Patents

Literature

1106results about How to "Wide range of materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of multi-position doped lithium iron phosphate positive electrode material and application thereof

ActiveCN101339994AWide range of materialsIncrease base capacityElectrode manufacturing processesPhosphorus compoundsElectricityLithium iron phosphate

The invention discloses a preparation method of a multi-place doped lithium iron phosphate anode material and an application thereof, which belong to the technical field of the preparation of electrochemical power materials. The multi-place doped lithium iron phosphate anode material is expressed by the following formula: Li1-xAxFe1-yByP1-zCzO4Ddelta, wherein, at least two of x, y, x and delta can not be expressed zero at the same time. Multi-place doped anode material lithium iron phosphate powder which is used in a secondary lithium-ion battery and has good crystallization performance and even composition is prepared by adopting a solid phase method and a simple mixing and drying process; compared with the method doping in a certain crystal lattice place, the multi-place doped anode material lithium iron phosphate powder has wide doping material source, which can greatly improve the basic capacity and cycling electrical performance of matrix and is applied to a stable industrialized production and non-high-purity materials. The multi-place lithium iron phosphate of the invention is taken as the anode material and is usually used in the secondary lithium-ion battery and the secondary lithium-ion battery is taken as a power source.

Owner:甘肃大象能源科技有限公司

Preparation method for quick preparing functional gradient material

ActiveCN1803348ASimple processImprove productivityProgramme controlComputer controlProduction rateGradient material

The invention discloses a rapid making method of functional gradient material, which comprises the following steps: grading the dosage according to the component ratio; affirming the laser manufacturing technological parameter for each layer; preheating each layer of powder to do thermal-insulating disposal; paving the powder on the working bench through powder feeding device; scanning layer by layer to realize the preparation of functional gradient material.

Owner:HUAZHONG UNIV OF SCI & TECH

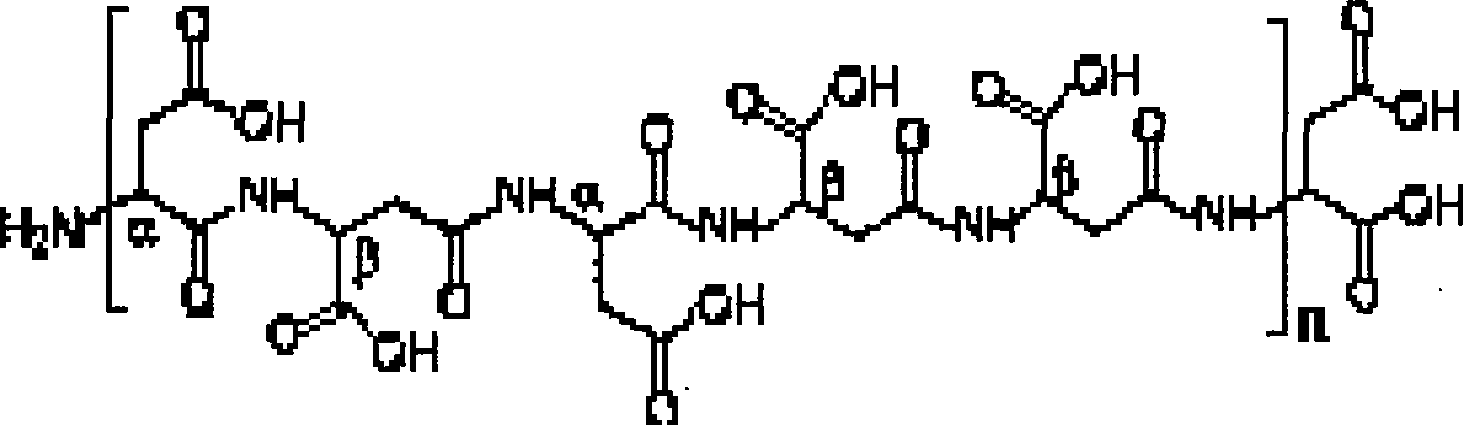

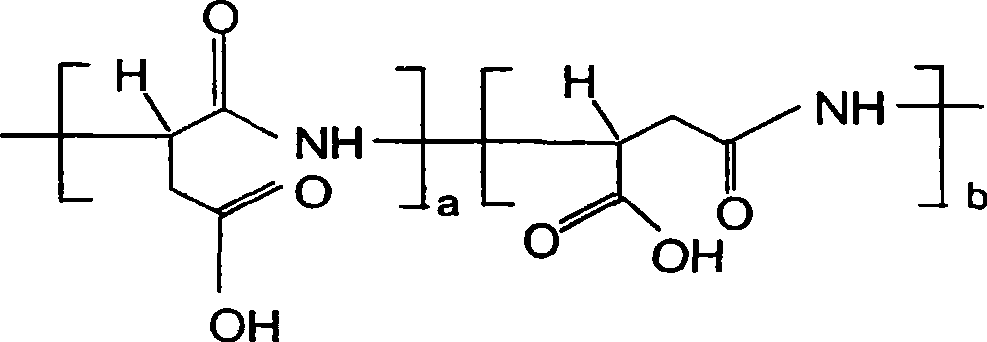

Synergistic slow release nitrogen fertilizer and preparation thereof

ActiveCN101434502AExtend the fertilizer periodImprove the absorption and utilization effectAgriculture gas emission reductionFertilizer mixturesMolten stateNitrification inhibitors

The invention relates to a synergistic fertilizer, in particular to a green and environmental protection synergistic slow-releasing nitrogen fertilizer which is mixed in ammonium nitrogen fertilizers or urea, and a preparation method thereof. The fertilizer constituents are as follows: nitrogen fertilizer, a biochemical inhibitor and a synergist, wherein, the weight portion ratio of the nitrogen fertilizer to the biochemical inhibitor to the synergist is equal to 1:0.005 to 0.1:0.0005 to 1; the biochemical inhibitor is a nitrification inhibitor, and the synergist is poly (aspartic acid). The preparation method is as follows: during the operation process of the nitrogen fertilizer, the biochemical inhibitor and the synergist are added into the fertilizer under the molten state of the fertilizer. The synergistic nitrogen fertilizer of the invention is suitable for various plants and soils. The fertilizer has notable disease-resistant, drought-resistant and lodging resistant effects on crops after being applied in soils, can effectively improve nutrients reserving power of soils and has certain effect on succession crops. Gain production can be increased by 8% to 30%, vegetable production can be increased by 14% to 60% and cash crop production can be increased by more than 30% by using the synergistic slow-releasing nitrogen fertilizer.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Aeroconcrete and preparation method thereof

InactiveCN101555113AWide range of materialsHigh strengthSolid waste managementMixing operation control apparatusBrickSteam pressure

The invention belongs to the field of building materials and relates to a concrete capable of comprehensively utilizing industrial and constructional waste. The raw material components of the concrete in terms of mass percentage content is as below: calcium materials which include 15-40 percent of high-sulfur petroleum coke clinker and 0-15 percent of cement, 59.95-70 percent of silicon material and 0.05-0.2 percent of foaming agent. The invention provides a new approach for reasonably and cleanly utilizing construction garbage, industrial residuals, high-sulfur petroleum coke clinker and other industrial wastes, breaks through the technical bottleneck of using a low-silicon material to produce aeroconcrete and expands the application scope of aeroconcrete materials. The preparation method is simple; and bricks, building blocks and walling materials of other forms, which are produced through a steam pressure curing process, not only have high strength, but also embody waste utilization, environment protection and resource saving, use raw materials which can be more widely obtained, can absolutely replace the existing walling materials of the same type, and have remarkable economic and social benefit and wide application prospect.

Owner:李秋义

Preparation method of anti-stress agent for fishing

InactiveCN101357223AHas an antioxidant effectAvoid side effectsOrganic active ingredientsDipeptide ingredientsAnti stressVitamin C

The invention relates to a method for preparing an anti-stress agent used for fishing, belonging to the technical field of aquatic product compound feed. The method is characterized in that glutamine dipeptide, rhubarb extract, vitamin C, vitamin E, potassium chloride, sodium chloride, anhydrous dextrose and a carrier are taken and fully mixed to be ground and prepared into dry powder. The raw materials of the invention has the advantages of stable source, simple preparation, wide material source and low cost; due to the stress principle of fish body, the anti-stress agent not only supplements Chinese herbal medicines, but also complements western medicine of glutamine dipeptide; the combination of Chinese herbal medicines and western medicine regulates the stress of fish body, and appropriately supplements the loss of Na<>, K<> caused by stress to control the stress of fish body. When in use, the anti-stress agent can be added into feed and directly splashed; the immunity and inhibiting ability of fish body can be improved, the capacity of resisting high temperature and high density as well as infection resistance for resisting hydrophile aeromonas can be improved, and the growth of the fish body can be accelerated.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

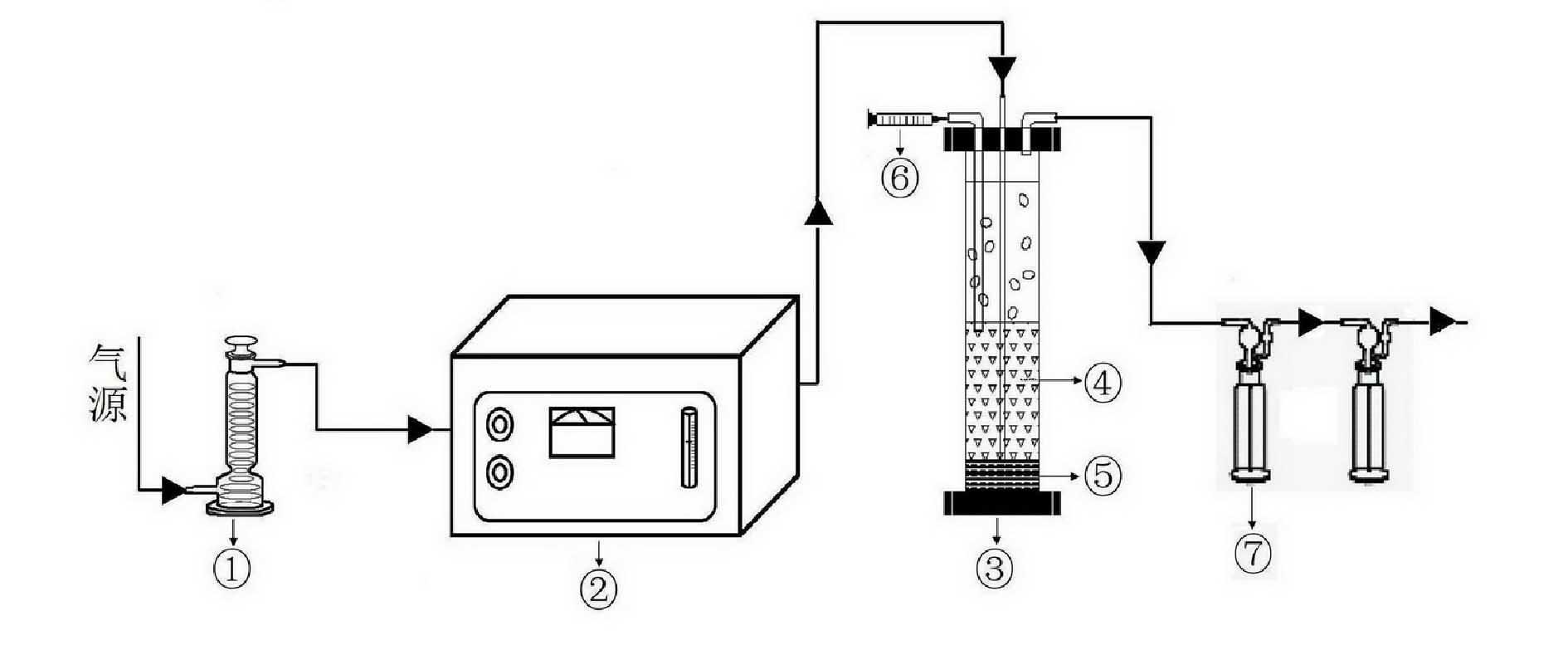

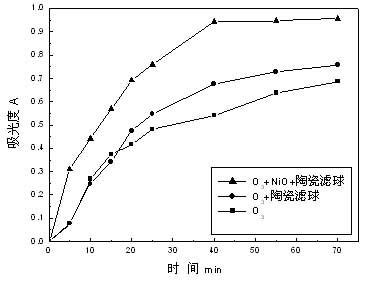

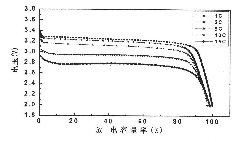

Preparation method of load-type metallic oxide ozone catalytic oxidation catalyst

InactiveCN102626629AHigh catalytic activityIncreased rate of catalytic degradationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention relates to a preparation method of a catalyst, in particular to a preparation method of a load-type metallic oxide ozone catalytic oxidation catalyst, which is characterized by comprising the following steps of (1) selecting ceramic filter bulbs to serve as a carrier, washing through deionized water, soaking for 24h by using diluted hydrochloric acid, and washing through the deionized water to effluent neuter for stoving; (2) dipping for 24h in nickel nitrate solution with the concentration of 0.1-1.0mol / L and drying; (3) roasting for 5h in a muffle furnace at 500 DEG C to obtain roasting objects; and (4) washing through the deionized water and stoving to obtain the load-type metallic oxide ozone catalytic oxidation catalyst. The preparation method is simple, low in cost, capable of greatly improving oxidation rate and efficiency of ozone on organic pollutant, good in product stability and capable of repeatedly using, and having important significant on application and dissemination of catalytic ozonation techniques.

Owner:WUHAN UNIV OF TECH

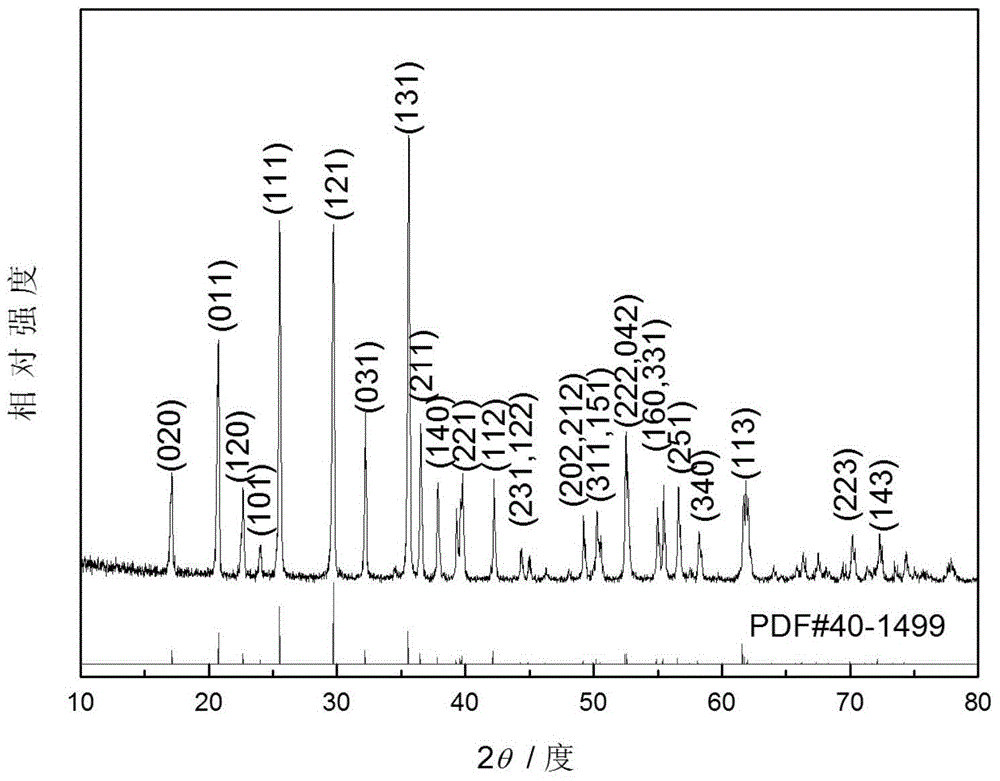

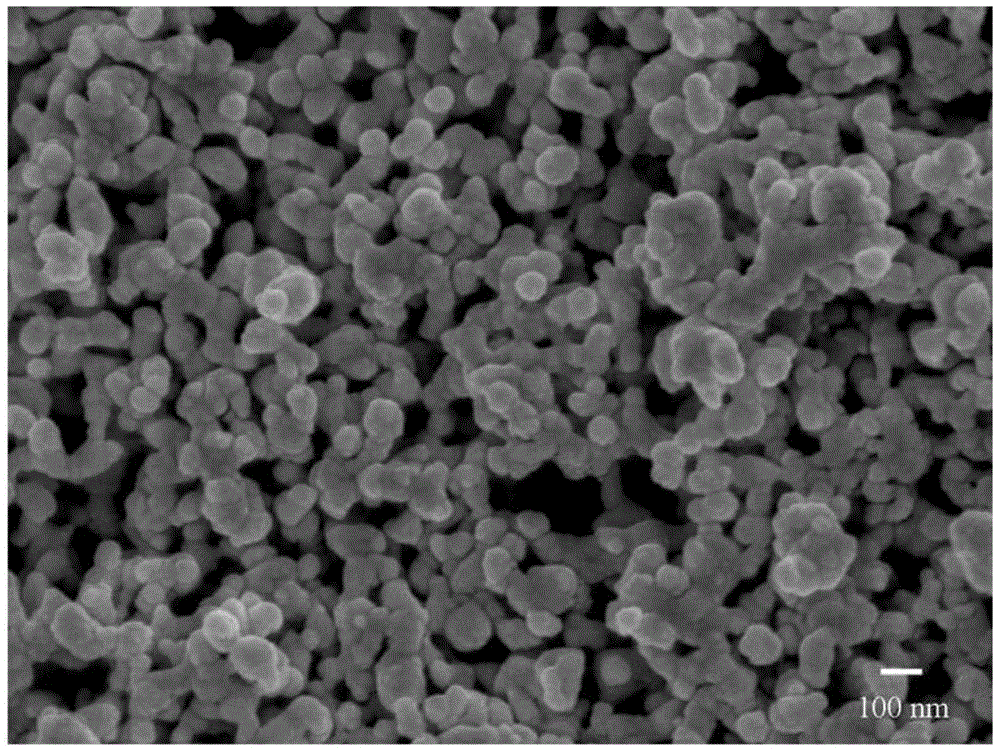

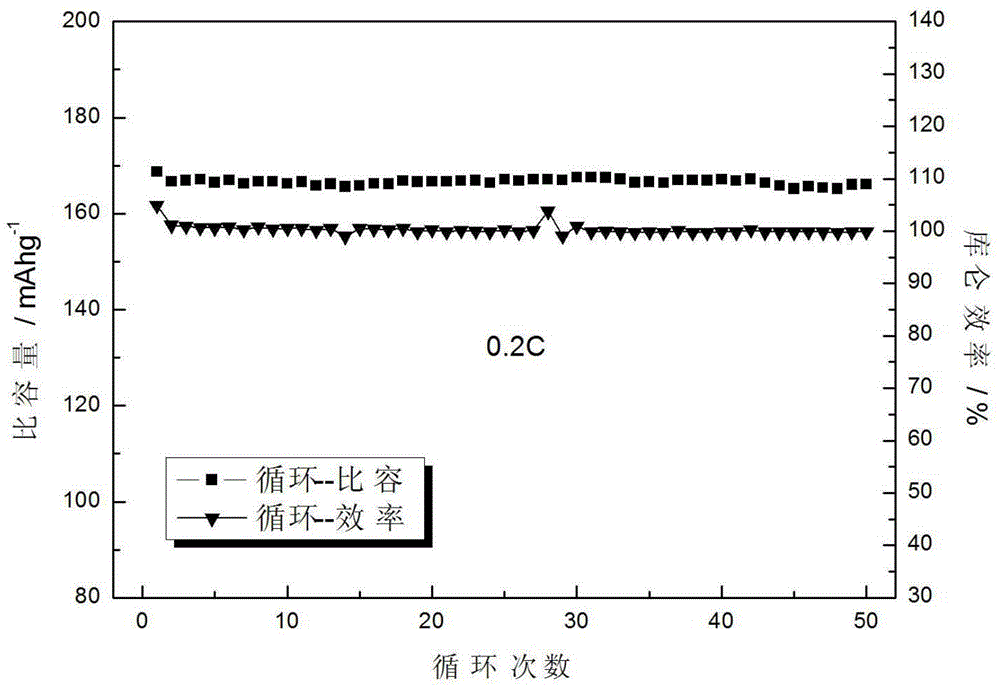

Multielement-doped lithium iron phosphate positive electrode material and preparation method thereof

InactiveCN101800315AIncrease volume capacityWide range of materialsCell electrodesLithium iron phosphateNiobium

The invention discloses a multielement-doped lithium iron phosphate positive electrode material and a preparation method thereof. The general formula of the multielement-doped lithium iron phosphate positive electrode material is Li1-xAxFe1-y-zNbyMzPO4, wherein x, y and z are more than zero and not more than 0.1. The preparation method comprises the following steps: mixing lithium source, iron source, phosphorus source, compound of A and carbon source, roasting at 400-800 DEG C, then quickly reducing the temperature to room temperature, crushing, grinding to obtain an intermediate, then mixing the intermediate with niobium compound, compound of M and carbon source, roasting at 400-850 DEG C, then quickly reducing the temperature to room temperature, grinding, and grading to obtain the product. The preparation method of the invention can obviously increase the tap density of the material; and the material can have higher specific capacity and volume specific capacity and excellent cycle performance, meanwhile the material is applicable to industrialized stable production and has wide application prospect in the battery positive electrode material field for energy sources.

Owner:QUFU ENERGY

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

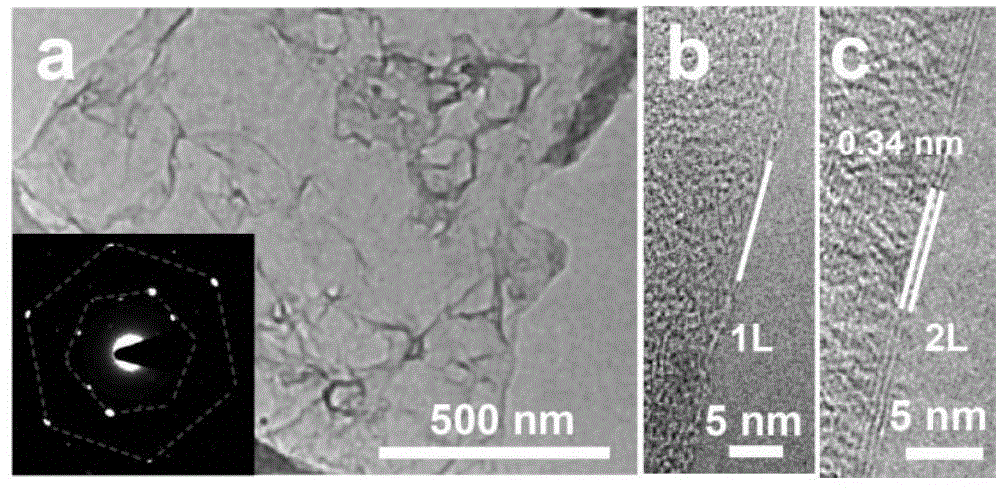

Method for preparing graphene from lignin

ActiveCN105439135ALow preparation temperatureSimple preparation processGrapheneNanotechnologyHigh energyHigh pressure

The invention discloses a method for preparing graphene from lignin. The method comprises steps as follows: a, lignin and aqueous alkali are mixed in a volume ratio of solid to liquid being 1:(5-10), the solution is heated to the temperature of 70-100 DEG C, and the insulation treatment time is 1-3 h; b, a material treated by alkali is filtered and washed, an obtained solid is dried at the temperature of 60-80 DEG C, and pretreated lignin is obtained; c, a catalyst is added to the pretreated lignin obtained in Step b, the mixture is fully mixed by a high-pressure homogenizer, non-homogenous lignin is homogenized and split, and cracked carbon and the catalyst are homogenized to be in a high energy obtaining state; d, the mixture is placed in an autoclave, inert gas is introduced, the pressure is increased at the speed of 0.1-1 MPa / s to 20-50 MPa, the mixture is heated to 500-800 DEG C and cooled to the normal temperature and pressure after being treated, and graphene is obtained. The lignin is decomposed at the high temperature and under the high pressure, high-energy carbon atoms are obtained, graphene grows under the action of the catalyst, with the adoption of the method, the preparation temperature of the graphene is reduced, and the preparation technology is simple, economical, environment-friendly and suitable for industrial production.

Owner:中航装甲科技有限公司

Antistaling agent for fruits or vegetable, and its prepn. method

InactiveCN1792179AEnhanced sense of maturityWidely distributedFruit and vegetables preservationOrganic acidAlcohol

An anti-staling agent for fruit and vegetables, especially for red bayberry, strawberry, mulberry fruit and cherry is proportionally prepared from chitosan, the extract of Vacciniaceae leaf, the extract of red bayberry leaf, organic acid, Ca salt, alcohol and water.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Full-section pre-reinforcing construction method for tunnel free-machining anchor bar

InactiveCN101487393AGood deformation propertiesConstruction method safetyUnderground chambersTunnel liningGlass fiberFiber

The invention discloses a tunnel easy-cutting anchor-rod full-section pre-consolidation construction method, comprising the following steps: firstly, survey design before construction is carried out, pre-consolidation is carried out to a face core body to be excavated by adopting an easy-cutting anchor rod according to the sampling analysis and classification of rock-soil, meanwhile, a measuring instrument is installed to monitor the change thereof, and then full-section excavation is carried out. The construction method takes the problem of how to deal with the 'core body to be excavated' in front of the face as the key for controlling the integral stability of the tunnel, an easy-cutting glass fiber anchor rod which is pre-consolidated along tunnel vertical full-section is used for improving the equivalent stiffness of the 'core body to be excavated' and controlling the deformation of the 'core body to be excavated' so as to cause arching effect around the tunnel to function naturally, thus guaranteeing the full-section, safe and quick excavation and drivage of the tunnel. The construction method is safe and reliable, can realize tunnel full-section mechanized and modernized construction, and has good production efficiency, continuous and stable construction progress, and controllable project cost.

Owner:中铁西南科学研究院有限公司

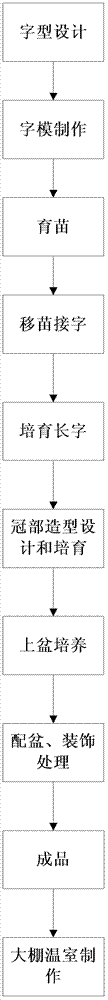

Word art potted landscape and manufacturing method thereof

InactiveCN103358801AWide range of materialsSeedling comprehensiveSpecial ornamental structuresHorticulture methodsArabic numeralsChinese characters

The invention provides a word art potted landscape cultivation technique which comprises comprehensive word art, including a foreign language word art, a Chinese character word art and an Arabic numeral word art; a word art potted landscape is easily available from trees, shrubs, vines and perennial trailing herbaceous plants, and also can be obtained by a plurality of seedling growing methods including seed propagation, cutting propagation, mound layering, ring-cutting reproduction, root stump propagation and the like; the technology combines a potted landscape cultivation technique and a typeface calligraphic art and utilizes nursery stock growth characteristics; by adopting a technical method that the growing nursery stock is reversely bound along a typeface character die rail and the turning position is subjected to twisting or stem-cutting and bud-retaining, a novel word art potted landscape can be obtained by methods including cutting off the stems, grafting, pruning and modeling, and artificially decorating and the like.

Owner:林慧

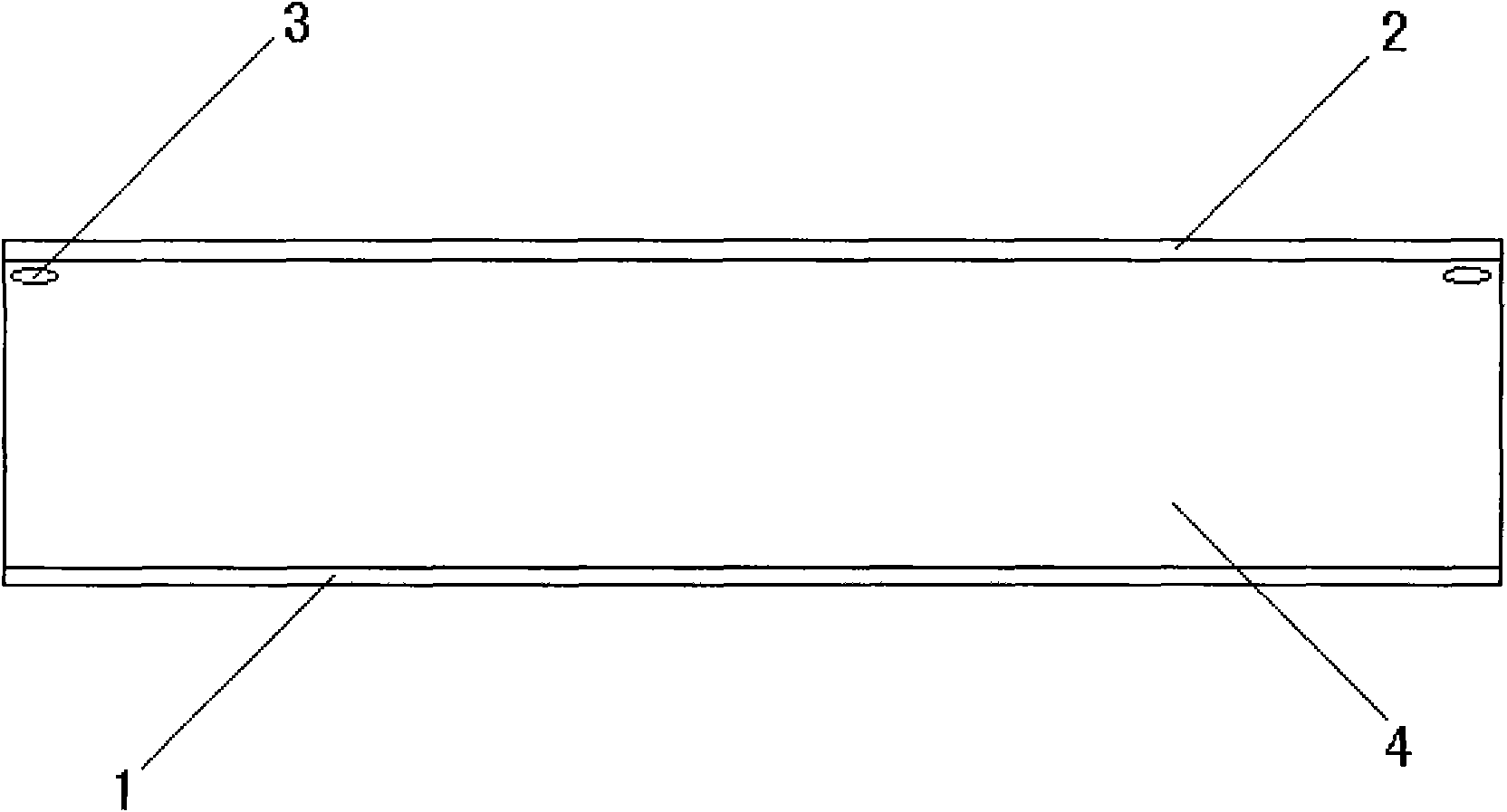

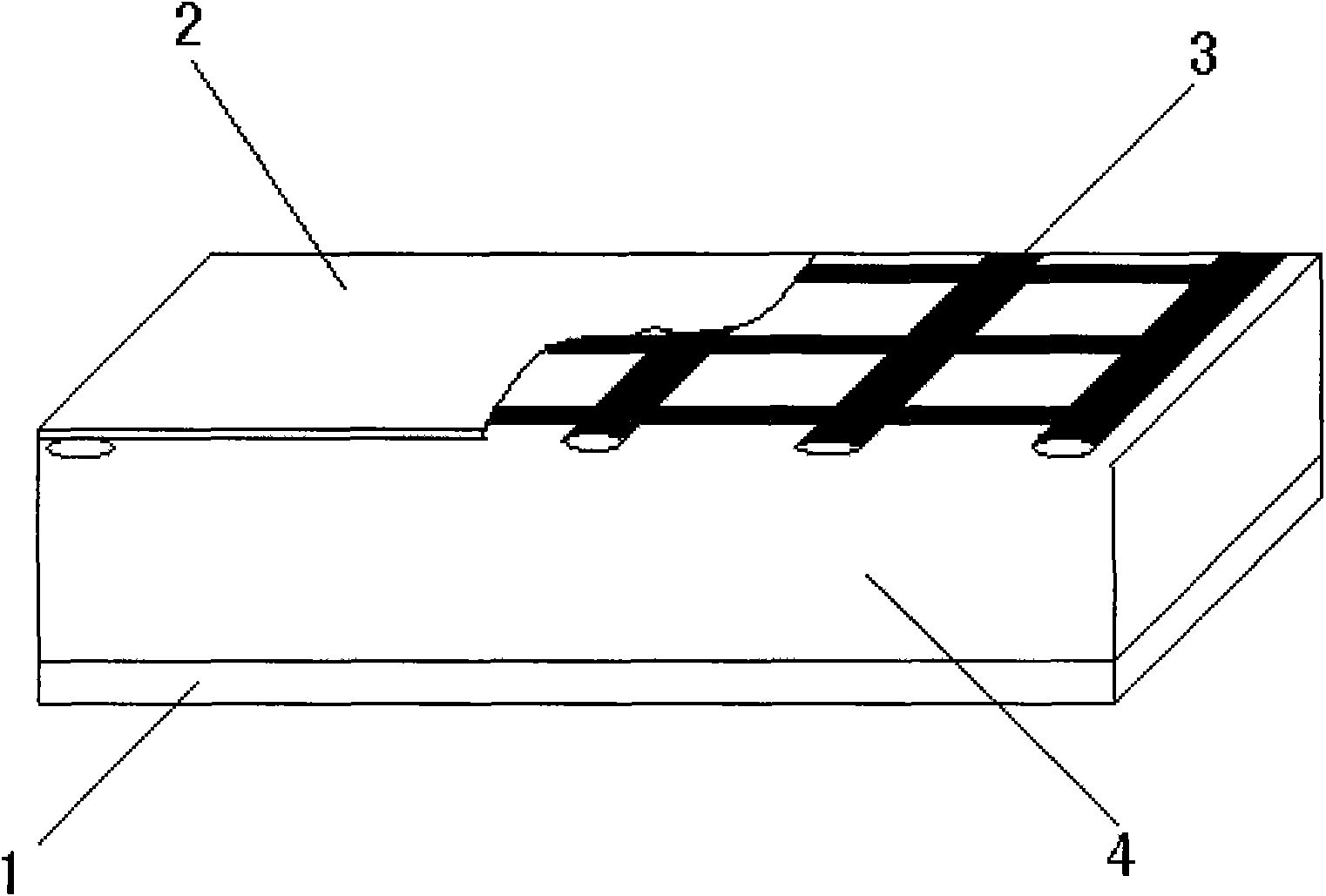

Composite heat insulation wallboard and manufacturing method thereof

InactiveCN101603351AHigh strengthImprove integrityCeramic shaping apparatusBuilding componentsSurface layerInsulation layer

The invention relates to a composite heat insulation wallboard and a manufacturing method thereof. The composite heat insulation wallboard is characterized by comprising a bottom surface layer; the top of the bottom surface layer is connected with a heat insulation layer made of a cement foaming material, a layer of grid-shaped metal framework is embedded in the heat insulation layer close to the top, and the top of the heat insulation layer is connected with a decorative layer; and the left and right sides or left, right, upper and lower sides of the metal framework are provided with circular tubes or square tubes exposed out of the heat insulation layer and used for mounting dry-hang clips. The composite heat insulation wallboard has the characteristics of light weight, high integral strength, good decoration performance and the like at the same time of ensuring the effects of heat insulation and heat isolation; and the manufacturing method is convenient to mount and operate on site, can finish a plurality of working procedures of heat insulation, decoration, reinforcement and the like at the same time during once mounting, and has strong practicability. The composite heat insulation wallboard and the manufacturing method thereof can be widely applied to the occasions of outer heat insulation of outer walls of various buildings or building roofs, and the like.

Owner:BEIJING GREEN GREAT WALL SYST ENG CORP

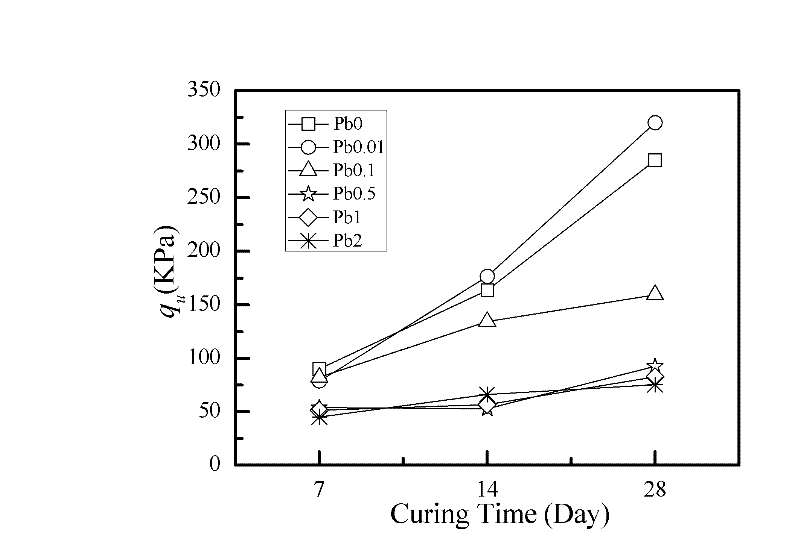

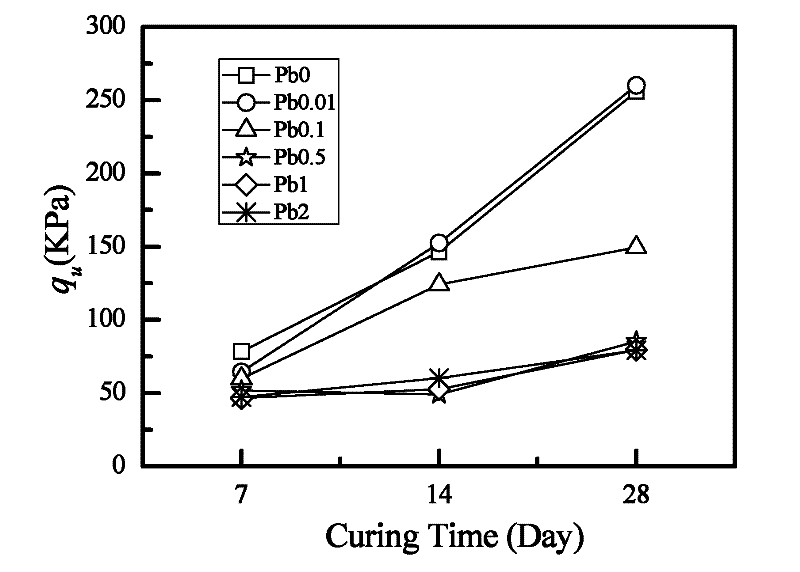

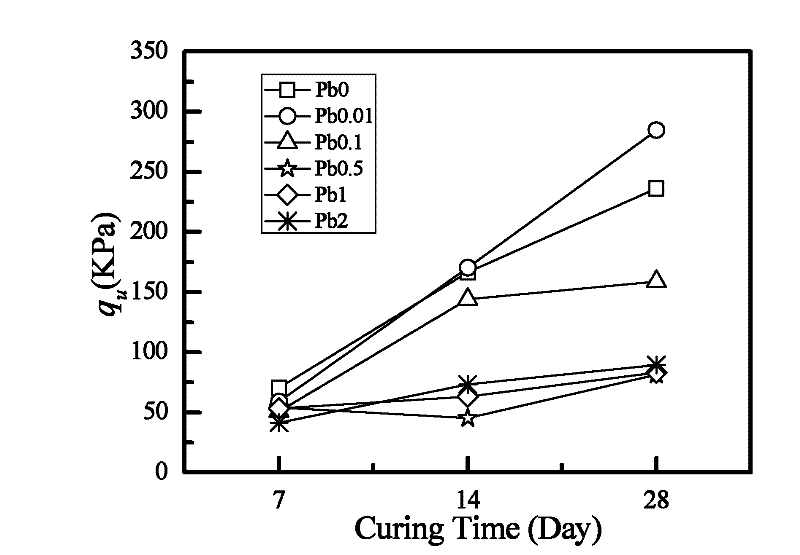

Curing agent for stabilizing heavy metal lead pollution area containing organic matter

ActiveCN102517026APromote repairImprove curing effectAgriculture tools and machinesOther chemical processesAfter treatmentPhosphate

The invention discloses a curing agent for stabilizing a heavy metal lead pollution area containing organic matter. The curing agent is composed of the following components including, by weight, 33%-40% of phosphate, 33%-40% of graining blast furnace slag and 20%-34% of magnesium oxide. The curing agent can be used during in-situ processing of the heavy metal pollution area containing organic matter pollution and is remarkable in curing effects, pH value of the pollution area is low after treatment by the curing agent, and corrosivity is small. Besides, the pollution area has high strength after treatment and can be directly used as a shallow-layer foundation, and the curing agent is environment-friendly and low in cost simultaneously.

Owner:SOUTHEAST UNIV

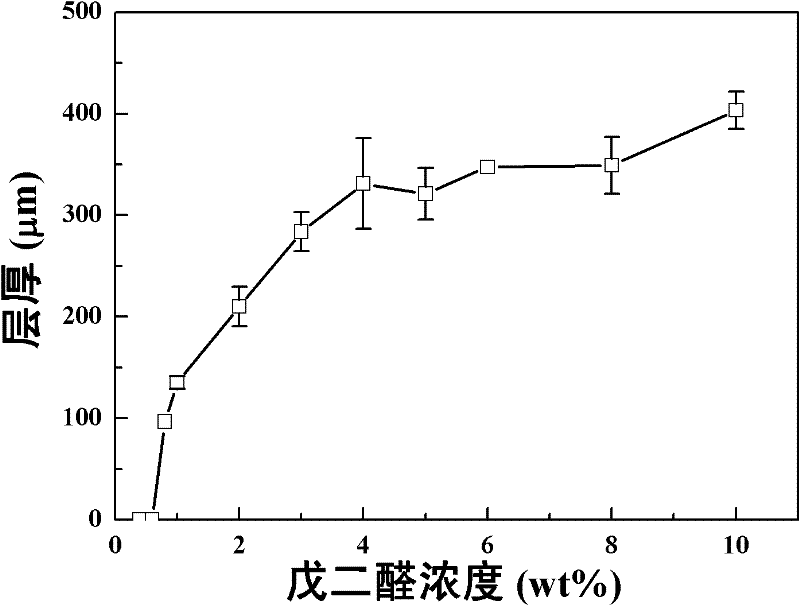

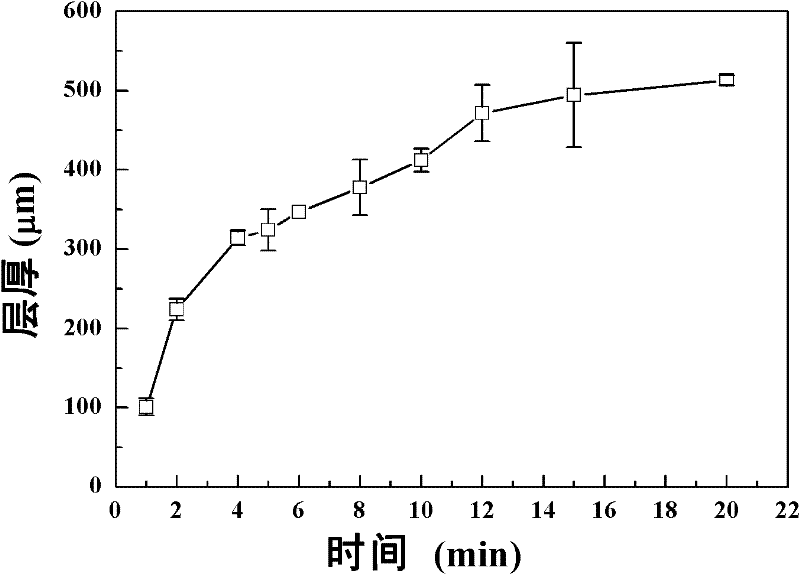

Multilayer aquagel, and preparation method and application thereof

InactiveCN102391537AWide range of materialsGood application prospectPharmaceutical delivery mechanismMacromolecular non-active ingredientsTissue engineeringChemistry

The invention relates to a high polymer aquagel, particularly a multilayer aquagel, and a preparation method and application thereof. The invention provides a multilayer aquagel with controllable shape and structure and onion pattern, and a preparation method and application thereof. The multilayer aquagel with onion pattern is composed of a gel core template and a multilayer film aquagel coated outside the gel core template. The preparation method comprises the following steps: 1) dissolving a material for preparing the gel core, and gelating to obtain the gel core template; 2) impregnating the gel core template in a crosslinking agent water solution, so that the gel core template adsorbs the crosslinking agent; 3) impregnating the gel core template with adsorbed crosslinking agent in a water-soluble macromolecular solution to obtain a monolayer-film-coated aquagel; and 4) repeating the step 2) and step 3) to obtain the product. The materials have wide sources, the shape and size of the template can be designed freely, and the shape of the multilayer aquagel can be designed as required; and the microstructure of each gel layer is a large-aperture network structure, so that the aquagel has wide application prospects in medicine embedment, medicine slow release and tissue engineering.

Owner:XIAMEN UNIV

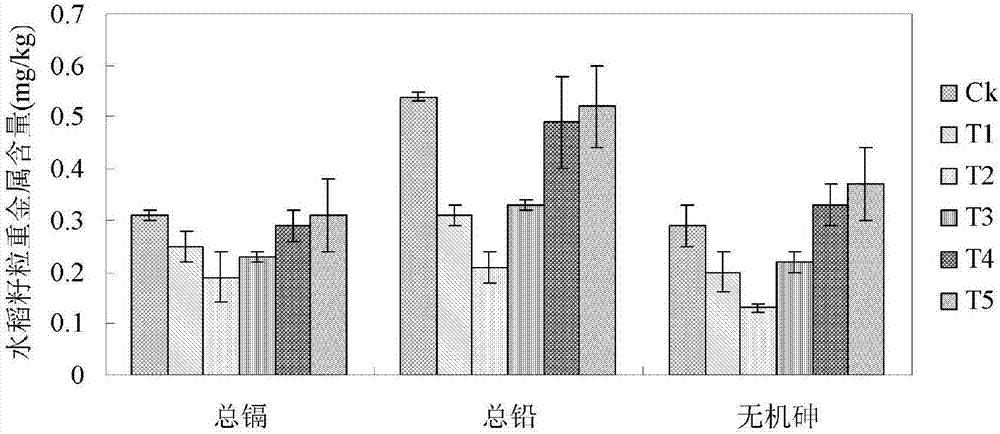

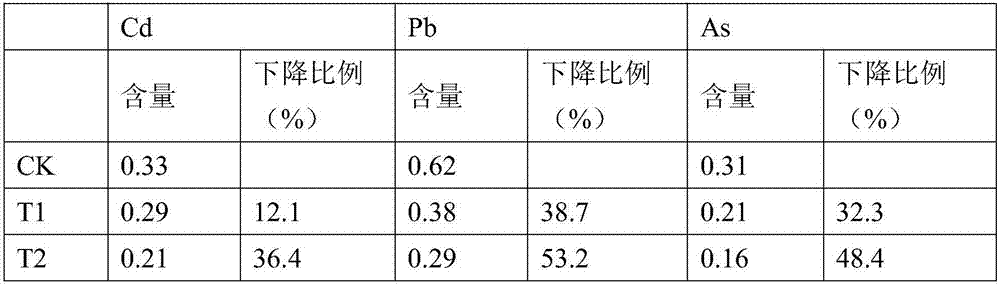

Soil heavy metal restoration agent and preparation method thereof

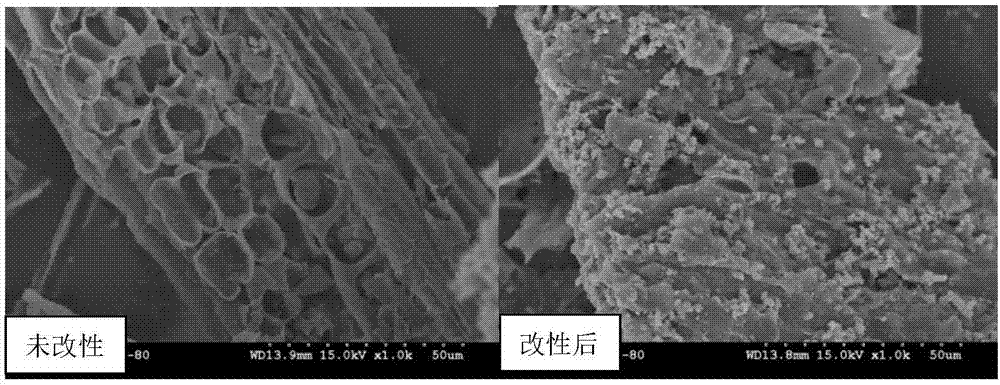

InactiveCN107502357AHas a passivation effectImprove enrichment capacityAgriculture tools and machinesOther chemical processesSoil heavy metalsManganese oxide

The invention discloses a soil heavy metal restoration agent and a preparation method thereof. Modified biomass charcoal impregnated by calcium-rich element and iron and manganese oxides is adopted as the carrier, and a nanoscale magnetic material is employed to coat the carrier. The product has a particle size of 0.25-5mm, and has a Fe content of 2-5%, a Mn content of 5-10%, and a Ca content of 10-15%. The restoration agent has certain restoration effect on single and compound pollution of cadmium, chromium, arsenic, lead and mercury under different pH backgrounds, thus having certain contribution effect on contaminated soil restoration and food safety. The restoration agent prepared by the method provided by the invention can fully and effectively utilize restoration materials with special passivation effect on heavy metals, and achieves the purpose of spectral restoration of heavy metal contaminated soil.

Owner:NANJING AGRICULTURAL UNIVERSITY

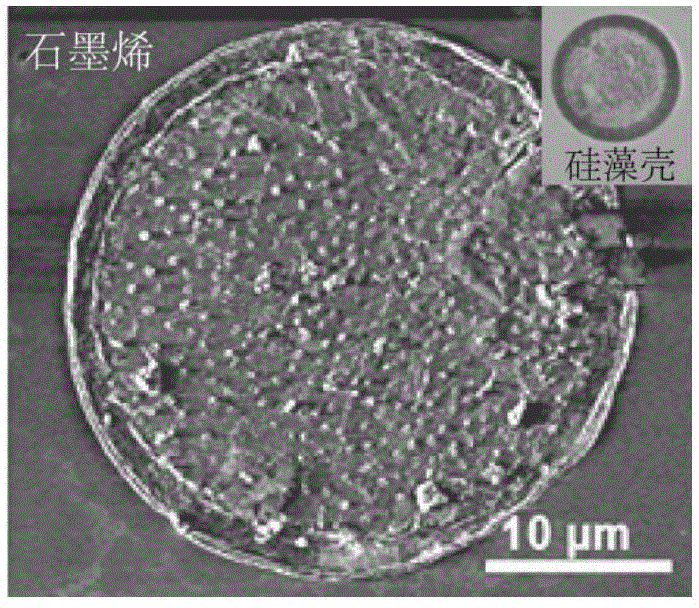

Method for macroscopically preparing high-quality graphene by using bio-mineralized material

The invention discloses a method for macroscopically preparing high-quality graphene by using bio-mineralized material. The method comprises the following steps: 1) calcining bio-mineralized material in chemical vapor deposition equipment and cooling to room temperature after calcination; 2) when the temperature of the equipment in the step 1) rises to 500-1300 DEG.C, introducing a carbon source under the protection of inert atmosphere to perform chemical vapor deposition reaction, soaking the reaction product in a non-oxidizing acid solution after the chemical vapor deposition reaction is finished, then cleaning and drying to obtain the graphene. The method disclosed by the invention is simple in process, high in efficiency, wide in raw material resource, and suitable for industrial continuous production. The graphene prepared by the invention is capable of duplicating the morphology of the used bio-mineralized material, and has characteristics of high degree of crystallinity, controllable layer number, high yield and strong conductivity; the graphene can be used for the field of transparent conducive films, flexible electronic apparatuses, new energy apparatuses and rubber composite superstrong material.

Owner:PEKING UNIV

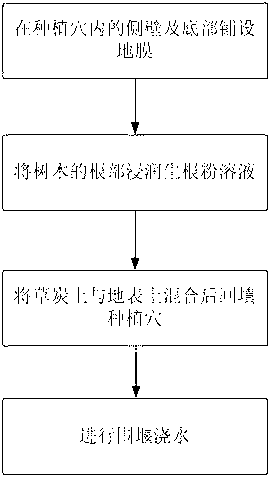

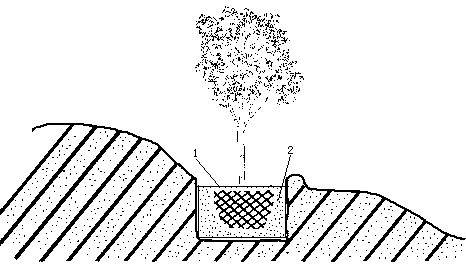

Method for planting trees in desert environment

ActiveCN103262775AGuaranteed survivalNormal growthForestryHorticultureHigh survival rateEarth surface

The invention relates to a method for planting trees in a desert environment. The method includes steps of a, laying mulching films on side walls and bottoms of planting holes; b, soaking all parts of roots of the trees in rooting powder solution and then placing the roots of the trees in the planting holes; c, filling grass carbon soil and earth surface soil mixtures into the planting holes; and d, enclosing the trees by barrages and watering the trees. Tree species suitable to grow in the desert environment are selected to mainly solve the problem of low survival rate of nursery trees in the desert environment, and the trees are planted in different locations of a desert according to characteristics of the different tree species, so that survival of the trees is guaranteed, the characteristics of the trees are sufficiently played, the trees can normally grow, the characteristics of sand prevention and water retention of the trees can be played, and the method has the advantages of simplicity, wide material source, low manufacturing cost and high survival rate of nursery trees.

Owner:北京正和恒基滨水生态环境治理股份有限公司

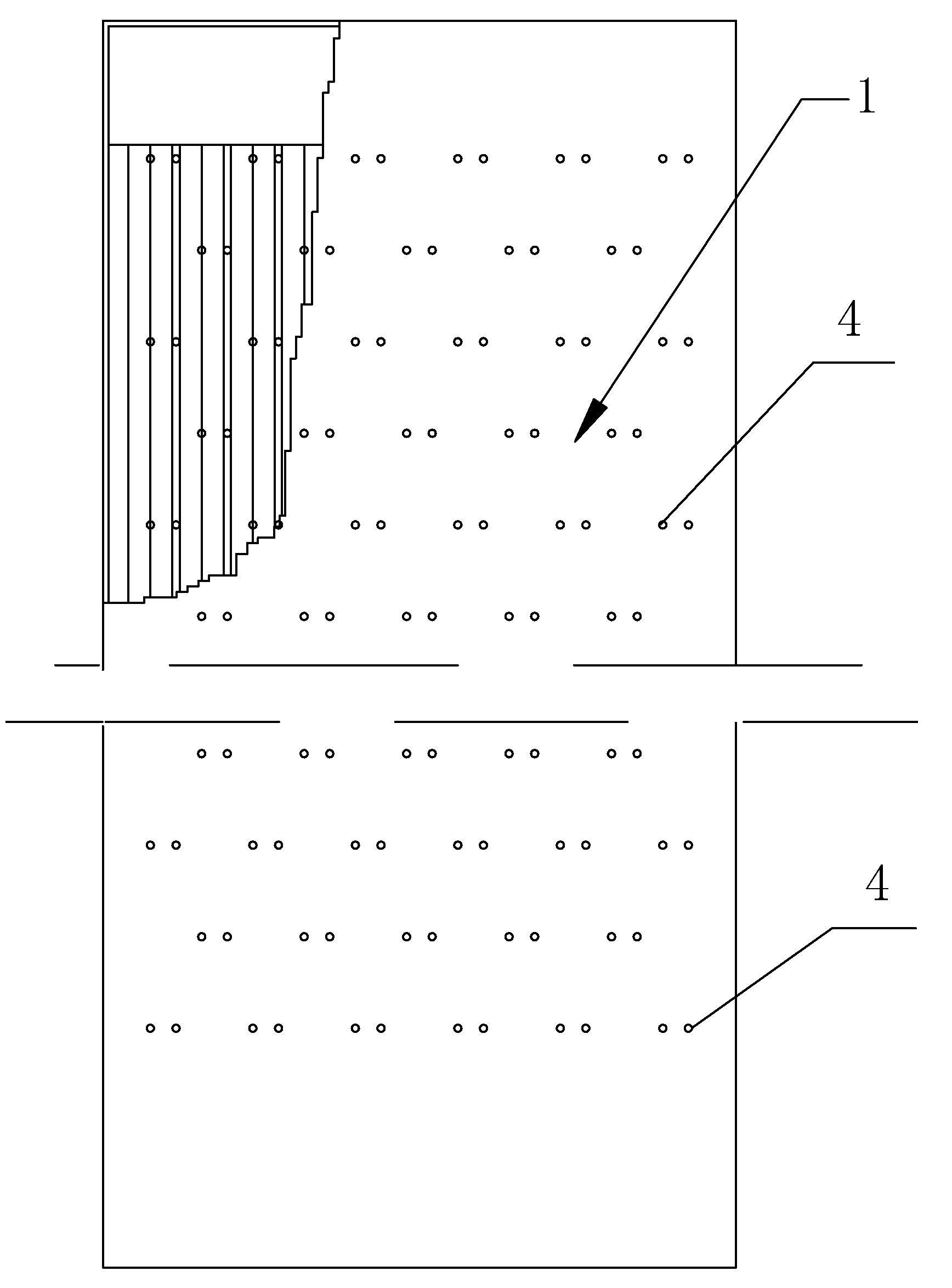

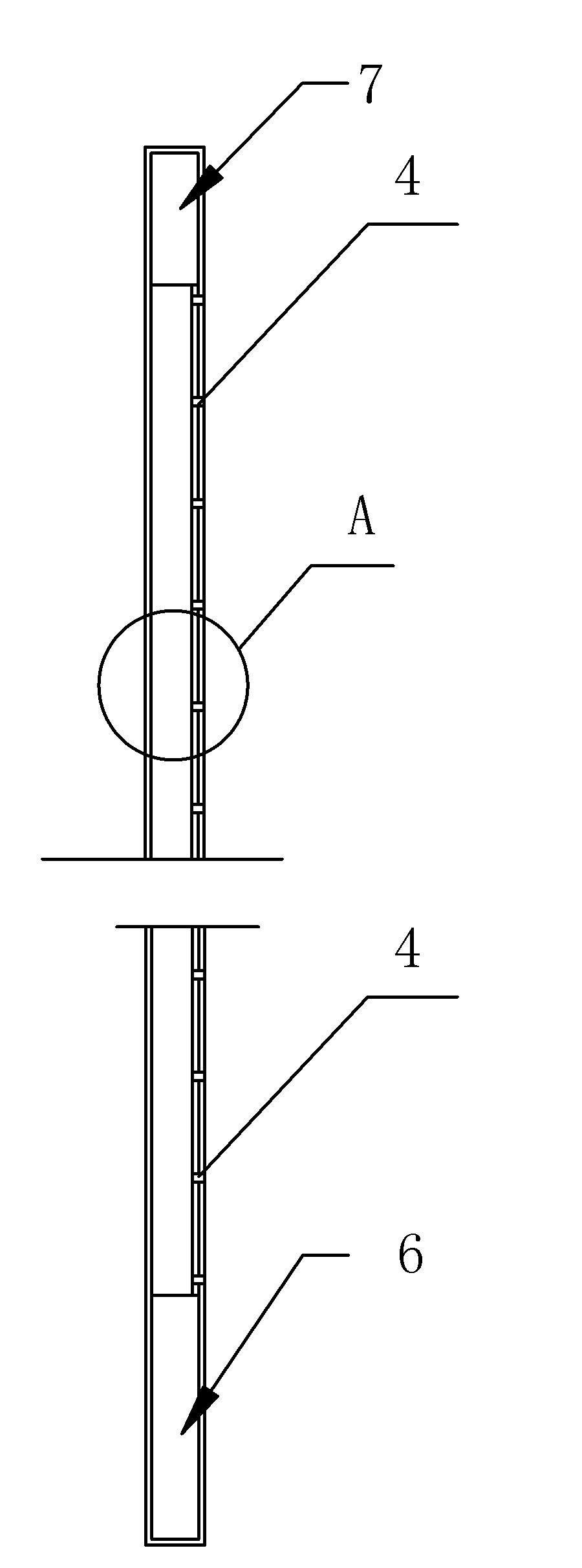

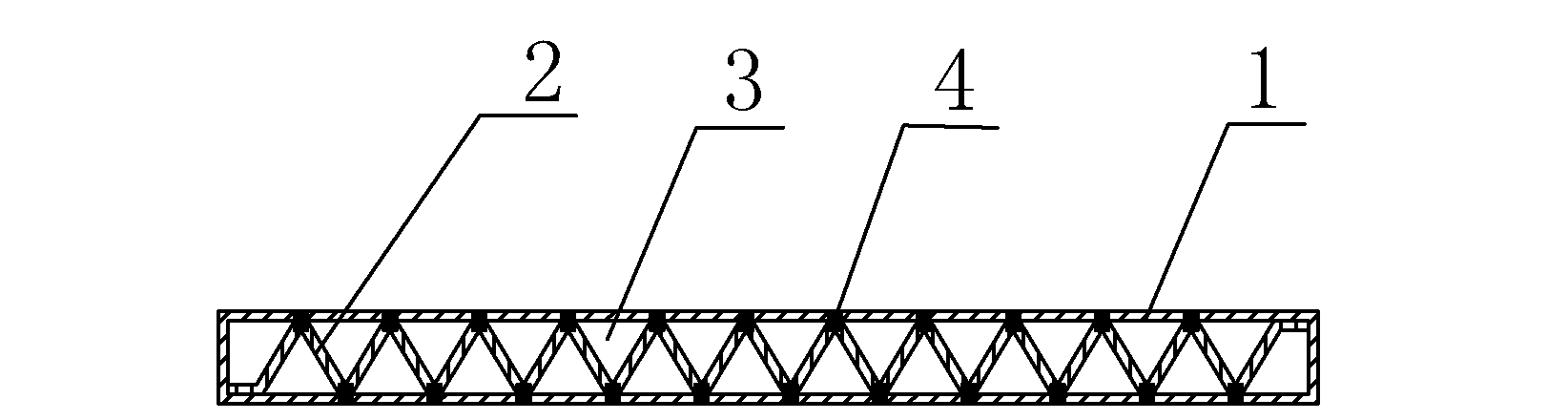

Plate-type pulsating heat pipe with double-side grooves

InactiveCN102121802AEnhance heat and mass exchangeImprove uniformitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSpot welding

The invention relates to a plate-type pulsating heat pipe with double-side grooves, comprising a casing and a bent plate. The cross section of casing is a rectangular closed box; the bent plate is a curved plate formed by a periodical winding shape, and the cross section of the bent plate is shaped like continuous triangles, or sinuidal or others periodic winding; the bent plate is inserted in the casing, and a plurality of pulsating grooves are formed between the bent plate and the inner surface of the casing, bent edges of the bent plate and the inner surface of the casing are connected through discontinuous spot welding, and slit communication is formed between the adjacent grooves; and the casing is closed, vacuumized and filled with working mediums. The plate-type pulsating heat pipe with the double-side grooves integrates the pulsating, flat plate, capillary and strengthening heat transfer and has excellent heat dissipation and cooling performances; the equivalent thermal conductive coefficient of the plate-type pulsating heat pipe with the double-side grooves is higher than that of an aluminum extruded heat radiator by more than two orders of magnitude and 2-3 times that of a related flat heat pipe; an excellent heat dissipation function is also provided by horizontal installation due to capillary grooves, and the application is facilitated. Therefore, the plate-type pulsating heat pipe with the double-side grooves is particularly suitable for heat dissipation and cooling of various chips and electronic components.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

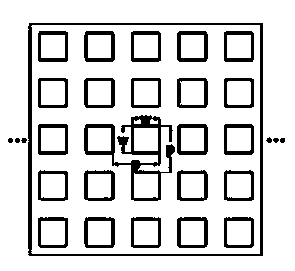

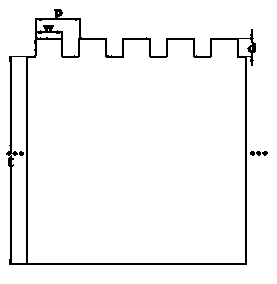

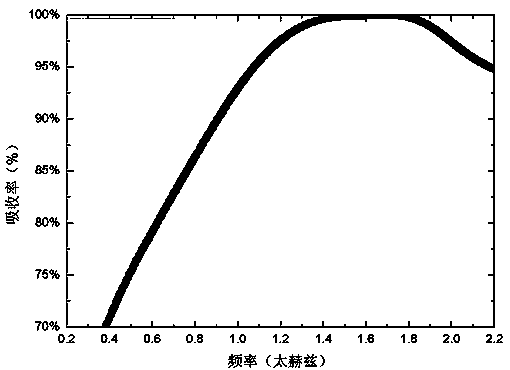

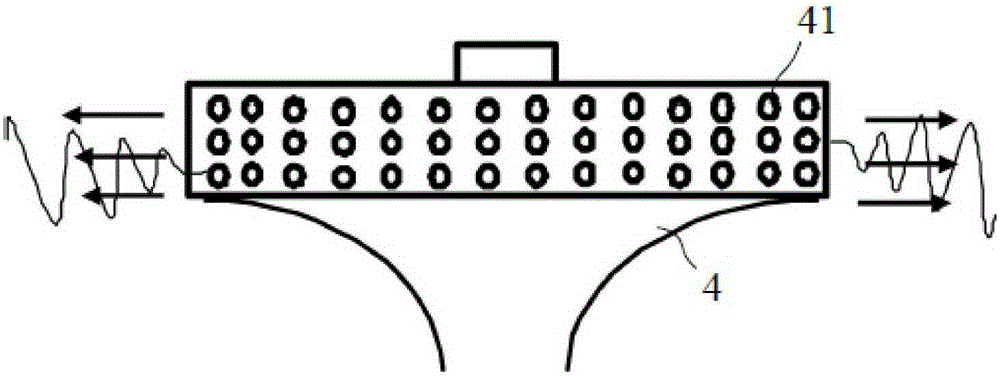

Manufacturing method for broadband THz wave absorber unrelated to wide-angle polarization

InactiveCN103969712AHigh absorption frequency bandIncrease the angle of incidenceAntennasOptical elementsHigh absorptionGrating

The invention relates to a manufacturing method for a broadband THz wave absorber unrelated to wide-angle polarization. The manufacturing method includes that semiconductor silicon with certain doping concentration is selected, a photolithography technique and an ICP (inductively coupled plasma) technique etching or a chemical corrosion technique are adopted on the surface of a silicon wafer to obtain periodically arranged grating layers with reduced reflectivity, and the rest part of the grating layers is a substrate layer with reduced transmissivity. By the arrangement, broadband absorber unrelated to the wide-angle polarization is realized in a THz band. Compared with a conventional metamaterial absorber, the high-doping silicon substrate absorber with the two-dimensional grating structure has the advantages of high absorption frequency band, unrelated to polarization, wide in incident angle and the like; the manufacturing method of the absorber is wide in material taking, simple and efficient, convenient to manufacture and wide in application range; the broadband THz absorber unrelated to the polarization can be manufactured according to actual application scenarios and demands, and absorption rate, absorption frequency band and absorption broadband can be regulated through regulation of structural parameters.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

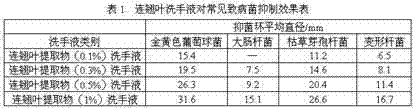

Forsythia suspensa leaf hand sanitizer and preparation method thereof

InactiveCN103767965AExtensive resourcesWide range of materialsAntibacterial agentsCosmetic preparationsAsparagus cochinchinensisAdditive ingredient

The invention relates to the field of daily cosmetics, and particularly relates to a mild type Chinese medicinal herb hand sanitizer with bacteriostatic, antibacterial and skin moisturizing effects, including a Chinese medicinal herb composition and an extraction process thereof and a preparation method of the hand sanitizer. A Forsythia suspensa leaf hand sanitizer comprises a functional component, a surfactant, a thickener, a humectant, a pH regulator, an anti-hard water agent, an aromatic, a pigment, a pearling agent and deionized water, wherein the functional component is Forsythia suspensa leaf extract, traditional Chinese medicine mixed extract, and Dioscorea opposita powder, and the traditional Chinese medicine mixed extract is mixed extract of Scutellaria baicalensis, Astragalus membranaceus and Asparagus cochinchinensis. The hand sanitizer provided by the invention has cleaning and antibacterial, skin moisturizing and skin caring effects, and does not cause dry hand skin, skin injury and other adverse effects even after frequent hand cleaning.

Owner:左权县桐峪镇嘉百岁农民专业合作社

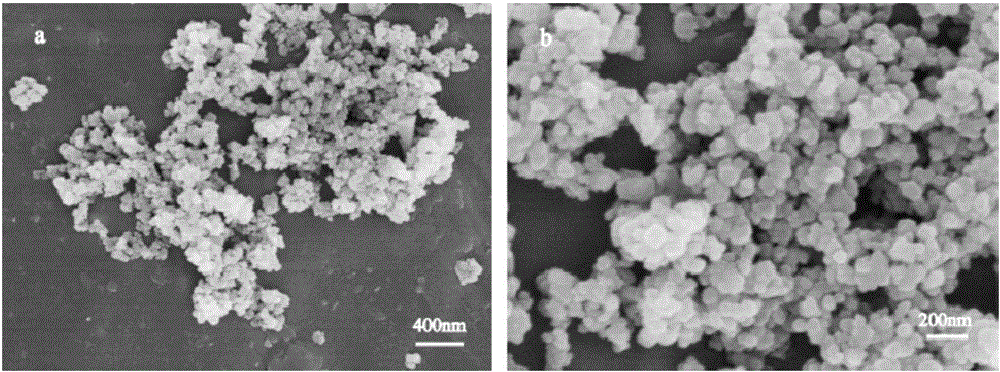

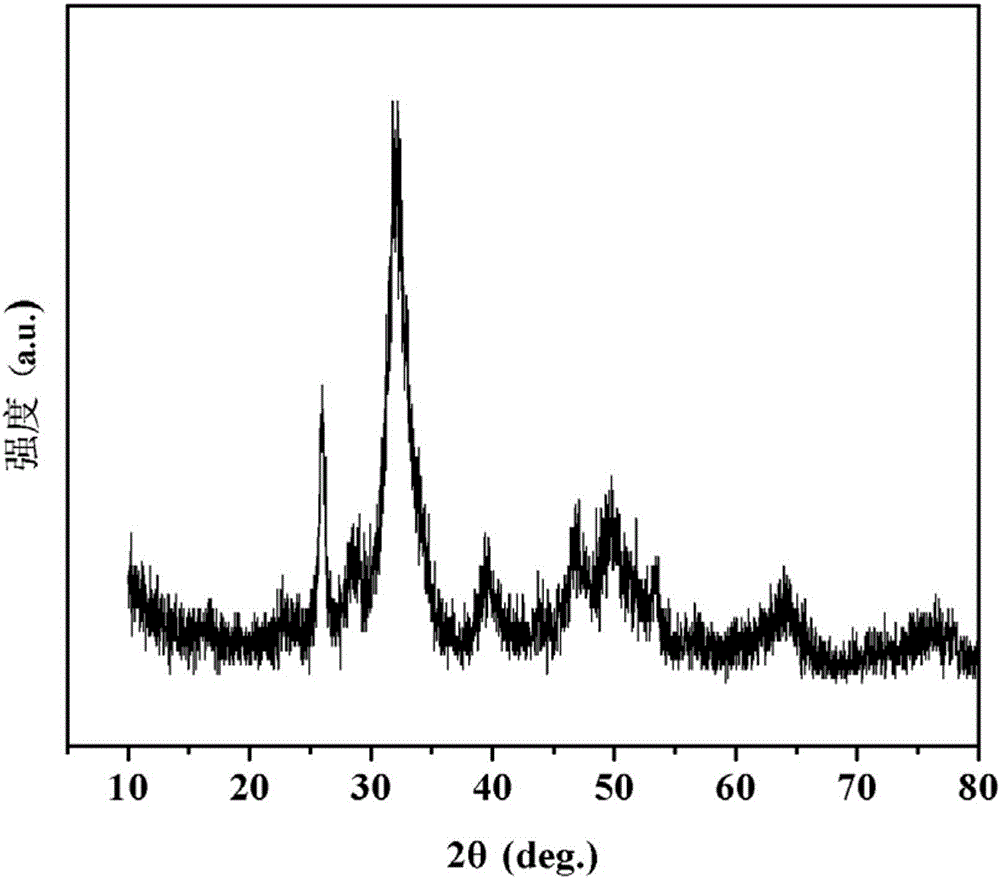

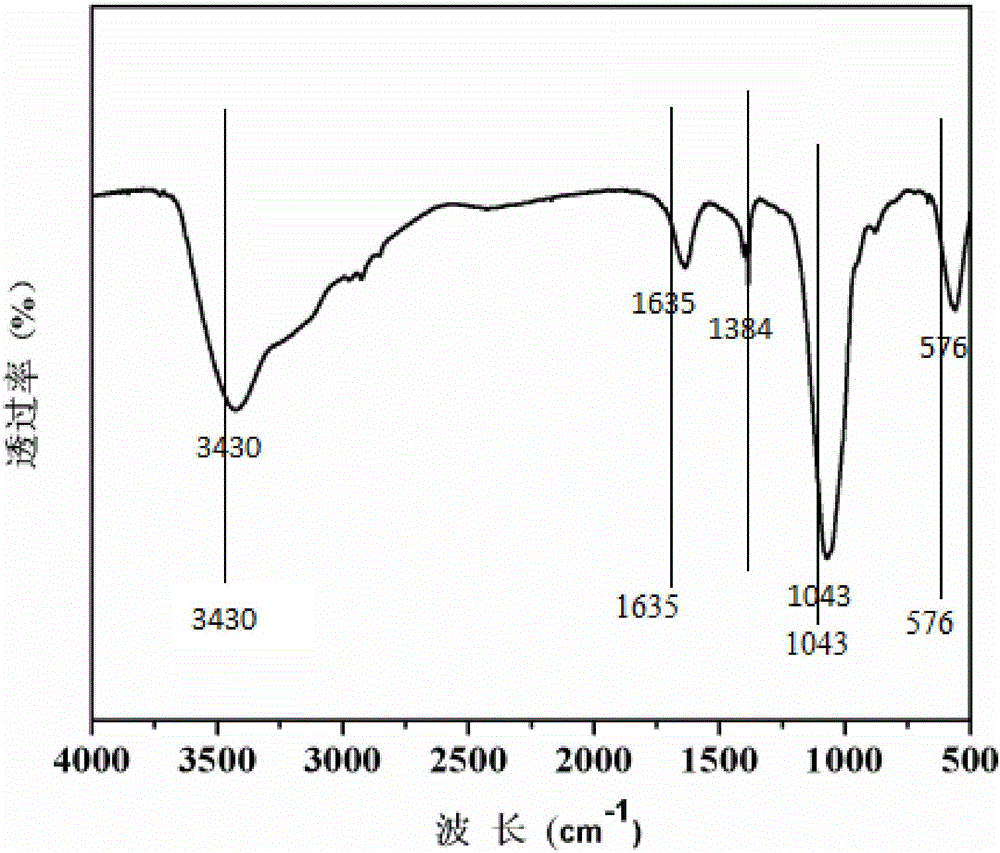

Method for preparing nano-hydroxyapatite

InactiveCN106044734AWide range of materialsTurn waste into treasureMaterial nanotechnologyWater contaminantsIonHeavy metals

The invention provides a method for preparing nano-hydroxyapatite. The method comprises the following steps of dissolving calcium-containing slag into acid, removing impurities which are not dissolved in the acid by means of filtering, adjusting a pH value to an alkaline level, removing impurities which are not dissolved in alkali by means of filtering again, and obtaining a calcium salt solution; mixing the calcium salt solution with a phosphate solution, adjusting the pH value of the mixed solution to the alkaline level, and reacting to obtain the nano-hydroxyapatite. Compared with the prior art, the nano-hydroxyapatite prepared according to the method provided by the invention has the advantages that factory slag is taken as a raw material, the factory slag is cheap and is easily and widely obtained, the effect of turning waste into treasure is achieved, the nano-hydroxyapatite is friendly and harmless to the environment, and the technology is simple; the dispersity is excellent, the particle diameters are uniform, and the adsorption of heavy metal ions in wastewater is beneficially performed; the prepared nano-hydroxyapatite has a proper mechanical property and an excellent processing property, and the environment can be prevented from secondary pollution during the process of treating heavy metal in the wastewater, therefore the nano-hydroxyapatite is widely used in the field of water treatment.

Owner:宝武集团环境资源科技有限公司

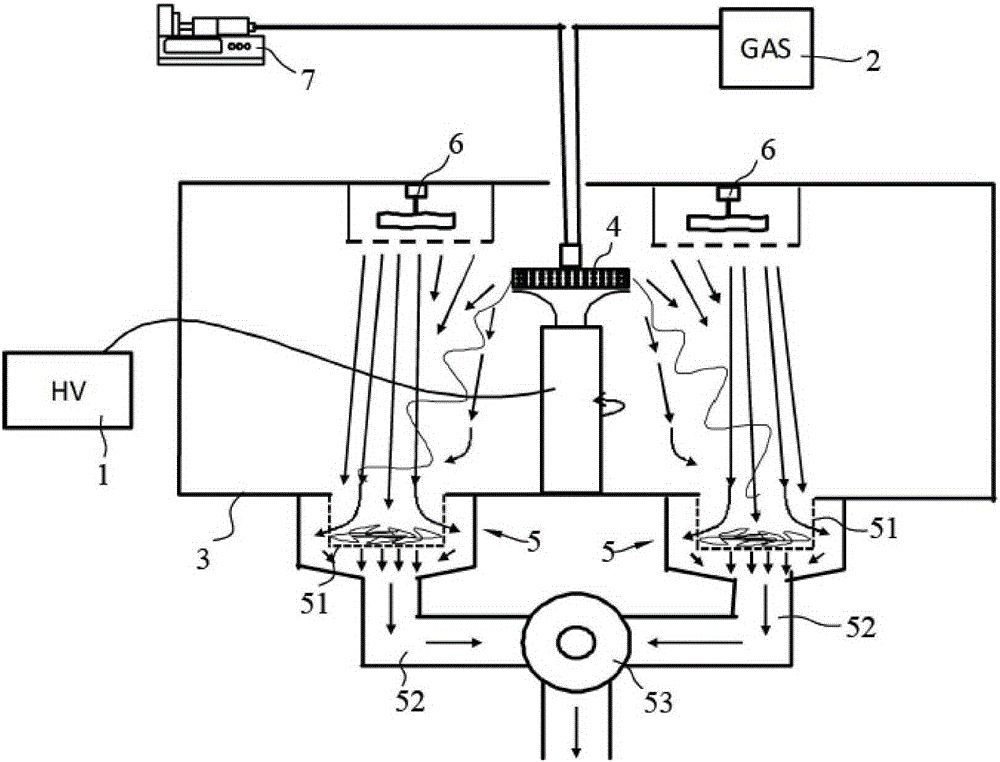

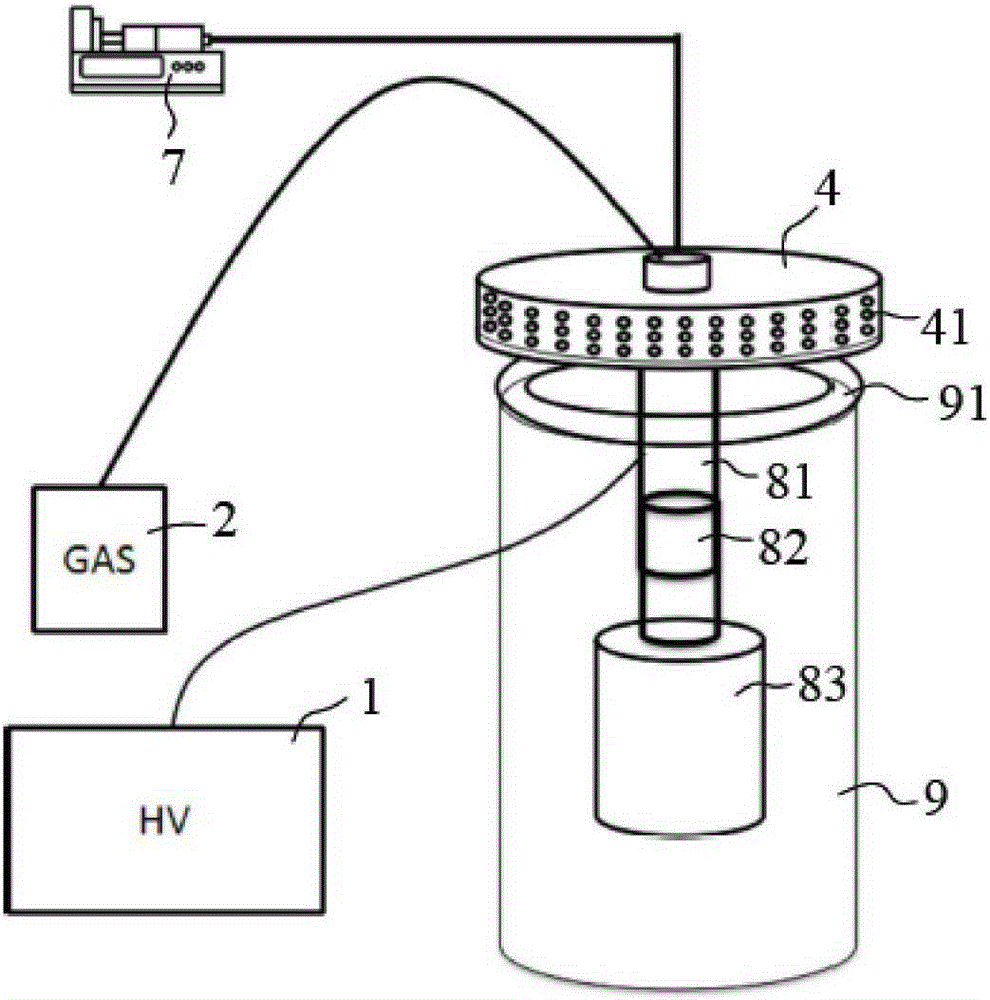

Centrifugal gas-electric spinning device by utilizing negative-pressure array

InactiveCN105350093AAirflow path controllableSimple structureNew-spun product collectionFilament/thread formingFiberEngineering

The invention discloses a centrifugal gas-electric spinning device by utilizing a negative-pressure array. The centrifugal gas-electric spinning device comprises a high-voltage alternating-current generator, an air supply device, a box body, a centrifugal sprayer, a centrifugal driving mechanism and negative-pressure receiving devices. The interior of the centrifugal sprayer is provided with a liquid storage cavity. Filament outlet holes are arranged in the centrifugal sprayer. Each negative-pressure receiving device comprises a collector, a negative-pressure pipe and a negative air-pressure generator. Negative-pressure pipe openings are formed by negative-pressure pipes in the bottom of the box body. Collectors are nested into the negative-pressure pipe openings. The multiple negative-pressure receiving devices are arrayed in an annular array with the centrifugal sprayer as the center. The high-voltage alternating-current generator is formed for generating an electric field. Airflow spraying out of the filament outlet holes is formed by the air supply device. The centrifugal gas-electric spinning device by utilizing the negative-pressure array has following beneficial effects: nanofibers are formed by sprayed polymers under airflow, an electric field, negative pressure and centrifugal force such that a three-dimensional structure is formed by nanofibers on the negative-pressure receiving devices; thickness of fiber disposition is increased; biological materials are better compatible and the application scope of technology materials is broad; and a support structure obtained is beneficial for cell growth of tissue engineering.

Owner:GUANGDONG UNIV OF TECH

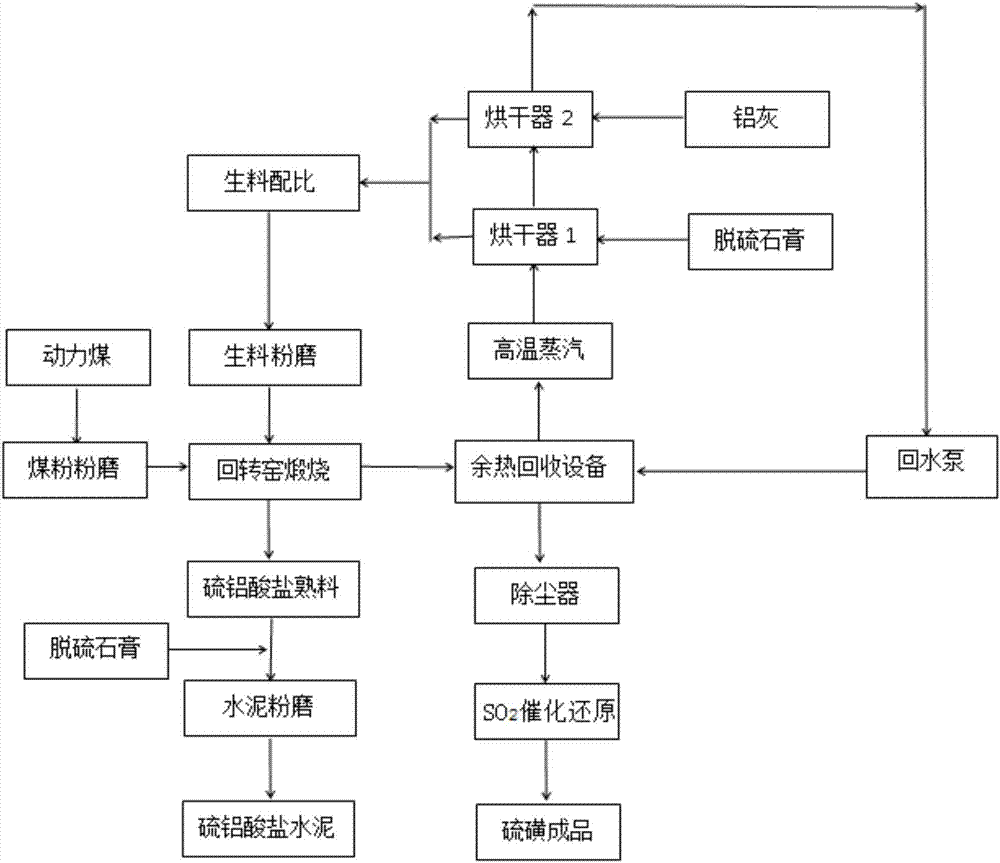

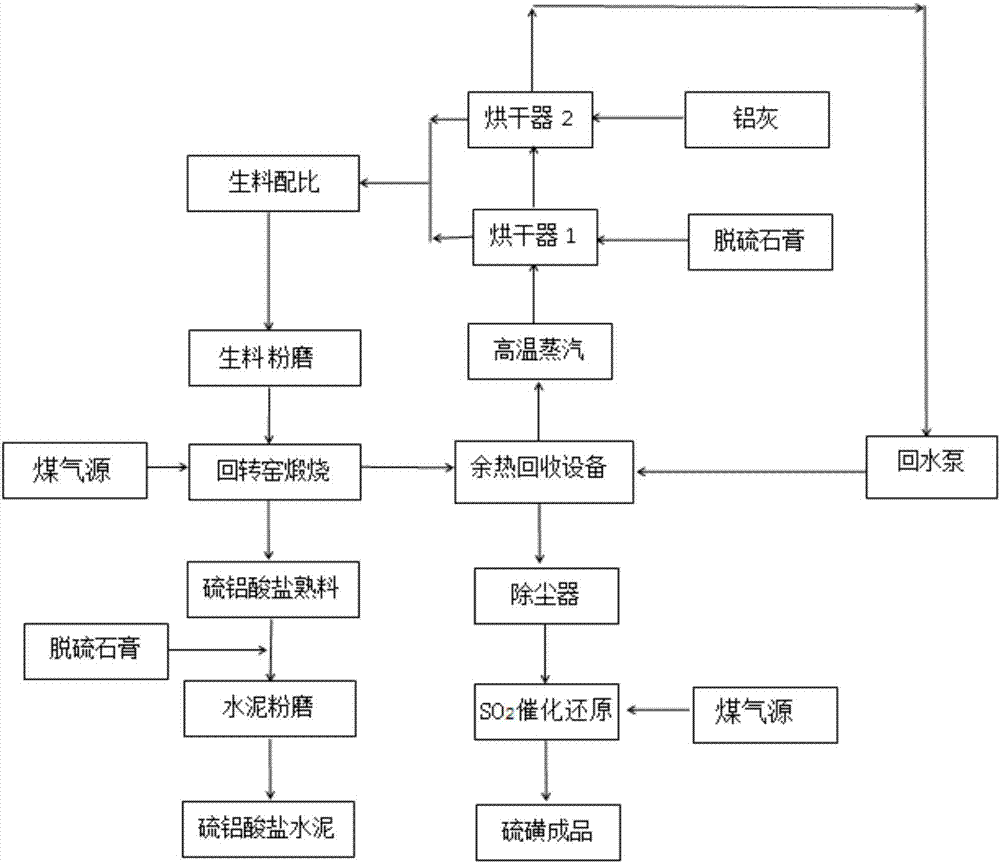

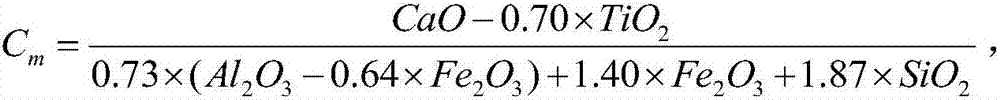

System and method for co-producing sulfo-aluminate cement and sulfur by use of desulfurized gypsum and aluminum ash

ActiveCN107056102AReduce usageMeet the formulation requirementsSulfur preparation/purificationCarbon monoxideCombustionSulfur product

The invention discloses a system and a method for co-producing sulfo-aluminate cement and sulfur by use of desulfurized gypsum and aluminum ash. The method comprises the following steps: (1) drying aluminum ash, and heating desulfurized gypsum for dehydration to obtain semi-hydrated gypsum; (2) mixing aluminum ash with semi-hydrated gypsum according to a preset ratio, pulverizing, and homogenizing; (3) calcining the pulverized and homogenized mixture of aluminum ash and semi-hydrated gypsum while adding coal dust to the mixture, and carrying out oxygen enriched combustion to obtain sulfo-aluminate cement clinker and sulfur dioxide-containing flue gas; (4) mixing sulfo-aluminate cement clinker and desulfurized gypsum according to a ratio, and pulverizing to obtain sulfo-aluminate cement; and (5) dedusting the sulfur dioxide-containing flue gas, and carrying out catalytic reduction to obtain a sulfur product, wherein the mass ratio of aluminum ash to desulfurized gypsum to carbon powder is (33-39):(61-66):1.

Owner:中芈(山东)环保科技有限公司

Method for preparing soft sweets by taking coarse food grains as raw materials

InactiveCN101978846AWide range of materialsOvercome browningConfectionerySweetmeatsLiquid glucoseSurface layer

The invention discloses a method for preparing soft sweets by taking coarse food grains as raw materials and relates to a soft sweet processing method. The method comprises the following steps of: (1) selecting the raw materials; (2) preparing raw stock; (3) mixing the raw stock and syrup and edible glue solution so as to obtain mixed liquid glucose; (4) injecting the liquid glucose into a mold, condensing and demolding so as to obtain sweet bodies; (5) brushing a surface layer on the surfaces of the sweet bodies; and (6) drying the sweet bodies until the water content of the sweet bodies is lowered to 16 percent. The method is characterized in that: the coarse food grain raw materials selected in the step (1) is one or the mixture of more of corn, pumpkin, sweet potato, purple potato, small potato, yam, mung bean and red bean; the surface layers of the sweet bodies obtained in the step (5) are made of glutinous rice flour; and in the step (6), the sweet bodies are dried at the temperature of 50+ / -1 DEG C and the humidity of 50+ / -5 percent for 48 hours. The method has the advantages that: the raw materials are readily available and the problem of browning and the problem of greasiness of the glutinous rice flour surface layers are solved; the soft sweets taste soft and accordant and have appropriate hardness; moreover, the shelf life of the coarse food grain soft sweets can be prolonged.

Owner:詹良解 +1

Granular fuel with crop straw and production thereof

InactiveCN1746274AWide range of materialsSimple processSolid fuelsWaste based fuelHigh densityEngineering

A crop straw particle fuel and its production are disclosed. The fuel is prepared by drying crop or plant waste under moisture content 16%, crushing them into powder with grain size under 8mm from side-rub multifunctional crusher, mixing one material or several materials with water, steam vaporizing, compression forming from special straw granulating flat die machine, cooling, and packing into particle fuel of which grain size is 6-9mm, length is 20-30mm and moisture content <=14wt%. Its advantages include low cost, high density, heat value and forming rate, simple process and no environmental pollution.

Owner:张建超

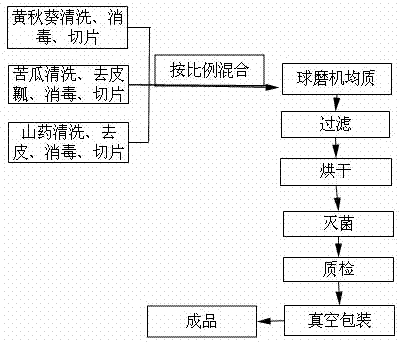

Blood glucose-lowering food containing okra and preparation method thereof

InactiveCN102813195ASimple preparation processEasy to operateMetabolism disorderFood preparationPEARDietary fiber

The invention provides a blood glucose-lowering food containing okra and a preparation method of the blood glucose-lowering food containing okra, wherein the blood glucose-lowering food is characterized by comprising components by weight as follows: 30-60 parts of okra, 15-45 parts of balsam pear and 15-45 parts of Chinese yam. The food uses okra, balsam pear and Chinese yam with higher value as raw materials, and above materials are pure natural plants and contains comprehensive nutrients, trace elements and dietary fibers necessary for human body; the finished product is obtained by mixing and grinding, filtering, drying and sterilizing; the preparation process is simple, the price is cheap, the taste is good, and the effect of lowering blood glucose is obvious; each component plays a role of supplementing each other in lowering blood glucose; adverse reactions caused by long-term consumption can be cancelled out; the applicable group is greatly enlarged; and the finished product used as the food is convenient to eat and has functions of improving microcirculation and improving organism immunity.

Owner:GUANGSHUI DONGCHEN AGRI SCI & TECH

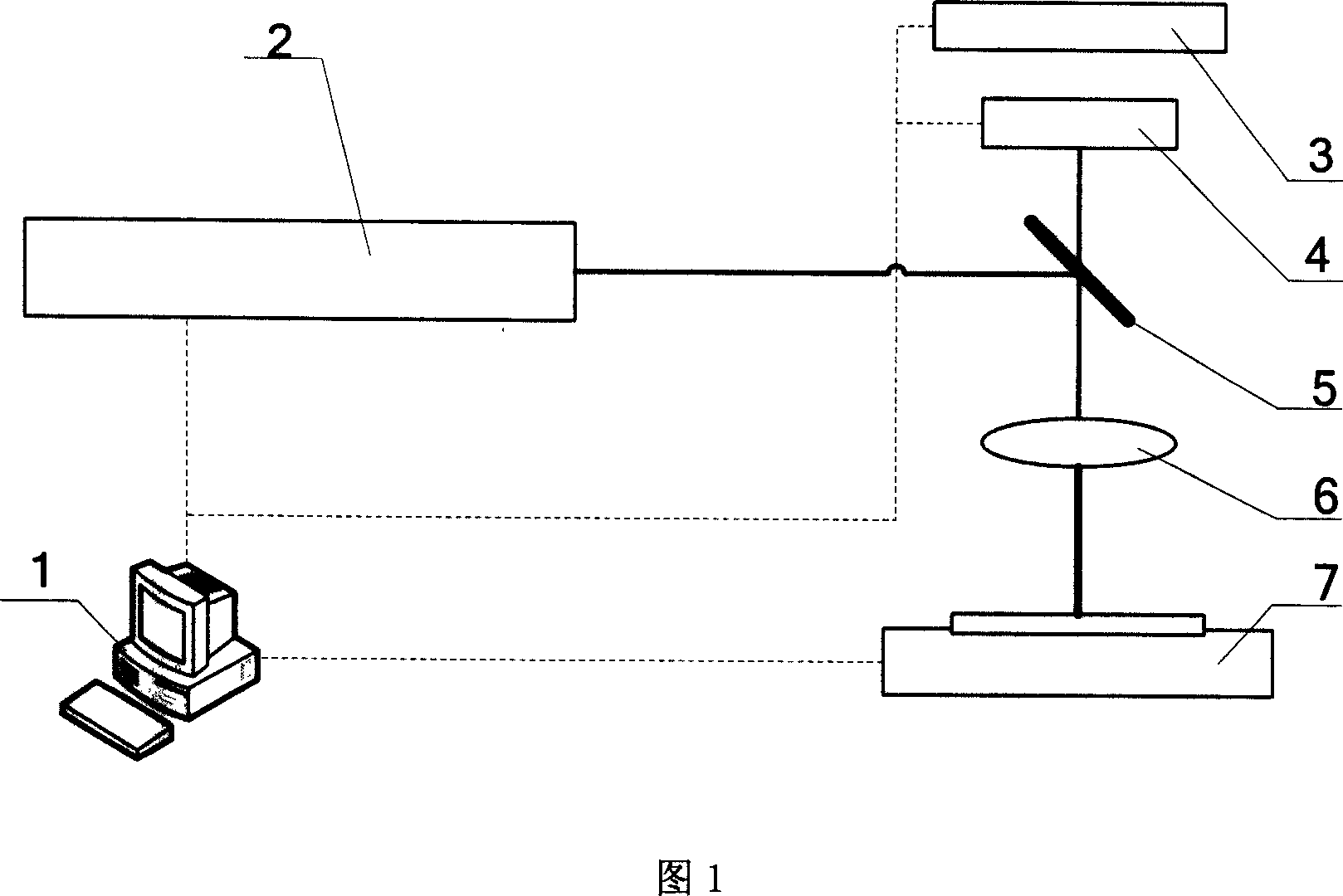

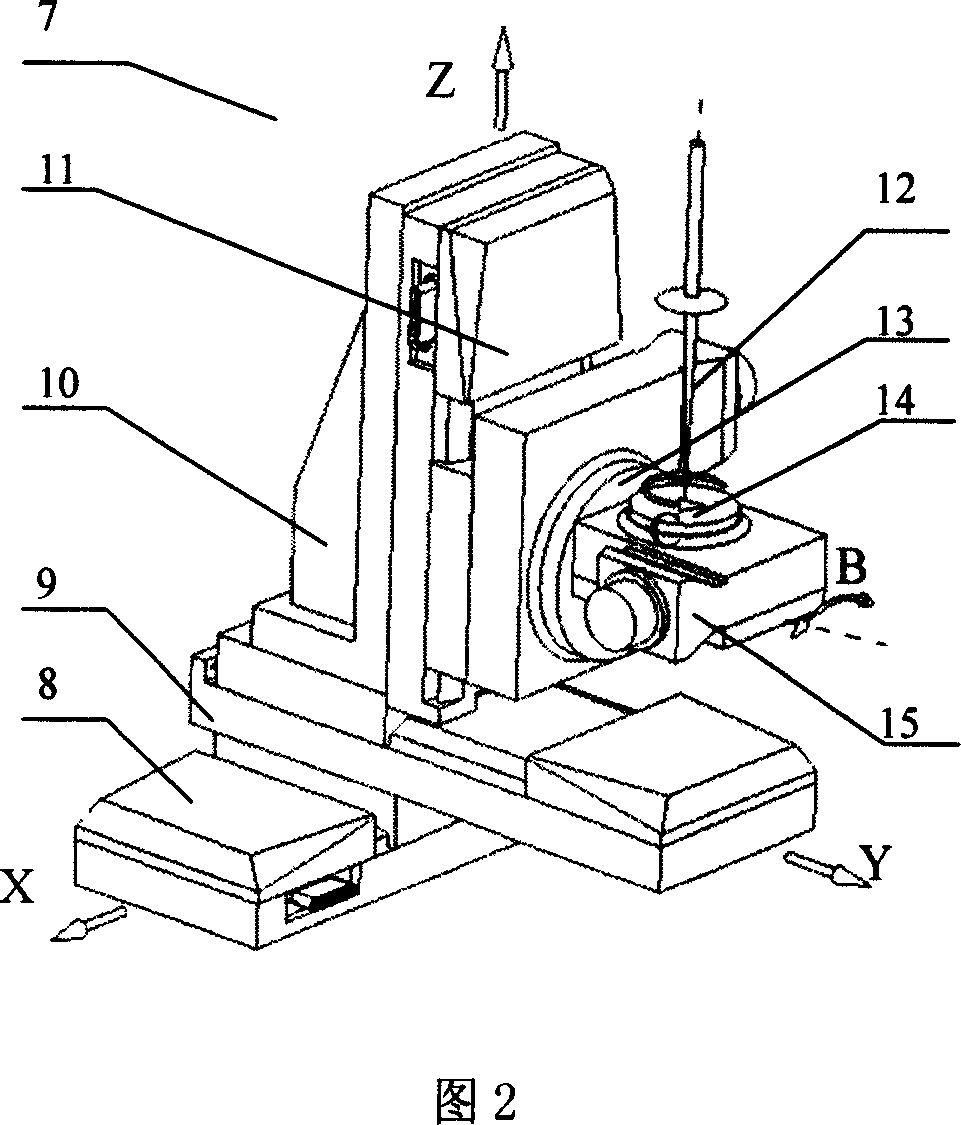

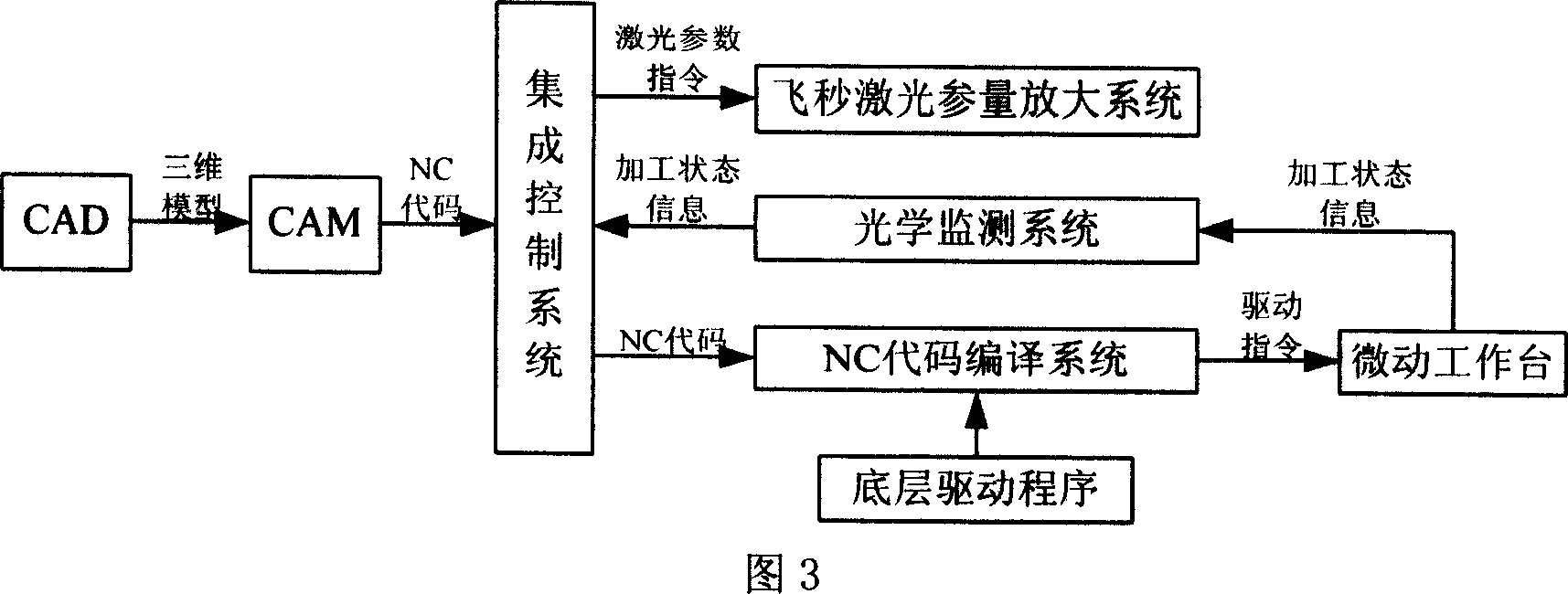

Femto-second laser ture three-D micro-nano-processing center

InactiveCN1947917ASolve processing problemsHigh resolutionLaser beam welding apparatusOptical elementsMicro nanoFemto second laser

A true-3D fm-class machining center with fs laser is composed of a fs laser generating-amplifying system, a reflector arranged on the laser output path of said laser generating-amplifying system by negative 45-degree angle, a multiple axles linked microbench under said reflector, a focusing lens between said reflector and microbench, a CCD sensor above said reflector, a LCD monitor, and an industrial control computer.

Owner:XI AN JIAOTONG UNIV

Method for synthesizing lithium ion battery cathode material lithium iron phosphate through in situ polymerizing and cladding

InactiveCN104638242AImprove cycle performanceEasy to manufactureElectrode thermal treatmentSecondary cellsIn situ polymerizationLithium-ion battery

The invention discloses a method for synthesizing lithium ion battery cathode material lithium iron phosphate through in situ polymerizing and cladding. The lithium iron phosphate is prepared by the following steps of (1) dissolving a phosphorus source in water and uniformly mixing, and then adding a polymer monomer into the mixed liquor under stirring and uniformly mixing, wherein the polymer monomer is one of phenylamine, pyrrole, crylic acid, vinyl cyanide, ethylene glycol, vinyl chloride and vinyl benzene; (2) slowly adding an iron source solution into the mixed solution prepared in the step (1), and mixing the two solutions to react so as to prepare a precursor solution; (3) adding a lithium source into the precursor solution, stirring intensely, and performing spray drying to prepare precursor powder; and (4) calcining the precursor powder at high temperature to prepare a nanoscale porous LiFePO4 / C sample. The material prepared by the method is relatively high in charge and discharge capacity, relatively good in rate capability and excellent in cycling performance. The lithium iron phosphate is synthesized by a solid-liquid combination method easy to be commercialized, the method is easy to operate and short in technological process; besides substituted sources are easily available, and the manufacturing cost is low.

Owner:CHONGQING TERUI BATTERY MATERIAL

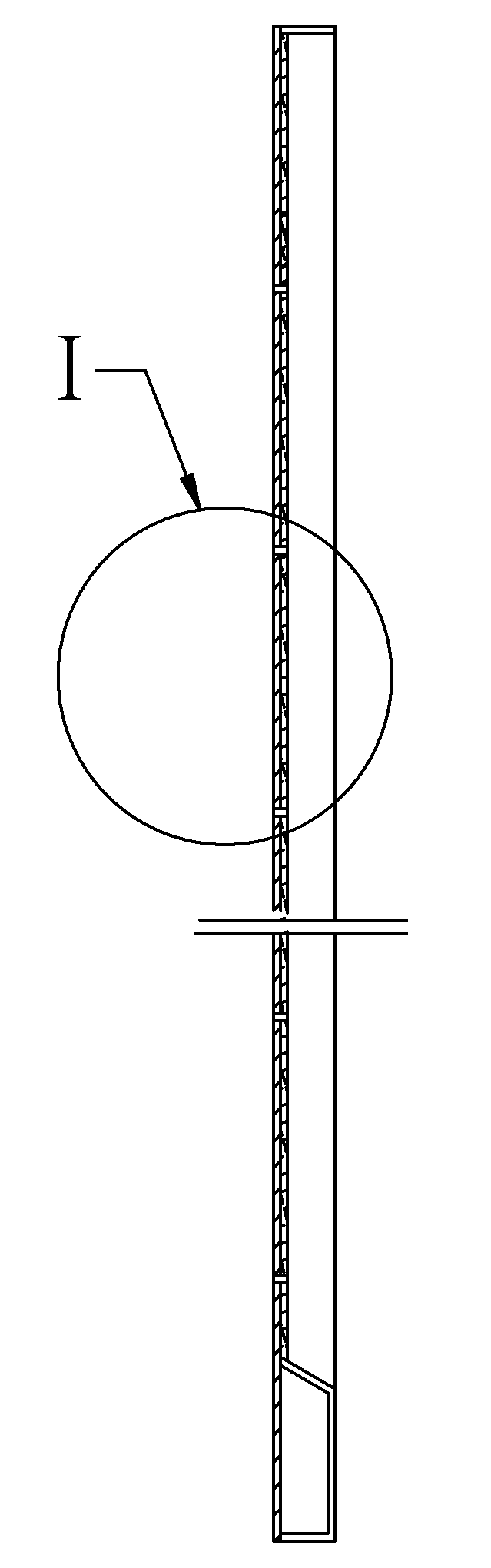

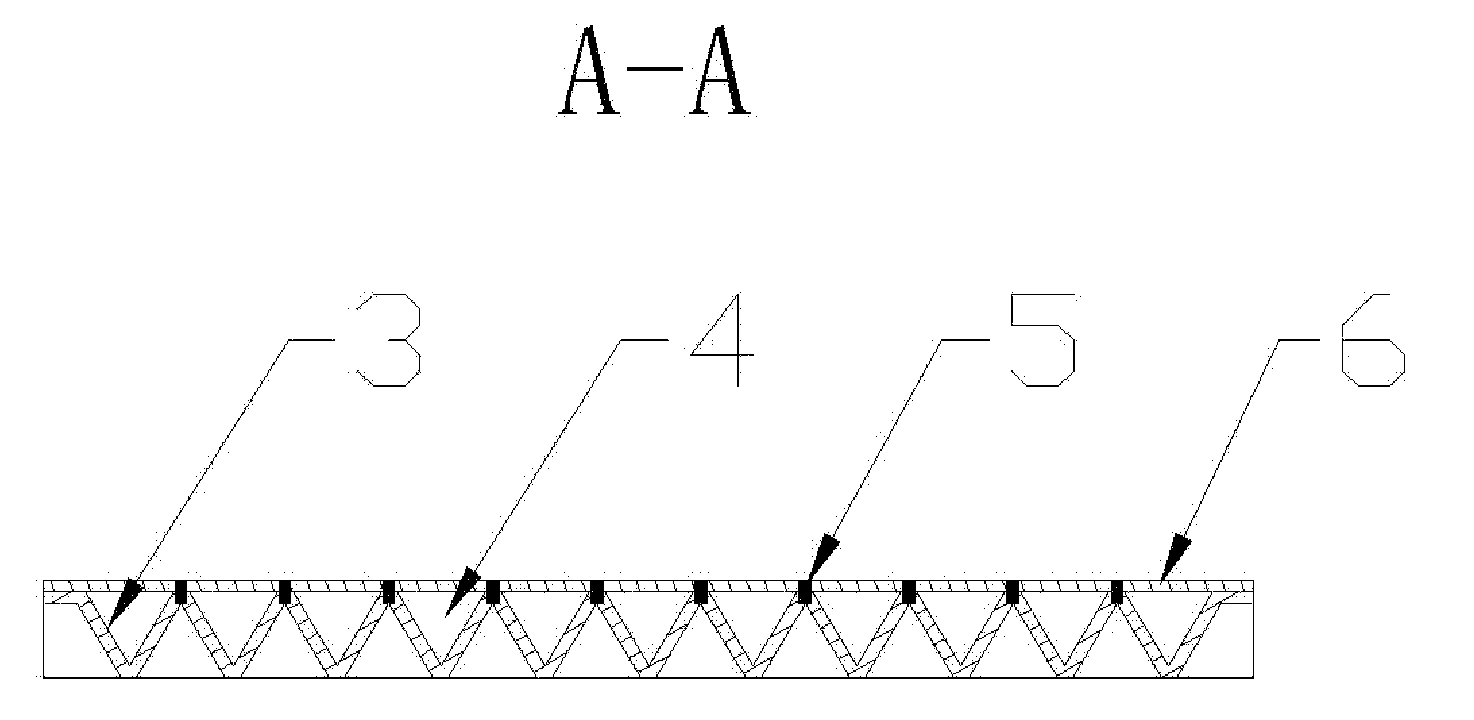

Single-sided corrugated plate type pulsating heat pipe

InactiveCN102128552AHigh heat transfer efficiencyExtensive sources of materialsSemiconductor/solid-state device detailsSolid-state devicesCurve shapeAluminium

The invention discloses a single-sided corrugated plate type pulsating heat pipe which comprises a bottom plate, a corrugated plate and a first communication cavity and is characterized in that: the bottom plate is a plane metal plate; one end of the bottom plate is provided with the first communication cavity in sealed connection with the bottom plate; the section of the corrugated plate is of a continuous triangular shape, sinusoidal shape or other periodical curve shape; the two ends along the extension direction of the wave of the corrugated plate are in sealed connection with the bottom plate; one end vertical to the extension direction of the wave of the corrugated plate is in sealed connection with the first communication cavity, and the other end is in sealed connection with the bottom plate; two adjacent troughs of the corrugated plate are welded on the bottom plate through spot welding to form multiple pulsating channels vertical to the extension direction of the wave of the corrugated plate; and adjacent channels are communicated through hair cracks. The equivalent coefficient of heat conductivity of the single-sided corrugated plate type pulsating heat pipe is two orders of magnitude higher than that of an aluminum extruded radiator and 2-3 times higher than that of the related flat heat pipe; and the single-sided corrugated plate type pulsating heat pipe can be horizontally mounted and is particularly suitable for recycling the ventilation energy of an air conditioner as well as radiating and cooling electronic devices.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com