Patents

Literature

3689results about How to "Reduce thermal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

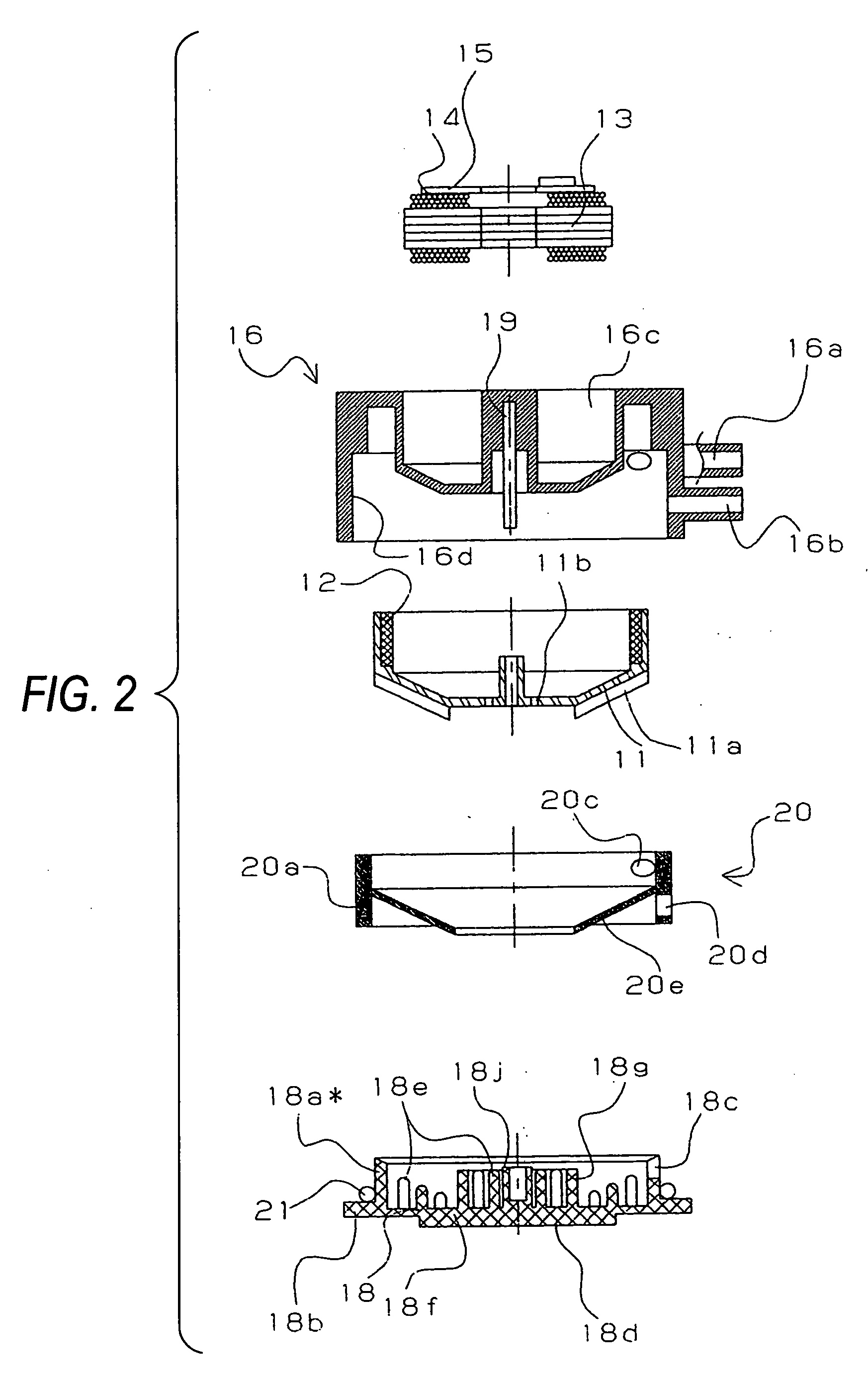

LED lighting system

InactiveUS20060193130A1Reduce heat resistance requirementsImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsHeat resistanceAdhesive

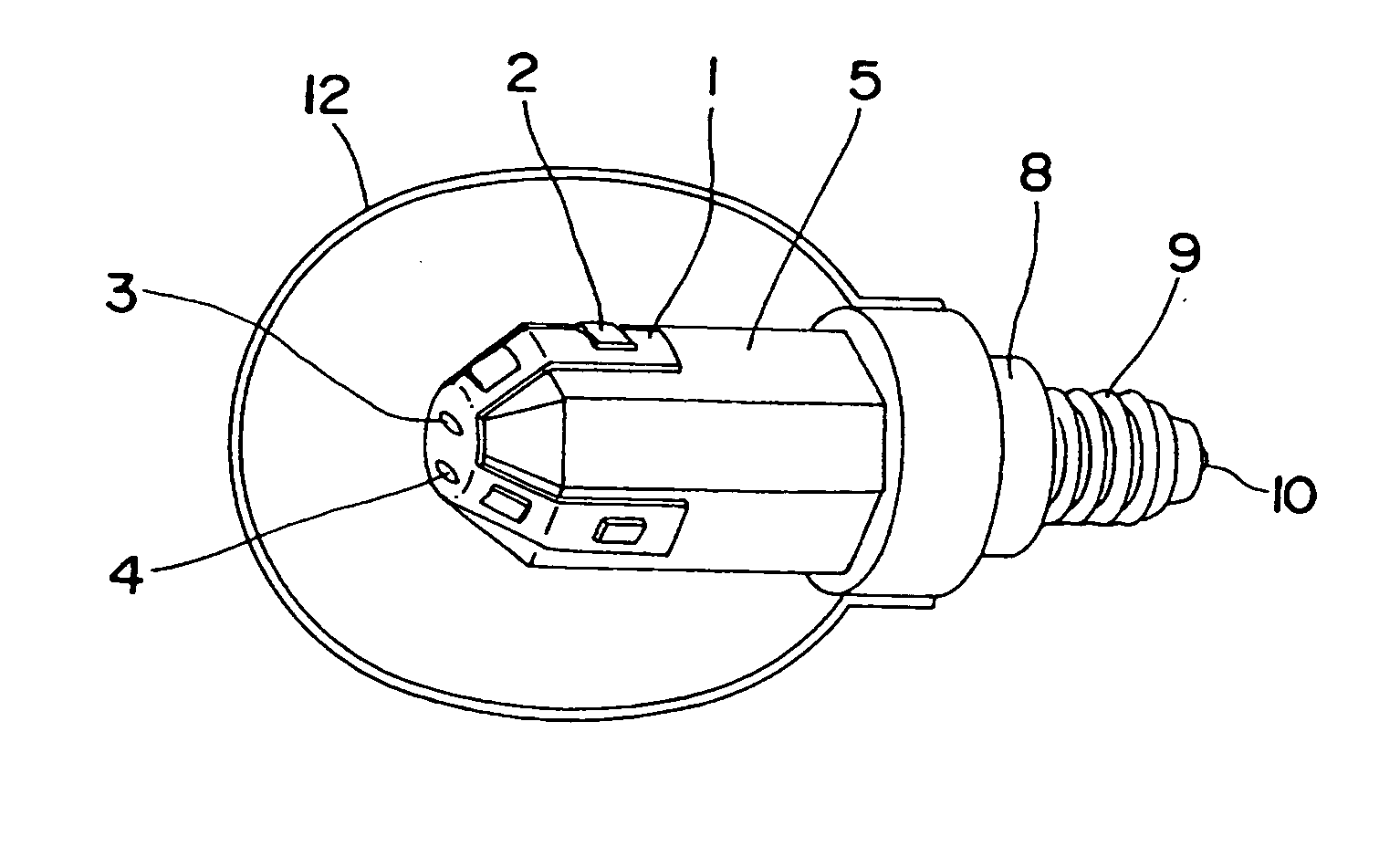

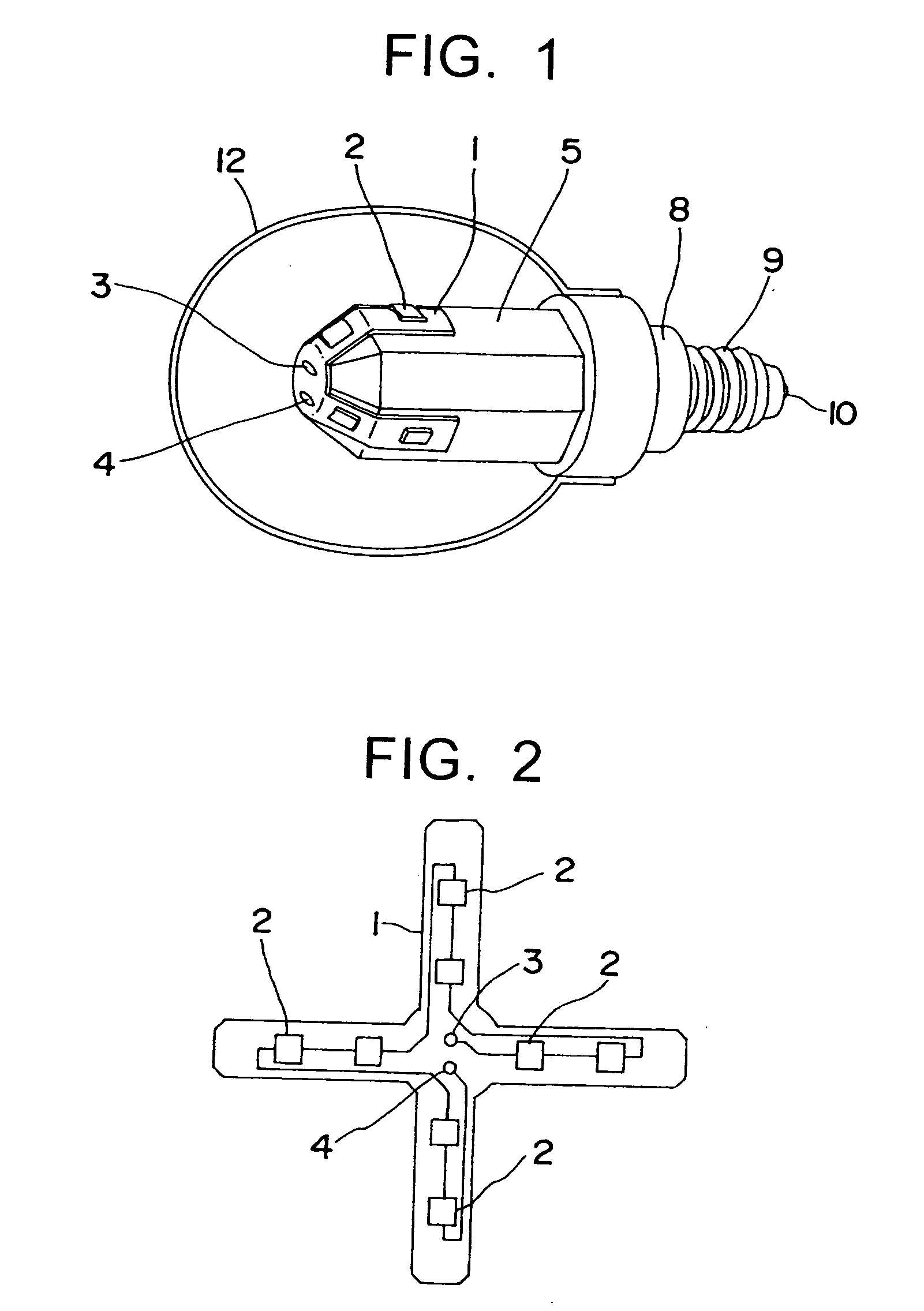

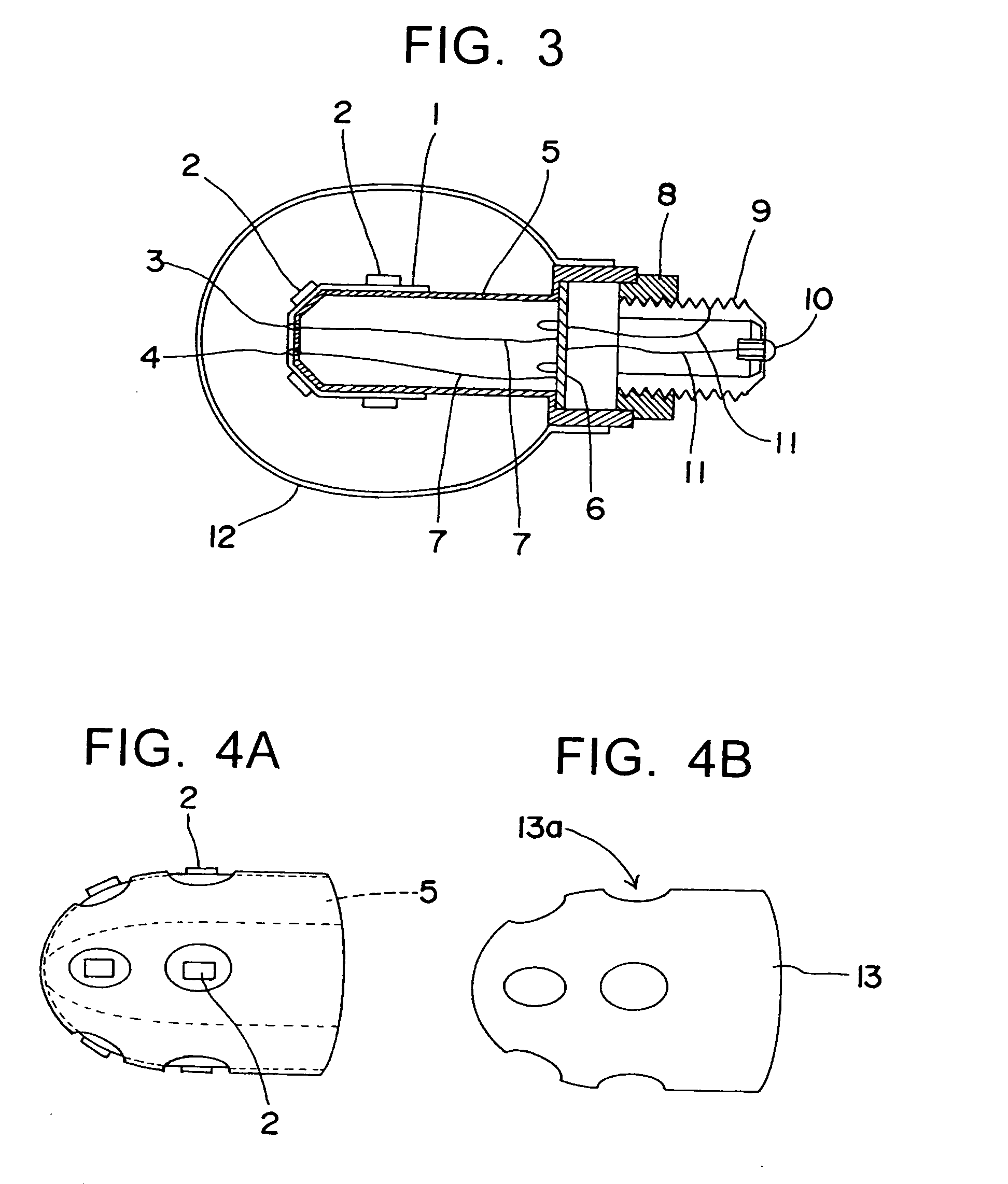

Provided is an LED lighting system with a smaller heat resistance of the LED, which can be produced by simpler mounting steps and is capable of three-dimensionally arranging the LEDs depending on required directivity of each system. A plurality of LEDs 2 are mounted on an FPC 1 which has a radial shape and can be flat when developed. The LEDs 2 connected by printed wiring to each other and linked to terminals 3 and 4 are attached on a surface of a core 5 made of a material having a high thermal conductivity. Heat generated at a p-n junction of the LEDs 2 is transmitted to the core 5 via the FPC 1 and a thermal-conductive adhesive.

Owner:ATEX CO LTD

Power semiconductor device

ActiveUS20070215903A1High blocking voltageLow thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

A power semiconductor device, having a first semiconductor region, and a second semiconductor region; mounted with a first electrode pad on a semiconductor substrate main surface at the inside surrounded by the third semiconductor region, mounted in the second semiconductor region, and a multilayer substrate having first and second wiring layers, to take out an electrode of the semiconductor chip; joining the first wiring layer part for the first electrode, mounted on the multilayer substrate, in a region opposing to the semiconductor substrate main surface at the inside surrounded by the third semiconductor region, and the first electrode pad, by a conductive material; joining the first wiring layer part for the first electrode, and the second wiring layer at a conductive part; and extending the second wiring layer to the outside of a region opposing the semiconductor substrate main surface at the inside surrounded by the third semiconductor region.

Owner:HITACHI LTD

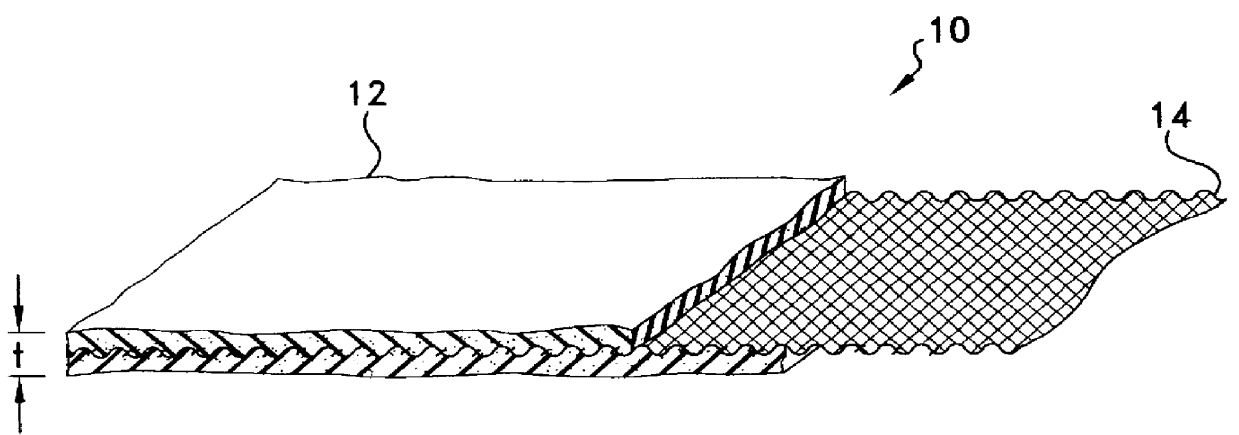

High dielectric strength thermal interface material

InactiveUS6096414AImprove performanceMaintain good propertiesOther chemical processesSynthetic resin layered productsThermal conductivityThermal transmittance

A thermally-conductive, electrically insulative interface for conductively cooling a heat-generating source, such as an electronic component, having an associated thermal dissipation member such as a heat sink. The interface is provided as a cured sheet of a curable material formulated as a blend of a curable silicone binder, and a particulate alumina, i.e., aluminum oxide (Al2O3), filler. The interface is observed to exhibit a thermal conductivity of at least about 0.8 W / m-K and a wet dielectric breakdown strength of at least about 475 Vac / mil.

Owner:PARKER INTANGIBLES LLC

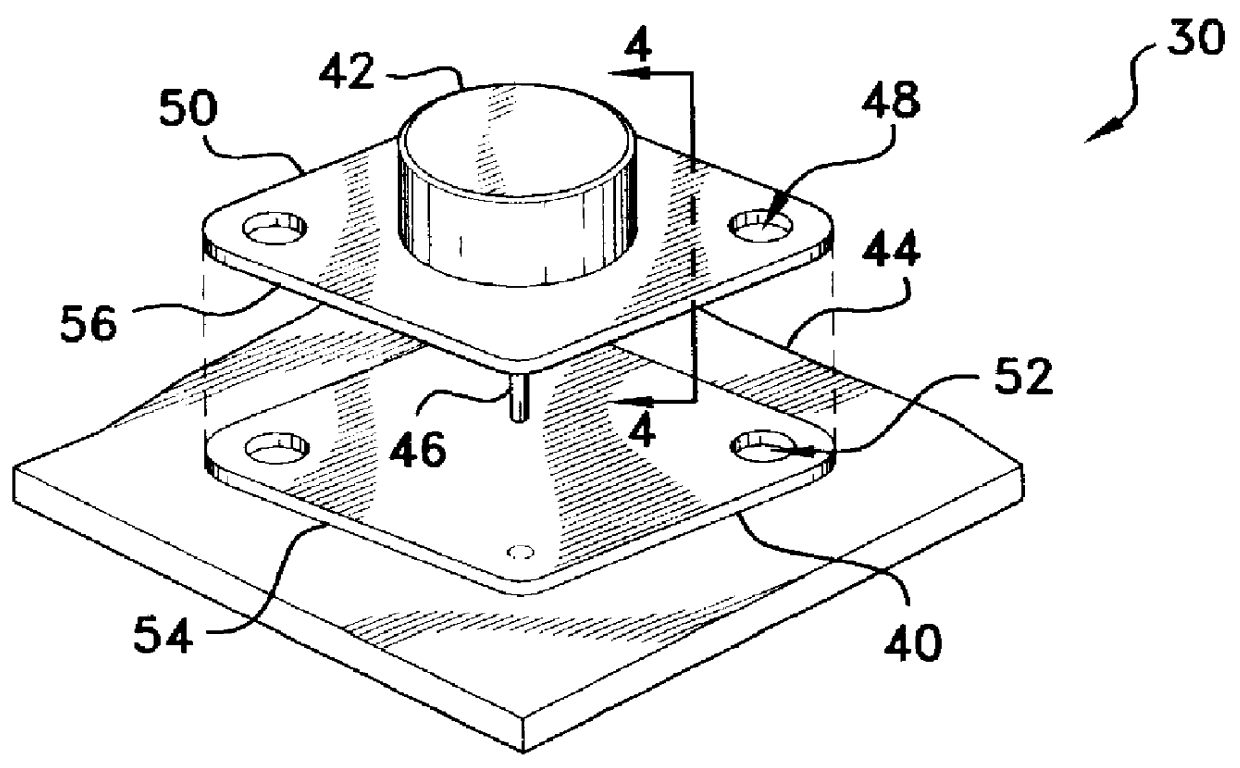

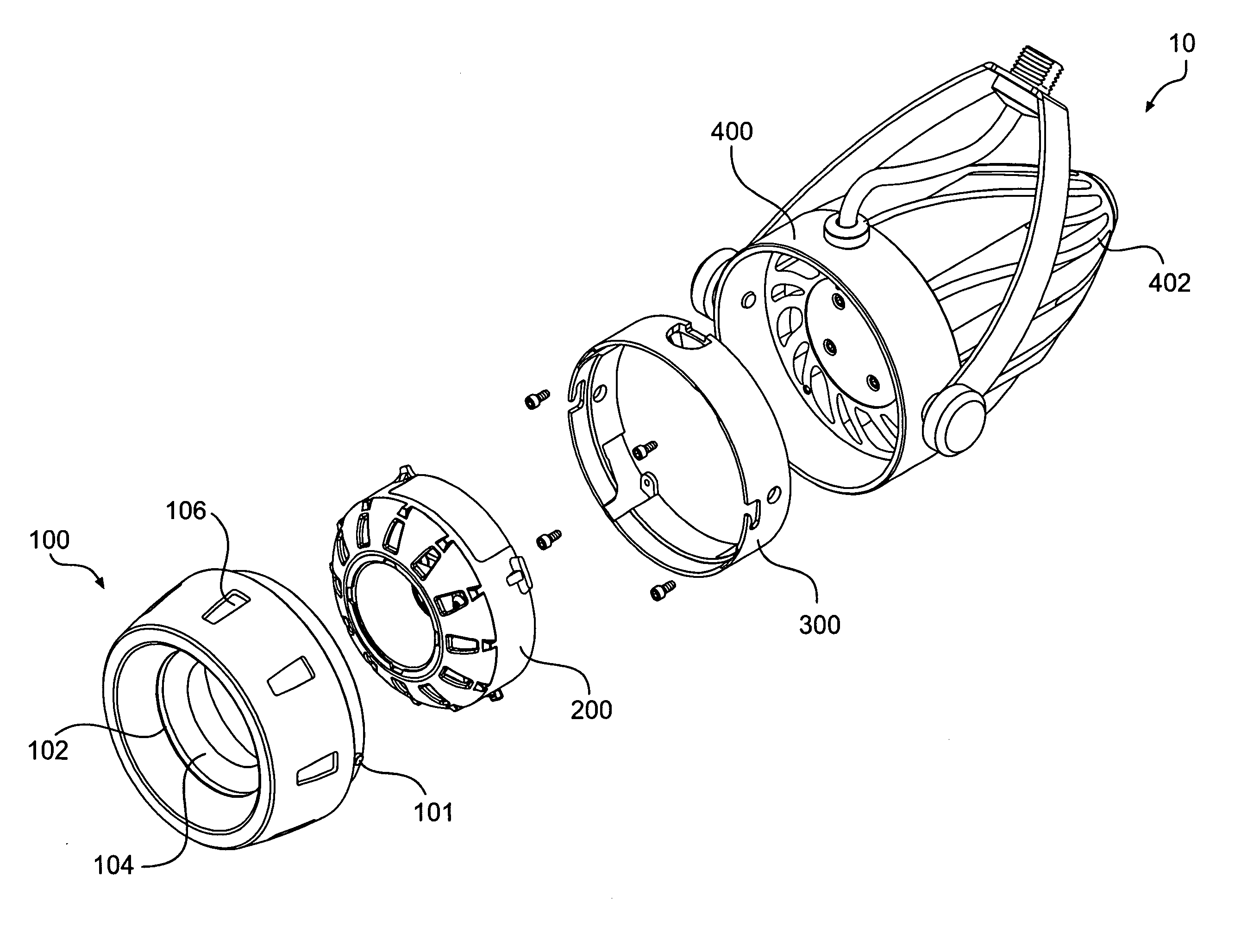

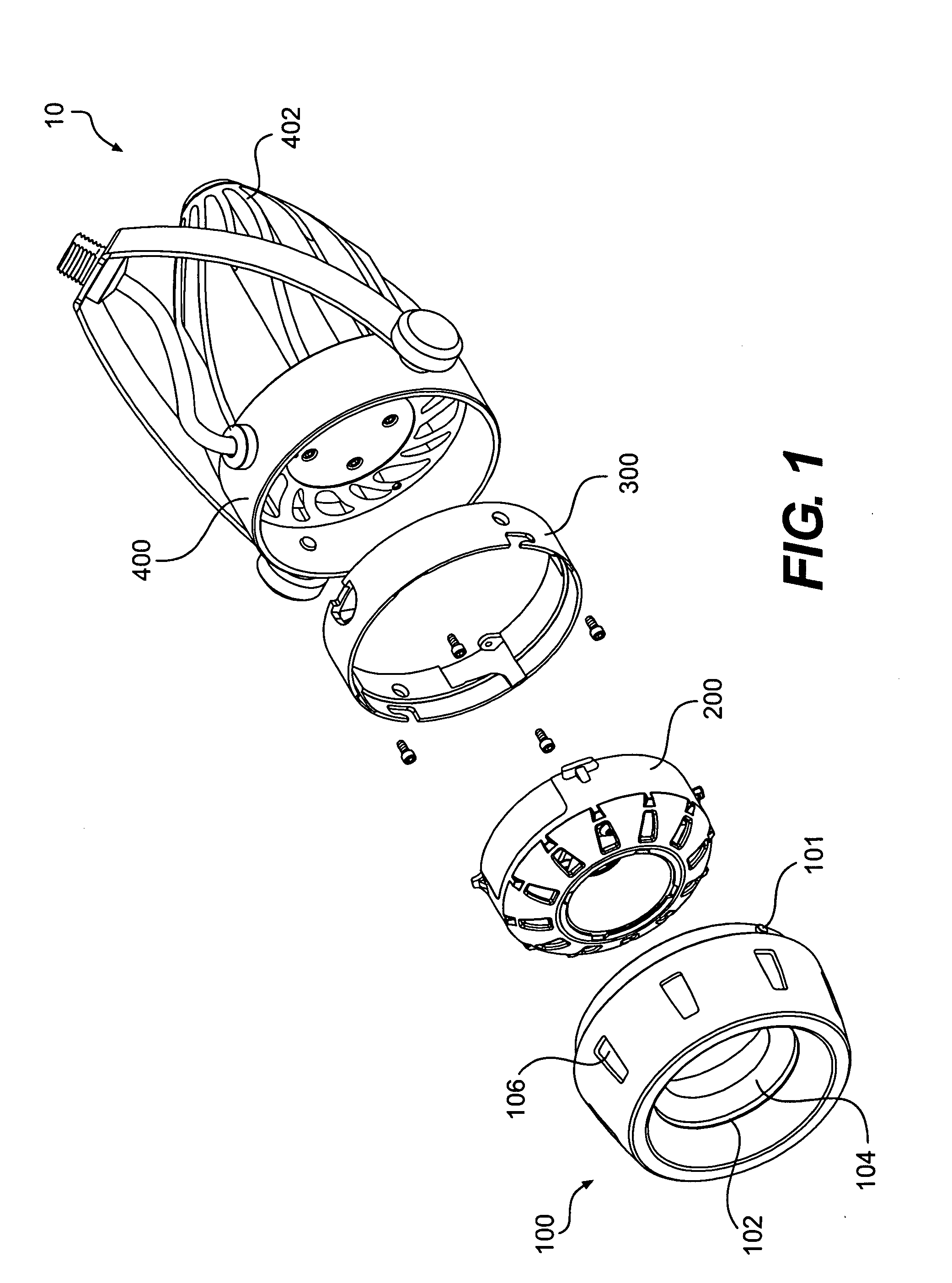

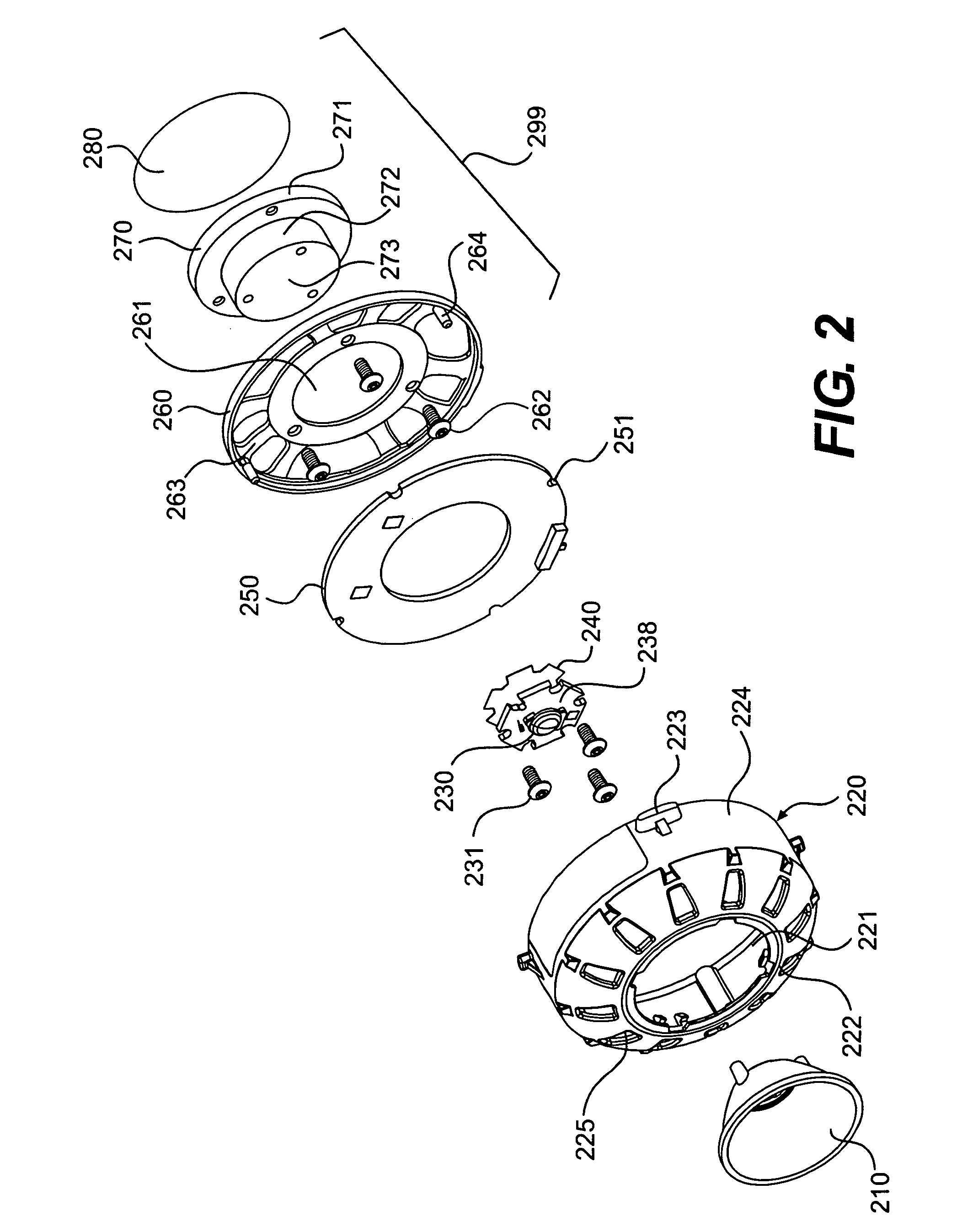

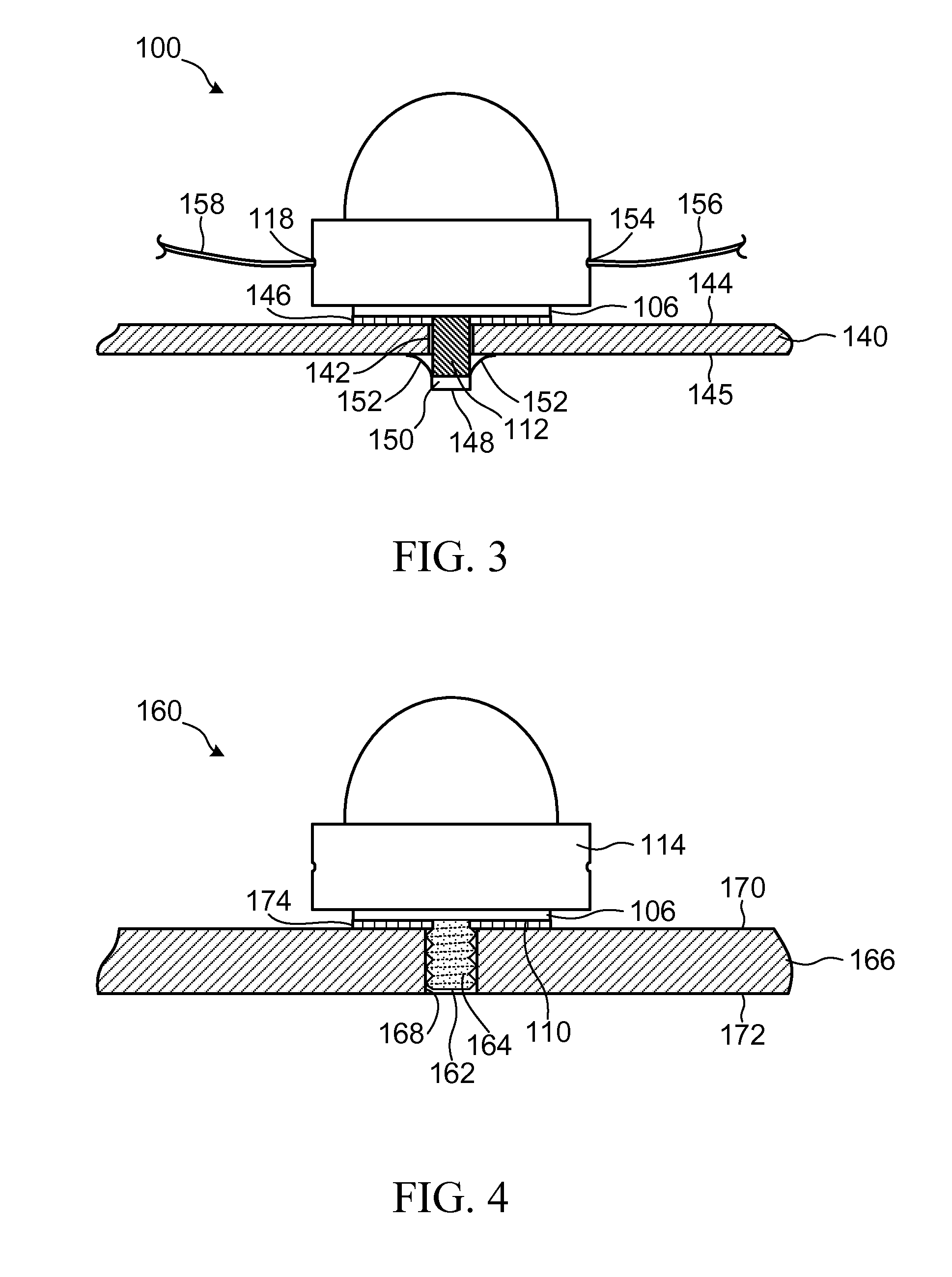

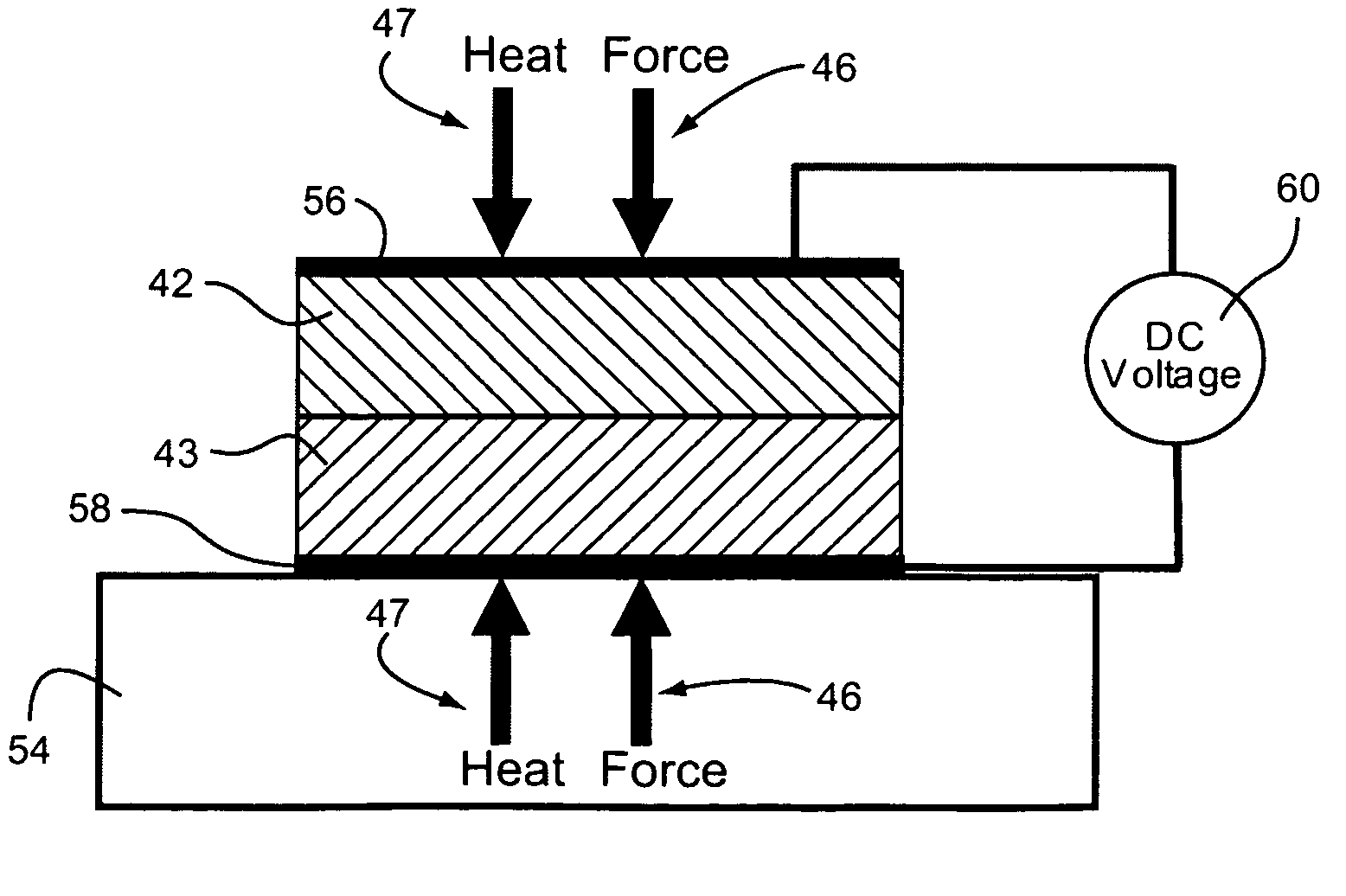

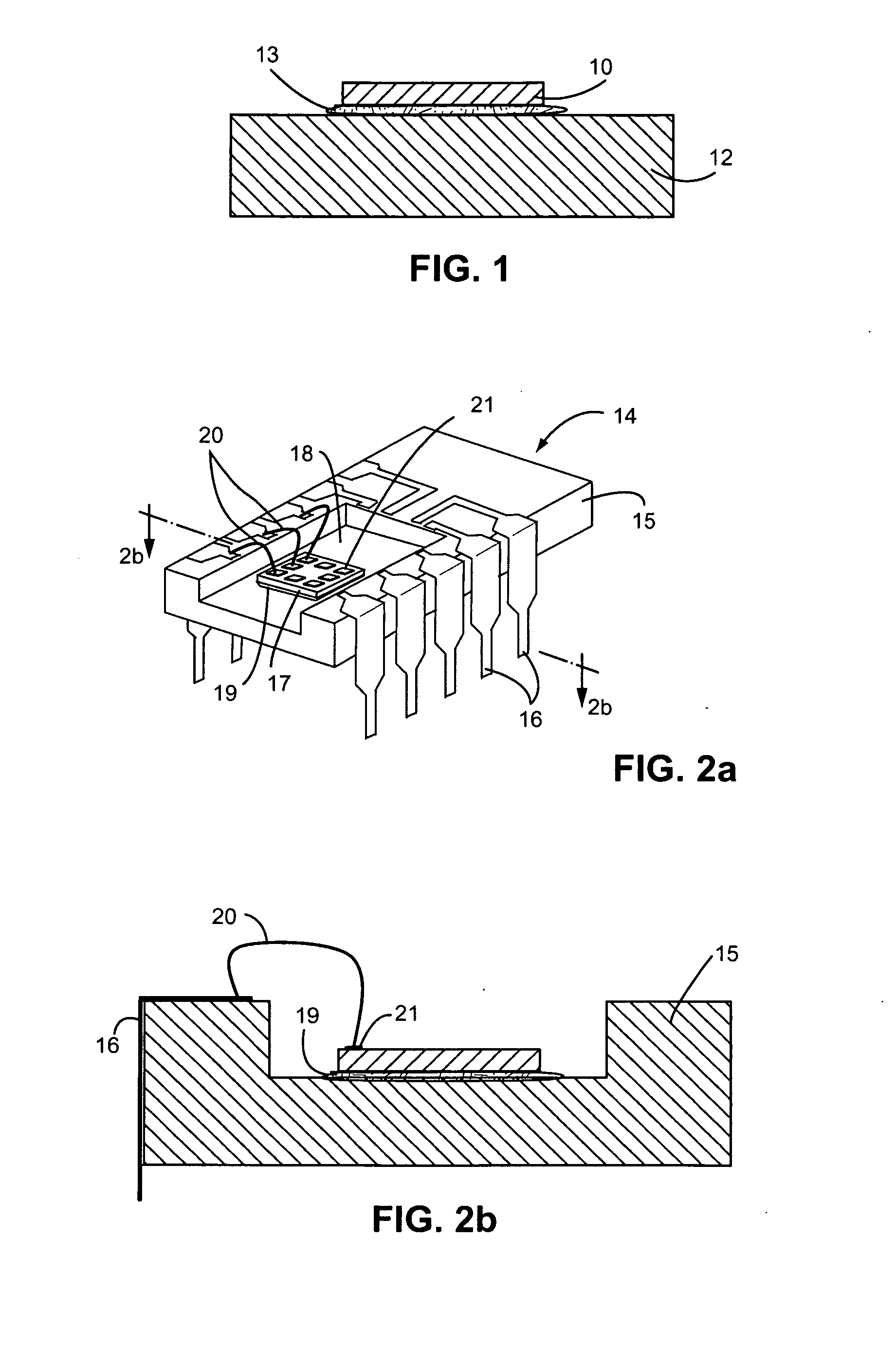

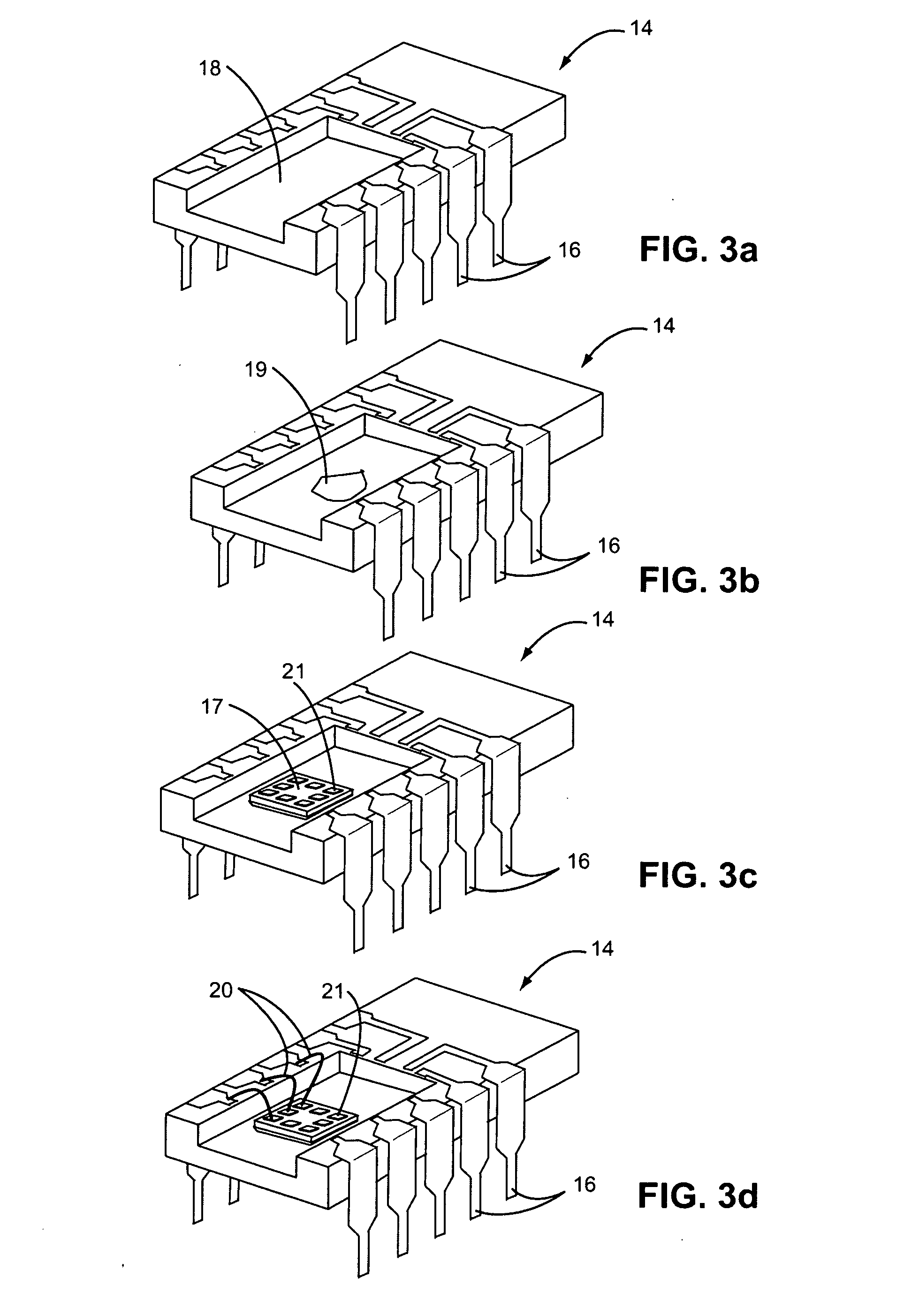

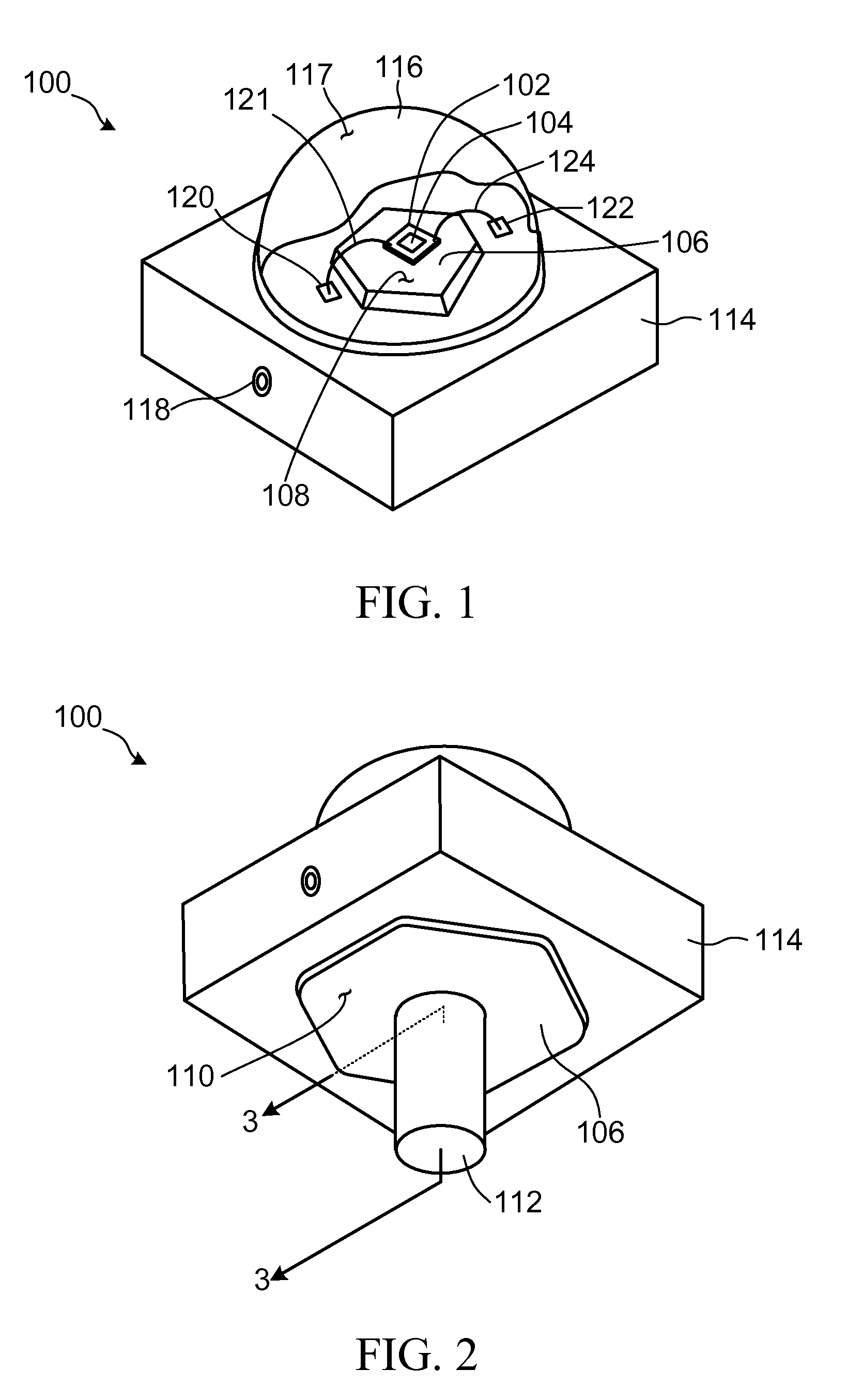

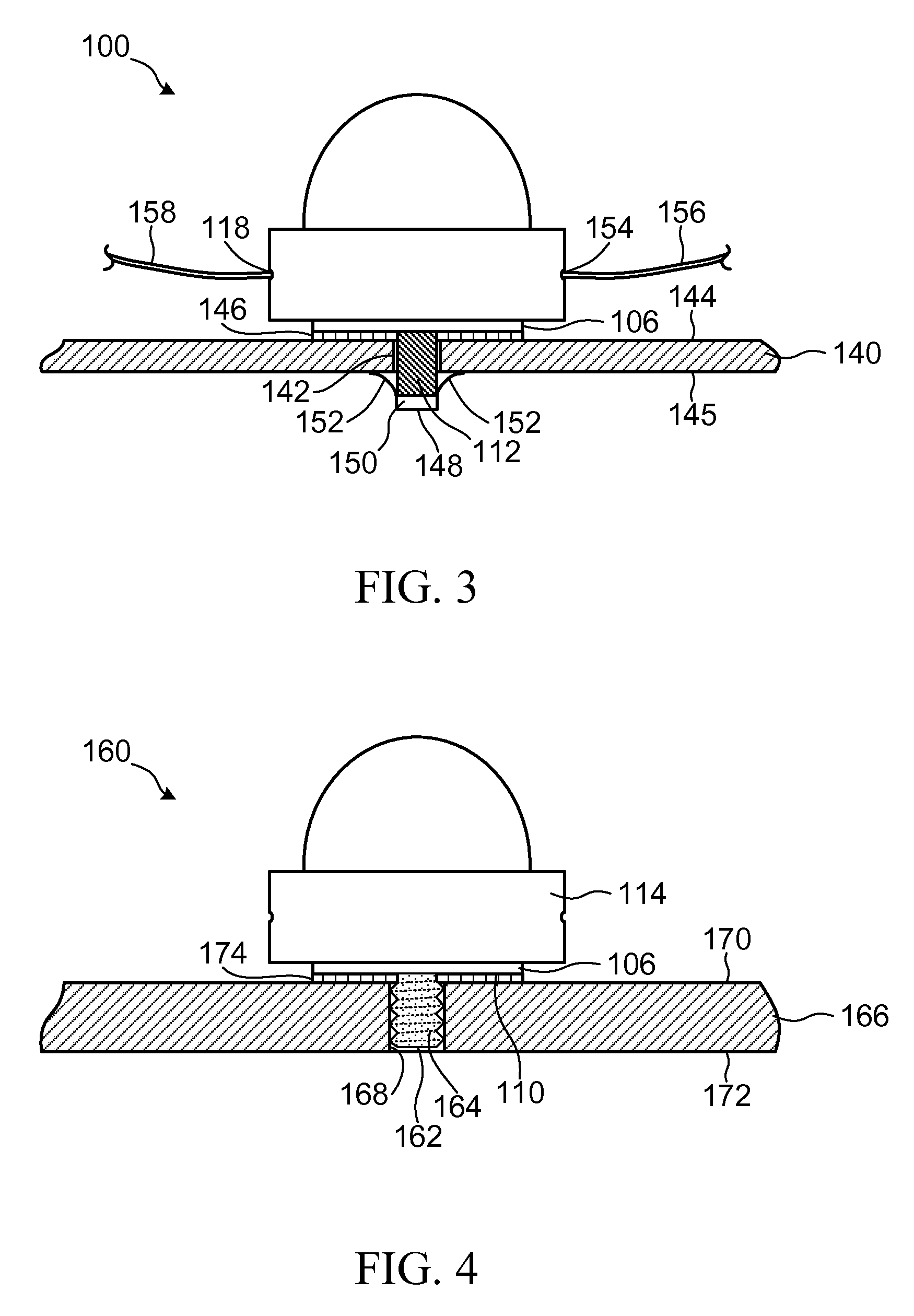

Light fixture assembly and led assembly

InactiveUS20090213595A1Reduce thermal resistanceWave amplification devicesLighting support devicesEffect lightEngineering

A removable light fixture assembly is provided. The light fixture assembly includes an LED lighting element and a compression element. Operation of the compression element from a first position to a second position generates a compression force which reduces thermal impedance between the LED assembly and a thermally-conductive housing.

Owner:KORRUS INC

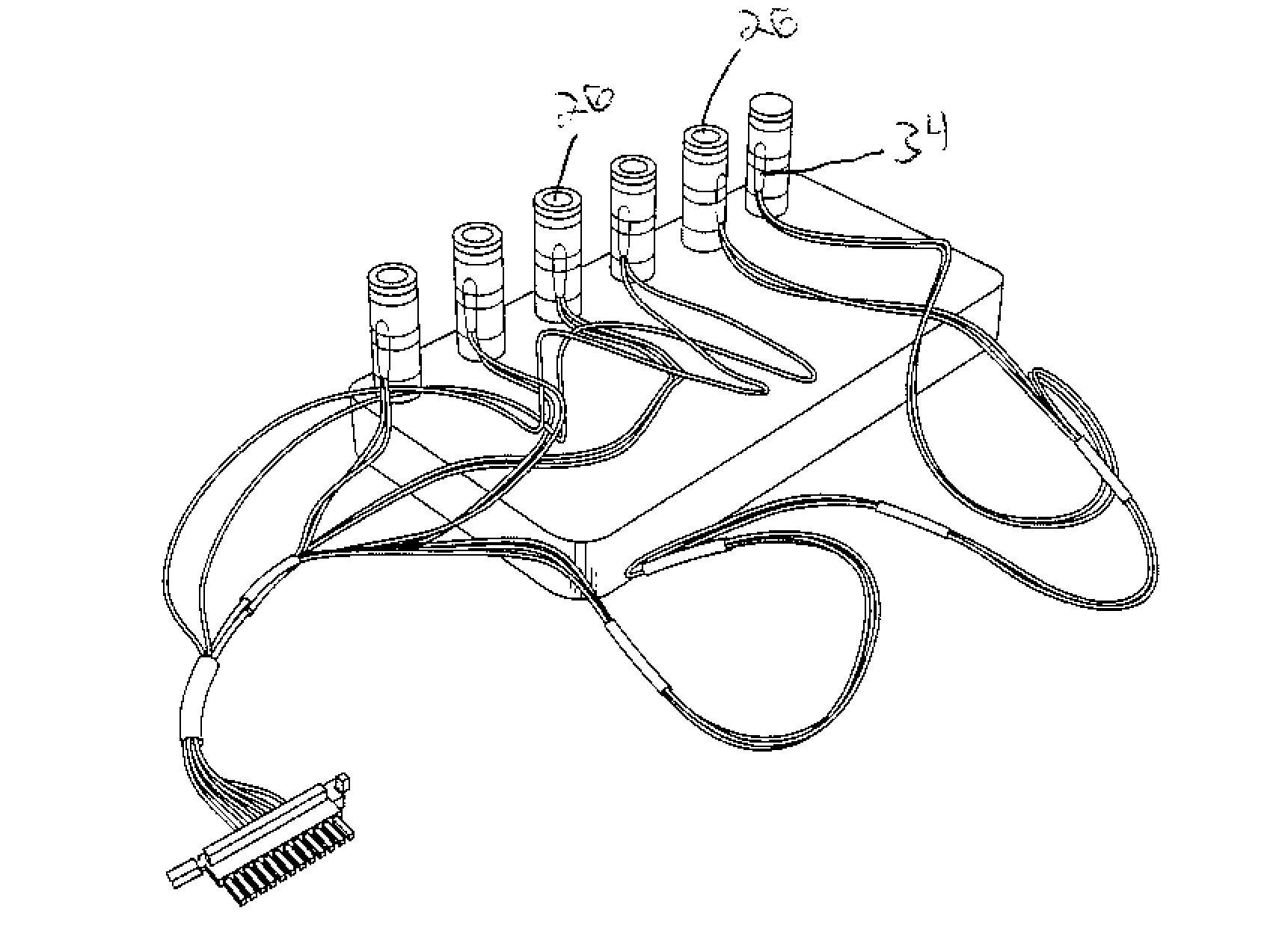

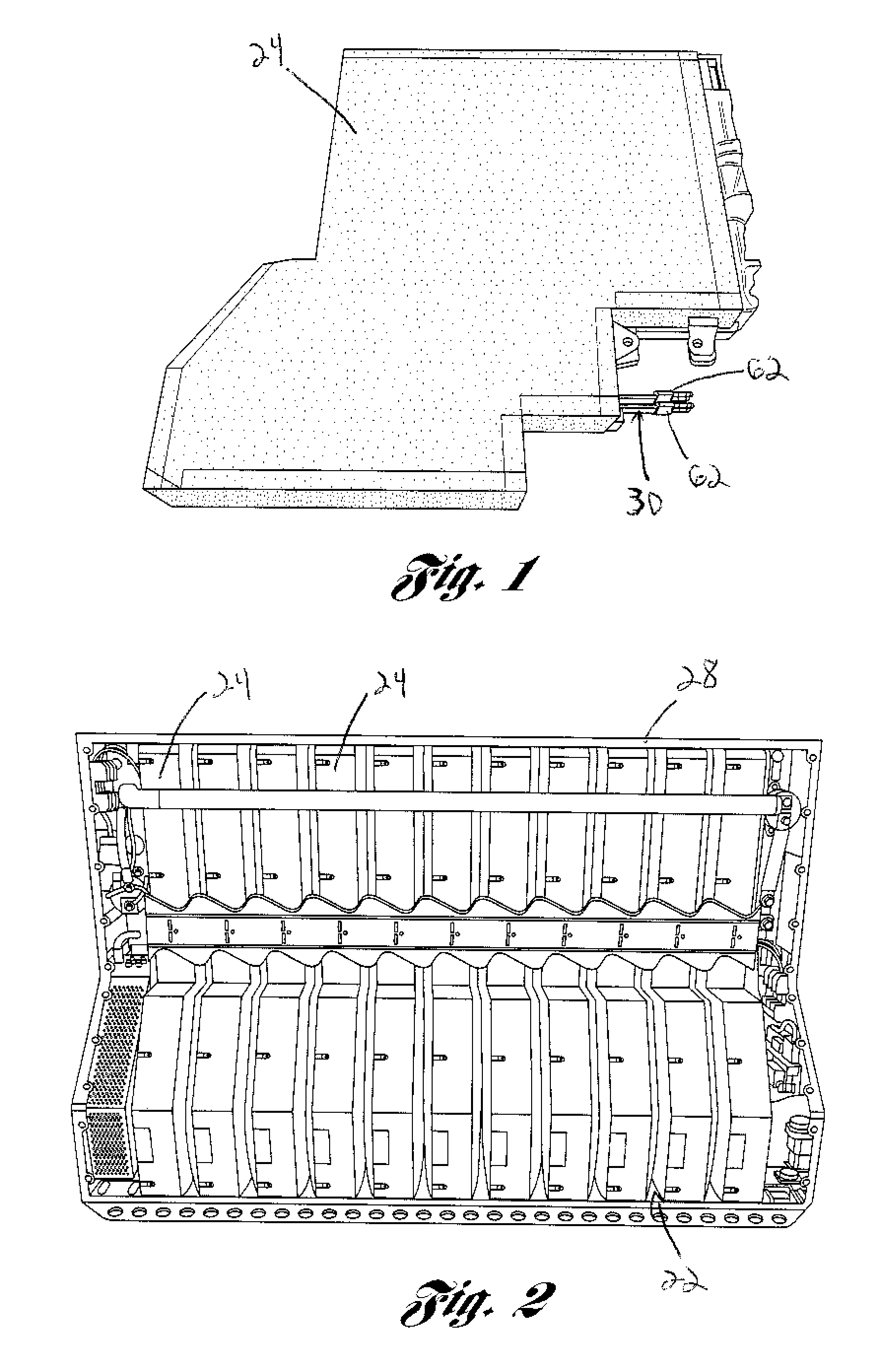

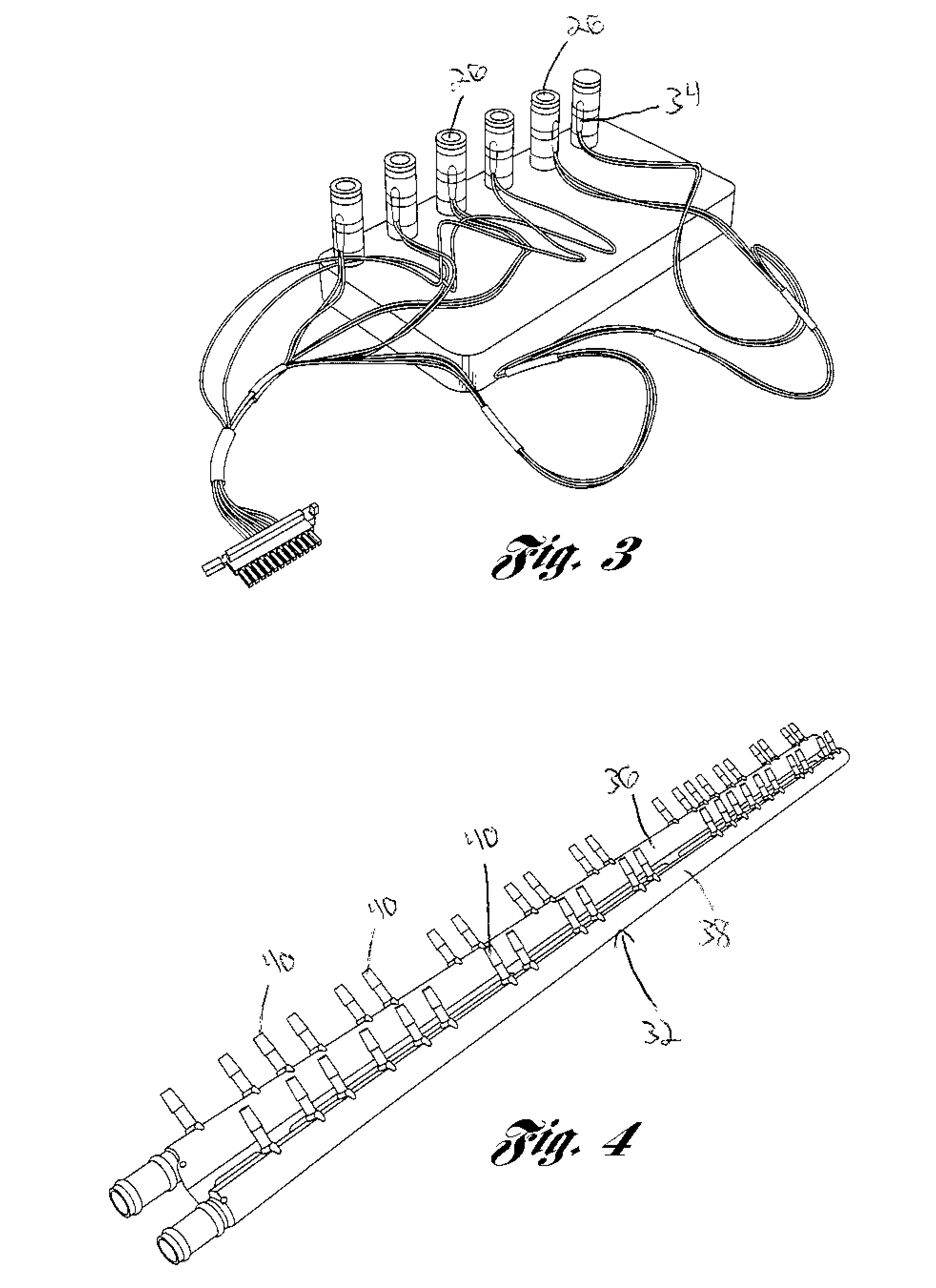

Battery pack thermal management system

InactiveUS20090023056A1Increase thermal massReduce temperature riseAir-treating devicesCell temperature controlElectrical resistance and conductanceThermal management system

A battery pack thermal management system for use in an electric car. The battery pack thermal management system includes a plurality of thermistors connected to a plurality of cells of a battery pack. A battery monitor board is connected to the thermistors. The system also includes a manifold and a plurality of cooling tubes connected to the manifold. A tube seal plug is arranged over an end of the cooling tube and an end fitting is arranged on an end of the cooling tube. The thermal management system will cool the battery pack to predetermined temperatures to increase the longevity of the battery pack within the electric vehicle.

Owner:TESLA INC

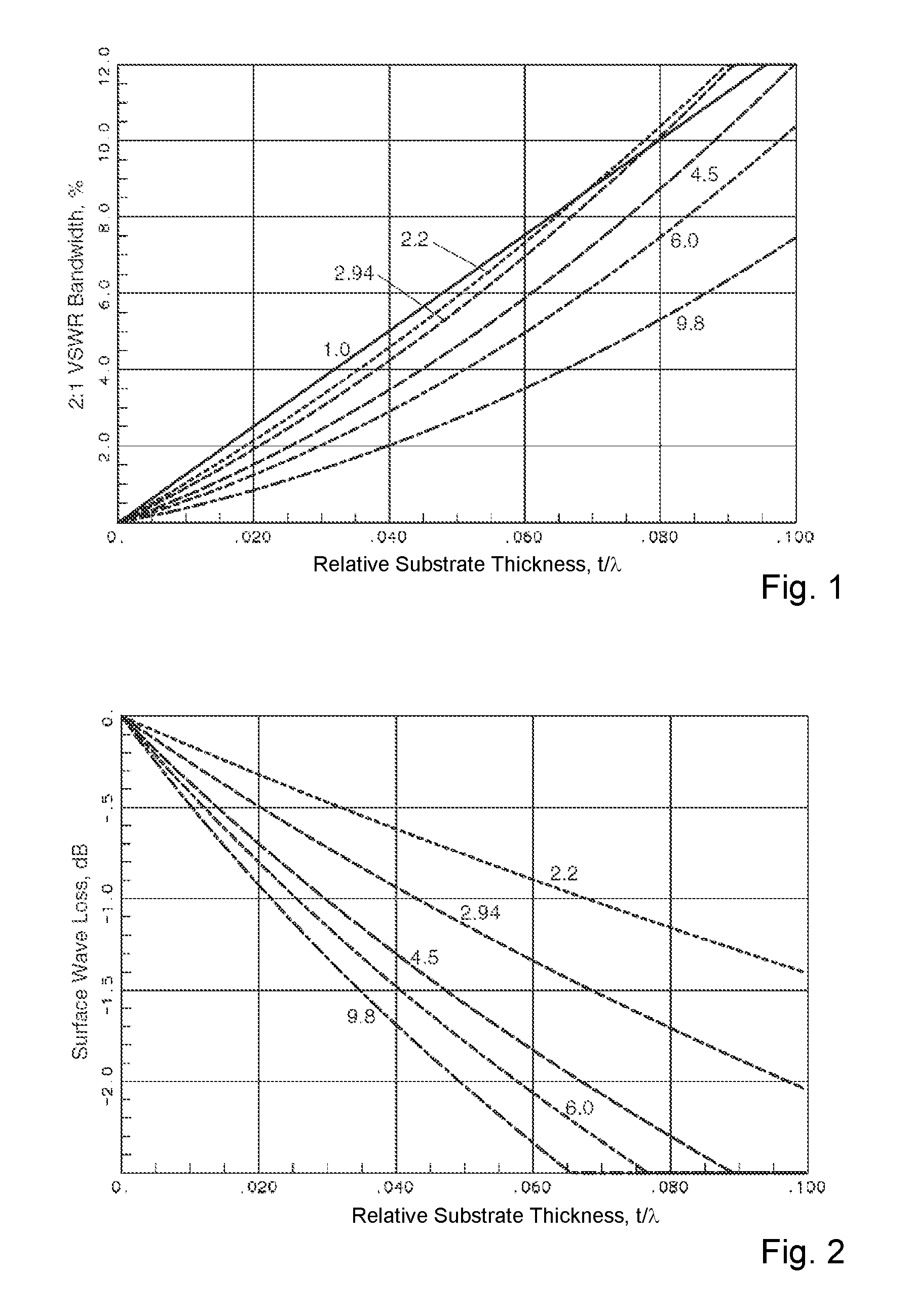

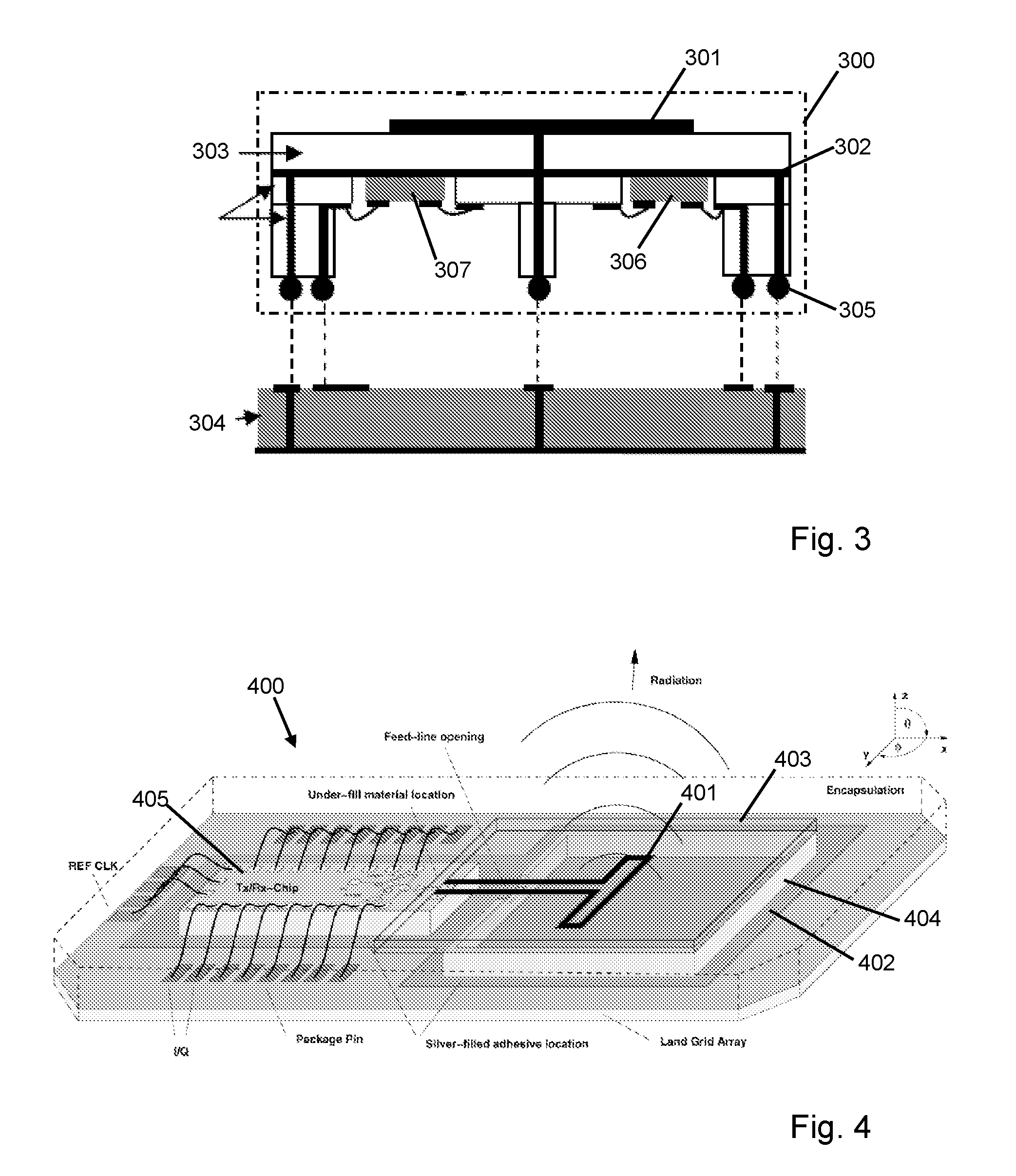

Millimetre-wave radio antenna module

ActiveUS20110285606A1Low costSpace saveSemiconductor/solid-state device detailsAntenna supports/mountingsElectricityEngineering

A millimetre-wave radio antenna module (600) comprising: an antenna substrate (603) having an antenna (602) provided on a face thereof; and a semiconductor die (601) comprising a wireless system IC, the die mounted on a face of the antenna substrate and configured to provide a signal to the antenna, wherein a ball grid array (605) is formed on a face of the antenna substrate for mounting the antenna module to a circuit board, the ball grid array being configured to define an air dielectric gap (606) between the antenna and the circuit board.

Owner:NXP BV

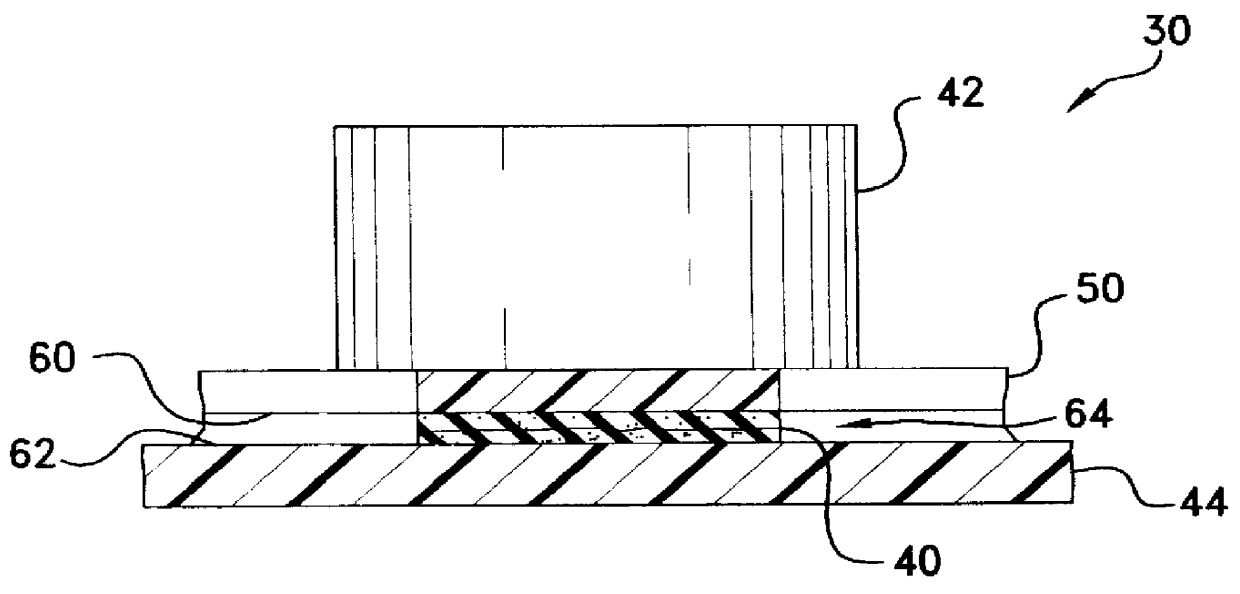

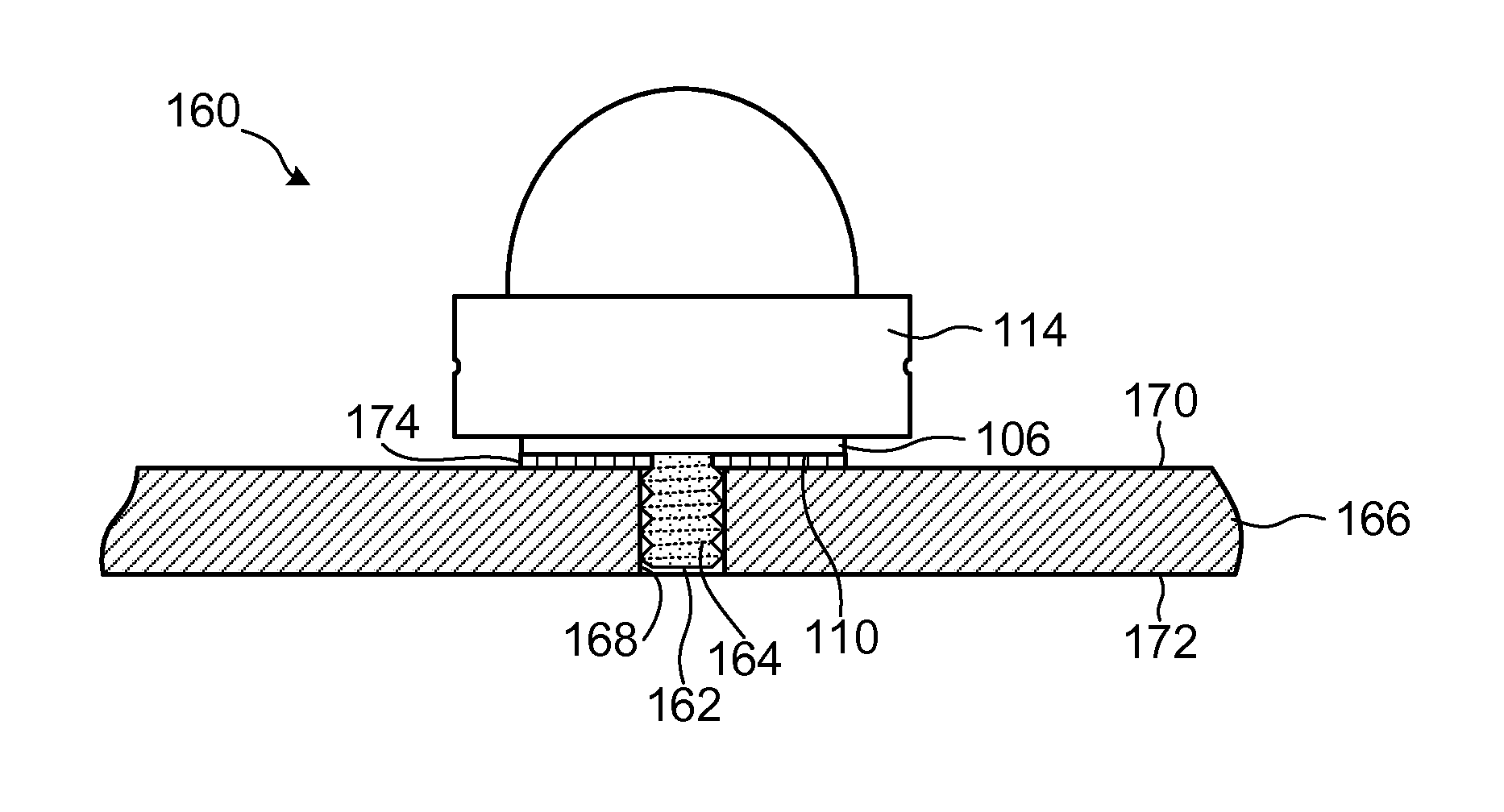

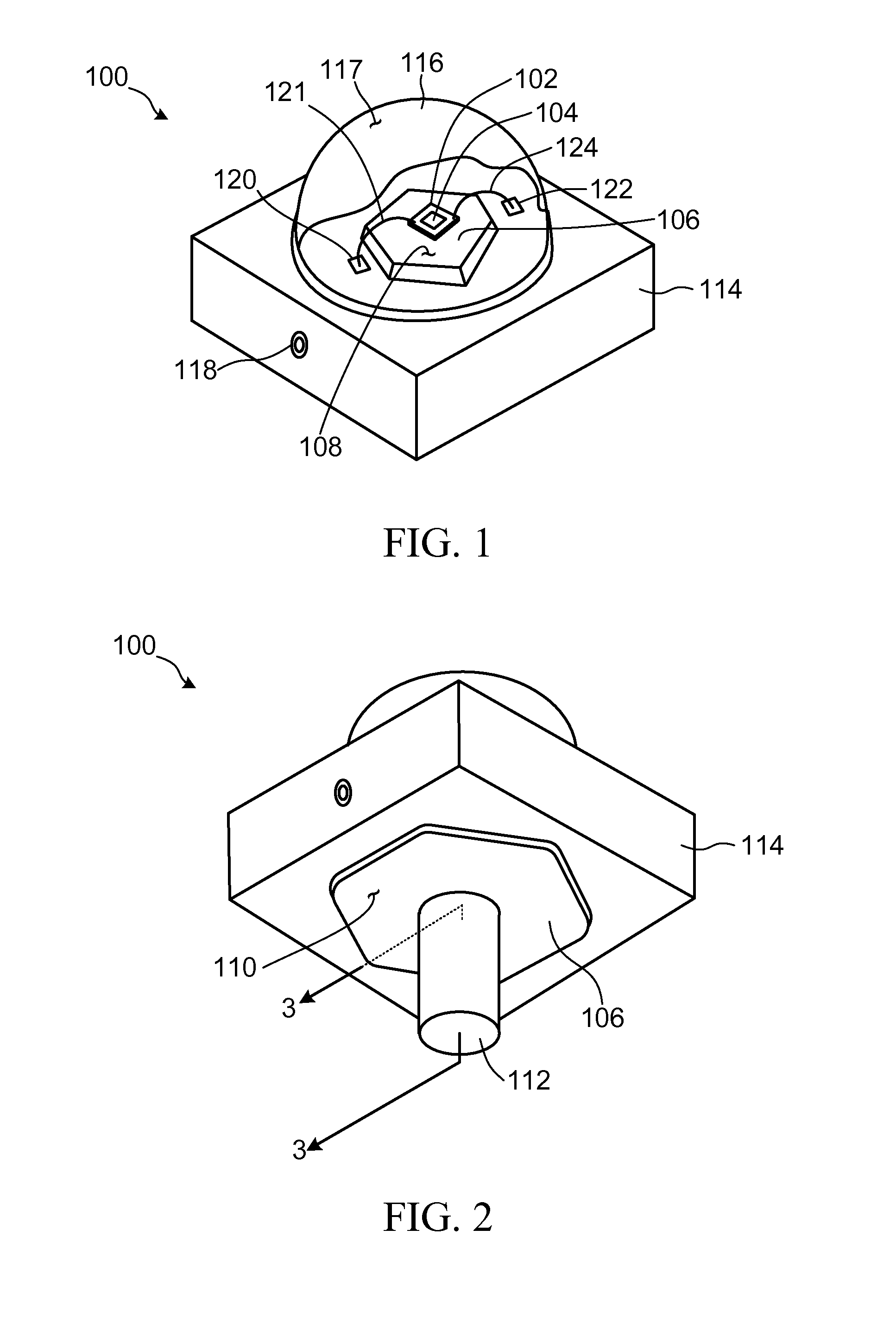

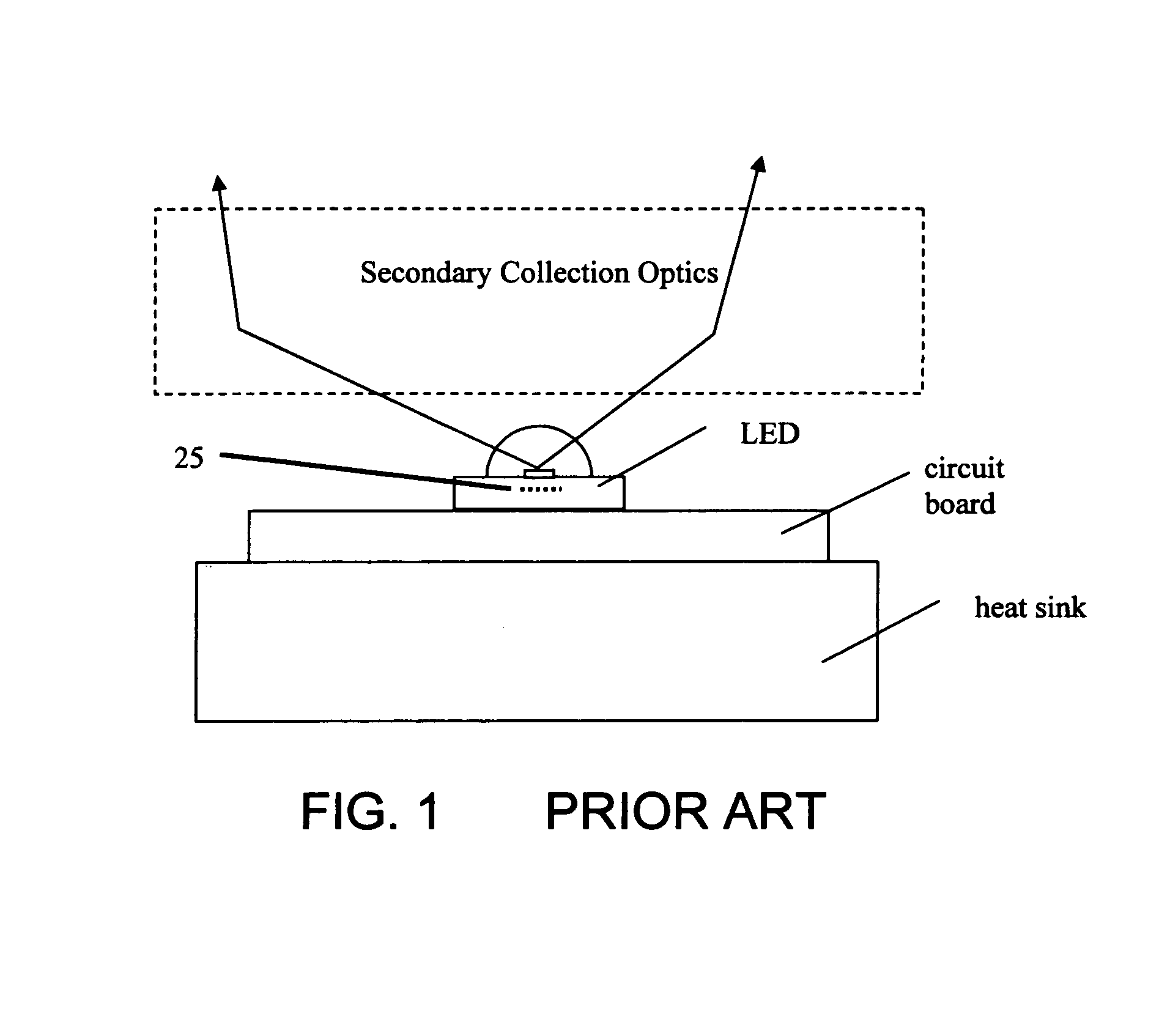

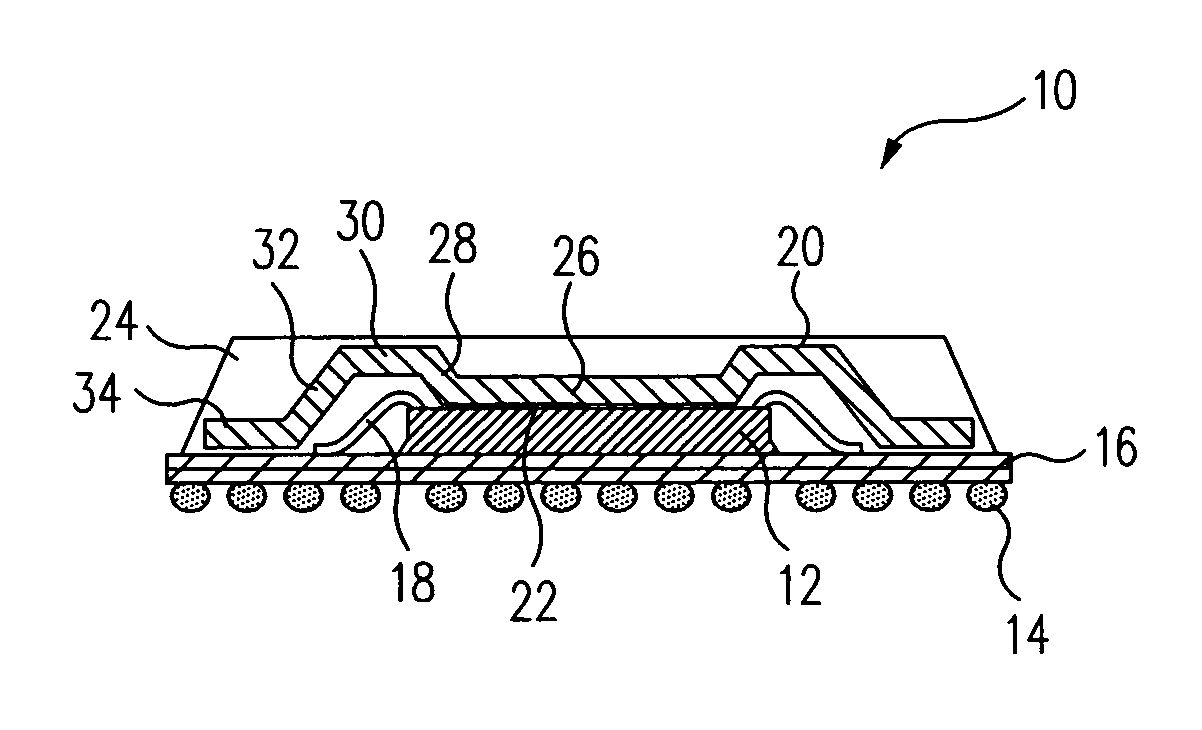

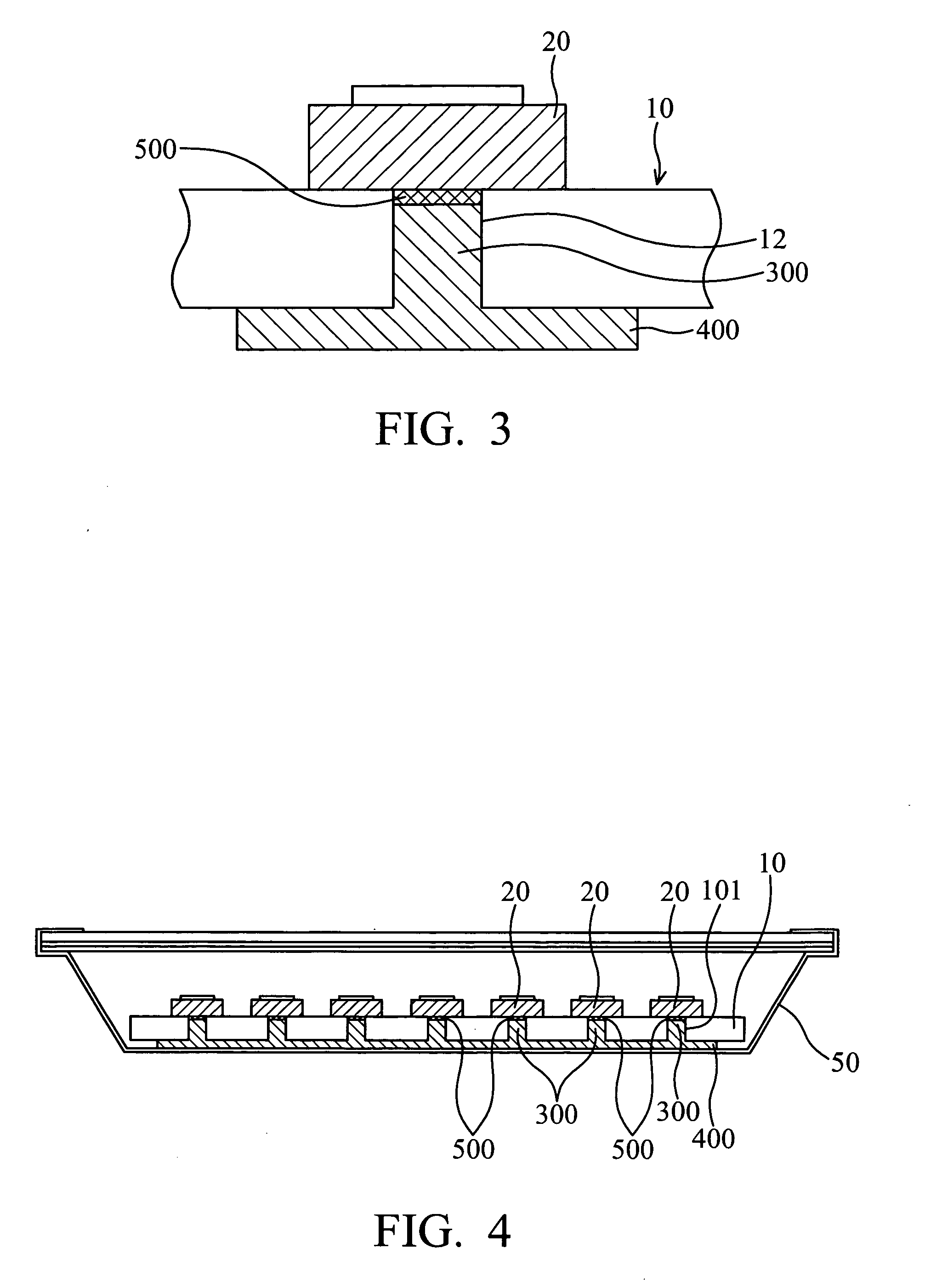

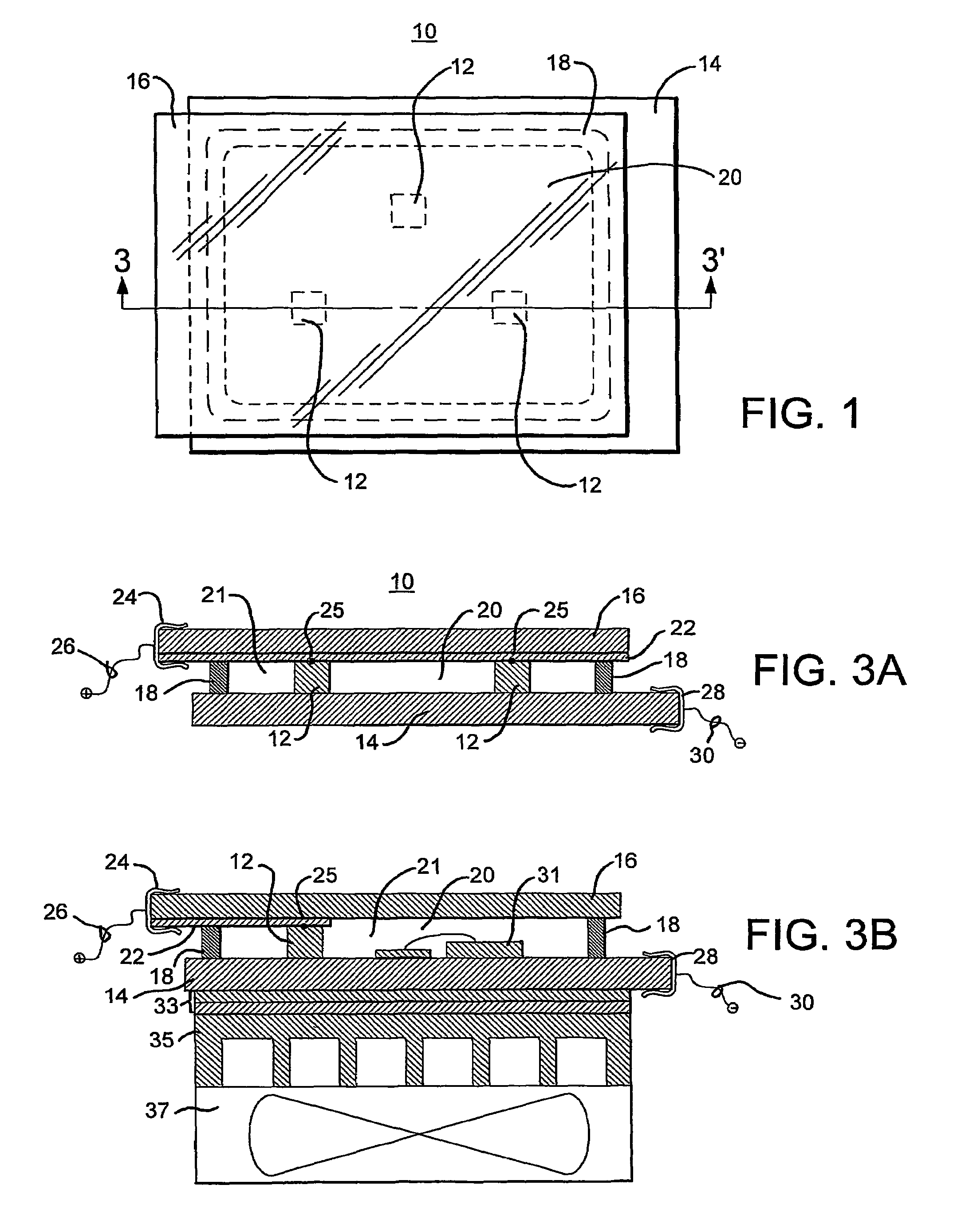

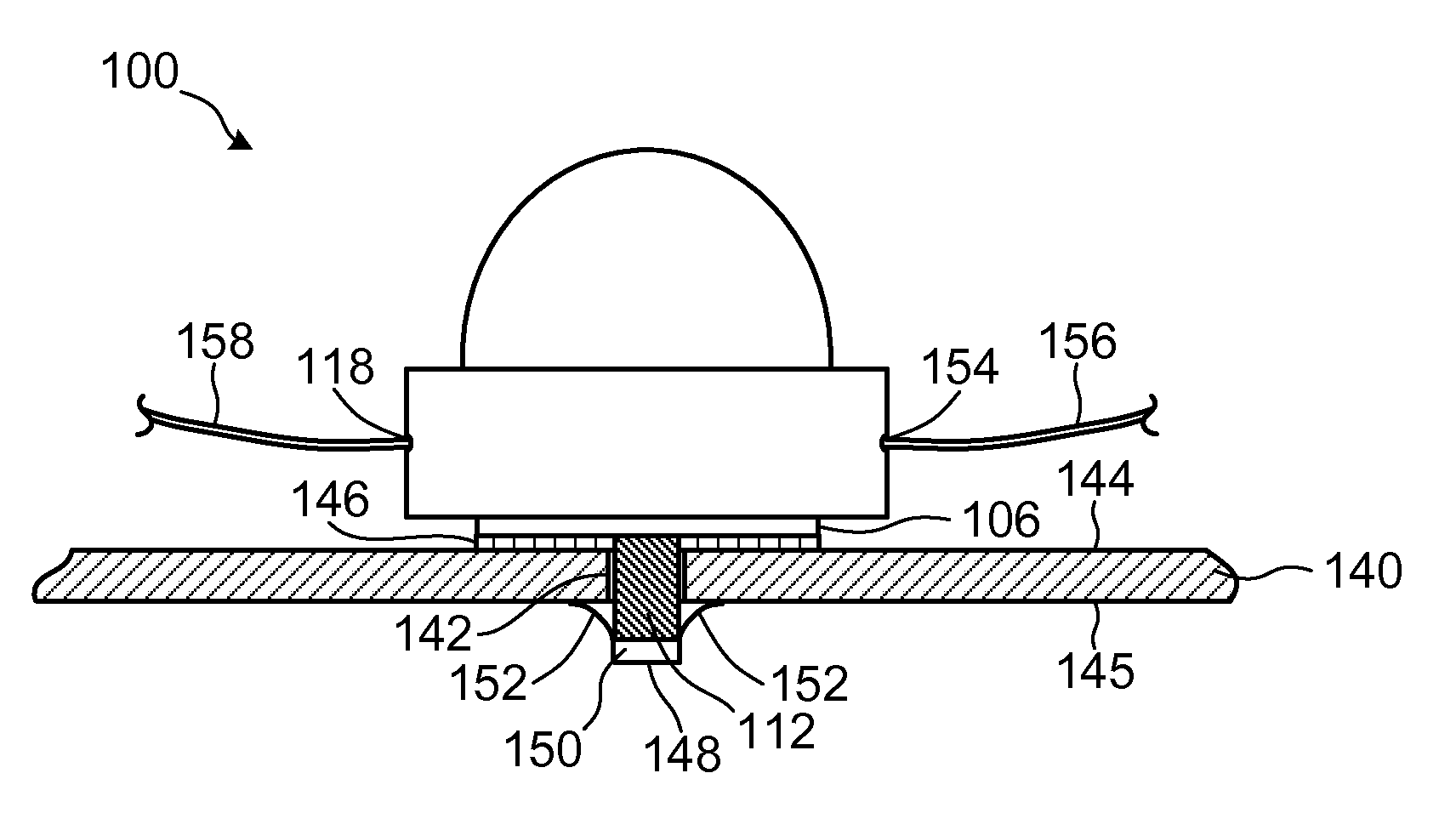

Light Emitting Diode for Mounting to a Heat Sink

ActiveUS20090154166A1Reduce thermal resistancePoint-like light sourceElectric circuit arrangementsAdhesiveEngineering

A light emitting diode (LED) apparatus for mounting to a heat sink having a front surface with an opening therein is disclosed. The apparatus includes a sub-mount, at least one LED die mounted on the sub-mount, and a thermally conductive slug having first and second areas. The first area is thermally coupled to the sub-mount and the second area has a post protruding outwardly therefrom. The post is operably configured to be received in the opening in the heat sink and to secure the LED apparatus to the heat sink such that the second area is thermally coupled to the front surface of the heat sink. Other embodiments for mounting an LED apparatus utilizing adhesive thermally conductive material, spring clips, insertion snaps, or welding are also disclosed.

Owner:LUMILEDS

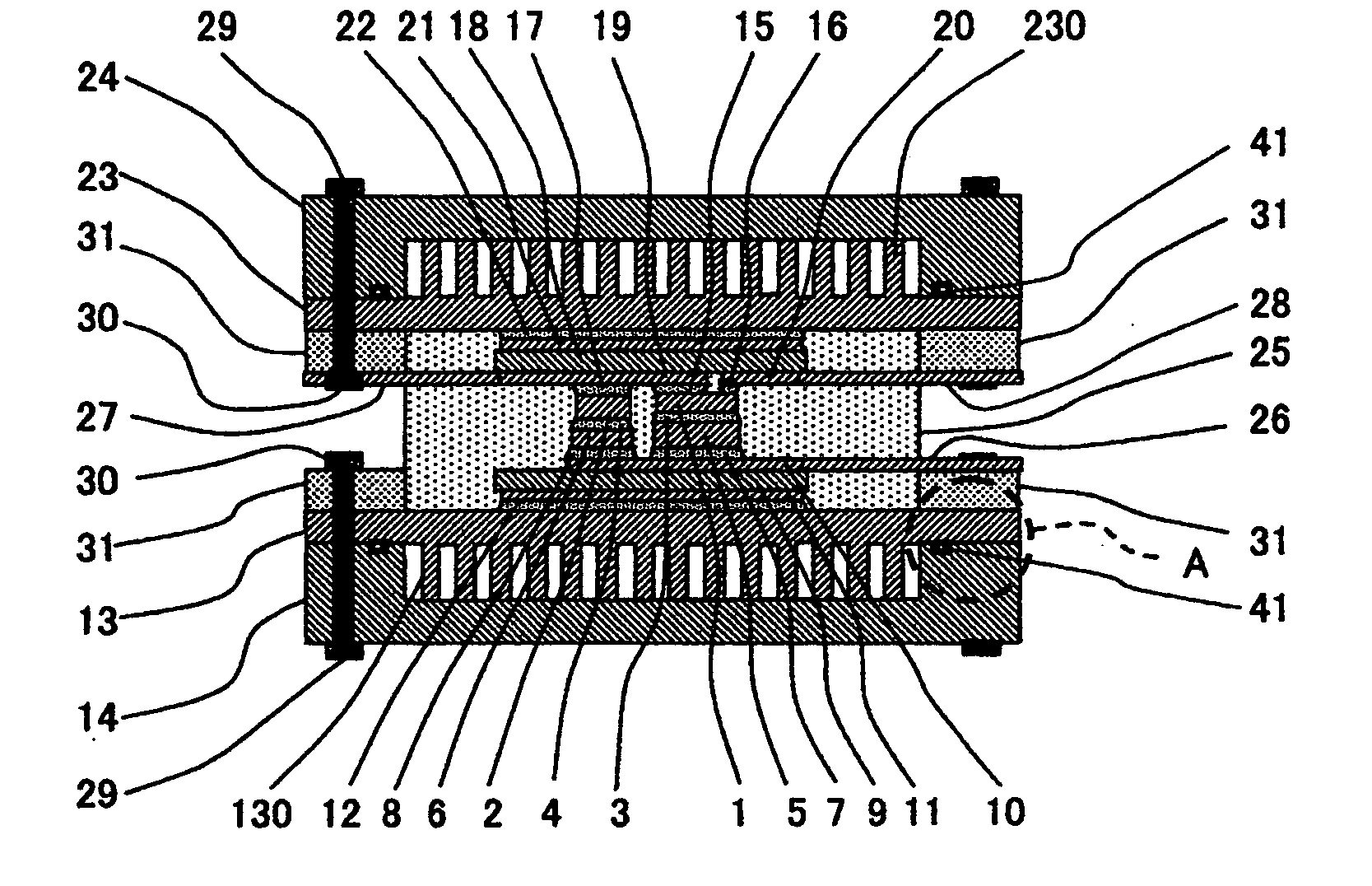

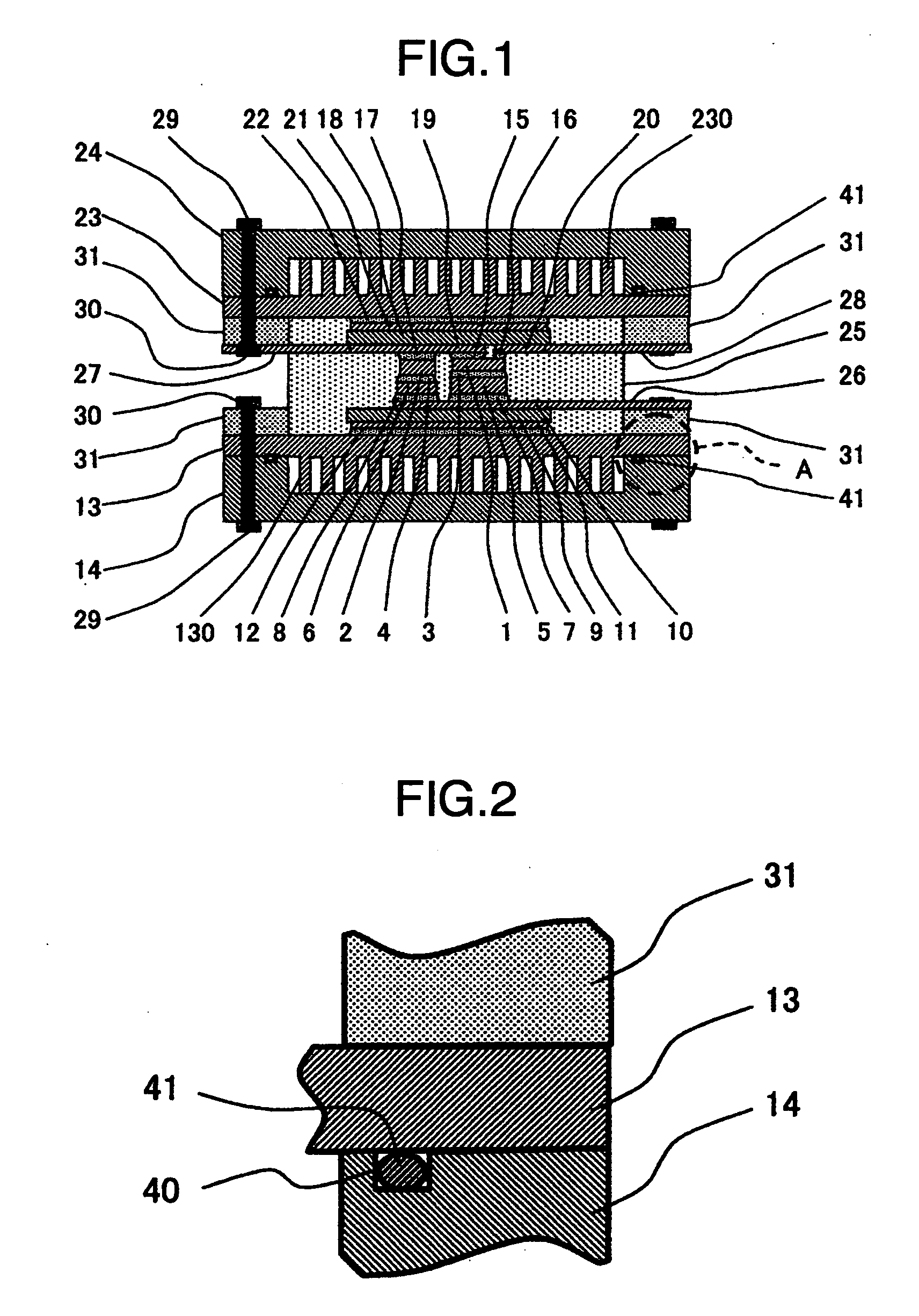

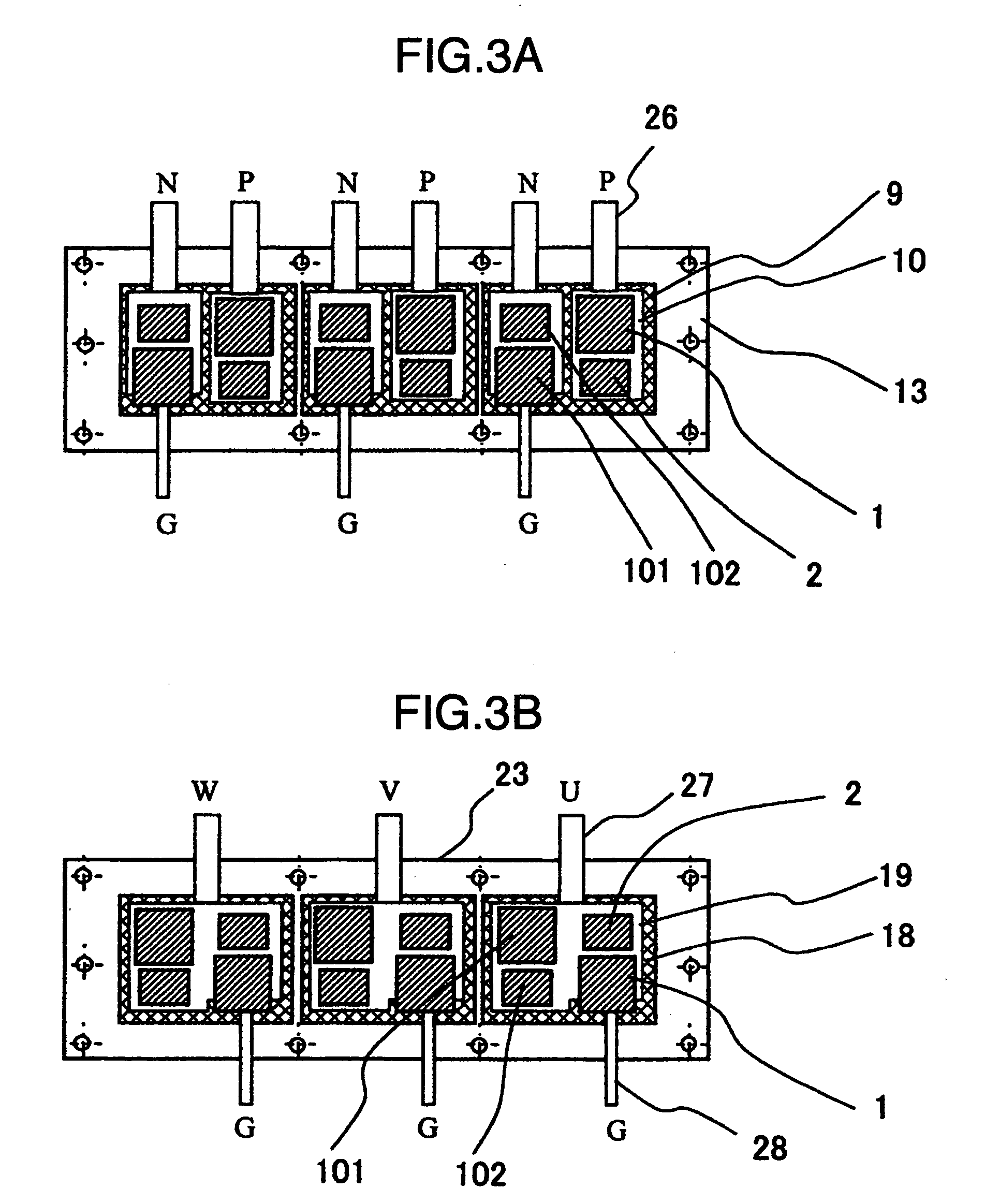

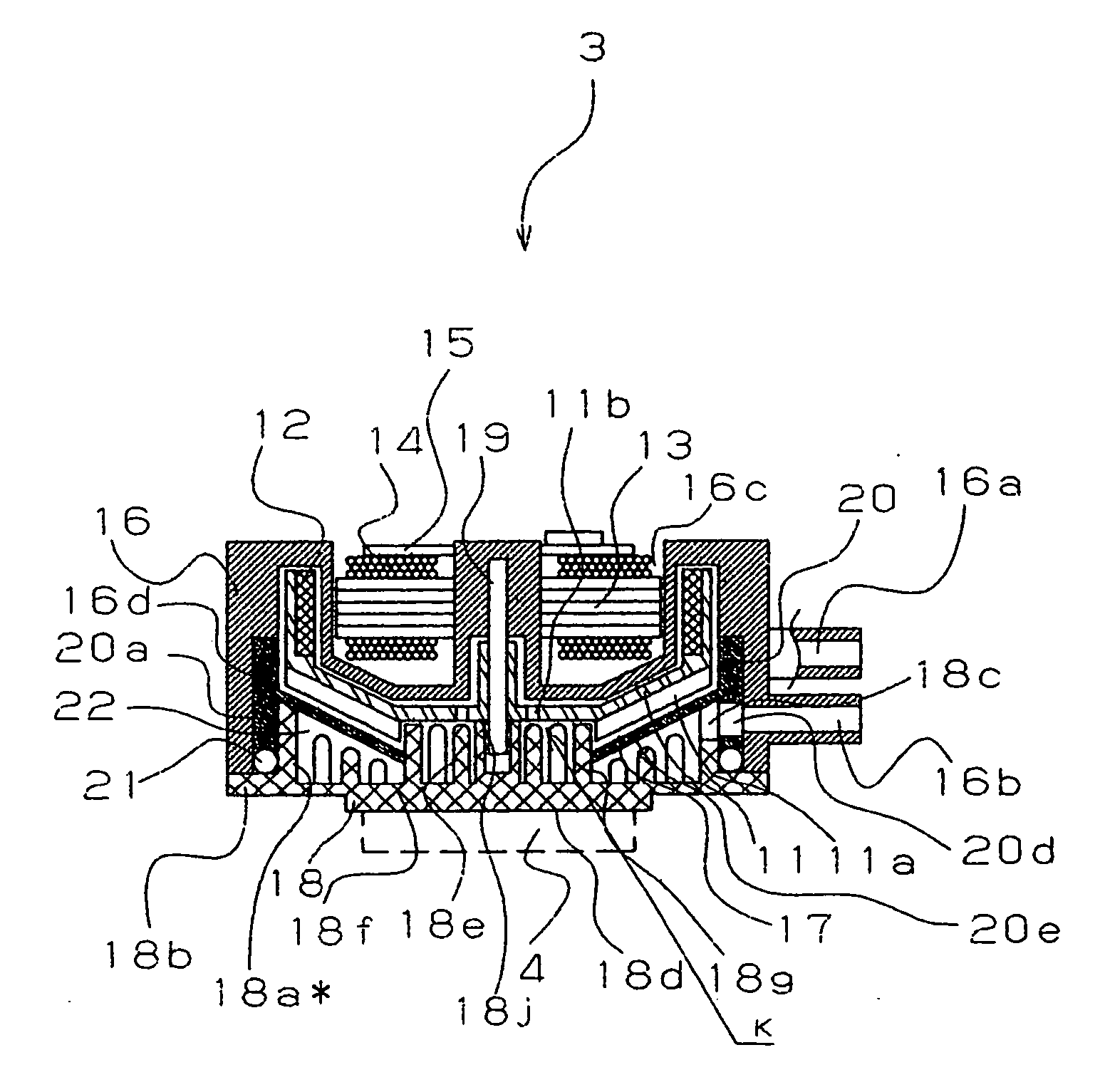

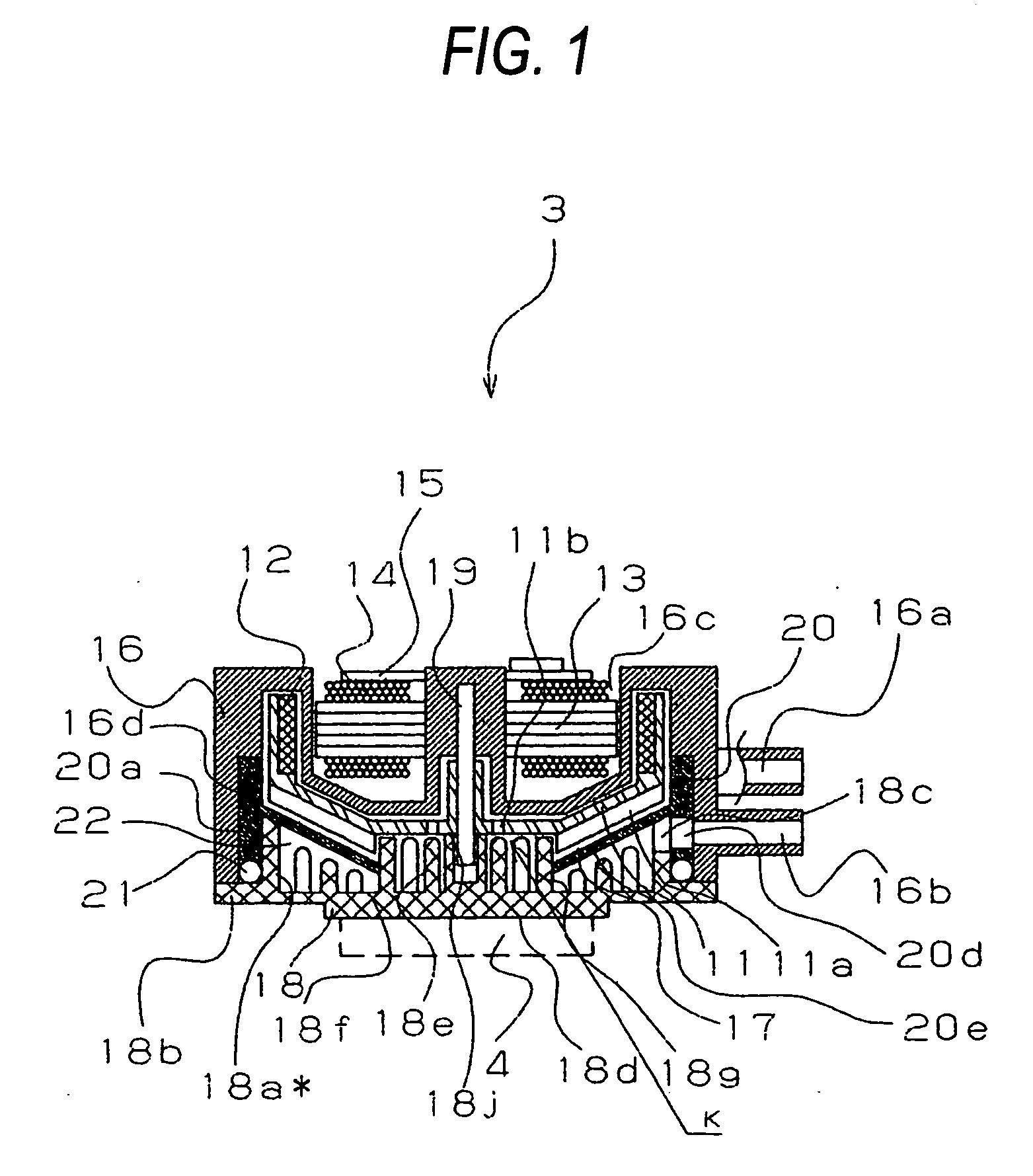

Power Semiconductor Module

InactiveUS20080224303A1Improve cooling effectThermal resistanceSemiconductor/solid-state device detailsConversion constructional detailsSemiconductor chipEngineering

A power semiconductor module with its thermal resistance and overall size reduced. Insulating substrates with electrode metal layers disposed thereon are joined to both the surfaces of a power semiconductor chip by using, for example, soldering. Metal layers are disposed also on the reverse surfaces of the insulating substrates and the metal layers are joined to the heat spreaders by using brazing. Heat radiating fins are provided on the heat radiating surface of at least one of the heat spreaders. The heat radiating side of each of the heat spreaders is covered by a casing to form a refrigerant chamber through which refrigerant flows to remove heat transmitted from the semiconductor chip to the heat spreader.

Owner:HITACHI LTD

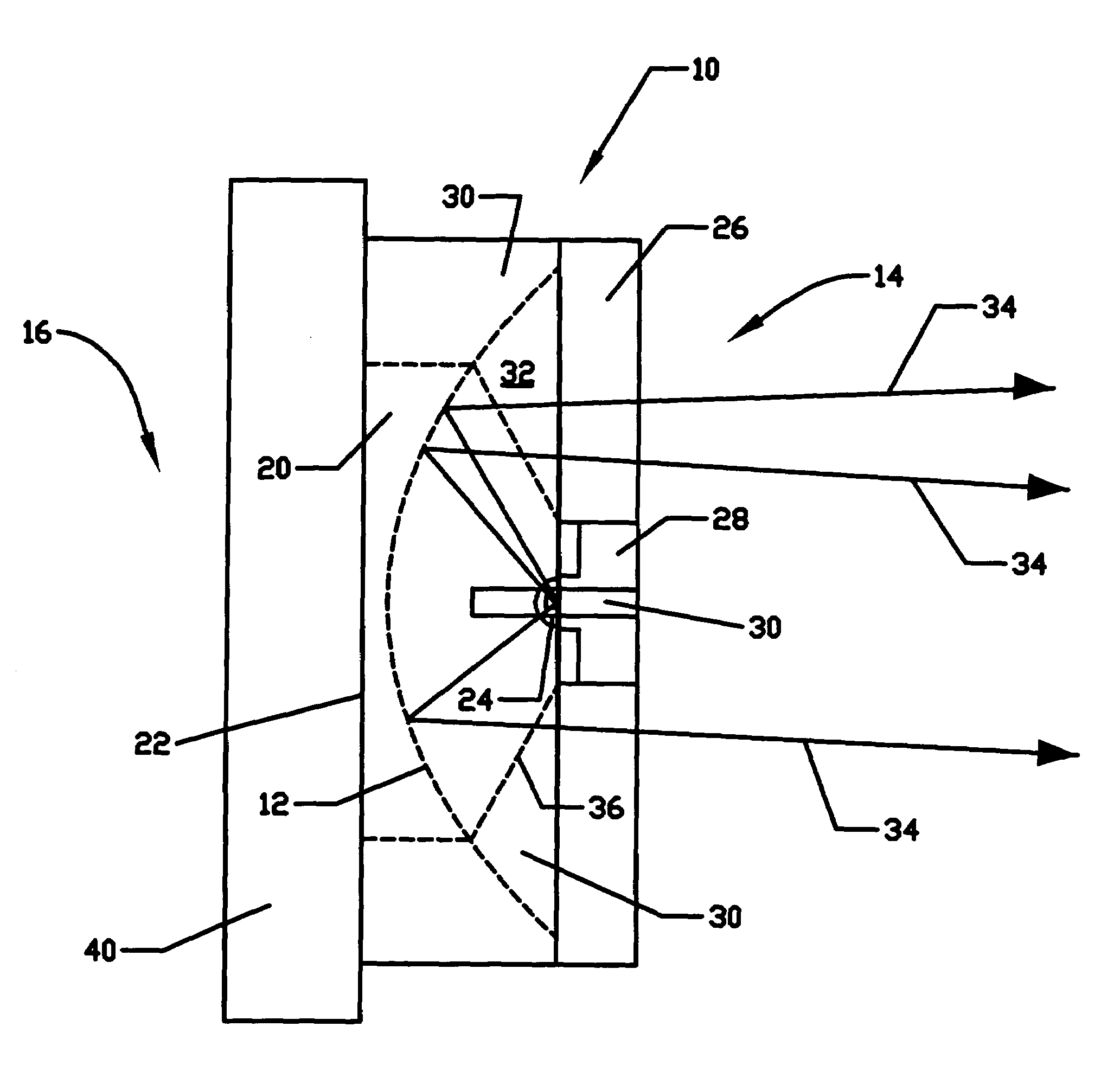

Back-reflecting LED light source

ActiveUS7246921B2Reduce thermal resistancePoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

An LED light source using back-reflecting collection optics with a supporting structure and heat sink to block only a small amount of light. A reflector has a front and back side with an LED positioned on the front side of the reflector. A heat conducting body is positioned at least partially between the reflector and the LED. The heat conducting body provides a pathway for heat to flow from the LED toward the back side of the reflector.

Owner:IDEAL IND LIGHTING LLC

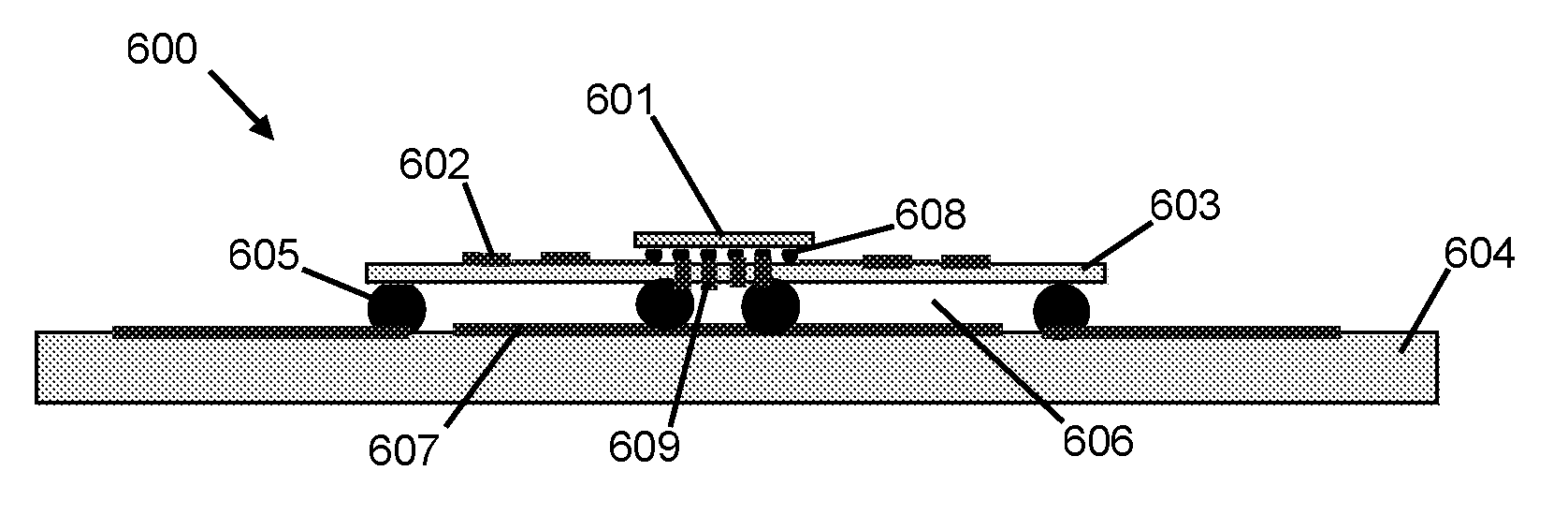

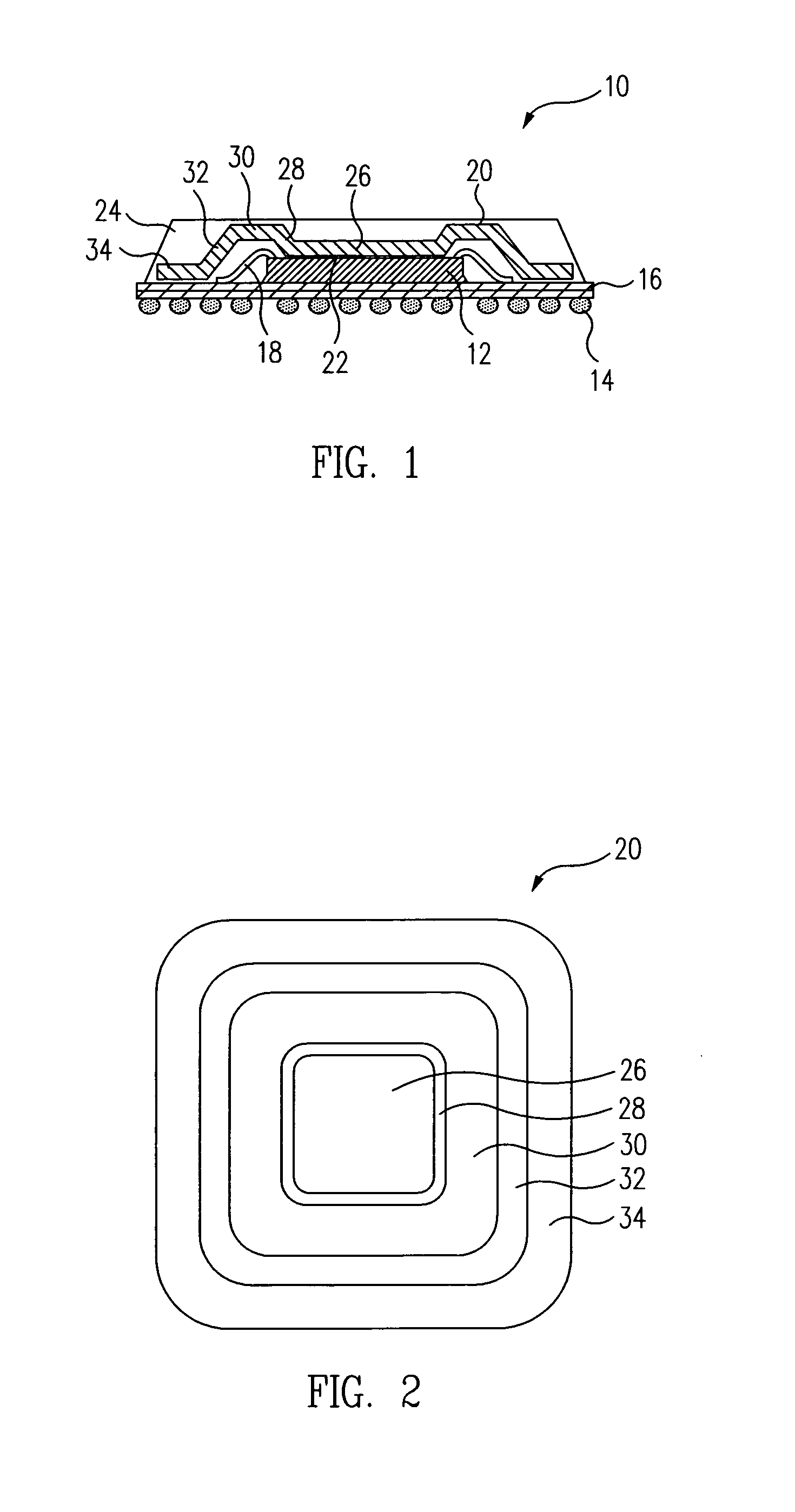

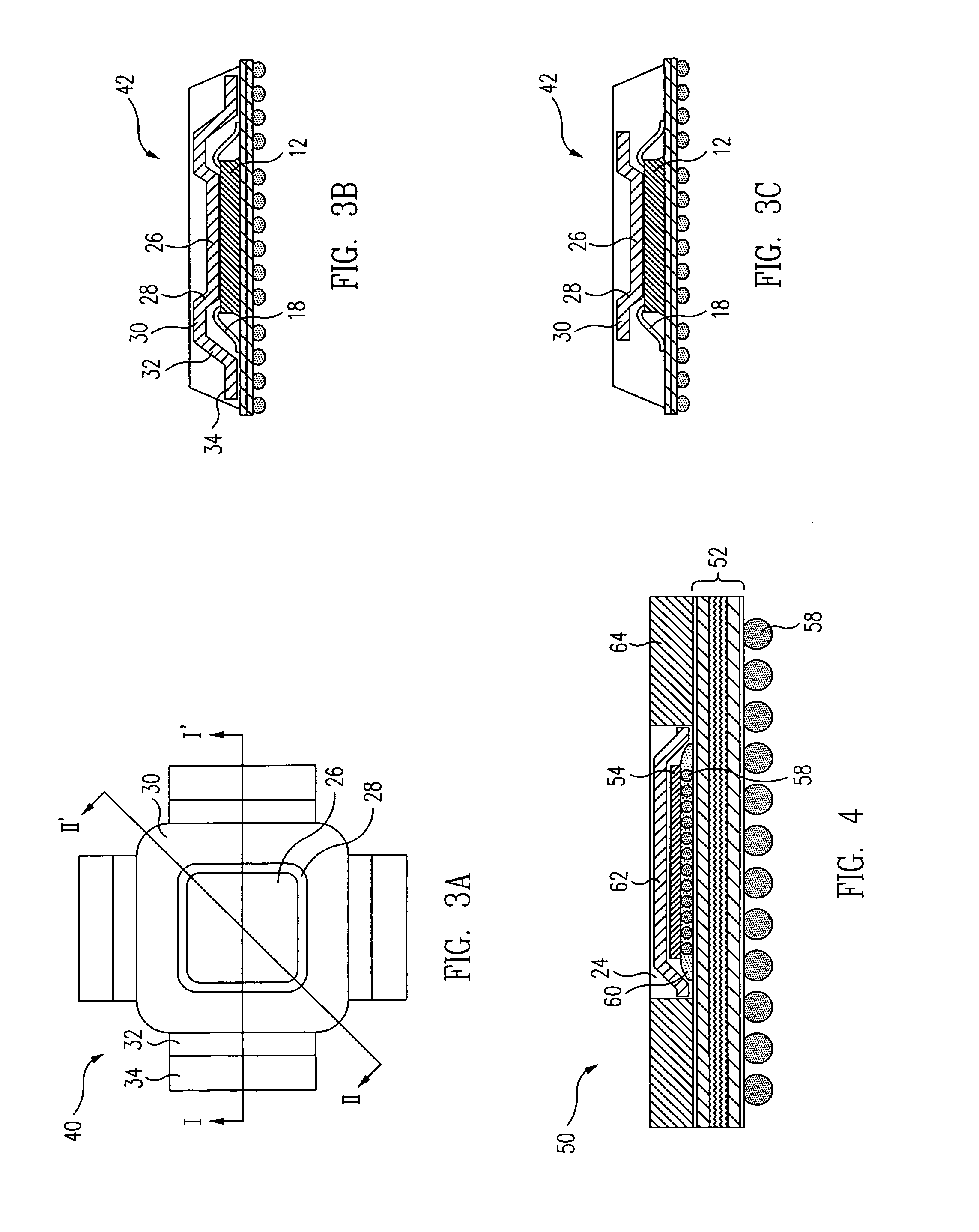

Embedded heat spreader ball grid array

InactiveUS7126218B1Reduce thermal resistanceSacrificing thermal performanceSemiconductor/solid-state device detailsSolid-state devicesInterconnectionBall grid array

A heat slug or spreader is attached directly to a surface of the die in a ball grid array (BGA) package. The heat spreader roughly conforms to the topological profile of the die, underlying substrate, and electrical interconnections between the die and the substrate, such as bond wires. The outer portion of the heat spreader substantially cover the outer portion of the substrate, or alternatively, cover only those portions extending in laterally from the sides of the chip and not the corners. An encapsulant completely covers the heat spreader and die.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

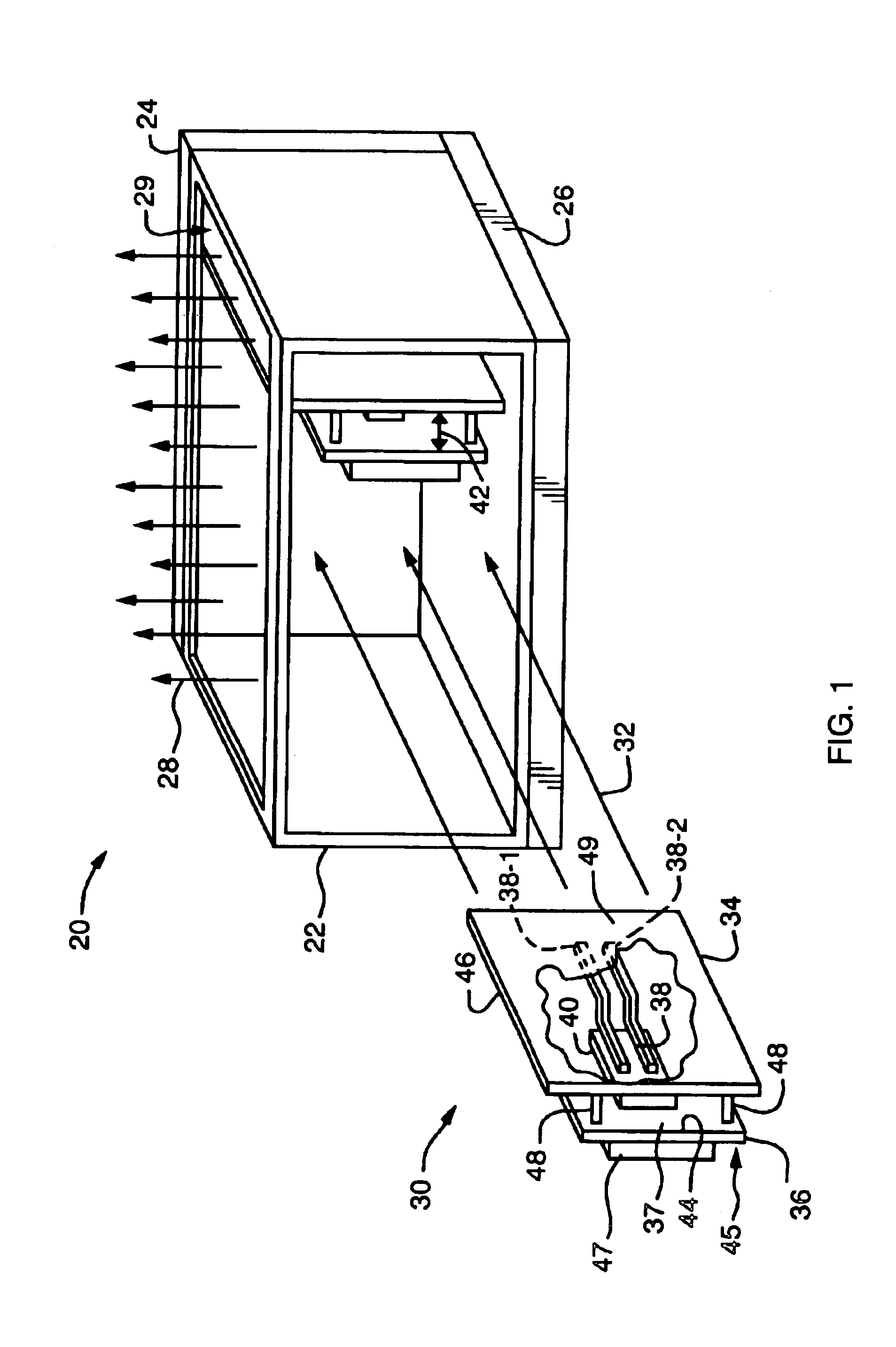

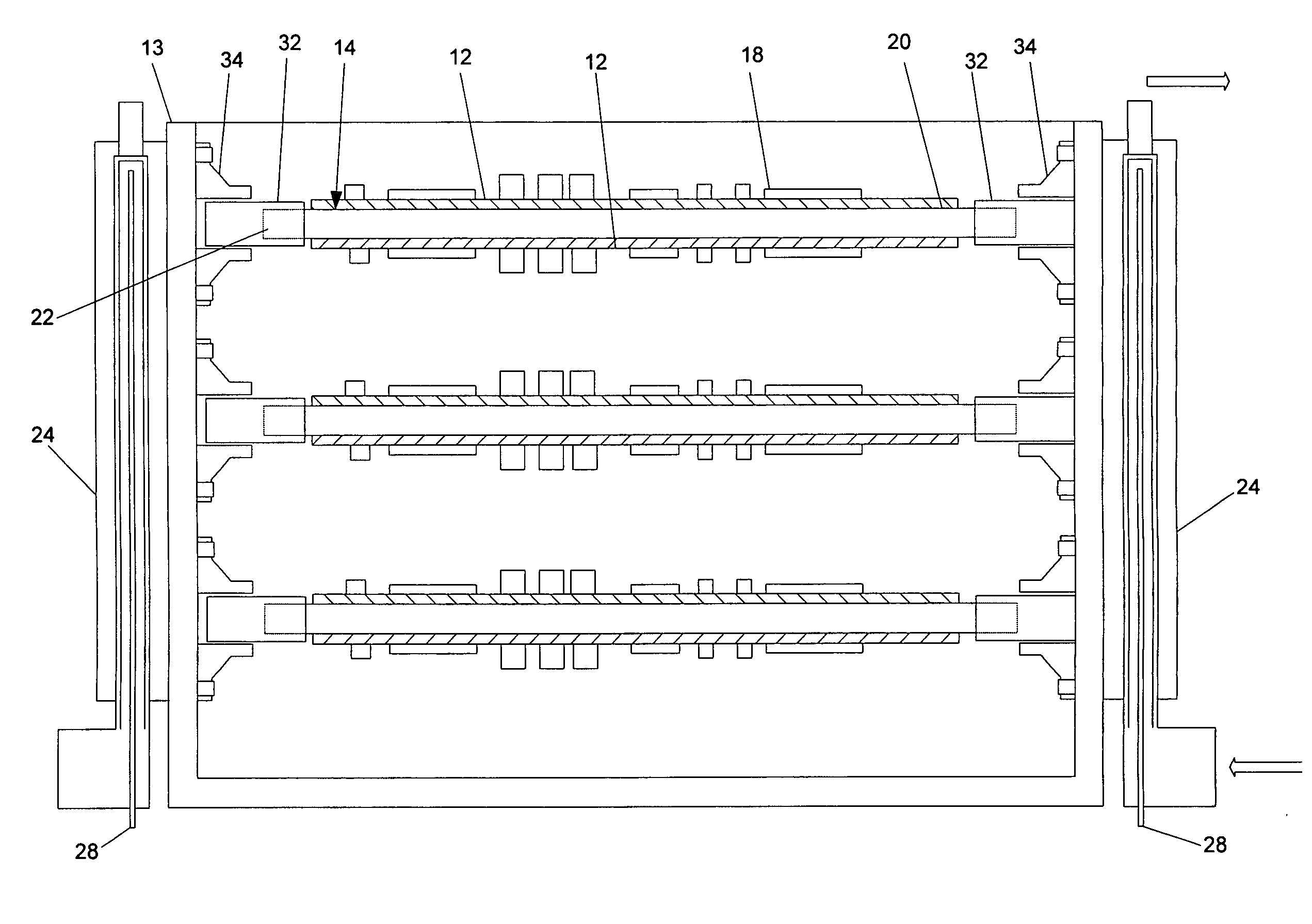

Liquid cooling systems for server applications

ActiveUS20090161312A1Reduce thermal resistanceIncrease surface areaDomestic cooling apparatusLighting and heating apparatusElectricityLocking mechanism

Mounting systems are provided for bringing a heat exchanger from a server rack into thermal contact with a heat exchanger from an electronics server. An engaging force is applied to the two heat exchangers to create thermal communication there between. A mounting mechanism is configured to isolate the engaging force applied to the two heat exchangers. The mounting mechanism may include an interlocking mechanism that prevents transfer of the applied force to the rest of the electronics server to lessen the possibility of disconnecting the electrical connections between the electronics server and the rack, and / or lessening mechanical stresses transferred to the electronics server and the rack chassis. The mounting mechanism also may be coupled to the electronics server locking mechanism such that the action of locking the electronics server into the rack causes the heat exchangers to engage in thermal contact.

Owner:VERTIV CORP

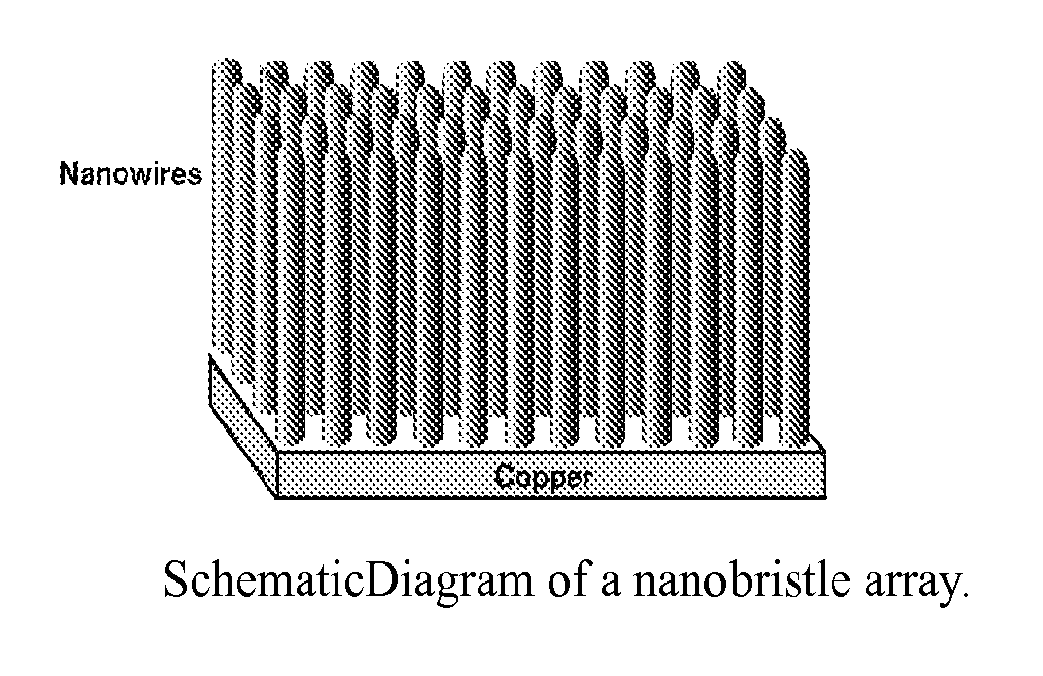

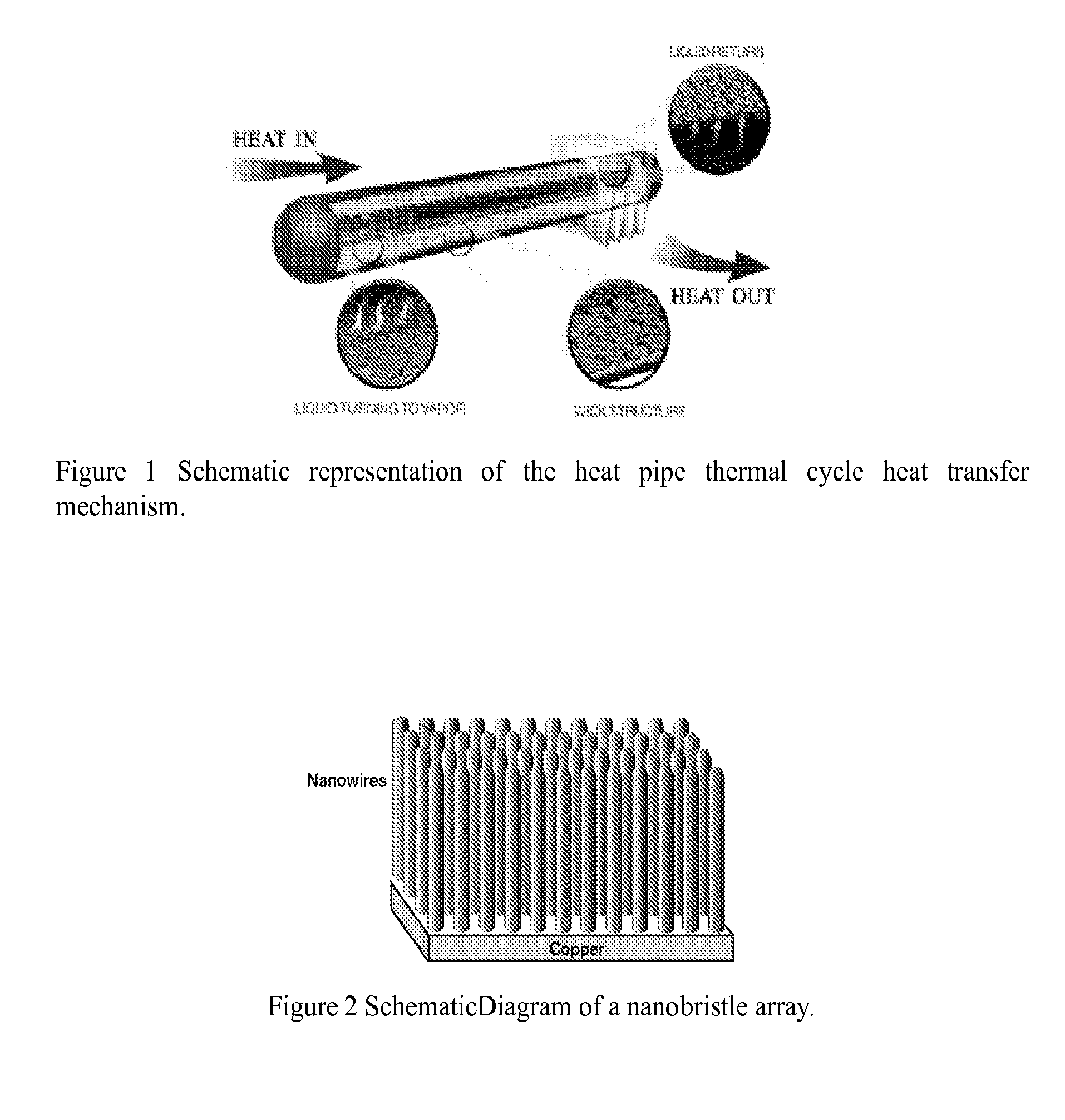

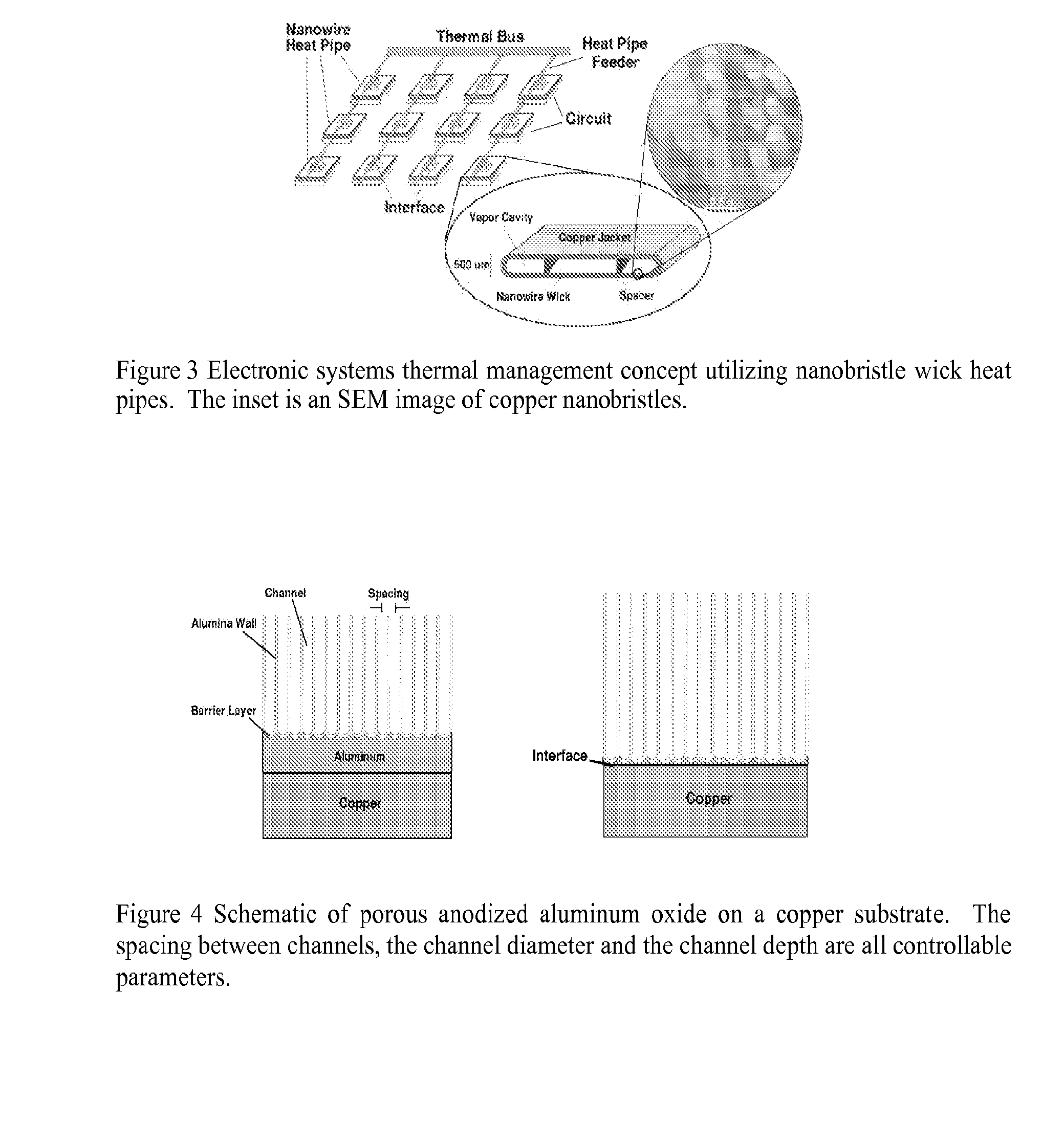

Heat Pipe with Nanostructured Wick

InactiveUS20100200199A1Improve efficiencyPerformance advantageMaterial nanotechnologyAnodisationNanowireBristle

A heat pipe with a nanostructured wick is disclosed, with the method of forming the nanostructured wick on a metal substrate. The wicking material is a pattern of metallic nanostructures in the form of bristles or nanowires attached to a substrate, where the bristles are substantially freestanding.

Owner:ILLUMINEX CORP

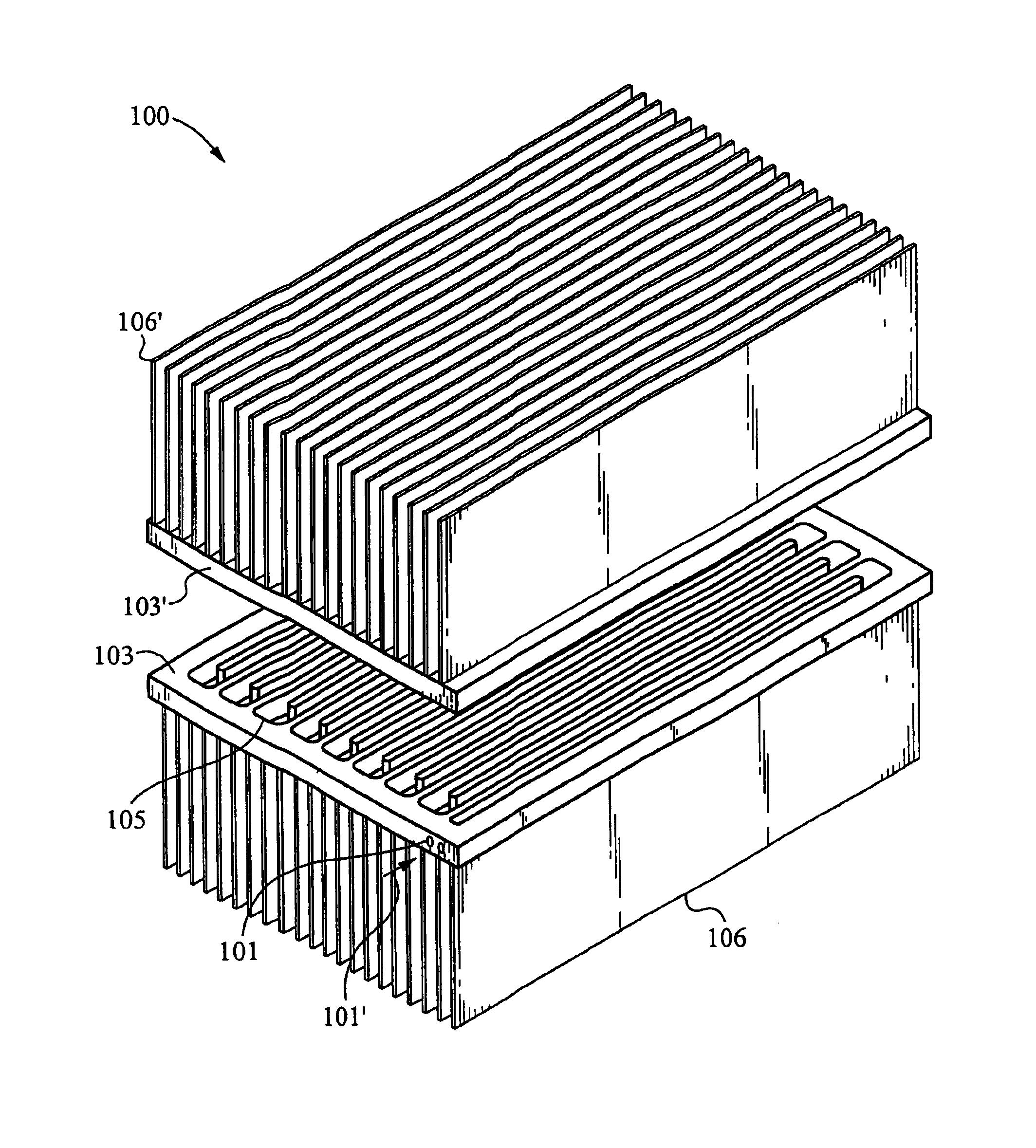

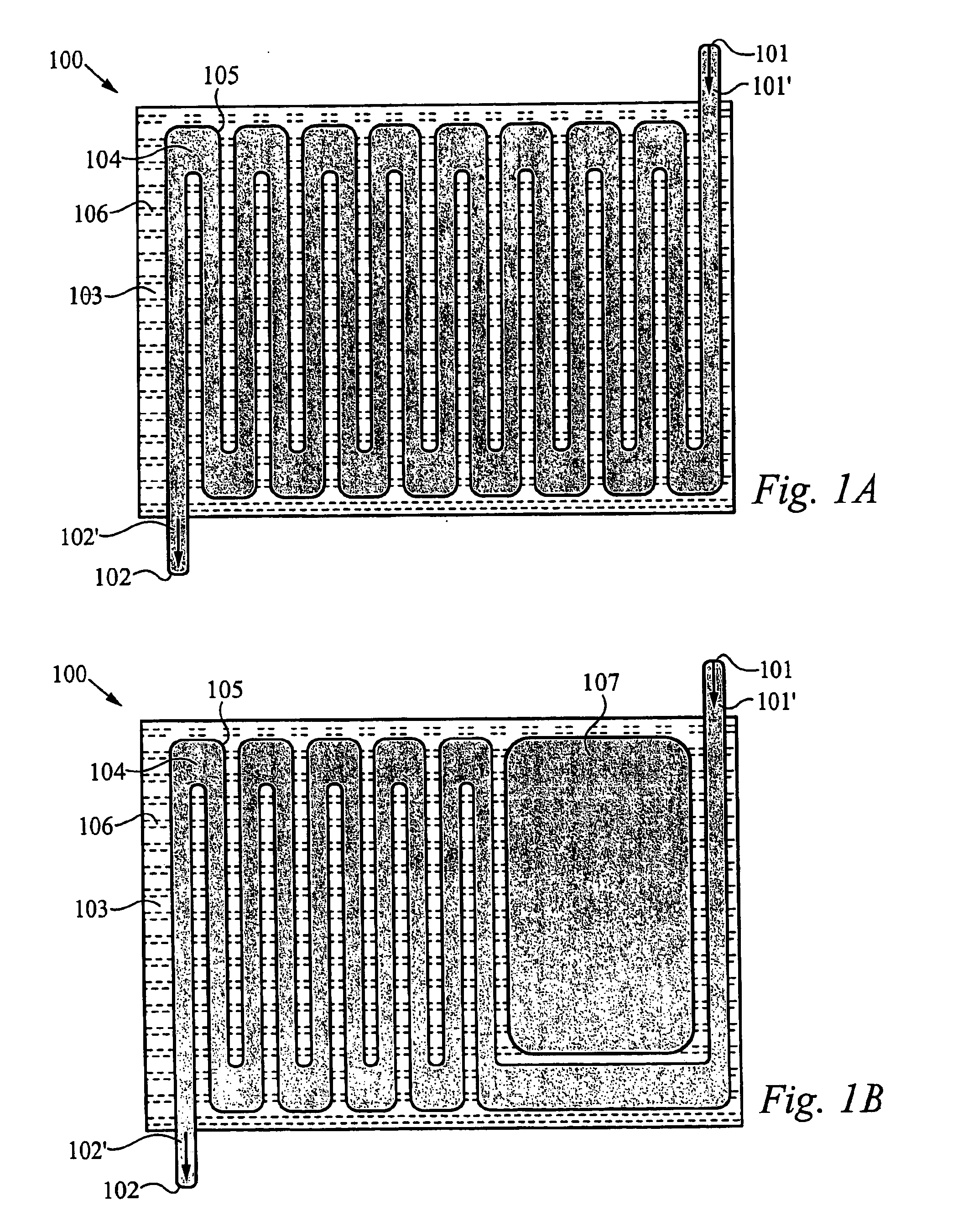

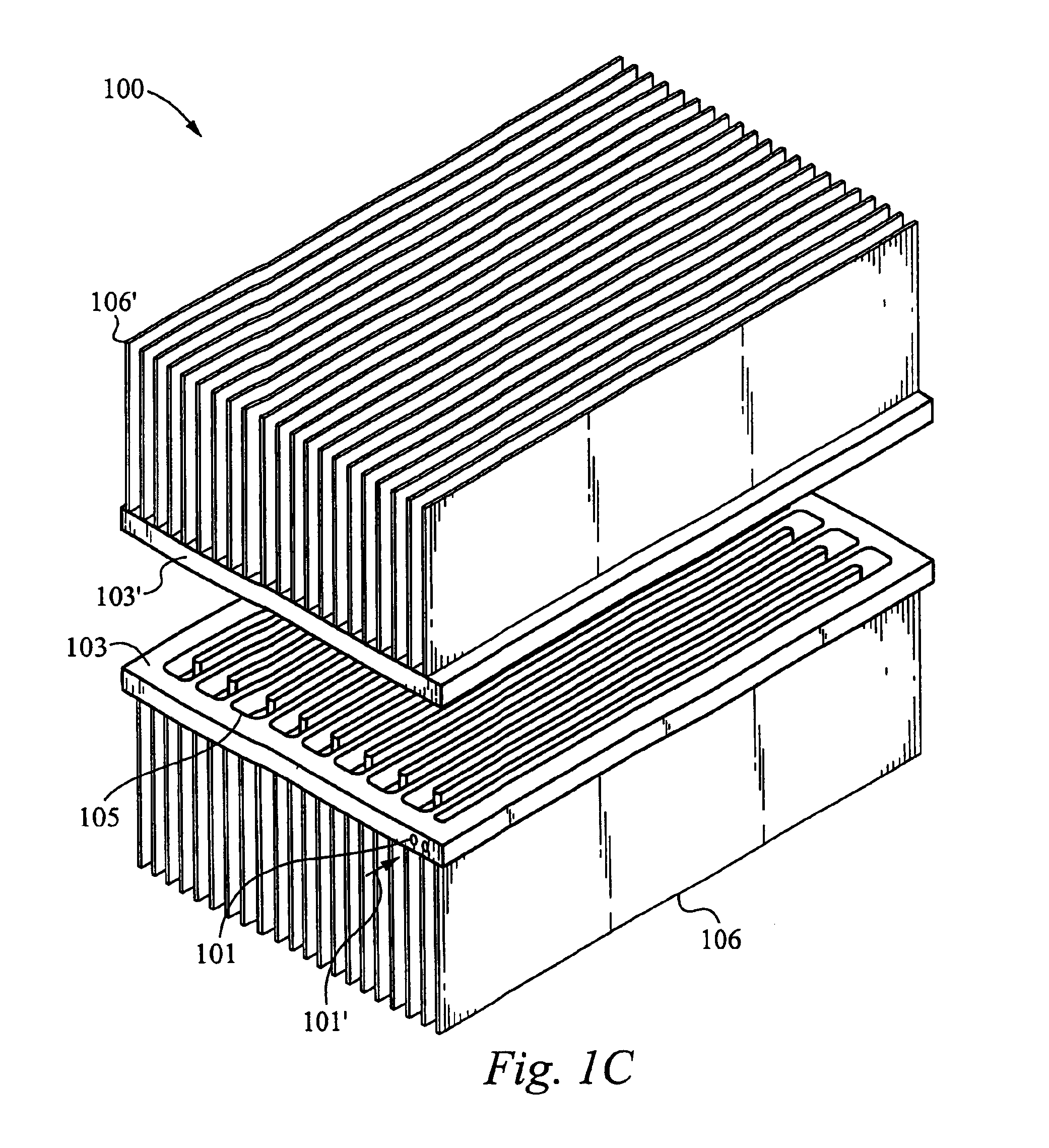

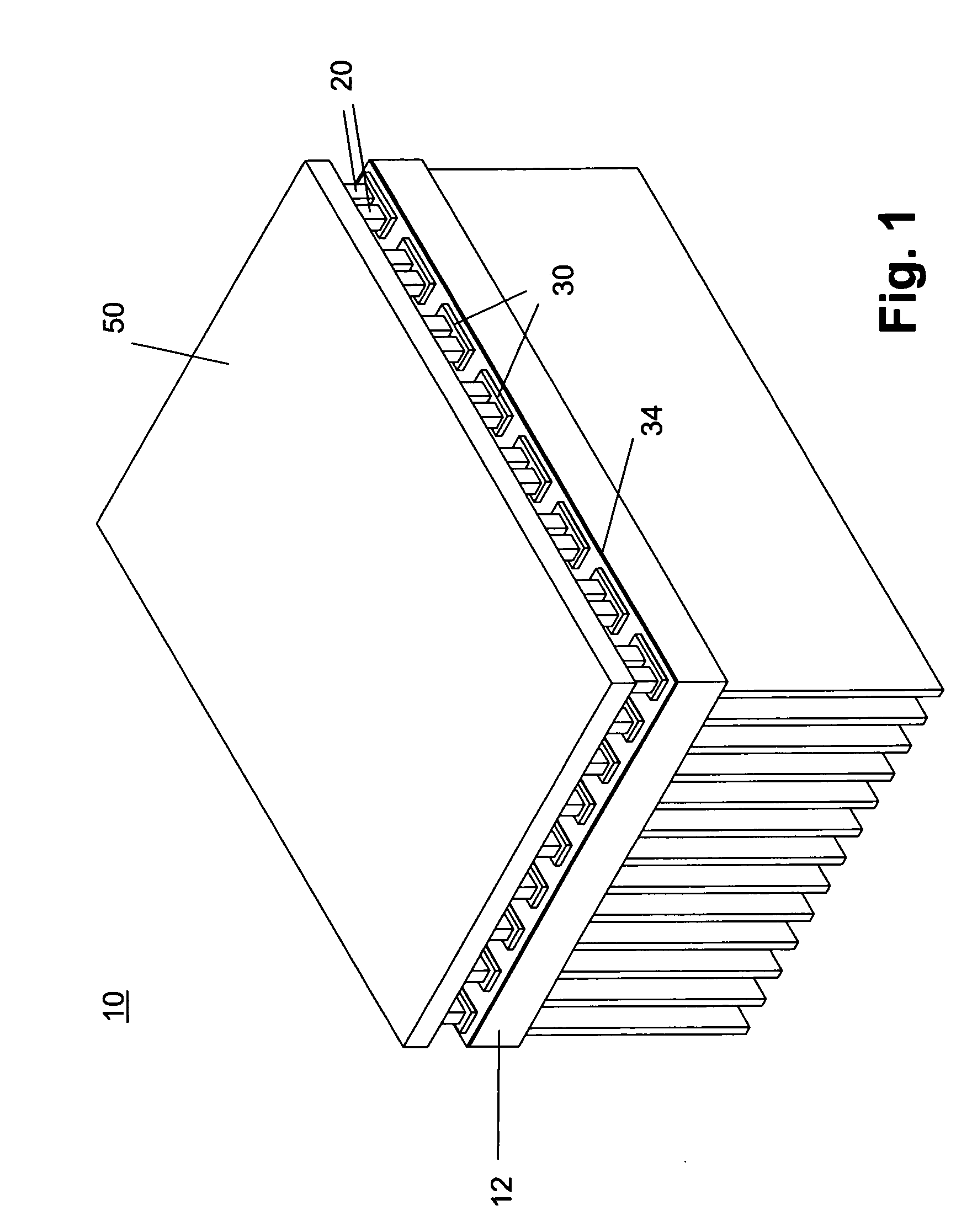

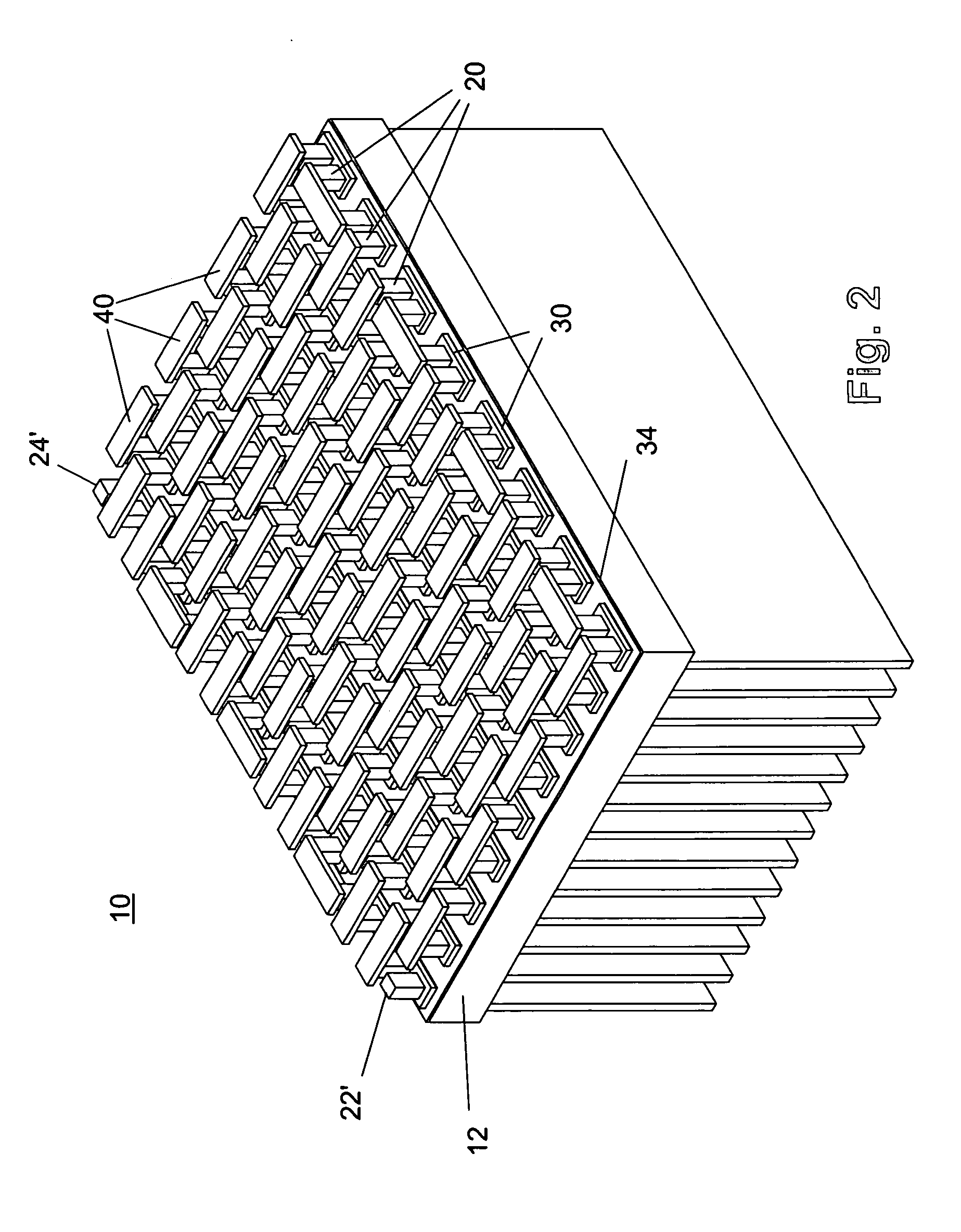

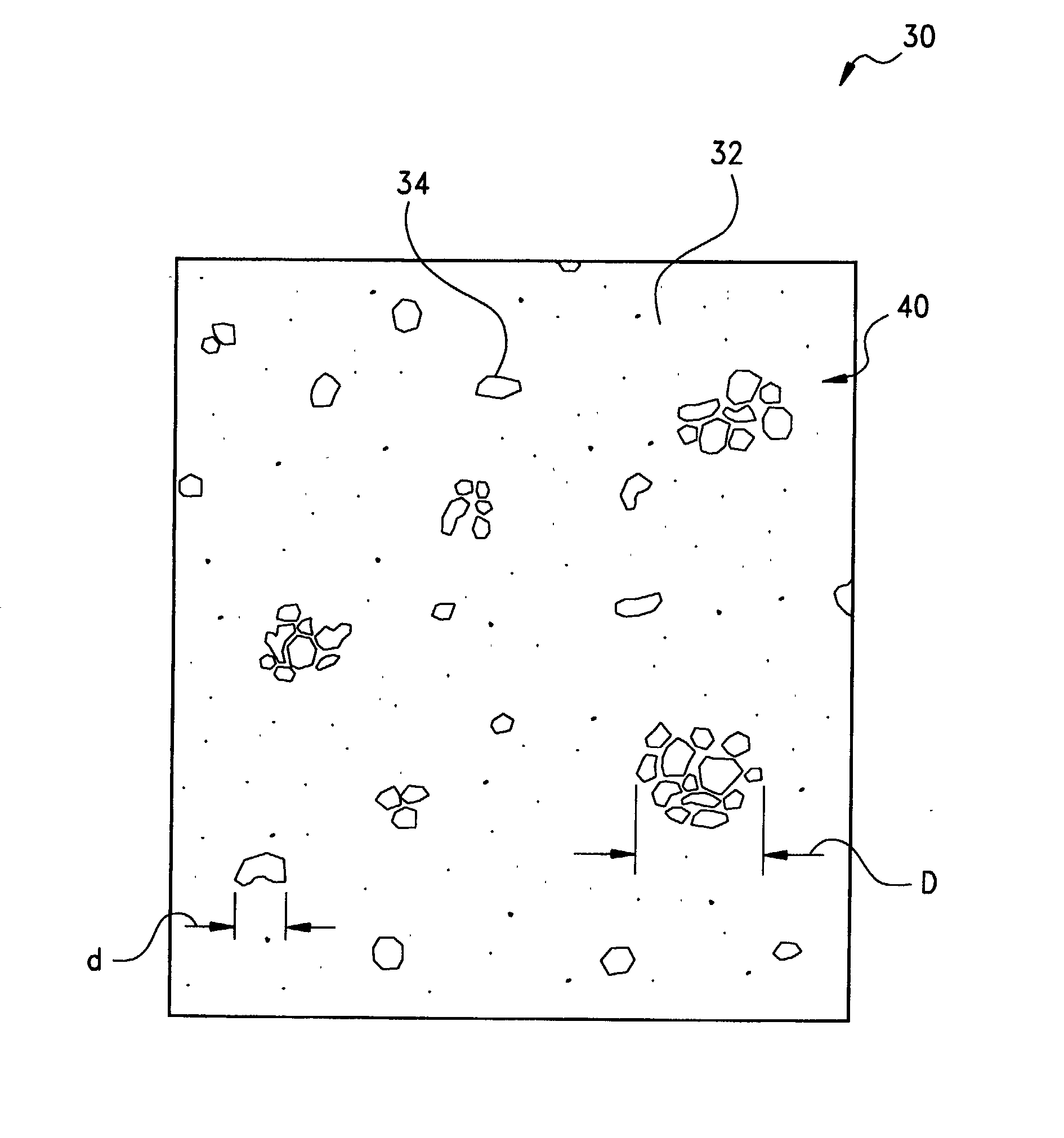

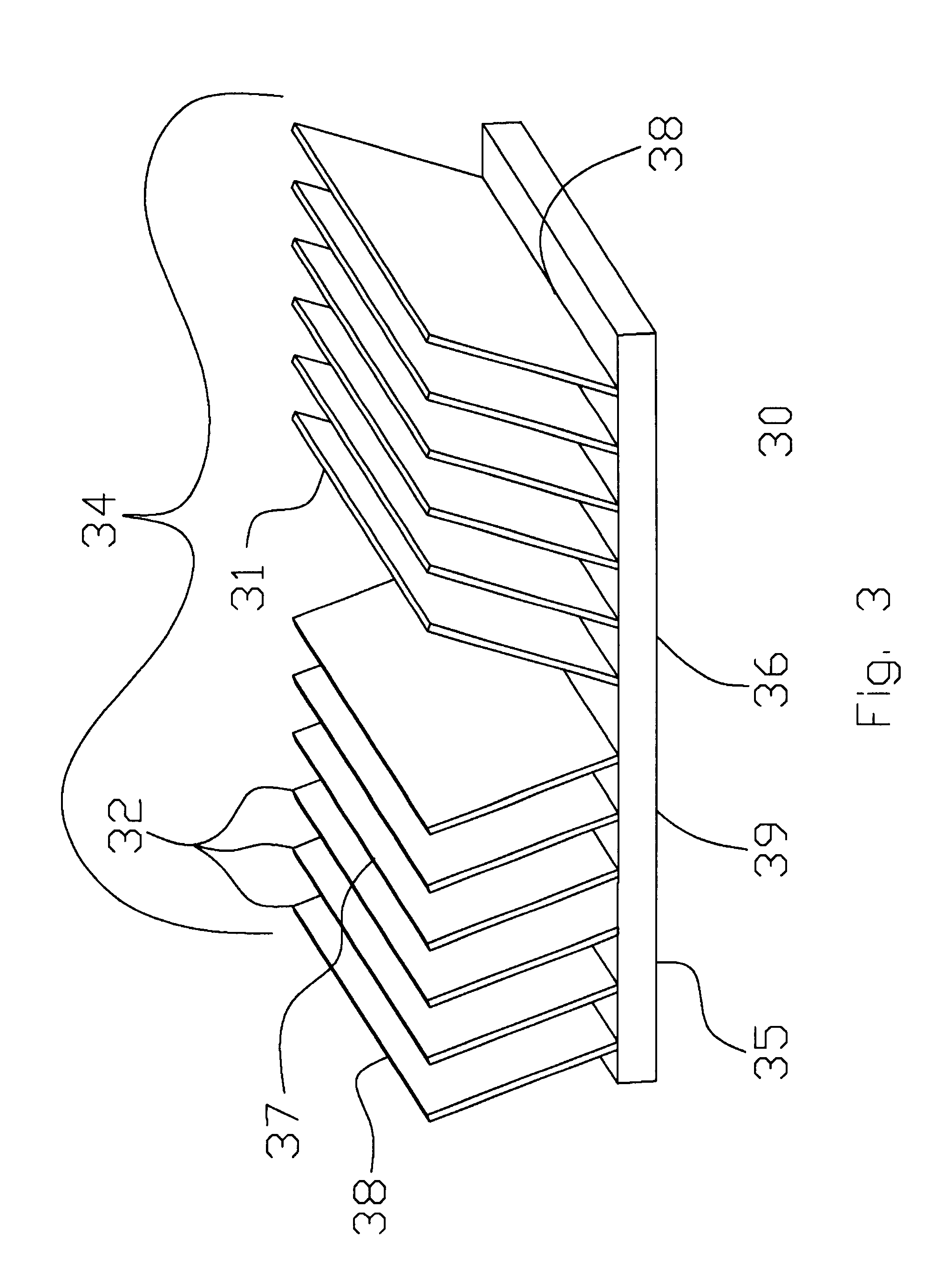

Channeled flat plate fin heat exchange system, device and method

ActiveUS6988535B2Reduction in amount of surface areaLow thermal resistanceSemiconductor/solid-state device detailsHeat exhanger conduitsUnit volumeCooling channel

A device, method, and system for a fluid cooled channeled heat exchange device is disclosed. The fluid cooled channeled heat exchange device utilizes fluid circulated through a channel heat exchanger for high heat dissipation and transfer area per unit volume. The device comprises a highly thermally conductive material, preferably with less than 200 W / m-K. The preferred channel heat exchanger comprises two coupled flat plates and a plurality of fins coupled to the flat plates. At least one of the plates preferably to receive flow of a fluid in a heated state. The fluid preferably carries heat from a heat source (such as a CPU, for example). Specifically, at least one of the plates preferably comprises a plurality of condenser channels configured to receive, to condense, and to cool the fluid in the heated state. The fluid in a cooler state is preferably carried from the device to the heat source, thereby cooling the heat source.

Owner:VERTIV CORP

Thermoelectric module with directly bonded heat exchanger

InactiveUS20050121065A1Improve thermal efficiencyReduce thermal resistanceThermoelectric device with peltier/seeback effectEngineeringThermoelectric element

A thermoelectric device with an improved thermal efficiency has an object to be heated or cooled having a surface, at least one electrically conductive lower pad bonded directly to the surface of the object using a thermally conductive dielectric material, at least one thermoelectric element coupled on one end to the electrically conductive pad, at least one electrically conductive upper pad coupled to an opposite end of the thermoelectric element, and electrical power connections coupled to the device.

Owner:FERROTEC USA CORP

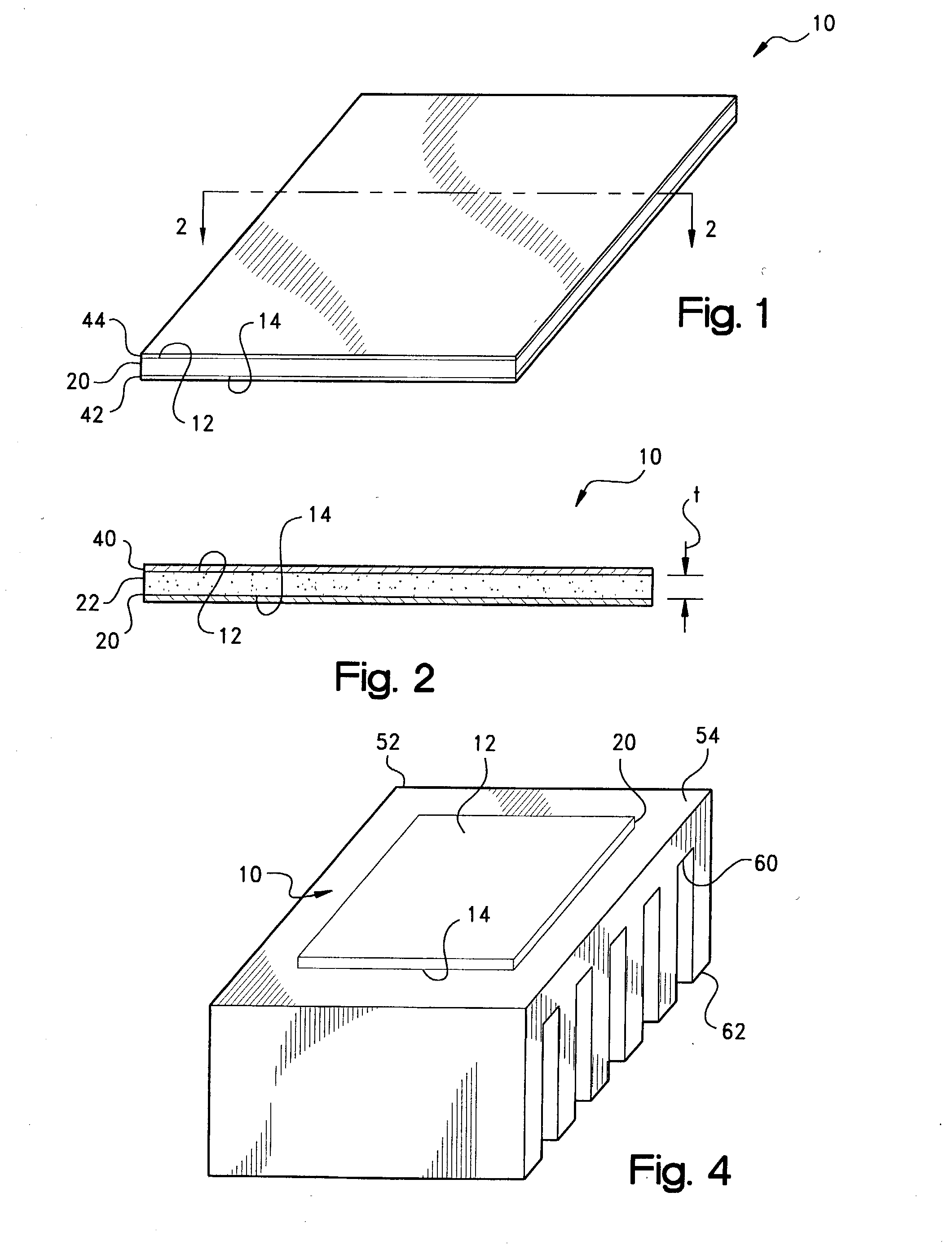

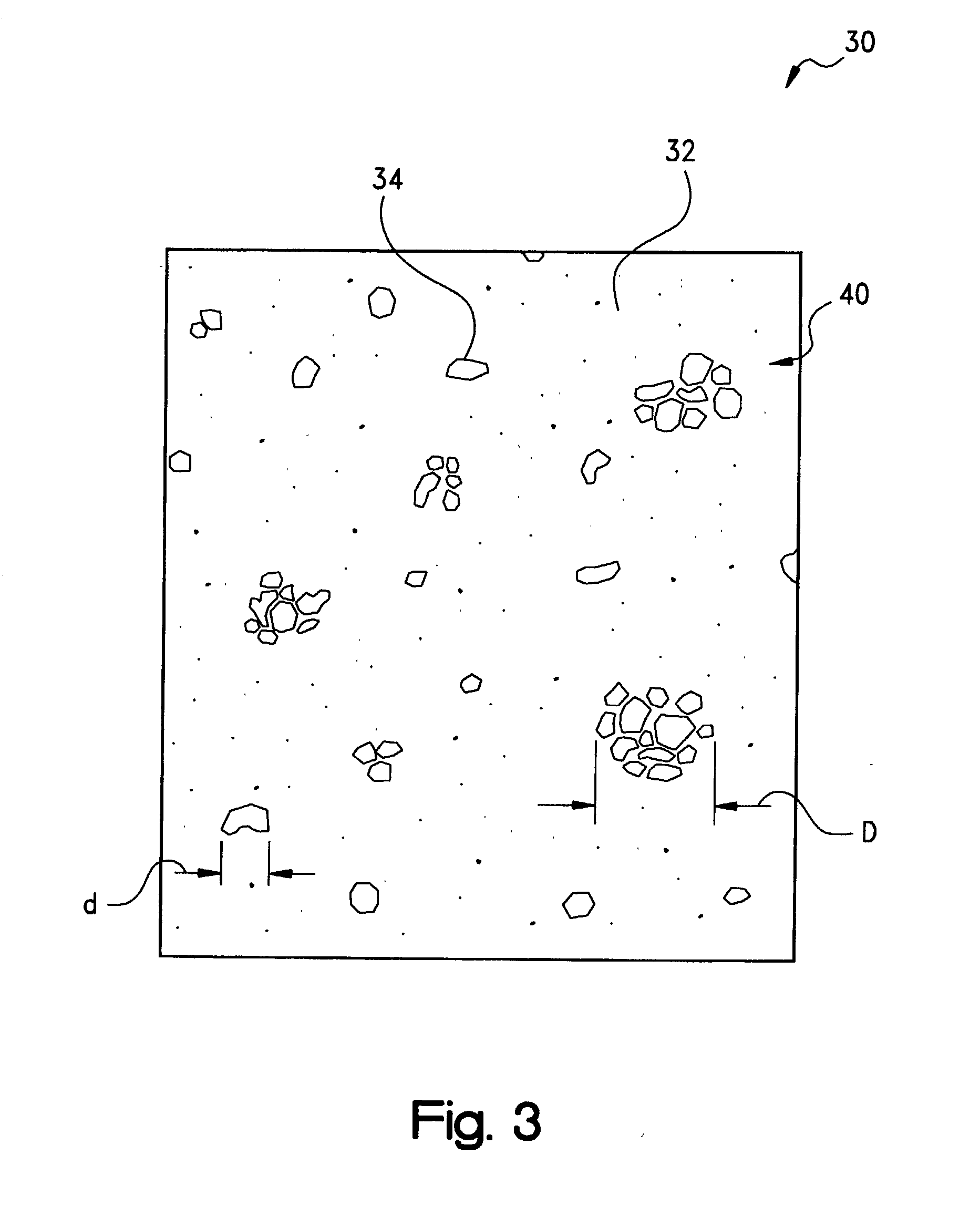

Thermal management materials having a phase change dispersion

InactiveUS20030152764A1Reduce thermal resistanceImprove heat transfer performanceSemiconductor/solid-state device detailsSynthetic resin layered productsMetal alloyRoom temperature

A thermally-conductive interface interposable intermediate a first heat transfer surface and an opposing second heat transfer surface to provide a thermal pathway therebetween. The interface includes a thermally-conductive compound formed into a layer which is conformable between the first and second heat transfer surface. The compound is an admixture of: (a) a polymeric constituent forming a continuous matrix in the layer; and (b) a dispersed constituent forming discrete domains within the matrix, the domains being form-stable at normal room temperature in a first domain phase and conformable between the first and second heat transfer surface in a second domain phase, and the domains having a domain transition temperature above normal room temperature from the first domain phase to the second domain phase. The dispersed constituent may be a fusible, i.e., low temperature melting, metal or metal alloy.

Owner:PARKER INTANGIBLES LLC

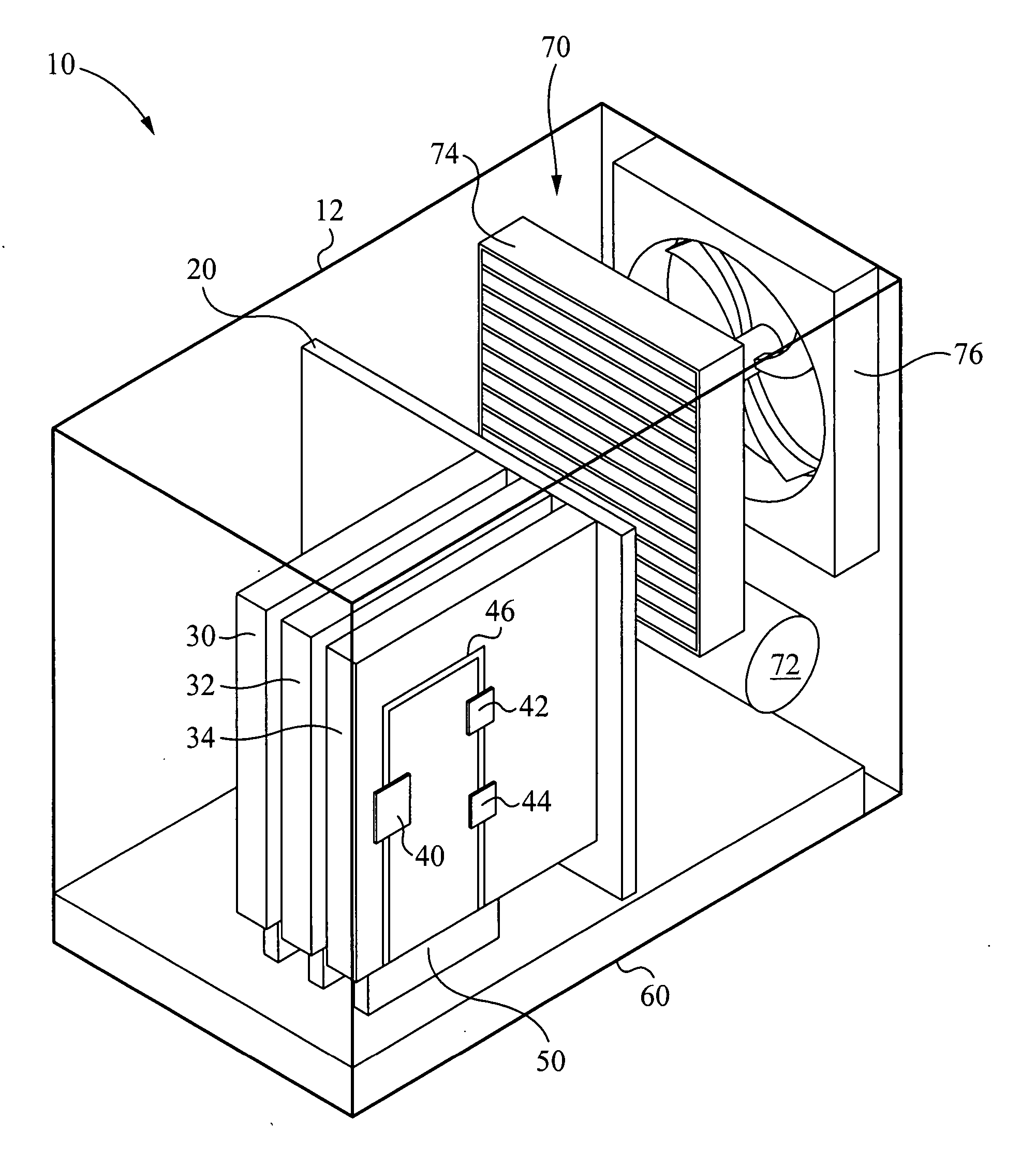

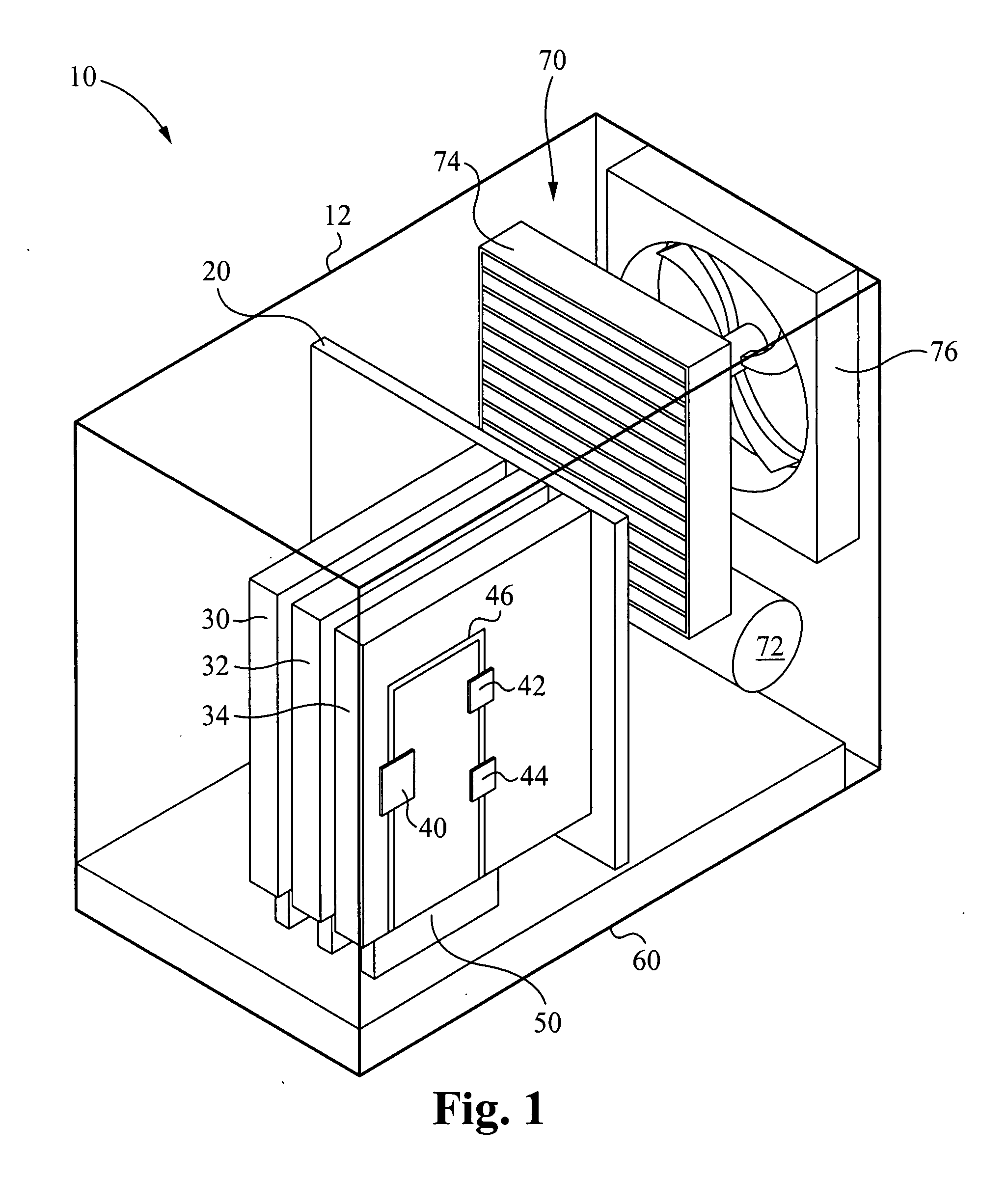

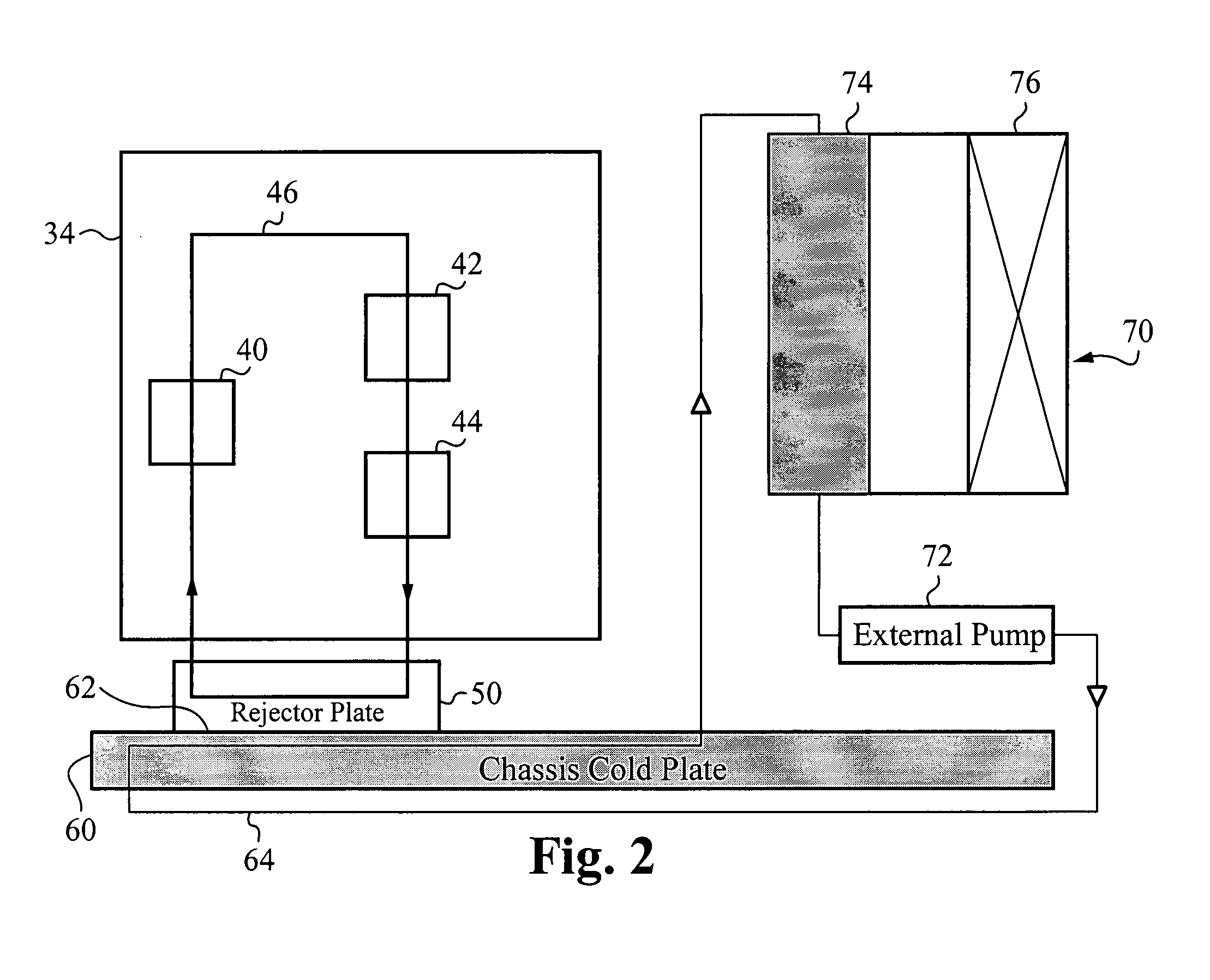

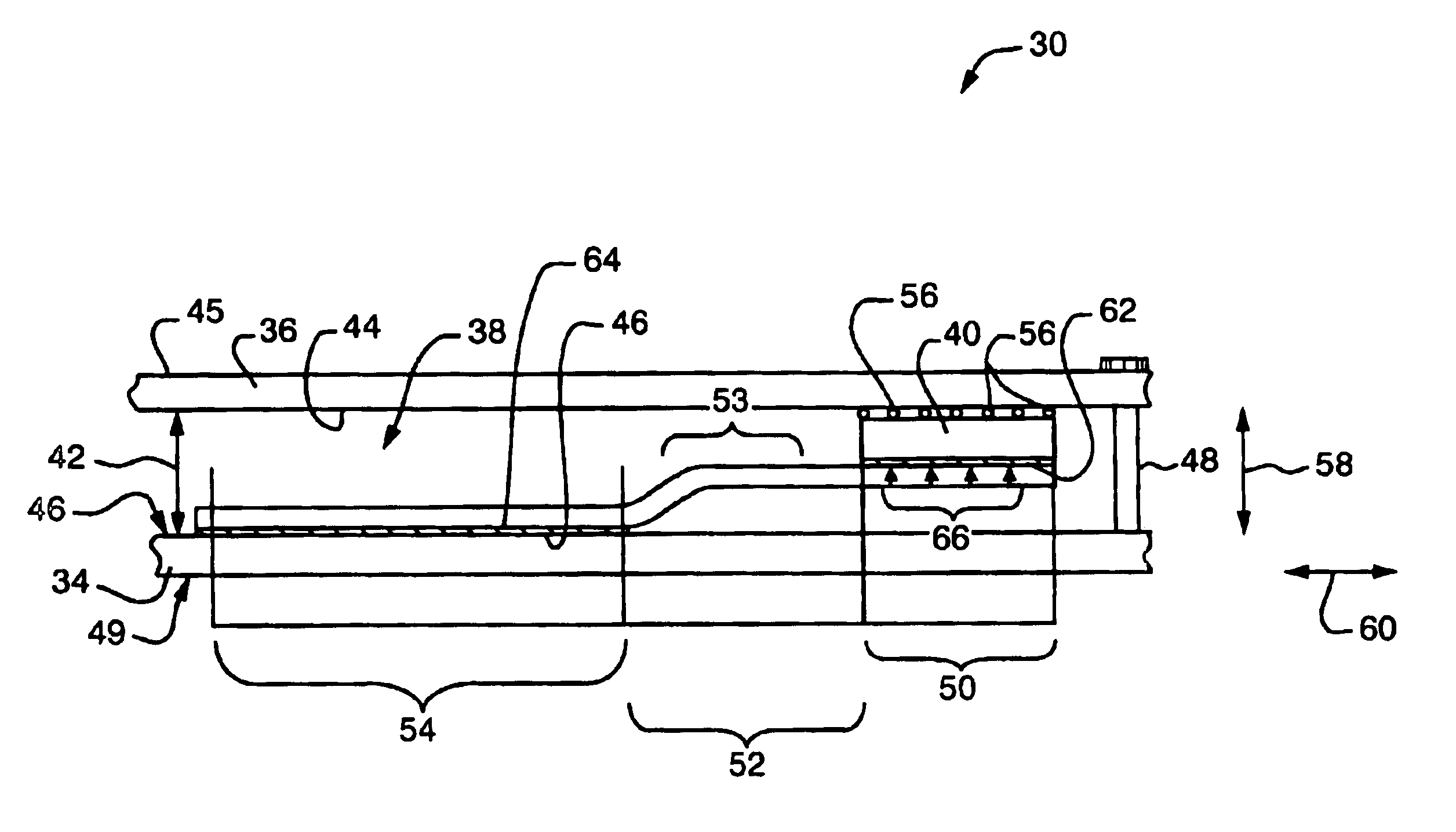

Liquid cooling loops for server applications

ActiveUS20070201210A1Reduce thermal resistanceIncrease surface areaSolid-state devicesFurniture partsElectricityLocking mechanism

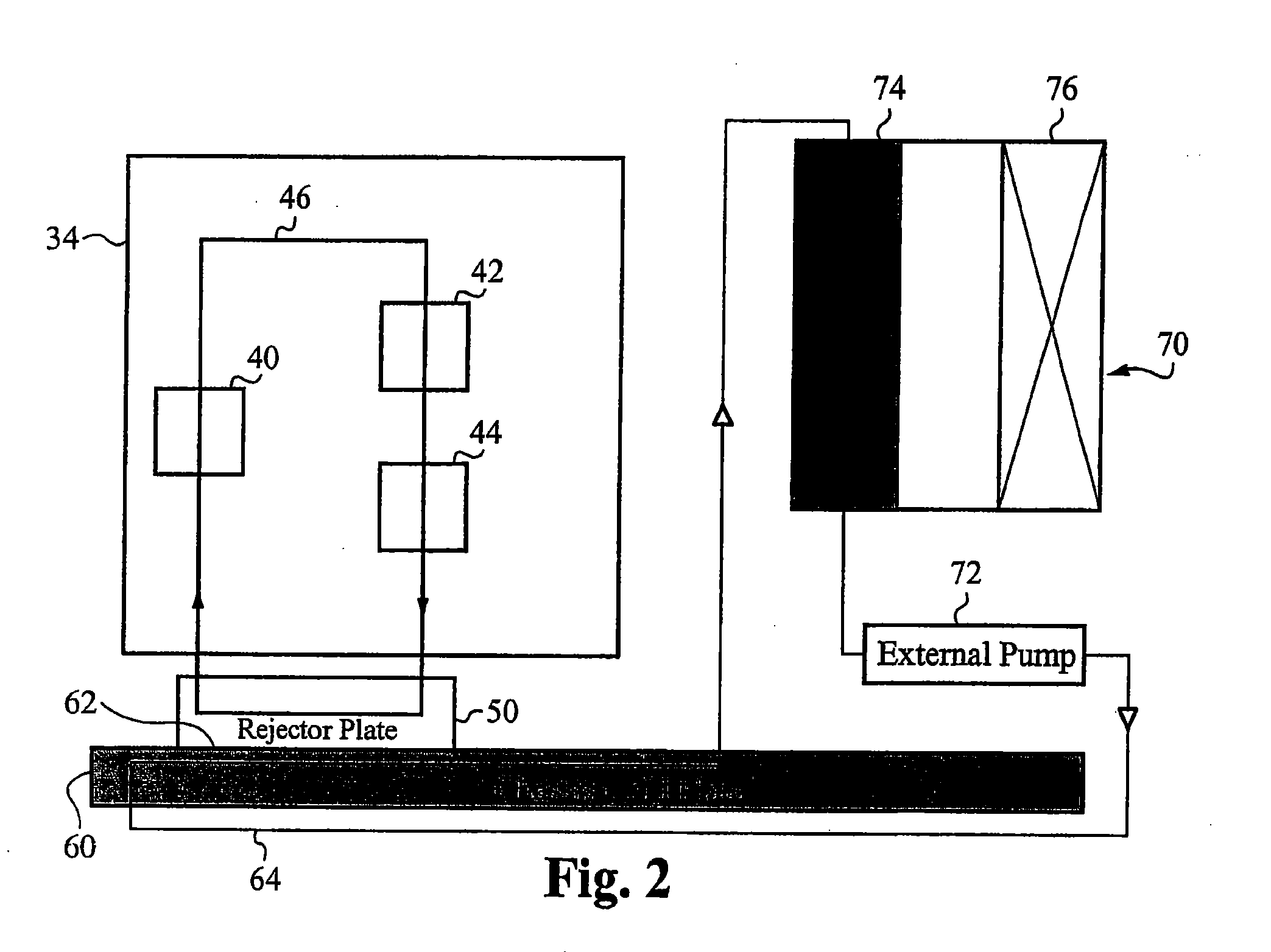

A mounting system provides mechanisms and form factors for bringing a heat exchanger from a server rack into thermal contact with a heat exchanger from a electronics server. To ensure good thermal contact, pressure is applied between the two heat exchangers, the rejector plate and the chassis cold plate. The mounting mechanism used to engage and disengage the heat exchangers is configured to isolate the force applied to the two heat exchangers. The mounting mechanism includes an interlocking mechanism that prevents transfer of the applied force to the rest of the electronics server. Without isolating this force, the force is applied to the electronics server and / or the rack chassis, possibly disconnecting the electrical connections between the electronics server and the rack, as well as providing mechanical stress to the electronics server and the rack chassis. The mounting mechanism is also coupled to the electronics server locking mechanism such that the action of locking the electronics server into the rack causes the heat exchangers to engage in thermal contact. This is a fail safe procedure since no separate process is required to engage the electronics server cooling loop.

Owner:LIEBERT

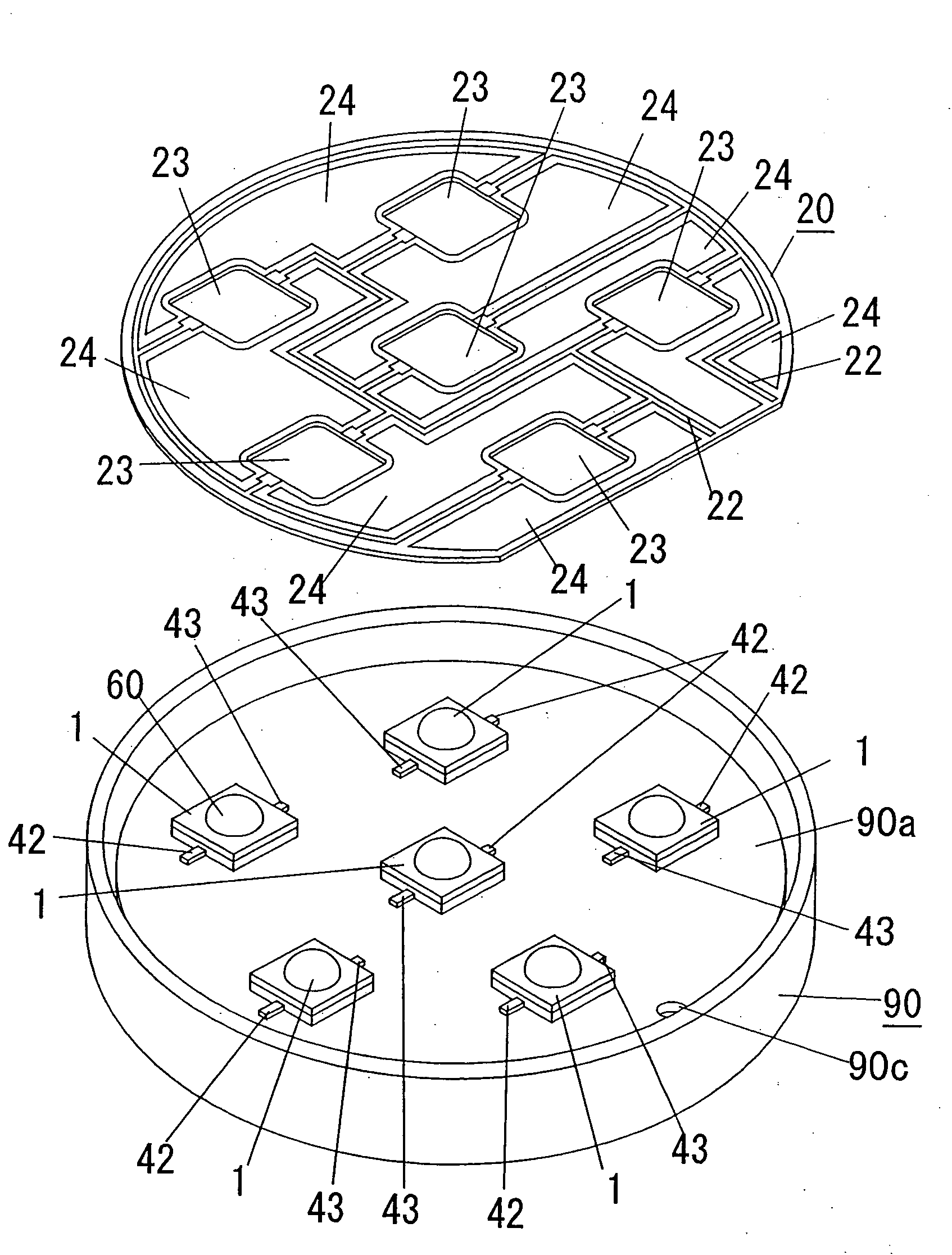

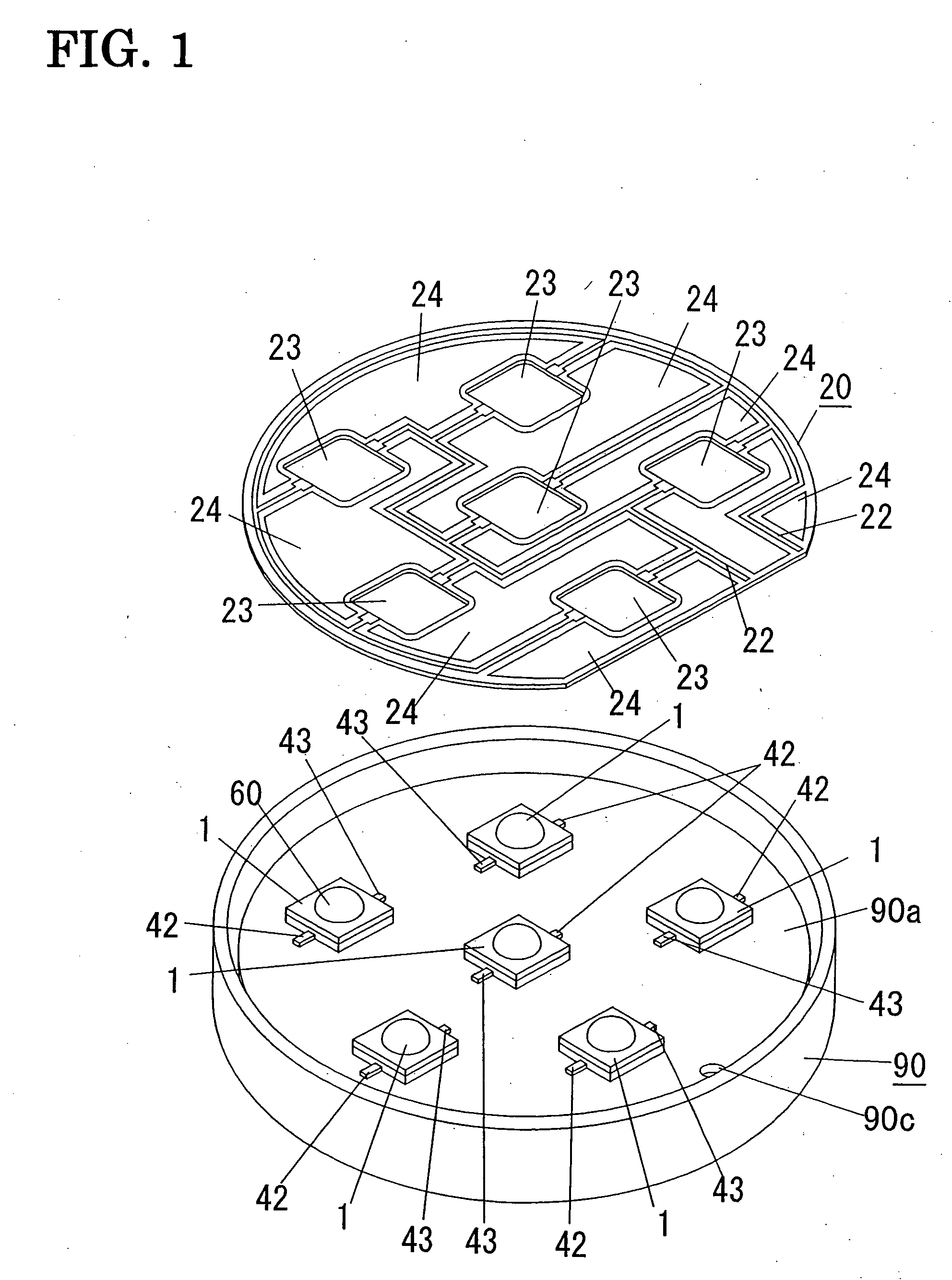

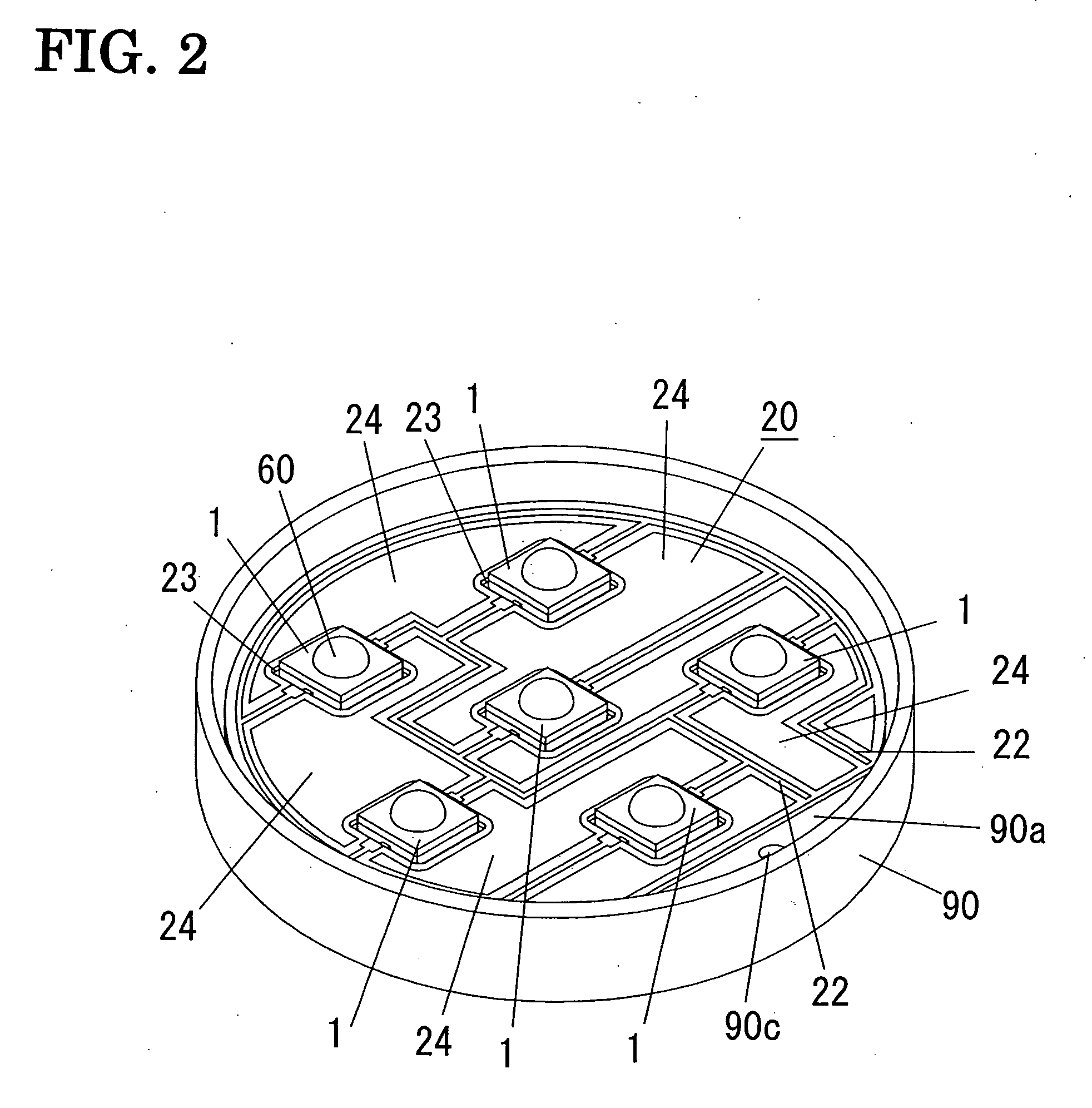

Lighting Apparatus With Leds

ActiveUS20090046456A1Inhibit temperature riseLow costPoint-like light sourcePortable electric lightingLight equipmentEffect light

A lighting apparatus with LED includes a metal-made main body 90; a plurality of LED chip units 1 each including an LED chip and a pair of lead terminals 42, 43 electrically connected to electrodes of the LED chip; and a dielectric layer 80 disposed between the main body 90 and each LED chip unit 1 for making electrical insulation therebetween as well as bond the same. The circuit board 20 is formed with a plurality of windows 23 through which the individual LED chip units 1 extend respectively with the lead terminals held in electrical contact with the circuit pattern of the circuit board at the circumference of the window, each of the LED chip units being thermally coupled at its bottom face with the main body 90 through the dielectric layer 80, and the heat generated in the LED chip is conducted to the main body through the dielectric layer without passing through the circuit board.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Low-temperature wafer bonding of semiconductor substrates to metal substrates

ActiveUS20090286382A1Lower resistanceReduce thermal resistanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceSemiconductor materials

A method of wafer or substrate bonding a substrate made of a semiconductor material with a substrate made from a metallic material is disclosed. The method allows the bonding of the two substrates together without the use of any intermediate joining gluing, or solder layer(s) between the two substrates. The method allows the moderate or low temperature bonding of the metal and semiconductor substrates, combined with methods to modify the materials so as to enable low electrical resistance interfaces to be realized between the bonded substrates, and also combined with methods to obtain a low thermal resistance interface between the bonded substrates, thereby enabling various useful improvements for fabrication, packaging and manufacturing of semiconductor devices and systems.

Owner:FOR NAT RES INITIATIVES

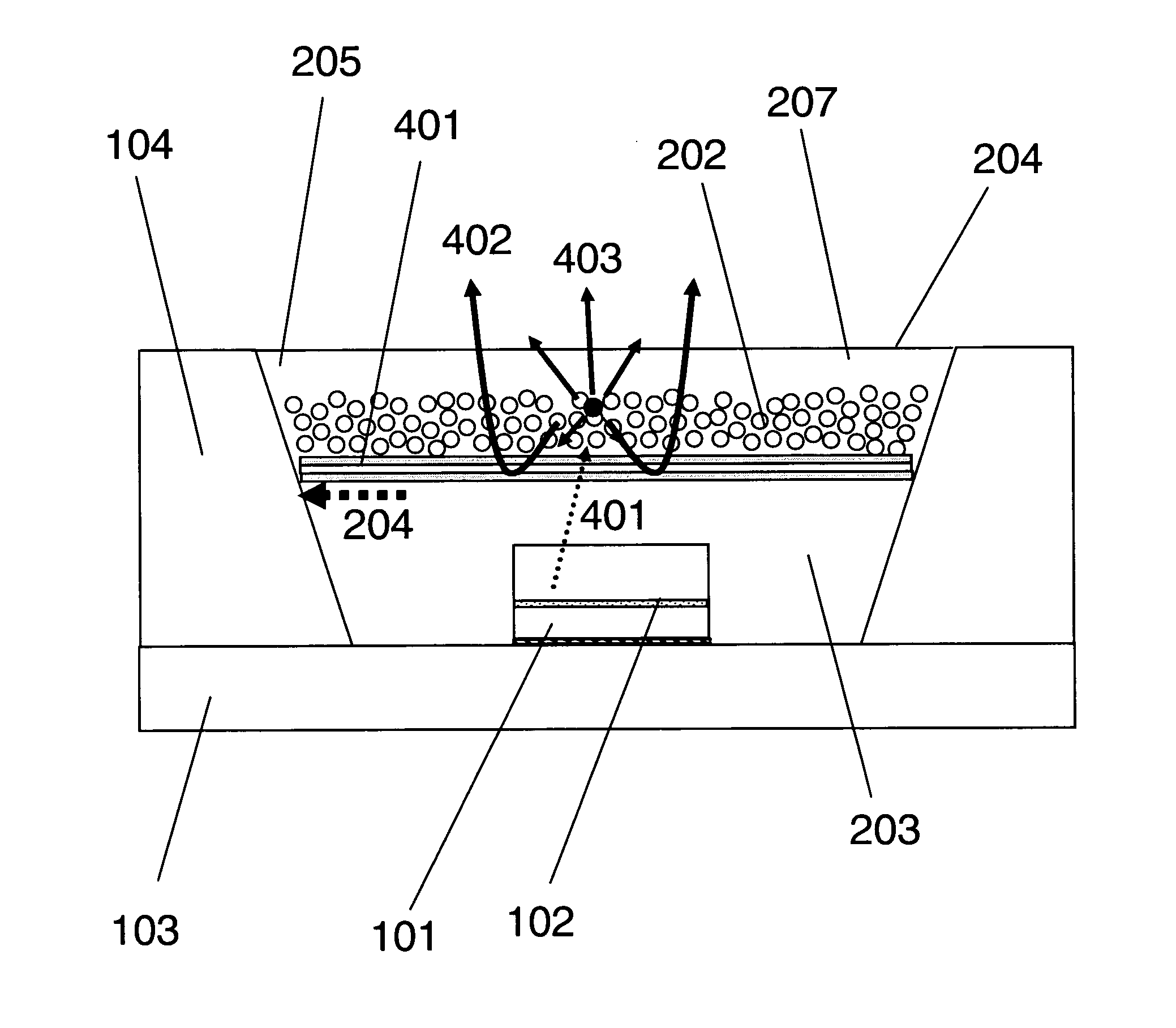

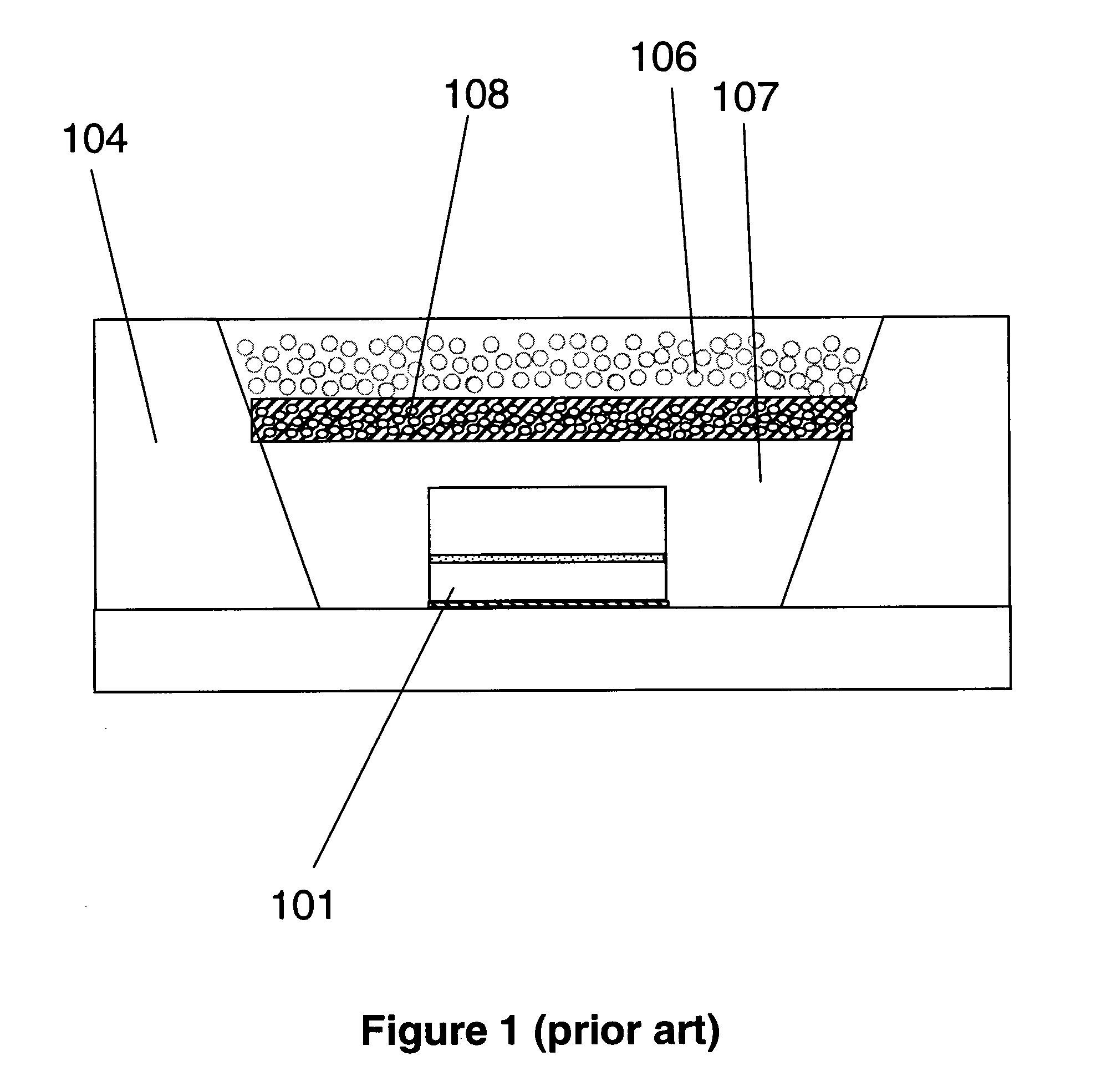

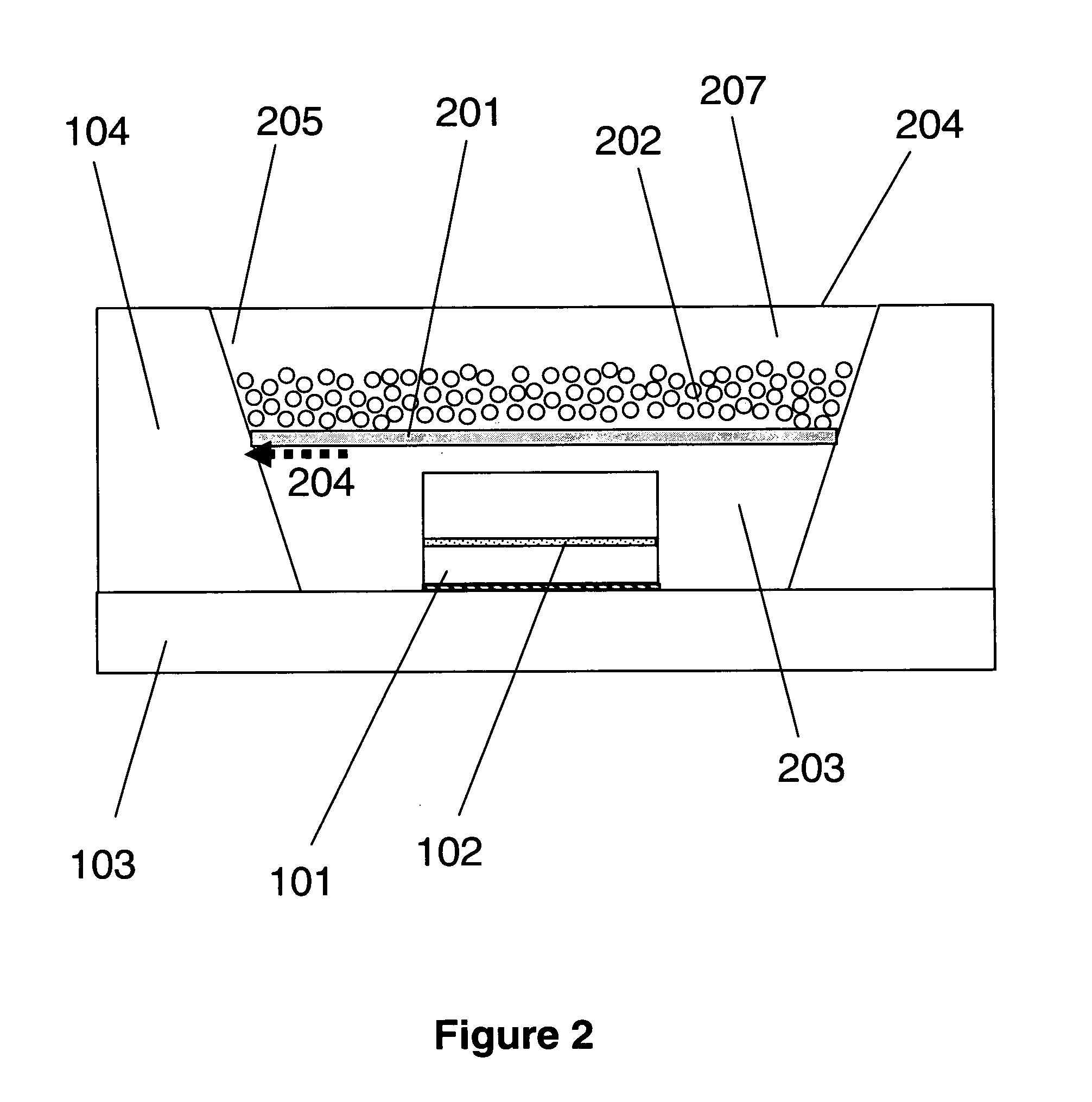

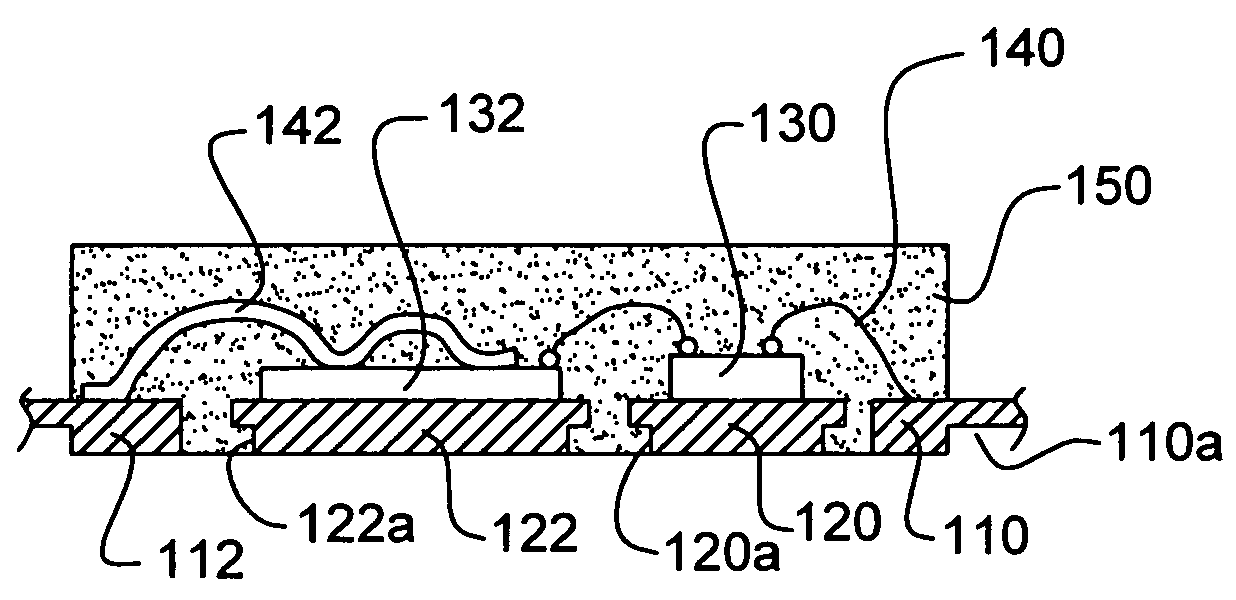

Light emitting module with optically-transparent thermally-conductive element

ActiveUS20110001157A1Extended service lifeThe process is compact and efficientSolid-state devicesSemiconductor/solid-state device manufacturingLength waveInorganic materials

A light emitting module with improved optical functionality and reduced thermal resistance is described, which comprises a light emitting device (LED), a wavelength converting (WC) element and an inorganic optically-transmissive thermally-conductive (OTTC) element. The WC element is capable of absorbing light generated from the LED at a specific wavelength and re-emitting light having a different wavelength. The re-emitted light and any unabsorbed light exits through at least one surface of the module. The OTTC is in physical contact with the WC element and at least partially located in the optical path of the light. The OTTC comprises one or more layers of inorganic material having a thermal conductivity greater than that of the WC element. As such, a compact unitary integrated module is provided with excellent thermal characteristics, which may be further enhanced when the OTTC provides a thermal barrier for vertical heat propagation through the module but not lateral propagation.

Owner:LUMILEDS HLDG BV

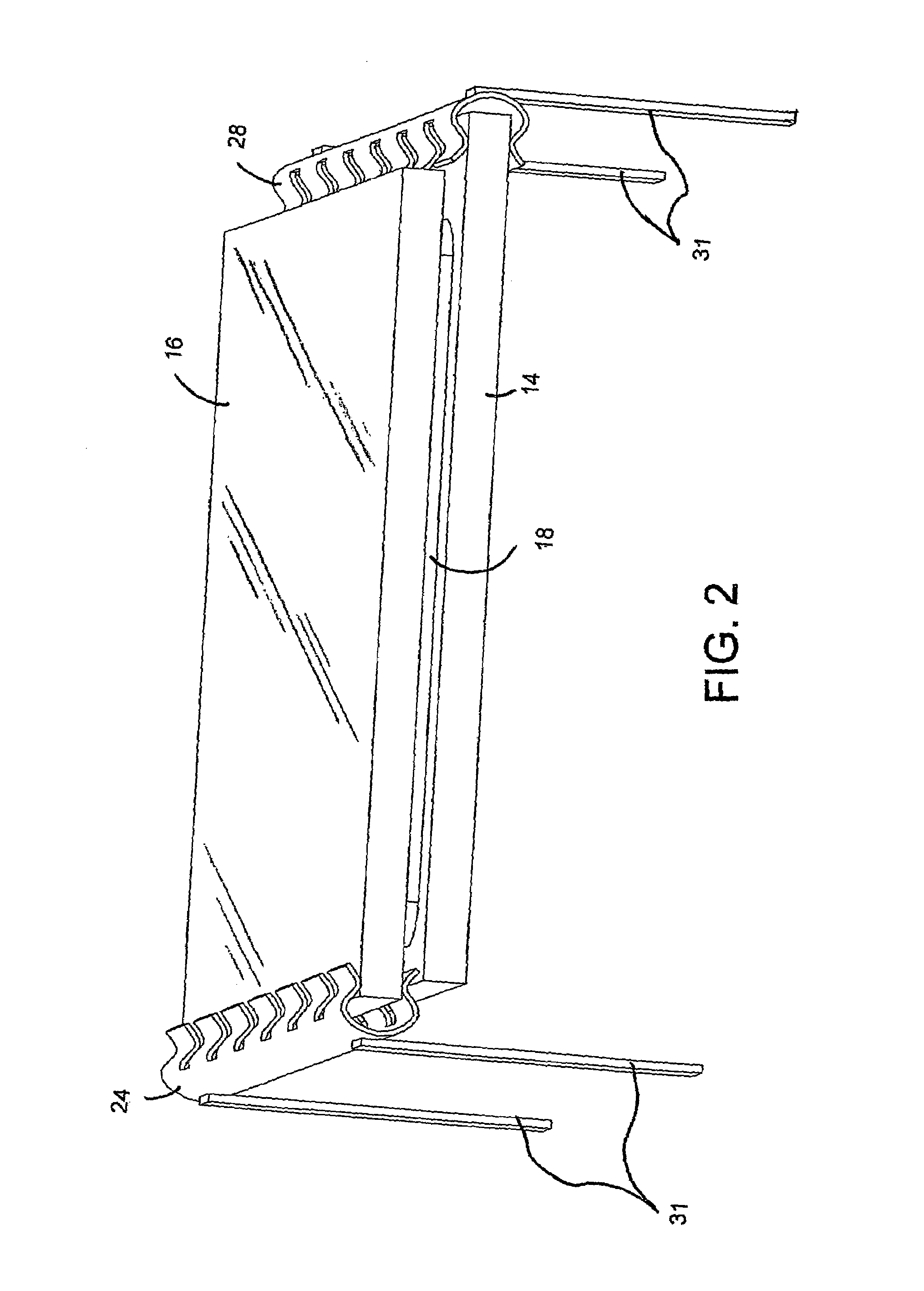

Methods and apparatus for cooling a circuit board component using a heat pipe assembly

ActiveUS6914780B1Limit amount of stressAdequate heat transferDomestic cooling apparatusDigital data processing detailsThermal conductivityEngineering

A circuit board assembly has a circuit board coupled to a support plane and defining a space between the circuit board and the support member. A circuit board component mounts to the circuit board and is oriented within the space defined by the circuit board and the support plane. A heat pipe assembly, located within the defined space, has a relatively high thermal conductivity, compared to other thermally conductive materials, and transfers heat from the circuit board component to the support plane or carrier tray associated with the circuit board. The heat pipe assembly has an input portion that contacts the circuit board component and an output portion that contacts the support plane. The heat pipe assembly also has a compliant portion having a lower stiffness relative to the stiffness of either the input portion or the output portion. The compliant portion of the heat pipe assembly allows for displacement of the input portion relative to the output portion to limit the amount of stress generated by the heat pipe assembly on the circuit board component.

Owner:CISCO TECH INC

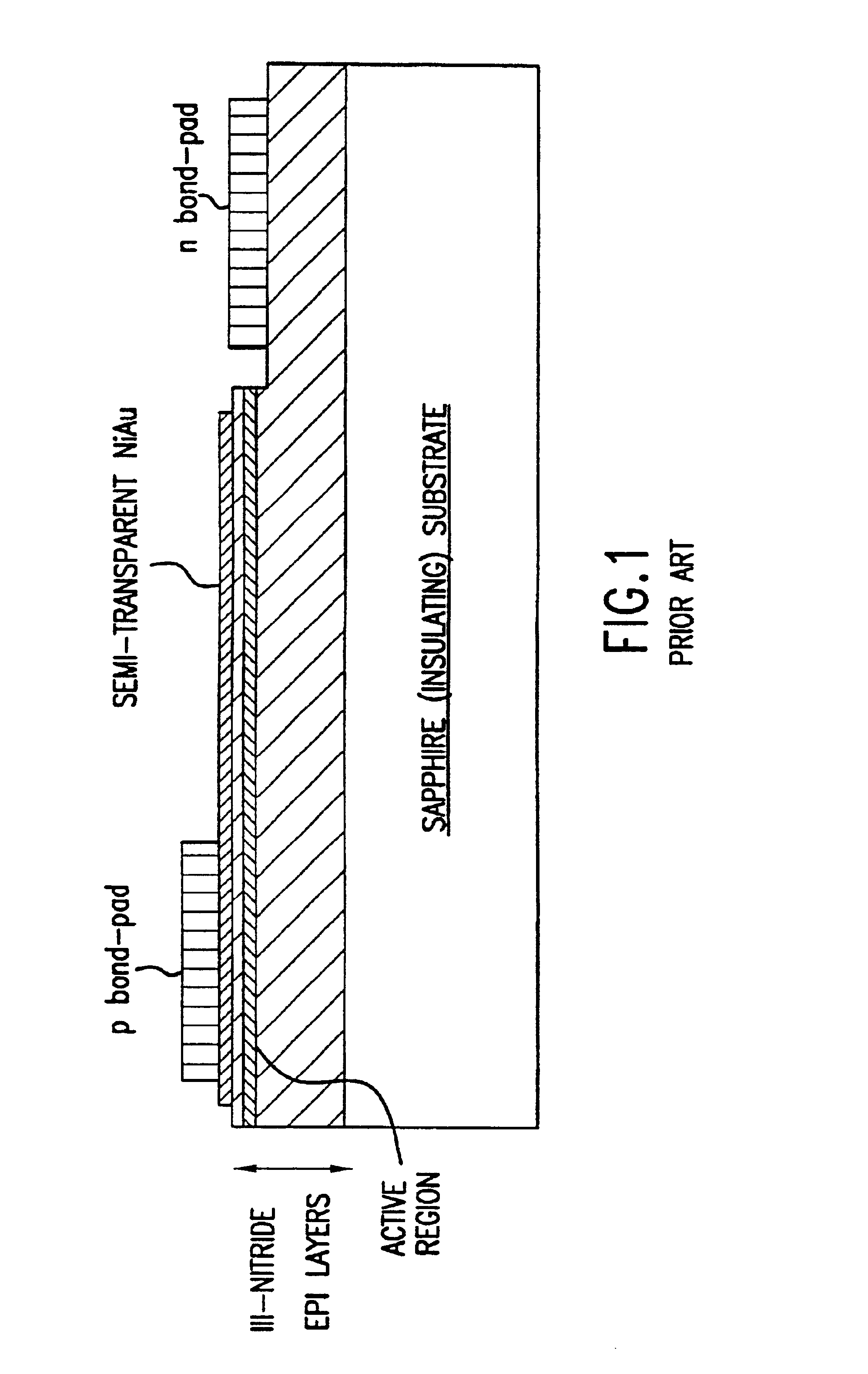

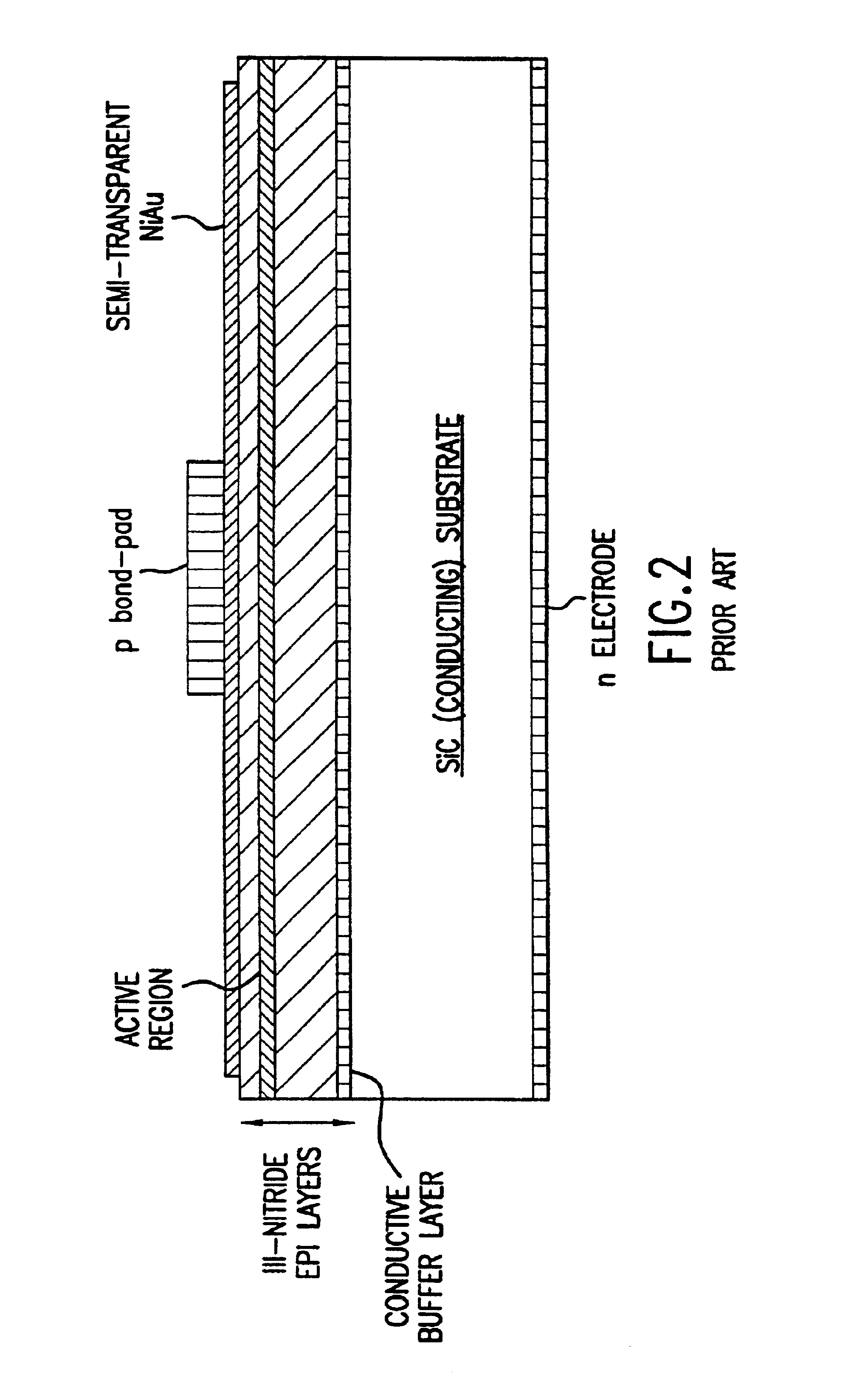

III-nitride light-emitting device with increased light generating capability

InactiveUS6844571B2Excellent current spreadingLow series resistanceStatic indicating devicesSolid-state devicesPeak valueElectricity

The present invention is an inverted III-nitride light-emitting device (LED) with enhanced total light generating capability. A large area device has an n-electrode that interposes the p-electrode metallization to provide low series resistance. The p-electrode metallization is opaque, highly reflective, and provides excellent current spreading. The p-electrode at the peak emission wavelength of the LED active region absorbs less than 25% of incident light per pass. A submount may be used to provide electrical and thermal connection between the LED die and the package. The submount material may be Si to provide electronic functionality such as voltage-compliance limiting operation. The entire device, including the LED-submount interface, is designed for low thermal resistance to allow for high current density operation. Finally, the device may include a high-refractive-index (n>1.8) superstrate.

Owner:LUMILEDS +1

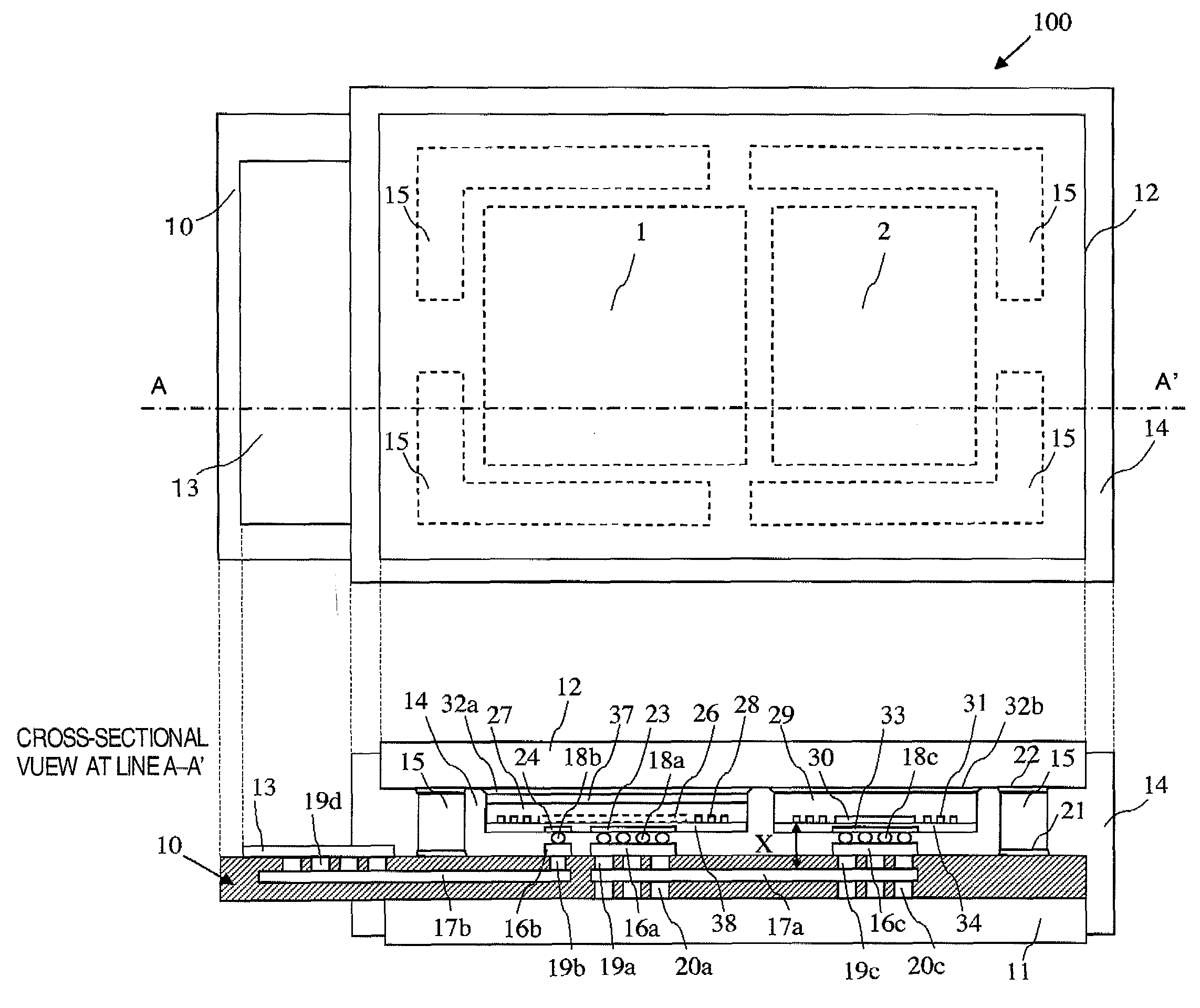

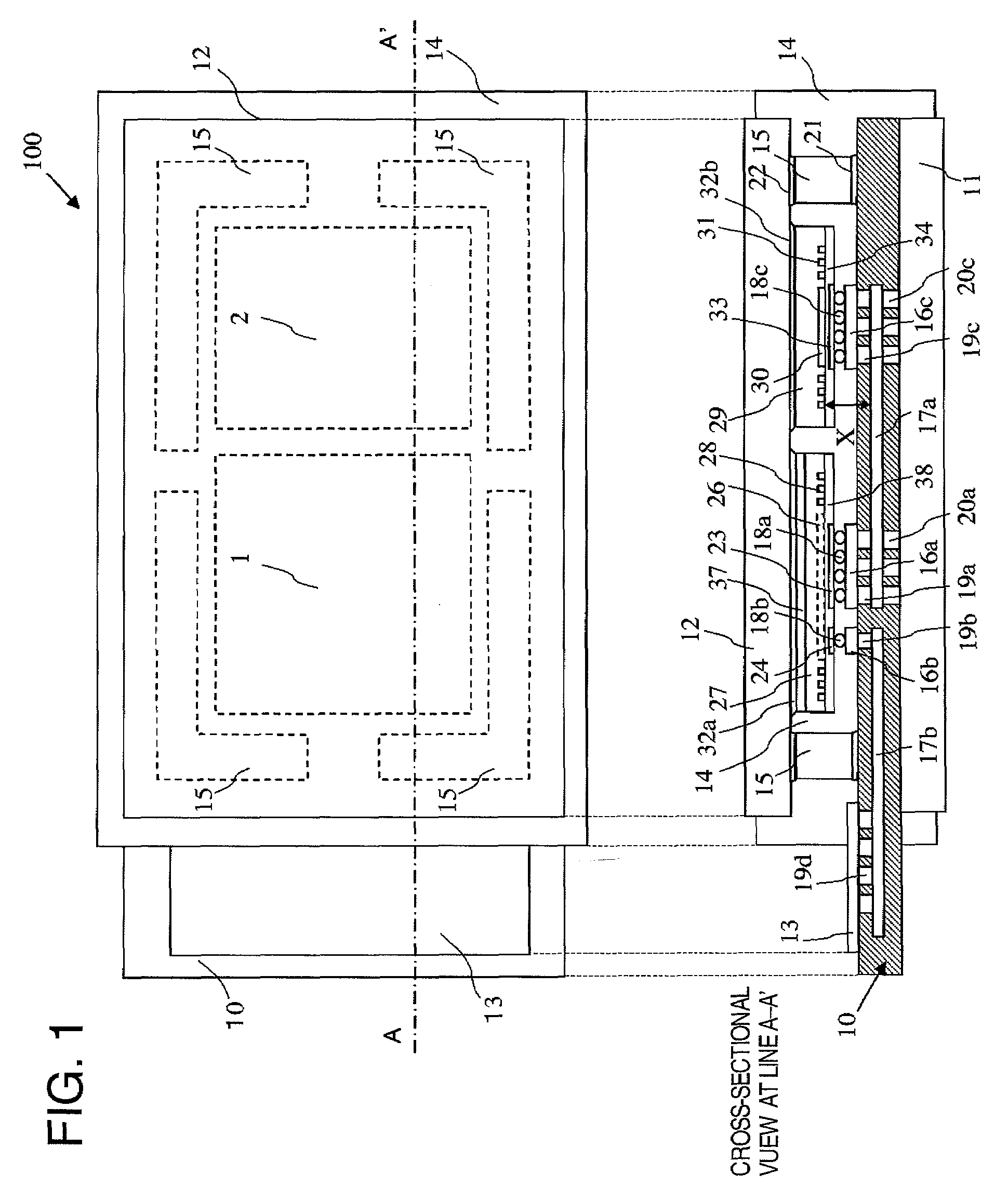

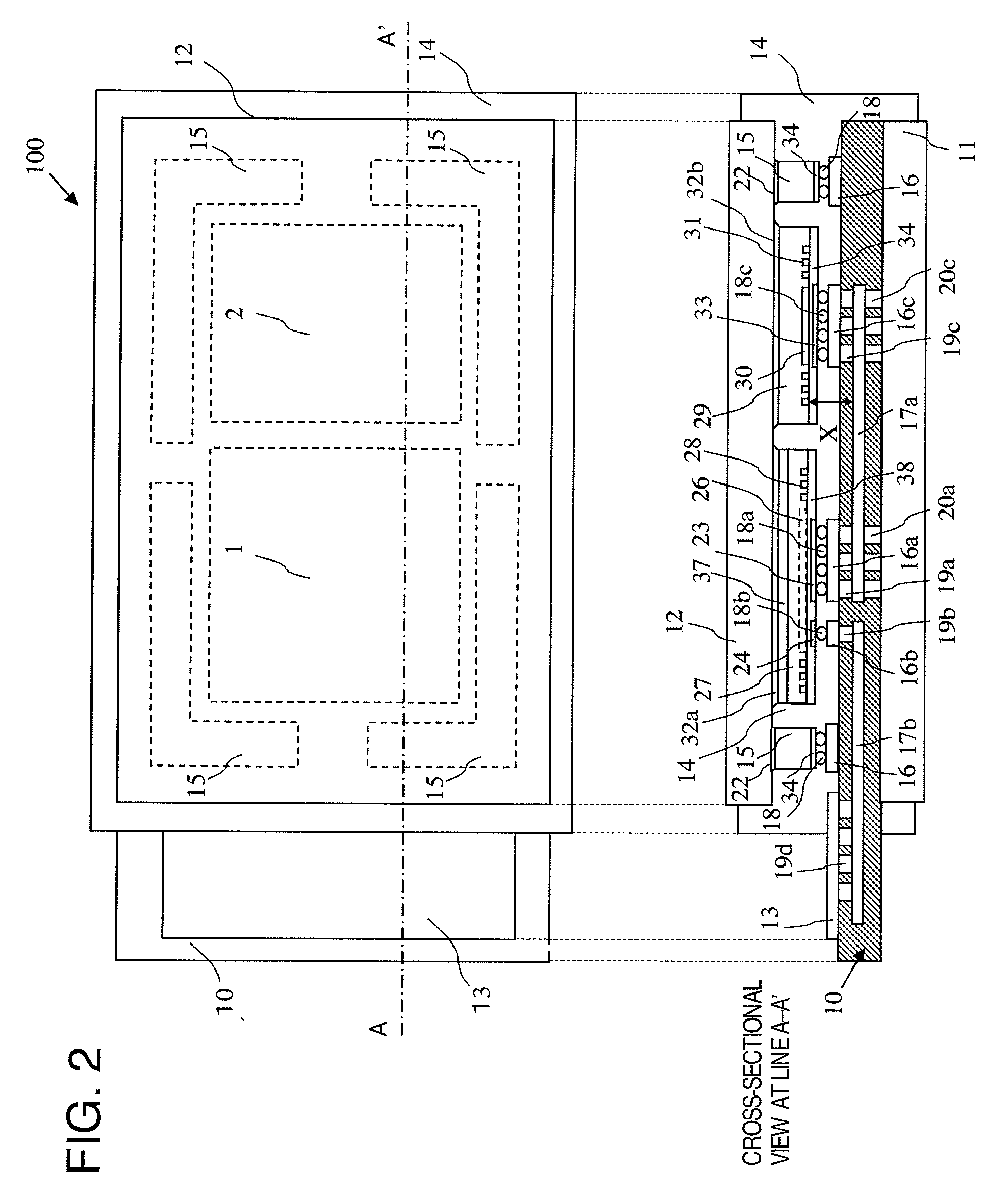

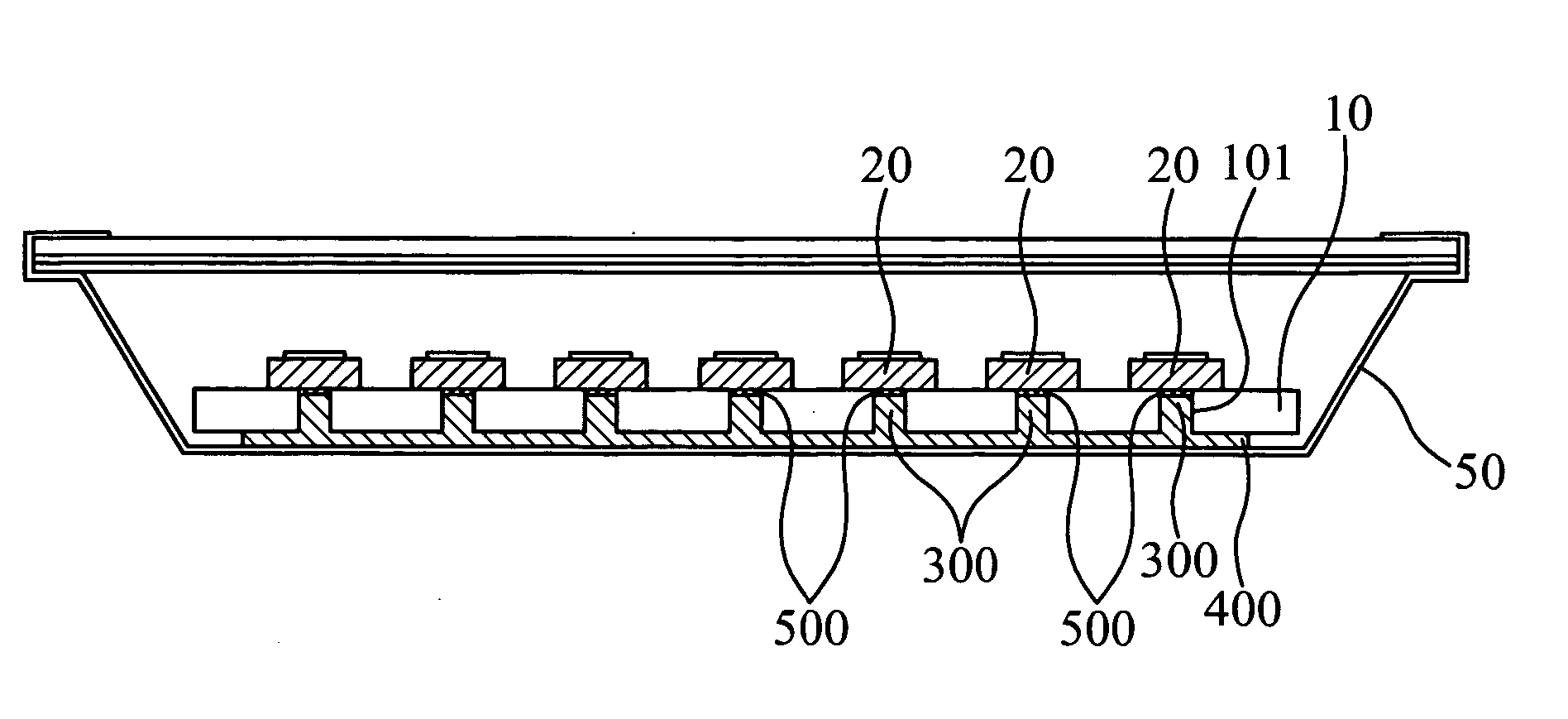

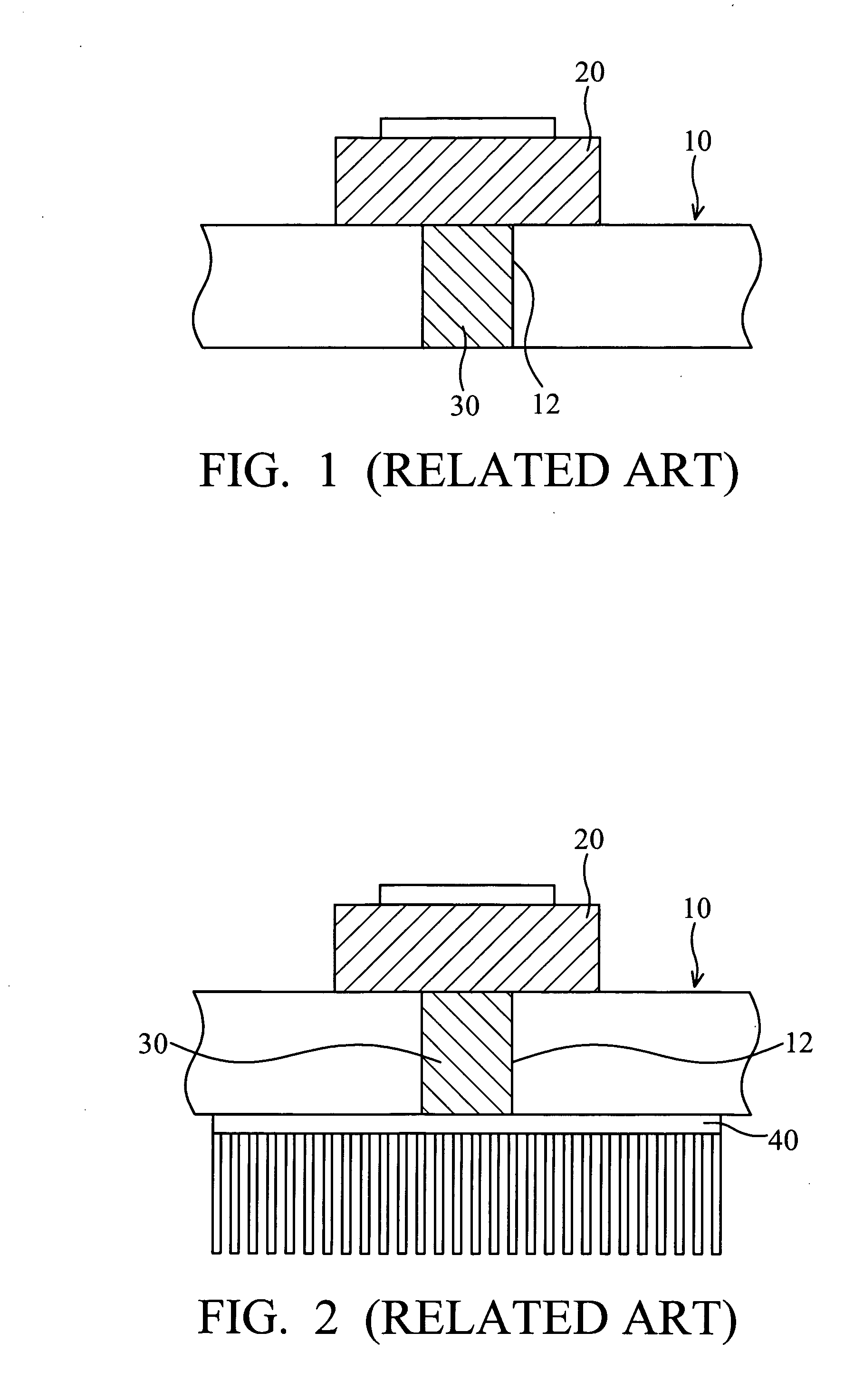

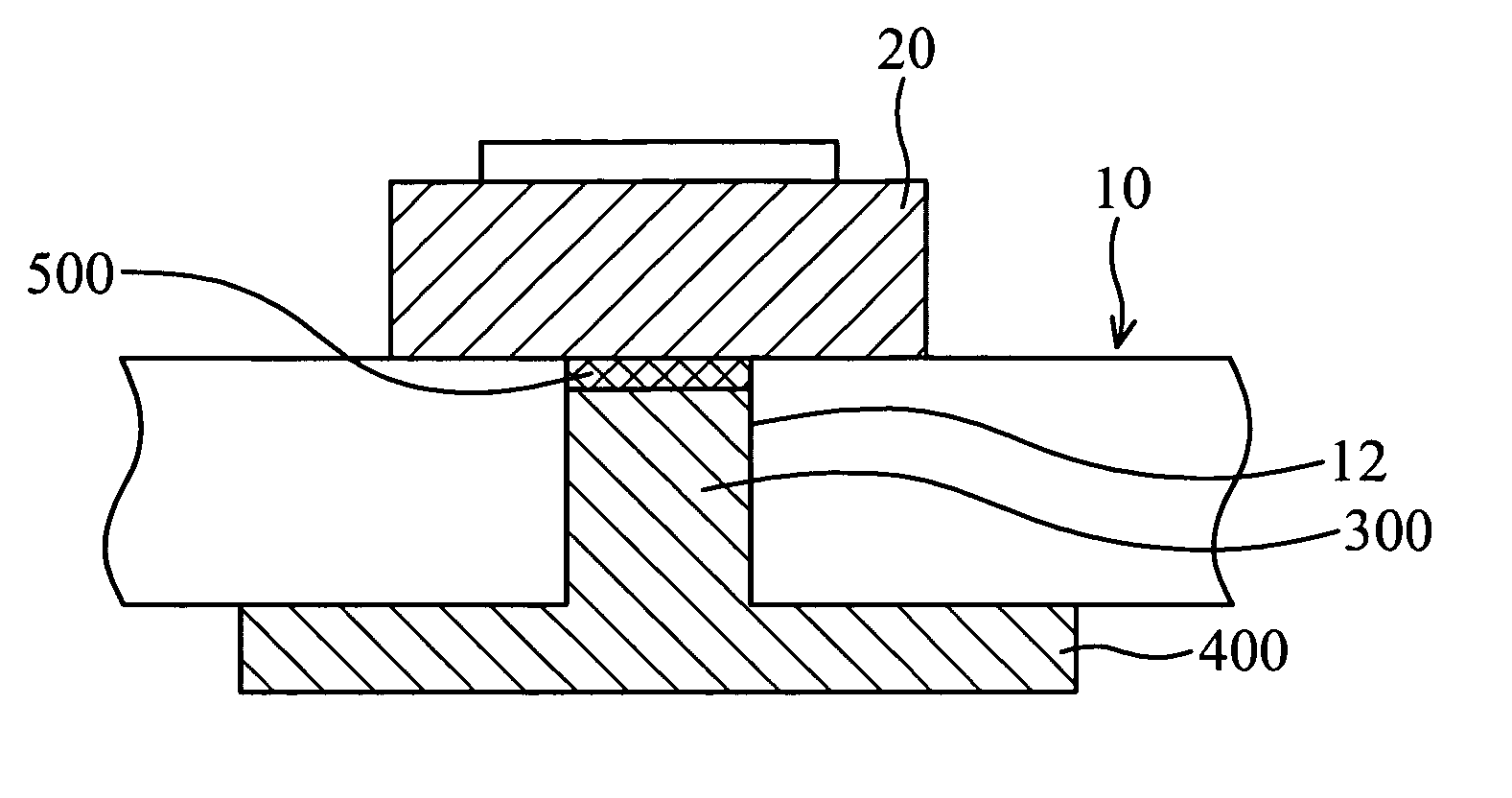

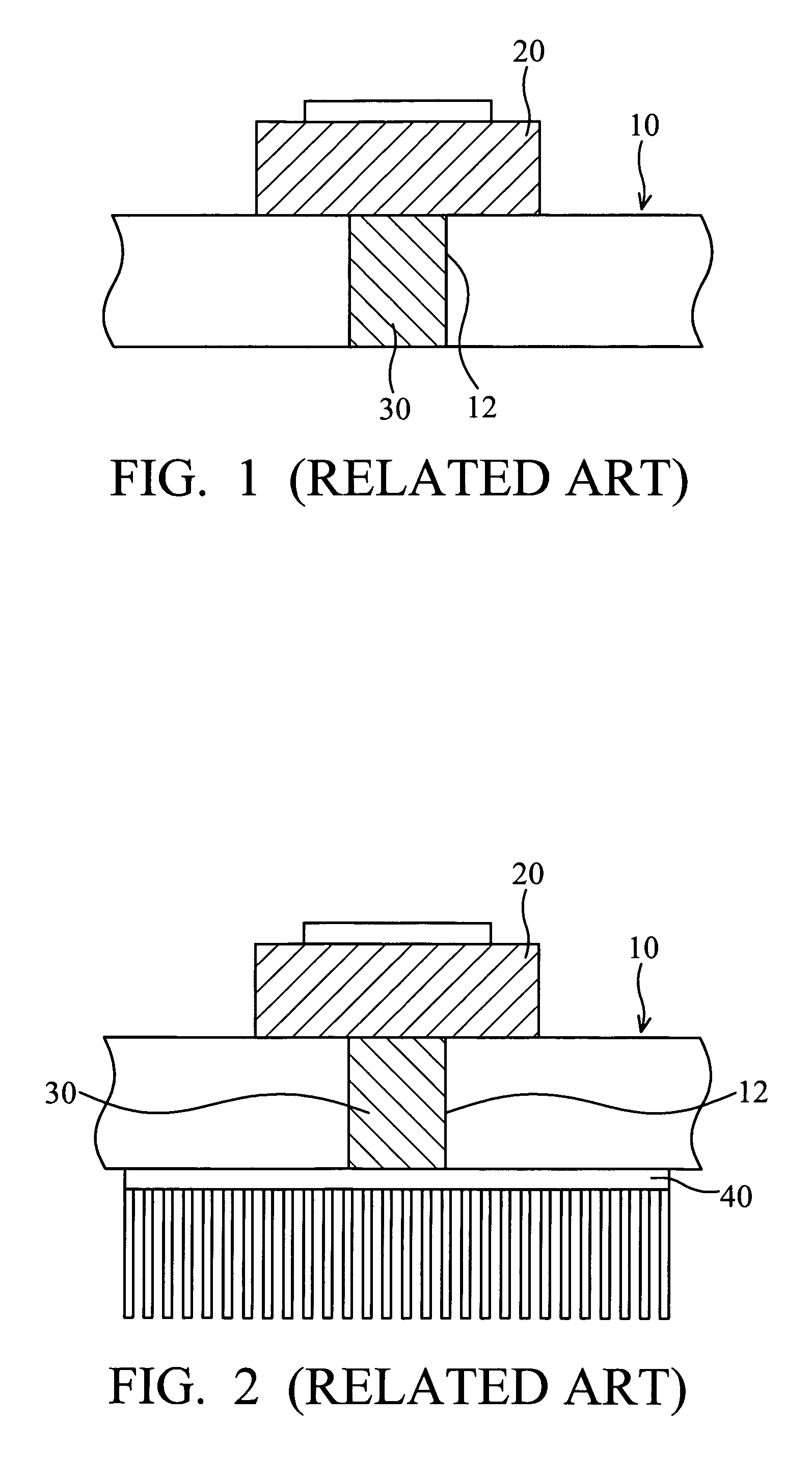

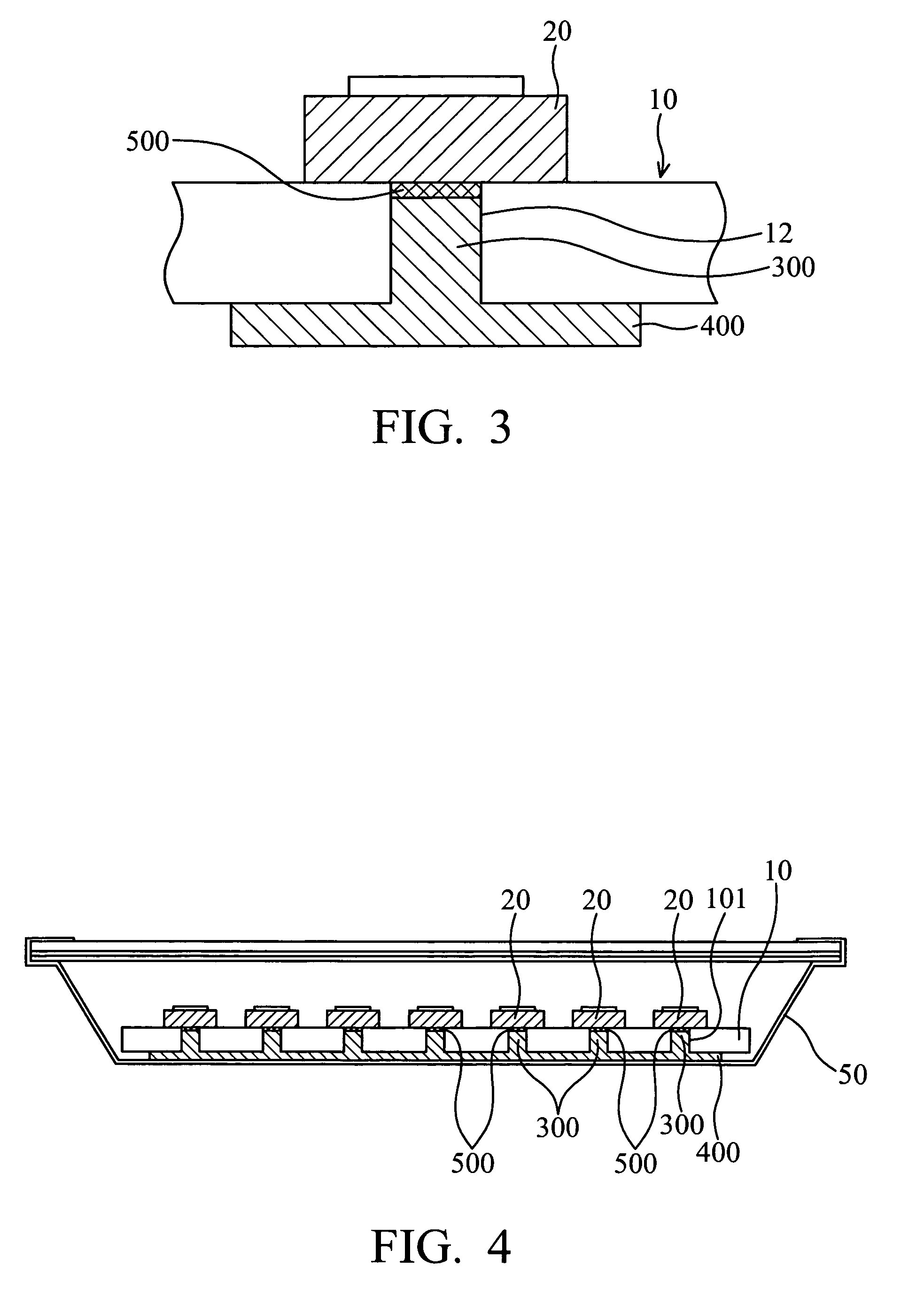

Backlight module and heat dissipation structure thereof

ActiveUS20050180142A1Easy to assembleImprove dissipation efficiencyPoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

A backlight module and heat dissipation structure thereof. The heat dissipation structure is used for a backlight module which comprises a circuit board having a through hole with a light emitting diode (LED) corresponding thereto and disposed on one side of the circuit board. The heat dissipation structure comprises a heat conducting portion thermo-conductively connected to the LED and positioned in the through hole, a thermal conductive element disposed between the heat conducting portion and the LED, and a heat dissipating portion thermo-conductively connected to the heat conducting portion. Heat from the LED is conducted through the thermal conductive element and the heat conducting portion to the heat dissipation portion.

Owner:AU OPTRONICS CORP

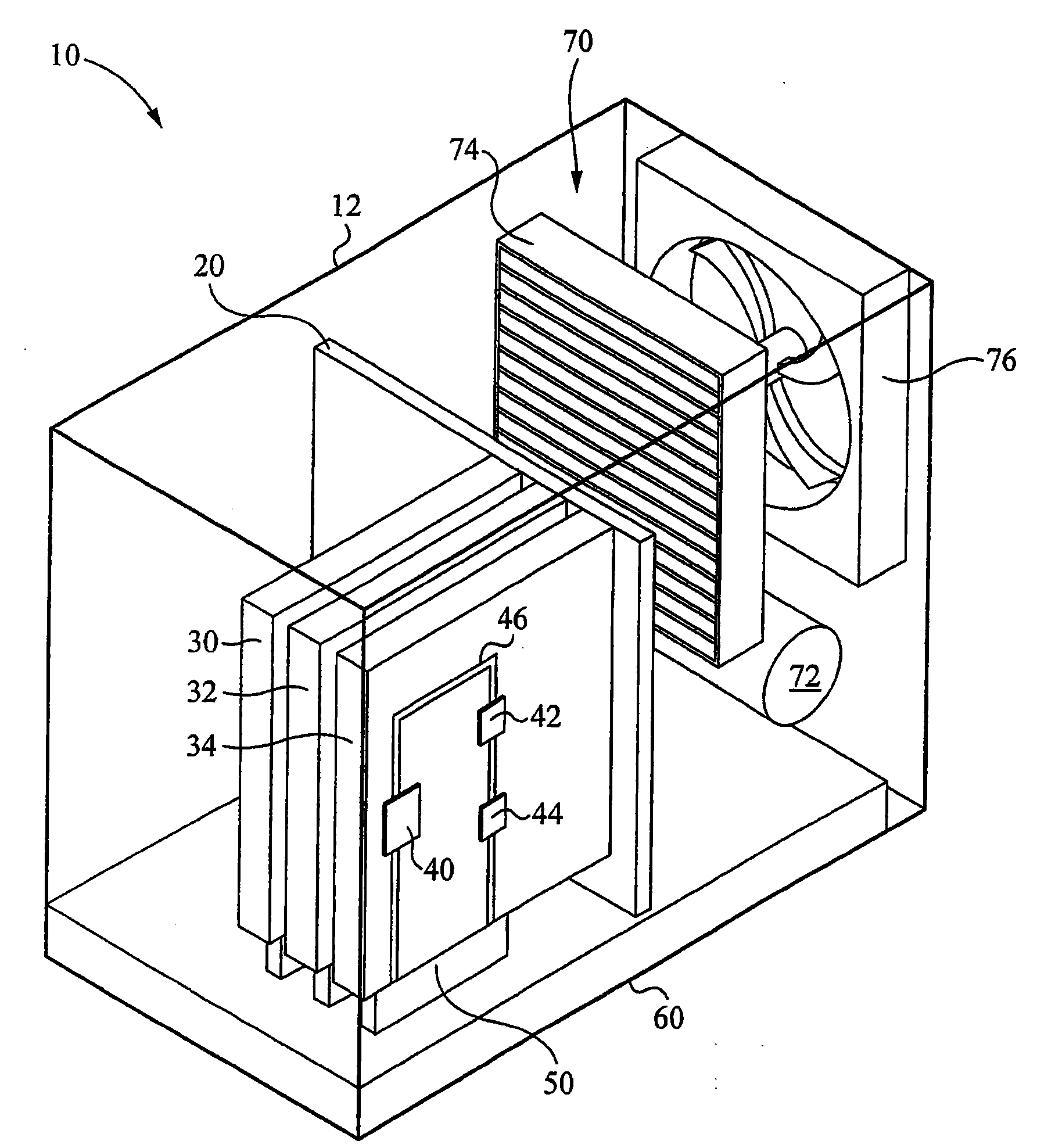

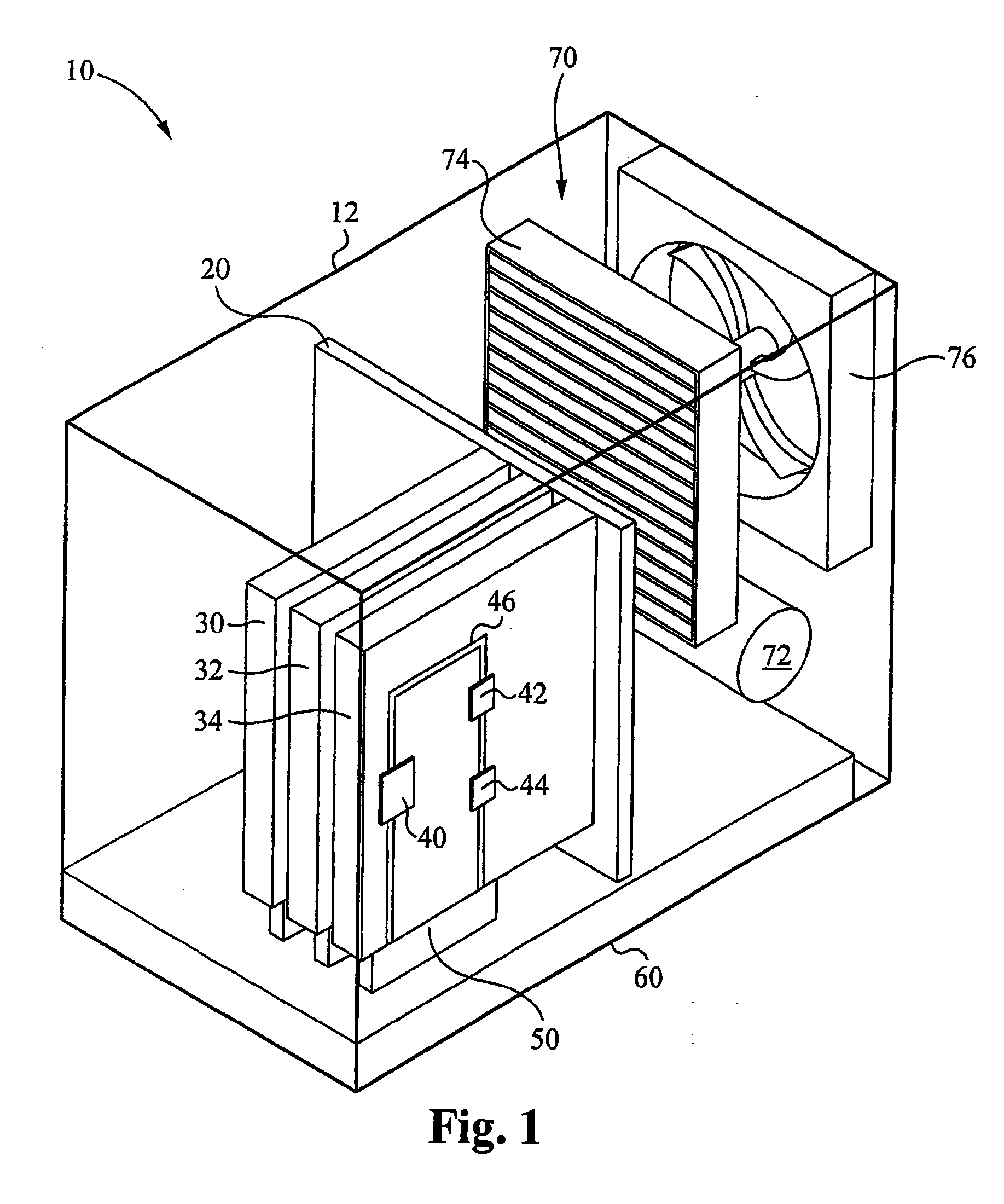

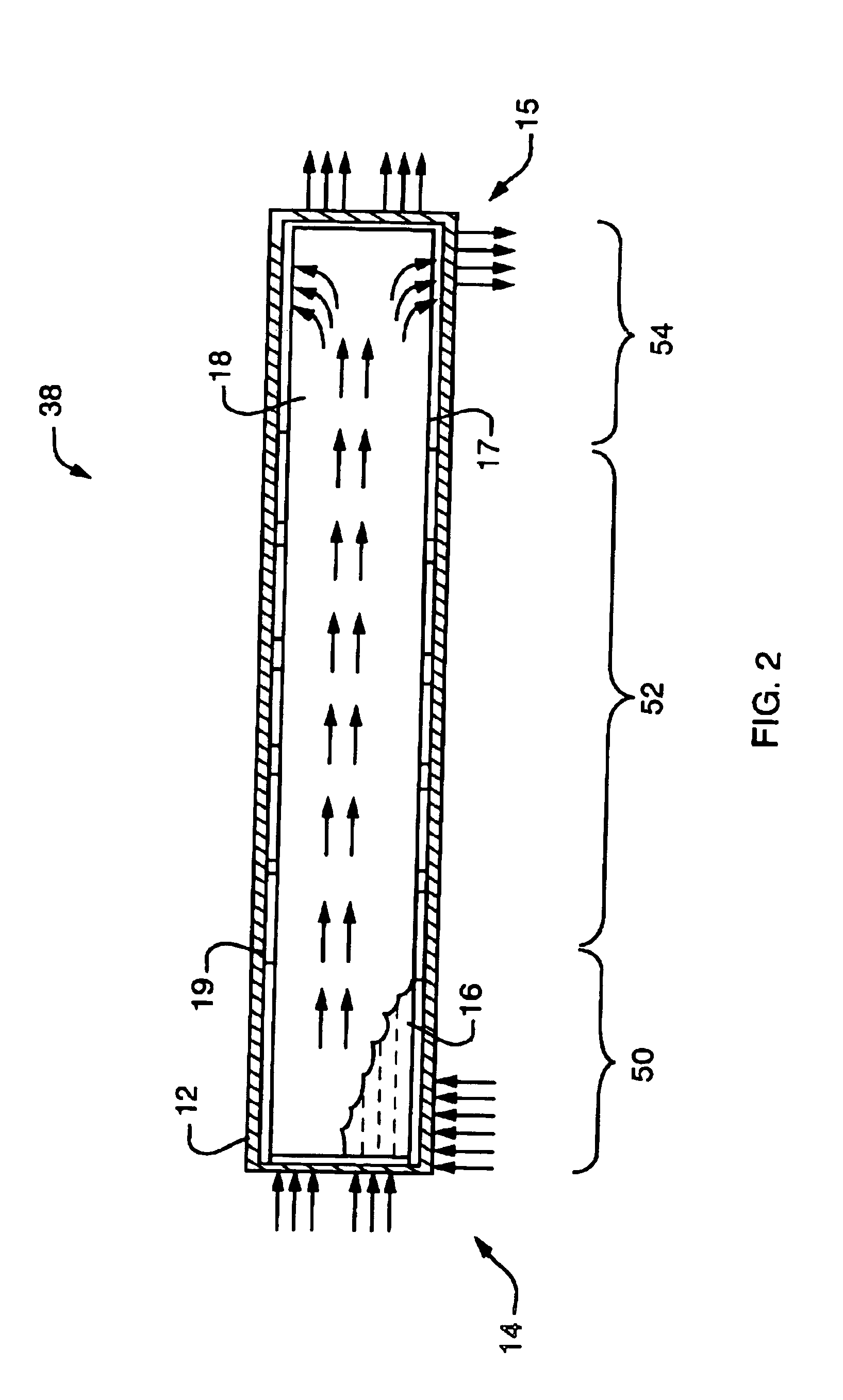

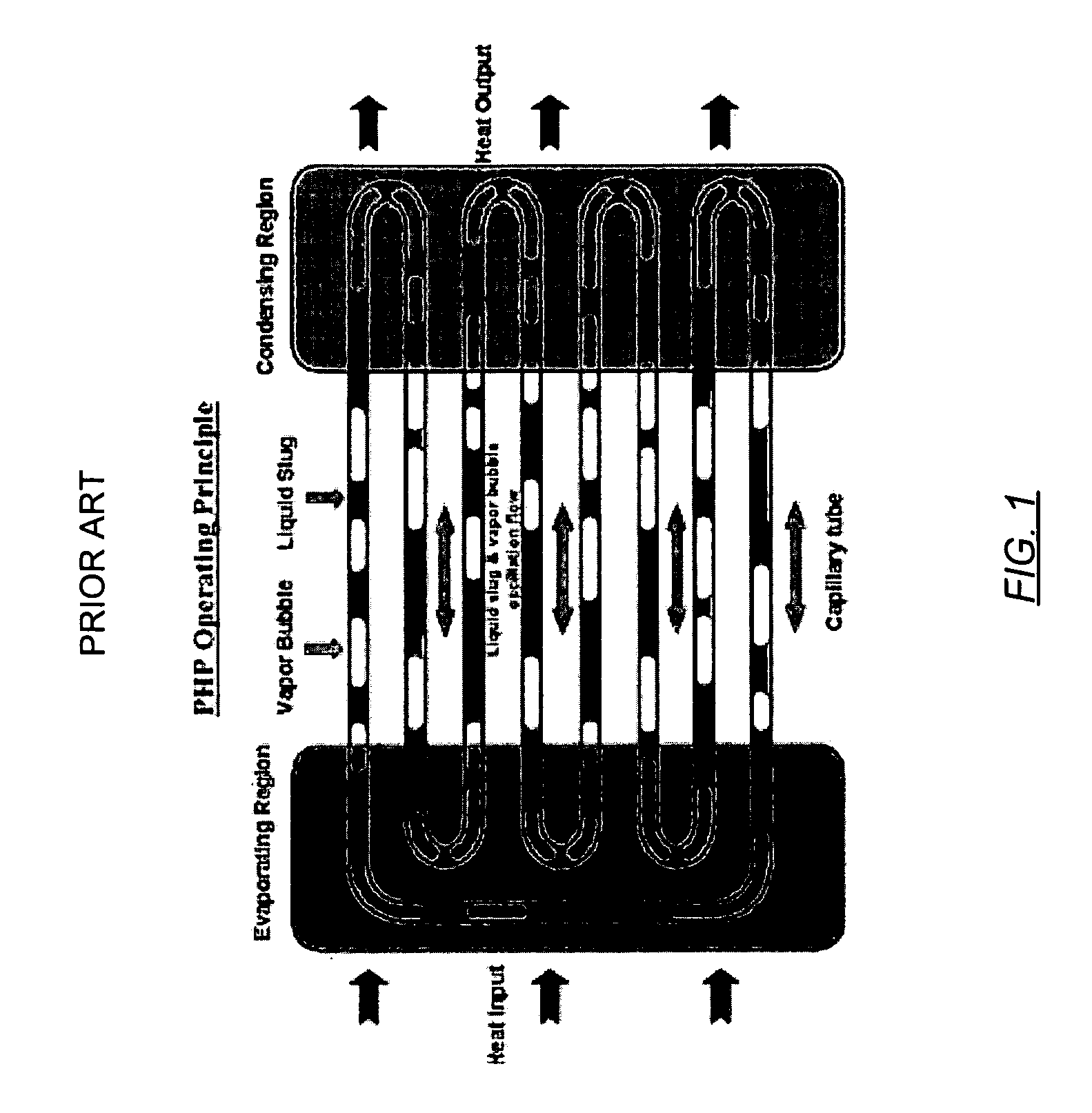

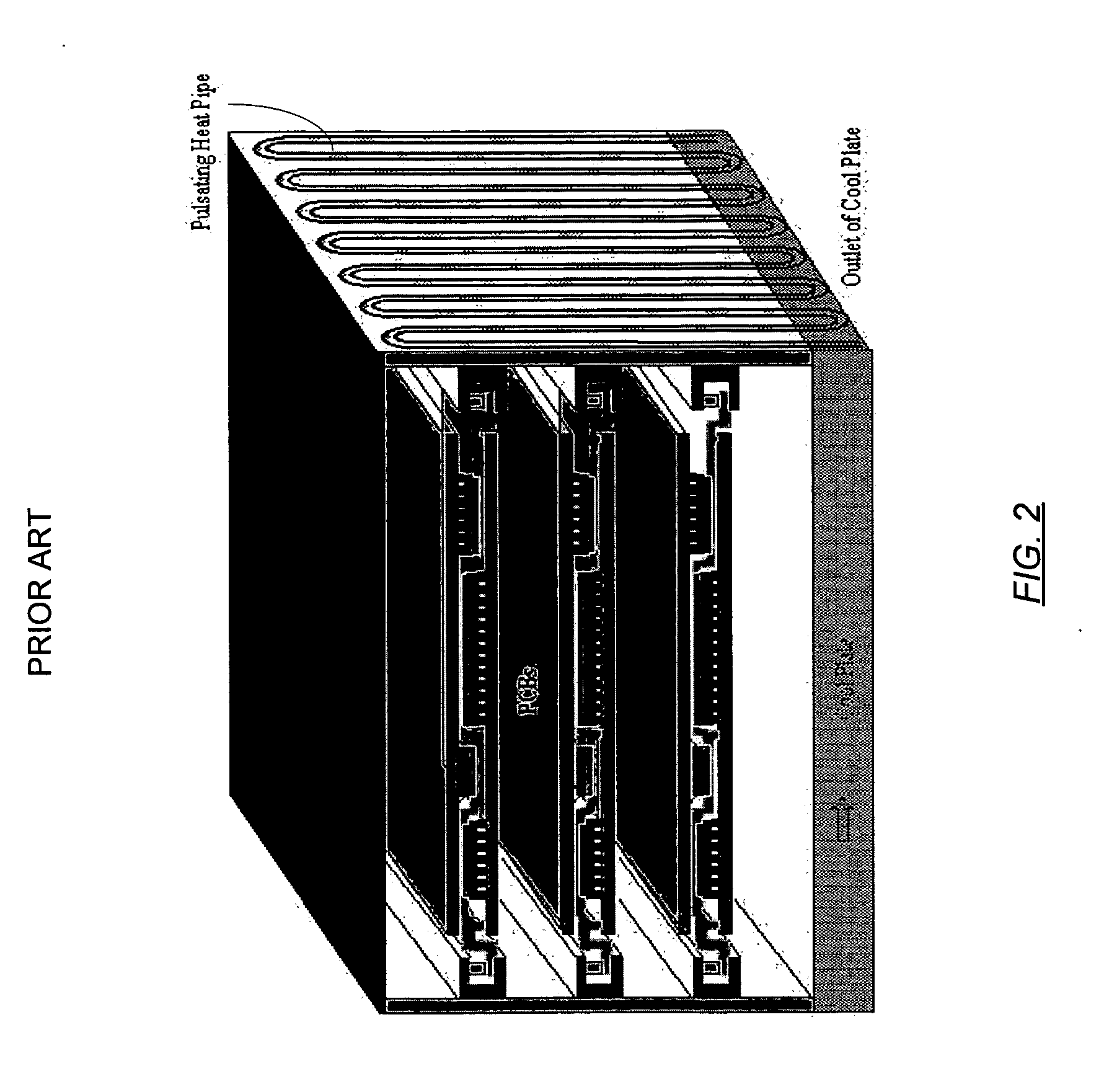

Cooling apparatus, system, and associated method

ActiveUS20060146496A1Readily and effectively transfer heat away from printed circuit boardMinimal amount of spaceCircuit fluid transportIndirect heat exchangersEngineeringPrinted circuit board

A cooling apparatus, system, and method are provided. The cooling apparatus includes at least one printed circuit board having opposed major surfaces, and at least one electrical component or other heat source positioned on one major surface of the printed circuit board. The cooling apparatus also includes a pulsating heat pipe having at least a portion that is positioned to either extend along and proximate to one of the major surfaces or be embedded within the printed circuit board. As such, the pulsating heat pipe is capable of transferring heat from the printed circuit board.

Owner:THE BOEING CO

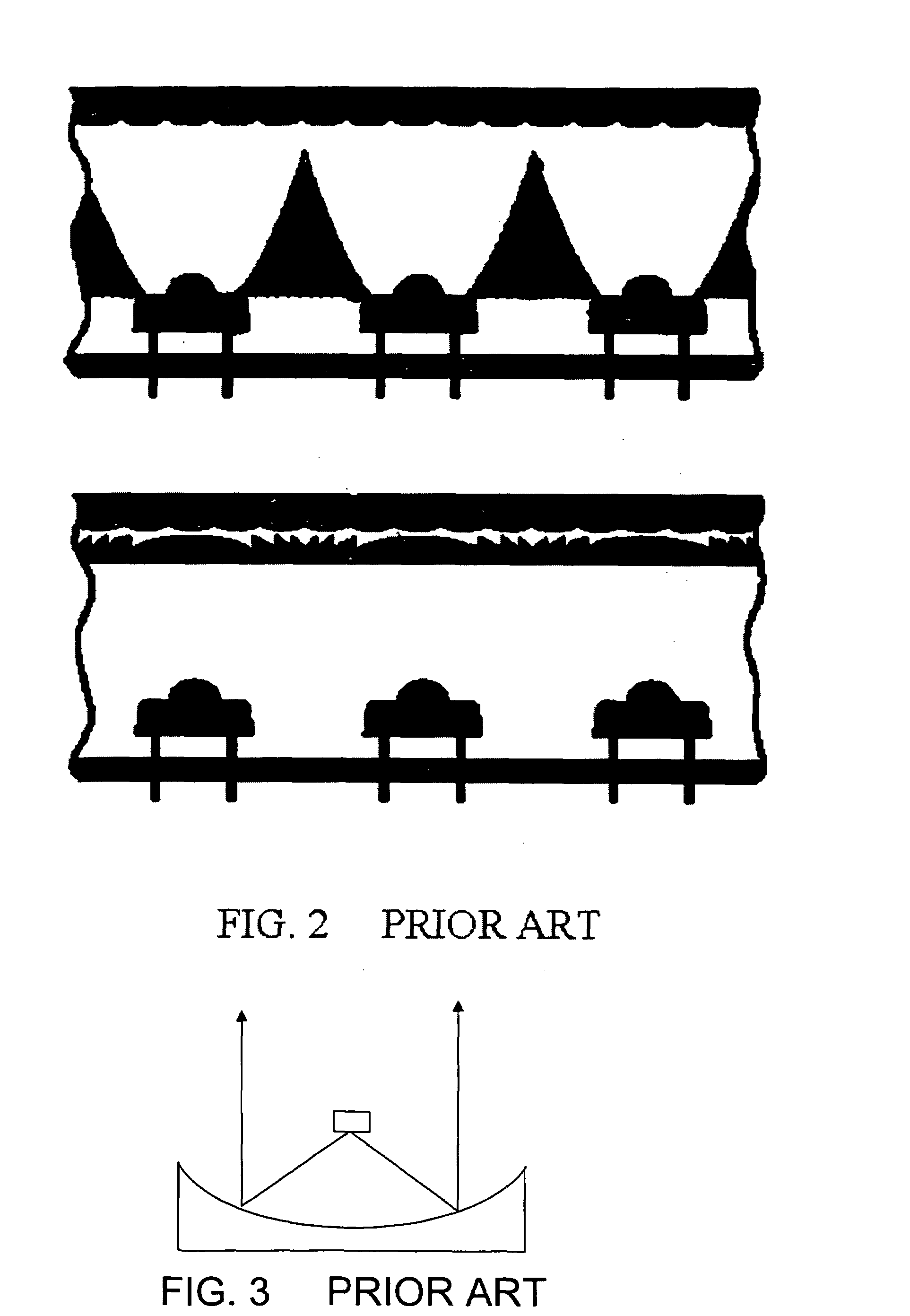

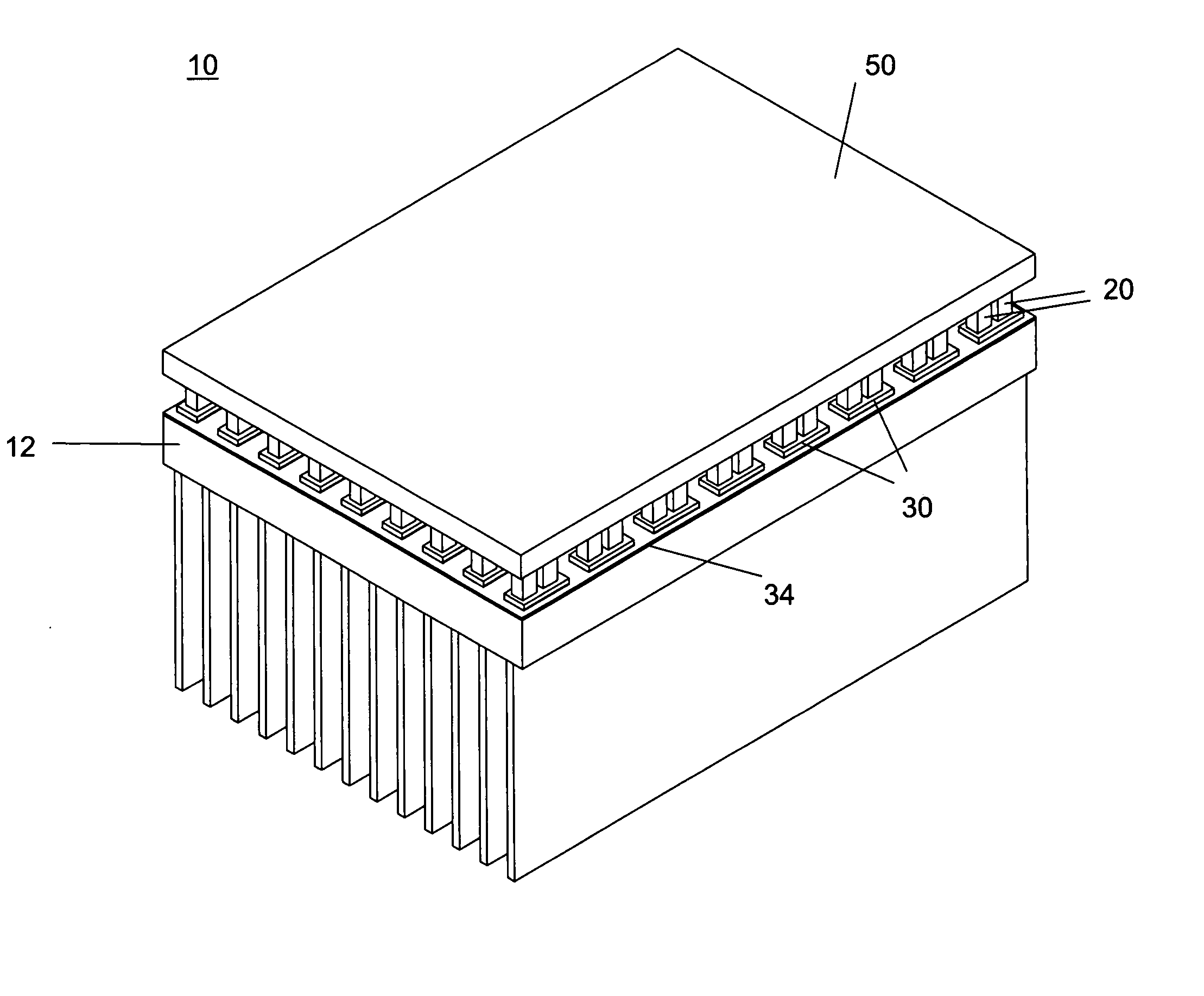

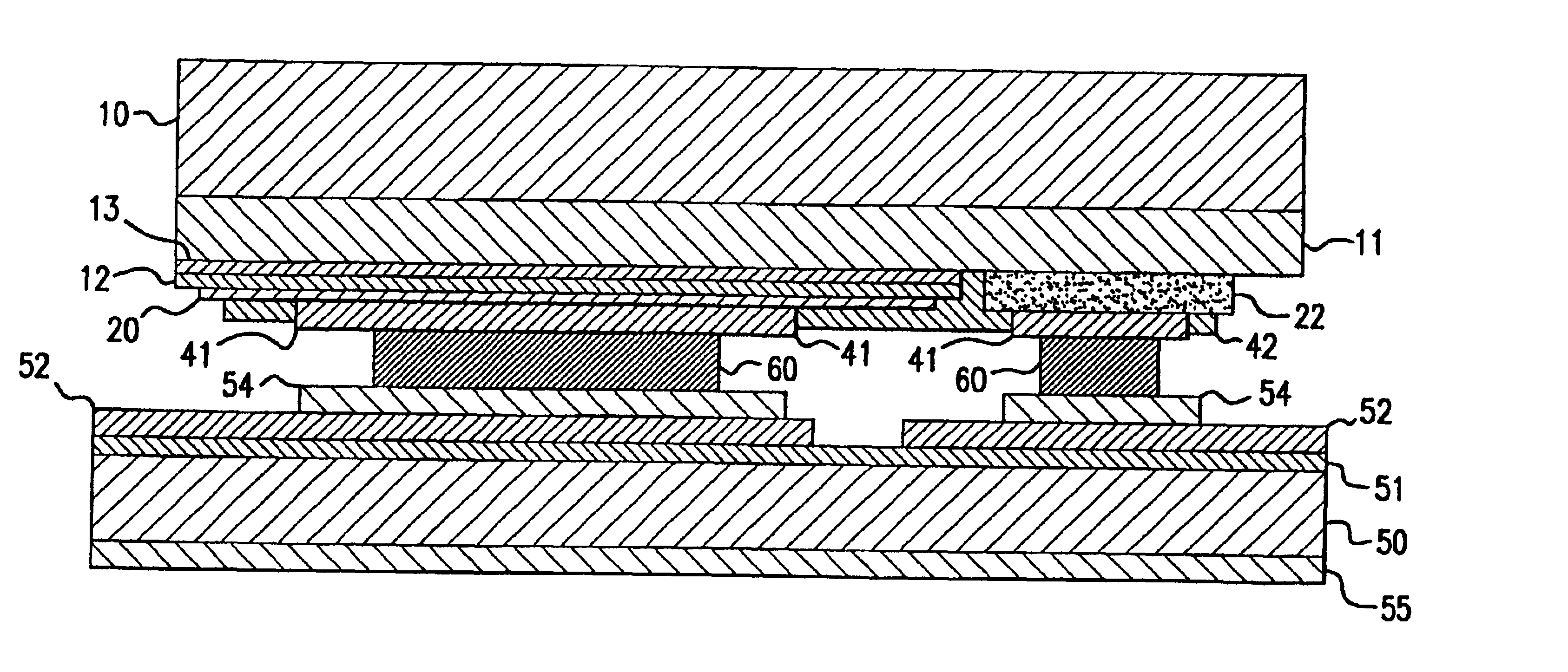

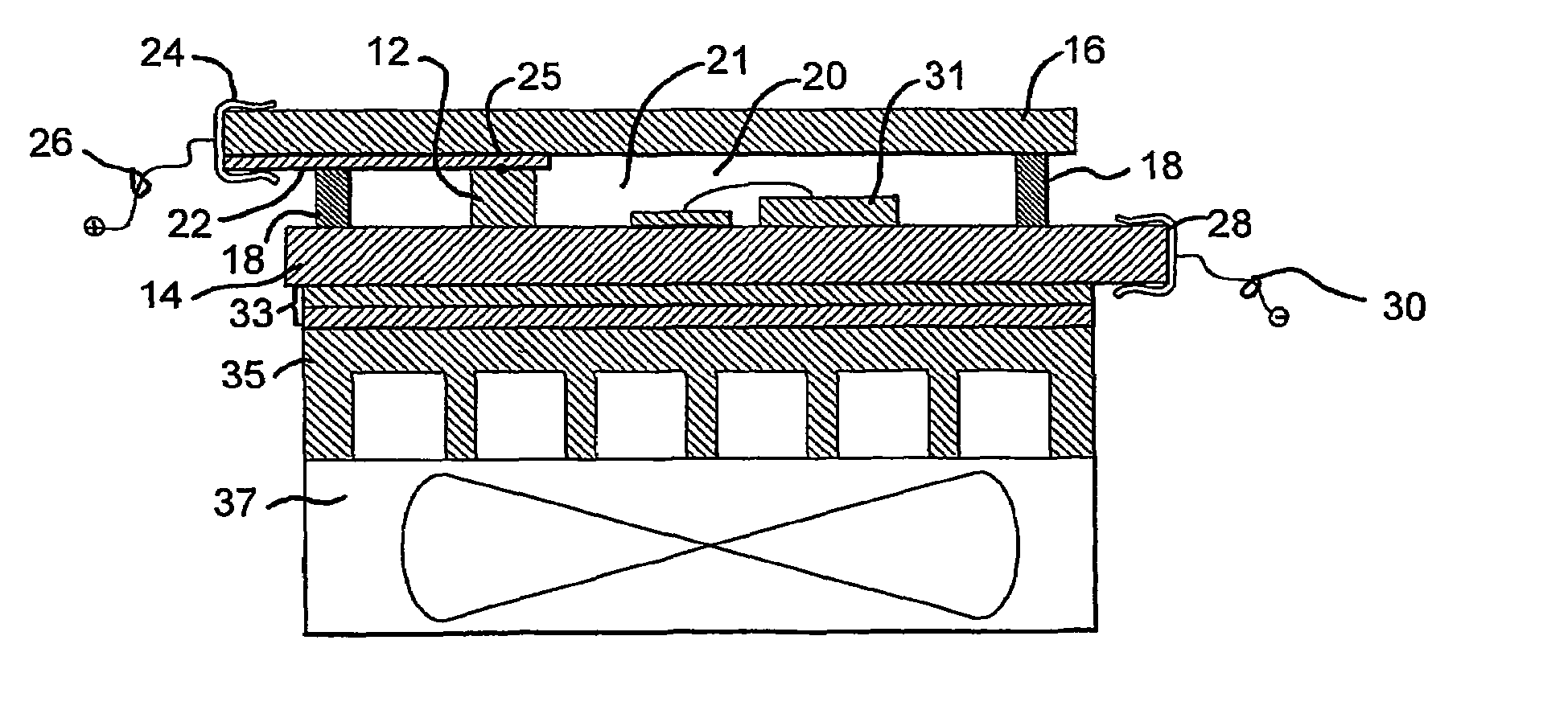

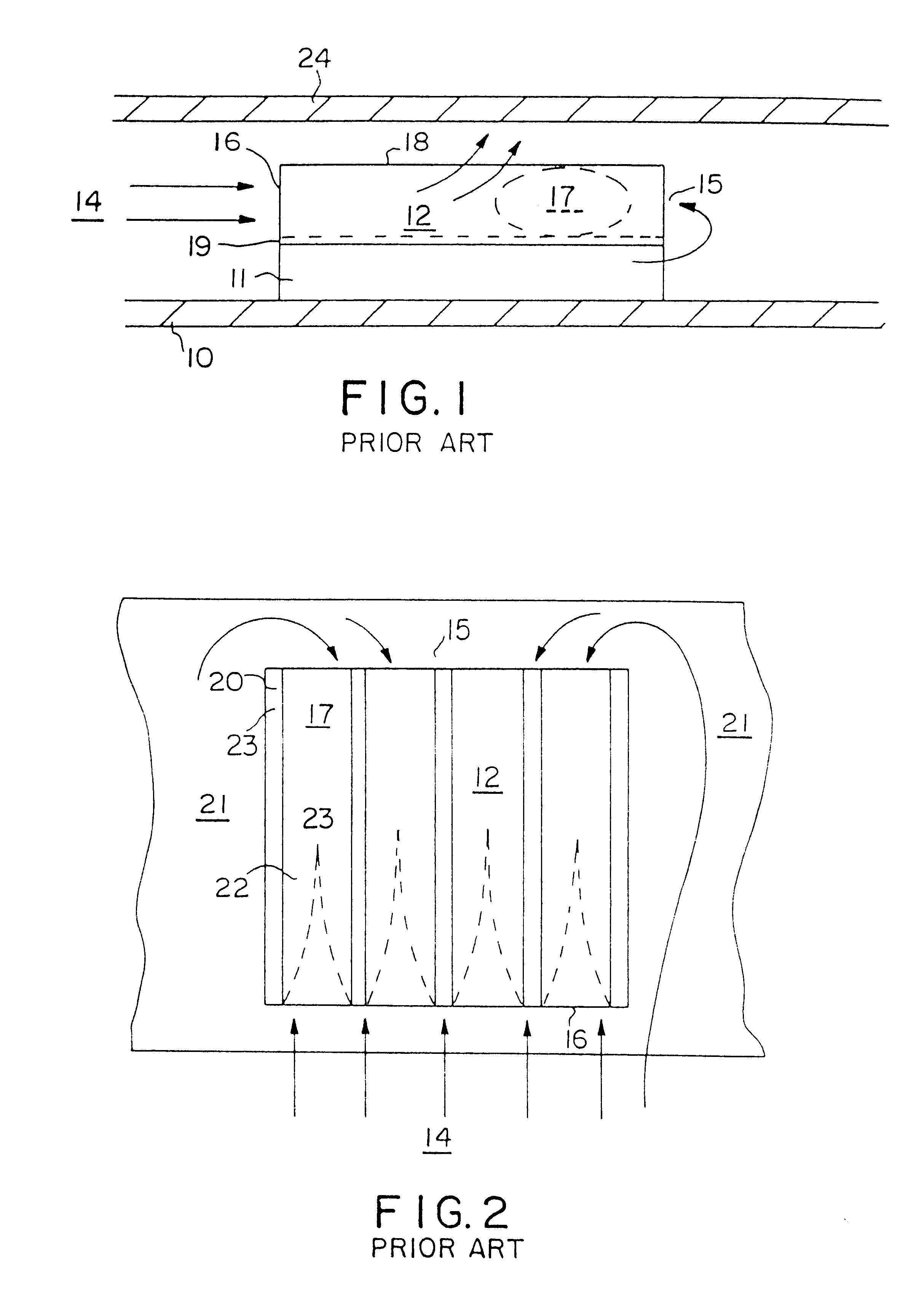

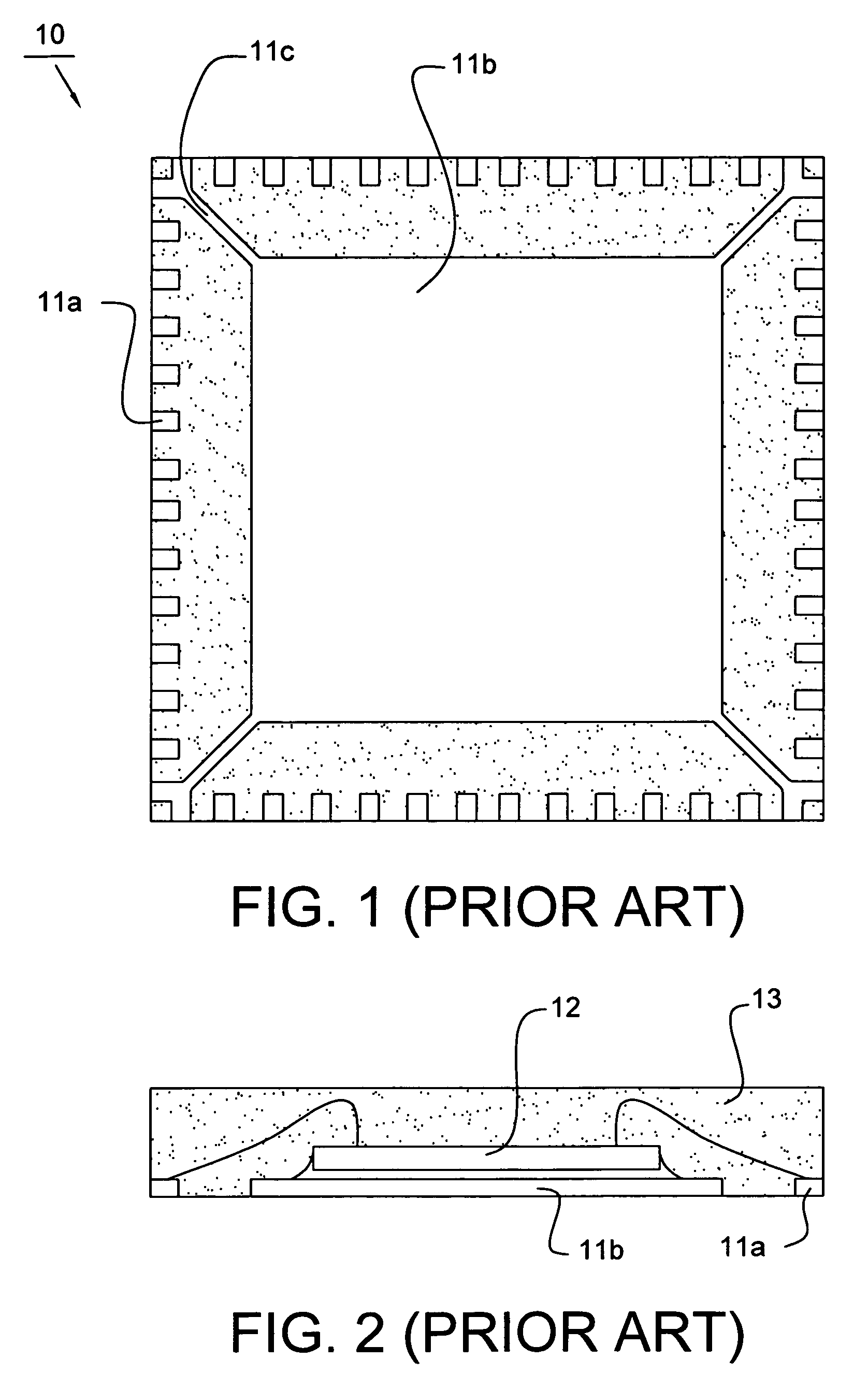

High power radiation emitter device and heat dissipating package for electronic components

InactiveUS7075112B2Increase powerReduce temperature riseSemiconductor/solid-state device detailsElectroluminescent light sourcesElectricityElectrical conductor

The electronic component package (10) of the present invention includes a sealed chamber; a liquid or gel (20) contained in the sealed chamber; at least one electronic component (12) disposed in the sealed chamber in physical and thermal contact with the liquid or gel (20); and at least one electrical conductor electrically coupled to the electronic component and extending out of the sealed chamber. The electronic component(s) (12) may include any one or combination of a radiation emitter, a thermal or optical sensor, a resistor, and a microprocessor or other semiconductor component.

Owner:GENTEX CORP

Backlight module and heat dissipation structure thereof

ActiveUS6966674B2Easy to assembleImprove efficiencyPoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

Owner:AU OPTRONICS CORP

Light emitting diode for mounting to a heat sink

ActiveUS7625104B2Reduce thermal resistancePoint-like light sourceLighting support devicesAdhesiveEngineering

Owner:LUMILEDS

Heatsink apparatus

InactiveUS20060171801A1Reduce thermal resistanceImprove cooling efficiencyPump componentsSemiconductor/solid-state device detailsPump chamberEngineering

A heatsink apparatus has a radiator and a centrifugal pump in a closed circulation channel for circulating a coolant, wherein the centrifugal pump contacting a heat-generating component dissipates heat from the heat-generating component through heat exchange with the coolant. The centrifugal pump includes: a lower casing provided with a contact surface that contacts the heat-generating component; an upper casing; a ring-shaped sealing member provided between the lower and upper casings so as to form a round heat transfer chamber between the ring-shaped sealing member and the lower casing and to form a pump chamber that houses an impeller between the ring-shaped sealing member and the upper casing; a guiding member provided protruding on the lower casing to make the round heat transfer chamber a circulation channel; and the round heat transfer chamber connecting to a through-hole formed in a central portion of the ring-shaped sealing member.

Owner:PANASONIC CORP

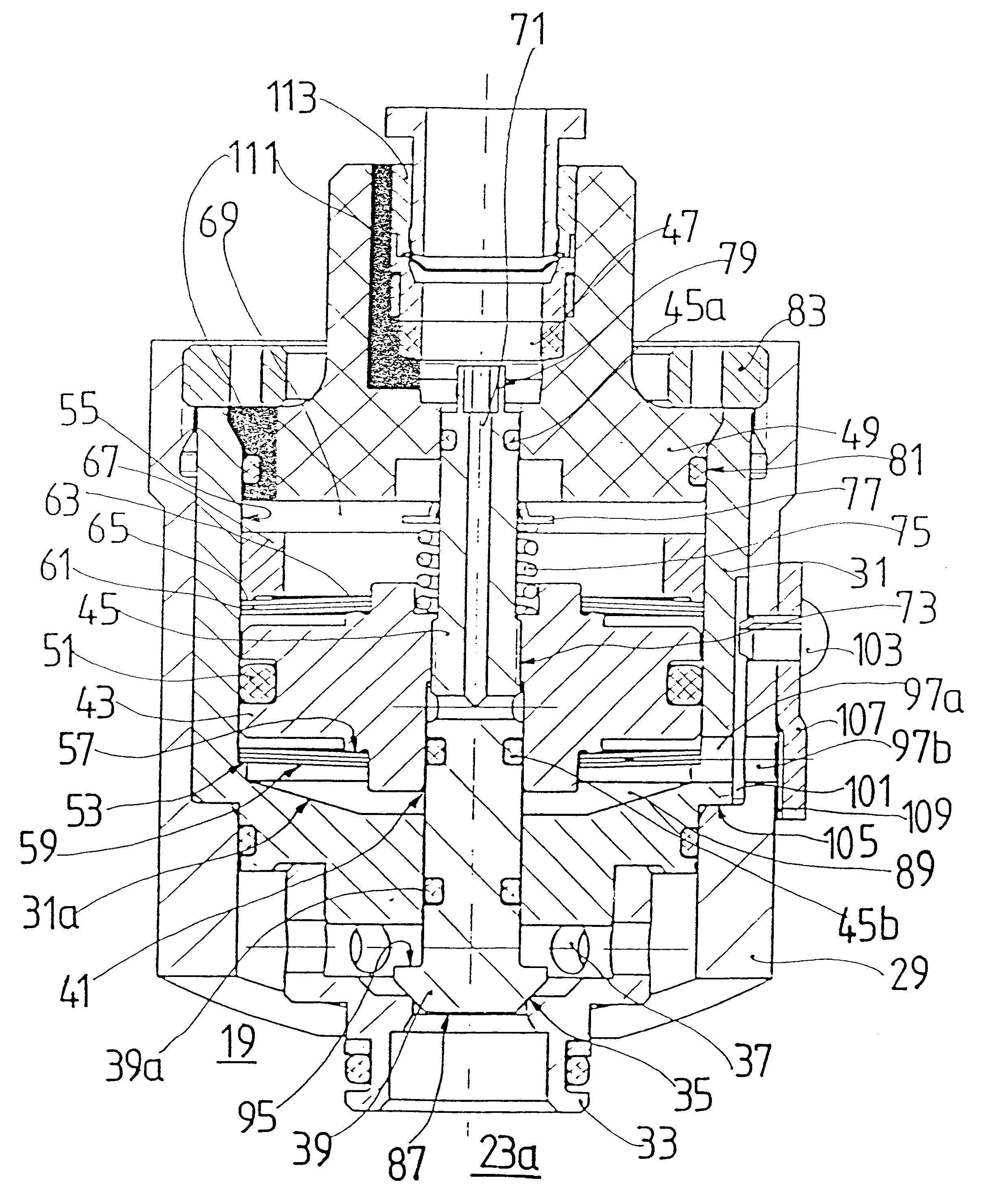

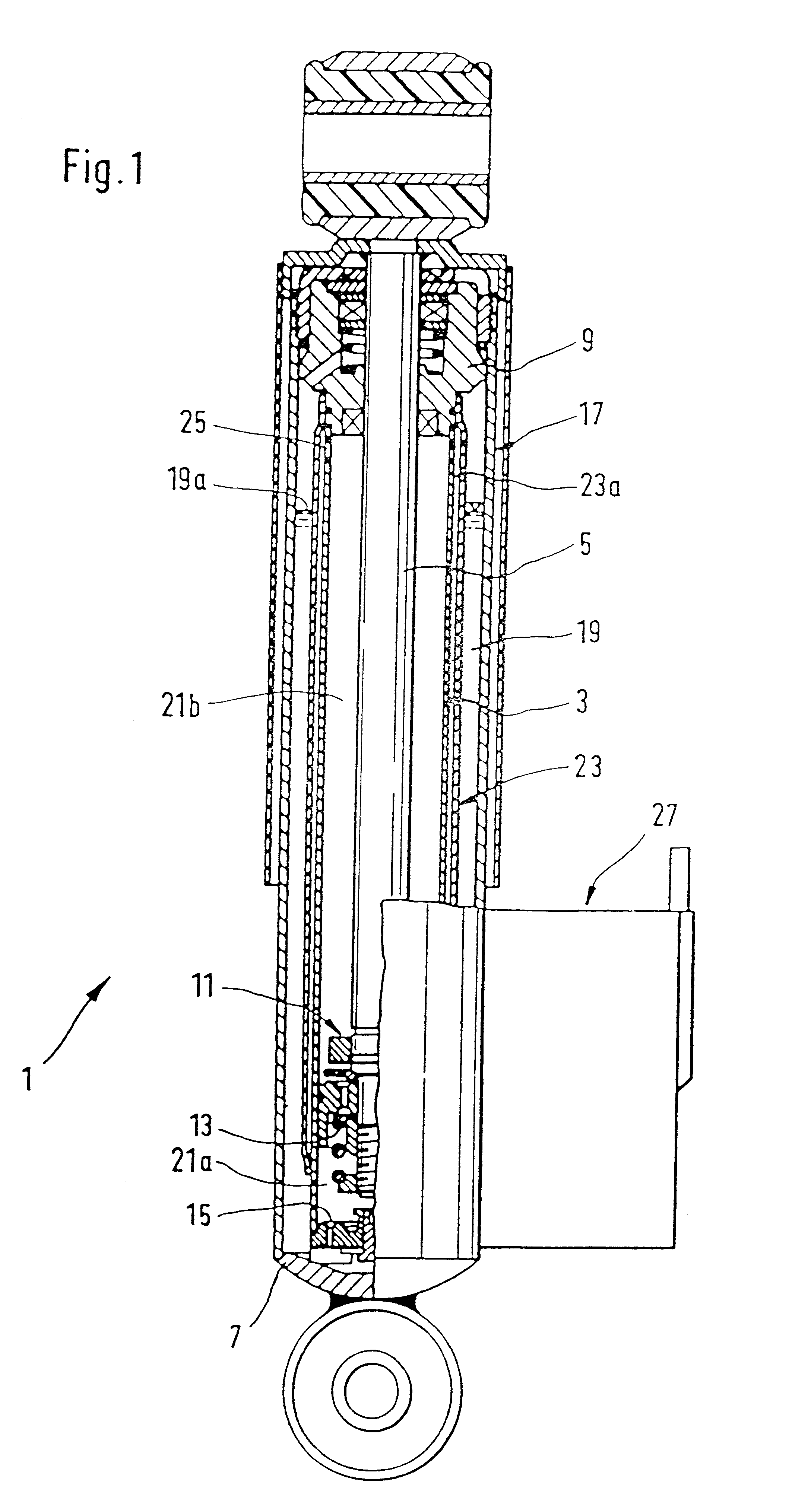

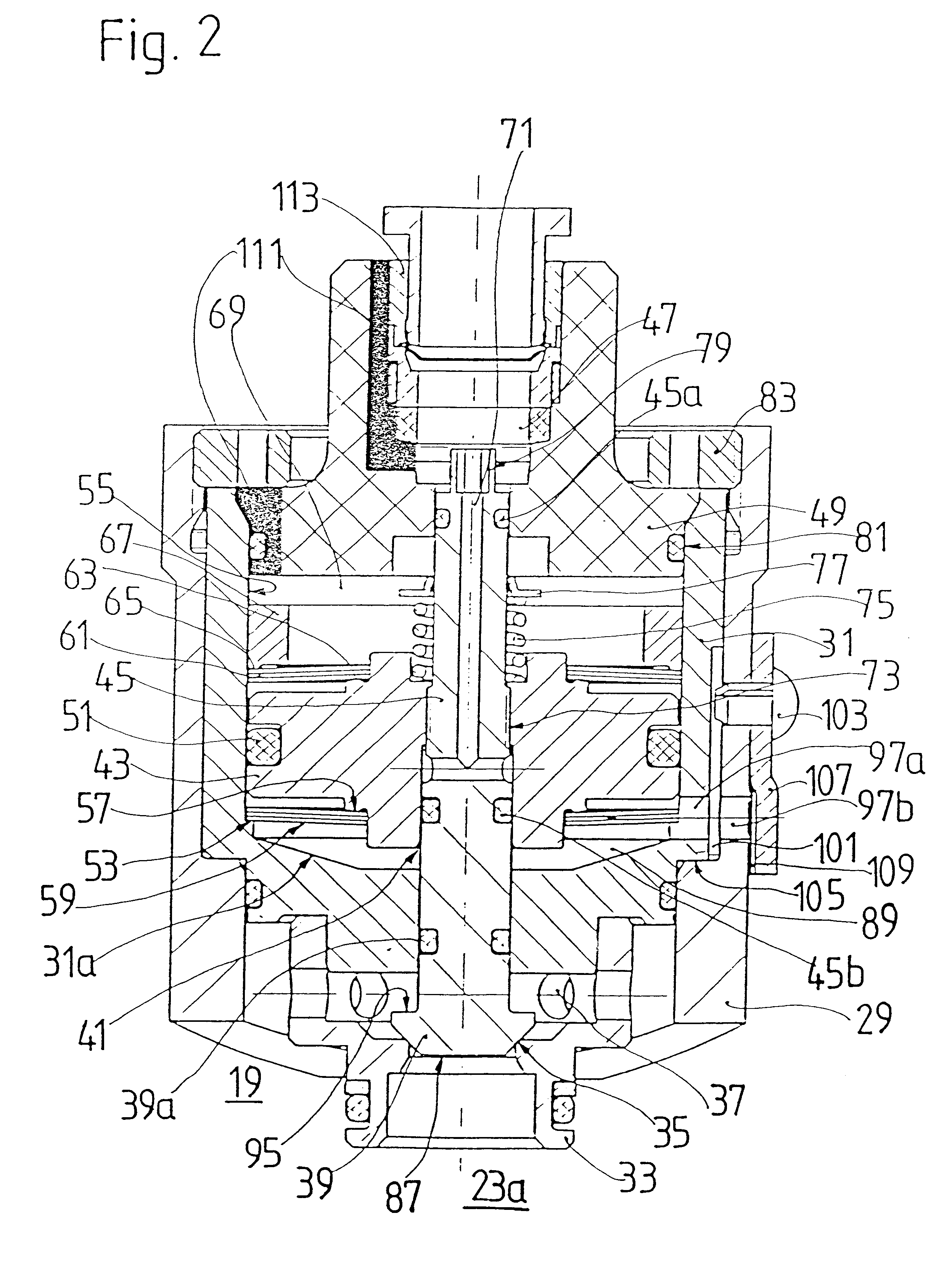

Valve which reacts as a function of pressure, especially for a vibration damper

InactiveUS6305512B1Reduce thermal resistanceIncrease control pressureSpringsSprings/dampers design characteristicsMechanical engineeringVibration damper

A pressure operated valve is provided including an adjusting device, a spring and a vent connection. The adjusting device is axially movably arranged in a pressure chamber defined in the valve and comprises a valve body and a pressure intensifier. A space between the valve body and valve face defines a valve passage cross section. The spring is operatively arranged for holding the pressure intensifier in a floating arrangement in the pressure chamber. The pressure intensifier has a first side exposed to a pressure in the pressure connection opening and a second side facing away from the pressure connection opening. The second side of the pressure intensifier and the adjusting device define a low pressure chamber within the pressure chamber. The vent connection is an inflow restrictor arranged between the lower pressure chamber and a space having a lower pressure than the low pressure chamber.

Owner:ZF FRIEDRICHSHAFEN AG

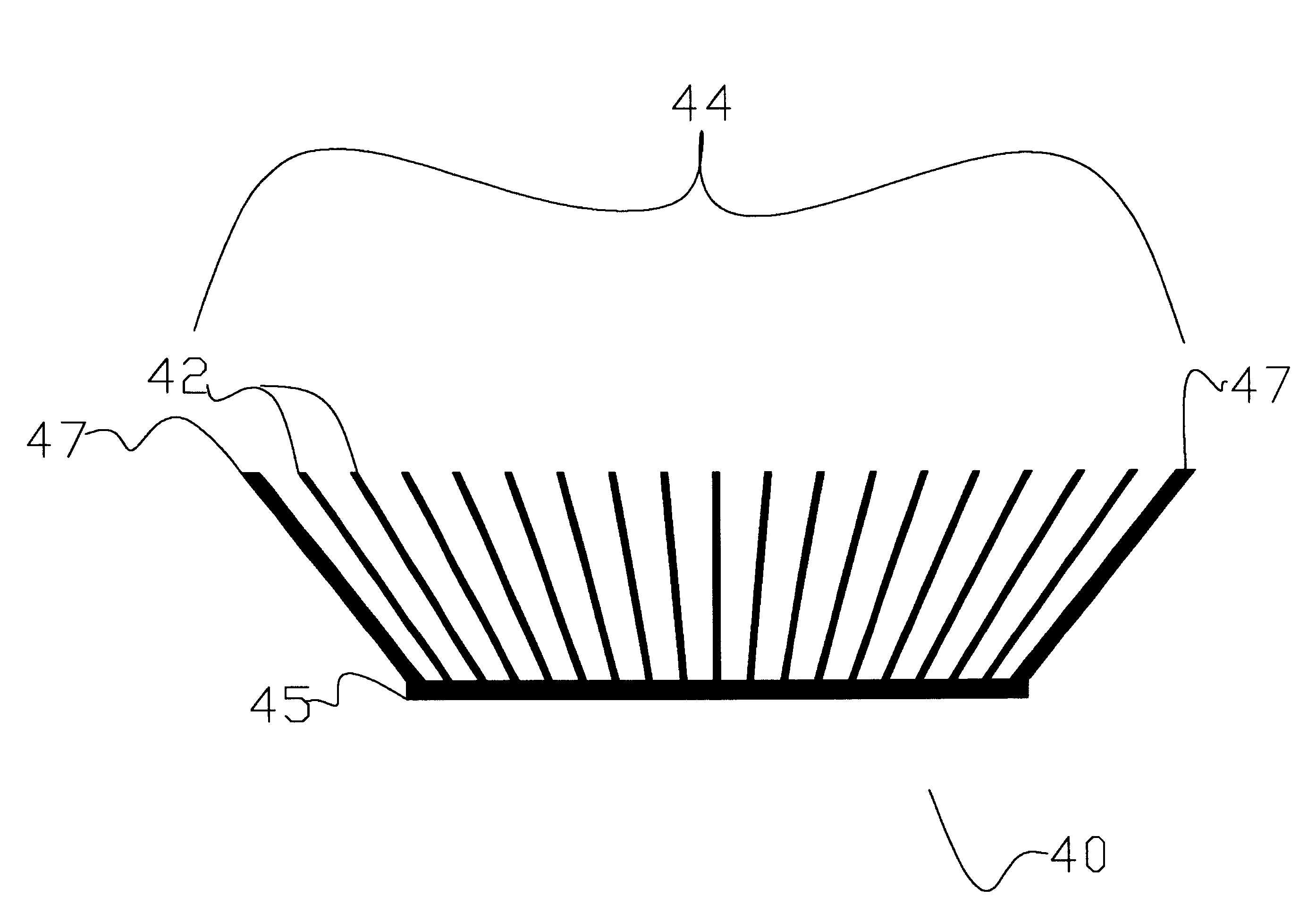

High performance fan tail heat exchanger

InactiveUS6308771B1Increased control volumeOptimize volumeSemiconductor/solid-state device detailsSolid-state devicesAcute angleEngineering

A novel plate fin heat exchanger adapted for high and low velocity fluid flows for dissipating heat from a heat generating component. The heat exchanger comprises an array of fins being affixed to and in thermal communication with a thermally conductive base, wherein the fins are arranged in a fan tail configuration for minimizing flow bypass, and further providing reduced thermal resistance for fluid passing through the fin field. The fins are affixed to and in thermal communication with the base at an acute angle, such that the effective width of the array of fins exceeds the width of the base. The enlarged effective width of the fin array in comparison to conventional heat exchanger provides an increased volume for fluid flow, thereby allowing a greater volume of fluid to enter the fin field and a greater surface area of plate fins for cooling the fluid passing through the heat exchanger. In addition, the heat exchanger comprises a fin density of at least ten fins per inch or greater of base length thereby providing a narrow channel heat exchanger with a fan tail. The aspect ratio of the individual channels between the fins, as compared to parallel fins affixed perpendicular to the base through an extrusion method, generates a reduced pressure drop across the heat exchanger. Accordingly, the heat exchanger of the present invention expands the envelope of cooling performance provided by fluid flow over an array of thermally conductive plates.

Owner:ADVANCED THERMAL SOLUTION

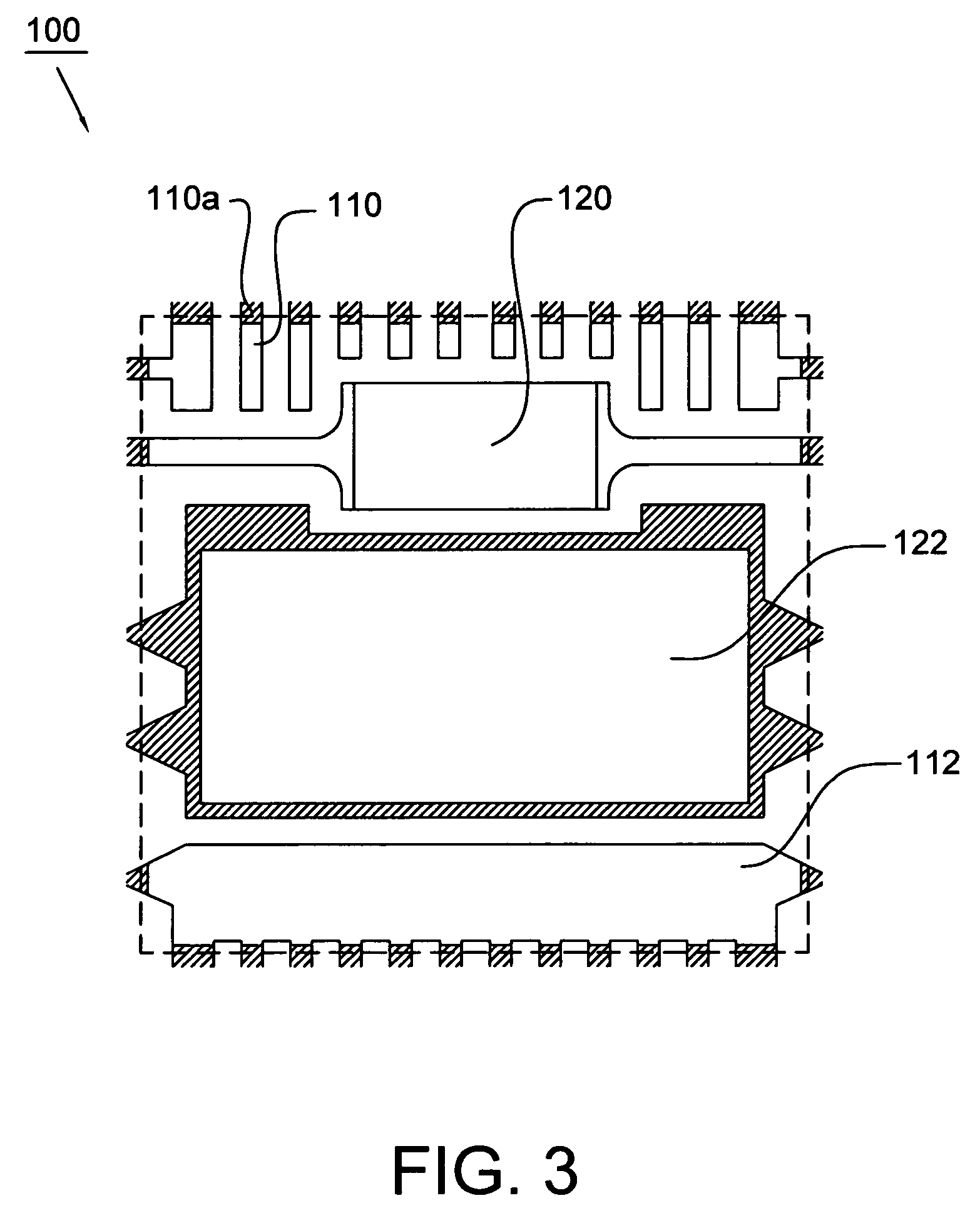

Leadless semiconductor package and manufacturing method thereof

ActiveUS7053469B2Reduce thermal resistanceLower on-resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A leadless semiconductor package mainly includes a semiconductor device securely attached to an upper surface of a die pad by solder paste and a plurality of leads arranged about the periphery of the die pad. The thickness of the leads and the die pad are within a range of 10 to 20 mils. The semiconductor device is electrically coupled to one of the leads. A package body is formed over the semiconductor device and the leads in a manner that the lower surfaces of the die pad and the leads are exposed through the package body. Preferably, the first semiconductor device is electrically coupled to one of the leads by at least one heavy gauge aluminum wire. The present invention further provides a method of producing the semiconductor package described above.

Owner:ADVANCED SEMICON ENG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com