Patents

Literature

146results about How to "High heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

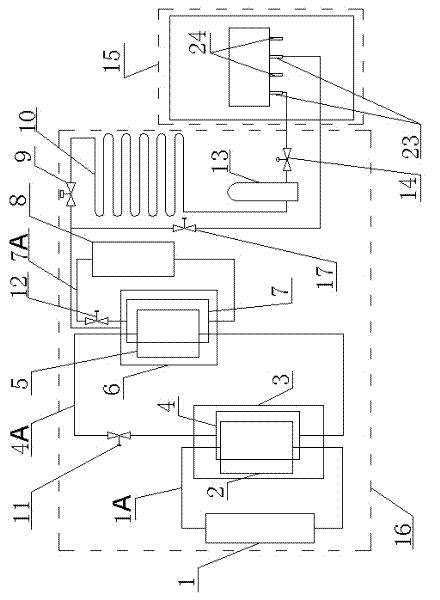

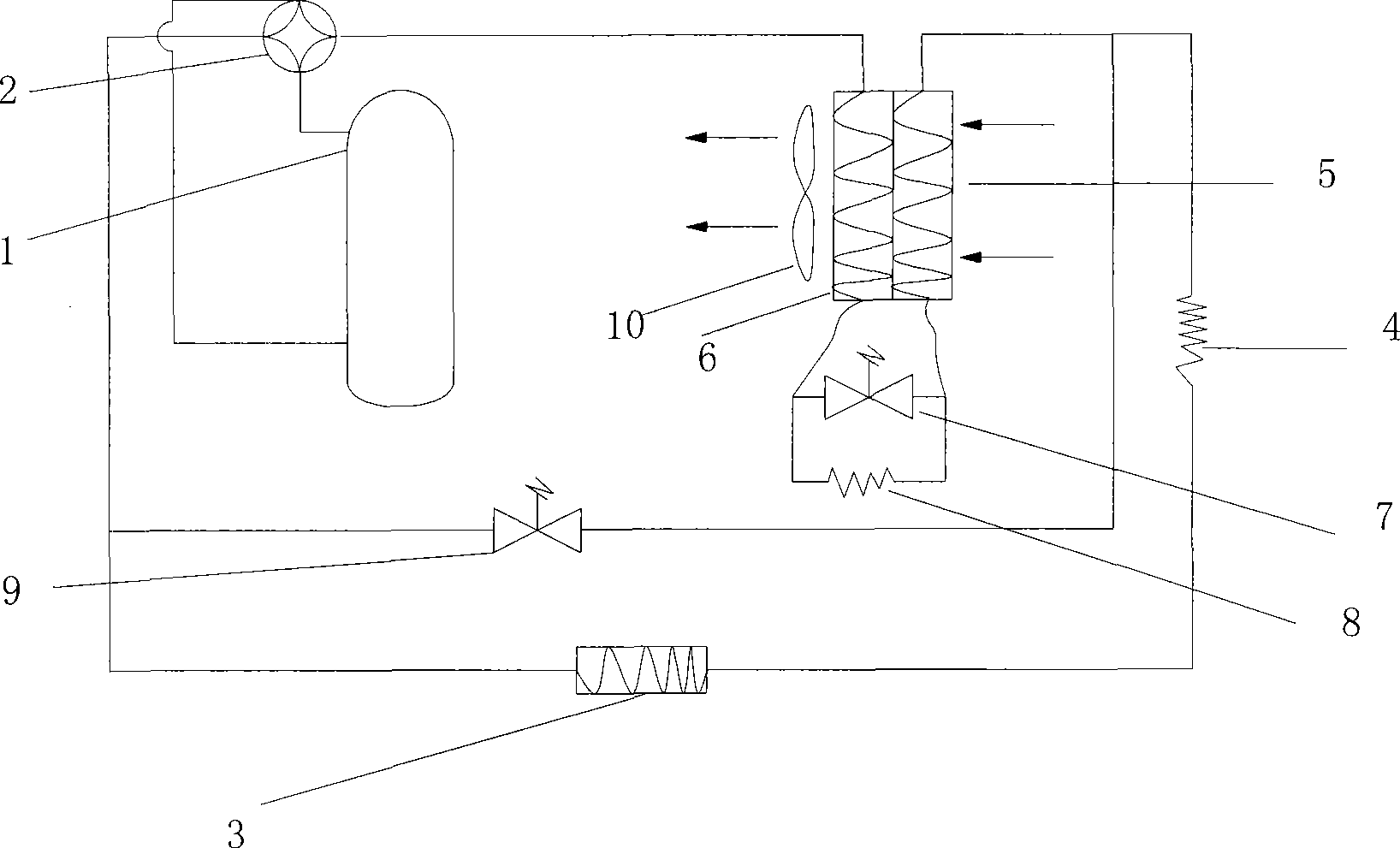

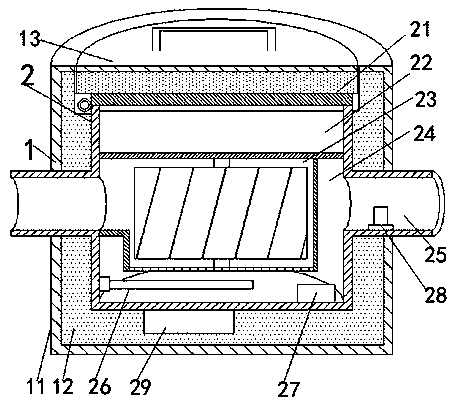

Internal-combustion engine assisted sea water desalinization/poor-quality water purification method and device thereof

ActiveCN101792191AHigh heat transfer efficiencyIncrease water productionWater/sewage treatmentEnergy based wastewater treatmentHeat transfer efficiencySeawater

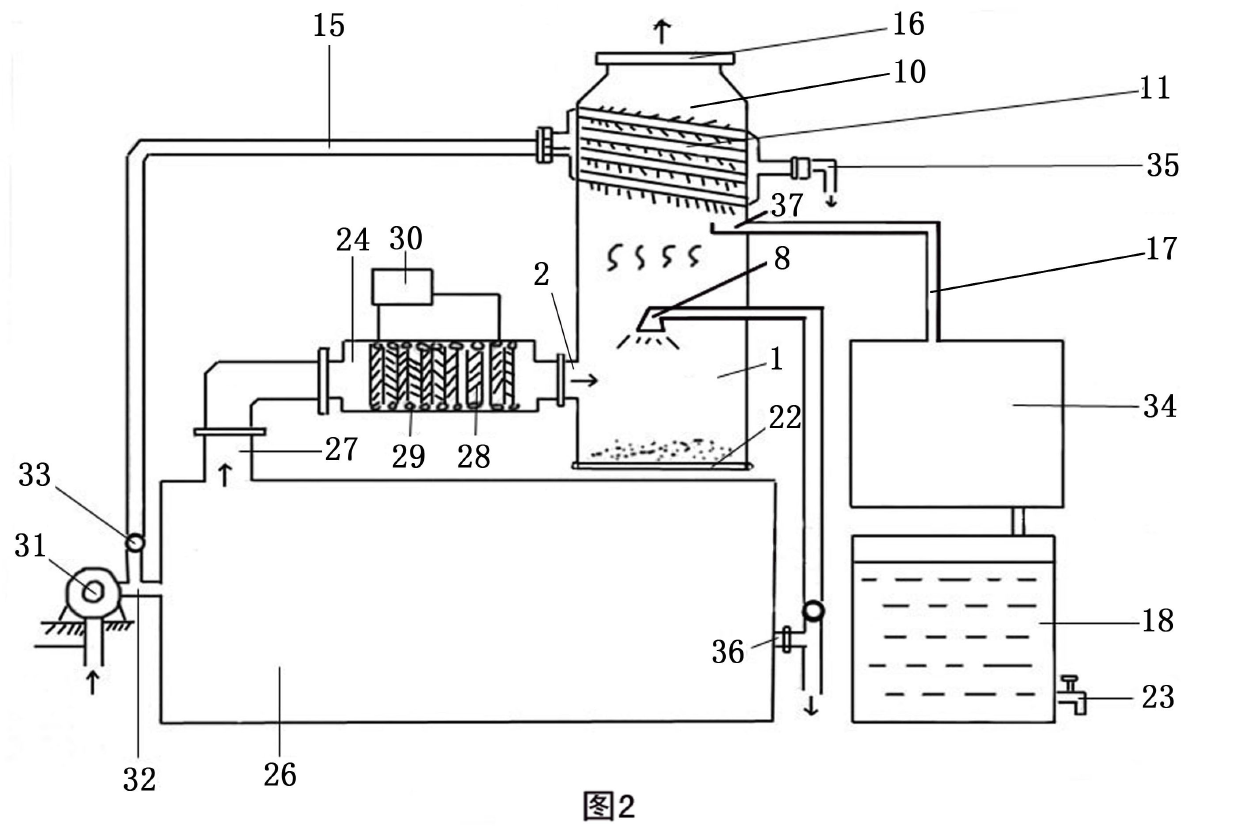

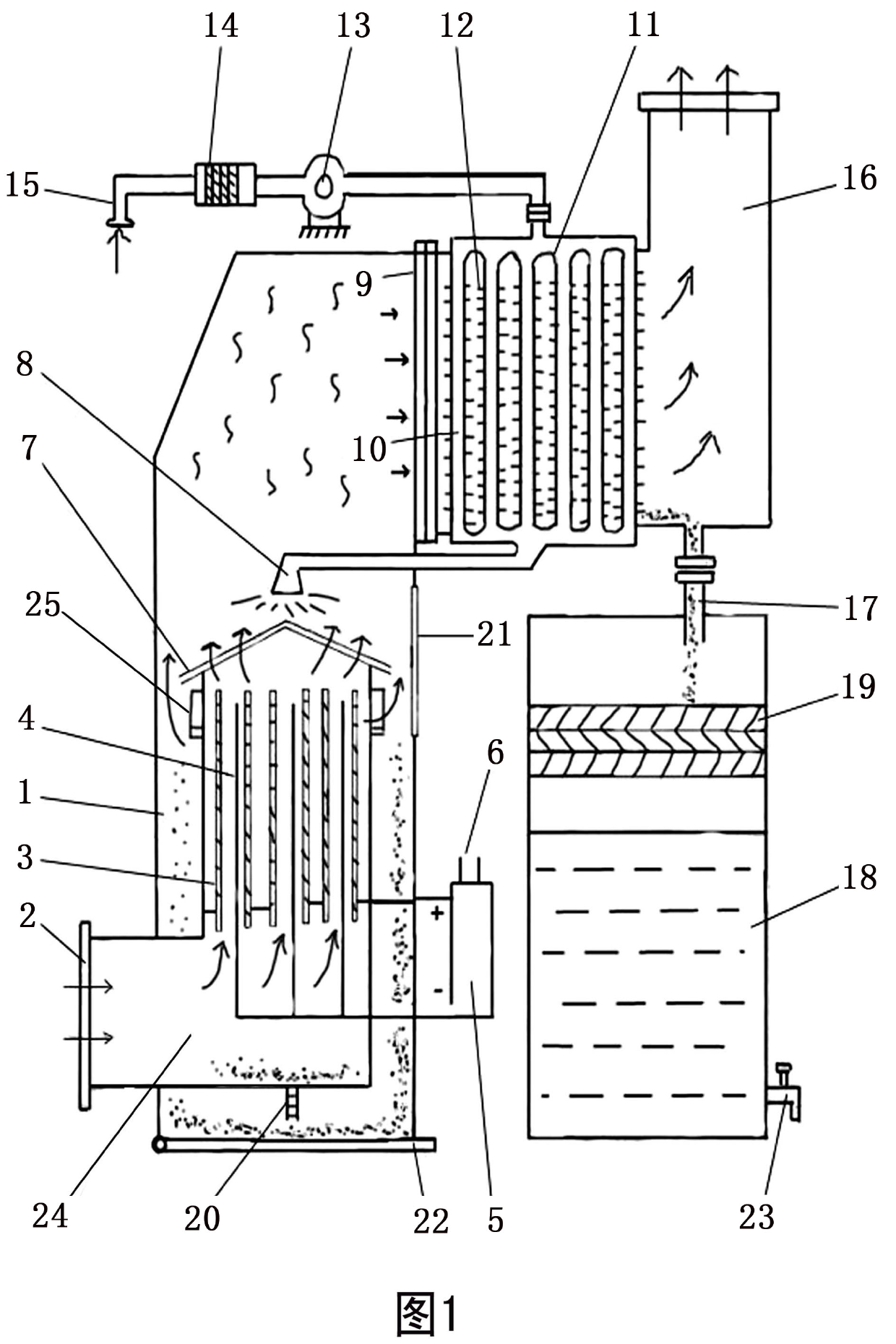

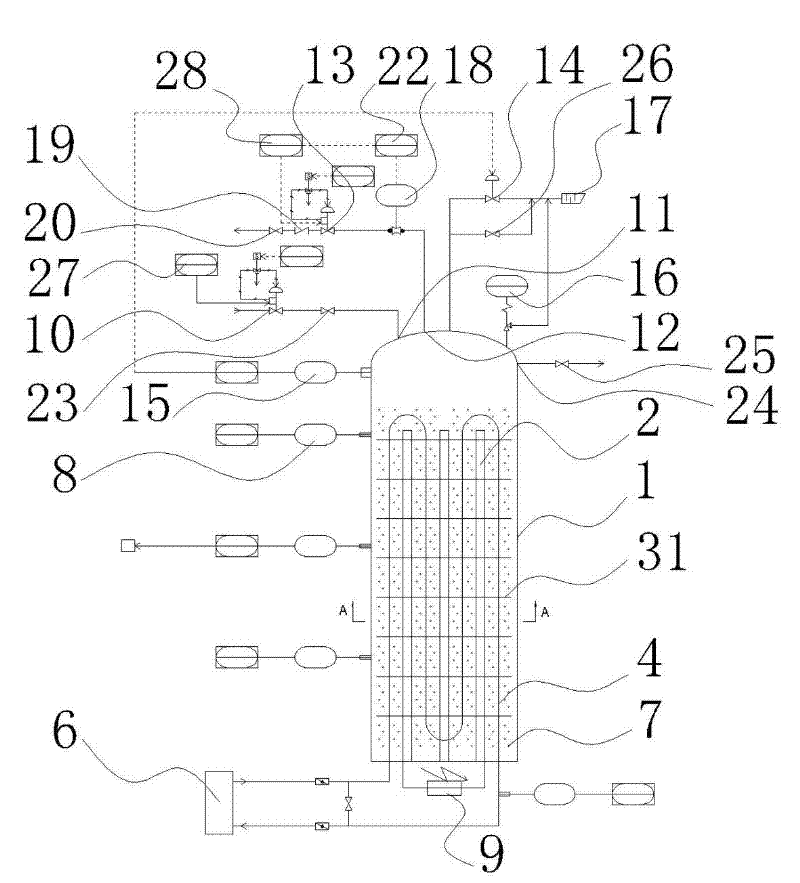

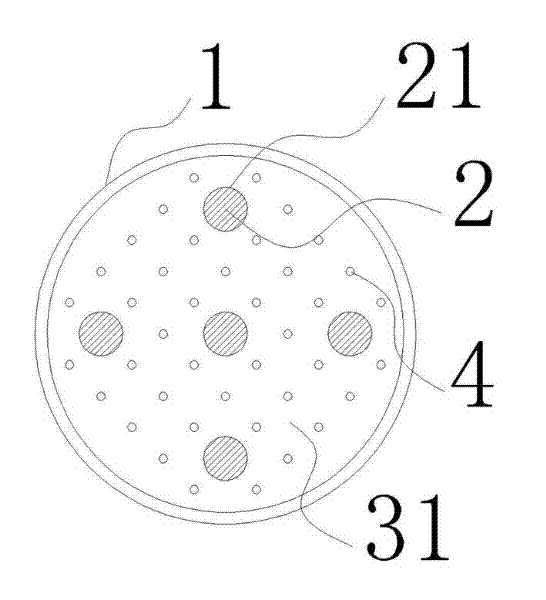

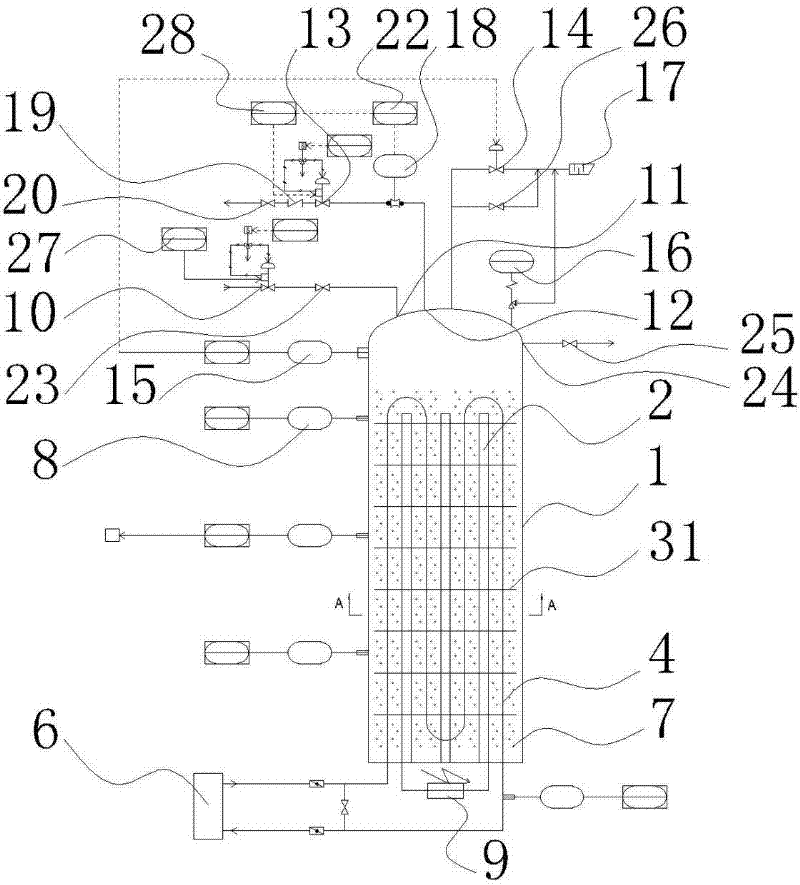

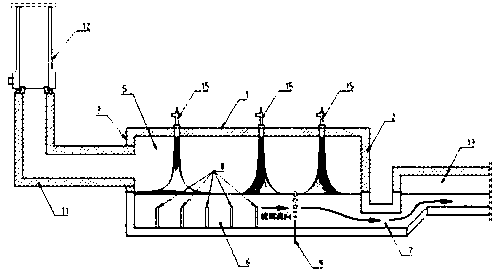

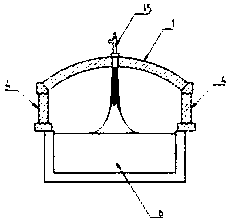

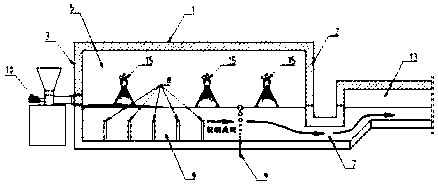

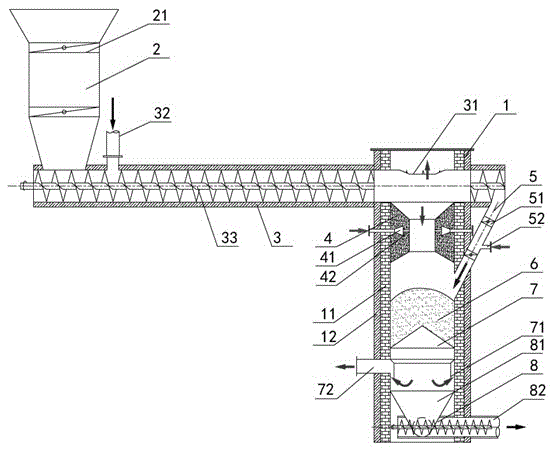

The invention discloses an internal-combustion engine assisted sea water desalinization / poor-quality water purification method and a device thereof. The method comprises the following steps: 1, purifying high-temperature tail gas exhausted from a smoke exhaust pipe of an internal-combustion engine; 2, allowing the purified high-temperature tail gas to enter an evaporation chamber from the bottom of the evaporation chamber, meanwhile, heating raw water to form high-temperature raw water by the high-temperature tail gas, then spraying the high-temperature raw water from a spraying nozzle arranged in the middle of the evaporation chamber to form atomized high-temperature raw water, and carrying out explosive evaporation on the high-temperature tail gas and the atomized high-temperature raw water after meeting in the evaporation chamber to form high-temperature water vapor; 3, allowing the water vapor to pass through a condensate heat exchange chamber arranged on the upper part of the evaporation chamber to form condensate water; and 4, discharging the condensate water from a condensate water discharge pipe, and inputting the condensate water after being purified into a drinking water cabinet. The invention can make full use of the residual heat of cooling water and the tail gas of the internal-combustion engine, has high heat transfer efficiency, large water production rate and good effluent quality, can be used in the places or units which use the internal-combustion engine, and can also be used as pretreatment equipment of various reverse osmosis systems, therefore, the invention can be widely used in small and medium-sized boats such as ocean-going ships or ocean-going fishing-boats and the like which have a long time for sailing at sea.

Owner:河北合盛科技有限公司

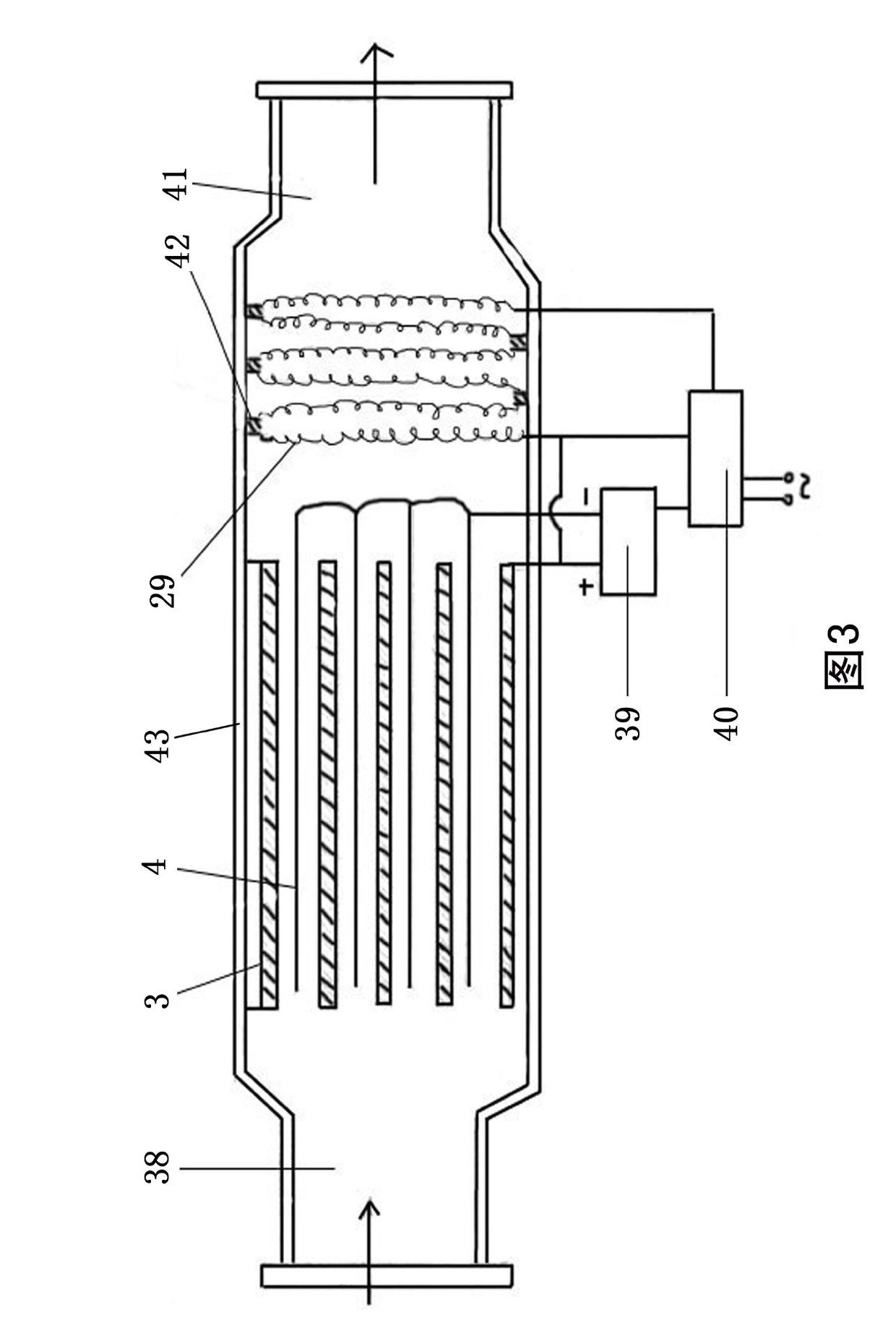

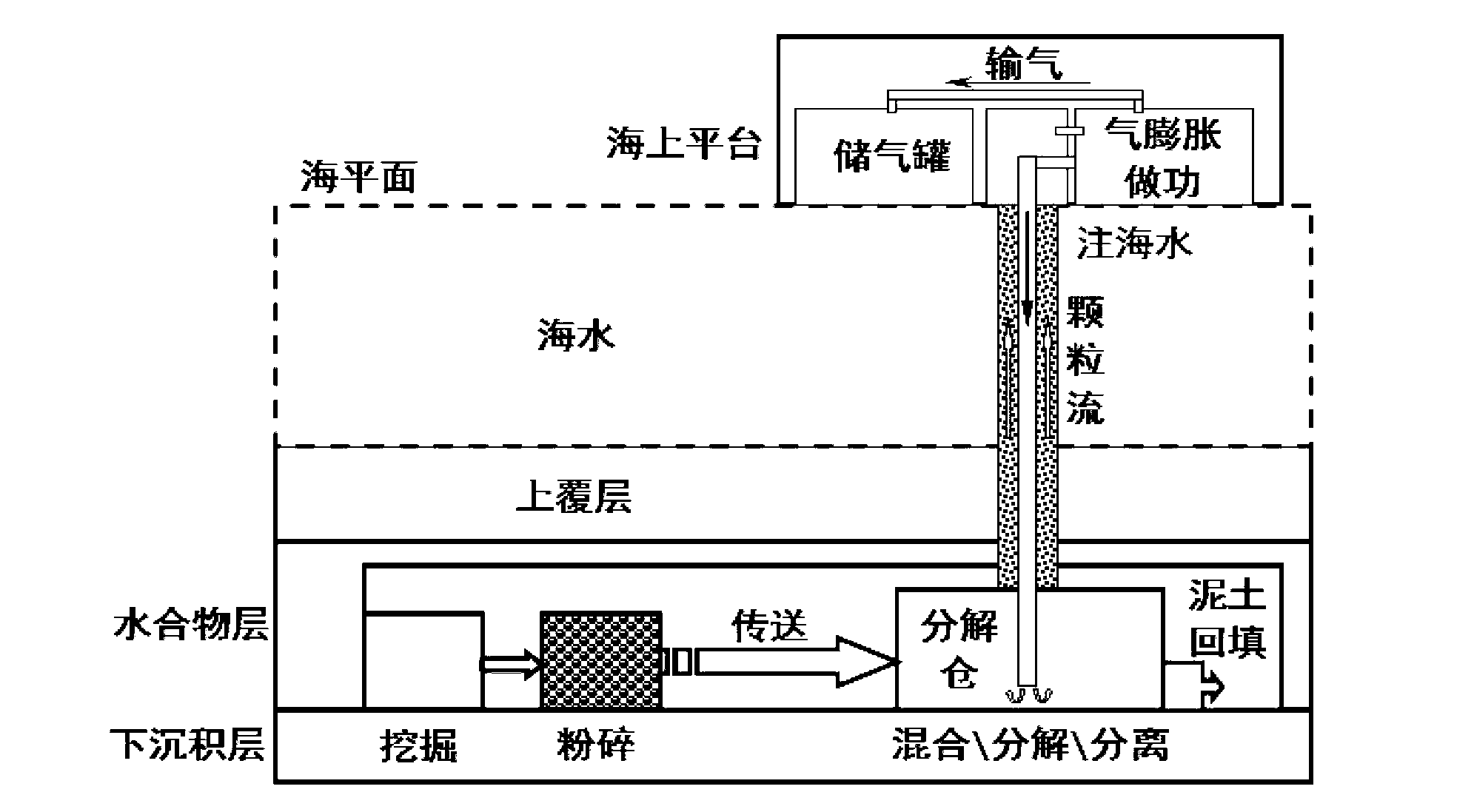

Mechanical-thermal hydrate exploiting method

The invention discloses a mechanical-thermal hydrate exploiting method. The mechanical-thermal hydrate exploiting method comprises the following steps: excavating a hydrate stratum, crushing hydrate sediment into hydrate sediment granules, and conveying the hydrate sediment granules into a decomposing chamber; stirring and mixing relatively hot seawater and the hydrate sediment granules in the decomposing chamber, partially decomposing the hydrate sediment granules, separating the obtained mixture, and removing the separated sediment; upwardly conveying the remaining mixture along an exploiting shaft, further decomposing the hydrate in the mixture in the conveying process, and separating the remaining mixture and generated gas from the sediment in the mixture; and collecting the obtained gas on an exploiting platform. By the method, hydrate decomposing heat can be supplied by a huge heat source from seawater and convective heat transfer; expansion energy of gas which is generated in a centralized way can be made full use; backfill of the sediment can restore certain stratum strength; and leakage of the hydrate decomposing gas from a covering layer can be avoided.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

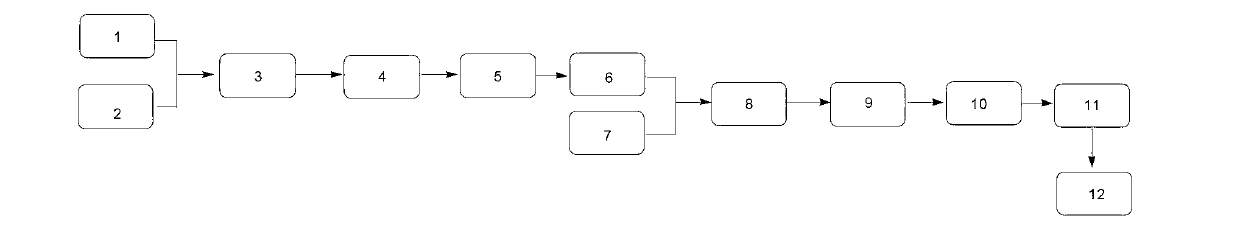

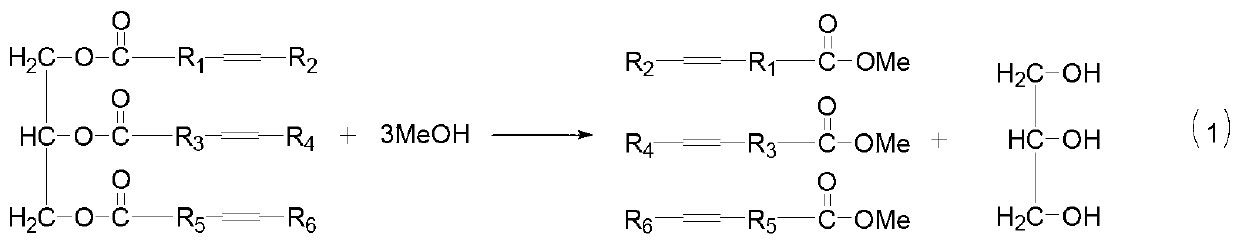

Method for preparing epoxidized fatty acid methyl ester with microreactor one-step method

ActiveCN102993133AImprove product qualityHigh epoxidation yieldOrganic chemistryDouble bondFatty acid methyl ester

The invention discloses a method for preparing epoxidized fatty acid methyl ester with microreactor one-step method, comprising the following steps: injecting oil and fat, low-carbon alcohol and basic catalyst in a first microstructure reactor of a microchannel modularized reaction device, wherein the mole ratio of oil and fat to low-carbon alcohol is 1:11-17, and remaining for 3-10 min at the temperature of 65-85 DEG C; mixing outlet material of the first microstructure reactor with hydrogen peroxide, organic acid, acidic catalyst and stabilizing agent in a second microstructure reactor of the microchannel modularized reaction device, wherein the mole ratio of number of double bonds in organic acid to number of double bonds in oil and fat is 11-17:1, and remaining 1-5 min at the temperature of 65-95 DEG C; guiding the outlet material of the first microstructure reactor in a separator, standing for demixing to remove aqueous solution at lower layer; washing an organic phase at the upper layer with water till the pH is 6.5-7.5; and drying to obtain epoxidized fatty acid methyl ester.

Owner:NANJING UNIV OF TECH

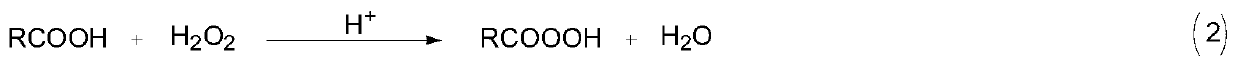

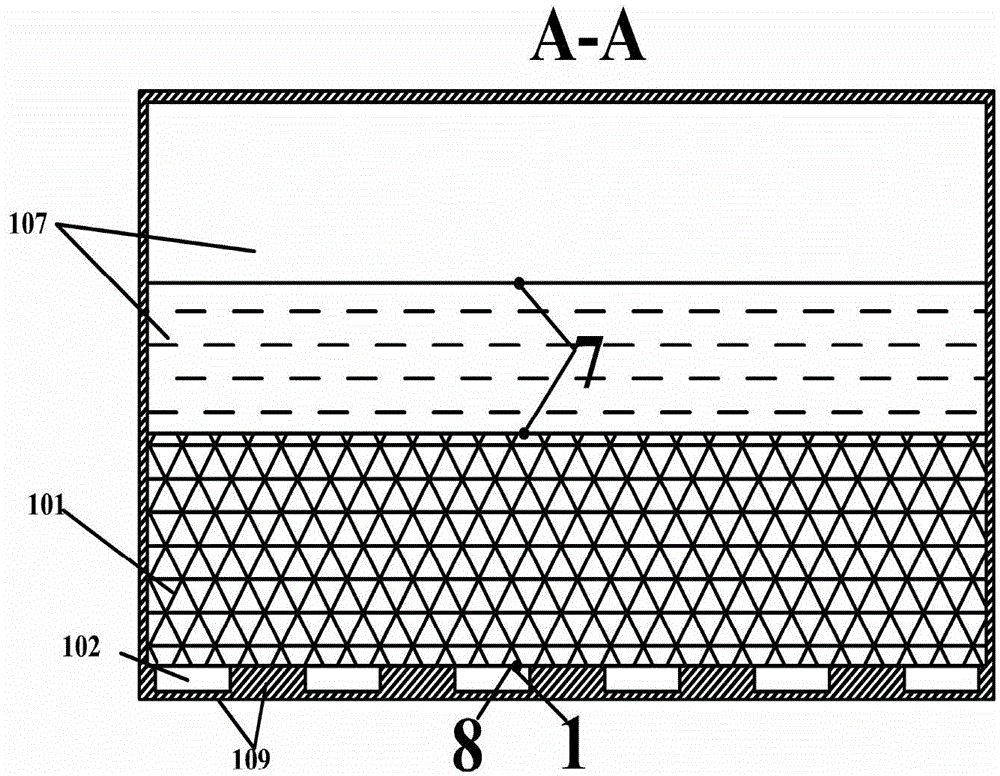

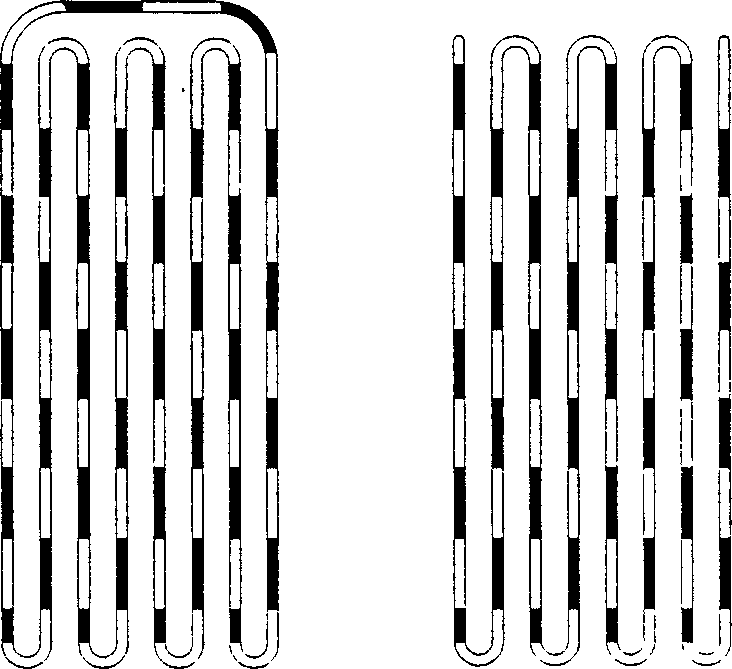

Plate-type pulsating heat pipe used in large power LED heat radiation

InactiveCN102691999AHigh heat transfer efficiencyImprove stabilityPoint-like light sourceLighting heating/cooling arrangementsHeat transfer efficiencyExternal connection

The invention discloses a plate-type pulsating heat pipe used in large power LED heat radiation, comprising a cover plate, a substrate, a capillary beam, a liquid plug, a cavity, a capillary beam lower bend set, a capillary beam upper bend set, a liquid feeding port and a LED chip installation screw hole. The capillary beam, the cavity communicated with the capillary beam bottom and the liquid feeding port positioned on the upper portion of the capillary beam and communicated with the capillary beam are milled on the substrate. A cross section of the capillary is a rectangular cross section or a triangular cross section. Two ends of each capillary beam are respectively independently connected with the cavity, and the connection positions are unsymmetric. The substrate and the cover plate are connected through vacuum brazing. The liquid feeding port is arranged with a valve and forms a sealed space that can form a vacuum environment. The installation screw hole is in external connection with the LED chip, and the cavity is equipped with a capillary core or a micro-channel structure. The heat pipe has the characteristics of stable work, high heat transferring efficiency, high heat transferring limit, and low temperature fluctuation in an evaporation zone.

Owner:NANCHANG UNIV

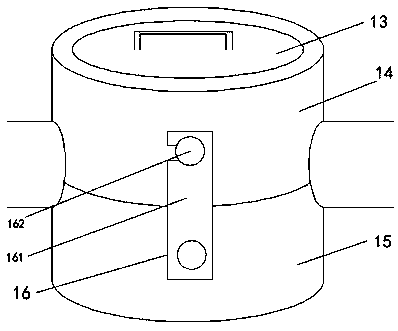

Hydrogen storing tank based on metal hydrogen storage principle

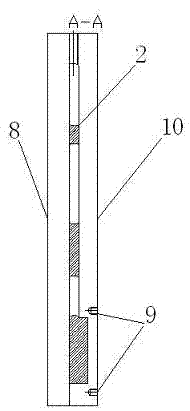

InactiveCN102401233AHigh heat transfer efficiencySimple structureContainer filling methodsPressure vesselsPhysicsWater pipe

The invention discloses a hydrogen storing tank, which has good safety and high hydrogen-storing density, is developed based on a meal hydrogen-storing principle and is favorable for solving the technical problems of poor safety, large energy consumption, low hydrogen-storing density and the like of the prior art for hydrogen storage. The hydrogen storing tank comprises a pressure storing tank, a hydrogen input port and a hydrogen output port, wherein the hydrogen input port and the hydrogen output port are arranged on the pressure storing tank, an input-end control valve is arranged on the hydrogen input port; and output-end control valve is arranged on the hydrogen output port; a plurality of powdery hydrogen-storing alloys are filled in the pressure storing tank; a plurality of heating pipe bundles are embedded in the hydrogen-storing alloys; the heating pipe bundles are fixed on a fin group in a penetration way and are connected with an electric heater power supply outside the pressure storing tank; a cooling water pipe is arranged on the fin group corresponding to the peripheries of the heating pipe bundles; two ends of the cooling water pipe extend to the outside of the pressure storing tank and are connected with a cooling water system; and the electric heater power supply, the input-end control valve and the output-end control valve are connected onto a control system.

Owner:LINDE ENG HANGZHOU

Glass fiber tank furnace structure and glass smelting method

ActiveCN103508652AHigh heat transfer efficiencyReduce erosionCharging furnaceTank furnacesCorrosionSmoke

The invention discloses a glass fiber tank furnace structure and a glass smelting method. The glass fiber tank furnace structure comprises a smelting part and a passage. The smelting part comprises a feeding tank for feeding a glass raw material, and a smelting pool for receiving the supplied materials and forming a glass liquid. A glass liquid separation device of the smelting pool and the passage is a throat or a baffle brick structure. The upper part of the smelting pool is provided with a crown, two side breast walls, a front wall, a back wall and a smoke flue. The smelting pool is divided into a zone A as a raw material zone, a zone B as a foam zone and a zone C as a clarification zone C along a glass melt flowing direction. The smelting pool is provided with at least one combustor, the combustor is installed on the crown or the breast walls, the combustor sprays flame to glass batch and the sprayed flame forms an included angle of 0-80 degrees with the two side breast walls and forms an included angle of 0 degree with the front wall or the back wall. The glass smelting method adopting the glass fiber tank furnace structure comprises that above the smelting pool of the glass fiber tank furnace structure, the at least one combustor is arranged on the crown or the breast walls; a gaseous oxidant and a gaseous, liquid or solid fuel fluid are supplied to the combustor; and the combustor sprays flame to the glass batch. The glass fiber tank furnace structure has the advantage of high heat transfer efficiency, small corrosion on a refractory material, long tank furnace service life, and energy saving.

Owner:JUSHI GRP CO

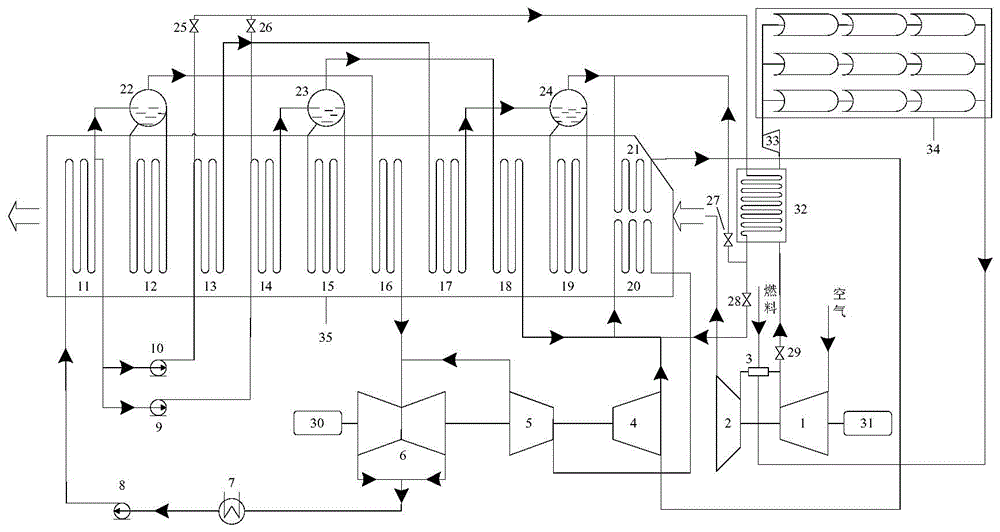

Solar heat-complementary combined cycle power generation system

ActiveCN104963776AHigh heat transfer efficiencyAvoid energy lossGas turbine plantsSteam engine plantsHigh pressurePlate fin heat exchanger

The invention discloses a solar heat-complementary combined cycle power generation system and belongs to the technical field of solar and gas turbine combined cycle power generation. A fifth adjusting valve, a gas-water heat exchanger, a cold air compressor, a trough concentrating and heat collecting mirror field form a trough solar sub system; by adopting gas turbine compressed air as a heat transfer medium, the integration temperature is not limited by physical properties of a heat transfer medium any longer; when the system works under a medium pressure integration mode, feed water at the outlet of a medium pressure feed pump is divided into two strands, one strand of water flows in a medium pressure economizer while the other strand of water is controlled by virtue of a second adjusting valve and a forth adjusting valve; when the system works under a high pressure integration mode, feed water at the outlet of a high pressure feed pump is divided into two strands, one strand of water flows in a first-stage high pressure economizer while the other strand of water is controlled by a first adjusting valve and a third adjusting valve; and air after being subjected to heat collection is injected into a gas turbine combustor so as to ensure relatively high solar heat-to-electricity efficiency. Compared with the tradtional solar heat-complementary combined cycle power generation system, the solar heat-complementary combined cycle power generation system disclosed by the invention has high thermodynamic and economic advantages.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

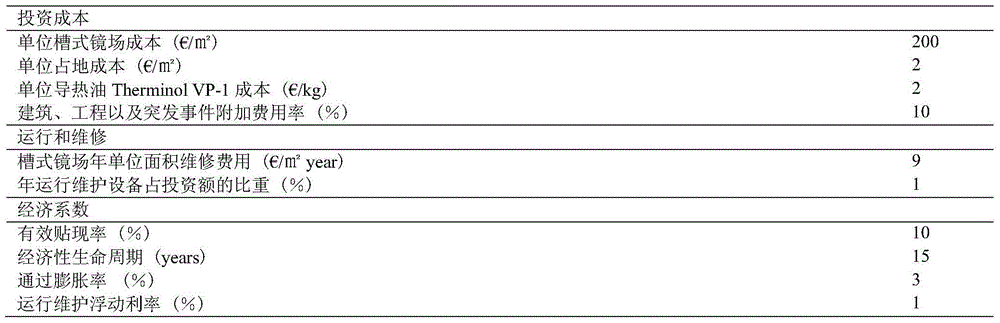

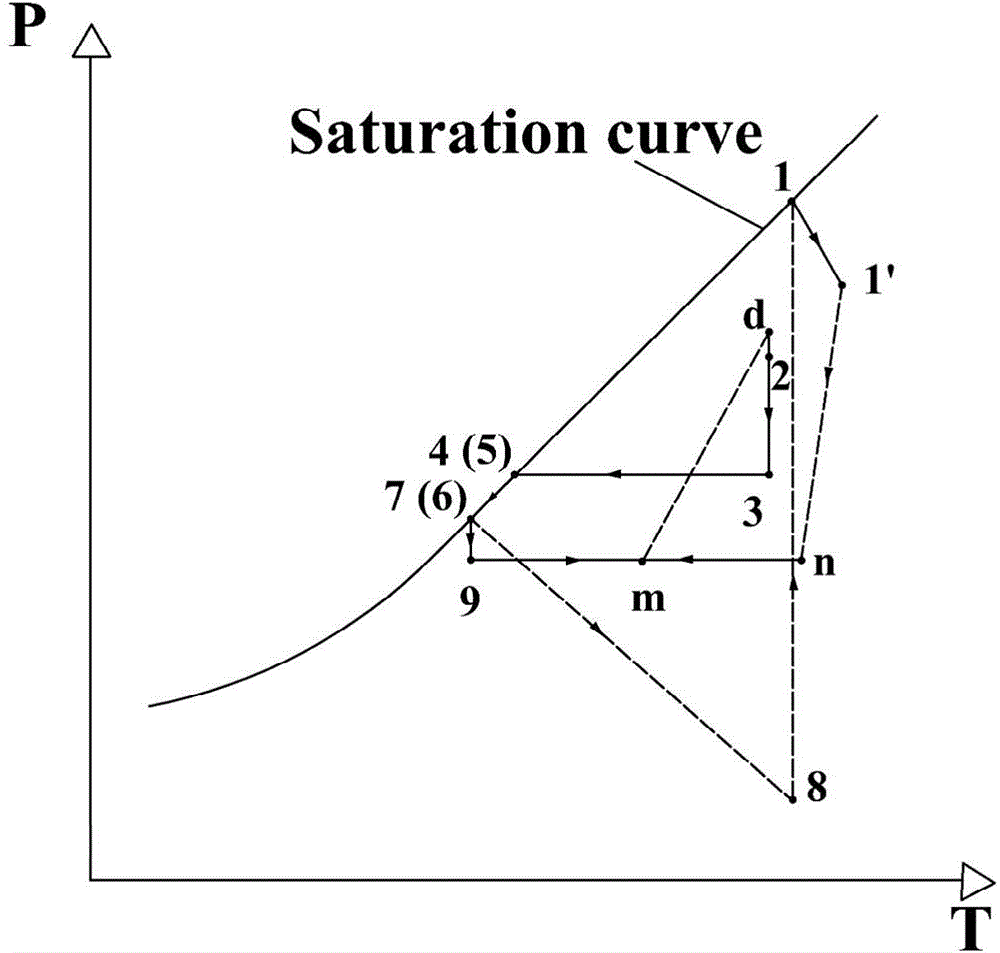

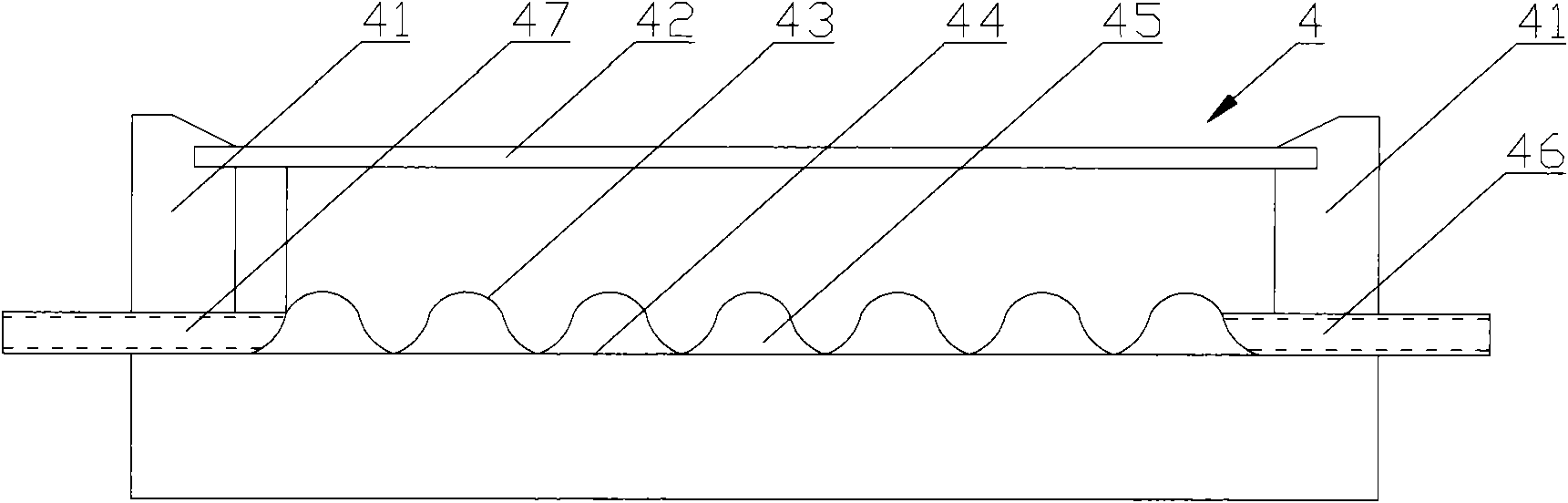

Ejector assisted slab-type loop heat pipe

ActiveCN104930893AHigh heat transfer efficiencyImprove heat dissipationIndirect heat exchangersCooling/ventilation/heating modificationsLiquid lineInjector

The invention discloses an ejector assisted slab-type loop heat pipe which comprises a main loop and a bypath loop; in the main loop, a capillary core in an evaporator is connected with a gas collection channel; an overheating gaseous working medium at an outlet of the gas collection channel injects a saturated gaseous working medium from a compensating chamber through an ejector; the mixed gaseous working medium is connected with an inlet of a condenser by a gas line pipeline; an outlet of the condenser is connected with an inlet of the compensating chamber by a liquid line pipeline; the compensating chamber and the capillary core are longitudinally processed together; the capillary core, the gas collection channel and the compensating chamber are wrapped in a housing of the evaporator; in the bypass loop, a saturated gaseous working medium generated from liquid gasification by absorption of heat leakage in the compensating chamber passes through a regulating valve and then enters the ejector; and through changing the opening of the regulating valve, the flow of the saturated gaseous working medium gasified in the compensating chamber due to different heat leakage quantity is ensured to be led away. The ejector assisted slab-type loop heat pipe is an economical, effective, and feasible improvement scheme, and the performance of the loop heat pipe can be improved effectively.

Owner:XI AN JIAOTONG UNIV

Frequency conversion magnetic levitation compression expansion engine set

ActiveCN101105346AReduce frictional power consumptionHigh heat transfer efficiencyPump componentsCompression machines using turbinesLubricationEvaporator

A variable frequency magnetic suspension compressional expansion assembly comprises a compressor, an evaporator and an expansion machine that are connected. A magnetic suspension bearing centrifugal compressor is directly connected with a radial flow type expansion machine via a shaft, the shaft is suspended on a left radial magnetic suspension bearing, a right radial magnetic suspension bearing and an axial magnetic suspension bearing, a variable frequency motor is provided between the left radial magnetic suspension bearing and the right radial magnetic suspension bearing and used for driving the centrifugal compressor; and the radial flow type expansion machine comprises an air inlet chamber and an air outlet pipe, nozzles and impellers are provided between the air inlet chamber and air outlet pipe and passed through the air inlet chamber and air outlet pipe, and the impellers are fixedly connected on the shaft. The power from expansion is transmitted to the compressor, and the refrigerant after expansion is entered into the evaporator to carry out evaporative cooling; after being evaporated in the evaporator, the refrigerant is sucked by the compressor to carry out circulatory flow; and the magnetic suspension bearings assure that the shaft does not contact with the bearings when the assembly operates, so that lubrication via lubricating oil is not needed.

Owner:广东西屋康达空调有限公司

Two-stage down-suction biomass gasifier

InactiveCN105602623AHigh heat transfer efficiencyReduce tar contentChemical industryGasification processes detailsTarProcess engineering

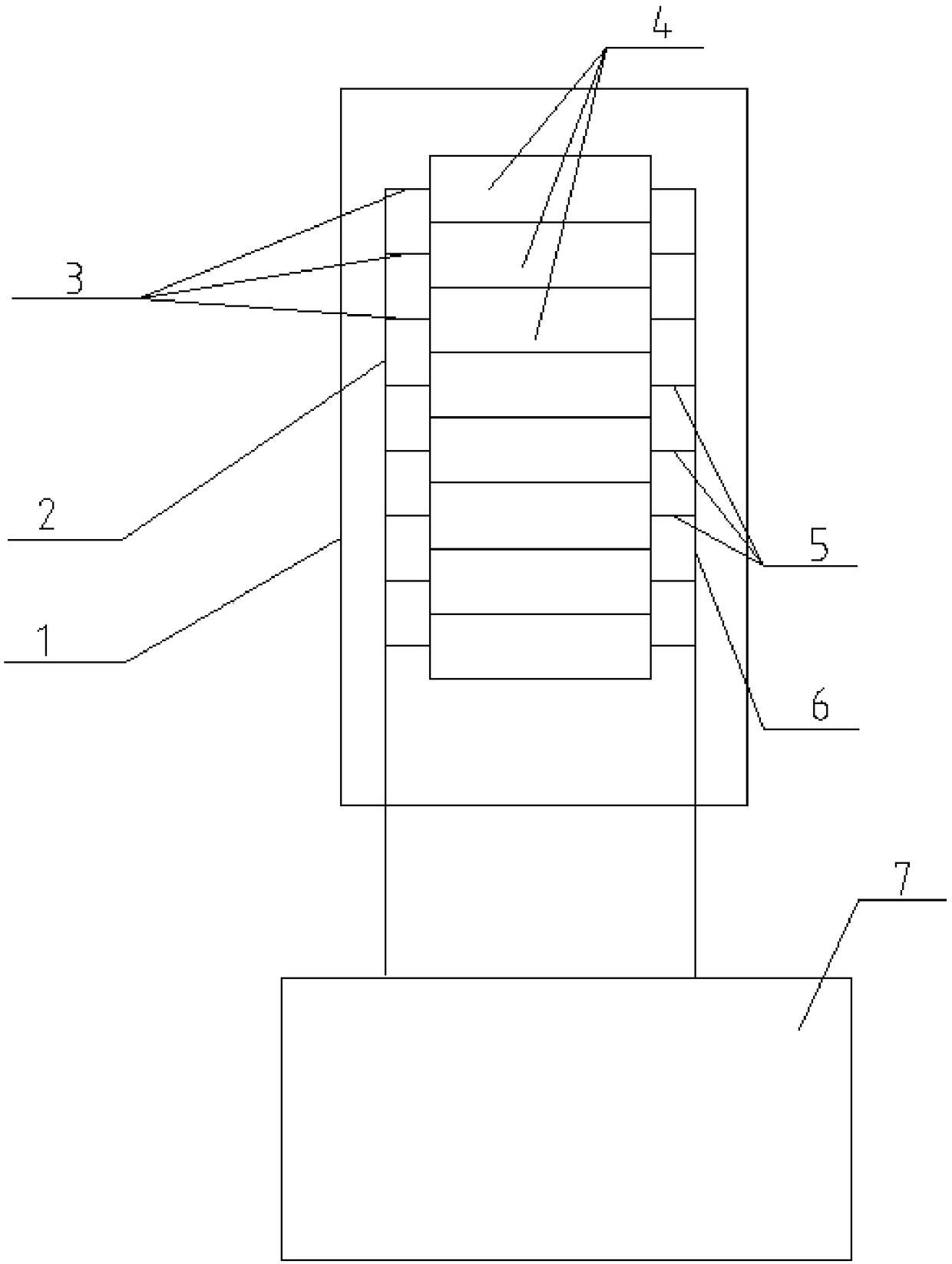

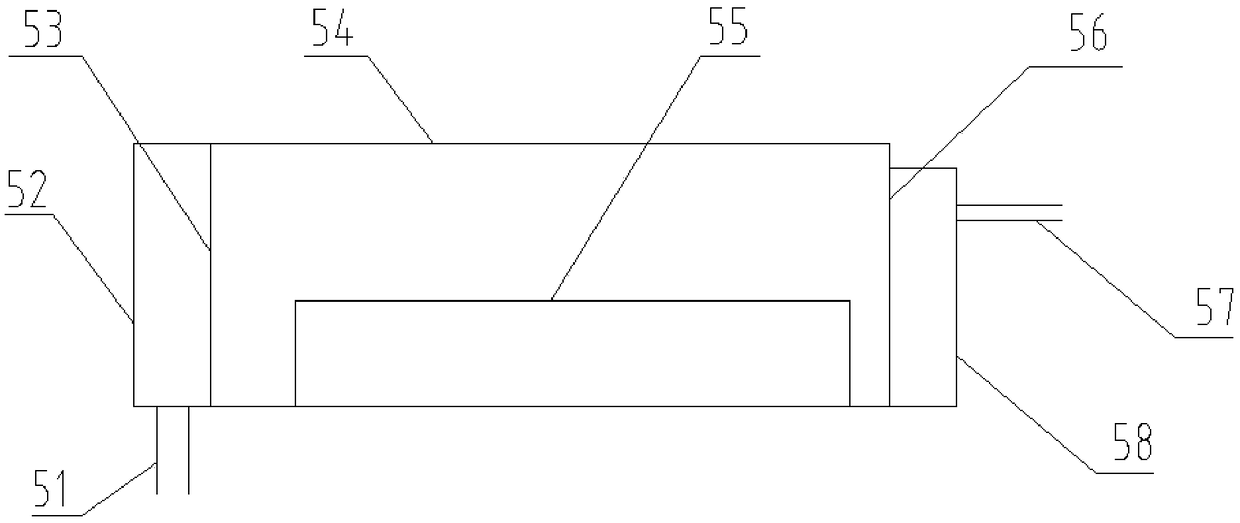

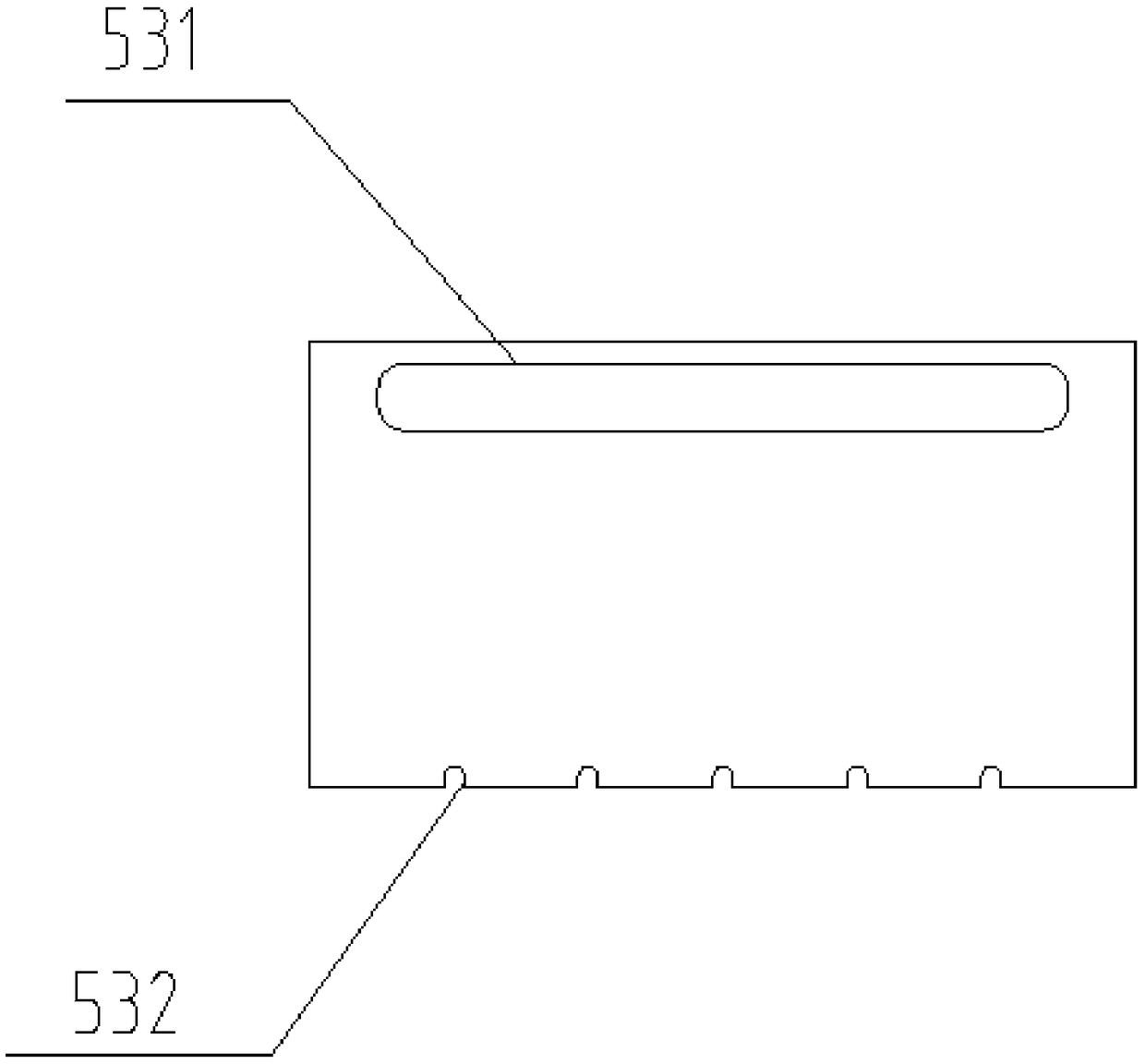

The present invention relates to a two-stage down-suction biomass gasifier, the upper part of a gasifier body is connected with a pyrolysis tube, a feed auger is arranged in the pyrolysis tube, the pyrolysis tube is provided with a pyrolysis gas outlet, one end of the pyrolysis tube is connected with a feed hopper, a side upper surface of a feed port of the pyrolysis tube is provided with a returning ash inlet, the feed hopper is internally provided with a two-stage cut-off brake valve, the other end of the pyrolysis tube is communicated with an accumulation ash carbon layer in the gasifier body by an ash falling pipe, the ash falling pipe is internally provided with a two-stage ash falling pipe cut-off brake valve and an ash falling pipe air inlet, an ash removal furnace grate, an ash retainer ring and an ash removal device are arranged under the accumulation ash carbon layer of the gasifier body, the ash removal device is connected with an ash discharge auger by an ash collection hopper, and the ash discharge auger is connected with the returning ash inlet. Tar efficient removal and biomass energy efficient conversion can be realized by pyrolysis and solid product separation and difference processing methods, and by homogeneous partial oxidation of pyrolysis components and smoldering combustion oxidation activation of solid coke, reactivity of the pyrolysis components and the solid coke are enhanced, and efficient tar removal and gasification conversion effects can be ultimately realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Liquid immersion cooled switch and switch set

PendingCN108966611AIncrease contact areaHigh heat transfer efficiencyCooling/ventilation/heating modificationsHeating elementCooling fluid

The invention relates to a liquid immersion cooled switch and a switch set. The liquid immersion cooled switch includes a switch body and a cooling device. The switch body includes a switch shell anda plurality of heat dissipation units arranged in the switch shell. Each heat dissipation unit includes a shell body and a heating element arranged in the shell body, wherein there is insulating coolant in the shell body, the heating element is located below the liquid level of the insulating coolant, and the shell body is provided with a liquid inlet and a liquid return port. The liquid inlets and the liquid return ports of the shell bodies are connected with the cooling device through pipes to form a closed loop. A pump for driving the insulating coolant to do circulating motion in the closed loop is arranged in the cooling device. According to the liquid immersion cooled switch and the switch unit provided by the invention, the heating elements inside the switch can be quickly cooled byimmersing the heating elements inside the switch in the insulating coolant.

Owner:广东西江数据科技有限公司

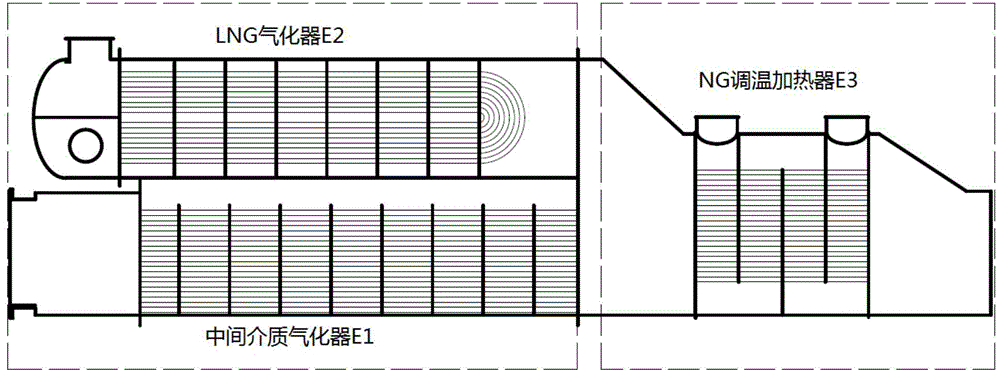

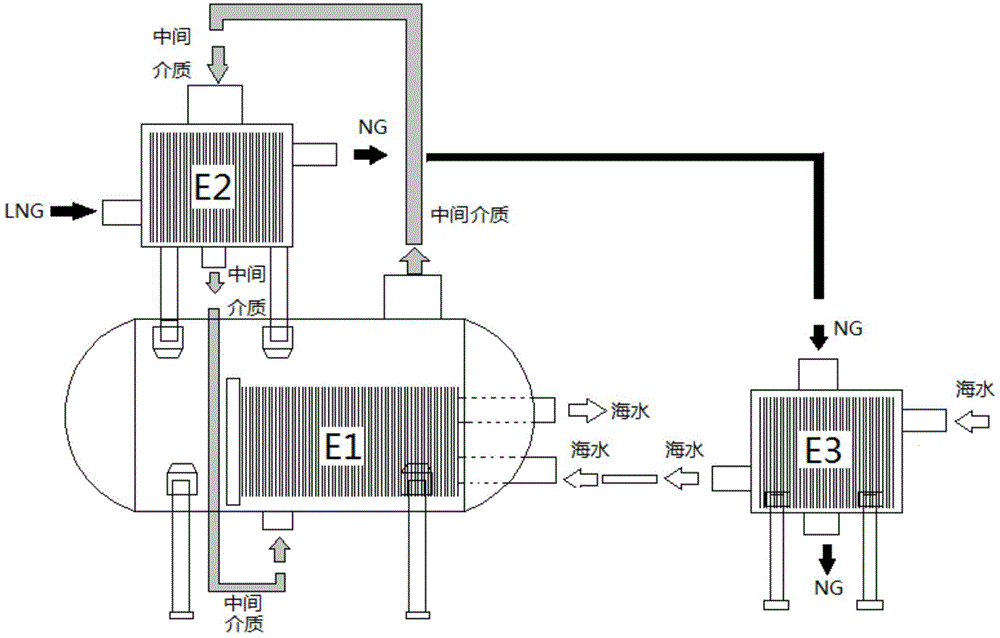

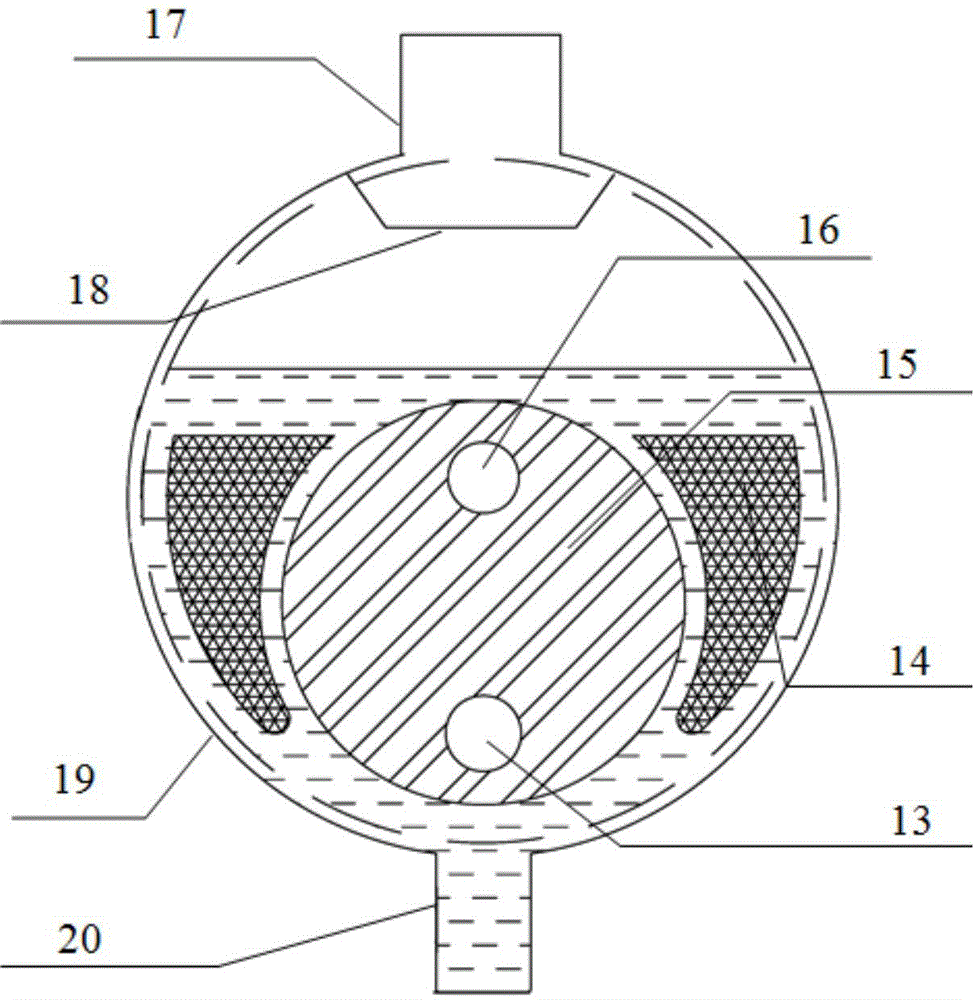

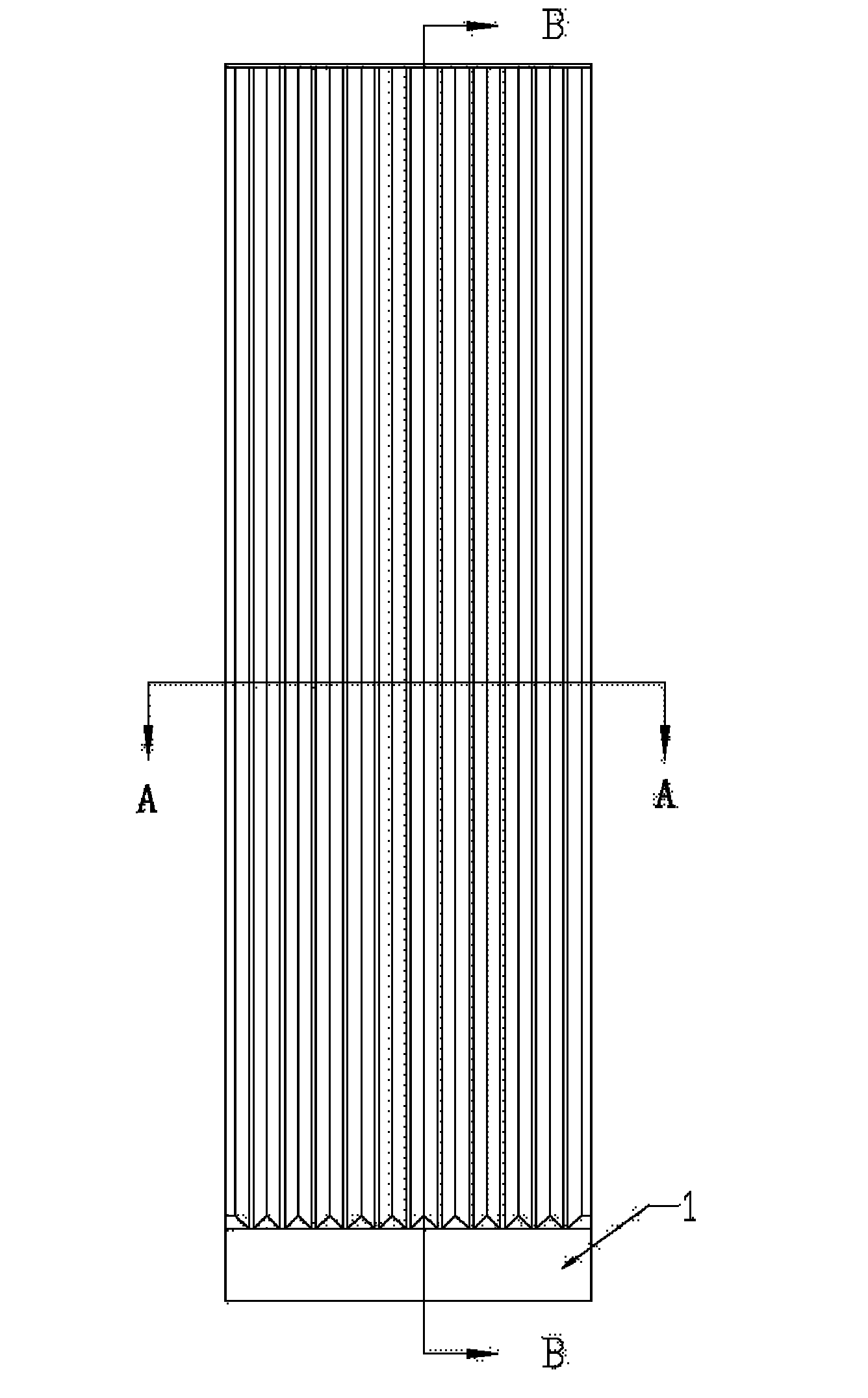

Plate-shell type middle fluid type gasifier

ActiveCN103822092AHigh heat transfer efficiencySmall temperature difference at the endNon-pressured vesselsPressure vesselsEvaporatorEngineering

The invention discloses a plate-shell type middle fluid type gasifier which is small in size, light in weight and capable of effectively reducing equipment cost, improving the reliability of the equipment and prolonging the service life of the equipment. The gasifier consists of a full-liquid type evaporator, a plate-shell type heat exchanger A and a plate-shell type heat exchanger B, wherein a plate travel runner inlet of the plate-shell type heat exchanger is used for inputting a medium to be gasified; the plate travel runner inlet is connected with a shell travel runner inlet of the plate-shell type heat exchanger B; the gasified medium is output from the shell travel outlet of the plate-shell type heat exchanger B; the plate travel runner inlet of the plate-shell type heat exchanger B is communicated with seawater; the plate travel runner outlet of the plate-shell type heat exchanger B is connected with the plate travel runner inlet of the full-liquid type evaporator; the plate travel runner outlet of the full-liquid type evaporator is communicated with the seawater; the shell travel runner inlet is connected with the shell travel runner outlet of the plate-shell type heat exchanger A; the shell travel runner outlet is connected with the shell travel runner inlet of the plate-shell type heat exchanger A.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

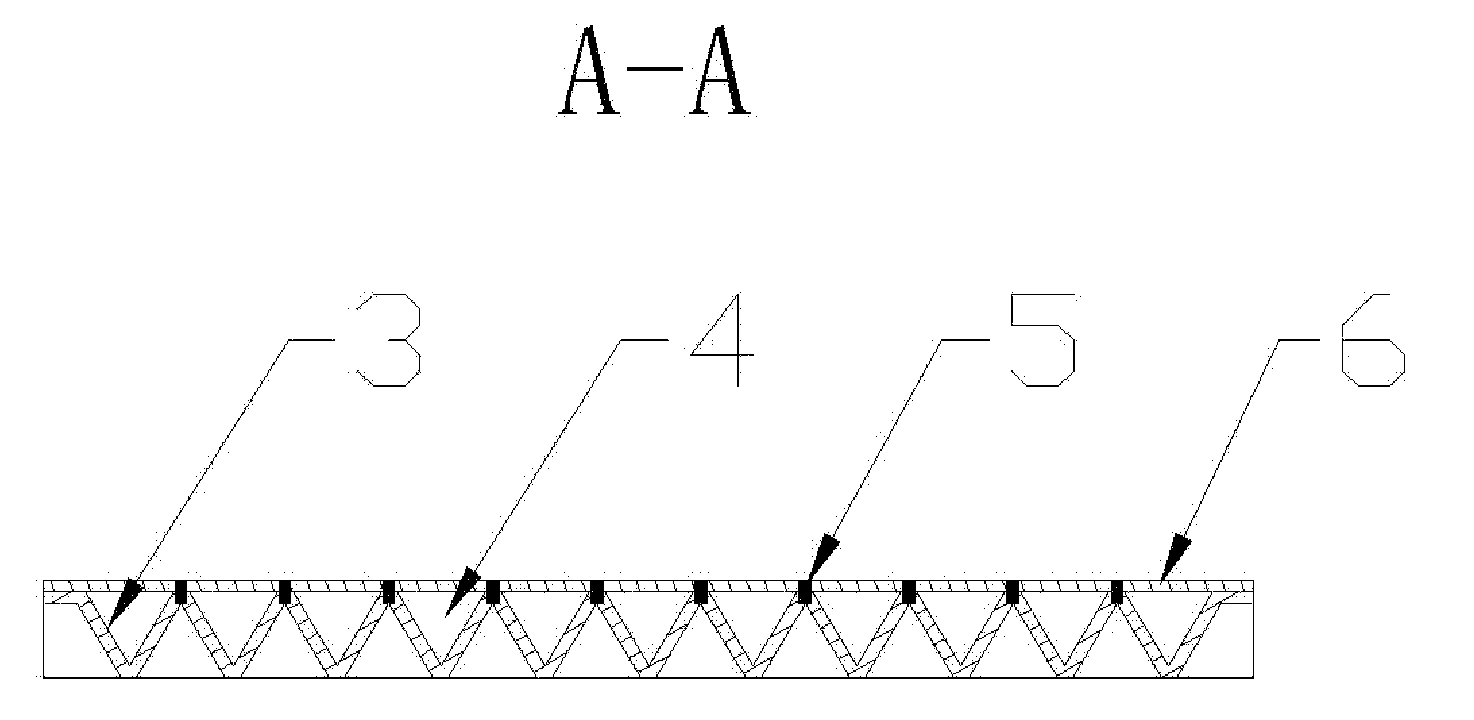

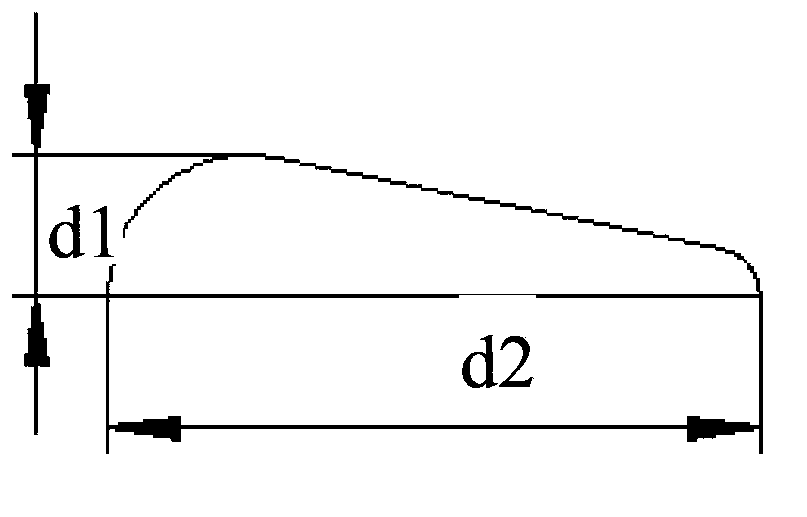

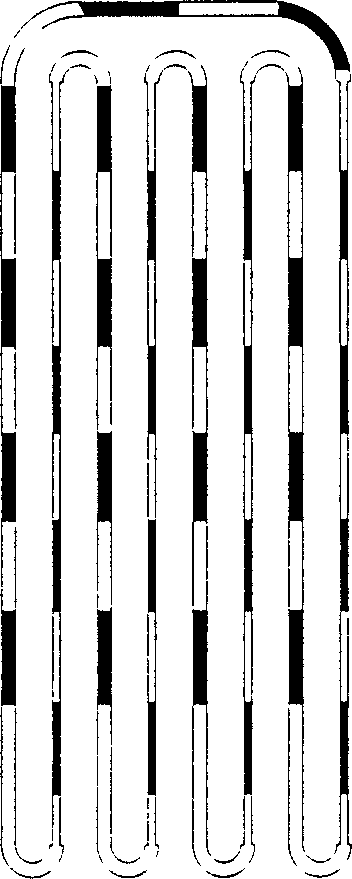

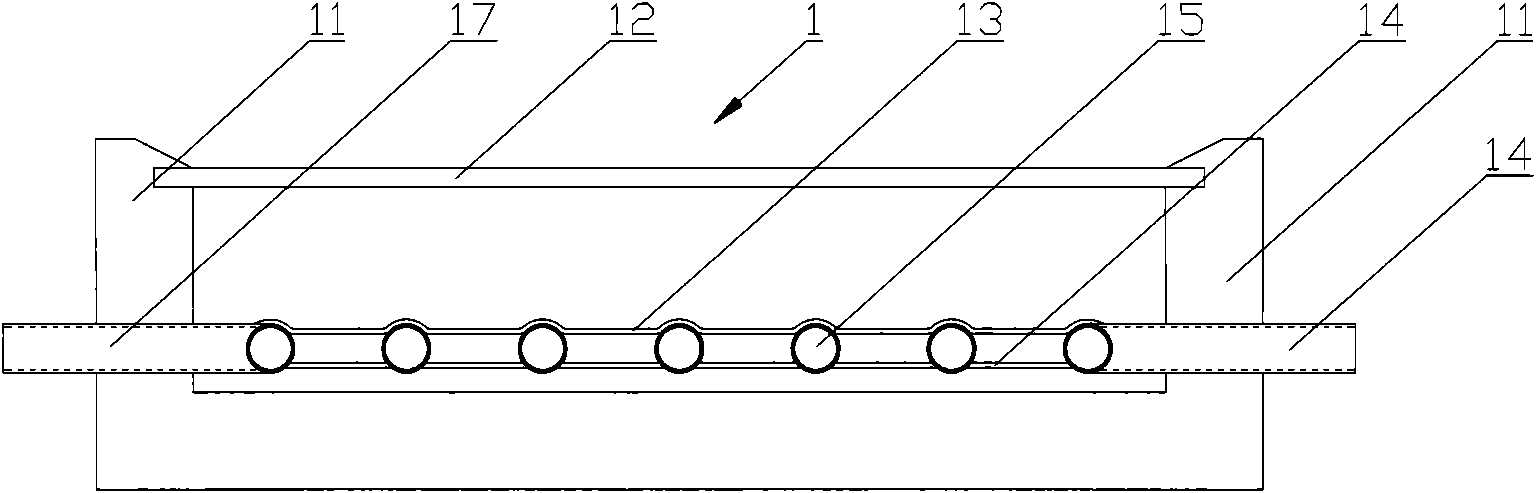

Single-sided corrugated plate type pulsating heat pipe

InactiveCN102128552AHigh heat transfer efficiencyExtensive sources of materialsSemiconductor/solid-state device detailsSolid-state devicesCurve shapeAluminium

The invention discloses a single-sided corrugated plate type pulsating heat pipe which comprises a bottom plate, a corrugated plate and a first communication cavity and is characterized in that: the bottom plate is a plane metal plate; one end of the bottom plate is provided with the first communication cavity in sealed connection with the bottom plate; the section of the corrugated plate is of a continuous triangular shape, sinusoidal shape or other periodical curve shape; the two ends along the extension direction of the wave of the corrugated plate are in sealed connection with the bottom plate; one end vertical to the extension direction of the wave of the corrugated plate is in sealed connection with the first communication cavity, and the other end is in sealed connection with the bottom plate; two adjacent troughs of the corrugated plate are welded on the bottom plate through spot welding to form multiple pulsating channels vertical to the extension direction of the wave of the corrugated plate; and adjacent channels are communicated through hair cracks. The equivalent coefficient of heat conductivity of the single-sided corrugated plate type pulsating heat pipe is two orders of magnitude higher than that of an aluminum extruded radiator and 2-3 times higher than that of the related flat heat pipe; and the single-sided corrugated plate type pulsating heat pipe can be horizontally mounted and is particularly suitable for recycling the ventilation energy of an air conditioner as well as radiating and cooling electronic devices.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

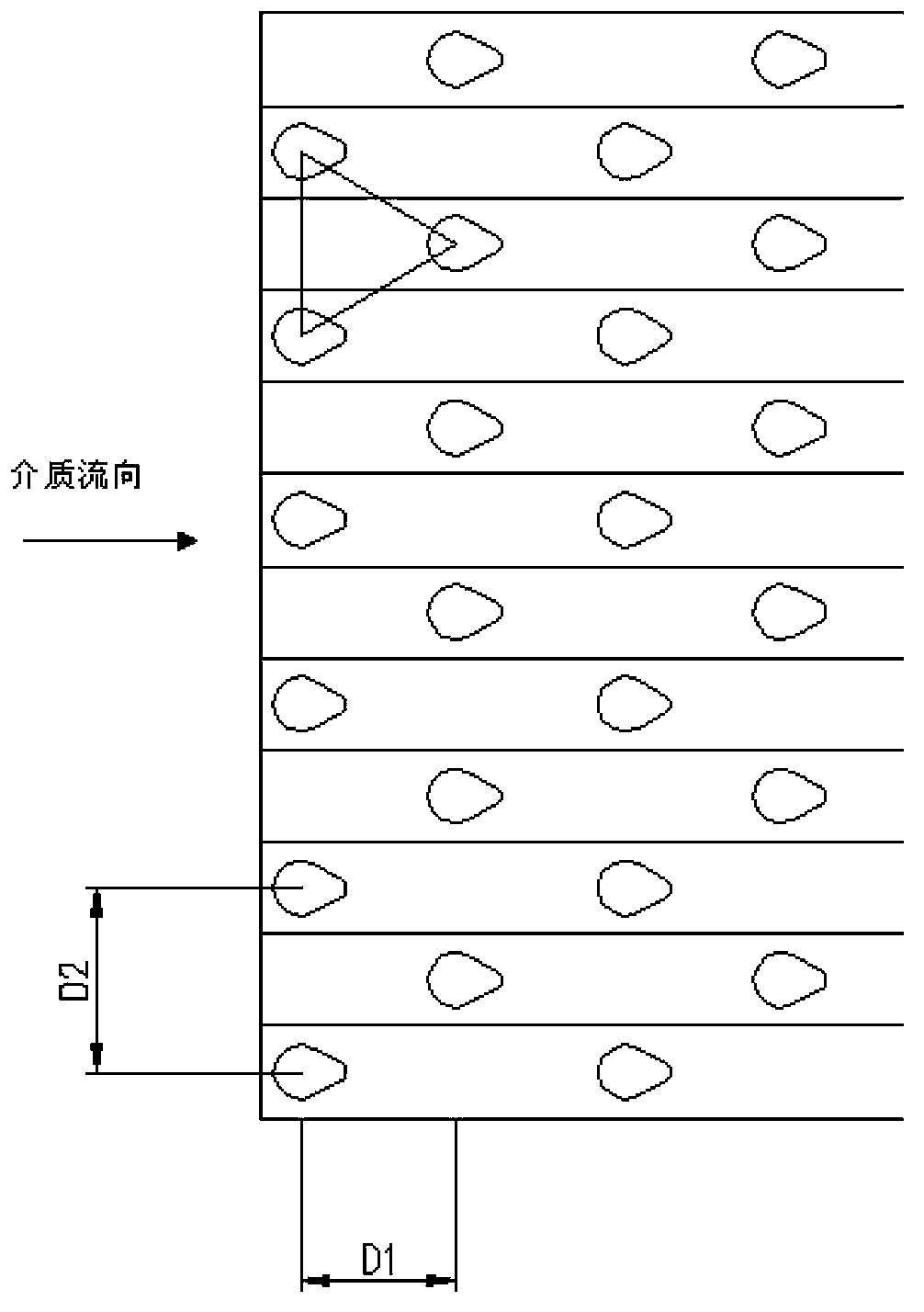

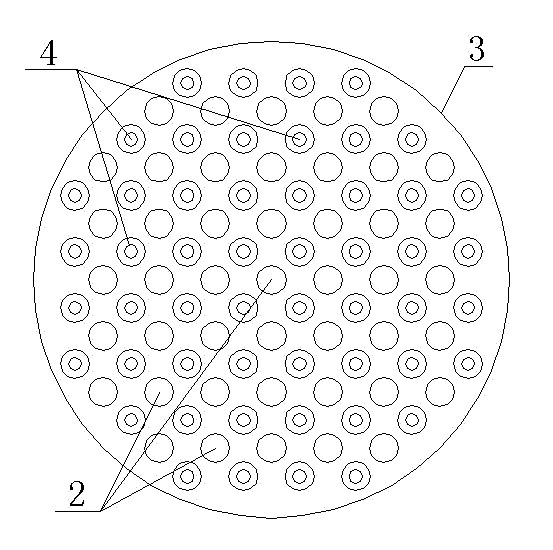

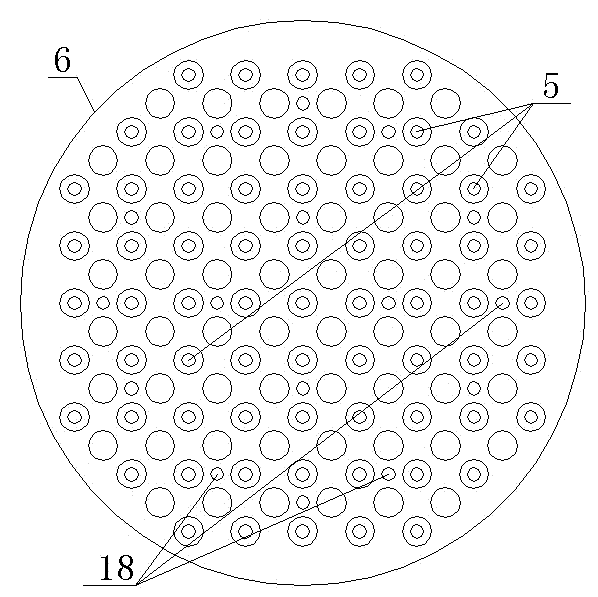

Heat exchanging pipe with reinforced heat transfer elements

ActiveCN103542759AReduce thicknessHigh heat transfer efficiencyTubular elementsHeat transfer efficiencyEngineering

Owner:PETROCHINA CO LTD +1

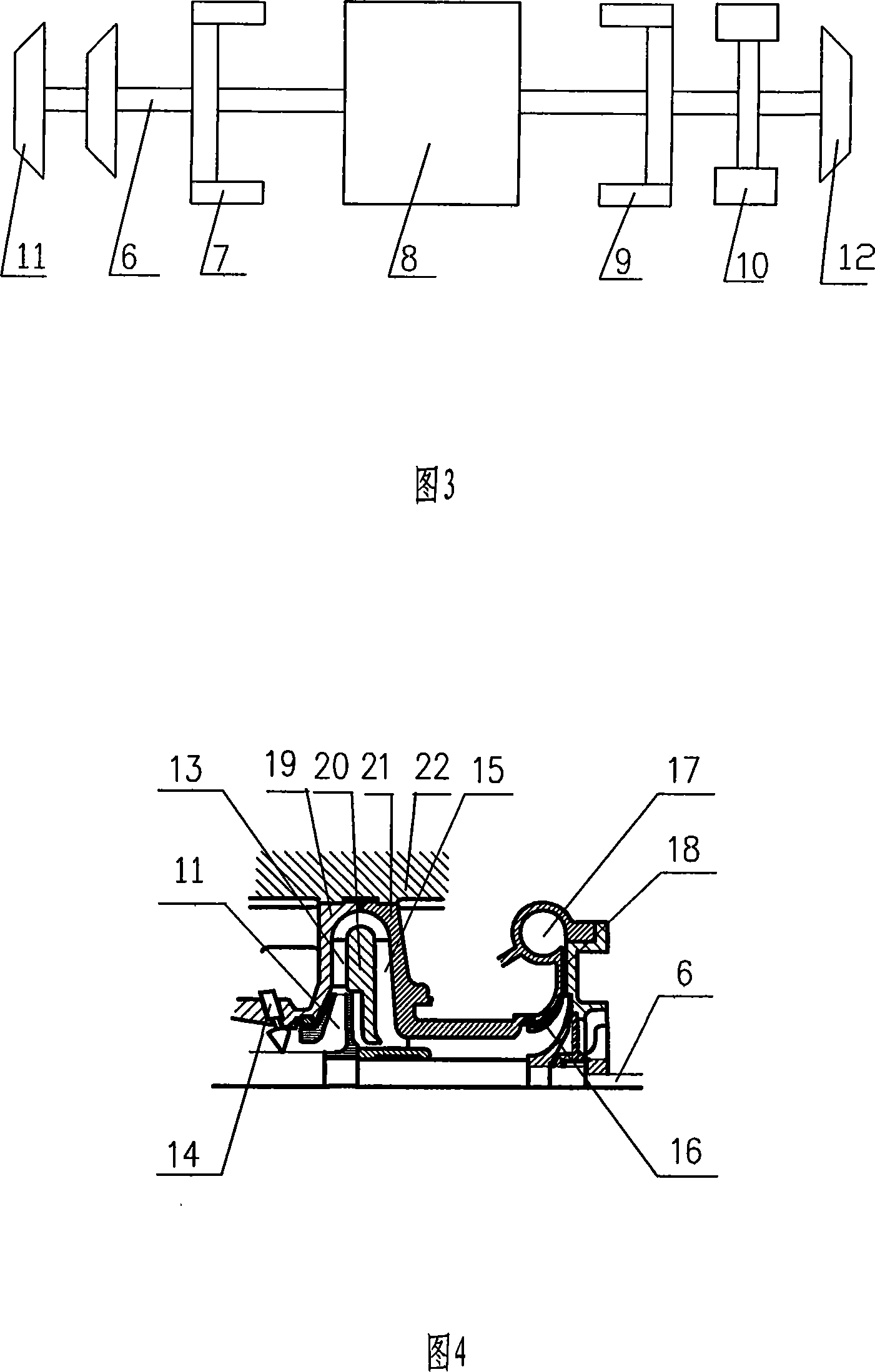

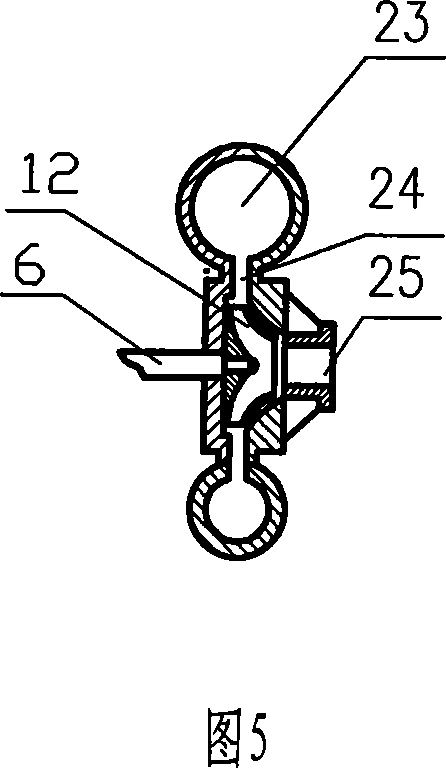

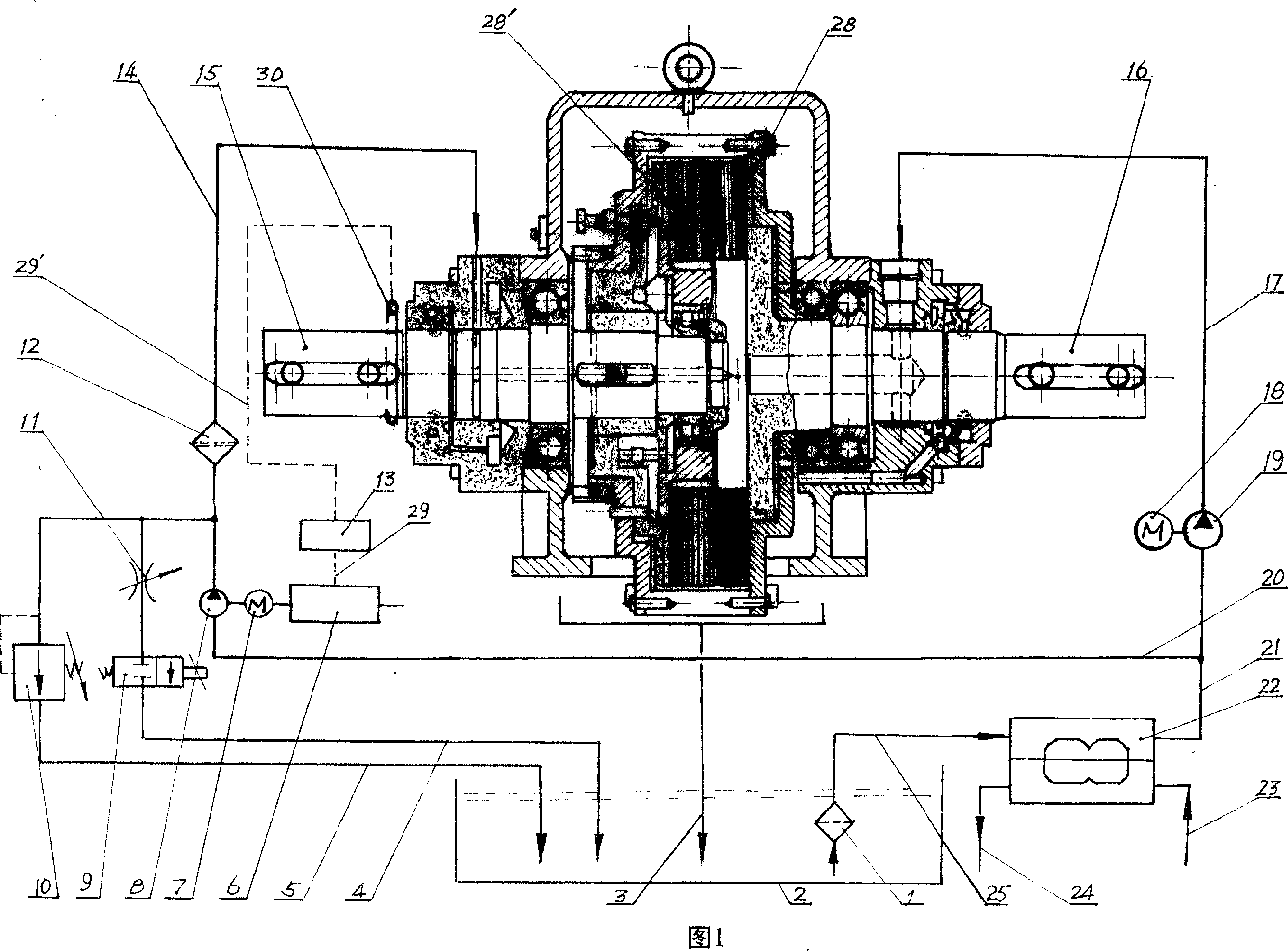

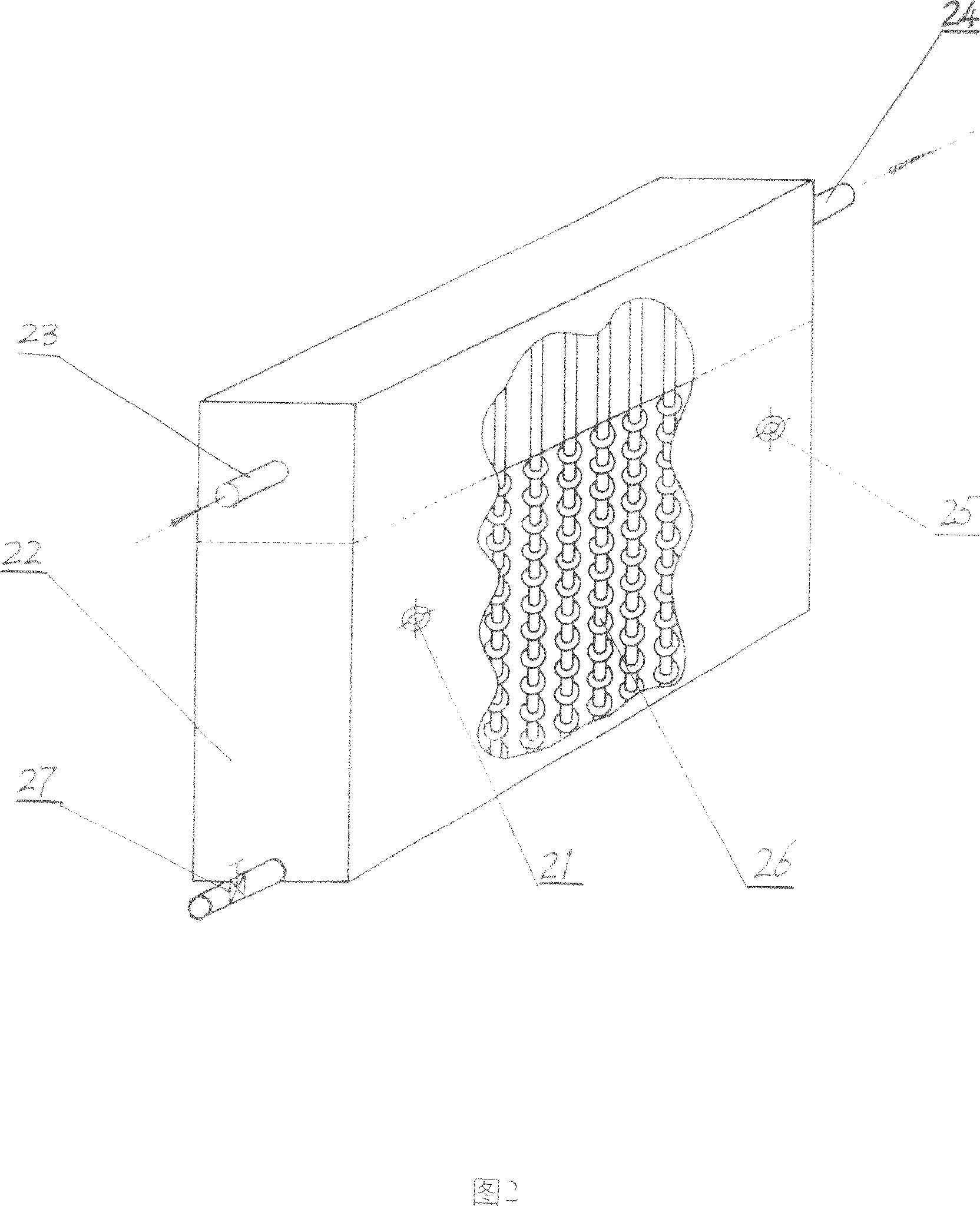

Hydraulic control system for viscosity speed regulation clutch

InactiveCN1928380AReduce volumeHigh heat transfer efficiencyFluid clutchesClutchHeat pipe heat exchanger

The invention discloses to a new hydraulic-control system applied in air fan, pump or hydro vicious speed governing clutch of soft-starting in other larger scale equipment. Hydraulic oil in oil tank 2 is used to lubricate, cool and transmit torque to positive frictional plate 28 and negative friction plate 28'through outlet pipe 21 of heat exchange of heat pipe 22, pump with lubricated oil 19, inlet of positive shaft 16 of clutch host by oil pipe 17; another oil is used to connect positive frictional plate 28 and negative friction plate 28'through oil delivery pipe 20, controlling oil pump 8, finish filter 12 and the inlet of negative shaft 15 by oil pipe 14. When adjusting speed, only setting speed value of controller 13 is changed. Controller 13 controls converter 6 and motor 7 to adjust speed and then oil pressure on inlet of negative 15 is changed.

Owner:夏学苏

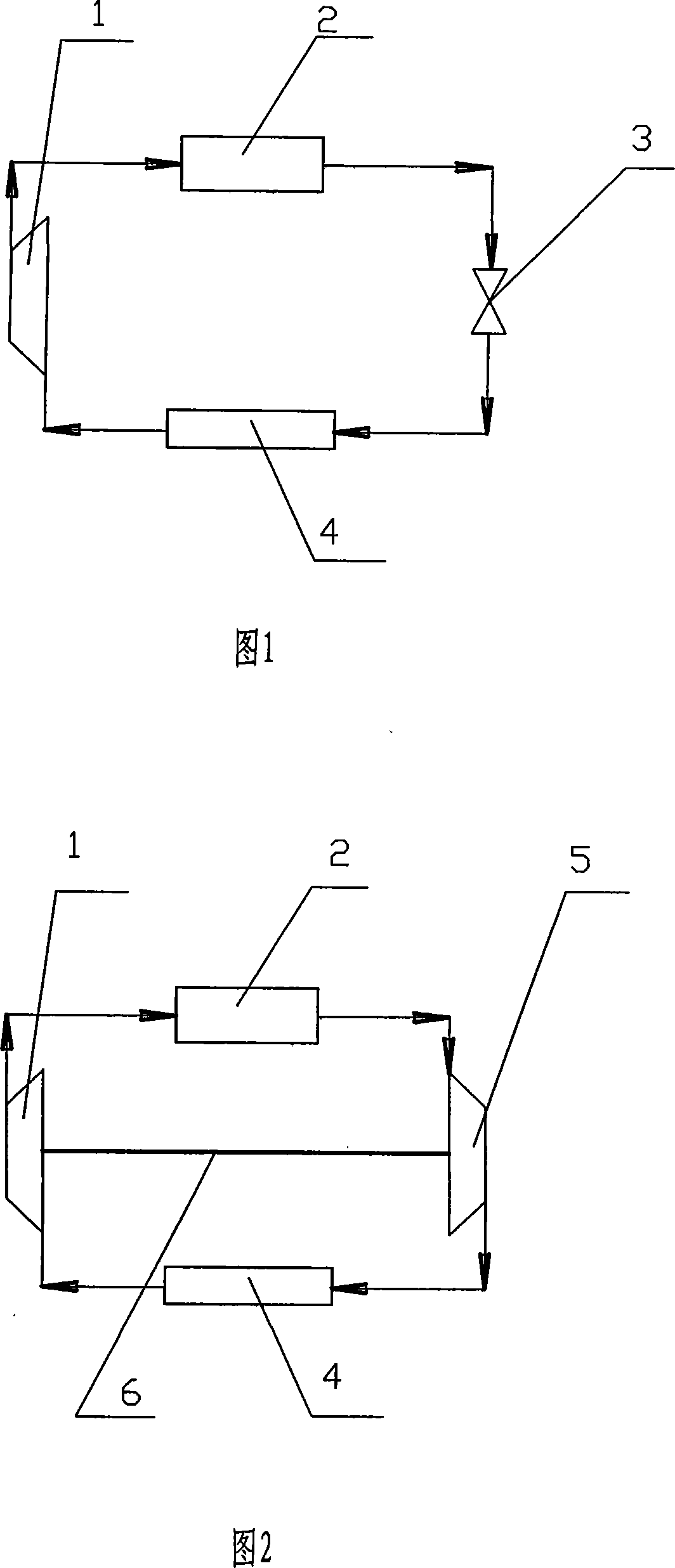

Solar energy refrigerator

ActiveCN102252480AHigh heat transfer efficiencySpeed up the refrigeration cycle processDomestic refrigeratorsSorption machinesHeat transfer efficiencyCollector device

The invention discloses a solar energy refrigerator. The solar energy refrigerator comprises a photo-thermal refrigerating system; the photo-thermal refrigerating system comprises a solar thermal collector which is used for converting solar energy into heat energy, a heat accumulator which is used for receiving and accumulating heat energy produced by the solar thermal collector, an adsorption bed in which refrigerating fluid is accommodated and which is used for adsorbing and desorbing the refrigerating fluid, a high-temperature heat pipe device which is used for transferring heat energy which is accumulated by the heat accumulator to the adsorption bed to ensure that the adsorption bed can desorb the refrigerating fluid, a low temperature heat pipe device which is used for dispersing heat in the adsorption bed into environment to ensure that the adsorption bed can adsorb the refrigerating fluid, and a refrigeration unit which is used for refrigerating by using the refrigerating fluid which is desorbed in the adsorption bed. The adsorption bed is heated and cooled by using the heat pipe devices, so that the heat transfer efficiency is high and the control of the heating and cooling processes is realized; and due to the adoption of the heat accumulation device, the adsorption bed can be heated by using accumulated heat when the sunshine is not sufficient. The low-temperature heat pipe device can accelerate the process of refrigeration cycle.

Owner:HENAN XINFEI ELECTRICAL EQUIP +1

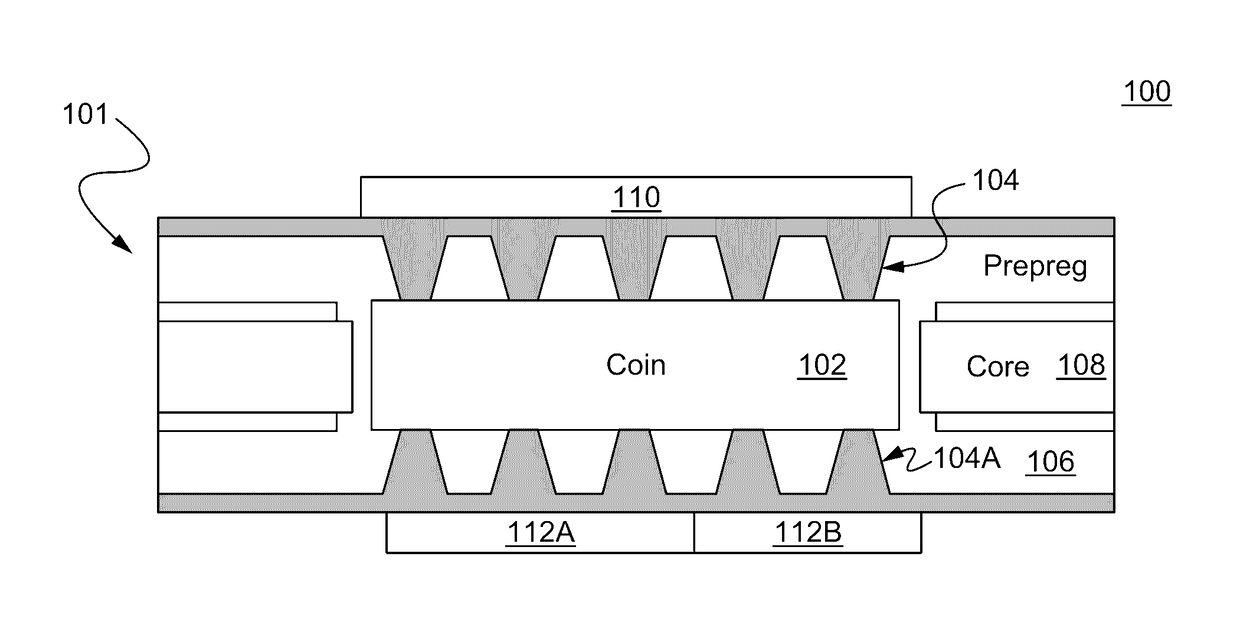

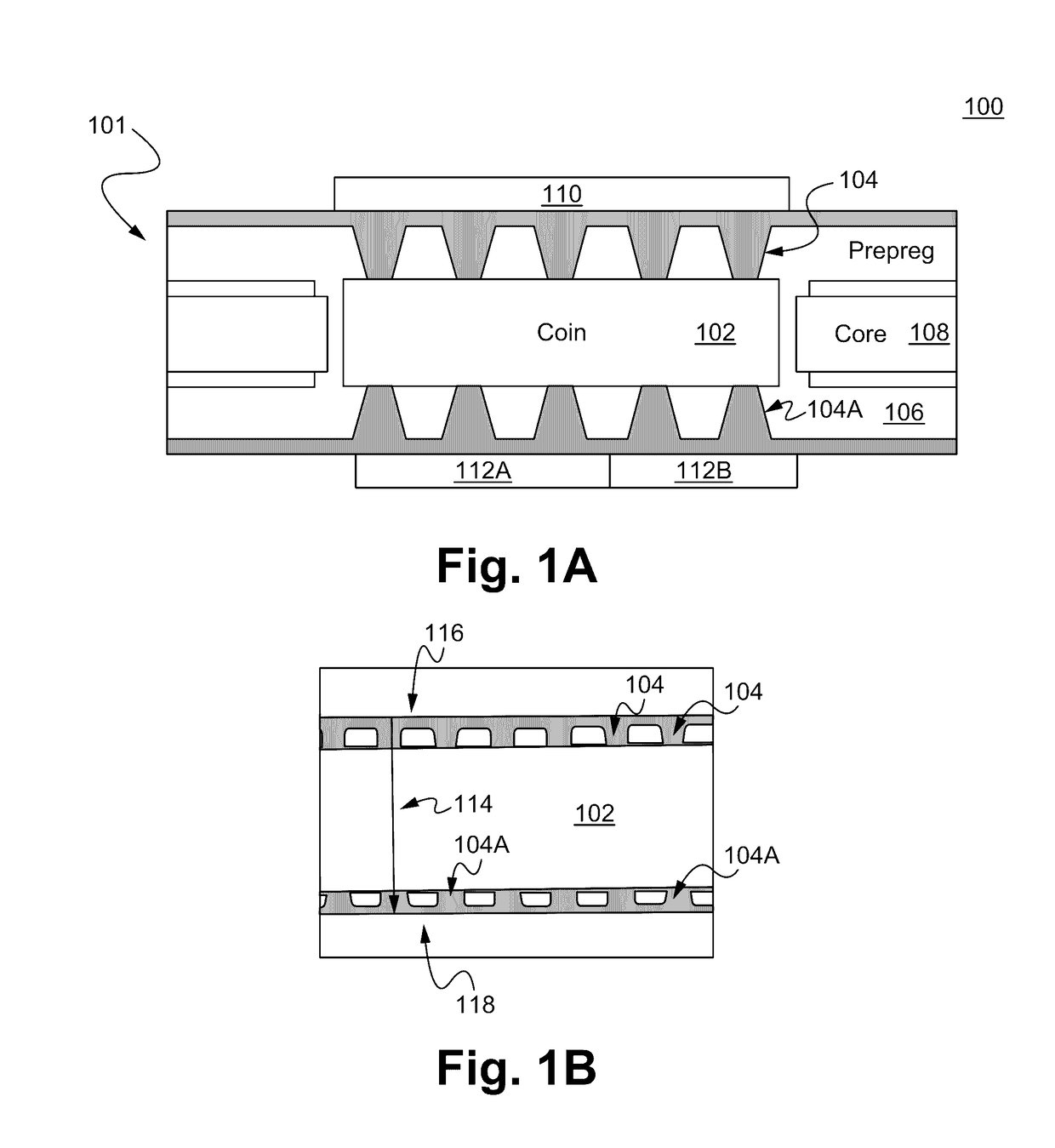

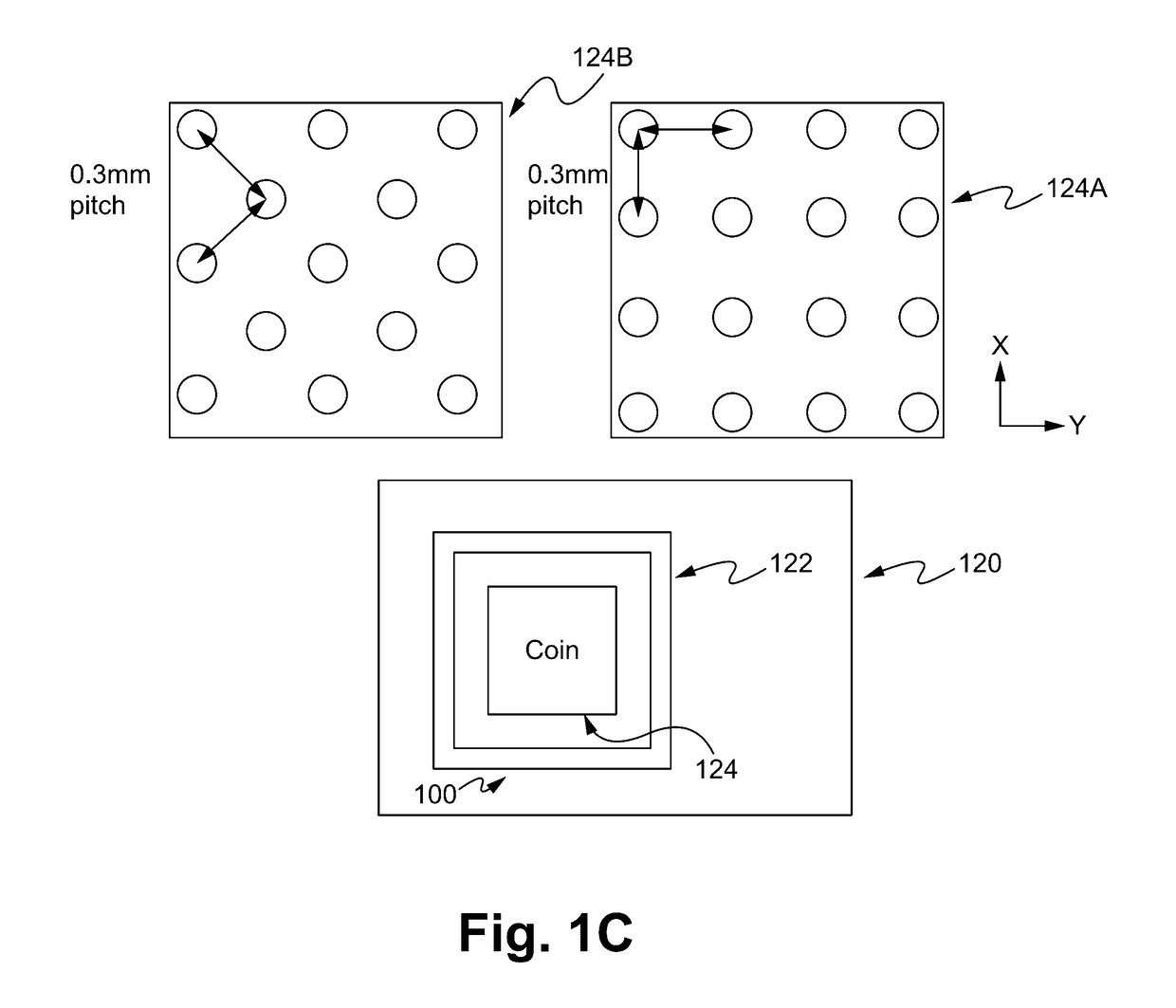

Embedded coins for HDI or SEQ laminations

ActiveUS9661738B1Enhanced heat transferHigh heat transfer efficiencyPrinted circuit aspectsSolid-state devicesEmbedded systemHigh density

A method of and a device for dissipating / transferring heat through one or more solid vias and embedded coins are disclosed. The method and device disclosed herein can be used to transfer heat for a High Density Interconnect (HDI) board.

Owner:FLEX LTD

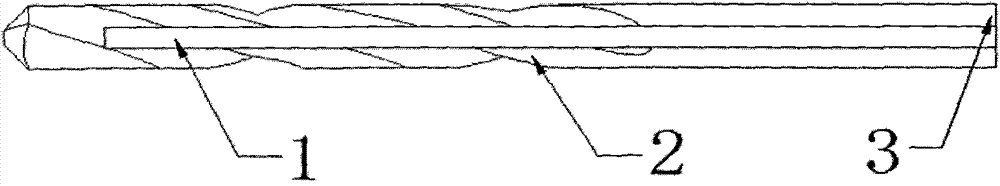

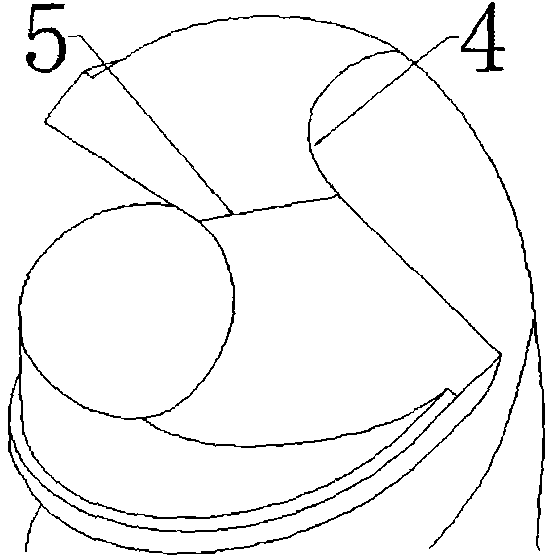

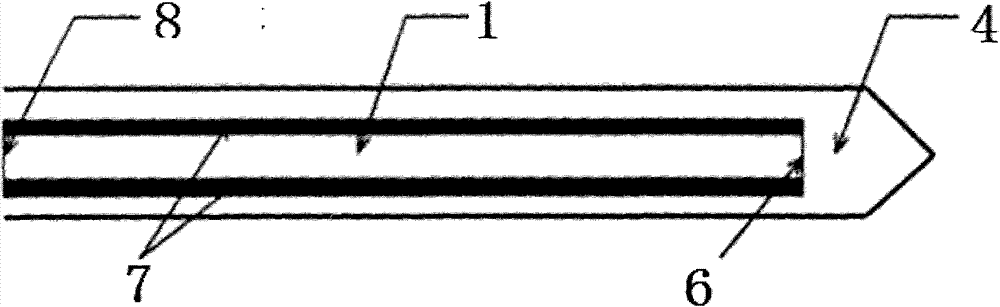

Method for prolonging service life of twist drill based on heat pipe phase changes

InactiveCN103537737AHigh heat transfer efficiencyReduce cutting temperatureTransportation and packagingTwist drillsHeat transfer efficiencyEngineering

The invention discloses an environment-friendly method for prolonging the service life of a twist drill based on heat pipe phase changes, so durability of a standard twist drill with a straight shank can be remarkably improved under a drilling especial for high-speed drilling machining condition. According to the method, a heat pipe theory and technology are brought in, heat pipe phase change heat transfer characteristics are made use of, cutting fluid is not adopted, and the cutting temperature of the main cutting edge and the cutting temperature of the chisel edge part of the twist drill are rapidly lowered with the help of a heat pipe to reduce the abrasion rate of the main cutting edge and the chisel edge part of the twist drill so that the purpose of prolonging the service life of the twist drill is achieved. Heat pipe phase change heat transferring is adopted in the method, so the heat pipe is higher than cutting fluid in heat transfer efficiency; the heat pipe technology is adopted, so the heat pipe is more environment-friendly than cutting fluid, and personal injuries to operation staff do not exist. In addition, the heat pipe adopted in the method is cheaper than the cutting fluid in market price, and therefore manufacturing cost of products of enterprises can be reduced.

Owner:ANHUI AGRICULTURAL UNIVERSITY

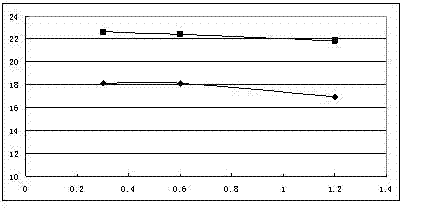

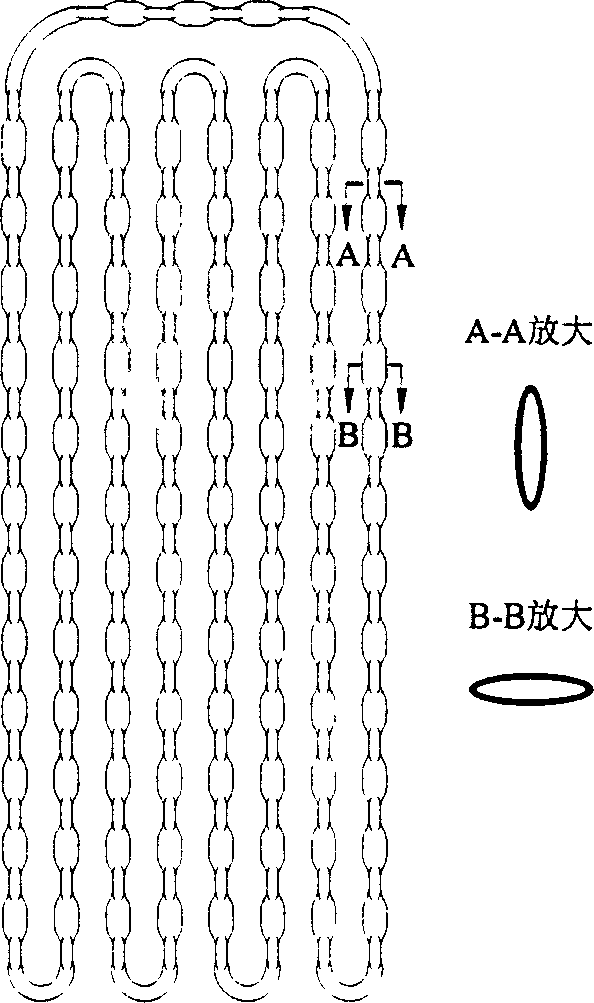

Heat transfer process for variable cross section intensive selfoscillatory flow heat pipe

InactiveCN1632441AImprove heat transfer performanceHigh heat transfer efficiencyIndirect heat exchangersHeat transfer modificationHeat transfer efficiencyOscillating flow

The invention provides a method for enhancing heat transfer of a self-excited oscillating flow heat pipe with a variable cross-section, and adopts a variable-section structure to enhance the heat transfer performance of the self-excited oscillating flow heat pipe. The self-excited oscillating flow heat pipe adopts two different tube diameters, and the tube diameters are changed and combined within the range of 0.5mm to 5.0mm, and are arranged alternately to form a self-excited oscillating flow heat pipe with variable cross-section, so that the fluid in the tube is heated at the heating end Then expand rapidly along the larger pipe diameter and flow to the condensation end; while the liquid condensed at the condensation end flows back to the heating end along the thinner pipe; due to the different curvature radii of the large and small pipe diameters, the surface tension generated by the liquid film Also different, the additional cycle power thus obtained. The present invention adopts the special-shaped section structure type and can also be elliptical, spiral, wedge-shaped or irregular. The invention has the advantages of high heat transfer efficiency, simple structure and easy processing.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

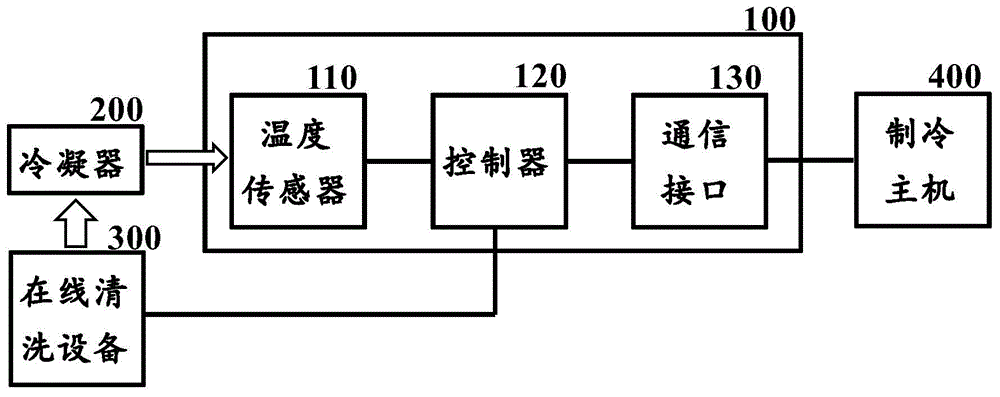

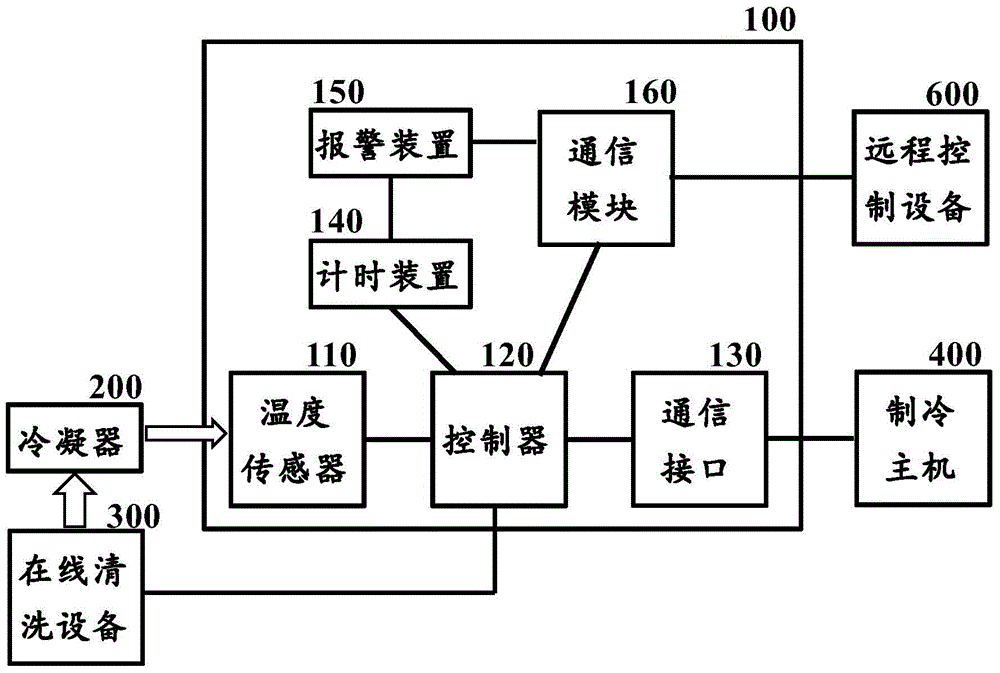

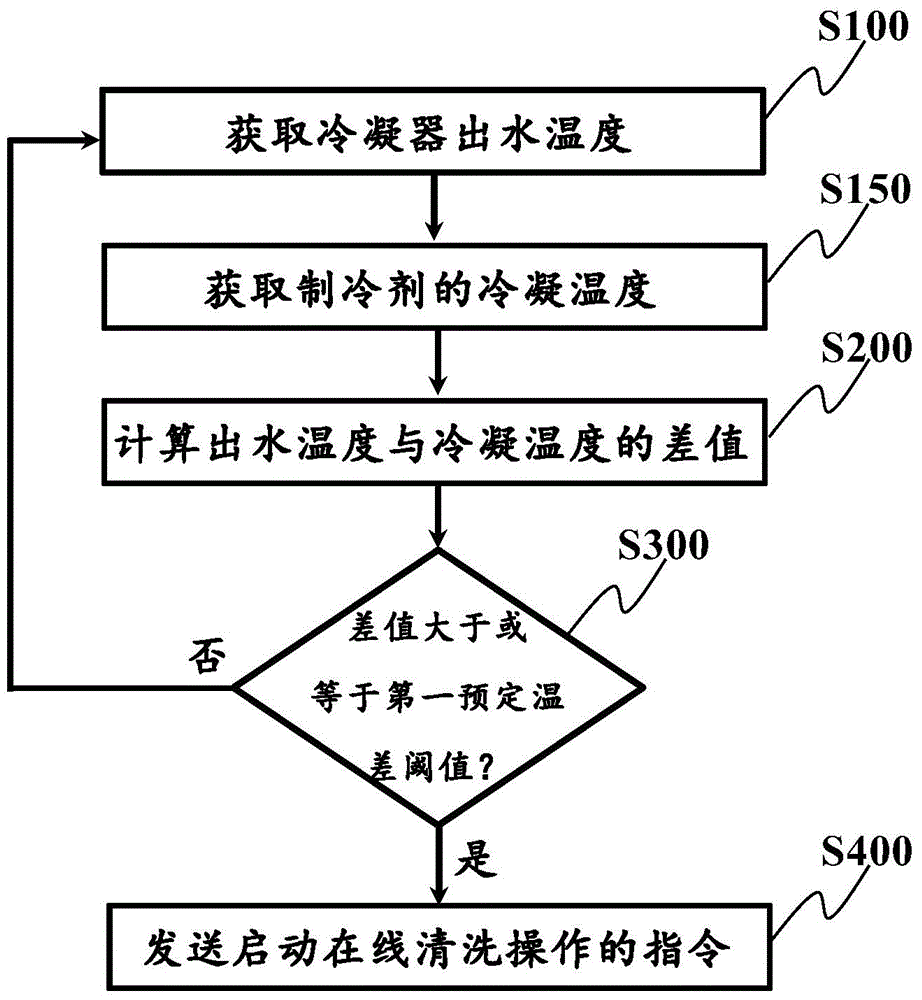

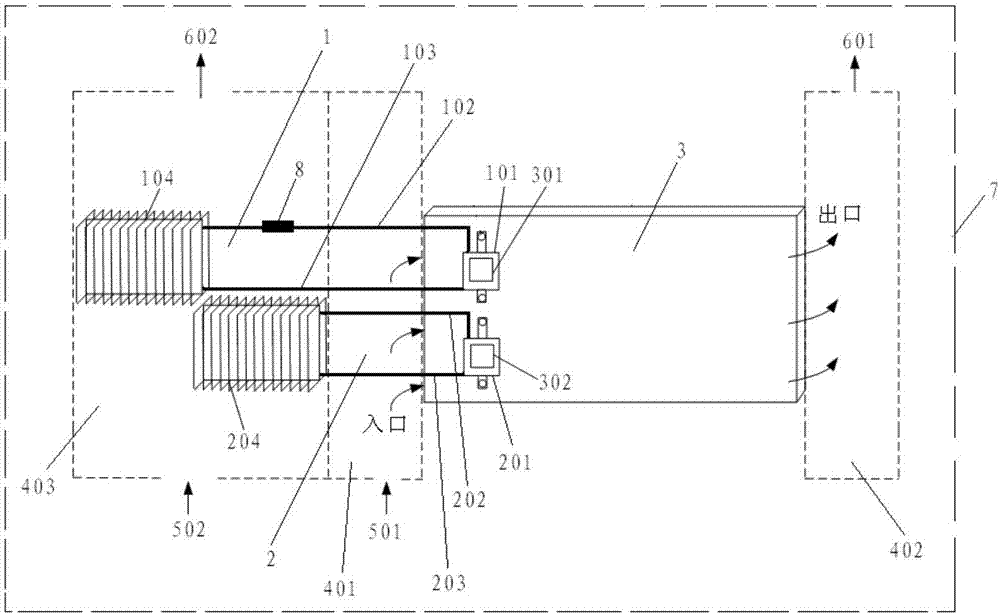

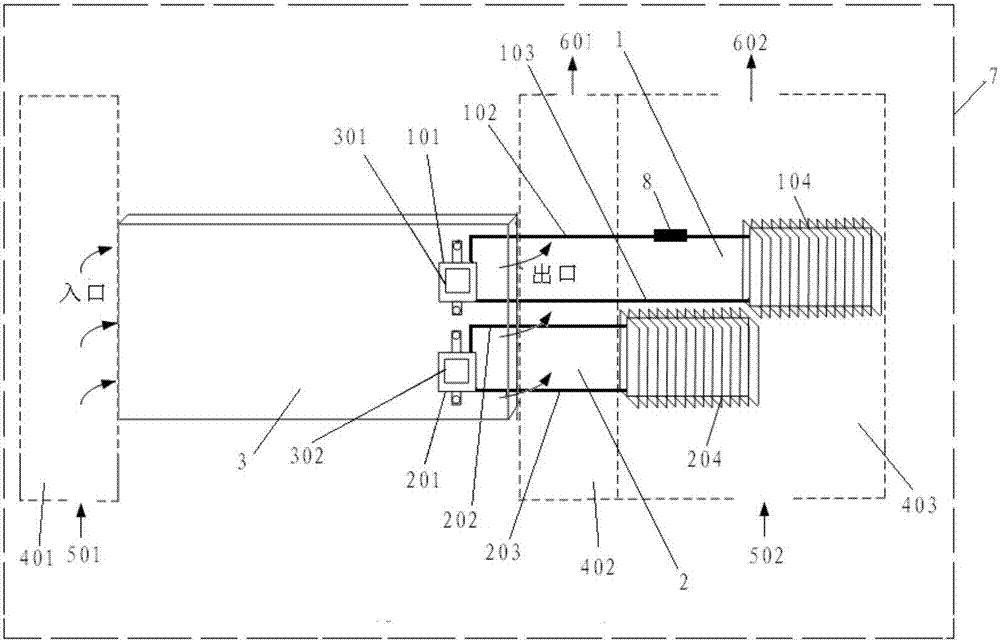

Control device and control method of condenser online cleaning equipment and central air conditioner

ActiveCN104406453AHigh heat transfer efficiencySure dirtCleaning heat-transfer devicesHeat transfer efficiencyRefrigerant

The invention discloses a control device and a control method of condenser online cleaning equipment and a central air conditioner. The control device of the condenser online cleaning equipment comprises a temperature sensor and a controller, wherein the temperature sensor is used for detecting the water draining temperature at a water outlet of the condenser, the controller is used for sending an instruction of starting the online cleaning to the condenser online cleaning equipment when the temperature difference between the water draining temperature of the condenser and the condensing temperature of a refrigerant flowing through the condenser is greater than or equal to a first preset temperature difference threshold value. The cleaning device has the advantage that the running of the condenser online cleaning equipment is automatically started by monitoring the actual running parameters, so the amount of dirt of the condenser is controlled within certain range, and higher heat transfer efficiency is guaranteed.

Owner:北京科创数联科技股份有限公司

Heat dissipation device and system for blade server chip

PendingCN106855741AHigh heat transfer efficiencyLower overall thermal resistanceDigital data processing detailsSemiconductor/solid-state device detailsEmbedded systemBlade server

The invention discloses a heat dissipation device and system for a blade server chip. The heat dissipation device comprises a first embedded heat pipe, a second embedded heat pipe arranged below the first embedded heat pipe and a blade server. The first embedded heat pipe comprises a first evaporator, a long gas pipeline, a long liquid pipeline and a first fin condenser which are connected in sequence. The second embedded heat pipe comprises a second evaporator, a short gas pipeline, a short liquid pipeline and a second fin condenser which are connected in sequence. The blade server comprises a first chip and a second chip which are arranged in the blade server, wherein the first evaporator and the second evaporator are in contact with and fixed with the first chip (301) and the second chip (302) respectively. A heat dissipation structure is simplified, the heat dissipation efficiency is improved, and the device cost is reduced.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

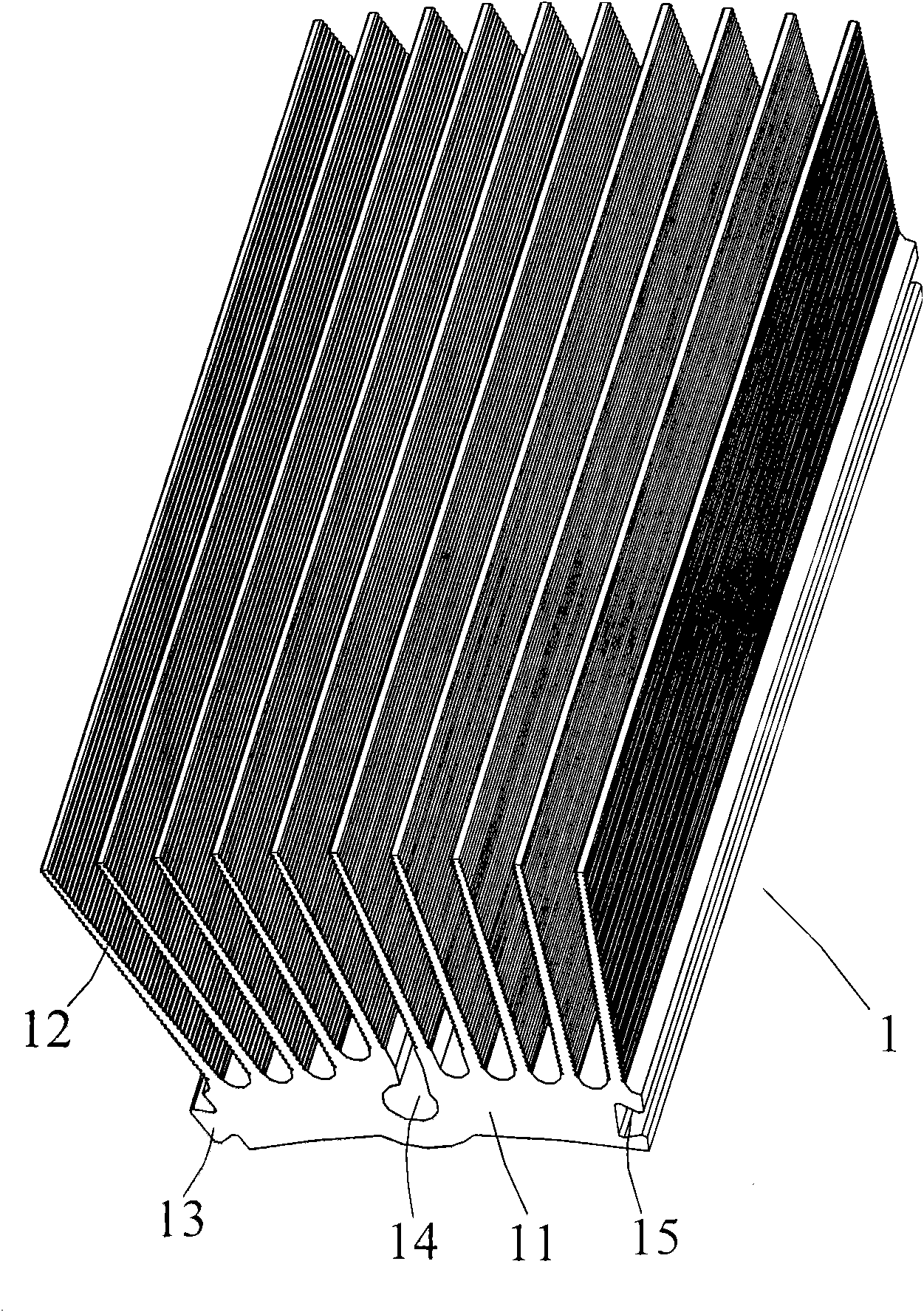

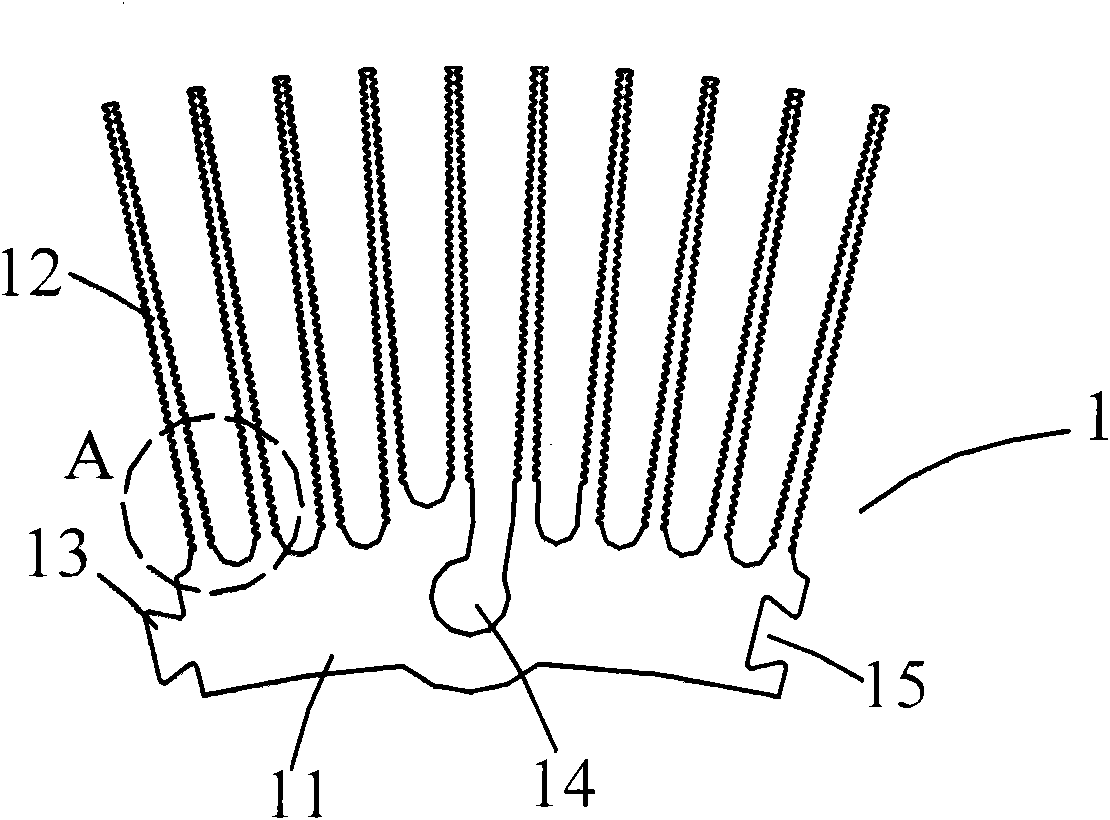

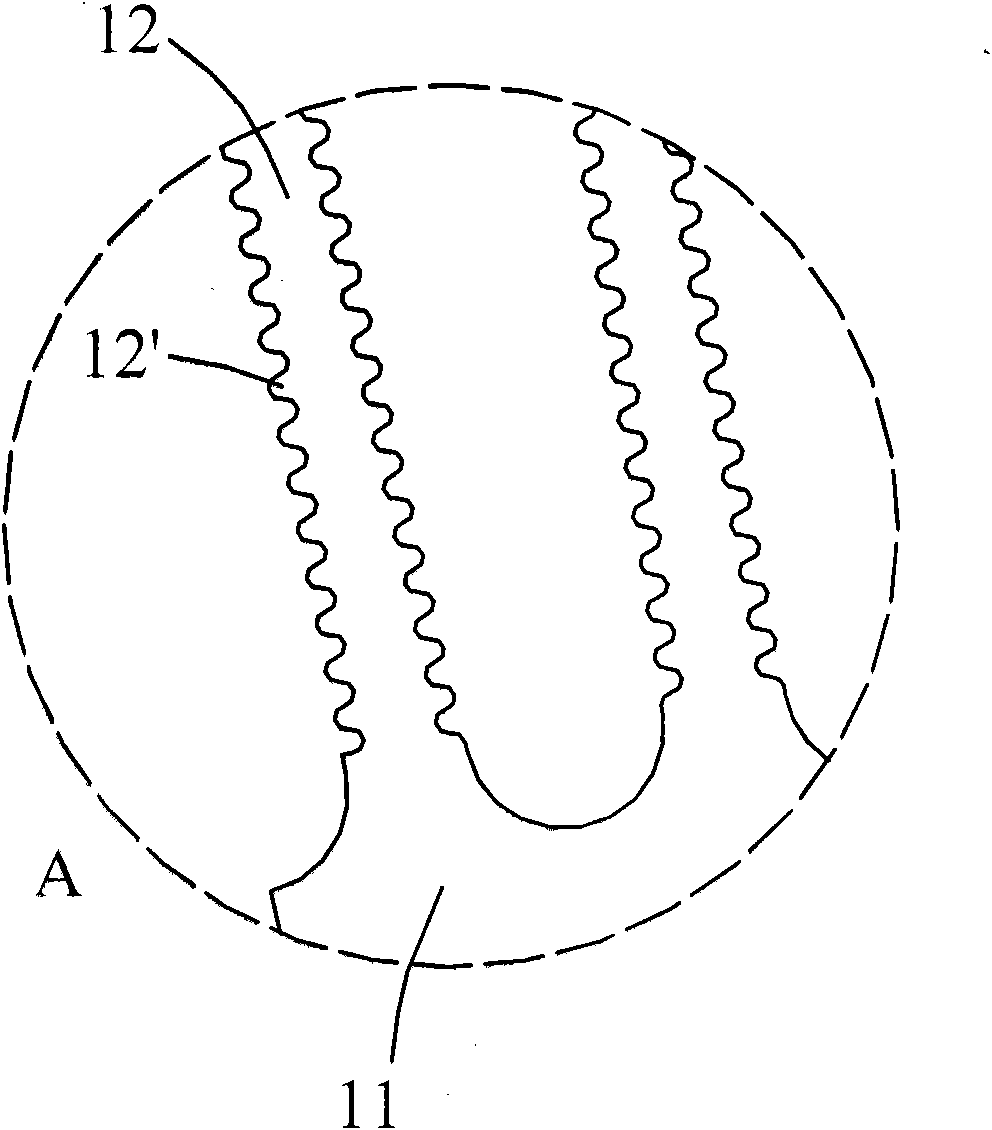

Radiating device for LED lamp and radiator component

InactiveCN101788134ASave development costsHigh heat transfer efficiencyPoint-like light sourceSemiconductor/solid-state device detailsEngineeringHeat spreader

The invention relates to a radiating device for an LED lamp and a radiator component. The radiator component comprises an arc-shaped plate. The outer arc surface of the arc-shaped plate extends outwards to form a plurality of spaced radiating fins, a connecting groove is arranged at one longitudinal end face of the arc-shaped plate along the longitudinal direction, a connecting convex strip is arranged at the other longitudinal end face of the arc-shaped plate along the longitudinal direction, and at least one heat-conduction pipe installing hole is longitudinally arranged at the upper edge of the arc-shaped plate. The bottom parts of the radiating fins are thick, the top parts are thin, and the convex strips are distributed on the surfaces of the radiating fins. The radiating device comprises a radiator, a heat-conduction piece and at least one heat super-conduction pipe. The radiator is composed of at least one radiator component. One end of the heat super-conduction pipe is inserted into the heat-conduction pipe installing hole on the heat-conduction piece, and the other end is inserted into the heat-conduction pipe installing hole on the radiator component. As the radiating device adopts the modular design, a mould of the radiator is single and the development cost of the mould can be saved. With good radiating effect and light weight, the radiating device can greatly save aluminum materials and reduce the cost.

Owner:陈鸿 +1

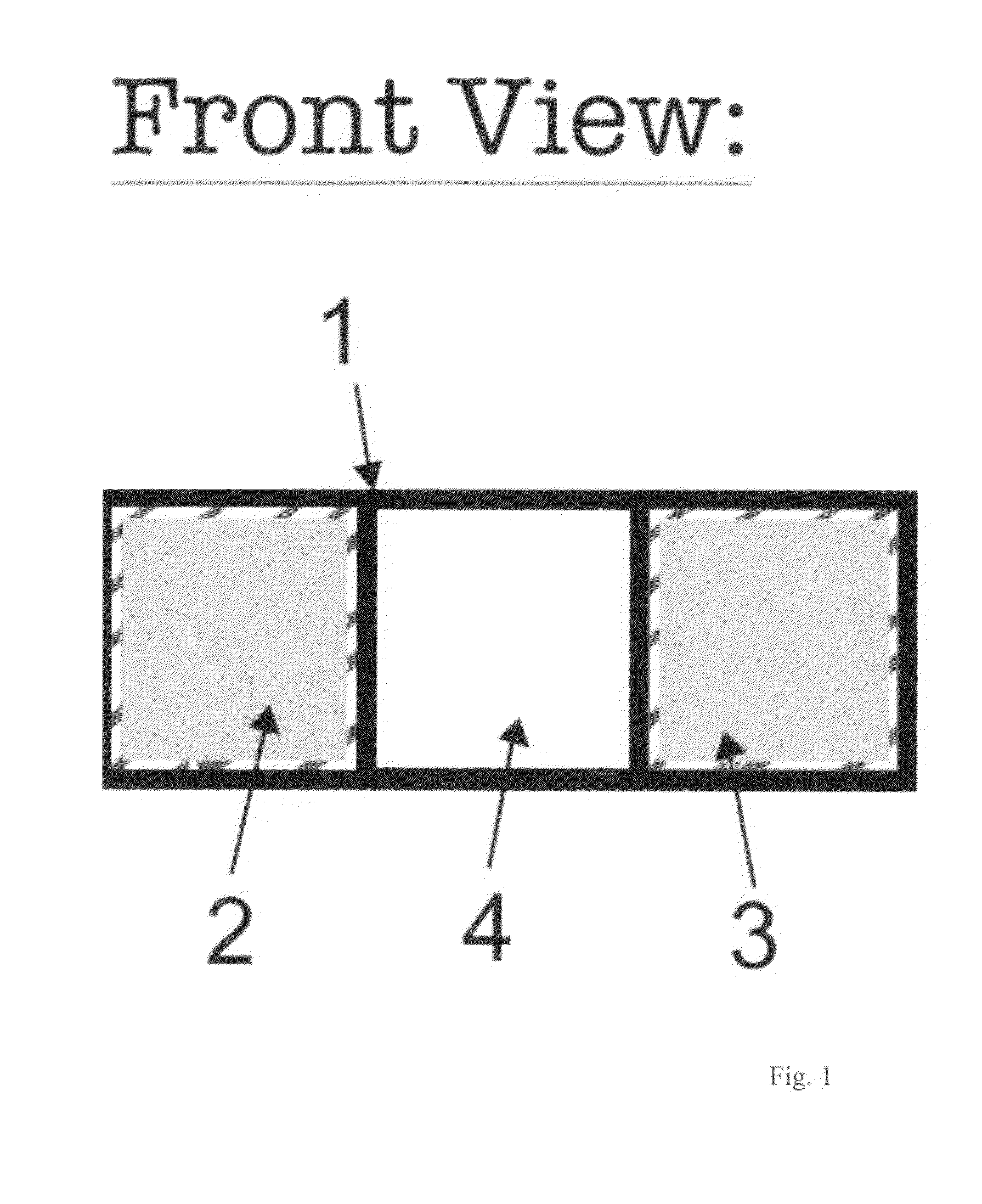

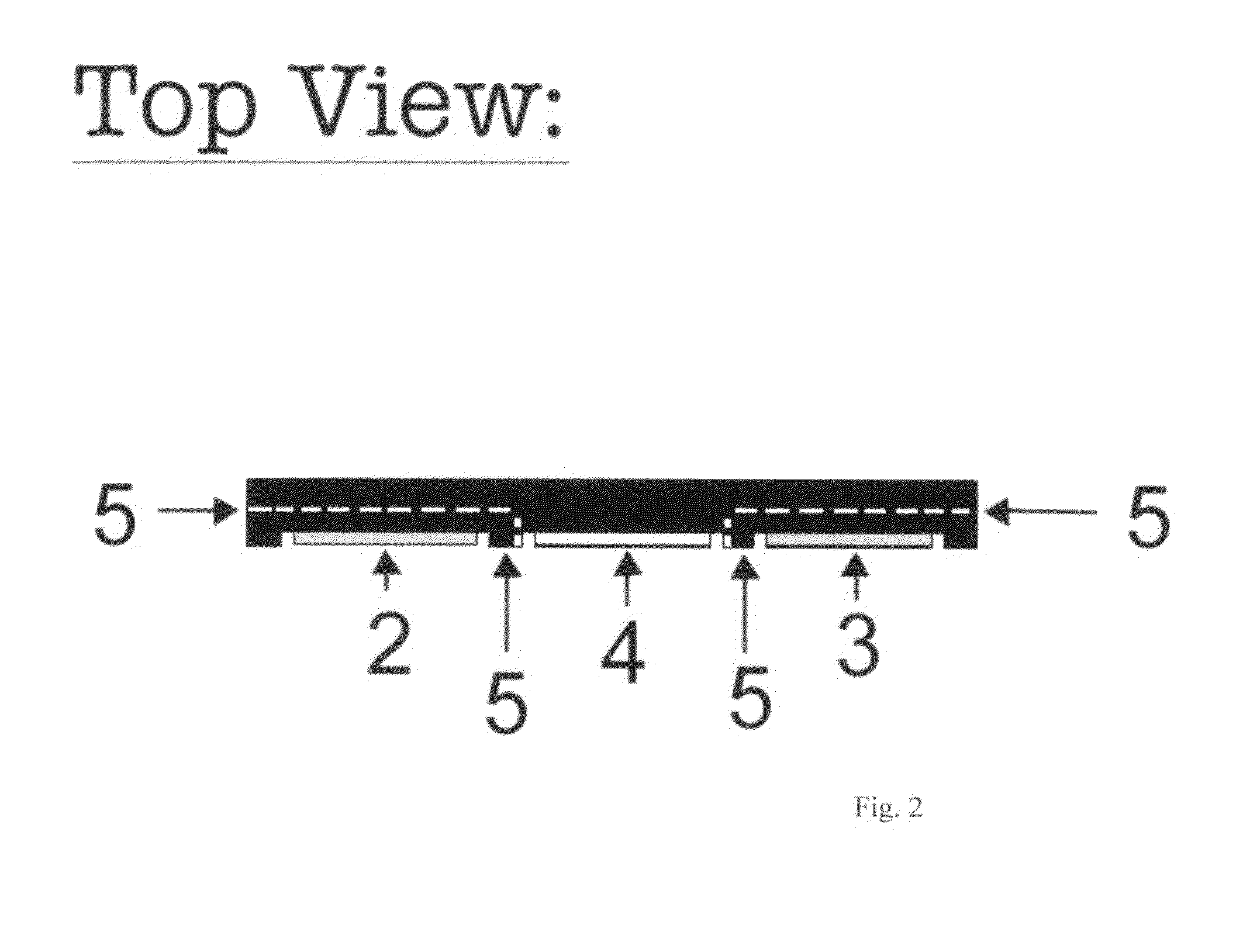

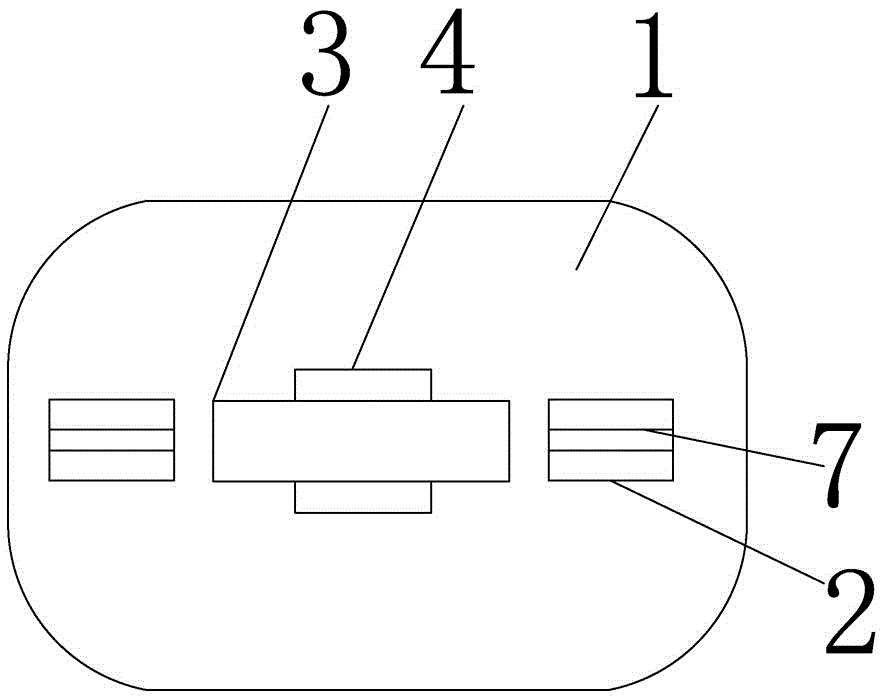

Thermal Array

ActiveUS20100210006A1High heat transfer efficiencyLow energyBioreactor/fermenter combinationsHeating or cooling apparatusThermal energySample temperature

Traditional thermocyclers are heating devices that change sample temperatures by adding heat energy into a sample block that is usually a large metal block and then extracting that heat energy out of the block in a process called ramping the temperature. Presented herein is a technology that eliminates the large mass sample block and ramping temperatures in a sample block and thus in a sample vessel. This design called a Thermal Array requires a fraction of the energy used to process a sample. In addition, the array allows a much smaller thermal cycler to be designed leading to portability of a device. This technology is designed to allow optimal polymerase chain reactions to be executed.

Owner:SPANGLER FR LEO

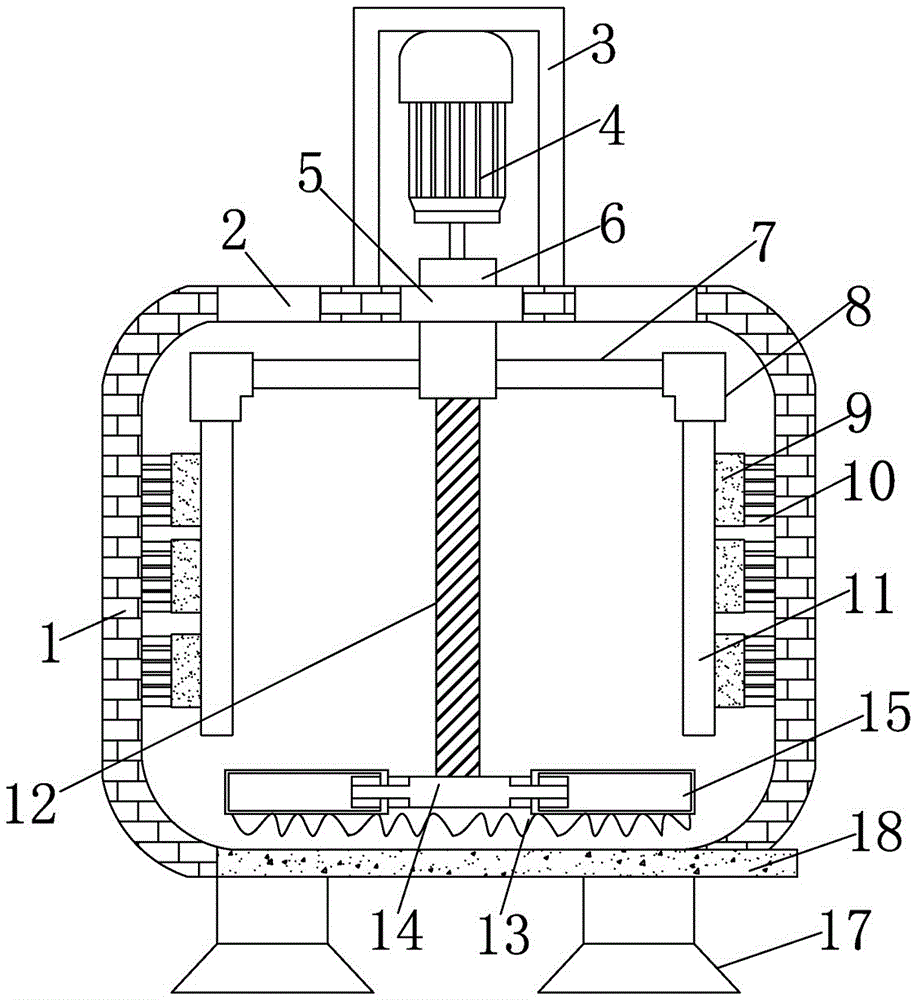

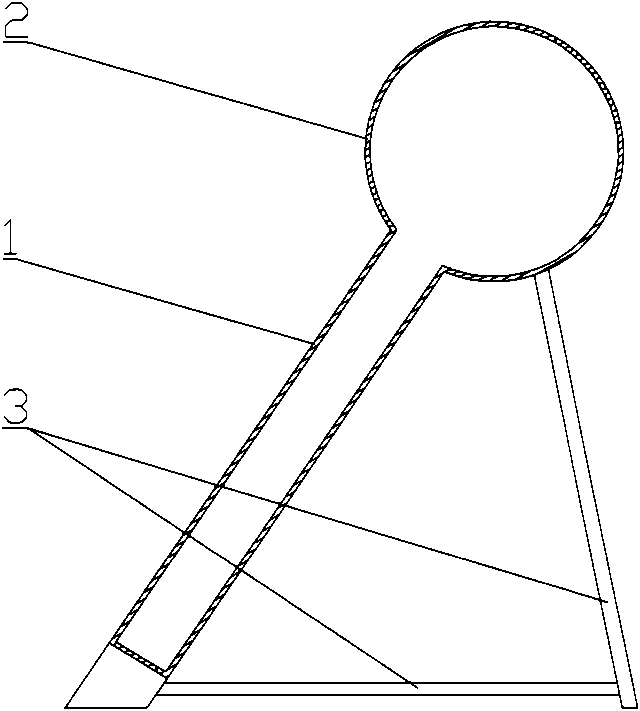

Smelting furnace with ash removal function

InactiveCN106595306AReduced residue build-upHigh heat transfer efficiencyCrucible furnacesHeat transfer efficiencyEngineering

The invention discloses a smelting furnace with an ash removal function. The smelting furnace comprises a furnace body. An inlet is formed in the top of the furnace body. A support is fixedly connected to the top of the furnace body. A motor is fixedly connected to a groove of the support and is fixedly connected with a rotary rod through a rotary shaft. The other end of the rotary rod penetrates a bearing embedded into the top of the furnace body and is inserted into an inner cavity of the furnace body. A middle shaft is fixedly connected to the side face of the other end of the rotary rod. A connecting piece is inserted into the other end of the middle shaft. According to the smelting furnace with the ash removal function, the motor, the rotary rod, the middle shaft, supporting rods and scraper plates are arranged, the scraper plates are driven to rotate around the inner wall of the furnace body for removing residues on the inner wall of the furnace body, residue accumulation is reduced, the heat transfer efficiency of the smelting furnace is improved, and the service life of the smelting furnace is prolonged; and a threaded rod, a connecting plate, sliding plates and elastic steel wires are arranged, and the threaded rod rotates to drive the connecting plate to rotate, so that the sliding plates are stressed and the cleaning area is increased, the residues at the bottom of the furnace body are removed through the elastic steel wires, and the heat transfer efficiency of the smelting furnace is improved.

Owner:湖北智权知识产权咨询有限公司

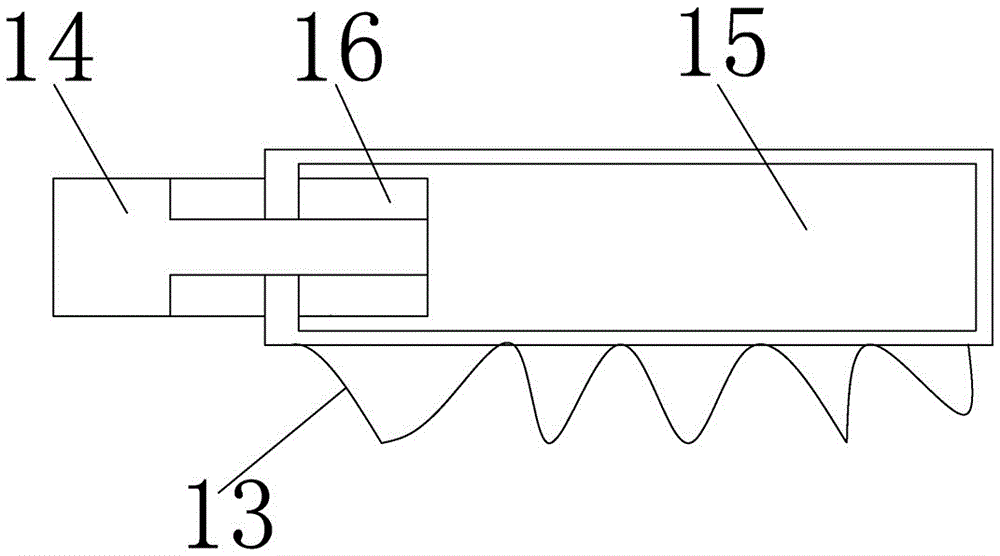

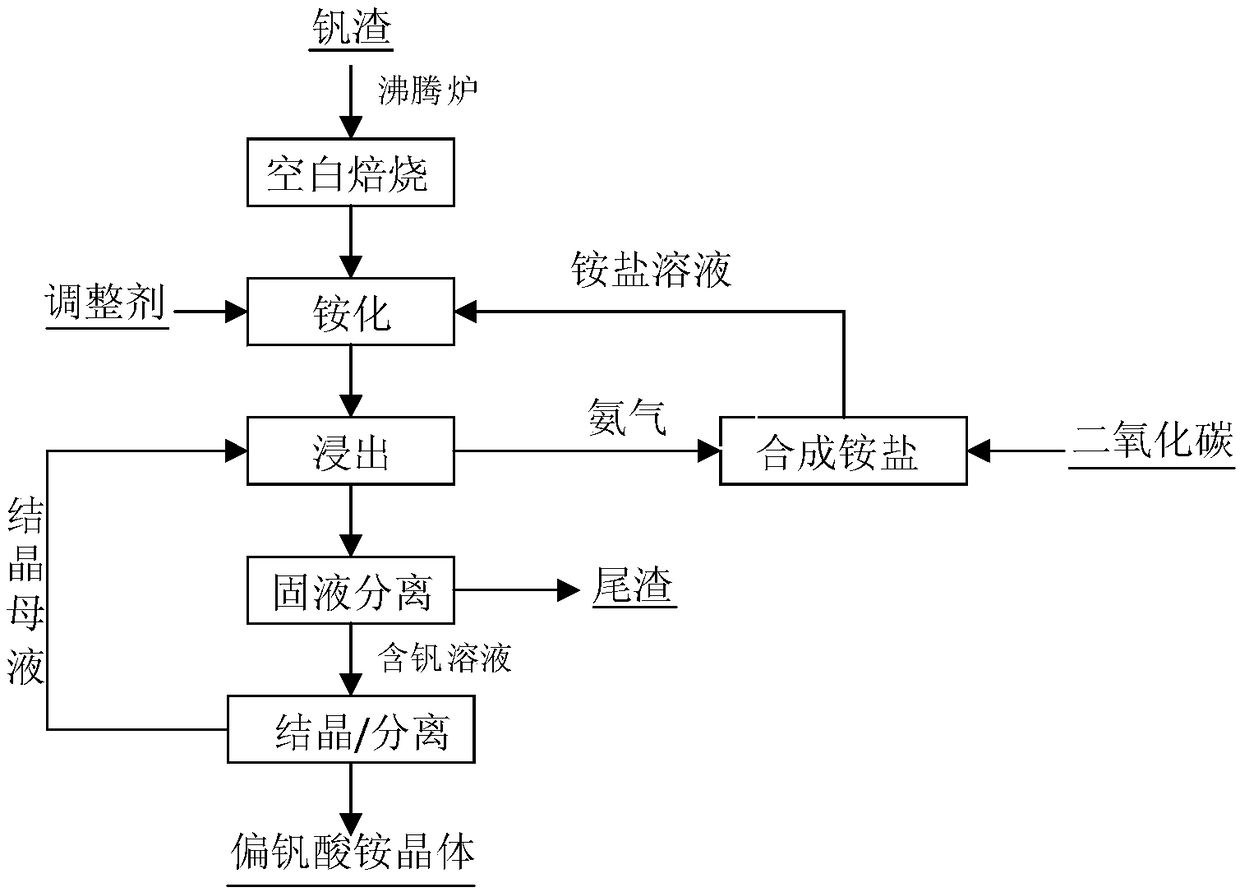

Method for extracting vanadium from vanadium slag through blank roasting and quaternarization

ActiveCN108149022AHigh heat transfer efficiencyGood mass transfer effectProcess efficiency improvementHeat transfer efficiencyAdverse effect

The invention relates to a method for extracting vanadium from vanadium slag through blank roasting and quaternarization. The method comprises the steps of adding the vanadium slag to a fluidized bedfurnace for blank roasting; mixing roasted clinkers obtained through blank roasting, ammonium salt solutions and regulators for quaternarization, and leaching upon completion of quaternarization; andobtaining vanadium-containing solutions after solid-liquid separation. According to the method provided by the invention, by adopting the fluidized bed furnace as equipment for roasting the vanadium slag, and adding an appropriate amount of the regulators, the heat transfer efficiency is improved, and the roasting time is shortened; the production energy consumption is reduced, and meanwhile the adverse effect of silicon-containing phases is eliminated; and the vanadium conversion rate by quaternarization and the solid-liquid separation performance are improved. With the method provided by theinvention, the phenomena of bonding and sintering hardly occur in the high-temperature roasting process, so that oxygen comes into sufficient contact with vanadium slag particles, and the vanadium conversion rate is improved greatly; meanwhile, the amount of ammonium salt and the production cost are reduced; the cyclic utilization of ammonium salt media can be achieved, and the whole process hasno waste water discharged; and the method has good application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-thermal conductivity eggshell type catalyst carrier and preparation method and application

ActiveCN104001556AHigh heat transfer efficiencySuitable for mass productionCatalyst carriersHydrocarbon from carbon oxidesThermal conductivityCorrosion

The invention relates to a high-thermal conductivity eggshell type catalyst carrier which is a metal ball, wherein the range of the average particle diameter of the metal ball is 1 to 5 mm, the specific surface area is 70 to 600 m<2> / g, the average pore diameter is 4 to 60 nm, the pore volume is 0.25 to 2.00 cm<3> / g, the thickness of a corrosion layer of the metal ball is 0.05 to 0.25 mm, and the corrosion layer is made of metal oxides. The high-thermal conductivity eggshell type catalyst carrier has the advantages of simplicity in preparation and controllable thickness of a shell layer and is suitable for large-scale industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Defrosting method for thermal pump air conditioner and air conditioner

ActiveCN101430153AUnobstructed air channelHigh heat transfer efficiencyHeat pumpsCorrosion preventionFrostEvaporator

The invention discloses a defrosting method of a heat pump air conditioner. The method comprises the following steps: adopting bypass tube bypass compressor containing a bypass solenoid valve and a front tube bank of an outdoor heat exchanger, and connecting the solenoid valve and a capillary tube between the front tube bank of the outdoor heat exchanger and a rear tube bank of the outdoor heat exchanger in parallel; the defrosting process comprises the following steps: closing the solenoid valve; opening the bypass solenoid valve; and causing the refrigerant to sequentially flow through the compressor, a four-way reversing valve, the bypass solenoid valve, the front tube bank of the outdoor heat exchanger, the capillary tube and the rear tube bank of the outdoor heat exchanger, and then flow through the four-way reversing valve and return to the compressor; during the flow process, taking the front tube bank of the outdoor heat exchanger as a condenser and the rear tube bank of the outdoor heat exchanger as an evaporator, and melting a frost layer on the surface of the front tube bank of the outdoor heat exchanger; and / or changing the conducting direction of the reversing valve to melt the frost layer on the surface of the rear tube bank of the outdoor heat exchanger. The invention also provides the heat pump air conditioner. The method can efficiently, quickly and safely remove the frost layer on the surface of the outdoor heat exchanger.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Solar heat-collecting core, heat collector and water heater

InactiveCN101551163AReduce thermal resistanceHigh heat transfer efficiencySolar heating energySolar heat devicesSolar waterCollector device

The invention discloses a solar heat-collecting core which comprises a heat collecting plate and a bottom plate overlapped below the heat collecting plate. A water flowing channels is arranged between the heat collecting plate and the bottom plate; the peripheries of the heat collecting plate and the bottom plate are sealed; and the water flowing channel is formed between the heat collecting plate and the bottom plate to make cold water in the water flowing channel be directly heated by the heat collecting plate. Additionally, the heat collecting plate also comprises a plurality of protruding parts. The invention also provides a solar water heater and a heat collector of the solar water heater. The water flowing channel of the solar heat-collecting core is directly formed by the heat collecting plate and the bottom plate, cold water to be heated in the water flowing channel can be directly heated by the heat collecting plate, thus the heat transfer efficiency is remarkably improved. After the protruding parts are arranged on the heat collecting plate, the light area of the heat collecting plate is enlarged, so that the photo-thermal converting efficiency is improved; on the other hand, the arrangement of the protruding parts can enlarge the heat-exchanging area between the heat collecting plate and cold water, thereby the heat conducting efficiency can be further improved.

Owner:宁波晟唐基业科能电器有限公司

Method for preparing polyethylene wax by using waste polyethylene plastic

InactiveCN104861096AHigh heat transfer efficiencyReduce temperature gradientPlastic recyclingBulk chemical productionSolventChemistry

The present invention relates to a method for preparing polyethylene wax by using waste polyethylene plastic. The method comprises: sequentially adding 100 g of waste polyethylene plastic, 15 mL of a solvent and 0.3 g of a catalyst to an autoclave, heating to a reaction temperature while stirring under the protection of nitrogen gas, cracking for a certain time, cooling to a room temperature, discharging the material, filtering, drying, and recovering the catalyst and the solvent to obtain the polyethylene wax, wherein the solvent is the petroleum refining byproduct heavy aromatic oil, the catalyst is Al-MCM-48, the reaction temperature is usually the temperature from the raw material melting point to 420 DEG C, and the cracking time is 1-5 h. According to the present invention, the heat transfer is quick and uniform, the cracking temperature is low, the time is short, the raw material conversion rate is high, the occurrence of the phenomena such as raw material winding aggregation and excessive cracking and carbonization coking caused by local overheating can be effectively prevented, and the product has characteristics of narrow molecular weight distribution, shallow color, high drop melting point, high hardness, low viscosity and the like.

Owner:胡浩斌

Anti-freezing water meter

PendingCN110987106AHigh heat transfer efficiencyImprove antifreeze effectVolumetric apparatus damage preventionHeat transfer efficiencyHeat conservation

The invention discloses an anti-freezing water meter. The water meter comprises a shell and a water meter body, wherein the shell is arranged outside the water meter body. The shell comprises a waterproof layer and a heat preservation layer, and the waterproof layer is arranged outside the heat preservation layer. A water wheel chamber is arranged in the middle of the water meter body, a dial plate chamber is arranged on the upper portion of the water wheel chamber, a meter cover is arranged on the dial plate chamber, a filtering chamber is arranged on the lower portion of the water wheel chamber, and a water inlet pipe is arranged on one side of the water wheel chamber. A heating device is arranged in the meter, so that the heat transfer efficiency is improved; heat preservation and waterprevention are realized on the water meter through the arranged shell; heating is performed through the arranged thermistor when the temperature is lower than a set temperature; heating is performedonly when water in the water meter stops flowing through an arranged flow switch; and the shell and the power source can be taken down when the air temperature is increased through an upper shell anda lower shell.

Owner:ANHUI EMI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com