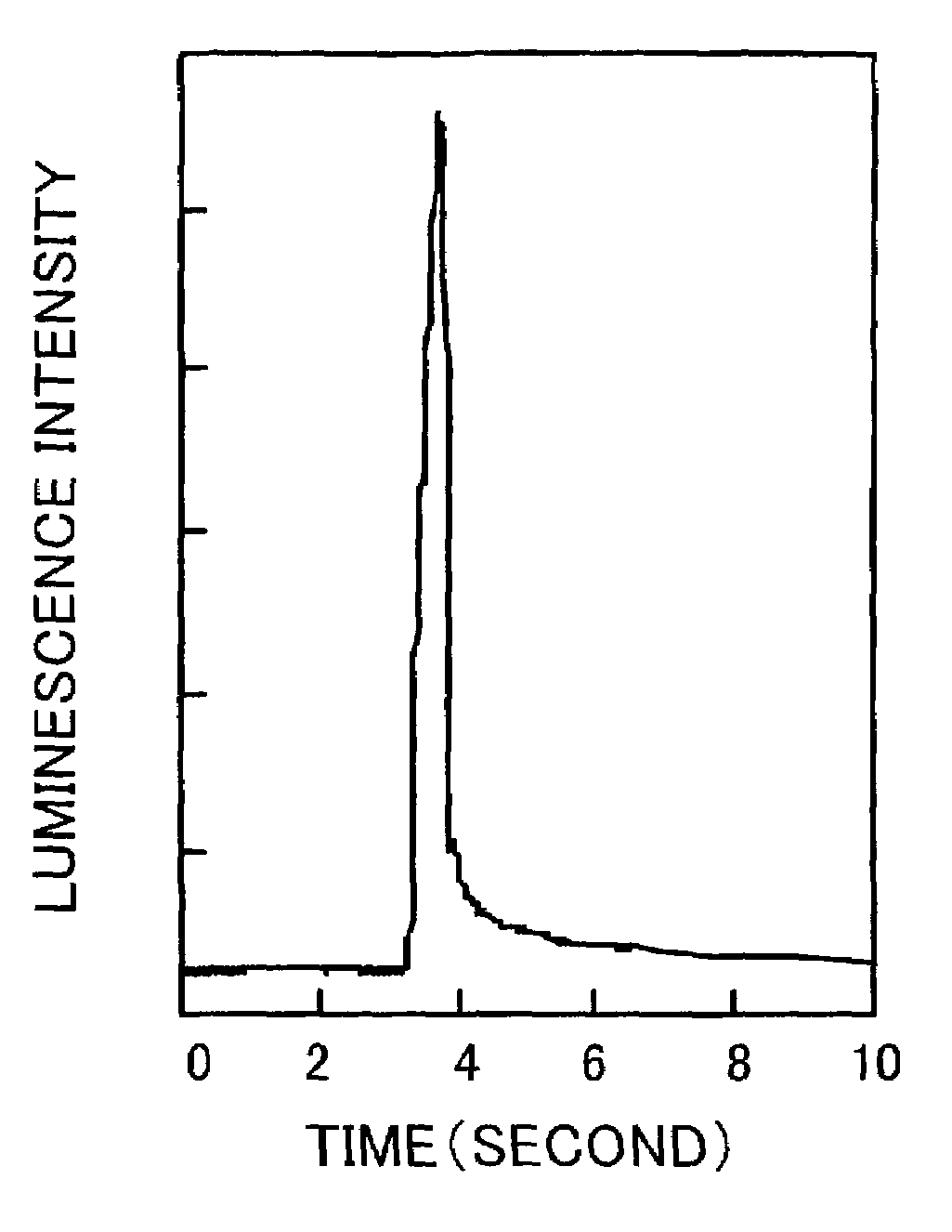

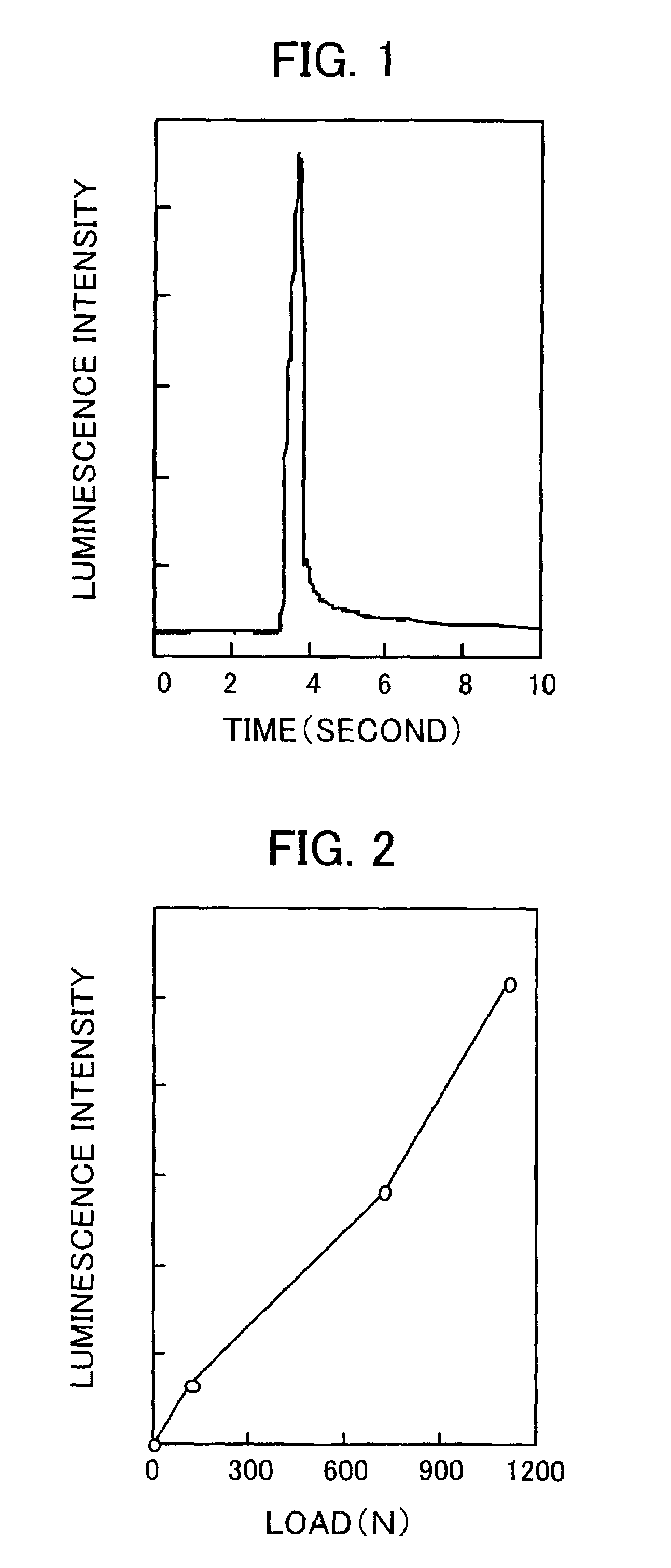

Mechanoluminescence material, producing method thereof, and usage thereof

InactiveUS7060371B2High luminous intensityIncrease heightDomestic articlesNatural mineral layered productsMischmetalPhysical chemistry

A mechanoluminescence material comprising a mother body material and a luminescence center added to the mother body material. The mother body material is constituted of at least one kind of oxide selected from alumino silicate, aluminate, silicate, tantalate, niobate, gallium oxide, and ZrO2, and the luminescence center is at least one kind selected from a rare earth metal and a transition metal which emits light when electrons excited by mechanical energy are restored to a normal state.

Owner:NAT INST OF ADVANCED IND SCI & TECH

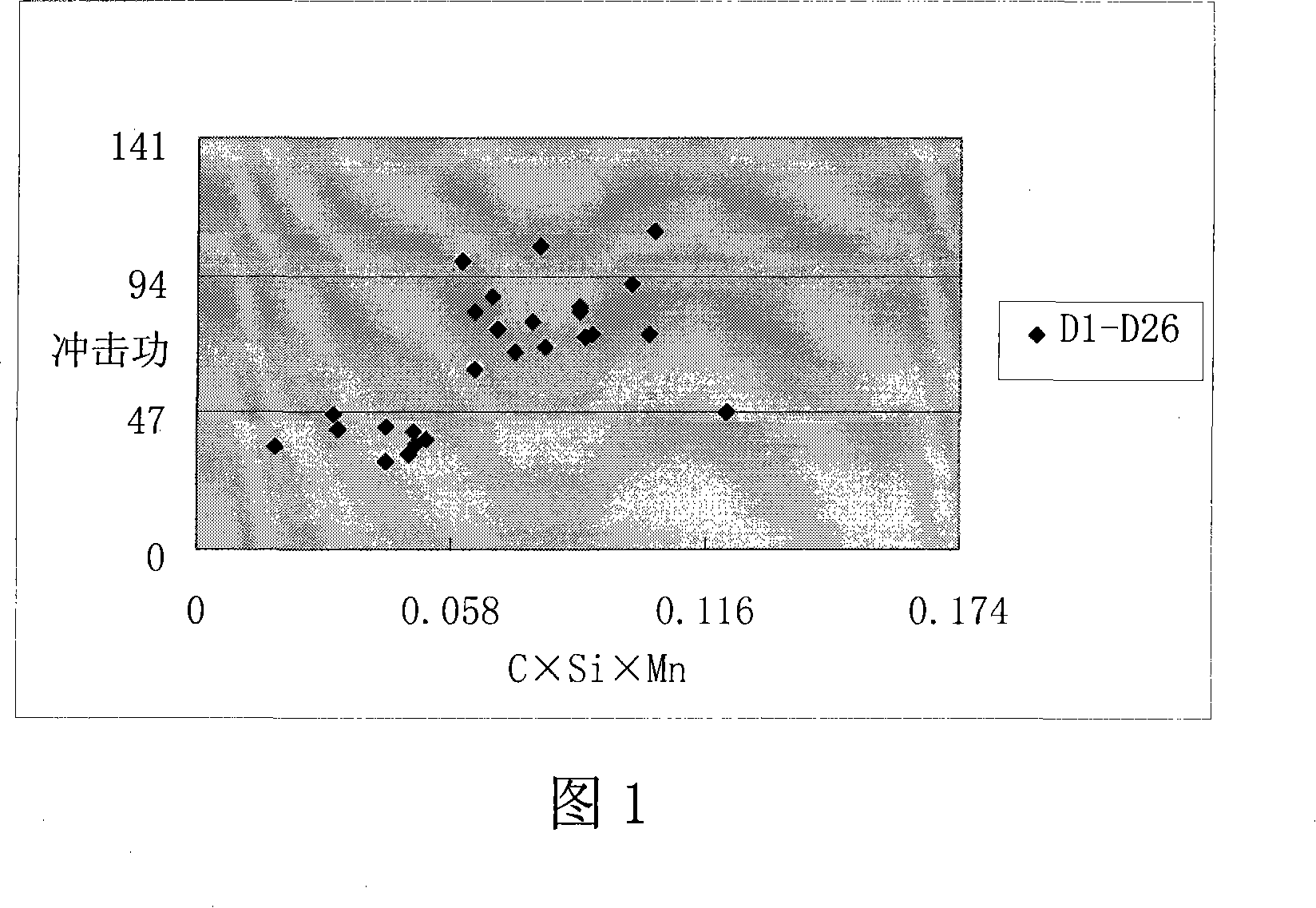

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Method of depositing rare earth oxide thin films

InactiveUS20090035949A1Eliminate the problemIncrease probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureMischmetal

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds or rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

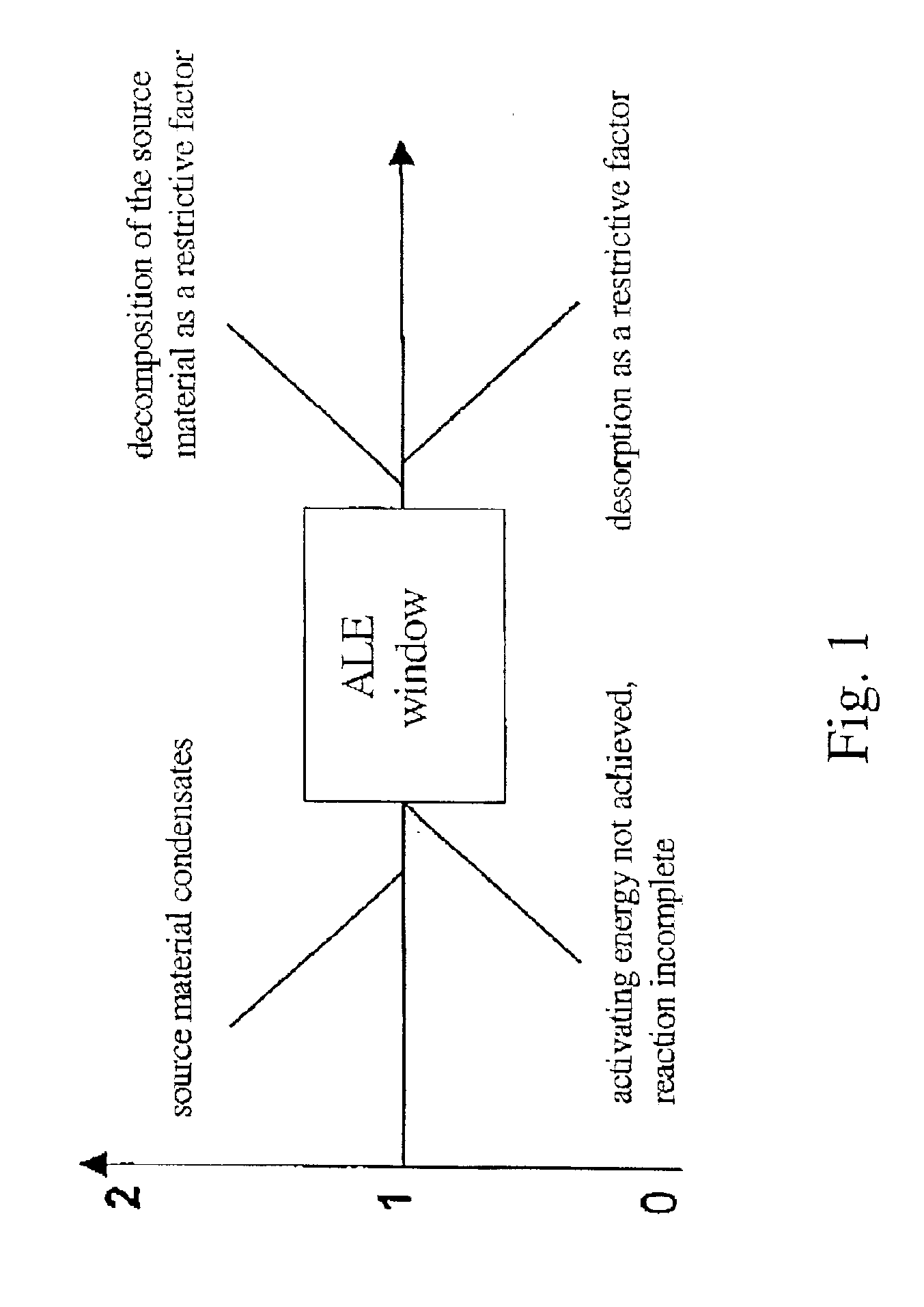

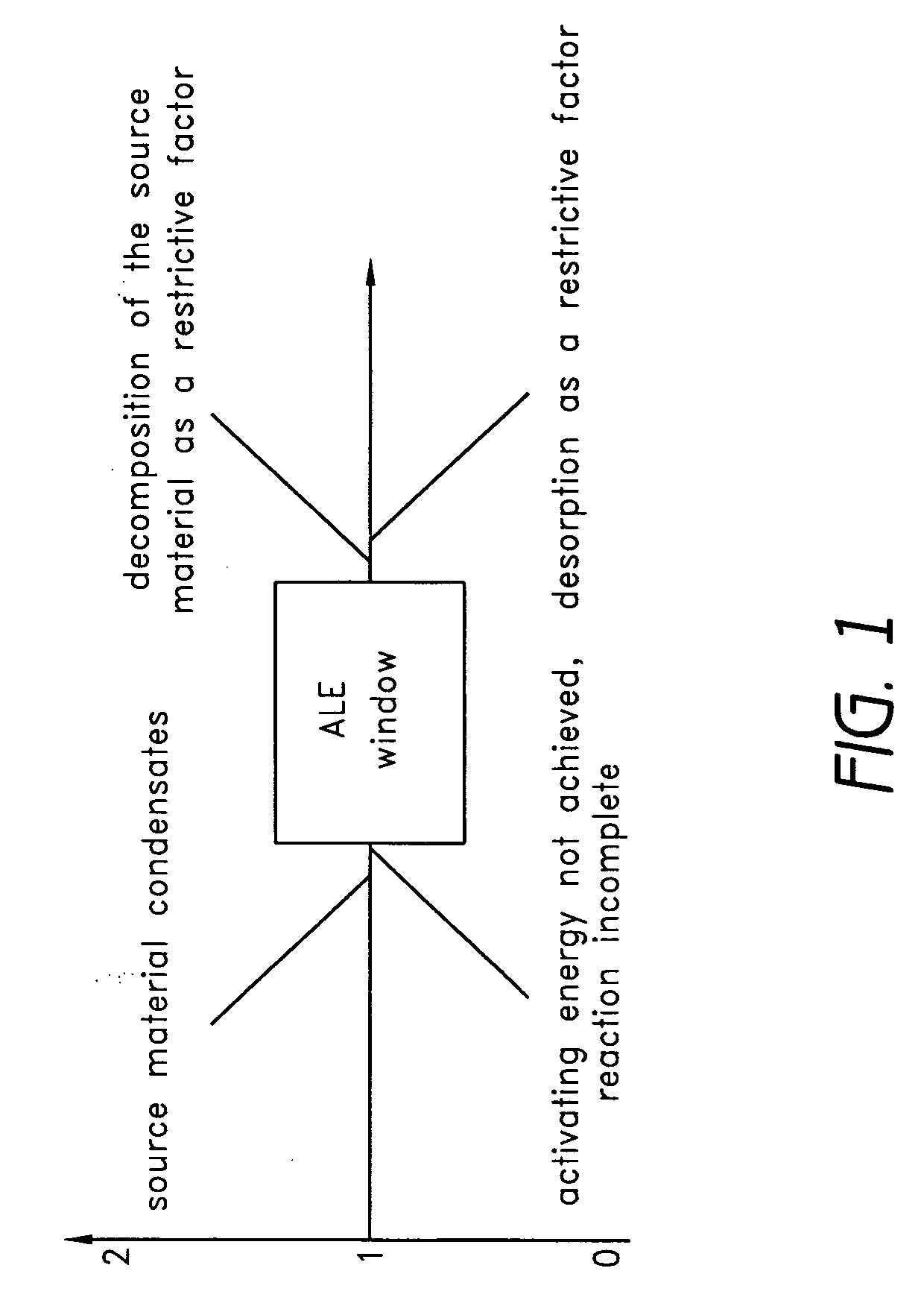

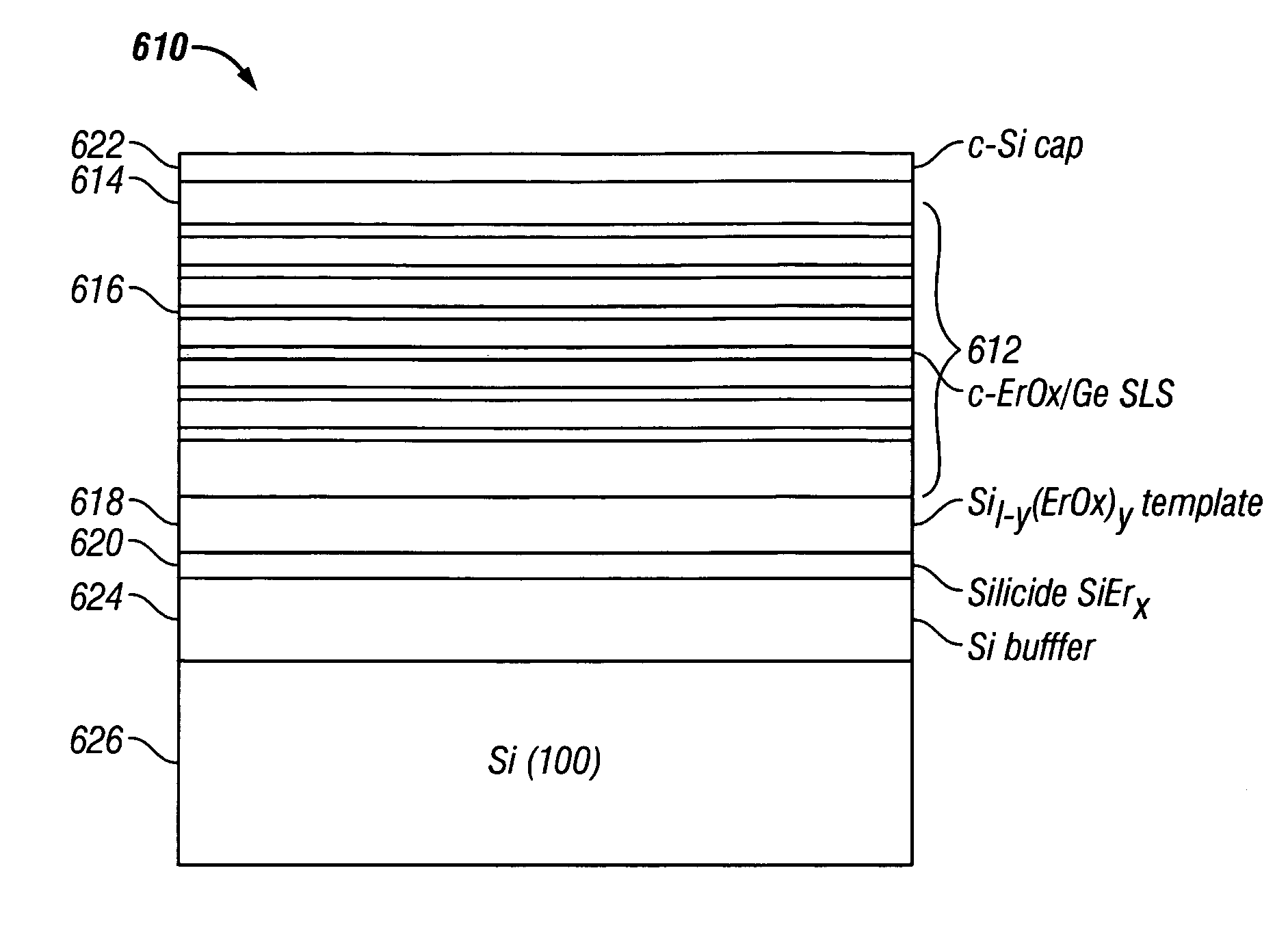

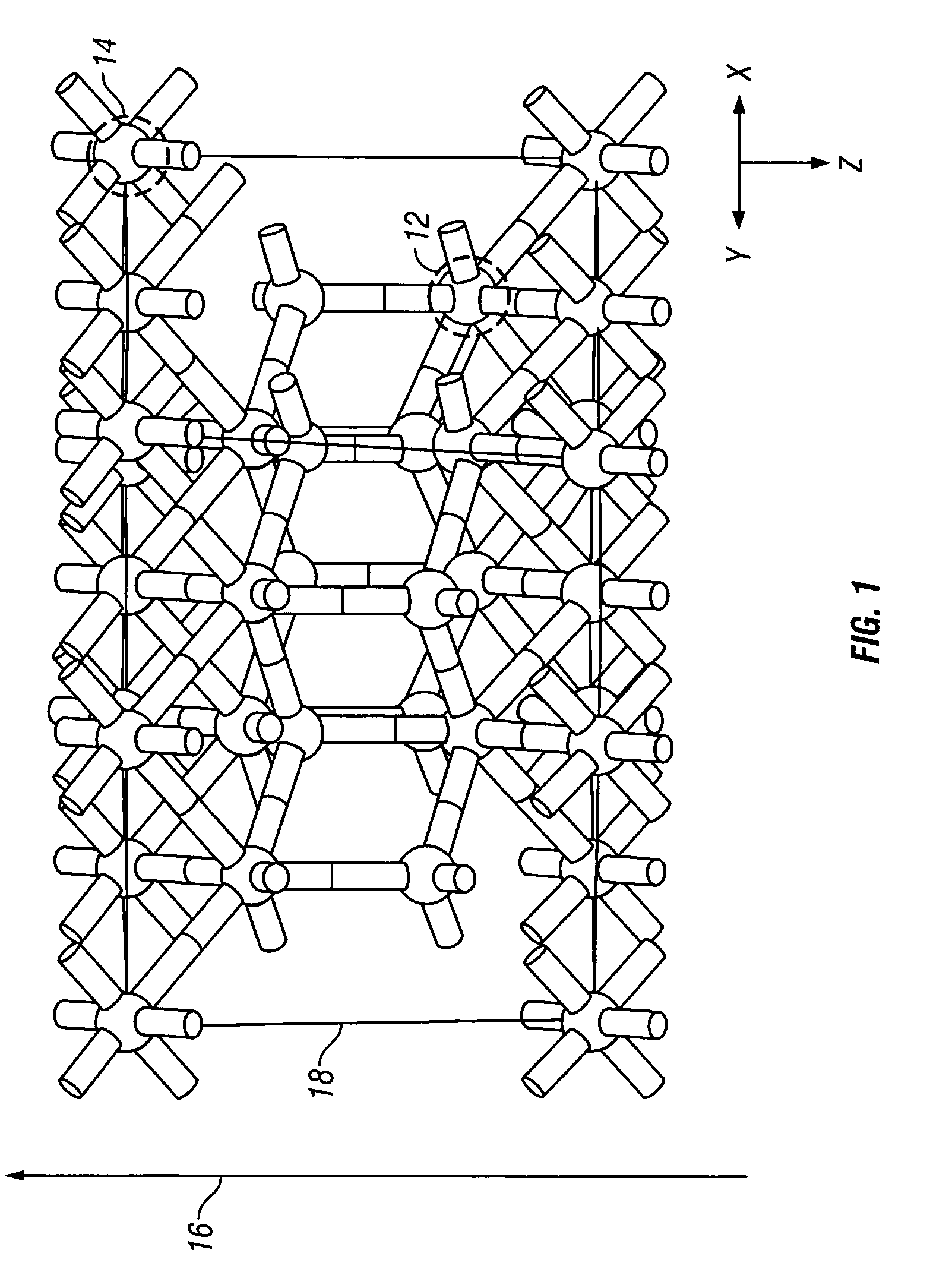

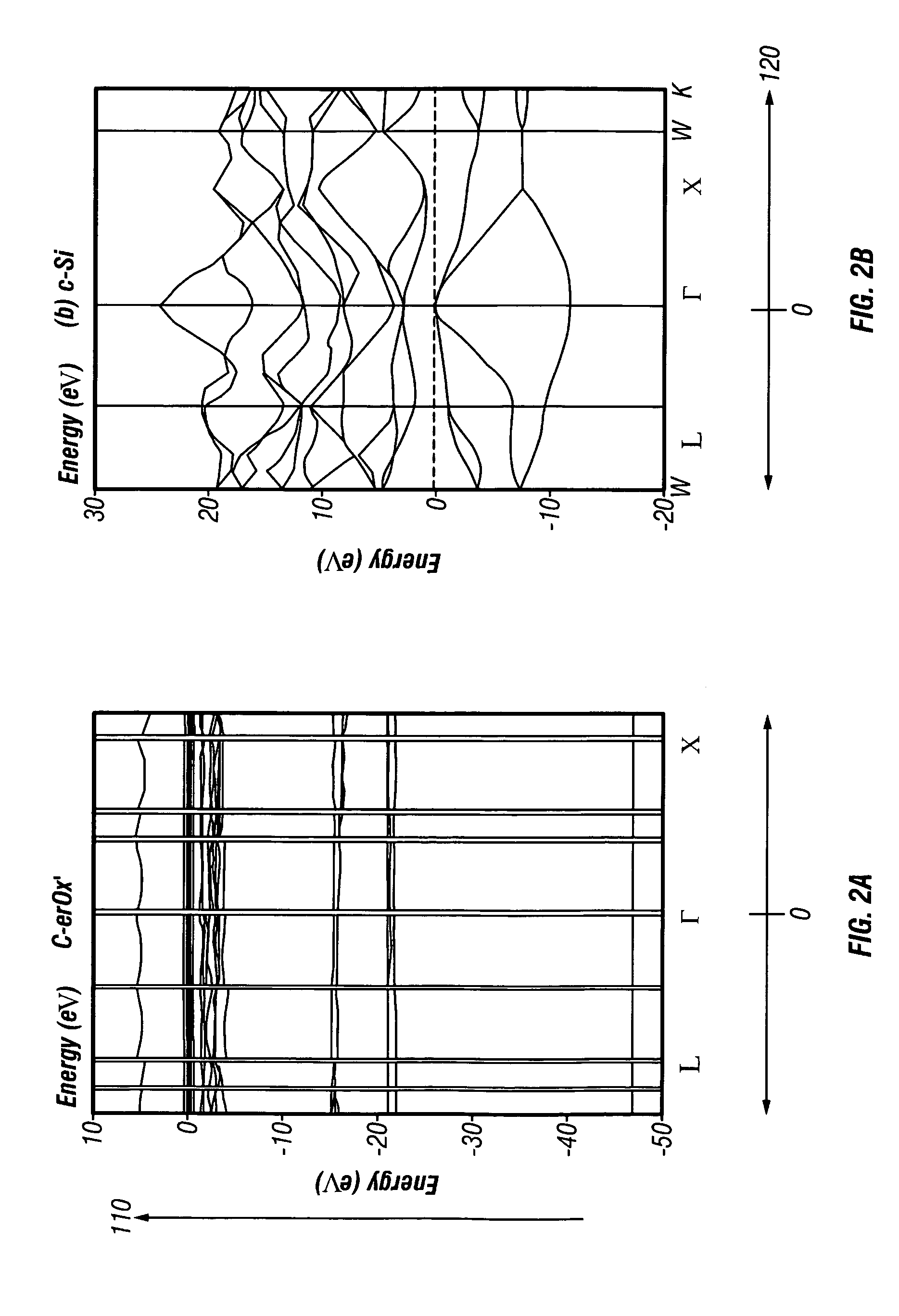

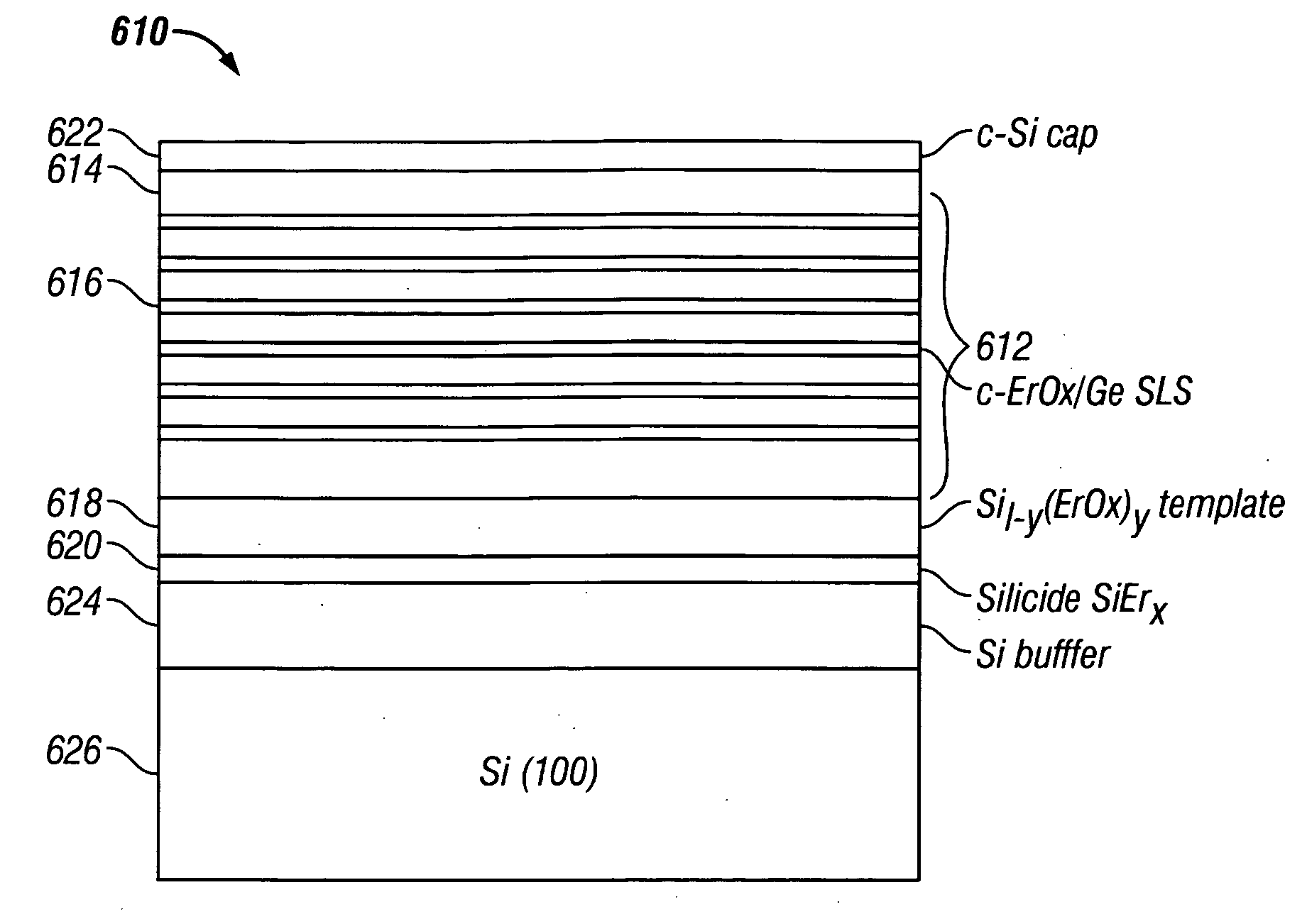

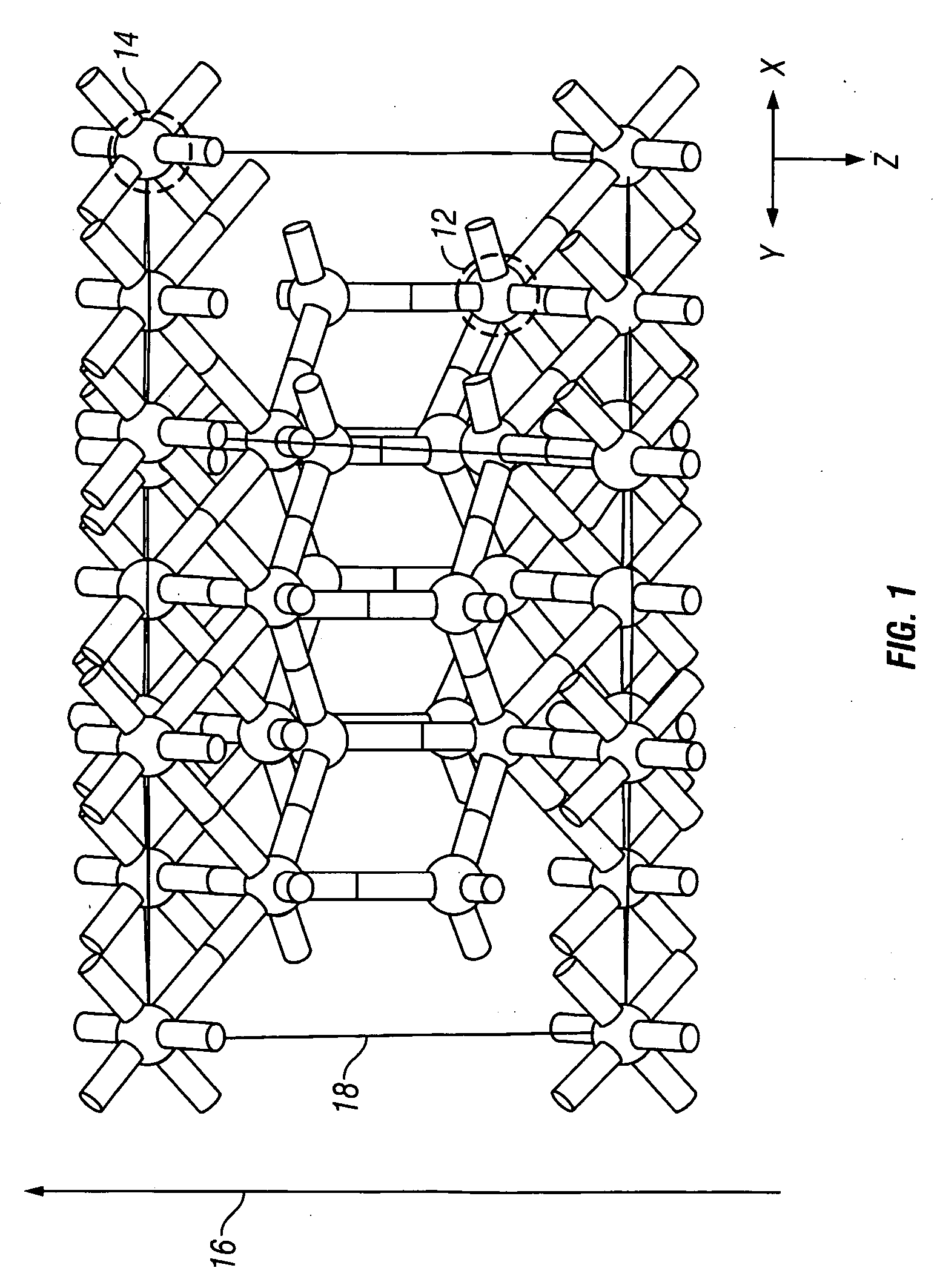

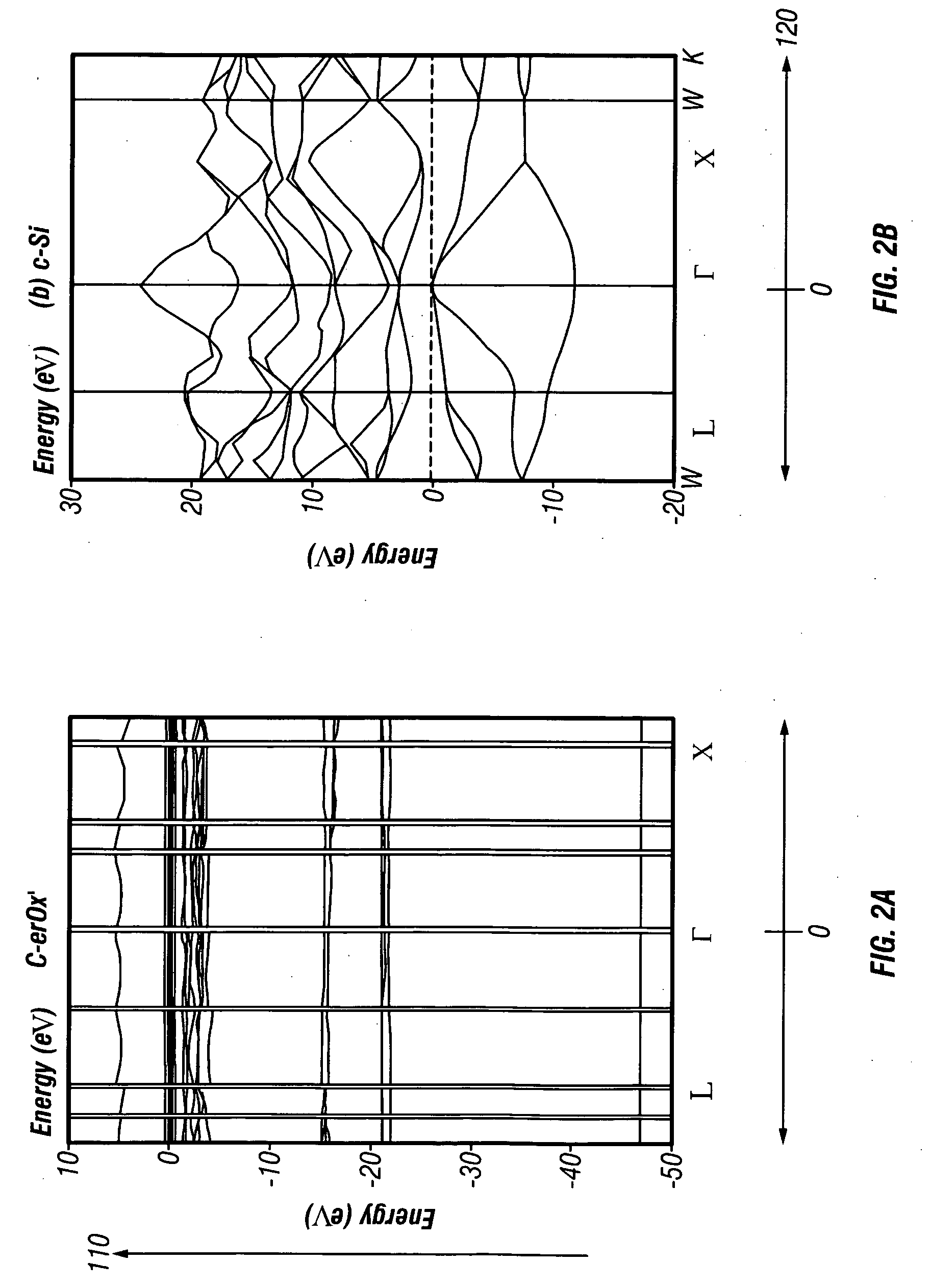

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

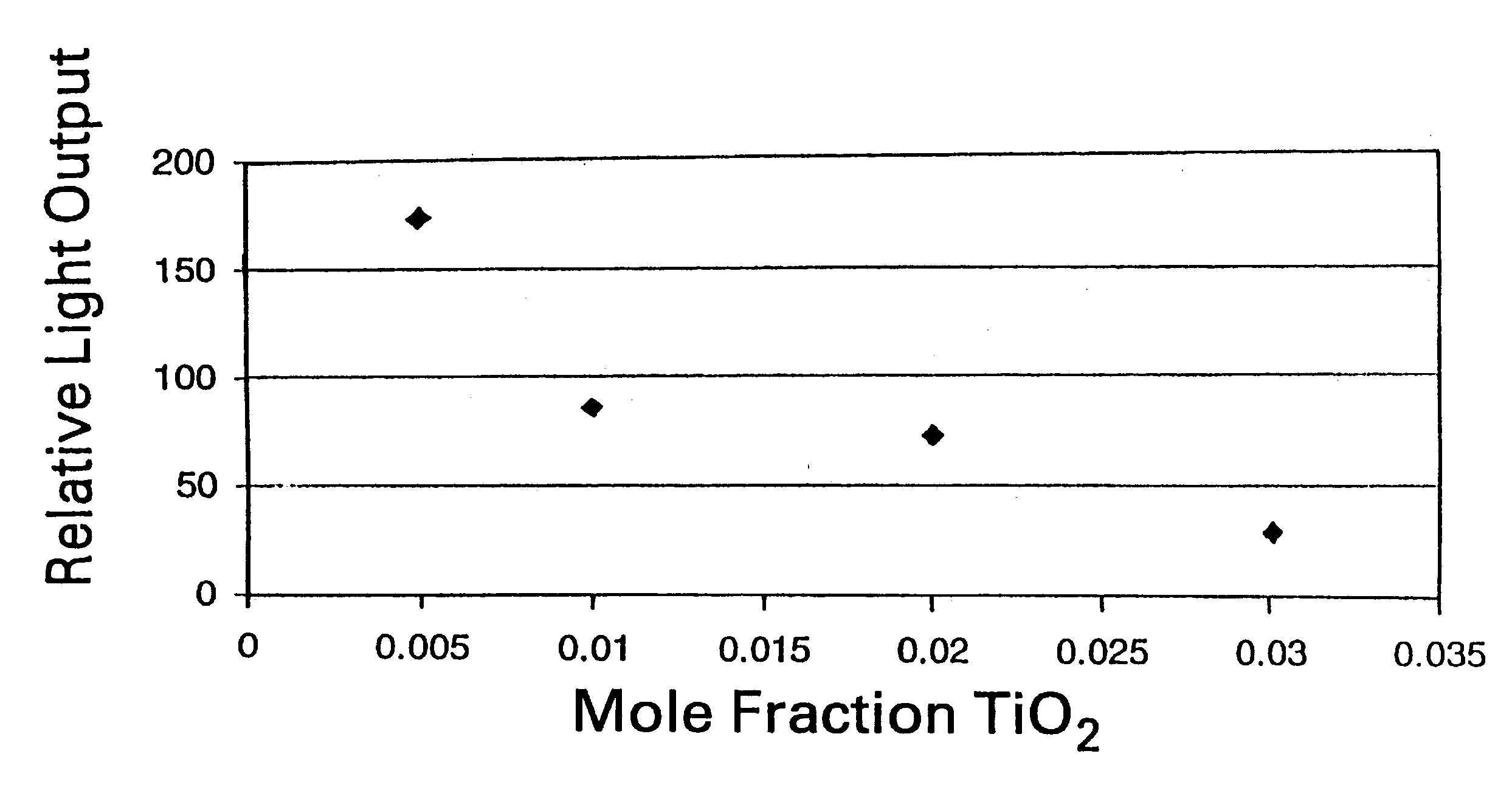

Titanium-doped hafnium oxide scintillator and method of making the same

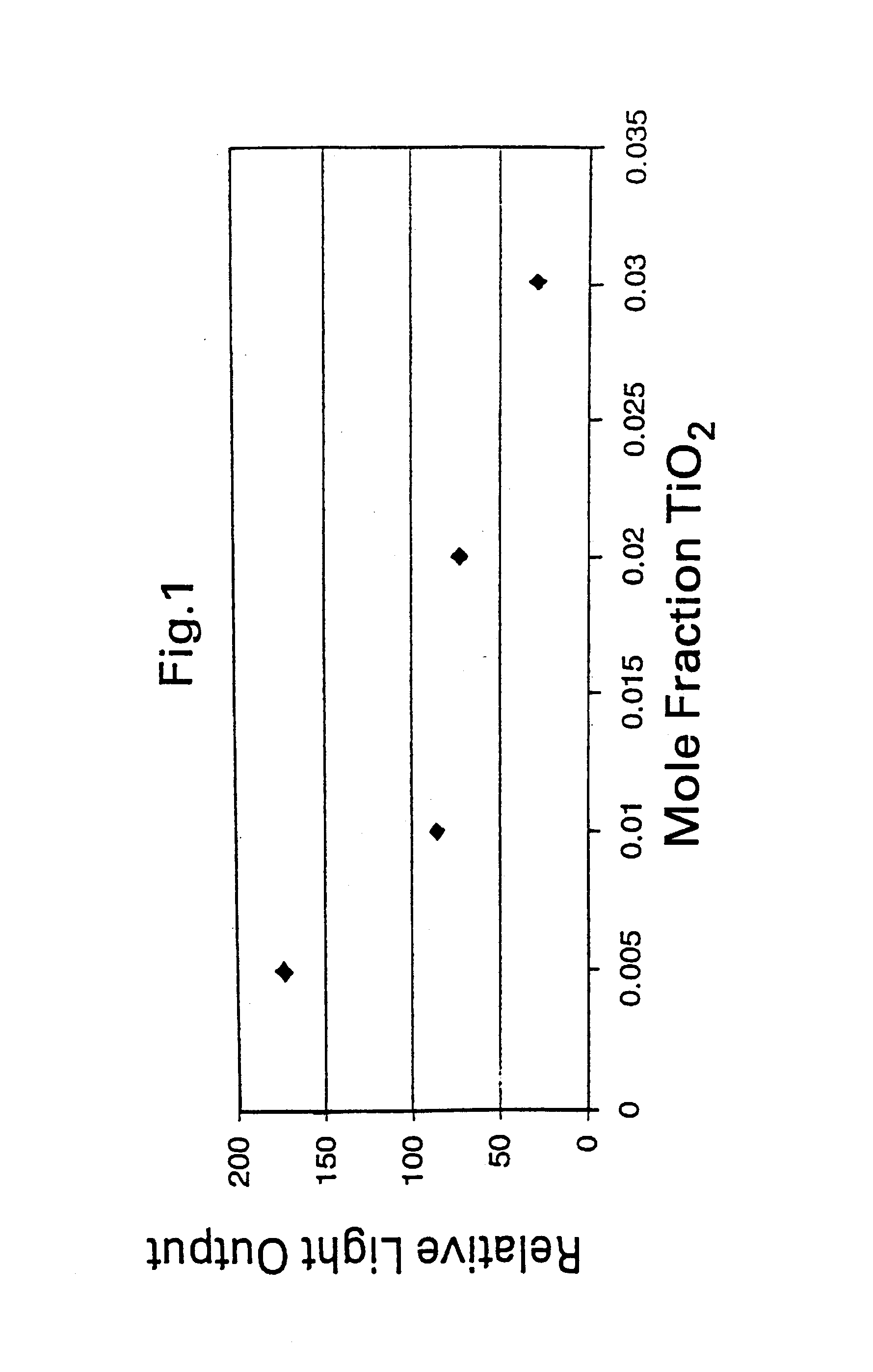

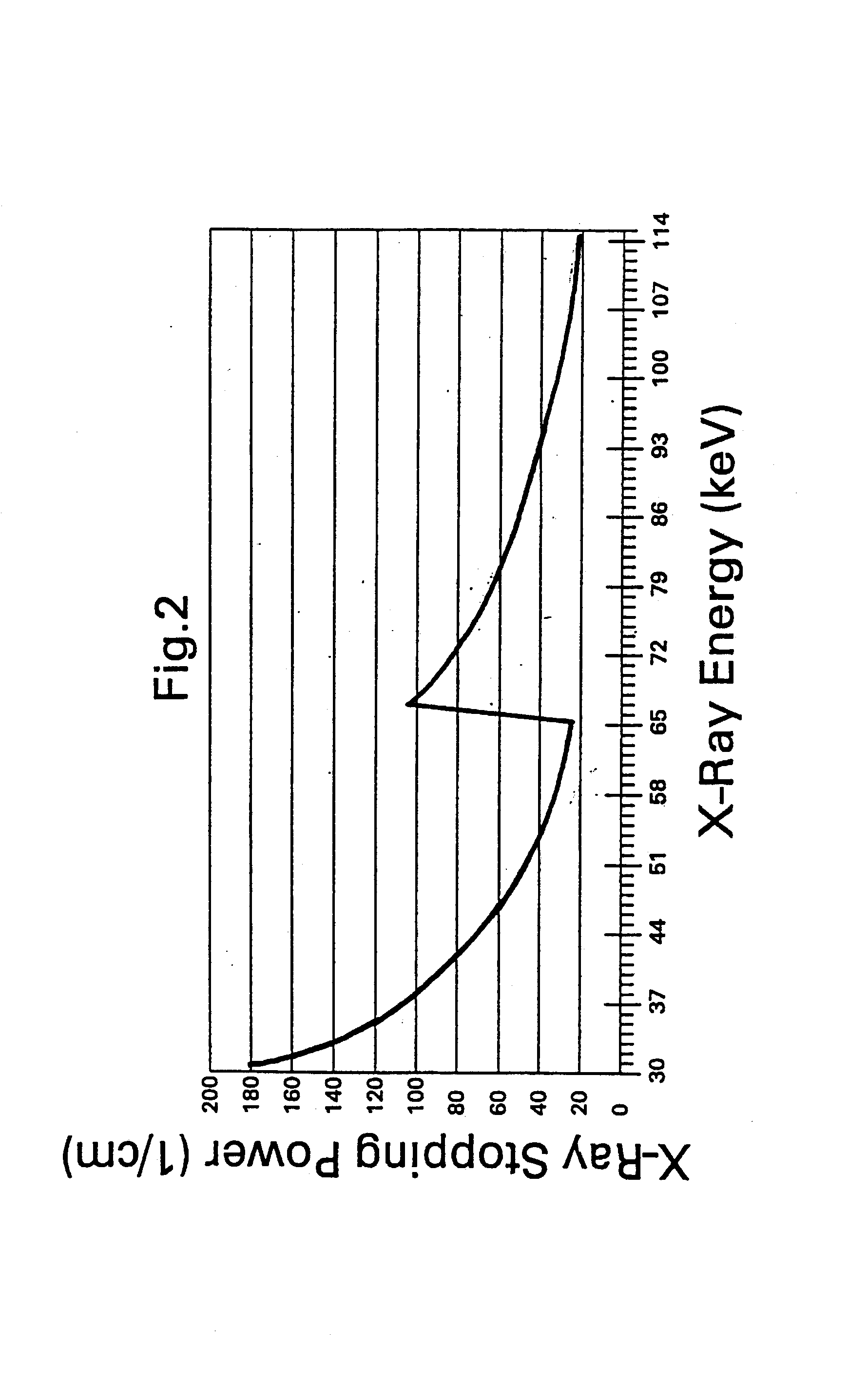

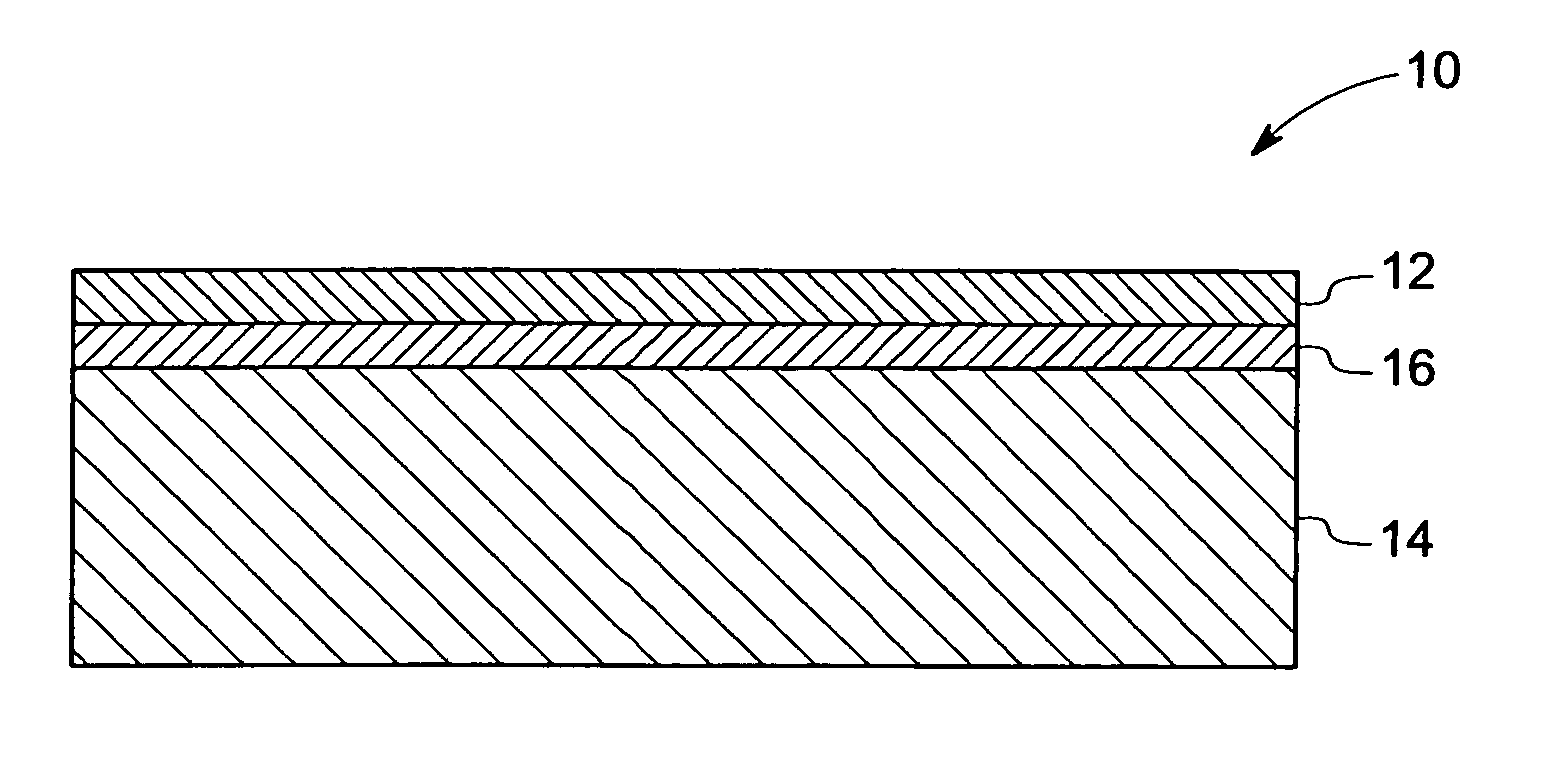

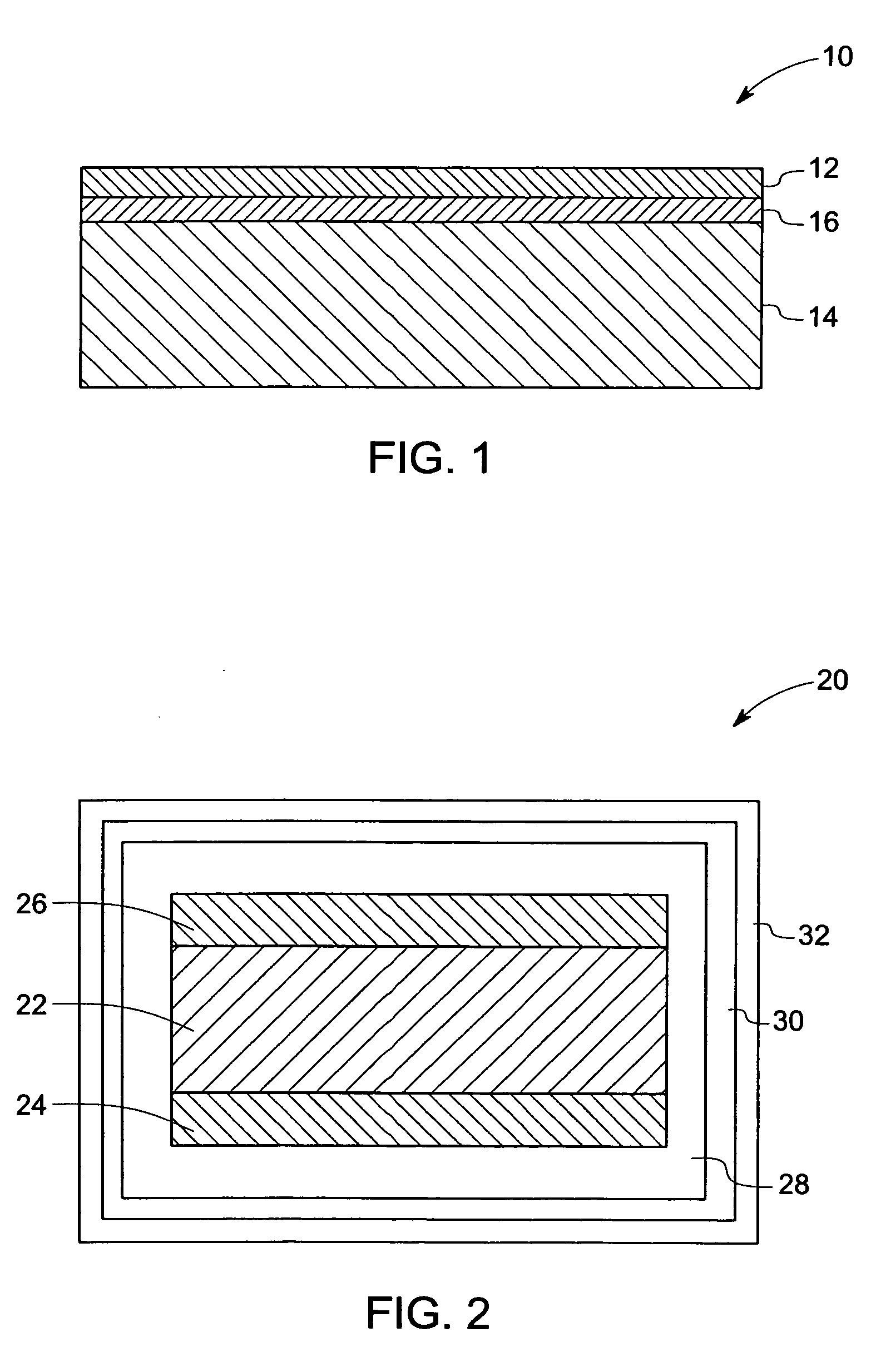

InactiveUS6858159B2Short decay timeImprove light outputMaterial analysis using wave/particle radiationRadiation/particle handlingRare earthX-ray

Hafnium oxide HfO2 scintillator compositions are doped with titanium oxide and at least an oxide of a metal selected from the group consisting of Be, Mg, and Li. The scintillator compositions can include sintering aid material such as scandium and / or tin and a rare earth metal and / or boron for improved transparency. The scintillators are characterized by high light output, reduced afterglow, short decay time, and high X-ray stopping power. The scintillators can be used as detector elements in X-ray CT systems.

Owner:GENERAL ELECTRIC CO

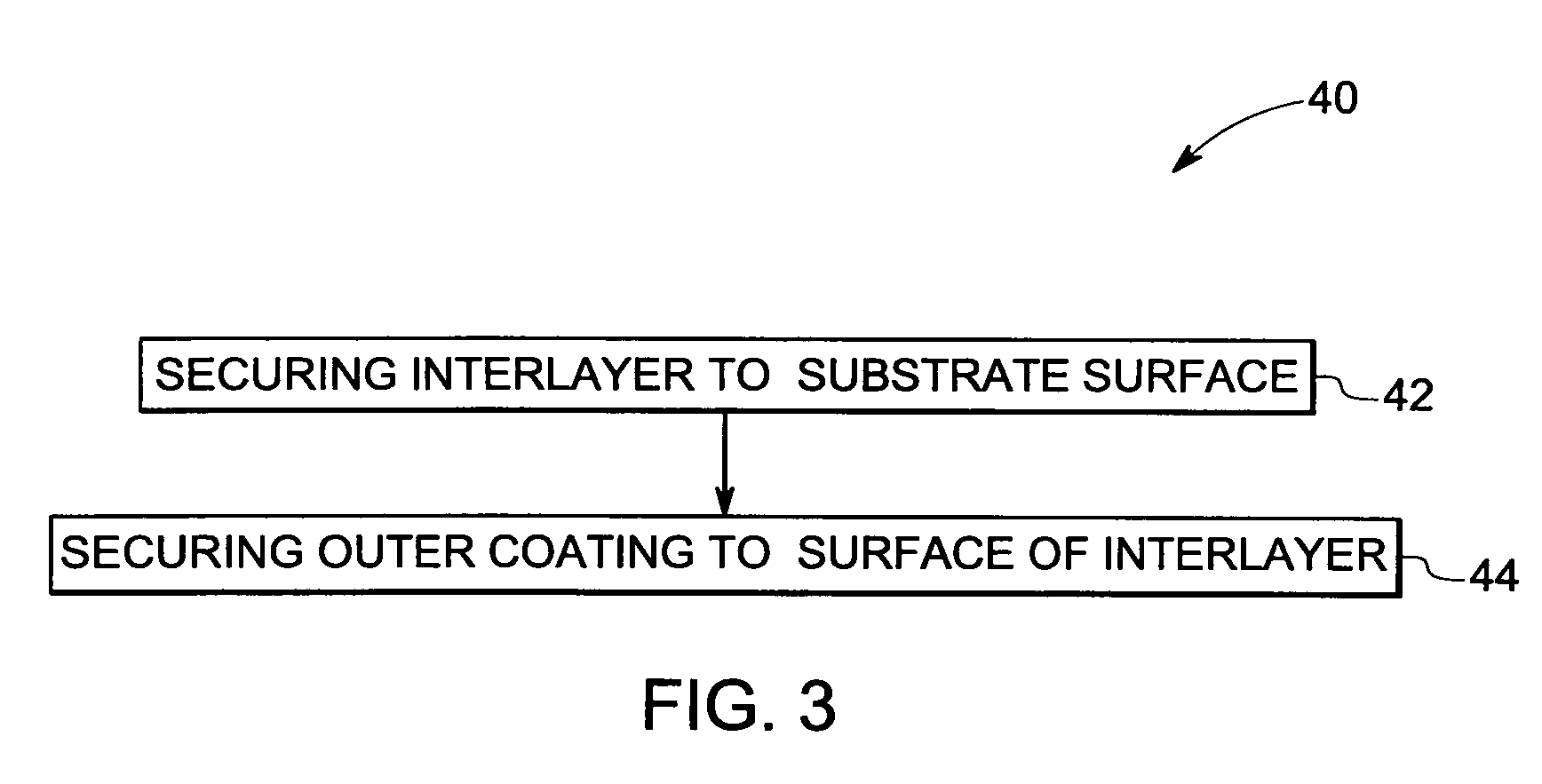

Coating structure and method

InactiveUS20060051602A1Extend article lifeGood thermal expansionLiquid surface applicatorsVacuum evaporation coatingRare earthThermal expansion

A coating structure including an outer coating comprising aluminum; and an interlayer disposed between a substrate and the outer coating is provided. The interlayer may include a rare earth metal, a transition metal, or a noble metal. The interlayer may have one or more property of being less responsive to halogen etching relative to the outer coating; having a coefficient of thermal expansion that is greater than the coefficient of thermal expansion of the substrate and less than the coefficient of thermal expansion of the outer coating or vice versa; having a color different from the color of the outer coating; having a electrical conductivity different from the electrical conductivity of the outer coating. A method of making is article is provided. The method may include securing an interlayer to a substrate surface, and securing an outer coating to a surface of the interlayer opposite the substrate.

Owner:GENERAL ELECTRIC CO

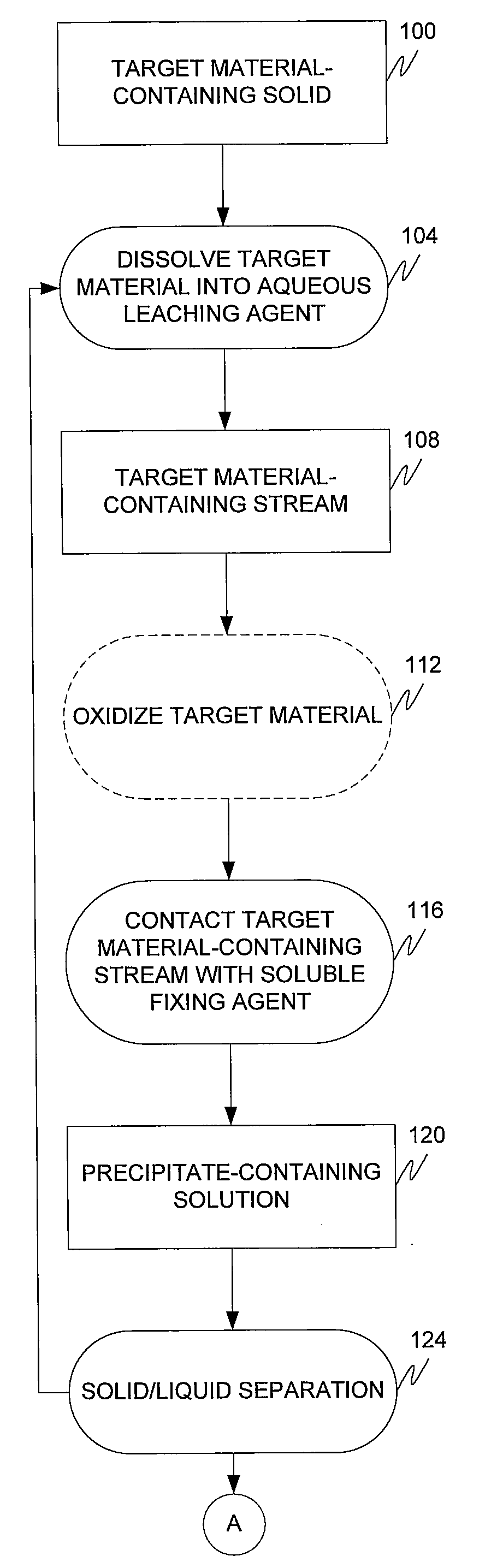

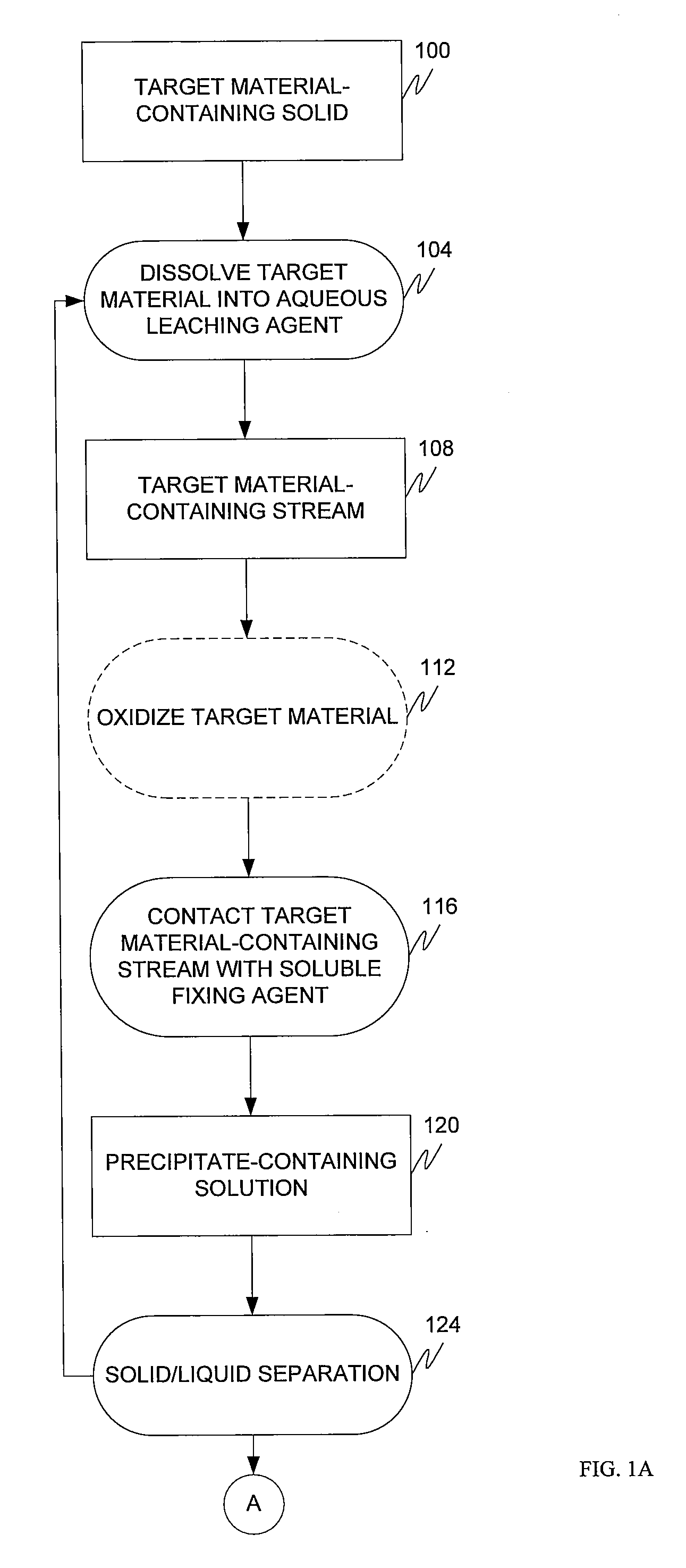

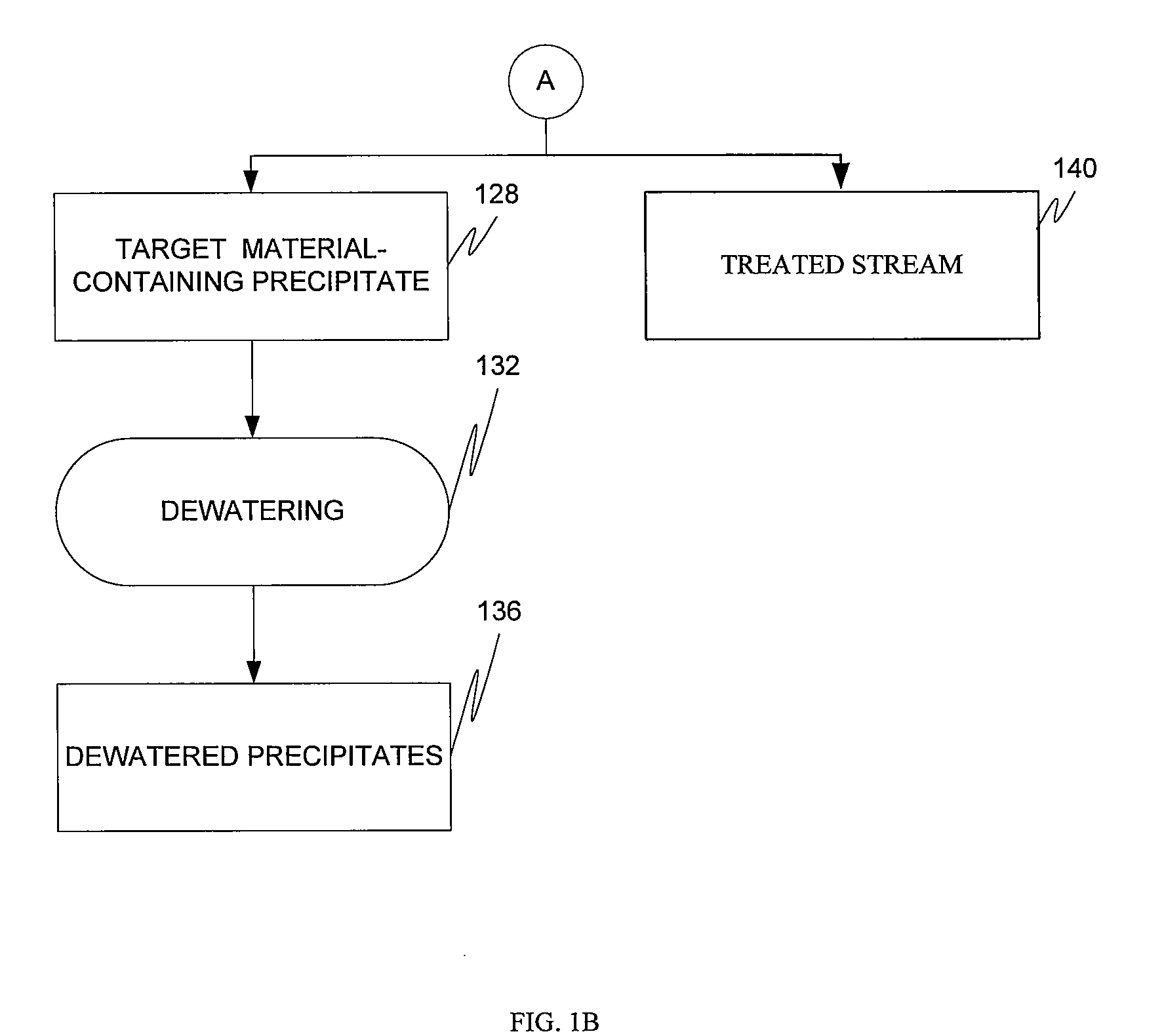

Target material removal using rare earth metals

InactiveUS20100155330A1Easily recoveredIncrease exposureWater treatment parameter controlOther chemical processesMetalMaterial removal

The present invention is directed to the removal of one or more selected target materials from various streams using a rare earth metal-containing fixing agent.

Owner:MOLYCORP MINERALS

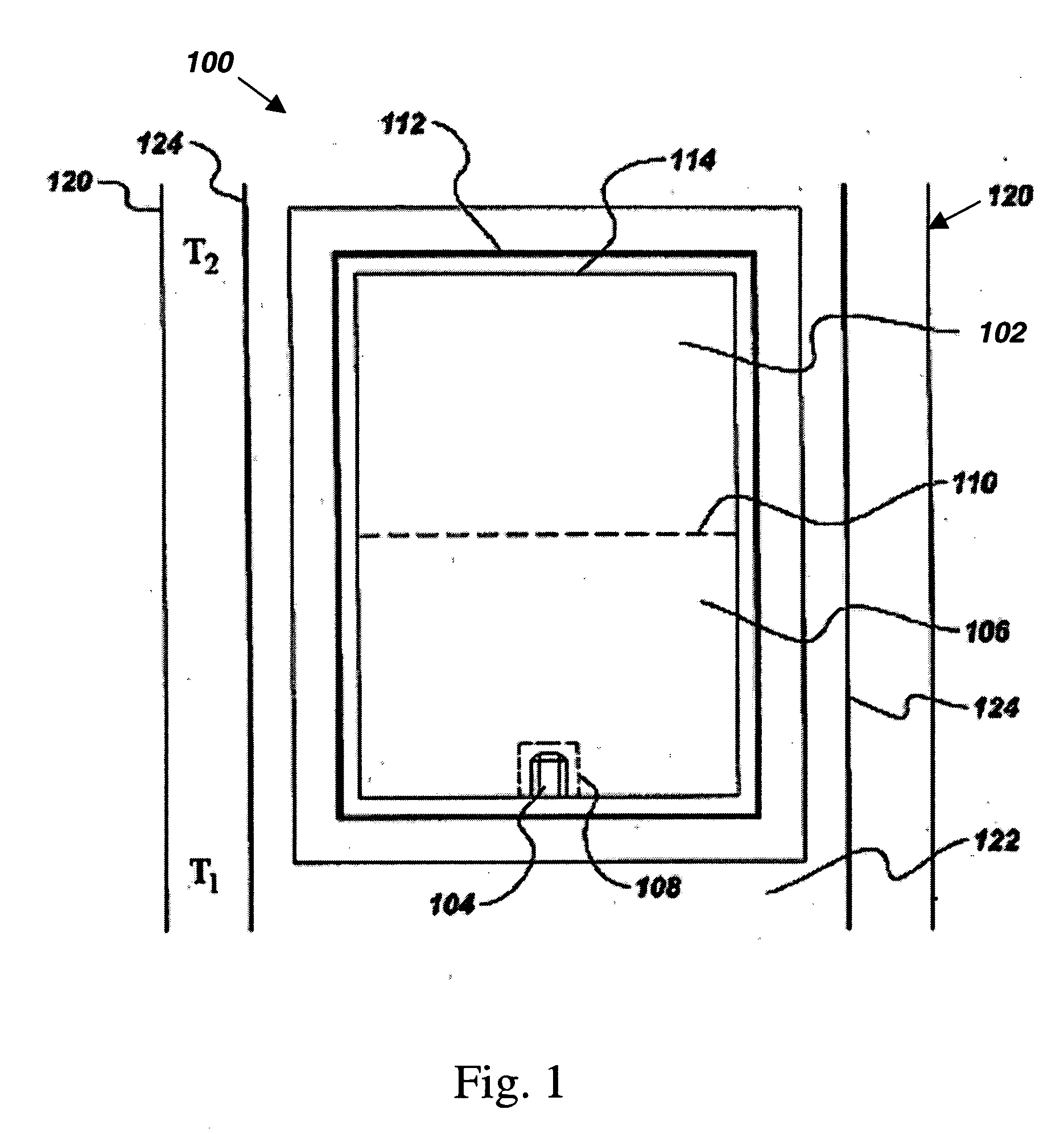

Method for controlling dopant profiles

InactiveUS6467313B1Improve performanceImprove concentrationGlass making apparatusMaterial analysis using wave/particle radiationDopantRare earth

The present invention discloses novel methods for fabricating glass articles, particularly optical fiber glass preforms, which may contain alumina, yttrium, lanthanum, erbium, or other rare earth metals as dopants. The glass articles made in accordance with the present invention exhibit radially uniform dopant profiles relative to conventional dopant methods. In addition, the overall concentration of the dopant is increased relative to analogous dopant methods.

Owner:CORNING INC

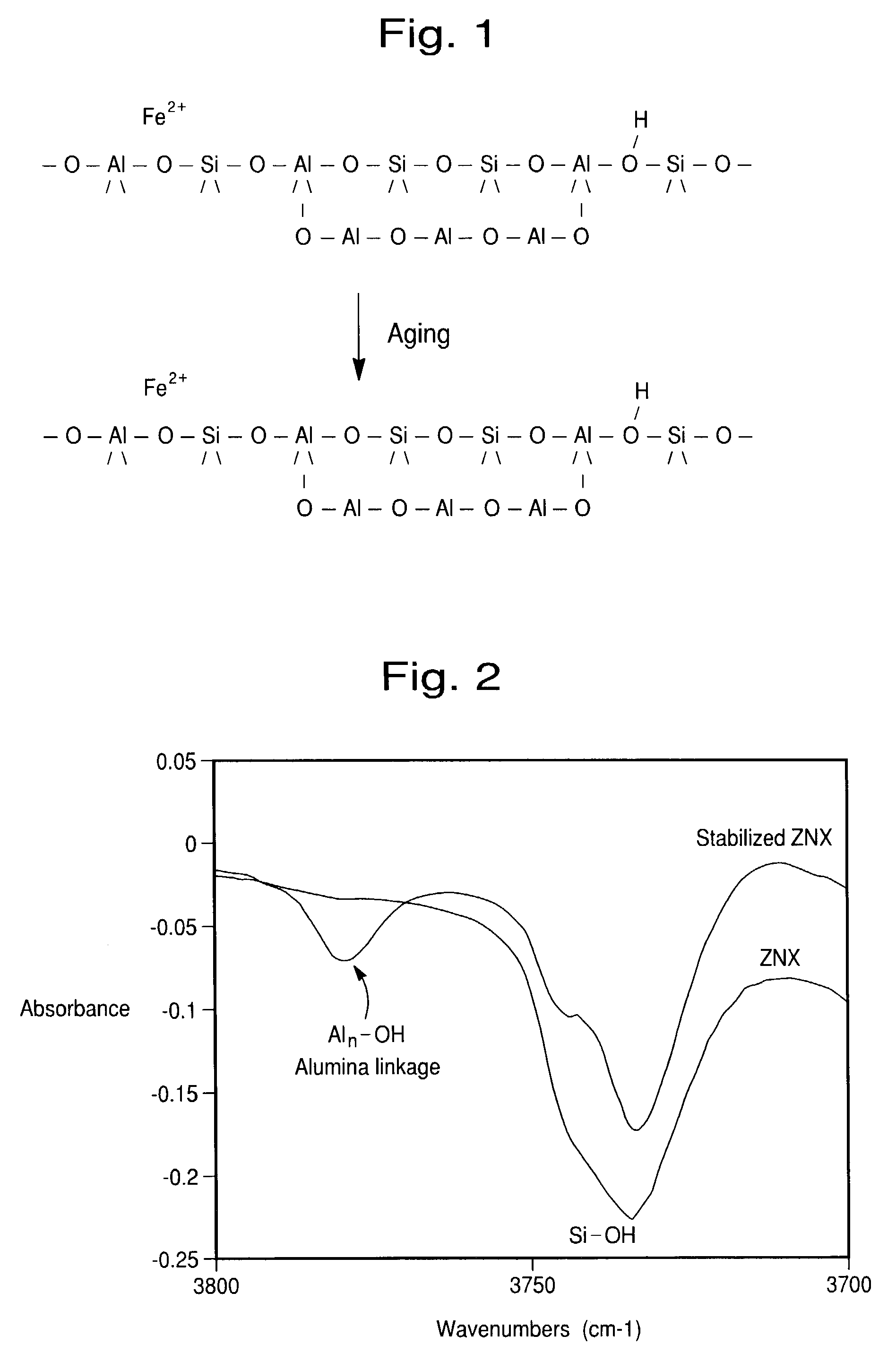

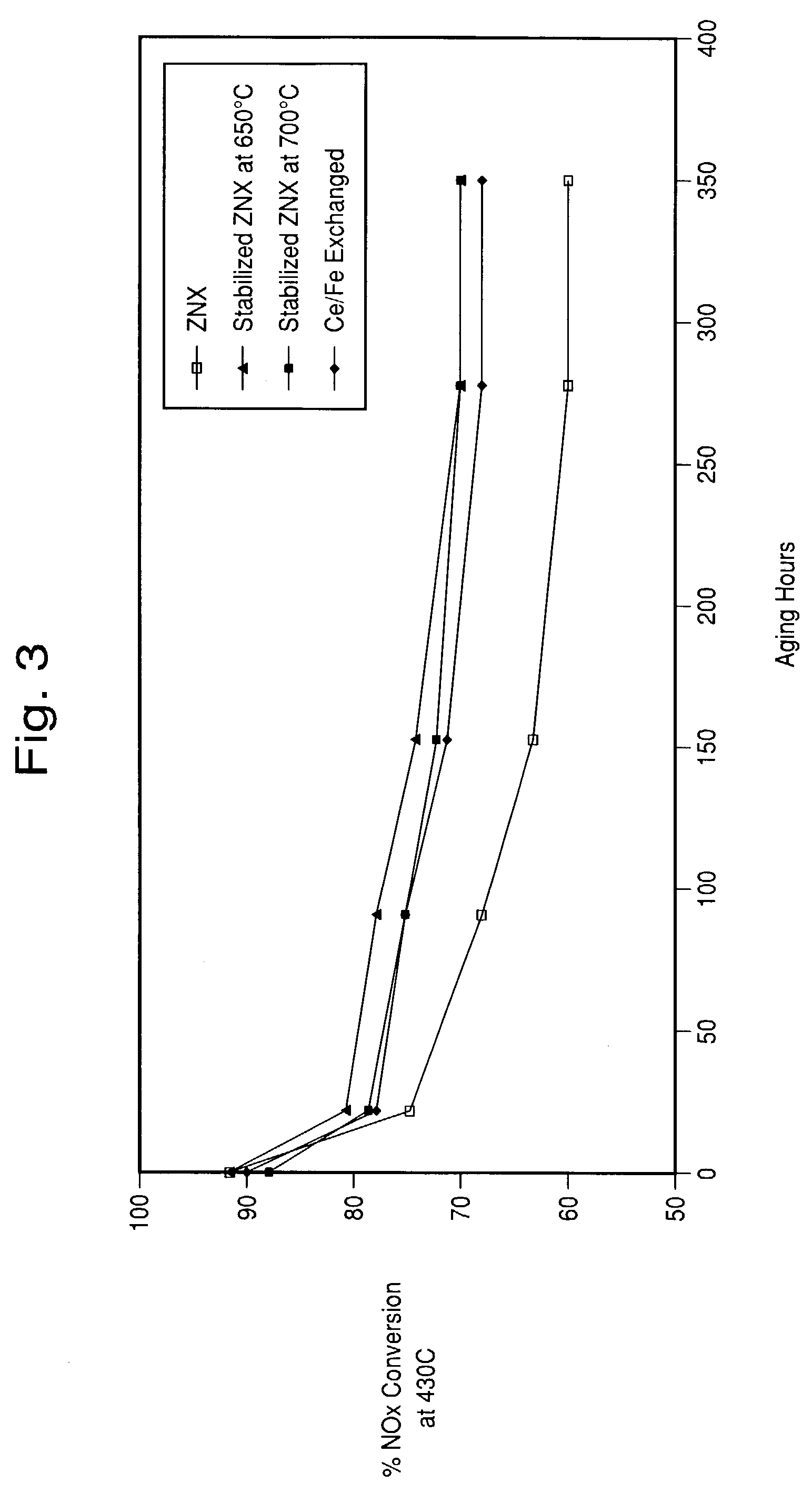

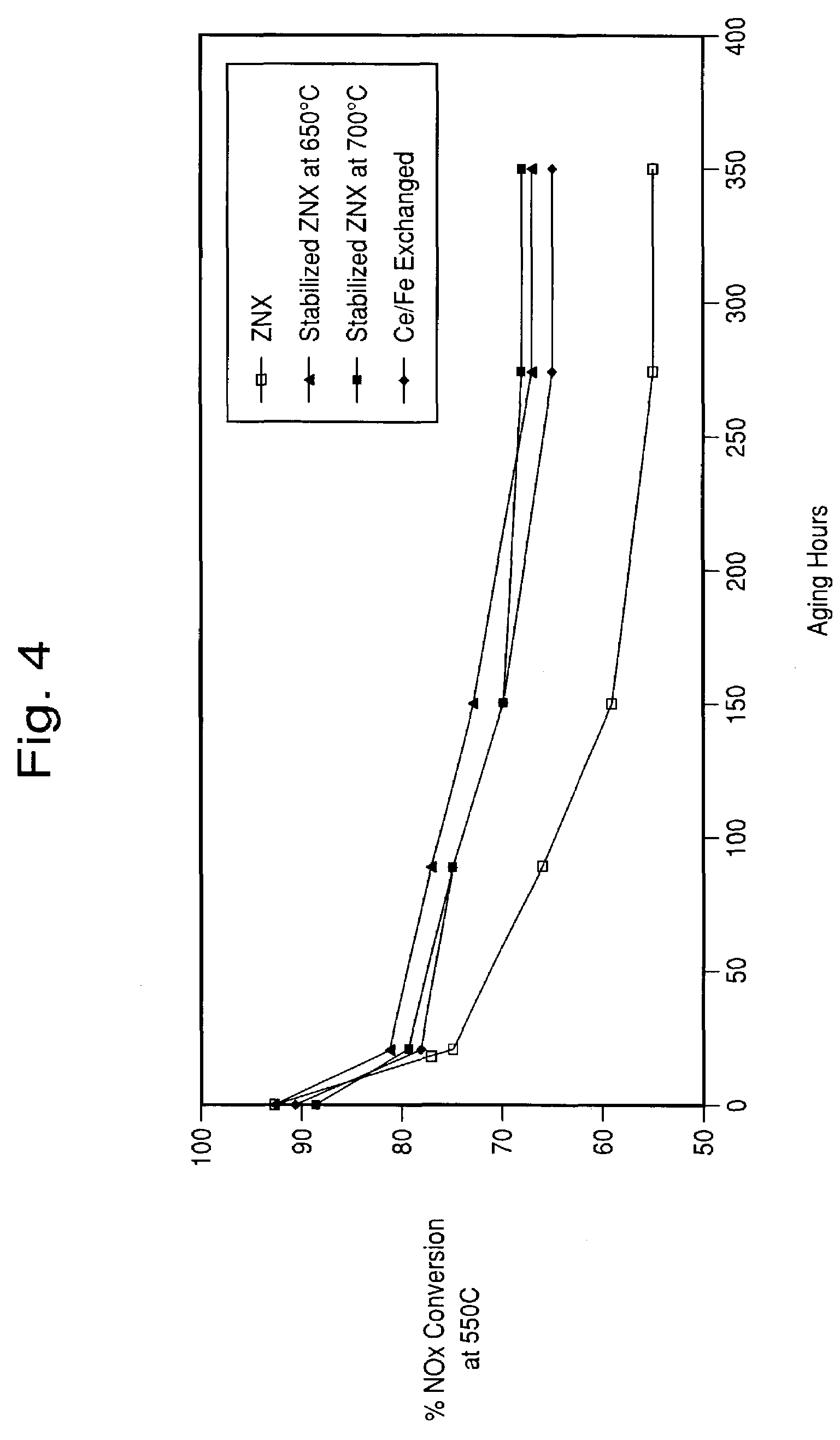

Hydrothermally stable metal promoted zeolite beta for NOx reduction

InactiveUS7118722B2Improve stabilityIncreasing silica to alumina ratioNitrogen compoundsMolecular sieve catalystsNH3 compoundAluminium oxide

The present invention is directed to a metal-promoted zeolite beta catalyst useful in the selective catalytic reduction of nitrogen oxides with ammonia in which the zeolite beta is pre-treated so as to provide the zeolite with improved hydrothermal stability.The stabilized beta zeolite is provided by incorporating into the zeolite structure non-framework aluminum oxide chains. The aluminum oxide chains can be incorporated into the zeolite structure by a unique steaming regimen or by treatment with rare earth metals, such as cerium. The treatment process is unlike well-known methods of dealuminizing zeolites for the purpose of increasing the silica to alumina ratio. In the present invention, the non-framework aluminum oxide is characterized by FT-IR by a peak at 3781±2 cm−1, which when present, stabilizes the zeolite against further dealumination such as under oxidizing and harsh hydrothermal conditions.

Owner:ENGELHARD CORP

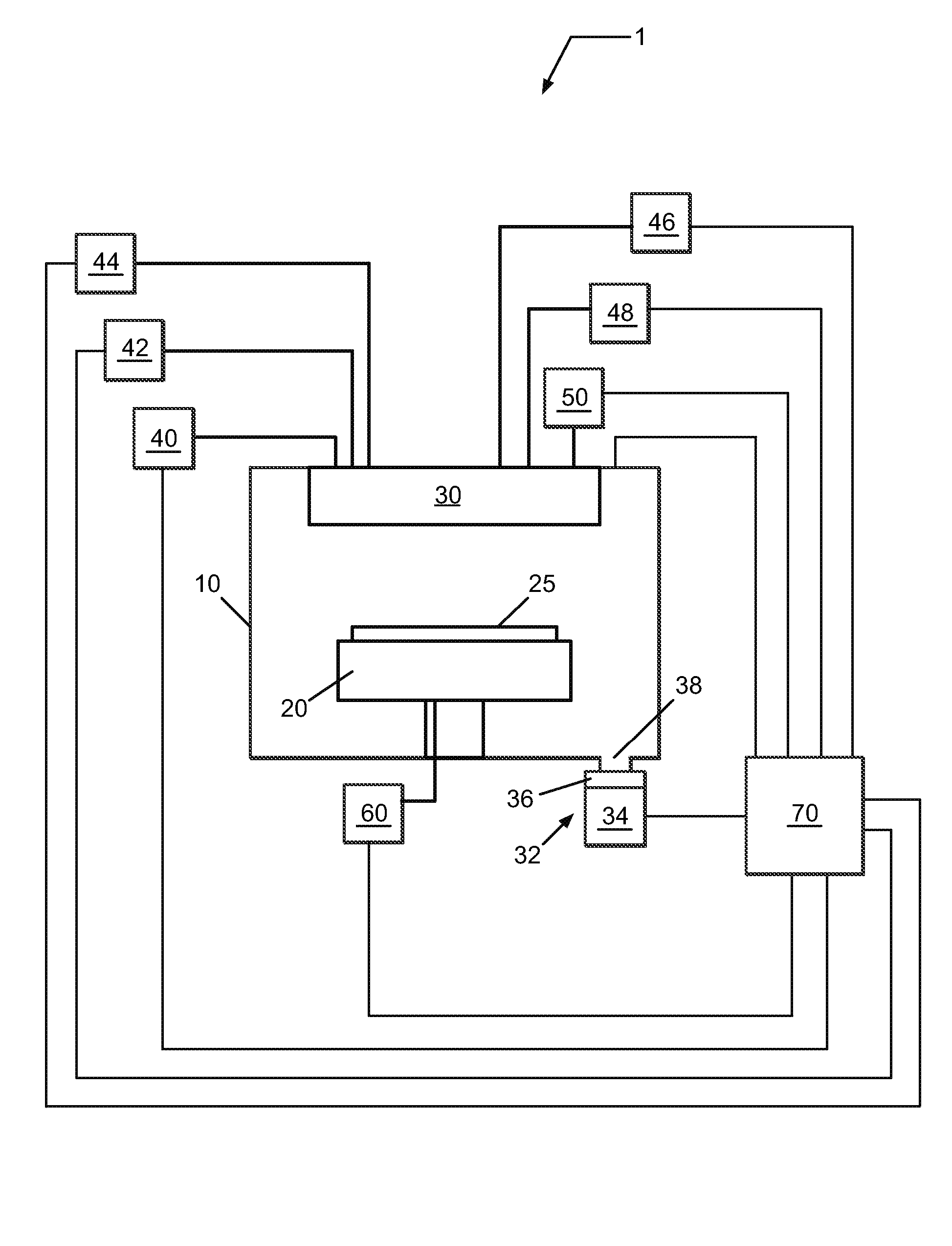

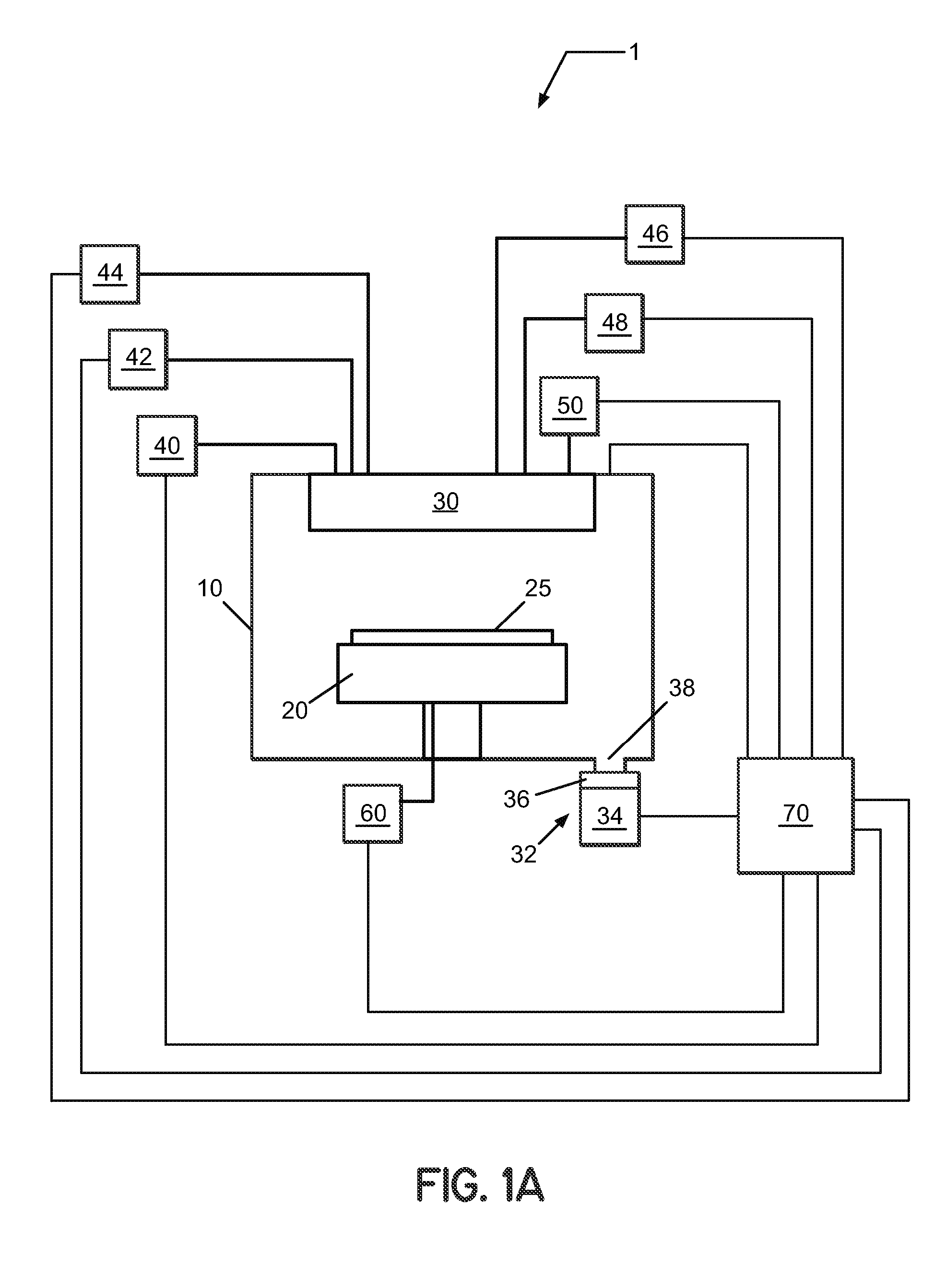

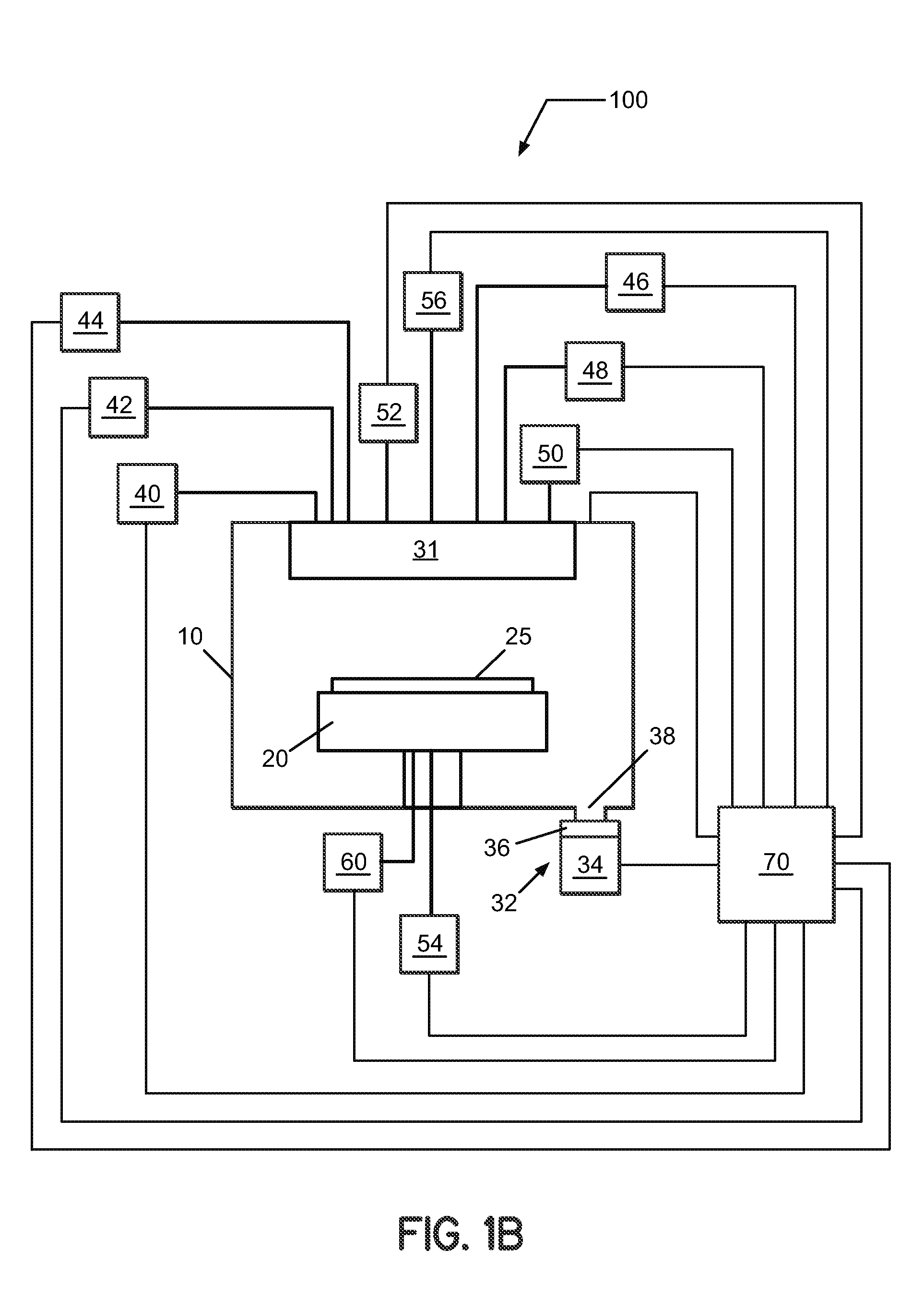

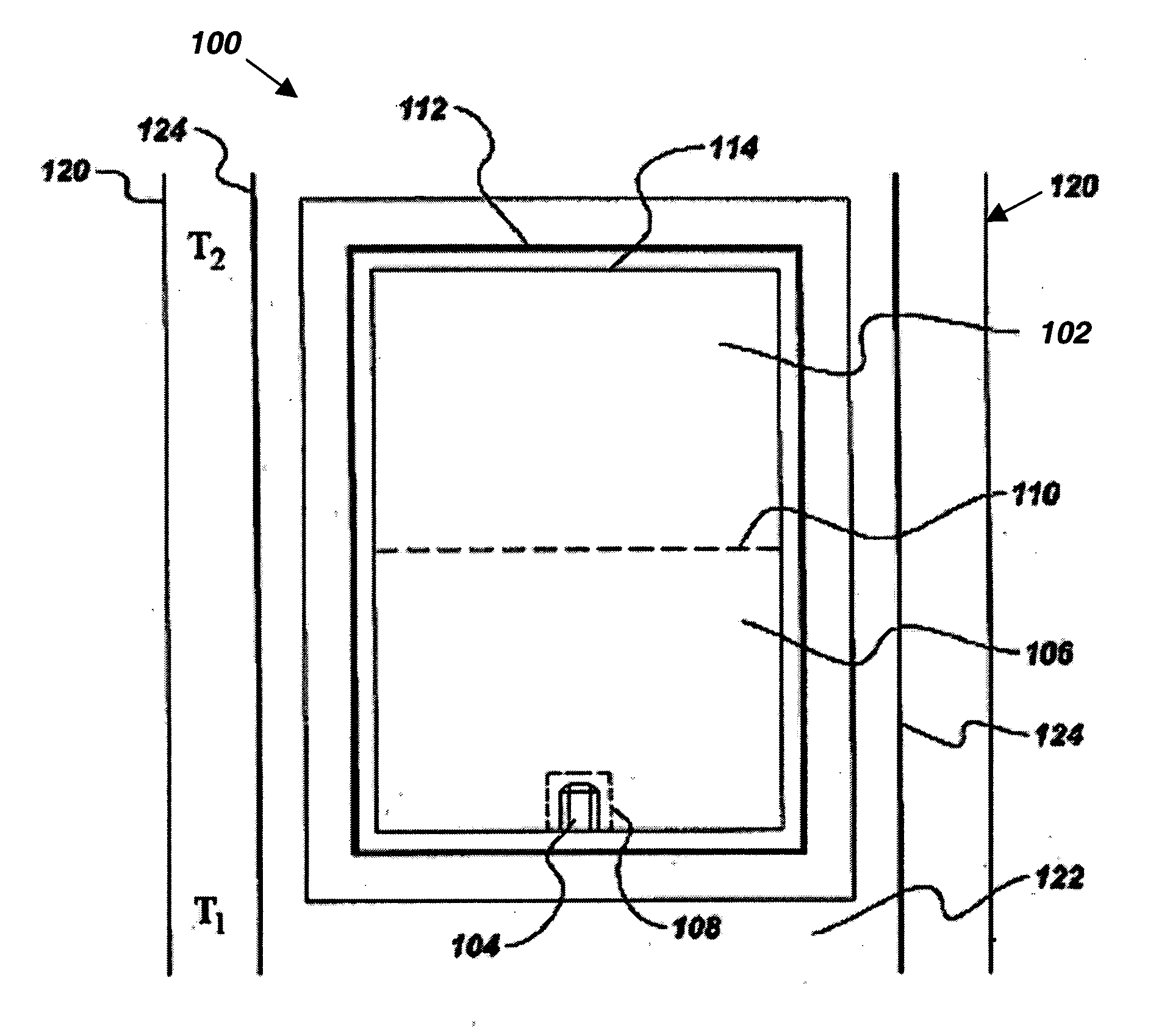

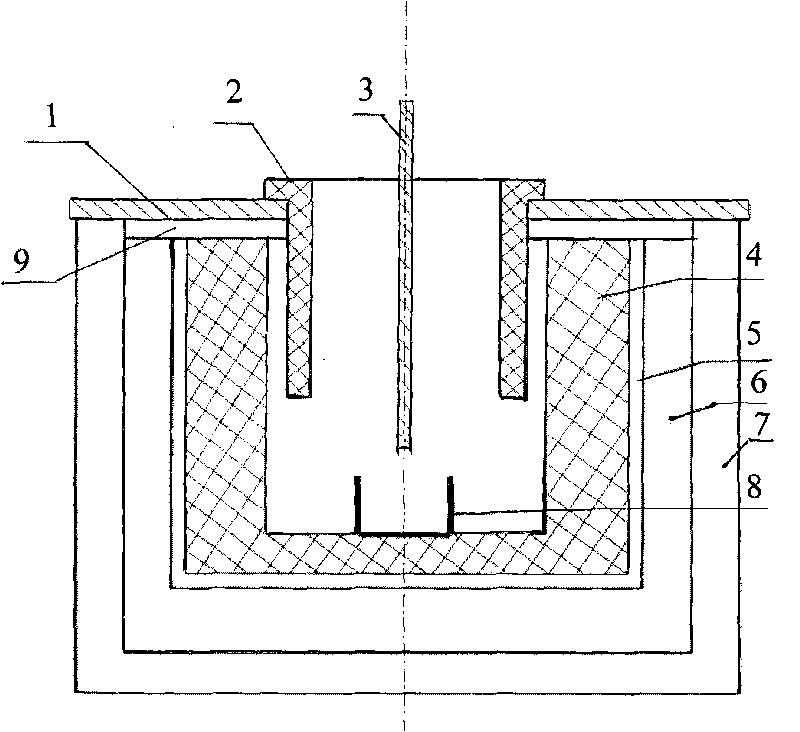

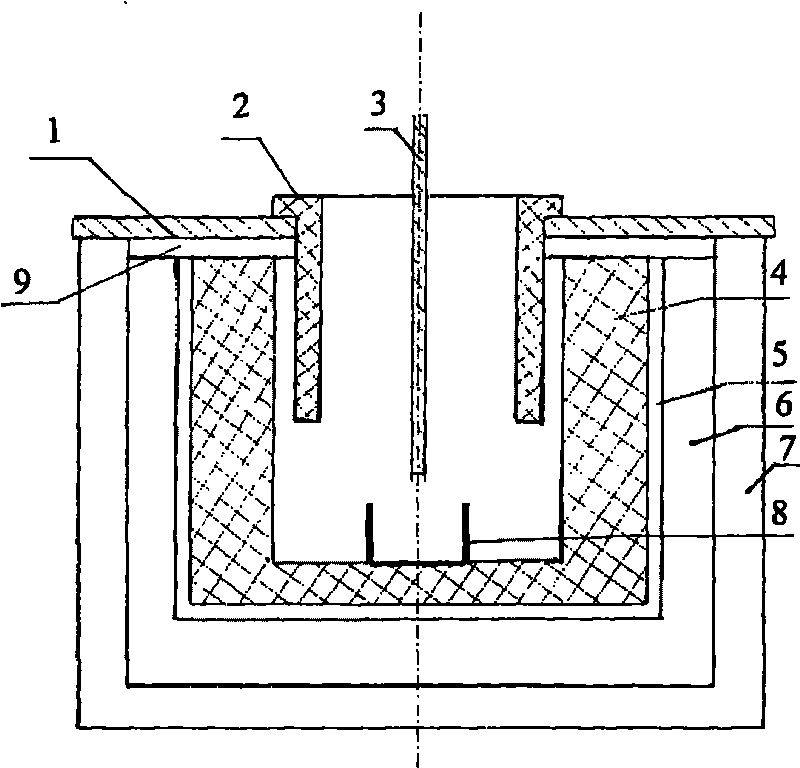

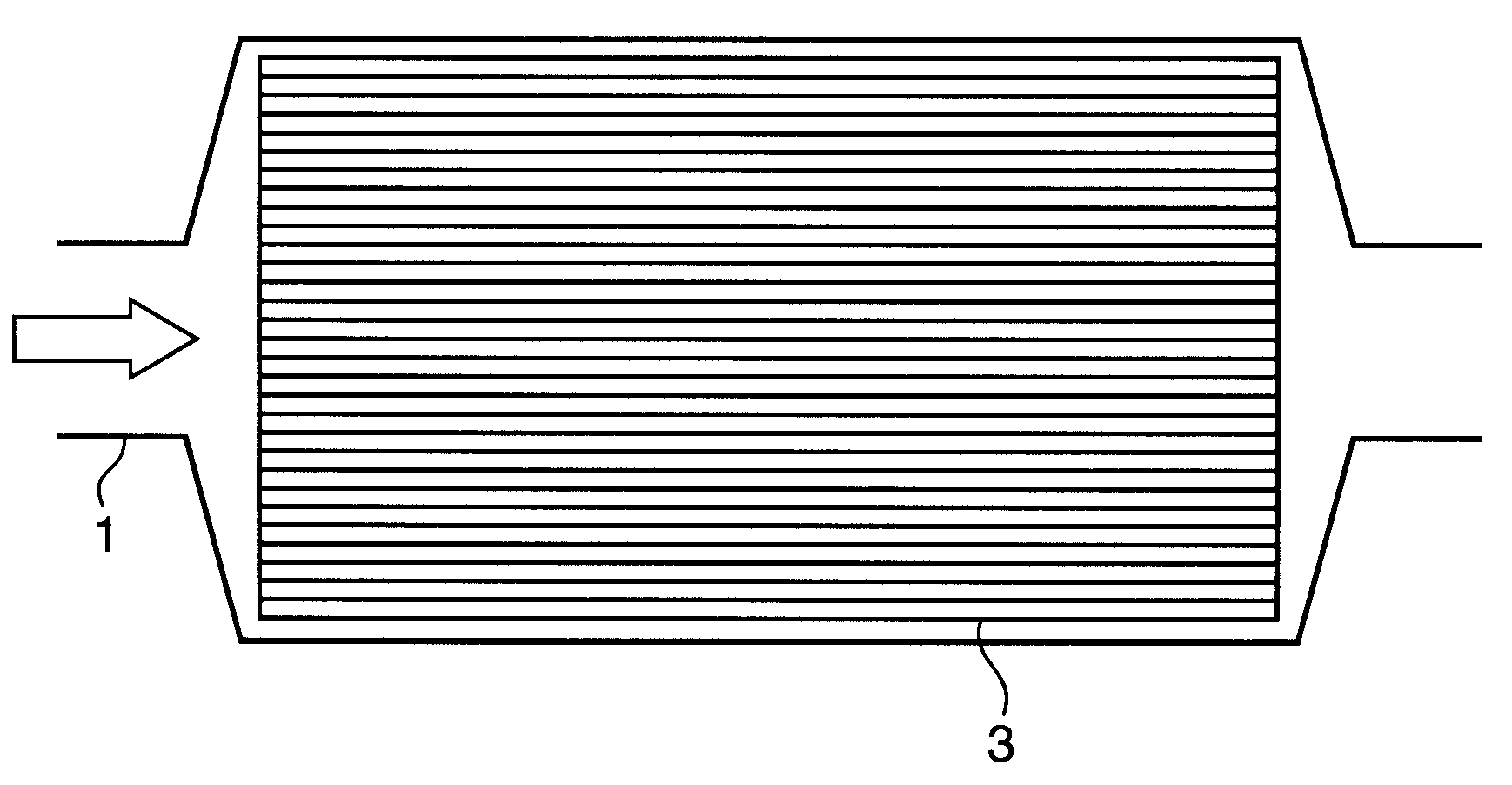

Rare earth aluminum alloy, and method and device for preparing same

The invention discloses a rare earth aluminum alloy, and a method and a device for preparing the same. The alloy contains at least one rare earth metal of lanthanum, cerium, praseodymium, neodymium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, lutetium, scandium and yttrium, the content of raw earth is 5 to 98 weight percent, and the balance is aluminum and inevitable impurities. The device for preparing the rare earth aluminum alloy is characterized in that: a) graphite serves as an electrolysis bath, a graphite plate is an anode, a tungsten bar is a cathode and a molybdenum crucible serves as a rare earth aluminum alloy receiver; b) the diameter of the tungsten bar is 30 to 55 mm; and c) the anode of the graphite consists of a plurality of graphite plates. The rare earth aluminum alloy, and the method and the device for preparing the same have the advantages that: the alloy has uniform components, little segregation and low impurity content; technology for preparing the rare earth aluminum alloy through fusion electrolysis can maximally replace a process for preparing single medium-heavy metal through metallothermic reduction, greatly reduce energy consumption and the emission of fluorine-containing tail gas and solid waste residue, improve current efficiency and metal yield and reduce the consumption of auxiliary materials and the energy consumption; and the rare earth aluminum alloys with different rare earth contents can be obtained by controlling different electrolytic temperatures and different cathode current densities.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Metal colloid and catalyst produced from such metal colloid

InactiveUS20060079396A1Inhibit aggregationHigh water-solubility of the colloidOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsAluminum IonMischmetal

Disclosed is a metal colloid comprising: a solvent composed of water or a mixed solvent of water and an organic solvent; cluster particles comprising one or more metal species; and a protective agent for protecting the cluster particles, characterised in that the protective agent comprises a polymeric material which can be bound to one or more ion species selected from the group consisting of alkali earth metal ions, transition metal ions, rare earth metal ions, an aluminum ion and a gallium ion, and the protective agent has one or more ion species selected from the group consisting of alkali earth metal ions, transition metal ions, rare earth metal ions, an aluminum ion and a gallium ion bounded thereto.

Owner:TANAKA PRECIOUS METAL IND

Nanometer titanium dioxide photocatalyst co-doped with boron and other elements and preparation method thereof

ActiveCN101596457AHas visible light catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRare earthHydrolysis

The invention relates to a nanometer titanium dioxide photocatalyst co-doped with boron and other elements and a preparation method thereof. The method uses titanate and boric acid as a titanium source and a boron source; the other doped elements comprise one or more of transition metal, rare-earth metal or nonmetal; and the method adopts acetic acid, nitric acid or citric acid as a hydrolysis catalyst and a mixture of alcohol and water as a reaction system and prepares the nanometer titanium dioxide photocatalyst co-doped with the boron and the other elements by a sol-gel reaction and calcinations. The nanometer titanium dioxide co-doped with the boron and other elements prepared by the method can absorb visible light and has catalytic activity of the visible light.

Owner:宁波曦昀高分子新材料有限公司

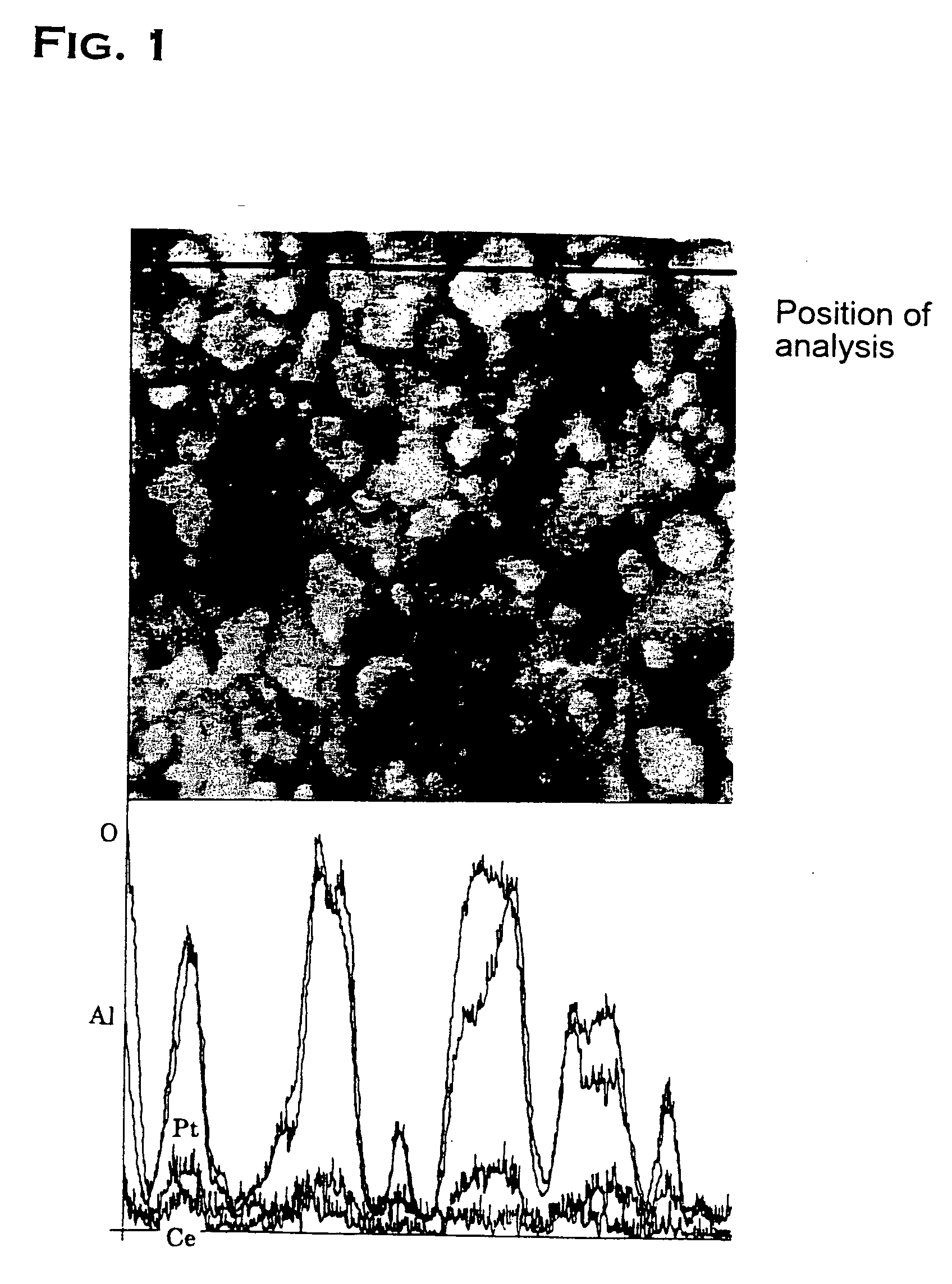

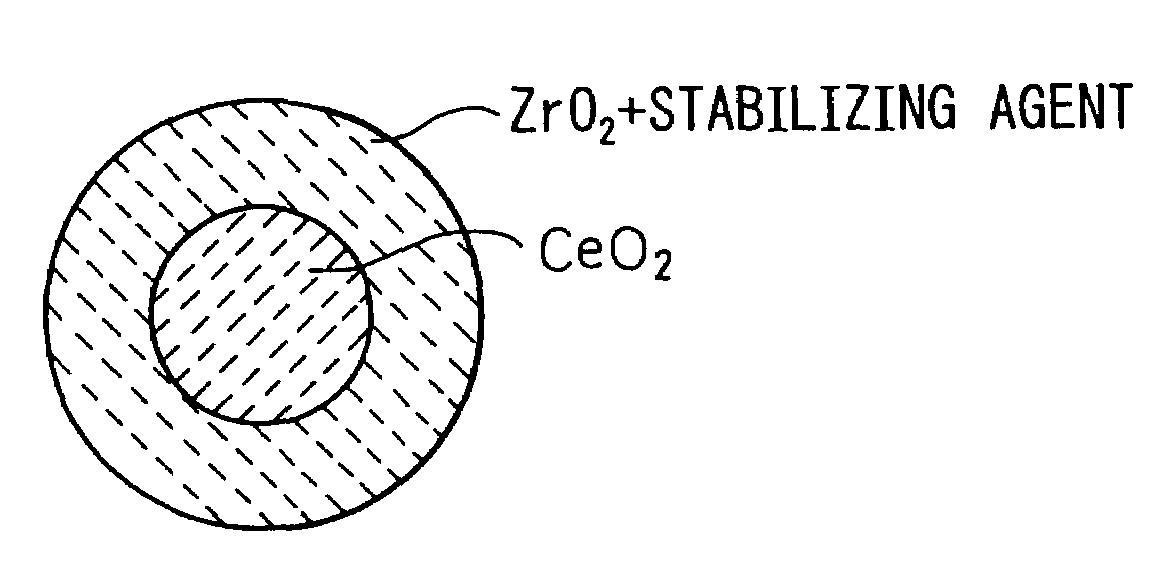

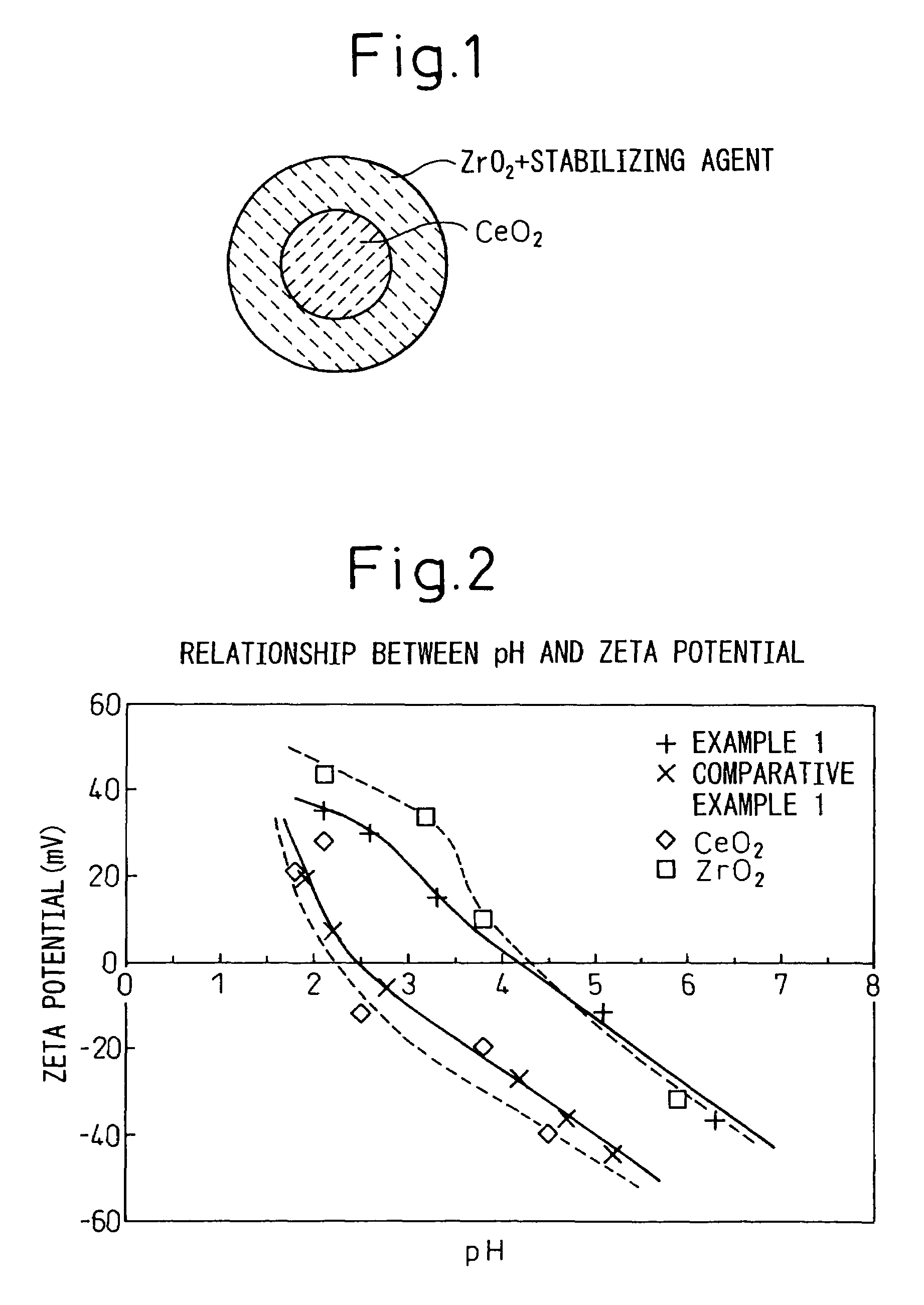

Cerium-zirconium composite metal oxide

ActiveUS7384888B2Increased durabilityIncrease capacityGas treatmentInternal combustion piston enginesMischmetalCerium

A cerium-zirconium composite metal oxide having improved durability at high temperature and a stable oxygen storage capacity is provided. The cerium-zirconium composite metal oxide is characterized in that the total mole number of Ce and Zr is at least 85% based on the total mole number of metal in the composite metal oxide, a molar ratio Ce / Zr is within a range from 1 / 9 to 9 / 1, and an isoelectric point of the composite metal oxide is more than 3.5. Preferably, the molar ratio Ce / Zr is within a range from 3 / 7 to 7 / 3 and the isoelectric point is within a range from 3.8 to 5.0, and the cerium-zirconium composite metal oxide contains a rare earth metal (excluding Ce) in a concentration of less than 15% by mole based on the total mole number of metal in the composite metal oxide. Also the present invention provides a cerium-zirconium composite metal oxide, characterized in that CeO2 forms a core surrounded by ZrO2.

Owner:TOYOTA JIDOSHA KK

Preparation method and application of rare earth metal hydroxide or vanadate nano material

InactiveCN101624206AEffective control compositionEffective control structureVanadium compoundsRare earth metal compoundsNanowireRare earth

The invention provides a controllable preparation method and an application of rare earth metal hydroxide or vanadate nano material by using an ionic liquid assisted hydrothermal method. The preparation method comprises the following steps of taking rare earth metal salt, metavanadate and sodium hydroxide as raw materials, mixing evenly, adding deionized water to form precipitate, adding mixed solution of imidazolium ionic liquid and anhydrous ethyl alcohol, stirring for 10-30 min, transferring into a hydrothermal reaction kettle, carrying out hydrothermal reaction for 1-8h under the temperature of 100-220 DEG C and obtaining rare earth metal hydroxide nano particles, nano rods or nano-wire materials. If the reaction time is prolonged to 16-148h, rare earth vanadate one-dimensional nano-wire and two-dimensional nanoflake materials can be prepared. The method provided by the invention can effectively adjust and control phases and features of rare earth metal hydroxide and vanadate nano materials, and has the advantages of mild reaction conditions, simple technique, low cost, high yield and the like, thus being hopeful to be widely applied in the fields such as luminescent devices, electrocatalytic components, permanent magnets, biological and medical industry and the like.

Owner:NANKAI UNIV

Negative electrode material for alkaline secondary zinc electrode

InactiveCN1595688AExtend your lifeImprove performanceAlkaline accumulatorsElectrode manufacturing processesZinc hydroxideManganese

The invention relates to negative electrode material for alkaline secondary zinc electrode , including calcium carbonate and millimicron oxide, the millimicron oxidation is transition metal or rare earth oxide. The mass percentage of calcium carbonate and millimicron oxide is: 80-98%, 2-20%, ratio of material is according to calcium carbonate [Ca(OH)2 .Zn(OH)2.XH2O(x=2,3)], in the condition of 150~500r / m and ratio of 3~20:1, by the protection of argon gas, calcium carbonate is formed by the mixture of calcium hydroxide(or calcium oxide), zinc hydroxide (or zinc oxide) and water after 5~25 hours. The invention has low cost, excellent property and no pollution, and multi-hole alkaline secondary zinc electrode made by mixture of calcium carbonate and millimicron oxide has better performance of discharge, suitable for various chargeable alkaline battery of Zn / Ni, Zn / Ag and Zn / Mn using Zn as negative electrode .

Owner:NANKAI UNIV

Steel with high mechanical strength and wear resistance

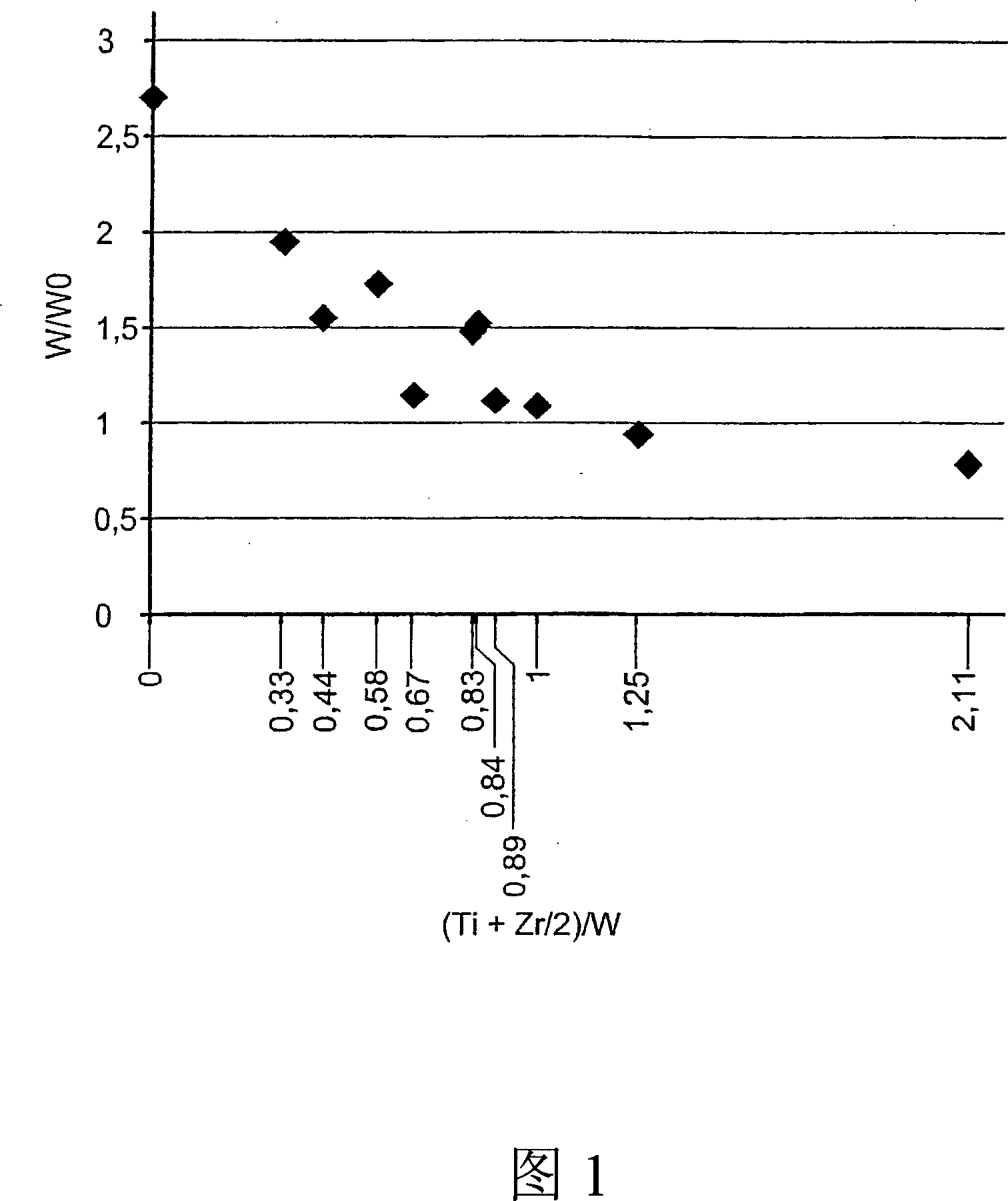

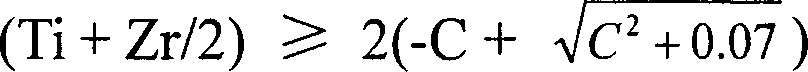

ActiveCN1957101AHardening does not changeLess detrimental to split poly seamsRare earthHigh wear resistance

The invention relates to a steel with high mechanical strength and wear resistance. More specifically, the invention relates to a method of reducing the segregated veins of a steel having high mechanical strength, high wear resistance and the following weight composition: 0.30% <= C <= 1.42%; 0.05% <= Si <= 1.5%; Mn <= 1.95%; Ni <= 2.9%; 1.1% <= Cr <= 7.9%; 0.61% <= Mo <= 4.4%; optionally V <= 1.45%, Nb <= 1.45%, Ta <= 1.45% and V+Nb / 2 + Ta / 4 <= 1.45%; less than 0.1% borium, 0.19% (S + Se / 2 + Te / 4), 0.01% calcium, 0.5% rare earths, 1% aluminium, 1 %copper; the remainder being iron and impurities resulting from the production thereof. The composition also comprises: 800 <= D <= 1150, where D = 540(C)<0.25> + 245 (Mo + 3 V + 1.5 Nb + 0.75 Ta)<0.30> + 125 Cr<0.20 >+ 15.8 Mn + 7.4 Ni + 18 Si. According to the invention, all or part of the molydenum is replaced by a double proportion of tungsten, such that W >= 0.21%, and Ti, Zr, C are adjusted so that, after said adjustment, Ti + Zr / 2 >= 0.2 W, (Ti + Zr / 2) * C >= 0.07, Ti + Zr / 2 <= 1.49 % and D is unchanged at 5 %. The invention also relates to the steel obtained and to a method of producing a steel part.

Owner:INDUSTEEL FRANCE

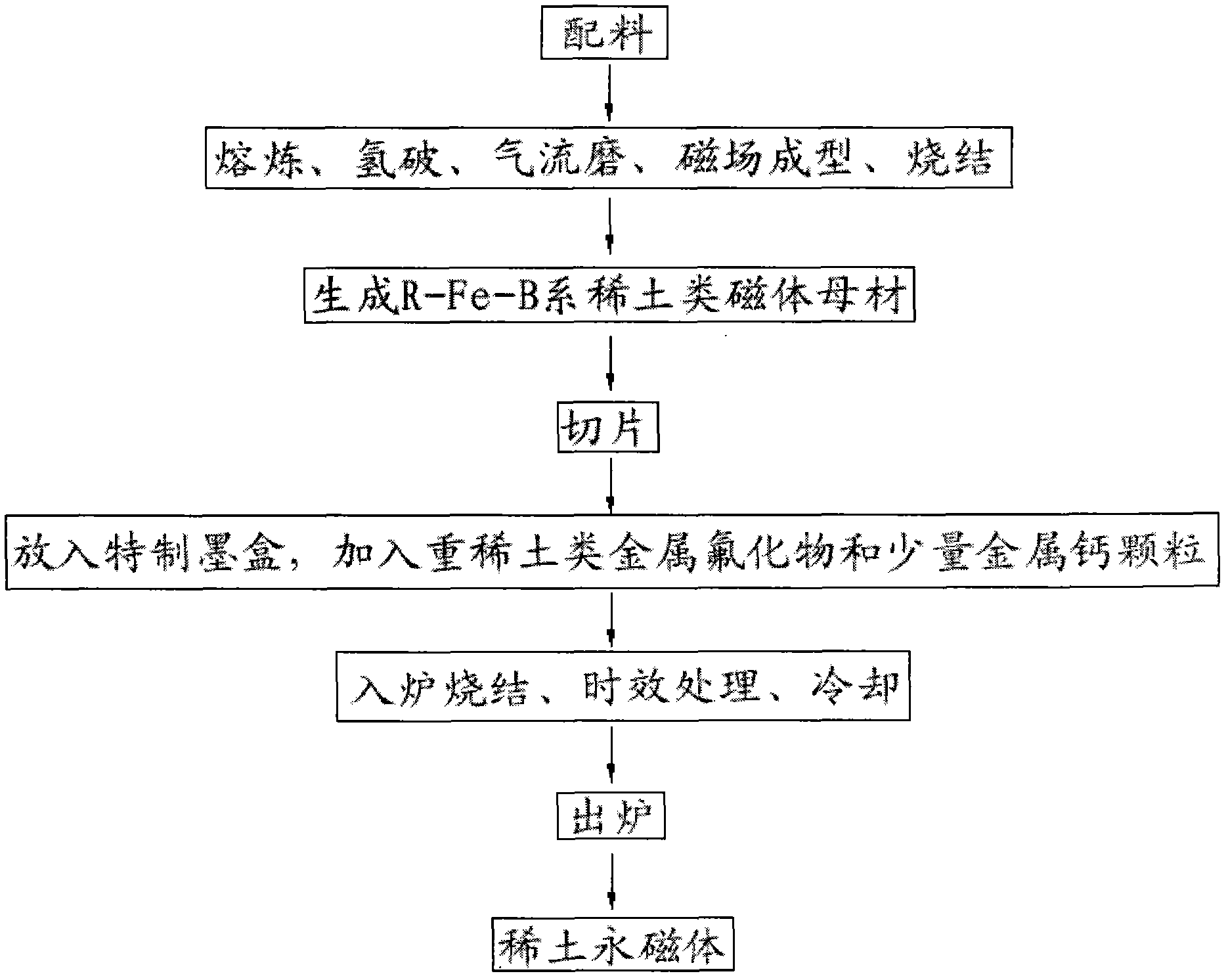

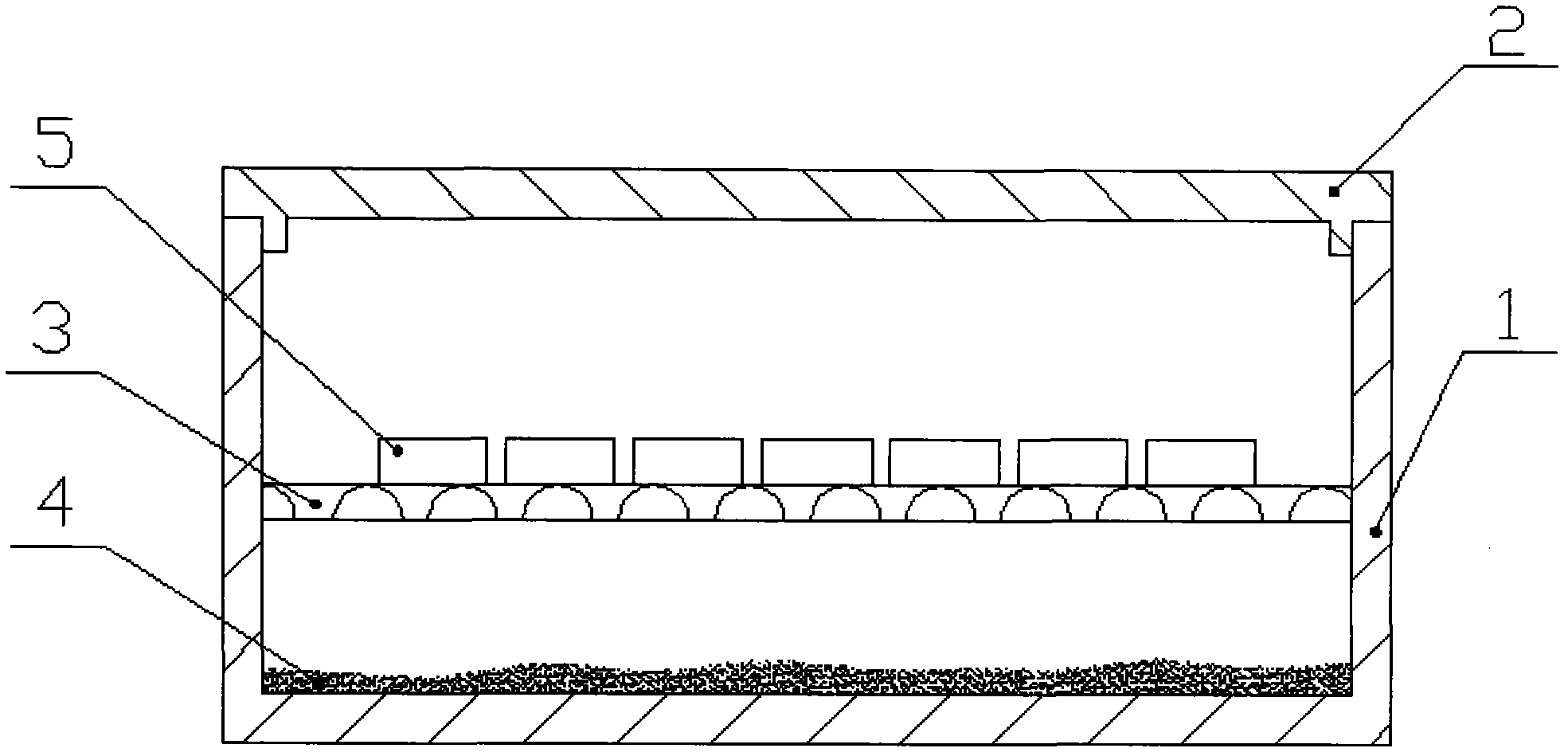

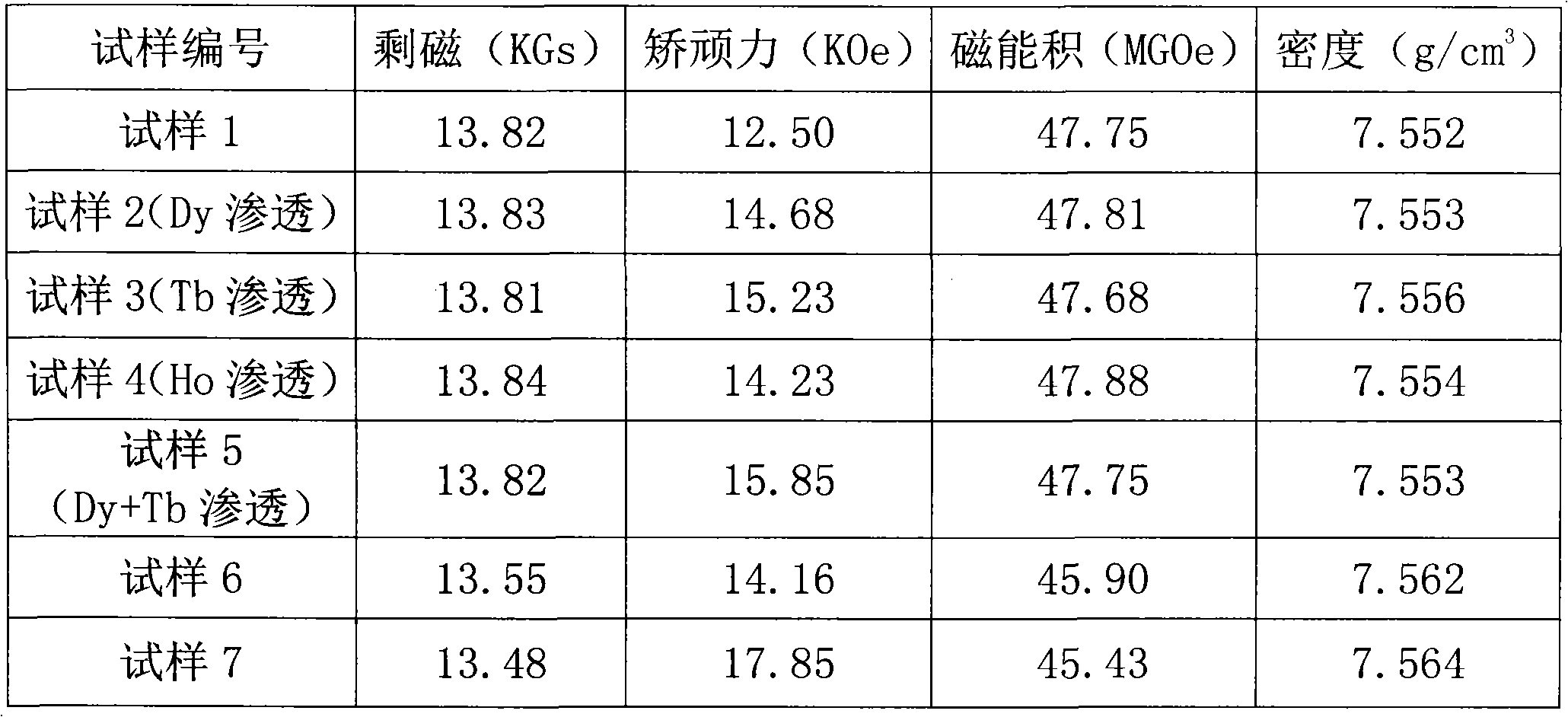

Method for preparing rare-earth permanent magnets by infiltration process and graphite box utilized in method

InactiveCN102568806AReduce manufacturing costReduce usagePermanent magnetsSolid state diffusion coatingRare earthMaterials science

Disclosed are a method for preparing rare-earth permanent magnets by the infiltration process and a graphite box utilized in the method. The method includes: preparing base materials of R (rare earth)-Fe (ferrum)-B (boron) rear earth magnets by prepared raw materials which are subjected to smelting, hydrogen decrepitation, magnetic field forming, sintering and the like; cutting the base material into slices with the thickness ranging from 2mm to 10mm; placing the slices into a specially-made graphite box and placing heavy rare earth type metal fluoride and a few of metal calcium particles into the bottom of the graphite box; sintering the graphite box in a sintering furnace, inflating air into the sintering furnace to cool the temperature to be lower than 60 DEG C, finally ageing magnets, then inflating Ar gas into the sintering furnace to cool the temperature to be lower than 60 DEG C after ageing, and finally obtaining the rare-earth permanent magnets. Elements including Dy (dysprosium), Tb (terbium), Ho (holmium) and the like are infiltrated into the crystal boundary of the R-Fe-B to prepare high-coercivity rare-earth permanent magnets by means of infiltration process, usage of heavy rare earth metal can be greatly reduced, and production cost of magnets can be effectively reduced. Additionally, the method for preparing rare-earth permanent magnets by the infiltration process is simple in operation and suitable for batch production.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

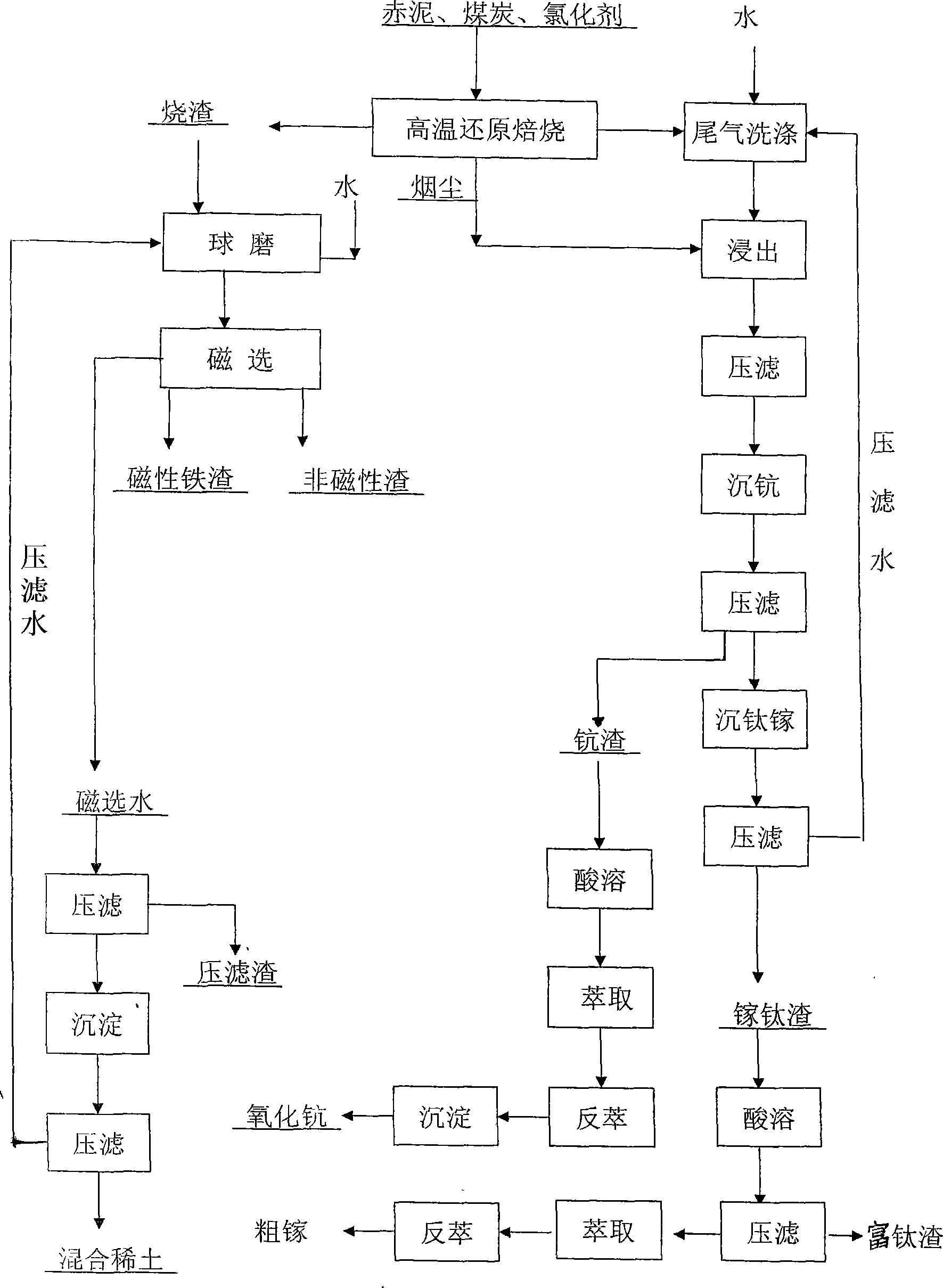

Comprehensive utilization method for red mud

InactiveCN101463426APromote environmental protectionGood benefitSolid waste managementProcess efficiency improvementWash waterRed mud

The invention discloses a method for comprehensively utilizing red mud, comprising the following steps: chloridizing roasting, namely roasting the mixture of the red mud, coal and calcium chloride; cinder treatment, namely obtaining magnetic iron slag and non-magnetic slag after magnetic separation is carried out to levigated cinder, and then separating the magnetic iron slag and non-magnetic slag; adding calcined soda or oxalic acid after levigation liquid and wash water are rich in mischmetal due to cyclic use, and then precipitating mischmetal slag; treatment of dry dust and circulation liquid, namely, after dry powder for roasting dust collection is collected, mixing the dry powder with scouring water which is used for tail gas circulation and then leaching soluble ScCl3 and GaCl3; after filter pressing, precipitating scandium by adding oxalic acid crystal in filtrate; carrying out filter pressing again, precipitating gallium and Ti(OH)4 by adding ammonia into the filtrate, dissolving obtained gallium-titanium slag with acid and then using P2O4 extractant to extract the gallium; and using extractant to extract the scandium after scandium precipitate is dissolved by acid, carrying out precipitation again by adopting back-extraction acid dissolving, and obtaining Sc2O3 by means of roasting. The method can realize recovery of valuable metals from the red mud, and secondary residual slag is totally used for building material production; and the method has environment protection effects and economic benefits, plays an important role in the development of recycling economy and is applicable to enterprises generating red mud.

Owner:张钦

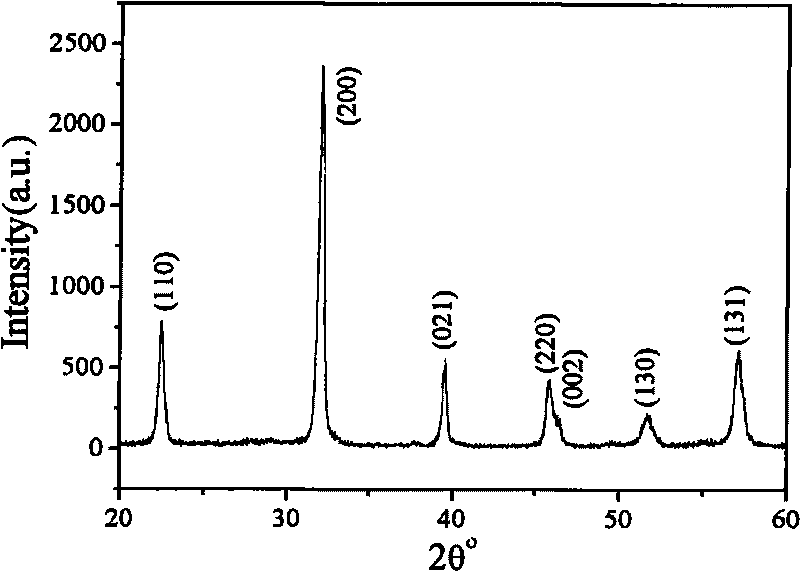

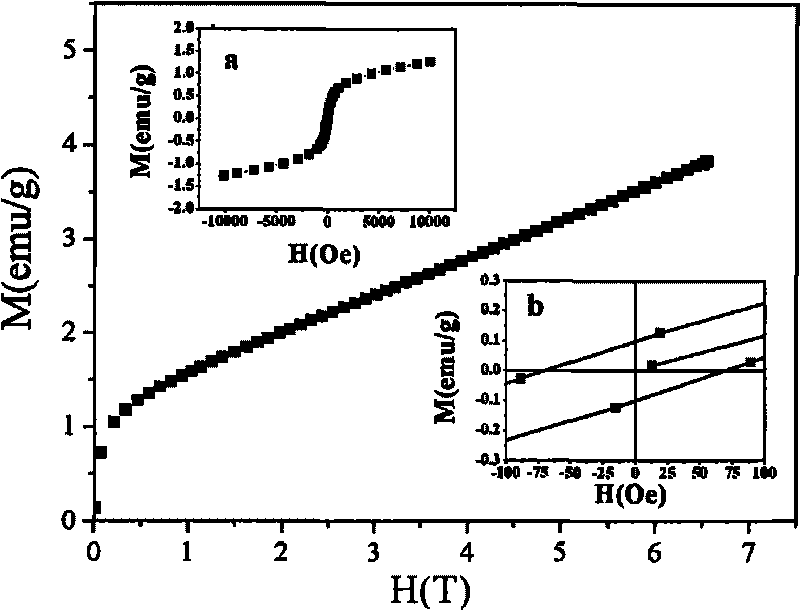

Rare earth/alkaline earth metal and transition metal doped bismuth ferrite nano multiferroic material and preparation method thereof

InactiveCN101734725AImprove magnetic propertiesExcellent magnetic permittivityNanostructure manufactureIron compoundsCapacitanceSolvent

The invention discloses a rare earth / alkaline earth metal and transition metal doped bismuth ferrite nano multiferroic material, and the chemical formula is Bi1-xRxFe1-yMyO3, wherein R is rare earth metal or alkaline earth metal, M is transition metal, x is not less than 0 and not more than 0.30, and y is not less than 0 and not more than 0.02. The preparation method has the steps of taking ferric nitrate, bismuth nitrate, rare earth / alkaline earth metal oxide or nitrate and transition metal nitrate as raw materials, taking ethylene glycol as a solvent, or using a specific additive for matching, mechanically stirring, forming even ethylene glycol solution, then aging at room temperature, evaporating and drying the obtained solution at the temperature of 160-250 DEG C, and carrying out thermal treatment at lower temperature for obtaining rare earth / alkaline earth metal A-site doped, transition metal B-site doped and rare earth / alkaline earth metal A-site and transition metal B-site co-doped bismuth ferrite nanoparticles of 20-100nm. The prepared nano multiferroic material has stable crystal quality, thereby having extensive application prospects in the fields of information storage, magnetic sensors of spin electronic devices, capacitor-inductor integrated devices and the like.

Owner:EAST CHINA NORMAL UNIV

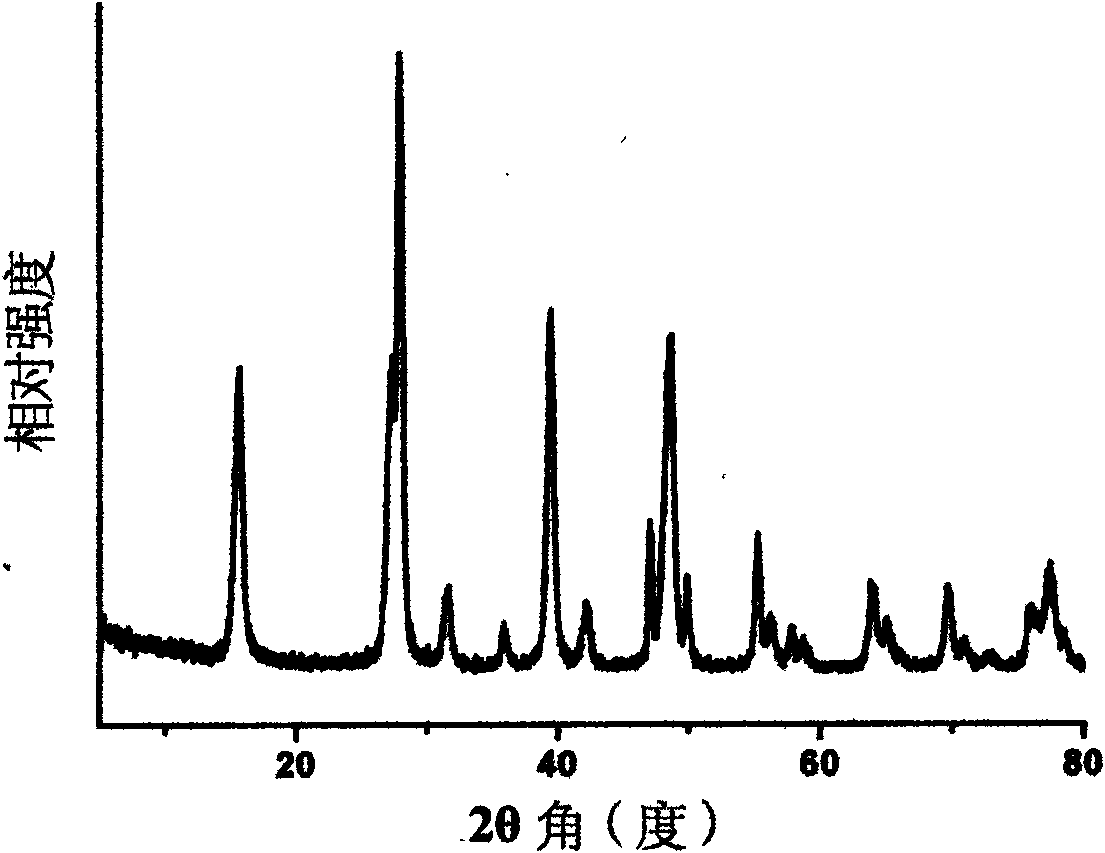

Catalytic material, production method therefor, and diesel particulate filter

Disclosed is a catalytic material for removing diesel particulates, which comprises a composite oxide which contains zirconium as a primary component and a rare-earth metal except for cerium and yttrium. The composite oxide has a crystallite diameter of 13 nm to 40 nm.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com