Patents

Literature

67results about How to "Valid settings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

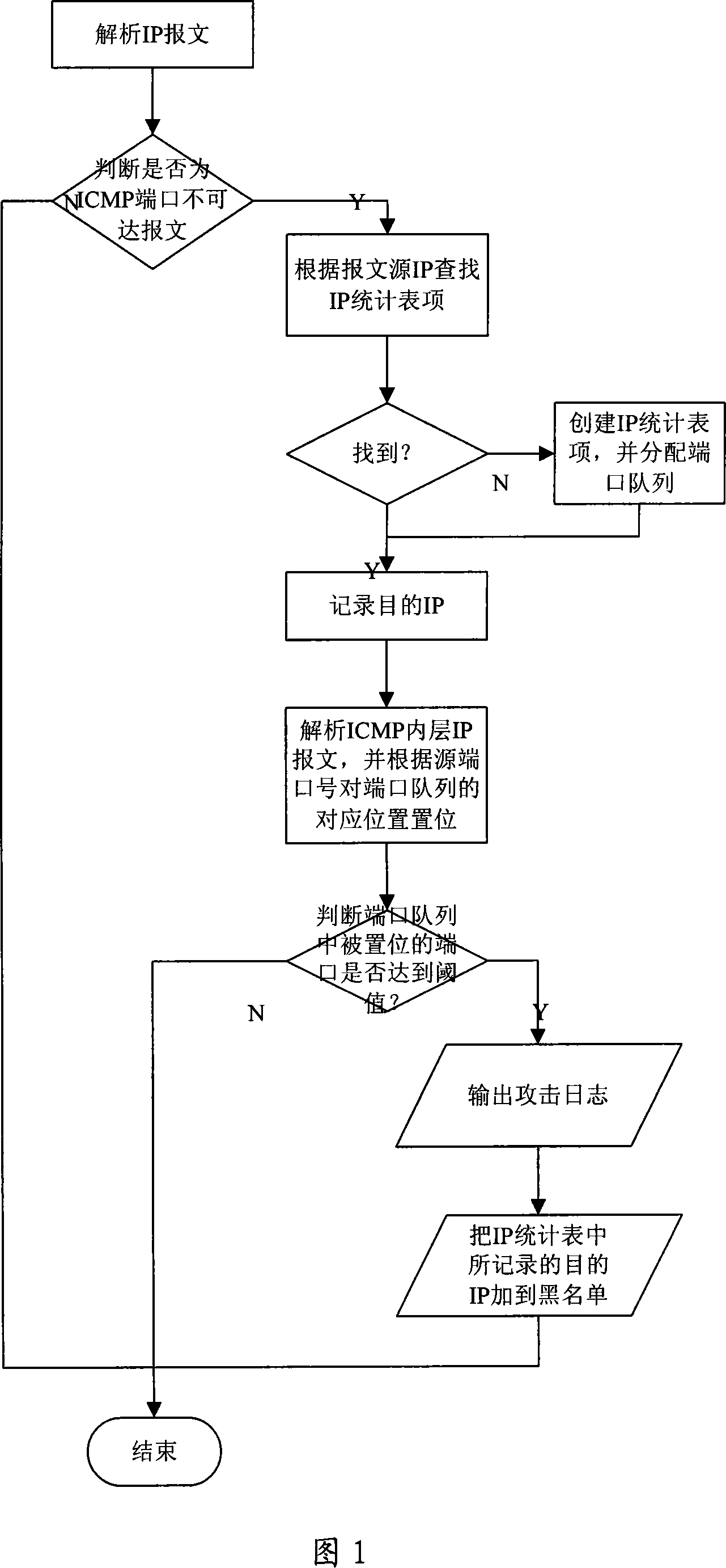

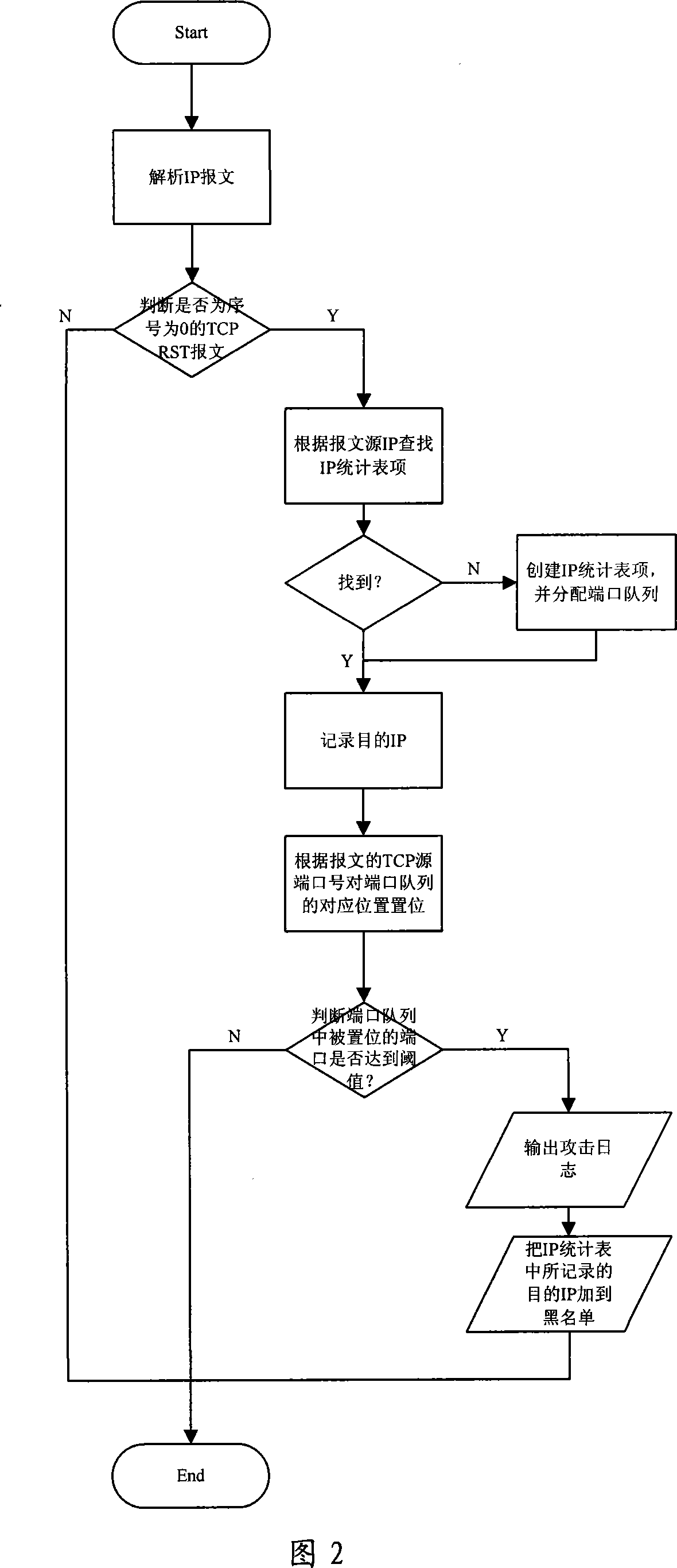

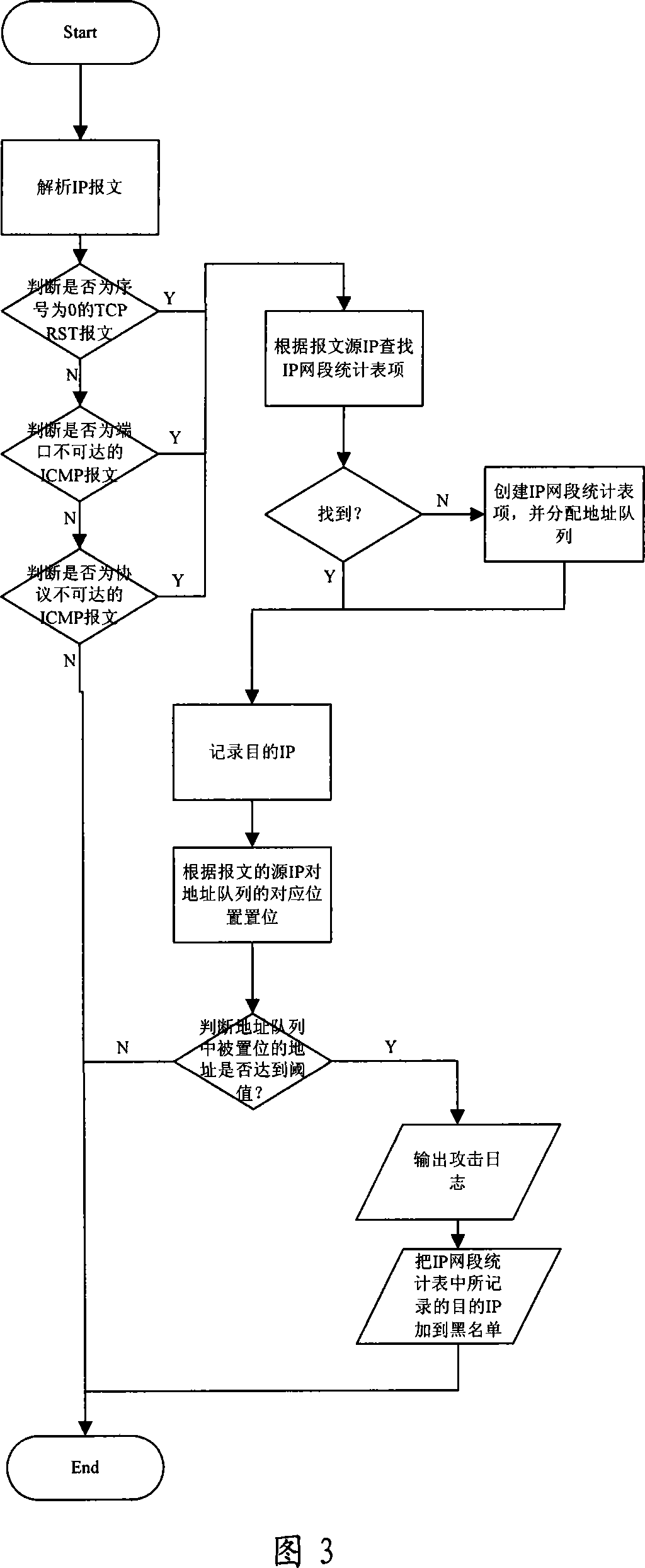

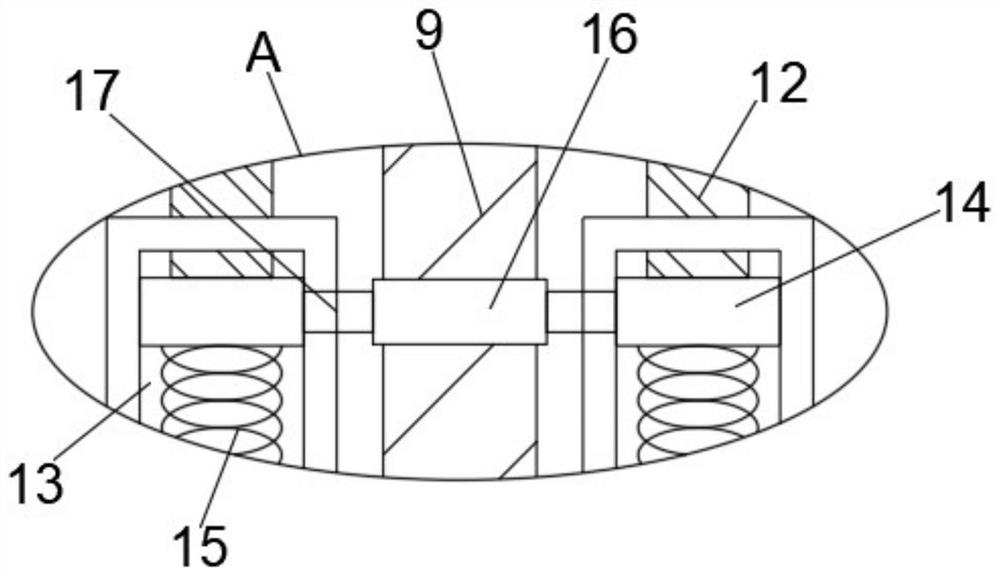

Method and device for detecting scanning attack

InactiveCN101123492AValid settingsPerformance advantageData switching networksSecuring communicationIp addressComputer science

After some embodiments, the present invention discloses a method and a device for detecting scan attacks. The present invention parses the received message information and records the information of the destination port or the IP address in the message information; then the times, for which the destination port or the IP address are recorded in a scheduled time, are counted; and finally when the recorded times of the destination port or the IP address reach a predetermined threshold, then the present invention judges that a scan attack occurs. The device of the present invention comprises a first unit, which parses the received message information and records the destination port or the IP address, a second unit, which is used to count the times for which the destination port or the IP address are recorded in a scheduled time, and a third unit, which is used to judge that a scan attack occurs when the recorded times of the destination port or the IP address reach a predetermined threshold. In every technical scheme of embodiment, the present invention effectively detects scan attacks according to the times of the port or protocol attack in a scheduled time, thus reducing the false alarm rate and the realization difficulty of scan detection.

Owner:NEW H3C TECH CO LTD

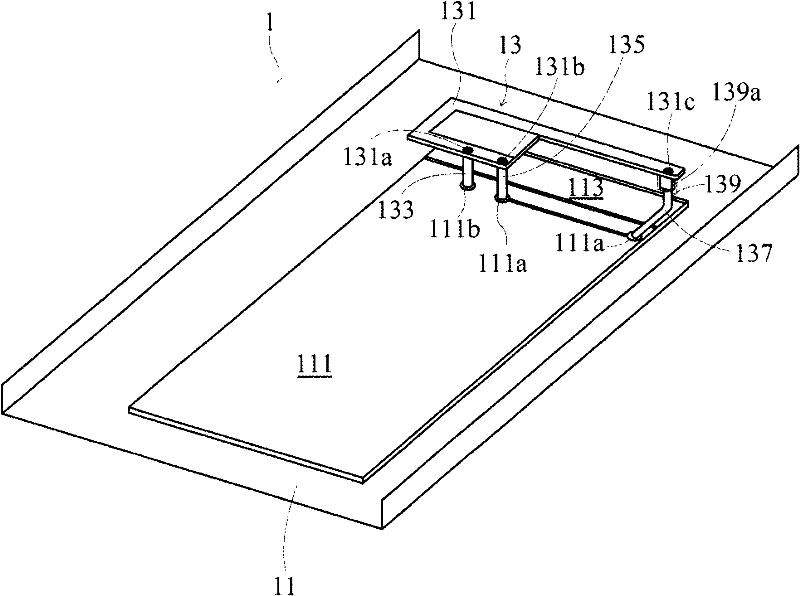

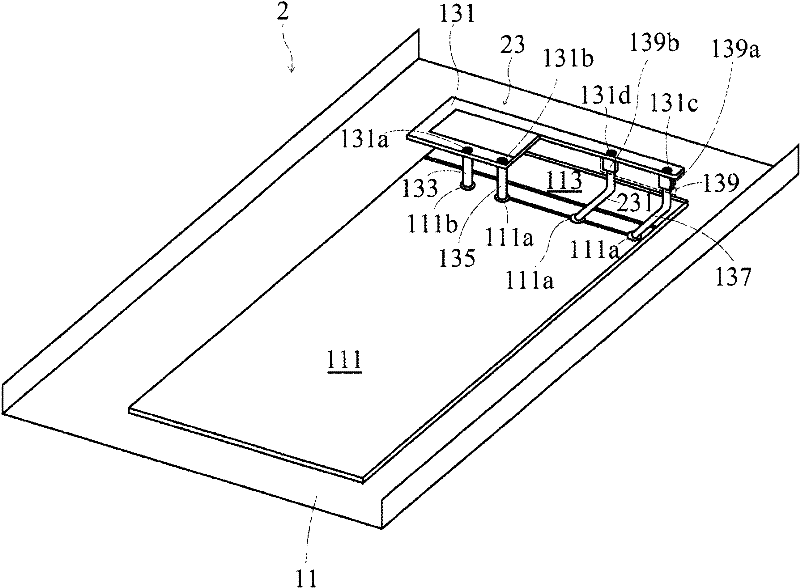

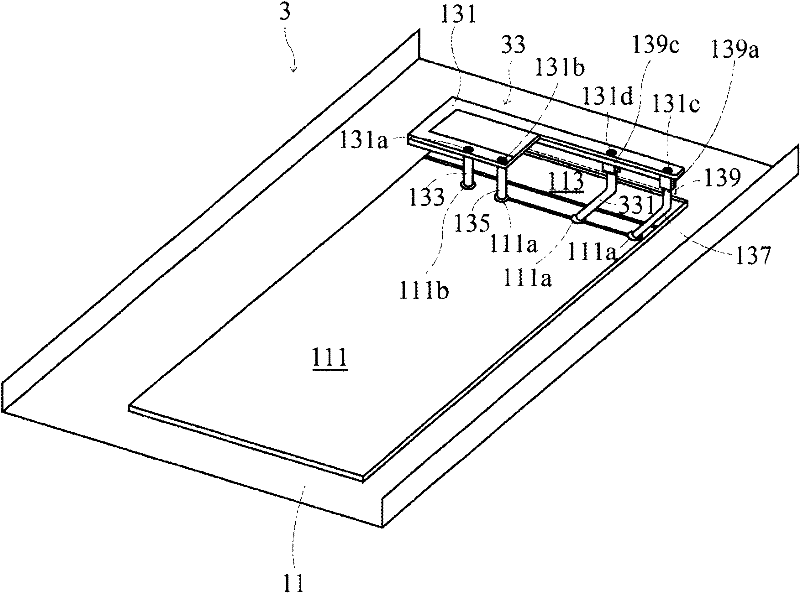

Handheld device and planar antenna thereof

ActiveCN102569990AMeet the needs of light and thinValid settingsSimultaneous aerial operationsAntenna supports/mountingsRadio frequencyCenter frequency

A handheld device and a planar antenna thereof are provided. The planar antenna comprises a radiator having a feeding point, a first short point and a second short point. The feeding point is coupled to a circuit board of the handheld device so that the handheld device transmits and receives a RF (radio frequency) signal through the radiator. The first short point is coupled to a ground of the circuit board so as to be grounded. A control element is disposed on the handheld device or the planar antenna in order to control the second short point to be selectively electrically coupled to the ground so that the planar antenna can operate at two different central frequencies. Furthermore, the planar antenna can operate at multiple central frequencies by changing a position of the second short point contacted to the radiator.

Owner:HTC CORP

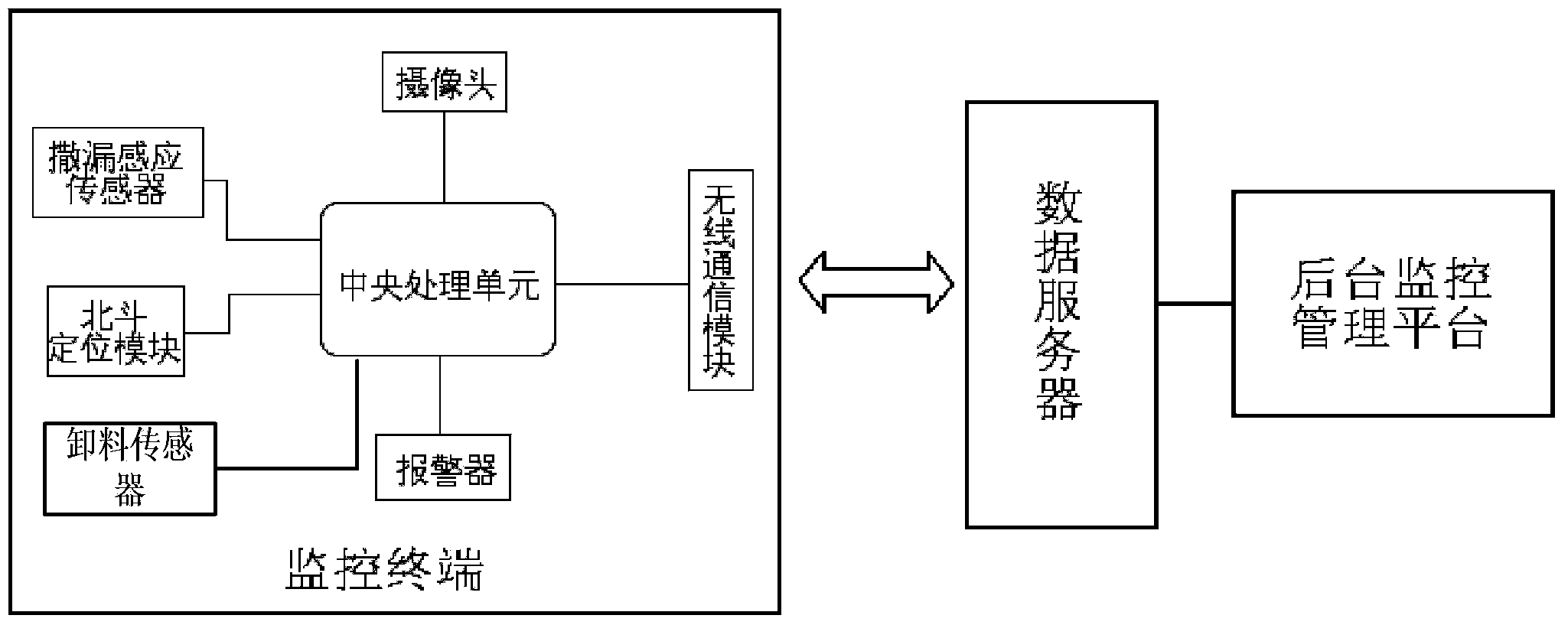

Monitoring method of vehicle leaking and sifting monitoring system

InactiveCN103473927APrecise positioningShort time to first fixDetection of traffic movementRelevant informationMonitoring system

The invention discloses a monitoring method of a vehicle leaking and sifting monitoring system. The method includes the following steps of firstly, installing a vehicle-mounted monitoring terminal on a vehicle, collecting relevant information in real time through the vehicle-mounted monitoring terminal, and then binding and sending induction information, position information and picture information to a data sever of a vehicle scheduling center to be stored through a wireless communication module; secondly, installing a monitoring and managing system on the data server, and then operating the monitoring and managing system on an operation interface of a background monitoring and managing platform; thirdly, recognizing and judging whether the induction information is the induction information indicating the occurrence of the sifting and leaking phenomenon or not or whether the induction information is discharging sensing information or not through the data server; fourthly, generating a corresponding control instruction and sending the corresponding control instruction to a central processor of the vehicle-mounted monitoring terminal through the data server according to the operation request of the monitoring and managing system so that a vehicle can be remotely monitored. The monitoring method allows real-time monitoring to be achieved, is high in work efficiency, and allows the sifting and leaking phenomenon of the muck vehicle to be effectively supervised and governed.

Owner:柳州天运寰通科技有限公司

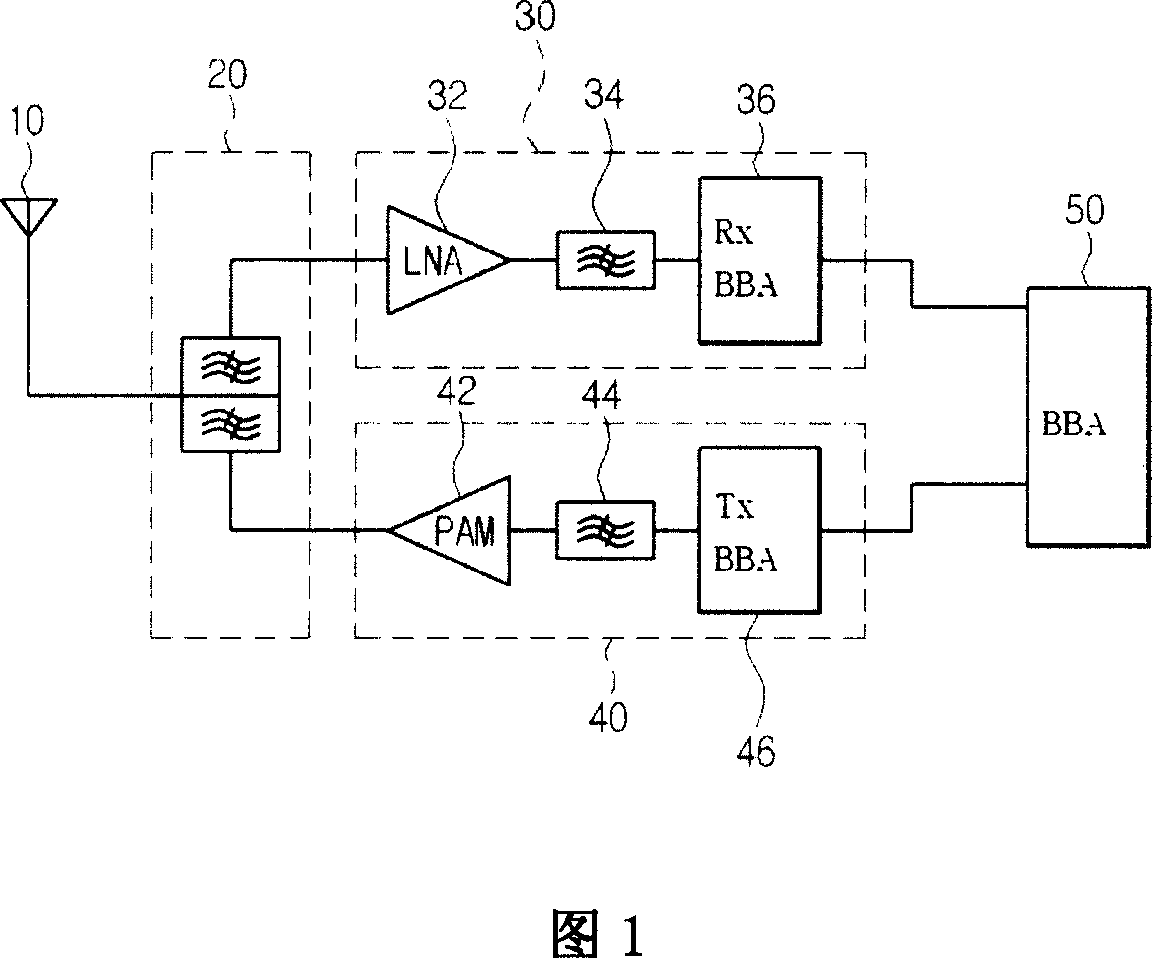

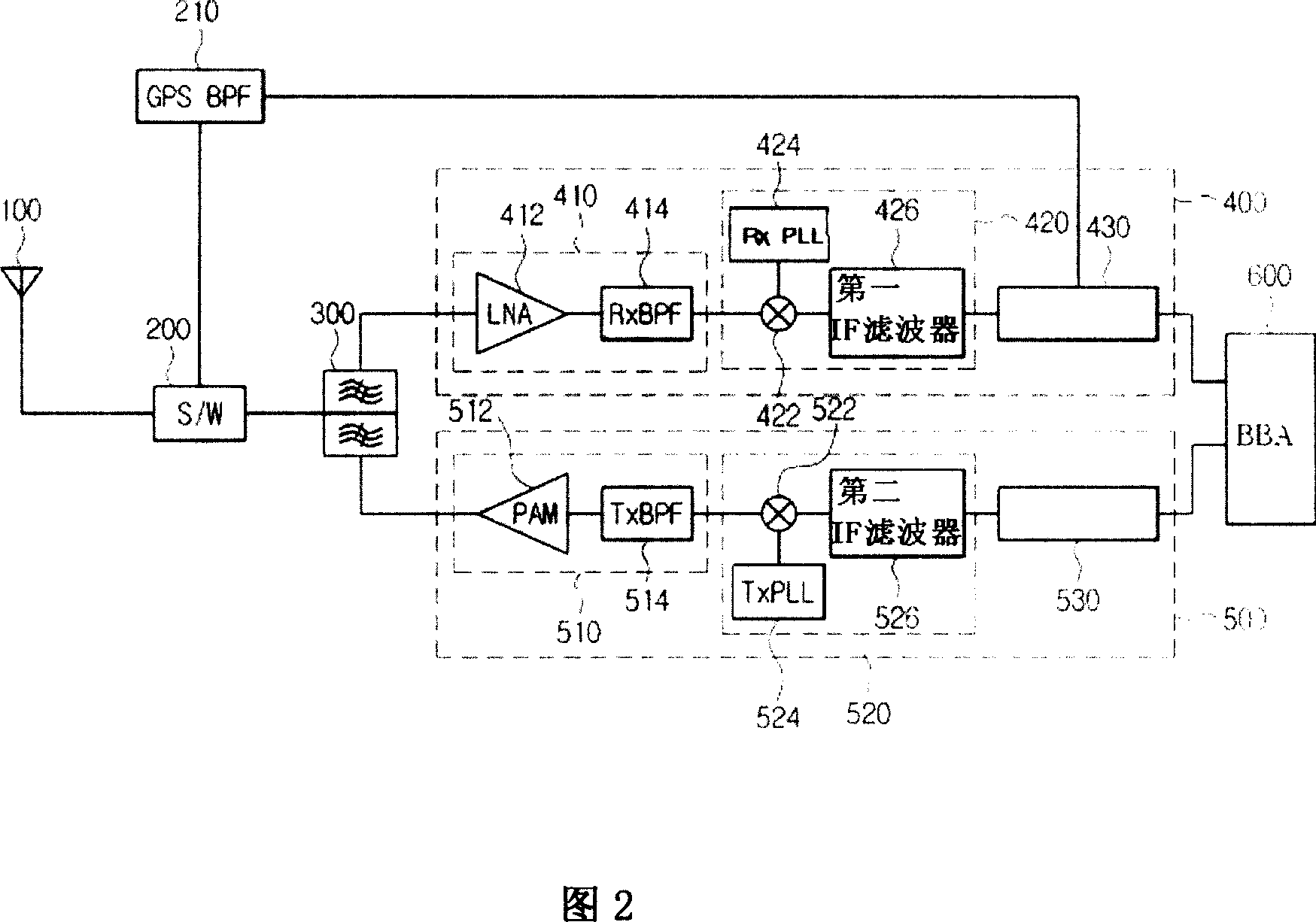

Front end module

InactiveCN1933343AOptimizing RF SignalsValid settingsRadio transmission for post communicationAntenna earthingsEngineeringGround plane

A front end module having a multilayered structure is provided. The front end module includes a transmitter, a receiver, and a duplex unit. A ground layer is provided with an ground pattern having a plurality of separated blocks on a surface of a substrate of the front end module.

Owner:LG INNOTEK CO LTD

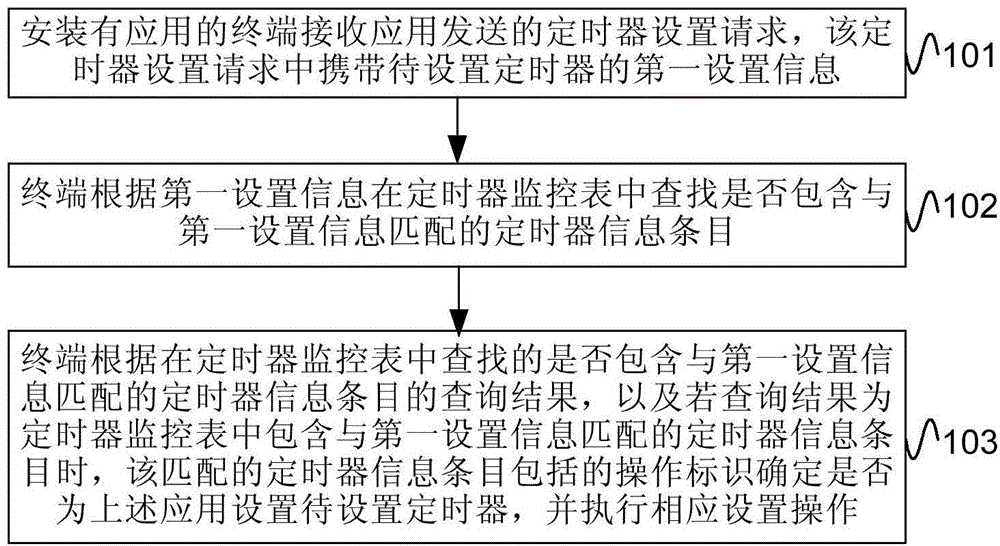

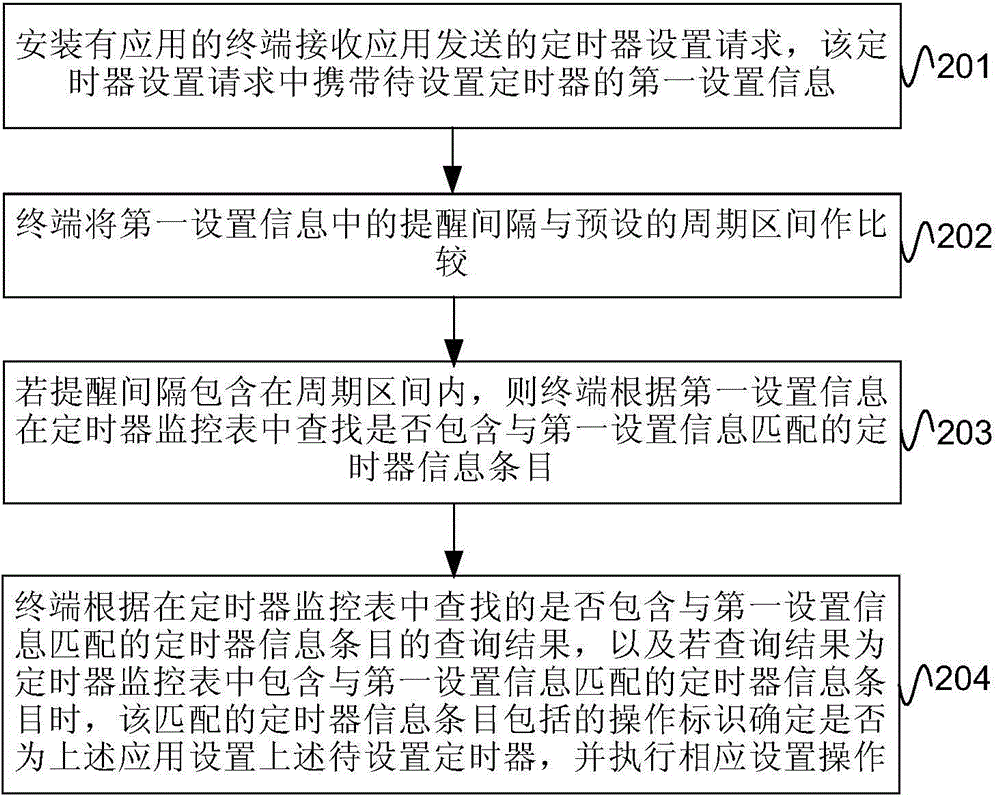

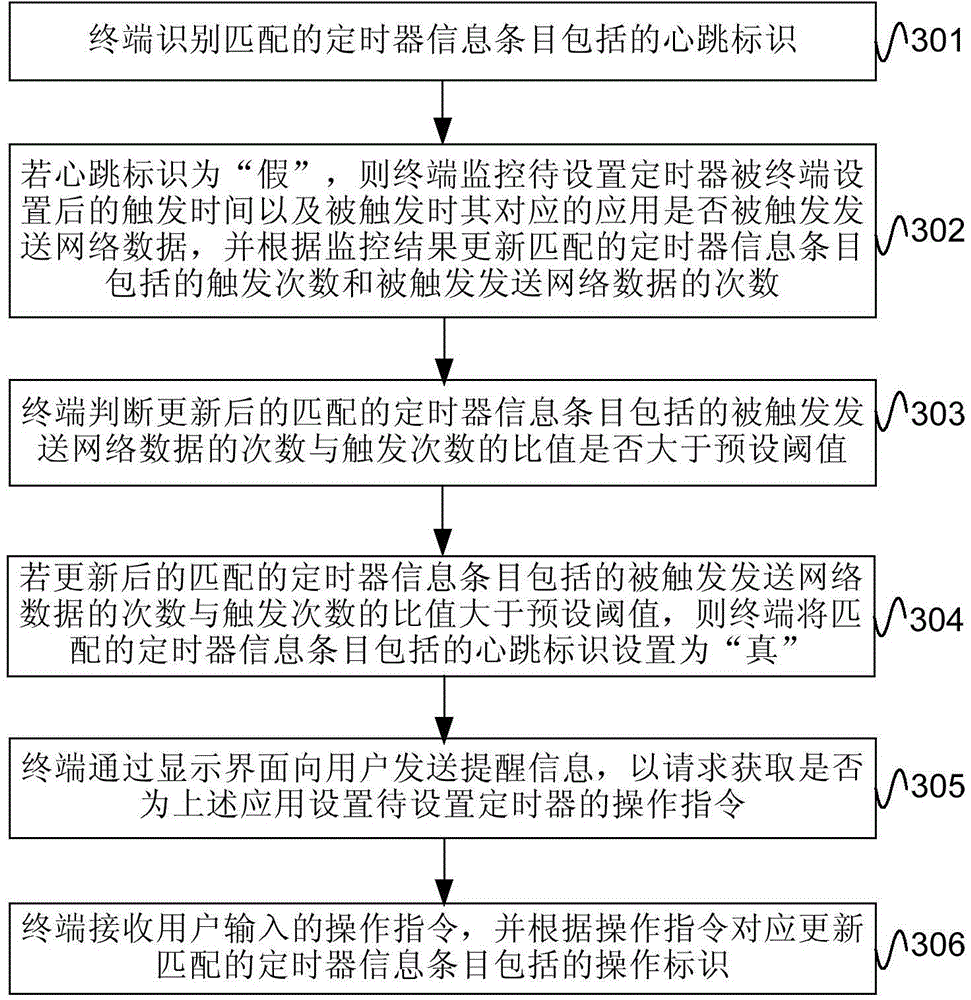

Timer setting method and terminal

ActiveCN104093199AEfficient managementValid settingsPower managementHigh level techniquesTimerMobile phone

The invention provides a timer setting method and terminal. The method comprises the following steps that the terminal provided with an application receives a timer setting request sent by the application, and the timer setting request carries first setting information of a timer to be set; the terminal inquires whether a timer monitoring table contains a timer information entry matched with the first setting information according to the first setting information; according to an inquiry result, if the inquiry result shows that the timer monitoring table contains the timer information entry matched with the first setting information, operation identification contained in the matched timer information entry is used for determining whether the timer to be set is set by the application, and corresponding setting operation is executed. The timer setting method and terminal solve the technical problems that in the prior art, a heartbeat timer in a mobile phone terminal cannot be effectively managed or set, and the situation that after the terminal is provided with a non-necessary heartbeat timer, resource waste is easily caused cannot be reduced or avoided.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Vehicle leaking and sifting monitoring system

InactiveCN103472805ALow costPrecise positioningRoad vehicles traffic controlProgramme total factory controlElectronic control systemMonitoring system

The invention discloses a vehicle leaking and sifting monitoring system. The vehicle leaking and sifting monitoring system is mainly composed of a monitoring terminal, a data server and a background monitoring and managing platform. The monitoring terminal comprises a central processing unit, a leaking and sifting inductive sensor, a discharging sensor, a compass positioning module, an alarm, a camera and a wireless communication module, wherein the leaking and sifting inductive sensor, the discharging sensor, the compass positioning module, the alarm, the camera and the wireless communication module are connected with the central processing unit, and the central processing unit of the monitoring terminal is further connected with a vehicle electronic control system. The central processing unit of the monitoring terminal collects sensing information of the leaking and sifting inductive sensor, sensing information of the discharging sensor and position information of the compass positioning module in real time, transmits the sensing information and the positioning information to the data server to be stored through the wireless communication module in real time, and analyzes the sensing information and the position information according to an instruction request of a monitoring and managing system. The monitoring system is low in invested equipment cost, can conduct real-time monitoring, is high in work efficiency and can effectively supervise and govern the sifting and leaking phenomenon of a muck vehicle.

Owner:柳州天运寰通科技有限公司

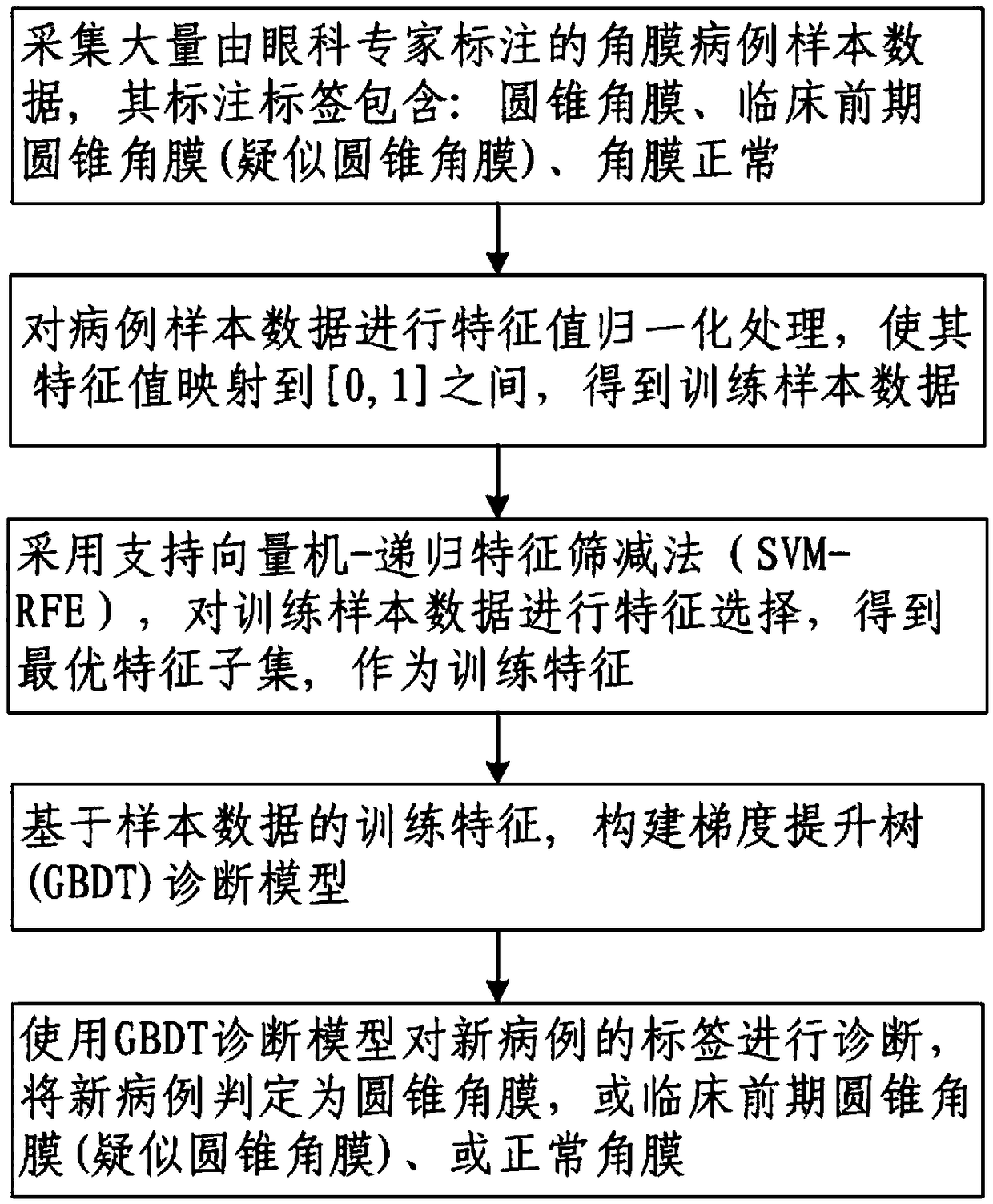

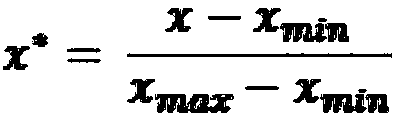

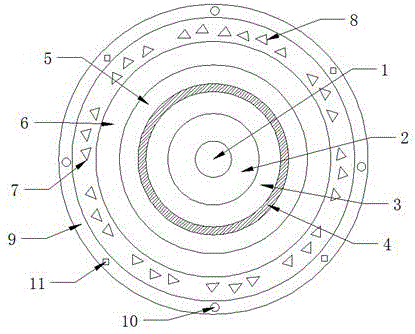

Method for diagnosing keratoconus cases based on machine learning

ActiveCN109036556AImprove the efficiency of clinical diagnosisImprove accuracyMedical automated diagnosisCharacter and pattern recognitionSupport vector machineKeratoconus

The invention relates to a method for diagnosing keratoconus cases based on machine learning. According to the method, a support vector machines-recursive feature elimination (SVM-RFE) algorithm and agradient boosting regression tree (ABDT) algorithm are applied to accurate diagnosis of the keratoconus cases. Furthermore for aiming at specific application cases, effective overall plan designing,process designing and algorithm parameter setting are performed. Through test of a large number of clinic instances, the diagnosis accuracy of the method is effectively improved and basically satisfies the requirement for clinic applications.

Owner:王雁 +1

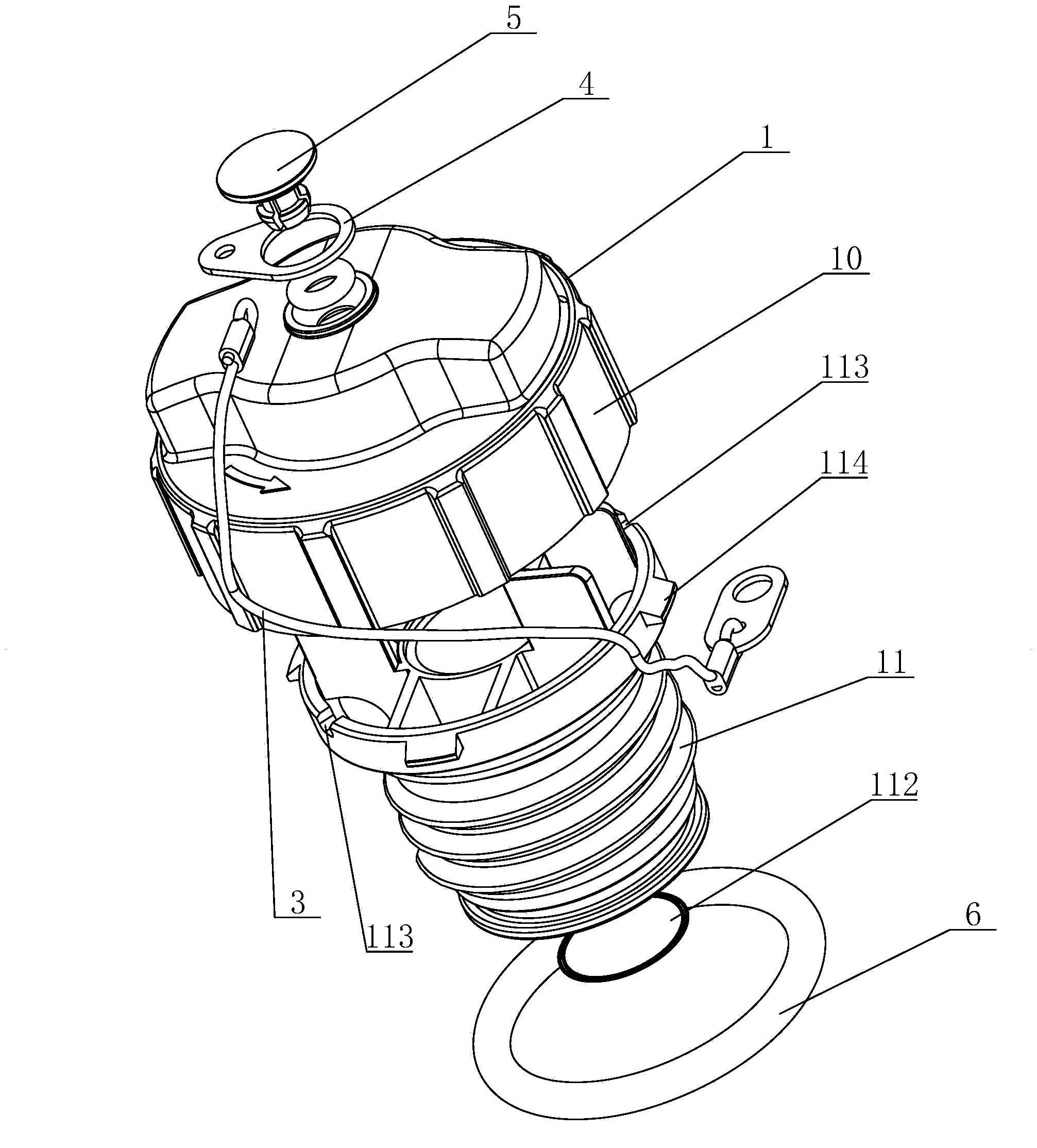

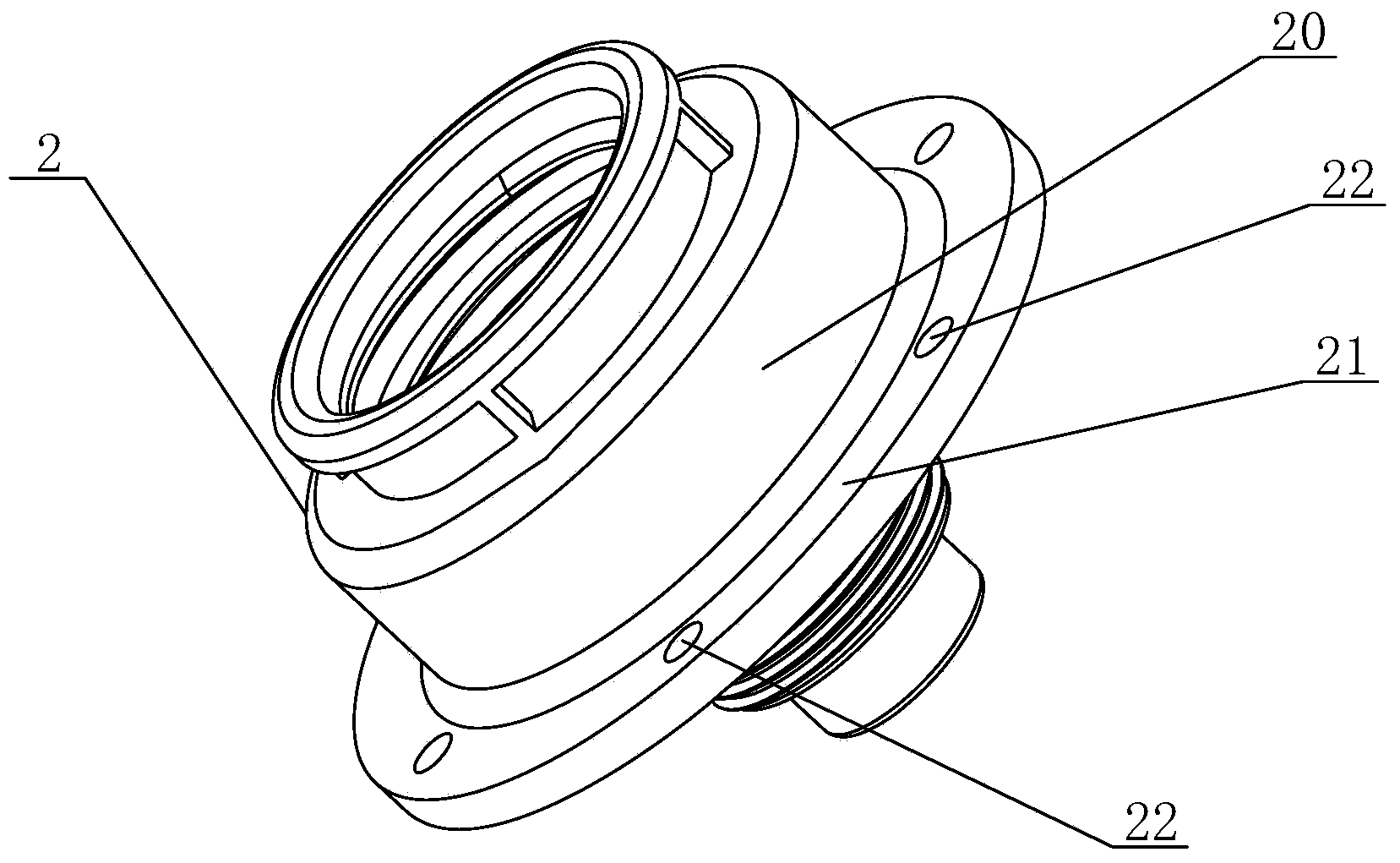

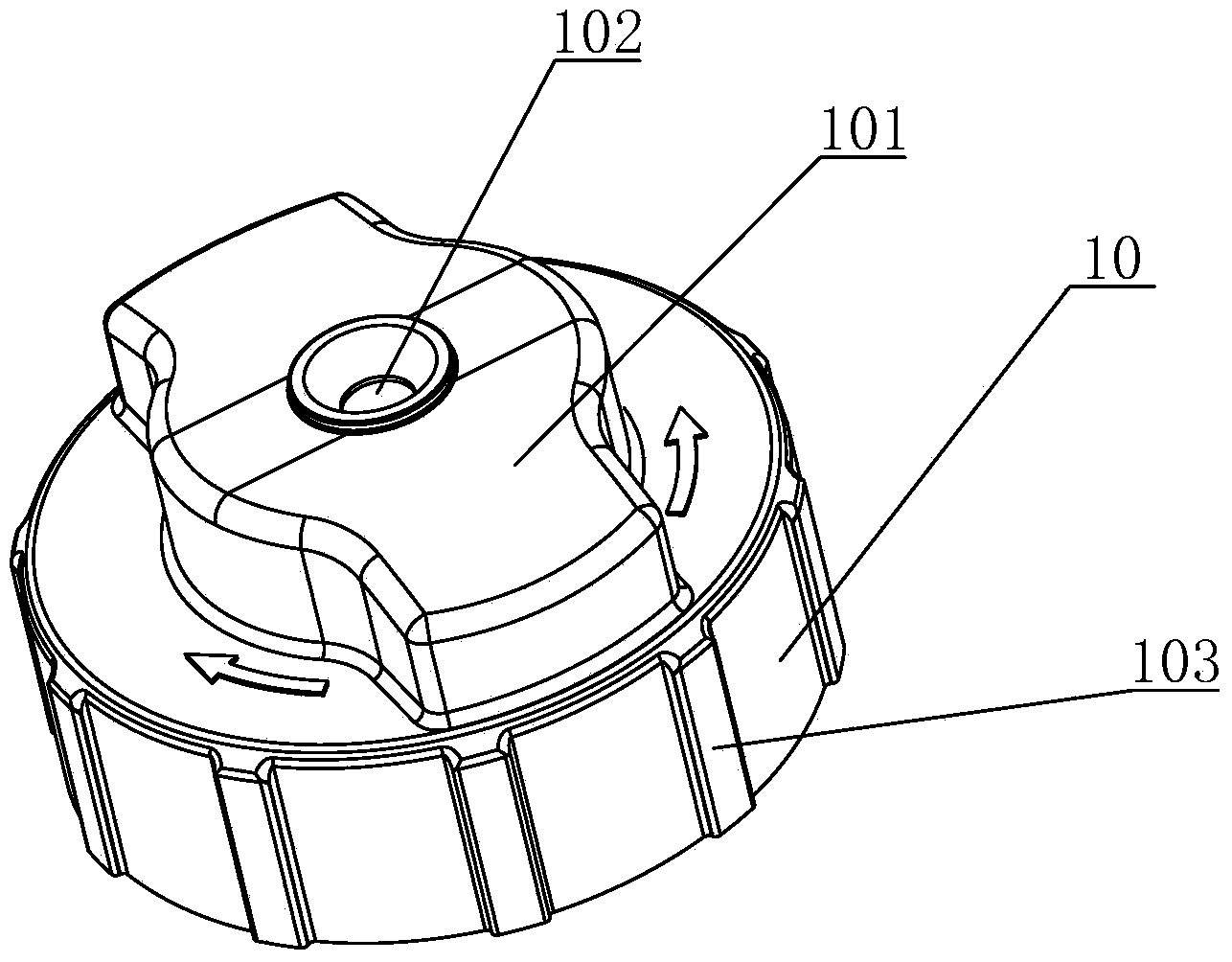

Urea solution tank filling assembly used for SCR system

ActiveCN104373178AAvoid entanglementGuaranteed normal rotationExhaust apparatusSilencing apparatusAgricultural engineeringBreathing

The invention discloses a urea solution tank filling assembly used for an SCR system. The urea solution tank filling assembly comprises a tank cover and a filling opening, the filling opening is formed in a urea solution tank, and a chain is connected between the filling opening and the tank cover. The tank cover comprises an upper outer cover body and a lower outer cover body, a ventilation cavity is formed in the center of the lower outer cover body, a plurality of ventilation holes are formed in the bottom of the ventilation cavity, ventilation film is arranged at the portion, located above the ventilation holes, of the ventilation cavity, a plurality of ventilation grooves are formed in the top of the lower outer cover body, the top of the lower outer cover body is connected with the interior of the upper outer cover body, the bottom of the lower outer cover body is connected with the filling opening, one end of the chain is connected to the top of the upper outer cover body in a rotatable mode, the other end of the chain is connected to the filling opening, and the filling opening is of an integrated structure. The urea solution tank filling assembly is convenient to assemble, and normal rotation of the tank cover can be guaranteed; in addition, expansion, caused by the fact that gas can not be effectively removed, of a tank body can be effectively prevented, and normal running of the system can be guaranteed.

Owner:KAILONG HIGH TECH

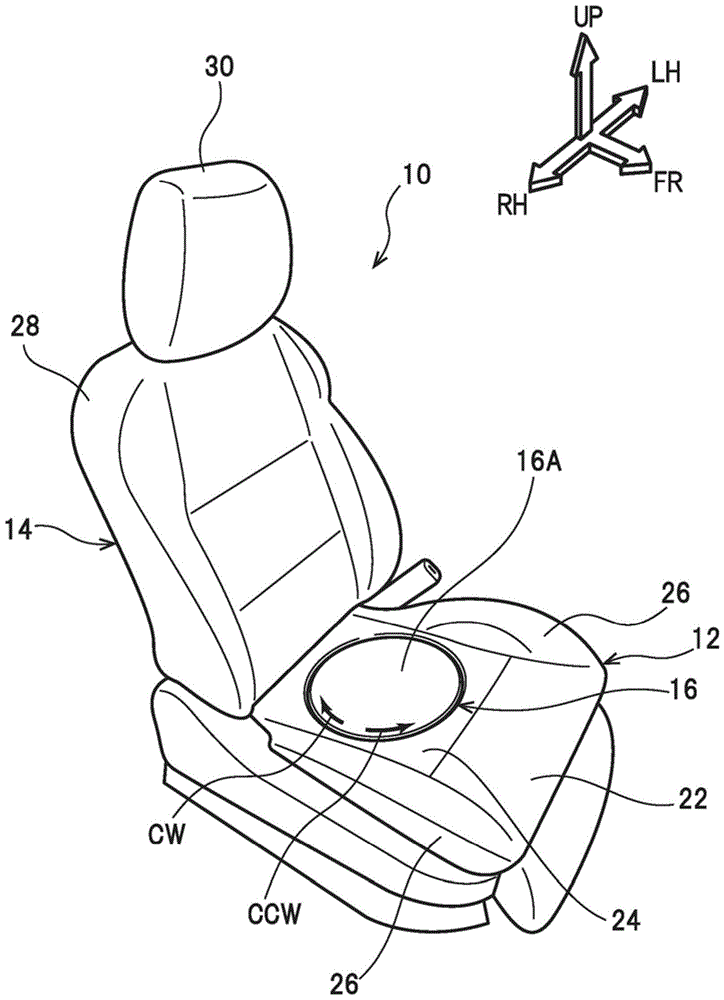

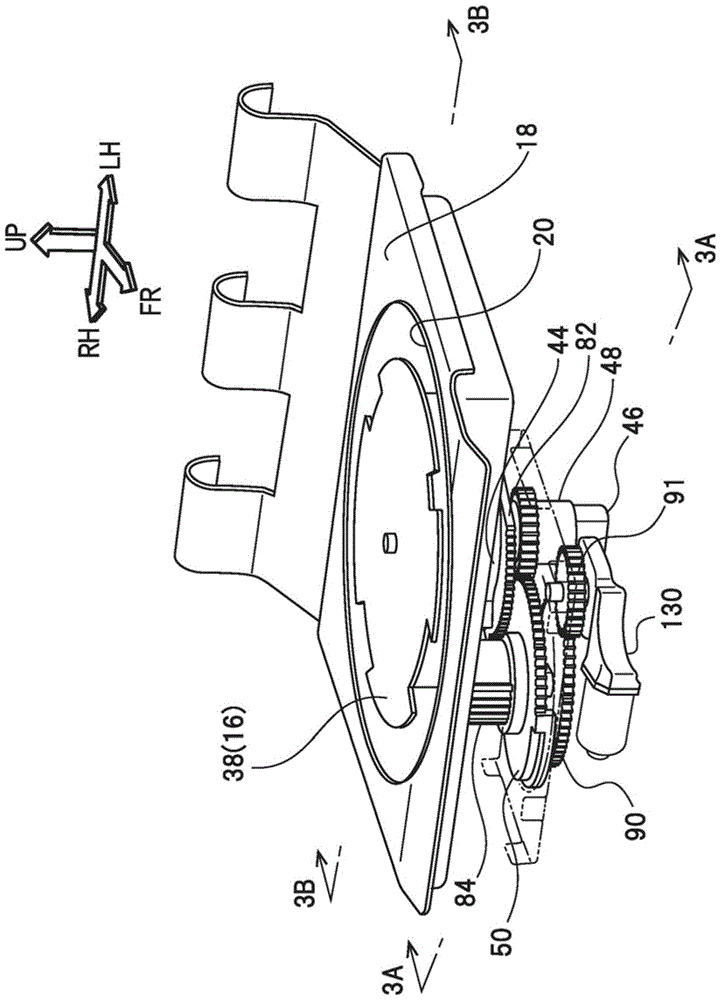

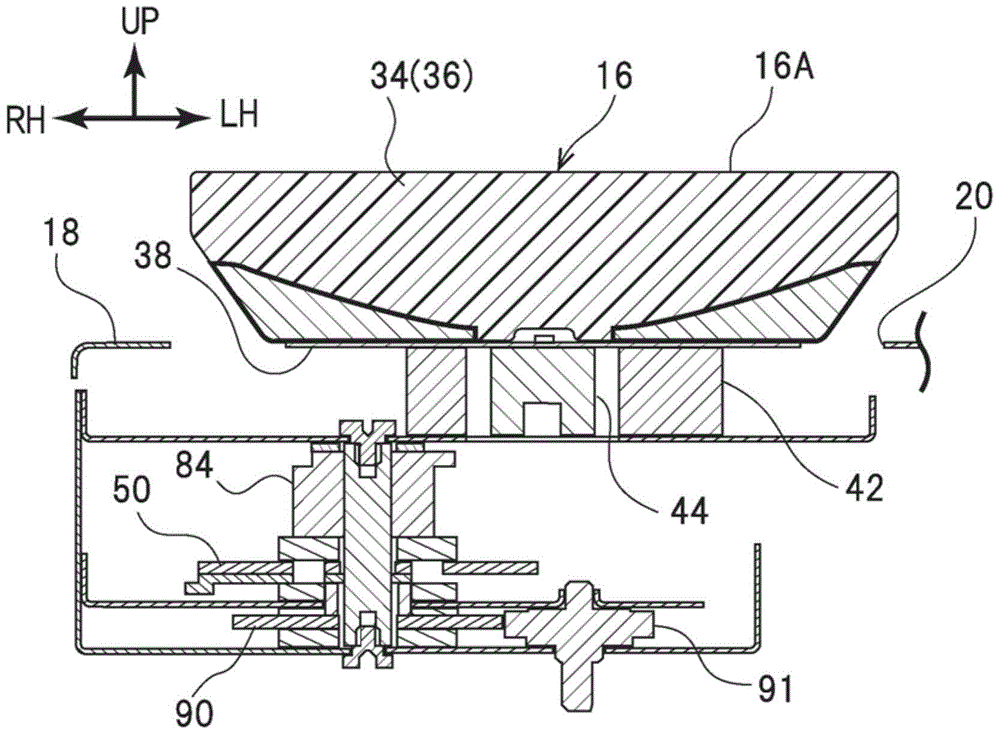

car seat

A vehicle seat is provided, which includes: a seat cushion on which an occupant sits and supports the buttocks and thighs of the occupant; and a rotating part disposed on A position on the seat pad that is in contact with the occupant's buttocks, and the rotating portion can rise relative to the seat surface of the seat pad, and then rotate with the up and down direction of the seat as the axial direction, and after the rotation decline.

Owner:NHK SPRING CO LTD

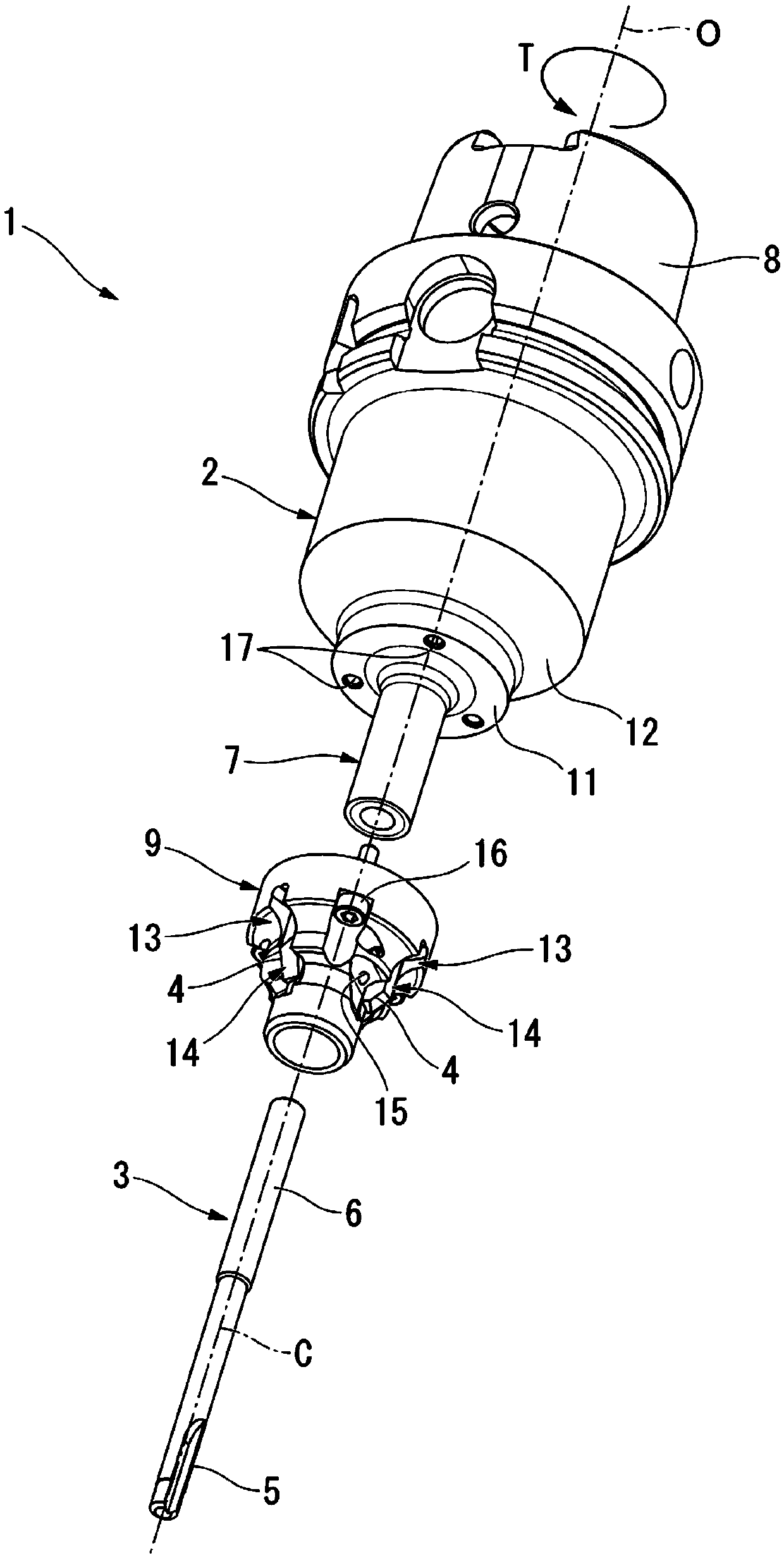

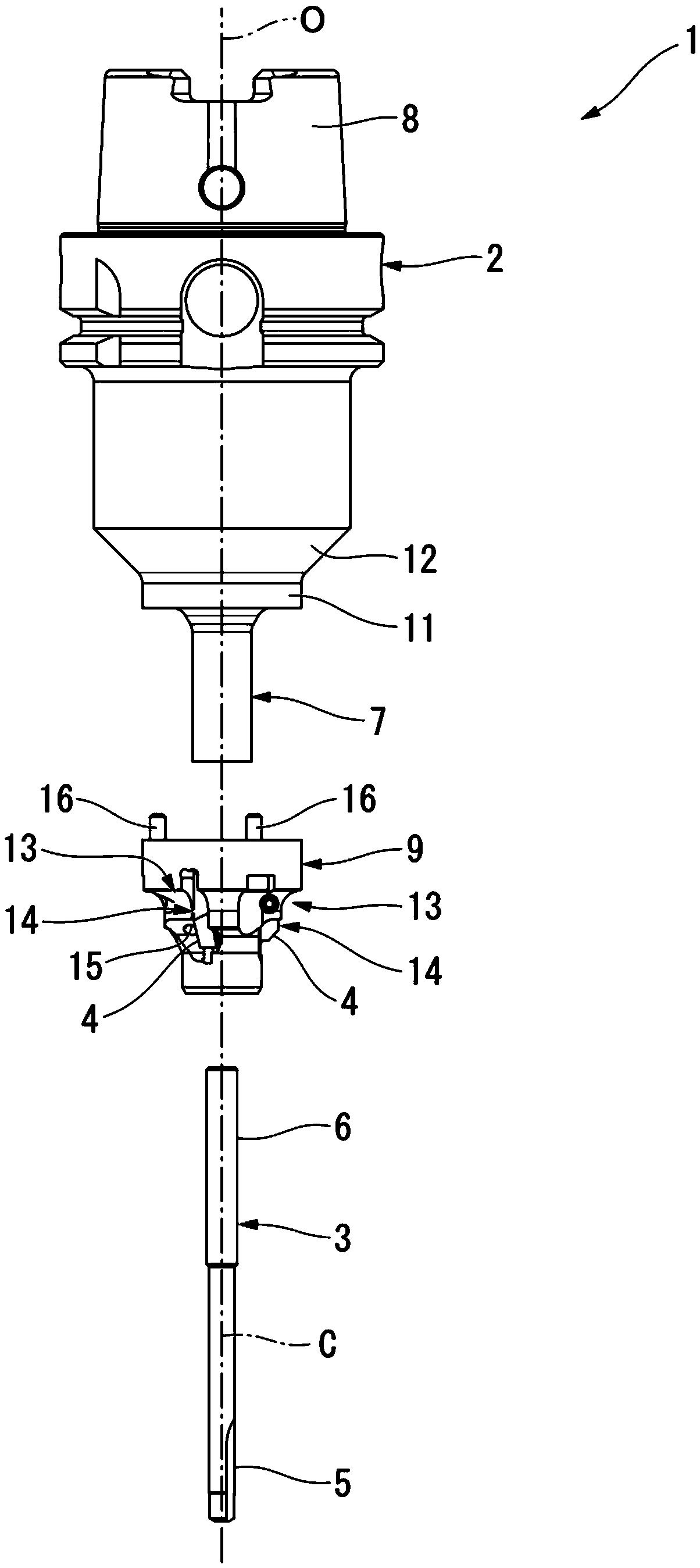

Cutting tool

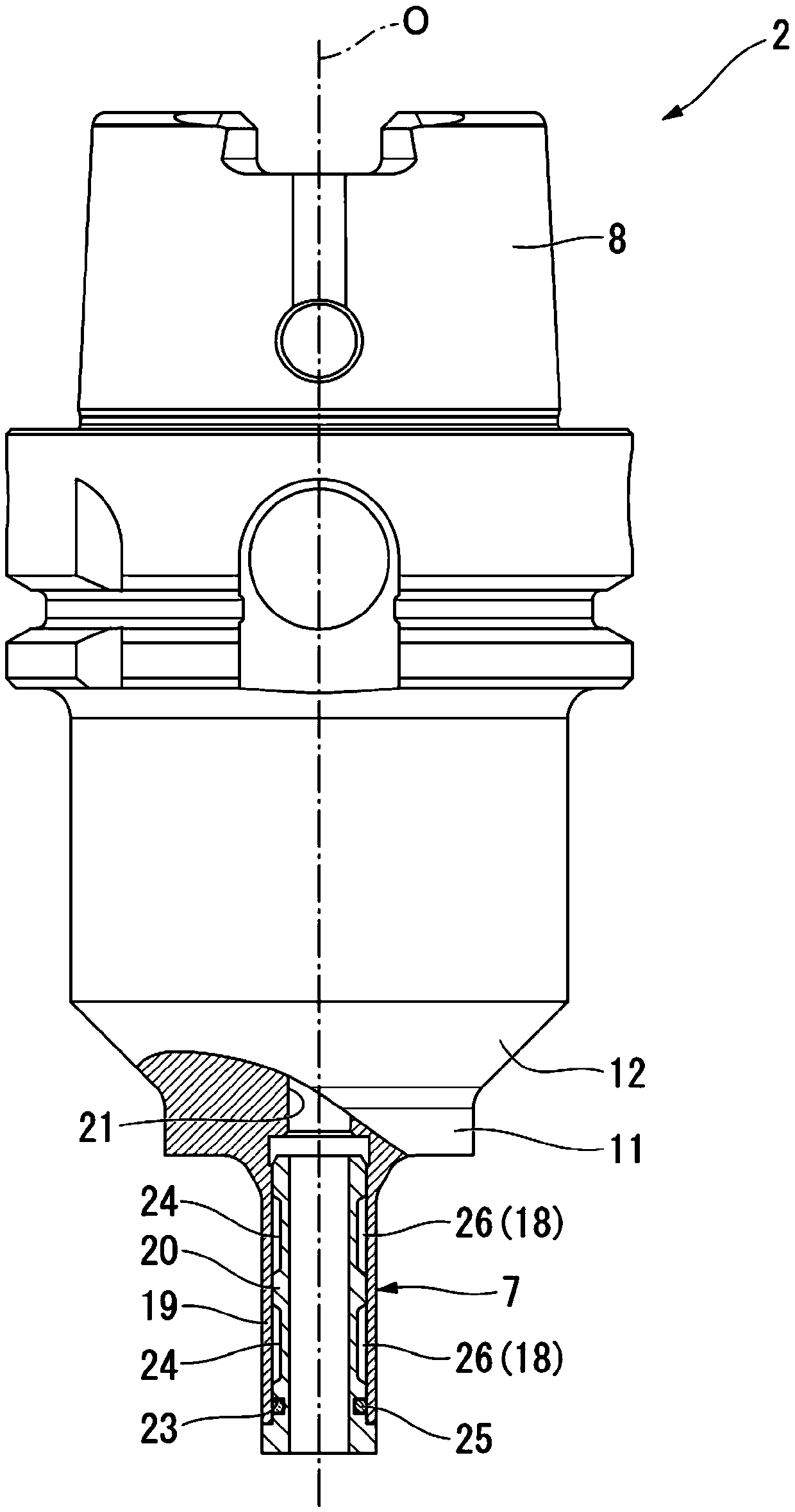

InactiveCN105517740AImprove rigidityReliable fastening stateTransportation and packagingExpansion mandrelsEngineering

This cutting tool (1) is provided with: a tool body (2) that rotates around an axis (O); a cylindrical part (7) provided at the tip on the distal side in the axis (O) direction of the tool body (2) and extending in the axis (O) direction; a boring tool (3) describing the shape of a shaft, detachably fitted on the radial-direction inner side of the cylindrical part (7) and extending so as to project from the cylindrical part (7) toward the distal side; and a head part (9) describing a cylindrical shape, fitted on the radial-direction outer side of the cylindrical part (7), and provided on the outer peripheral section thereof with a cutting blade. The peripheral wall of the cylindrical part (7) is provided with an outer wall (19), an inner wall (20), and a fluid chamber (18) defined between the outer wall (19) and the inner wall (20), the interior of the fluid chamber being filled with fluid. The pressure of the fluid in the fluid chamber (18) is increased, whereby the outer wall (19) elastically deforms toward the radially outward side and presses against the head part (9), and the inner wall (20) elastically deforms toward the radially inward side and presses against the boring tool (3).

Owner:MITSUBISHI MATERIALS CORP

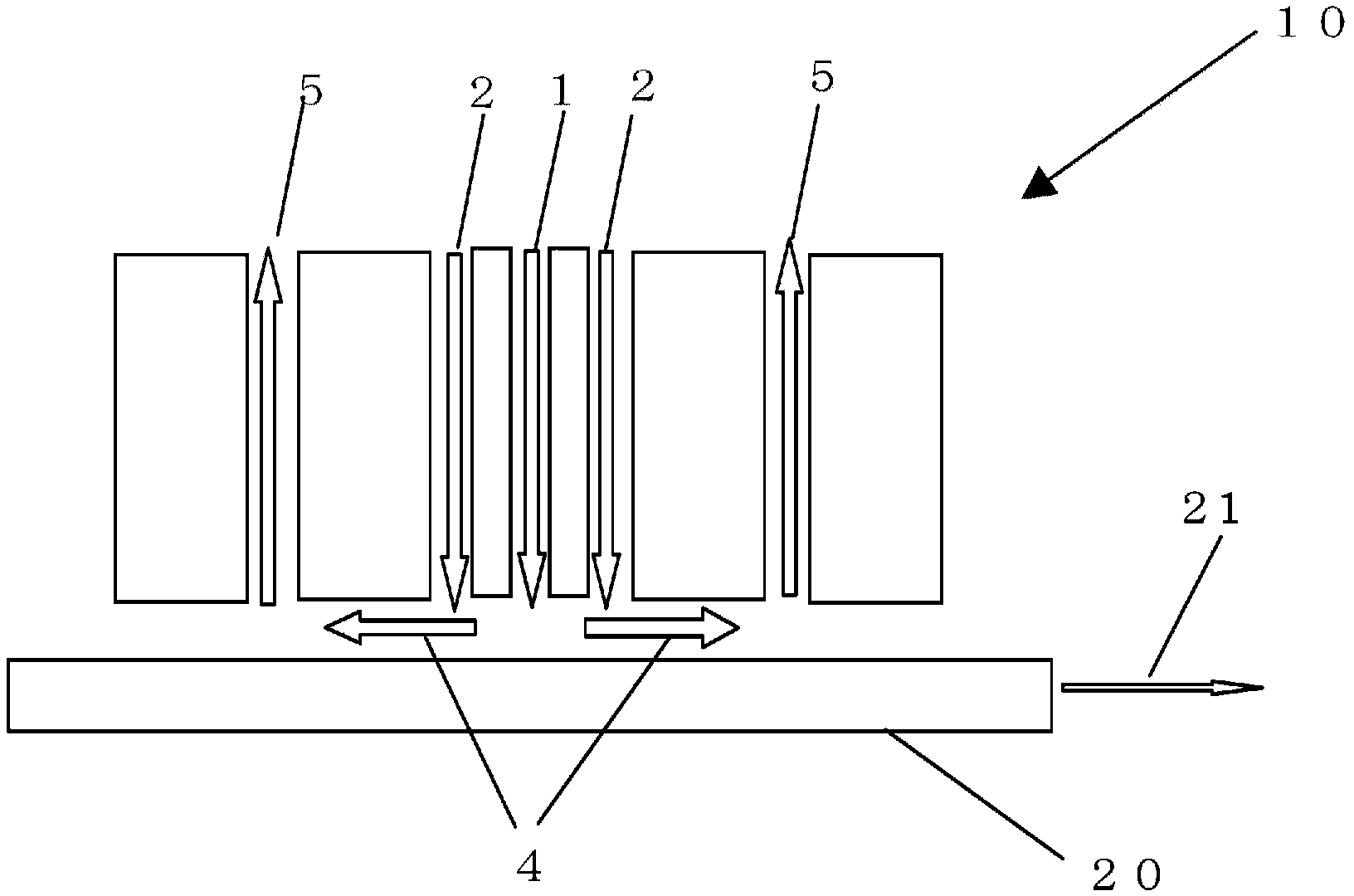

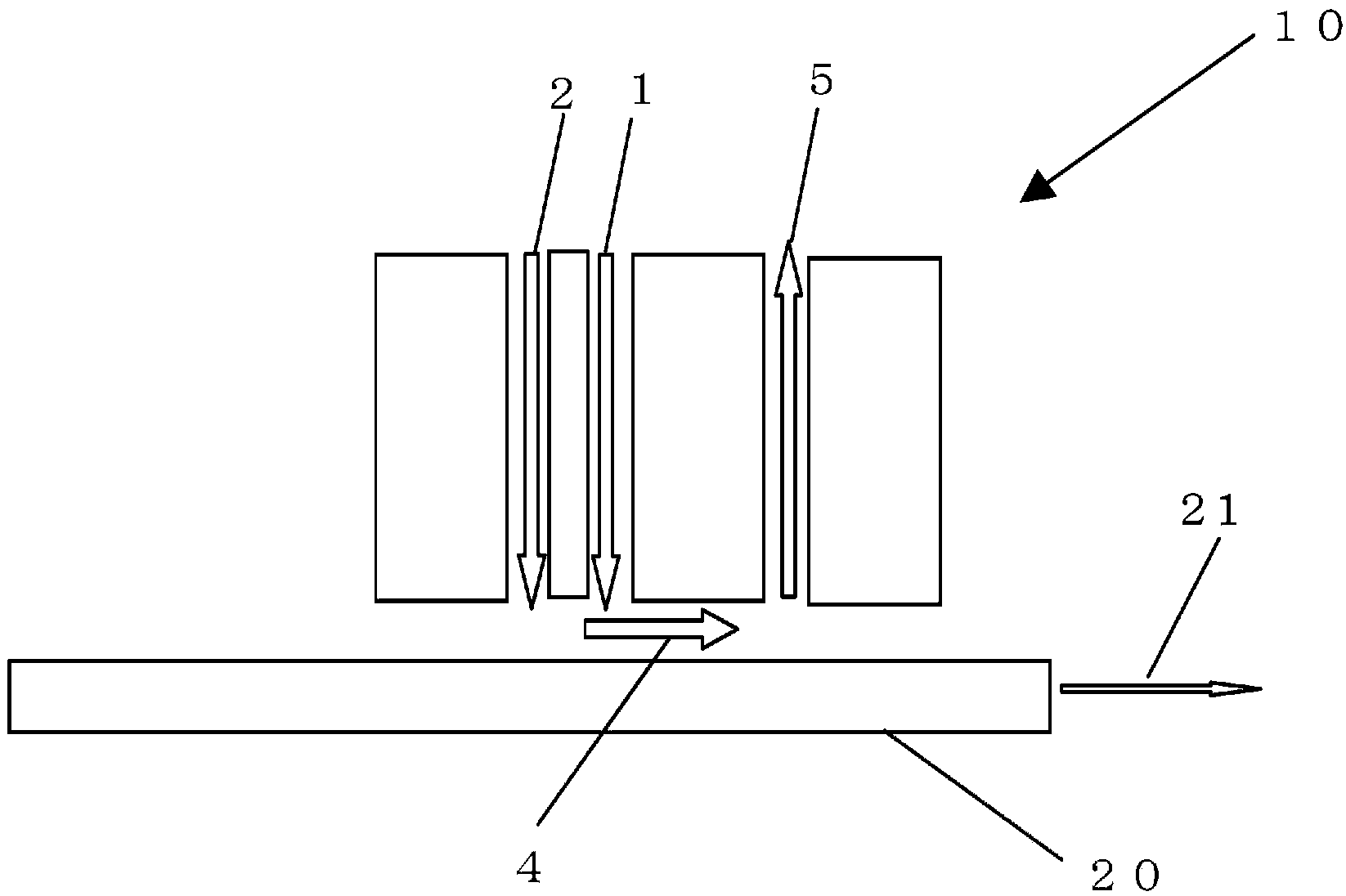

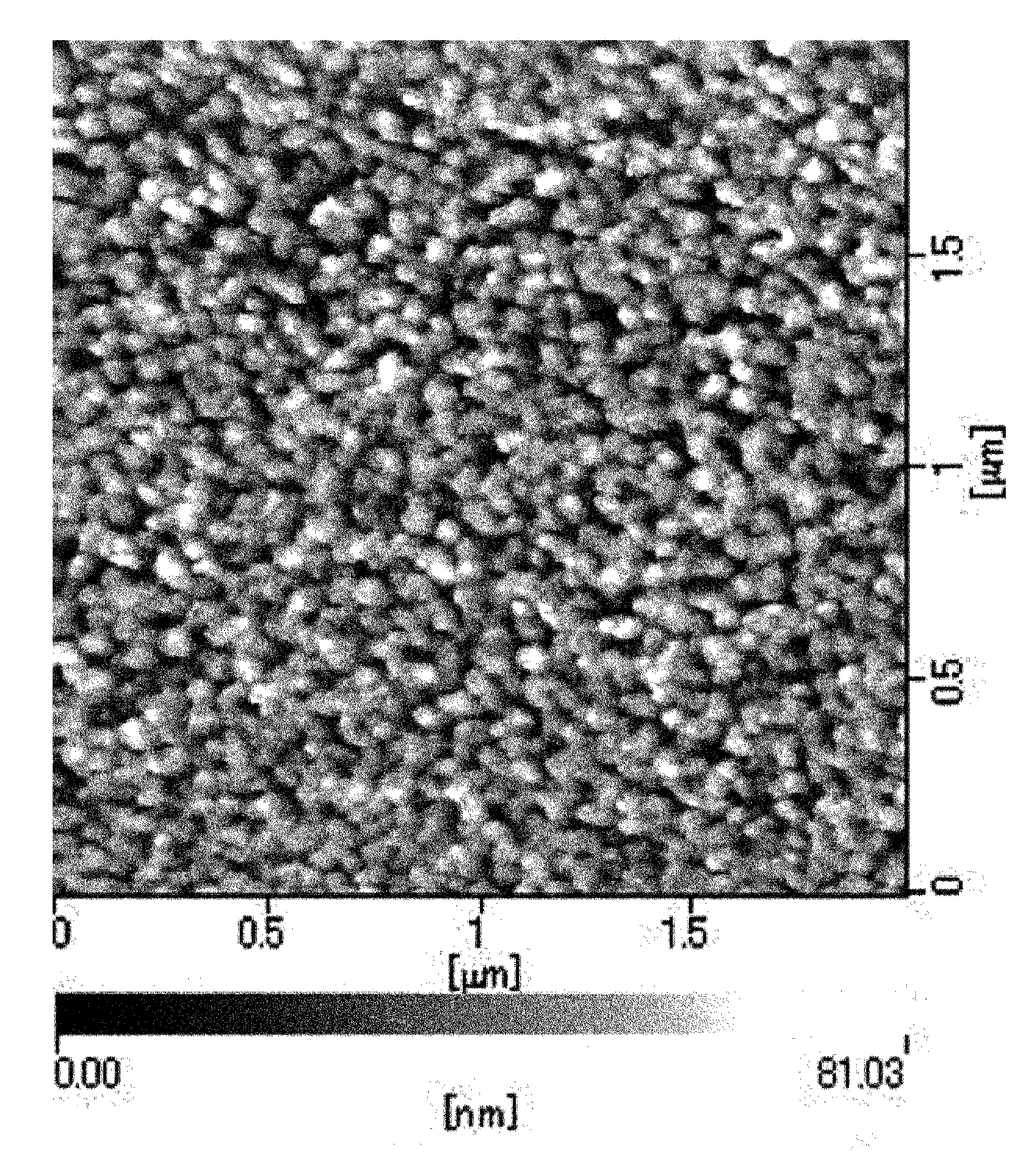

Method for producing surface-treated glass substrate

The present invention efficiently obtains in a short period of time a glass substrate having a low refraction index layer exhibiting excellent properties in which the refraction index is low. A glass substrate is produced by subjecting at least one surface of a glass substrate, that is being conveyed when the temperature of the glass substrate is within 400°C and Tg+60°C (Tg being the glass transition temperature of the glass substrate), to surface treatment by bringing the glass substrate into contact with liquid or gas containing molecules having fluorine atoms in the structure thereof.

Owner:ASAHI GLASS CO LTD

Protection method for avoiding collision of cutting head

ActiveCN109048092AValid settingsDetermine the detection distanceLaser beam welding apparatusMotor driveResponse delay

The invention discloses a protection method for avoiding collision of a cutting head. The protection method comprises the following steps that firstly, the side of the cutting head is provided with asensor, and the sensor is in communication connection with a servo motor driving the cutting head; secondly, the maximum movement speed of the cutting head is acquired, the maximum response delay timeof the servo motor is acquired, and the minimum sensing safety distance of the sensor is worked out according to a following formula; and thirdly, the sensor is started and detects a barrier in frontof the cutting head when the cutting head moves. According to the protection method for avoiding collision of the cutting head, by means of the arrangement of the first step, the second step and thethird step, the purpose that the cutting head is provided with the sensor, then, the servo motor is stopped in time after the senor senses the barrier, and the problem that the cutting head collides with the barrier and consequently the cutting head is damaged is avoided can be effectively achieved.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

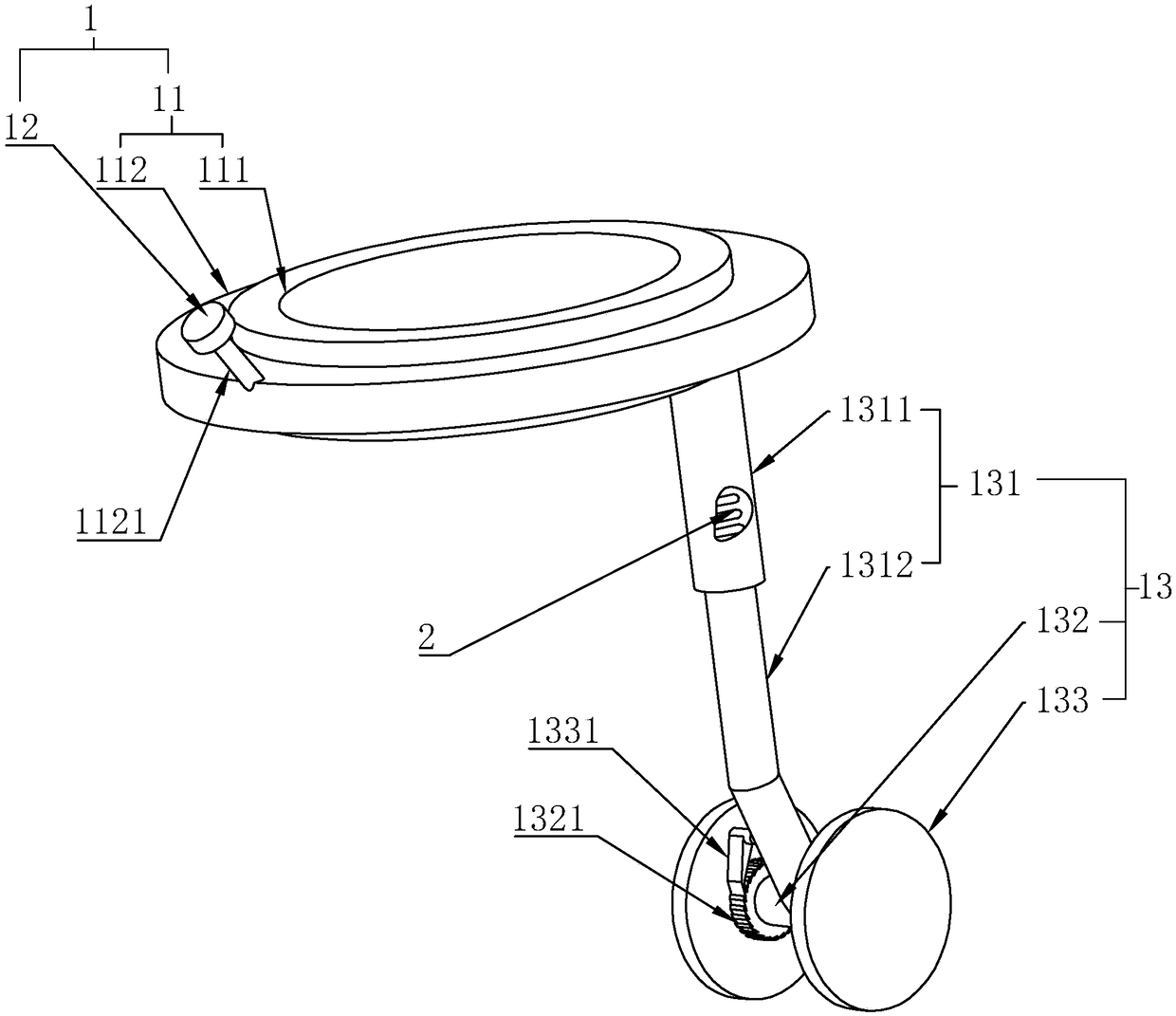

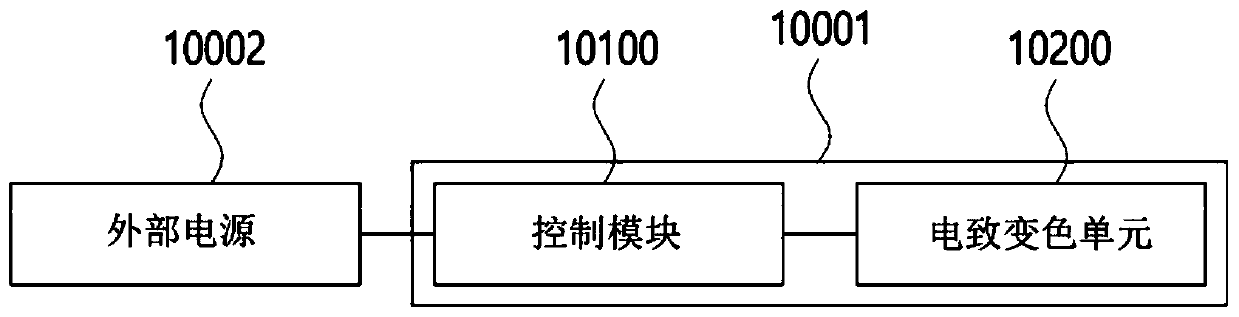

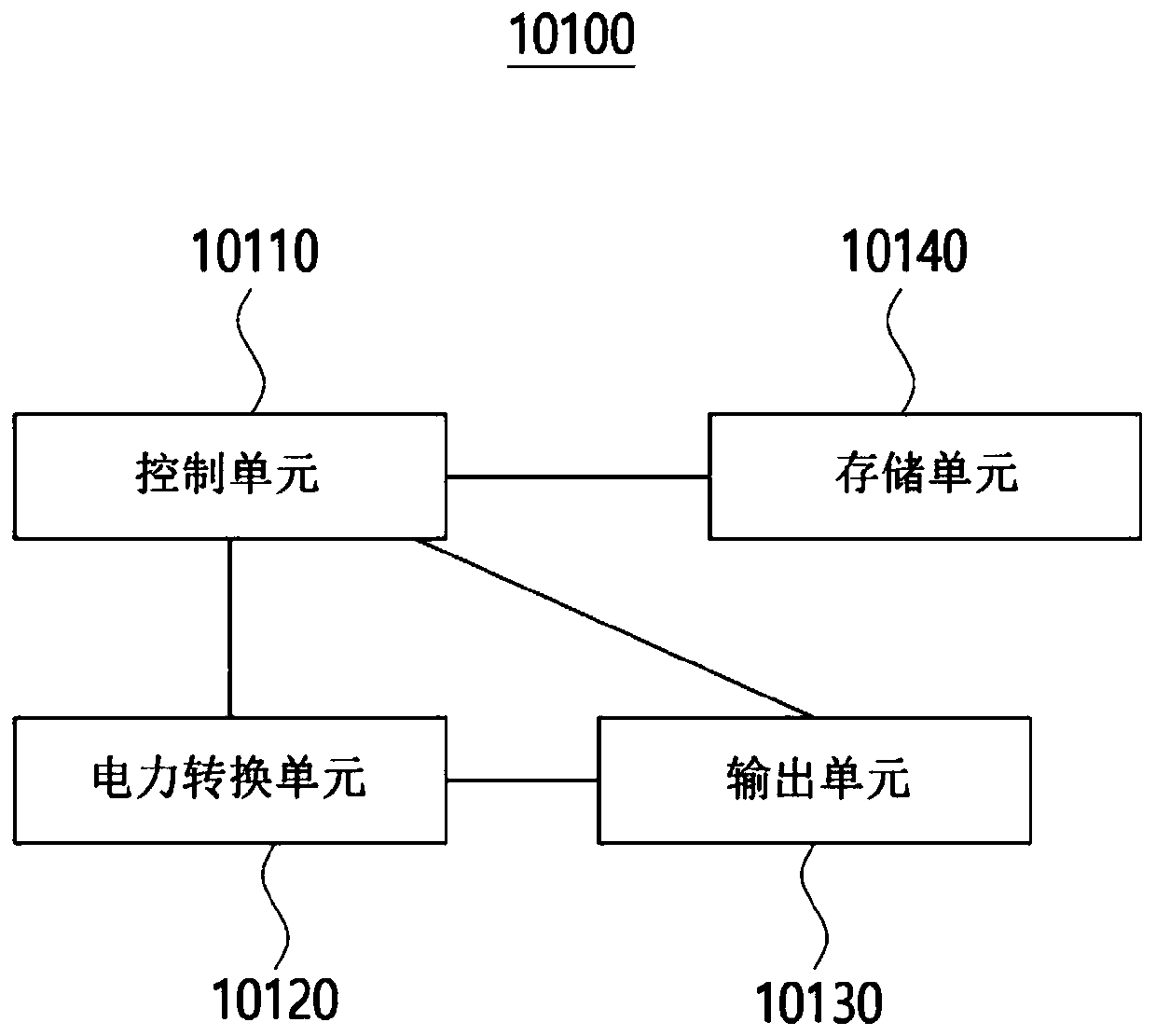

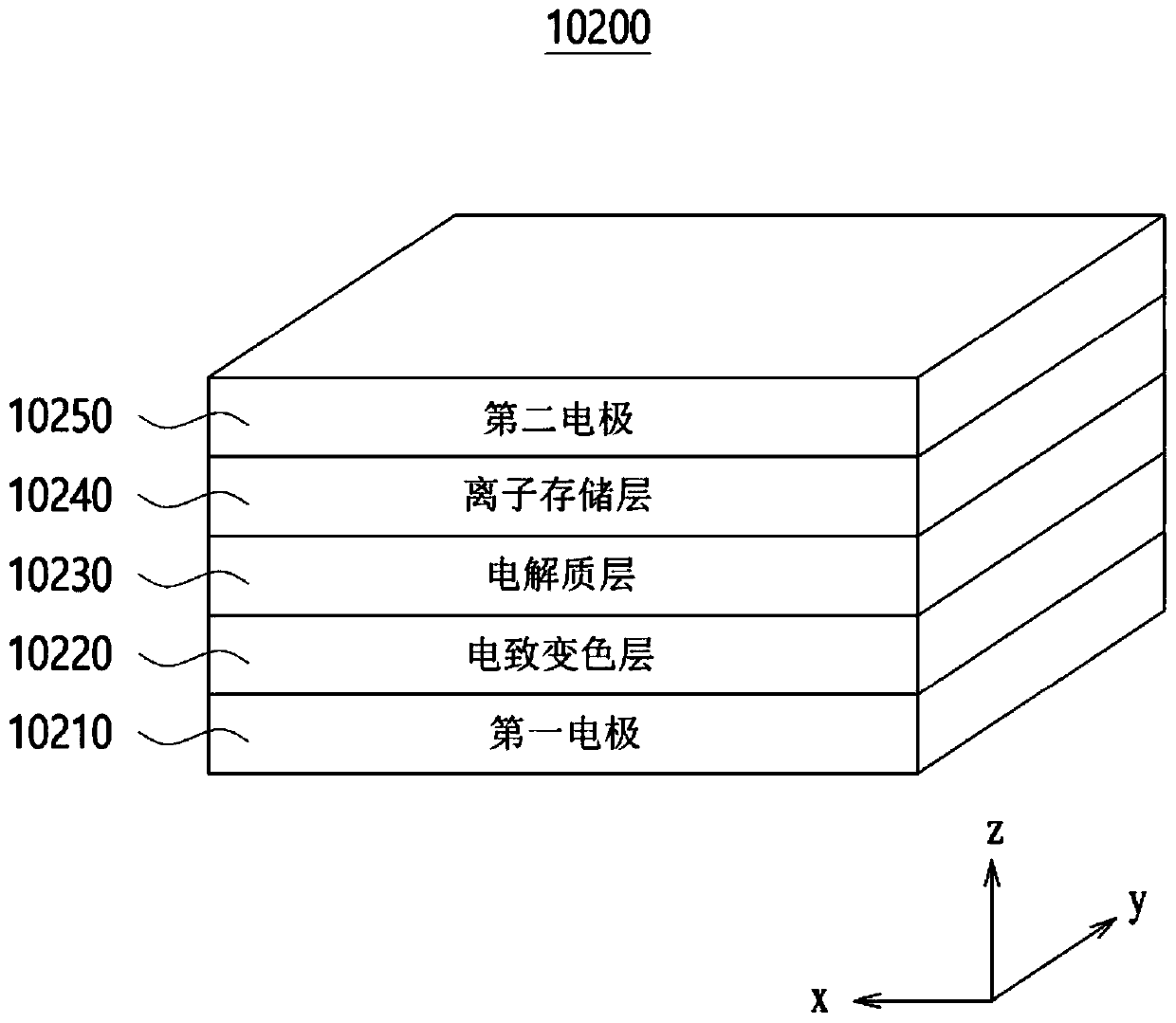

Electrochromic element and electrochromic device including same

ActiveCN110383163AReduces discoloration changesReduce power consumptionStatic indicating devicesSteering linkagesEngineering physicsMaterials science

An embodiment of the present application provides an electrochromic device comprising an electrochromic element, wherein the electrochromic element enters a second state when a first voltage is applied to the electrochromic element in a state where the electrochromic element has a first state, and the electrochromic element enters a third state when the first voltage is applied to the electrochromic element in a state where the electrochromic element has a fourth state.

Owner:LEAPHIGH INC

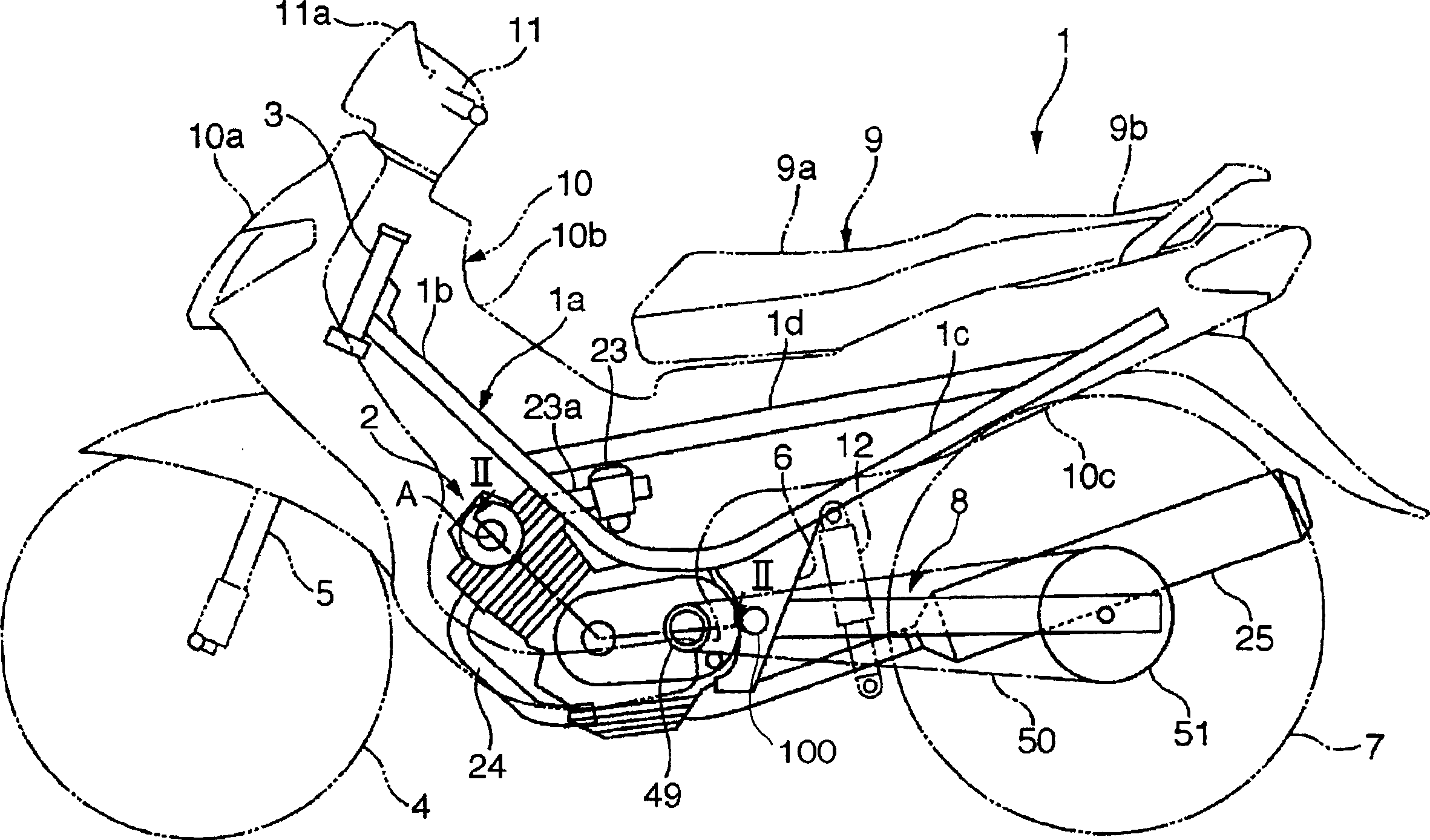

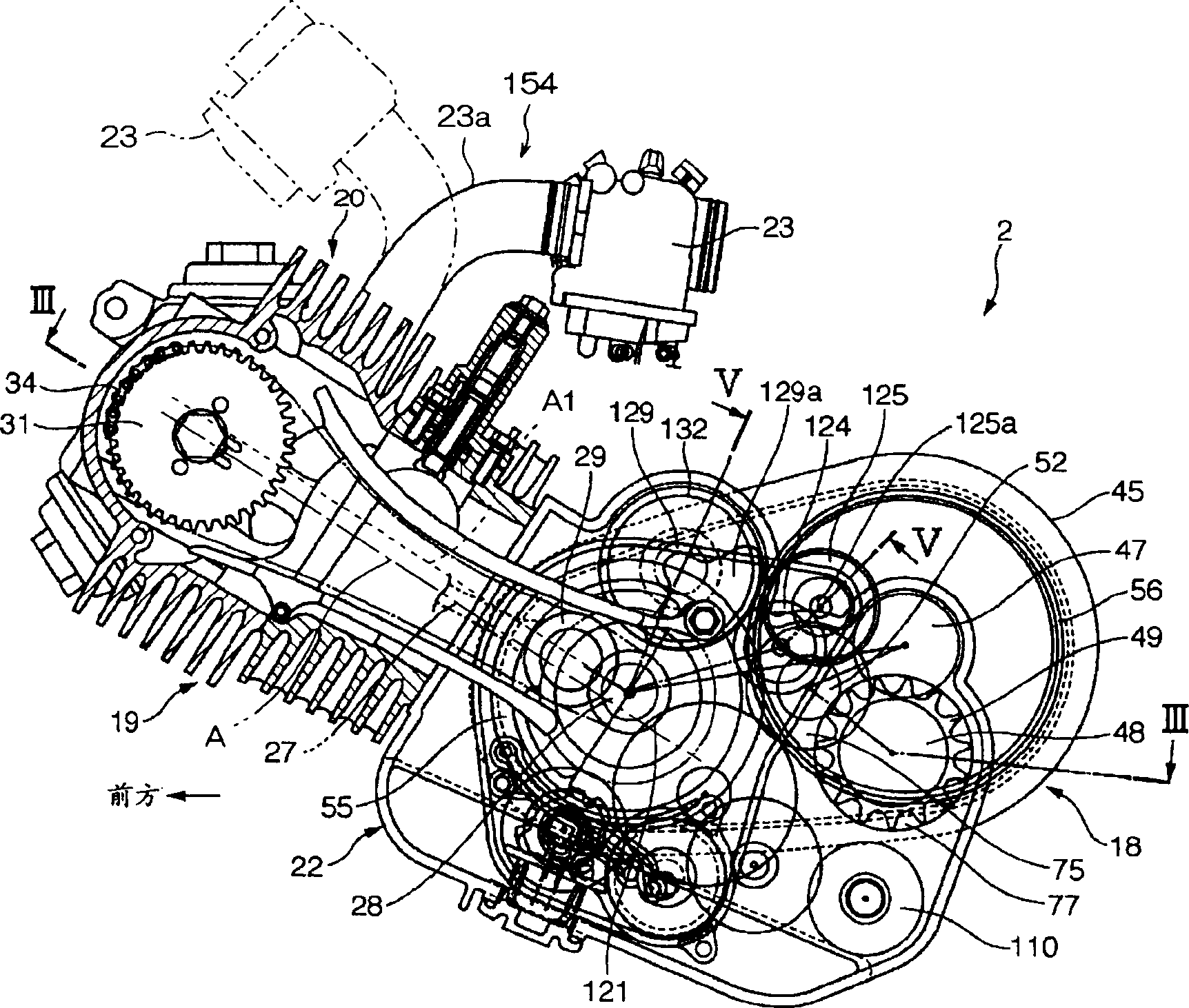

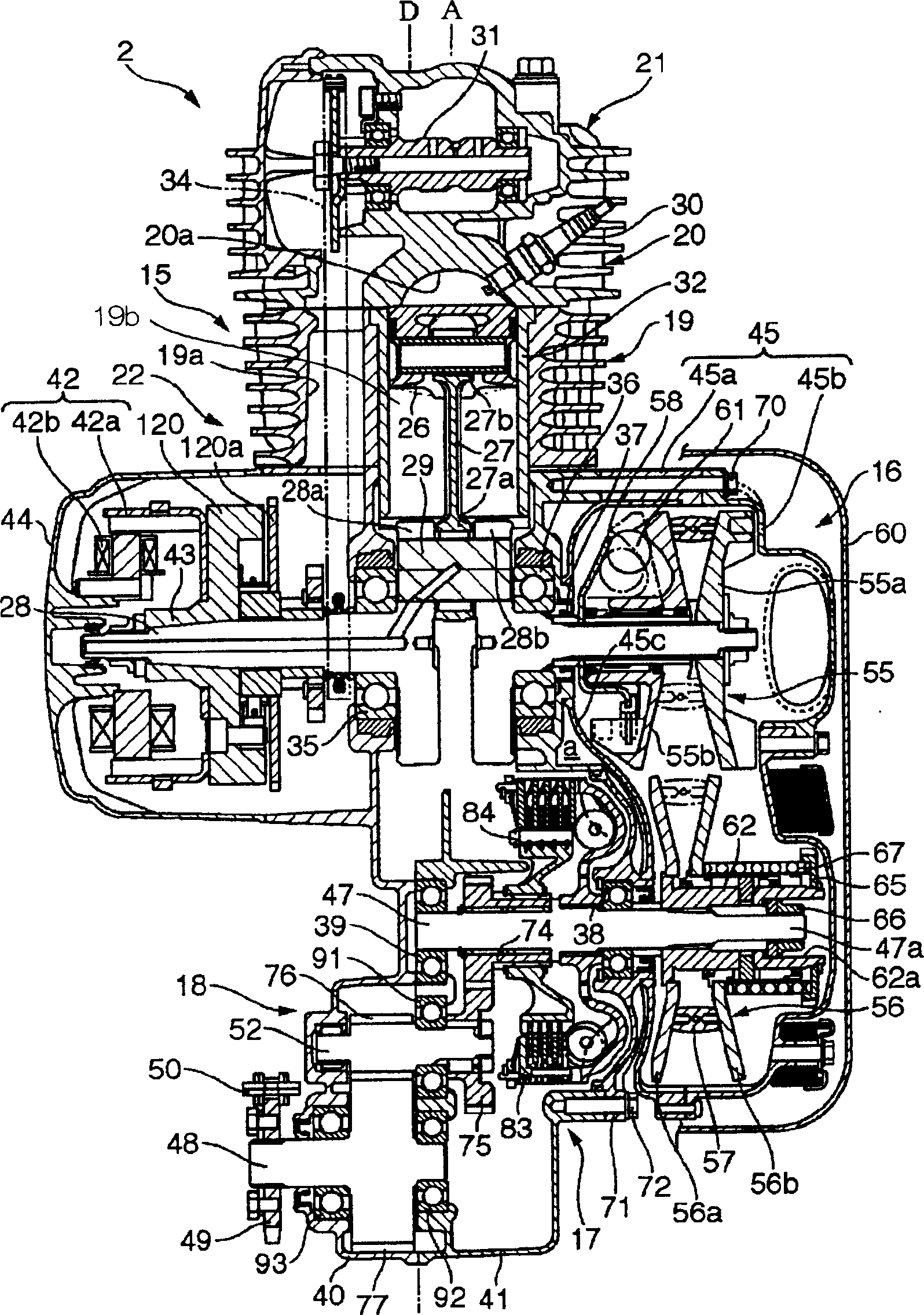

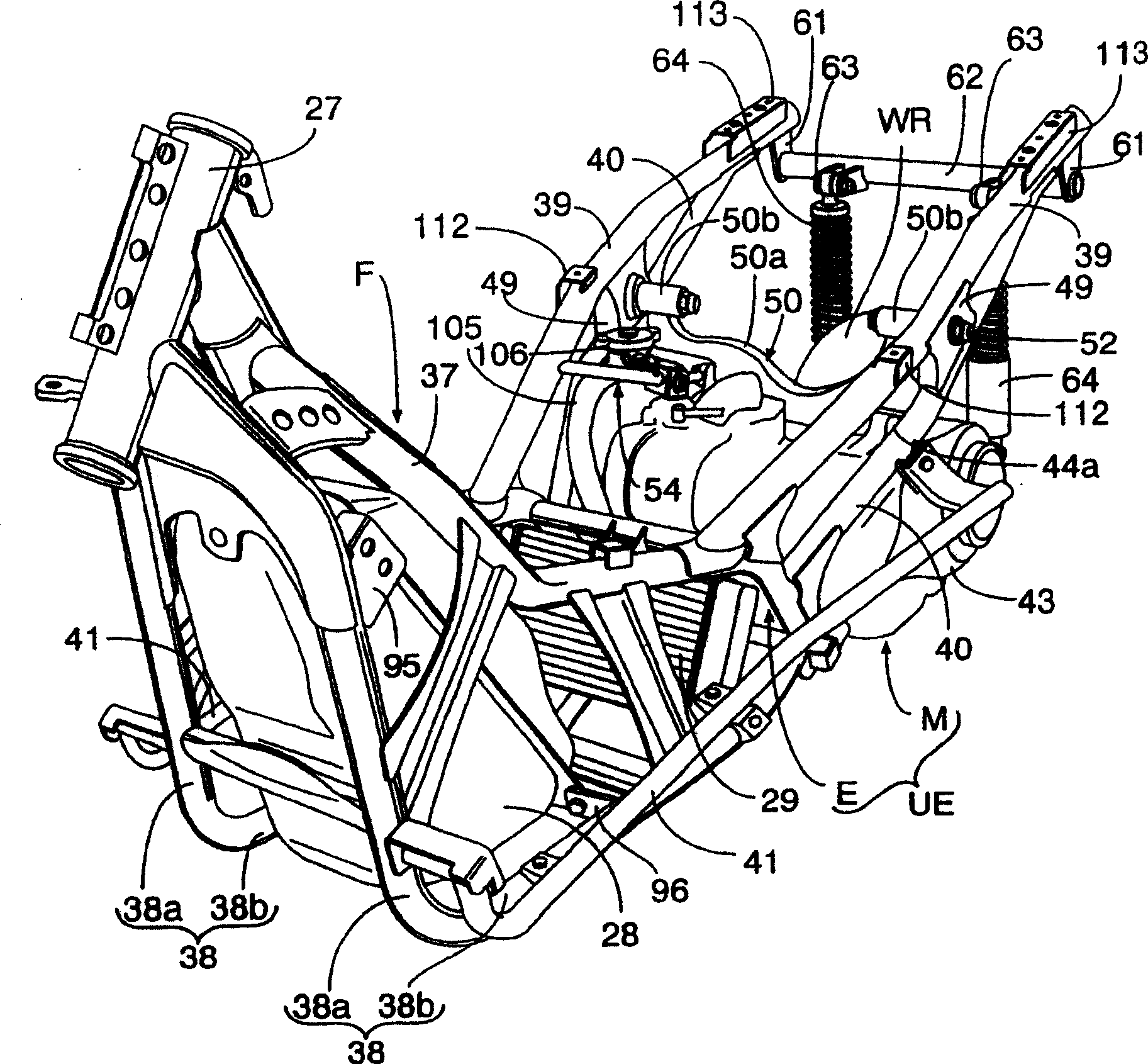

Engine for saddle riding-type vehicle and saddle riding-type vehicle with the same

ActiveCN1871417AIncrease freedomAvoid interferenceCasingsChain/belt transmissionAutomatic transmissionDrive shaft

An engine has components and devices such as a cylinder block (19) inside which a cylinder is formed, a crankshaft (28), a drive shaft (48), an automatic speed changer, and a balancer weight (129a). The automatic speed changer has a primary sheave, a secondary sheave, and a V-belt carried on the primary sheave and the secondary sheave. The automatic speed changer is received in a speed changer case (45). In a side view, the axis (C) of the crankshaft (28) is offset upward from the center line (A) of the cylinder.

Owner:YAMAHA MOTOR CO LTD

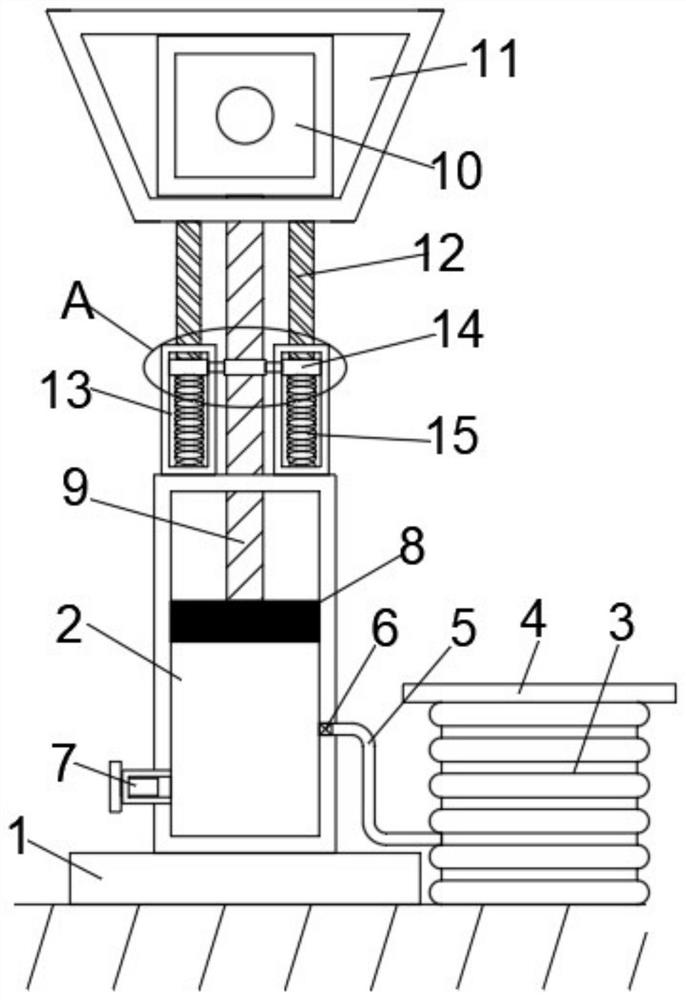

Monitoring device for information collection of sewage treatment system

InactiveCN112303407AShort stayAvoid pollutionTelevision system detailsColor television detailsWater treatment systemSewage

The invention discloses a monitoring device for information collection of a sewage treatment system. The monitoring device comprises a base arranged on the ground, a fixed seat is fixedly arranged onthe base, an airbag pipe is fixedly arranged on one side of the base, the airbag pipe is also fixedly arranged on the ground, a pedal plate is fixedly arranged at the upper end of the airbag tube, thelower end of the air bag pipe communicates with a ventilation pipe, the other end of the ventilation pipe is arranged on the side wall of the fixed seat in a communicated mode, a one-way valve is fixedly arranged at the end, on the side wall of the fixed seat, of the ventilation pipe, the one-way valve is arranged towards the interior of the fixed seat, a vent hole is further formed in the side wall of the fixed seat, and a piston is slidably arranged in the fixed seat. According to the monitoring device, the height of the monitoring device can be conveniently adjusted by pedaling for inflating, so that a worker does not need to work beside the sewage pool for a long time and does not need to touch the polluted monitoring equipment on the surface beside the sewage pool with hands.

Owner:南京东南博康环境科技有限公司 +1

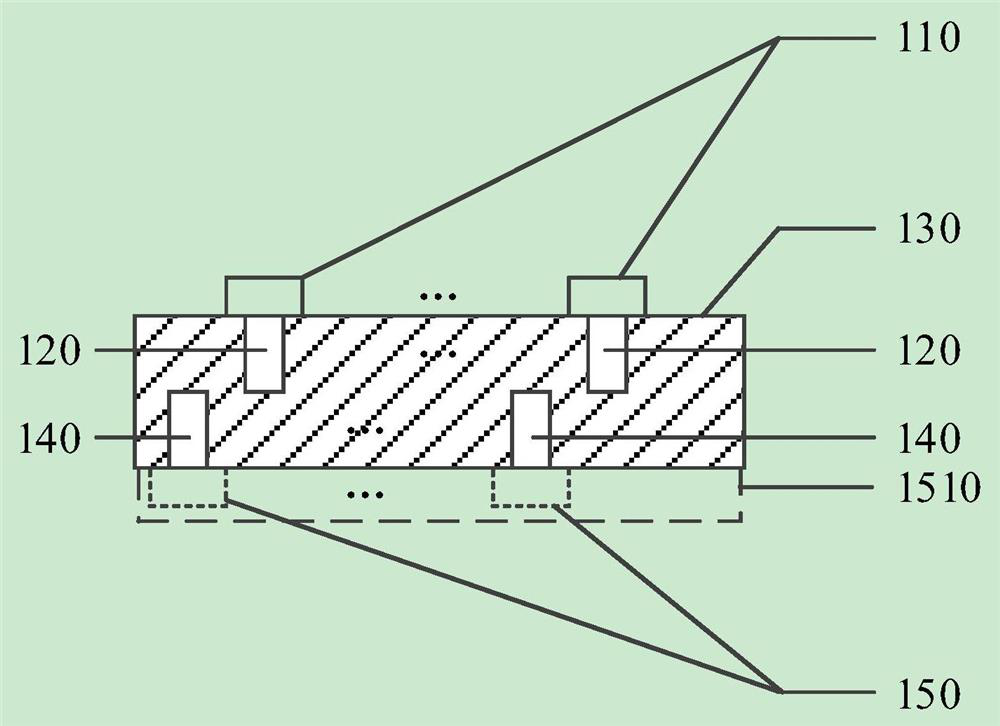

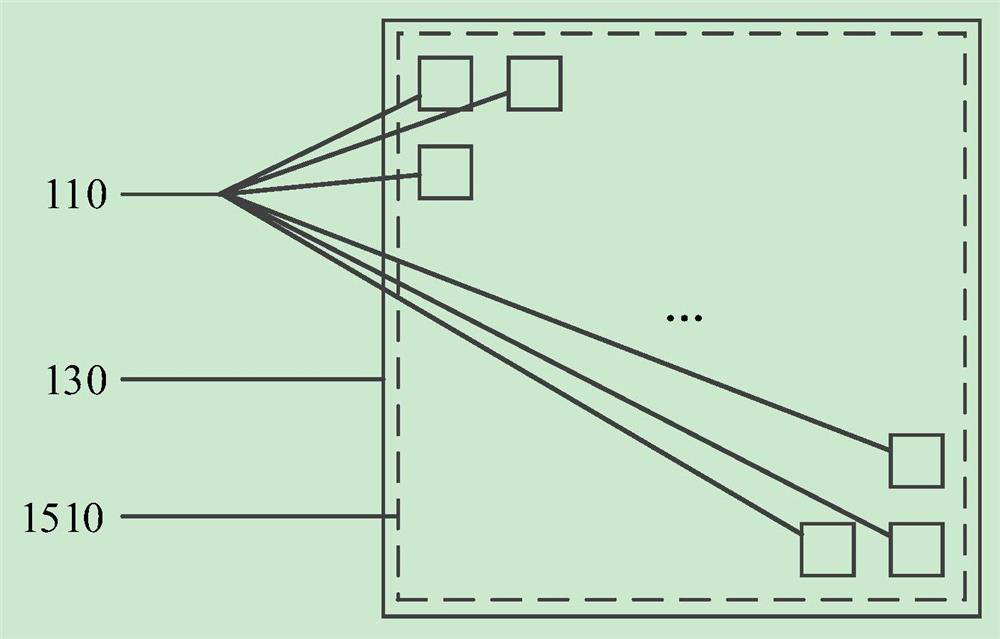

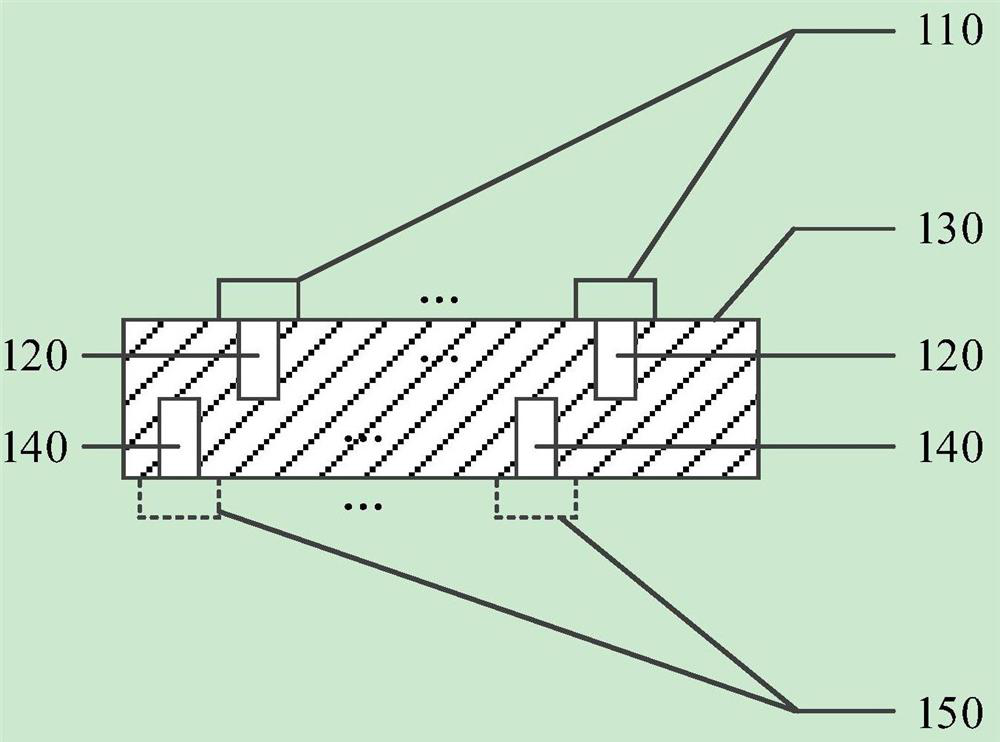

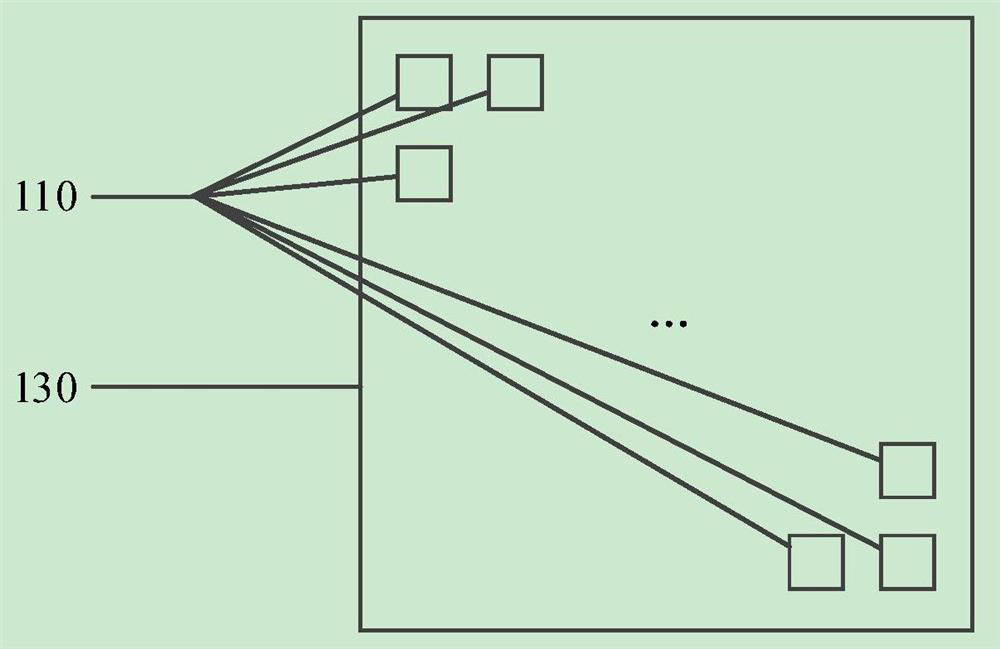

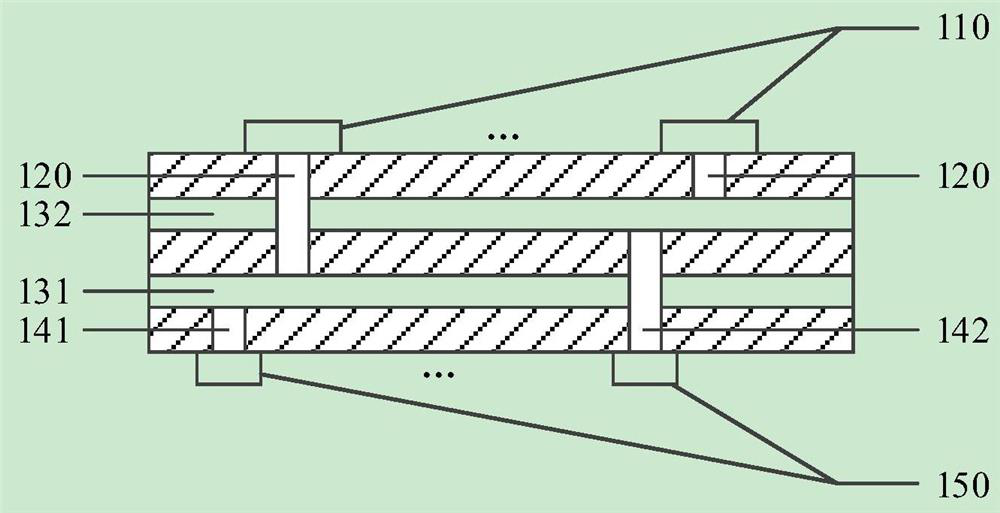

Terminal connection structure, display unit and display

PendingCN113496971AValid settingsSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceElectrical connection

The invention relates to the technical field of display, and discloses a terminal connection structure, which comprises a plurality of terminals, a plurality of terminal side conductive holes, an electric connection layer and a plurality of light-emitting device side conductive holes, wherein the electrical connection layer can be electrically connected with the plurality of light-emitting devices in the light-emitting device layer through the plurality of light-emitting device side conductive holes, and can be electrically connected with the plurality of terminals through the plurality of terminal side conductive holes; the plurality of terminals are arranged in an array and do not exceed the coverage range of the light-emitting device layer. According to the terminal connection structure, even if the size of the light-emitting device is very small, the terminals used for leading wires from the light-emitting device can be effectively arranged. The invention further discloses a display unit and a display.

Owner:BEIJING IVISUAL 3D TECH CO LTD +2

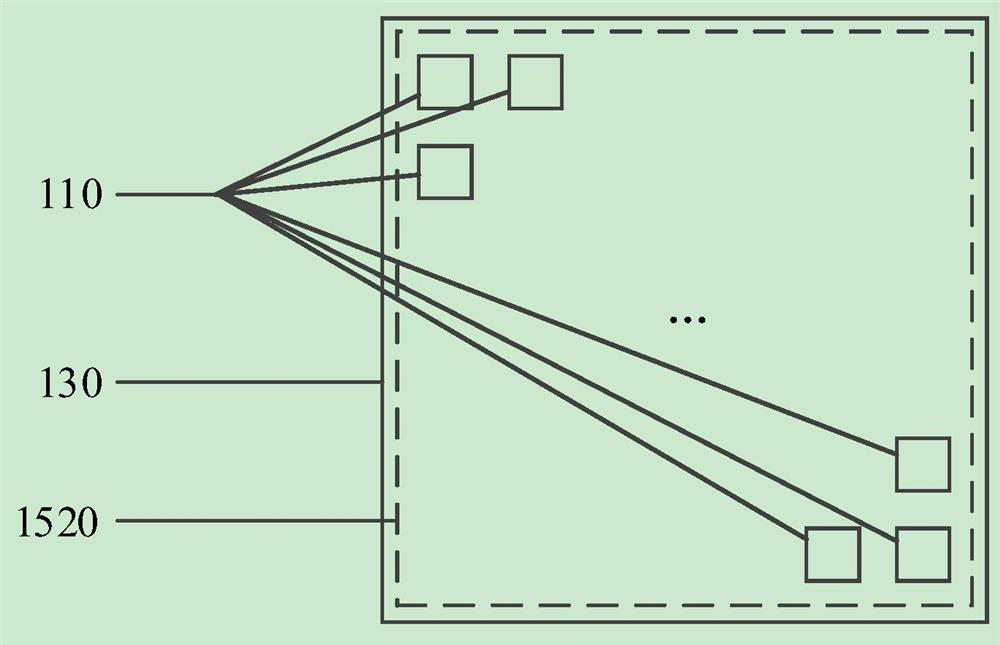

Terminal connection structure, display unit and display

PendingCN113496973AValid settingsSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceElectrical connection

The invention relates to the technical field of display, and discloses a terminal connection structure, which comprises a plurality of terminals, a plurality of terminal side conductive holes, an electric connection layer and a plurality of light-emitting device side conductive holes. The electrical connection layer can be electrically connected with the plurality of light emitting devices through the plurality of light emitting device side conductive holes, and can be electrically connected with the plurality of terminals through the plurality of terminal side conductive holes; the plurality of terminals are arranged in an array. According to the terminal connection structure, even if the size of the light-emitting device is very small, the terminal used for leading wires from the light-emitting device can be effectively arranged. The invention further discloses a display unit and a display.

Owner:BEIJING IVISUAL 3D TECH CO LTD +2

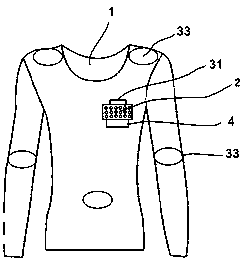

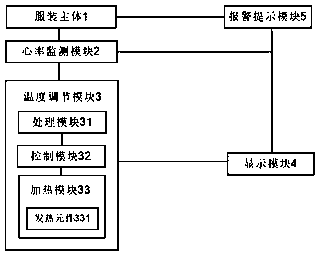

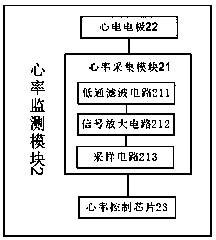

Heart rate adjusting clothes and control method thereof

The invention discloses heart rate adjusting clothes. The clothes comprises a clothes body, a heart rate monitoring module and a temperature adjusting module, wherein the heart rate monitoring moduleis arranged on the chest position of the clothes body and is used for detecting heart rate data in real time when a user wears the clothes; the temperature adjusting module is connected with the heartrate monitoring module and comprises a processing module, a control module and a heating module, and the processing module, the control module and the heating module are successively connected in order. The processing module analyzes heart rate data of the heart rate monitoring module to generate a heart rate change analyzing result; the control module outputs temperature control data according to the heart rate change analyzing result; the heating module adjusts the heating temperature according to the temperature control data; the heart rate monitoring module monitors the real-time heart rate of a user to make the heart rate application be timely and accurate; the temperature adjusting module makes heating control of the clothes be safe and effective according to the real-time heart rate monitoring of the corresponding clothes heating temperature.

Owner:泉州市加达智能科技有限公司

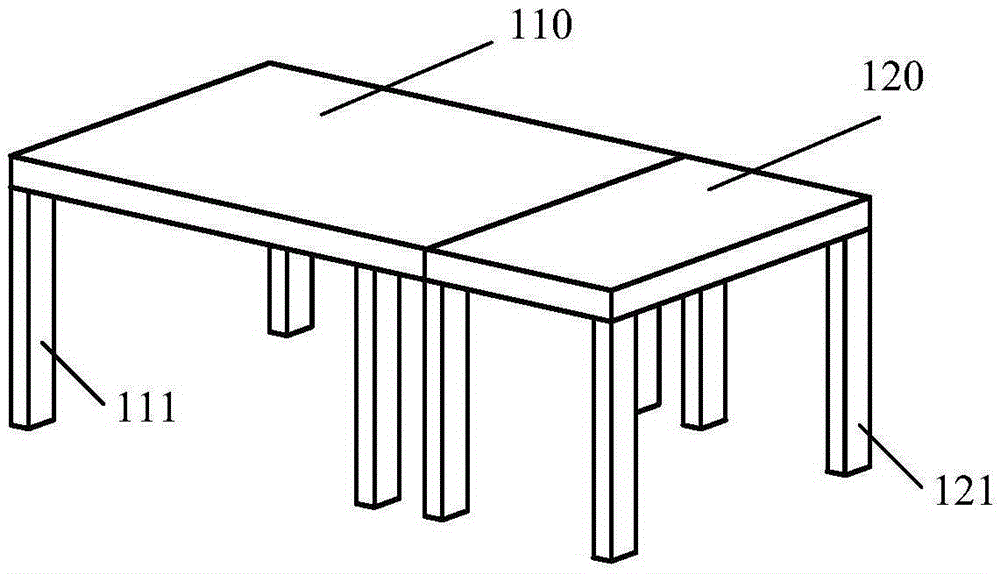

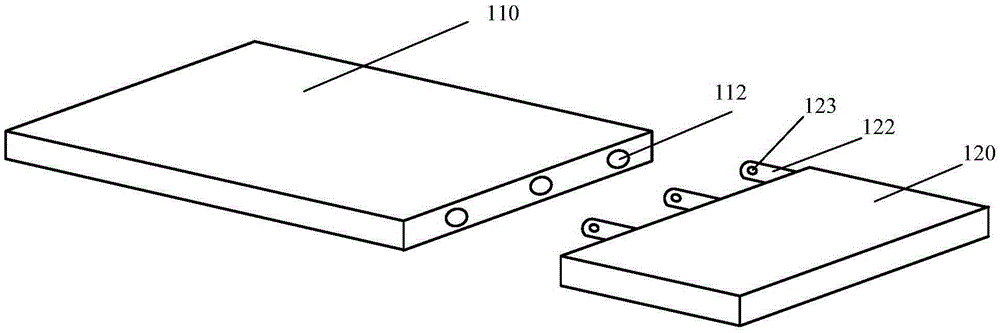

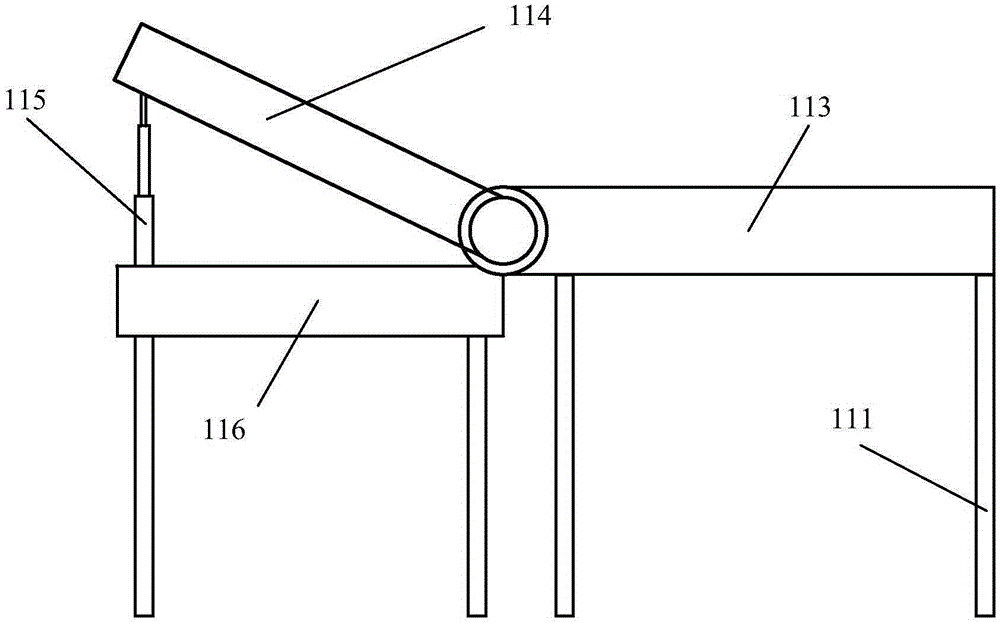

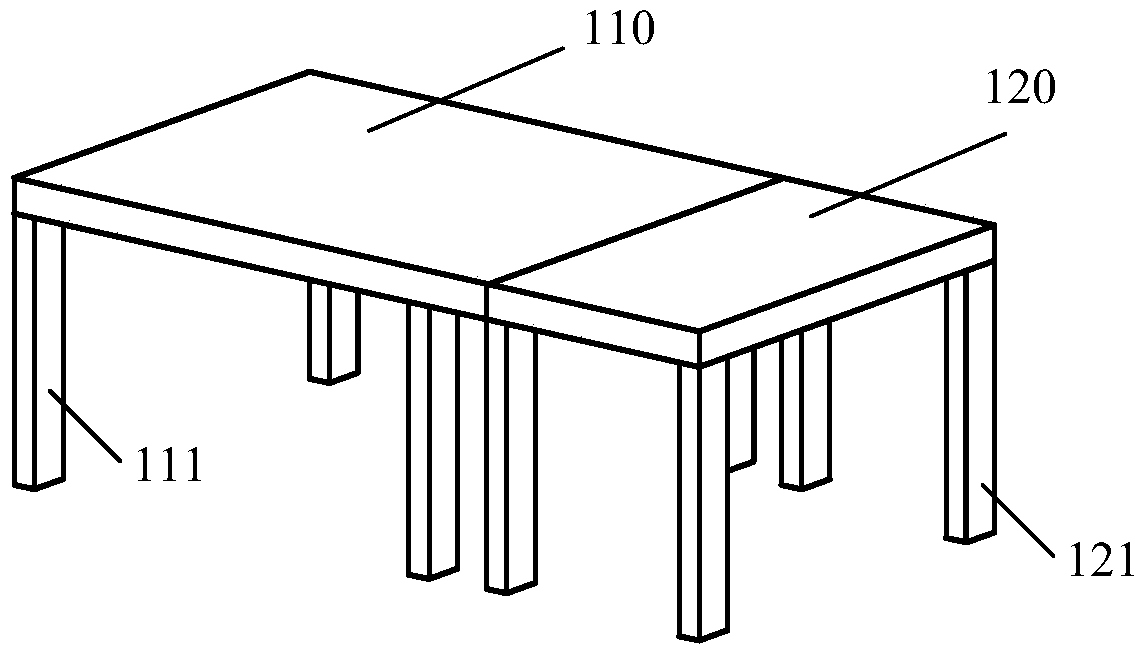

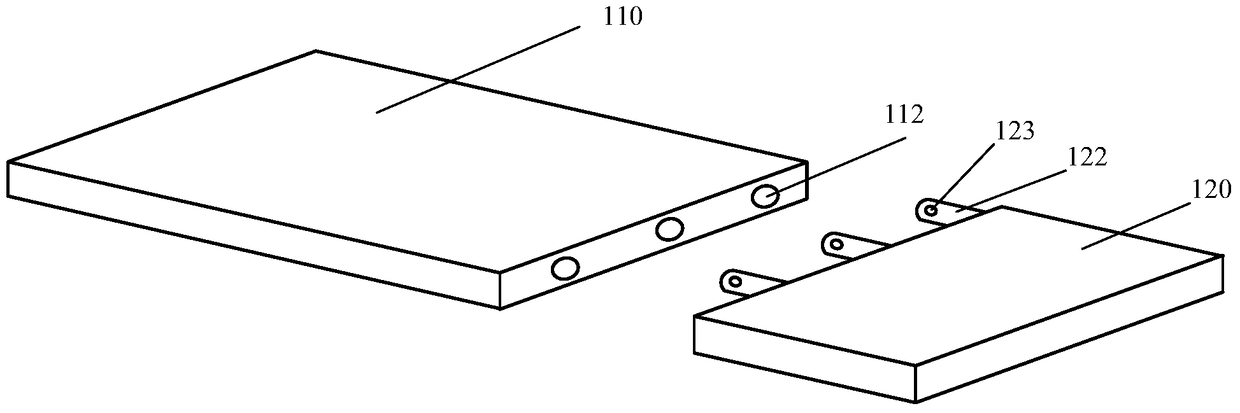

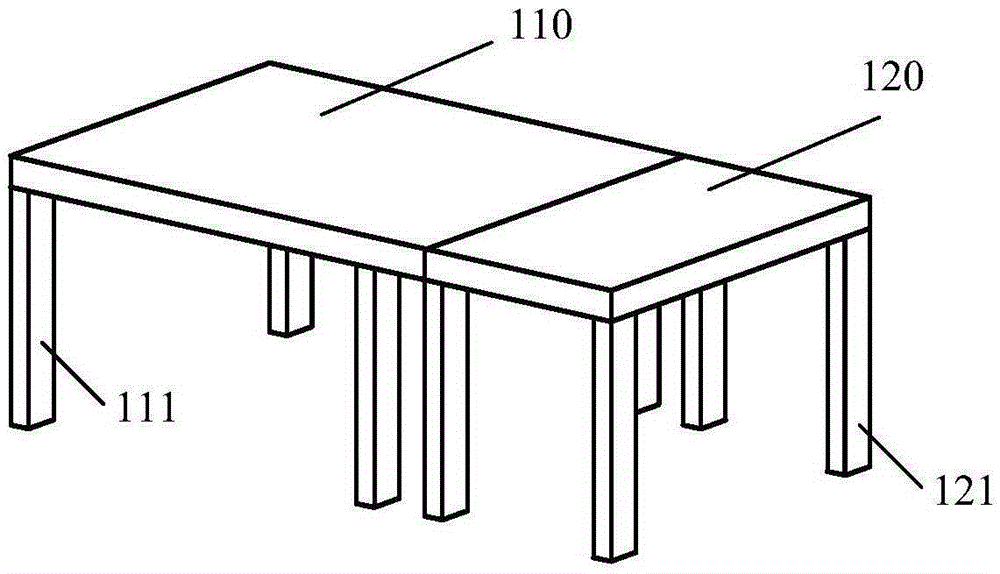

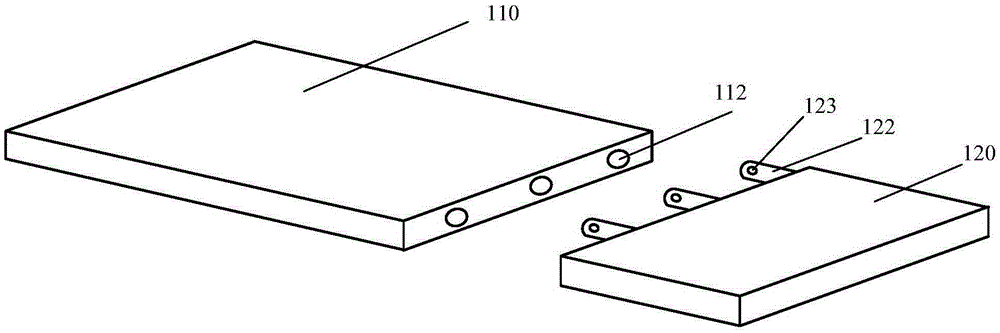

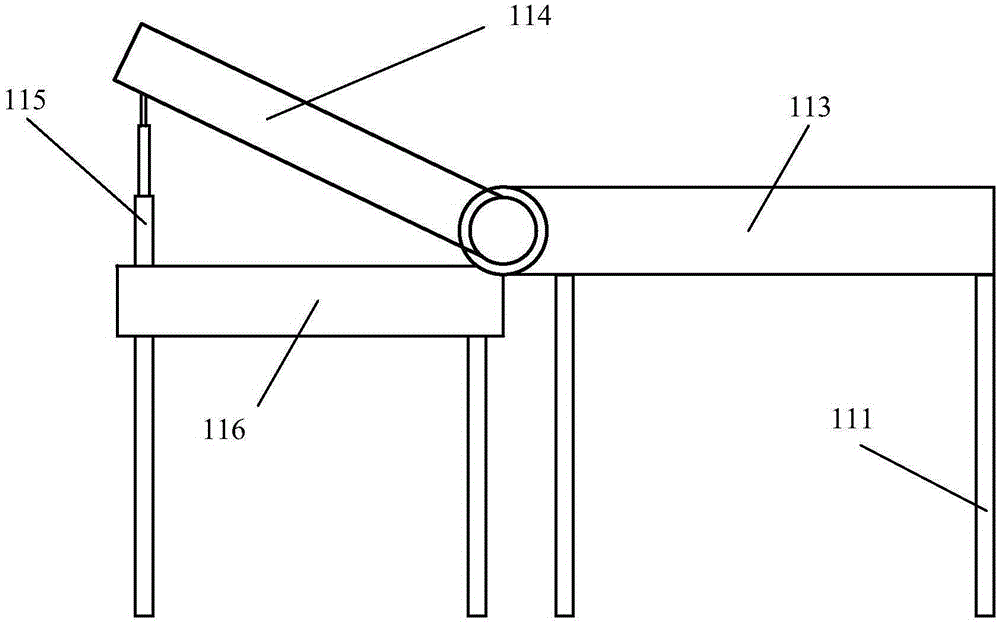

Nursing bed

ActiveCN105287133AOptimize and adjust the structureValid settingsNursing bedsAmbulance serviceEngineeringFixed position

The invention discloses a nursing bed. The nursing bed comprises a bed body. The bed body is provided with a fixed part and a movable part. The movable part is arranged on the fixed part in a separable mode. The fixed part is provided with at least one fixing position used for fixing the movable part. Due to the adoption of the scheme and the design of the fixed part and the movable part, the structure which gives users certain movement freedom and is effectively provided with a sickbed and the structure for conveniently adjusting the sickbed are obtained, the technical effect that the users can move a part of the sickbed by themselves and other technical effects are achieved, certain assistance for free movement is given to the users, and the nursing bed is particularly suitable for users of the rehabilitative period or users with available hands.

Owner:铜陵顺光电子信息技术有限公司

nursing device

ActiveCN105287134BSuitable for useOptimize and adjust the structureWheelchairs/patient conveyanceNursing bedsWheelchairFixed position

The invention discloses a nursing device. The nursing device comprises a bed body. The bed body is provided with a fixed part and a movable part. The movable part is arranged on the fixed part in a separable mode. The fixed part is provided with at least one fixing position used for fixing the movable part. A wheelchair serves as the movable part and comprises a backrest part and a seat part connected with the backrest part. A hook is arranged on the backrest part and connected with one fixing position in a hung mode.

Owner:JIANGSU XINLEI MALT

Adjustable nursing bed

ActiveCN105287132AOptimize and adjust the structureValid settingsNursing bedsAmbulance serviceEngineeringControl theory

The invention discloses an adjustable nursing bed. The adjustable nursing bed comprises a bed body which is provided with a fixed portion and a moving portion, the moving portion is detachably arranged on the fixed portion, and multiple second support parts are arranged on the moving portion; one or more fixing positions are arranged on the fixed portion and used for fixing the moving portion, and multiple first support parts are further arranged on the fixed portion; an electrically controlled adjusting portion is arranged on each support part, a height adjusting controller is arranged on the bed body, and the height adjusting controller is used by all the electrically controlled adjusting portions which are used for adjusting the heights of all the support parts under the control of the height adjusting controller.

Owner:徐州坤鹏医疗器械有限公司

Antifreeze and anti-mouse warning cable

InactiveCN105529099ASimple and reasonable structureEasy access to cablesInsulated cablesPower cablesEngineeringElectrical conductor

The invention discloses an antifreeze and anti-mouse warning cable, comprising a conductor, an insulating layer, a first heat conducting layer, a heating layer, a second heat conducting layer, a flame retardant layer, a sheath, capsule particles, an outer sheath, a reflective stripe and a luminous line, wherein the insulating layer is extrusion wrapped at the outside of the conductor, the first heat conducting layer is extrusion wrapped at the outside of the insulating layer, the heating layer is extrusion wrapped at the outside of the first heat conducting layer, the second heat conducting layer is extrusion wrapped at the outside of the heating layer, the flame retardant layer is extrusion wrapped at the outside of the second heat conducting layer, the sheath is extrusion wrapped at the outside of the flame retardant layer, and the outer sheath is extrusion wrapped at the outside of the sheath. The antifreeze and anti-mouse warning cable disclosed by the invention has a simple and reasonable structure, and has the advantages of antifreeze and anti-mouse.

Owner:ANHUI RUIHAO CABLE

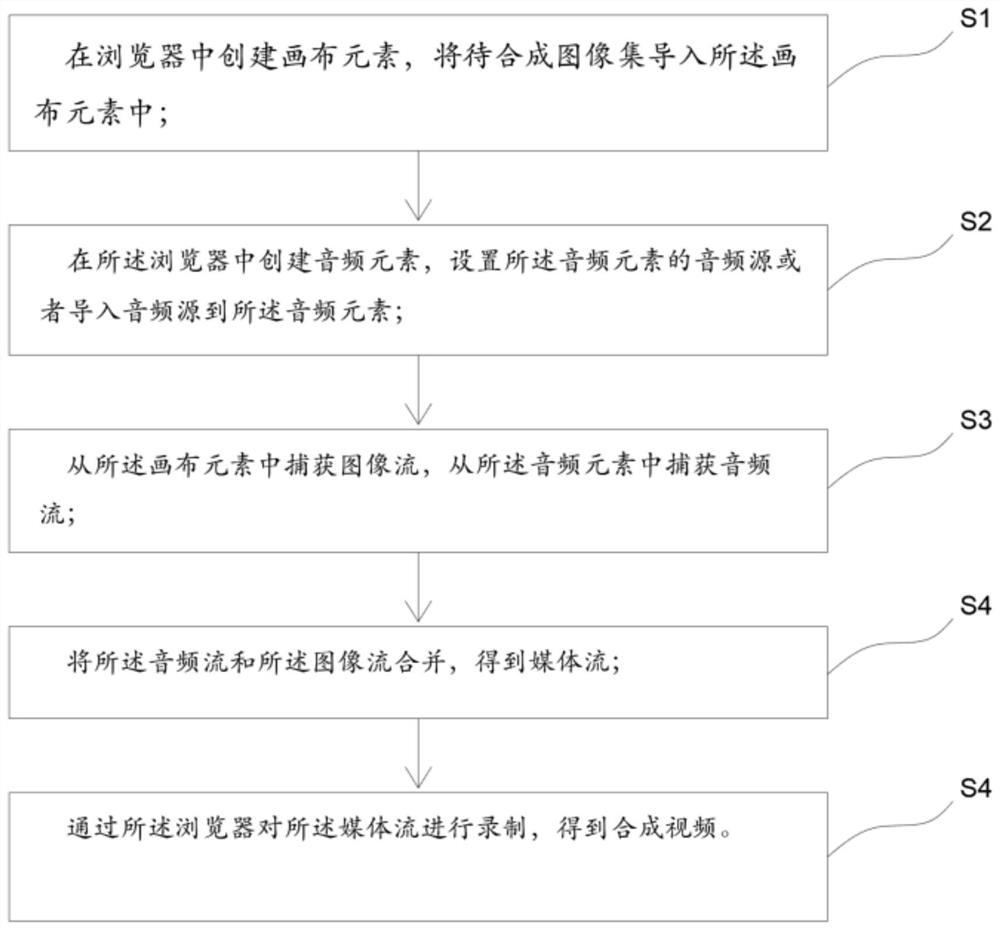

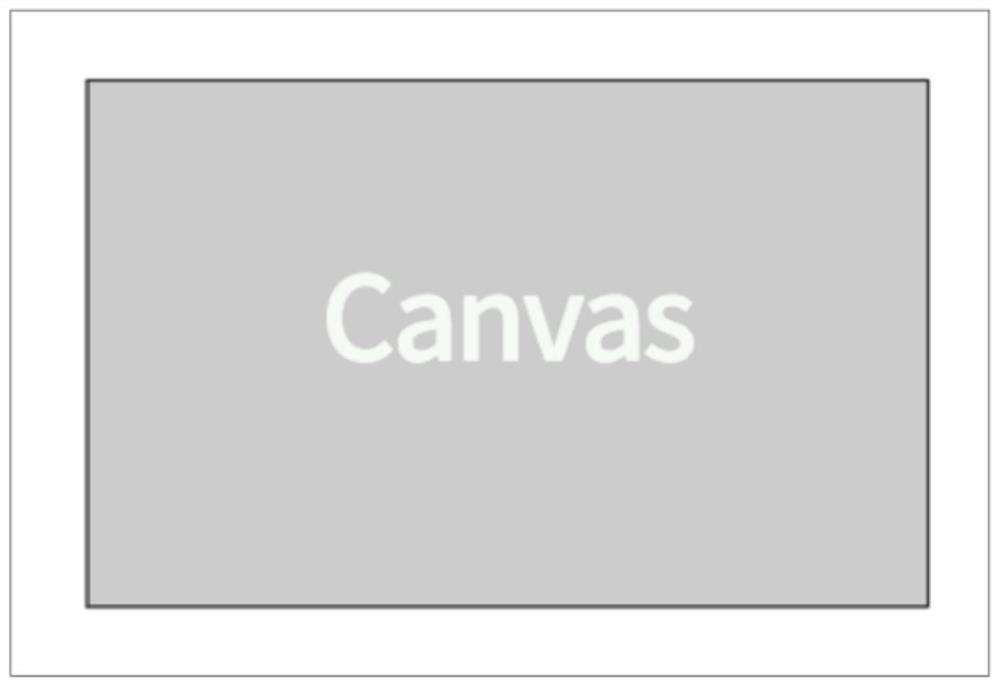

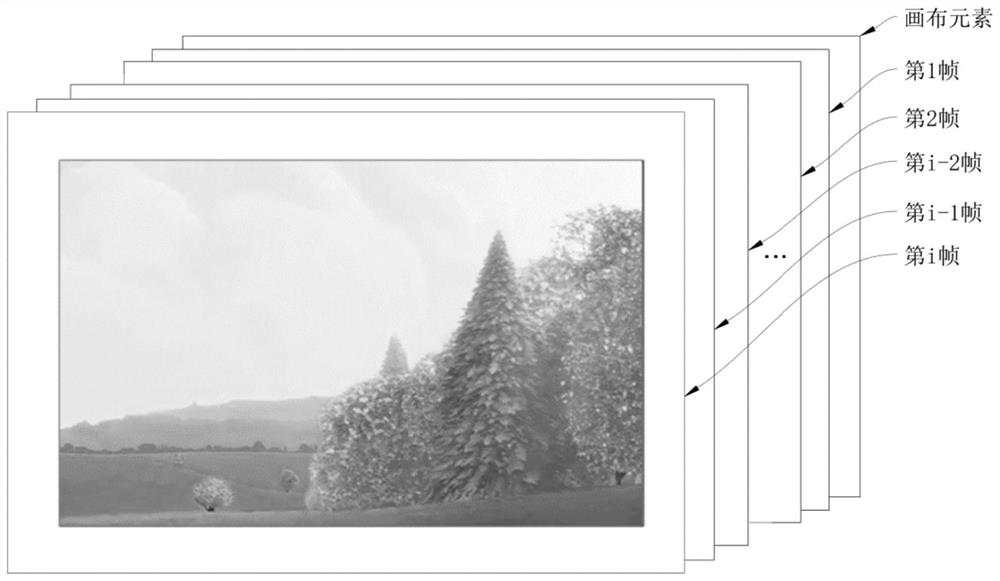

Browser-based video synthesis method and system and storage device

PendingCN113938619ASolve technical problems that cannot composite videoValid settingsTelevision system detailsColor television detailsComputer hardwareComputer graphics (images)

The invention relates to a browser-based video synthesis method and system, and a storage module, and the method comprises the following steps: creating canvas elements in a browser, and importing a to-be-synthesized image set into the canvas elements; creating an audio element in a browser, and setting an audio source of the audio element or importing the audio source into the audio element; capturing an image stream from the canvas element, and capturing an audio stream from the audio element; combining the audio stream and the image stream to obtain a media stream; and calling a recording function of a browser to record the media stream to obtain a synthesized video. According to the method and the device, the canvas elements are created, and the to-be-synthesized image set is imported into the canvas elements, so the images can be spliced into the video in the browser, and the audio can be obtained by creating the audio elements and obtaining the audio. And finally, the video and the audio are merged and imported into the recording function, so that the technical problem that the existing browser cannot synthesize the video is solved.

Owner:GAODING XIAMEN TECH CO LTD

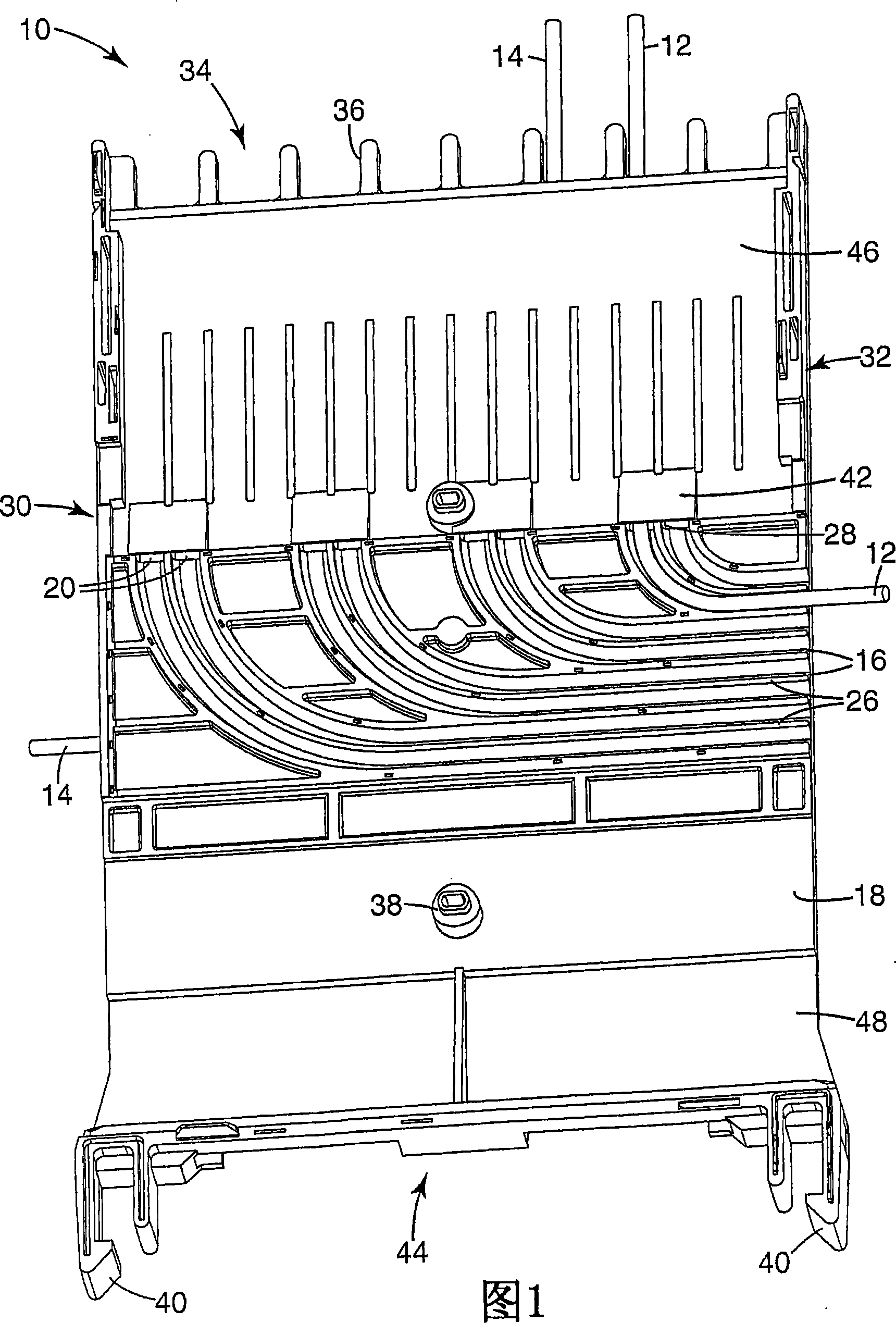

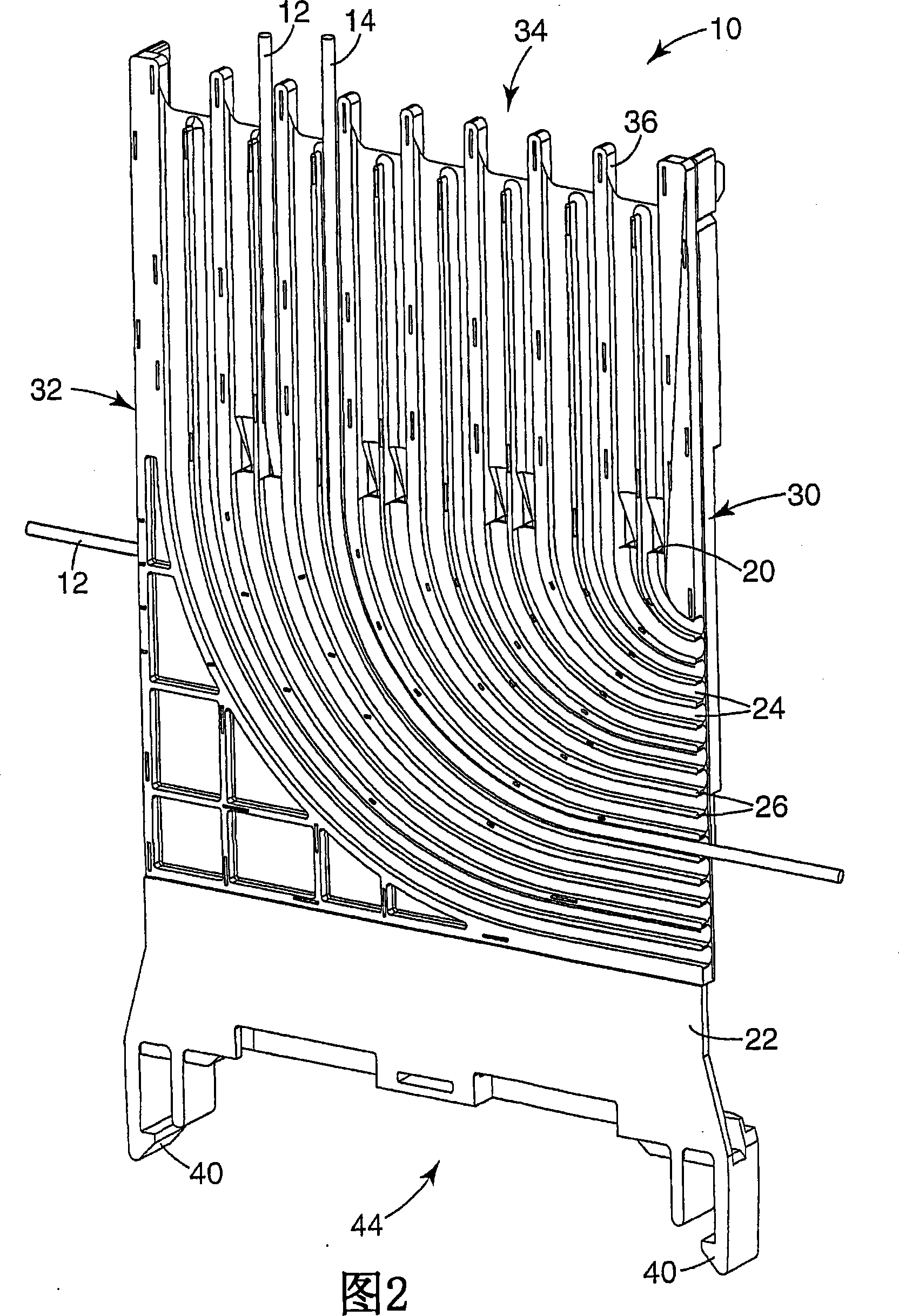

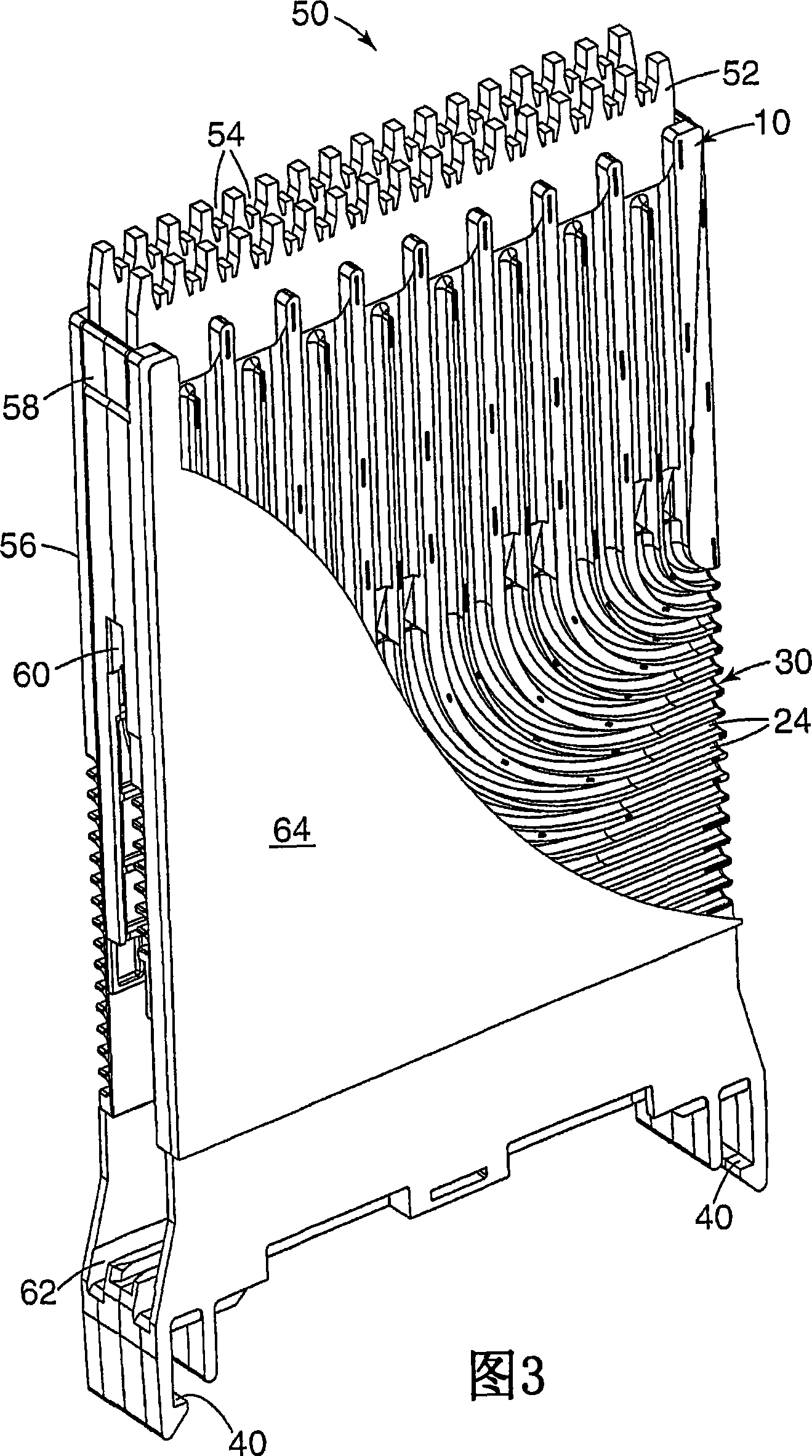

Wire guide plate and assembly as well as a telecommunications module comprising at least one wire guide plate

InactiveCN101103492AImplement bootstrapValid settingsElectrically conductive connectionsSelection arrangementsMechanical engineeringTelecommunications

Owner:3M INNOVATIVE PROPERTIES CO

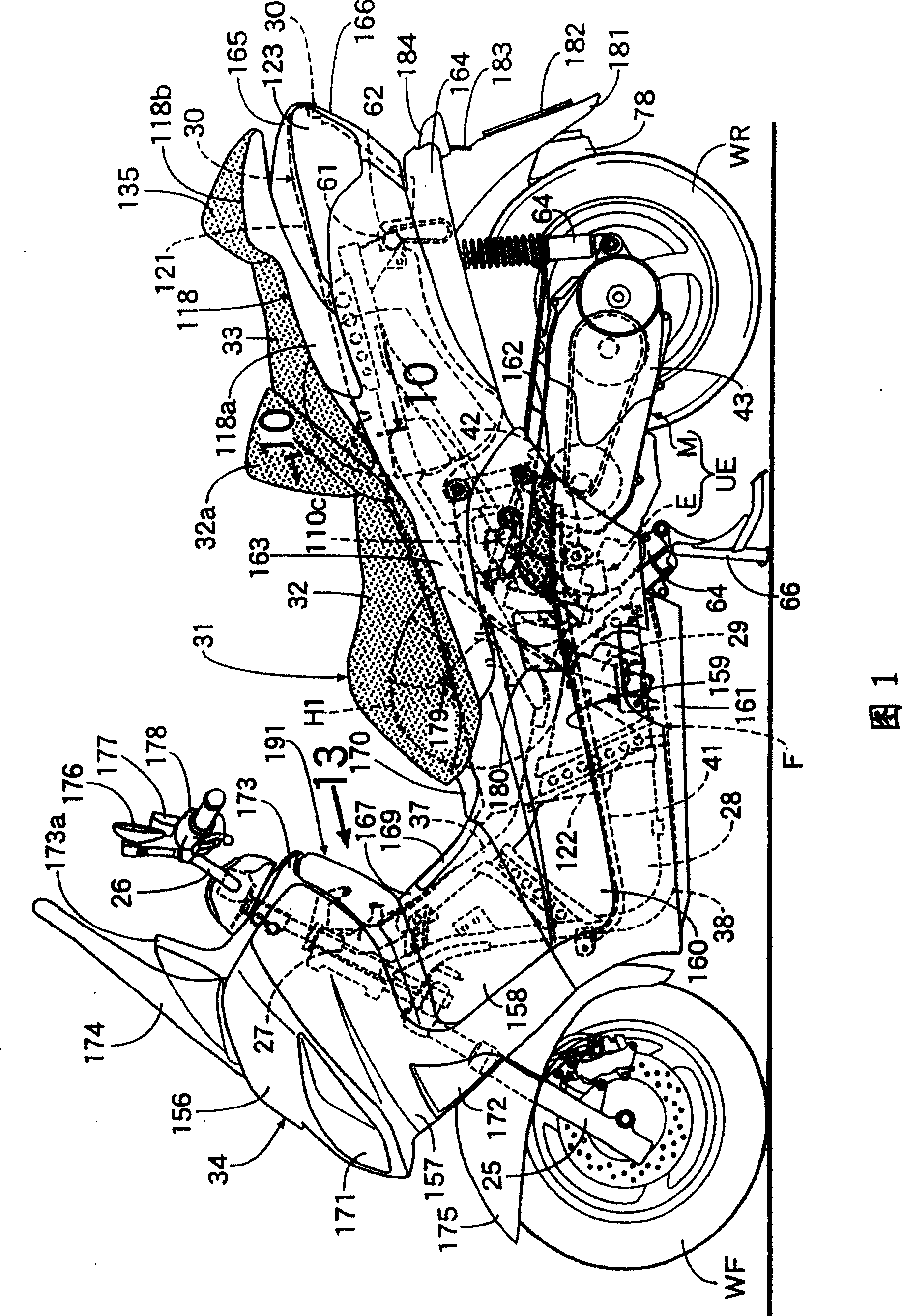

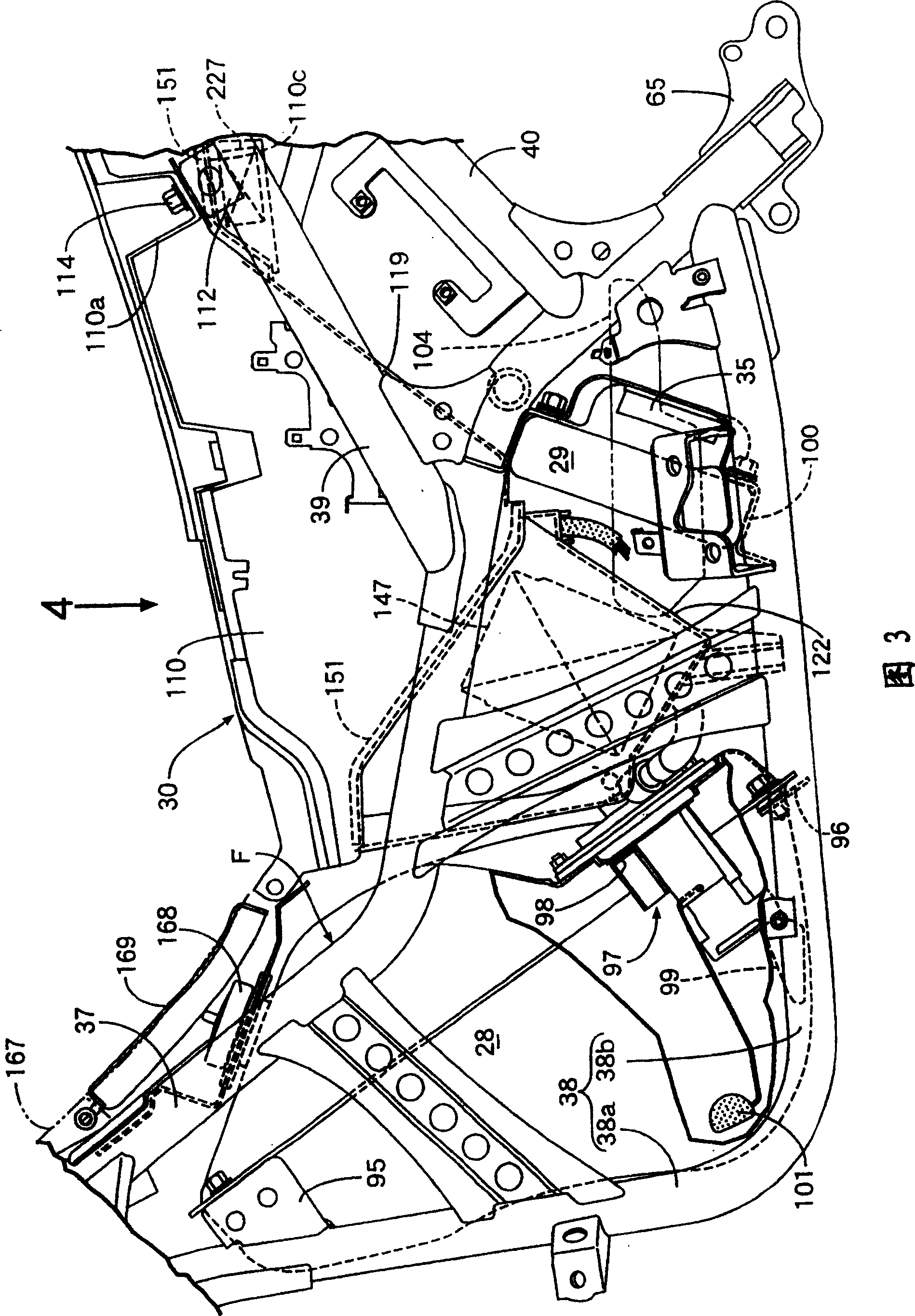

Luggage storage device for a motorcycle

InactiveCN100500501CIncrease volumeConvenient to accommodateOptical signalMotorised scootersEngineeringCushion

The invention sets a larger capacity of a storage box and store a lengthy object in the storage box in a storage device for a motorcycle in which the storage box having a front helmet storage part arranged below a front seat and a rear helmet storage part arranged below a rear seat constituting a tandem type riding seat with the front seat, is arranged below the riding seat so as to extend from below a front end of the riding seat to near an upper part of a rear cushion suspending a rear wheel to a rear part of a vehicle body frame. A rear expansion part 121 rearwardly expanded than a rear end of the rear seat 33 is provided at a rear part of the storage box 30.

Owner:HONDA MOTOR CO LTD

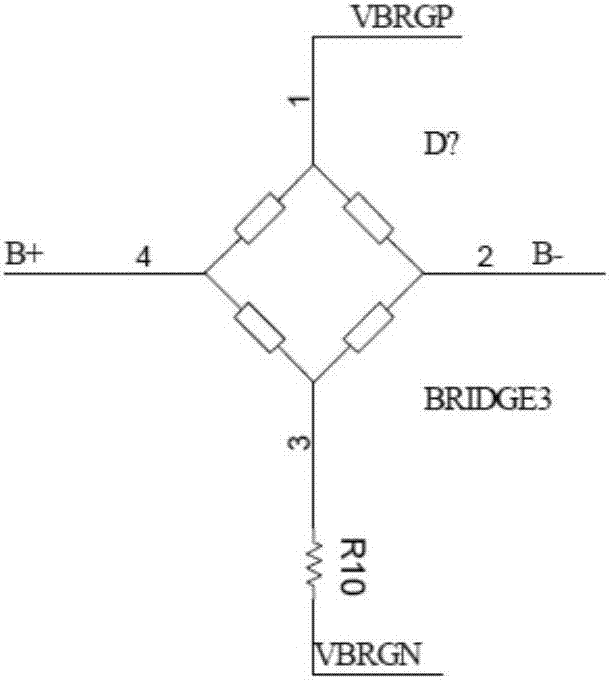

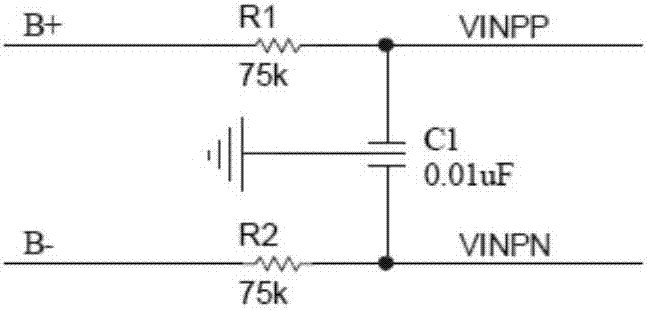

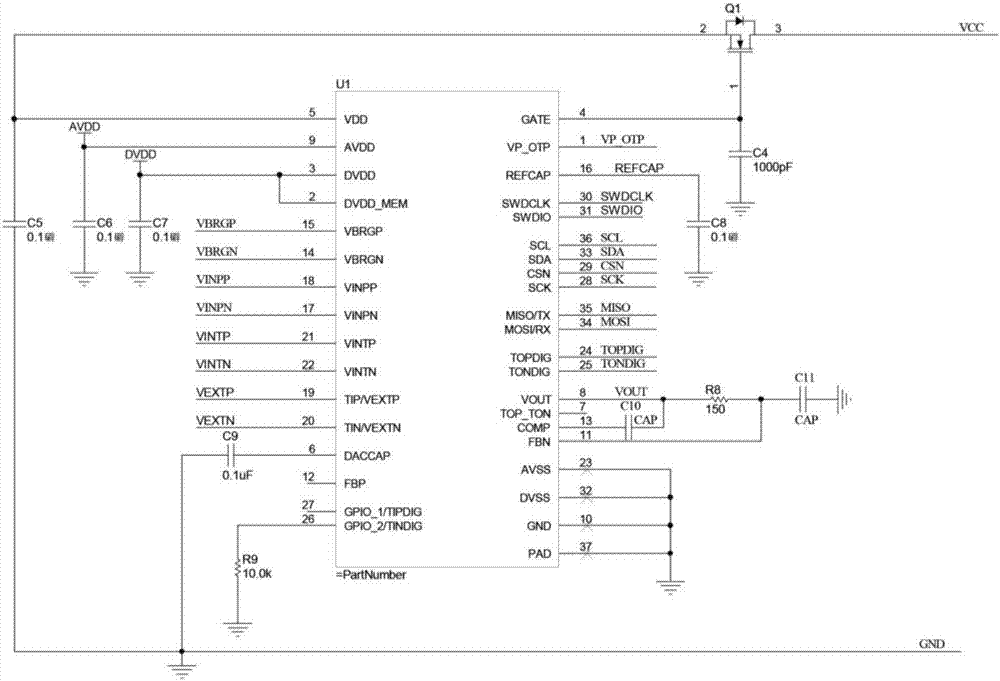

Temperature pressure compensation method for improving output precision of embedded pressure sensor

ActiveCN106895929ARealize the fitting calculationEffective fitForce measurement using piezo-resistive materialsTemperature stressEngineering

The invention provides a temperature pressure compensation method for improving output precision of an embedded pressure sensor. The method is characterized in that a pressure signal of the pressure sensor and bridge resistance change are acquired by employing a sensor signal processing chip, and pressure output is converted into a multiterm expression based on temperature pressure; multiterm fitting based on the least square method for different temperature pressures is carried out through a host computer, and a multiterm expression coefficient is calculated. The method is advantaged in that fitting calculation of multiple temperature points and multiple pressure points can be flexibly realized, in practice, temperature points and pressure points can be effectively set according to experiences based on a piezoresistive pressure sensor to acquire more effective fitting.

Owner:慧石(上海)测控科技有限公司

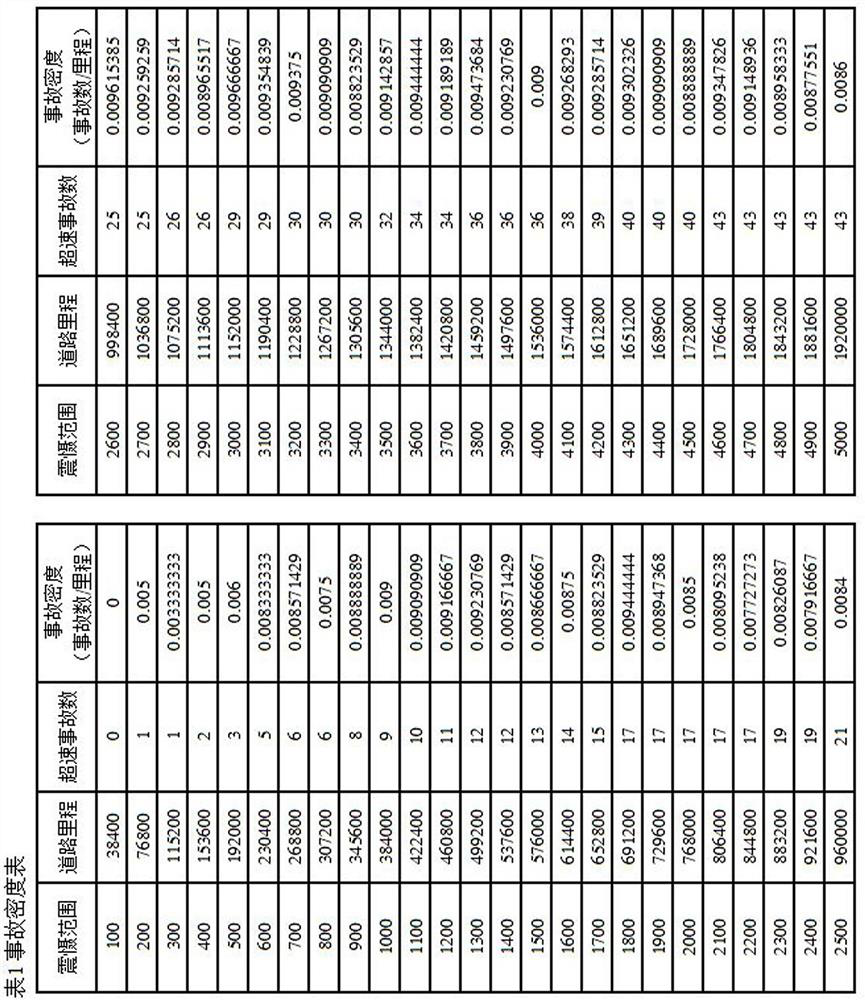

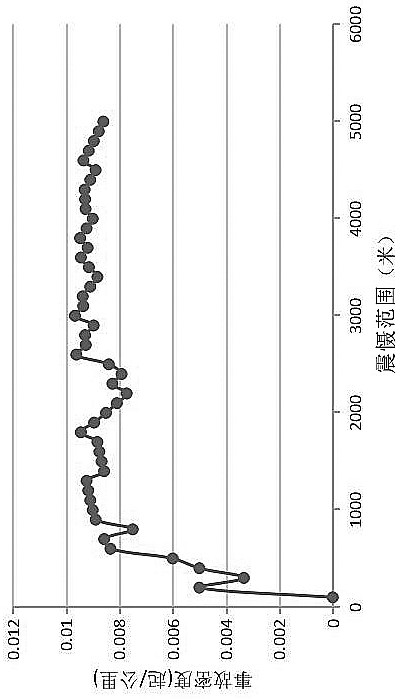

Expressway single-point speed measurement equipment deterrent range analysis method

ActiveCN112509336AAccurate range of deterrenceShock range is effectiveDetection of traffic movementReliability engineeringElectrical and Electronics engineering

The invention provides an expressway single-point speed measurement equipment deterrent range analysis method, which comprises the steps of calculating the upstream and downstream accident densities of single-point speed measurement equipment on the basis of the existing single-point equipment and accident big data, and accurately measuring and calculating the effective deterrent range interval ofthe single-point speed measurement equipment for overspeed violation through an accident density distribution curve trend chart. Measurement and calculation basic data is obtained based on historicaldata and does not depend on personal experience of technicians, and it is ensured that the accurate and objective deterrent range of the speed measurement equipment is obtained.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY

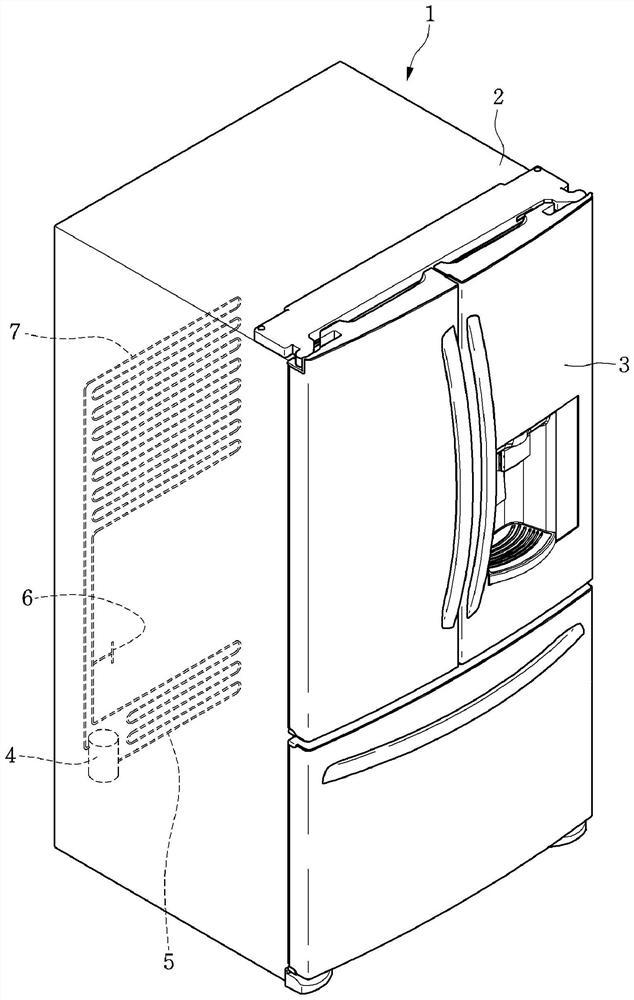

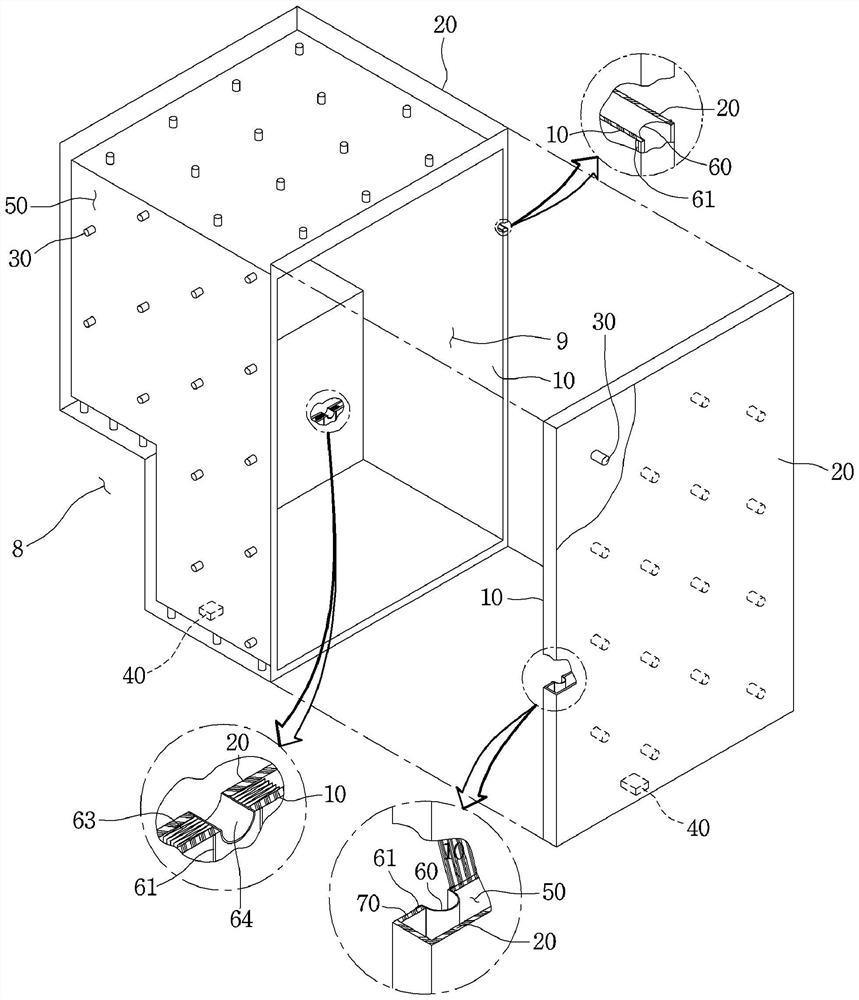

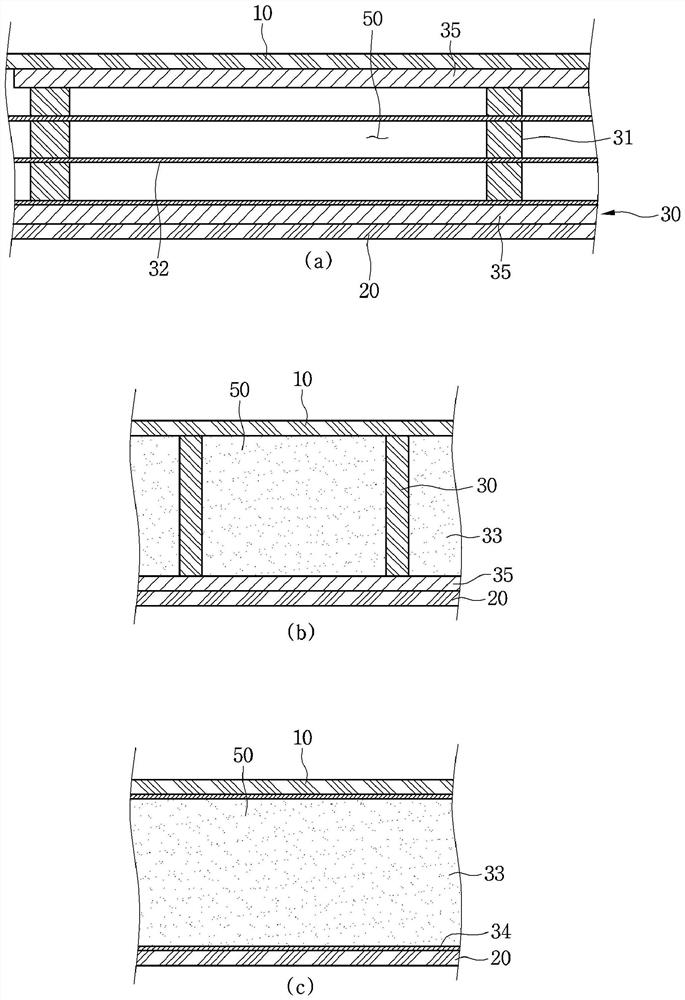

Vacuum adiabatic body and refrigerator

PendingCN114080531AValid settingsPromote expansionThermal insulationDomestic refrigeratorsIceboxEngineering

Provided is a vacuum adiabatic body. The vacuum adiabatic body includes a mullion configured to divide the first space into two spaces and a connection pipe supported on the mullion so as to be fixed in position, the connection pipe being configured to connect the two space to each other. According to the embodiment, the vacuum adiabatic body may increase in strength, and also, a passing path of defrosting water may be secured.

Owner:LG ELECTRONICS INC

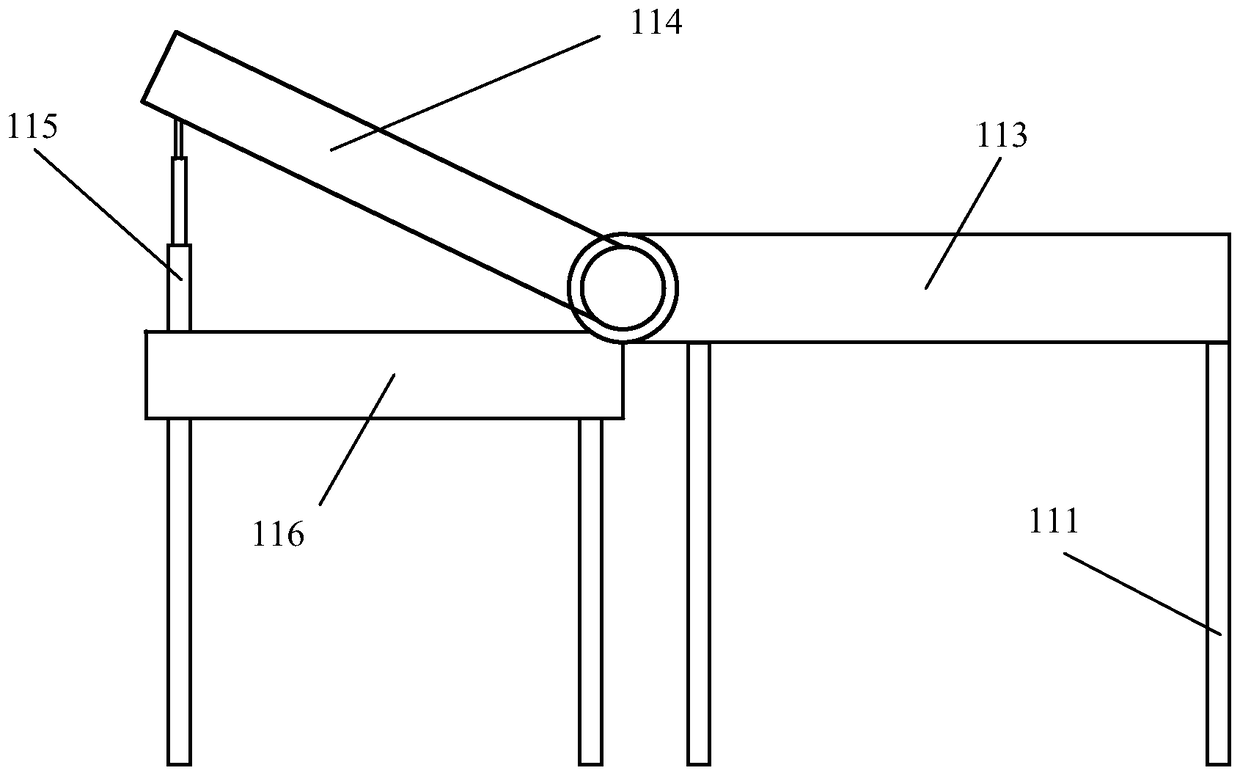

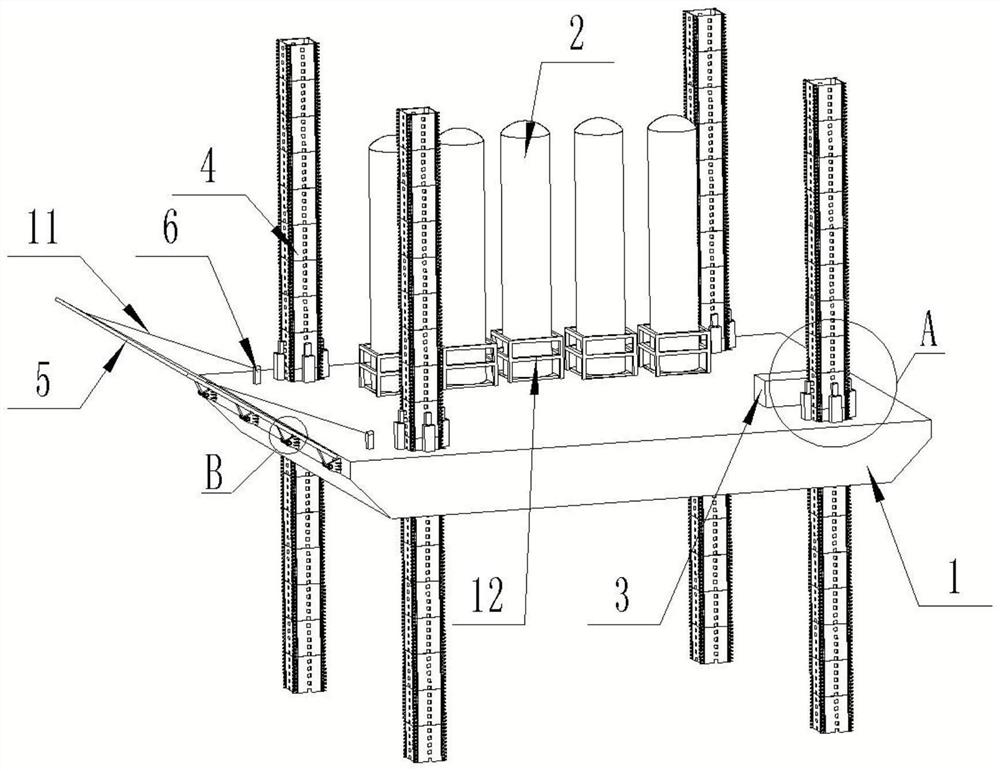

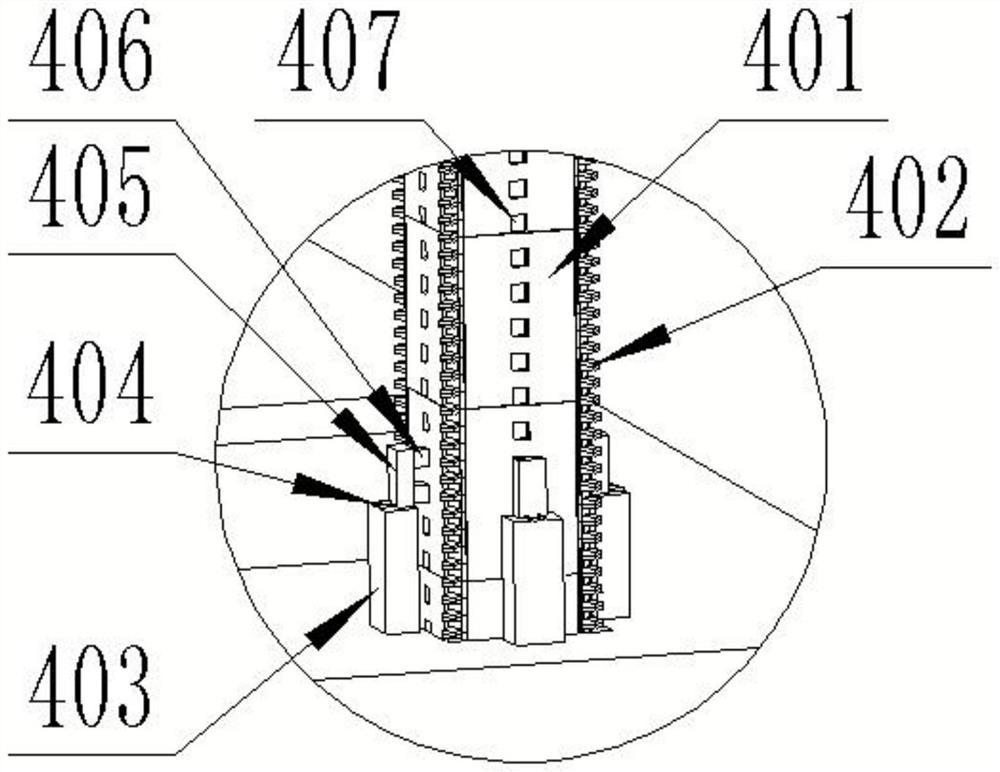

Overwater height-adjustable mobile mixing plant and use method thereof

PendingCN114378954AReduce operating costsImprove efficiencyMixing operation plantAgricultural engineeringFloating platform

The invention relates to an overwater height-adjustable movable mixing plant and a using method thereof.The height-adjustable movable mixing plant comprises a floating platform, a plurality of mixing plant bodies and a control room are arranged above the floating platform, gear type lifting height-adjusting assemblies are arranged at the four corners of the upper surface of the floating platform, and a feeding butt strap is hinged to one side of the upper surface of the floating platform; the feeding butt strap is connected with a traction device. According to the using method, the gear type lifting and heightening assembly is used for controlling the floating platform to transfer materials and transfer sites. Effective arrangement of the water concrete mixing plant is achieved, meanwhile, compared with a concrete mixing ship, the operation cost is lower, the efficiency is higher, meanwhile, unsafe factors easily generated by water transportation land commercial mixing are avoided, and the influence of unfavorable external factors such as waves on the mixing plant is avoided during operation of the concrete mixing plant.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

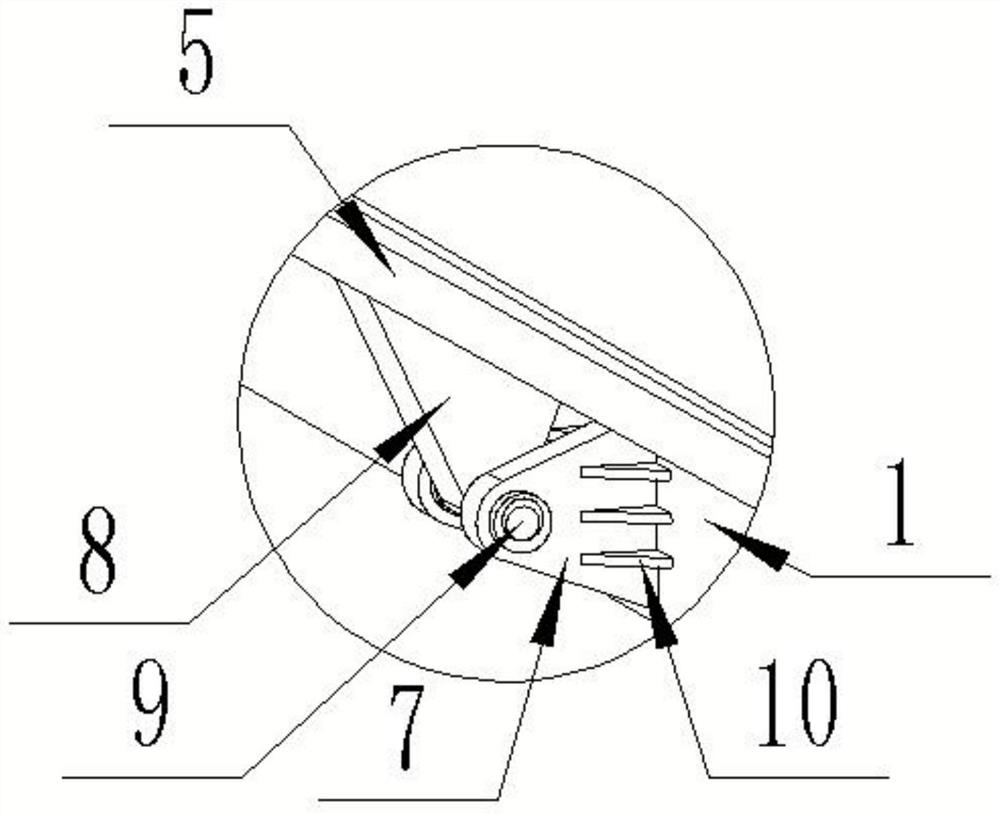

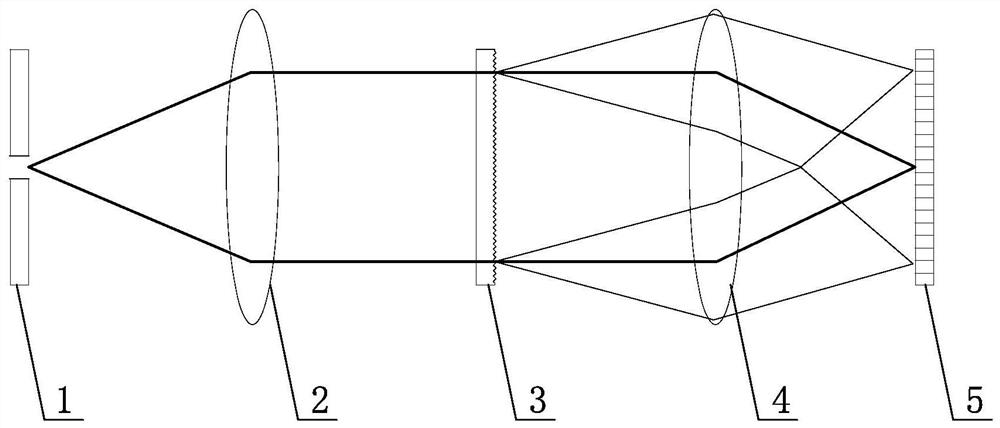

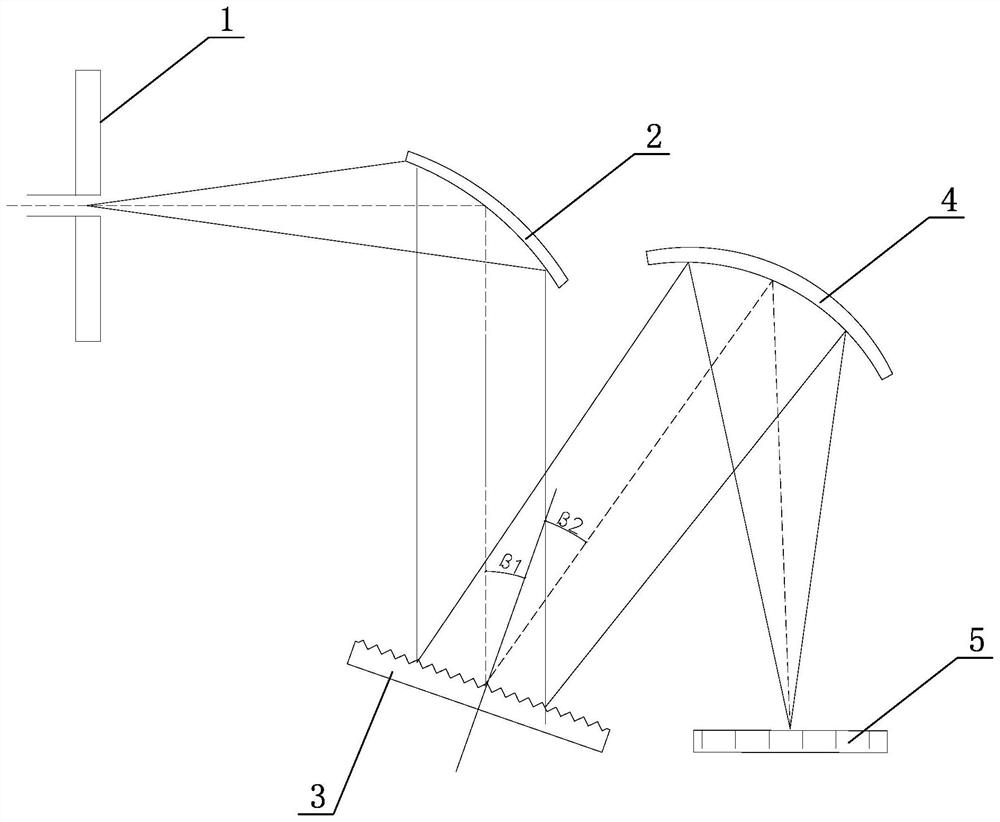

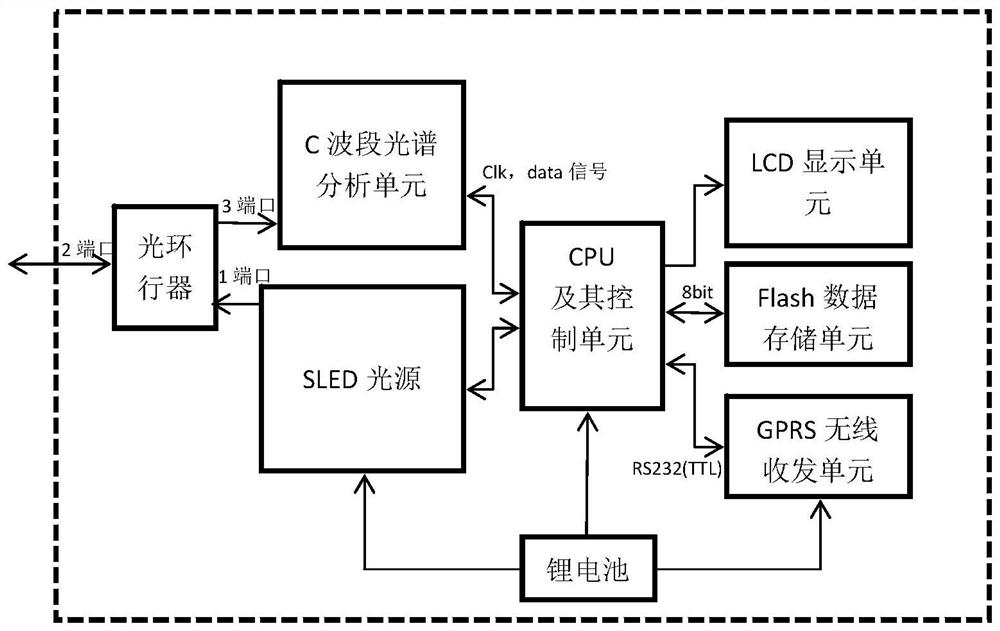

Wireless Handheld Fiber Bragg Grating Demodulator

ActiveCN110207735BValid settingsReduce volumeUsing optical meansConverting sensor output opticallyWireless transceiverGrating

The invention discloses a wireless handheld fiber grating demodulator. The invention includes an optical circulator, a C-band spectrum analysis unit, an SLED light source, a CPU and its control unit; the optical circulator has three ports, the first port is connected to the SLED light source, the second port is connected to an external sensor, and the third port is connected to the C-band Spectral analysis unit; the CPU and its control unit include CPU processor, spectral data acquisition and communication and fitting unit, exposure time control unit, SLED power control unit and conversion processing unit; the CPU and its control unit, SLED light source and GPRS wireless transceiver unit are powered by a lithium battery. The present invention has a small overall volume, does not need an external power supply, and the collected data can be sent wirelessly; the spectrum can be effectively set in the optimal linear amplification area, so that the sensing and monitoring accuracy and stability can be optimally processed.

Owner:浙江省建筑科学设计研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com