Patents

Literature

88results about How to "Have environmental benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

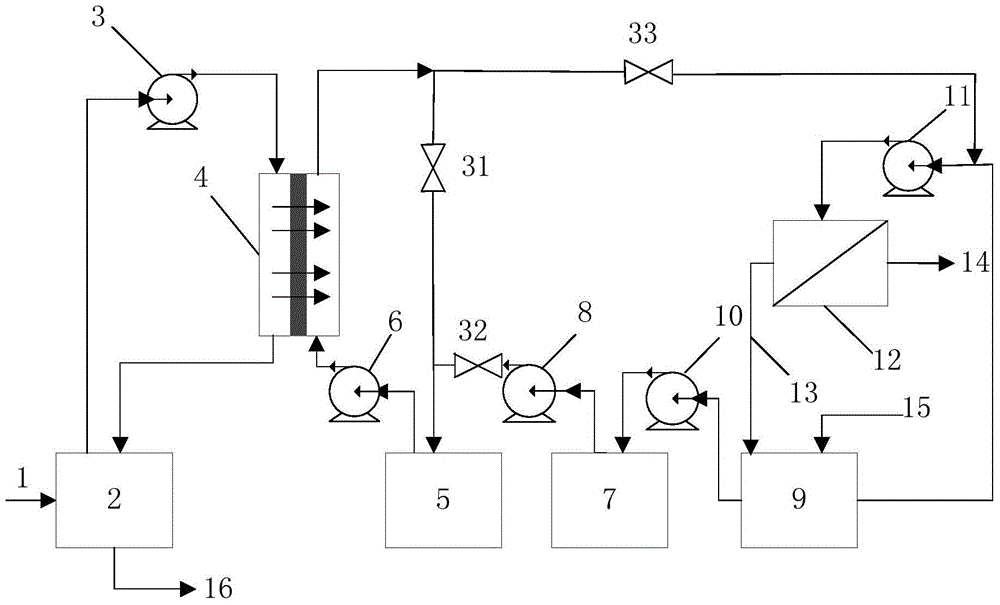

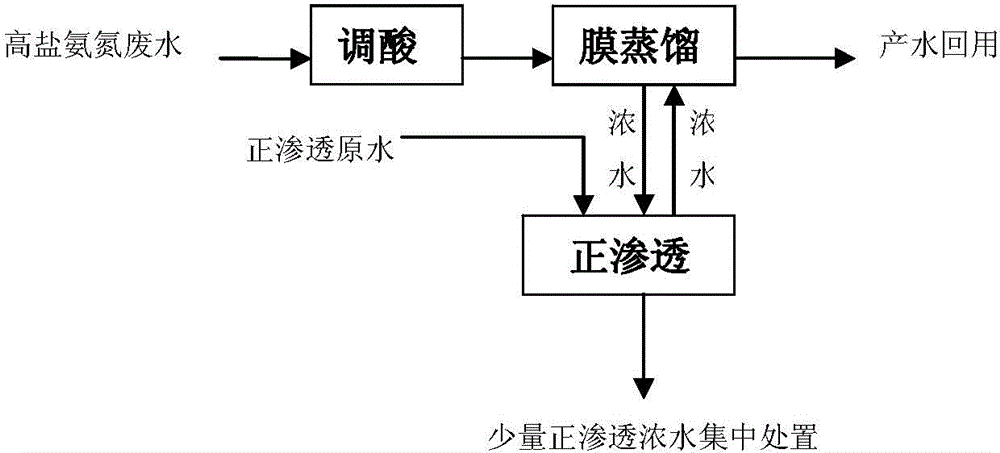

Forward osmosis coupled membrane distillation wastewater treatment apparatus and method thereof

ActiveCN104591457AEfficient use ofSimple methodWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater resourcesWastewater

The invention provides a forward osmosis coupled membrane distillation wastewater treatment apparatus and a method thereof. The apparatus includes a first stage forward osmosis unit or a second stage forward osmosis unit and a membrane distillation unit. The above forward osmosis unit is composed of a forward osmosis raw water pool, a forward osmosis raw water pump, a forward osmosis membrane module, a forward osmosis driving liquid pool and a forward osmosis driving liquid pump; the membrane distillation unit is composed of a membrane distillation thick water raw water pool, a membrane distillation thick water pump, membrane distillation, a membrane distillation water heating pool, a membrane distillation thick water raw water pump, a membrane distillation water feeding pump and a membrane distillation assembly; and the forward osmosis unit is connected with the membrane distillation unit through a pipeline and a valve. The method comprises the following steps: high salinity wastewater treated by the membrane distillation unit is used as a forward osmosis driving liquid, membrane distillation thick water is diluted through continuous concentration of forward osmosis feeding liquid side raw water, the diluted membrane distillation thick water returns to the membrane distillation unit and is continuously treated, and above steps are cycled. The apparatus and the method effectively solve the treatment problem of the membrane distillation thick water, and maximally recover the water resource in the wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

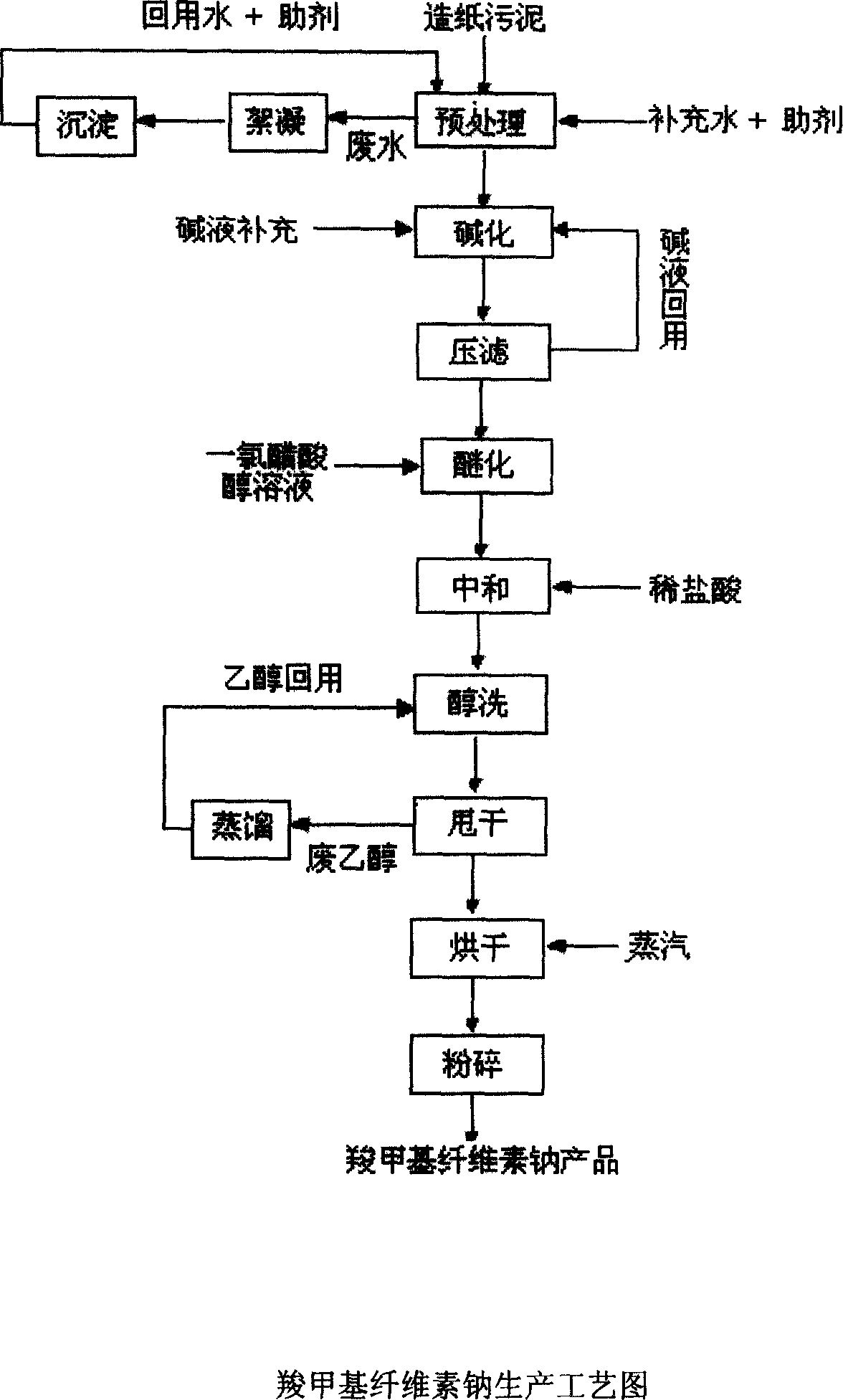

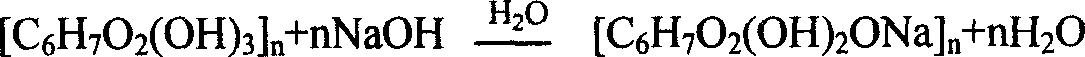

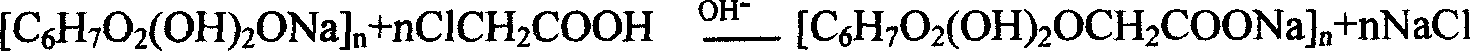

Process of producing sodium carboxymethyl cellulose with papermaking sludg as material

InactiveCN101020718ASolve a big problemIn line with the development modelCarboxymethyl celluloseCellulose

The process of producing sodium caboxymethyl cellulose with papermaking sludge with water content not higher than 80 wt% as material includes pre-treatment of the material, alkalizing, pressure filtering, etherizing, neutralizing, alcohol washing, spin drying, stoving and crushing. The present invention has facile material, waste utilization, low production cost, simple technological process, no secondary pollution and environment friendship.

Owner:北京盖雅技术中心有限公司

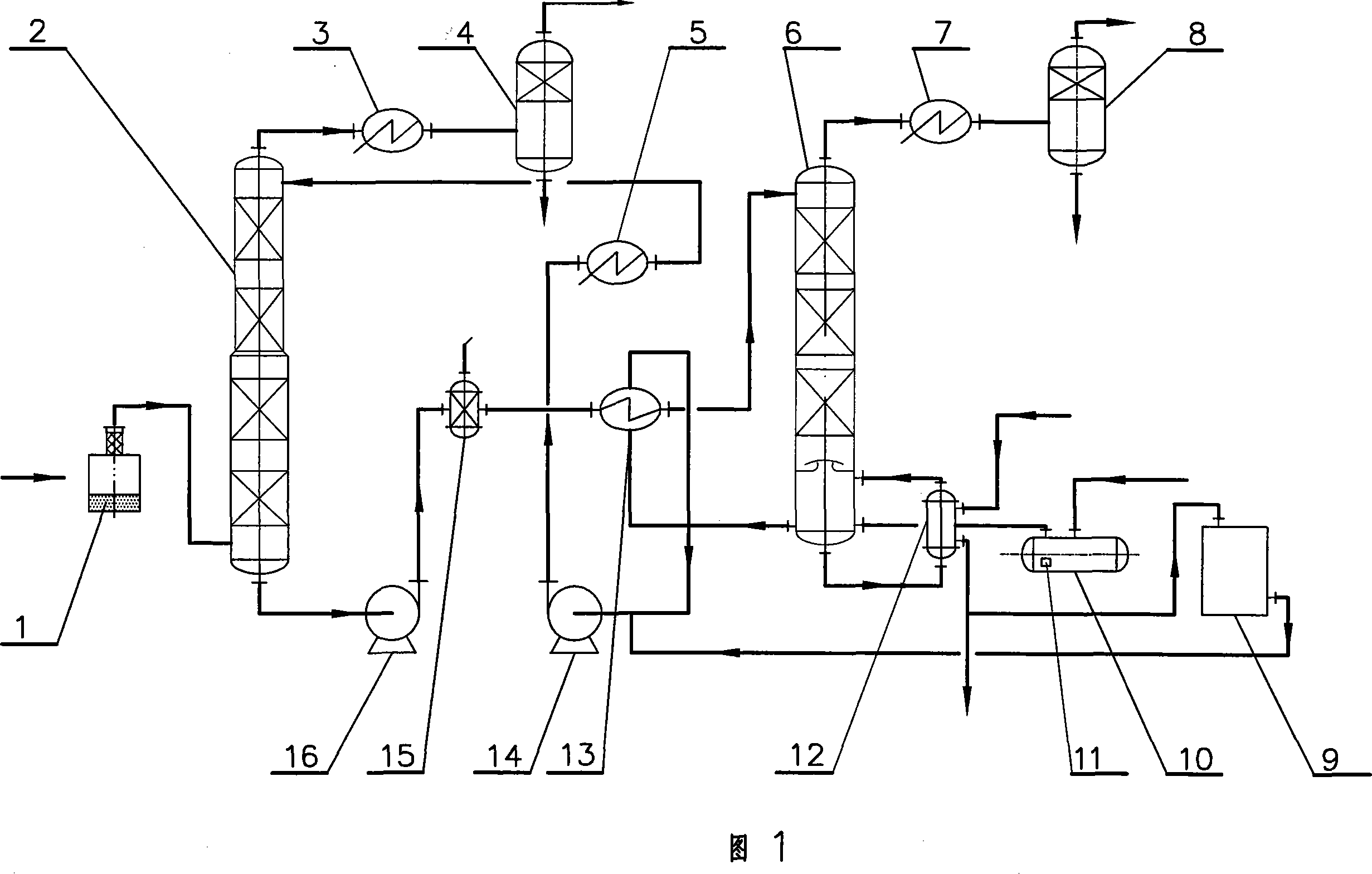

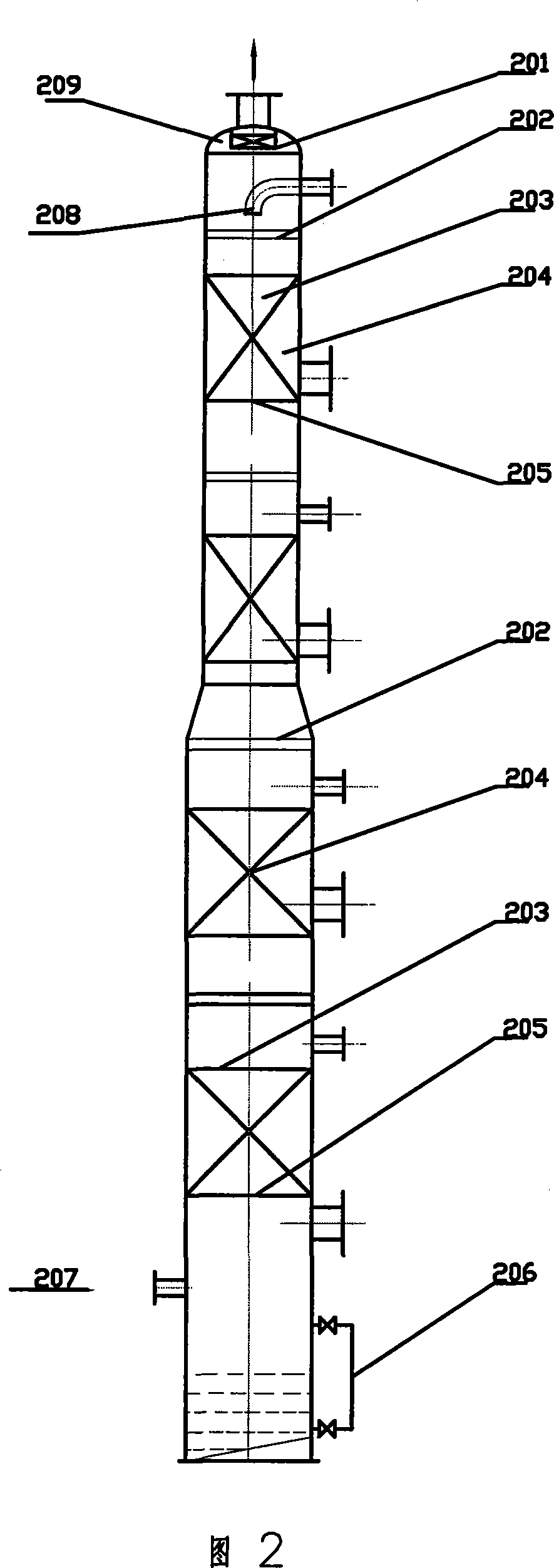

Biogas cleaning equipment and purifying technique thereof

InactiveCN101108988AHave environmental benefitsGood environmental benefitsGaseous fuelsWaste based fuelFiberReboiler

The invention relates to the biogenetic gas purification field, in particular to a biogenetic gas purifying equipment and a purifying technique. The equipment comprises an absorption tower, a desorption tower, a reboiler, a heat exchanger, a cooler, a separator, an absorbent holding tank and a pump. The invention is characterized in that: firstly, the absorption tower is a different diameter tower featuring with small upper section and large lower section and the upper-and-lower tower diameter ratio ranges between 0.75 and 0.85; secondly, a catcher with metal mesh is added inside the former material gas inlet of the adsorbption tower; thirdly, a fiber rod filter is arranged at the outlet of the rich solution outlet of the absoption tower. The technique adopts the water solution as the absorption solution with MEDA main solute and multi-amine activator, and the operation parameters are 30 kPa to 40 kPa operation pressure inside the tower ranges, 45 DEG C. to 55 DEG C. temperature at the tower top of the tower and 50 DEG C. to 60 DEG C. at the bottom, 25 to 35 (m3G / m3L) gas-liquid ratio, 2.56 to 4.28Kmol per m3 absorption solution concentration, and 1 to 2.5LCO2 per L lean solution concentration. The invention is used to remove the impurities of CO2, H2S, HCN and the organic sulfur from the biogenetic gas, coal bed gas and coke-oven gas to meet the purification requirement.

Owner:LIAONING KAITIAN RENEWABLE ENERGY & ENVIROMENT

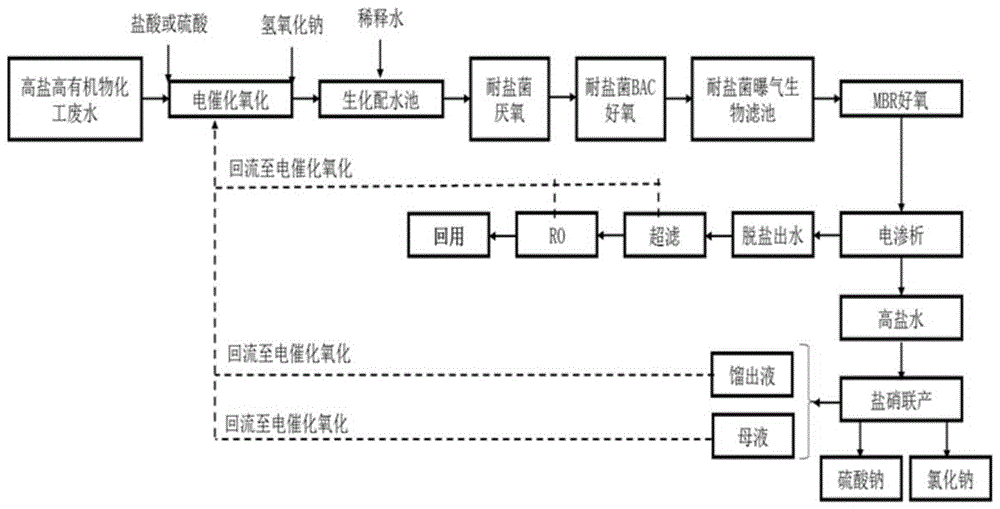

Recycling treatment system and treatment method of high-salinity high-organic-matter chemical wastewater

ActiveCN106495396ARealize resourcesReduce SS contentWater contaminantsTreatment with aerobic and anaerobic processesElectricityUltrafiltration

The invention discloses a recycling treatment system of high-salinity high-organic-matter chemical wastewater. The recycling treatment system comprises an electrocatalytic oxidation device, a halotolerant bacteria biochemical system, an MBR aerobic device, an electroosmosis unit, an ultrafilter and an RO unit, the halotolerant bacteria biochemical system comprises a halotolerant bacteria anaerobic device, a halotolerant bacteria aerobic device and a halotolerant biological aerated filter. The invention further discloses a treatment method of the high-salinity high-organic-matter chemical wastewater. By the recycling treatment system and the treatment method, the problem of recycling treatment of the high-salinity high-organic-matter chemical wastewater is solved effectively, recycling rate of water and salt is high, no wastewater is discharged basically, no solid waste is generated, generated water is high in quality, generated salt is high in purity, and water resources and salt in the high-salinity high-organic-matter chemical wastewater are recycled to greatest extent; zero discharging of wastewater in the process of enterprise production is realized, and the recycling treatment system and the treatment method have important environment benefit.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

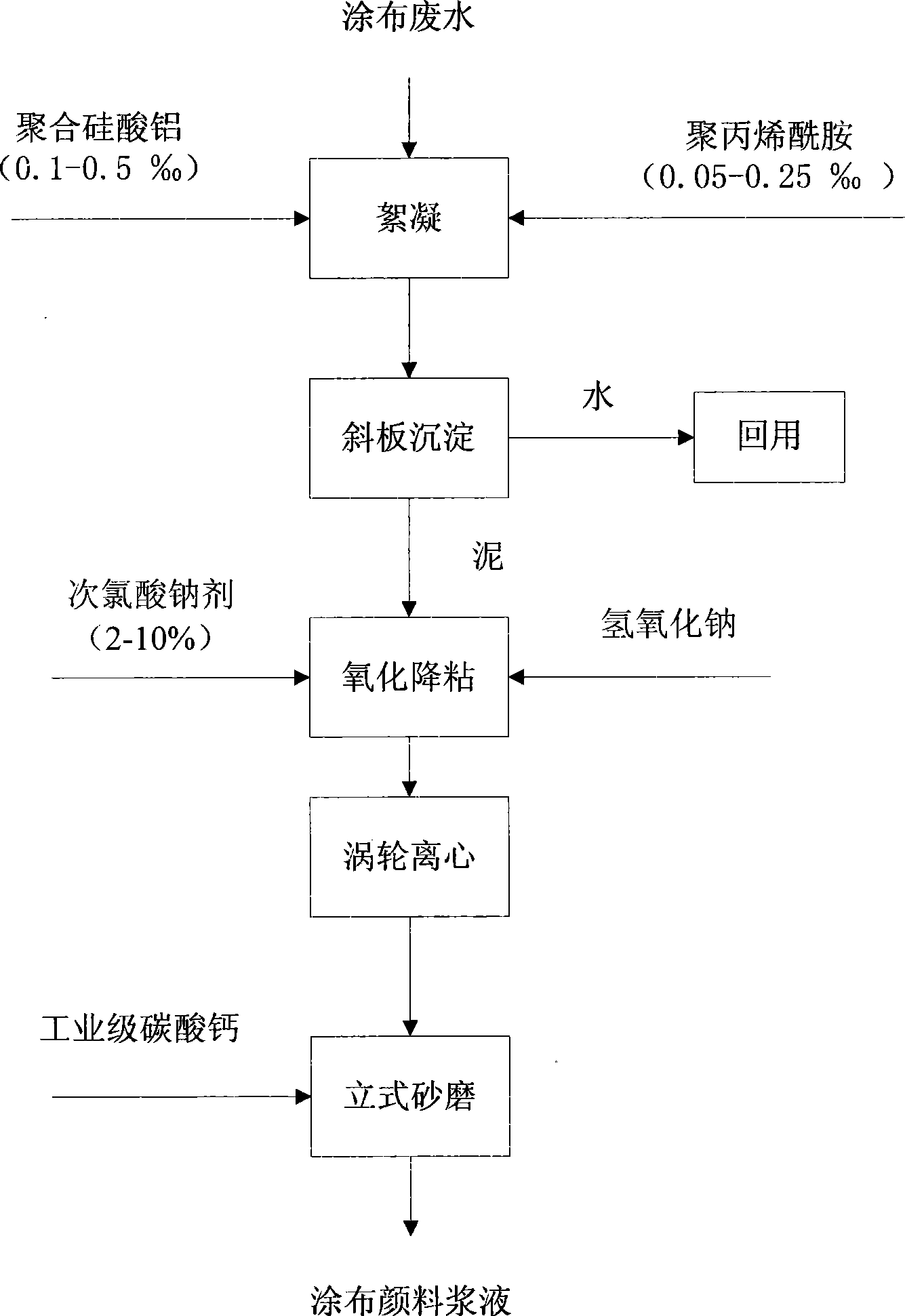

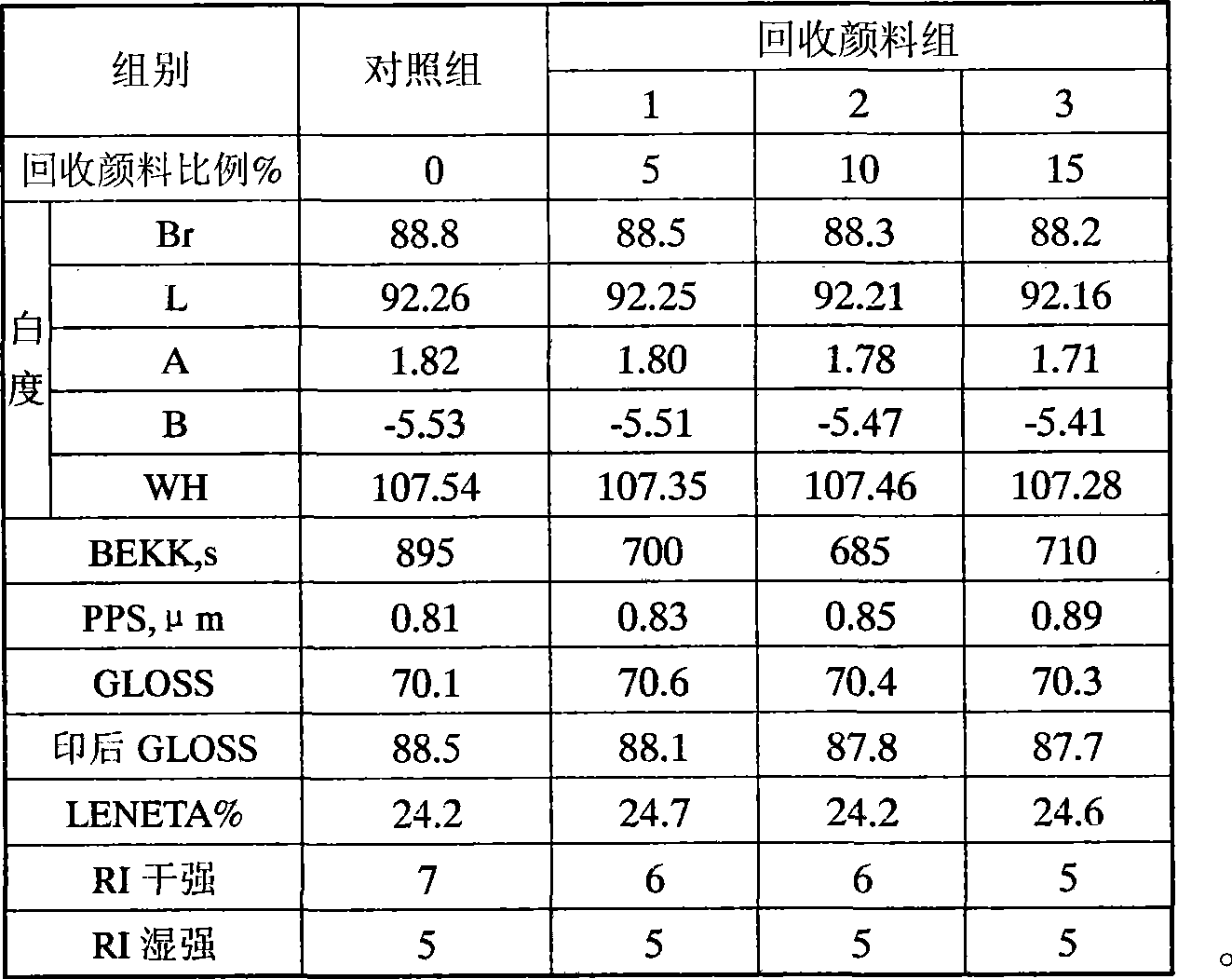

Reutilization process for painting and coating pigment pf paper mill

InactiveCN101367589AIn line with the development modelThe process steps are simpleSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSocial benefitsCentrifugation

The invention provides a process of recovering and treating the paper mill coating pigment and the secondary use as the coating pigment. The process comprises flocculating, inclined lamellar precipitation, oxidation and viscosity reduction, turbine centrifugation and vertical foundry mill. The treatment object is the paper mill coating wastewater. The step of the process is simple, and the process can not generate the secondary pollution. The quality of the products passes the coating tests and the paper reaches the related standards of the enterprise. The process is a novel technology with environmental benefit, economic benefit and social benefit.

Owner:北京盖雅技术中心有限公司

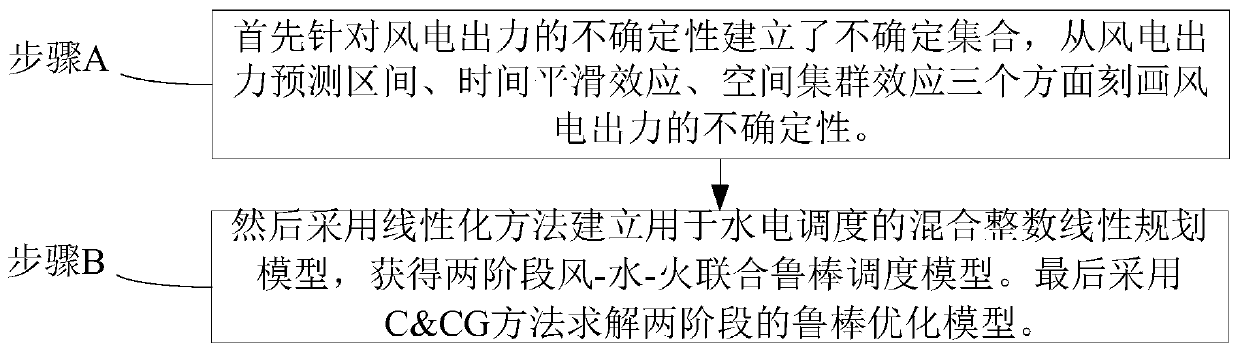

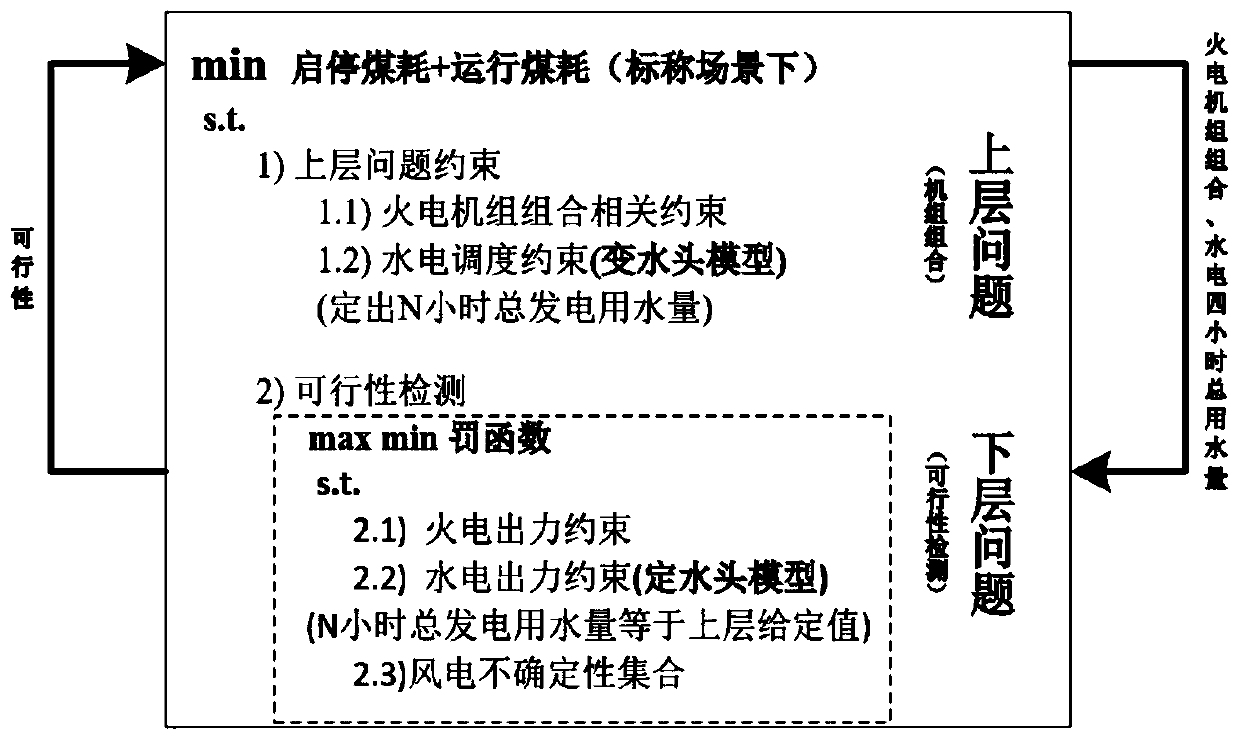

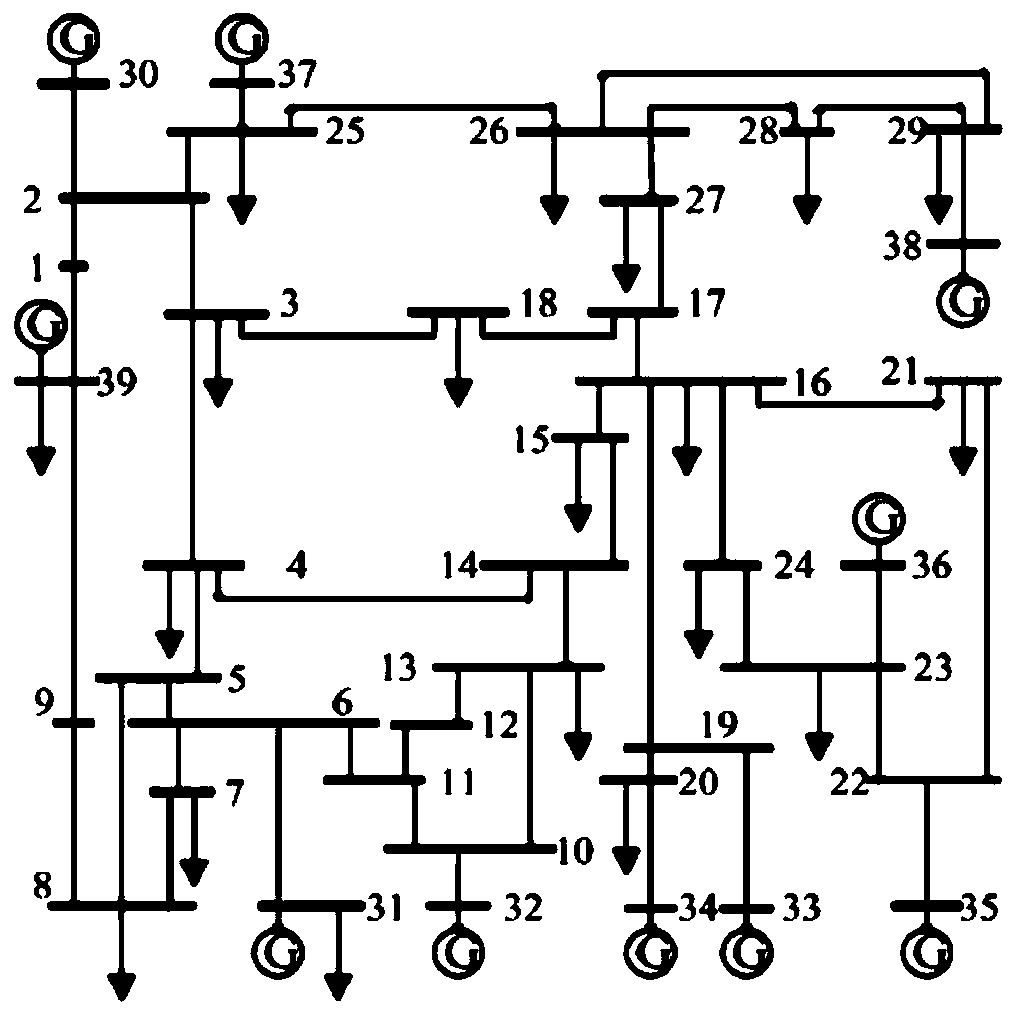

Wind-water-fire joint robust unit combination method

InactiveCN110212579AImprove effectivenessImprove absorption capacitySingle network parallel feeding arrangementsWind energy generationEngineeringPower dispatch

The invention provides a wind-water-fire joint robust unit combination method. Firstly, an uncertain set is established for the uncertainty of wind power output, and the uncertainty of the wind poweroutput is described in three aspects of a wind power output prediction interval, a time smoothing effect and a spatial cluster effect. Then, a mixed integer linear programming model for water and power dispatching is built by using a linearization method, and the model is integrated in a robust unit combination model considering wind and power dispatching to obtain a wind-water-fire joint robust dispatching model. Finally, a robust optimization model in two phases is solved by adopting a C&CG method. Compared with a traditional robust unit combination model, the wind-water-fire joint robust unit combination model has the advantages that the operation cost is reduced, and the starting number and the running time of thermal power units are reduced, so that the carbon emission is reduced, andthe environmental benefit is achieved; the wind power consumption capacity of a system is increased due to the addition of water power; and the problem of a unit combination containing cascade hydropower stations can be solved within a reasonable time range.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +2

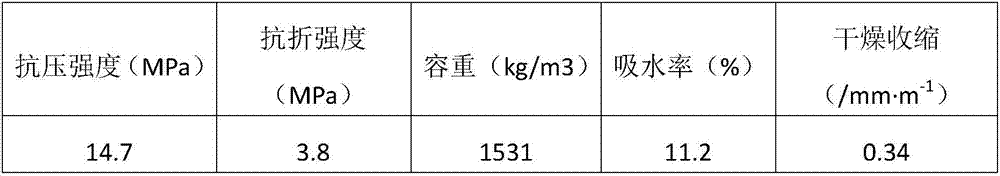

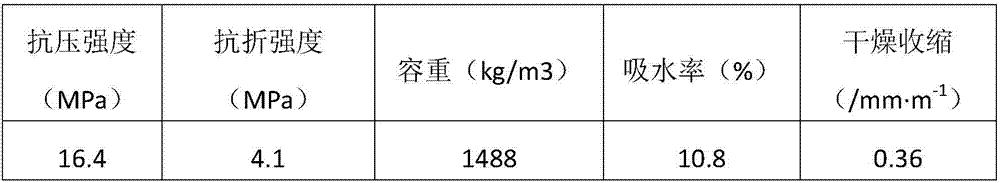

Technology for preparing base geopolymer eco-material

InactiveCN107043233AShorten drying timeShorten the production cycleSolid waste managementCement productionSocial benefitsBrick

The invention relates to a technology for preparing a base geopolymer eco-material. The technology comprises the steps of taking a proper amount of kaolin, calcining, grinding and sieving to obtain metakaolin; mixing the following raw materials evenly in parts by weight: 50-70 parts of domestic waste incineration fly ash, 30-50 parts of metakaolin, 10-20 parts of an excitant and a dry material, doping 10-30 parts of water, stirring evenly and injecting the mixture into a die for compaction; putting the mold into a drying oven for dry maintenance and then dismantling the die; and finally further maintaining a brick body after the die is dismantled in the drying oven of 30-80 DEG C for 12-21d to obtain the base geopolymer eco-material. A novel environment-friendly functional material is produced by using the metakaolin and the domestic waste incineration fly ash. The industrial wastes can be utilized through adjusting measures to local conditions, so that land and water resources are effectively protected and environmental pollution is controlled. The technology has significant environmental, economic and social benefits.

Owner:NANJING UNIV OF TECH

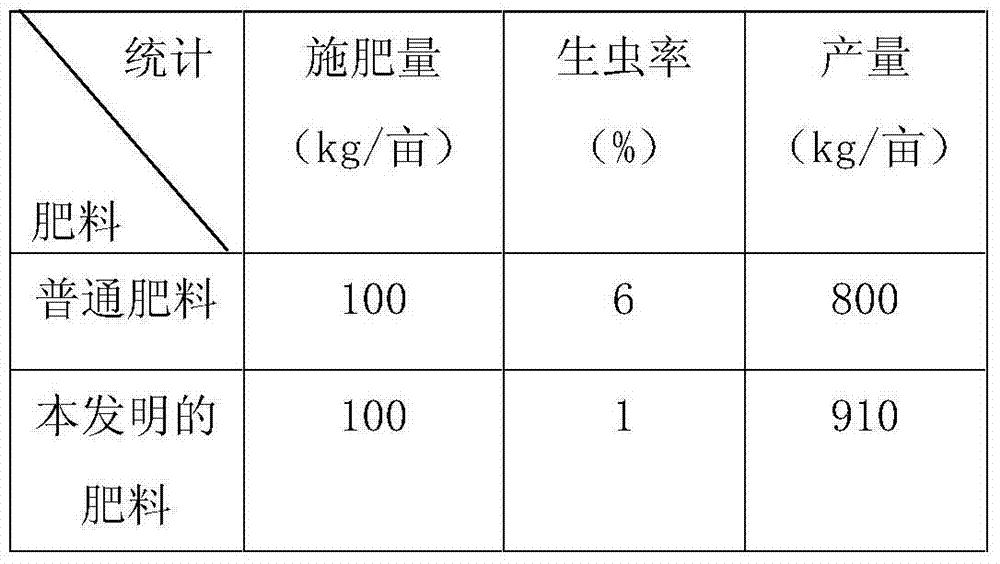

Insect-proofing organic fertilizer and preparation method thereof

The invention discloses an insect-proofing organic fertilizer which is prepared from the following raw materials in parts by weight: 200 to 230 parts of chicken manure, 30 to 34 parts of castor bean, 20 to 23 parts of garlic stems, 10 to 12 parts of radix sophorae flavescentis, 10 to 12 parts of broadleaf sawdust, 12 to 14 parts of bones, 2 to 3 parts of plant ash, 3 to 4 parts of bran, 4 to 5 parts of talcum powder, 20 to 23 parts of urea, 40 to 45 parts of calcium superphosphate, 2 to 3 parts of borax, 5 to 6 parts of zinc sulfate, 3 to 4 parts of manganese sulfate, 2 to 3 parts of manganese sulfate, 3 to 4 parts of ammonium molybdate, 1 to 2 parts of calcium carbonate powder, 2 to 3 parts of sodium bicarbonate, 3 to 4 parts of EM (Effective Microorganism) agent, 4 to 6 parts of coating agent and a proper amount of water. The insect-proofing organic fertilizer is rich in organic nutrition, namely that the diversification of nutrient elements is realized, so that the yield and quality of a plant are improved; the soil structure and the soil fertility are also improved to a certain extent through the added raw materials, so that an important significance for promoting agricultural mechanization and ecological food sharing is achieved. Thus, the insect-proofing organic fertilizer has a broad prospect. In addition, the insect-proofing capacity and disease-resisting capacity of a crop are improved through the addition of the castor bean, the garlic stems, the radix sophorae flavescentis and the like, so that the breeding of soil microorganisms is promoted; moreover, the pollution to the environment is avoided. Thus, the insect-proofing organic fertilizer has certain economic and environmental benefits.

Owner:DANGTU COUNTY KEHUI TRADING

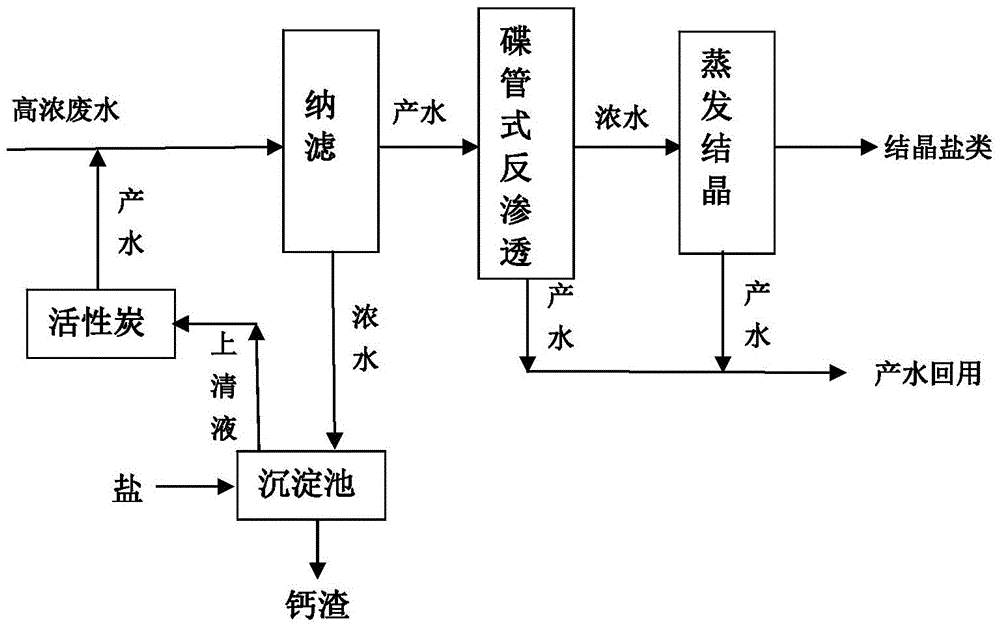

High concentration wastewater zero-emission method

ActiveCN105621769ASolve the problem of advanced treatment and even zero dischargeEasy for reverse osmosis treatmentMultistage water/sewage treatmentEnergy based wastewater treatmentHigh concentrationReverse osmosis

The present invention relates to the field of industrial wastewater treatment, and specifically relates to a high concentration wastewater zero-emission method. According to the high concentration wastewater zero-emission method, nanofiltration, disc tube reverse osmosis (dt-ro) and evaporation crystallization are used for treatment of high concentration wastewater. Firstly the nanofiltration is used for removing hardness and other multivalent ions and some organic matters in wastewater, then the disc tube reverse osmosis (dt-ro) is used for deep concentration treatment of the high concentration wastewater with the hardness and some organic matters being removed, and salt solids in concentration water are crystallized by evaporation crystallization treatment of reverse osmosis concentration water after disc tube reverse osmosis deep concentration treatment, and then are concentrated for drying treatment. The disc tube reverse osmosis producing water and the evaporation and crystallization producing water produced in the treatment process both can be reused in the production process. According to the high concentration wastewater zero-emission method, the high concentration wastewater emission problem can be solved, meanwhile the recovery of water resources is maximized, and high concentration wastewater zero-emission is basically realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

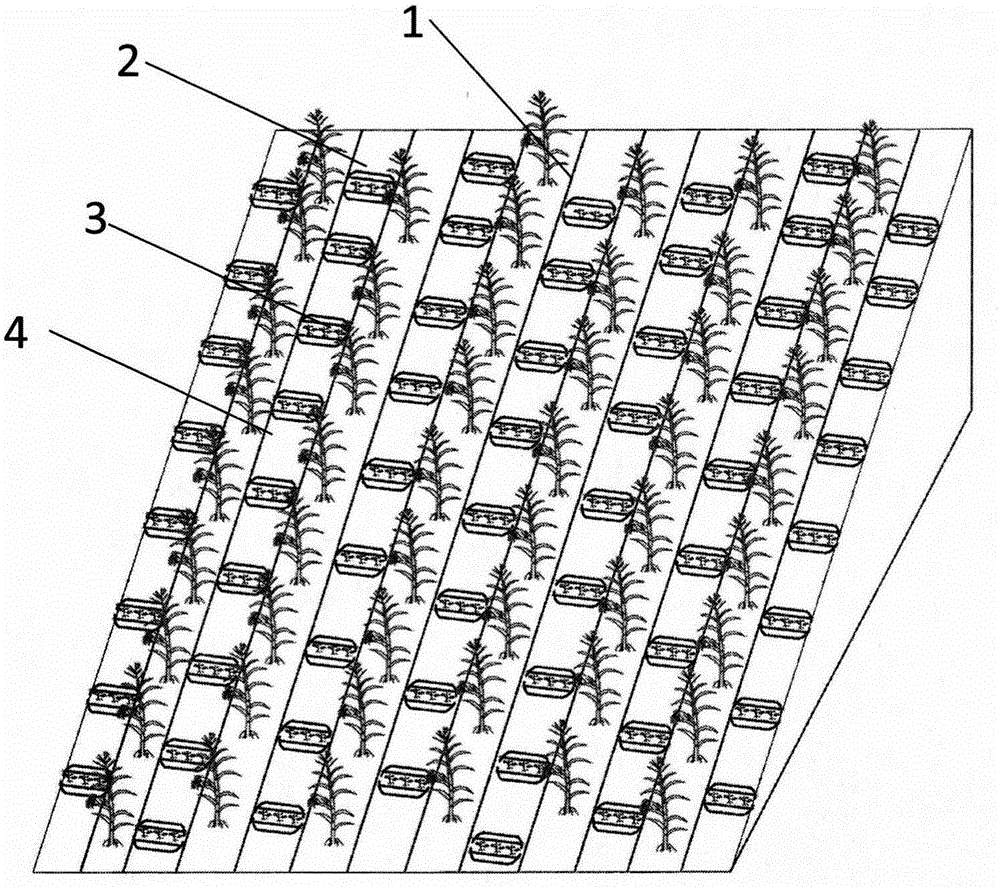

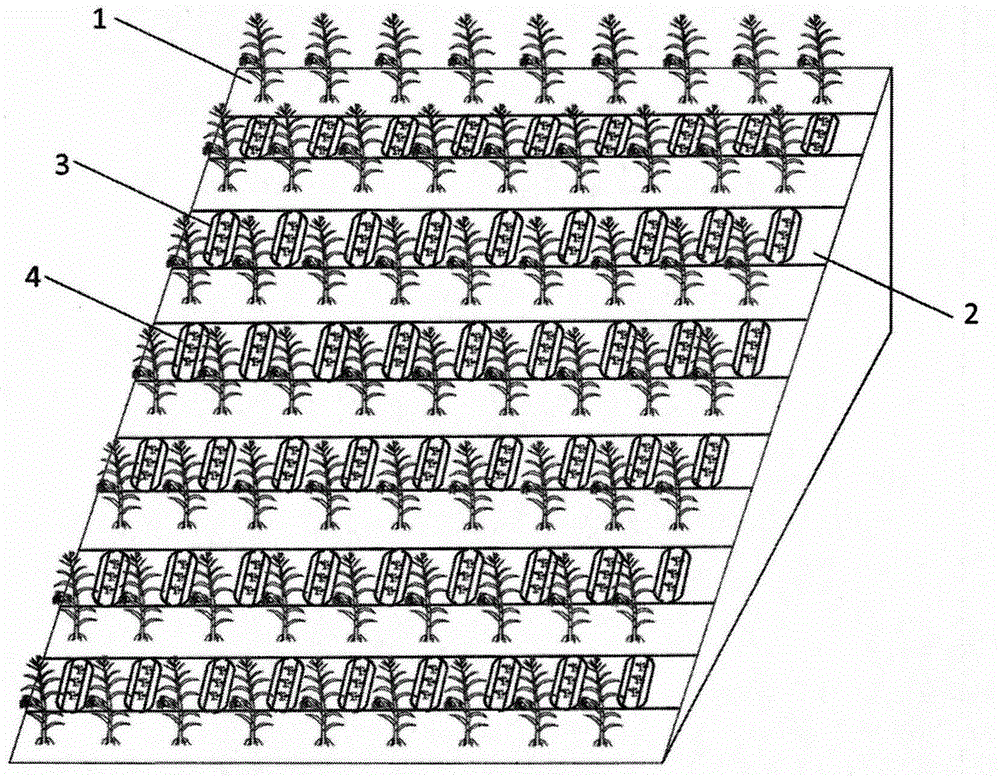

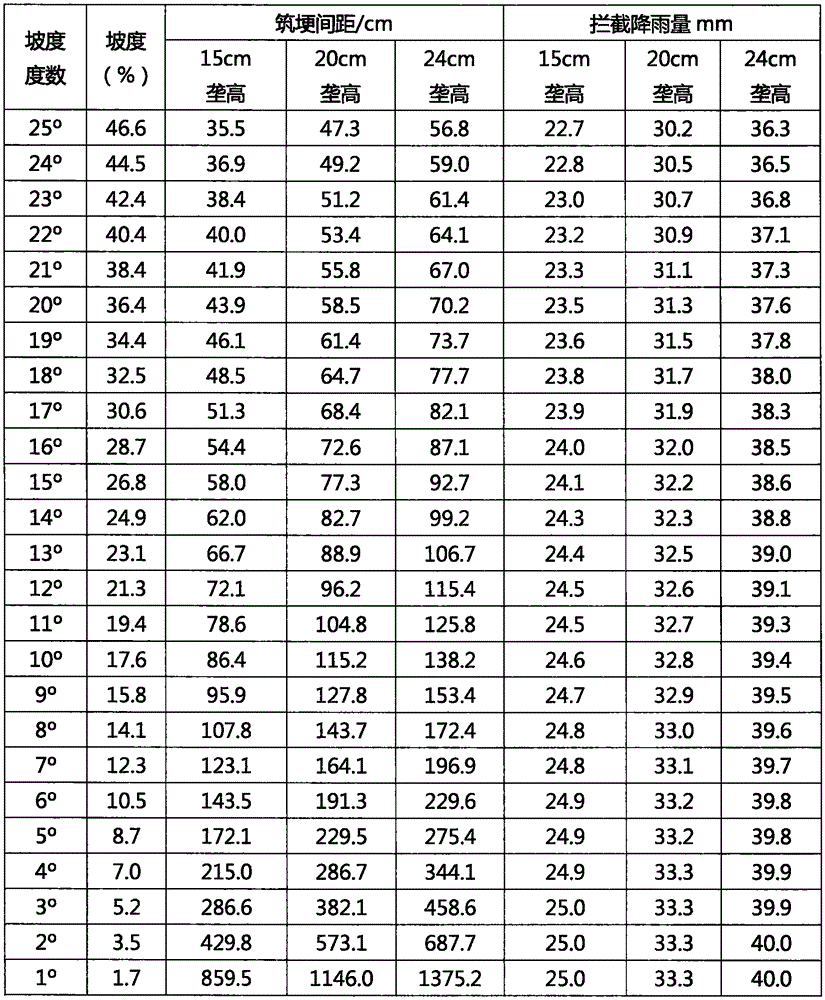

Hedge earth bank ridge-direction pitting field having functions of conserving water, soil, nitrogen and phosphorus and cultivation method

InactiveCN105145068AImprove retentionIncrease moisture contentHorticultureSoil-working methodsEconomic benefitsNitrogen

The invention relates to a hedge earth bank ridge-direction pitting field having functions of conserving water, soil, nitrogen and phosphorus. The field comprises ridges and multiple earth banks, and the ridges comprise ridge bodies and furrows; the multiple ridge bodies and the multiple furrows are arranged in parallel and at intervals; multiple earth banks are arranged in each furrow in the extending direction of the corresponding furrow, and each earth bank is provided with a hedge. The invention further relates to a cultivation method of the ridge-direction pitting field. The cultivation method comprises the steps of measuring the slope and length of the field; making selection between downslope ridge culture or cross-slope ridge culture according to the measured slope and length, and arranging the multiple furrows and ridge bodies, wherein the furrows and the ridge bodies are arranged in parallel and at intervals; arranging the multiple earth banks in each furrow in the extending direction of the corresponding furrow; planting plants on each earth bank for forming the corresponding hedge. According to the hedge earth bank ridge-direction pitting field and the cultivation method, the hedges are reasonably arranged, the stability and firmness of the earth banks are improved, meanwhile, the water, soil, nitrogen and phosphorus conservation effects are greatly improved, the water and soil conservation effect is made to be more ideal, environmental benefits are achieved, and meanwhile economic benefits are combined.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Formulation of environment-friendly paperboard regenerated by papermaking sludge and waste textile fibre material

InactiveCN101555673AImprove impact resistanceImprove sound absorptionFibreboardTextile fiberEcological environment

The invention belongs to the technical field of environment-friendly paperboard, in particular relates to a formulation of environment-friendly paperboard regenerated by papermaking sludge and waste textile fibre material. The formulation comprises the following components by weight percentage: 70-95% of papermaking sludge and 5-30% of waste textile fibre material, the water content of the papermaking sludge is 85-95%, the content of long fibre is less than 30%, the length of the fibre in the waste textile fibre material is 5-15mm and the diameter thereof is 0.001-0.01mm. The papermaking sludge is the papermaking sewage from paper industry and used as one raw material of the invention, and the waste textile fibre material is mainly from the waste fibre of spinning mills and used as the other raw material of the invention, so as to change the waste into the valuable. The prepared paperboard has light weight, good shock resistance, good sound absorption effect and heat insulation effect. The invention not only saves social resources, but also protects the ecological environment, and solves the big problems of the paper industry and the textile industry. The formulation is a new technique with environmental benefit, economic benefit and social benefit.

Owner:DONGGUAN SHENGYIN ENVIRONMENTAL TECH

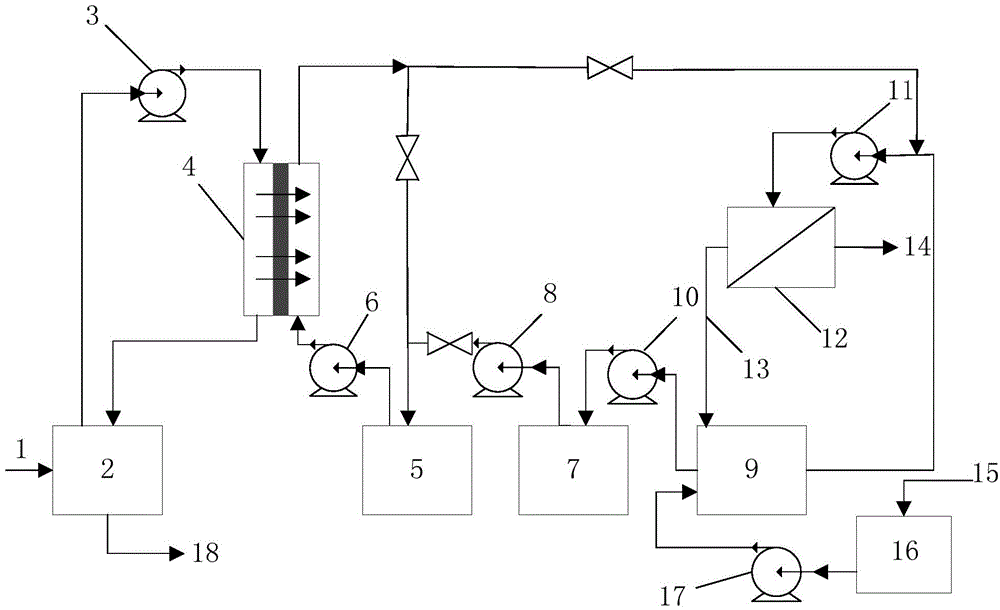

High salinity and high ammonia nitrogen wastewater treatment method

ActiveCN104591423AHigh recovery rateEmission reductionWater contaminantsMultistage water/sewage treatmentWater resourcesWater quality

The invention discloses a high salinity and high ammonia nitrogen wastewater treatment method. The method adopts a membrane absorption + nanofiltration + forward osmosis process flow. The method comprises the following steps: converting ammonia nitrogen in wastewater by adopting membrane absorption with a sulfuric acid solution as an absorption liquid to form ammonium sulfate; concentrating the ammonium sulfate solution through adopting nanofiltration; carrying out forward osmosis concentration treatment with the concentrated ammonium sulfate solution as a forward osmosis driving liquid and the high salinity wastewater with ammonia nitrogen removed through the membrane absorption as a forward osmosis inlet liquid; and diluting the ammonium sulfate solution as the driving liquid, and returning parts of the diluted ammonium sulfate solution to a nanofiltration unit for cycle concentration treatment. The method effectively solves the treatment problem of the high salinity and high ammonia nitrogen wastewater, allows the water recovery rate to be high, and allows the quality of produced water to be good. The method is adopted to carry out cycle concentration treatment of the high salinity and high ammonia nitrogen wastewater, so the discharge amount of concentrated water is extremely small, and the water resource in the high salinity and high ammonia nitrogen wastewater is maximally recovered.

Owner:CHINA PETROLEUM & CHEM CORP +1

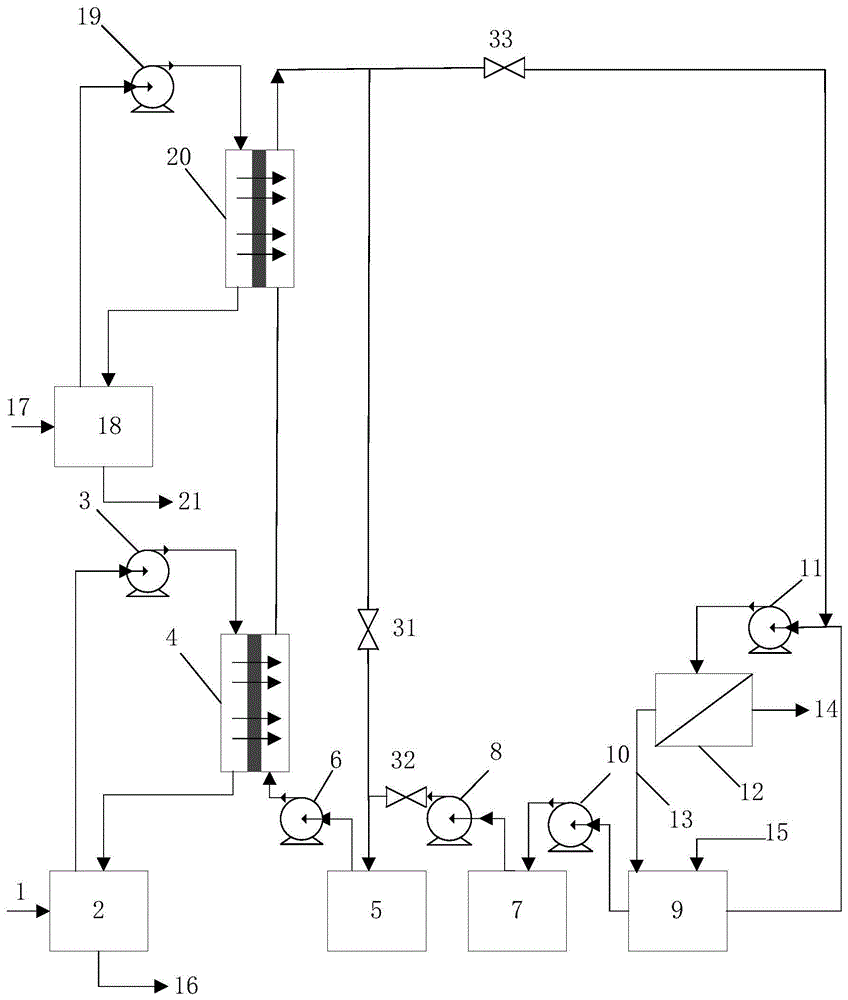

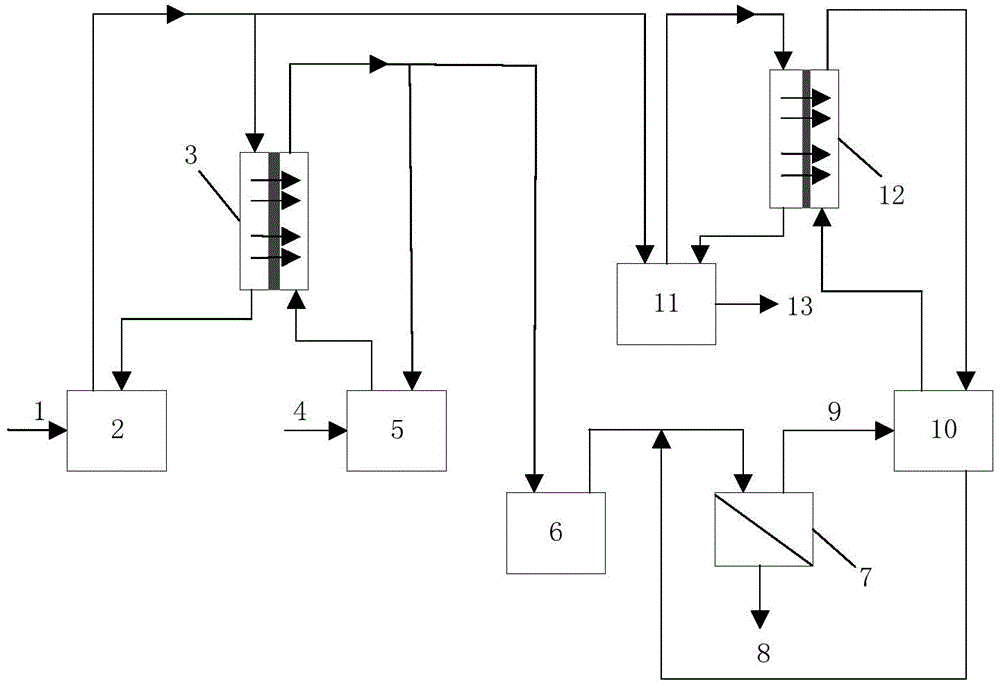

High salinity ammonia nitrogen wastewater treatment method

The invention discloses a high salinity ammonia nitrogen wastewater treatment method. The method adopts an acid adjustment + membrane distillation + forward osmosis process flow. The method is characterized in that acidity adjustment pretreatment of high salinity ammonia nitrogen wastewater is carried out according to the characteristics of wastewater and the characteristic of most ammonia nitrogen existing in the ammonia nitrogen wastewater with a low pH value as NH<+>, a membrane distillation technology is adopted to concentrate the acid adjusted high salinity ammonia nitrogen wastewater, high salinity membrane distilled concentrated water is used as a driving liquid of forward osmosis and is diluted through the continuous concentration of raw water at a forward osmosis inlet liquid side, and when the membrane distilled concentrated water is diluted to a specific concentration, the diluted concentrated water returns to a membrane distillation unit and is continuously concentrated. The process flow is cycled, and the advanced concentration treatment of the high salinity ammonia nitrogen wastewater is carried out to obtain a large amount of pure water and solve a problem that the membrane distilled concentrated water generated in the high salinity ammonia nitrogen wastewater treatment is difficult to treat, so the wastewater recovery rate is maximally improved, and the method has important environmental benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

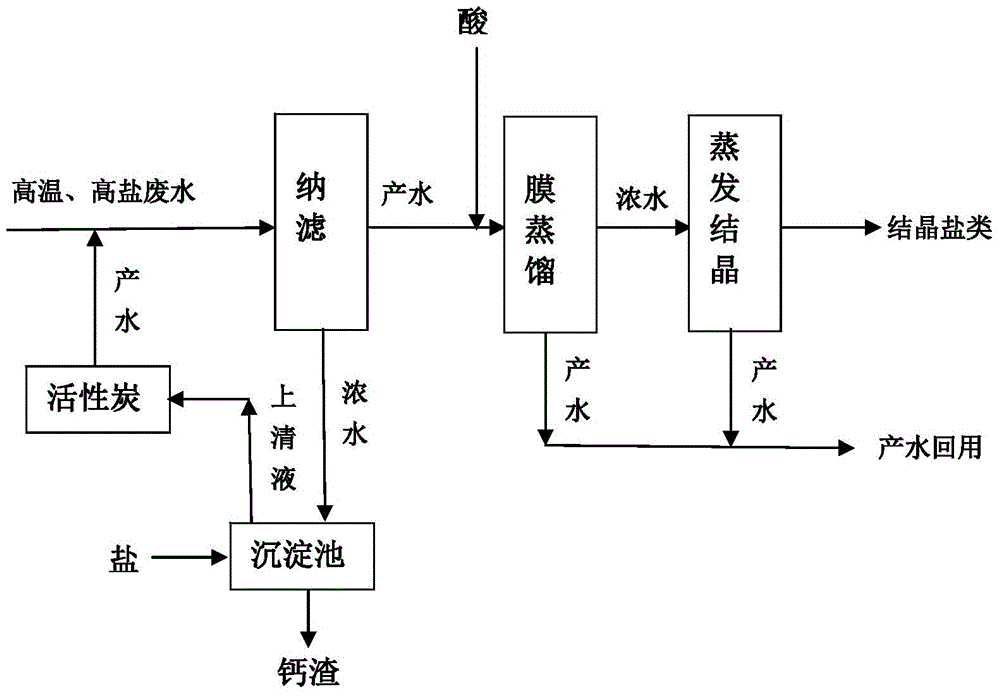

High-temperature high-salinity wastewater zero-discharging method

ActiveCN105198141ASolve the problem of advanced treatment and even zero dischargeEfficient use ofMultistage water/sewage treatmentMembrane distillationProduced water

The invention relates to a high-temperature high-salinity wastewater zero-discharging method. Firstly, a high-temperature-resisting nanofiltration membrane is adopted to remove multivalent ions and a little amount of organic matter in wastewater, then a membrane distillation technology is adopted to conduct deep concentration treatment on the wastewater, membrane-distillation concentrated water is subjected to evaporative crystallization treatment to enable salt in the membrane-distillation concentrated water to crystallize out, and centralized drying disposal is performed. Salt is added into the nanofiltration concentrated water produced in the treatment process to perform precipitation treatment so as to obtain calcium residues, centralized drying disposal is performed, supernate obtained after precipitation is subjected to activated carbon adsorption, and producing water obtained after activated carbon adsorption and nanofiltration feed water are mixed and fed into a nanofiltration unit for circular treatment. Membrane-distillation producing water and evaporative-crystallization producing water can be both reused for a production process. By means of the high-temperature high-salinity wastewater zero-discharging method, residual heat of the wastewater itself is effectively utilized while wastewater zero discharging is achieved, the energy consumption of the whole technological process is reduced, and efficient utilization of waste water resources and energy is achieved. The high-temperature high-salinity wastewater zero-discharging method has remarkable social benefit and environmental benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biological multi-effect vegetable fertilizer and preparation method thereof

InactiveCN103553793AWide range of materialsImprove fertilizer efficiencyFertilizer mixturesDisease damagePhosphoric acid

The invention discloses a biological multi-effect vegetable fertilizer, which is prepared from the following raw materials in parts by weight: 120 to 150 parts of soybean cake, 100 to 120 parts of silkworm excrement, 100 to 120 parts of sawdust, 60 to 70 parts of sepiolite powder, 40 to 50 parts of weathered coal, 50 to 60 parts of medical stone, 30 to 40 parts of fishbone dust, 20 to 30 parts of waste tobacco material, 50 to 60 parts of garlic stem, 30 to 35 parts of calcium superphosphate, 40 to 45 parts of diammonium phosphate, 12 to 15 parts of potassium chloride, 10 to 12 parts of silicon dioxide, 5 to 9 parts of potassium sulfate, 2 to 3 parts of manganese sulfate, 6 to 9 parts of EM (effective microorganism), 10 to 15 parts of soil conditioner and a proper amount of water. The fertilizer is prepared from waste in life and industrial production, and has the advantages of wide material sources, low cost, high fertilizer efficiency, nutrient balance and the like, the requirements of vegetable growth on nutrients can be met, the resistance of vegetables to pest and disease damage can be improved, and the yield and quality of the vegetables can be improved; the prepared fertilizer also has the effects of improving the physical and chemical properties of soil, enhancing the water retention, nutrient maintenance and nutrient supply capability of the soil and increasing beneficial bacteria, soil microorganisms and populations, and has certain economic and environmental benefits.

Owner:ANHUI WANLI ECOLOGICAL LANDSCAPE

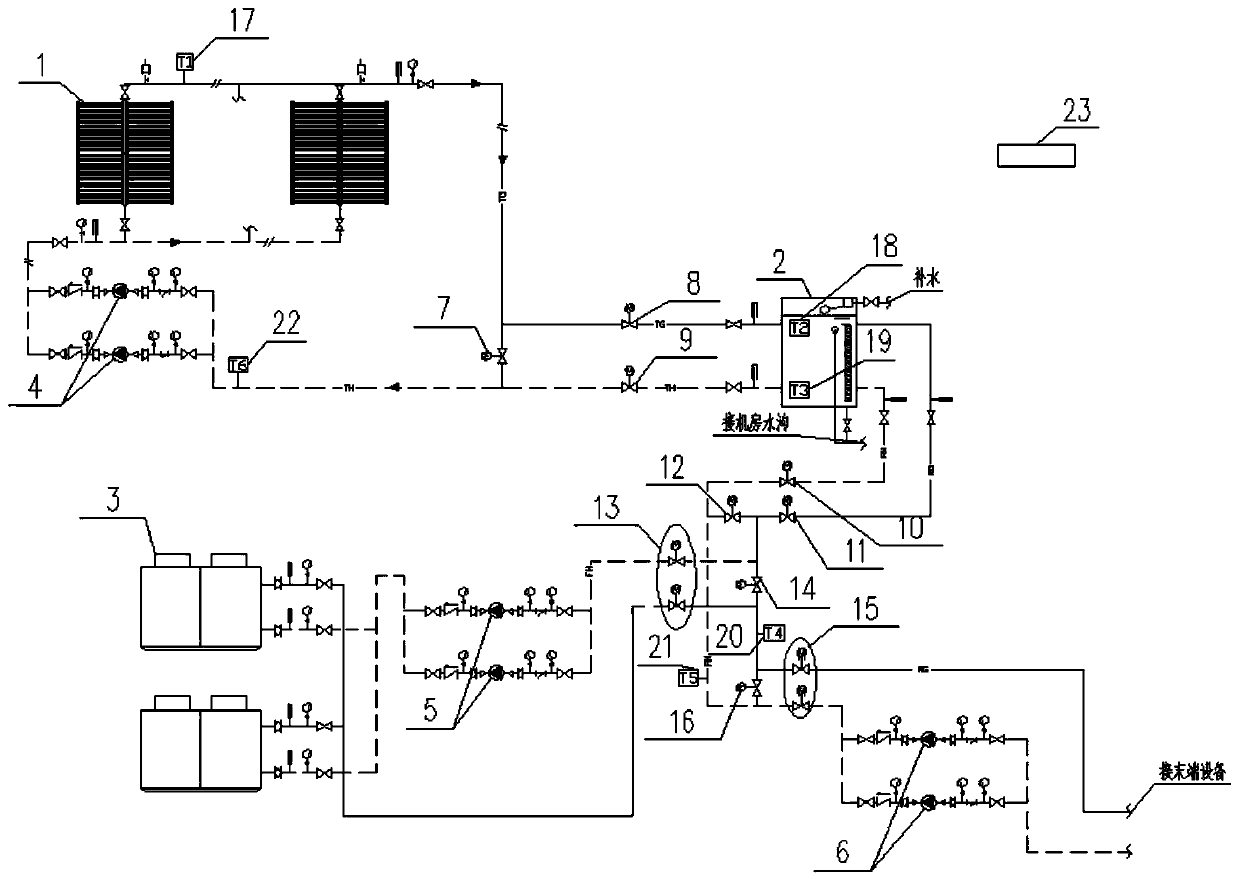

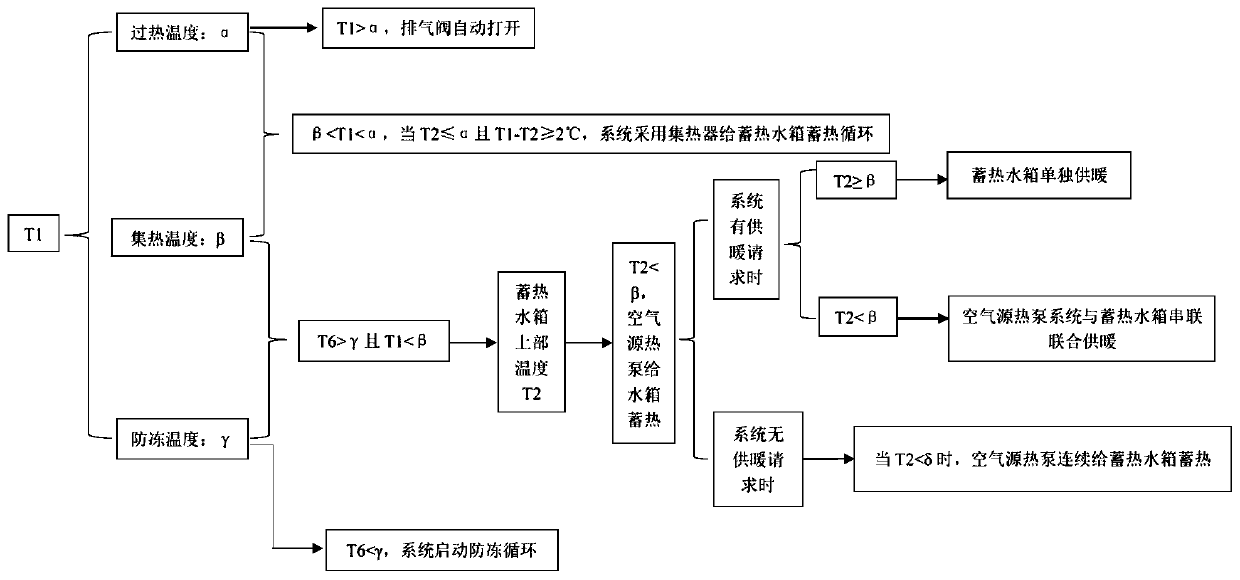

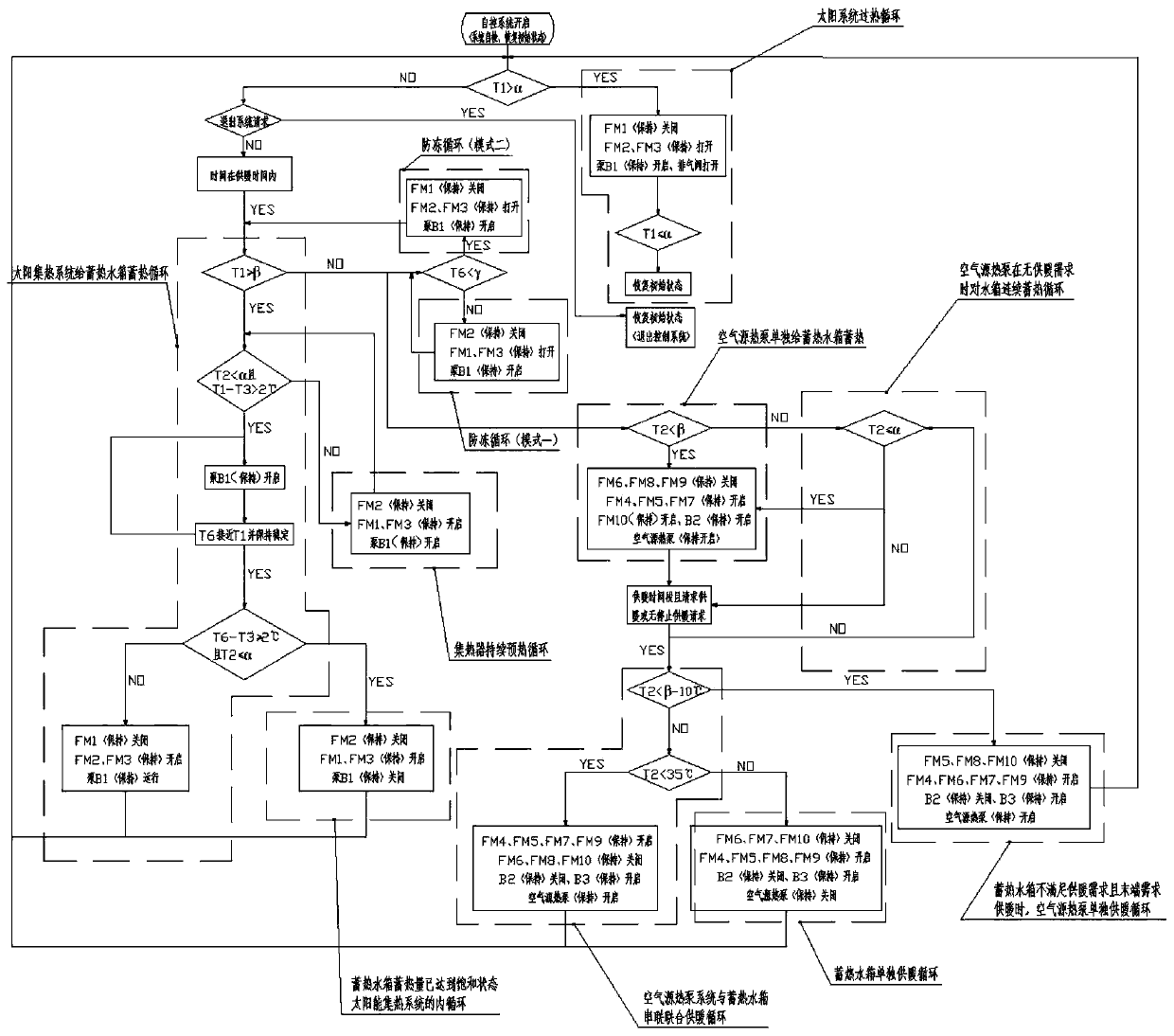

Solar coupled air source heat pump complementary heating system and control method

ActiveCN111207434ATo achieve complementary useFix instabilitySolar heating energySolar heat collector controllersCollector deviceEngineering

The invention discloses a solar coupled air source heat pump complementary heating system and a control method. The heating system is composed of a solar heat collection system, an air source heat pump system, a heat storage water tank and end equipment, wherein the heat storage water tank is connected between the solar heat collection system and the air source heat pump system; the solar heat collection system involves a solar heat collector connected to the heat storage water tank through a pipeline, a temperature probe T1 is arranged on the pipeline, a temperature probe T2 and a temperatureprobe T3 are arranged on the upper part and the lower part of the heat storage water tank, a water outlet of the heat storage water tank is connected with a solar-side circulation water pump throughthe lower circulation pipe section, a temperature probe T6 is arranged at the water inlet of the circulation water pump, the upper circulation pipe section and the lower circulation pipe section of the heat collection system are shortly connected through a water pipe, and electric two-way valves are arranged on an upper circulation pipeline, a lower circulation pipeline and a short connection pipeline correspondingly. The solar coupled air source heat pump complementary heating system solves the problem that an existing solar energy and air energy heating technology is used, so that overheating and undercooling of the cycle side of the solar heat collection are considered to appear.

Owner:SICHUAN PROVINCIAL ARCHITECTURAL DESIGN & RES INST

Low-salt recycling technology for mechanical cutting emulsified liquid waste

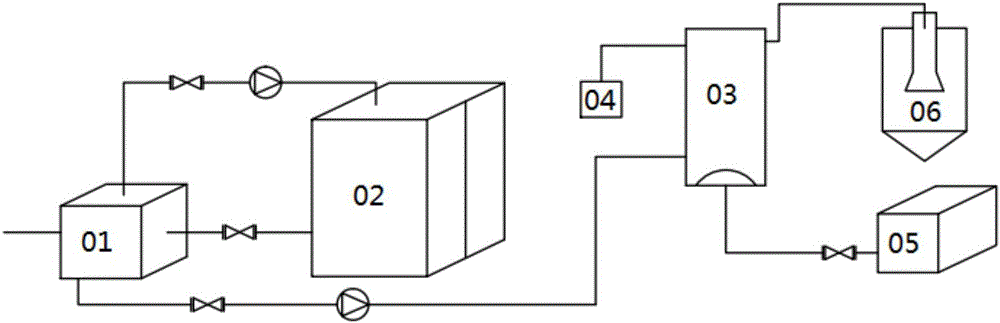

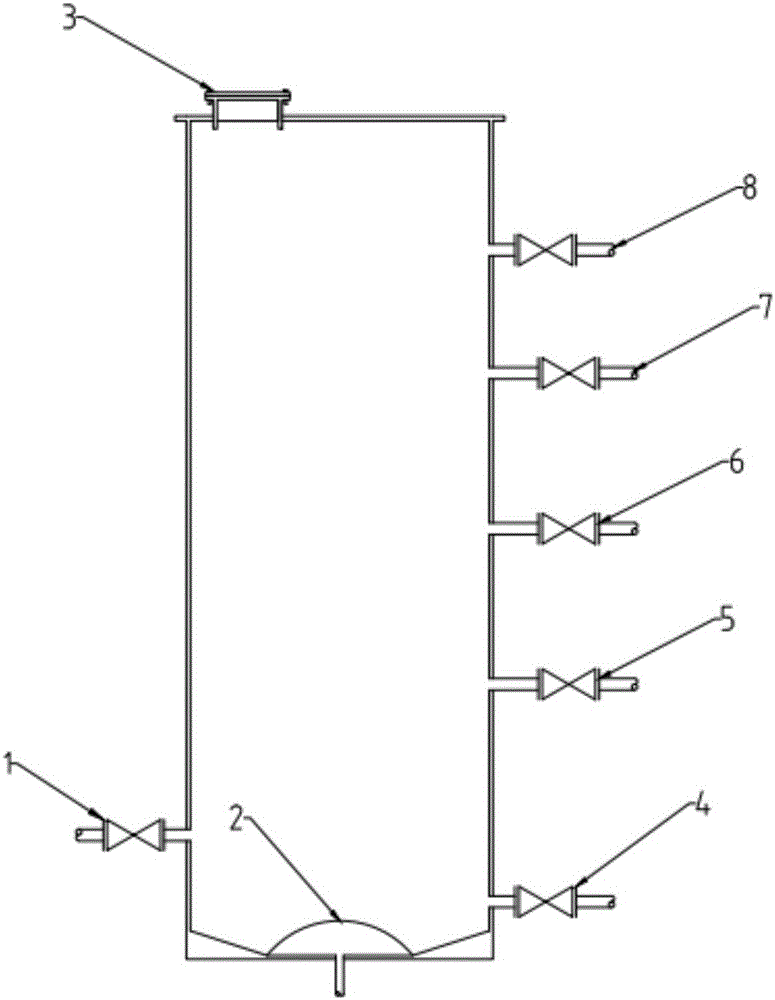

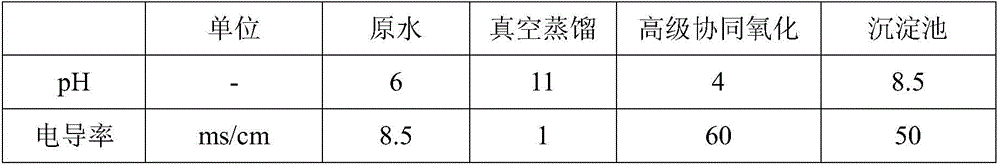

ActiveCN105906118AReduce salt contentReduce loadWater treatment compoundsMultistage water/sewage treatmentLubricationVacuum distillation

A low-salt recycling technology for mechanical cutting emulsified liquid waste includes vacuum distillation separation and microbubble ozone / H2O2 / Fe2+collaborative multistage combined advanced oxidation so as to achieve distillation and concentration of the mechanical cutting emulsified liquid waste and recycling of clear water. The low-salt recycling technology for the mechanical cutting emulsified liquid waste has the advantages that low-concentration distilled clear fluid is obtained via a vacuum distillation technique, and accordingly salt content of wastewater is decreased, oil can be separated from water effectively, the concentration ratio and wastewater recycling quantity are increased, chemical feeding quantity is decreased and treatment cost is reduced; by the aid of the microbubble catalytic ozonization / H2O2 / Fe2+ combined advanced oxidation technique, stability of residual emulsified oil in the distilled clear fluid is destroyed, recycling efficiency and feasibility of the emulsified liquid waste are guaranteed, and pollution of the oil-containing emulsified liquid waste to the environment can be reduced while water resources can be used fully to alleviate water resource shortage; the low-salt recycling technology can be used for treating and recycling emulsified liquid waste produced during machining and particularly during engine lubrication and cleaning.

Owner:SHANGHAI JIAO TONG UNIV

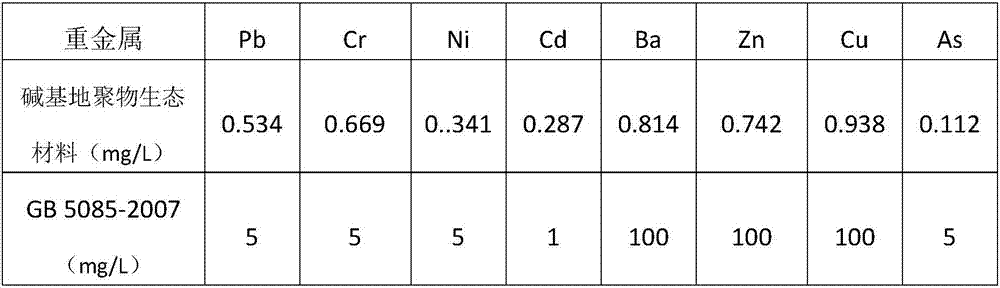

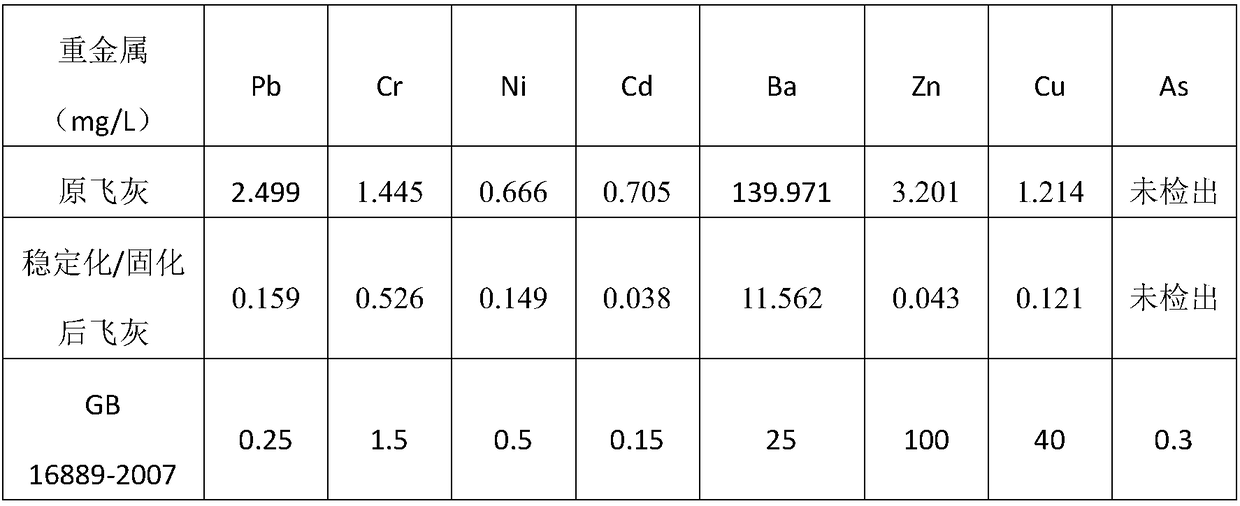

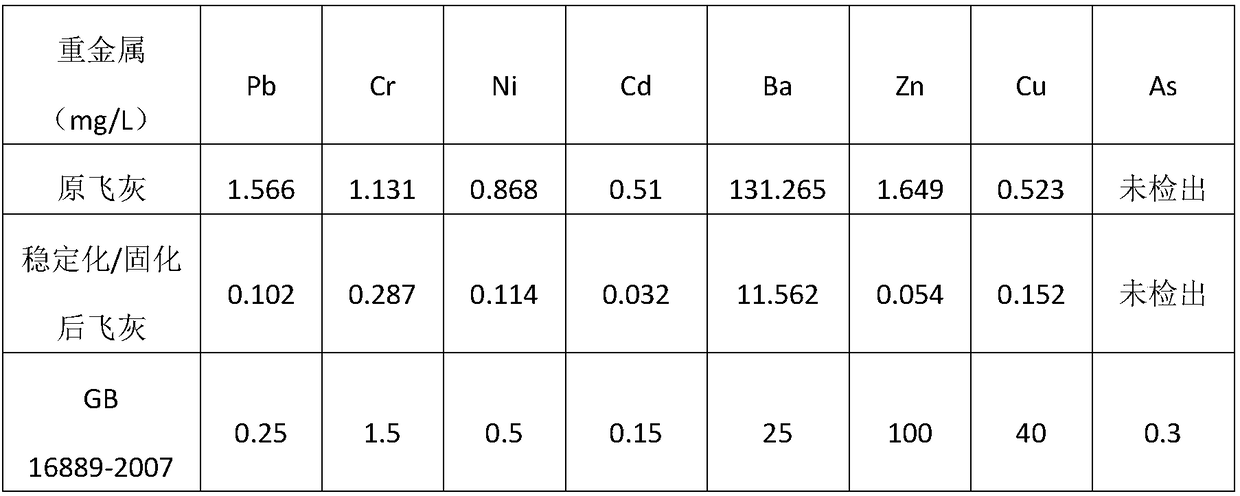

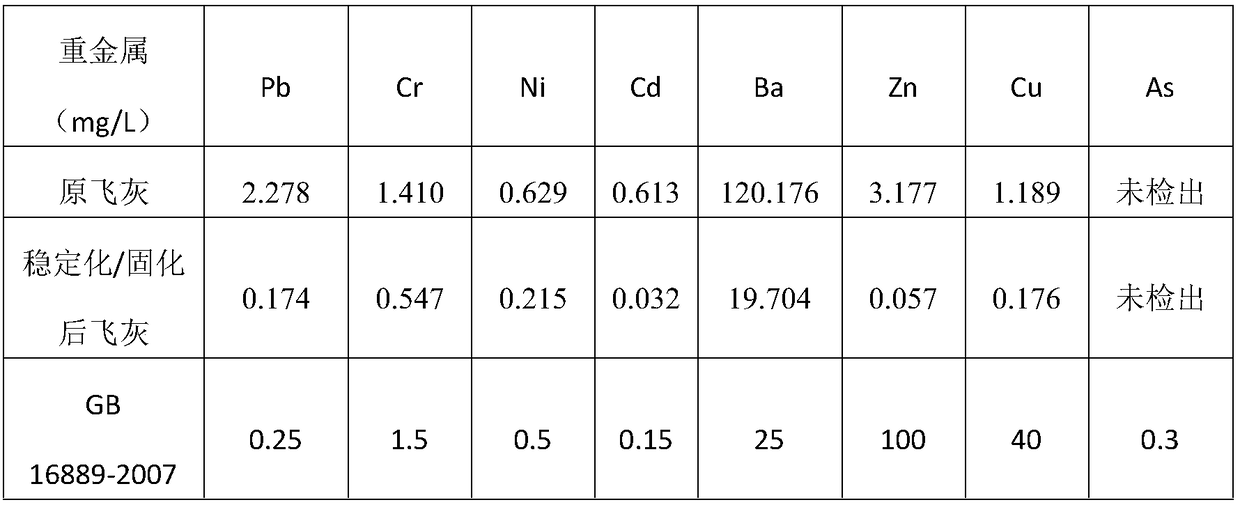

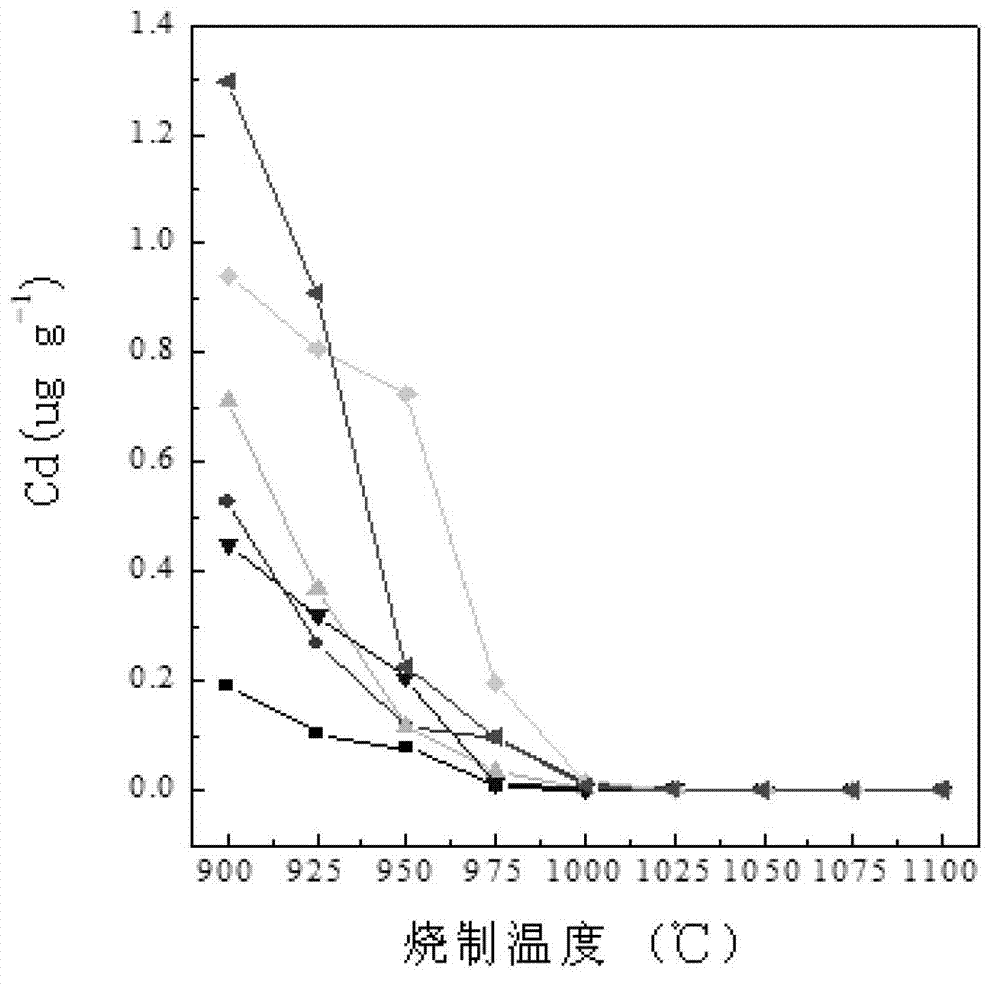

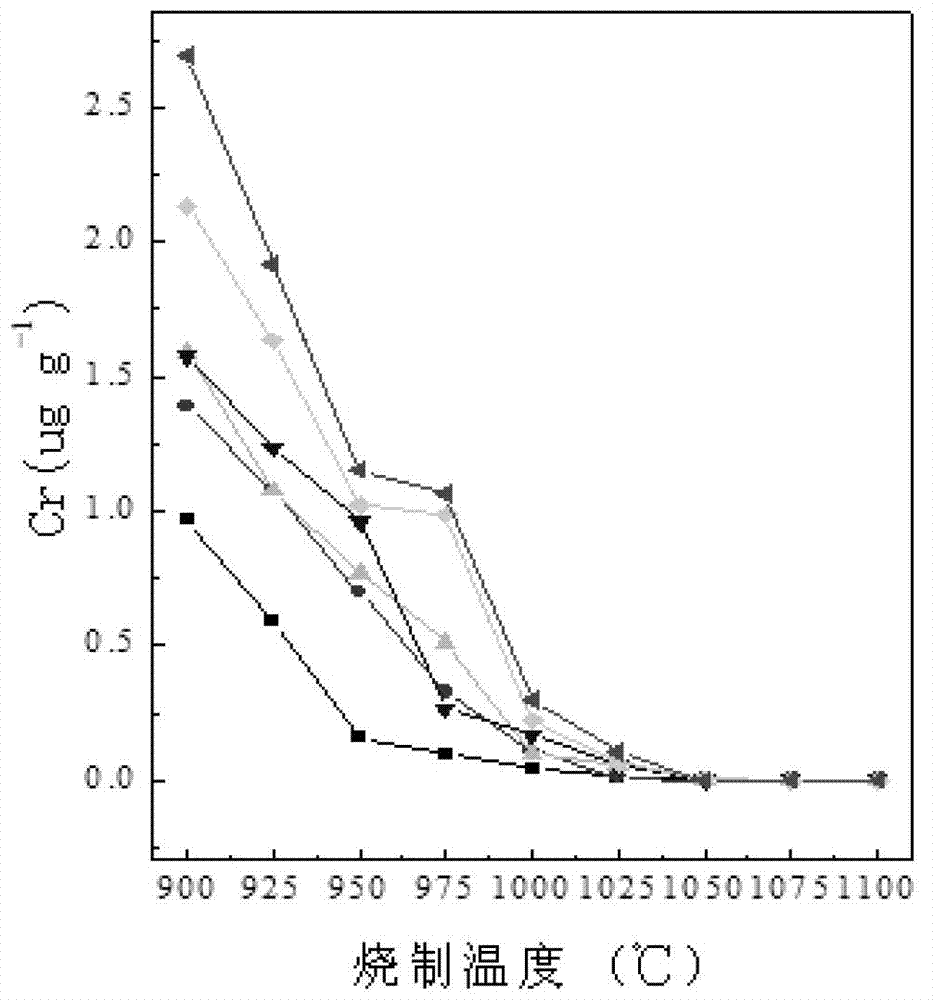

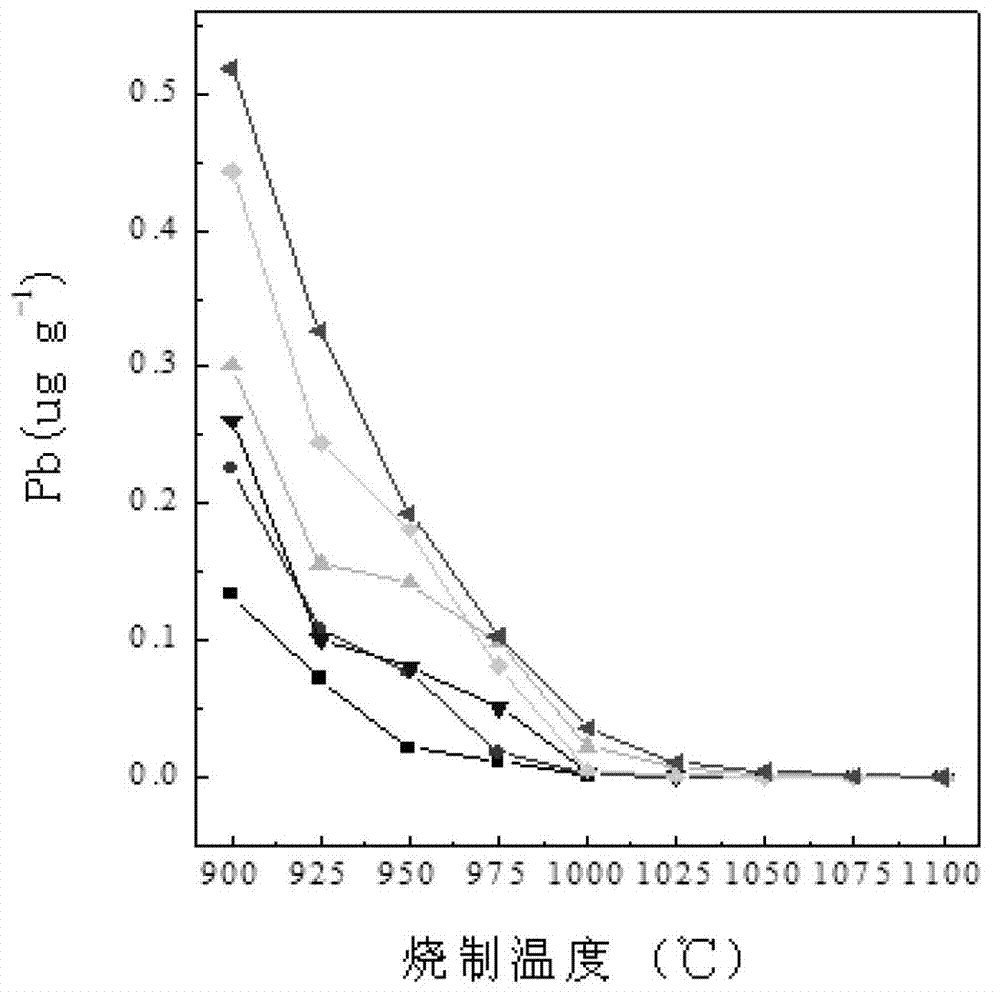

Process for gelling solidifying of heavy metals in municipal solid waste incineration fly ash by adding mineral powder

InactiveCN109092851AEfficient use ofAchieve reuseSolid waste disposalTransportation and packagingSocial benefitsDistilled water

The invention relates to a process for gelling solidifying of heavy metals in municipal solid waste incineration fly ash by adding mineral powder. The process comprises the steps that 80-120 parts ofthe municipal solid waste incineration fly ash are taken and placed in a container, 4-6 parts of pretreatment agents and 60-80 parts of water are added, stirring and drying are performed sequentially,and grinding and sieving are performed for standby application; 70-85 parts of pre-treated waste incineration fly ash and 15-30 parts of mineral powder admixtures are taken and mixed uniformly in a blender, then 3-5 parts of exciting agents and 35-50 parts of distilled water are taken to prepare an alkali solution to be added into the mixture, and the mixture is placed in the blender to stir to aslurry state; the slurry is taken out and beaten into a mud pie and sealed in a constant temperature climate box for curing, and then a solidified body is placed in a water curing box for curing for5-28d to obtain a gelling solidified body. The municipal solid waste incineration fly ash is subjected to gelling solidifying by being added with the mineral powder, the migration of the heavy metalsis effectively reduced, industrial waste can be used according to local conditions, water and soil resources are protected, and environmental pollution is controlled. Significant environmental, economic and social benefits are achieved.

Owner:NANJING UNIV OF TECH

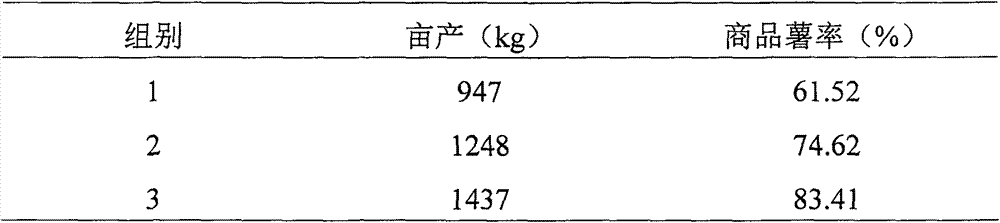

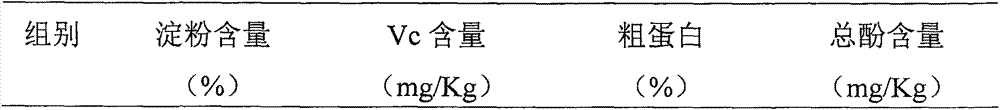

Cultivation substrate for sweet potato seedling

ActiveCN106941906APoor palatabilityAvoid pollutionExcrement fertilisersOrganic fertiliser preparationDiseasePotassium hydroxide

The invention belongs to the field of agricultural cultivation, and specifically relates to a cultivation substrate for a sweet potato seedling. The cultivation substrate is prepared through the following steps: (1) material fermentation: a step of uniformly mixing the following components in parts by weight: 30 parts of sweet potato stalk powder, 30 parts of blue algae, 10 parts of cow dung, 0.5 part of potassium hydroxide, 0.2 part of urea and 0.06 part of a fertilizer fermenting agent, carrying out stacking decomposing, guaranteeing the content of water to be 40 to 50% and a temperature to be 50 to 60 DEG C during the period of stacking decomposing, and carrying out turning once every 15 days until the state of decomposing is achieved, i.e., humus is obtained; and (2) substrate mixing: a step of weighing the following components in parts by weight: 40 parts of the humus, 20 parts of plant ash, 10 parts of pinewood sawdust, 10 parts of coarse sand, 0.8 part of sodium stearoyl lactylate and 0.005 part of a fungicide, and carrying out uniform mixing so as to obtain the cultivation substrate for the sweet potato seedling. The substrate provided by the invention can significantly improve commodity characteristics, disease resistance and yield of sweet potato, and enhances the quality of the sweet potato.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST

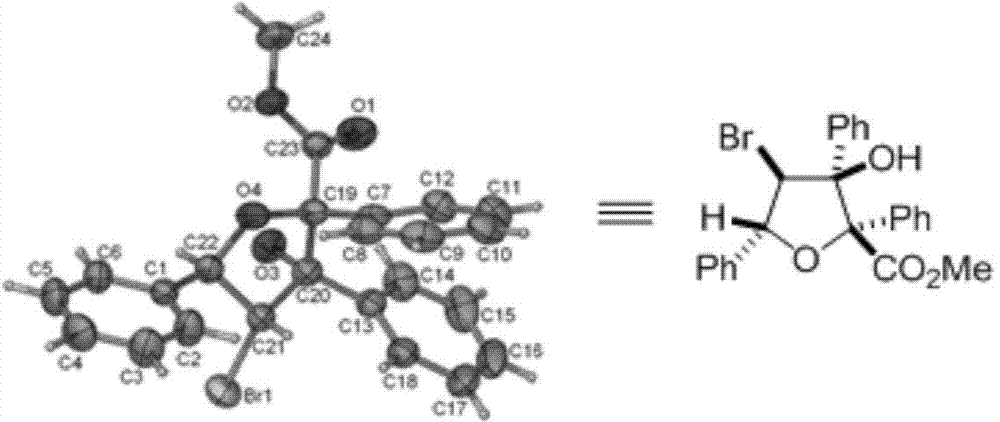

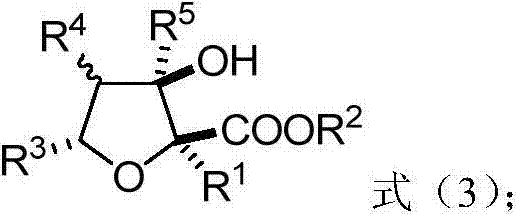

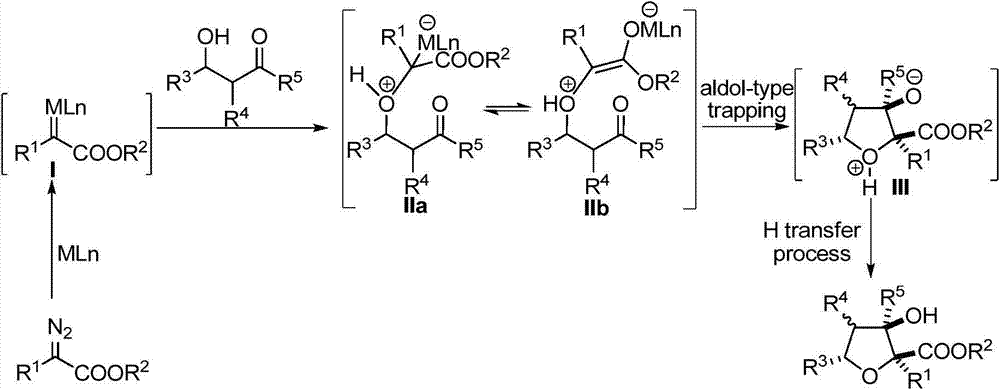

Polysubstituted tetrahydrofuran derivatives as well as synthesis method and application thereof

ActiveCN104744410AHigh yieldGood diastereoselectivityOrganic chemistryMetabolism disorderMolecular sieveCarbonyl group

The invention relates to polysubstituted tetrahydrofuran derivatives and a chemical synthesis method thereof. The chemical synthesis method comprises the following steps: carrying out one-step reaction on raw materials (a diazo compound and a 3-hydroxyl-carbonyl flavone compound) in an organic solvent in the presence of a metal catalyst and an additive which is a molecular sieve shown in the specification; and carrying out column chromatography purification to obtain the target product. The chemical synthesis method of the polysubstituted tetrahydrofuran derivatives has the advantages of environmental benefit, step economy, atom economy, diastereoselectivity and high yield; in addition, the reaction conditions are mild, the applicability of the substrate range is wide and the operation is simple and safe. The invention discloses that the polysubstituted tetrahydrofuran derivatives with multiple chiral centers have PTPlB inhibiting effect; and therefore, the polysubstituted tetrahydrofuran derivatives are important chemical engineering, chemical and medical intermediates and have a wide prospect in the field of pharmaceutical chemicals.

Owner:EAST CHINA NORMAL UNIVERSITY

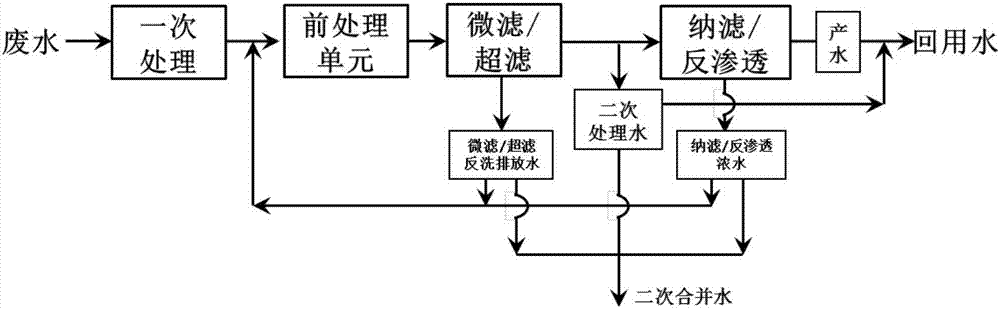

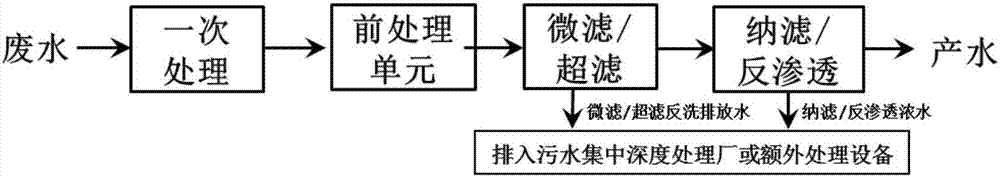

Advanced treatment method for waste water

InactiveCN107215998AIncrease the amount of waterImprove water resource utilizationMultistage water/sewage treatmentWaste water treatment from textile industryCurrent technologyProcessing cost

The invention belongs to the field of advanced treatment of waste water. Primary treatment of the waste water is allowed to carry out, so that primary treatment water is obtained, the primary treatment water passes through a pretreatment unit and a membrane treatment unit, so that produced water is obtained, partial nanofiltration and / or reverse osmosis concentrated water and partial microfiltration and / or ultrafiltration backwash discharge water return to the pretreatment unit and pass through the pretreatment unit, and microfiltration and / or ultrafiltration are allowed to carry out, so that secondary treatment water is obtained. Partial secondary treatment water merges with the produced water to obtain reuse water, and the utilization rate of water is improved under the conditions that the recovery rates of the nanofiltration and reverse osmosis are not improved. The secondary treatment water without merging with the produced water merges with the unreturned water to obtain secondary merging water, which can be used in the fields of landscape water and Industrial cooling water. The method fully utilizes the current technologies, and the recovery rate of the system is improved without influencing the service life of a membrane, and the processing cost of every ton of water is reduced, and meanwhile, the nanofiltration or reverse osmosis concentrated water and microfiltration or ultrafiltration backwash discharge water are treated and then reused, sewage charges are reduced, and the utilization rate of the water is improved.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

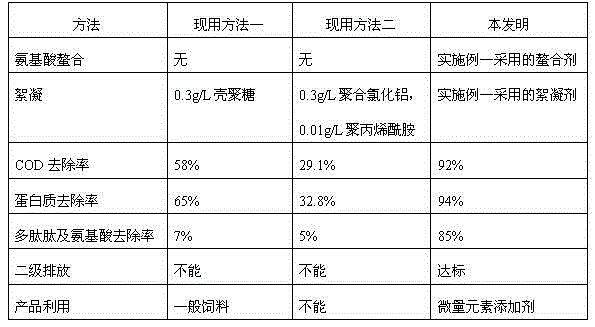

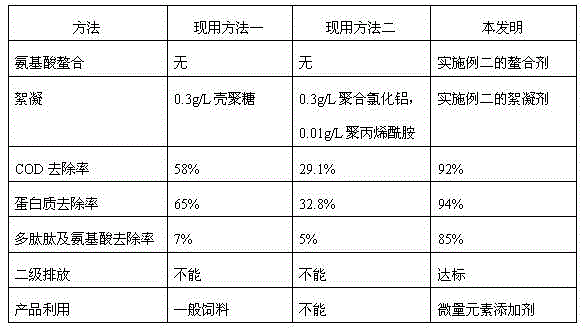

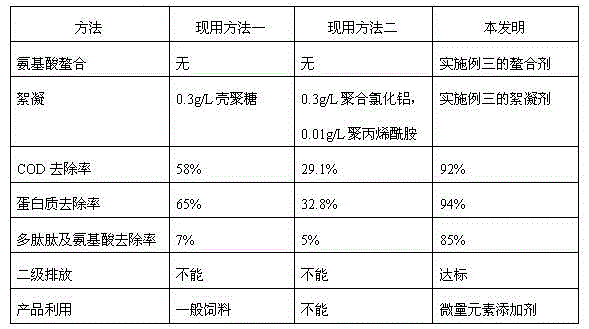

Method for treating casing processing wastewater and application of treatment product

InactiveCN103951116AReduce processing difficultySolve application limitationsMultistage water/sewage treatmentAmino acid synthesisUltrafiltration

The invention discloses a method for treating casing processing wastewater. The method comprises the following steps: (1) regulating the PH value of the casing processing wastewater to be 6.0-7.0 with hydrochloric acid with mass concentration of 10%, thus obtaining a solution I; (2) adding a chelating agent to the obtained solution I, thus obtaining a solution II; (3) adding a coagulant aid to the obtained solution II, thus obtaining a solution III; (4) adding a flocculant to the obtained solution III, thus obtaining a solution IV; (5) enabling the obtained solution IV to stand for 1-3 hours, collecting the supernatant, and then filtering the precipitate; (6) drying the filtered precipitate; (7) treating the collected supernatant with ultrafiltration and nanofiltration membranes. The method has the advantages that polypeptides and amino acids, which are not easy to extract, in the casing processing wastewater are extracted by synthesizing an amino acid chelate with the polypeptides and amino acids, so that the extraction ratio is high; the reclaimed water can be recycled, thus saving the resources; the treatment method is simple, is easy to control and simultaneously has economic and environmental benefits.

Owner:CHONGQING TIANSHI ANIMAL PROD

Method for preparing ceramsite by water supply sludge and sewage sludge

InactiveCN102731063AIncrease leachingHave environmental benefitsCeramic materials productionClaywaresSludgeSewage

The invention discloses a method for preparing ceramsite by water supply sludge and sewage sludge, which relates to the method for preparing ceramsite for buildings. The invention is to solve the problem that current water supply sludge and sewage sludge influence the environment and cause damage. The method comprises the steps of: mixing the water supply sludge with the sewage sludge; then adding silicate substances and mixing; and finally placing the mixture in a comminutor to extrude and form, naturally drying, sintering and performing furnace cooling to obtain the ceramsite for buildings. The method for preparing ceramsite by water supply sludge and sewage sludge is used for building materials.

Owner:HARBIN INST OF TECH

Lean cemented concrete prepared from aggregate chip iron tailings sand and polycarboxylate water reducer

InactiveCN105481320ARealize rational utilizationReduce pollutionSolid waste managementWater useFineness modulus

The invention relates to lean cemented concrete prepared from aggregate chip iron tailings sand and polycarboxylate water reducer. The concrete is prepared from 100-130 parts of cement, 50-75 parts of fly ash, 115-120 parts of mineral powder, 250-280 parts of tailings sand, 830-850 parts of aggregate chips, 780-800 parts of pebbles, 175-185 parts of water and 3.8-3.9 parts of the polycarboxylate water reducer, wherein the sand ratio ranges from 0.58 to 0.59, the fineness modulus of the aggregate chips is 3.1, the fineness modulus of the tailings sand is 1.7, and the particle size of the pebbles is 5-31.5 mm continuous grading. Commonly-produced aggregate chips and the iron tailings sand are used for replacing machine-made sand and river sand which need to be produced by grinding the pebbles according to grading, production cost is reduced, adaptability of fine aggregate and the polycarboxylate water reducer is improved, and water use amount is reduced. Meanwhile, viscosity of the concrete is improved, good flowability and cohesiveness of the concrete are guaranteed, and adverse influences caused by small amount of cement are reduced.

Owner:青岛磊鑫混凝土有限公司

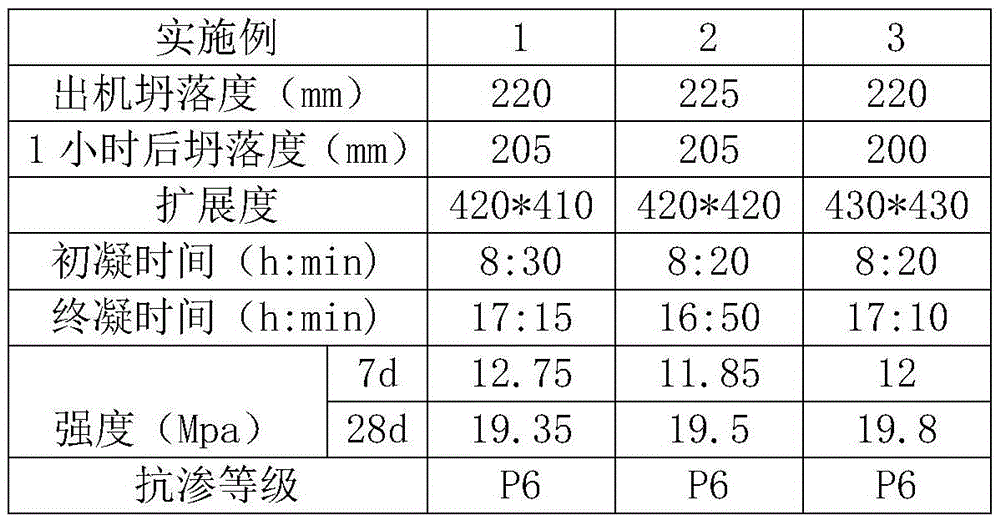

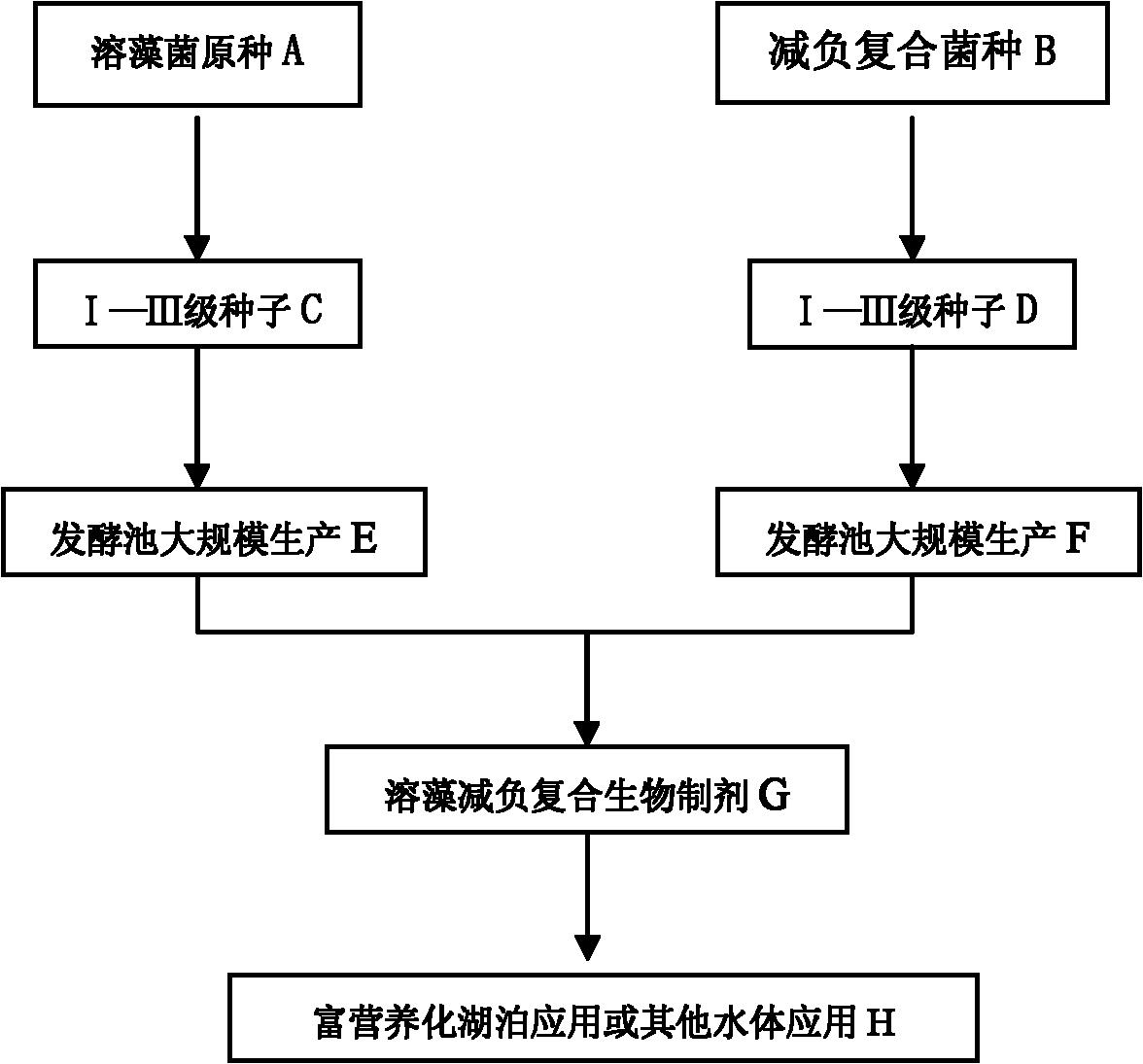

Preparation method of alga-lysing burden-alleviating compound biological agent

ActiveCN102115725AEcological balance purificationMaintain ecological balanceFungiBacteriaBiotechnologyMicrobiology

The invention discloses a preparation method of an alga-lysing burden-alleviating compound biological agent, which comprises the following steps: A, culture of level-I and level-II strains: (1) preparing a culture medium; (2) culturing level-I seeds; and (3) culturing level-II seeds; B, culture of level-III seeds: (1) culturing level-III seeds of alga-lysing bacteria; and (2) culturing level-III seeds of burden-alleviating compound agents; and C, large-scale production: (1) preparing a culture medium; (2) carrying out large-scale fermentation production of alga-lysing bacteria; (3) carrying out large-scale fermentation production of burden-alleviating compound agents; and (4) preparing the alga-lysing burden-alleviating compound biological agent, and packaging. The method is feasible, is convenient to operate, reduces the eutrophic water body and controls the outbreak of the blue-alga bloom. The alga-lysing burden-alleviating compound biological agent is easy to culture, has low cost, is suitable for factory production, does not pollute the water body and has environmental and social benefits.

Owner:武汉昌宝环保工程有限公司

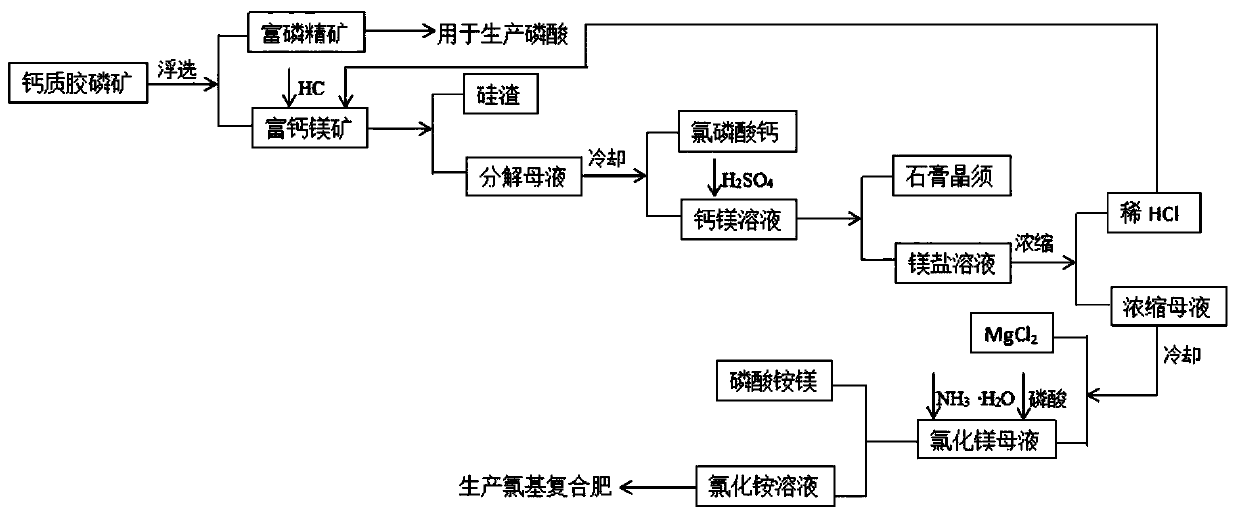

Method for producing phosphate concentrate from calcareous collophanite and by-producing gypsum whiskers and magnesium ammonium phosphate

PendingCN111483989AImprove Phosphorus TasteIncrease added valuePolycrystalline material growthFrom normal temperature solutionsMagnesium phosphateO-Phosphoric Acid

The invention provides a method for producing phosphate concentrate from calcareous collophanite and by-producing gypsum whiskers and magnesium ammonium phosphate, and the method comprises the following steps: separating the phosphate concentrate and calcium-rich and magnesium-rich tailings from the calcareous collophanite by flotation, and carrying out acidolysis on the calcium-rich and magnesium-rich tailings to extract available valuable elements in the tailings, thereby obtaining the gypsum whiskers and the ammonium magnesium phosphate product. The method comprises the following steps: firstly, carrying out flotation on the calcareous collophanite; comprehensively utilizing calcium, magnesium and phosphorus elements in the tailings obtained by flotation; the phosphorus taste of the collophanite is improved, the collophanite can be directly used for wet-process phosphoric acid production, meanwhile, a series of problems generated by the tailings are solved, the added value of the collophanite is increased, the negative influence on the environment is reduced, and a very good guiding effect is provided for development and utilization of the collophanite.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

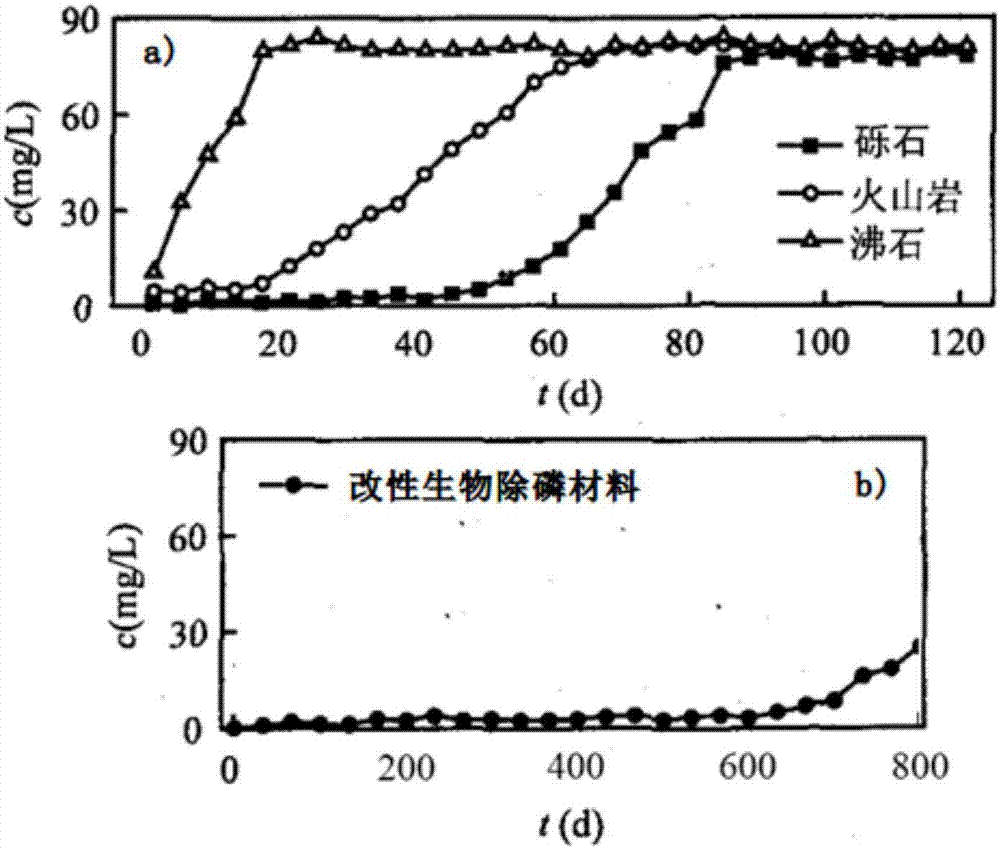

Compound shellfish modified biological phosphorus removal material and preparation method and application thereof

InactiveCN107265582AAchieve reuseSimple processWater contaminantsWater/sewage treatment by flocculation/precipitationMytilus coruscusWastewater

The invention discloses a compound shellfish modified biological phosphorus removal material and a preparation method and application thereof. In the method, mytilus coruscus shells, oyster shells and scallop shells are taken as raw materials and smashed according to a certain proportion, and the smashed raw materials are subjected to preheating treatment, calcining treatment and heat-preserving treatment to obtain a powdery compound shellfish modified biological phosphorus removal material, and the phosphorus removal material is applied to phosphorus removal of wastewater. The compound shellfish modified biological phosphorus removal material has the advantages of simple preparation process, realization of recycling of waste resources, and certain social, economic and environmental benefits. The prepared modified biological phosphorus removal material has a removal rate of 90 percent or more for phosphorus in water bodies, and has very high phosphorus removal and water purification capabilities. The phosphorus removal effect and the maintenance time can be improved remarkably in an adding way that the modified biological phosphorus removal material is wrapped with a slow-release package, and the slow-release package is added into a water body.

Owner:鲲瑛(上海)生物科技有限公司

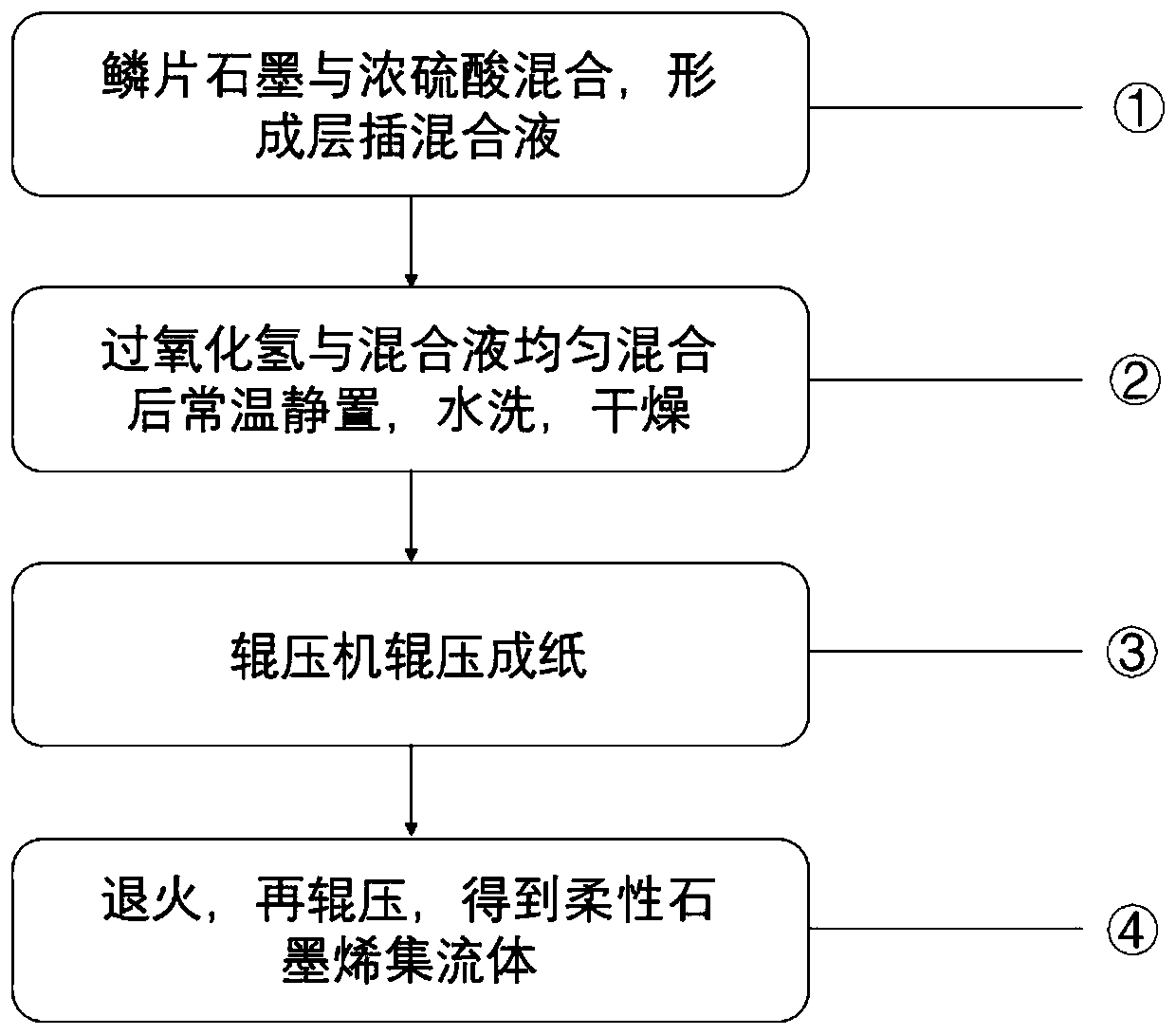

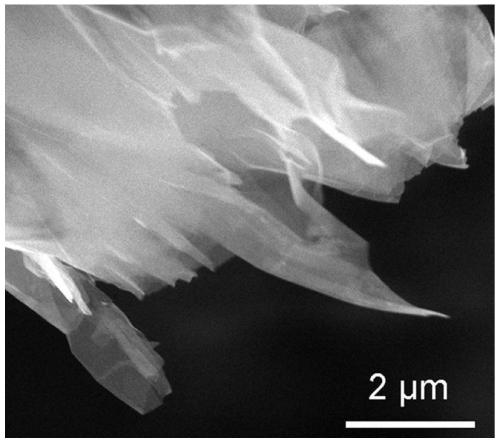

Method capable of obtaining flexible graphene current collectors in batches

InactiveCN111086984AEasy to operateSmall size limitElectrode carriers/collectorsGrapheneChemistryEngineering

The invention discloses a method capable of obtaining flexible graphene current collectors in batches. The method comprises the following steps: (1) mixing concentrated sulfuric acid and crystalline flake graphite so as to prepare a mixed solution; (2) adding hydrogen peroxide with a concentration of 30% into the mixed solution, carrying out stirring, then carrying out standing at a normal temperature, carrying out washing with water, and carrying out drying so as to obtain graphene powder; and (3) rolling the graphene powder into paper by using a rolling technology, then carrying out annealing, and carrying out rolling again so as to obtain flexible graphene paper. According to the preparation method for the flexible graphene current collectors provided by the invention, the flexible graphene current collectors with high conductivity, light weight and hydrophilicity can be obtained in batches by using rolling equipment through simple and low-cost puffing stripping and rolling technologies and preparation from powder to paper.

Owner:SOUTH CHINA UNIV OF TECH

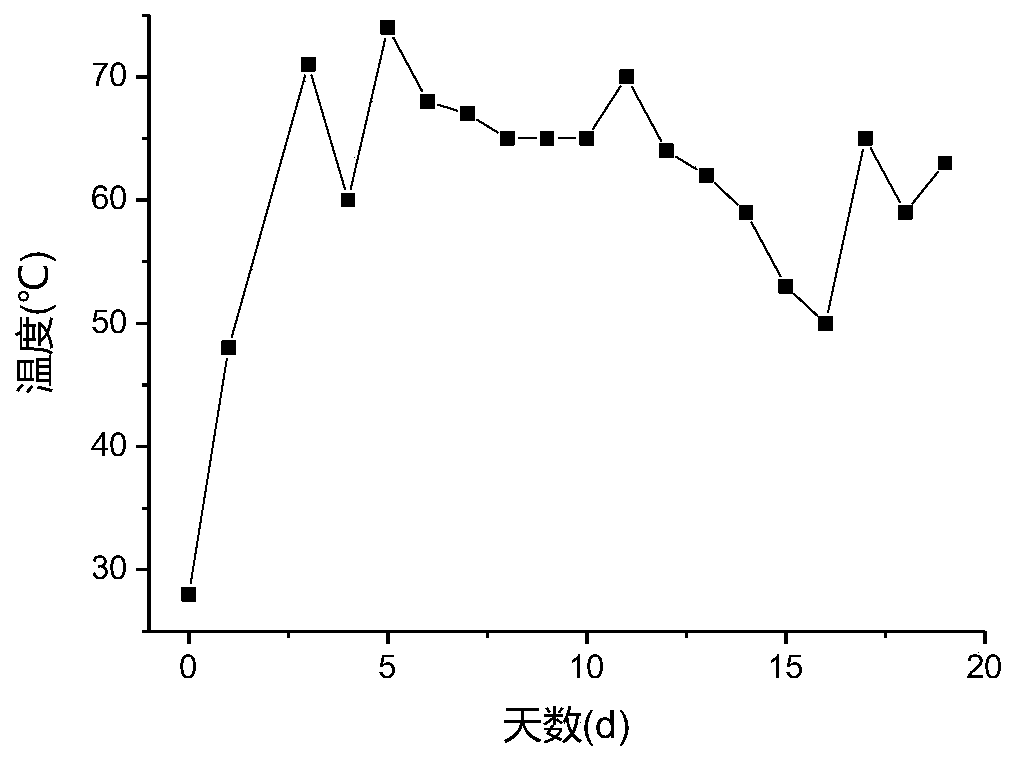

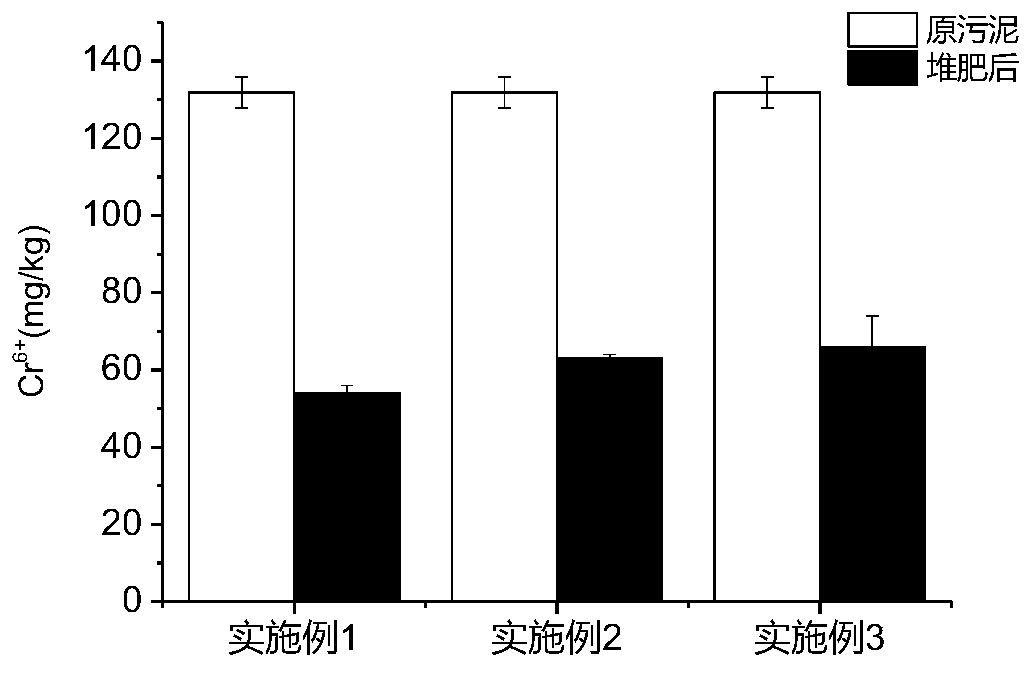

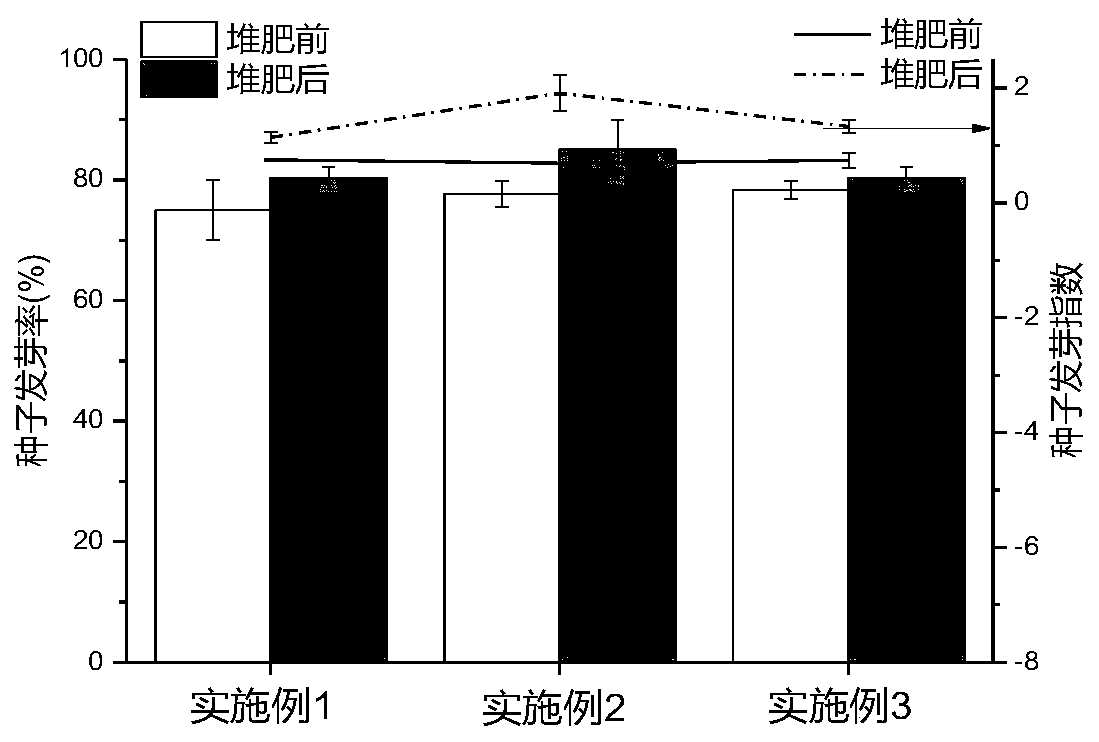

Treatment method for reducing toxicity of tanning sludge

InactiveCN110218126AEasy to operateHigh quality and environmentally friendly and practicalBio-organic fraction processingExcrement fertilisersSodium BentoniteDecomposition

The invention provides a treatment method for reducing toxicity of tanning sludge and belongs to the field of treatment of solid wastes. The treatment method mainly comprises the following steps: performing pre-composting and fine composting treatment, taking tanning sludge as a raw material, preferentially taking straws, chicken manure, fly ash and bentonite as filled materials to mix with co-composting manure, performing thorough decomposition to reduce biotoxicity, and fixing heavy metals so as to achieve aims of hazard-free treatment and recycling. Most of the materials involved in the method disclosed by the invention are wastes and are cheap and wide in source, the process is simple in operation, process parameters are easily controlled, and large-scale production is facilitated. Therefore, the method disclosed by the invention has a certain environmental and economic benefits.

Owner:BEIJING NORMAL UNIVERSITY

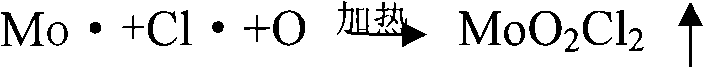

Method for volatilizing and enriching molybdenum from molybdenum tailings

InactiveCN101514403AHigh volatile enrichment rateImprove high temperature stabilityProcess efficiency improvementFiltrationThermal insulation

A method for volatilizing and enriching molybdenum from molybdenum tailings relates to a process for utilizing the molybdenum tailings for enriching and recovering the molybdenum. The molybdenum tailings are firstly ground, and the water content thereof is regulated to 30-40%WT to lead the molybdenum tailings to form slurry of the molybdenum tailings. Then, hydrofluoric acid is added in the slurry of the molybdenum tailings, hydrochloric acid is further added after the bubbles disappear and the reaction is complete; after that, the slurry of the molybdenum tailings is heated to 200-250 DEG C, a cover is used for thermal insulation for 30-50min to promote the formation of chloride of the molybdenum, then the cover is removed, and the drying is carried out at 65 DEG C. Finally, the thermal treatment of the molybdenum tailings after the pretreatment with the acid is carried out at 900 DEG C, thereby generating flue gas containing the molybdenum and silicon tetrafluoride and the residues of the thermal treatment, and the residues are used as road-building materials; the collected flue gas is condensed; when the temperature is lower than 250 DEG C, substances containing the molybdenum or molybdenum compounds are recovered; the silicon tetrafluoride in the flue gas is absorbed and hydrolyzed by using water, the filtration is carried out, and filtrate is fluorosilicic acid solution. The process of the invention is simple and easy to control, the products during the process can be recovered, the cost is low, the method has no environmental pollution, and the high temperature volatilization rate of the molybdenum achieves 70 percent-98.6 percent.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com