Hydrogen storing tank based on metal hydrogen storage principle

A hydrogen storage tank and hydrogen storage technology, applied in the field of hydrogen storage tanks, can solve the problems of high energy consumption, low hydrogen storage density, poor hydrogen storage safety, etc., and achieve high hydrogen storage density, improved heat transfer efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

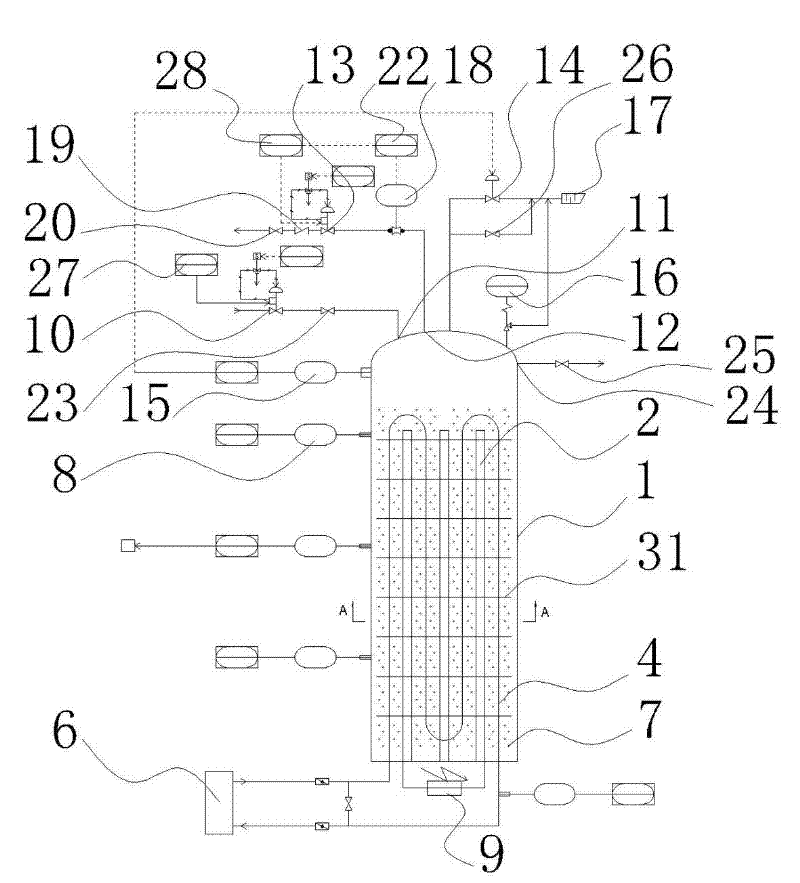

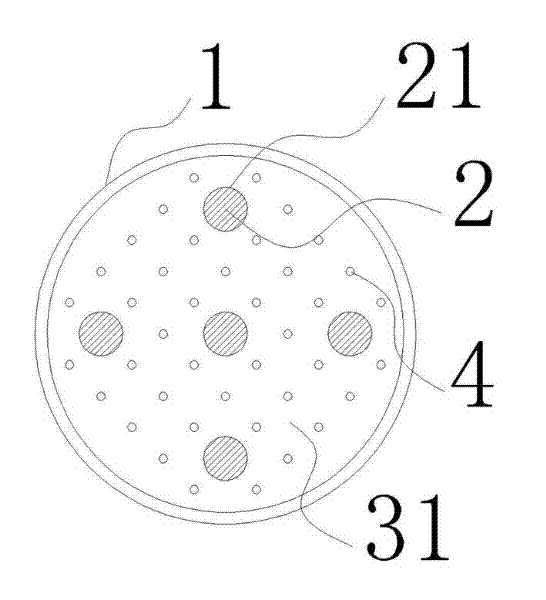

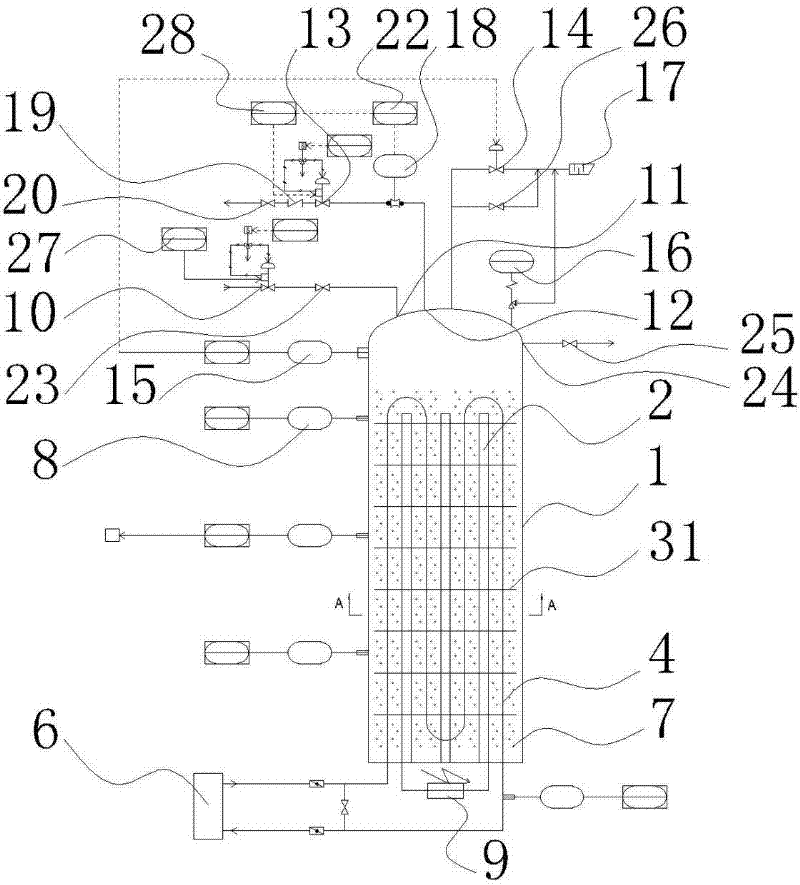

[0020] Such as figure 1 As shown, a hydrogen storage tank based on the metal hydrogen storage principle of the present invention includes a cylindrical pressure storage tank 1 placed upright, with a hydrogen input port 11 and a hydrogen gas inlet 11 at the top of the pressure storage tank 1. Output port 12, in order to facilitate the vacuuming of the pressure storage tank 1, there is also a vacuum interface 24 on the top of the pressure storage tank 1, and a vacuum manual isolation valve 25 is installed on the pipeline connected to the vacuum interface 24. The port 11 is equipped with an input control valve 10, the input control valve 10 is a pneumatic cut-off valve, and its switch is controlled by a solenoid valve. The opening of the end control valve 10 can also be controlled by an input end manual controller 27 . An output end control valve 13 is installed on the hydrogen output port 12, and a flow meter 18 is also installed on the connecting pipeline between the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com