Heat Pipe with Nanostructured Wick

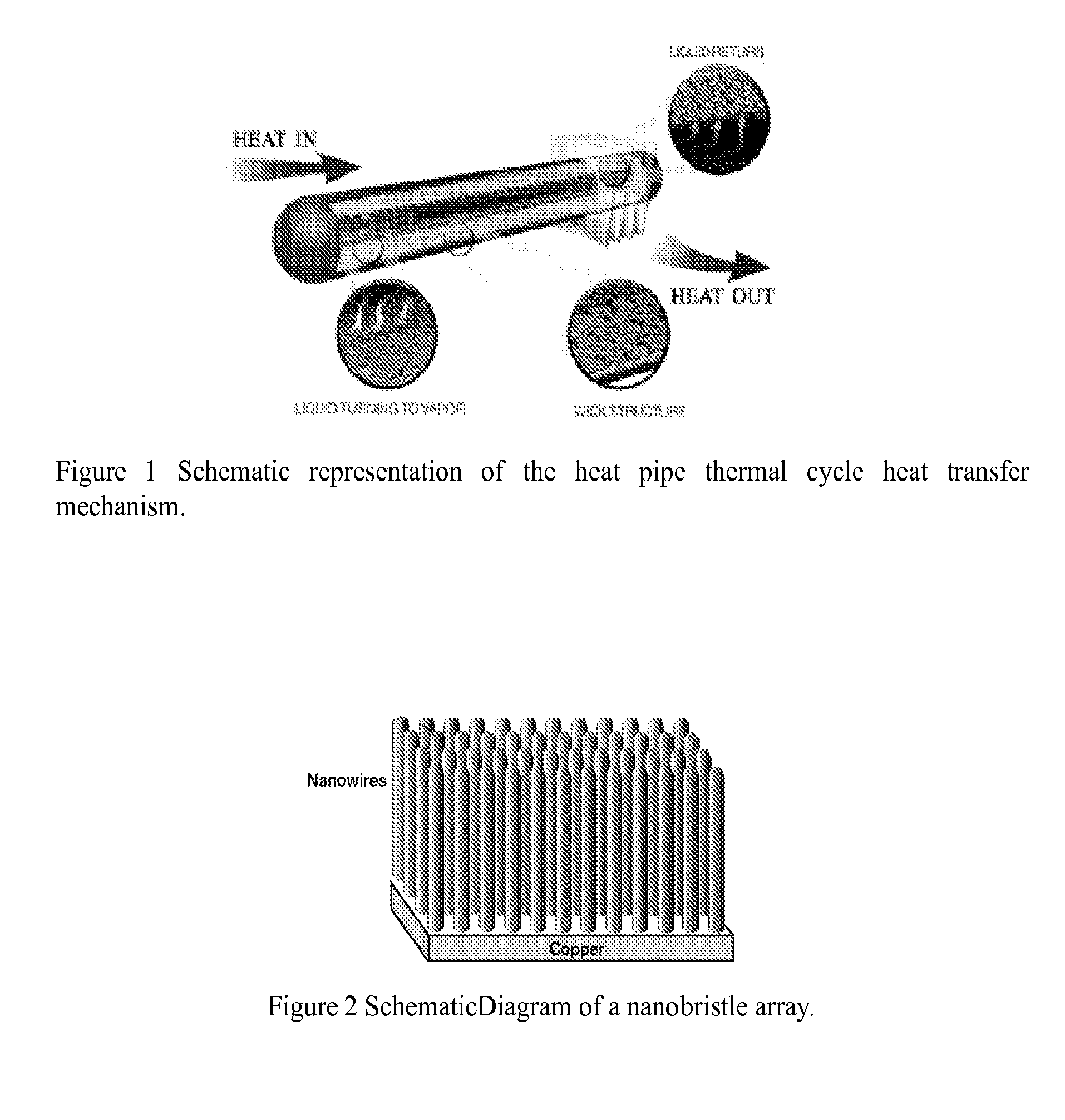

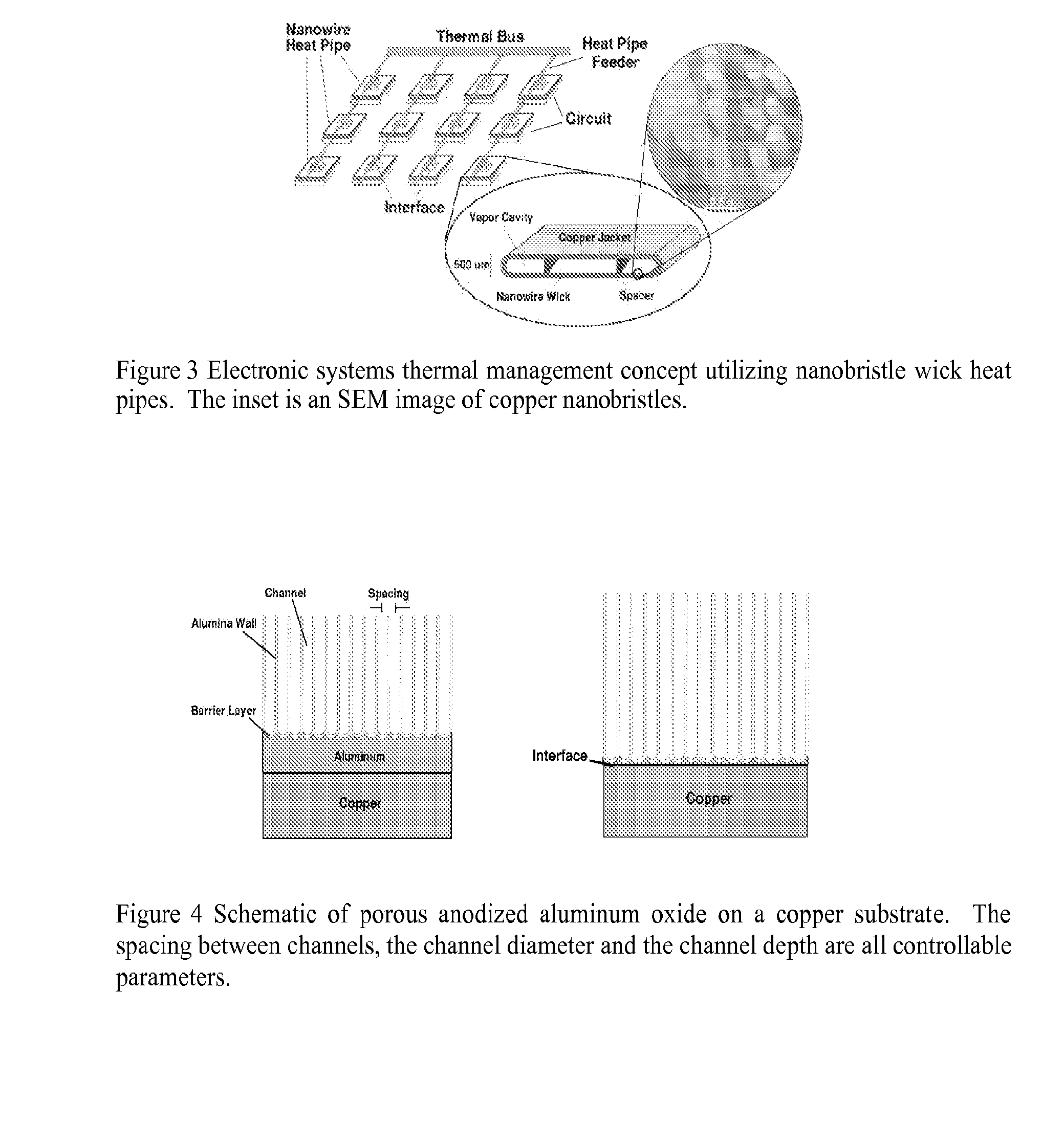

a nano-structured, heat pipe technology, applied in indirect heat exchangers, semiconductor/solid-state device details, lighting and heating apparatus, etc., can solve the problems of increasing fluid flow, significantly reducing the thermal resistance of the nano-bristle structure, etc., to achieve no operating cost, high efficiency, and more efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case # 1

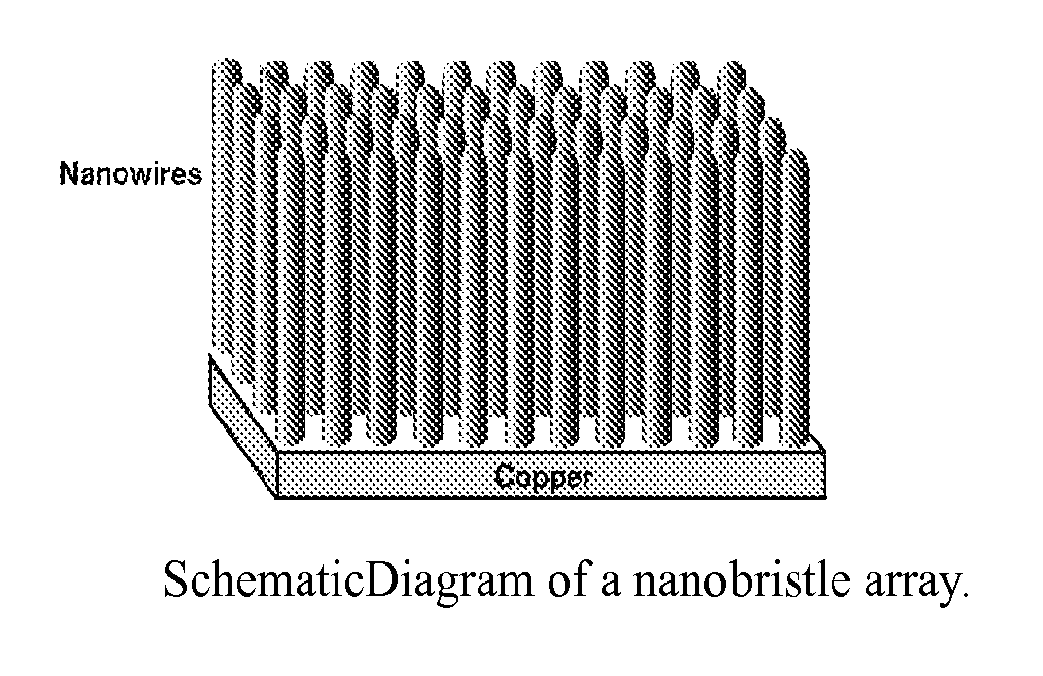

Case #1: if C=20 nm, D=10 nm, L=1 μm, BSR=125.6

Case #2: If C=250 nm, D=200 nm, L=100 μm, BSR=1962.5

case # 3

Case #3: If C=100 nm, D=60 nm, L=200 μm, BSR=3600

[0059]In this case, BSR is calculated based on only the outer cylindrical area of the nanowires.

For case #2, on a 1 cm piece of material, the nanowire tips occupy about 0.50 cm2, justifying their exclusion from the calculation.

[0060]By lengthening the nanowires and placing them on narrower spacing one can get the BSR up to approximately 3,600, that is, Case #3. Typical sintered metal powder wicks exhibit a BSR of about 35. The wicking material disclosed in U.S. Pat. No. 4,015,659 discloses a material with a BSR estimated to be approximately 5 to approximately 50, depending on a range of whisker length of 100 microns to 1 millimeter. Practitioners of ordinary skill will recognize that if the length of the nanowire is too long relative to its diameter, then it is more likely to crack or otherwise fail. In the preferred embodiment, the aspect ratio of the nanowires should be less than approximately 2500 to 1. The aspect ratio is defined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com