Patents

Literature

1460 results about "Single hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

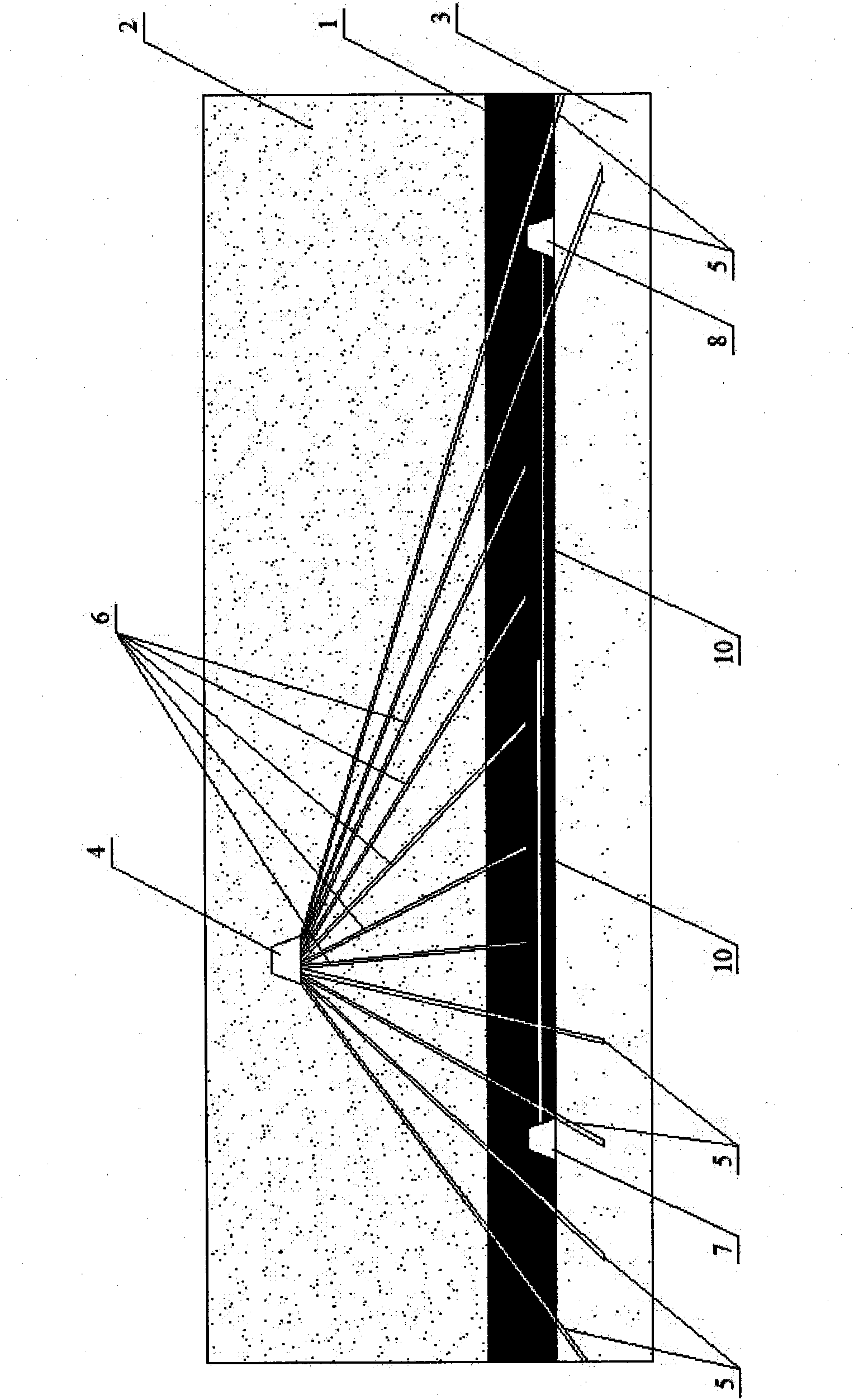

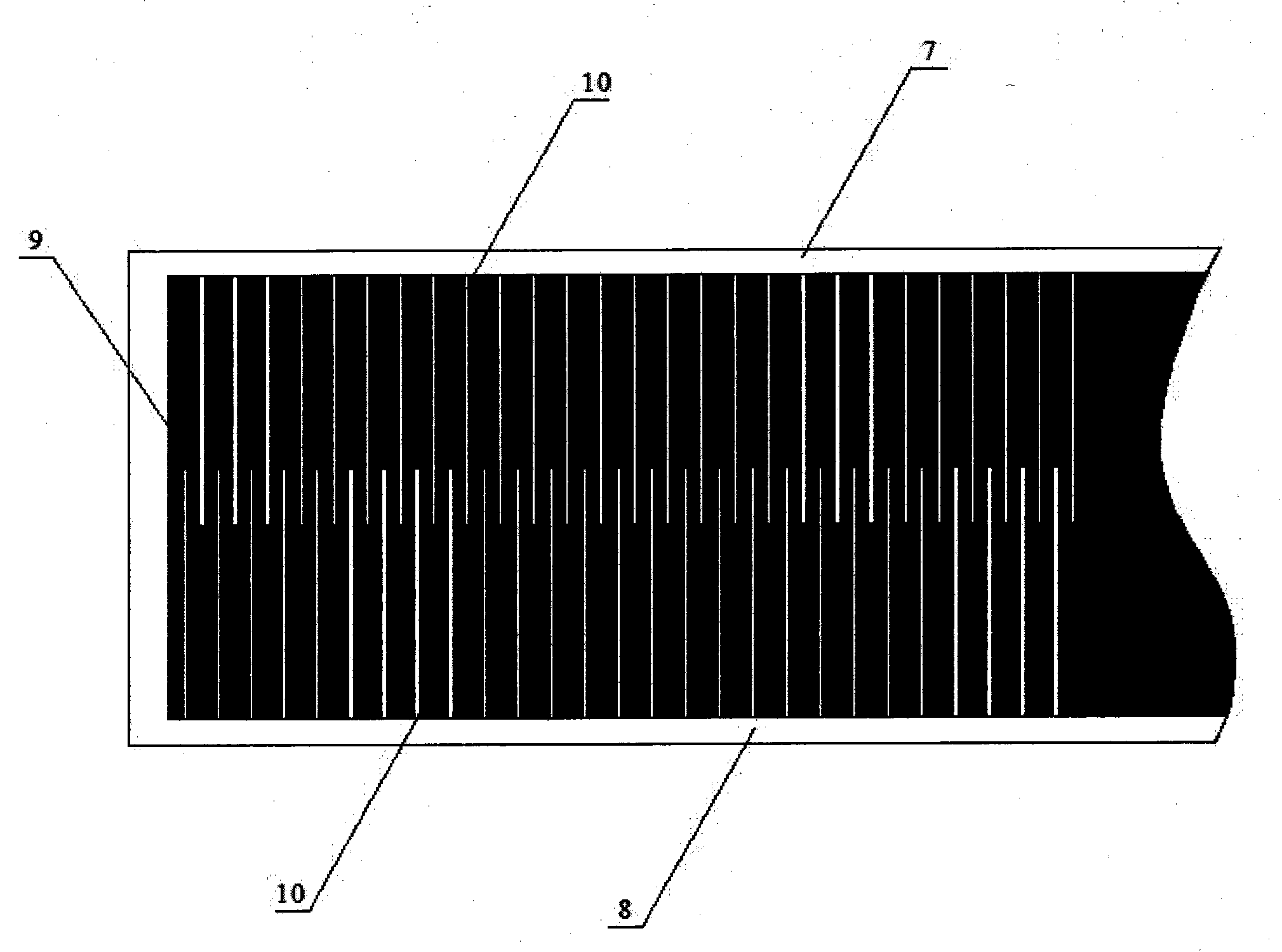

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

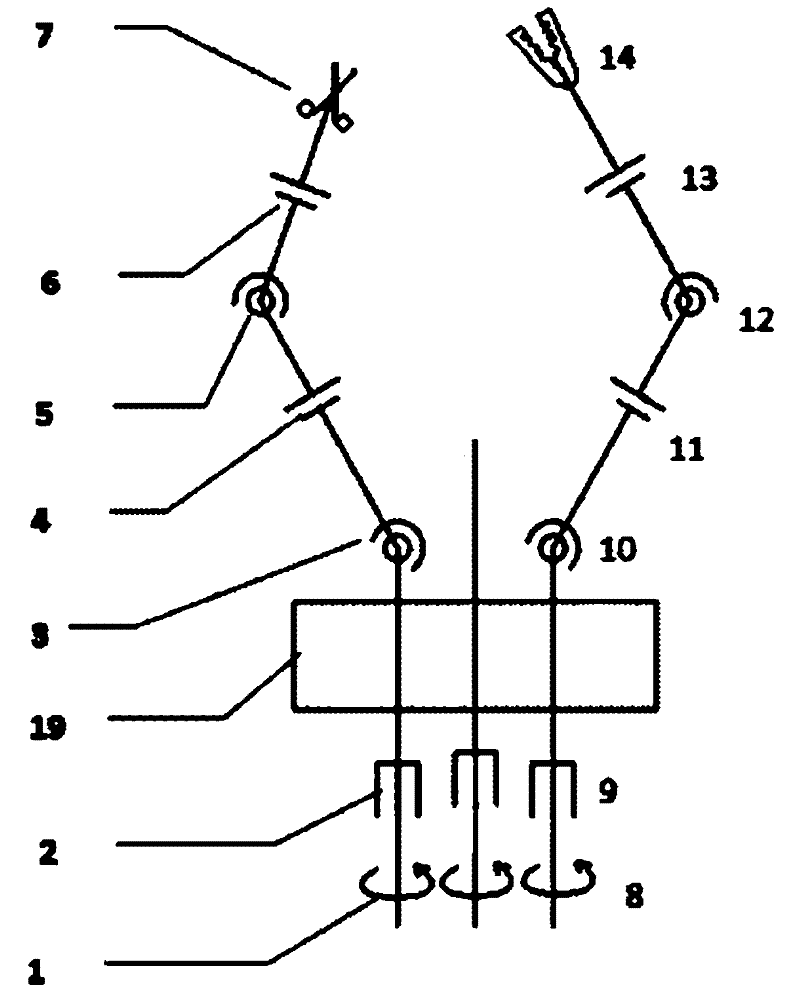

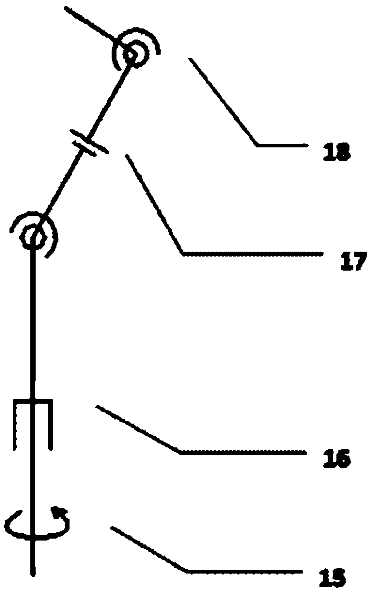

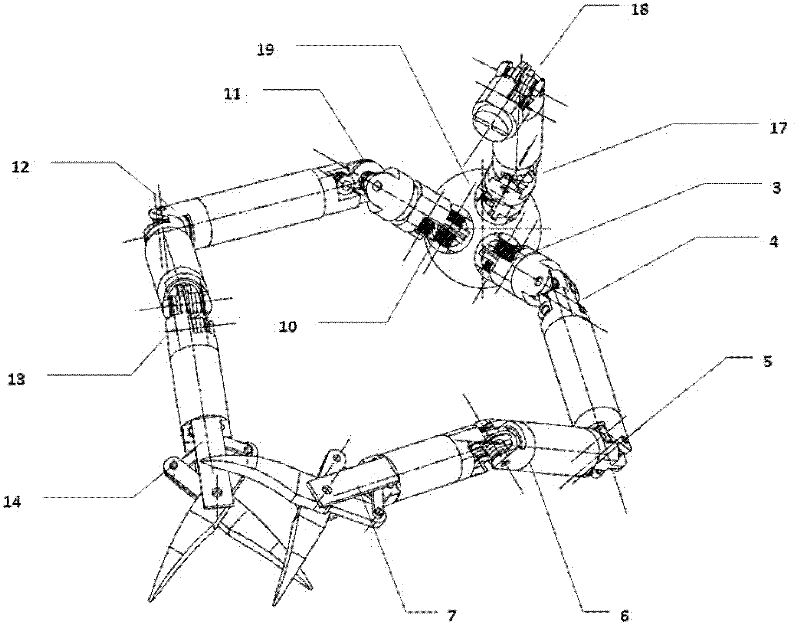

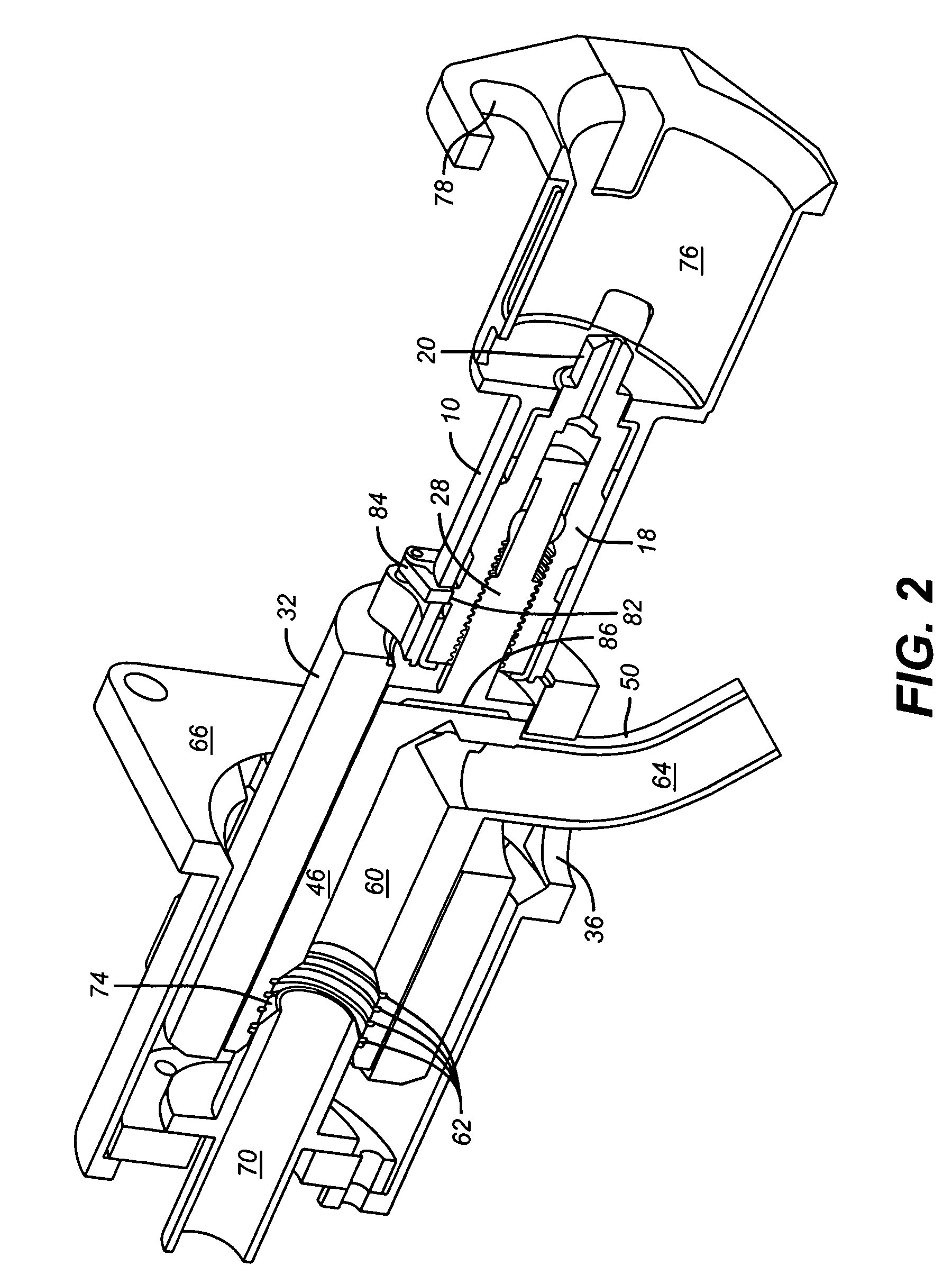

Multi-degree-of-freedom single-wound-hole robot flexible hand for celiac minimally invasive surgery

ActiveCN102499759ARealize single wound surgeryFlexible operationDiagnosticsSurgical robotsSurgical operationAbdominal cavity

The invention discloses a multi-degree-of-freedom single-wound-hole robot flexible hand for celiac minimally invasive surgery, which comprises two seven-degree-of-freedom mechanical arms and a five-degree-of-freedom mechanical arm. Tail ends of the seven-degree-of-freedom mechanical arms are provided with scalpels, the tail end of the five-degree-of-freedom mechanical arm is provided with a cameral, seven degrees of freedom of each seven-degree-of-freedom mechanical arm include the rotation degree of freedom around a center shaft of the arm, the arm front and back stretching and retracting degree of freedom, the horizontal swinging degree of freedom, the vertical swinging degree of freedom, the horizontal swinging degree of freedom, the vertical swinging degree of freedom and the tool degree of freedom which are successively arranged from the root of the seven-degree-of-freedom mechanical arm, the front and back stretching and retracting degree of freedom and the rotation degree of freedom around a center line of the arm are arranged at the tail end, which contacts with a mouth gag, of the five-degree-of-freedom mechanical arm, three planar swinging degrees of freedom deeply penetrate into the mouth gag and are successively arranged from the root of the five-degree-of-freedom mechanical arm, and transmission of each degree of freedom is controlled via a steel wire. The multi-degree-of-freedom single-wound-hole robot flexible hand is a single-hole operation multi-degree-of-freedom mechanism, and can realize surgical operations including incising, pulling, suturing and the like, so that operability and accuracy of the surgery are improved.

Owner:SHANGHAI JIAO TONG UNIV

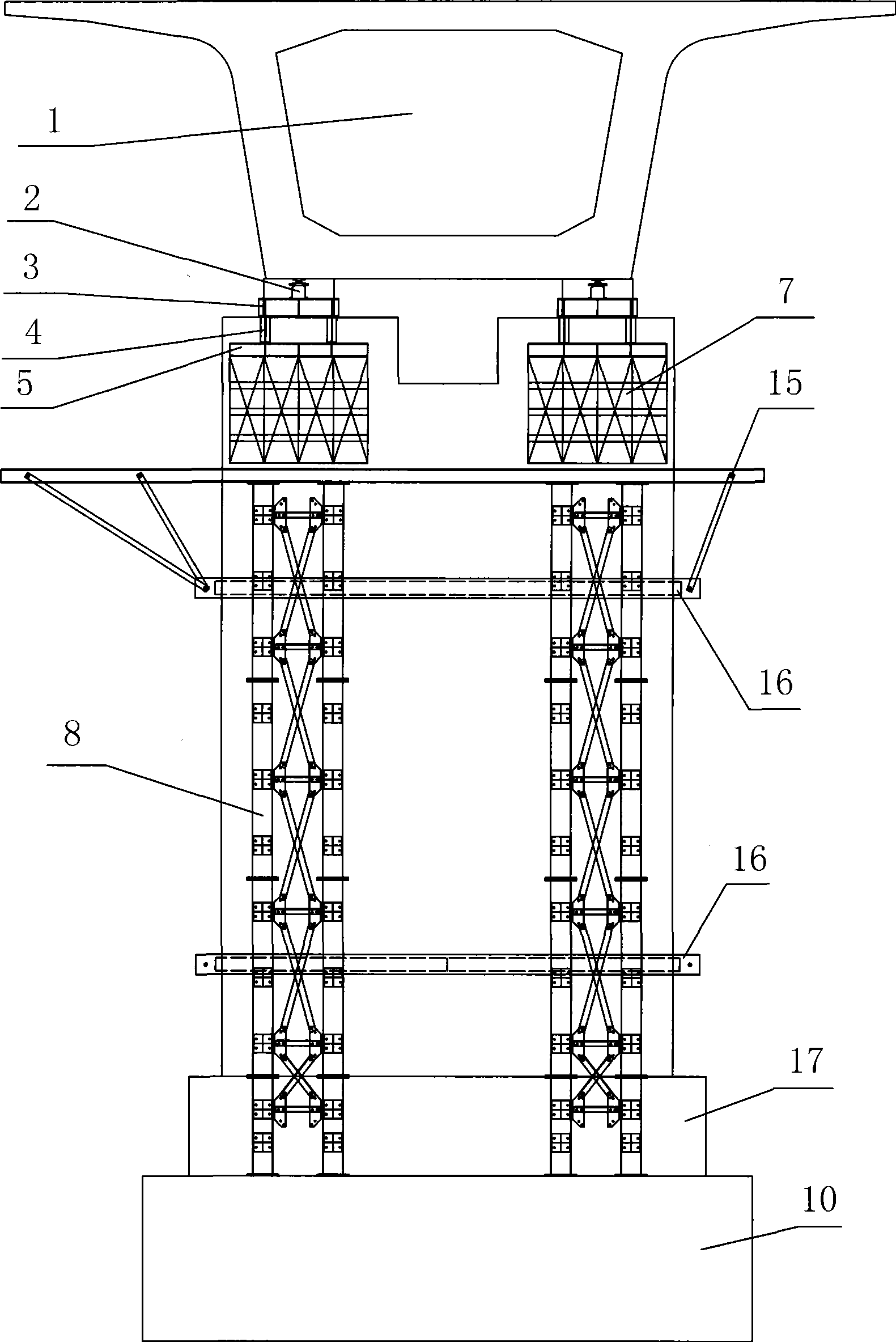

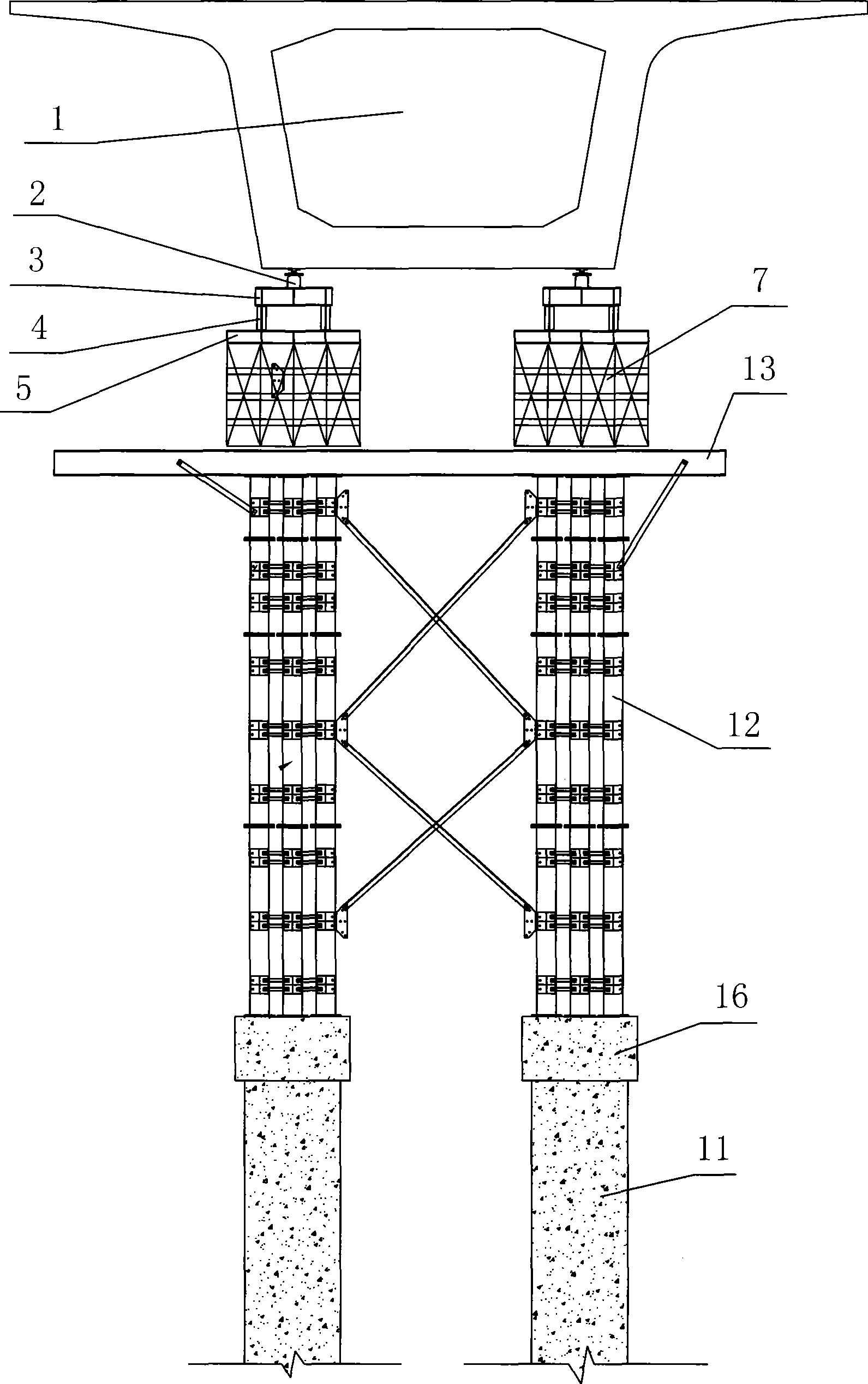

Segment-assembling simply supported box girder movable falsework construction method

The invention discloses a segment assembled simple box girder movable trestle construction method. The required construction simple box girder has single hole or multiple holes, and is assembled by a plurality of longitudinal (i.e. along bridge direction) segment box grinders; the method comprises the following steps: prefabricating all the segment box girders for assembling the simple box girder in concentration; assembling and erecting the first hole grinder, which comprises the steps of: assembling and erecting the trestle (i.e. assembling platform), hanging the segments on to the assembling platform according to the assembling sequence and adjusting the arch degree, line style and position accurately, constructing the segments on the assembling platform by segment assembling construction technology until complete the whole hole grinder construction, and dismounting the trestle and moving to the next hole grinder; and performing the subsequent hole grinders in order according to the construction steps of the first hole grinder. the invention achieves the advantages of simple steps, low construction difficulty, short construction cycle and low onetime fund investment; can solves the practical problems existing in the segment assembling construction process of current large-span bridge fabrication machine.

Owner:CHINA RAILWAY FIRST GRP CO LTD

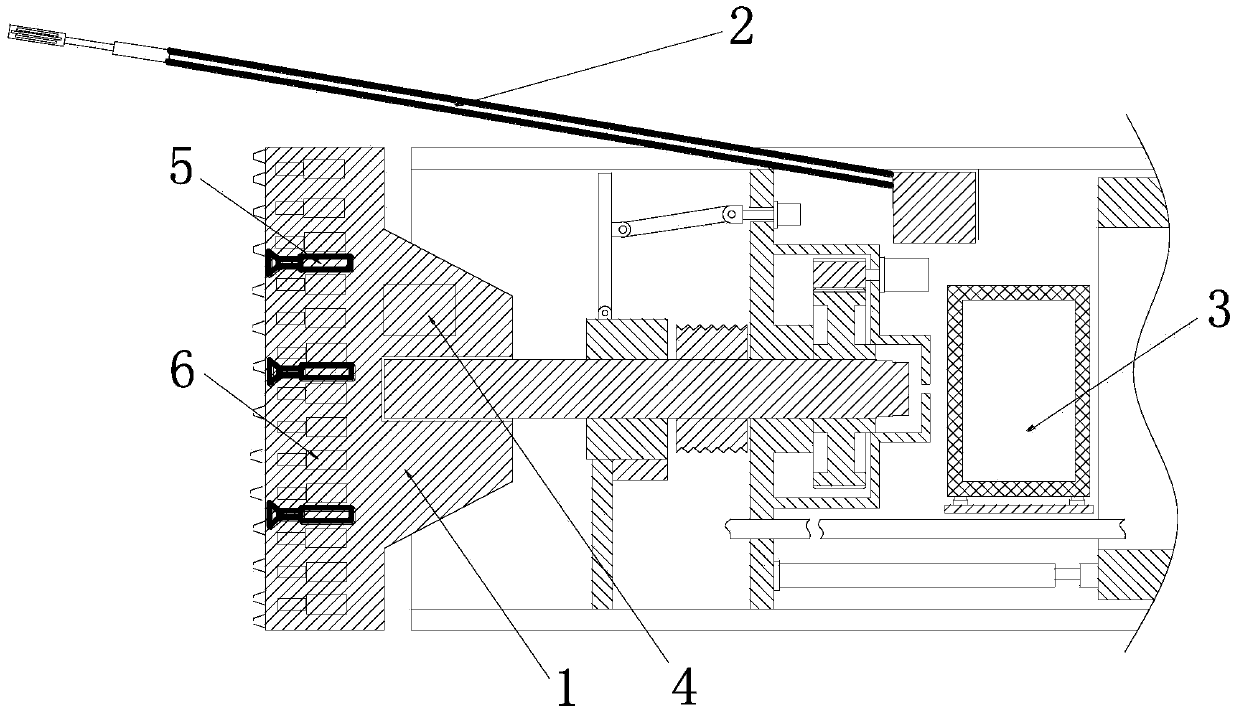

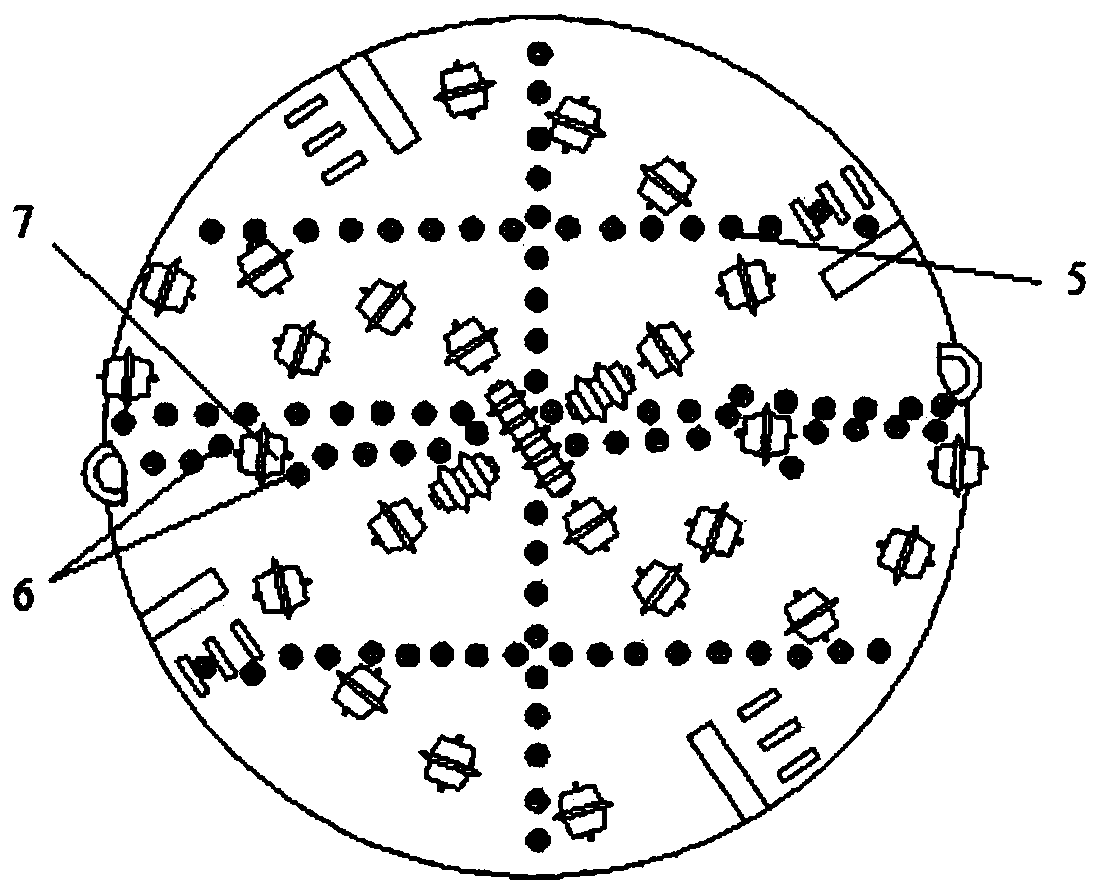

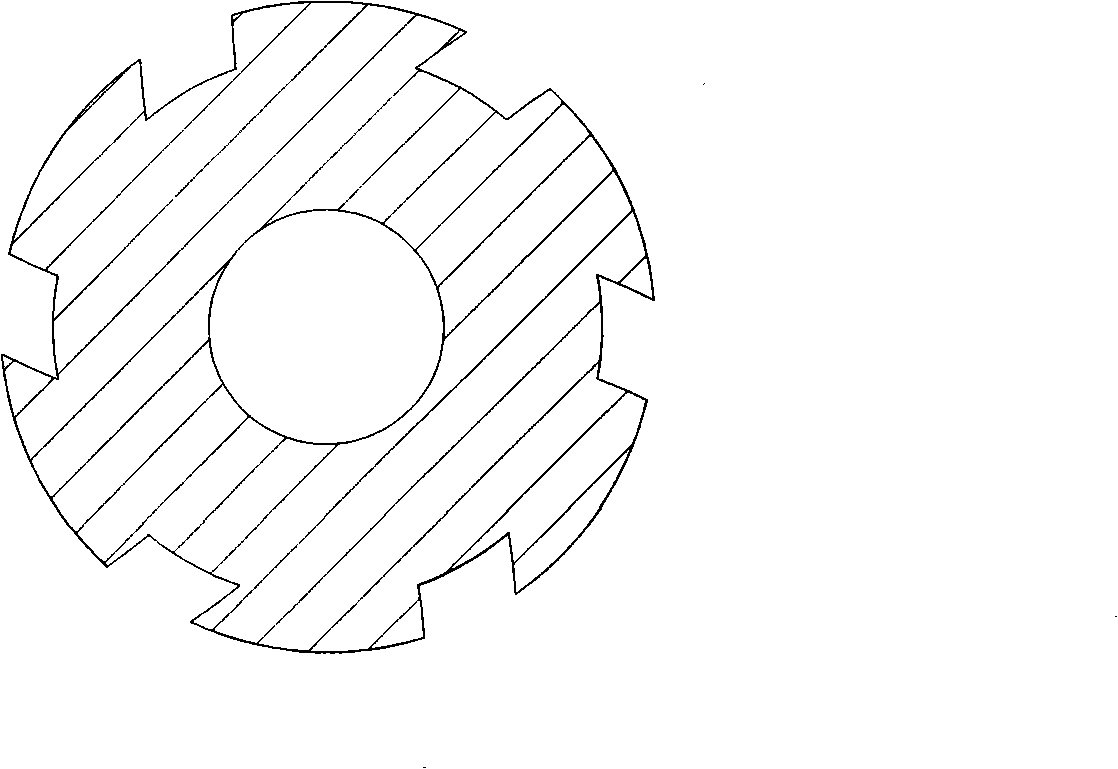

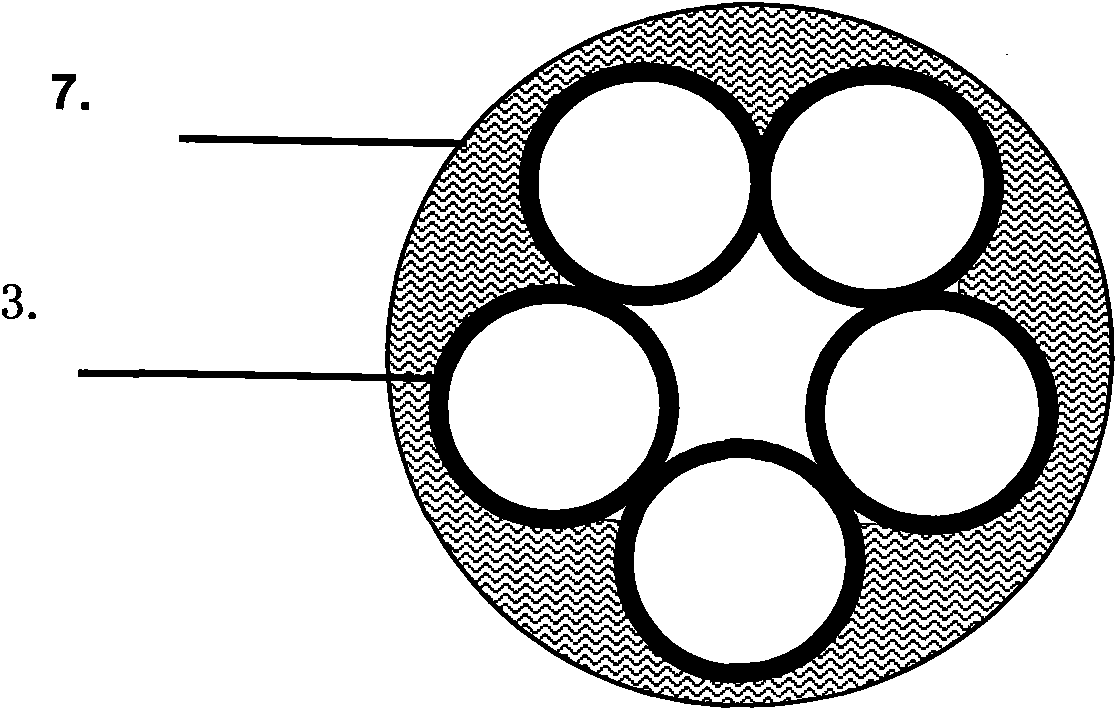

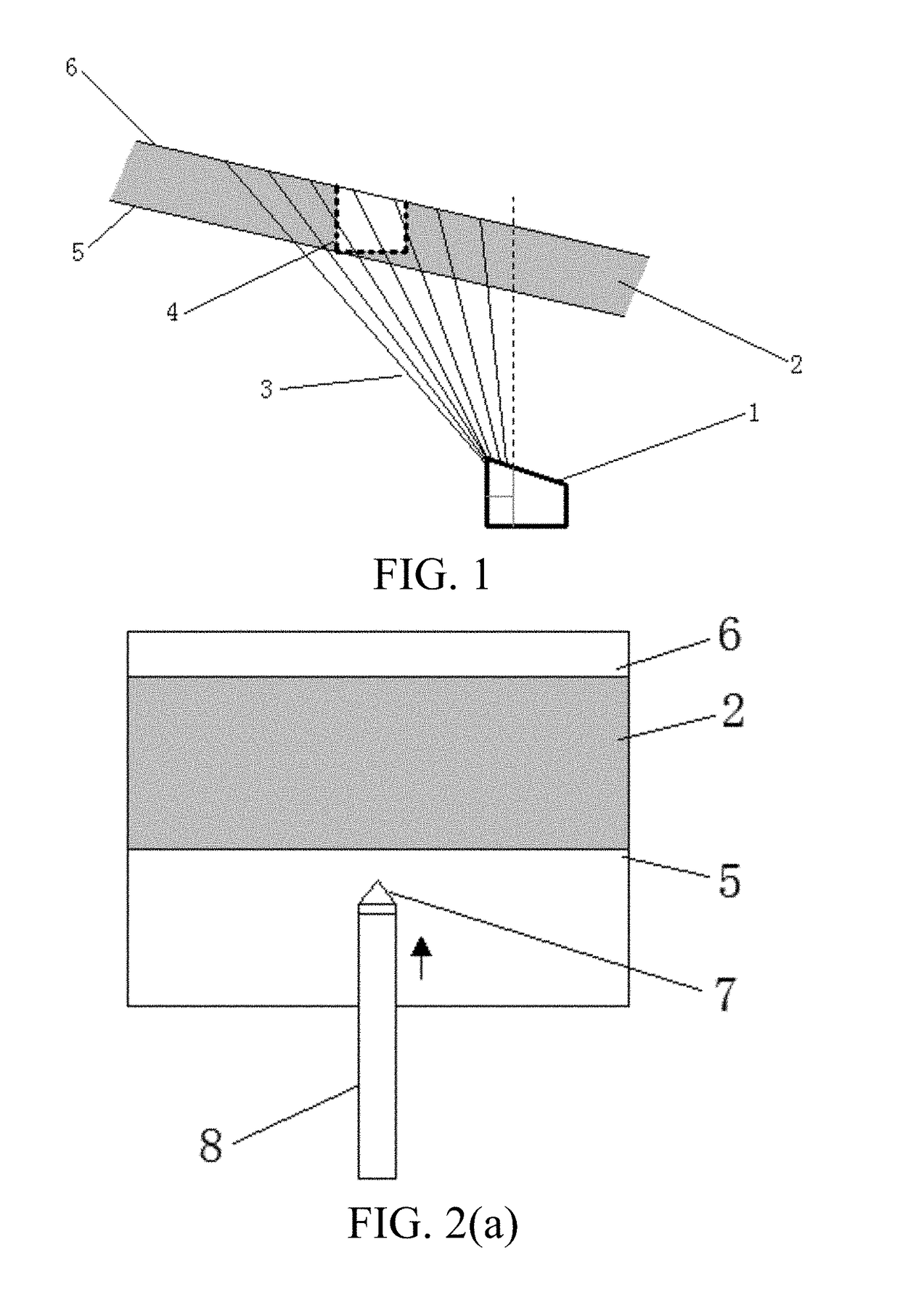

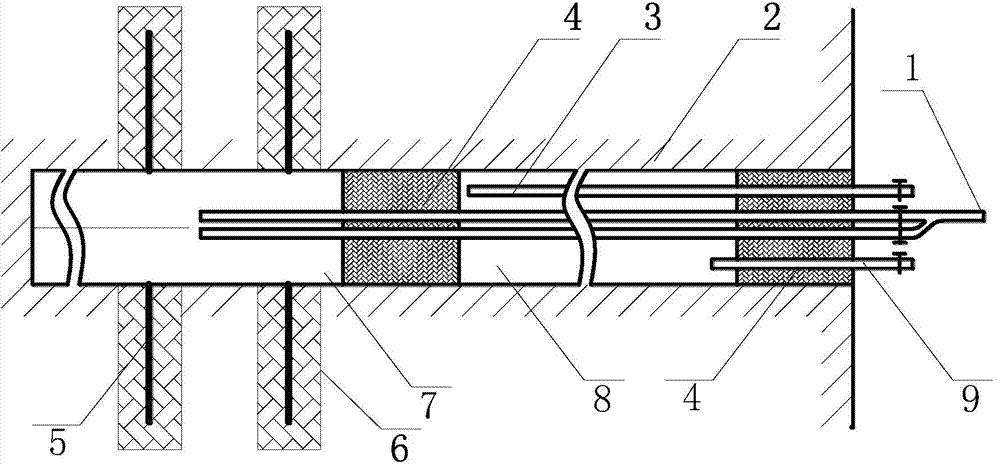

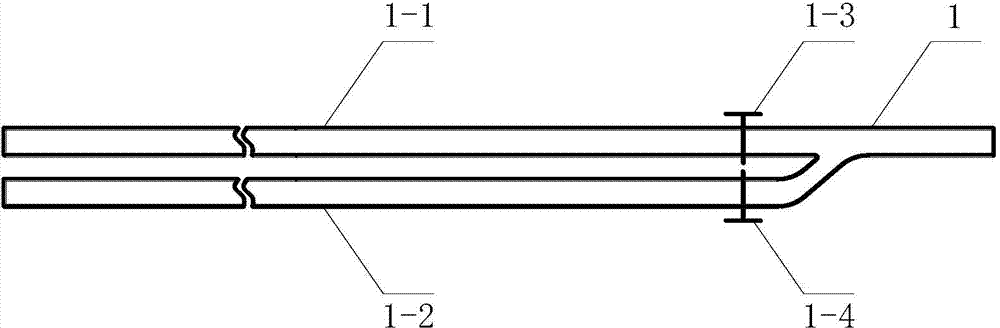

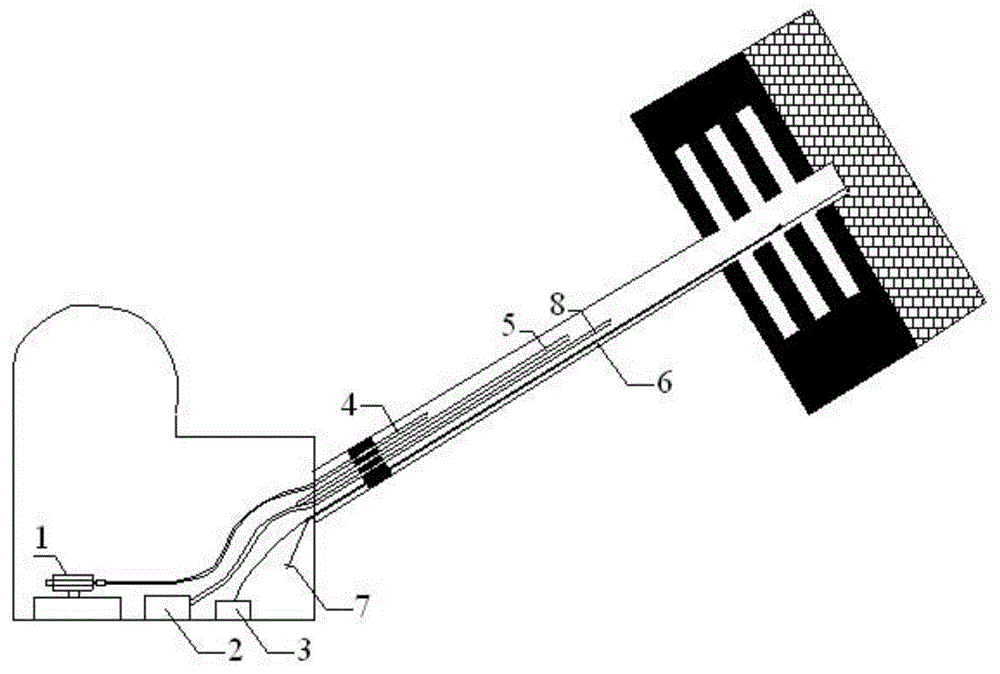

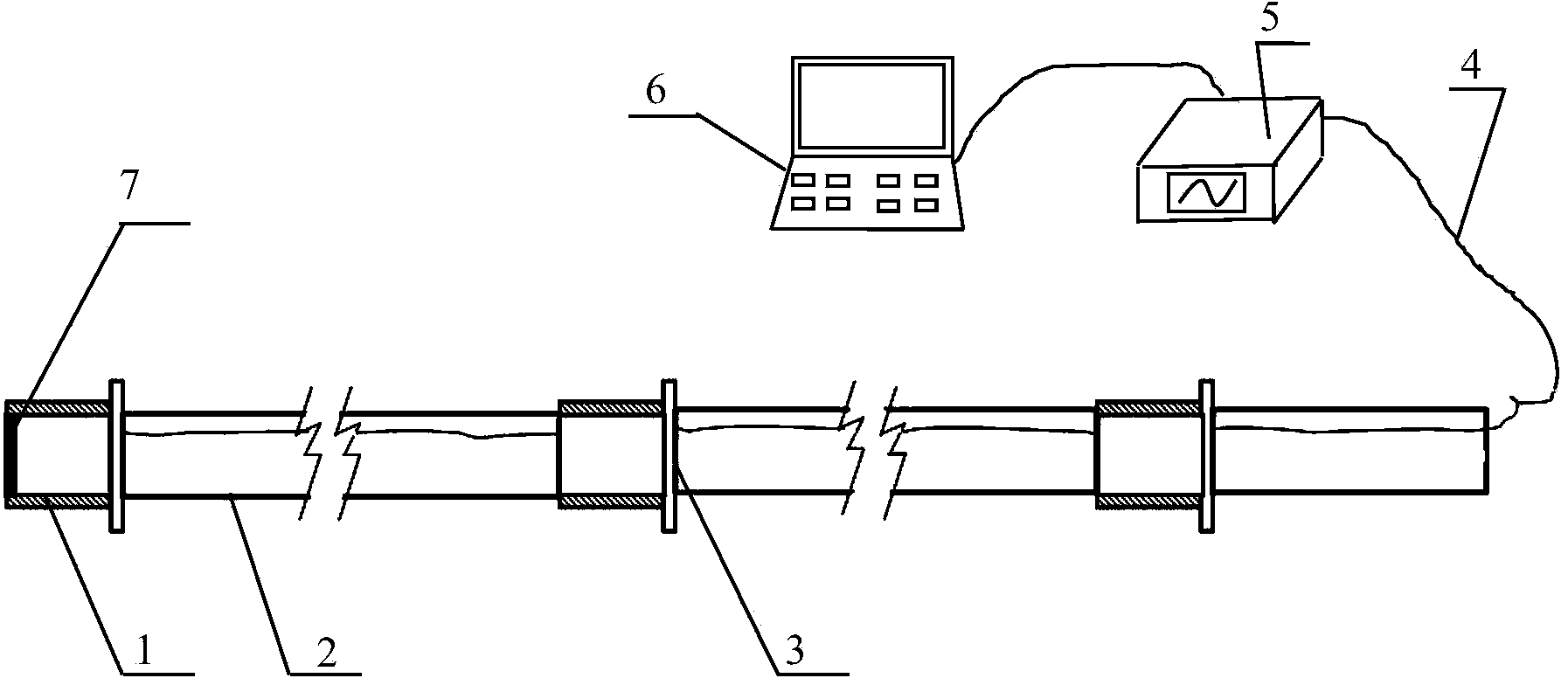

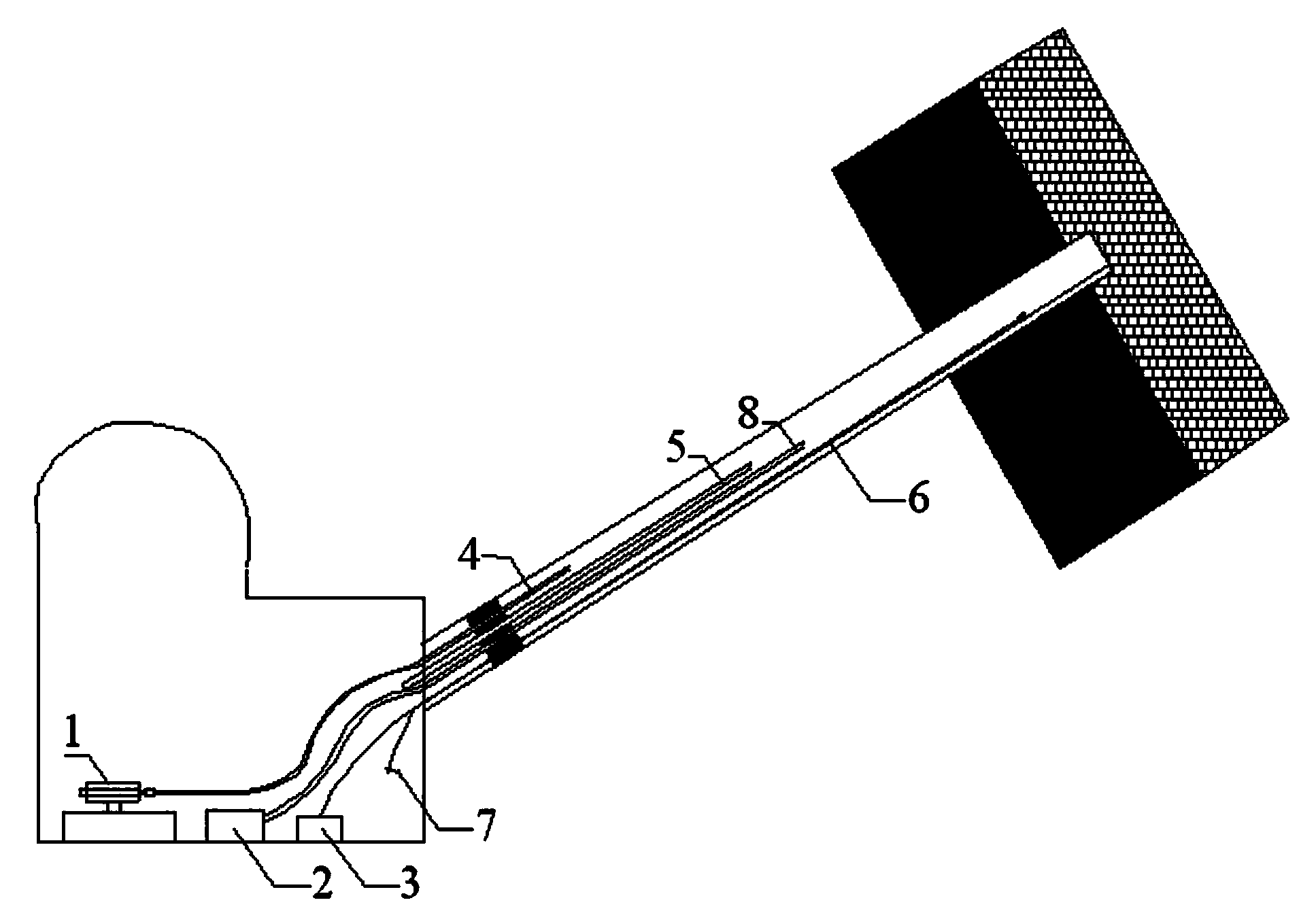

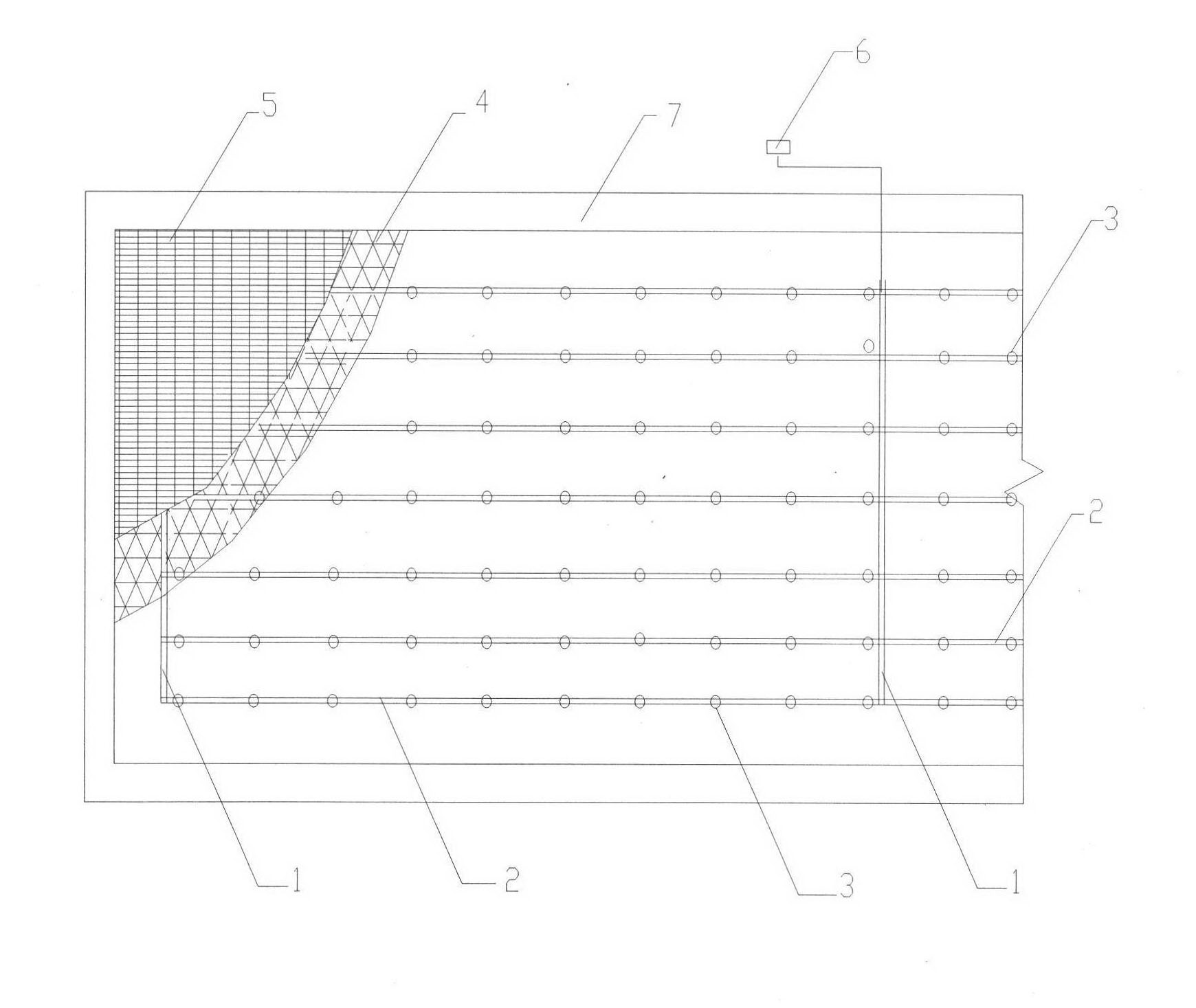

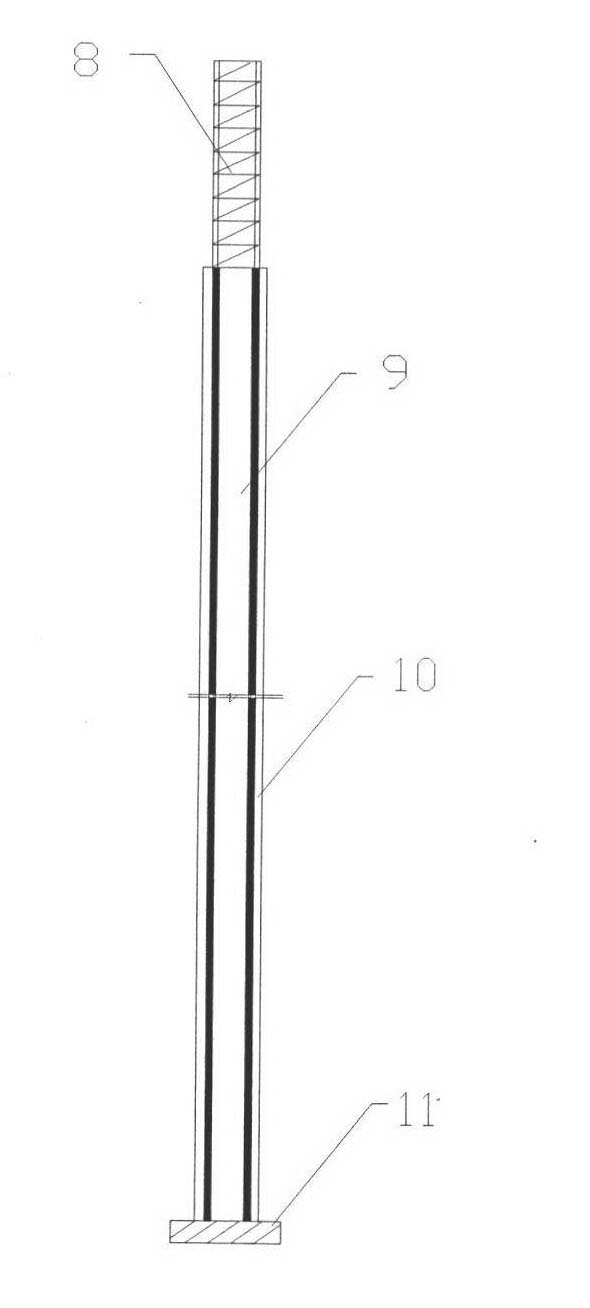

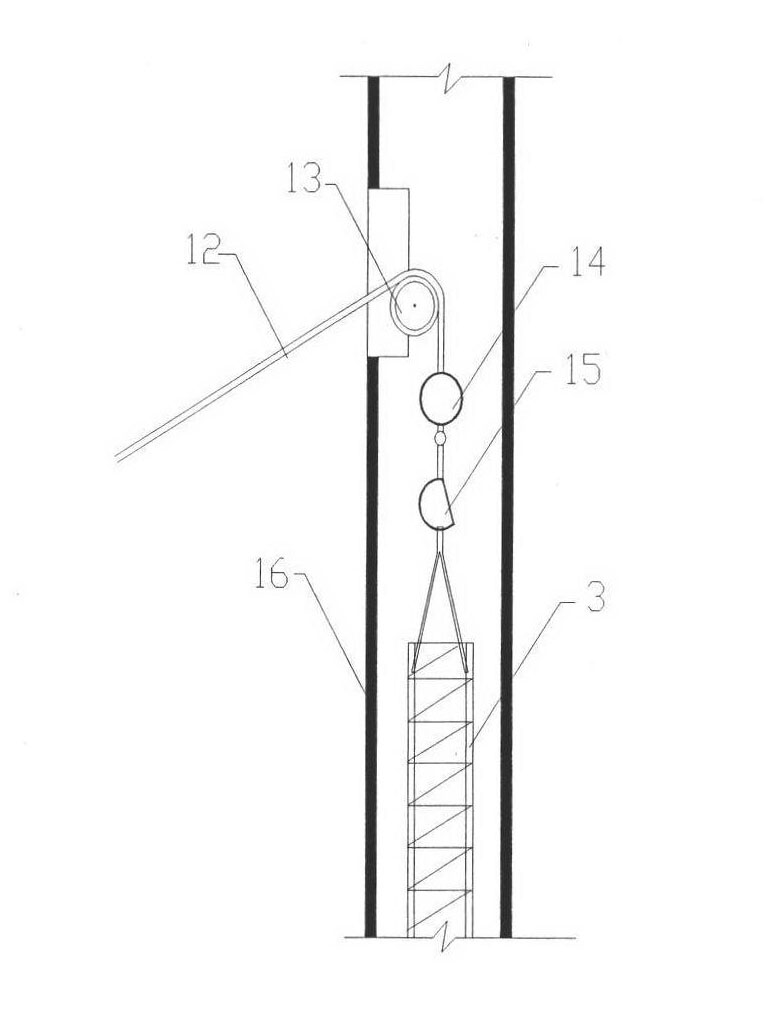

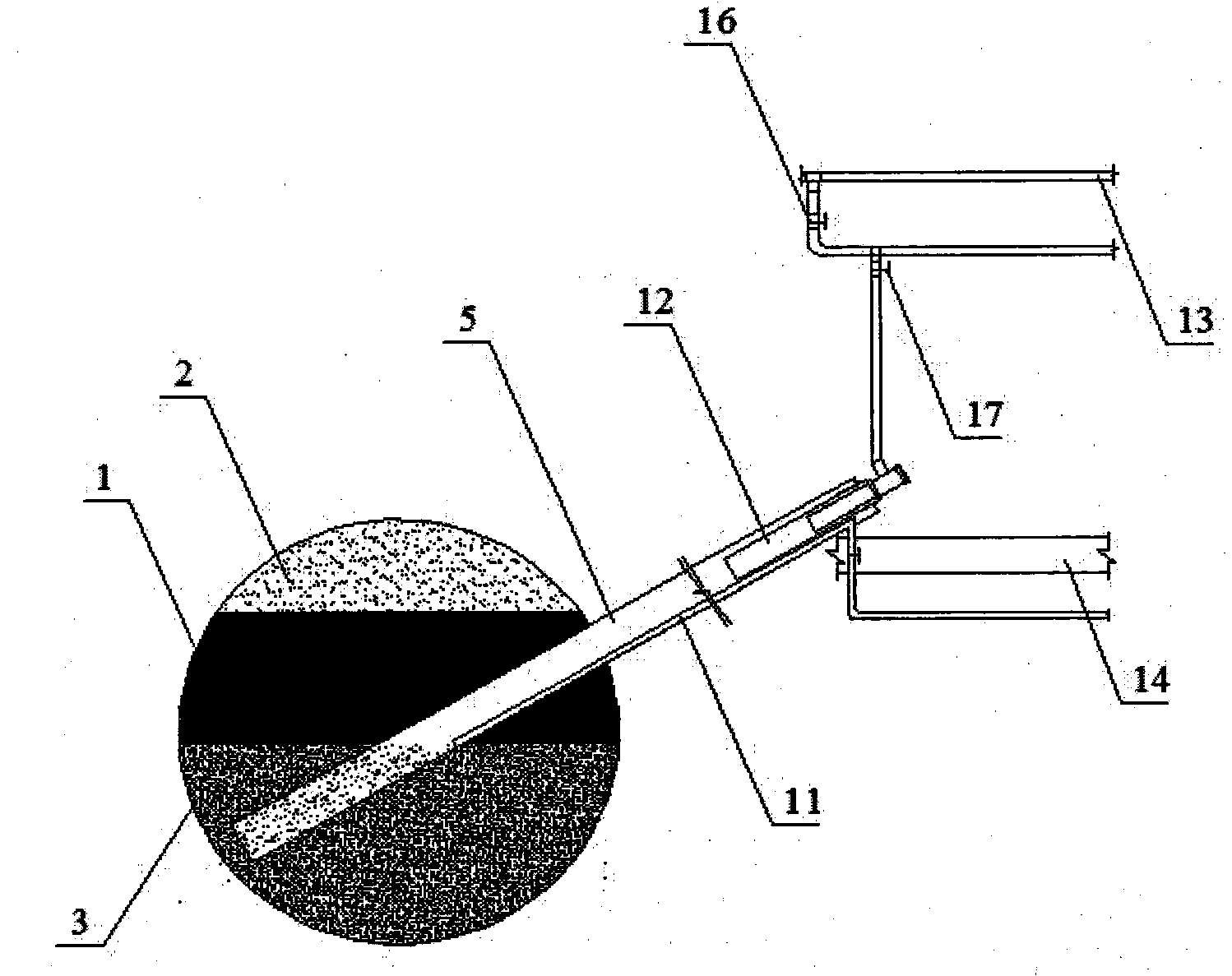

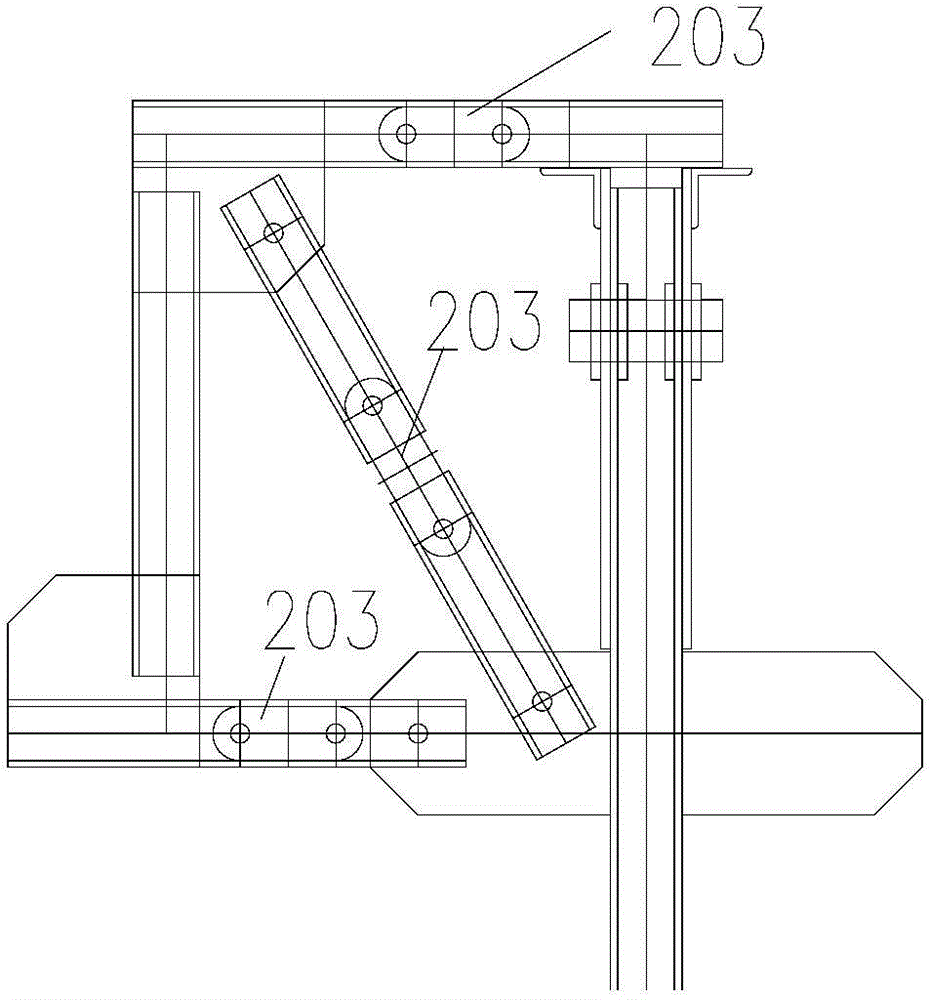

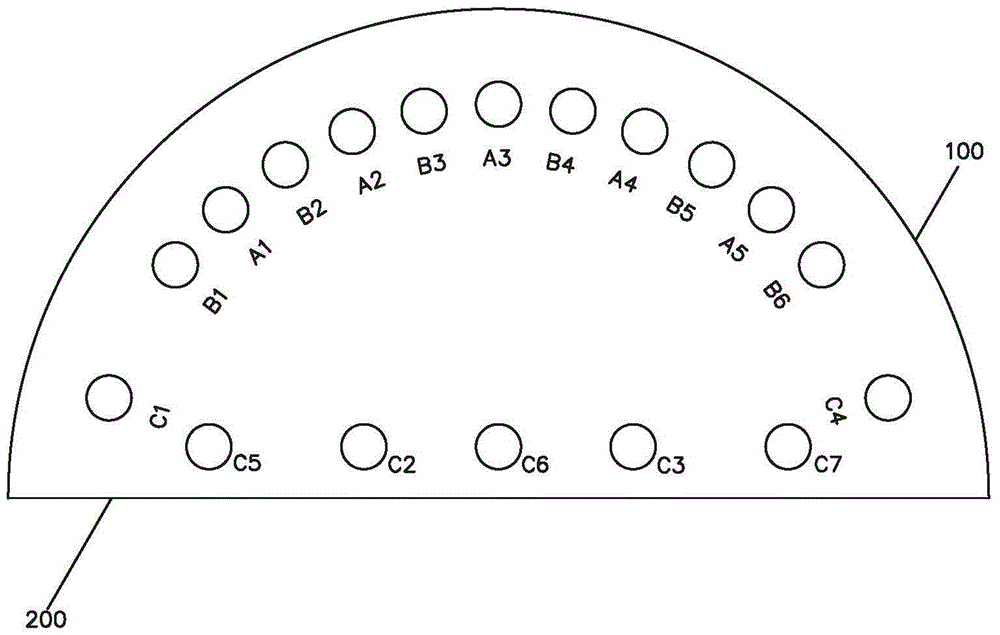

Carrying device of three advance geology forecasting instruments on TBM (Tunnel Boring Machine)

ActiveCN103698806AAdvancement of Geological Forecasting AbilitySimple structureSeismic signal receiversRadarEngineering

The invention discloses a carrying device of three advance geology forecasting instruments on a TBM (Tunnel Boring Machine). The carrying device comprises a transmission supporting and shock absorption device, a telescopic transmission system and an instrument cabin protection device, wherein the transmission supporting and shock absorption device is convenient for carrying power supplying / measuring electrodes, and installing seismic wave vibration exciters and a seismic wave sensor on a TBM cutter disk; the telescopic transmission system is convenient for carrying an oblique single-hole geology radar transmitting and receiving antenna above a TBM rear support; the instrument cabin protection device plays a protection role when the TBM is in boring operation and is convenient for carrying an instrument cabin controlling the whole detection work at the inner part of the TBM rear support. According to the carrying device disclosed by the invention, the integration of detection instruments and the TBM is realized, the detection space and the detection time of a full-face excavation tunnel are fully utilized, the detection instruments are automatically and quickly distributed on a working surface of the TBM, an advance detection hole is drilled, the three advance geology forecasting instruments are successfully carried, the detection efficiency of advance geology forecasting and the automation and rapidity level are increased, and the advance geology forecasting capacity of the TBM is obviously enhanced.

Owner:山东百廿慧通工程科技有限公司

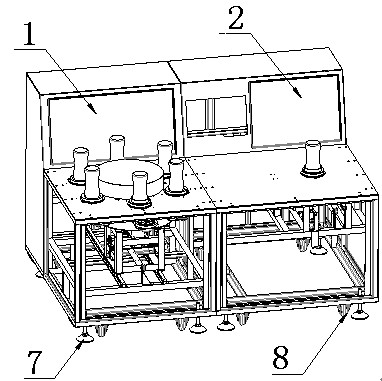

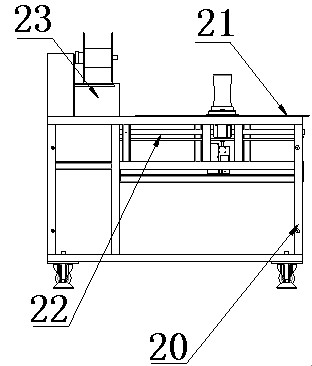

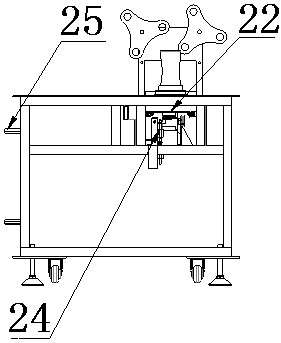

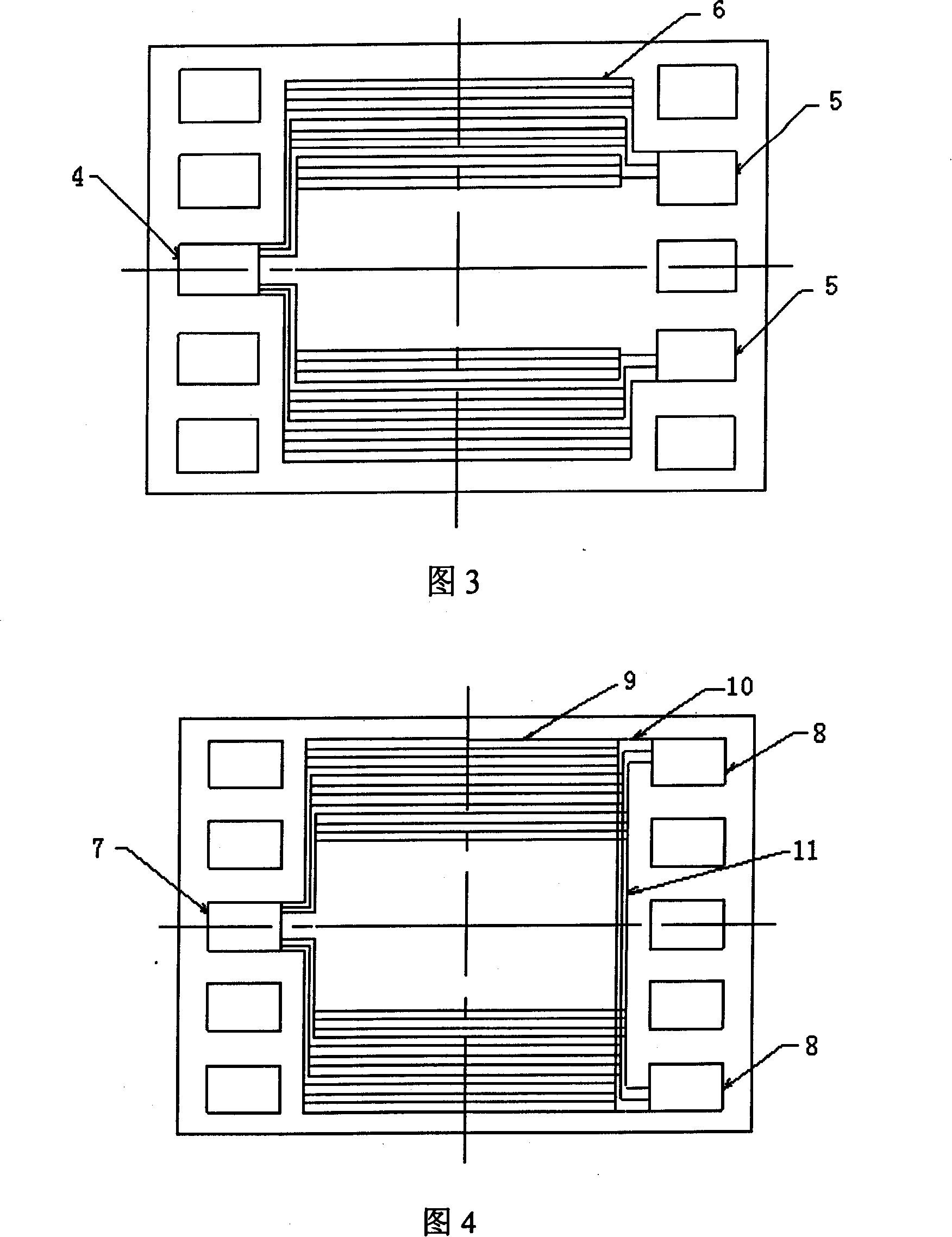

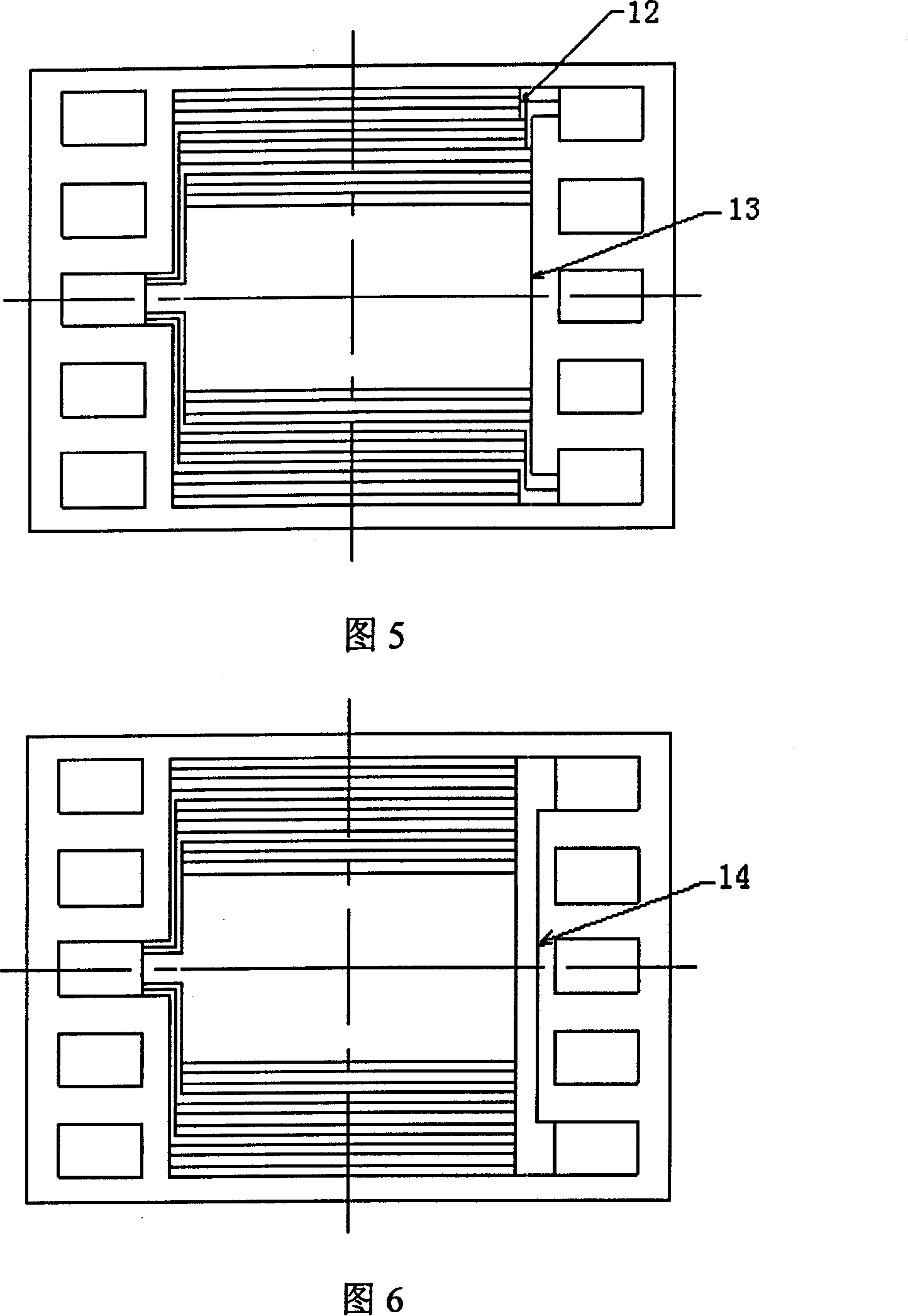

Combined drug delivery machine and drug delivery method thereof

The invention discloses a combined drug delivery machine composed of a single-hole drug delivery mechanism and a porous drug delivery mechanism. The porous drug delivery mechanism comprises a rack, a drug unloading plate, a drug receiving mechanism and a sealing machine, wherein the drug unloading plate and the sealing machine are arranged above the rack; and the drug receiving mechanism is arranged under the drug unloading plate. The single-hole drug delivery mechanism comprises a rack, a drug unloading plate, a rail, a sliding plate and a sealing machine, wherein the drug unloading plate and the sealing machine are arranged on the rack; the sliding plate is arranged on the rail; and the rail is arranged under the drug unloading plate. A drug delivery method based on the combined drug delivery machine, which can deliver drugs by respectively using the single-hole drug delivery mechanism and the porous drug delivery mechanism, comprises the steps of: assembling a medicine bottle and a medicine glass, unloading drugs, sealing the opening of the medicine bottle and taking down the medicine glass. Controlled by mechanically automated programs, the drug delivery speed is fast, the time and the labor power are saved and cross contamination of drugs is avoided, so that the drugs are clean and the machine is easy to disassemble and convenient to maintain.

Owner:SICHUAN NEO GREEN PHARMA TECH DEV

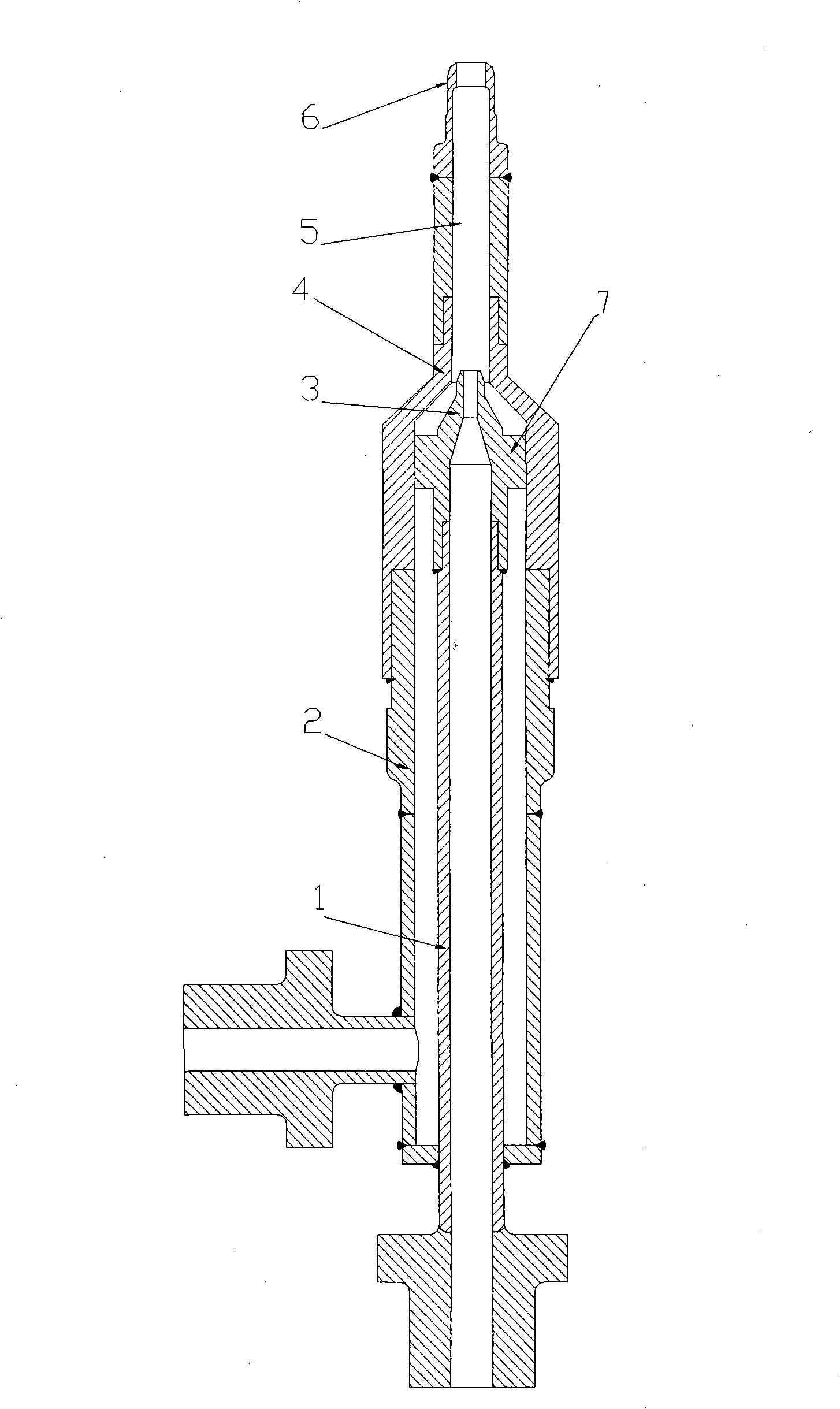

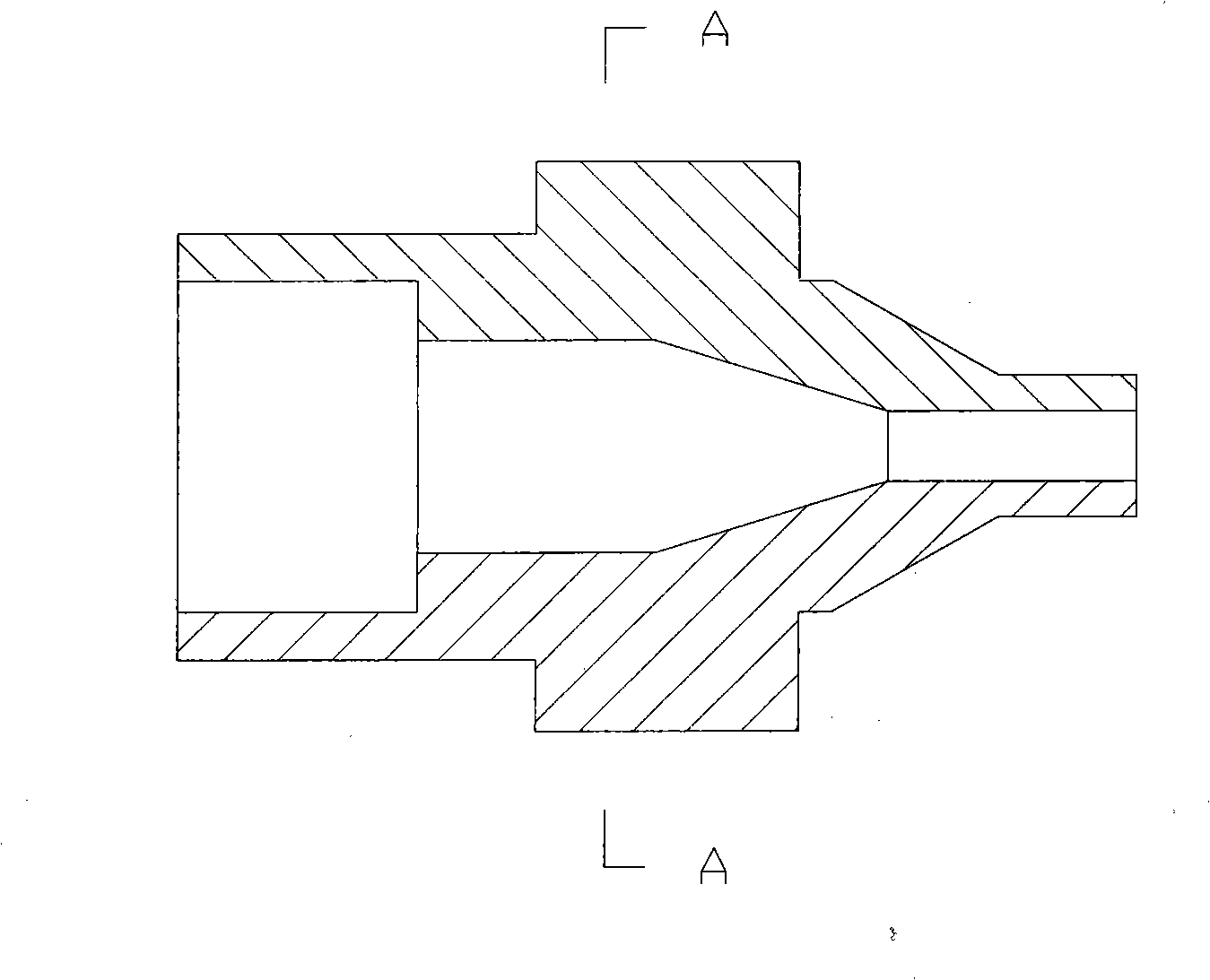

High-speed jet gas-liquid mixing-phase ejector

InactiveCN101491794AGuaranteed high-speed jetStrong penetrating powerLiquid spraying apparatusJet flowGas phase

The invention relates to a fluid ejector, and aims to provide a gas-liquid mixed phase ejector for ejecting at a high speed. The ejector comprises a liquid phase inlet pipe and a gas phase inlet pipe which are provided with a quick coupler respectively; the tail end of the liquid phase inlet pipe is connected with a liquid phase nozzle; the tail end of the gas phase inlet pipe is connected with a gas phase nozzle; the liquid phase nozzle is a single-hole nozzle; a flow passage from the liquid phase inlet pipe to the liquid phase nozzle has smooth transition; the gas phase inlet pipe encloses the outside of the liquid phase inlet pipe to form an annular gas phase flow passage; the gas phase nozzle encloses the outside of the liquid phase nozzle and is connected with a mixed phase flow passage; the tail end of the mixed phase flow passage is connected with an outlet nozzle; and an outlet circulation sectional area of the outlet nozzle is smaller than that of a circulation sectional area of the mixed phase flow passage. The liquid phase nozzle has high-speed outlet liquid flow, and the high-speed outlet liquid flow is interacted with high-speed gas phase flow in the mixed phase flow passage to realize atomization and once more acceleration, thereby the ejector greatly weakens boundary layer effect on the outlet, avoids that liquid drops separating from main jet flow are convergent to drop on the outlet, and can flexibly adjust and control atomization fineness and distribution.

Owner:ZHEJIANG UNIV +1

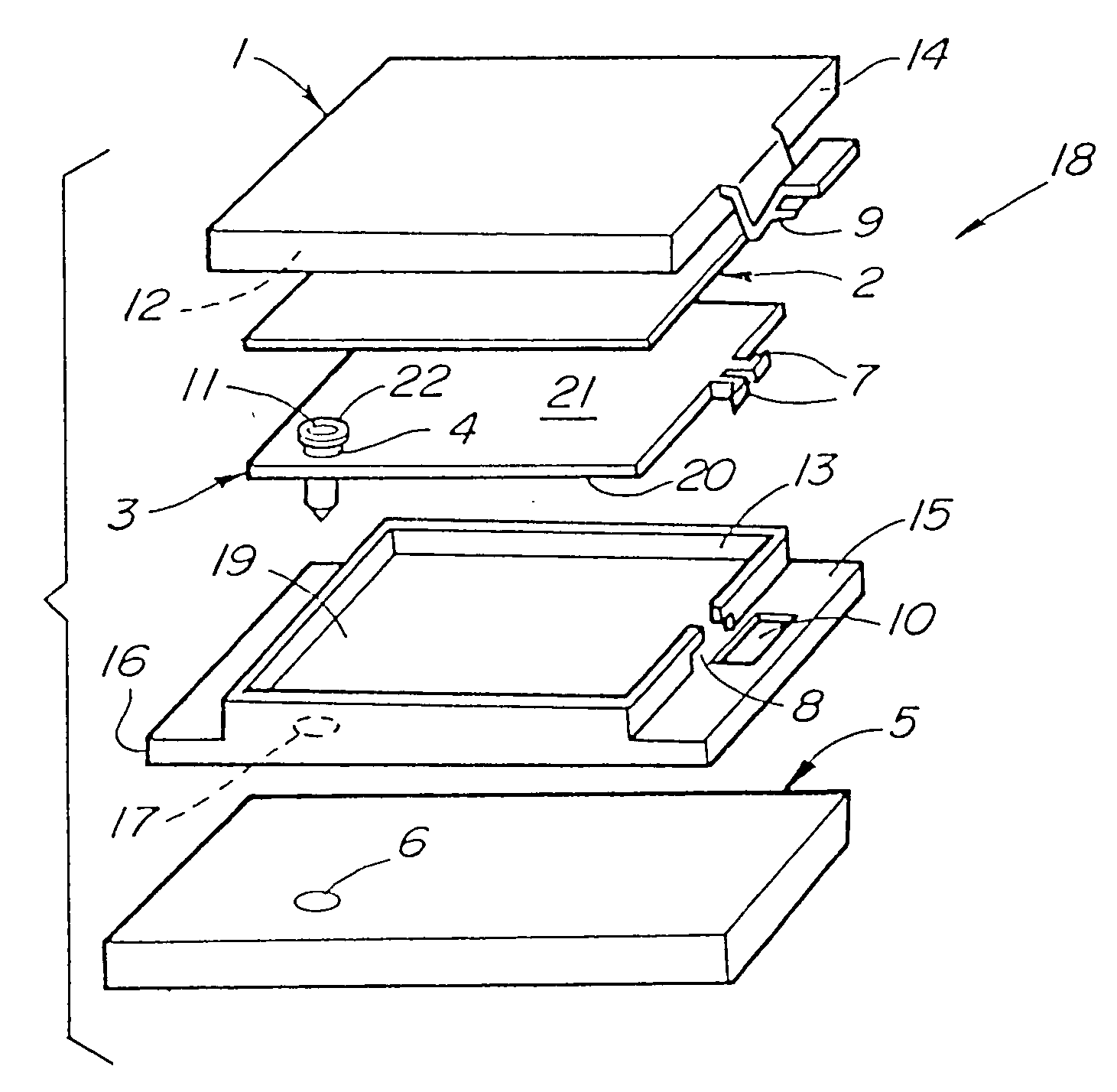

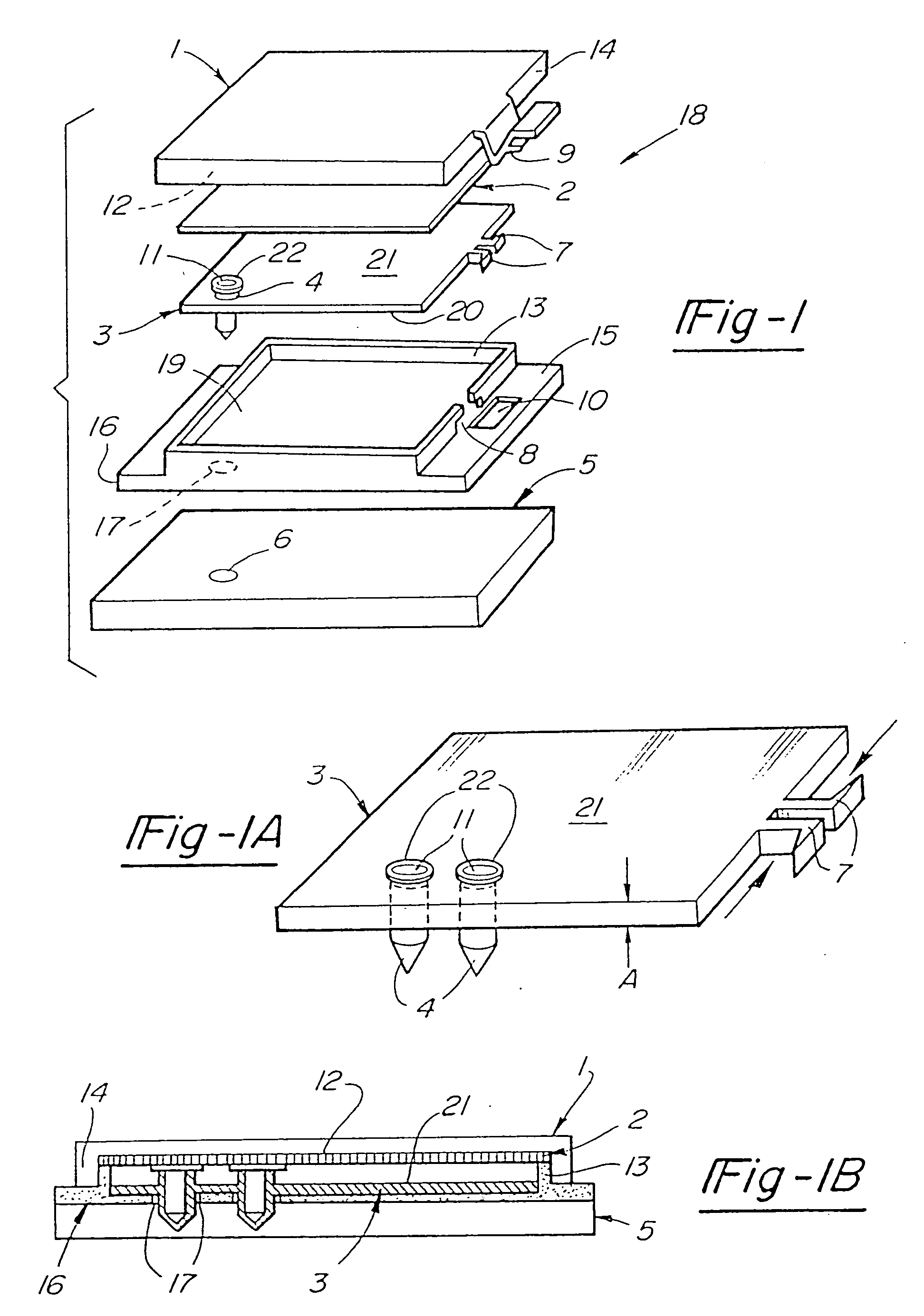

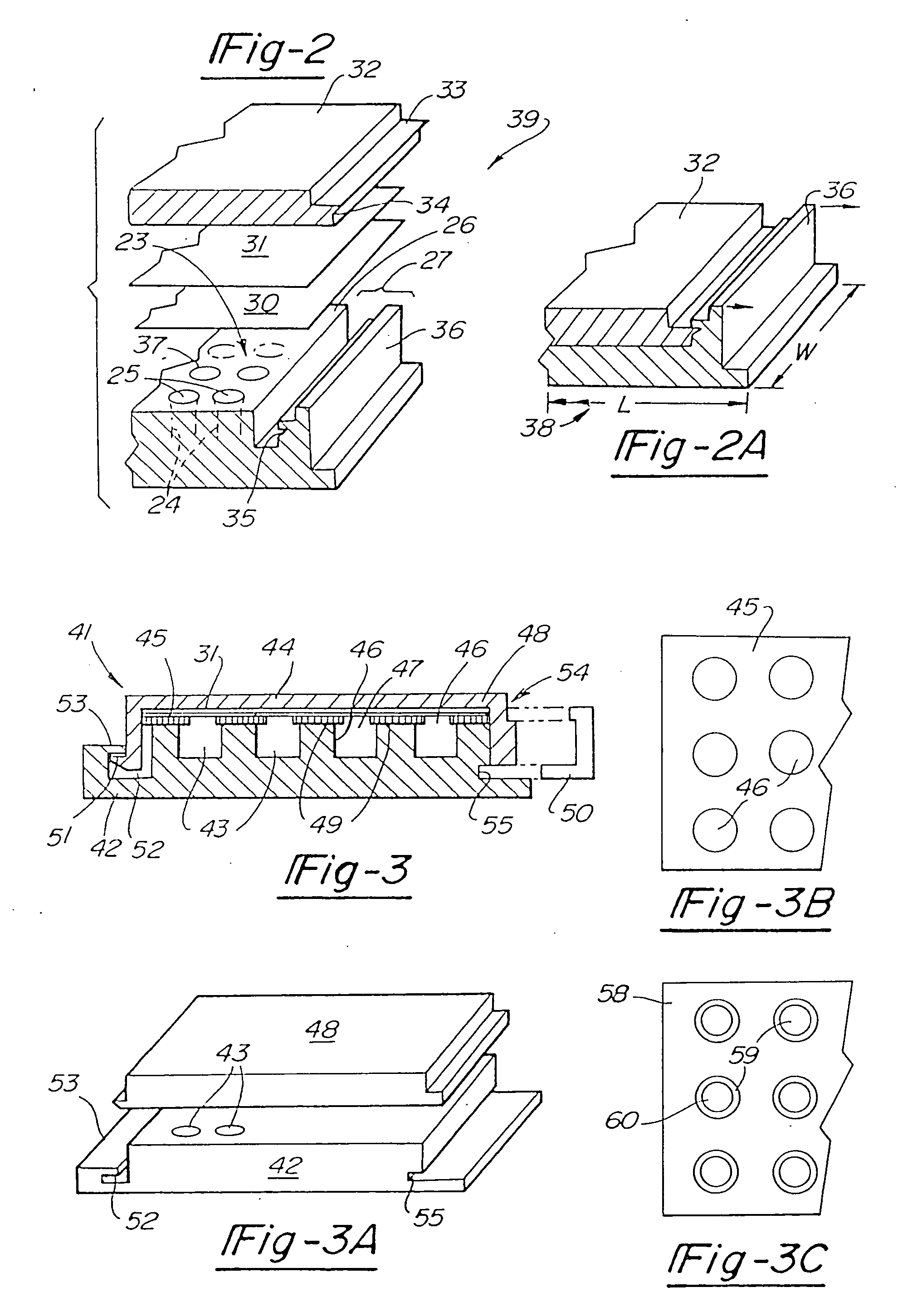

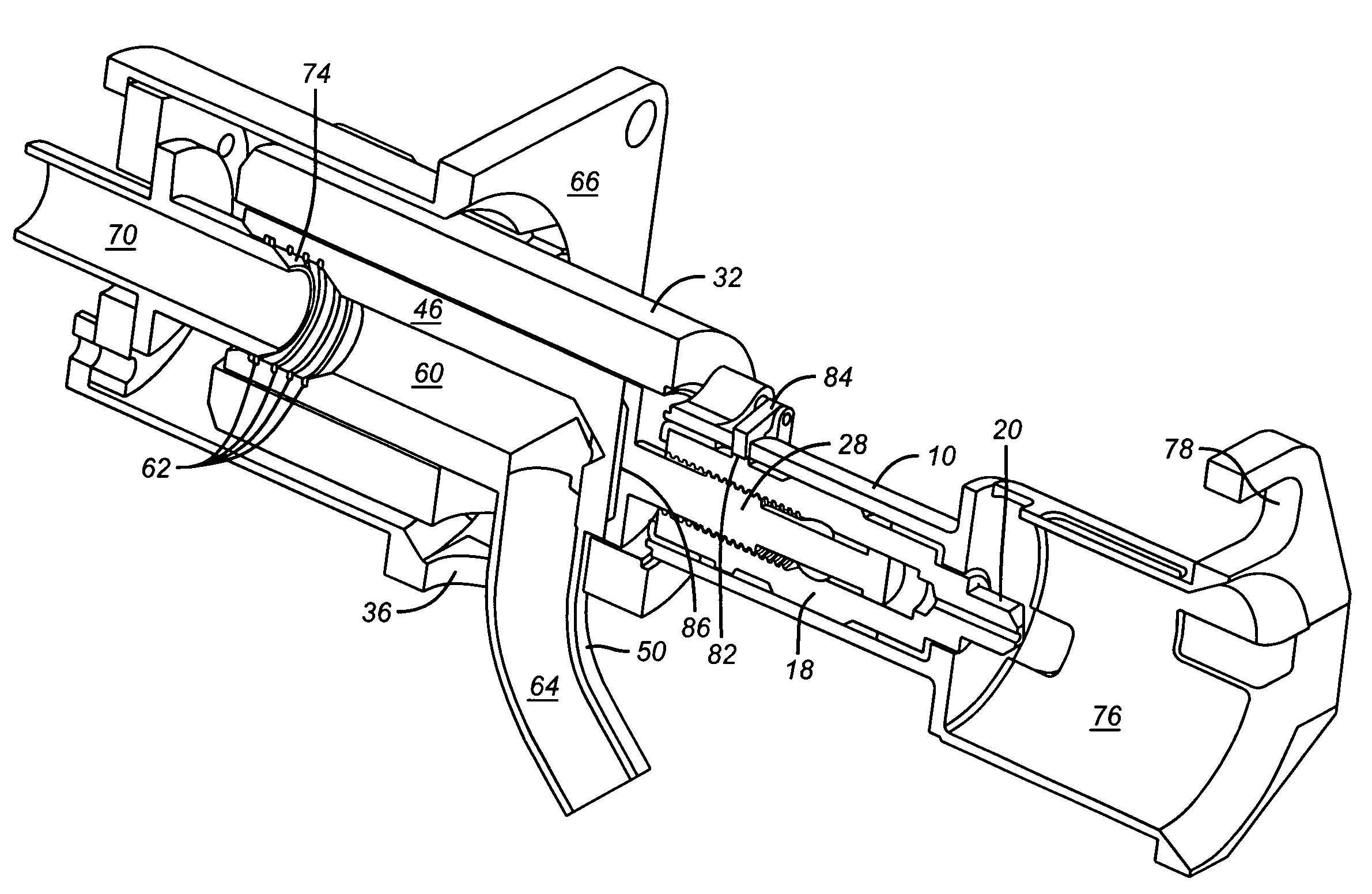

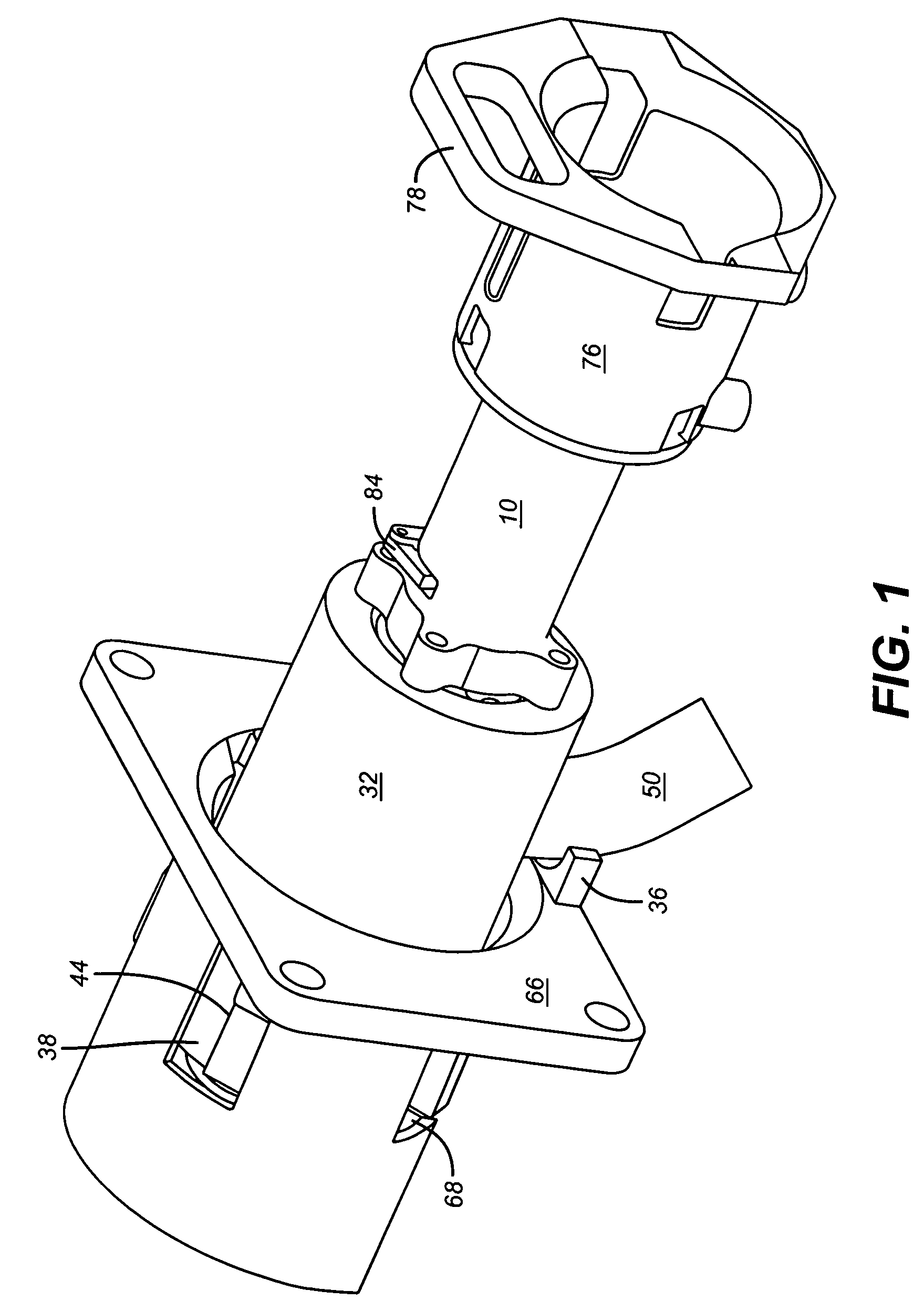

Method and apparatus for preventing cross-contamination of multi-well test plates

InactiveUS20050019225A1Avoid pollutionAnalysis using chemical indicatorsLaboratory glasswaresWell testEngineering

A multi-well plate which prevents cross-contamination of samples through the use of a resilient gasket which covers a majority of the top of the plate and is compressed by a lid having a clamp assembly. It thus provides a sealing assembly for arrays of containers of any size or shape. The gaskets may be unitary sheets with or without an array of openings corresponding to the well openings or may consist of discrete single well gaskets. A multi-tube array is also provided which can be sealed without the need of a gasket or tight-fitting caps. A multi-well plate is also disclosed in which samples can be gas-equilibrated without the risk of microbial contamination.

Owner:SANADI ASHOK RAMESH

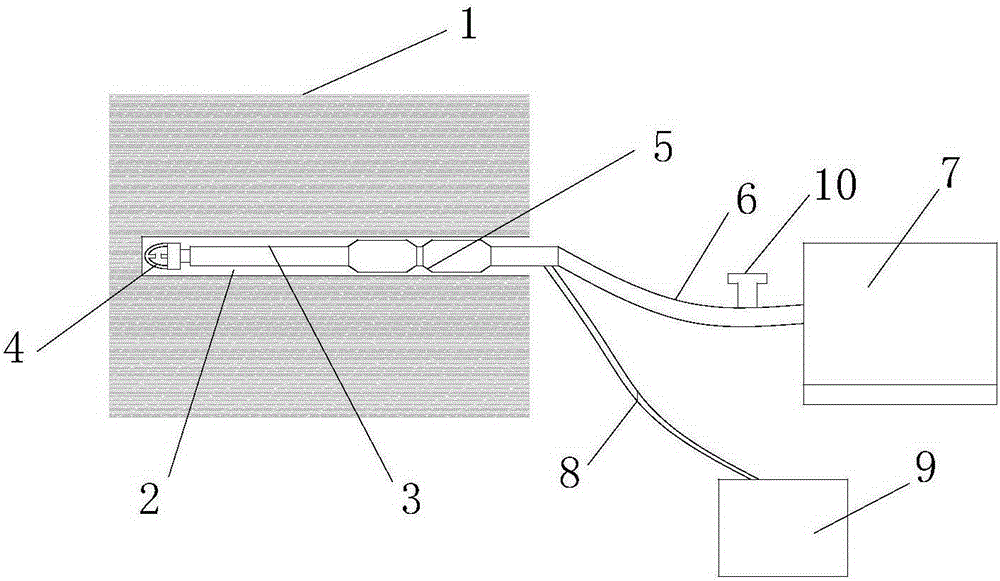

Coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method

ActiveCN105275443AIncrease the number of cracksIncrease the lengthFluid removalGas removalShock waveHigh energy

The invention relates to a coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method suitable for increasing extraction radius and total extraction amount of gas extraction drilling. The method comprises the following steps that: a borehole extends from one side of a laneway to a coal seam is constructed; a high-voltage pulse discharger which is installed at the front end of a fracturing steel pipe is sent to the bottom of the borehole; a hole packer, which is separated from the orifice of the borehole by 2 to 3m, is installed on the borehole; the outer end of the fracturing steel pipe is connected with a high-pressure pump station through a high-pressure rubber hose; and the high-voltage pulse discharger is connected with a high-voltage electric pulse generator through a cable; after water with a certain pressure is injected into the borehole, the high-voltage electric pulse generator is started so as to apply high-power electric knock assisted hydraulic fracturing to the coal seam; after the high-power electric knock assisted hydraulic fracturing, the high-voltage pulse discharger and the fracturing steel pipe are quitted; and a gas extraction pipeline is connected into the borehole. According to the method of the invention, high energy released by high-voltage electric pulses is utilized to form shock waves in the water, and therefore, a large number of cracks can be formed in the coal seam, and primary cracks are extended. With the method adopted, the permeability coefficient of a coal body can be increased by 100 to 300 times, and single-hole gas extraction efficiency can be effectively improved.

Owner:CHINA UNIV OF MINING & TECH

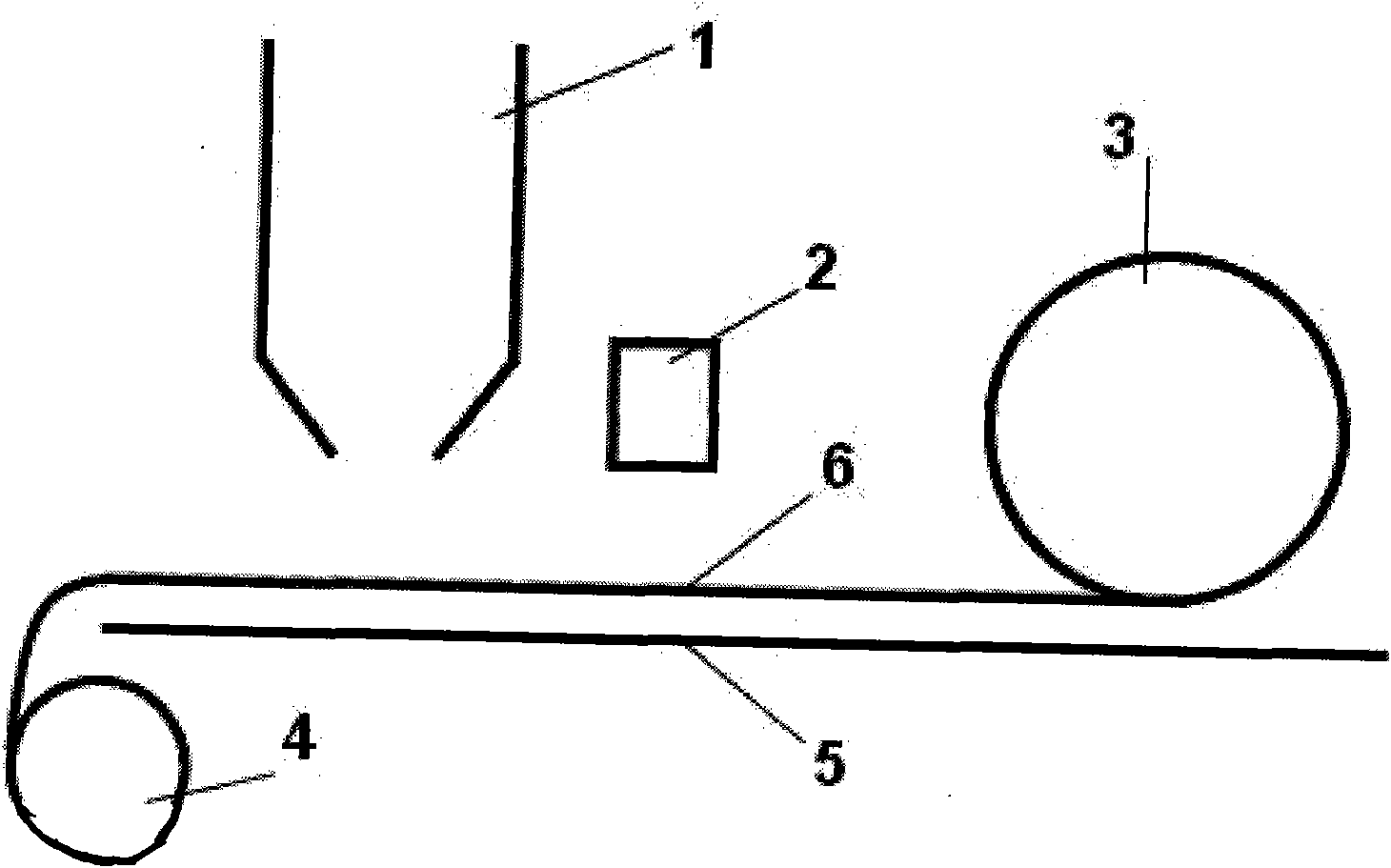

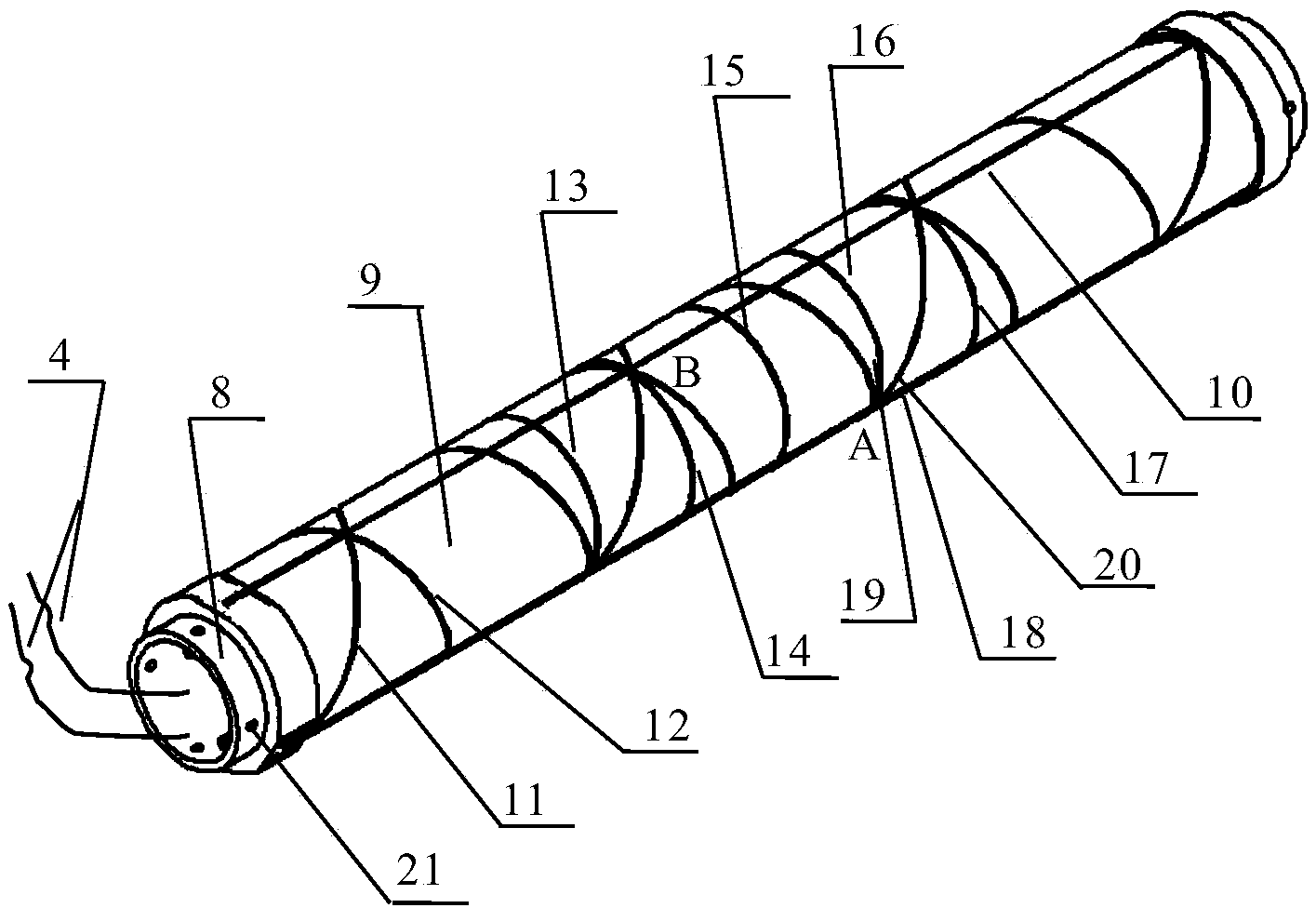

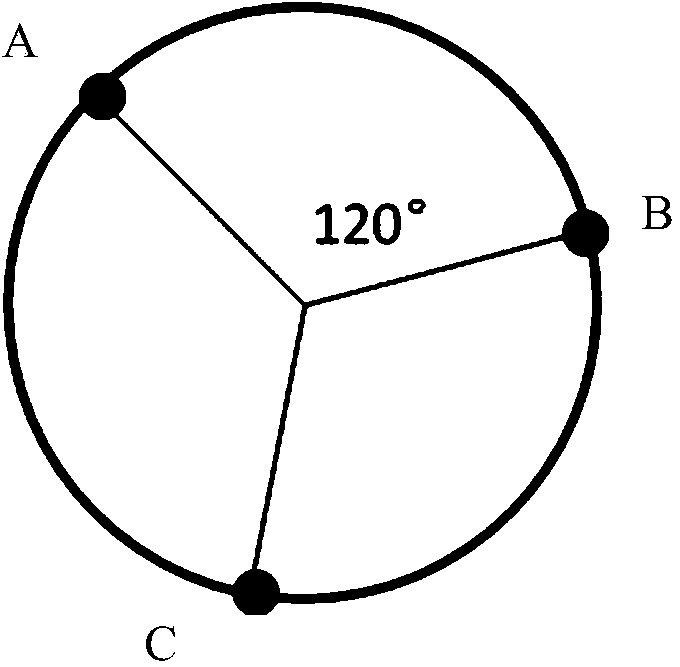

Glass-steel reinforced plastic pipe and manufacturing method thereof

InactiveCN101832430AImprove mechanical propertiesImprove anti-corrosion performanceRigid pipesGlass fiberHoneycomb

The invention relates to a glass-steel reinforced plastic pipe which comprises a plastic internal mold pipe and a glass-steel reinforced layer, wherein the glass-steel reinforced layer is prepared by winding on the plastic internal pipe and adopting a winding technology for producing a glass steel pipe; the plastic internal mold pipe is a common PVC (Polyvinyl Chloride) pipe, a common PE (Polyethylene) pipe or a common PP (Polypropylene) pipe conventionally; and the internal mold pipe can be a single-hole pipe form or a combined perforated pipe form formed by binding a plurality of single-hole plastic pipes and also can be a ready-made porous plastic pipe (such as a PVC honeycomb pipe or a plum pipe). The glass-steel reinforced plastic adopts a form of evenly and repeatedly winding glass fiber on the plastic internal mold pipe in a meshy way, thereby enabling the internal and external binding force to be far stronger than that of reinforced forms of adhering, fastening mechanical fasteners and extruding; and the pipe has the characteristics of excellent mechanical property, favorable anticorrosion property and wearing resistance as well as favorable tenacity and is especially suitable for pipeline construction which needs to be deeply buried and externally expose.

Owner:江浩

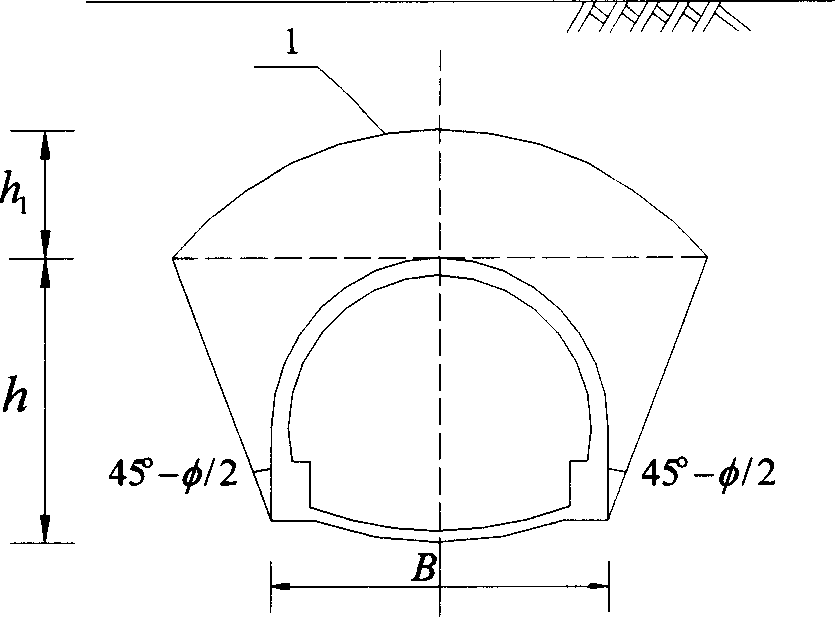

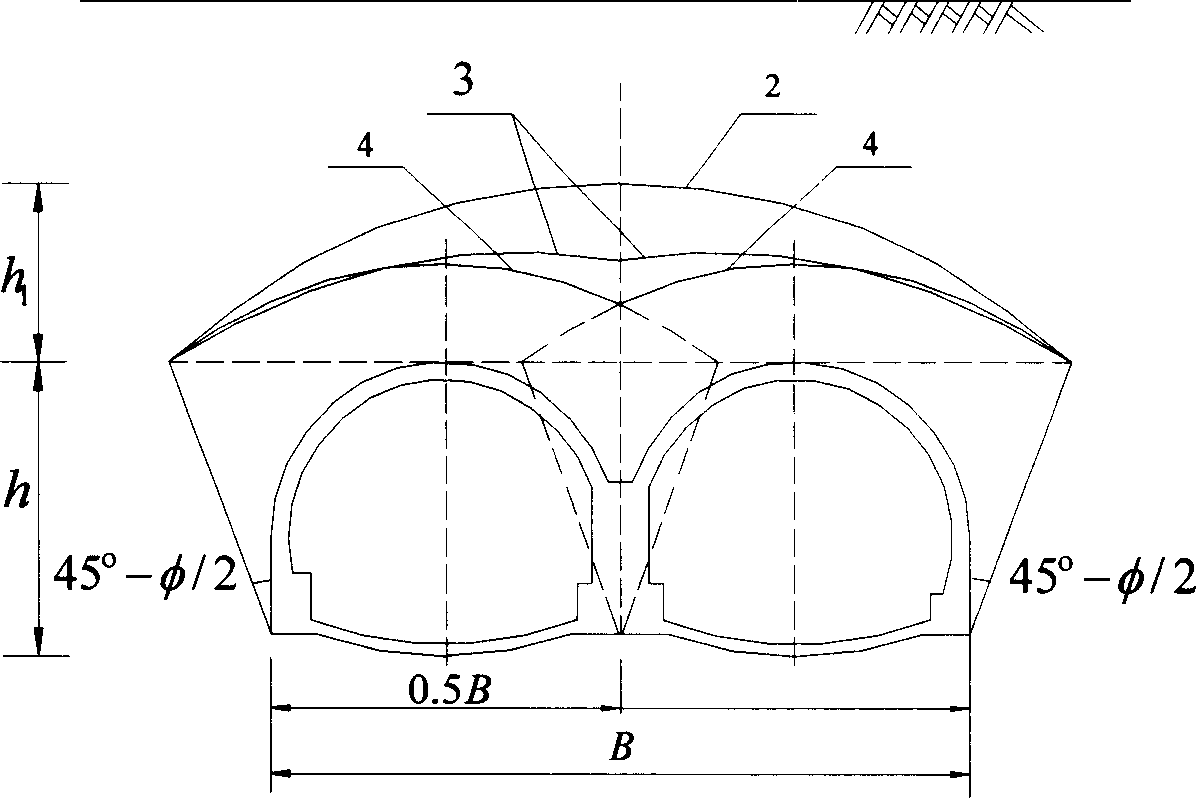

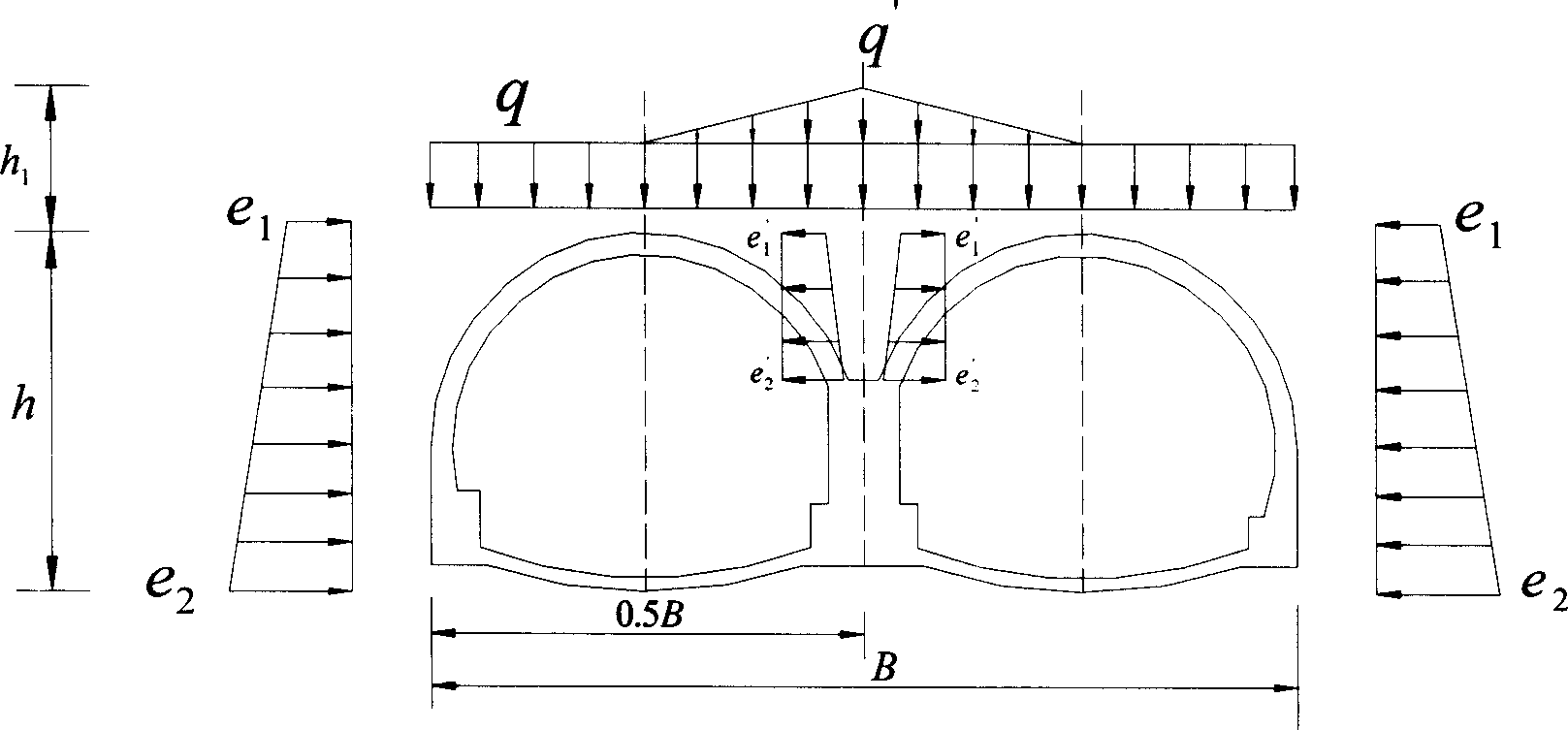

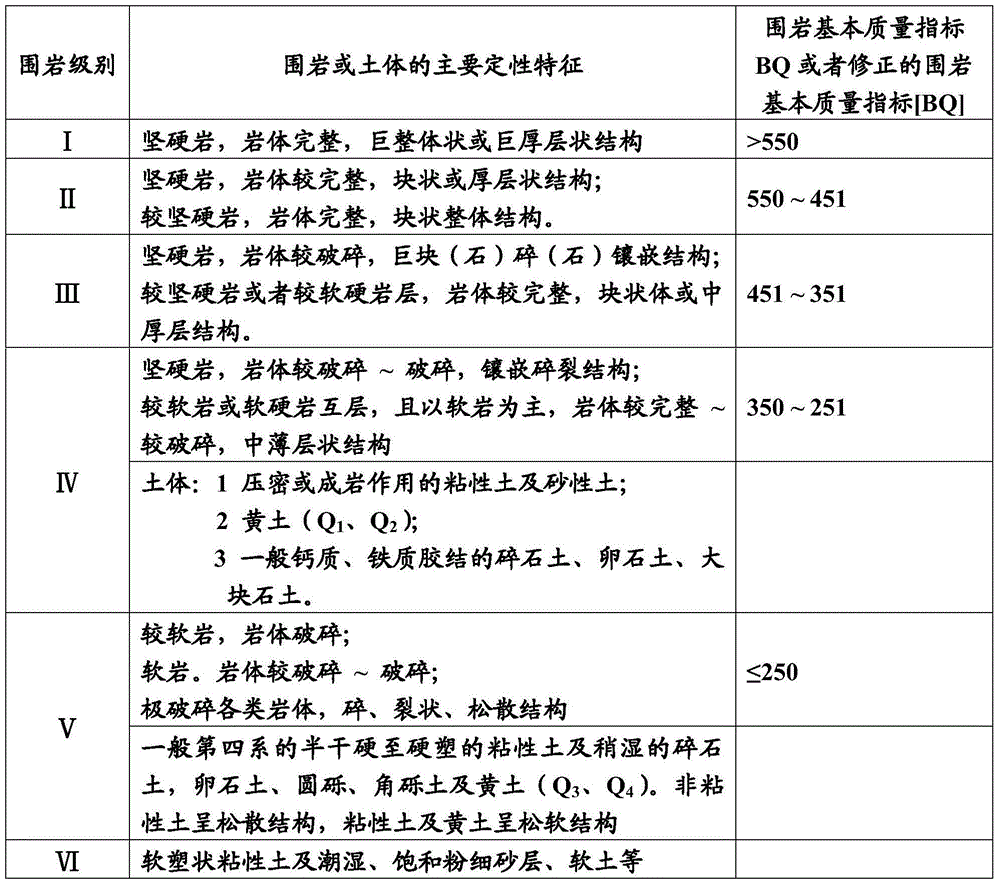

Method for determining load of multiple-arch tunnel

A method for confirming load of multi-arch tunnel includes confirming load mode of deep buried multi-arch tunnel based on suppose of double caving arch, confirming deep-shallow buried boundary of multi-arch tunnel according to deep-shallow burying boundary dividing manner in JTGD70-2004 specification for single hole tunnel and confirming load mode of shallow buried multi-arch tunnel by considering dead weight of triangle block at wall top in multi-arch tunnel.

Owner:TONGJI UNIV

Method for expanding excavation of large-diameter shield tunnel for subway station construction through pile arch wall support

InactiveCN104632235AFlexible construction planningRaise the ratioUnderground chambersTunnel liningSubway stationFlue

The invention relates to a method for expanding excavation of a large-diameter shield tunnel for subway station construction through a pile arch wall support. The method comprises the steps that a single-hole double-track tunnel of a station portion is used as a part of the station structure, pipe segment structures at the bottom and the top of a shield are reserved, and a bottom longitudinal beam, a middle partition wall and a top longitudinal beam of the station structure are constructed; the remaining station structures on the two sides of the shield tunnel are formed through expanding excavation, an air flue at the end of the station is used as a working plane, expanding excavation is carried out on the two sides of the large-diameter shield tunnel by the adoption of a hole pile method, the pipe segment structures on the two sides of the shield are removed in the expanding excavation process, and meanwhile the connection measure between a cast-in-place structure and the remaining pipe segments is taken to form the single-layer double-span side platform subway station. The method for expanding excavation of the large-diameter shield tunnel for subway station construction through the pile arch wall support has the advantages of being definite in stress, reasonable in conversion, convenient to construct and the like.

Owner:BEIJING MUNICIPAL CONSTR +3

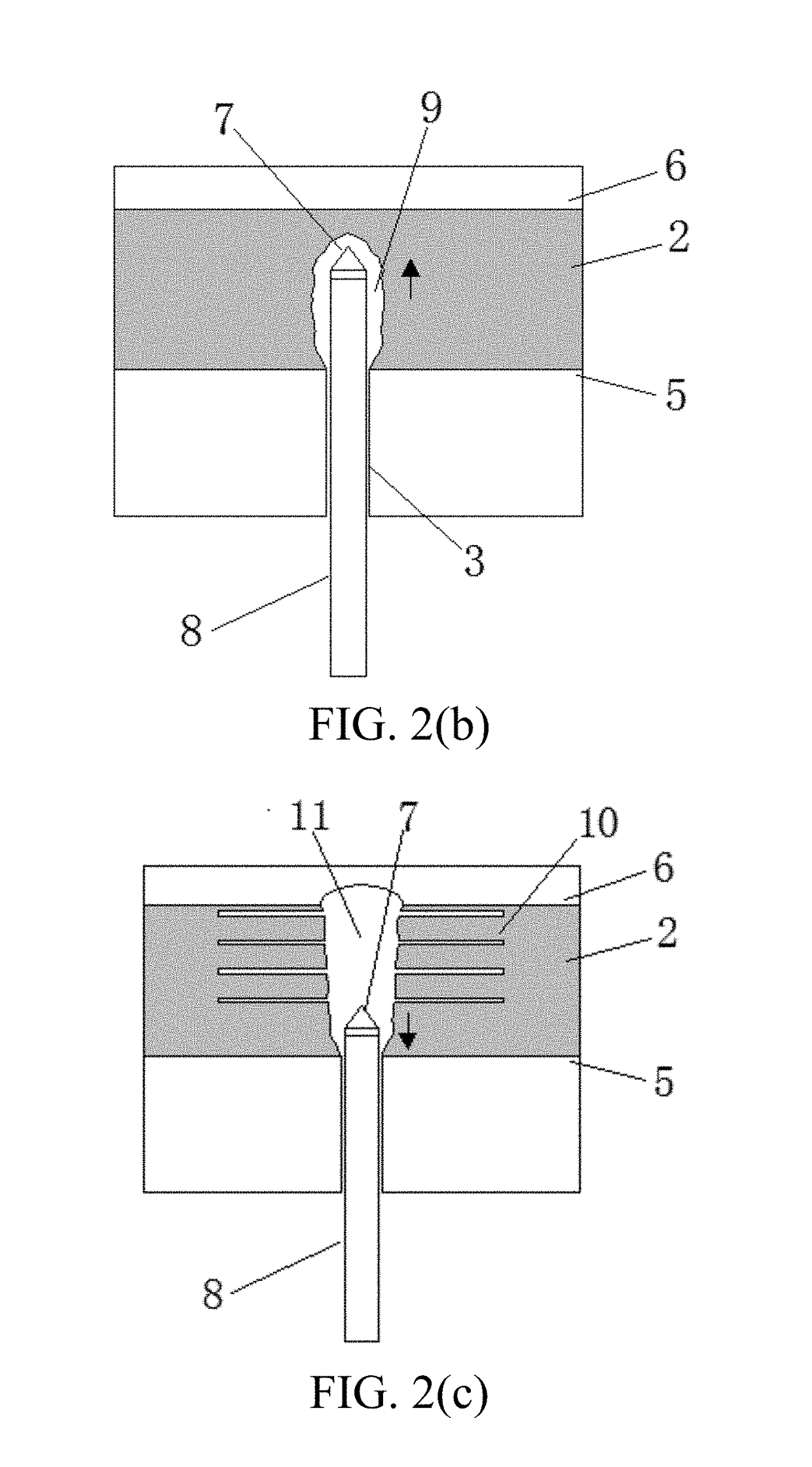

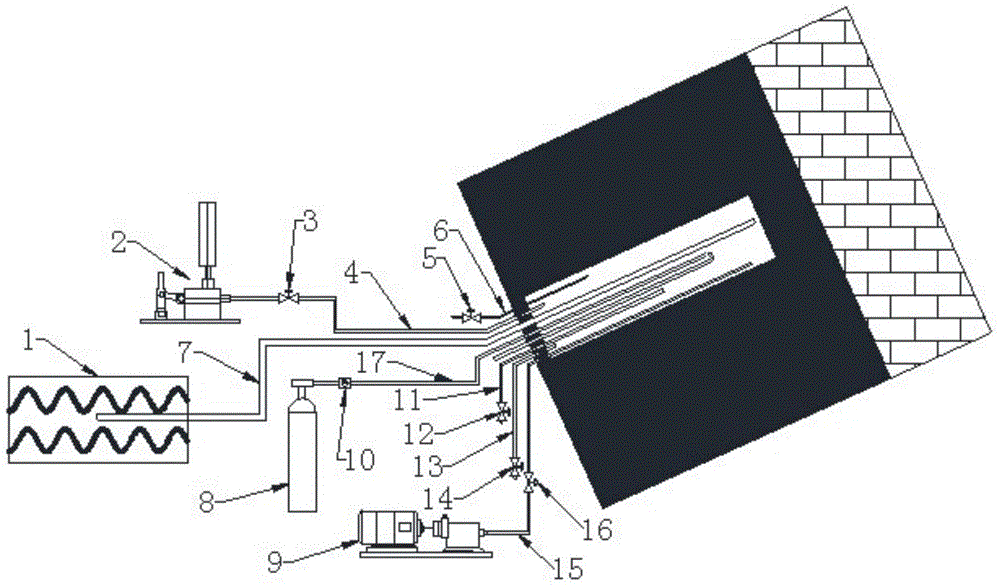

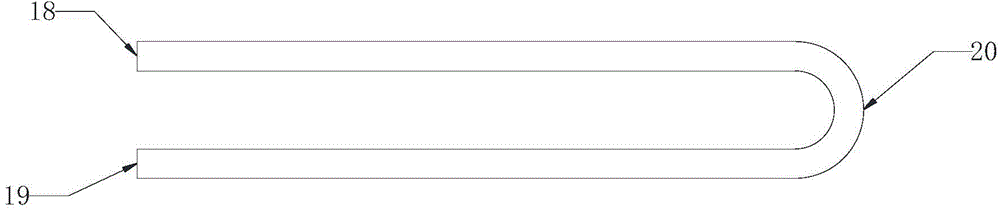

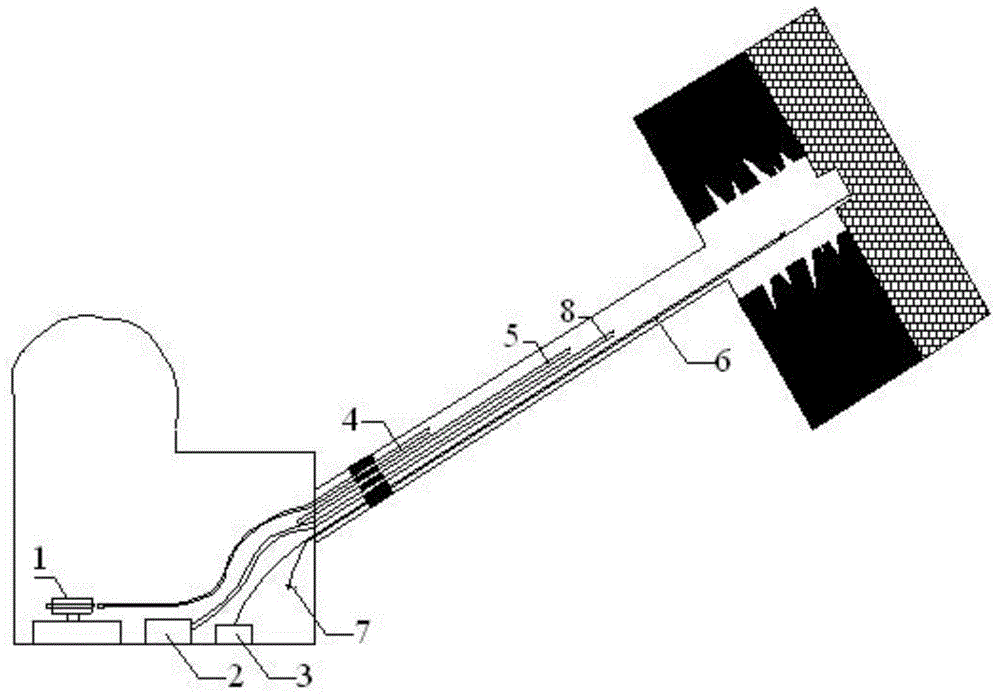

Method of performing combined drilling, flushing, and cutting operations on coal seam having high gas content and prone to bursts to relieve pressure and increase permeability

ActiveUS20170370156A1Simple processEfficient amplificationConstructionsLiquid/gas jet drillingWell drillingDesorption

The present invention relates to a “drilling-flushing-slotting” coupled pressure relief and permeability increasing method for a high gas outburst coal seam, which is more particularly suitable for the pressure relief and permeability increasing when gas of a roadway band of the high gas outburst coal seam is pre-extracted through crossing boreholes. On the basis of the crossing borehole pre-extraction measures for the coal seam gas, the hydraulic flushing and the hydraulic slotting are reasonably combined, and a “drilling-flushing-slotting” dedicated device is utilized to implement the coupled operation of “low pressure drilling-medium pressure flushing-high pressure slotting” in a borehole, so that the coal in the pre-extraction area is deformed and moved to form network cracks, passages are provided to the desorption flow of the gas, and the gas is easier to extract. The method can enlarge the single-hole pressure relief influence range, increase the gas permeability of the coal seam, improve the gas extraction efficiency, reduce the number of pre-extraction boreholes, shorten the pre-extraction time and have good applicability to the coal seams in different occurrence states. The present invention can reduce the number of the crossing boreholes by 32.5% and can reduce the length of each crossing borehole by 42.9%, is remarkable in coal roadway regional outburst eliminating effect, and obviously increases the tunneling speed.

Owner:CHINA UNIV OF MINING & TECH

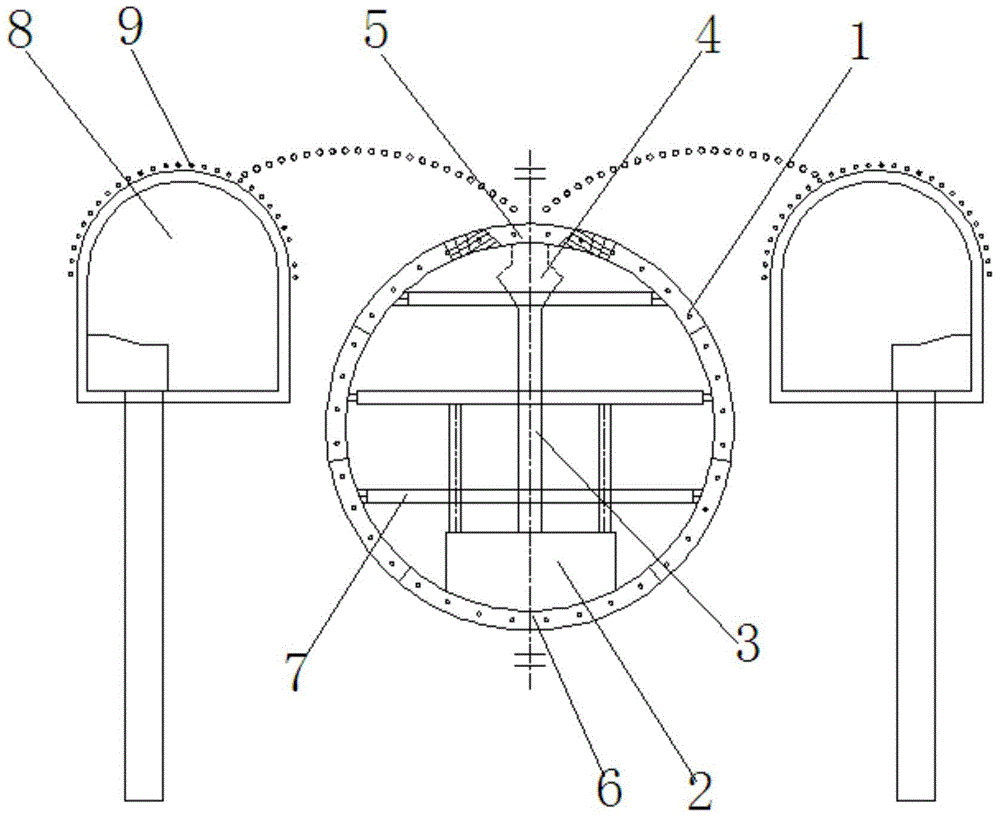

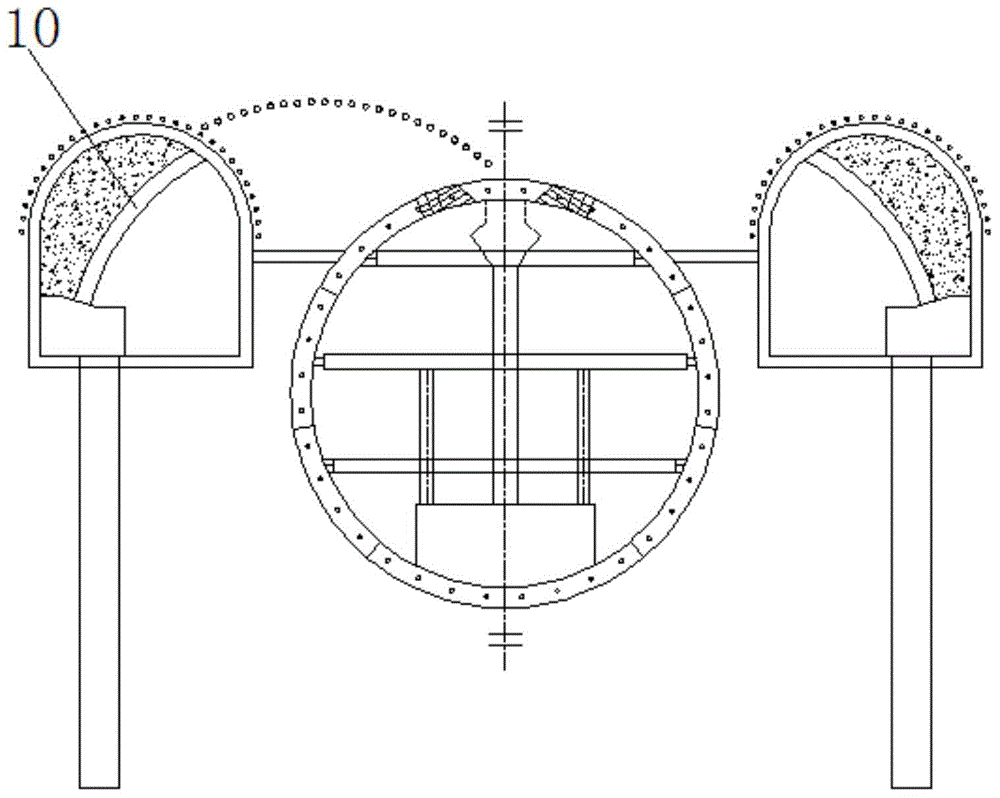

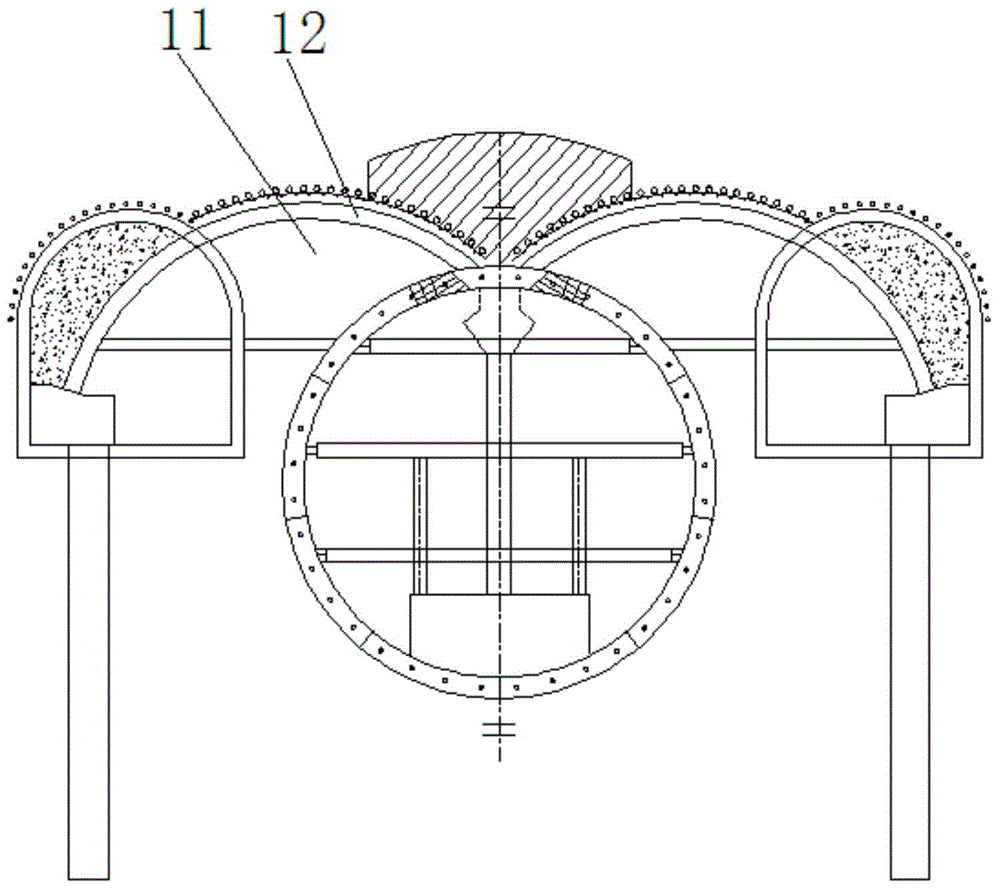

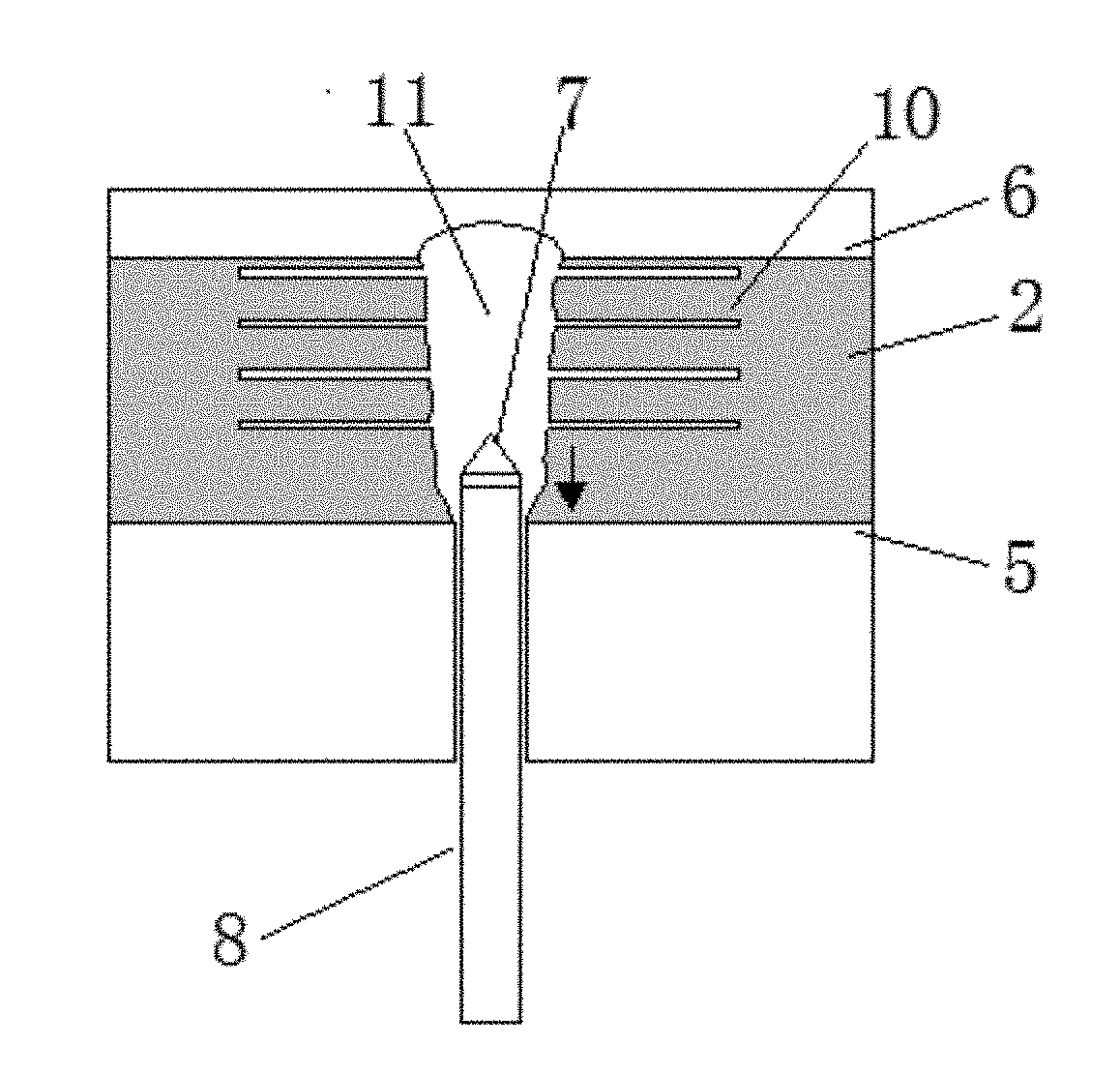

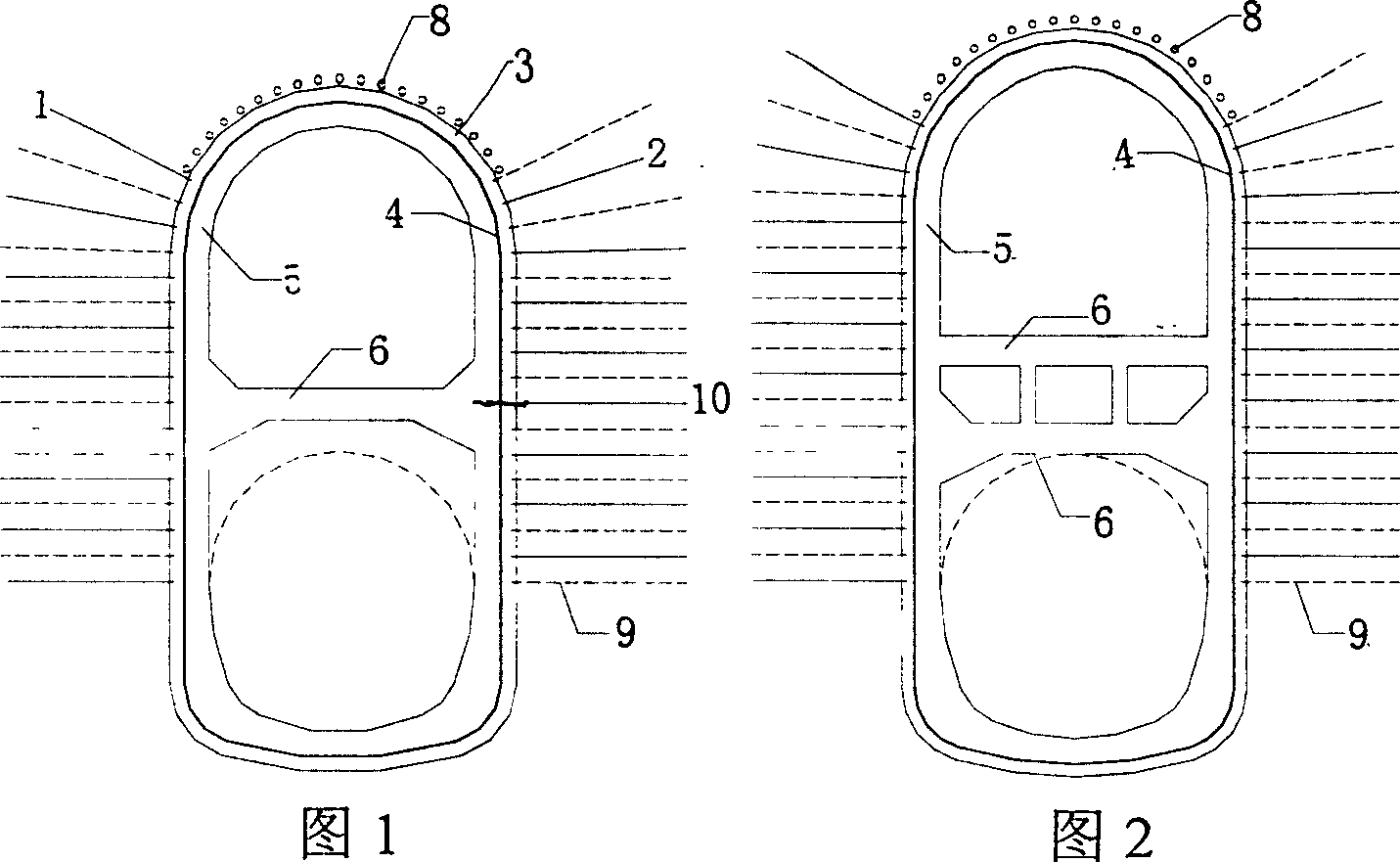

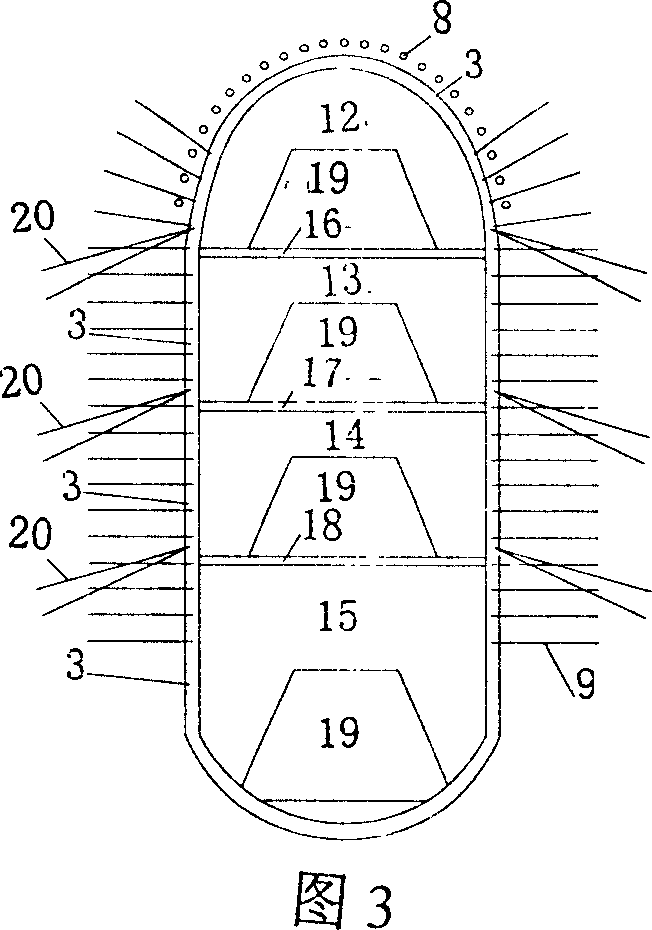

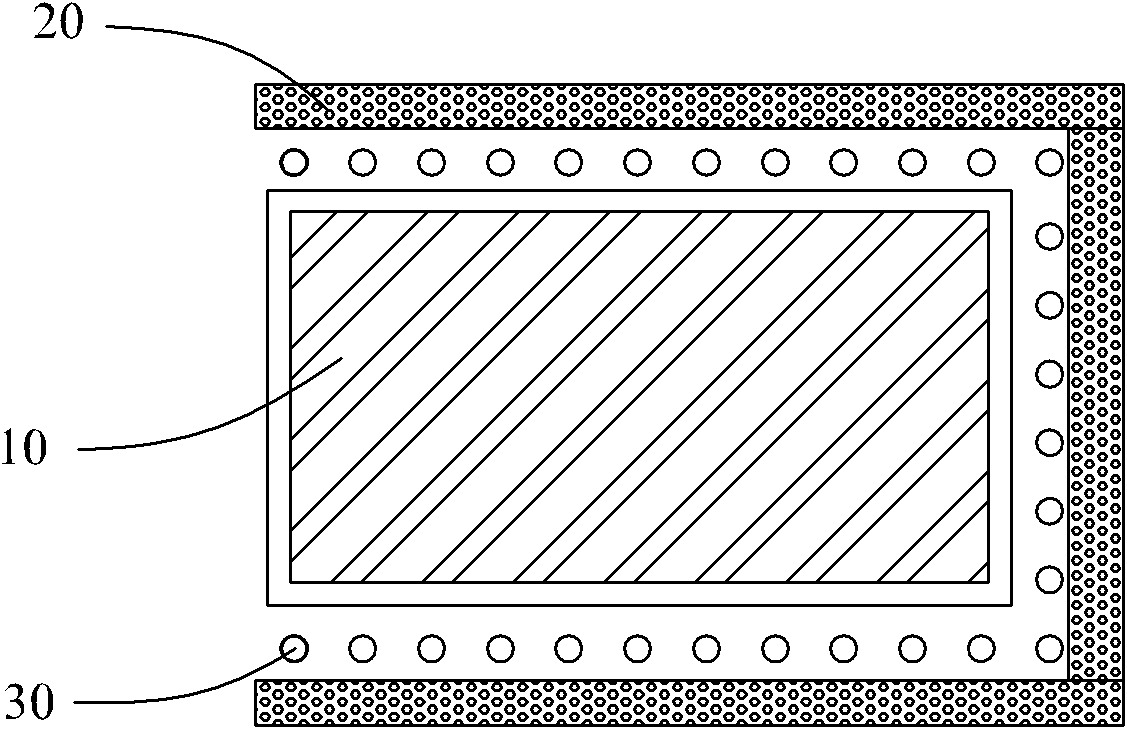

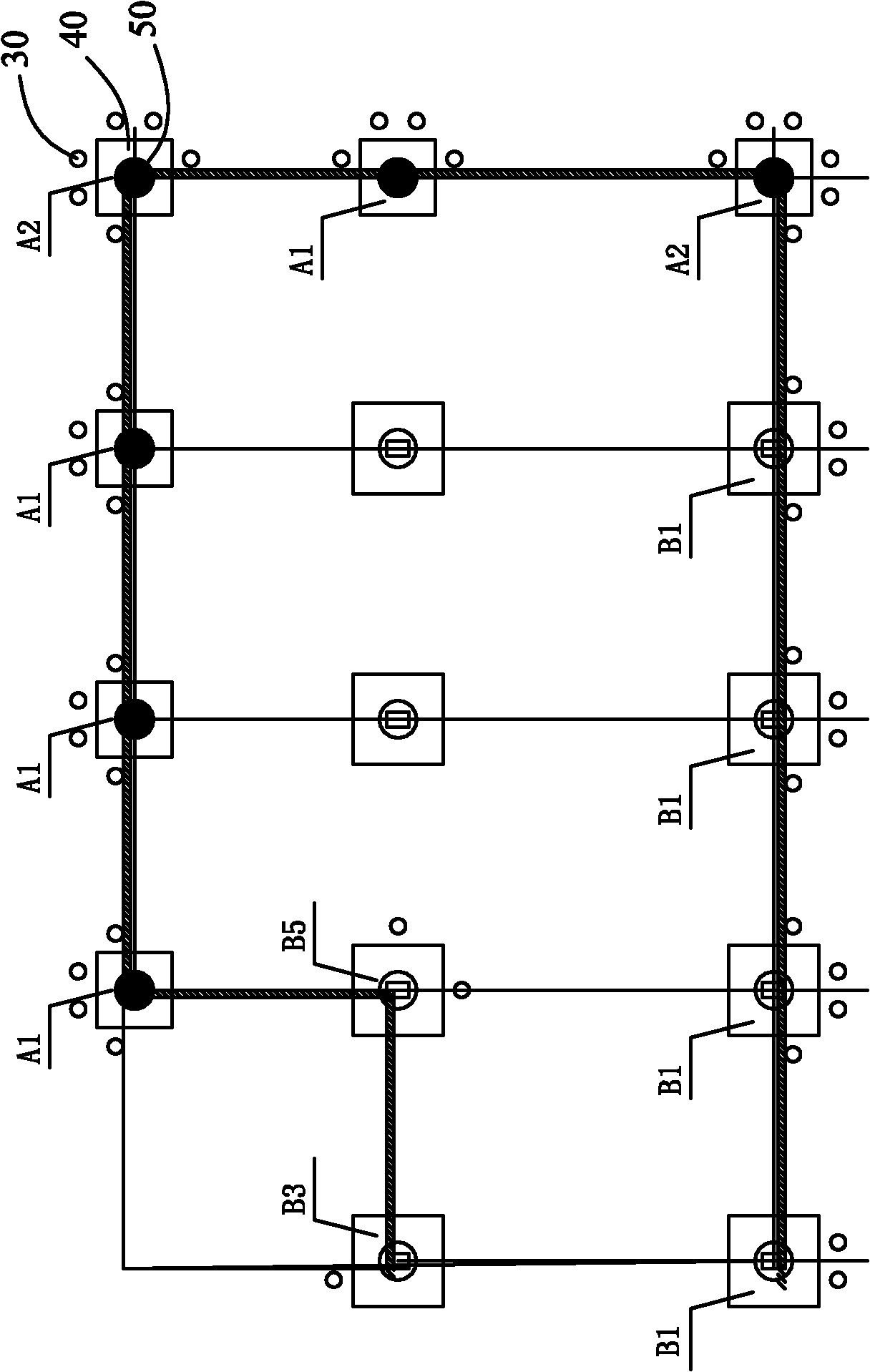

Single-hole double-layer overlapping tunnel structure and construction method thereof

InactiveCN101067374AOvercome deficienciesImprove safety, reliability and stabilityUnderground chambersTunnel liningSingle holeBuilding construction

The invention provides a single hole double layer overlapping tunnel structure including the single hole tunnel which the high side wall with the high / stride ratio is bigger than 2, the composite lining structure in the single wall and the upper / lower overlapping tunnel set in the middle of the high side wall. The invention also provides the constructing method. The invention can build the two-line tunnels in the limit room under ground and decrease the environment influence, the underpinning number of the pile foundation and the cost.

Owner:铁道第二勘察设计院 +2

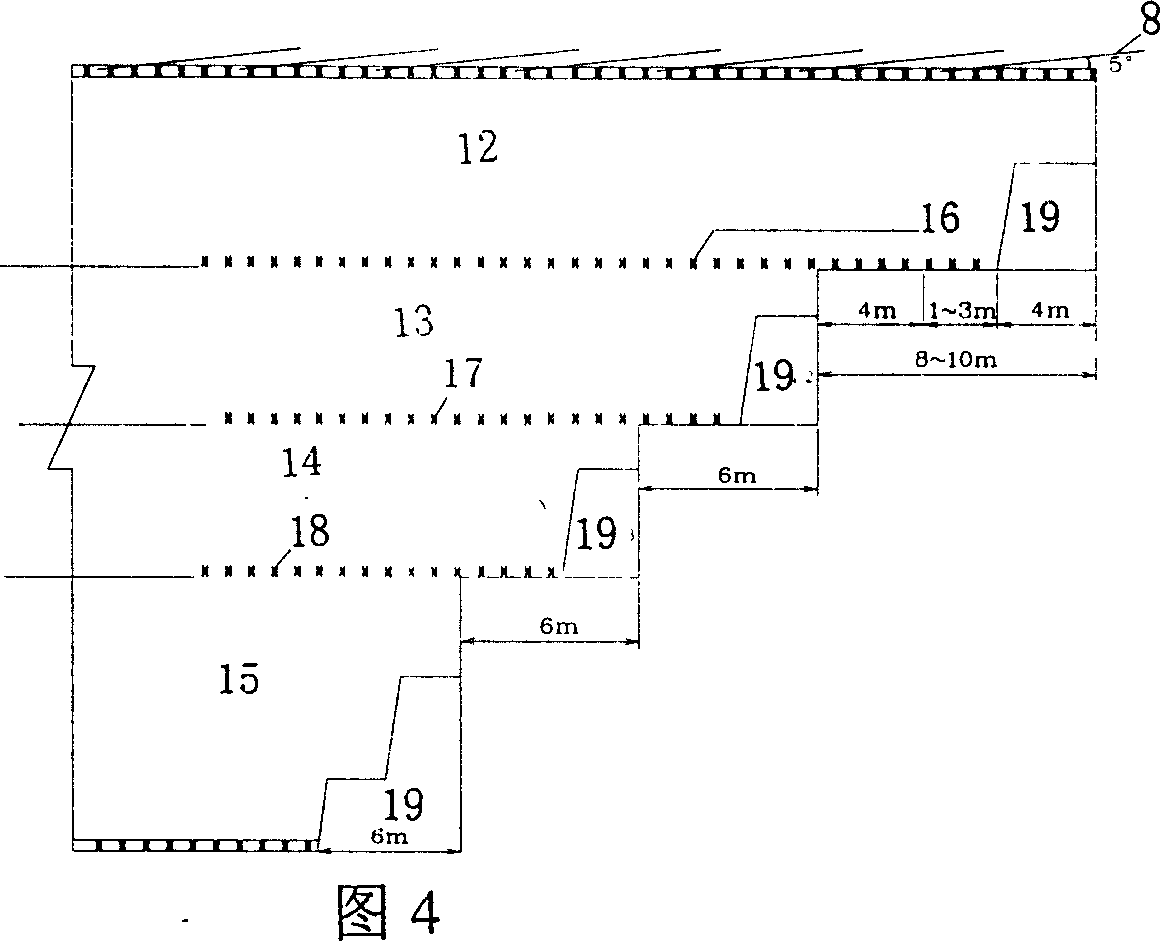

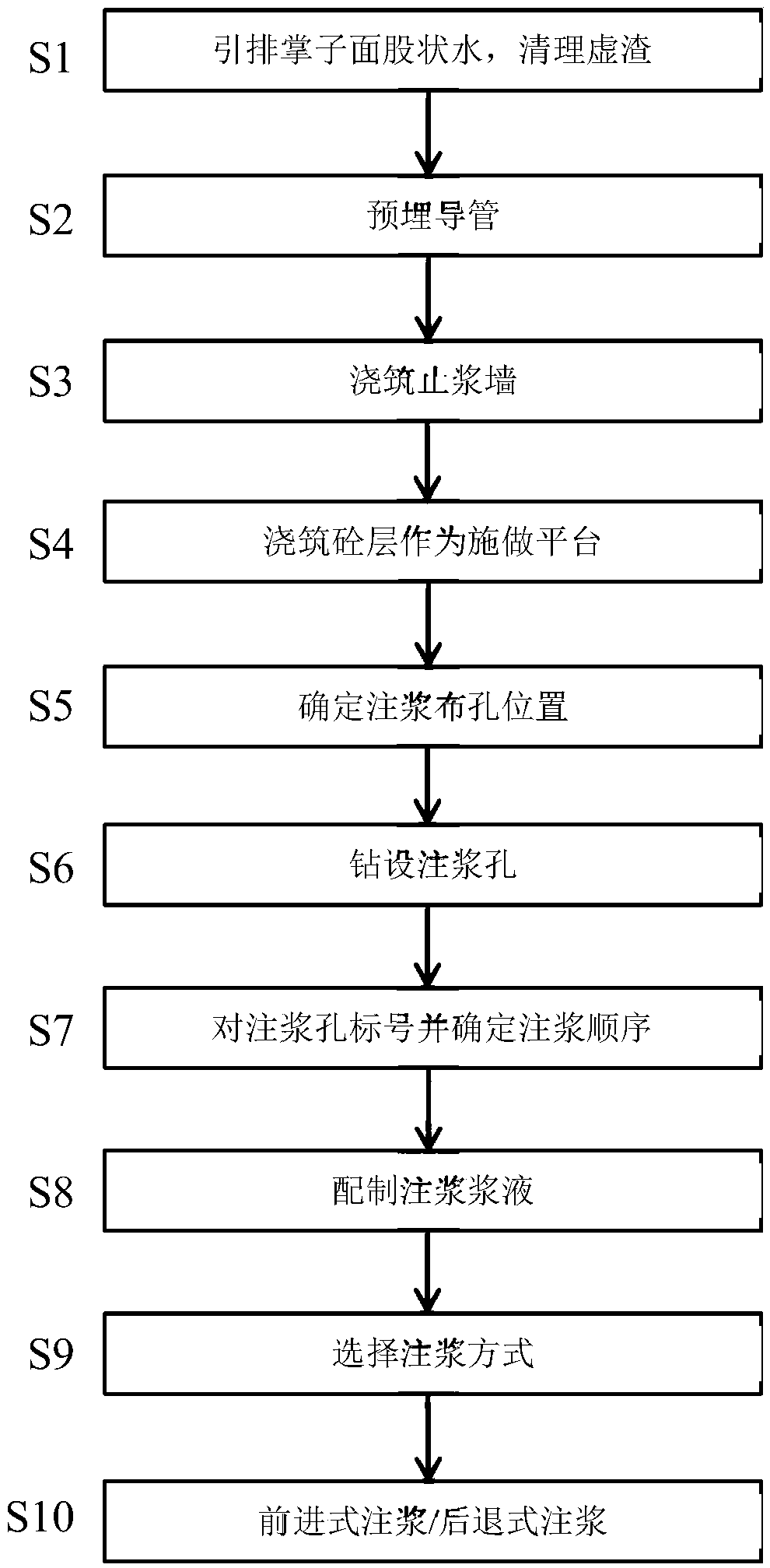

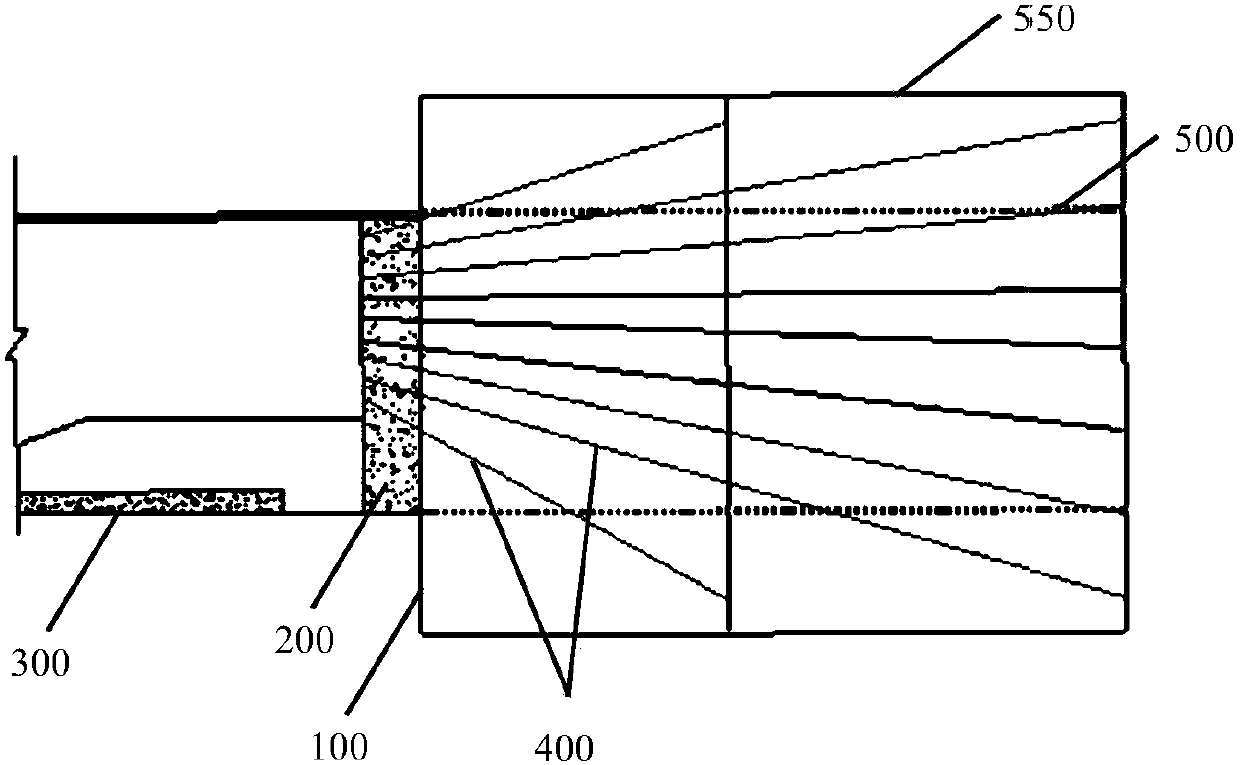

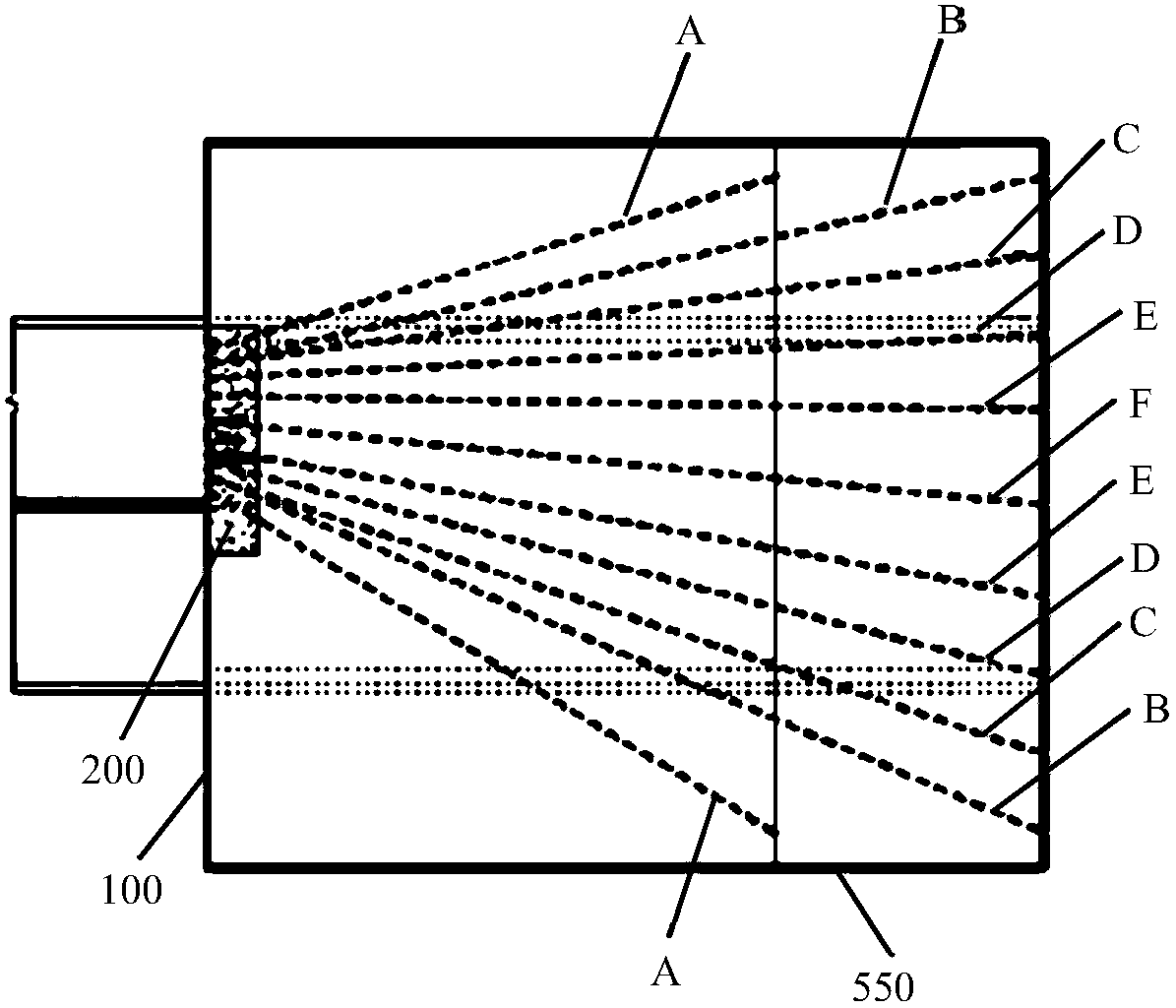

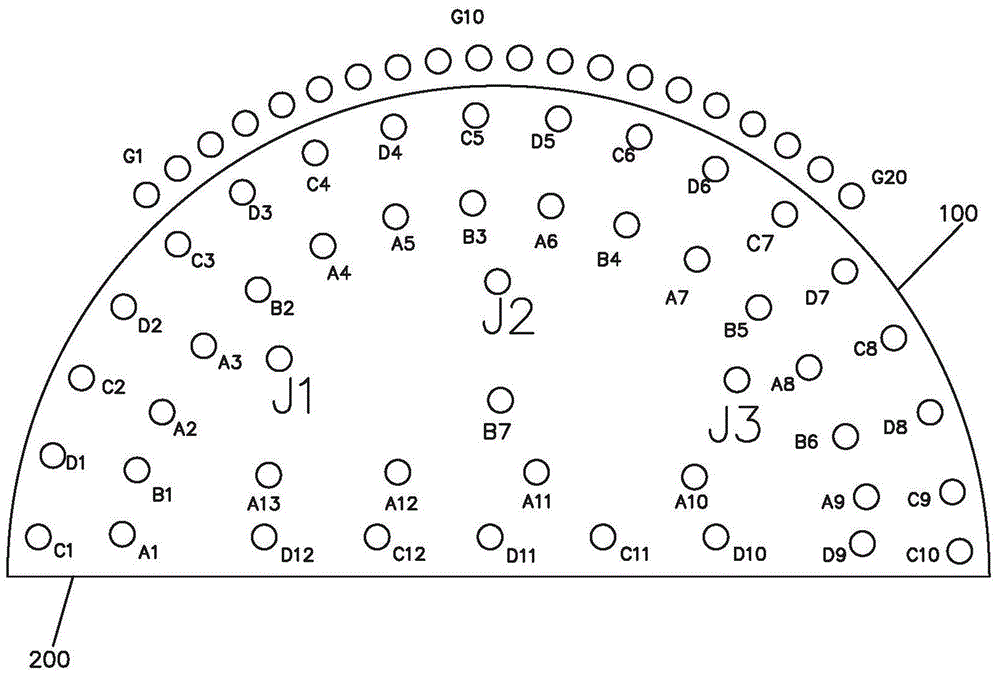

Whole-section front pre-grouting construction method

ActiveCN107642360AReduce emergencies such as floodingReduce the chance of secondary reworkUnderground chambersTunnel liningRock boltSteel tube

The invention discloses a whole-section front pre-grouting construction method. The method comprises the steps that concrete is used for pouring a blocked concrete wall with the thickness being 2.5-5m inside a face, and 2-4 rows of mortar anchors are adopted on the peripheral edge of the blocked concrete wall to be embedded into surrounding rock; a 8-10 m range is reserved behind the blocked concrete wall for leveling and compacting, and then a concrete layer is poured to be adopted as an application platform. A grouting hole is determined outside the counter line within the radial reinforcing range, an outer ring grouting hole final hole is within 4-6 m outside the excavated counter line, and the hole forming position and the final hole position of the grouting hole are distributed in anannular mode; the grouting hole is drilled, the diameter of the grouting hole is set to be 40-70 mm, the hole depth is set to be 5-30 m, multiple seamless steel tubes with the diameter being 35-50 mmcontinue to be ejected into the hole, the length of the seamless steel tubes is 3-5 m, 20-30 cm is exposed outside, the array pitch of the grouting hole is 1-1.5 m, and the grouting hole is formed ina quincunx mode. The single-hole water outlet amount is measured, and whether drill rod retrograding grouting or segmentation advanced grouting is adopted is determined according to the single-hole water outlet amount.

Owner:北京瑞威世纪铁道工程有限公司

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

Granite stone paint and preparation method thereof

The invention relates to a granite mineral varnish, which is prepared by raw material according to the following percentage by weight, water-based resin 10-25 parts, film forming additive 1-3 parts, propylene glycol 0.5-2 parts, mildew preventive 0.1-0.5 parts, defoaming agent 0.1-0.3 parts, color quartz sand 60-80 parts, color compound rock slices 8-30 parts and thickening agent 0.5-2 parts. The process for preparing the granite mineral varnish of the invention comprises the following steps: adding water-based resin, film forming additive, propylene glycol, mildew preventive, defoaming agent and thickening agent into a dispensing tank according to proposition, adding color quartz sand after evenly stirring, and then evenly stirring, adding color compound rock slices, and obtaining granite mineral varnish end products after evenly stirring. The granite mineral varnish has the advantages that first, excellent simulation effect, no matter near viewing or remote viewing, textures are lively, which has no difference with natural granite mineral varnish, second, excellent anti-fouling performance, third, big binding strength, fourth, excellent artificial aging (more than 800h), fifth, simple construction, only single-gun single-hole is needed, and the single gun is colorful.

Owner:HANGZHOU SENLESHI COATING

Drilling, cutting, pressing and pumping method

The invention provides a drilling, cutting, pressing and pumping method which is suitable for gas extraction of coal seams which are high in gas and low in gas permeability. The drilling, cutting, pressing and pumping method comprises punching a drill hole according to the design requirements through a drilling machine; replacing a hydraulic seam cutting drill bit after a drill rod is withdrawn, continuing to drill to the bottom of the drill hole and withdrawing the drill rod to perform hydraulic seam cutting; sealing the drill hole and performing gas drainage after the hydraulic seam cutting is achieved; switching a drainage pipeline into a pulse water injection pump station when the gas drainage capacity is in the attenuation trend and fracturing the coal seams in a pulse hydraulic fracturing mode. According to the drilling, cutting, pressing and pumping method, the effective influence range of a single hole of gas extraction drilling of the coal seams can be increased by more than 30%, the gas flow of the single hole can be improved by more than 30%, the gas extraction rate can be improved by more than 20%, the operation is simple, the influence range of drilling pressure relief can be improved, and the concentration and the efficiency of the gas extraction of the drilling can be improved.

Owner:CHINA UNIV OF MINING & TECH

Hydraulic cutting and gas explosion combined enhancing extraction method for fracturing coal body in drill hole

ActiveCN104314606ALower adsorption potentialFacilitate desorptionFluid removalGas removalHigh concentrationShock wave

The invention discloses a hydraulic cutting and gas explosion combined enhancing extraction method for fracturing a coal body in a drill hole. The hydraulic cutting and gas explosion combined enhancing extraction method is suitable for high-efficiency extraction of underground gas of a coal mine. The enhanced extraction method comprises the following steps: firstly, forming a slot by using a hydraulic cutting technology, relieving the pressure and increasing permeability, and desorbing and gushing gas; secondly, pressing air into a sealed drill hole by using an air pump, wherein the air and the gushed gas from the drill hole form gas mixed gas with the concentration of 9-10 percent; detonating the mixed gas by an ignition device to form an explosive shock wave; fracturing the coal body under the guiding action of the slot. The slot provides a greater explosion space, so that the power of explosion is enhanced and a fracture network in the coal body can be fully constructed; besides, the adsorption potential of gas can be remarkably reduced and the desorption and the flowing of the gas are promoted by the heat effect generated by explosion, so that the aim of enhancing the gas extraction of a coal bed with high-concentration gas and low permeability is achieved. The enhanced extraction method has the advantages of safety, reliability, low cost, simplicity, feasibility, time conservation and force conservation; the influence range of effective pressure relief of single holes can be remarkably widened, and the extraction rate of the gas in the coal bed is increased by over 80 percent.

Owner:CHINA UNIV OF MINING & TECH

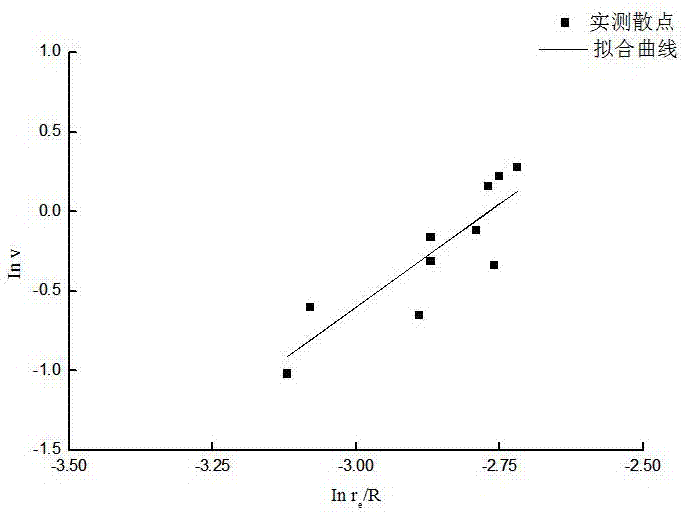

Method for predicting peak vibration velocities of shallow-buried tunnel blasting construction surface particles

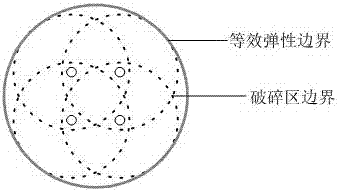

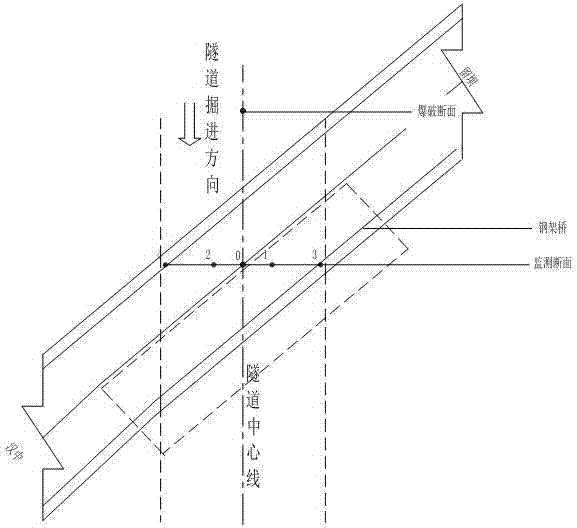

The invention relates to a method for predicting peak vibration velocities of shallow-buried tunnel blasting construction surface particles. The method comprises the following steps of: firstly obtaining a peak particle vibration velocity theoretical equation under a porous initiating condition on the basis of a principle that porous blasting is equivalent to single-hole blasting, and correcting the peak particle vibration velocity theoretical equation; carrying out linear regression analysis on a peak particle vibration velocity of a measurement point, fitting parameters, topography and geology-related coefficients and blasting vibration attenuation indexes, and substituting the parameters, the coefficients and the indexes into the peak particle vibration velocity theoretical equation under the porous initiating condition; and finally substituting a known blast hole radius, an explosive density, a charging diameter and a distance between a surface particle and a blasting source into the peak particle vibration velocity theoretical equation so as to calculate a peak vibration velocity of the surface particle. According to the method, the existing single-hole blasting theoretical equation is corrected to obtain the peak particle vibration velocity theoretical equation under the porous initiating condition, so that the influences, on the peak vibration velocity, of explosive nature, rock performance and charging parameters can be reflected, and the blasting peak vibration velocities of fixed points on the surface can be calculated according to the practical blasting parameters and geological conditions.

Owner:XIAN TECHNOLOGICAL UNIV

Single bore high flow junction plate

Described herein a single bore, high flow junction plate and flow line assembly adapted for use subsea. This junction plate may be adapted for use with a torque tool manipulated by a remotely operated vehicle (“ROV”).

Owner:OCEANEERING INTERNATIONAL

Three-dimensional stress test device for single-hole multi-point hollow fiber grating inclusion in rock mass engineering

InactiveCN104280167AAdaptableSolve the problem of insufficient couplingForce measurement by measuring optical property variationFiberEpoxy

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

In-borehole gas explosion coal body cracking forced extraction method

The invention discloses an in-borehole gas explosion coal body cracking forced extraction method, and is applied to the efficient extraction of underground gas of a coal mine. An air pump is used for pressing air into a sealed borehole, the air and gas gushed from the borehole are premixed to form mixed gas at concentration of 9 to 10 percent, and the mixed gas is detonated by virtue of an ignition device to form explosion waves to crack a coal body to construct a fracture network; meanwhile, by thermal effects achieved by explosion, the adsorption potential of the gas can be remarkably lowered, and the desorption and the flowing of the gas can be promoted, so that the aim of forced gas extraction of a high-gas low-air-permeability coal seam is fulfilled. The method is low in cost, simple, easy, time-saving and labor-saving; the effective pressure relief influence scope of a single hole can be remarkably widened, and the gas extraction efficiency of the coal seam can be improved by over 40 percent.

Owner:CHINA UNIV OF MINING & TECH

Method for processing soft soil foundation of high vacuum drainage filter pipe capable of being grouted

InactiveCN102206939ASlow down the vacuum decay rateShorten drainage consolidation timeSoil preservationDeformation effectEngineering

The invention relates to a method for processing a soft soil foundation of a high vacuum drainage filter pipe capable of being grouted, comprising the following steps of: sinking the high vacuum vertical drainage filter pipe: putting a plate machine in place, installing a traction device of the high vacuum vertical drainage filter pipe in a pile pipe of the plate machine, sinking in place, and lifting the pile pipe of the plate machine; pre-pressing and draining the high vacuum vertical drainage filter pipe: arranging a vacuum pipeline system, draining and pre-pressing the high vacuum vertical drainage filter pipe and then downloading in a vacuum way; and grouting the high vacuum vertical drainage filter pipe: trying to grout so as to determine pressure and single-hole grouting quantity of double grouting processes, grouting cement paste firstly, grouting cement mortar secondarily, and compositely maintaining the foundation. By means of the method, the disadvantages, such as continuous secondary solidification and sedimentation of post-construction field soil, damages of the foundation and the structure and high maintenance cost, can be solved; the vacuum transfer loss is reduced;the secondary hole-forming cost is reduced; the property of soft soil is changed; the bearing capacity of the field soil is improved; and the sedimentation and deformation effects can be reduced.

Owner:李燕青

Regional forced gas extraction method for single low-permeability outburst thick coal seam

ActiveCN104100292AEliminate the problem of blank bands in extractionImprove extraction efficiencyGas removalHigh pressure waterHigh pressure

The invention provides a regional forced gas extraction method for a single low-permeability outburst thick coal seam. The regional forced gas extraction method comprises the steps of (a) excavating a rock gangway in a rock fissure zone and drilling a lower-position seam through hole downwards, (b) drilling a high-position seam through hole downwards in the rock gangway, (c) starting a high-pressure water-injection pump station, performing hole expanding operation on the coal seam through sections of the drilled holes under the conditions of the water pressure of 10-20MPa, the flow rate of 8m<3> / h and the single-hole coal output greater than 5t, (d) sealing the drilled holes and carrying out drainage strip networking extraction operation after the hole expanding operation is finished, (e) after the extraction is up to the standard, carrying out tunneling operation of an air return way and a transportation roadway, and meanwhile, drilling a bedding pre-extraction hole in the working face and carrying out the hole sealing and networking extraction operations, and (f) continuously extracting the gas of the goaf in the rock gangway during the recovery of the working face. The regional forced gas extraction method is capable of converting a high-gas outburst coal seam into a low-gas outburst risk-free coal seam, comprehensively guaranteeing safe production of the working face, and meanwhile, obviously increasing the coal roadway tunneling speed.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

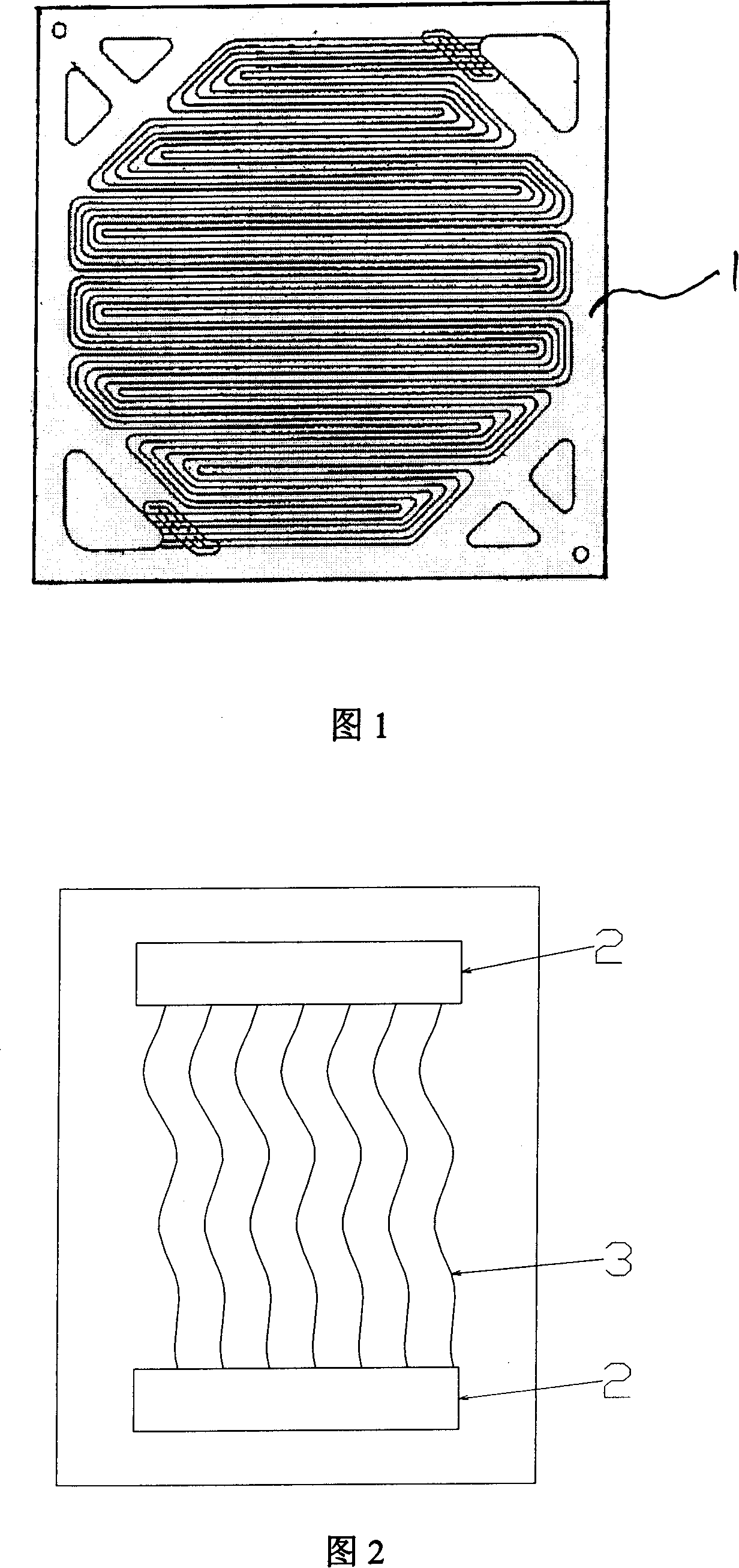

A fuel battery flow guiding polarized plate without water blockage

The invention relates to fuel battery guiding board which is not easy to stop water, the guiding board is guiding two-way board, said guiding two-way board comprises positive air guiding groove, negative hydrogen guiding groove, middle cooling flow interlayer, said flow hole which air or hydrogen in and out is single hole for in, two or more hole for out, guiding groove and connecting groove which connects guiding groove are set between flow hole for air or hydrogen, the guiding groove and connecting groove are all designed to direct flow groove or nearly direct flow groove; said flow hole for cooling liquid is single hole or double holes or more holes for in, two holes or more holes for out, guiding groove and connecting groove which connects guiding groove are set between flow hole for cooling liquid, the guiding groove and connecting groove are all designed to direct flow groove or nearly direct flow groove. Comparing with current technique, the invention can make liquid flow on liquid field evenly, freely; jam of guiding groove can be avoided.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

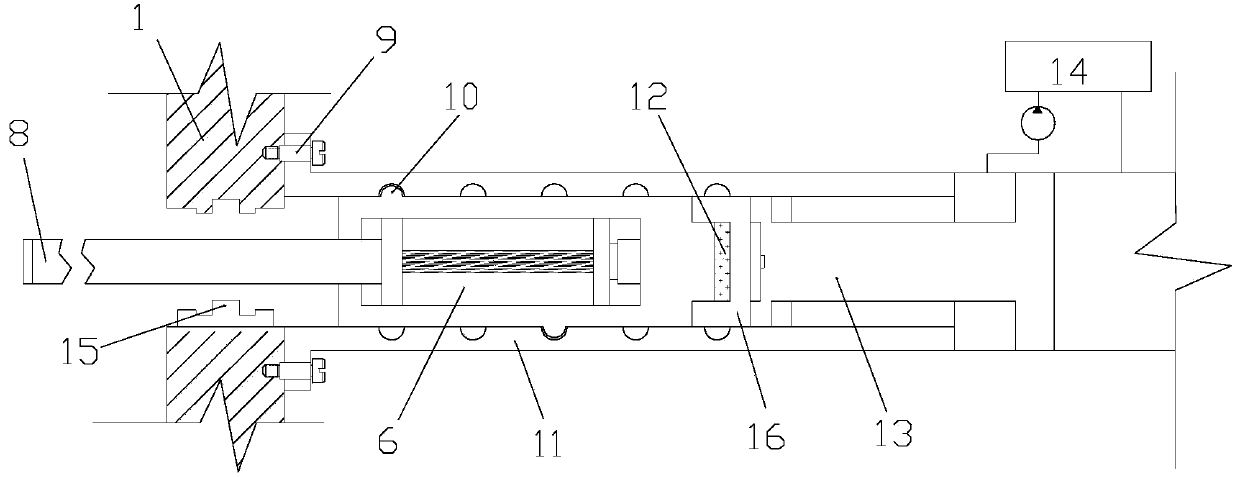

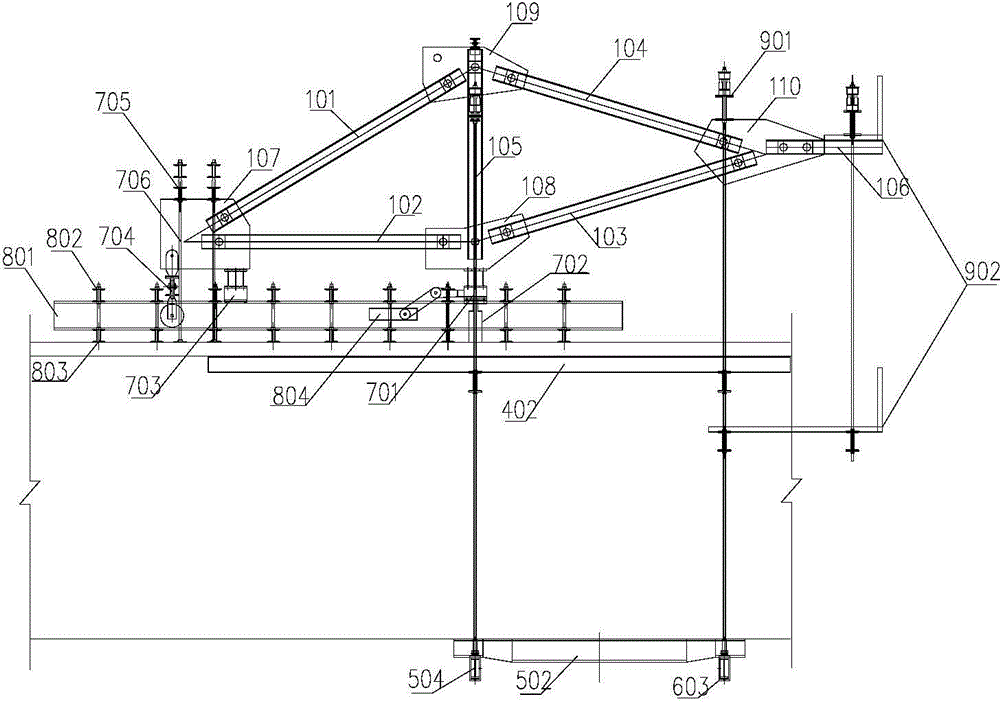

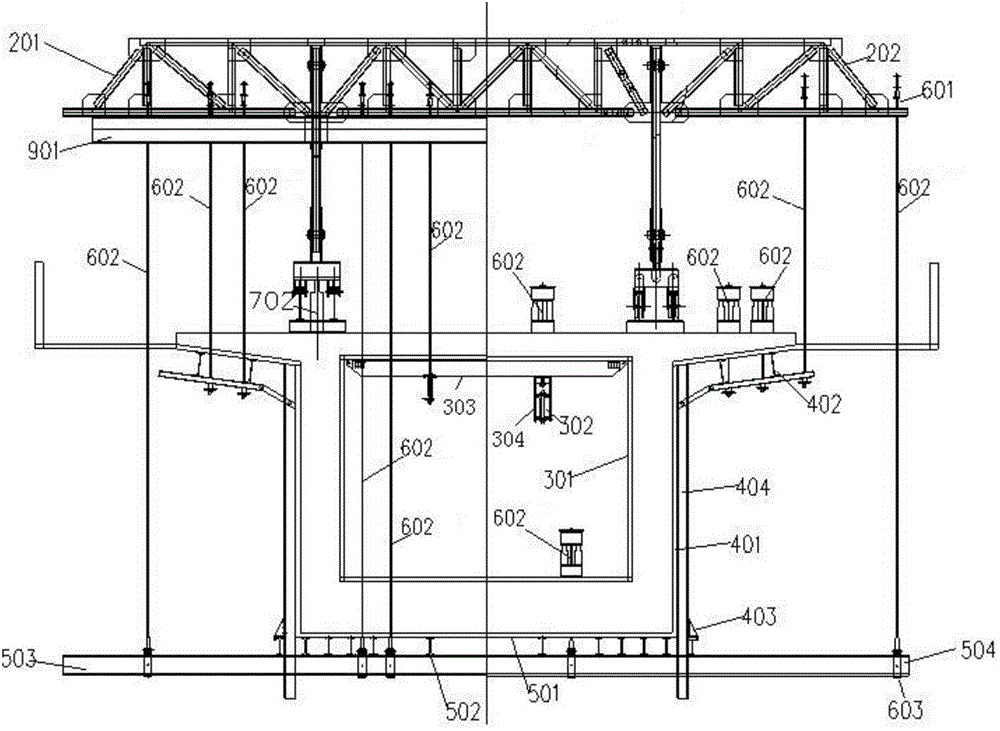

Self-travelling diamond-shaped pin-connected truss-type form traveler structure and form traveler travelling and constructing method

InactiveCN104631343AEven by forceMeet stability requirementsBridge erection/assemblyEconomic benefitsJackscrew

Disclosed are a self-travelling diamond-shaped pin-connected truss-type form traveler structure and a form traveler travelling and constructing method. A form traveler is mainly composed of a main truss system, a horizontal connection system, an internal formwork system, an external formwork system, a bottom formwork platform system, a hanging system, an anchoring system and a travelling system. The main truss system is composed of two main trusses and horizontal bracings, and each single main truss is composed of a lower chord, an upper chord, a diagonal rod and a vertical rod which are connected into a whole via single-hole bolt pins through joint boxes. The two main trusses are connected by the spacing-adjustable horizontal bracings. A rear anchoring system is connected to the rear of the lower chords of the main trusses. The travelling system comprises a section rail located under the main trusses, a left-handed wheel, rollers, a travelling pushing jack and the like. The self-travelling diamond-shaped pin-connected truss-type form traveler structure is quick to install, the spacing between the main trusses and the positions of hanging rods can be adjusted according to the section forms of different box girders on the basis that load bearing is satisfied, the optimal stress state is formed, universality is high, turnover rate of the form traveler is increased greatly, project cost is saved, and economical benefit is obvious.

Owner:HOHAI UNIV

Method for increasing permeability in drilling holes in cold expansion and heat driving mode

InactiveCN104632271ALower adsorption potentialFacilitate desorptionInsulationFluid removalDesorptionEngineering

The invention discloses a method for increasing the permeability in drilling holes in a cold expansion and heat driving mode and is suitable for efficient extraction of underground coal mine gas. Firstly, the extraction drilling holes are formed in a coal bed in a staggered mode and strengthened; water is injected in the strengthened extraction drilling holes through a water injection pump, the water is refrigerated to be condensed into ice, a coal body is cracked through the volume expansion of icing of the water body, and an original crack is expanded; then, heat pipes are used for heating the drilling holes, the ice is transformed into water, and the water is discharged out of the drilling holes; lastly, the heat pipes are used for continually heating the coal body in the drilling holes to form a stable temperature field, the gas adsorption potential is obviously reduced through the heat effect, gas desorption is promoted, so that the purpose of strengthening gas extraction is achieved, the range of the single-hole effective pressure relief influence can be obviously enlarged, and the coal bed gas extraction efficiency is increased by 40% or more. The method is safe, reliable, low in cost, simple, practical and capable of saving time and labor.

Owner:CHINA UNIV OF MINING & TECH

Advanced detection, grouting reinforcement and excavation method of wide separation fracture of high-pressure water-rich tunnel

InactiveCN103982201AShorten the construction periodSave timeUnderground chambersTunnel liningGeomorphologyHigh pressure water

The invention discloses an advanced detection, grouting reinforcement and excavation method of a wide separation fracture of a high-pressure water-rich tunnel. The advanced detection, grouting reinforcement and excavation method comprises determining the level of surrounding rock of the tunnel to reach above the third level through advanced geological detection on the tunnel; building a wall for grouting on the tunnel face and drilling at least three detection and drain holes in the lower middle portion of the wall for grouting; calibrating at least fifteen grouting hole positions on the wall for grouting along the inner circumference of a tunnel excavation contour line separately; measuring the water yield of every detection and drain hole after drilling grouting of the at least fifteen grouting hole positions is achieved; performing direct tunneling when the maximum water yield of the single hole is measured to be not more than 10 liters every meter*minute; increasing and drilling detection and drain holes when the maximum water yield of the single hole is measured to be more than 10 liters every meter*minute and not more than 20 liters every meter*minute until the maximum water yield of the single hole is measured to be not more than 10 liters every meter*minute and performing the tunneling; performing whole section curtain grouting construction when the maximum water yield of the single hole is measured to be more than 20 liters every meter*minute and performing the tunneling.

Owner:北京中铁瑞威工程检测有限责任公司

Enhanced extraction method for fracturing coal body by multistage gas explosion in drill hole

ActiveCN104314605ALower adsorption potentialFacilitate desorptionFluid removalGas removalSingle holeGas explosion

The invention discloses an enhanced extraction method for fracturing a coal body by multistage gas explosion in a drill hole. The enhanced extraction method is suitable for high-efficiency extraction of underground gas of a coal mine. Air is pressed in a sealed drill hole by using an air pump; the air and gas gushed from the drill hole form gas mixed gas with the concentration of 9-10 percent; the mixed gas is detonated by an ignition device to form an explosive shock wave for fracturing the coal body around the drill hole; the later-stage explosion is realized on the basis of the previous-stage explosion, so that cracks of the coal body around the drill hole are further expanded; besides, the shock wave compress the coal body to form a greater explosion space, and the power of explosion is enhanced. By multistage explosion, a fracture network in the coal body can be fully constructed; besides, the adsorption potential of gas can be remarkably reduced and the desorption and the flowing of the gas are promoted by the heat effect generated by explosion, so that the aim of enhancing the gas extraction of a coal bed with high-concentration gas and low permeability is achieved. The enhanced extraction method has the advantages of low cost, simplicity, feasibility, time conservation and force conservation; the influence range of effective pressure relief of single holes can be remarkably widened, and the extraction rate of the gas in the coal bed is increased by over 60 percent.

Owner:CHINA UNIV OF MINING & TECH

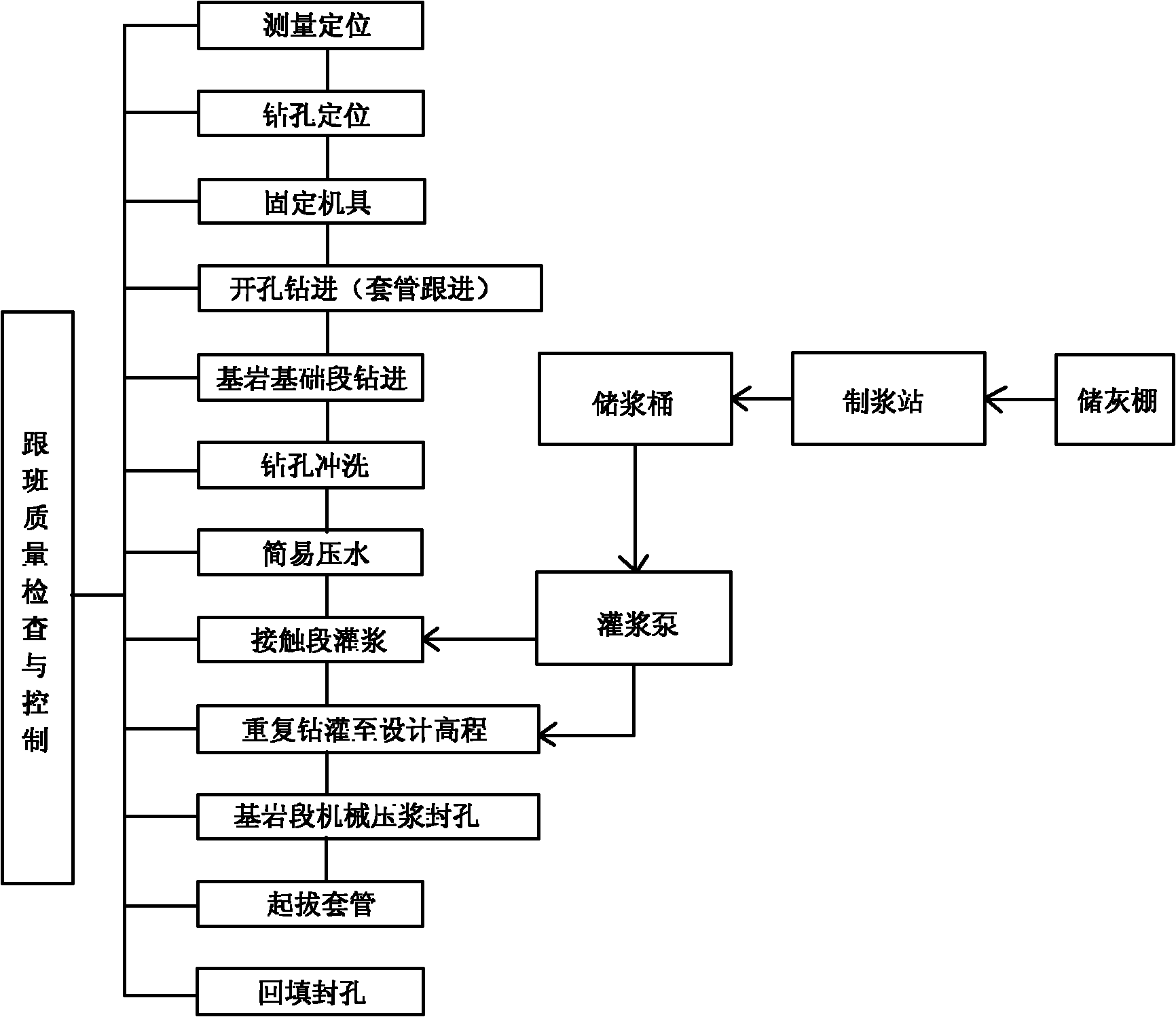

Method for treating uneven settlement of building

InactiveCN102061697AConstruction safetyConstruction stabilitySoil preservationPoly vinyl chlorideGrout

The invention provides a method for treating the uneven settlement of a building, which comprises the steps: (1) positioning a drill hole: during preparing for the construction, fixing a tool, feeding a PVC (poly vinyl chloride) sleeve after drilling, drilling a hole at a preset depth, washing the drill hole, and simply pressing water; (2) grouting a contacting section: during grouting, building a vertically-distributed grout stopping wall, and grouting according to the same axes direction after grouting the grout stopping wall; and repeatedly drilling and grouting to a designed altitude; (3) backwards filling the grout to seal the hole: mechanically pressing the grout to seal the hole at the whole hole of a bed rock section, withdrawing the sleeve, backwards filling the grout to seal the hole, and organizing the data of the single hole and submit the date; and (4) monitoring the lift value of a plurality of settlement points of the building to ensure the next grouting quantity. By introducing a design and construction method of grouting by means of dynamic tracking, the method for treating the uneven settlement of the building is good for popularizing and using the grouting technology for the uneven settlement of the peripheral structure and building in the engineering construction such as a foundation pit and a tunnel.

Owner:中铁六局集团有限公司广州工程分公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com