Nickel-cobalt bimetallic phosphide electrocatalyst as well as synthesis method and application thereof

A phosphide electro-synthesis method technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of cost limitation and high scarcity, and achieve convenient operation, simple steps, and increased ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

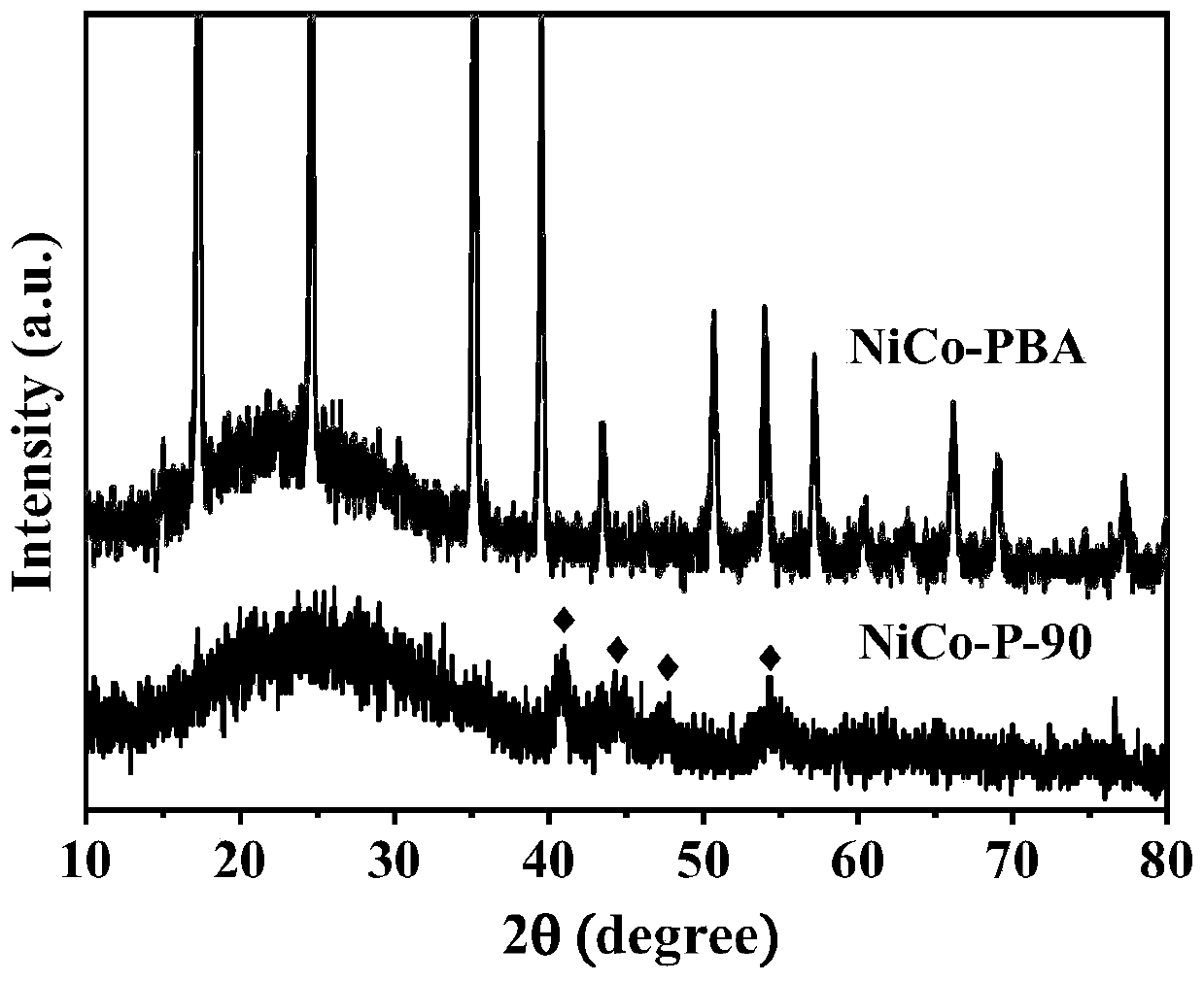

[0028] A kind of preparation method of nickel cobalt phosphorus double metal phosphide:

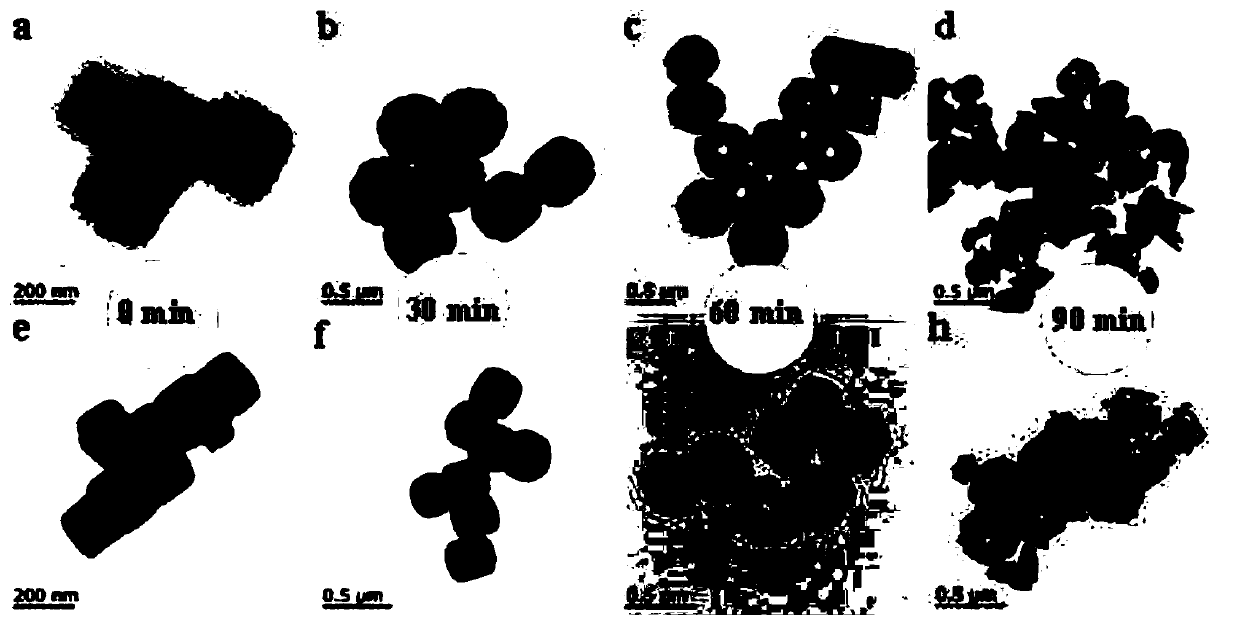

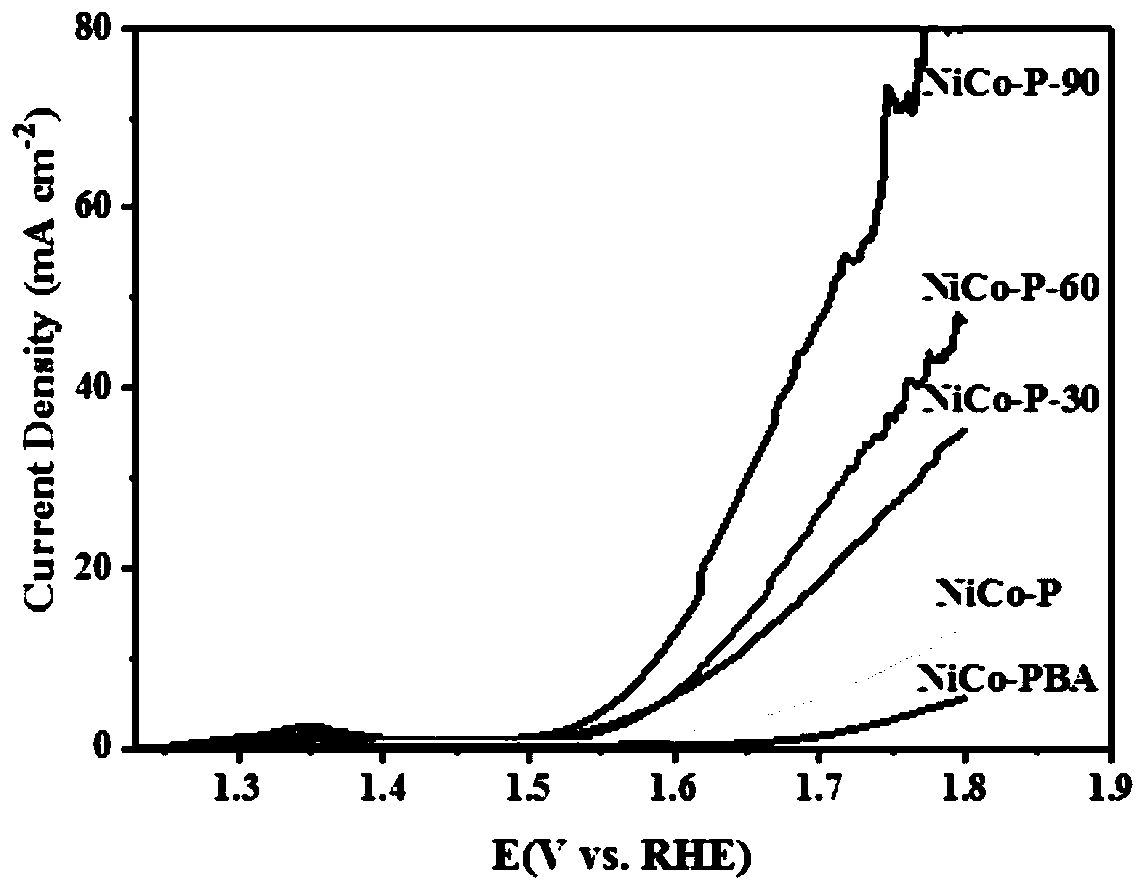

[0029] (1) Weigh 0.1330g of potassium cobaltcyanide and dissolve in 20mL of deionized water until a clear solution A is formed. Weigh 0.1426g of nickel chloride hexahydrate and 0.2353g of trisodium citrate and dissolve in 20mL of deionized water to form a clear solution B. Pour solution A into solution B, stir well and leave to age for 5 days. Wash with ethanol and deionized water by centrifugation three times, and then dry in a vacuum oven. A gray-blue sample NiCo-PBA was obtained.

[0030] (2) Weigh 20 mg of the above-prepared NiCo-PBA precursor and add it to 10 mL of ethanol and stir evenly. Measure 2.5 mL of ammonia water and add 20 mL of deionized water, and slowly add it dropwise to the ethanol containing NiCo-PBA, stir for 60 min, and centrifuge Wash with water and alcohol, and dry to obtain hollow NiCo-PBA-60.

[0031] (3) Weigh 0.6gNaH 2 PO 2 Place it upstream of the semi-c...

Embodiment 2

[0033] A kind of preparation method of nickel cobalt phosphorus double metal phosphide:

[0034] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that the amount of ammonia water is 5 mL.

Embodiment 3

[0036] A kind of preparation method of nickel cobalt phosphorus double metal phosphide:

[0037] (1) Weigh 0.1330g of potassium cobaltcyanide and dissolve in 20mL of deionized water until a clear solution A is formed. Weigh 0.1764g of nickel nitrate hexahydrate and 0.2647g of trisodium citrate and dissolve in 20mL of deionized water to form a clear solution B. Pour solution A into solution B, stir well and leave to age for 3 days. Wash with ethanol and deionized water by centrifugation three times, and then dry in a vacuum oven. A gray-blue sample NiCo-PBA was obtained.

[0038](2) Weigh 20 mg of the above-prepared NiCo-PBA precursor and add it to 10 mL of ethanol and stir evenly. Measure 2.5 mL of ammonia water and add 20 mL of deionized water, and slowly add it dropwise to the ethanol containing NiCo-PBA, stir for 90 min, and centrifuge Wash with water and alcohol, and dry to obtain hollow NiCo-PBA-90.

[0039] (3) Weigh 0.6gNaH 2 PO 2 Placed upstream of the semi-close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com