Patents

Literature

151 results about "Biogenic gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biogenic gases are gases critical for, and produced by, living organisms. In the contemporary atmosphere, they include oxygen, nitrogen, water vapour, carbon dioxide, carbon monoxide, methane, ozone, nitrogen dioxide, nitric acid, ammonia and….

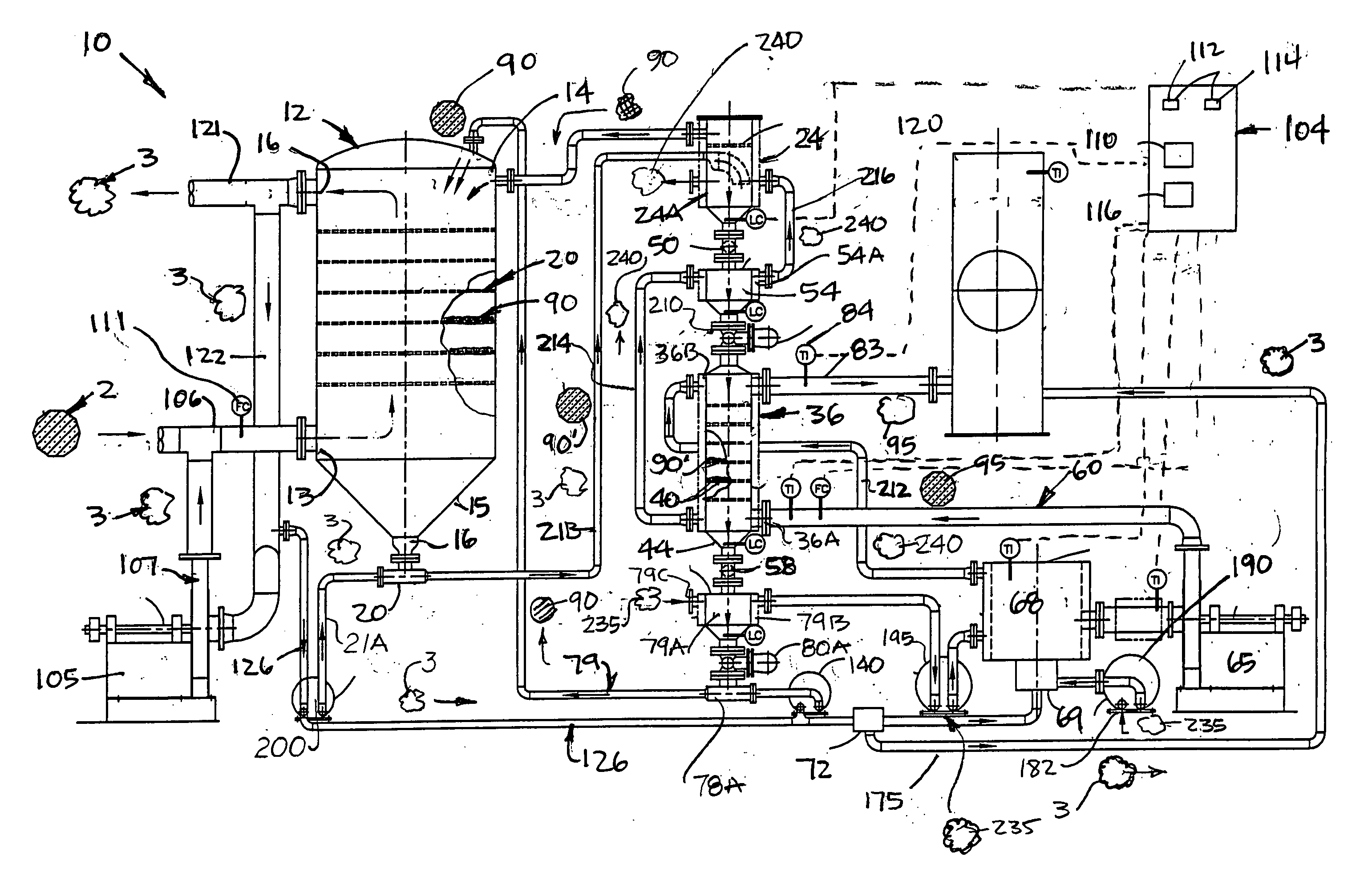

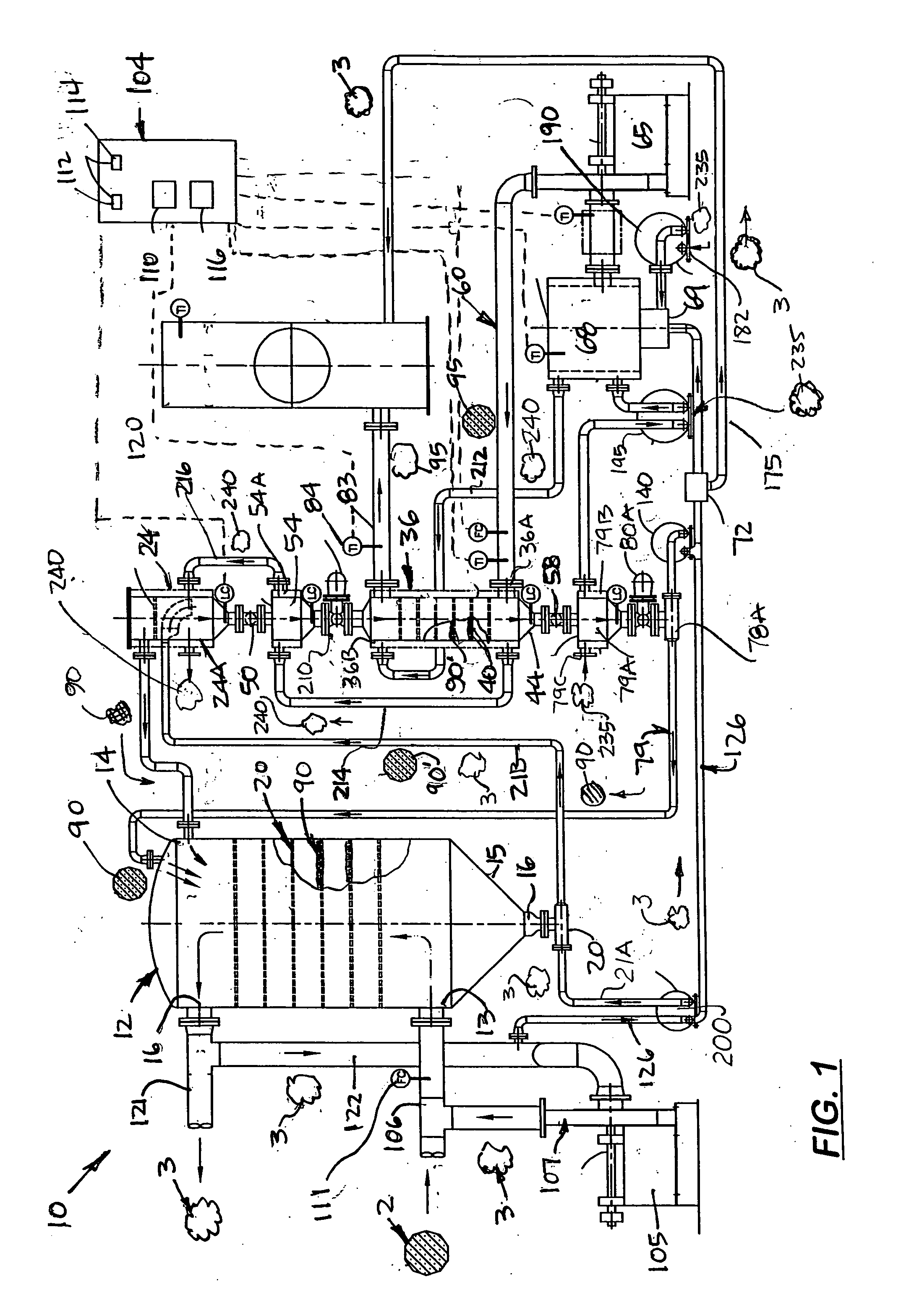

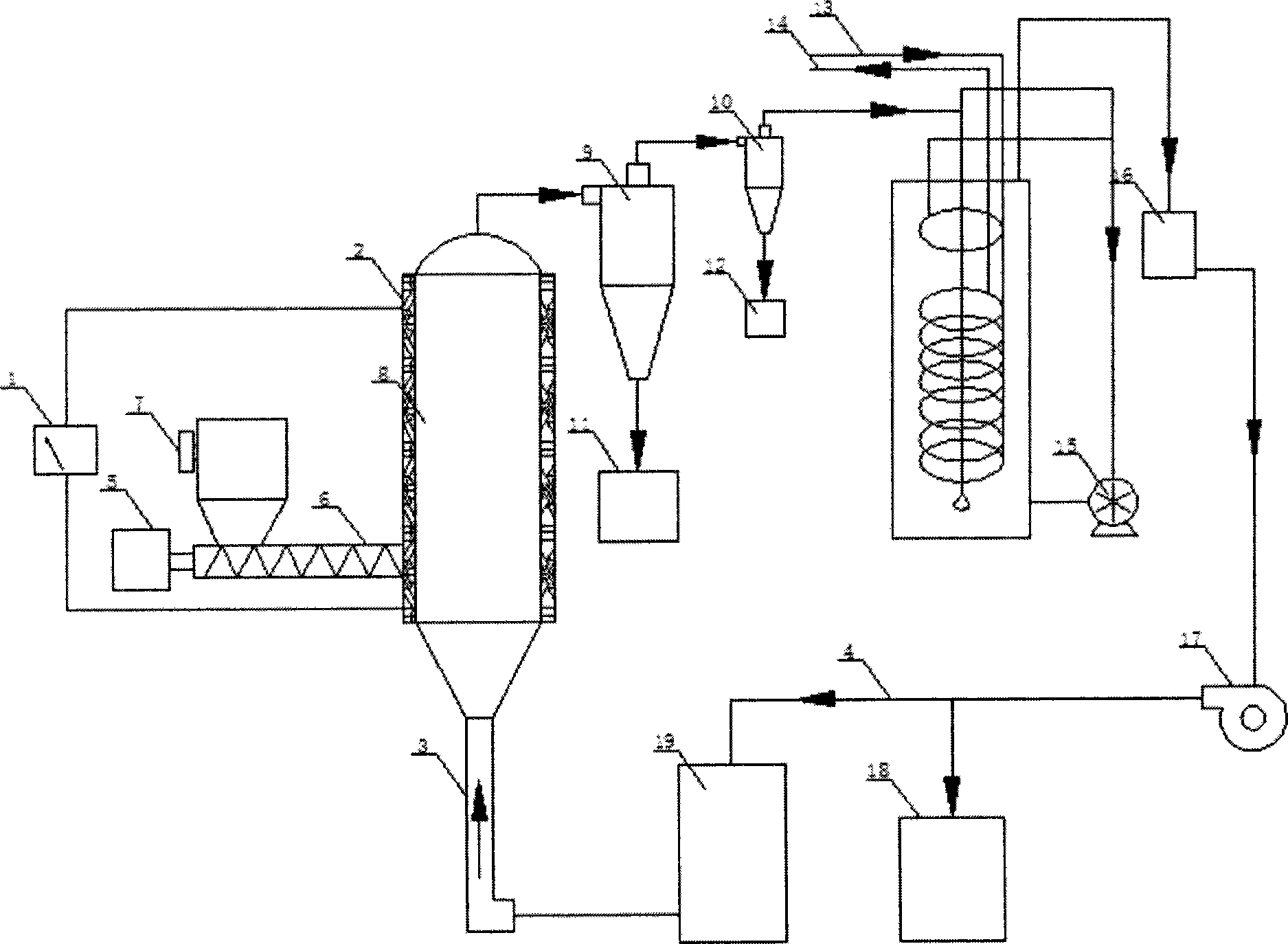

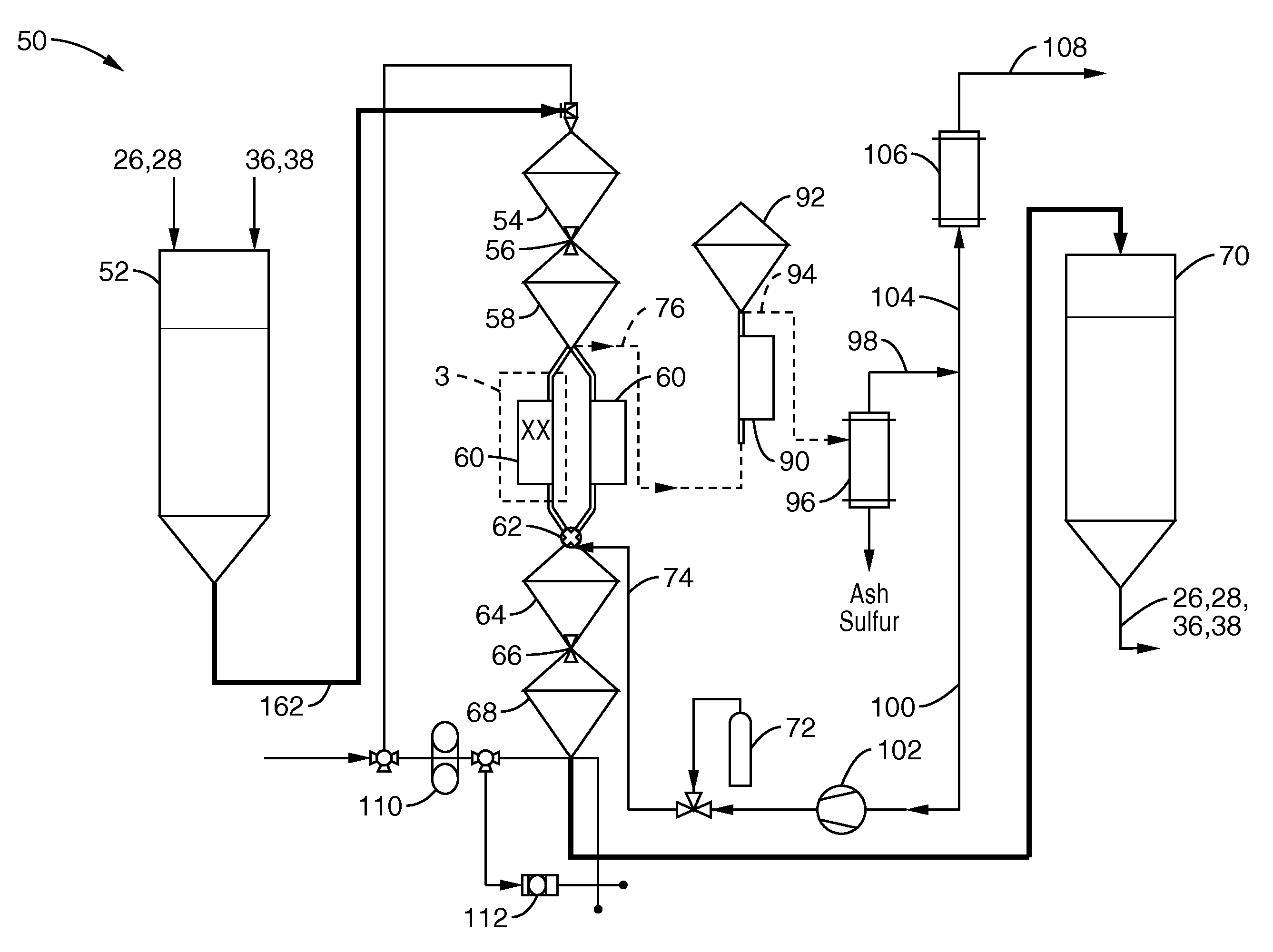

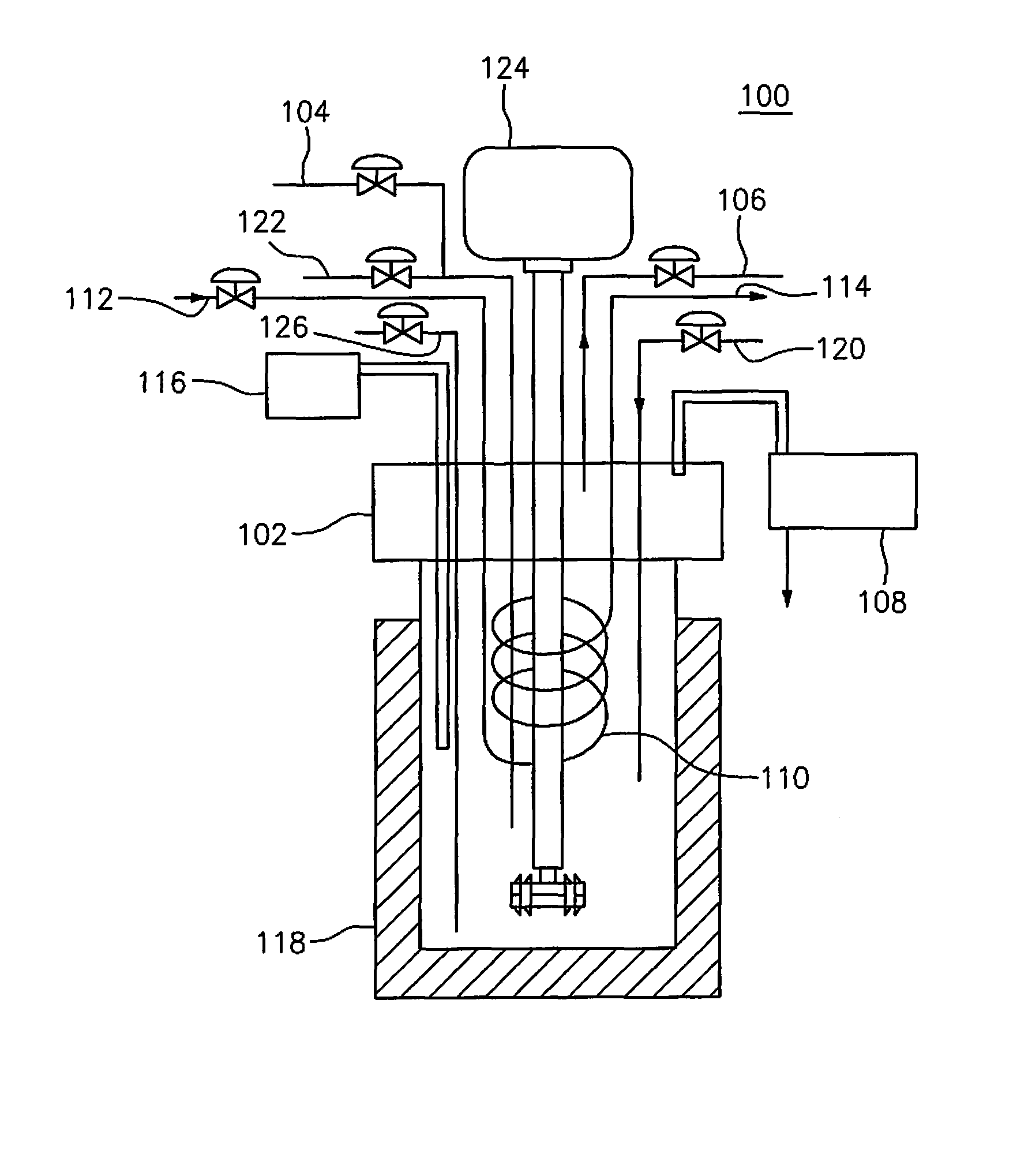

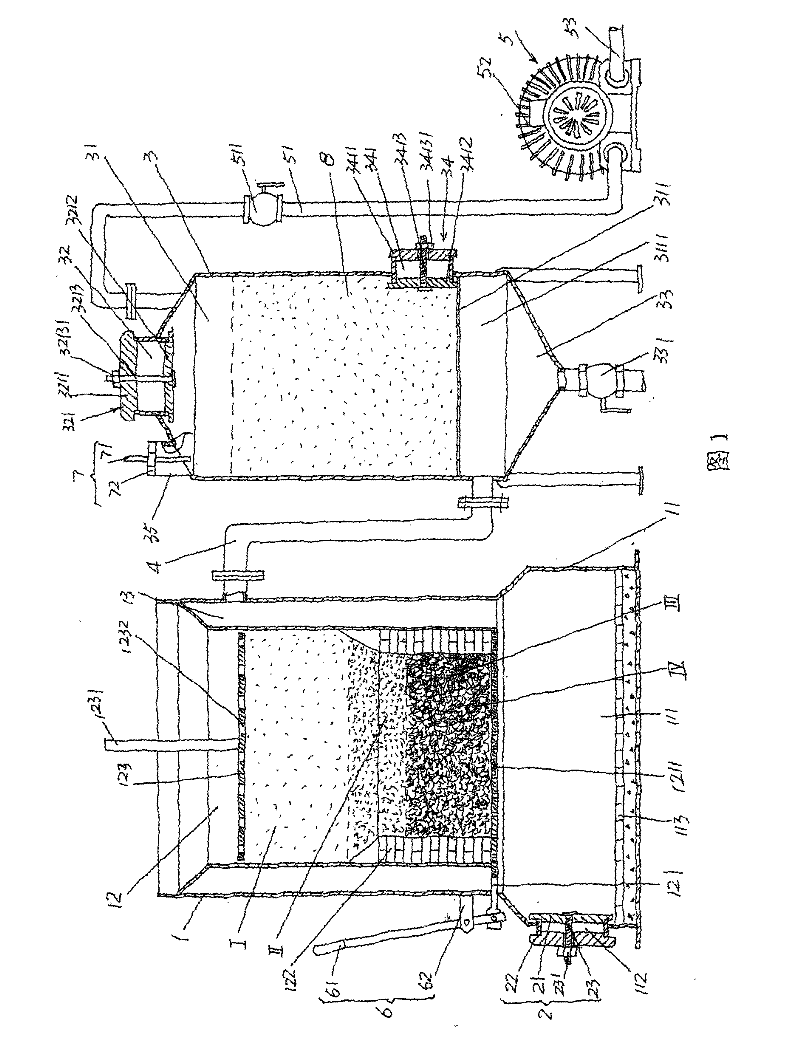

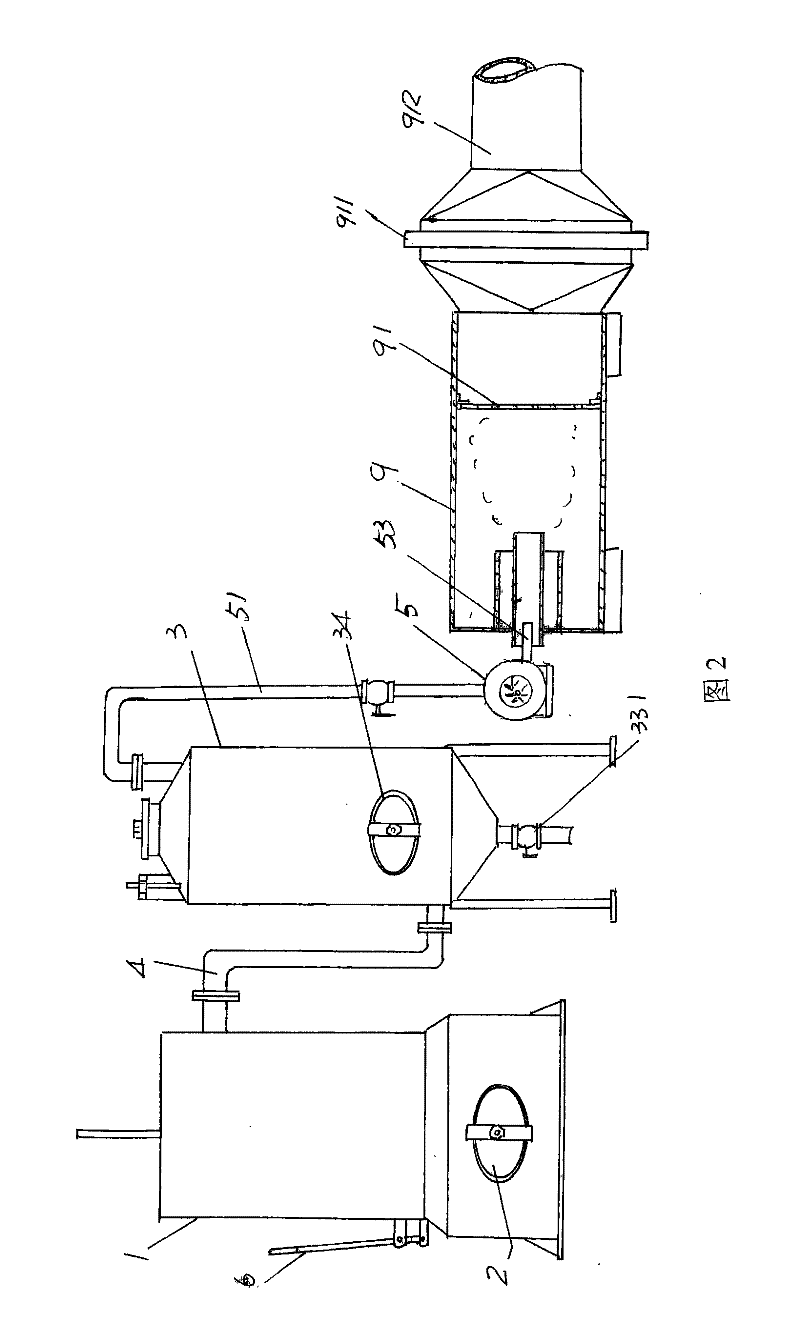

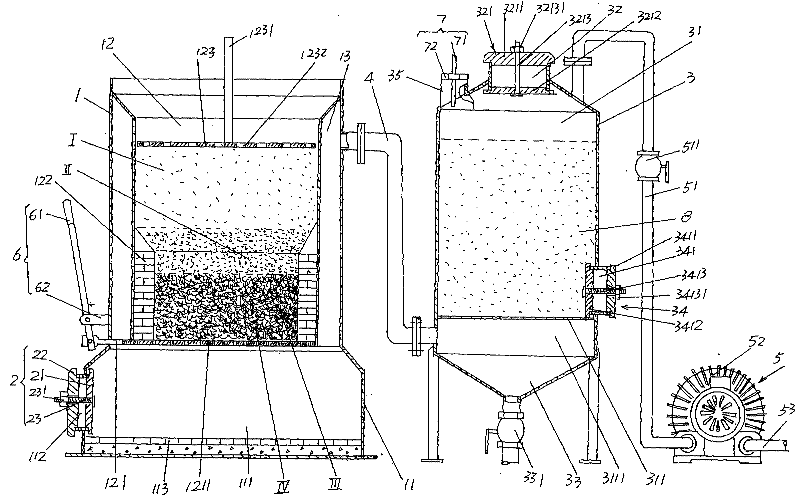

Method and apparatus for solids processing

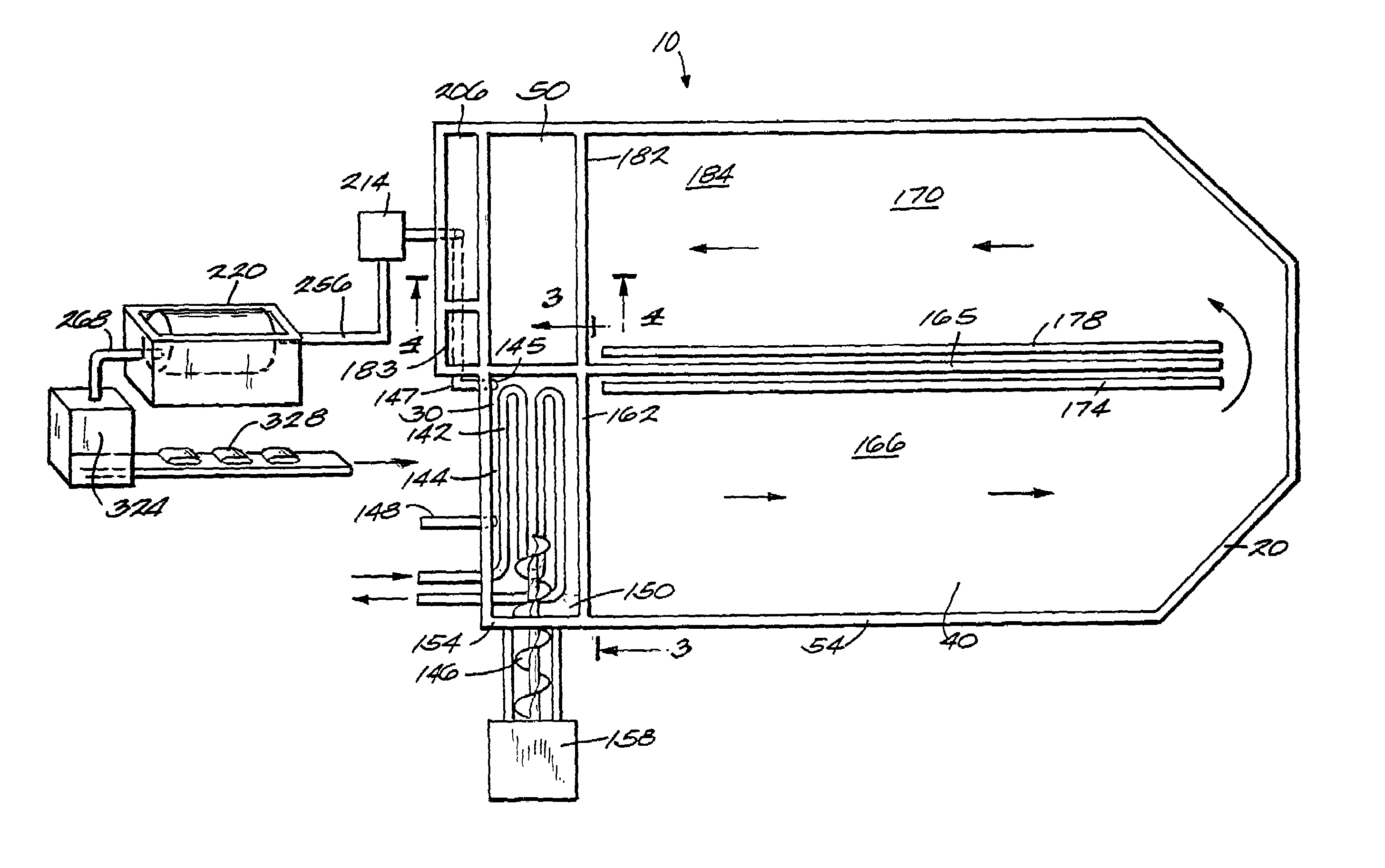

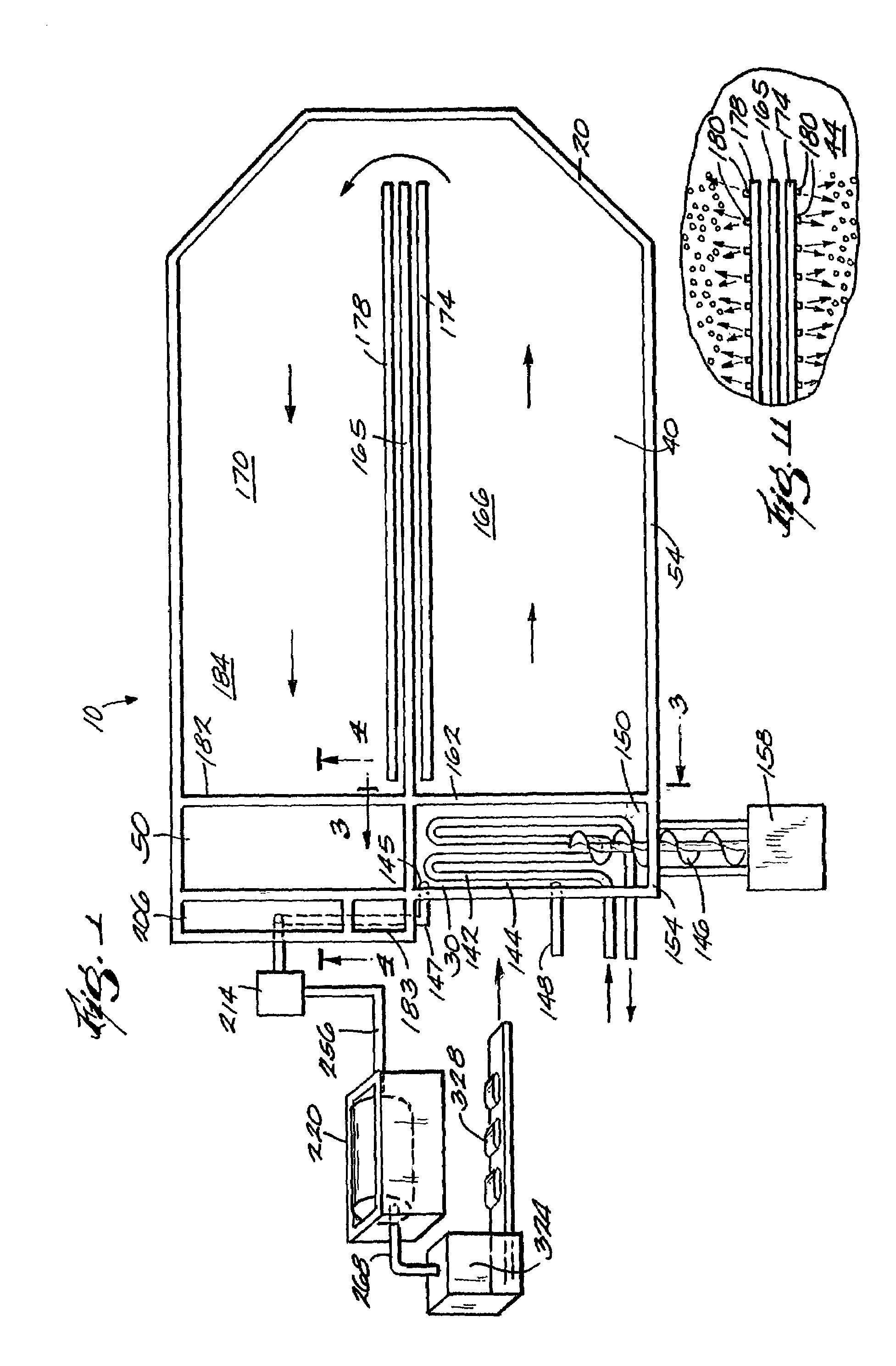

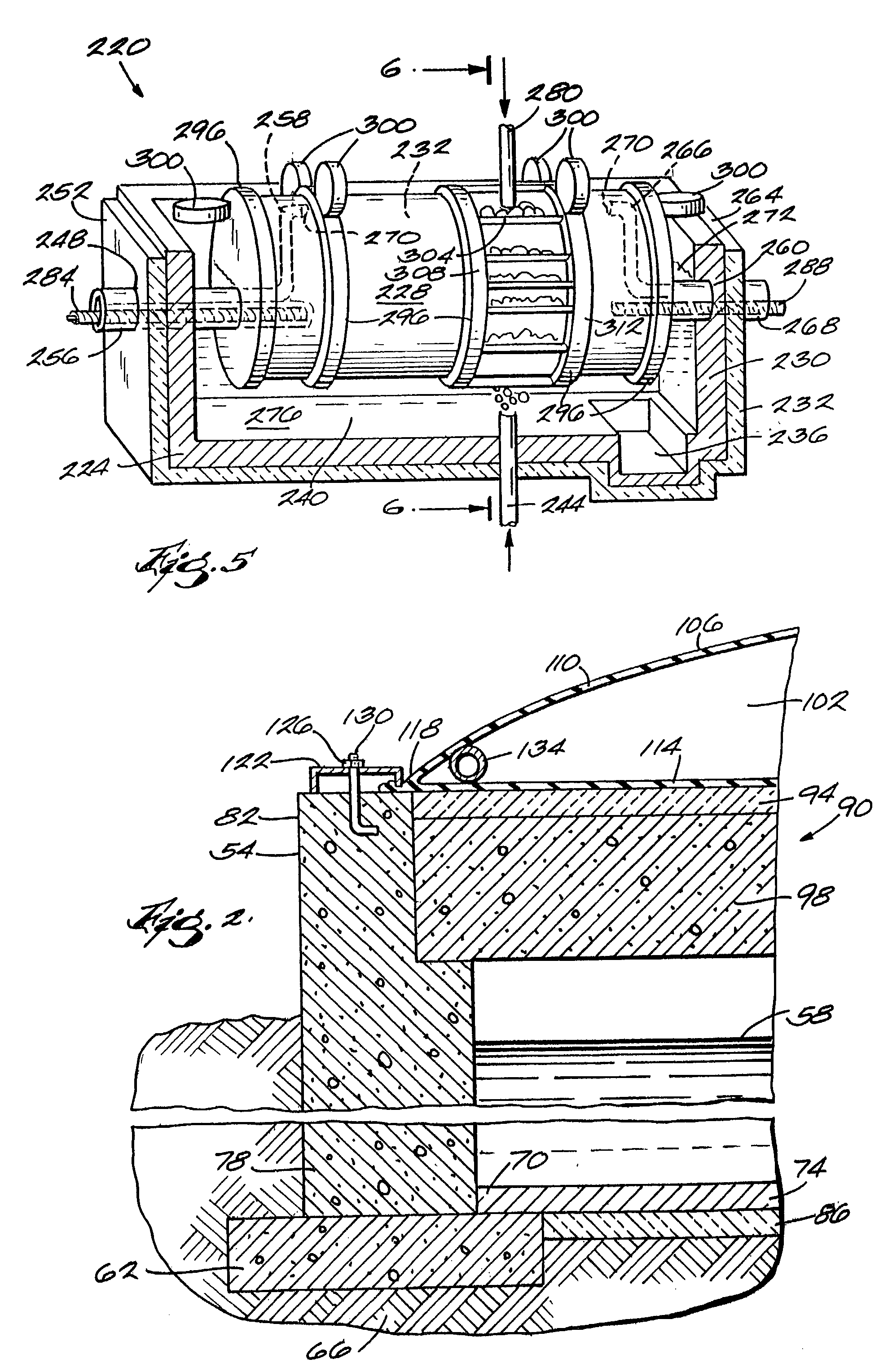

InactiveUS7078229B2Minimize end waste productMaximize energy efficiencyBioreactor/fermenter combinationsBio-organic fraction processingWaste processingProcess engineering

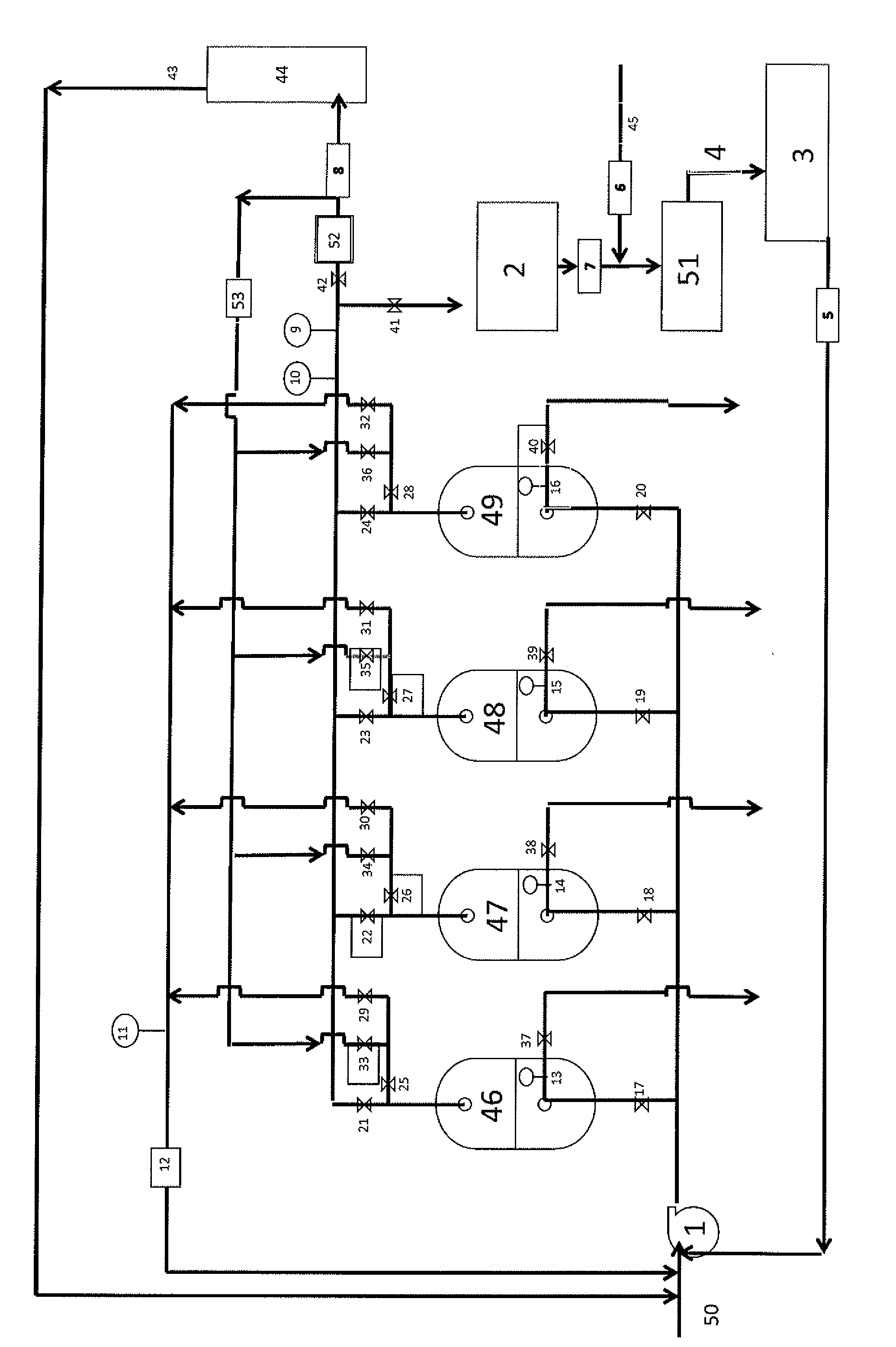

This invention provides a waste-processing system capable of processing high-solids wastes such as manure. This invention provides a compact U-shaped digester that allows for recycling of activated sludge to improve the efficiency of the process. Efficiency is also improved through a sludge heating design that creates a current in the digester and efficiently heats the sludge. A composter is provided to further process the sludge through aerobic digestion to create usable fertilizer. Finally, one embodiment provides a turbine that is fueled by biological gases from the digester to generate heat and electricity to be used by the system.

Owner:DVO LICENSING

Chemical amendments for the stimulation of biogenic gas generation in deposits of carbonaceous material

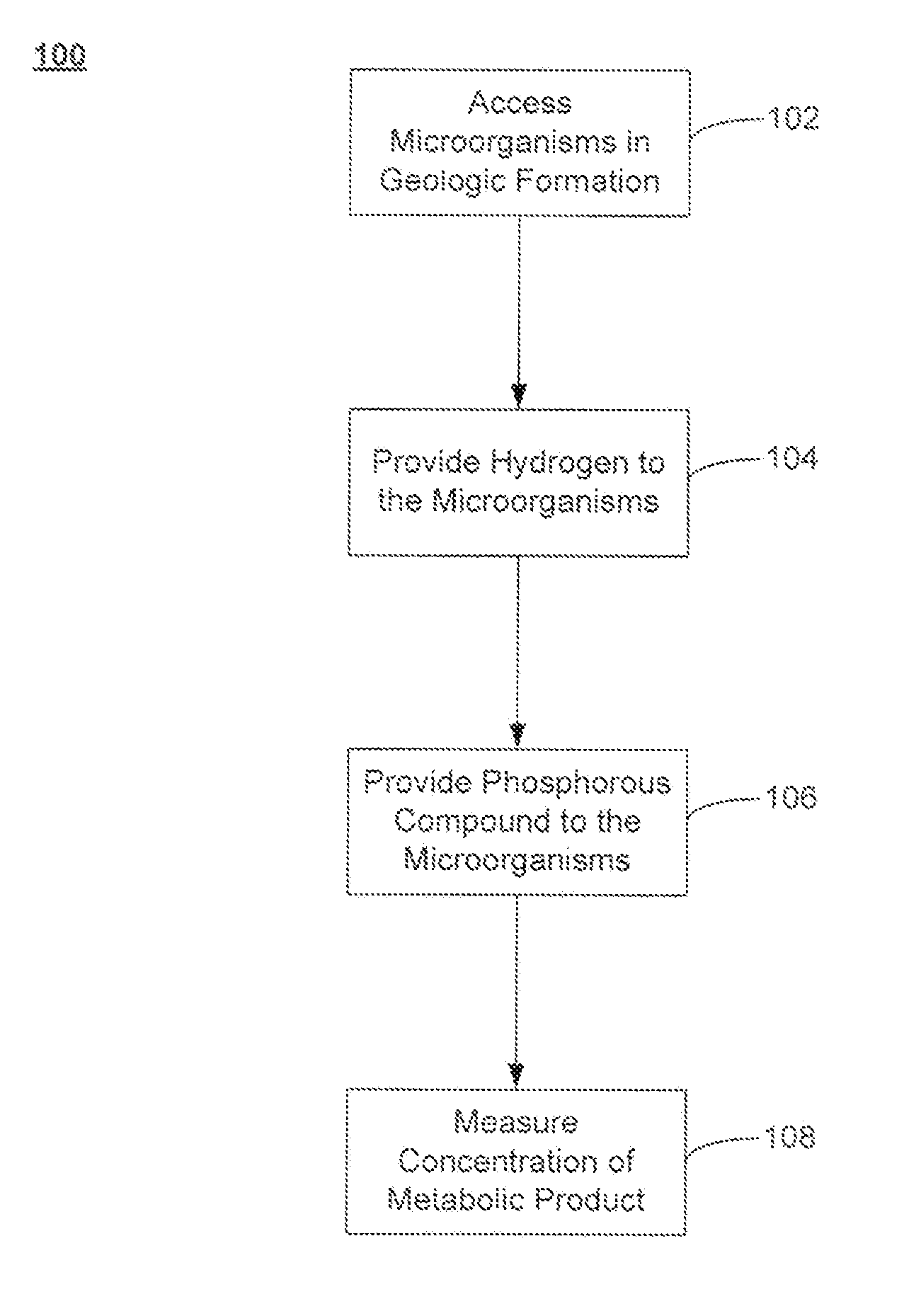

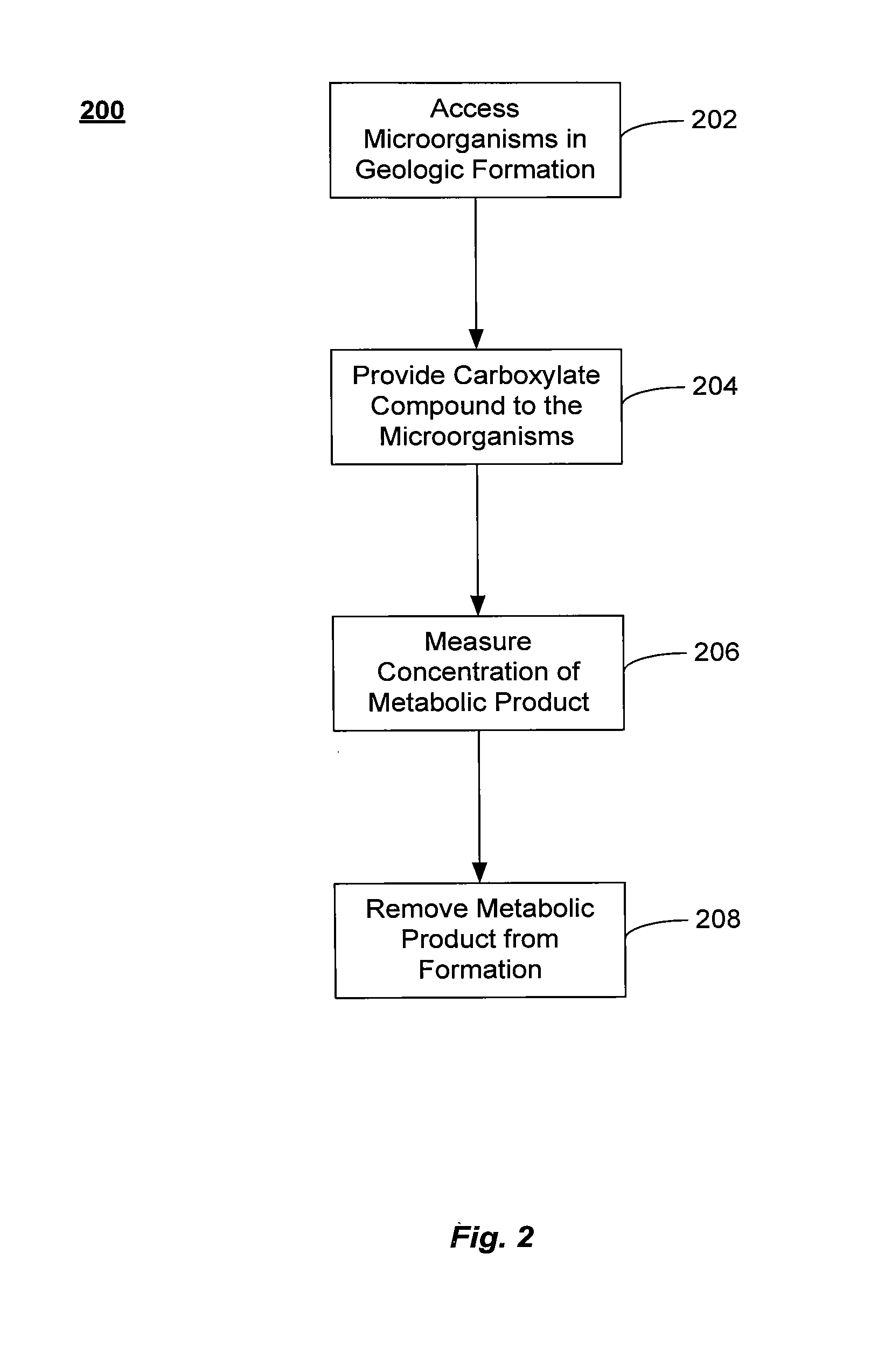

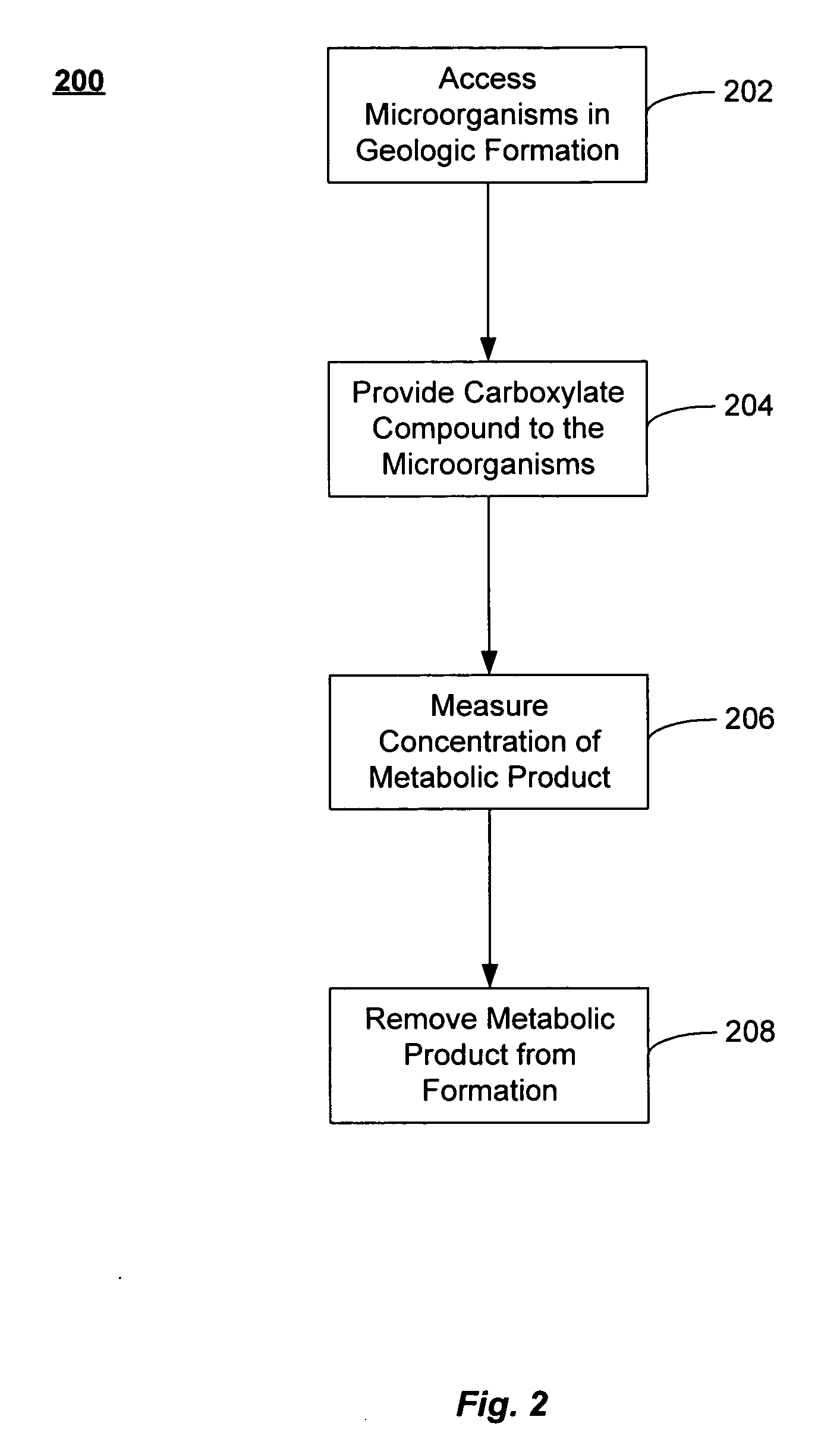

Methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content are described. The methods may include accessing a geologic formation that includes carbonaceous material. The methods may also include introducing an amendment to the geologic formation. The amendments may further include removing compounds with enhanced hydrogen content from the formation.

Owner:LUCA TECH

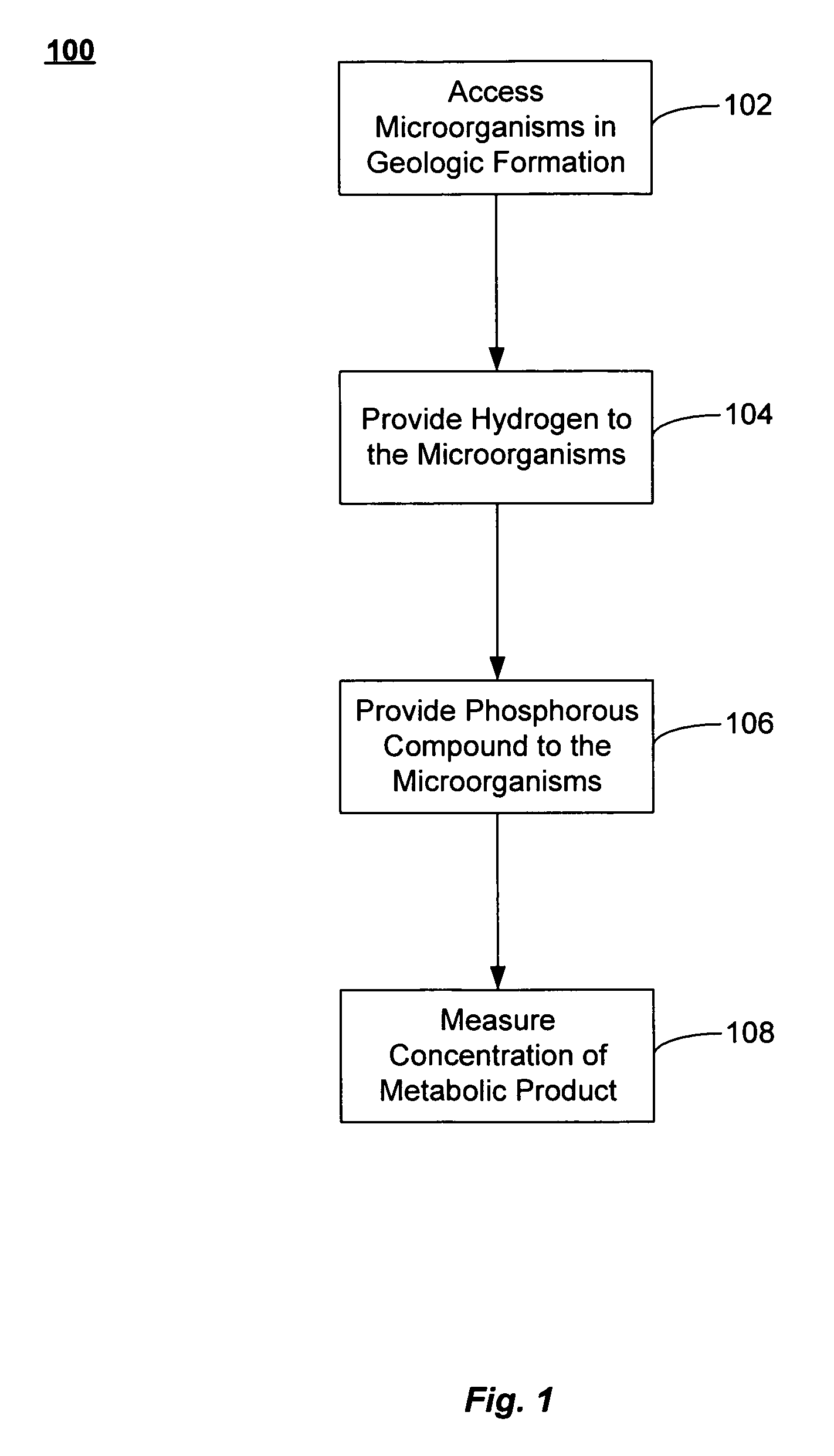

Chemical amendments for the stimulation of biogenic gas generation in deposits of carbonaceous material

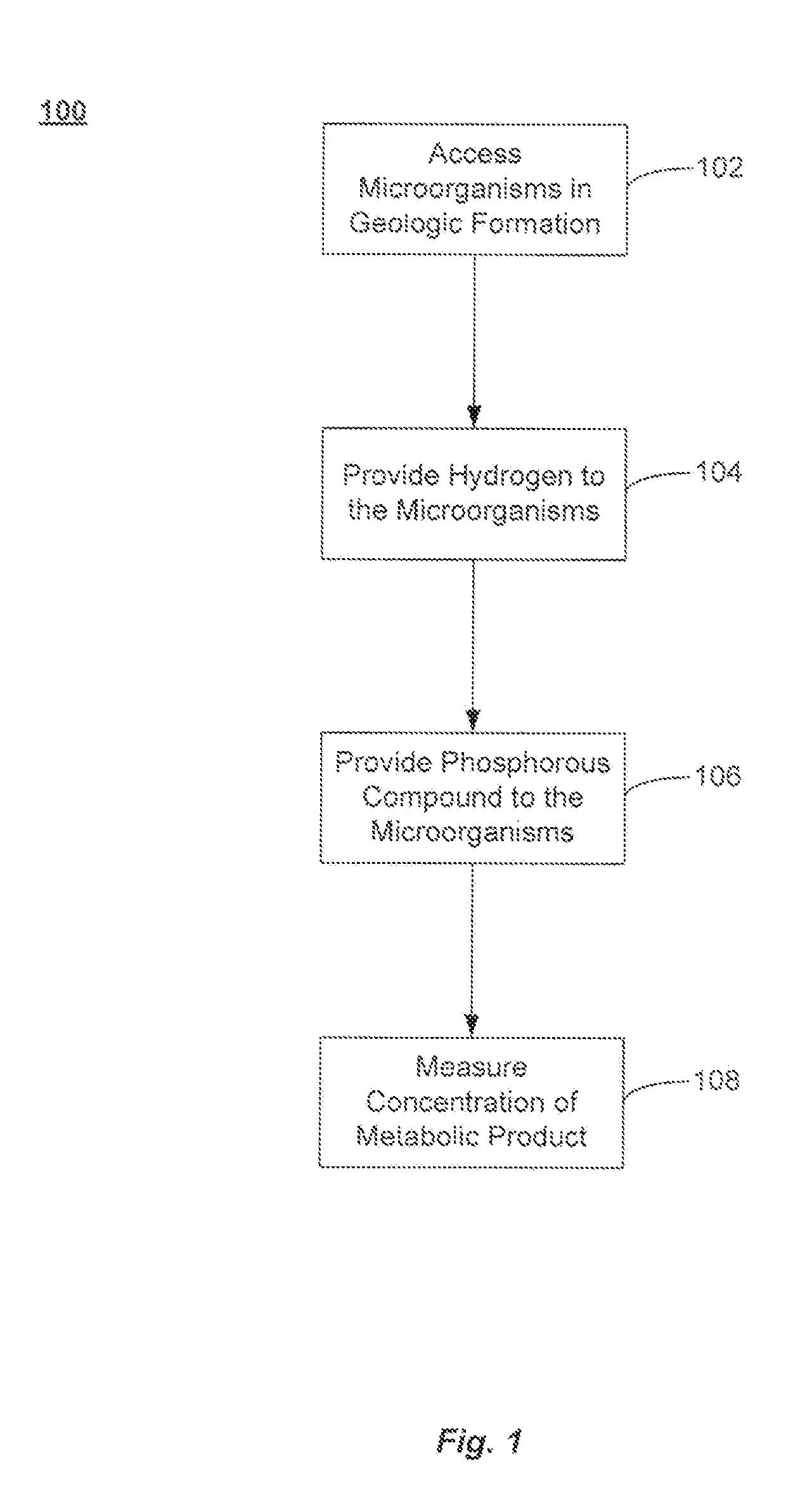

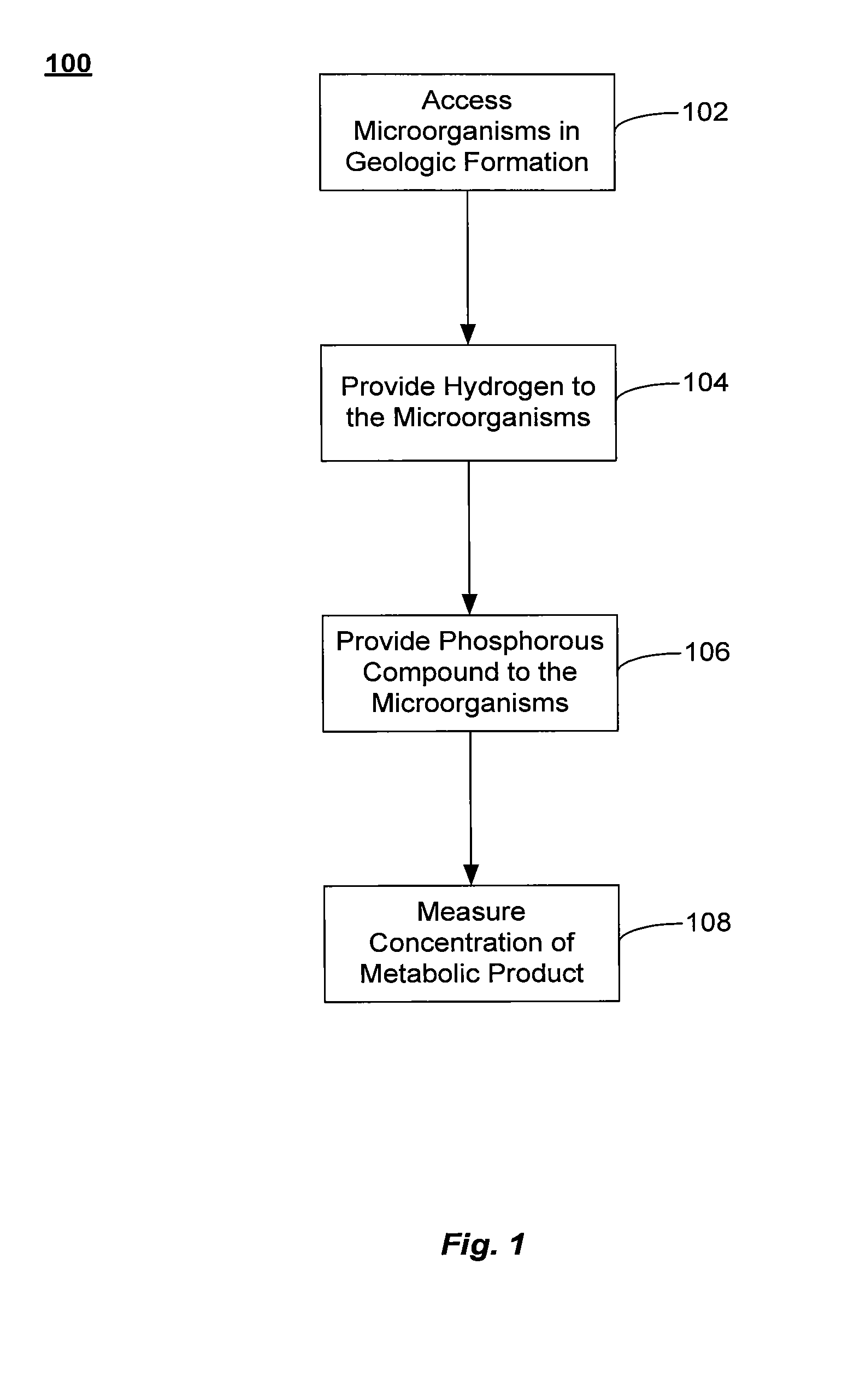

ActiveUS20070295505A1High hydrogen contentRelieves nutritional deficiencyWaste based fuelFluid removalMicroorganismHydrogen content

Methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content are described. The methods may include accessing a consortium of microorganisms in a geologic formation that includes a carbonaceous material. They may also include providing a phosphorous compound to the microorganisms. The phosphorous compound stimulates the consortium to metabolize the carbonaceous material into a metabolic product with enhanced hydrogen content. Also, methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content by providing a yeast extract amenment to a consortium of microorganisms is described. The yeast extract amendment stimulates the consortium to metabolize carbonaceous material in the formation into the metabolic product with enhanced hydrogen content.

Owner:TRANSWORLD TECH

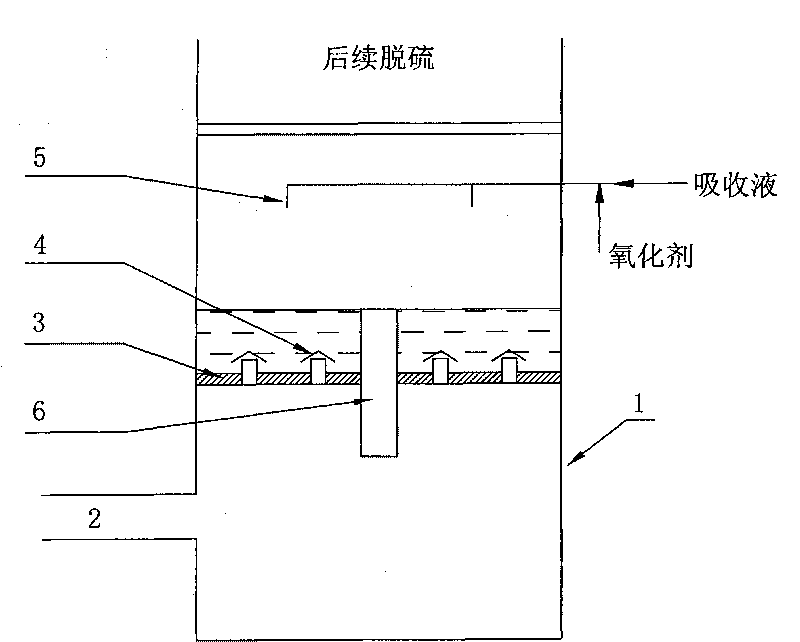

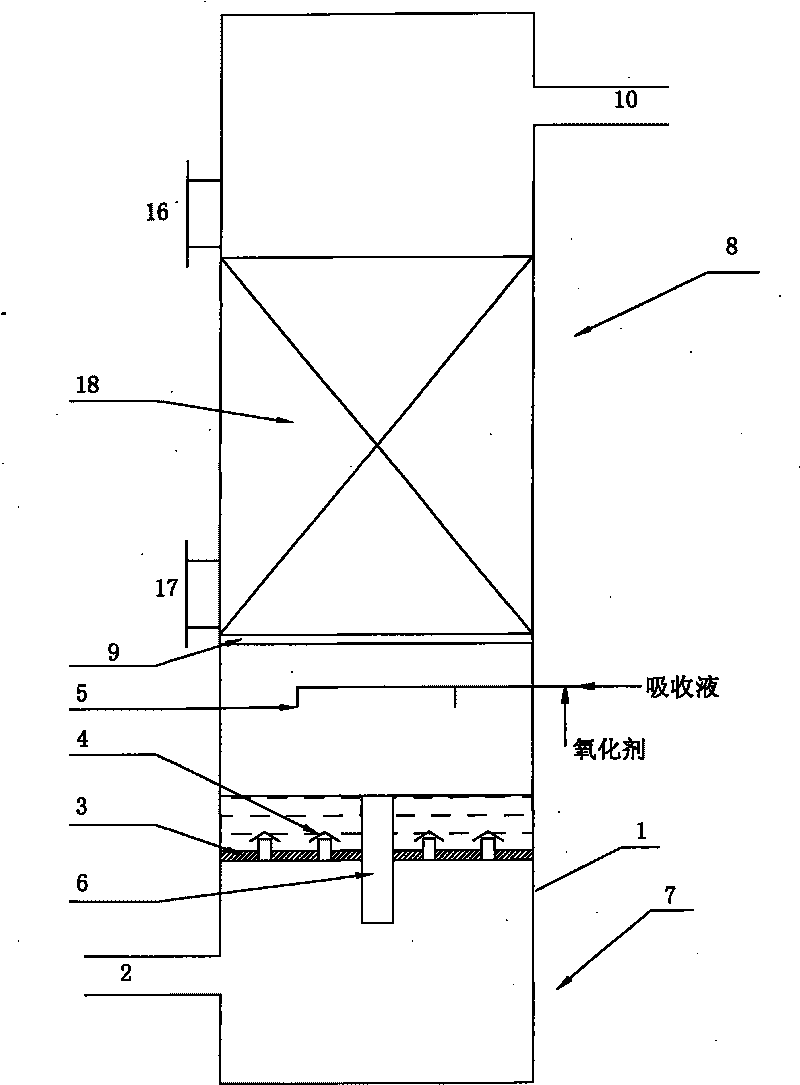

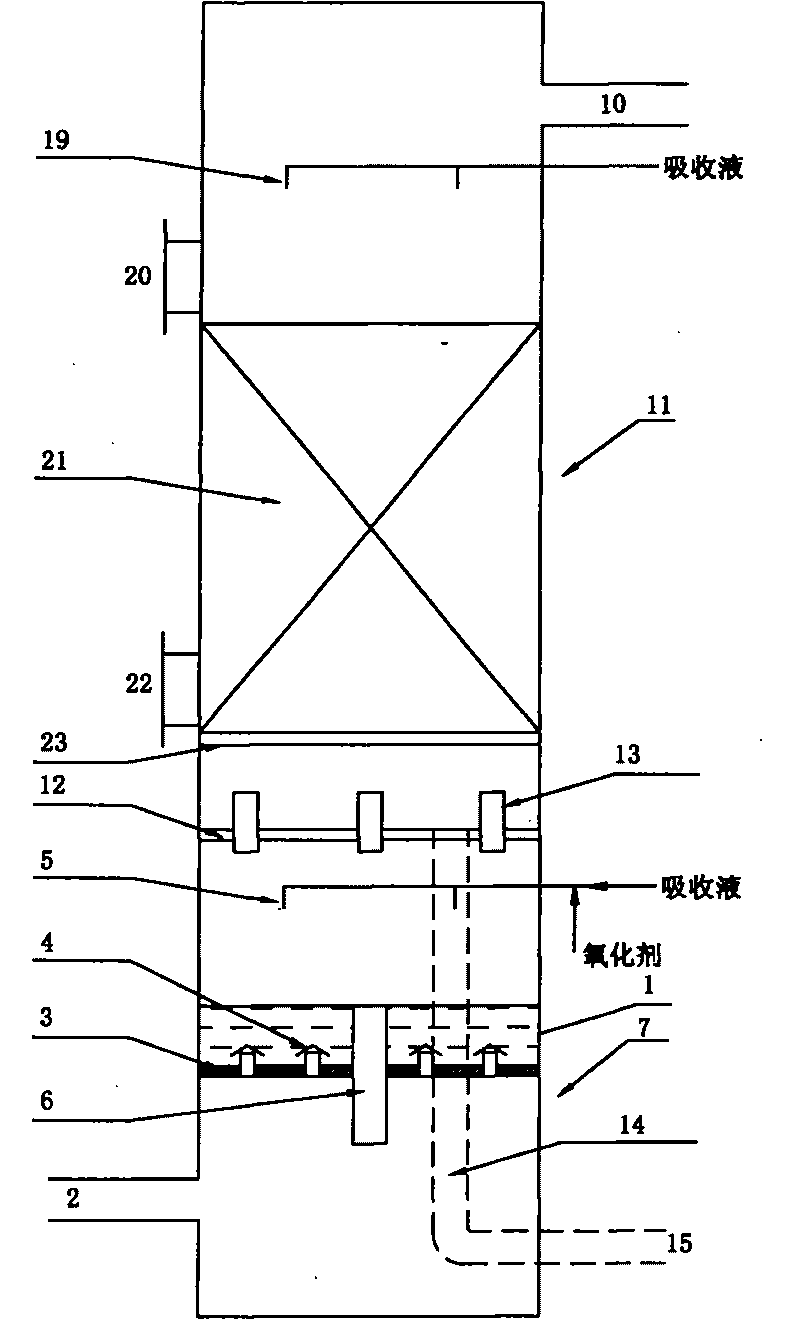

Method for depriving sulfureted hydrogen in biogas and device

The invention provides a method for depriving sulfureted hydrogen in biogas, which is characterized by comprising the following steps: firstly, introducing the biogas into a bubble column plate absorption oxidation device, and absorbing sulfureted hydrogen in the biogas by utilizing sprayed absorption solution containing an oxidant; secondly, controlling the air velocity in a hollow tower of the bubble column plate absorption oxidation device to be 0.2-1.5m / s, wherein the height of the liquid on a plate grid is 0.2-0.8m; and finally sending the biogas absorbed by absorption solution to a subsequent dry-type desulfurizing tower, a wet-type desulfurizing tower or a biological desulfurizing tower for depriving sulfureted hydrogen further. The invention also discloses three devices for depriving sulfureted hydrogen in the biogas by utilizing the combination of the bubble column plate absorption oxidation devices, a desulfuration device using the common dry method and wet method. The invention has simple method, and can effectively and quickly carry out desulfuration at constant pressure.

Owner:NANJING UNIV

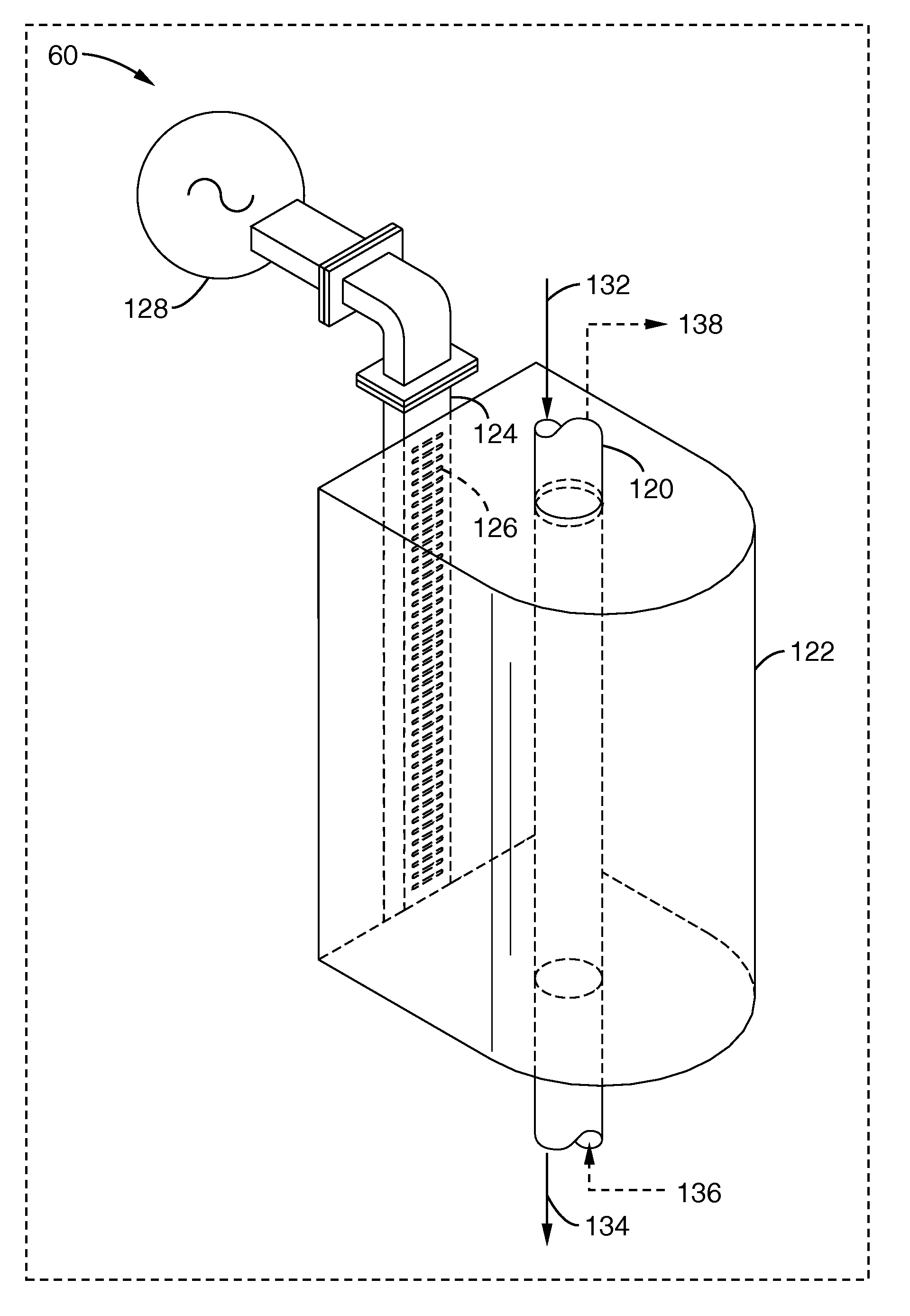

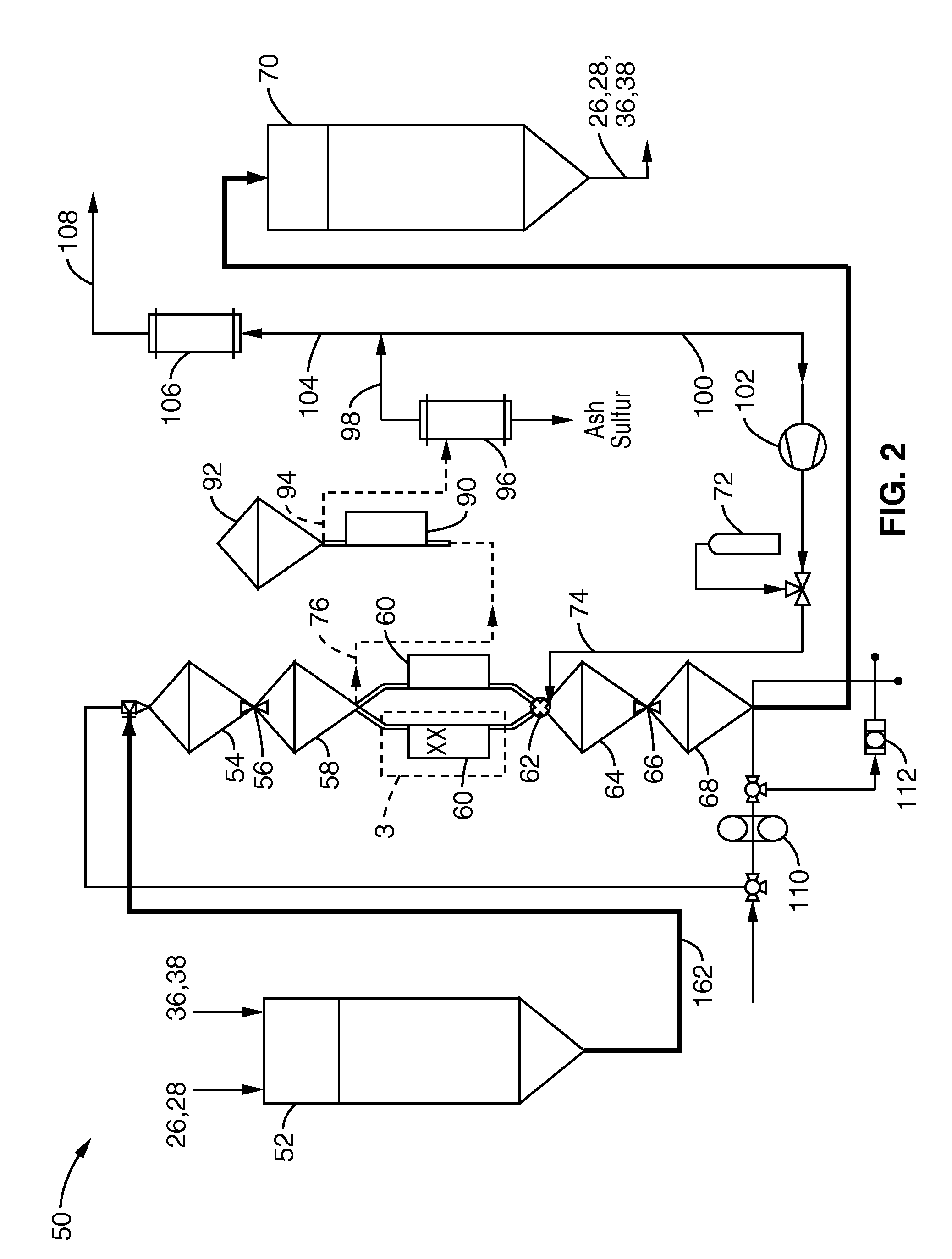

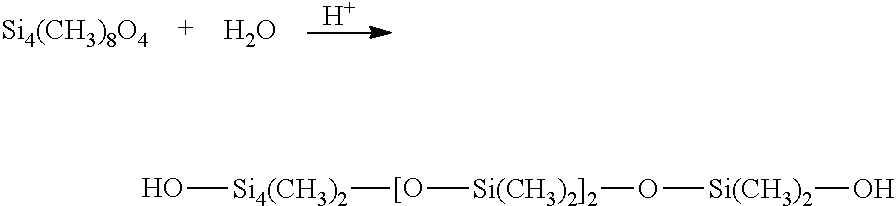

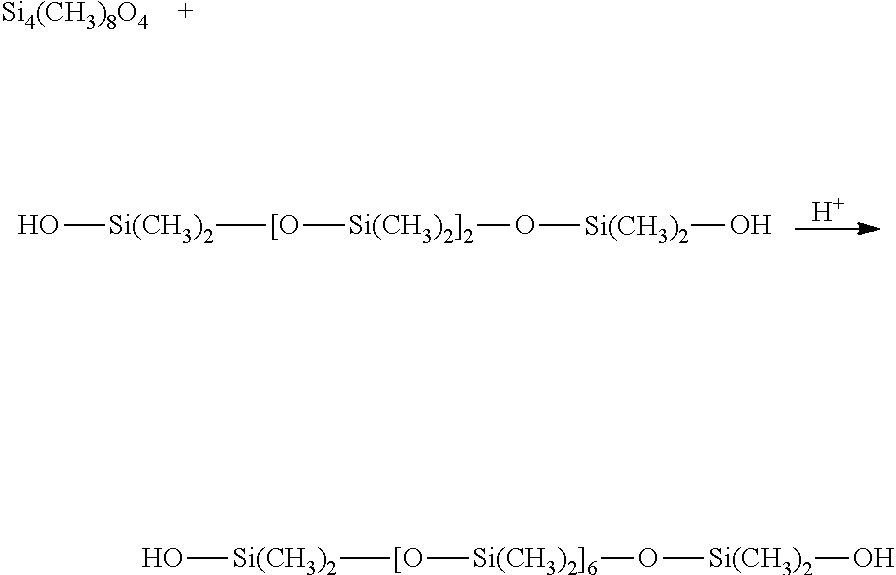

Microwave induced destruction of siloxanes and hydrogen sulfide in biogas

ActiveUS20080179177A1Facilitate desorptionLimiting the number of activation cyclesGas treatmentOther chemical processesBiogenic gasSilicon dioxide

The invention is an apparatus and method to remove hydrogen sulfide and siloxanes from biogas and destroy the contaminants in microwave reactors. Hydrogen sulfide and siloxane are removed from biogas using an adsorbent media such as activated carbon. The media is regenerated in a microwave reactor where the hydrogen sulfide and siloxane are removed in a sweep gas. In one process, siloxane is oxidized to silicon dioxide in a second microwave reactor and removed with a filter. Hydrogen sulfide if first oxidized to sulfur dioxide, then reduced to sulfur in a third microwave reactor and removed with a filter. In another process, siloxane is combined with water to form silicon dioxide and hydrogen sulfide is reduced to elemental sulfur in a microwave reactor. These reactants are removed with a filter. The remaining sweep gas containing hydrogen and low molecular weight hydrocarbons is returned to the biogas stream.

Owner:C MICRO SYST +1

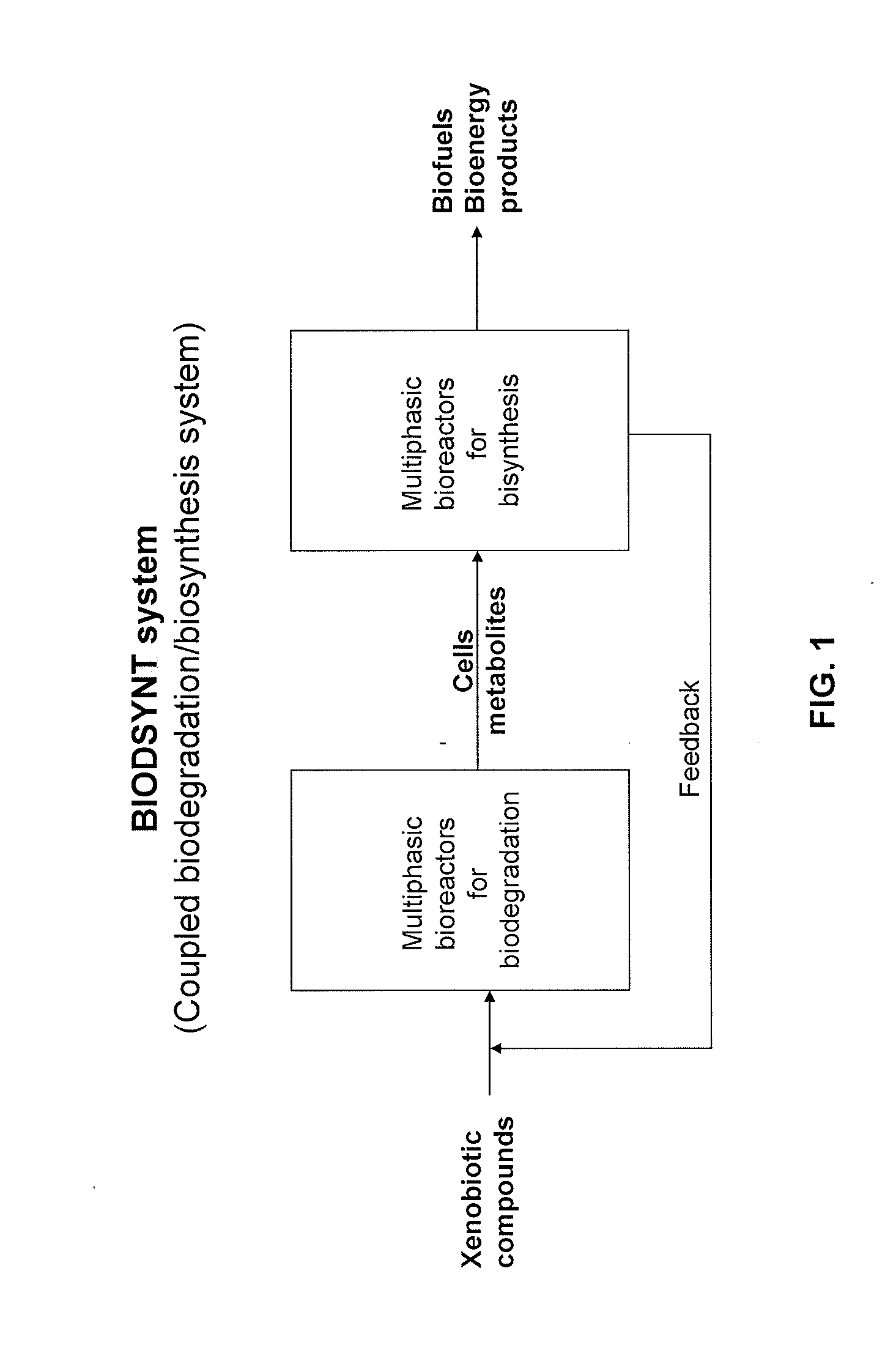

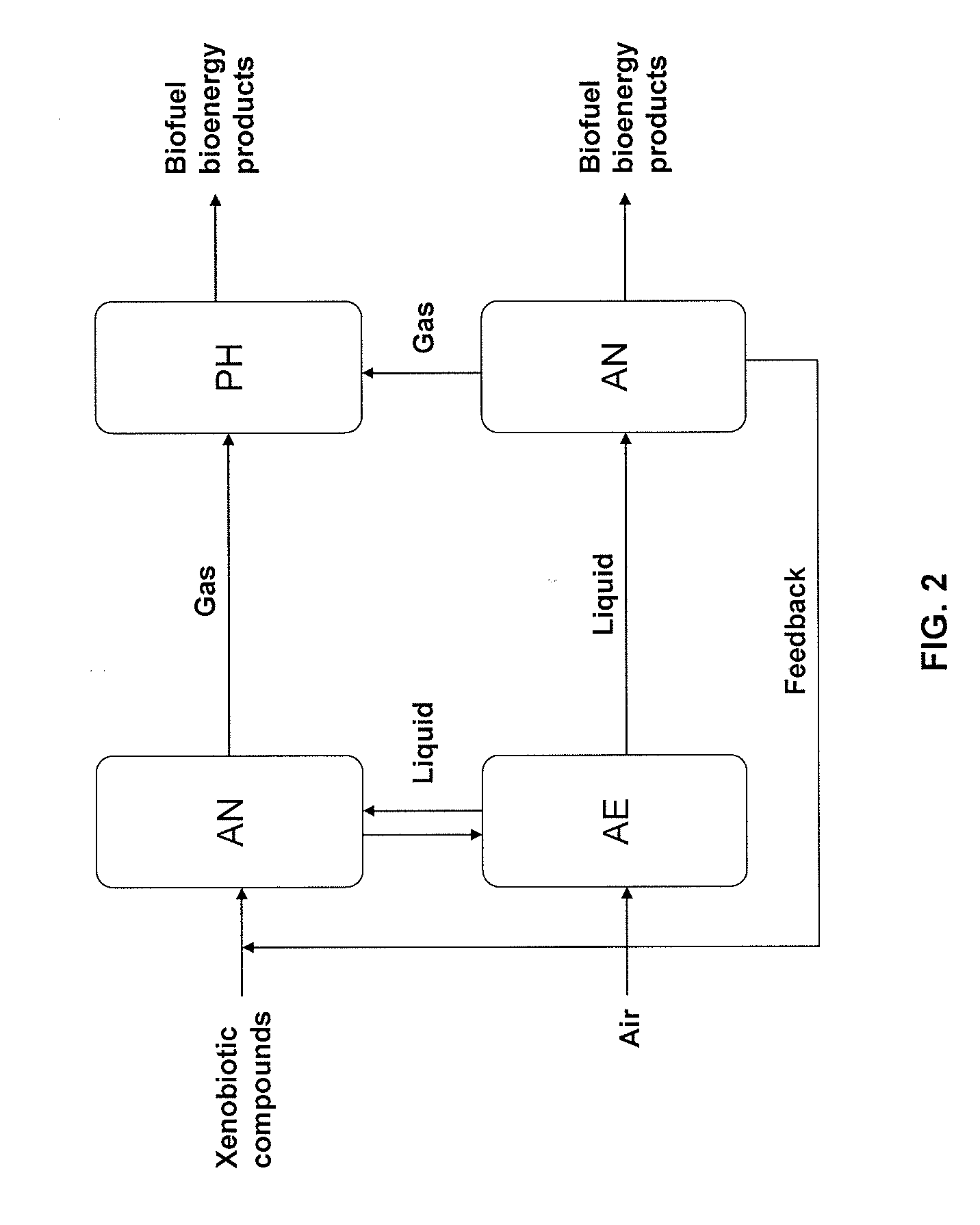

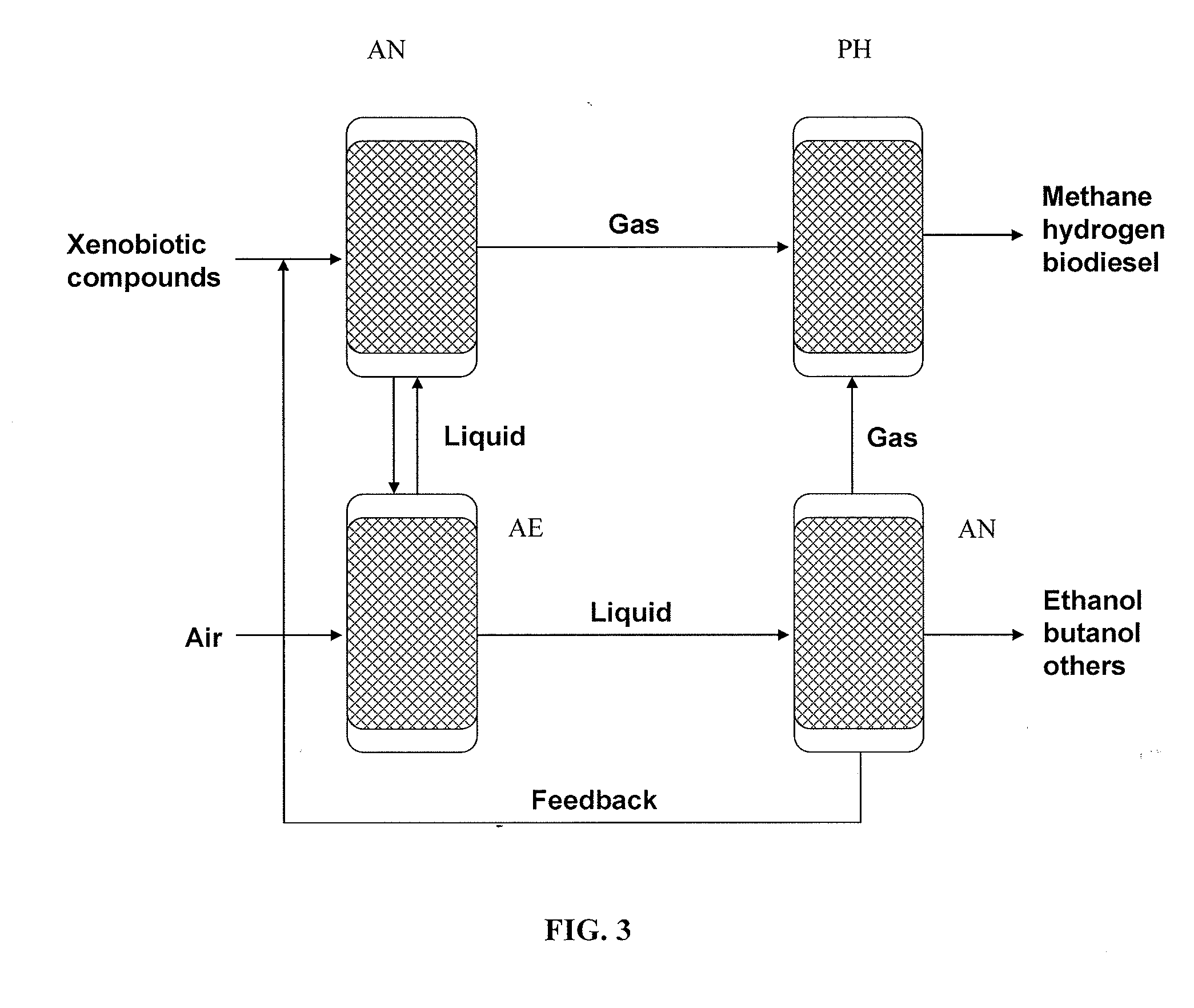

Methods and systems for producing biofuels and bioenergy products from xenobiotic compounds

InactiveUS20100159539A1Reduce contaminationReduce pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselDecomposition

The present invention provides methods and systems for producing biofuel and bioenergy products using, as starting raw material, xenobiotic materials or compounds. The xenobiotic materials or compounds may originate from industrial or chemical plants, municipal waste, pharmaceutical products, cosmetic and personal care products, or other sources, and may include aliphatic and aromatic hydrocarbons, chlorinated organic solvents and other halogenated hydrocarbons, as well as heteroaromatic compounds. In accordance with the invention, these materials act as a carbon source to support the metabolism of xenobiotic-degrading microorganisms, thereby producing biomass and / or biogas that may be converted to bioenergy products by microbial synthesis. For example, the biomass may be converted to products such as ethanol, methanol, butanol, and methane, among others. The biogas may be converted to hydrogen gas and biodiesel, among others. Thus, the present invention couples the microbial breakdown (decomposition) of xenobiotic materials with the microbial synthesis of biofuel, thereby supplying needed (inexpensive) energy products, while reducing environmental pollution and contamination, and reducing the costs associated with disposal of hazardous waste.

Owner:ASCON MIGUEL +1

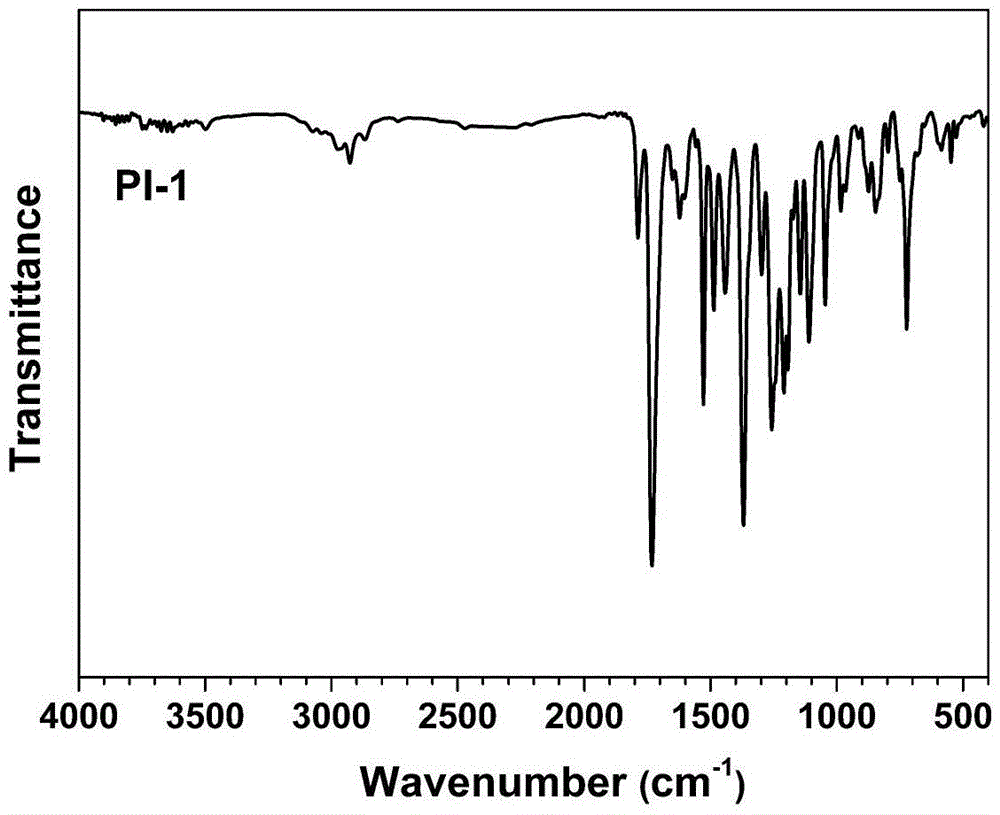

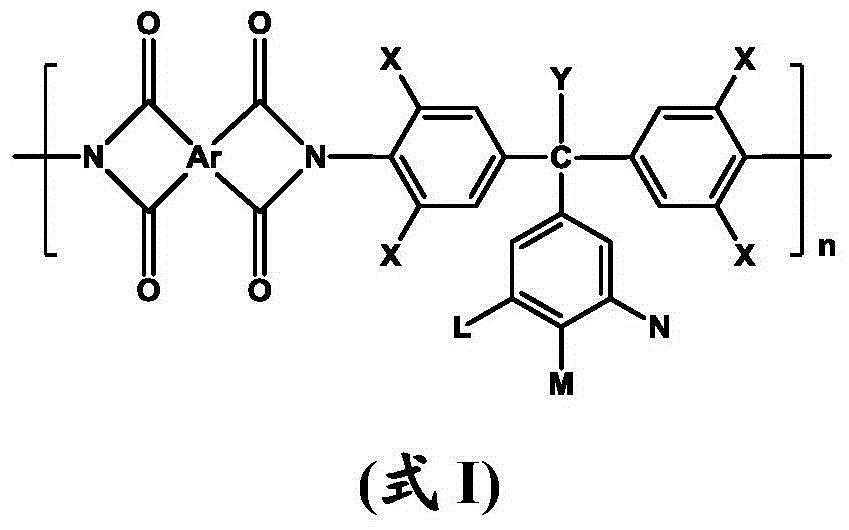

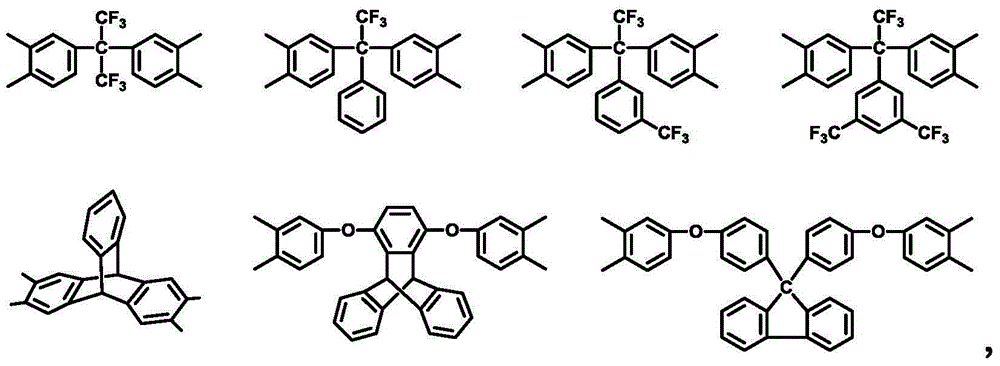

Polyimide gas separation membrane as well as preparation method and applications thereof

ActiveCN104829853AImprove permeabilityHigh selectivityProductsSemi-permeable membranesHeat resistancePermeability coefficient

The invention discloses a polyimide gas separation membrane as well as a preparation method and applications thereof. The separation membrane is made of a polyimide resin which is shown in a formula I and has a fluorobenzene side group containing structure. The polyimide gas separation membrane has the characteristics of high permeability and high selectivity, the permeability coefficient to CO2 is greater than or equal to 180 barrer, the selective coefficient to CO2 / CH4 is greater than 30, and the separation membrane shows excellent heat resistance and mechanical properties. The gas separation membrane has an important application value in various CO2-related separation and recovery applications such as the separation of carbon dioxide and methane in biological gas, the removal of acid gases such as carbon dioxide and the like, the recovery of carbon dioxide in tertiary oil recovery of oil fields, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

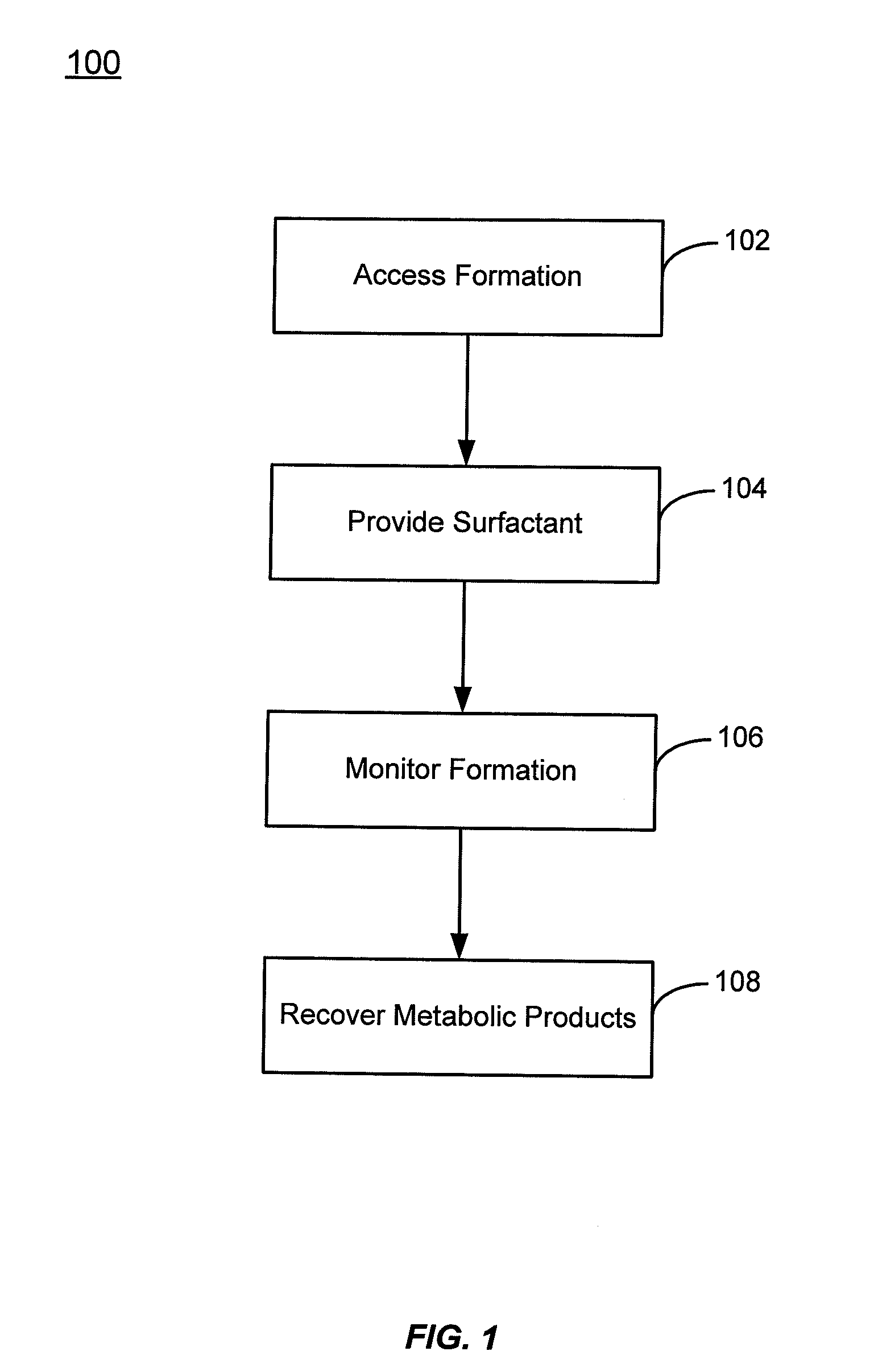

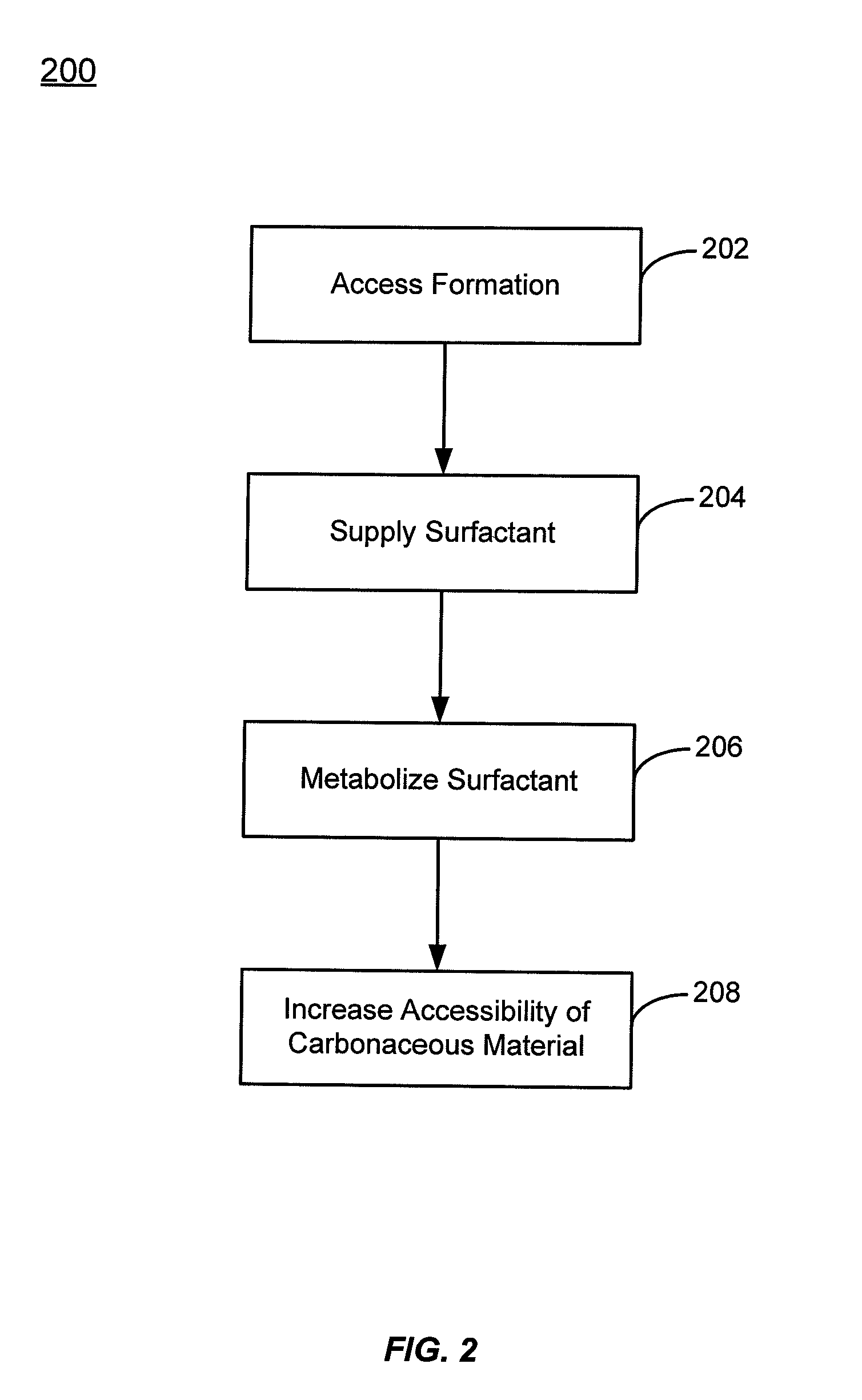

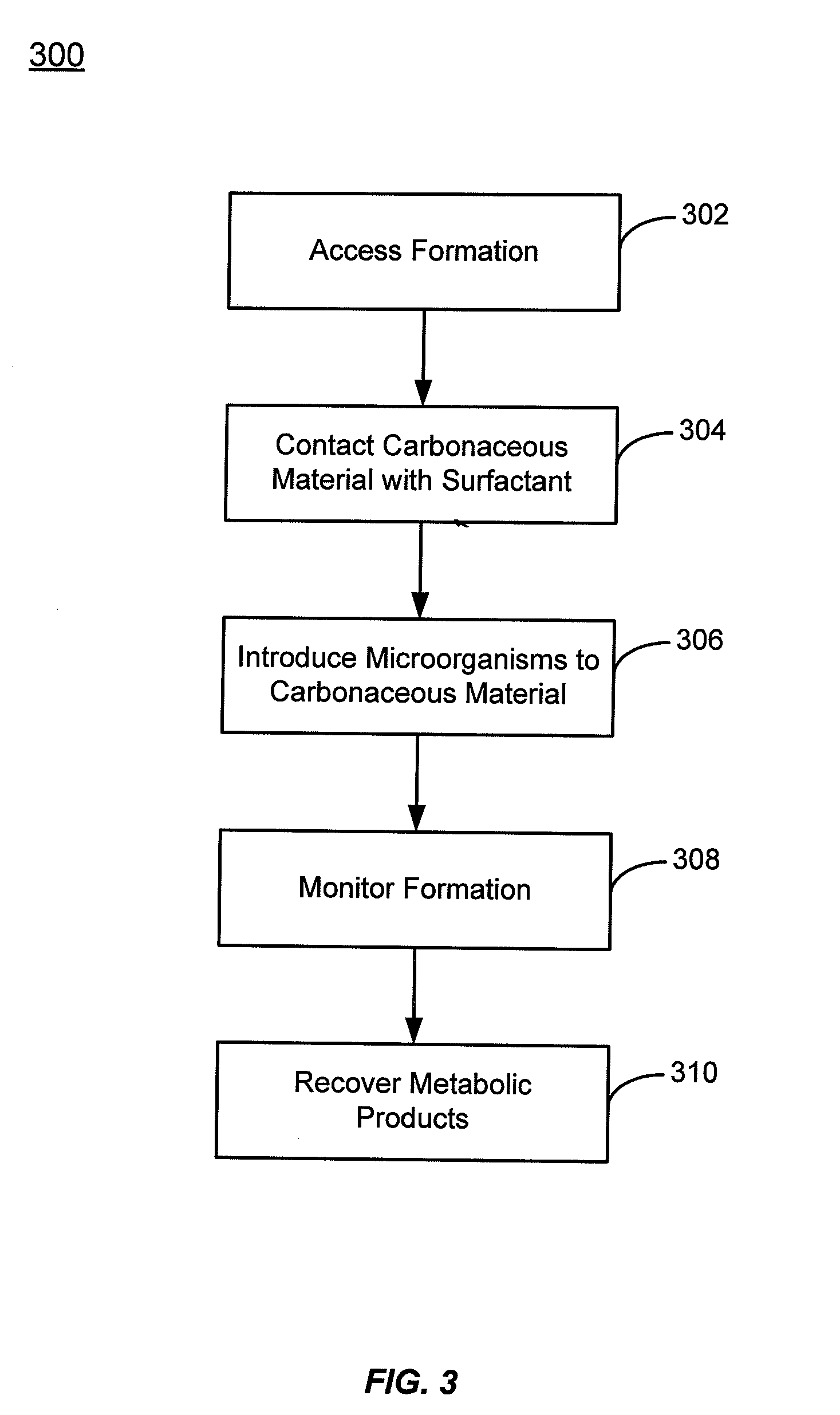

Surfactant amendments for the stimulation of biogenic gas generation in deposits of carbonaceous materials

InactiveUS20100248321A1Increase biogenic productionImprove accessibilityFluid removalDrilling compositionMicroorganismHydrogen content

Methods of conditioning a carbonaceous material in a subterranean geologic formation for metabolism into a compound with enhanced hydrogen content by a microorganism consortium are described. The methods may include the steps of accessing the subterranean geologic formation through an access point, and contacting the carbonaceous material with a surfactant. The microorganism consortium can utilize the surfactant as a first nutrient source. The surfactant also increases accessibility of the carbonaceous material as a second nutrient source for the microorganism consortium. The microorganism consortium metabolizes the carbonaceous material into the compound with the enhanced hydrogen content.

Owner:TRANSWORLD TECH

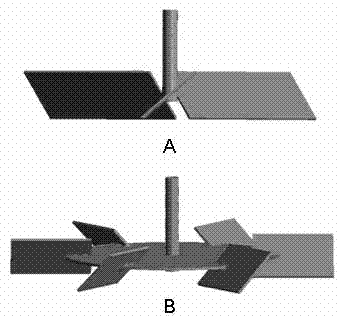

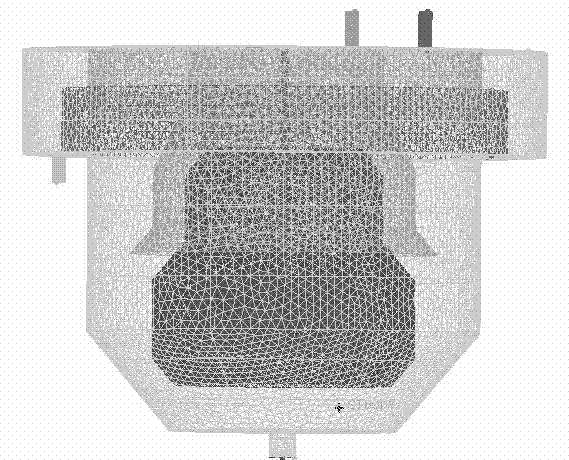

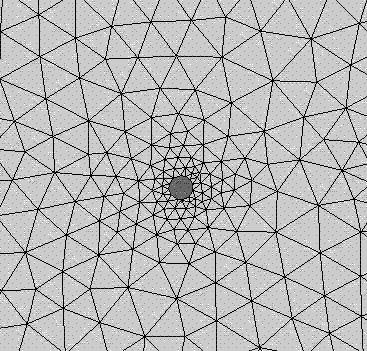

Optimization design method of anaerobic continuous flow agitator bath type biological hydrogen production reactor

InactiveCN102855342ASimple designSolve engineering problemsSpecial data processing applicationsContinuous flowAgitator

The invention belongs to the field of environment protection, and in particular relates to an optimization design method of an anaerobic continuous flow agitator bath type biological hydrogen production reactor. The method comprises the following steps: researching reactor internal flow field characteristics of different types of stirring paddles under the conditions of different paddle-bath diameter ratios and different agitating speeds and influence on hydrogen production process, by using a numerical simulation software based on computational fluid mechanics technology; obtaining detailed flow field information, such as velocity field, turbulence energy and dissipation rate thereof, biogas integration rate and shearing rate distribution by adopting a two-phase flow model, and analyzing and comparing different flow field information obtained through simulation according to influence on hydrogen production process by the various flow field information, thereby determining an optimal stirring paddle style and agitating speed combination, and providing an effective method for the optimization design of the agitator bath reactor. The optimization design method of the anaerobic continuous flow agitator bath biological hydrogen production reactor is mature in technology, avoids the blindness of hydraulic design of the reactor using an empirical or semiempirical association method, and has the advantages of being visual in optimization cycle effect and short in optimization cycle, saving cost, and the like.

Owner:TONGJI UNIV

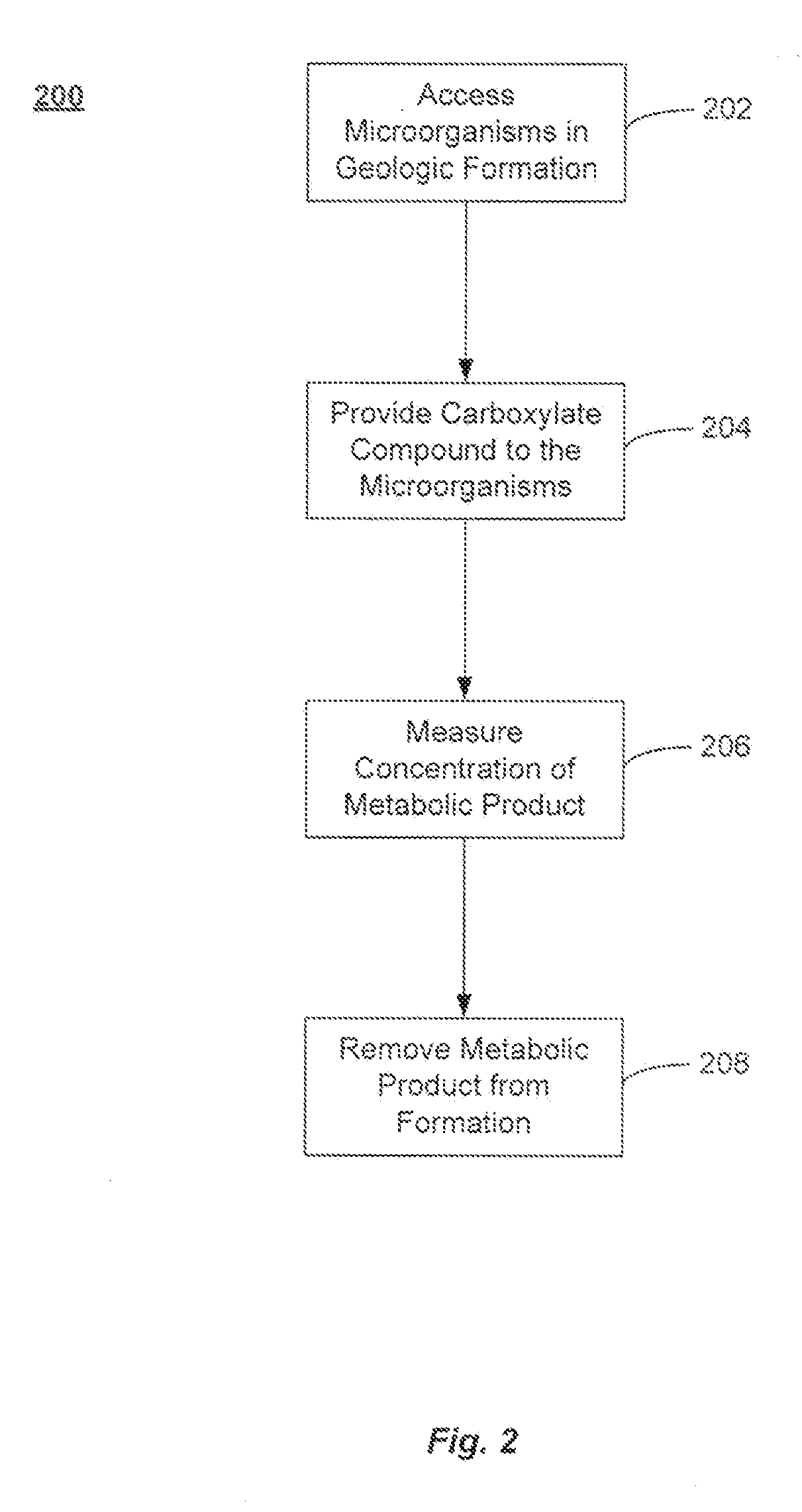

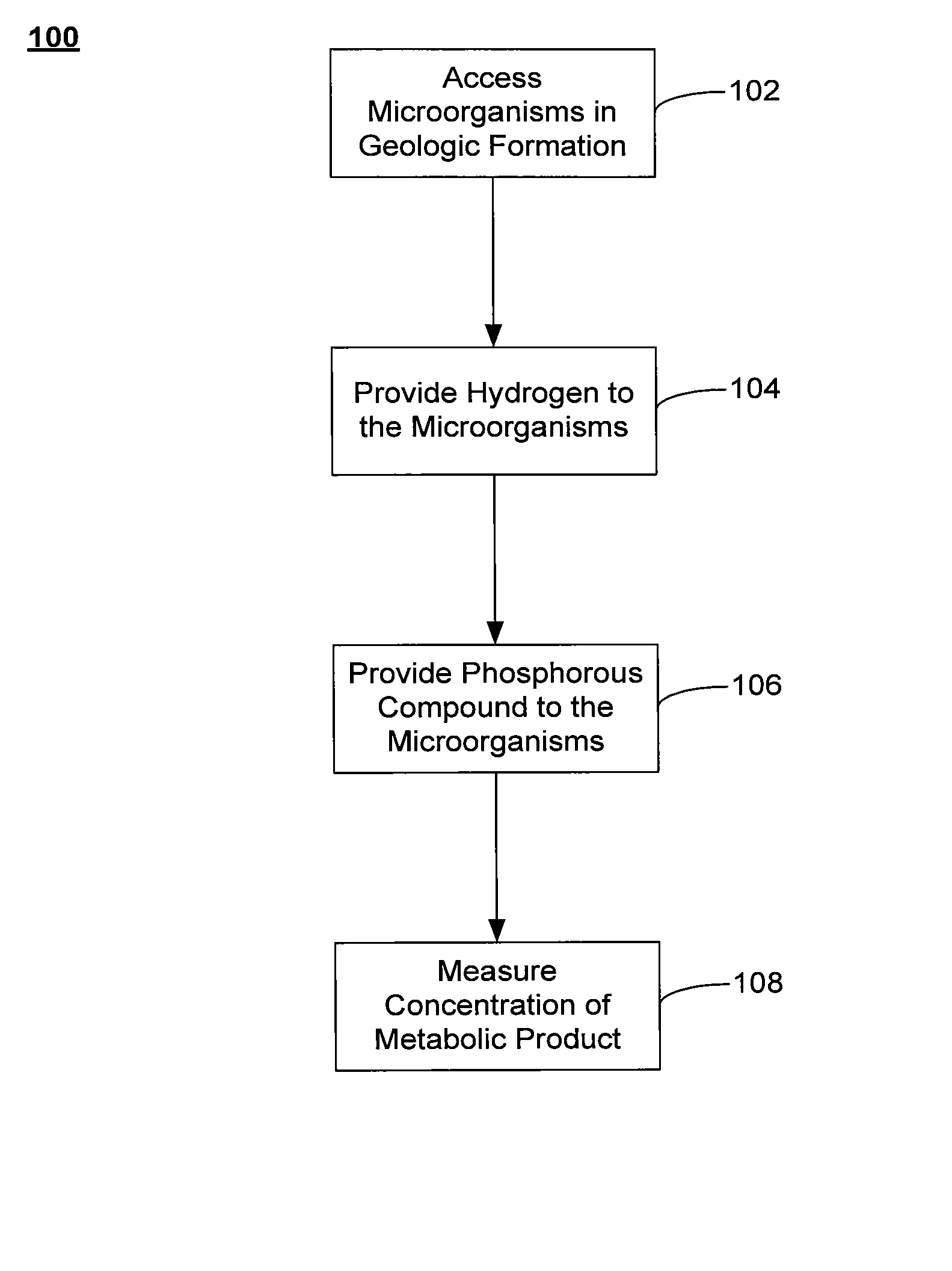

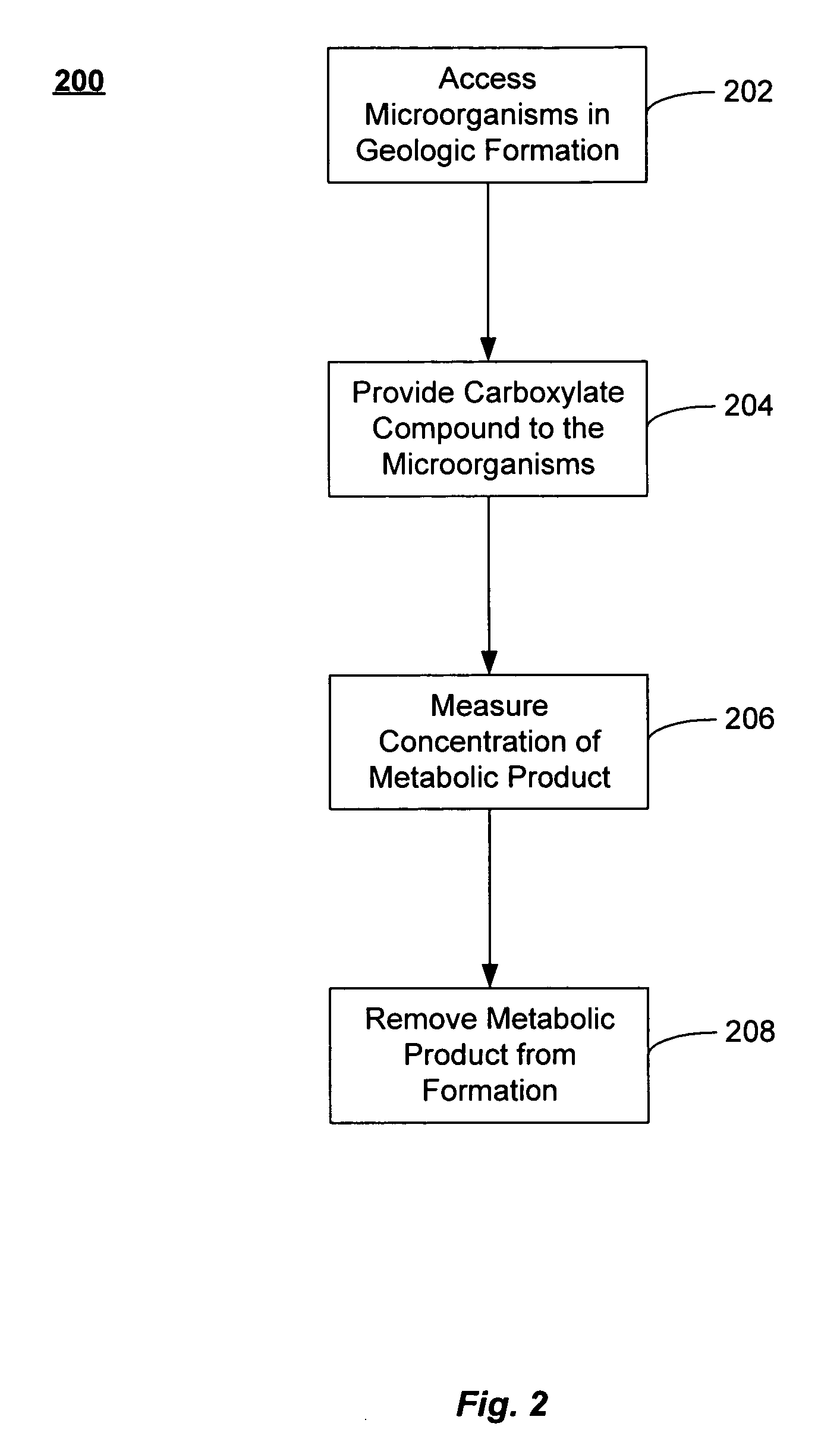

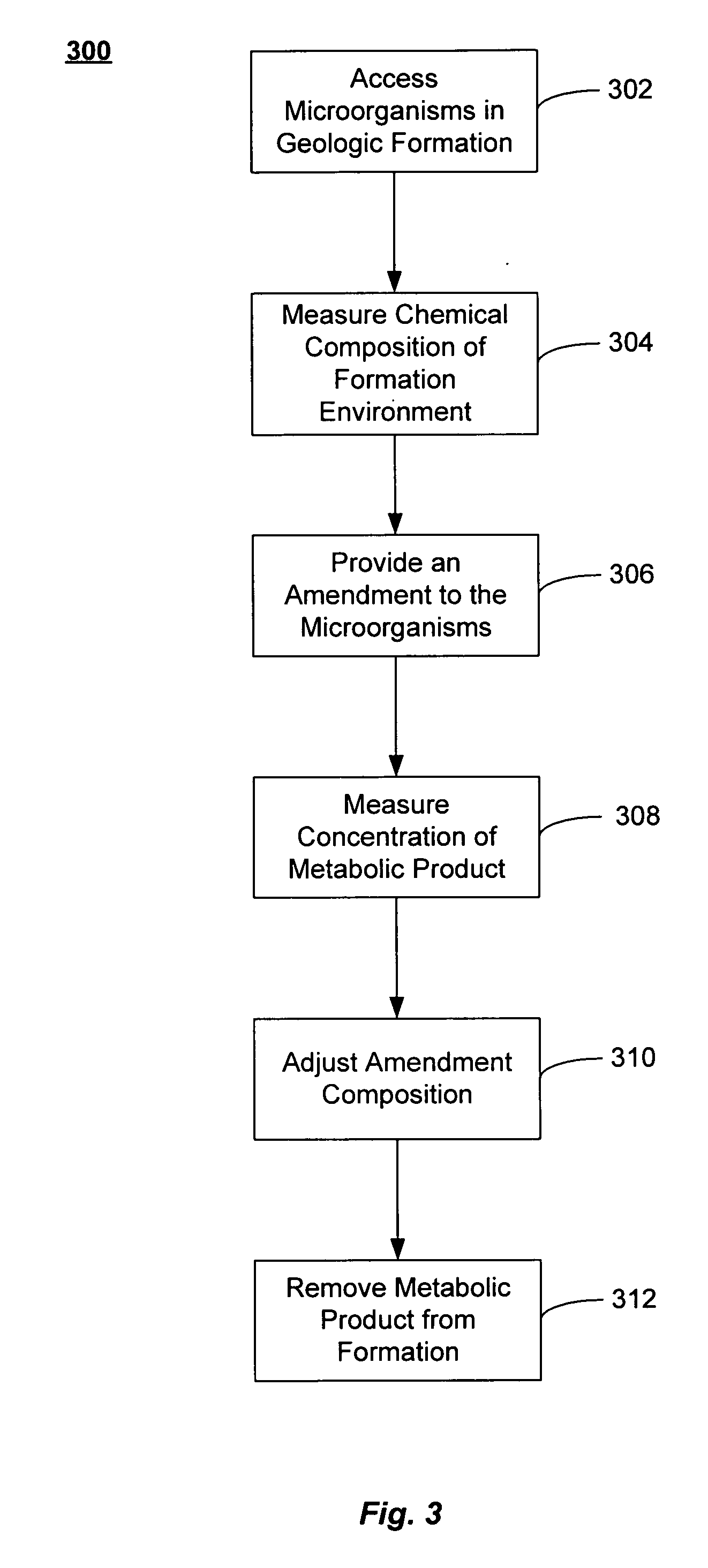

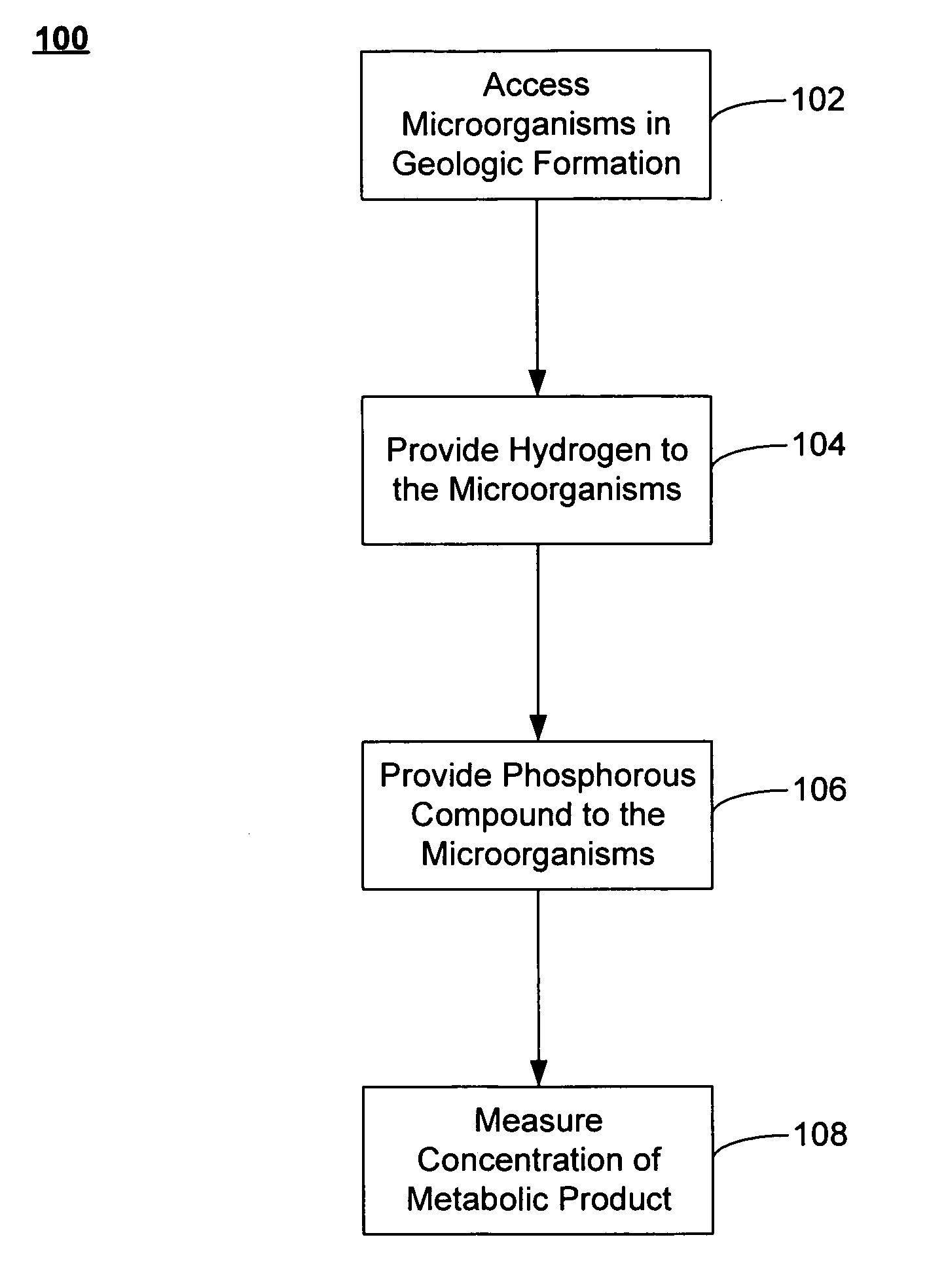

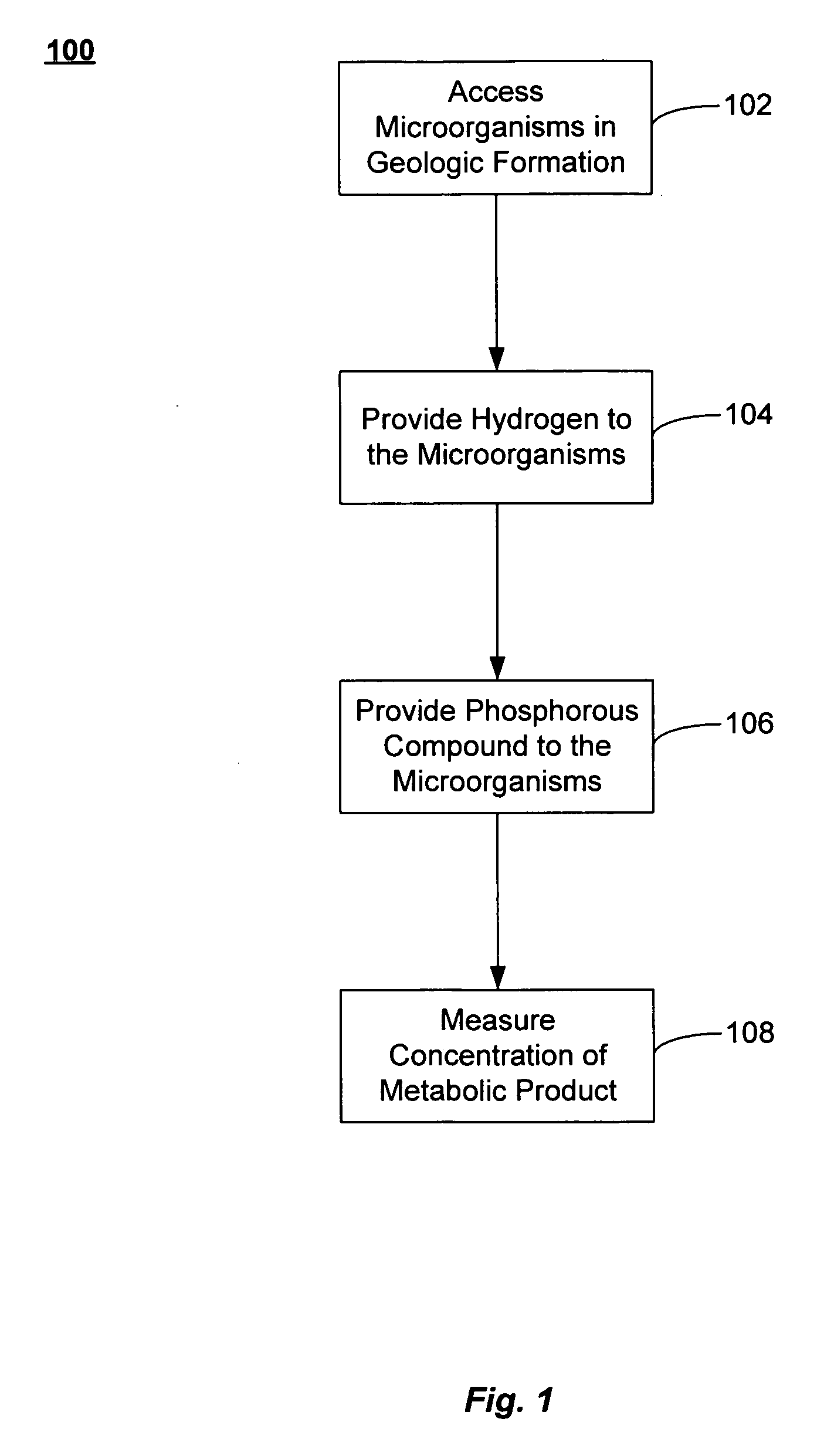

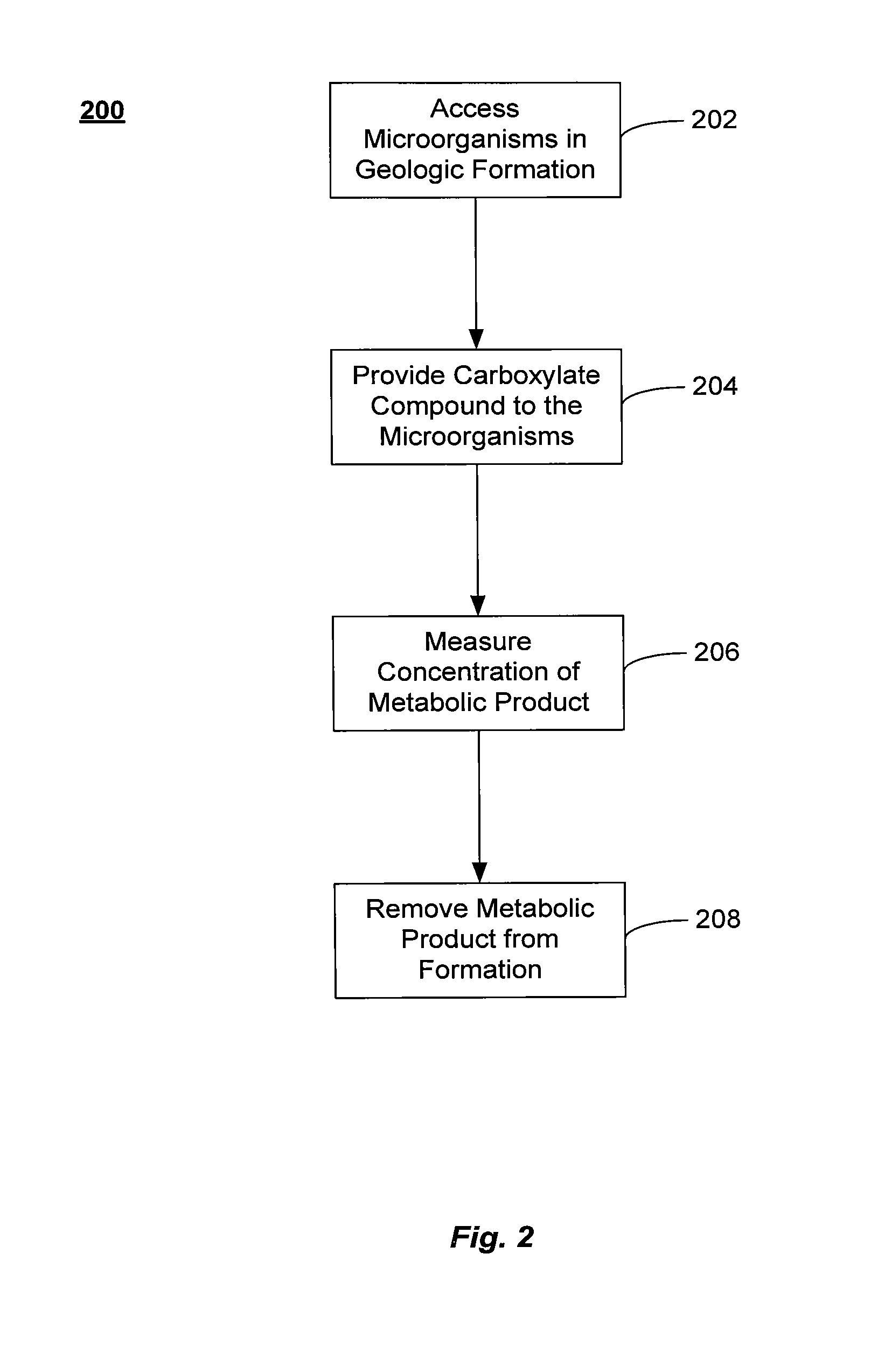

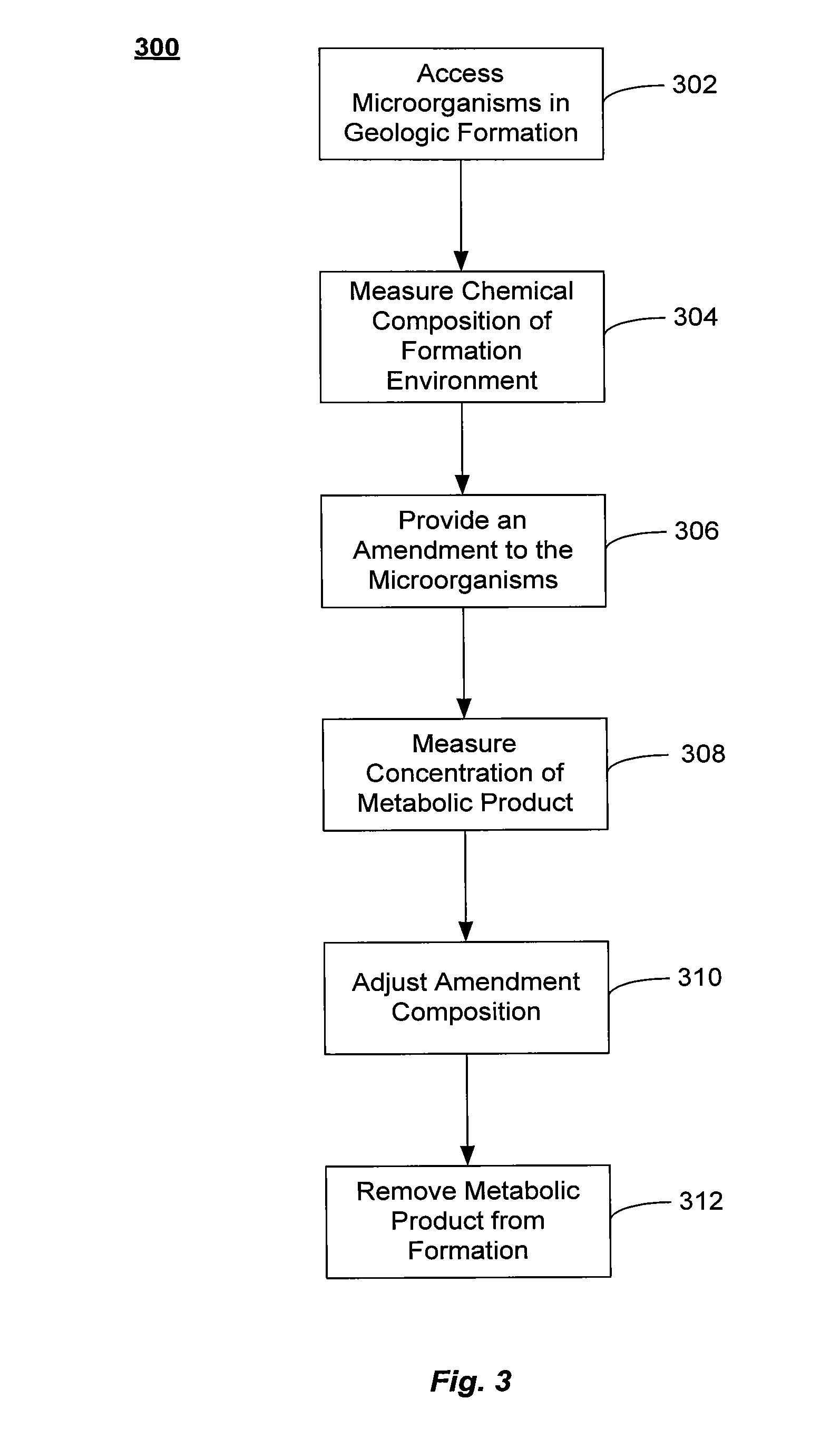

Chemical amendments for the stimulation of biogenic gas generation in deposits of carbonaceous material

Methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content are described. The methods may include accessing a consortium of microorganisms in a geologic formation that includes a carbonaceous material. They may also include providing hydrogen and one or more phosphorous compounds to the microorganisms. The combination of the hydrogen and phosphorous compounds stimulates the consortium to metabolize the carbonaceous material into the metabolic product with enhanced hydrogen content. Also, methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content by providing a carboxylate compound, such as acetate, to a consortium of microorganisms is described. The carboxylate compound stimulates the consortium to metabolize carbonaceous material in the formation into the metabolic product with enhanced hydrogen content.

Owner:TRANSWORLD TECH

Chemical amendments for the stimulation of biogenic gas generation in deposits of carbonaceous material

Methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content are described. The methods may include accessing a consortium of microorganisms in a geologic formation that includes a carbonaceous material. They may also include providing hydrogen and one or more phosphorous compounds to the microorganisms. The combination of the hydrogen and phosphorous compounds stimulates the consortium to metabolize the carbonaceous material into the metabolic product with enhanced hydrogen content. Also, methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content by providing a carboxylate compound, such as acetate, to a consortium of microorganisms is described. The carboxylate compound stimulates the consortium to metabolize carbonaceous material in the formation into the metabolic product with enhanced hydrogen content.

Owner:TRANSWORLD TECH

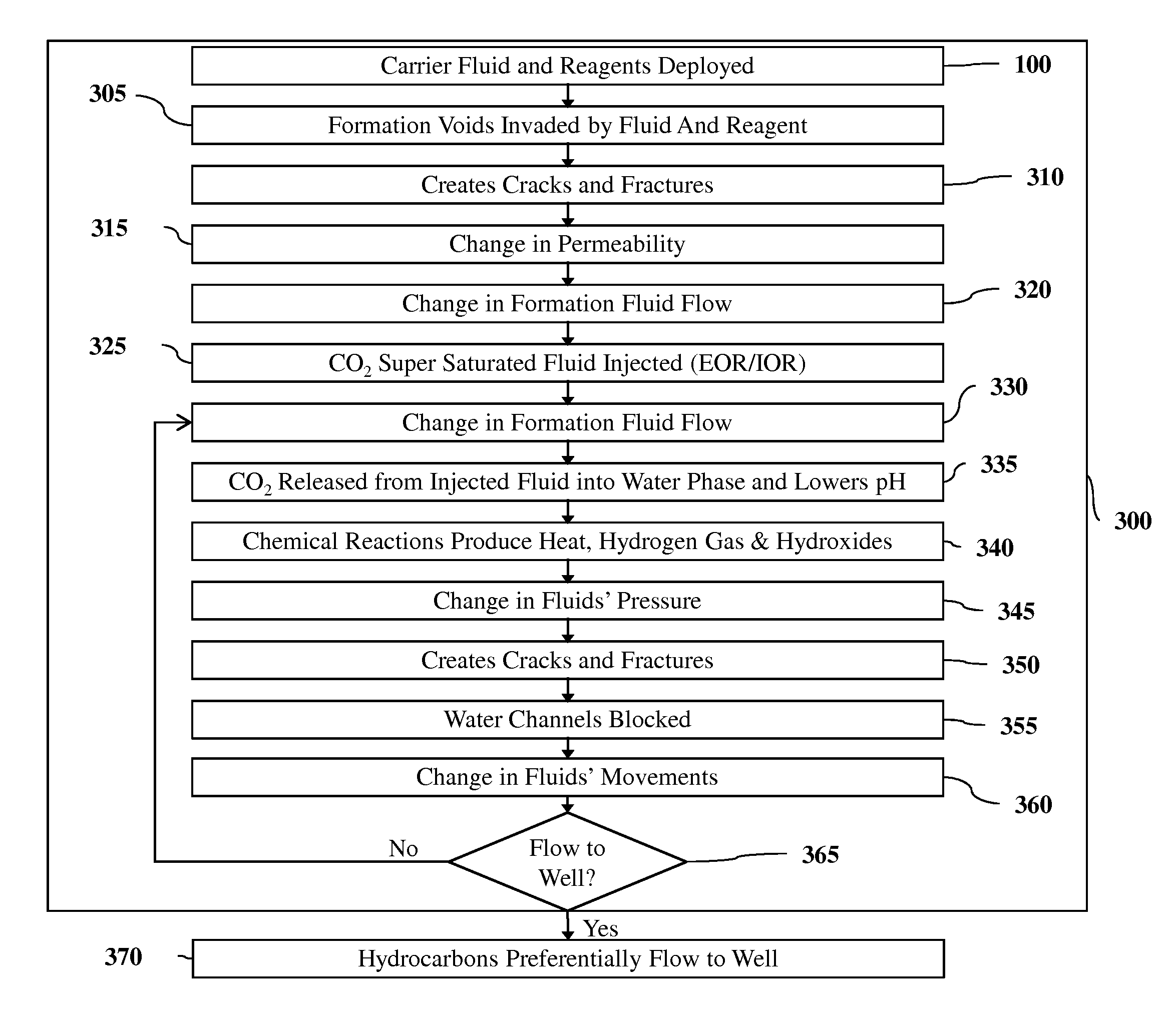

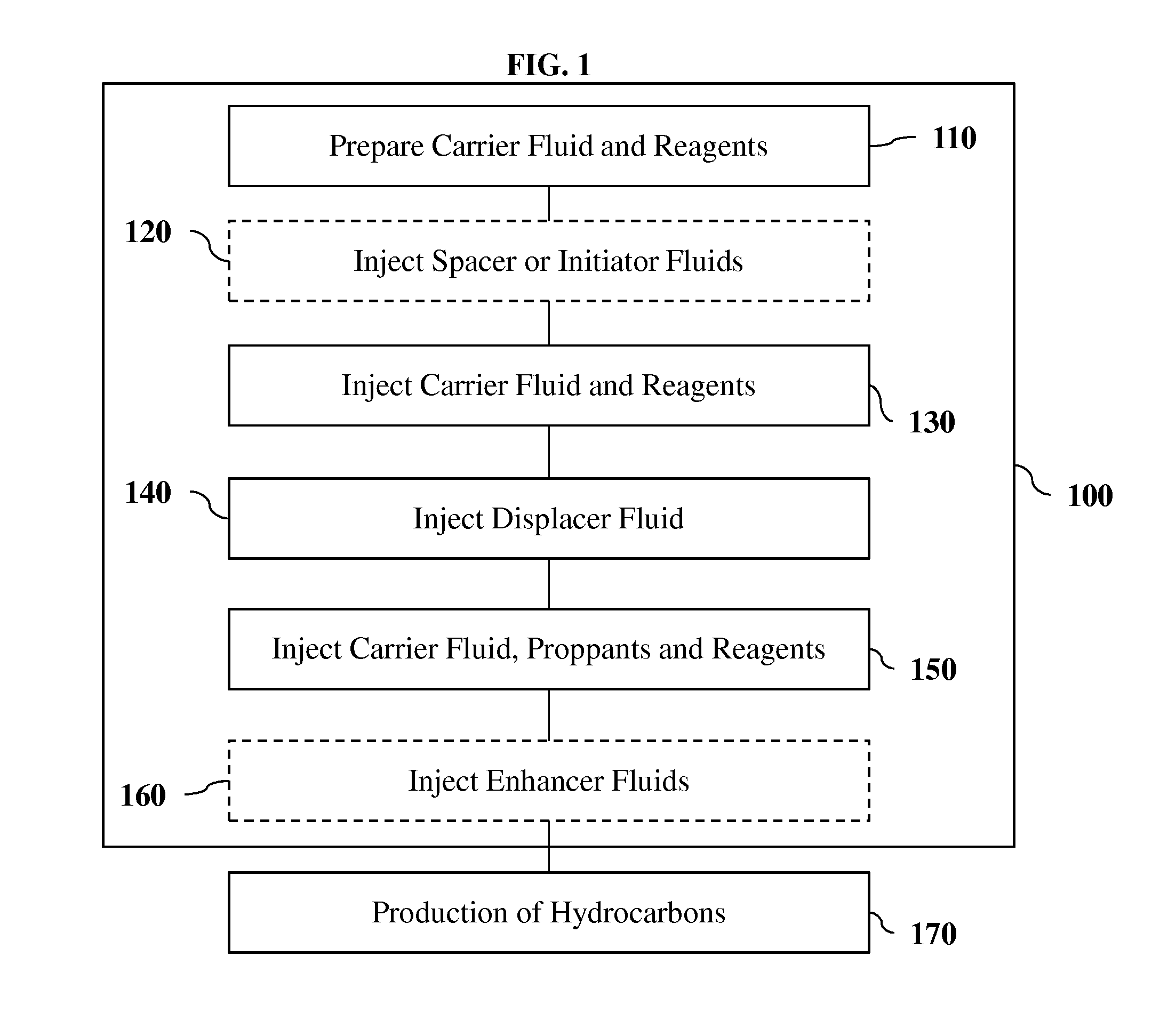

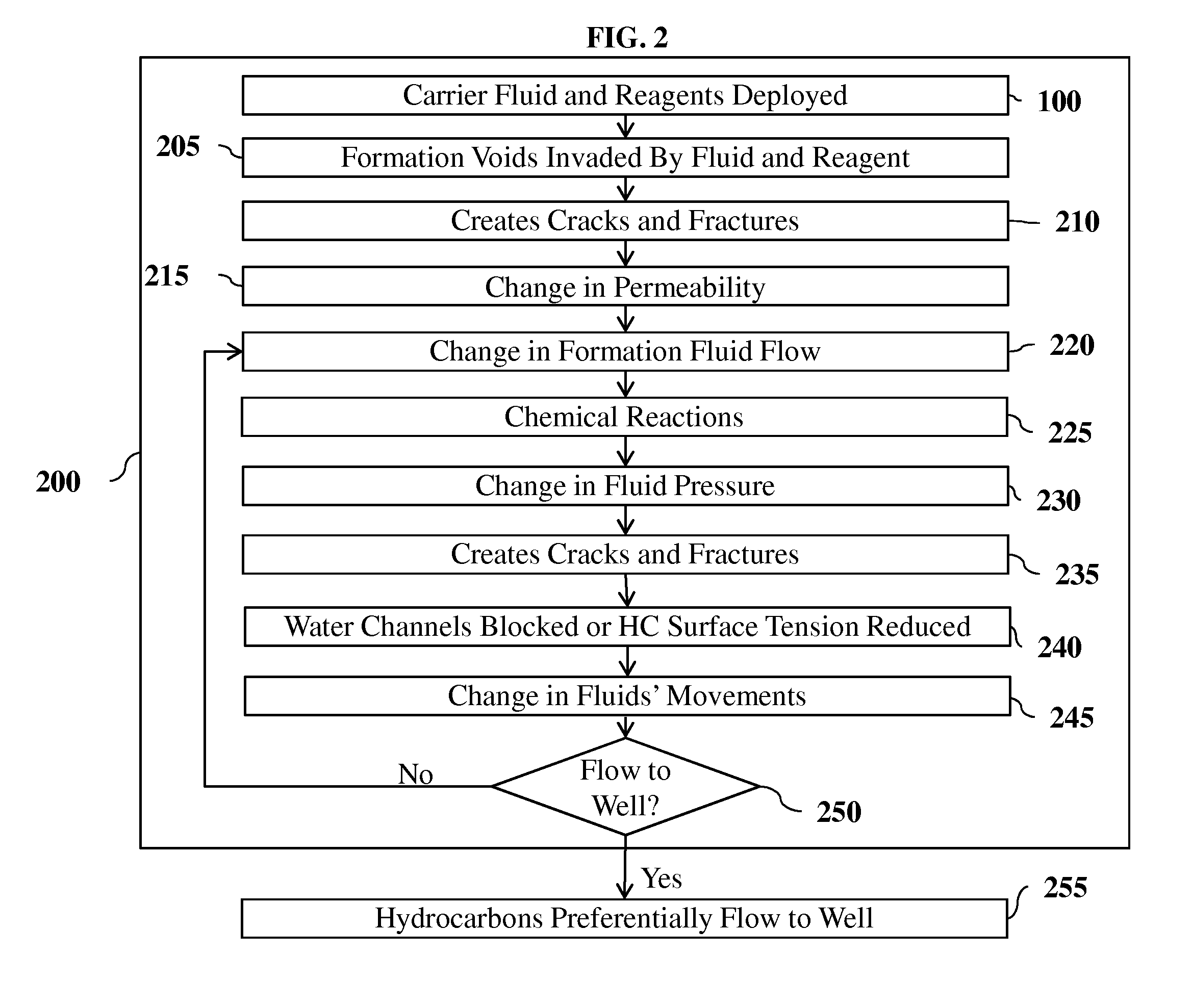

Increased Resource Recovery by Inorganic and Organic Reactions and Subsequent Physical Actions that Modify Properties of the Subterranean Formation which Reduces Produced Water Waste and Increases Resource Utilization via Stimulation of Biogenic Methane Generation

ActiveUS20130068462A1Facilitates micro accumulationPromote accumulationFluid removalDrilling compositionAlkalinityHydrogen

Methods of resource recovery include reagents placed in a subterranean formation. The reagents generate heat, hydrogen gas and alkalinity which changes fluid flow characteristics. The forces of the reactions create fractures and cracks far from the well bore. These cracks and fractures are sealed if water is being transmitted through or near the reactions. As a result, the targeted fluids more efficiently flow to the well, along with decreased amounts of water waste, while stimulating generation of biogenic gases in the subterranean formations.

Owner:PANTANO JOHN

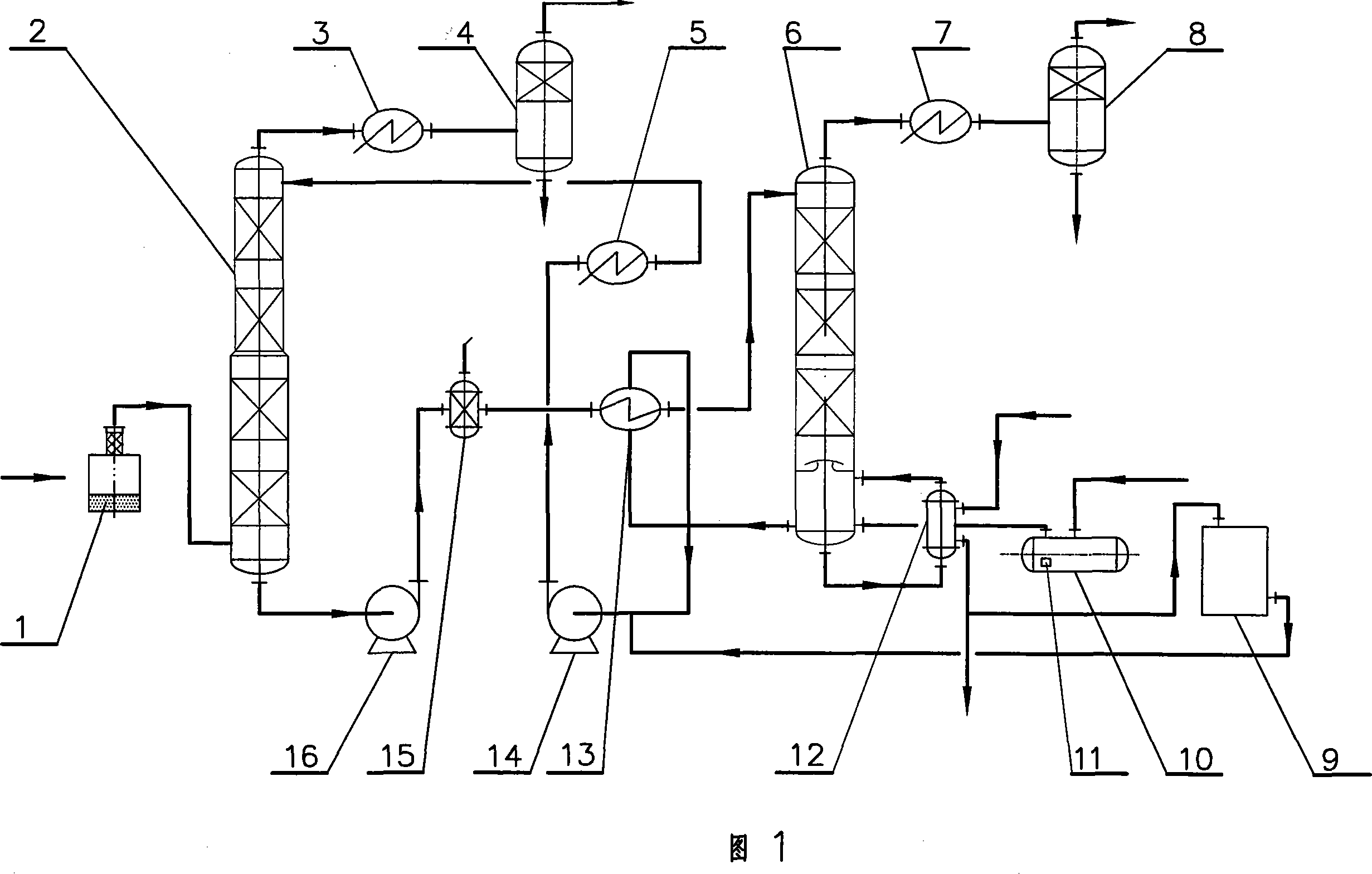

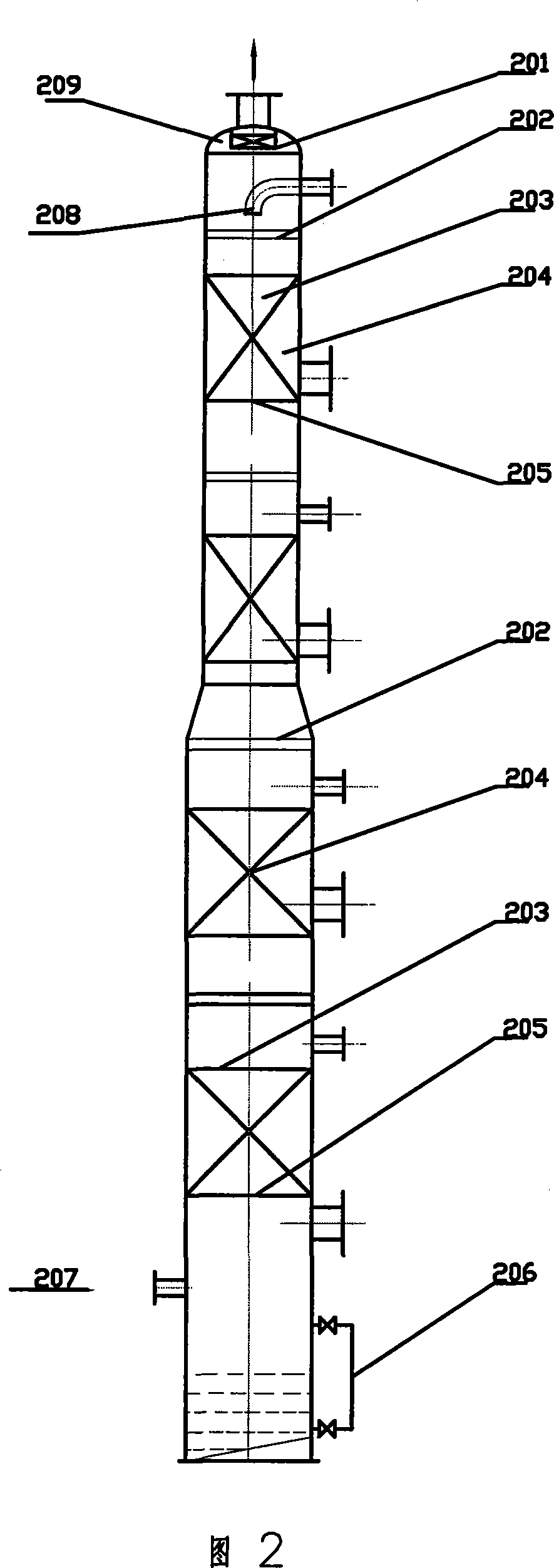

Biogas cleaning equipment and purifying technique thereof

InactiveCN101108988AHave environmental benefitsGood environmental benefitsGaseous fuelsWaste based fuelFiberReboiler

The invention relates to the biogenetic gas purification field, in particular to a biogenetic gas purifying equipment and a purifying technique. The equipment comprises an absorption tower, a desorption tower, a reboiler, a heat exchanger, a cooler, a separator, an absorbent holding tank and a pump. The invention is characterized in that: firstly, the absorption tower is a different diameter tower featuring with small upper section and large lower section and the upper-and-lower tower diameter ratio ranges between 0.75 and 0.85; secondly, a catcher with metal mesh is added inside the former material gas inlet of the adsorbption tower; thirdly, a fiber rod filter is arranged at the outlet of the rich solution outlet of the absoption tower. The technique adopts the water solution as the absorption solution with MEDA main solute and multi-amine activator, and the operation parameters are 30 kPa to 40 kPa operation pressure inside the tower ranges, 45 DEG C. to 55 DEG C. temperature at the tower top of the tower and 50 DEG C. to 60 DEG C. at the bottom, 25 to 35 (m3G / m3L) gas-liquid ratio, 2.56 to 4.28Kmol per m3 absorption solution concentration, and 1 to 2.5LCO2 per L lean solution concentration. The invention is used to remove the impurities of CO2, H2S, HCN and the organic sulfur from the biogenetic gas, coal bed gas and coke-oven gas to meet the purification requirement.

Owner:LIAONING KAITIAN RENEWABLE ENERGY & ENVIROMENT

Self-regulating bio-gas treatment system

A self-regenerating bio-gas treatment system that uses the bio-gas instead of atmospheric are as media transport between adsorber and desorber tanks. Each tank includes at least four horizontally stacked and evenly spaced apart, perforated trays each capable being filled with fluidized carbon which migrates downward in the adsorber tank to remove contaminants from the bio-gas. With the bio-gas function as its media transport, the carbon media continuously moves downward over the perforated trays and eventually collected in the bottom of the adsorber tank. The spent carbon is then delivered to the desorber tank. The desorber tank is filled with an inert gas produced by an inert gas generator which causes the carbon media to be regenerated. The inert gas strips the carbon media of contaminates and is then delivered to a ground flare. The carbon media is returned to the adsorber tank and re-used to treat bio-gas. A plurality of heat exchangers, blowers, valves and interconnecting conduits keep the bio-gas, the inert gas, and the carbon media continuously flowing through the system thereby enabling the system to be used at different sizes of landfills or treatment plants.

Owner:SNAP ENERGY SYST

Novel spouted circulating fluid bed timber rapid pyrolysis apparatus and technological process

InactiveCN101486918AOutstanding advantagesHighlight positive effectsBiofuelsSpecial form destructive distillationAutomatic controlReaction temperature

The invention discloses a novel spouted circulating fluidized bed timber quick pyrogenation device and a process method. The device comprises a spouted fluidized bed reactor, a fluidizing agent circulatory system, a monitoring system, a heating system, a feeding system, a gas-solid separation system, a charcoal collecting system, a condensation system, a fluidizing agent dehumidification system, a pressure stabilizing system, an incondensable gas collecting system and other parts. The process method includes process procedures such as putting the pre-processed materials in the feeding system, controlling the reaction temperature, the flow and other process parameters of the device and collecting the products such as bio-oil, charcoal and biogas, etc,. The timber quick pyrogenation device has the advantages of simple and compact structure, stable operation, large material application scope and easy automatic control; and the process method thereof has the advantages of simple operation, low operation cost, high production efficiency and good product quality.

Owner:北京海润川投资咨询有限公司

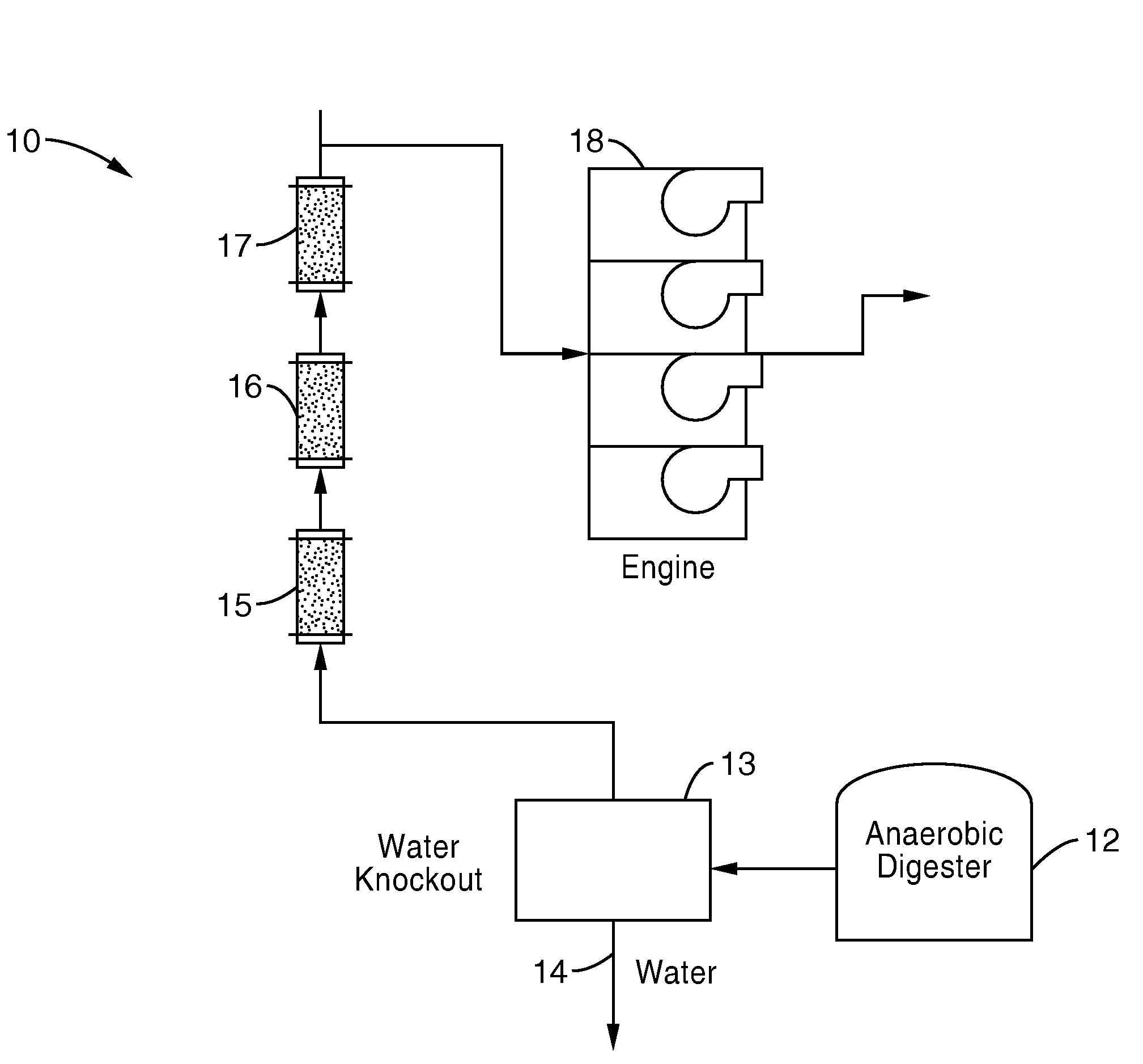

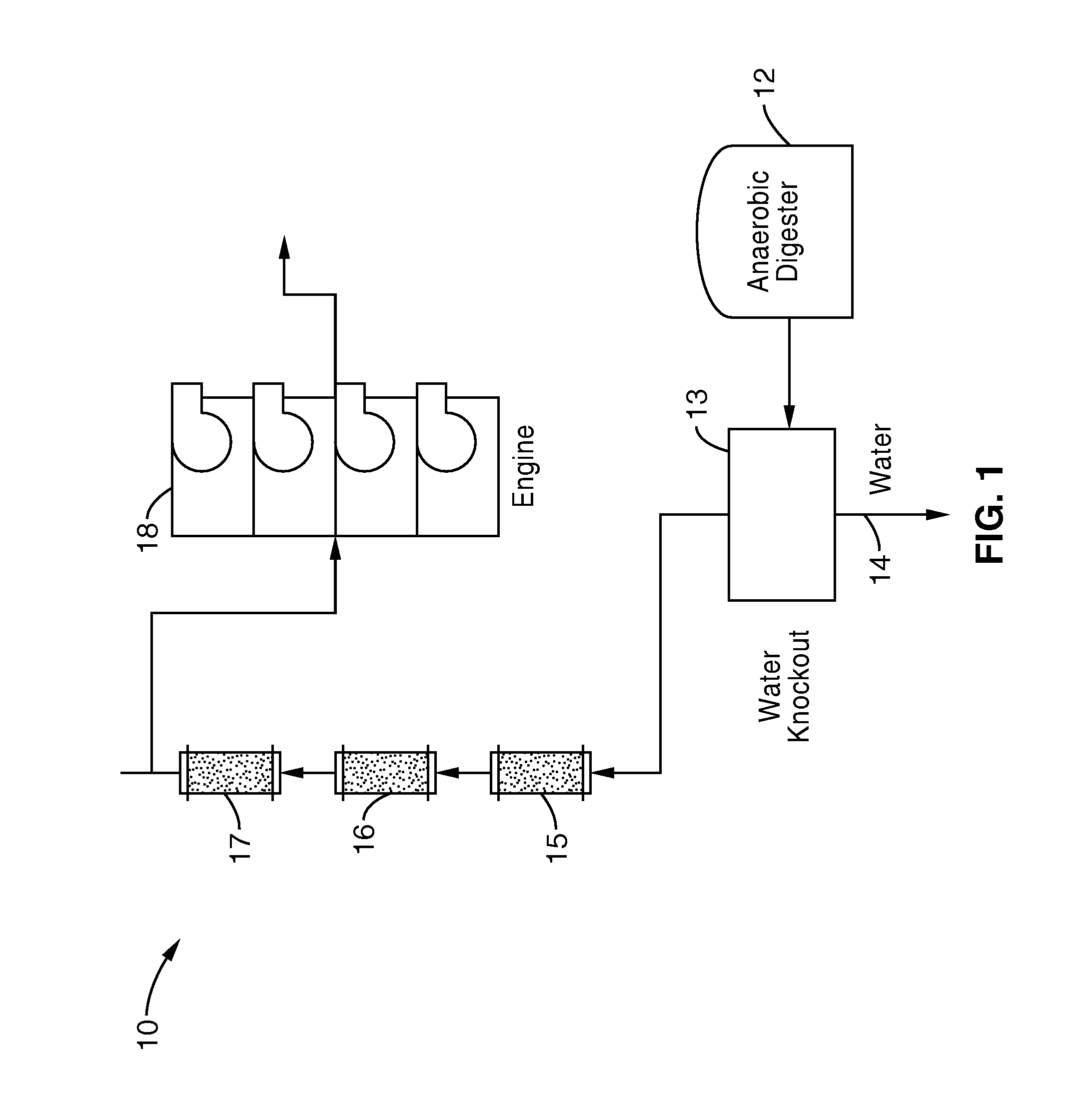

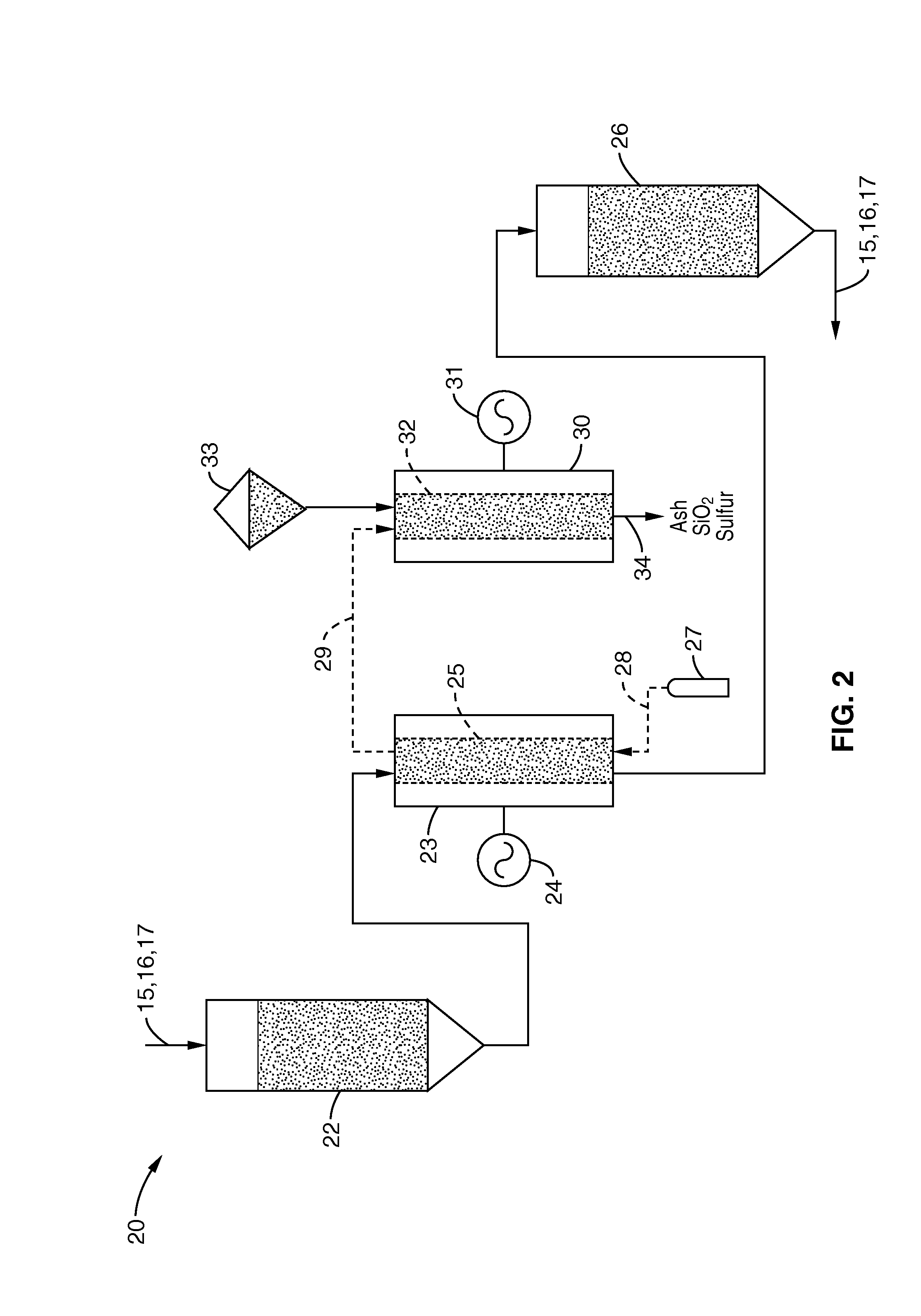

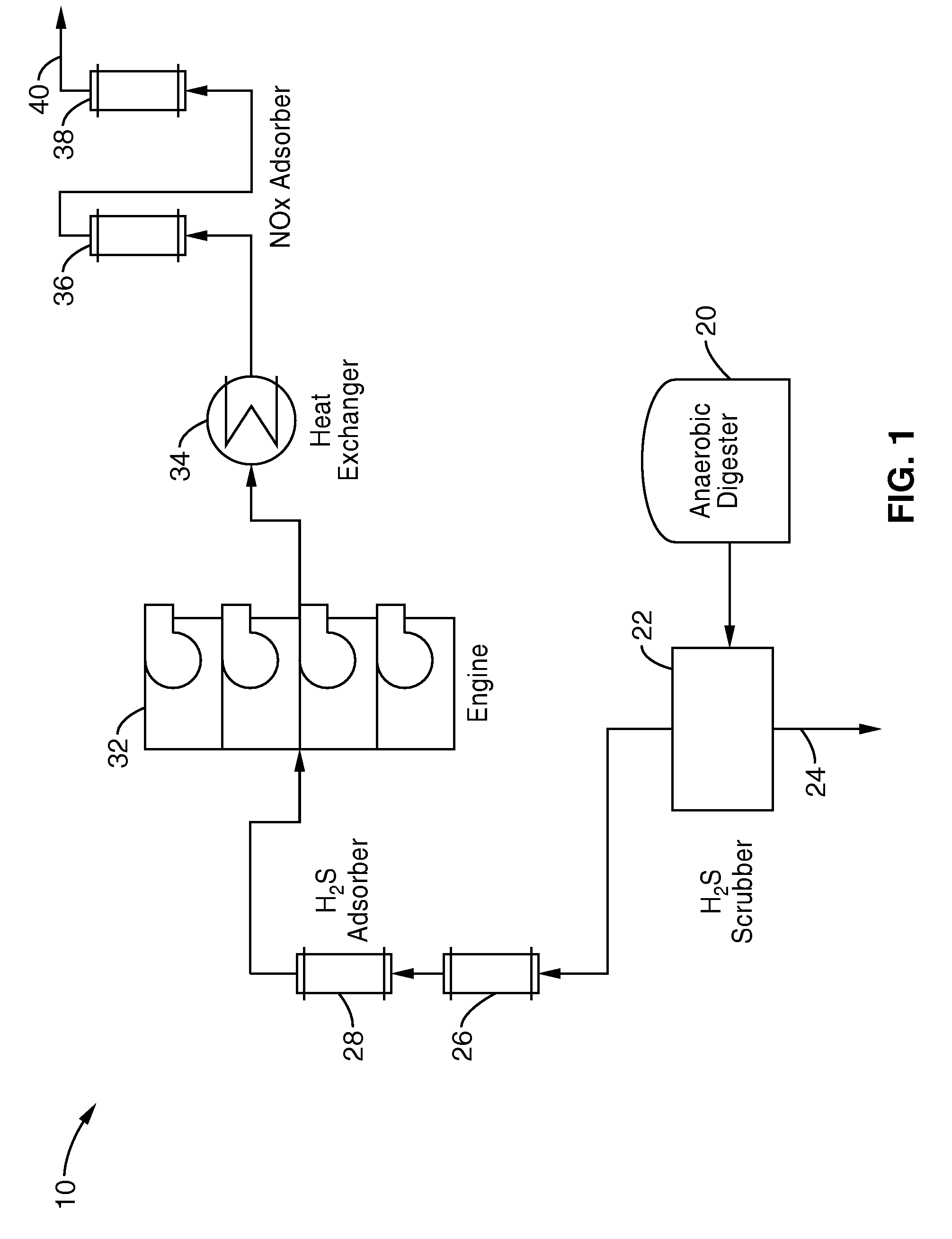

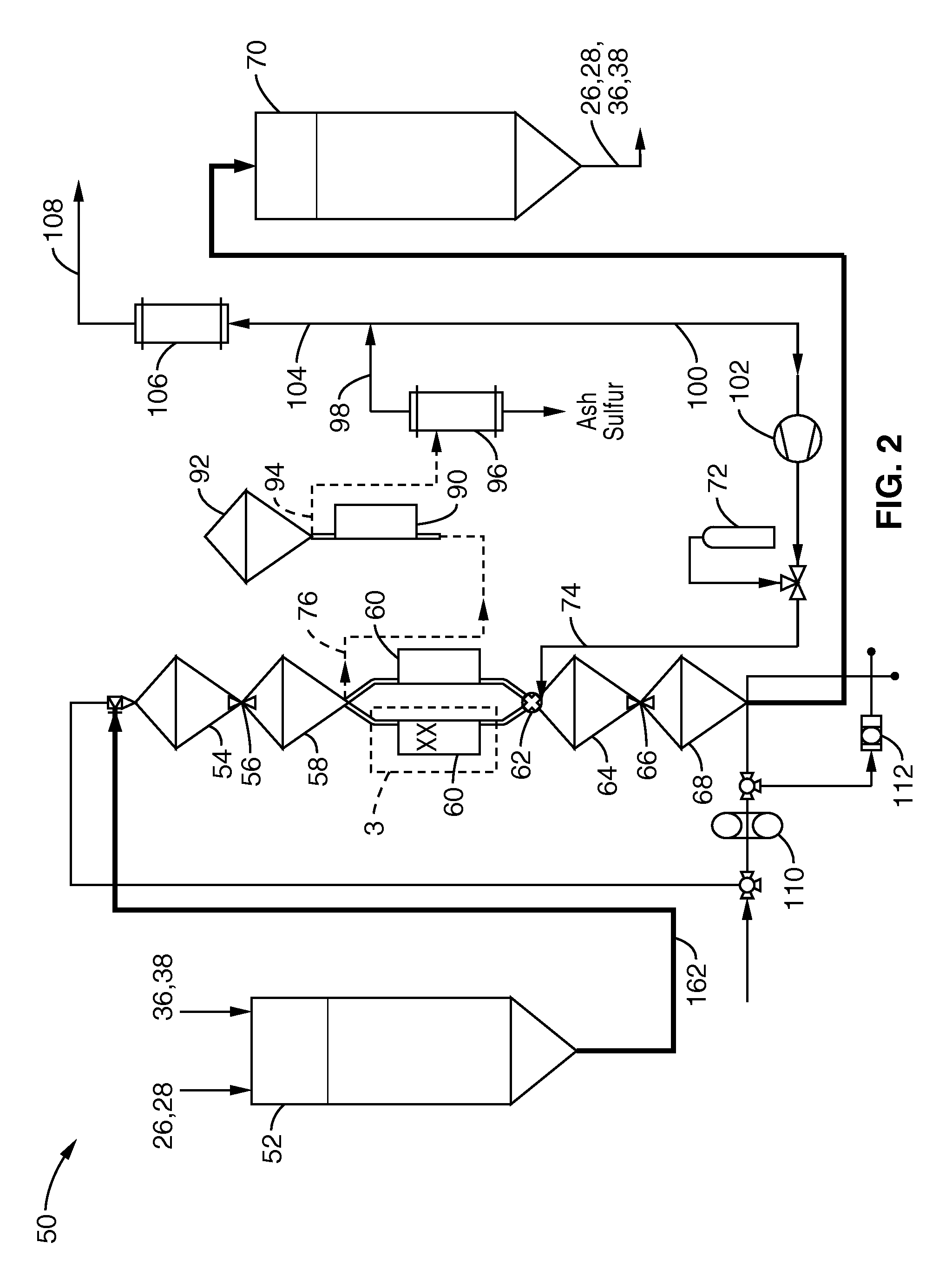

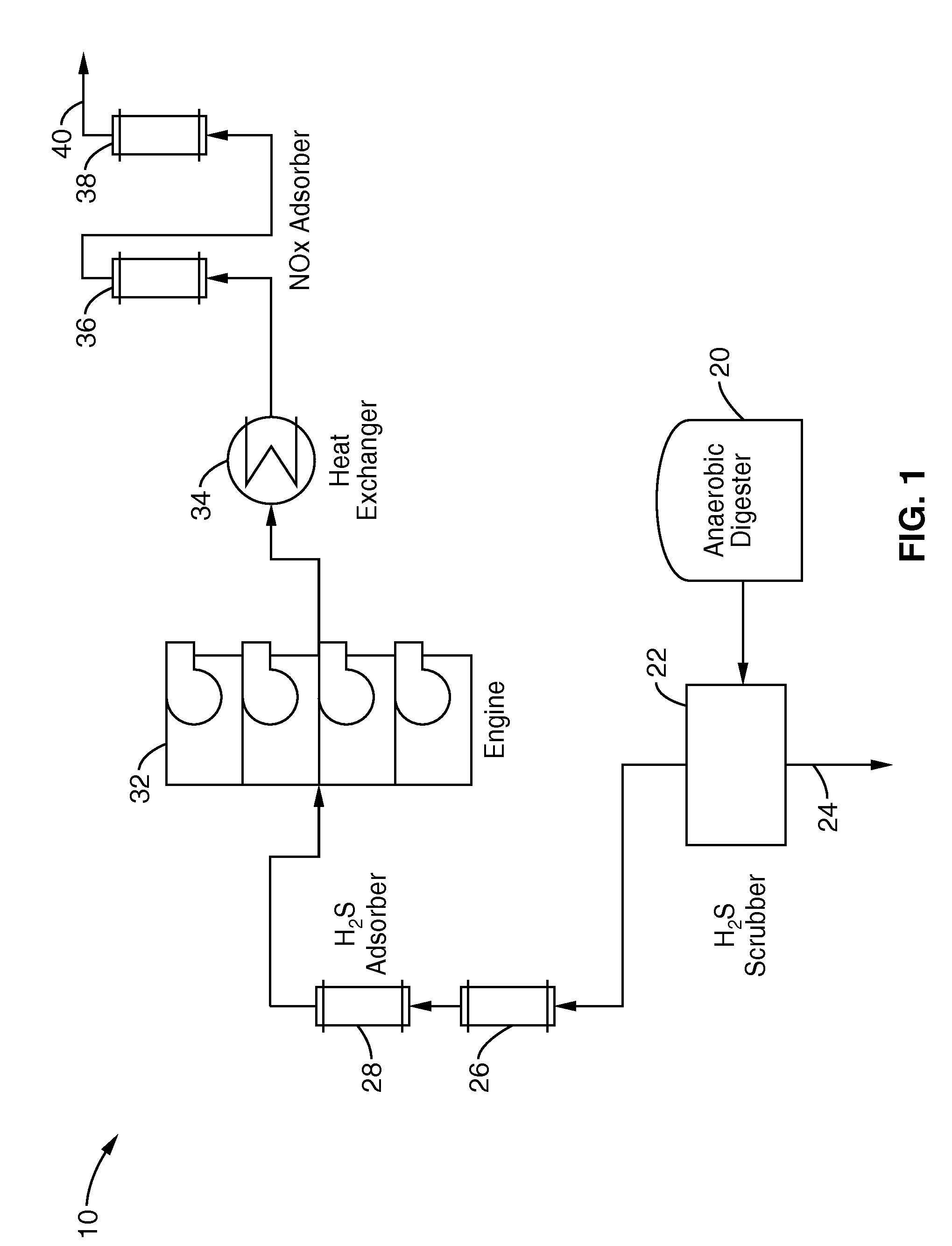

Microwave induced destruction of impurities from biogas and nitrogen oxides from engine exhaust

Granulated Activated Carbon (GAC) is used to remove hydrogen sulfide (H2S) from the biogas produced in an anaerobic digester. The cleaned biogas is then combusted in a reciprocating engine. The exhaust of the engine is passed through a heat exchanger and then through GAC in an adsorber to adsorb nitrogen oxides (NOx) and any sulfur oxides (SOx). The GACs containing NOx, H2S, and SOx, are transported to a microwave reactor, mixed, and exposed to microwave energy. The H2S and NOx are desorbed from the GAC and chemically combined to produce nitrogen, carbon dioxide, sulfur and water. Unreacted nitrogen oxides or hydrogen sulfide are transported to a second reactor containing carbon media to be reacted by a further microwave process. Sulfur is removed with a filter as a solid and the remaining inert components are vented to the atmosphere. The GAC is regenerated and reused to remove additional H2S and NOx.

Owner:C MICRO SYST +1

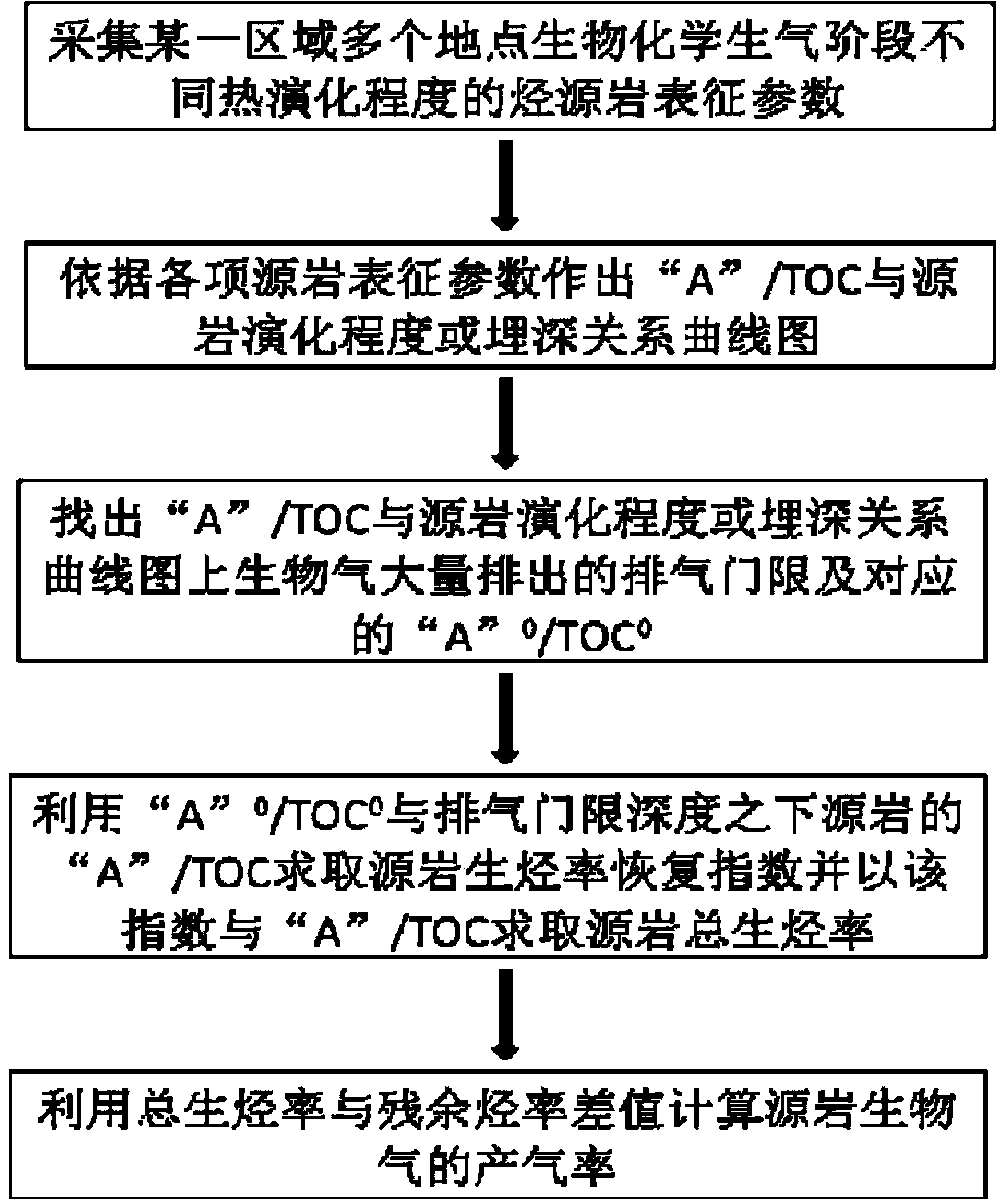

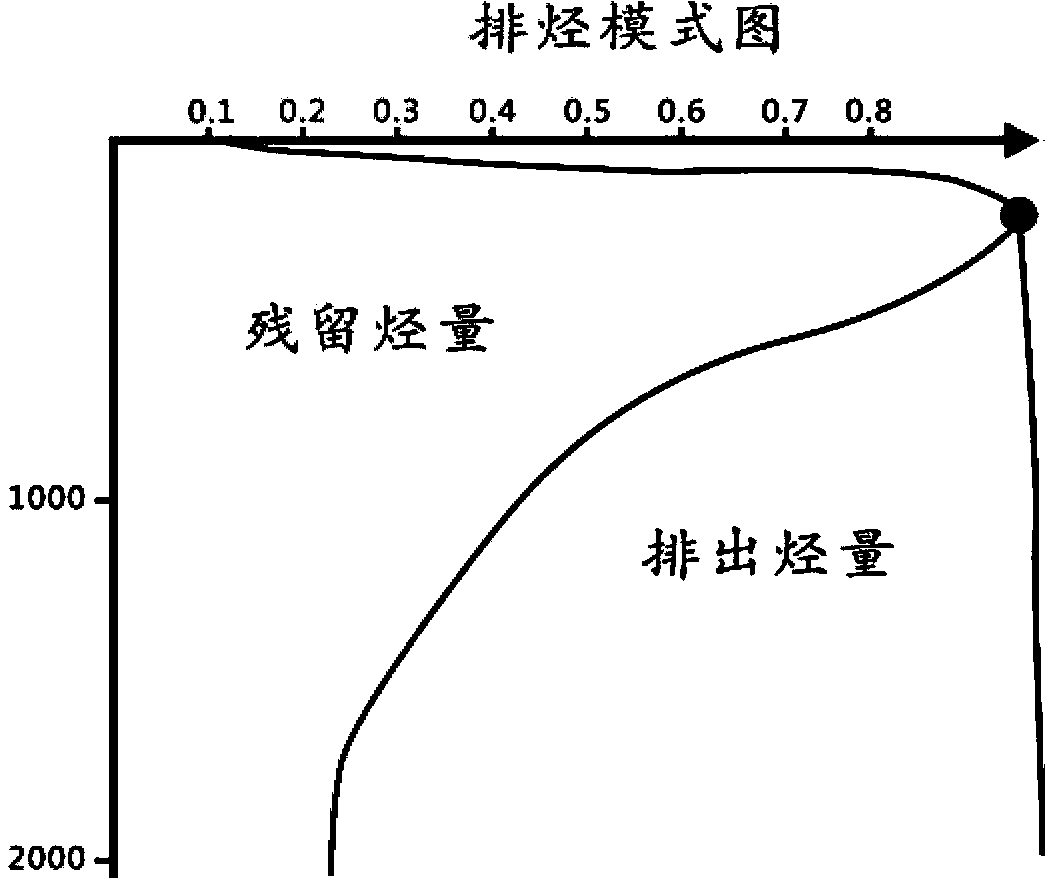

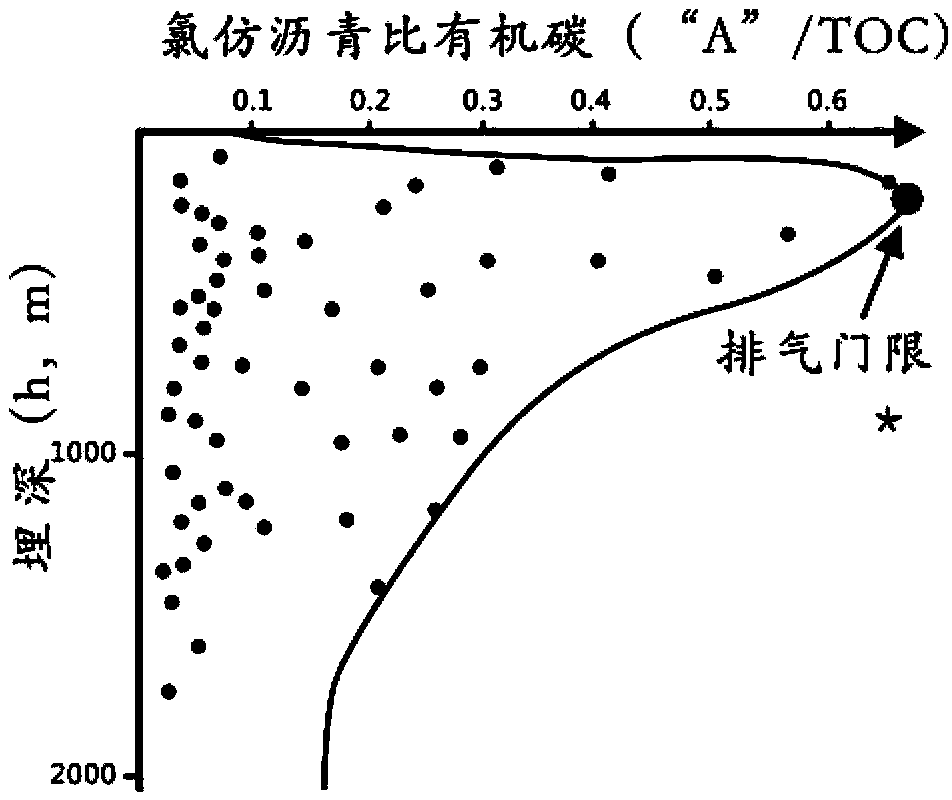

Method for determining gas production rate of organic matrix in biochemical gas production stage

ActiveCN103852569AGas production rate is convenientThe gas production rate is easily obtainedFuel testingProduction rateGeneration rate

The invention provides a method for determining a gas production rate of an organic matrix in a biochemical gas production stage, and belongs to the technical field of oil and gas resource evaluation. The method comprises the following specific steps: collecting four characterization parameters of a source rock in the biochemical gas production stage of one area, namely residual hydrocarbon amount of chloroform bitumen "A", vitrinite reflectance Ro reflecting the thermal evolution degree of the source rock, organic carbon content TOC and burial depth h; establishing a graph of relation of "A" / TOC and Ro or h according to the characterization parameters of the source rock; determining the exhaust threshold of a biogenic gas according to the graph, wherein the value at the threshold is "A"<0> / TOC<0>; calculating the restoration index of the hydrocarbon generation rate of the source rock according to "A" / TOC and "A"<0> / TOC<0> under different Ro or h conditions, and calculating the total hydrocarbon generation rate of the source rock under a variety of maturity conditions through the index and the "A"<0> / TOC<0>; calculating the gas production rate of the biogenic gas of the source rock according to the difference value of the total hydrocarbon generation rate and the residual hydrocarbon rate. By adopting the method, the problems of the original methods of calculating gas production rate, such as simulation experiment and the like are solved, and important technical support is provided for biogenic gas resource evaluation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Microwave induced destruction of impurities from biogas and nitrogen oxides from engine exhaust

Granulated Activated Carbon (GAC) is used to remove hydrogen sulfide (H2S) from the biogas produced in an anaerobic digester. The cleaned biogas is then combusted in a reciprocating engine. The exhaust of the engine is passed through a heat exchanger and then through GAC in an adsorber to adsorb nitrogen oxides (NOx) and any sulfur oxides (SOx). The GACs containing NOx, H2S, and SOx, are transported to a microwave reactor, mixed, and exposed to microwave energy. The H2S and NOx are desorbed from the GAC and chemically combined to produce nitrogen, carbon dioxide, sulfur and water. Unreacted nitrogen oxides or hydrogen sulfide are transported to a second reactor containing carbon media to be reacted by a further microwave process. Sulfur is removed with a filter as a solid and the remaining inert components are vented to the atmosphere. The GAC is regenerated and reused to remove additional H2S and NOx.

Owner:C MICRO SYST +1

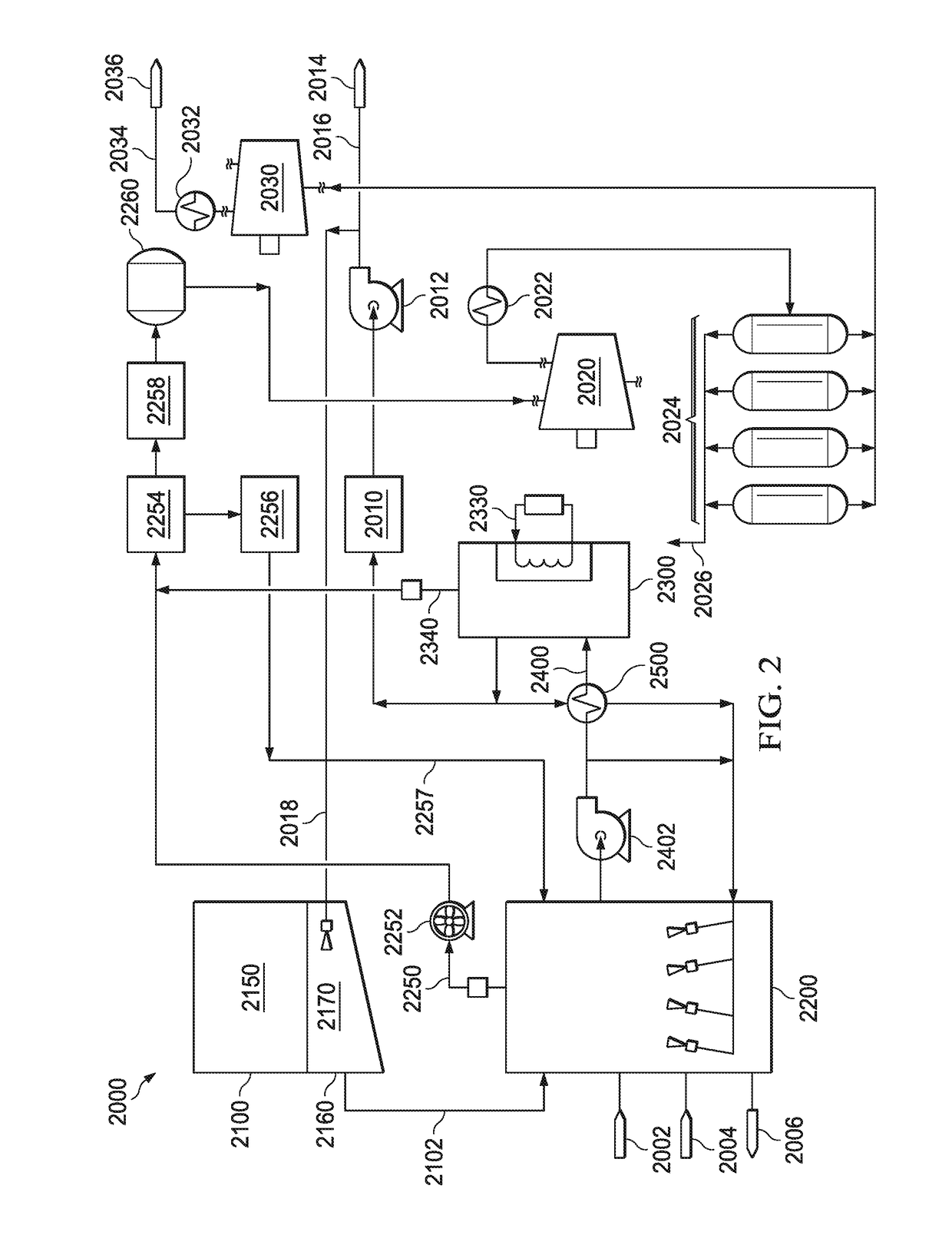

Systems and Methods for Processing Biogas

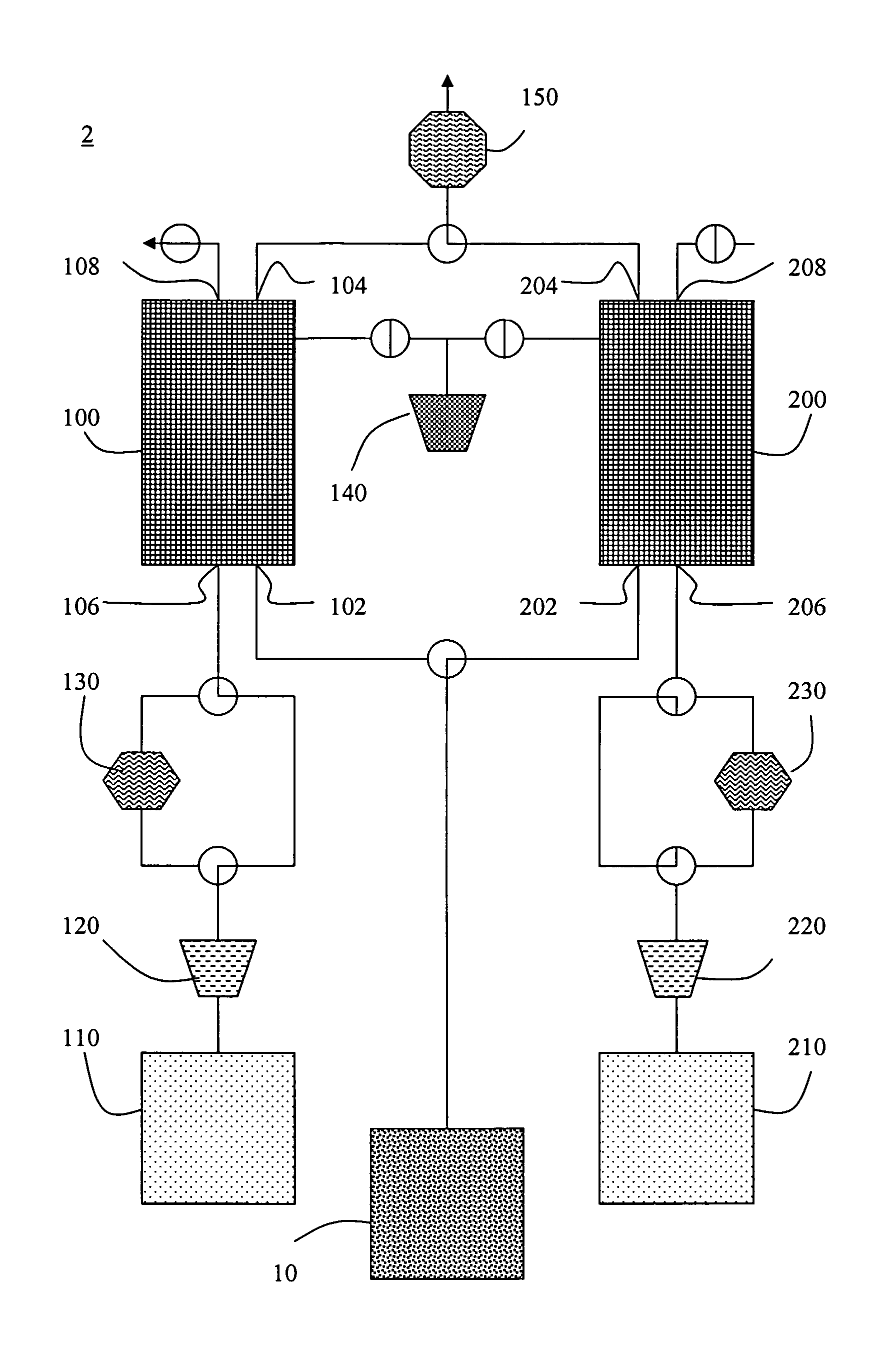

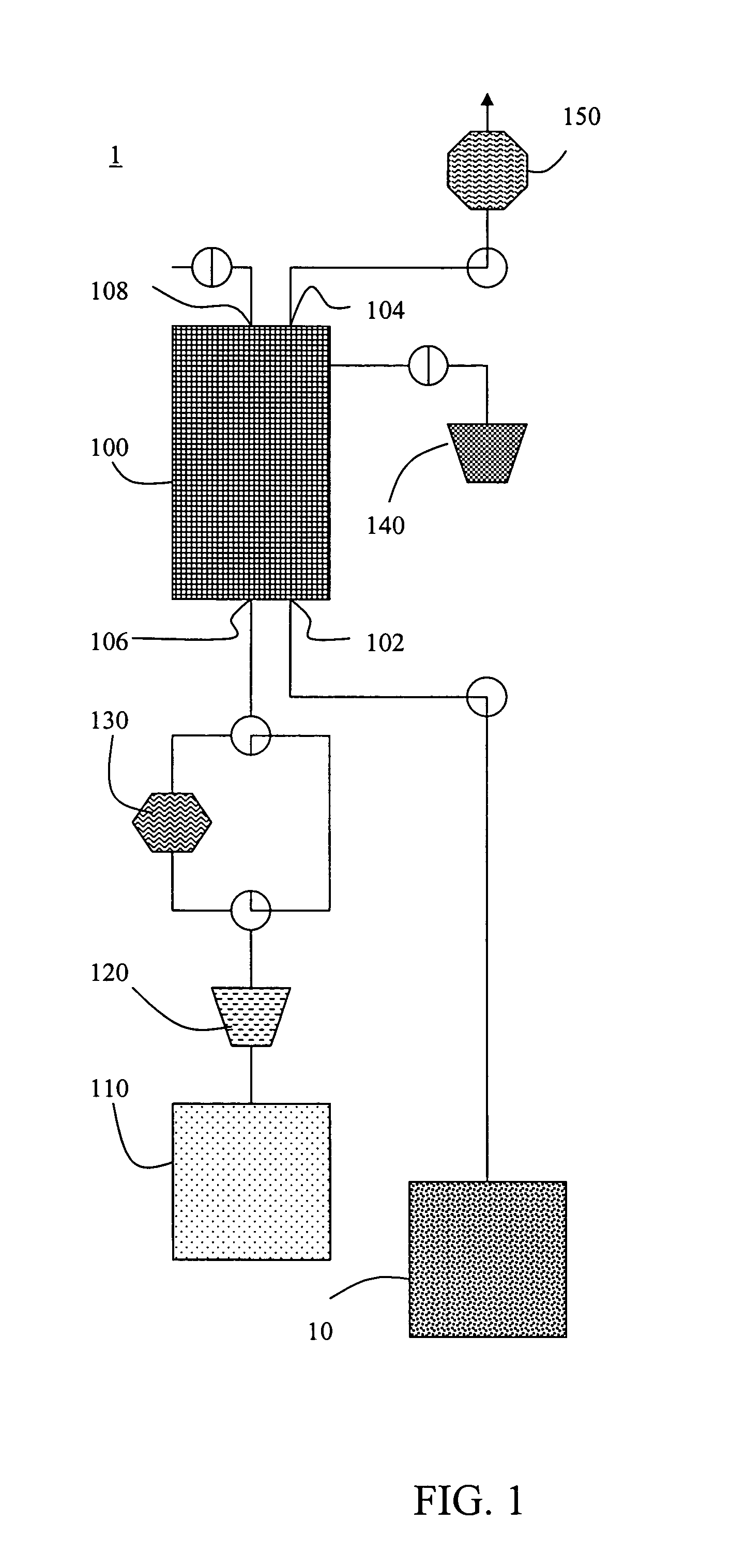

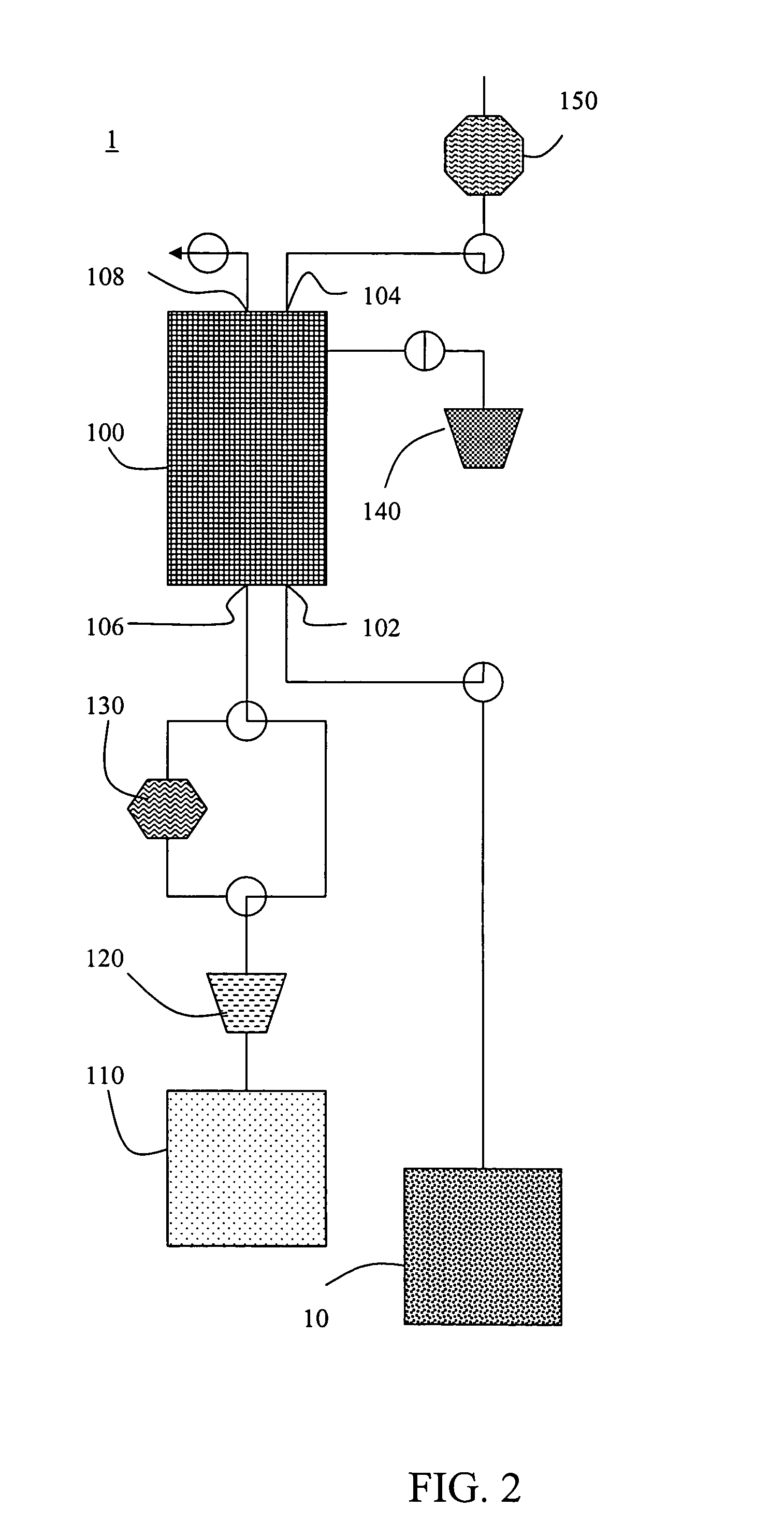

PendingUS20180079672A1Improve throughputPromote biotransformationWaste water treatment from animal husbandryTreatment involving filtrationEngineeringOxygen

The present disclosure relates, according to some embodiments, to systems and methods for processing organic compounds, such as manure or other organic waste. Embodiments may comprise a first containment or mixing chamber, a first anaerobic chamber, and a second anaerobic chamber. A first anaerobic chamber may receive organic compounds from a first containment or mixing chamber, and may provide a fluid stream to a second anaerobic chamber. The second anaerobic chamber may comprise a substrate, such as lava rock, with bacteria growing thereon. Further, biogas generated in one or both of the first anaerobic chamber and the second anaerobic chamber may be purified in a first stage using a water scrubber to remove a majority of the carbon dioxide and other contaminants from the biogas, and in a second stage using a pressure swing adsorption unit to reduce carbon dioxide and other contaminants to pipeline acceptable levels. Further yet, carbon dioxide and hydrogen sulfide gases generated during the biogas purification process may be injected into a water-containing chamber in the presence of bacteria and oxygen to convert the hydrogen sulfide to elemental sulfur and / or sulfate

Owner:J S MEYER HLDG CO

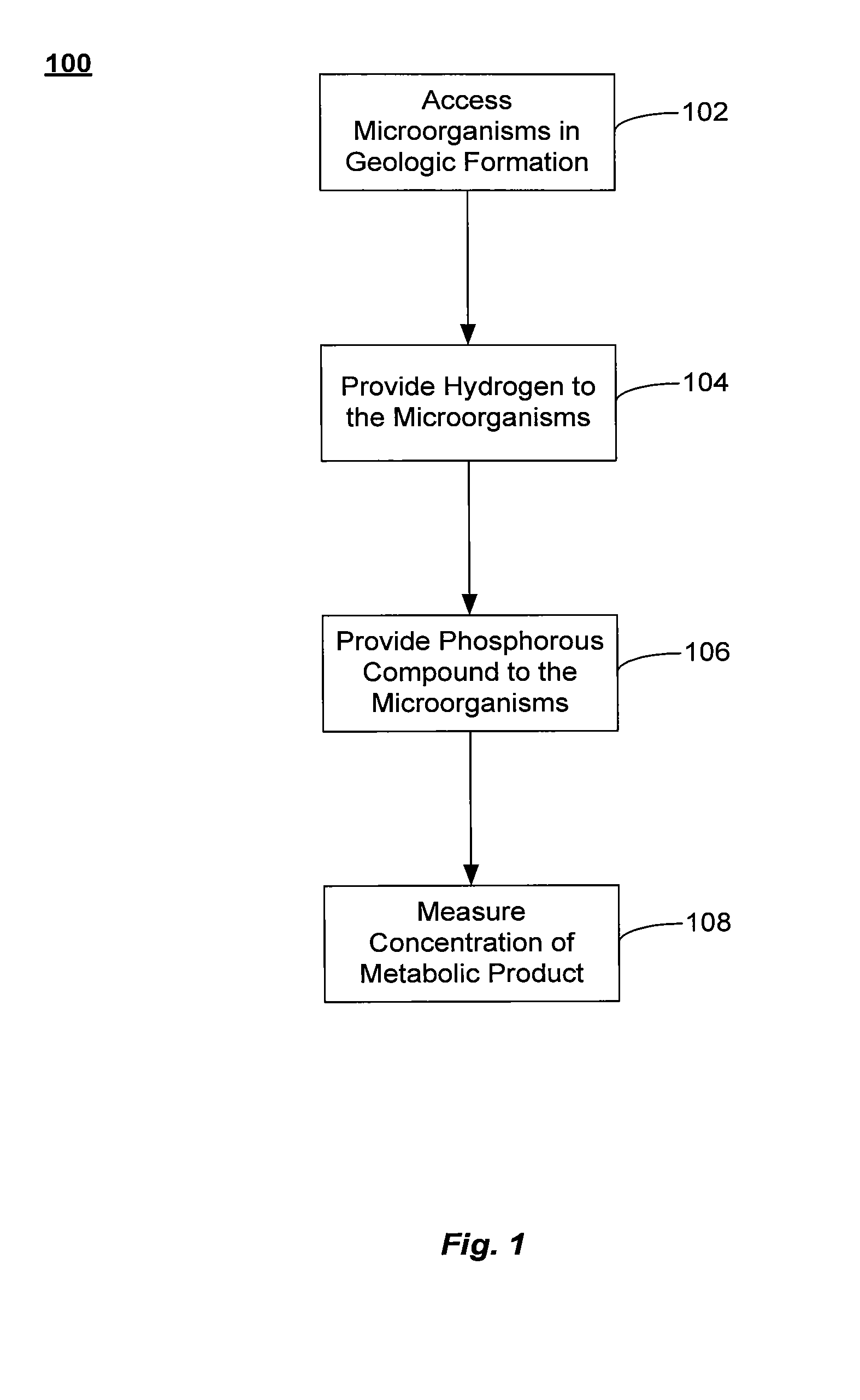

Chemical amendments for the stimulation of biogenic gas generation in deposits of carbonaceous material

Methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content are described. The methods may include accessing a consortium of microorganisms in a geologic formation that includes a carbonaceous material. They may also include providing a phosphorous compound to the microorganisms. The phosphorous compound stimulates the consortium to metabolize the carbonaceous material into a metabolic product with enhanced hydrogen content. Also, methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content by providing a yeast extract amendment to a consortium of microorganisms is described. The yeast extract amendment stimulates the consortium to metabolize carbonaceous material in the formation into the metabolic product with enhanced hydrogen content.

Owner:TRANSWORLD TECH

Siloxane removal process

Biogas released from landfills and sewage treatment plants is freed of siloxane contaminants by passing the biogas through a bed containing activated alumina, which absorbs the siloxanes. When the activated alumina becomes saturated with siloxanes, the absorption capability of the activated alumina can be recovered by passing a regeneration gas through the bed of activated alumina. A system containing two or more beds of activated alumina can use one bed to remove siloxanes from biogas while one or more of the other beds are being regenerated.

Owner:PARKER INTANGIBLES LLC

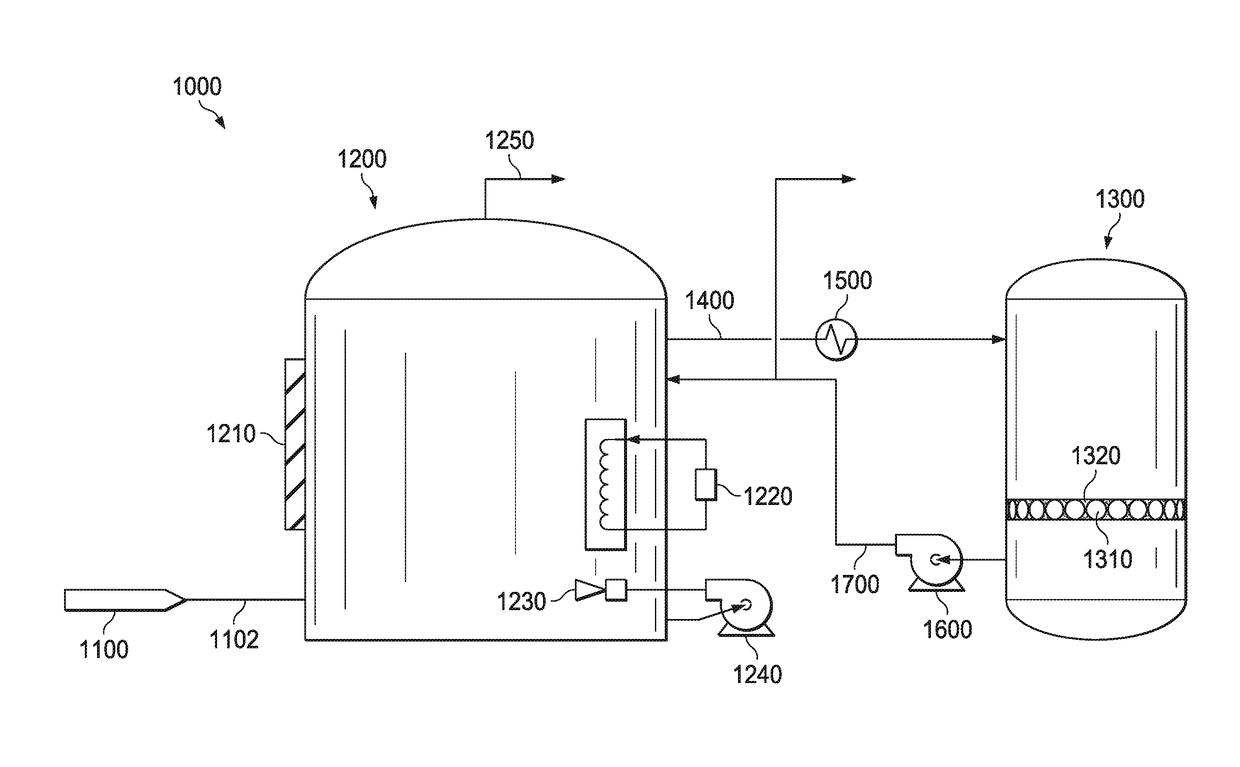

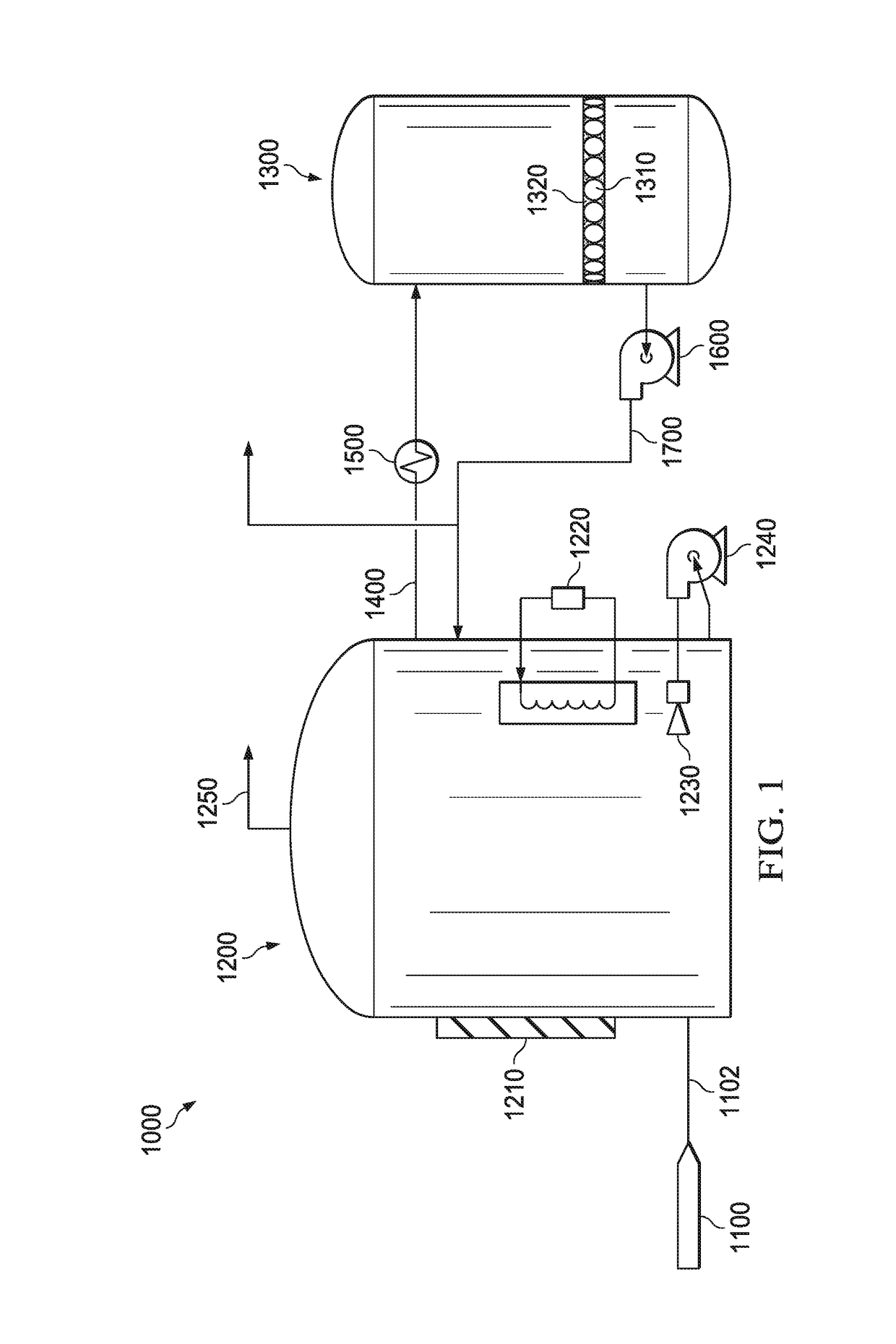

Biogas purification apparatus and method for operation thereof

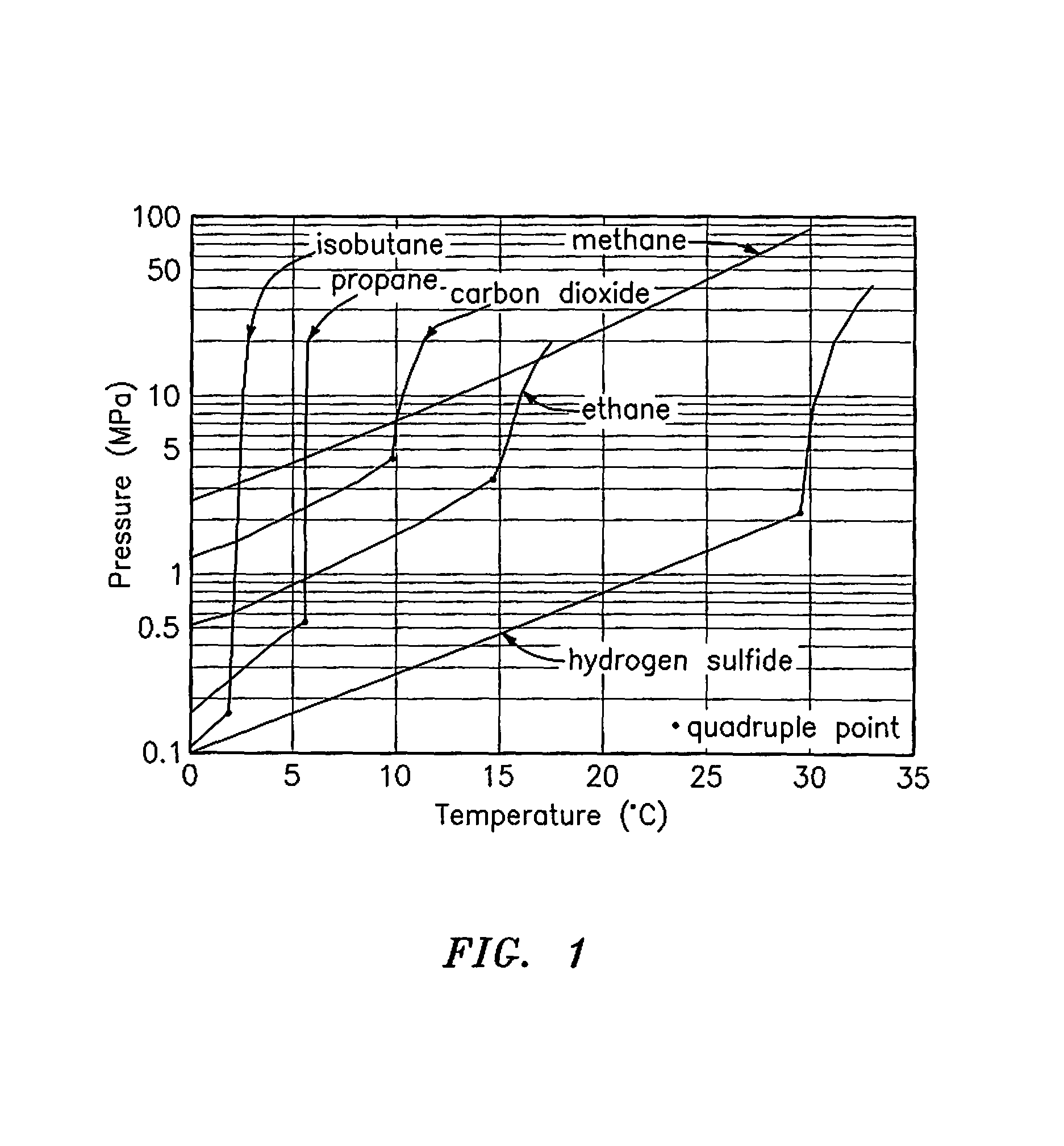

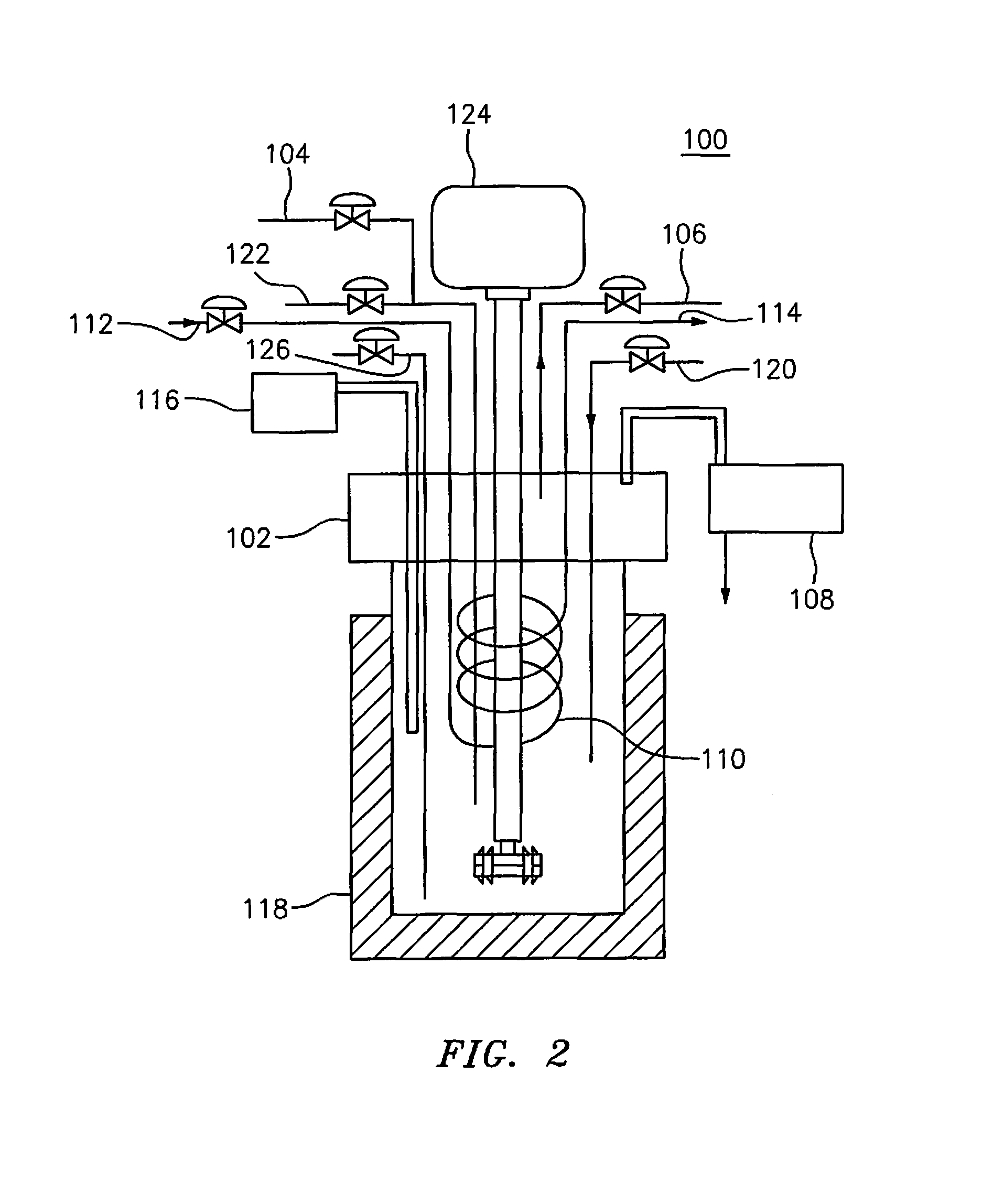

ActiveUS8828124B1Reduced water requirementsIncrease pressureSolidificationLiquefactionPurification methodsGas passing

A biogas purification method includes injecting biogas into a pressure vessel, cooling the pressure vessel to a first predetermined temperature and pressurizing the pressure vessel to a predetermined pressure. The method further includes visually monitoring separation of a biogas impurity from a product gas during an induction period, isolating the product gas from the biogas impurity at a clathrate formation equilibrium by removing the product gas from the pressure vessel and passing the product gas through water to yield a purified gas.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Regenerative Adsorption Process for Removal of Silicon-Containing Contaminants from Process Gas Using a Neutral Adsorbent Media

InactiveUS20140366726A1Reduced useful lifeShorten regeneration timeGas treatmentGaseous fuelsSorbentSewage treatment

A natural gas-containing stream such as biogas from landfills and sewage treatment plants is freed of siloxane contaminants by passing the biogas through a bed containing an adsorbent having a neutral surface, which adsorbs the siloxanes. When the bed of neutral adsorbent is filled to capacity, the adsorbent bed is heated to remove the siloxanes and regenerate the bed. The neutral adsorbent reduces disadvantageous reactions between the adsorbent and siloxane and other impurities in the natural gas-containing stream.

Owner:GUILD ASSOCS

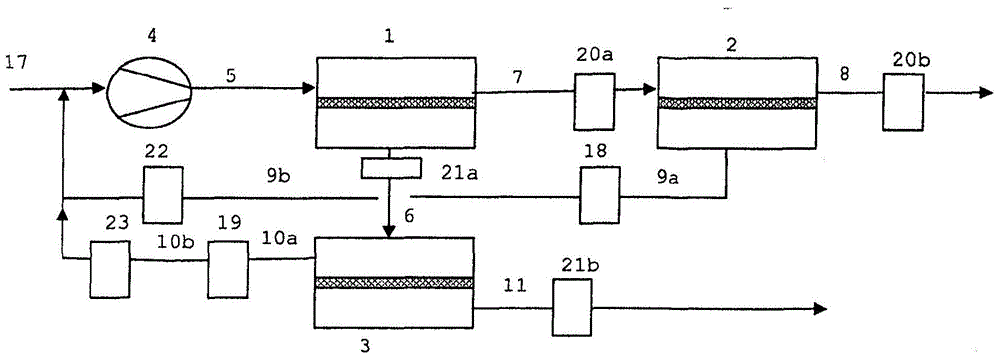

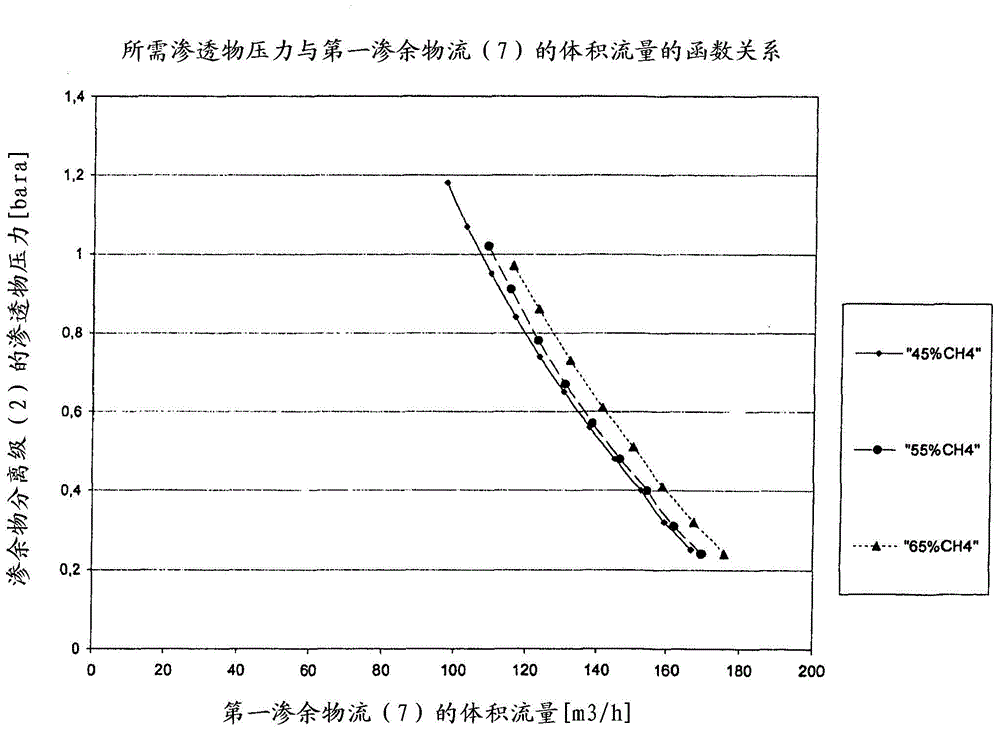

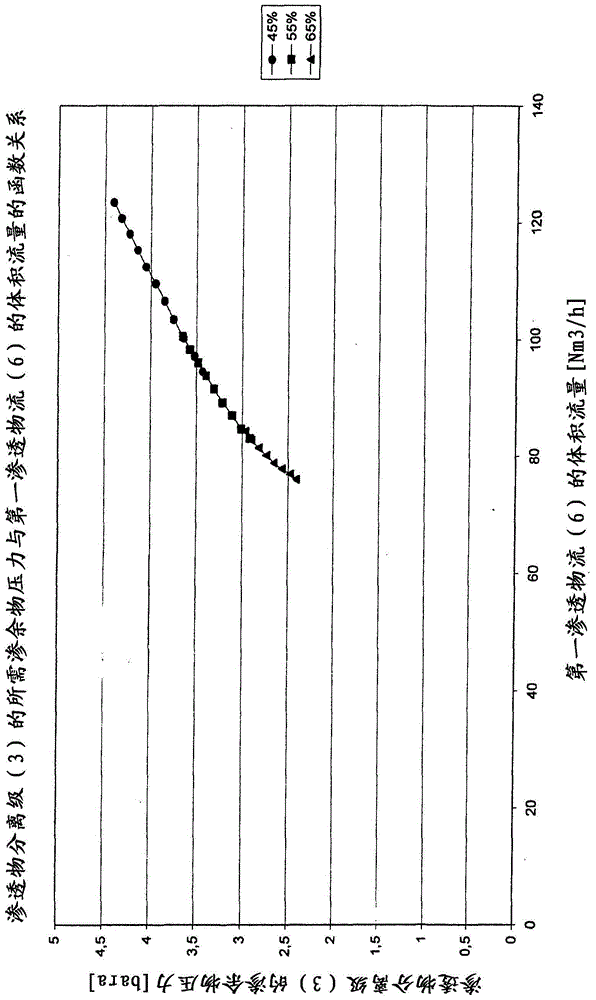

Control of gas composition of a gas separation system having membranes

ActiveCN104797322AReduce size requirementsLower energy requirementsWaste based fuelBiomass after-treatmentSyngasGas composition

The invention relates to a method for controlling a gas separation system comprising membrane separation stages, a system controlled by said method and use of said system for separation of gas mixtures, in particular in the preparing of biogas or natural gas or synthesis gas.

Owner:EVONIK OPERATIONS GMBH

Biological gasifying furnace

InactiveCN101531925BEfficient use ofCombined combustion mitigationCombustible gas productionBioelectric Energy SourcesEngineering

The invention relates to a biological gasifying furnace, and belongs to the technical field of furnaces. The biological gasifying furnace comprises a furnace body, at least one cleaning hole opening and closing device, a purifying cylinder, an adapting pipe and a fuel gas lead-out device, wherein the furnace body consists of a base, a furnace chamber and a spacer bush, the base corresponds to thelower part of the furnace chamber, the lateral part is provided with a cleaning hole, and the spacer bush is formed between the inner wall of the furnace body and the outer wall of the furnace chamber; the cleaning hole opening and closing device is arranged on the cleaning hole; the purifying cylinder is provided with a filter material chamber, the top of the purifying cylinder is provided with a filter material intake which is matched with a first opening and closing door, the bottom of the purifying cylinder is provided with a tar hopper of which the bottom is provided with a valve, the lower lateral part of the purifying cylinder is provided with a filter material outlet which is matched with a second opening and closing door, the bottom of the filter material chamber is provided witha filter material cushion, and a bleed air chamber is formed between the filter material cushion and the tar hopper; one end of the adapting pipe is connected with the furnace body and communicated with the spacer bush, while the other end is connected with the lower lateral part of the purifying cylinder and communicated with the bleed air chamber; and the fuel gas lead-out device is connected and communicated with the purifying cylinder. The biological gasifying furnace has the advantages of making biological energy source utilized effectively and protecting the environment.

Owner:常熟市多能铆焊厂

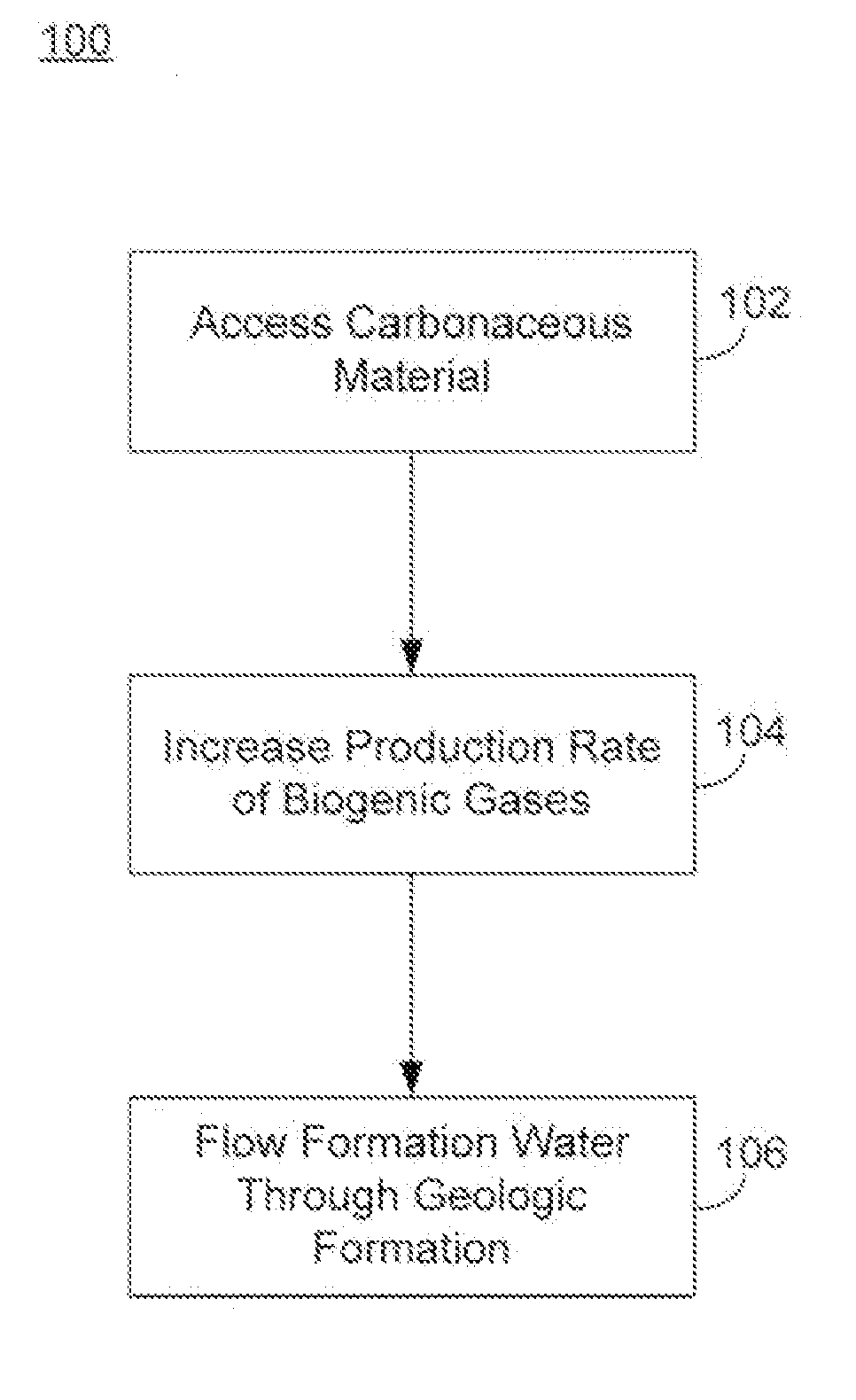

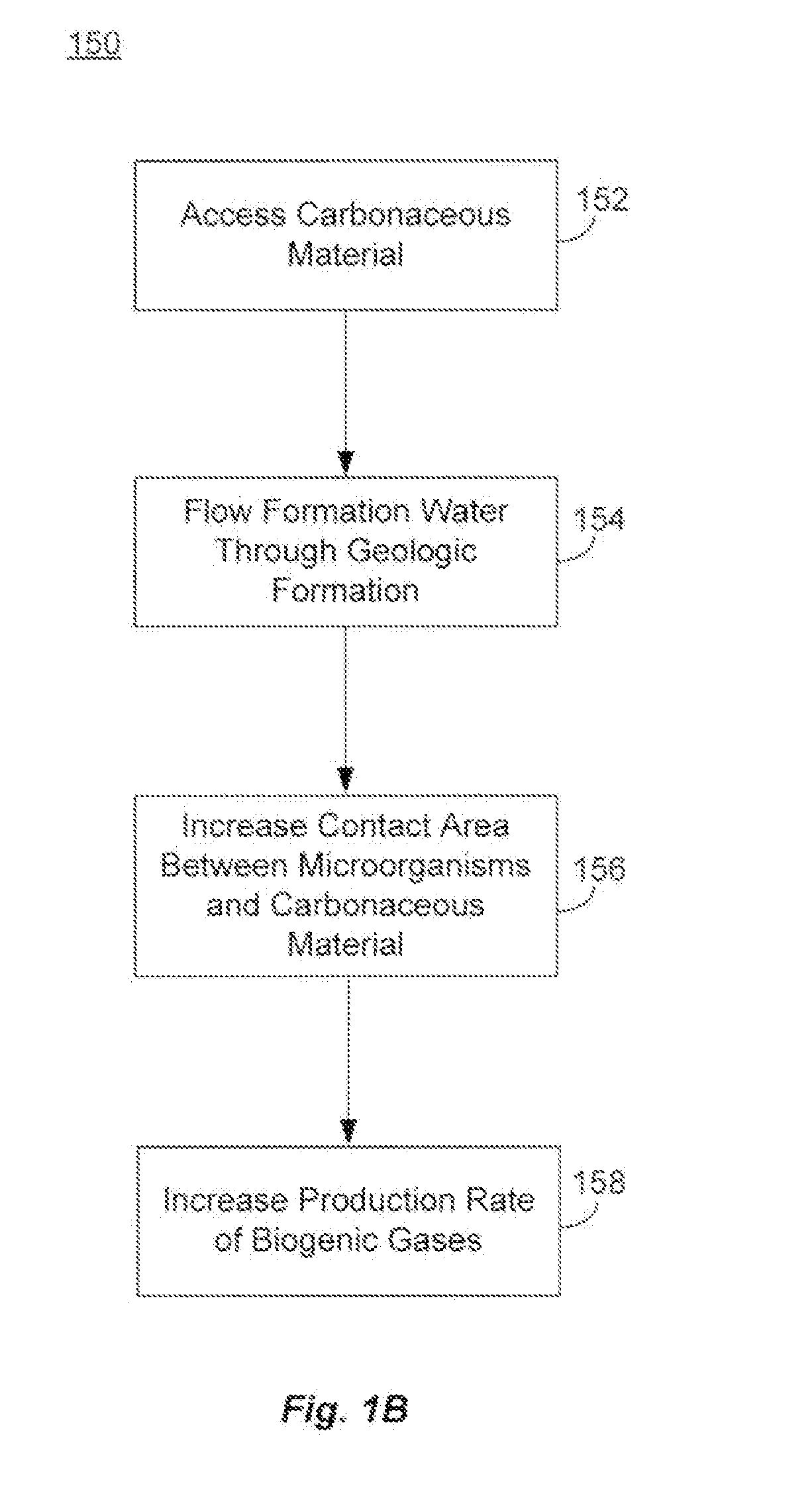

Biogenic fuel gas generation in geologic hydrocarbon deposits

InactiveUS20110139439A1Increase productionIncrease ratingsGas production bioreactorsWaste based fuelBiofuelBiogenic gas

Methods to enhance biogenic gas production in an anaerobic geologic formation containing carbonaceous material are described. The methods may include the steps of accessing the anaerobic formation, increasing a rate of production of the biogenic gases in the anaerobic formation, and flowing formation water within the anaerobic formation after the increase in the production of biogenic gases. Also described are methods to redistribute formation water in an anaerobic geologic formation containing carbonaceous material. The methods may include the steps of locating a reservoir of the formation water within the anaerobic formation, forming at least one channel between the reservoir and at least a portion of the carbonaceous material, and transporting the formation water from the reservoir to the carbonaceous material through the channel. Further described are methods of accumulating biogenic gas in an anaerobic geologic formation to enhance biogenic gas production.

Owner:TRANSWORLD TECH

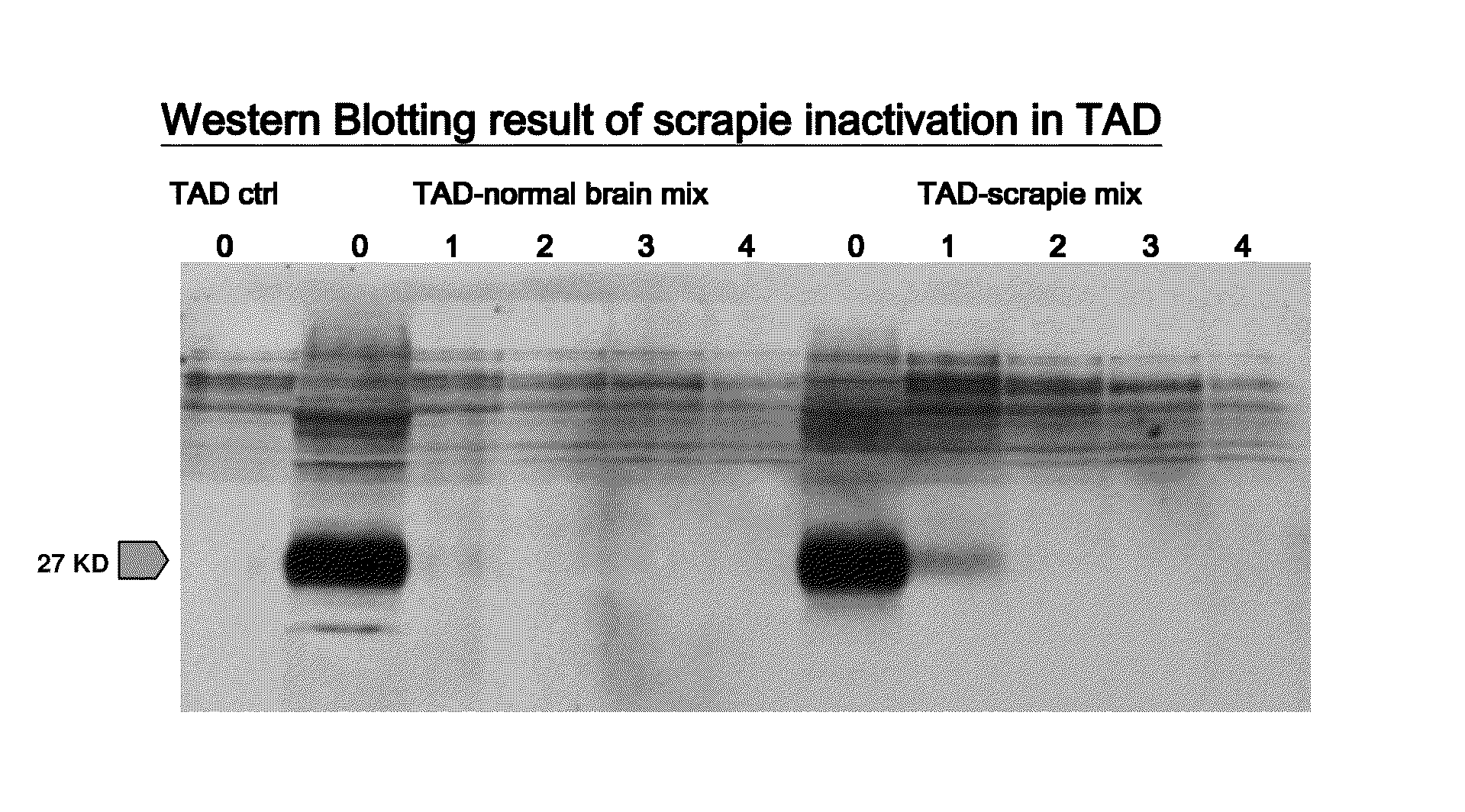

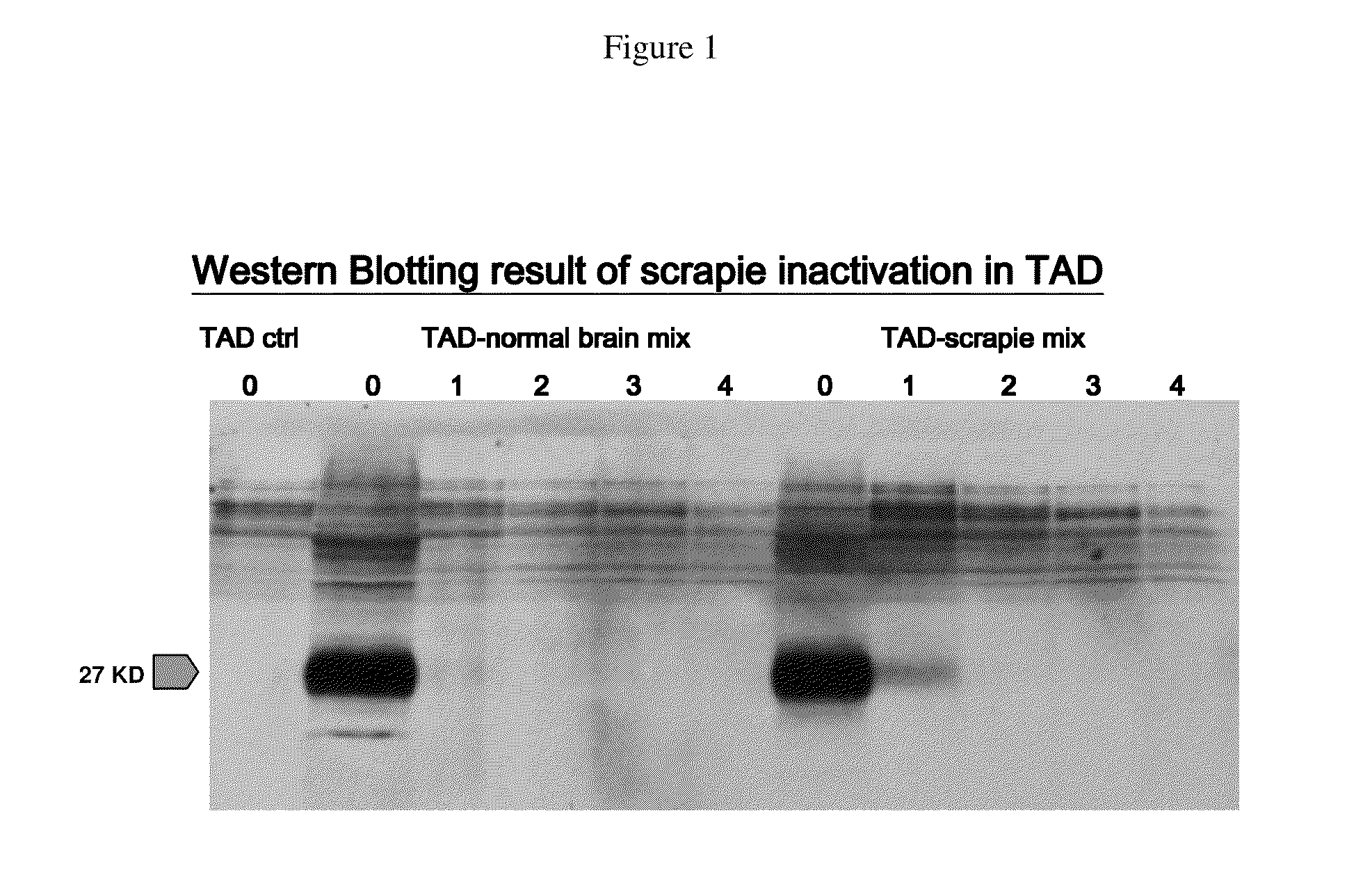

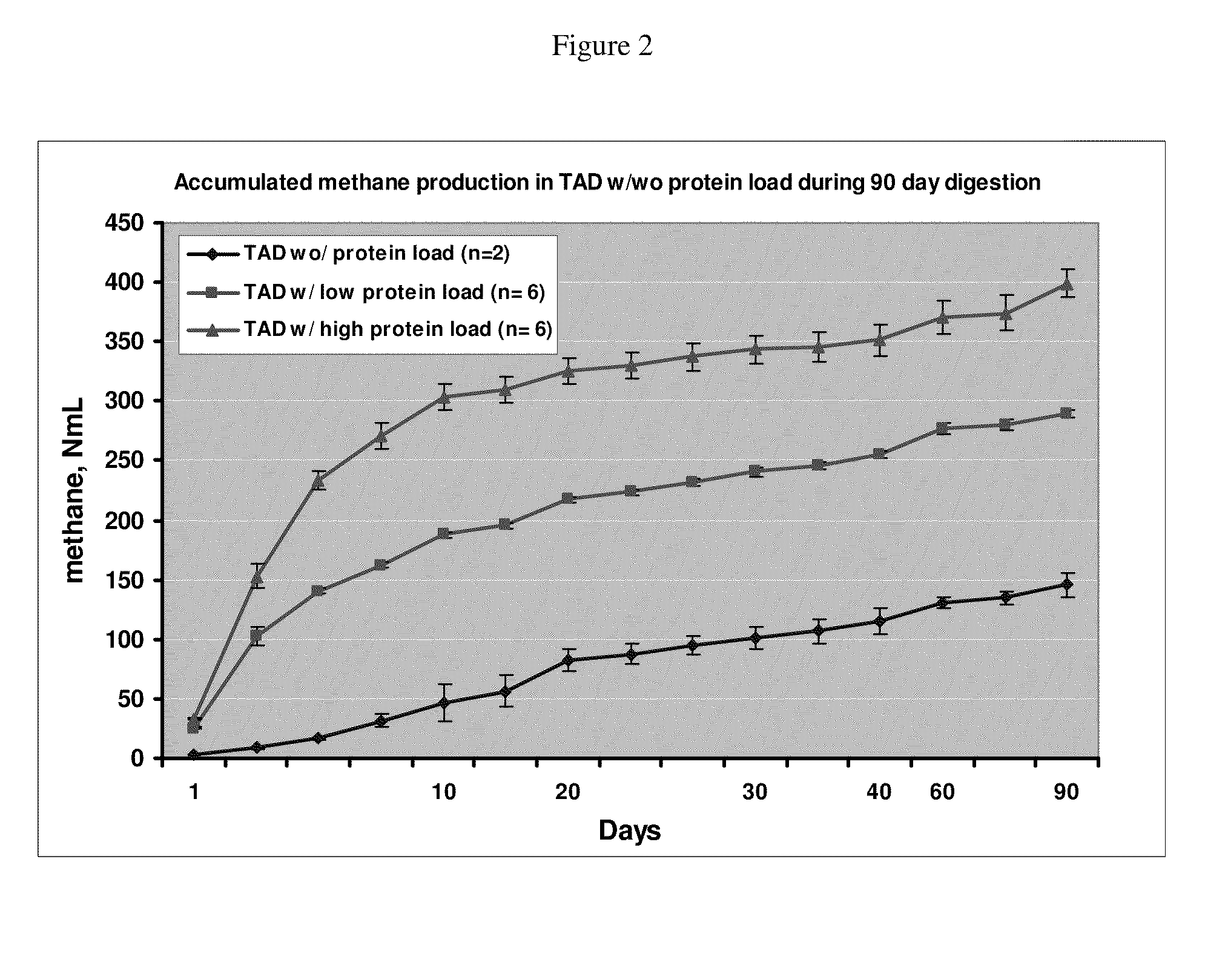

Use of Anaerobic Digestion to Destroy Biohazards and to Enhance Biogas Production

InactiveUS20100297740A1Lower titerStable rateSolid waste disposalGaseous fuelsSpecified risk materialBiogas production

The invention relates to systems and methods for using the anaerobic digestion (AD) process, especially thermophilic anaerobic digestion (TAD), to destroy biohazard materials including prion-containing specified risk materials (SRM), viral, and / or bacterial pathogens, etc. The added advantage of the invention also includes using feedstocks that may contain such biohazard materials to achieve enhanced biogas production, in the form of improved biogas quality and quantity.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

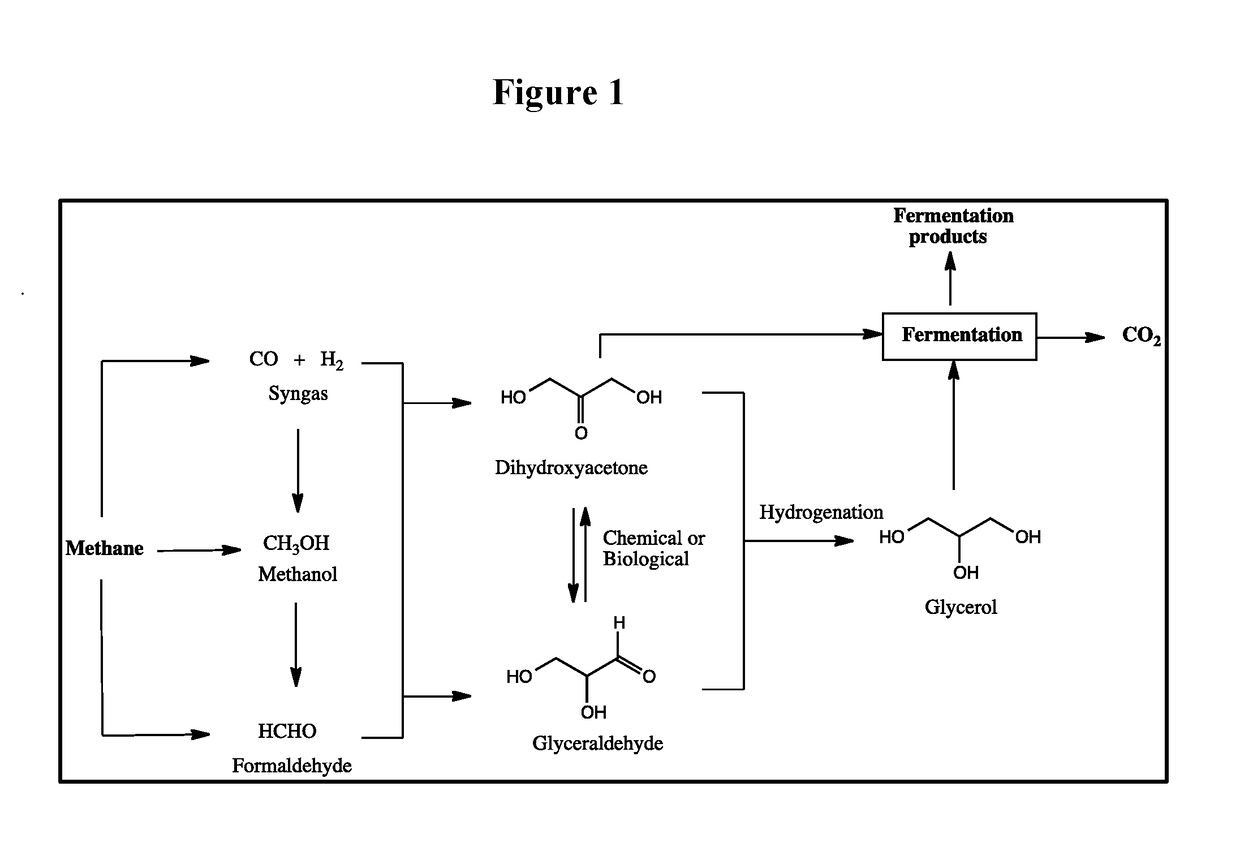

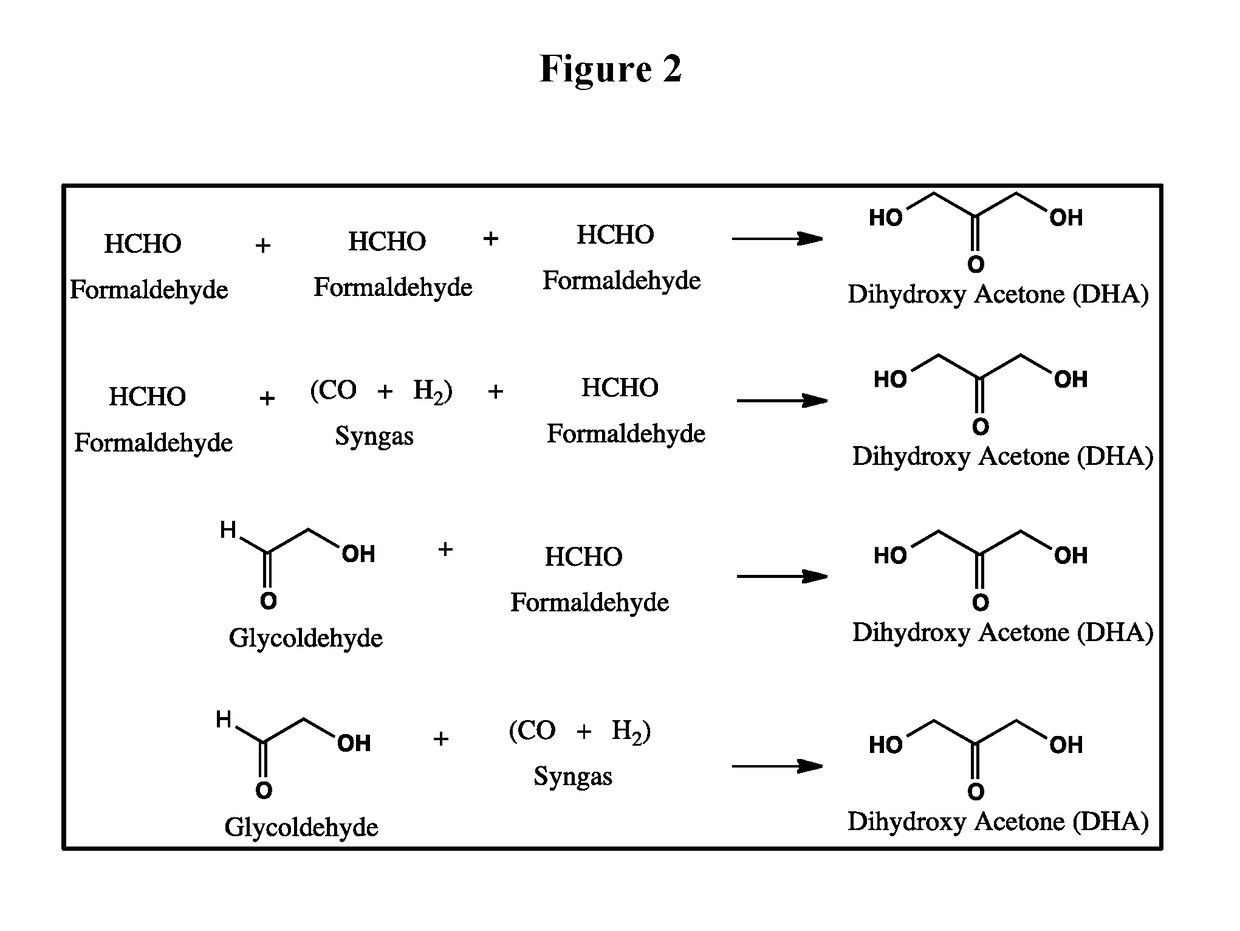

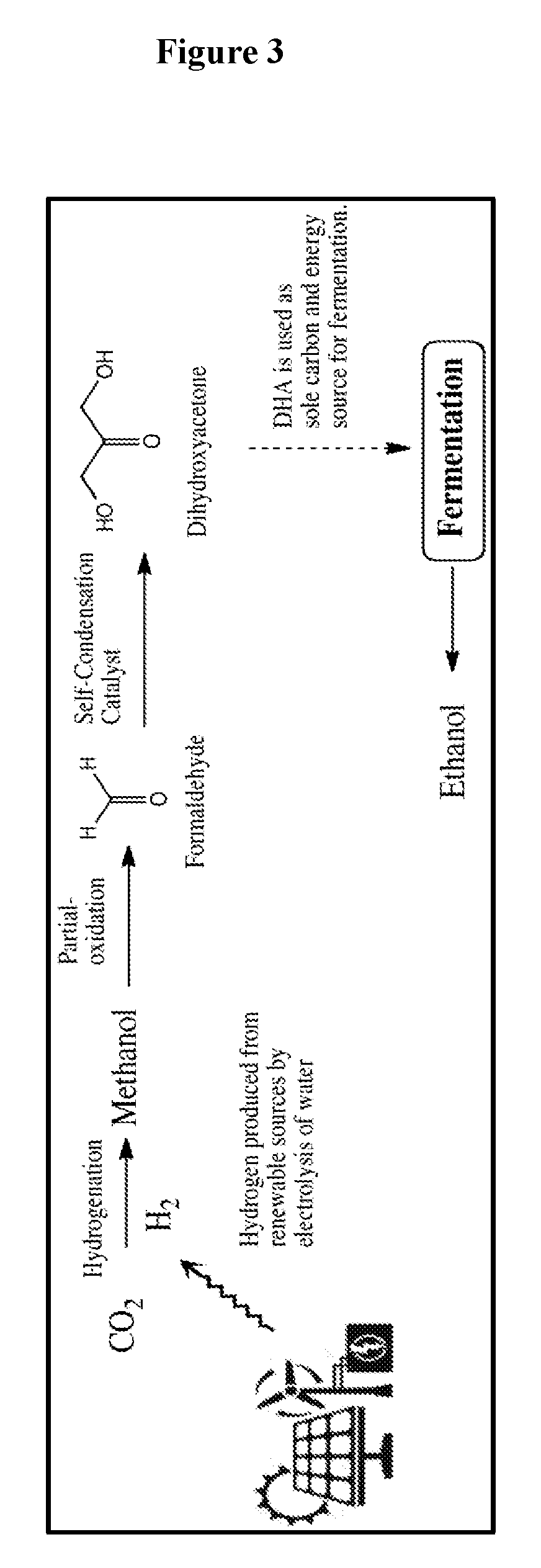

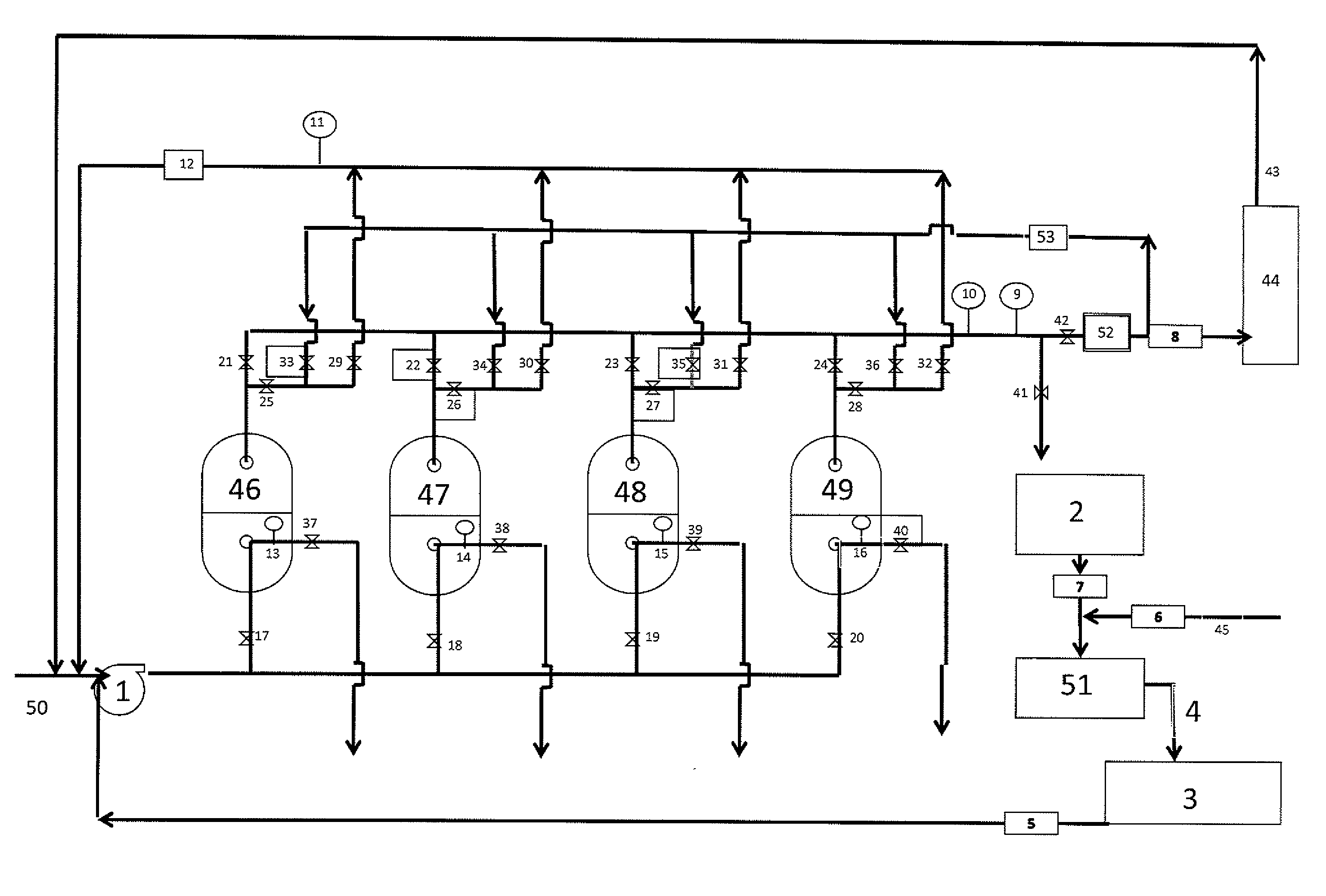

Biological fermentation using dihydroxyacetone as a source of carbon

The present invention relates to the use of hydrocarbons derived from natural gas in the fermentative production of biochemicals including biofuels. More specifically, the present invention provides the method for manufacturing dihydroxyacetone (“DHA”) from natural gas, biogas, biomass and CO2 released from industrial plants including electricity-generating plants, steel mills and cement factories and the use of DHA as a source of organic carbon in the fermentative production of biochemicals including biofuels. The present invention comprises three stages. In the first stage of the present invention, syngas and formaldehyde are produced from natural gas, biogas, biomass and CO2 released from industrial plants. In the second stage of the present invention, formaldehyde and syngas are condensed to produce DHA. In the third stage of the present invention, biochemicals including biofuels are produced from DHA using fermentation process involving wild type or genetically modified microbial biocatalysts.

Owner:KEMBIOTIX LLC

Dual Purpose Gas Purification by Using Pressure Swing Adsorption Columns for Chromatographic Gas Separation

A process wherein a gas mixture of a reformate gas comprised predominantly of hydrogen and carbon oxides, and a biogas comprised predominantly of methane and carbon dioxide is passed through a pressure swing adsorption unit. Contaminants, such as carbon oxides, are adsorbed and a methane-rich stream and a hydrogen-rich stream are separately recovered. The methane-rich stream is sent to steam methane reforming that results in a reformate comprised primarily of hydrogen which is then combined with the biogas feed stream and sent to pressure swing adsorption.

Owner:JANGBARWALA JUZER

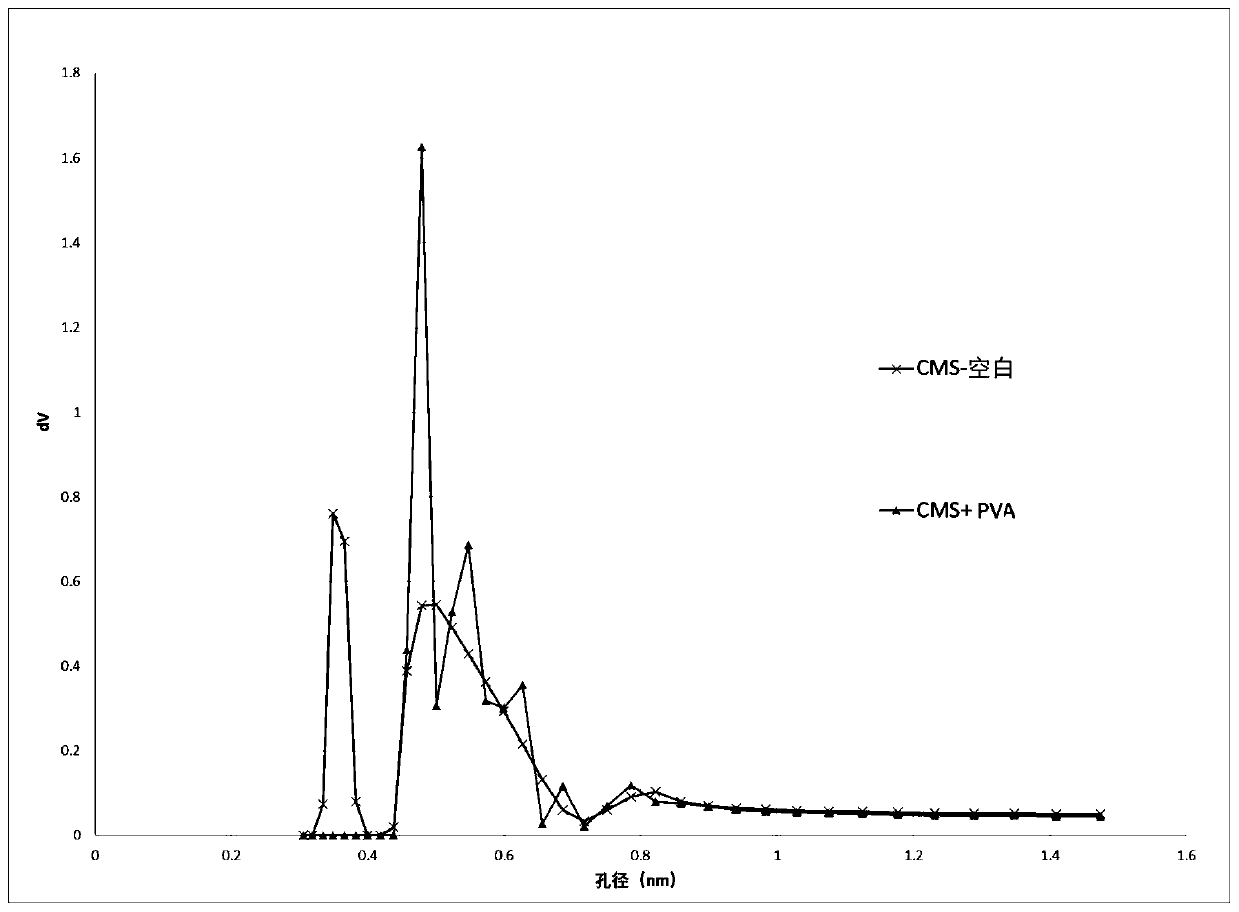

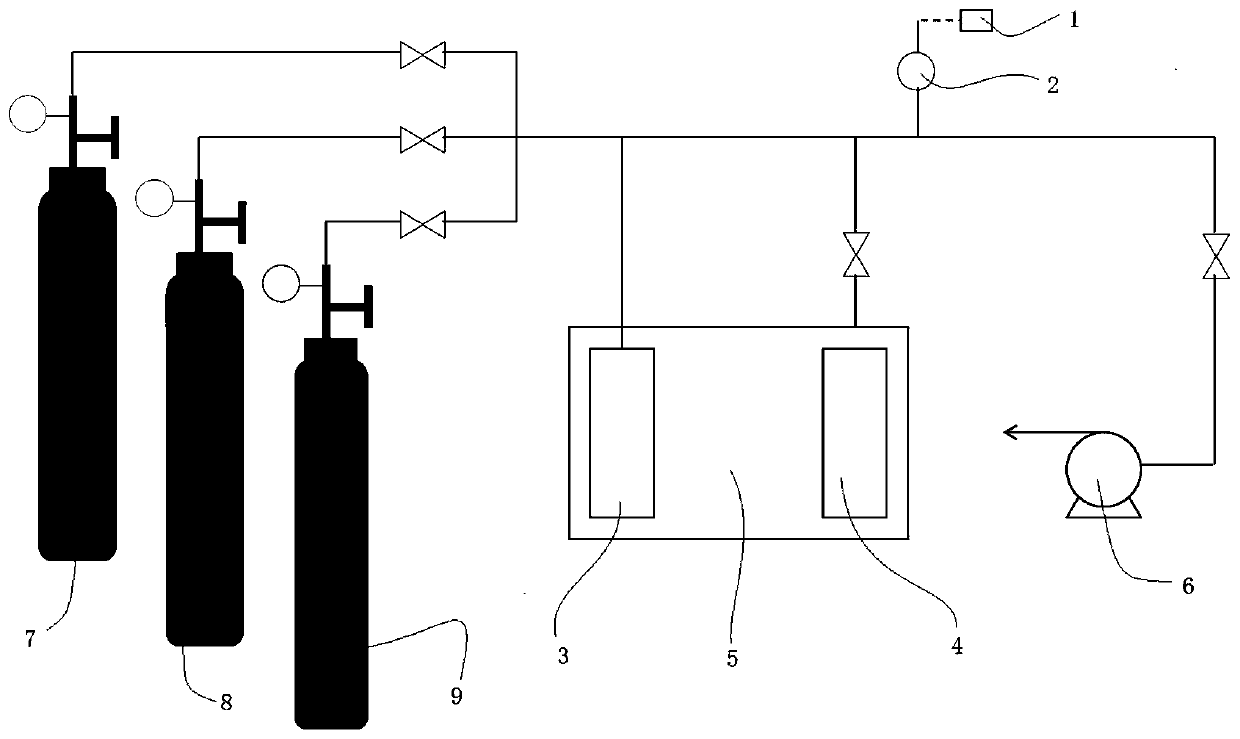

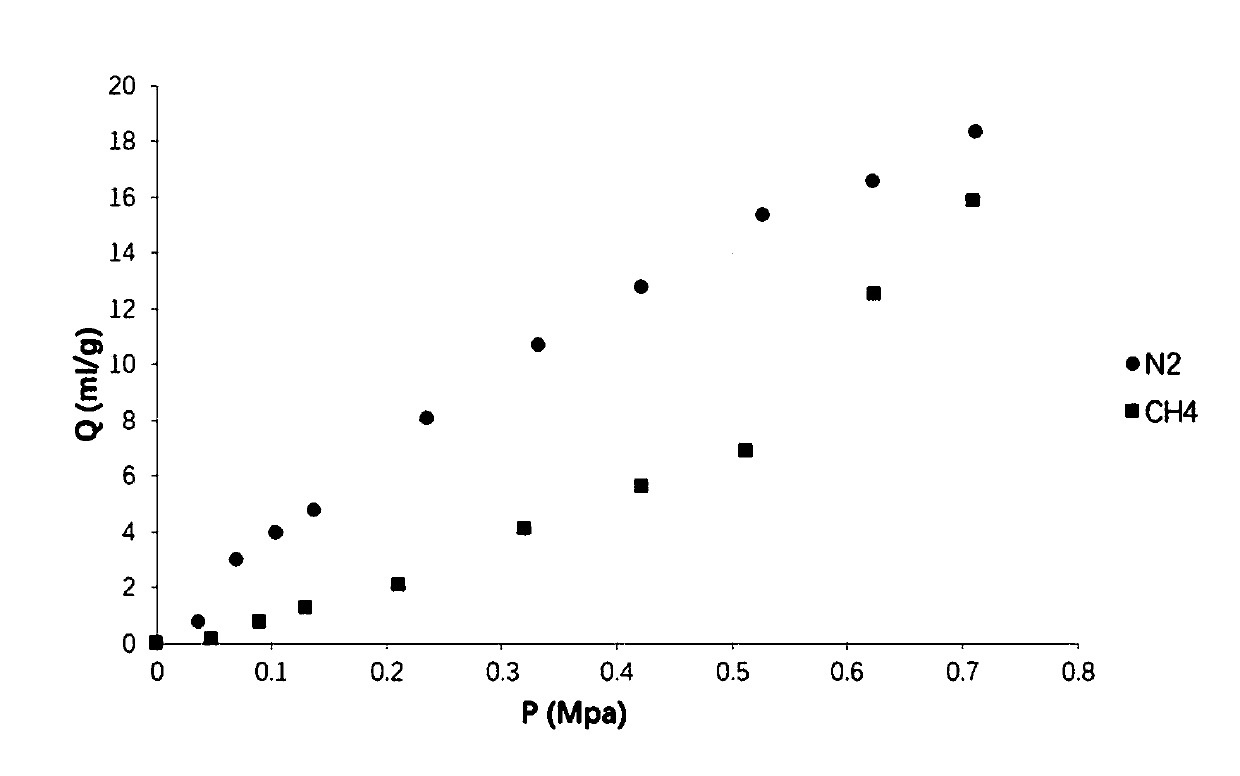

Organically modified molecular sieve and preparation method and application thereof

ActiveCN110773125AThe preparation method is simple and controllableReduce energy consumptionGas treatmentMethane captureMolecular sieveSorbent

The invention relates to an organically modified molecular sieve and a preparation method and application thereof, belonging to the technical field of adsorbents. To overcome technical problems in theprior art, the invention provides the preparation method of the organically modified molecular sieve. The method comprises the following steps: impregnating a molecular sieve with an organic matter solution, performing solid-liquid separation, and drying the obtained solid to obtain the modified molecular sieve. According to the invention, the molecular sieve is subjected to impregnation modification so as to successfully prepare the organically modified molecular sieve; the preparation method is simple and controllable in process, low in energy consumption and low in cost; the obtained modified molecular sieve can be used as a selective adsorbent for N2 / CH4, O2 / CH4, (N2 + O2) / CH4 and other systems; in particular, when the modified molecular sieve is used for separation of N2 / CH4, the adsorption amount of CH4 is low, and the separation ratio of nitrogen to methane is large; and the modified molecular sieve can be applied to purification of methane in coalbed methane, oilfield gas or biogas.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com