Spinal fixation device

a technology of fixation device and spine, which is applied in the field of spinal fixation device, can solve the problems of screw that may slowly become less secure, and achieve the effects of reducing the risk of fracture, facilitating healing, and facilitating healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

is hereafter described with specific reference being made to the drawings in which:

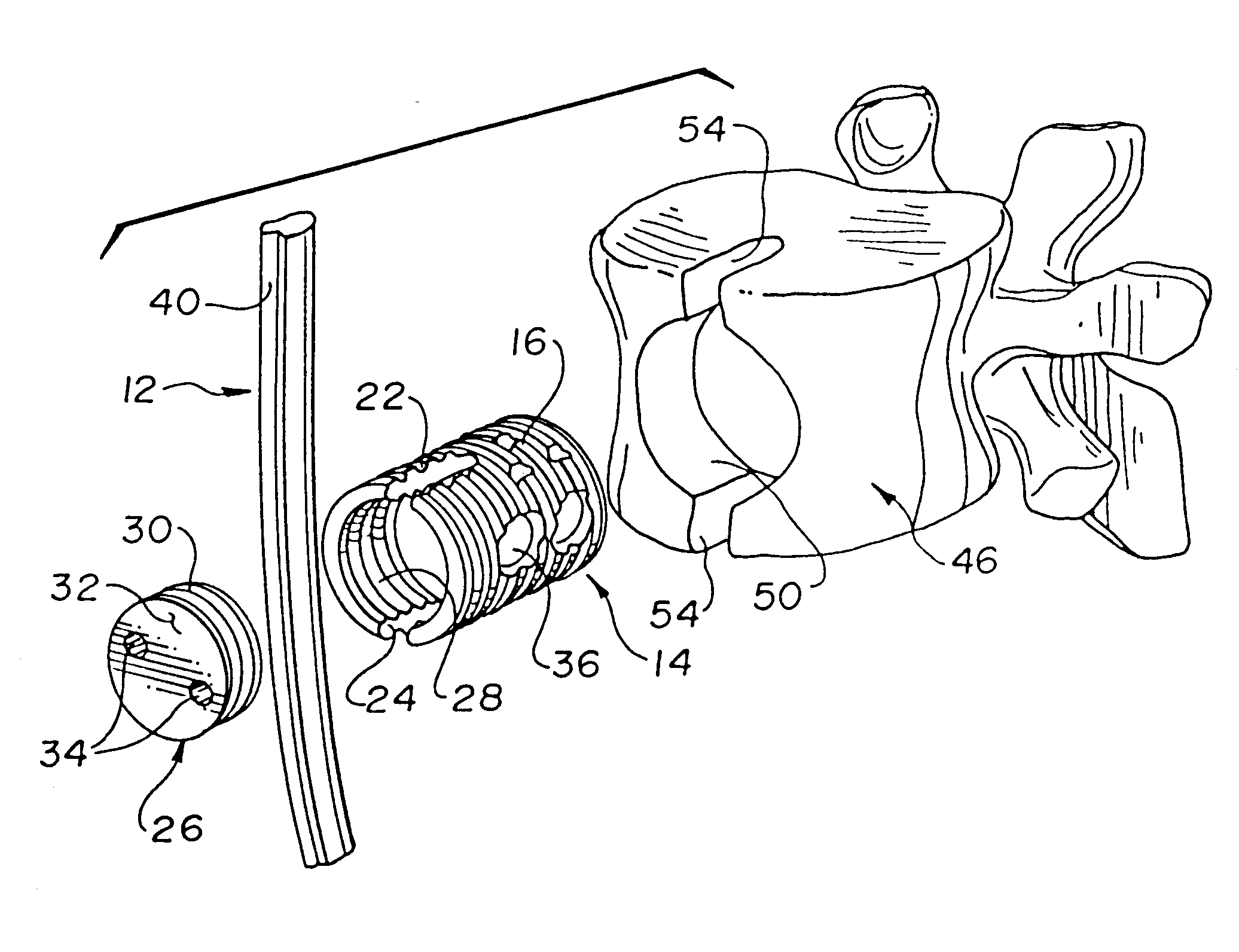

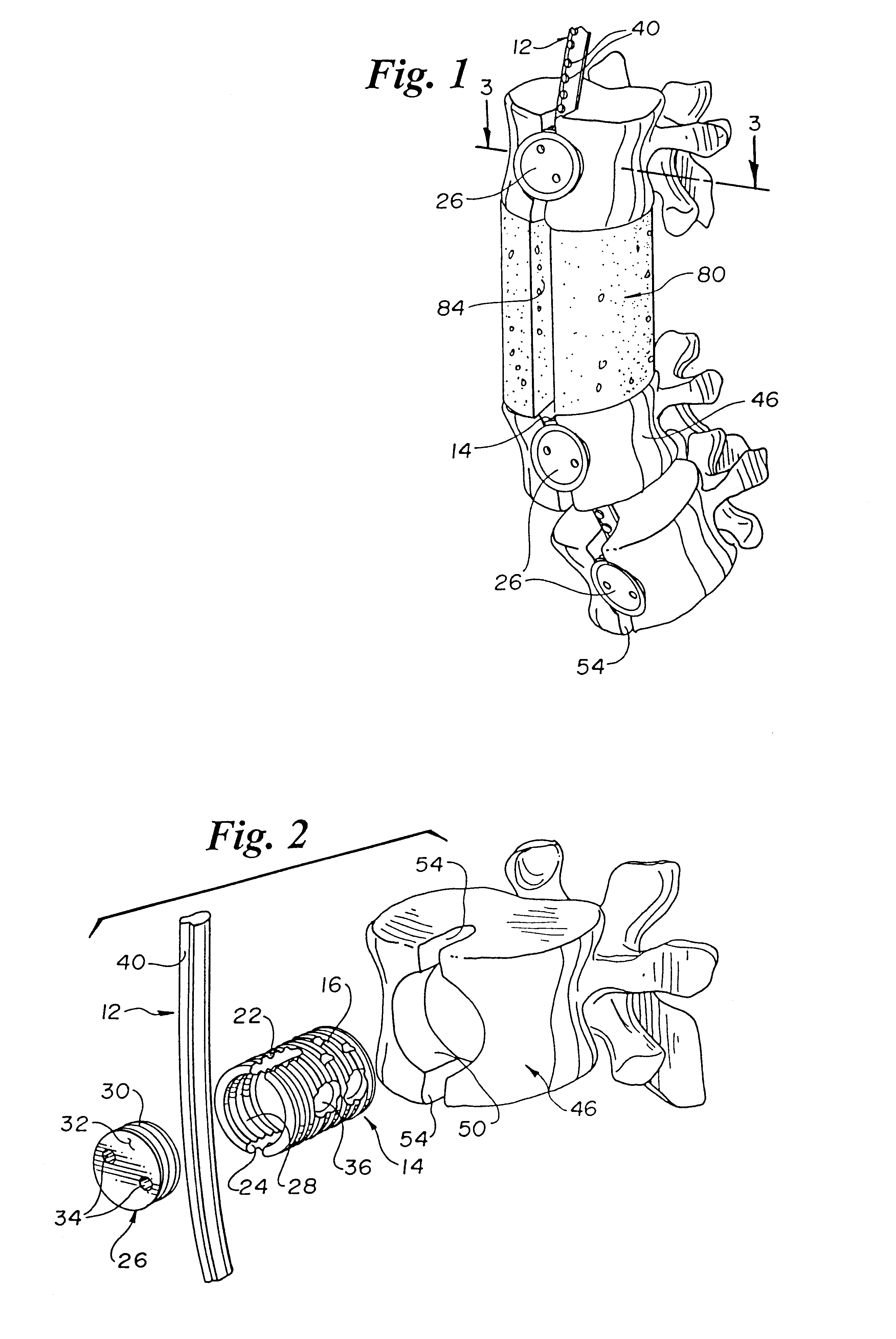

FIG. 1 is a perspective view of the device of the invention securing vertebrae together;

FIG. 2 is an exploded view of the rod, screw, cap and prepared vertebrae;

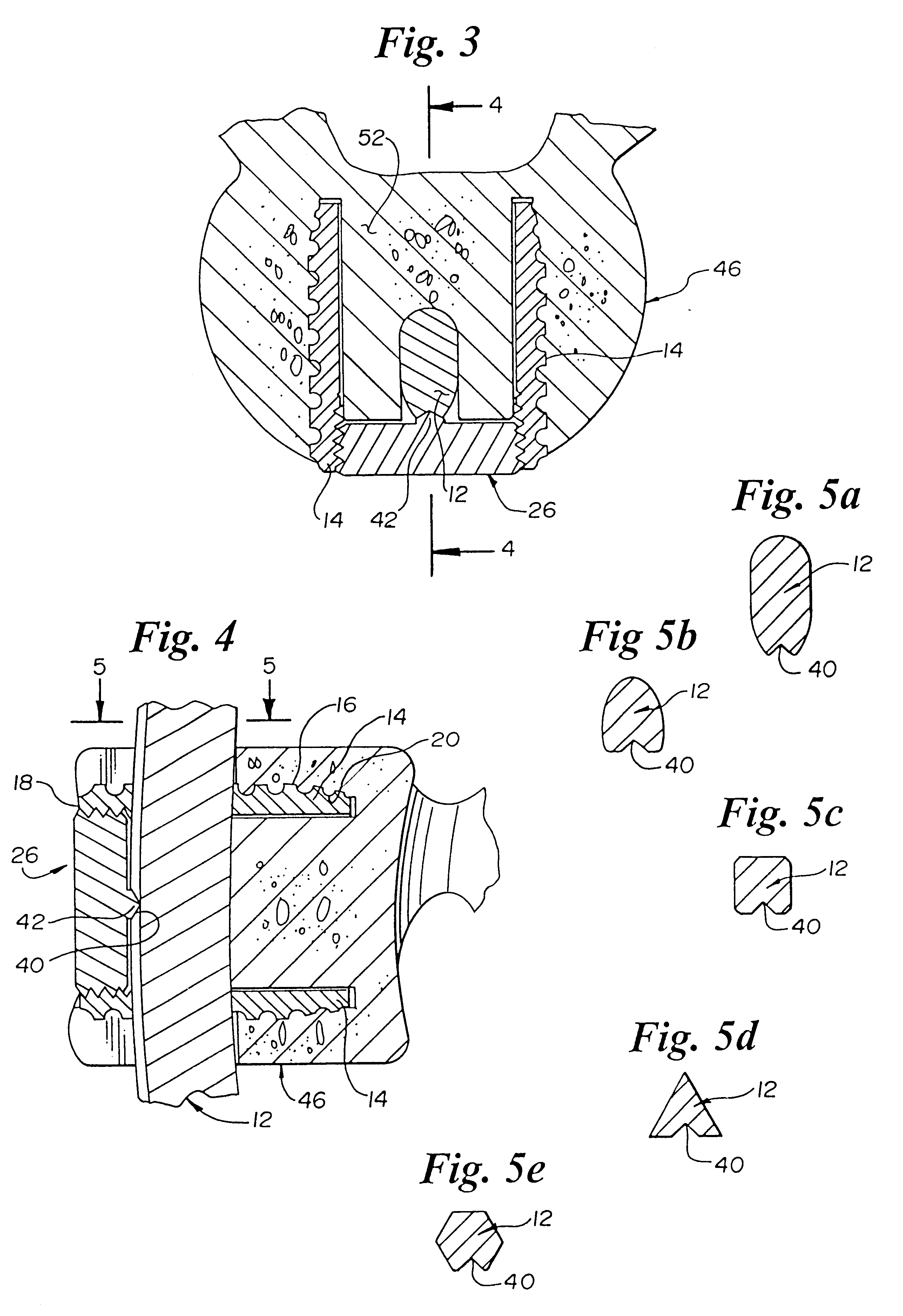

FIG. 3 is a cross-sectional view taken through line 3--3 of FIG. 1;

FIG. 4 is a cross-sectional view taken through line 4--4 of FIG. 3;

FIG. 5a is a cross-sectional view taken through line 5--5 of FIG. 4 showing the rod in cross-section;

FIG. 5b is a cross-sectional view taken through line 5--5 of FIG. 4 showing an alternate rod in cross-section;

FIG. 5c is a cross-sectional view taken through line 5--5 of FIG. 4 showing an alternate rod in cross-section;

FIG. 5d is a cross-sectional view taken through line 5--5 of FIG. 4 showing an alternate rod in cross-section;

FIG. 5e is a cross-sectional view taken through line 5--5 of FIG. 4 showing an alternate rod in cross-section;

FIG. 6 is a cross-sectional view similar to FIG. 3 with an overcap design;

FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com