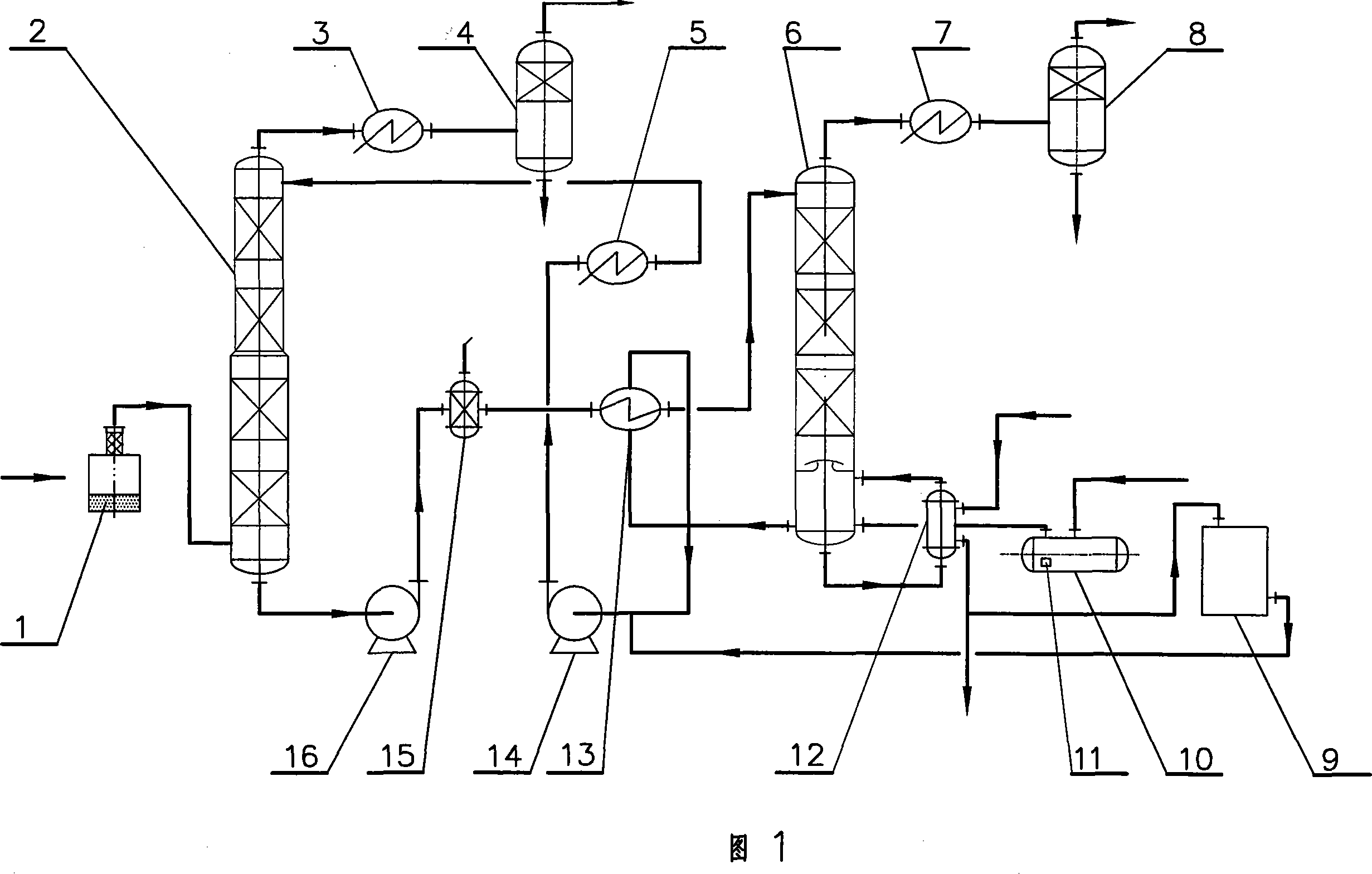

Biogas cleaning equipment and purifying technique thereof

A technology of purification equipment and purification process, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc. It can solve the problems of low methane yield, difficulty in adopting large-scale high-pressure absorption purification process, and low LFG output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 1. Processing raw gas volume: 15000m 3 / d LFG

[0073] 2. Composition of raw gas and purified gas (V%)

[0074] CH 4 CO 2 o 2 other

[0075] Raw material gas 55~60 35~40 0.3~0.7 1.8~3.2

[0076] Purified gas 96~98 2~3 0.5~1.0 2~3

[0077] The methane recovery rate is >96%, and the purified gas contains H 2 S3

[0078] 3. Process conditions

[0079] 1) Gas-liquid ratio: m 3 Gas / m 3 Solution 25~35

[0080] m 3 Gas / m 3 stock solution * 50~70

[0081] 2) Solution concentration 2.56~4.28kmol / m 3 ;Concentration of poor solution 1~2.5LCO 2 / L solution

[0082] 3) Temperature: (℃)

[0083] Absorption tower: 45-55 at the top of the tower

[0084] Tower bottom 55~65

[0085] Desorption tower: bottom 102~108

[0086] Tower top 85~92

[0087] 4) Tower pressure

[0088] Absorption tower: 35~40kPa

[0089] Desorption tower: normal pressure

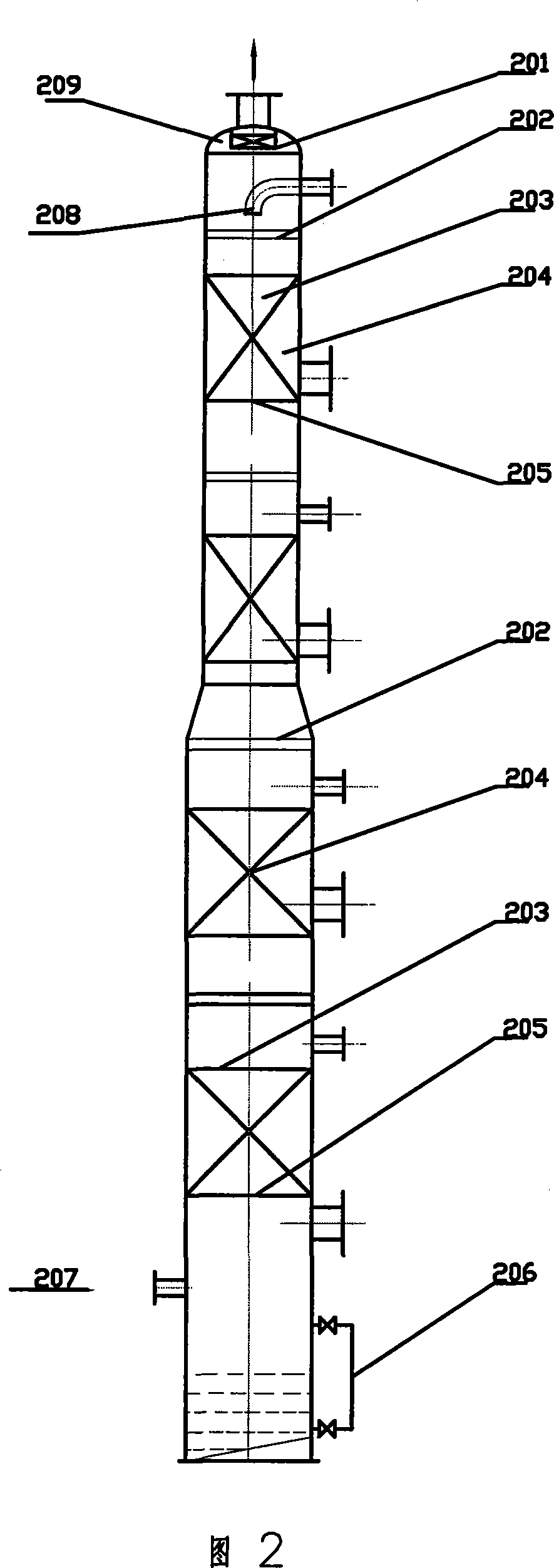

[0090] 4. Main equipment

[0091] Absorption tower:...

Embodiment 2

[0094] 1. Processing raw gas: fermented biogas (biogas)

[0095] Scale: 40000m 3 / d

[0096] 2. Composition of raw gas and purified gas: (V%)

[0097] CH 4 CO 2 o 2

[0098] Raw material gas 55~65 30~40 0.2~0.6

[0099] Purified gas 96~98 <0.8 0.5~1.0

[0100] CH 4 Recovery rate > 96%, H in purified gas 2 S depends on raw material gas H 2 S content and take technological measures, generally can be 3 .

[0101] 3. Process conditions

[0102] 3) Gas-liquid ratio: 80-90m 3 Gas / m 3 the solution

[0103] 4) Solution concentration: 2.56~4.28kmol / m 3

[0104] Barren solution concentration: 1.5~2.5 LCO 2 / L solution

[0105] 5) Temperature (℃)

[0106] Absorption tower: 55-60 at the top of the tower

[0107] Tower bottom 60~70

[0108] Desorption tower: 105~110 at the bottom of the tower

[0109] Tower top 88~92

[0110] 6) Tower pressure

[0111] Absorption tower: 0.5MPa

[0112] Desorption tower: 15~20kPa.

[0113] 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com