Patents

Literature

894results about How to "Facilitate desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

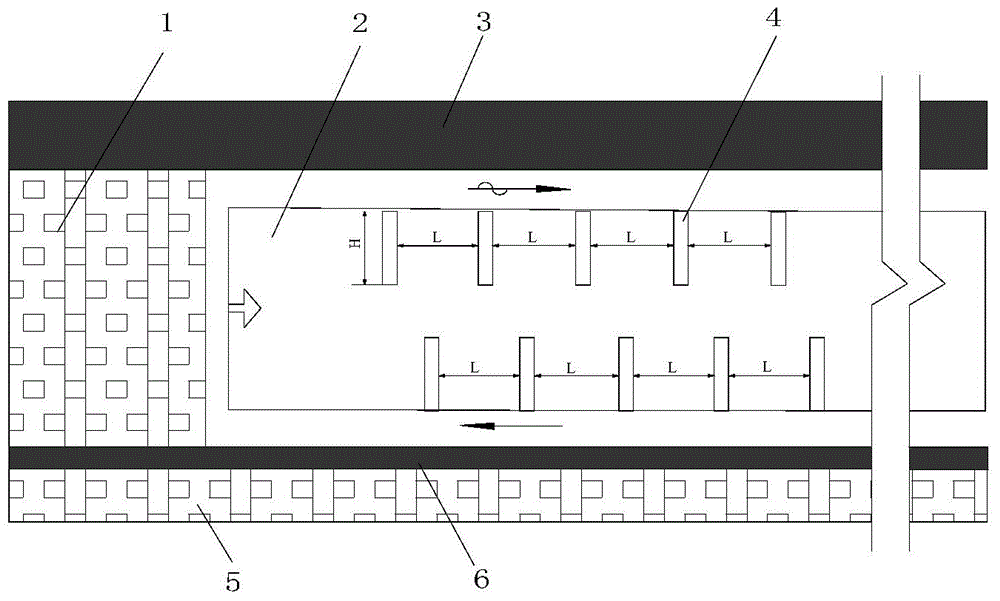

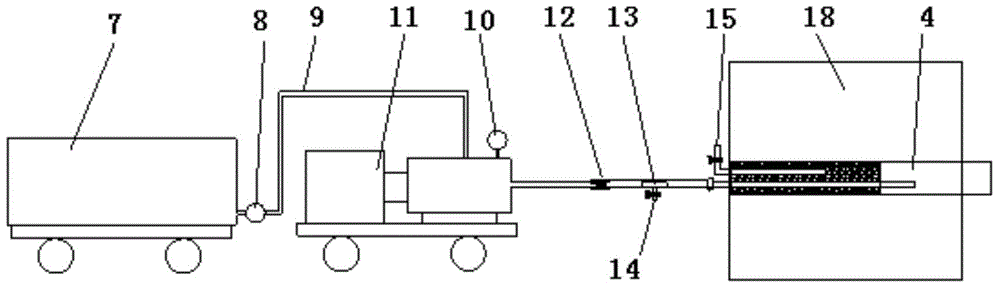

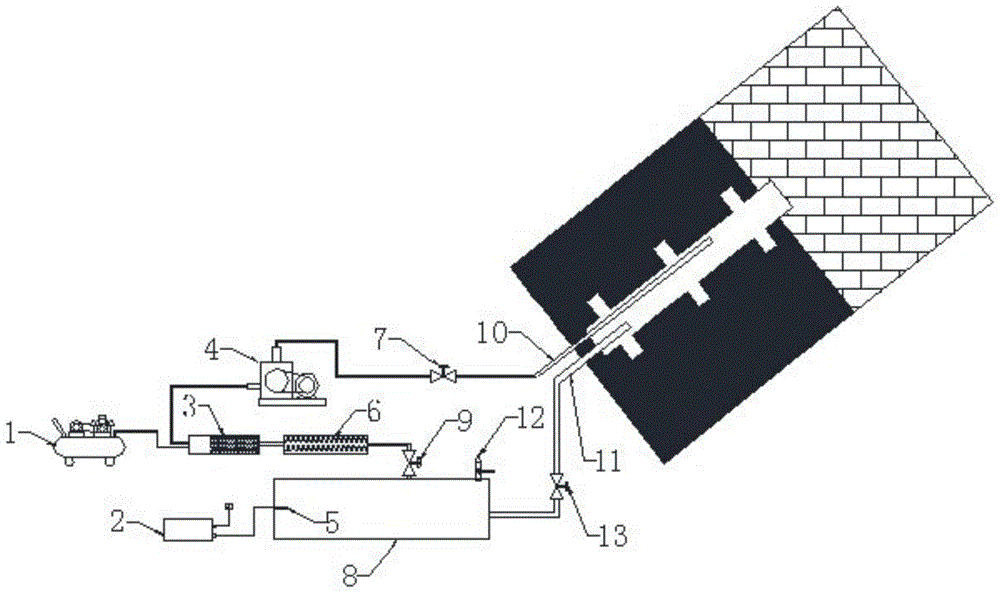

Coal seam liquid carbon dioxide fracturing device and method

The invention discloses a coal seam liquid carbon dioxide fracturing device and method. The device comprises a supplying unit for supplying liquid carbon dioxide, a fracturing pump, a hole packer, a first pipeline and a second pipeline; the hole packer is used for being placed in a drill hole in a coal seam to be fractured and comprises an grouting pipe, a first hole sealing capsule, a second hole sealing capsule and a fracturing pipe, one end of the grouting pipe and one end of the fracturing pipe penetrate through the first hole sealing capsule and are fixed on the first hole sealing capsule, the other end of the fracturing pipe penetrates through the second hole sealing capsule and is fixed on the second hole sealing capsule, and the other end of the grouting pipe is located between the first hole sealing capsule and the second hole sealing capsule. The coal seam liquid carbon dioxide fracturing device and method are capable of increasing the output of a mine and improving permeability of the coal seam and lump coal output rate.

Owner:XIAN UNIV OF SCI & TECH

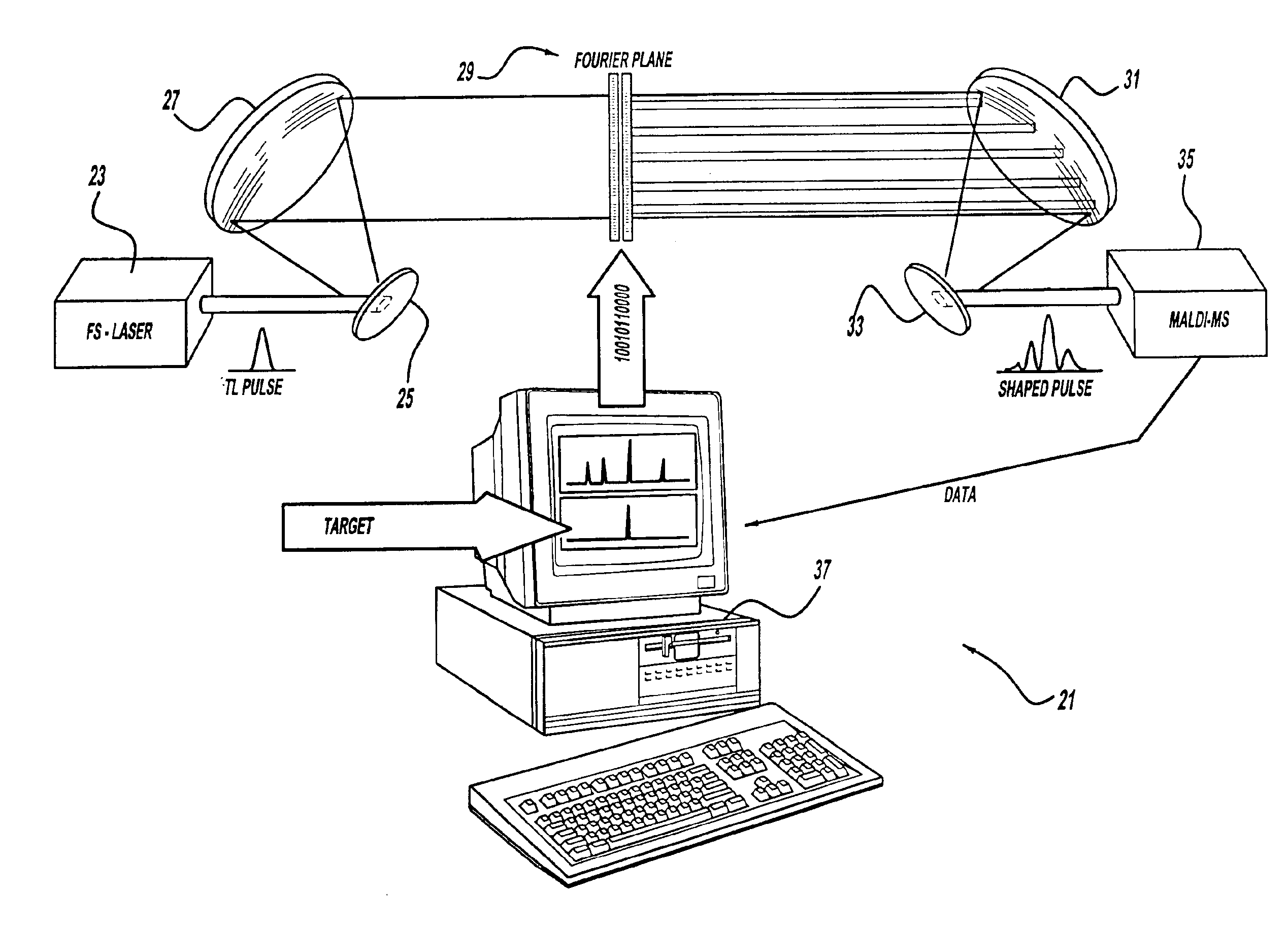

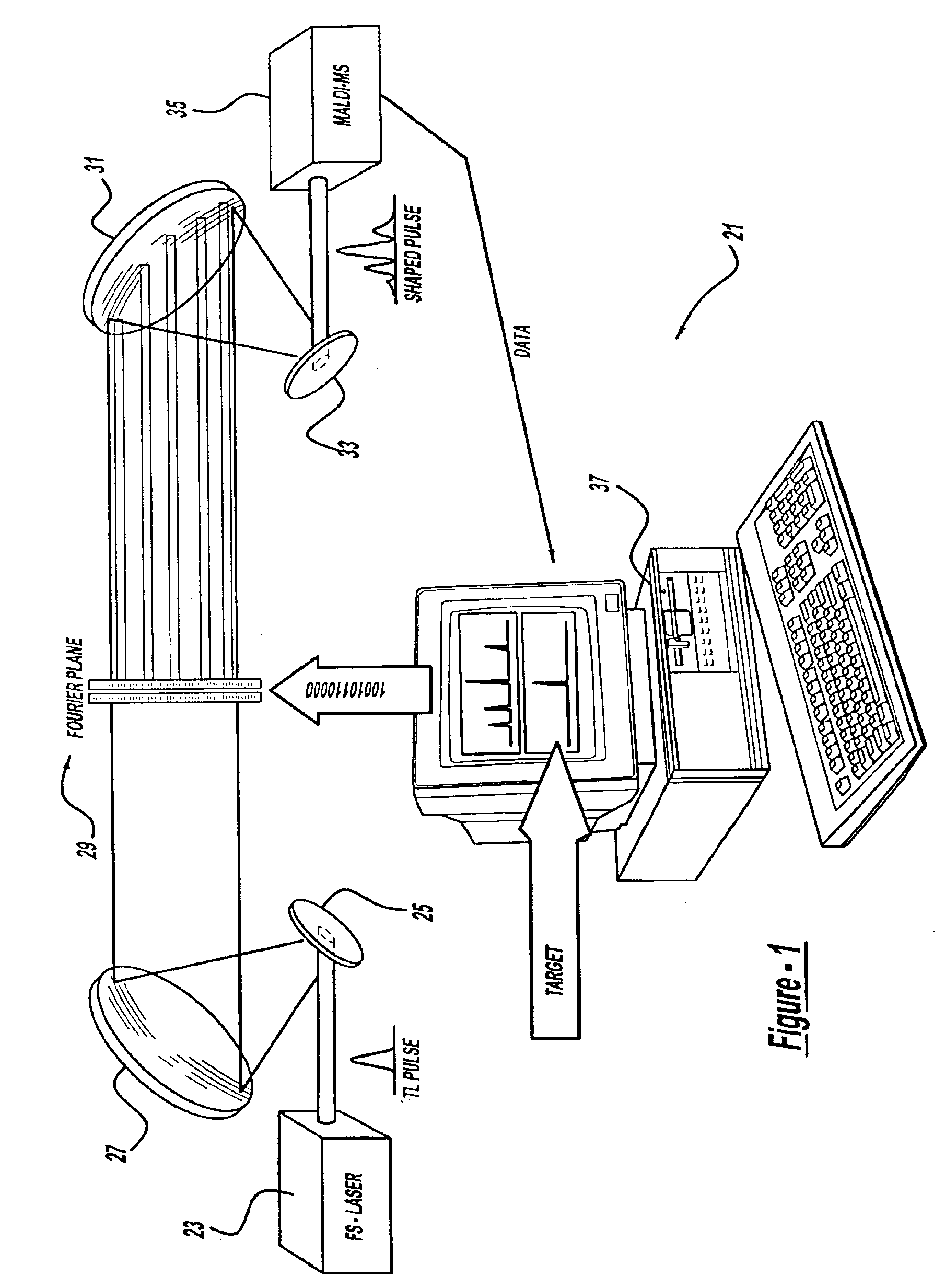

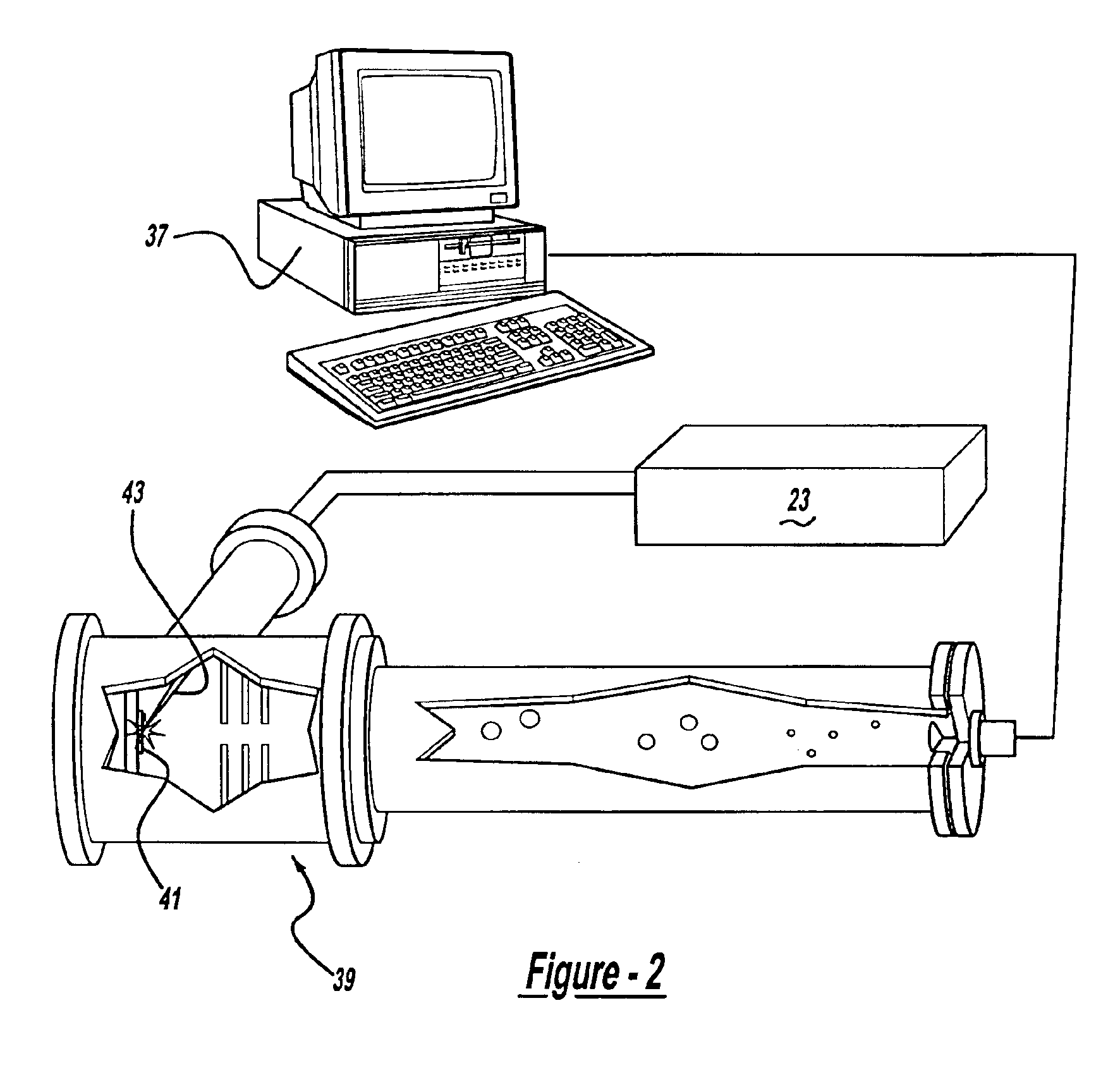

Control system and apparatus for use with laser excitation or ionization

InactiveUS7105811B2Way fastMaximize sensitivityLaser detailsIon sources/gunsPhotodynamic therapyControl system

A control system and apparatus for use with laser ionization is provided. In another aspect of the present invention, the apparatus includes a laser, pulse shaper, detection device and control system. A further aspect of the present invention employs a femtosecond laser and a mass spectrometer. In yet other aspects of the present invention, the control system and apparatus are used in MALDI, chemical bond cleaving, protein sequencing, photodynamic therapy, optical coherence tomography and optical communications processes.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

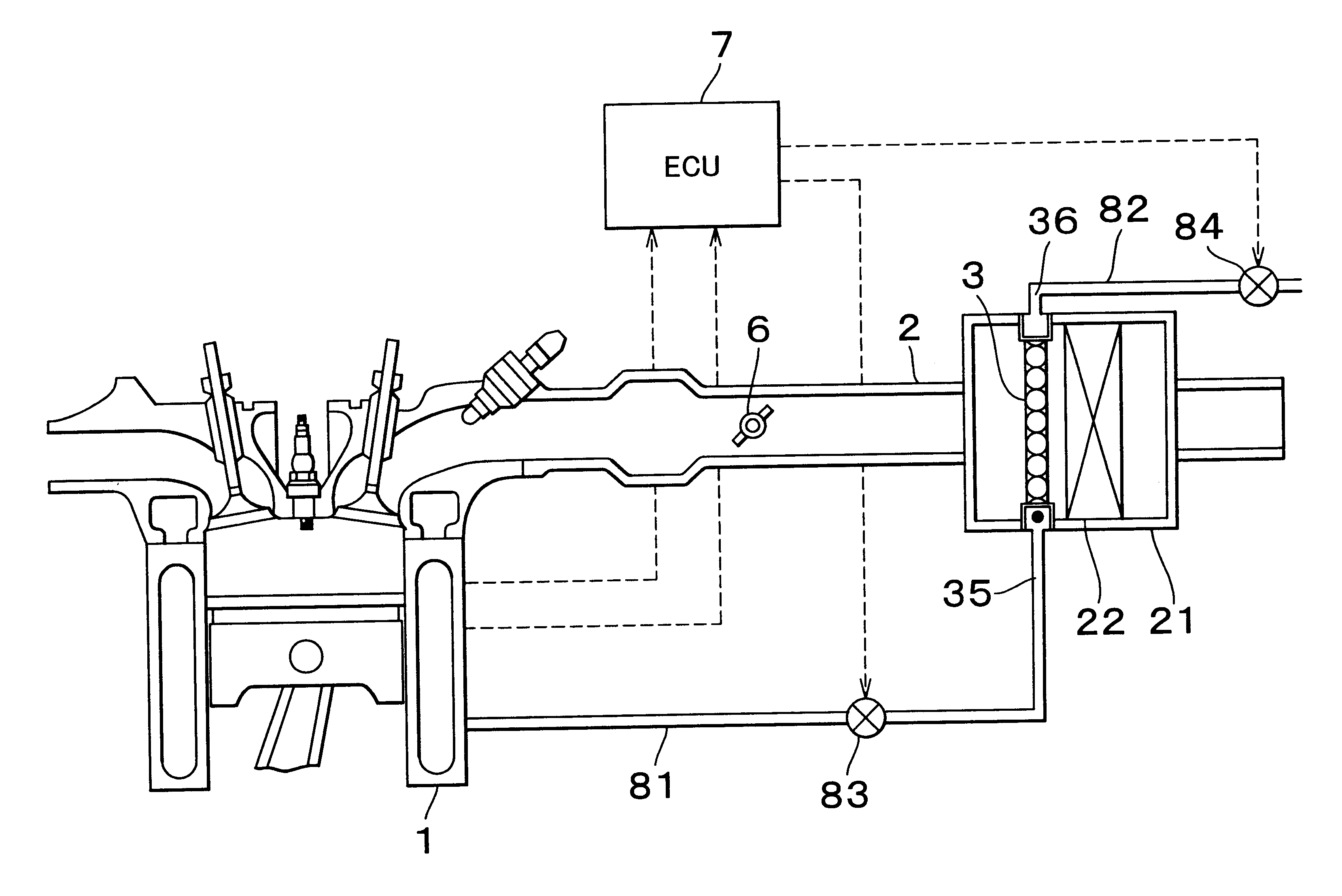

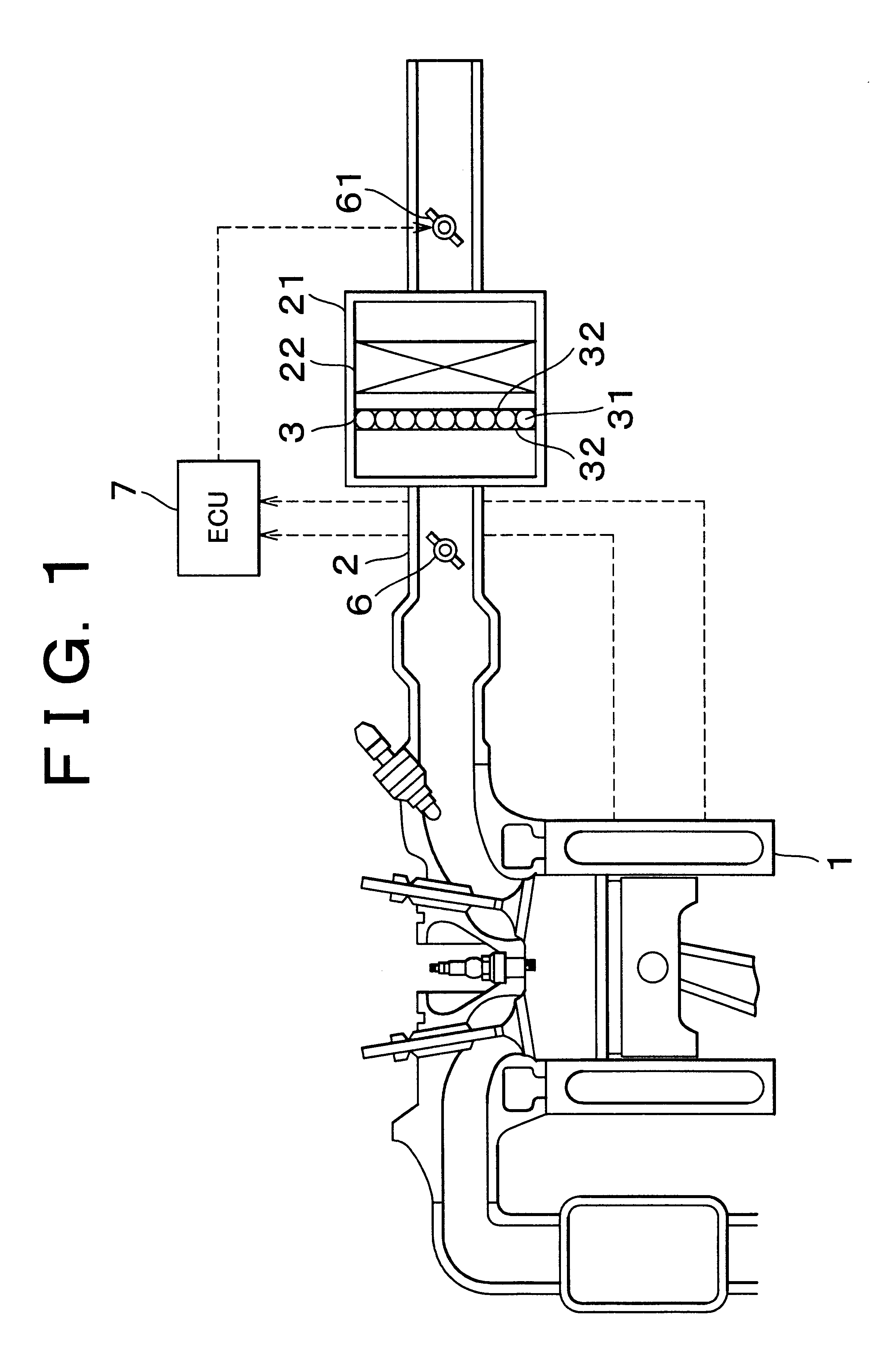

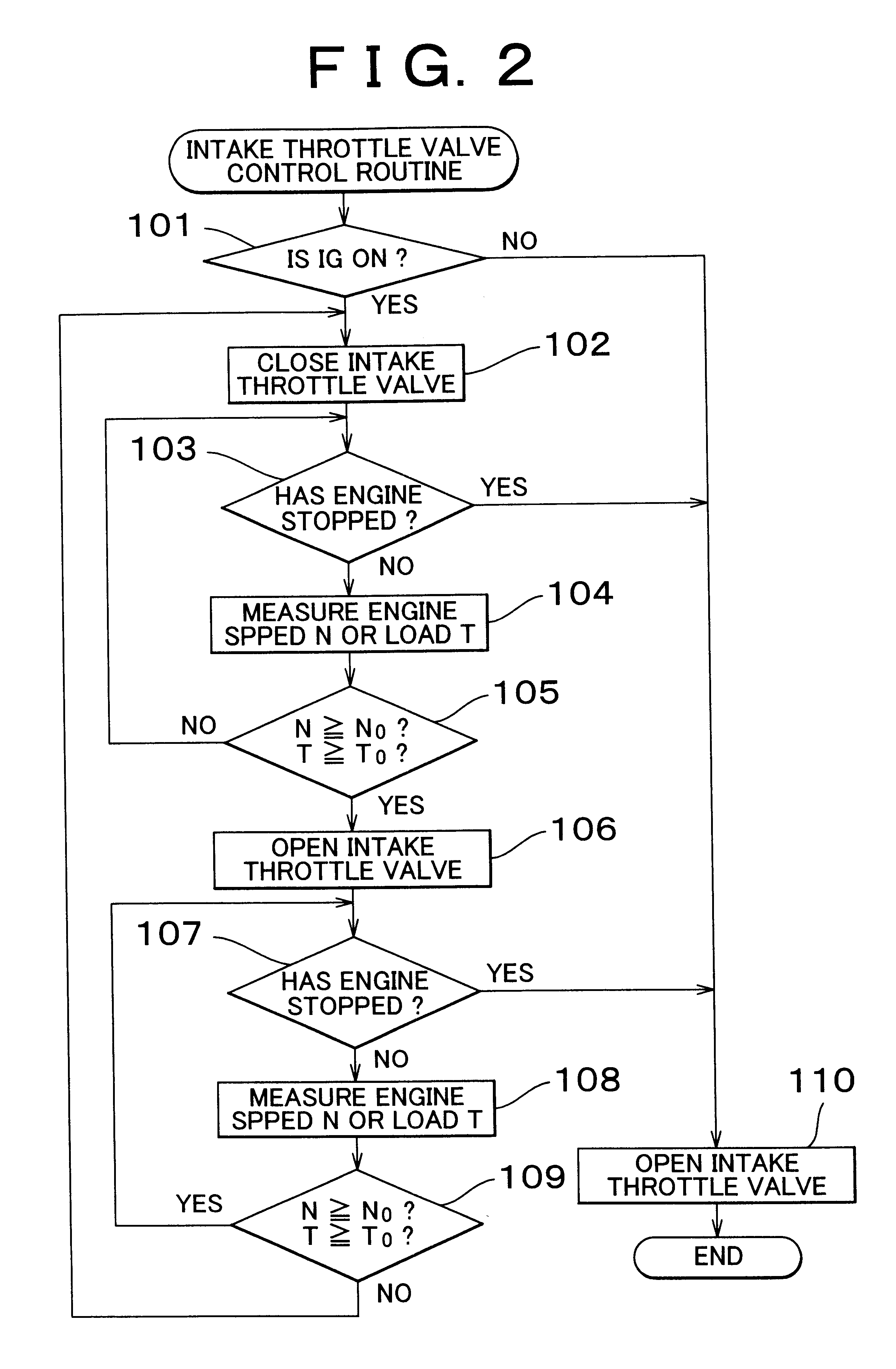

Fuel vapor adsorption device of internal combustion engine and method of desorbing fuel vapor from fuel vapor adsorbent

InactiveUS6698403B2Efficient desorptionImprove the desorption effectNon-fuel substance addition to fuelMachines/enginesDesorptionExternal combustion engine

An absorbent, such as, for example, an active carbon, is provided in an intake air passage, for example, in an air cleaner, to efficiently adsorb fuel vapor. To ensure that fuel vapor adsorbed into the intake air passage can be efficiently desorbed even when there is only a small amount of the intake air, an intake throttle valve is provided upstream of the adsorbent and an opening of the intake throttle valve is throttled so as to decompress an area near the adsorbent. Desorption of fuel vapor also can be efficiently promoted by using a heater to directly heat the adsorbent in the intake air passage or by heating the intake air to indirectly heat the adsorbent.

Owner:TOYOTA BOSHOKU KK +1

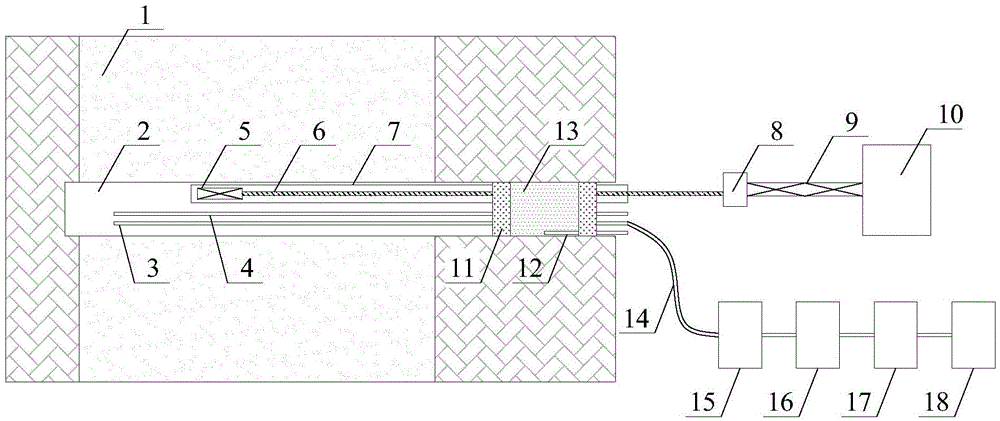

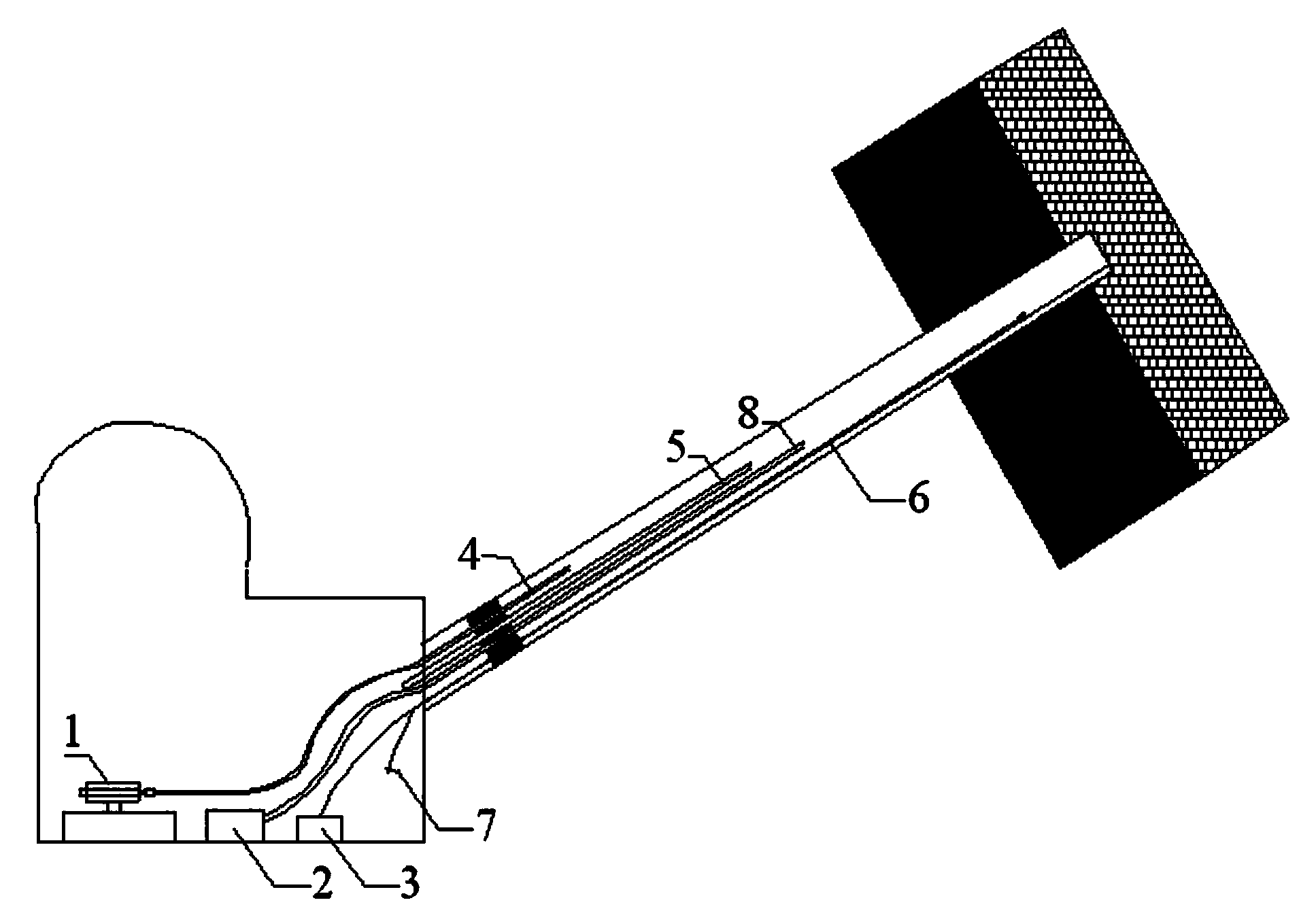

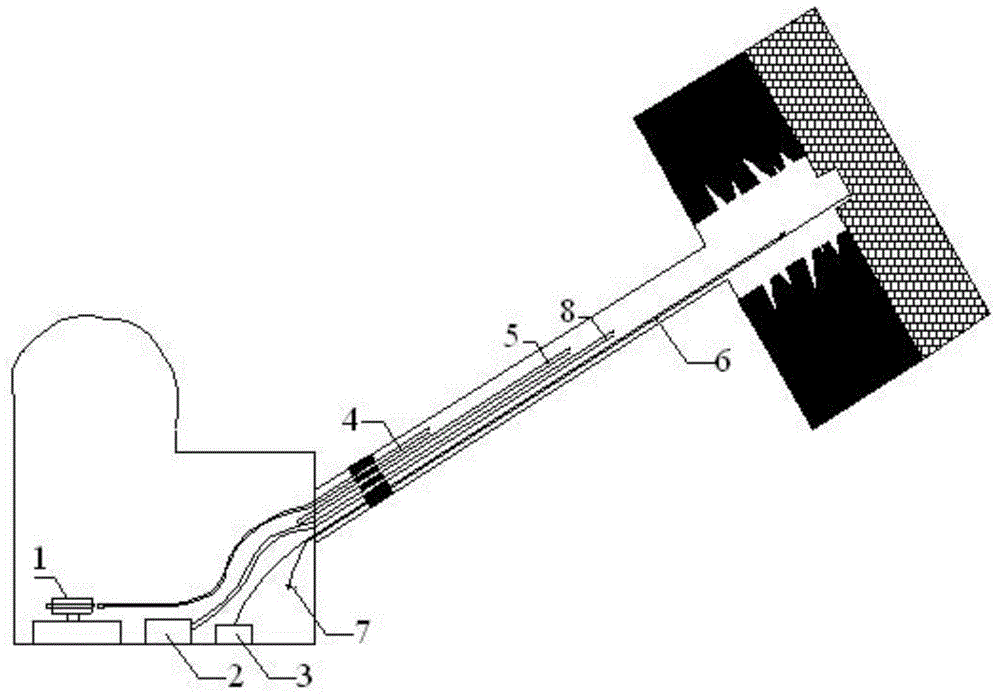

Microwave-assisted extraction and hydrofracture cooperative coal seam anti-reflection method

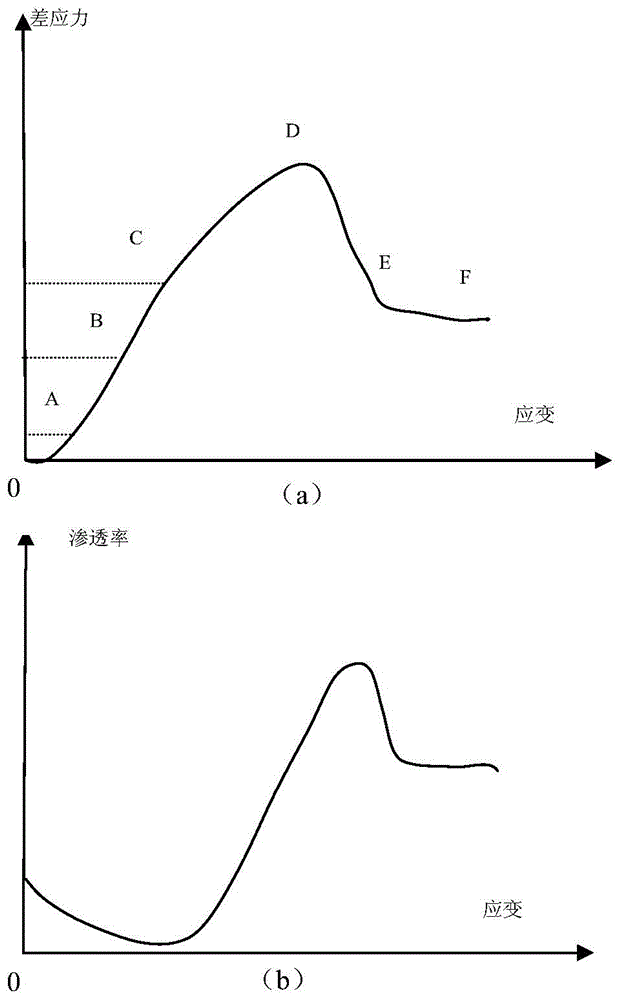

ActiveCN105484720ADredging holes and fissuresIncrease contact areaFluid removalGas removalPorosityDesorption

The invention provides a microwave-assisted extraction and hydrofracture cooperative coal seam anti-reflection method and belongs to the technical field related to coal mine down-hole hydraulic fracturing. The method includes the steps that a microwave antenna is connected to the innermost end of a coaxial waveguide tube and sent into a fracturing drill hole, the outer most end of the coaxial waveguide tube is connected with a waveguide tube converter, the waveguide tube converter is connected with a rectangular waveguide tube, and the rectangular waveguide tube is connected with a microwave generator; organic solvent and high pressure water are mixed, hydrofracture is conducted on the drill hole through a fracturing tube, meanwhile, the microwave generator is turned on, radiation drilling is conducted through the microwave antenna, fracturing is conducted, a seepage is provided for the solvent, the organic solvent dissolves small organic molecules in coal so that a chambering effect is generated, and methane desorption is promoted through the heat effect of microwaves. According to the method, hydrofracture, solvent extraction and microwave radiation are combined, the porosity and permeability of the coal seam are greatly improved, methane desorption is promoted, and thus the methane extraction effect is greatly improved.

Owner:CHINA UNIV OF MINING & TECH +1

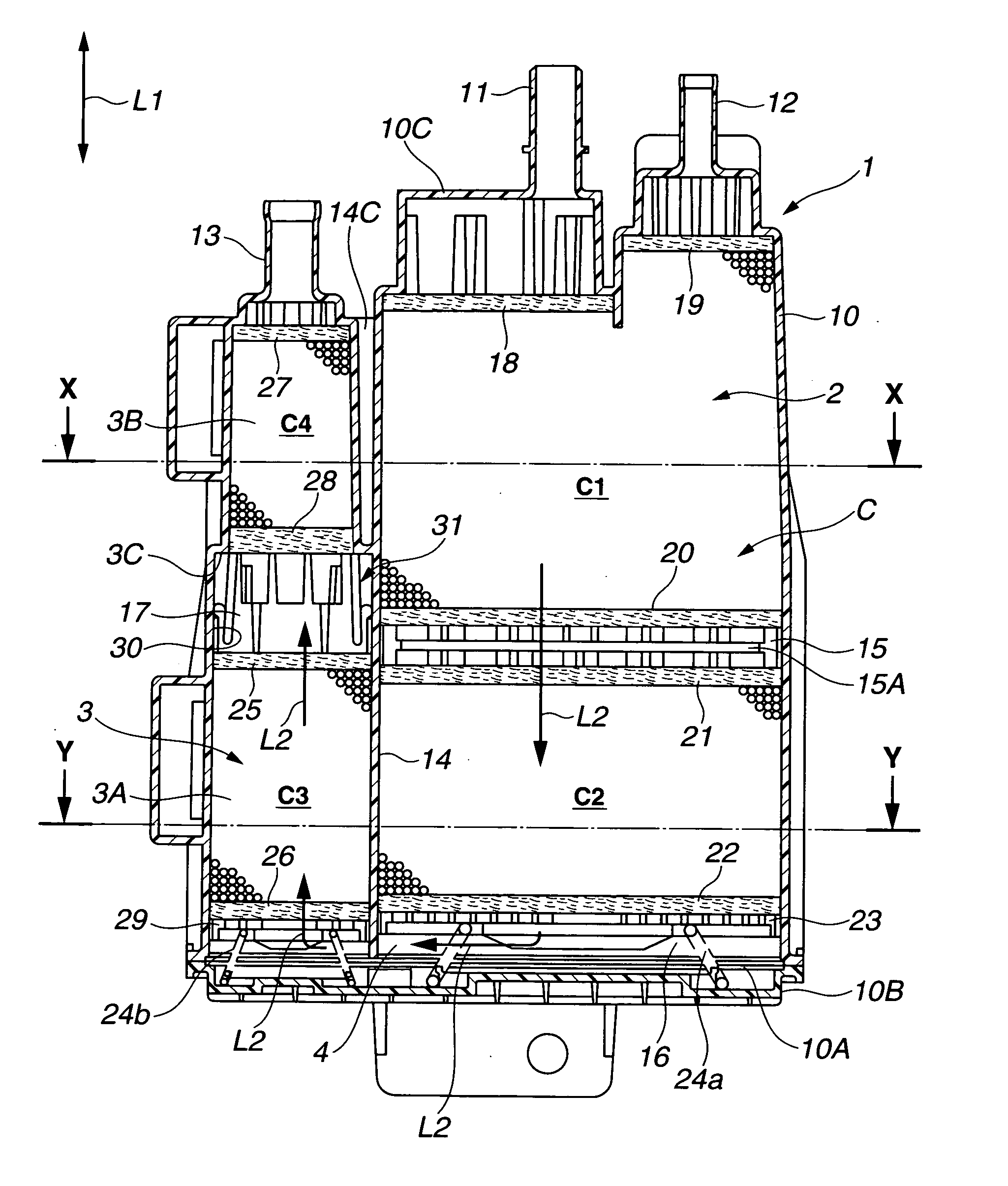

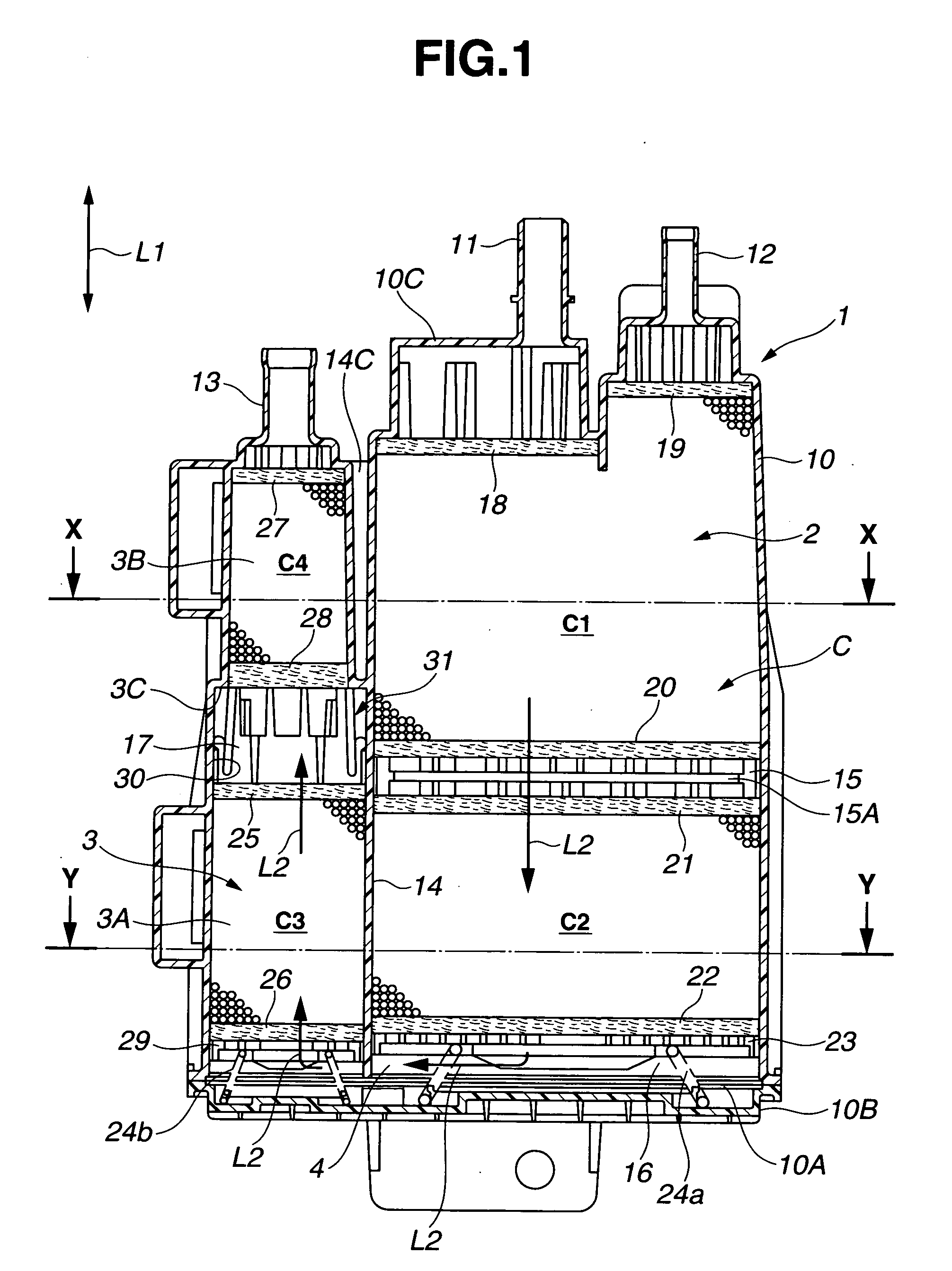

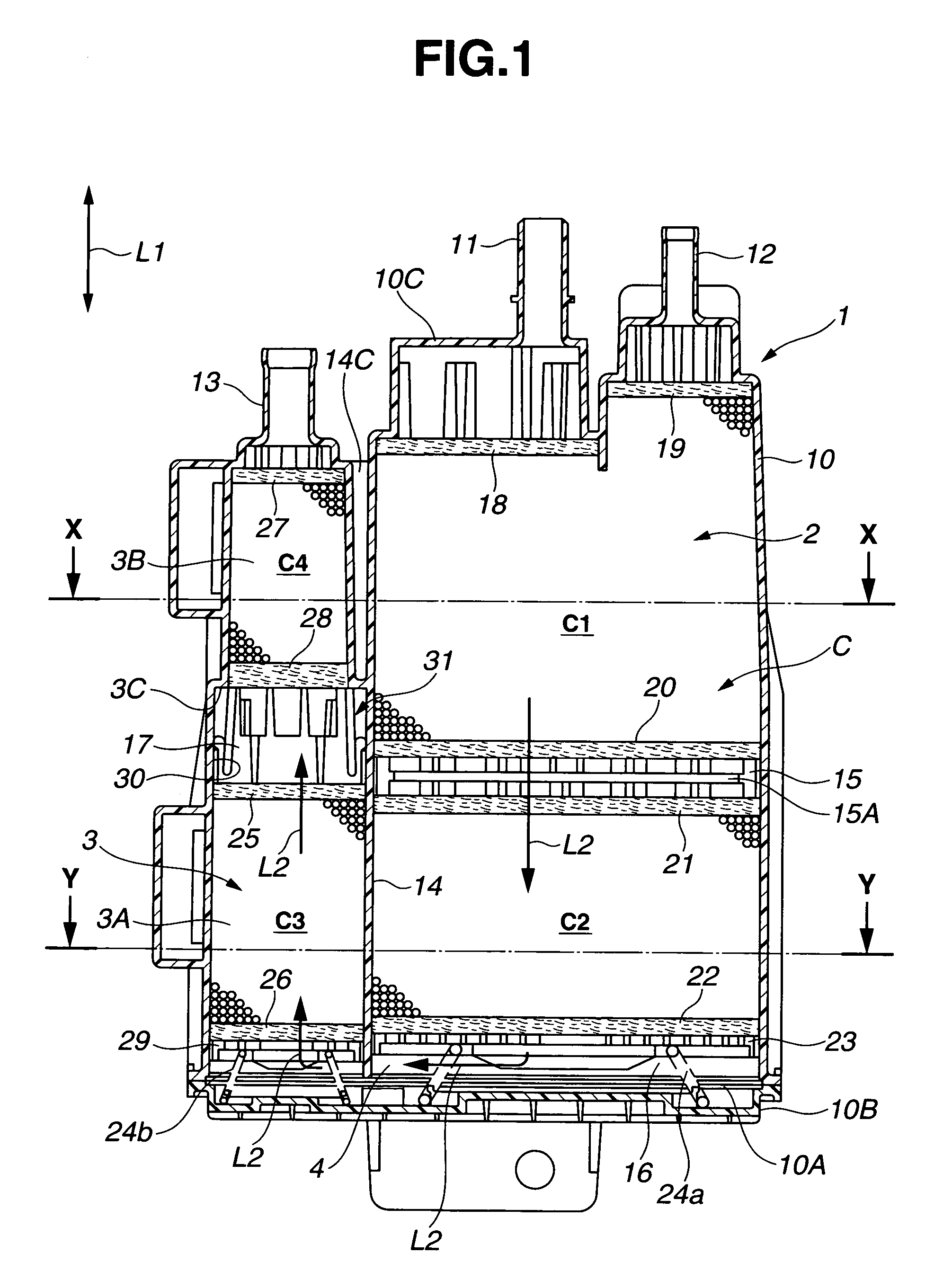

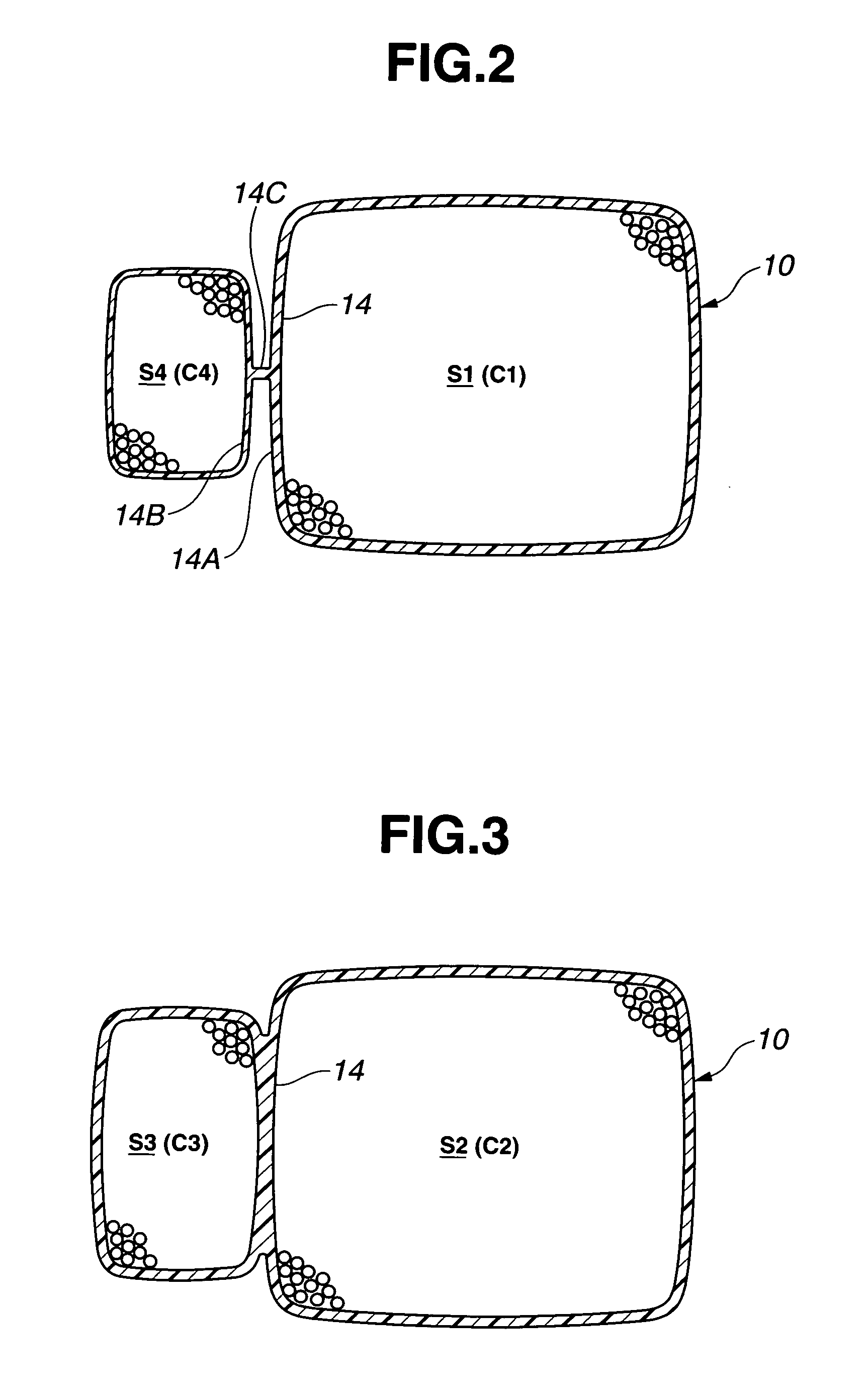

Fuel vapor storage canister

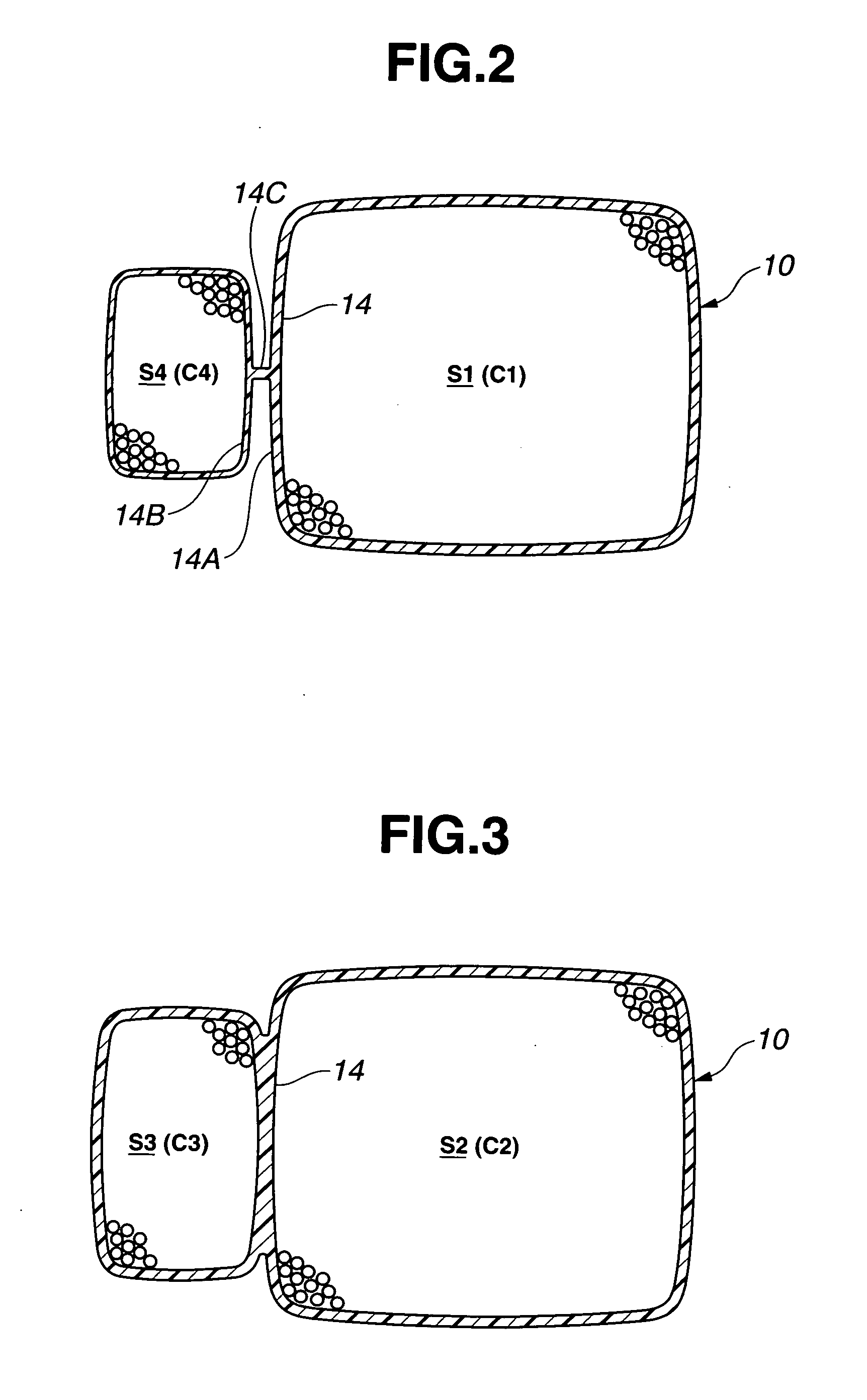

InactiveUS20070119306A1Improve adsorption capacityFacilitate desorptionNon-fuel substance addition to fuelIsotope separationProcess engineeringFuel vapor

A fuel vapor storage canister for an automotive vehicle, includes a casing formed thereinside with charge, purge and drain ports connected to a gas passage. First, second, third and fourth adsorption layers are disposed in the gas passage and arranged in order of first, second, third and forth adsorption layers from side of the charge port along a longitudinal direction of the gas passage. Each adsorption layer includes a fuel vapor adsorbent. Additionally, a first space section is formed between the first and second adsorption layers. A second space section is formed between the second and third adsorption sections. A third space section is formed between the third and fourth adsorption sections. Each space section has a width in the longitudinal direction of the gas passage.

Owner:MAHLE FILTER SYST JAPAN CORP

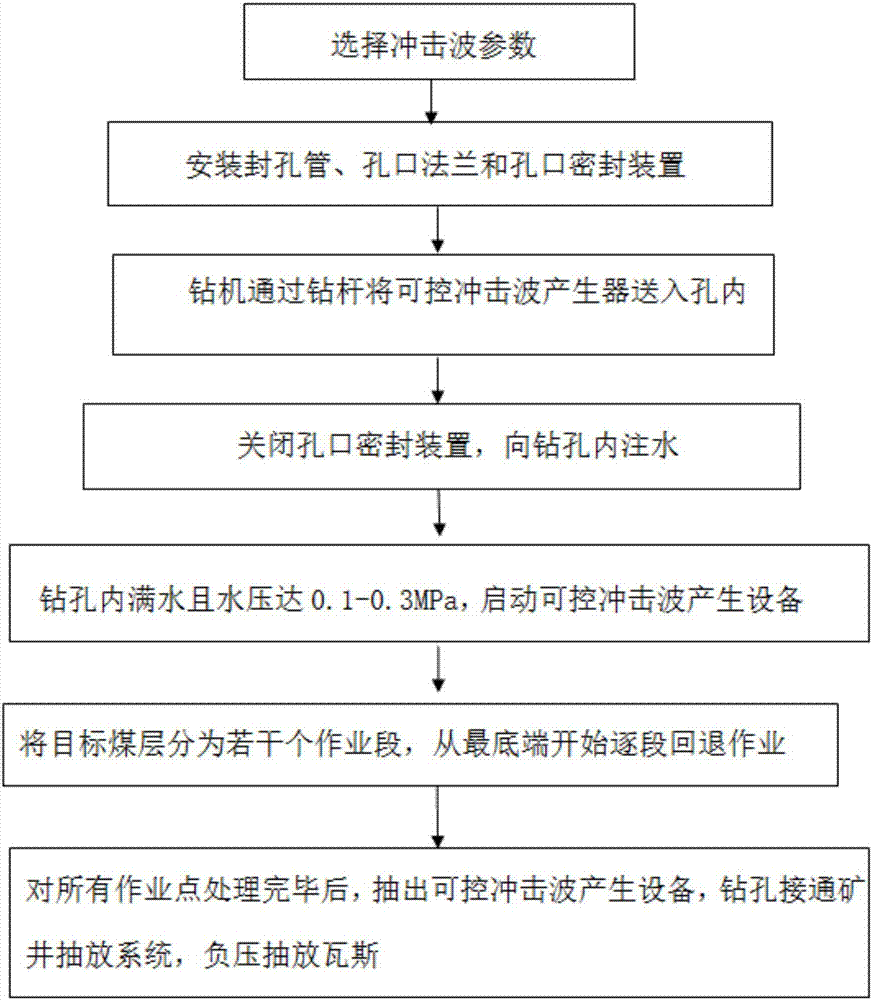

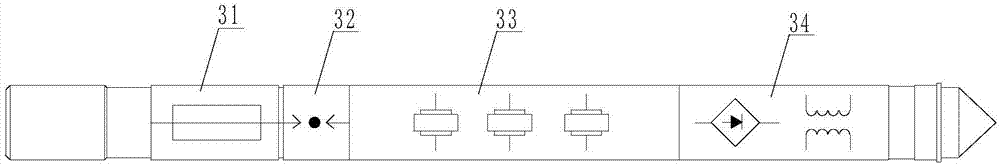

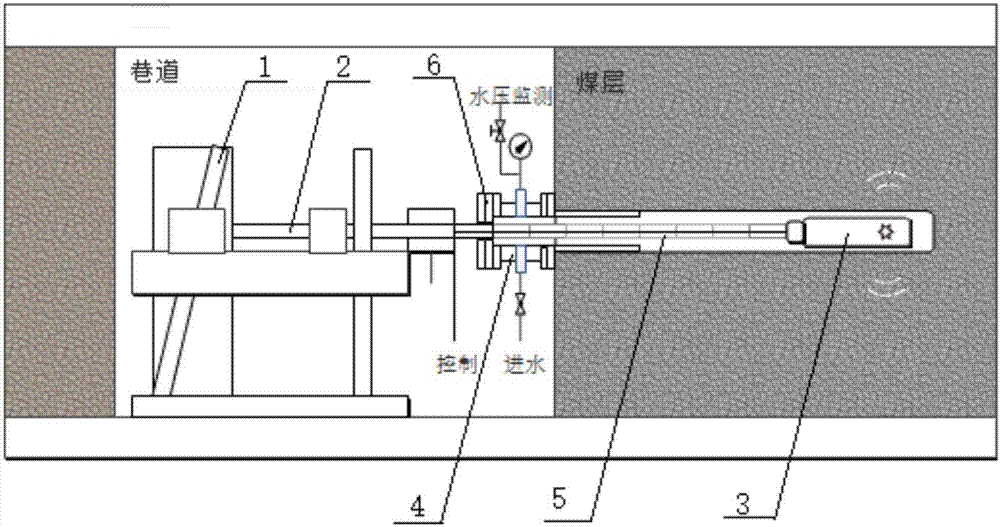

Coal mine down-hole drilling penetration improvement method based on controllable shock wave technology

InactiveCN107956505APrevent collapseAvoid the problem of rock burstFluid removalGas removalShock waveEngineering

The invention belongs to the field of energy and coal mine safety, and particularly relates to a coal mine down-hole drilling penetration improvement method based on a controllable shock wave technology. The method aims at solving the problems of high labor intensity and low safety of an existing gas treatment mode. Controllable shock wave generation equipment is pushed to the interior of a drilling hole, and after a hole opening sealing device is installed at a hole opening of the drilling hole, water is injected to the drilling hole; after the drilling hole is fully filled with the water, operation is conducted segment by segment, the middle of each operation segment is used as an operation point of shock waves, and repeated impact is conducted on each operation point multiple times. Under the effect of the injected water in the hole, the shock wave generation equipment does not need to work under the environment with explosive gas, and the shock waves are also efficiently coupled toa coal bed.

Owner:XI AN JIAOTONG UNIV

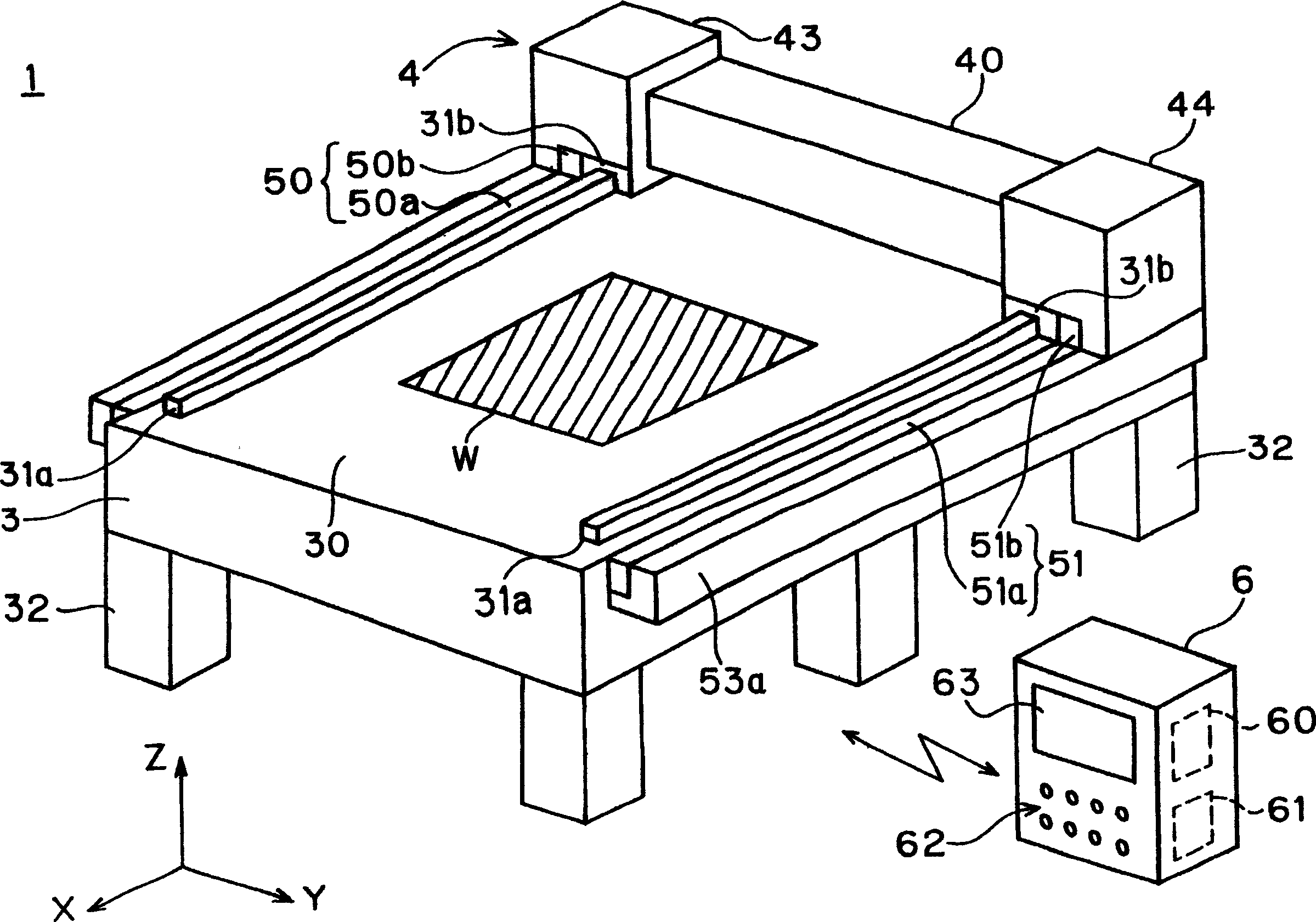

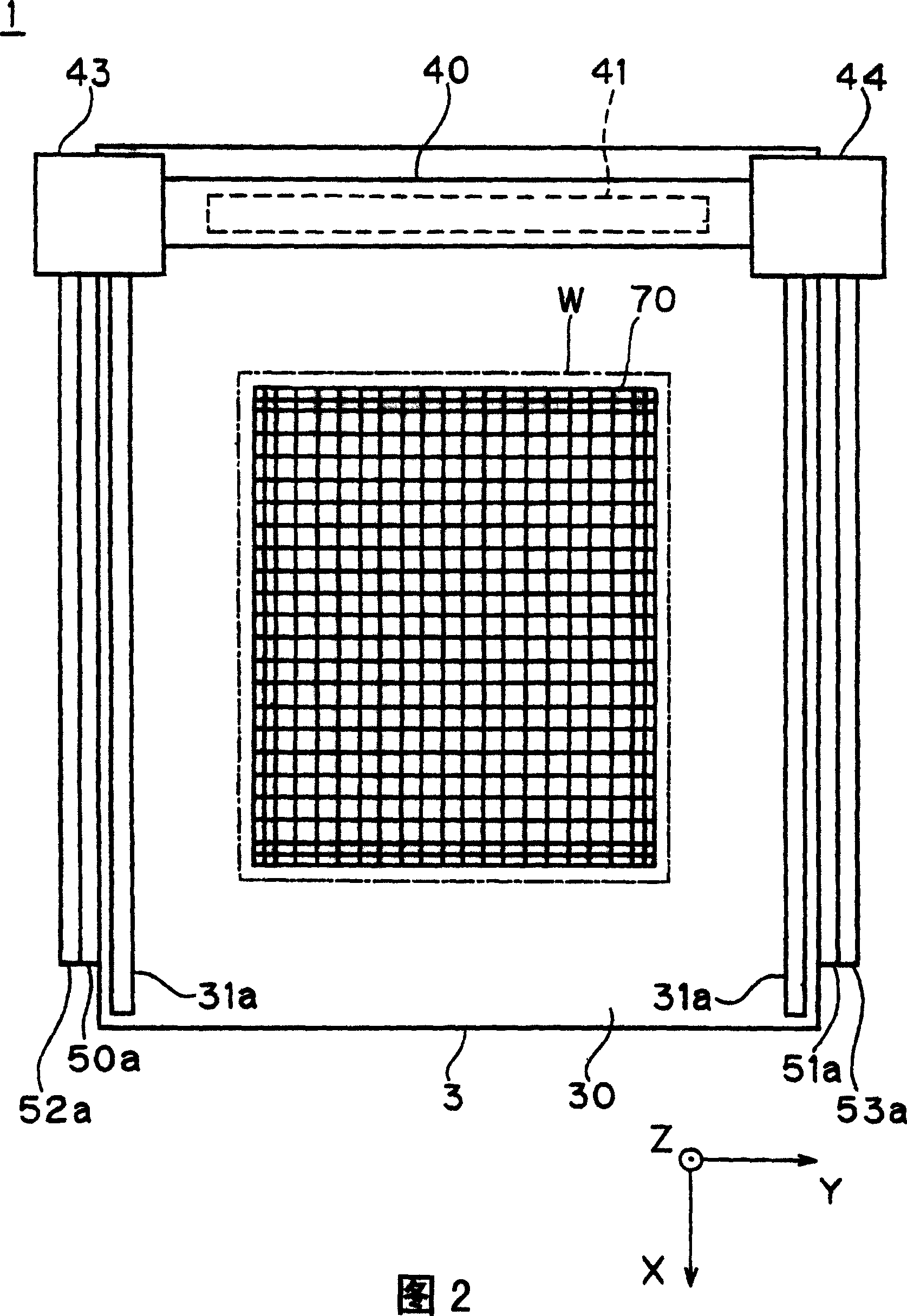

Substrate treater and treating method

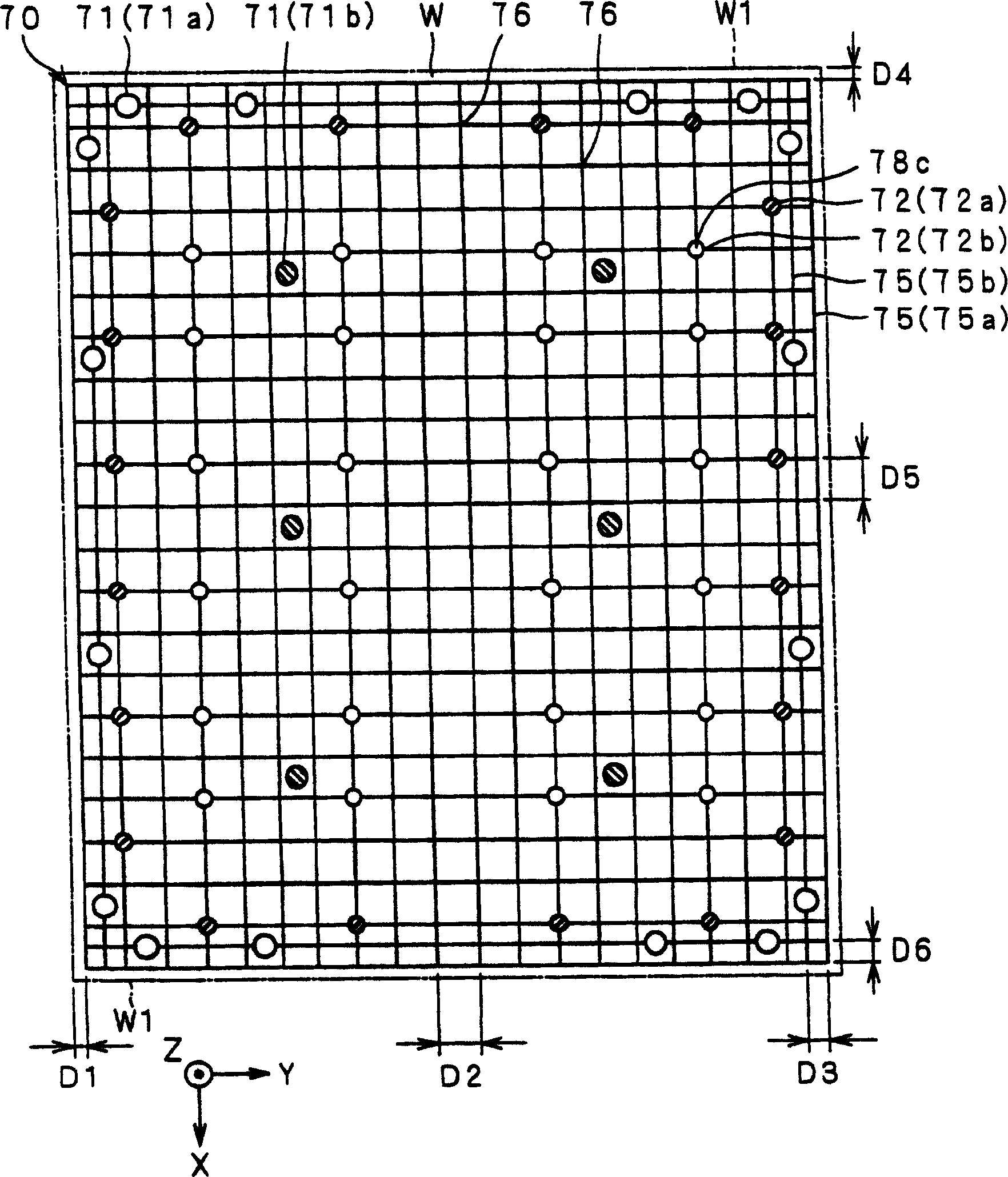

ActiveCN1591816AImprove adsorption capacityReduce manufacturing costGripping headsSemiconductor/solid-state device manufacturingEngineeringVacuum pump

This invention is to provide a substrate treating device which can satisfactorily attract a substrate to its substrate placing part and, at the same time, from which the substrate attracted to the substrate placing section can be removed satisfactorily even when the size of the substrate is increased. A plurality of adsorption grooves 75 formed on the holding surface of the substrate treating device in a grid-like state are connected to each other at grid points 76. A part of the grid points 76 communicates with suction holes 72. The suction holes 72 are connected to a vacuum pump in communicating states through piping. End-section lifter pins 71a and central-part lifter pins 71b are independently provided in vertically movable states. Consequently, (1) the substrate treating device can attract the whole bottom surface of an angular substrate W even when the device does not have many attraction holes in the holding surface and (2) can attract the angular substrate W to the holding surface from the vicinity of the central part of the substrate W to the end section of the substrate W.

Owner:DAINIPPON SCREEN MTG CO LTD

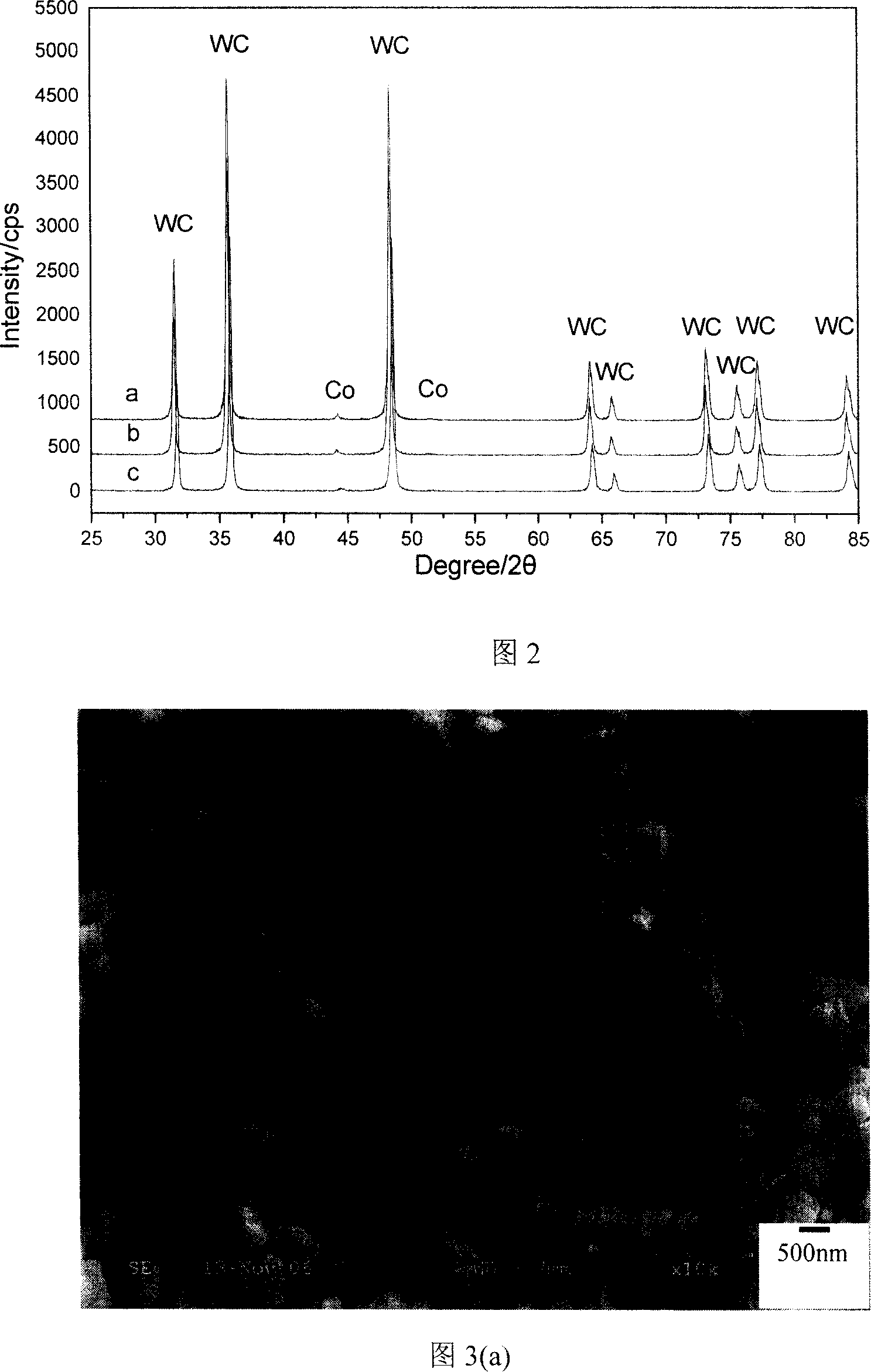

Simple fast preparing process of superfine WC-Co composite powder

The simple fast preparation process of superfine WC-Co composite powder belongs to the field of nanometer powder preparing technology. The preparation process includes the following steps: mixing WO2.9, Co3O4 and carbon black material in the required Co content; ball milling the mixture in a ball milling into superfine powder and cold pressing; heating in a vacuum furnace at vacuum condition to produce redox and carbonizing reaction at heating rate of 15-30 deg.c / min, reaction temperature 1050-1150 deg.c for 3-4 hr. The present invention has simple preparation path and short technological process, and obtains WC-Co composite powder of average particle size smaller than 400 nm.

Owner:BEIJING UNIV OF TECH

Fuel vapor storage canister

InactiveUS7322343B2Improve adsorption capacityFacilitate desorptionNon-fuel substance addition to fuelIsotope separationMobile vehicleProduct gas

A fuel vapor storage canister for an automotive vehicle, includes a casing formed thereinside with charge, purge and drain ports connected to a gas passage. First, second, third and fourth adsorption layers are disposed in the gas passage and arranged in order of first, second, third and forth adsorption layers from side of the charge port along a longitudinal direction of the gas passage. Each adsorption layer includes a fuel vapor adsorbent. Additionally, a first space section is formed between the first and second adsorption layers. A second space section is formed between the second and third adsorption sections. A third space section is formed between the third and fourth adsorption sections. Each space section has a width in the longitudinal direction of the gas passage.

Owner:MAHLE FILTER SYST JAPAN CORP

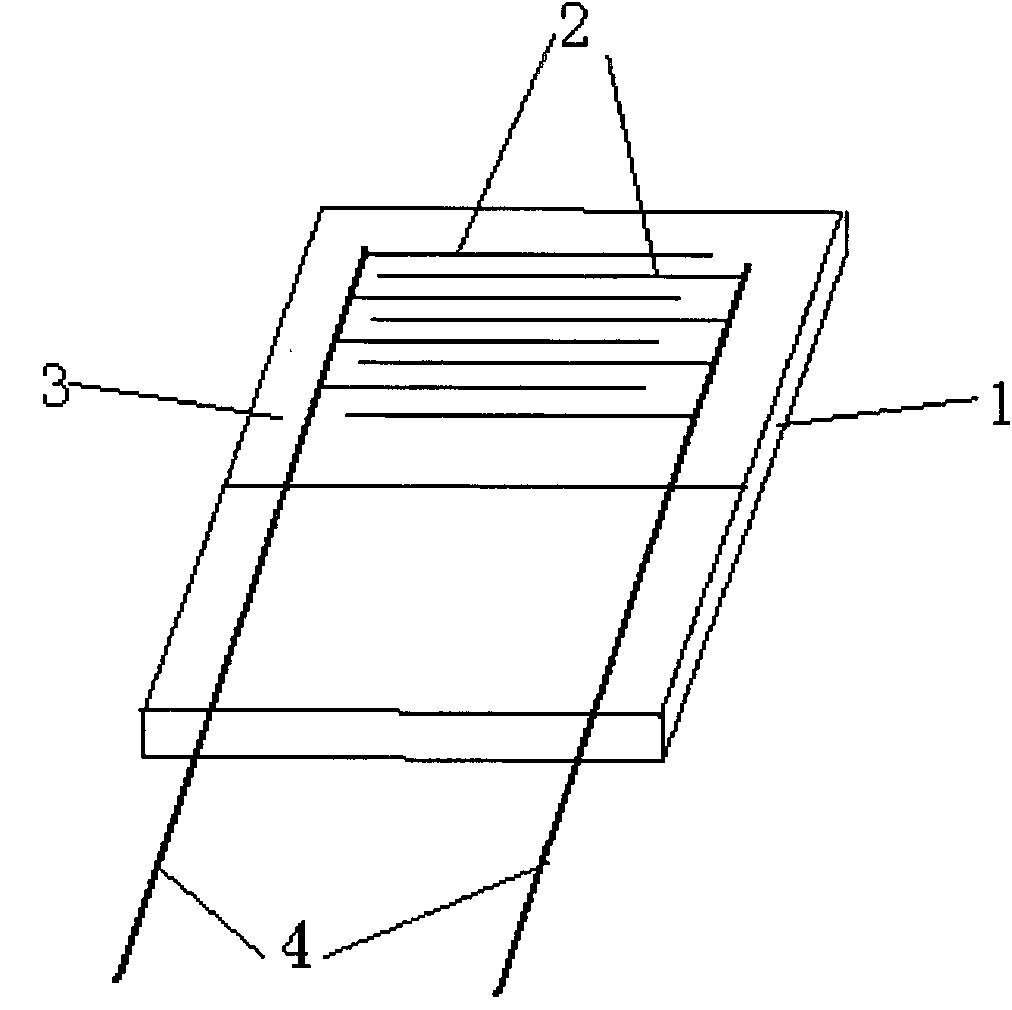

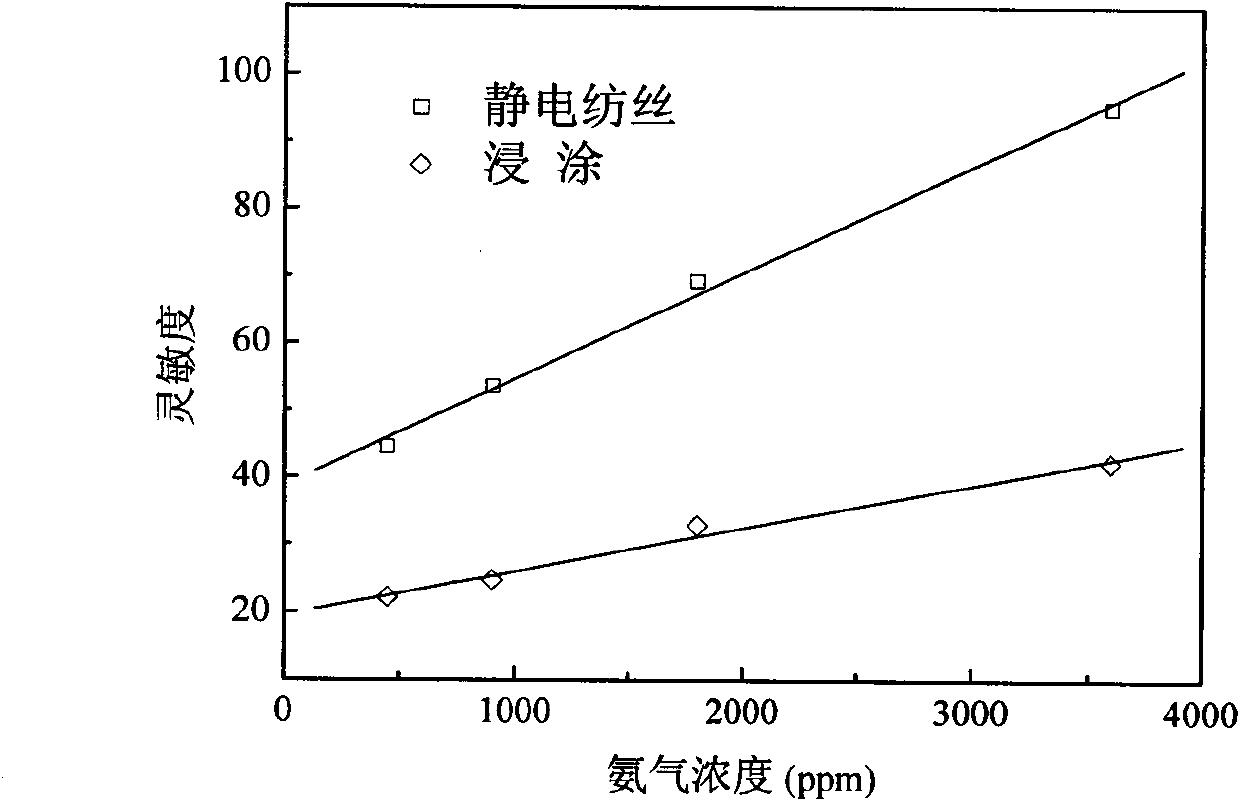

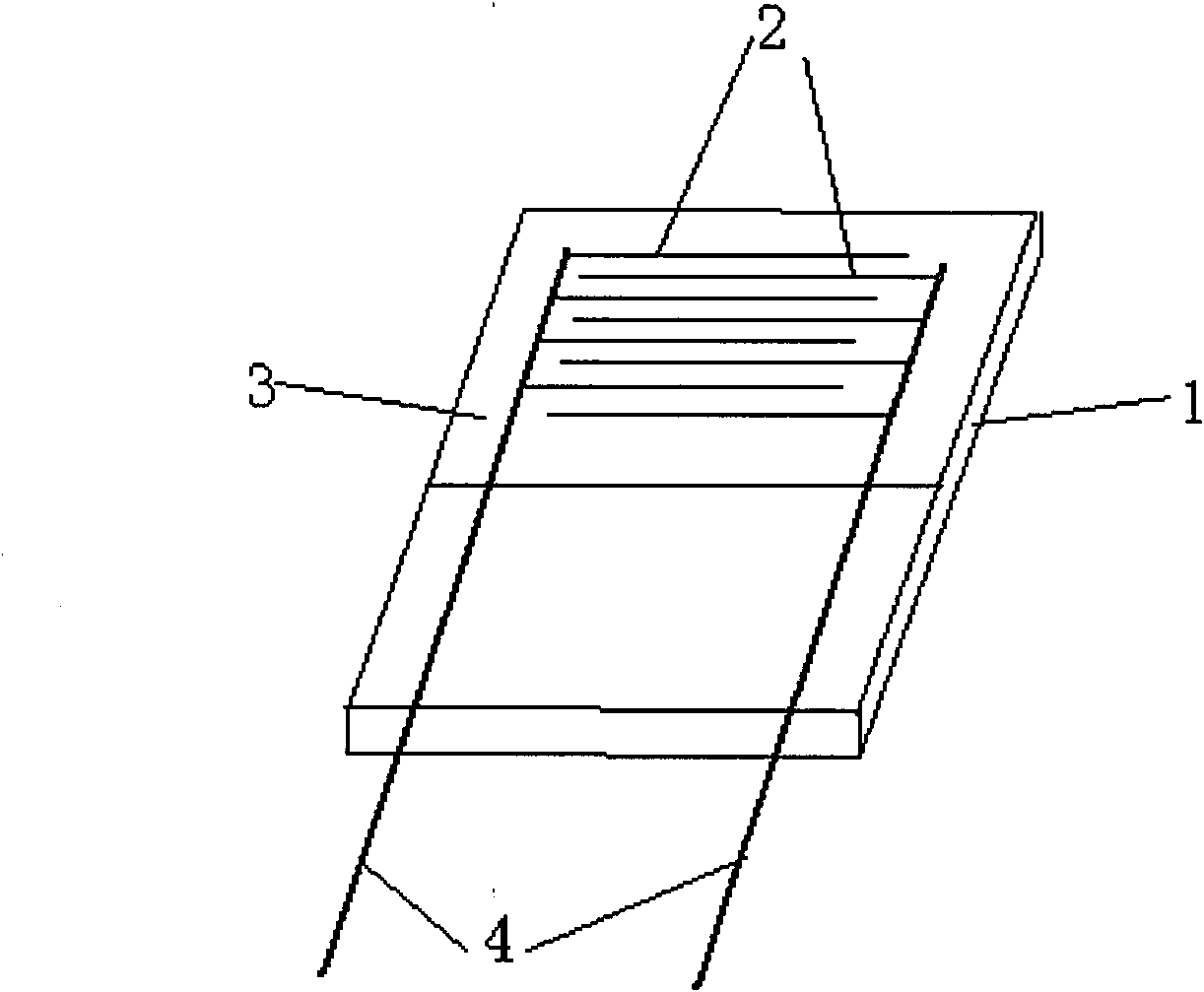

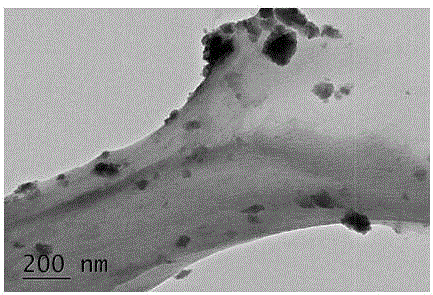

Polypyrrole/polyvinylidene fluoride nano fiber composite resistance type film gas-sensitive element and manufacturing method thereof

InactiveCN101907593AFacilitated DiffusionImprove adsorption capacityMaterial resistanceFiberResponse sensitivity

The invention discloses a polypyrrole / polyvinylidene fluoride nano fiber composite resistance type film gas-sensitive element and a manufacturing method thereof. The method comprises the following steps of: depositing polyvinylidene fluoride nano fiber on a ceramic matrix electrode with golden interdigital by adopting an electrostatic spinning method, and then compounding polyaniline on the polyvinylidene fluoride nano fiber by gas phase in-situ polymerization to obtain a polypyrrole / polyvinylidene fluoride nano fiber composite gas-sensitive film. The preparation process is simple, has low cost, and is particularly suitable for batch production. The prepared gas-sensitive element has the advantages of high response sensitivity on ammonia gas at room temperature, good linearity and the like, has good response repeatability on high-concentration ammonia gas, and can be widely applied to room temperature on-line detection of ammonia gas concentration in an industrial and agricultural production process and an atmospheric environment.

Owner:ZHEJIANG UNIV

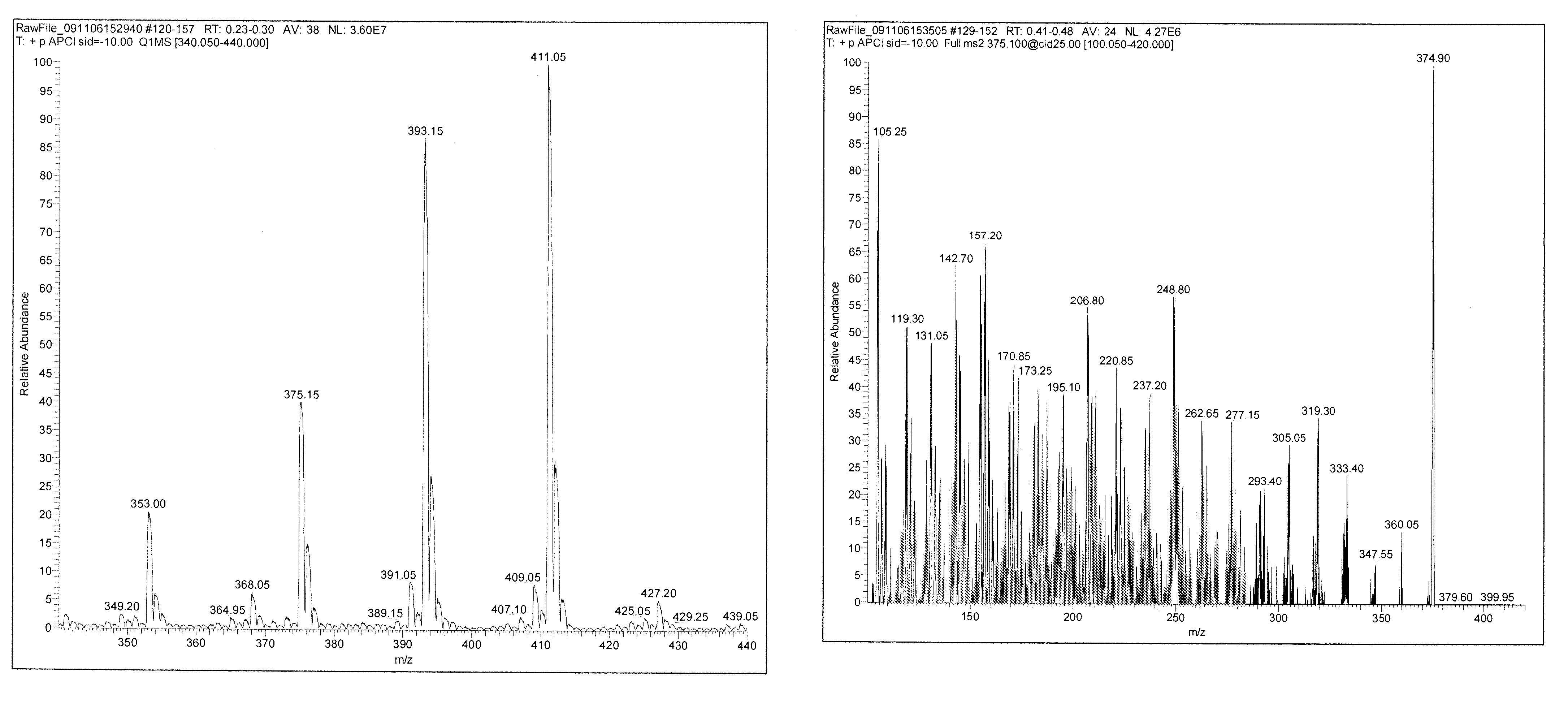

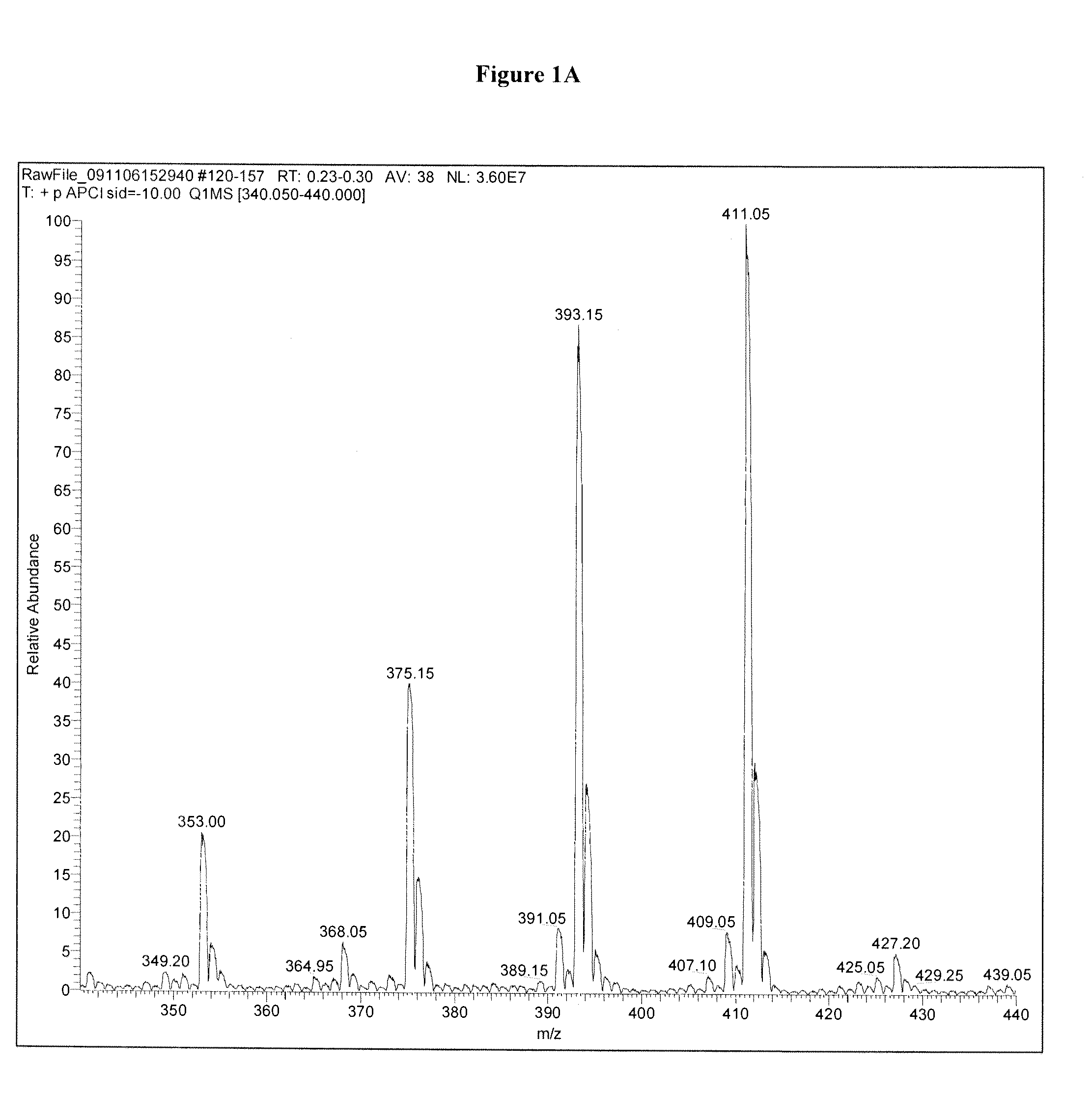

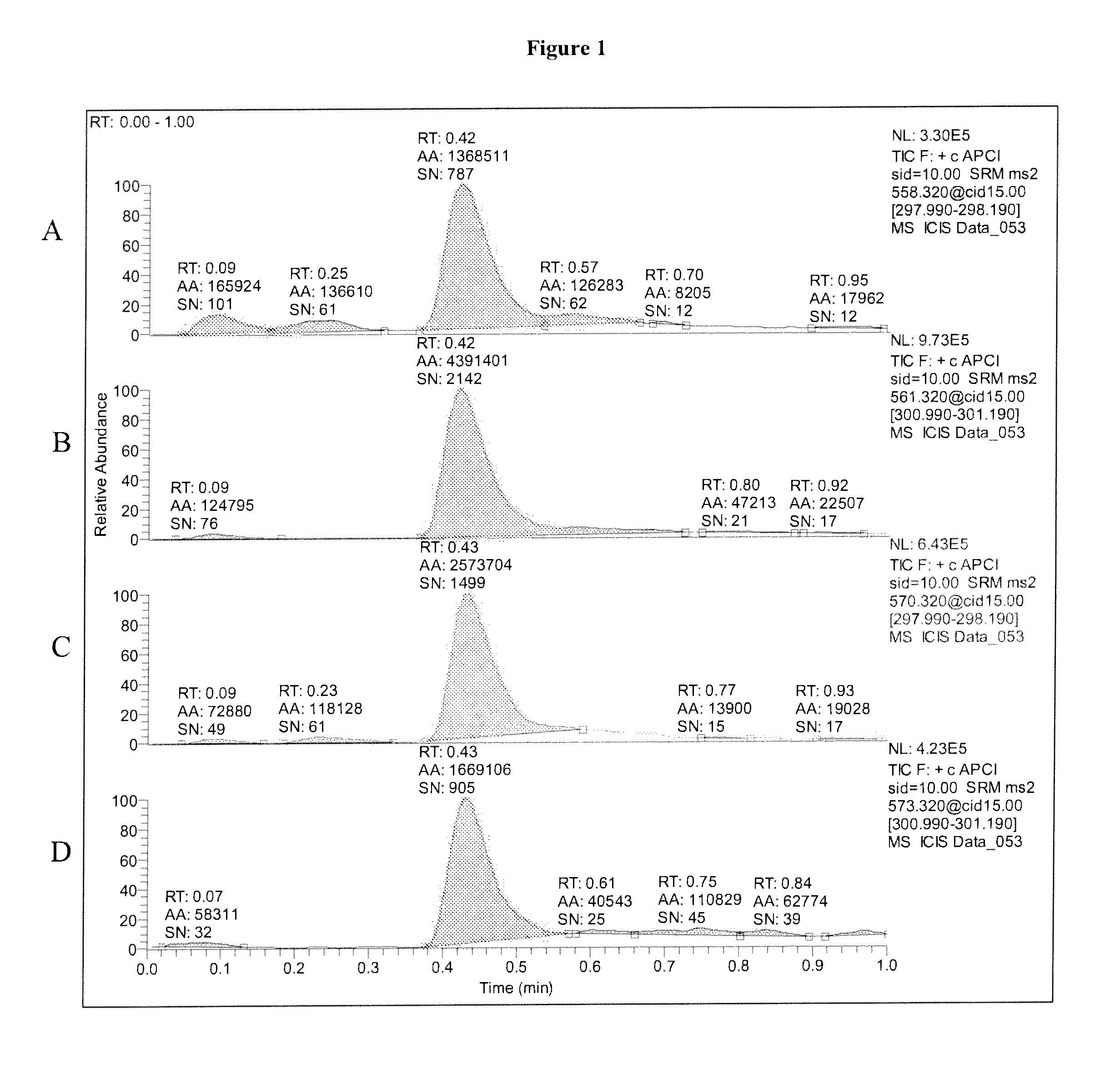

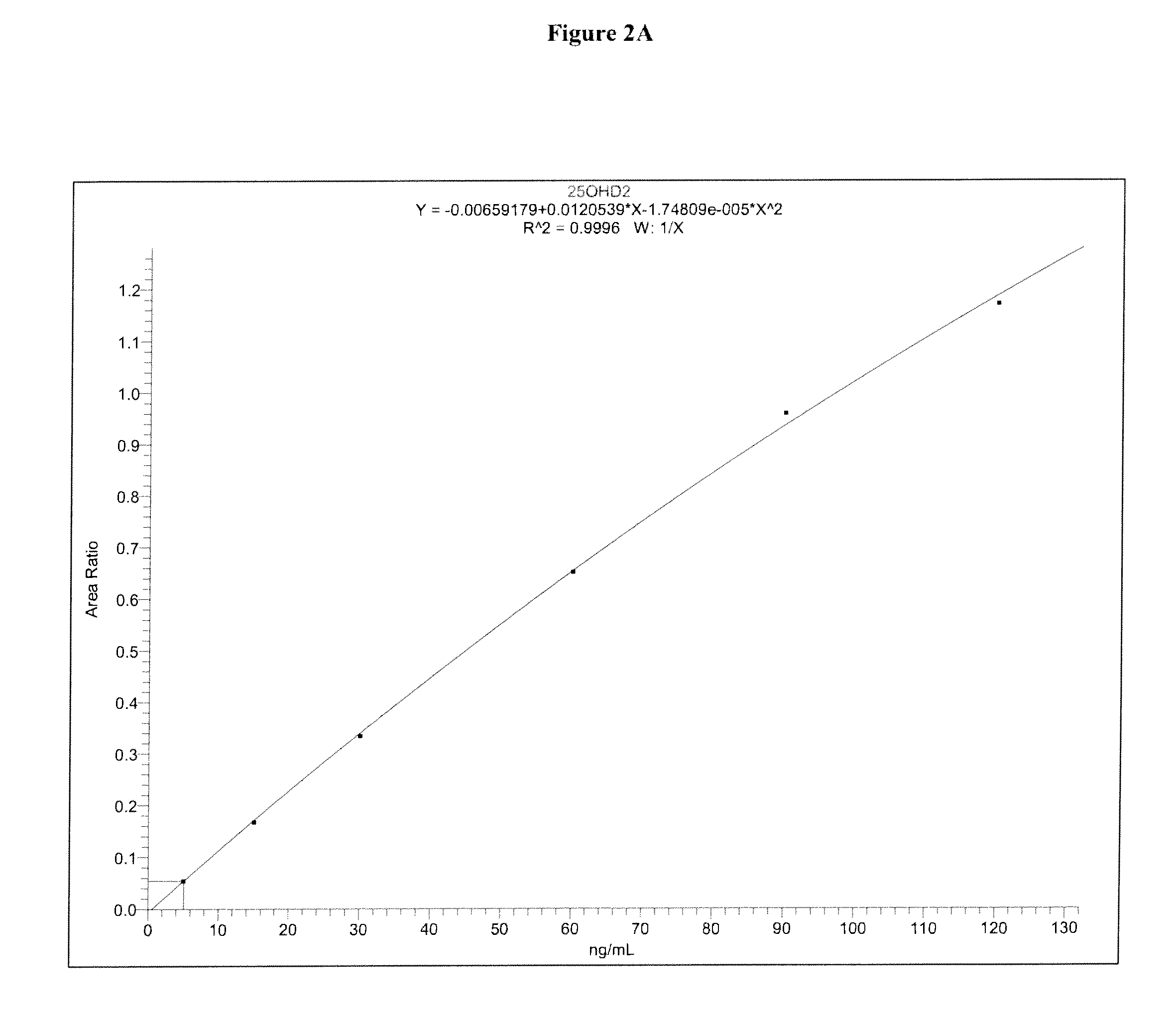

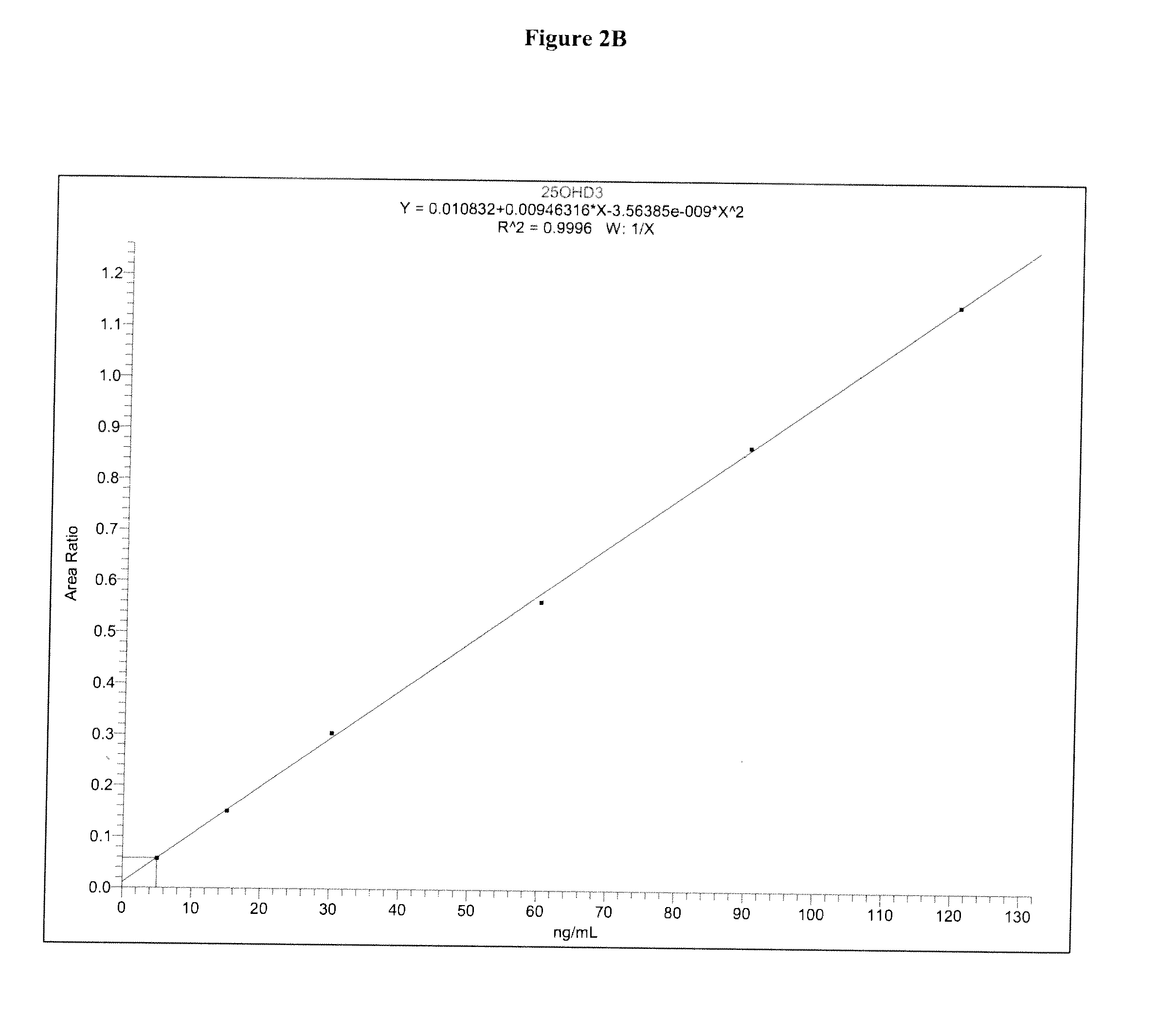

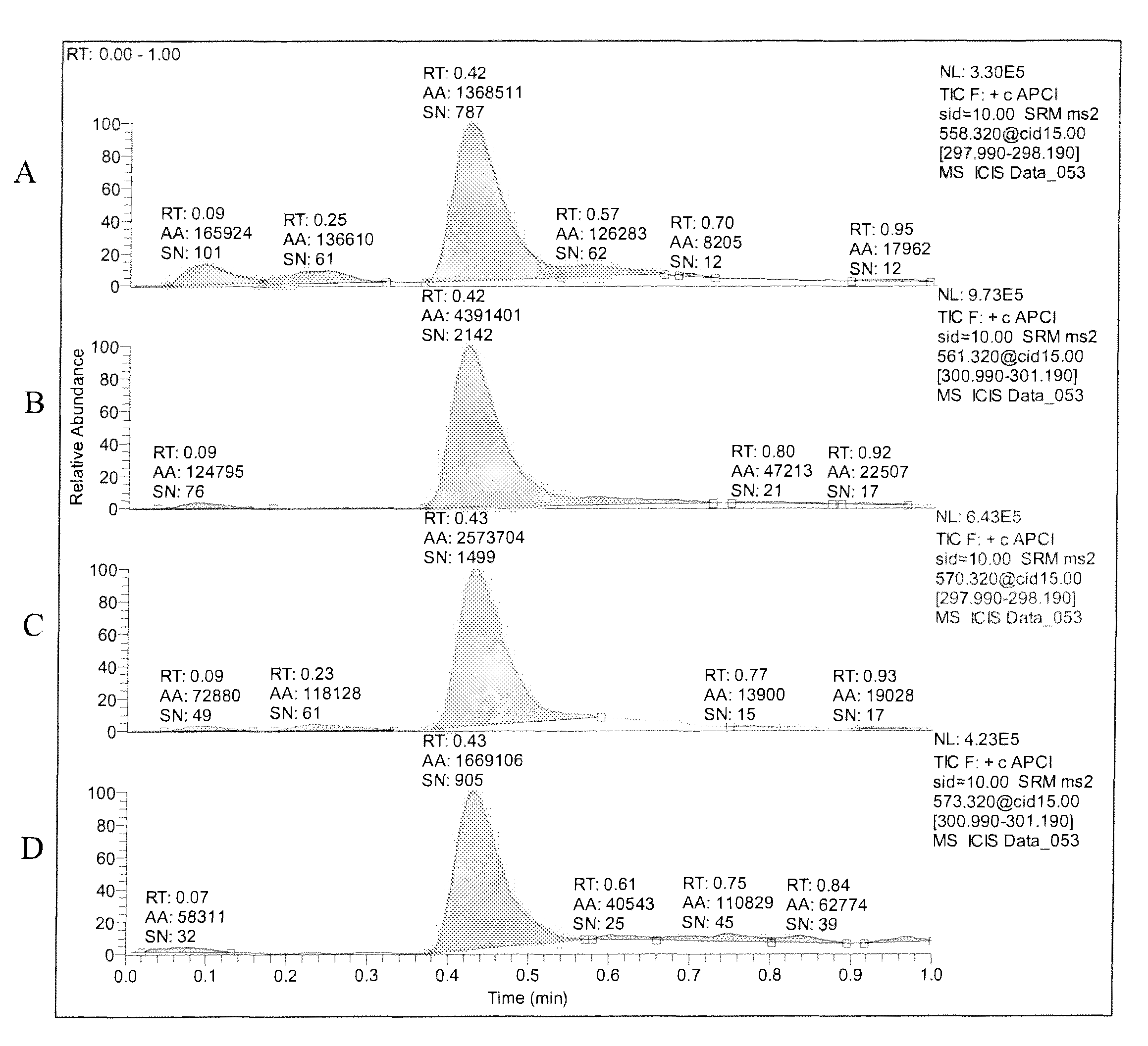

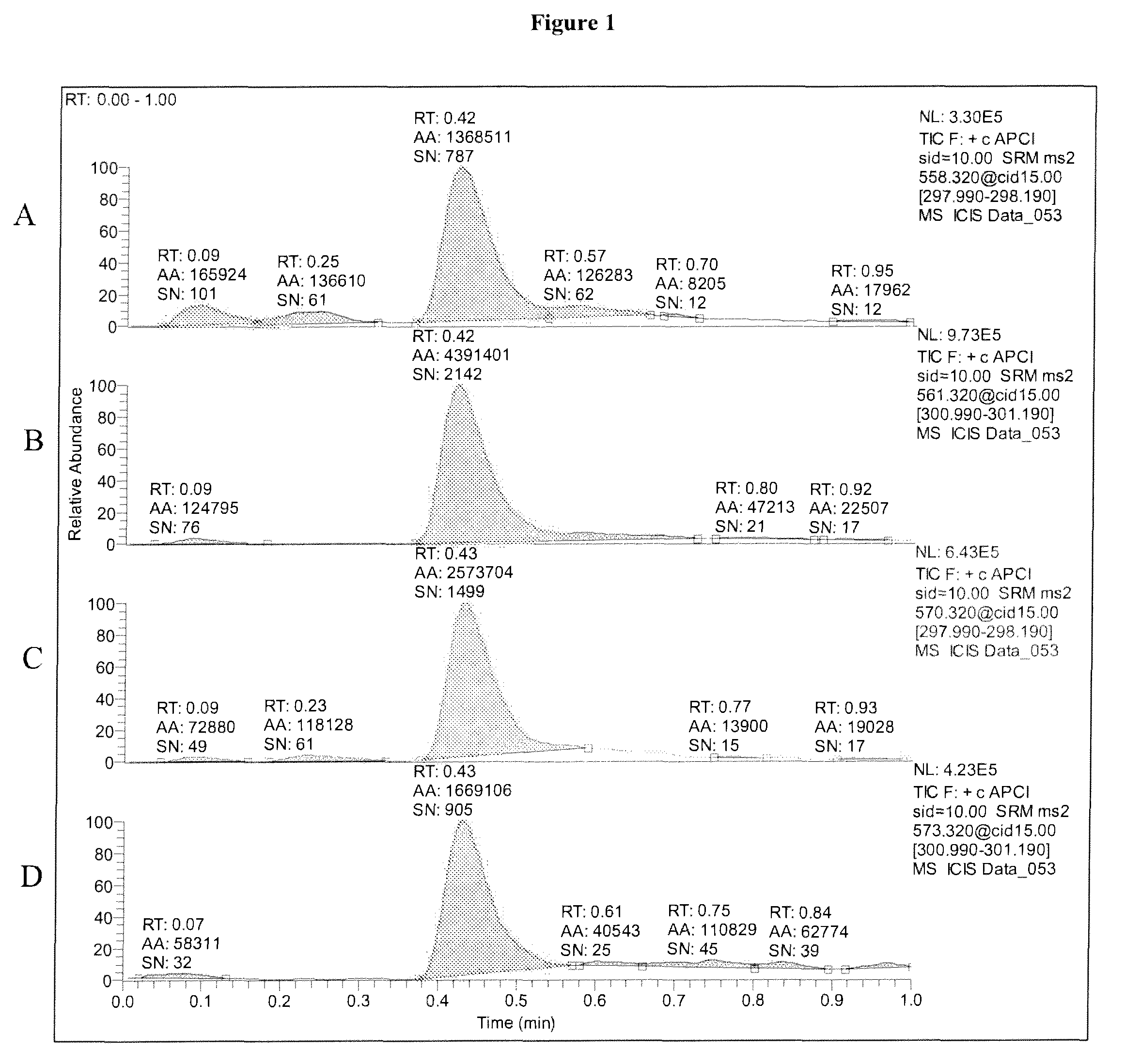

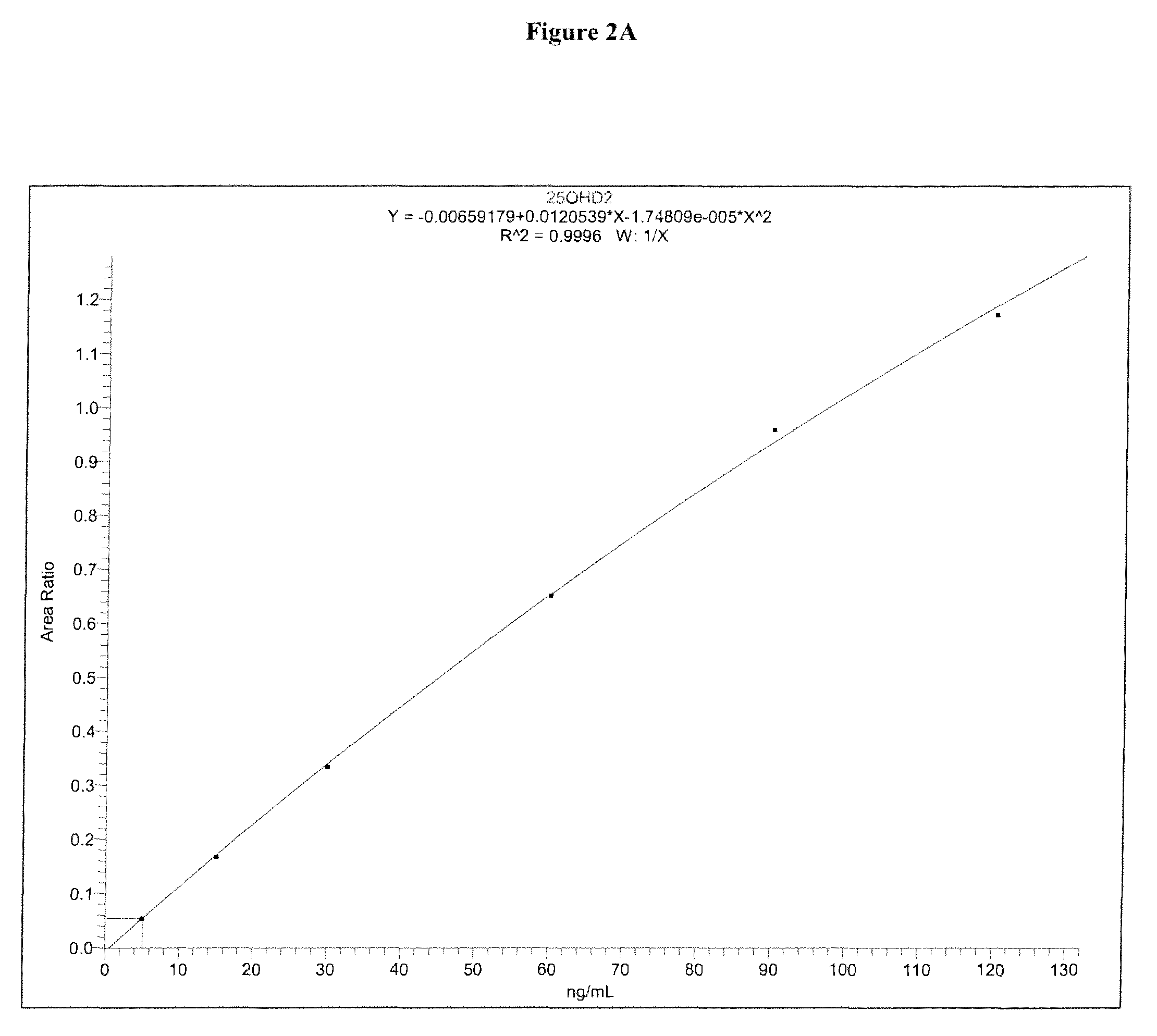

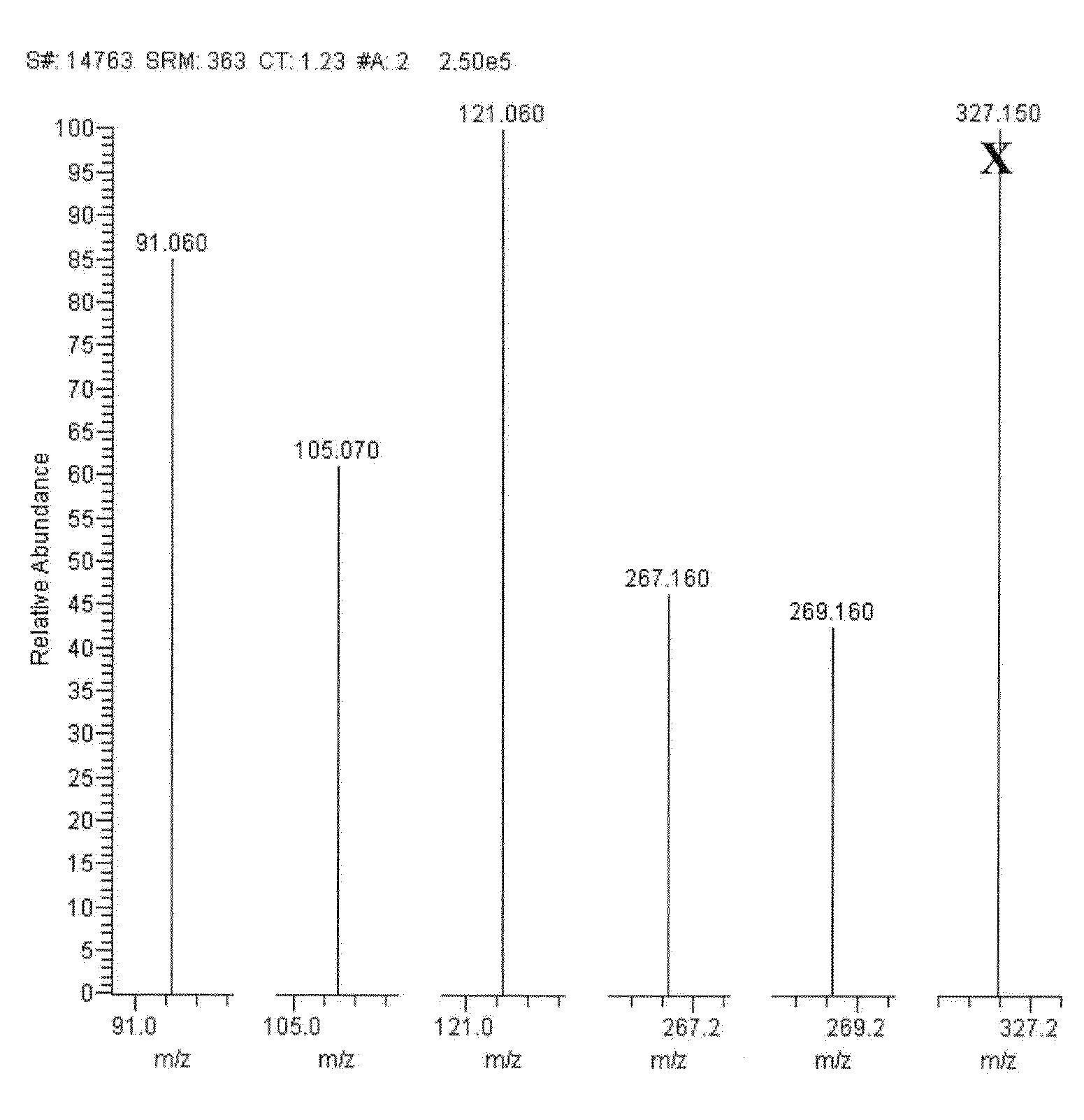

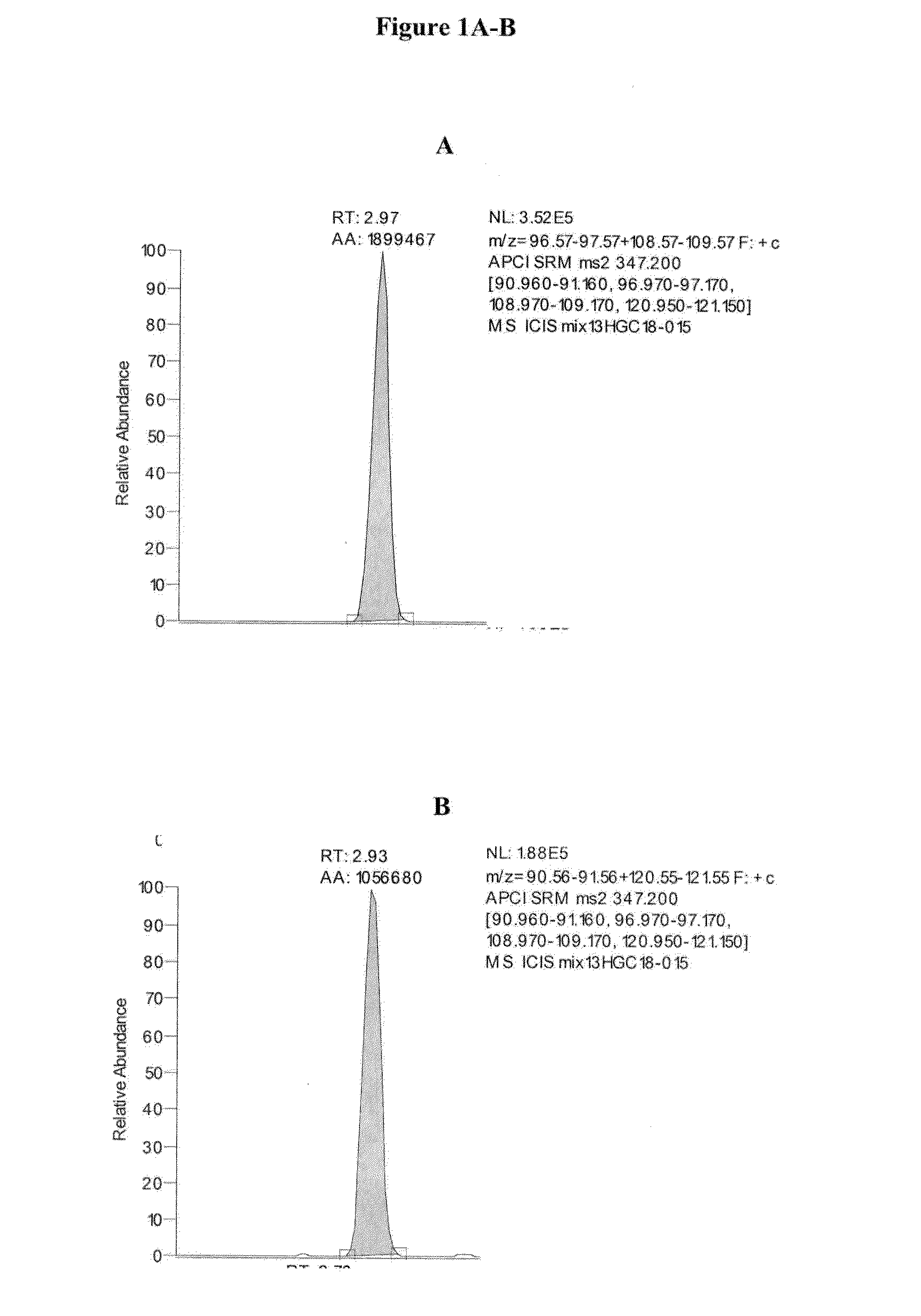

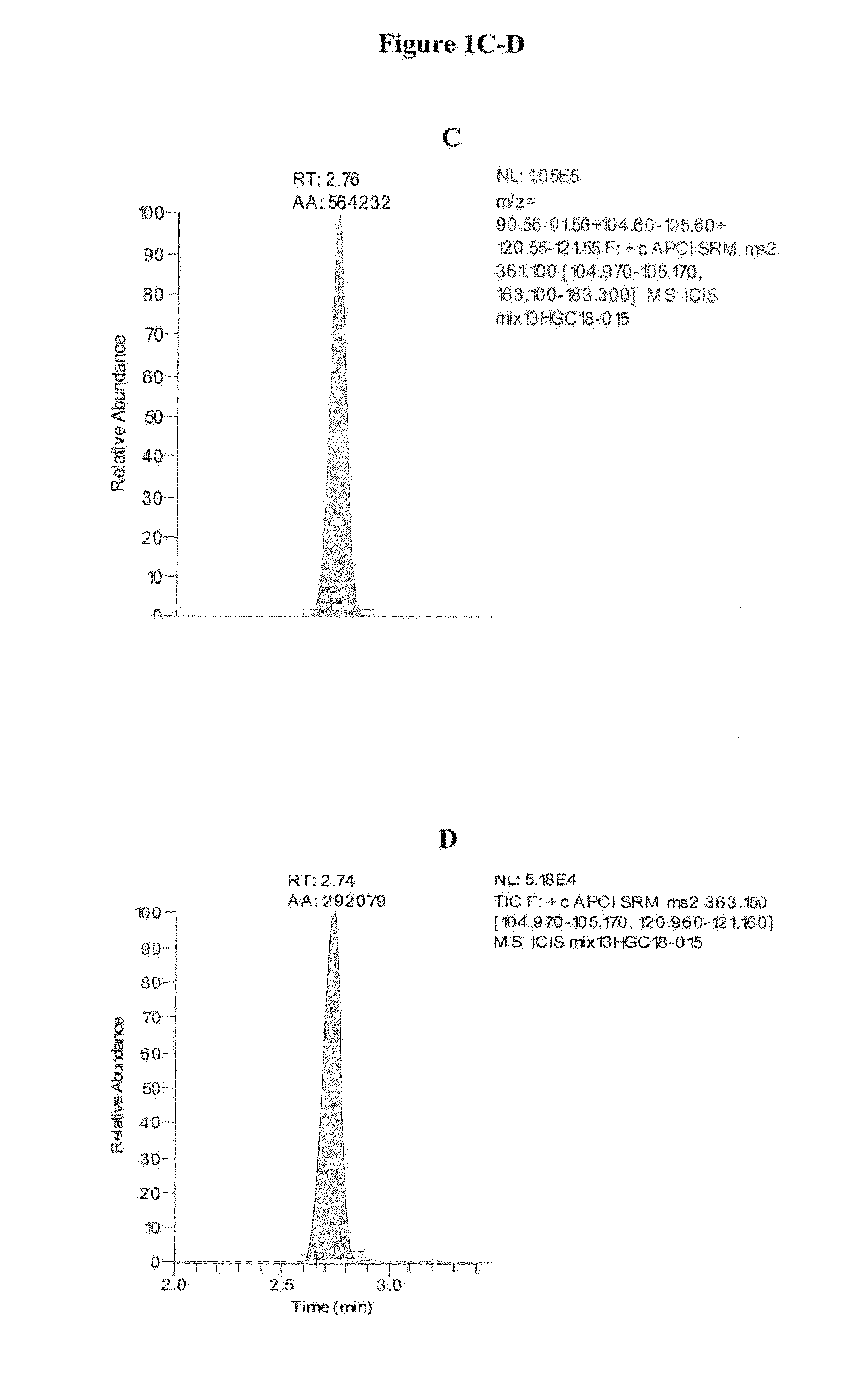

Methods for detecting dihydroxyvitamin D metabolites by mass spectrometry

ActiveUS8084269B2Facilitate desorptionGood removal effectParticle separator tubesIsotope separationMetaboliteMass Spectrometry-Mass Spectrometry

Provided are methods of detecting the presence or amount of a dihydroxyvitamin D metabolite in a sample using mass spectrometry. The methods generally comprise ionizing a dihydroxyvitamin D metabolite in a sample and detecting the amount of the ion to determine the presence or amount of the vitamin D metabolite in the sample. In certain preferred embodiments the methods include immunopurifying the dihydroxyvitamin D metabolites prior to mass spectrometry. Also provided are methods to detect the presence or amount of two or more dihydroxyvitamin D metabolites in a single assay.

Owner:QUEST DIAGNOSTICS INVESTMENTS INC

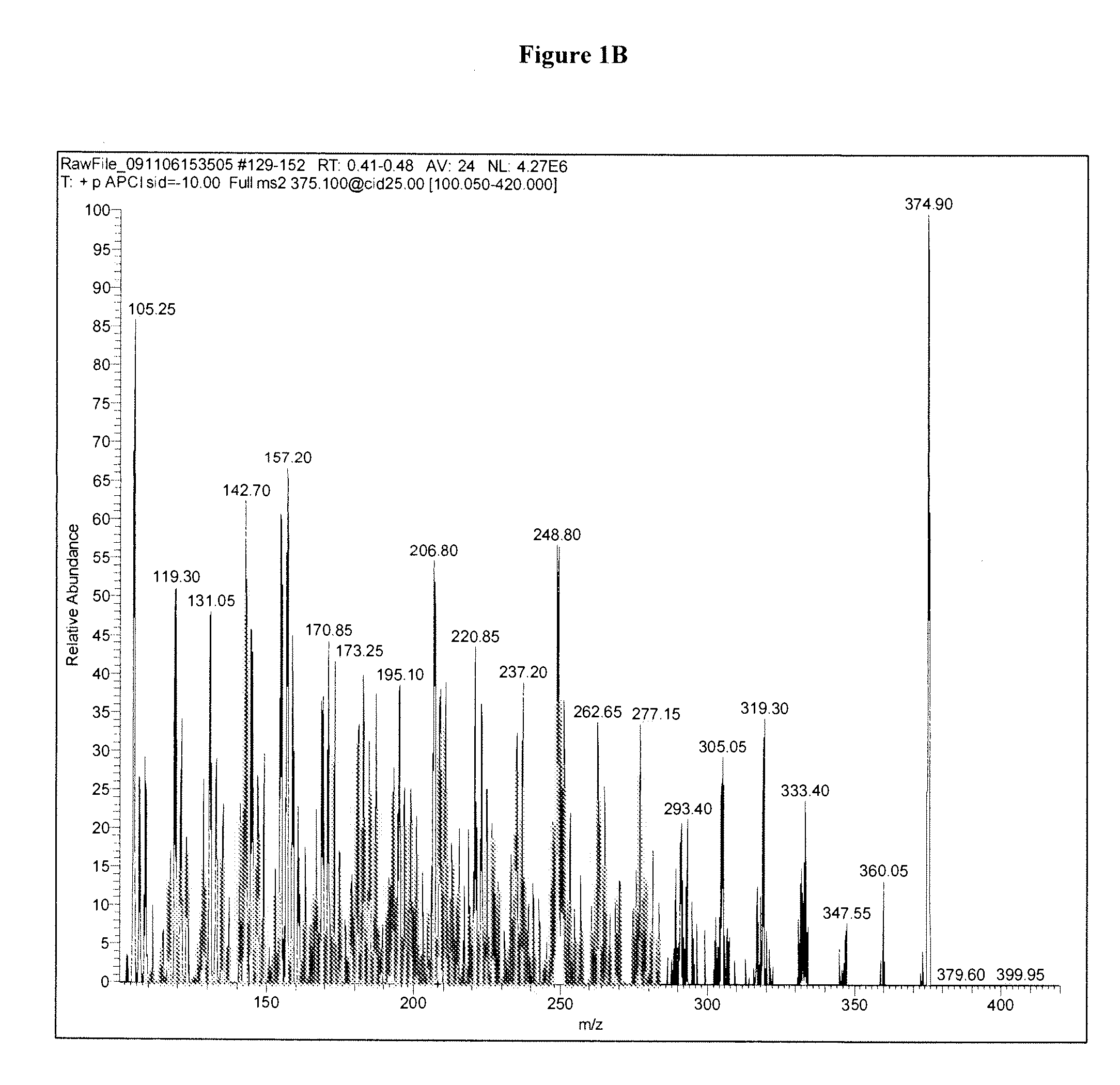

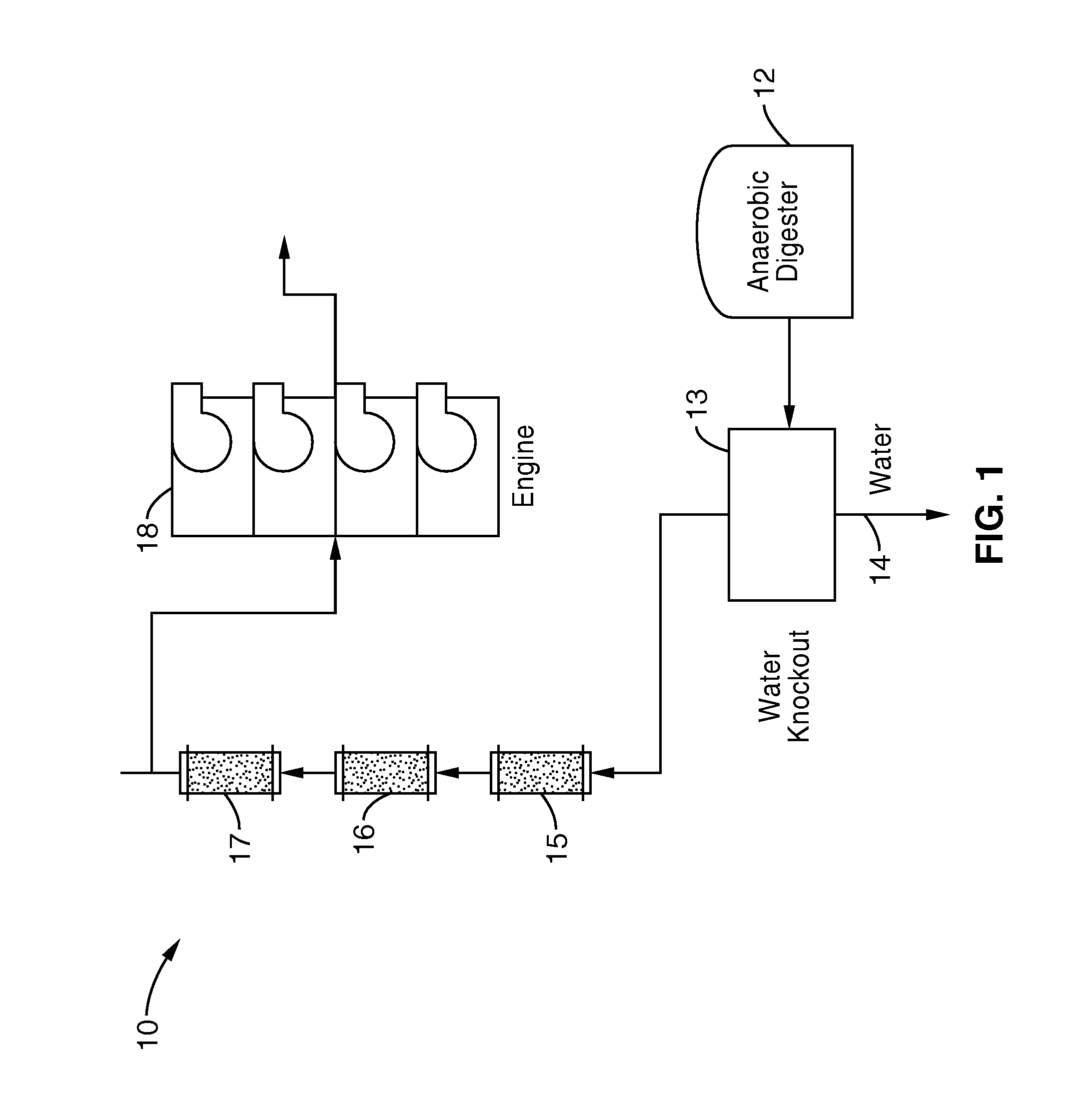

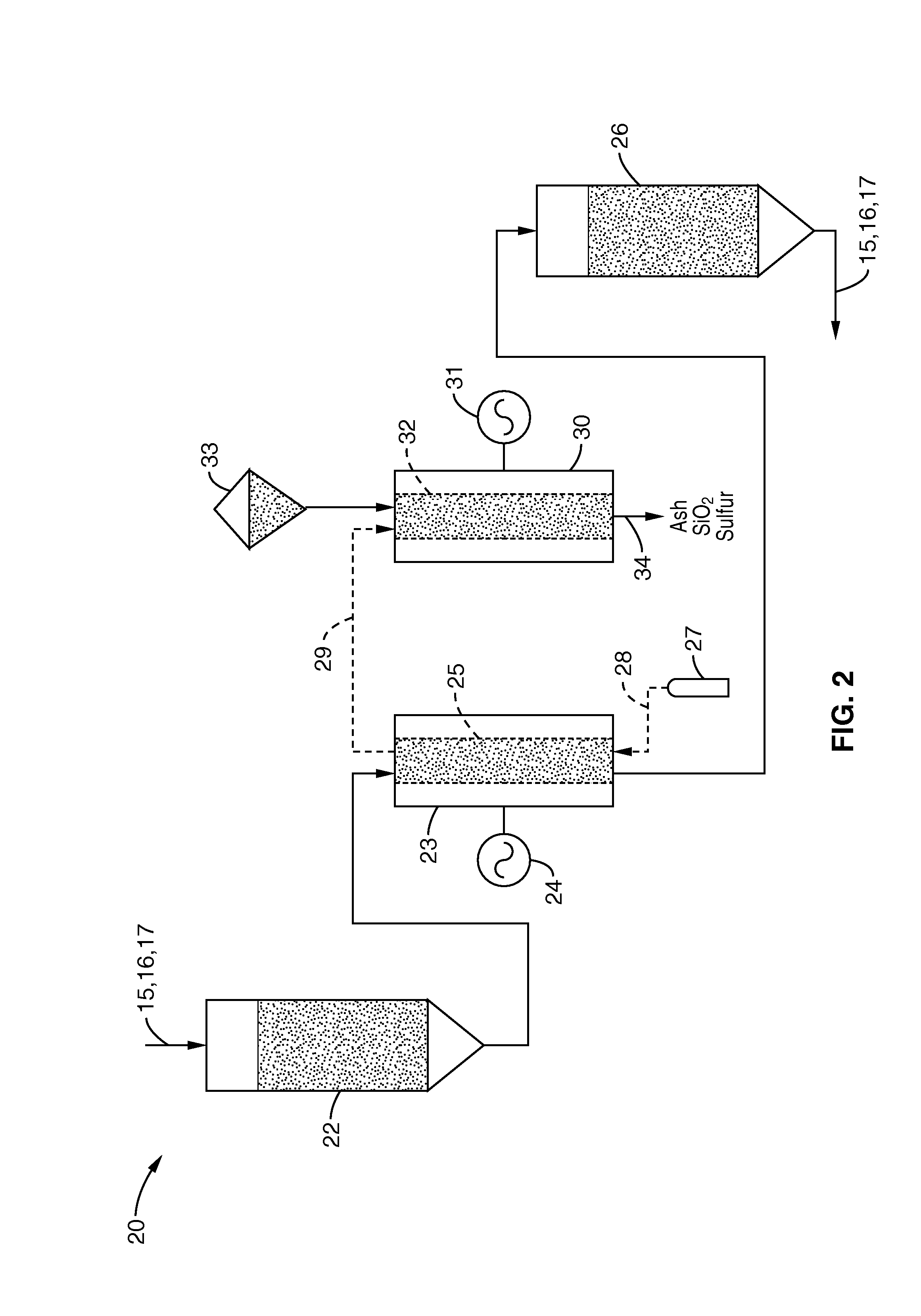

Microwave induced destruction of siloxanes and hydrogen sulfide in biogas

ActiveUS20080179177A1Facilitate desorptionLimiting the number of activation cyclesGas treatmentOther chemical processesBiogenic gasSilicon dioxide

The invention is an apparatus and method to remove hydrogen sulfide and siloxanes from biogas and destroy the contaminants in microwave reactors. Hydrogen sulfide and siloxane are removed from biogas using an adsorbent media such as activated carbon. The media is regenerated in a microwave reactor where the hydrogen sulfide and siloxane are removed in a sweep gas. In one process, siloxane is oxidized to silicon dioxide in a second microwave reactor and removed with a filter. Hydrogen sulfide if first oxidized to sulfur dioxide, then reduced to sulfur in a third microwave reactor and removed with a filter. In another process, siloxane is combined with water to form silicon dioxide and hydrogen sulfide is reduced to elemental sulfur in a microwave reactor. These reactants are removed with a filter. The remaining sweep gas containing hydrogen and low molecular weight hydrocarbons is returned to the biogas stream.

Owner:C MICRO SYST +1

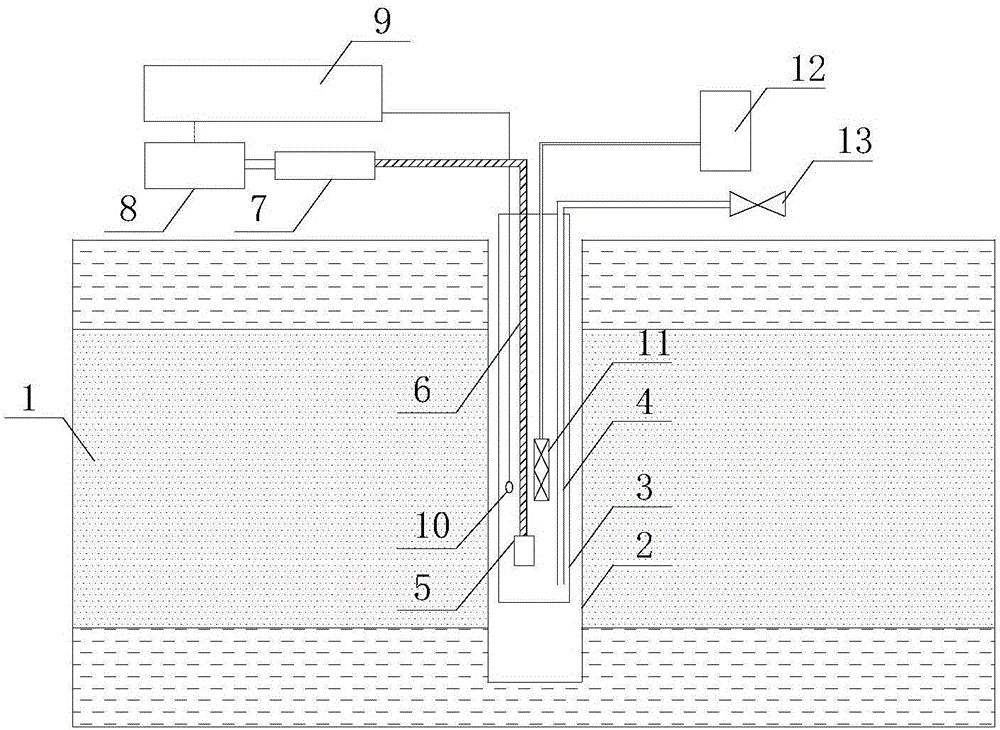

Microwave and ultrasonic synergistic enhanced coalbed methane recovery method

ActiveCN106499366AFacilitate desorptionEasy to moveFluid removalGas removalUltrasonic generatorMicrowave

The invention discloses a microwave and ultrasonic synergistic enhanced coalbed methane recovery method. The microwave and ultrasonic synergistic enhanced coalbed methane recovery method is especially suitable for a spongy high gas coalbed. The microwave and ultrasonic synergistic enhanced coalbed methane recovery method comprises the following steps: feeding a microwave antenna and an ultrasonic transducer into a ground well; enabling the microwave antenna and the ultrasonic transducer to be respectively connected with a microwave generator and an ultrasonic generator; turning on the microwave generator and the ultrasonic generator, and disturbing a coal body by elastic waves; meanwhile, using microwave heating to promote desorption of coalbed methane and hastening pores and fissures in the coalbed; migrating the coalbed methane to the ground well under the microwave and ultrasonic synergic action; finally, recovering the coalbed methane. The microwave and ultrasonic synergistic enhanced coalbed methane recovery method disclosed by the invention has important significance for improving the recovery of the coalbed methane and improving the safety of coal mining.

Owner:CHINA UNIV OF MINING & TECH

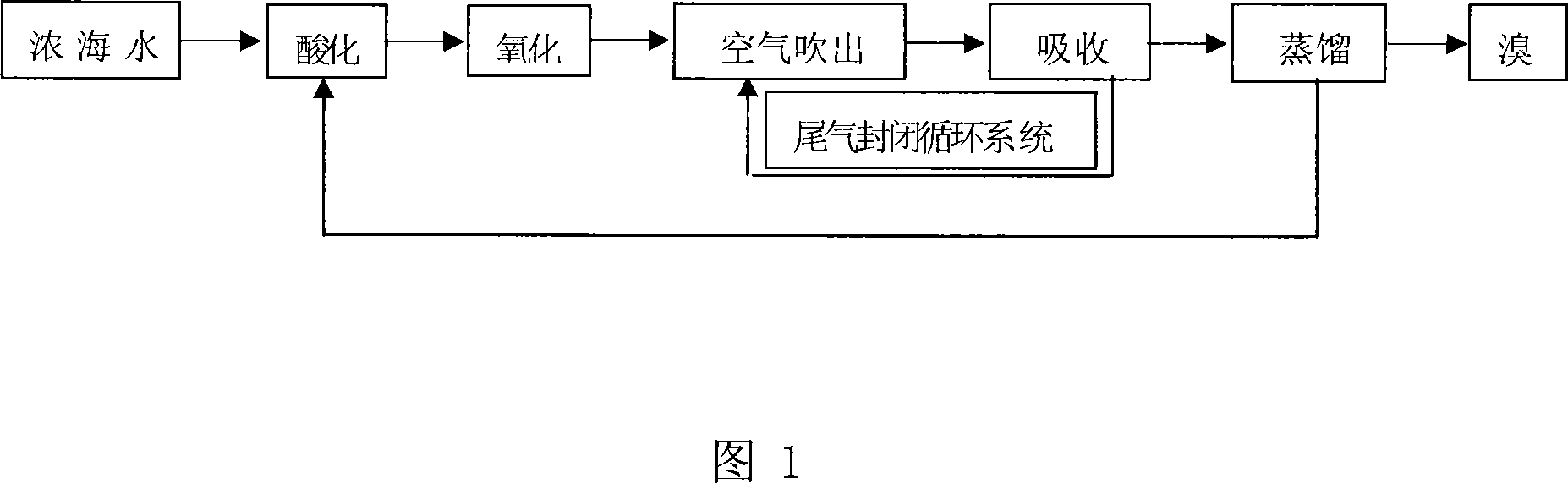

Technology process for producing bromide using concentrated seawater

ActiveCN101045529AIncrease acquisition rateFacilitate desorptionBromine/hydrogen-bromideWater desalinationProcess equipment

Owner:天津海晶科技发展有限公司

Cutting-exploding coupled coal anti-reflection method in drilled hole

ActiveCN104612746AFacilitate desorptionLower adsorption potentialFluid removalGas removalHigh energyDesorption

Provided is a cutting-exploding coupled coal anti-reflection method in a drilled hole. A large number of effective seam grooves are formed in a coal seam through a hydraulic cutting seam technology, and therefore effective decompression can be performed on coal within a certain range, and methane gas desorption seepage is promoted. Through a sucking pump, methane gas in the drilled hole is pumped into a closed explosive vessel arranged outside the drilled hole. High-pressure and high-temperature mixed methane gas with the concentration being 9.5% to 10.5% can be formed in the explosive vessel. The mixed gas is detonated through an igniting device, high-energy gas is formed, the drilled hole is impacted under guiding of a guiding pipe, and the coal further fractures on the basis of original seam grooves. Initial explosion temperature, initial pressure and igniting energy are reasonably selected according to the coal bed condition, optimal explosive capacity is formed in the explosive vessel, fracture network expansion is fully promoted, methane gas adsorption potential can be remarkably reduced, methane gas desorption is promoted, and the purpose of intensifying methane gas extraction is achieved. The method is simple, safe, reliable, low in cost and easy to operate, and time and labor are saved.

Owner:CHINA UNIV OF MINING & TECH

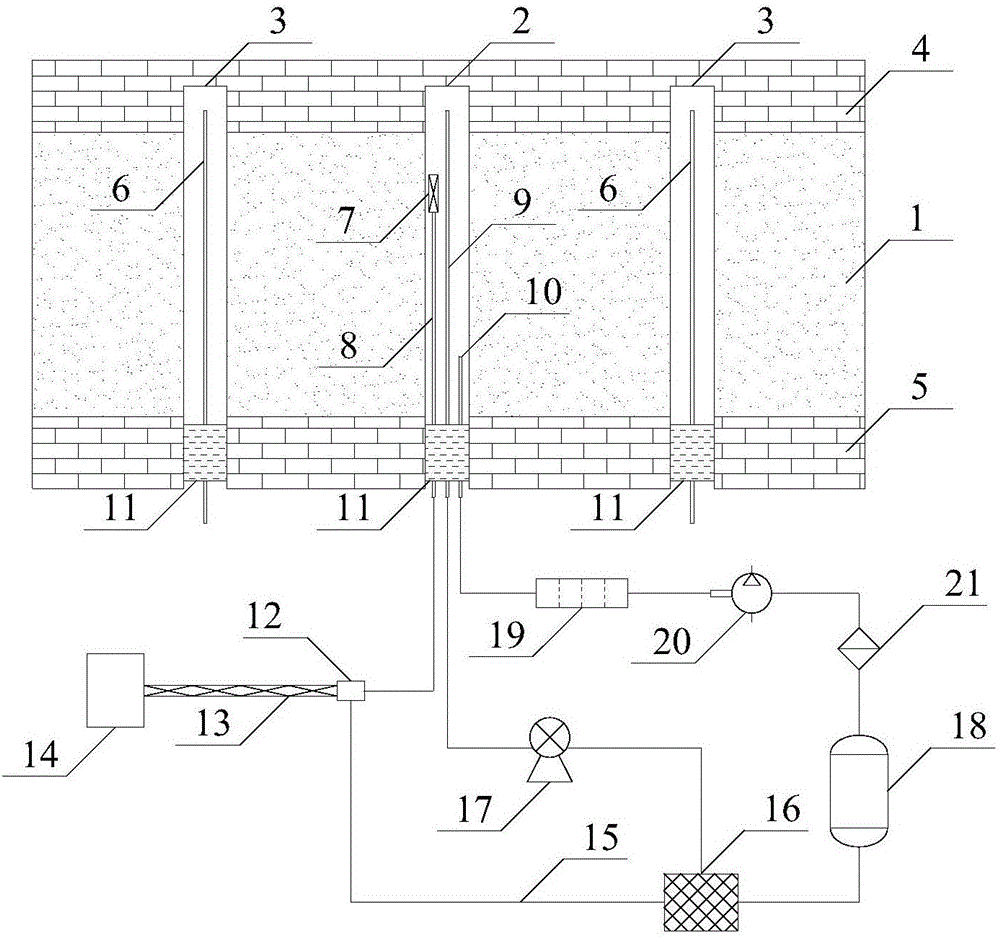

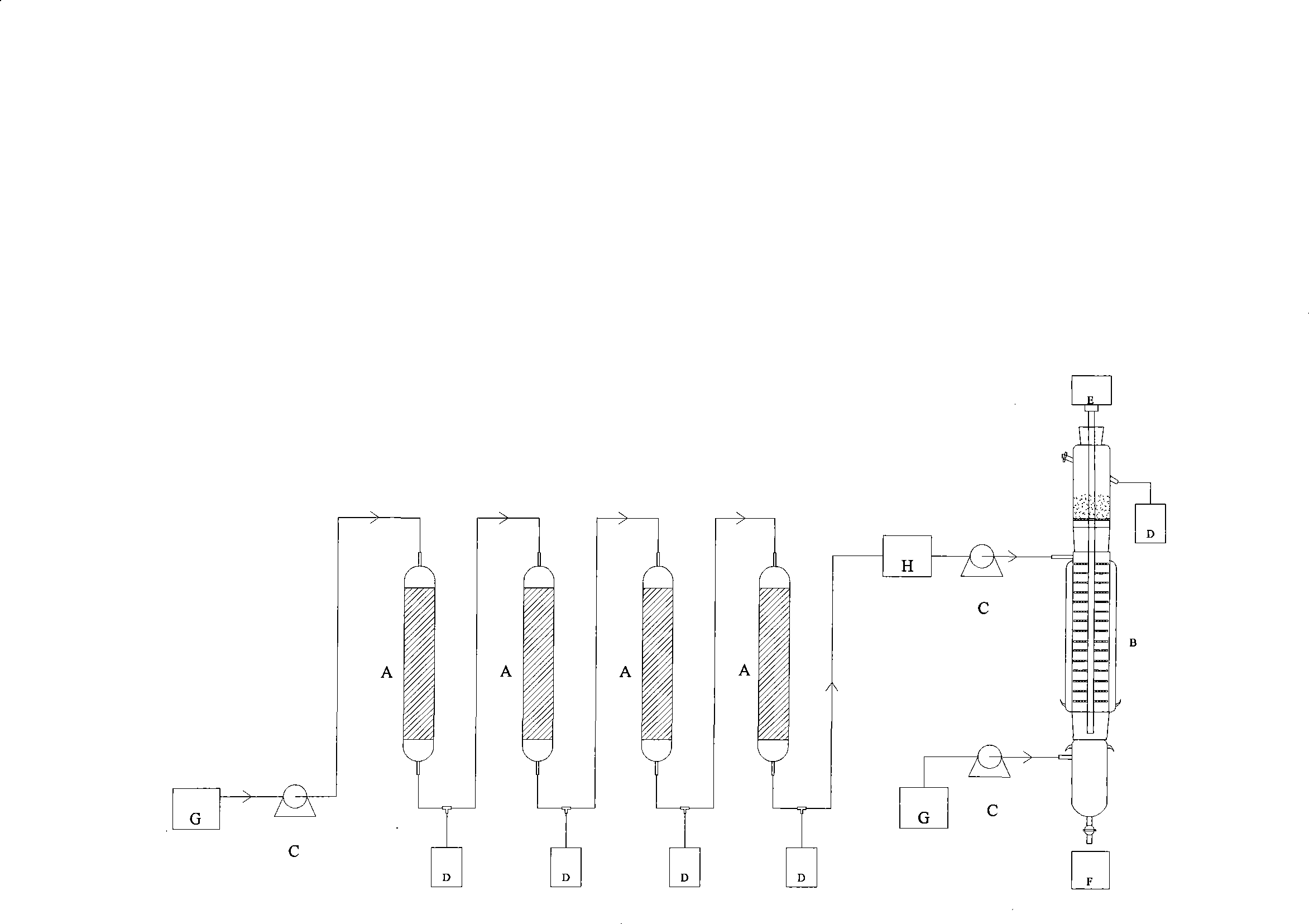

Microwave-assisted supercritical carbon dioxide cyclic fracturing system and microwave-assisted supercritical carbon dioxide cyclic fracturing method

ActiveCN106285604AImprove diffusion abilityImprove adsorption capacityFluid removalGas removalPorosityDesorption

The invention relates to a microwave-assisted supercritical carbon dioxide cyclic fracturing system and a microwave-assisted supercritical carbon dioxide cyclic fracturing method. The microwave-assisted supercritical carbon dioxide cyclic fracturing system comprises a liquid carbon dioxide tank, a heater, a boosting pump, a fracturing pipe, a return pipe, a three-phase separator, an air compressor and a cooler which form a loop to achieve supercritical carbon dioxide cyclic fracturing, and a fracture network is formed in a coal seam. According to the microwave-assisted supercritical carbon dioxide cyclic fracturing method, the coal seam and carbon dioxide are subjected to microwave heating to ensure that the carbon dioxide is in the supercritical state for a long time, and heat effect of microwave heating is capable of fracturing coal masses, dredging pores and promoting gas desorption. The microwave-assisted supercritical carbon dioxide cyclic fracturing system and the microwave-assisted supercritical carbon dioxide cyclic fracturing method have the advantages that the supercritical carbon dioxide high in diffusivity is capable of going deep into coal mass pores and fractures quite easily as well as dispelling gas; operation costs are reduced effectively and the construction technology is simplified effectively through cyclic fracturing; microwave radiation is combined with supercritical carbon dioxide cyclic fracturing to increase porosity and permeability of the coal seam greatly and promote gas desorption, so that gas extraction effects are improved substantially, and the system and the method are highly practical in the field.

Owner:CHINA UNIV OF MINING & TECH +1

In-borehole gas explosion coal body cracking forced extraction method

The invention discloses an in-borehole gas explosion coal body cracking forced extraction method, and is applied to the efficient extraction of underground gas of a coal mine. An air pump is used for pressing air into a sealed borehole, the air and gas gushed from the borehole are premixed to form mixed gas at concentration of 9 to 10 percent, and the mixed gas is detonated by virtue of an ignition device to form explosion waves to crack a coal body to construct a fracture network; meanwhile, by thermal effects achieved by explosion, the adsorption potential of the gas can be remarkably lowered, and the desorption and the flowing of the gas can be promoted, so that the aim of forced gas extraction of a high-gas low-air-permeability coal seam is fulfilled. The method is low in cost, simple, easy, time-saving and labor-saving; the effective pressure relief influence scope of a single hole can be remarkably widened, and the gas extraction efficiency of the coal seam can be improved by over 40 percent.

Owner:CHINA UNIV OF MINING & TECH

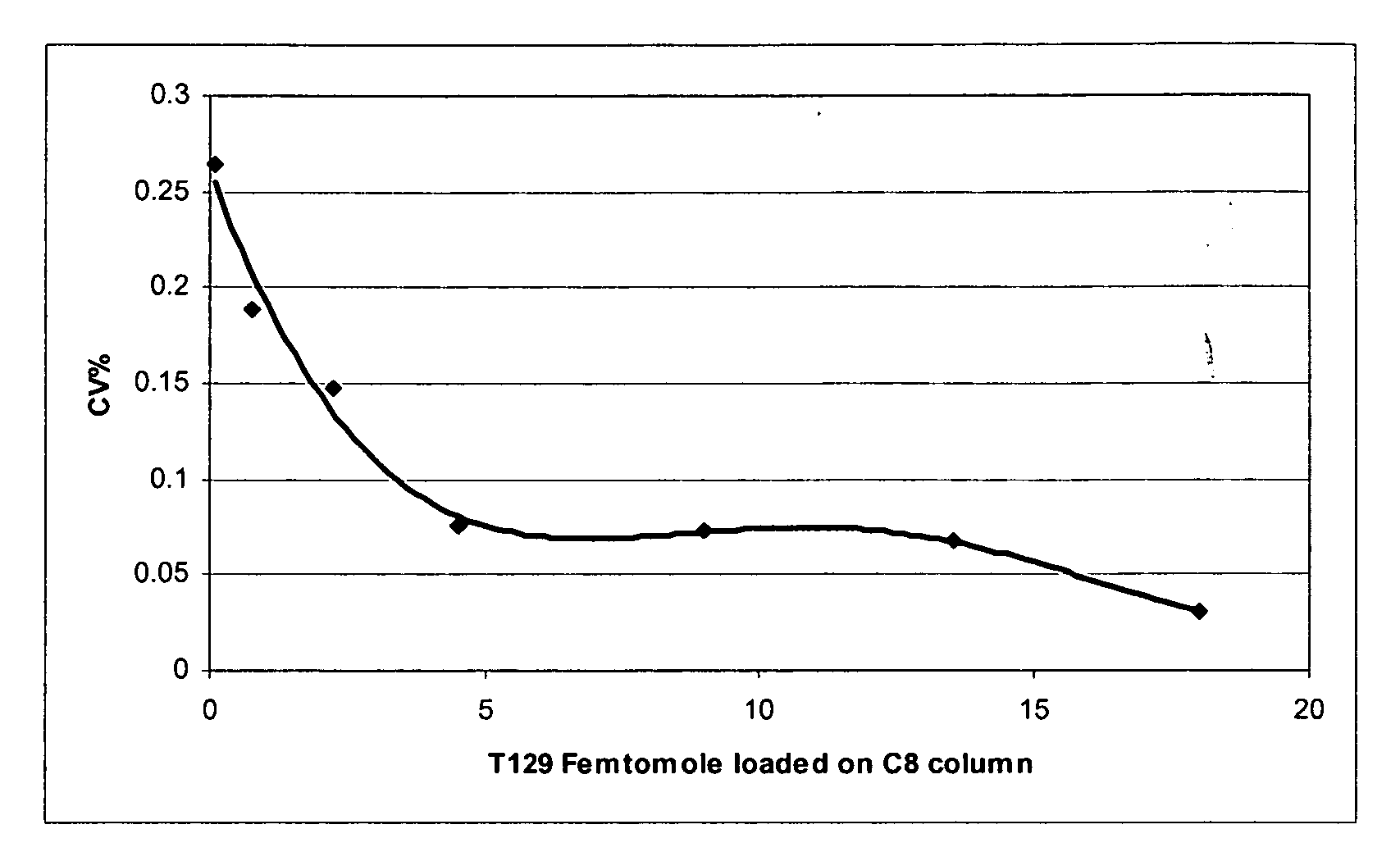

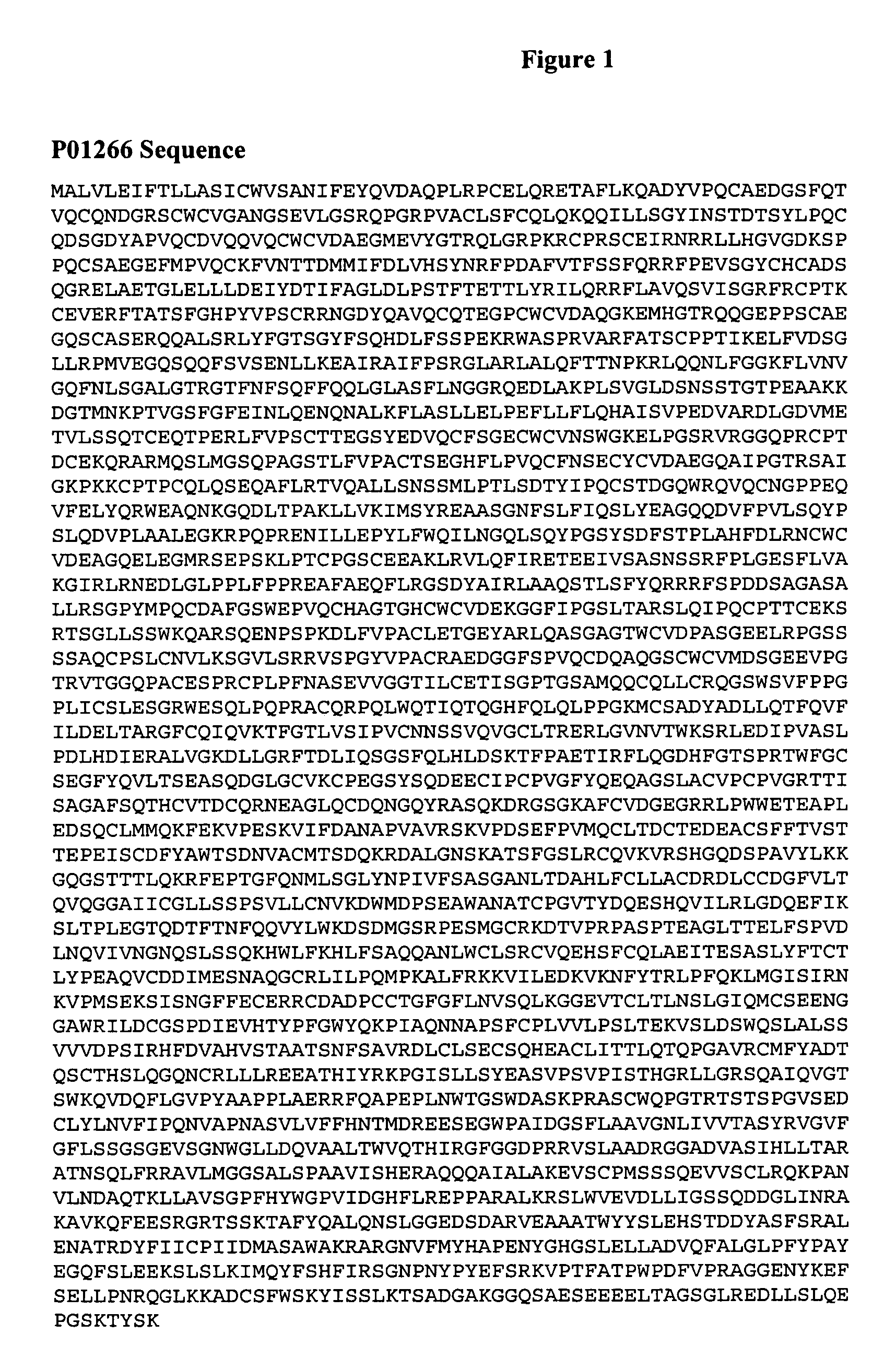

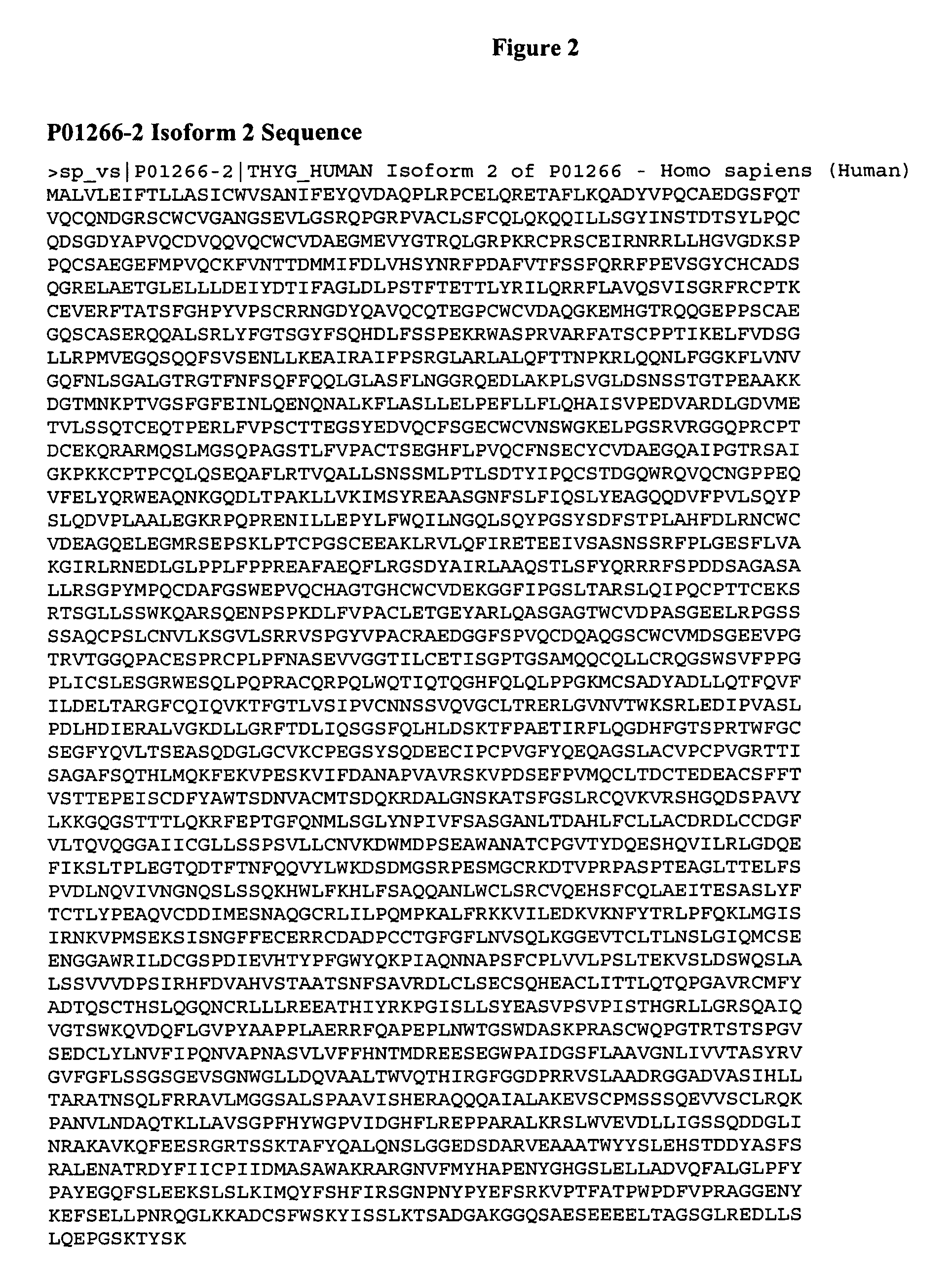

Thyroglobulin quantitation by mass spectrometry

ActiveUS20090148951A1Avoid condensationSolvent is evaporatedMicrobiological testing/measurementDisease diagnosisTest sampleMass Spectrometry-Mass Spectrometry

Provided are methods for determining the amount of thyroglobulin in a sample using various purification steps followed by mass spectrometry. The methods generally involve purifying thyroglobulin in a test sample, digesting thyroglobulin to form peptide T129, purifying peptide T129, ionizing peptide T129, detecting the amount of peptide T129 ion generated, and relating the amount of peptide T129 ion to the amount of thyroglobulin originally present in the sample.

Owner:QUEST DIAGNOSTICS INVESTMENTS INC

Enhanced extraction method for fracturing coal body by multistage gas explosion in drill hole

ActiveCN104314605ALower adsorption potentialFacilitate desorptionFluid removalGas removalSingle holeGas explosion

The invention discloses an enhanced extraction method for fracturing a coal body by multistage gas explosion in a drill hole. The enhanced extraction method is suitable for high-efficiency extraction of underground gas of a coal mine. Air is pressed in a sealed drill hole by using an air pump; the air and gas gushed from the drill hole form gas mixed gas with the concentration of 9-10 percent; the mixed gas is detonated by an ignition device to form an explosive shock wave for fracturing the coal body around the drill hole; the later-stage explosion is realized on the basis of the previous-stage explosion, so that cracks of the coal body around the drill hole are further expanded; besides, the shock wave compress the coal body to form a greater explosion space, and the power of explosion is enhanced. By multistage explosion, a fracture network in the coal body can be fully constructed; besides, the adsorption potential of gas can be remarkably reduced and the desorption and the flowing of the gas are promoted by the heat effect generated by explosion, so that the aim of enhancing the gas extraction of a coal bed with high-concentration gas and low permeability is achieved. The enhanced extraction method has the advantages of low cost, simplicity, feasibility, time conservation and force conservation; the influence range of effective pressure relief of single holes can be remarkably widened, and the extraction rate of the gas in the coal bed is increased by over 60 percent.

Owner:CHINA UNIV OF MINING & TECH

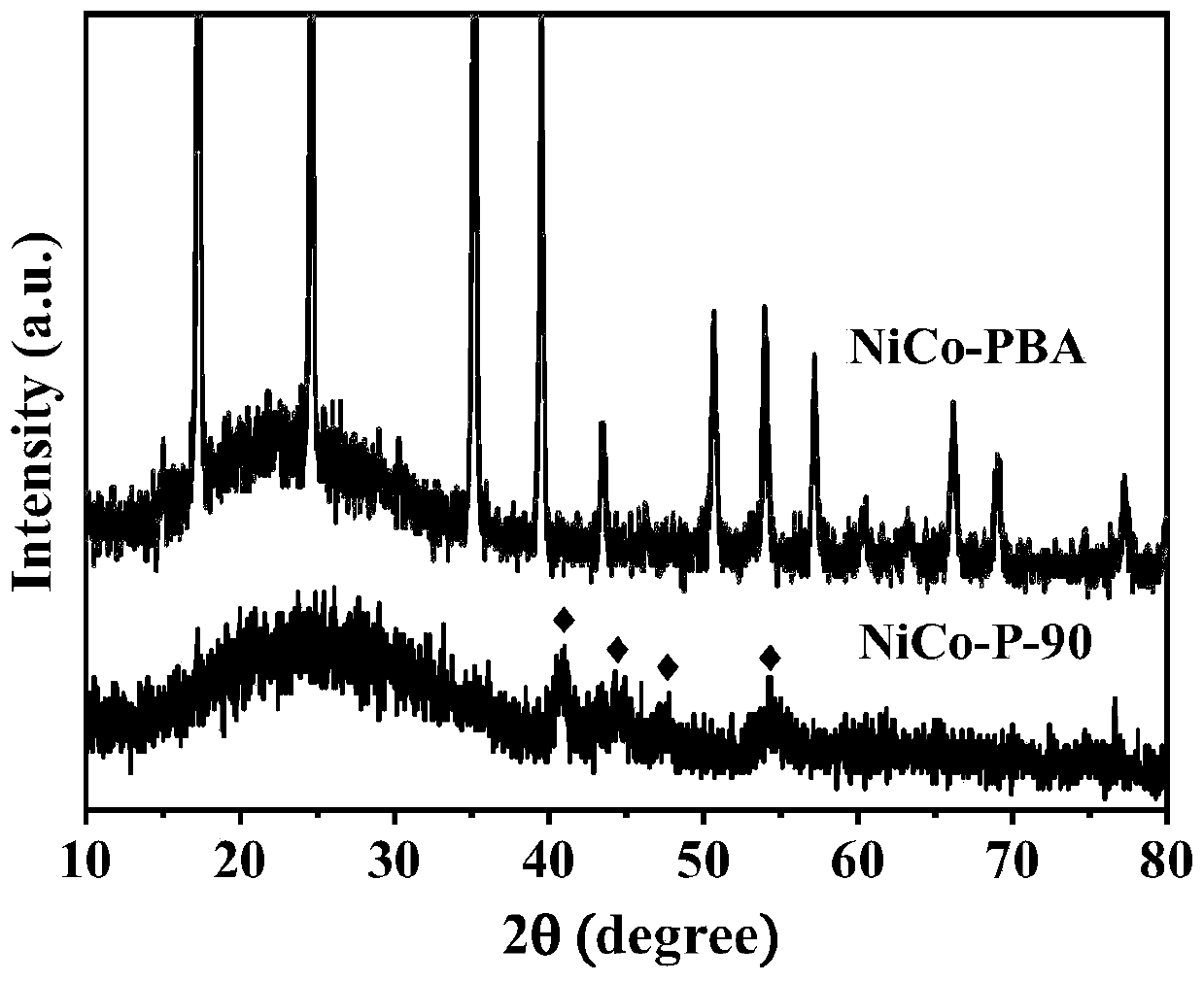

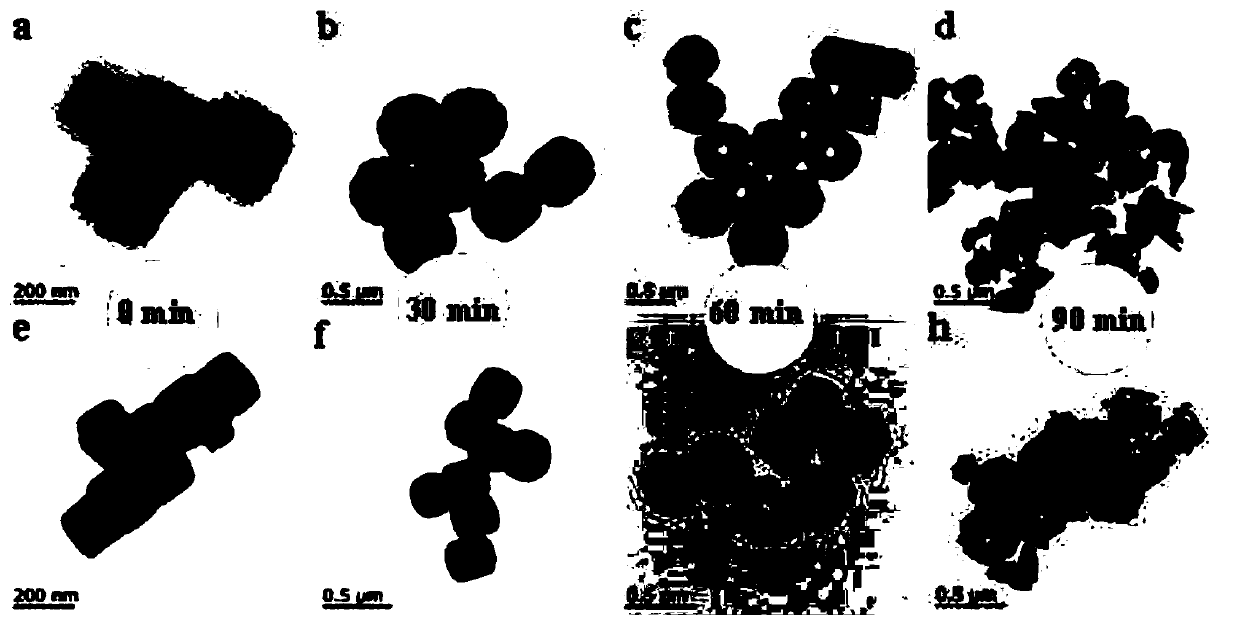

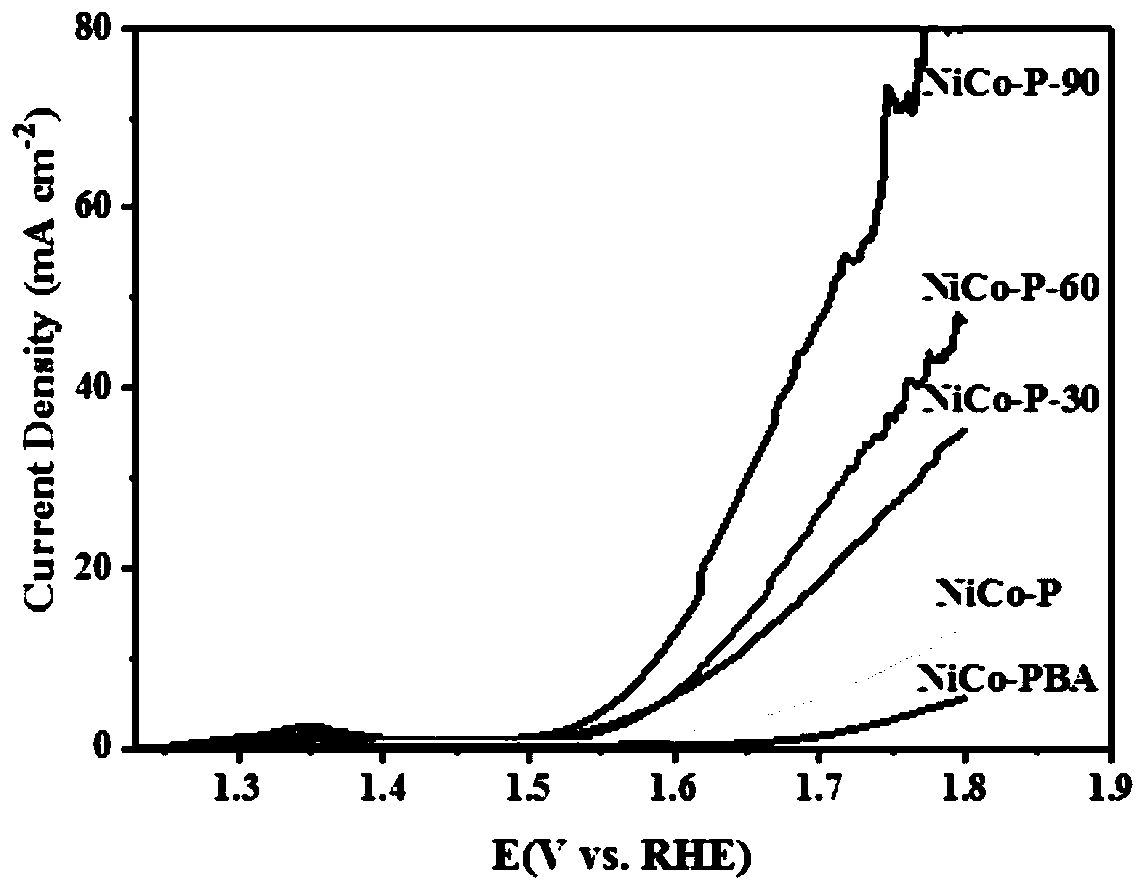

Nickel-cobalt bimetallic phosphide electrocatalyst as well as synthesis method and application thereof

InactiveCN109999861ASimple stepsRaw materials are easy to getCatalyst activation/preparationElectrodesSynthesis methodsPrussian blue

The invention belongs to the field of nanomaterials, and discloses a nickel-cobalt bimetallic phosphide electrocatalyst as well as a synthesis method and an application thereof. The Prussian blue analogue precursor synthesized through simple aging reaction is further subjected to low-temperature phosphating reaction, and a NiCoP multi-hollow porous nanocube electrocatalyst is obtained. The seriesof bimetallic phosphides have lower charge transfer resistance and reaction barrier for oxygen evolution reaction, and have superior performance in electrocatalytic oxygen evolution reaction. Besides,the catalyst is low in cost and convenient to operate, adopts a simple process and has superior catalytic performance, and basic application research is provided for the materials in the field of electrocatalysis.

Owner:JIANGSU UNIV

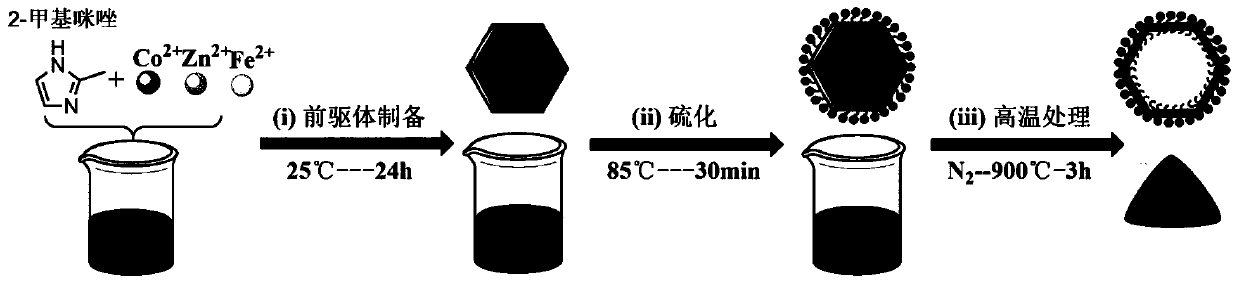

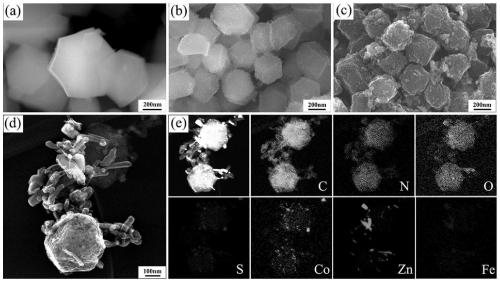

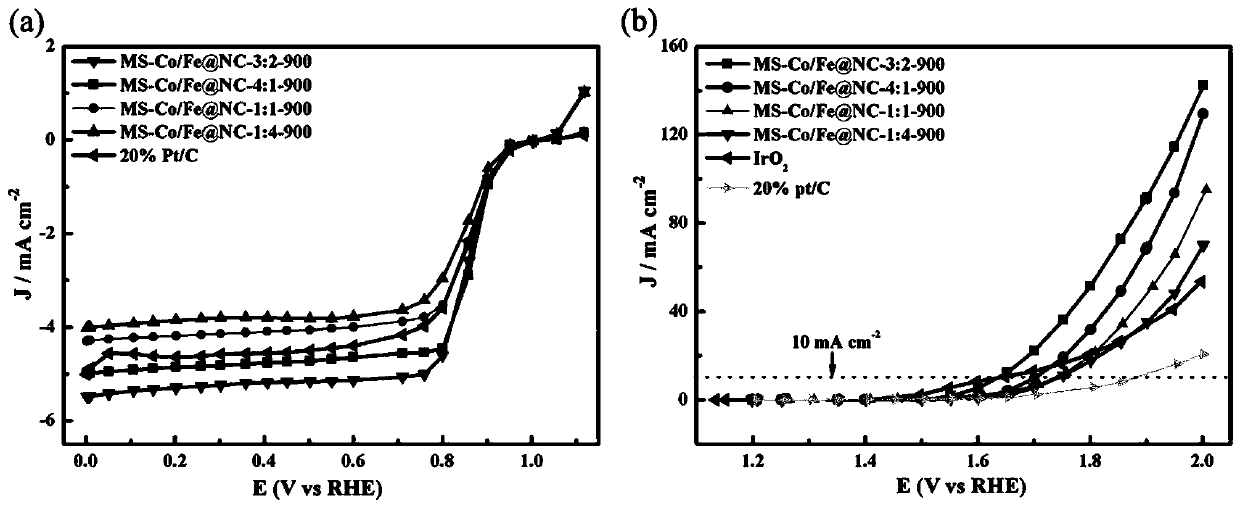

Multi-metal MOFs derived oxygen reduction/oxygen evolution double-function catalytic material, and preparation method thereof

ActiveCN109926084ALow costHigh specific surface areaPhysical/chemical process catalystsCell electrodesReactive siteCatalytic oxidation

The invention discloses a multi-metal MOFs derived oxygen reduction / oxygen evolution double-function catalytic material, and a preparation method thereof. The preparation method comprises following steps: room temperature coprecipitation is adopted to synthesis a Zn / Co / Fe multi-metal ZIF precursor; then sulfuration and sintering treatment technology is adopted for combination of oxygen reduction reaction (ORR) active sites (Co / Fe-N-C) and oxygen evolution reaction (OER) active sites (Co / Fe-S) on a monomer material, so that the double ORR / OER electrocatalyst which is low in cost and possesses the performance as good as that of commercially available catalysts is obtained. According to the preparation method, two important factors, including active site distribution and catalytic mechanism,with great influences on material performance are taken into comprehensive consideration, realization of the optimal material catalytic oxidation reduction / oxygen evolution reaction efficiency is taken as a design principle, optimization design is adopted to obtain the best Zn / Co / Fe ratio in the precursor, and the catalyst is provided with the best catalytic performance. The multi-metal MOFs derived oxygen reduction / oxygen evolution double-function catalytic material possesses both high efficiency oxygen reduction and oxygen evolution performance, is high in specific surface area, is abundantin micropores, and is uniform in active site dispersion; and the cost is much lower than that of commercially available precious metal catalyst catalytic materials.

Owner:XI AN JIAOTONG UNIV

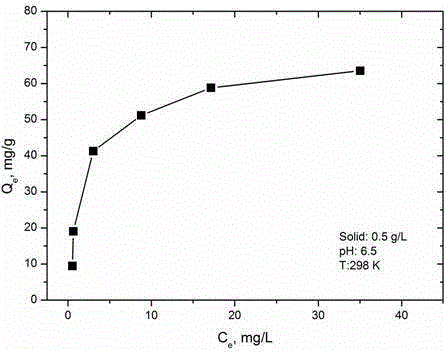

Biomass-based nanometer lanthanum oxide dephosphorization composite adsorbent and preparation method thereof

InactiveCN105214629ASynthesis process is simple and cleanLow costOther chemical processesWater/sewage treatment by sorptionRice strawBiomass

The invention discloses a biomass-based nanometer lanthanum oxide dephosphorization composite adsorbent and a preparation method thereof. According to the composite adsorbent, biomass anion exchange resin is taken as a matrix, and nanometer lanthanum oxide is loaded on the biomass anion exchange resin; the load of the nanometer lanthanum oxide is 0.5 to 22.6 percent by weight percentage of lanthanum; the biomass anion exchange resin is alkali quaternary ammonium group-contained biomass anion exchange resin, and is prepared by performing aminated modification on a biomass material by taking N,N-dimethylformamide as solvent, epichlorohydrin as an etherifying agent and trimethylamine or triethylamine or urea as an aminating agent; the biomass material is selected from maize straw, soybean straw, cassava straw, rice straw, wheat straw, bamboo reed, saw dust or a mixture thereof. The composite adsorbent disclosed by the invention is low in cost and high in adsorption capacity.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Vitamin d metabolite determination utilizing mass spectrometry following derivatization

ActiveUS20110133068A1Avoid condensationSolvent is evaporatedComponent separationIsotope separationMass Spectrometry-Mass SpectrometryMass spectrometry imaging

Owner:QUEST DIAGNOSTICS INVESTMENTS INC

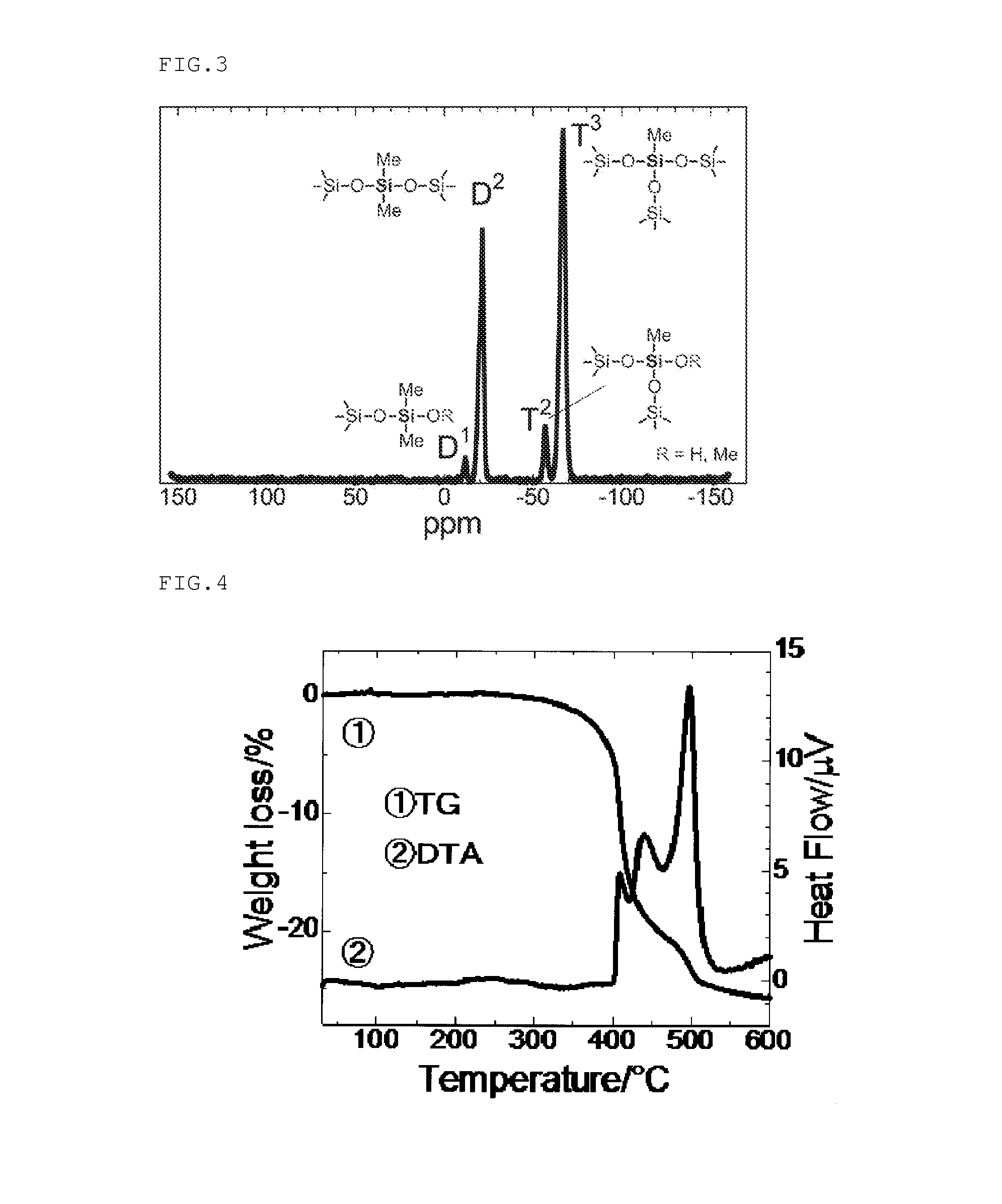

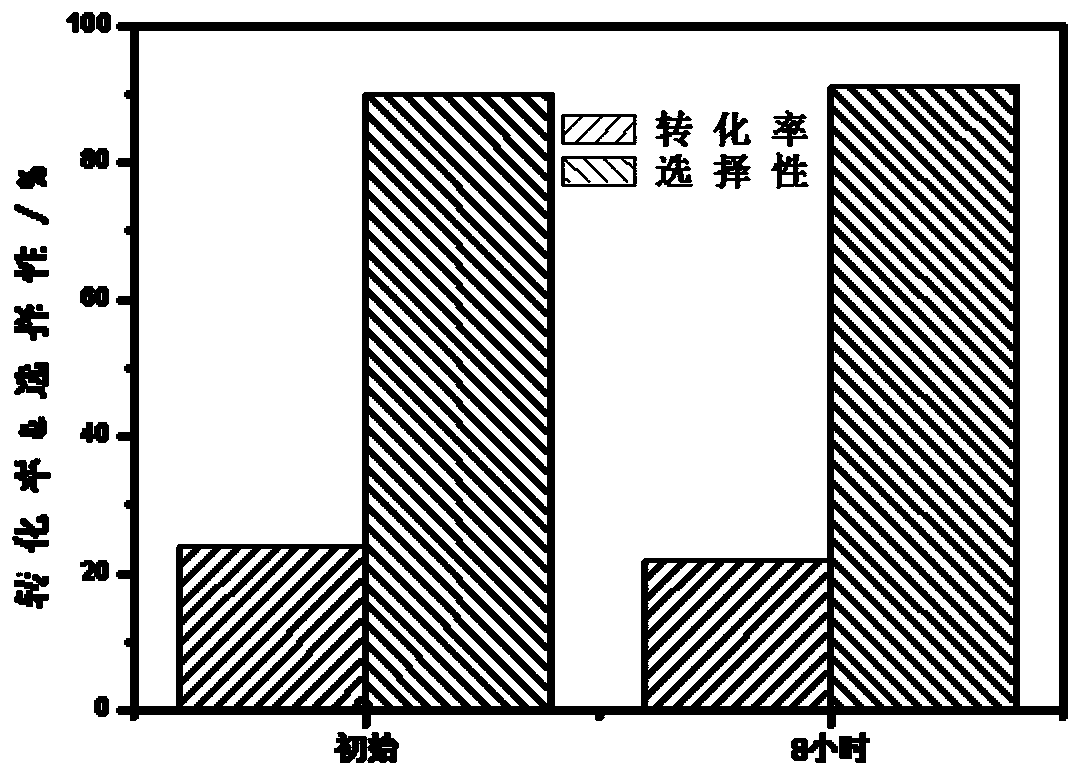

Monolithic silicone and method of separation, purification and concentration therewith

ActiveUS20140076070A1Increase flexibilityHigh porosityWithdrawing sample devicesPreparing sample for investigationSolventPolymer chemistry

The present invention provides a monolithic silicone in the form of an aerogel or a xerogel having flexibility and capable of dissolving molecules of a substance. This silicone monolithic body having continuous through passages is synthesized by copolymerizing starting materials of both a bifunctional alkoxysilane and a trifunctional alkoxysilane or tri- or higher functional alkoxysilanes through a sol-gel reaction for forming a Si—O network while causing phase separation.

Owner:KYOTO UNIV +1

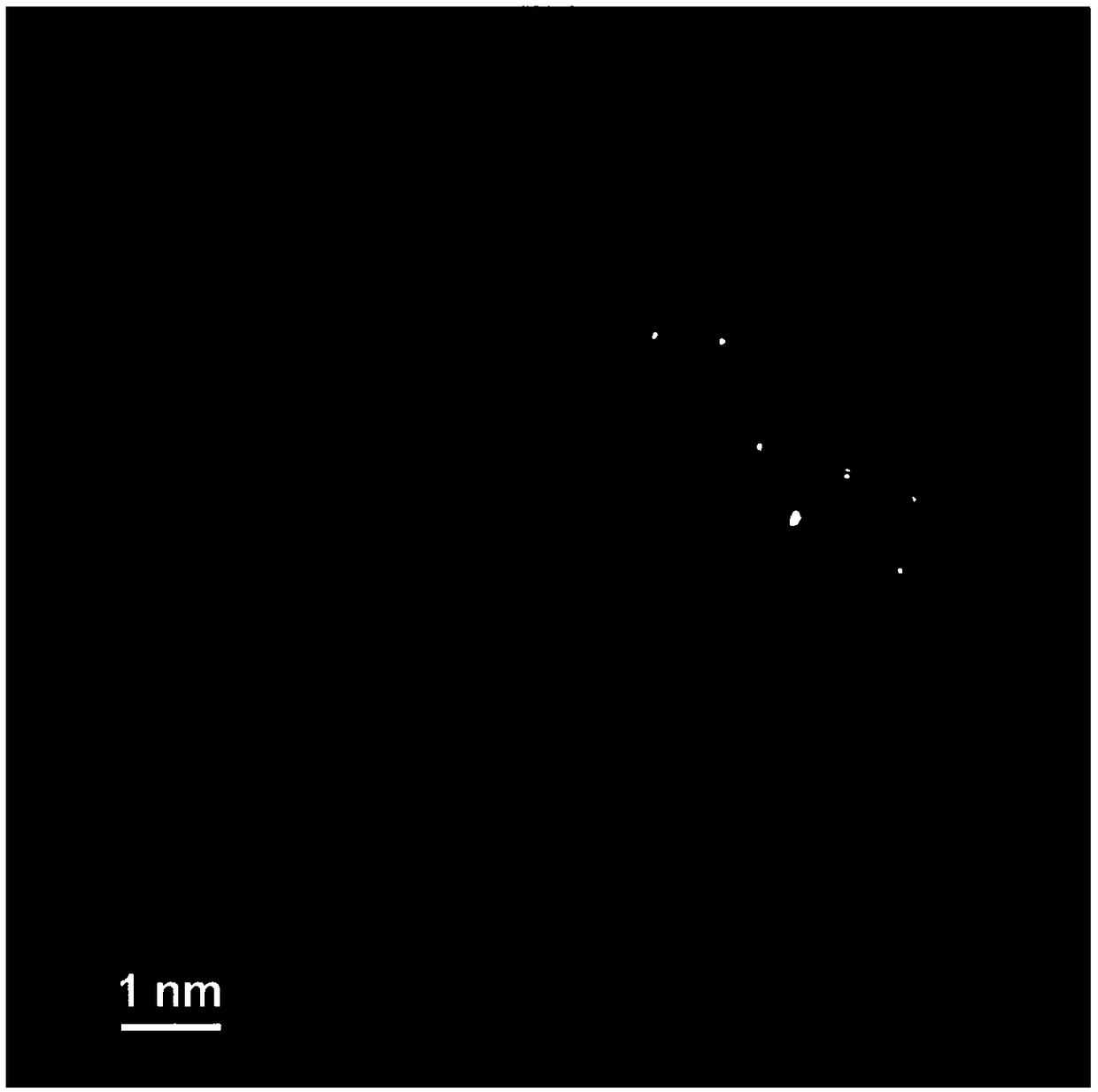

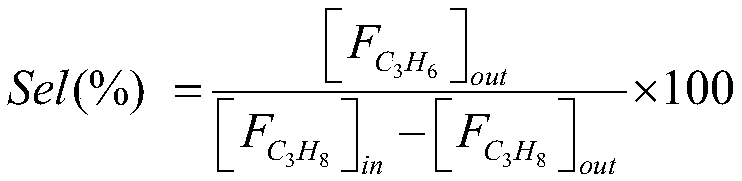

Aluminum oxide loaded PtCu monatomic alloy catalyst and preparation method and application thereof

ActiveCN108620092AHigh activityPt content decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention discloses an aluminum oxide loaded PtCu monatomic alloy catalyst and a preparation method and application thereof. The catalyst takes Al2O3 as a carrier, takes Cu as an auxiliary, and loads a small amount of active components Pt; the mass percent of Pt is 0.025%-0.15%, and the mass percent of Cu is 5%-20%; and during preparation, a co-impregnation method is used, the Al2O3 carrier isimpregnated in an aqueous solution of chloroplatinic acid and copper nitrate, the PtCu / Al2O3 catalyst is obtained after drying and roasting and high-temperature reduction, and the catalyst has high activity and high stability, and is low in price and low in toxicity. The catalyst is suitable for reaction for producing olefin by dehydrogenation through low alkane, and is particularly suitable forreaction for producing propylene by dehydrogenation through propane in a hydrogenation atmosphere, the dehydrogenation activity is quite high under the condition of high temperature, the selectivity of the propylene can reach 90% or above, the stability is good, the use amount of Pt is small, the utilization rate is high, and compared with an industrial Pt series catalyst, the aluminum oxide loaded PtCu monatomic alloy catalyst is cheaper.

Owner:TIANJIN UNIV

Novel method for preparing high-purity chlorogenic acid

InactiveCN101503356AReduce decompositionHigh purityOrganic compound preparationMetabolism disorderChlorogenic acidOrganic solvent

The invention provides a new method for preparing high purity chlorogenic acid, comprising the steps: after the stock solution of the chlorogenic acid is processed by washing impurity and eluting through at least four levels of macroporous resin series connection adsorption column, and then the eluate is regenerated for continuous countercurrent extraction, so that the high purity chlorogenic acid is obtained. The method is applicable to light concentration stock solution of the chlorogenic acid, and can complete the process of absorbing, washing impurity, eluting, regenerating, countercurrent extracting and recycling the solvent in a semicontinuous way; the handling capacity of samples is large, the operation is simple, the production cost can be lowered, the residual organic solvent is reduced, and the environmental pollution is relieved.

Owner:NANJING UNIV OF TECH

Vitamin D metabolite determination utilizing mass spectrometry following derivatization

ActiveUS7977117B2Facilitate desorptionGood removal effectComponent separationIsotope separationMass Spectrometry-Mass SpectrometryMass spectrometry imaging

Owner:QUEST DIAGNOSTICS INVESTMENTS INC

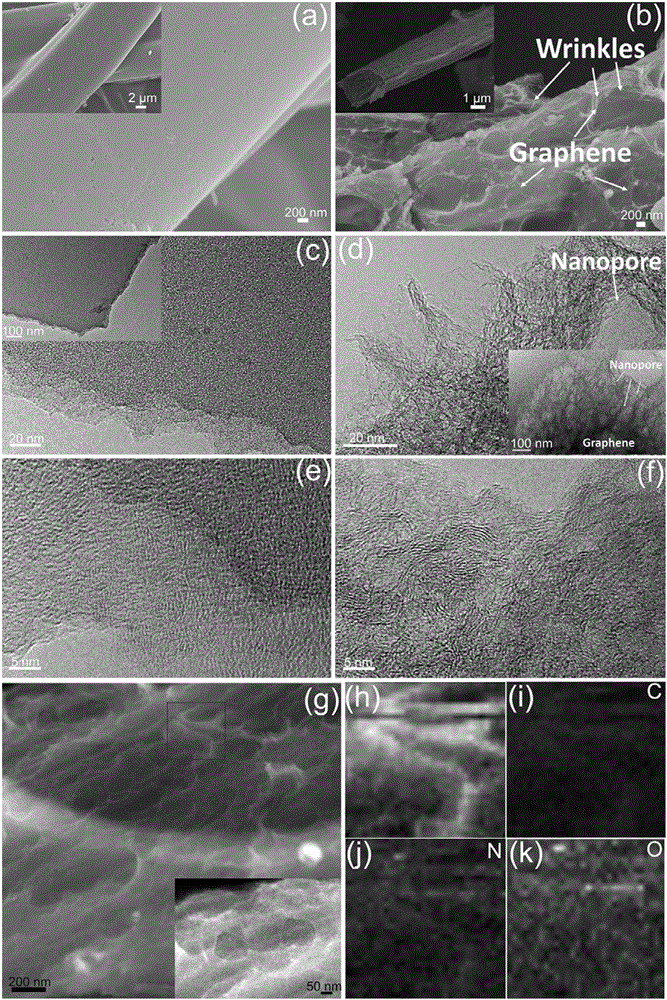

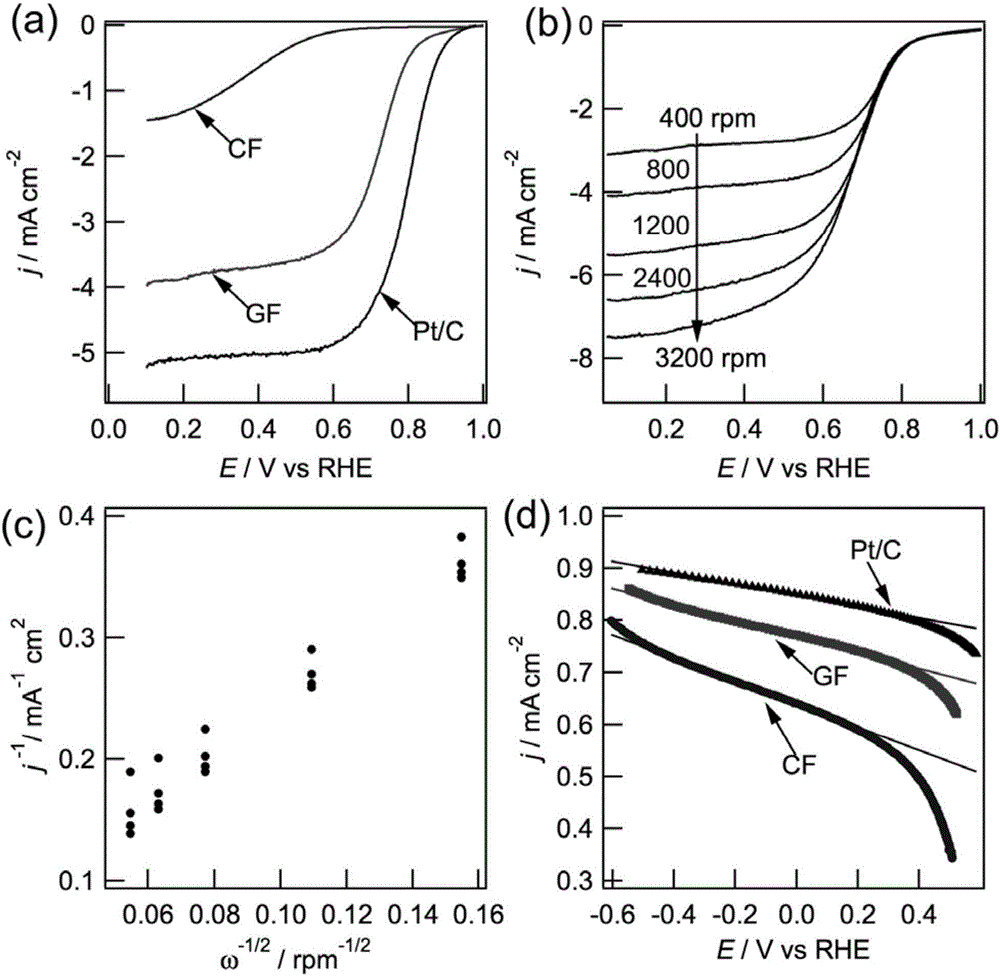

Silk-derived nitrogen-doped graphene fibers

The invention discloses silk-derived nitrogen-doped graphene fibers. The silk-derived nitrogen-doped graphene fibers are obtained by the steps of activating the pre-processed silk fibers, then carrying out high-temperature carbonization on the fibers, and cooling. According to the graphene fibers, the oxygen reduction catalysis material is prepared by taking the biomass silk fibers as the carbon source, so that the graphene fibers are large in specific surface area and high in porosity, and diffusion and gas desorption can be facilitated; due to the porous structure characteristic, the graphene fibers are relatively high in catalytic activity, acid resistance, alkali resistance and stability; and meanwhile, the graphene fibers are not required to be loaded to an electrode, instead, the graphene fibers can be directly used as a working electrode for carrying out oxygen reduction catalysis.

Owner:ZHEJIANG SCI-TECH UNIV

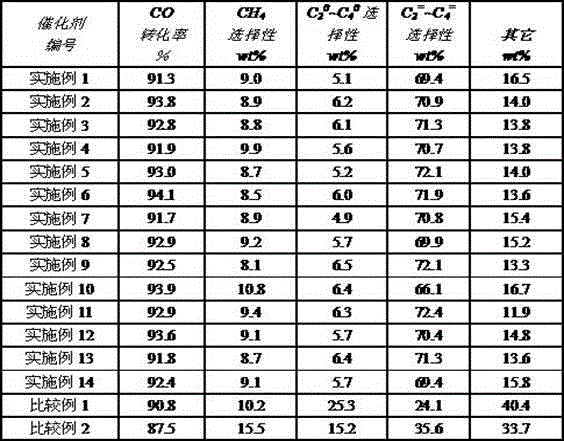

Catalyst for directly preparing low-carbon olefin from microspherical synthesis gas, as well as preparation method thereof

ActiveCN104549296AImprove wear performanceReduce wear rateHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasFluidized bed

The invention relates to a catalyst for directly preparing a low-carbon olefin from a microspherical synthesis gas, and is mainly used for solving the problems that the existing co-precipitation Fischer-Tropsch catalyst preparation technology comprises the following steps: firstly co-precipitating and then pulping and spray-forming, so that the slurry is substantially a non-homogenous body dispersed by adopting a physical method, the finial catalyst finished product is uneven and the hydrocarbon products on the catalyst are widely distributed. The problems are well solved by adopting the technical scheme that the preparation method comprises the following steps: firstly precipitating a part of components, then carrying out peptization on the obtained precipitates by using the salt solution of non-precipitated components to obtain chemically evenly dispersed sol, then spray-drying the sol, and then roasting at high temperature. The preparation method can be used for industrial production for a catalyst for synthesizing the low-carbon olefin from the synthesis gas. The catalyst is applicable to but not limited to such reactors as a fluidized bed and a slurry-state bed in which catalyst grains are required to be distributed according to the certain distribution rule.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mass spectrometry assay for congenital adrenal hyperplasia

ActiveUS20100155595A1Avoid condensationSolvent is evaporatedComponent separationFuel lighters11-DesoxycortisolHydrocortisone

Methods are provided for detecting the amount of one or more CAH panel analytes (i.e., pregnenolone, 17-OH pregnenolone, progesterone, 17-OH progesterone, dehydroepiandrosterone (DHEA), androstenedione, testosterone, deoxycorticosterone, 11-deoxycortisol, and cortisol) in a sample by mass spectrometry. The methods generally involve ionizing one or more CAH panel analytes in a sample and quantifying the generated ions to determine the amount of one or more CAH panel analytes in the sample. In methods where amounts of multiple CAH panel analytes are detected, the amounts of multiple analytes are detected in the same sample injection.

Owner:QUEST DIAGNOSTICS INVESTMENTS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com