Patents

Literature

4194results about How to "Improve mechanical stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

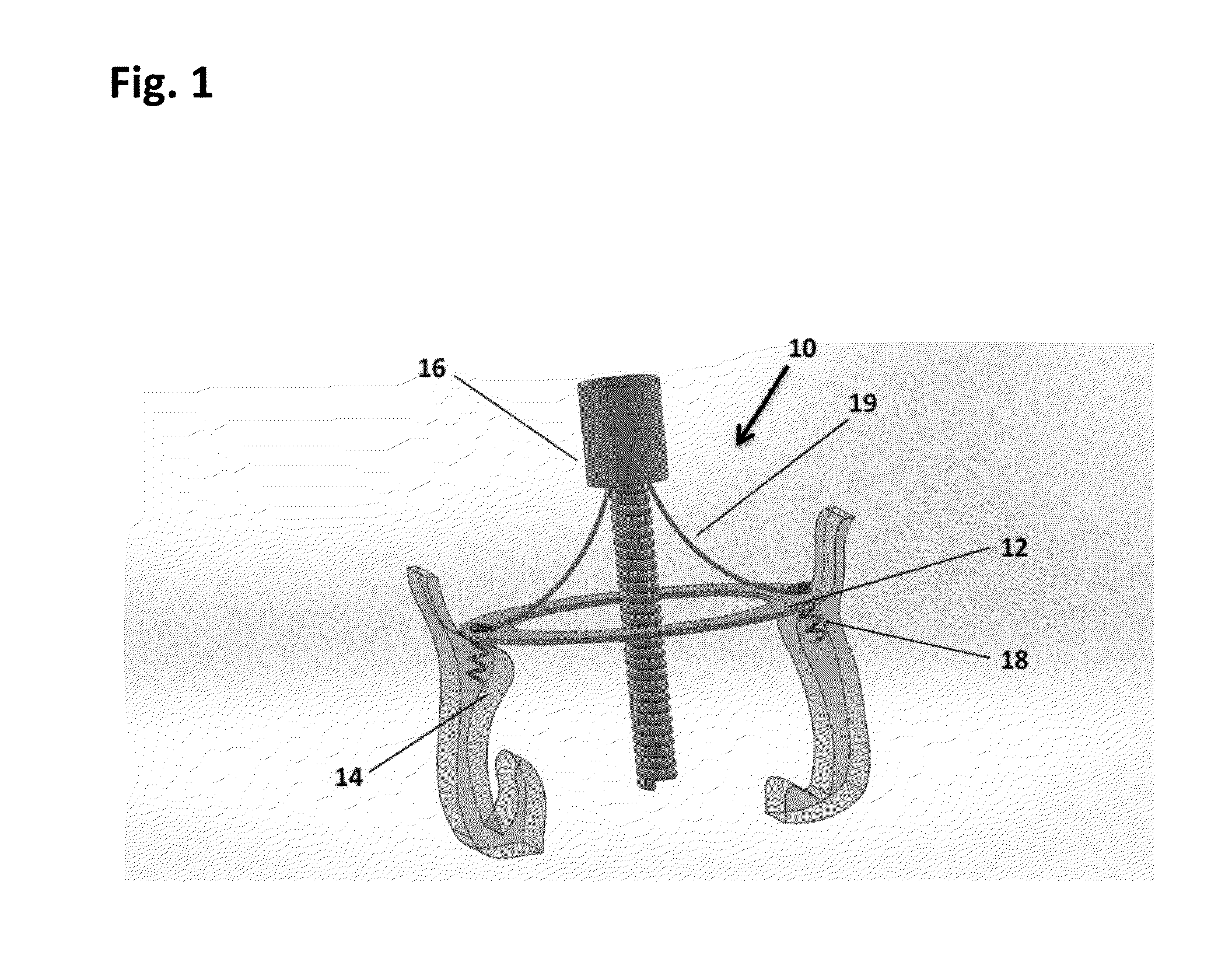

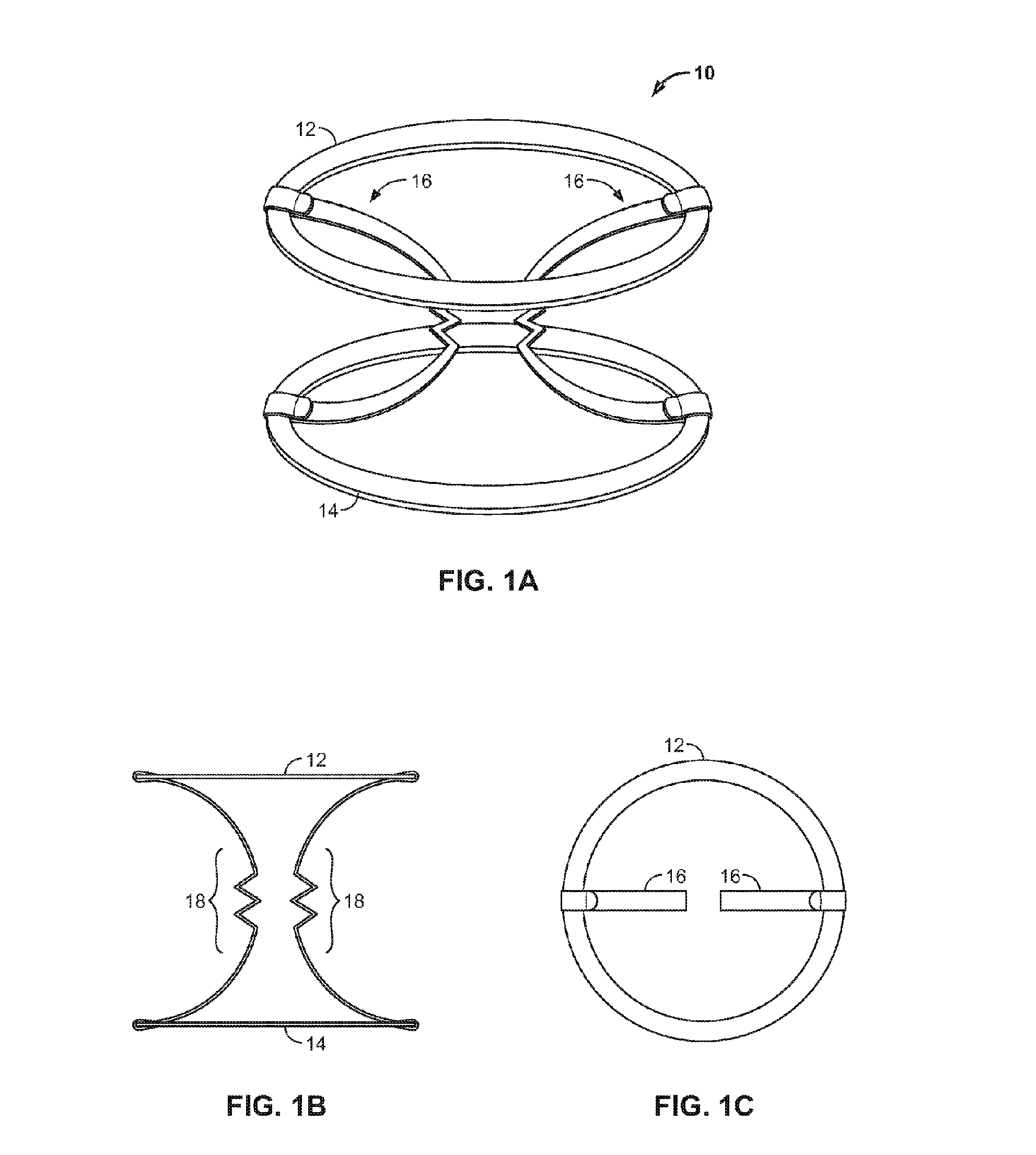

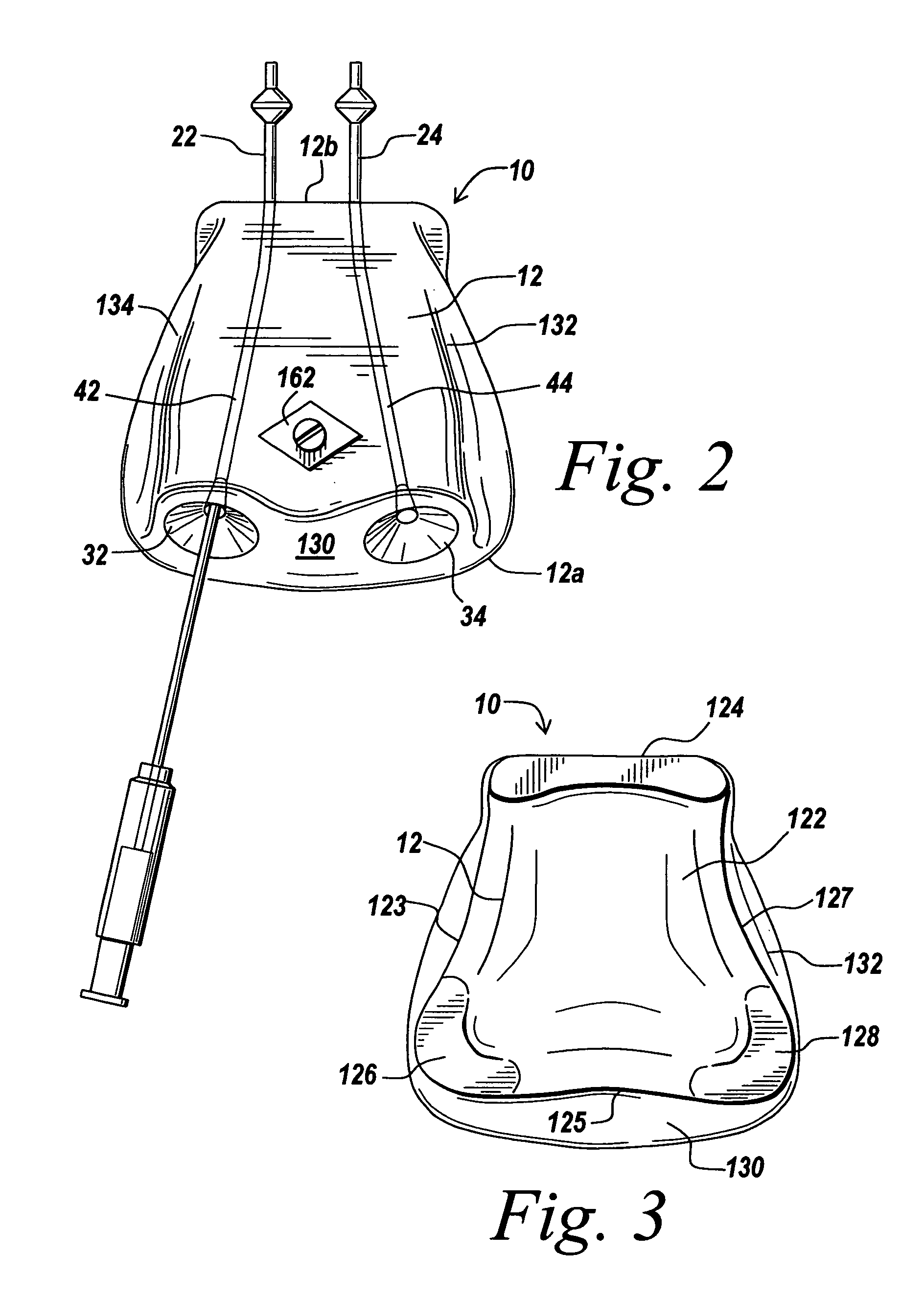

Single-ring cardiac valve support

The present invention is primarily directed a prosthetic cardiac valve support device adapted for endovascular delivery to a cardiac valve, comprising a single ring-shaped support element having an inner diameter and an outer diameter, wherein said support element has an outer perimeter that is entirely rigid, wherein said support element is fitted with one or more intra-ventricular and / or intra-atrial stabilizing elements, and wherein said support element has a collapsed delivery configuration and a deployed configuration.

Owner:MVALVE TECH

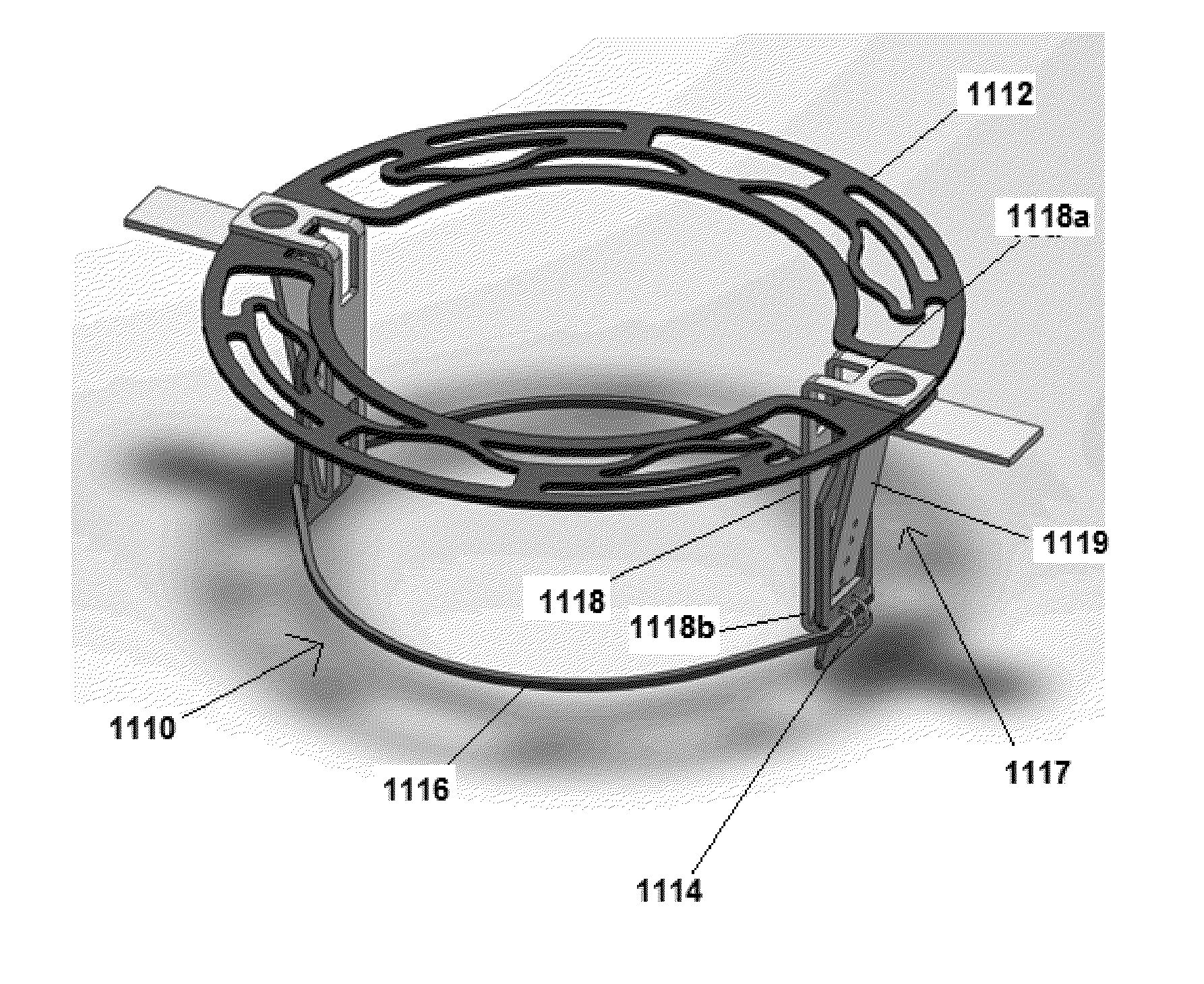

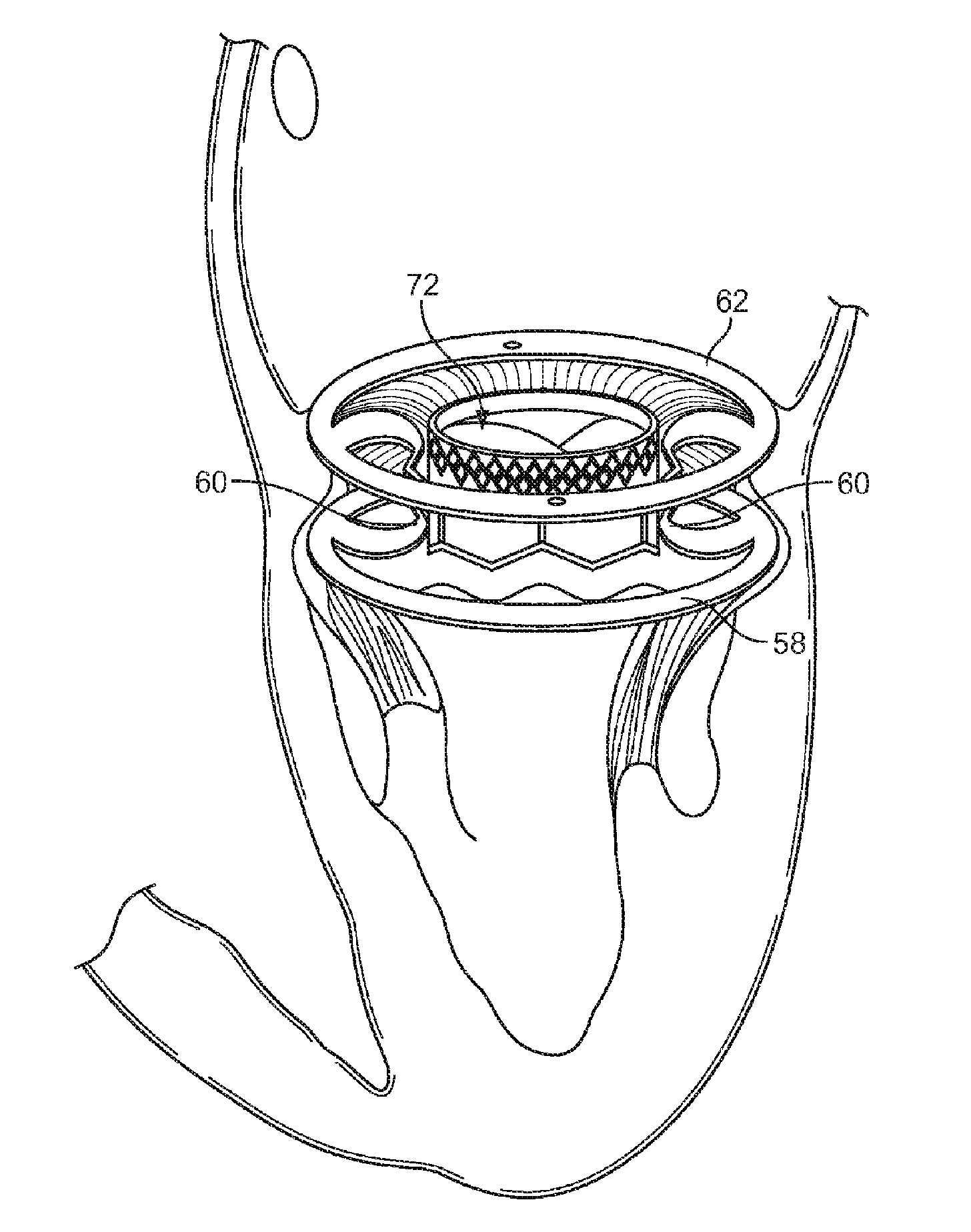

Cardiac valve support structure

InactiveUS20140005778A1Prevent paravalvular leakagePrevent leakageStentsAnnuloplasty ringsHeart valve

Owner:MVALVE TECH

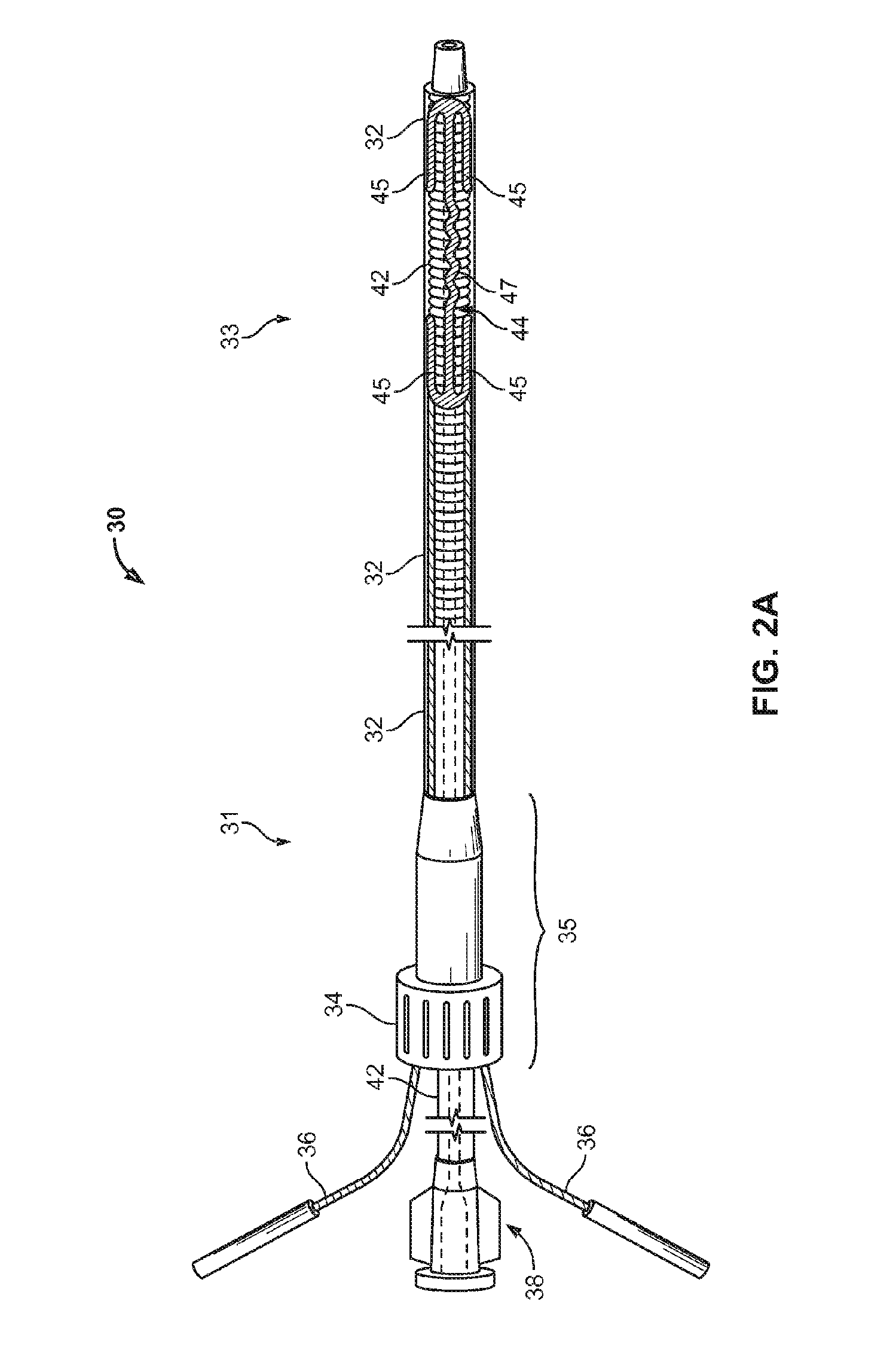

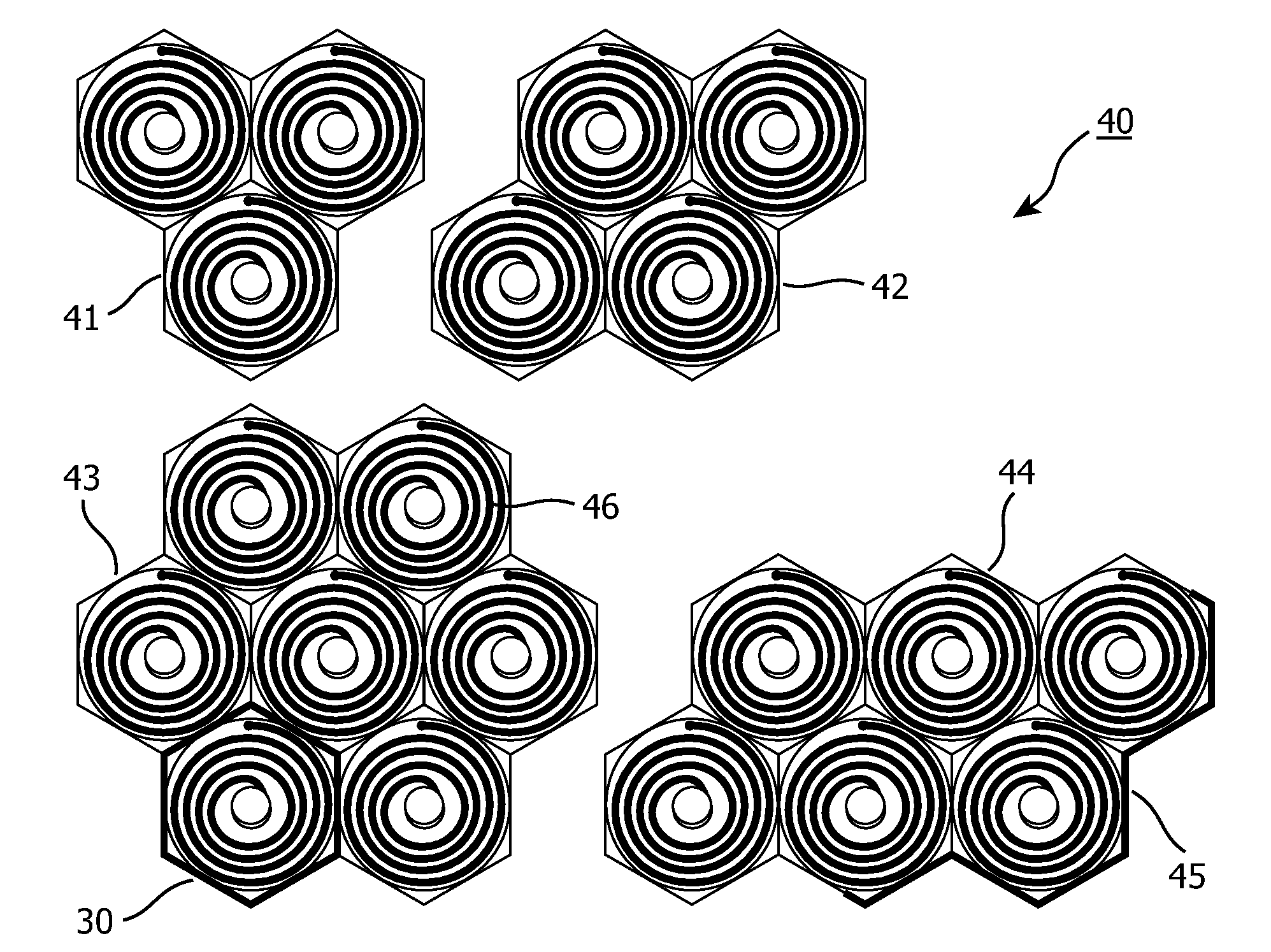

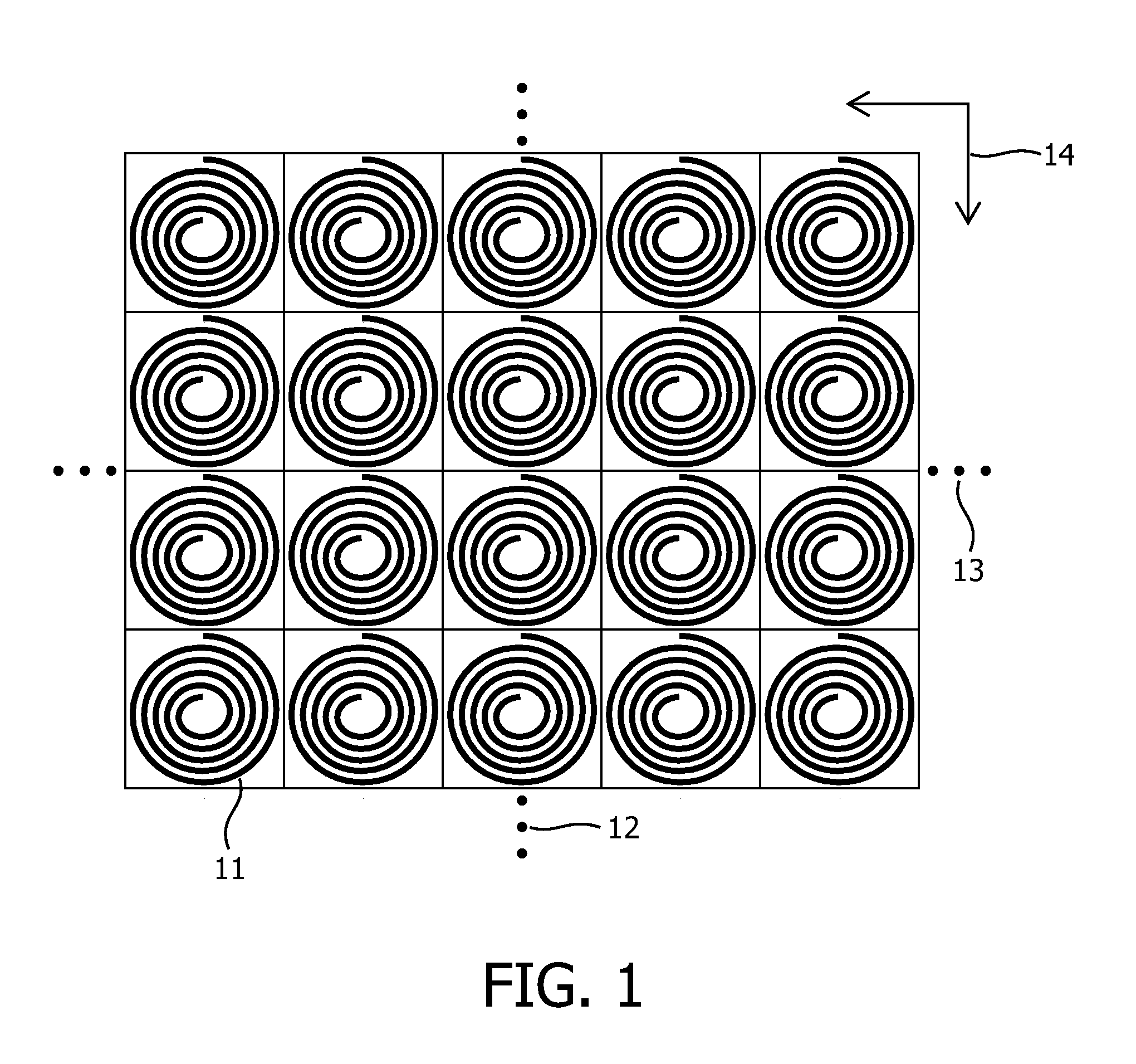

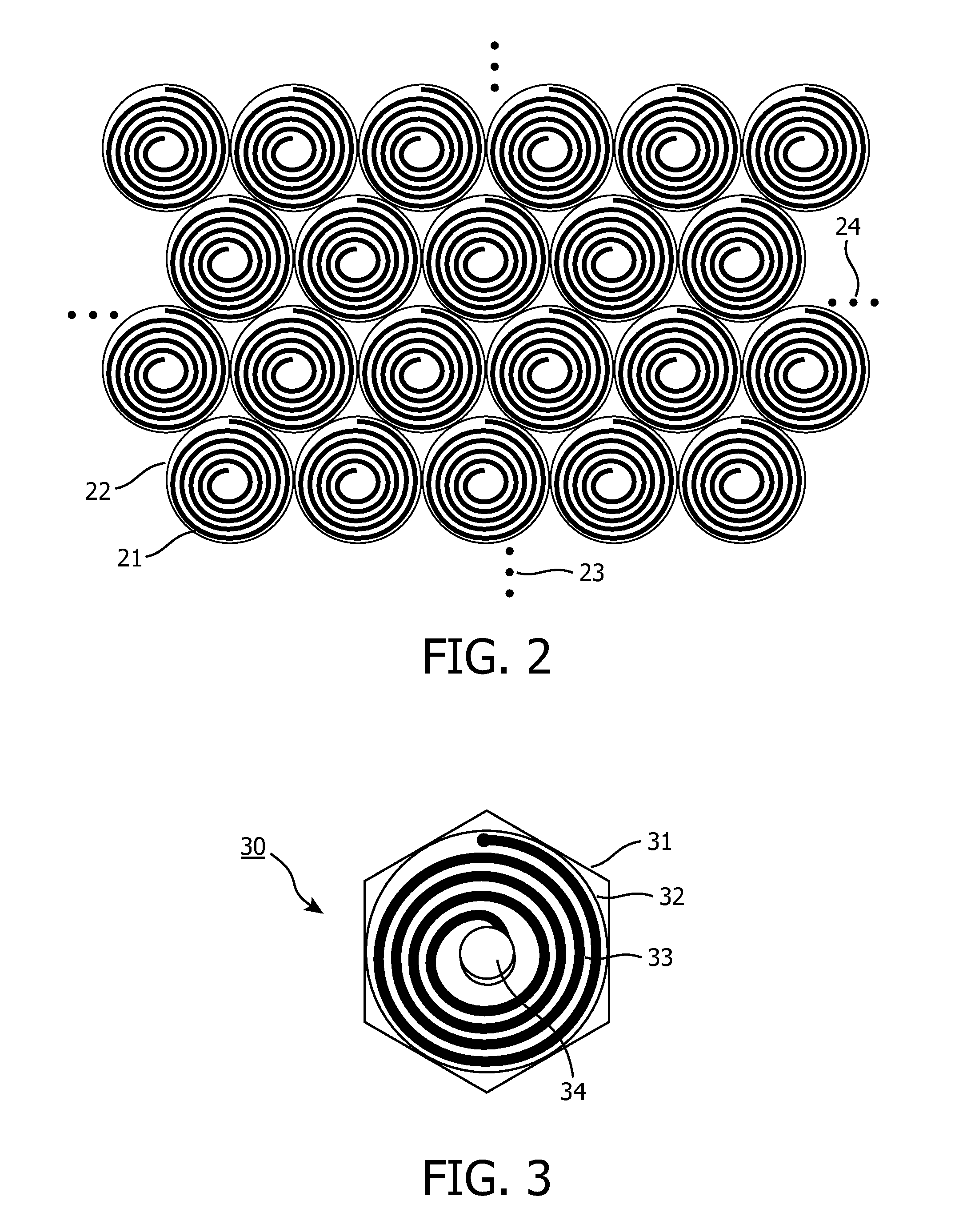

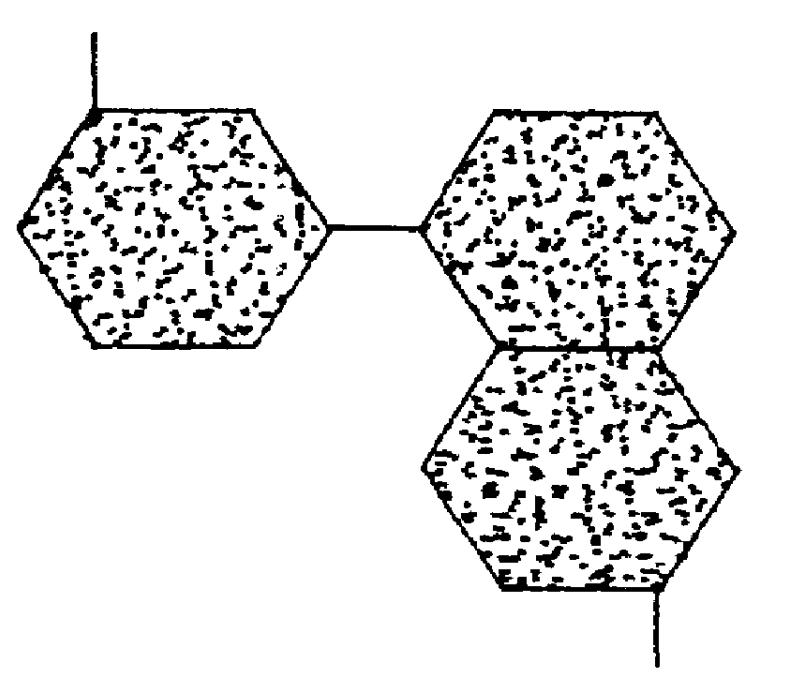

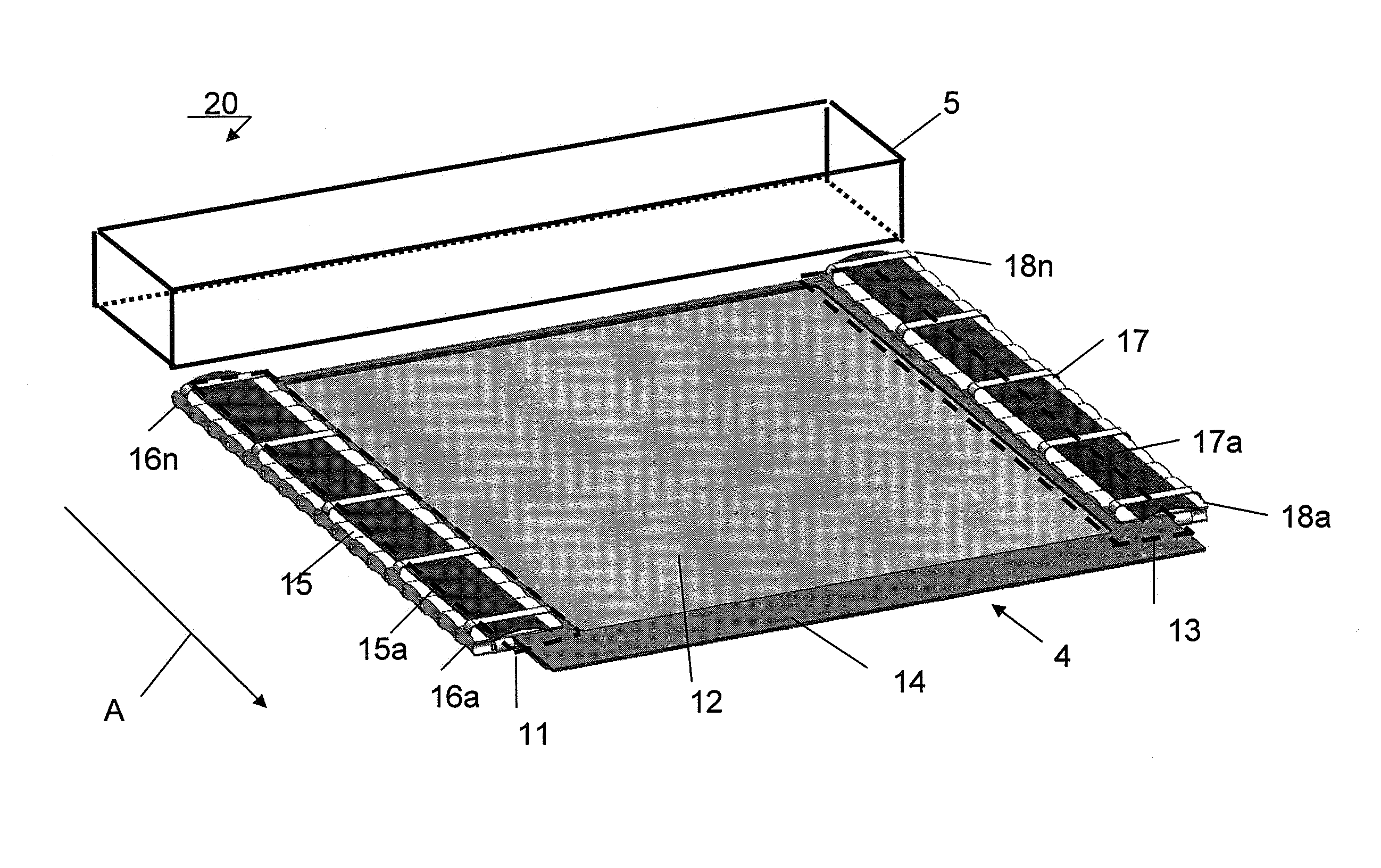

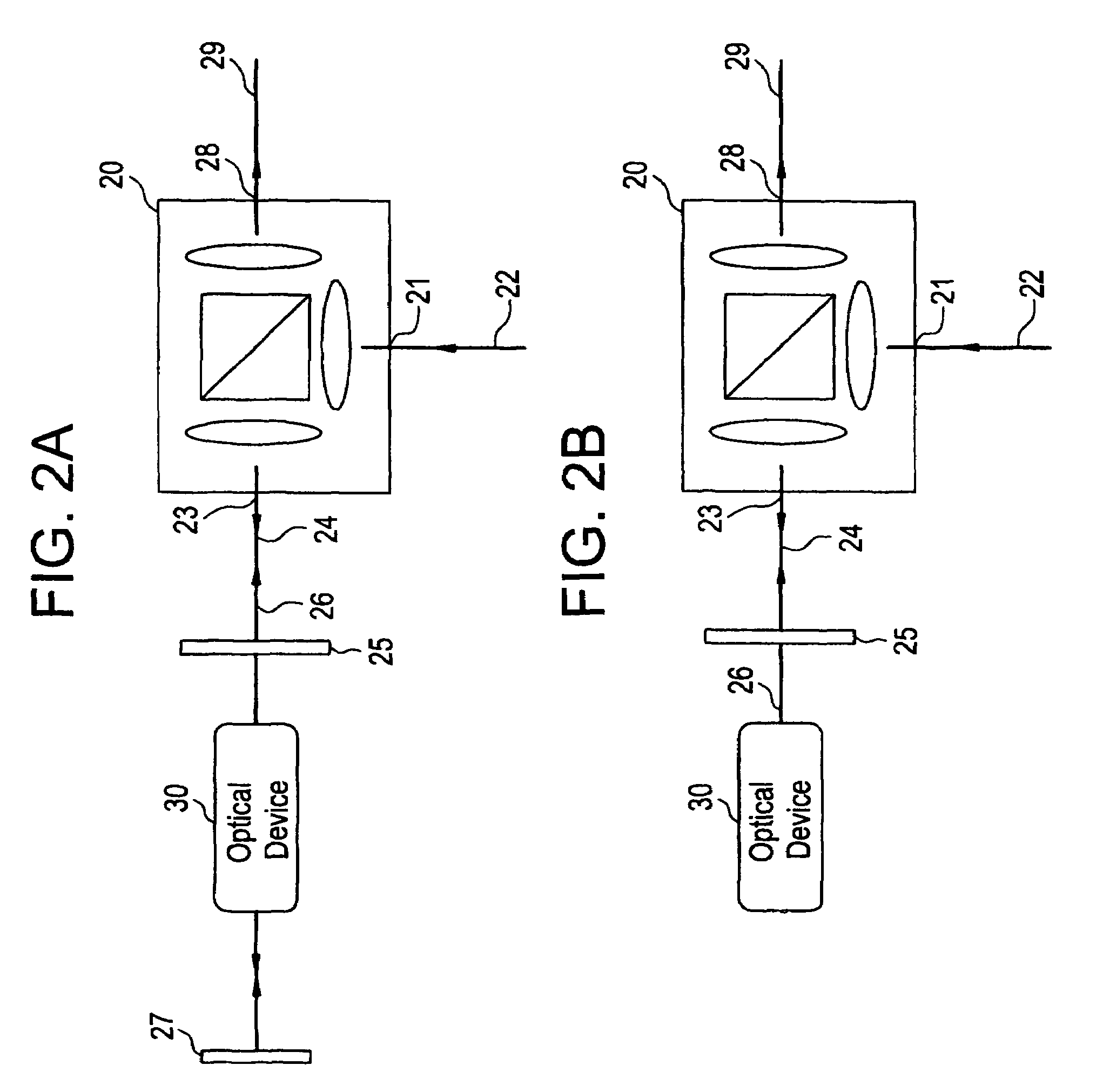

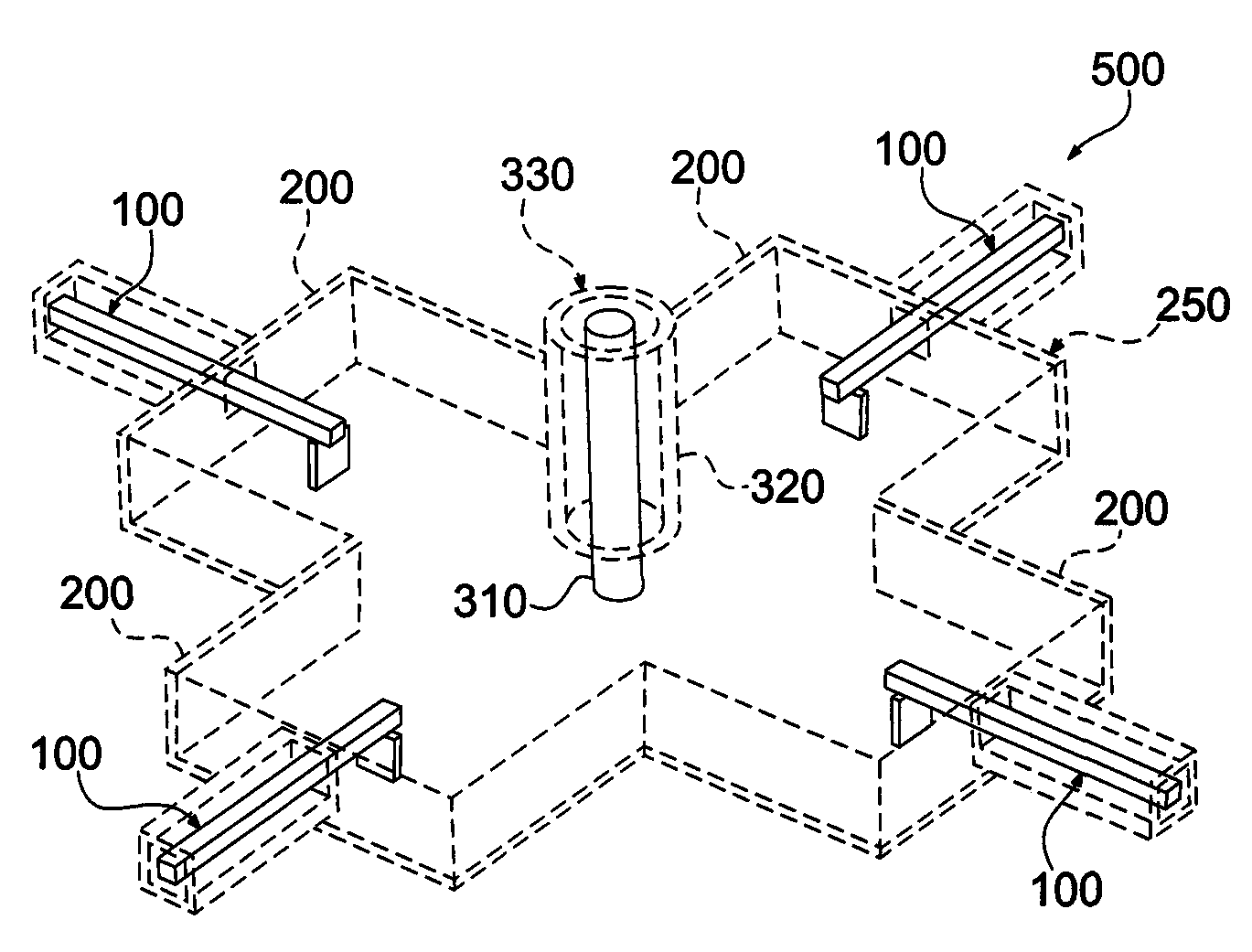

Transmitter module for use in a modular power transmitting system

ActiveUS20130069444A1Improve power stabilityImprove mechanical stabilityTransformersCoupling device detailsElectric power transmissionTransmitter coil

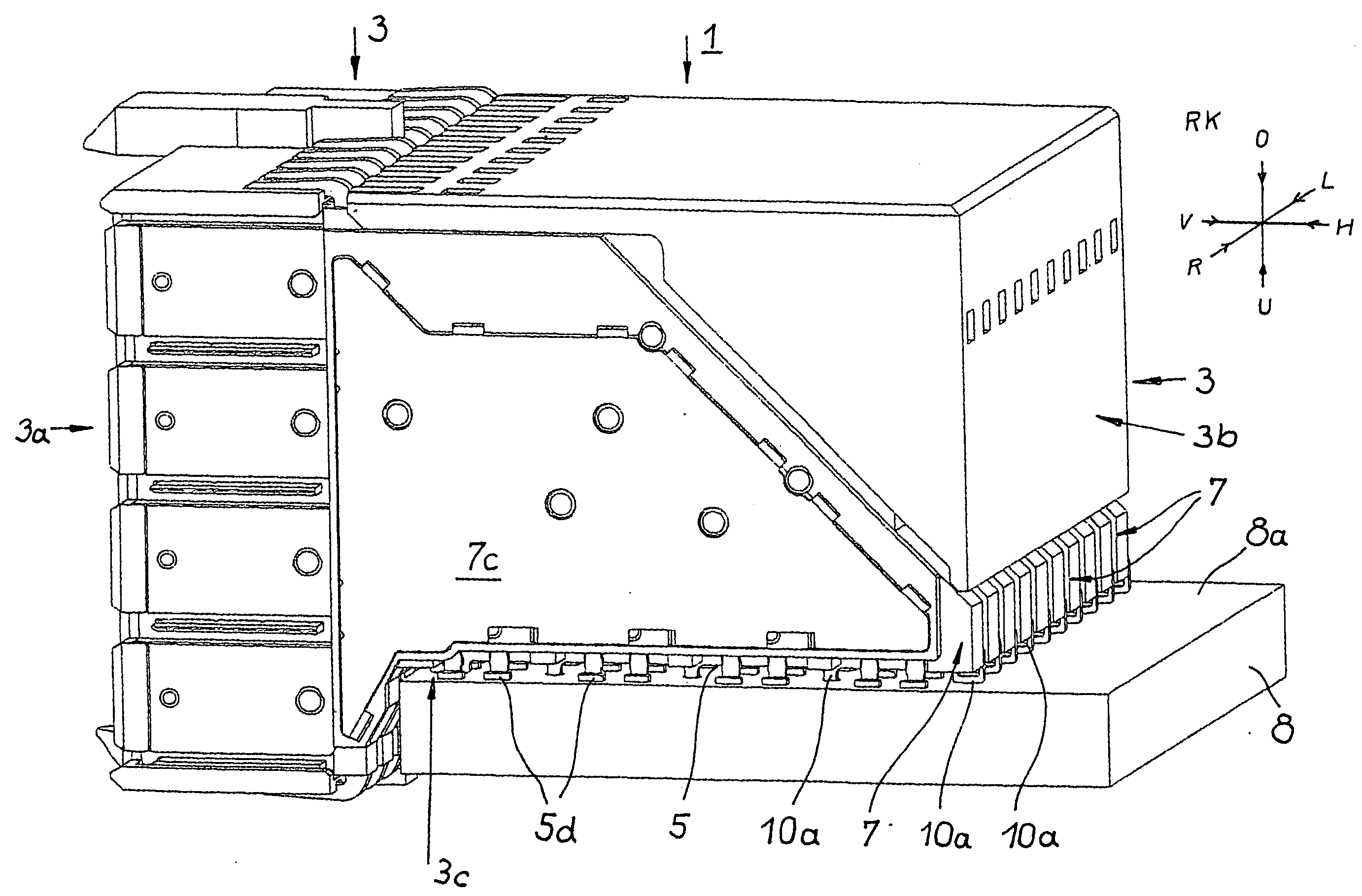

A modular power transmitting system comprises multiple transmitter modules being connected together for transmitting power inductively to a receiver. The transmitter module is connected with other transmitter modules for transmitting power inductively to the receiver, wherein the transmitter module (40) comprises at least one transmitter cell (30), each transmitter cell having one transmitter coil (33) by which the transmitter cell transmitting power to the receiver, the transmitter module having an outer periphery (45) being shaped so as to fit to neighboring transmitter modules for forming an power transmitting surface, the at least one transmitter cell being arranged such that the power transmitting surface is constituted by an uninterrupted pattern of adjacent transmitter coils extending in said surface, and interconnection units (110,111) for connecting with neighboring transmitter modules for sharing a power supply.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Low dielectric constant materials and method

InactiveUS6051321AImprove rotational flexibilityTightly boundSemiconductor/solid-state device detailsSynthetic resin layered productsElectrical conductorCopper

Intermetal dielectric (IMD) and interlevel dielectric (ILD) that have dielectric constants (K) ranging from 2.0 to 2.6 are prepared from plasma or photon assisted CVD (PACVD) or transport polymerization (TP). The low K dielectric (LKD) materials are prepared from PACVD or TP of some selected siloxanes and F-containing aromatic compounds. The thin films combine barrier and adhesion layer functions with low dielectric constant functions, thus eliminating the necessity for separate adhesion and barrier layers, and layers of low dielectric constant. The LKD materials disclosed in this invention are particularly useful for <0.18 .mu.m ICs, or when copper is used as conductor in future ICs.

Owner:CANON USA

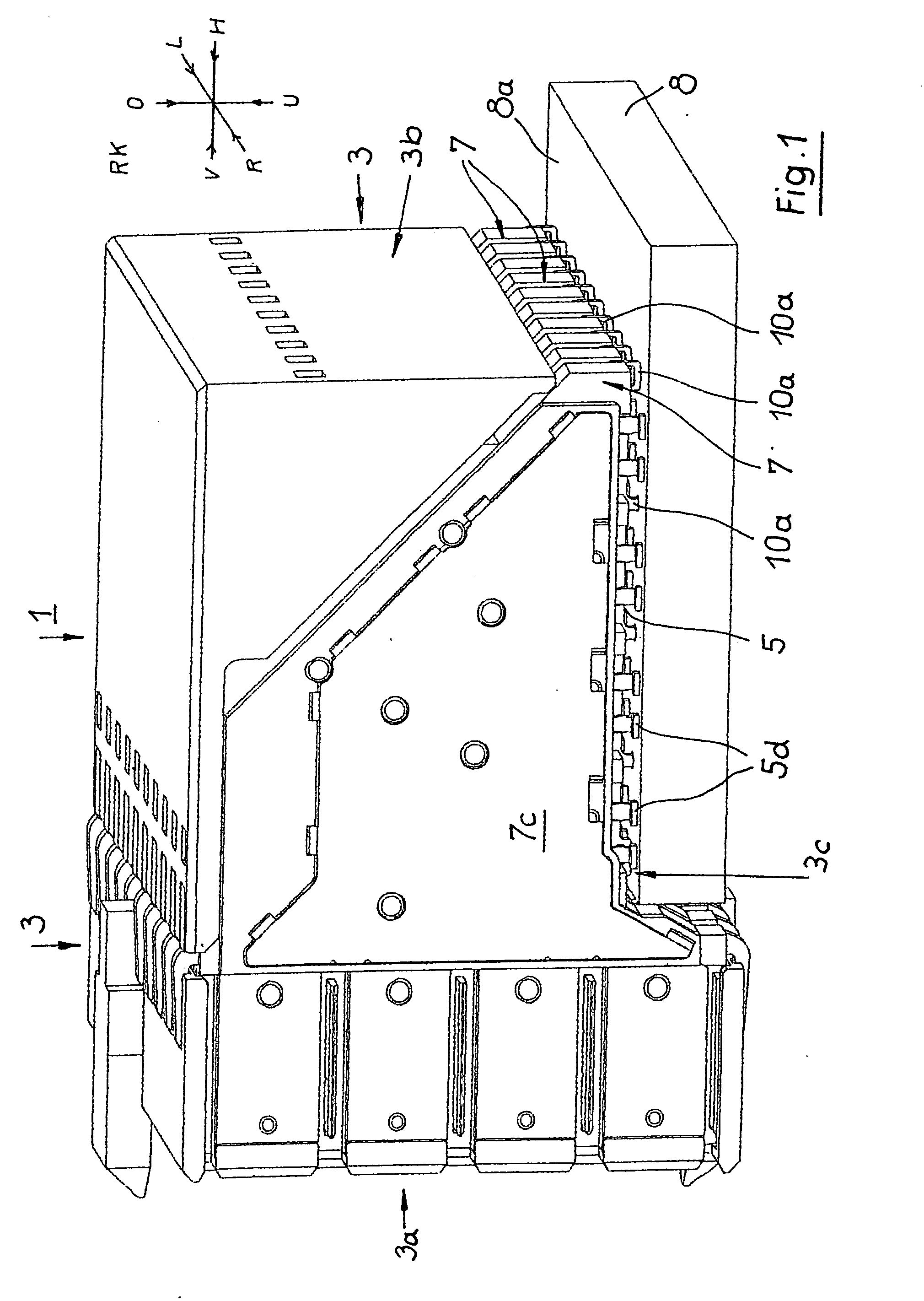

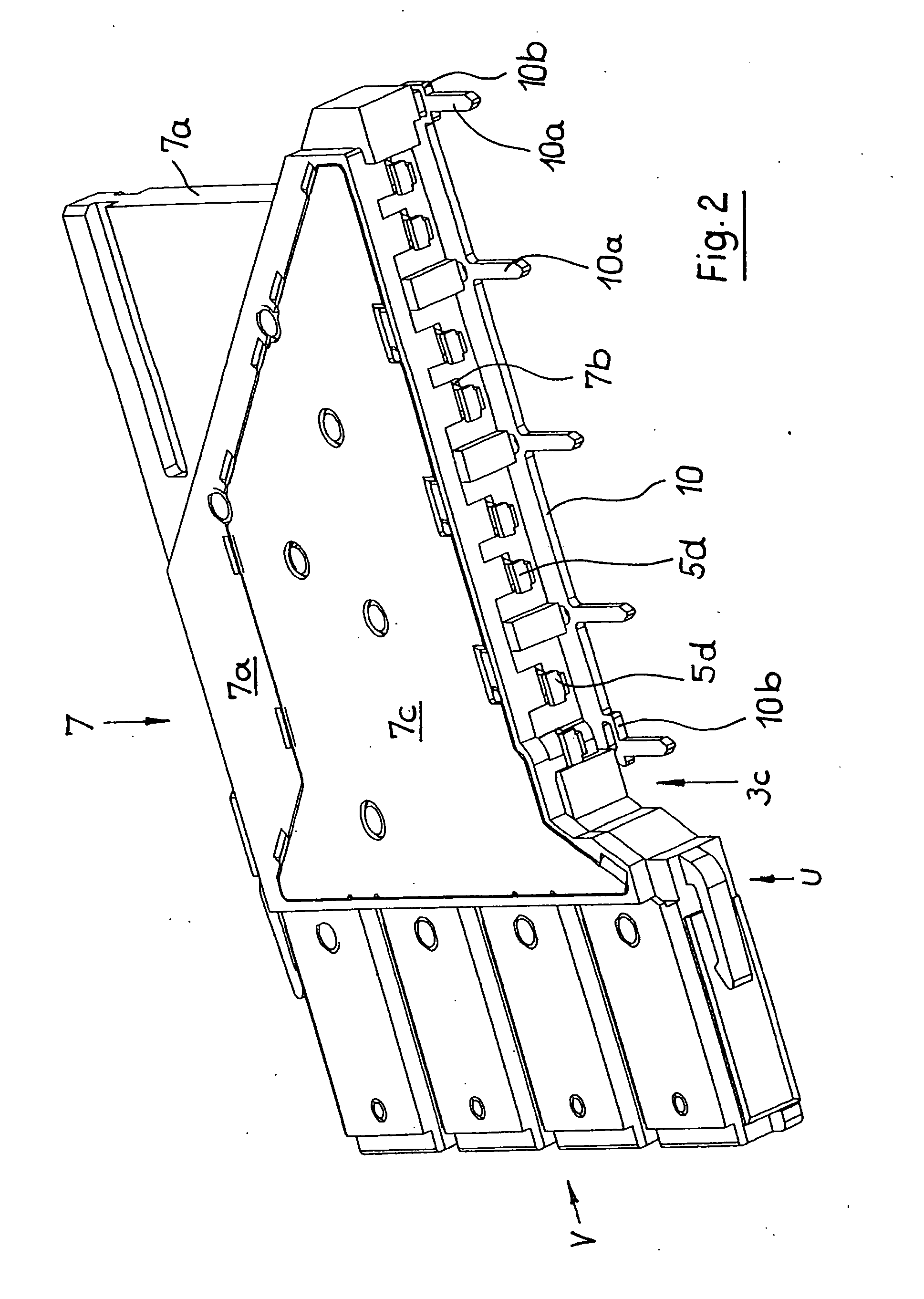

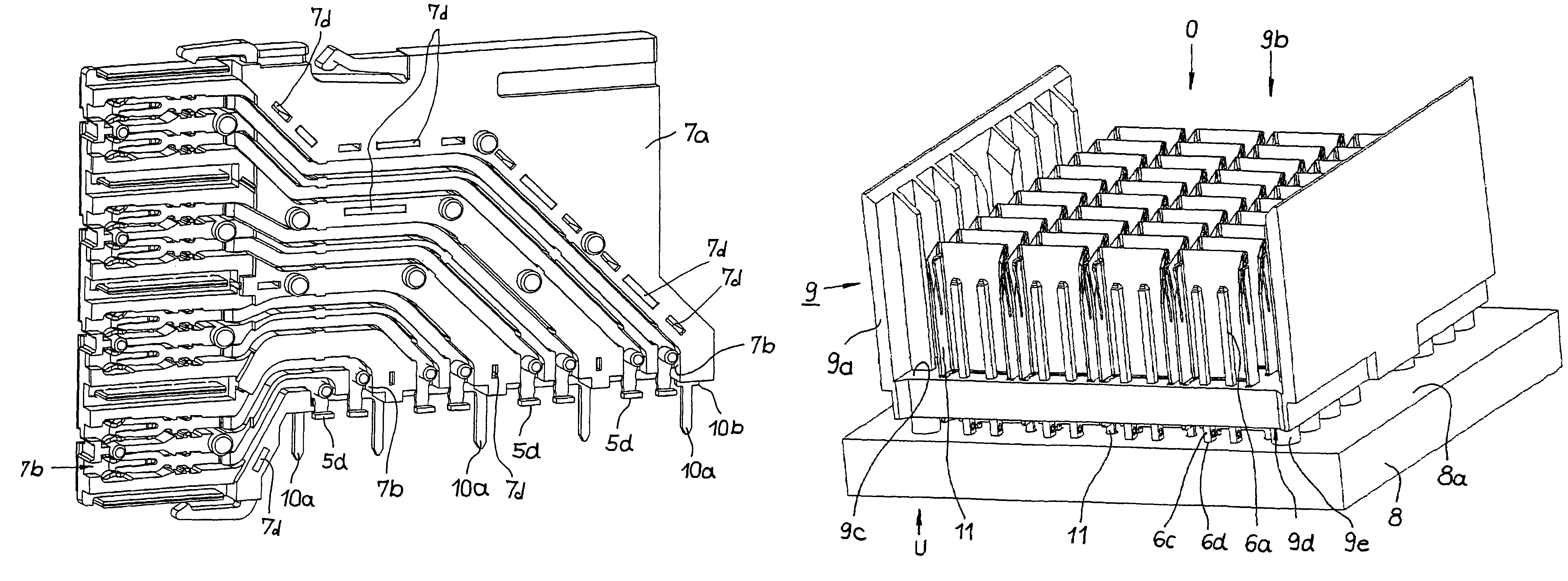

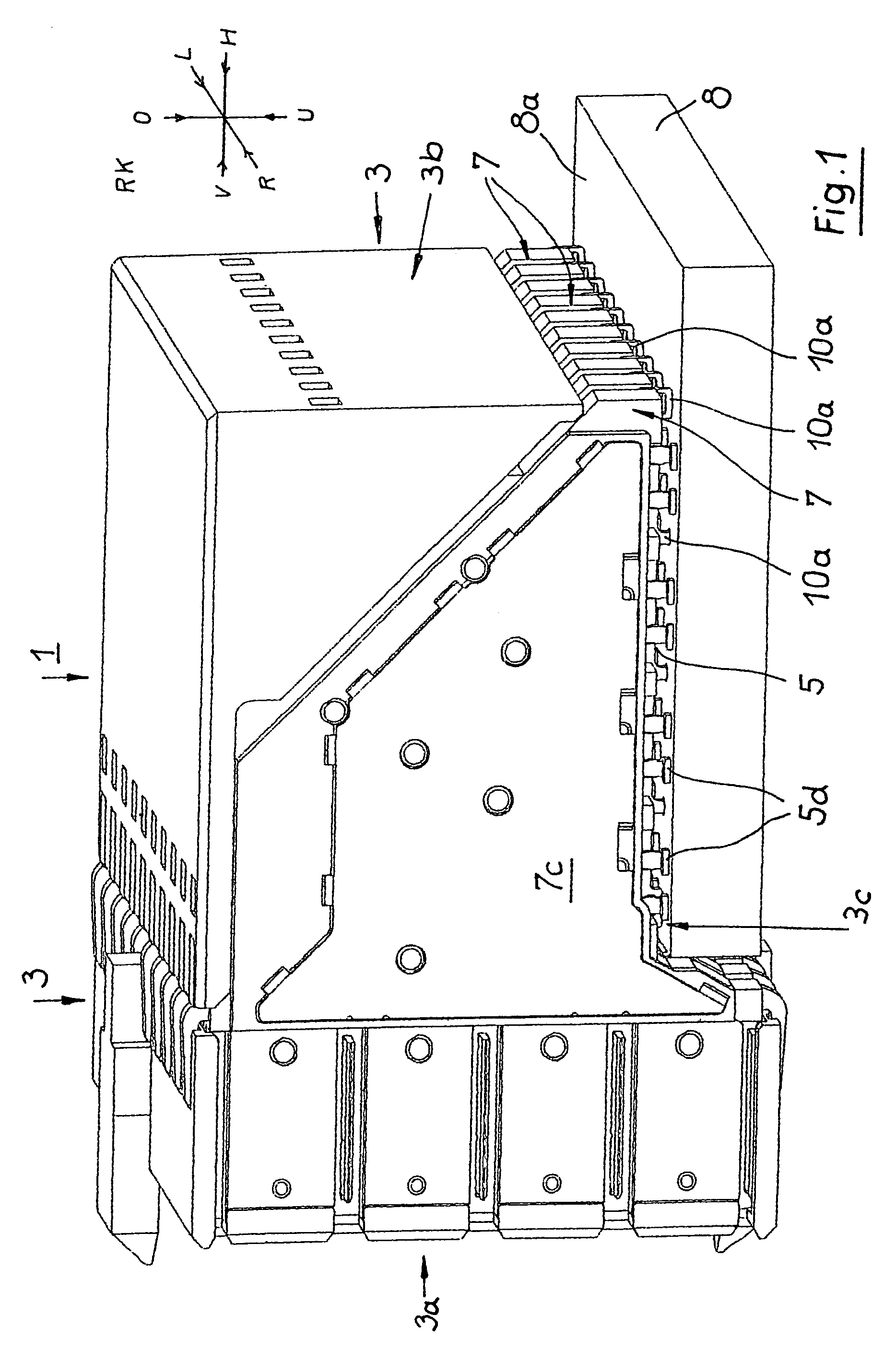

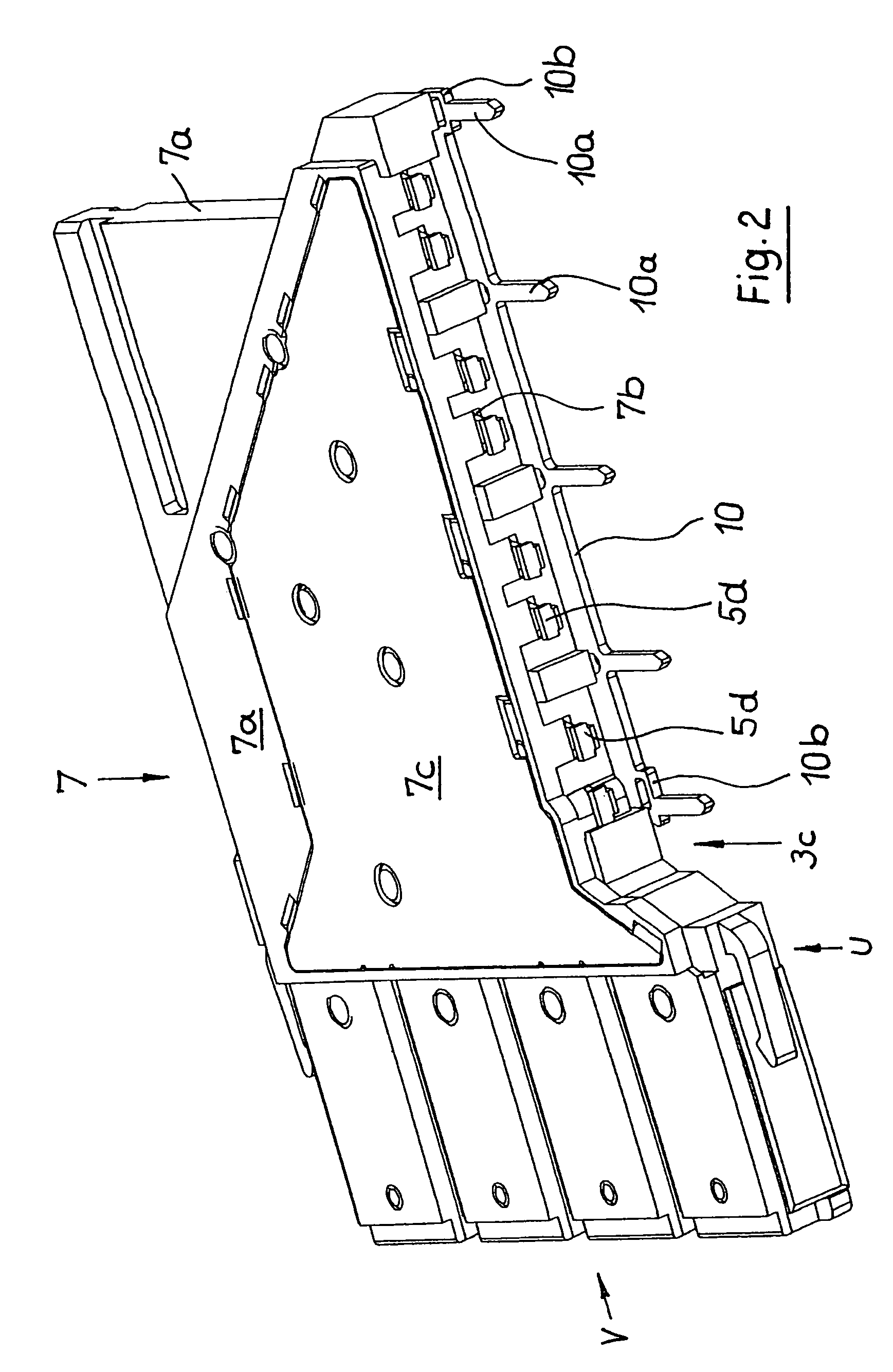

Electronic Device With A Flexible Display

ActiveUS20110043976A1Improve mechanical stabilityPrevent flexible displayDigital data processing detailsElectrical apparatus contructional detailsDisplay deviceEngineering

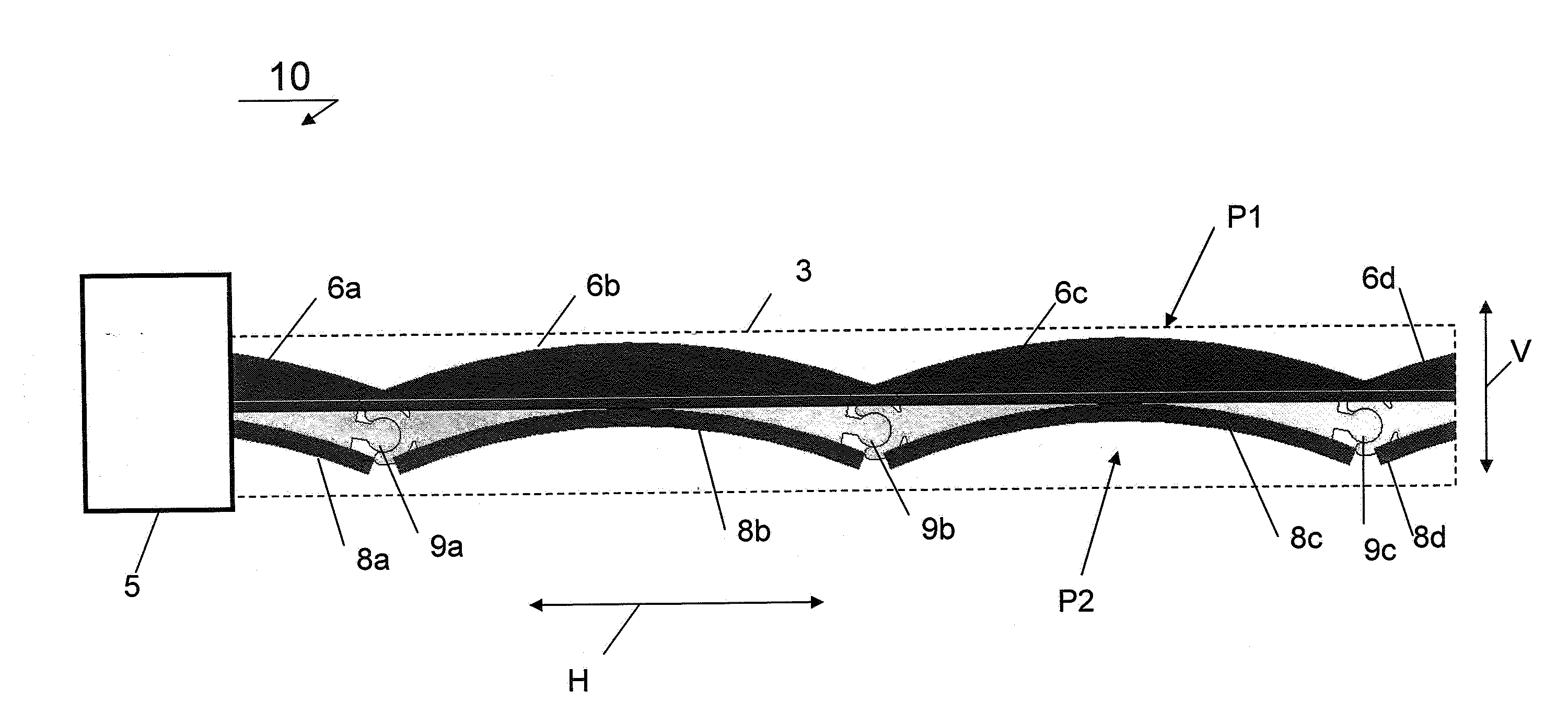

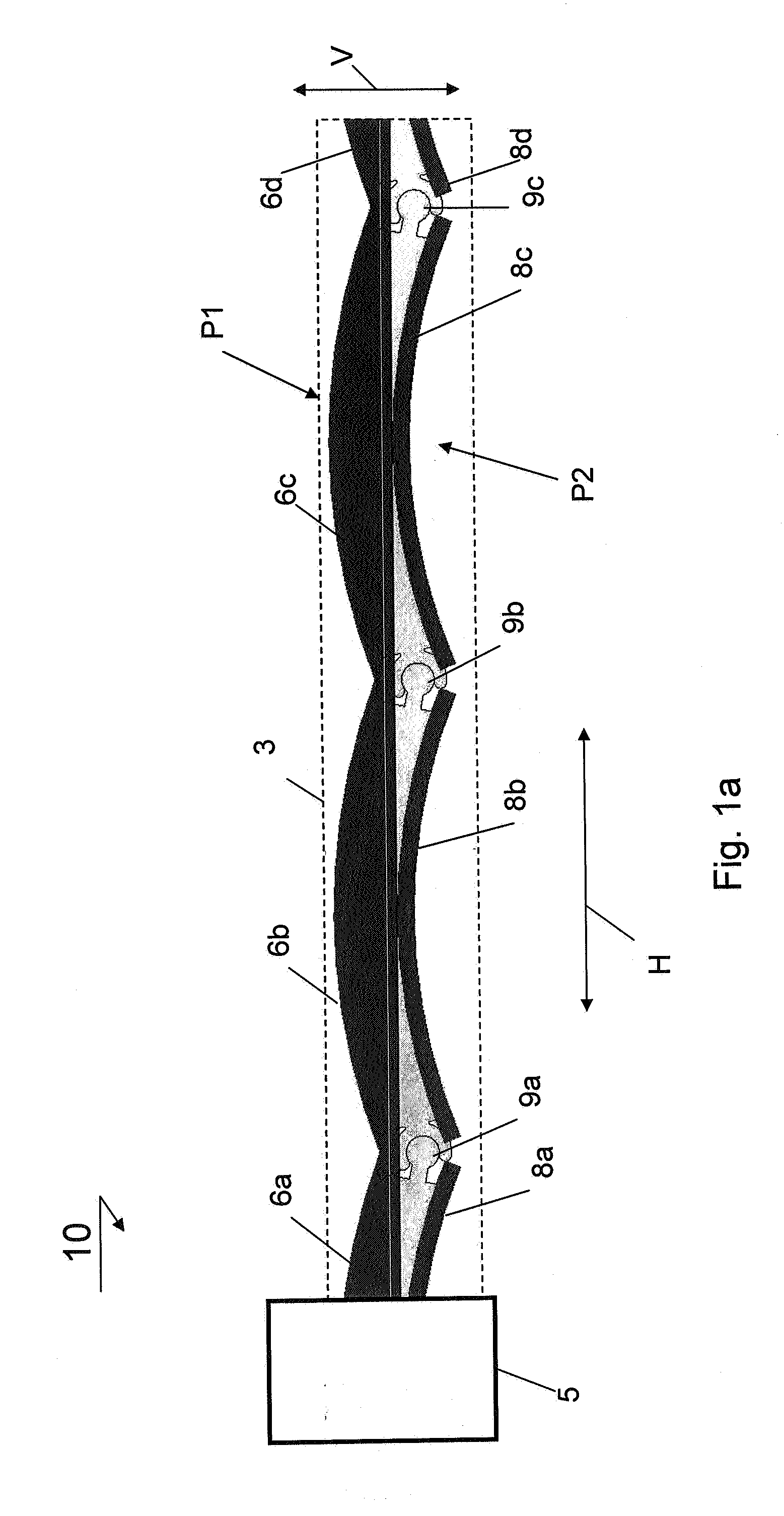

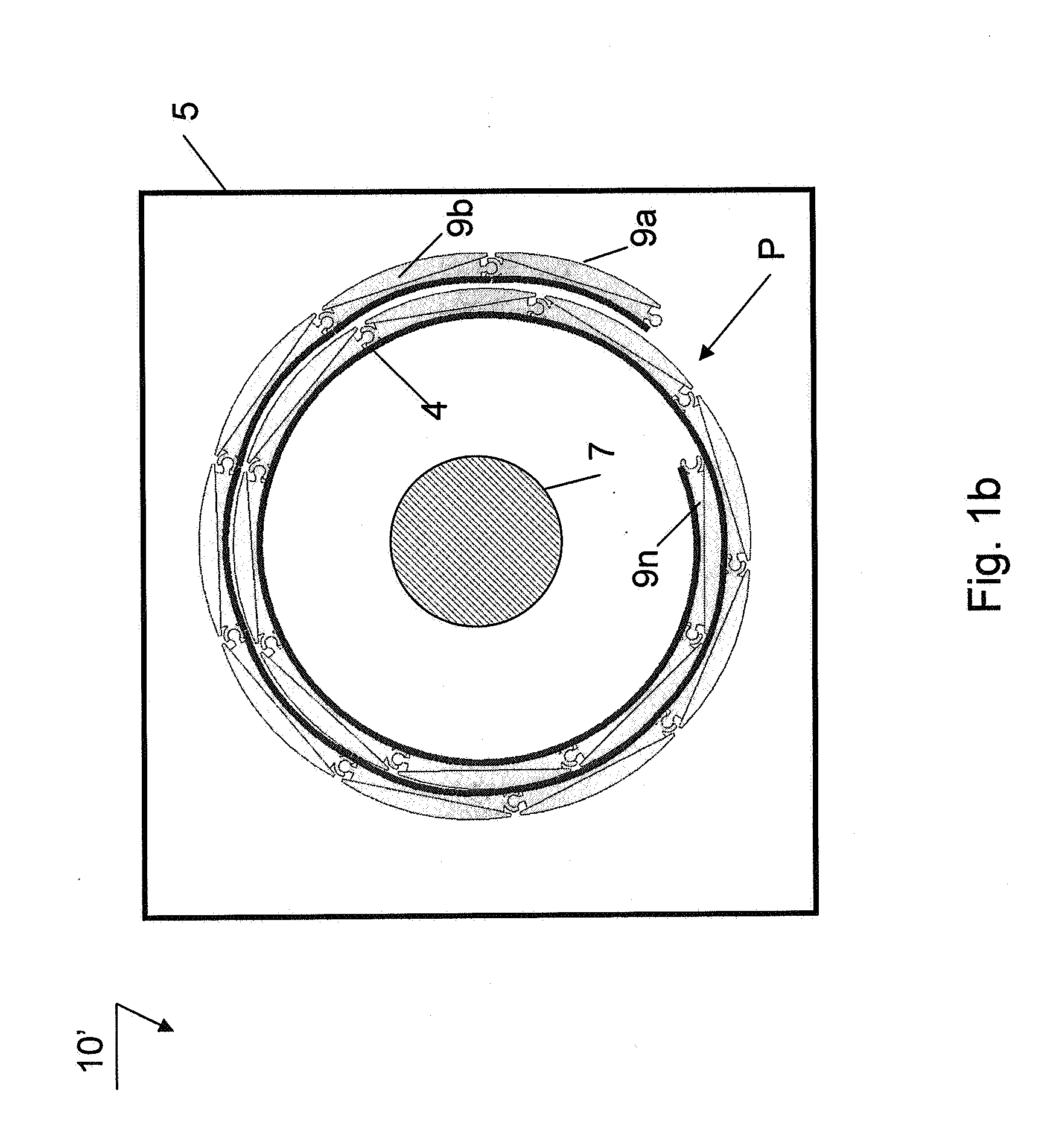

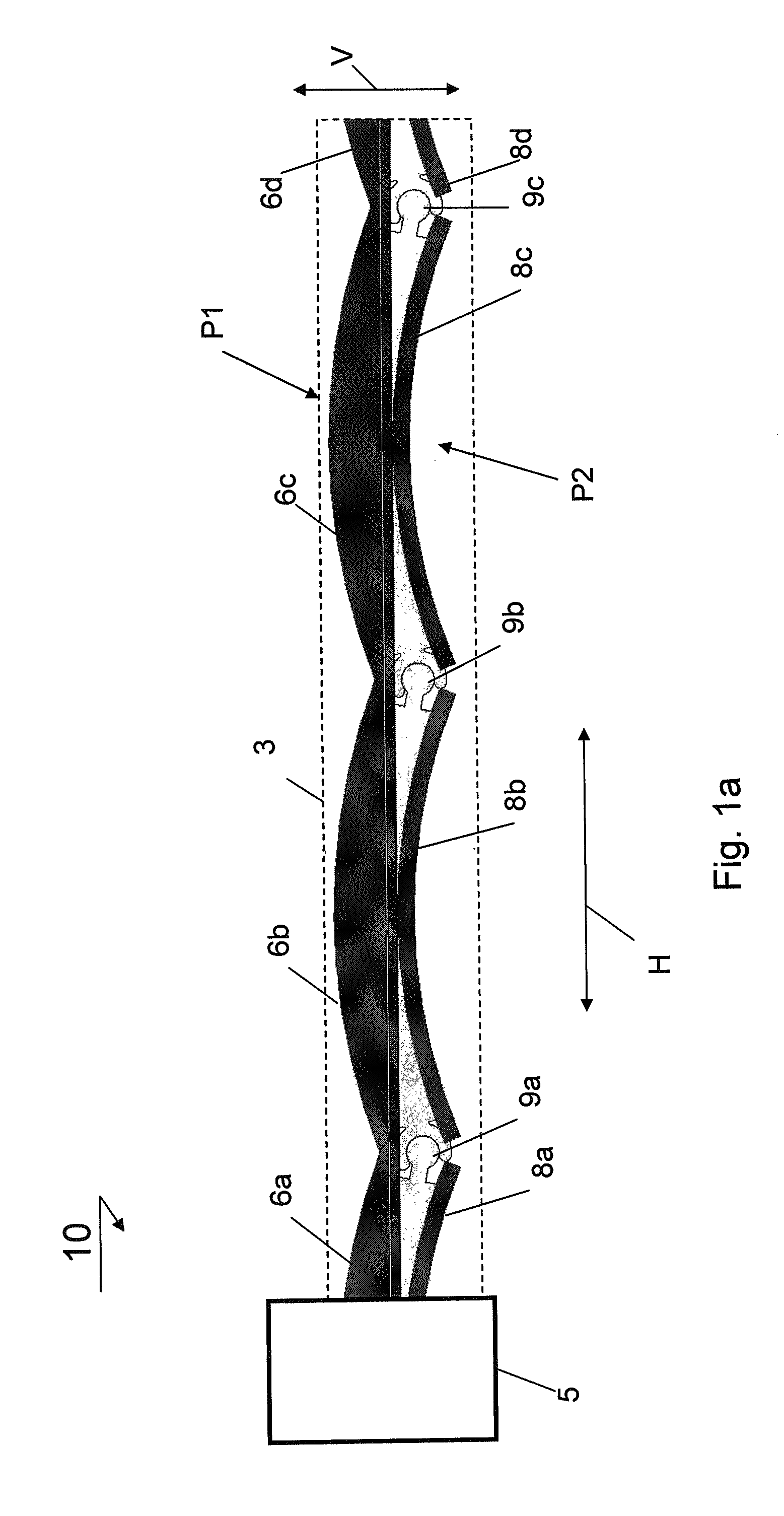

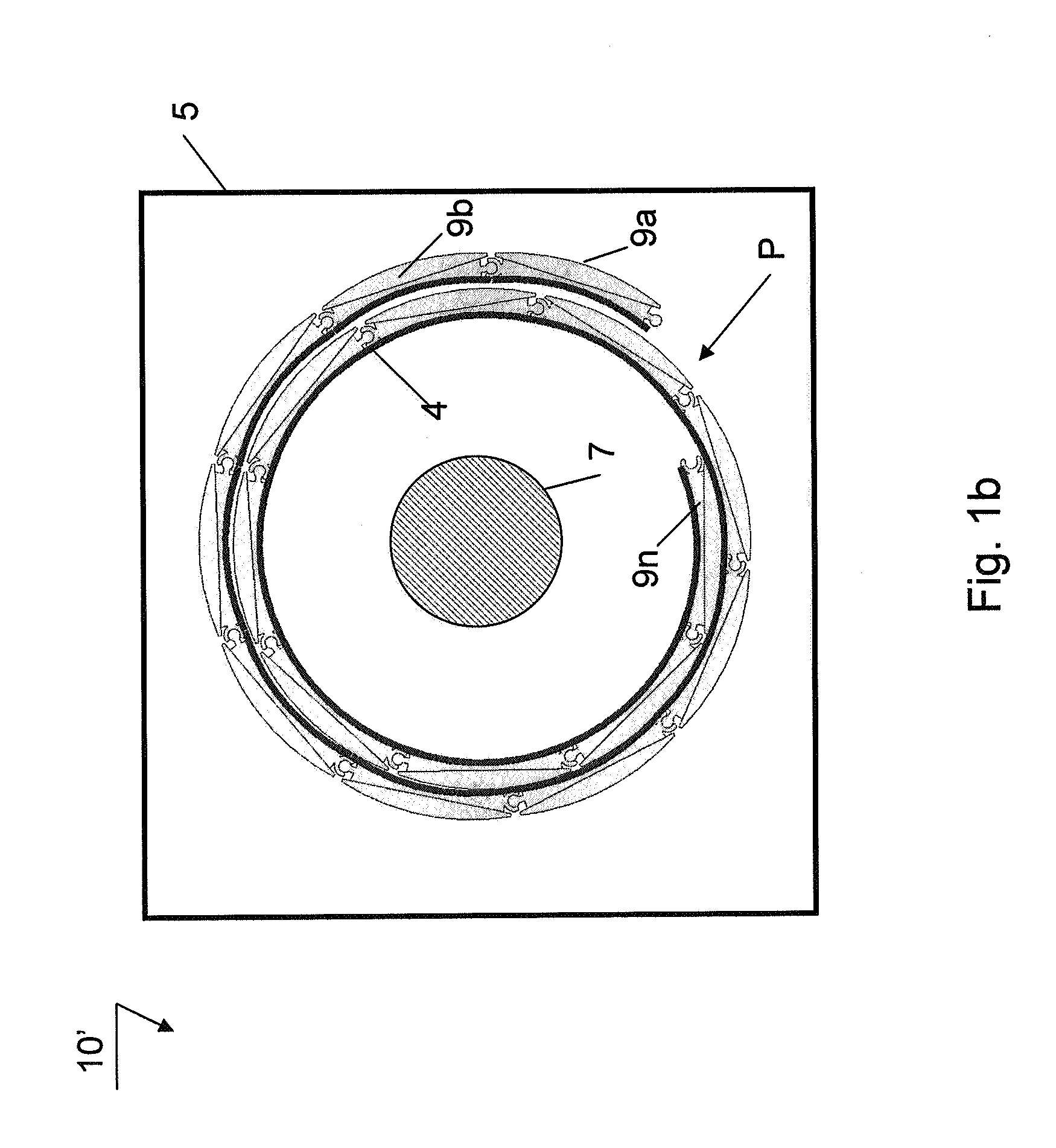

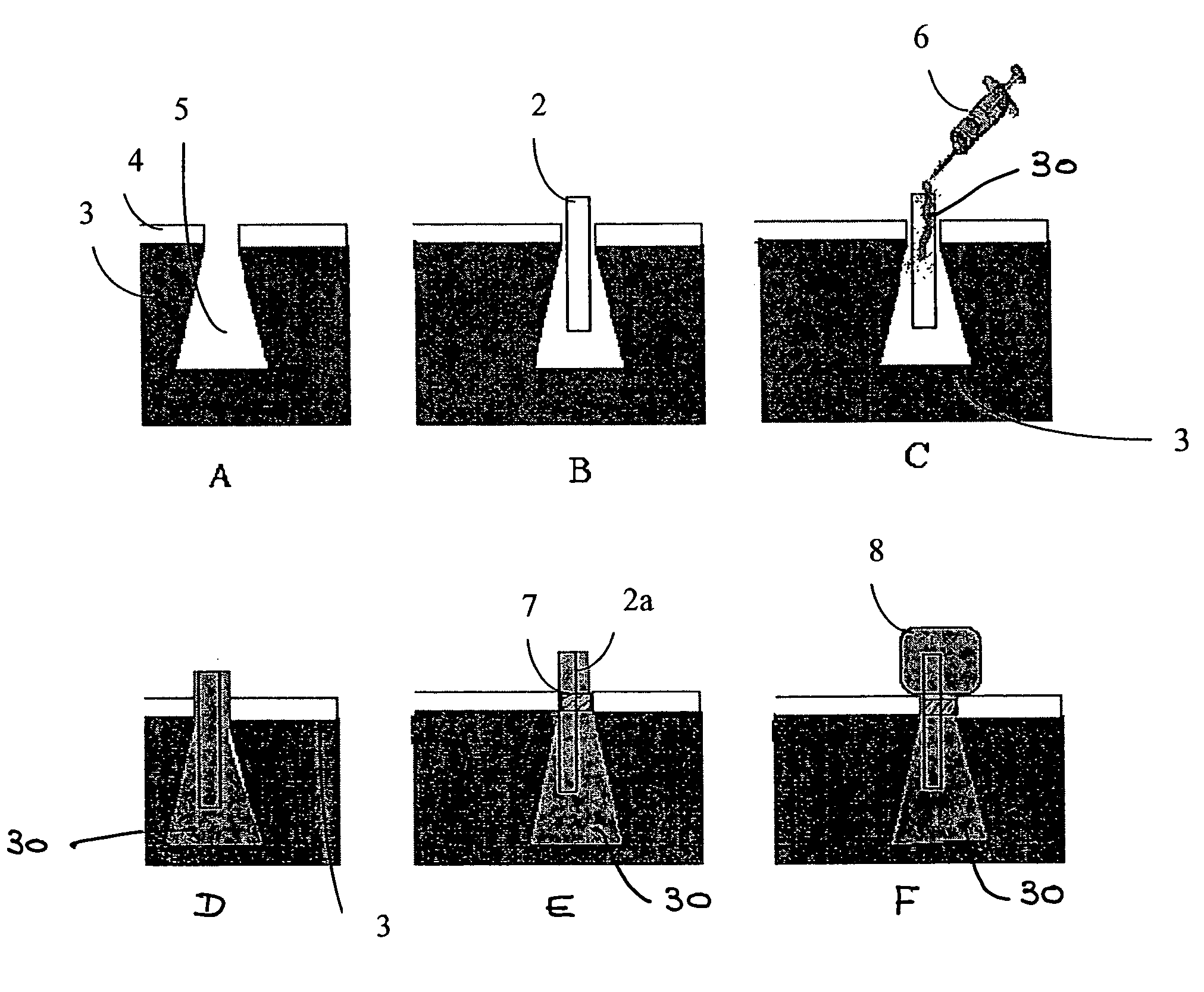

The invention relates to an electronic apparatus 10 comprising with a flexible display 2, which may be extendable from a housing 5 upon use. In accordance with the invention, the edge portions 3 are provided with an edge protector having an upper surface P1 and a lower surface P2, said edge protector being comprised of segments 6a, 6b, 6c, 6d, 8a, 8b, 8c, 8d, which may be interconnected by hinges 9a, 9b, 9c. The segments of the edge protector are arranged above and below the edge portions of the flexible display 2 and are preferably displaceable during translation of the flexible display from a collapsed to an extended state and back. Preferably, the hinges 9a, 9b, 9c are arranged for enabling a vertical V and / or a horizontal H displacement of the segments. The segmented edge protector is arranged for being moved together with the display and to be stored together with it, so that the segments 6a, 6b, 6c, 6d, 8a, 8b, 8c, 8d substantially do not loose contact with the edge portion during storage.

Owner:SAMSUNG ELECTRONICS CO LTD

Plug-and-socket connector

ActiveUS20070155241A1High mechanical strengthGood electrical parametersCoupling protective earth/shielding arrangementsElectronic systemsEngineering

A multi-pole, multi-row plug-and-socket connector with shielding, for placement on printed circuit boards, circuit cards, and similar electrical components, which can be used in an electrical or electronic system includes electrical contact parts for the transmission of signals, which possess a connection section on one end and an electrically conductive attachment section on the other end, as well as an electrical shielding, which possesses at least one electrically conductive contact section. The free ends of the electrically conductive attachment sections of the electrical contact parts are SMD contacts. The at least one electrically conductive contact section of the shielding is, at the same time, an attachment pin which projects into a passage hole of the printed circuit board when the plug-and-socket connector is disposed on the same, for the purpose of connective soldering using THR technology.

Owner:ERNI PRODION GMBH

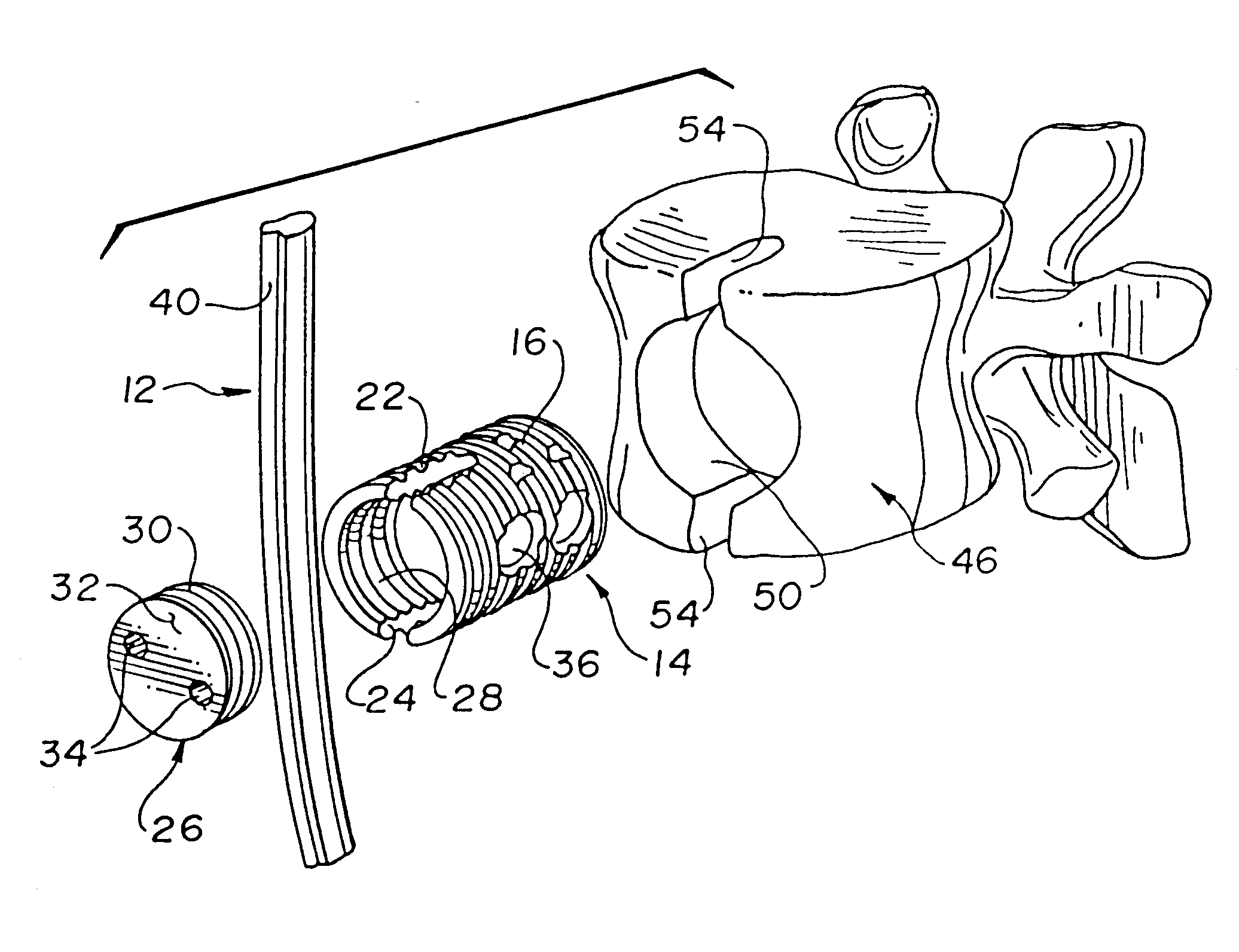

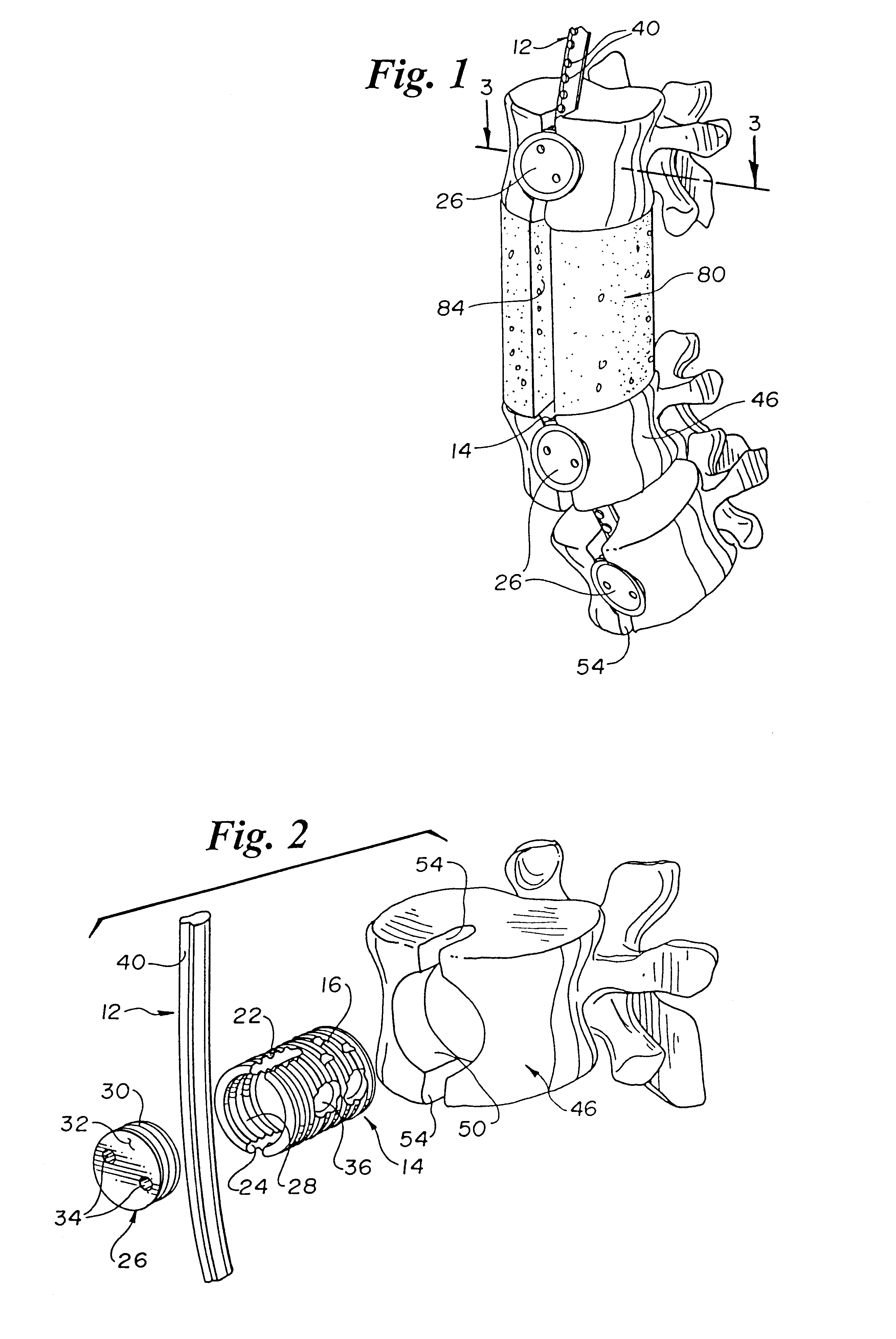

Spinal fixation device

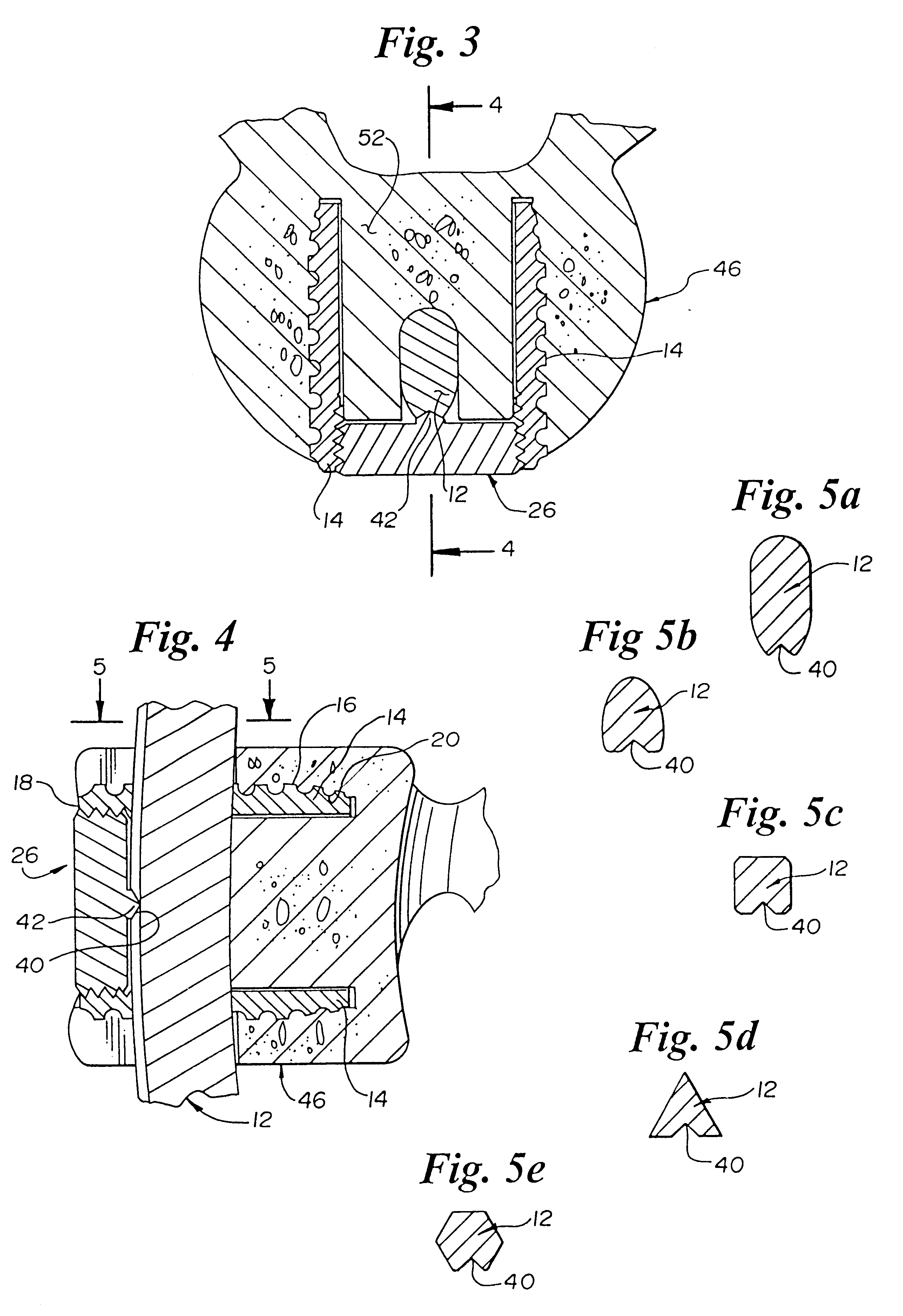

InactiveUSRE37479E1Increase surface areaImprove mechanical stabilityInternal osteosythesisBone implantHole sawBiomedical engineering

An spinal fixation device for stabilizing vertebrae. A hollow screw is inserted into a hole saw recess in each adjoining vertebrae. A channel is cut into the vertebrae into which a joining rod is inserted such that no part of the device protrudes above the bone. A locking cap is used to secure the rod to the screws.

Owner:SPINEOLOGY

Water-Absorbing Polysaccharide and Method for Producing the Same

InactiveUS20080009616A1Drying processImprove retentionSugar derivativesBaby linensPolyphosphatePhosphoric acid

The present invention relates to a process for producing a water-absorbent polysaccharide including the process steps of bringing into contact an uncrosslinked polysaccharide with a polyphosphate or a polyphosphoric acid as crosslinking agent in the presence of water to form a polysaccharide gel and crosslinking the polysaccharide gel. The invention further relates to a water-absorbent polysaccharide obtainable by this process, a water-absorbent polysaccharide, a composite, a process for producing a composite, a composite produced by this process, the use of the water-absorbent polysaccharides or of the composites as well as the use of polyphosphates.

Owner:EVONIK DEGUSSA GMBH

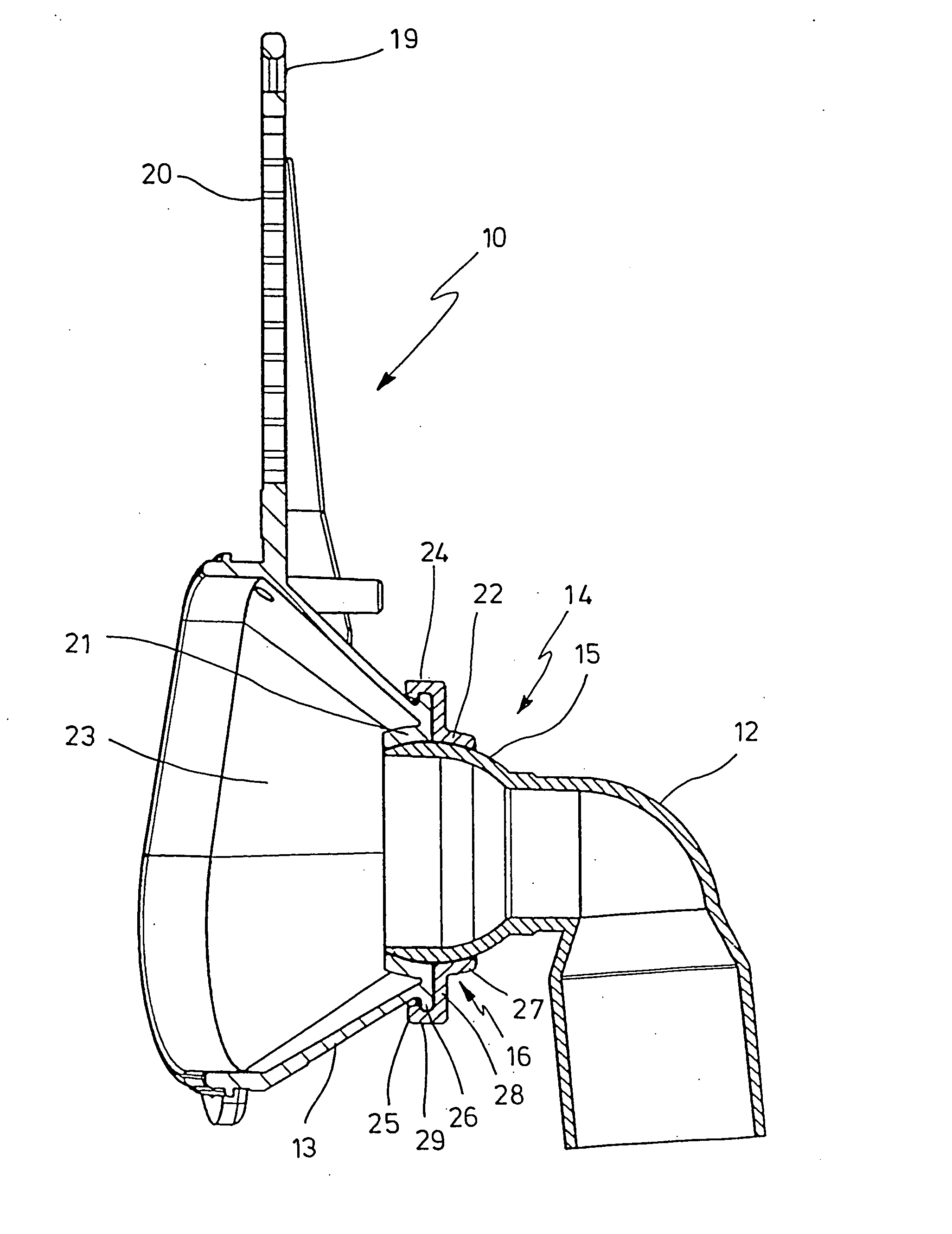

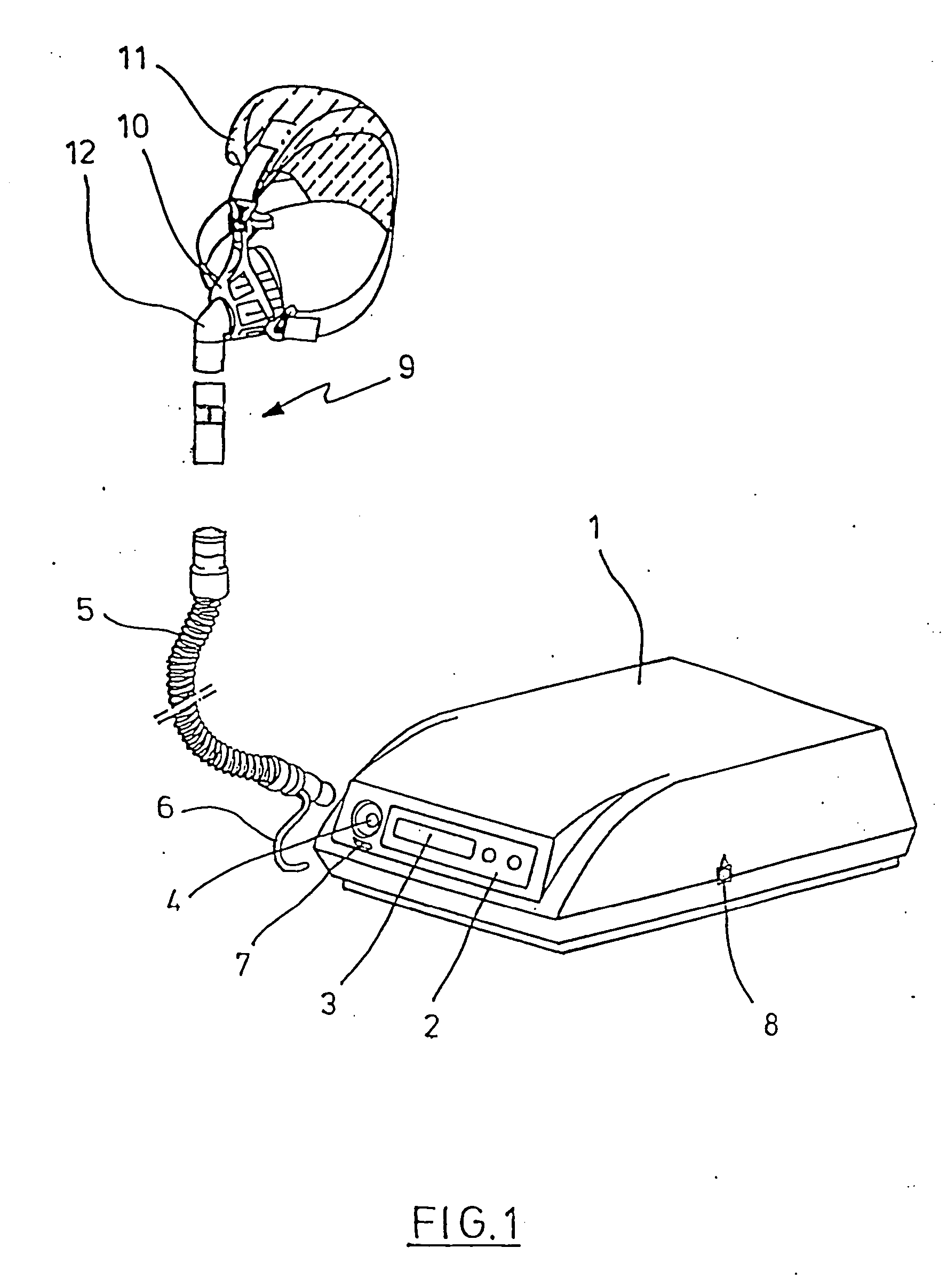

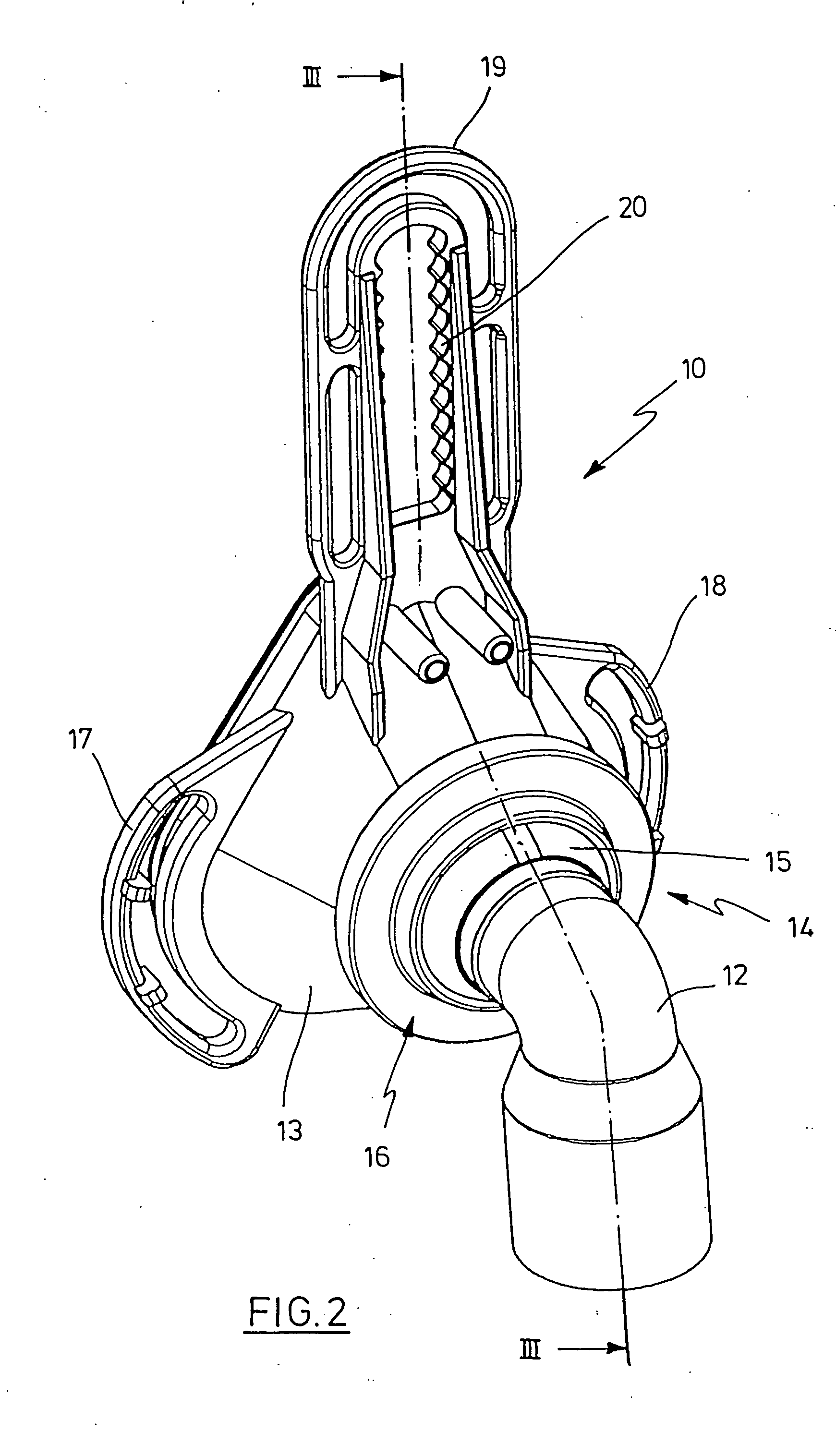

Ventilation device

InactiveUS20050150497A1Improve mechanical stabilityEasy to assembleRespiratory masksBreathing masksBreathing gasEngineering

A device used for ventilation includes a ventilation mask that can be connected to a respiratory gas hose. The ventilation mask has a respiratory gas hose coupling that is movably connected by a joint with the base of the ventilation mask. The joint is a ball-and-socket joint, which has an inner part that is shaped like a spherical segment and an outer shell for guiding the inner part. The outer shell is constructed from at least two shell segments that can be connected with each other.

Owner:WEINMANN GERATE FUR MEDIZIN

Plug-and-socket connector

ActiveUS7267515B2High mechanical strengthGood electrical parametersCoupling protective earth/shielding arrangementsElectronic systemsEngineering

A multi-pole, multi-row plug-and-socket connector with shielding, for placement on printed circuit boards, circuit cards, and similar electrical components, which can be used in an electrical or electronic system includes electrical contact parts for the transmission of signals, which possess a connection section on one end and an electrically conductive attachment section on the other end, as well as an electrical shielding, which possesses at least one electrically conductive contact section. The free ends of the electrically conductive attachment sections of the electrical contact parts are SMD contacts. The at least one electrically conductive contact section of the shielding is, at the same time, an attachment pin which projects into a passage hole of the printed circuit board when the plug-and-socket connector is disposed on the same, for the purpose of connective soldering using THR technology.

Owner:ERNI PRODION GMBH

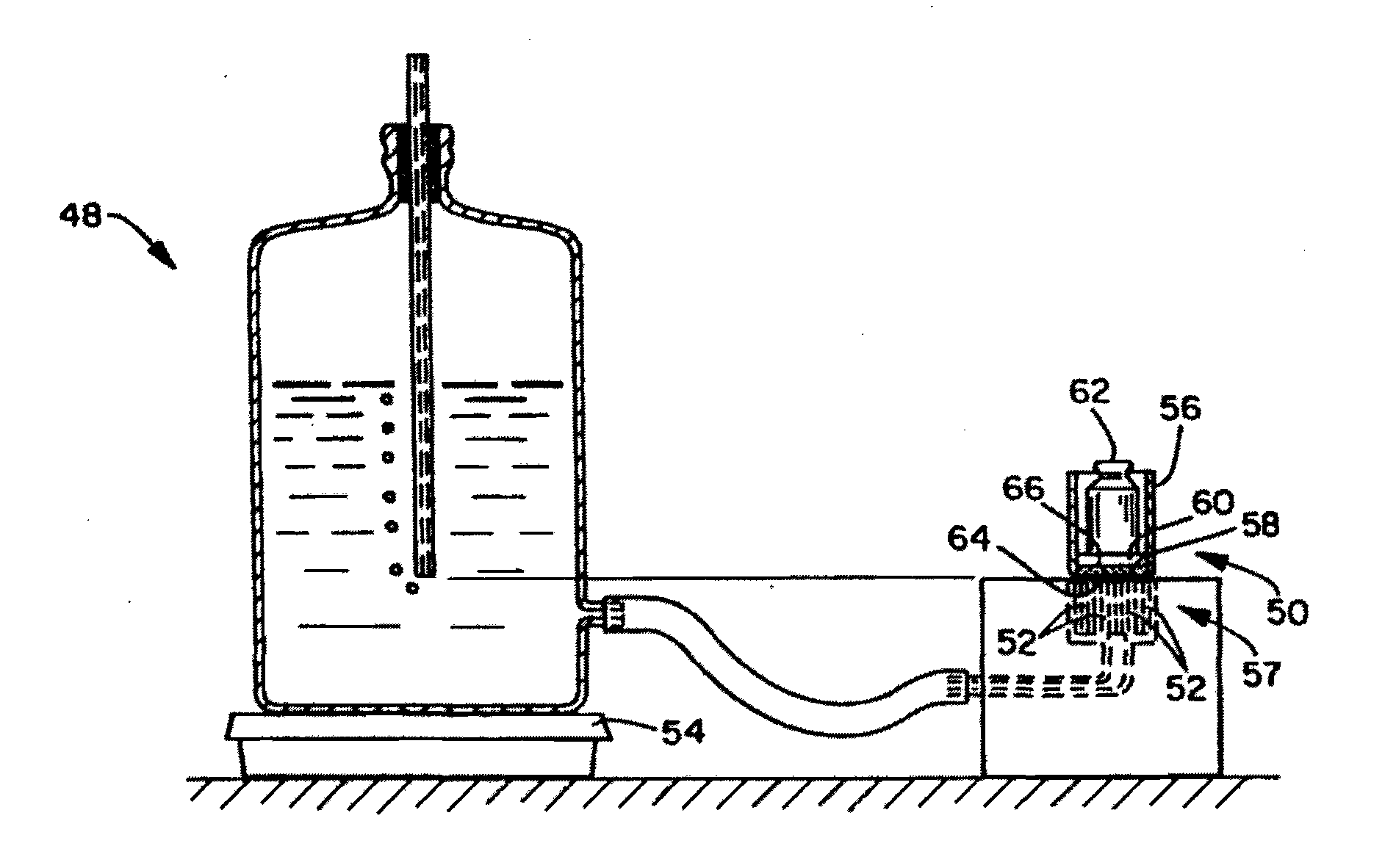

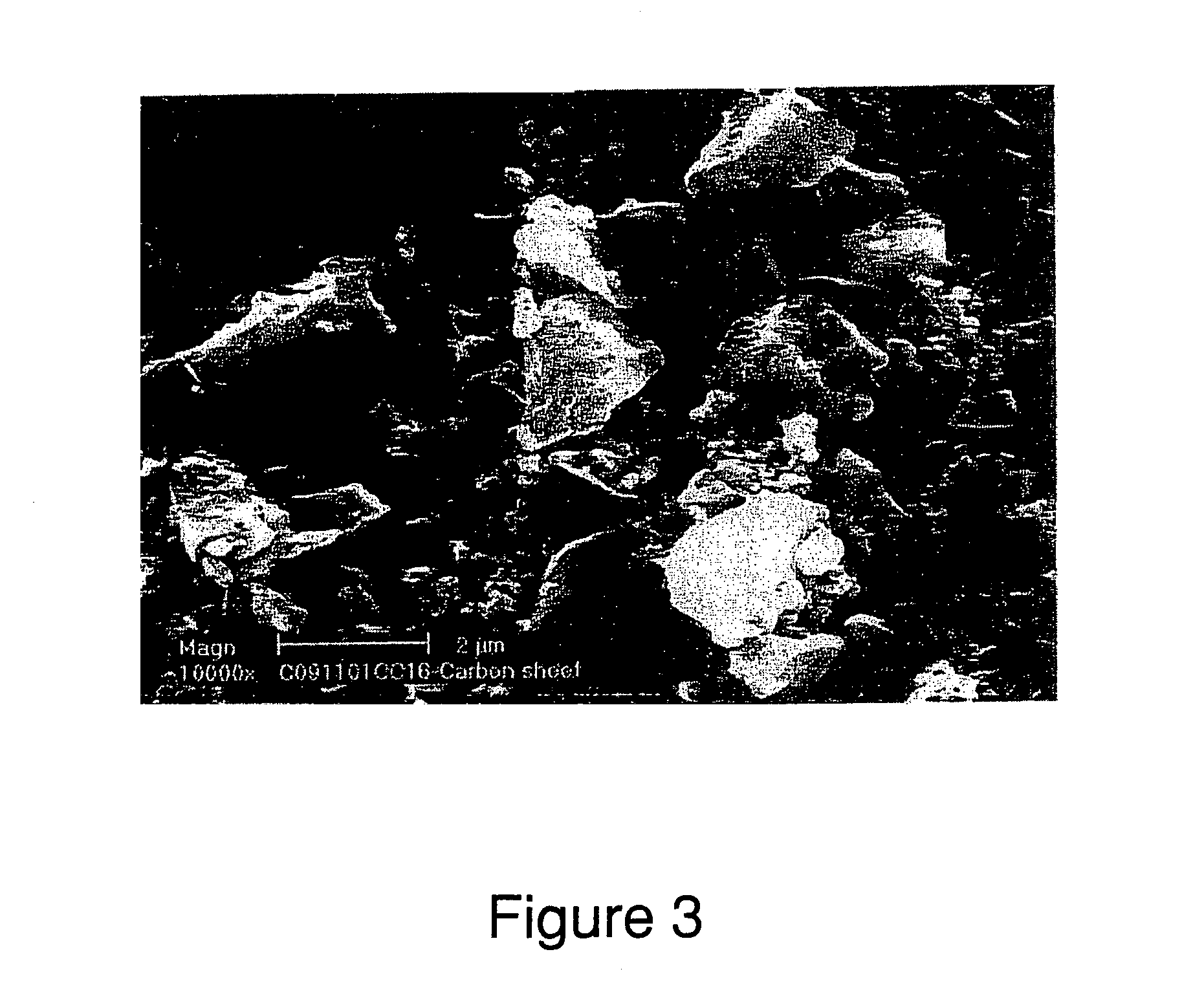

Adsorbent sheet material for parallel passage contactors

ActiveUS7077891B2Maximize capacityImprove efficiencyMaterial nanotechnologyOther chemical processesParticulatesSorbent

An adsorbent material fabricated into a reinforcement-free, self-supported coherent thin sheet and configured for use as a parallel passage contactor element in adsorption / separation applications with gases and liquids is disclosed. The adsorbent sheet material is obtained by enmeshing fine adsorbent particulates in a polymer binder. Particulates include but are not limited to carbon particles, inorganic oxides particles, or ceramic particles, or synthetic polymer resin particles. The adsorbent sheet advantageously contains a large volume percentage of active adsorbent particles. The parallel passage contactor device fabricated from the adsorbent sheet material is characterized by minimal mass transfer resistance and better separation efficiency expressed as height equivalent to a theoretical plate, while it maintains most of the adsorptive properties of the starting particulates, and can be used in gas separation applications with short adsorption cycles, such as rapid pressure swing adsorption, rotary concentrators, rapid electric swing adsorption.

Owner:AIR PROD & CHEM INC

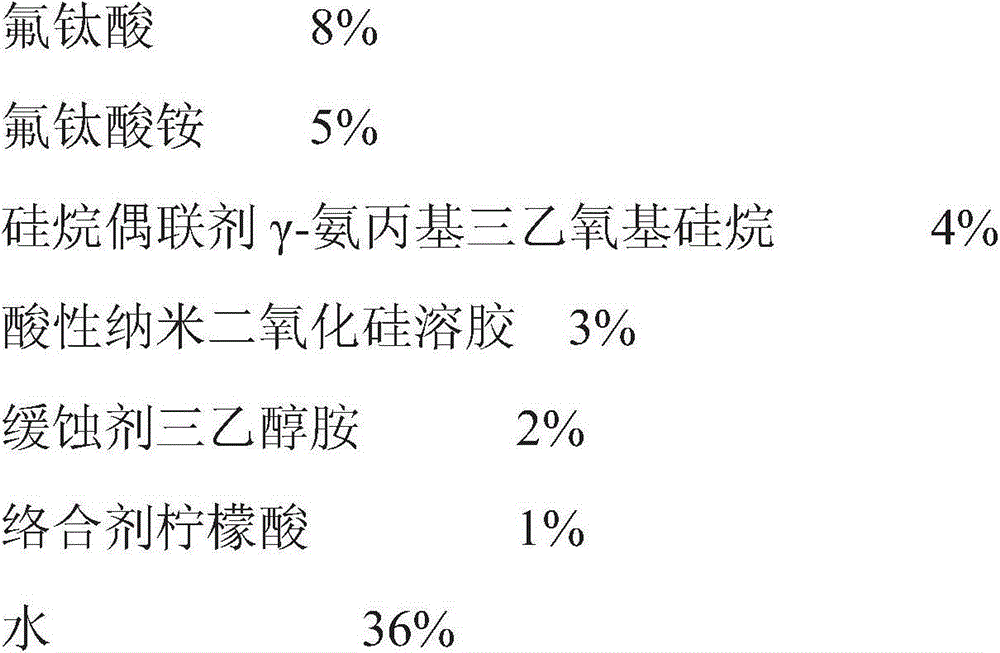

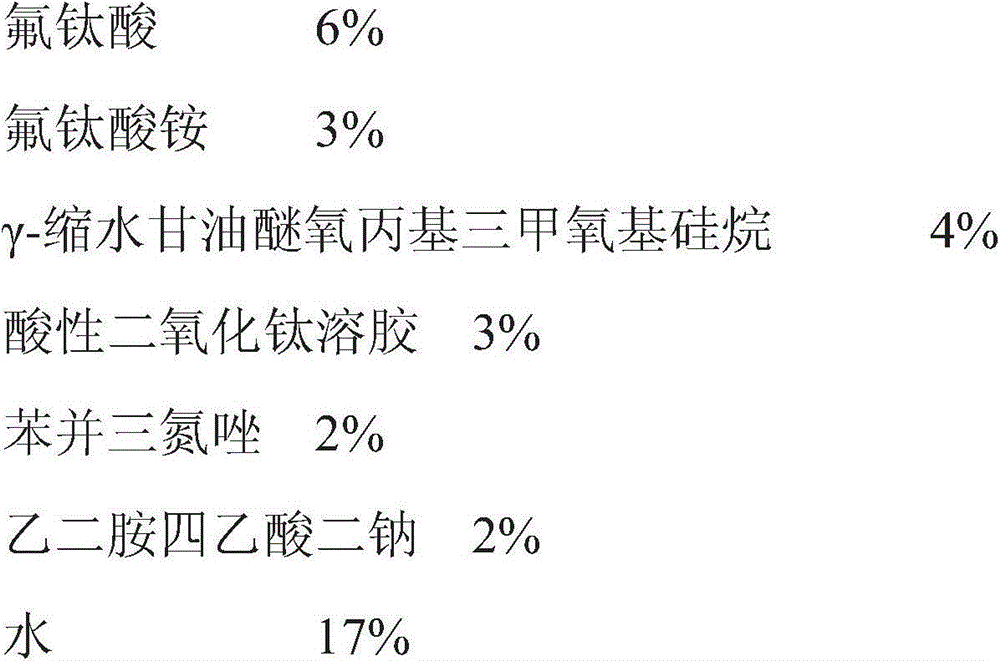

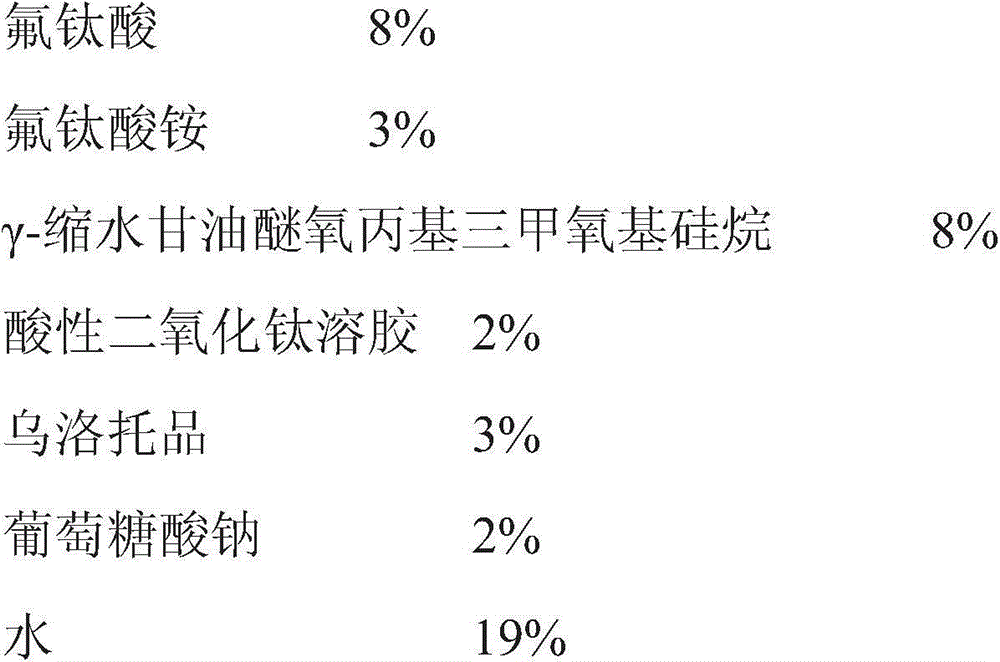

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

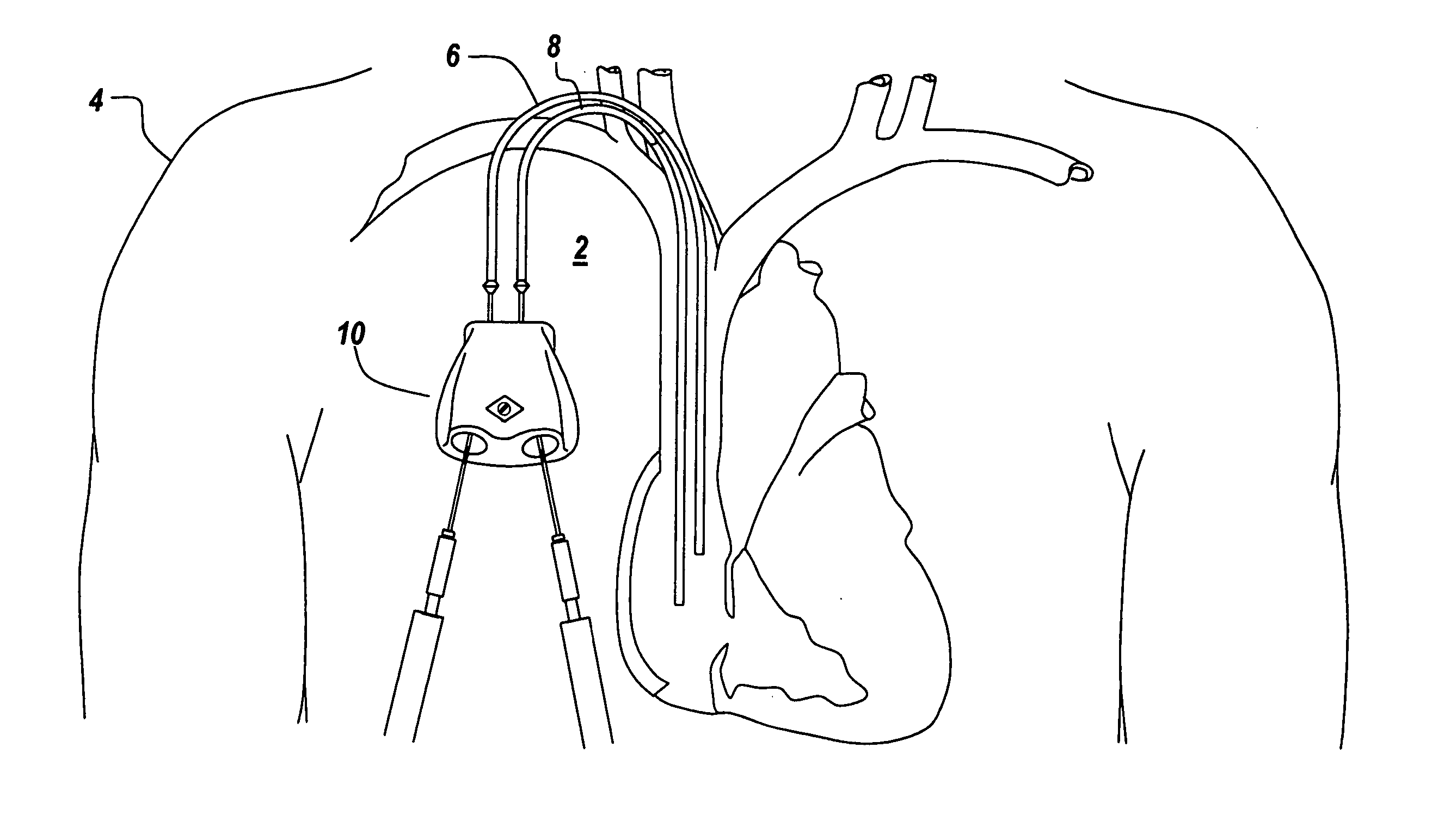

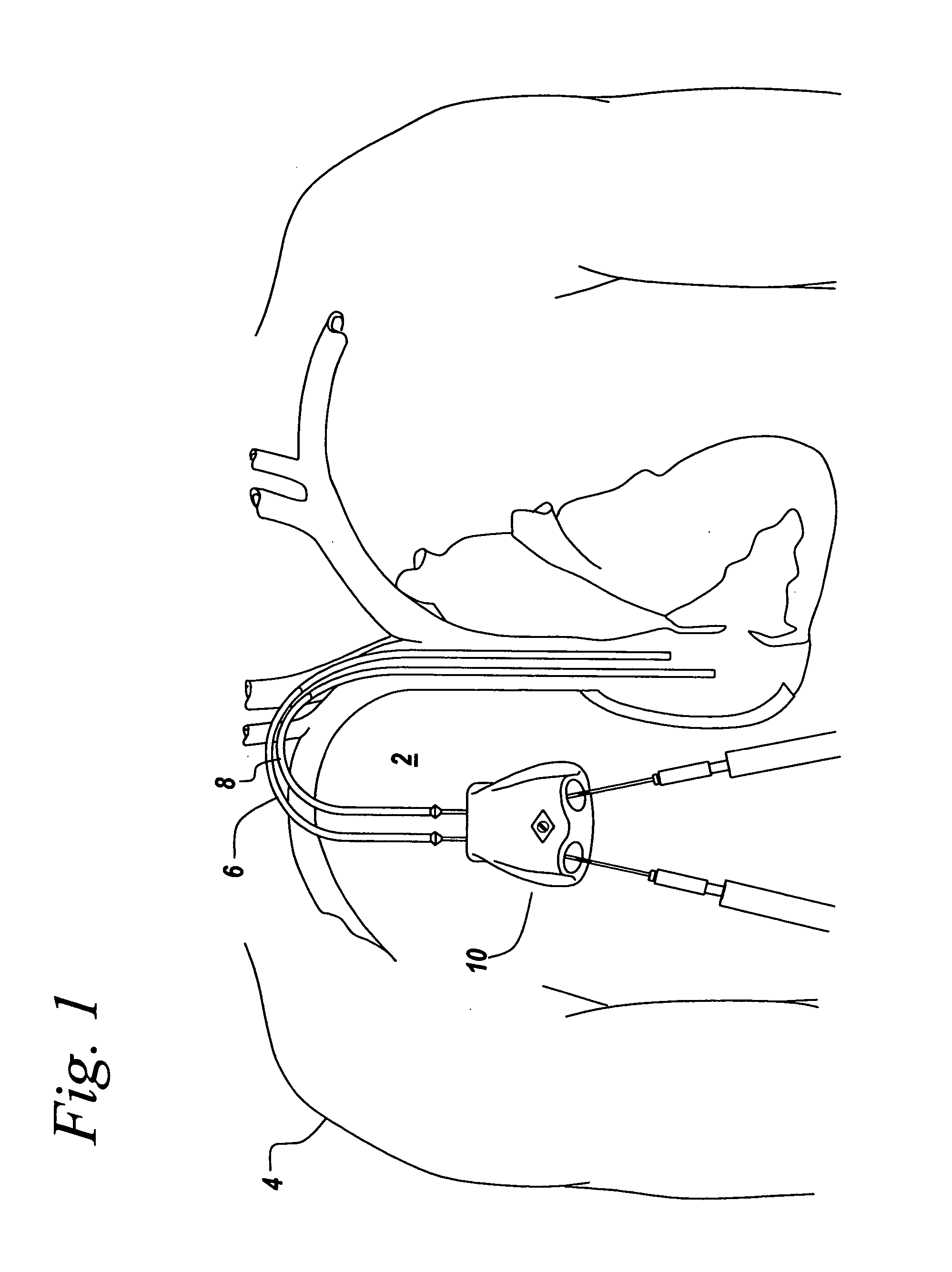

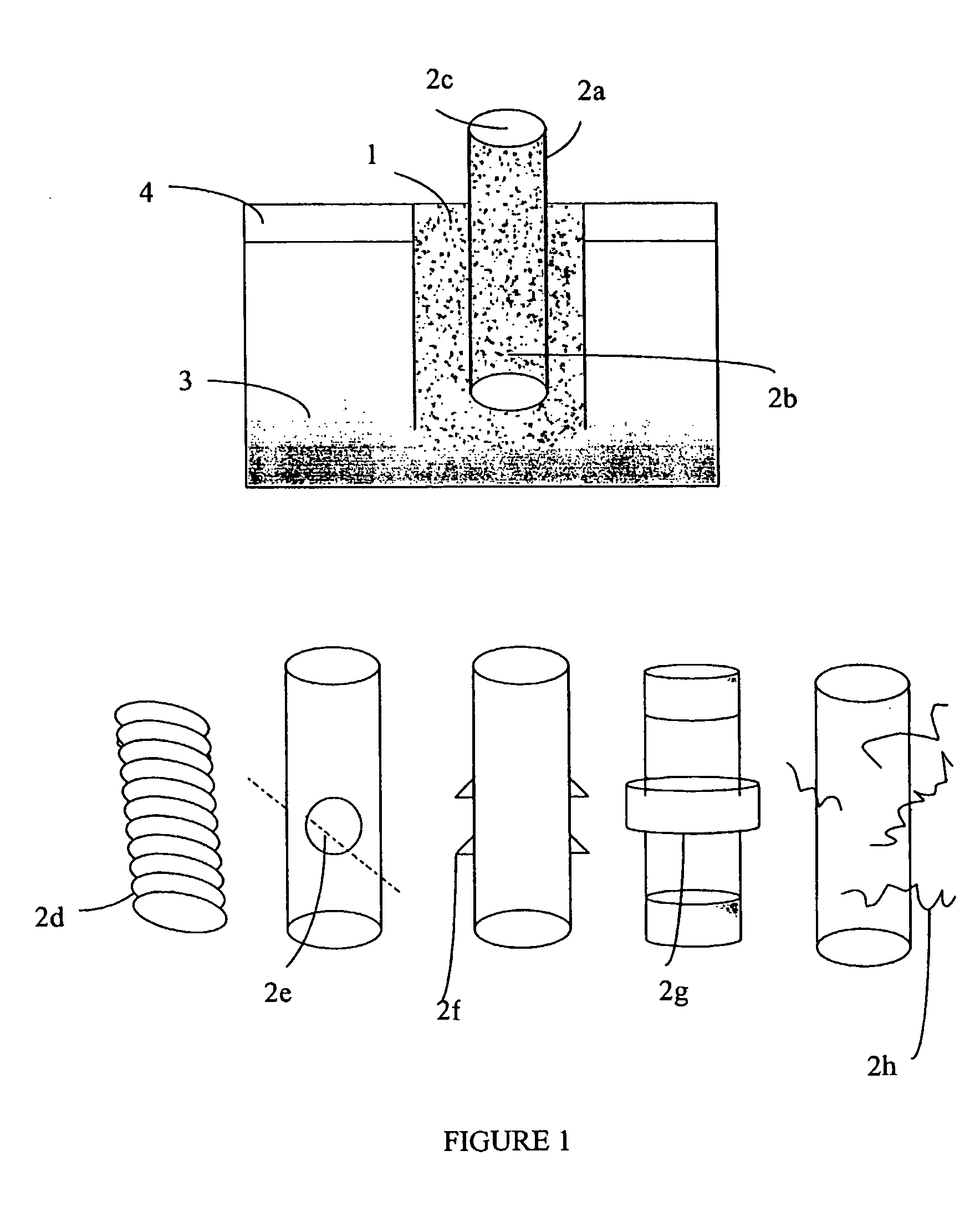

Subcutaneous needle connection system

InactiveUS20070083156A1Improve mechanical stabilityImprove sealingMedical devicesCatheterHemodialysisHaemodialysis machine

An apparatus for establishing a re-usable, recurring, mechanical connection to an organ within a patient is provided. A subcutaneous needle connection system for providing bidirectional, straight and turbulent-free fluid flow access to a vascular system of a patient includes a housing defining a needle access opening for receiving a needle, a cannula opening in communication with the vascular system and a passageway connecting the needle access opening to the cannula opening. The housing can additionally have a second needle access opening connected to a second cannula opening via a second passageway. The subcutaneous needle connection system allows for blood to be removed from the vascular system via one cannula opening, passed to a hemodialysis system via a needle inserted in an associated needle access opening, treated using the hemodialysis system, and returned to the vascular system via the other needle access opening and associated cannula opening. The implantable needle connection system provides enhanced mechanical stability under the skin, improved fluid flow dynamics, improved needle hole healing potential of the skin, and improved needle edge interfacing to minimize flow turbulence and blood cell trauma during use.

Owner:ATRIUM MEDICAL

Electronic device with a flexible display

ActiveUS8654519B2Improve mechanical stabilityPrevent flexible displayDigital data processing detailsElectrical apparatus contructional detailsDisplay deviceFlexible display

The invention relates to an electronic apparatus 10 comprising with a flexible display 2, which may be extendable from a housing 5 upon use. In accordance with the invention, the edge portions 3 are provided with an edge protector having an upper surface P1 and a lower surface P2, said edge protector being comprised of segments 6a, 6b, 6c, 6d, 8a, 8b, 8c, 8d, which may be interconnected by hinges 9a, 9b, 9c. The segments of the edge protector are arranged above and below the edge portions of the flexible display 2 and are preferably displaceable during translation of the flexible display from a collapsed to an extended state and back. Preferably, the hinges 9a, 9b, 9c are arranged for enabling a vertical V and / or a horizontal H displacement of the segments. The segmented edge protector is arranged for being moved together with the display and to be stored together with it, so that the segments 6a, 6b, 6c, 6d, 8a, 8b, 8c, 8d substantially do not loose contact with the edge portion during storage.

Owner:SAMSUNG ELECTRONICS CO LTD

High power fiber chirped pulse amplification system utilizing telecom-type components

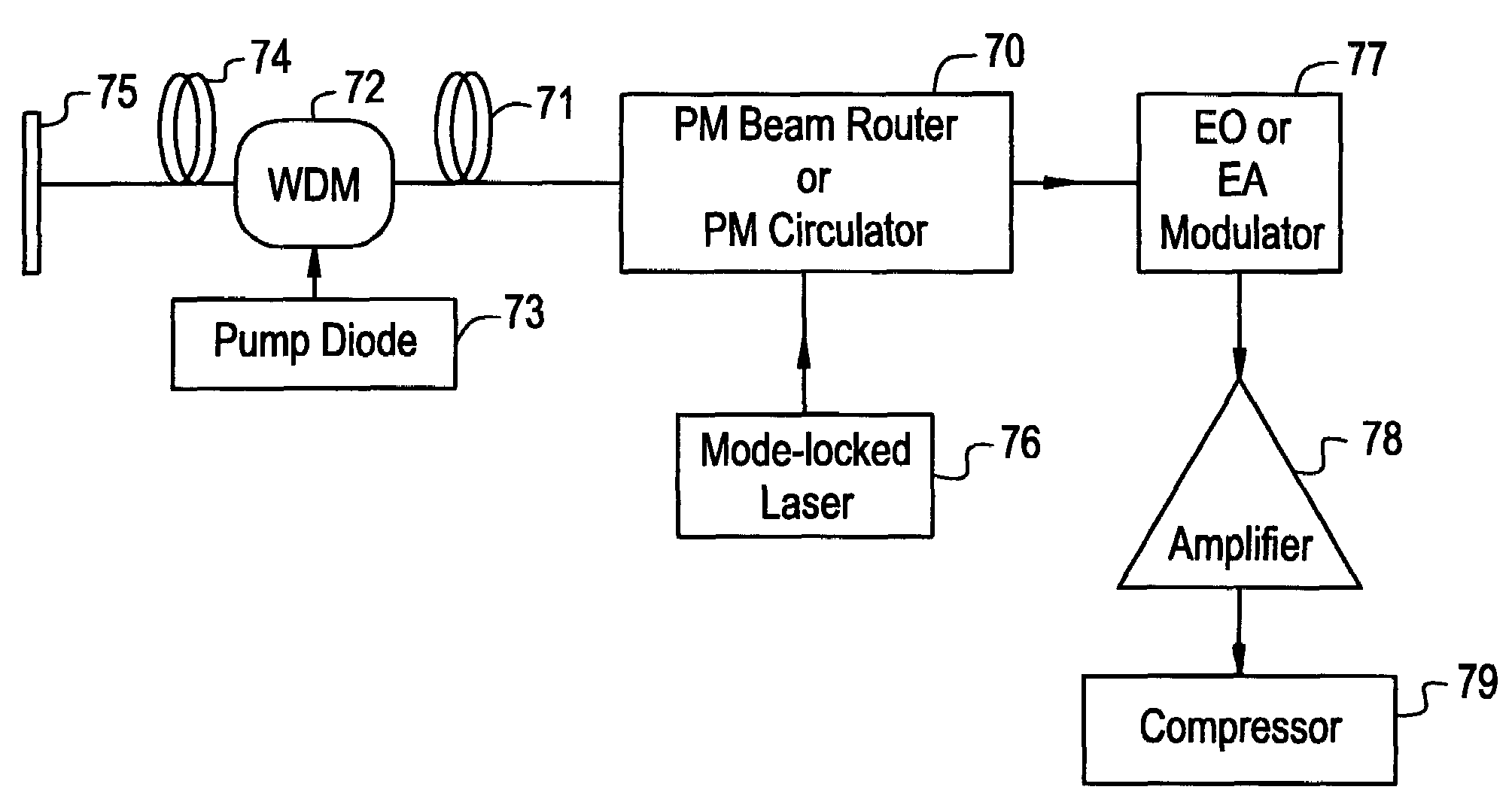

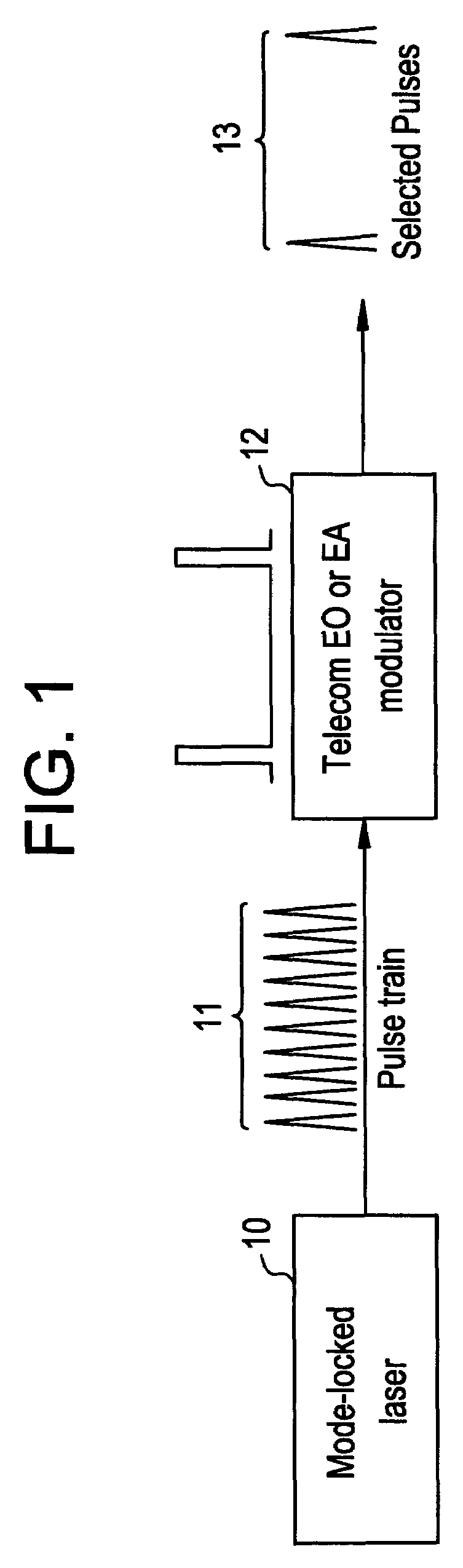

InactiveUS7113327B2Improve mechanical stabilityLaser arrangementsActive medium materialFiberChirped pulse amplification

An erbium fiber (or erbium-ytterbium) based chirped pulse amplification system is illustrated. The use of fiber amplifiers operating in the telecommunications window enables the implementation of telecommunications components and telecommunications compatible assembly procedures with superior mechanical stability.

Owner:IMRA AMERICA

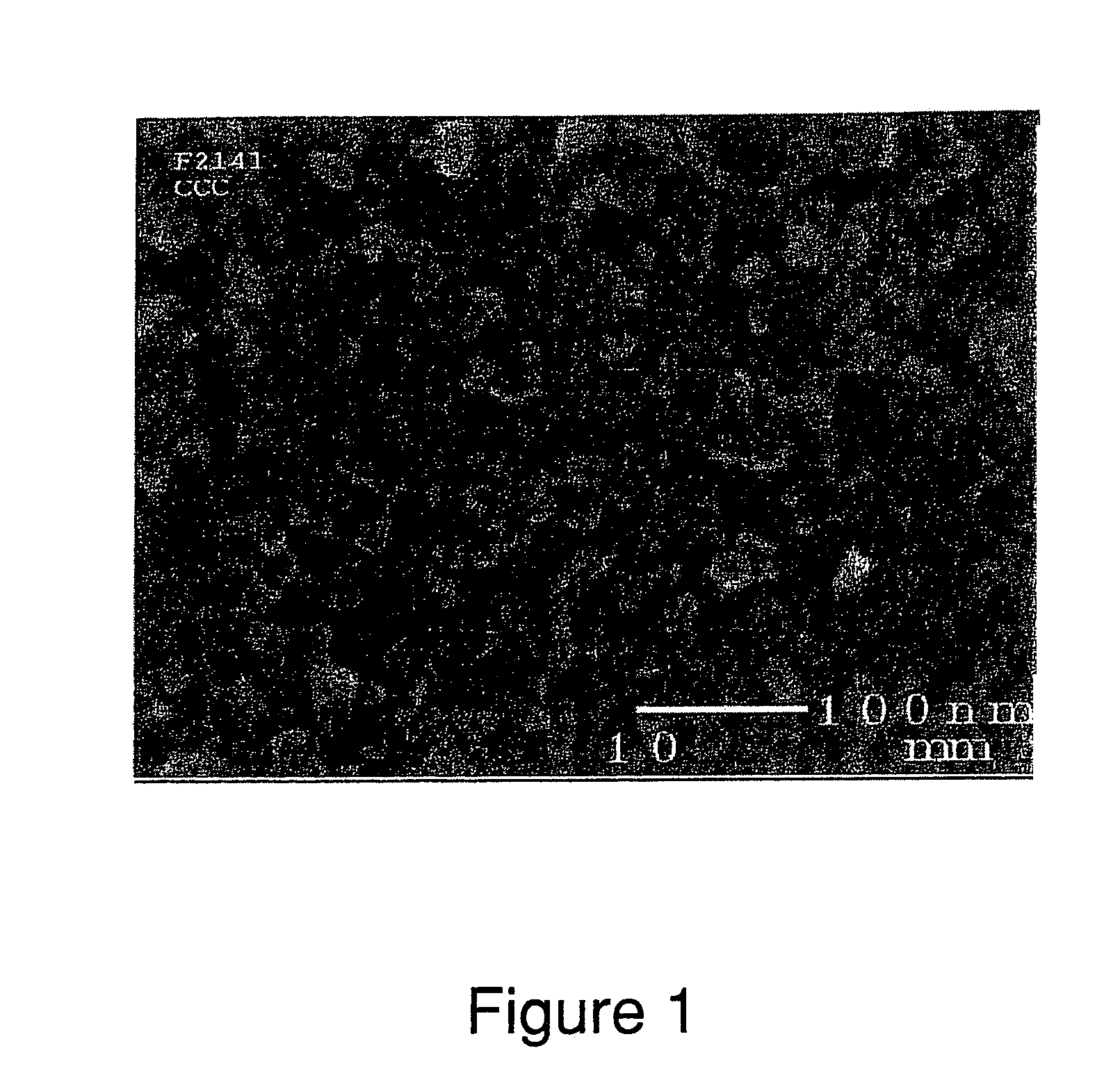

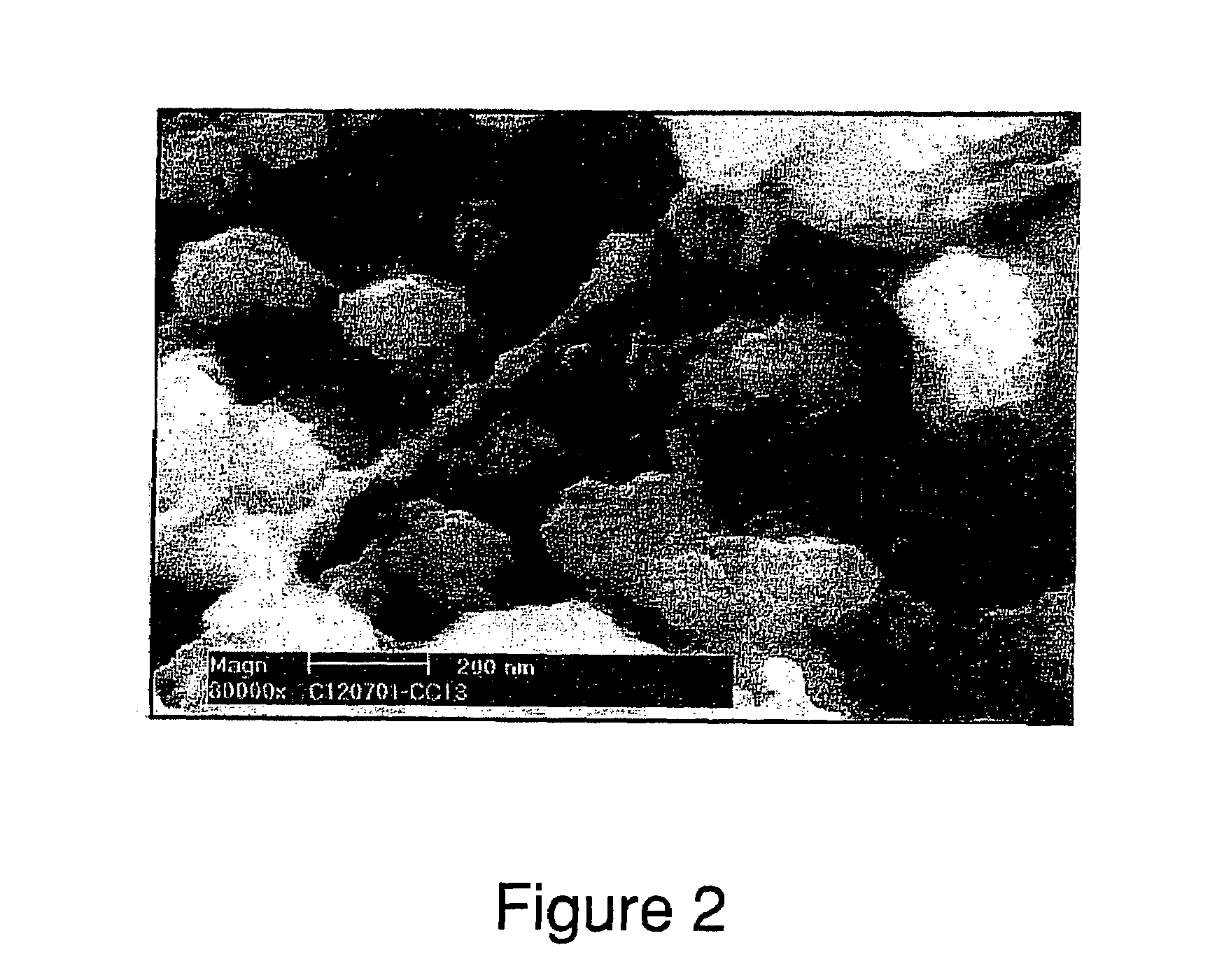

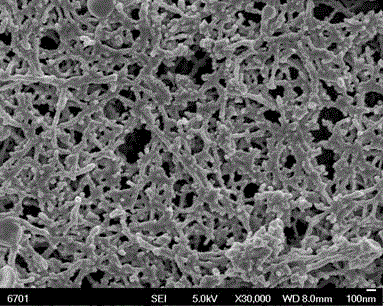

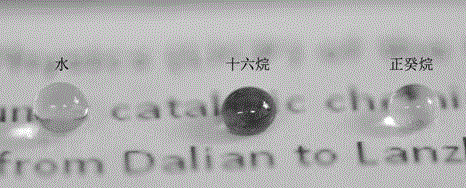

Large-scale preparation method of transparent super-hydrophobic/super-amphiphobic coating

InactiveCN106800885AExcellent superhydrophobic/superamphiphobic propertiesHigh transparencySpecial surfacesCoatingsNanoparticle ComplexAlcohol

The invention discloses a large-scale preparation method of a transparent super-hydrophobic / super-amphiphobic coating. The method comprises the steps of ultrasonically dispersing nano particles into an alcohol-water mixed system and carrying out hydrolysis and condensation reaction on the nano particles and fluoride-free or fluorine-containing organosilane under the acid or alkali catalysis action to prepare a transparent suspension liquid of a fluoride-free or fluorine-containing organosilane polymer-nano particle compound; and applying the transparent suspension liquid of the compound on the surface of a substrate material through spraying or dip-coating to obtain the transparent super-hydrophobic / super-amphiphobic coating with good performance. Preparation of the transparent super-hydrophobic / super-amphiphobic coating of 10-100m<2> can be completed within an hour; large-scale preparation of the large-area transparent super-hydrophobic / super-amphiphobic coating is achieved for the first time; the preparation method is low in cost and simple in process; and the prepared coating has excellent super-hydrophobic or super-amphiphobic property, relatively good mechanical stability, chemical stability and environment stability, and has a wide application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

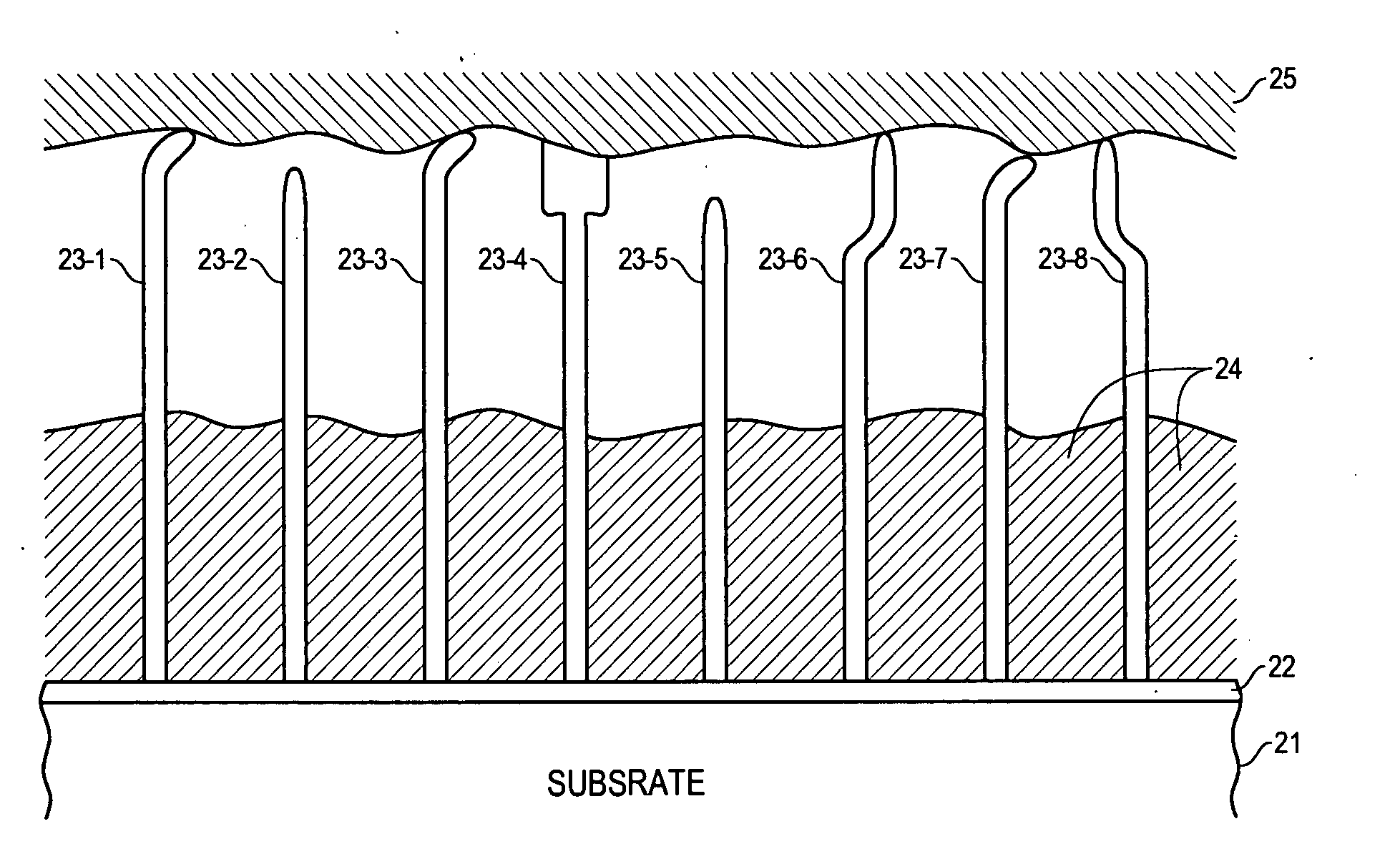

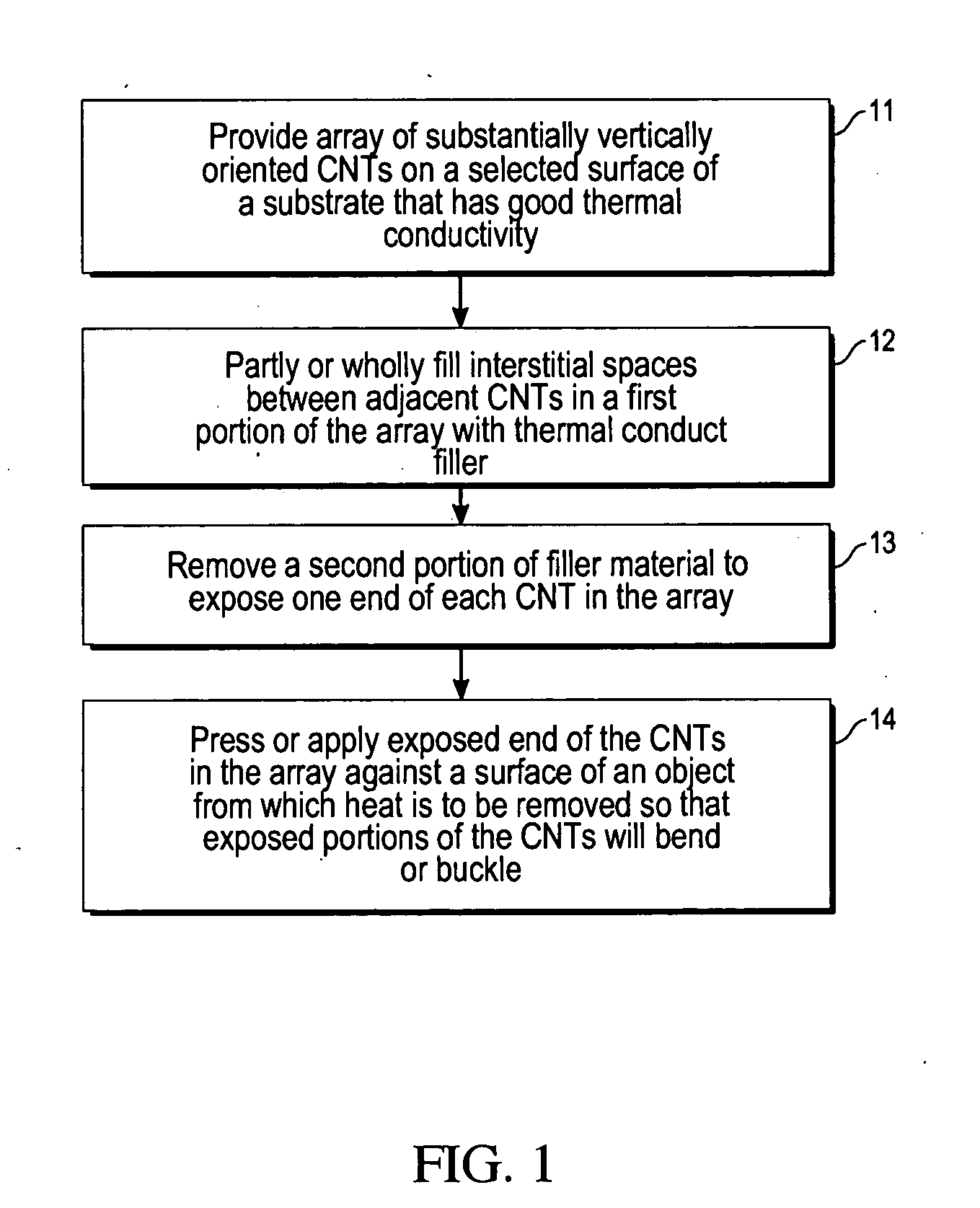

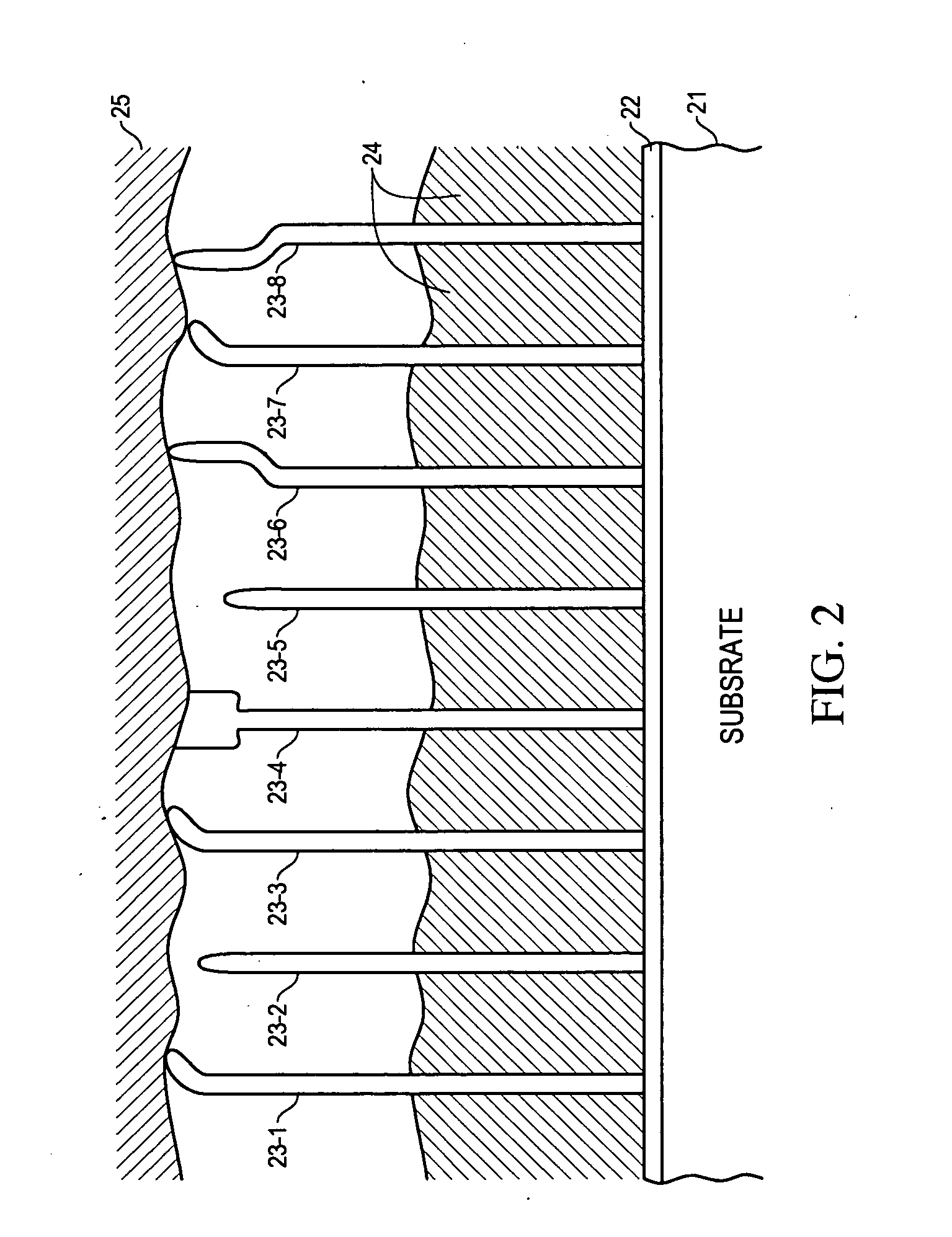

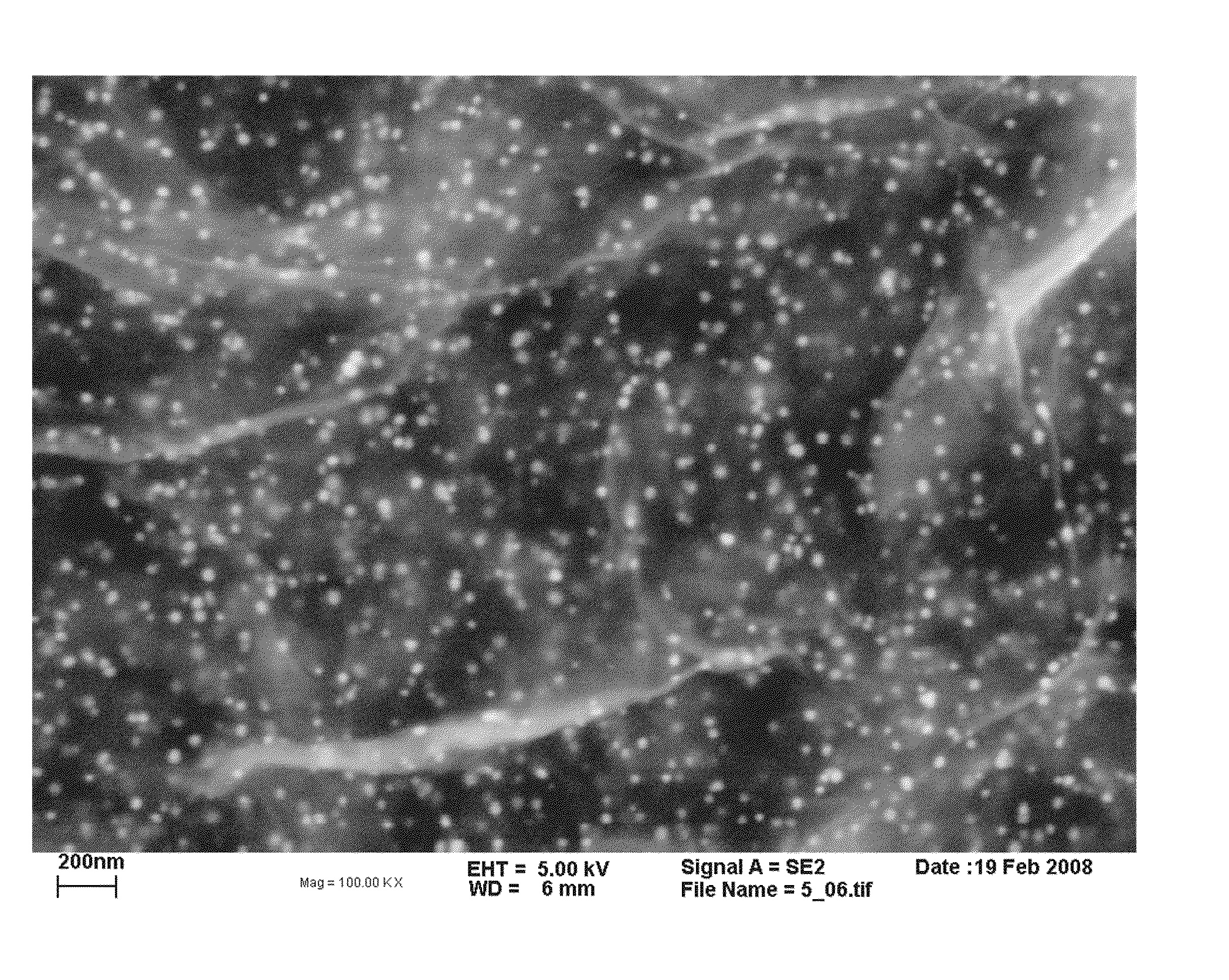

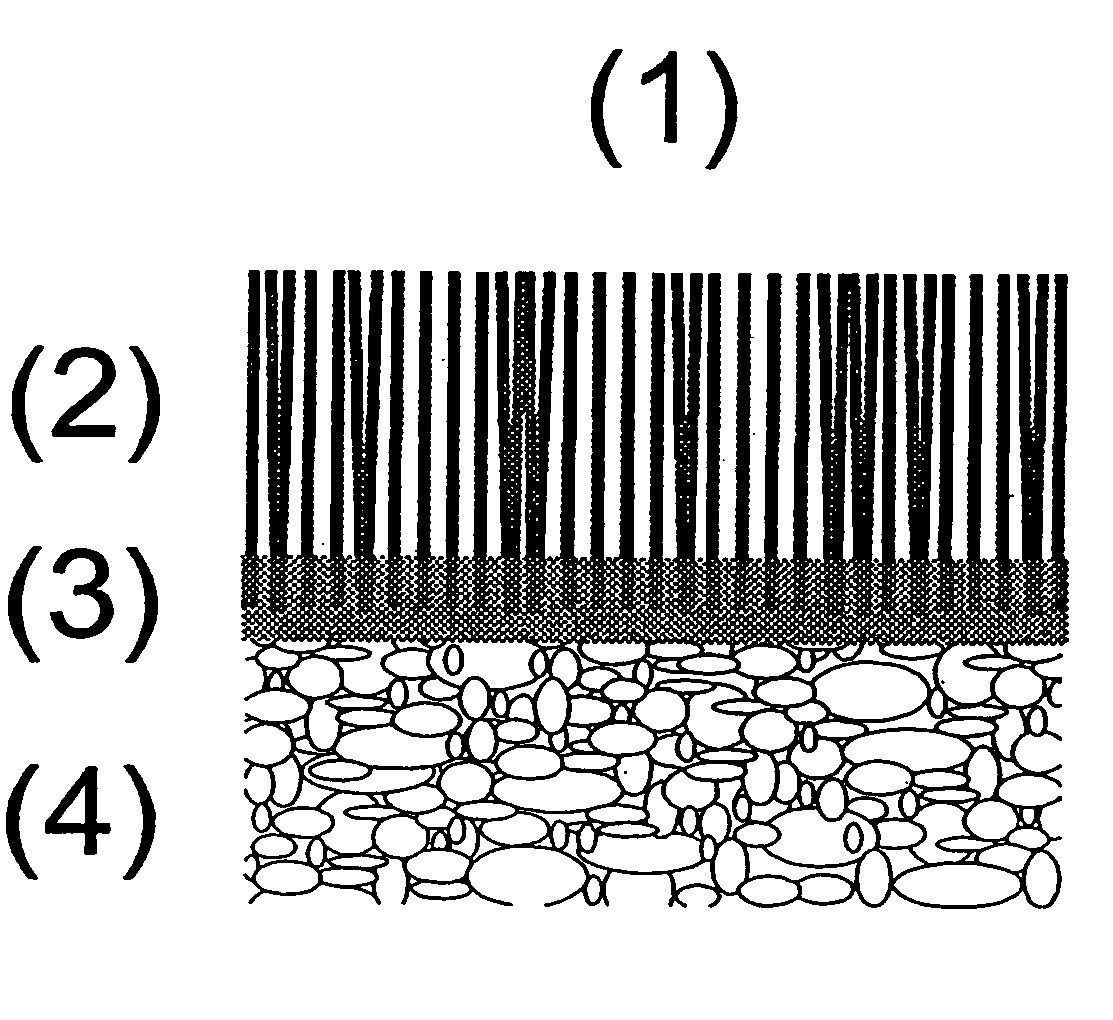

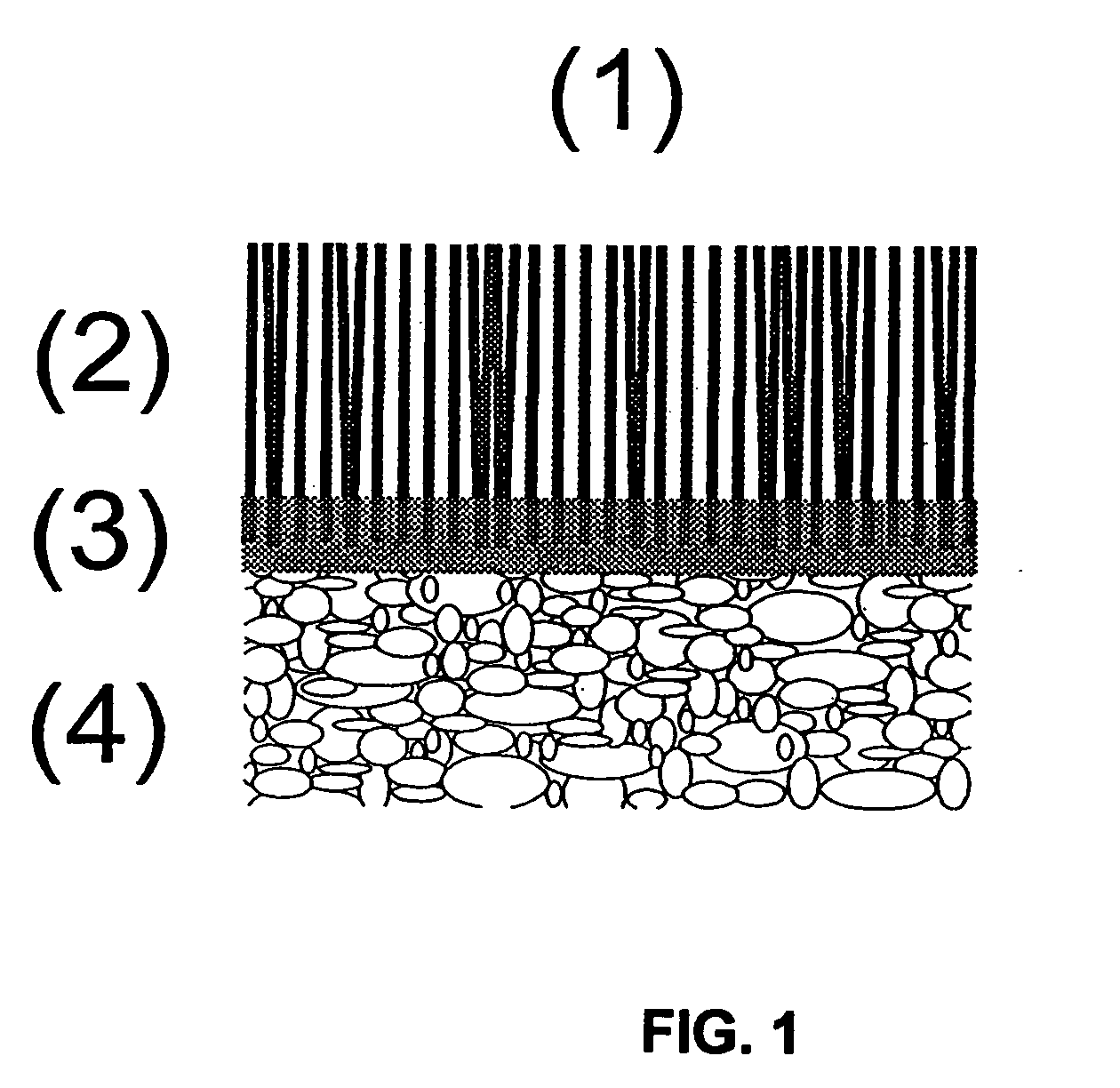

Nanoengineered thermal materials based on carbon nanotube array composites

InactiveUS20050224220A1High mechanical strengthImprove cooling effectMaterial nanotechnologySemiconductor/solid-state device detailsHeat fluxFilling materials

A method for providing for thermal conduction using an array of carbon nanotubes (CNTs). An array of vertically oriented CNTs is grown on a substrate having high thermal conductivity, and interstitial regions between adjacent CNTs in the array are partly or wholly filled with a filler material having a high thermal conductivity so that at least one end of each CNT is exposed. The exposed end of each CNT is pressed against a surface of an object from which heat is to be removed. The CNT-filler composite adjacent to the substrate provides improved mechanical strength to anchor CNTs in place and also serves as a heat spreader to improve diffusion of heat flux from the smaller volume (CNTs) to a larger heat sink.

Owner:SAMSUNG ELECTRONICS CO LTD +1

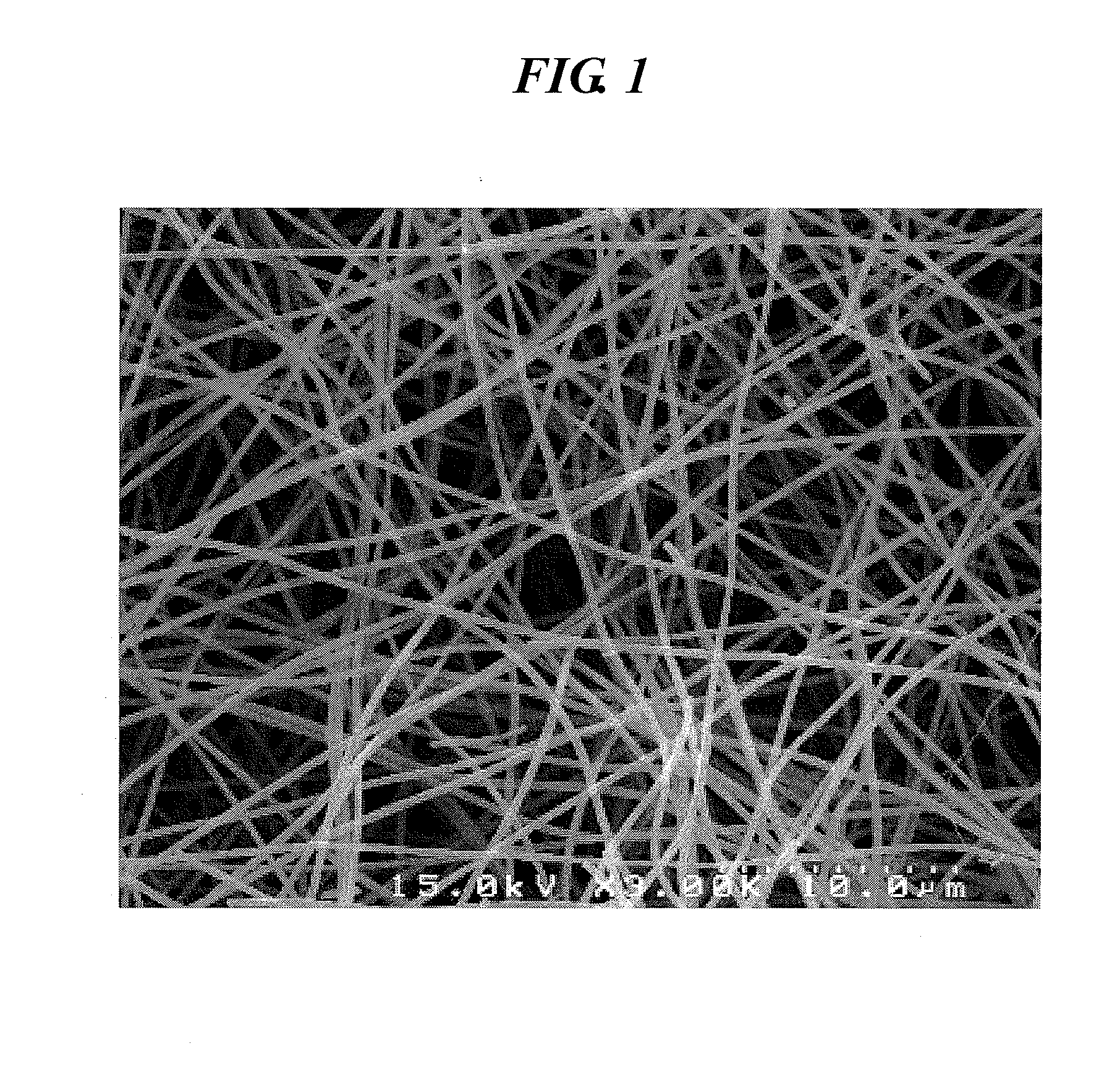

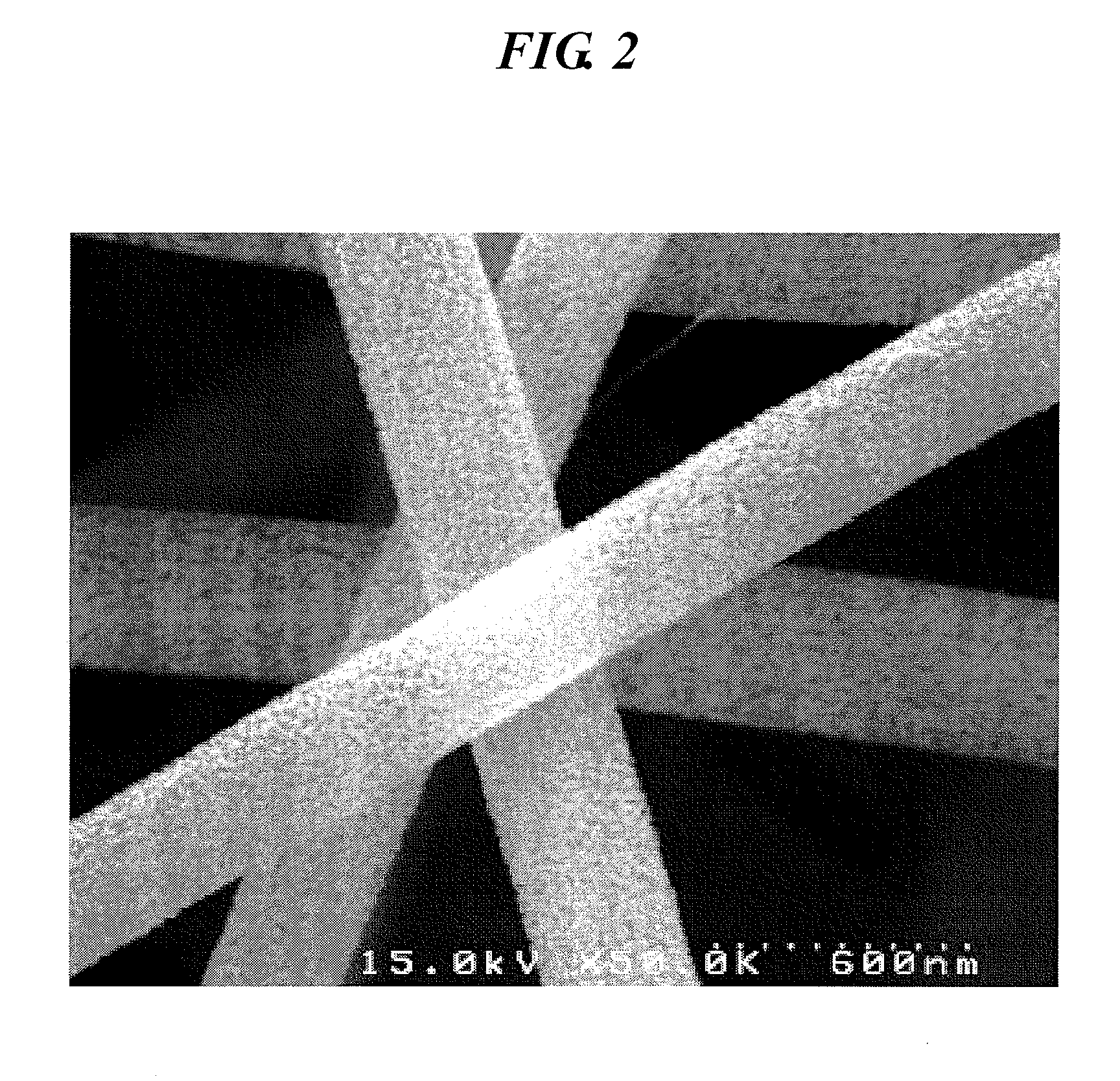

Nanofiber and preparation method thereof

InactiveUS20110151255A1Simple structureExcellent thermalMaterial nanotechnologyElectric discharge heatingFiberNanoparticle

A nanofiber, which is prepared by using a fabrication method comprising the steps of spinning a spinning solution prepared by dissolving at least one precursor for metal, metal oxide, or metal complex oxide with a polymer mixture comprising at least two polymers having different molecular weights and glass transition temperatures in a solvent and thermally treating the spun fiber, comprises close-packed nanoparticles of a metal, a metal oxide, a metal complex oxide or a mixture thereof and has excellent structural, thermal, and mechanical stability as well as a uniform fiber-shape.

Owner:KOREA INST OF SCI & TECH

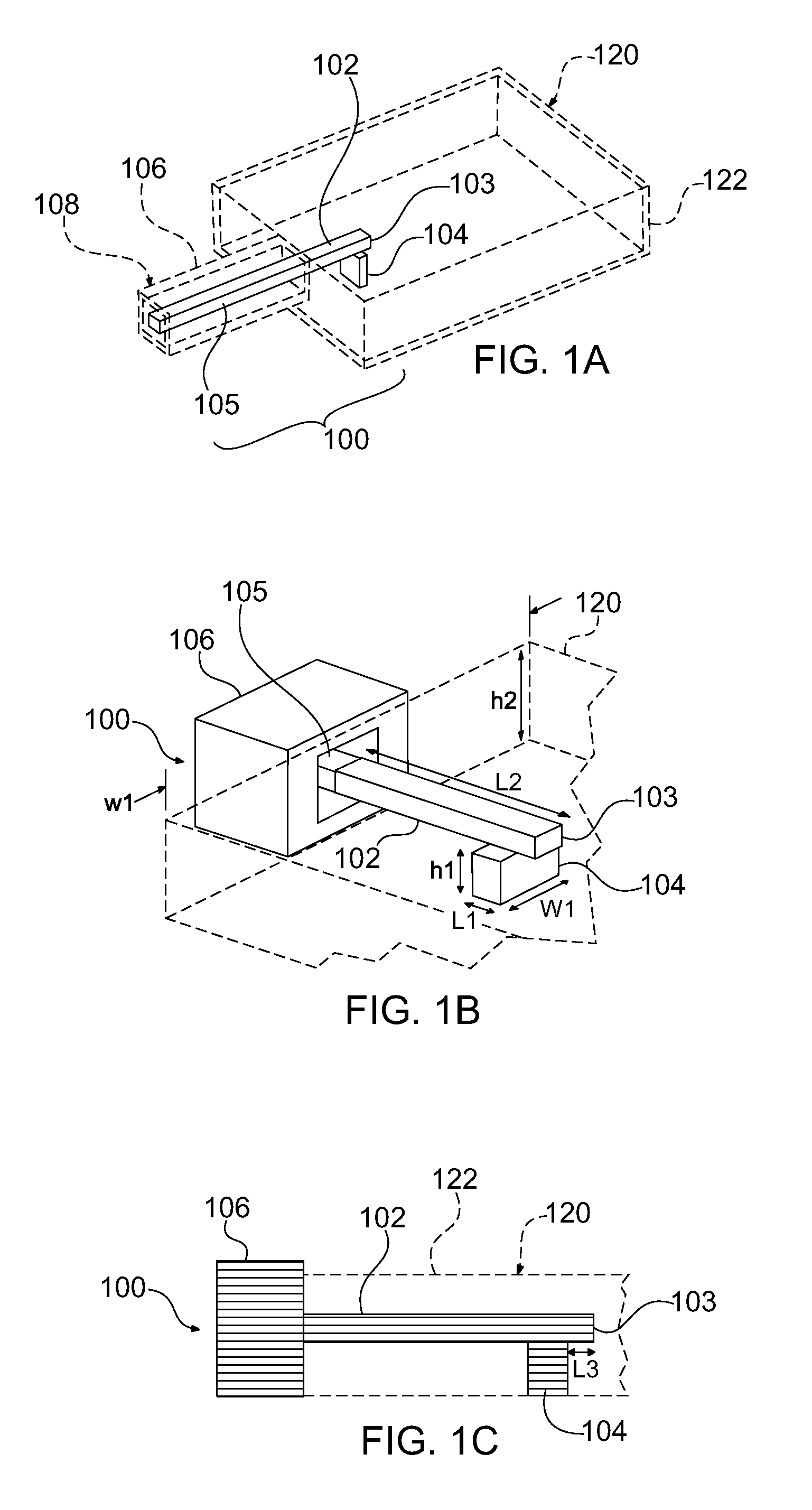

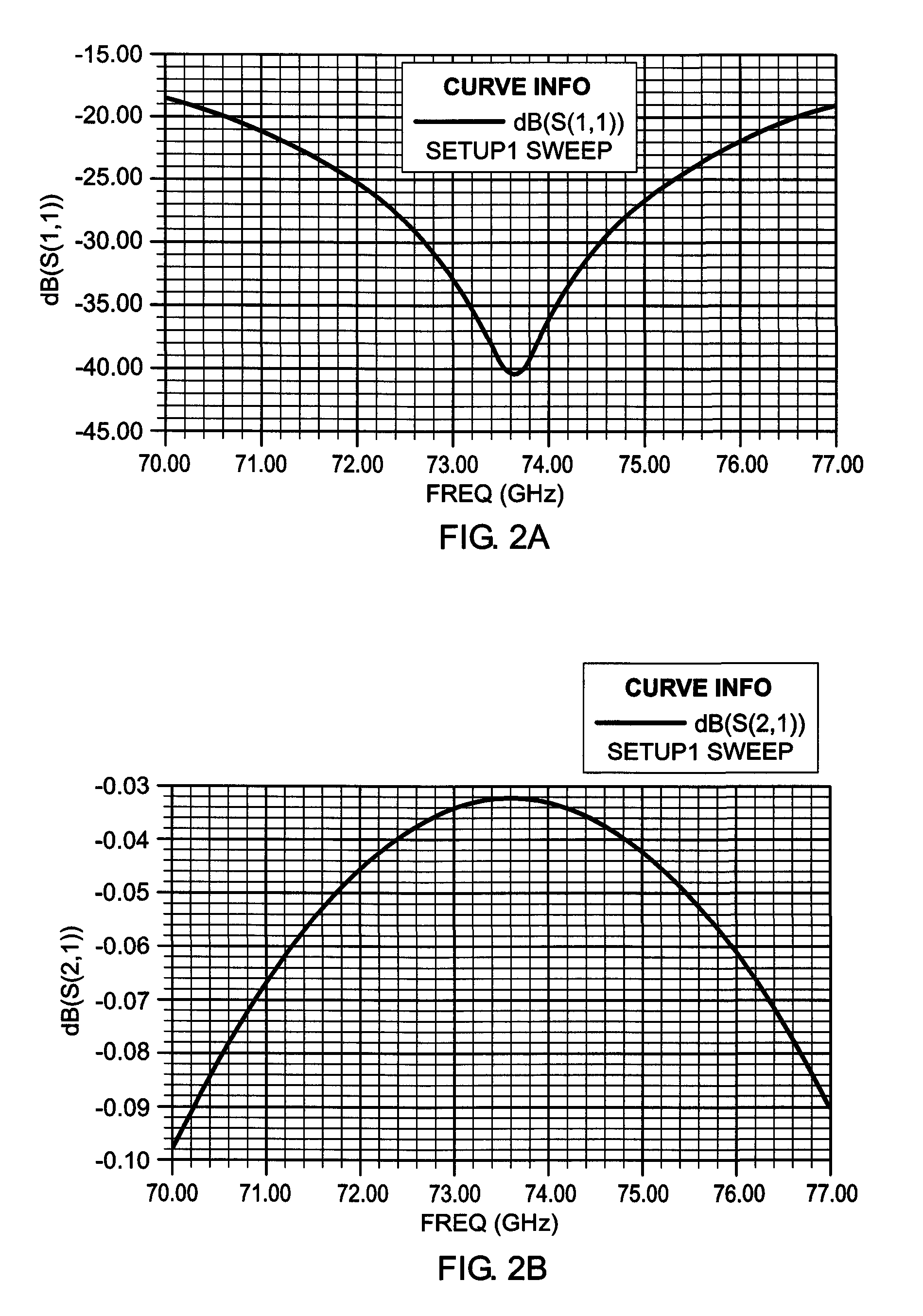

High frequency power combiner/divider

InactiveUS9065163B1Improve isolationOverall SSPA may be improvedPower amplifiersWaveguidesPower combinerHigh frequency power

Radio frequency (RF) power amplifiers are provided which may include high power, wideband, microwave or millimeter-wave solid state power amplifiers based on waveguide power combiner / dividers.

Owner:CUBIC CORPORATION

Stable dispersions of single and multiple graphene layers in solution

ActiveUS20100301279A1Improved propertyInhibition formationMaterial nanotechnologyCell electrodesColloidCvd graphene

Disclosed is a method for producing colloidal graphene dispersions comprising the steps of(i) dispersing graphite oxide in a dispersion medium to form a colloidal graphene oxide or multi-graphene oxide dispersion(ii) thermally reducing the graphene oxide or multi-graphene oxide in dispersion.Dependent on the method used for the preparation of the starting dispersion a graphene or a multi-graphene dispersion is obtained that can be further processed to multi-graphene with larger inter-planar distances than graphite. Such dispersions and multi-graphenes are for example suitable materials in the manufacturing of rechargeable lithium ion batteries.

Owner:BELENOS CLEAN POWER HLDG

Polymeric dental implant

InactiveUS7287983B2Effective anchoringImprove mechanical stabilityDental implantsImpression capsExtracted toothAbutment

The present invention relates to a polymeric implant, especially useful for dental medicine. More specifically, the present invention relates to a polymerizable device comprising an artificial tooth's root and an abutment anchored therein and to a kit comprising interalia the same. The present invention also relates to a method for implanting the implant in the alveolar bore of previously extracted tooth.

Owner:POLYDENT MEDICAL DEVICES

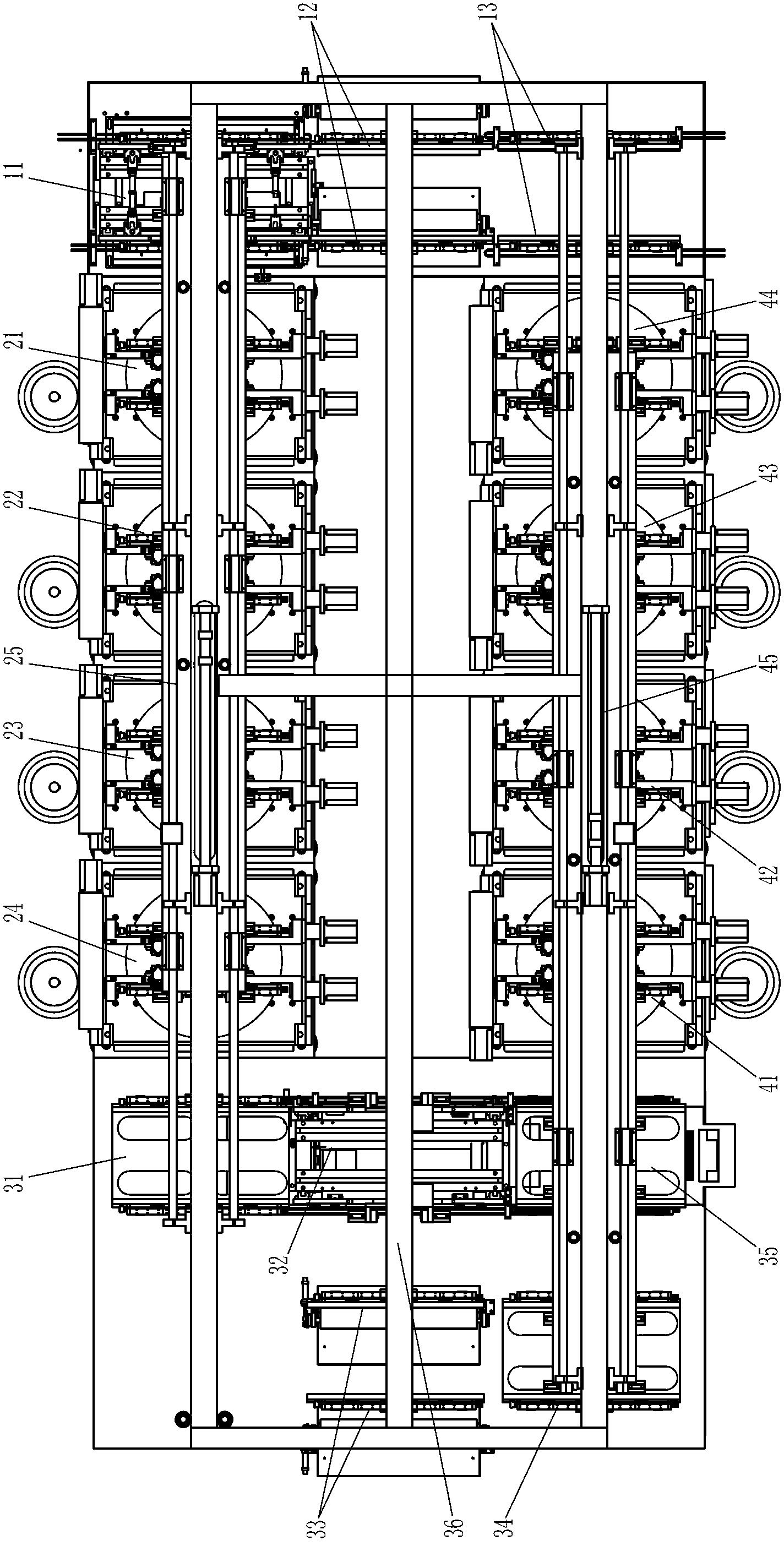

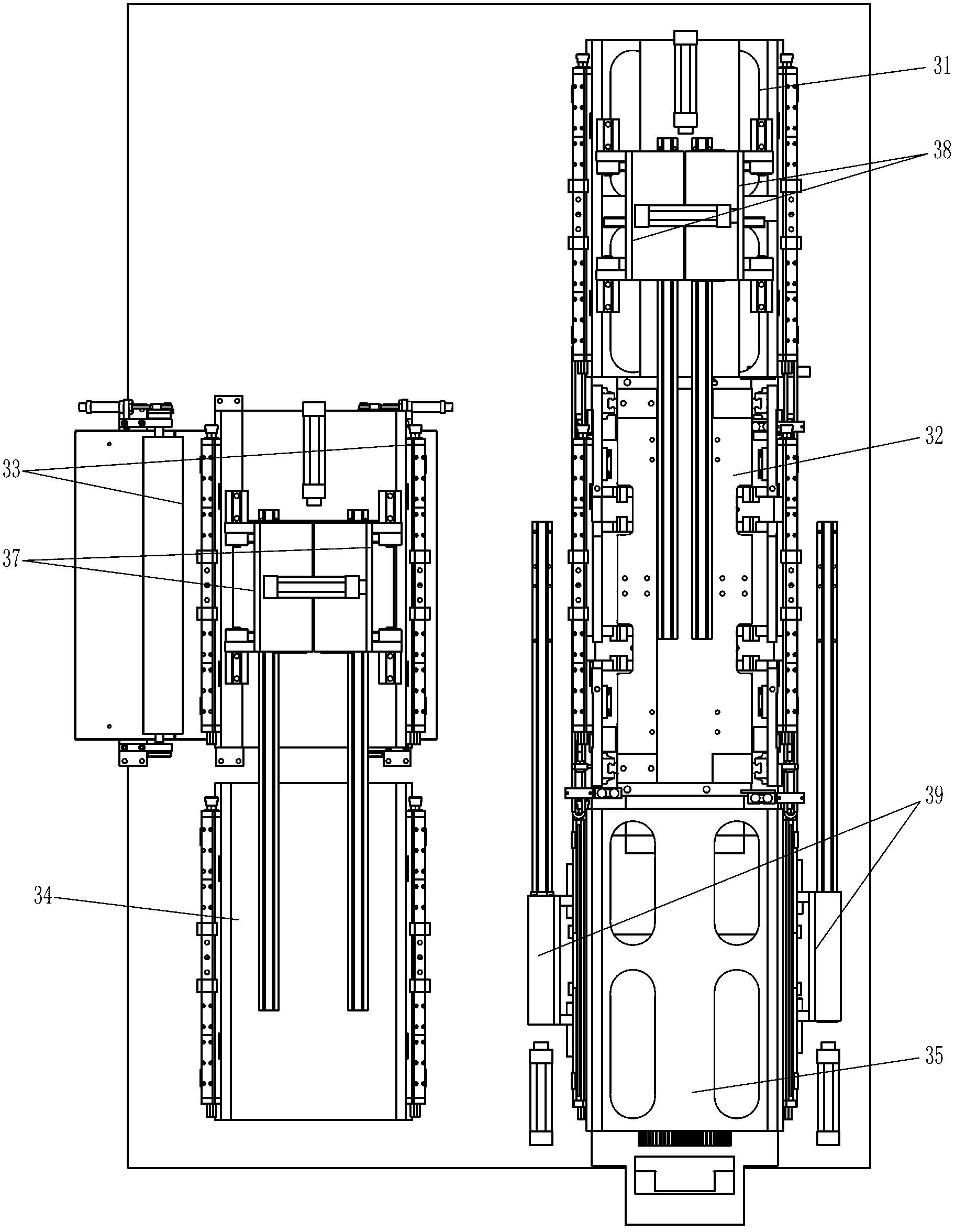

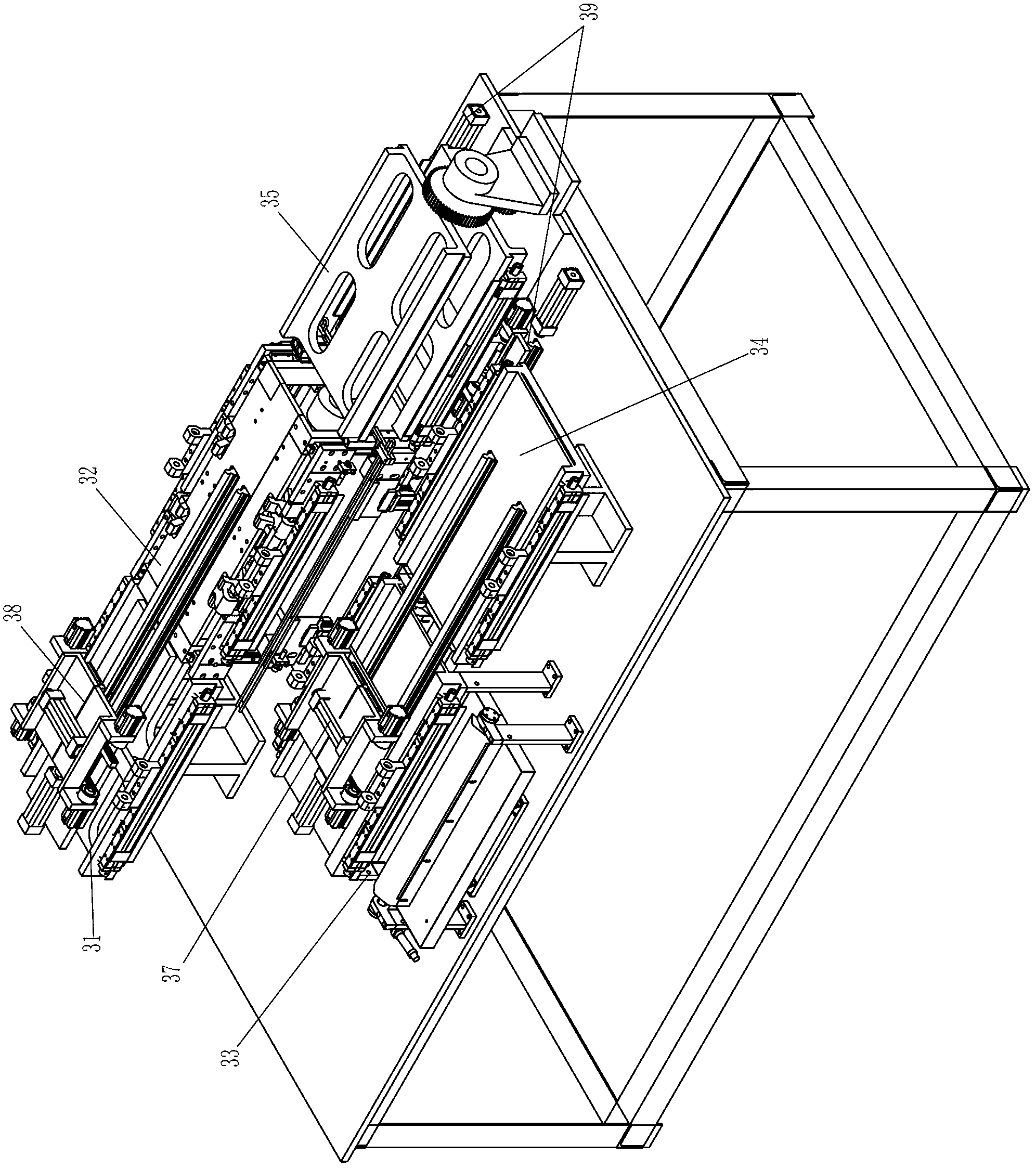

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

Gels derived from polypropylene grafted alkyl vinylether-maleimide copolymers

InactiveUS6191217B1Promote absorptionImprove mechanical stabilityAnti-corrosive paintsBuilding insulationsPolymer sciencePolypropylene

The present invention teaches a method for enabling the formation of a high damping, soft polymer gel. The method includes: reacting a poly(alkyl vinylether-co-maleimide) polymer with a maleated polyalkylene and an alkyl diamine under substantially dry conditions sufficient to form a polyalkylene grafted poly(alkyl vinylether-co-maleimide) polymer product; and, dispersing the polyalkylene grafted poly(alkyl vinylether-co-maleimide) polymer product with an extender oil sufficient to form the gel. The present invention also contemplates a polymer gel composition, a polymer composition and an article manufactured from the polymer gel composition.

Owner:BRIDGESTONE CORP

X-ray anode and process for its manufacture

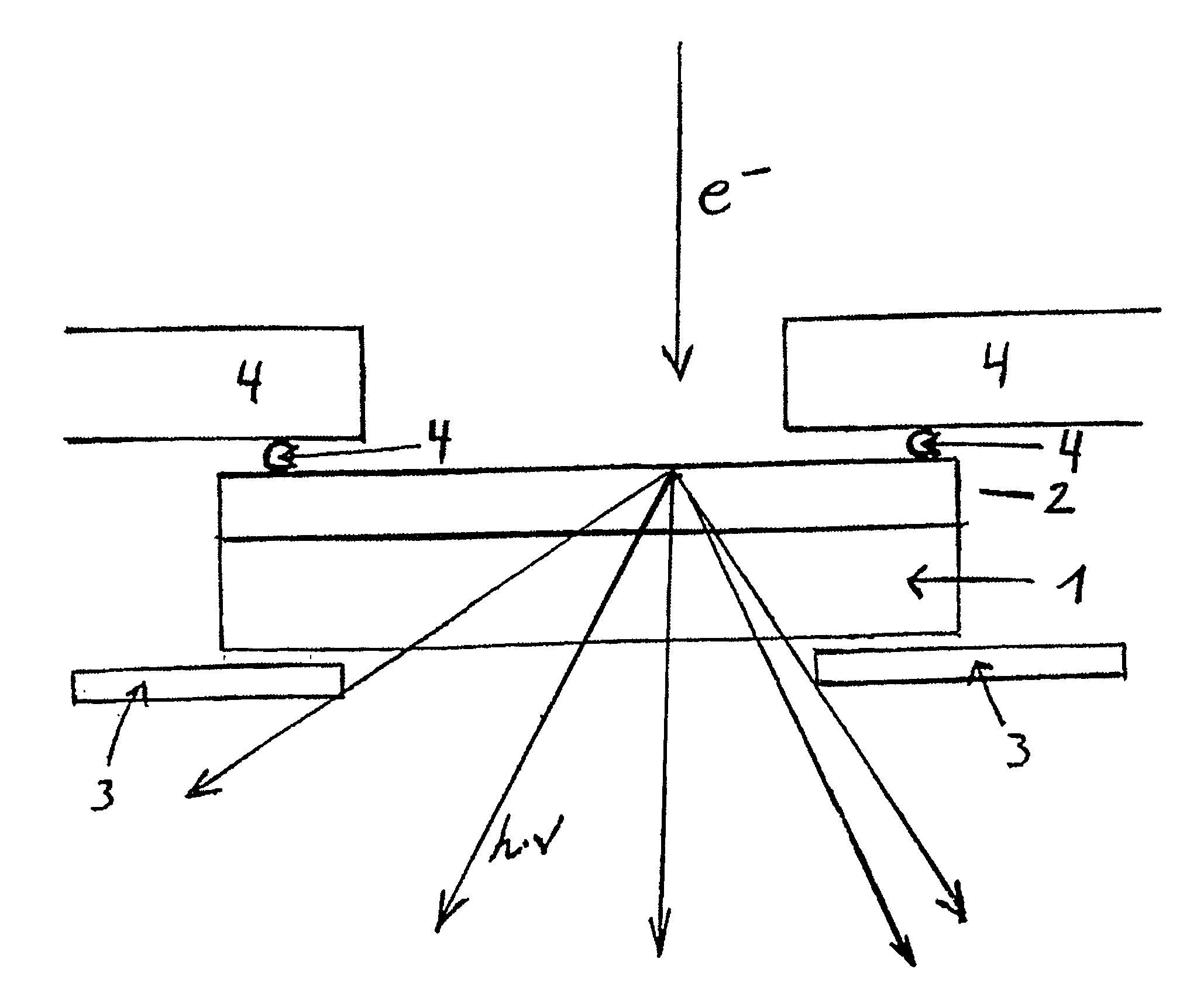

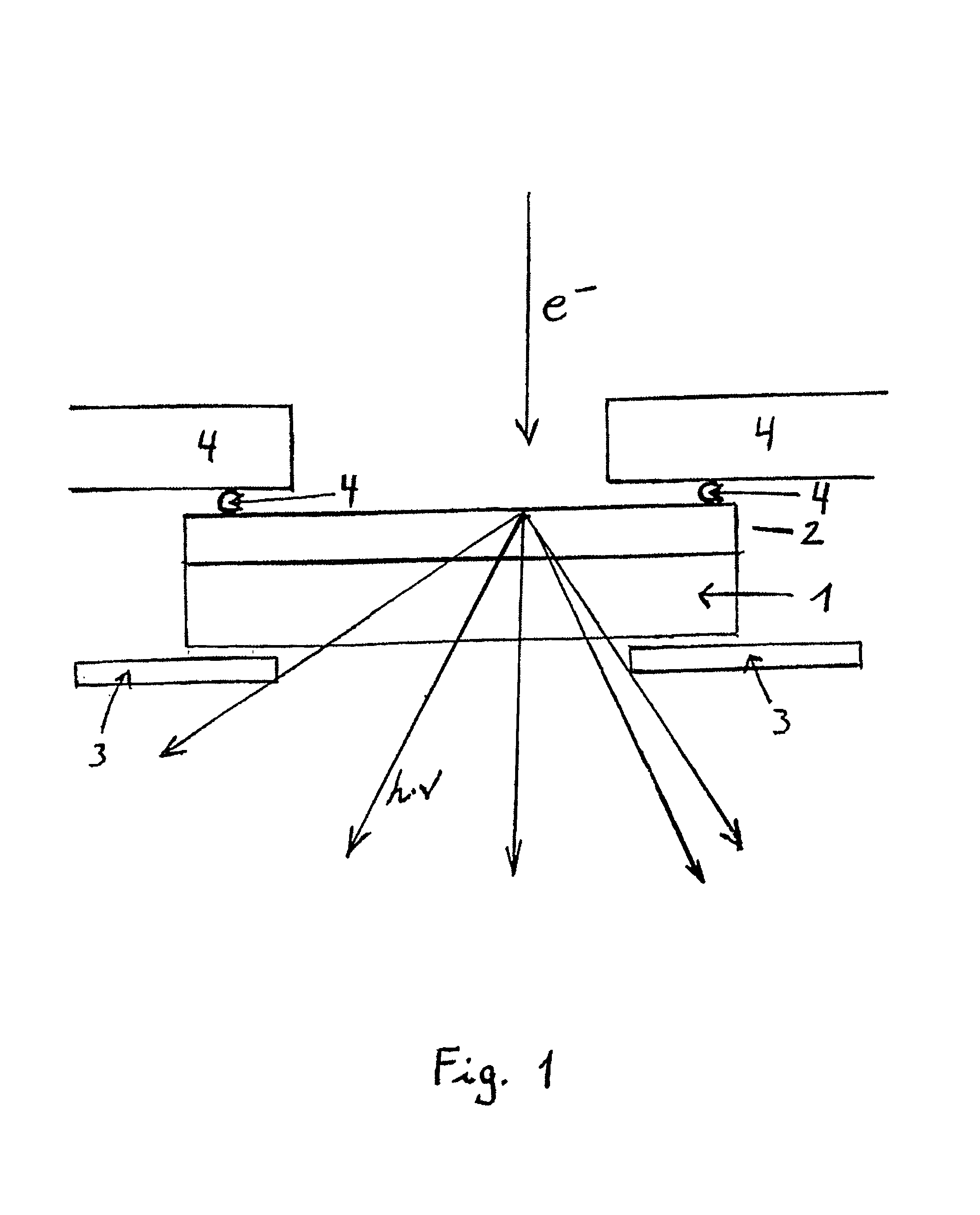

InactiveUS6850598B1Improve the heating effectReduce absorptionRadiation/particle handlingX-ray tube electrodesSoft x rayImage resolution

The invention relates to an x-ray anode and a process for its manufacture. The x-ray anode is characterized in that the anode material is embodied as a layer on a diamond window. The x-ray anode is preferably used with x-ray units which require as selective as possible x-radiation production to achieve as high as possible radiation intensity. Use in x-ray microscopes in which a high radiation intensity guarantees the highest resolutions is particularly preferred.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Prosthetic Devie for Cartilage Repair

InactiveUS20070244484A1Improve mechanical stabilityRapid cartilage growthBone implantLigamentsFiberMedicine

A prosthetic device for repairing or replacing cartilage or cartilage-like tissue is described. The prosthetic device comprises at least one layer of highly oriented fibers, a base component and a stabilization area provided in between. Said fibers are aligned to more than 50% in a direction perpendicular to the base component.

Owner:STIFUNG DR H C ROBERT MATHYS

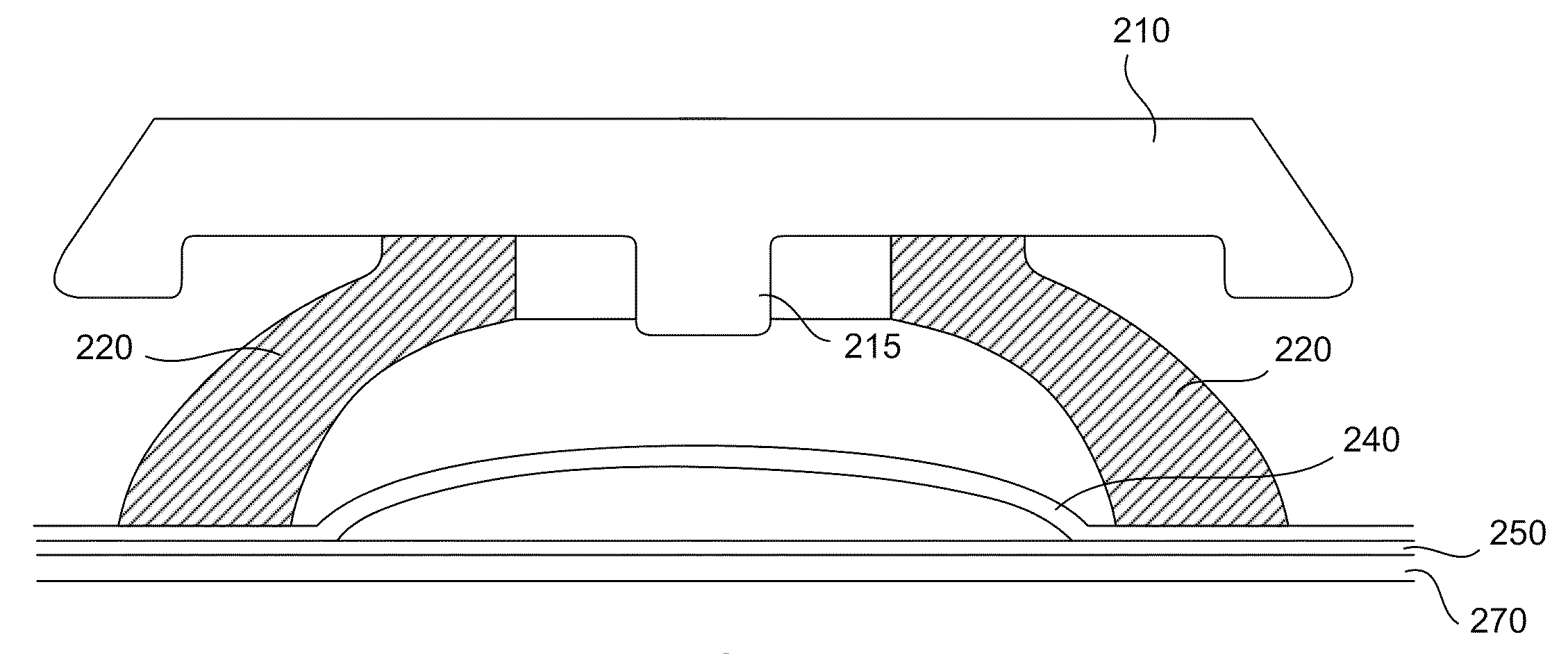

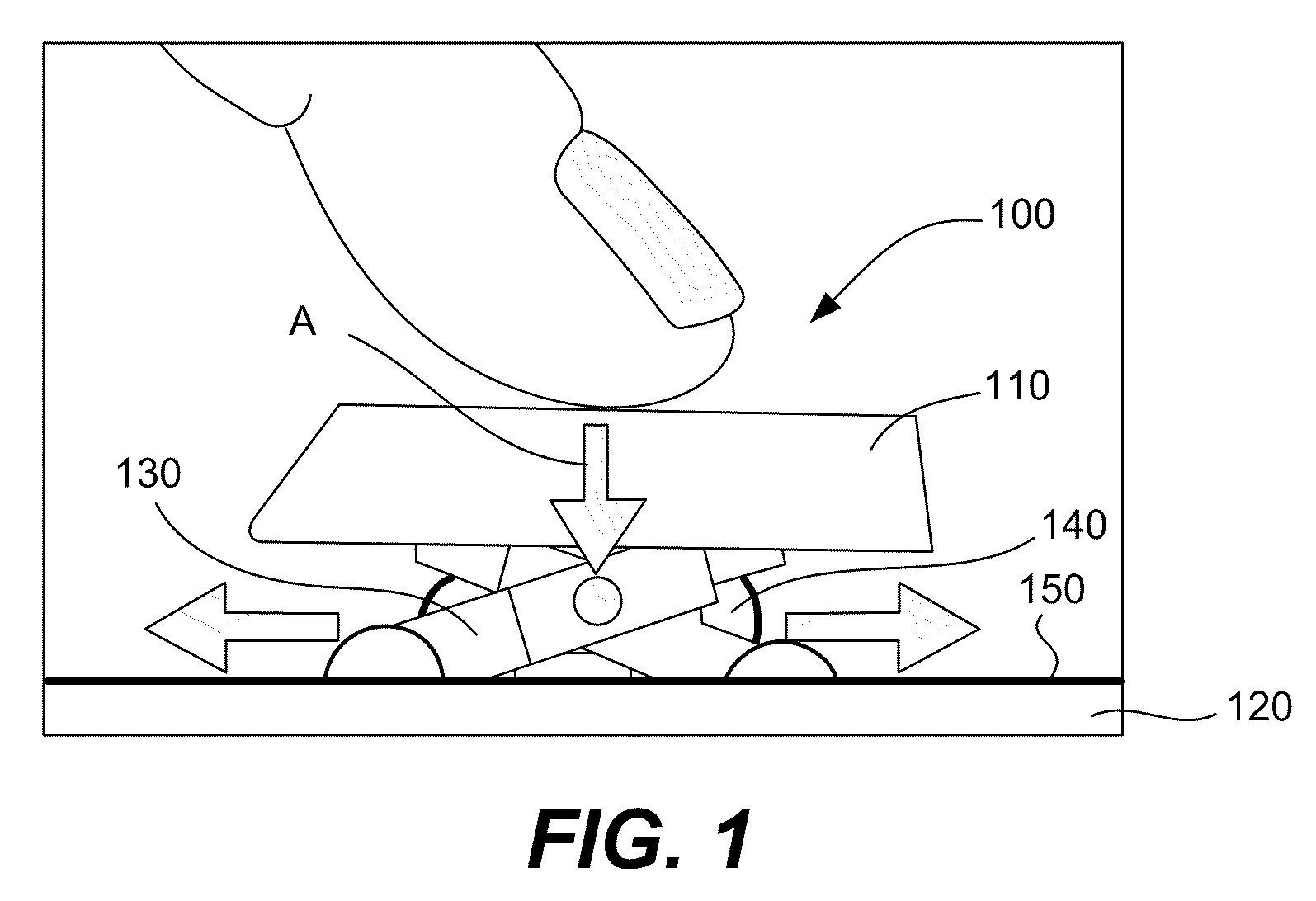

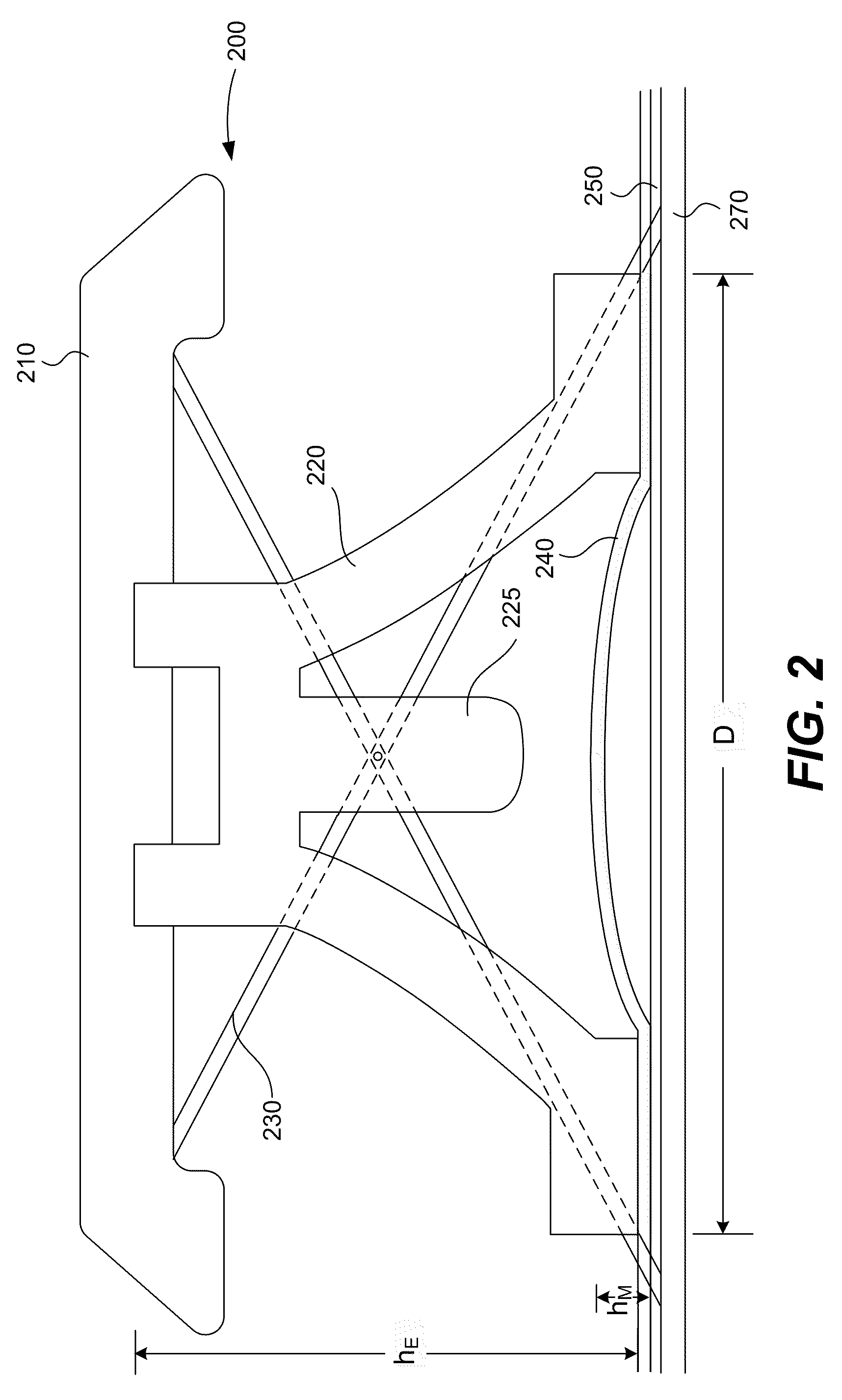

Stacked metal and elastomeric dome for key switch

ActiveUS9012795B2Positive tactile responseShorten driving distanceContact surface shape/structureContact operating partsElastomerEngineering

A low travel keyboard and methods of fabrication are described. The low-travel keyboard is suitable for a thin-profile computing device, such as a laptop computer, netbook computer, desktop computer, etc. The keyboard includes a key cap positioned over stacked elastomeric and metal domes. The quick force drop of the metal dome provides the crisp “snappy” feel for the user and the elastomeric dome provides the ability for longer travel than the metal dome alone. The metal dome also activates the switch circuitry of the membrane on printed circuit board. The stacking of the elastomeric metal domes takes advantage of the abrupt force drop in the metal dome buckling and applies it to the elastomeric dome force, making it possible to design a low-travel key while still maintaining or improving the tactile feeling of the key switch.

Owner:APPLE INC

Large pore volume composite mineral oxide beads, their preparation and their applications for adsorption and chromatography

InactiveUS6613234B2Good chemical stabilityEasy to packIon-exchange process apparatusOther chemical processesPhysical chemistryHafnia

The present invention provides porous mineral oxide beads which have large pore volumes and enhanced stability. The beads are based on a tetravalent metal oxide, such as zirconia, titania or hafnia. These highly porous beads are produced from a mixture of tetravalent mineral oxides, mineral pore inducing agents which are oxides or salts of trivalent metals, and optional binders. The porous mineral beads can be filled with a polymer gel and used for adsorption and chromatography applications.

Owner:PALL CORP

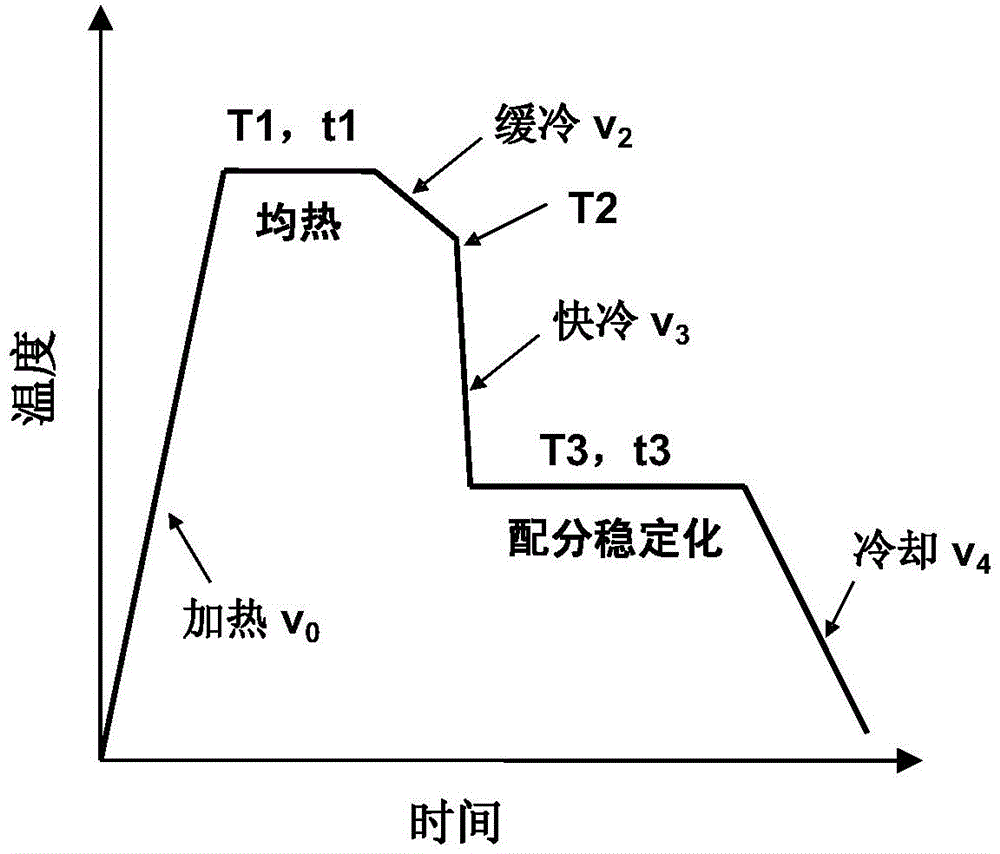

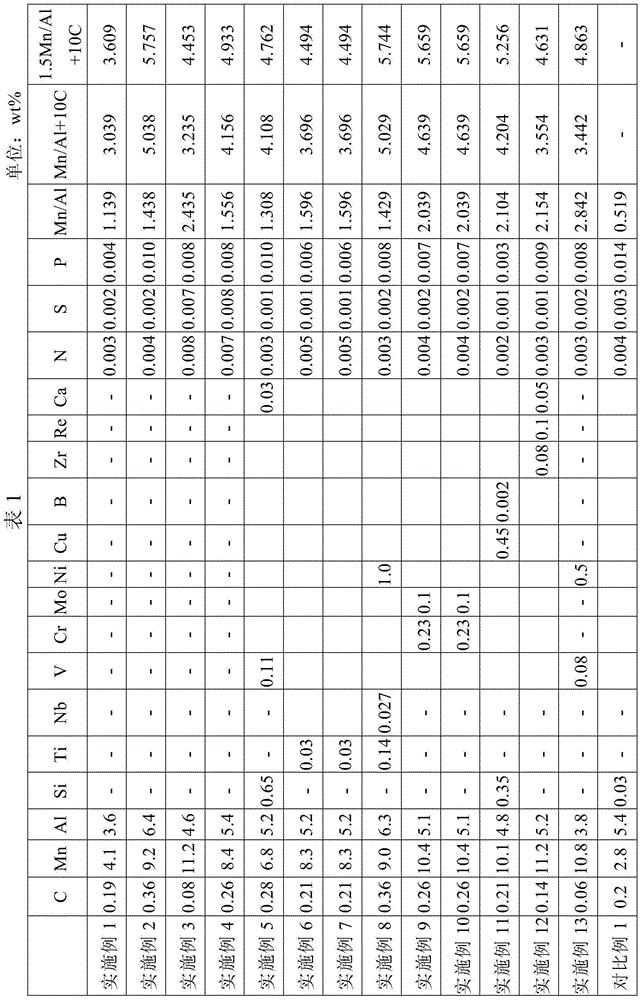

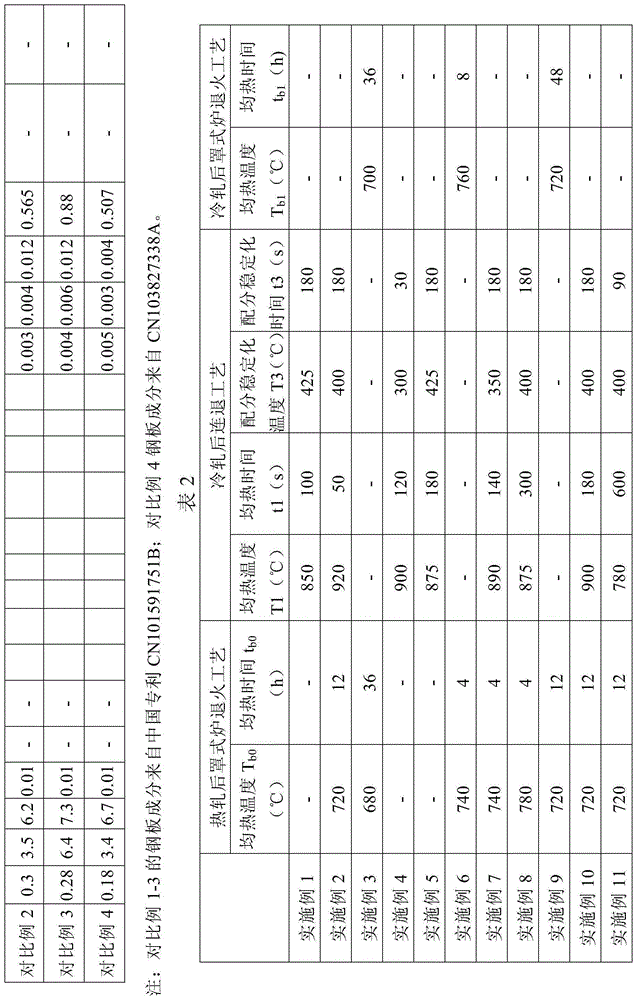

Ferrite low-density high-strength steel and manufacturing method thereof

A ferrite low-density high-strength steel and manufacturing method thereof. The ferrite low-density high-strength steel chemical comprises the following chemical components composition by mass percentage: 0.05-0.40% of C, 4.0-12.0% of Mn, 3.0-7.0% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.01% of N, and the balance of Fe and inevitable impurity elements. The above elements satisfy the following relationship: 1.0<Mn / Al, 3.5 <1.5Mn / Al+10C, and Mn / Al + 10C <5.2 The manufacturing method comprises hot rolling, annealing, pickling, cold rolling and annealing to prepare the low-density high-strength steel plate. In addition to ferrite, the microstructure of the steel plate also contains 6-40% of residual austenite. The low-density high-strength steel plate has tensile strength no less than 800MPa, elongation no less than 25%, and density less than 7500kg / m<3>.

Owner:BAOSHAN IRON & STEEL CO LTD

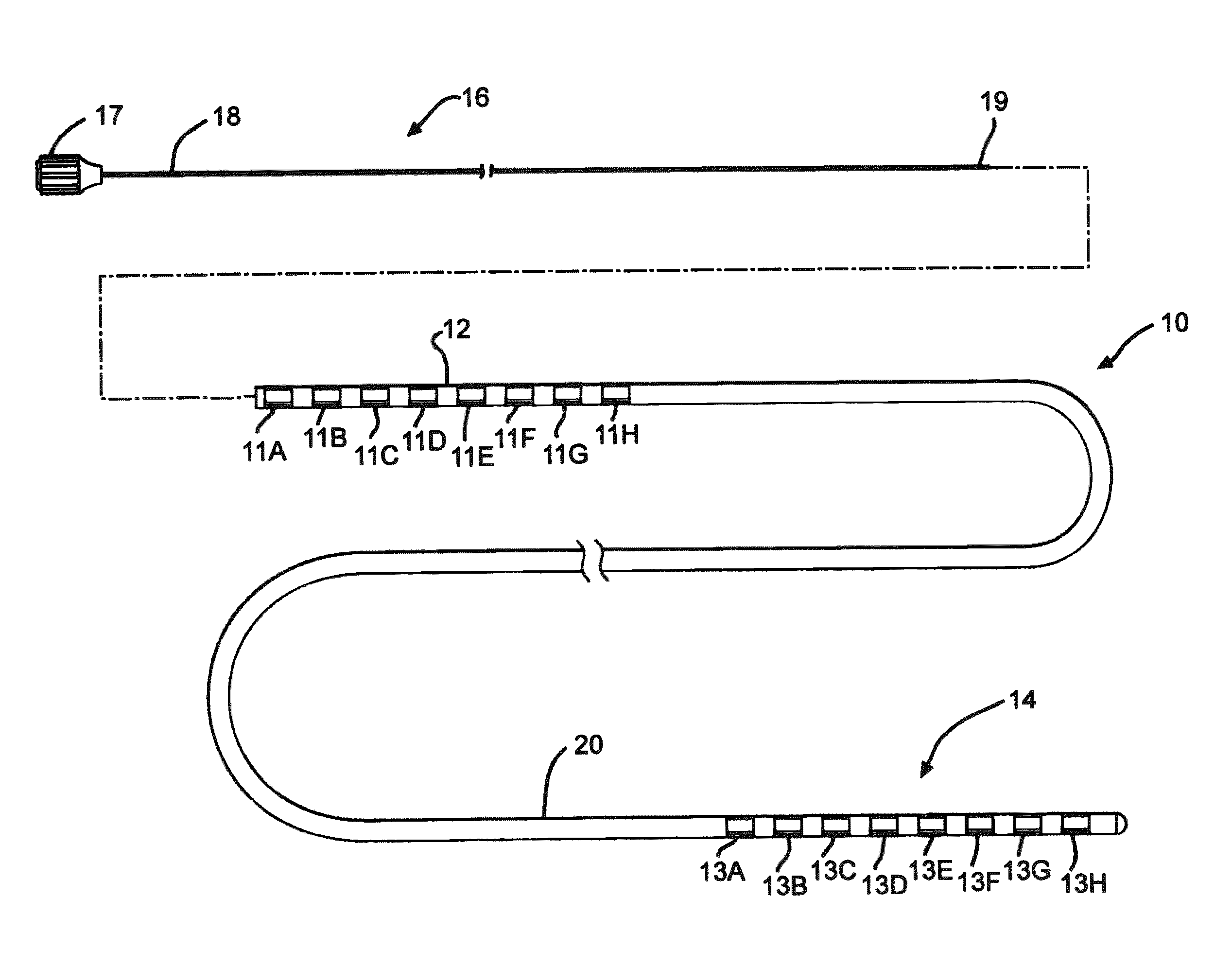

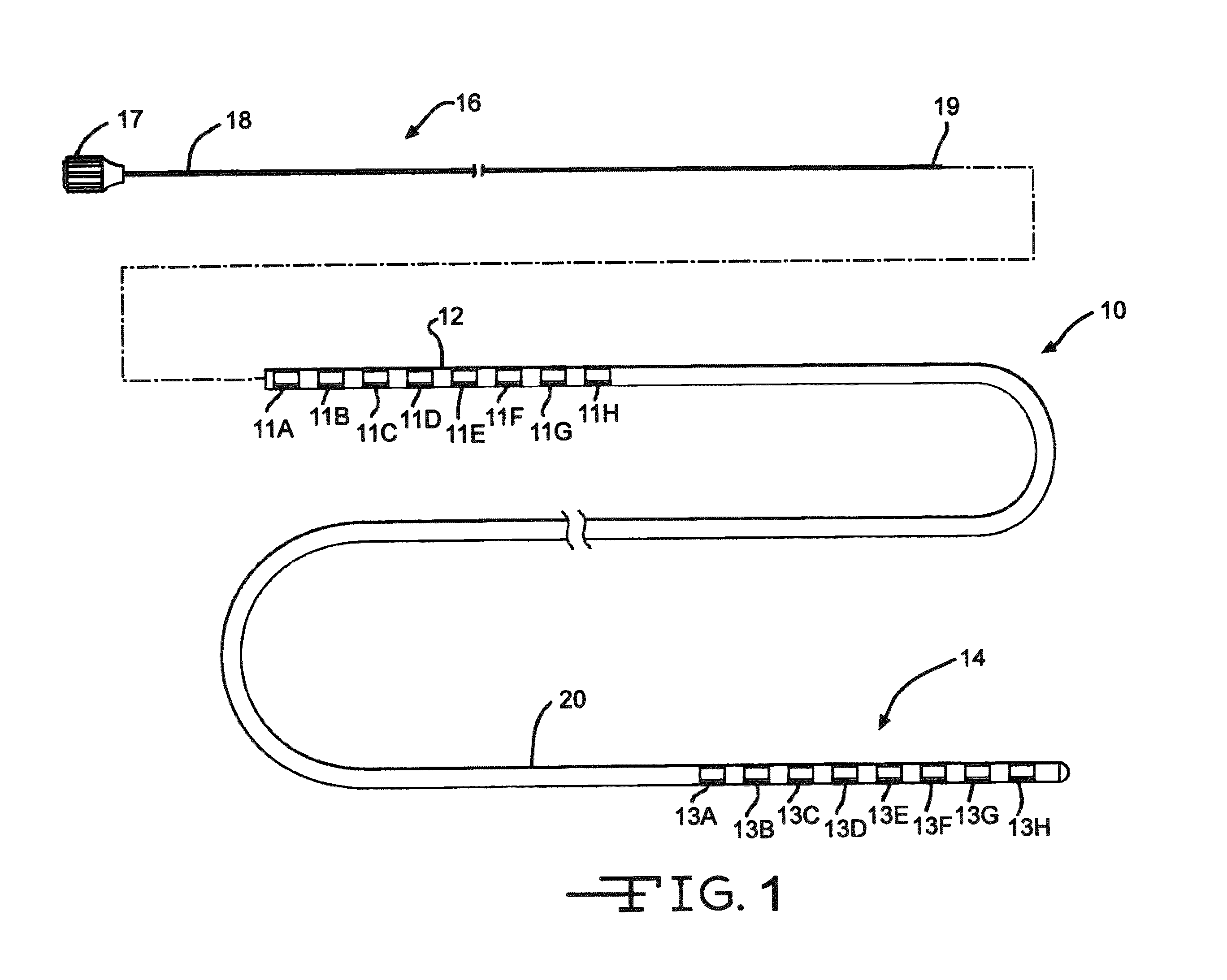

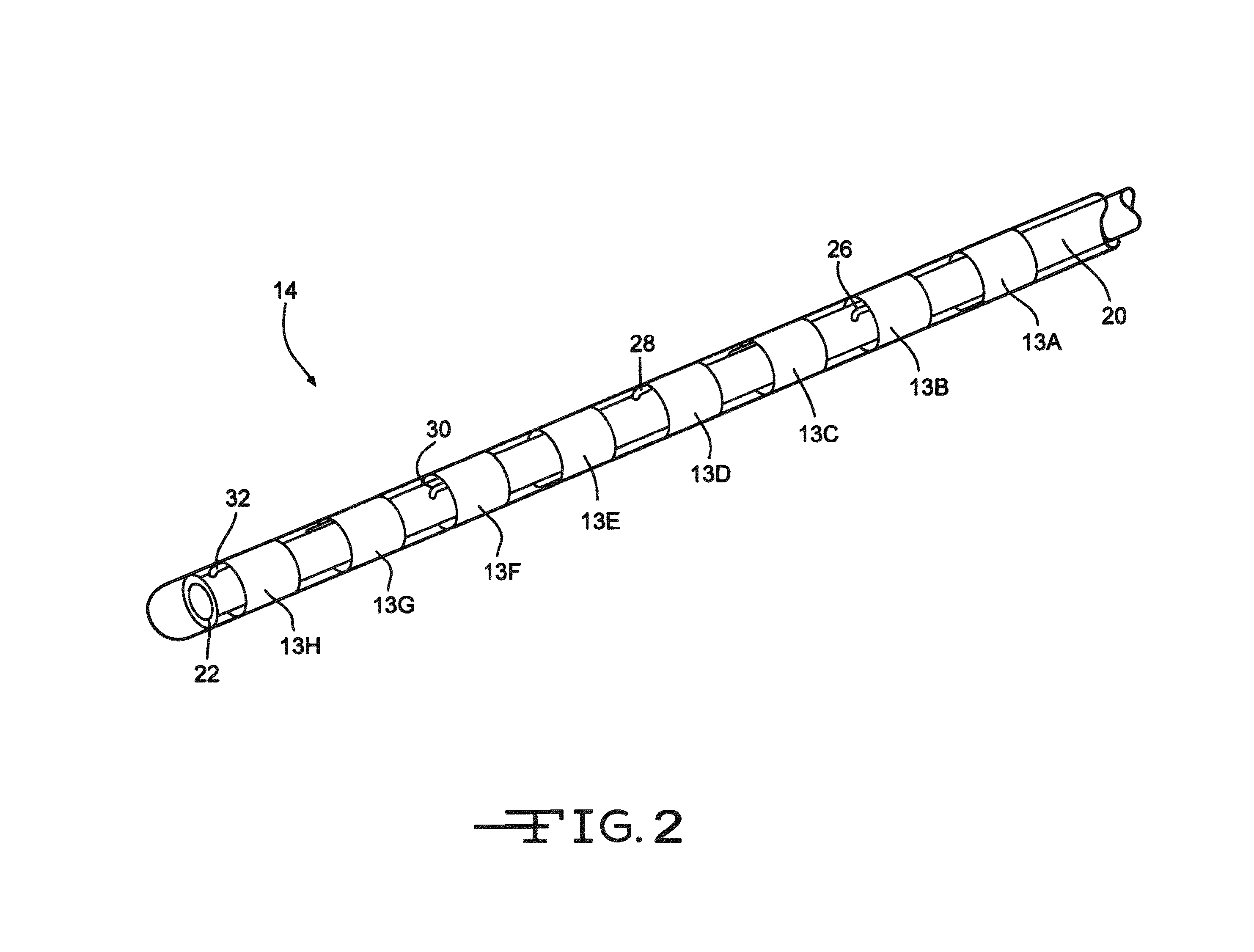

Stimulation lead design and method of manufacture

ActiveUS7957818B2Improve rigidityPlace safeSpinal electrodesWave amplification devicesElectricityElectrical conductor

Owner:CIRTEC MEDICAL CORP

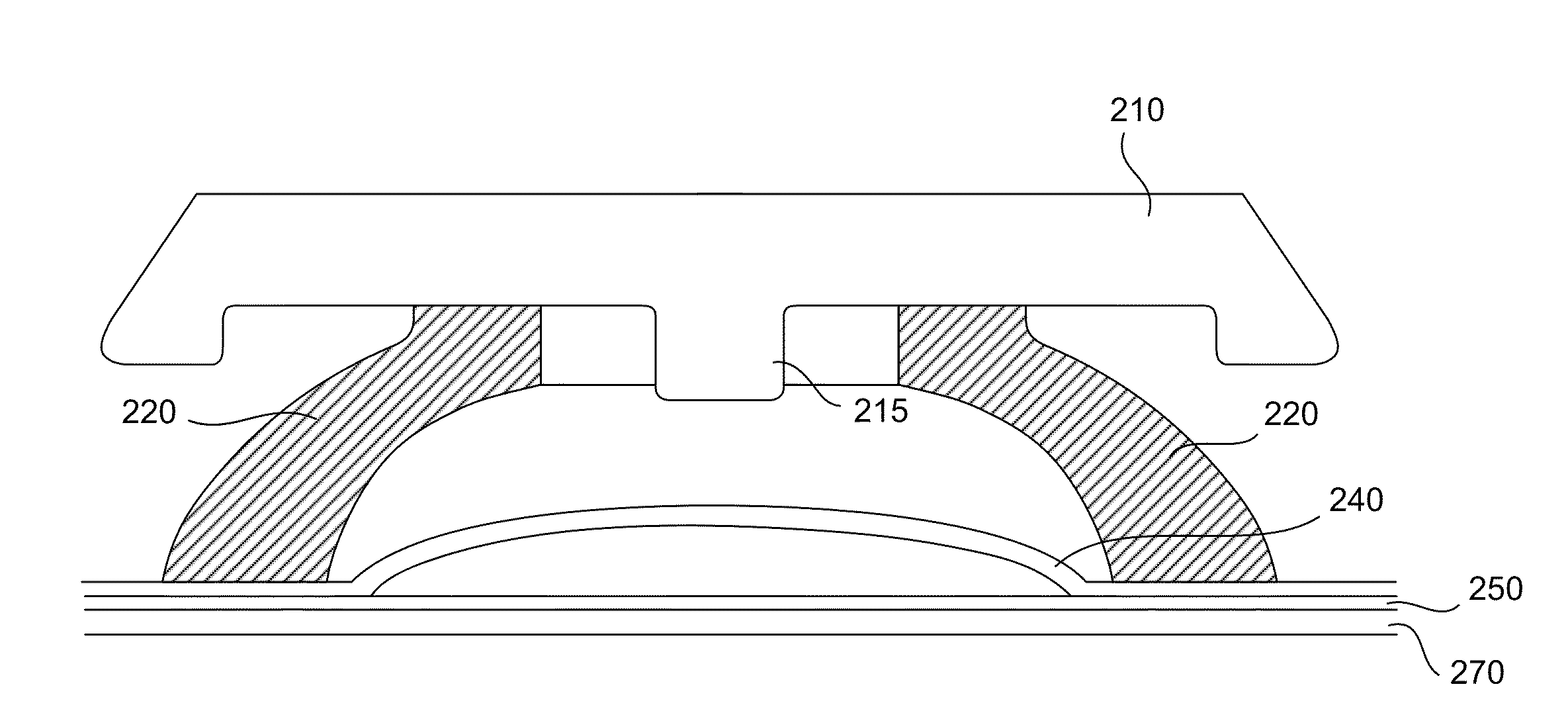

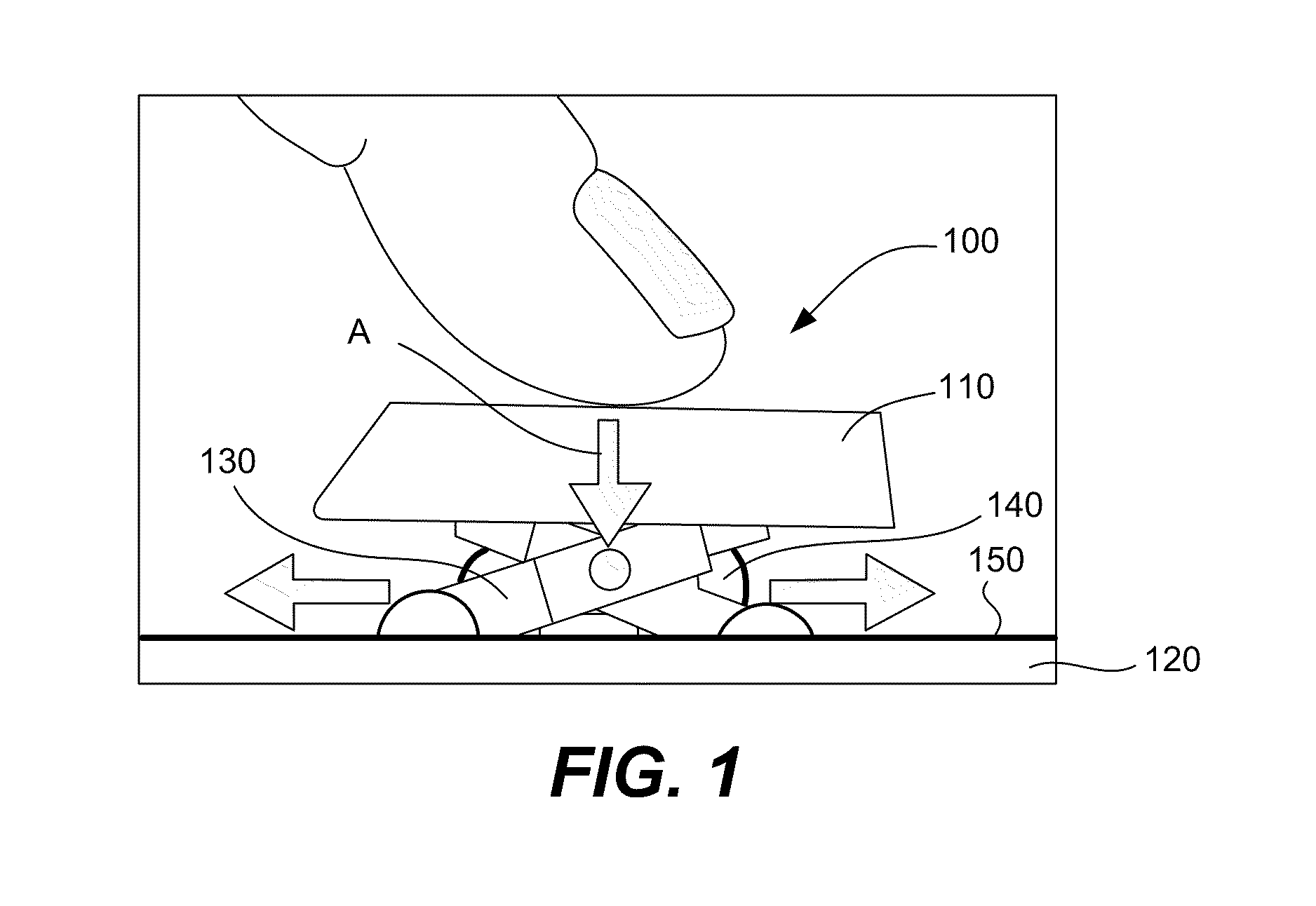

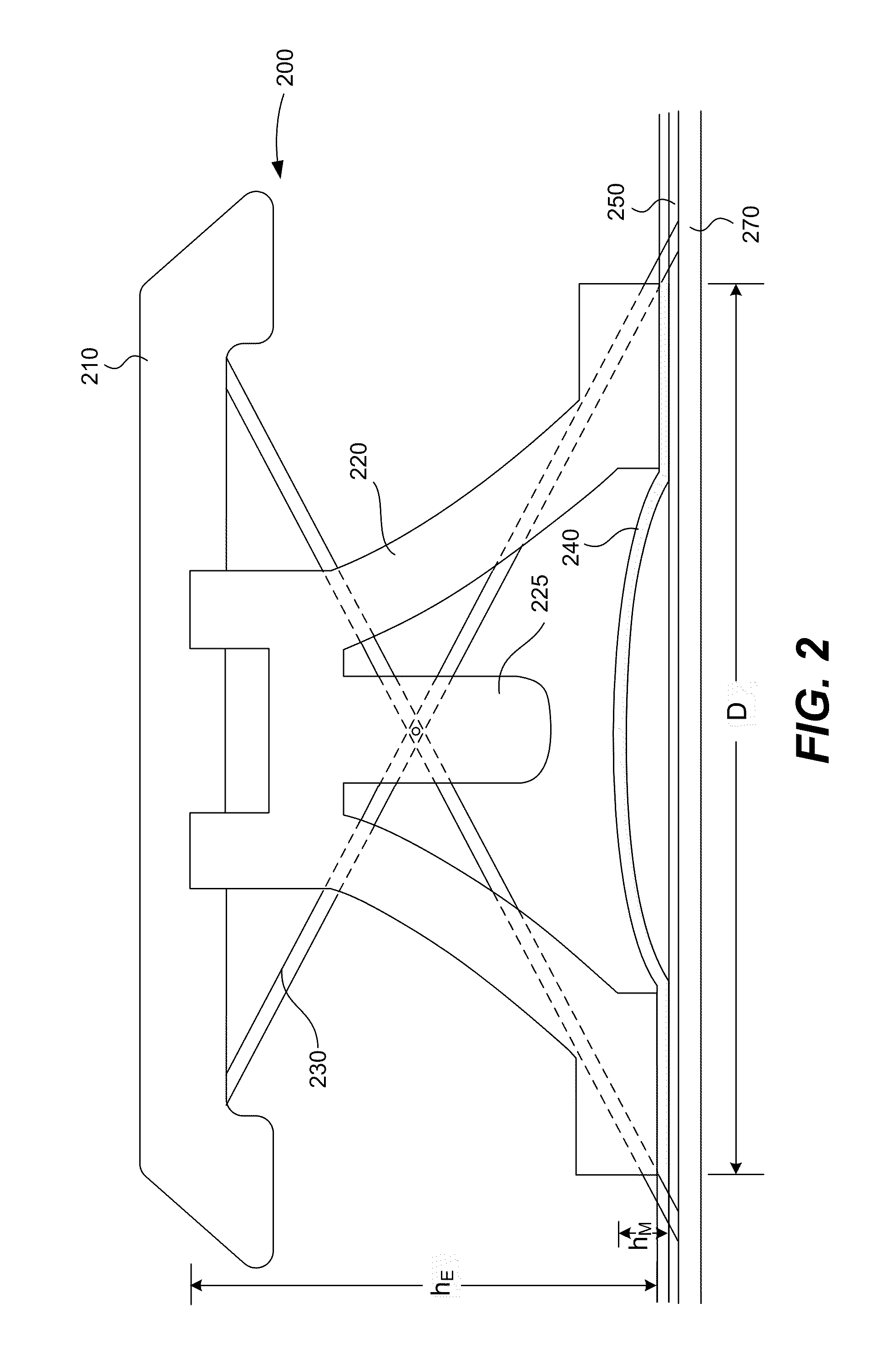

Stacked metal and elastomeric dome for key switch

ActiveUS20110203912A1Reduces travel distanceAdditional mechanical stabilityContact operating partsSelector switchesKey switchPrinted circuit board

A low travel keyboard and methods of fabrication are described. The low-travel keyboard is suitable for a thin-profile computing device, such as a laptop computer, netbook computer, desktop computer, etc. The keyboard includes a key cap positioned over stacked elastomeric and metal domes. The quick force drop of the metal dome provides the crisp “snappy” feel for the user and the elastomeric dome provides the ability for longer travel than the metal dome alone. The metal dome also activates the switch circuitry of the membrane on printed circuit board. The stacking of the elastomeric metal domes takes advantage of the abrupt force drop in the metal dome buckling and applies it to the elastomeric dome force, making it possible to design a low-travel key while still maintaining or improving the tactile feeling of the key switch.

Owner:APPLE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com