Advanced detection, grouting reinforcement and excavation method of wide separation fracture of high-pressure water-rich tunnel

A water-rich tunnel, grouting reinforcement technology, applied in tunnels, tunnel lining, earthwork drilling and mining, etc., can solve the problems of long grouting period, lagging construction period, slow construction progress, etc., to save construction period, improve construction efficiency, The effect of saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

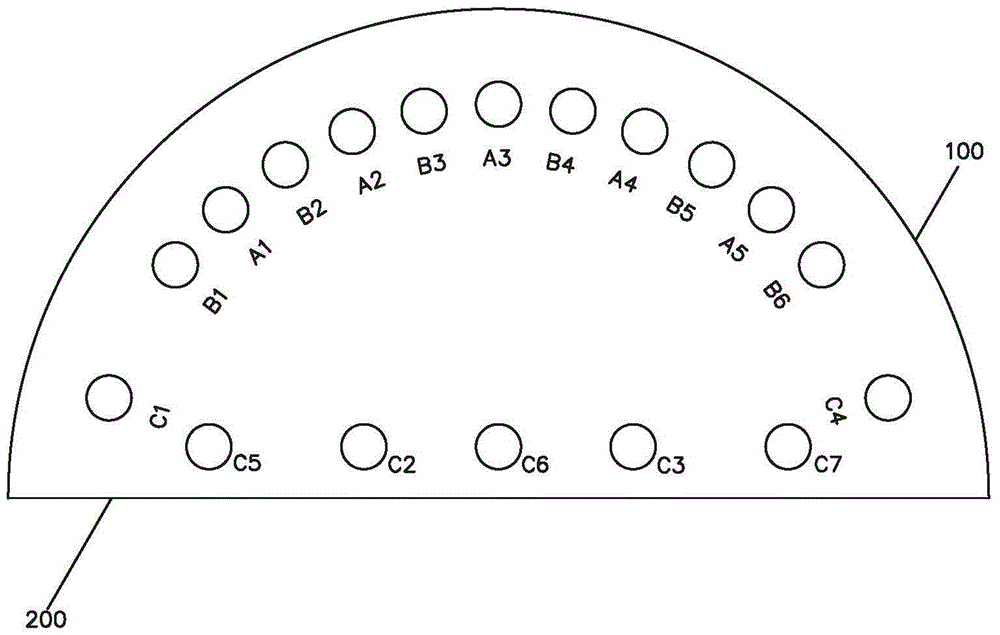

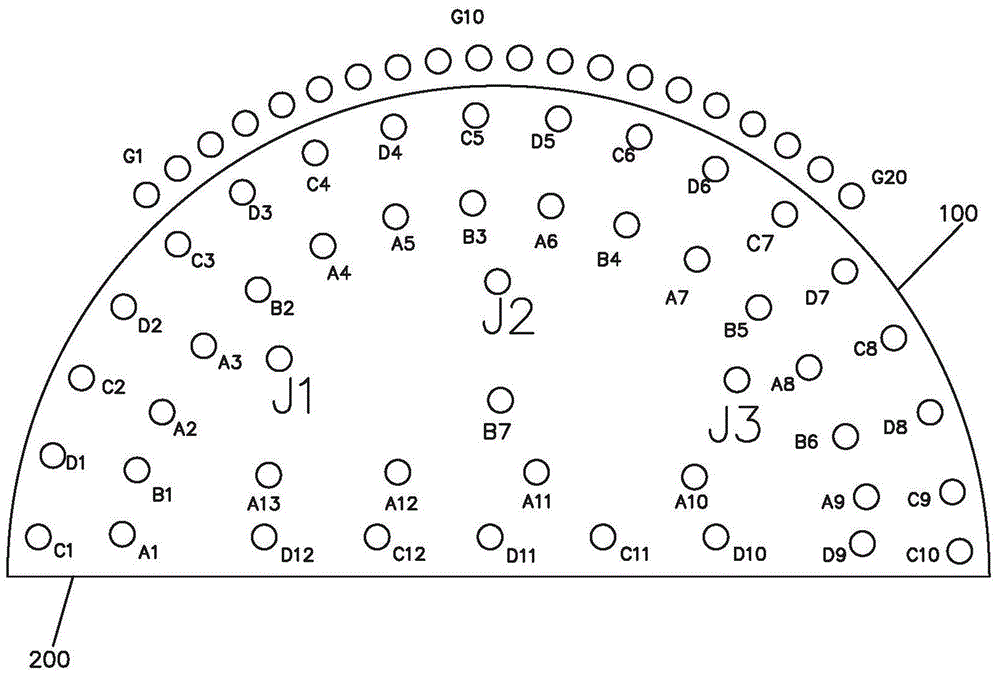

[0040] Next, the excavation method for the advanced detection and grouting reinforcement of the wide-stretched cracks of the high-pressure water-rich tunnel of the present invention will be described in detail with reference to the accompanying drawings.

[0041] According to a non-limiting implementation, the excavation method of the present invention for the early detection of wide-spread cracks in high-pressure water-rich tunnels includes the following steps.

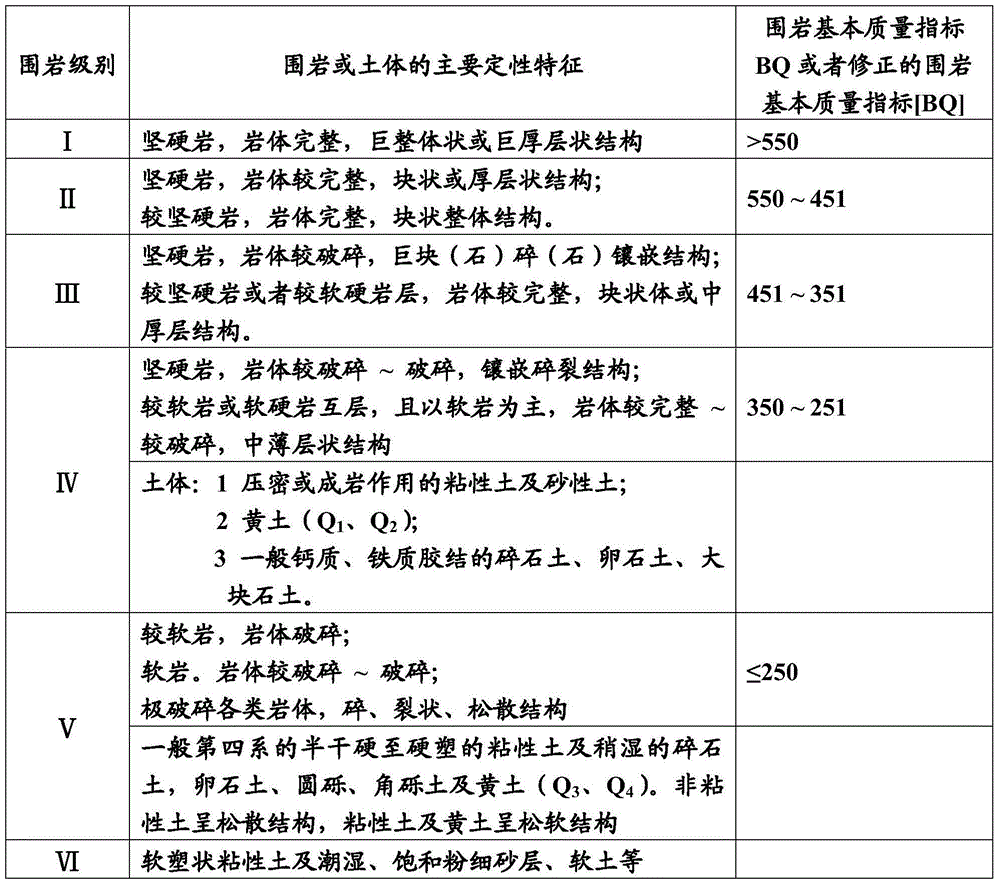

[0042] First, the seismic reflection method combined with the ground radar method is used to determine that the grade of the surrounding rock of the tunnel is above grade three, which can be grade I, II or III in Table 1.

[0043] A grout-stop wall shall be constructed on the face of the tunnel, and the thickness of the grout-stop wall shall be 4 meters. And on the left and right sides of the middle and lower part of the grout wall, two detection-drainage holes are respectively drilled, and the length of the detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com