Patents

Literature

334results about How to "Performance advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

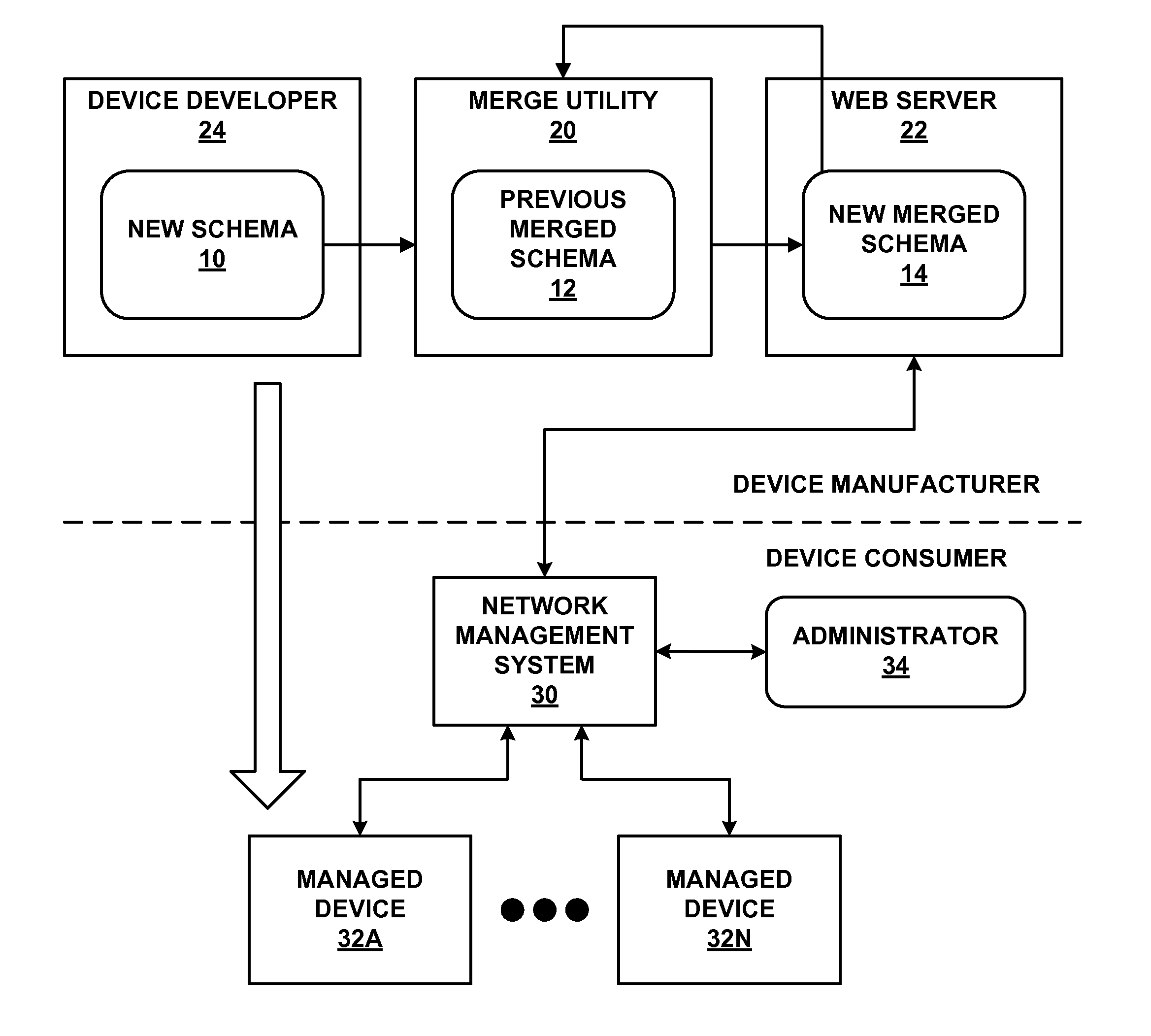

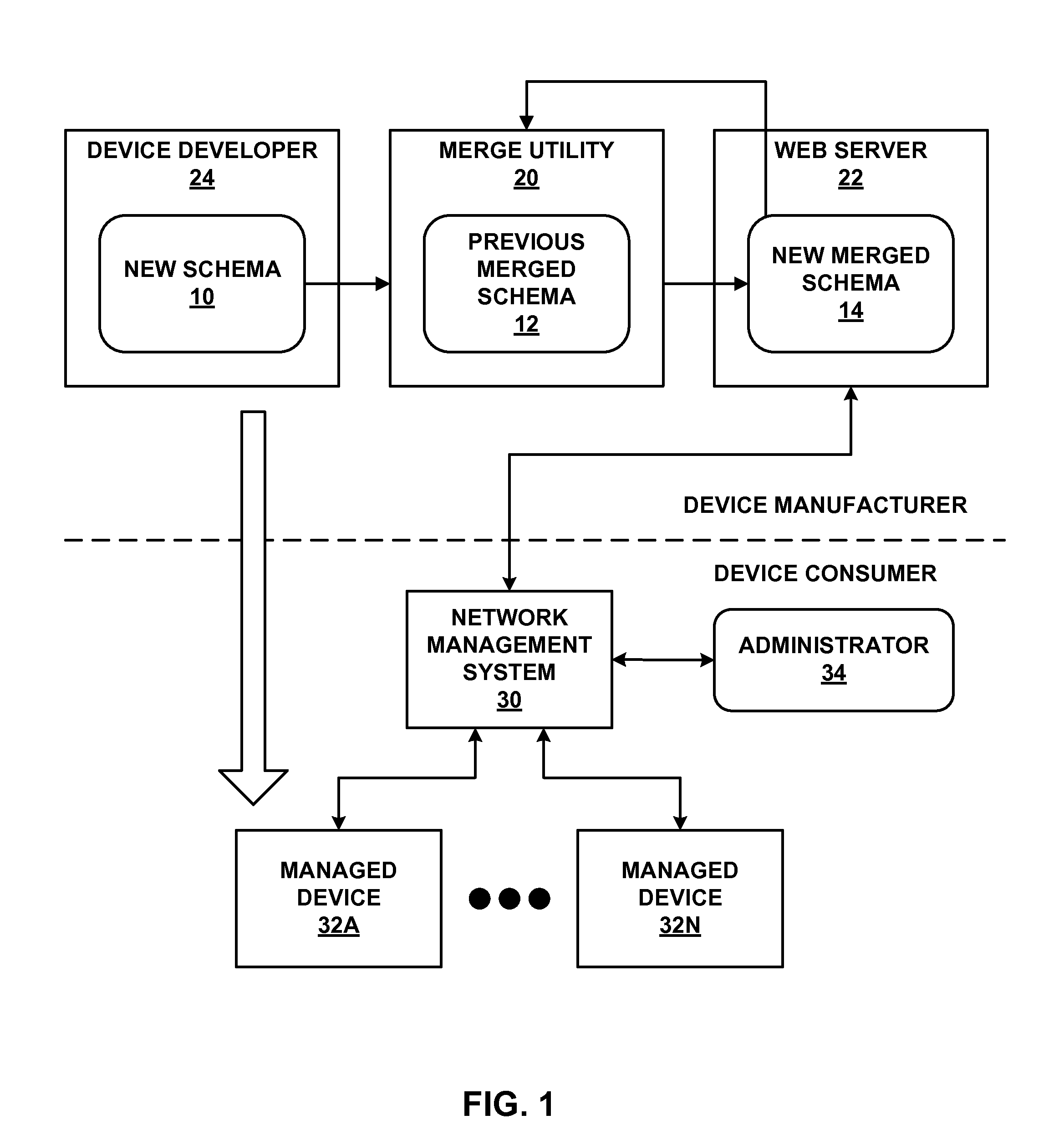

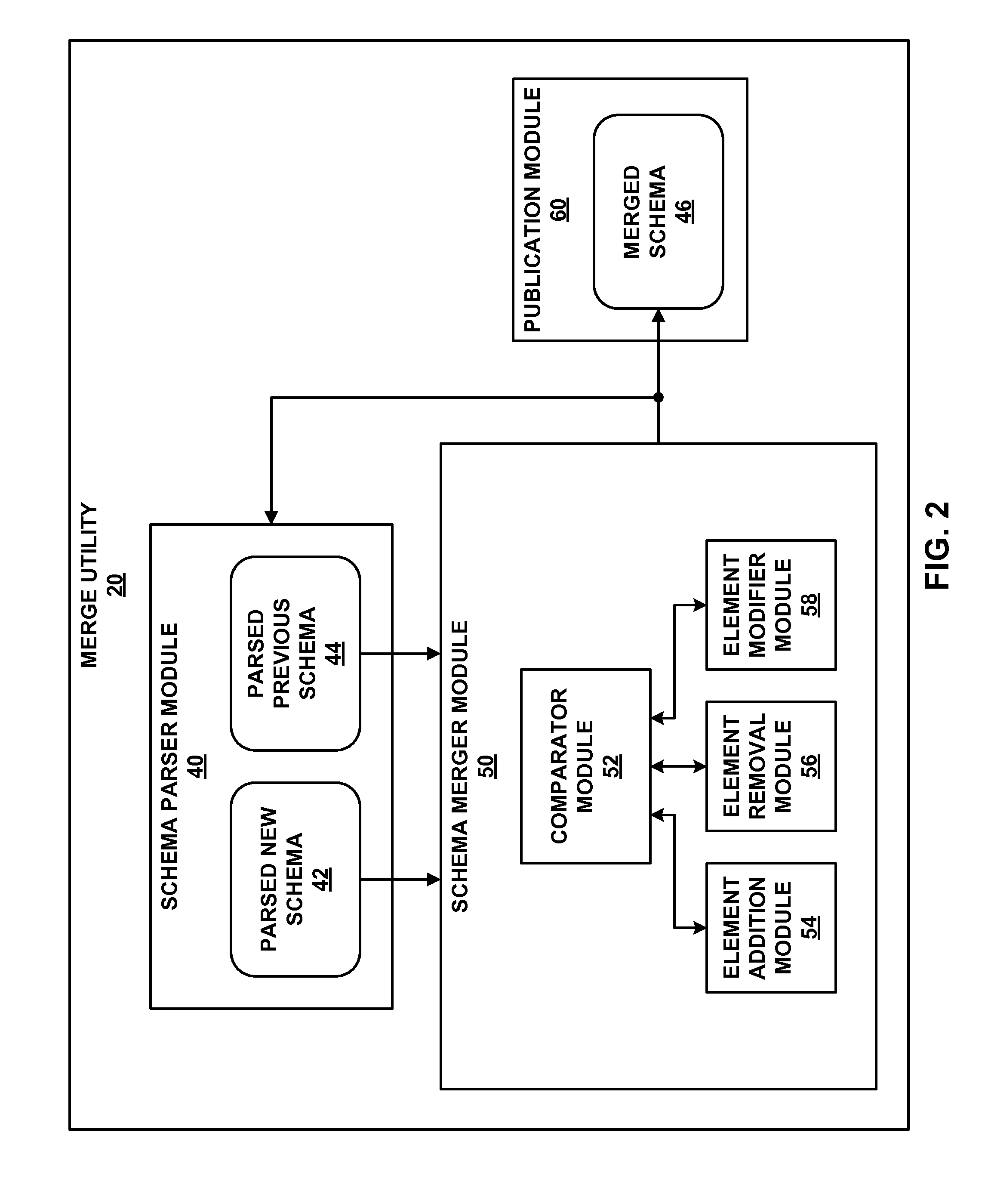

Merging network device configuration schemas

Owner:JUMIPER NETWORKS INC

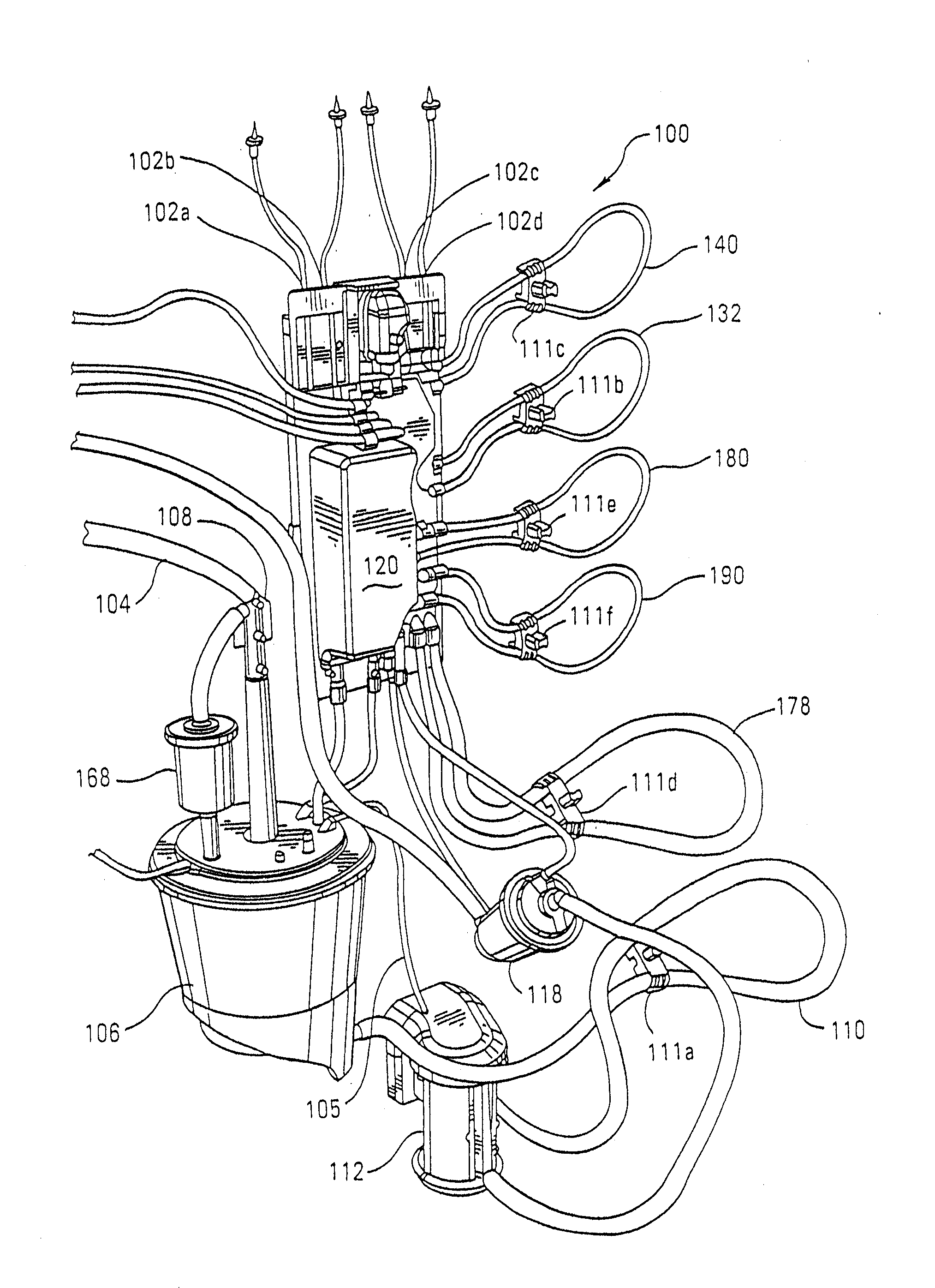

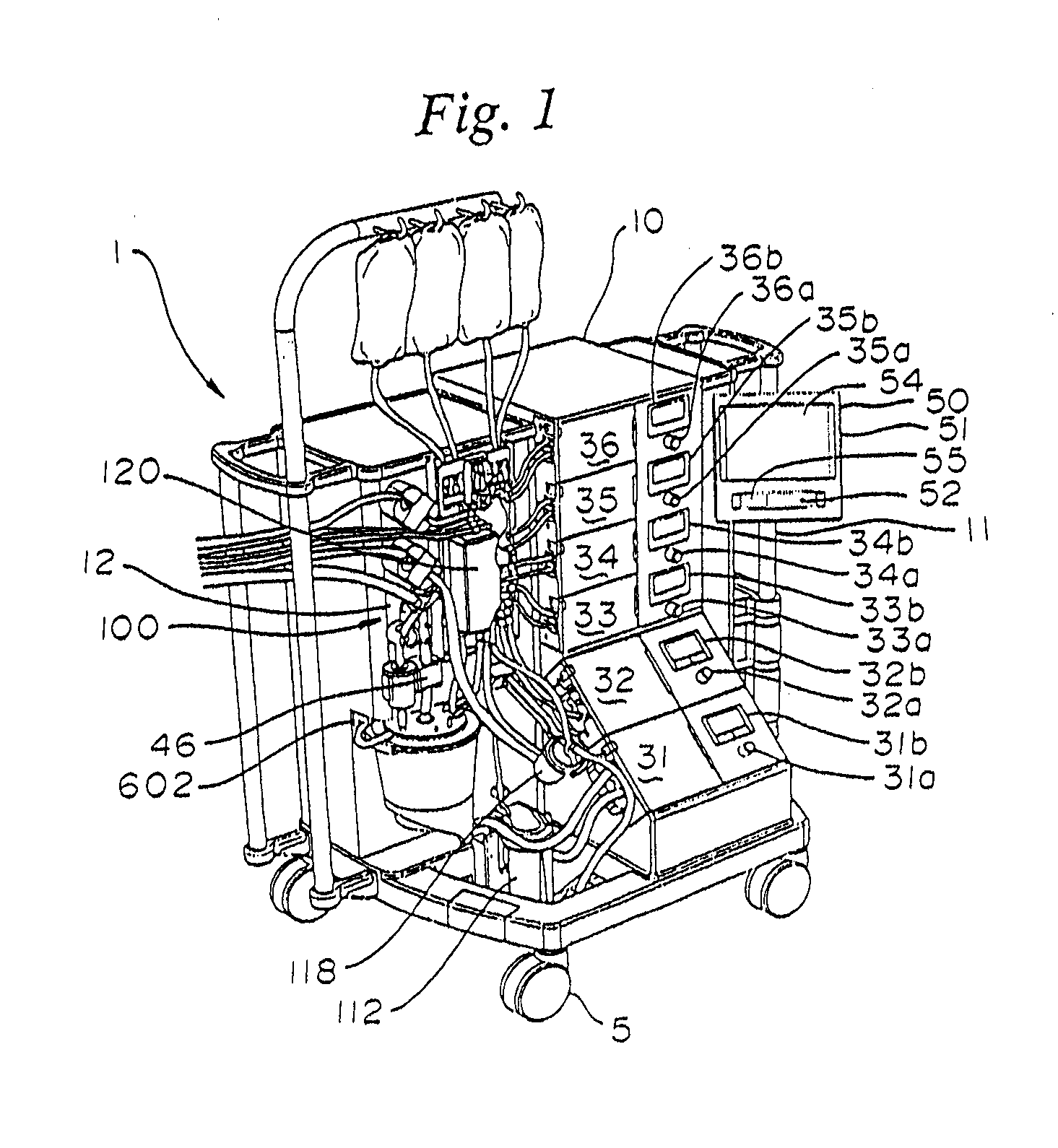

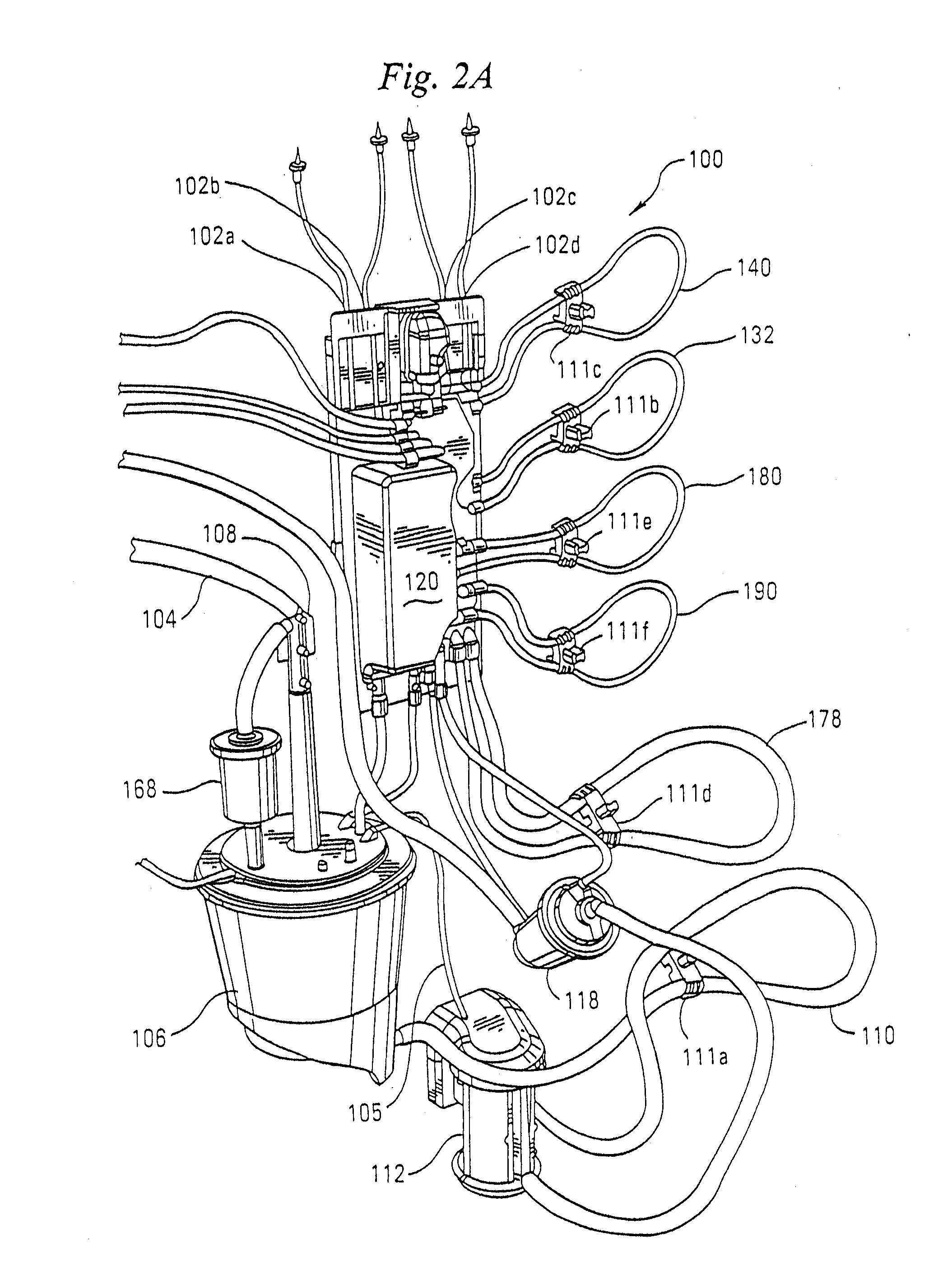

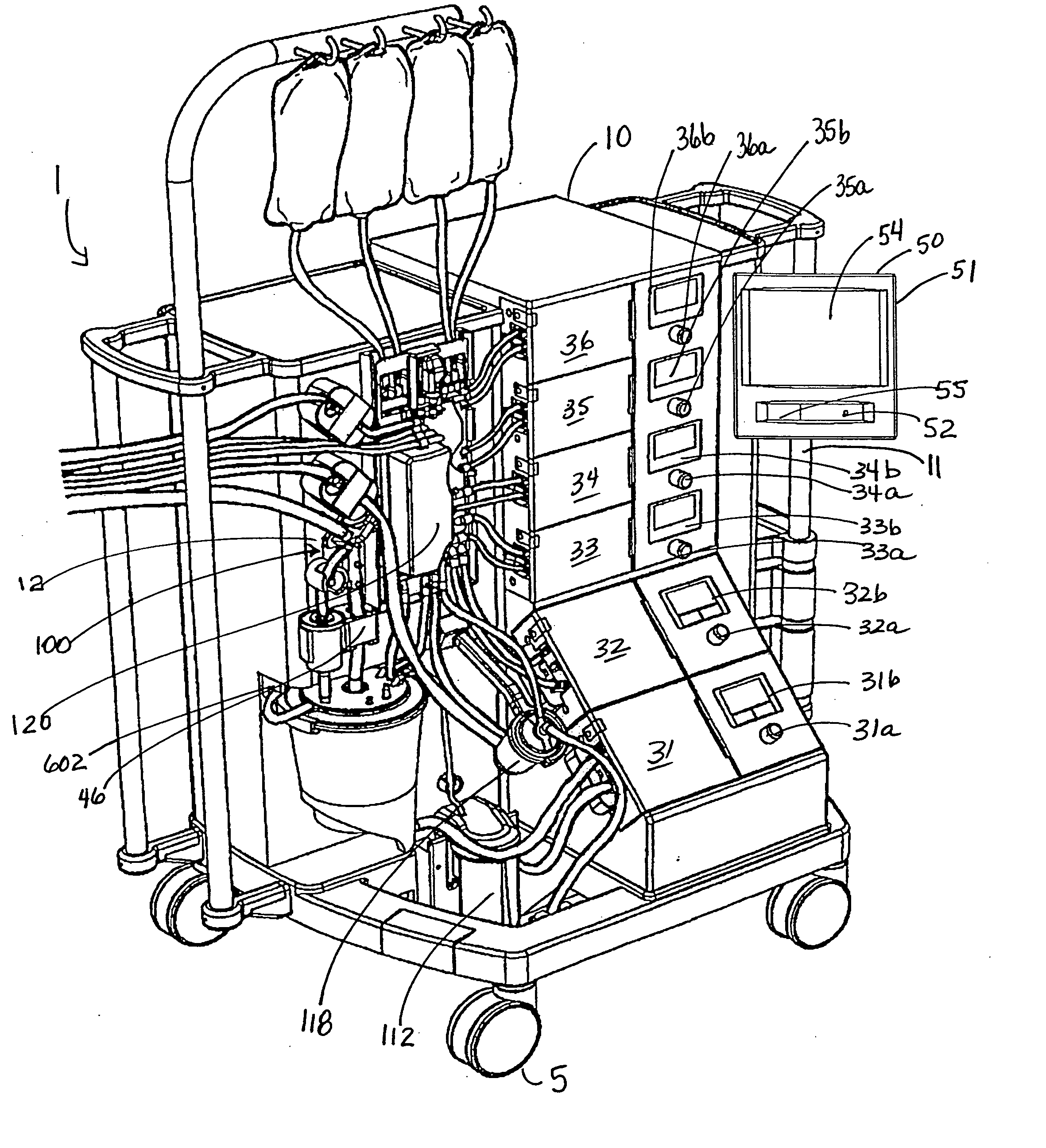

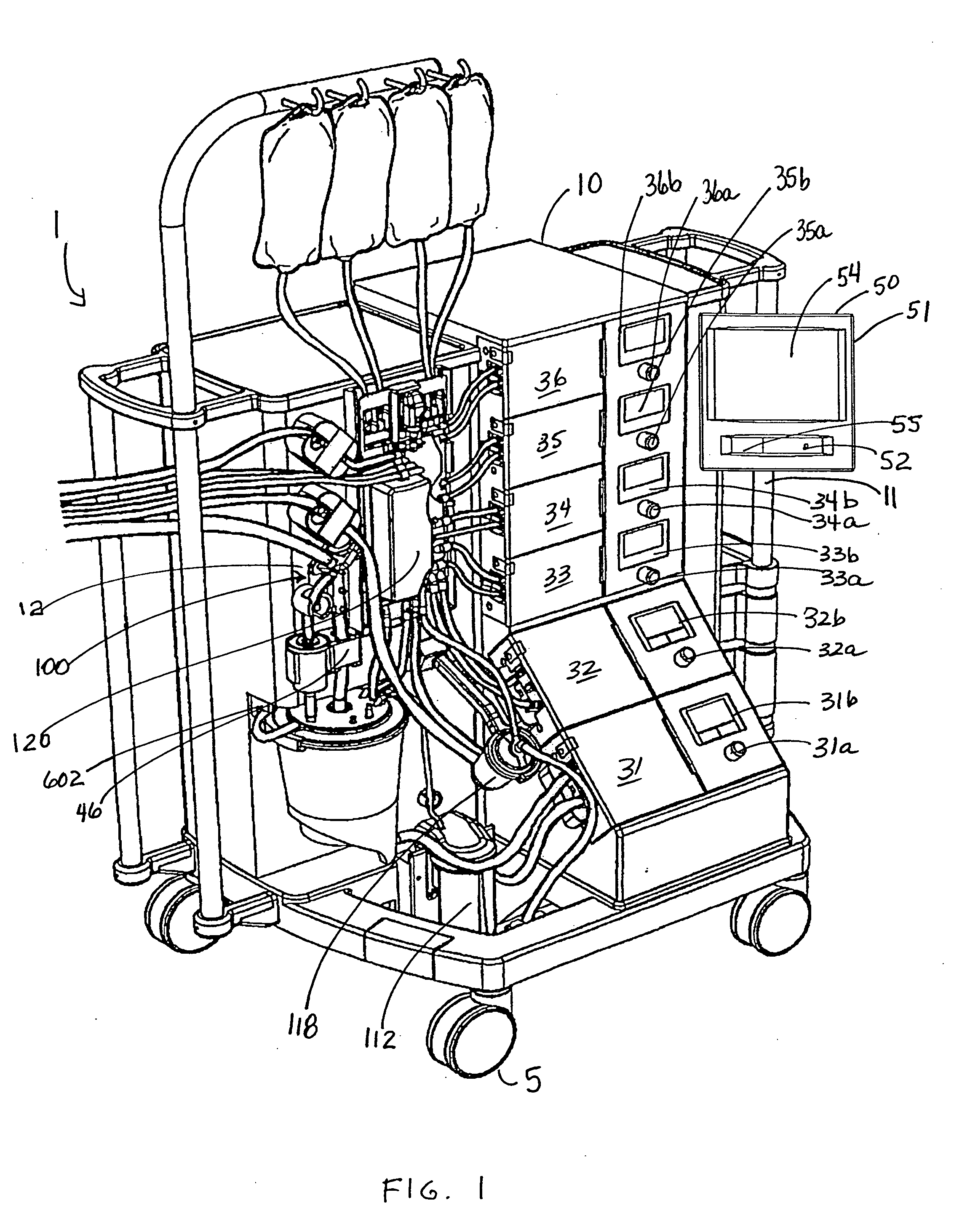

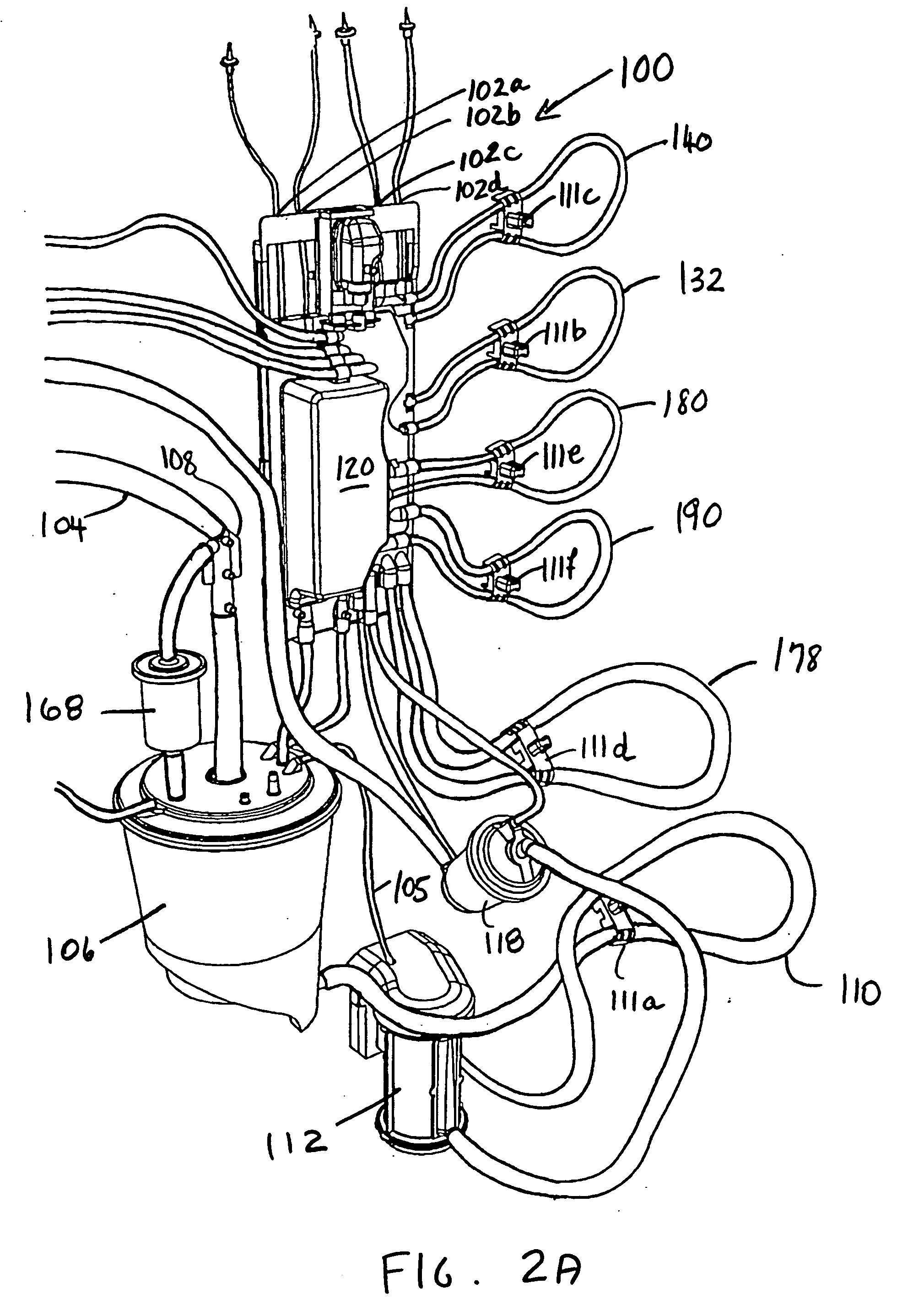

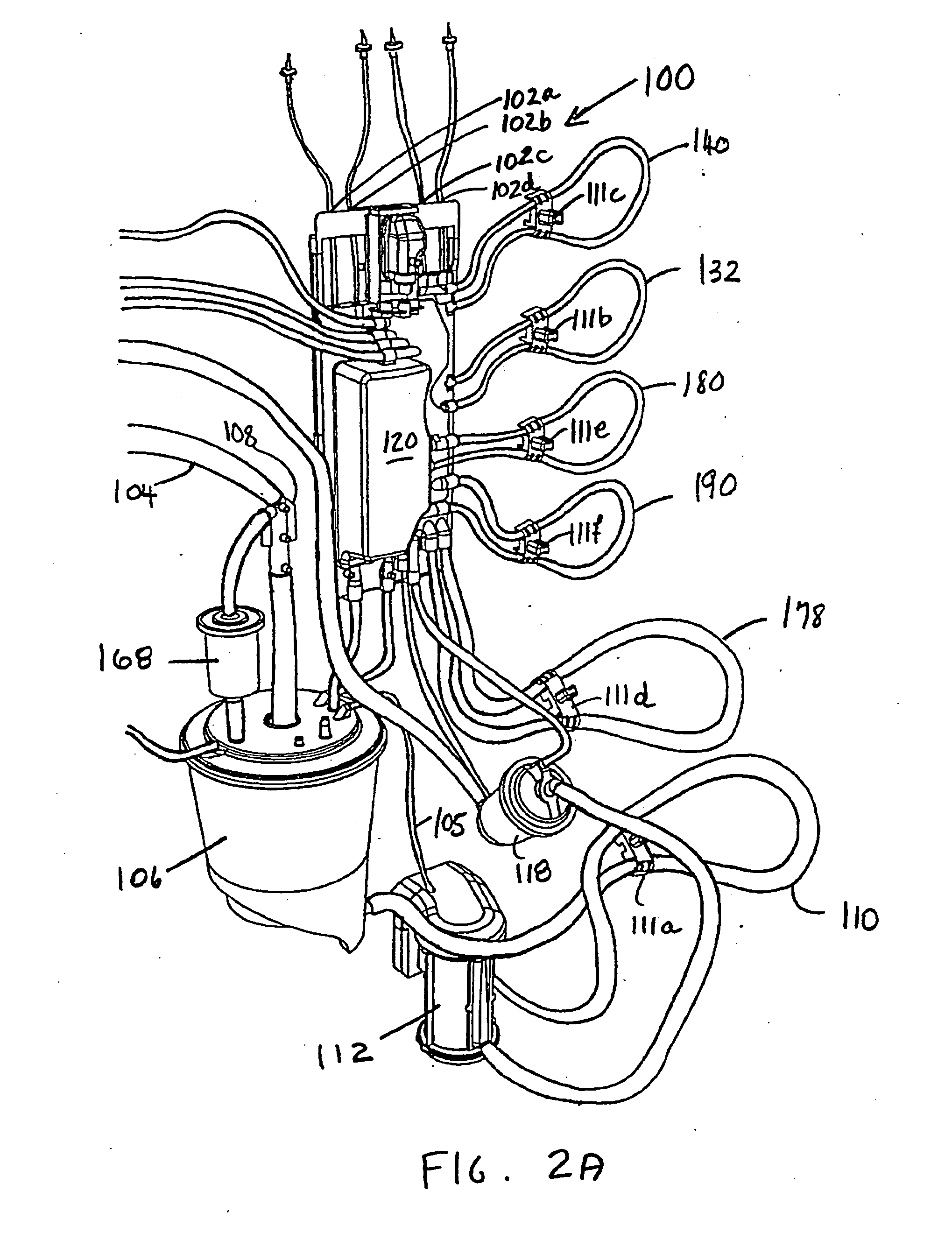

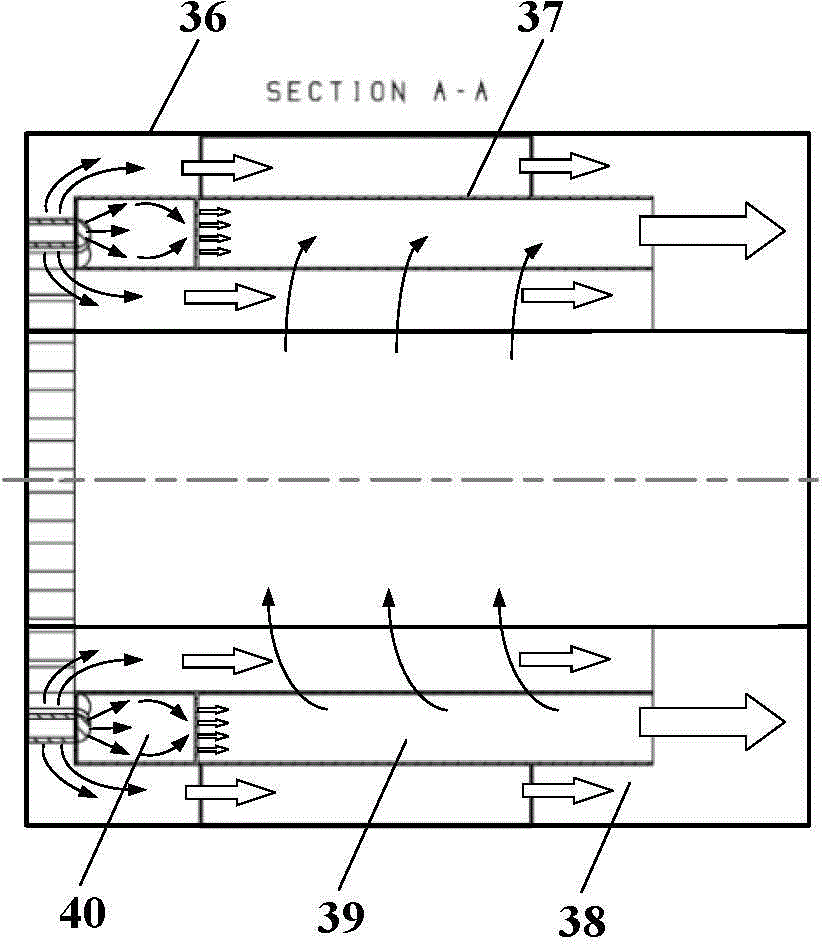

Disposable cartridge for a blood perfusion system

InactiveUS20080027368A1Simplified interconnection/disconnectionSimple setupDialysis systemsMedical devicesCardioplegiasEngineering

A disposable cartridge for use in extracorporeal blood perfusions systems that have a control unit for controlling the flow of fluids. The cartridge has a housing defining a plurality of internal passageways that connect to a cardiopulmonary circuit, a cardioplegia circuit and a suction circuit. The cartridge may be fitted with one or more of a bubble trap, a filter, and a valve.

Owner:SORIN GRP USA INC

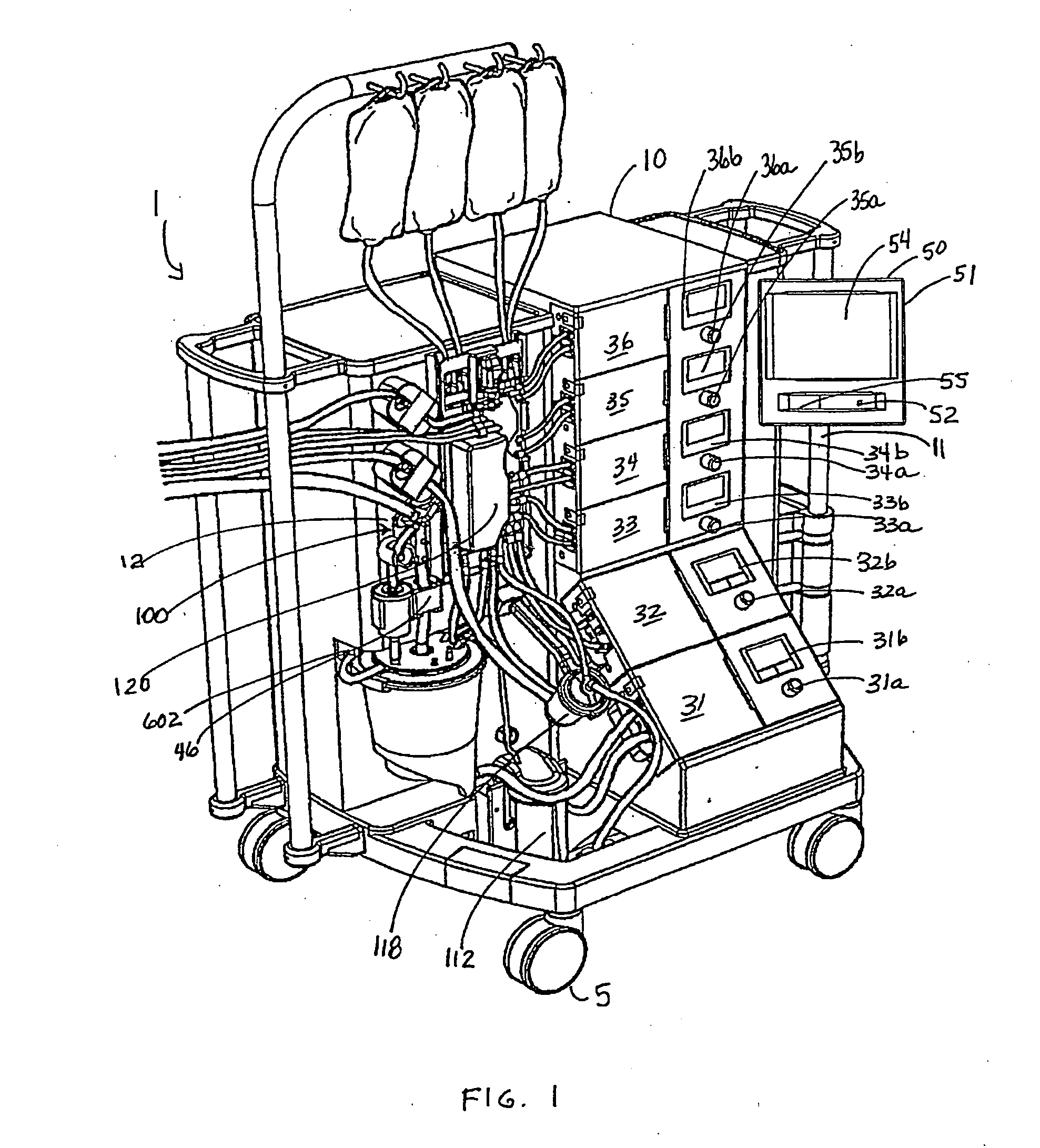

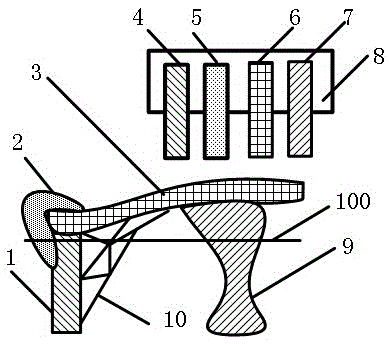

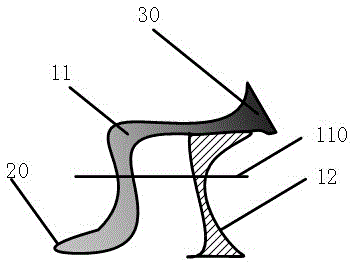

Blood perfusion system

ActiveUS20060167400A1Simplified interconnection/disconnectionSimple setupOther blood circulation devicesMedical devicesVenous bloodDisplay device

An extracorporeal blood perfusion system includes a disposable assembly and a control unit having a control interface region. The interface region includes pump assemblies for selective pumping of venous blood, arterial blood, cardioplegia solution, suctioned blood and blood removed from the left ventricle. Valve assemblies control the flow of fluids through the assembly and to / from the patient and sensors monitor various fluid parameters including temperature and pressure within the various fluid circuits. The user interface is a functional screen interface for effecting the operation of the control unit and valve assemblies. The screen interface may be a touch screen having objects that corresponds to the component interface region. The display may be selectively controlled to provide graphic depictions of disposable assembly components with corresponding narrative instructions.

Owner:SORIN GRP USA INC

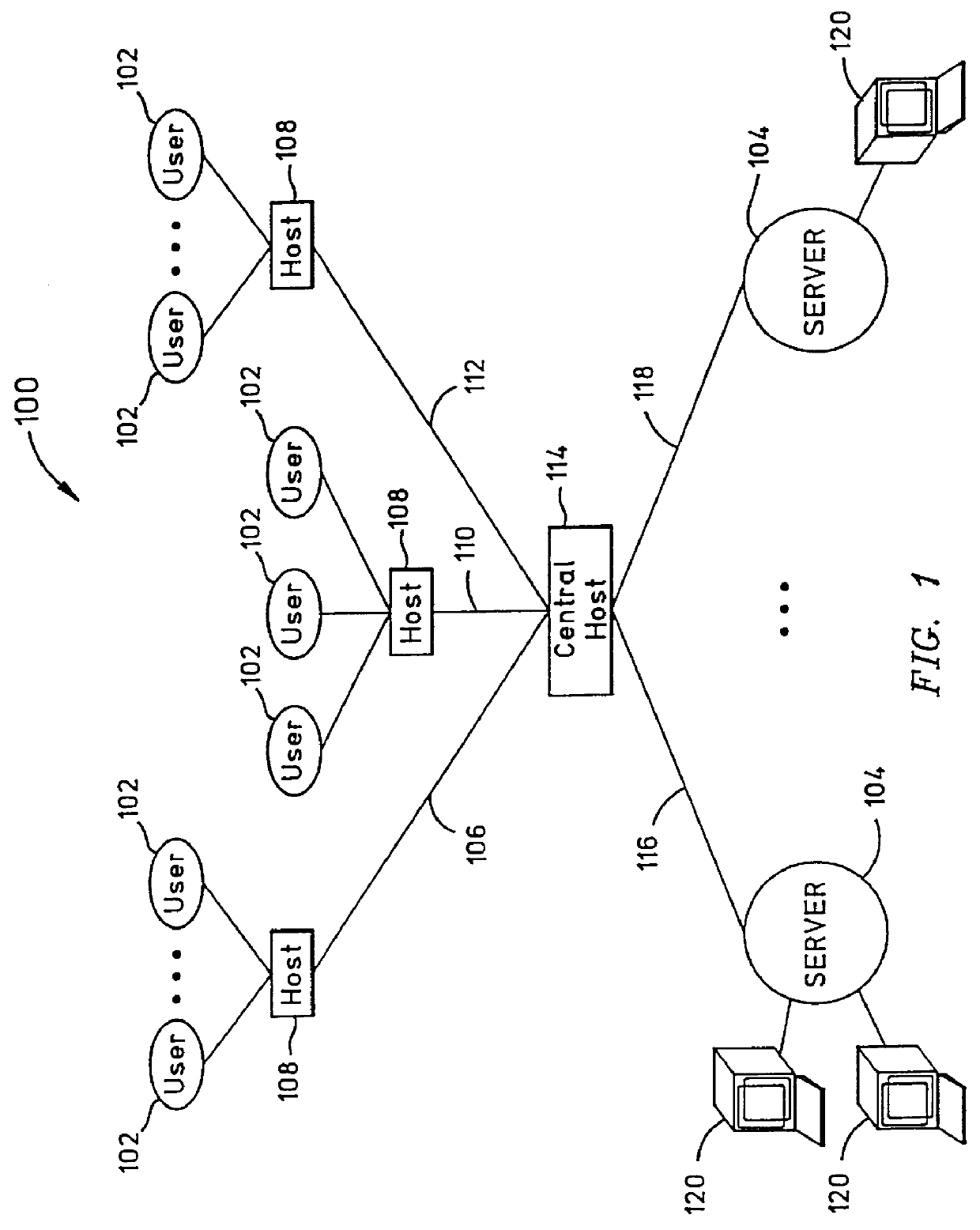

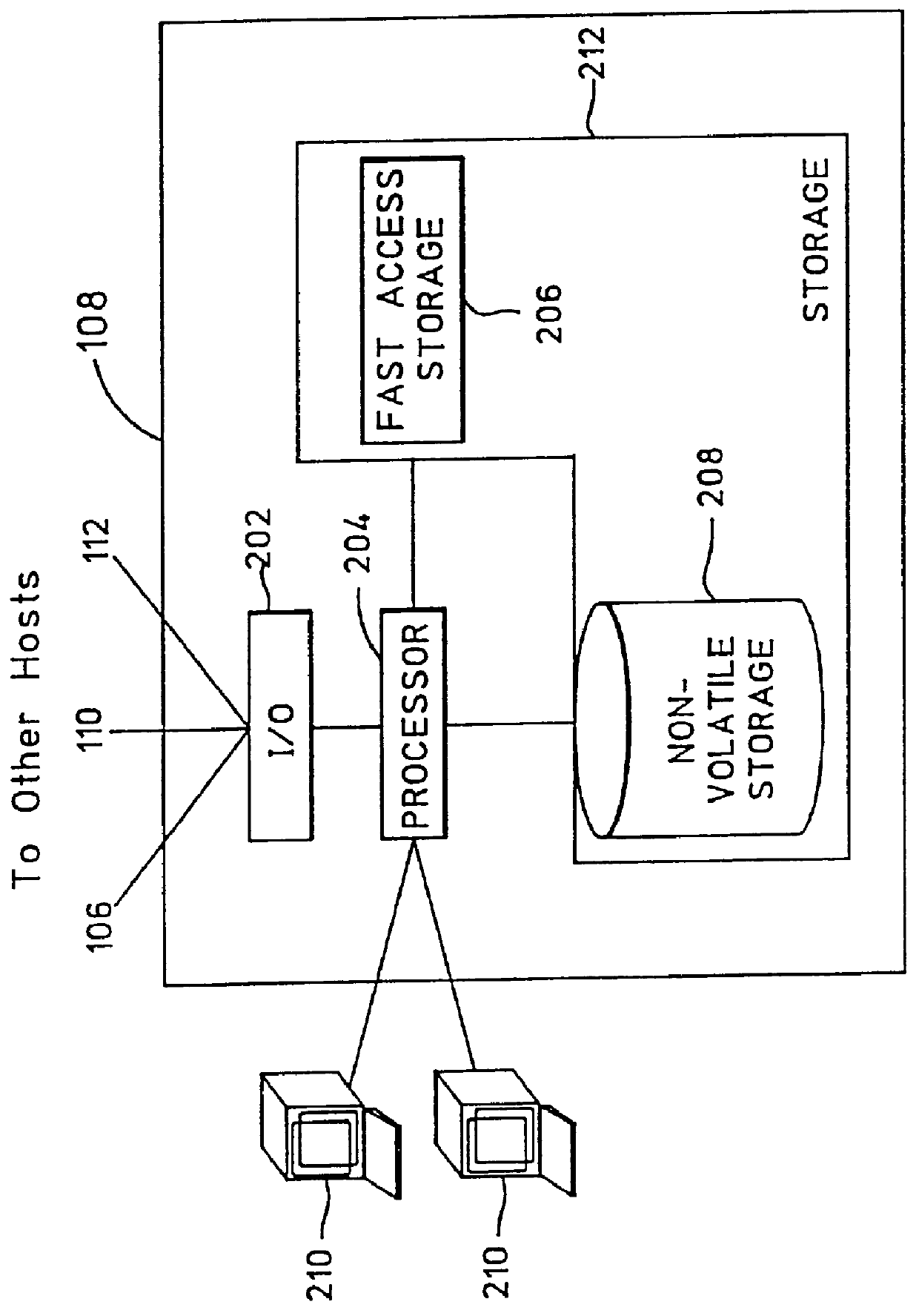

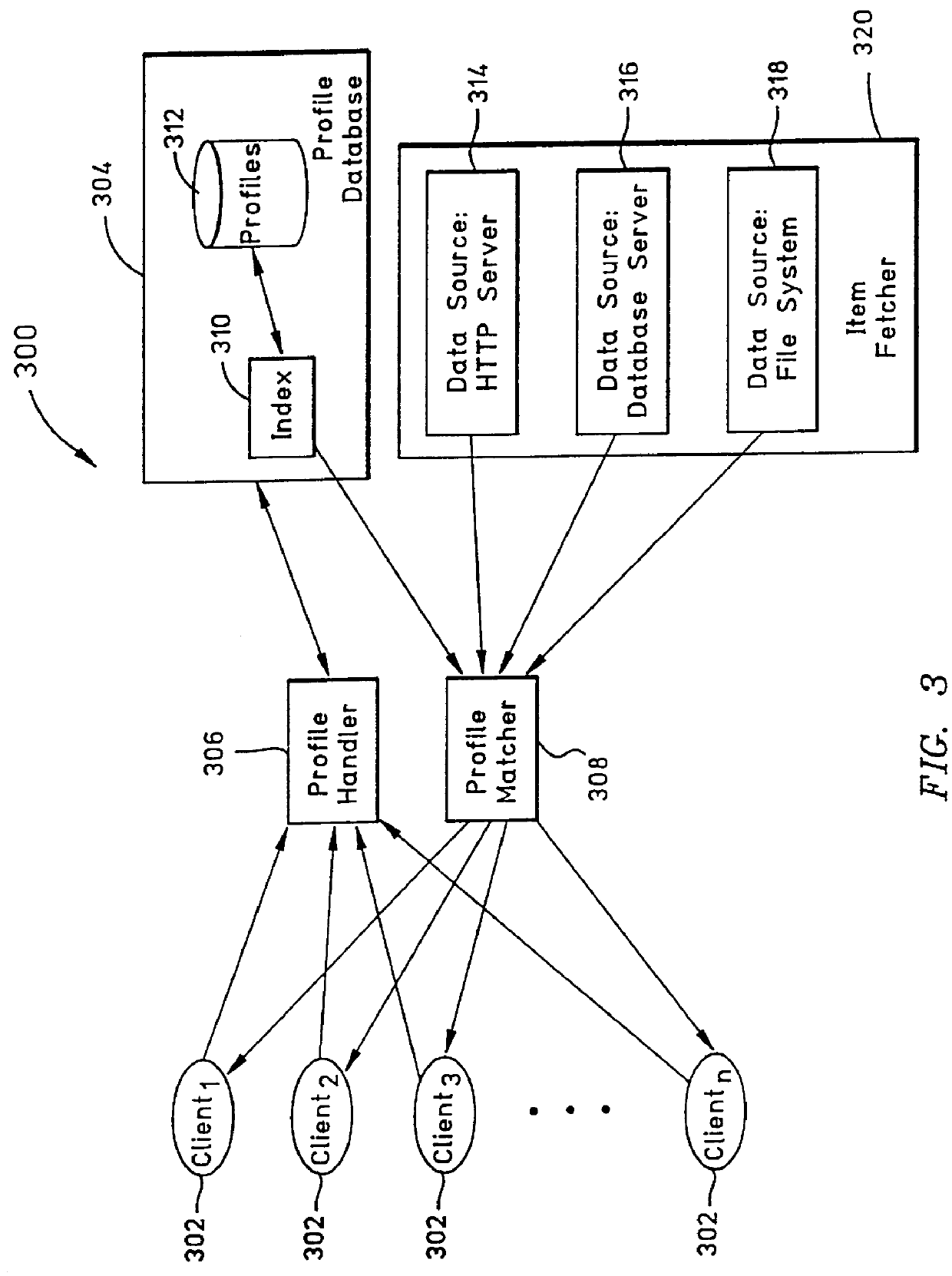

Method and apparatus for efficient profile matching in a large scale webcasting system

InactiveUS6108645AImprove performanceNear-optimal performanceData processing applicationsDigital data information retrievalDocument preparationUser profile

A method and apparatus for efficiently matching a large collection of user profiles against a large volume of data in a webcasting system. The method removes redundant patterns in user profiles and information content to improve matching performance based on a Boolean-based query language. Users can select desired information content by choosing a set of predicates to assert the properties for each cyberspace document desired. Boolean operators of AND, OR and NOT connect predicates together on the information items that will be pushed to them. The method includes dynamic cost / credit adjustment based profile indexing and matching.

Owner:IBM CORP

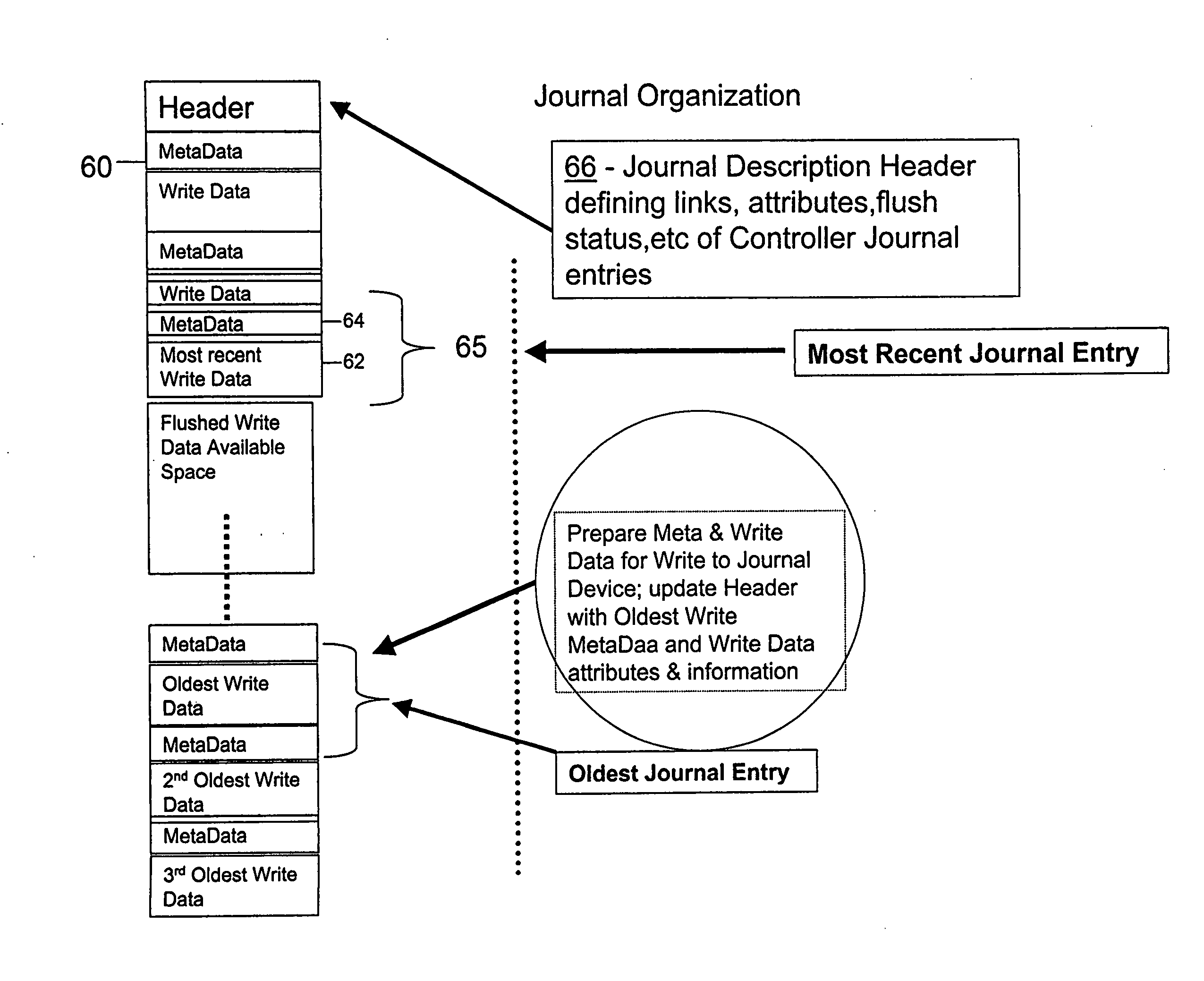

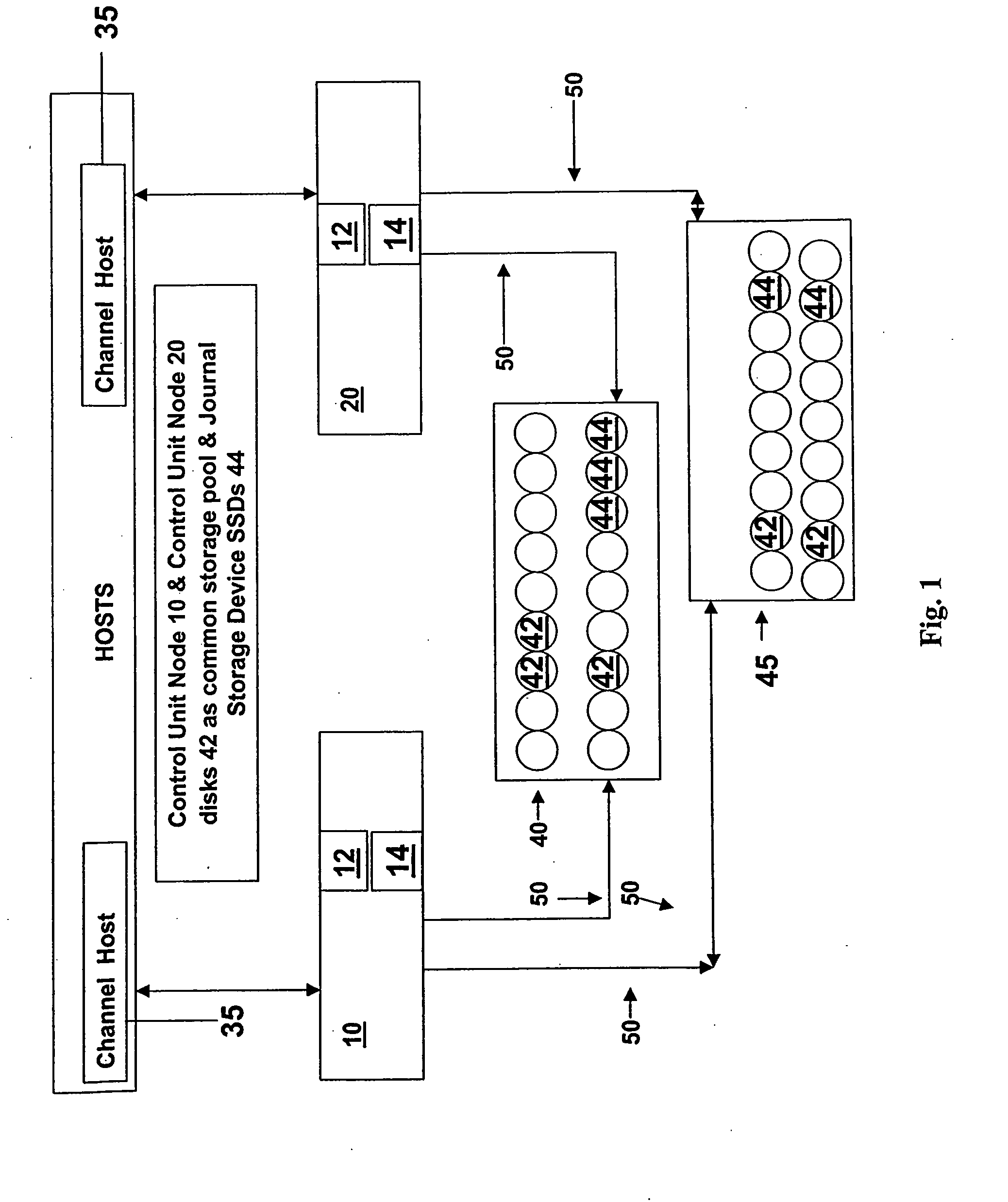

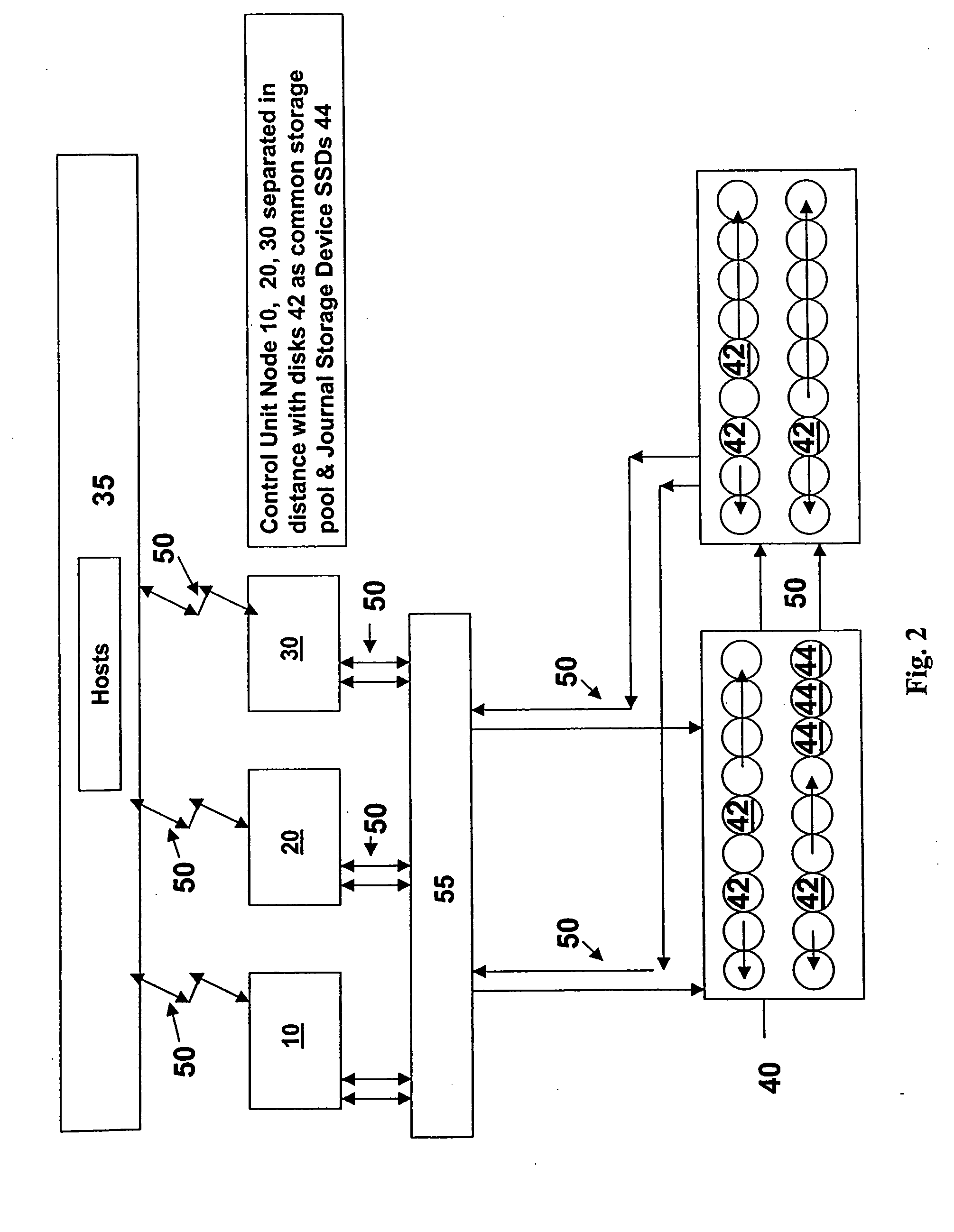

Storage control unit with memory cash protection via recorded log

InactiveUS20090031083A1Performance advantageEasy accessError detection/correctionMemory adressing/allocation/relocationControl storeDatabase

A “Logging” method and apparatus is provided to protect control unit cached data not yet written to backing storage disk drives. This recording mechanism will copy “WRITE DATA” to a log at a target logically or physically external (to the storage controllers) location equally common to all members of the set of distributed storage control units managing a common storage pool. Upon the failure of one the members of the set of control units, the “Log” information is available to insure that pending “write” data is written to the proper location on the disk drives upon a recovery action. One of the surviving members of the set assumes control of the storage managed by the failing unit by utilizing the recorded information to insure that data not written to backing storage (disks) up to the point of failure is then written to the disk backing storage. The surviving member of the set recovering the failing control unit storage (disk set) ownership will thereby “flush” (WRITE) the Journaled WRITE DATA to the backing storage disk drives before allowing normal operations to proceed.

Owner:DIGI DATA CORP

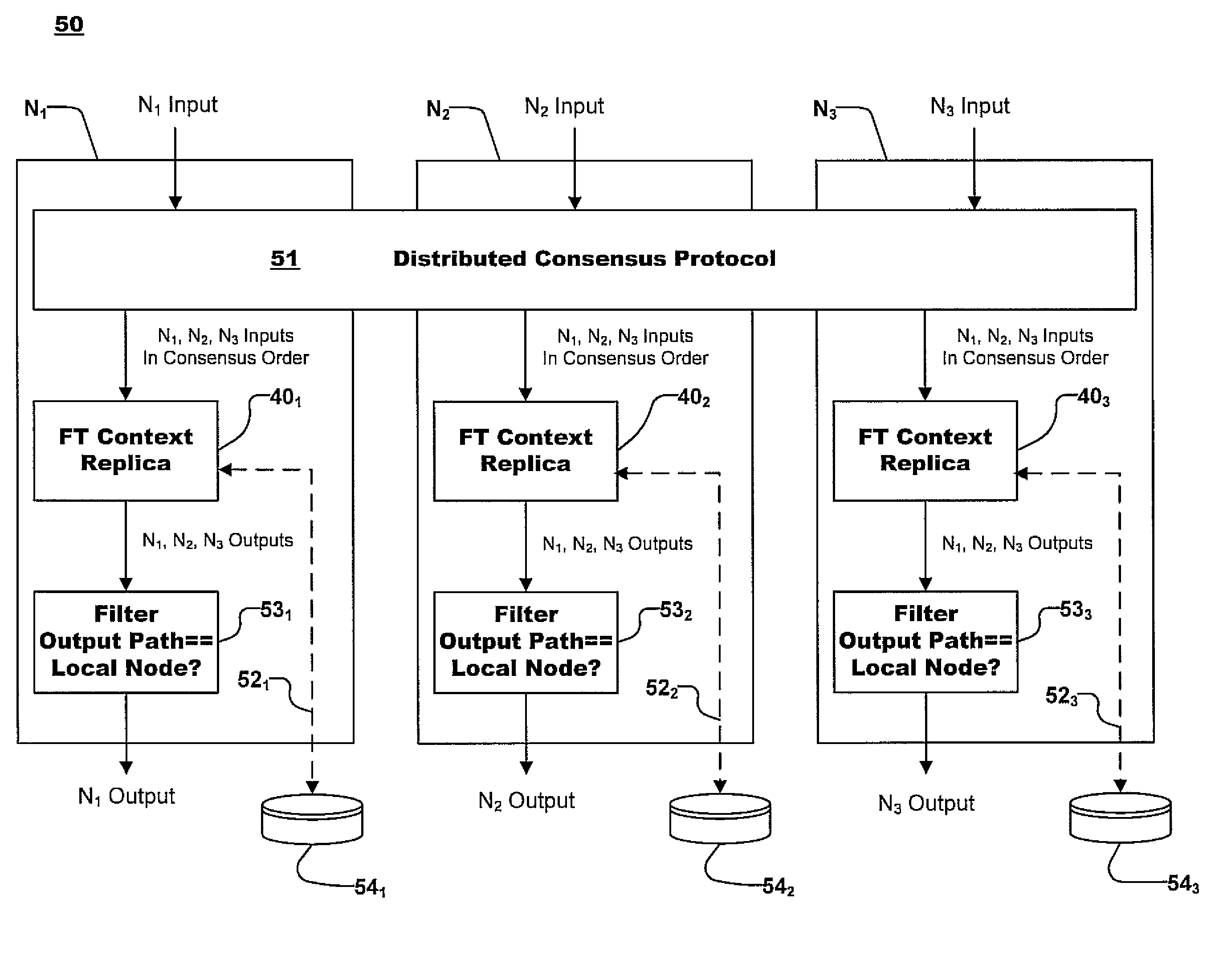

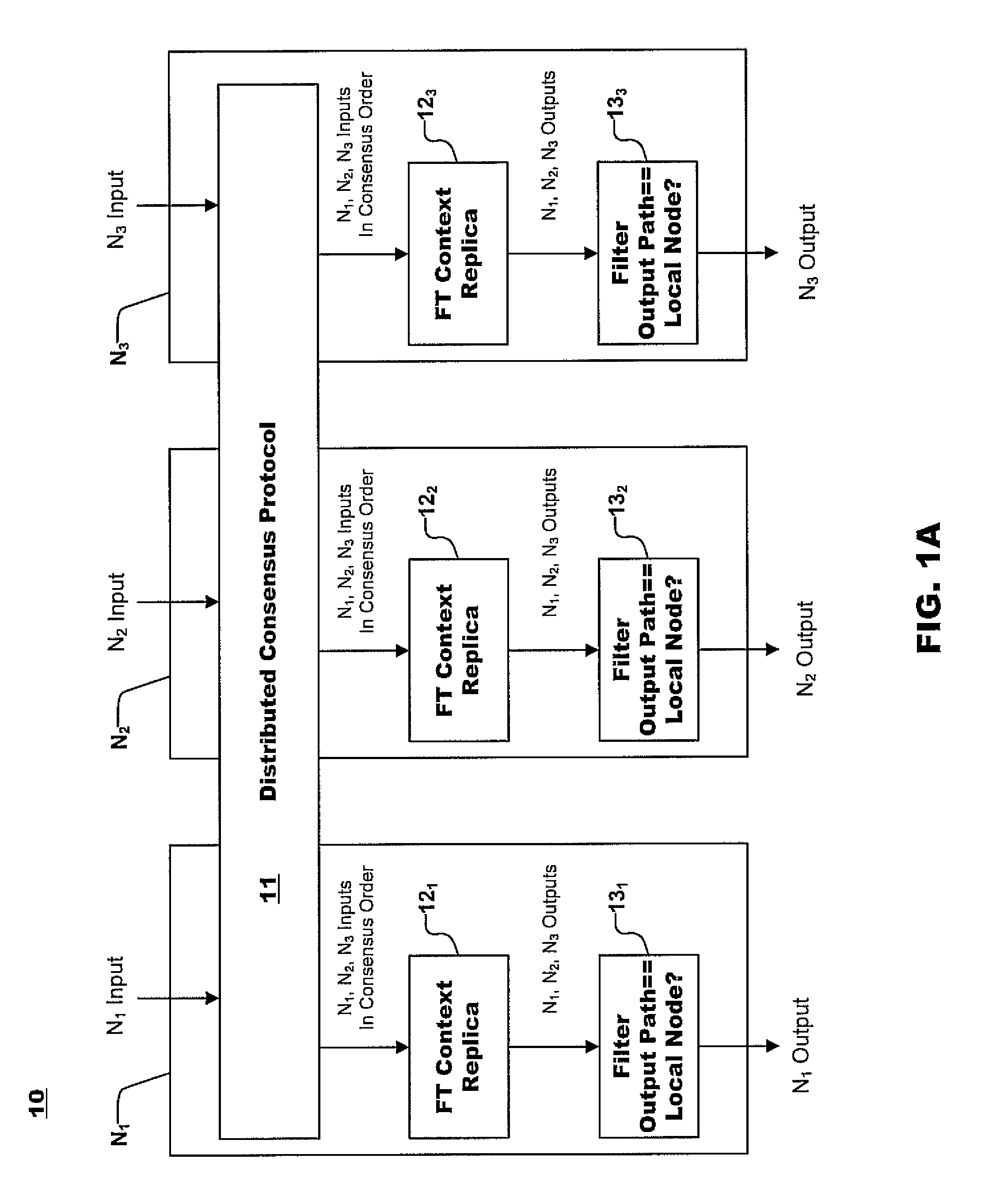

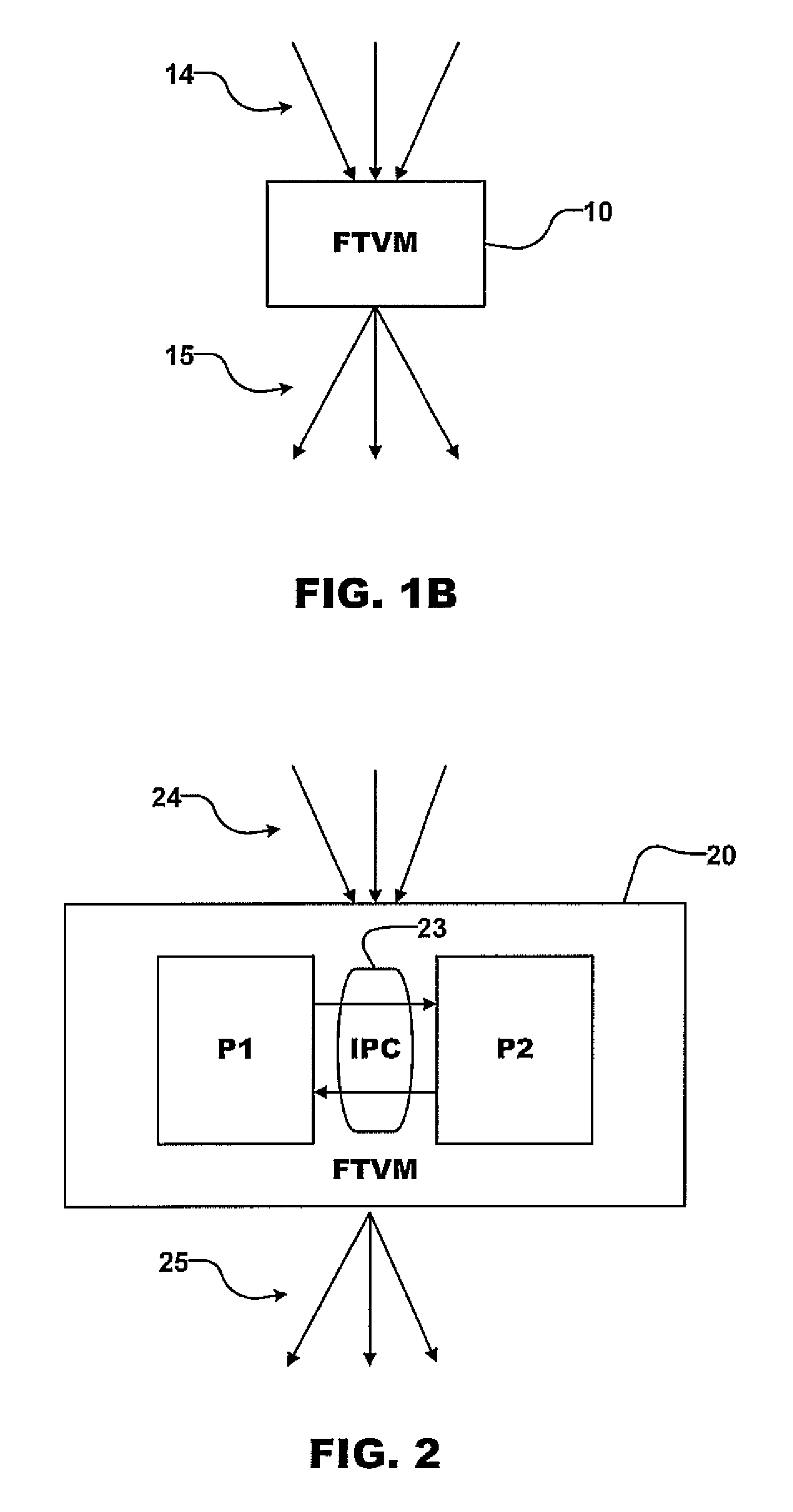

Systems and methods for implementing fault tolerant data processing services

InactiveUS20090276654A1Lower latencyPerformance advantageError detection/correctionDatabase serverData store

Systems and methods are provided to implement fault tolerant data processing services based on active replication and, in particular, systems and methods for implementing actively replicated, fault tolerant database systems in which database servers and data storage servers are run as isolated processes co-located within the same replicated fault tolerant context to provide increased database performance.

Owner:IBM CORP

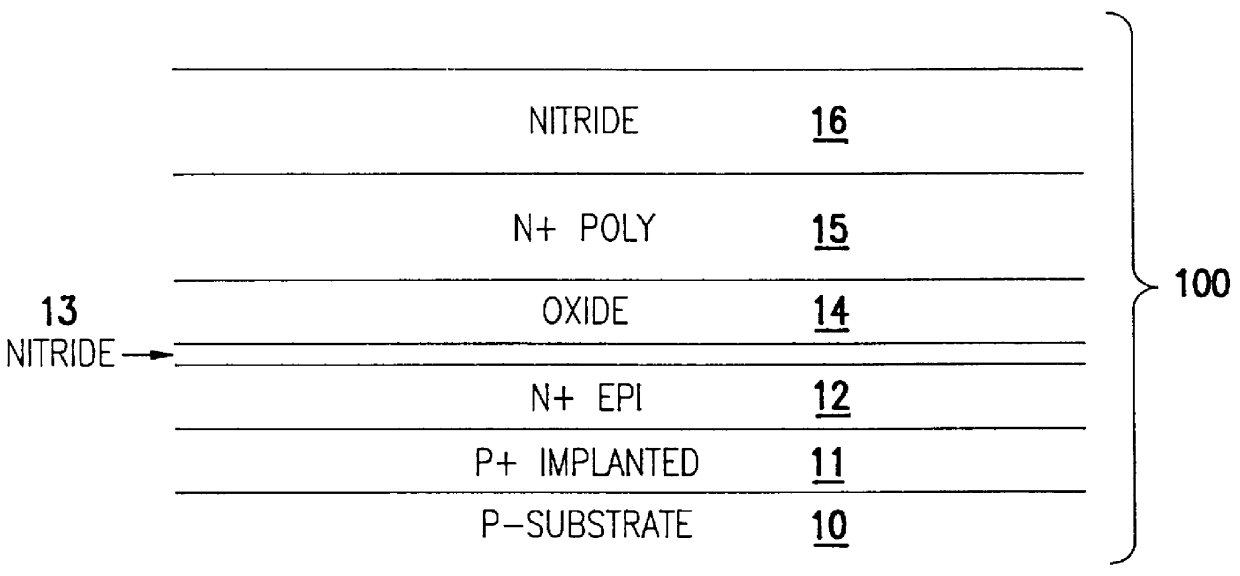

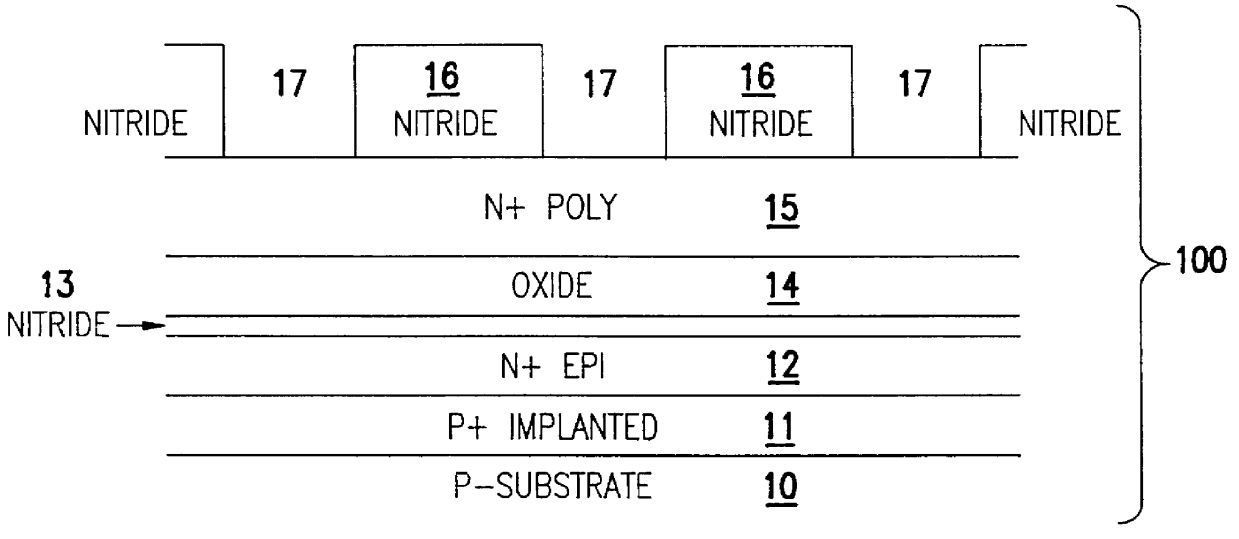

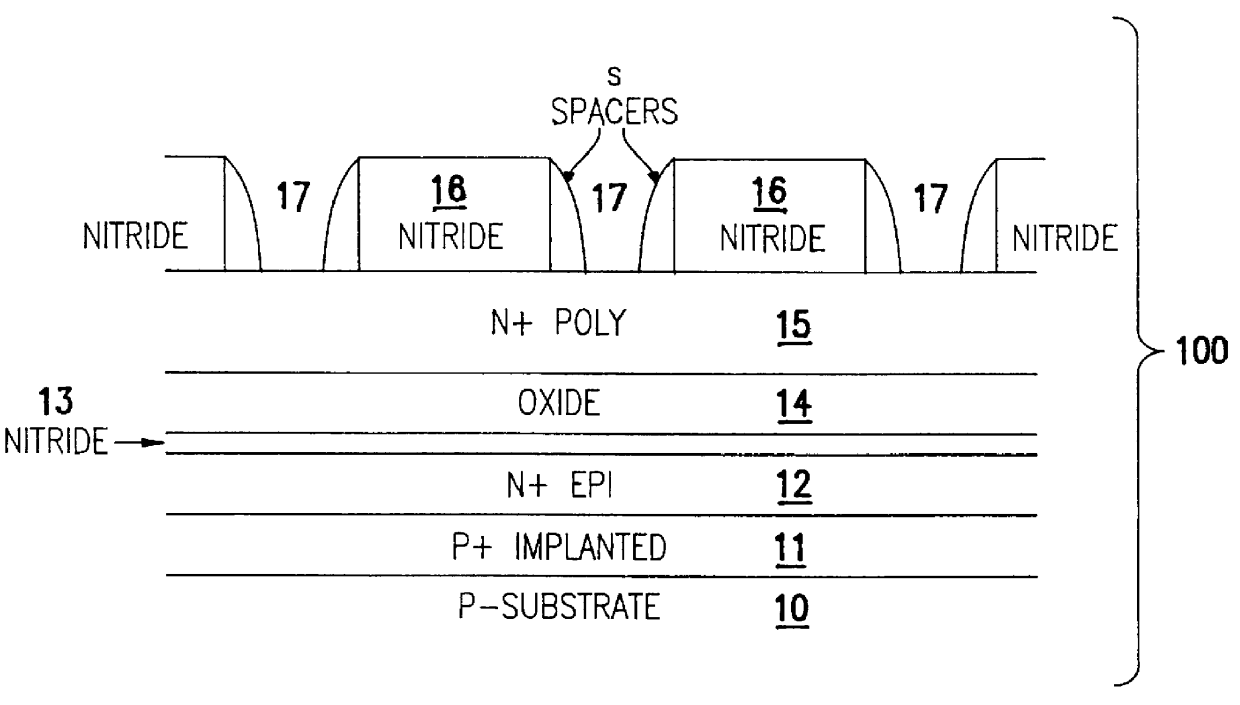

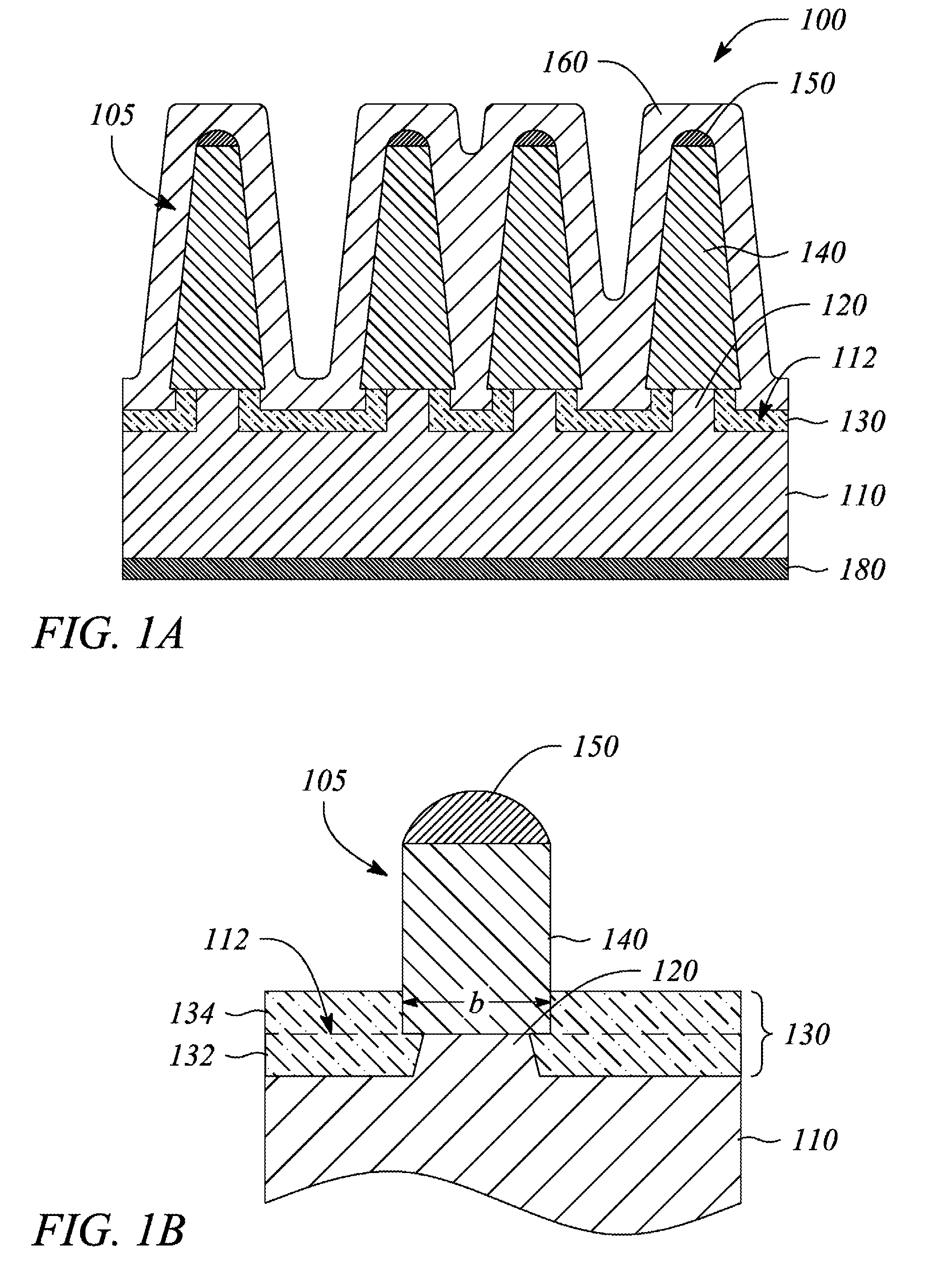

Power transistor having vertical FETs and method for making same

InactiveUS6060746ALower resistanceEasy to controlTransistorSolid-state devicesMOSFETElectrical and Electronics engineering

A power transistor having of a plurality of vertical MOSFET devices combined in parallel to achieve high-performance operation and methods of fabricating this device.

Owner:IBM CORP

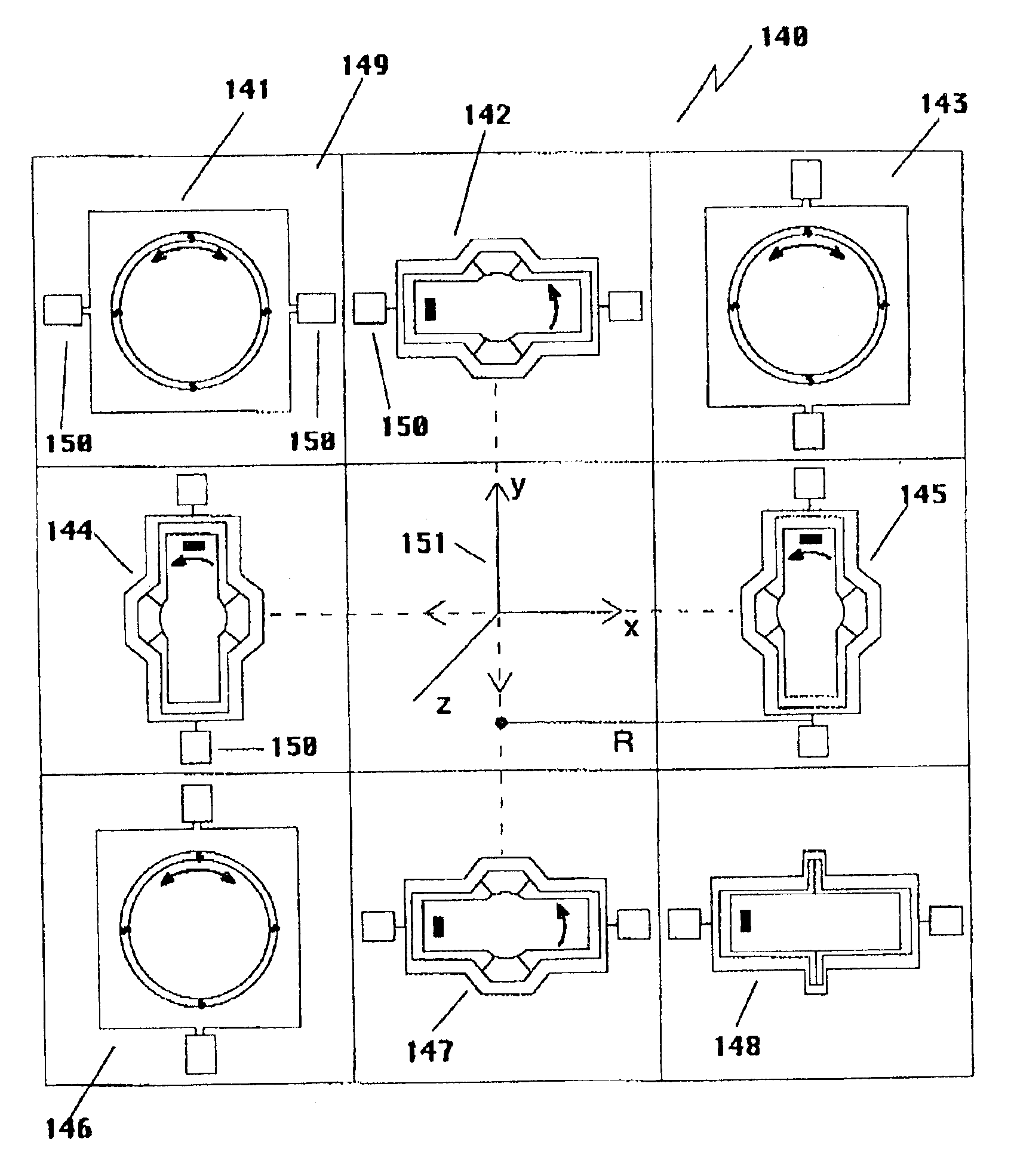

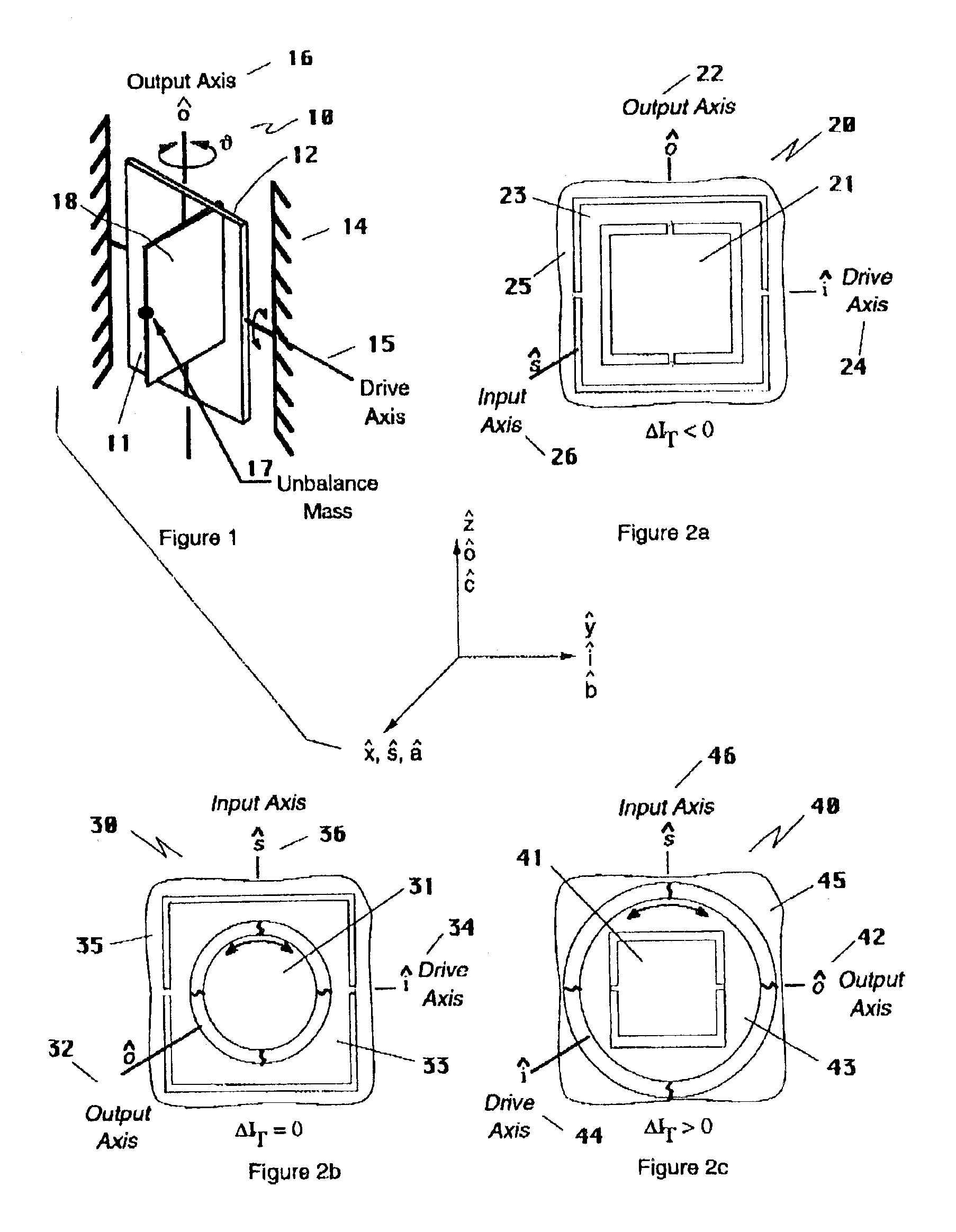

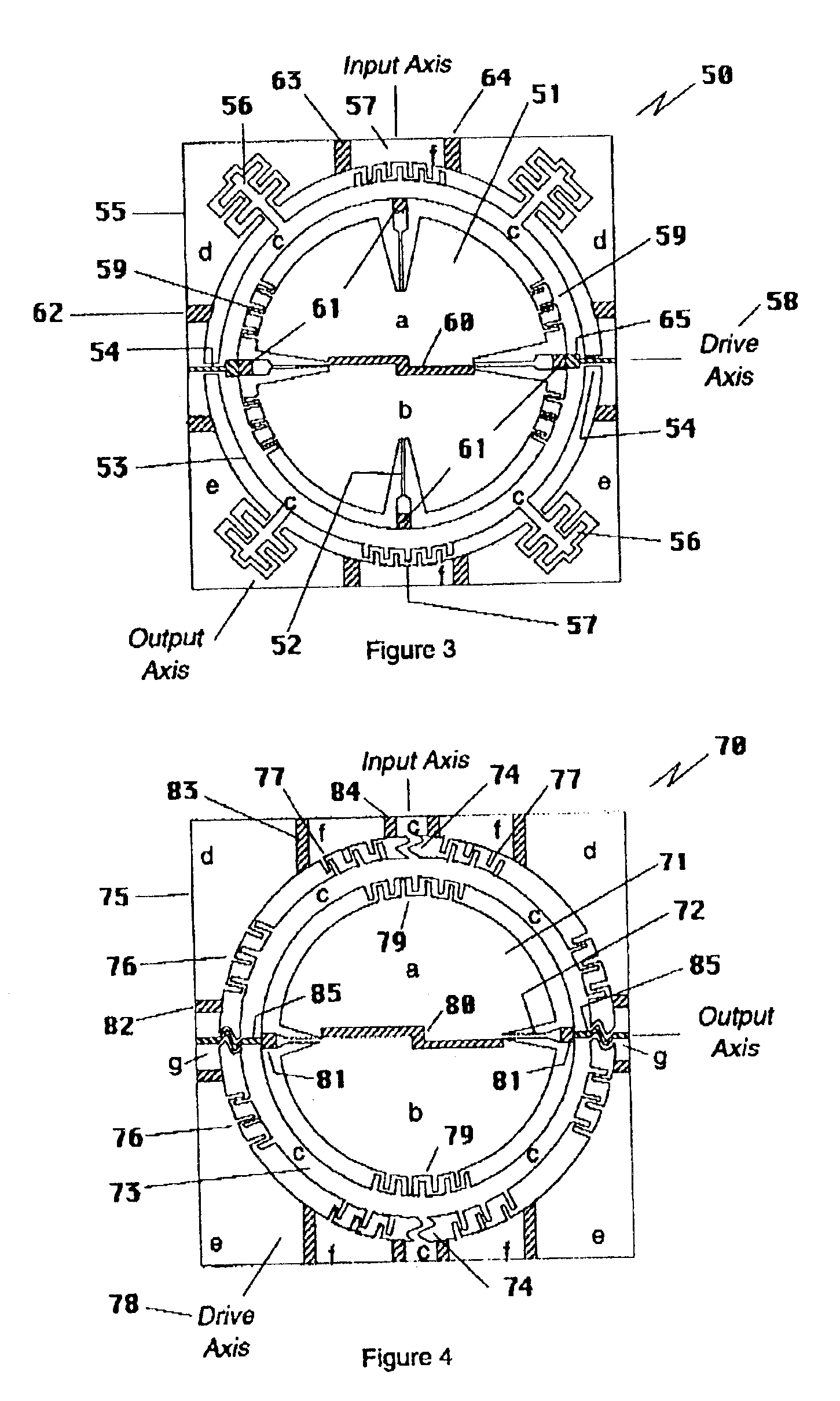

Planar inertial measurement units based on gyros and accelerometers with a common structure

InactiveUS6859751B2Simple structural designEasy to buildAcceleration measurement using interia forcesDigital computer detailsAccelerometerGyroscope

Inertial Measurement Units based on integrated designs to reduce alignment and assembly costs. Integration also leads to performance improvement, increased miniaturization and simplification as well as reduced cost. Also disclosed are gyroscopes and accelerometers that are identical, yet by their mechanization, can be made to act as separate sensors. Miniaturization and simplification is improved by combining instruments that can share a common member. Savings in space and complexity are also possible in the electronics when elements are shared.

Owner:MILLIE SENSOR SYST & ACTUATORS

Process for formulating a customized skin care product

InactiveUS7349857B2Performance advantageStability of product can be controlledPigmenting treatmentVacuum evaporation coatingBiometric dataAdditive ingredient

The invention relates to a method and a process of determining individual skin structure and function at a point in time for the purpose of determining and formulating skin care products that remedy the deficiencies observed in the skin. Objective and repeatable dermal biometric instrumentation techniques can be used to measure skin moisture content, sebum content, firmness and elasticity properties, skin thickness, transepidermal water loss, skin pH and to perform a photo analysis of the face with UV and visible light. By customizing the skin care products, the individually added active ingredients can be controlled, the diluents can be modified, dermal penetration rates can be controlled, the surfactant systems can be adjusted, and the stability of the product can be controlled. To prevent the loss of active materials in the product, the skin care product is manufactured for an individual consumer and is only sold in a quantity of a three months supply. Additionally, a variety of ingredients can be combined that a mass produced product cannot contain due to stability / compatibility issues. This invention overcomes the limitations in formulating skin products for the mass market by providing a product designed with objective biometric data and created for the specific clinical condition of an individual's skin.

Owner:MANZO ROBERT P

Filter with varying cell channels

InactiveUS6843822B2Increase capacityEfficient and cost-effectiveCombination devicesInternal combustion piston enginesSquare cross sectionHoneycomb structure

Owner:CORNING INC

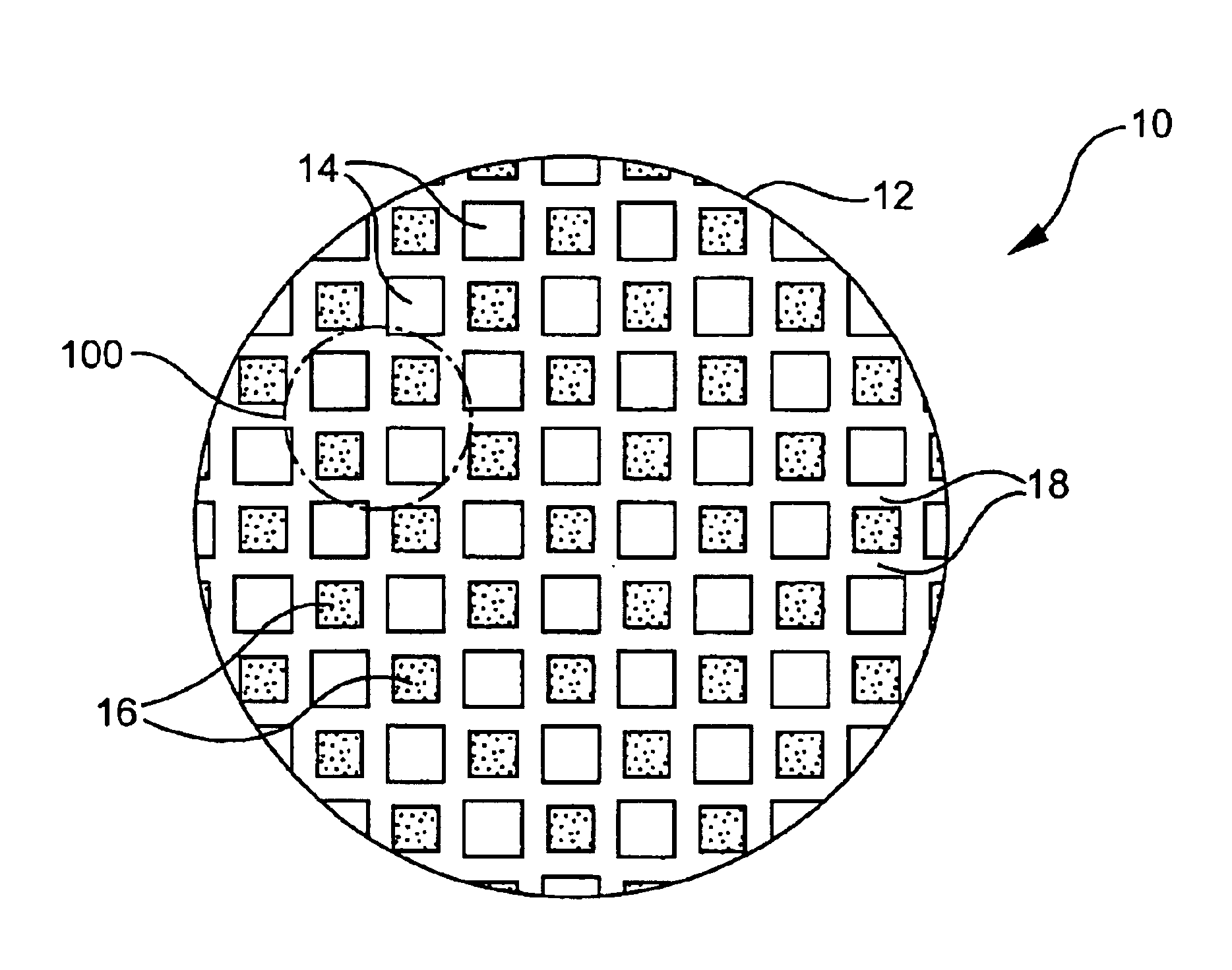

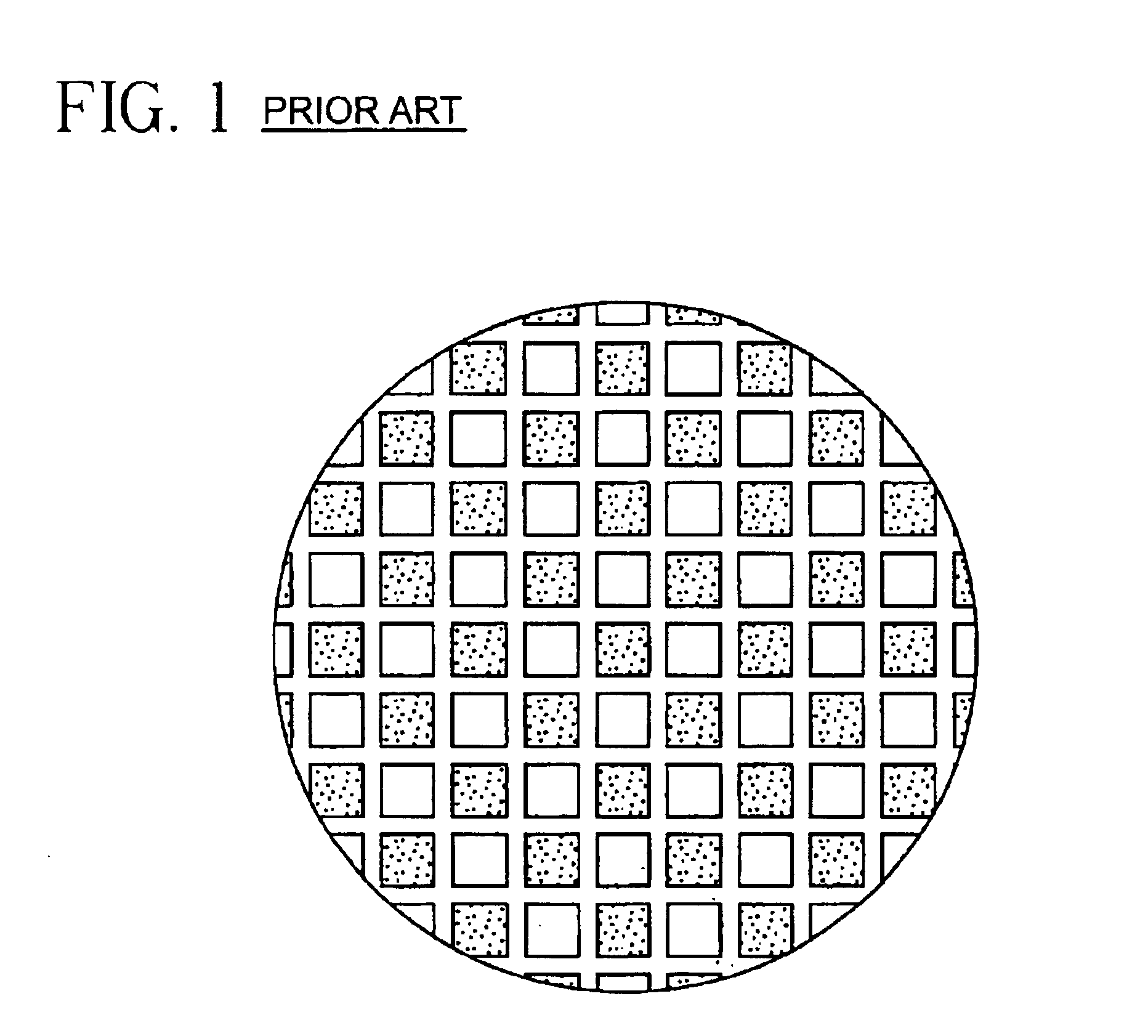

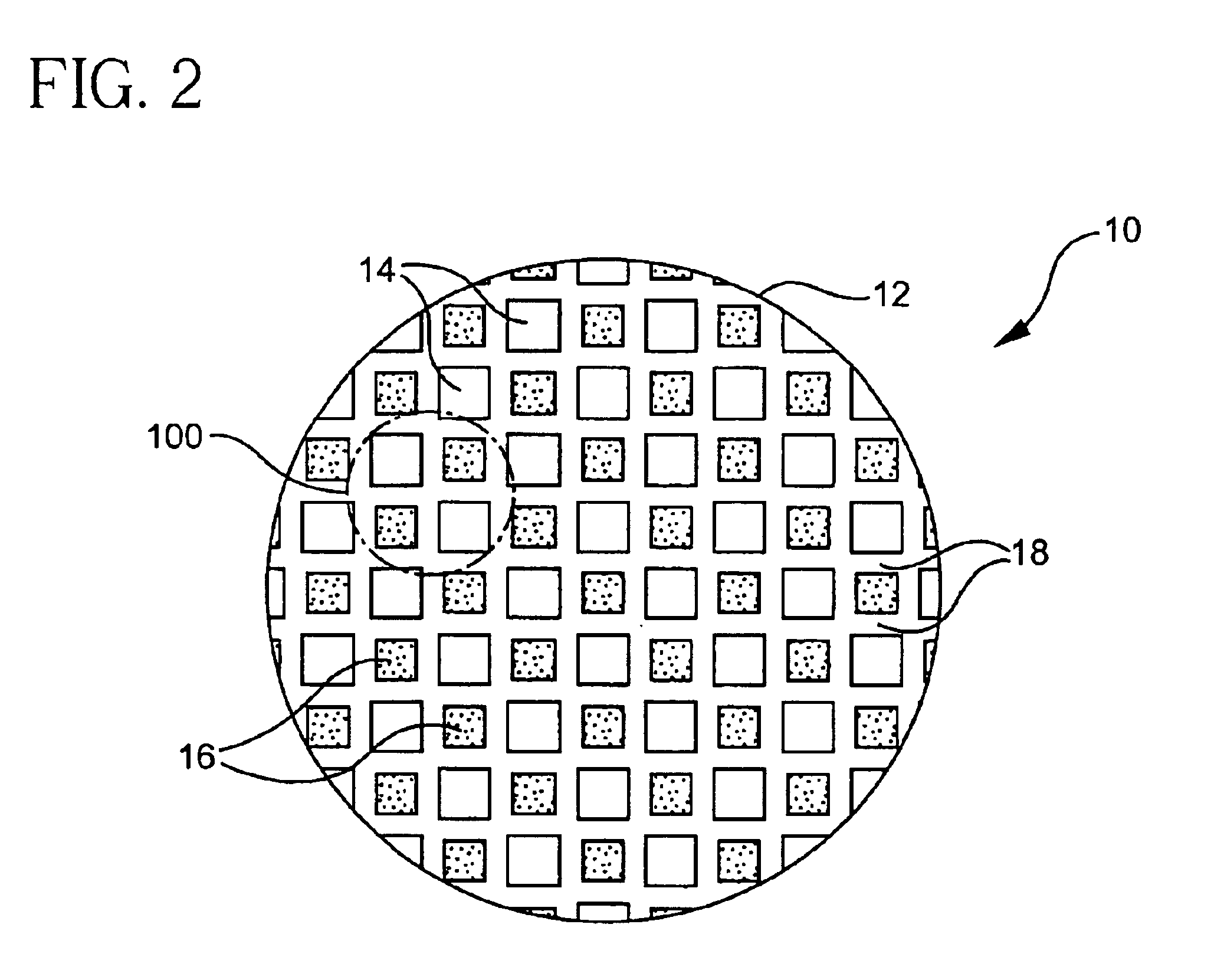

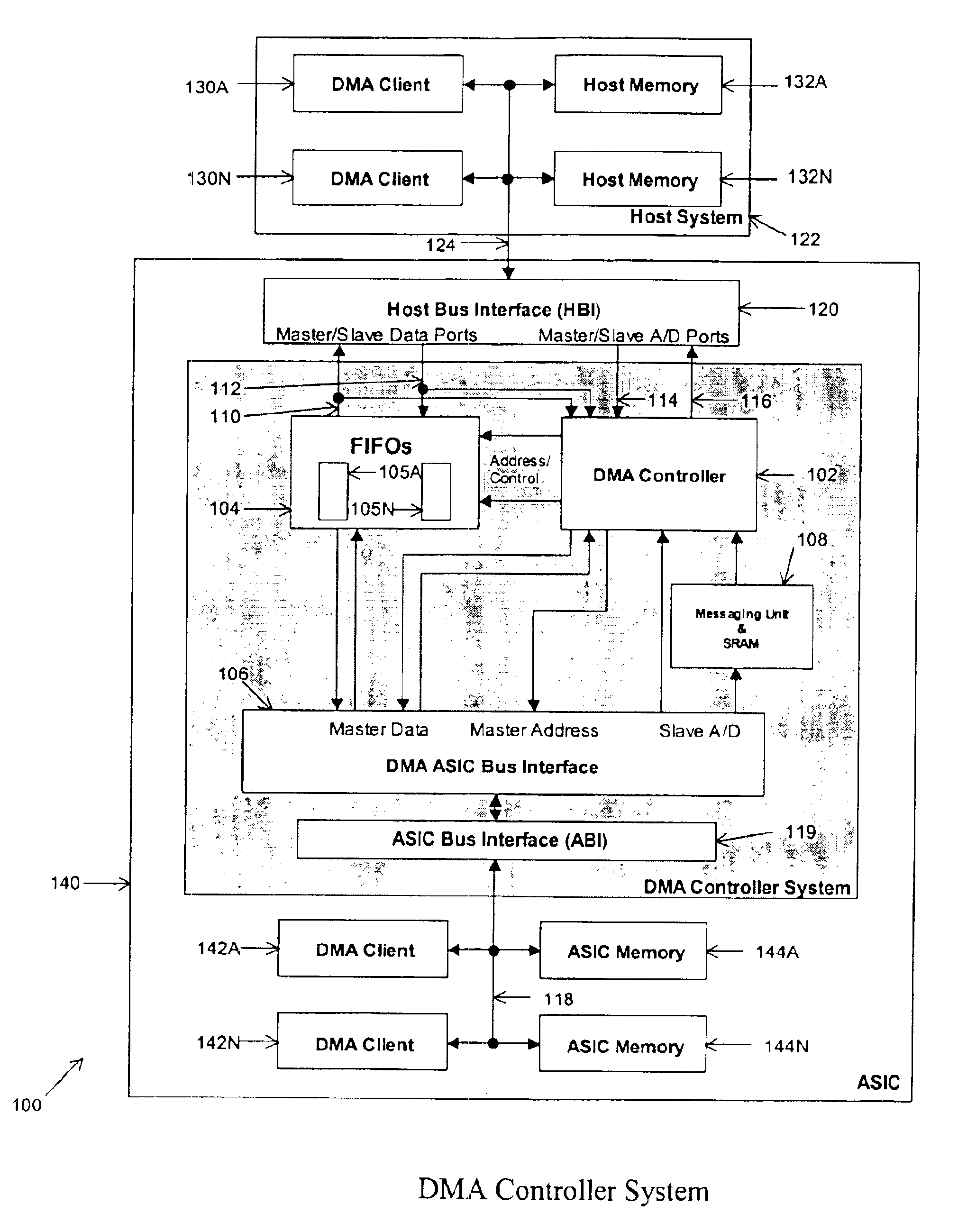

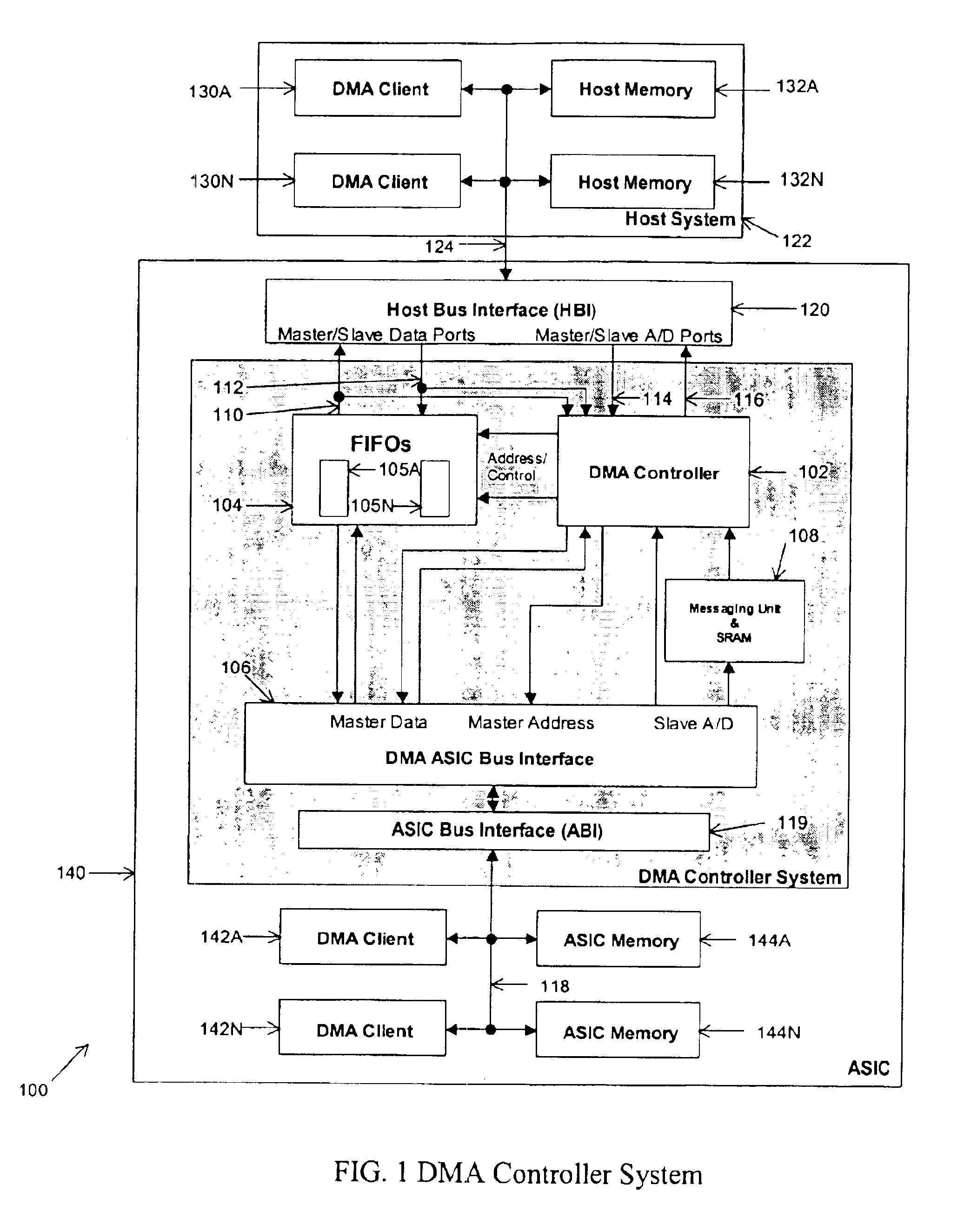

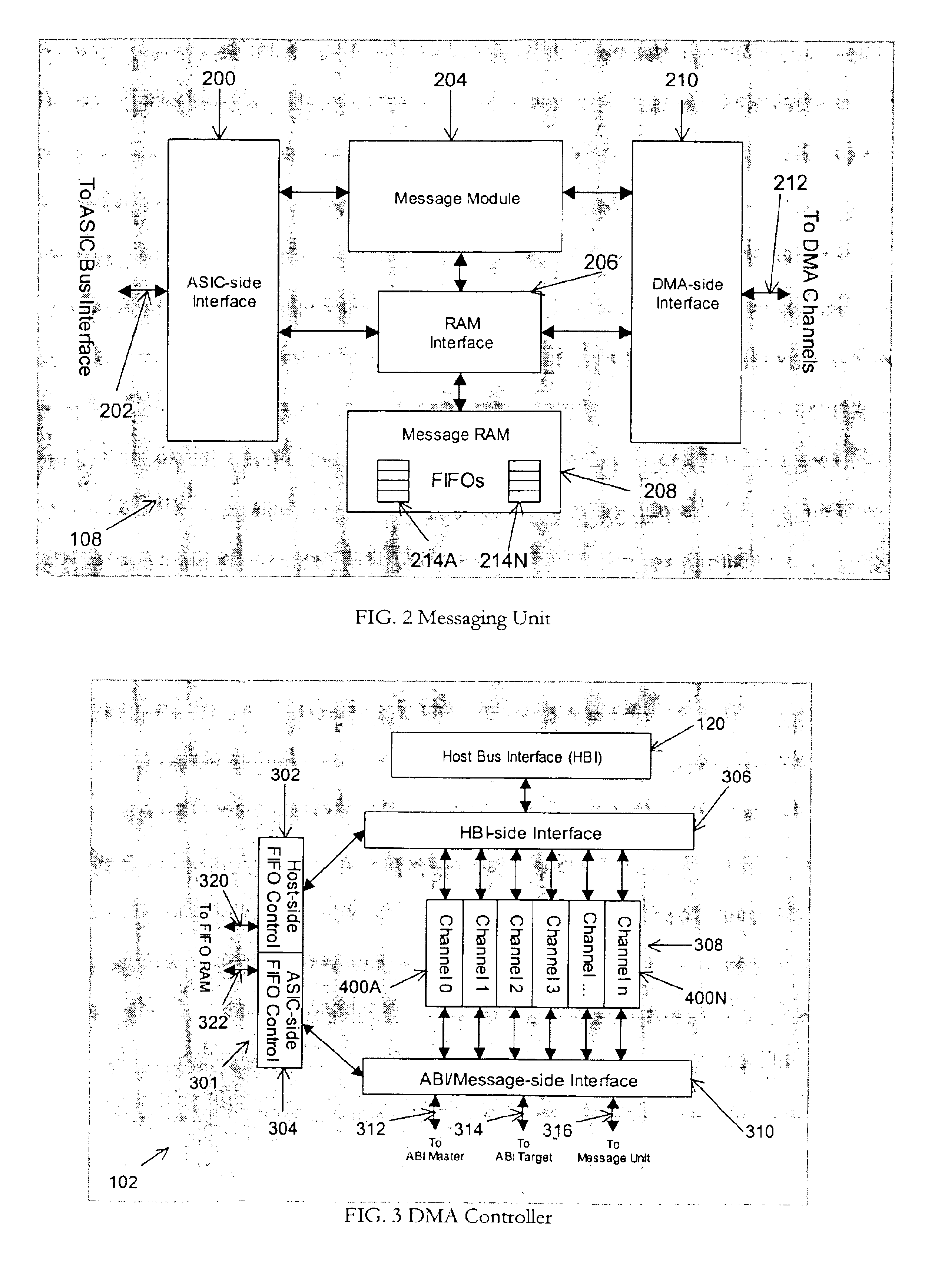

Direct memory access controller system with message-based programming

InactiveUS6874054B2Performance advantageEasy to operateProgram initiation/switchingRedundant data error correctionDirect memory accessTransfer system

A data transfer system comprising a first bus interface, a second bus interface, a first-in-first-out memory, a controller and a message unit. The message unit is operable to queue a plurality of data transfer request messages from the first bus interface and the second bus interface. The controller is operable to process each data transfer request message and transfer data between the first bus interface, the first-in-first-out memory and the second bus interface. The controller is configured to calculate error detection codes (EDCs) and chain EDC values.

Owner:AVAGO TECH INT SALES PTE LTD

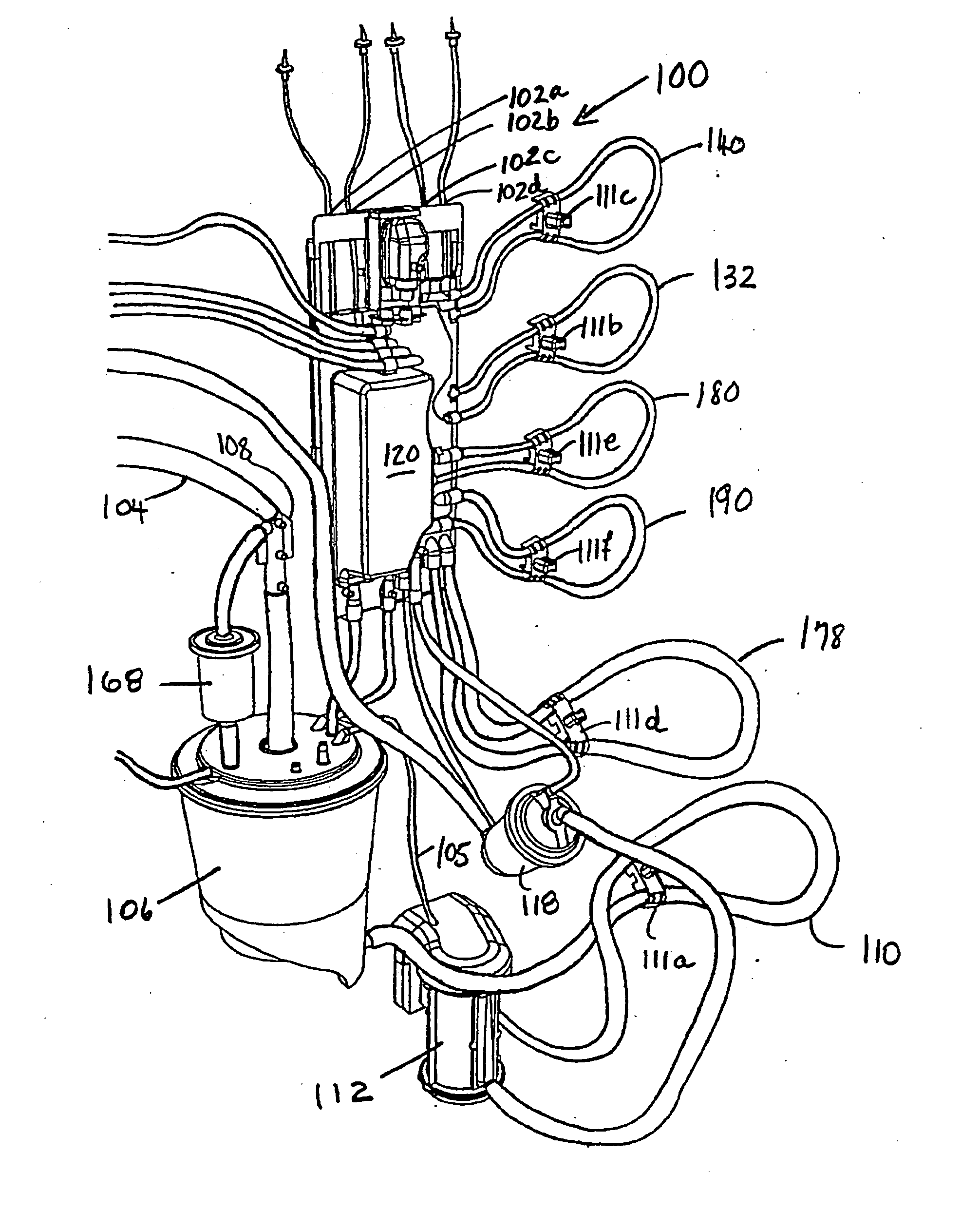

Disposable cartridge for a blood perfusion system

InactiveUS20060015056A1Simplified interconnection/disconnectionSimple setupOther blood circulation devicesMedical devicesPerfusionBiomedical engineering

A disposable cartridge for use in extracorporeal blood perfusions systems that have a control unit for controlling the flow of fluids. The cartridge has a housing defining a plurality of internal passageways that connect to a cardiopulmonary circuit, a cardioplegia circuit and a suction circuit. The cartridge may be fitted with one or more of a bubble trap, a filter, and a valve.

Owner:SORIN GRP USA INC

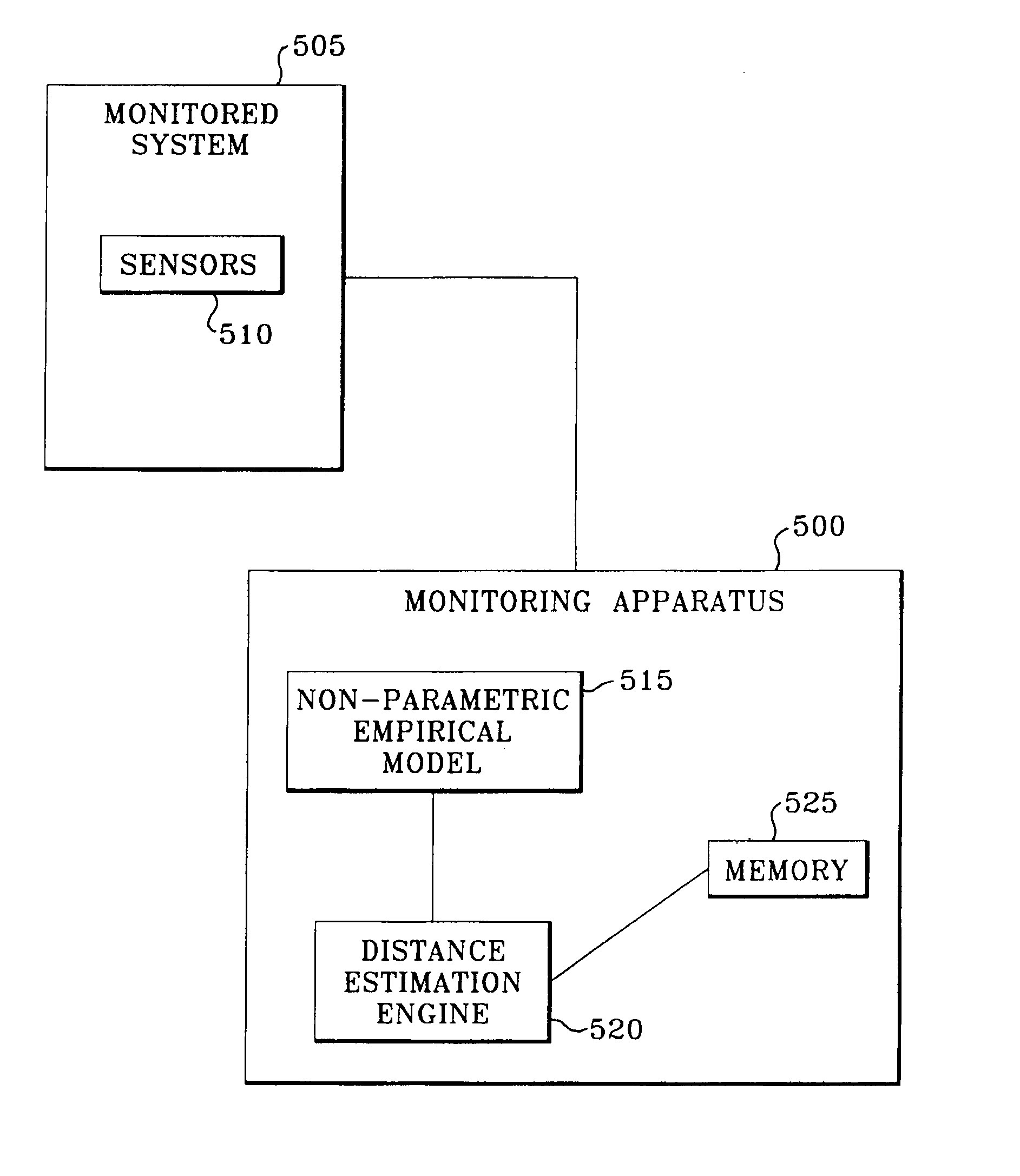

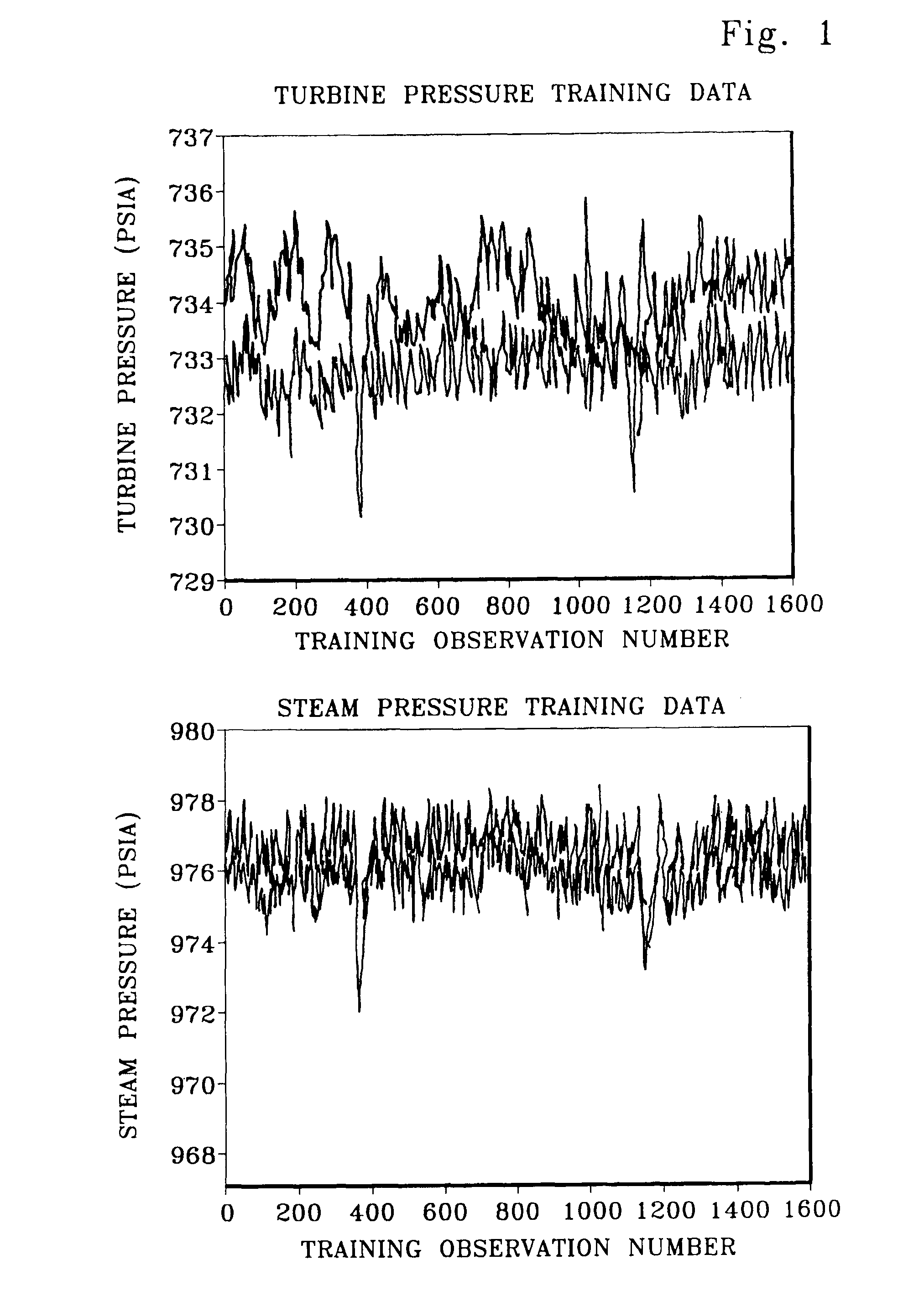

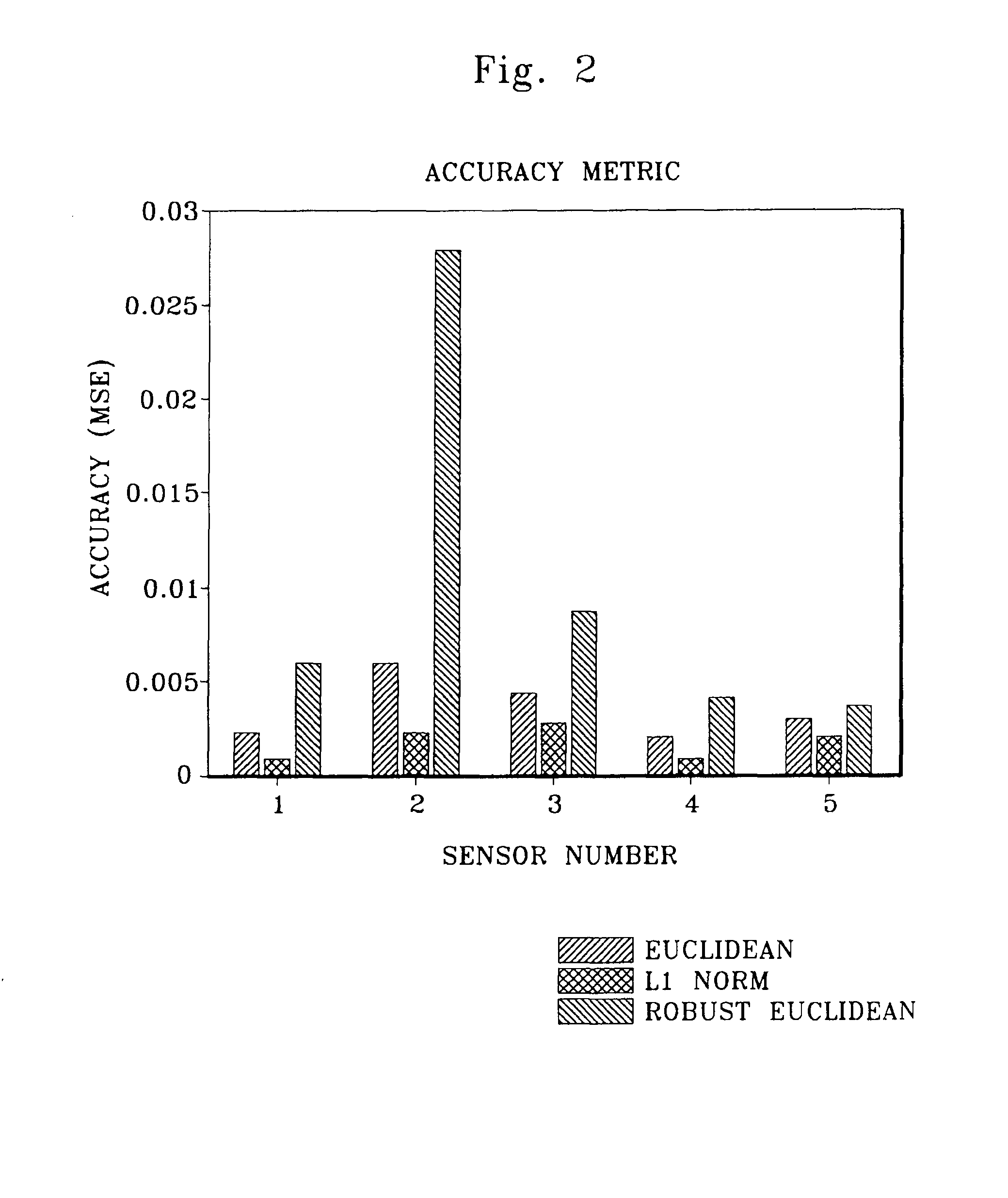

Robust distance measures for on-line monitoring

ActiveUS8311774B2Improve model performanceRobust distance metricNuclear energy generationSimulator controlComputer scienceDistance measurement

An apparatus and associated method are utilized for monitoring an operation of a system characterized by operational parameters. A non-parametric empirical model generates estimates of parameter values in response to receiving a query vector of monitored parameters for a model characterizing the system. A distance estimation engine (a) determines robust distances between the query vector and each of a set of predetermined historical vectors for the non-parametric empirical model based on an implementation of an elemental kernel function; (b) determines weights for the monitored parameters based on the robust distances; and (c) combining the weights with the predetermined historical vectors to make predictions for the system.

Owner:SMARTSIGNAL CORP

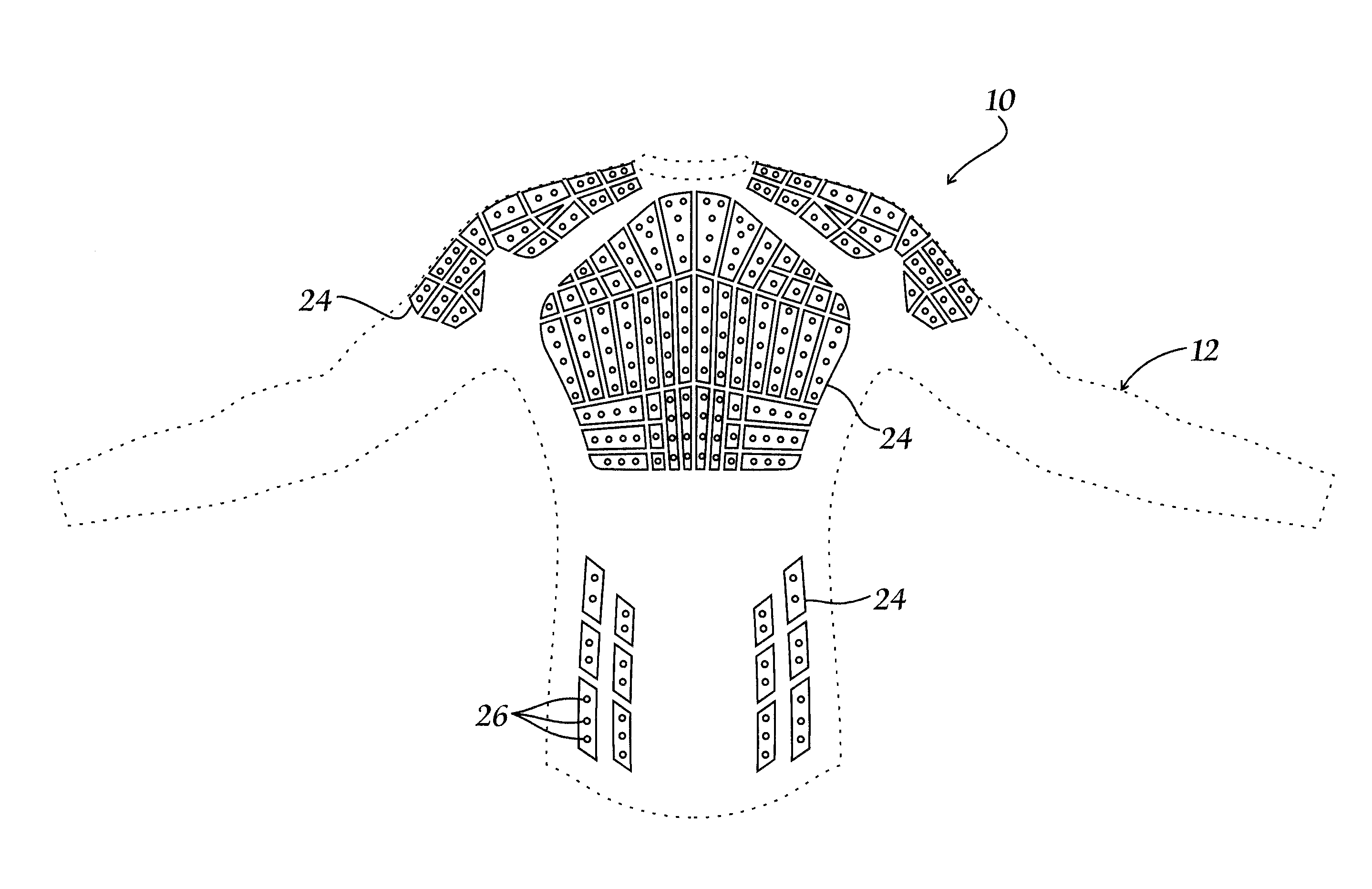

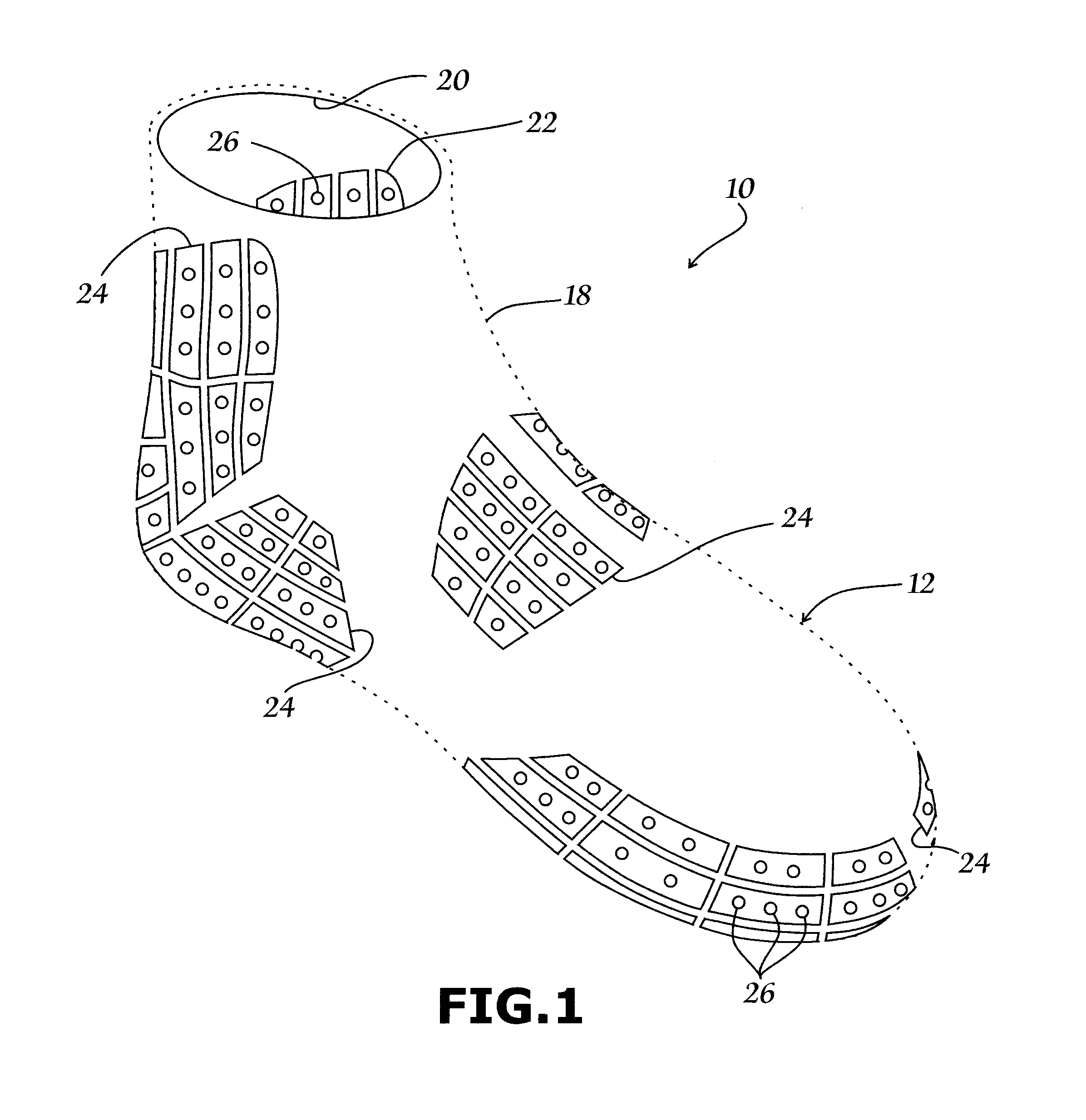

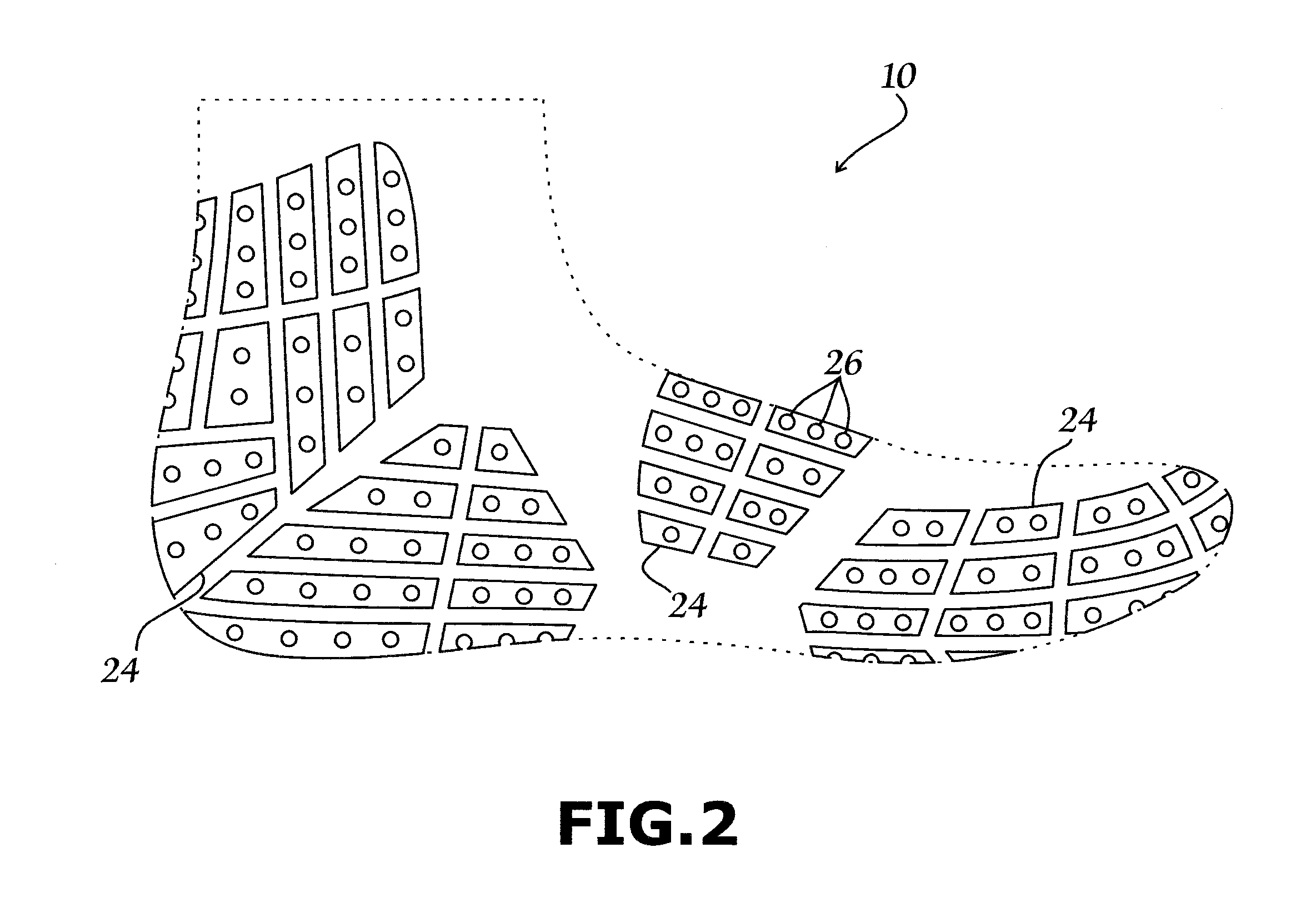

Wearable article with correspondingly aligned interior and exterior grip material

InactiveUS20140223630A1Prevent movementEliminate relative motionGarment special featuresGlovesBiomedical engineering

A wearable article provides a non-slip connection between the wearer's bare skin and the surface of an adjacently located object. The wearable article includes correspondingly aligned and shaped interior and exterior grip material segments at one or more locations on the wearable article. The interior grip material segments and correspondingly aligned and shaped exterior grip material segments serve to significantly diminish and potentially eliminate all relative movement between the user's skin, the grip material on the inner facing surface of the wearable article, the material defining the wearable article, the grip material on the outer facing surface of the wearable article, and the surface of an adjacently located object. The correspondingly aligned and shaped interior and exterior grip material segments on the wearable article may be arranged in different sizes and patterns to suit the movements typically executed during a particular physical or sporting activity.

Owner:JOHNSON RANDALL L

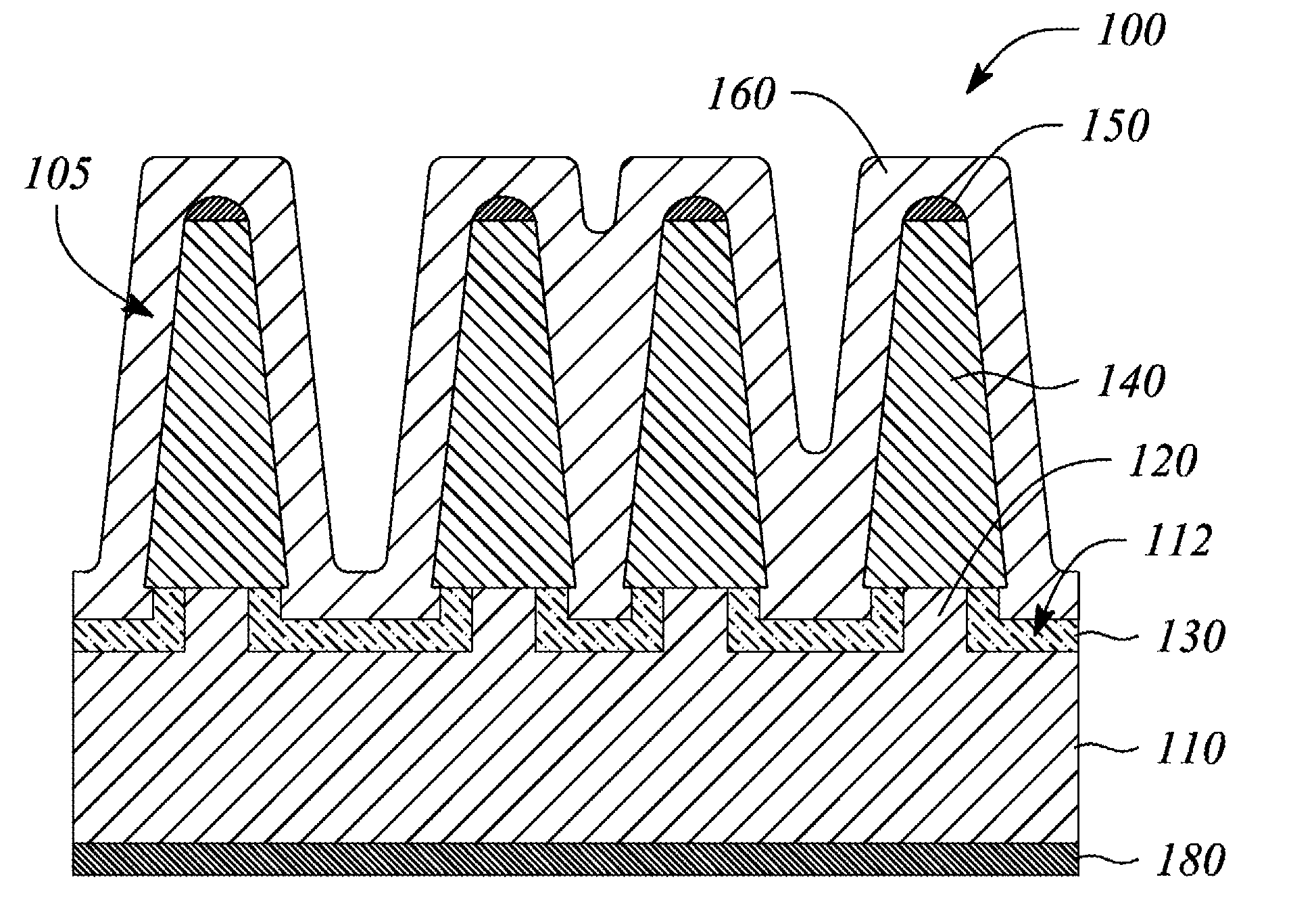

Photovoltaic Structure And Method Of Fabication Employing Nanowire In Stub

InactiveUS20110272014A1Cost and manufacturing advantagePerformance advantageFinal product manufactureSemiconductor/solid-state device manufacturingNanowireNanoparticle

A photovoltaic structure of a photovoltaic cell and a method of fabricating a photovoltaic structure, employ a nanowire having a base connected to a stub and an electrical isolation layer surrounding the stub. The stub is a constituent of a substrate surface. The nanowire extends away from the substrate surface and is wider than the stub. The nanowire base overlies a part of the isolation layer that is adjacent to the stub. A semiconductor junction comprises the nanowire. The method includes forming the stub; growing the nanowire from the stub; and conformally coating the nanowire. A nanoparticle is applied to the substrate surface. The isolation layer is created on and embedded in the substrate surface using the nanoparticle as a mask. A portion of the substrate surface underlying the nanoparticle forms the stub. The nanoparticle catalyzes nanowire growth on the stub. The stub is narrower than the nanoparticle.

Owner:HEWLETT PACKARD DEV CO LP

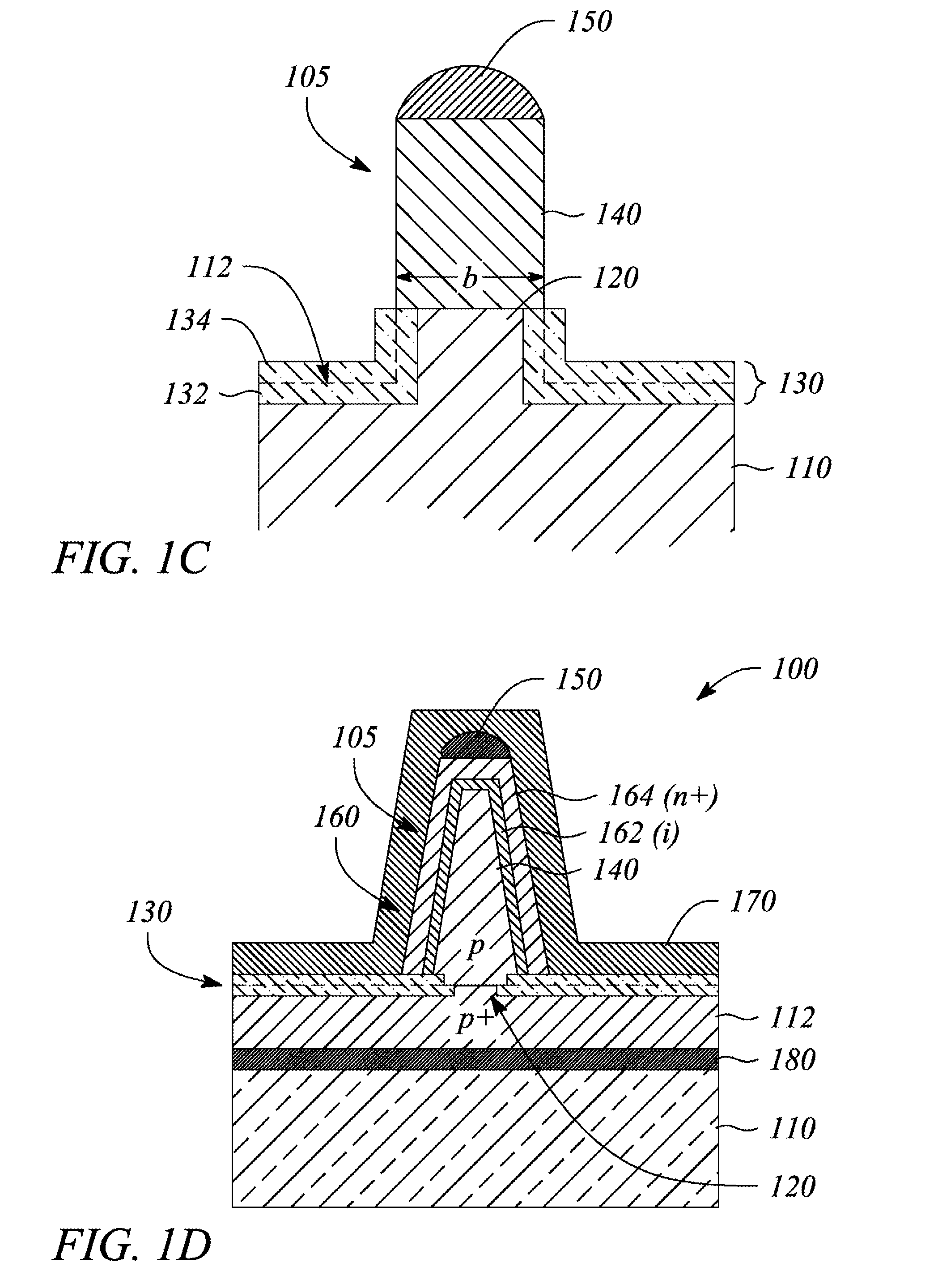

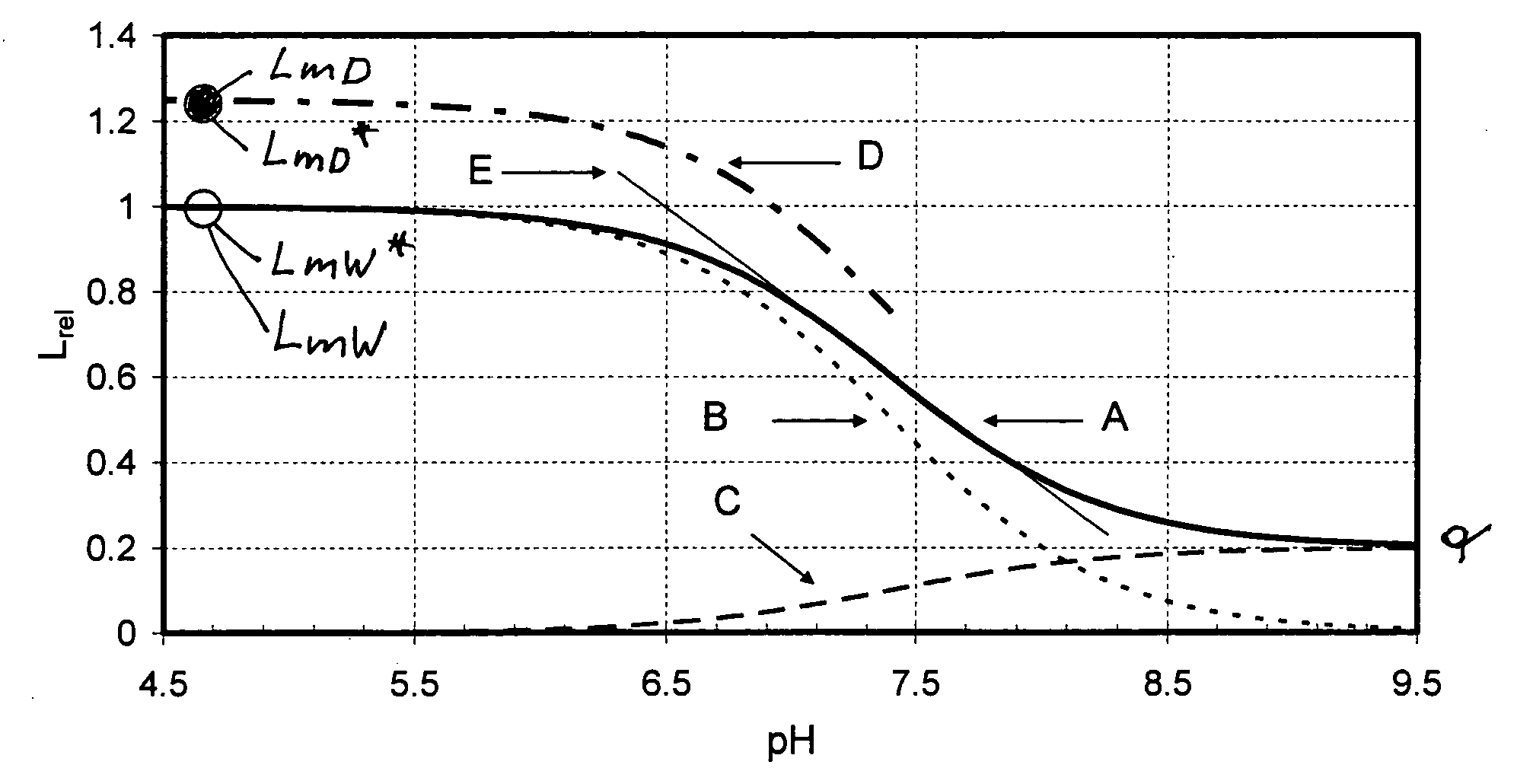

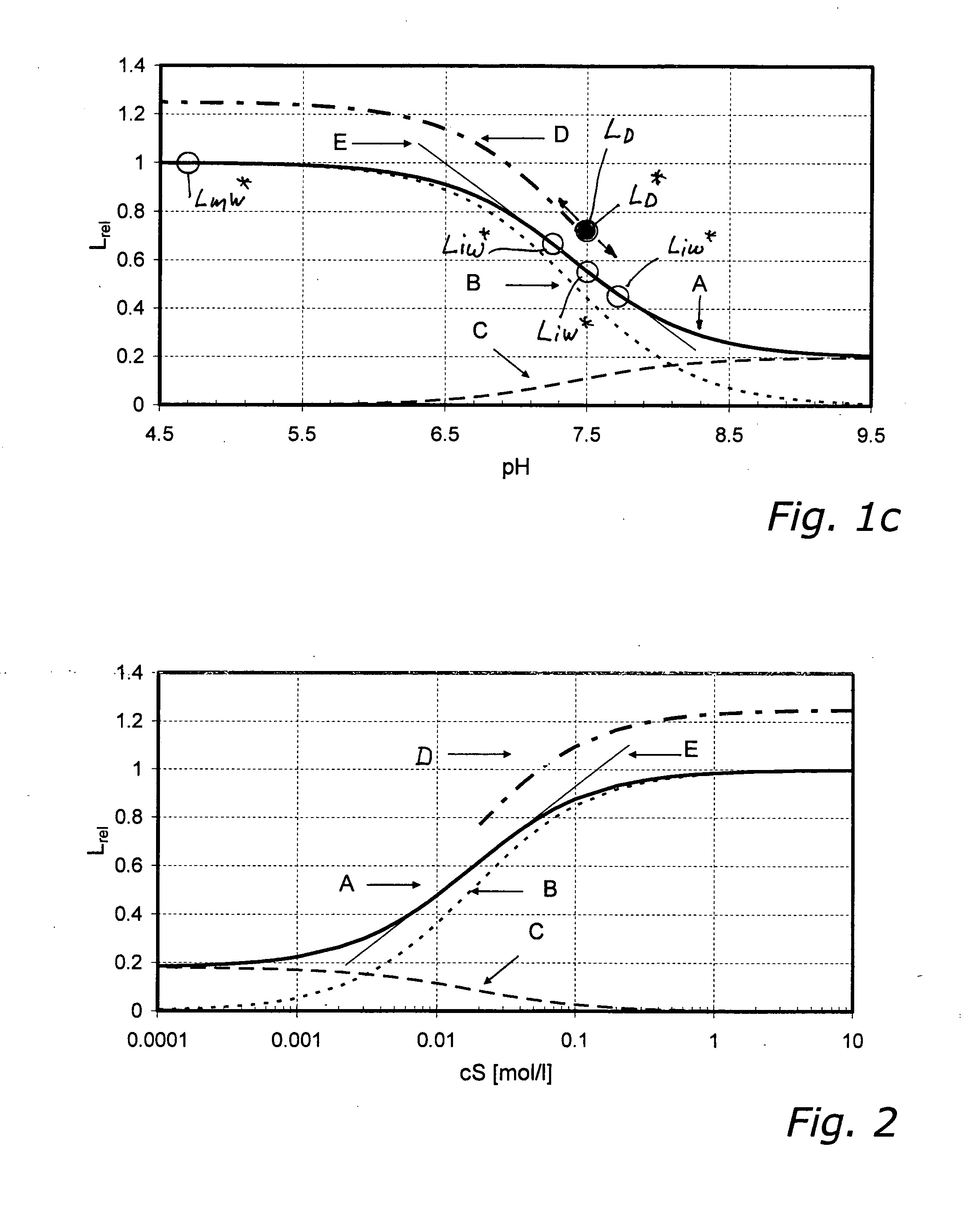

Method for the Determination of the Concentration of a Non-Volatile Analyte

ActiveUS20080215254A1Performance advantagePhotometry using reference valueMaterial analysis by observing effect on chemical indicatorAnalyteLuminescence

The invention relates to a method for the determination of the concentration of a non-volatile analyte in an aqueous sample medium, with the use of an optical sensor which contains a luminescent dye and is calibrated at the user site by means of a single-point-calibration. To enable the user to completely dispense with all calibration media a luminescence measurement value is obtained at the user site with the sensor in contact with the aqueous or bloodlike sample medium, which value is referenced to the relative characteristic obtained at the factory site and to a measured dry calibration value obtained at the user site, the concentration of the non-volatile analyte being deduced from these data.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

Multi-material building three-dimensional printing and molding method

The invention discloses a three-dimensional printing and molding method for manufacturing a multi-material building or a large-size object layer by layer by adopting a plurality of nozzles, a plurality of types of materials and a three-dimensional printing technology. The three-dimensional printing and molding method comprises the following steps: establishing a three-dimensional CAD (Computer Aided Design) solid model of the multi-material building according to a pre-three-dimensional printed multi-material building; slicing and layering the three-dimensional CAD solid model to obtain machining information including solid structure information, material distribution information, movement tracks and the like of each layer; in a printing process of the multi-material building, conveying a plurality of types of molding materials by adopting a plurality of printing heads respectively, stacking layer by layer and carrying out printing and molding; carrying out treatment including polishing, spraying, wire arrangement, supporting removal and the like of the printed building model so as to obtain the building containing a plurality of types of materials. With the adoption of the three-dimensional printing and molding method, the integration of designing and manufacturing of a three-dimensional structure and a material of the multi-material building is realized; the comprehensive performance of the building is greatly improved; the three-dimensional printing and molding method is particularly applicable to the printing and molding of a functional building, and has a wide application prospect in the field of molding of buildings or models of landscape sculptures, artificial hills, home furniture and the like.

Owner:南京三帝智能装备制造有限公司

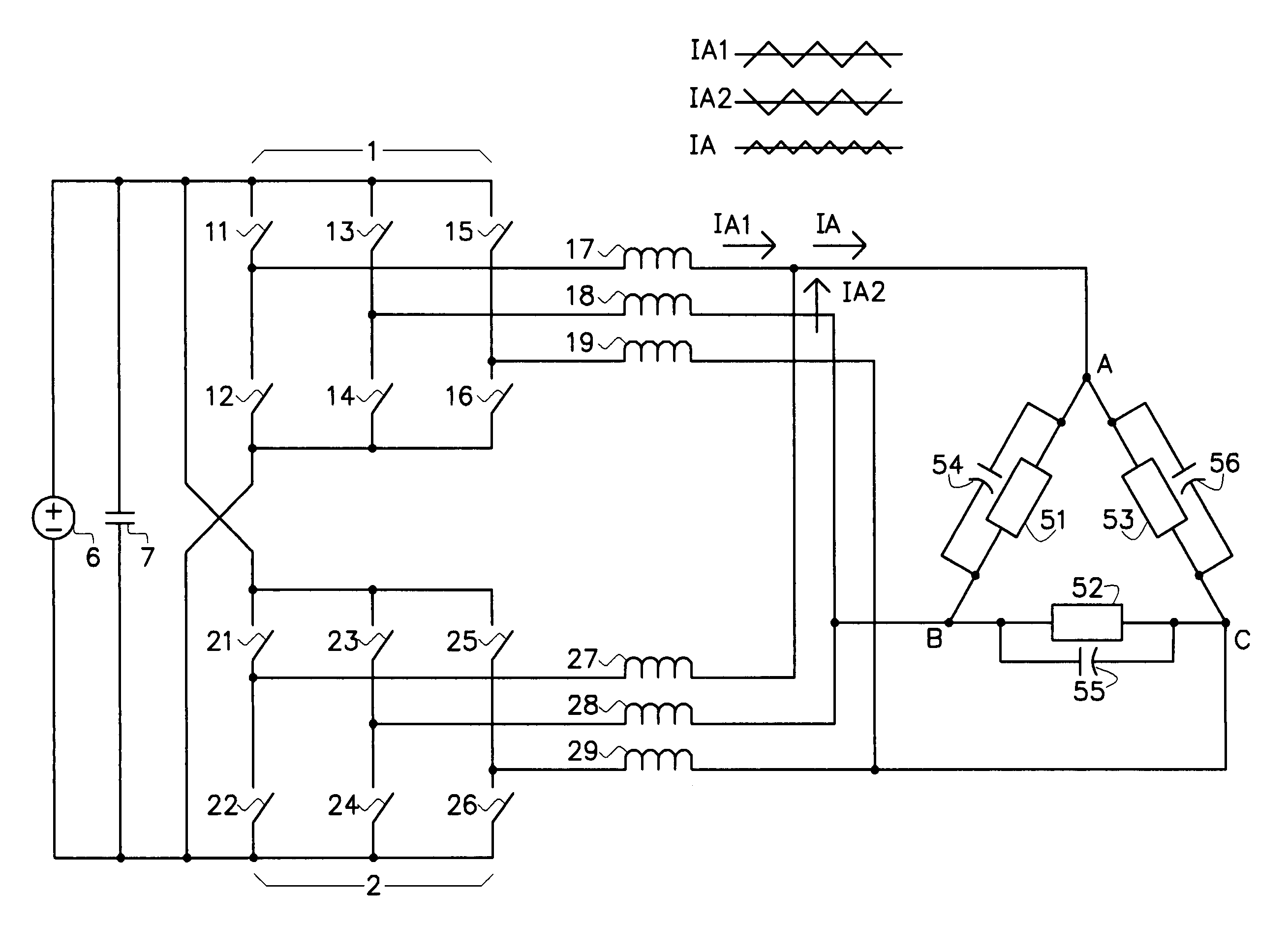

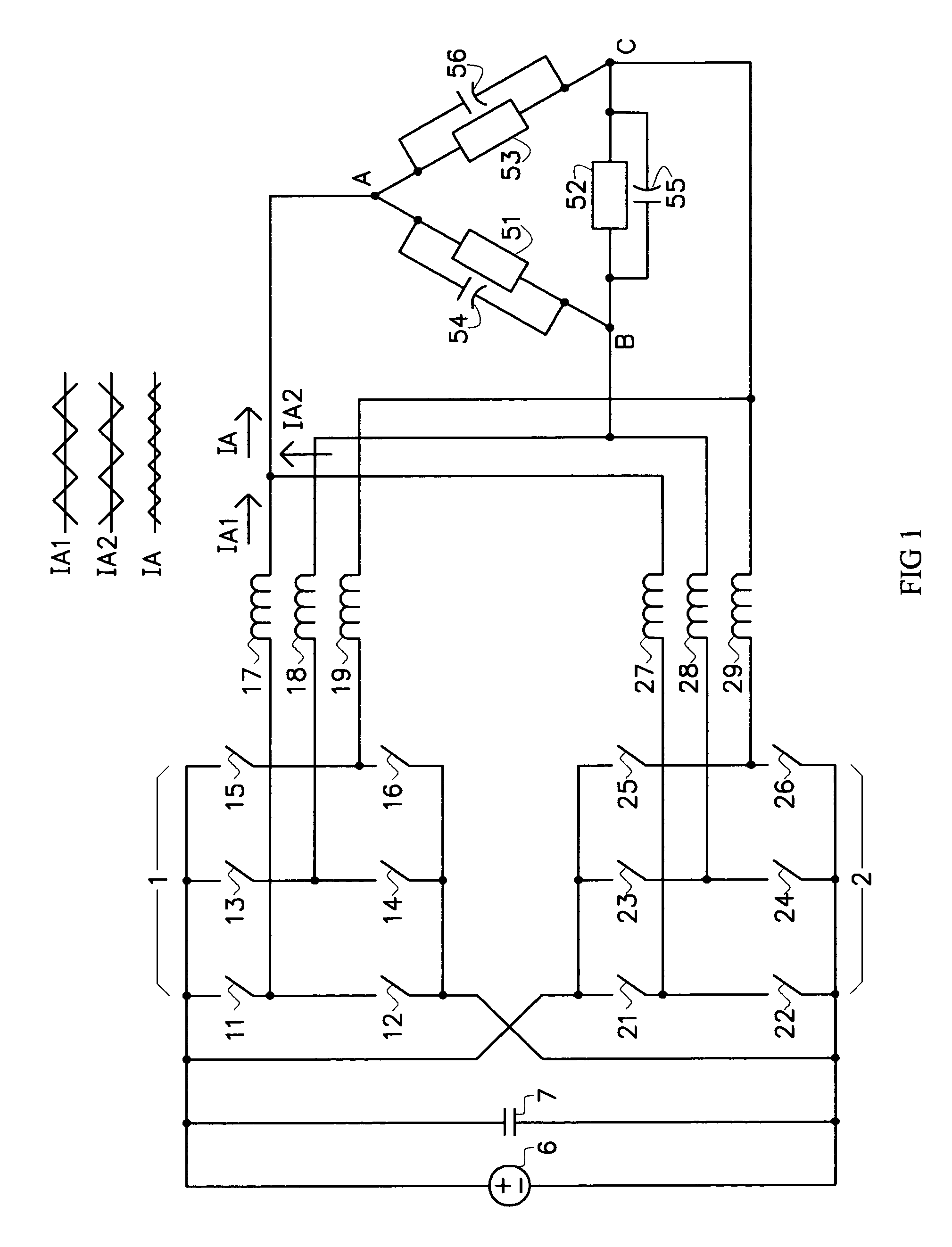

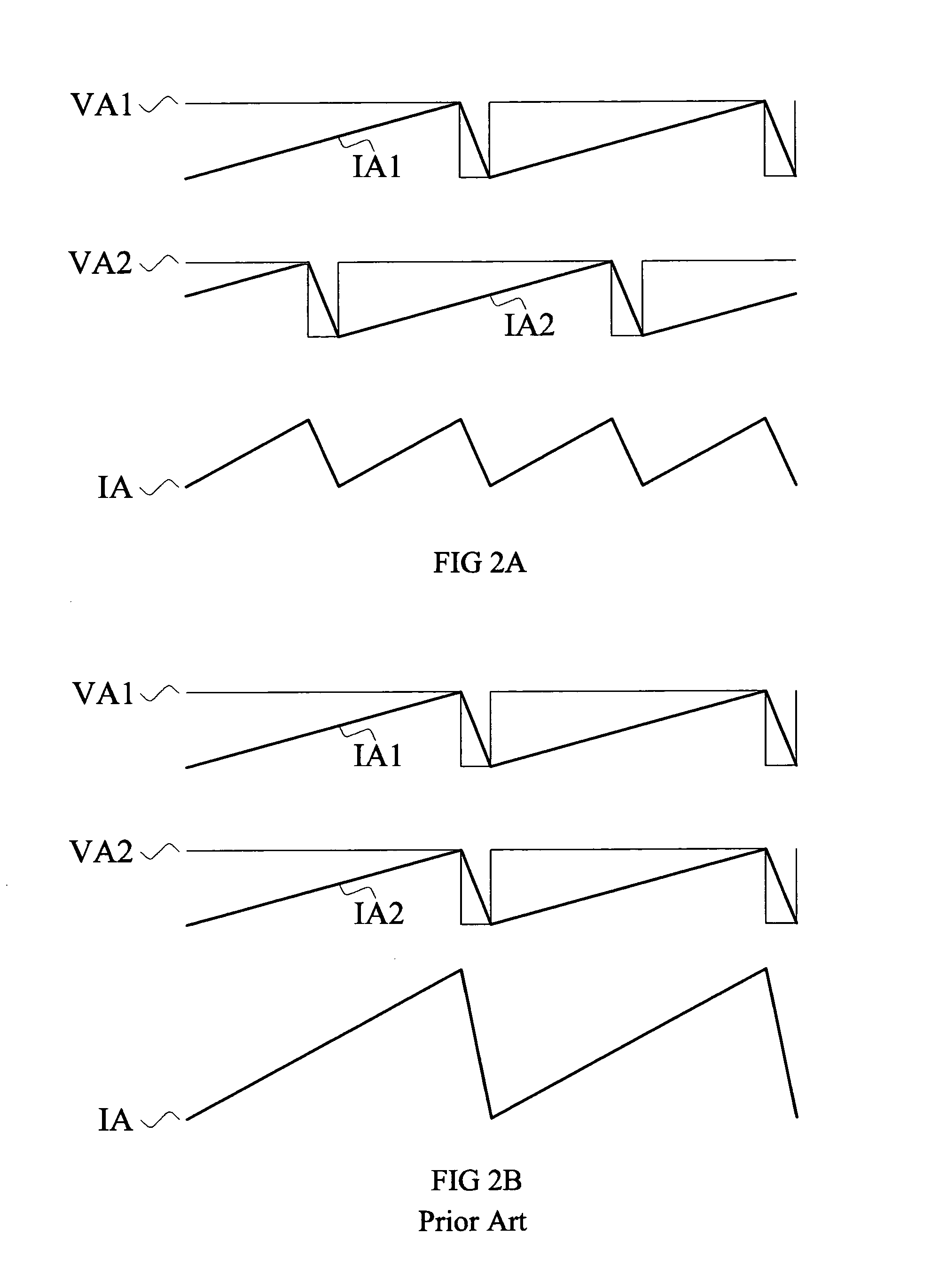

Power converter with ripple current cancellation using skewed switching techniques

InactiveUS7046527B2Optimum ripple current cancellationPerformance advantageDc circuit to reduce harmonics/ripplesDc-ac conversion without reversalEngineeringElectrical and Electronics engineering

The invention is an electrical power converter using multiple, high frequency switching elements where the individual switching elements are operated in a synchronous, time-skewed arrangement to provide optimum ripple current cancellation.

Owner:SCHNEIDER ELECTRIC SOLAR INVERTERS USA

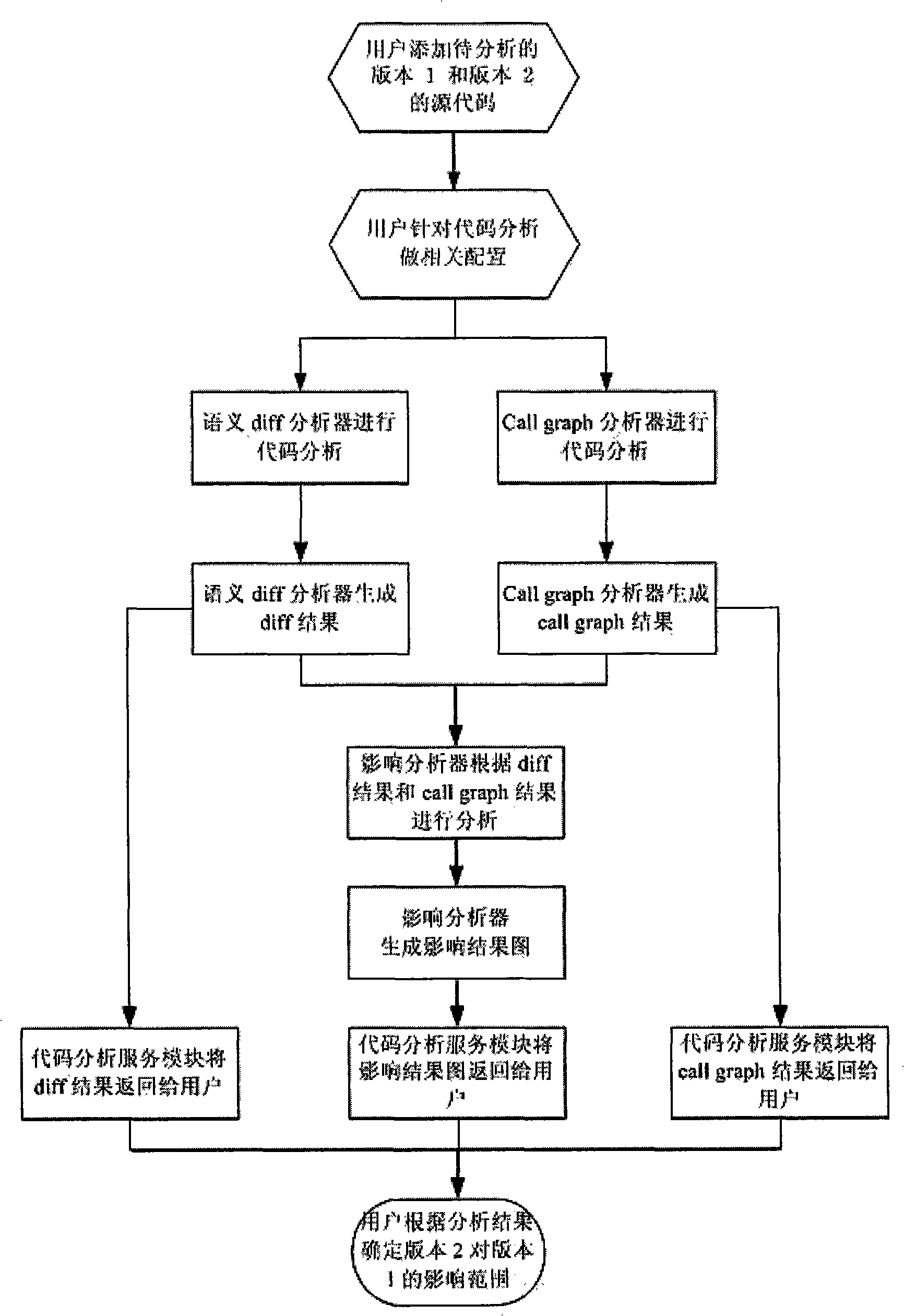

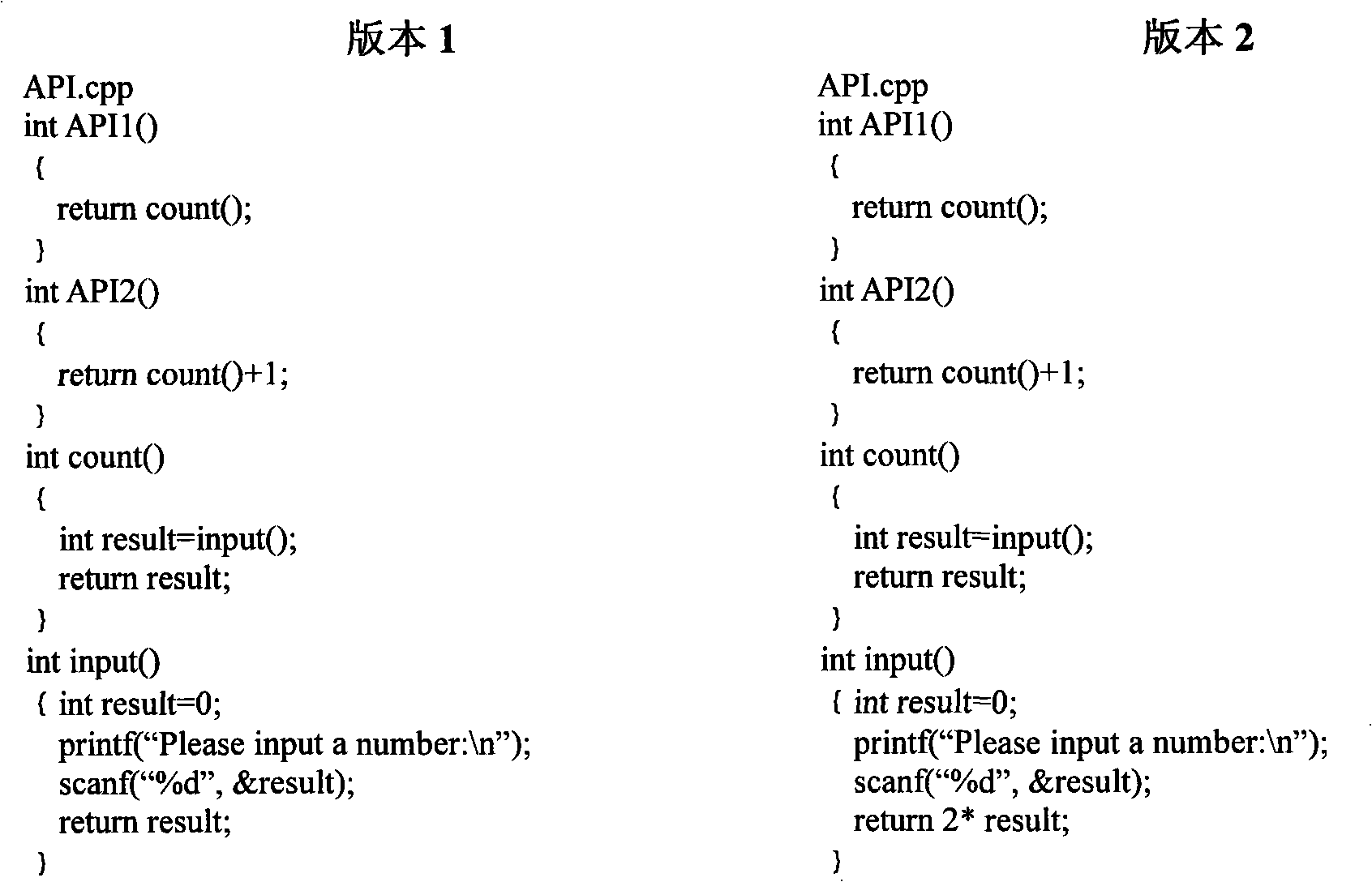

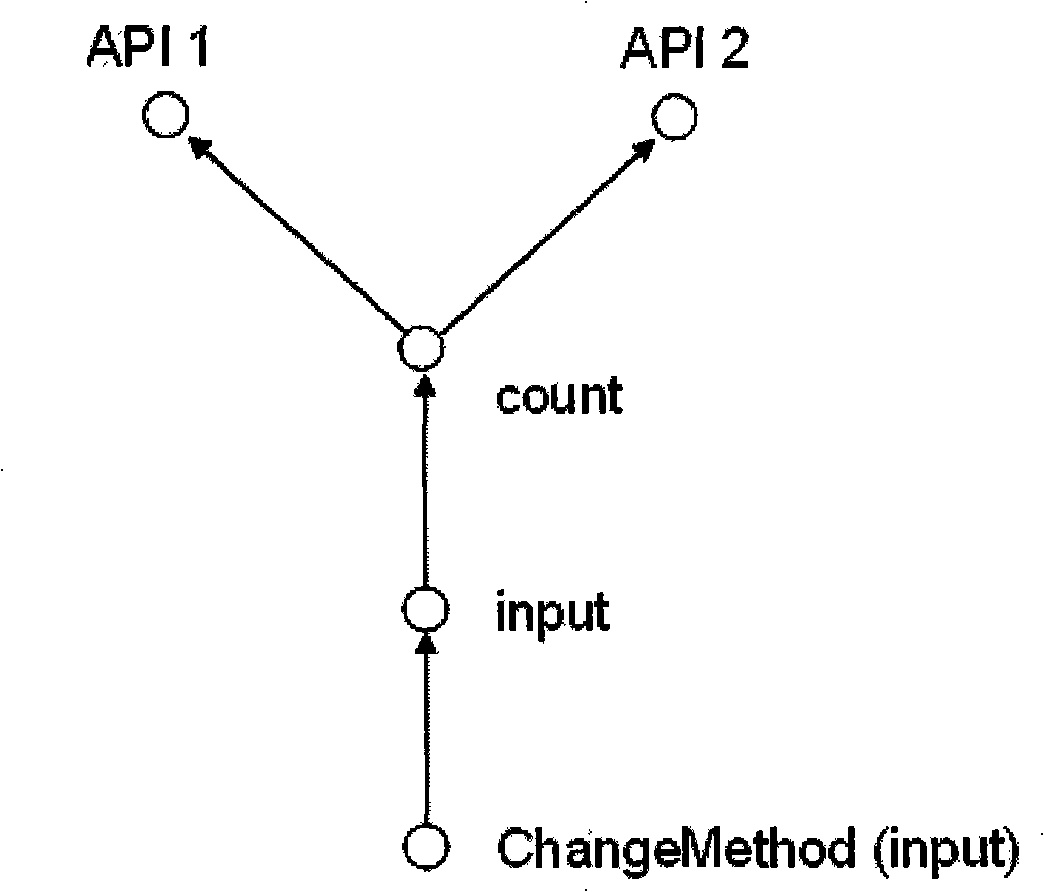

Method for determining function point changing through code analysis

ActiveCN101286119AAccurate analysisPerformance advantageSpecific program execution arrangementsFunction pointStructure relation

The invention relates to a method for determining the change of functional points by analysing the change of codes: firstly, all changes of source codes to be compared are searched and collected on textual level and a diff result is generated; secondly, an incidence relation between the modified source codes and an interface function or method by analysing the structure relation of the source codes to be compared and a call graph result is generated; the diff result and the call graph result are finally analysed, all affected interface functions or methods are output in the form of graph or statement to generate an affected result graph. By the code analysis, the external function point which is affected when the version is updated, thus effectively assisting the testing and updating operation of new software versions.

Owner:ARRAY NETWORKS BEIJING

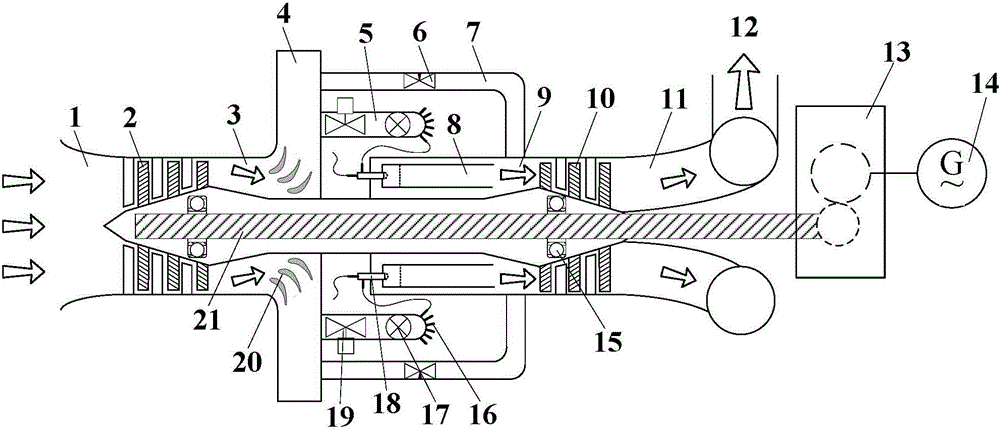

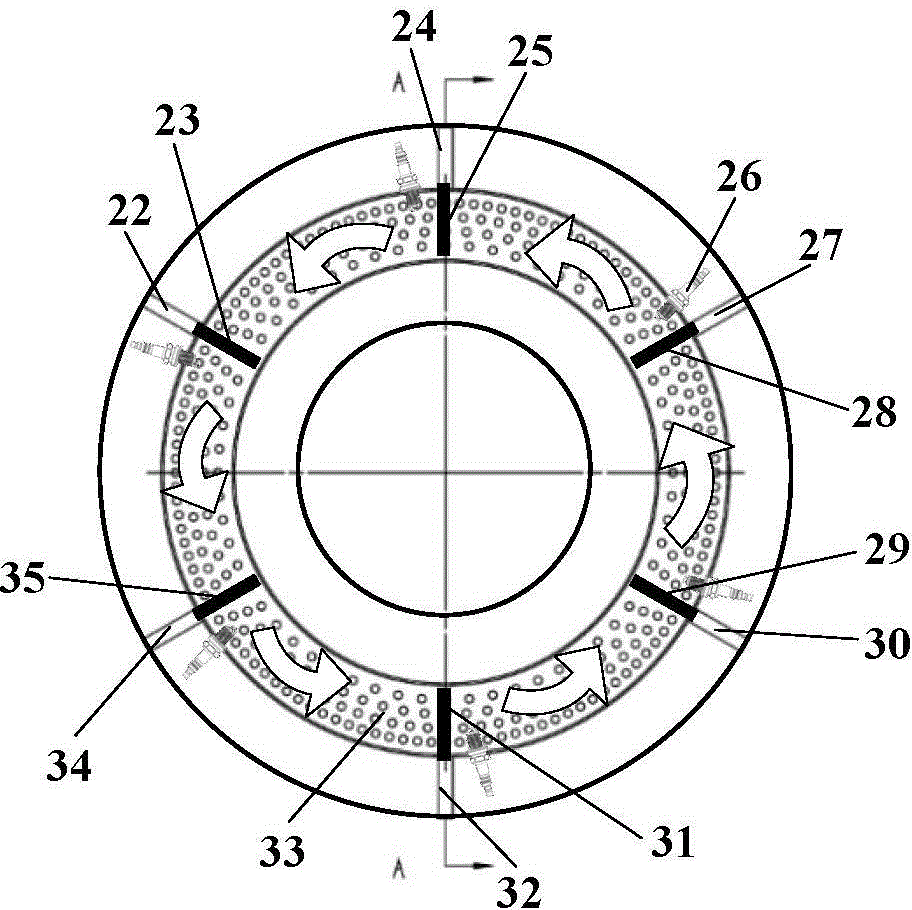

Rotary knocking gas turbine

InactiveCN104153884AImprove cycle thermal efficiencyLower Burn Control SystemGas turbine plantsJet propulsion plantsCombustion chamberGas compressor

The invention discloses a rotary knocking gas turbine. The rotary knocking gas turbine comprises a gas inlet passage, a diffusion section and a gas storage chamber which are connected in sequence from left to right, wherein a gas compressor is arranged at the downstream of the gas inlet passage; a rotary knocking combustion chamber is positioned at the right end of the gas storage chamber, the right end of the rotary knocking combustion chamber is connected with a mixing chamber, a turbine and an exhaust pipe in sequence, a plurality of nozzles are annularly arranged on the left end face of the rotary knocking combustion chamber at equal intervals, and six ignition plugs are uniformly arranged on the circumference of the rotary knocking combustion chamber; an air passage and a combustion passage are arranged on each nozzle, the gas storage chamber is communicated with the rotary knocking combustion chamber through a gas supply passage and the air passages of the nozzles, and the mixing chamber is communicated with the gas storage chamber through a gas escape bypass; a rotor is arranged between the gas compressor and the turbine, the gas compressor of a rotating component of the gas turbine and the turbine are connected with a casing of a static bearing component of the gas turbine through two bearings, and one end of the rotor is led out from the gas exhaust pipe. When the rotary knocking gas turbine is used, the leading-out end of the rotor is connected with a generator assembly through a speed changer.

Owner:XIAN THERMAL POWER RES INST CO LTD

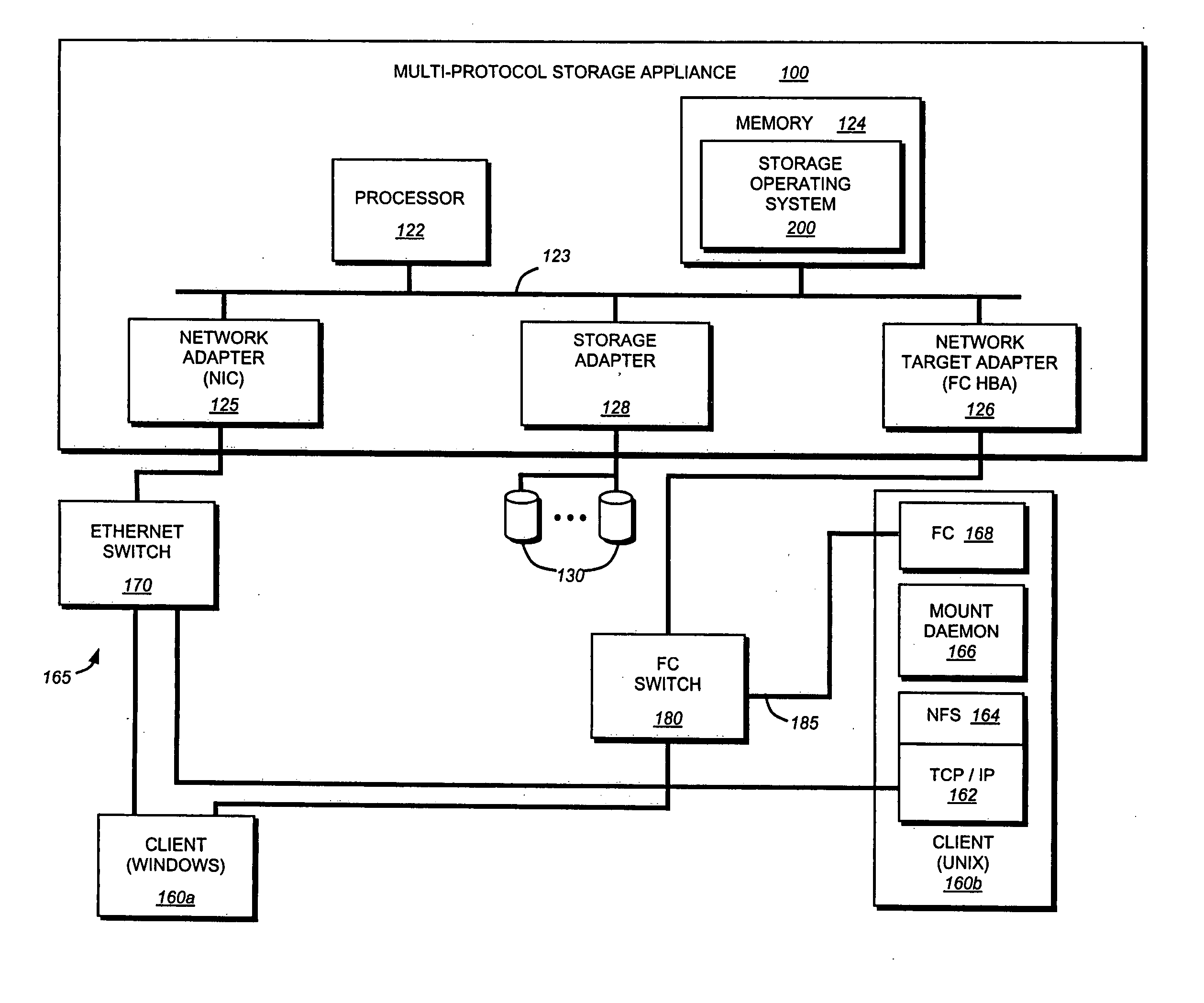

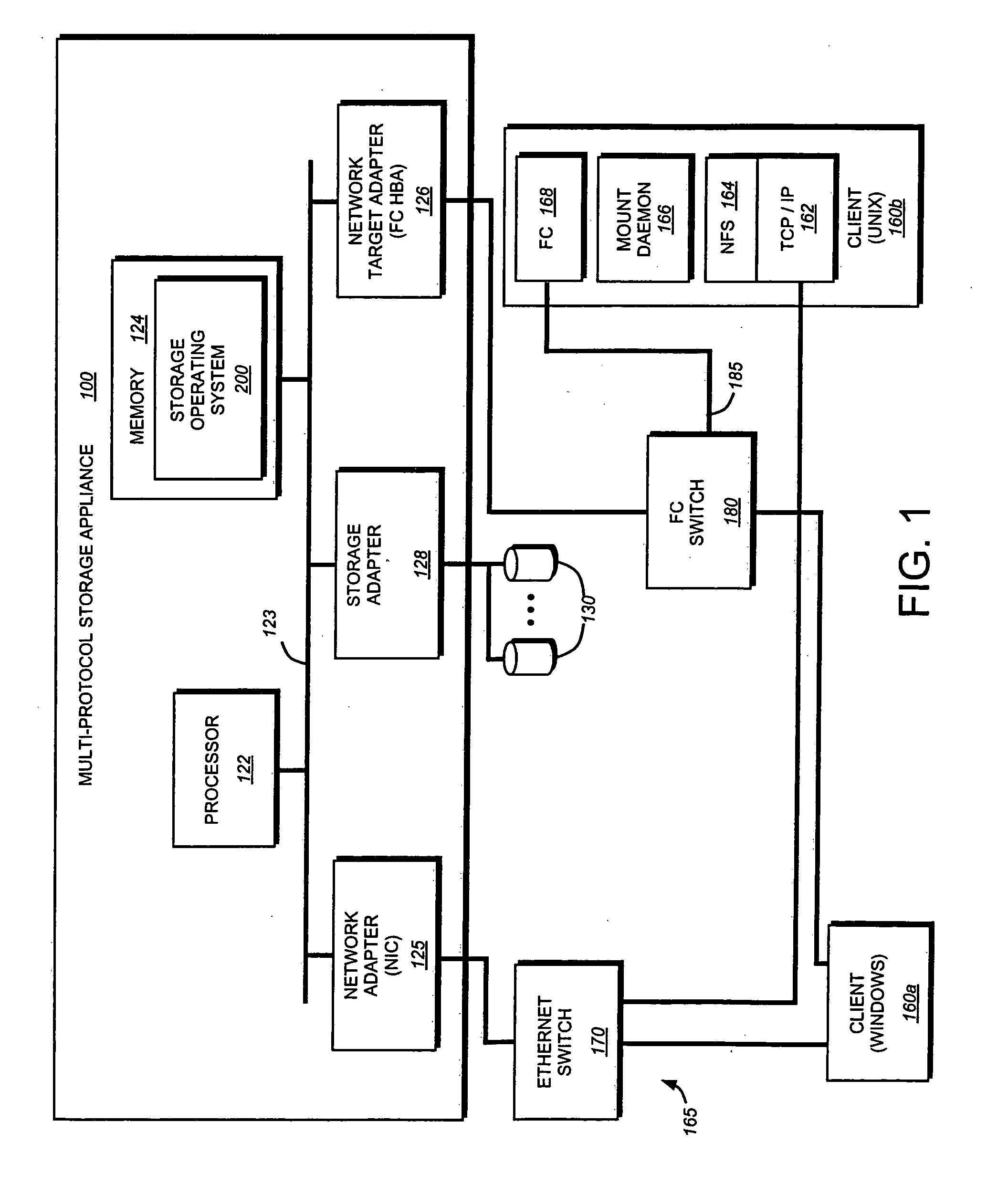

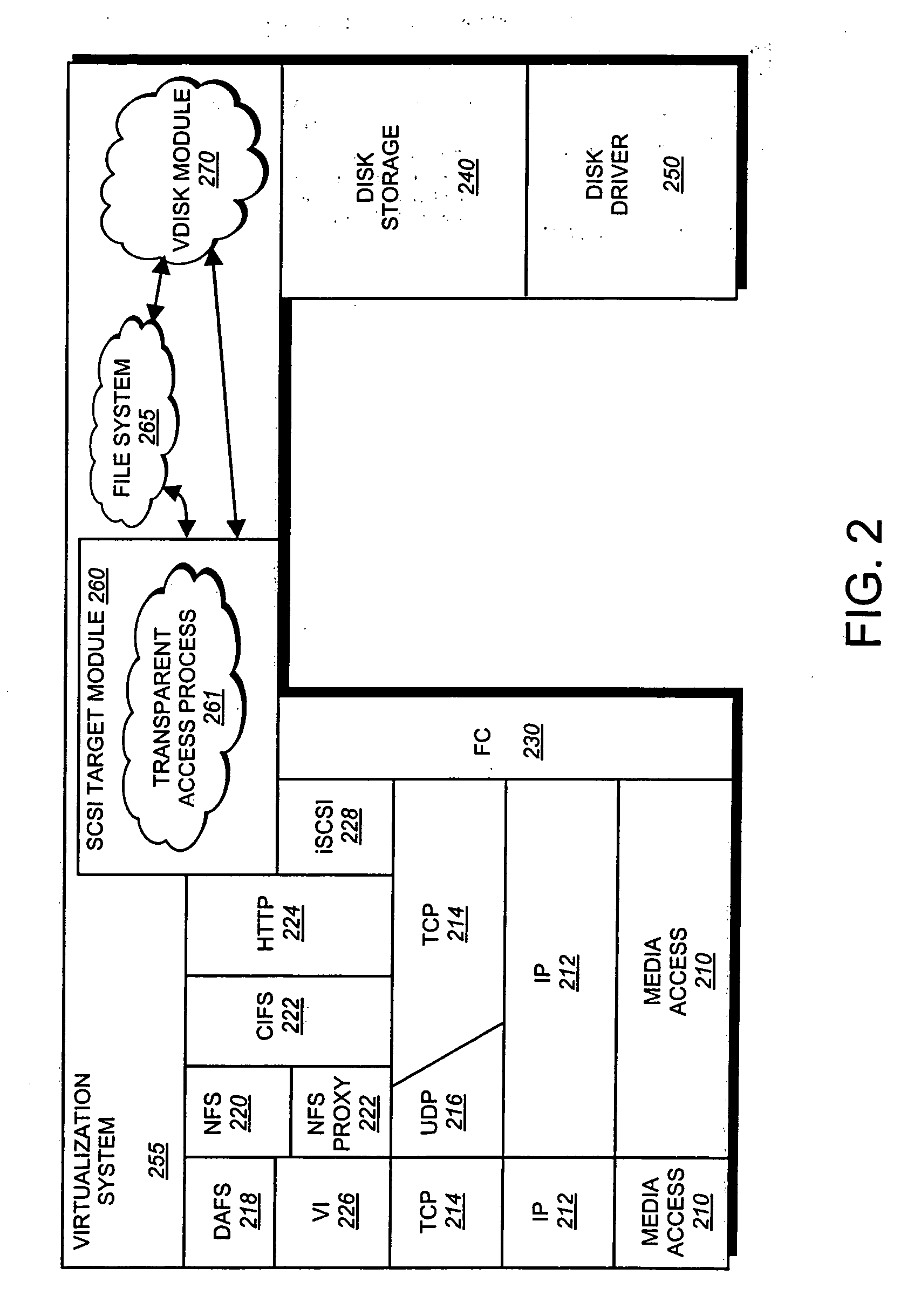

System and method for transparently accessing a virtual disk using a file-based protocol

ActiveUS20070100792A1Reduce usagePerformance advantageData processing applicationsDigital data processing detailsClient-sideNew device

A system and method enabling transparent access to blocks, such as virtual disks, stored on a storage system using a file-based protocol. The system and method traps in-coming file-based protocol open commands to check for a predetermined modification to the file name. If the system and method detects the predetermined modification, then the virtual disk associated with the file name is exported to the client issuing the open command and the client receives a response from the storage system. The client, in response to receiving the response to the open command, creates a new device instantiation for reading and writing raw data to the virtual disk.

Owner:NETWORK APPLIANCE INC

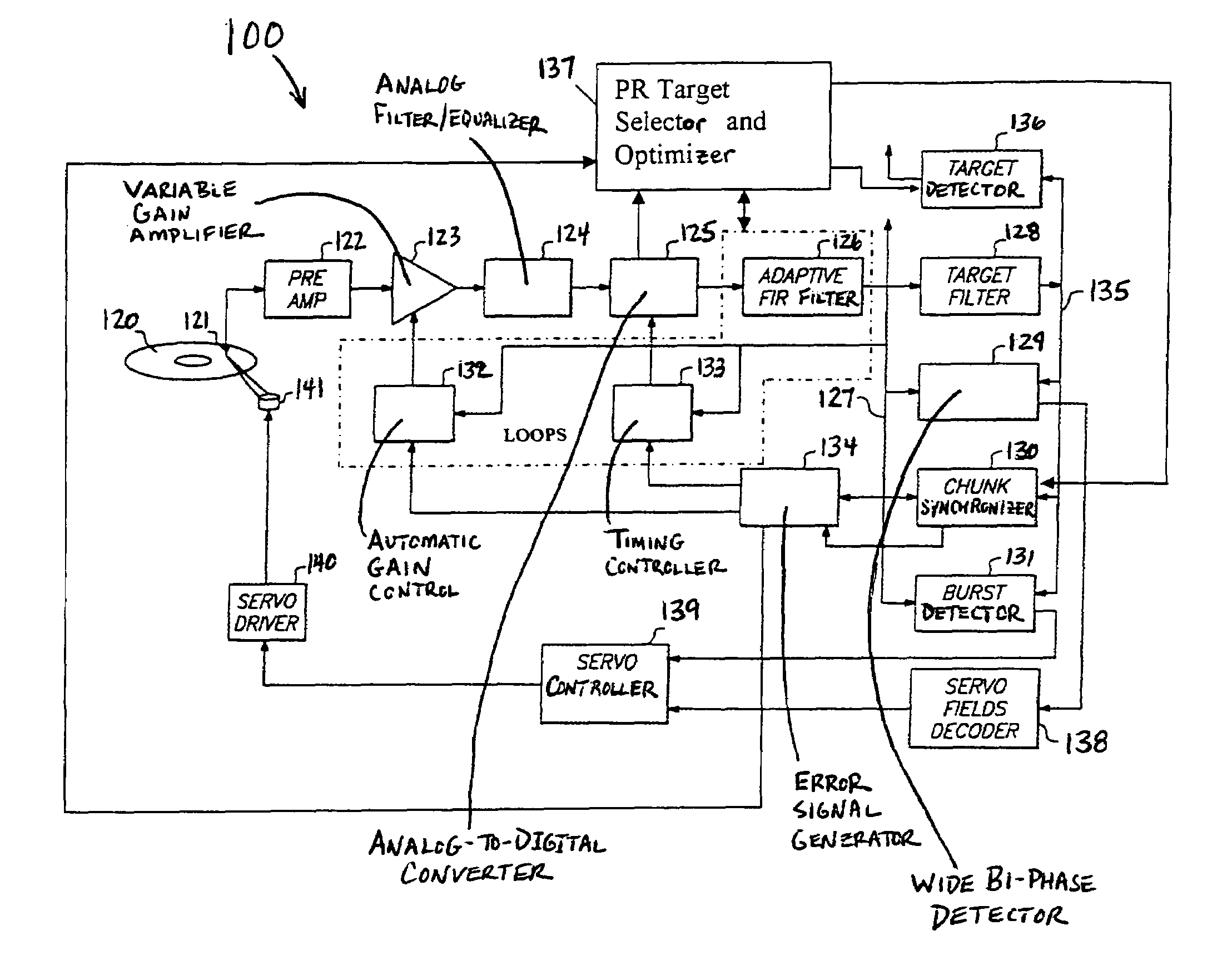

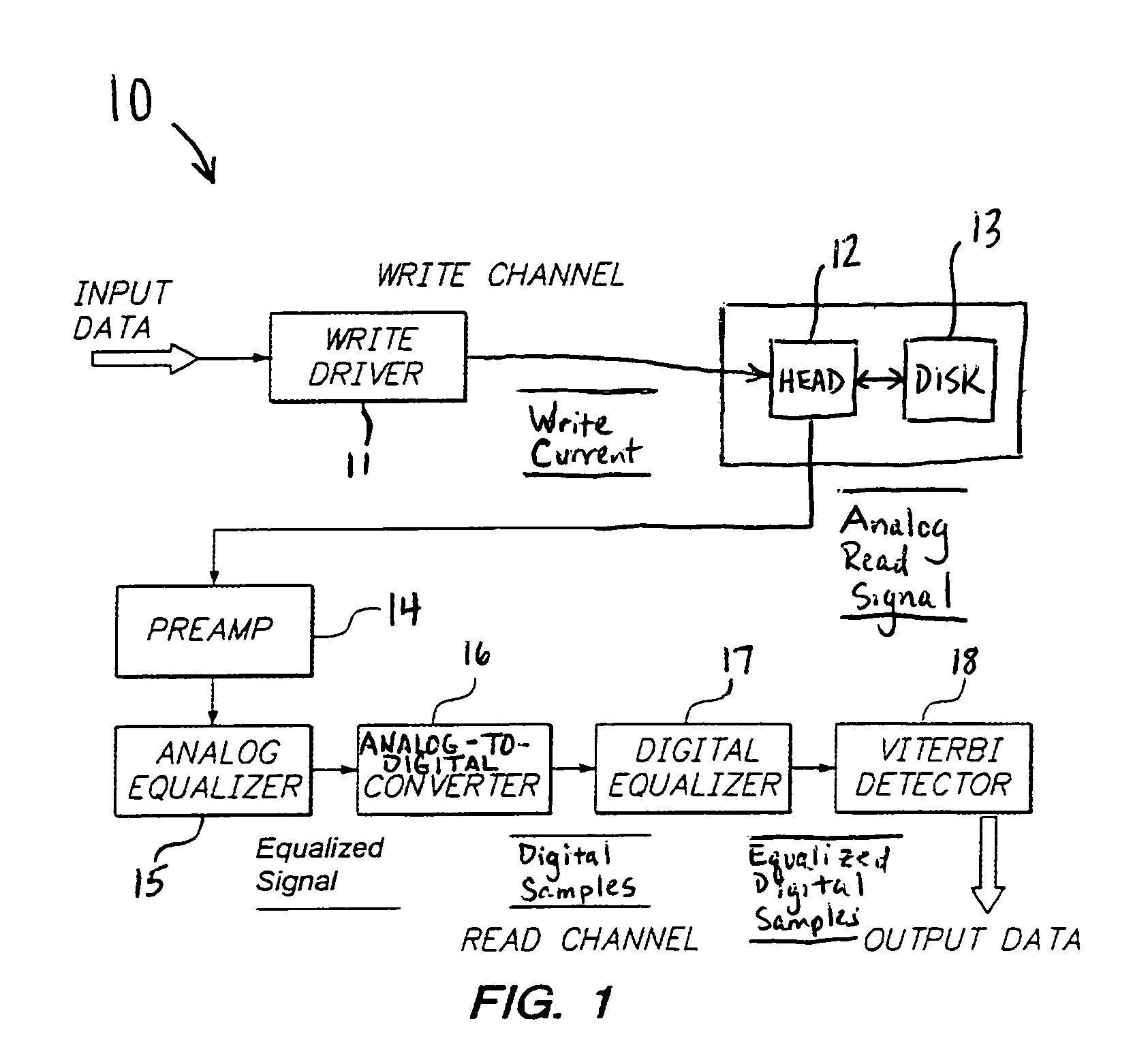

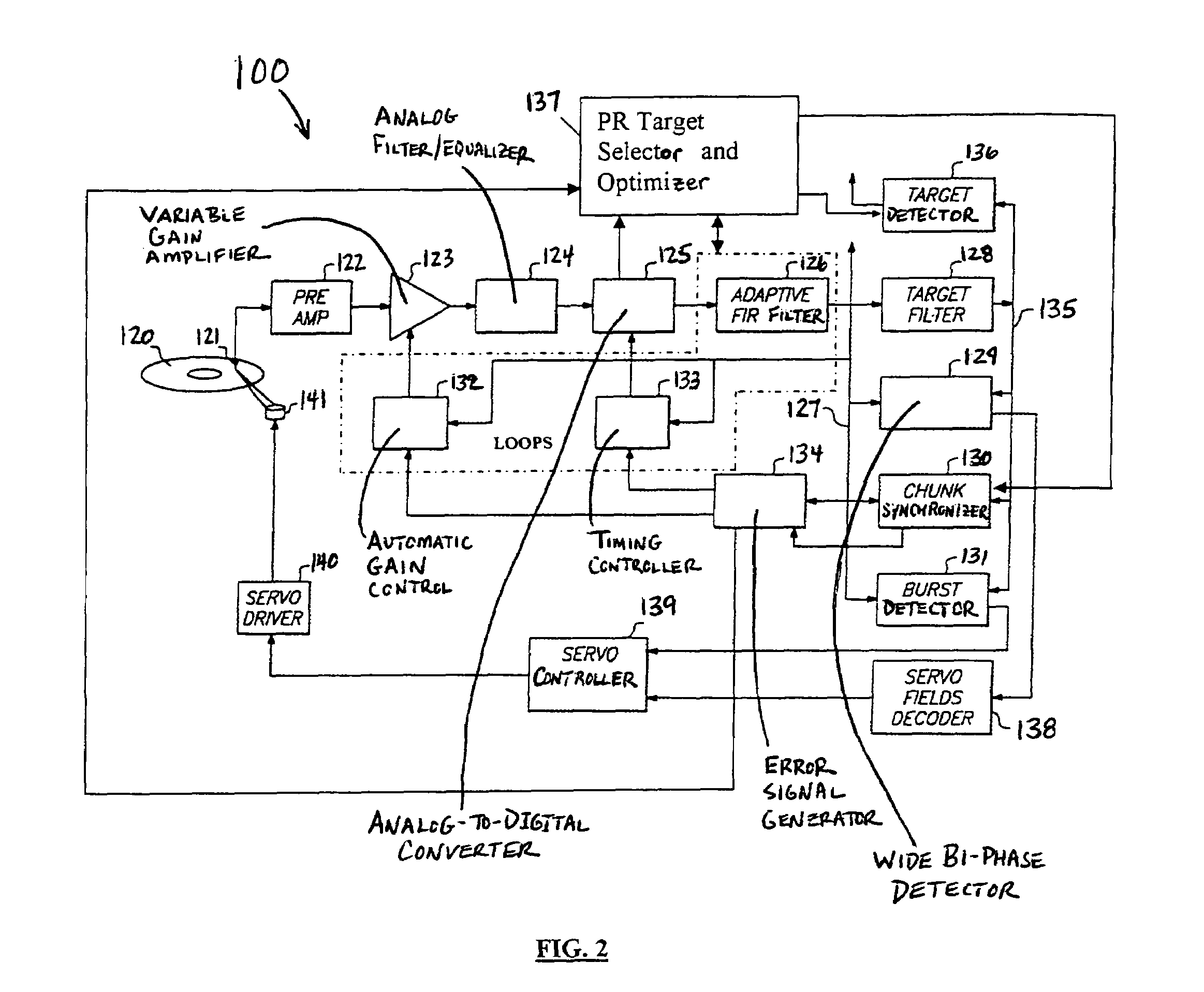

Flexible partial response targets for data detectors

InactiveUS7440208B1Significant performance benefitWithout compromising performanceModification of read/write signalsRecord information storageAlgorithmData detection

Automatically optimizing and programming features of a disk drive read channel for a selected partial response (PR) target. This enables flexible PR targets to be used in the read channel. The flexible PR targets can have arbitrary coefficients, and the channel features (parameters, functions and algorithms) that are dependent on the flexible PR targets are automatically adapted and programmed in hardware or firmware. With flexible PR targets, the read channel can support longitudinal and perpendicular recording without compromising performance.

Owner:MAXTOR

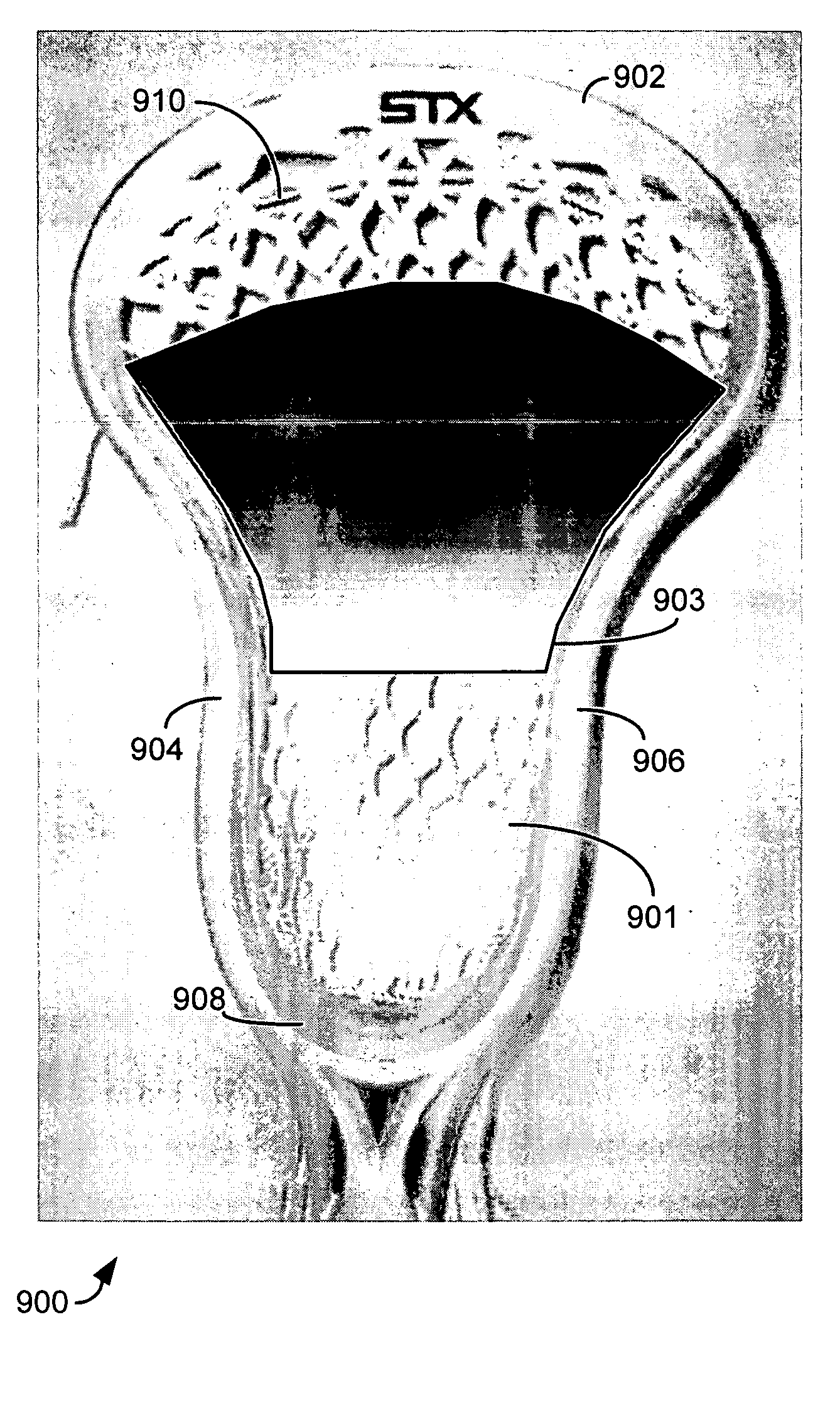

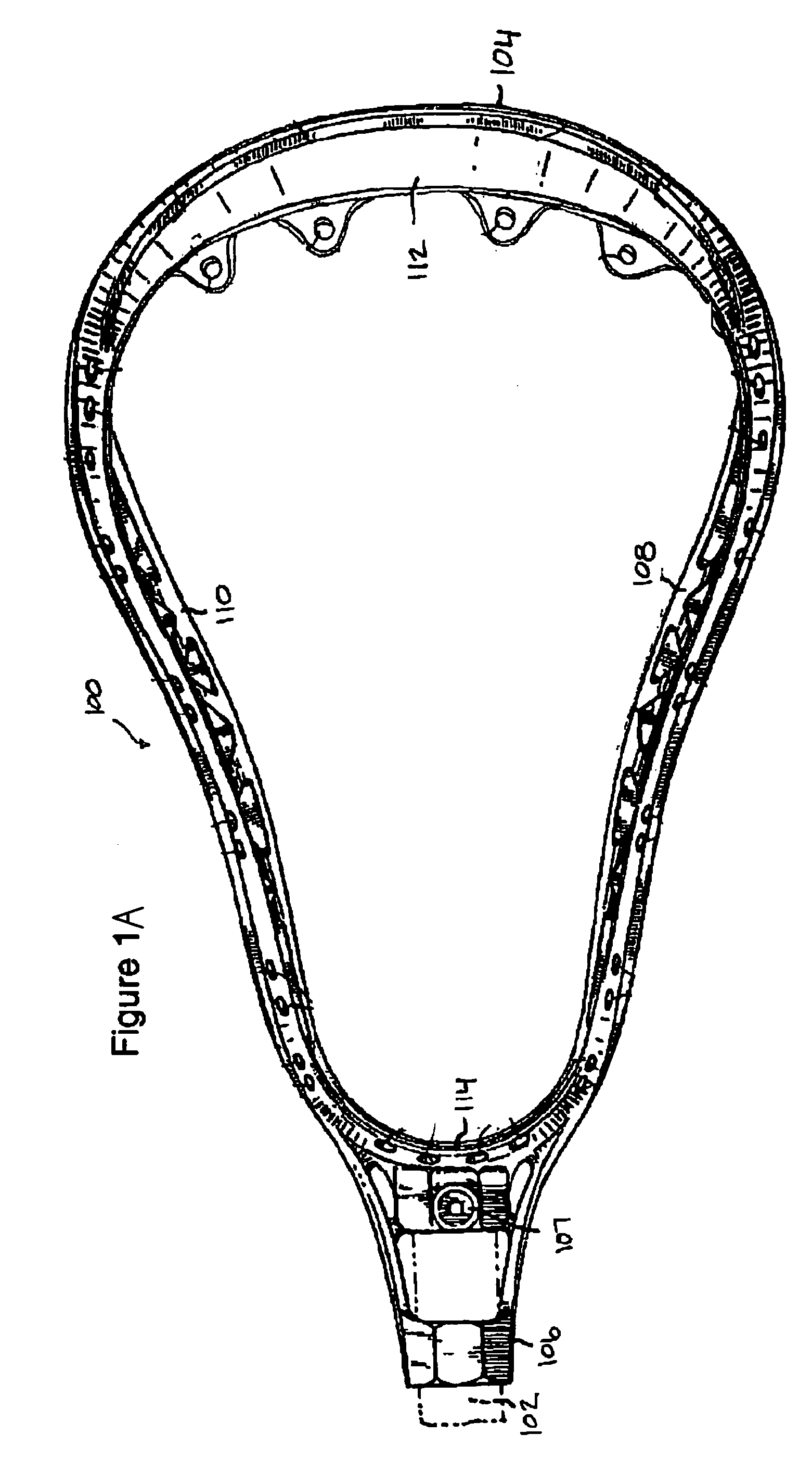

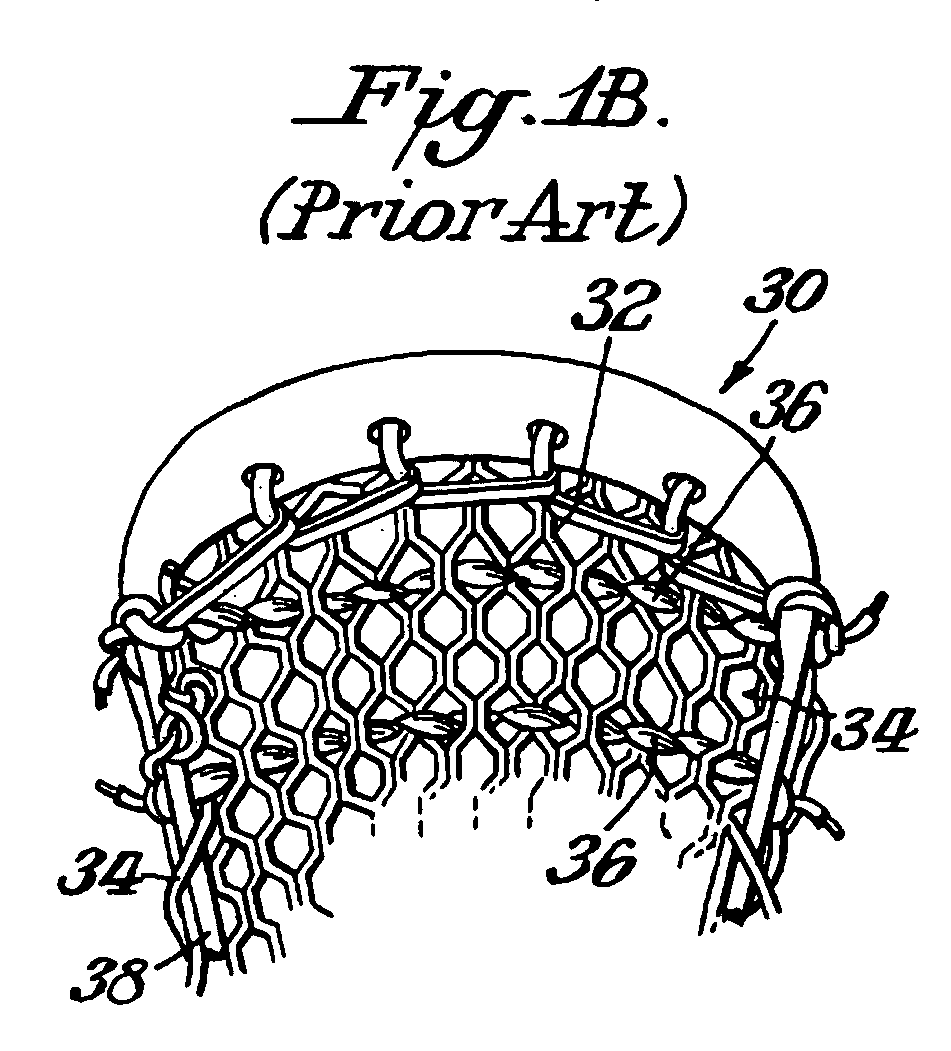

Soft mesh lacrosse head pocket having selectively coated strings

ActiveUS7278936B2Eliminates or minimizes many of the drawbacksPerformance advantageThrow gamesStringed racketsBall releaseEngineering

Owner:WM T BURNETT IP

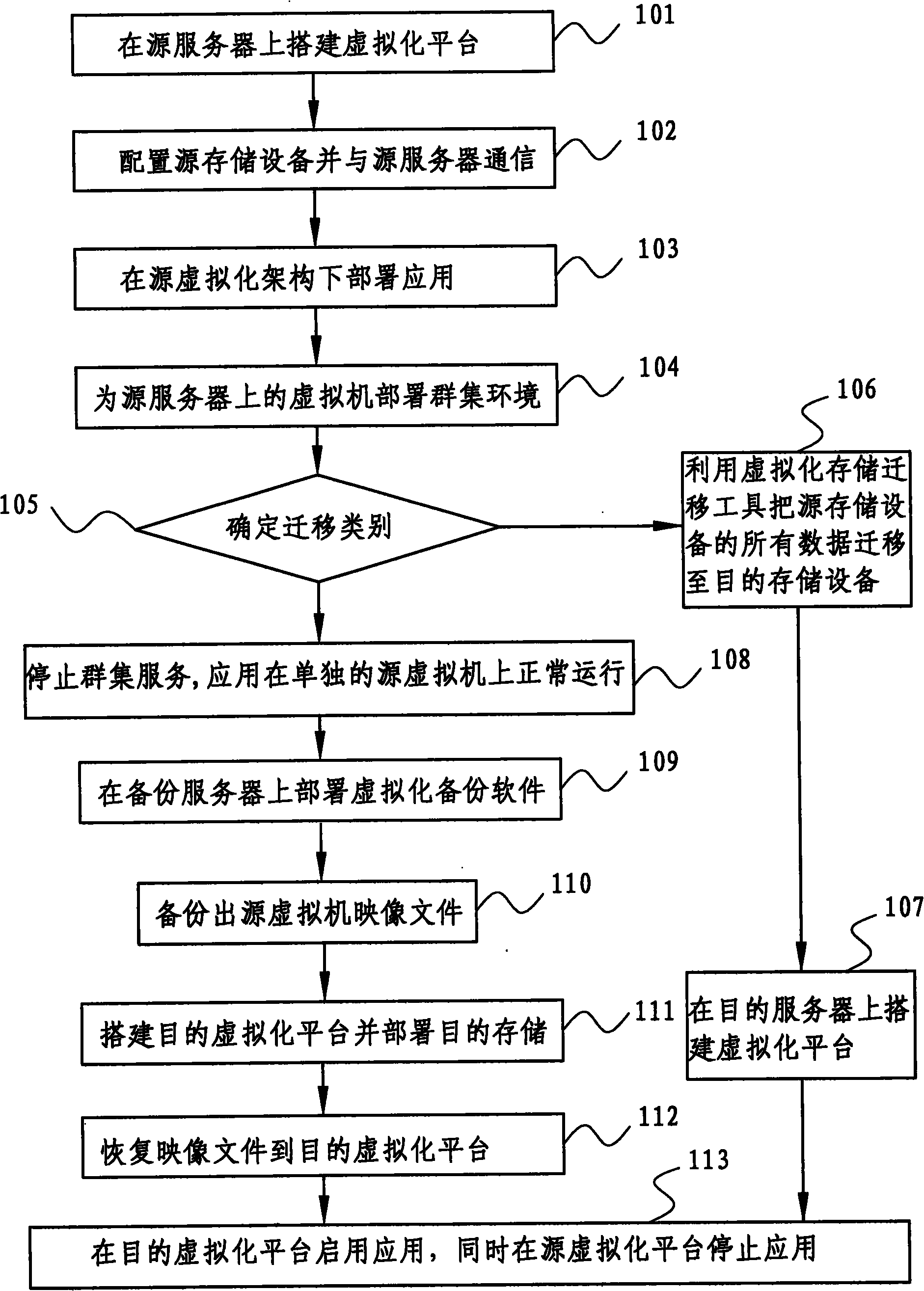

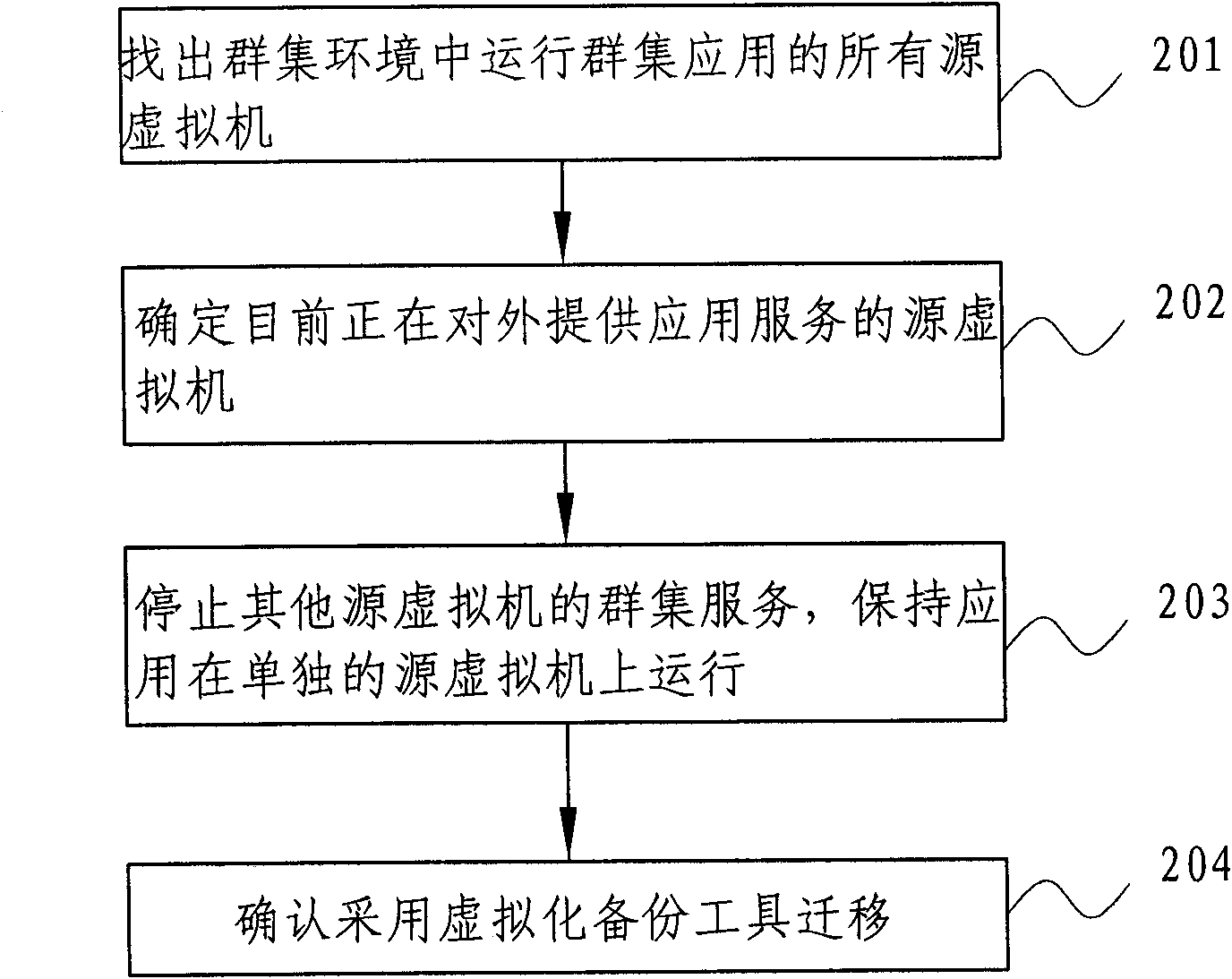

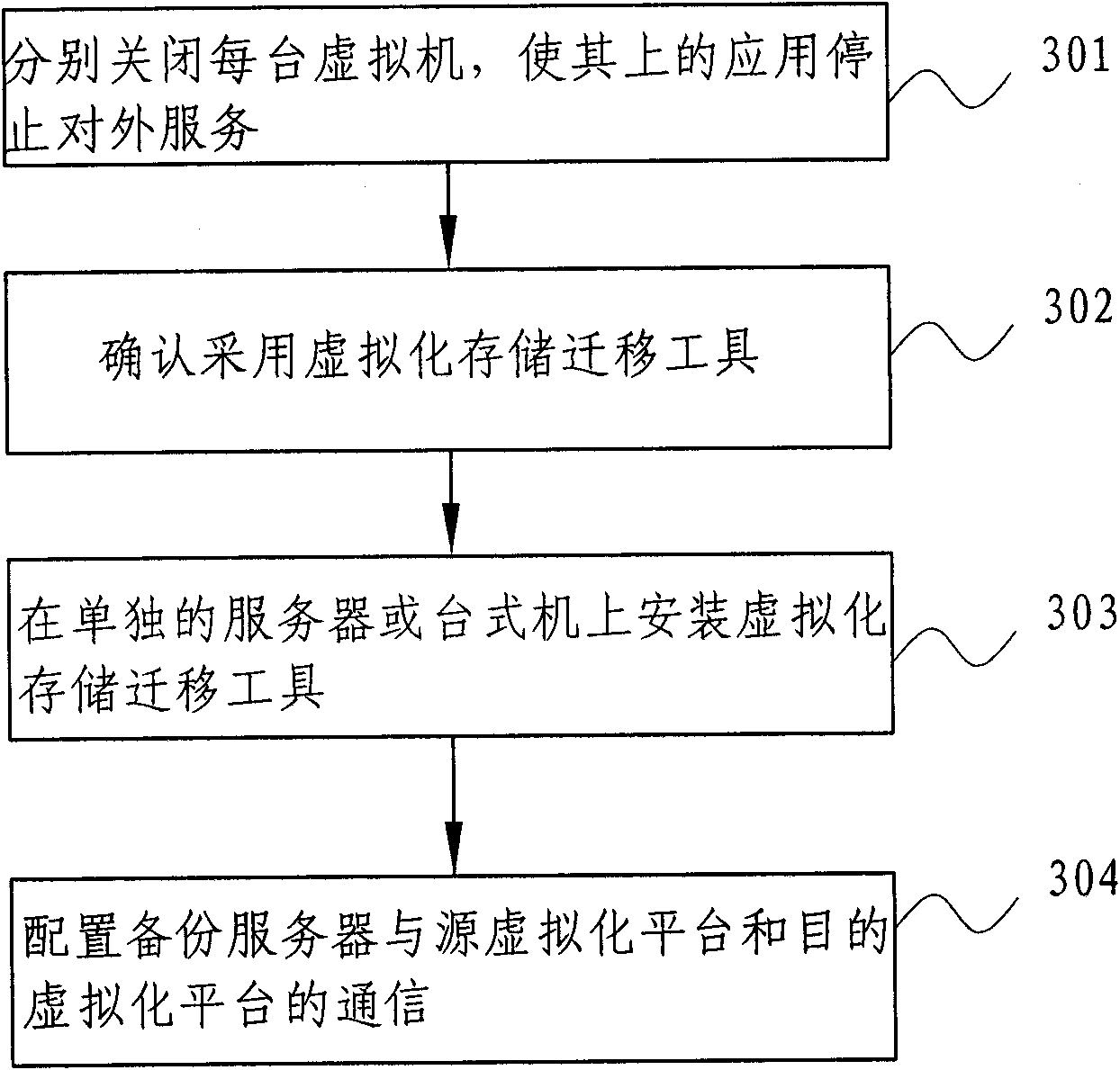

Method for realizing platform migration by using virtualization technology

InactiveCN101819545APerformance advantageCost advantageTransmissionSoftware simulation/interpretation/emulationVirtualizationTrunking

The invention discloses a method for realizing platform migration by using virtualization technology. The method comprises the following steps of: building a virtualization platform on a source server, configuring a source memory device and establishing mapping relationship between the original memory device and the source server to form a source virtualization platform; determining whether the migration is online migration or offline migration, if the migration is the online migration, stopping trunking services and normally operating application on a single source virtual machine so as to ensure the non-interruption of the services; deploying virtualization backup software on a backup server to form a virtualization backup tool; backing up a mapping file of the source virtual machine by using the virtualization backup tool; building, deploying and storing a target virtualization platform; recovering the mapping file to the target virtualization platform; and starting the application on the target virtualization platform and stopping the application on the source virtualization platform at the same time so as to realize the cross-hardware platform online migration of the application. In the method, as the online backup function of the virtualization backup tool is utilized, so that all the services operated in a trunking environment are not interrupted.

Owner:山东超云信息技术有限公司

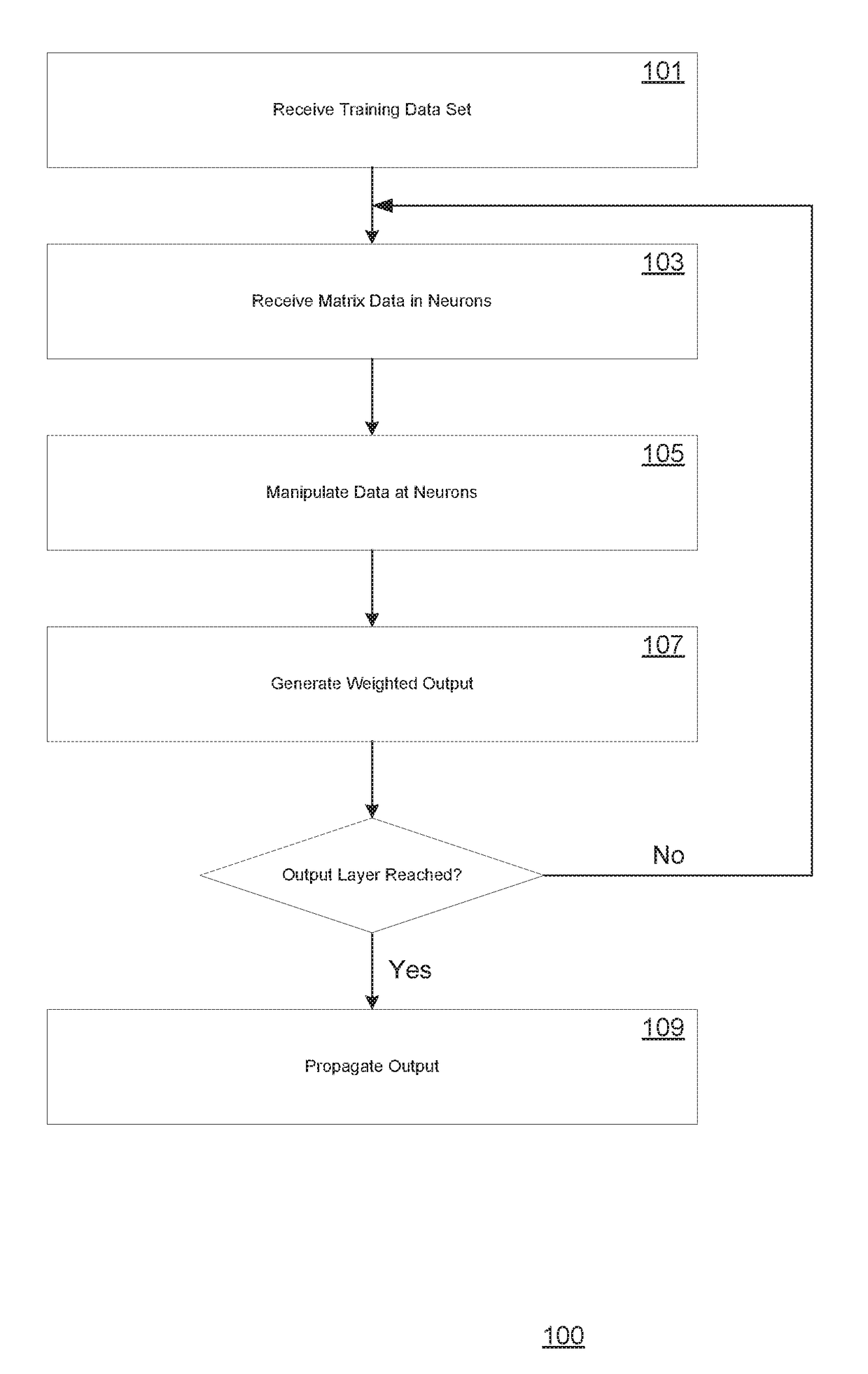

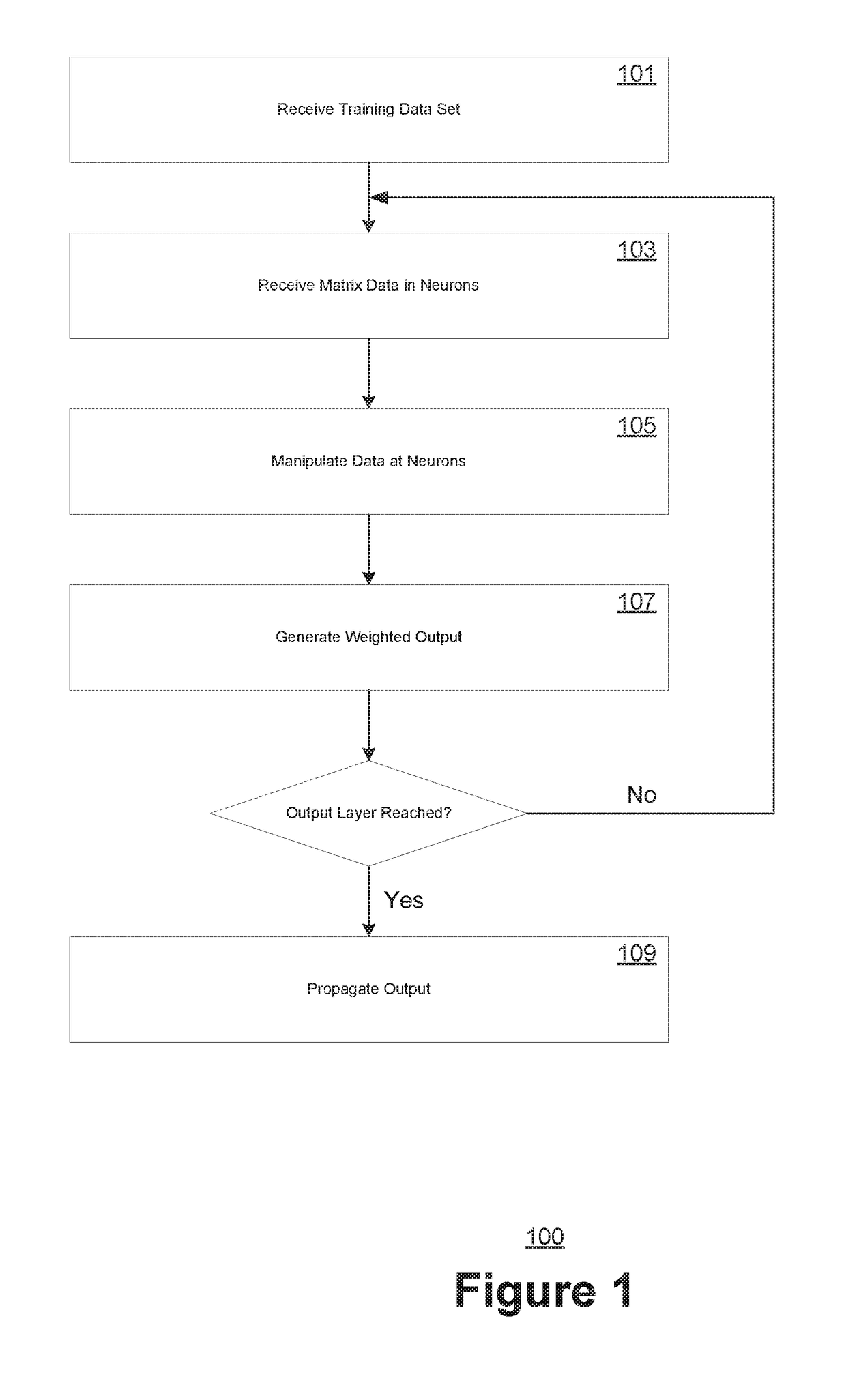

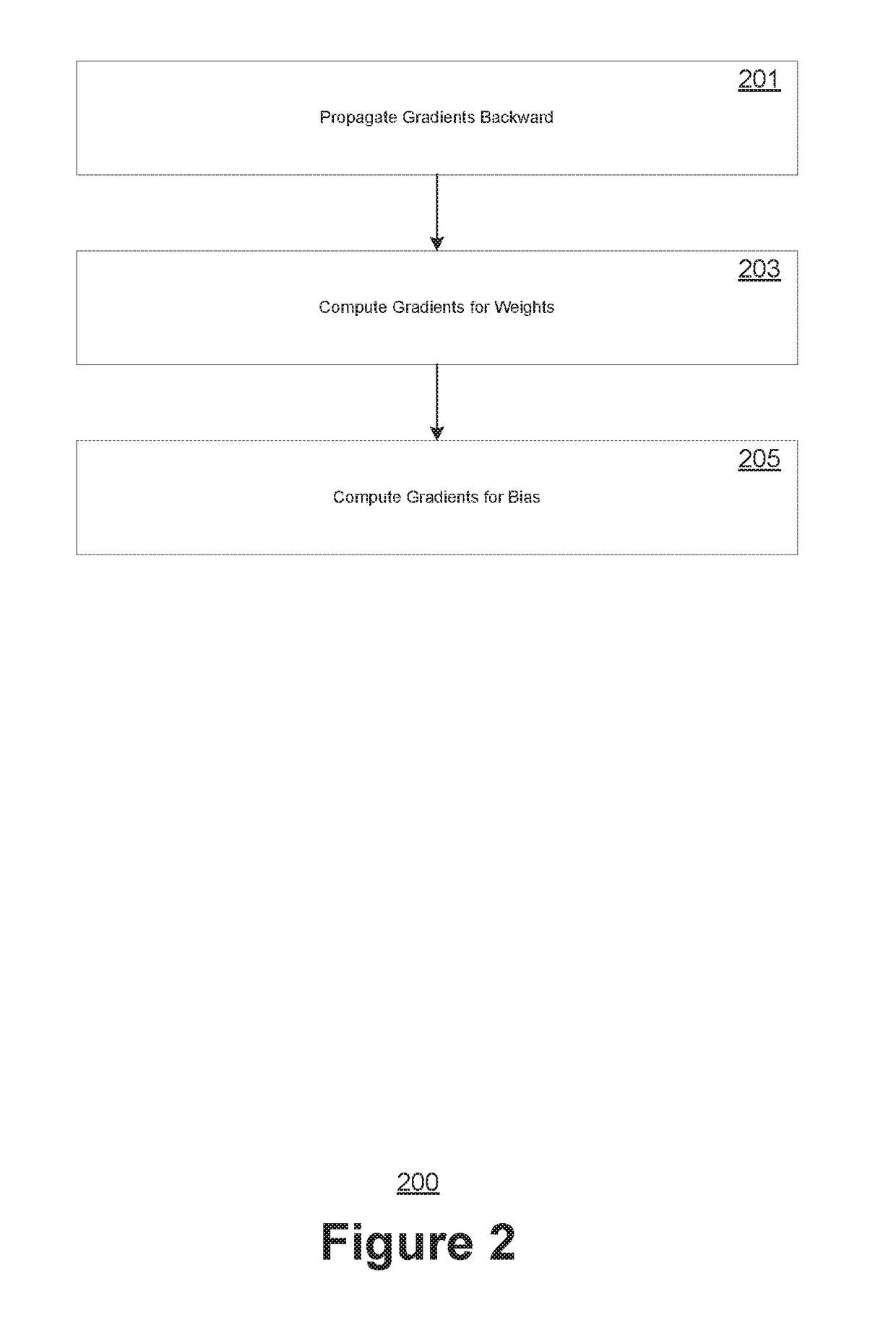

Tensor processing using low precision format

PendingUS20170372202A1Accelerated trainingOperation accuracyNeural architecturesPhysical realisationMatrix additionAlgorithm

Aspects of the present invention are directed to computer-implemented techniques for improving the training of artificial neural networks using a reduced precision (e.g., float16) data format. Embodiments of the present invention rescale tensor values prior to performing matrix operations (such as matrix multiplication or matrix addition) to prevent overflow and underflow. To preserve accuracy throughout the performance of the matrix operations, the scale factors are defined using a novel data format to represent tensors, wherein a matrix is represented by the tuple X, where X=(a, v[.]), wherein a is a float scale factor and v[.] are scaled values stored in the float16 format. The value of any element X[i] according to this data format would be equal to a*v[i].

Owner:NVIDIA CORP

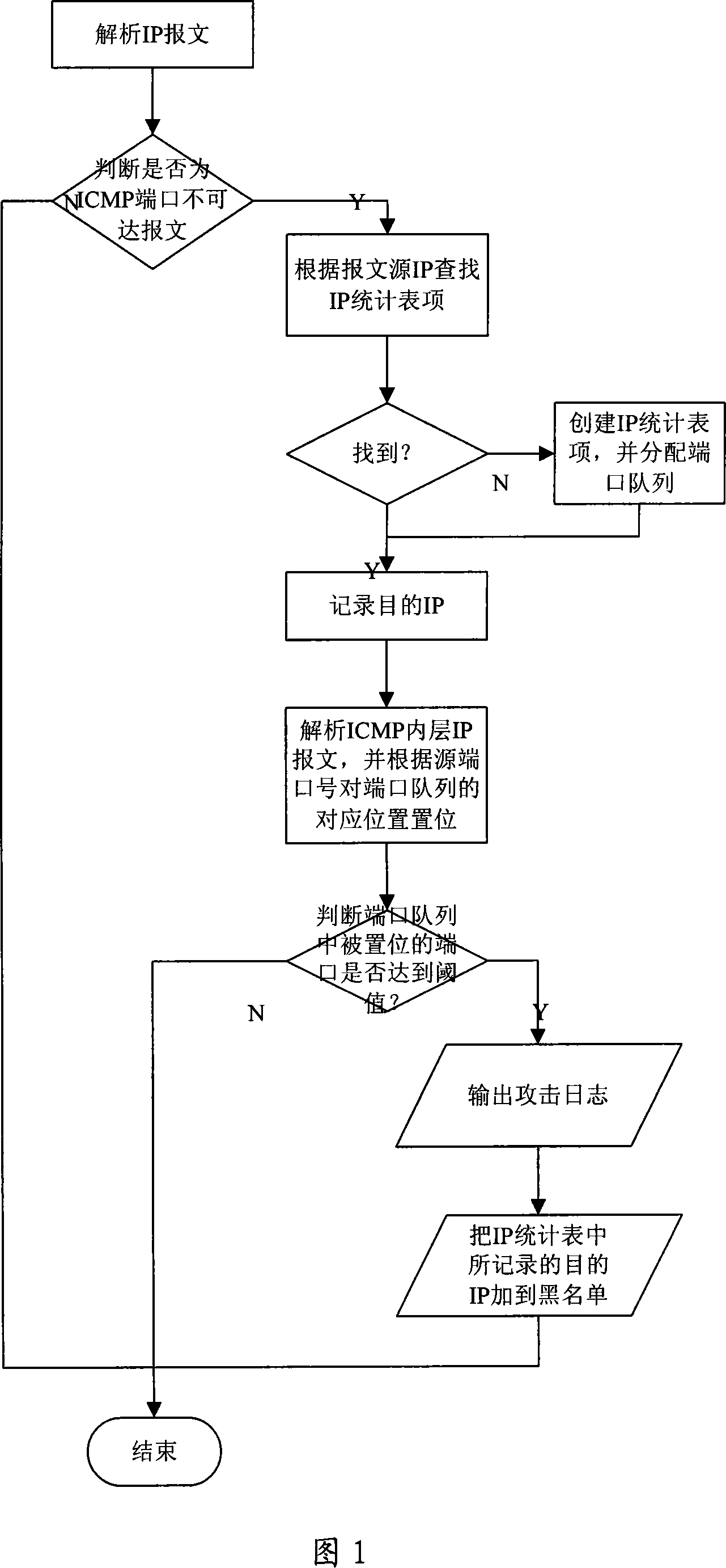

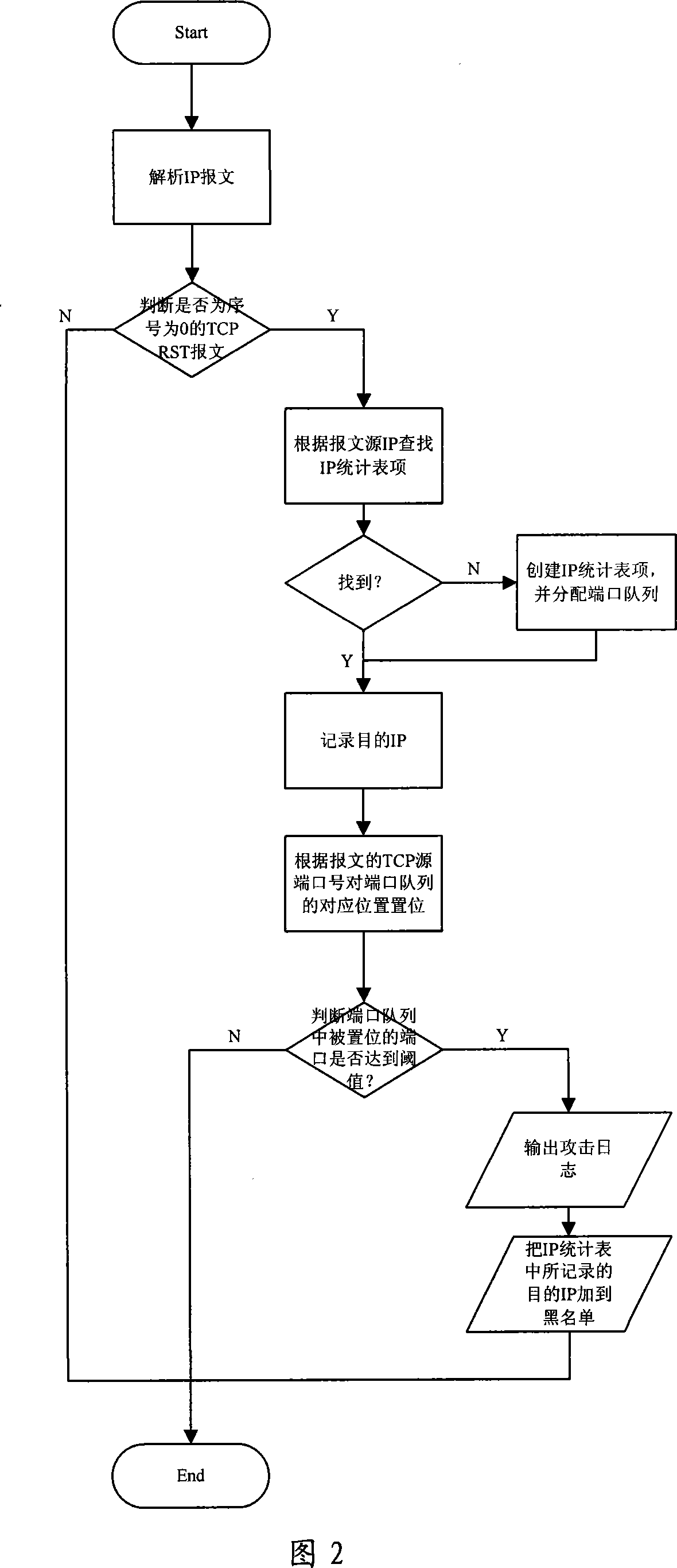

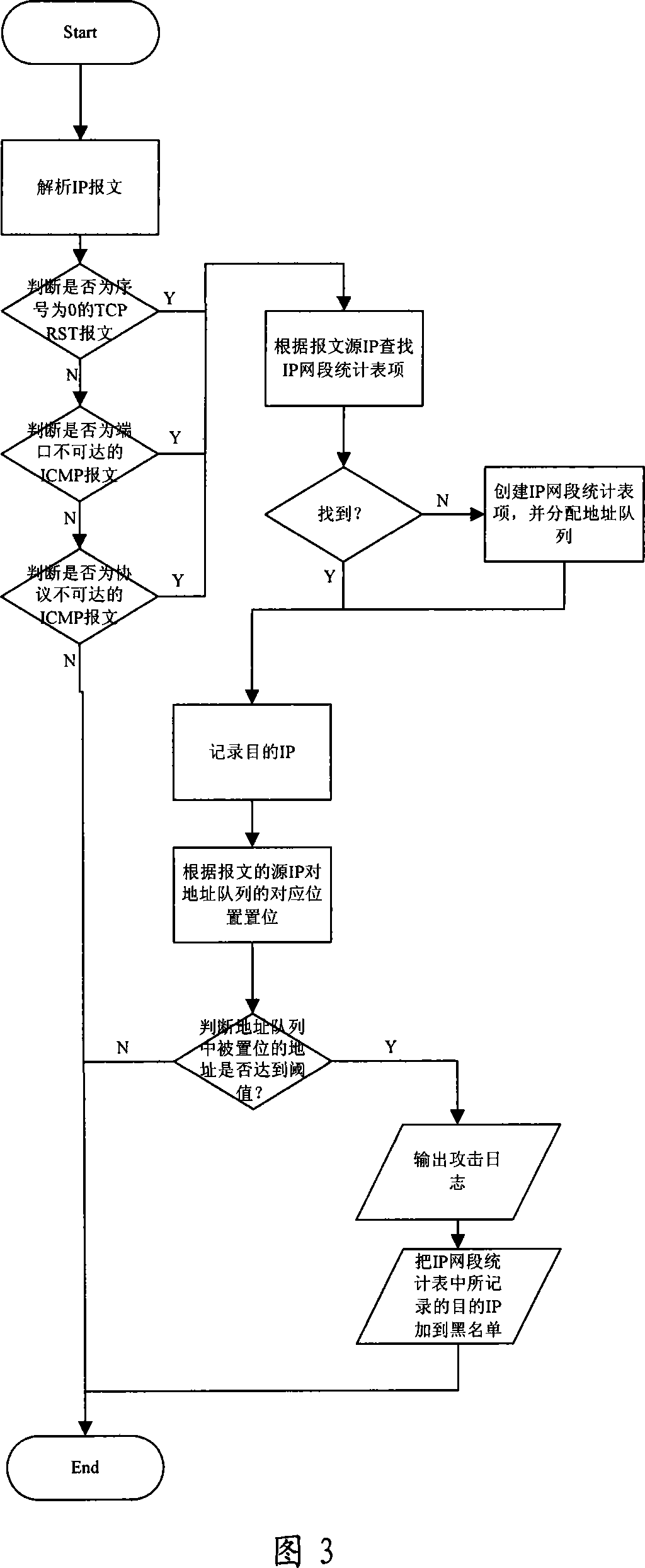

Method and device for detecting scanning attack

InactiveCN101123492AValid settingsPerformance advantageData switching networksSecuring communicationIp addressComputer science

After some embodiments, the present invention discloses a method and a device for detecting scan attacks. The present invention parses the received message information and records the information of the destination port or the IP address in the message information; then the times, for which the destination port or the IP address are recorded in a scheduled time, are counted; and finally when the recorded times of the destination port or the IP address reach a predetermined threshold, then the present invention judges that a scan attack occurs. The device of the present invention comprises a first unit, which parses the received message information and records the destination port or the IP address, a second unit, which is used to count the times for which the destination port or the IP address are recorded in a scheduled time, and a third unit, which is used to judge that a scan attack occurs when the recorded times of the destination port or the IP address reach a predetermined threshold. In every technical scheme of embodiment, the present invention effectively detects scan attacks according to the times of the port or protocol attack in a scheduled time, thus reducing the false alarm rate and the realization difficulty of scan detection.

Owner:NEW H3C TECH CO LTD

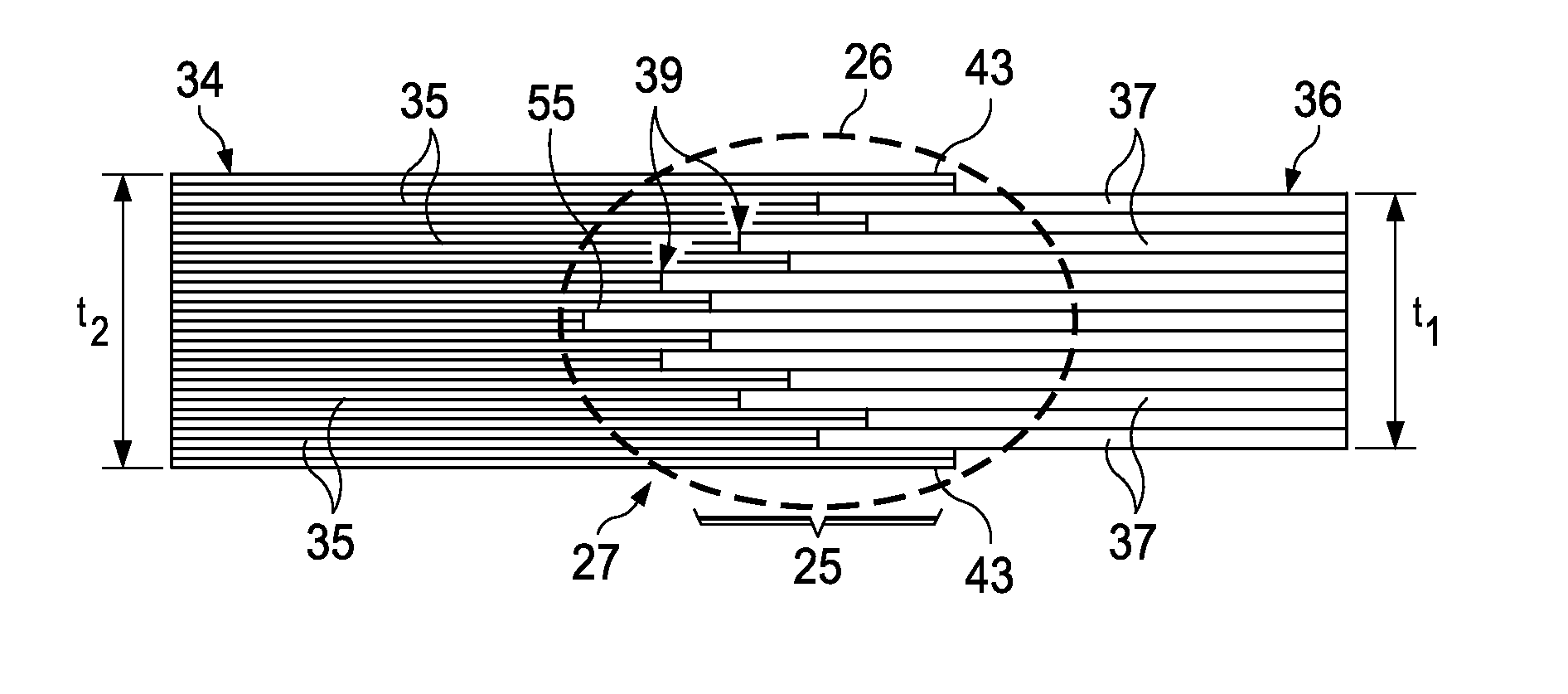

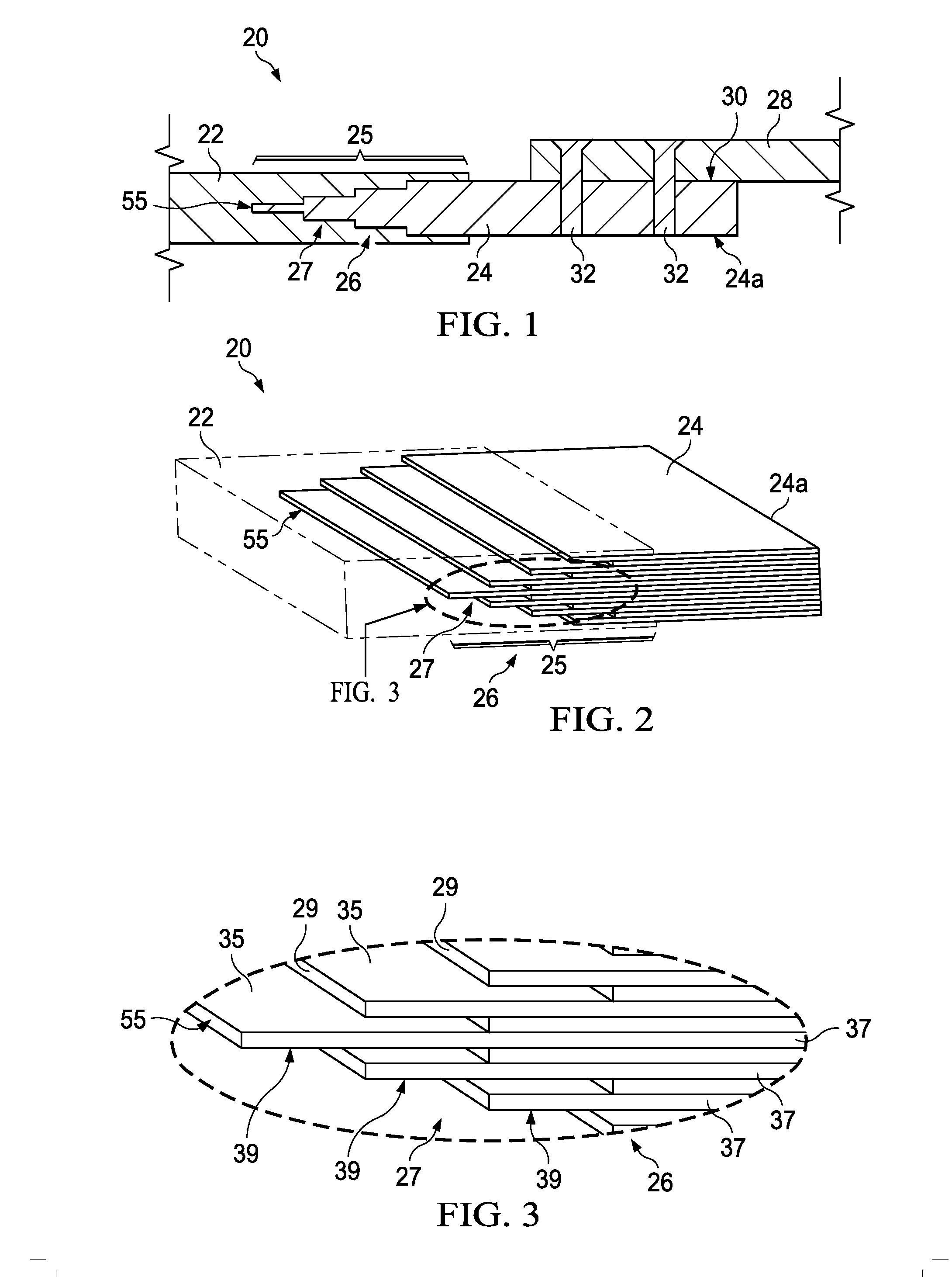

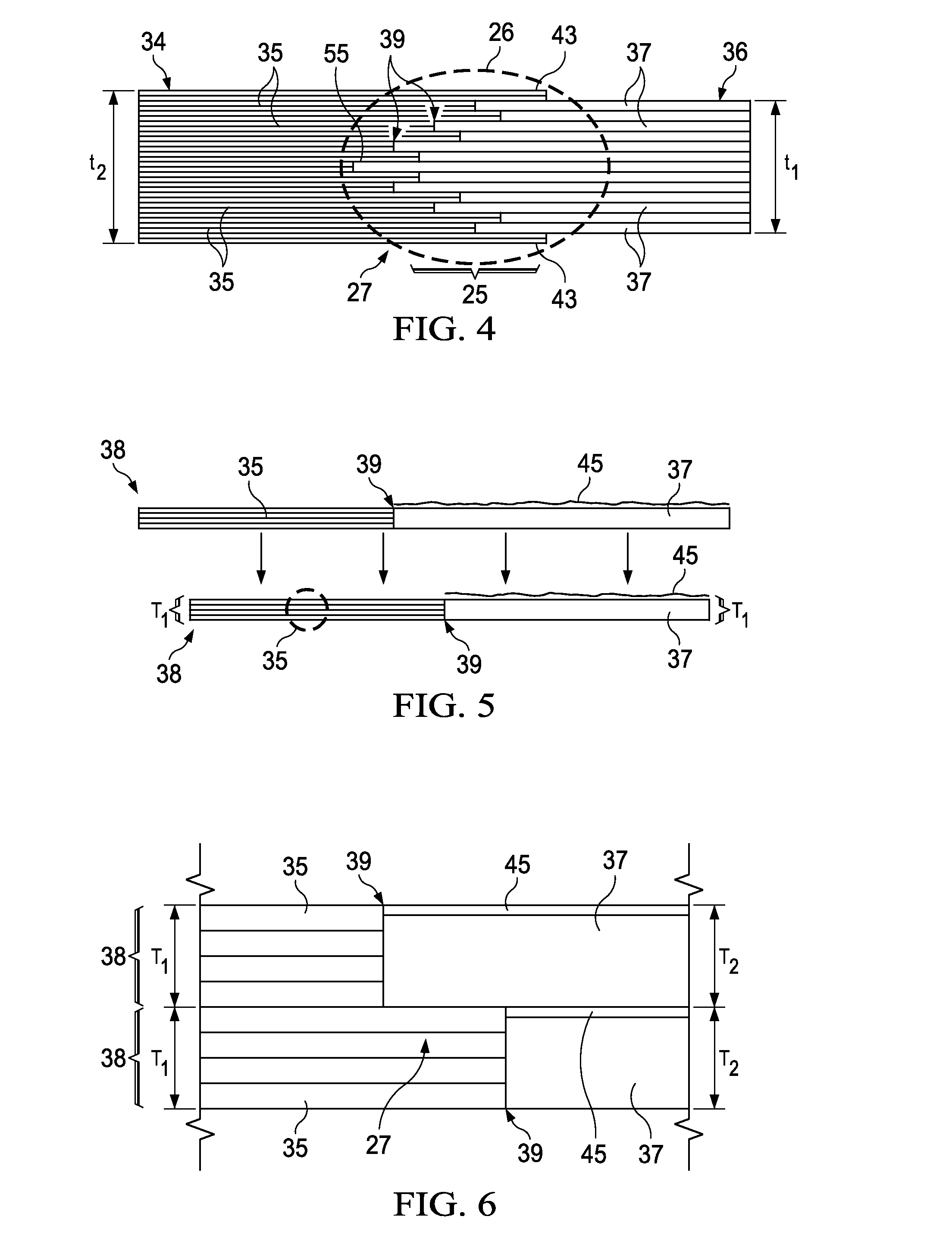

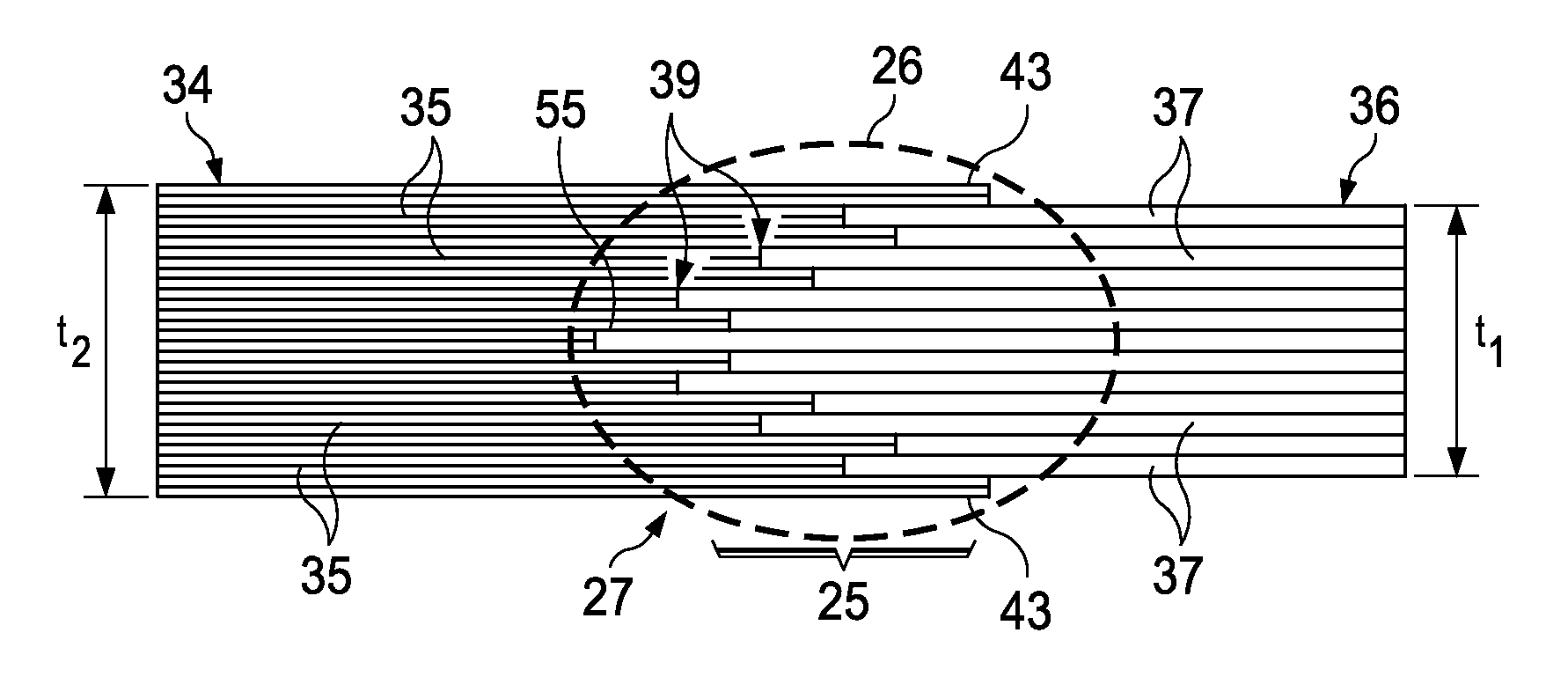

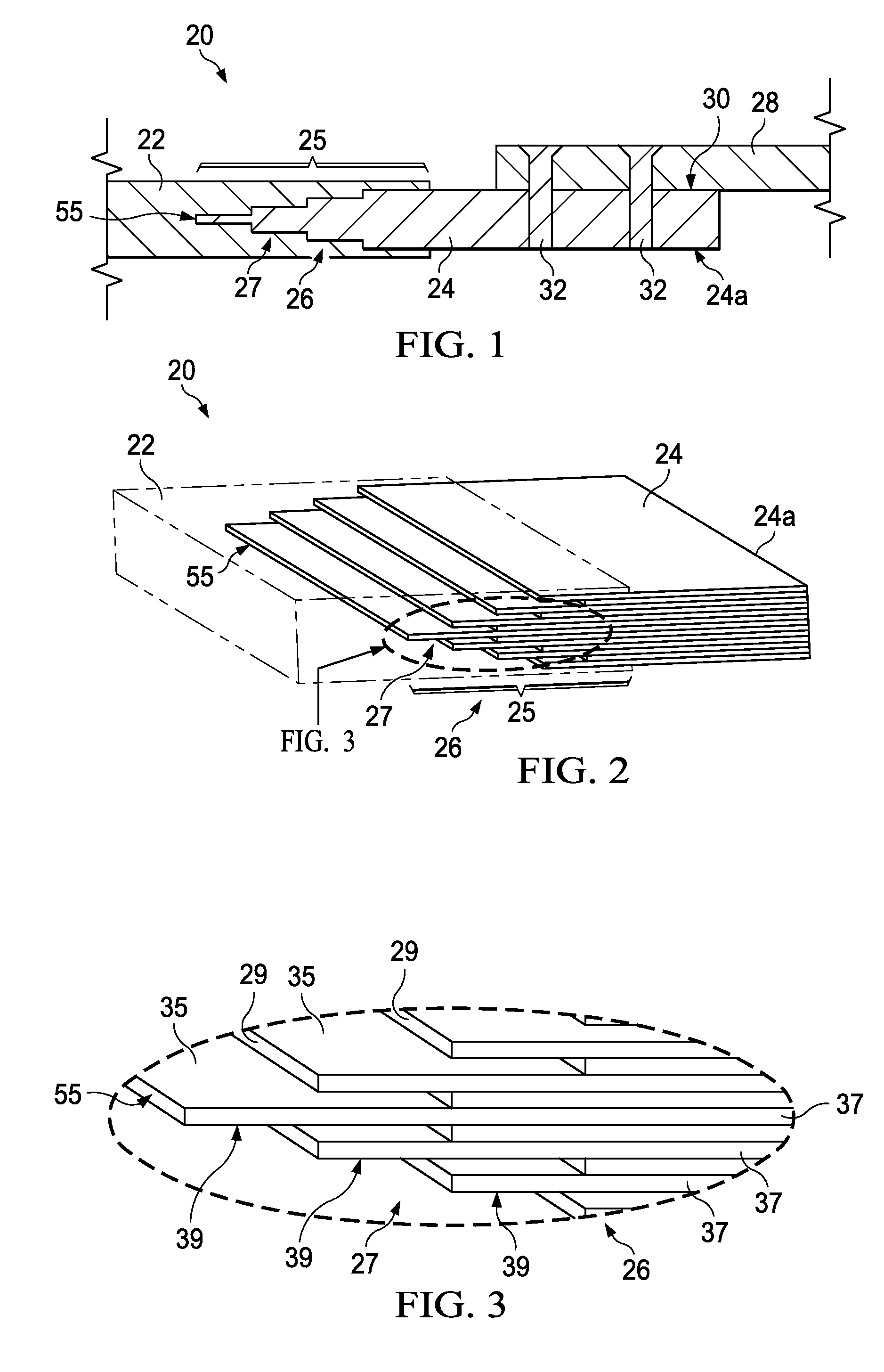

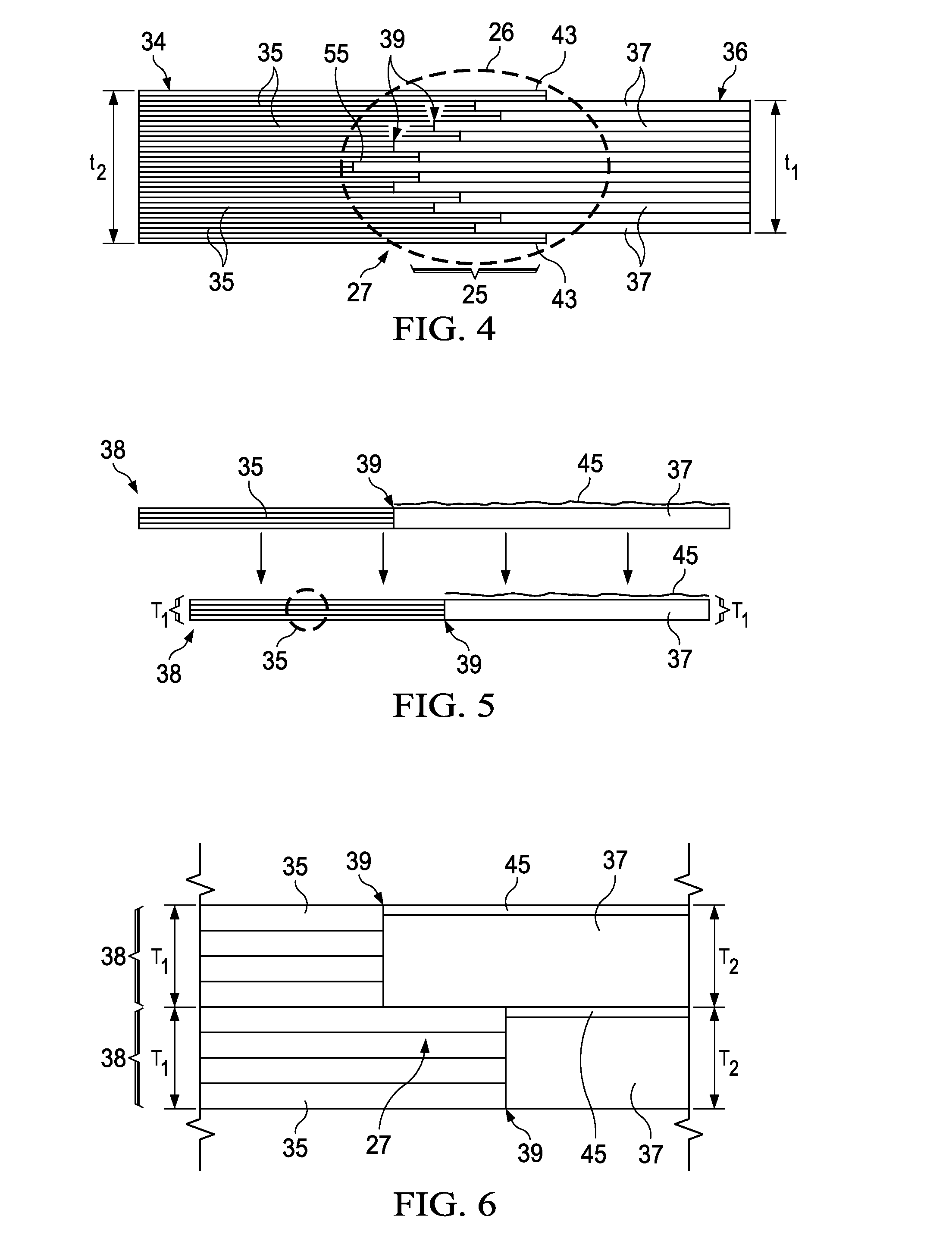

Multi-Layer Metallic Structure and Composite-to-Metal Joint Methods

ActiveUS20130075526A1Reduce eliminate possibilityReduce occurrence and propagationFuselage framesExtrusion containersFiberMetal sheet

A composite structure comprises stacked sets of laminated fiber reinforced resin plies and metal sheets. Edges of the resin plies and metal sheets are interleaved to form a composite-to-metal joint connecting the resin plies with the metal sheets.

Owner:THE BOEING CO

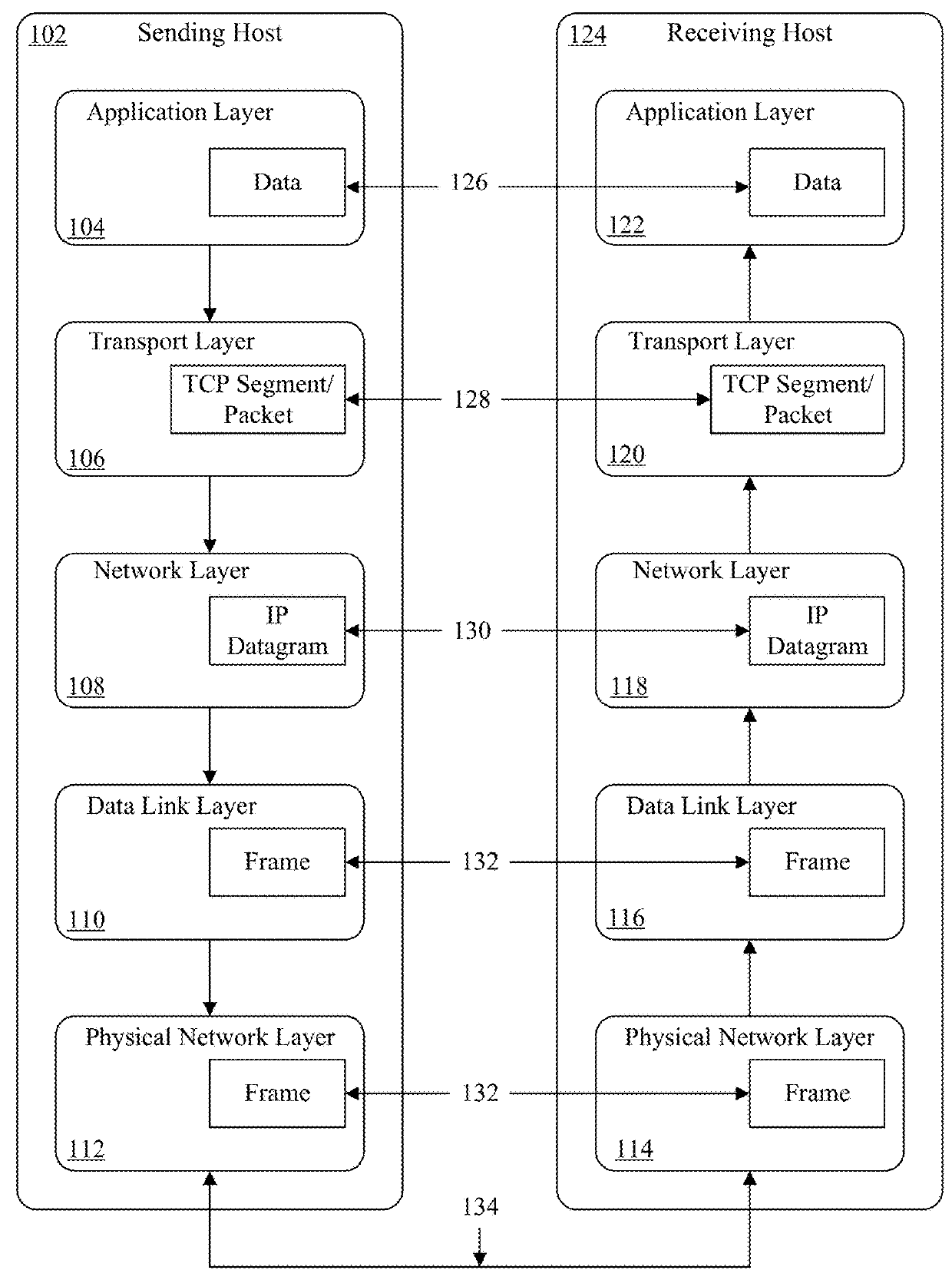

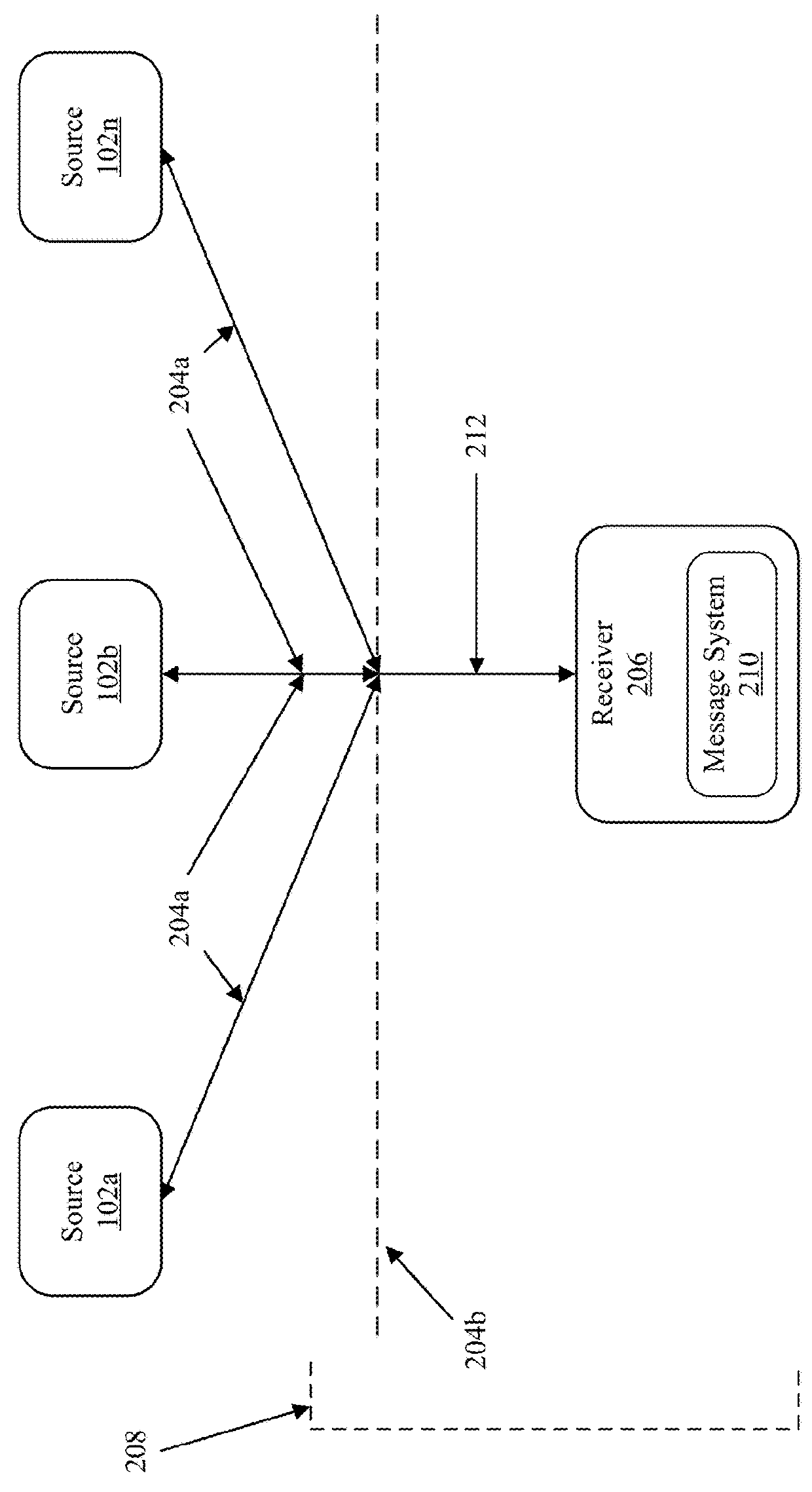

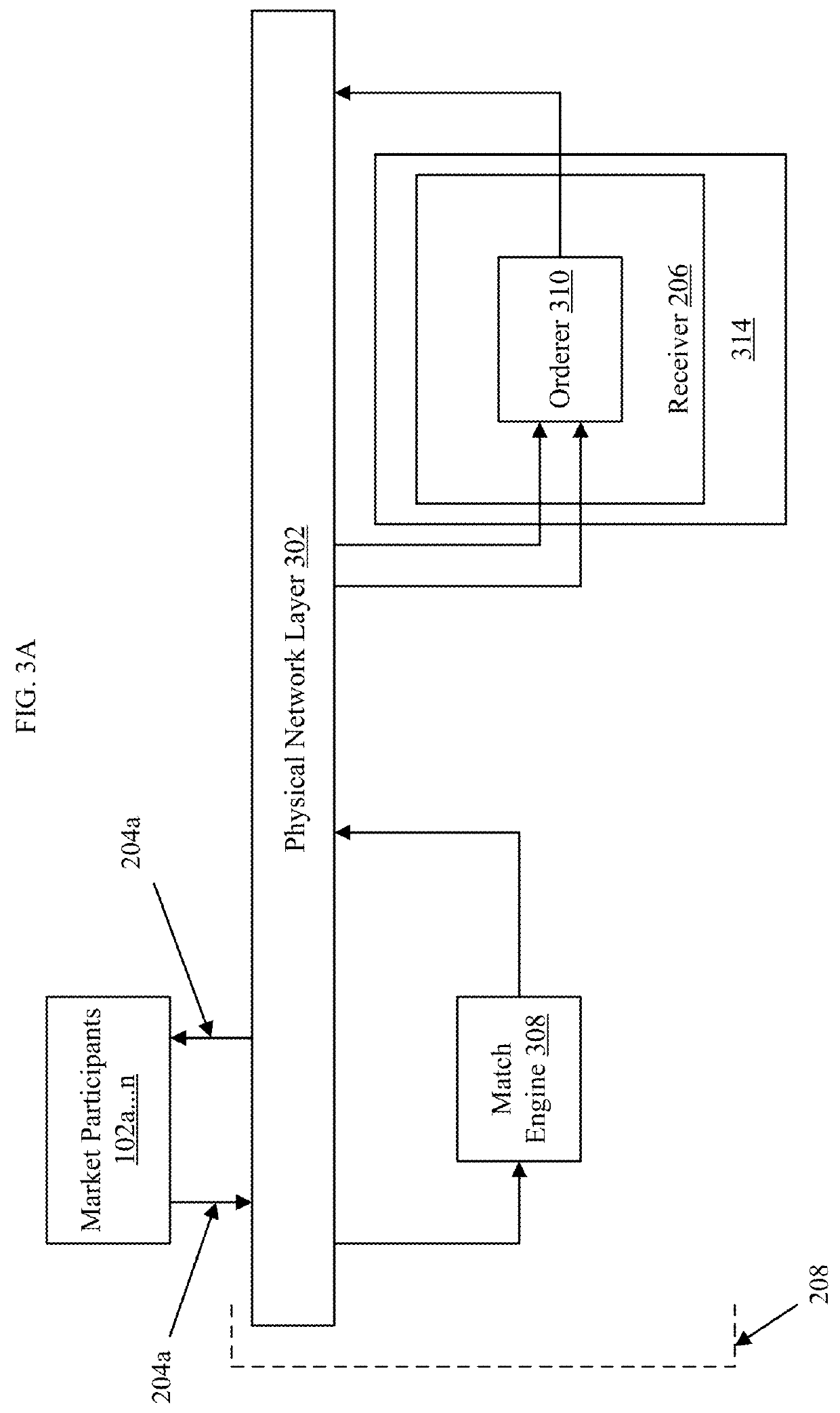

Message processing protocol which mitigates optimistic messaging behavior

ActiveUS20180183901A1Increase transaction volumeMaintain performanceFinanceData switching networksMessage processingMessage passing

The disclosed embodiments relate to implementation, such as by a message processing system architecture, of a message handling system and / or protocol which mitigates optimistic messaging behavior. As used herein optimistic messaging behavior may at least refer to the transmission, in whole or in part, of a message, or of one or more messages of a sequence thereof, to a receiving system, such as the system implemented by the disclosed embodiments, prior to the sender determining that the message(s) is / are desired, alone or in conjunction with subsequently canceling or otherwise invalidating the message(s) once it has been determined that it is not desired. The disclosed embodiments mitigate such behavior by detecting and taking action with respect to these types of messages to deter optimizing behavior which may or may not be manipulative, while maintaining reliable message handling under increasing processing loads with minimal impact on users being able to send messages to the system.

Owner:CHICAGO MERCANTILE EXCHANGE

Multi-layer metallic structure and composite-to-metal joint methods

ActiveUS8993084B2Reduce eliminate possibilityReduce occurrence and propagationFuselage framesLaminationFiberMetal sheet

A composite structure comprises stacked sets of laminated fiber reinforced resin plies and metal sheets. Edges of the resin plies and metal sheets are interleaved to form a composite-to-metal joint connecting the resin plies with the metal sheets.

Owner:THE BOEING CO

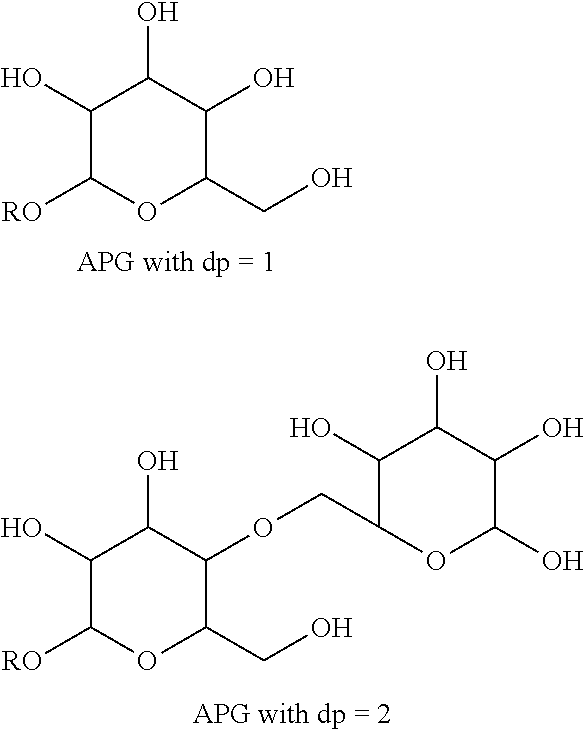

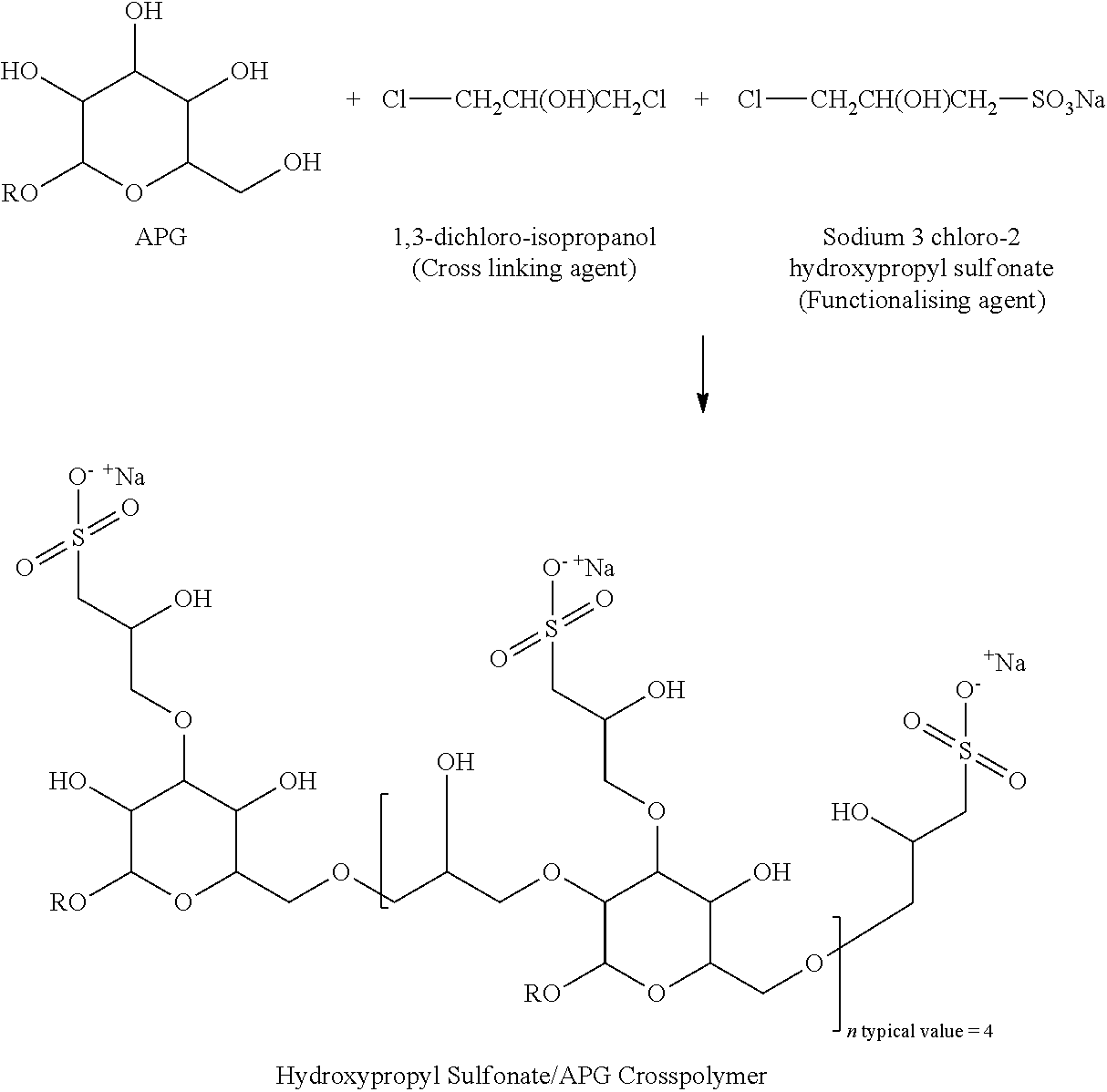

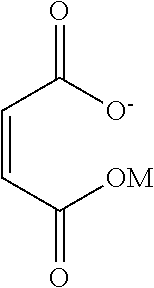

Surfactant composition

ActiveUS20150126417A1Reduce corrosionImproved aquatic toxicityFlushingDrilling compositionSURFACTANT BLENDHydrocarbon

The invention provides a synergistic surfactant composition comprising: (a) from 5 to 95 wt % of a first surfactant which is selected from derivatives of alkyl polyglucosides and mixtures thereof; and (b) from 5 to 95 wt % of a second surfactant which is selected from: amphoteric surfactants, cationic surfactants, anionic surfactants, non-ionic surfactants, and mixtures thereof. This surfactant composition may be used to generate foam that is used for unloading a liquid from a hydrocarbon reservoir. It may be that the liquid unloading of foam generated using the surfactant composition is greater than that of foam generated from the first and second surfactants when they are foamed individually.

Owner:ENERGY SOLUTIONS (US) LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com